Patents

Literature

590 results about "Heat leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

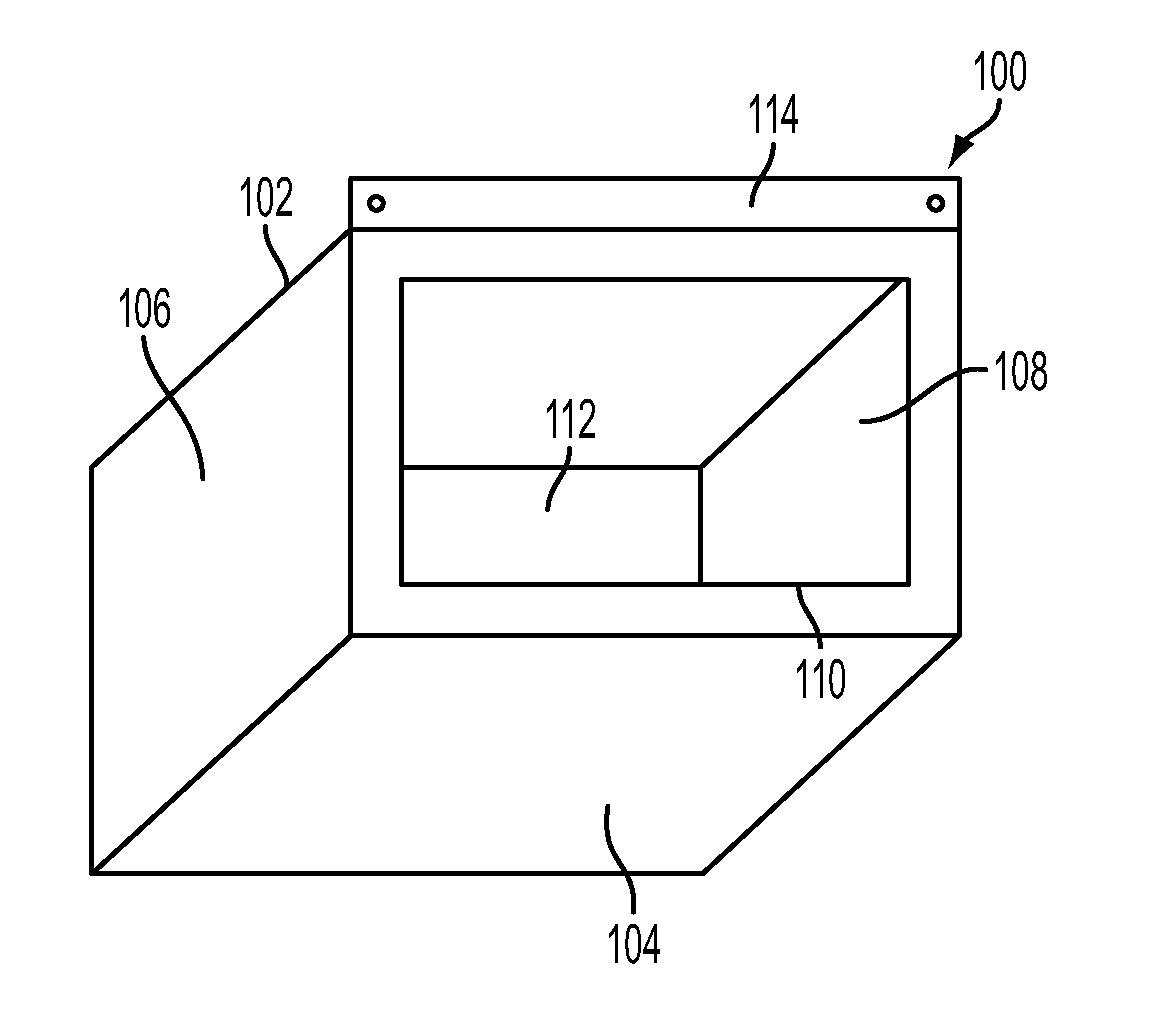

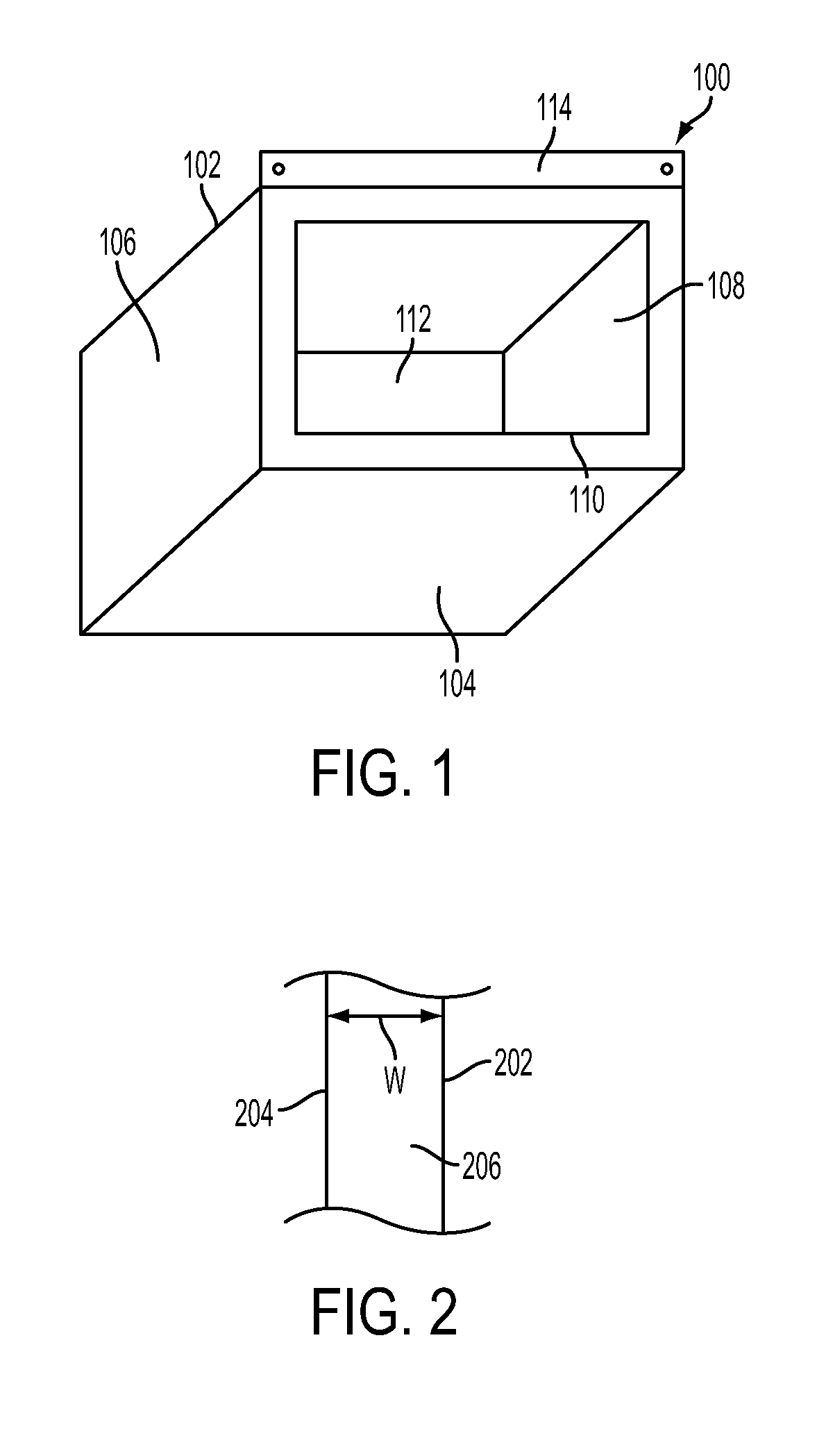

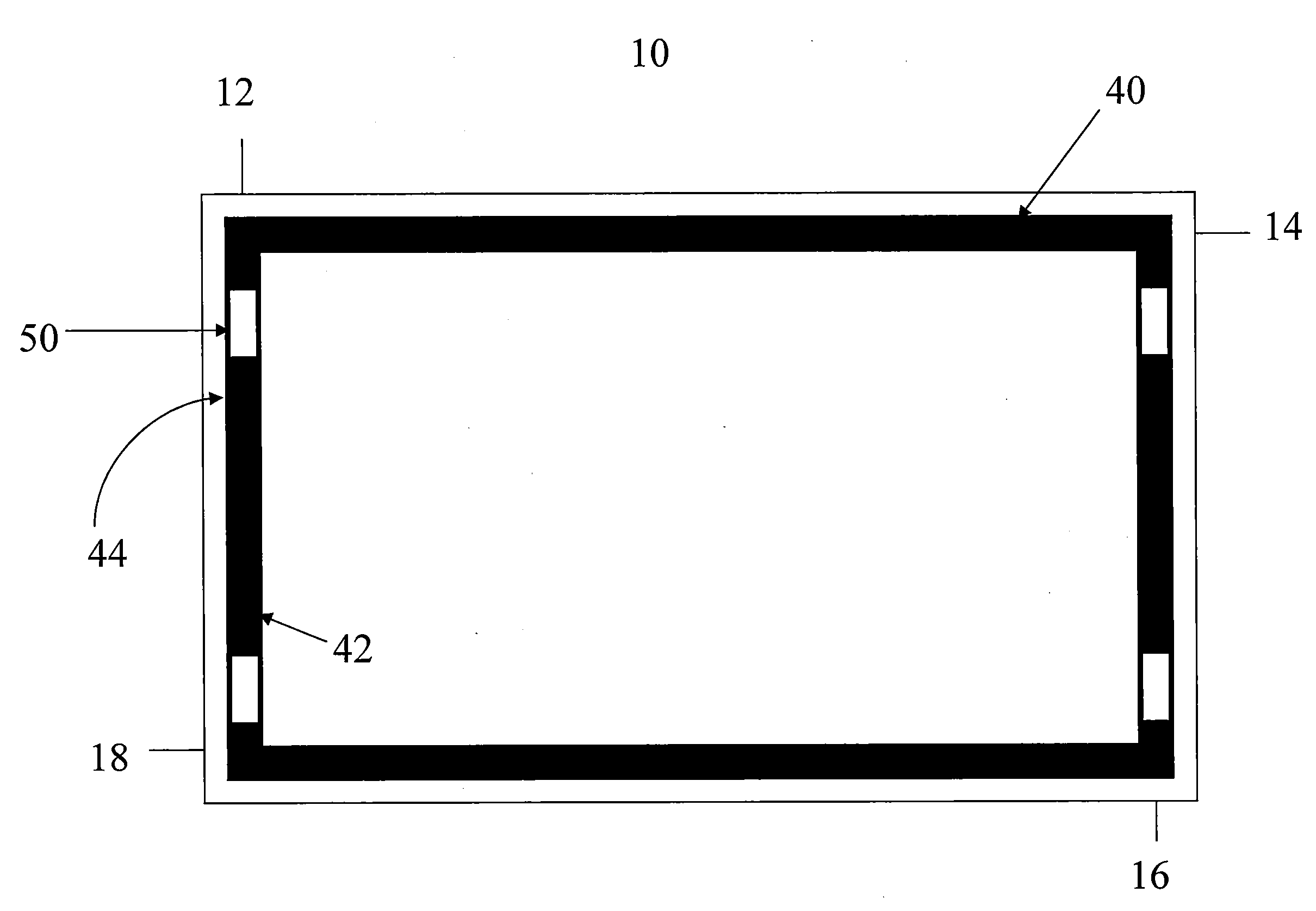

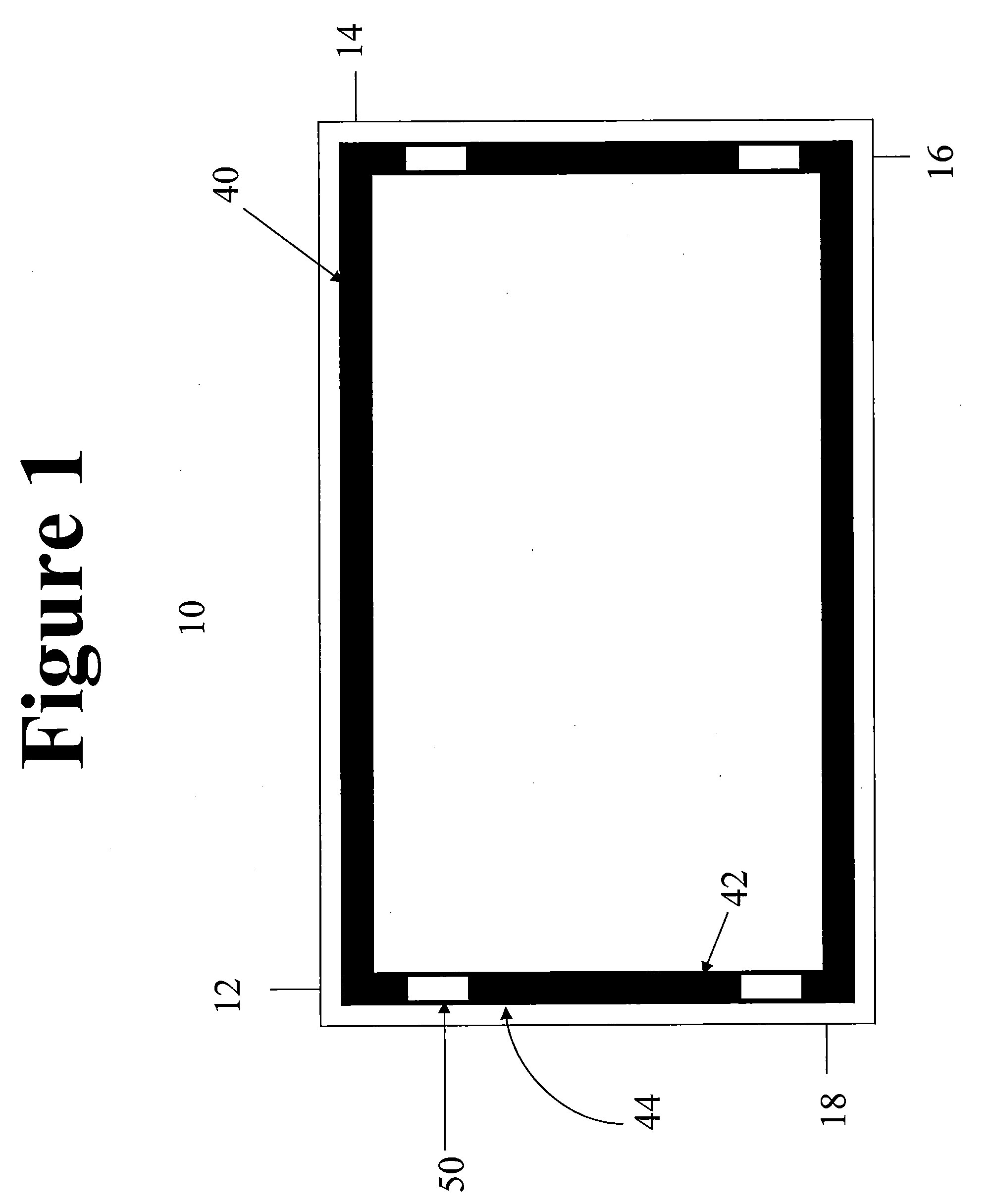

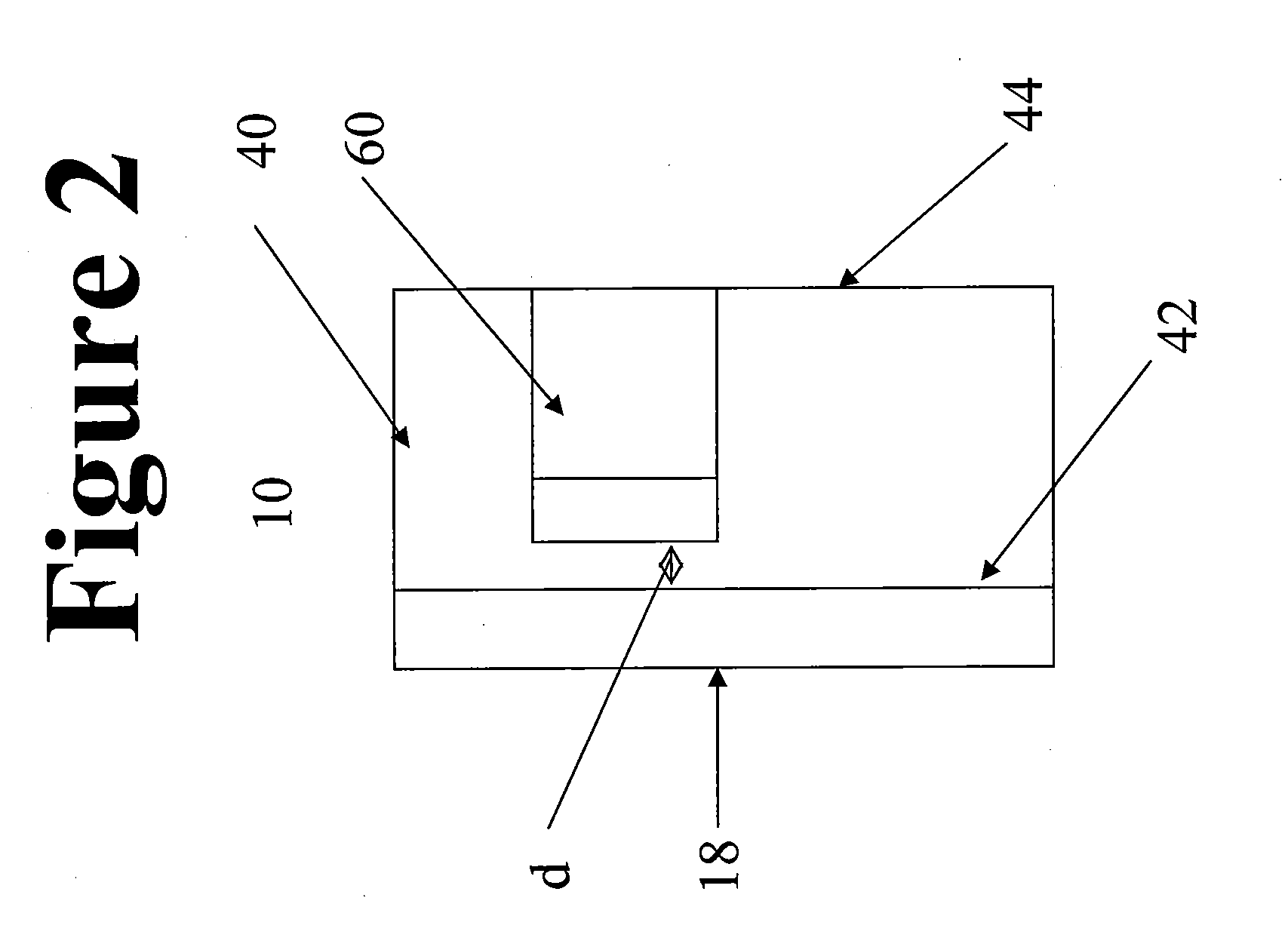

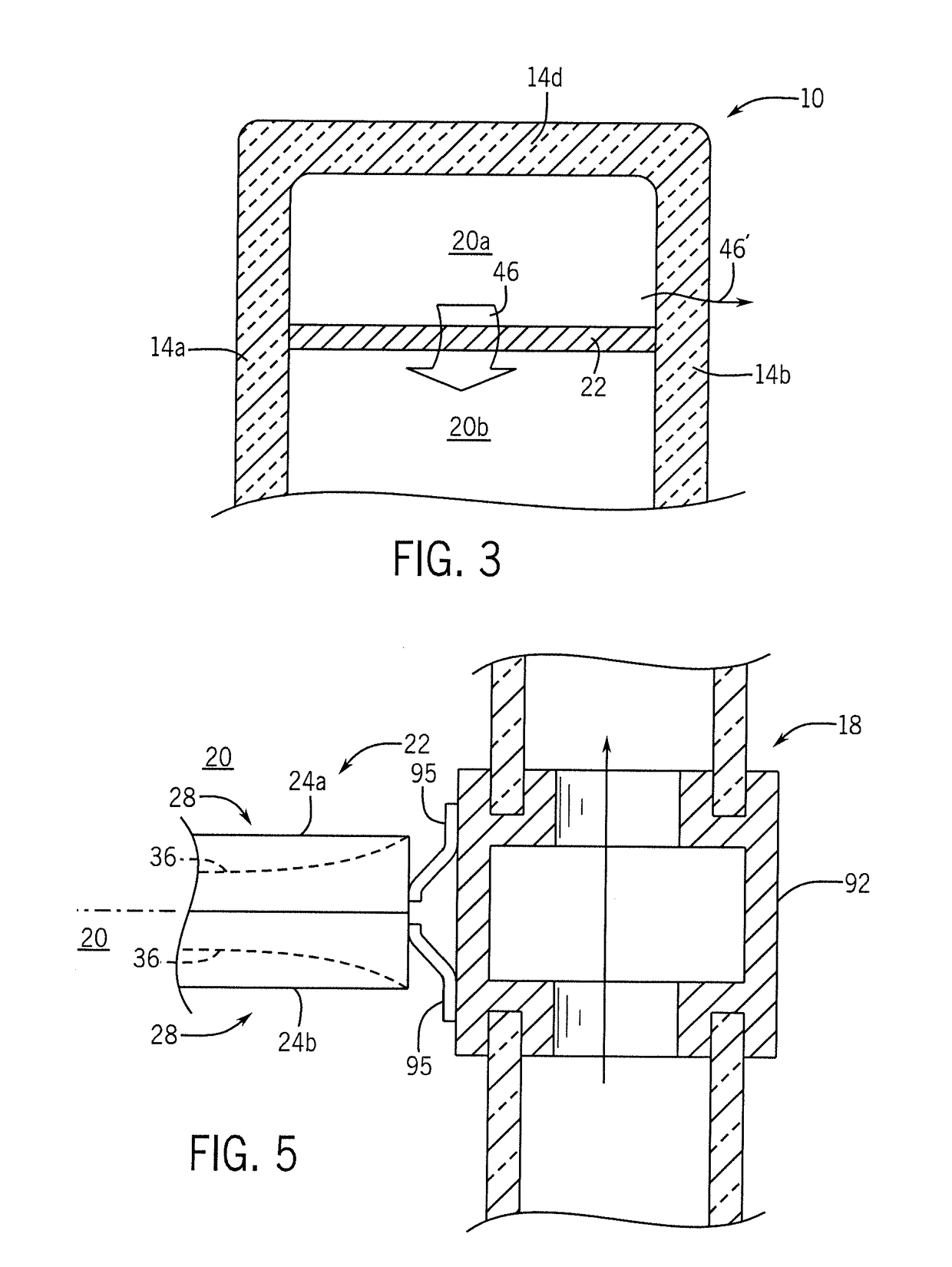

Casing for heating/cooling units

InactiveUS20110120166A1Easy and efficient to manufactureEasily and efficiently manufactured and marketedDomestic cooling apparatusLighting and heating apparatusDouble wallWindow opening

Owner:ICE AIR

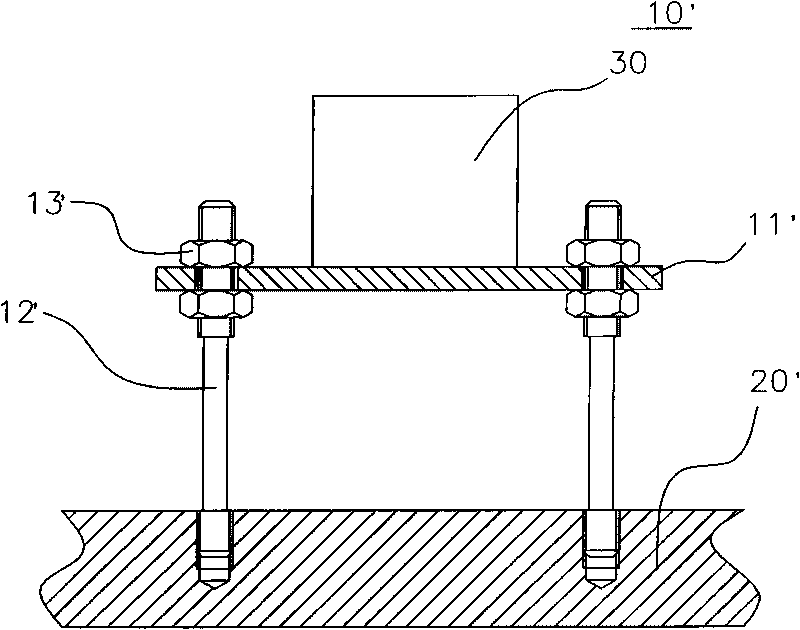

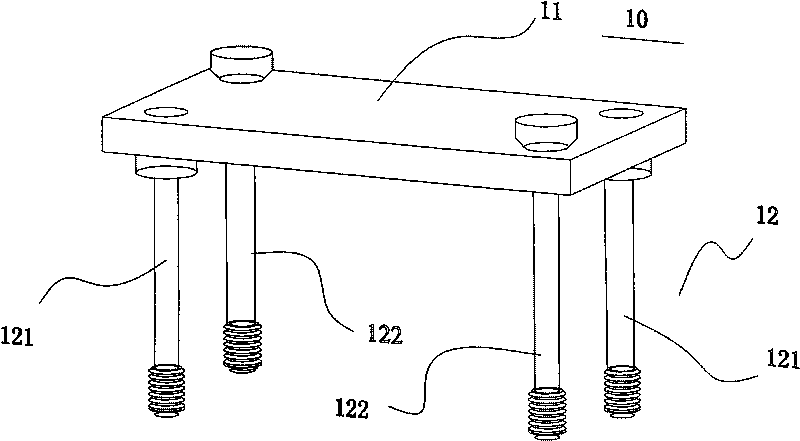

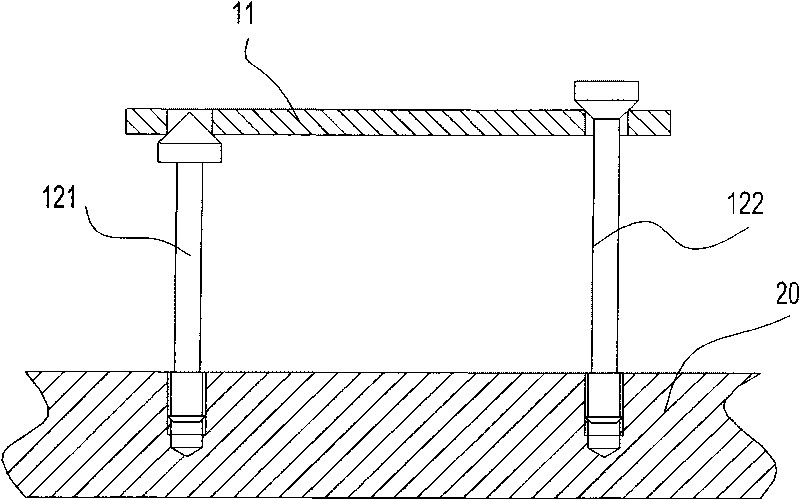

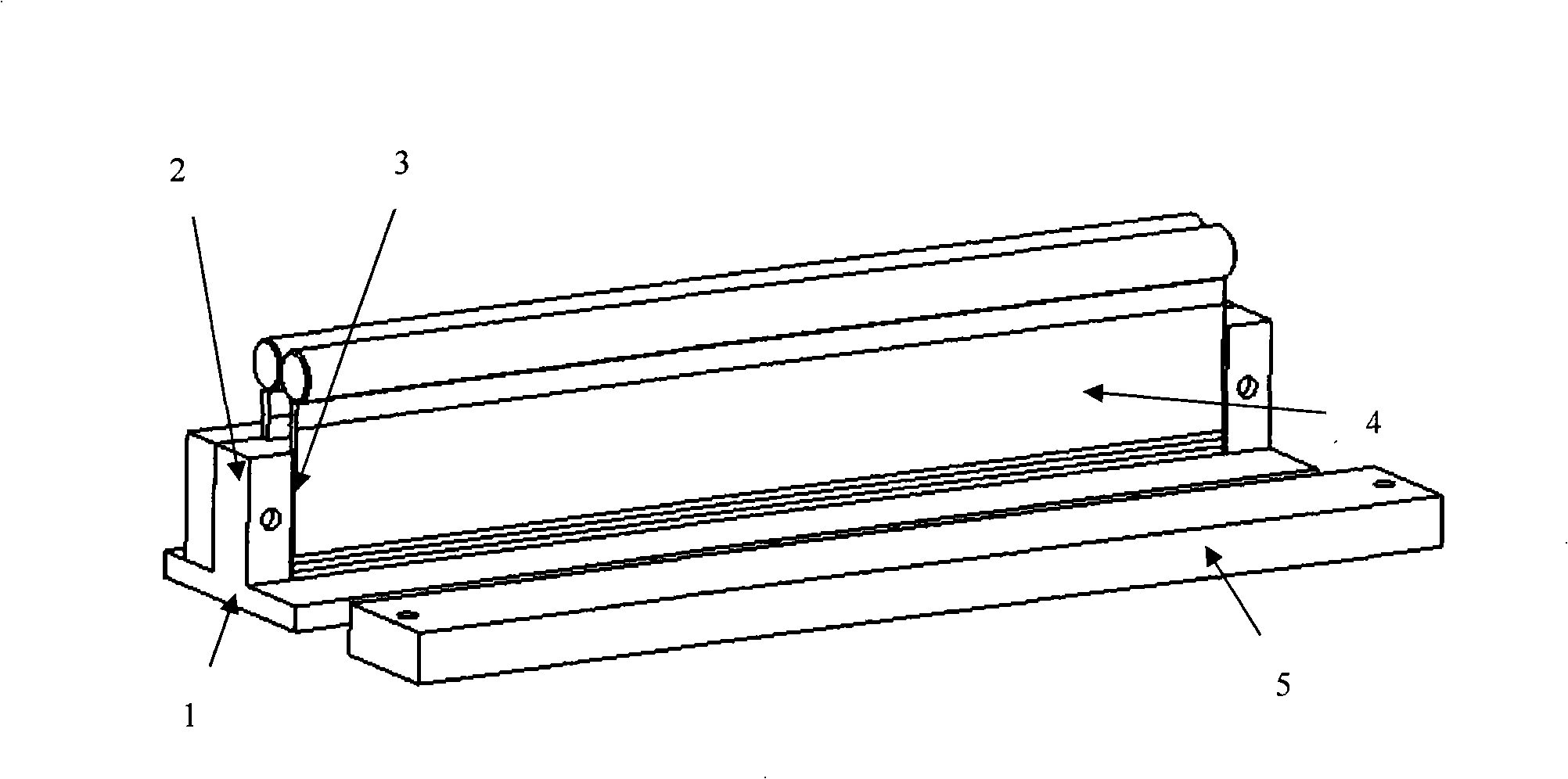

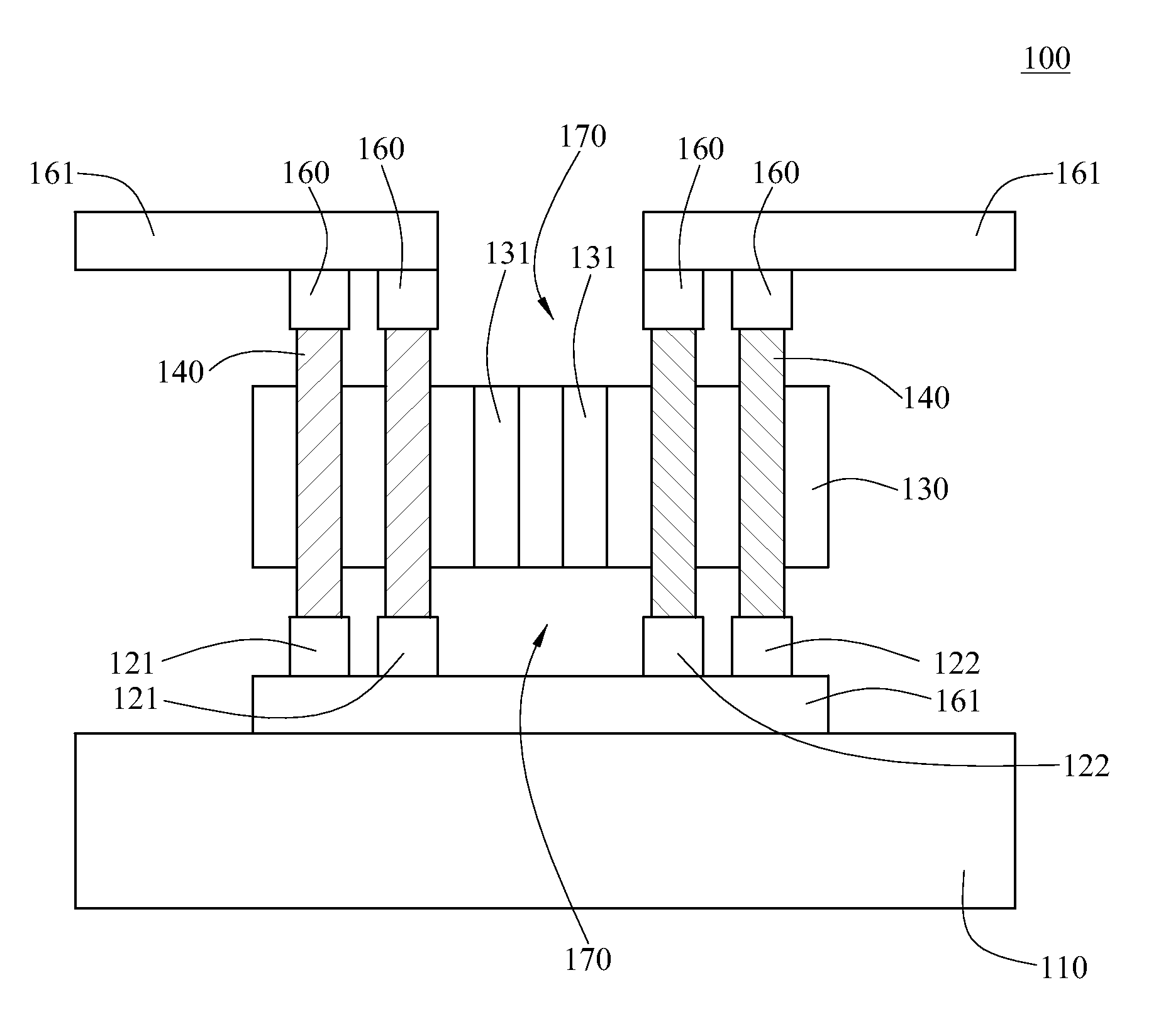

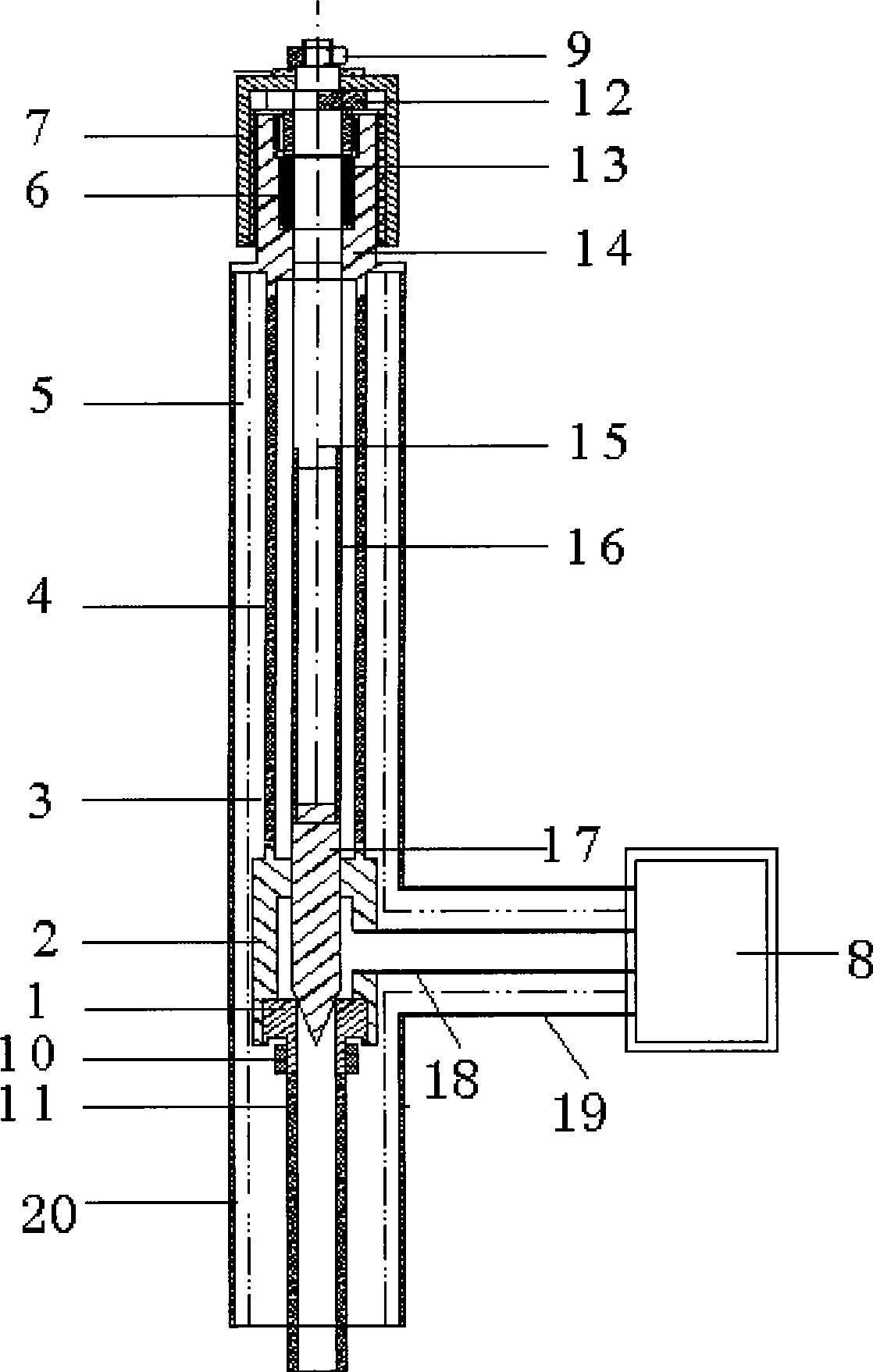

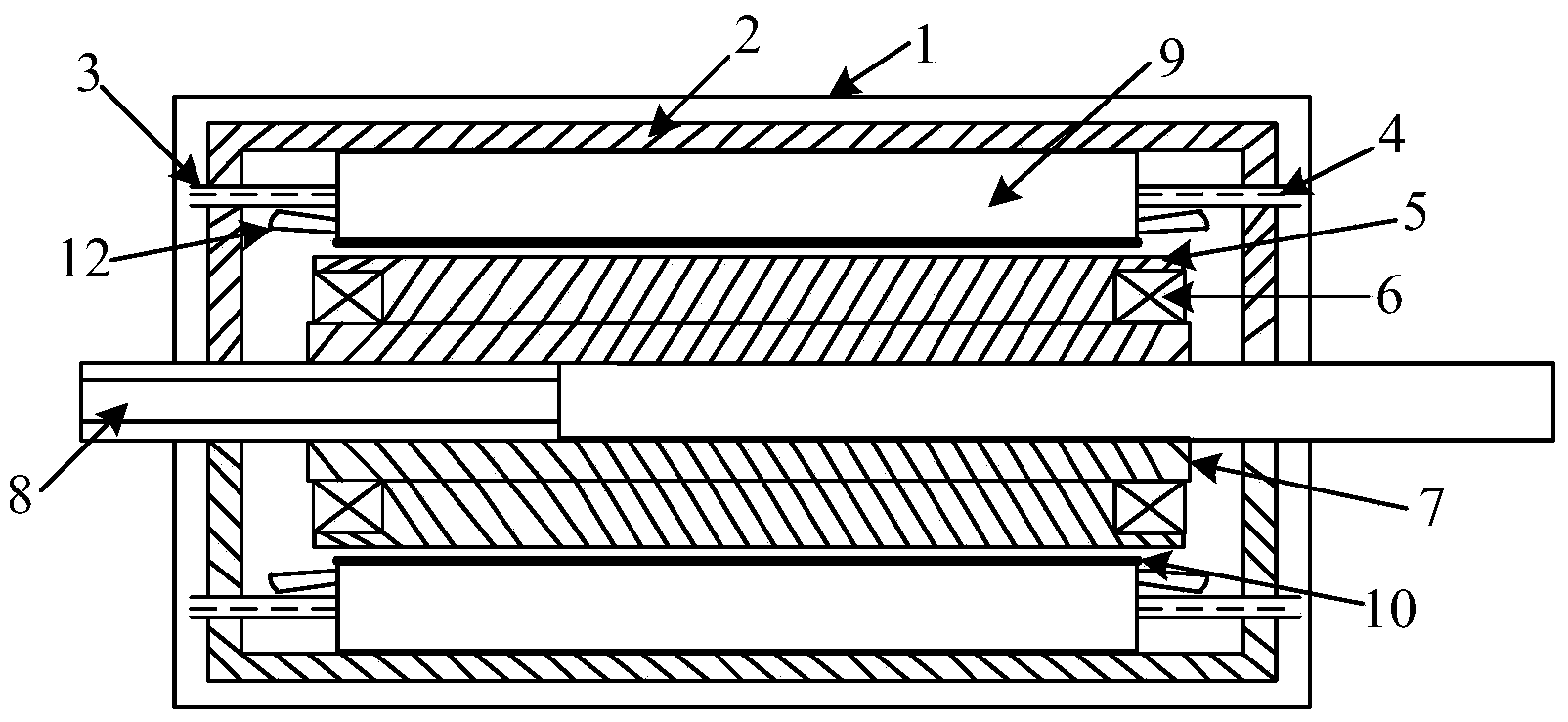

Adiabatic supporting device

ActiveCN101738127AGuaranteed stabilityReduce thermal contact areaHeat exchanger casingsEngineeringVacuum chamber

An adiabatic supporting device is used for supporting low temperature devices in a low temperature vacuum system. The supporting device comprises a cold platform with a plurality of mounting holes and support bars used for supporting the cold platform. The bottoms of the support bars are fixedly connected with a vacuum chamber. The support bars comprise upward ejecting support bars and downward pressing support bars. The upper parts of the upward ejecting support bars are matched with the mounting holes by way of point contact or line contact and the upward ejecting support bars provide upward ejecting force to the cold platform. After the downward pressing support bars pass through the mounting holes, the tops of the downward pressing support bars are matched with the mounting holes by way of point contact or line contact and the downward pressing support bars provide downward pressing force to the cold platform. The upward ejecting force reaches equilibrium with the downward pressing force. The supporting device furthest reduces the heat contact area under the premise of ensuring the stability of the mechanical structure and changes from the original nut surface contact to the current line contact or point contact, thus reducing heat leakage from the vacuum chamber to the cold platform and greatly reducing heat load.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

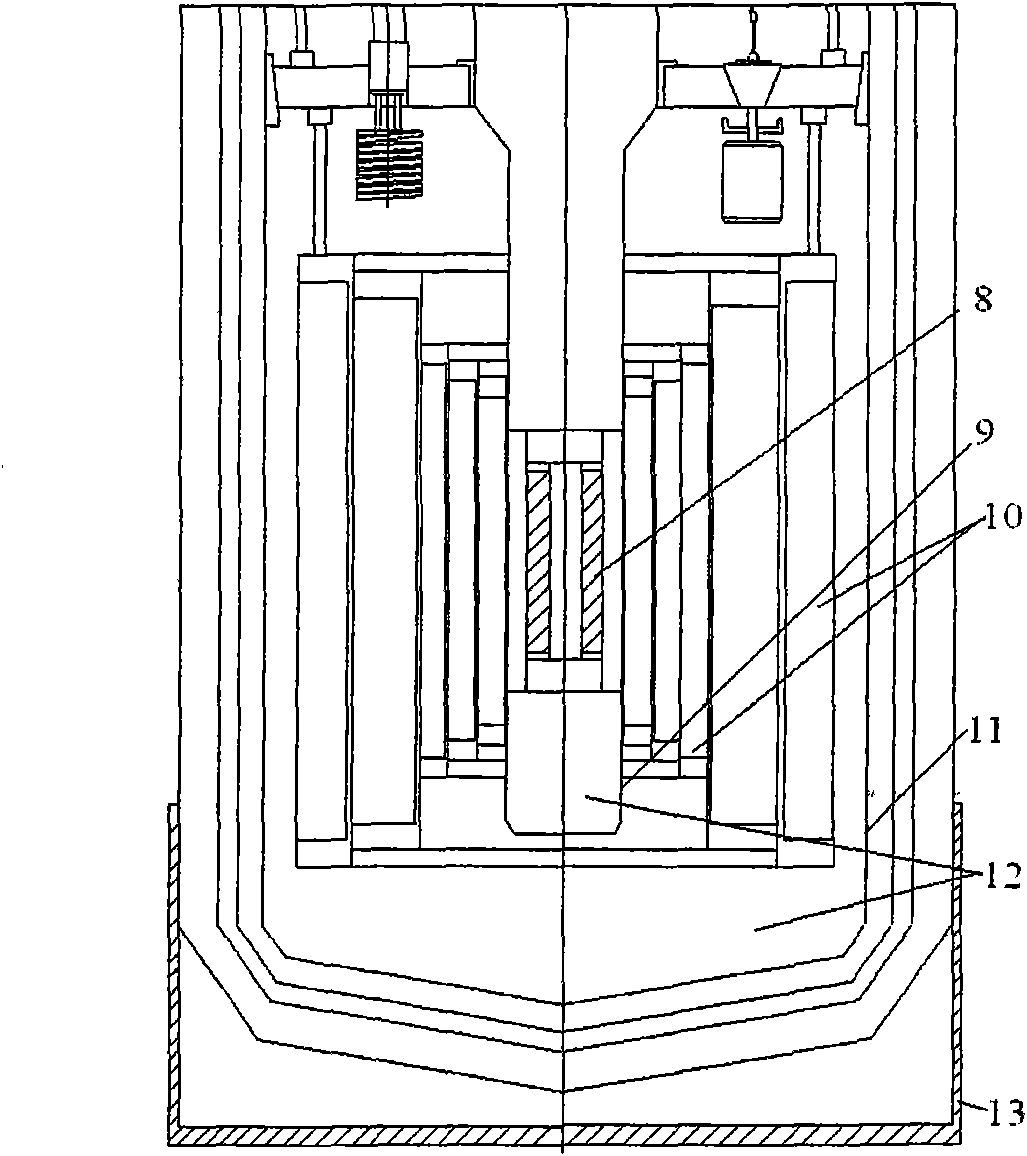

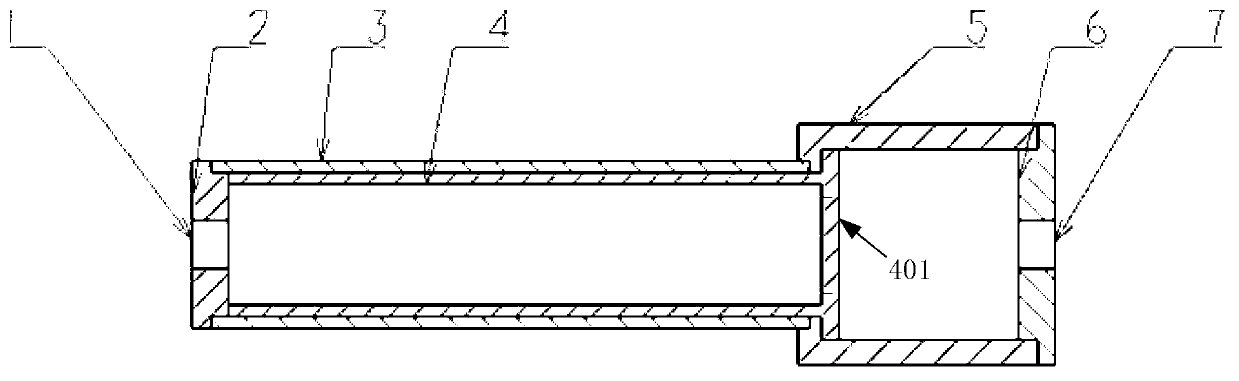

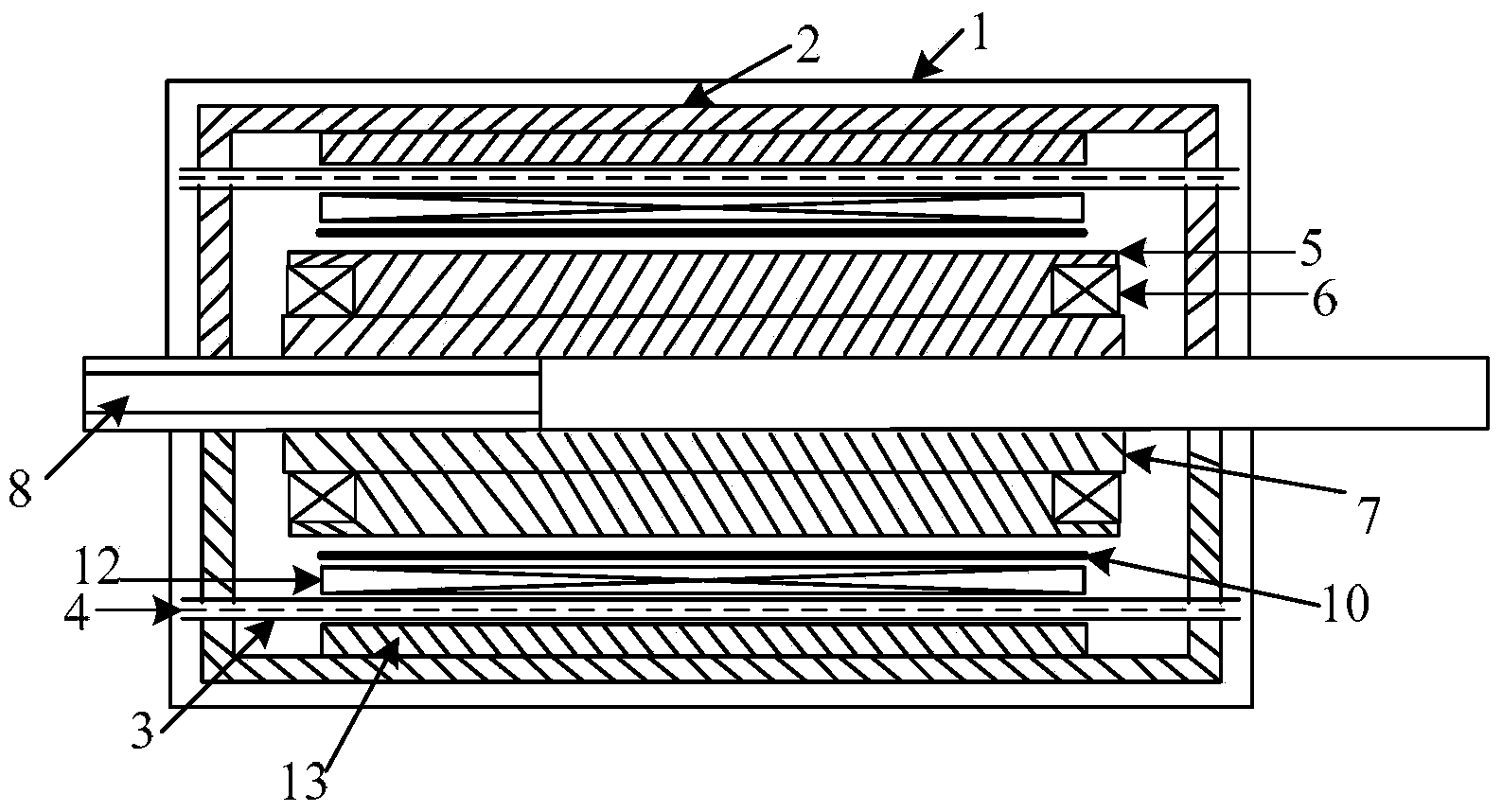

Conduction cooling superconducting magnet dewar convenient for loading and unloading

The invention relates to a conduction-cooled superconducting magnet Dewar with easy loading-unloading, comprising a Dewar cylinder. The conduction-cooled superconducting magnet Dewar is characterized in that the Dewar cylinder is a hollow annular cylinder, the middle of the annular cylinder is provided with a room temperature hole, an annular copper cold shield is arranged in the Dewar cylinder, a refrigerator and a superconducting magnet are arranged in the copper cold shield, a vacuum pumping port is arranged on the Dewar cylinder, a measuring device is arranged on an upper cover of the Dewar cylinder and the Dewar cylinder is in a vacuum state. Compared with the prior Dewar container, the conduction-cooled superconducting magnet Dewar is simpler, has small conduction heat leakage, and has the advantages of easy installation and disassembly; the refrigerator is used for conducting and cooling without a low temperature liquid (such as liquid helium and so on) cooling system; because of simple and safe system, a first-level cold junction of the refrigerator is operated under a temperature of 77K, thereby realizing heat sink of the copper cold shield, an electric lead and a support device; the first-level cold junction of the refrigerator adopts soft connection, thereby reducing temperature increment of the magnet due to vibration of the refrigerator; and the conduction-cooled superconducting magnet Dewar has the advantages of easy operation of manufacture, processing and installation, and is applicable to scale production.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Highly effective flat-type loop heat-pipe apparatus

InactiveCN1703142ASimple structureSimple manufacturing processInstrumental cooling apparatusCooling/ventilation/heating modificationsEngineeringLoop heat pipe

This invention relates to one plate effective circuit heating tube device in conduction and electronic cooling field, which is characterized by the following: providing one plate circuit integration vapor and compensation structure; the first liquid absorptive chip acting as industry substances vapor, the second chips acts to enlarge the system capillary abstracting function with its holes structure easy to arrive the first absorptive chip and acts to reduce the system heat leakage; the first liquid absorptive chip comprises level groove and vertical groove.

Owner:SUN YAT SEN UNIV

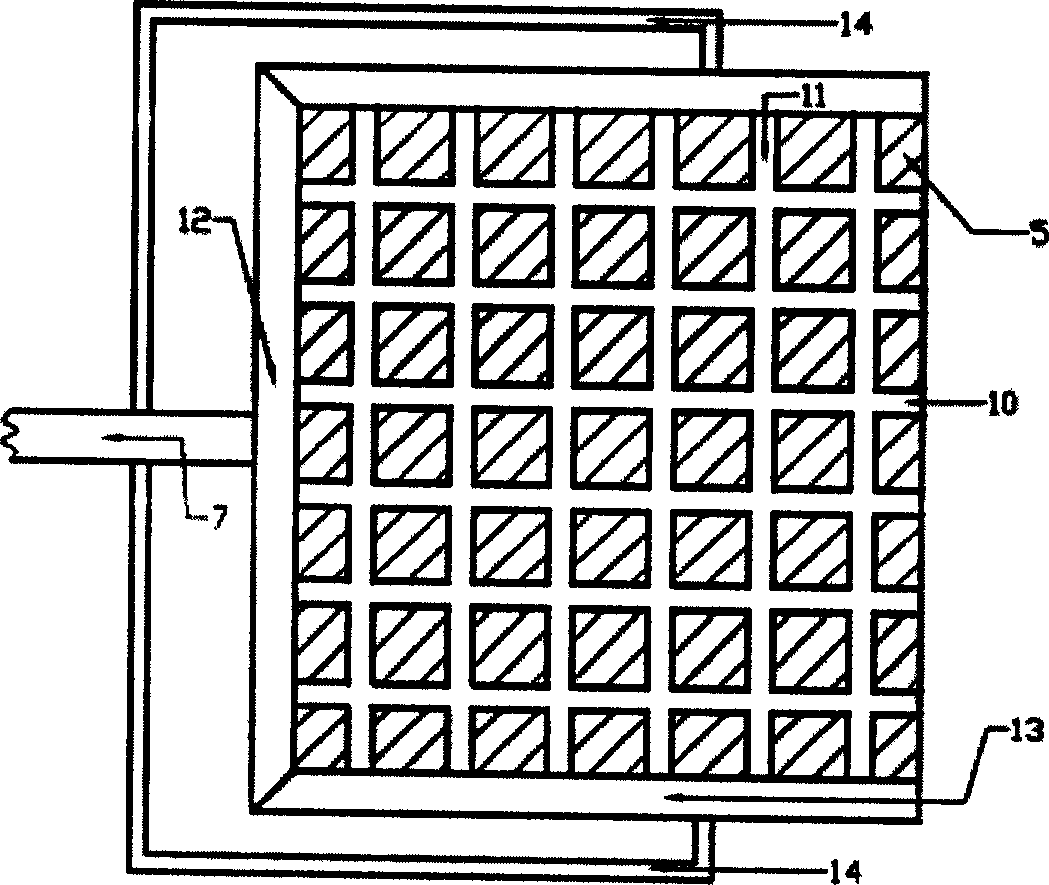

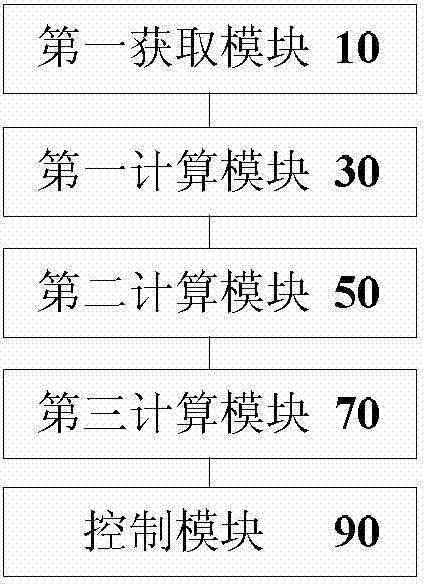

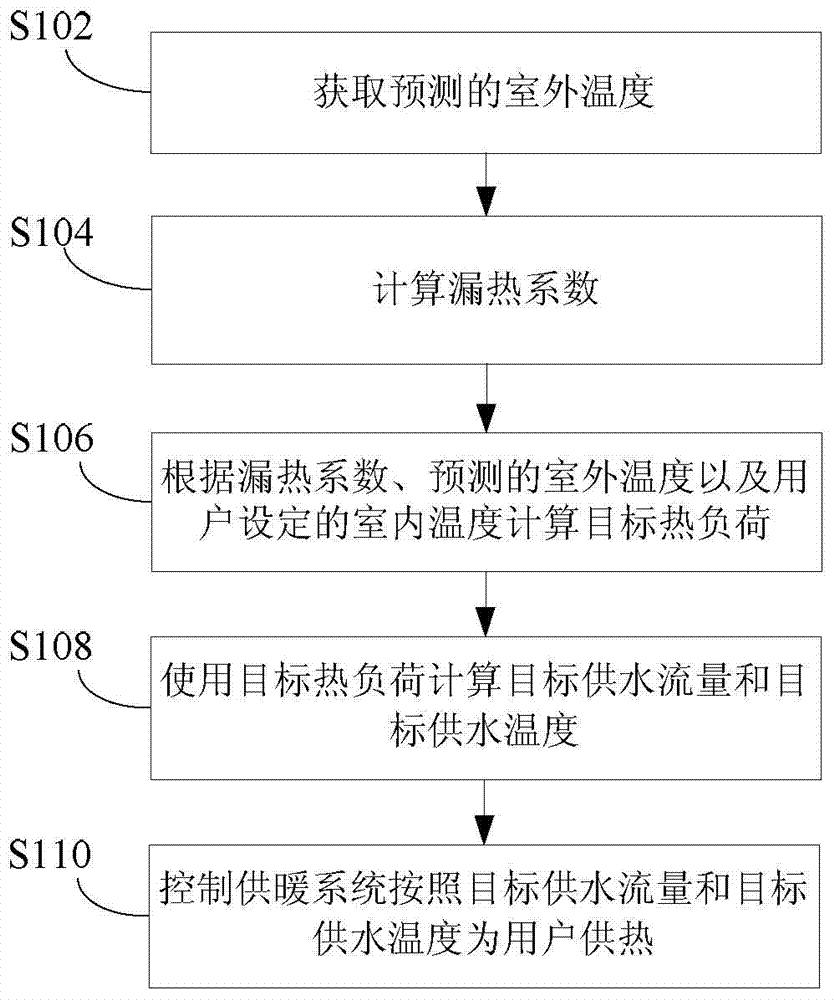

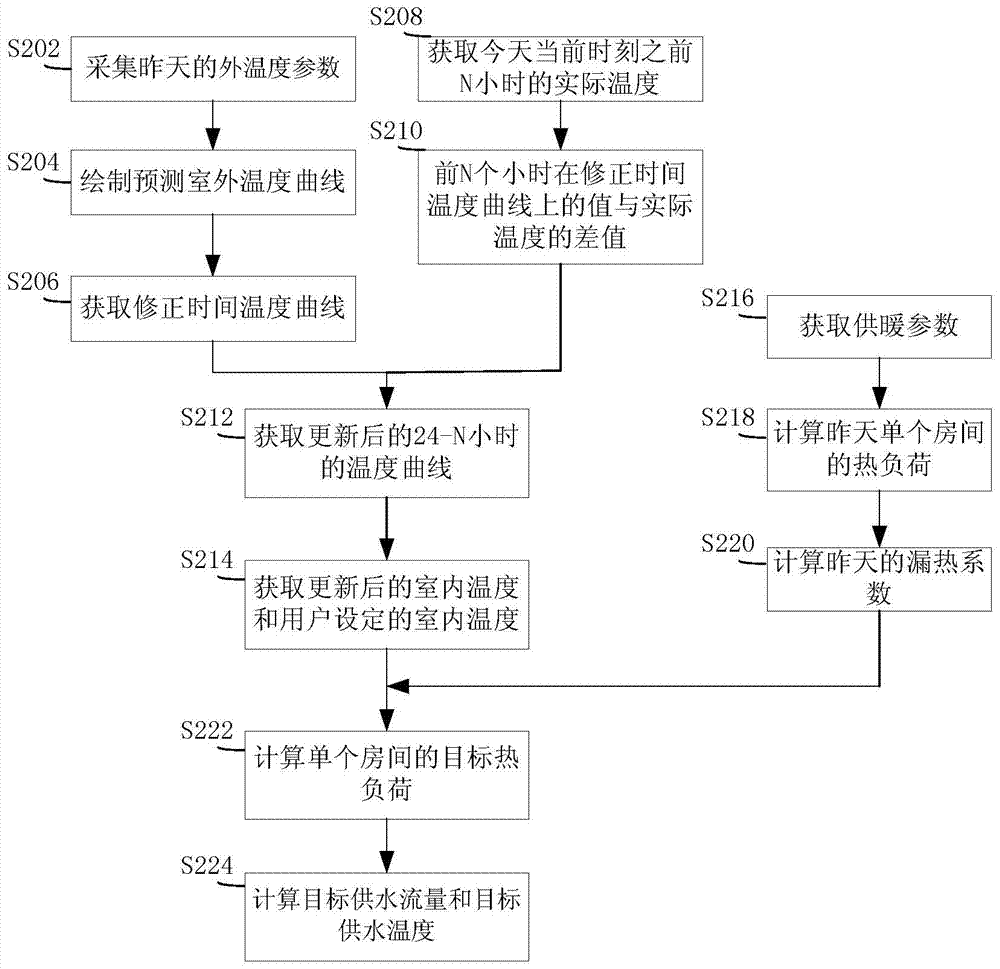

Control method and device of heating system

ActiveCN104515194AReduce wasteImprove energy savingLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringOutdoor temperature

The invention discloses a control method and a device of heating system, wherein the control method comprises the following steps: obtaining a predicted outdoor temperature; calculating a heat leakage coefficient; calculating a target heat load based on the heat leakage coefficient, the predicted outdoor temperature and a user designated indoor temperature; using the target heat load to calculate a target water supply flux and a target water supply temperature; and controlling the heating system to supply heat to the user based on the target water supply flux and the target water supply temperature. By using the control method and device of heating system, the problems that the adjustment is delayed and the energy resource is wasted because the floor heated room in the prior art uses the same water supply temperature and flux in supplying heat; therefore, the effect of adjusting the water supply flux and the water supply temperature of the heating system based on the real-time outdoor temperature is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

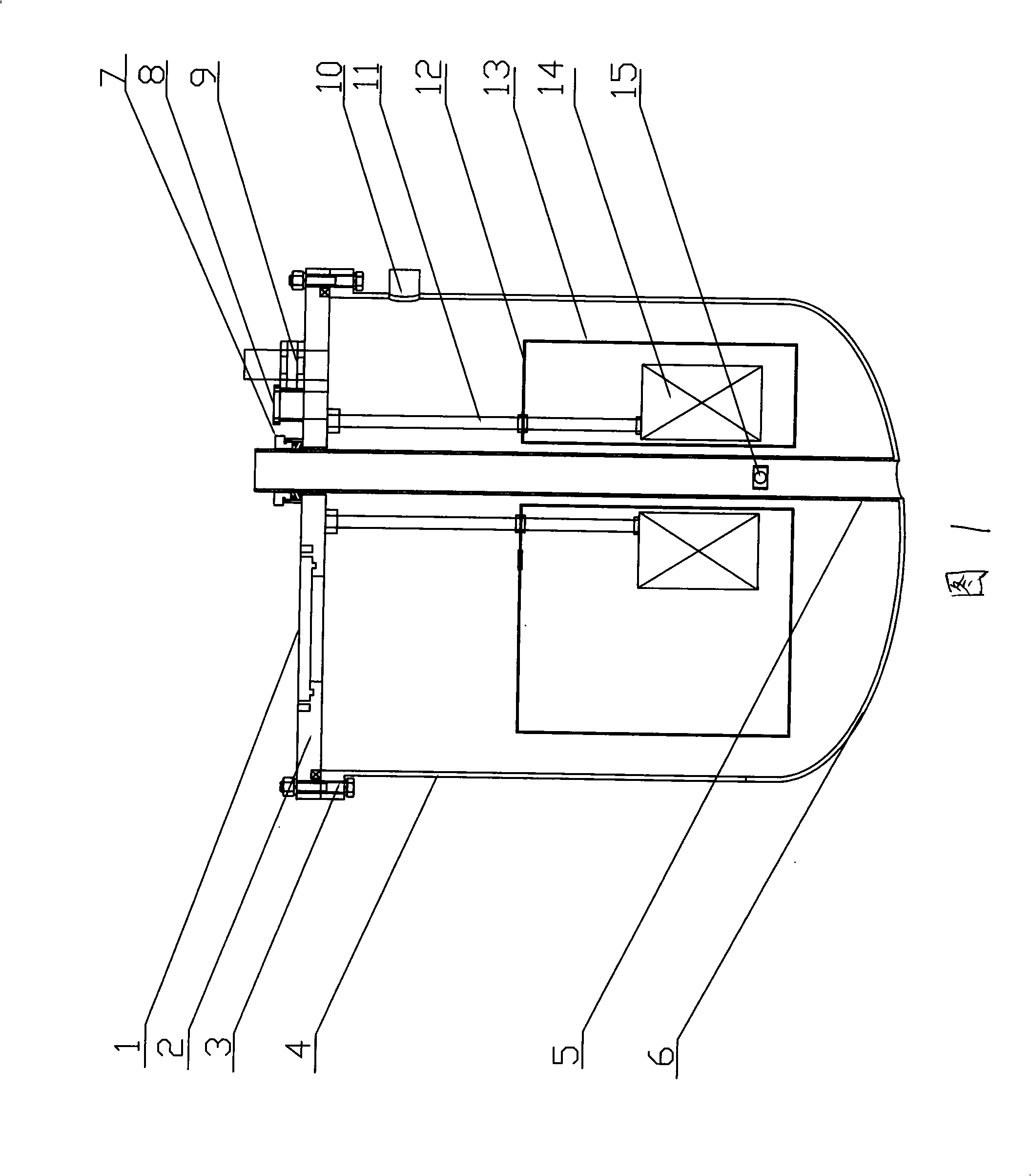

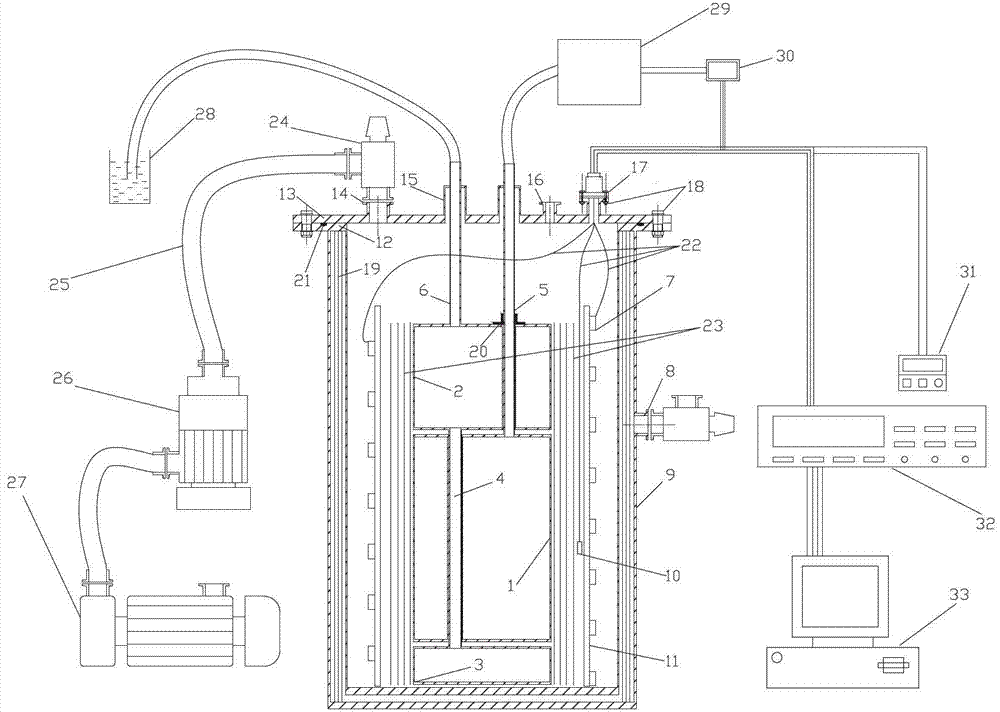

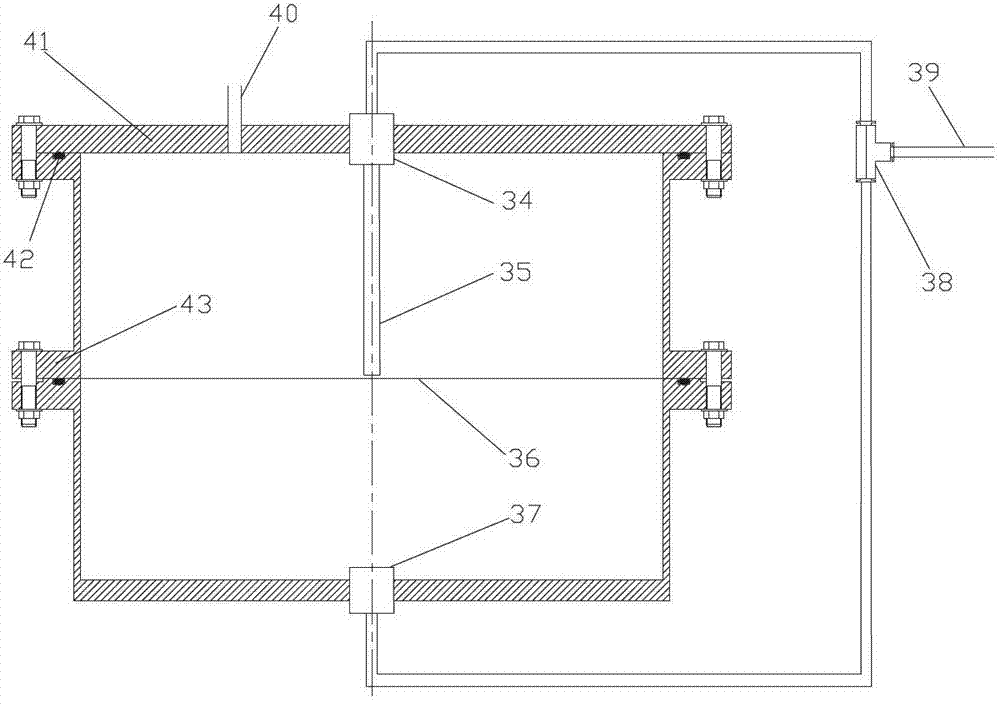

Device for testing performance of low-temperature vacuum multilayer heat-insulation material based on thermal protection

The invention discloses a device for testing performance of a low-temperature vacuum multilayer heat-insulation material based on thermal protection. The device comprises a vacuum outer cover, a blind plate end cover flange, an upper protective cavity, a testing cavity, a lower protective cavity, a back pressure stabilizing device, a controllable electric heating system, a temperature and flow-rate sensing system, a liquid nitrogen filling system, a data collecting-processing system and a vacuum pumping system, wherein the upper protective cavity and the lower protective cavity are used for insulating heat leakage in the vertical direction and connected with the blind plate end cover flange of the vacuum outer cover through thin-wall steel tubes; the testing cavity is connected with the blind plate end cover flange through the same thin-wall steel tube structure as the protective cavities. An insulating material testing sample of the device can be replaced at will, the temperature distribution inside the insulating material and the evaporation rate of stored liquid under different thermal boundary temperature conditions can be measured, and the heat leakage percentage and the material apparent thermal conductivity can be further obtained by the evaporation rate.

Owner:SHANGHAI JIAO TONG UNIV

Thermoelectric cooling systems

InactiveUS20130291564A1High coefficient of performance and ease of operationEasy to operateIndirect heat exchangersMachines using electric/magnetic effectsThermoelectric coolingMetallurgy

The present disclosure provides a thermoelectric cooling system with improved performance. The thermoelectric cooling system comprises a thermoelectric cooling unit. The thermoelectric cooling unit comprises a thermoelectric device, heat pipes, condenser fins, a cold sink and a cold fan. The thermoelectric cooling unit can be easily assembled with a chamber which contains a fluid to be cooled. The thermoelectric cooling system comprises screws to attach the thermoelectric cooling unit to the chamber, and sealant rings to prevent heat leakage in the thermoelectric cooling system. Further, the present disclosure provides a thermoelectric cooling system with a freezer part and a refrigerator part. The freezer part encloses the cold sink and the cold fan. The freezer part is cooled by the thermoelectric device, and the refrigerator part is cooled by walls of the freezer part. Further, the present disclosure provides a thermoelectric cooling system for use as a wine cooler.

Owner:SHEETAK INC

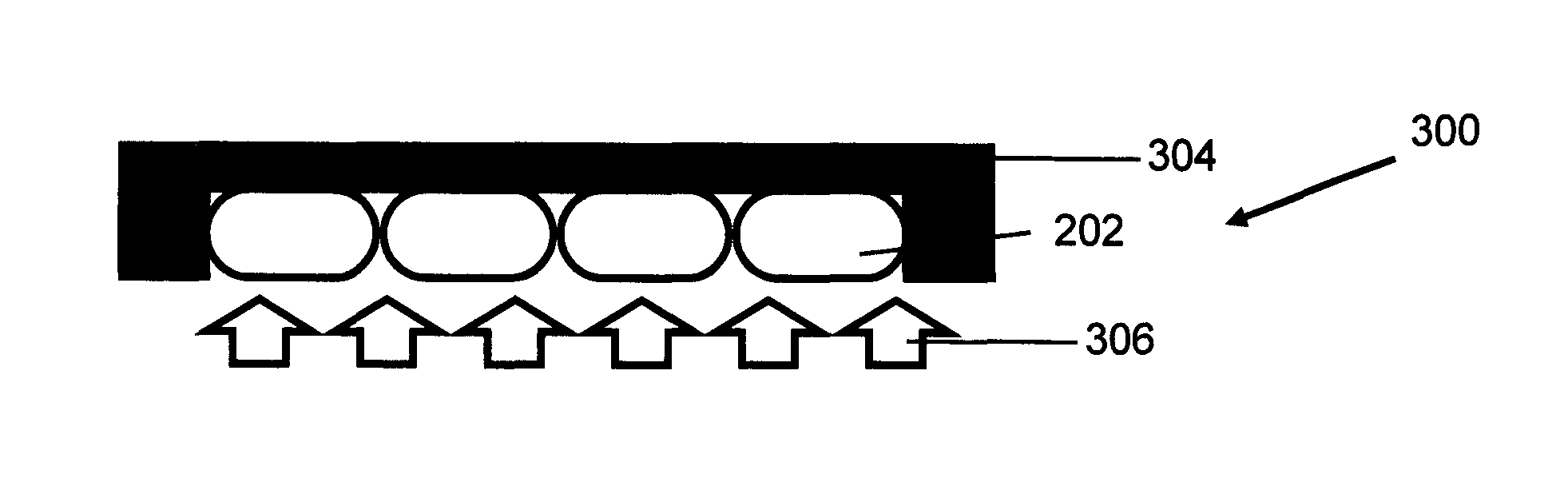

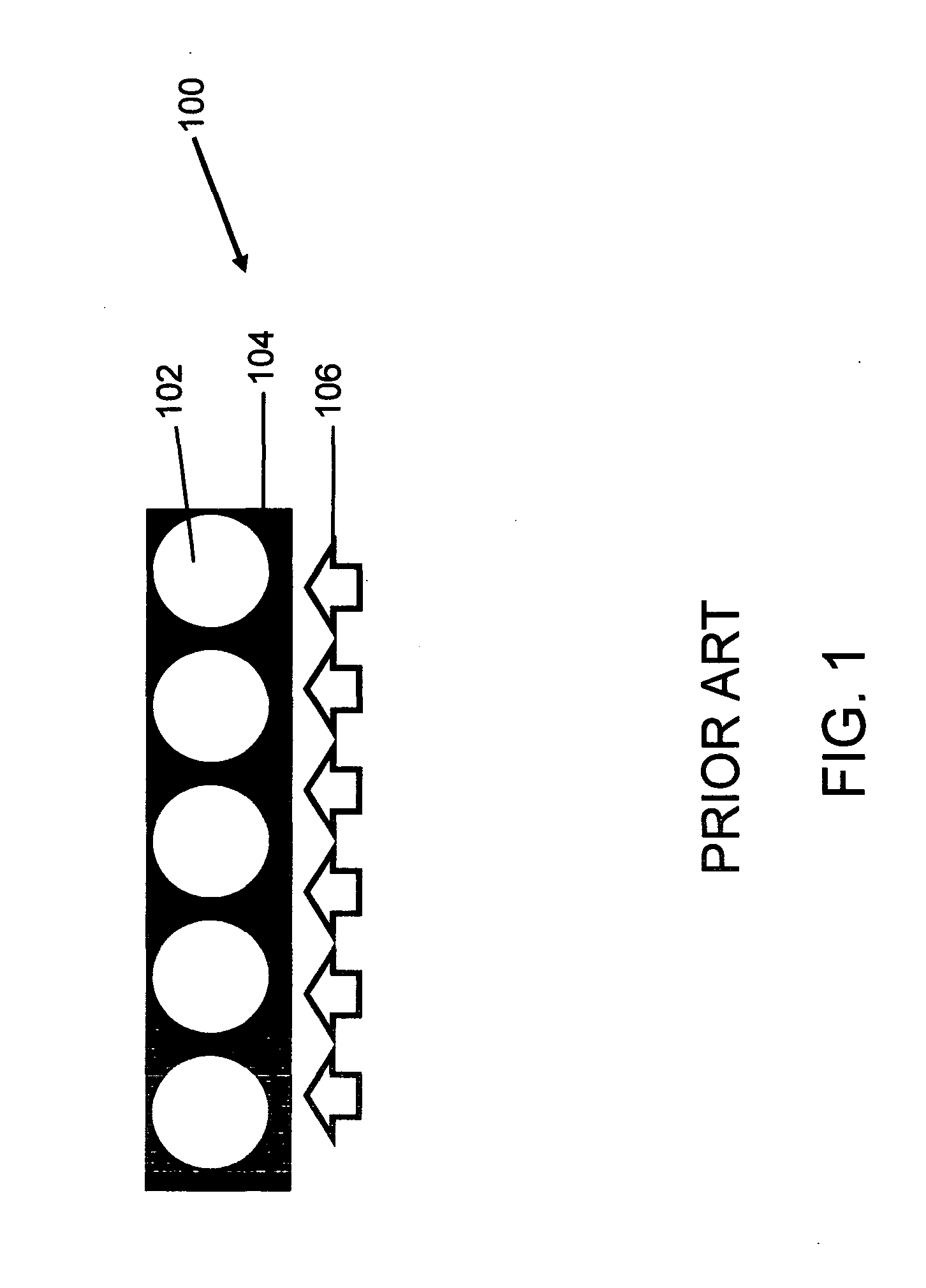

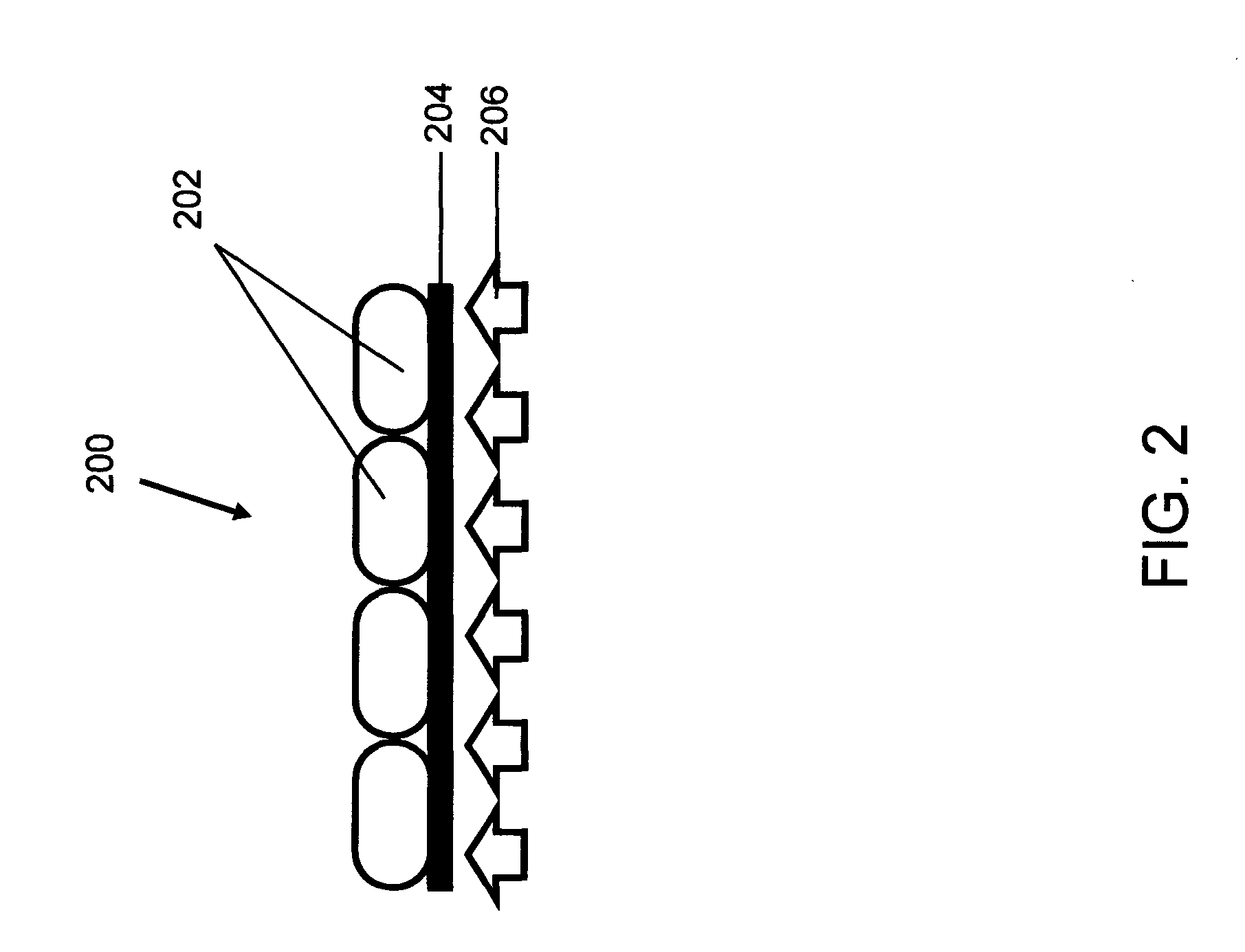

Heat pipes and thermoelectric cooling devices

ActiveCN102510990AEffective regulationThermoelectric device with peltier/seeback effectIndirect heat exchangersThermoelectric coolingNuclear engineering

In various embodiments of the present invention, a thermoelectric cooling device with a thermoelectric device, heat pipe and a heat sink is provided. The thermoelectric device is connected to a chamber through a metal standoff. The chamber contains a fluid that needs to be cooled. The metal standoff has a shape, e.g. a bevel shape, to minimize heat leakage into the fluid. The heat pipes are preferably connected to the thermoelectric device with a Thermal Interface Material (TIM). In one embodiment, the heat pipes are attached to the thermoelectric device through screws which have an insulating standoff so as to minimize heat leakage into the fluid. In another embodiment of the present invention, two stage thermoelectric cooling devices with multiple heat pipes and common heat sink are provided to cool the fluid.

Owner:SHEETAK INC

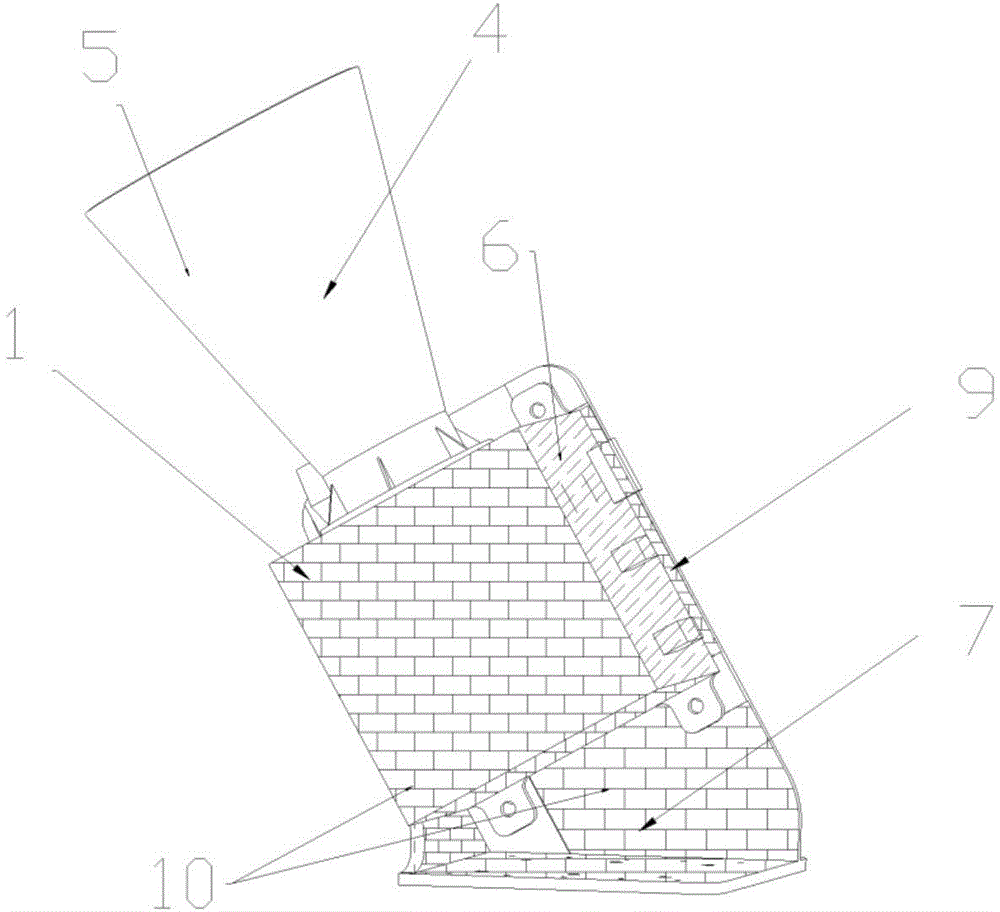

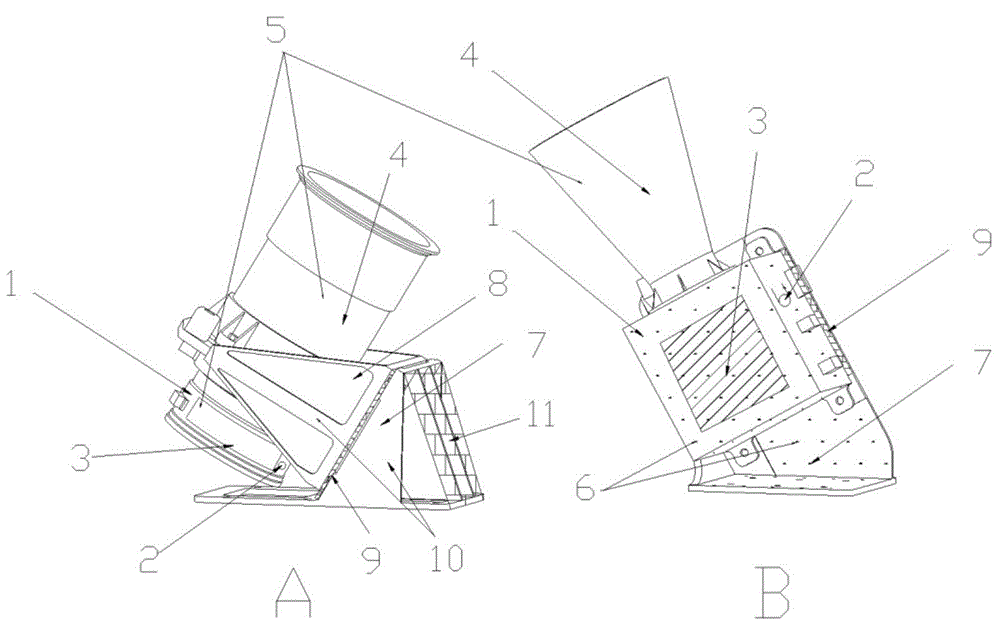

Star sensor sub-low temperature independent thermal control device of orbit transfer vehicle

ActiveCN104443441ALarge thermal resistanceReduced heat leakage compensationCosmonautic environmental control arrangementEngineeringThermistor

The invention provides a star sensor sub-low temperature independent thermal control device of an orbit transfer vehicle. The device comprises an imported star sensor A, a domestic star sensor B, thermistors (2), heaters (3), light shields (4), F46 films (5), an S781 white paint thermal control coating (6), mounting supports (7), a self support (8), heat insulation pads (8), a plurality of layers of heat insulation components (10) and thermal protection layers (11). Thermal resistance between stars and the star sensors is increased through the heat insulation pads, heat leakage compensation is greatly reduced, and a foundation is laid for independent temperature control over the star sensors. According to the sub-low temperature design requirement, the S781 white paint thermal control coating is adopted to increase the temperature adaptability of a star sensor motive track. The heat insulation components and the protection layers are adopted, and the radiation influence of a 25N engine on the imported star sensor A is effectively prevented. The device is convenient to implement, high in reliability and adaptability and small in total occupied resource, and the heat radiation of the engine can be effectively prevented.

Owner:SHANGHAI SATELLITE ENG INST

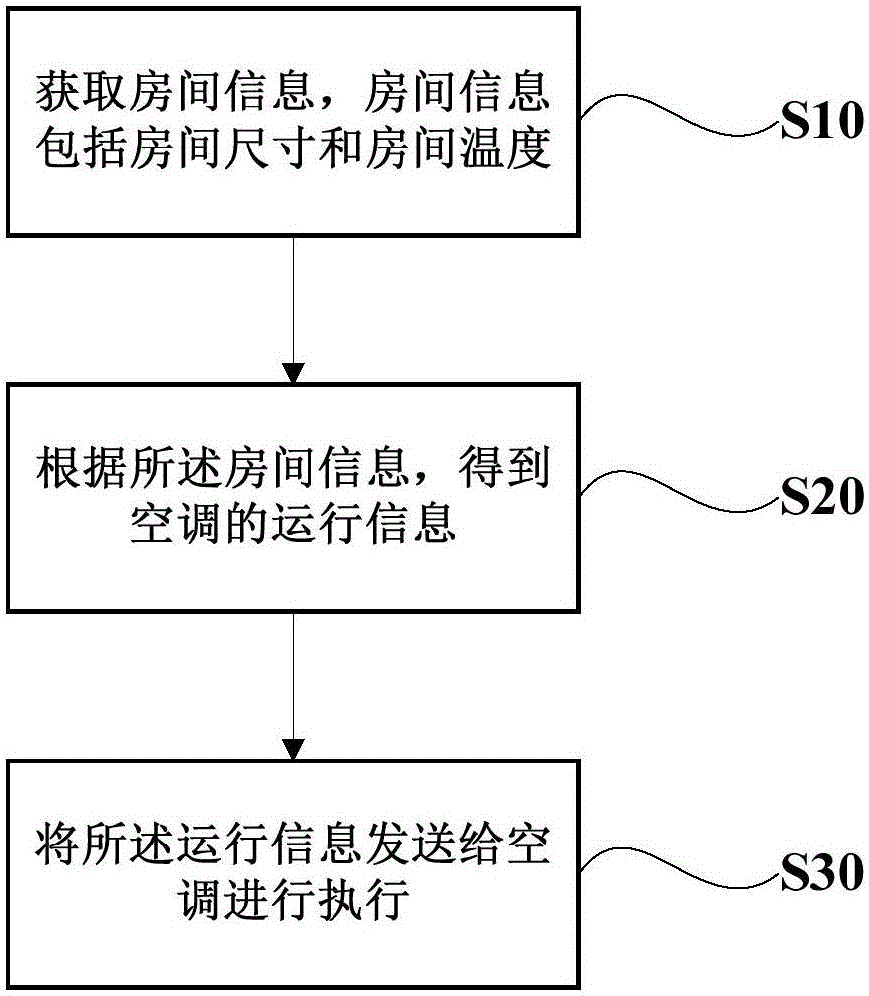

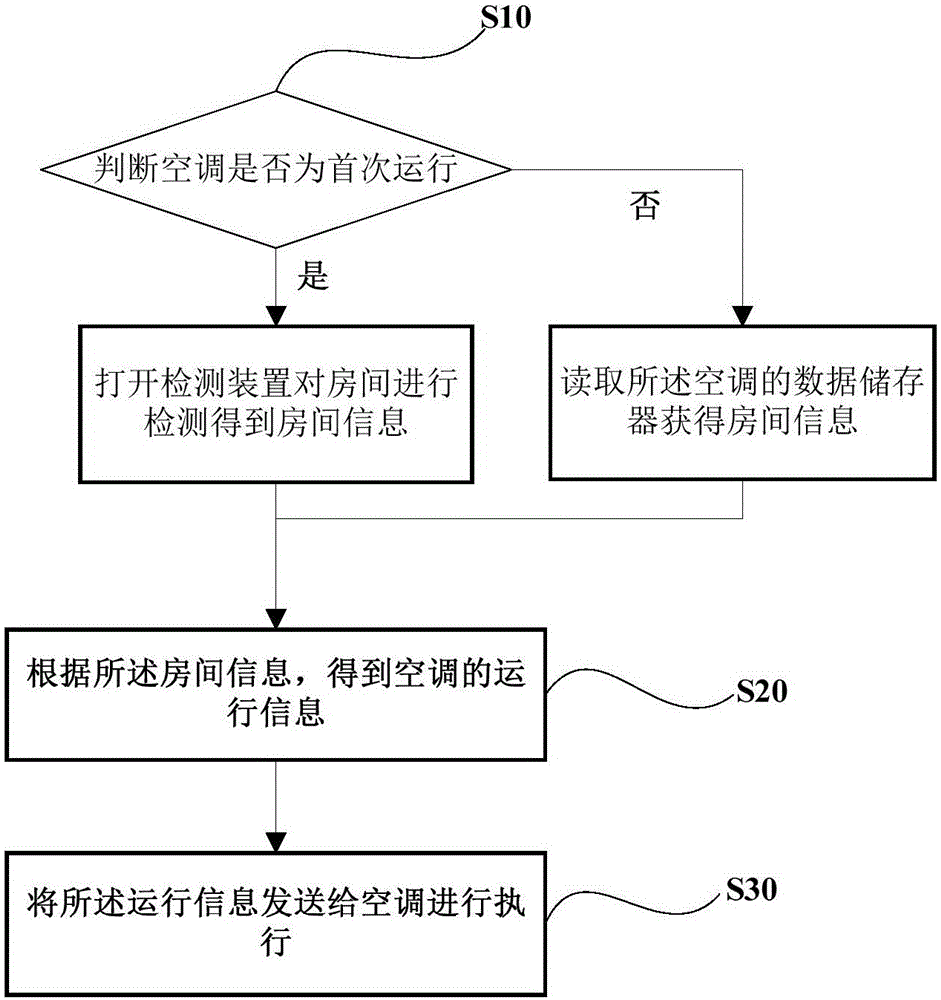

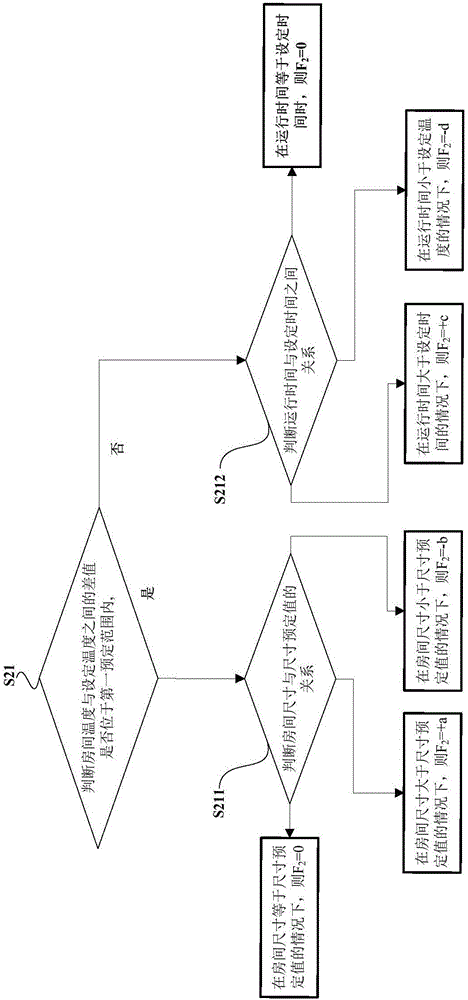

Air conditioner control method and air conditioner control system

ActiveCN105091239ASolve wasteEasy to controlMechanical apparatusSpace heating and ventilation safety systemsTemperature controlControl system

The invention provides an air conditioner control method and an air conditioner control system. The air conditioner control method includes the following steps that room information is acquired, wherein the room information comprises room sizes and / or room heat leakage; according to the room information, operating information of an air conditioner is acquired; and the operating information is transmitted to the air conditioner to be executed. According to the air conditioner control method and the air conditioner control system, the problems that in the air conditioner operating process, temperature control is inaccurate, and energy is wasted in the prior art are effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

First-stage pullable binary coaxial current lead structure

InactiveCN102360694AReduce quench problemsAvoid the problem of excessive Joule heatingCoupling contact membersSuperconducting magnets/coilsHigh magnetic field strengthPower flow

The invention discloses a first-stage pullable binary coaxial current lead structure, and relates to a binary current lead technology. The structure comprises a first-stage current lead connected with a high-temperature part, a second-stage current lead connected with a low-temperature part and a pullable heat exchanger which is connected with the first-stage current lead and the second-stage current lead respectively and is positioned between the first-stage current lead and the second-stage current lead. The first-stage pullable binary coaxial current lead structure has the advantages of compact structure, stable performance, reliable operation, low heat leakage and convenience in disassembly and assembly, has the capacity of reducing heat leakage in an entire excitation process and subsequent normal operation, and is particularly suitable for a superconducting magnet with conduction cooling, less liquid helium and high magnetic field strength and operating in a closed loop.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

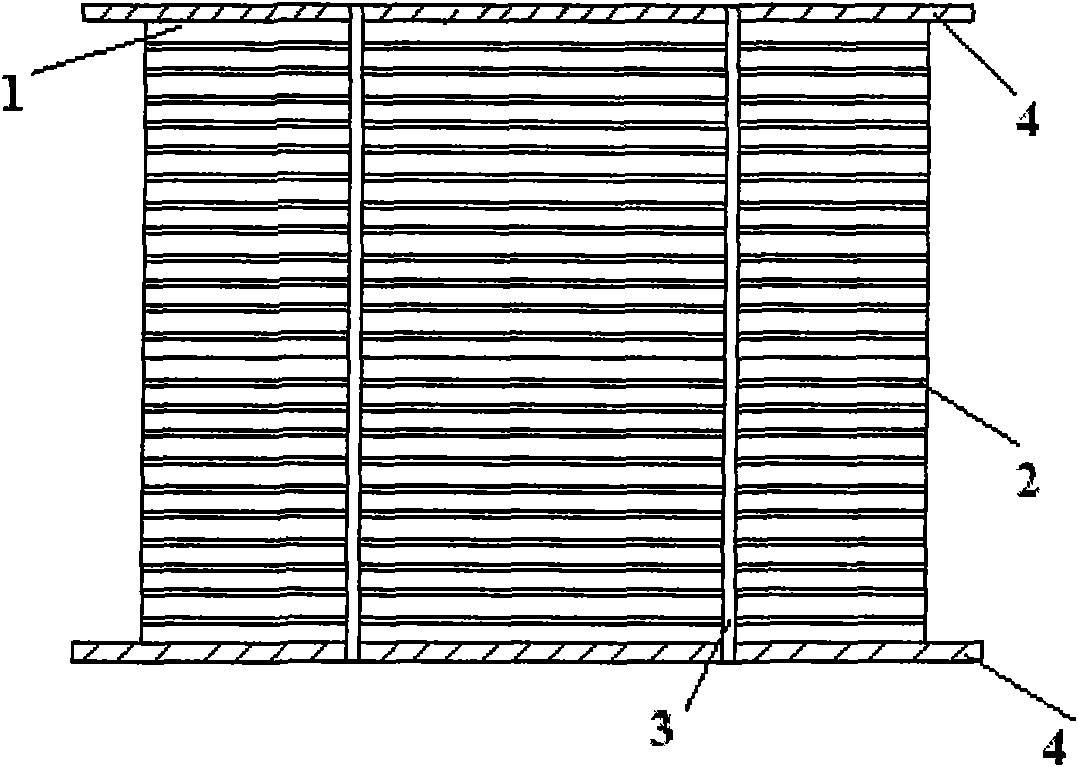

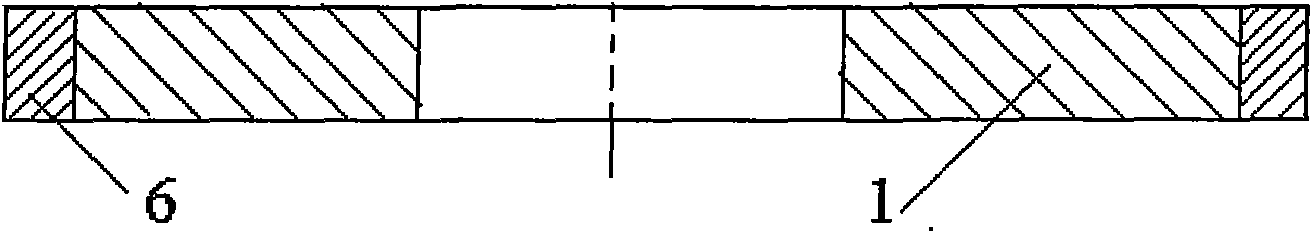

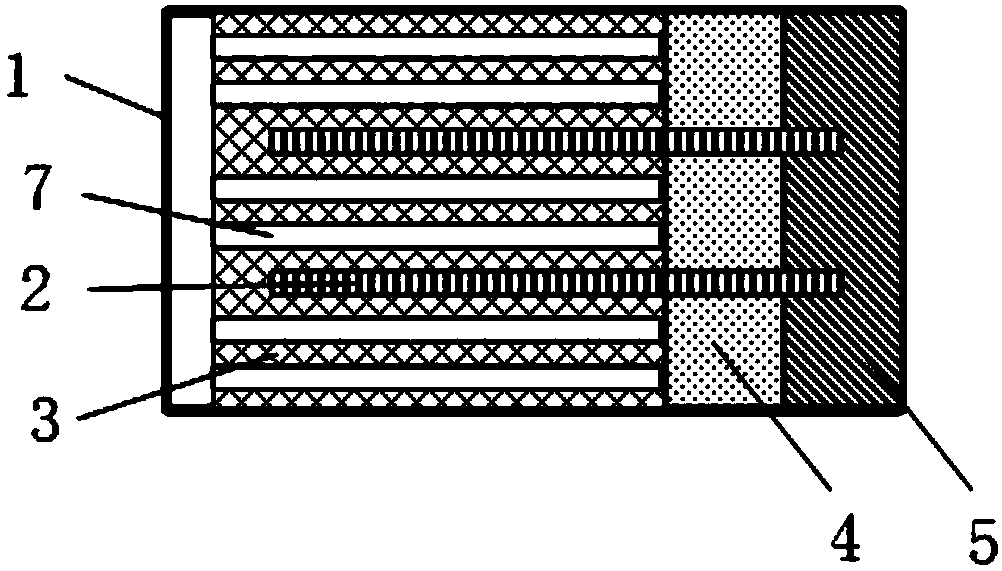

Superconducting magnet system of inserted YBCO-Bitter type high-temperature superconducting coil

ActiveCN101577165AQuench preventionSimple structureInductances/transformers/magnets manufactureSuperconducting magnets/coilsEpoxyHigh-temperature superconductivity

The invention relates to a superconducting magnet system of an inserted YBCO-Bitter type high-temperature coil. The inserted YBCO-Bitter type high-temperature superconducting coil (8) is inserted into an inner hole of a peripheral superconducting coil (10) formed by NbTi and Nb3Sn. The inserted YBCO-Bitter type high-temperature superconducting coil (8) is positioned in a low-temperature container (9); the peripheral superconducting coil (10) is arranged in a low-temperature container (11); and the low-temperature containers (9 and 11) are filled with liquid helium (12). The inserted YBCO-Bitter type high-temperature superconducting coil (8) is formed by superposing of multiple YBCO ring pieces (1) which are embedded in a stainless steel ring (6). High-purity copper ring pieces (2) plated with an aluminum nitride film are arranged between the YBCO ring pieces (1). The multiple YBCO ring pieces (1) and the multiple high-purity copper ring pieces (2) are superposed along the same shaft, are assembled together by a stainless steel central hole tube (3) and an end flange (4), and are cured into a whole body after being soaked by epoxy resin. The superconducting magnet system has simplified structure, little heat leakage of system and stable generated magnetic field.

Owner:NINGBO JANSEN NMR TECH CO LTD

Super-conduction stacking brazing method and mold for high-temperature supercurrent down-lead

InactiveCN101409129AThe brazing process is correctQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesAmpereAlloy

The invention discloses a superconducting stack soldering method for a high-temperature superconducting current lead wire and a mold thereof; superconducting tapes to be soldered and soldering ribbons are alternately arranged in a mold cavity which is made of metal materials with good thermal conductivity; a mold core and a counterweight are pressed on the superconducting tapes, the mold is heated to the soldering temperature under the vacuum condition, the temperature is kept for 10-15 minutes, and then the mold is rapidly cooled to the solidification point of soldering filler metals to complete the soldering. The critical current of the low-heat conductivity high-temperature superconducting tapes under a 77K self-field is only 100-120A which is much less than the thousands to tens of thousands of amperes of operating current of a large superconducting magnet, so that the superconducting tapes can be used by soldering into a stack. The price of the bismuth-based superconducting tape which takes Ag-5.3wt% Au alloy as a substrate is 5-6 times than the price of the ordinary bismuth-based superconducting tape; while the offer of a superconducting stack of foreign high-temperature superconducting companies is almost doubled again. The method and the mold for soldering the superconducting stack can ensure that the current carrying performance is not deteriorated, the longitudinal heat leakage is not increased, the soldering among the superconducting tapes is uniform and the requirements on the resistance performance in a low layer can be met.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

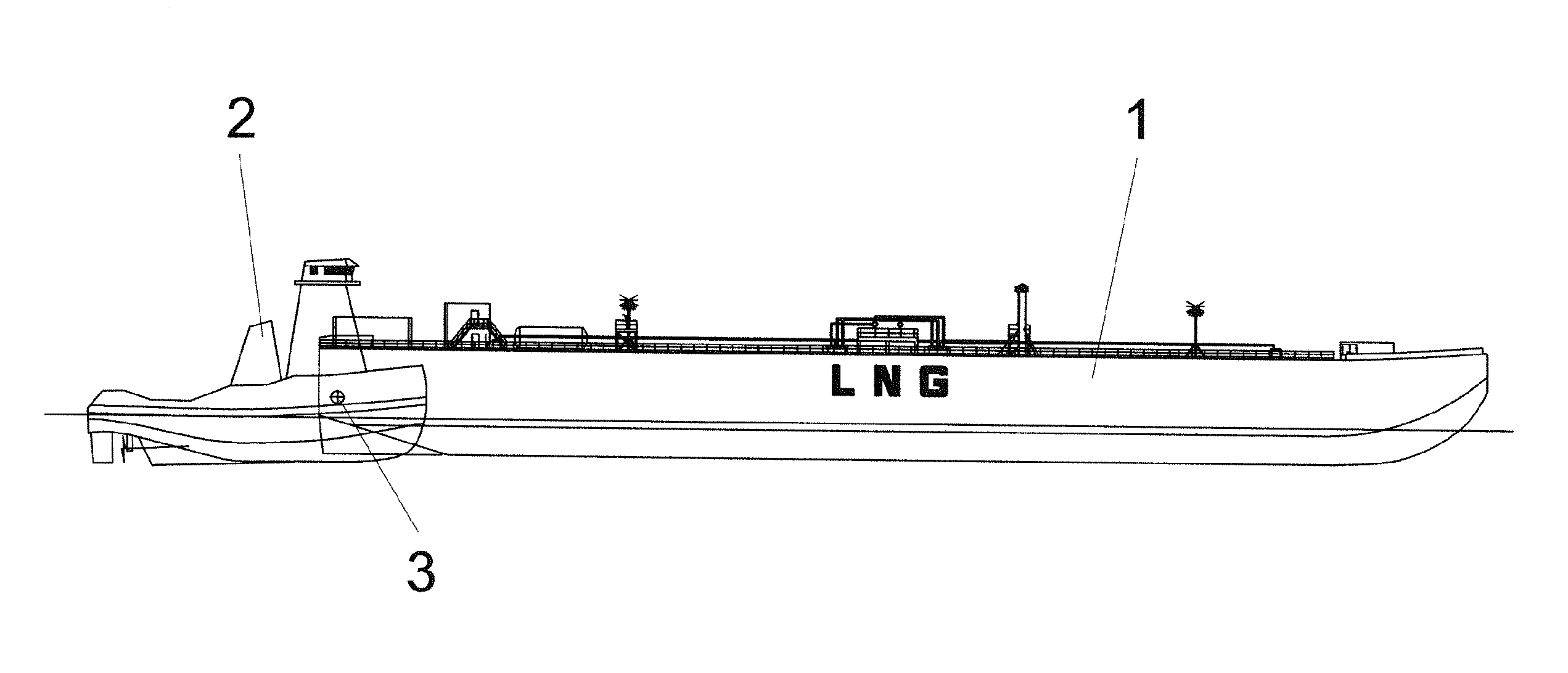

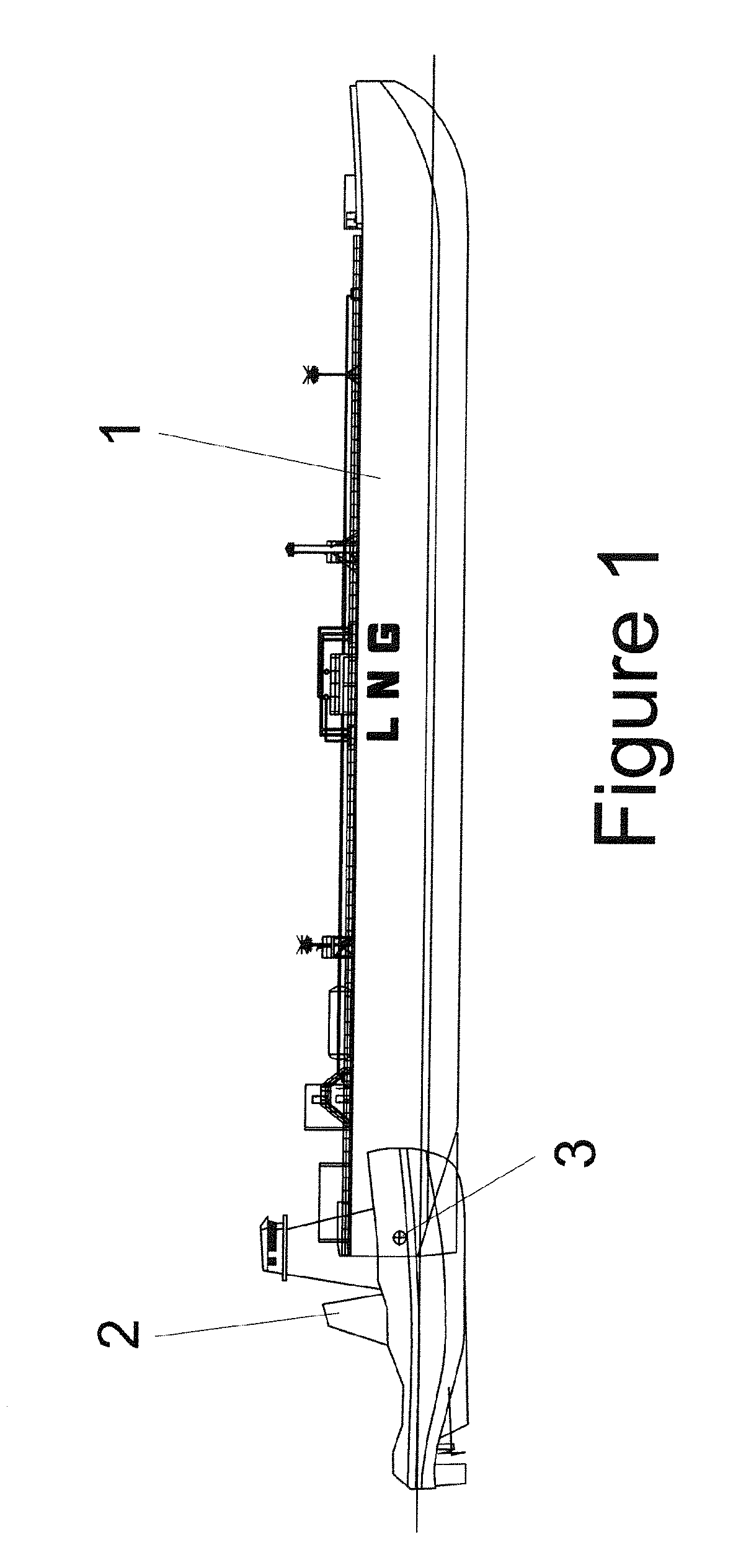

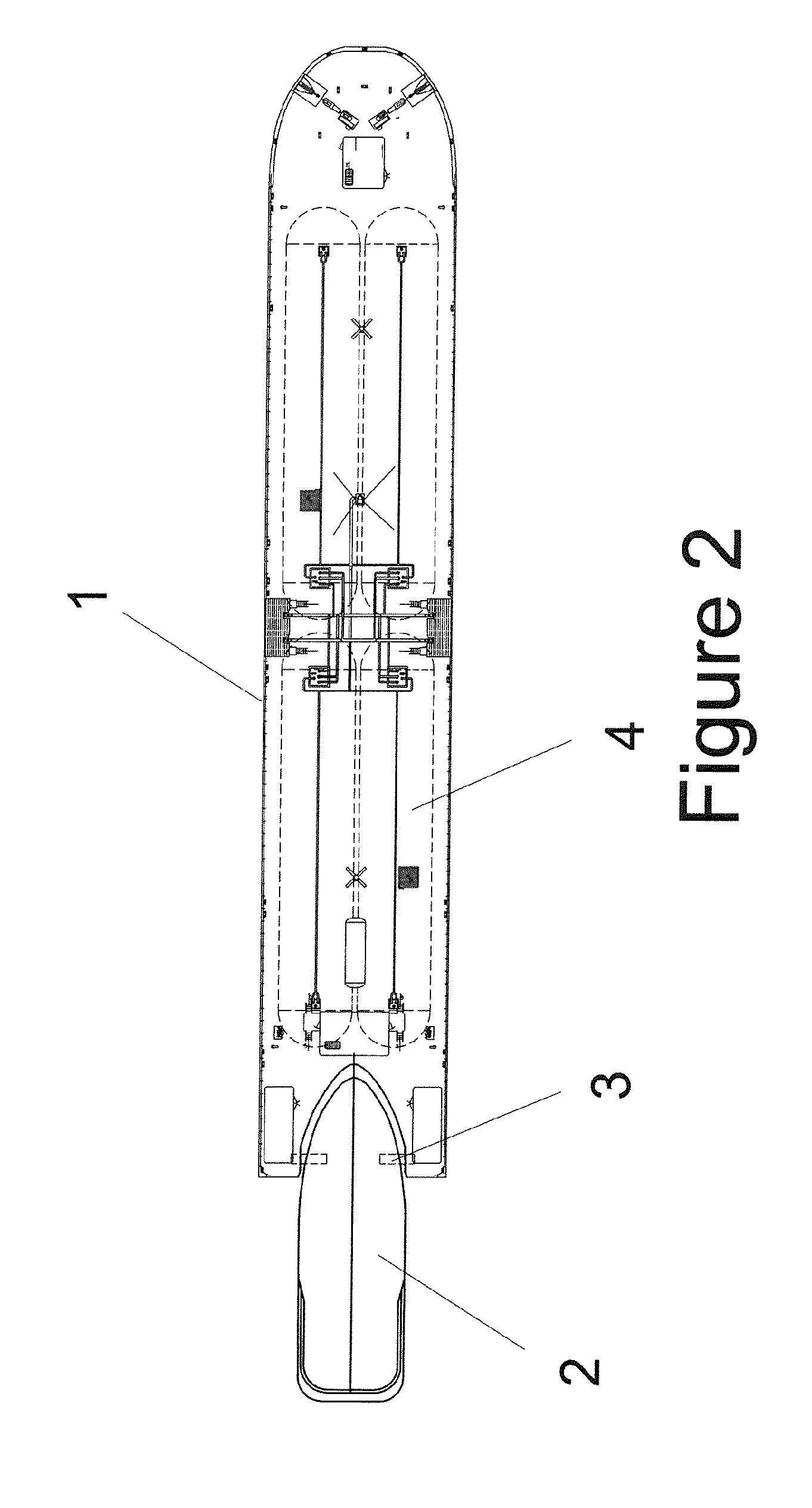

System and method for transferring natural gas for utilization as a fuel

InactiveUS20130199616A1Eliminate needInhibition releaseAuxillariesPipe couplingsNatural gas fuelEngineering

Natural gas is produced when LNG that is contained in an insulated LNG cargo tank(s) of a non-self-propelled LNG carrier (i.e., a barge) evaporates as a result of heat leakage through the walls of the insulated cargo tank(s). The natural gas is transferred from the barge to a tugboat or a towboat that is equipped with natural gas burning engines through a flexible gas transfer assembly so that the tugboat is powered by the natural gas fuel. The pressure in the cargo tank(s) on the barge is, therefore, effectively managed to prevent or substantially reduce the buildup of pressure within the LNG cargo tank(s). The LNG can then be contained within the LNG cargo tank(s) for an appropriate period of time and can be delivered at an appropriate and acceptable equilibrium pressure and temperature.

Owner:ARGENT MARINE MANAGEMENT

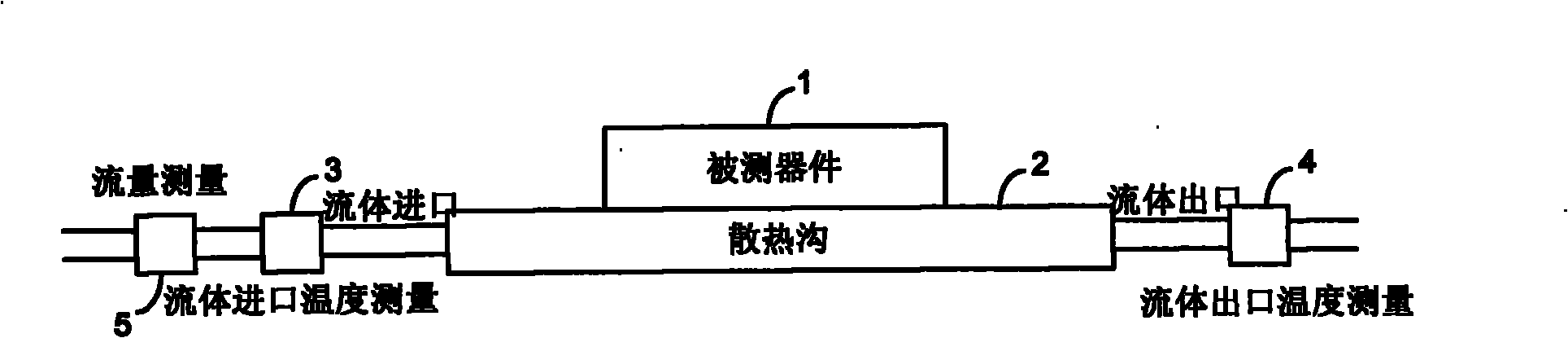

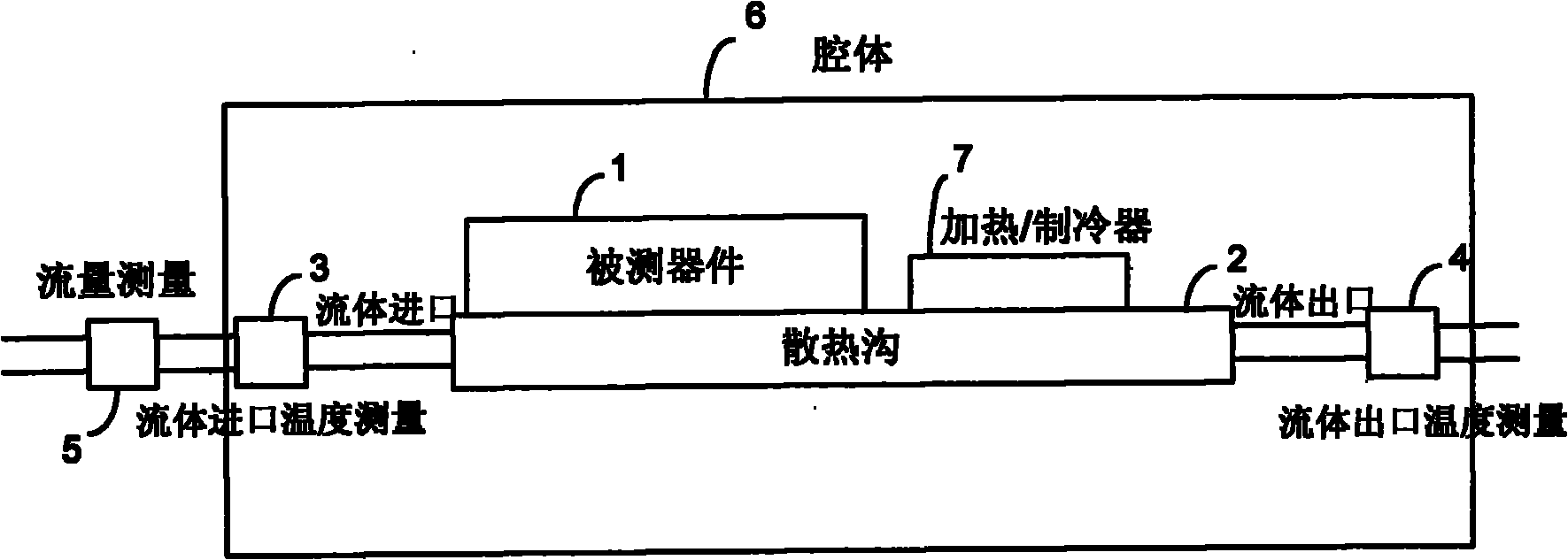

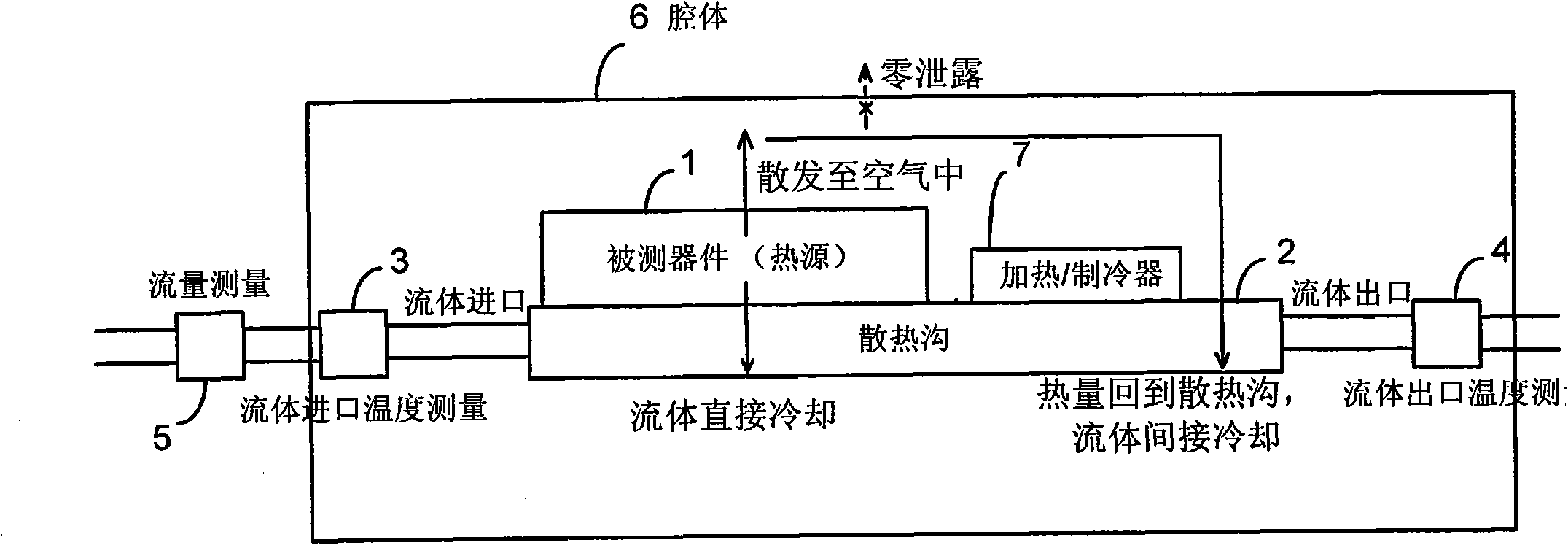

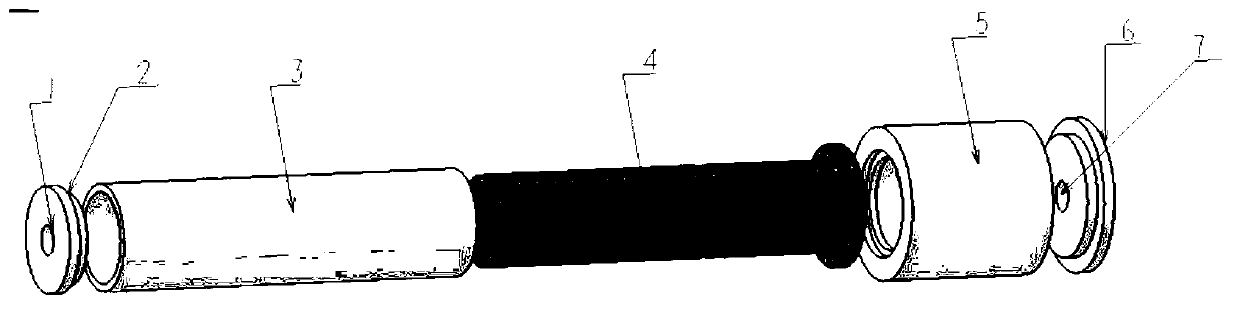

Method for measuring energy loss of power electronic device of high-power converter

InactiveCN101968509AReduce measurement errorElectrical measurementsCalorimeterThermal insulationEngineering

Owner:乌云翔

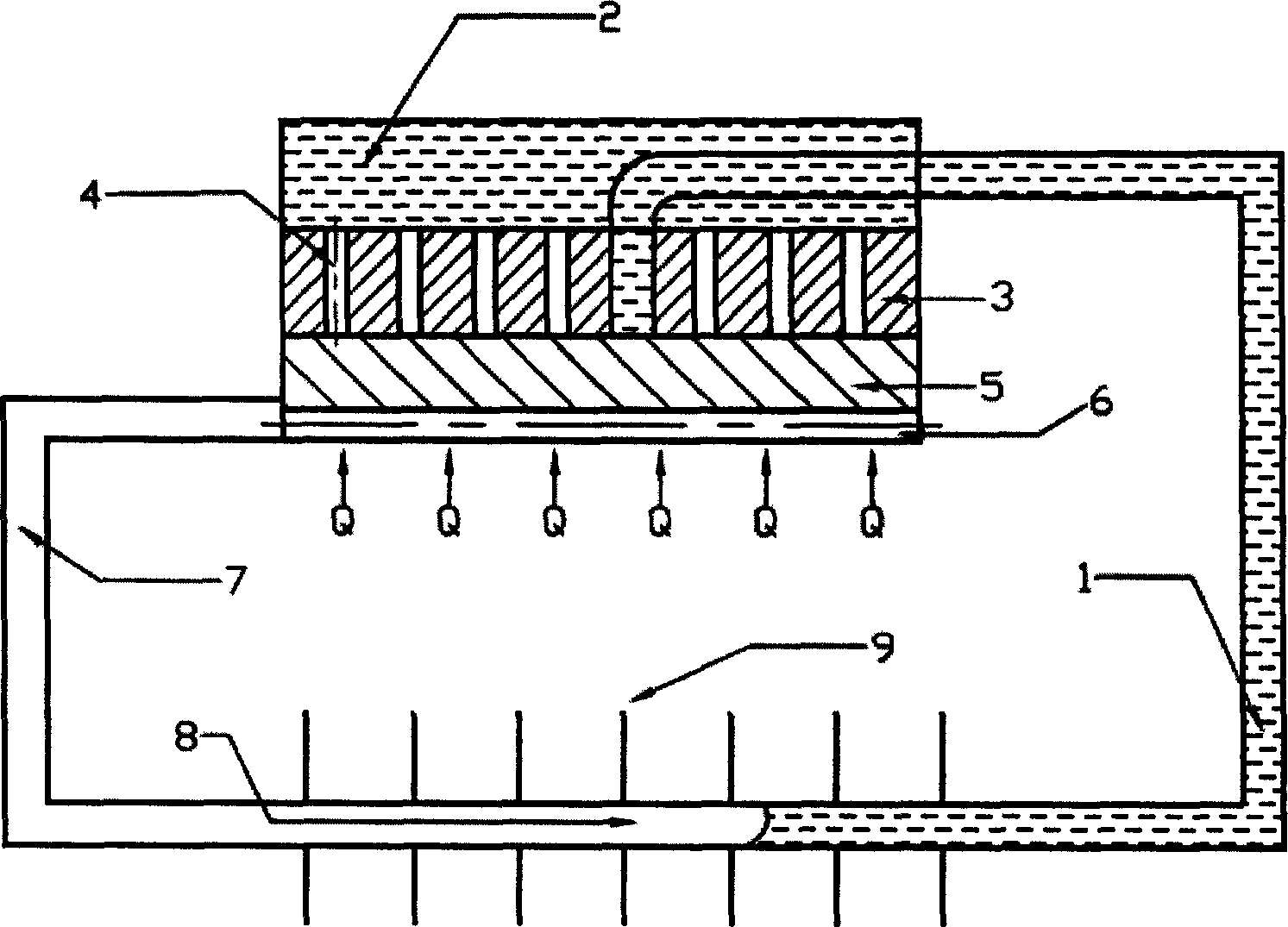

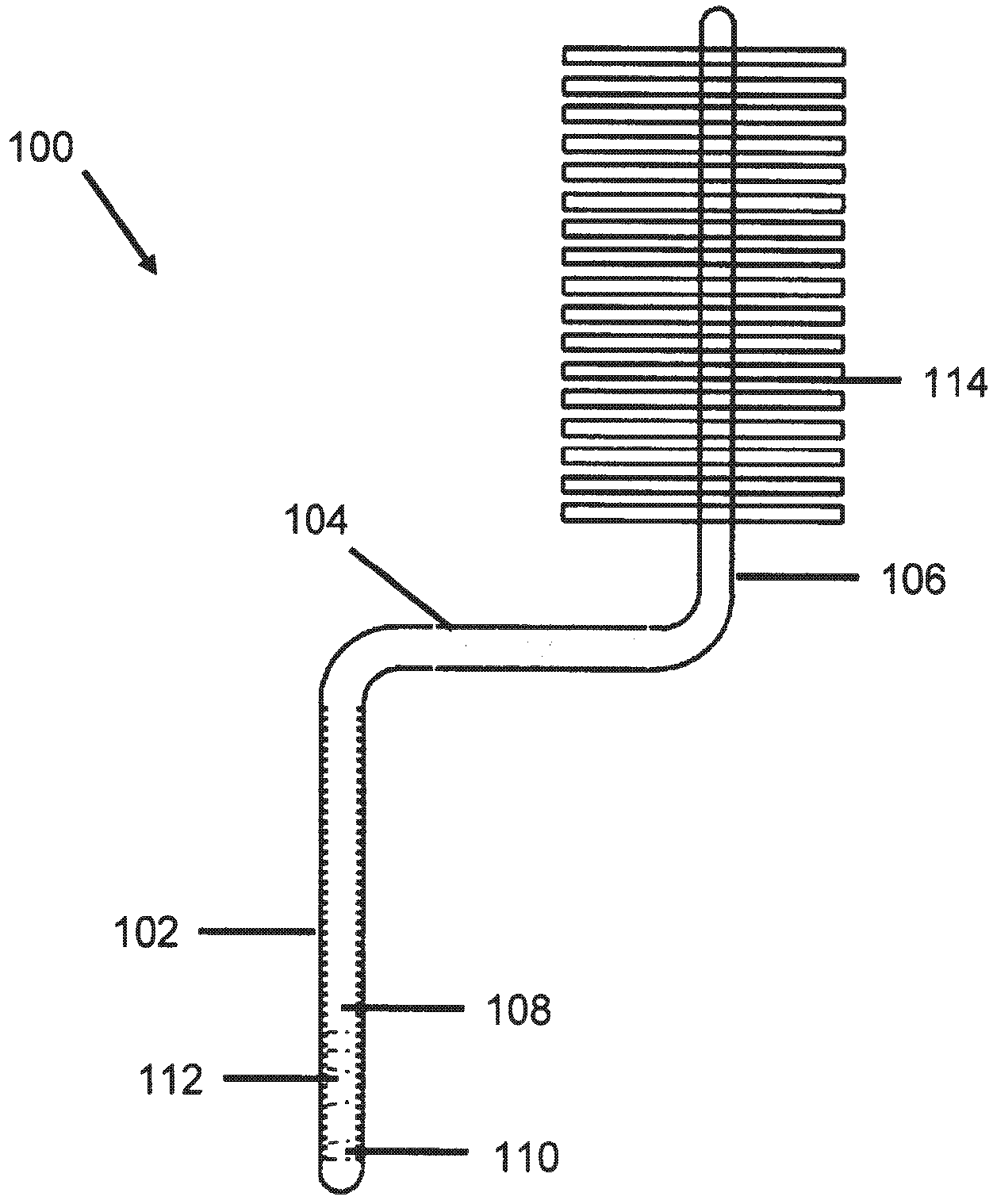

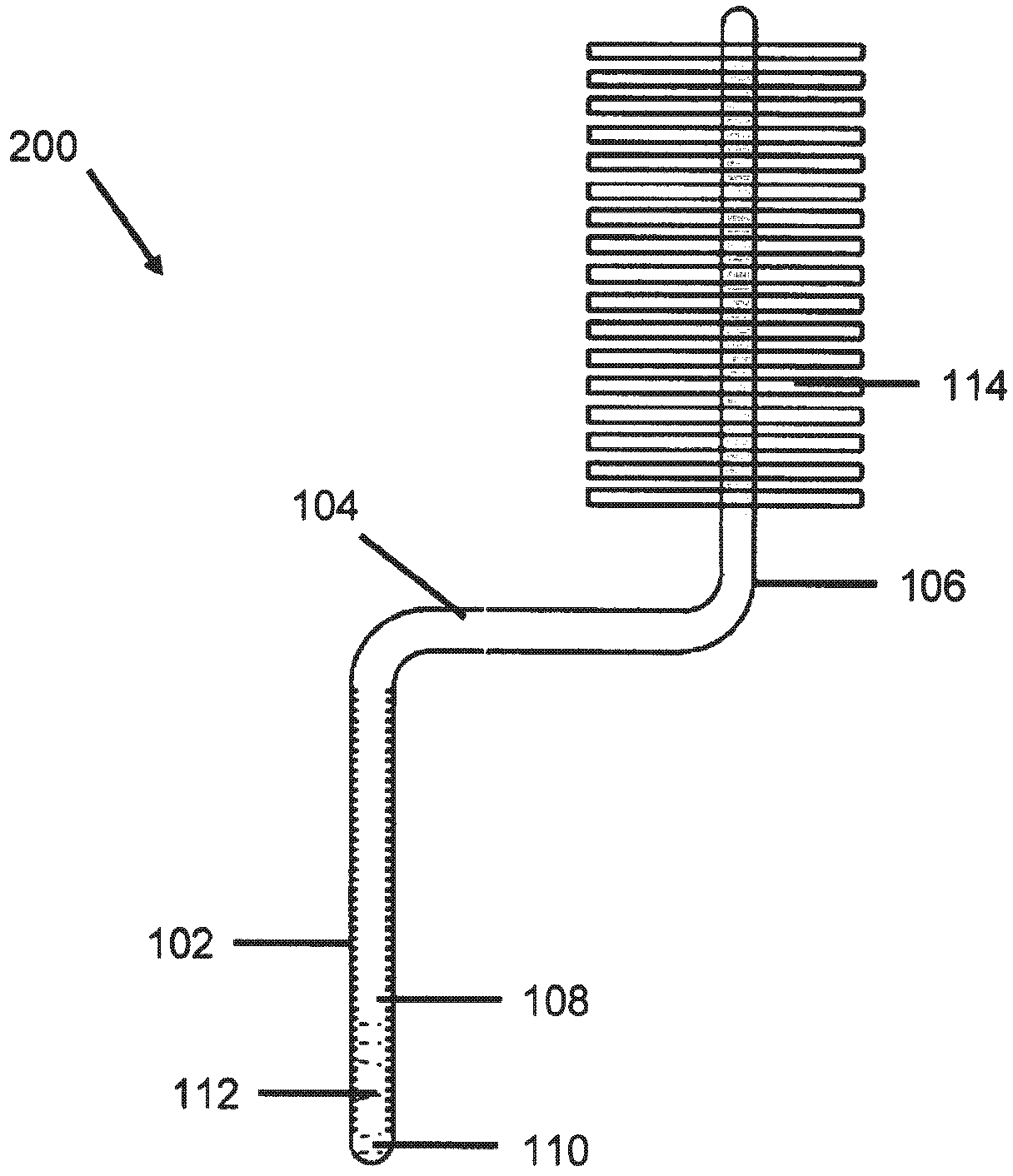

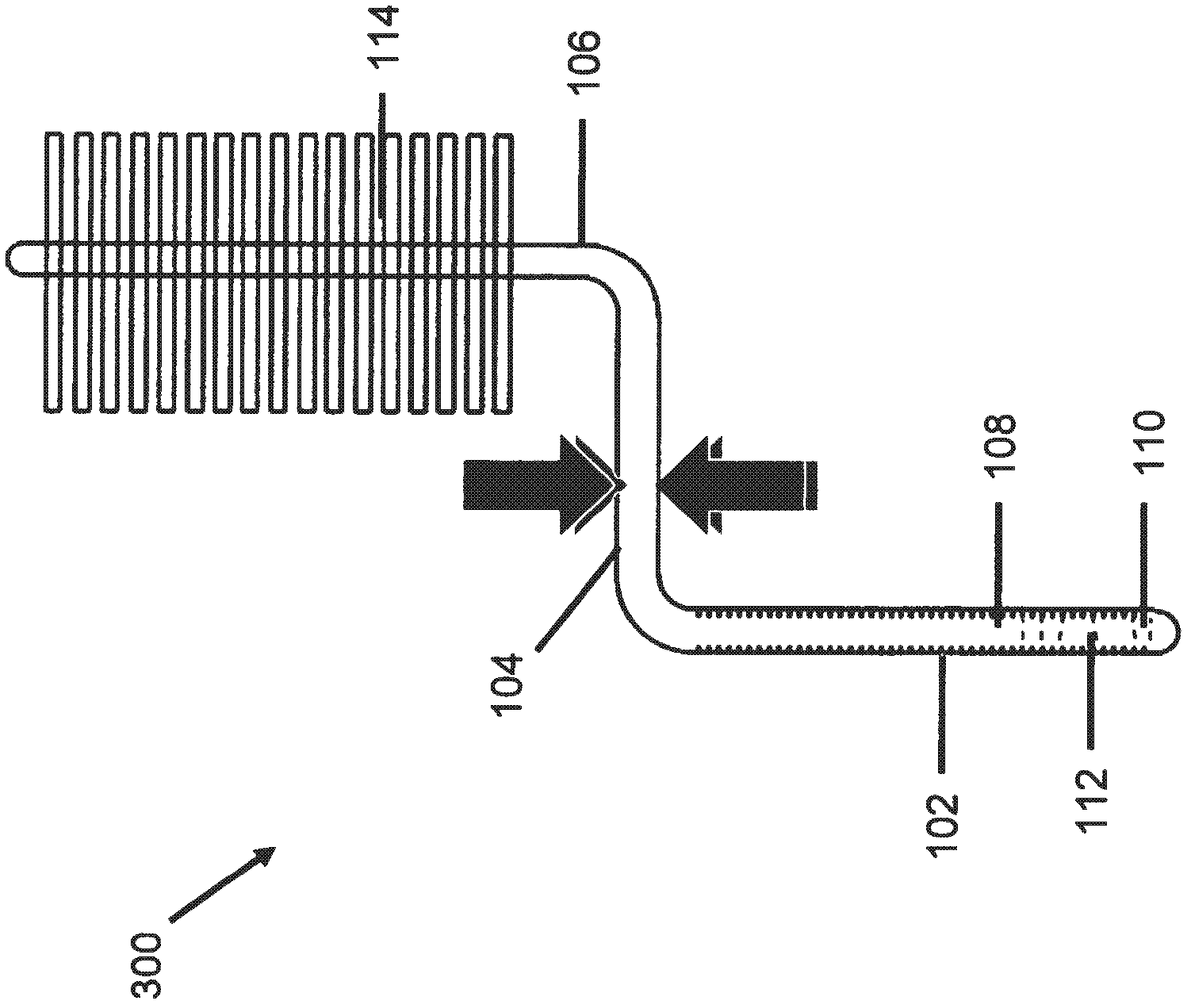

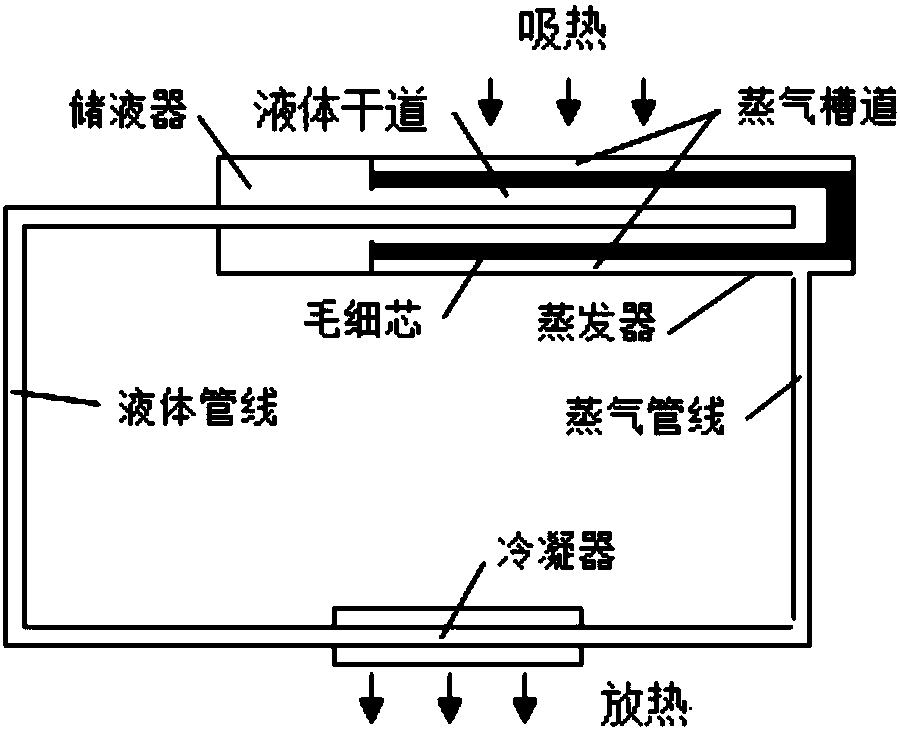

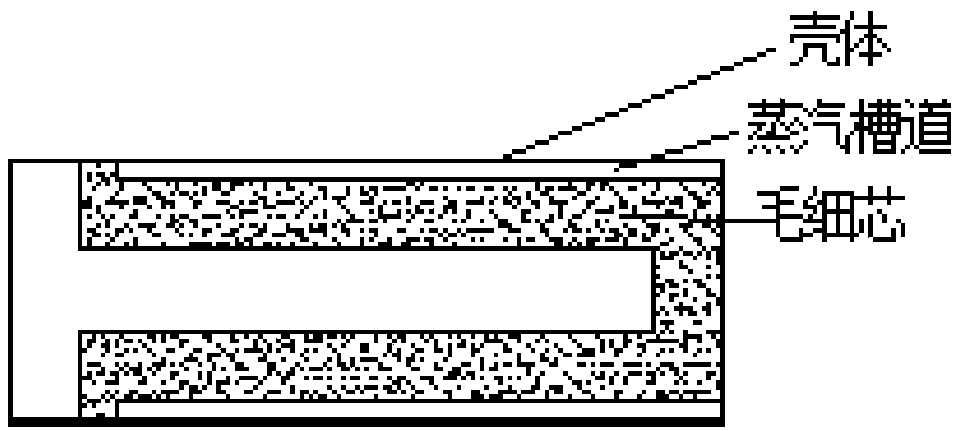

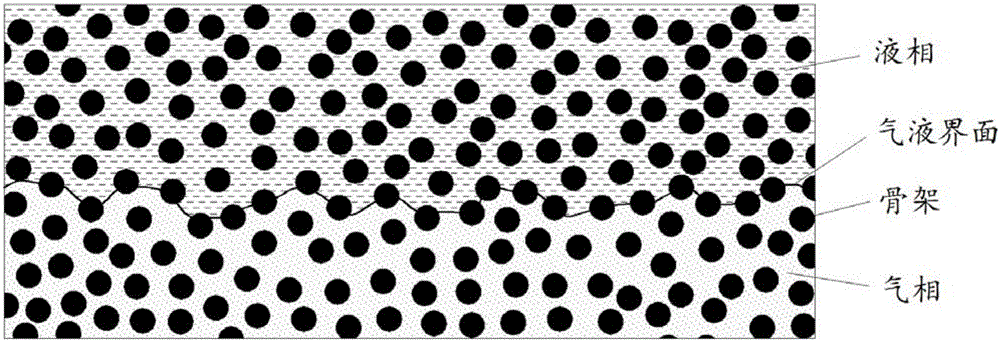

Evaporator and liquid reservoir used for loop heat pipe and application thereof

InactiveCN103344143AReduce heat leakageSimple designIndirect heat exchangersHeat exhanger sealing arrangementMicro-loop heat pipeCapillary pressure

The invention discloses an evaporator and a liquid reservoir used for a loop heat pipe and belongs to the technical field of evaporators. A capillary core structure is adopted for spacing inner spaces of the evaporator and the liquid reservoir, liquid in the liquid reservoir can enter the evaporator through the capillary core, meanwhile the liquid is heated and evaporated to generate steam in the evaporator, and the steam flows out of a steam outlet in an end cover of the evaporator. Due to the fact that the capillary core can generate capillary pressure, the steam in the center of the evaporator can be effectively prevented from entering the liquid reservoir, distribution and flowing of the gas liquid are controlled, and then heat leakage from the evaporator to the liquid reservoir is effectively reduced. The distribution and a flowing route of the gas liquid in the evaporator are adjusted initiatively, therefore the radial heat leakage from the evaporator to the liquid reservoir can be completely eliminated, and the purpose that the heat leakage from the evaporator to the liquid reservoir is effectively reduced is achieved so that starting performance and running stability and reliability of the loop heat pipe can be improved.

Owner:BEIHANG UNIV

Cryogenic insulation attachment

InactiveUS20110031861A1Prevent heat leakageSolidificationLiquefactionProcess engineeringHeat leakage

An attachment means of insulation within a container to prevent heat leakage from the ambient to an apparatus located within the container that operates at a cryogenic temperature.

Owner:CONOCOPHILLIPS CO

Full-vacuum horizontal liquefied natural gas (LNG) submerged pump pool

InactiveCN103711720AImprove the cooling effectLow running costPump componentsPumpsThermodynamicsIn vehicle

The invention discloses a full-vacuum horizontal liquefied natural gas (LNG) submerged pump pool. The full-vacuum horizontal LNG submerged pump pool comprises a pump pool body, a submerged pump pool and a support. A liquid outlet device which is arranged on the inner side of a pump pool cap is in a structure of high vacuum and heat insulation and an outer casing tube which is arranged on the outer side of the pump poop cap is fixedly connected with a vacuumized joint. The vacuumized joint is communicated with the liquid outlet device and the structure of high vacuum and heat insulation of the full-vacuum horizontal LNG submerged pump pool is formed by the vacuumized joint and a high-vacuum and heat-insulated interlayer between an outer cylinder and inner cylinder of the full-vacuum horizontal LNG submerged pump pool. According to this arrangement, all ways of heat leakage, such as convention, conduction and radiation can be eradicated so that good cold-insulated effect can be ensured. The rate of evaporation per day of LNG in the full-vacuum horizontal LNG submerged pump pool can be reduced by 21.5% to 31.5% compared with the vertical submerged pump pool in the prior art. The full-vacuum horizontal LNG submerged pump pool can be used for filling vehicles or transporting vehicle-mounted LNG, so as to greatly improve the economic benefit of LNG filling stations, LNG transportation and filling vehicles.

Owner:河南开元气体装备有限公司

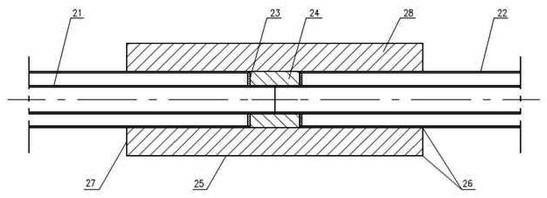

Vacuum heat insulating low-temperature pipe joint

ActiveCN102352940AEasy to installReduce heat leakageThermal insulationPipe protection by thermal insulationEngineeringMulti-layer insulation

The invention discloses a vacuum heat insulating low-temperature pipe joint, which comprises inner pipes for low-temperature liquid to flow through and outer pipes sleeved outside the inner pipes and connected with the inner pipes, wherein a vacuum space is formed between each inner pipe and each outer pipe; spliced positions of the two inner pipes are welded together through a bushing; heat preserving barrels are sleeved on the joints of the two outer pipes; the two end parts of each heat preserving barrel are provided with a welded loop which is welded with the outer walls of the outer pipes respectively; a section of internal heat isolating pipe and a section of external heat isolating pipe which are sleeved together and extend towards the two outer sides are arranged between the end parts of the joints and the inner pipe walls of the two outer pipes respectively to constitute a vacuum interlayer enclosed space between the inner pipe and the outer pipe; a plurality of vacuum heat insulating layers are formed outside the bushing at the spliced position of each inner pipe; a steel wire is arranged outside the heat insulating layers for fixing; and the heat preserving barrel at the joint of each outer pipe is provided with a vacuumizing valve. The vacuum heat insulating low-temperature pipe joint has the characteristics of low heat leakage, simple and attractive appearance andthe like.

Owner:杭州杭氧低温液化设备有限公司

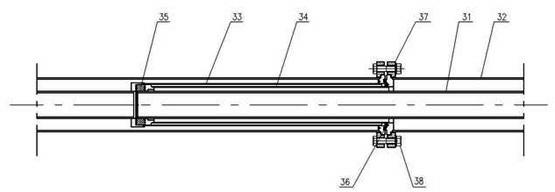

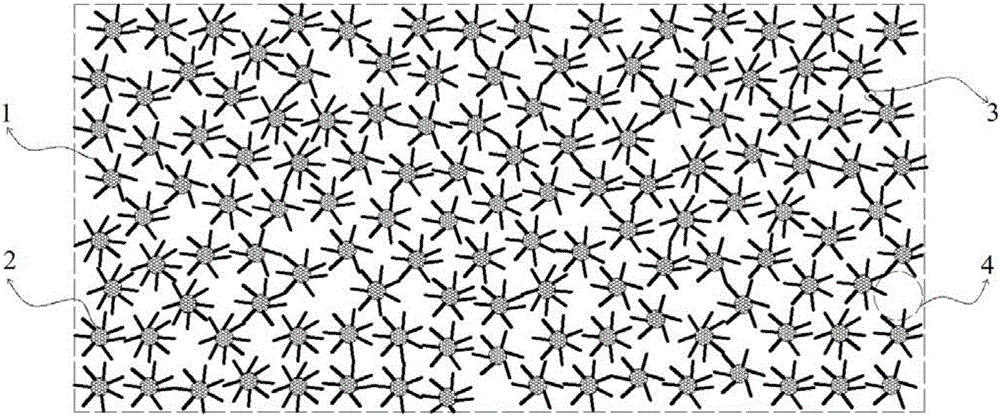

High-power flat evaporator resistant to positive pressure, processing method of flat evaporator and flat-plate loop heat pipe based on evaporator

ActiveCN107782189AHigh compressive strengthSuitable for positive pressure working mediumIndirect heat exchangersThermal insulationPositive pressure

The invention provides a high-power flat evaporator resistant to positive pressure, a processing method of the flat evaporator and a flat-plate loop heat pipe based on the evaporator and belongs to the technical field of spacecraft structures. The evaporator comprises a casing, reinforcing ribs and a capillary core, wherein the reinforcing ribs and the capillary core are located in the casing, andthe strength of the whole evaporator can meet the requirement of positive pressure resistance by means of arrangement of the reinforcing ribs; the capillary core is formed by combining an evaporationcore, a thermal insulation core, a sealing core and a transmission core, liquid supply with low flow resistance can be realized on the basis of high permeability of the transmission core, heat-transfer capability of the loop heat pipe is improved substantially, and the problems of long liquid supply path and high flow resistance of a large-area evaporator are solved; with adoption of the transmission core and the thermal insulation core with low thermal conductivity, the phenomenon of heat leakage from the evaporator to a liquid accumulator can be reduced, meanwhile, good permeability is achieved, flow resistance in the capillary core is reduced, and operating stability of a product is improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

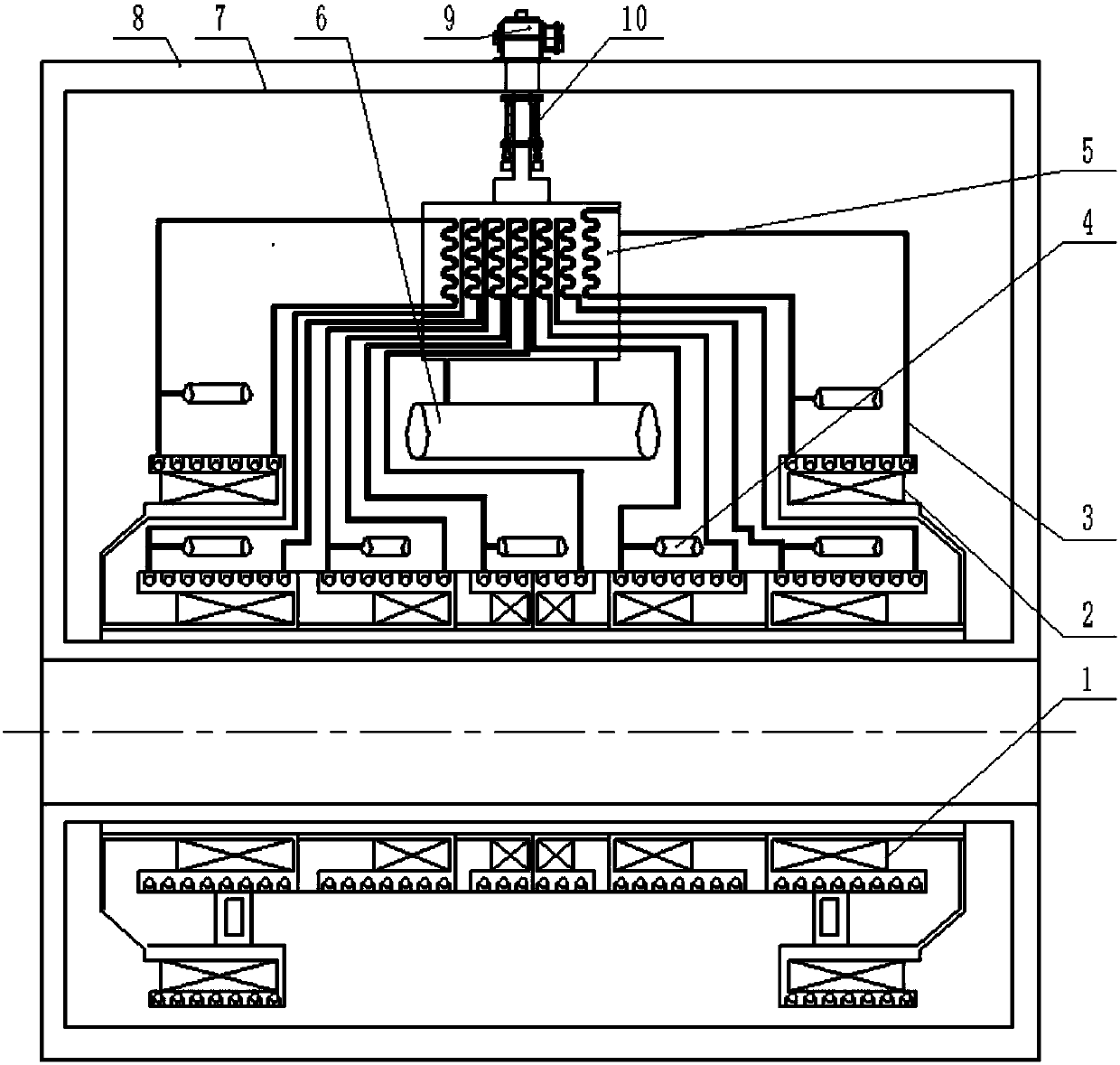

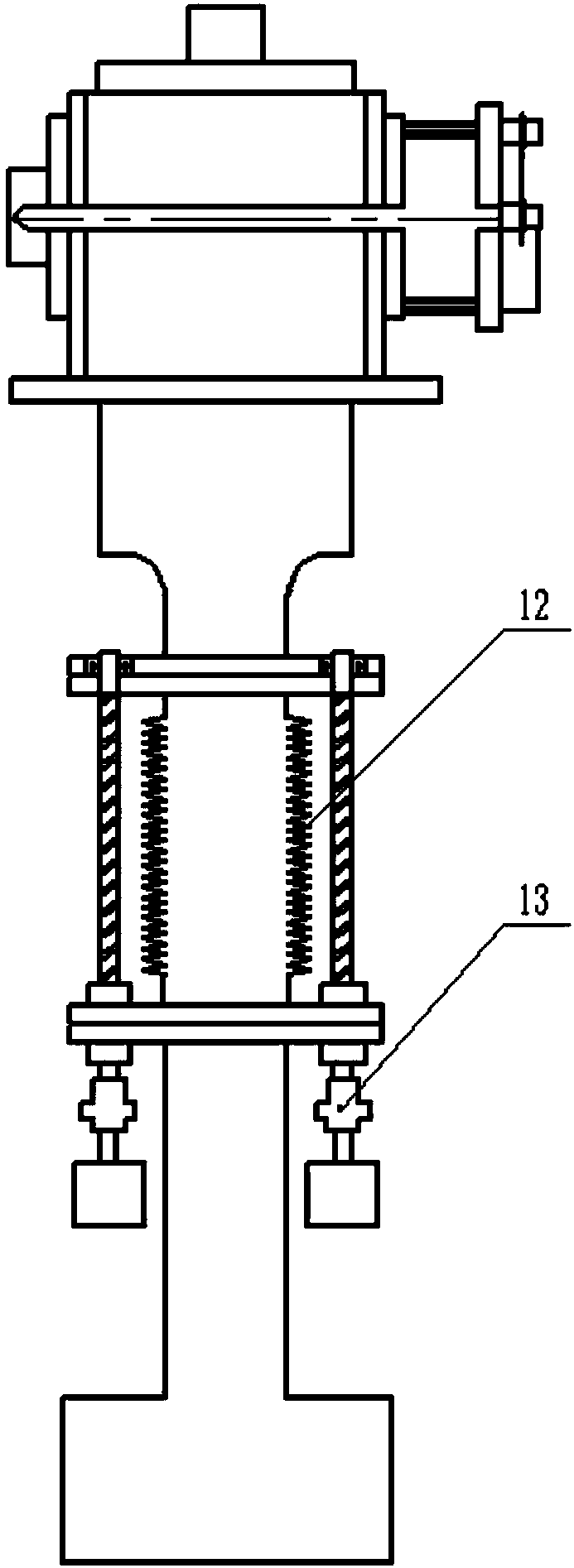

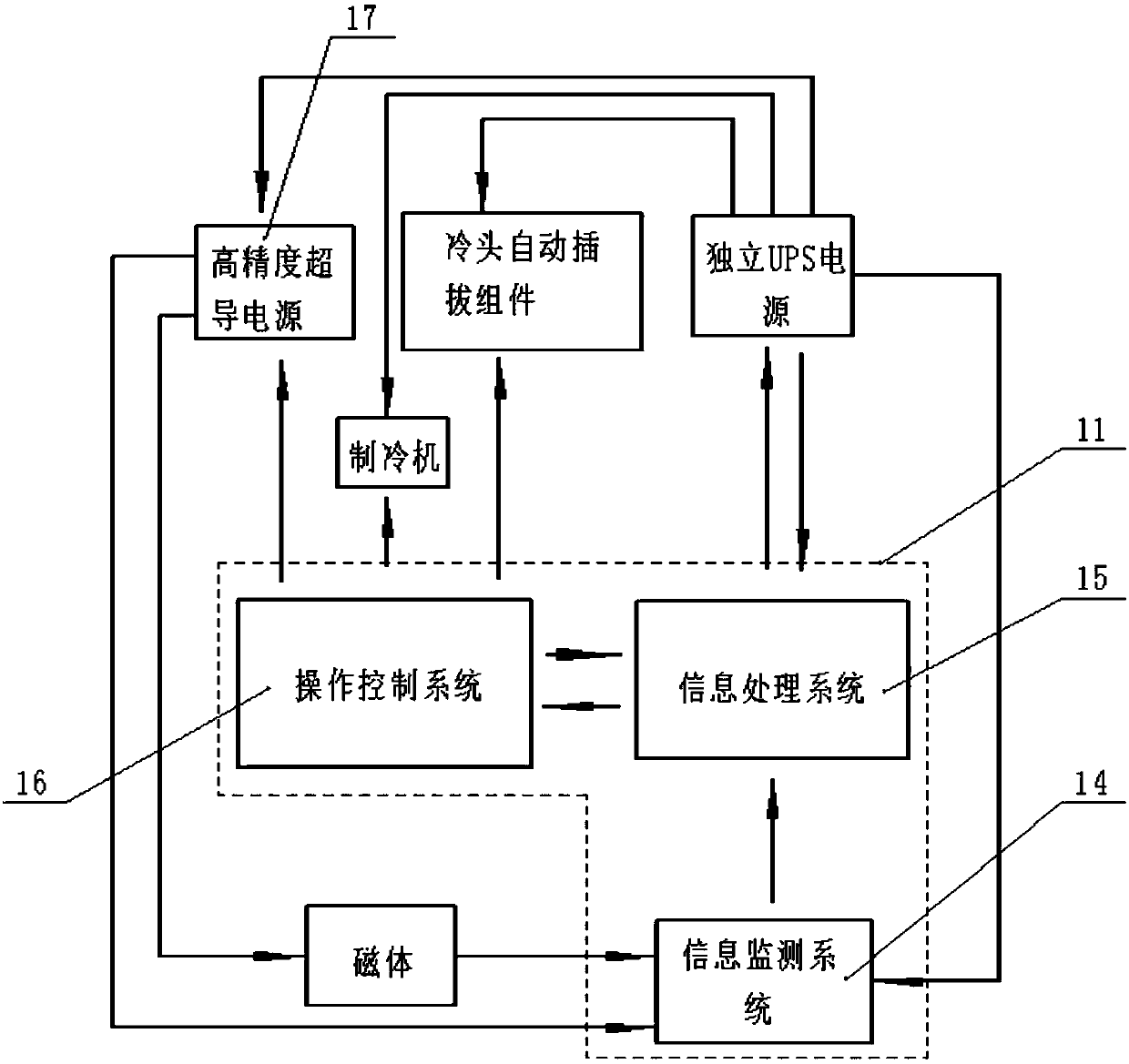

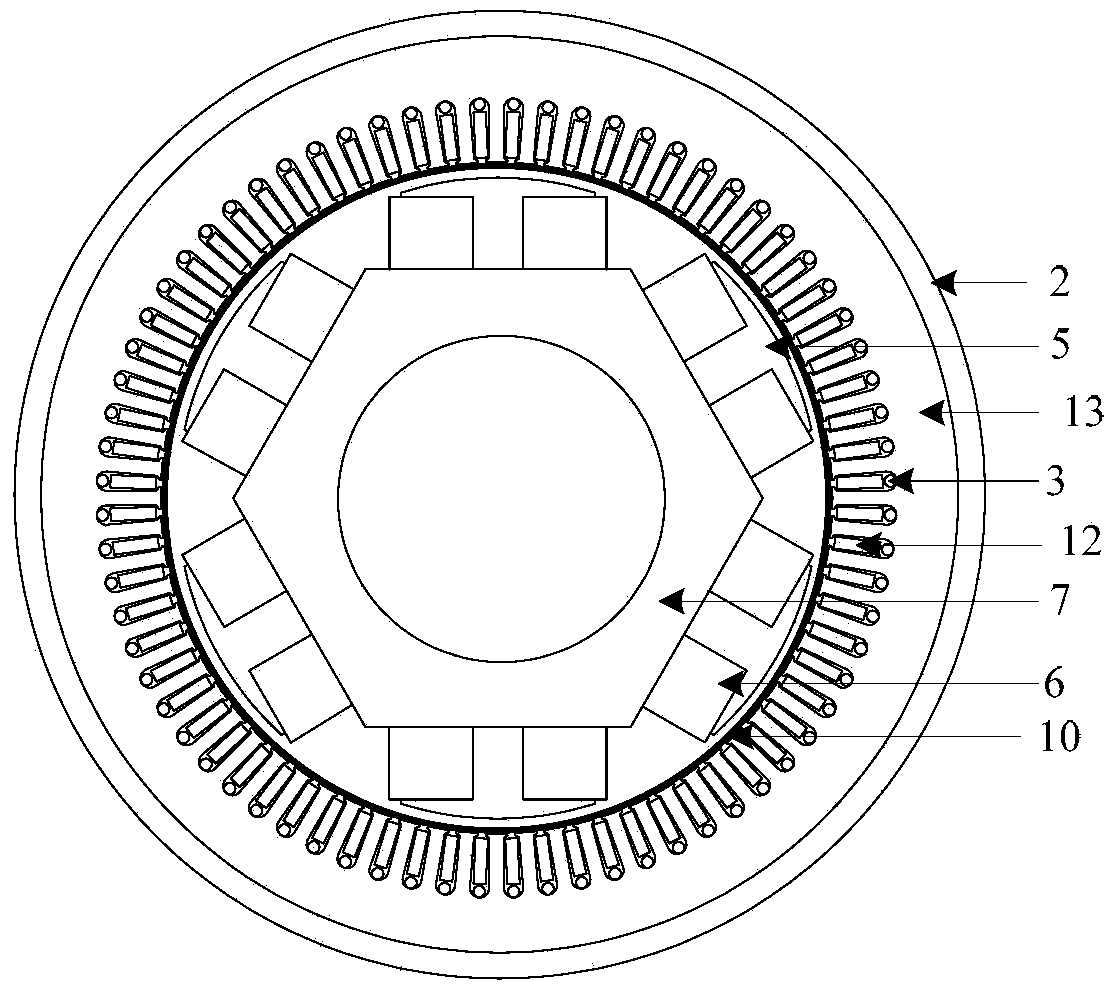

Intellectualized liquid-helium-free magnetic resonance whole-body imaging superconducting magnet system

ActiveCN108022711AEfficient cooling efficiencyMeet cooling needsMagnetic measurementsSuperconducting magnets/coilsRefrigerated temperatureStorage tank

The invention discloses an intellectualized liquid-helium-free magnetic resonance whole-body imaging superconducting magnet system. The intellectualized liquid-helium-free magnetic resonance whole-body imaging superconducting magnet system comprises a vacuum container, a helium liquid storage box and a refrigerator, wherein a main magnetic field superconducting coil is arranged in a radial insidespace of the vacuum container, a shielding magnetic field superconducting coil is arranged in a radial outside space of the vacuum container, and a heat pipe air storage tank is placed in an idle areabetween the main magnetic field superconducting coil and the shielding magnetic field superconducting coil; the helium liquid storage box is communicated with a liquid storage box and air storage tank, is also connected with the main magnetic field superconducting coil or the shielding magnetic field superconducting coil through a helium self-oscillating heat pipe, and the helium self-oscillatingheat pipe is further communicated with the heat pipe air storage tank; the refrigerator is fixed to the vacuum container through a cold head automatic insertion and extraction assembly; the first-level cold head of the refrigerator is in close contact with a thermal radiation screen assembly, and the second-level cold head of the refrigerator is in close contact with the helium liquid storage box. By means of the intellectualized liquid-helium-free magnetic resonance whole-body imaging superconducting magnet system, the problems are solved that an existing superconducting magnet system is poor in cooling performance, once the refrigerator stops work, a magnet loses heat quickly due to excessive heat leakage, and the superconducting magnet system is complicated to maintain and poor in reliability.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

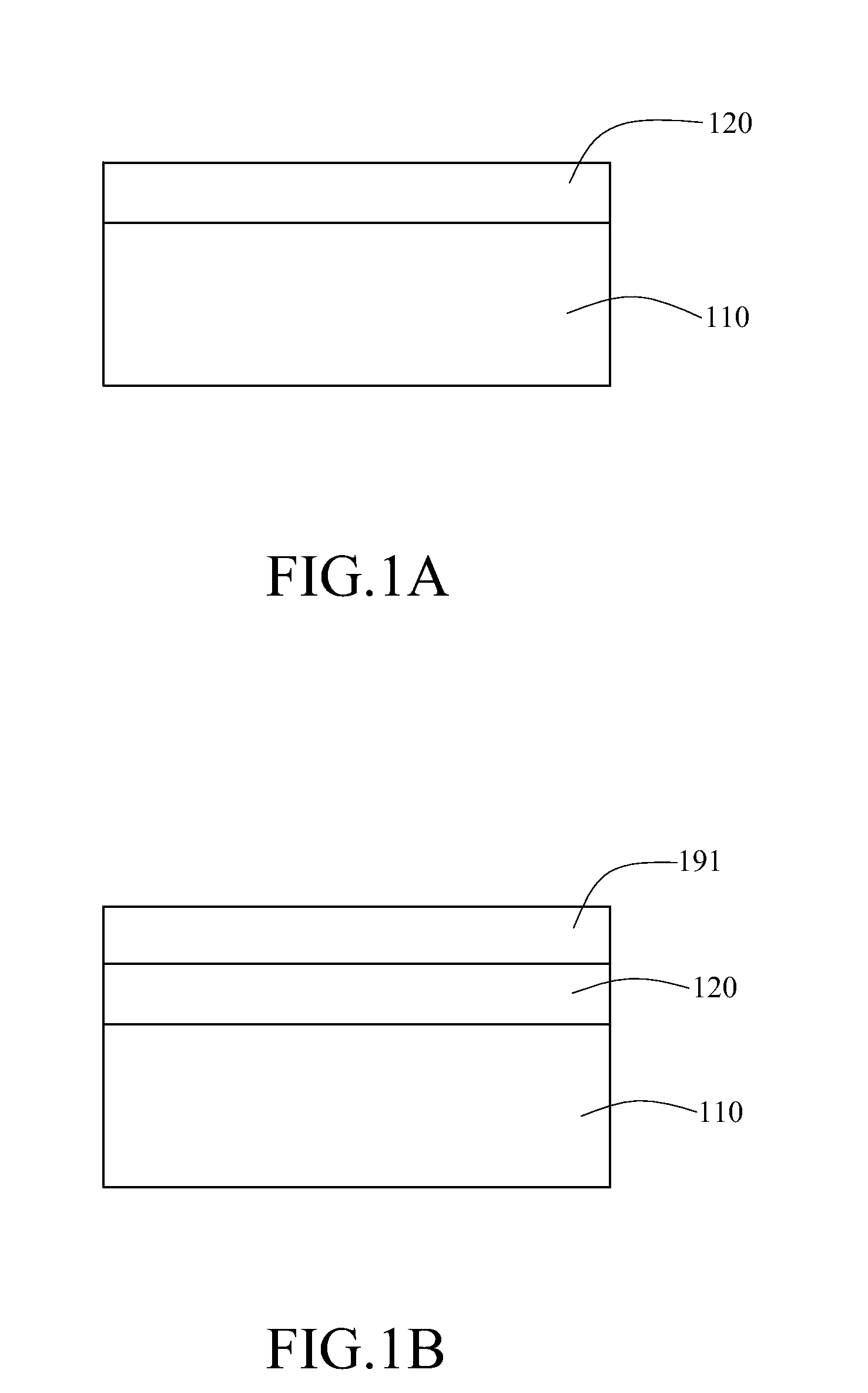

Thermoelectric nanowire array with low heat leakage and manufacturing method thereof

InactiveUS20100162728A1Low thermal conductivityImprove performanceLiquid/solution decomposition chemical coatingMachines using electric/magnetic effectsNanowire arrayThermal dissipation

A thermoelectric nanowire array with a low heat leakage and a manufacturing method thereof are described. Nanowire array units separated from each other are formed on a substrate, and an air wall is formed at a region on the substrate free of the nanowire array units. Or, a polymeric material having a low thermal conductivity is combined with a template material so as to form a composite template structure for nanowires to deposit therein. With the design of the air wall or the composite template structure, the thermal reflow phenomenon of the thermoelectric nanowire array is avoided, thereby greatly improving a thermal dissipation efficiency of the thermoelectric nanowire array.

Owner:IND TECH RES INST

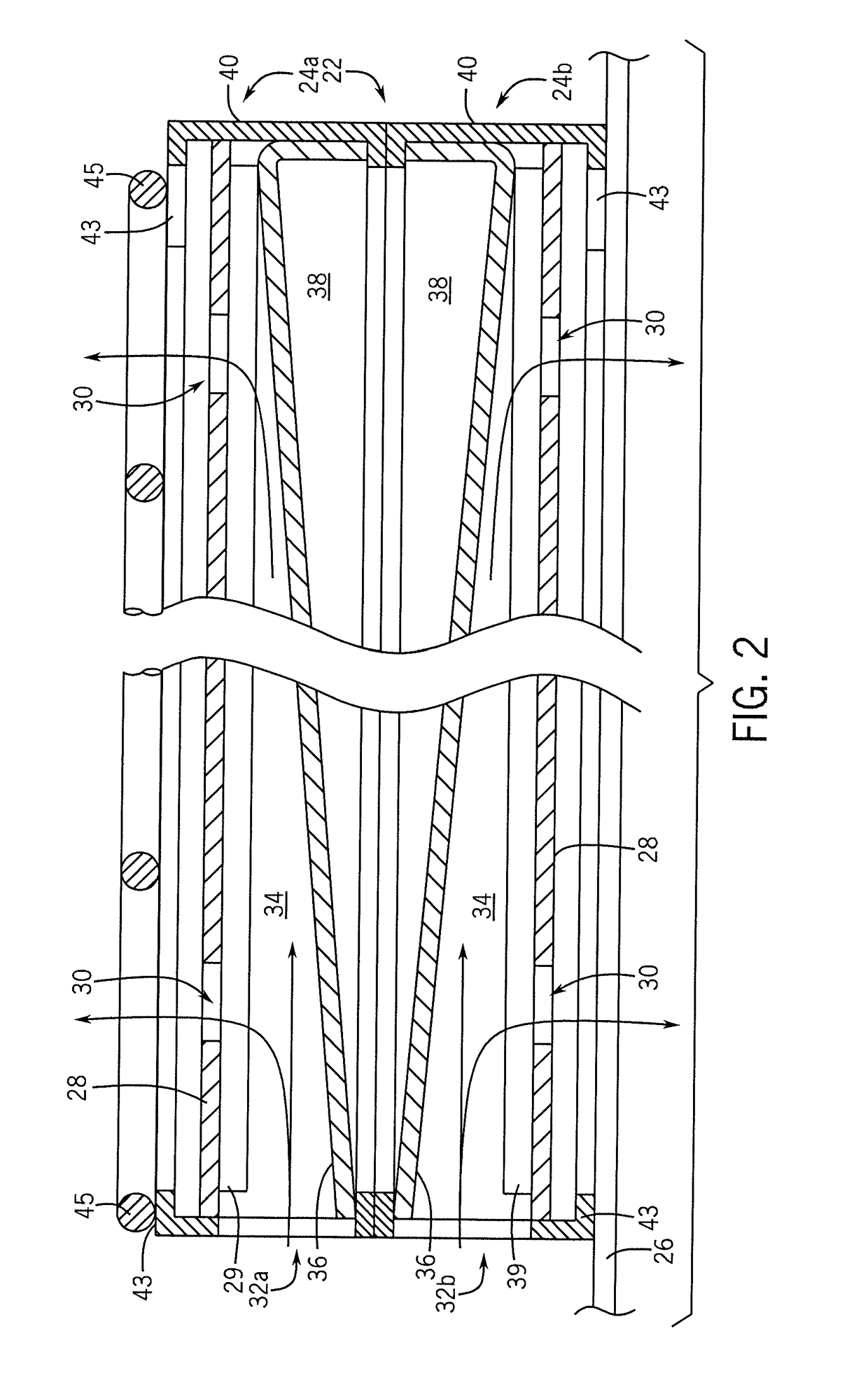

Thermal Management System for Multizone Oven

ActiveUS20190056118A1Solve the thickerReduce thicknessDomestic stoves or rangesStoves/ranges shelves or racksTemperature controlEngineering

A multi-zone, proximate-air oven using air delivered from the shelves provides a compact height through the use of low profile shelves. Intercavity heat leakage is managed by active insulation techniques making use of the oven feedback temperature control and controlled cavity loading.

Owner:ALTO SHAAM

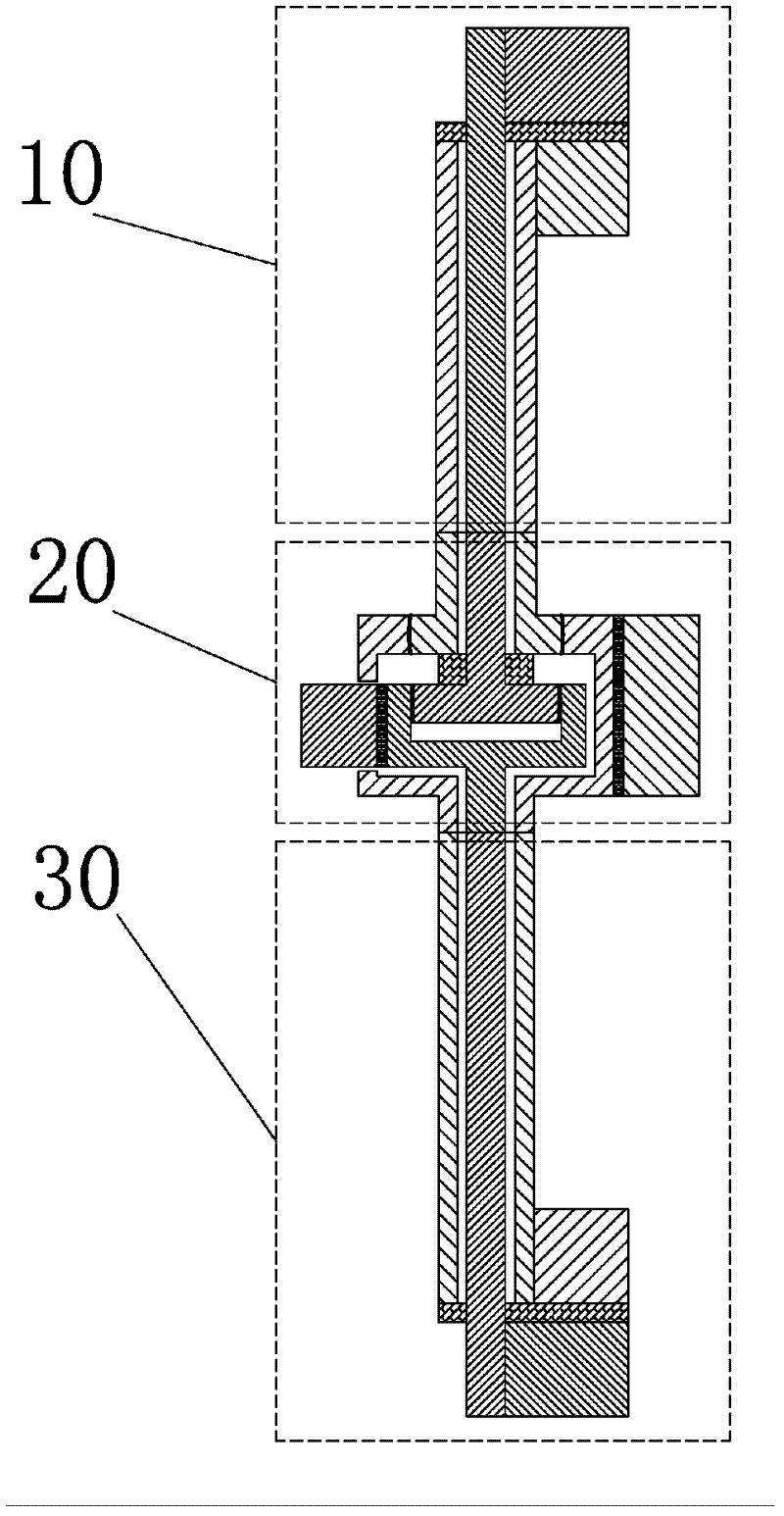

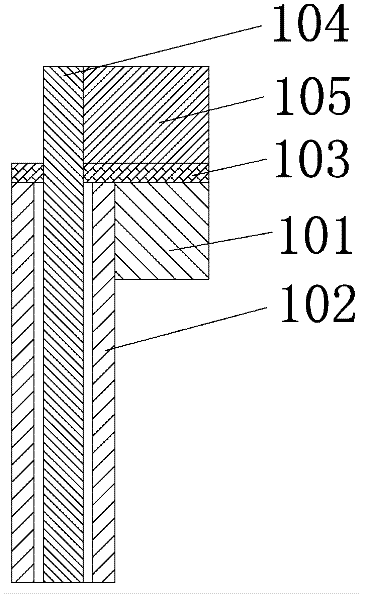

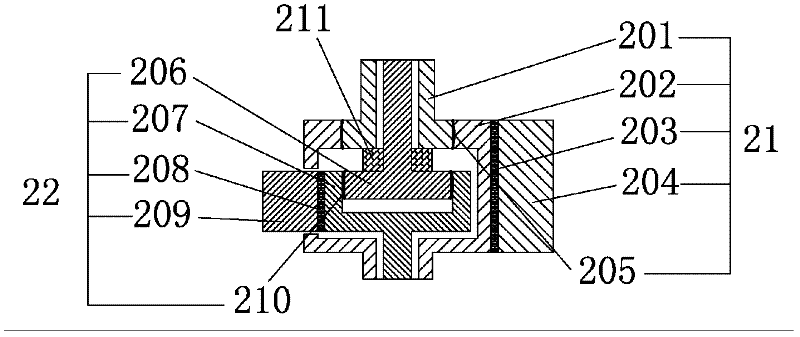

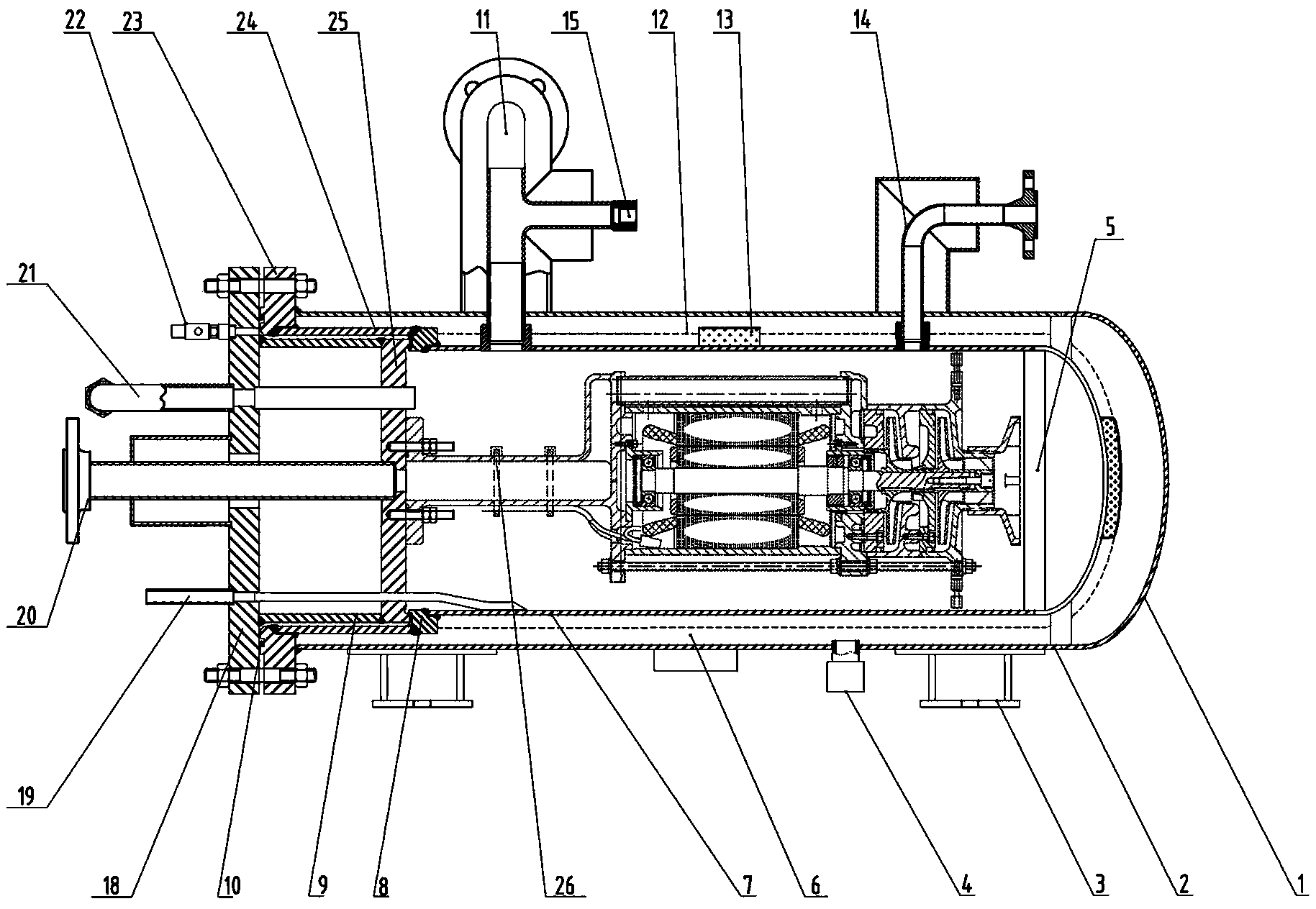

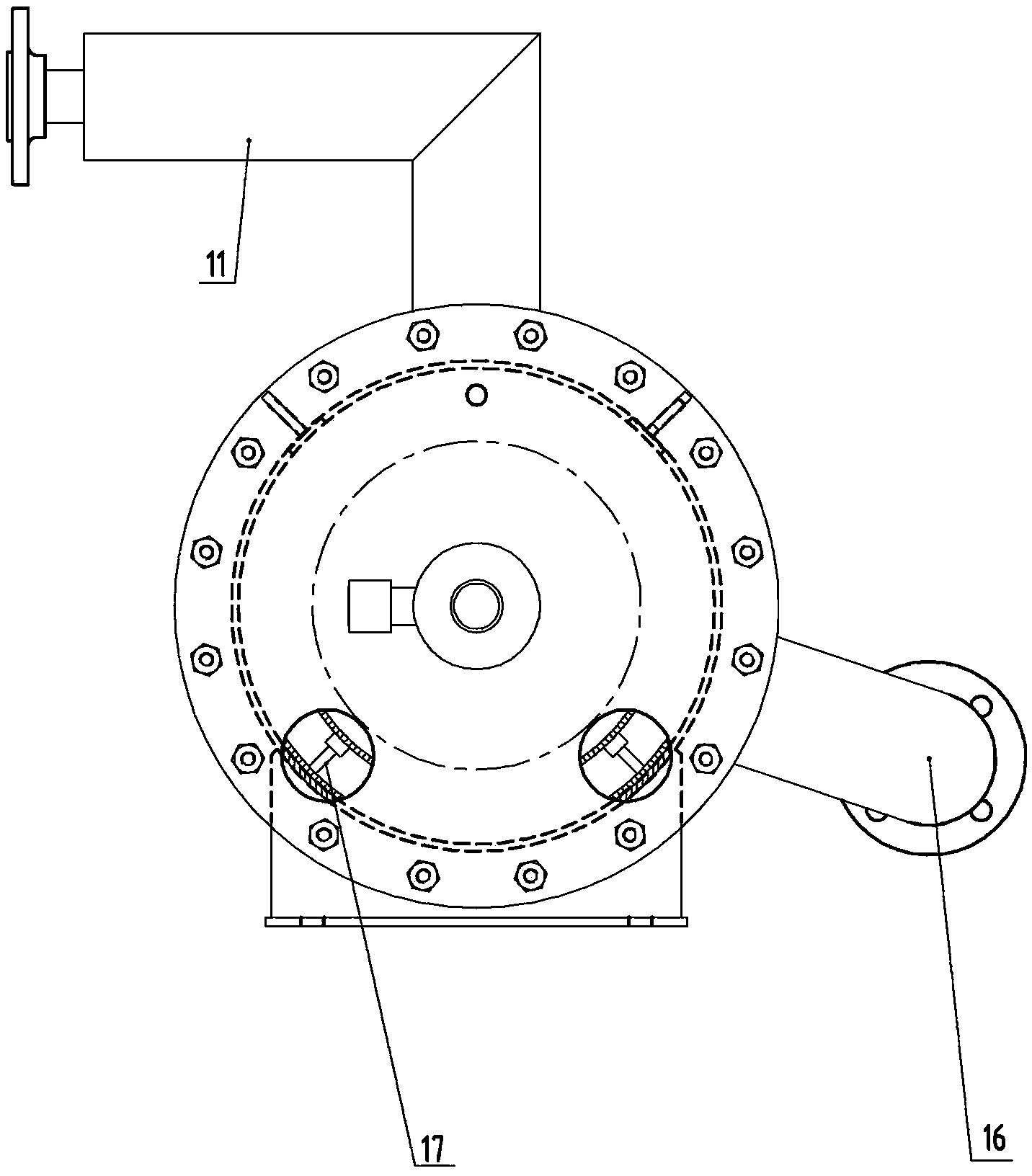

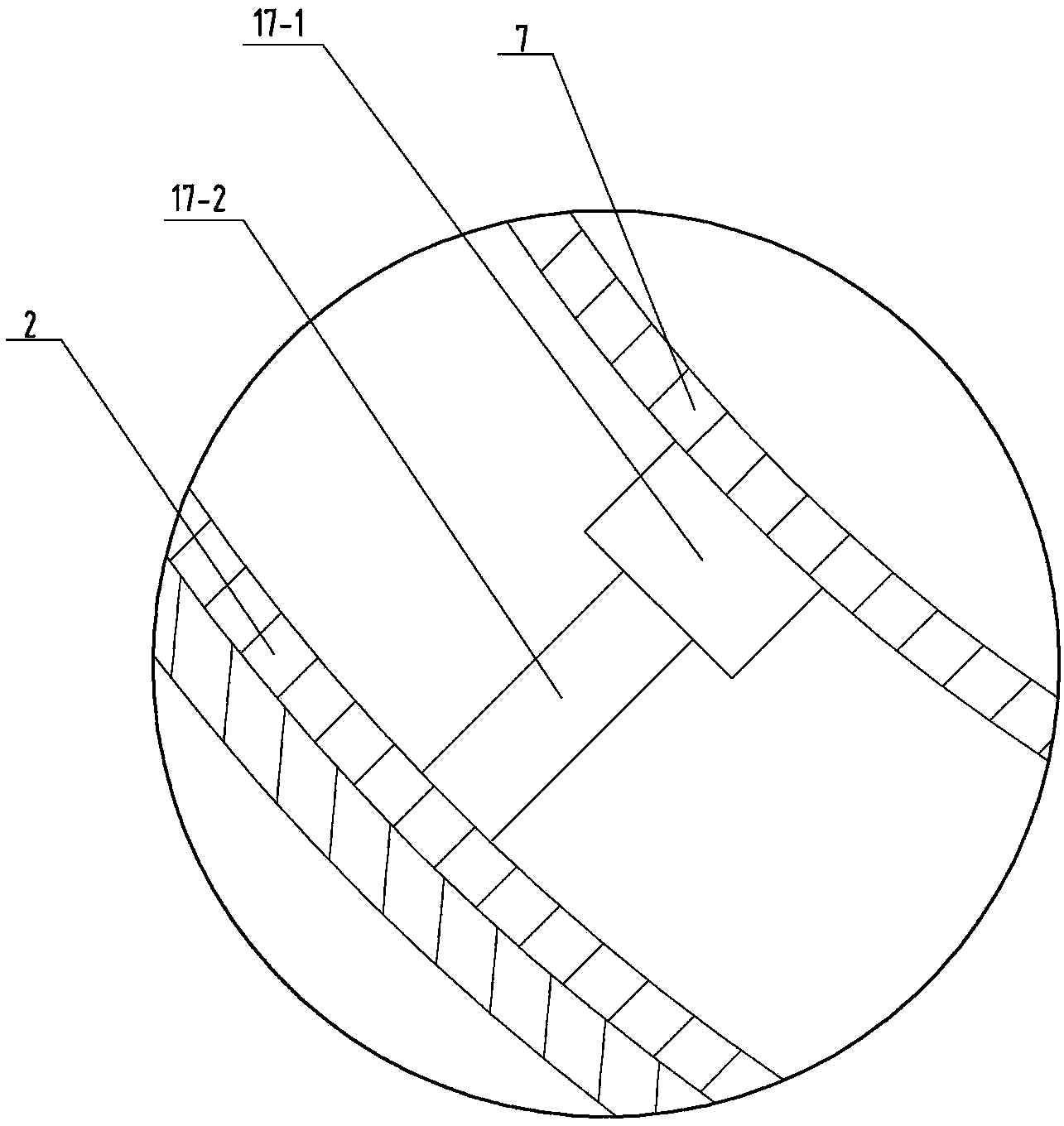

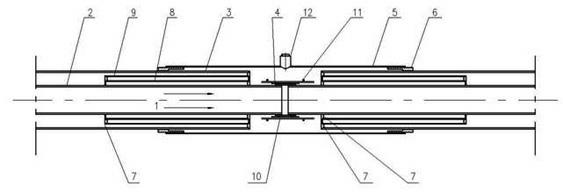

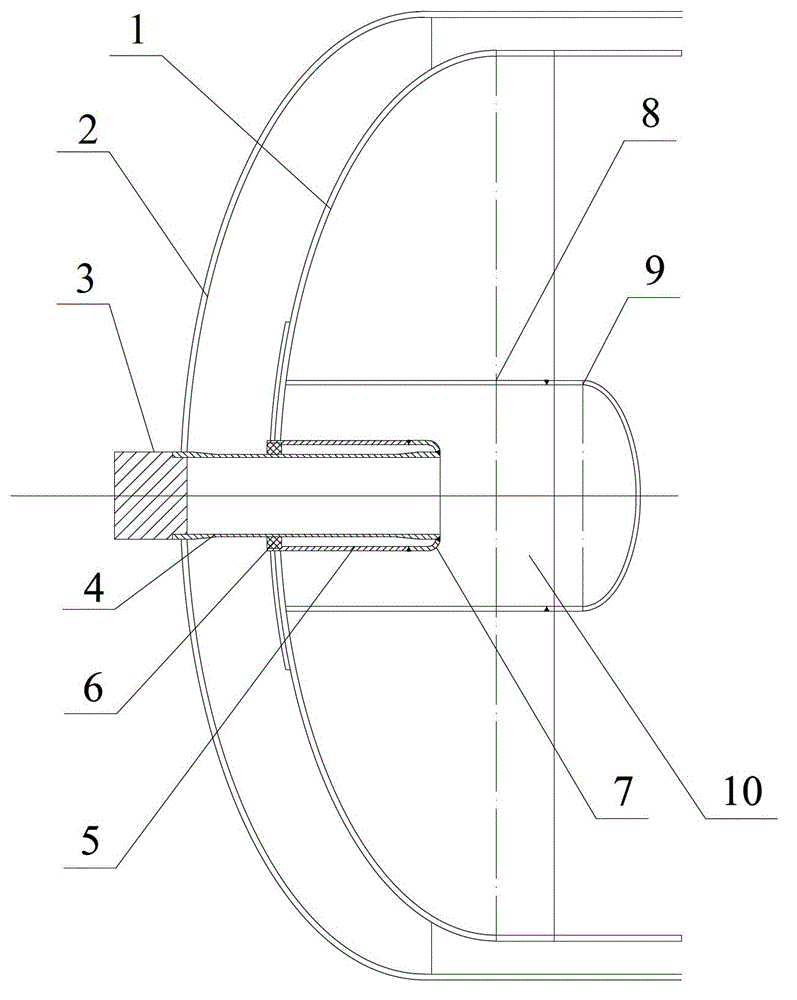

Flow control valve of large-sized low temperature device

The invention discloses a flow control valve of a large low-temperature device, comprising a vacuum valve sleeve; the upper end of an outer tube of the vacuum valve sleeve is connected with a valve cover; a step hole is opened in the center of the valve cover; the step hole is internally provided with a slide-fit valve rod; a bonnet is fixed at the upper end of the valve rod; the bonnet and the valve cover are connected by a thread; an inner tube of the vacuum valve sleeve is sheathed outside the valve rod without contact; the upper end of the vacuum valve sleeve inner tube is connected with the lower end of the valve cover; the lower end of the vacuum valve sleeve inner tube is connected with a valve body; the lower end of the valve body is fixedly connected with a valve seat; a liquid outlet is opened at the lateral wall of the cylinder-shaped valve body; the liquid outlet is connected with an inner tube of a low-temperature device connecting tube; a vacuum valve sleeve outer tube, a vacuum perfusion tube outer tube and a low-temperature device connecting tube outer tube are welded together and processed by vacuumization together; a valve core penetrates the valve body from top to bottom, the cone-shaped lower end of the valve core is pressed against the valve mouth of the valve seat, and the lower end of the valve mouth is connected with a vacuum perfusion tube inner tube. The invention excellently resolves the problems of heat leakage and leakage, namely, the valve can not be frosted when regulating liquid helium flow, and the valve does not leak when regulating cold helium and high-pressure supercritical helium flow.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

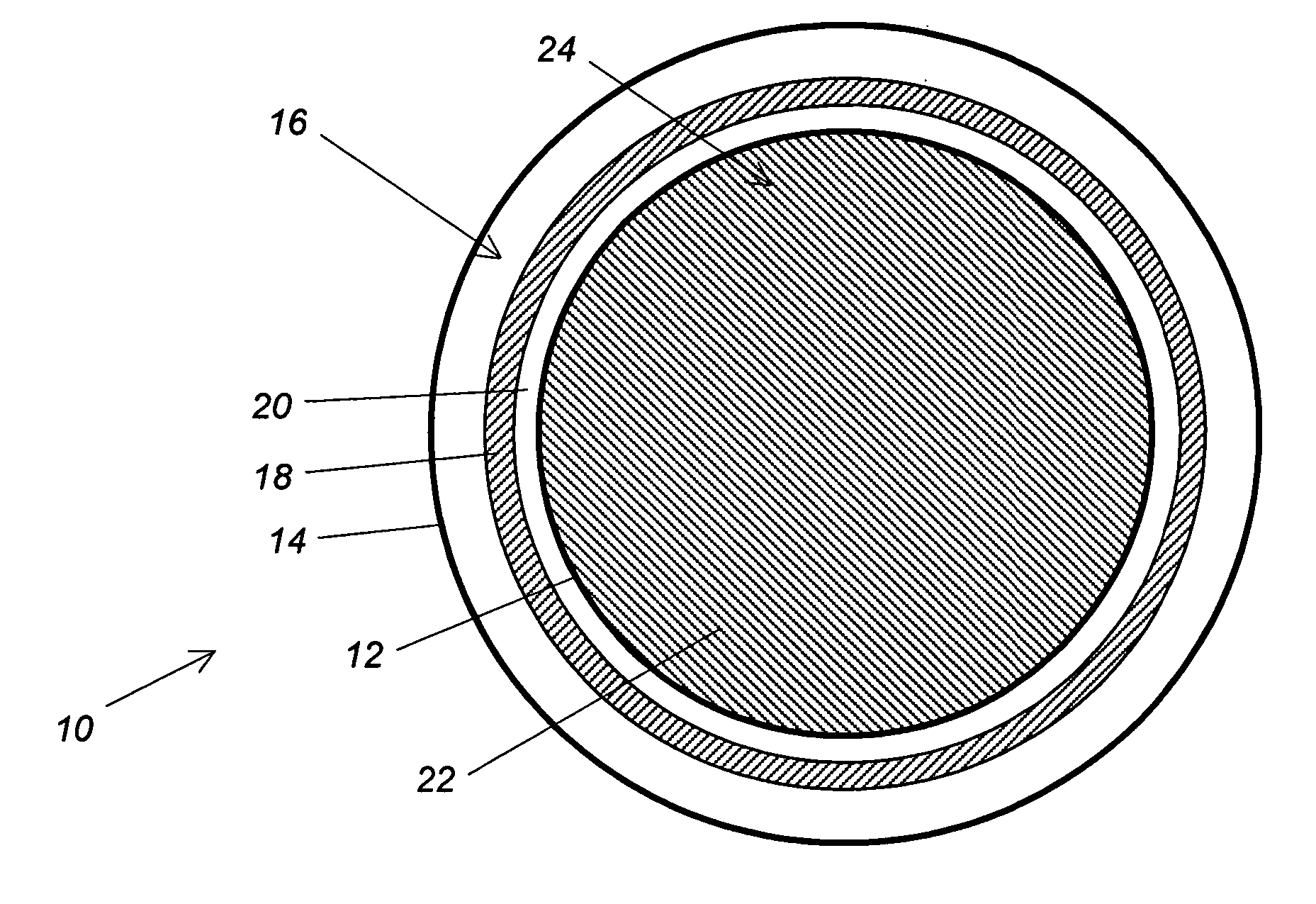

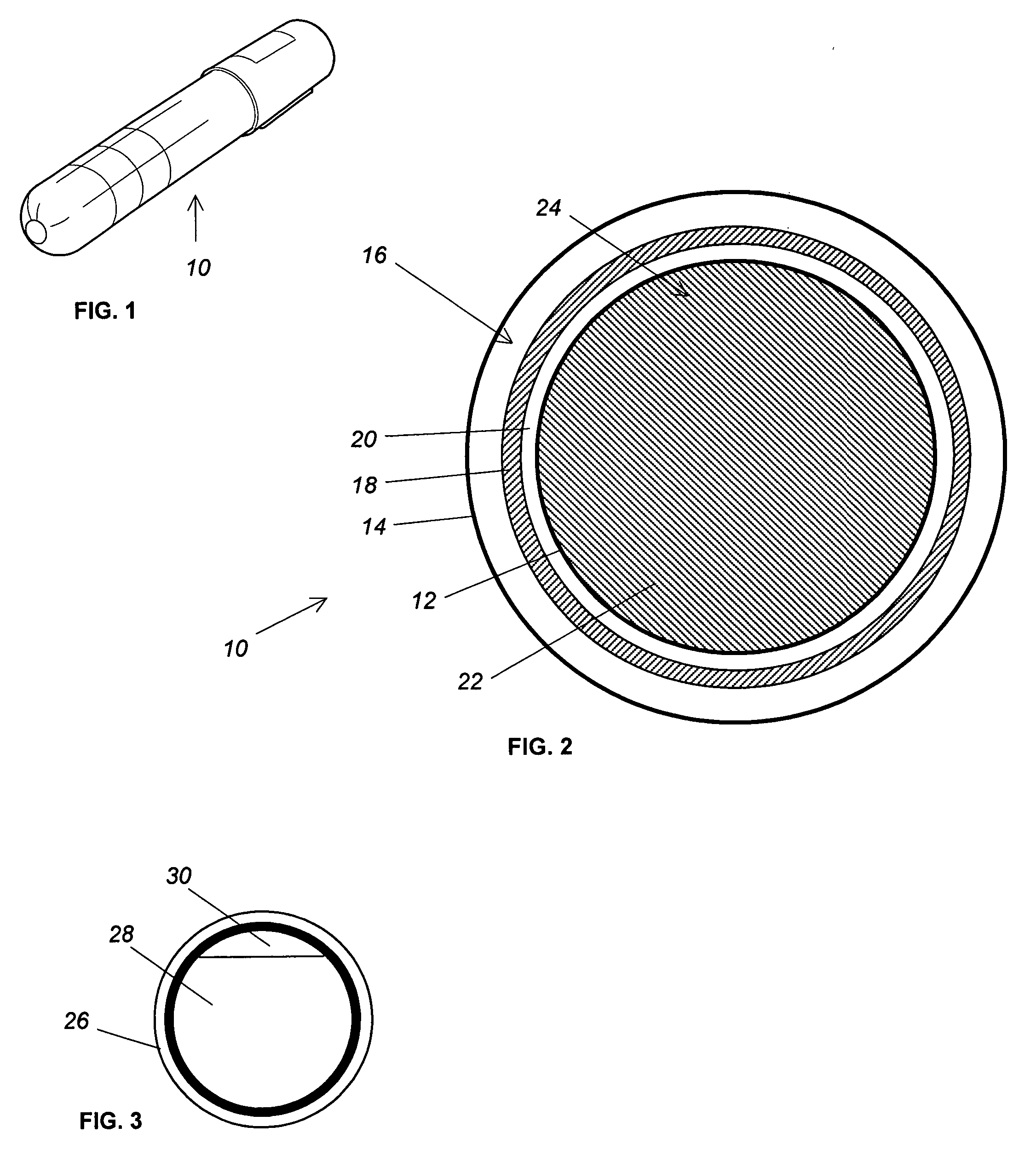

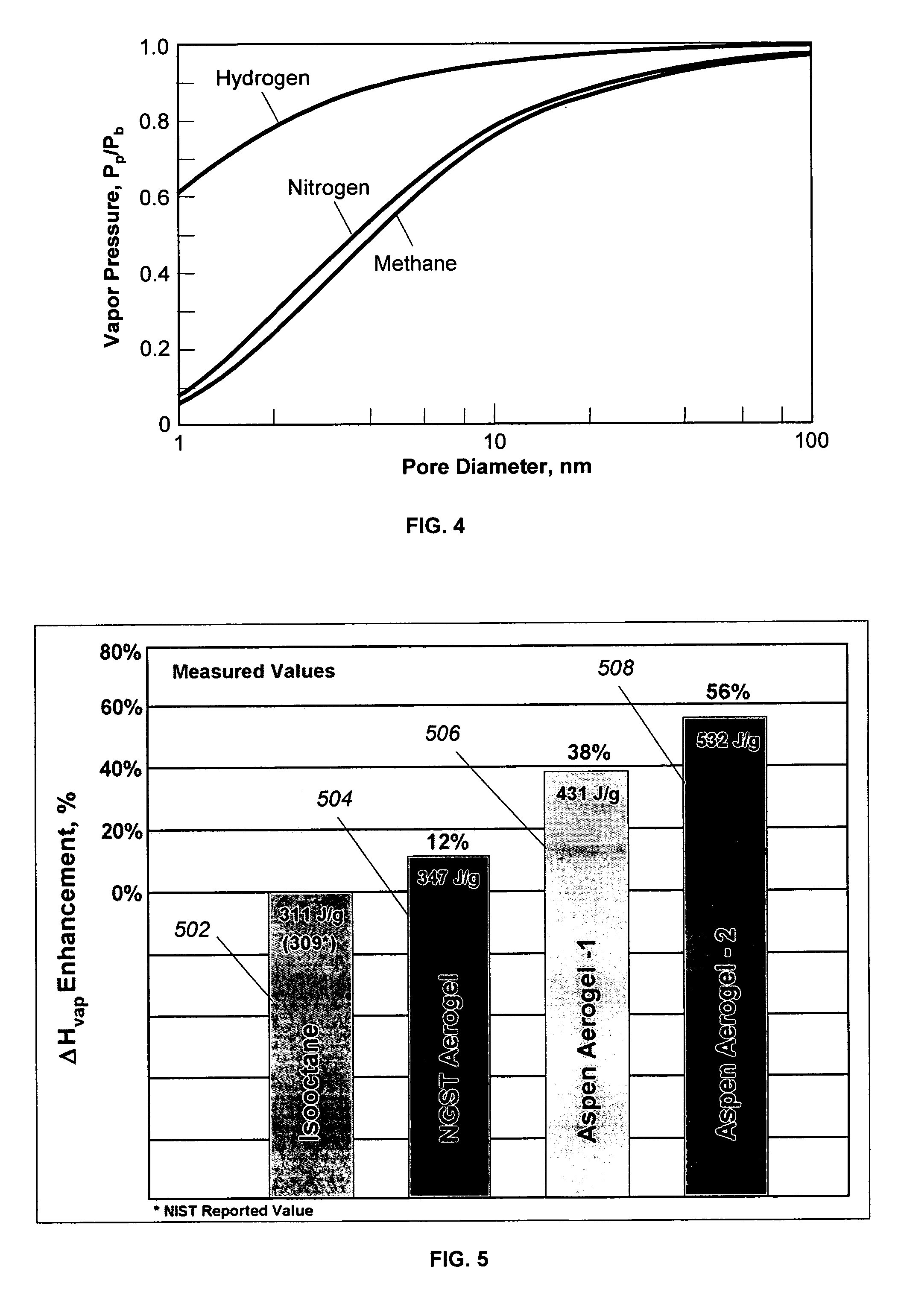

Reduced boiloff cryogen storage

InactiveUS20060218940A1Low vapor pressureReduce leak rateVessel geometry/arrangement/sizeVessel wallsEngineeringHigh surface

A long-term cryogen storage system comprising a storage tank shell substantially filled by a nanoporous material in which a stored cryogen is subject to a dramatically lower boil-off rate than when stored in its bulk state. The nanoporous material provides a storage medium in which the cryogen has a higher surface energy term due to extreme surface curvature provided by the nanopores of the storage medium. As a result, the cryogen exhibits an altered thermodynamic state relative to its bulk fluid state and has a substantially reduced vapor pressure, an effectively higher vaporization enthalpy (ΔHv), and a lower boiloff rate for a given rate of heat leakage through the storage tank shell.

Owner:NORTHROP GRUMAN CORP

Superconducting motor with ultra-low loss

InactiveCN103532345AImprove power densityReduce lossDynamo-electric machinesSuperconducting electric machineSuperconducting Coils

The invention discloses a superconducting motor with ultra-low loss, which comprises an enclosure, a stator and a rotor, wherein the rotor is in an iron-core-free structure and mainly comprises a pole shoe, a rotor spider and a hollow rotating shaft; the pole shoe is wound with an exciting winding; the exciting winding is a superconducting coil; for the stator, a cooling tube is arranged in each stator slot based on the traditional structure; the enclosure comprises a housing; a spiraltron is wound on the outer side of the housing; a heat-proof radiation layer is arranged on a tooth surface of the stator; and cooling media are charged into the spiraltron, the cooling tubes, collecting tubes and the hollow rotating shaft. The superconducting motor with the ultra-low loss is very low in motor loss; the efficiency of the superconducting motor can reach above 99%; no dewar is arranged in an air gap; and the small air gap becomes possible; the motor is low in heat leakage and high in power density; and the refrigeration cost is low.

Owner:SOUTHEAST UNIV

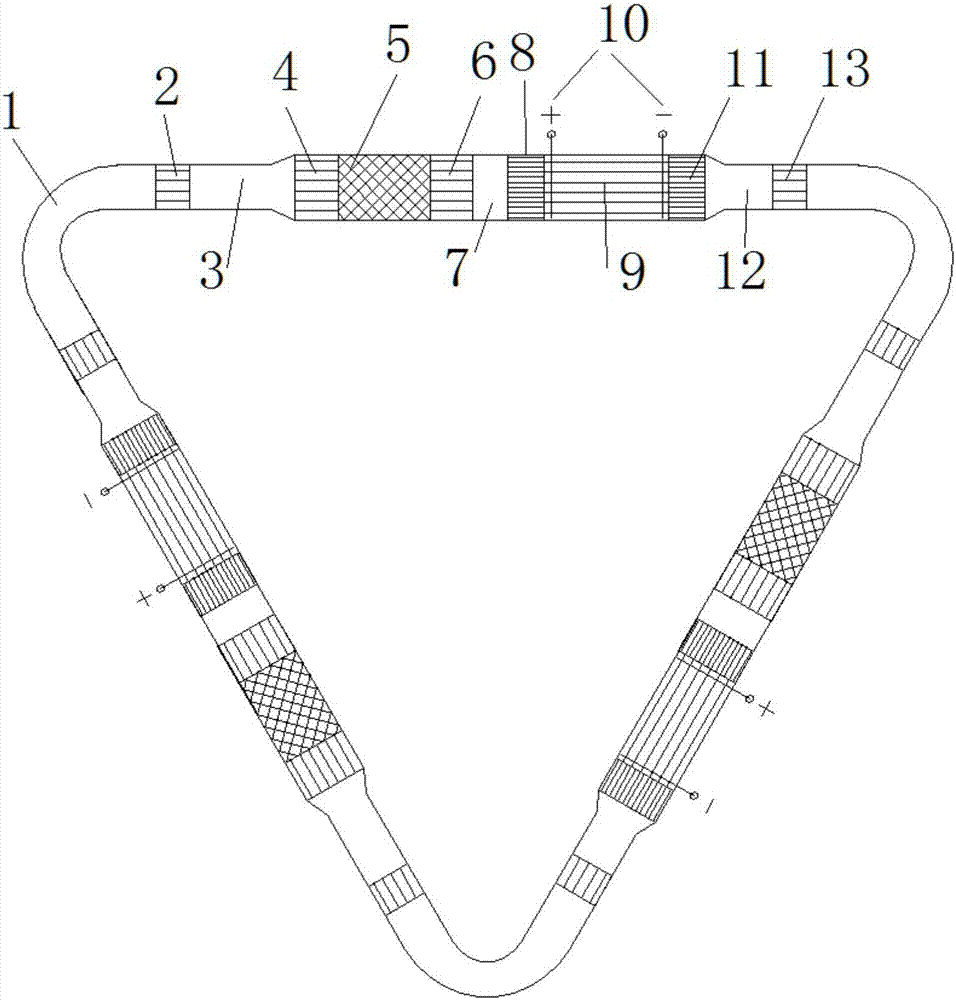

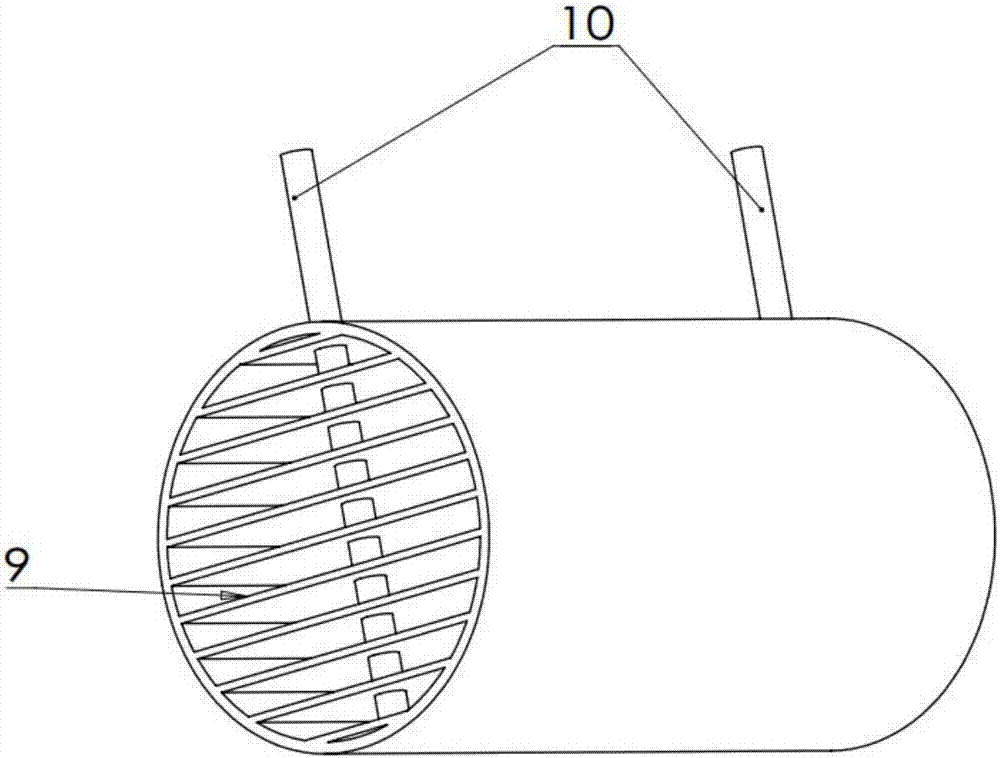

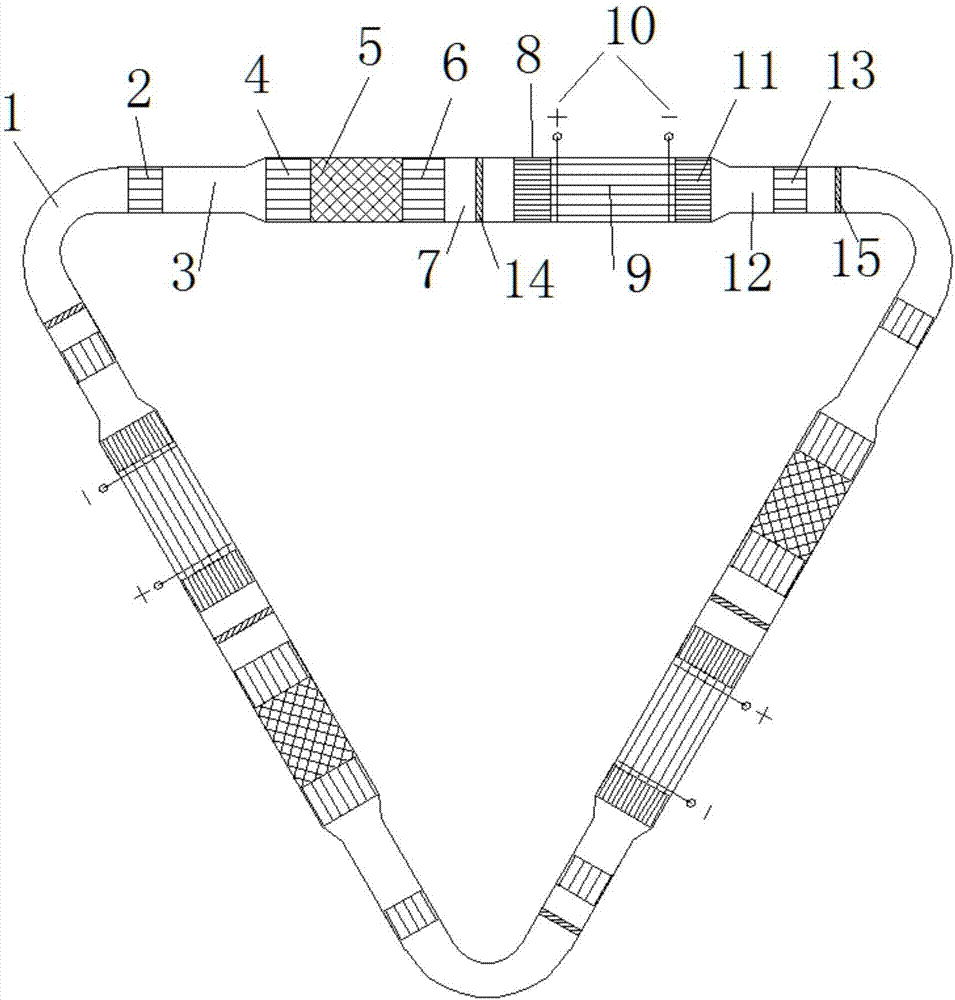

Thermoacoustically driven solid refrigerator

ActiveCN107401852AImprove reliabilityCompact structureMachines using electric/magnetic effectsSuperheatersEngineeringRefrigerated temperature

The invention discloses a thermoacoustically driven solid refrigerator which is free of movement parts, low in vibration and capable of improving performance thereof. The refrigerator comprises a plurality of thermoacoustic engine components connected in an end-to-end manner and a plurality of electric card refrigeration units disposed in a thermoacoustic engine loop. Each thermoacoustic engine component comprises a resonance tube, a thermal buffer tube side room temperature heat exchanger, a thermal buffer tube, a high temperature side heat exchanger, a regenerator, an engine side room temperature heat exchanger and a connecting chamber. The thermoacoustic engine components connected in an end-to-end manner form a travelling wave loop; in the loop, each thermal buffer tube is used for isolating heat leakage between each high temperature side heat exchanger and the corresponding thermal buffer tube side room temperature heat exchanger; each resonance tube is a metal hollow tube and used for controlling whole-machine running frequency and sound field distribution characteristics. Each electric card refrigeration unit comprises a refrigerator side room temperature heat exchanger, an electric card material, a cold side heat exchanger, a refrigerator side thermal buffer tube, a second refrigerator side room temperature heat exchanger and two connecting electrodes, wherein each end of each electric card material is connected with one connecting electrode.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

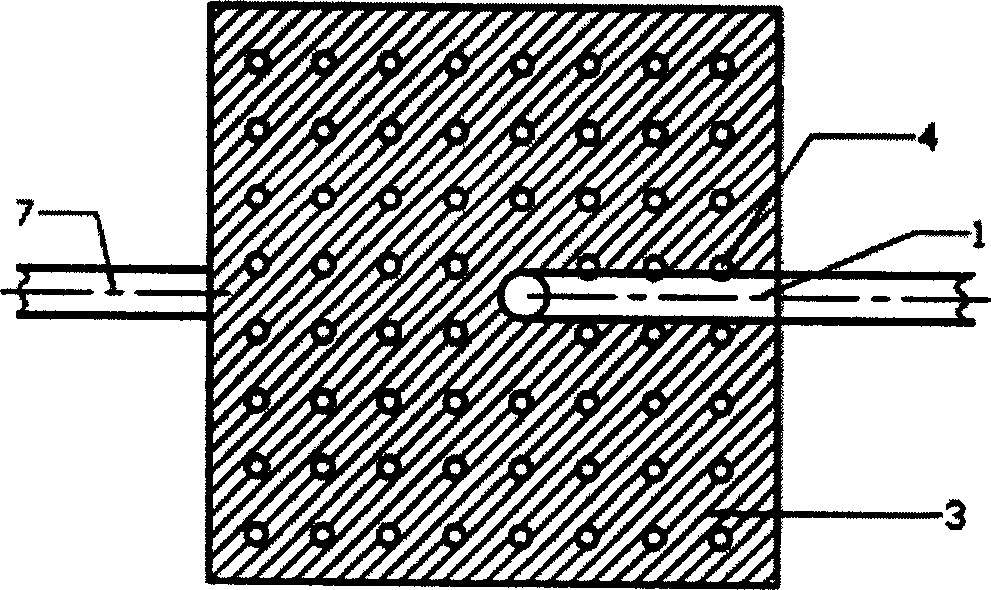

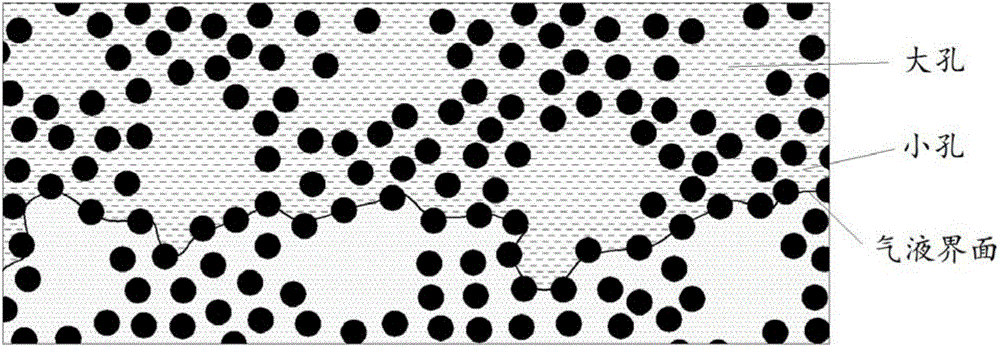

Powder-microfiber composite porous capillary core applicable to loop heat pipe system

ActiveCN105928403AHigh capillary suctionLower effective thermal conductivityIndirect heat exchangersSuction forcePorous medium

The invention discloses a powder-microfiber composite porous capillary core applicable to a loop heat pipe system and belongs to the technical field of porous medium phase change heat transmission and flow. The capillary core adopts metal powder and microfiber for mixing and sintering, and the metal powder is connected through the microfiber, so that a double-aperture porous medium structure is realized, wherein the double apertures comprise a small aperture formed by microfiber among powder and a large aperture formed between particles and powder. The unique structure of the capillary core enables the capillary core to have the flow heat transmission properties of high capillary suction force, low flow resistance, high surface evaporativity and low effective heat conductivity. When the powder-microfiber composite porous capillary core is applied to the loop heat pipe system, the internal heat transmission medium can be intensified, the evaporation phase-change interface of a working medium can be stabilized, heat leakage to a compensation cavity can be reduced, the temperature fluctuation of system operation can be eliminated or weakened so as to improve the operating property of a loop heat pipe.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Novel LNG (Liquefied Natural Gas) vehicle-mounted gas bottle liner support structure

ActiveCN102865456ALow thermal conductivityAvoid contactContainer filling methodsContainer discharging methodsGas cylinderEngineering

The invention relates to a novel LNG (Liquefied Natural Gas) vehicle-mounted gas bottle liner support structure which is characterized in that a liner of a gas bottle is supported and fixed on a housing of the gas bottle; the support structure mainly consists of a liner end closure, a housing end closure, a manifold header, a support neck tube, an extension tube and a glass reinforced plastic ring; a reinforcing tube is sleeved outside the extension tube; one end of the reinforcing tube is fixedly connected with the inner wall of the liner end closure and the other end is fixedly connected with a second tube cap; and a vacuum cavity is formed between the reinforcing tube and the extension tube through vacuumizing. The novel LNG vehicle-mounted gas bottle liner support structure provided by the invention has few welding seams and is convenient to manufacture, and at the same time heat transfer is reduced and heat leakage amount is greatly reduced.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Superconducting Current Pump

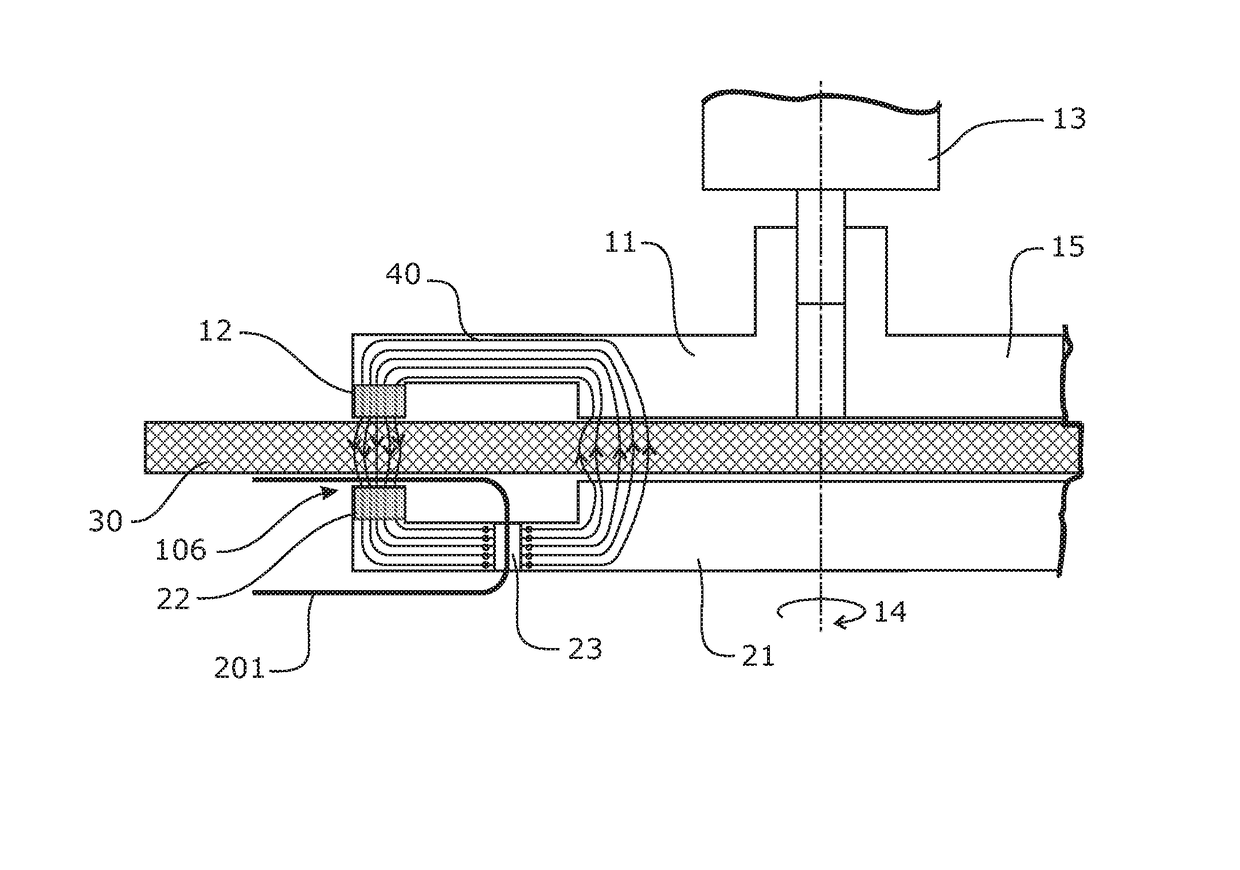

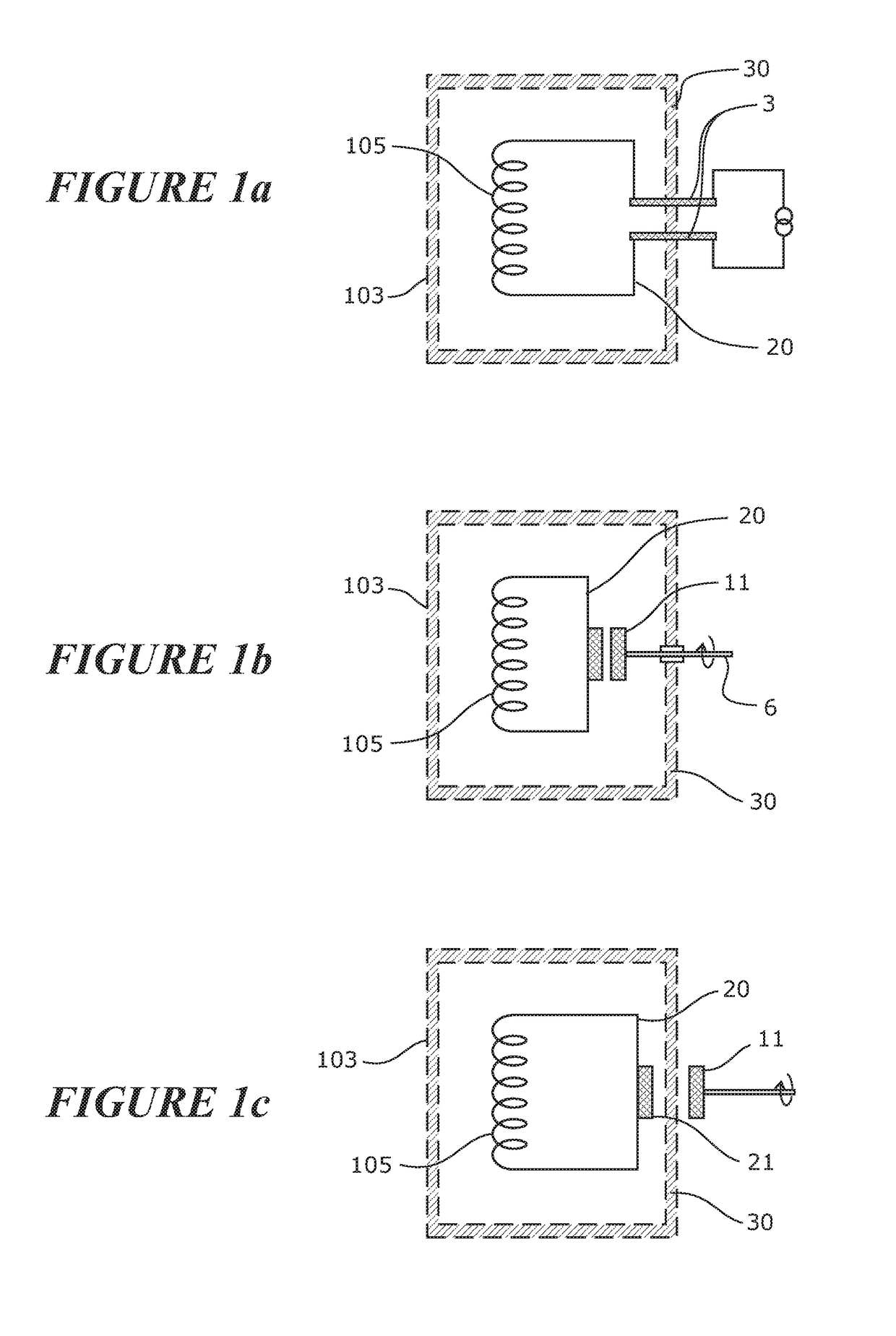

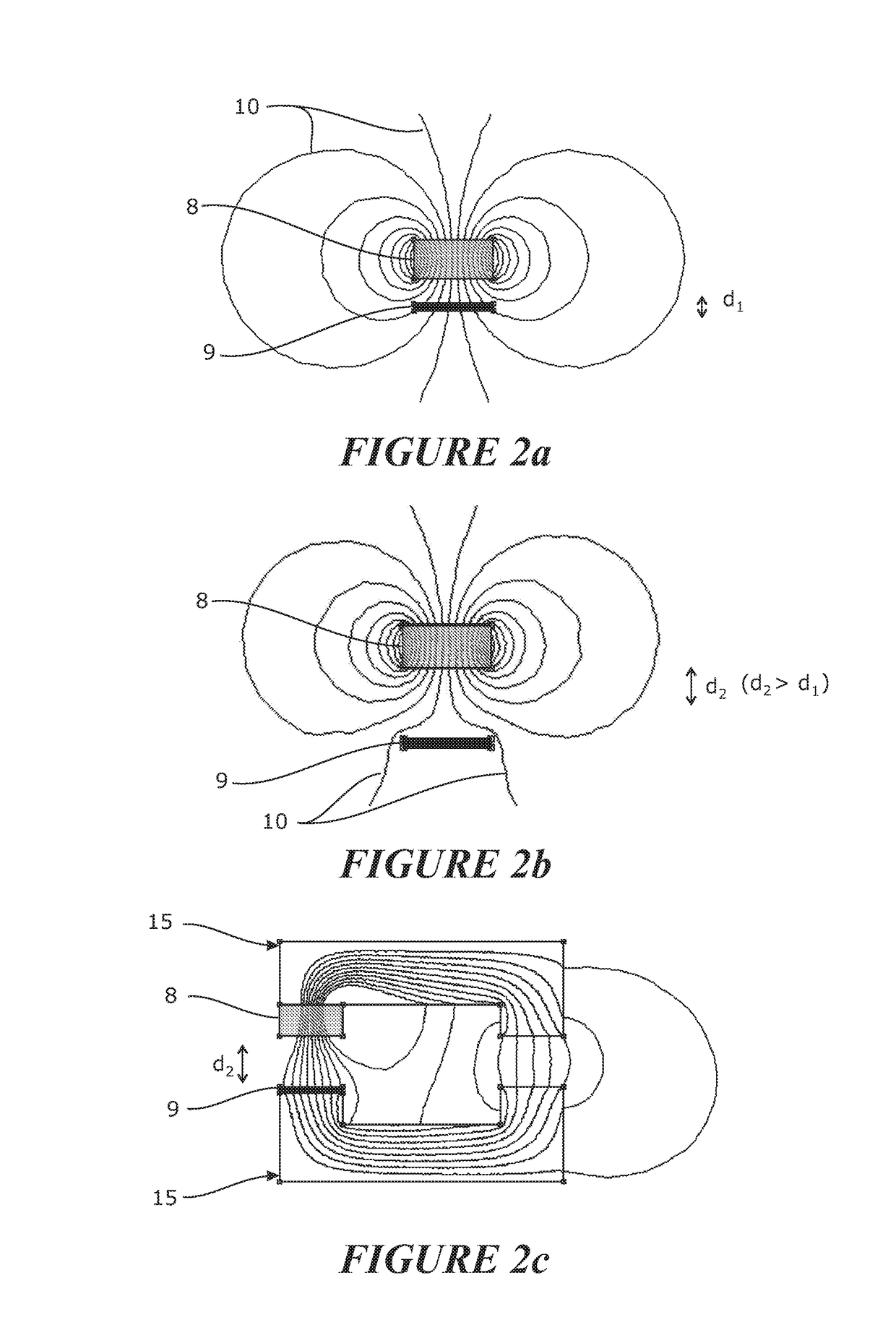

ActiveUS20170236627A1Improve reliabilityComplex and time-consumeDC motor speed/torque controlMagnetic measurementsDrive motorPhysics

A superconducting current pump arranged to cause a DC electrical current to flow through a superconducting circuit accommodated within a cryogenic enclosure of a cryostat comprises a rotor external to the cryogenic enclosure and a stator within the cryogenic enclosure, the rotor and stator separated by a gap through which passes a thermally insulating wall of the cryogenic enclosure, the rotor and the stator comprising at least in part a ferromagnetic material to concentrate magnetic flux in a magnetic circuit across the gap between the rotor and the stator and through the wall, so that movement of the rotor external to the cryogenic enclosure relative to the stator within the cryogenic enclosure induces a DC transport current to flow around the superconducting circuit within the cryogenic enclosure. There is no coupling between a drive motor external to the cryogenic enclosure and an internal rotor which may introduce a path for heat leakage into the cryostat, in turn increasing the heat load and thus increasing the cooling power required to maintain the cold components within the cryogenic enclosure at the low operating temperature required.

Owner:VICTORIA LINK LTD +7

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com