Production process of novel high-performance TPU composite material

A composite material and polymer technology, applied in the field of composite material preparation, can solve problems such as insufficient mechanical strength, inability to be widely used, poor air permeability, etc., and achieve the goal of increasing diversification, increasing physical and mechanical properties and aesthetics, and maintaining strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

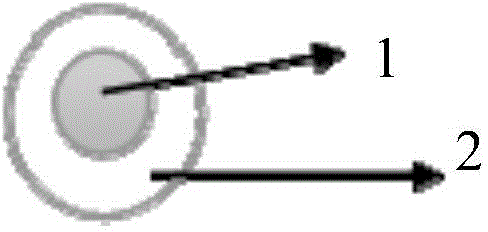

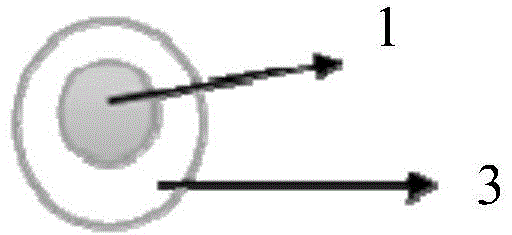

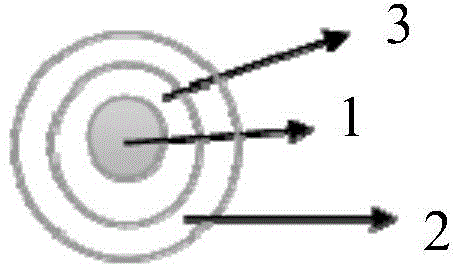

Image

Examples

Embodiment 1

[0054] Carry out the preparation of TPU composite material according to the following steps:

[0055] (1) 65 parts by weight of polymer polyols are placed in a reaction kettle and heated to 80° C. The polymer polyols are polytetrahydrofuran ether glycol with a molecular weight of 1000 and polyethylene adipate glycol with a molecular weight of 3000 Butanediol ester polyol; then add 0.3 parts by weight of antioxidant, 0.2 parts by weight of two (2,2,6,6-tetramethyl-4-piperidinyl) sebacate hindered amine photostabilizer agent, 0.8 parts by weight of montan wax and / or erucamide wax lubricants and 2 parts by weight of carbodiimide hydrolysis-resistant agent, fully stirred to obtain a polymer polyol mixed solution, wherein the antioxidant β-(4-hydroxy-3,5-di-tert-butylphenyl) propanoic acid n-octadecyl ester, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propanoic acid ] pentaerythritol ester or bis [(2,4-di-tert-butylphenyl) phosphite] pentaerythritol ester;

[0056] (2) adding ...

Embodiment 2

[0064] (1) 70 parts by weight of polymer polyols are placed in a reaction kettle and heated to 86° C. The polymer polyols are polytetrahydrofuran ether glycol with a molecular weight of 1000 and polyethylene adipate glycol with a molecular weight of 3000 Butanediol ester polyol; then add 0.3 parts by weight of antioxidant, 0.2 parts by weight of two (2,2,6,6-tetramethyl-4-piperidinyl) sebacate hindered amine photostabilizer agent, 0.8 parts by weight of montan wax and / or erucamide wax lubricants and 2 parts by weight of carbodiimide hydrolysis-resistant agent, fully stirred to obtain a polymer polyol mixed solution, wherein the antioxidant β-(4-hydroxy-3,5-di-tert-butylphenyl) propanoic acid n-octadecyl ester, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propanoic acid ] pentaerythritol ester or bis [(2,4-di-tert-butylphenyl) phosphite] pentaerythritol ester;

[0065] (2) Add 31 parts by weight of 1,4-cyclohexane diisocyanate at a temperature of 62° C. to the polymer polyol...

Embodiment 3

[0073] Carry out the preparation of TPU composite material according to the following steps:

[0074] (1) 80 parts by weight of polymer polyols are placed in a reaction kettle, and heated to 90°C. The polymer polyols are polytetrahydrofuran ether glycol with a molecular weight of 1000 and polyethylene adipate glycol with a molecular weight of 3000 Butanediol ester polyol; Then add 0.6 weight part of antioxidant, 0.45 weight part of two (2,2,6,6-tetramethyl-4-piperidinyl) debacate hindered amine light stabilizer agent, 0.6 parts by weight of montan wax and / or erucamide wax lubricants and 4 parts by weight of carbodiimide hydrolysis-resistant agent, fully stirred to obtain a polymer polyol mixed solution, wherein the antioxidant β-(4-hydroxy-3,5-di-tert-butylphenyl) propanoic acid n-octadecyl ester, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propanoic acid ] pentaerythritol ester or bis [(2,4-di-tert-butylphenyl) phosphite] pentaerythritol ester;

[0075] (2) adding 32 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com