Patents

Literature

808 results about "Cotton thread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cotton thread is a type of filament made from spun cotton. It is generally durable, and does not stretch or break easily. This type of thread is used in a variety of crafting projects and clothing construction. Cotton is a kind of fiber that grows on cotton plants.

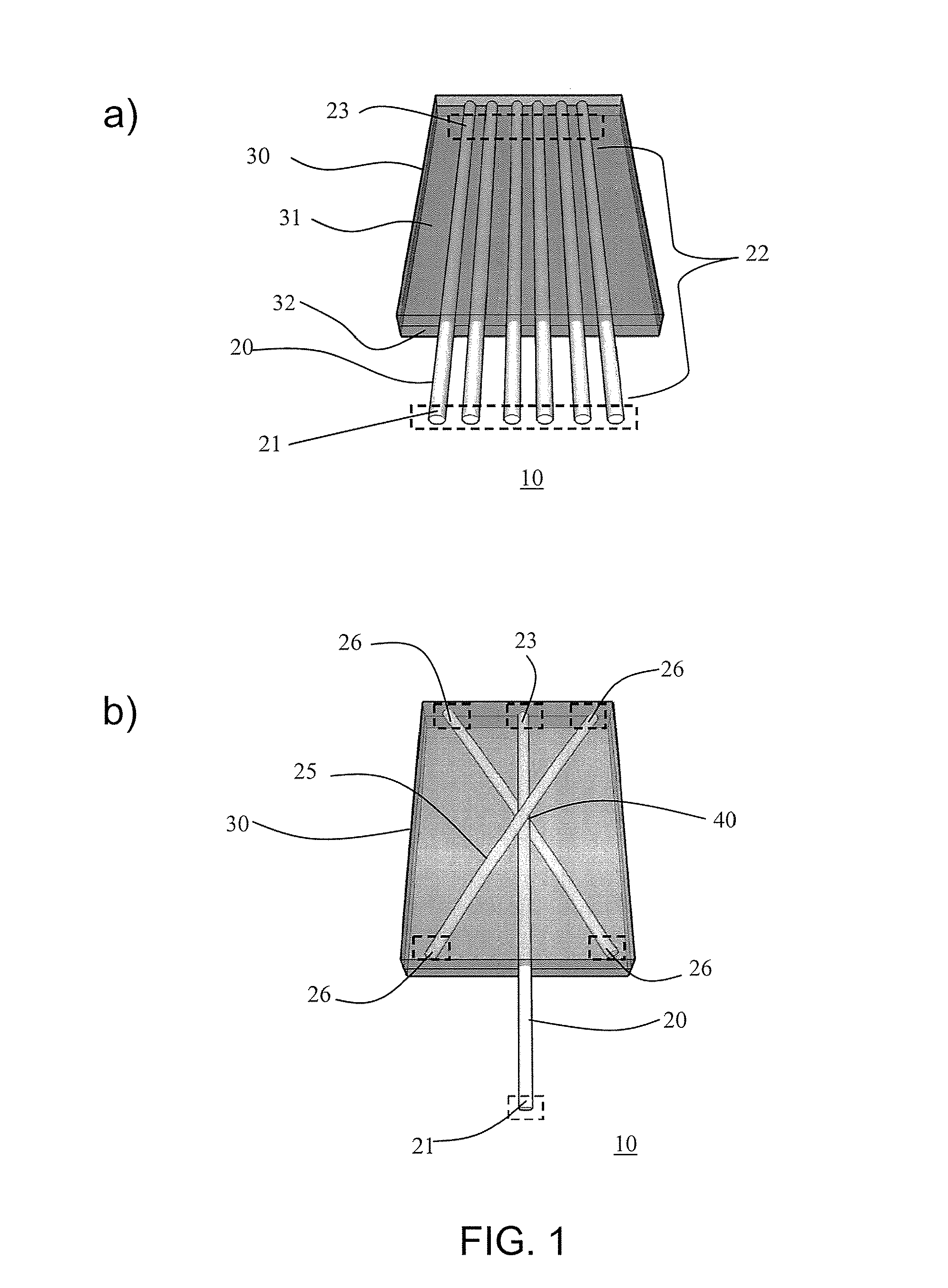

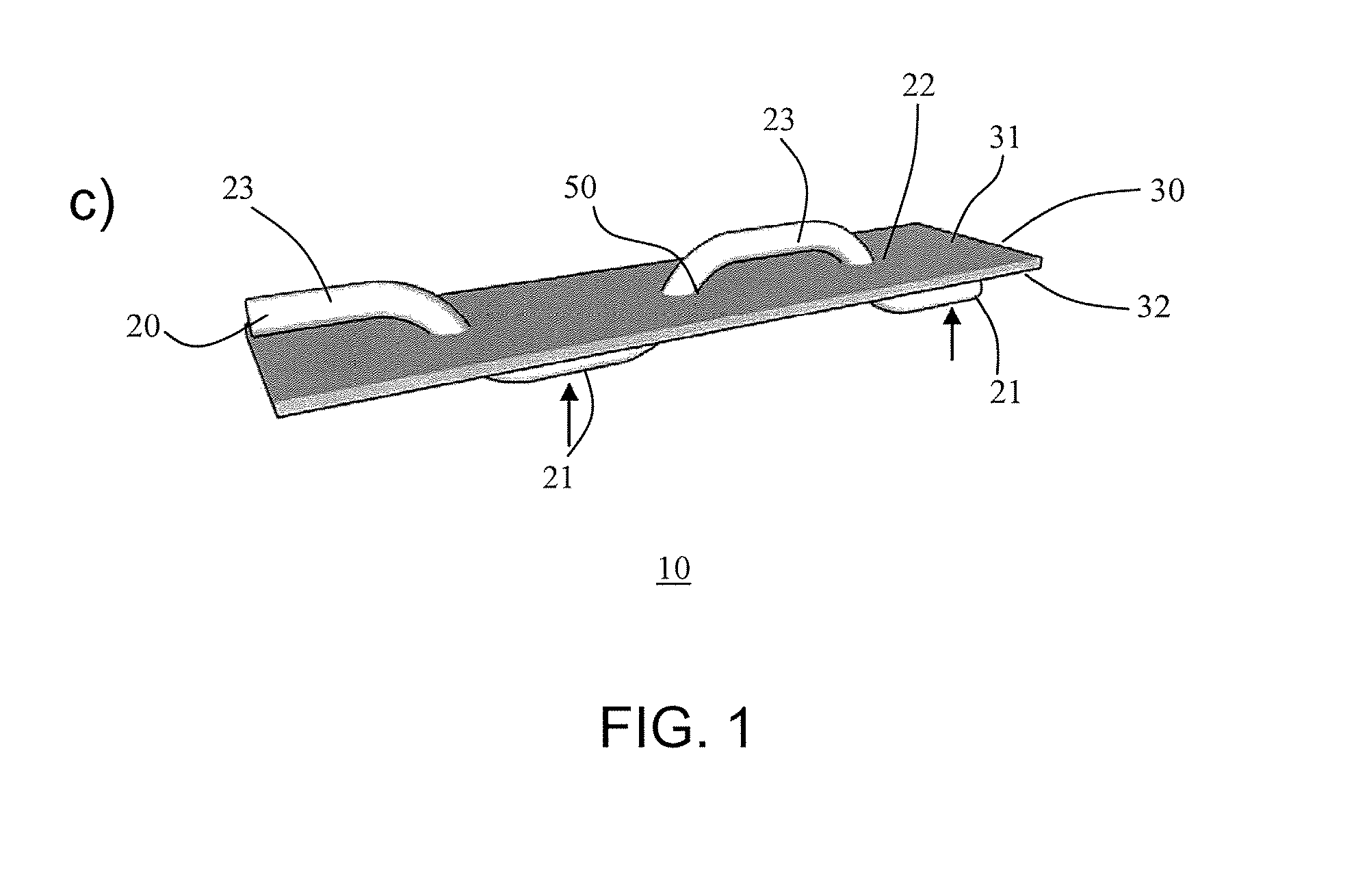

Cotton thread as a low-cost multi-assay diagnostic platform

ActiveUS20110189786A1Convenient running low-costConvenient portableAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorAnalyteMechanical engineering

Hydrophilic threads as platforms for inexpensive, low volume, portable diagnostic systems, and methods of making the same are described. A diagnostic system includes a hydrophilic loading thread having an inlet zone at a proximal end; a testing zone at a distal end; and an intermediate zone located between the inlet zone and the testing zone, wherein the testing zone does not directly contact the inlet zone. In another aspect, a diagnostic system includes (i) a hydrophilic loading thread that includes an inlet zone at a proximal end and an intermediate zone at a distal end; and (ii) one or more additional hydrophilic threads that contact the intermediate zone of the loading thread. A method of detecting the presence or absence of an analyte in a fluid sample includes applying the sample to an inlet zone of a diagnostic system that includes a hydrophilic loading thread with an inlet zone at a proximal end; an intermediate zone; and a testing zone at a distal end; wherein the testing zone does not directly contact the inlet zone.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

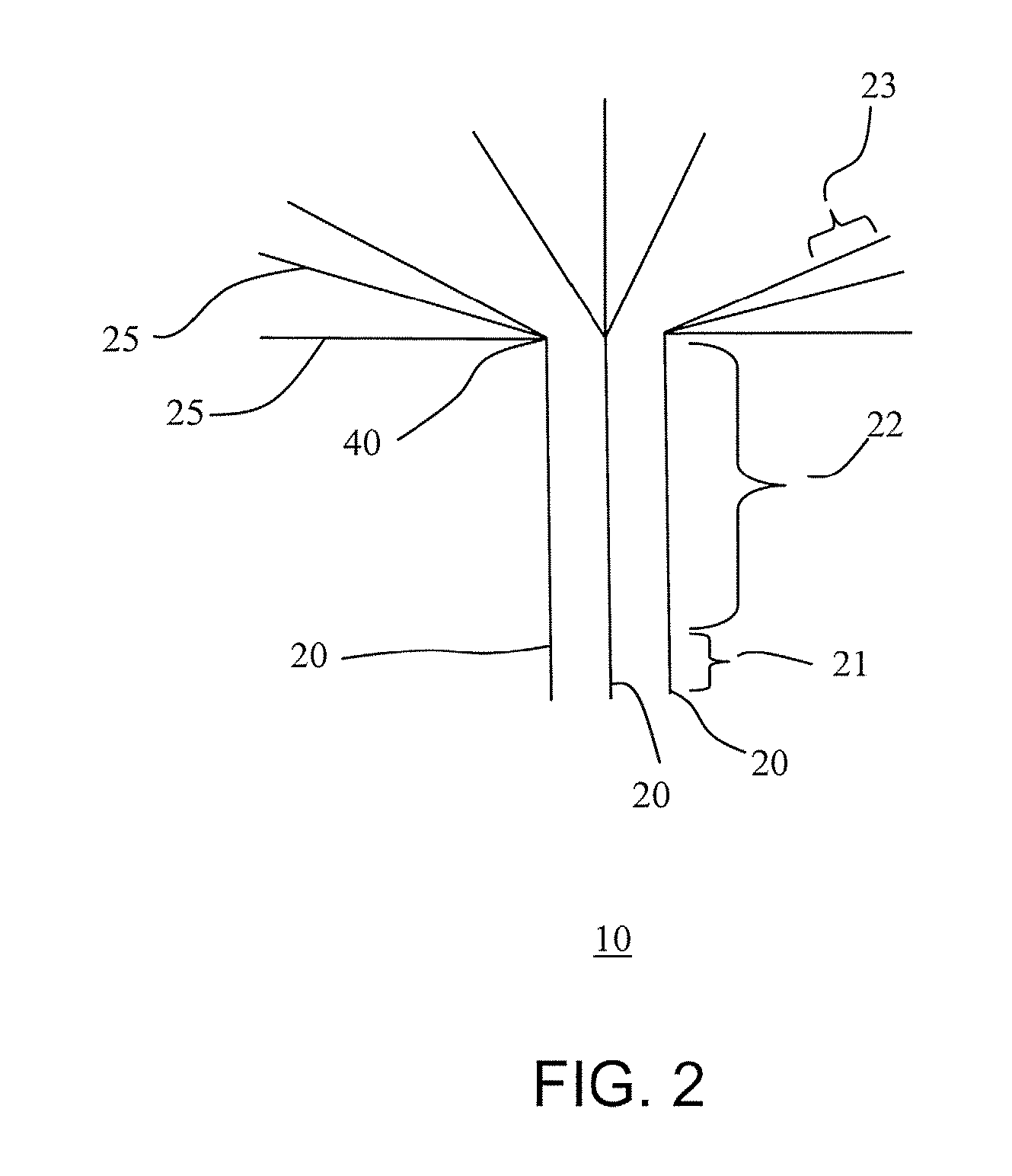

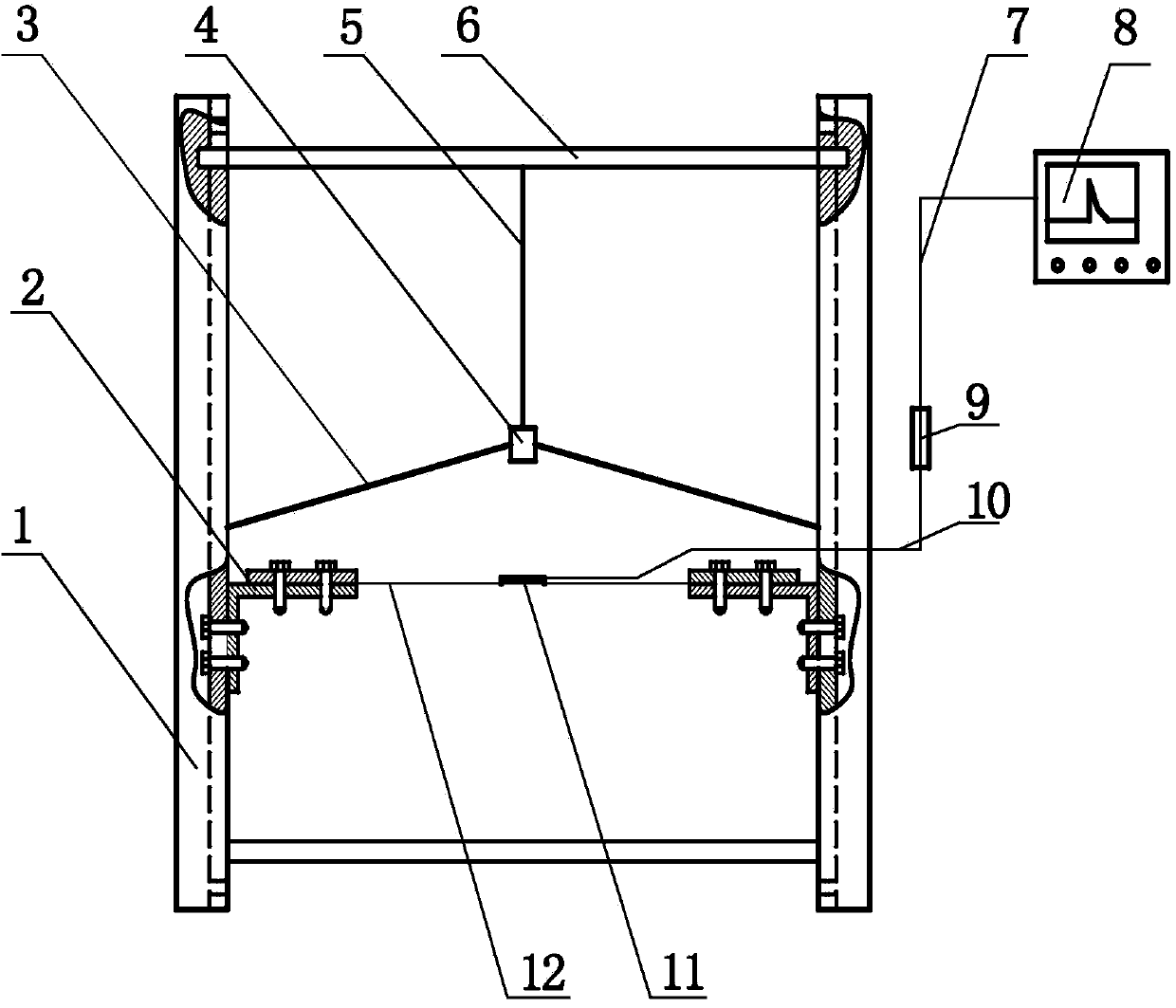

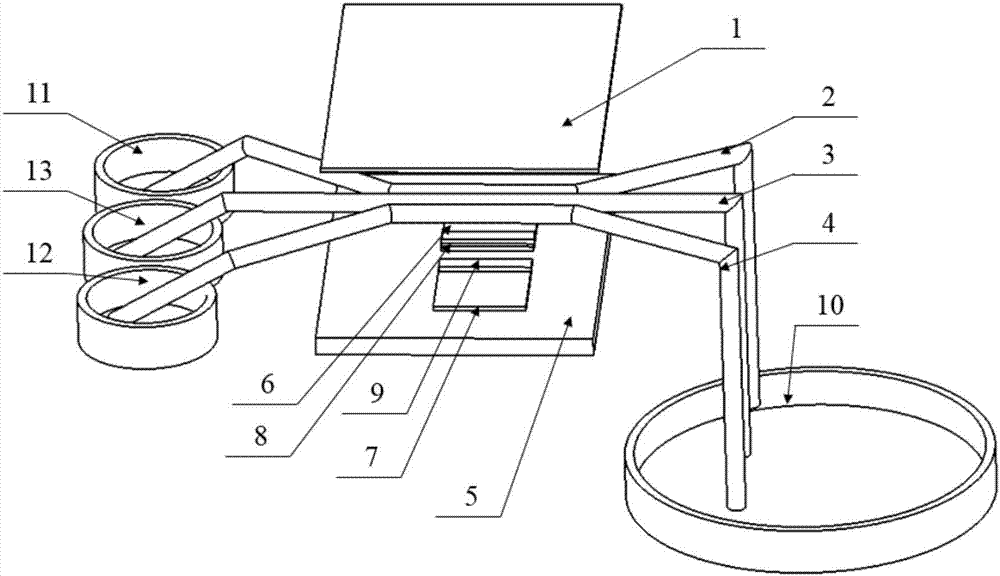

Torsional high-accuracy micro-thrust measuring system

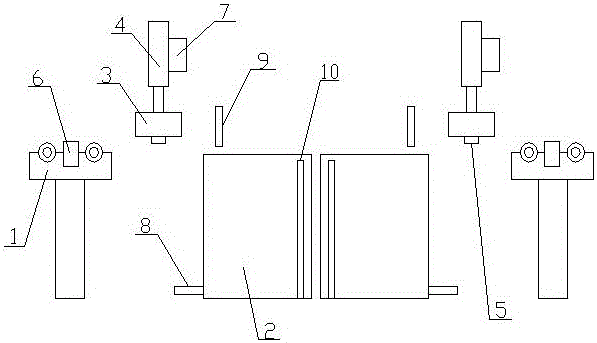

InactiveCN102169035AMeet the experimental measurement requirementsSimple structureApparatus for force/torque/work measurementLinear displacementCotton thread

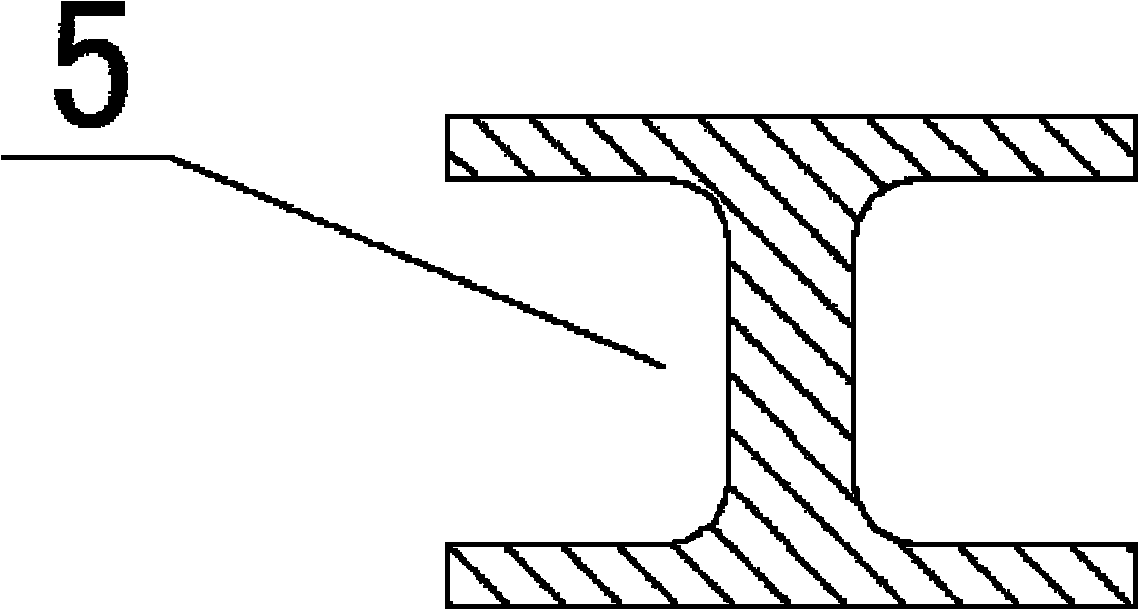

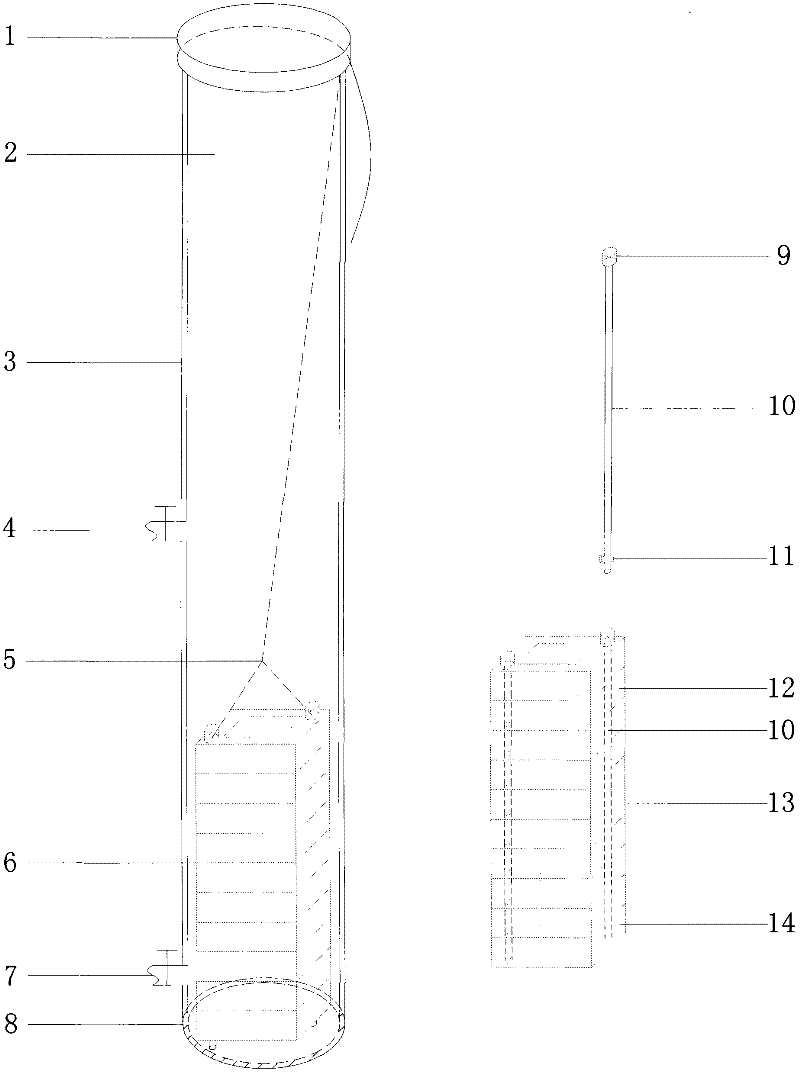

The invention discloses a torsional high-accuracy micro-thrust measuring system. A transverse lever of a support frame is provided with a position adjuster; the bottom end of a rigid shaft is connected with a paraffin solidified cup; a fin structure is arranged in the paraffin solidified cup and is centrosymmetrically arranged on the lower part of the rigid shaft by taking the rigid shaft as a central shaft; the long arm end of a thrust lever is provided with a micro-thruster and a linear displacement sensor matched with the micro-thruster; the short arm end of the thrust lever is provided with a weight balancing cup; the thrust lever is connected with the top end of the rigid shaft in a horizontal state through a flexible hinge; one end of a connecting line is connected to the position adjuster by suspending, and the other end of the connecting line is connected to the axis of the flexible hinge; the position adjuster connected to the upper end of the connecting line can be used for freely adjusting the position of a cotton thread suspending line; and a rotating lever system is suspended on the position adjuster through the upper end of the connecting line. The measuring system has a small structure, small size, high accuracy and a good application prospect, is convenient to use, and can meet the practical measuring requirement of a micro-thrust device.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

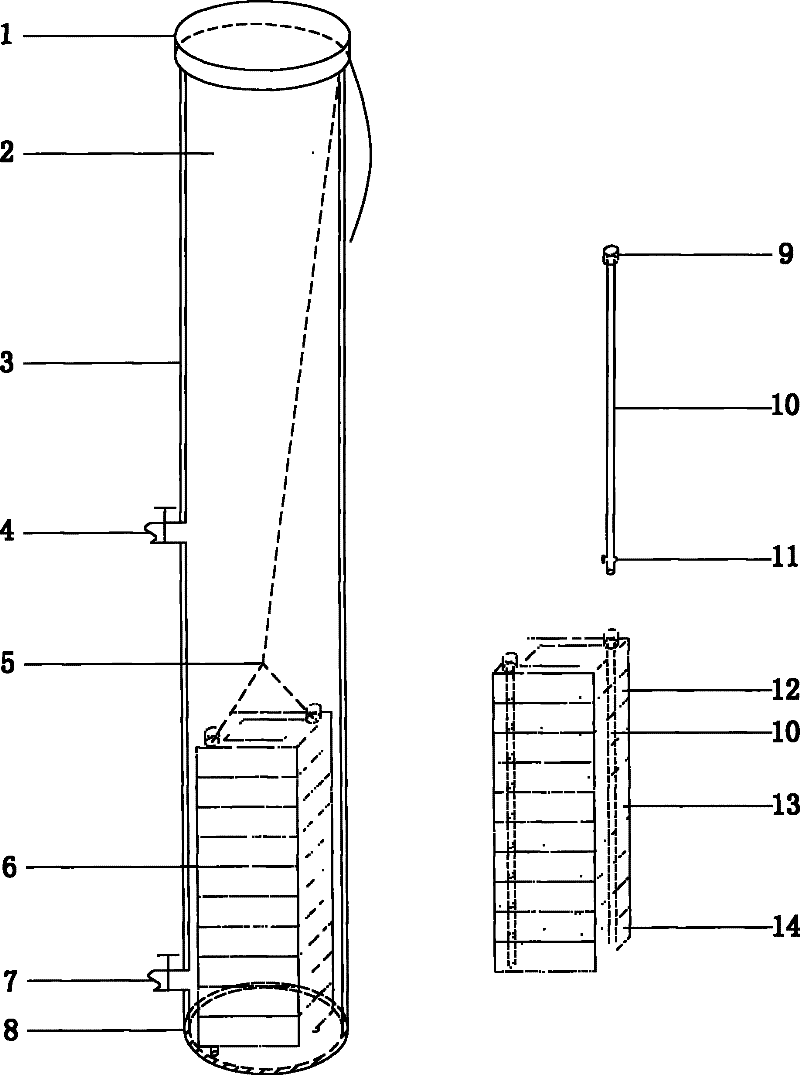

Water-sediment compound simulation test device for accurately layering and collecting sediment

ActiveCN102175491ASimple structureEasy to operateWithdrawing sample devicesCotton threadSampling valve

The invention relates to a water-sediment compound simulation test device which is formed by combining a testing column with a built-in layering testing cylinder, wherein an outer cylinder top cover is transparent and detachable; a sampling valve is arranged on a side face; the water replenishing and water sampling operations can be carried out conveniently; and a dewatering valve is arranged on the bottom of the side face. If the device is used for a test, an inner cylinder is taken out firstly, and then the inner cylinder is slowly descended to the outer cylinder by taking a cotton thread by hand after being filled with the acquired field sediment, an evacuation valve is closed, water is slowly filled in from the top of the outer cylinder, and then the test is started. When the sedimentsample is needed to be taken, the following operations are performed: exhausting the water of the outer cylinder by using the evacuation valve of the outer cylinder and then taking out the inner cylinder by taking the cotton thread by hand; taking off a PVC (polyvinyl chloride) short plug from one bottom corner of the inner cylinder and pulling out a PVC long nail from an inner cylinder top corner corresponding to the bottom corner by firmly holding a nail cap; inserting gaskets in layers by starting from the top layer and rotating the inner cylinder and gaskets by using the PVC long nail at another corner as a shaft; and then vertically moving the gaskets downwards, thereby guiding the sediment on the layers to fall onto the gaskets. Different layered sediment samples can be convenientlyand accurately acquired by performing the operations layer by layer.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

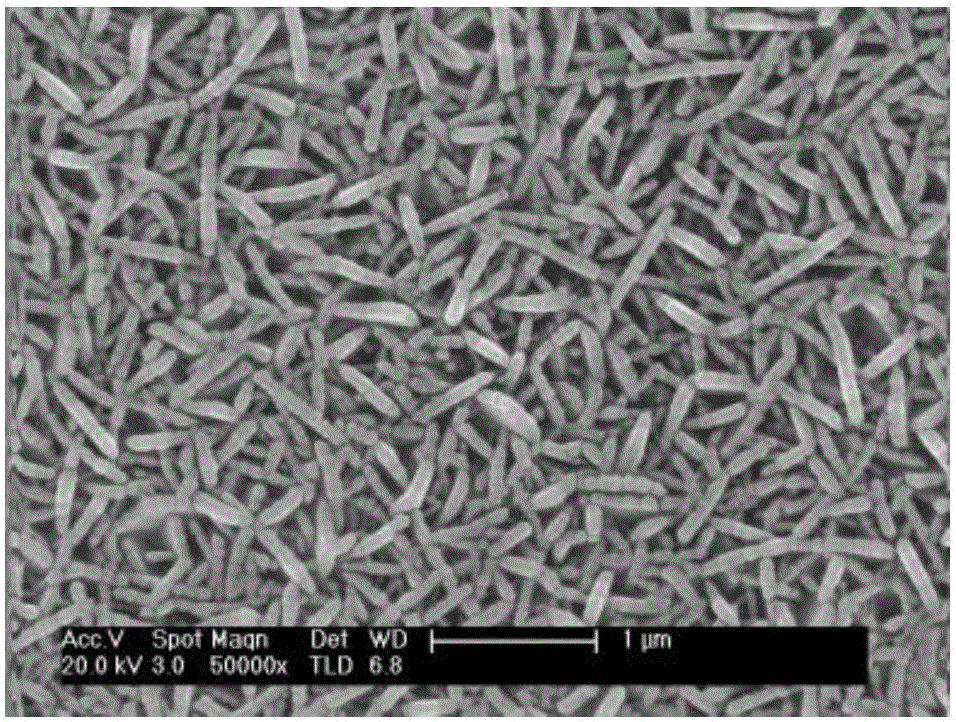

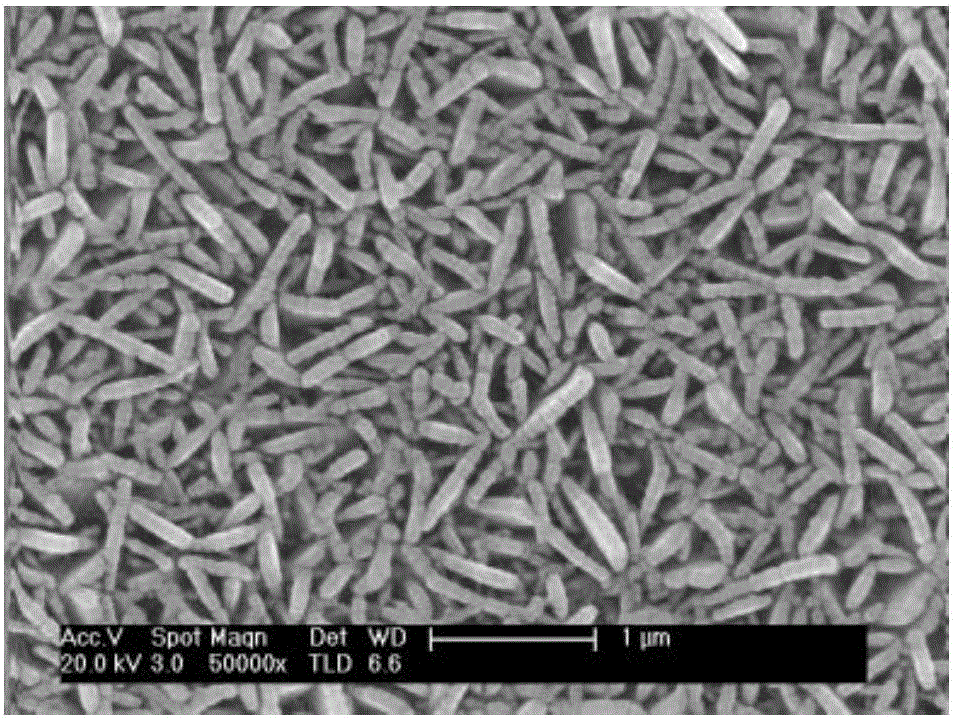

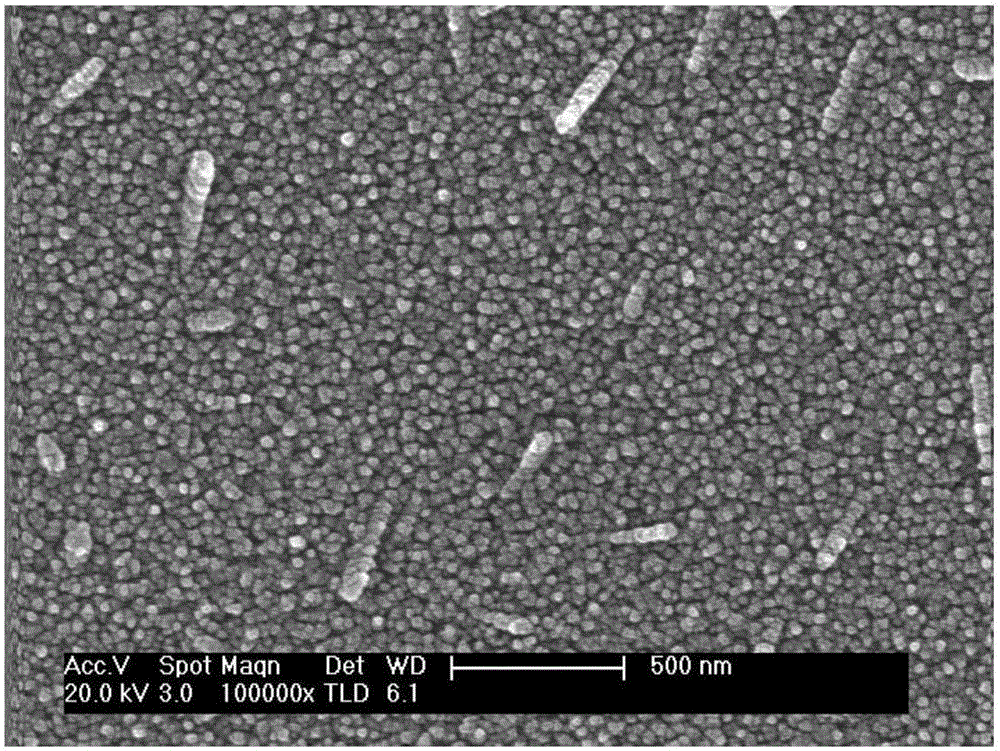

Transparent super-hydrophobic nano-array and preparation method thereof

ActiveCN105776317AReduce concentrationControl growth rateZinc oxides/hydroxidesNanotechnologyDesorptionSpray coating

The invention discloses a transparent super-hydrophobic nano-array and a preparation method thereof. The preparation method comprises the following steps: firstly coating the surface of a substrate with zinc oxide seed crystal sol by virtue of a spin coating method or a spray coating method, so as to obtain a uniform nano-seed crystal layer; then controlling the hanging altitude and the position in a low-concentration growth solution prepared from KOH and Zn(NO3)2 by virtue of a vertical cotton thread hanging technique, so as to obtain a transparent zinc oxide nano-array, and carrying out fluorination to construct excellent super-hydrophobicity; and carrying out double-surface coating, sintering and growth on the substrate, so as to obtain the transparent super-hydrophobic nano-array on two surfaces of the substrate. Liquid drops with condensed and frosted surfaces are of a sphere shape, small in sizes, extremely easy to combine and bounce, high in desorption rate and low in coverage rate, present excellent frosting resistance and have important application prospects in products of building exterior glass, solar cells, automotive glass and the like, and furthermore, concepts can be provided for application of dropwise condensation, frosting resisting, freezing resisting and the like.

Owner:SOUTHEAST UNIV

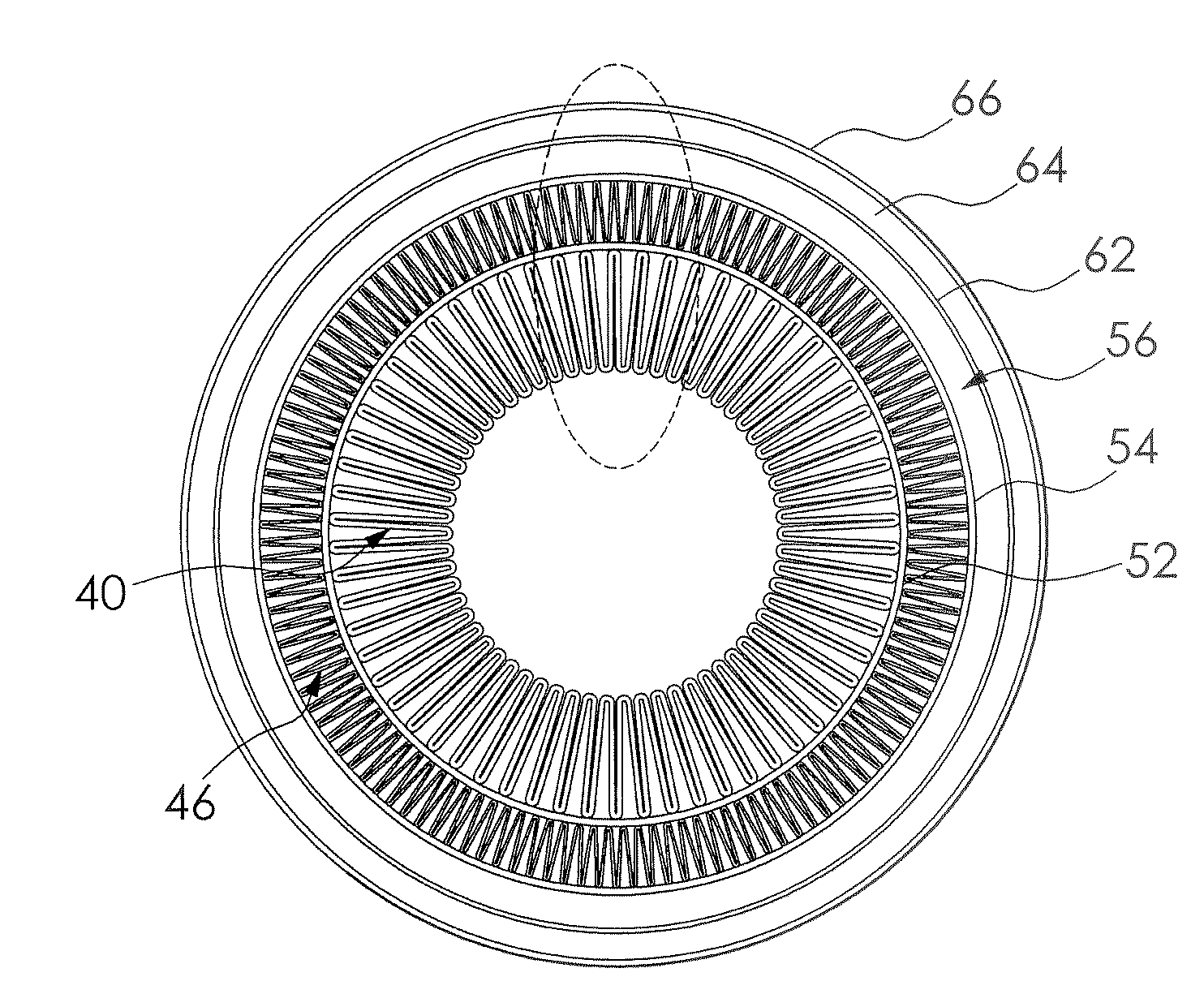

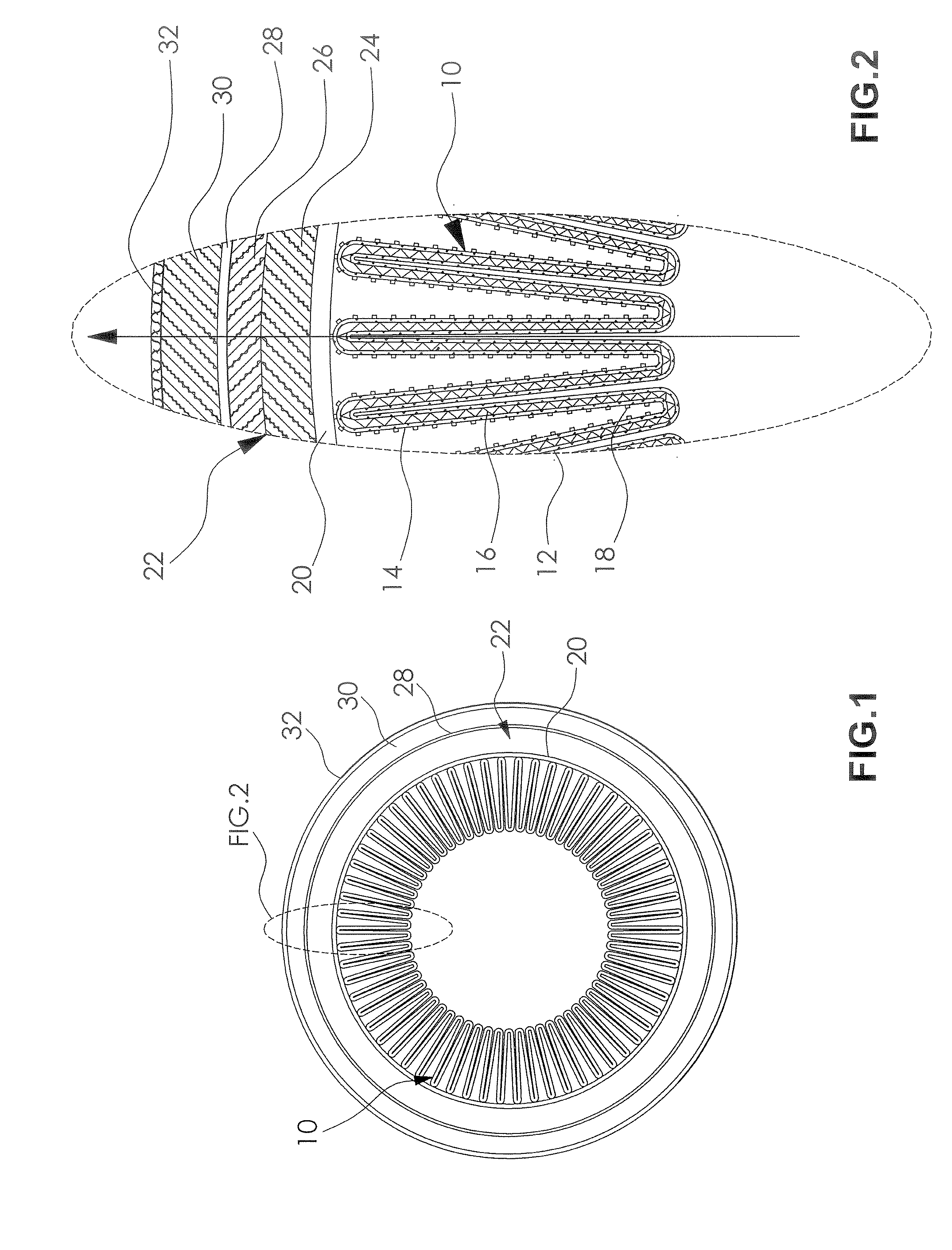

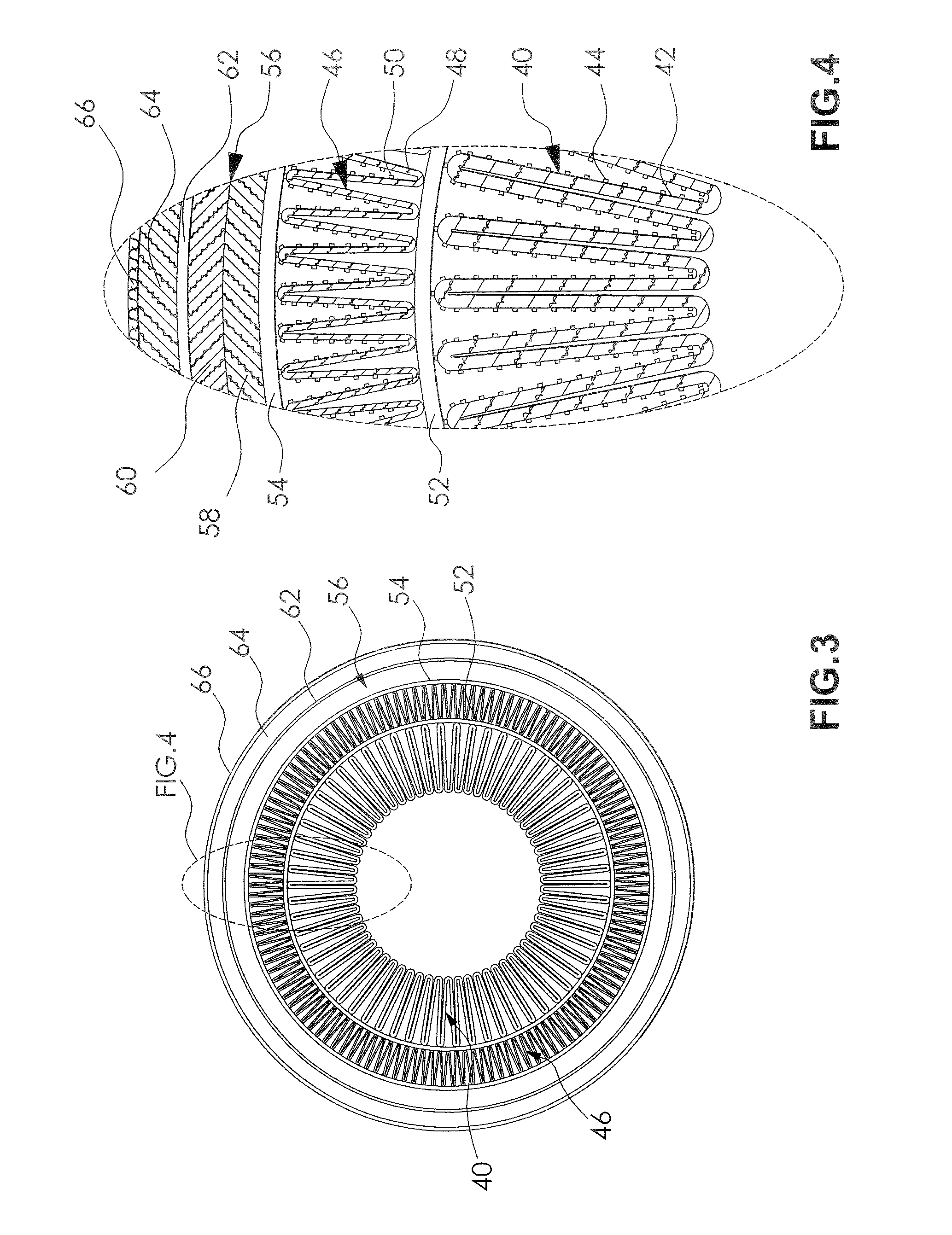

Bio-resistant filter coalescer cartridge

A filter coalescer cartridge for treating jet fuels is disclosed. The filter coalescer cartridge has spaced apart filter / coalescer layers to effectively remove particulate contaminates and water from the transient fuel being treated. The outer most layer is a knitted sock material formed from cotton threads including a metallic silver disposed thereon to provide an anti-microbial property to the sock material.

Owner:VELCON FILTERS

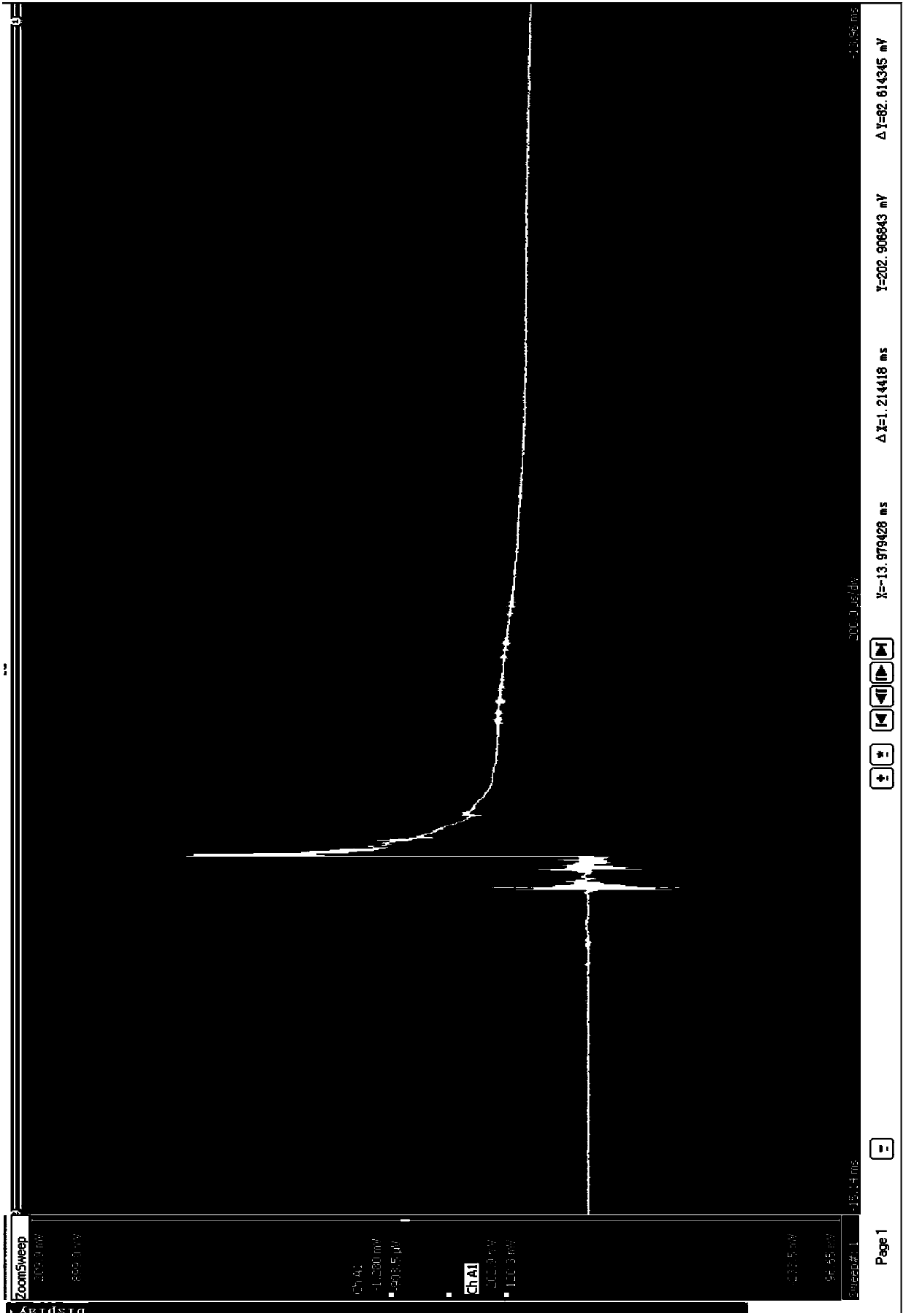

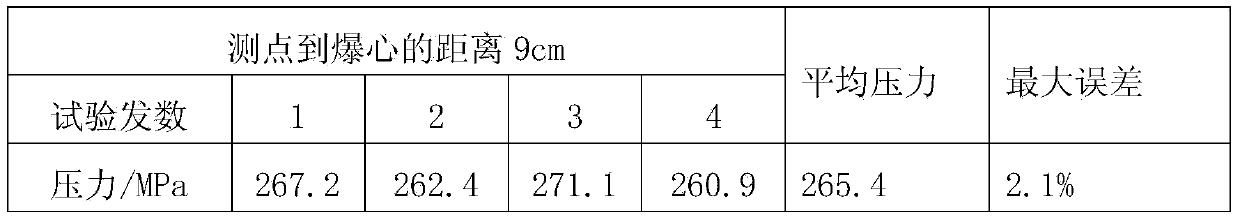

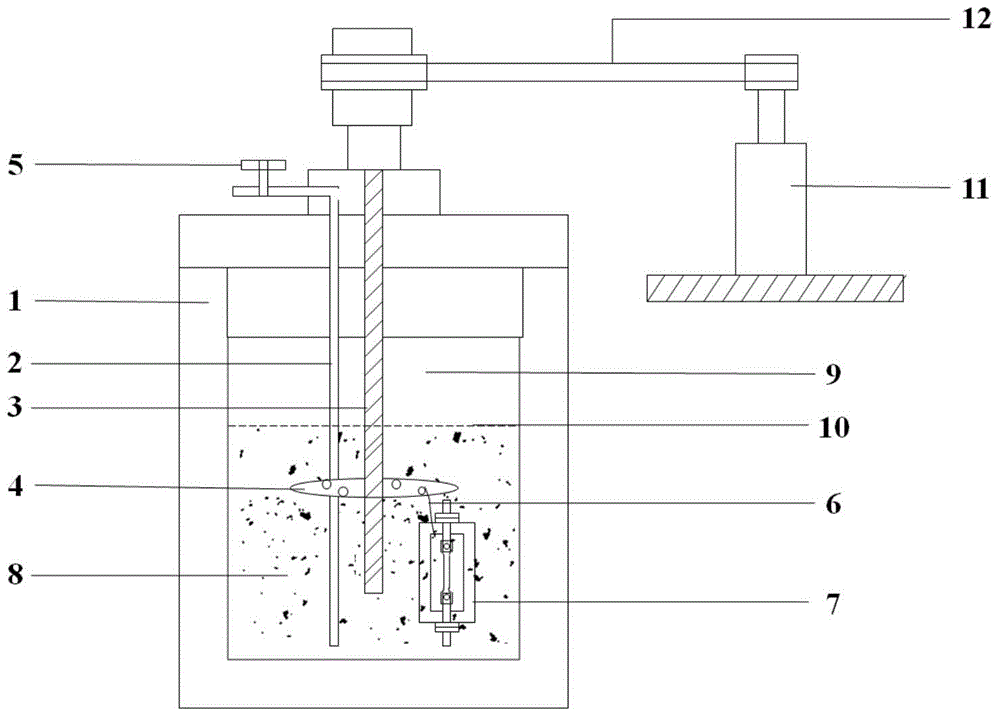

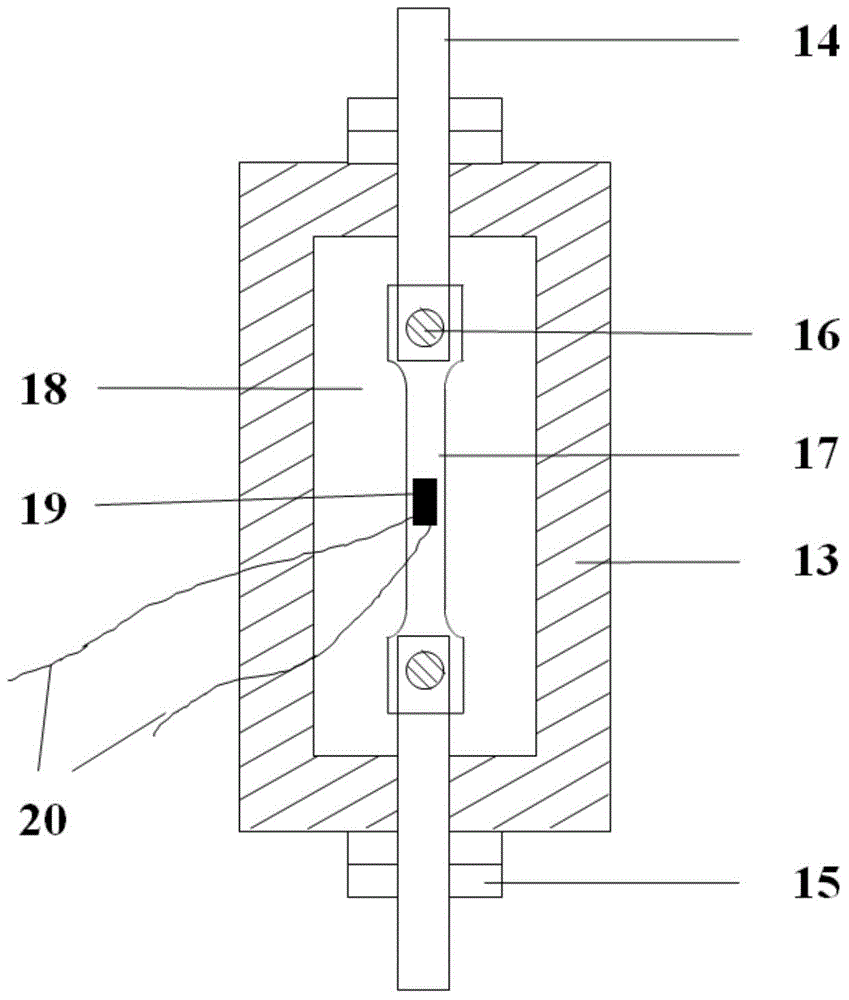

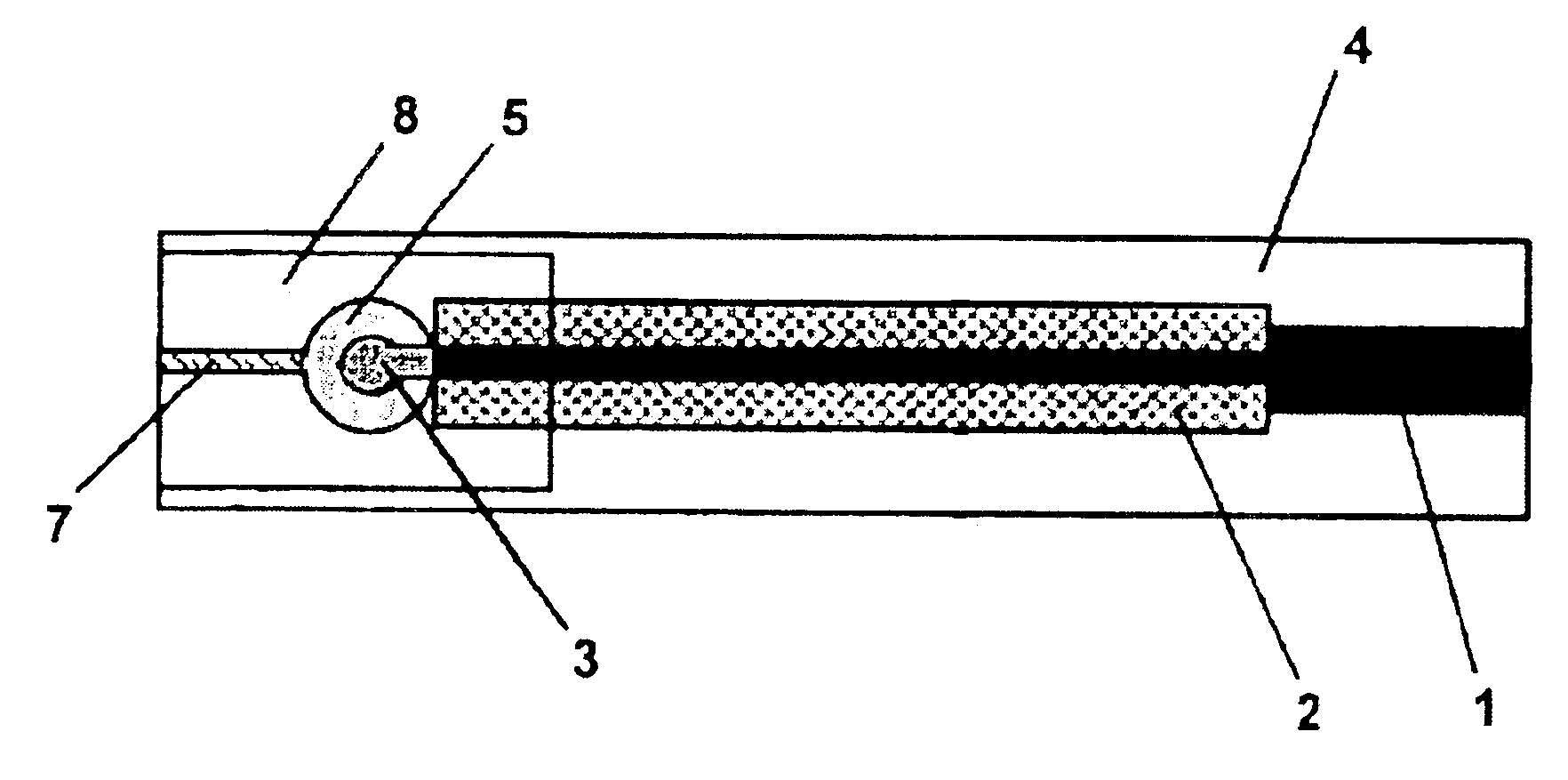

Method for measuring near field blast wave pressure of underwater explosion of explosive

InactiveCN104034468AThe testing process is simpleSimple method test componentApparatus for force/torque/work measurementDetonatorUnderwater explosion

The invention discloses a method for measuring near field blast wave pressure of underwater explosion of an explosive. The measuring method is characterized in that a thin-film stress gauge is glued on cotton cloth by use of an epoxy adhesive, the thin-film stress gauge is welded with a coaxial cable, the other end of the coaxial cable is connected with a charge amplifier, the charge amplifier is connected with a signal wire, and the other end of the signal wire is connected with a data acquisition instrument. The cotton cloth glued with the thin-film stress gauge is put on a test support, a sample is fixed in a position away from the thin-film stress gauge by a certain distance by use of a cotton thread and an enameled wire, a detonator is connected to the sample, the test support is sunk in water, the technical parameters of the data acquisition instrument are set, the test sample is detonated, and the near field output pressure of underwater explosion of the sample is measured. The method can be applied to testing in a small pool; the test process is simple, and the test data can be obtained directly without secondary deduction. The test components are simple and easy to manufacture, and relatively low in cost. The method is capable of measuring the underwater near field blast wave pressure of samples at a hectogram level.

Owner:XIAN MODERN CHEM RES INST

Experimental method for simulating stress corrosion of metal material under working conditions

InactiveCN104931372AImprove stress stabilityHigh accuracy of load and strain valuesWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceExperimental methodsEnvironmental design

The invention discloses an experimental method for simulating the stress corrosion of a metal material under working conditions, belongs to the technical field of metal corrosion simulation, and solves the problem in the prior art that a sample device cannot truly simulate solution scouring in the working environment. The experimental method comprises the following steps: firstly, designing related experimental parameters according to the actual working environment; then respectively connecting a test piece to an upper loading part and a lower loading part through pins, mounting respectively corresponding nuts, adhering a strain gage to the center of the test piece, connecting the stress gage to a strain meter through a wire, loading load onto the test piece through the upper loading part and the lower loading part; finally, after loading a certain stress, taking down the strain gage, suspending a loading mechanism on a circular tray through a high-temperature-resistant cotton thread, placing the loading mechanism in a vessel body, and starting to do an experiment and record related data according to the conventional method. The experimental method can be used for testing related properties of the metal test piece which is corroded at high temperature and high pressure, such as the corrosion rate and the tensile property.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Ice-cold jean fabric

InactiveCN101824691AAesthetically pleasingWith cooling effectBiochemical fibre treatmentWoven fabricsFiberPolymer science

The invention discloses an ice-cold jean fabric, which comprises wraps and wefts, wherein cotton threads are used as the wraps and cellulose reduction treatment is performed on the cotton threads to make cotton fiber threads thin; and polyster fibers are used as the wefts and ice-cold mica ores are added in the polyster fibers, and the superfine ice-cold polyster fibers can be prepared by spinning. Prepared by the processes of weaving, jean cloth finishing and post-treatment, the ice-cold jean fabric is identical with the jean cloth in appearance, but light, soft and breathable. The clothes made of the fabric have elegant appearances and offer an ice-cold effect when worn in summer.

Owner:SUZHOU SHUANGLUN CHEM FIBER

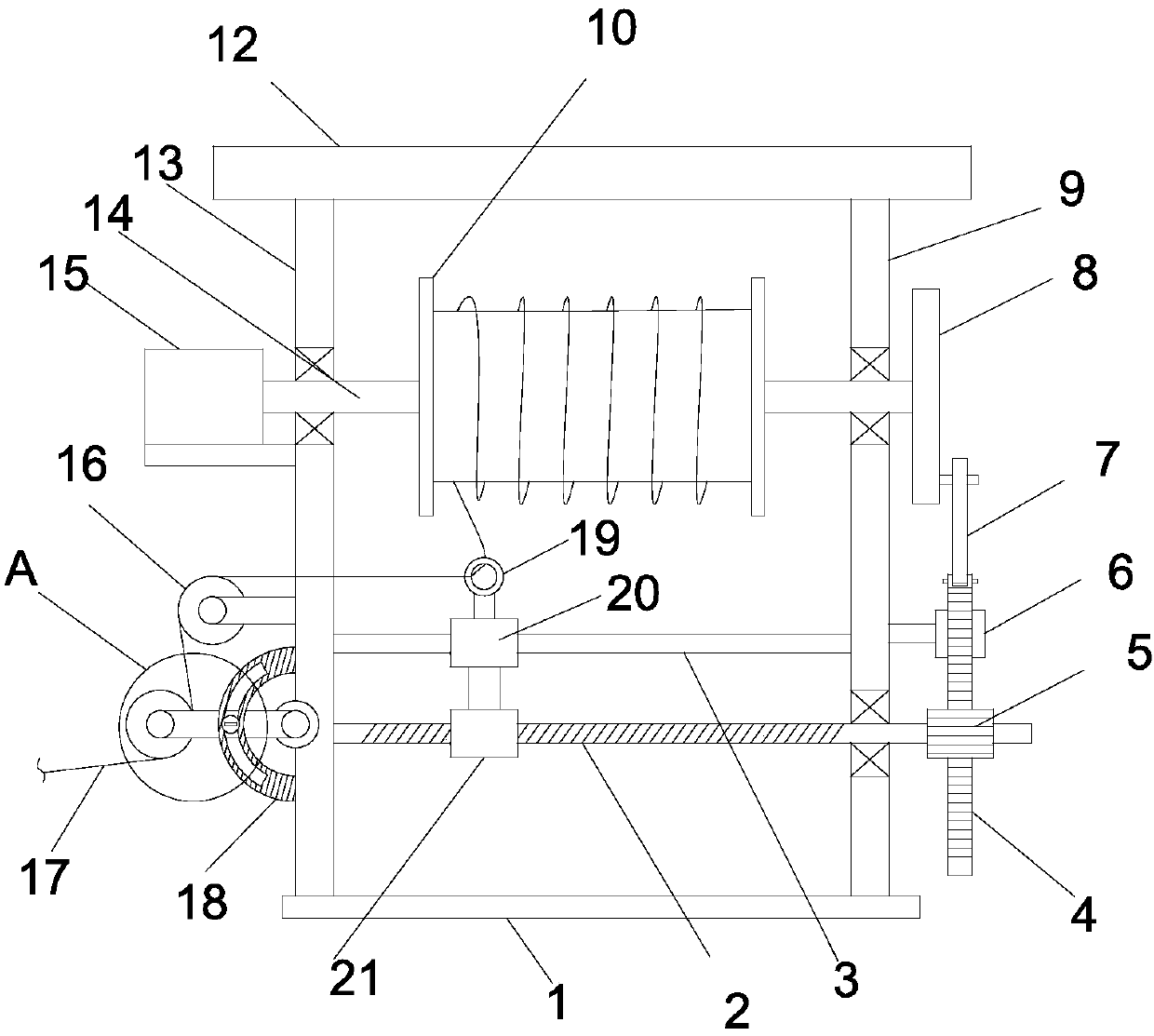

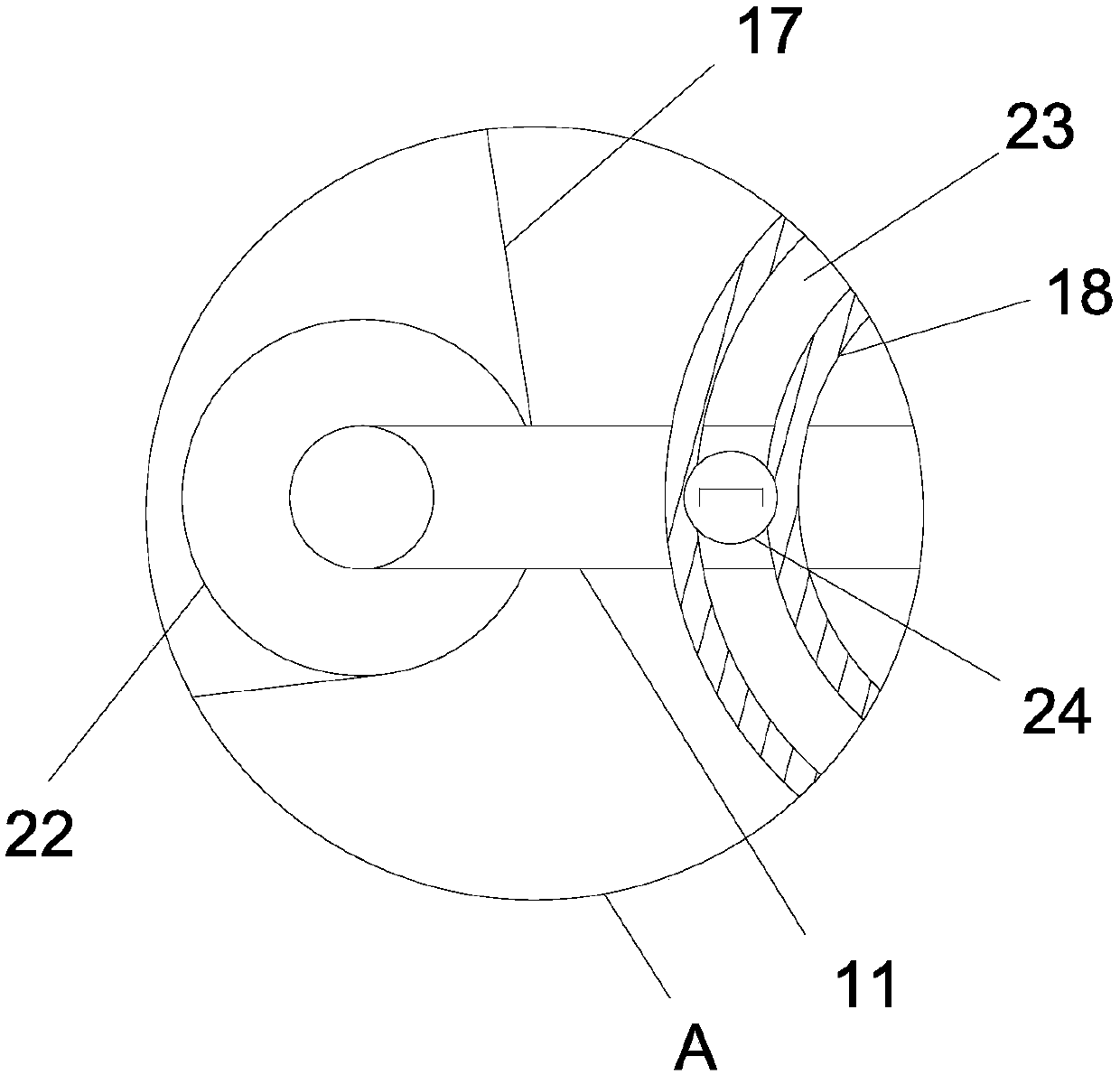

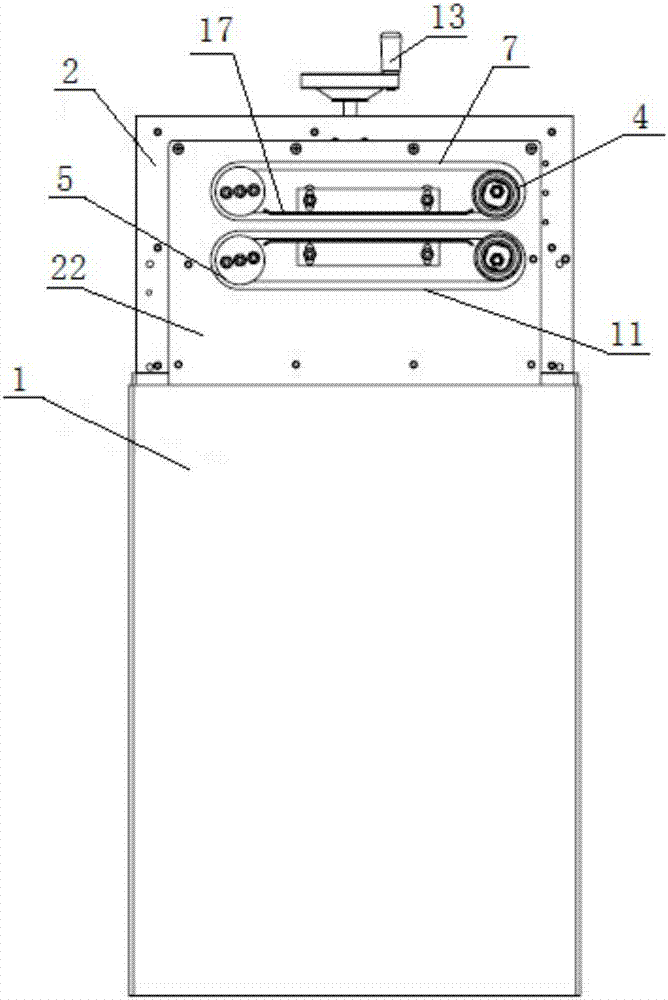

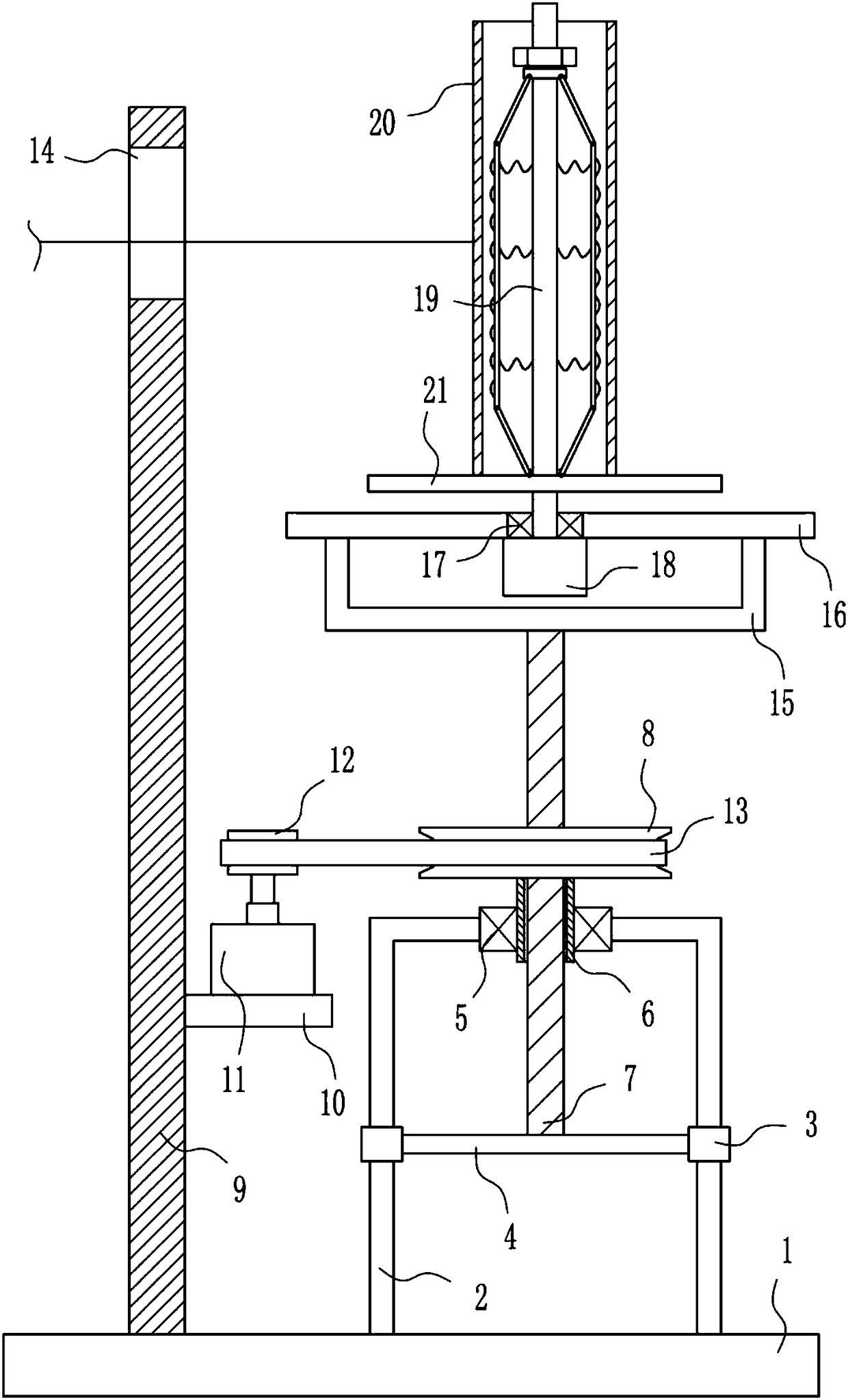

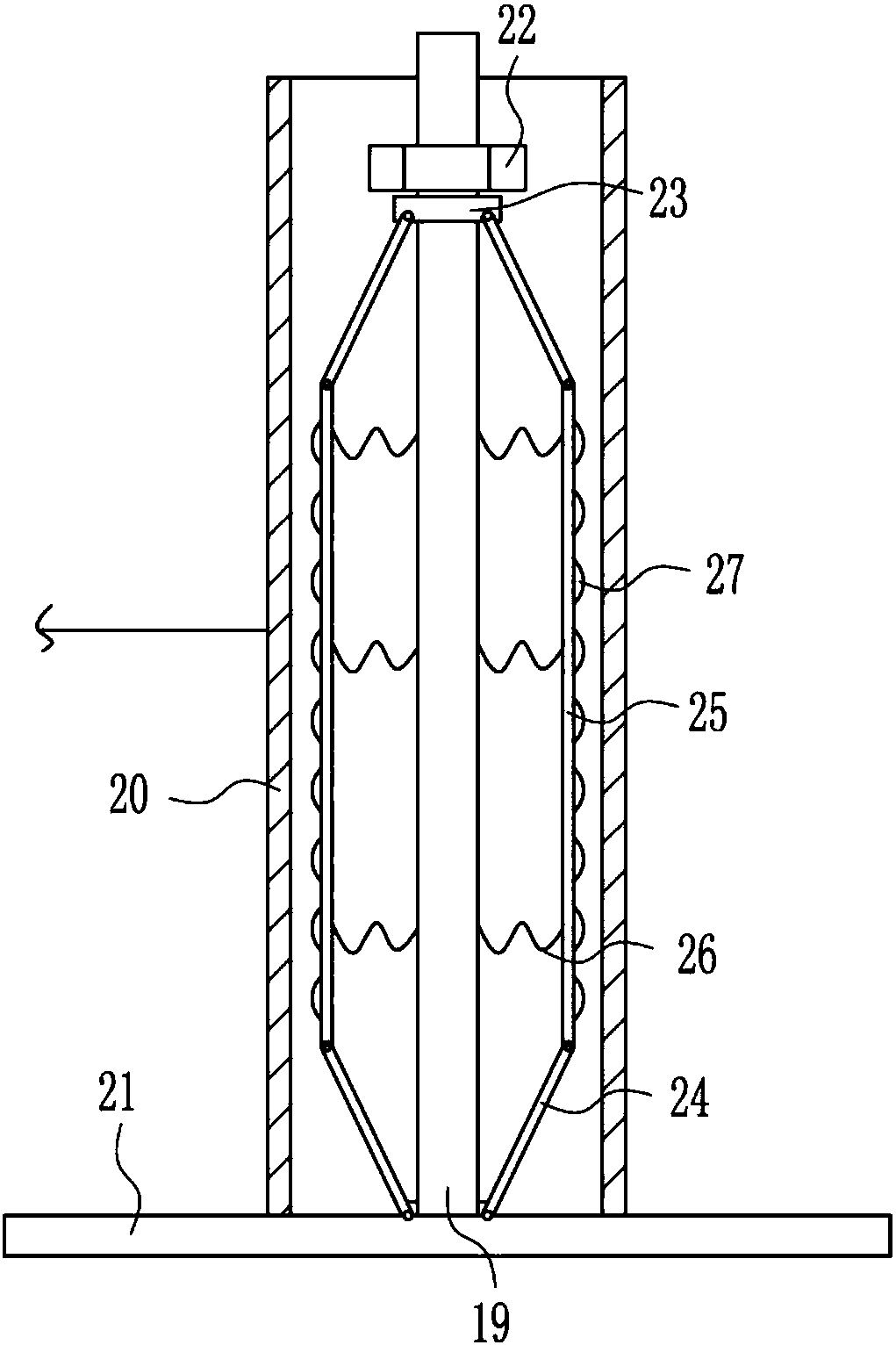

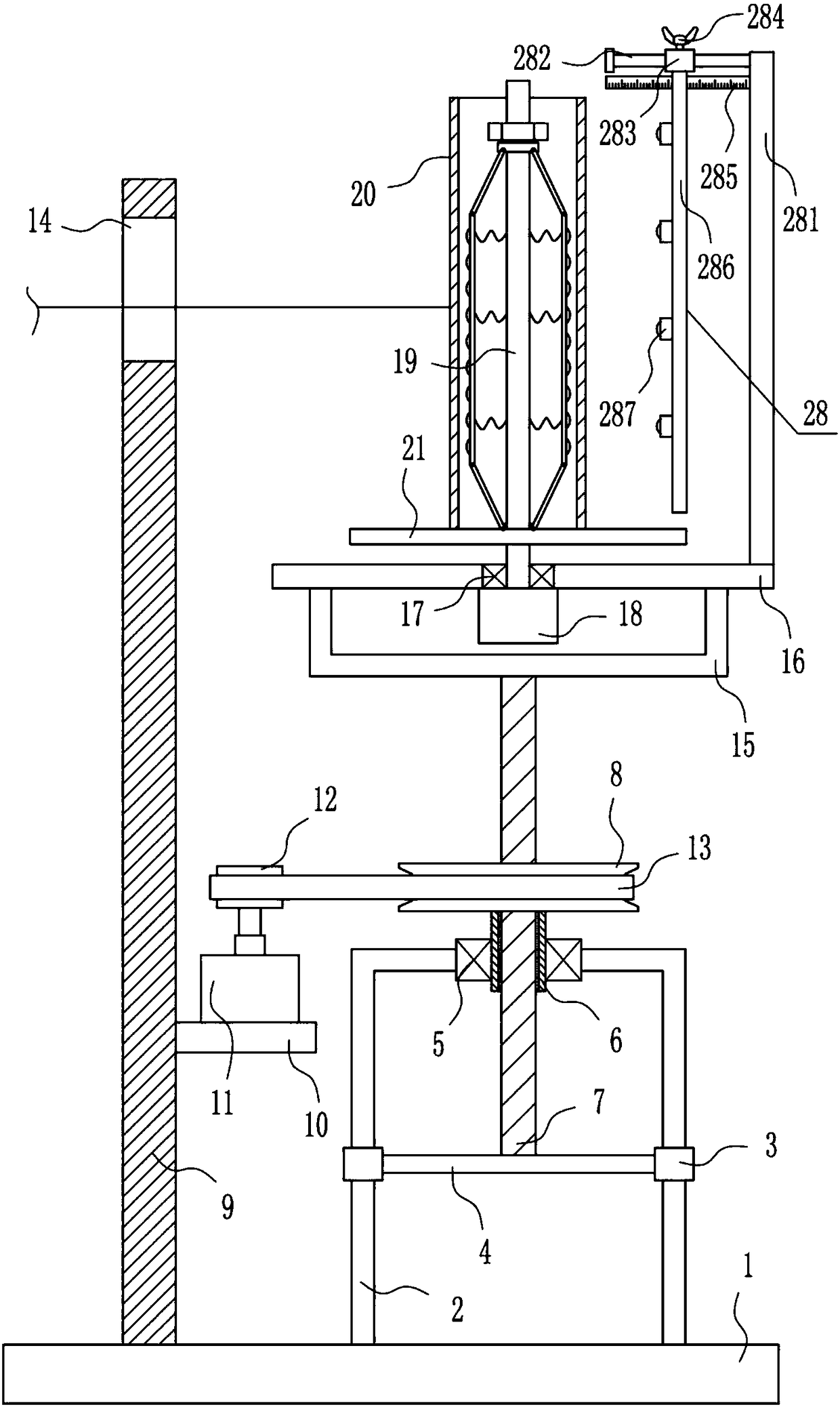

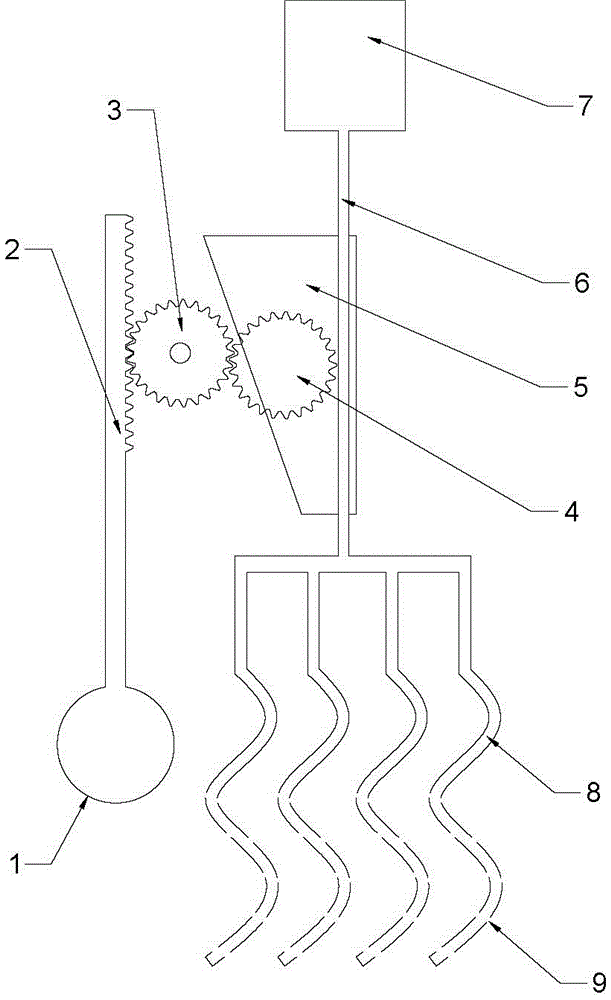

Thread winding device with tensioning adjusting device

The invention discloses a thread winding device with a tensioning adjusting device. The thread winding device with the tensioning adjusting device comprises a bottom plate, wherein a left vertical plate and a right vertical plate are vertically and fixedly installed on the bottom plate, a top plate is horizontally and fixedly installed at the upper ends of the left vertical plate and the right vertical plate, a driving motor is arranged on the left side of the left vertical plate, a straight rack is vertically and slidably arranged in a limiting sleeve, and the right end of a lead screw is fixedly provided with a cylindrical gear which is meshed with the straight rack in a sleeved manner; a supporting rod is rotationally arranged on the left side wall of the left vertical plate, an adjusting pulley is rotationally arranged at the end of the supporting rod, an arc-shaped limiting plate is fixedly installed on the left side wall of the left vertical plate, and a limiting slot is formed in the arc-shaped limiting plate. According to the thread winding device with the tensioning adjusting device, moving of the thread winding device can be achieved through the driving motor, a cotton thread is drawn by a limiting ring to move back and forth in the length direction of a thread winding roller, and therefore the cotton thread can be evenly wound on the surface of the thread winding roller; and the situation that the cotton thread is concentratedly wound on a certain position of the thread winding roller is avoided, uniform winding of the cotton thread is achieved, winding knottingof the cotton thread is avoided, and the winding quality is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

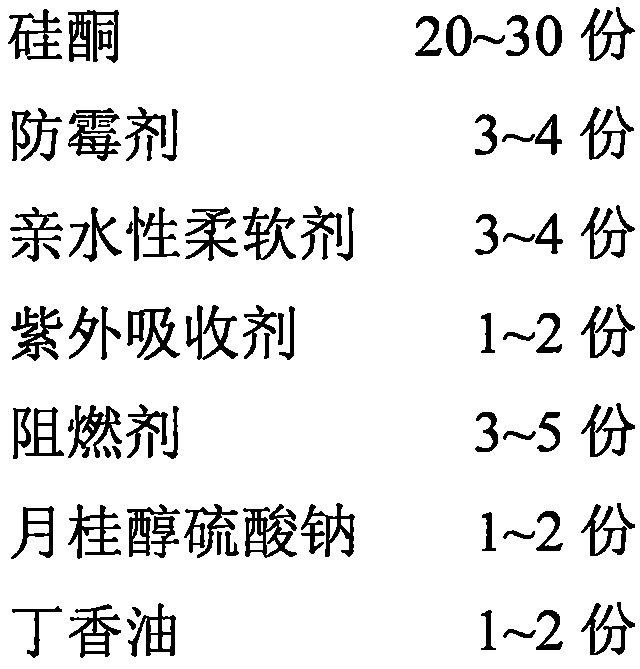

Novel high-performance TPU composite material and preparation method thereof

The invention relates to a novel high-performance TPU composite material and a preparation method thereof. The core part of the TPU composite material is a silk yarn or a cotton thread, and a layer of TPU material is wrapped on the outer surface of the core part. The preparation method comprises the following steps: firstly, extruding the TPU material by using an extruder; and then, wrapping the TPU on the silk yarn or the cotton thread by virtue of a wrapping technology to form another kind of yarn so as to obtain the TPU composite material provided by the invention. The material can be wound to form a coil or can be directly prepared into a textile. By jointly weaving the silk yarn or the cotton thread and the TPU material, the TPU composite material which is good in air permeability and high in mechanical strength is manufactured. The composite material further has the advantages of wear resistance, flame resistance, yellowing resistance, mould proof, bacteria prevention and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

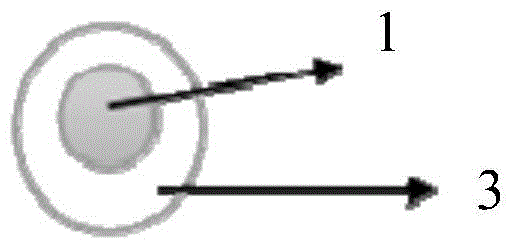

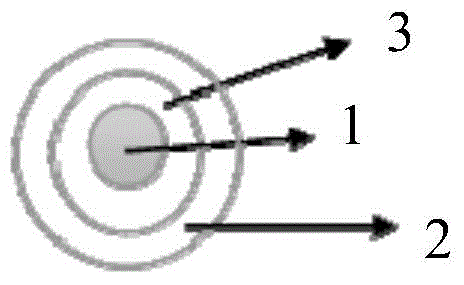

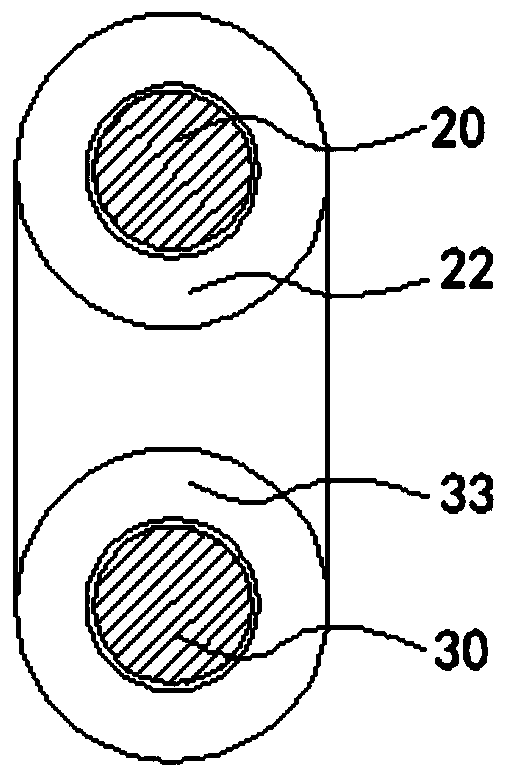

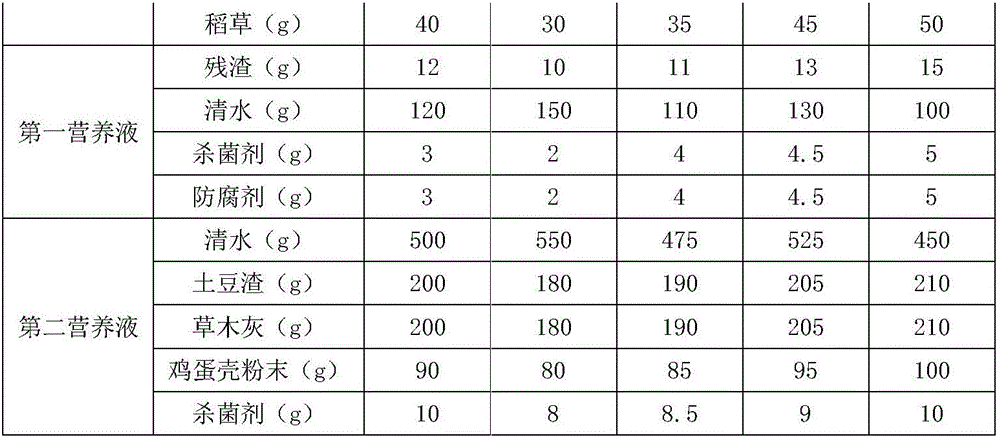

Cotton-thread-based passive micro-fluid fuel cell

ActiveCN107293764AAchieve continuous flowSimplify accessory equipmentElectrolyte stream managementFuel cell detailsChemical industryFuel cells

The invention discloses a cotton-thread-based passive micro-fluid fuel cell, which comprises an anode carbon paper and a cathode carbon paper; the cotton-thread-based passive micro-fluid fuel cell is characterized in that a first cotton thread and a second cotton thread are arranged on the anode carbon paper and the cathode carbon paper; the first cotton thread and the second cotton thread are isolated by a third cotton thread; one end of the first cotton thread is inserted to a first inlet culture dish, anode electrolyte is stored in the first inlet culture dish; one end of the second cotton thread is inserted to an inlet culture dish, and cathode electrolyte is stored in a second inlet culture dish; one end of the third cotton thread inserted to a third inlet culture dish, and isolating liquid is stored in the third inlet culture dish; the other ends of the first cotton thread, the second cotton thread and the third cotton thread are inserted to an outlet culture dish; the faces where the anode carbon paper and the cathode carbon paper are in contact with the cotton threads are coated with an anode catalyst layer and a cathode catalyst layer. By means of the capillary force of the cotton thread and the gravity, the continuous flow of the cathode fluid and the anode fluid is realized. The cotton-thread-based passive micro-fluid fuel cell can be widely applied to energy source, chemical industry, environment-friendly, and other domains.

Owner:CHONGQING UNIV

Multifunctional composite fabric

InactiveCN102452194AAesthetically pleasingImprove insulation effectSynthetic resin layered productsYarnSurface layer

The invention relates to multifunctional composite fabric, which comprises a surface layer, an inner layer and an intermediate layer combined and sewed together. The surface layer is formed by triangular abnormal chinlon yarns and cotton threads interweaved. The intermediate layer is a moisture absorption and sweat releasing fiber layer and the inner layer is a heat insulating layer. The surface layer, the intermediate layer and the bottom layer are superposed and sewed and composited by cotton or silk or artificial fiber according to a regulated trace. The sewed and composited fabric is washed by water or washed by water after being dyed, and then the open area of the sewed and composited fabric is hollowed. The invention has the advantages of environmental protection, heat insulation and moisture absorption and sweat releasing.

Owner:CHANGSHU XINTEDU GARMENTS

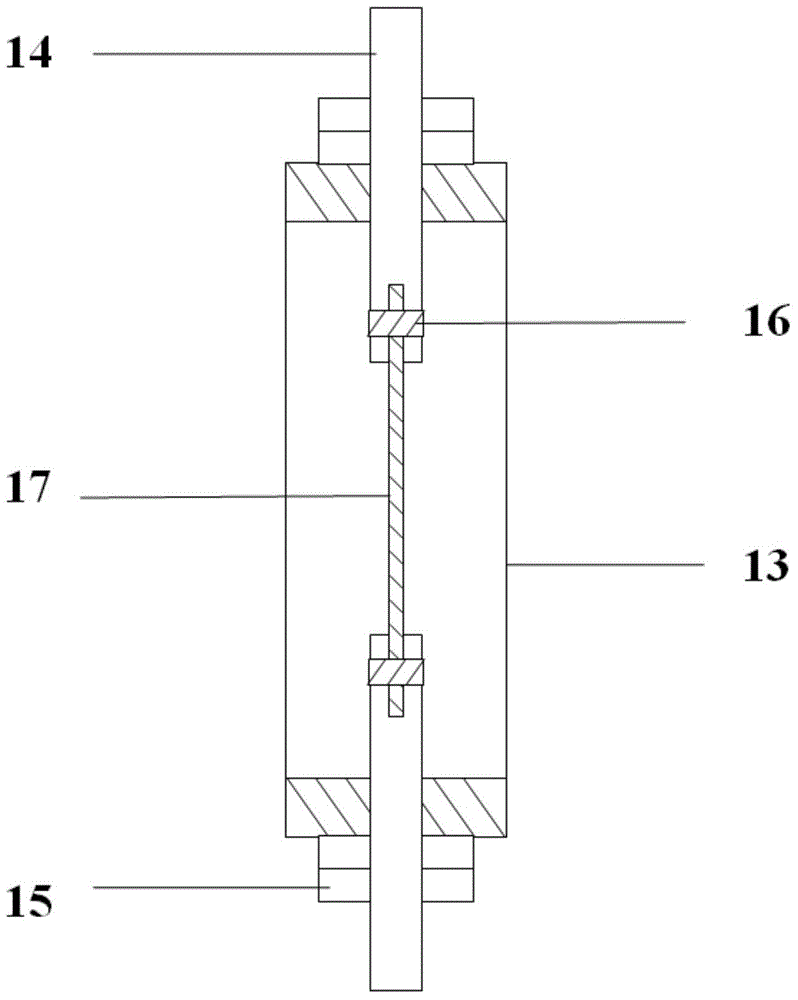

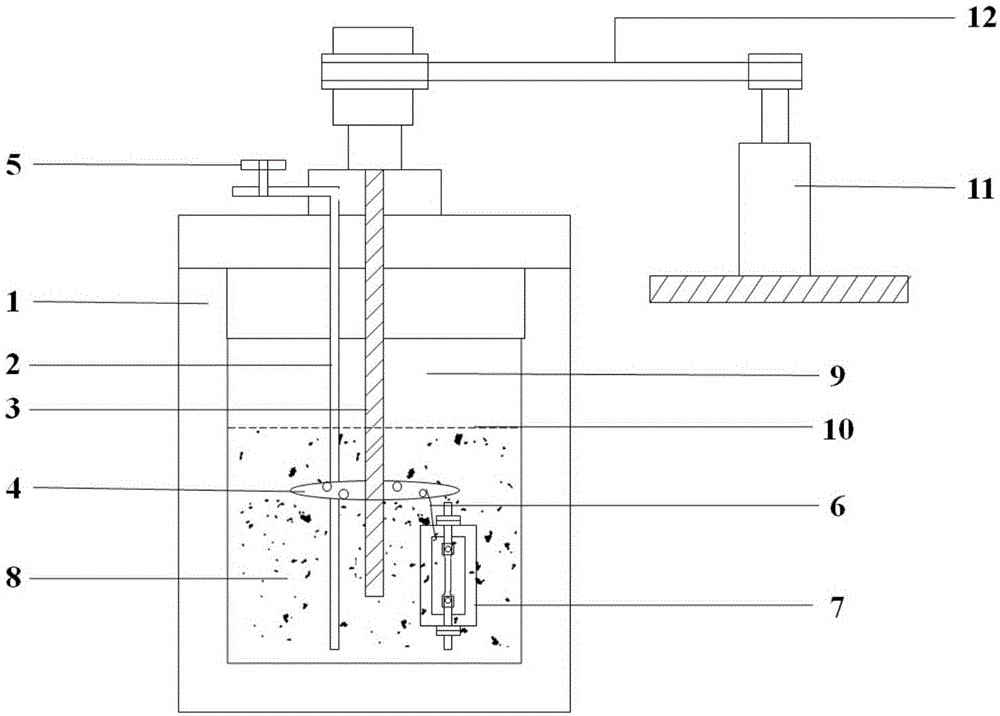

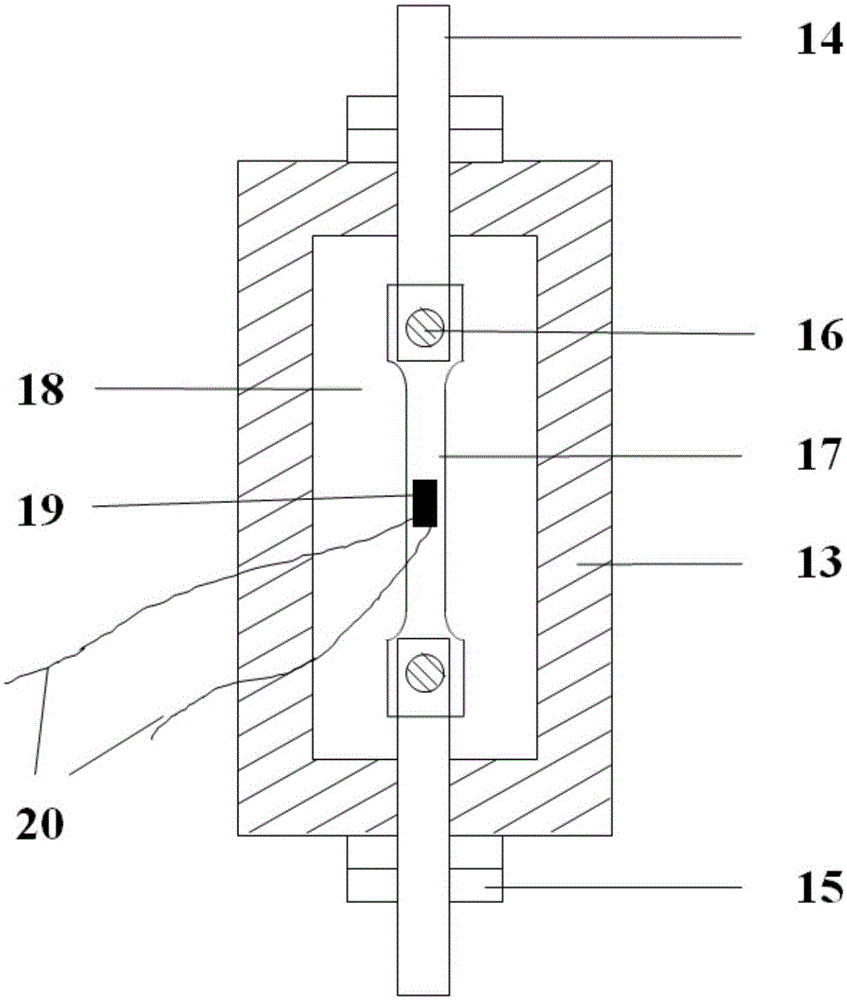

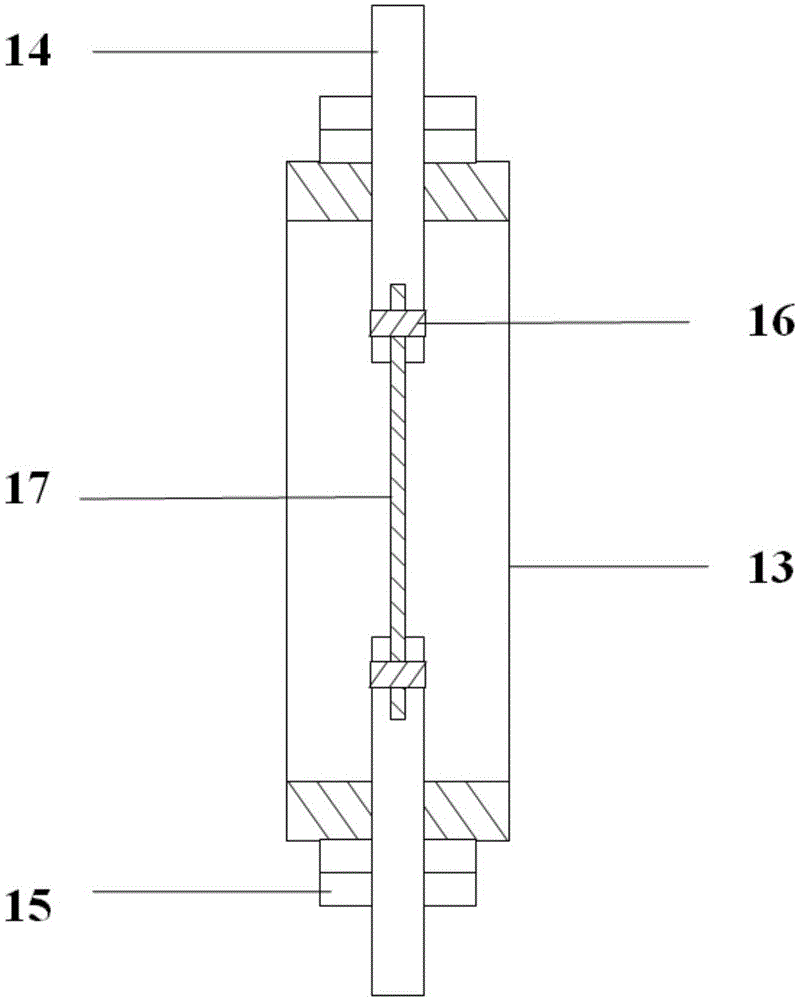

Experimental apparatus for simulating stress corrosion of metal material under actual working conditions

InactiveCN105021455AImprove stress stabilityHigh accuracy of load and strain valuesWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention discloses an experimental apparatus for simulating stress corrosion of a metal material under actual working conditions, belonging to the technical field of simulation of metal corrosion. The apparatus overcomes the problem that a conventional sample apparatus cannot authentically simulate solution scouring in a working condition environment. The experimental apparatus comprises a testing mechanism, loading mechanisms and a rotary mechanism, wherein a circular pallet is arranged on a mixer shaft of the rotary mechanism and is provided with four small holes which are uniformly distributed along the circumferential direction of the circular pallet, a metal test piece of each loading mechanism is located in the cavity of the loading clamp, a foil gauge is attached onto the central part of the metal test piece and is connected with a strain gauge through a lead, loading is realized by applying pressure onto upper and lower loading ends of the loading mechanisms, and all the loading mechanisms are hung onto the small holes through cotton threads. The experimental apparatus provided by the invention can test related performances of the metal test piece after corrosion under high temperature and high pressure conditions, e.g., corrosion rate and tensile properties.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

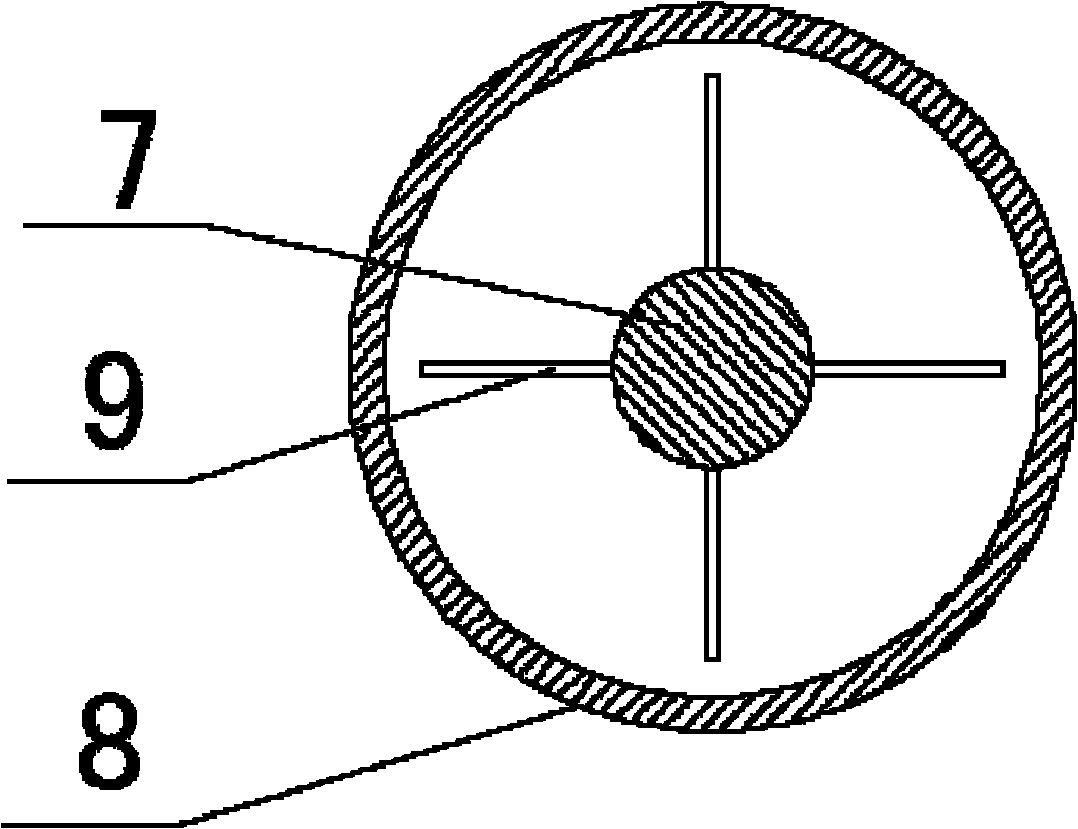

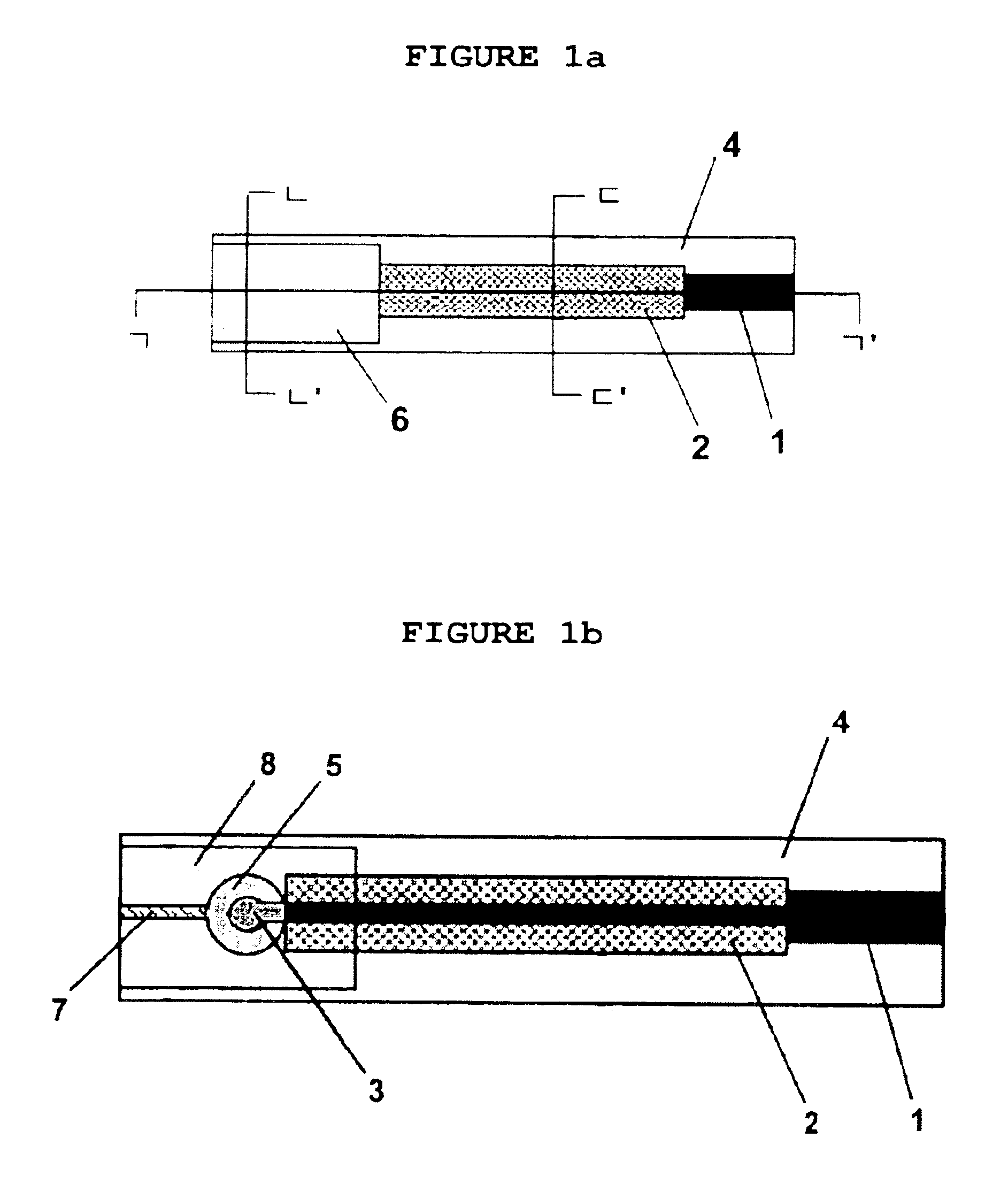

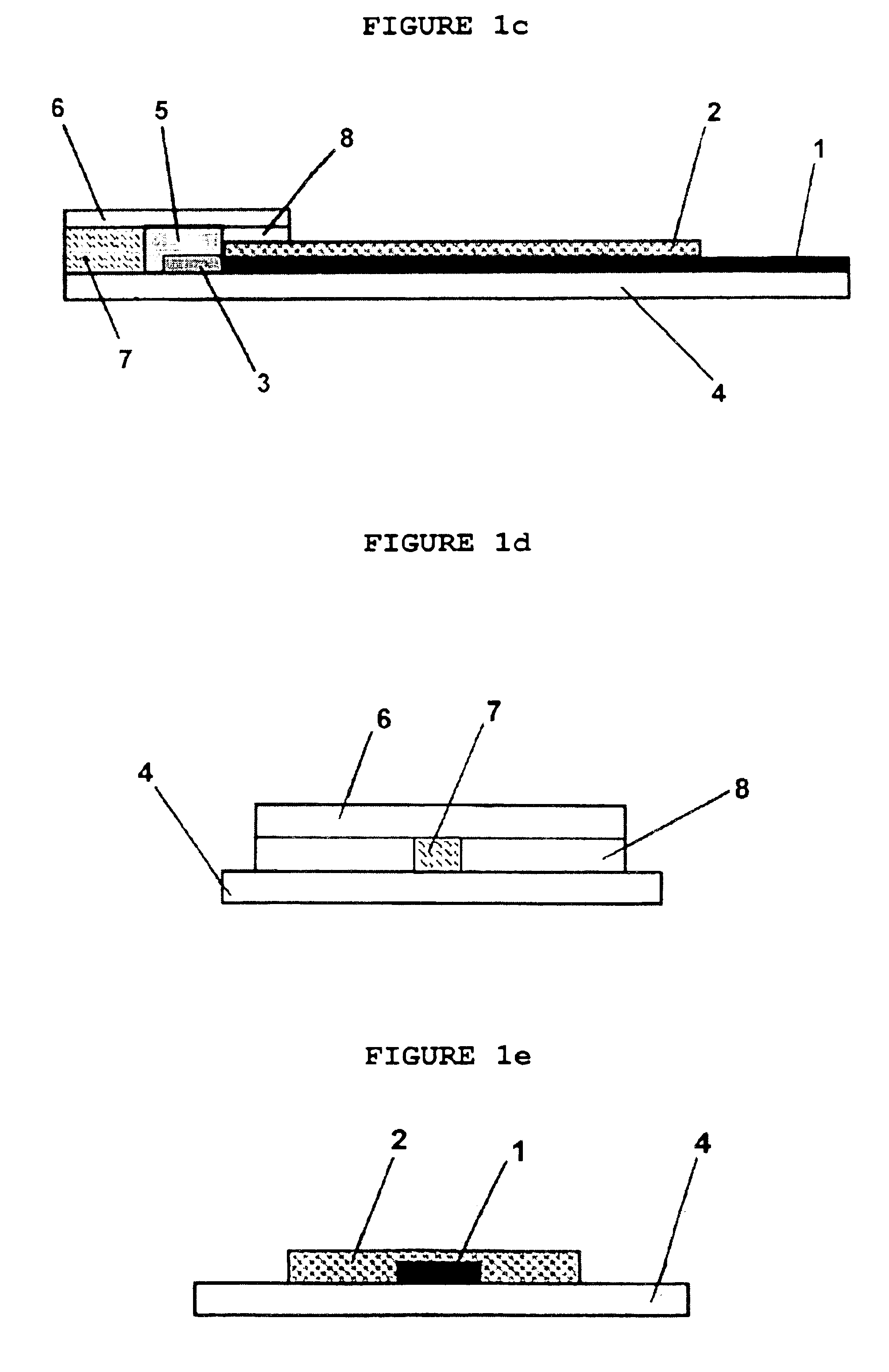

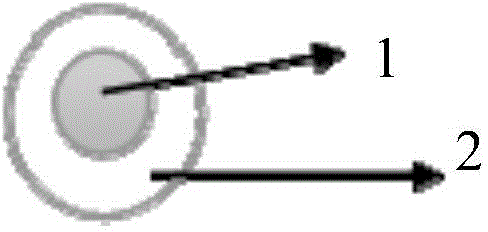

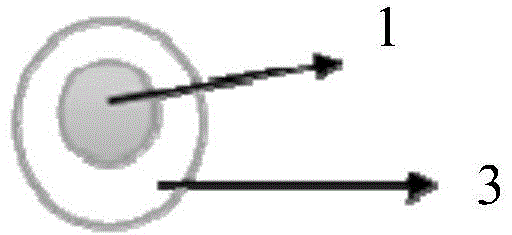

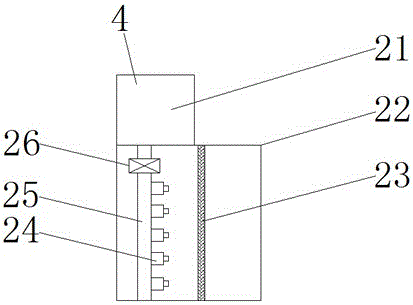

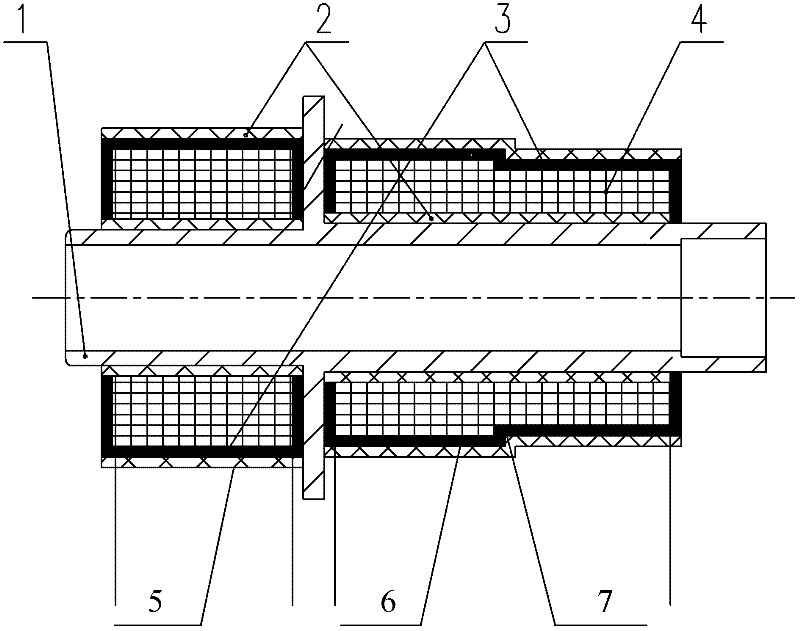

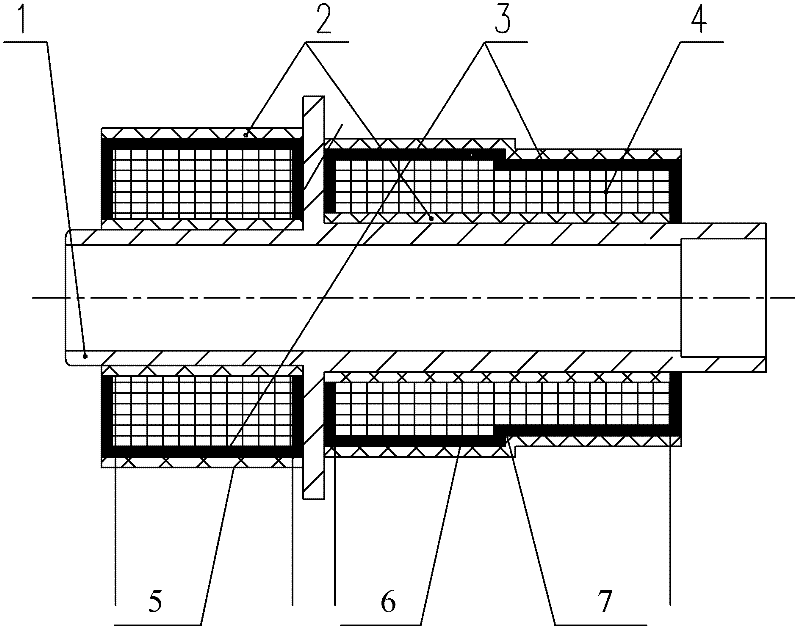

Planar reference electrode

The present invention disclose a method for fabricating planar reference electrodes. Particularly, the present invention relates to the planar reference electrode comprising plate (4); electrode connection (1); electrode (3); insulating membrane (2); inner reference solution (5); junction (7 or 9); and protecting membrane (6, 8 or 9), and processes for fabrication thereof, in which the junction is composed of porous material such as cotton thread, glass fiber, cellulose nitrate, cellulose acetate, filter paper and any material that can produce capillary action; porous polymer membrane; or a capillary either directly printed on the substrate or inserted with a thin film. The planar reference electrode of the present invention exhibit stable electric potential and short activation period, and may be used in both potentiometry and voltammetry. The planar reference electrodes of the present invention can be easily miniaturized and mass produced.

Owner:CHA GEUN SIG

Production process of novel high-performance TPU composite material

The invention relates to a production process of a novel high-performance TPU composite material. The production process comprises the following steps: firstly, extruding a TPU material by using an extruder; and then, wrapping the TPU on a silk yarn or a cotton thread by virtue of a wrapping technology so as to obtain the TPU composite material provided by the invention. The material can be wound to form a coil or can be directly prepared into a textile. By jointly weaving a fiber layer and the TPU material, the TPU composite material which is good in air permeability and high in mechanical strength is manufactured. The composite material further has the advantages of wear resistance, flame resistance, yellowing resistance, mould proof, bacterial prevention and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

Textile towel fabric

ActiveCN107268157AGood drapabilityEffective antibacterial and antifungalLayered productsFibre treatmentYarnPolyester

The invention provides a textile towel fabric. The fabric comprises a three-layer composite fabric layer, its upper layer fabric and lower layer fabric are consistent in fabric structure, both the upper layer fabric and the lower layer fabric comprise warp and weft, the warp is made of cotton fiber and polyester in a blending mode, while the weft is made of Chinese hemp fiber, and abaca fiber and cotton fiber in a blending mode, the average width of the gap between the yarns of the warp is greater than 100 micro meters, and the average width of the gap between the yarns of the weft is greater than 80 micro meters; the middle layer fabric is formed between the upper layer fabric and the lower layer fabric, and the three-layer composite fabric layer is woven into one body through cotton threads, the middle fabric layer is made of fiber-forming polymer and cotton fiber in a blending mode, a net surface is formed on the middle layer, fiber holes are formed in the net surface, and a layer of bamboo fiber or seaweed fiber is formed on the two sides of the middle layer fabric by spunlace. The textile towel fabric has the advantages of being puffy, full and thick in appearance, comfortable in hand feel, good in water absorption, and effective in improving wool effect and further improving hand feel and product quality.

Owner:YUEYANG BAOLI TEXTILE

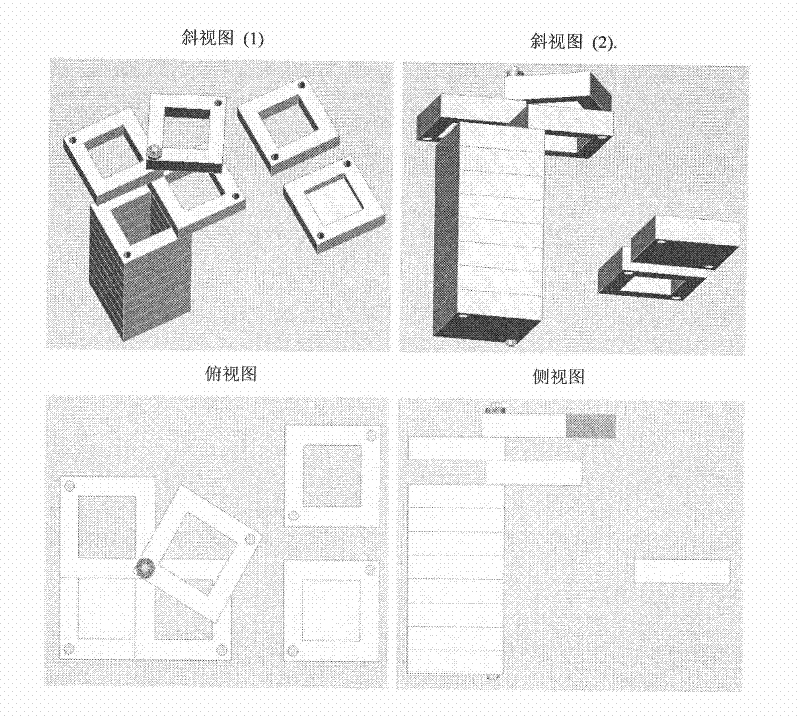

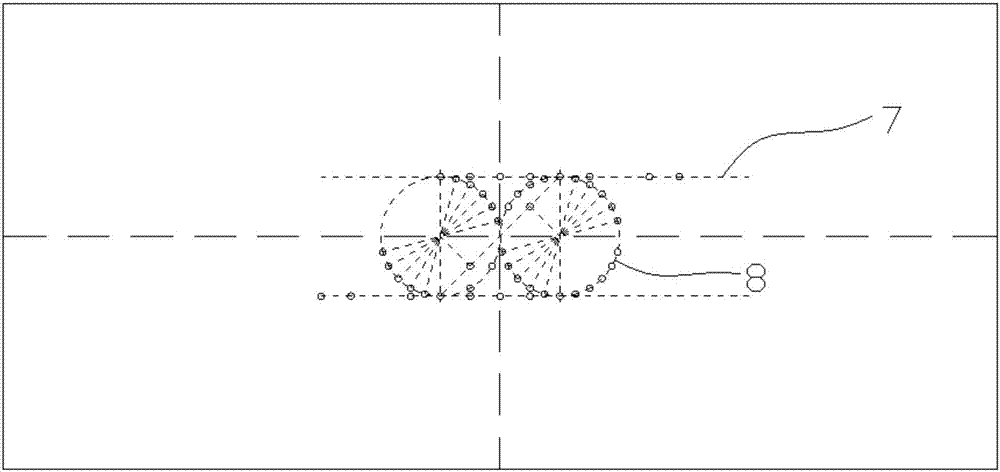

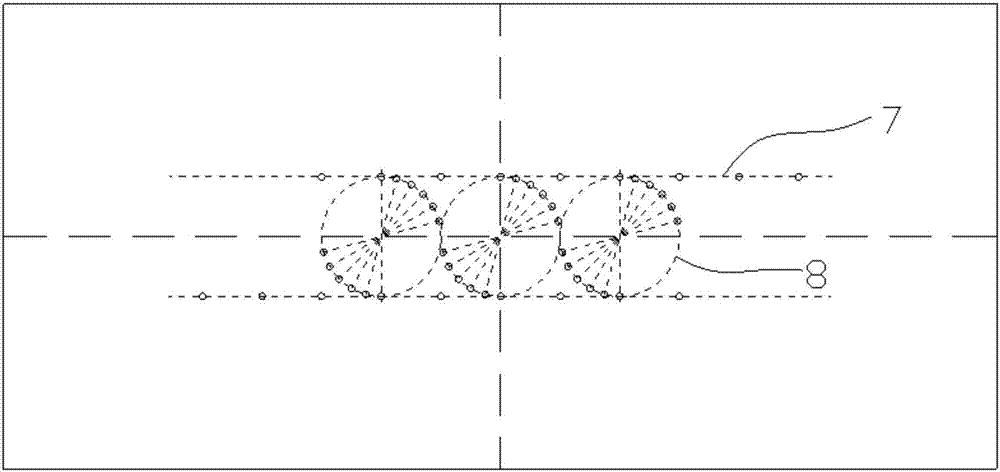

Manufacture device and method of hydrological coupling test three-dimensional fracture rock sample

ActiveCN106989968AAchieve positioningCrack localization achievedPreparing sample for investigationPolyesterGeomorphology

The invention relates to a manufacture device and method of a hydrological coupling test three-dimensional fracture rock sample; the manufacture method comprises a three-dimensional fracture precision positioning sample mold and a high-pressure injection fracture preforming device; the three-dimensional fracture precision positioning sample mold comprises side plate I, side plate II, a bottom plate and positioning porous plates and can provide precision positioning for multiple three-dimensional fractures and forming of a sample. The high-pressure injection fracture preforming device comprises polyester film boxes, cotton threads, rubber water pipes, mandrels and manual screws, and can preform high-pressure injection three-dimensional fractures and form an injection passage. By combining annularly distributed holes and transversely distributed holes, the positioning porous plates are used to allow precision positioning for the angle, spacing and spatial positions of the multiple three-dimensional fractures; the small-diameter rubber water pipes and mandrels to preform hydraulic passages in the sample and communicate the open fractures, high-pressure injection of water is achieved for the open fractures. The manufacture device and method are simple in structure, convenient to operate and good positioning precision and are widely applicable to the hydraulic coupling test for three-dimensional fracture rock materials.

Owner:SHANDONG UNIV

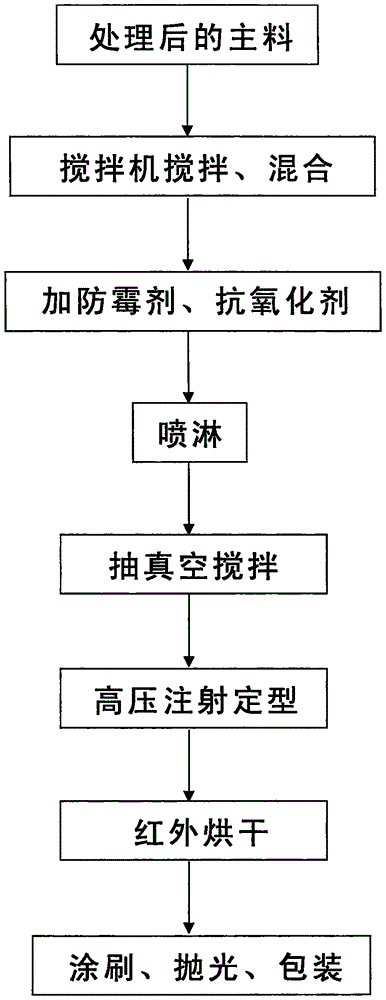

Process of preparing degradable tableware and containers by using straws and shell fibers

The invention relates to a process of preparing degradable tableware and containers by using straws and shell fibers. The process comprises a pre-treatment process and a preparation process. The pre-treatment process comprises the following steps: dehydrating crushed and screened main materials; using hemp threads or pure cotton threads as reinforced fibers and cutting and processing the threads or pure cotton threads into pieces; mixing and stirring bone glue, carrageenan and water; and then adding sticky rice glue to continuously stir the mixture. The preparation process comprises the following steps: stirring the treated main materials and reinforced fibers, adding a mildew preventive and an antioxidant and spray-adding a glue mixed solution under the stirring condition, vacuumizing and stirring; then performing high-pressure injection moulding; feeding a bottom plate into infrared drying and ironing and shaping steps; performing smearing, infiltrating or spraying treatment by using wood wax oil or vegetal paint; performing polishing and inspecting treatment; and then finally performing packaging and putting in storage.

Owner:CHONGQING JINHAOMEI MELAMINE PROD CO LTD

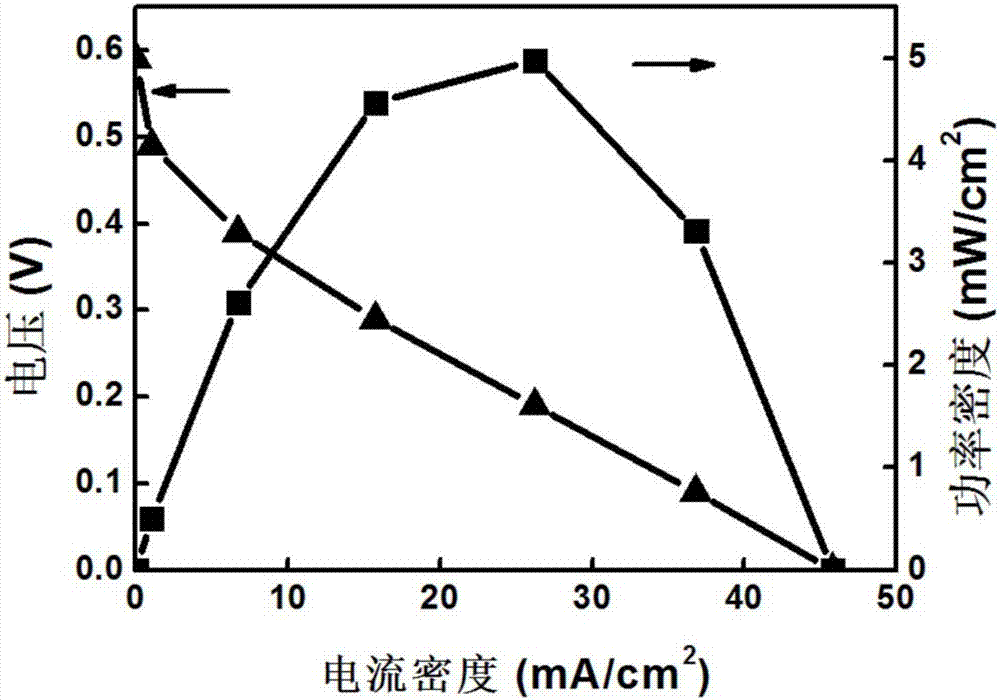

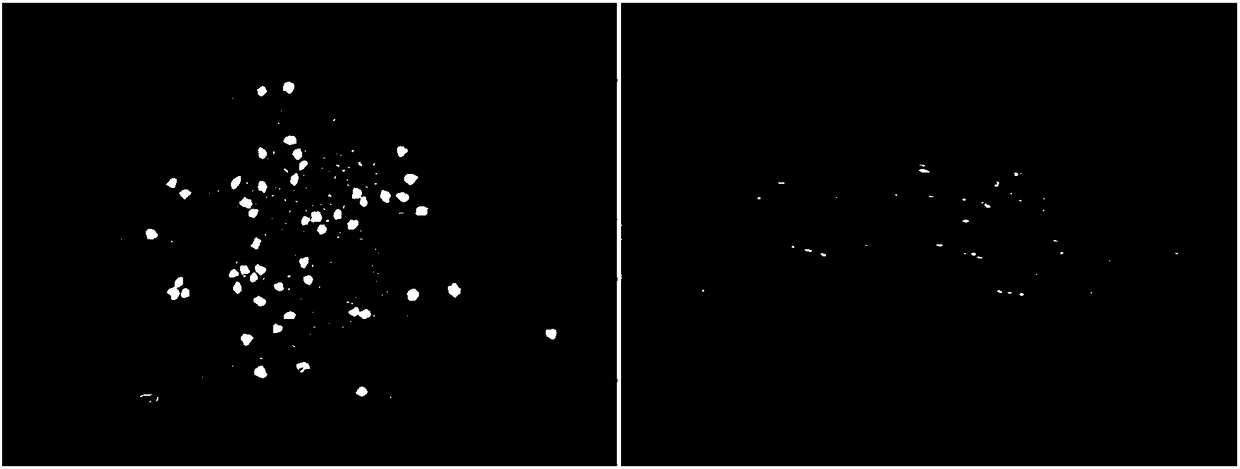

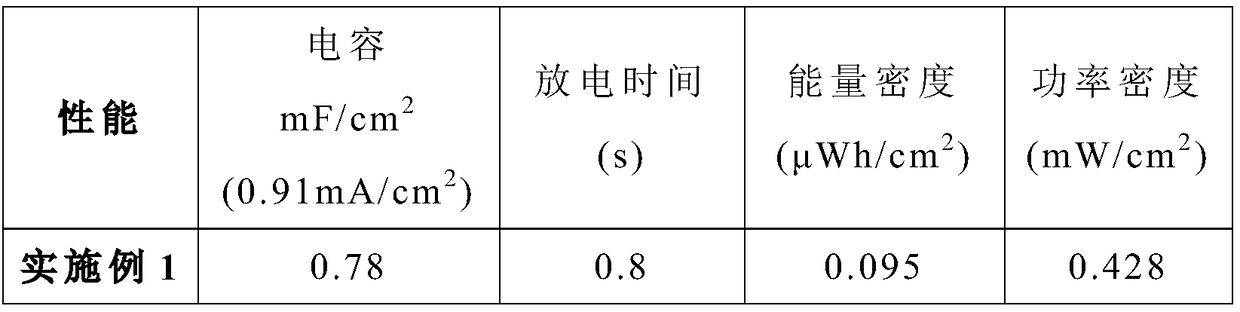

Preparation method of flexible supercapacitor based on metal wires/cotton threads/polymer composite yarns

ActiveCN108109855ALow costImprove controllabilityHybrid capacitor electrodesHybrid/EDL manufactureYarnPolypyrrole

The invention belongs to the technical field of preparation of capacitors, and specifically discloses a preparation method of a flexible supercapacitor based on metal wires / cotton threads / polymer composite yarns. The surface of the supercapacitor includes the metal wires, the cotton threads and conductive polymers. The preparation process includes: performing blending on the metal wires and the cotton threads to obtain metal wire / cotton thread composite yarns, and then dipping the composite yarns into a PEDOT:PSS solution; by respectively regarding the dipped composite yarns, Ag / AgCl and platinum sheets as work electrodes, reference electrodes and counter electrodes, performing electrochemical deposition in a pyrrole solution to enable the surface thereof to form polypyrrole, and obtainingyarn-shaped combined electrodes through washing and drying; and winding the two yarn-shaped combined electrodes to assemble a linear supercapacitor. According to the preparation method, the operationis simple, the capacitor has high flexibility and knittability, multiple supercapacitors can be connected in series and in parallel to respectively improve the voltage and the current, the process issimple, and the industrial production is easy.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

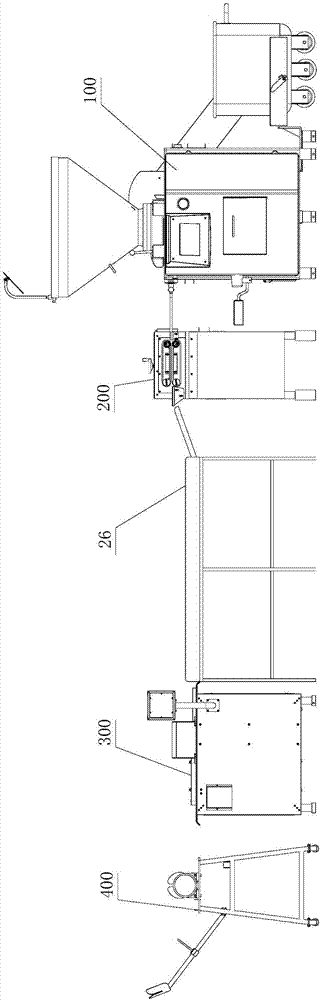

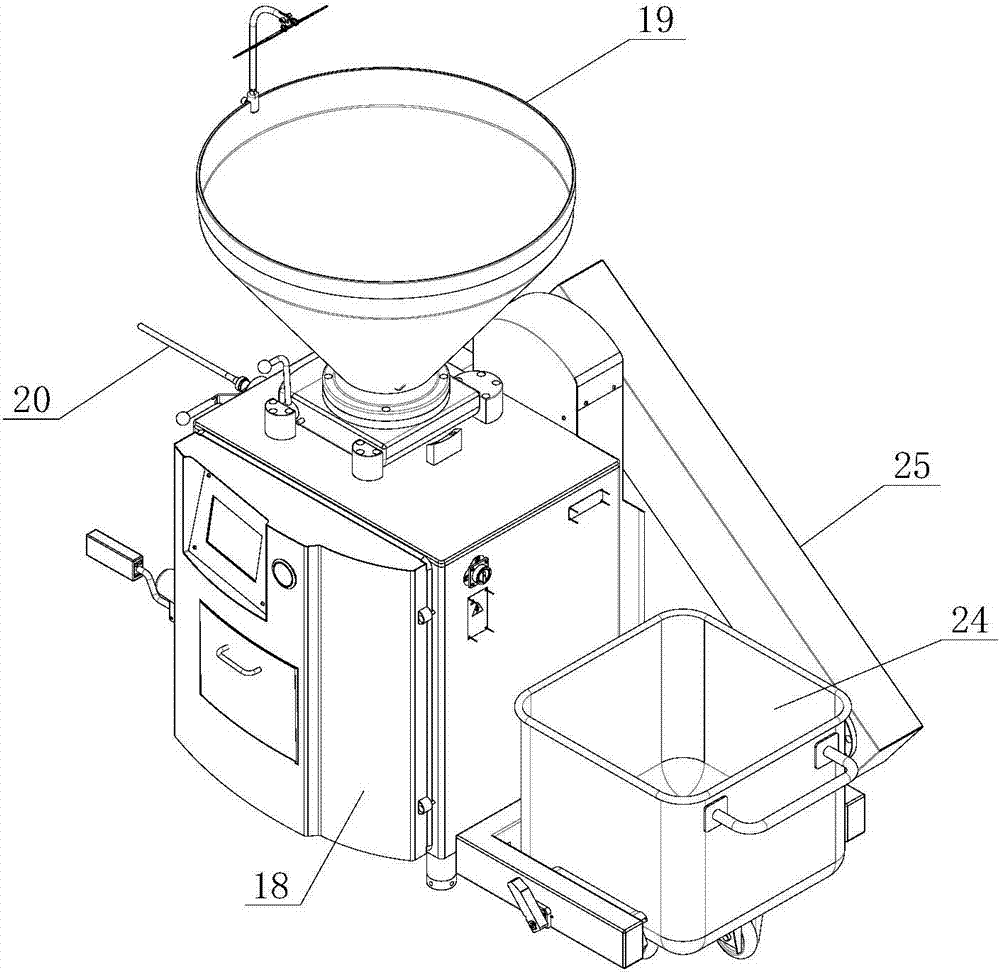

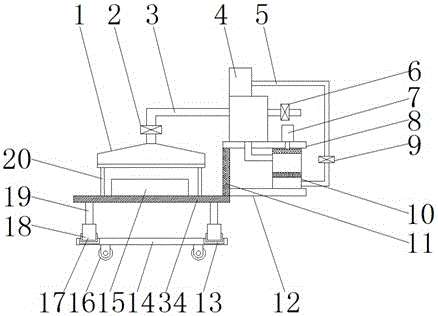

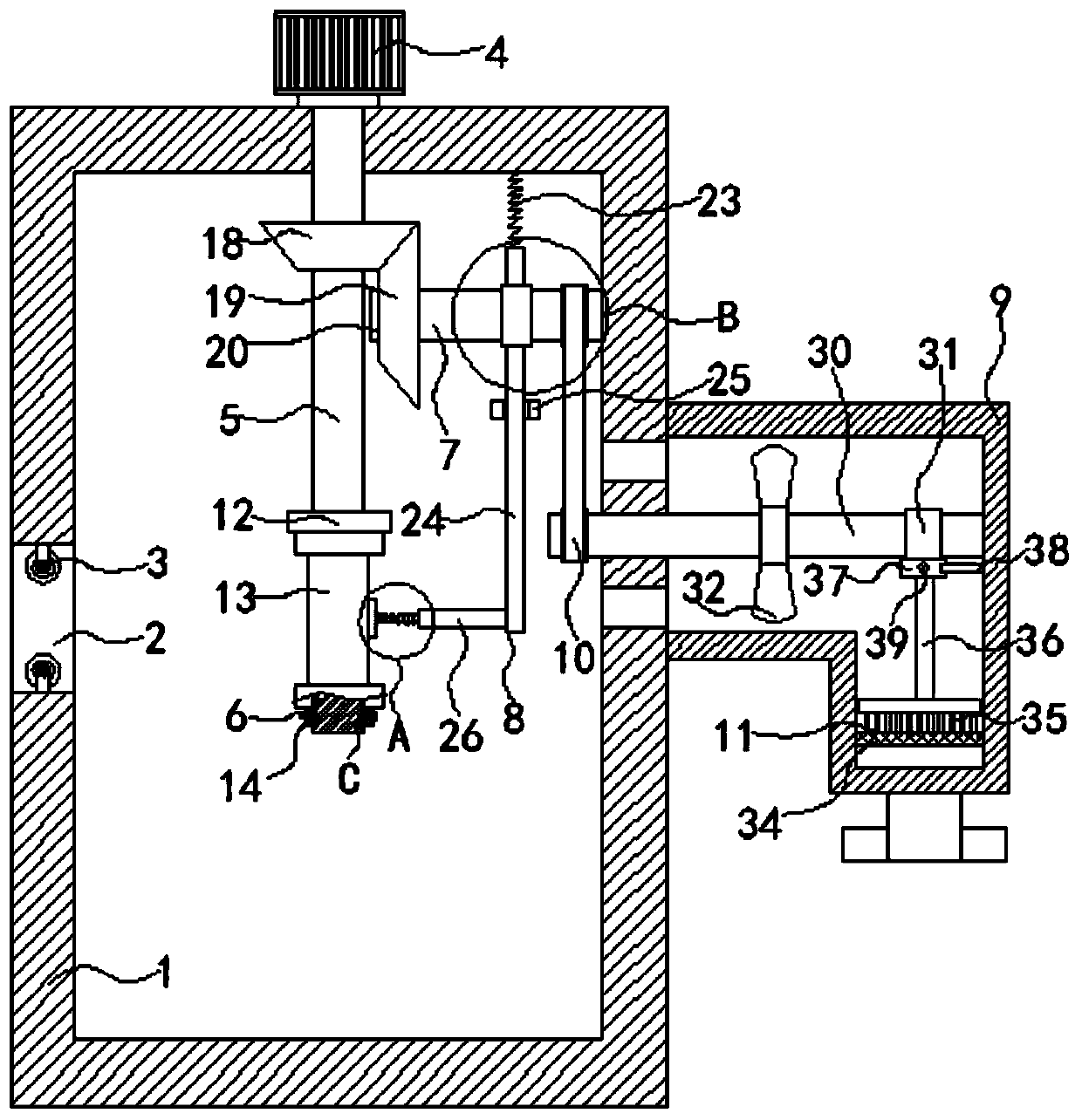

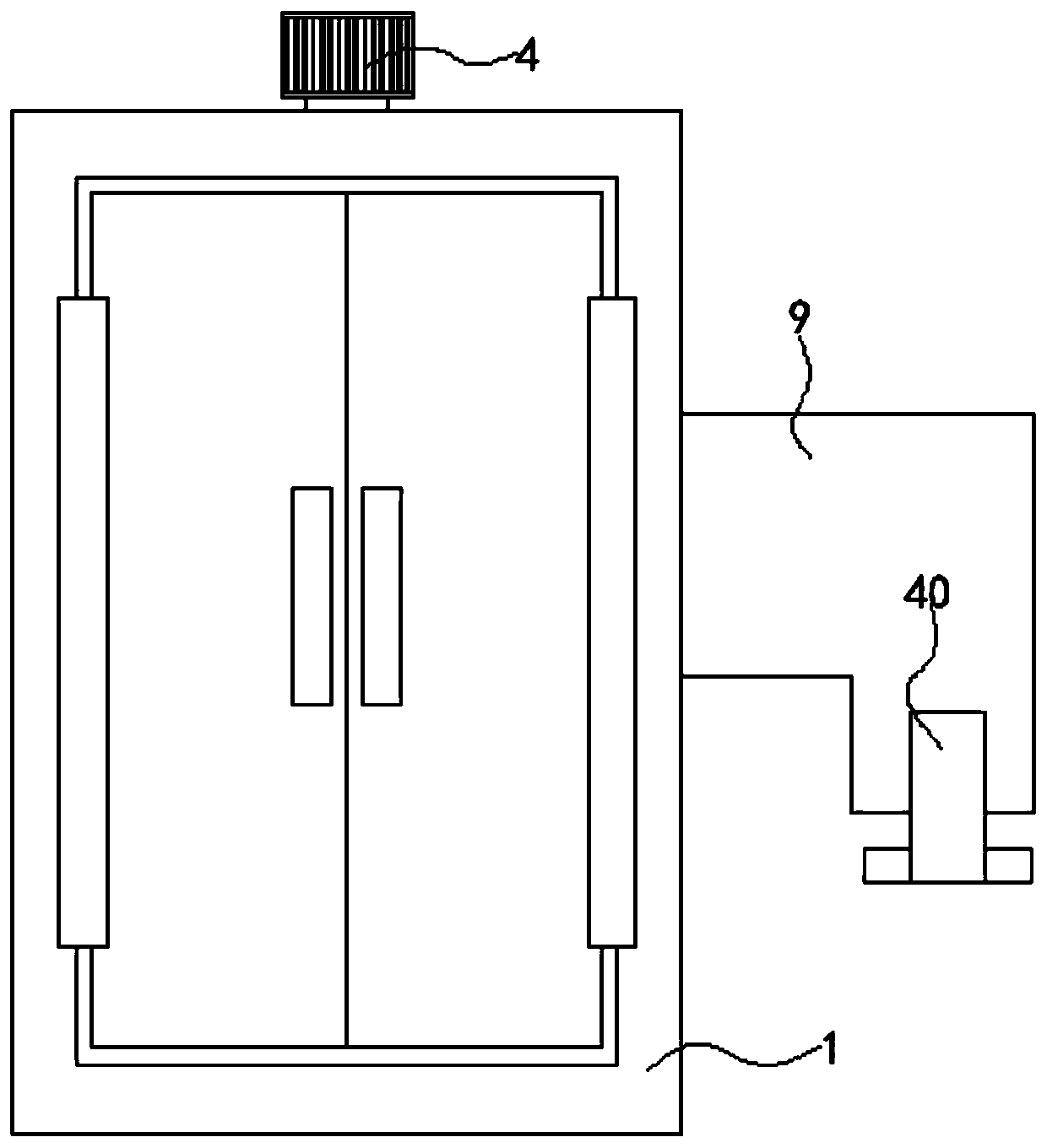

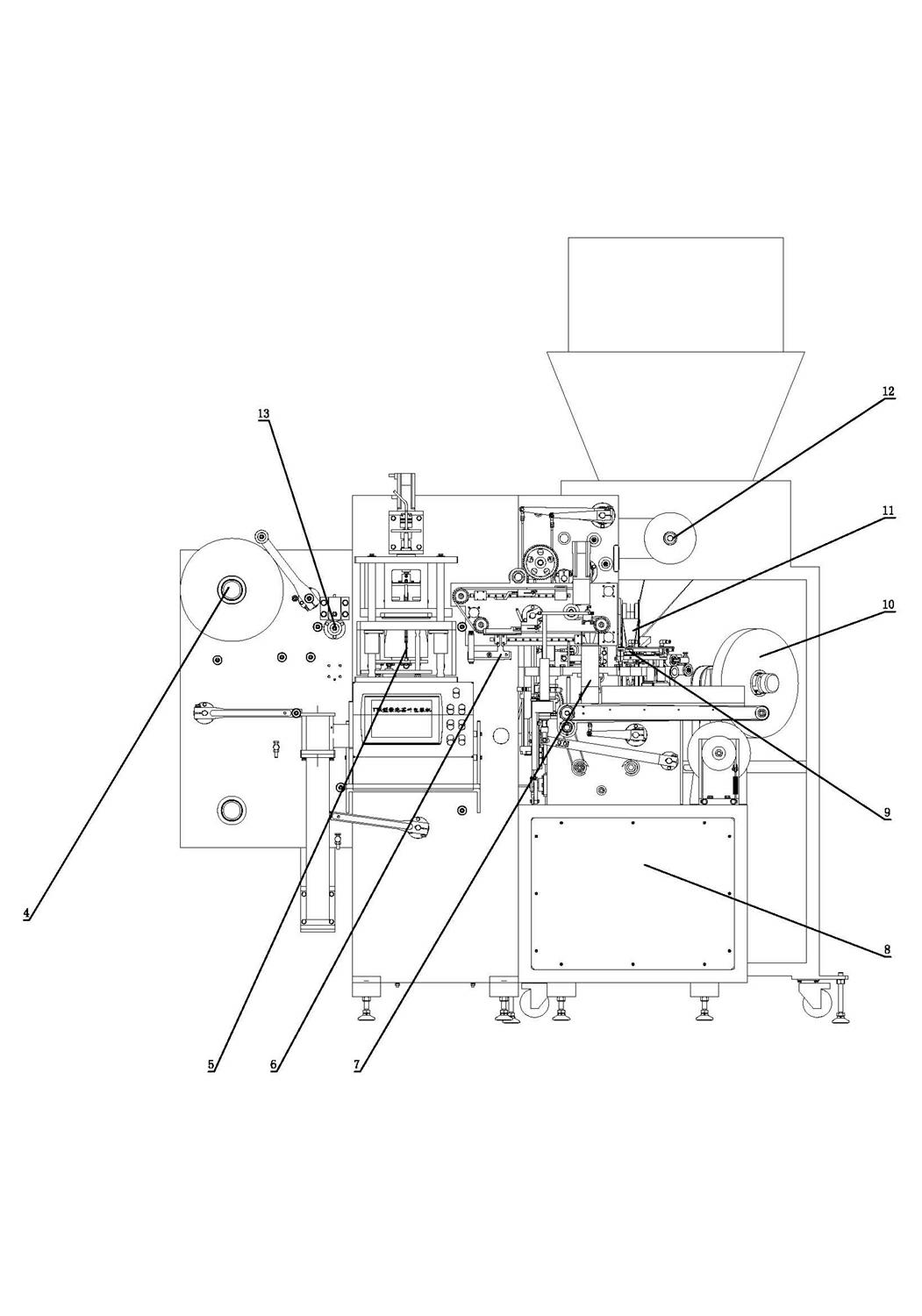

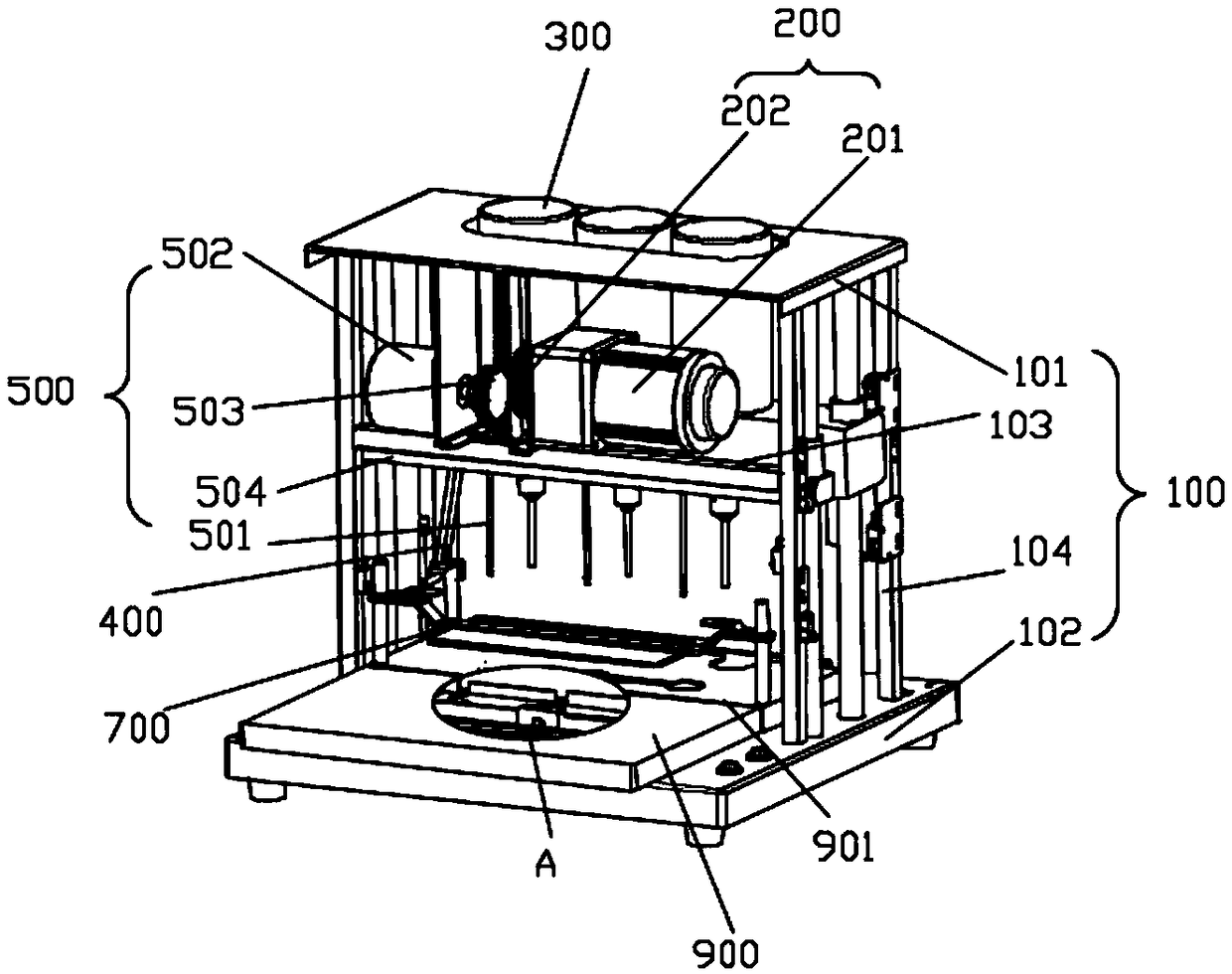

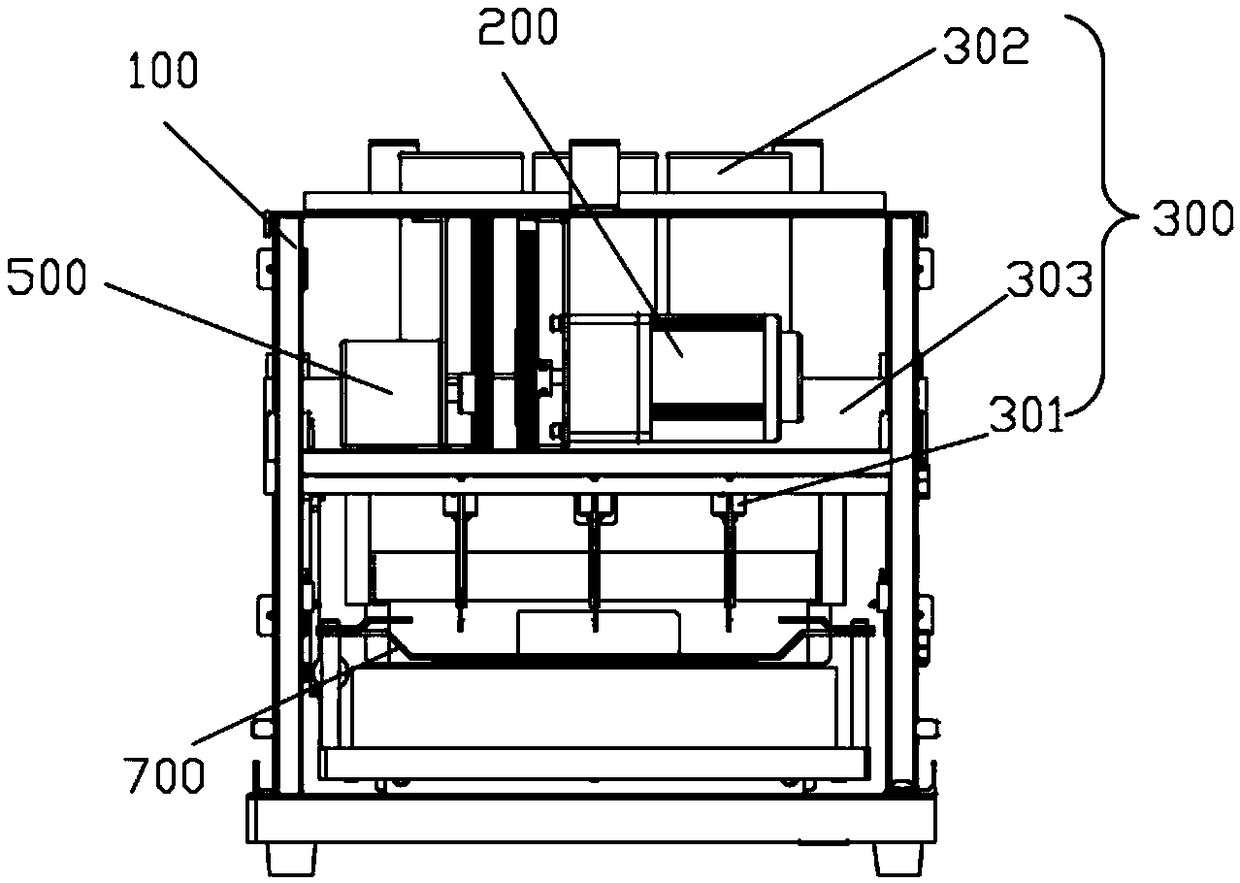

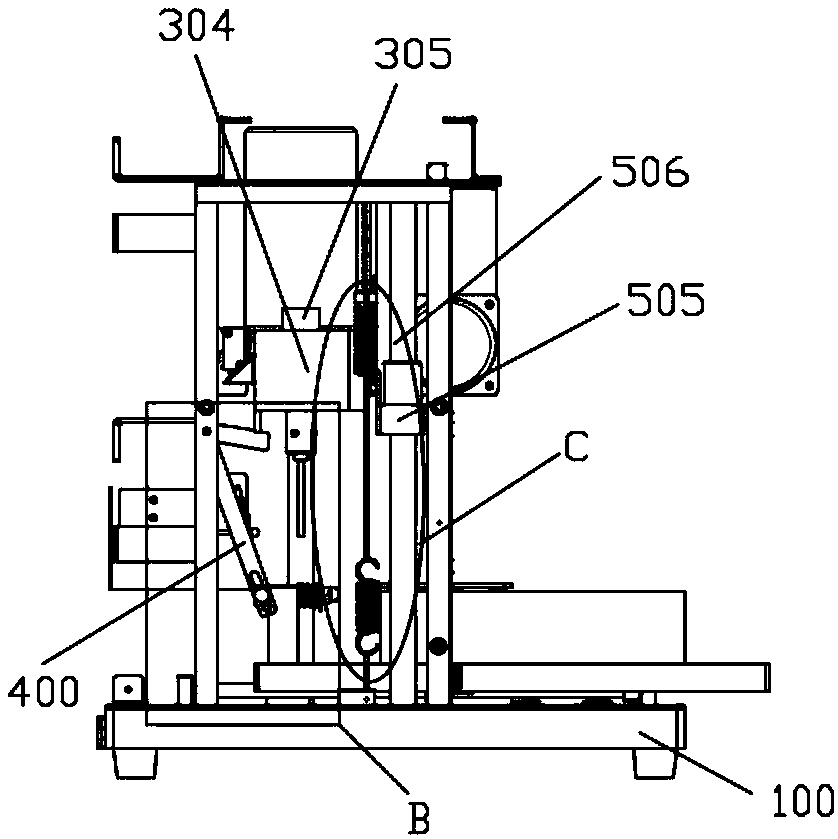

Production line for producing sausage product

ActiveCN107041413AReduce manufacturing costSmall footprintSausage skin tying apparatusSausage filling/stuffing machinesProduction lineEngineering

The invention relates to the field of sausage product processing, and discloses a production line for producing a sausage product. The production line comprises a filling device, a drawing device, a working table, a thread binding device and a thread removing device, wherein the filling device is used for automatically filling a casing; the drawing device is used for guiding and transmitting forwards the casing filled with sauce; the working table is used for temporarily storing a sausage product to be subjected to thread binding; the thread binding device is used for carrying out length determination, segmentation and thread binding on the sausage product; the thread removing device is used for removing cotton threads on segments of the fumigated or cooked sausage product subjected to thread binding; the thread binding device comprises a segment clamping mechanism for carrying out pre-constriction on the sausage product, a thread binding mechanism for winding and binding the sausage product at constricted positions by adopting the cotton threads so as to segment the sausage product, and a fixed-length drawing mechanism for drawing an initial position of the sausage product at a set drawing distance so as to enable the sausage product to be segmented at a fixed length. The integral production line for producing the sausage product, which is disclosed by the invention, is small occupied space, simple operation, convenience in maintenance, low production cost, high production efficiency, uniformness of the filled sausage product and high quality.

Owner:佛山市奥楷机械科技有限公司

Textile equipment with dedusting and humidifying functions

InactiveCN107520216AMeet needsImprove suction performanceCombination devicesLighting and heating apparatusYarnWater storage tank

The invention discloses textile equipment with dedusting and humidifying functions. The textile equipment comprises hydraulic telescopic rods, a water-permeable thin film, a second exhaust fan, a first booster pump and a mounting plate. The hydraulic telescopic rods are arranged to be used for adjusting the height of a base so that the height of a textile machine body can be adjusted, and hence the requirements of operators of different heights are met. The water-permeable thin film is arranged to be used for adsorbing cotton thread scraps and dust entering a dedusting and humidifying box and meanwhile humidifying the air. The humidified air in the dedusting and humidifying box can be exhausted out of an air outlet pipe through the second exhaust fan so that the air in a workshop can be humidified, and the phenomenon that the air in the workshop is excessively dried and thus yarns can be broken easily in the spinning process is avoided. Filtered sewage in a filtering tank can enter a water storage tank through a first water guide pipe with the first booster pump, and therefore water resources can be recycled. The environmental protection property of the equipment is improved, dedusting and humidifying cost of the workshop is reduced, and equipment practicability is improved.

Owner:HUZHOU DONGKAI TEXTILE CO LTD

Spinning cotton thread winding device

The invention relates to a winding device, in particular to a spinning cotton thread winding device, and aims at achieving the technical purpose of providing the spinning cotton thread winding devicewhich is capable of saving time and labor and uniform in winding and does not influence later usage of a cotton thread. The spinning cotton thread winding device is provided and comprises a bottom plate, an n-shaped frame, guide sleeves, a connecting plate, a first bearing block, an inner thread sleeve, a screw, a first belt wheel, a vertical plate, a fixing plate, a first motor and the like. Then-shaped frame is arranged on the right side of the top of the bottom plate, the guide sleeves are arranged on the left side and the right side of the n-shaped frame, the connecting plate is arrangedbetween the inner side faces of the guide sleeves on the left side and the right side, and the first bearing block is embedded in the middle of the top of the n-shaped frame. Through a triggering device, the cotton thread amount of a coiling block reel can be controlled, and the needed amount is achieved; through a guiding device, the cotton thread is not loose and is better wound around a coilingblock, and the effects that the time and labor are saved, winding is uniform, and the later usage of the cotton thread is not influenced are achieved.

Owner:JIANGSU XIANGHE TEXTILE

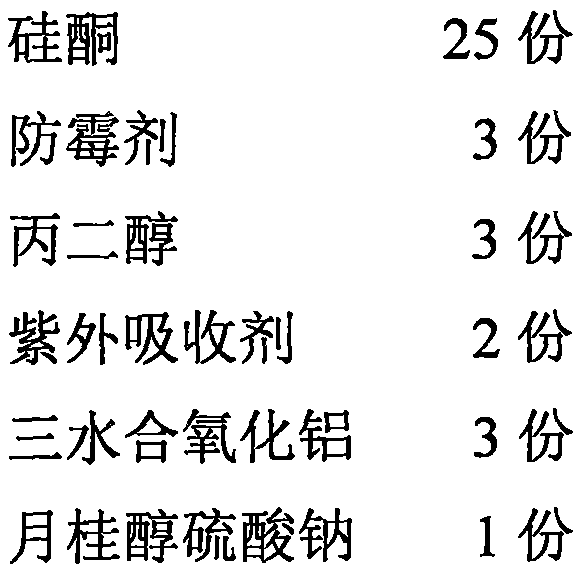

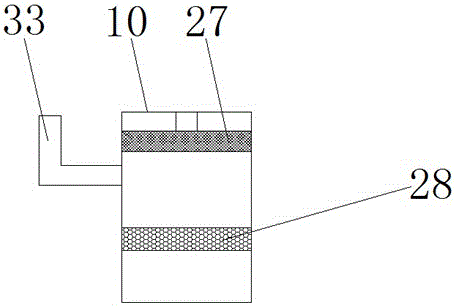

Disassembly-convenient winding device for sewing cotton thread production

The invention discloses a disassembly-convenient winding device for sewing cotton thread production. The winding device comprises a box body; a feed port is formed in the side wall of the box body; guide wheels are fixedly connected to the top and the bottom of the feed port; the upper end of the box body is fixedly connected with a driving motor; an output end of the driving motor is fixedly connected with a first rotating shaft; the first rotating shaft is arranged by vertically penetrating through the top of the box body, and extends into the box body; a thread winding part and a transmission mechanism are arranged on the part, positioned in the box body, of the first rotating shaft; the transmission mechanism is rotationally connected with the inner wall of the box body; the top of thebox body is fixedly connected with a leveling mechanism; and the leveling mechanism and the transmission mechanism are in engaged connection. The winding device realizes centralized collection of floating cotton fibers through the leveling mechanism, a dust sucking mechanism, a filter mechanism and the like, and can level and compact cotton threads during winding to improve the beauty of the cotton threads.

Owner:徐州顺泰纺织科技股份有限公司

Dyeing device for cotton thread

ActiveCN108796889ASpeed up pad dyeingImprove dyeing efficiencyTextile treatment containersTextile treatment machine arrangementsElectric machineryEngineering

The invention relates to the technical field of textile equipment, and particularly discloses a dyeing device for cotton thread, which comprises a rotating power motor, a frame and a dyeing barrel, wherein the bottom wall of the dyeing barrel is rotatably connected with a central rod; the inner side wall of the dyeing barrel is provided with a groove; a permeable layer is fixedly arranged in the groove; the permeable layer seals the notch of the groove, and an inner tooth ring is arranged on the inner side wall of the dyeing barrel; a gear is meshed with the inner gear ring, the gear is connected with an axial rod, the gear is rotatably connected with the axial rod, and a radial rod is fixedly connected between the axial rod and the central rod; a rotating shaft is coaxially connected withthe gear, the rotating shaft is fixed on the gear, the rotating shaft is coaxially connected with a thread roller, a cavity is arranged inside the thread roller, and a plurality of through holes arearranged on the side wall of the thread roller; one end of the rotating shaft, far away from the gear, is a threaded end, the threaded end is connected with a nut, and a sub plate is arranged betweenthe nut and the thread roller. The device is used for dyeing the cotton thread to solve the problem that when excessive dyestuff is added, the dyestuff can be deteriorated due to improper storage, thereby causing unnecessary waste.

Owner:绍兴金楚印染有限公司

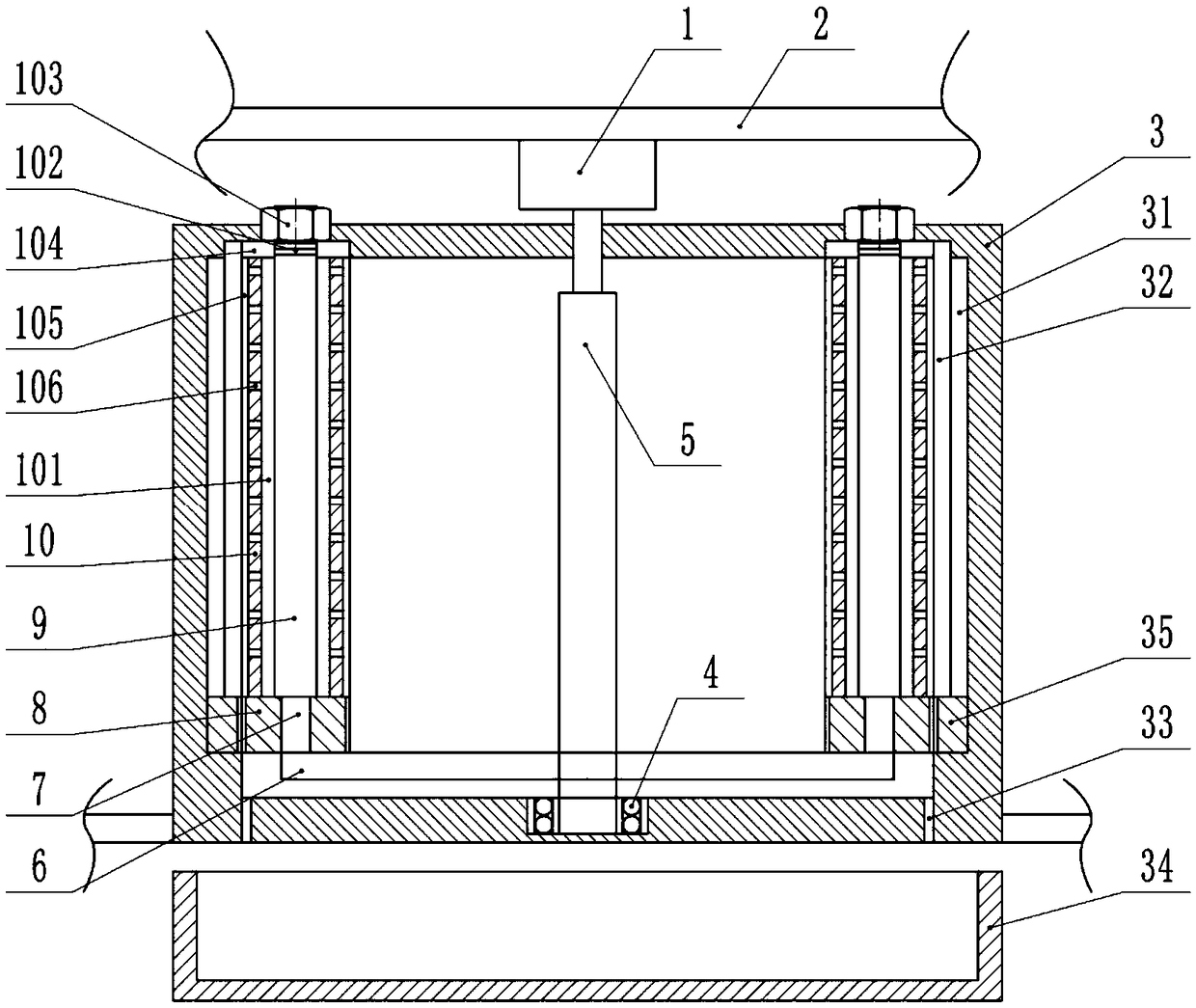

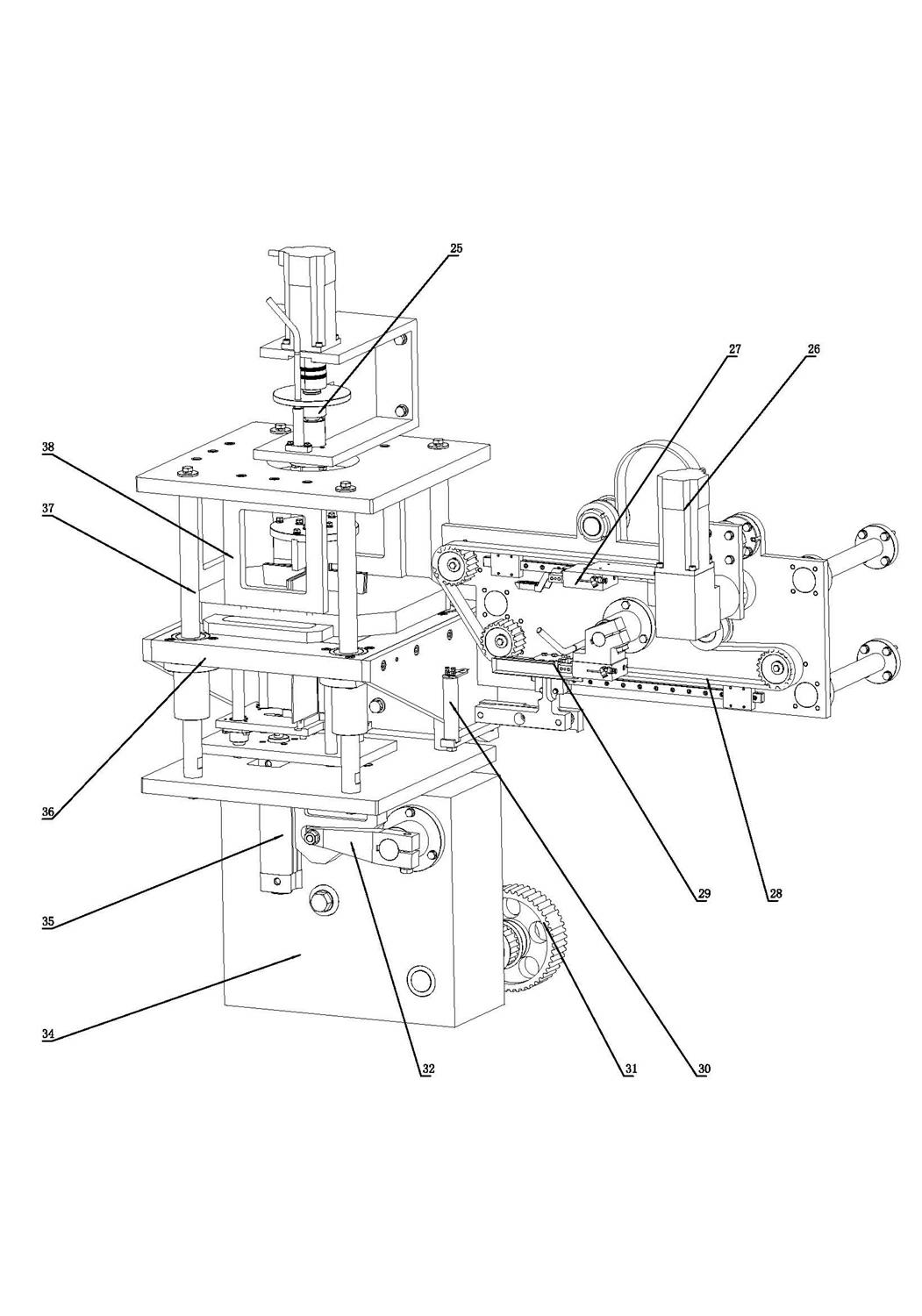

Ladder winding method for transformer type sensor coil

InactiveCN102522194AMeet special use requirementsUsing electrical meansCoils manufactureCopper wireCotton thread

The invention provides a ladder winding method for a transformer type sensor coil. The ladder winding method comprises the following steps of: wrapping the outer surface of a framework winding region for two circles by using non-alkali glass fiber cloth dipped with insulating varnish; then drying; flatly winding an enamel round copper wire at the framework winding region, and brushing the insulating varnish once when one layer of the enamel round copper wire is wound; after the layers of the specified number are flatly wound, continuously winding the enamel round copper wire in a specified region according to requirements, and brushing the insulating varnish once when one layer of the enamel round copper wire is wound; after the winding is completed, wrapping the coil for two circles by using a polytetrafluoroethylene film; then wrapping the coil for two circles by using the non-alkali glass fiber cloth; then binding by using cotton threads; and finally drying. After a sensor is assembled by using the coil wound by the invention, the sensor is mounted on a spout afterburner fuel regulator and is used for completing test run and check test run together with an engine, and special use requirements of the engine can be completely satisfied.

Owner:SHAANXI BAOCHENG AVIATION INSTR

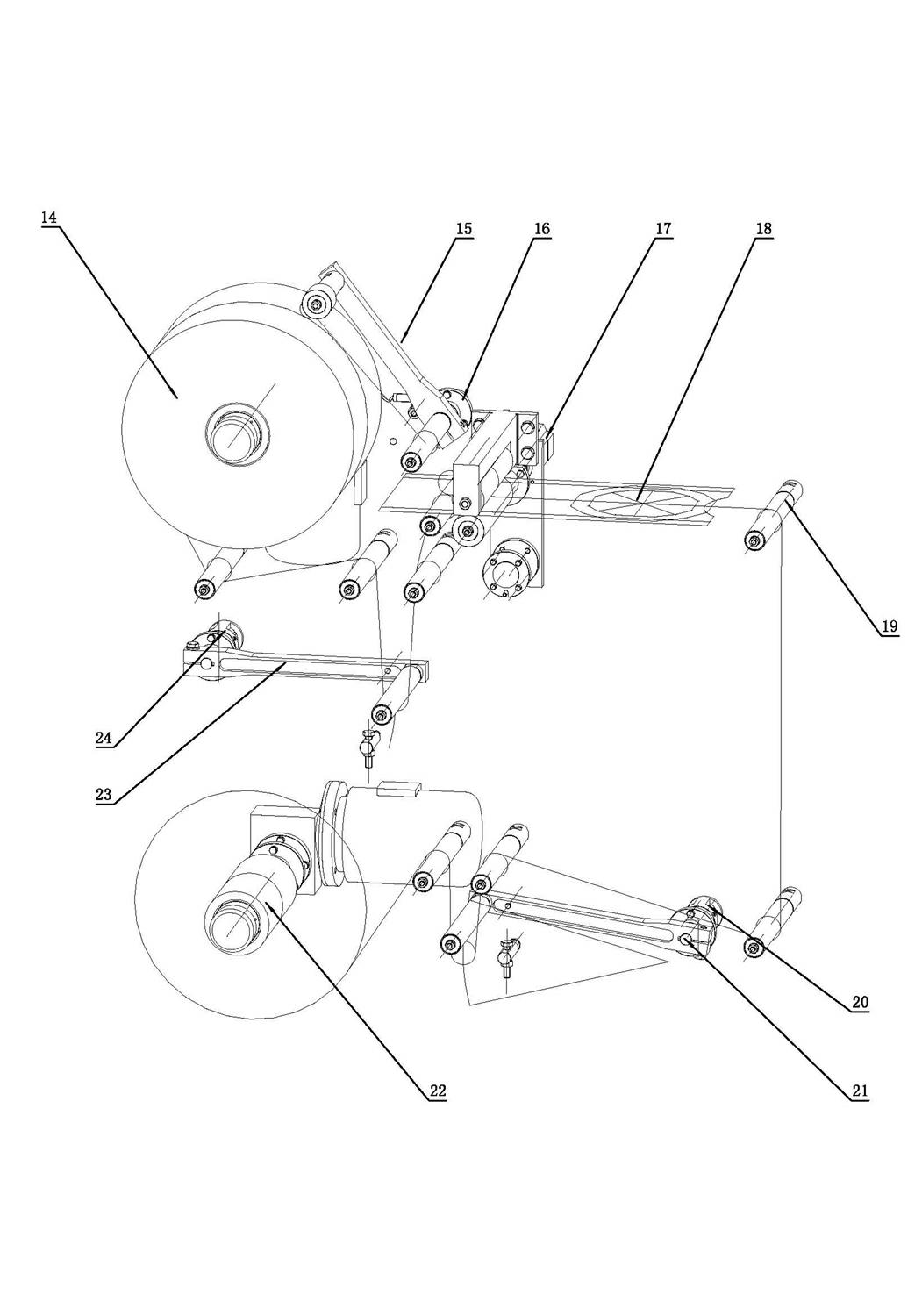

A tower bag forming device

InactiveCN102294844ACompact structureImprove automationEnvelopes/bags making machineryPunchingEngineering

The invention relates to a tower-shaped bag forming device. The tower-shaped bag forming device comprises a box body, wherein the box body is provided with an inner bag film material feeding and coiling device, a tea bag outline punching and blanking device, a tea bag side welding device, a tea bag discharging device, a tea bag forming and transferring mechanism, a label feeding and forming device, a measuring and feeding device, a cotton thread feeding and conveying and forming device and an inner bag film material traction mechanism. The tower-shaped bag forming device has the advantage that: 1) the structure is compact, single equipment finishes the whole process from feeding materials and packaging materials to automatically forming and producing and discharging tea bags, and the degrees of automatism and intelligence are high; and 2) the conventional operation which requires a great deal of manpower is completely carried out by equipment at present, the consistency of the products is good, the efficiency is improved, and the production cost is reduced.

Owner:中华全国供销合作总社杭州茶叶研究院 +1

Cotton yarn multicolored dyeing and weaving device

InactiveCN105821607AControl dyeing timeImprove dyeing efficiencyMoving yarn parts treatmentYarnEngineering

The invention provides a cotton yarn multicolored dyeing and weaving device. The cotton yarn multicolored dyeing and weaving device comprises two yarn guide devices and at least two dyeing buckets, wherein the dyeing buckets are arranged between the two yarn guide devices in parallel; pressing heads are arranged on the two sides of the dyeing buckets and pressing air cylinders are arranged at the upper ends of the pressing heads; yarn passing grooves are formed in the dyeing buckets; limiting blocks are arranged at the lower ends of the pressing heads; stepping motors are arranged on the yarn guide devices; and cotton yarns on the yarn guide devices are driven by the stepping motors to move. By setting the plurality of dyeing buckets to dye the cotton yarns by sections and pressing the cotton yarns into the dyeing buckets for dyeing by the pressing heads under the driving of the pressing air cylinders, the cotton yarns are dyed by sections in one step; the stepping motors are arranged to drive the cotton yarns to move, and pressing time of the pressing heads is controlled by a time relay, so that the dyeing time of the cotton yarns is controlled and the dyeing efficiency is improved.

Owner:WUHU FUCHUN DYEING & WEAVING

Mosquito-repelling odor-removing health-care bed sheet

The invention discloses a mosquito-repelling odor-removing health-care bed sheet which comprises a surface layer and an underlayer, wherein the surface layer is made of linen goods, the underlayer is made of cotton fabric, and the two layers are fixedly connected by cotton thread. The mosquito-repelling odor-removing health-care bed sheet can effectively balance skin secretion, enhance immunity, relieve pressure, repel mosquito, clean air and dissipate fragrance, in addition, and the surface layer made of natural linen goods fabric has the advantages of moisture absorption, heat conduction, ventilation and the like, as well as obvious health-care function.

Owner:NANTONG JINYUE FASHION DESIGN

Porous strip thread binding machine and porous strip thread binding method

The invention provides a porous strip thread binding machine and a porous strip thread binding method, relating to the technical field of binding equipment. The porous strip thread binding machine comprises a support frame, a lifting mechanism, a drilling mechanism, a ranging abdication mechanism, a thread hooking mechanism, a thread feeding mechanism and a sliding table, wherein one surface of the sliding table is in contact with a sliding table frame plate, and the other surface of the sliding table is used for placing to-be-bound objects; the thread hooking mechanism and the supporting mechanism are connected with the support frame, the thread hooking mechanism and the drilling mechanism are arranged in parallel, and the lifting mechanism is connected with the drilling mechanism; the ranging abdication mechanism is arranged on the side surface of the support frame, one end of the ranging abdication mechanism is connected with the drilling mechanism, and the other end of the rangingabdication mechanism is connected with the sliding table; hooking needles are arranged at a thread hooking end of the thread hooking mechanism; the thread feeding mechanism is connected with the baseplate of the support frame, and a groove for placing cotton threads is formed in the sliding table; and multiple hooking needles and drilling tools are arranged. According to the porous strip thread binding machine, the technical problem of low binding production efficiency in the prior art is solved. The porous strip thread binding machine is controlled by virtue of a hooking needle driving mechanism and a drilling driving mechanism, so that the machining efficiency is high.

Owner:ZHONGCHAUNGEN TIANJIN TECH CO LTD

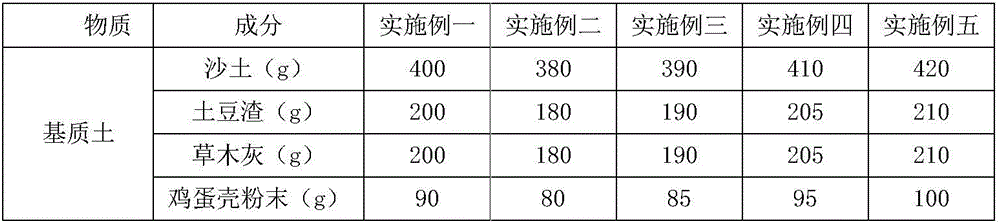

Cultivation method of peony

The invention relates to the field of plant cultivation, and discloses a cultivation method of a peony. The cultivation method comprises the following steps: truncating a peony plant to obtain a stock, selecting a bud, grafting the bud to the stock, healing a grafted part with a healing agent, conveying a first nutritional solution to the peony grafted part with a cotton thread after branch leaves of the peony are rotted to increase the grafting survival rate, then performing covering and conservation measures on the grafted plant, preparing a second nutritional solution from liquid in which potato dregs, plant ash and egg shell powder are soaked, watering the peony with a limited automatic watering device through a liquid guide pipe to enable nutrition to be absorbed in a more balanced, and cultivating a potted peony. Compared with the prior art, the cultivation method of the peony is higher in peony transplanting survival rate and higher in grafting survival rate.

Owner:延安丹荟牡丹产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com