Patents

Literature

41results about How to "Achieve continuous flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

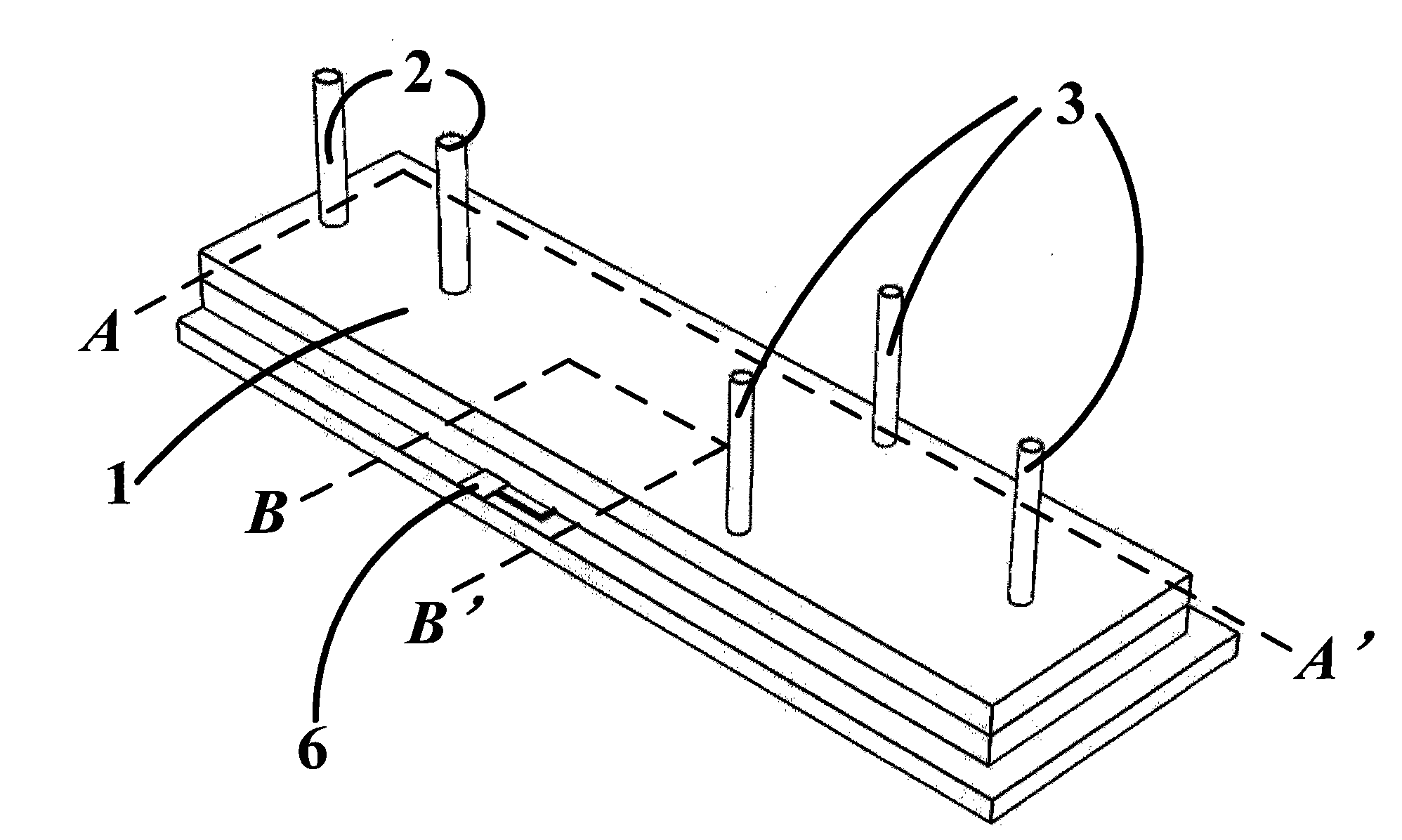

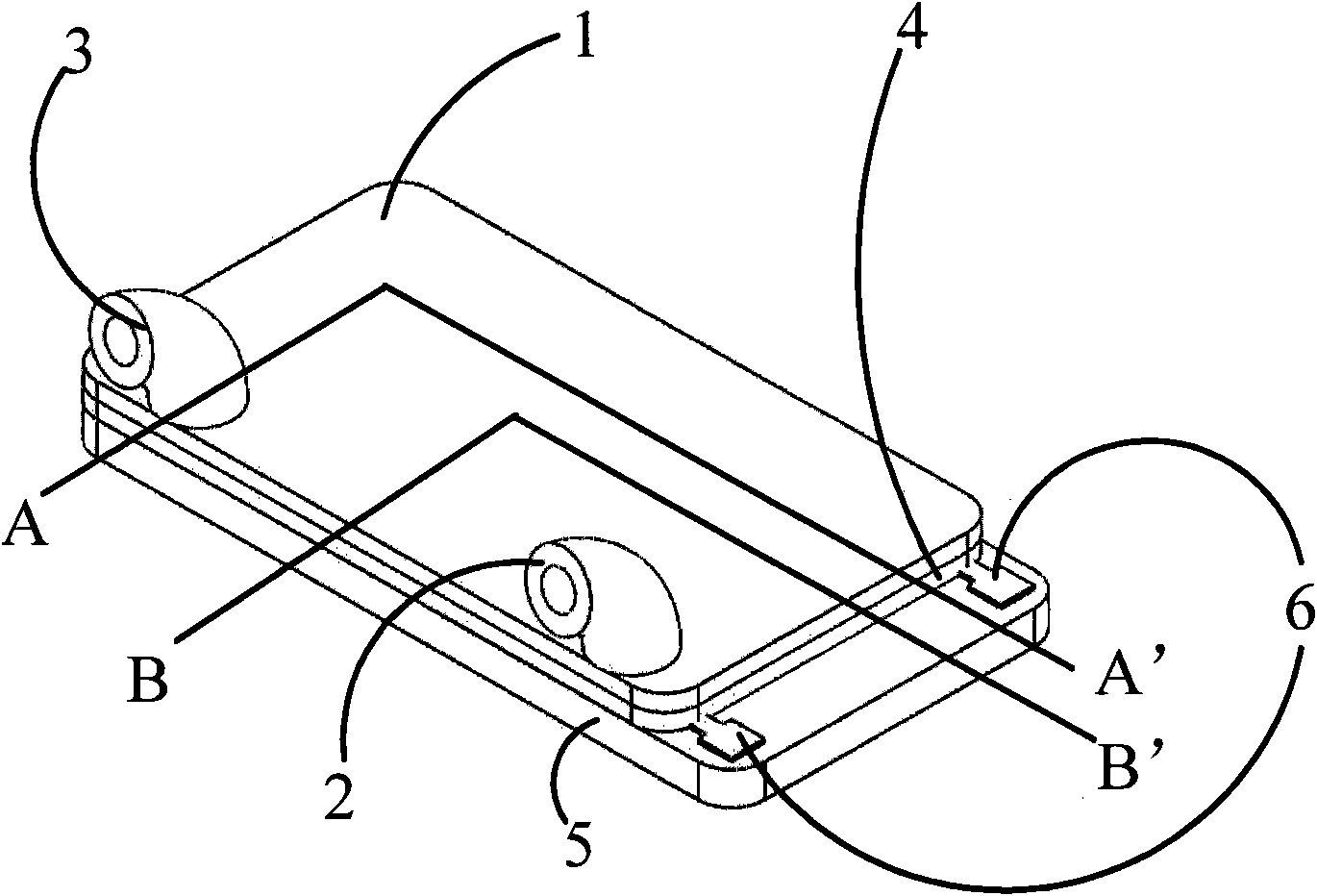

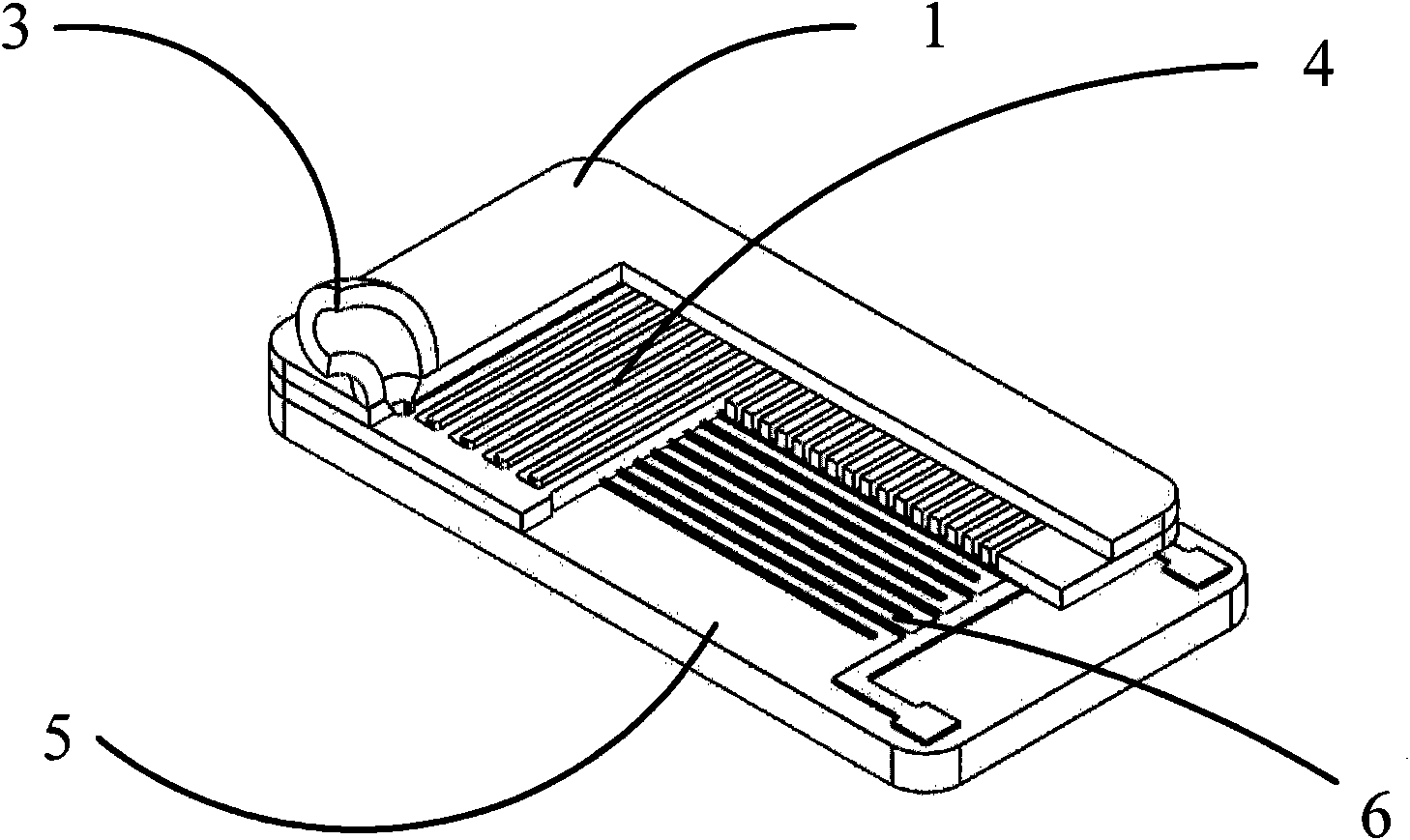

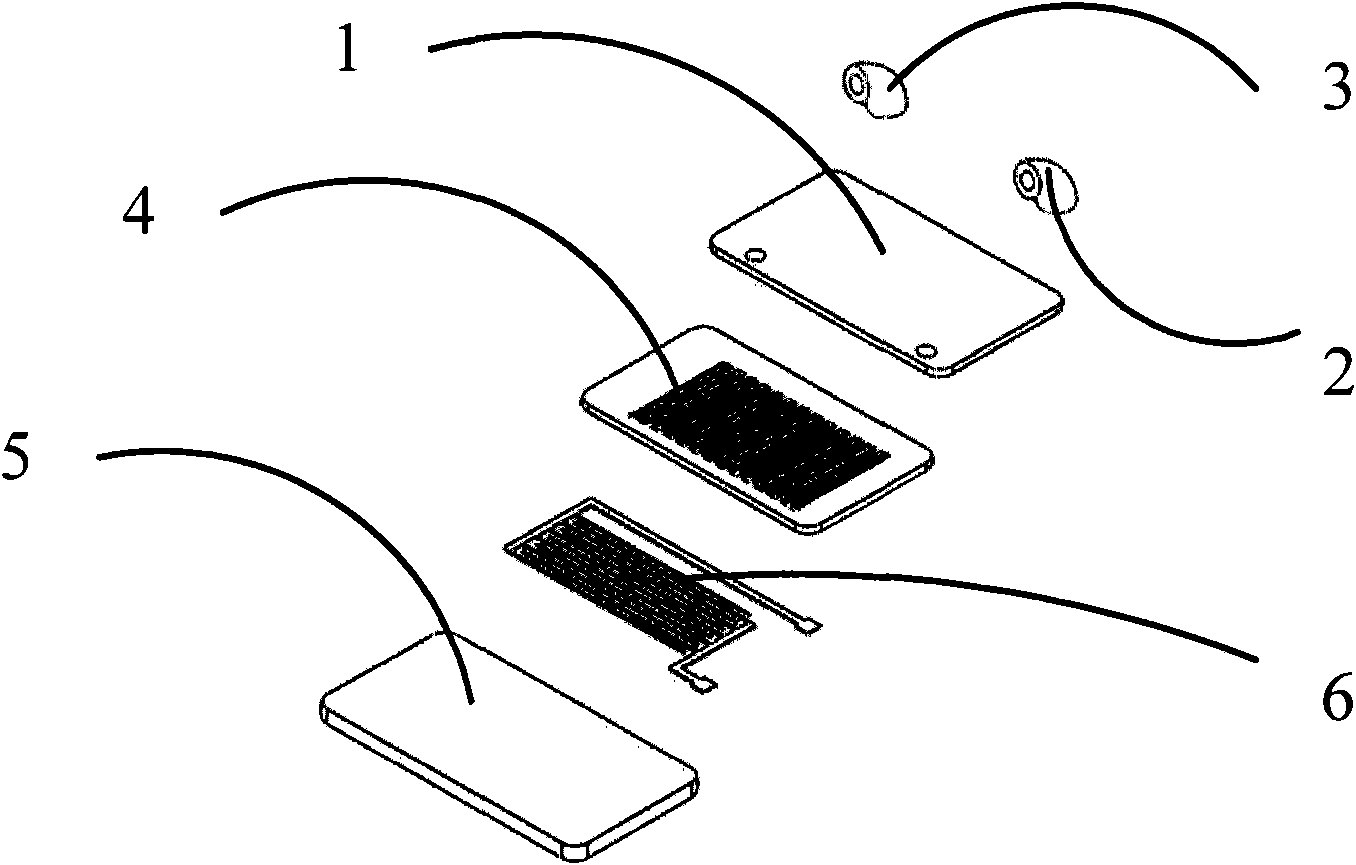

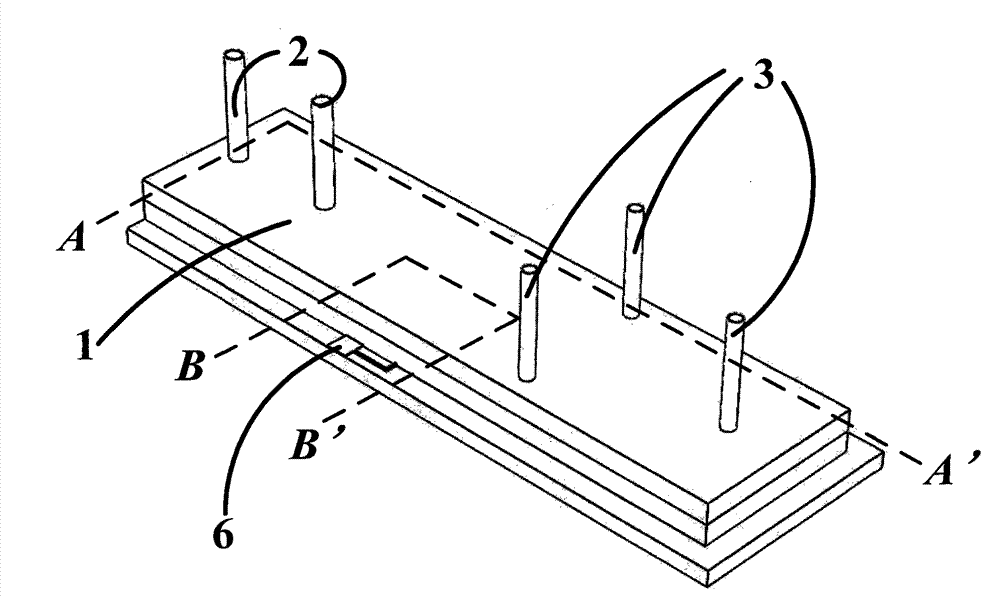

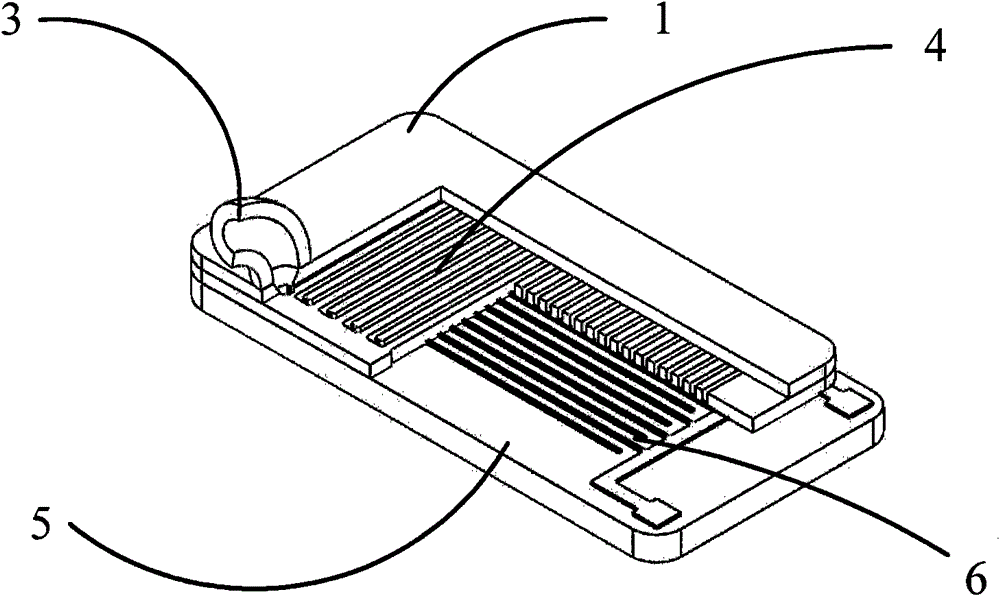

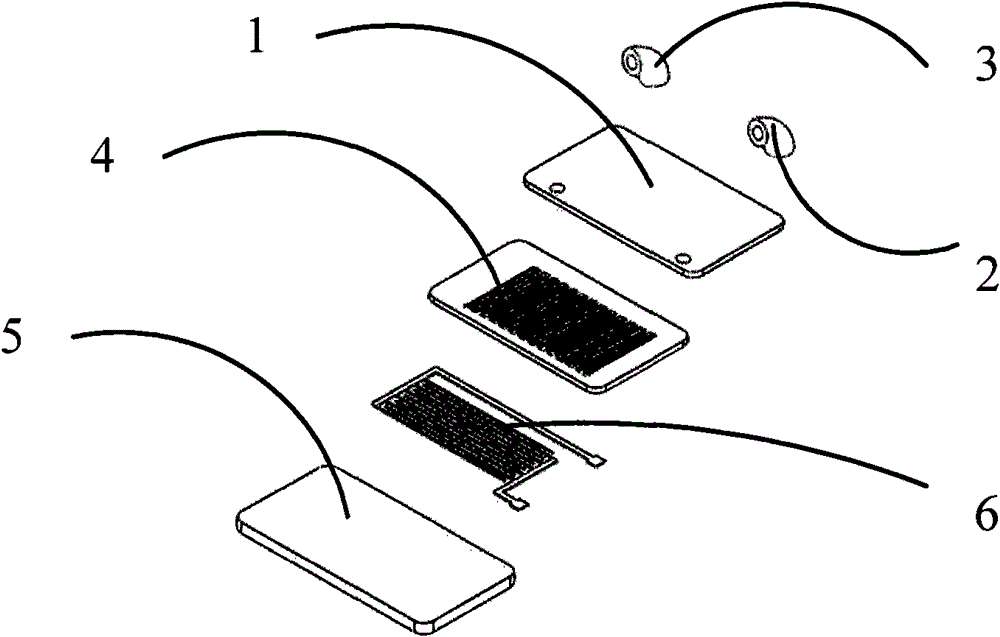

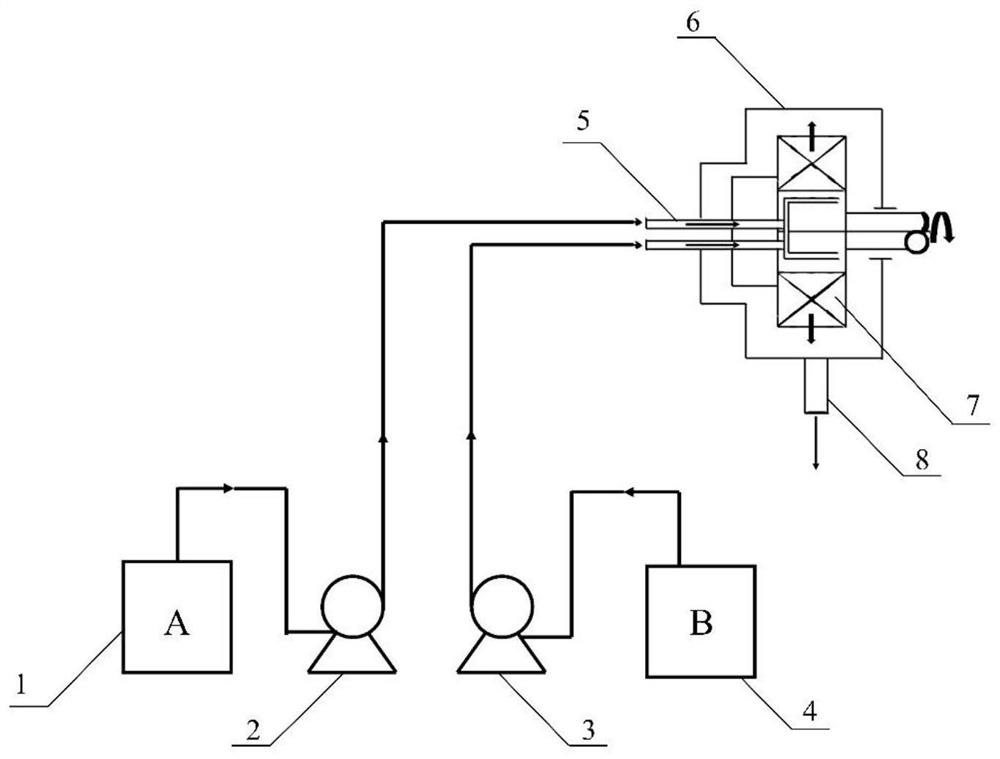

Flow type electroporation device and system

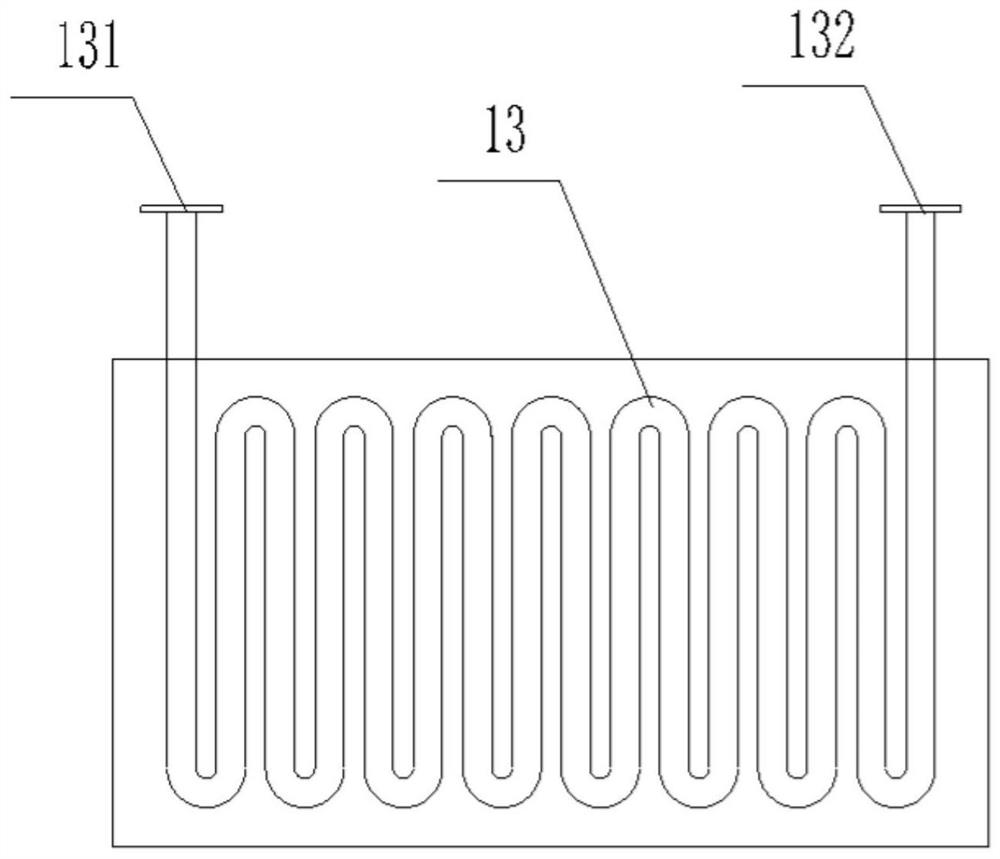

InactiveCN101928666AAchieve continuous flowEasy to handleStress based microorganism growth stimulationElectricityMain channel

The invention discloses a flow type electroporation device and a system, and the system comprises the flow type electroporation device, a channel, an injection pump and a voltage source, wherein the flow type electroporation device comprises a substrate and electrodes which are made on the substrate and are arranged in parallel and in pairs, and each pair of the electrodes comprise an anode and acathode which are oppositely arranged; the channel is arranged above the electrodes and limits fluid to flow; an initial end of the channel is provided with a plurality of inlet branch channels whichconverge into a main channel, a terminating end is provided with a plurality of outlet branch channels, and a plurality of head covers for fluid inlets and outlets are arranged above the channel; theinjection pump is connected to inlets and outlets of the head covers in the flow type electroporation device and limits the flow speed of the fluid; and the voltage source is connected with the electrodes through electrical connectors and sets and produces pulse voltage. The flow type electroporation system utilizes the fluid channel and the connected injection pump to realize continuous flow of various suspensions in the fluid channel, thereby enabling the process that cells are subjected to electroporation to be continuous and realizing rapid treatment of a large number of samples.

Owner:PEKING UNIV

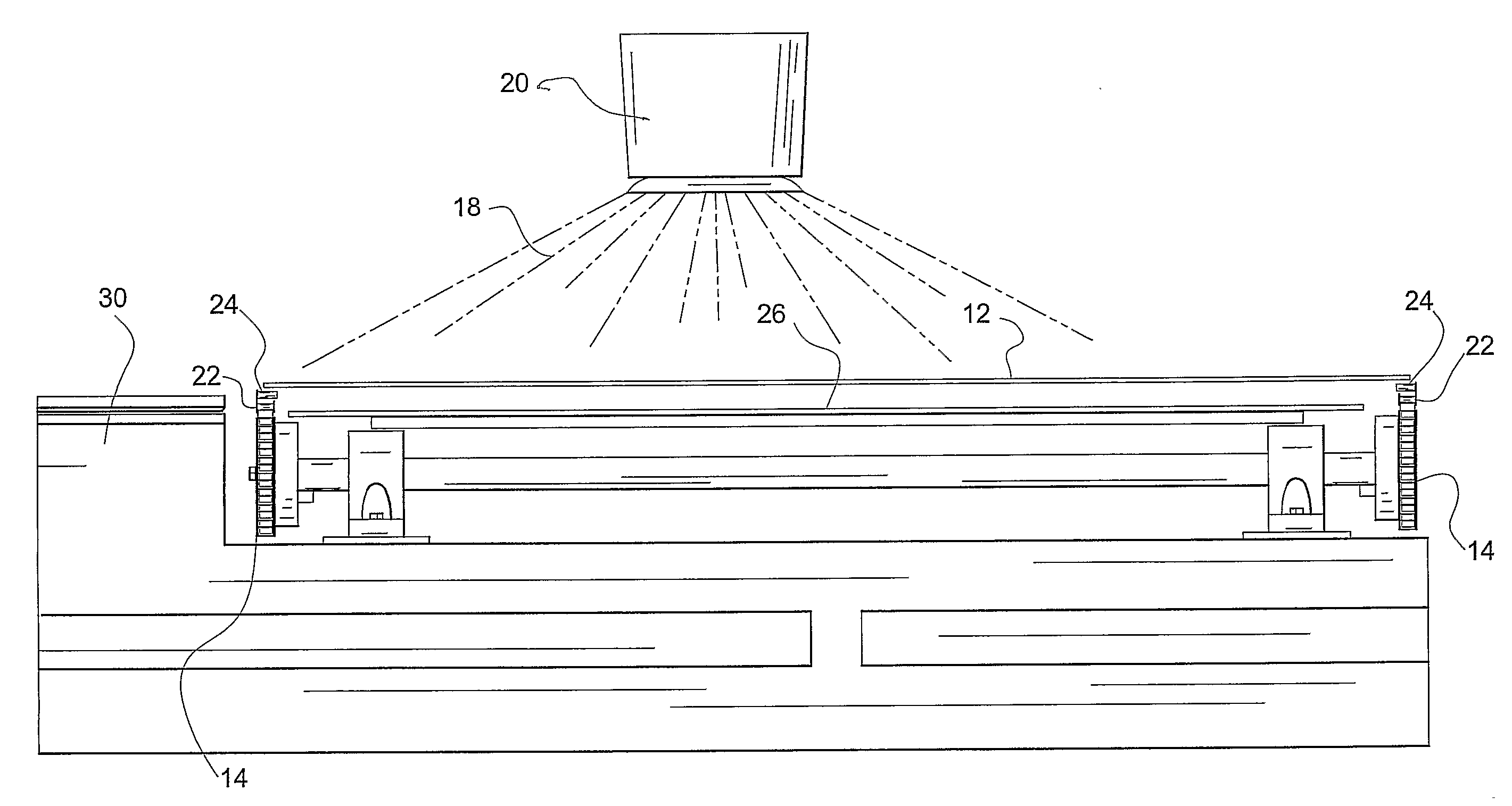

Process and Apparatus for Coating Substrates by Spray Pyrolysis

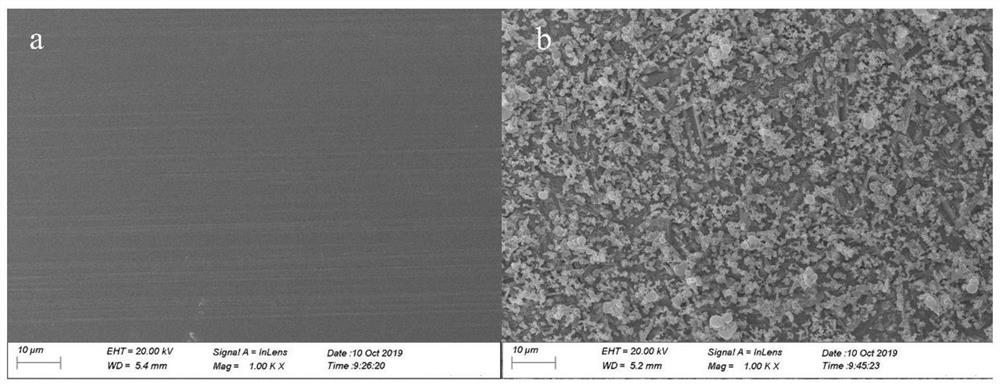

InactiveUS20080193638A1Achieve continuous flowMolten spray coatingLiquid/solution decomposition chemical coatingSpray pyrolysisSolvent

Apparatus and a process for applying a metal oxide coating to a substrate, the process comprising the steps of providing a solution of a metal compound in a solvent, spraying the solution onto the surface of a hot substrate, and pyrolyzing the solution to form a coating of metal oxide on the substrate.

Owner:INNOVATIVE THIN FILMS +1

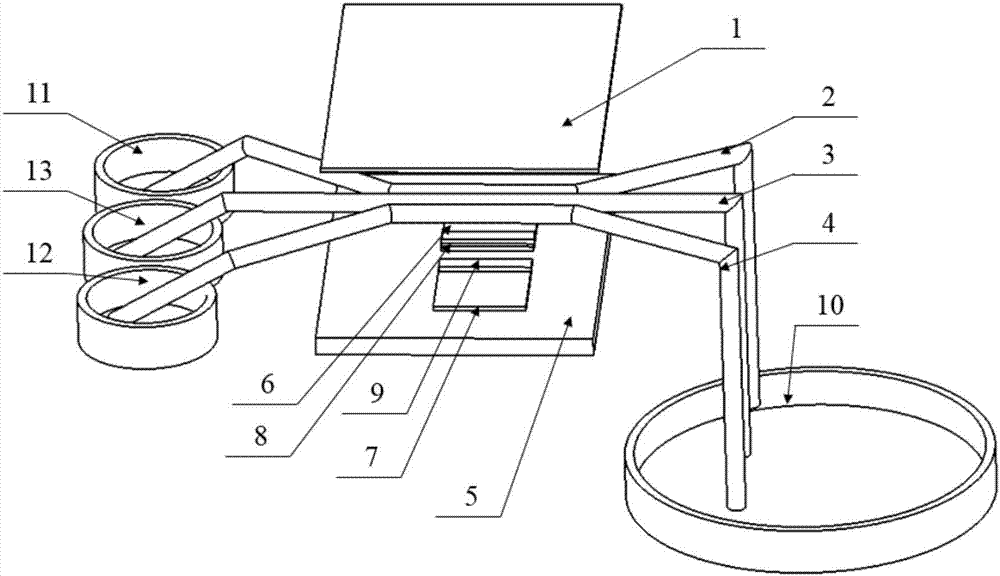

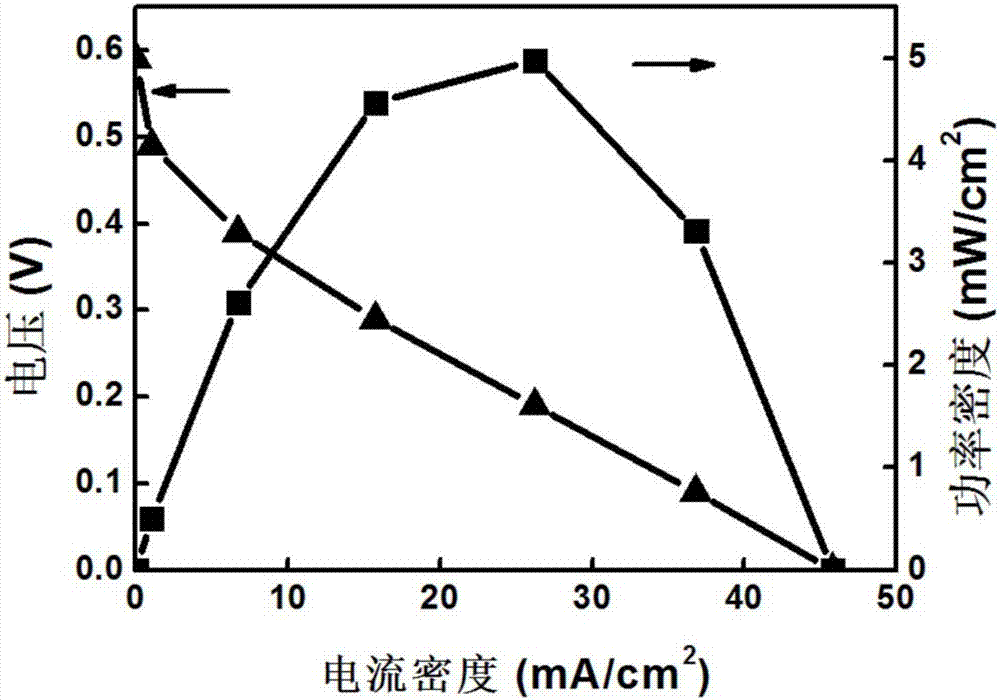

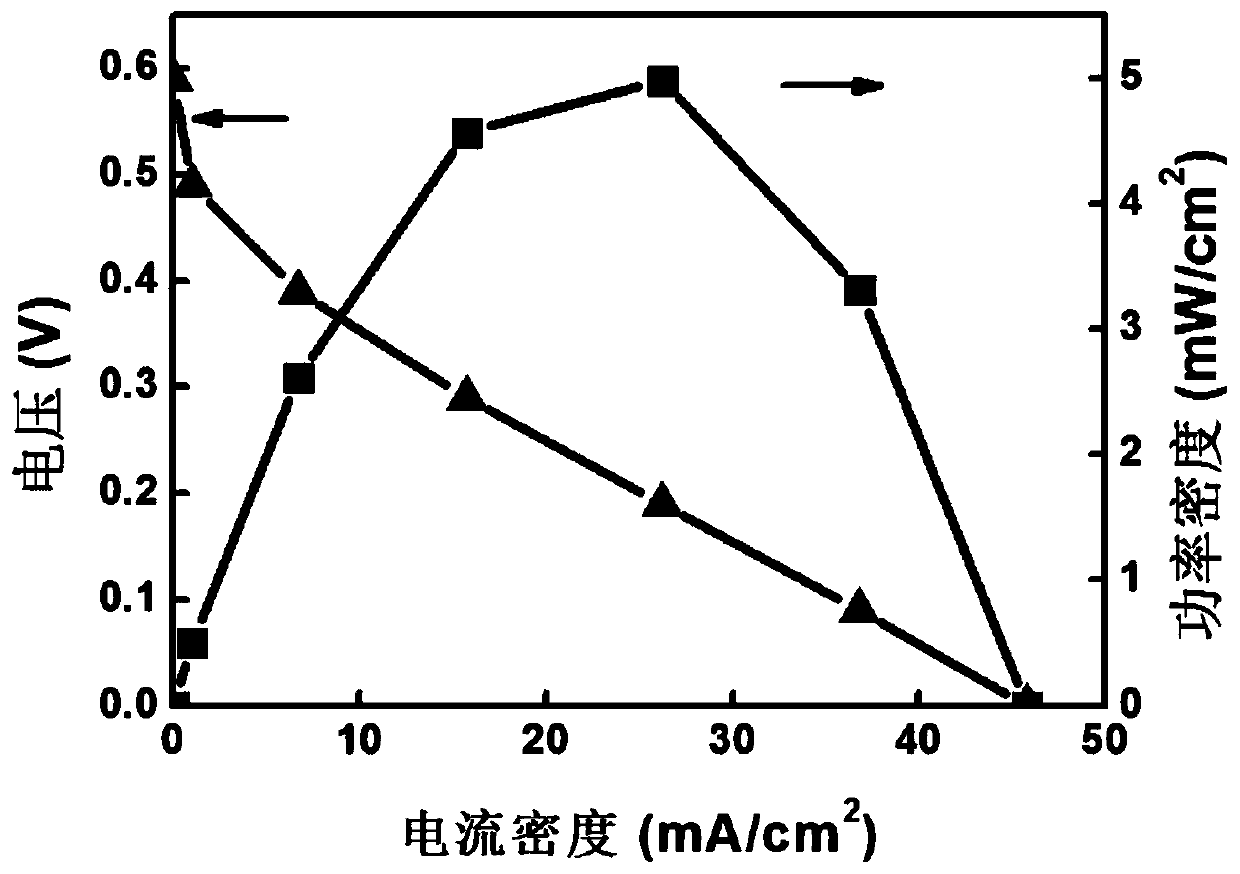

Cotton-thread-based passive micro-fluid fuel cell

ActiveCN107293764AAchieve continuous flowSimplify accessory equipmentElectrolyte stream managementFuel cell detailsChemical industryFuel cells

The invention discloses a cotton-thread-based passive micro-fluid fuel cell, which comprises an anode carbon paper and a cathode carbon paper; the cotton-thread-based passive micro-fluid fuel cell is characterized in that a first cotton thread and a second cotton thread are arranged on the anode carbon paper and the cathode carbon paper; the first cotton thread and the second cotton thread are isolated by a third cotton thread; one end of the first cotton thread is inserted to a first inlet culture dish, anode electrolyte is stored in the first inlet culture dish; one end of the second cotton thread is inserted to an inlet culture dish, and cathode electrolyte is stored in a second inlet culture dish; one end of the third cotton thread inserted to a third inlet culture dish, and isolating liquid is stored in the third inlet culture dish; the other ends of the first cotton thread, the second cotton thread and the third cotton thread are inserted to an outlet culture dish; the faces where the anode carbon paper and the cathode carbon paper are in contact with the cotton threads are coated with an anode catalyst layer and a cathode catalyst layer. By means of the capillary force of the cotton thread and the gravity, the continuous flow of the cathode fluid and the anode fluid is realized. The cotton-thread-based passive micro-fluid fuel cell can be widely applied to energy source, chemical industry, environment-friendly, and other domains.

Owner:CHONGQING UNIV

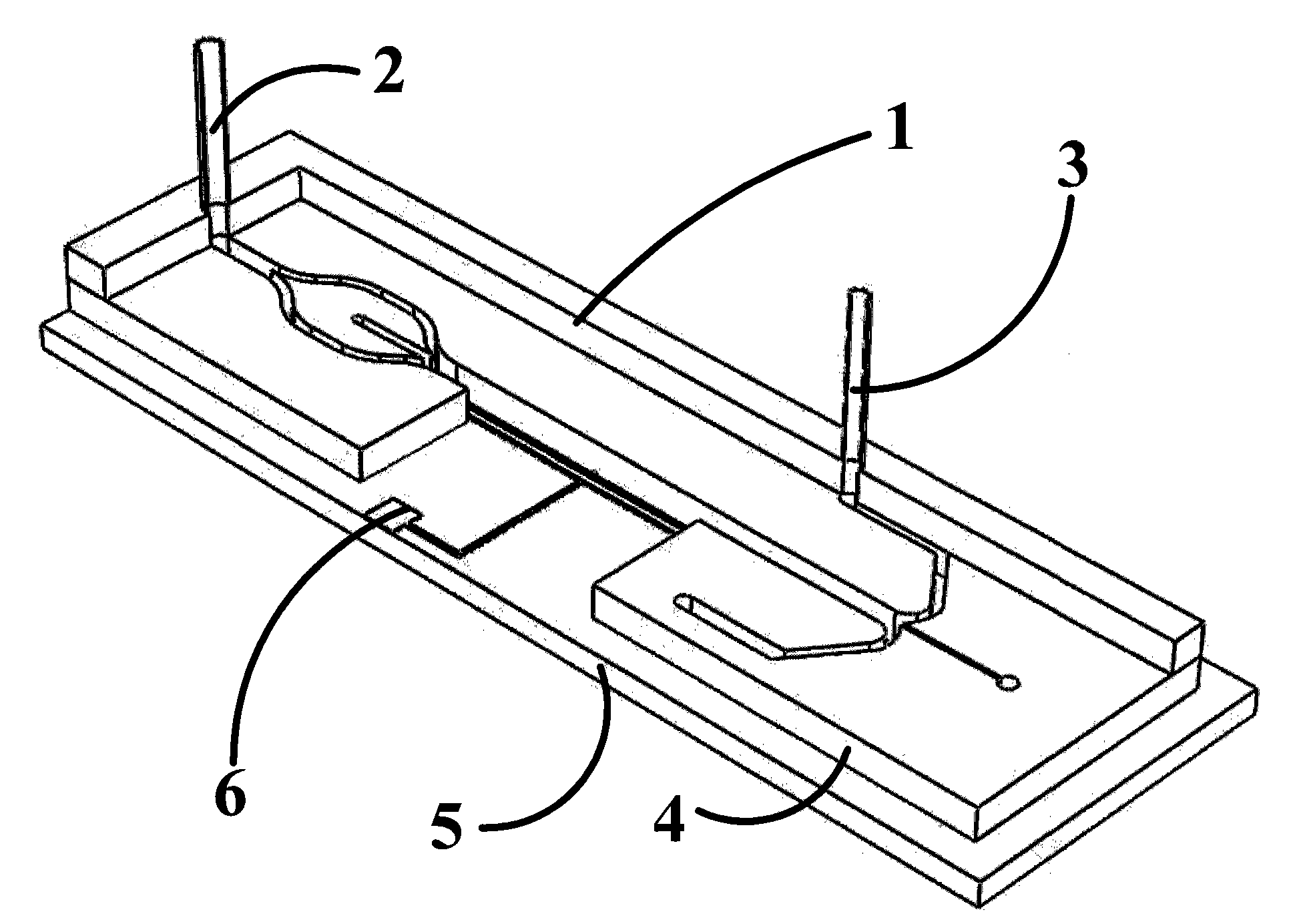

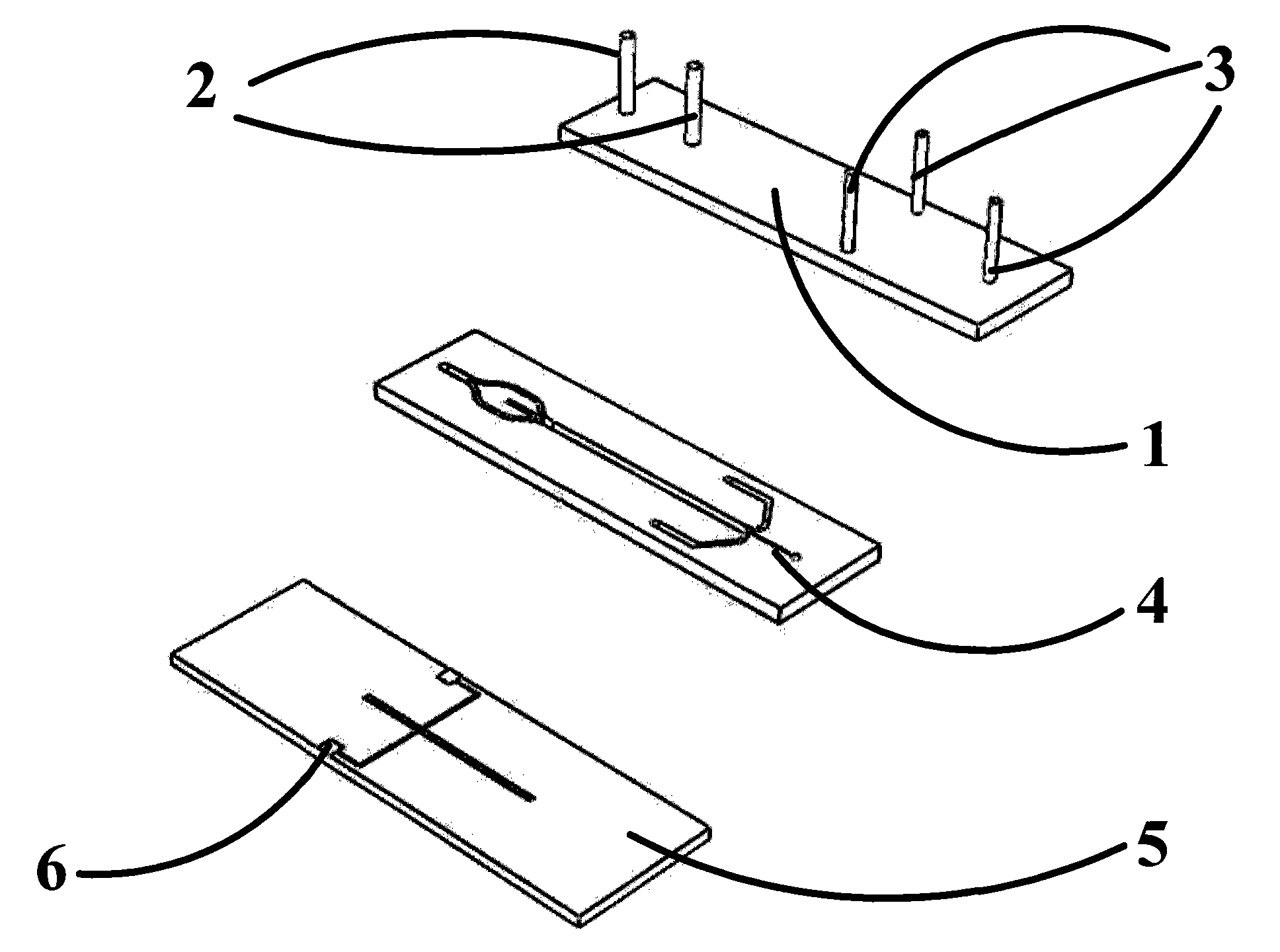

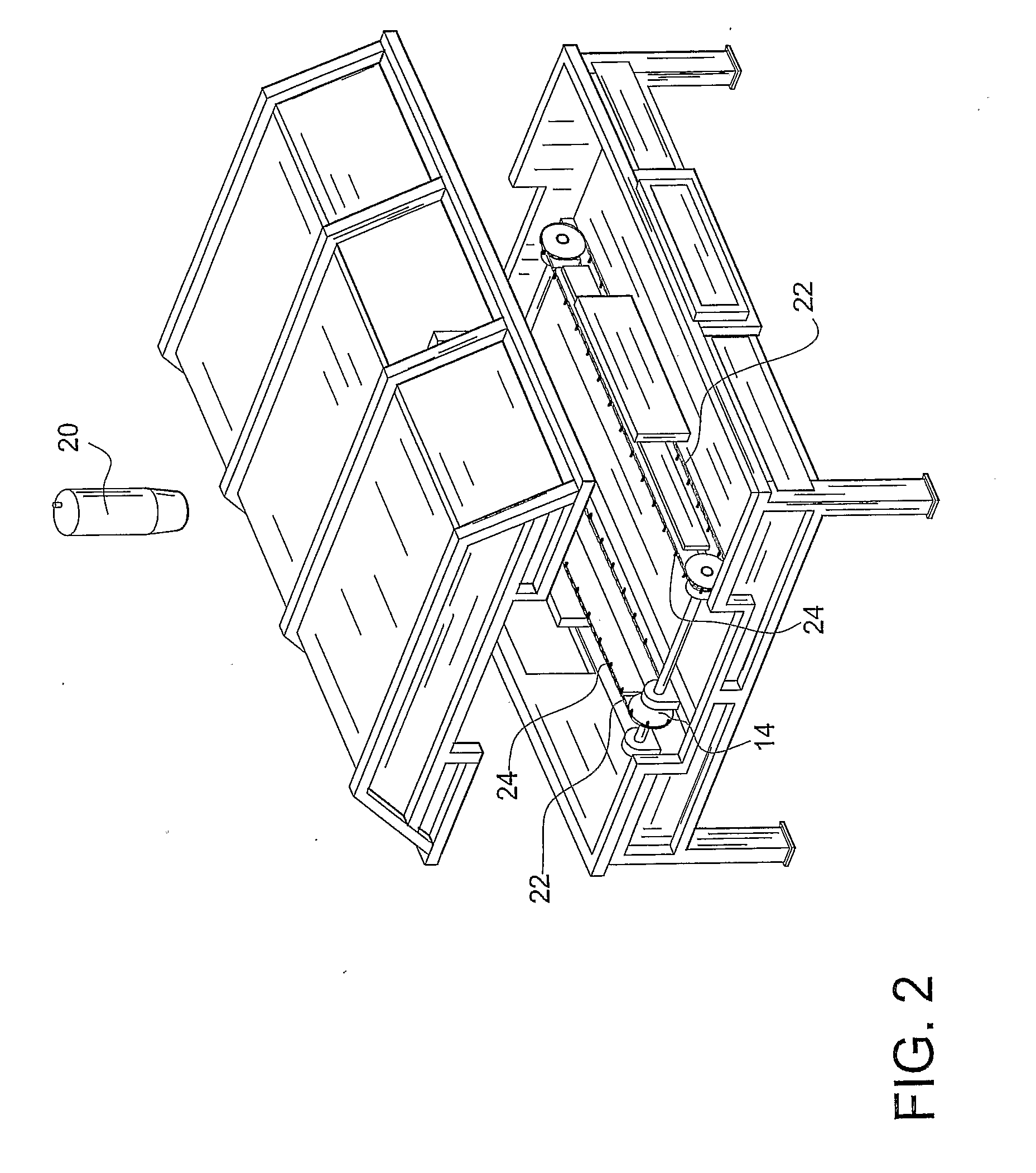

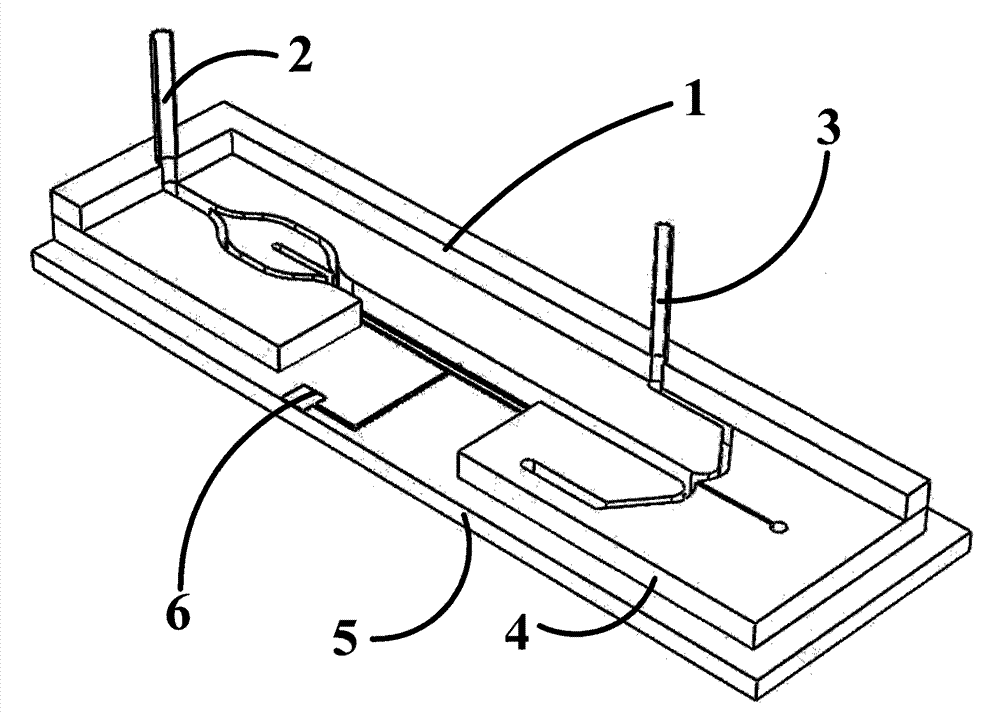

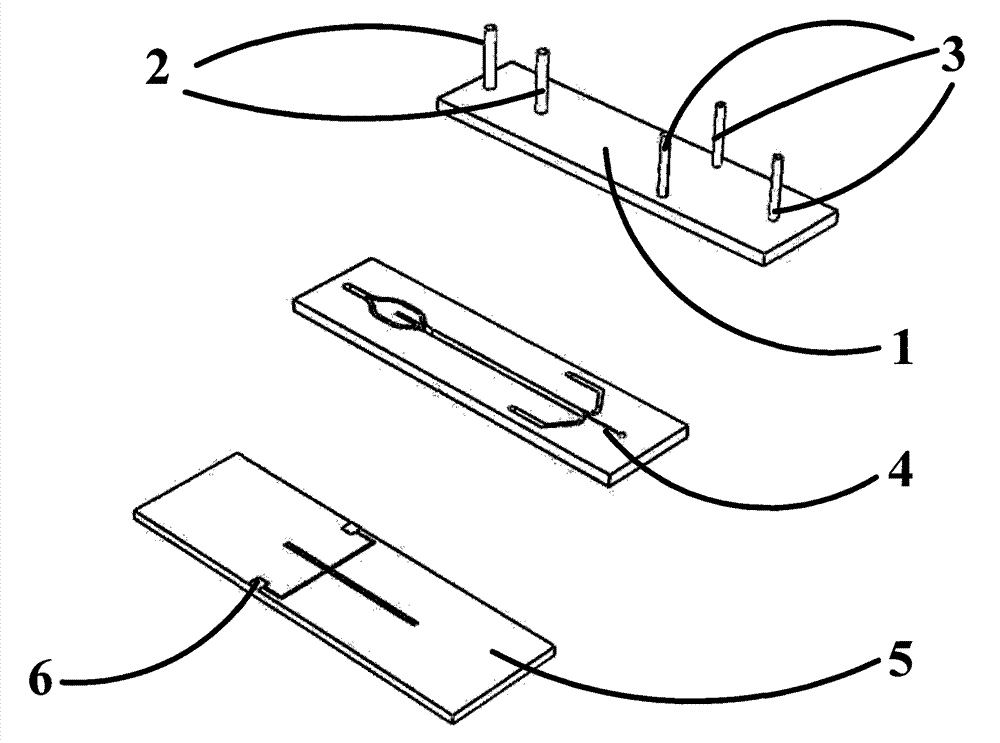

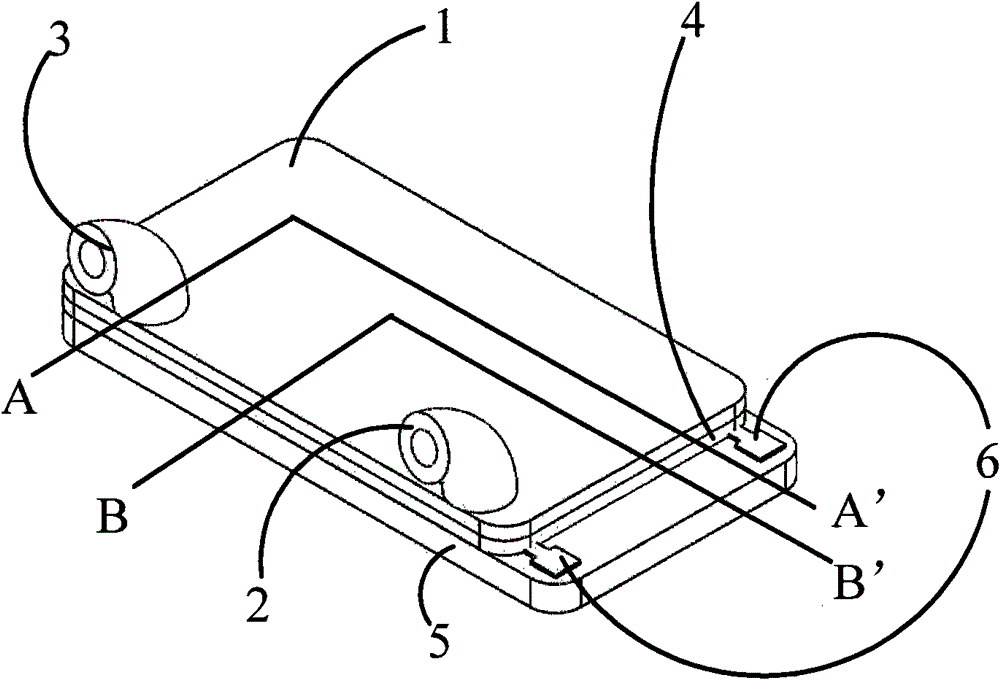

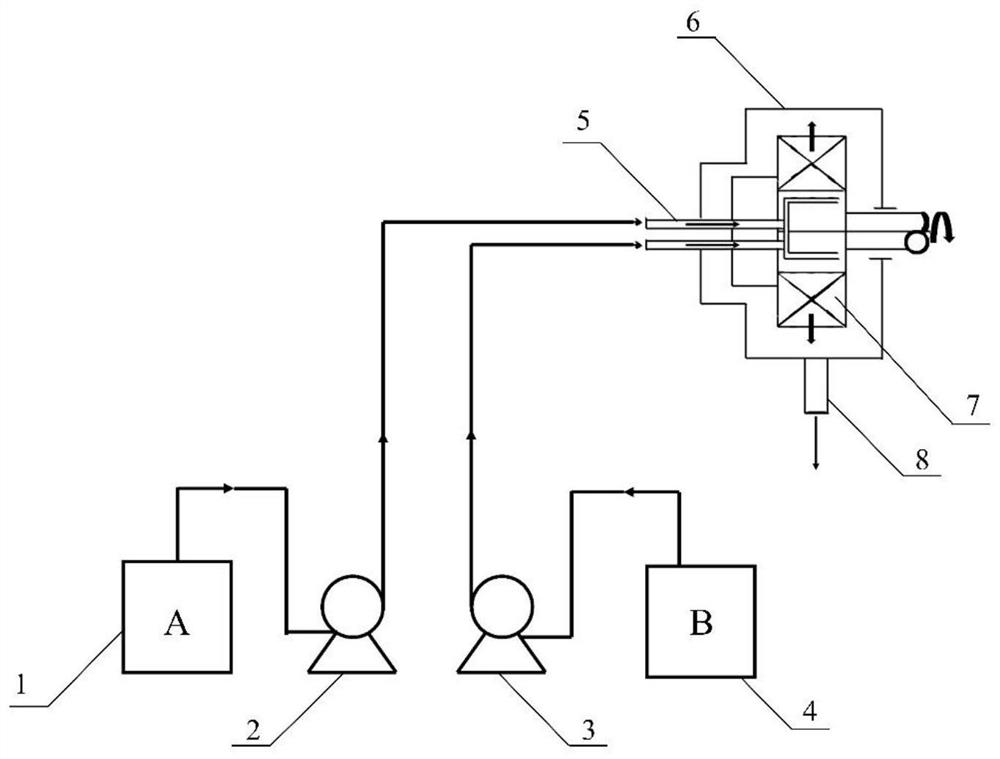

Flow electroporation device and system

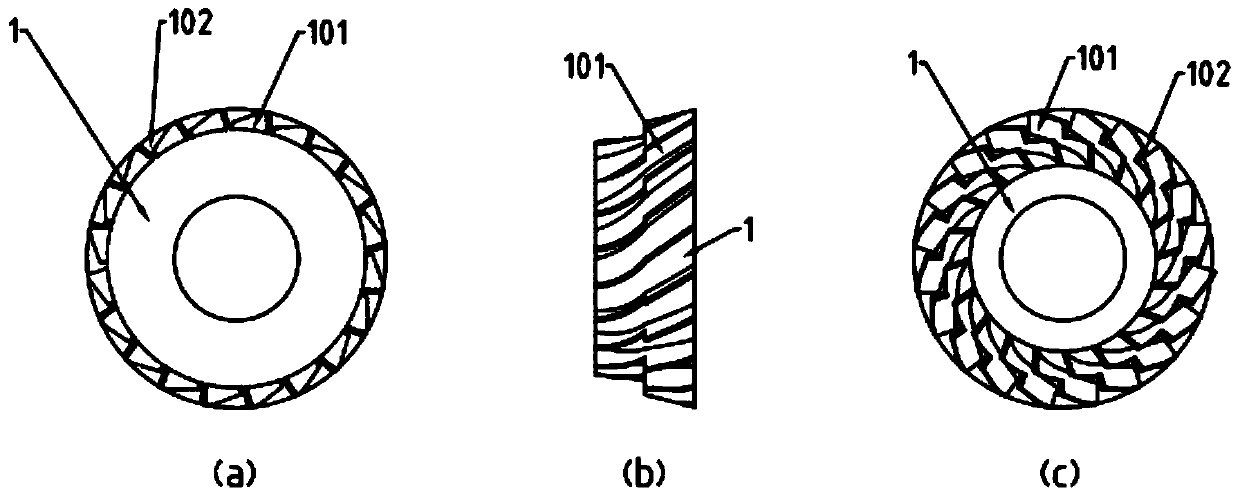

ActiveCN101857836ASmall sizeReduce distanceStress based microorganism growth stimulationElectricityContinuous flow

The invention discloses a flow electroporation device and a system. The system comprises a flow electroporation device, an injection pump and a voltage source, wherein the flow electroporation device comprises a substrate, electrodes arranged on the substrate, a channel for limiting fluid to flow, a top cover of an inlet and an outlet of fluid, the electrodes are arranged in a crossing way; each pair of electrodes comprise an anode and an cathode which are oppositely arranged, and the channel is arranged on the electrodes; the top cover is arranged above the channel, and the injection pump isconnected to the inlet and the outlet of the top cover in the flow electroporation device through a pipeline and is used for controlling the flow rate of the fluid; and the voltage source is connected with the electrodes through electric connecting pieces and is used for setting and producing pulse voltage. The flow electroporation system utilizes the fluid channel and the injection pump connected with the fluid channel to realize the continuous flow of various suspensions in the fluid channel, so that the fast treatment of a large number of samples can be continuously realized in the processthat cells are electroporated.

Owner:ETTA BIOTECH

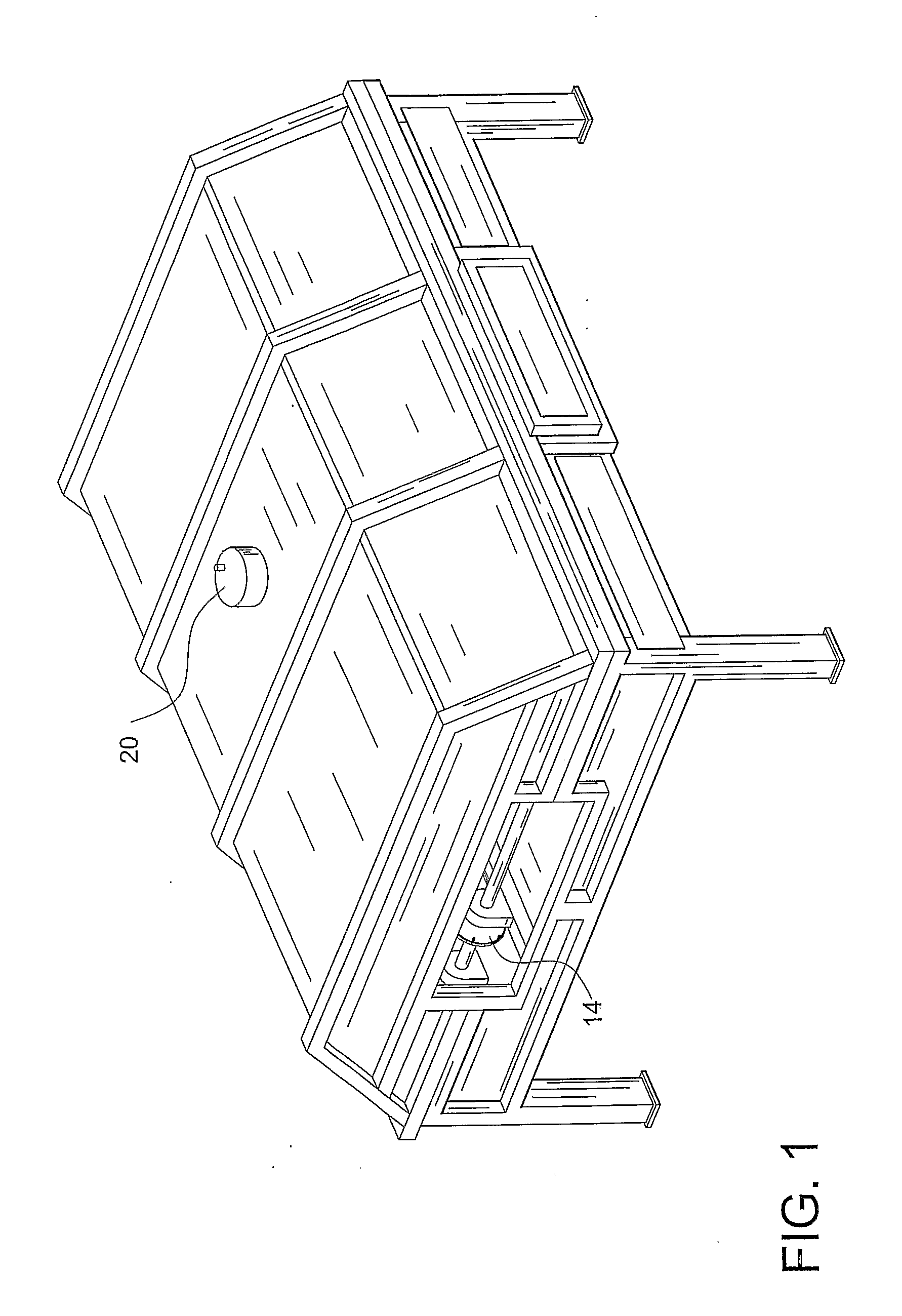

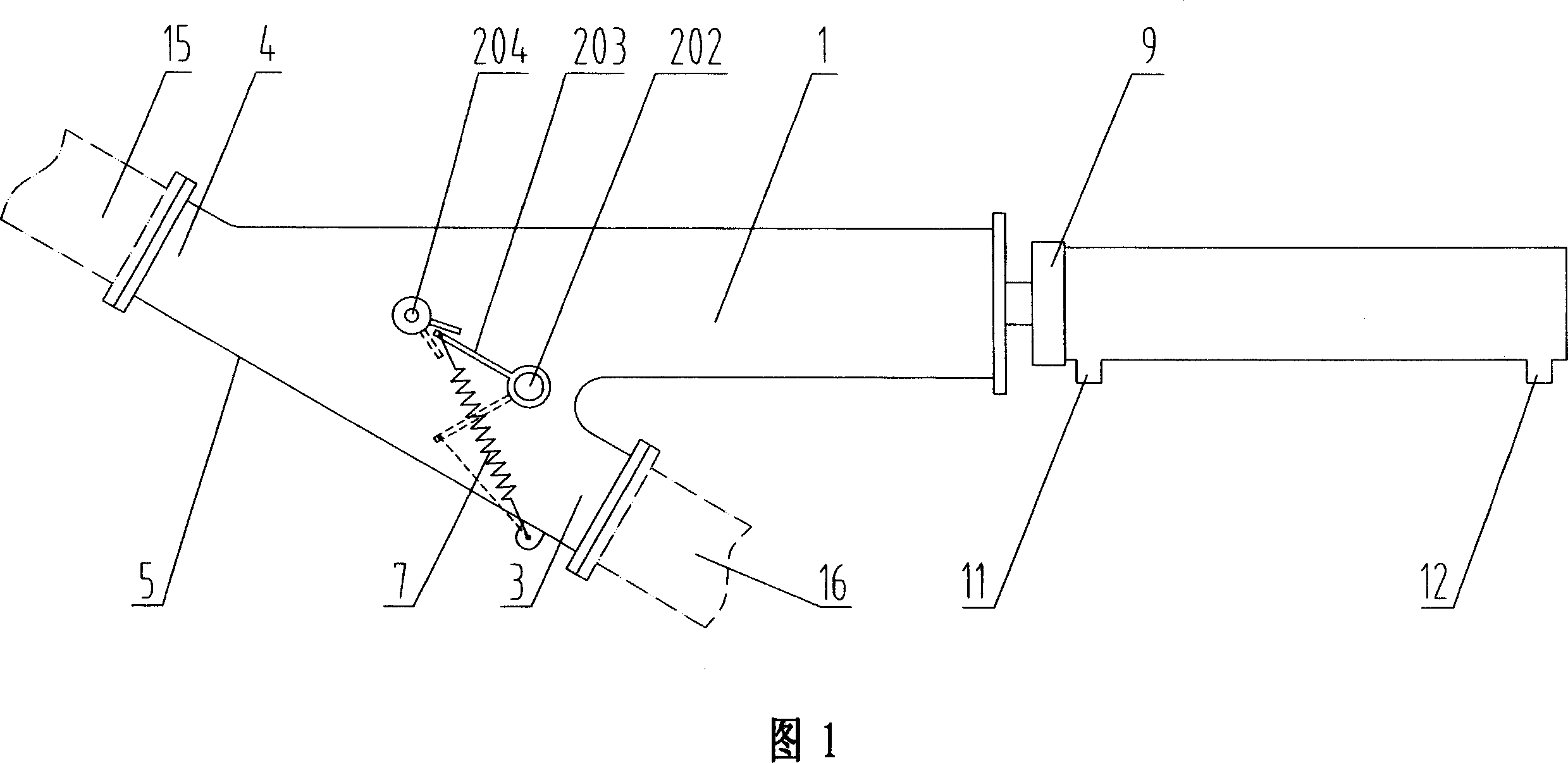

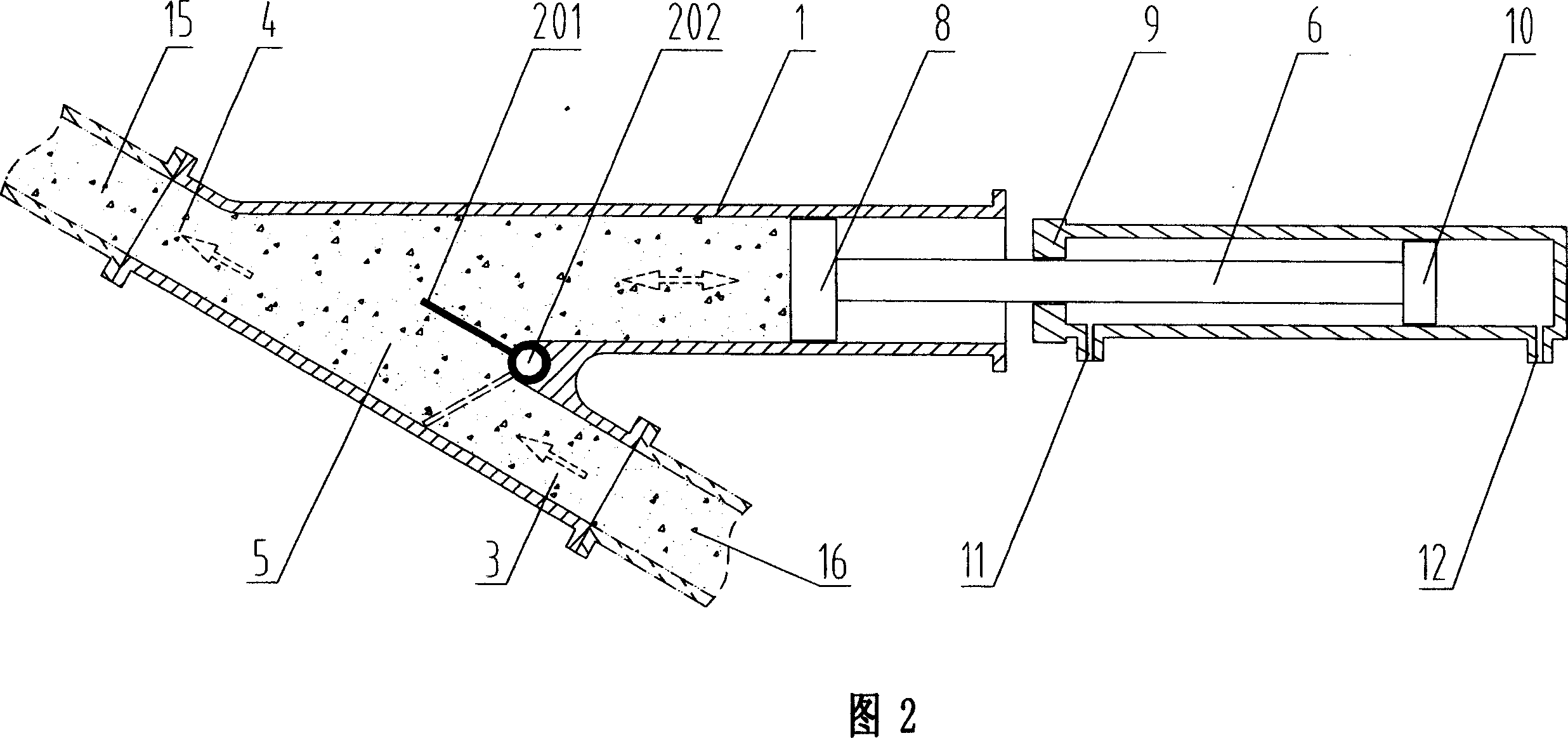

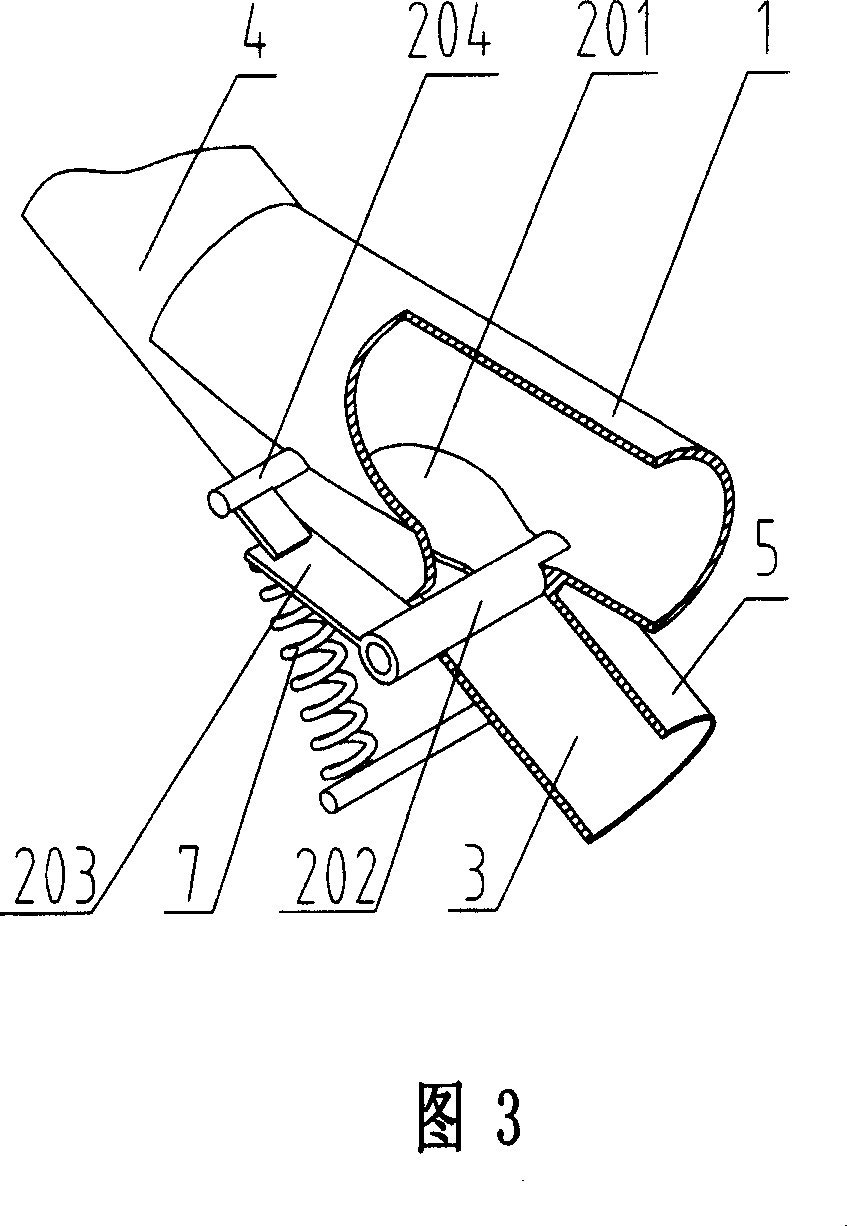

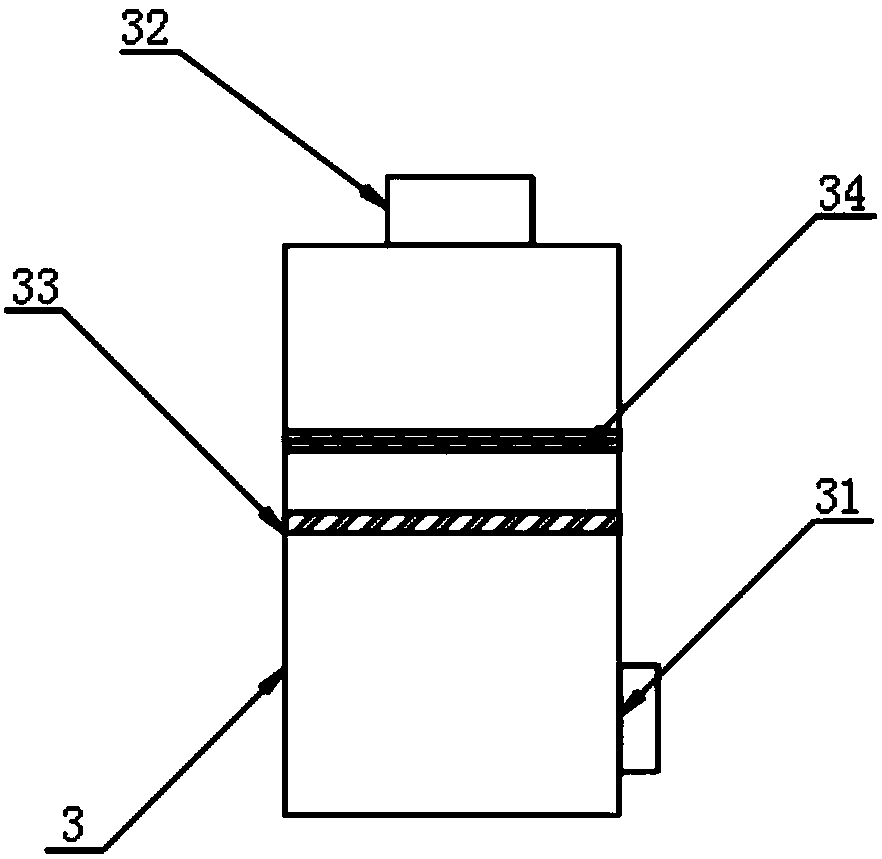

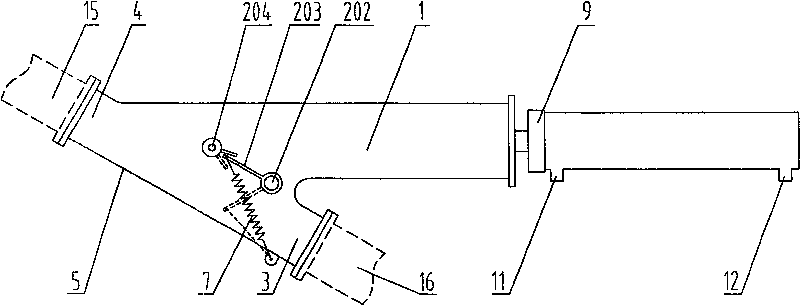

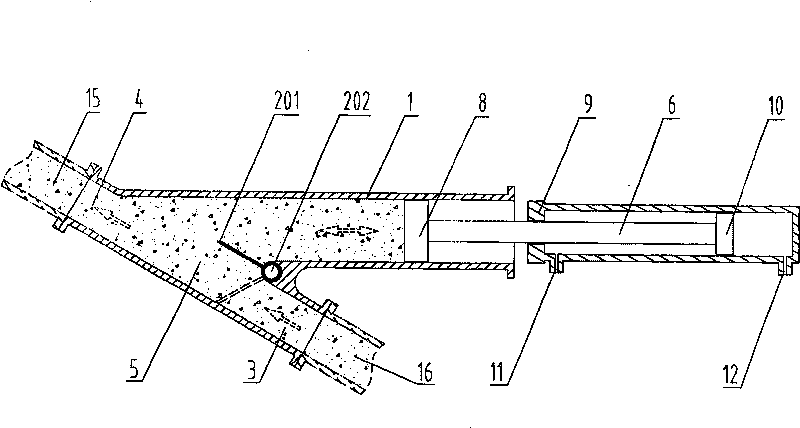

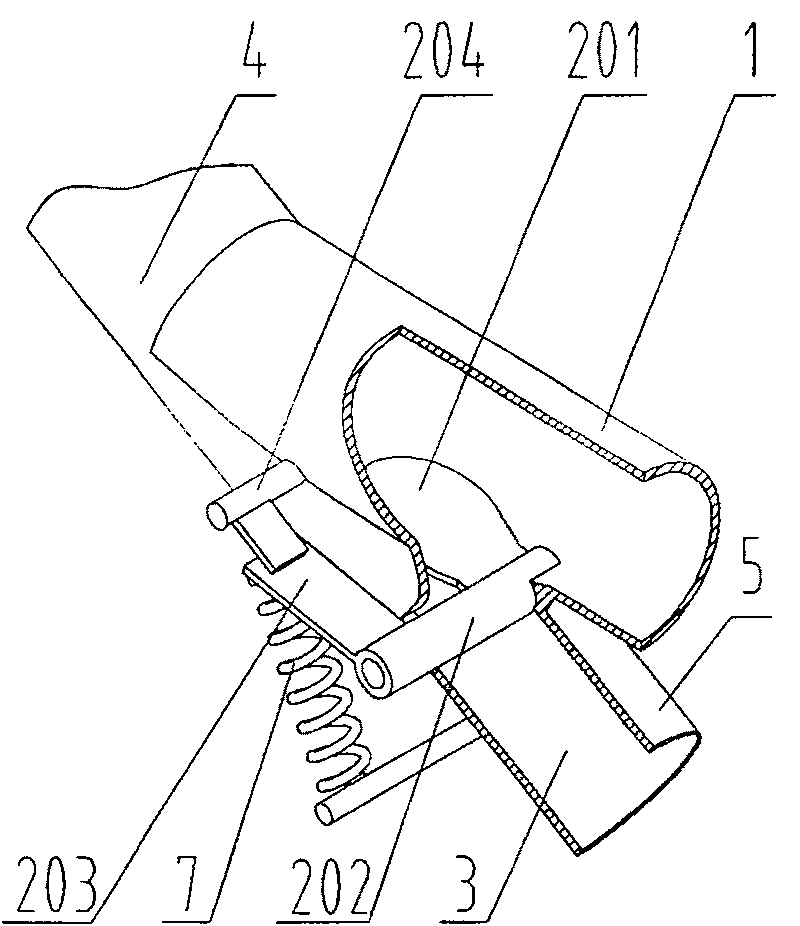

Device for suppressing pulsated impact of slurry flow in concrete pump vehicle

ActiveCN1951657AReduce vibrationAchieve continuous flowDischarging apparatusPipe elementsRefluxTransmission channel

The invention relates to a device used to restrain the slurry fluid impulse impact of concrete pump. Wherein, it comprises transmission channel, feeding cylinder and controller; the feeding cylinder is through to the transmission channel; the feeding cylinder has feeding piston and feeding piston rod; the feeding piston rod is connected to the controller; between the feeding cylinder and the material inlet of transmission channel, there is a switch valve for avoiding reflux of slurry. The invention has simple structure, to realize continuous flow of slurry, and reduce the impulse impact.

Owner:SANY AUTOMOBILE MFG CO LTD

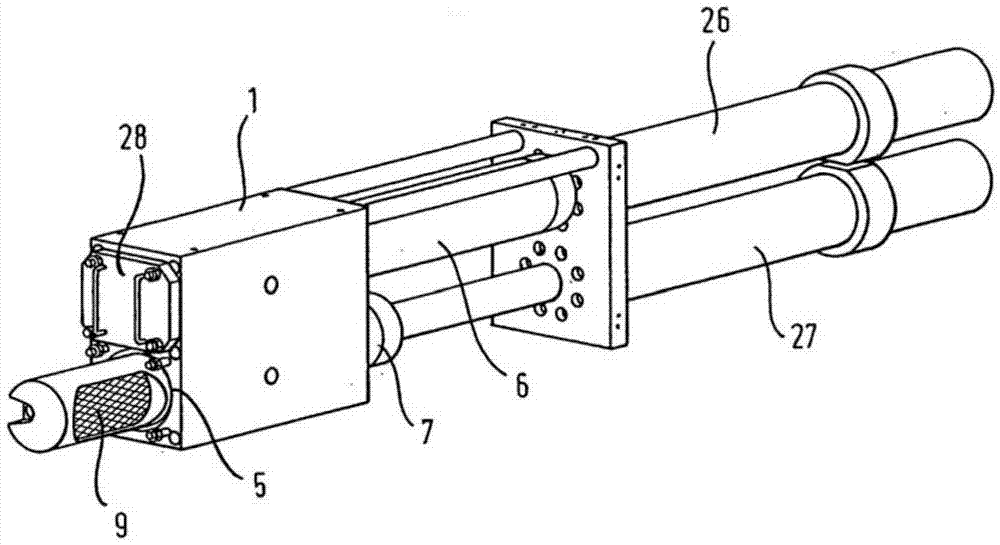

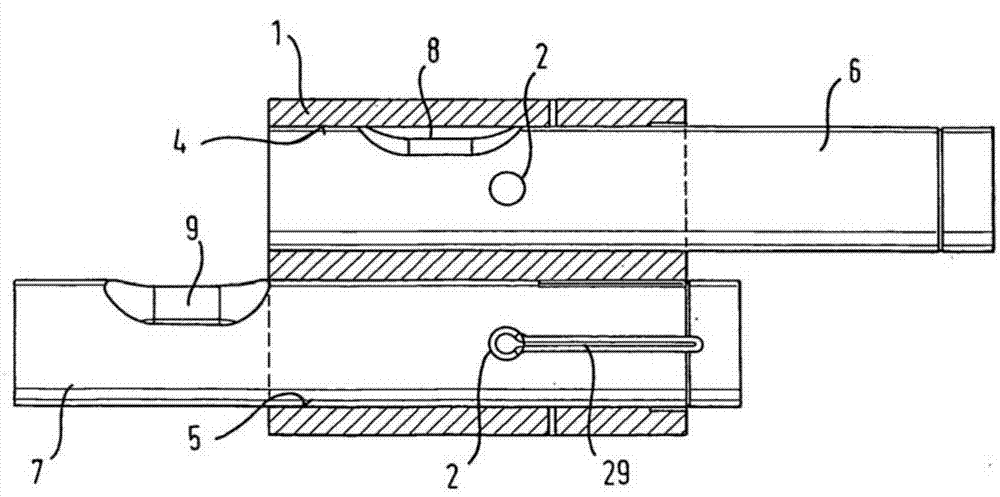

Device for filtering a fluid

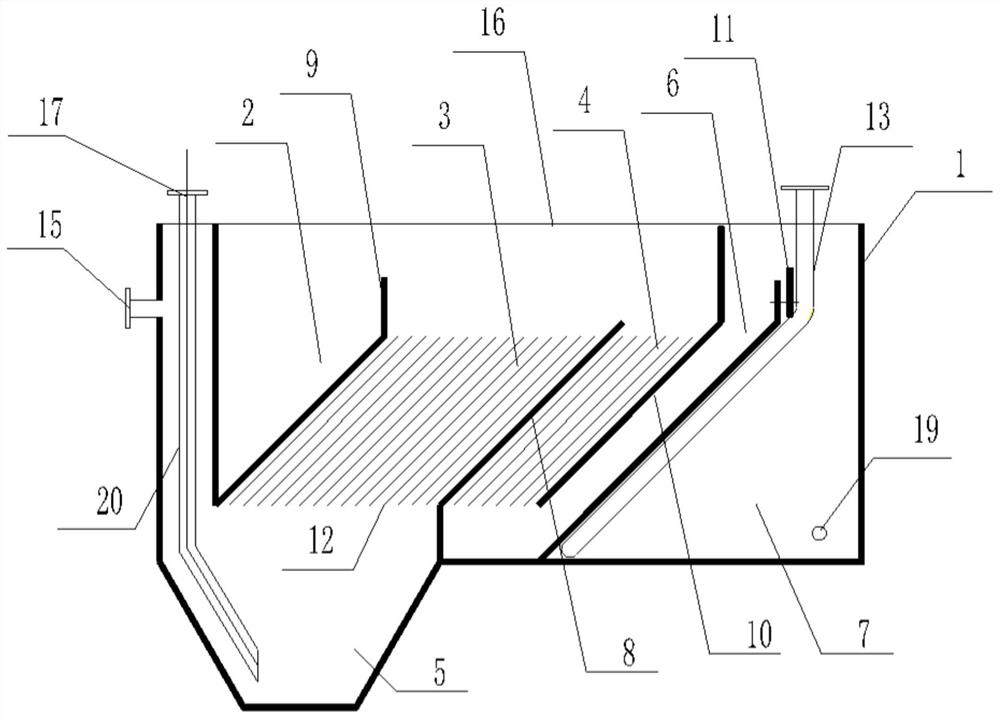

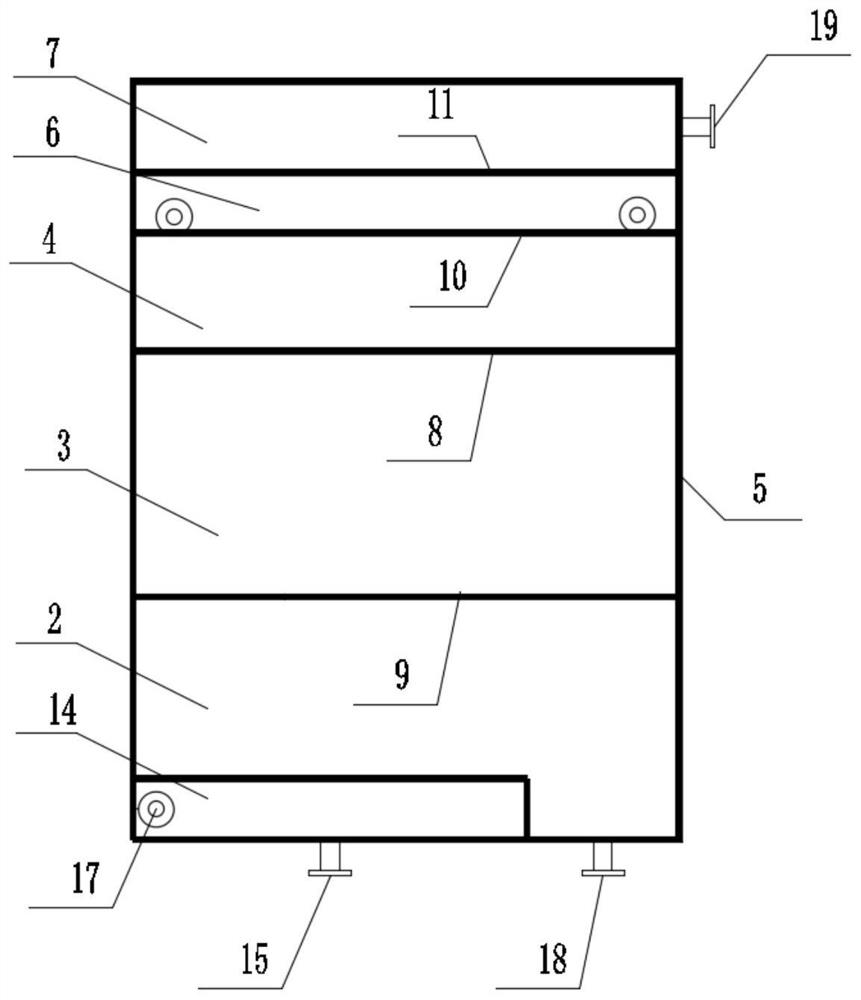

InactiveCN104203364AEnsure continuous melt flowGuaranteed volumeStationary filtering element filtersAxial displacementEngineering

The invention relates to a device for filtering a thermoplastic melt, comprising a housing (1) having at least one fluid feed channel (2) and at least one fluid discharge channel (3) and having at least two bores (4, 5) which are in fluid communication with the fluid feed channel and the fluid discharge channel, respectively. In each of the bores a respective bolt (6, 7) is axially movable, radially rotatable and mounted in a fluid-tight manner, and each of the bolts is provided with a filter unit (8, 9) having an inflow side and an outflow side. The bolts can each be moved at least between a filtering position and a back-flushing position, and each of the bolts can be moved into a filling position in which via a respective clean fluid channel (12, 13) fluid flows from the outflow side of the respective filter unit to a storage space (14, 15) produced by the movement of the respective bolt in the respective bore. As the respective bore is moved into the back-flushing position the fluid again flows through the respective filter unit to the at least one back-flushing channel and out of the housing.

Owner:马格自动化有限责任公司

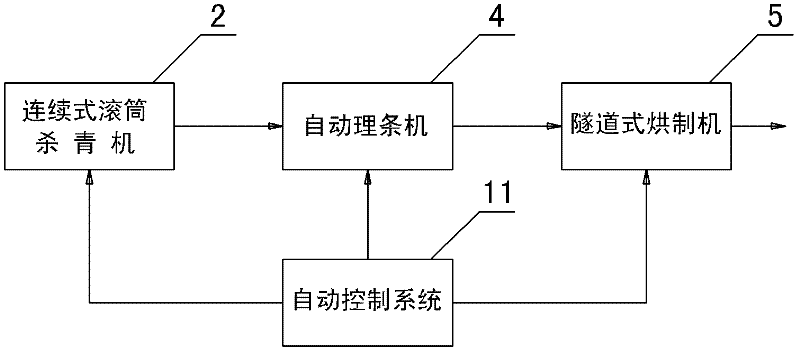

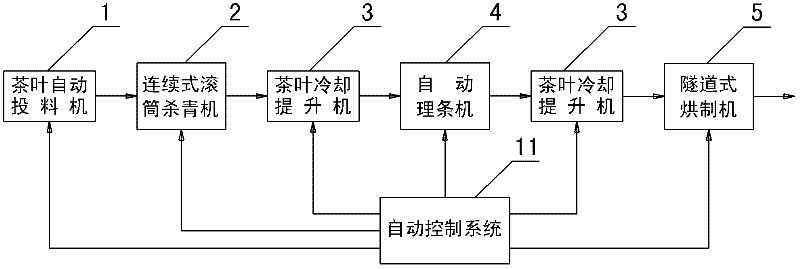

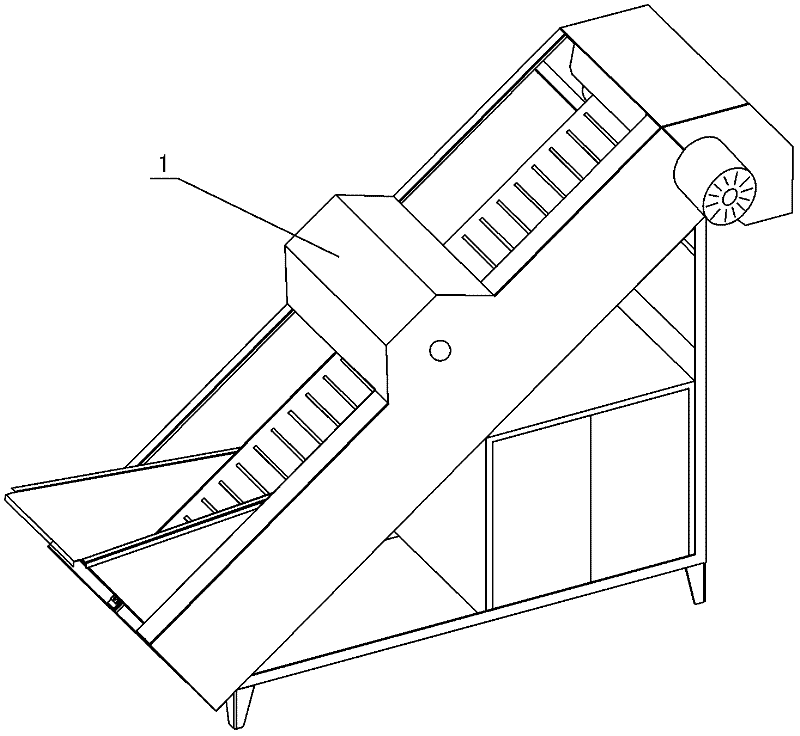

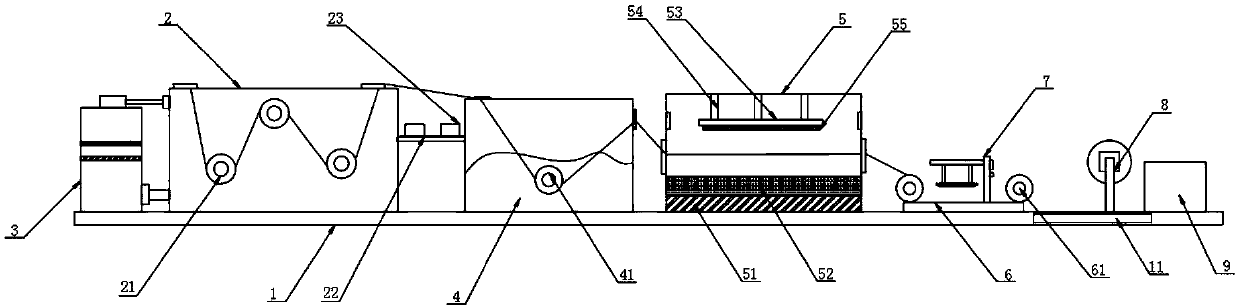

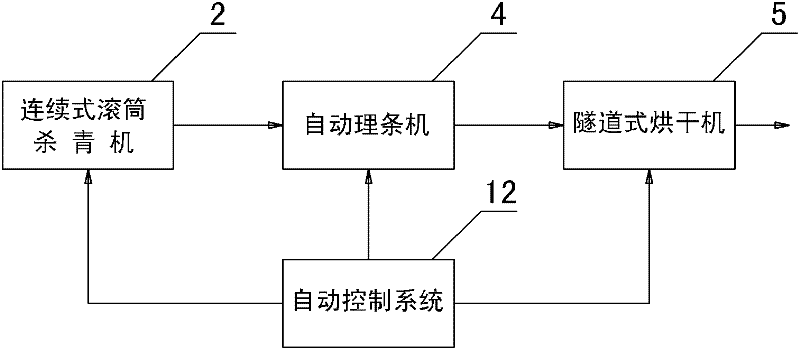

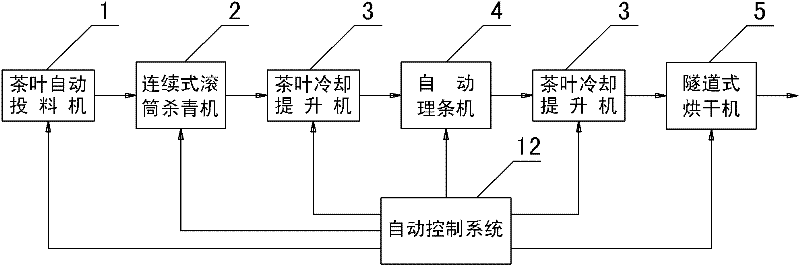

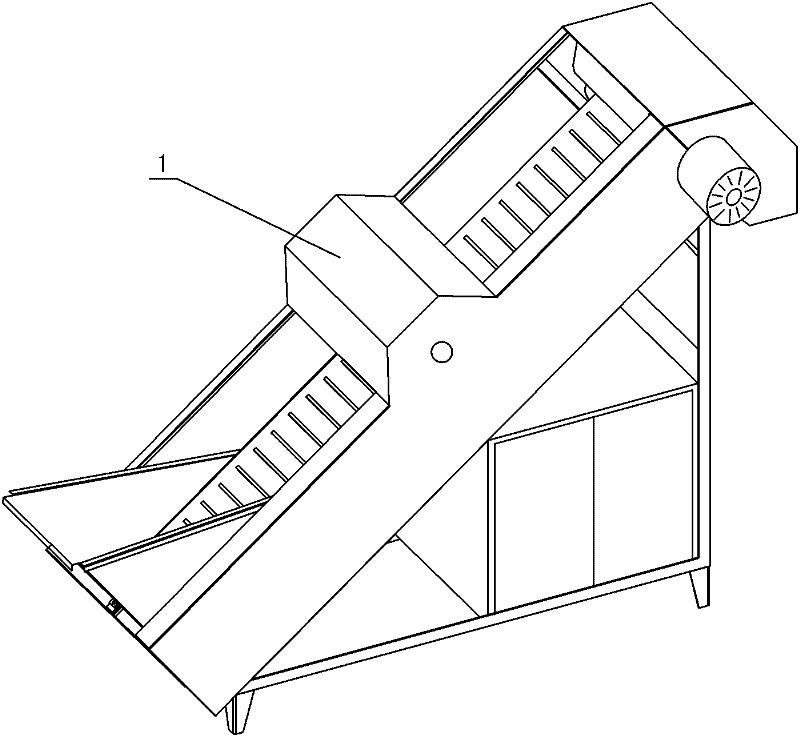

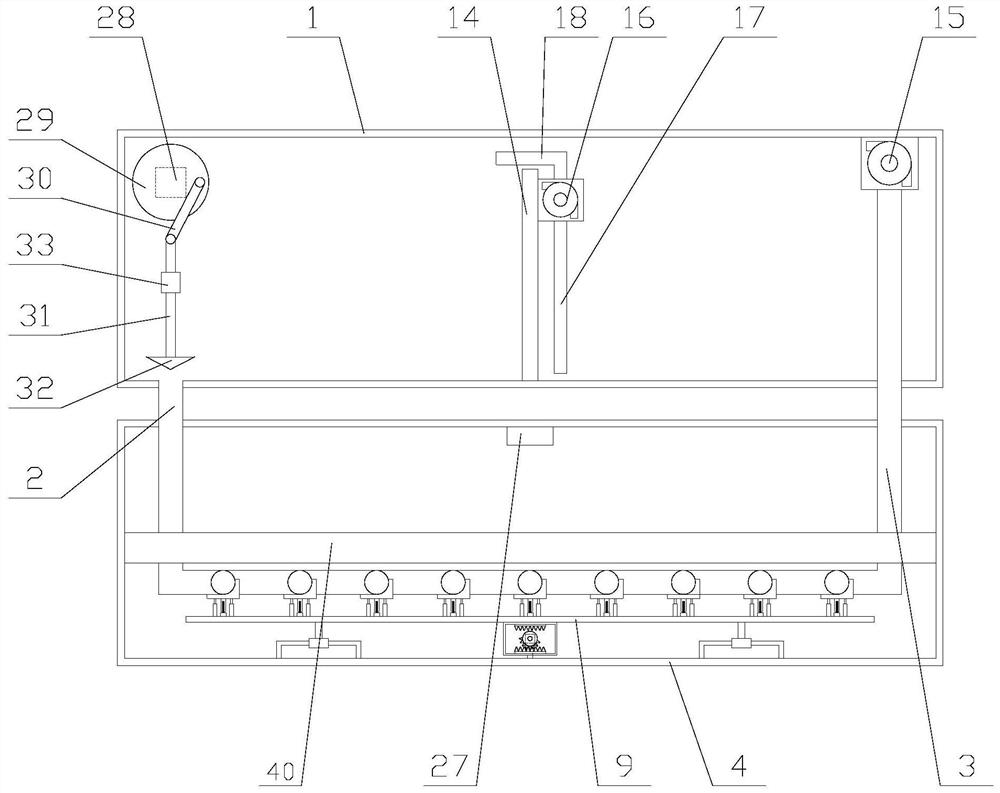

Automatic production complete plant for Maofeng tea

ActiveCN102630767AAchieve continuous flowFully automatedPre-extraction tea treatmentFlavorAutomatic control

The invention discloses an automatic production complete plant for Maofeng tea. The automatic production complete plant comprises a continuous rotary-drum type de-enzyming machine, an automatic tea management machine and a tunnel drier, all of which are mutually connected, wherein the tunnel drier comprises a stand and a drying tunnel, the drying tunnel is arranged on the stand, two sides of the drying tunnel are of sealing structures, the top of the drying tunnel is provided with a heater, and the bottom of the drying tunnel is provided with a tea conveyer belt. The automatic production complete plant for the Maofeng tea further comprises an automatic control system which is connected with and controls all machining devices on the automatic production complete plant. The automatic production complete plant disclosed by the invention effectively solves problems that the machining of the Maofeng tea is dispersive, the quality of the Maofeng tea is irregularly and labor and device resources are waste during present Maofeng tea production. The automatic production complete plant for the Maofeng tea, disclosed by the invention, has the advantages of high automation degree, stability and safety in operation, small dust pollution, no damage on the Maofeng tea, and Maofeng tea finished products have fragrant flavor and high quality grade, thus being high in promotion value.

Owner:浙江丰凯机械股份有限公司

Flow type electroporation device and system

InactiveCN101928666BAchieve continuous flowEasy to handleStress based microorganism growth stimulationElectricityMain channel

The invention discloses a flow type electroporation device and a system, and the system comprises the flow type electroporation device, a channel, an injection pump and a voltage source, wherein the flow type electroporation device comprises a substrate and electrodes which are made on the substrate and are arranged in parallel and in pairs, and each pair of the electrodes comprise an anode and acathode which are oppositely arranged; the channel is arranged above the electrodes and limits fluid to flow; an initial end of the channel is provided with a plurality of inlet branch channels whichconverge into a main channel, a terminating end is provided with a plurality of outlet branch channels, and a plurality of head covers for fluid inlets and outlets are arranged above the channel; theinjection pump is connected to inlets and outlets of the head covers in the flow type electroporation device and limits the flow speed of the fluid; and the voltage source is connected with the electrodes through electrical connectors and sets and produces pulse voltage. The flow type electroporation system utilizes the fluid channel and the connected injection pump to realize continuous flow of various suspensions in the fluid channel, thereby enabling the process that cells are subjected to electroporation to be continuous and realizing rapid treatment of a large number of samples.

Owner:PEKING UNIV

Water-cooling fire exit door structure

InactiveCN105178817AProtection securityAchieve continuous flowFireproof doorsFire rescueEngineeringFeeding tube

The invention relates to the technical field of protecting doors, and discloses a water-cooling fire exit door structure. The water-cooling fire exit door structure comprises a door frame and a door sheet, wherein a water storage cavity is formed in the door sheet; a water inlet and a water outlet are formed in the water storage cavity; the water inlet is positioned below the water outlet; rotary sleeves are respectively fixed on the water inlet and the water outlet of the door sheet, and are hermetically inserted in sleeves which are fixedly arranged on the door frame; a through hole is formed in each rotary sleeve; liquid flows through the through holes; one end, which is far away from the corresponding rotary sleeve, of each sleeve is connected with a water feeding tube or a water draining tube; and the water feeding tube is connected with a water pump. By the scheme, a traditional hinge type door opening and closing mode is guaranteed, condensate water in the water storage cavity of the door sheet flows continuously, and the water-cooling fire exit door structure is safe and reliable, and is reasonable in structure.

Owner:CHONGQING SHUANGCHI DOORS & WINDOWS

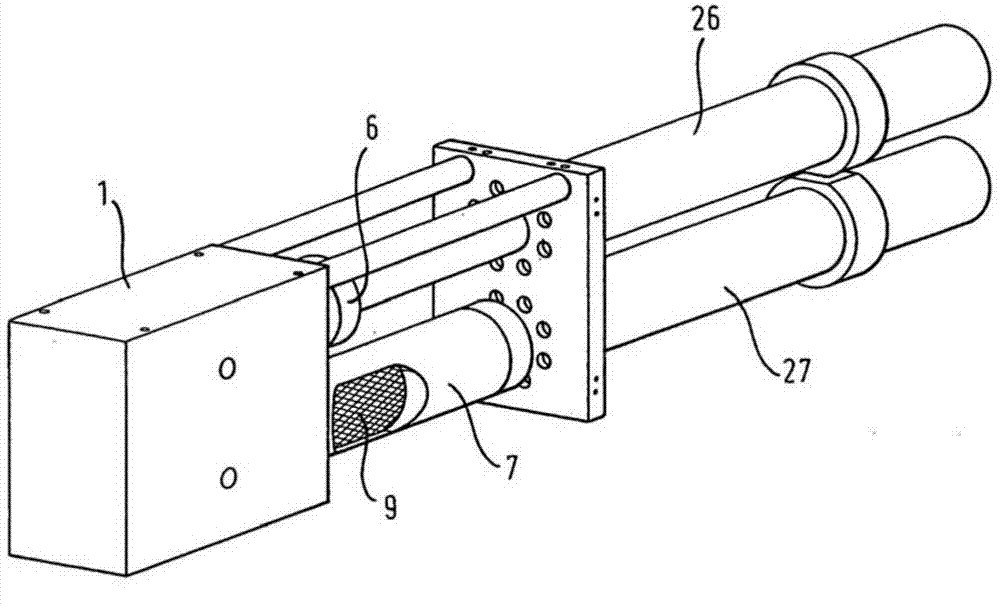

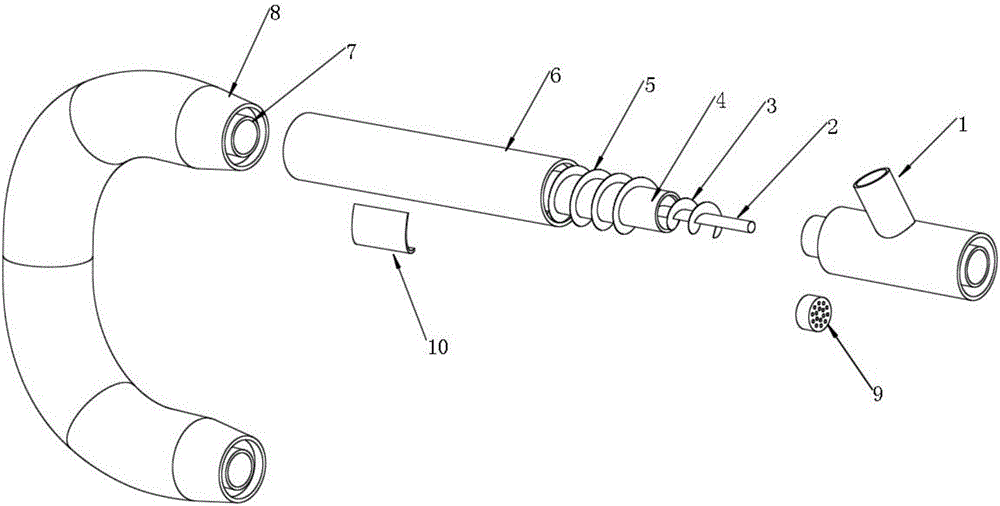

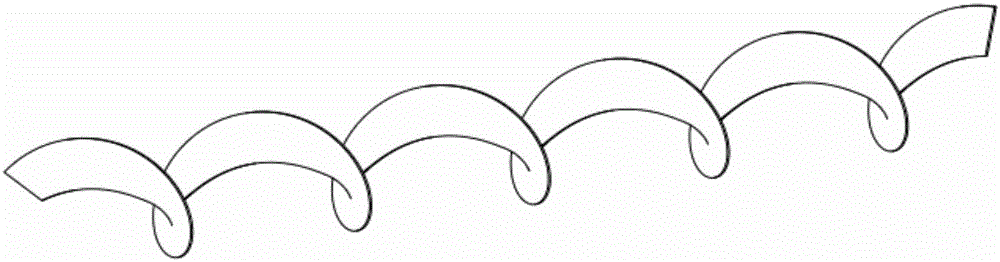

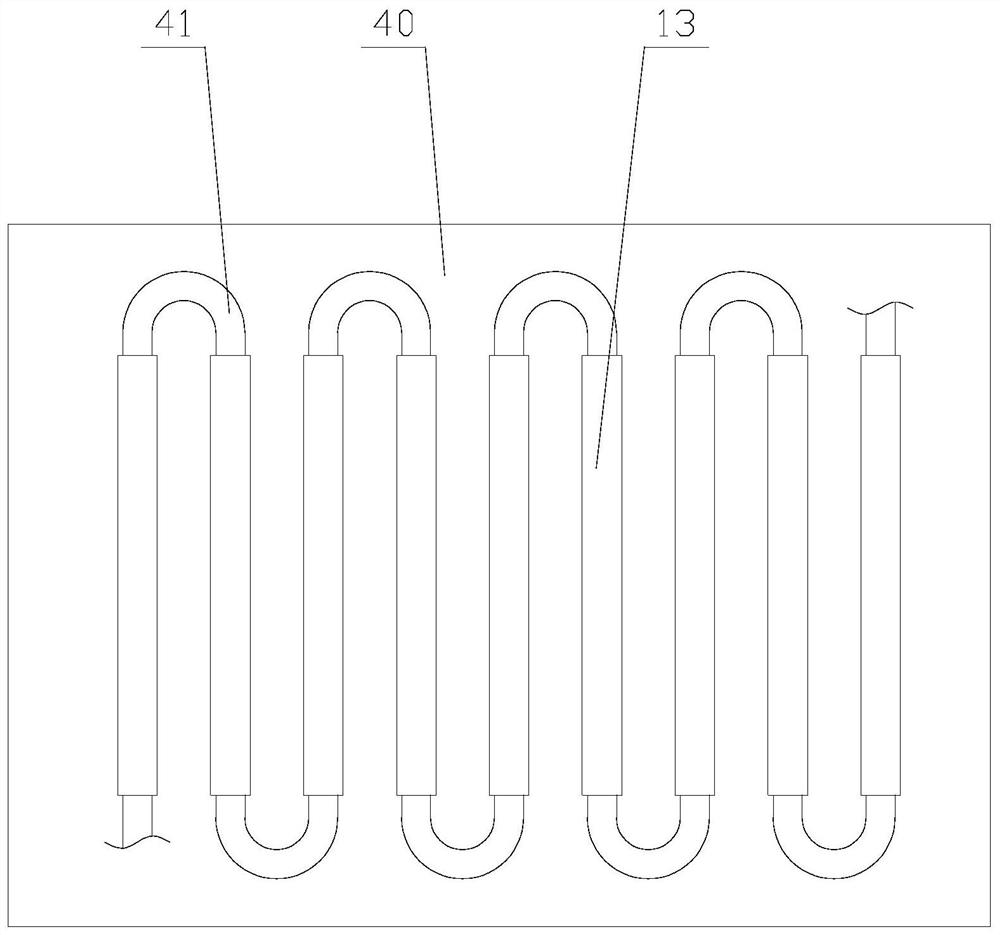

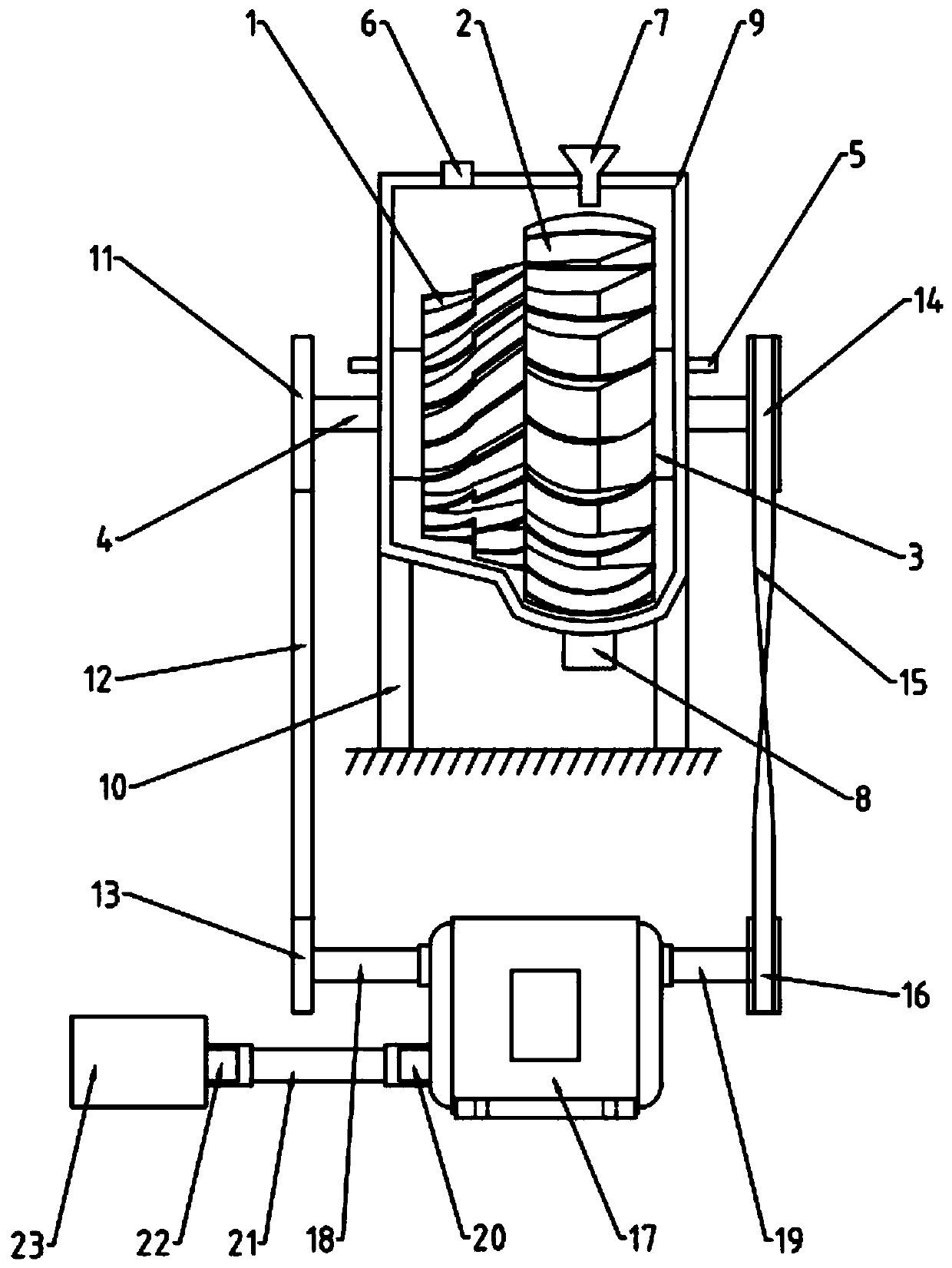

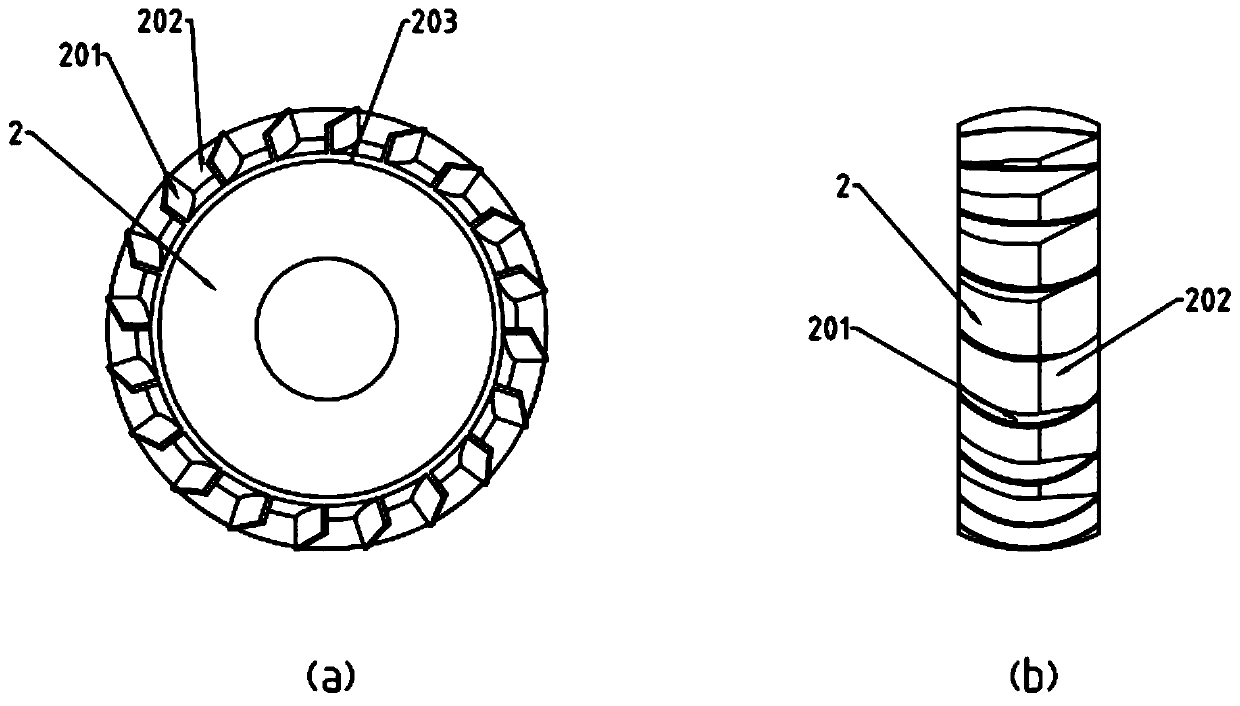

Internal and external dual-spiral-flow centrifugal separation type heat exchanger

InactiveCN106482547ALarge heat transfer temperature differenceImprove heat transfer effectStationary tubular conduit assembliesTubular elementsVapor liquidContinuous flow

The invention provides an internal and external dual-spiral-flow centrifugal separation type heat exchanger. The internal and external dual-spiral-flow centrifugal separation type heat exchanger mainly aims at solving the problem that the heat exchange efficiency of cold and hot media is low, and is especially suitable for heat exchange of vapor-liquid two-phase media. The internal and external dual-spiral-flow centrifugal separation type heat exchanger is characterized in that the device has an internal spiral channel structure and an external spiral channel structure; an internal branch pipe (2) is arranged in an inner pipe (4) of a straight pipe section, a set of internal spiral pieces (3) are fixed around the inner branch pipe, and the outer edges of the internal spiral pieces make contact with the inner wall of the inner pipe (4) of the straight pipe section; a set of external spiral pieces (5) are fixed around the outer wall of the inner pipe (4) of the straight pipe section, and the outer edges of the external spiral pieces make contact with the inner wall of an outer pipe (6) of the straight pipe section. After the heat exchange device and a medium accelerator are used in cooperation, internal and external dual-spiral-flow continuous flow of the cold and hot media can be achieved, the heat exchange temperature difference and the heat exchange area are increased, vibration is lowered, and the heat exchange effect between the media is effectively improved.

Owner:NORTHEAST GASOLINEEUM UNIV

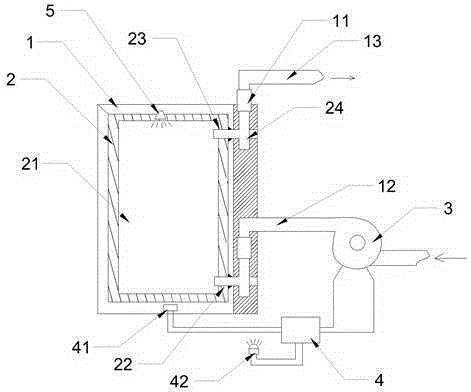

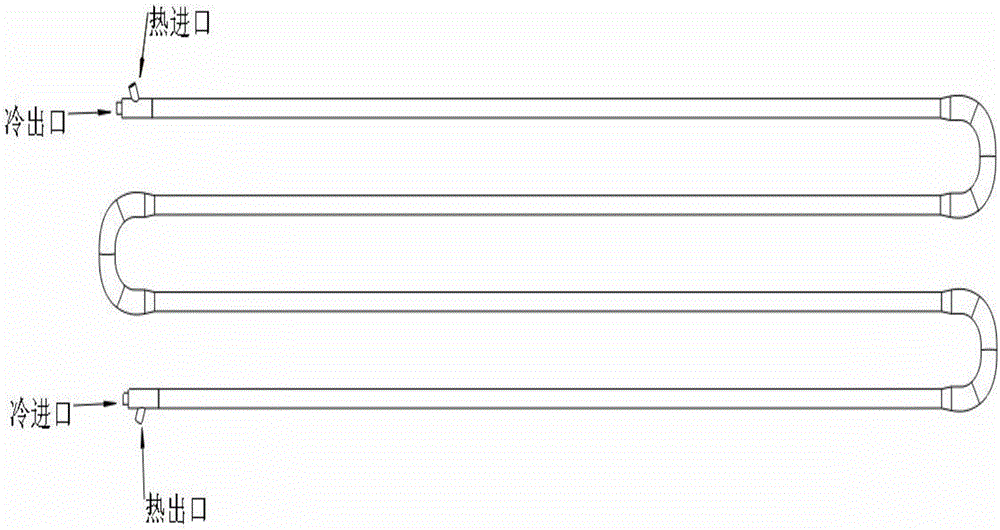

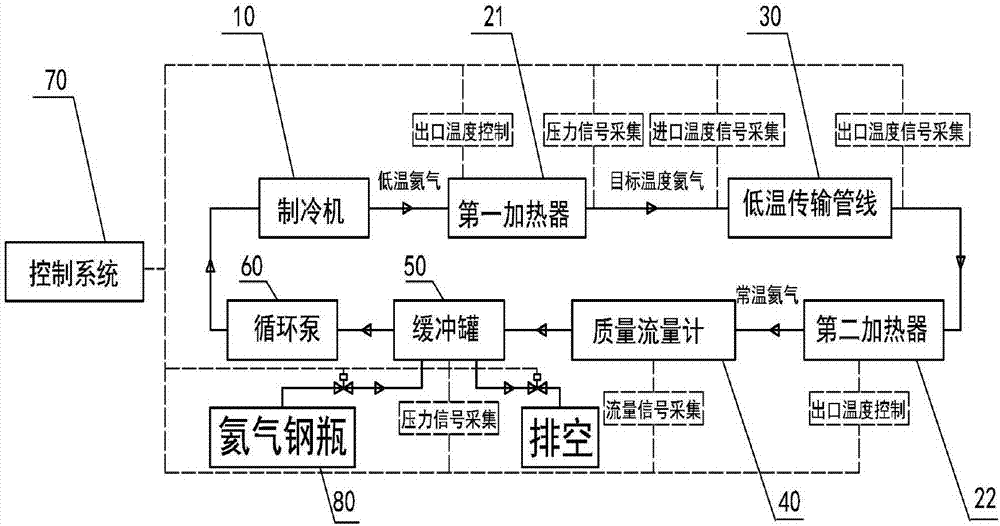

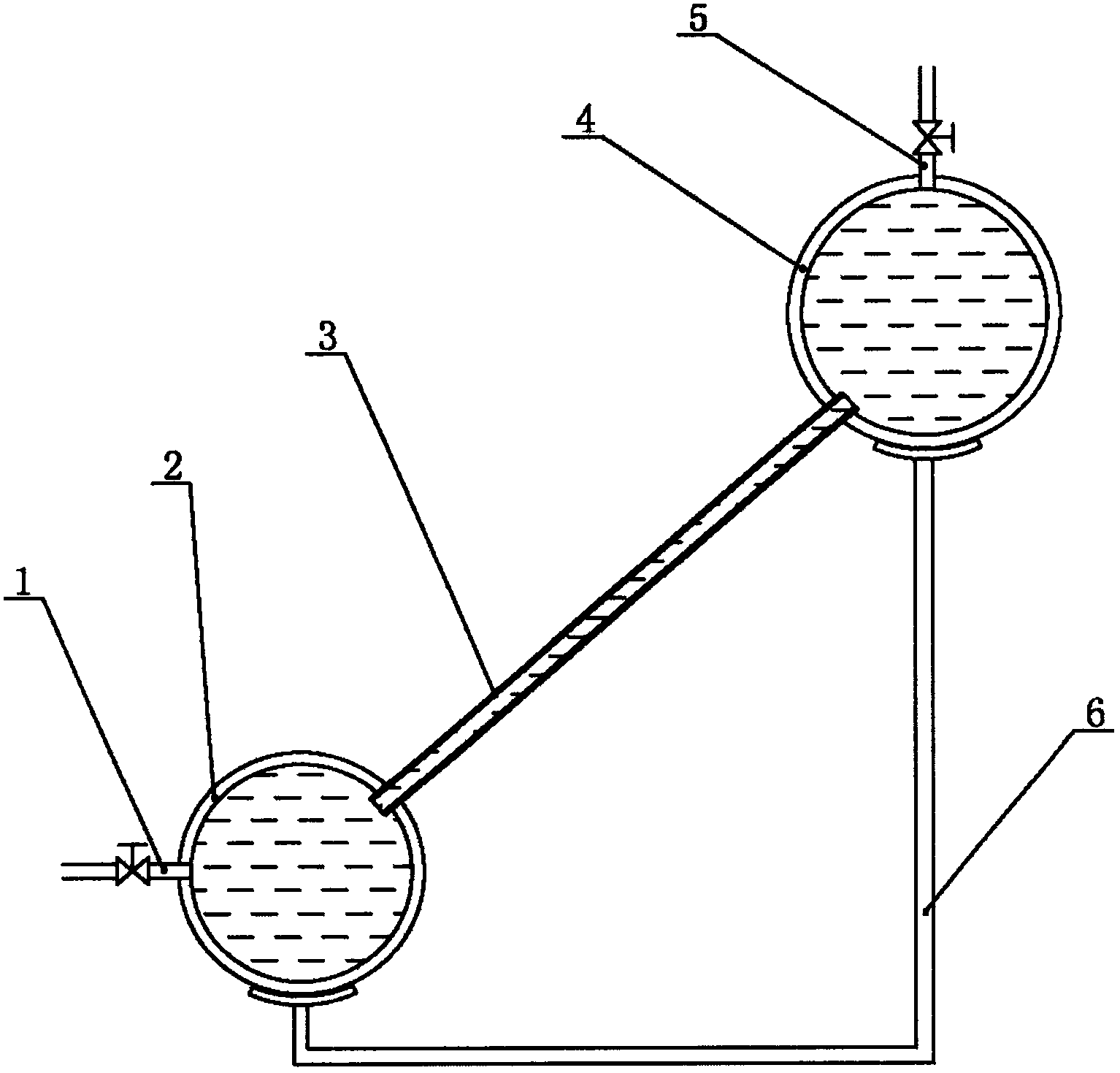

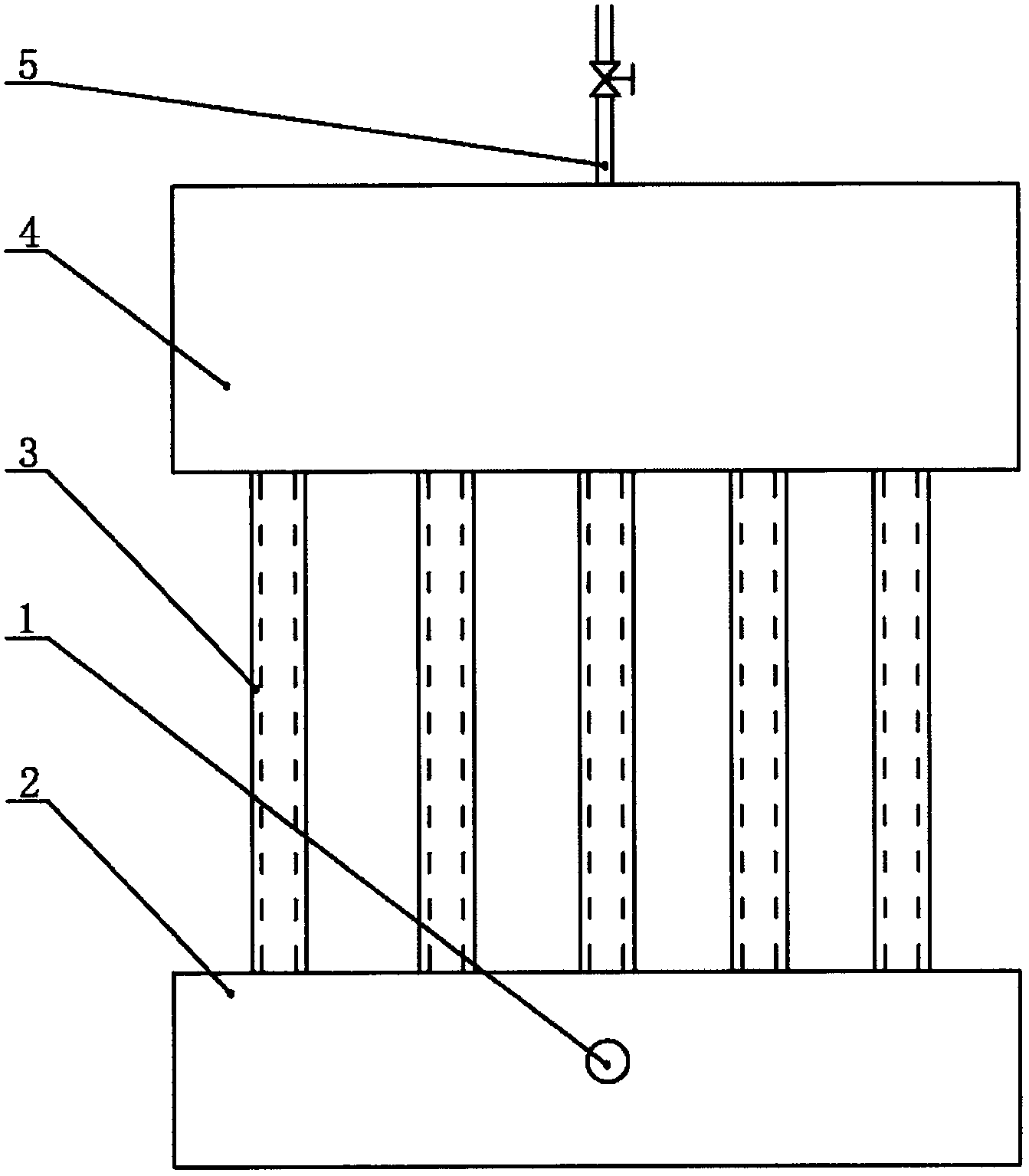

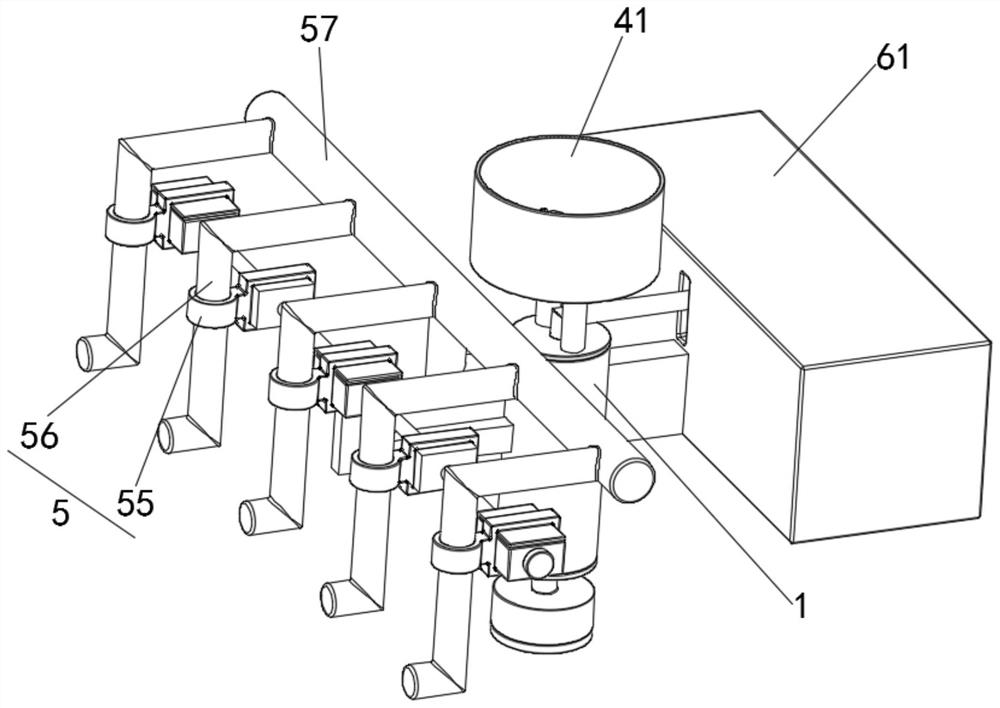

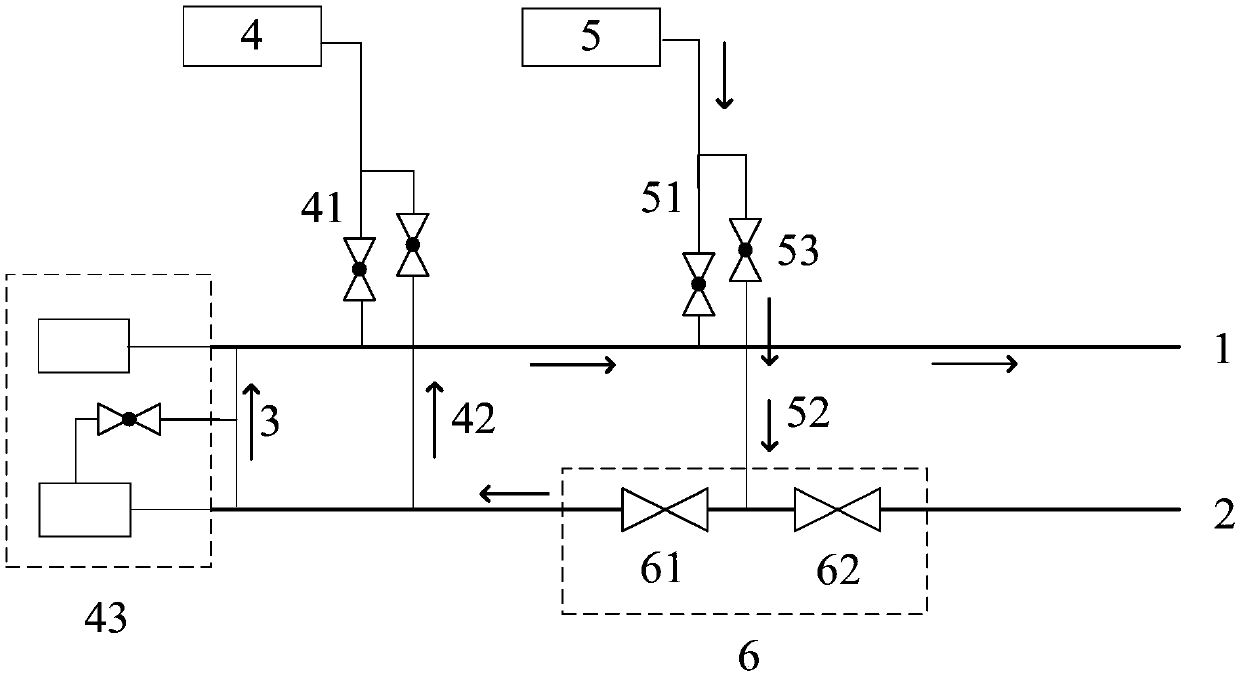

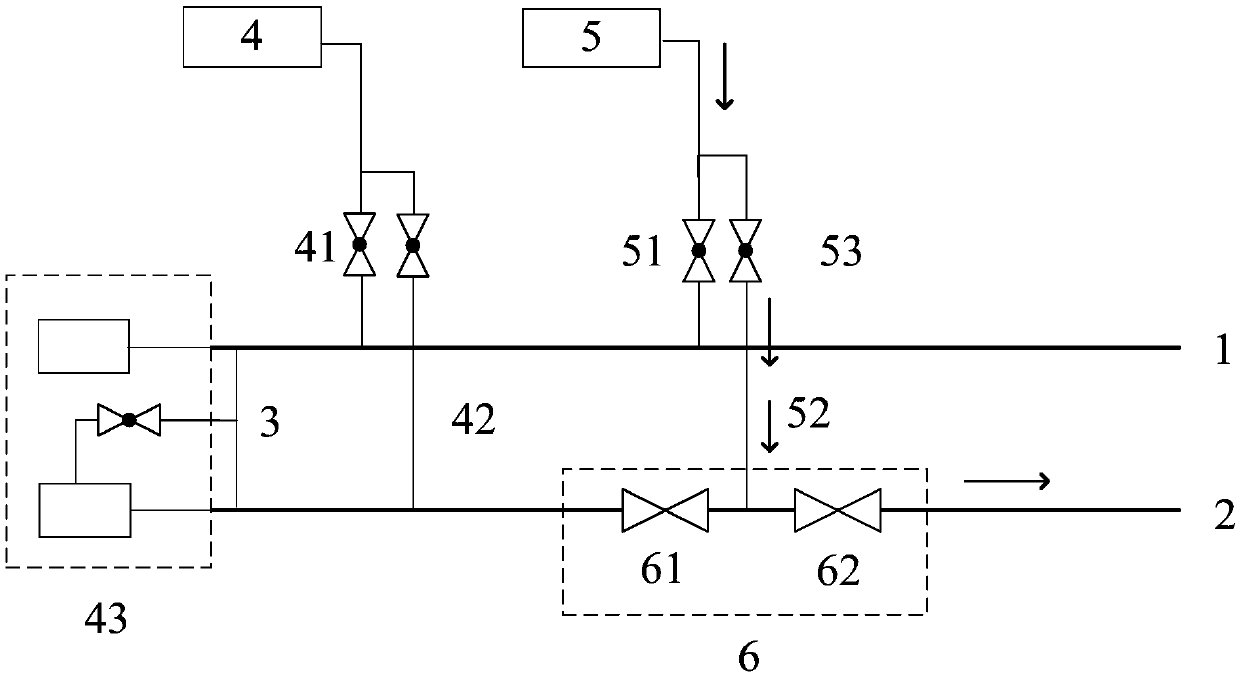

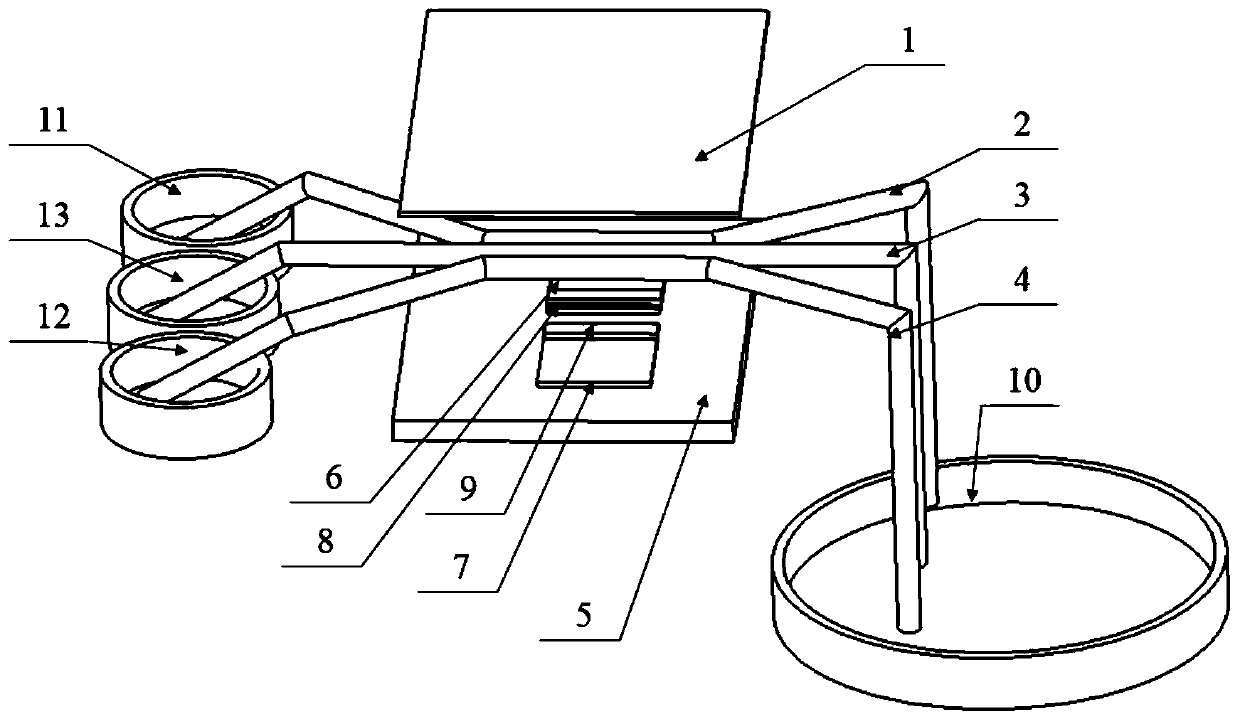

Test device and test method for testing heat leakage of low-temperature fluid transmission pipeline

PendingCN107238450AAchieve continuous flowAccurately calculate the heat leakage valuePipeline systemsCalorimeterBuffer tankControl system

The present invention discloses a test device and a test method for testing the heat leakage of a low-temperature fluid transmission pipeline. The device comprises a fluid for test purpose, a control system, a refrigerating machine, a first heater, a low-temperature transmission pipeline, a second heater, a mass flow meter, a buffer tank and a circulating pump, wherein the refrigerating machine, the first heater, the low-temperature transmission pipeline, the second heater, the mass flow meter, the buffer tank and the circulating pump are sequentially and circularly connected along the fluid transmission direction. The invention also discloses a test method based on the device. The device and the method can efficiently utilize the low-temperature fluid for test purpose, so that the heat leakage amount of the low-temperature fluid transmission pipeline can be accurately tested. Meanwhile, the device and the method can be used for testing different low-temperature transmission pipelines and are good in test universality.

Owner:VACREE TECH

Full-automatic line production packaging system

InactiveCN109610119AExtended service lifeAutomate packaging workSucessive textile treatmentsFilament handlingAgricultural engineeringDyeing

The invention discloses a full-automatic line production packaging system which comprises a working table, wherein a dyeing chamber is arranged at the top of the working table; a backflow chamber is connected with one side of the dyeing chamber; an oil soaking chamber is arranged on the other side of the dyeing chamber; a shaping chamber is arranged on one side of the oil shaking chamber; a cutting platform is arranged on the outer side of the shaping chamber; a cutting device is fixedly arranged at the top of the cutting platform; third guide rollers are arranged on both sides of the cuttingdevice. Due to adoption of the dyeing chamber, the oil soaking chamber and the shaping chamber, a produced cotton line passes through the dyeing chamber, the oil soaking chamber and the shaping chamber in sequence, the cotton line is dyed in the dyeing chamber and is further conveyed into the oil soaking chamber, the service life of the cotton line can be prolonged after soaking with an antibacterial liquid, the cotton line is later fed into the shaping chamber, the cotton line is heated by a heating plate in the shaping chamber, a first lifting plate is pushed by an electronic push rod to move downwards to enable a pressing plate to tightly compress and shape the cotton line, the operation is repeated, then automatic packaging on the produced cotton line can be achieved, the working efficiency can be improved, and the time can be saved.

Owner:NANTONG GOD OF HORSES THREAD

Novel vacuum-tube type solar collector

InactiveCN103423880ASimple structureGood flow characteristicsSolar heating energySolar heat devicesSolar thermal collectorEngineering

Owner:潘琴

Flow electroporation device and system

ActiveCN101857836BAchieve continuous flowEasy to handleStress based microorganism growth stimulationElectricityContinuous flow

The invention discloses a flow electroporation device and a system. The system comprises a flow electroporation device, an injection pump and a voltage source, wherein the flow electroporation device comprises a substrate, electrodes arranged on the substrate, a channel for limiting fluid to flow, a top cover of an inlet and an outlet of fluid, the electrodes are arranged in a crossing way; each pair of electrodes comprise an anode and an cathode which are oppositely arranged, and the channel is arranged on the electrodes; the top cover is arranged above the channel, and the injection pump isconnected to the inlet and the outlet of the top cover in the flow electroporation device through a pipeline and is used for controlling the flow rate of the fluid; and the voltage source is connected with the electrodes through electric connecting pieces and is used for setting and producing pulse voltage. The flow electroporation system utilizes the fluid channel and the injection pump connected with the fluid channel to realize the continuous flow of various suspensions in the fluid channel, so that the fast treatment of a large number of samples can be continuously realized in the processthat cells are electroporated.

Owner:ETTA BIOTECH

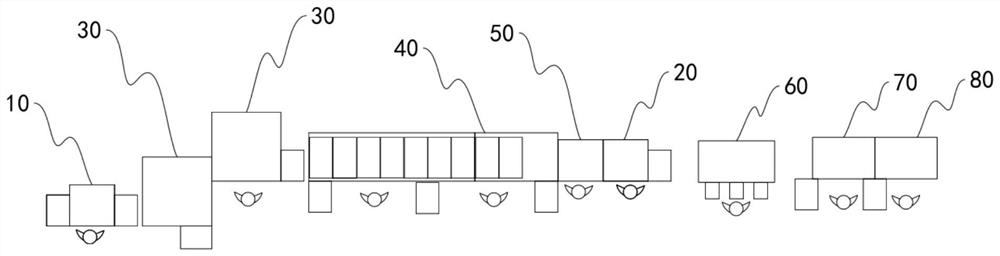

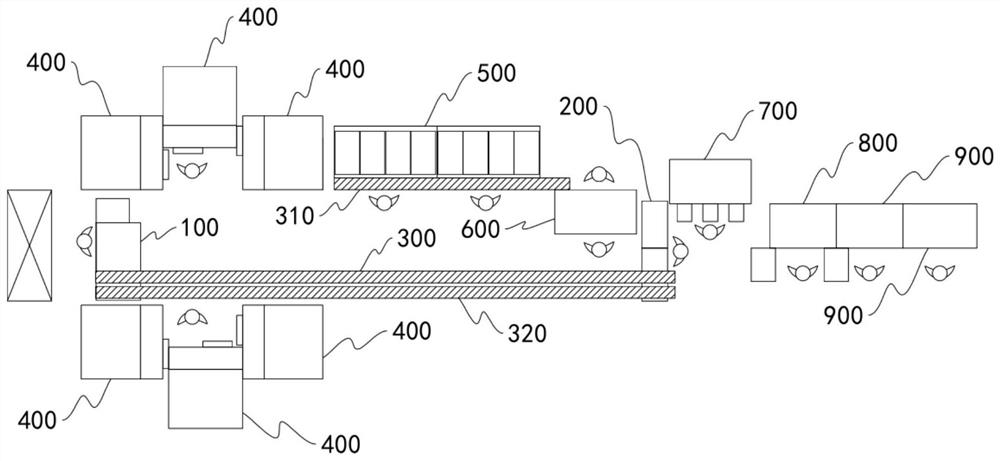

Complete equipment for flow-line production of Maofeng tea (produced in Huangshan Mountain, Anhui, China)

ActiveCN102640811AAchieve continuous flowStreamliningPre-extraction tea treatmentQuality levelAutomatic control

The invention discloses complete equipment for flow-line production of Maofeng tea (produced in Huangshan Mountain, Anhui, China). The complete equipment comprises a continuous cylinder inactivating machine, an automatic tea carding machine, a tunnel type dryer and an automatic control system, wherein the continuous cylinder inactivating machine, the automatic tea carding machine and the tunnel type dryer are connected with one another; the tunnel type dryer comprises a rack and a drying tunnel arranged on the rack; a heating device is arranged at the top of the drying tunnel; a tea leaf conveying belt and supporting flat plates adhered to the tea leaf conveying belt are arranged at the bottom of the drying tunnel; a stripped plucking device perpendicular to the movement direction of the tea leaf conveying belt is arranged between the supporting flat plates; and the automatic control system is connected with all processing equipment and is used for controlling all the processing equipment on the complete equipment for the flow-line production of the Maofeng tea. The complete equipment for the flow-line production of the Maofeng tea has high automation degree, stability and safety in operation and small dust pollution and does not damage tea leaves; and a finished product of the Maofeng tea has aromatic flavor, high quality level and very high popularization value.

Owner:浙江丰凯机械股份有限公司

Sewage treatment flocculation device based on biofilm process treatment technology

PendingCN114853138AAchieve continuous flowWell mixedRotary stirring mixersTransportation and packagingFlocculationSewage treatment

The invention relates to the technical field of sewage treatment, and discloses a sewage treatment flocculation device based on a biofilm process treatment technology, the sewage treatment flocculation device comprises a mixing cylinder, the mixing device comprises a piston block, a first fixed block, a first rotating cover, a second fixed block, a second rotating cover and a promoting device, the piston block is slidably connected to the interior of the mixing cylinder, and the piston block is slidably connected to the interior of the mixing cylinder. A first fixing block is fixedly connected to the piston block, a first rotating cover is rotatably connected to the outer side of the first fixing block, and a second fixing block is fixedly connected to the inner bottom side wall of the mixing cylinder. According to the sewage treatment flocculation device based on the biofilm process treatment technology, through the cooperative action of a second motor, a rotating disc, a connecting rod, a sliding block, a track plate, a track shell, a moving rod, a piston block, a first rotating cover, a second rotating cover, a mixing cylinder, a first motor, a screw rod, a filter cylinder and a rotating fan, the purpose of accelerated mixing of a flocculating agent and water is achieved; therefore, the problem of low flocculation effect is solved.

Owner:江苏汇泽通环境科技有限公司

Oil-water separation device and oily sludge drying system

ActiveCN113087174AImprove separation efficiencyAchieve a separationWater treatment parameter controlSludge treatment by de-watering/drying/thickeningWater storageSludge

The invention relates to an oil-water separation device and an oily sludge drying system. The oil-water separation device comprises a box body, and an oil storage area, a first separation area, a second separation area, a sludge storage hopper, a water level adjusting area and a water storage area which are arranged in the box body, wherein the sludge storage hopper is communicated with the first separation area, and the second separation area is communicated with the water level adjusting area; a separation partition plate is arranged between the first separation area and the second separation area; a first inner partition plate is arranged between the first separation area and the oil storage area; a second inner partition plate is arranged between the second separation area and the water level adjusting area; a water level adjusting weir plate is arranged between the water level adjusting area and the water storage area; the top surface heights of the separating partition, the first inner partition and the water level adjusting weir plate are sequentially increased; the height of the second inner partition plate is larger than that of the water level adjusting weir plate and smaller than or equal to that of the upper plane of the box body. The oil-water separation device is simple in structure, good in oil-water separation effect, high in separation efficiency, convenient to maintain and high in practicability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

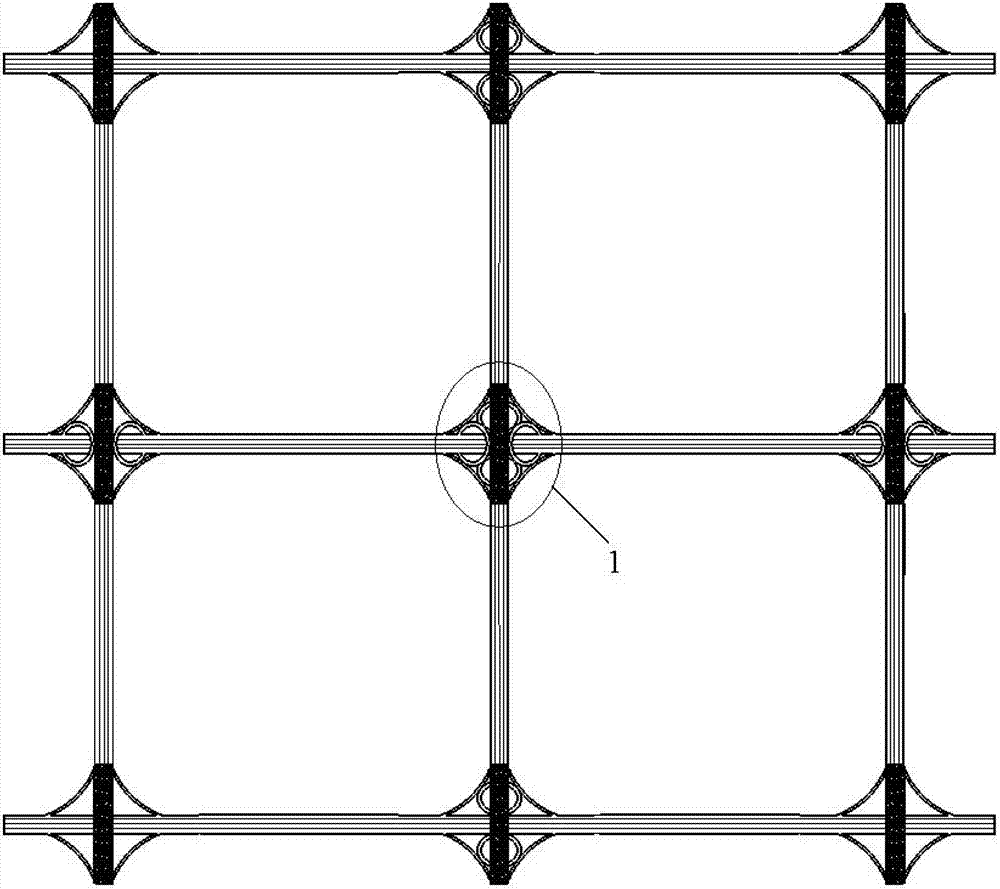

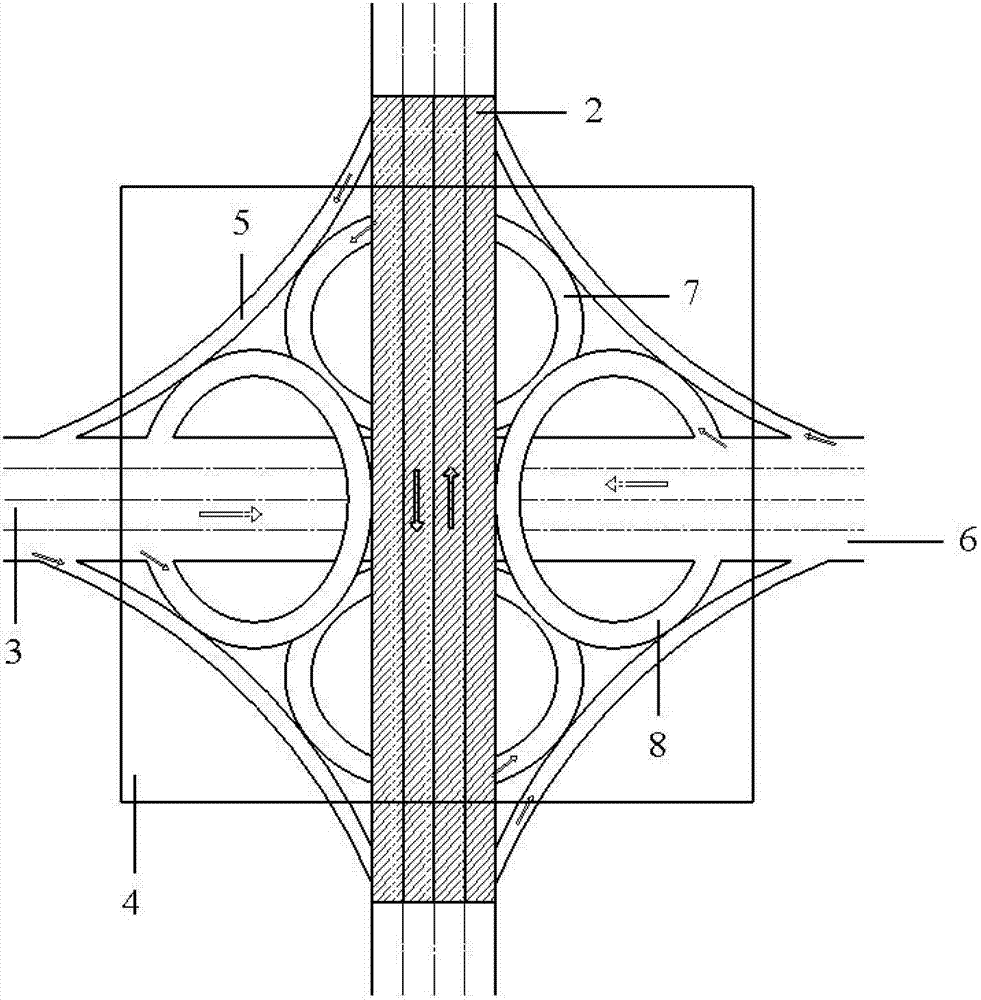

Half-storey ultra-compact overpass unit

A half-storey ultra-compact overpass unit relates to the technical field of overpass systems and comprises a plurality of half-storey ultra-compact overpasses. Each half-storey ultra-compact overpass comprises an upper overpass face and a lower overpass face which are intersected, the lower overpass face is concaved and arranged under a horizontal road surface, and the upper overpass face is convex and arranged above the lower overpass face in an erected mode. The half-storey ultra-compact overpass unit is characterized in that an isobathic area is arranged in the intersected area of the upper overpass face and the lower overpass face, right turn bridges for turning right are respectively arranged at four turning corners intersected by the upper overpass face and the lower overpass face, two ends of each right turn bridge are in gradual change shapes and respectively connected onto right turn lanes of the upper overpass face and the lower overpass face. The half-storey ultra-compact overpass unit has the beneficial effects of being low in construction cost and wide in application range, not only effectively relieving traffic condition of jammed road intersections of big cities, but also greatly reducing the influence on neighboring environment of the overpass unit.

Owner:蒋红心

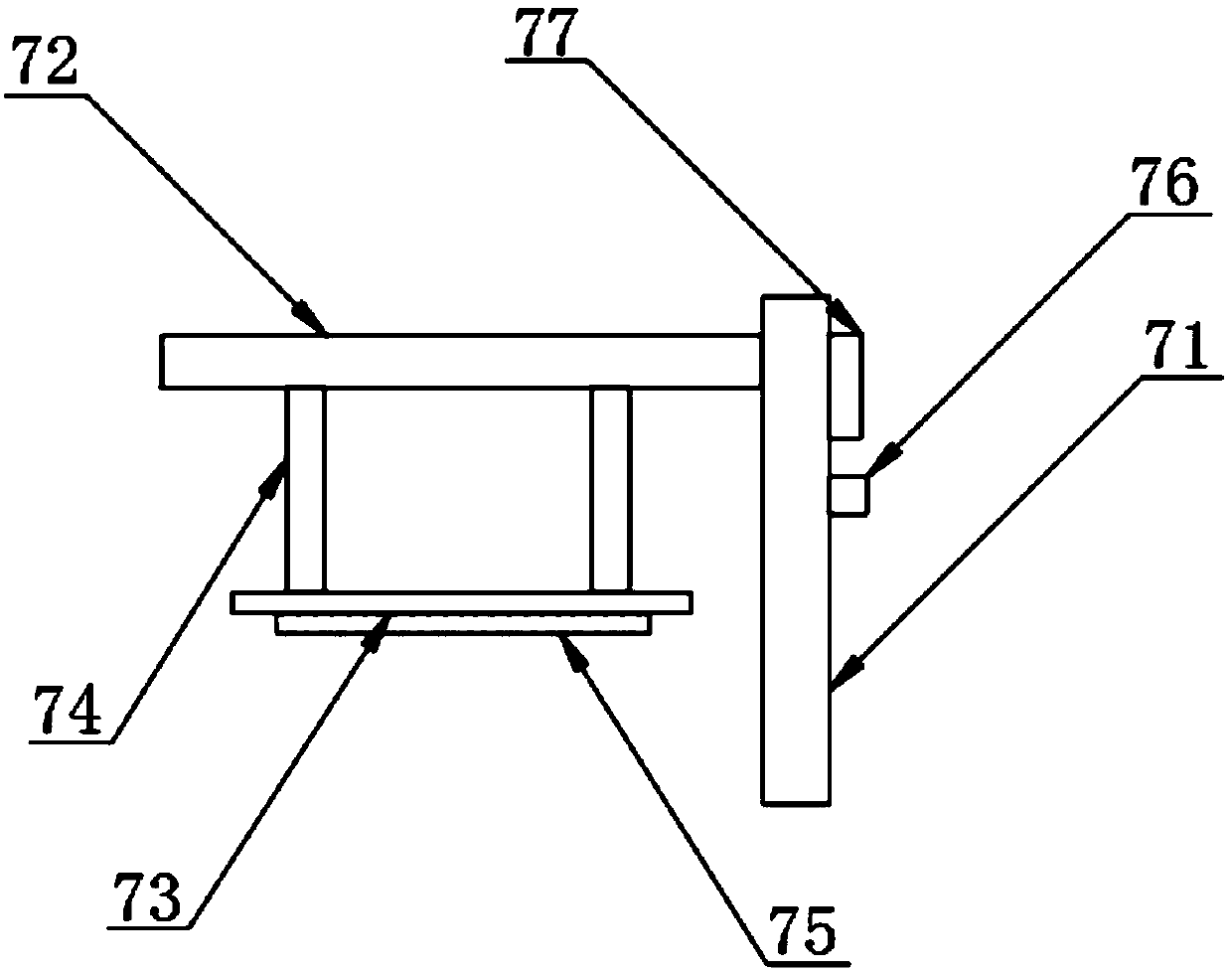

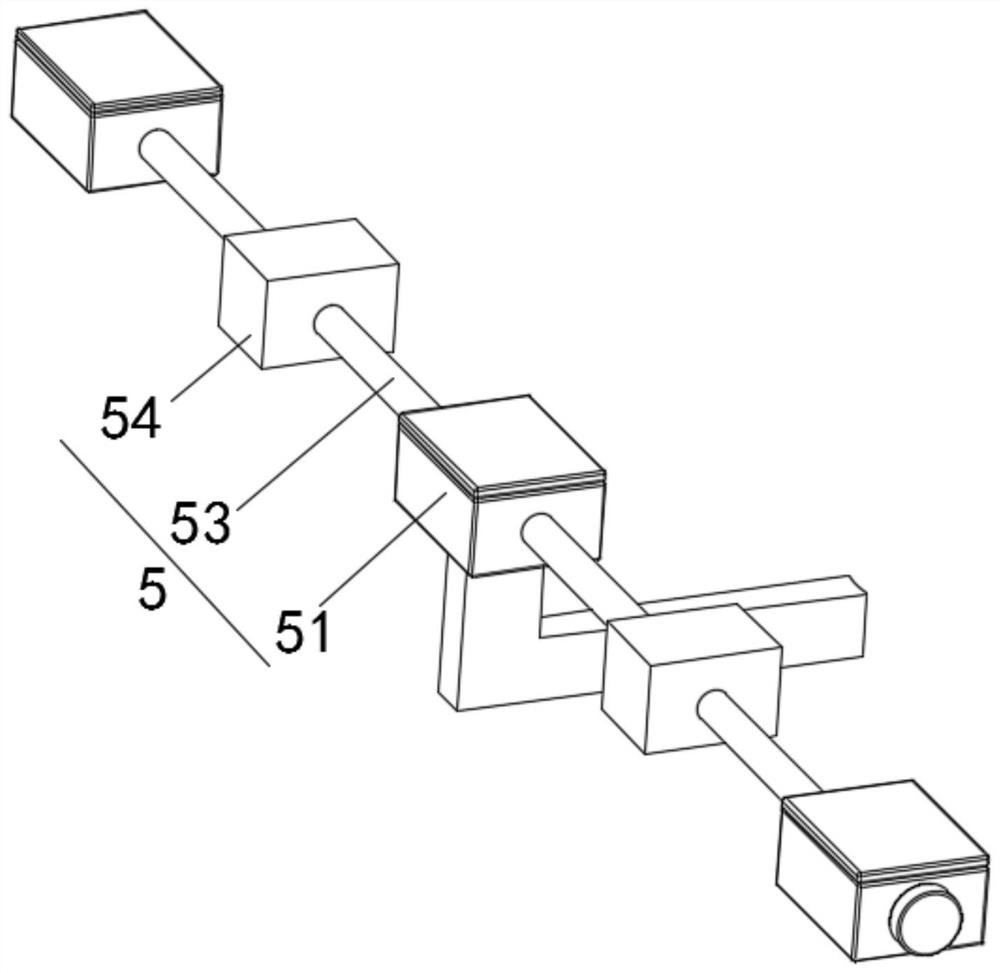

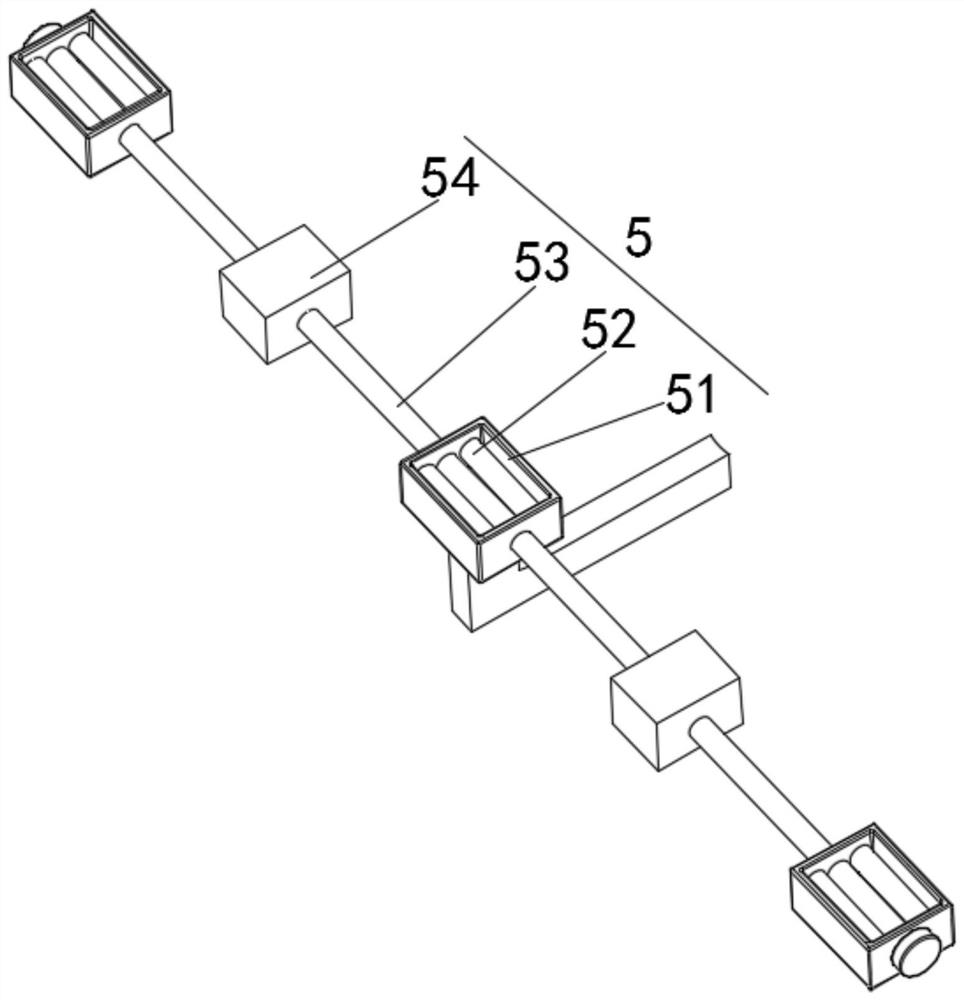

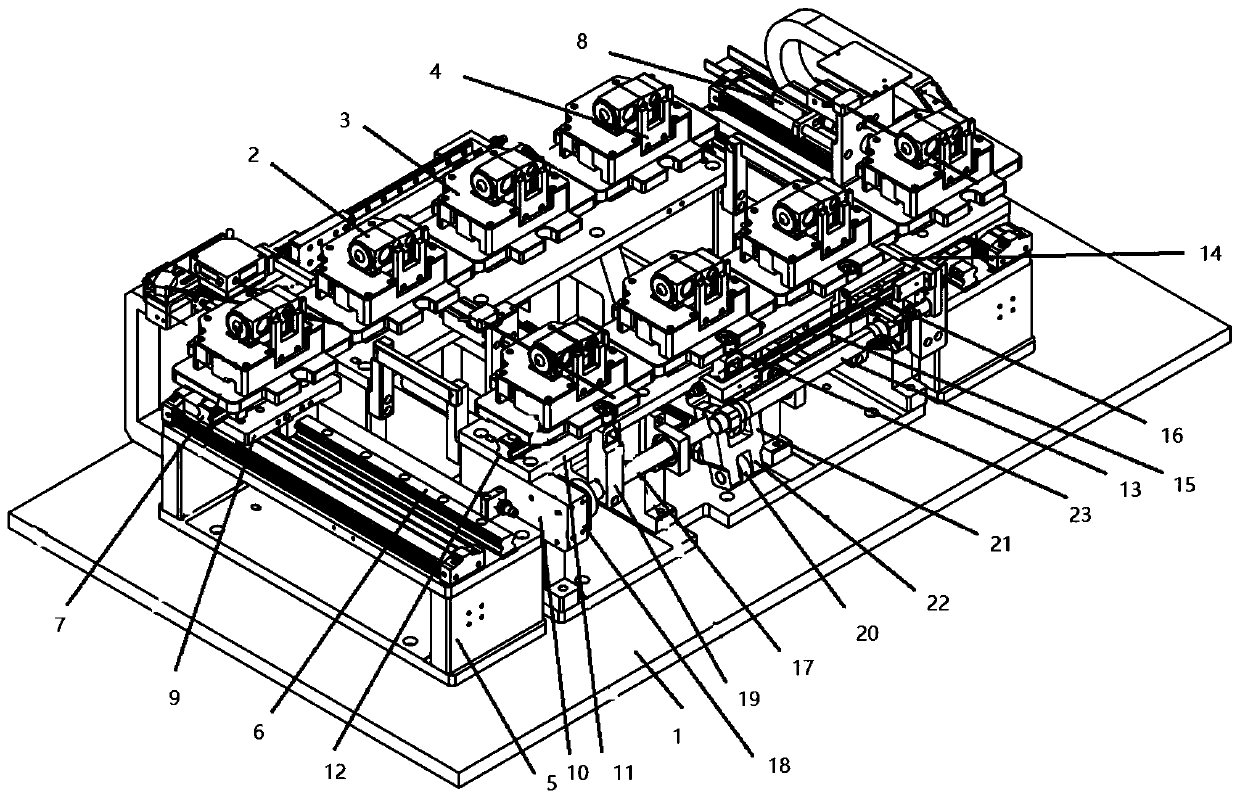

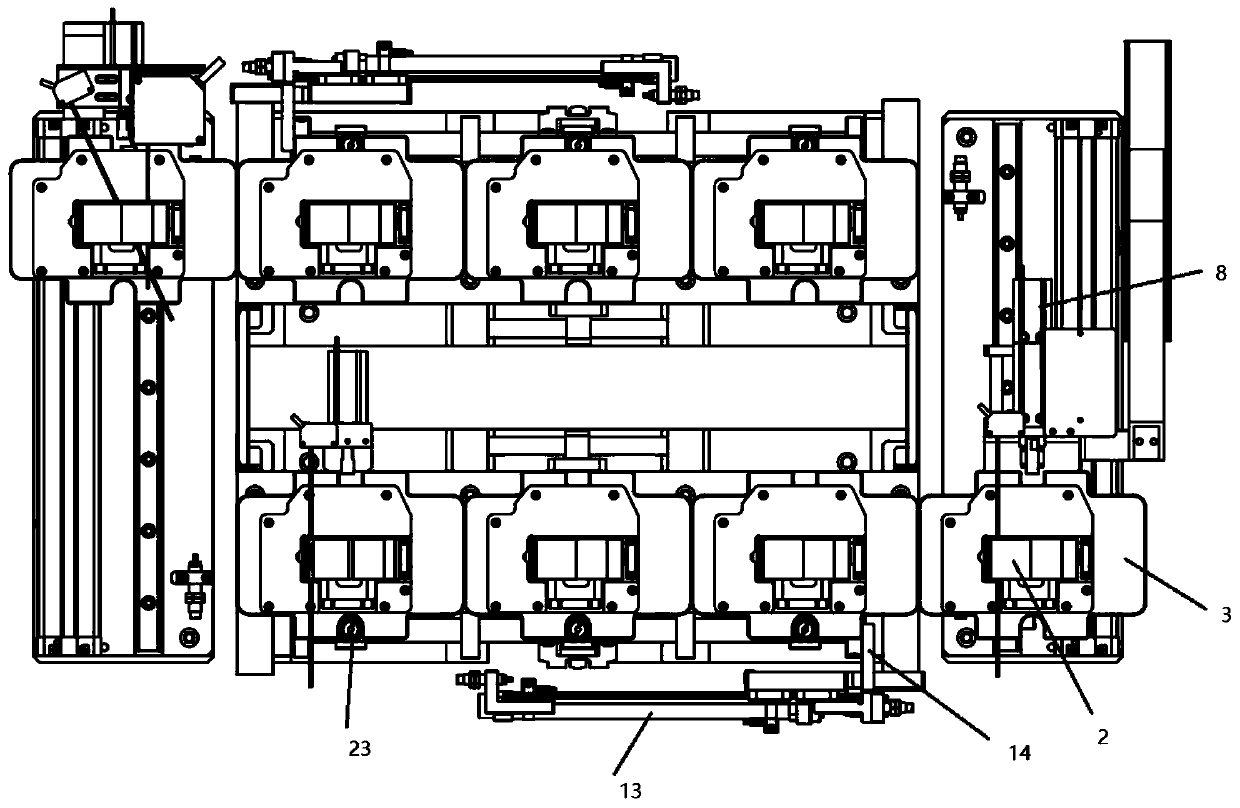

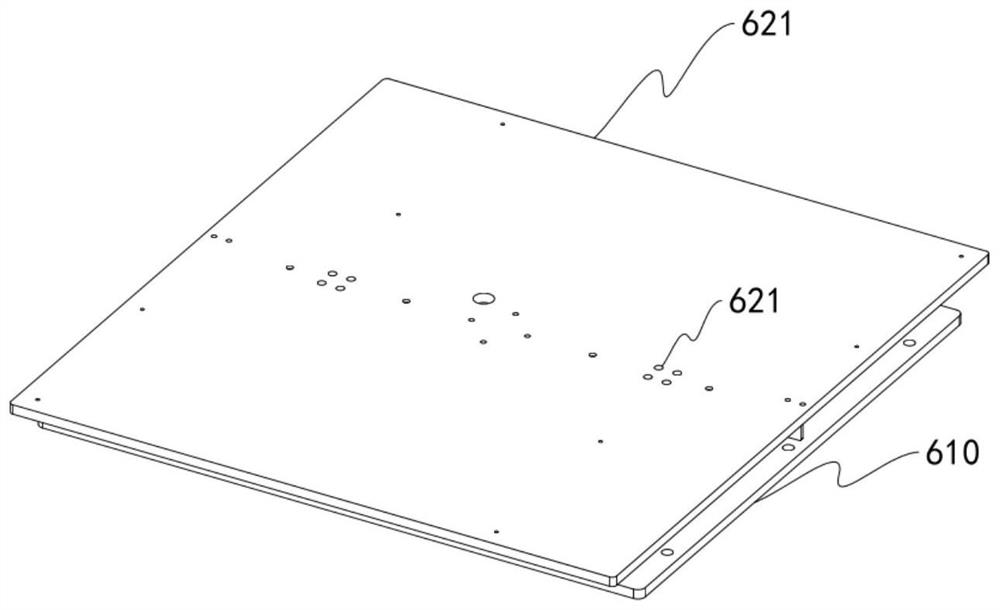

Carrier circulating mechanism

The invention discloses a carrier circulating mechanism. The carrier circulating mechanism comprises a base, a carrier used for carrying products, carrier transplanting mechanisms, carrier linear conveying mechanisms and a carrier positioning mechanism, the carrier transplanting mechanisms, the carrier linear conveying mechanisms and the carrier positioning mechanism are all fixedly installed on the base and used for linear conveying of the carrier on the base, and the carrier is arranged to be a square plate, the two groups of carrier transplanting mechanisms are oppositely arranged on the front side and the rear side of the base, the two groups of carrier linear conveying mechanisms are oppositely arranged on the left side and the right side of the base, and the head parts and the tail parts of the two groups of carrier transplanting mechanisms correspond to the head parts and the tail parts of the two groups of carrier linear conveying mechanisms correspondingly, so that a square conveying path of carriers is formed, and the carrier positioning mechanism is used for positioning the carrier on the carrier linear conveying mechanism. According to the carrier circulating mechanism,the automation degree is improved, the workload of operators is reduced, the measuring period is greatly shortened, the working efficiency is improved, and the production cost is reduced.

Owner:林育键

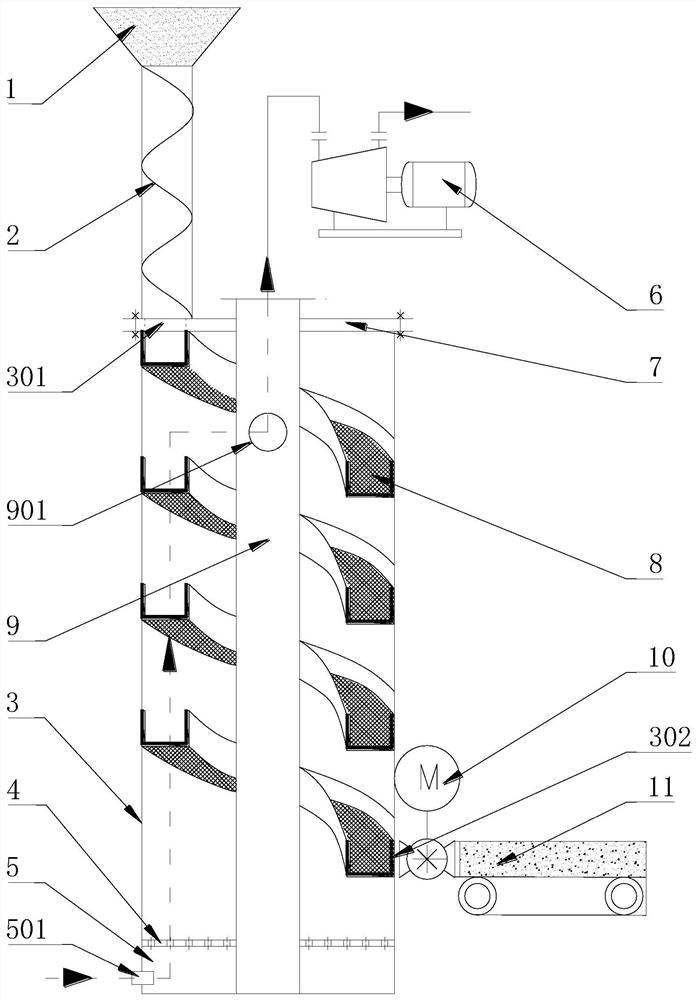

A countercurrent solid-state distillation column with a spiral slide

ActiveCN111035949BAchieve continuous flowIncrease productivityFermented solutions distillation/rectificationVacuum pumpingEnergy technology

The invention discloses a countercurrent solid-state distillation tower with a spiral slide, which belongs to the field of biological energy technology and process equipment. A steam chamber is arranged at the bottom of the tower body, and a steam distributor is used to isolate the steam chamber from the tower body, and the spiral slide is fixed. Installed on the inside of the tower body and above the steam chamber, there is a central conduit in the center of the tower body, which is inserted directly into the bottom of the tower and isolated from the steam chamber; the gas outlet of the central conduit is connected to the vacuum pumping device, and the central conduit There is an air outlet on the upper part of the tower, and the stripped steam enters the central conduit from the air outlet and is discharged out of the tower; a spiral slide is installed on the inner wall of the tower body. The structural design of the spiral slide used in the present invention can realize the continuous flow of solid granular materials and full contact with steam, so that the solid-state distillation process can realize continuous production and improve production efficiency; and the residence time of materials in the tower can be controlled, both It not only takes into account the advantages of simple operation of batch distillation, but also ensures the need of continuous production.

Owner:TSINGHUA UNIV

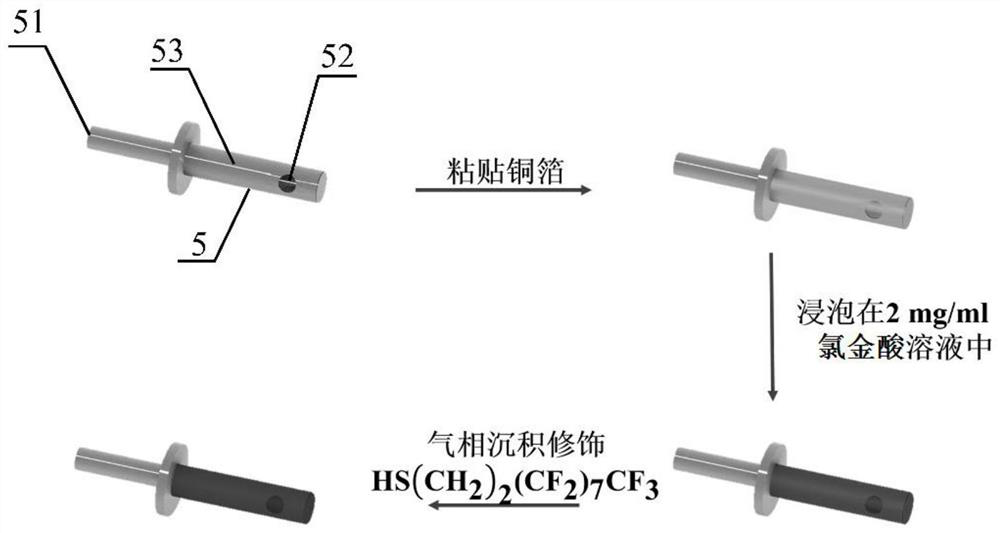

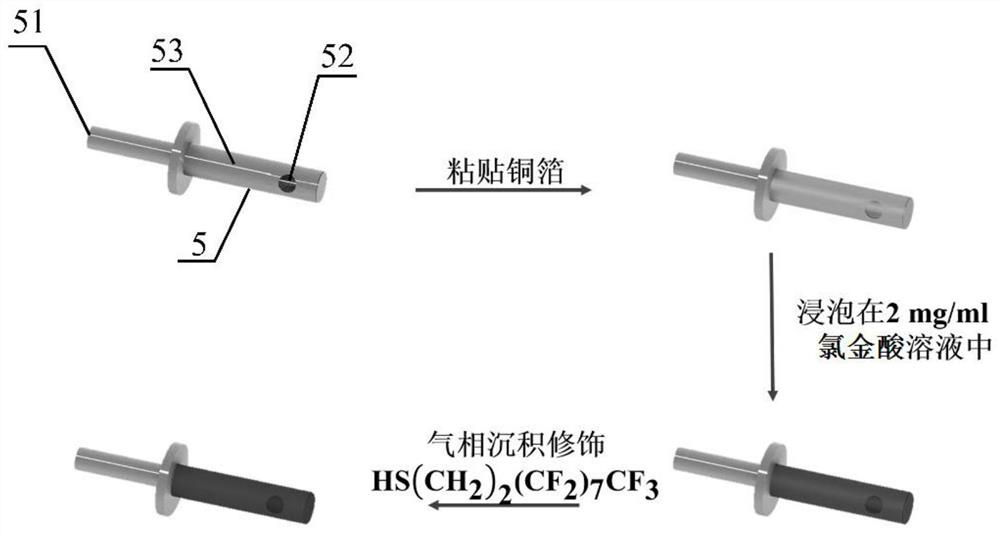

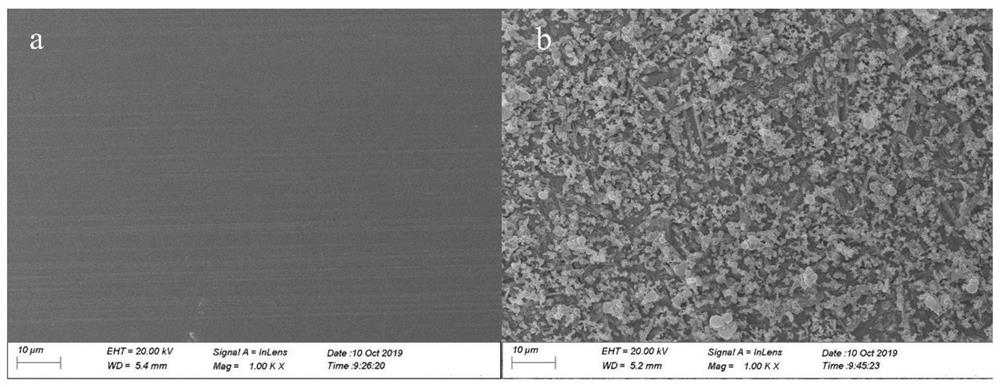

Method for enhancing mixing performance of rotating packed bed based on liquid distributor with super-hydrophobic surface

ActiveCN111659311AWell mixedImprove the mixing effectTransportation and packagingPretreated surfacesSuperhydrophobeEngineering

The invention discloses a method for enhancing the mixing performance of a rotating packed bed based on a liquid distributor with a super-hydrophobic surface. The rotating packed bed is suitable for asystem containing liquid in raw materials. The surface of the liquid distributor of the rotating packed bed is modified with a super-hydrophobic coating so that the liquid distributor has the super-hydrophobic surface, raw materials are not adhered to the surface of the liquid distributor after flowing out of an outlet of the liquid distributor and continuously flow into the rotating packed bed,and the mixing effect of the rotating packed bed on the raw materials is enhanced. It is known that the wettability of the solid surface can influence the flowing condition of liquid in the rotating packed bed, the surface of the liquid distributor is modified with the super-hydrophobic coating so that the liquidity of the liquid in the rotating packed bed is improved, and the mixing effect of therotating packed bed on the liquid is further improved. The rotating packed bed is expected to be applied to chemical preparation and laboratory microminiature experiments in the field of biological medicine.

Owner:BEIJING UNIV OF CHEM TECH

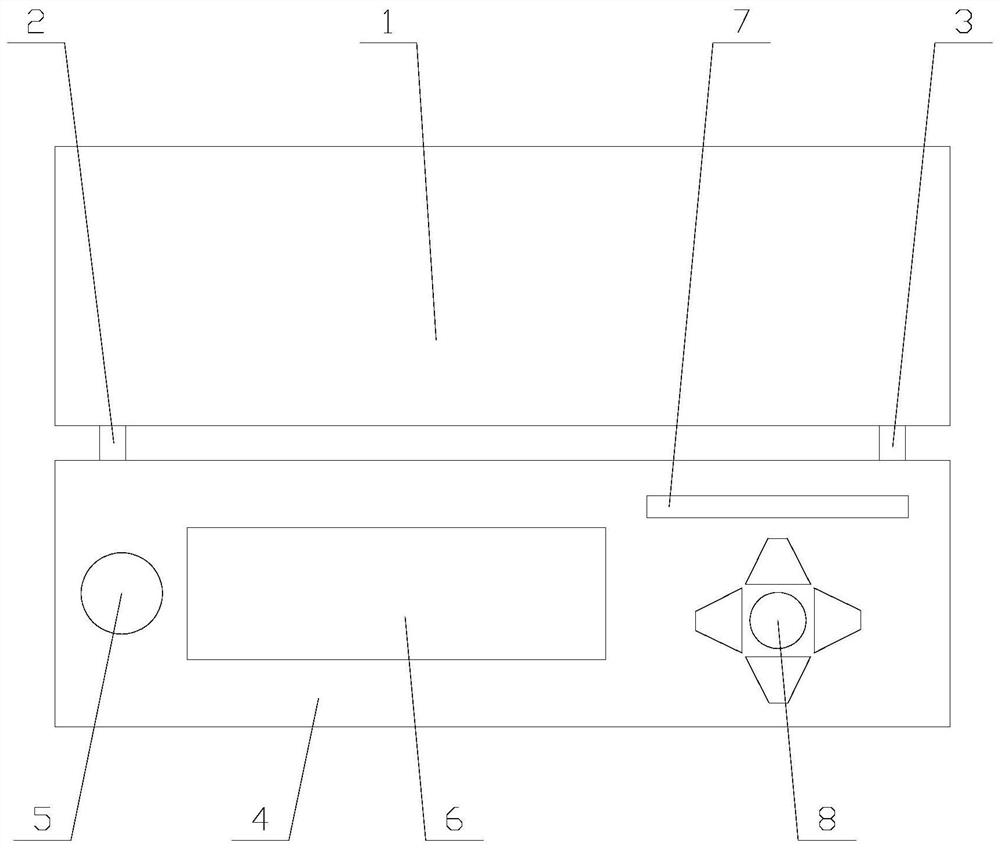

An intelligent digital video conversion box with efficient cooling function

ActiveCN108600799BWide range of actionAchieve continuous flowSelective content distributionSelection arrangementsDigital videoWater storage

The invention relates to an intelligent digital set top box with an efficient cooling function. The intelligent digital set top box comprises a body. The body comprises a water storage tank, a water inlet pipe, a water outlet pipe and a set top box. A circuit board, a PLC and a cooling mechanism are set in the set top box. A water storage mechanism is set in the water storage box. The cooling mechanism comprises a cooling pipe, a reciprocation plate, a reciprocation assembly and a plurality of abutting assemblies. Each abutting assembly comprises a first motor, a first drive shaft, a bushing and an abutting block. The water storage mechanism comprises a clapboard, a circulation assembly and a backflow assembly. According to the intelligent digital set top box with the efficient cooling function, through utilization of the cooling mechanism, the cooling pipe abuts on the circuit board, the cooling pipe is driven to move, and water solution in the cooling pipe absorb heat at each part ofthe circuit board, so the cooling is realized. Through utilization of the water storage mechanism, the opening and closing of the water inlet pipe is controlled. Through utilization of a first waterpump, the water solution flows into the cooling pipe continuously, so the cooling capability is ensured, a cooling effect is improved, and the practicability of equipment is improved.

Owner:嘉兴市佳丝宝喷织股份有限公司

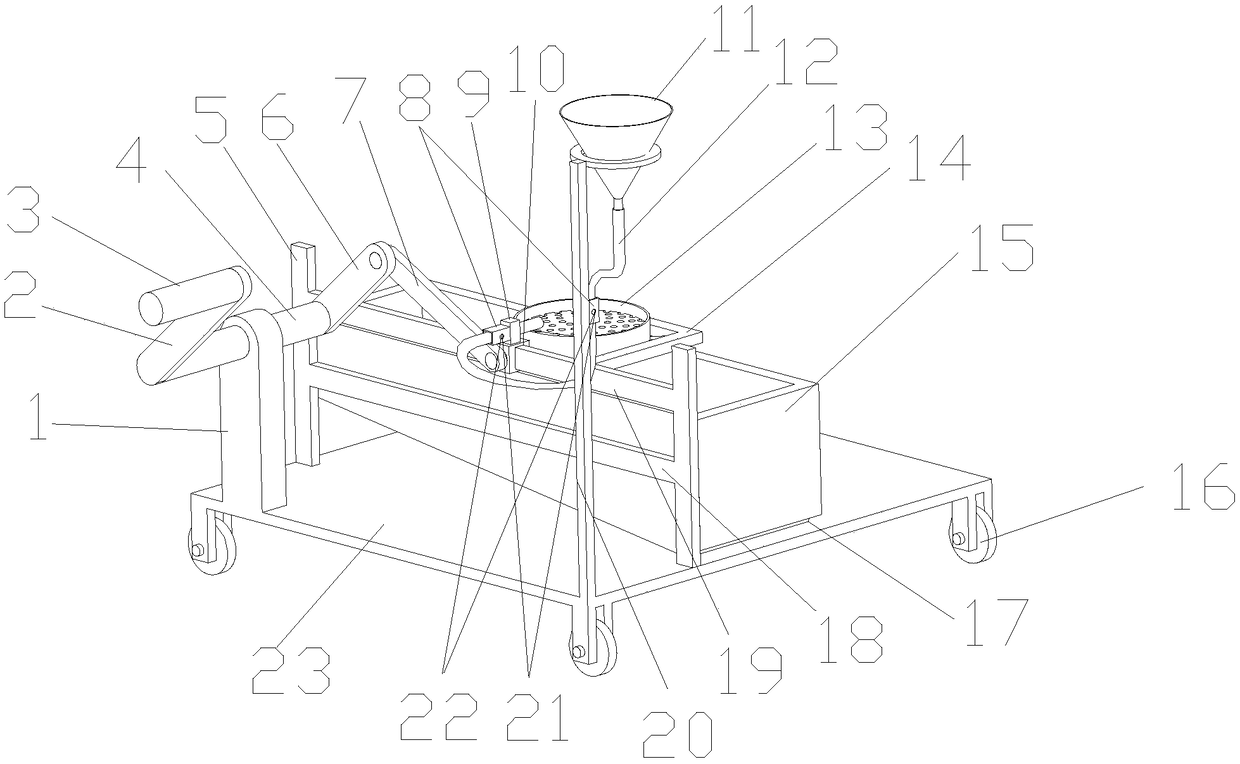

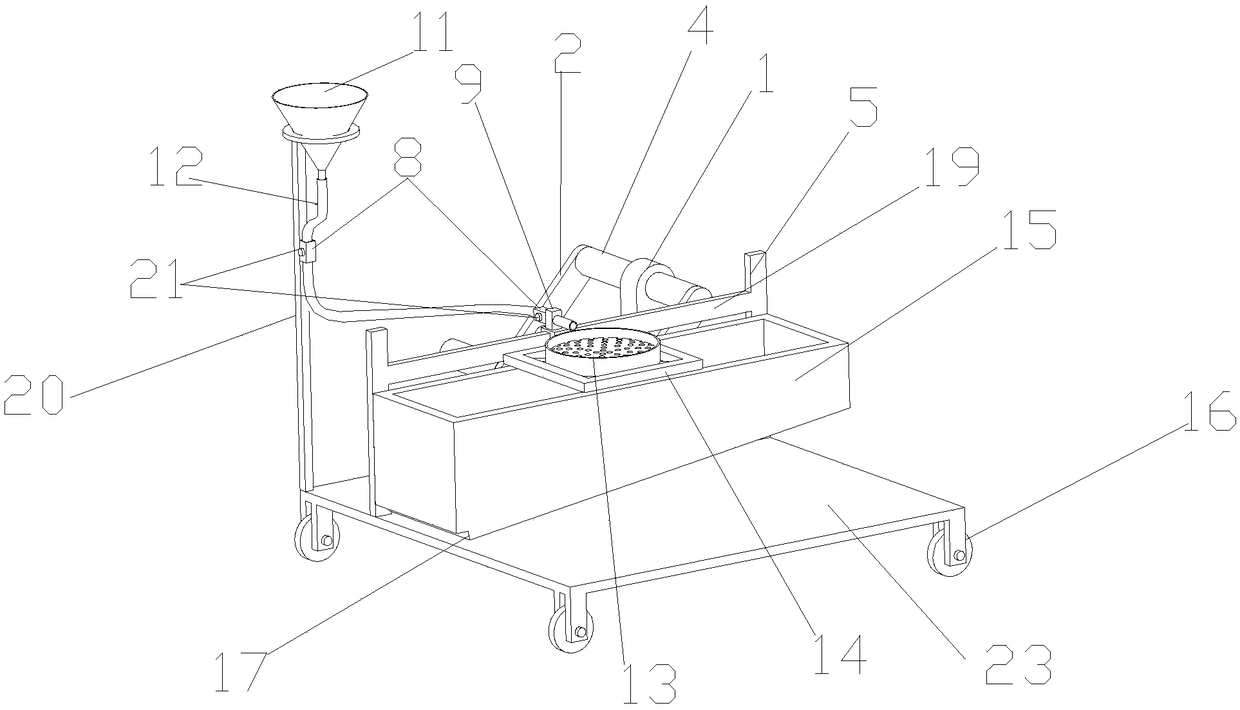

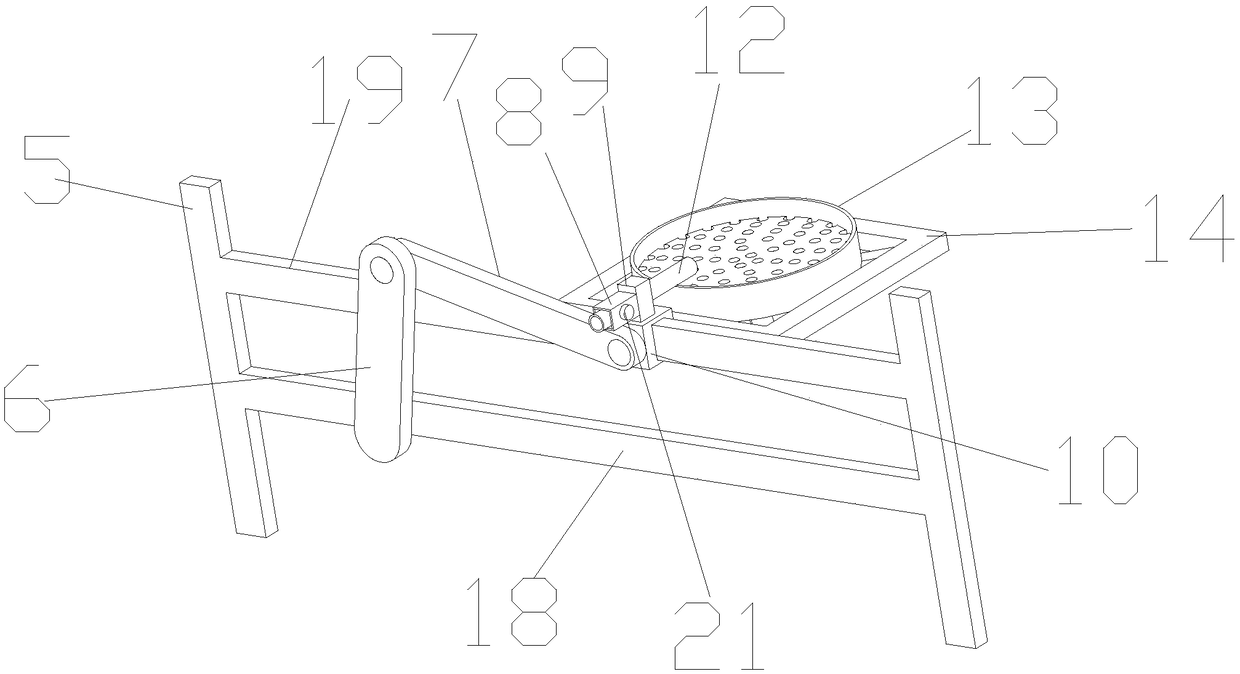

Hand rocking type water-jet abrasive sieving device

InactiveCN108855894ARealize the screening workAchieve continuous flowSievingScreeningEngineeringCircular motion

The invention relates to a hand rocking type water-jet abrasive sieving device, which is characterized by comprising a bottom plate. A rotating shaft is arranged on a handle support which is arrangedon the upper left side of the bottom plate, the right end of the rotating shaft is connectedly welded to the left end of a crank, the right end of the crank is hinged to the left end of a connecting rod, and the right end of the connecting rod is hinged to the left end of a slide sleeve. The slide sleeve and a guide rail are matched coaxially, and the guide rail is fixed to a supporting frame which is arranged at the upper middle end of the bottom plate. By arrangement of the crank, the connecting rod and the slide sleeve, circular motion of the handle is converted into bilateral reciprocatingmotion of the slide sleeve on the guide rail. By arrangement of a hopper and a hose, continuous abrasive pouring is realized. By arrangement of an abrasive collection tank, abrasion collection is realized. By arrangement of a cross shaft, stability of the abrasive collection tank can be improved. In addition, the hand rocking type water-jet abrasive sieving device is simple in structure, convenient to operate, economical and practical.

Owner:ANHUI UNIV OF SCI & TECH

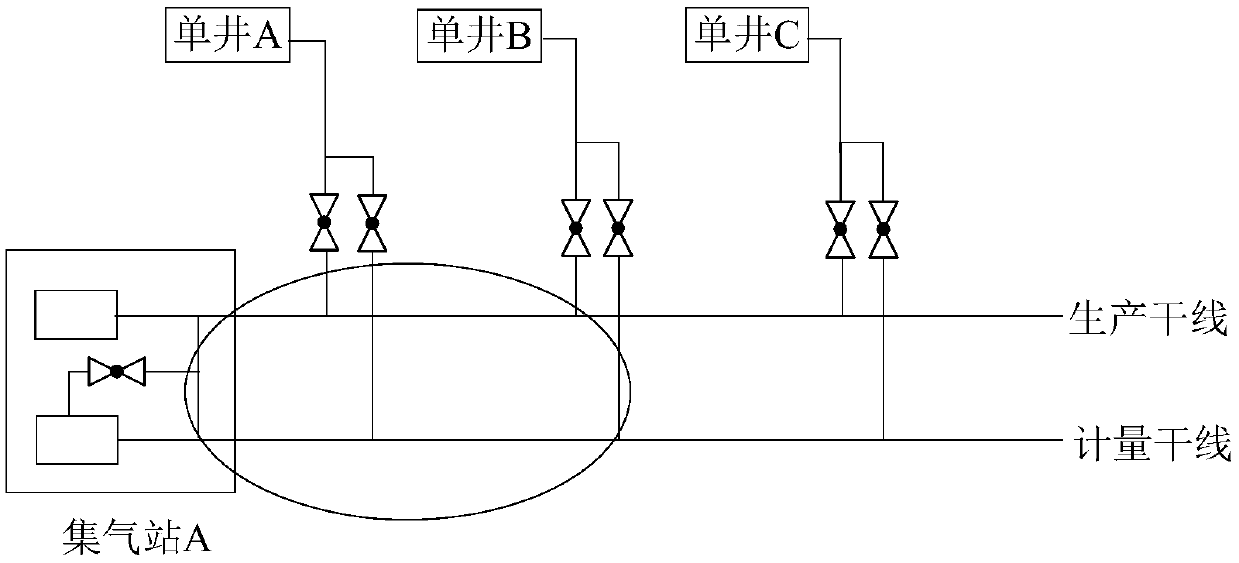

Anti-freezing-blockage natural gas collecting and conveying system and anti-freezing-blockage method for natural gas collecting and conveying system

ActiveCN110864224ASafe and stable operationDoes not affect switchingPipeline systemsMechanical engineeringPetroleum engineering

The invention provides an anti-freezing-blockage natural gas collecting and conveying system and an anti-freezing-blockage method for the natural gas collecting and conveying system. The natural gas collecting and conveying system comprises a gas collecting main line and a metering main line, one end of the gas collecting main line and one end of the metering main line communicate through a connecting pipeline, the ends, facing the connecting pipeline, of the gas collecting main line and the metering main line are provided with a first gas collecting branch line and a first metering branch line respectively, the first gas collecting branch line and the first metering branch line are used for communicating the gas collecting main line and the metering main line with a first single well respectively, the first single well does not pass a well fluid into the gas collecting main line and the metering main line, a second gas collecting branch line and a second metering branch line are usedfor communicating the gas collecting main line and the metering main line with a second single well respectively, a first control mechanism is arranged at the communicating position between the secondmetering branch line and the metering main line, and the flow direction of a well fluid from the second single well in the metering main line is controlled through the first control mechanism. According to the natural gas collecting and conveying system, through reverse flow of the well fluids in the pipelines, the purposes of freezing-blockage prevention and pipeline protecting are achieved.

Owner:PETROCHINA CO LTD

Mobile phone module production line

PendingCN111953837AOptimize and adjust the structureIncrease productivitySubstation equipmentMechanical conveyorsEngineeringTouchscreen

The invention discloses a mobile phone module production line which comprises a mobile phone module fixture mounting station, a mobile phone module fixture detaching station and a first output conveying belt for connecting the mobile phone module fixture mounting station and the mobile phone module fixture detaching station, and a plurality of mobile phone module portrait testing stations are arranged on the two sides of the mobile phone module fixture mounting station correspondingly. A plurality of touch screen characteristic test stations are arranged on one side of the first output conveying belt, a mobile phone backlight module lighting test station is arranged between the touch screen characteristic test stations and the mobile phone module clamp dismounting station, and a second output conveying belt is arranged between the touch screen characteristic test stations and the mobile phone backlight module lighting test station. An input conveying belt is further arranged between the mobile phone module clamp disassembling station and the mobile phone module clamp installing station, and a mobile phone module sealing performance testing station, a mobile phone film pasting and nameplate printing station and a mobile phone module appearance inspection station are sequentially arranged on the side, away from the mobile phone backlight module lighting testing station, of the mobile phone module clamp disassembling station.

Owner:四川金东迪科技有限公司

Device for suppressing pulsated impact of slurry flow in concrete pump vehicle

ActiveCN1951657BReduce vibrationAchieve continuous flowDischarging apparatusPipe elementsRefluxTransmission channel

The invention relates to a device used to restrain the slurry fluid impulse impact of concrete pump. Wherein, it comprises transmission channel, feeding cylinder and controller; the feeding cylinder is through to the transmission channel; the feeding cylinder has feeding piston and feeding piston rod; the feeding piston rod is connected to the controller; between the feeding cylinder and the material inlet of transmission channel, there is a switch valve for avoiding reflux of slurry. The invention has simple structure, to realize continuous flow of slurry, and reduce the impulse impact.

Owner:SANY AUTOMOBILE MFG CO LTD

A Method for Enhancing Mixing Performance in Rotating Packed Beds Based on Liquid Distributors with Superhydrophobic Surfaces

ActiveCN111659311BWell mixedImprove the mixing effectTransportation and packagingPretreated surfacesSuperhydrophobeChemical preparation

The invention discloses a method for strengthening the mixing performance of a rotating packed bed based on a liquid distributor with a superhydrophobic surface. The rotating packed bed is suitable for a system containing liquid in the raw material, and a superhydrophobic coating is modified on the surface of the liquid distributor of the rotating packed bed. The liquid distributor has a super-hydrophobic surface, the raw material does not adhere to the surface of the liquid distributor after flowing out from the outlet of the liquid distributor, and the raw material flows into the rotating packed bed in a continuous state, thereby strengthening the mixing effect of the rotating packed bed on the raw materials. The present invention realizes that the wettability of the solid surface can affect the flow of the liquid in the rotating packed bed, and the flow of the liquid in the rotating packed bed affects the mixing performance of the rotating packed bed. The present invention modifies the superhydrophobic coating on the surface of the liquid distributor , to improve the fluidity of the liquid in the rotating packed bed, and then improve the mixing effect of the rotating packed bed on the liquid. The rotary packed bed of the invention is expected to be applied in chemical preparation in the field of biomedicine and laboratory miniature experiments.

Owner:BEIJING UNIV OF CHEM TECH

Self-circulation drying device

InactiveCN110274451AAchieve continuous flowDry evenlyDrying gas arrangementsDrying solid materialsMechanical engineering

The invention discloses a self-circulation drying device which comprises a drying chamber (9) and a support (10). A first runner (1) and a second runner (2) are arranged in the drying chamber (9), and the top of the drying chamber (9) is provided with a material injection opening (7) and an exhaust opening (6). The side face of the drying chamber (9) is provided with an air inlet (5), and the lower portion of the drying chamber (9) is provided with a discharging opening (8). The outer side face of the first runner (1) is provided with multiple first baffles (101), and the outer side of the second runner (2) is provided with multiple second baffles (201). The rotating directions of the second runner (2) and the adjacent first runner (1) are opposite. A middle shaft sleeve (3) and a rotating shaft (4) are arranged in the first runner (1) and the second runner (2). The rotating shaft (4) is connected with a power input device on the outer side. The self-circulation drying device is simple in structure, repeated cycled flowing of materials can be achieved, the materials are dispersed evenly, and the drying efficiency is greatly improved.

Owner:QILU INST OF TECH

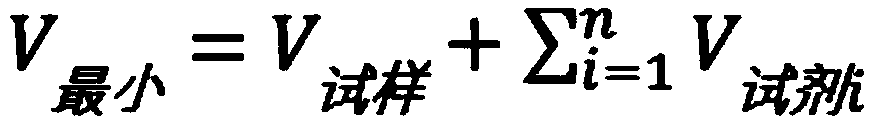

Injection method suitable for marine instrument

InactiveCN111289681AConsistent chemical reactionImprove stabilityChemical methods analysisChemical reactionEngineering

The invention relates to the technical field of ocean detection, in particular to an injection method suitable for an ocean instrument. A sample and a reagent exist at each moment; then, the materialsare fully mixed through a mixing part; the mixed liquid with stable components is formed, the consistency of the chemical reaction degree of the mixed liquid is guaranteed, quantitative pump valve systems are adopted in power systems of a sample and a reagent, the single sample injection process is controllable and adjustable, continuous flowing of the liquid is achieved in the whole liquid pathsystem through continuous repeated sample injection, and the stability of detection data is good.

Owner:杭州浅海科技有限责任公司

A cotton thread-based passive microfluidic fuel cell

ActiveCN107293764BAchieve continuous flowSimplify accessory equipmentElectrolyte stream managementFuel cell detailsChemical industryFuel cells

The invention discloses a cotton-thread-based passive micro-fluid fuel cell, which comprises an anode carbon paper and a cathode carbon paper; the cotton-thread-based passive micro-fluid fuel cell is characterized in that a first cotton thread and a second cotton thread are arranged on the anode carbon paper and the cathode carbon paper; the first cotton thread and the second cotton thread are isolated by a third cotton thread; one end of the first cotton thread is inserted to a first inlet culture dish, anode electrolyte is stored in the first inlet culture dish; one end of the second cotton thread is inserted to an inlet culture dish, and cathode electrolyte is stored in a second inlet culture dish; one end of the third cotton thread inserted to a third inlet culture dish, and isolating liquid is stored in the third inlet culture dish; the other ends of the first cotton thread, the second cotton thread and the third cotton thread are inserted to an outlet culture dish; the faces where the anode carbon paper and the cathode carbon paper are in contact with the cotton threads are coated with an anode catalyst layer and a cathode catalyst layer. By means of the capillary force of the cotton thread and the gravity, the continuous flow of the cathode fluid and the anode fluid is realized. The cotton-thread-based passive micro-fluid fuel cell can be widely applied to energy source, chemical industry, environment-friendly, and other domains.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com