Patents

Literature

3628results about How to "Decrease productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

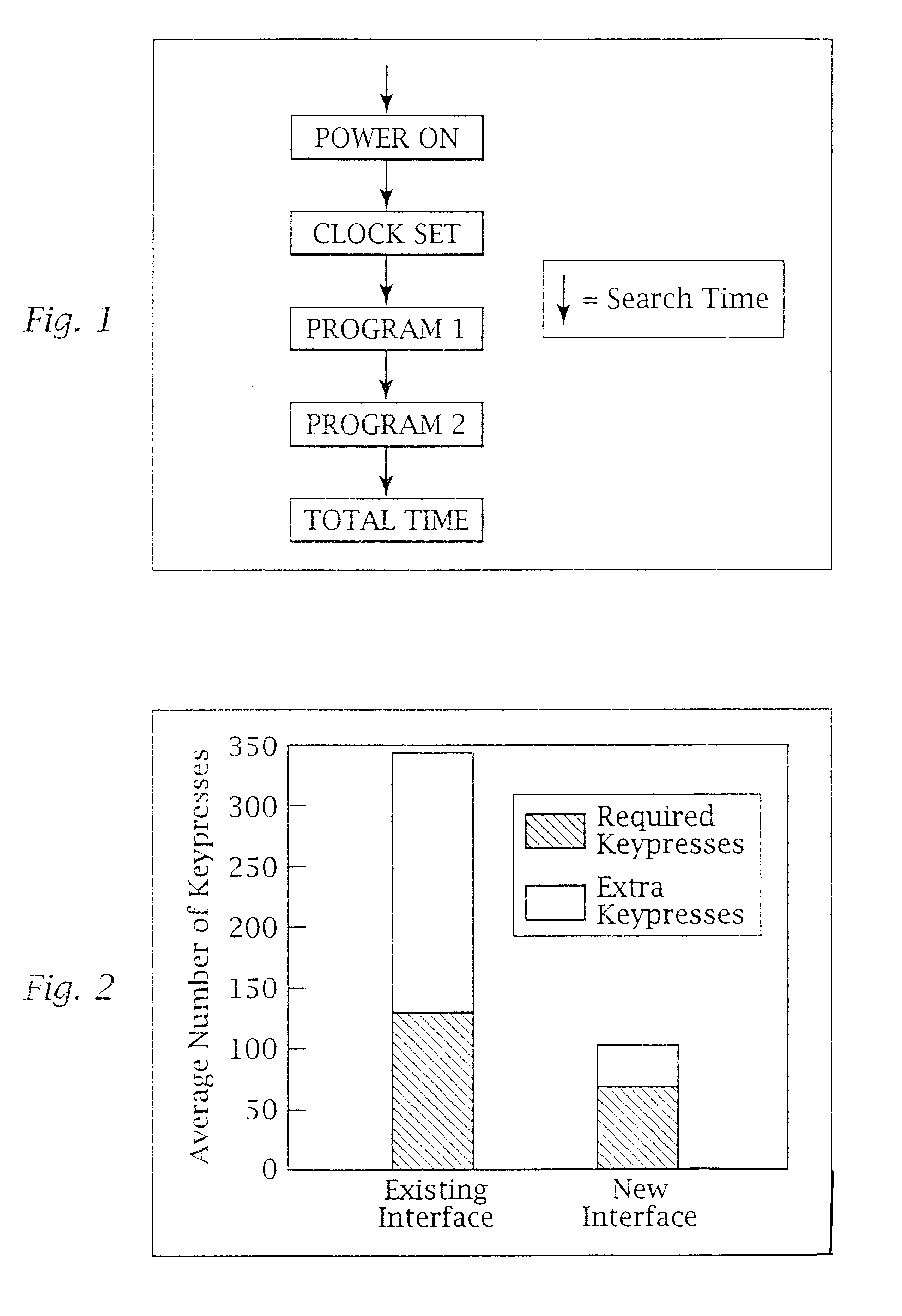

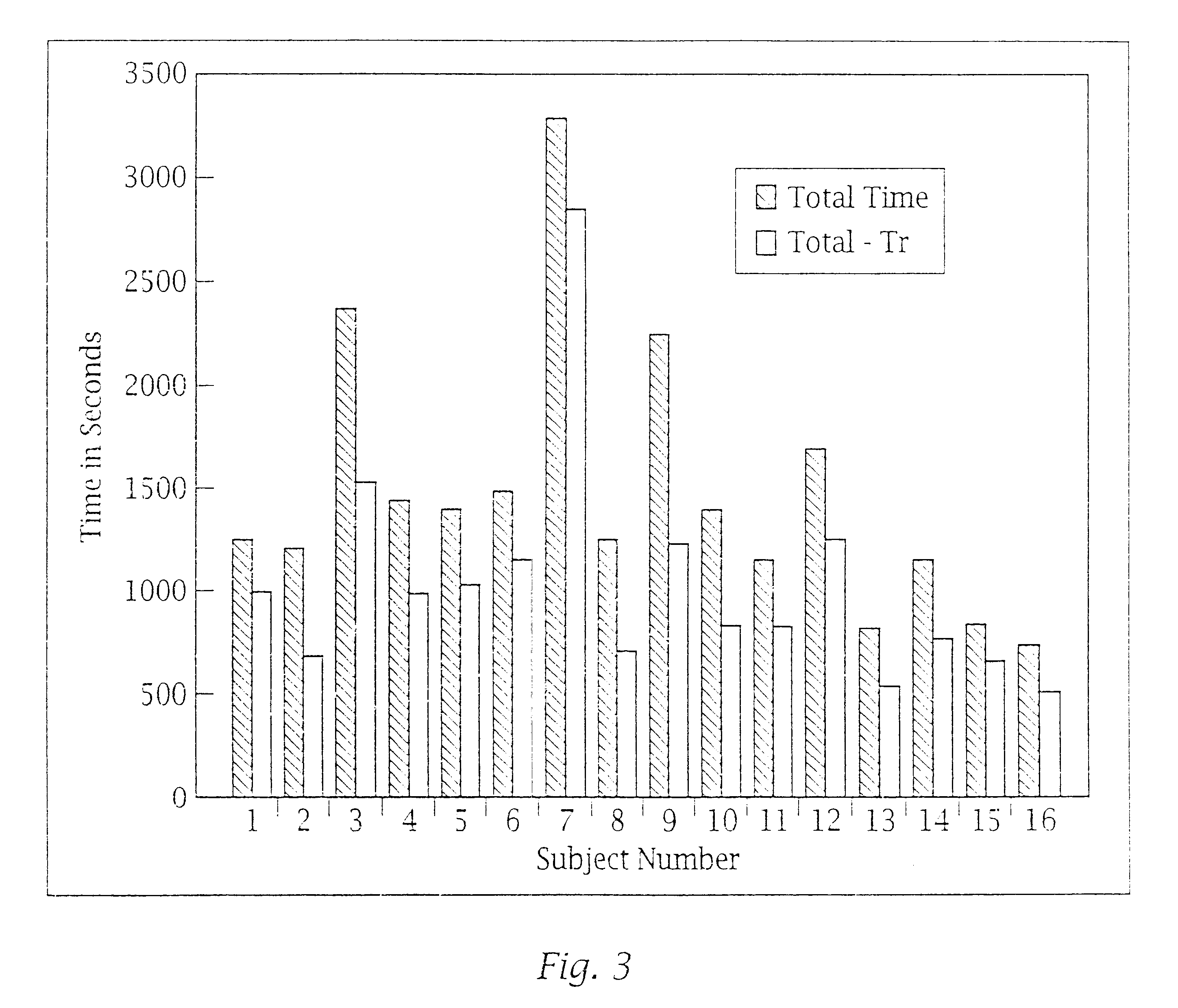

Ergonomic man-machine interface incorporating adaptive pattern recognition based control system

InactiveUS6081750ADecrease productivityImprove the environmentComputer controlSimulator controlHuman–machine interfaceData stream

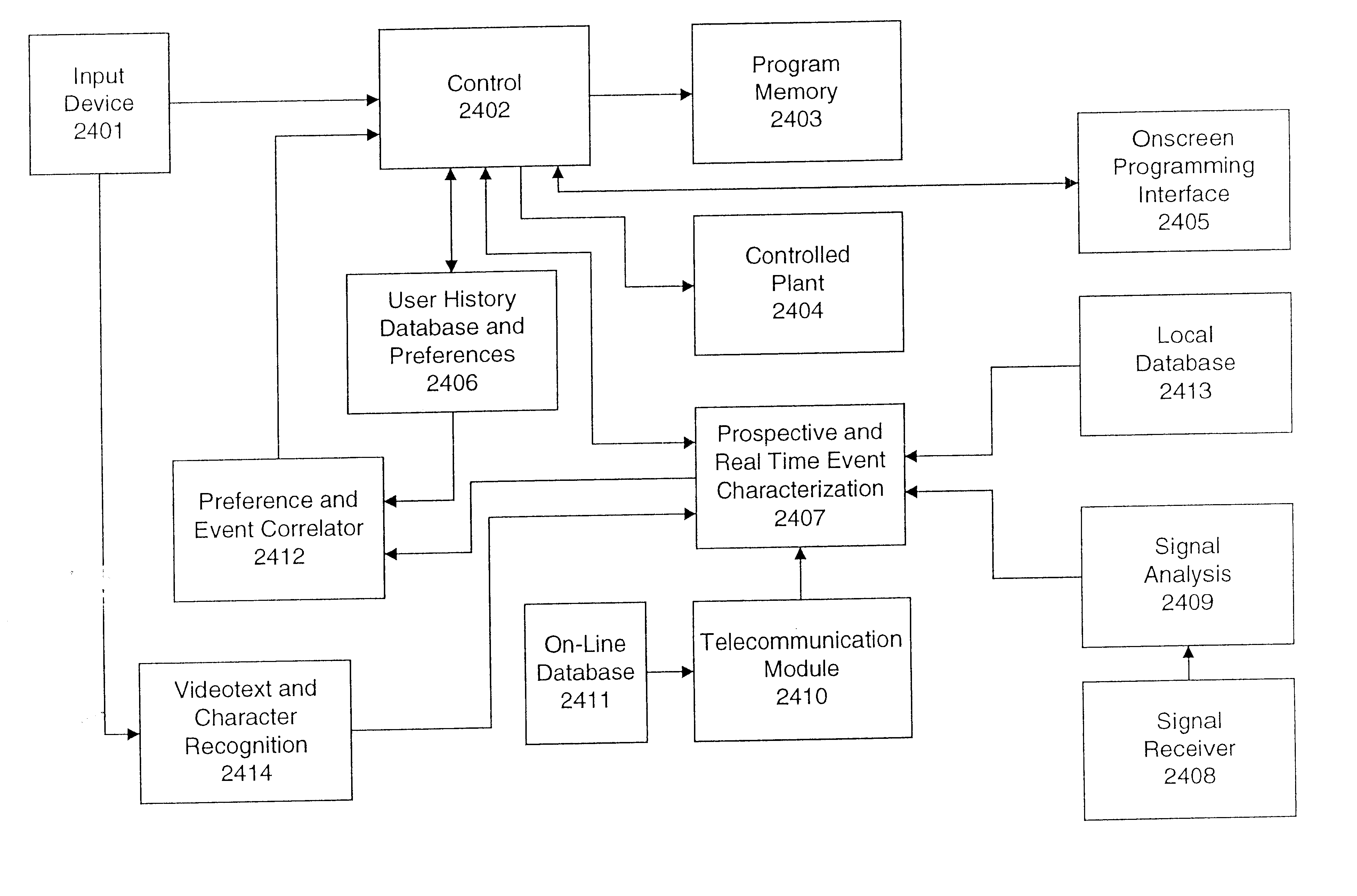

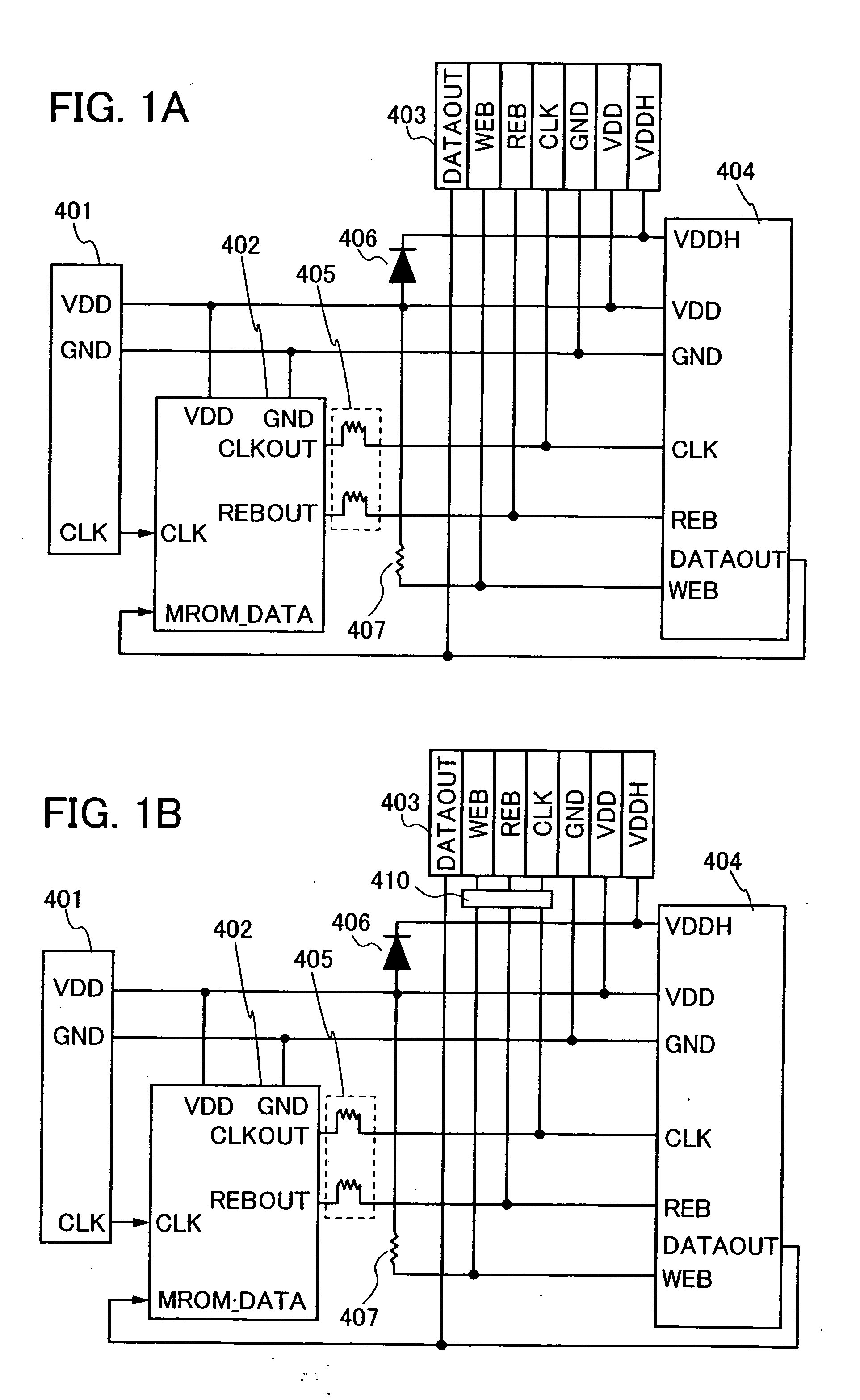

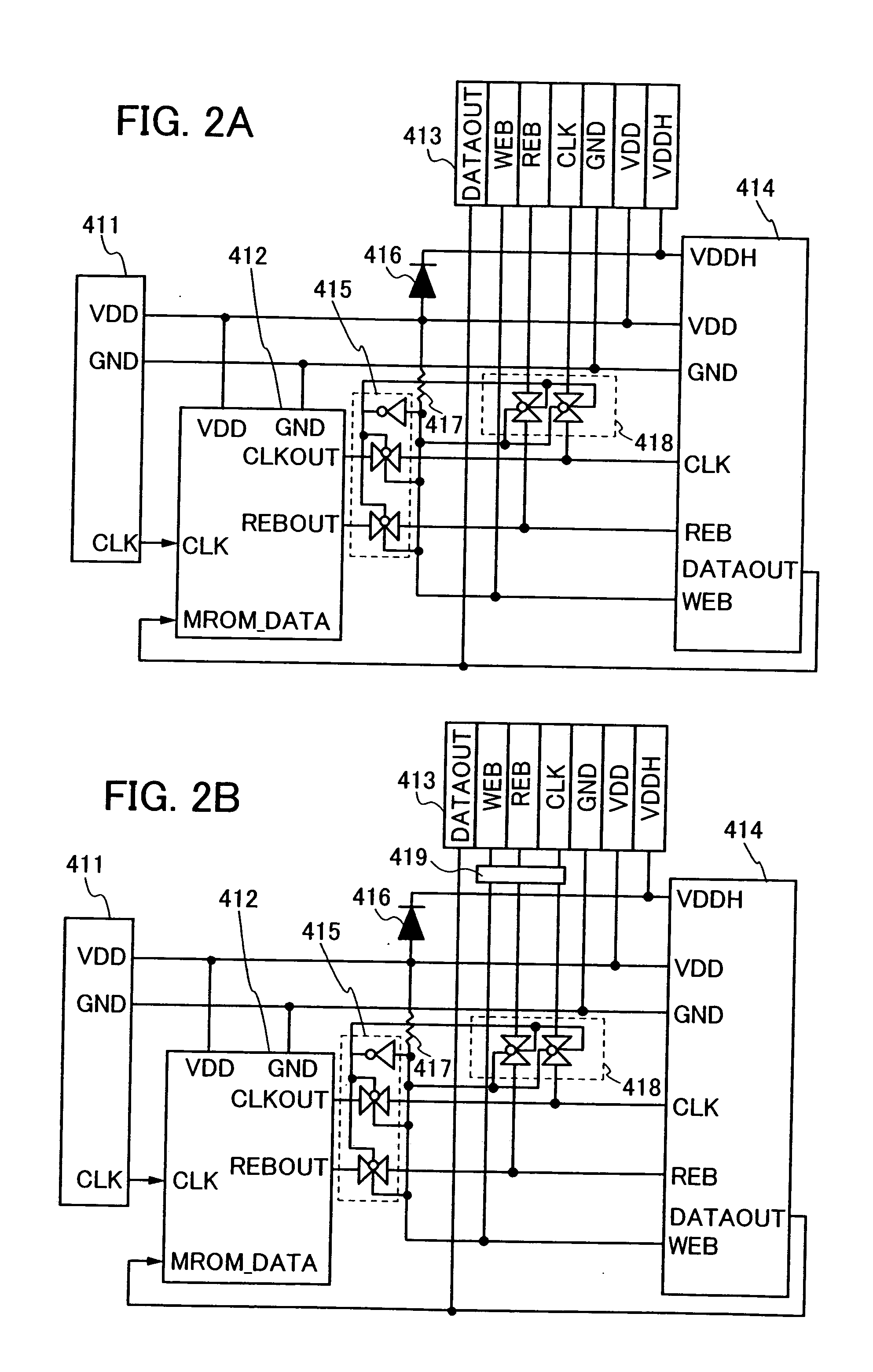

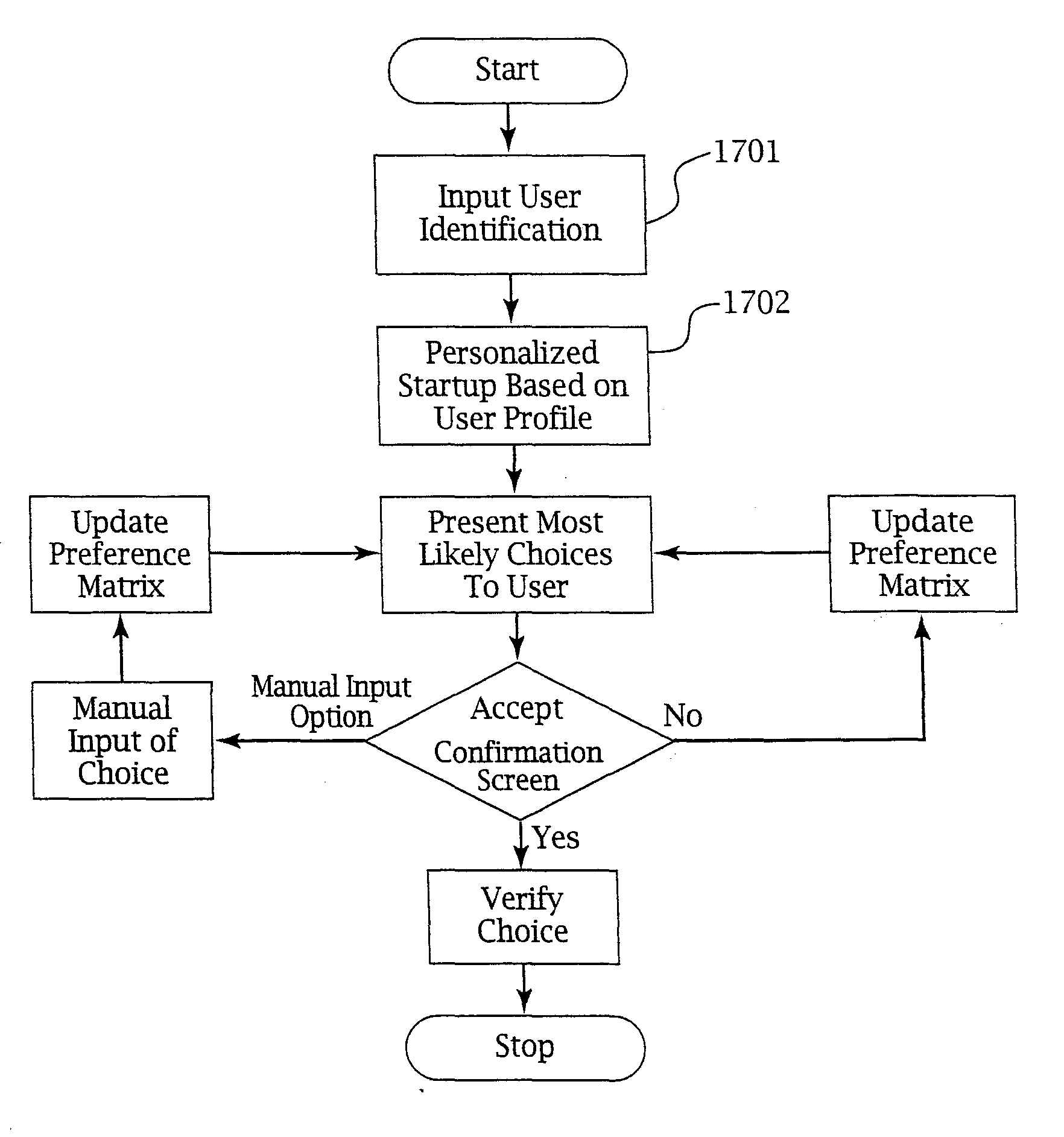

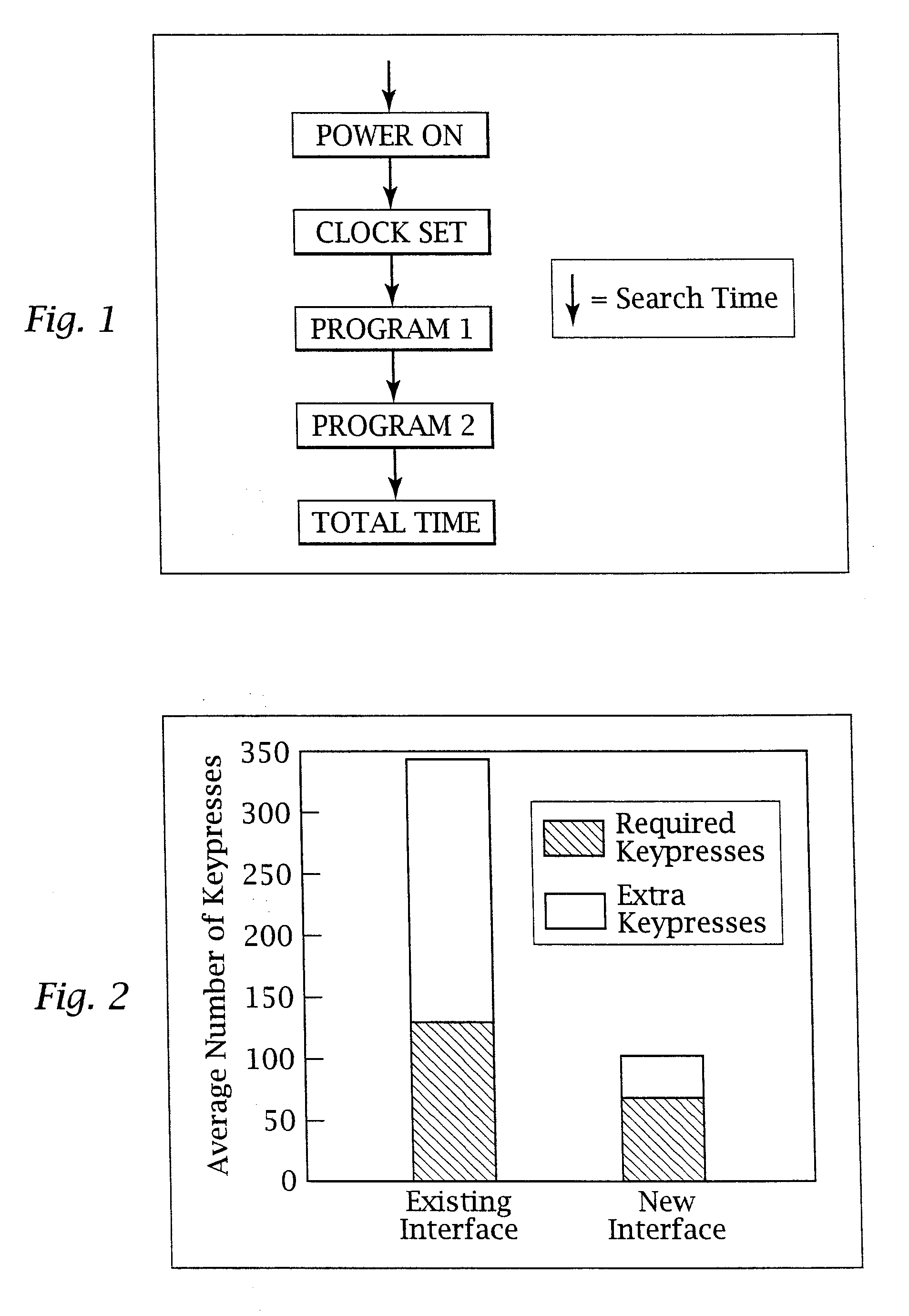

An adaptive interface for a programmable system, for predicting a desired user function, based on user history, as well as machine internal status and context. The apparatus receives an input from the user and other data. A predicted input is presented for confirmation by the user, and the predictive mechanism is updated based on this feedback. Also provided is a pattern recognition system for a multimedia device, wherein a user input is matched to a video stream on a conceptual basis, allowing inexact programming of a multimedia device. The system analyzes a data stream for correspondence with a data pattern for processing and storage. The data stream is subjected to adaptive pattern recognition to extract features of interest to provide a highly compressed representation which may be efficiently processed to determine correspondence. Applications of the interface and system include a VCR, medical device, vehicle control system, audio device, environmental control system, securities trading terminal, and smart house. The system optionally includes an actuator for effecting the environment of operation, allowing closed-loop feedback operation and automated learning.

Owner:BLANDING HOVENWEEP

Ergonomic man-machine interface incorporating adaptive pattern recognition based control system

InactiveUS6418424B1Minimal costAvoid the needTelevision system detailsDigital data processing detailsHuman–machine interfaceData stream

An adaptive interface for a programmable system, for predicting a desired user function, based on user history, as well as machine internal status and context. The apparatus receives an input from the user and other data. A predicted input is presented for confirmation by the user, and the predictive mechanism is updated based on this feedback. Also provided is a pattern recognition system for a multimedia device, wherein a user input is matched to a video stream on a conceptual basis, allowing inexact programming of a multimedia device. The system analyzes a data stream for correspondence with a data pattern for processing and storage. The data stream is subjected to adaptive pattern recognition to extract features of interest to provide a highly compressed representation which may be efficiently processed to determine correspondence. Applications of the interface and system include a VCR, medical device, vehicle control system, audio device, environmental control system, securities trading terminal, and smart house. The system optionally includes an actuator for effecting the environment of operation, allowing closed-loop feedback operation and automated learning.

Owner:BLANDING HOVENWEEP

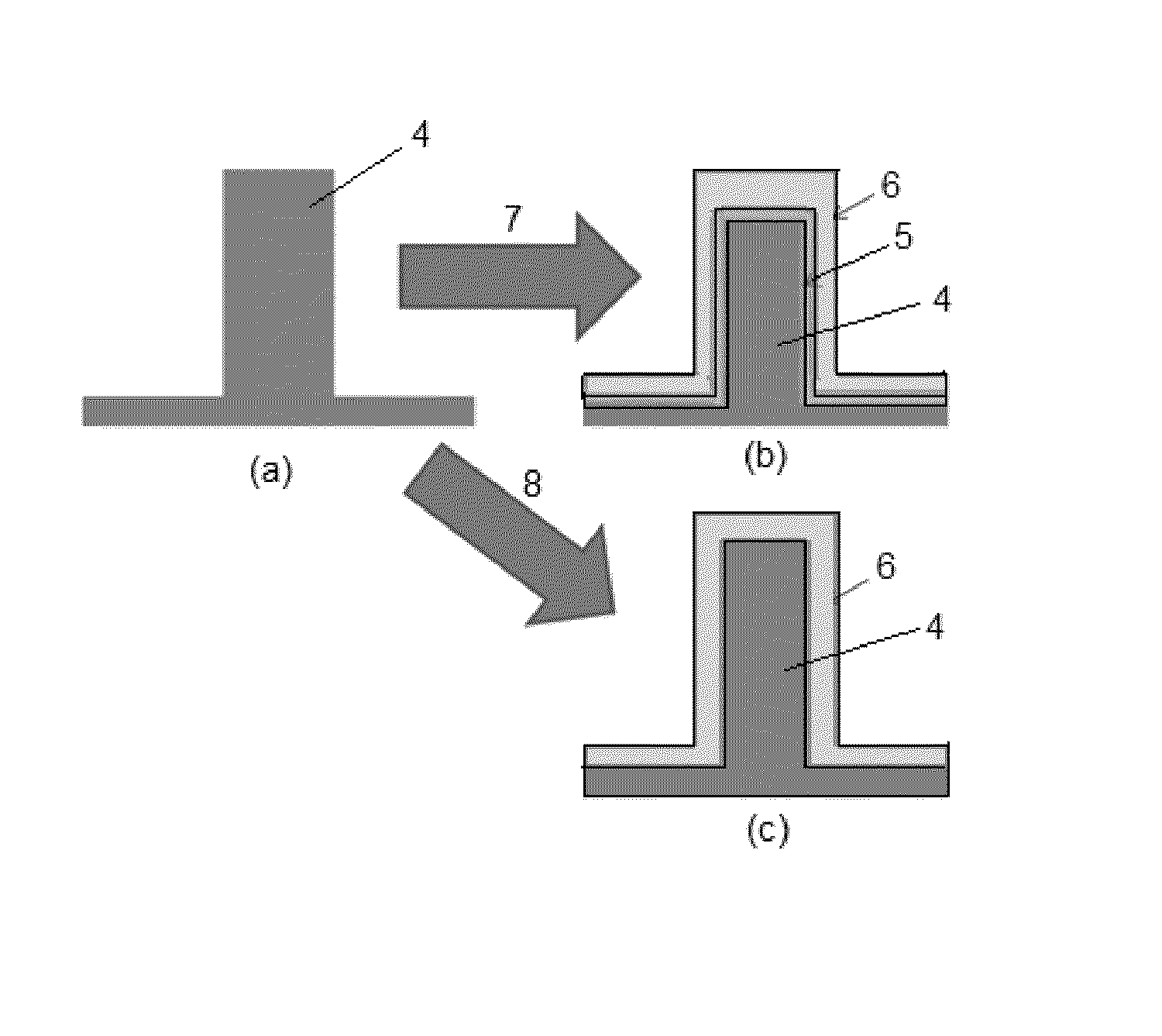

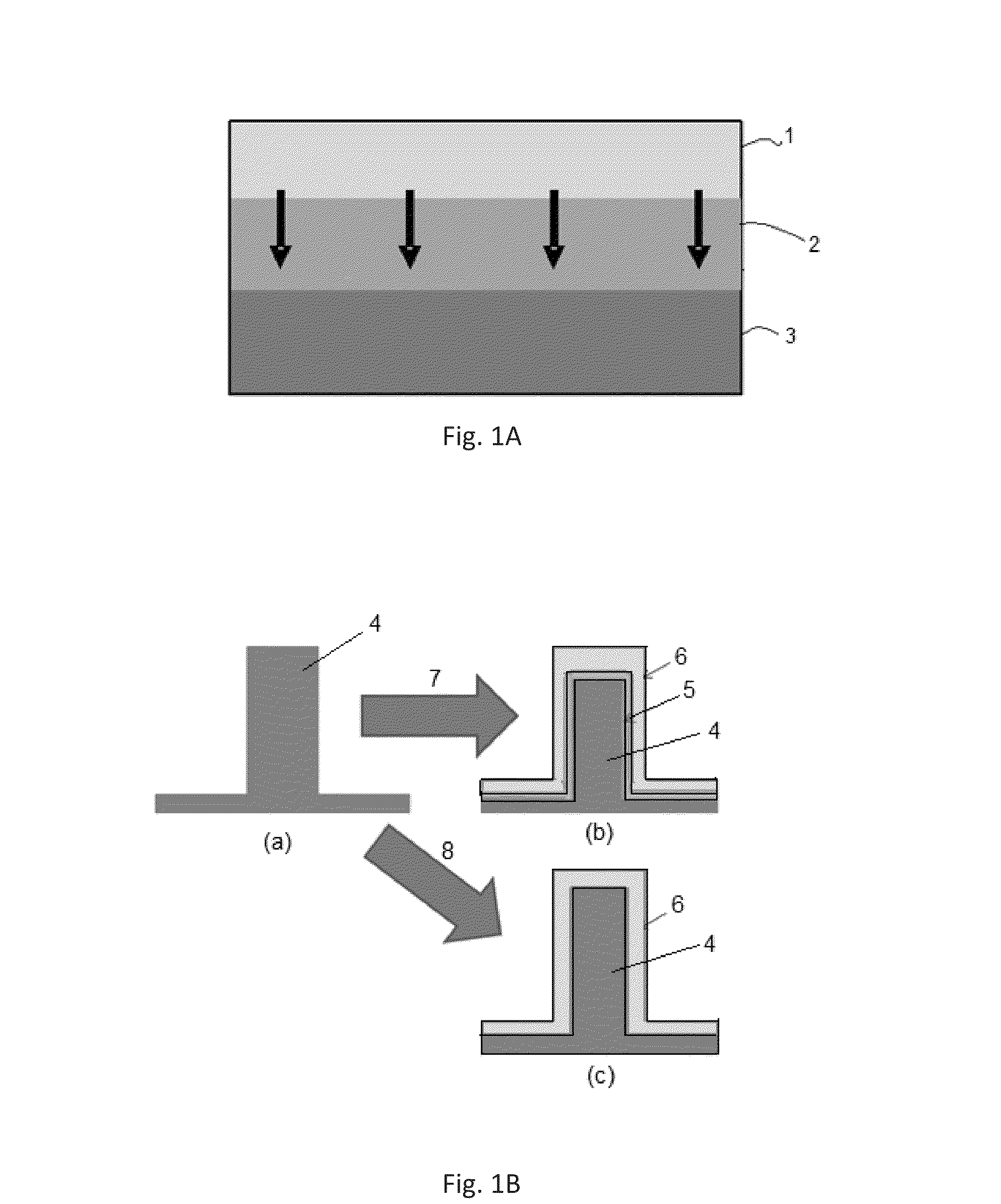

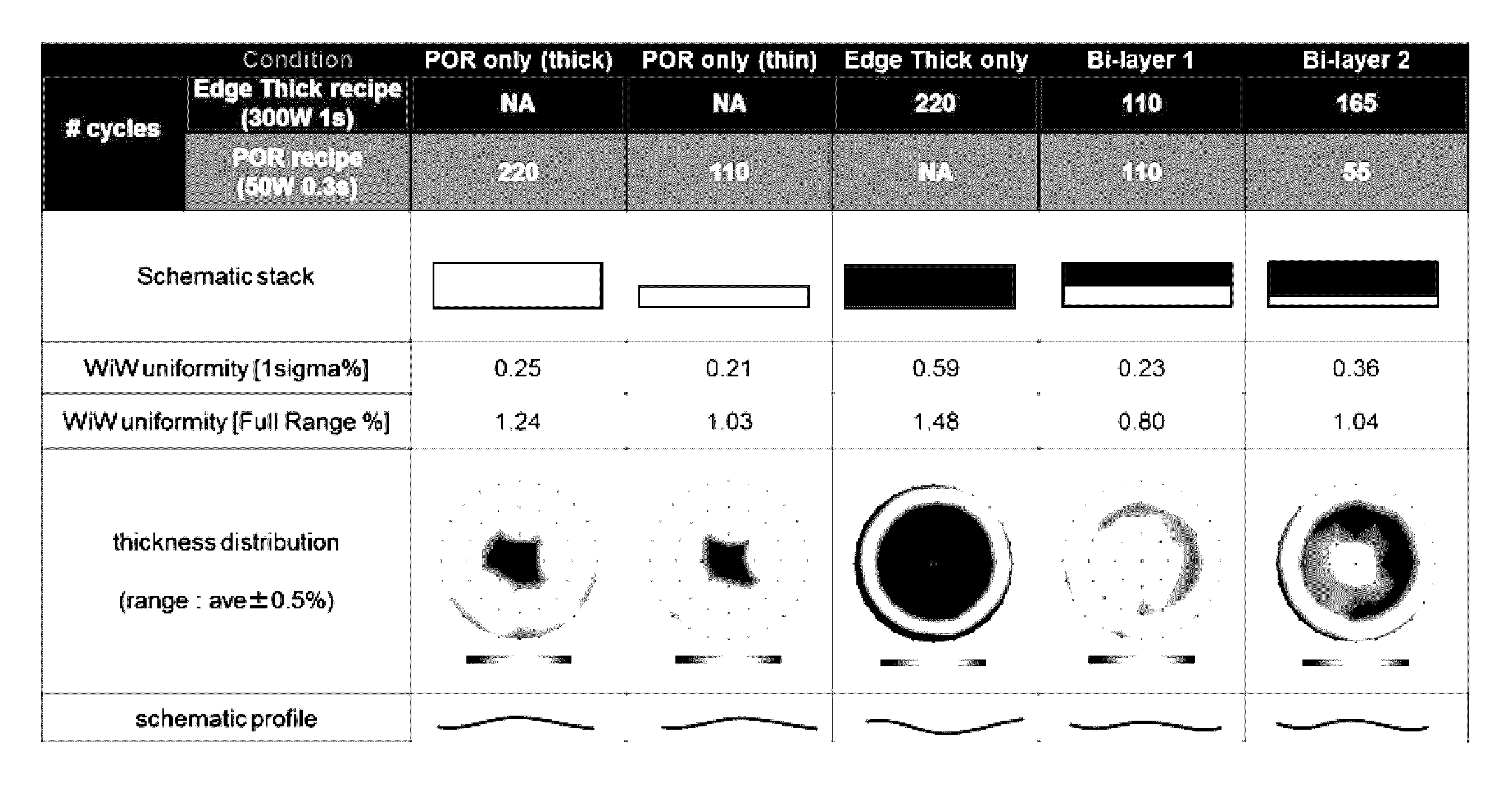

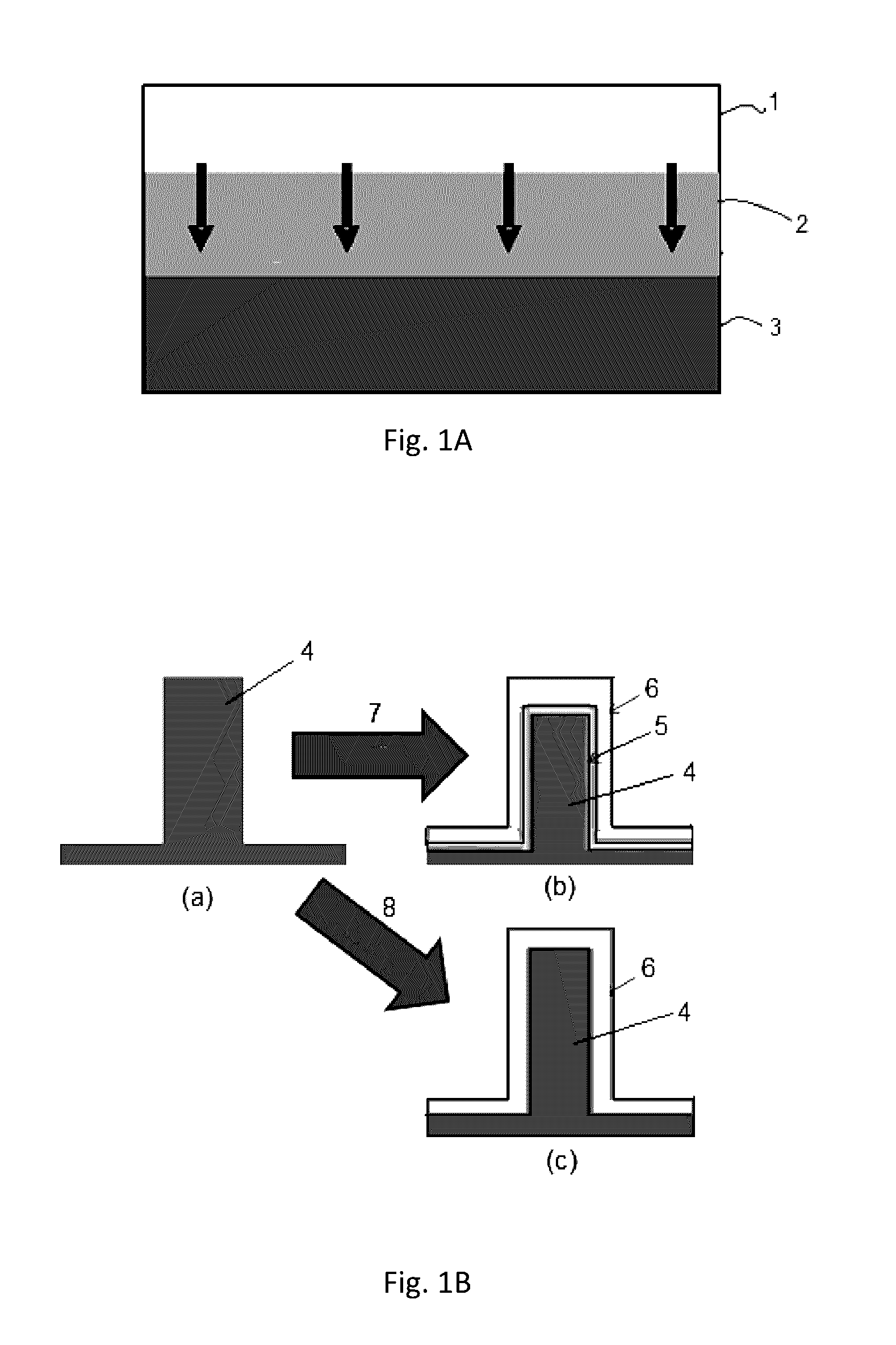

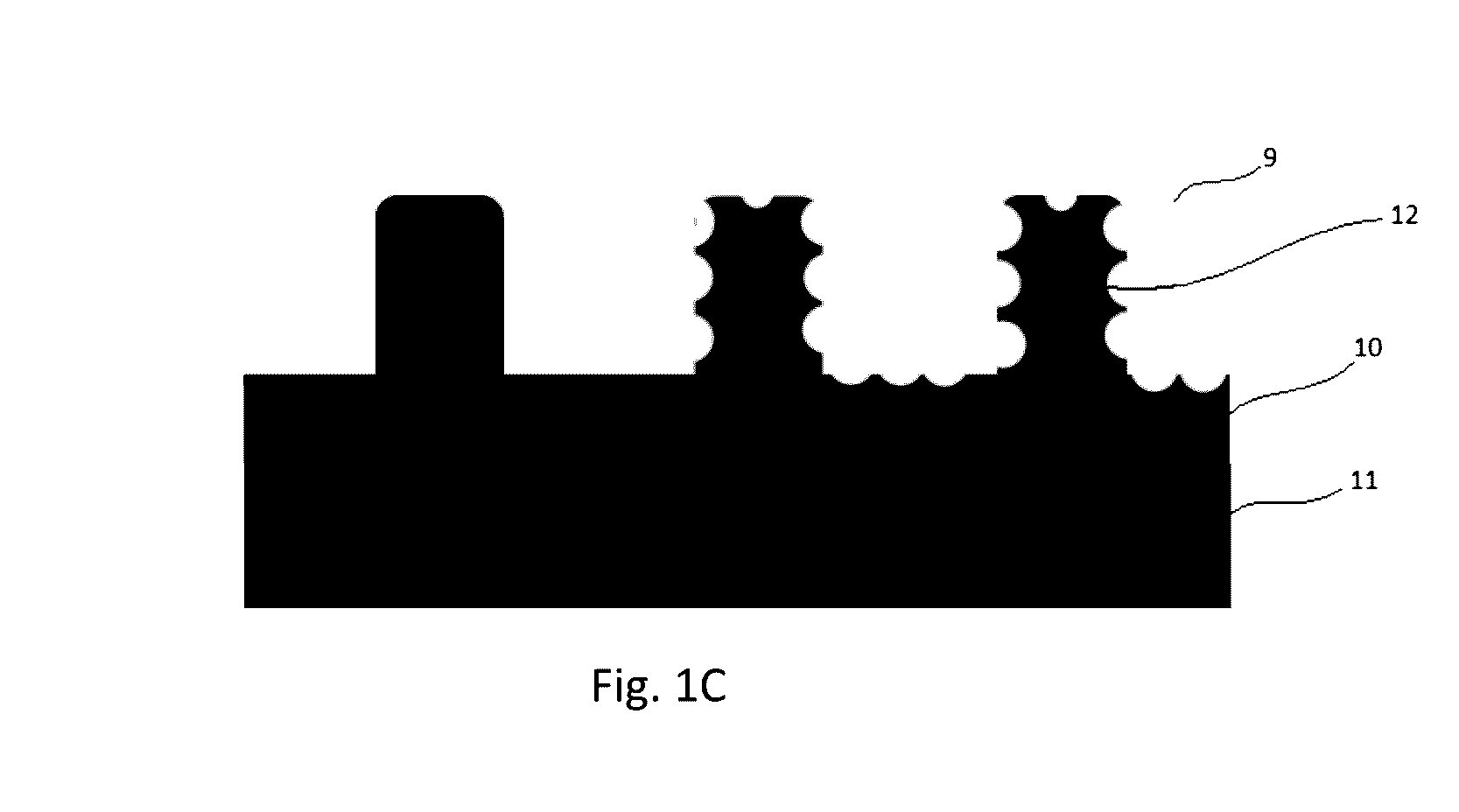

Low-Oxidation Plasma-Assisted Process

ActiveUS20150315704A1Improve film qualitySuppressing of layerElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOxide

A method for forming an oxide film by plasma-assisted cyclic processing, includes: (i) supplying a precursor to a reaction space wherein a substrate is placed; (ii) applying a first RF power to the reaction space for a first period of time without supplying a precursor; and (iii) applying a second RF power to the reaction space for a second period of time without supplying the precursor, wherein the first RF power is lower than the second RF power, and / or the first period of time is shorter than the second period of time.

Owner:ASM IP HLDG BV

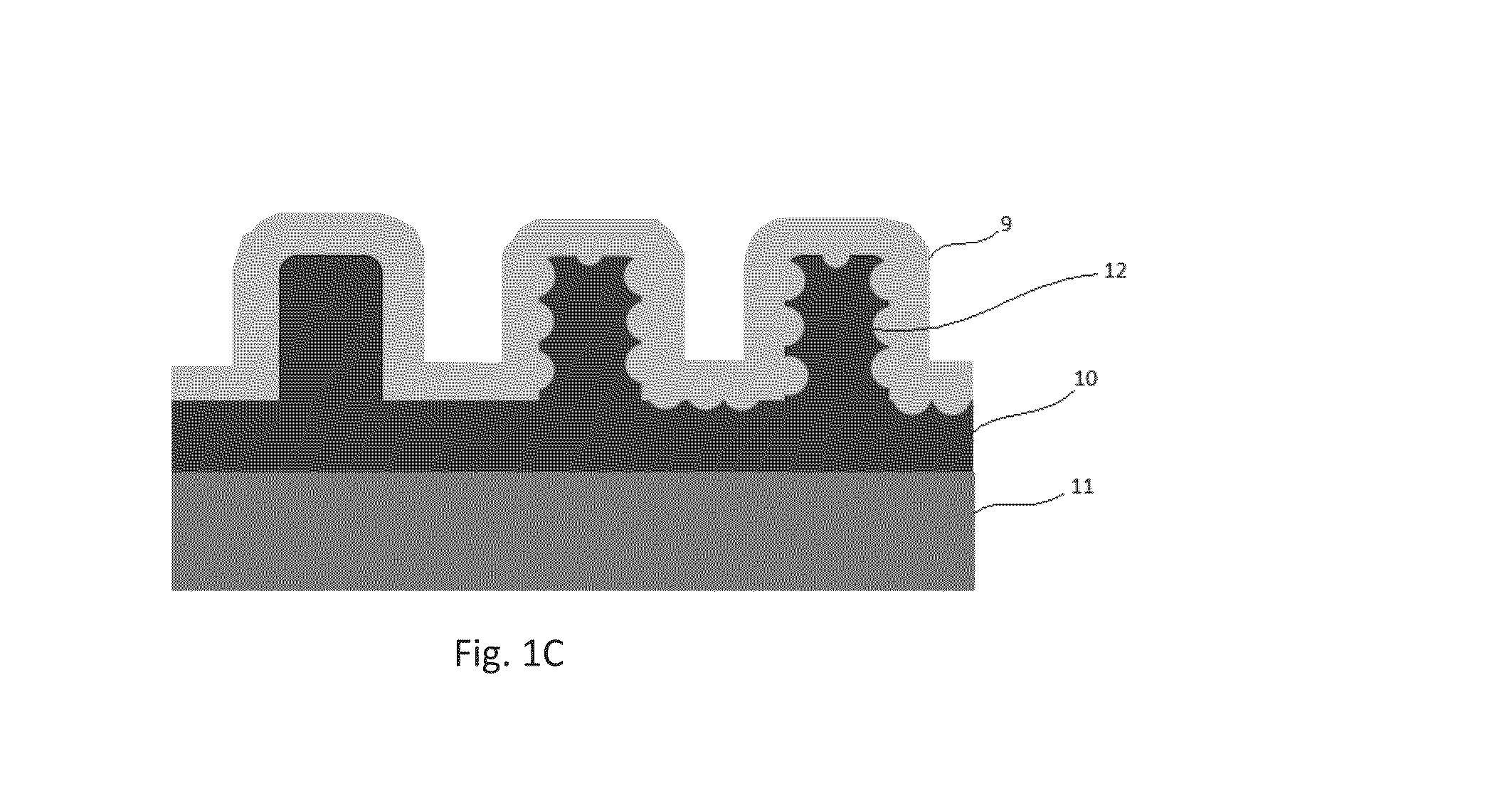

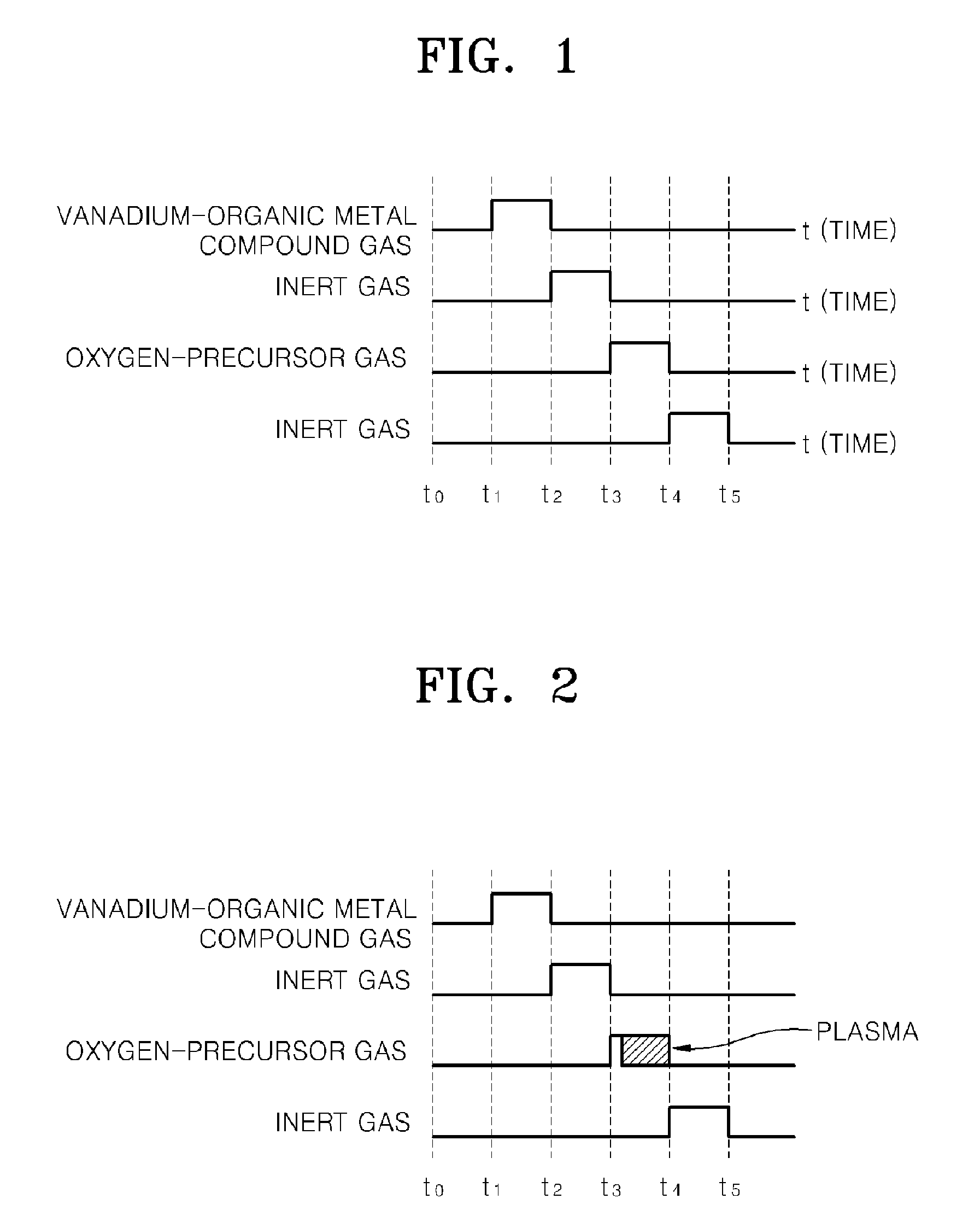

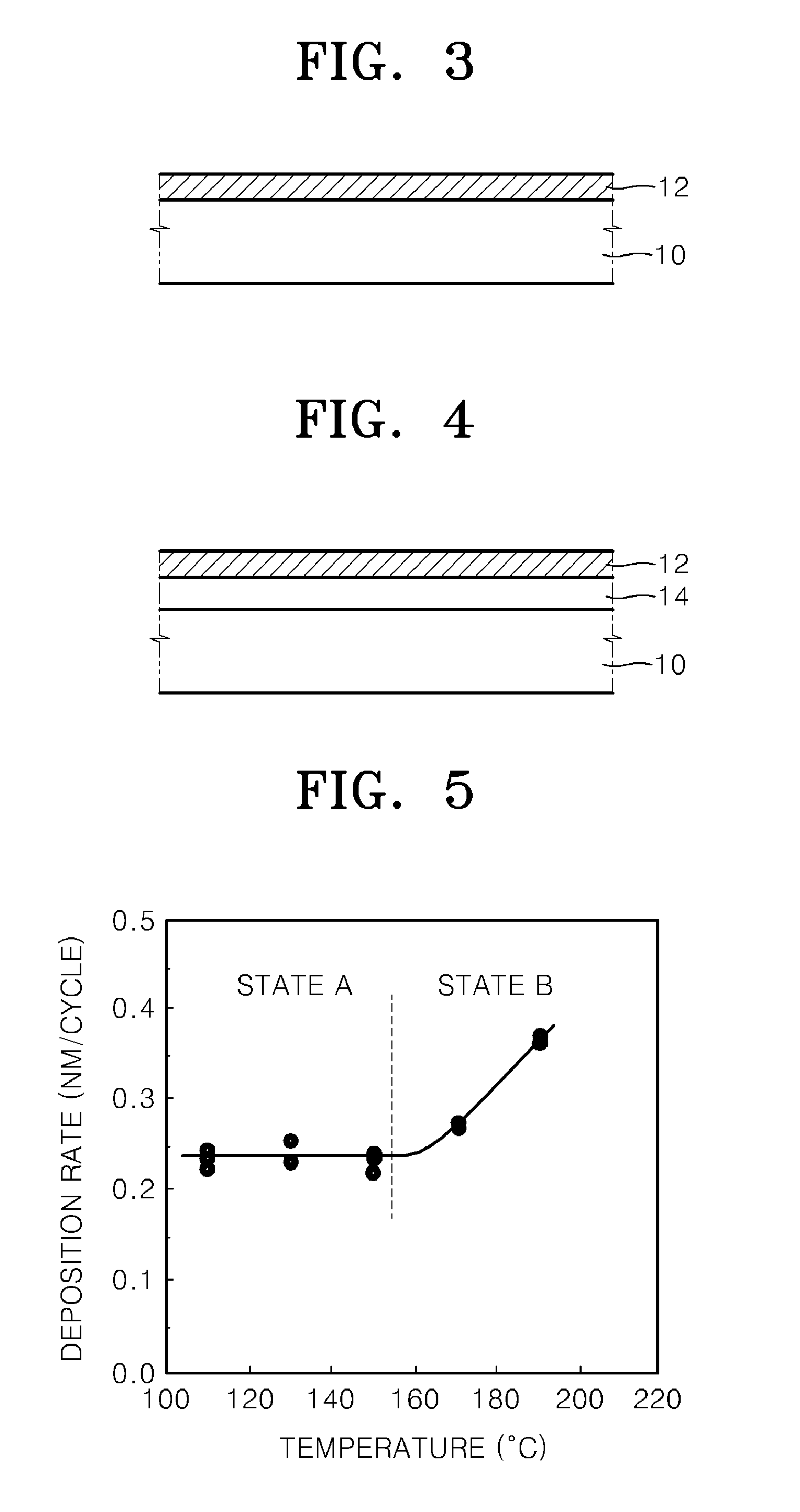

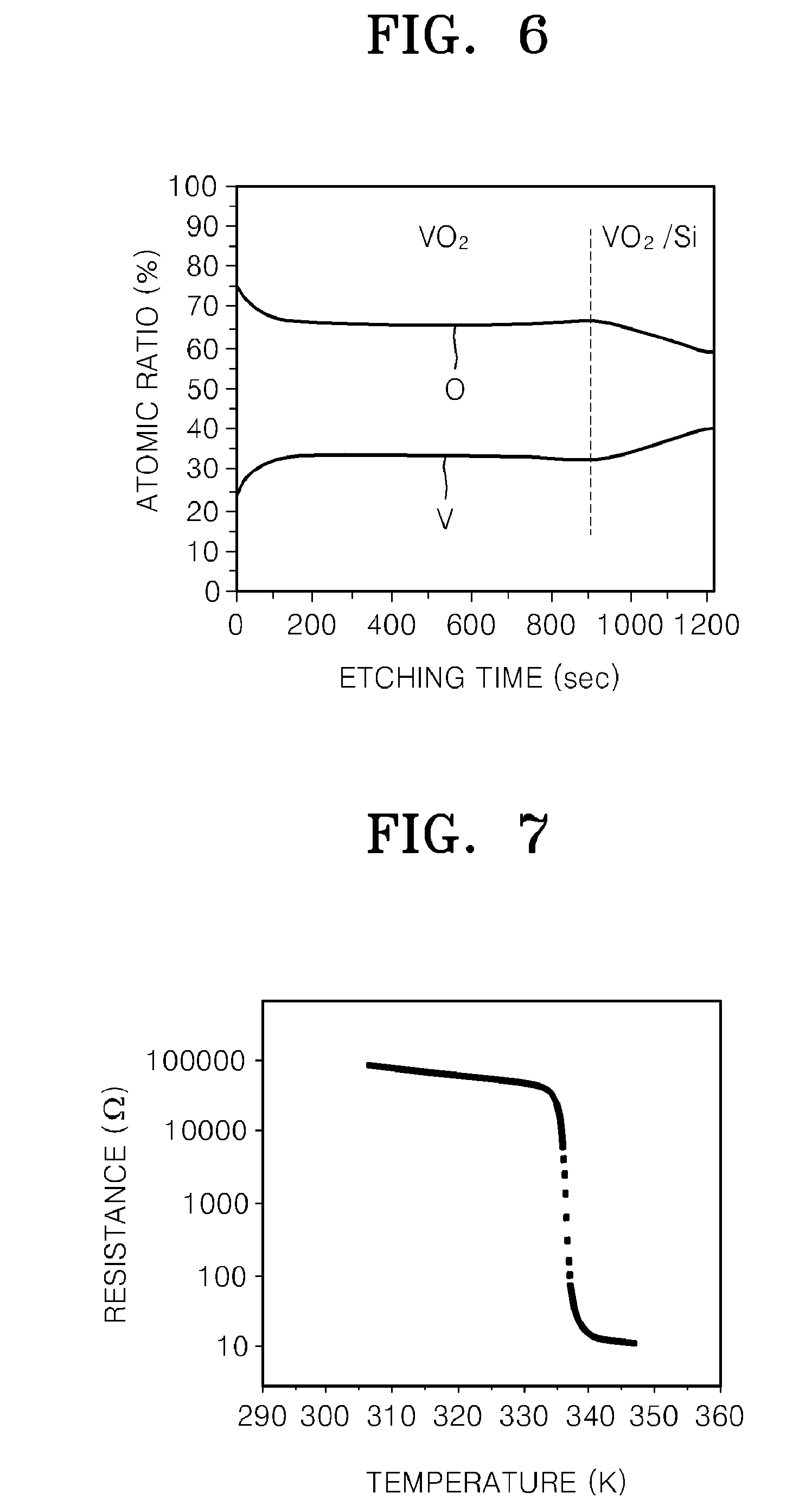

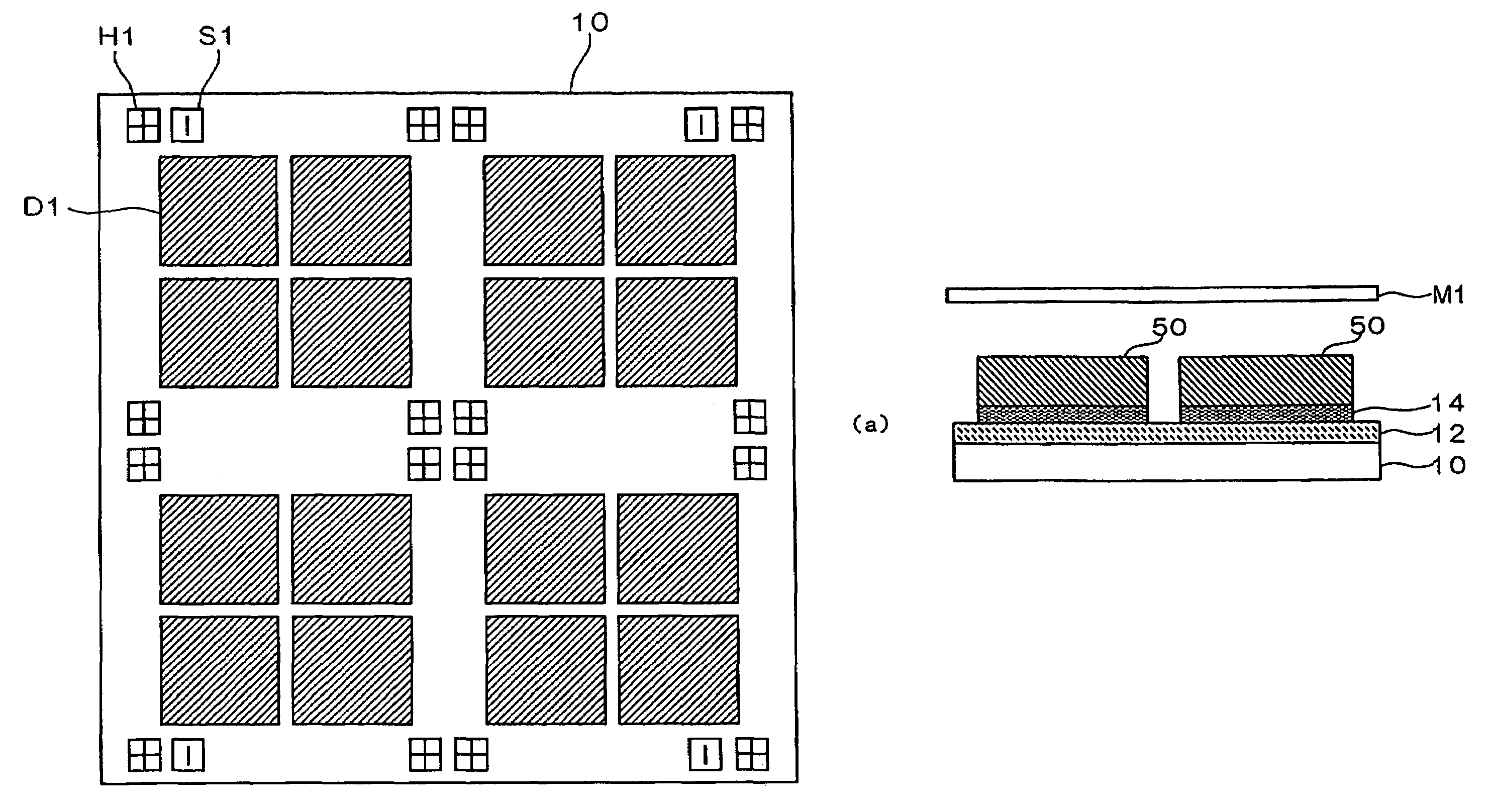

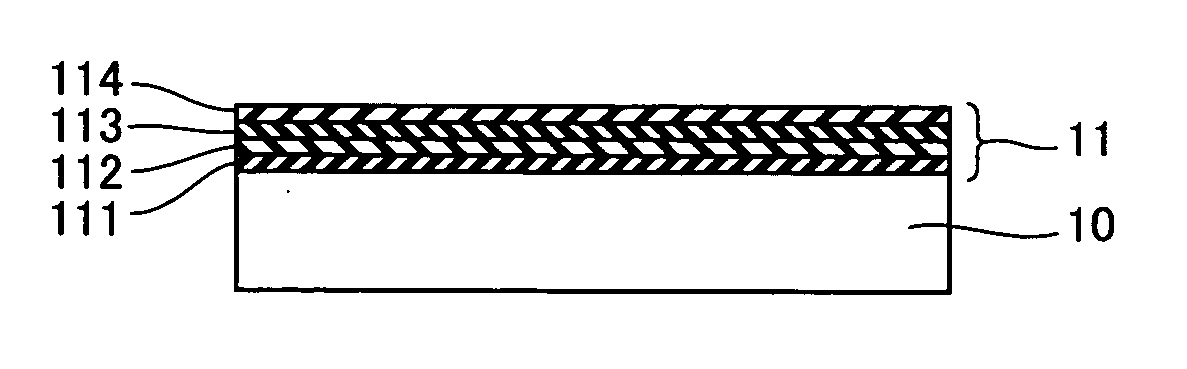

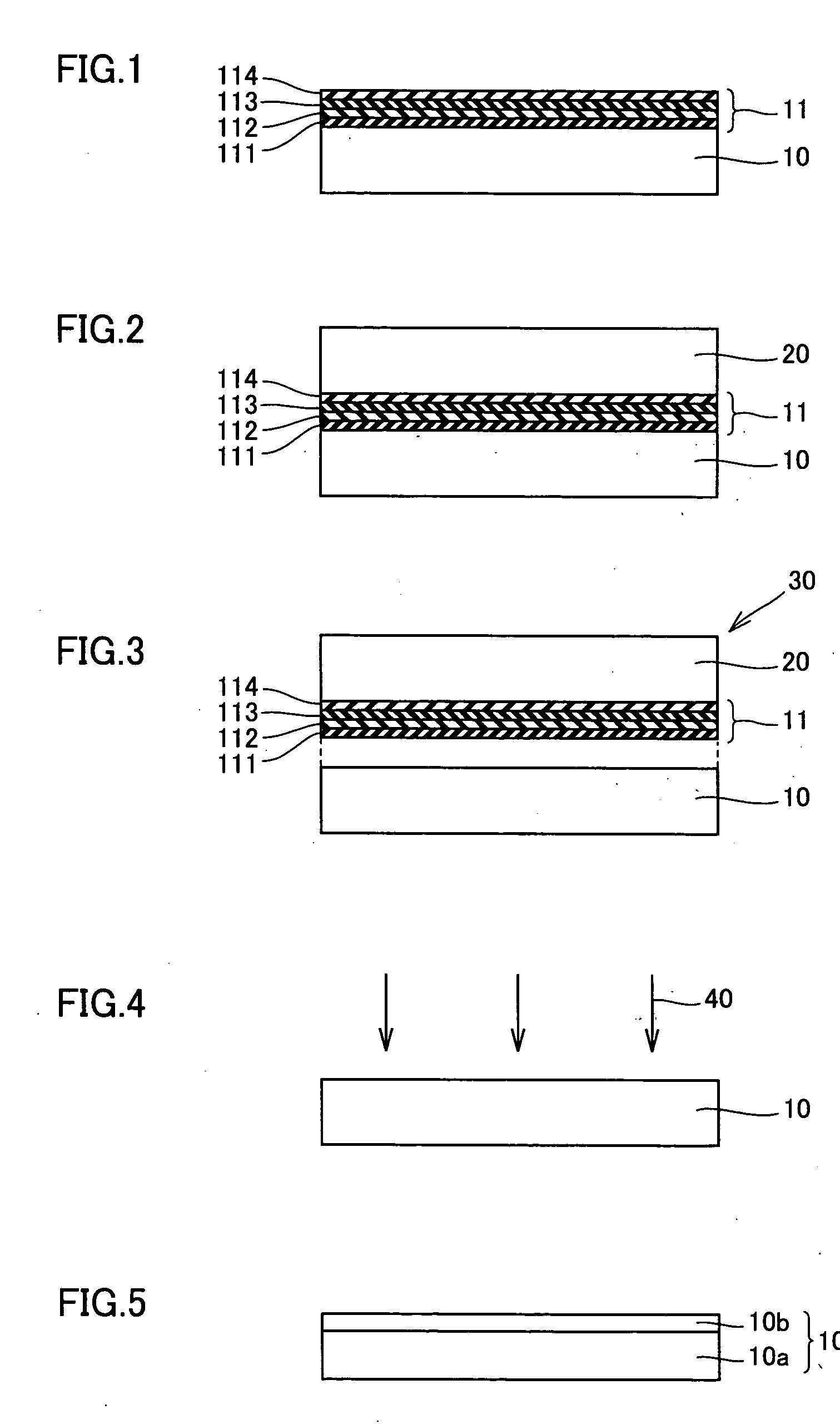

Method of Manufacturing Vanadium Oxide Thin Film

InactiveUS20090011145A1Uniform thicknessComposition is stableChemical vapor deposition coatingPlasma techniqueOxygenMaterials science

Provided is a method of manufacturing a large-sized vanadium oxide thin film having a uniform surface, uniform film thickness and stable composition. According to the method, a vanadium-organometallic compound gas is injected into a chamber to form adsorption layer where molecules of the vanadium-organometallic compound are adsorbed on the surface of a substrate. After that, an oxygen precursor is injected into the chamber and thus allowed to accomplish surface-saturation reaction with the adsorbed materials to fabricate a vanadium oxide thin film.

Owner:ELECTRONICS & TELECOMM RES INST

Low-oxidation plasma-assisted process

ActiveUS9464352B2Suppressing of layerImprove film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingPhysical chemistryRadio frequency

A method for forming an oxide film by plasma-assisted cyclic processing, includes: (i) supplying a precursor to a reaction space wherein a substrate is placed; (ii) applying a first RF power to the reaction space for a first period of time without supplying a precursor; and (iii) applying a second RF power to the reaction space for a second period of time without supplying the precursor, wherein the first RF power is lower than the second RF power, and / or the first period of time is shorter than the second period of time.

Owner:ASM IP HLDG BV

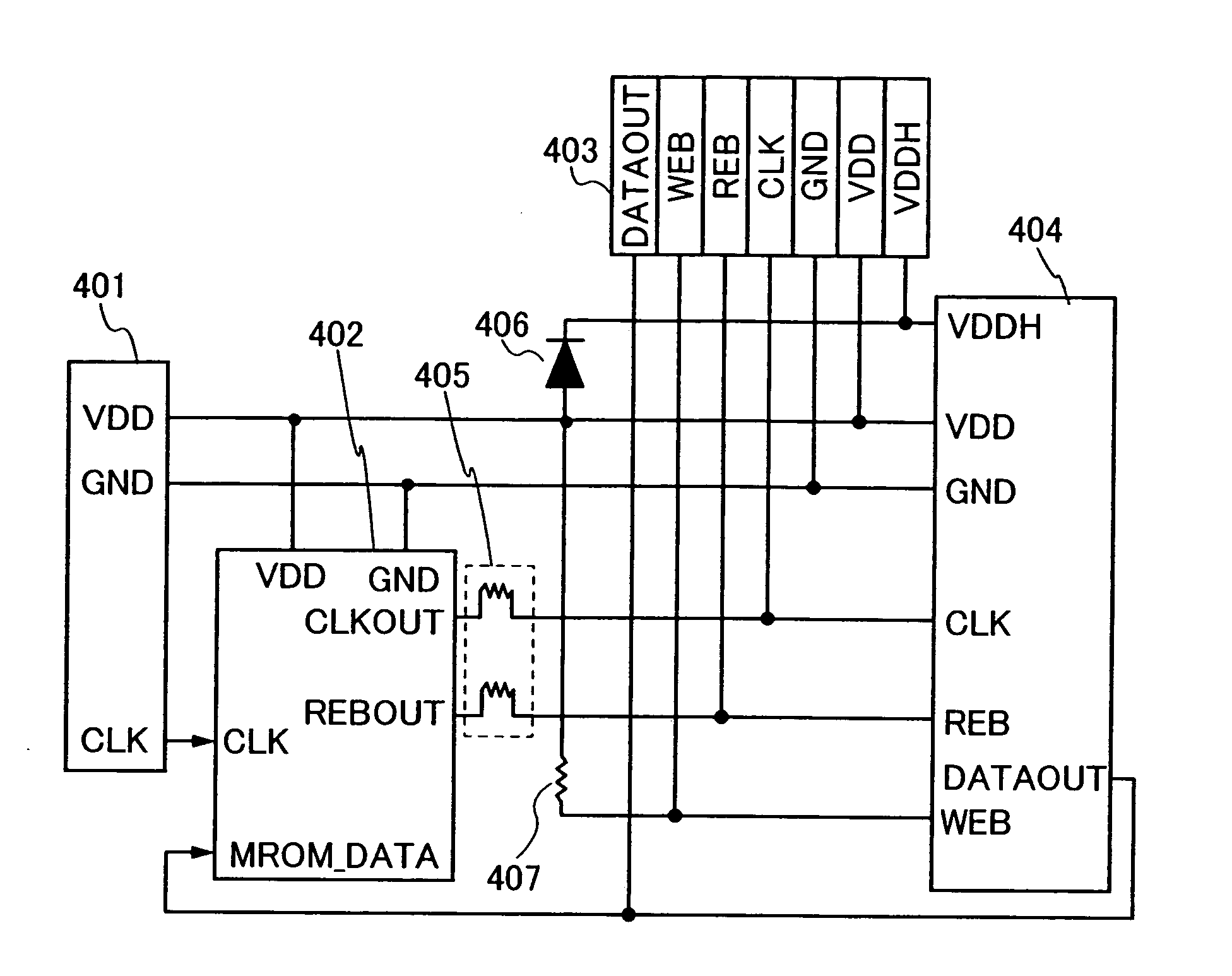

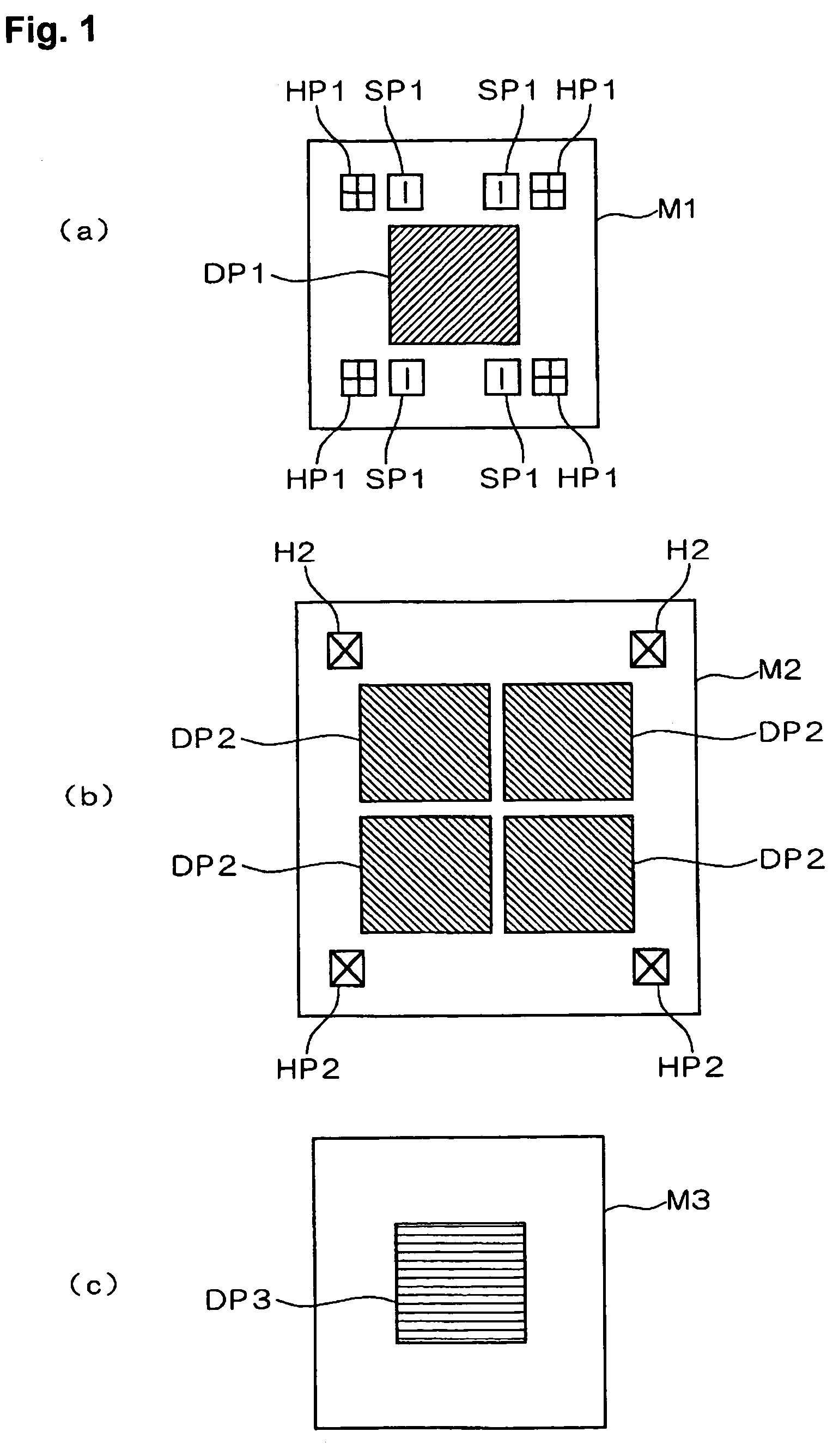

Semiconductor device and operating method thereof

InactiveUS20070123189A1Lower unit costReduce memory areaNanoinformaticsSolid-state devicesOrganic memoryBit line

In an organic memory which is included in a radio chip formed from a thin film, data are written to the organic memory by a signal inputted with a wired connection, and the data is read with a signal by radio transmission. A bit line and a word line which form the organic memory are each selected by a signal which specifies an address generated based on the signal inputted with a wired connection. A voltage is applied to a selected memory element. Thus writing is performed. Reading is performed by a clock signal or the like which are generated from a radio signal.

Owner:SEMICON ENERGY LAB CO LTD

Ergonomic man-machine interface incorporating adaptive pattern recognition based control system

InactiveUS20070061735A1Decrease productivityImprove the environmentTelevision system detailsRecording carrier detailsHuman–machine interfaceData stream

An adaptive interface for a programmable system, for predicting a desired user function, based on user history, as well as machine internal status and context. The apparatus receives an input from the user and other data. A predicted input is presented for confirmation by the user, and the predictive mechanism is updated based on this feedback. Also provided is a pattern recognition system for a multimedia device, wherein a user input is matched to a video stream on a conceptual basis, allowing inexact programming of a multimedia device. The system analyzes a data stream for correspondence with a data pattern for processing and storage. The data stream is subjected to adaptive pattern recognition to extract features of interest to provide a highly compressed representation which may be efficiently processed to determine correspondence. Applications of the interface and system include a VCR, medical device, vehicle control system, audio device, environmental control system, securities trading terminal, and smart house. The system optionally includes an actuator for effecting the environment of operation, allowing closed-loop feedback operation and automated learning.

Owner:BLANDING HOVENWEEP

System and method for online communications management

ActiveUS20120278388A1Removal of block activityDecrease productivityMultiple digital computer combinationsOffice automationCommunications managementComputer science

A system and method are disclosed. One or more processors prioritize at least some tasks and actions associated with a user. A to-do list is provided that includes the prioritized task. First electronic data event information representing a sending or receiving of data associated with at least one of the tasks is received and at least one of the tasks and at least some of the actions are reprioritized. The to-do list is modified based at least on the reprioritizing, and is provided to the user.

Owner:KLEINBART KYLE +4

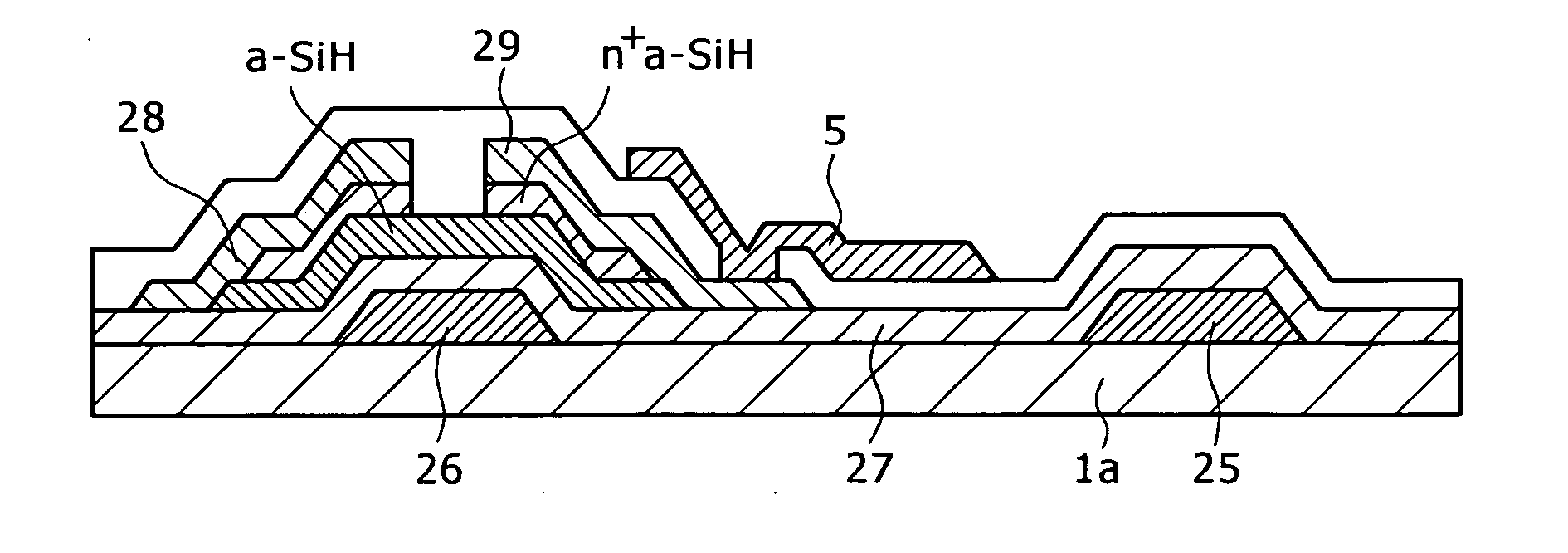

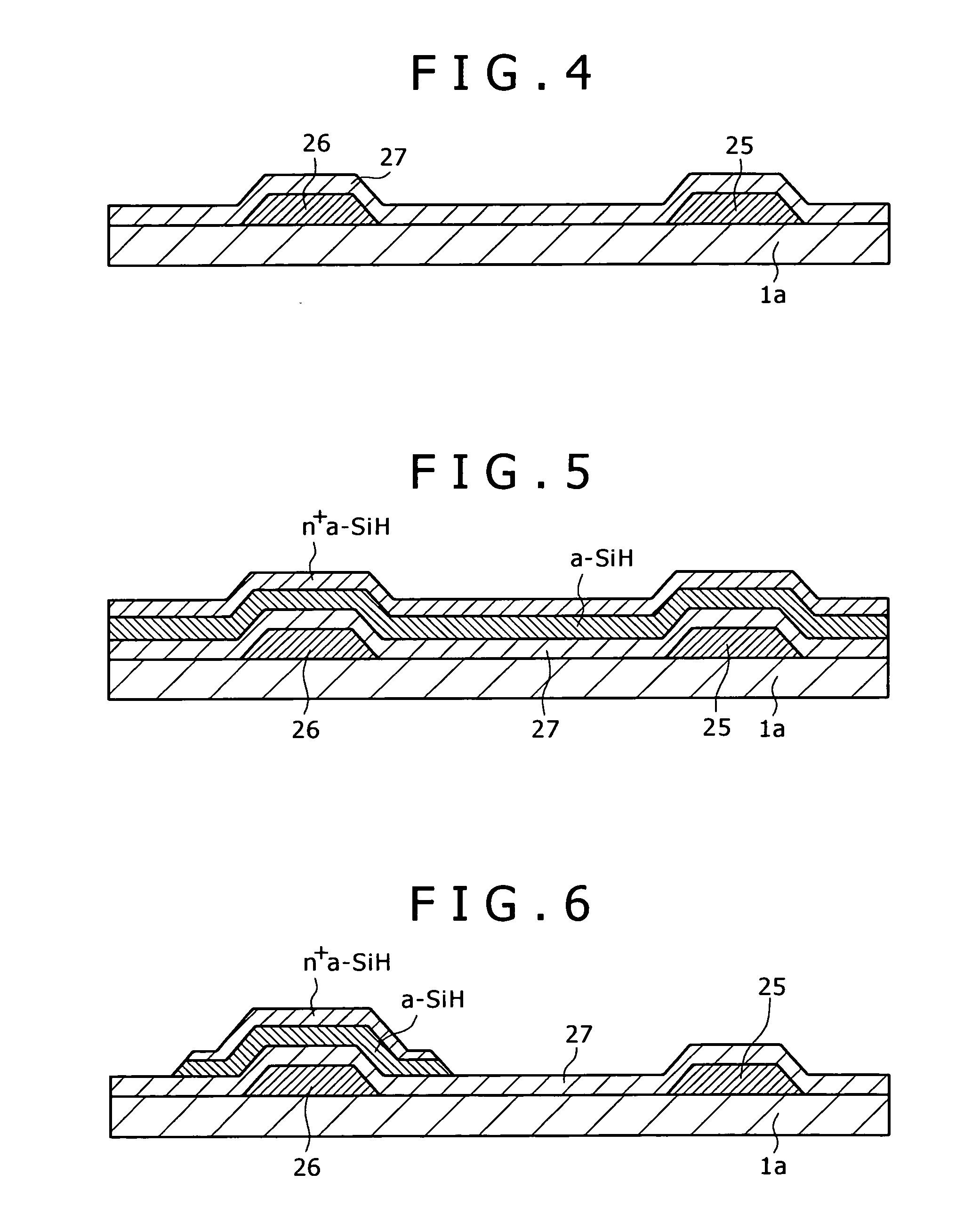

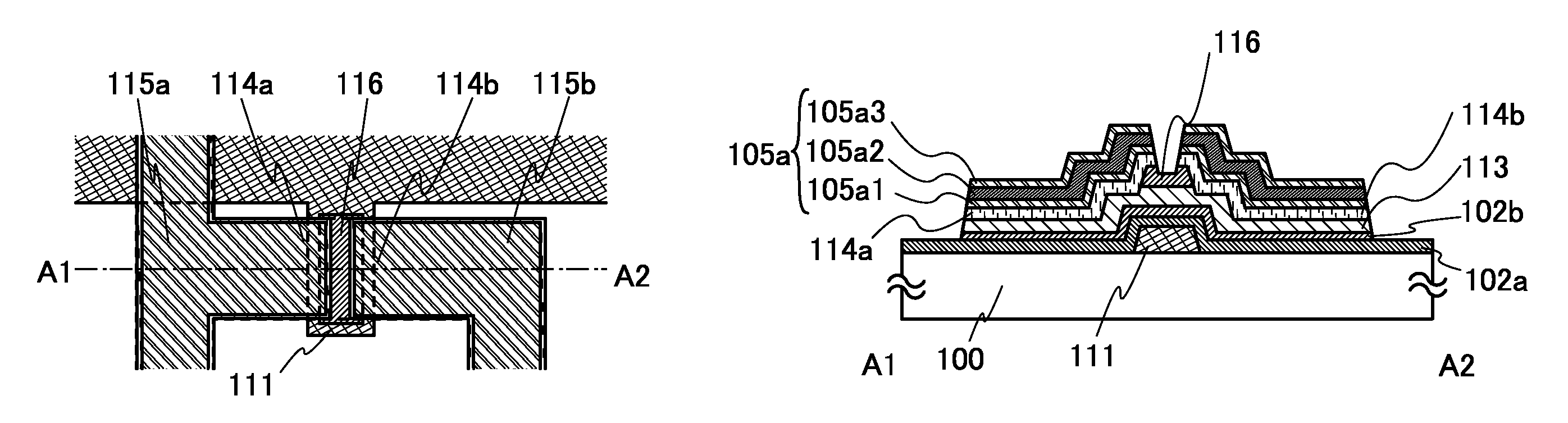

Method for fabricating semiconductor device, and electro-optical device, integrated circuit and electronic apparatus including the semiconductor device

InactiveUS7547589B2High resolutionDecrease productivityTransistorOther printing matterProduction rateEngineering

The invention provides a technique that enables formation of minute patterns on an uneven substrate in volume production without reducing productivity. The method for fabricating a semiconductor device includes: first patterning a semiconductor film on a substrate to form element regions, each of which will be provided with a source / drain region and a channel region, second forming a gate insulating film covering segments of the patterned semiconductor film in the respective element regions, third forming gate electrodes on the gate insulating film at predetermined positions, and fourth forming the source / drain region and the channel region in each element region. At least the gate electrodes are formed by a process including an exposure step through a holographic exposure mask in the third step, and by a process including an exposure step through a projection exposure mask, the element regions are formed in the first step, and the source / drain regions and the channel regions are formed in the fourth step.

Owner:SEIKO EPSON CORP

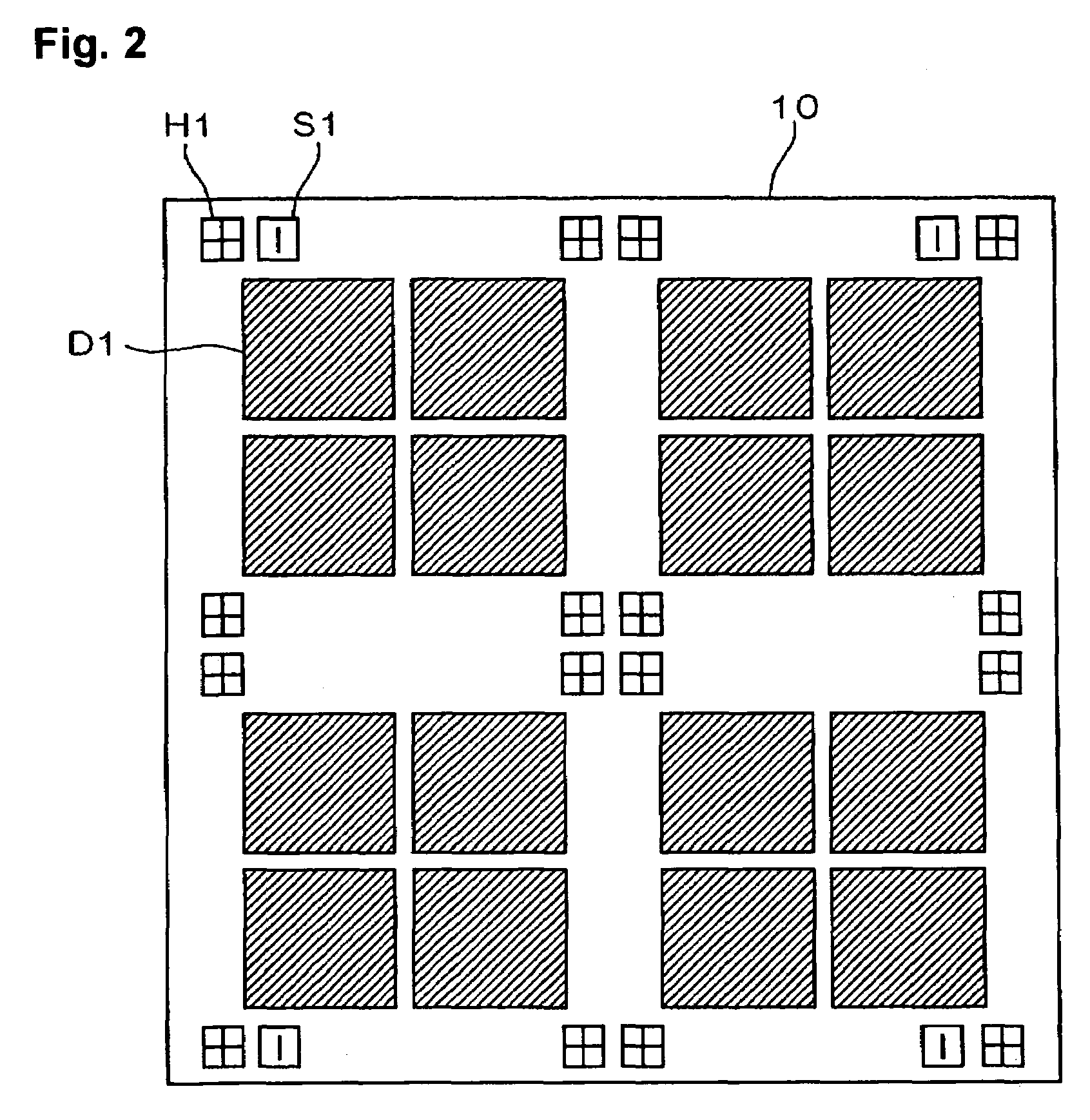

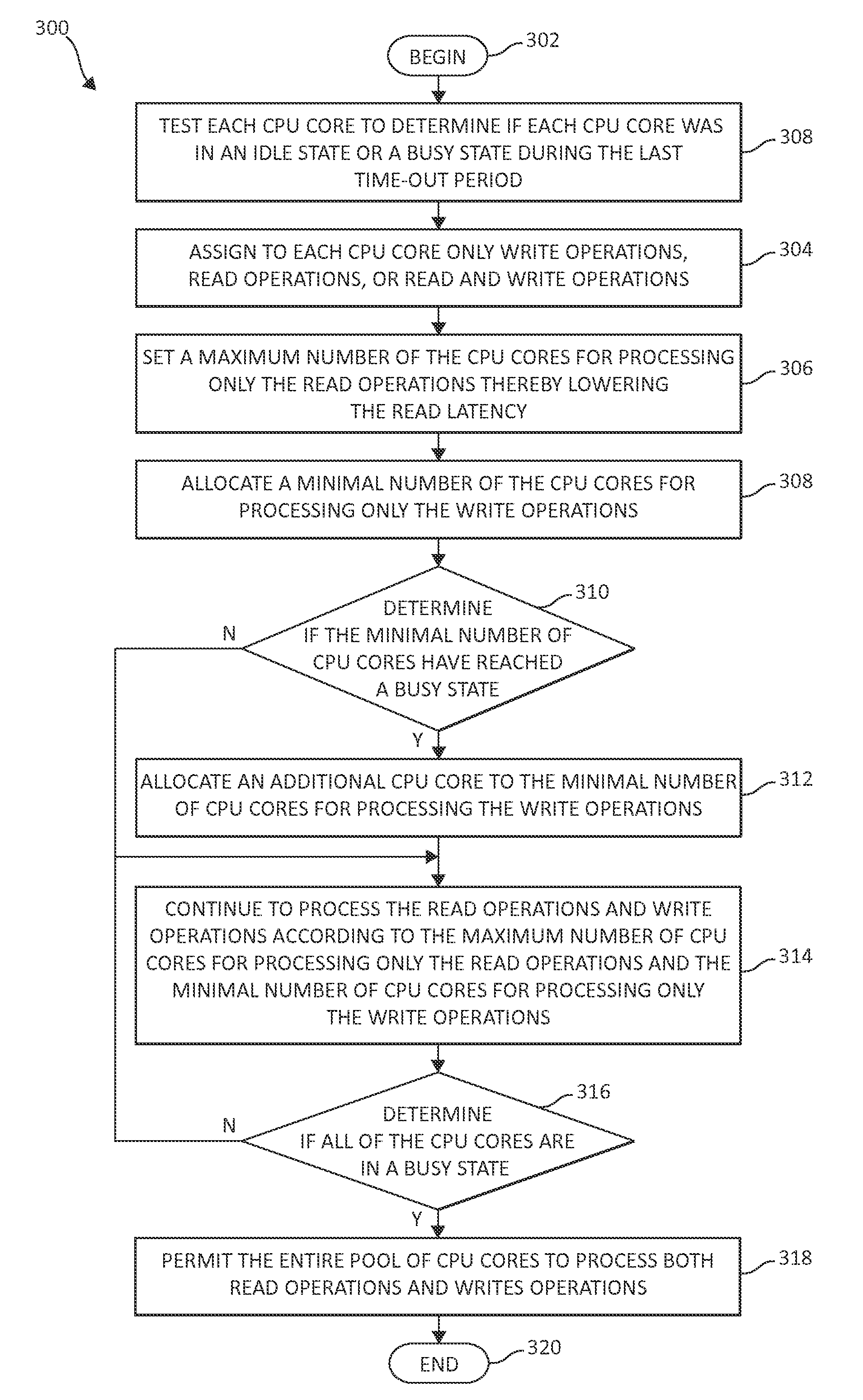

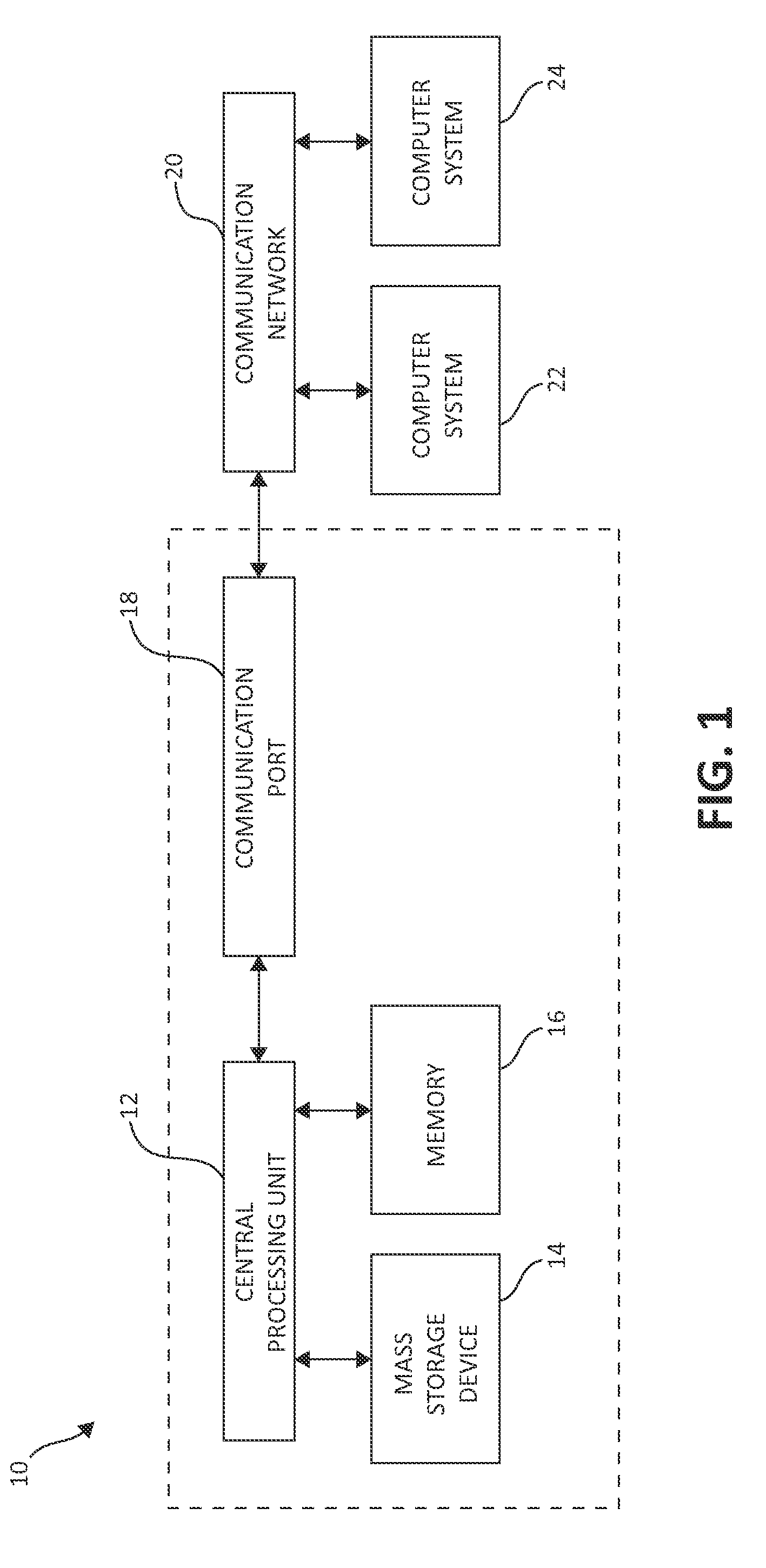

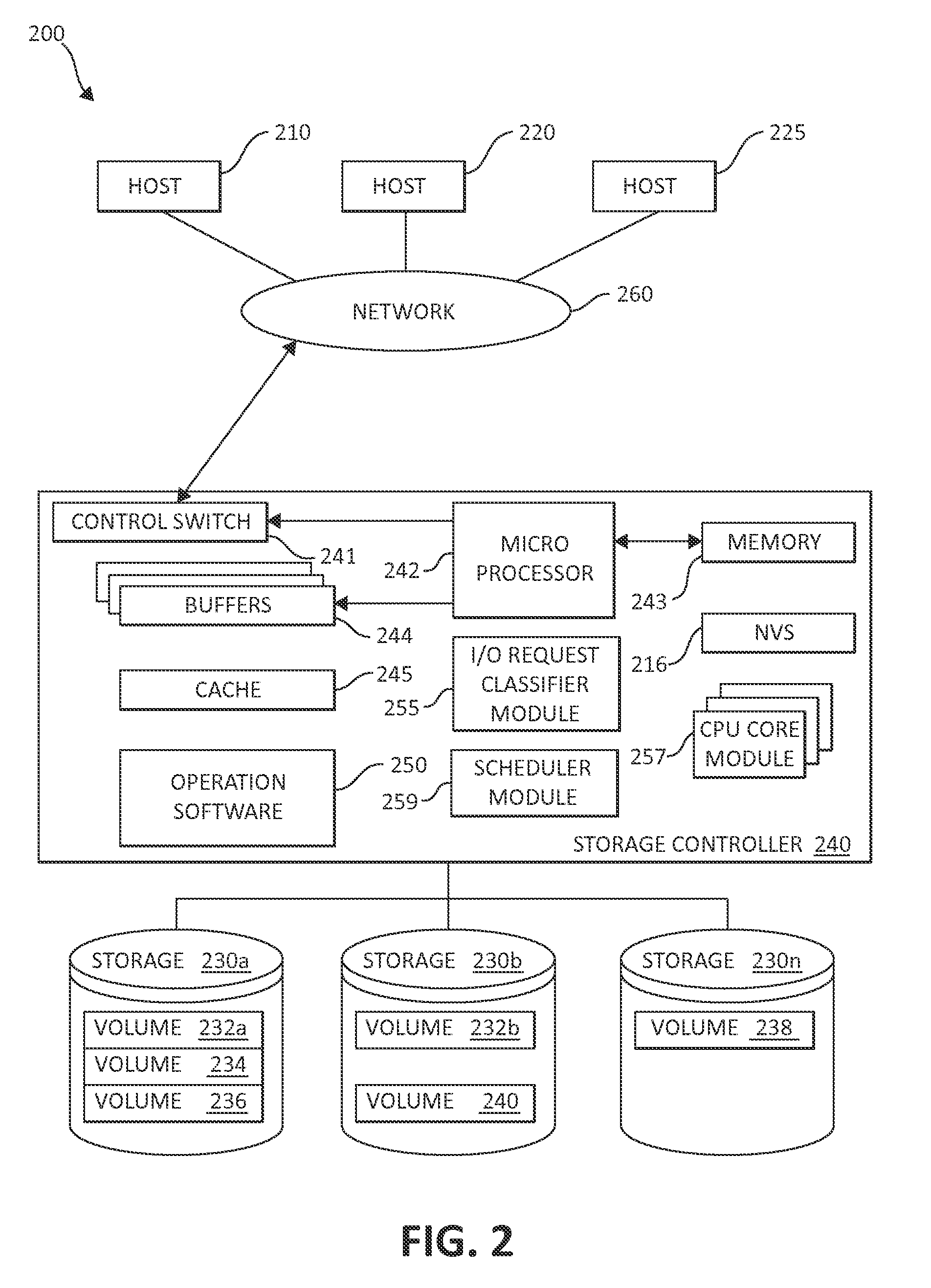

Reducing read latency using a pool of processing cores

ActiveUS8930633B2Avoid read latencyLower read latencyInput/output to record carriersHardware monitoringProcessing coreComputer science

Owner:INT BUSINESS MASCH CORP

Method of recovering and reproducing substrates and method of producing semiconductor wafers

InactiveUS20050037595A1Efficiently and economically be producedDecrease productivitySemiconductor/solid-state device manufacturingNitrideSemiconductor

A method of recovering a first substrate, including the steps of: sticking a second substrate on a semiconductor layer epitaxially grown on the first substrate; and separating the semiconductor layer and the first substrate. Furthermore, a method of reproducing a first substrate, including the step of surface processing the first substrate separated. Furthermore, a method of reproducing a first substrate, including the step of homoepitaxially growing the first substrate surface processed. Furthermore, a method of producing a semiconductor wafer, including the step of epitaxially growing a semiconductor layer on a first substrate. Thus a group III nitride or similar, expensive substrate can be used to efficiently and economically, epitaxially grow a group III nitride or similar semiconductor layer.

Owner:SUMITOMO ELECTRIC IND LTD

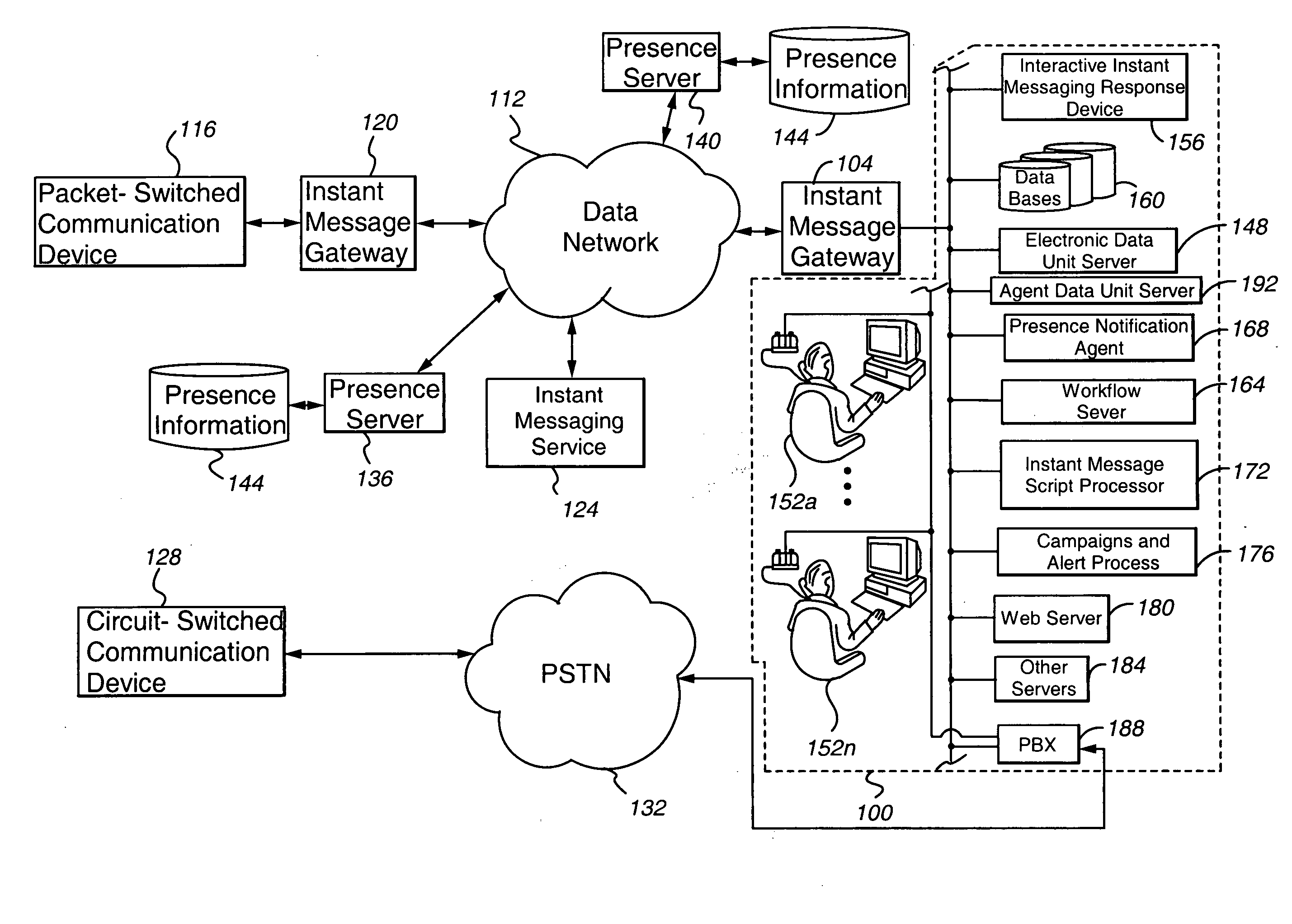

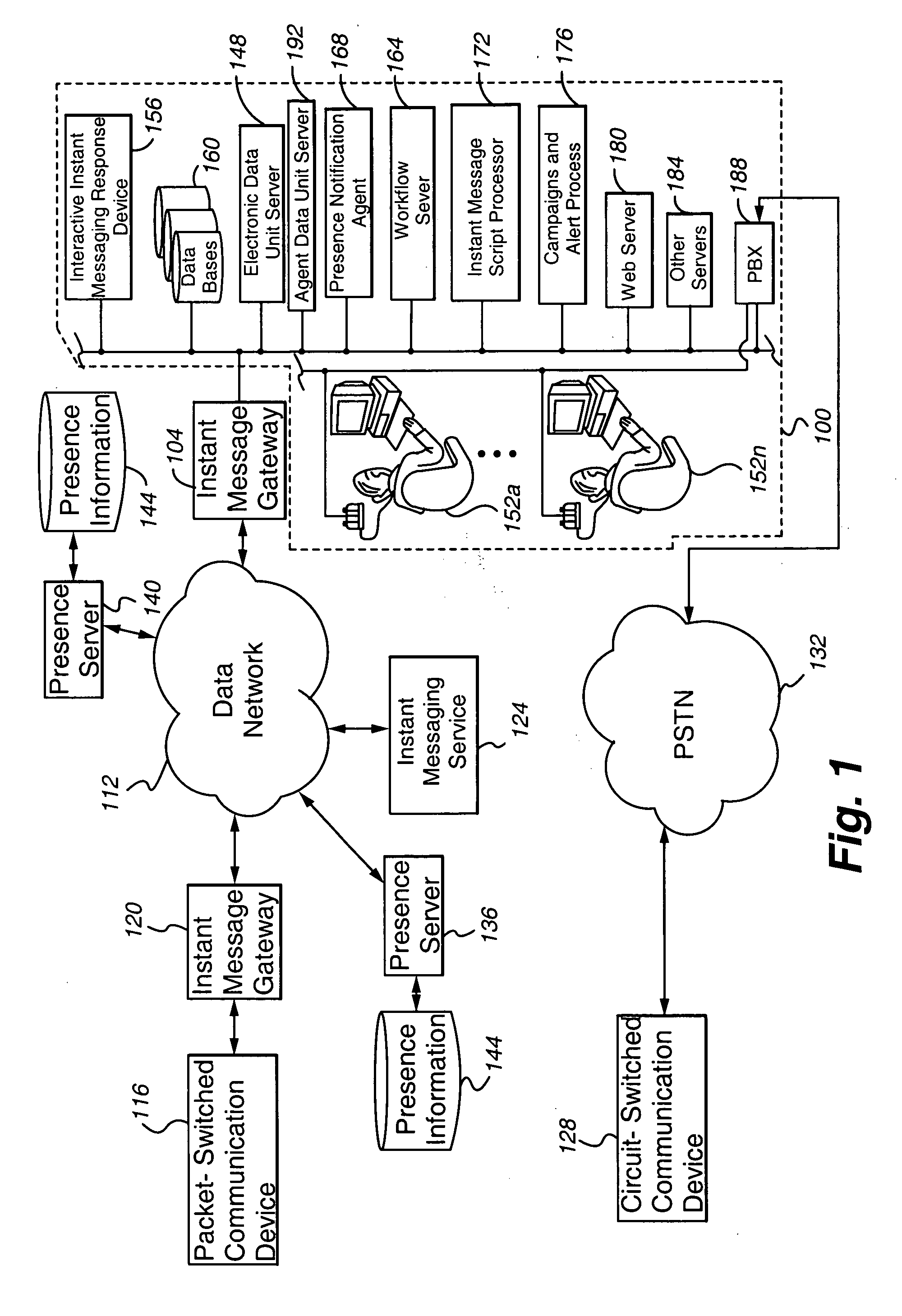

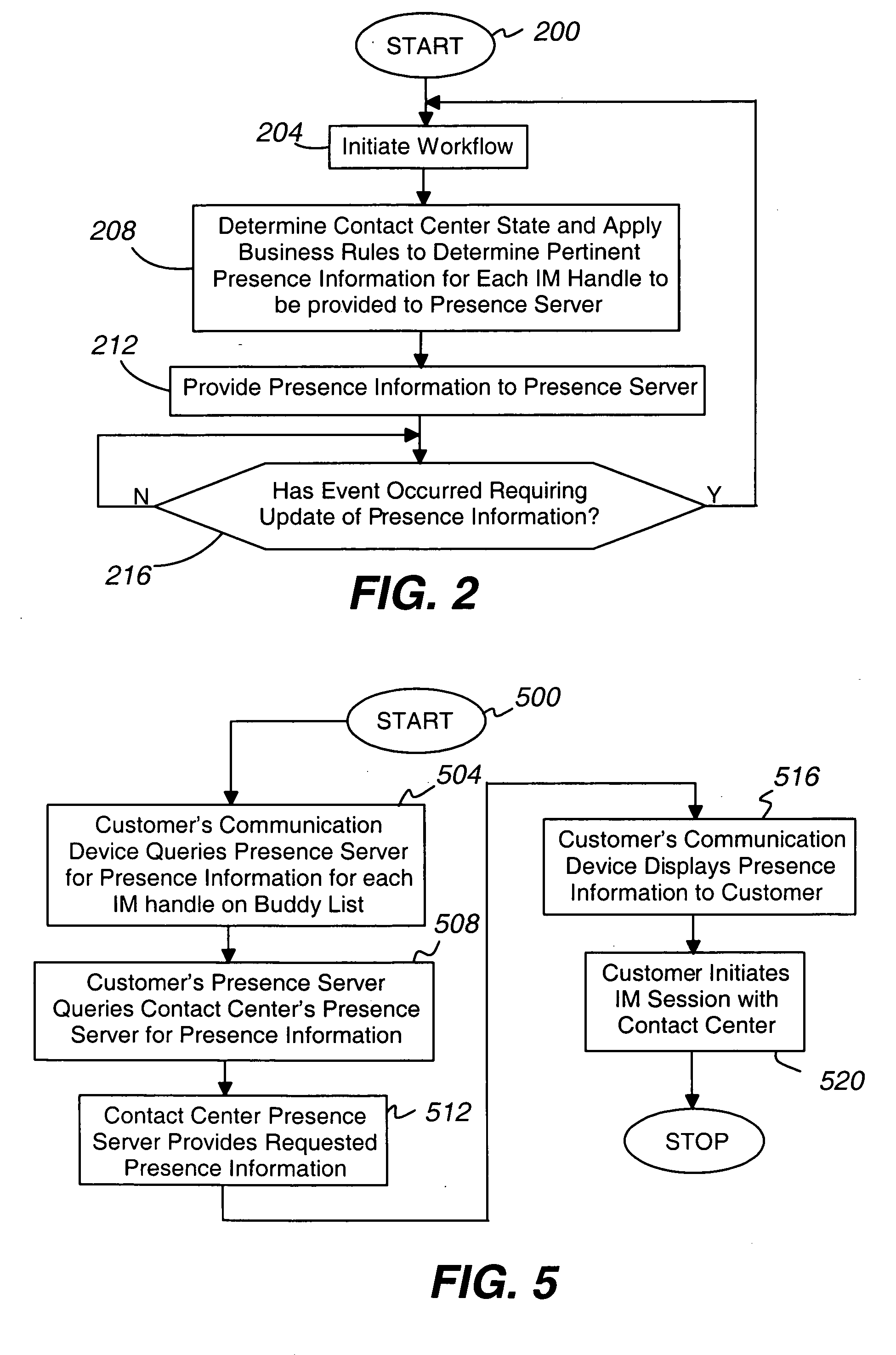

Using business rules for determining presence

ActiveUS20050187781A1Reduce expensesEfficient and customer attractiveSpecial service for subscribersData switching networksMessage passingBusiness rule

The present invention provides various contact center embodiments for interacting with customers using instant messaging. In one embodiment, the contact center is configured to receive instant message notifications from a customer when the customer is available for contact by instant messaging. In another embodiment, the contact center is configured to route sessionless instant messages only to a selected agent for a specified period of time. In another embodiment, the contact center is configured to provide to customers presence information for administered instant message addresses before the customers contact the contact center. In another embodiment, the contact center is configured to perform an outbound instant messaging campaign or alert with customers.

Owner:AVAYA INC

Preparation of recombinant factor VIII in a protein free medium

InactiveUS6171825B1Eliminate and at least greatly reduce riskImprove productivityFactor VIICulture processFactor iiManganese

Recombinant Factor VIII can be produced in relatively large quantities on a continuous basis from mammalian cells in the absence of any animal-derived proteins such as albumin by culturing the cells in a protein free medium supplemented with polyol copolymers, preferably in the presence of trace metals such as copper. In very preferred embodiments, the medium includes a polyglycol known as Pluronic F-68, copper sulfate, ferrous sulfate / EDTA complex, and salts of trace metals such as manganese, molybdenum, silicon, lithium and chromium. With an alternative medium which included trace copper ions alone (without polyol copolymers) we were also able to enhance the productivity of Factor VIII in recombinant cells such as BHK cells that are genetically engineered to express Factor VIII.

Owner:BAYER HEALTHCARE LLC +1

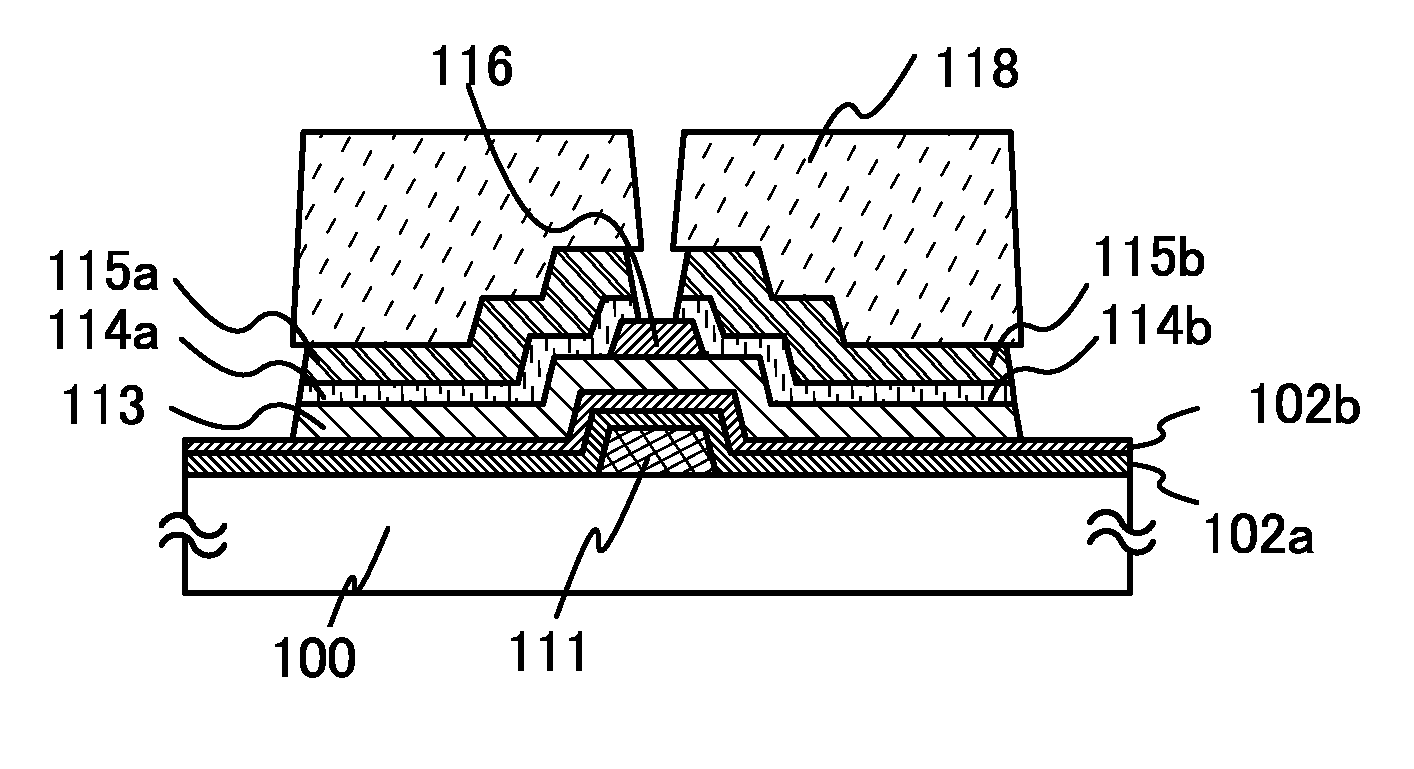

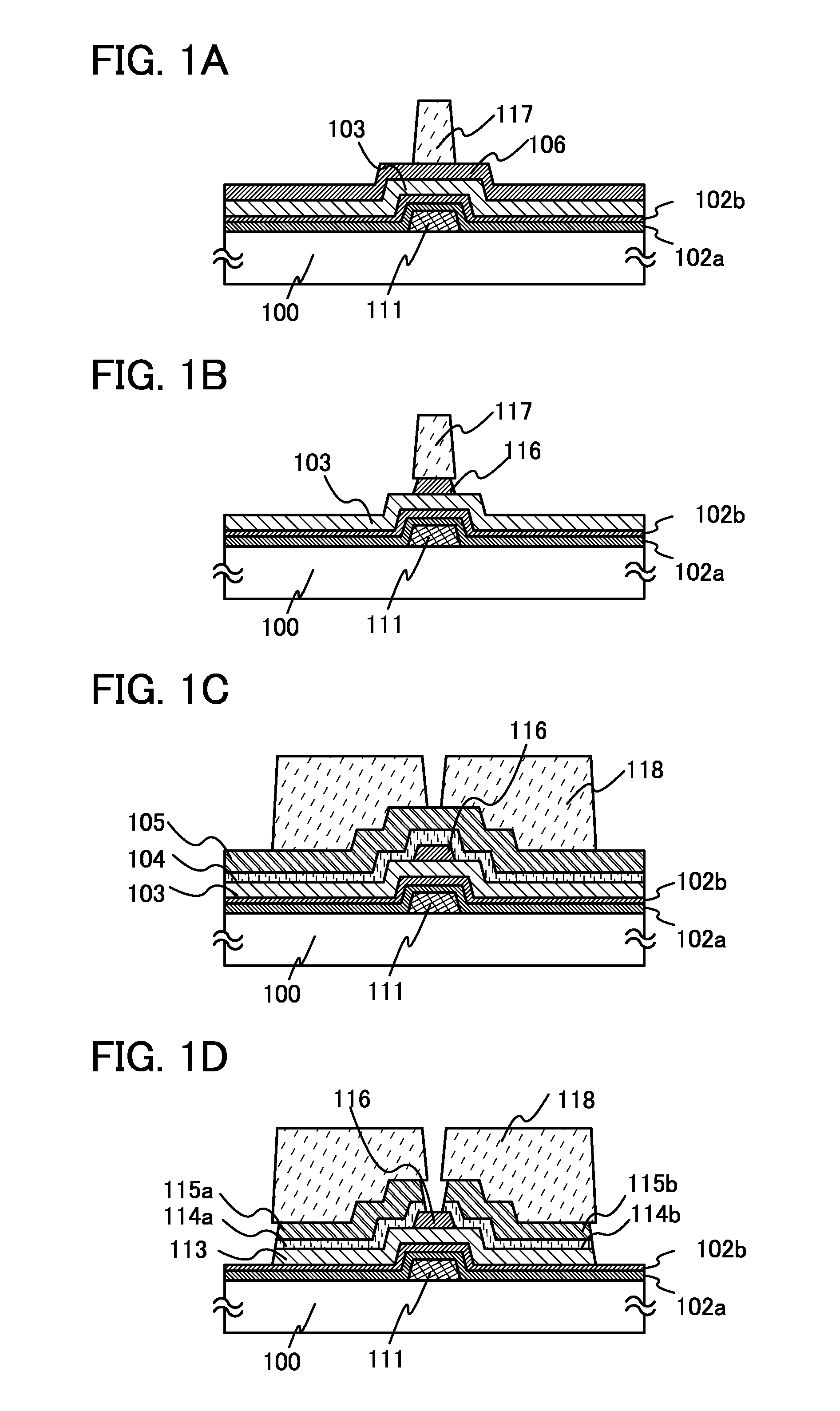

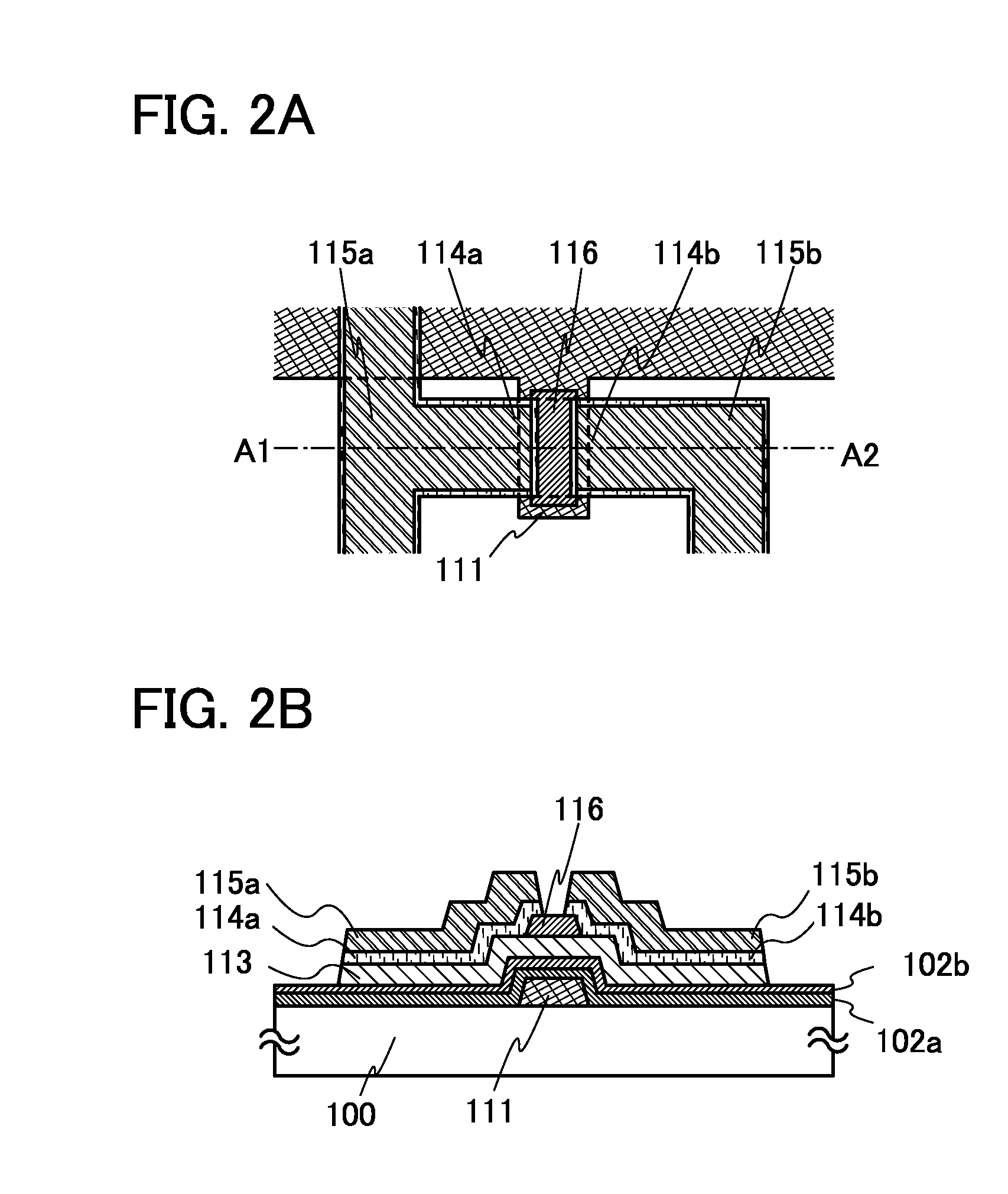

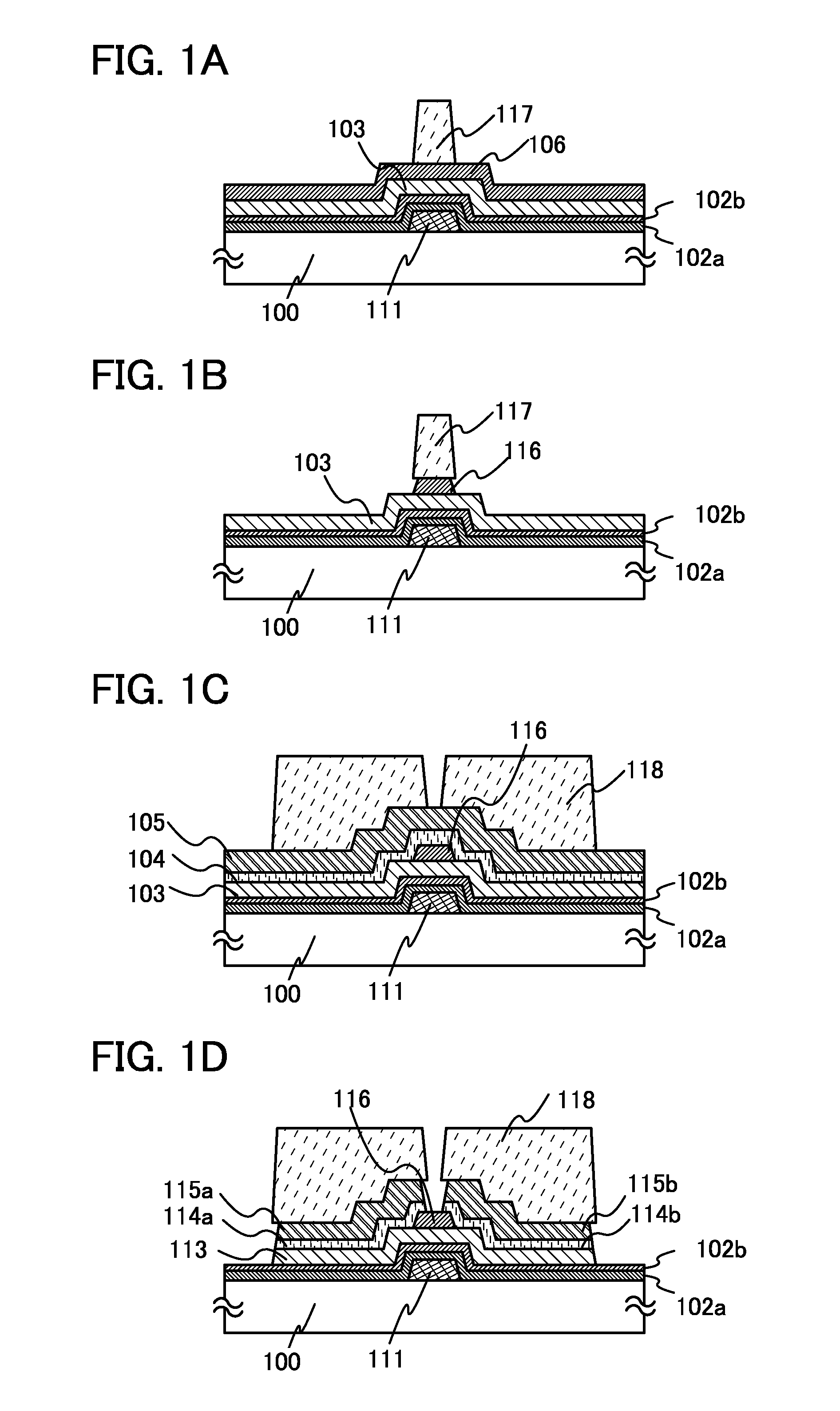

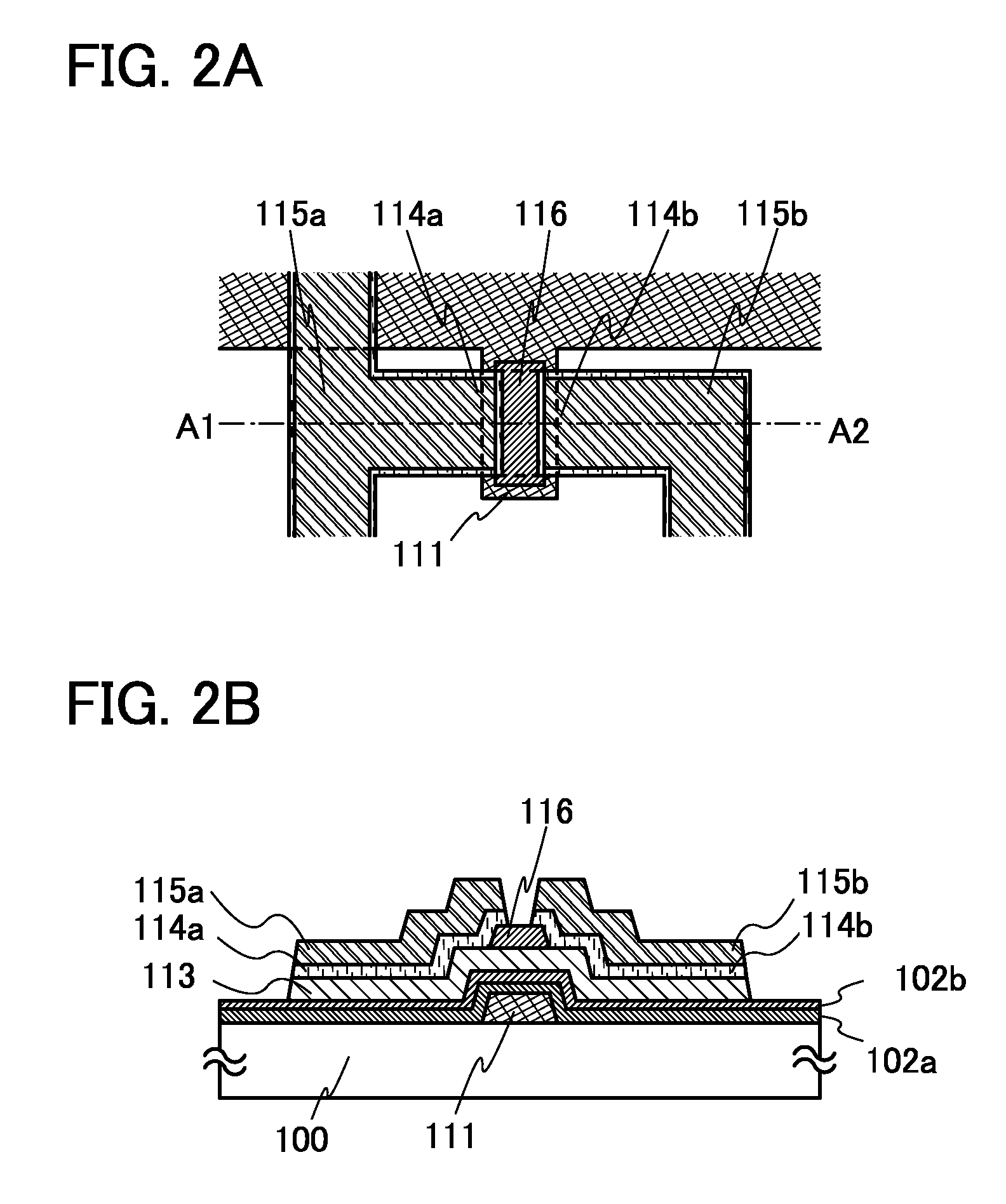

Method for manufacturing semiconductor device

ActiveUS20100035379A1Small photocurrentLow parasitic capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorResist

To provide a method by which a semiconductor device including a thin film transistor with excellent electric characteristics and high reliability is manufactured with a small number of steps. After a channel protective layer is formed over an oxide semiconductor film containing In, Ga, and Zn, a film having n-type conductivity and a conductive film are formed, and a resist mask is formed over the conductive film. The conductive film, the film having n-type conductivity, and the oxide semiconductor film containing In, Ga, and Zn are etched using the channel protective layer and gate insulating films as etching stoppers with the resist mask, so that source and drain electrode layers, a buffer layer, and a semiconductor layer are formed.

Owner:SEMICON ENERGY LAB CO LTD

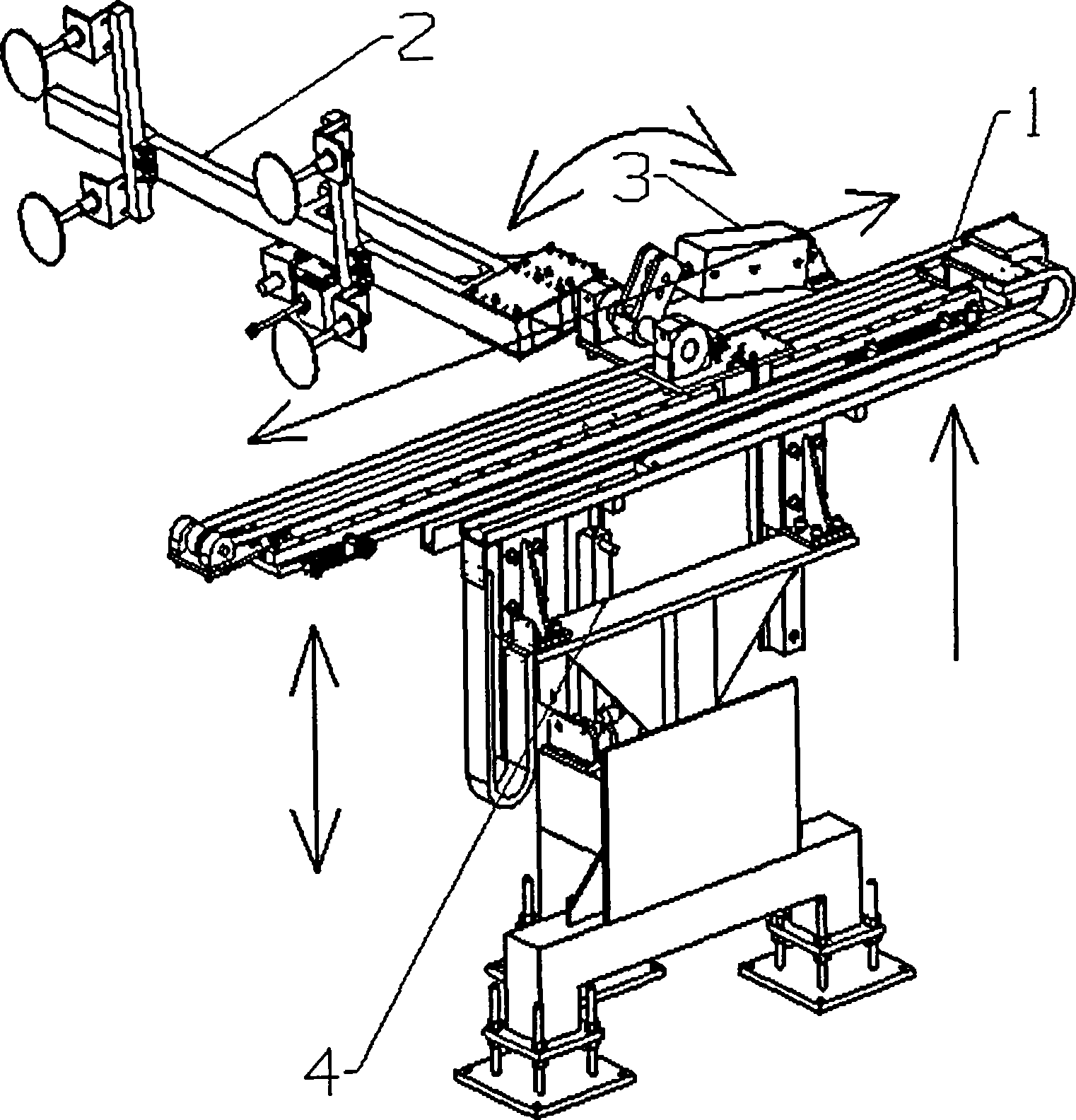

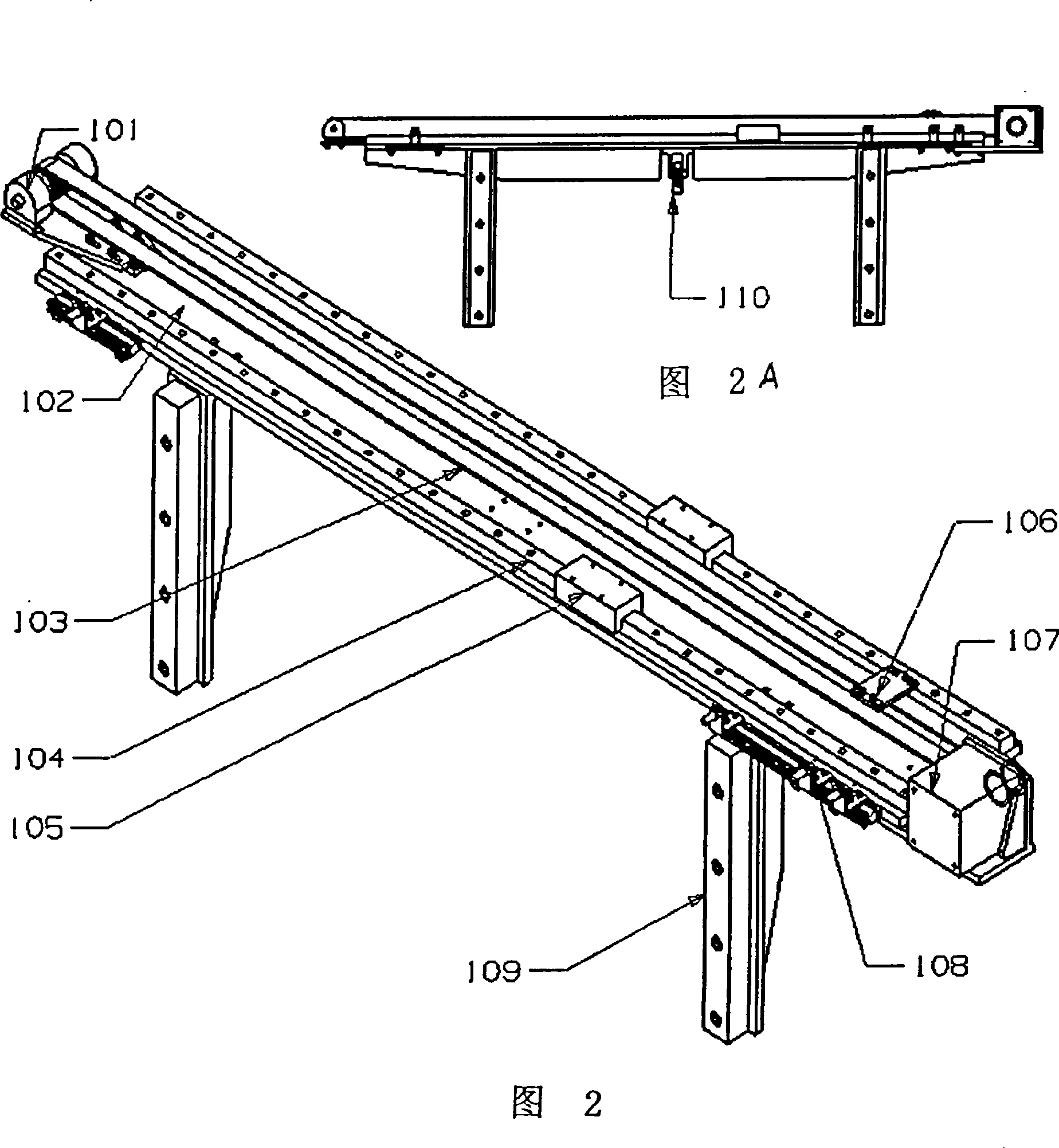

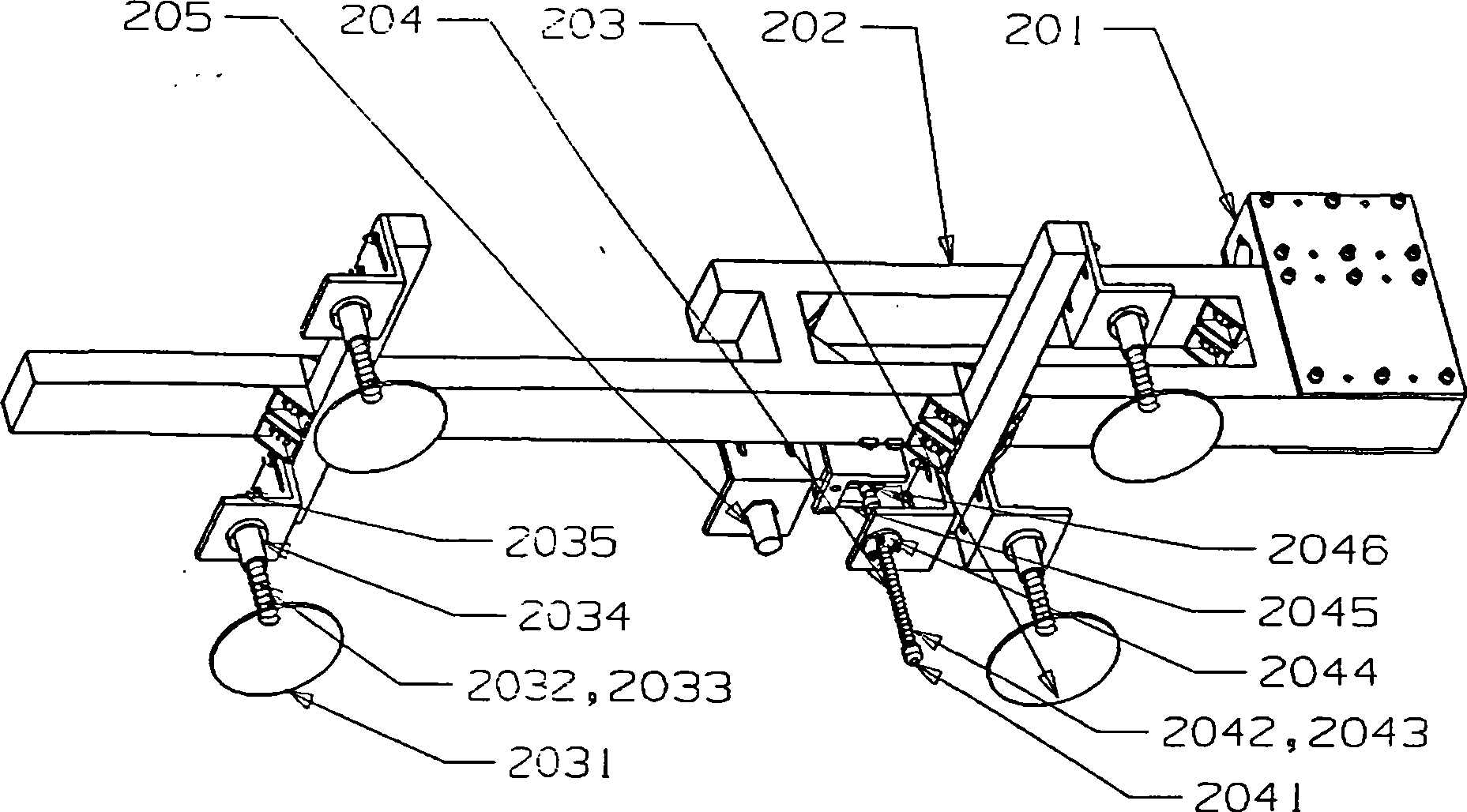

Automatic original-glass fetching manipulator of automobile glass pre-treatment production line

InactiveCN101417422ADecrease productivityExtended duty cycleProgramme-controlled manipulatorJointsRotational axisProduction line

The invention relates to an automatic loading machine hand of car glass pre-treatment production lines, comprising a driving mechanism platform, a grabbing arm and a sense touch mechanism, an arm rotary mechanism and a rising and falling buffering mechanism; wherein, the driving mechanism platform is arranged on the rising and falling buffering mechanism which consists of 3 three-foot single-leg frames; the grabbing arm and the sense touch mechanism are connected with a rotation axis of the arm rotary mechanism. The invention has the advantages that the rising and falling movements along a Z shaft direction are carried out by using a dual action cylinder to drive the driving mechanism platform to move from left to right along an X shaft direction, when rising, the grabbing glass is lifted by 300mm so as to separate glass on a stacking frame and avoid a ledge on the stacking frame; when falling, the grabbing glass is led to fall by 300mm to put the glass on a conveyer moving in a Y shaft direction; the device is delicate and aesthetic in shape, and small in occupation space; the design concept is innovative, novel, practical and prospective; the structure is simple; therefore, the machine hand can be easily made, assembled, and programmed and the manufacturing price is low.

Owner:上海耀皮康桥汽车玻璃有限公司

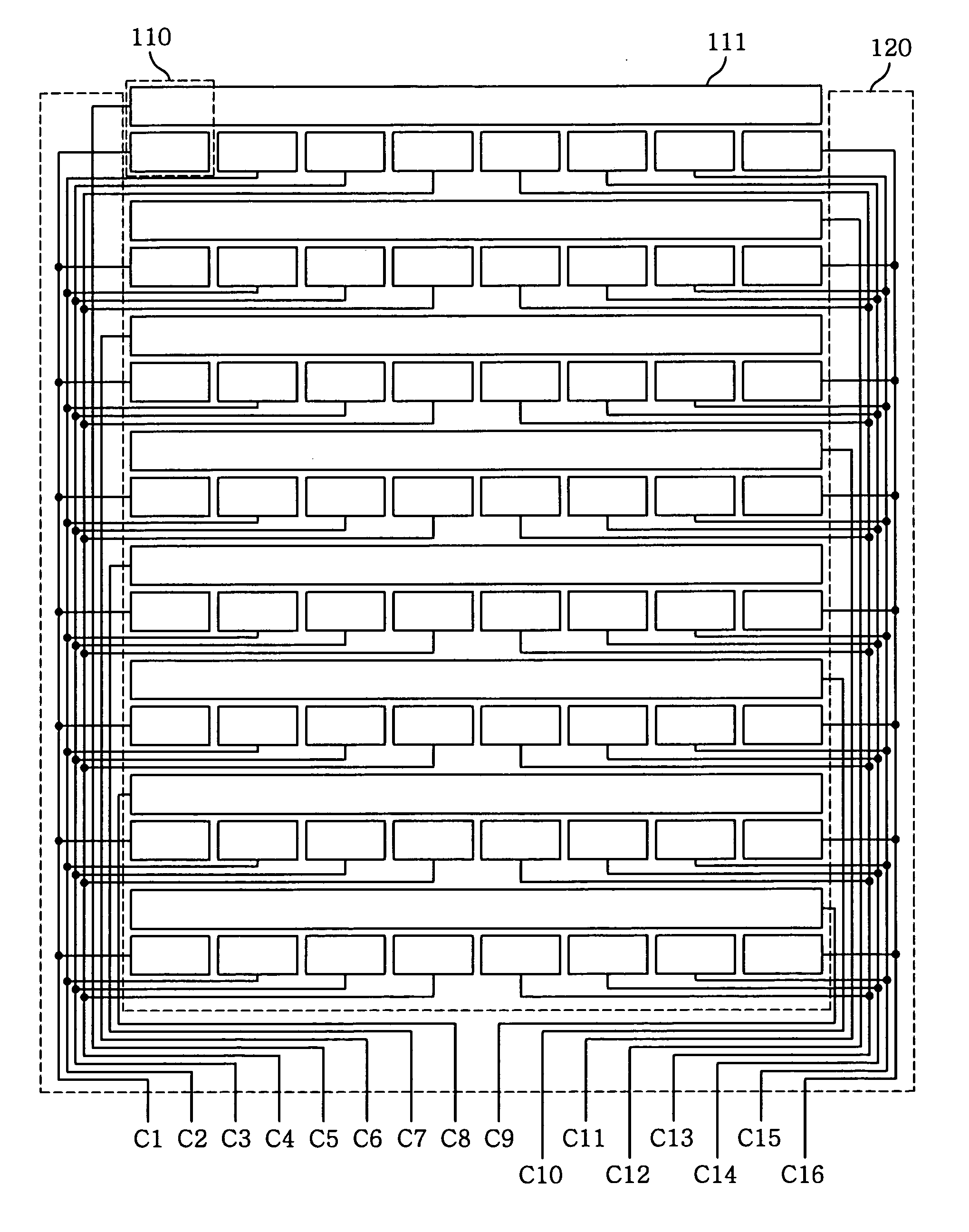

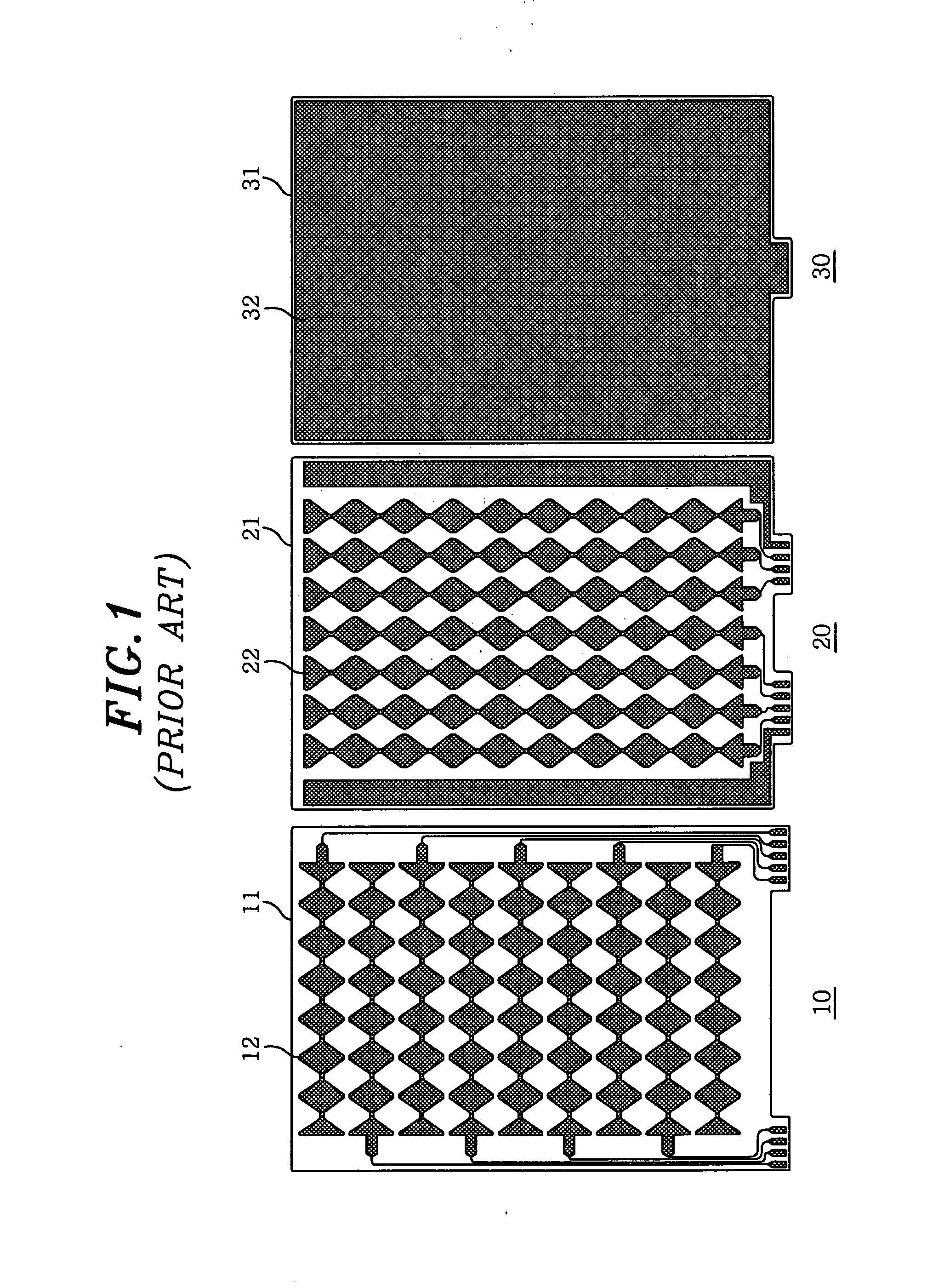

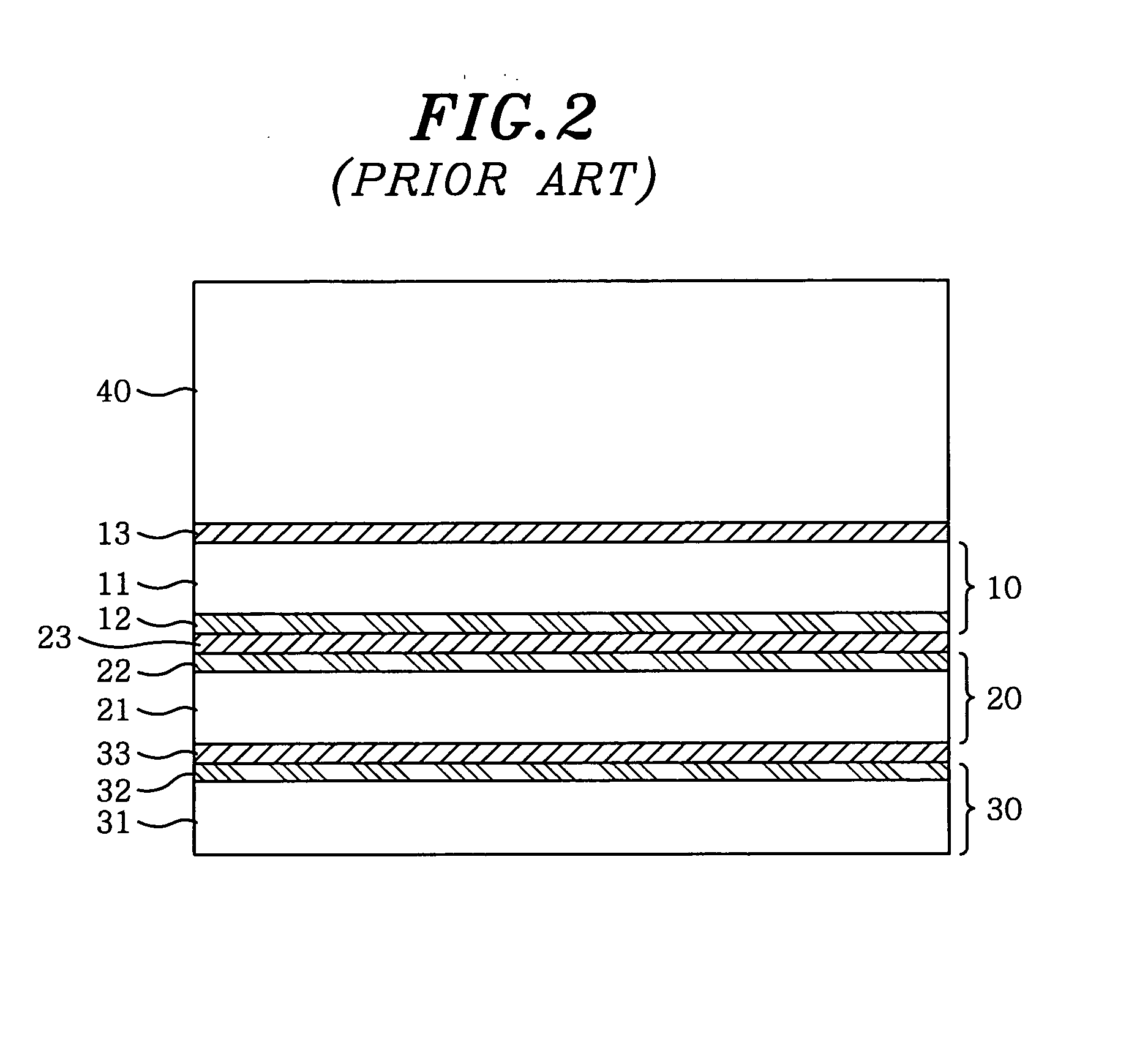

Touch location detecting panel having a simple layer structure

ActiveUS20100090979A1Layer structure is simpleReduce manufacturing costCathode-ray tube indicatorsInput/output processes for data processingLocation detectionEngineering

Owner:MELFAS

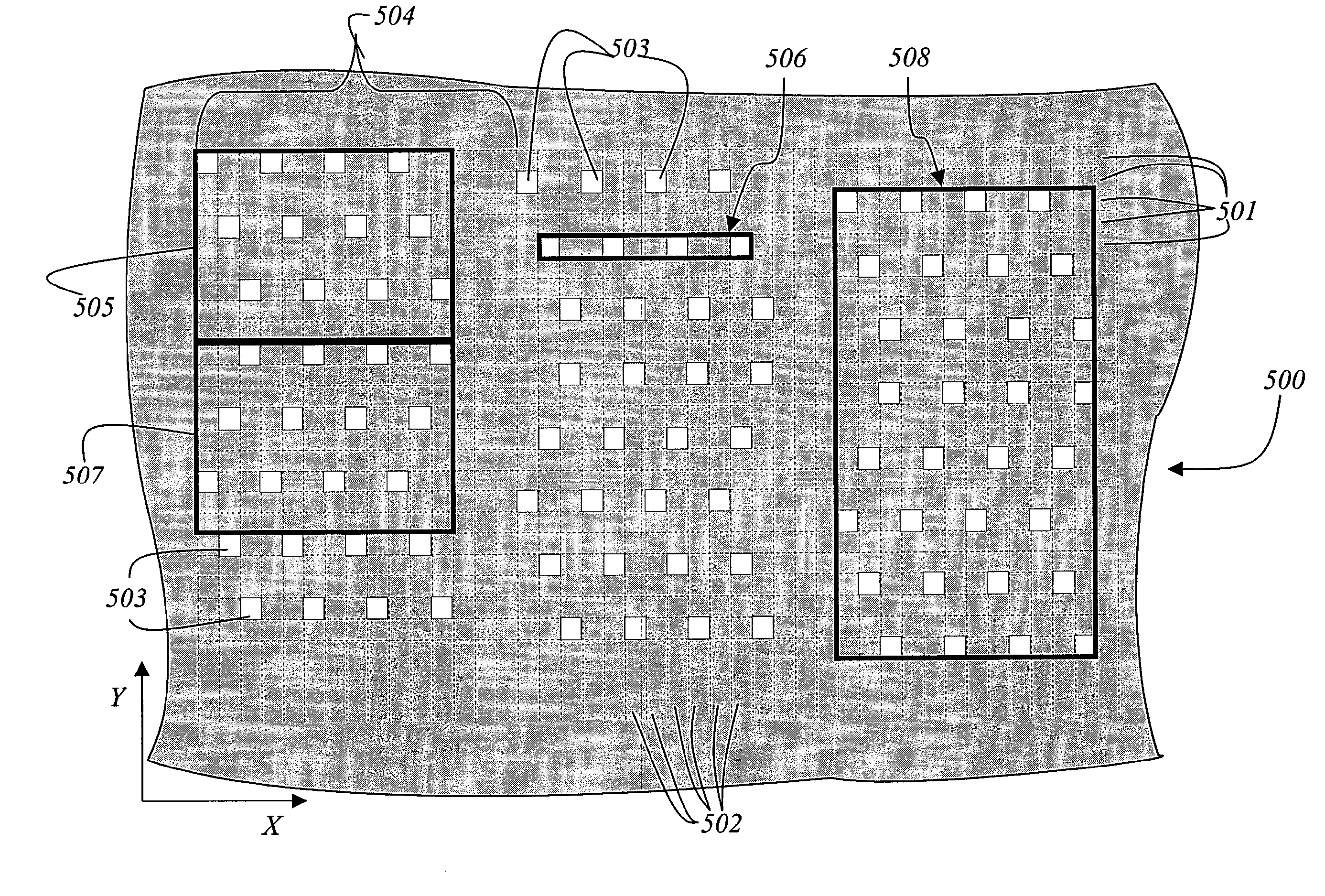

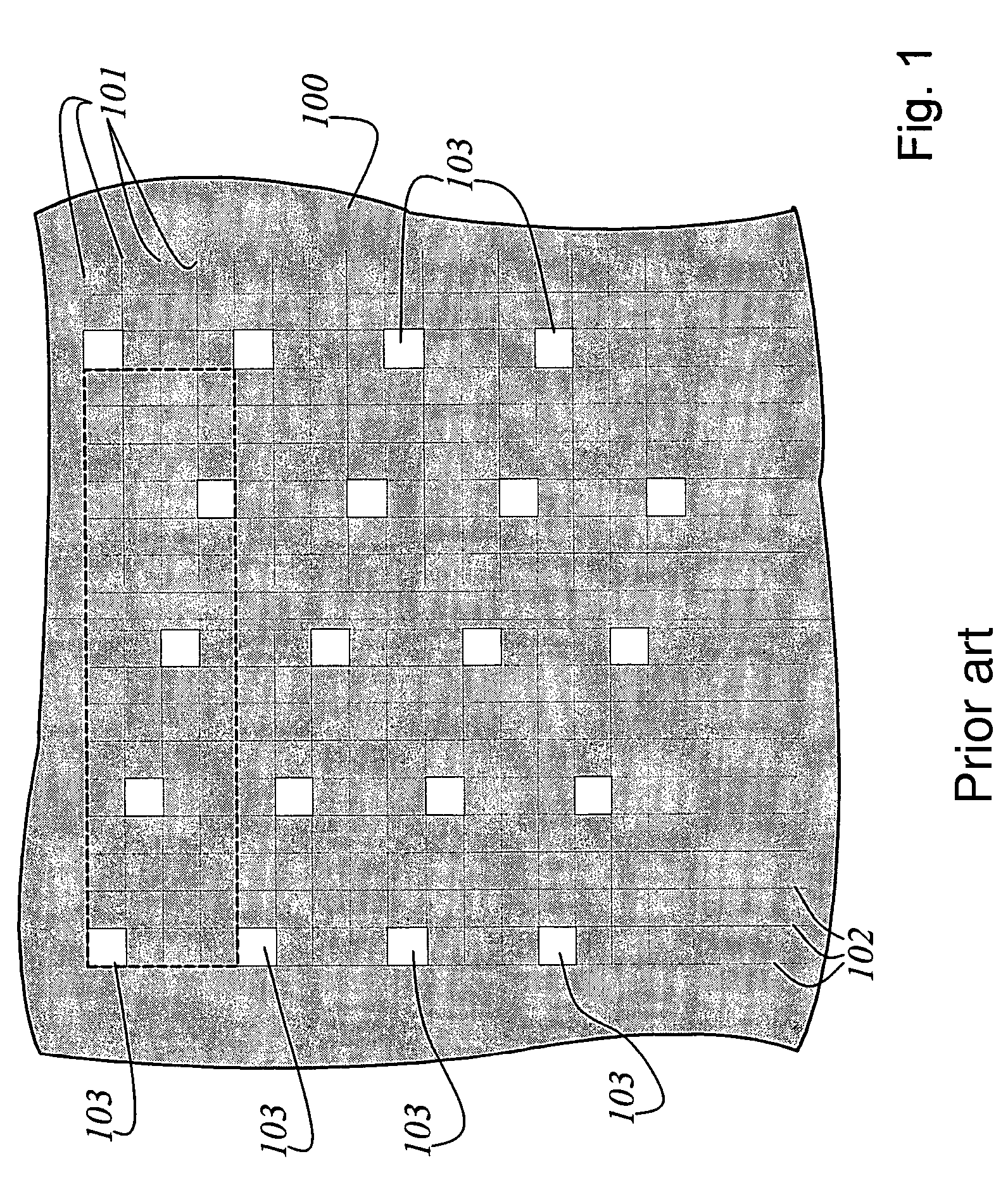

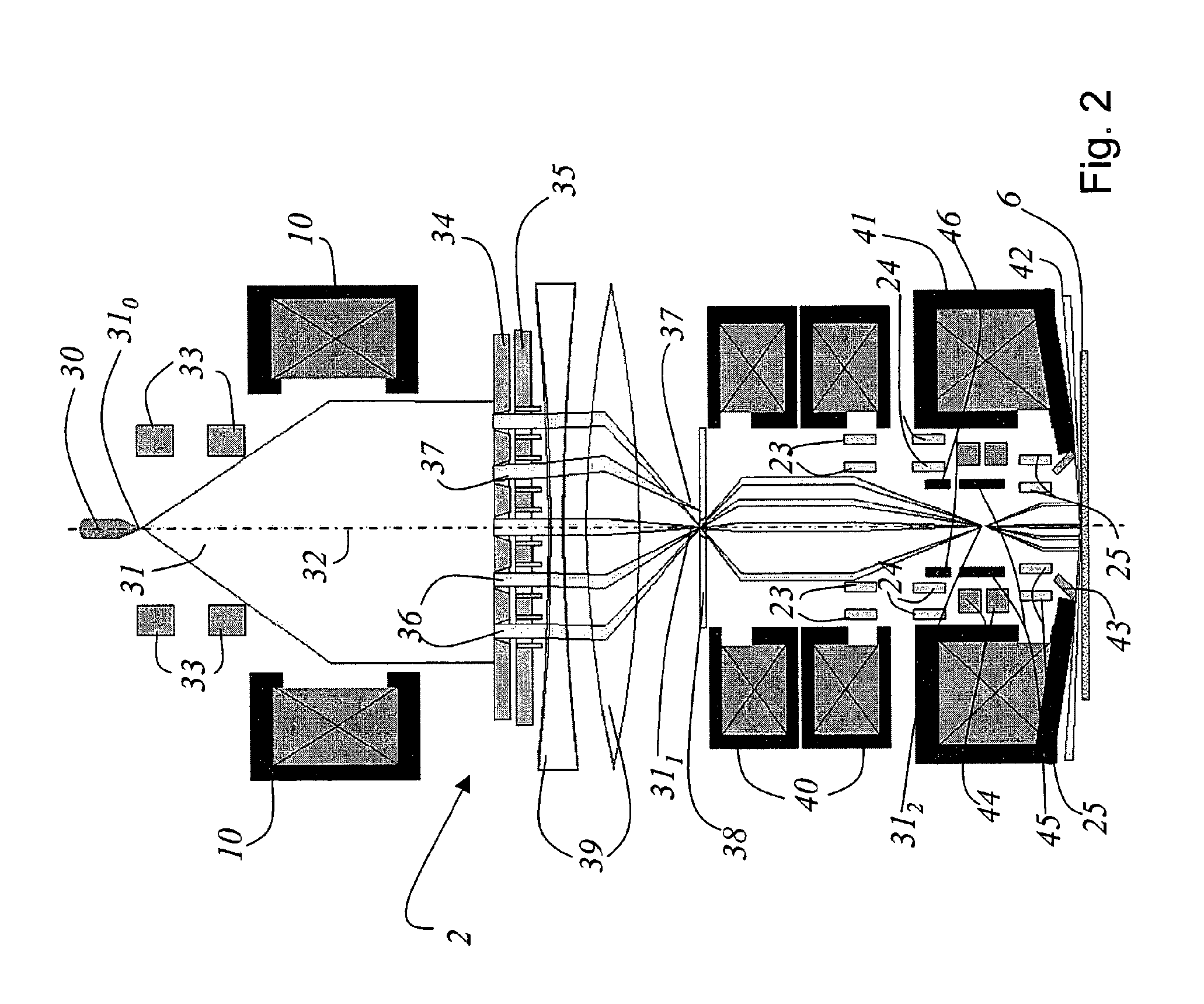

Multi-beam modulator for a particle beam and use of the multi-beam modulator for the maskless structuring of a substrate

InactiveUS7741620B2Avoids elaborate and cost-intensive stepDecrease productivityStability-of-path spectrometersNanoinformaticsParticle beamLight beam

The invention discloses a multibeam modulator which generates a plurality of individual beams from a particle beam. The particle beam illuminates the multibeam modulator at least partially over its surface. The multibeam modulator comprises a plurality of aperture groups composed of aperture row groups. The totality of all aperture rows defines a matrix of m×n cells, where m cells form a row, and k openings are formed in each row. The density of openings within a row is inhomogeneously distributed.

Owner:VISTEC ELECTRON BEAM

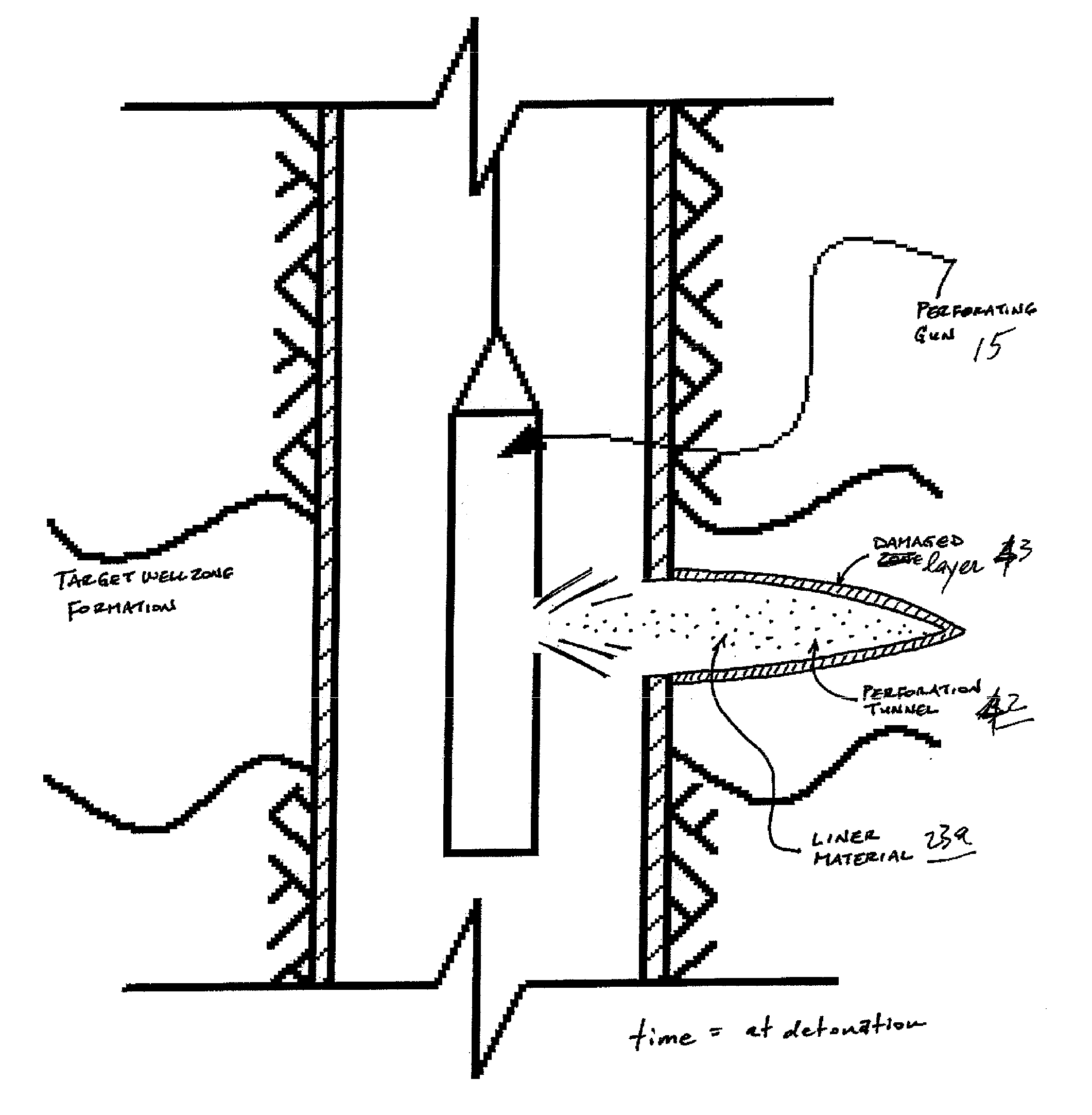

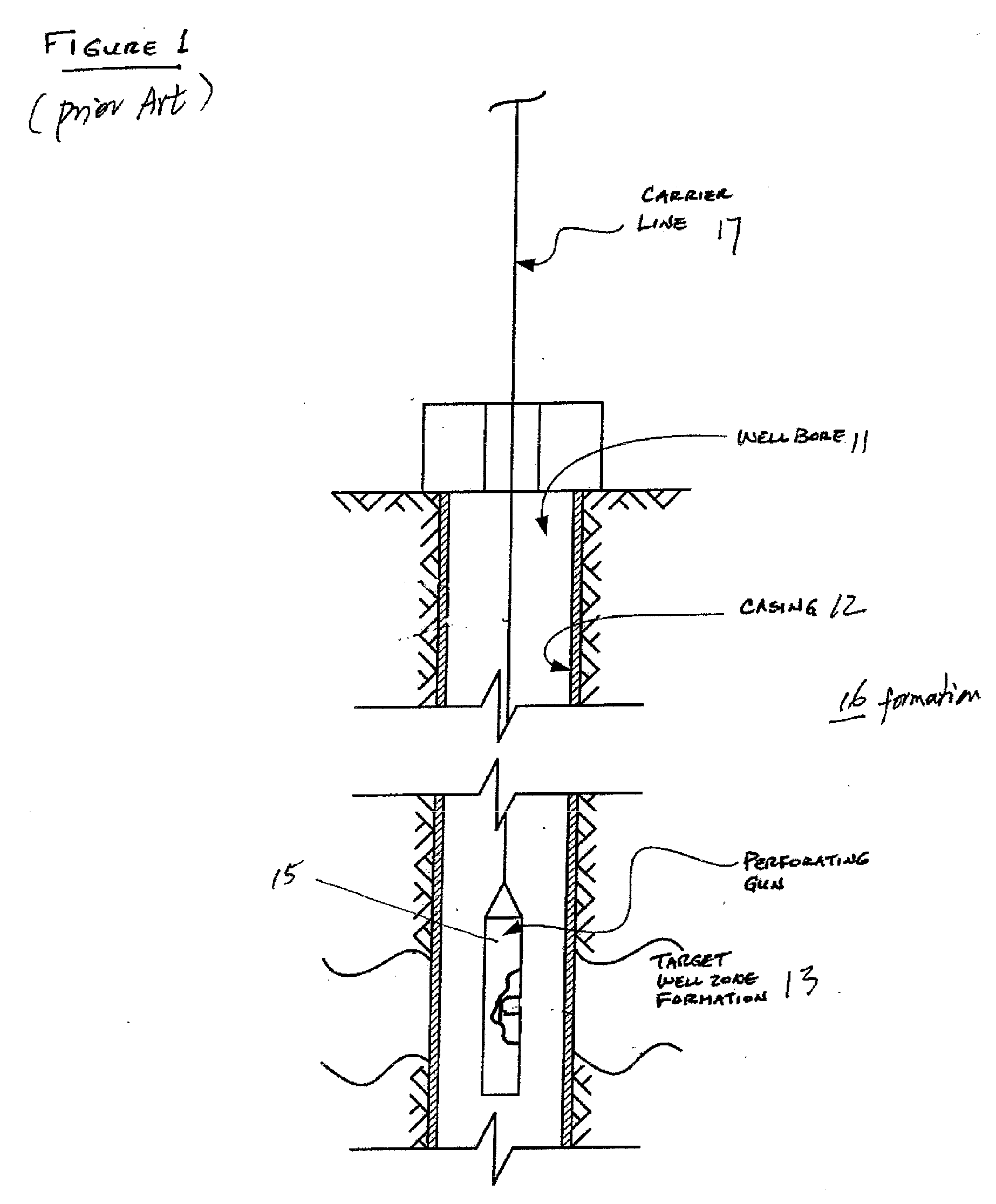

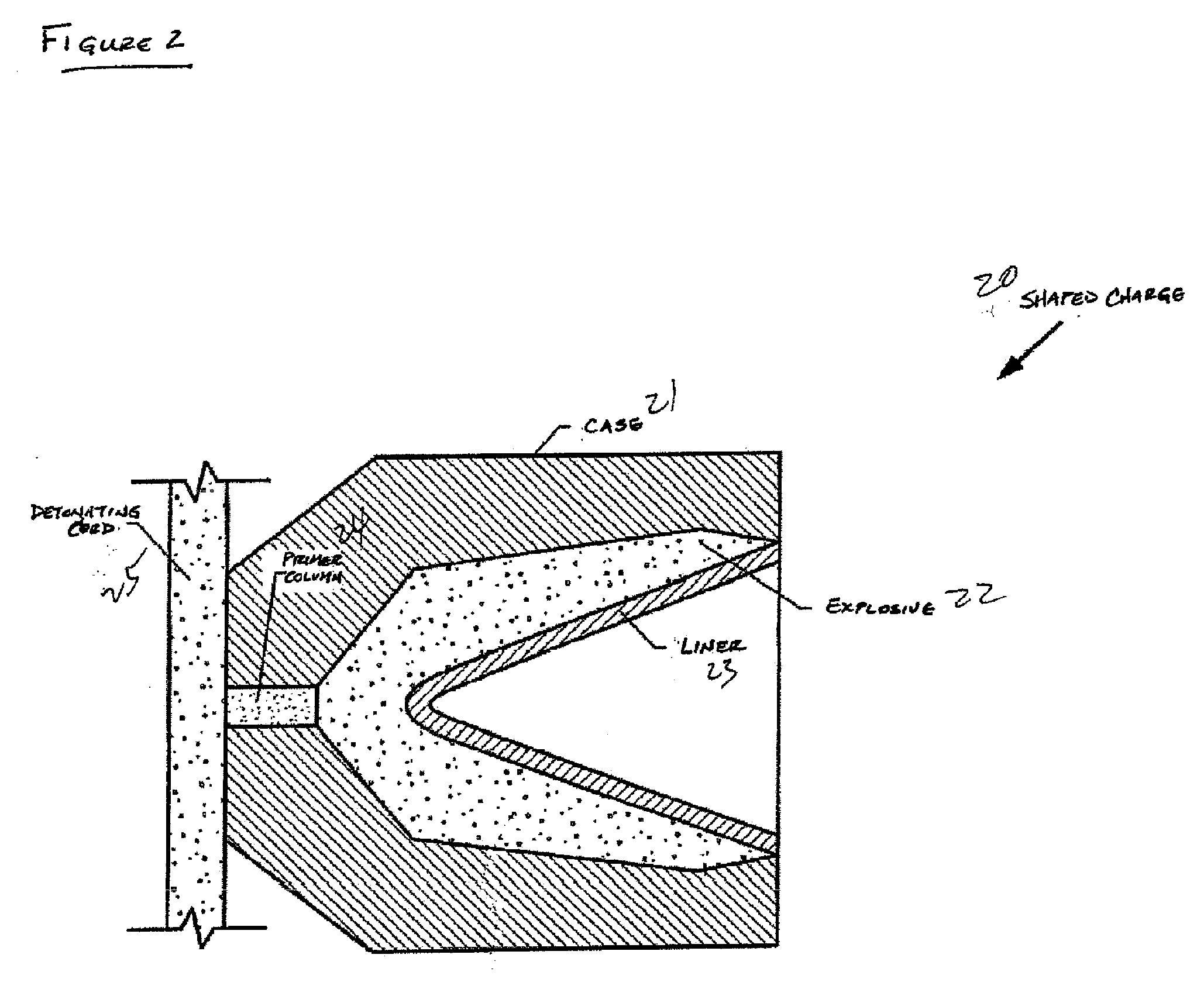

Shaped Charges for Creating Enhanced Perforation Tunnel in a Well Formation

ActiveUS20060266551A1Reduce penetrationDecrease productivityNuclear explosivesFluid removalShaped chargeEngineering

A shaped charge includes a charge case; an explosive disposed inside the charge case; and a liner for retaining the explosive in the charge case, wherein the liner comprises a material reactive with a component of an earth formation. A method for perforating in a well includes disposing a perforating gun in the well, wherein the perforating gun comprises a shaped charge having a charge case, an explosive disposed inside the charge case, and a liner for retaining the explosive in the charge case, wherein the liner includes a material that can react with a component of an earth formation; detonating the shaped charge to form a perforation tunnel in a formation zone; and allowing the material comprising the liner to react with the component of the earth formation.

Owner:SCHLUMBERGER TECH CORP

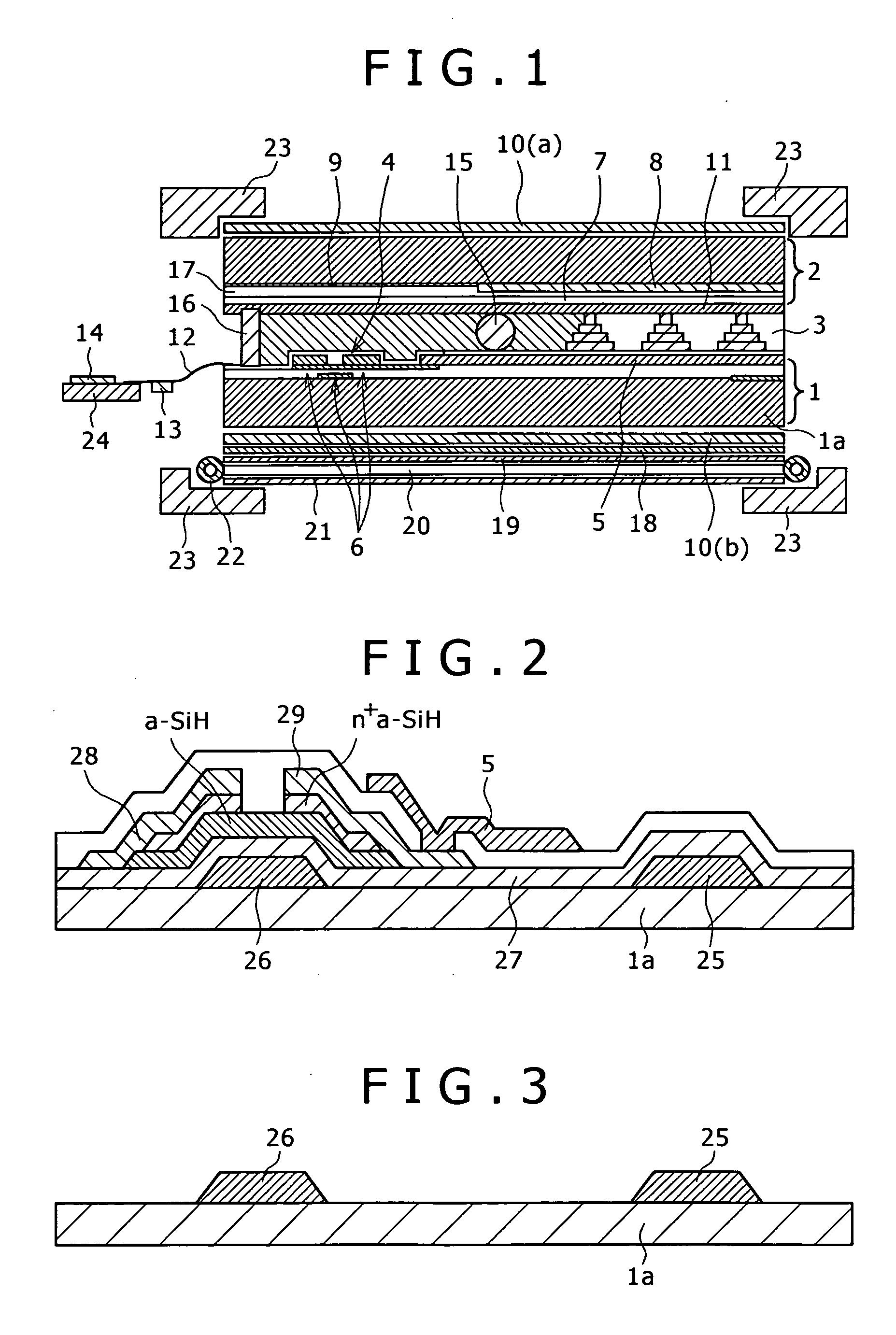

Display device

InactiveUS20060275618A1Low electrical connection resistivityImprove display qualitySolid-state devicesNatural mineral layered productsLiquid-crystal displayDisplay device

A display device in which interconnection—electrode comprising a Cu alloy film having a lower electrical resistivity than Al alloy and a transparent conductive film are directly connected not by way of a refractory metal thin film, wherein the Cu alloy film contains Zn and / or Mg in a total amount from 0.1 to 3.0 at %, or Ni and / or Mn in a total amount from 0.1 to 5 at %, thereby enabling the direct connection at low resistivity between the Cu alloy film and the transparent electrode without using a barrier metal, and giving high display quality in a case of application, for example, to a liquid crystal display.

Owner:KOBE STEEL LTD

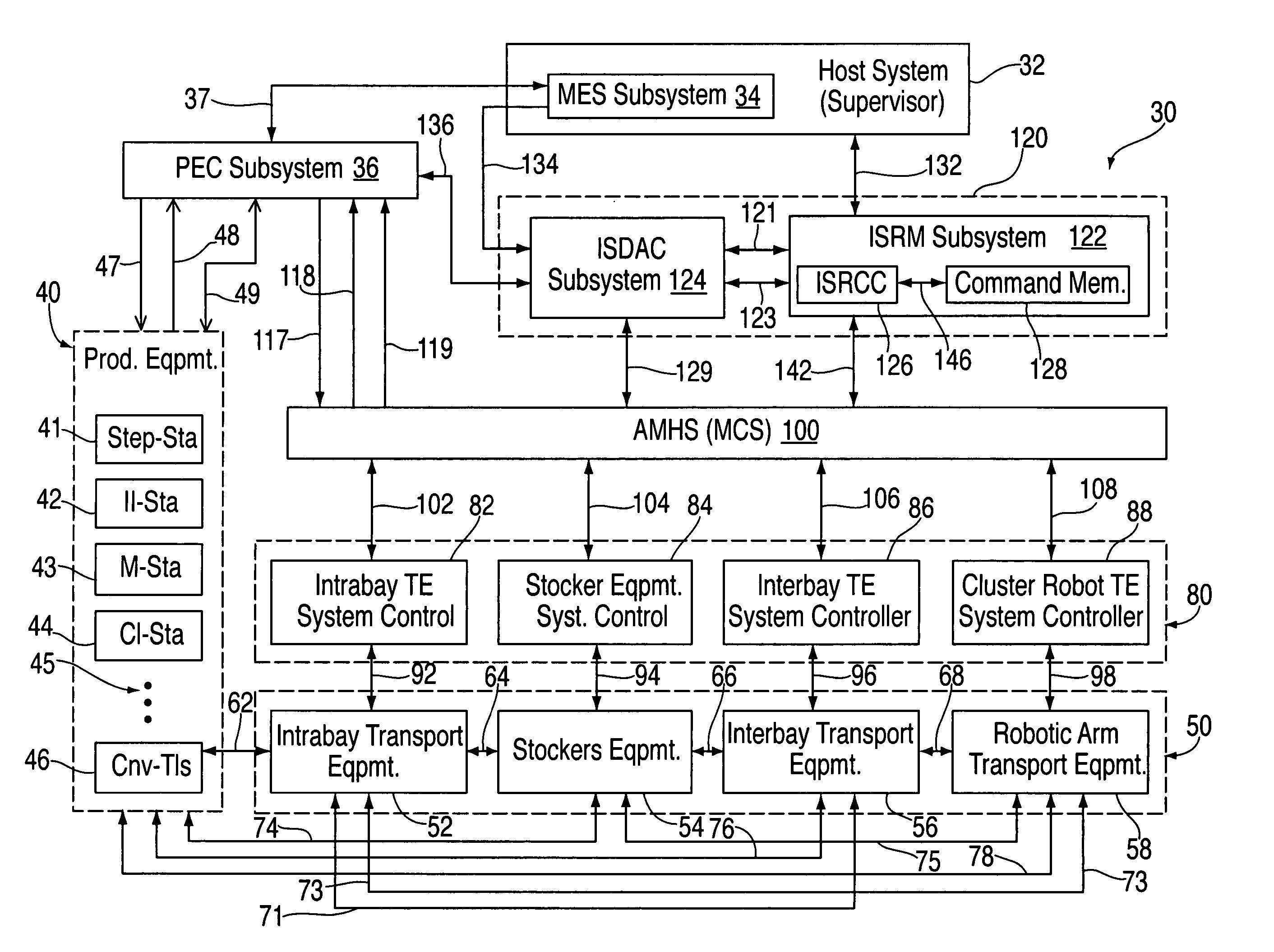

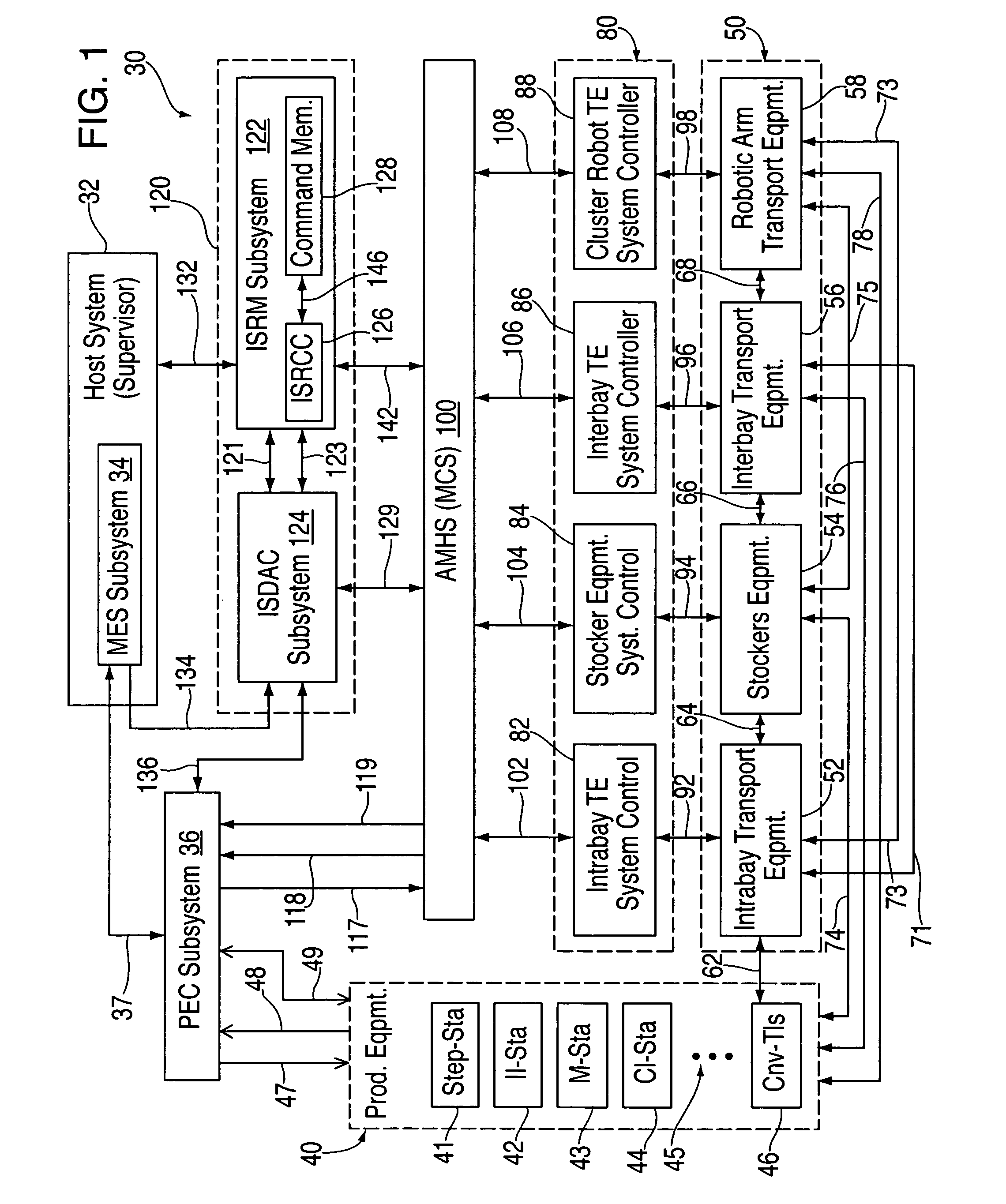

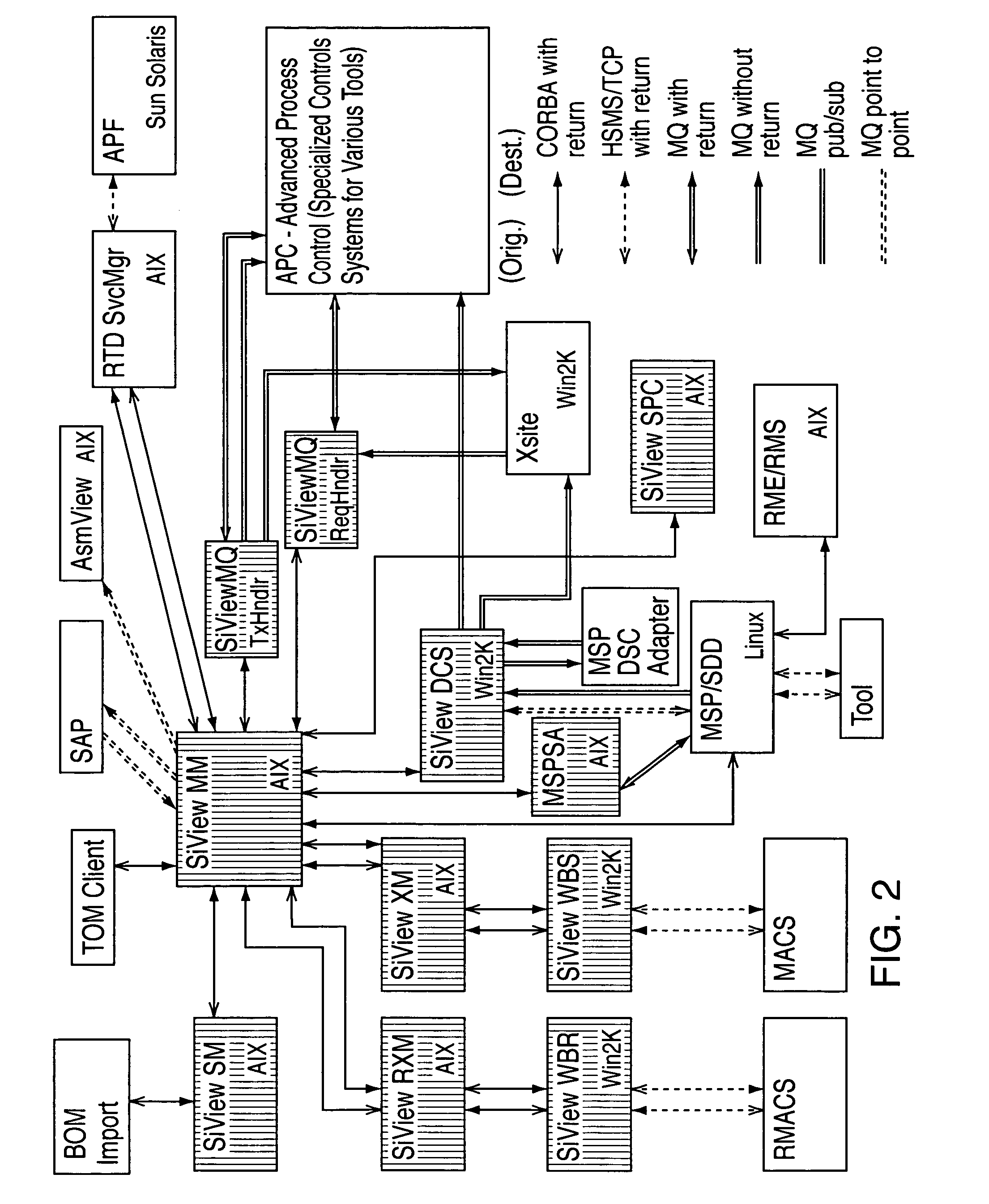

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS20050075748A1Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateImage resolution

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:IBM CORP

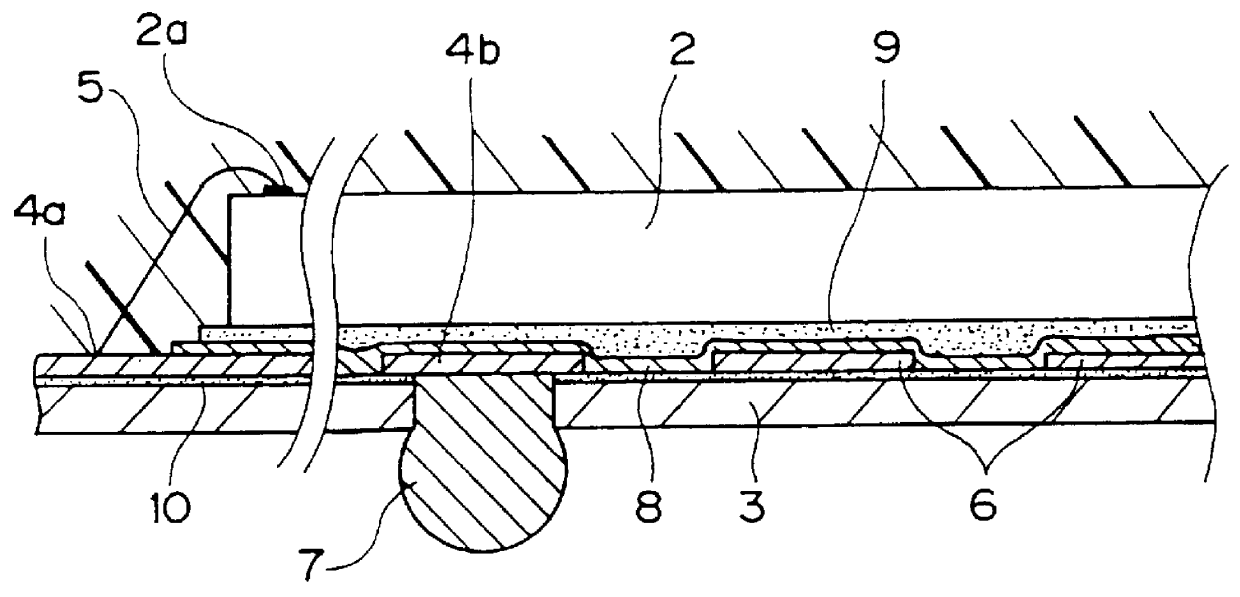

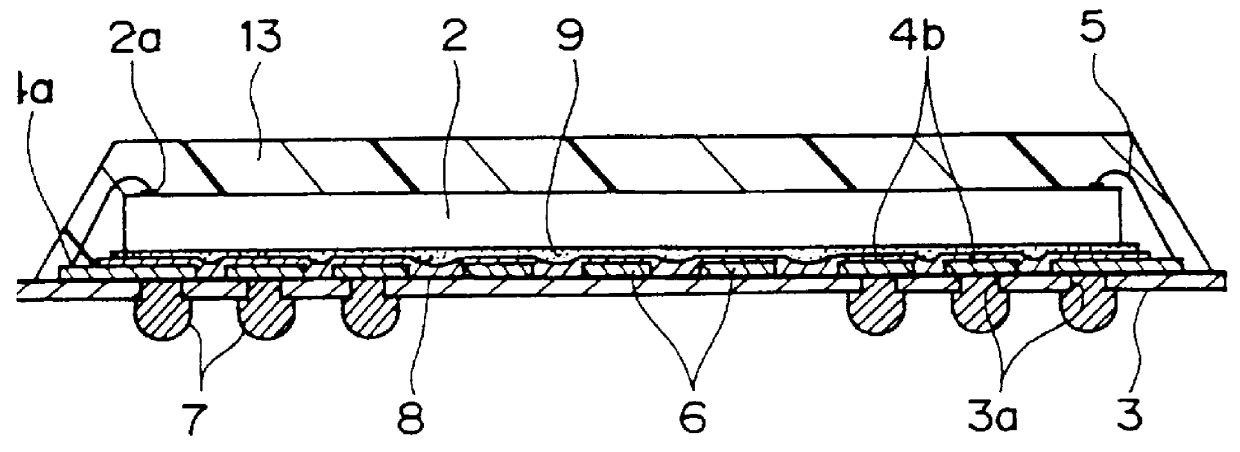

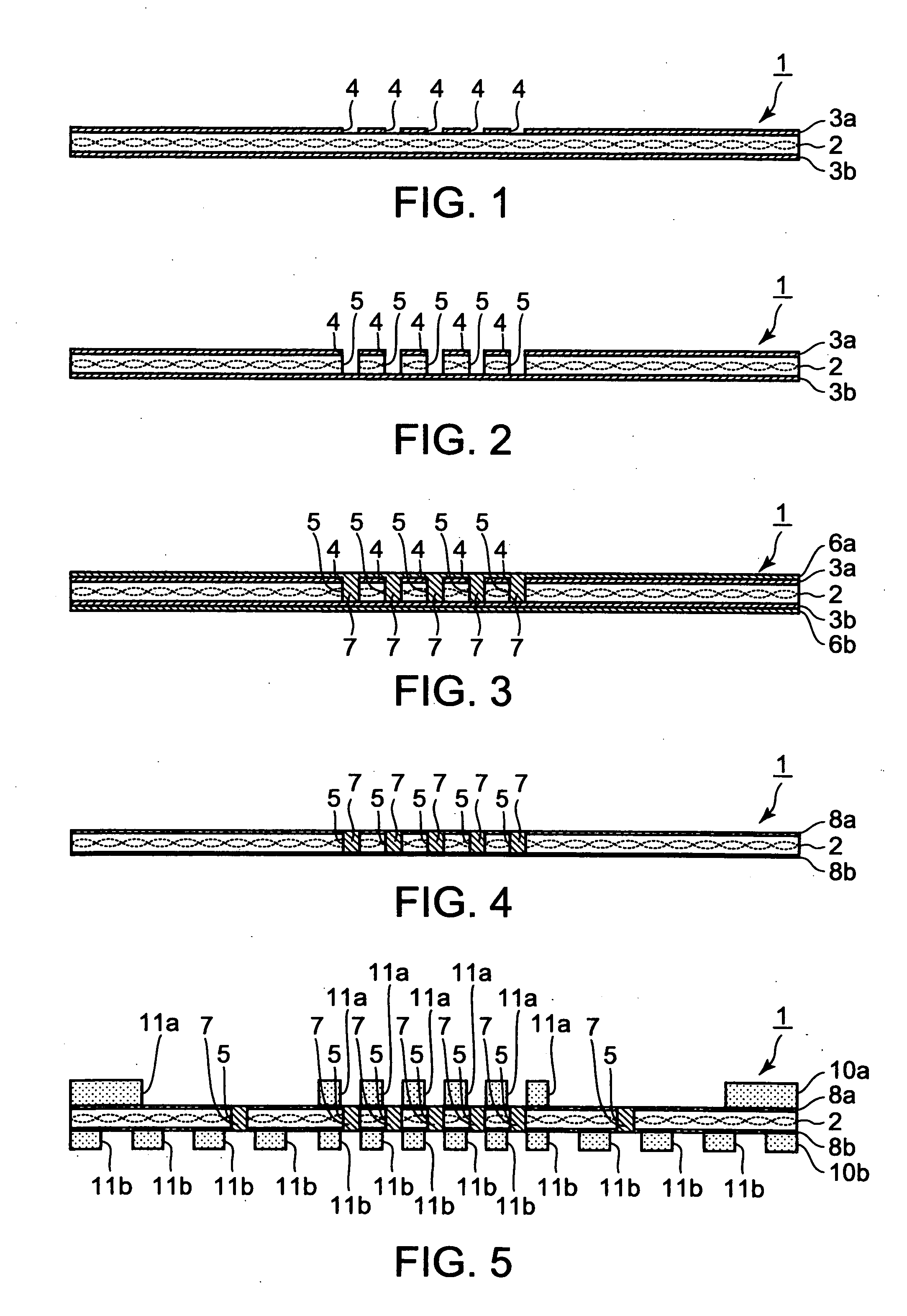

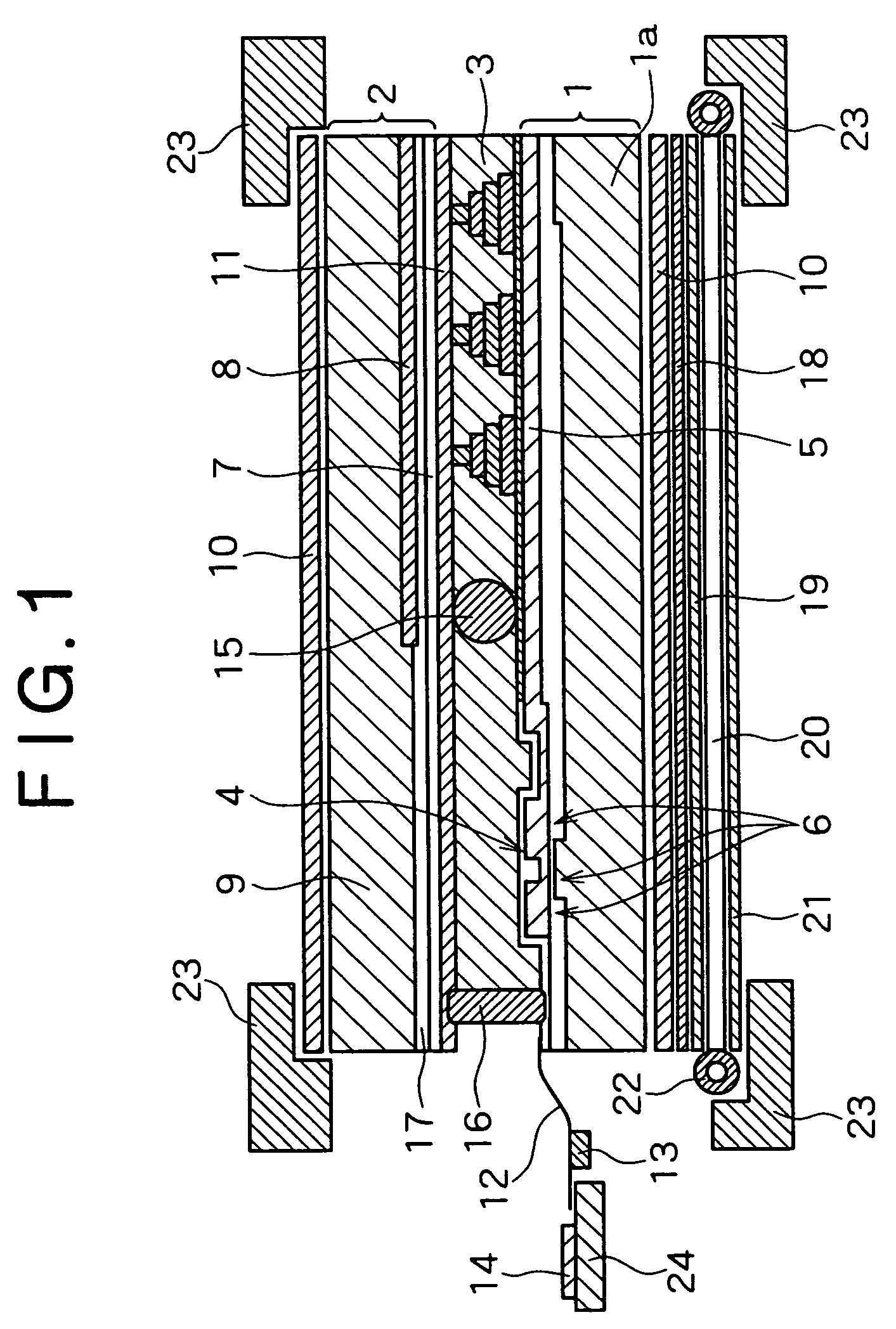

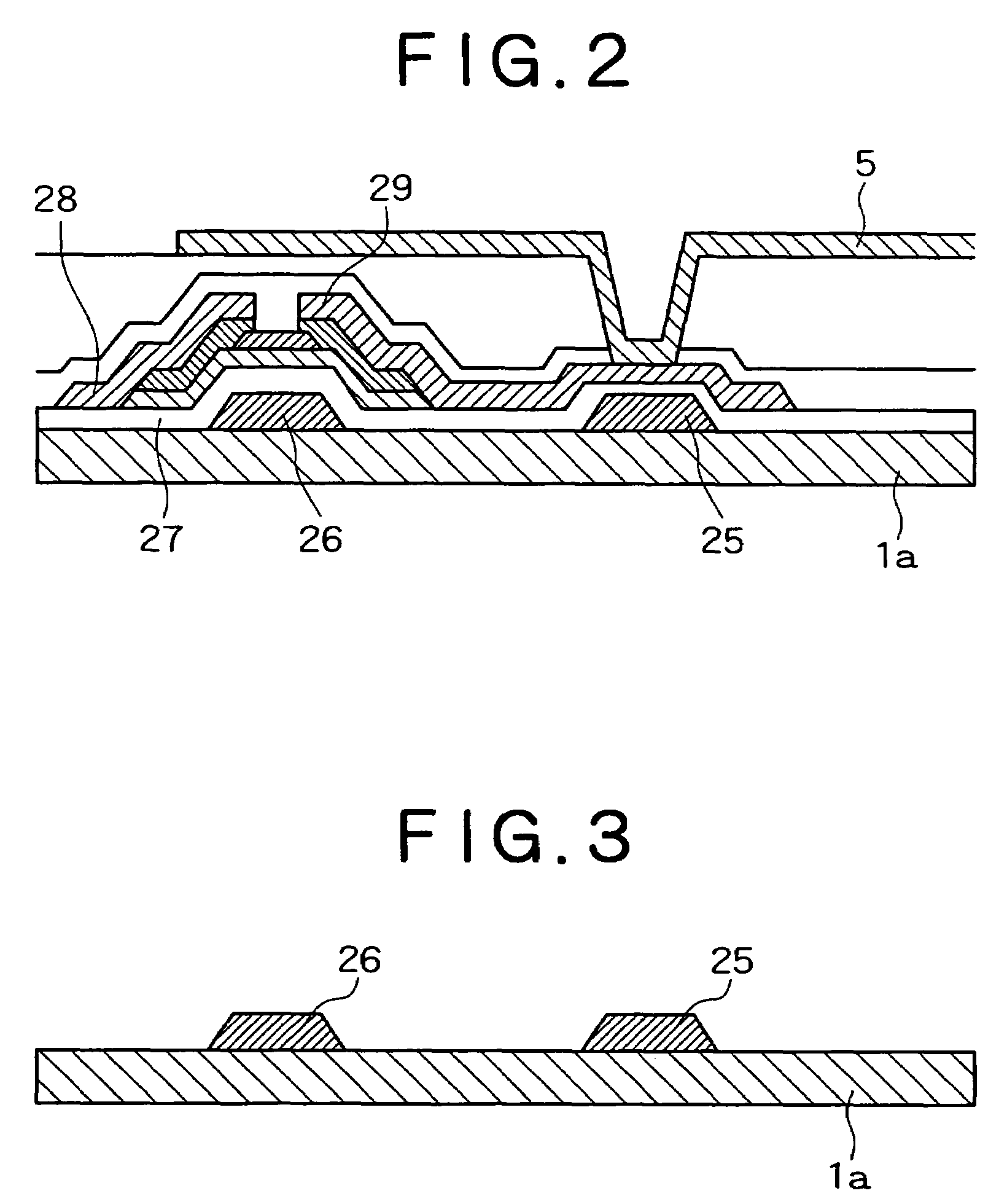

Semiconductor device and manufacturing method

InactiveUS6087717AAvoid separationAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorElectrical connection

To completely suppress or minimize the voids formed between the insulating substrate and the IC chip in order to prevent the problems of separation and cracking of the chip caused by the aforementioned voids. The present invention is preferably adopted for the Chip Six Package type package or other package types equipped with solder bumps or other external connecting terminals directly beneath the IC chip. For insulating substrate (3), on its chip-carrying surface, there is pattern element (6) in the region beneath the IC chip and free of conductor pattern elements (4) in addition to conductor pattern element (4) for forming electrical connection between the electrode pads and the external connecting terminals of the chip. Said pattern element (6) divides said region into plural small regions A. IC chip (2) is bonded through die paste on insulating substrate (3) such that an end of conductor pattern element (4), pattern element (6) and divided small regions A are covered. Pattern element (6) acts to reduce the shifting of die paste (9) before curing due to the surface tension. As a result, the formation of voids beneath the chip can be completely prevented or minimized.

Owner:TEXAS INSTR INC

Method for manufacturing semiconductor device

ActiveUS8343817B2Increase the number ofDecrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingResistN type conductivity

To provide a method by which a semiconductor device including a thin film transistor with excellent electric characteristics and high reliability is manufactured with a small number of steps. After a channel protective layer is formed over an oxide semiconductor film containing In, Ga, and Zn, a film having n-type conductivity and a conductive film are formed, and a resist mask is formed over the conductive film. The conductive film, the film having n-type conductivity, and the oxide semiconductor film containing In, Ga, and Zn are etched using the channel protective layer and gate insulating films as etching stoppers with the resist mask, so that source and drain electrode layers, a buffer layer, and a semiconductor layer are formed.

Owner:SEMICON ENERGY LAB CO LTD

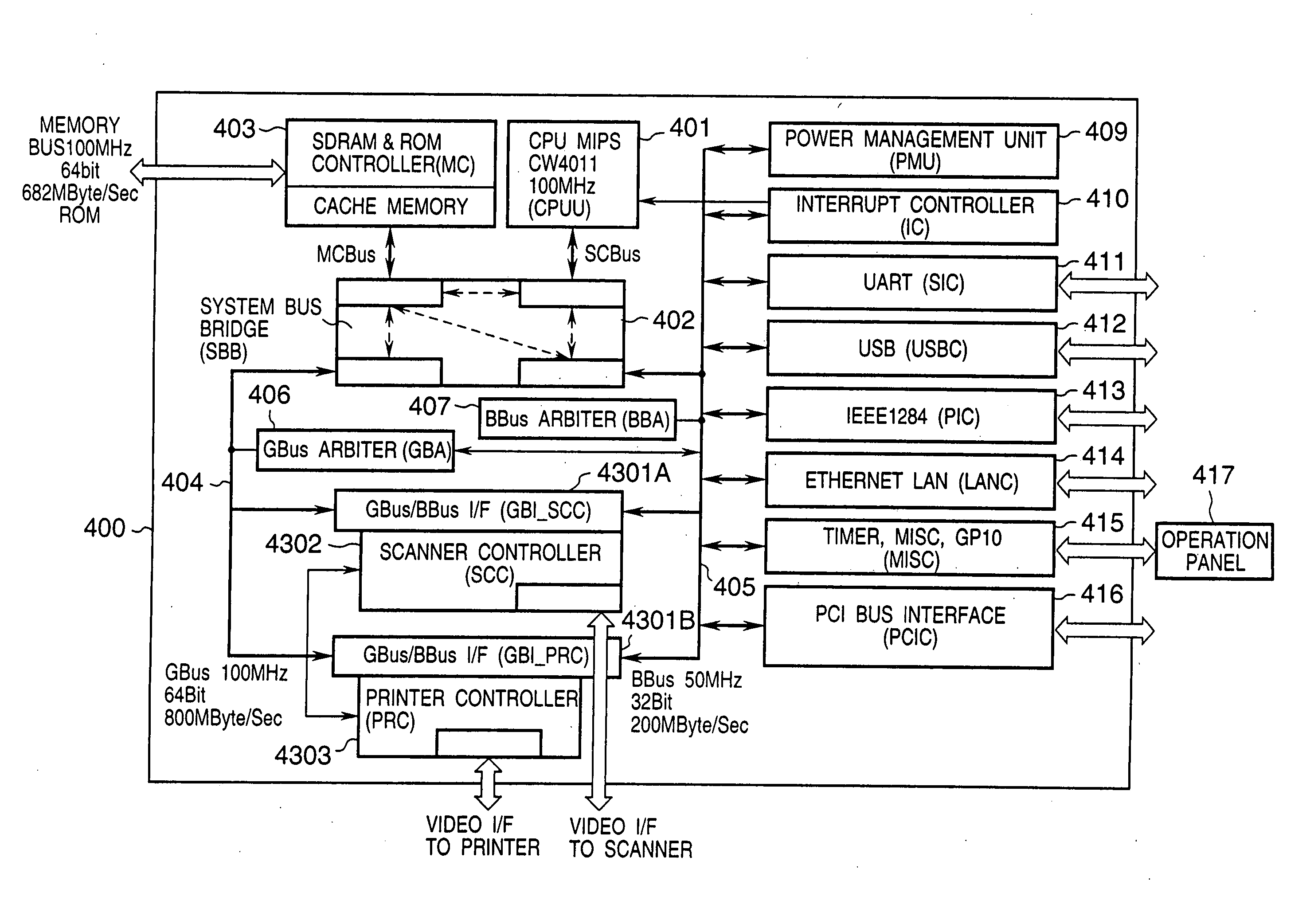

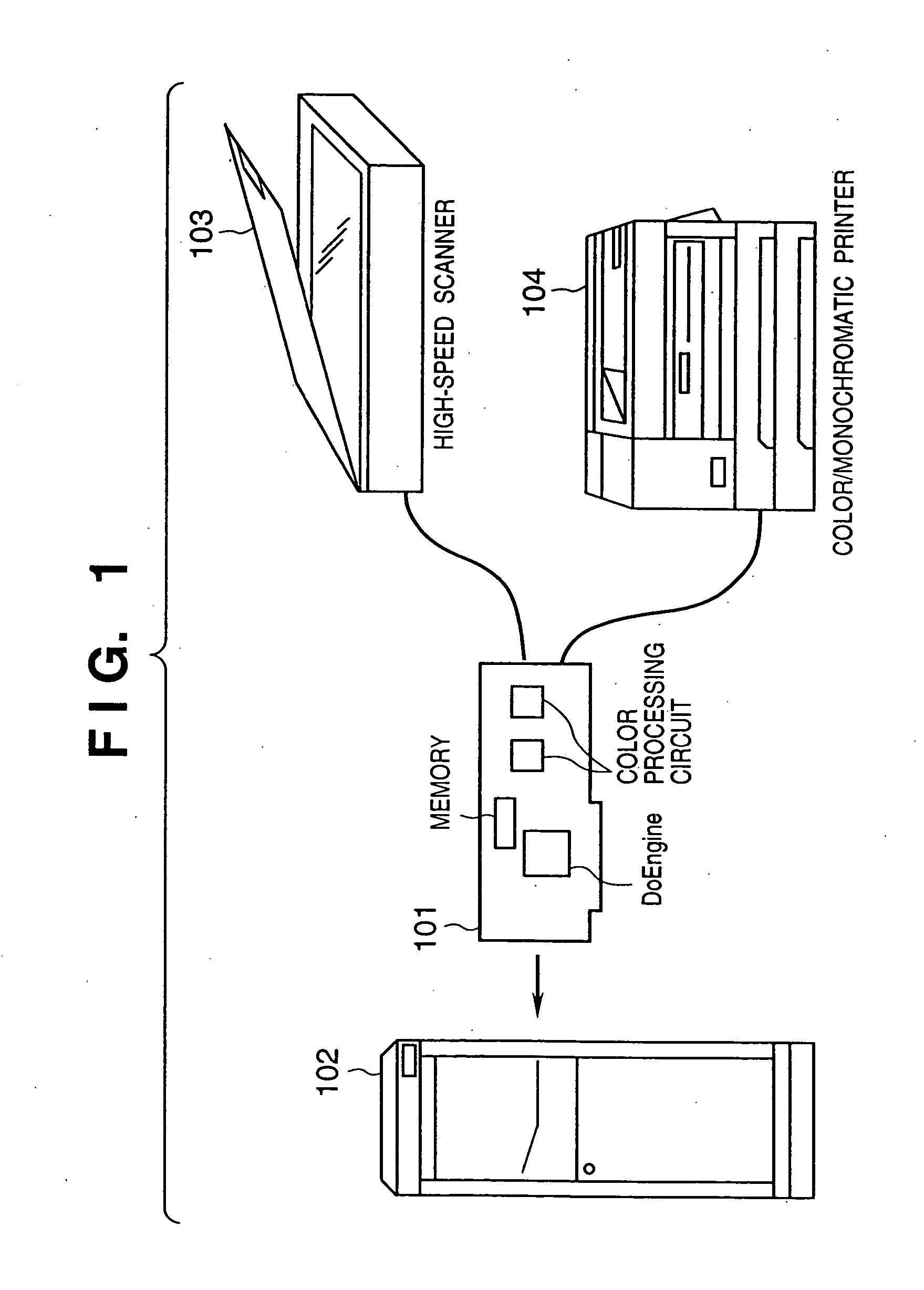

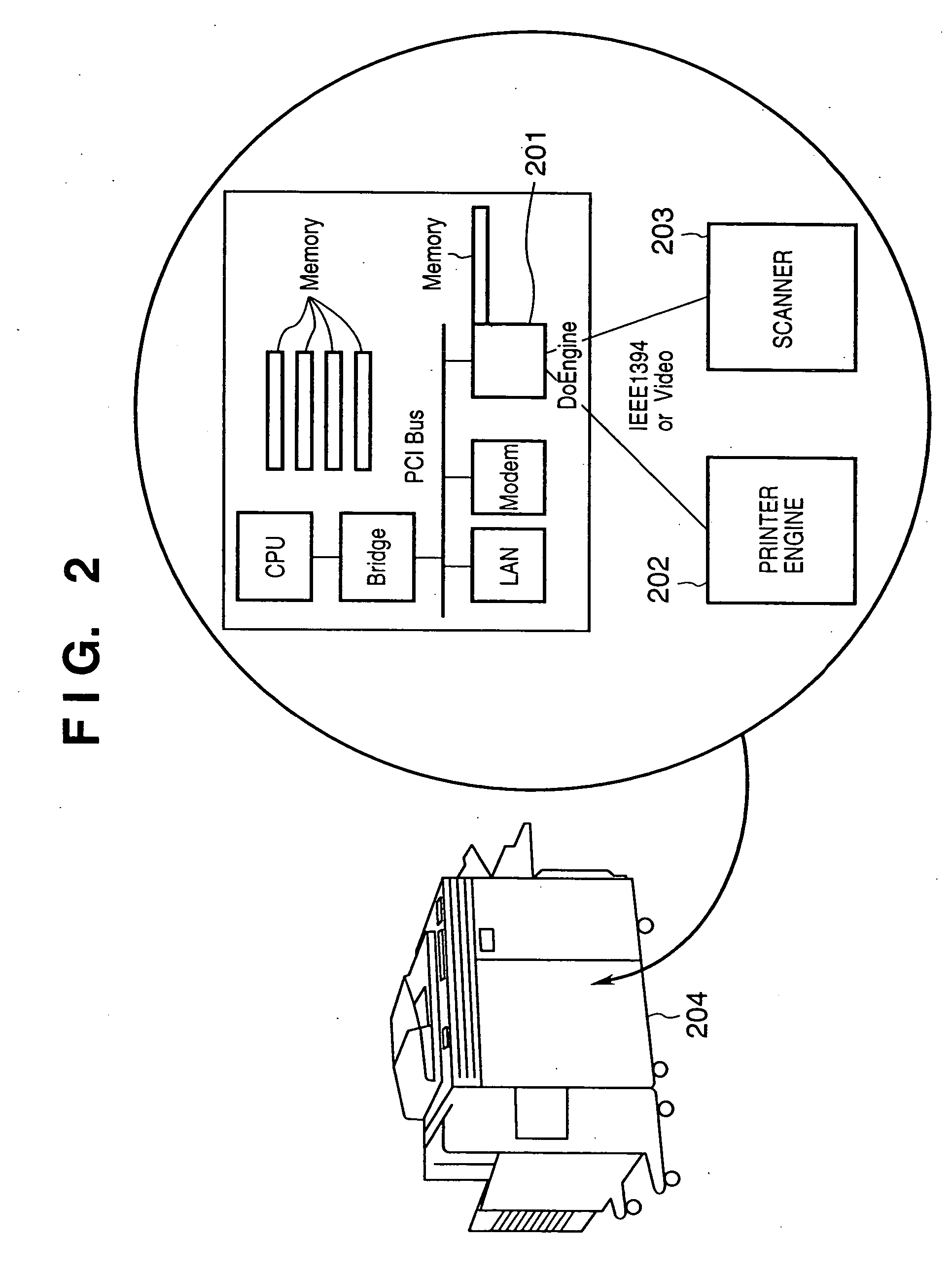

Input/output control apparatus

InactiveUS20050021883A1Reduce image dataLow efficiencyDigitally marking record carriersDigital computer detailsMemory controllerInput/output

Image data scanned by way of a scanner controller is transferred from a memory controller to a memory by way of a G bus. A CPU reduces the image data stored in the memory by thinning processing or the like, and displays the image data on an operation panel by way of a B bus and interface. In this manner, an image can be input using the first bus while data transferred by way of the first bus is output by way of the second bus. This enables processing using image data which is being input, such as processing of immediately displaying an input image.

Owner:CANON KK

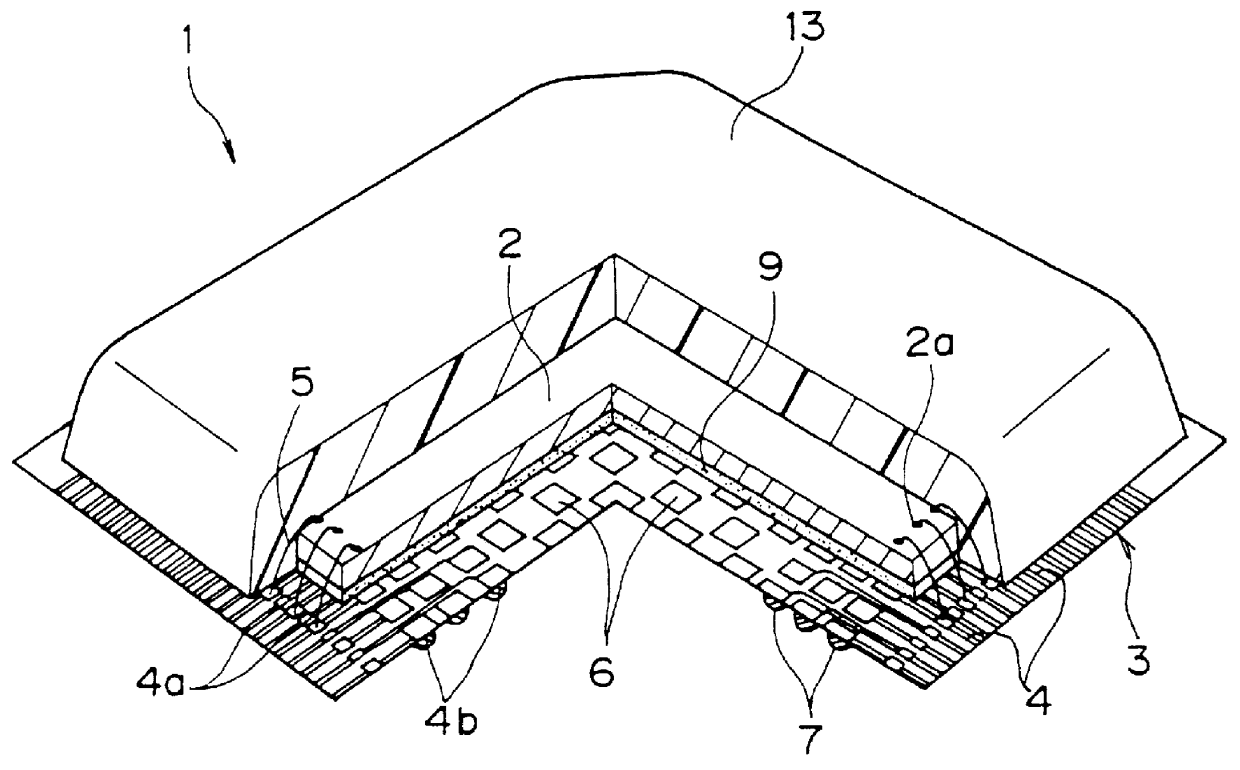

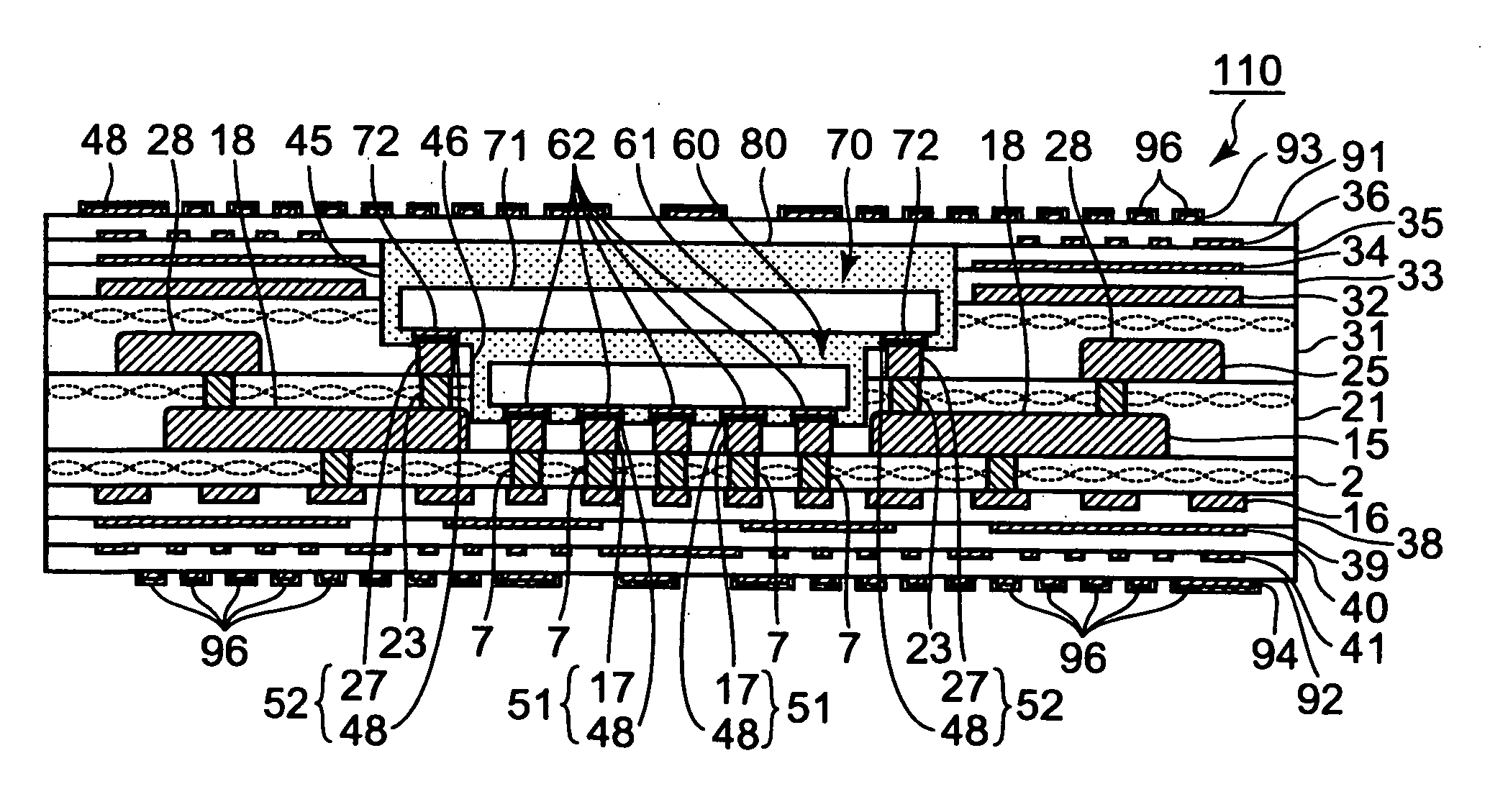

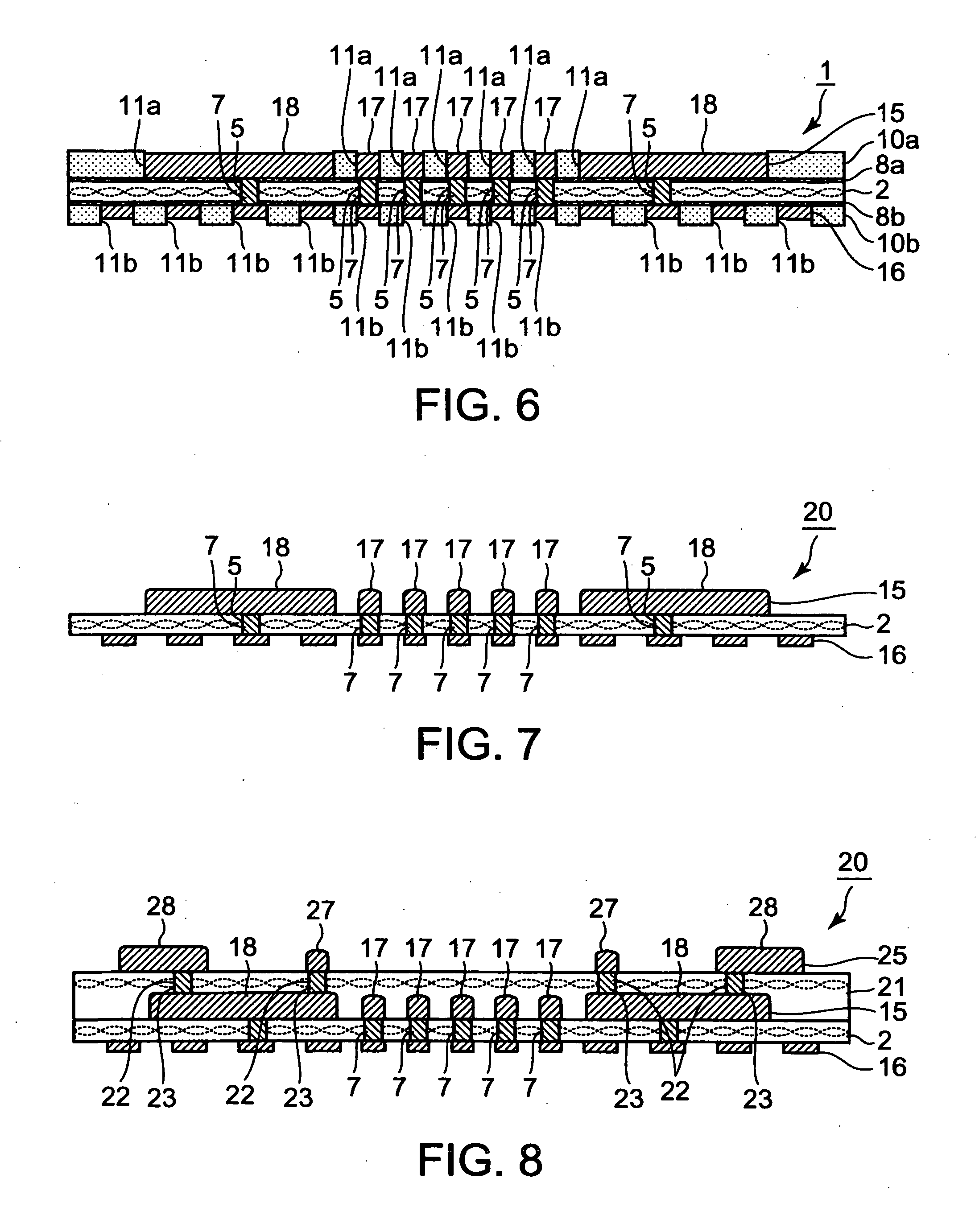

Printed circuit board, production method therefor, electronic-component carrier board using printed circuit board, and production method therefor

InactiveUS20080296056A1Decrease productivitySemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerEngineering

A printed wiring board has a substrate having a first surface and a second surface on both sides of the substrate. A cavity is provided on the first surface. The cavity caves in towards the second surface. Several bumps are formed in the cavity as protruding towards the first surface. An insulation layer is filled in the cavity. The bumps are isolated from one another by the insulation layer. The top of each bump that protrudes towards the first surface and a zone in the cavity and close to the top are exposed in the cavity without being covered by the insulation layer.

Owner:MEIKO ELECTRONICS CO LTD

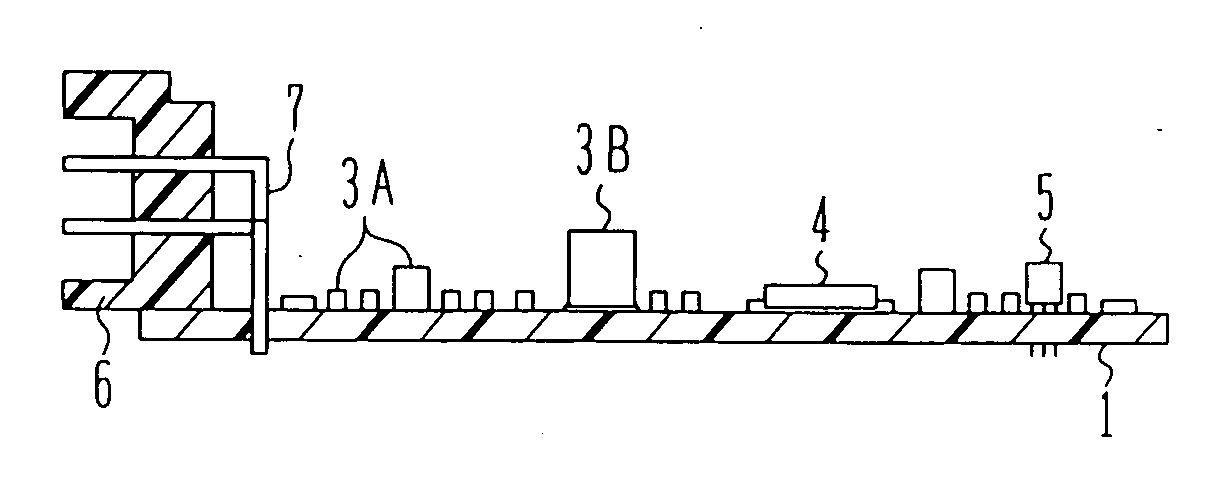

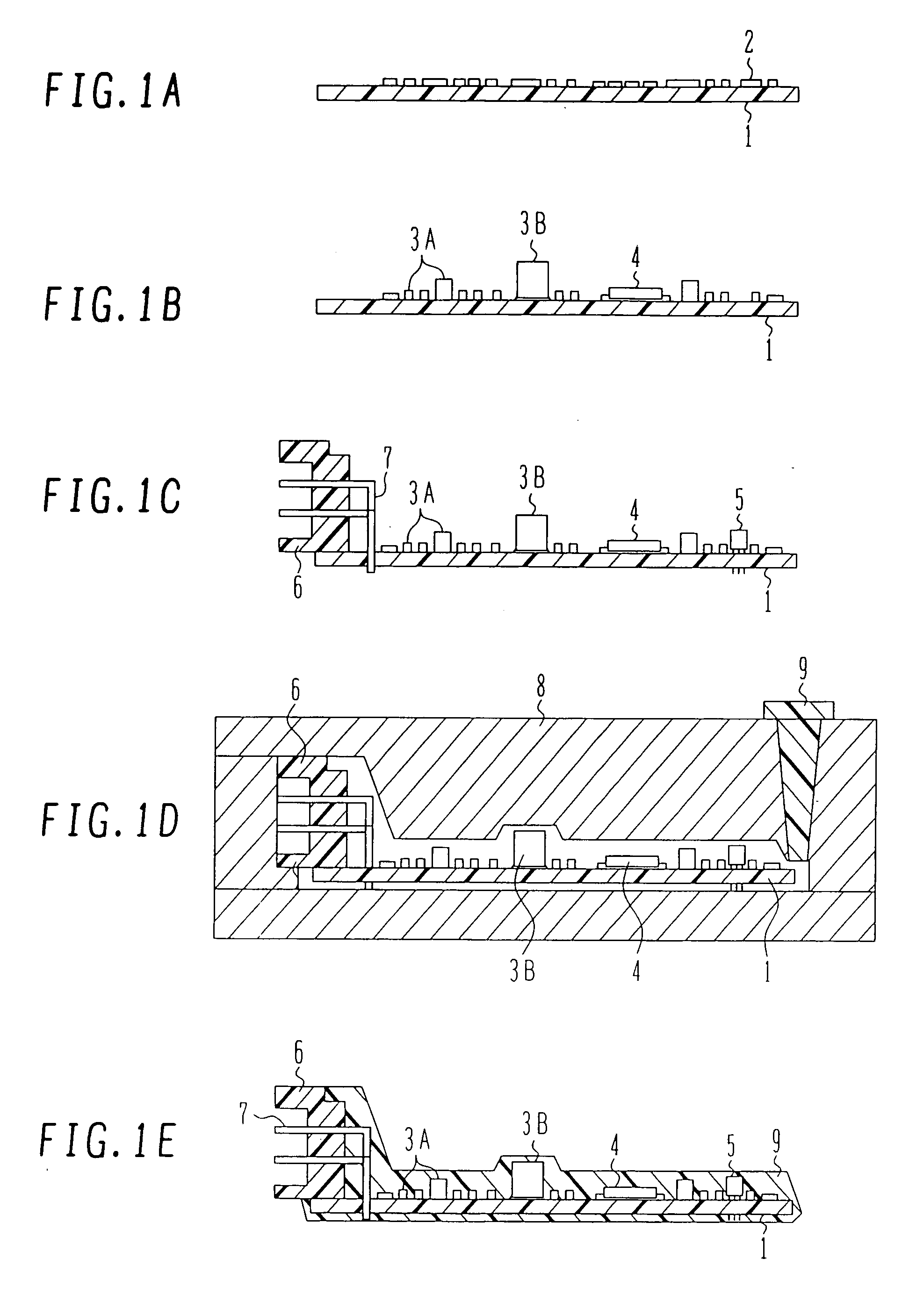

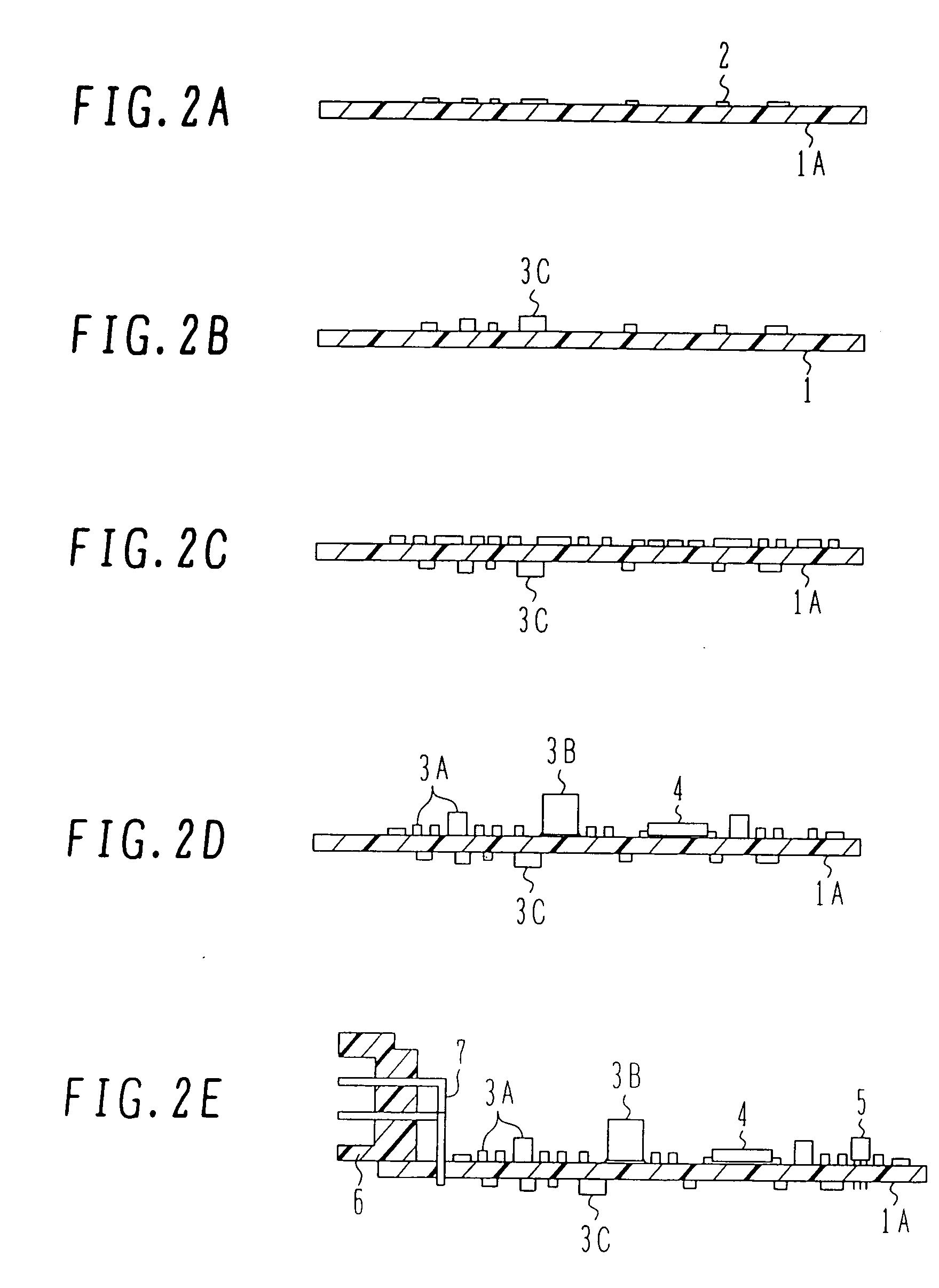

Module and method for fabricating the same

InactiveUS20060272150A1Enhance reliability and productivitySmall sizePrinted circuit assemblingLine/current collector detailsProduction rateSolid-state

A module having a smaller size with enhanced reliability and productivity, and a method for fabricating the module. The module comprises a connector (6) having metal terminals for connection, and a circuit board (1) mounting electronic components. The connector (6) and the board (1) are connected to each other through metal leads (7). The surface of the connector (6) on the side being connected to the board, the metal leads 7, and the electronic components are sealed with the same thermosetting resin (9). The thermosetting resin (9) is in solid state at temperatures of 40° C. or below before curing, and the thickness of the thermosetting resin (9) sealing the electronic components is changed depending on the heights of the electronic components.

Owner:EGUCHI SYUUJI +3

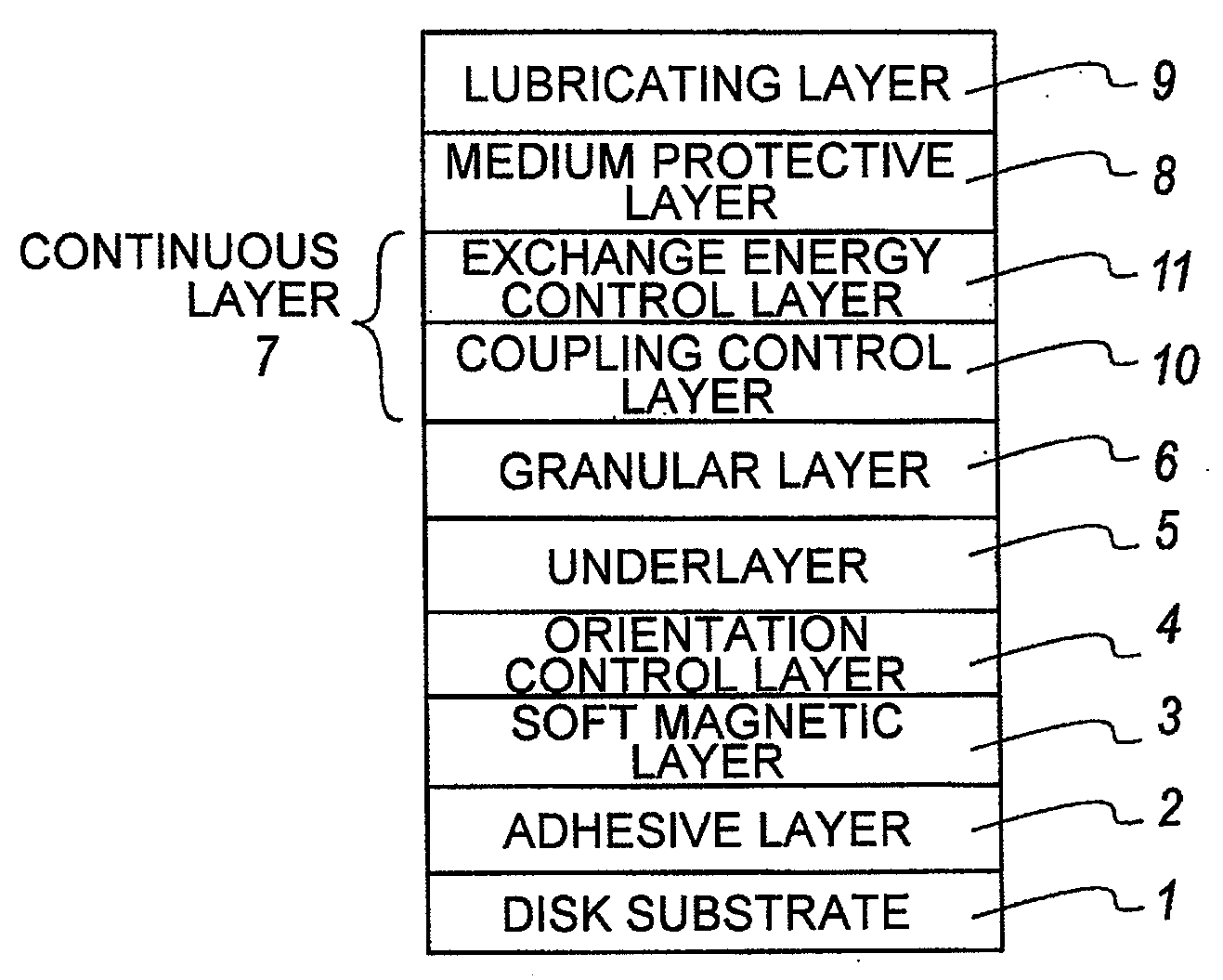

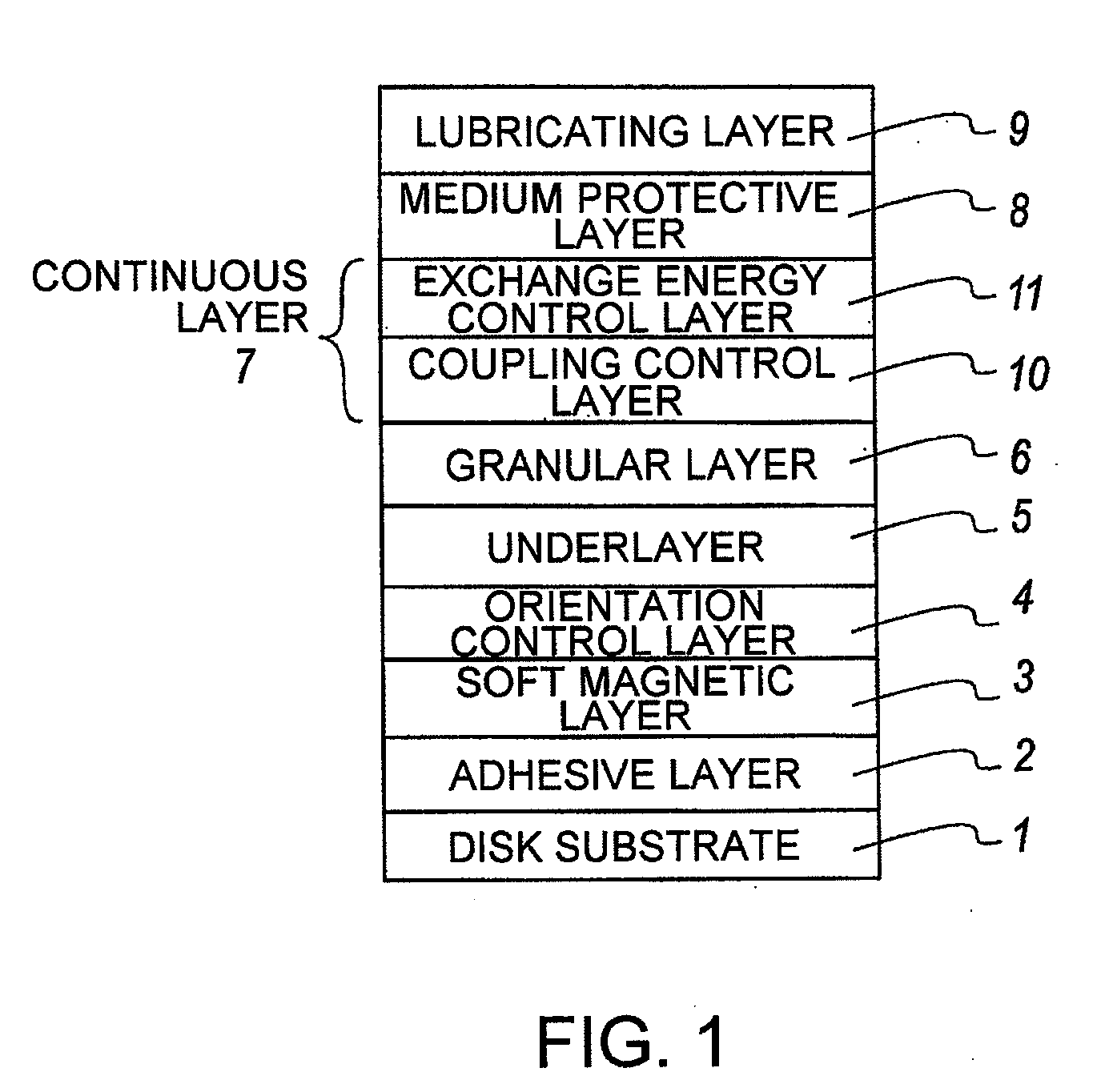

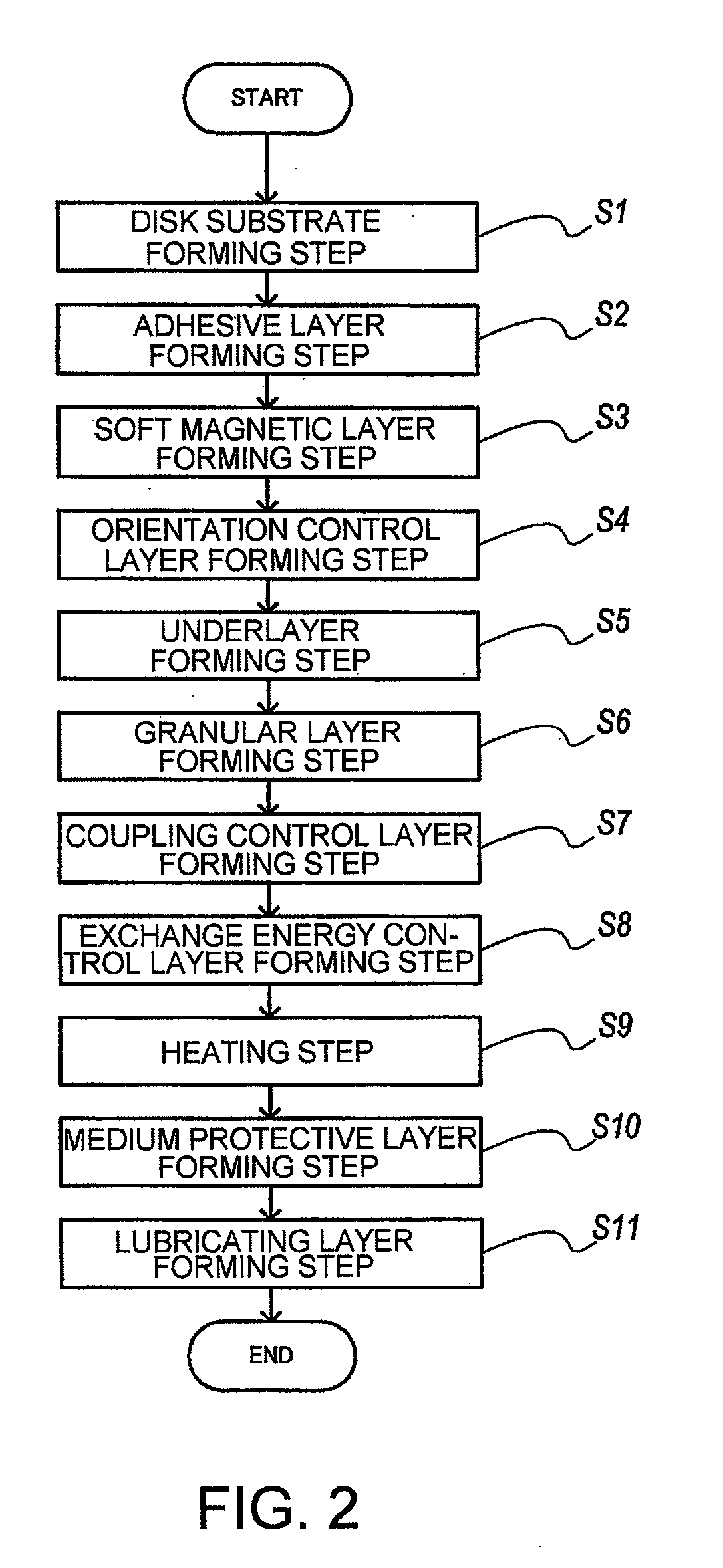

Perpendicular magnetic recording medium manufacturing method

InactiveUS20090191331A1Improve characteristicEnhance nucleationRecord information storageSpecial surfacesMagnetic layerMaterials science

[Object] To provide a manufacturing method that can easily enhance a reversed domain nucleation magnetic field of a magnetic recording layer in a perpendicular magnetic recording medium having, over a substrate, a soft magnetic layer, the magnetic recording layer having a granular structure, and a continuous layer having a high perpendicular magnetic anisotropy.[Solution] A perpendicular magnetic recording medium manufacturing method according to this invention is characterized by including a soft magnetic layer forming step of forming a soft magnetic layer over a substrate, a magnetic recording layer forming step of forming a magnetic recording layer having a granular structure as an upper layer of the soft magnetic layer, a continuous layer forming step of forming a continuous layer having a perpendicular magnetic anisotropy as an upper layer or a lower layer of the magnetic recording layer, and a heating step of heating a medium, obtained by forming the continuous layer in the continuous layer forming step, for improving a value of a reversed domain nucleation magnetic field.

Owner:WD MEDIA SINGAPORE PTE

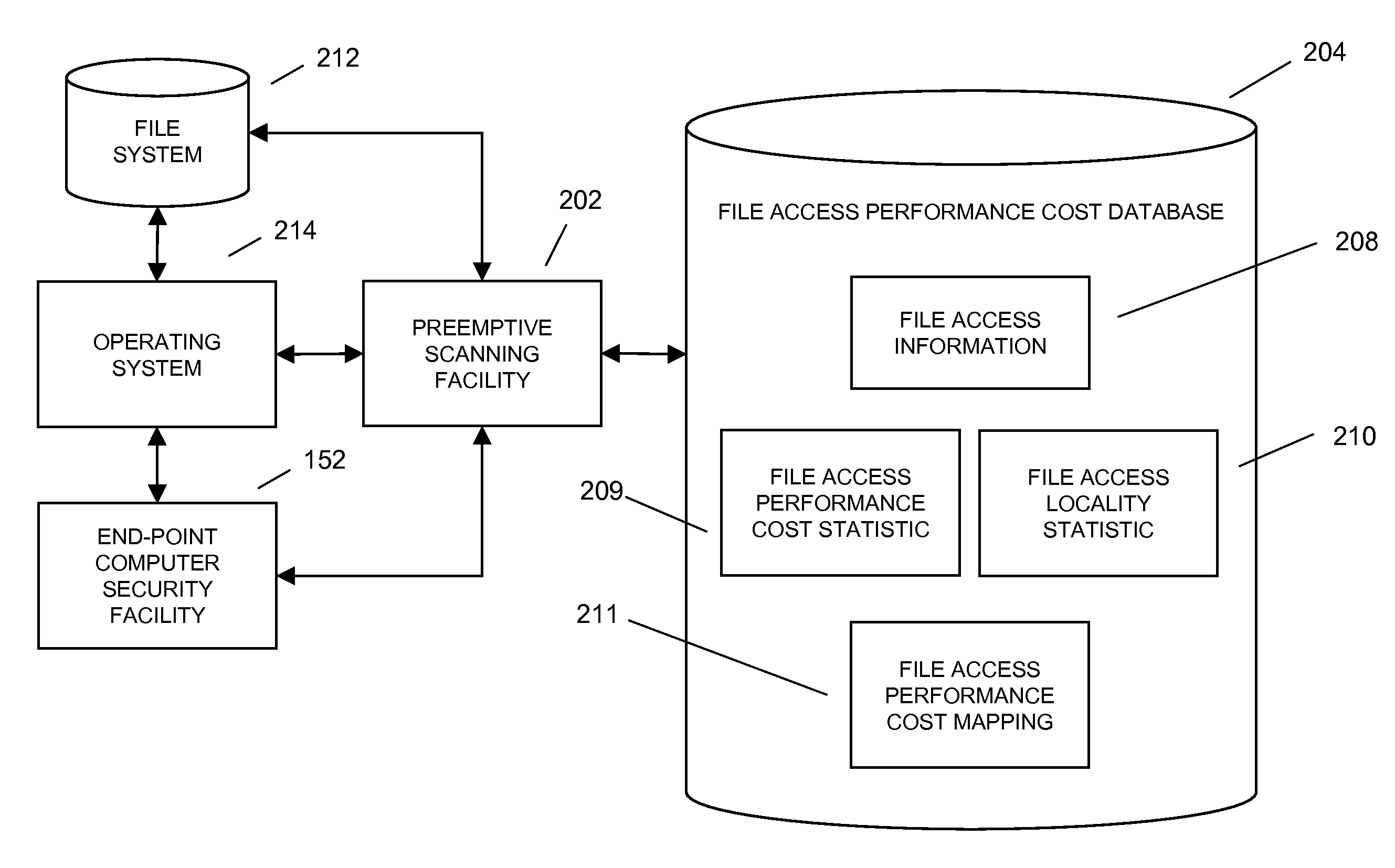

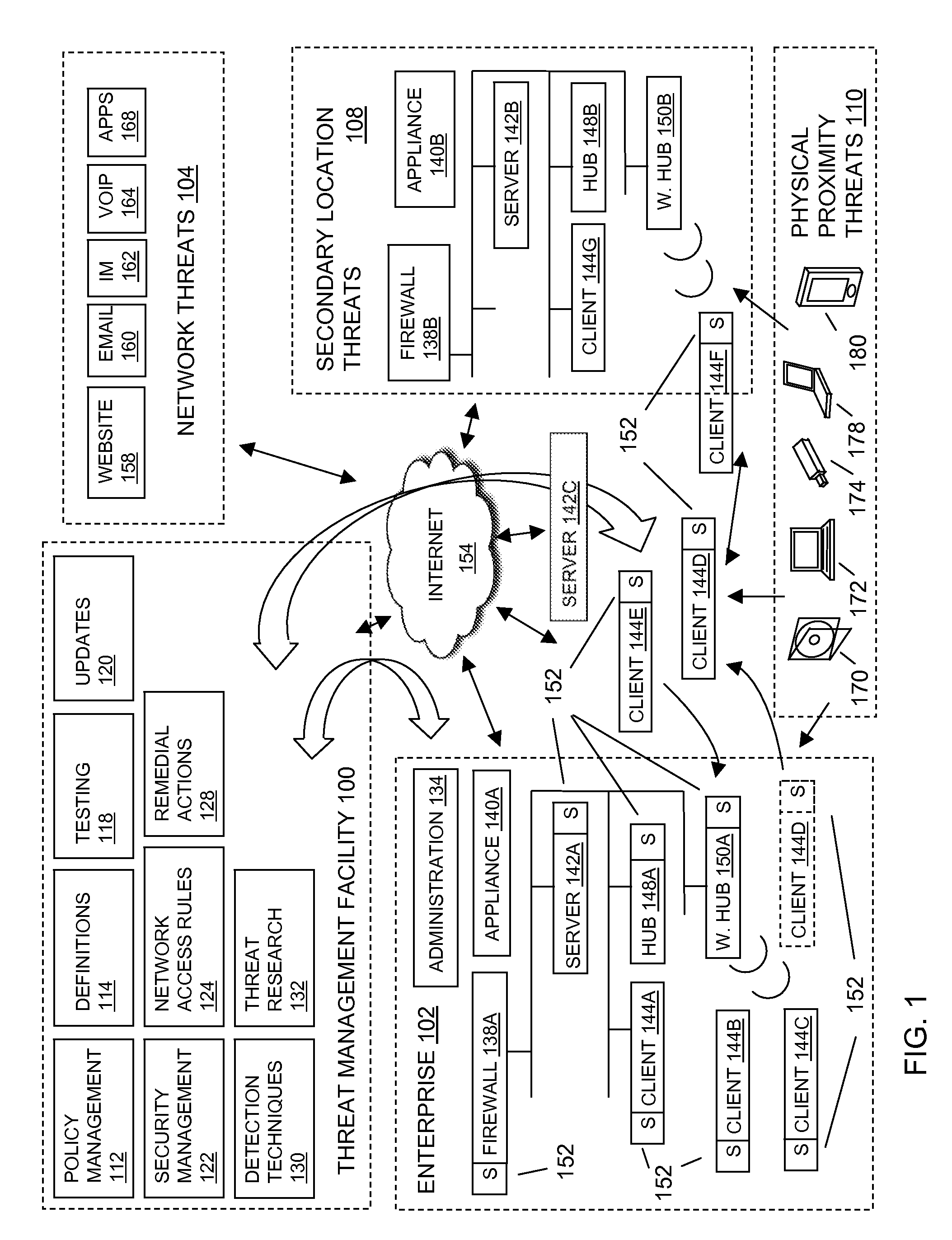

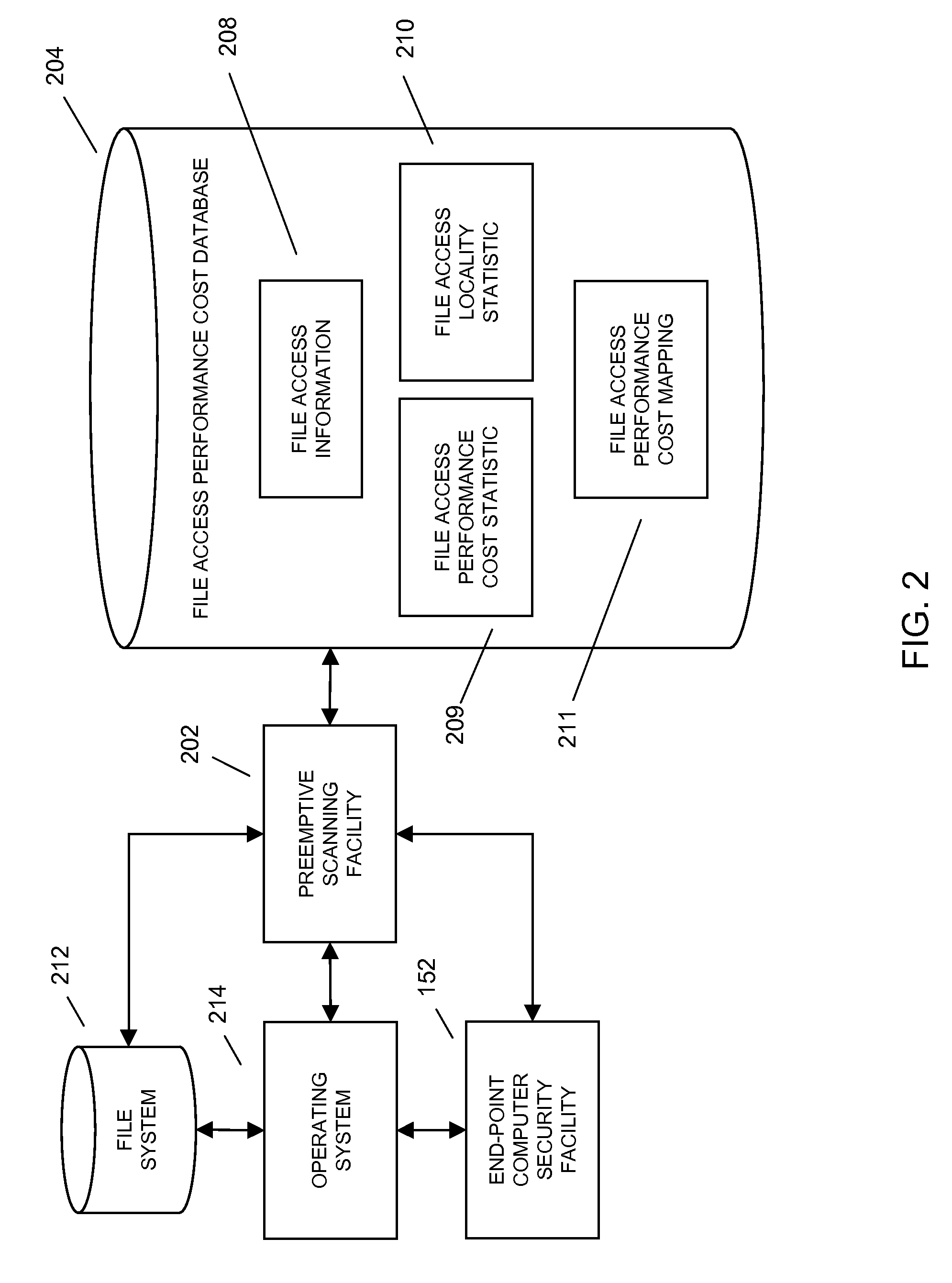

Method and system for preemptive scanning of computer files

ActiveUS20100242109A1Extended file access delayShorten access timeDigital data information retrievalMemory loss protectionOperational systemFile system

In embodiments of the present invention improved capabilities are described for reducing computer file access time associated with on-access scanning through predictive preemptive scanning, where the prediction may be enabled through the development and use of a file access performance cost mapping of a computing facility's file system. In a first step, file access information describing a pattern of each of a plurality of computer files that have been accessed in a computer file system may be collected. In a second step, the file access information may be processed to generate a file access performance cost statistic for each of the plurality of computer files, where the file access performance cost statistic may be a measure of the time aggregate effect on the computing facility's system performance associated with the access of the file. In a third step, the file access performance cost statistic may be maintained for each of the plurality of files accessed by the computing facility. In a fourth step, the file access performance cost mapping of the computing facility's file system relating to the plurality of computer file may be generated, where the file access performance cost mapping may provide an indication of which of the plurality of files in the file system produce the greatest time aggregate file access effect based on the computing facility's system performance. Finally, in a fifth step, files from the computer file system may be pre-scanned based on the file access performance cost mapping. In embodiments, pre-scanning may access at least one of the plurality of files for scanning prior to the file being called for a use, such as by an operating system, an application, a utility program, and the like. The step of pre-scanning may be performed during periods of low computing facility processing activity, and may result in a reduced need to scan the computer file when the computer file is accessed for use.

Owner:SOPHOS

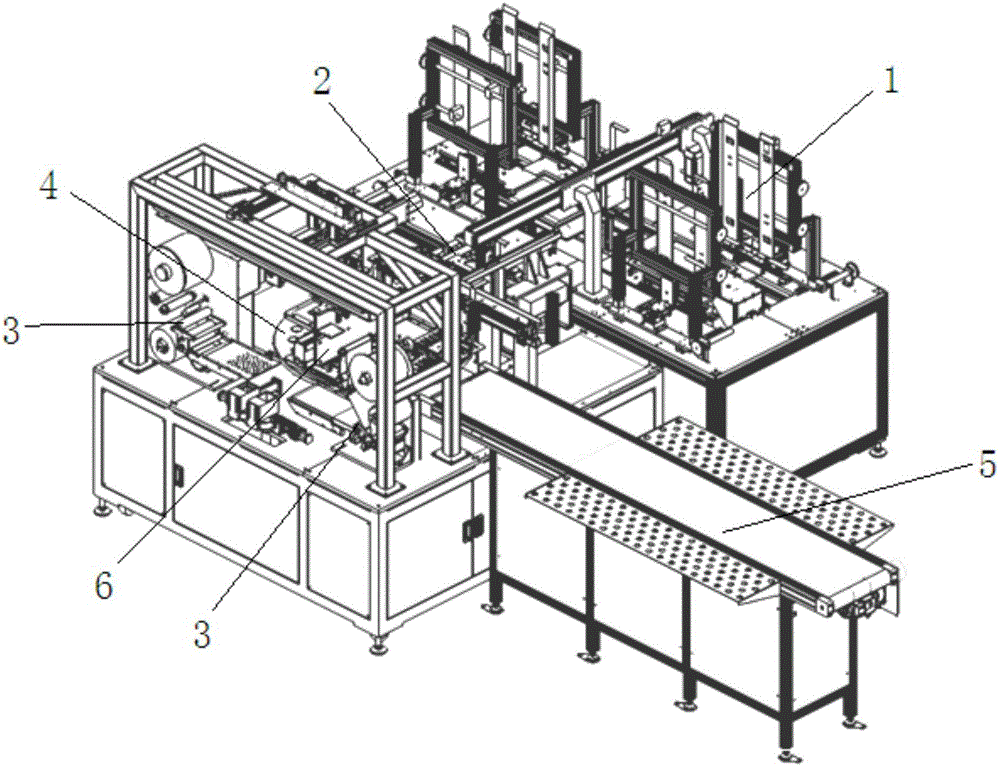

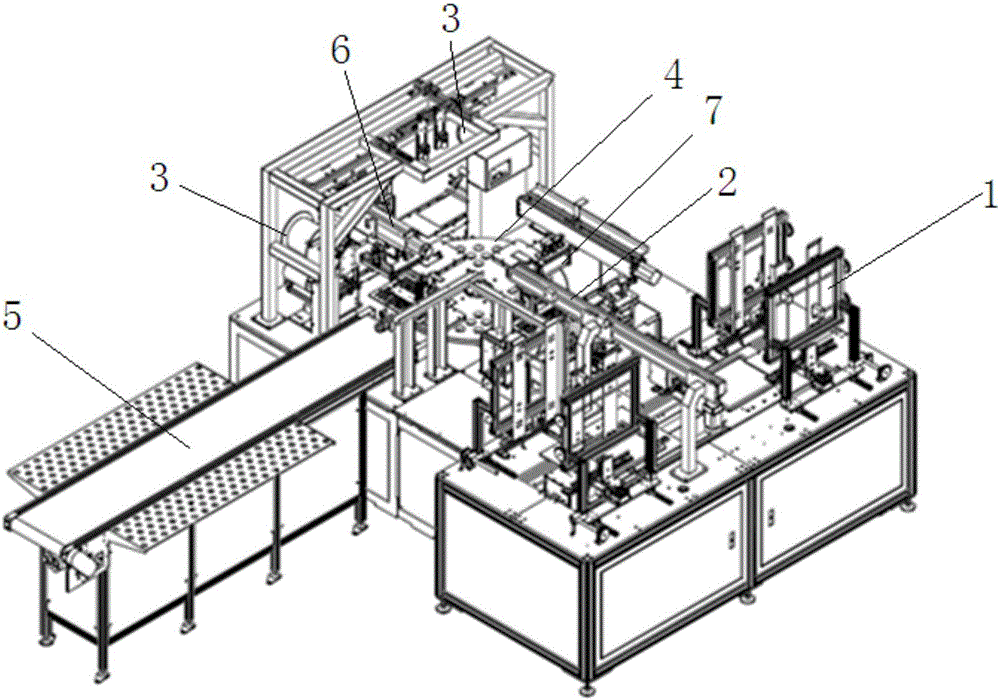

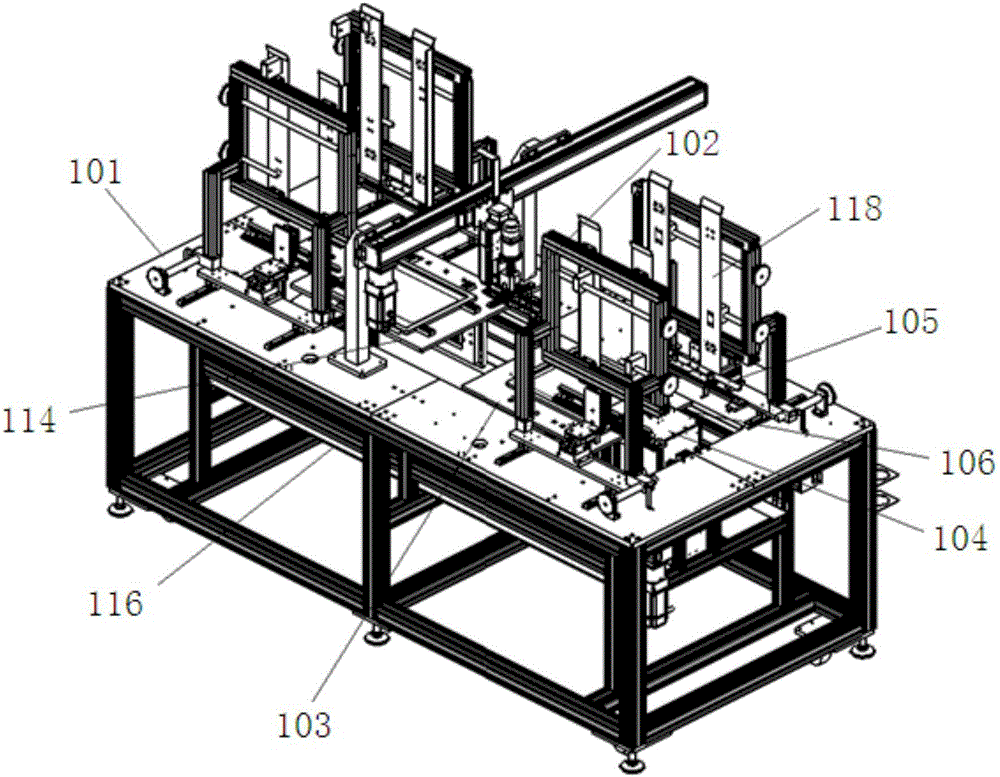

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

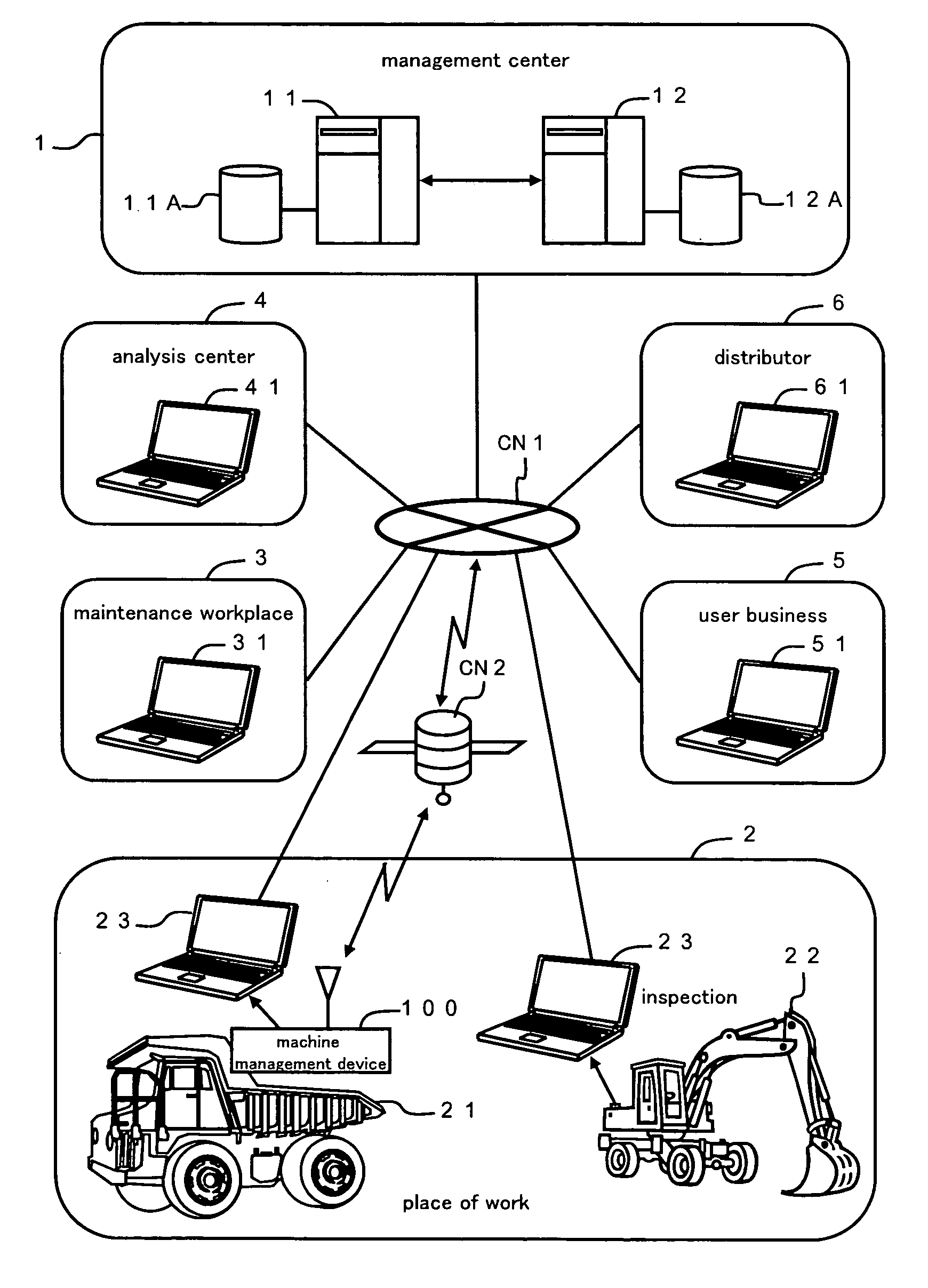

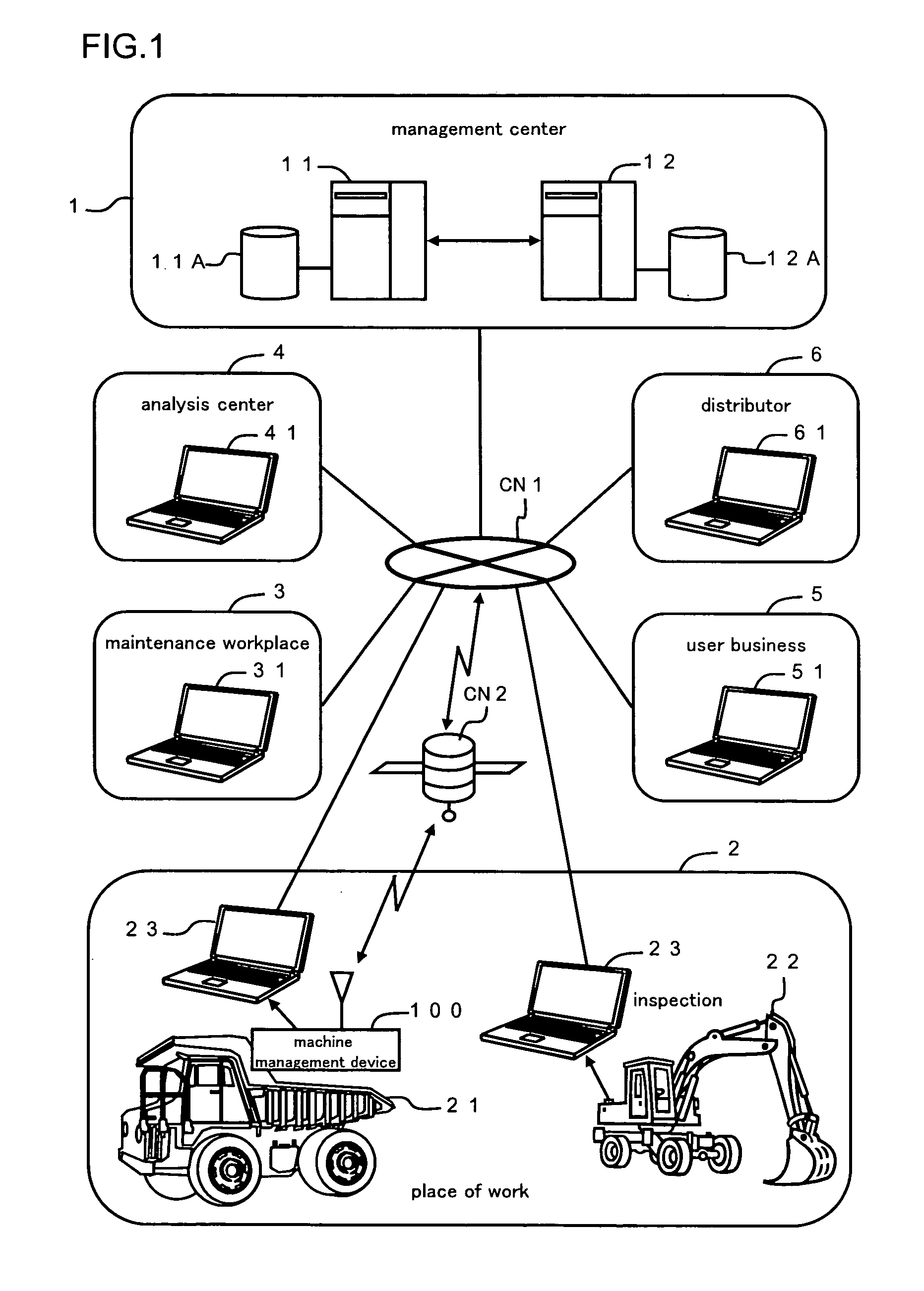

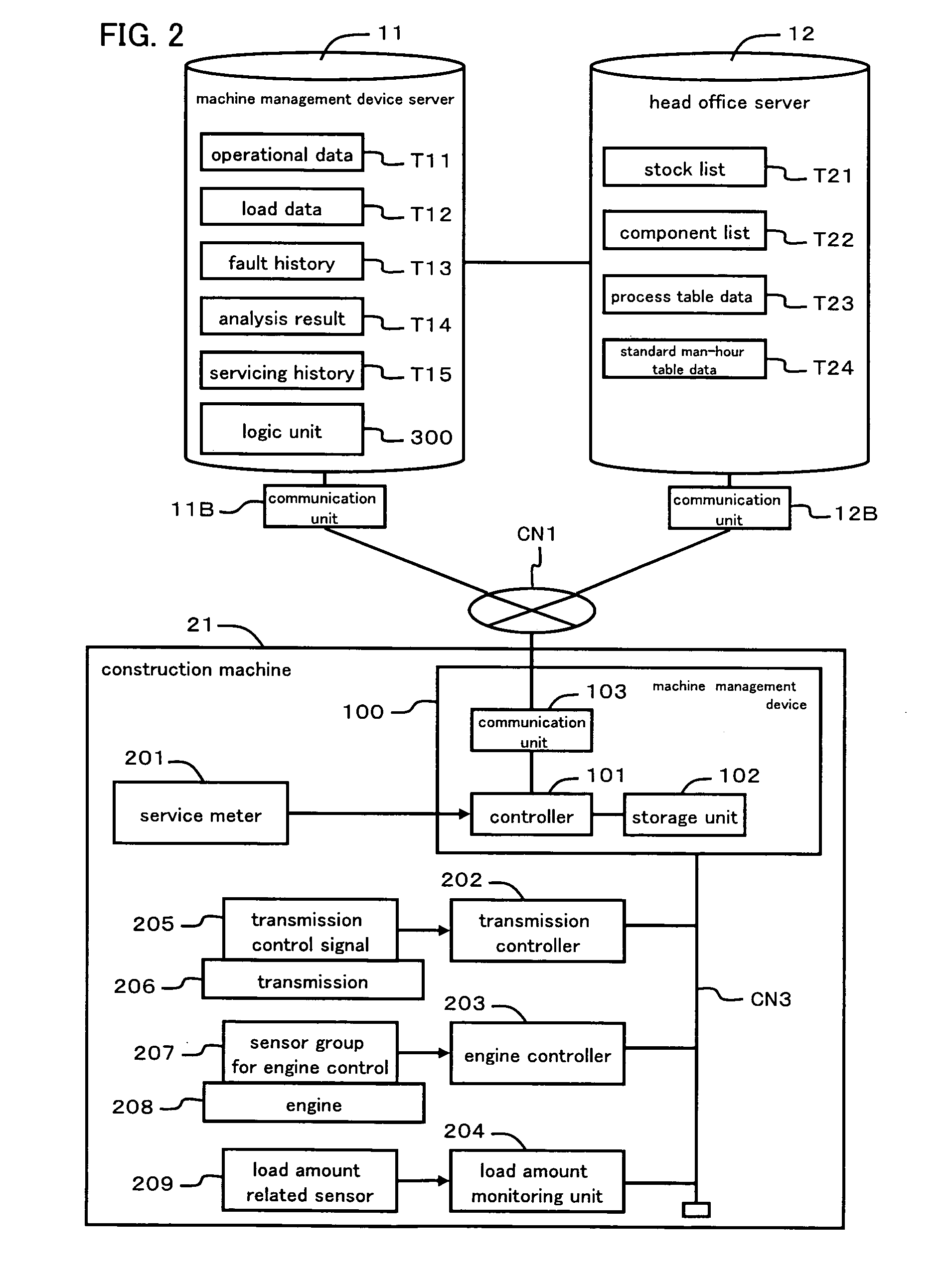

System for construction machine maintenance based on predicted service life

ActiveUS8533018B2Improve accuracyWorking capability of the maintenance workplace is exceededForecastingSoil-shifting machines/dredgersMachine maintenancePaper document

To predict the service life of a construction machine more accurately, and to make it possible to draw up an appropriate overhaul implementation plan at an early stage.A first service life prediction unit 311 predicts the service lives of main components such as an engine and the like, based upon their actual wear states. And a second service life prediction unit 312 predicts the service lives of the same components, based upon their cumulative load amounts. An order setting unit 320 selects the ones of these two predicted service lives which are the shorter, and sets a priority order for overhaul in order of shortness of predicted service life. An overhaul schedule table generation unit 330 creates a schedule table D1 based upon this priority order. The contents of this schedule table D1 are decided upon by a judgment unit 340, and, if necessary, are corrected by a correction unit 341. And a plan creation unit 350 creates an overhaul implementation plan document D2 and the like, based upon the corrected schedule table D1a. The result of the overhaul task and the present states of components are tested, and these test results are reflected by the service life prediction units 311 and 312.

Owner:KOMATSU LTD

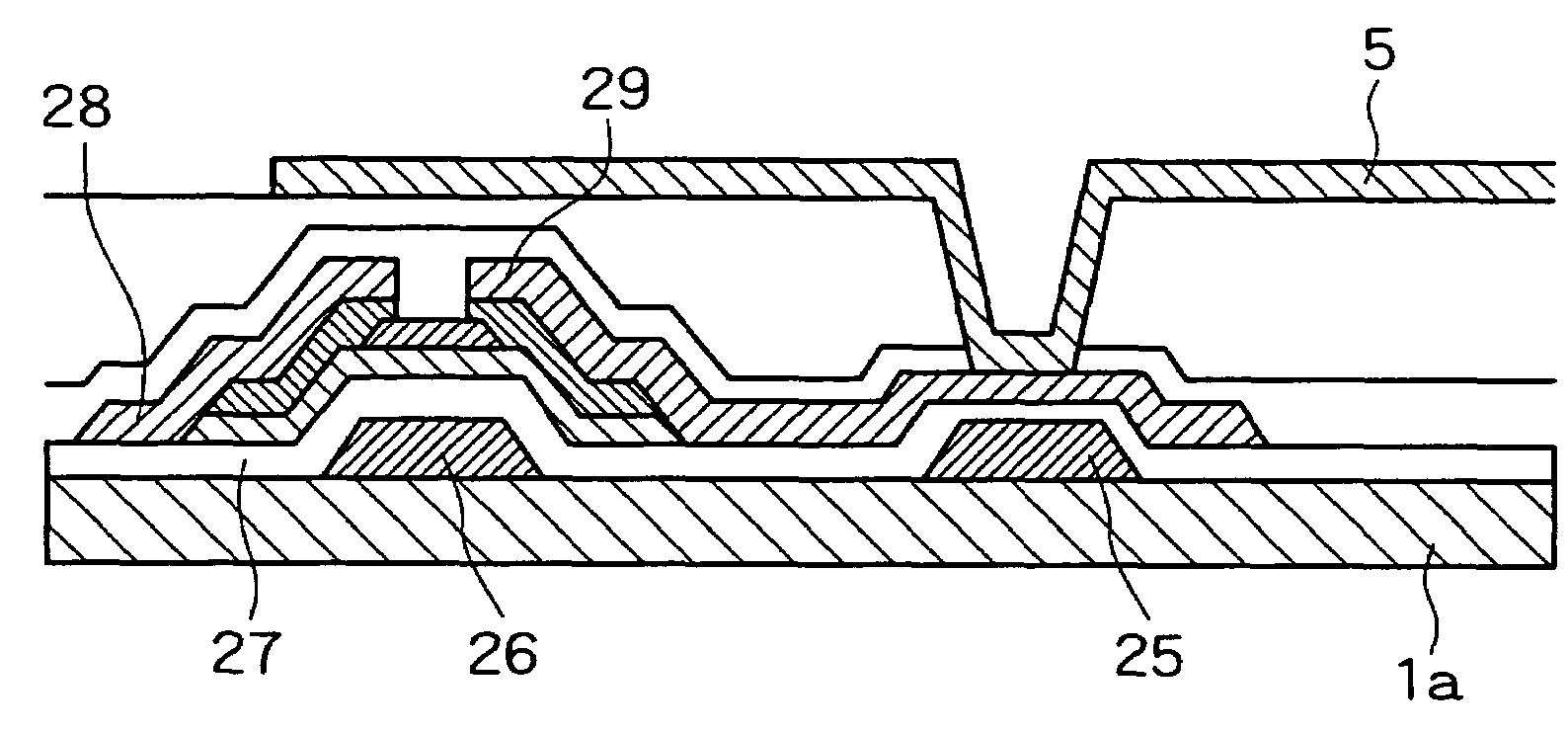

Display device and method for production thereof

ActiveUS7365810B2Increase resistanceQuality improvementStatic indicating devicesNon-linear opticsDisplay deviceTransparent conducting film

A display device and a method for production thereof. The display device comprises a substrate, thin film transistors and a transparent conductive film which are formed on the substrate, and an aluminum alloy film which electrically connects the thin film transistors to the transparent conductive film, such that there exists an oxide film of said aluminum alloy at the interface between said aluminum alloy film and said transparent conductive film, said oxide film having a thickness of 1 to 10 nm and containing oxygen in an amount no more than 44 atom %. The display device has the aluminum alloy film and the transparent conducive film in direct contact with each other, obviating the necessity of barrier metal between them.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com