Patents

Literature

1239 results about "Lead structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

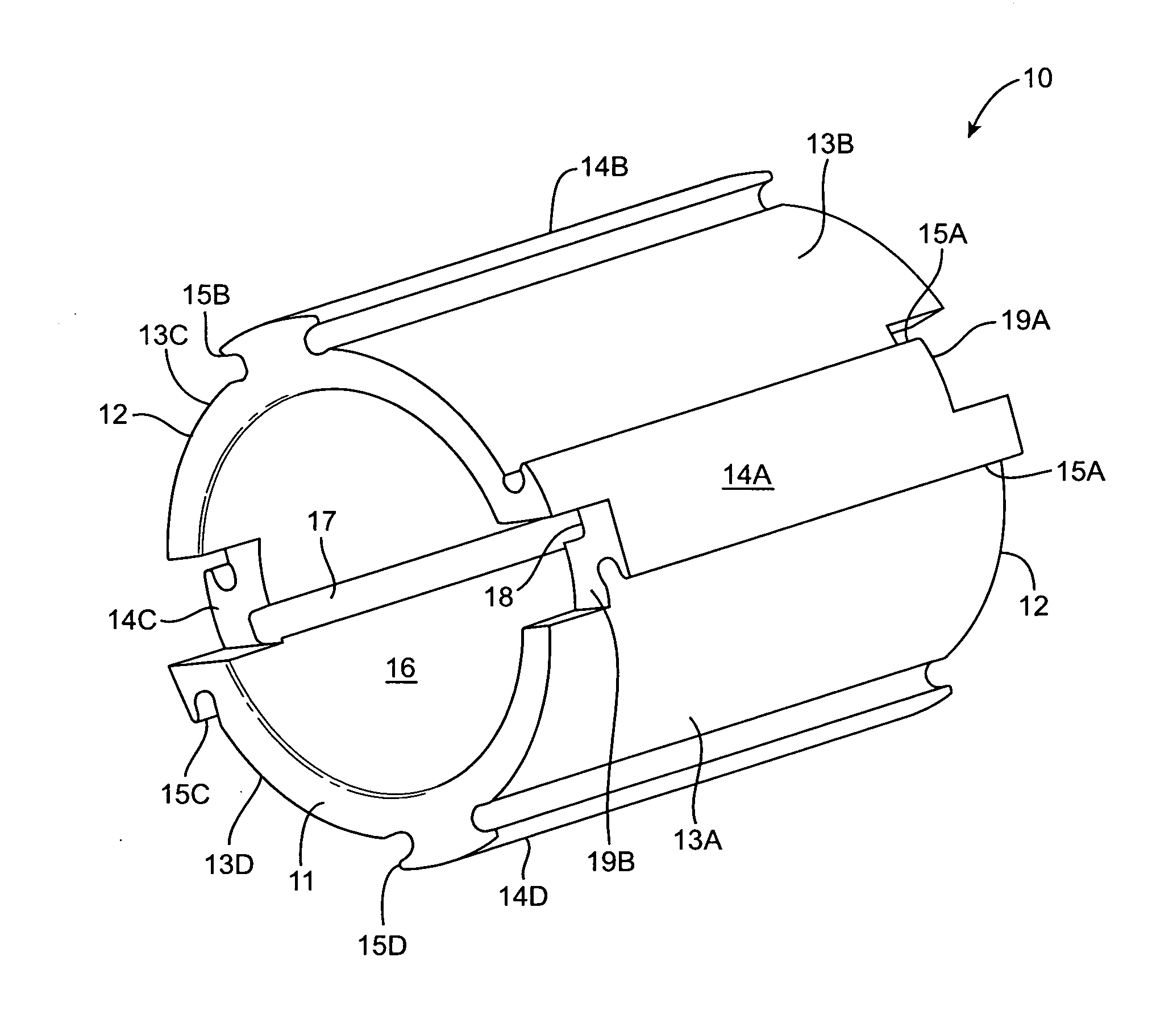

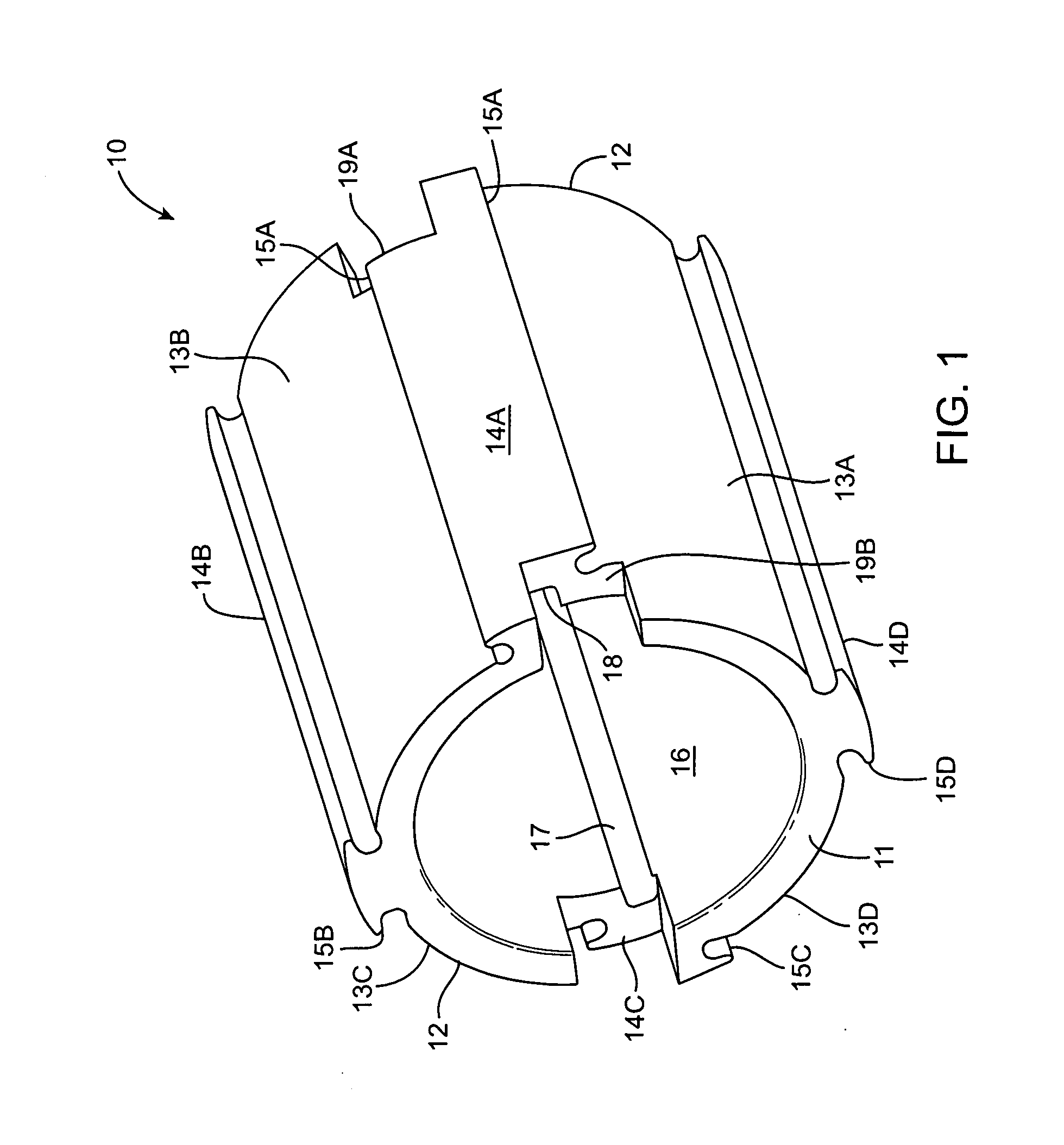

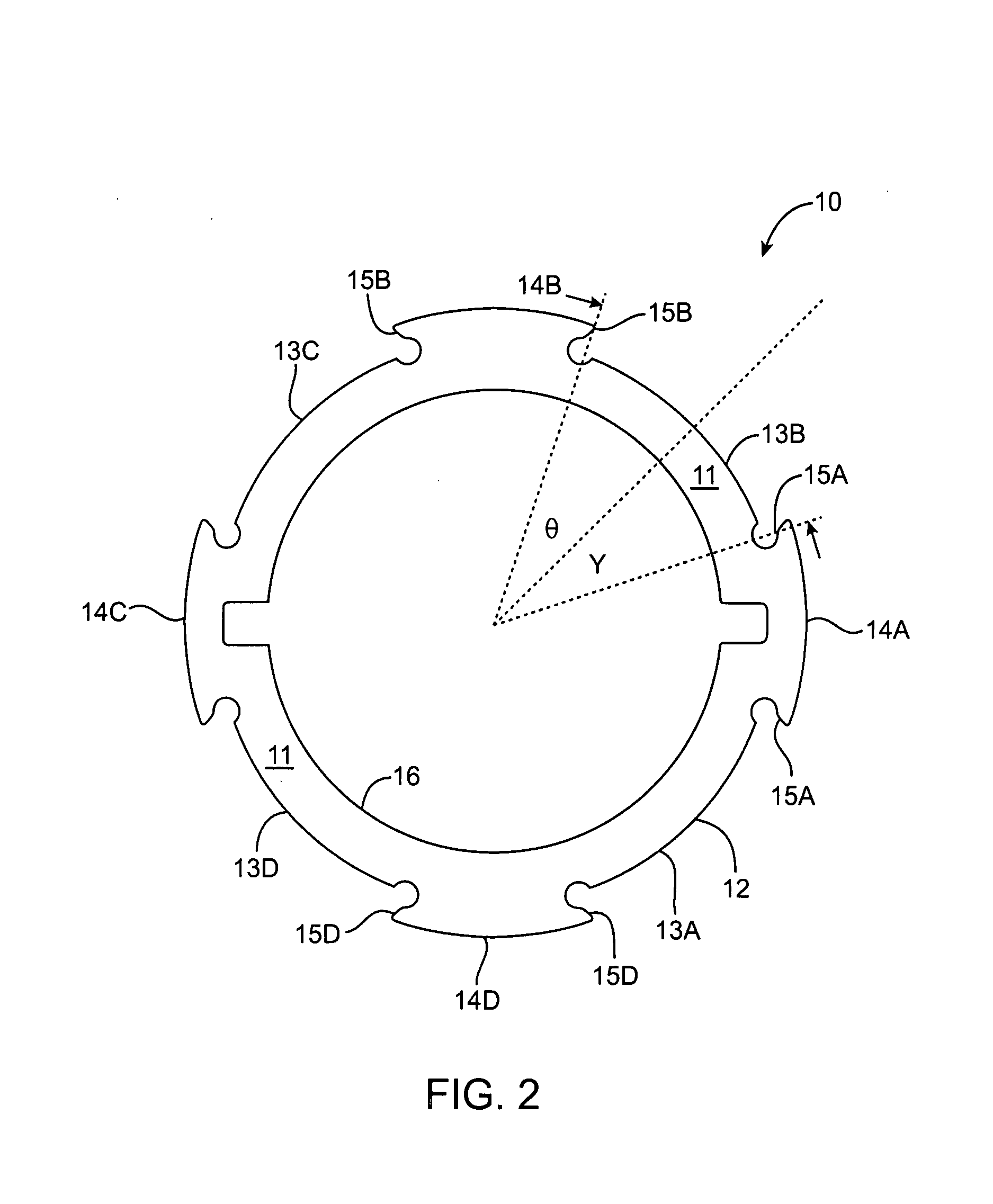

Electrode support

InactiveUS20080114230A1Electrode increaseTransvascular endocardial electrodesDiagnostic recording/measuringLead structureBiomedical engineering

Electrode supports configured to provide a foundation for a segmented electrode on a flexible lead structure are provided. Also provided are electrode structures, leads that include the same, implantable pulse generators that include the leads, as well as systems and kits having components thereof, and methods of making and using the subject devices.

Owner:PROTEUS DIGITAL HEALTH INC

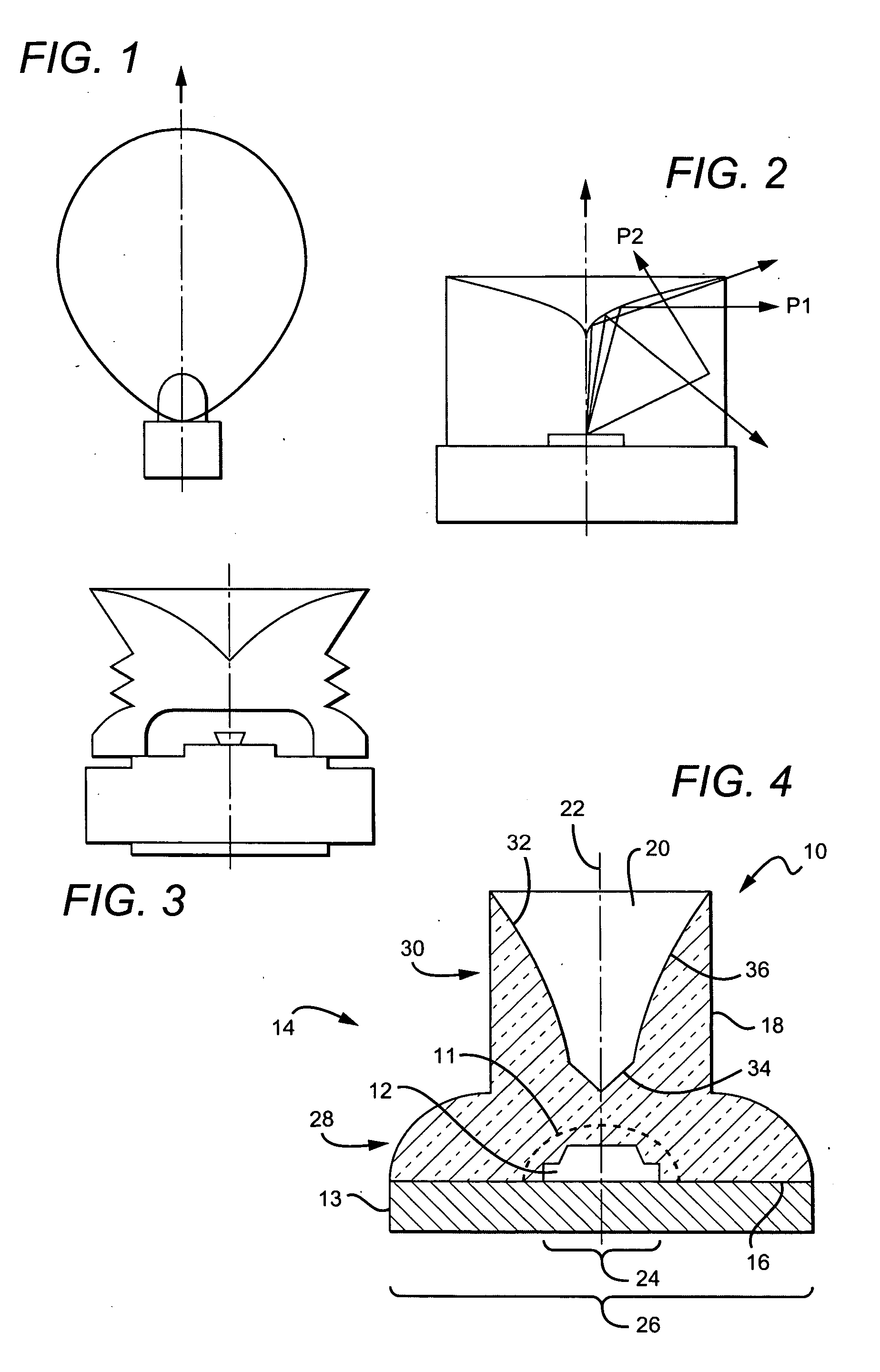

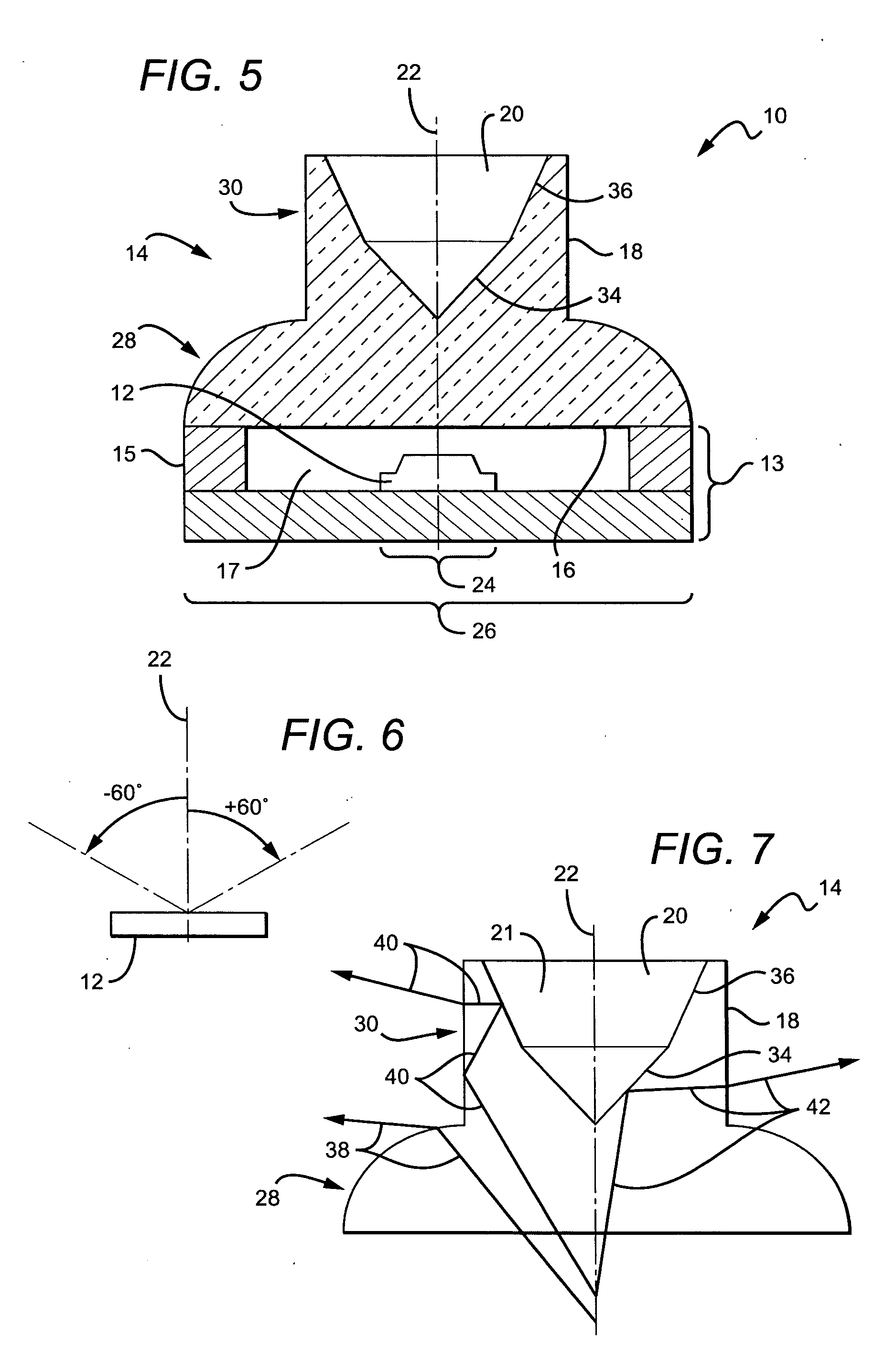

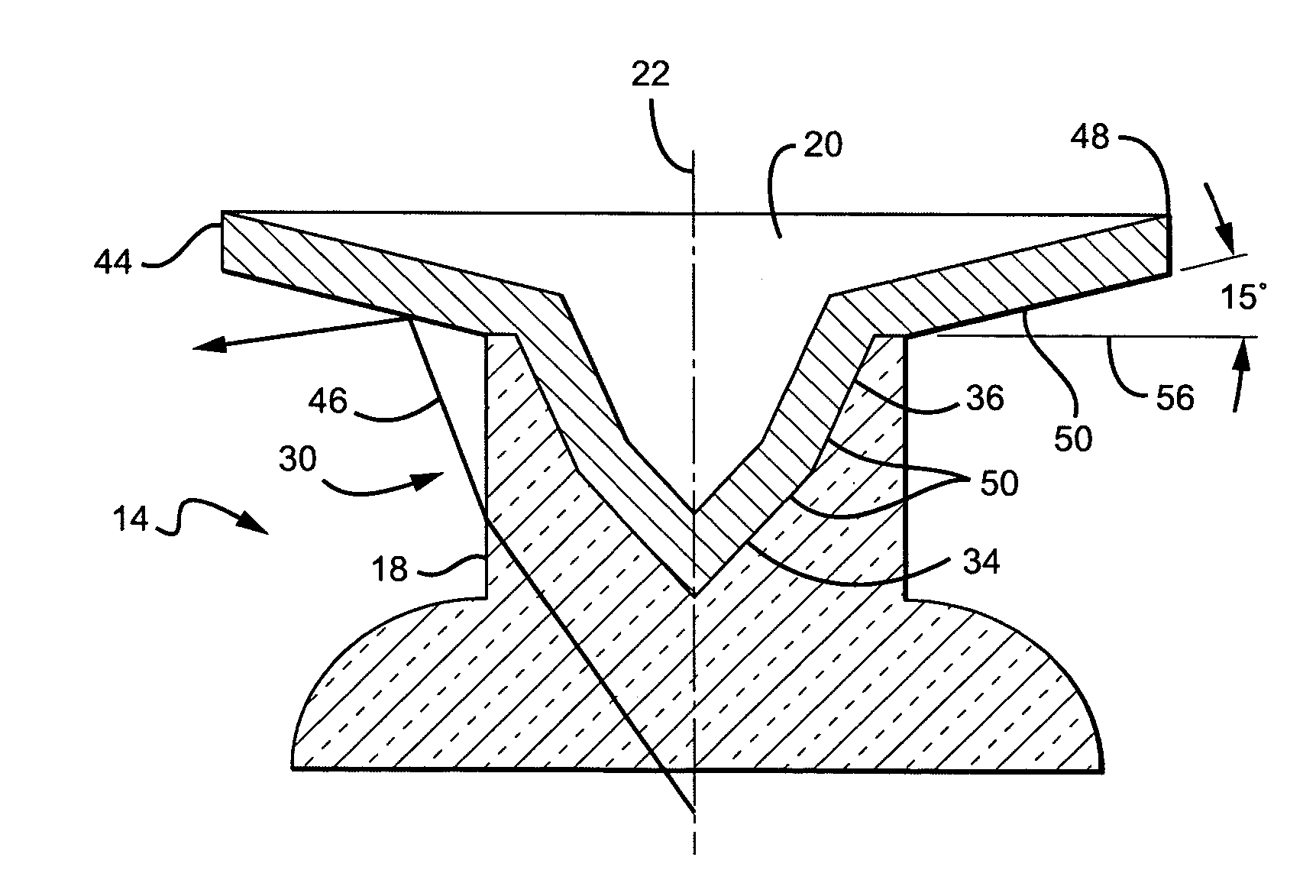

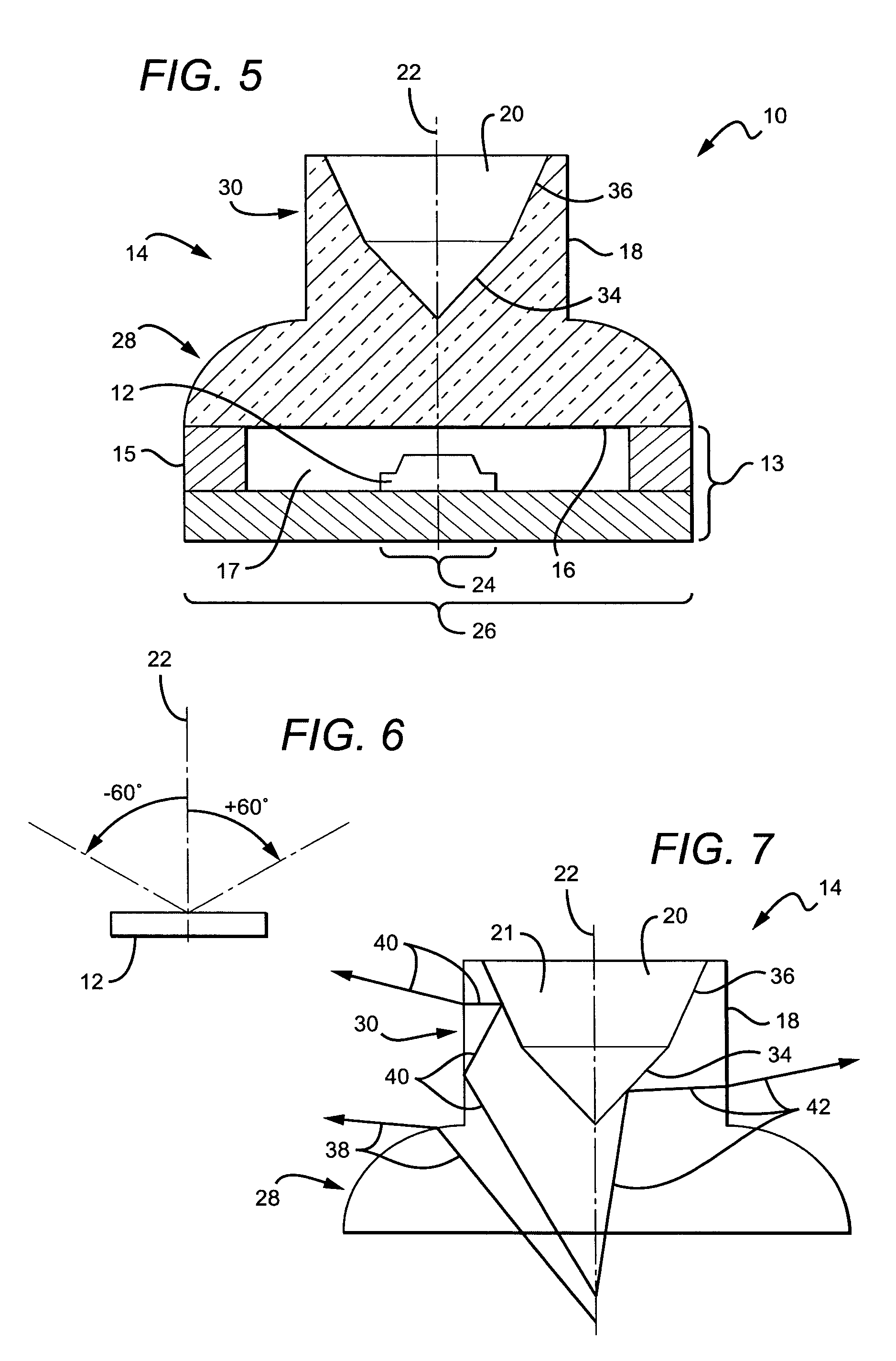

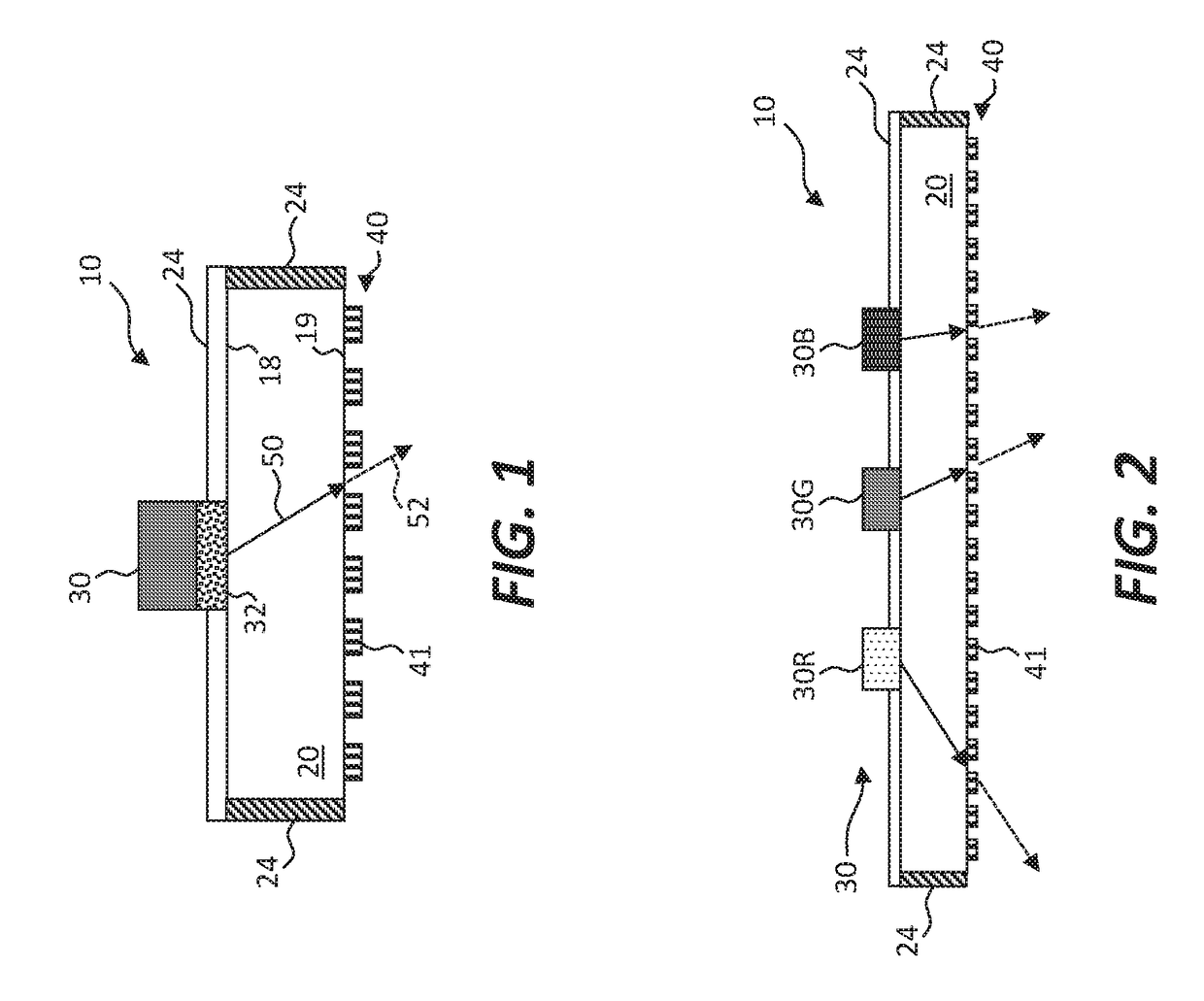

Side-emitting optical coupling device

ActiveUS20060076568A1Semiconductor/solid-state device manufacturingCondensersDielectricOptical coupling

An LED package includes a LED structure that outputs light in a pattern about an axis and an optical coupling device with a central axis. The coupling device is positioned relative to the LED structure and accepts light from the LED. The coupling device includes a first dielectric interface surface that is substantially cylindrical with respect to the central axis, and a reflecting surface. The first dielectric interface surface accepts a first portion of light from the LED structure and directs it toward the reflecting surface. The reflecting surface accepts the light from the first dielectric interface surface and directs it toward the first dielectric interface surface in a direction substantially perpendicular to the central axis.

Owner:CREELED INC

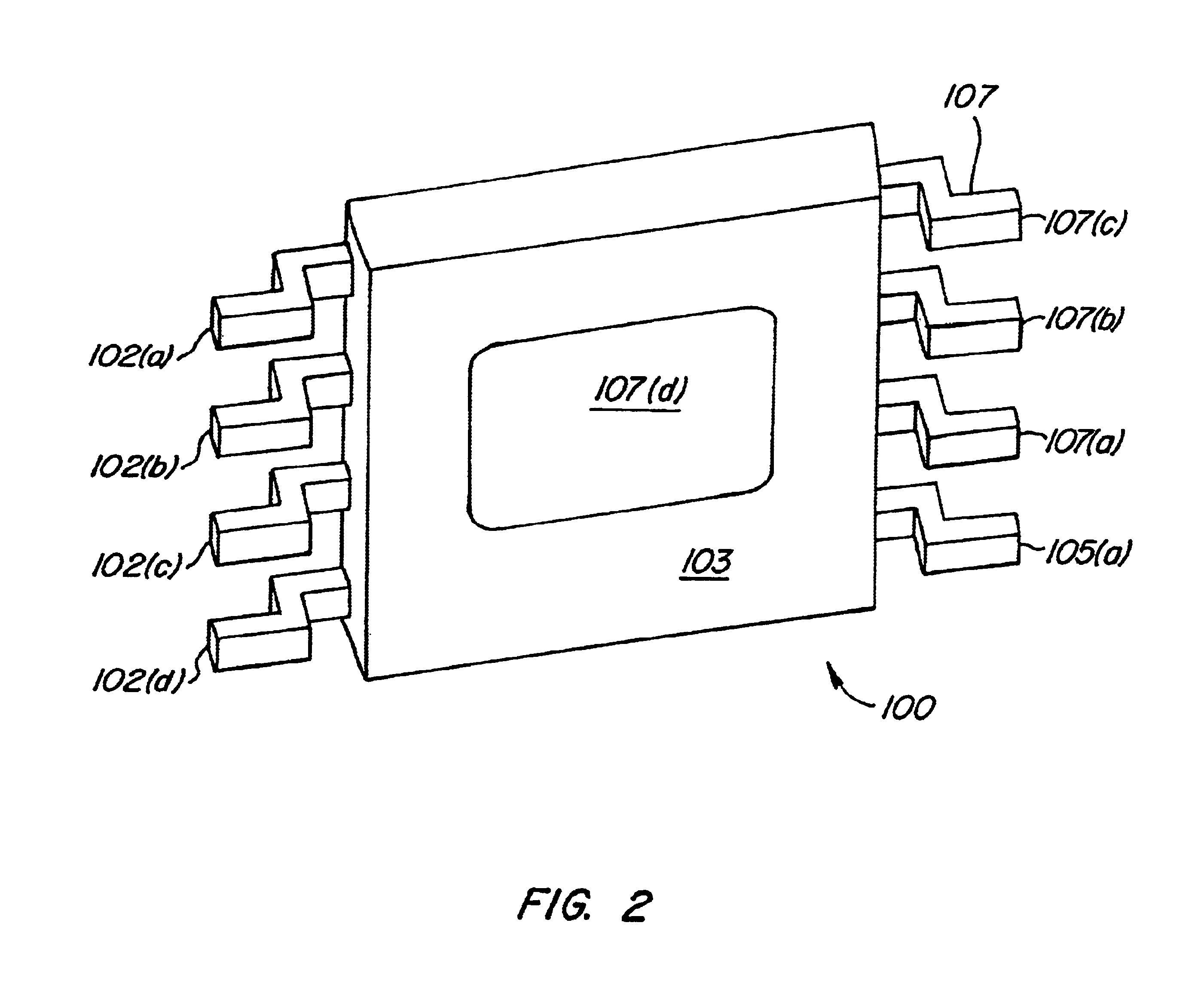

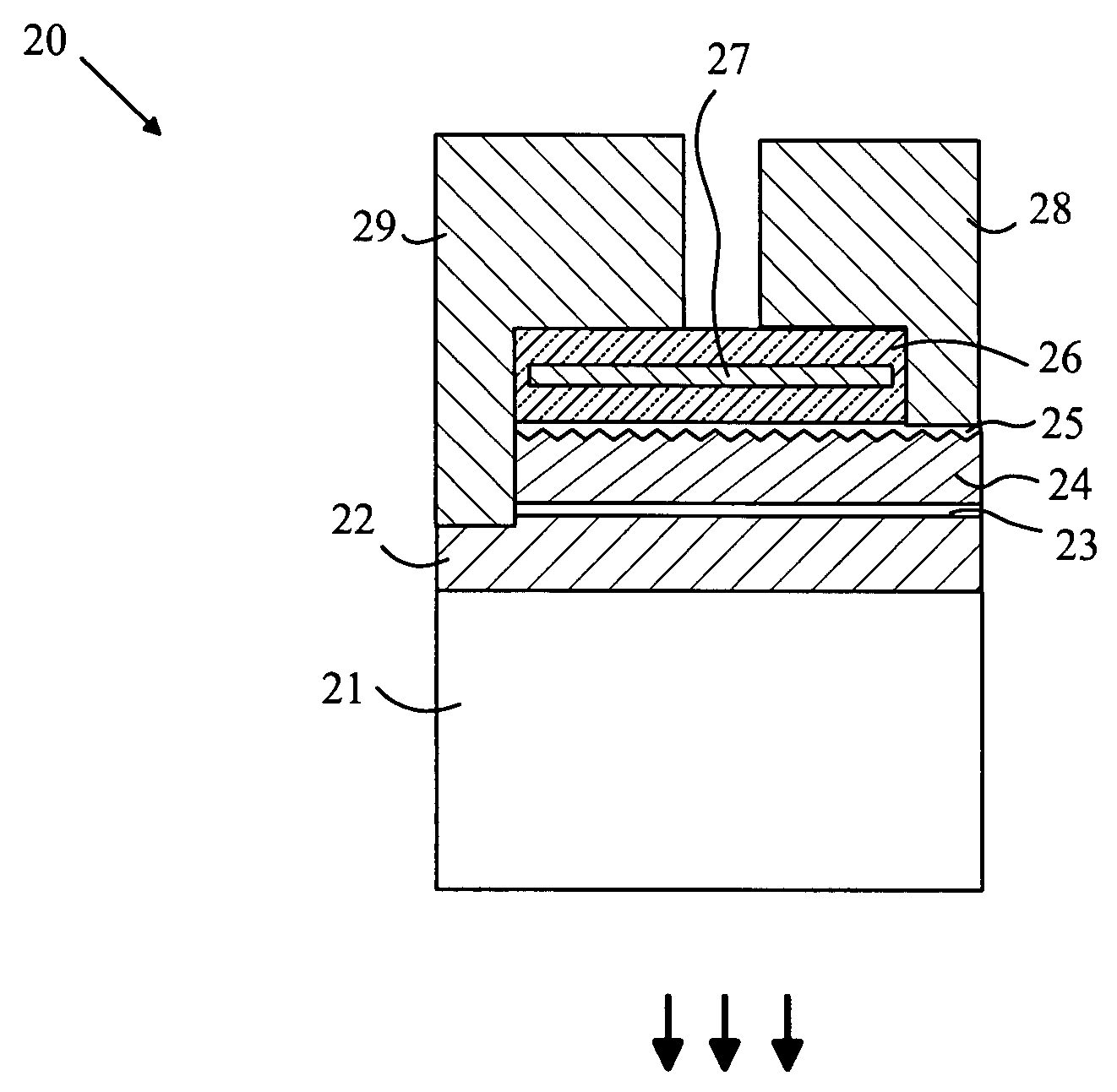

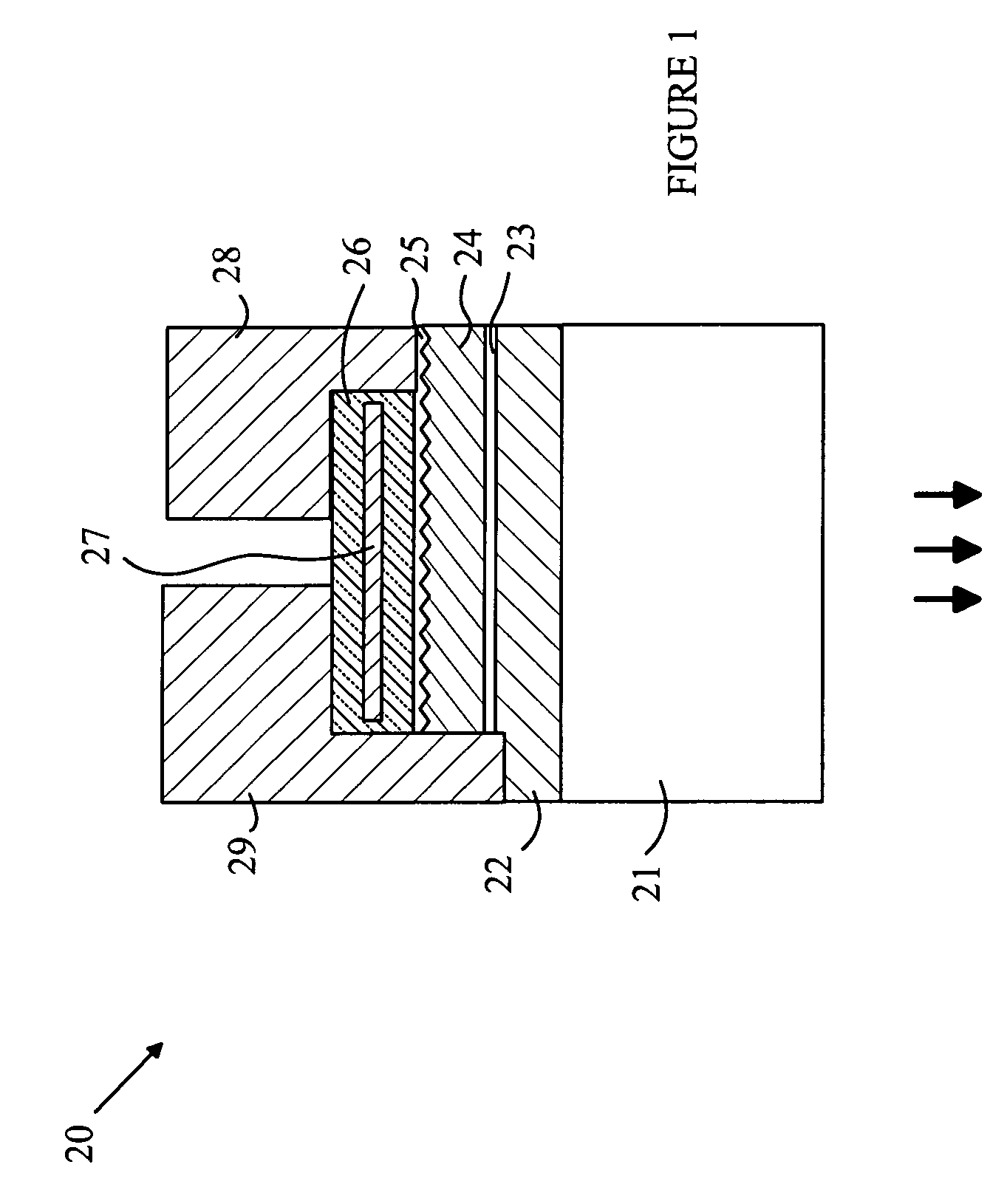

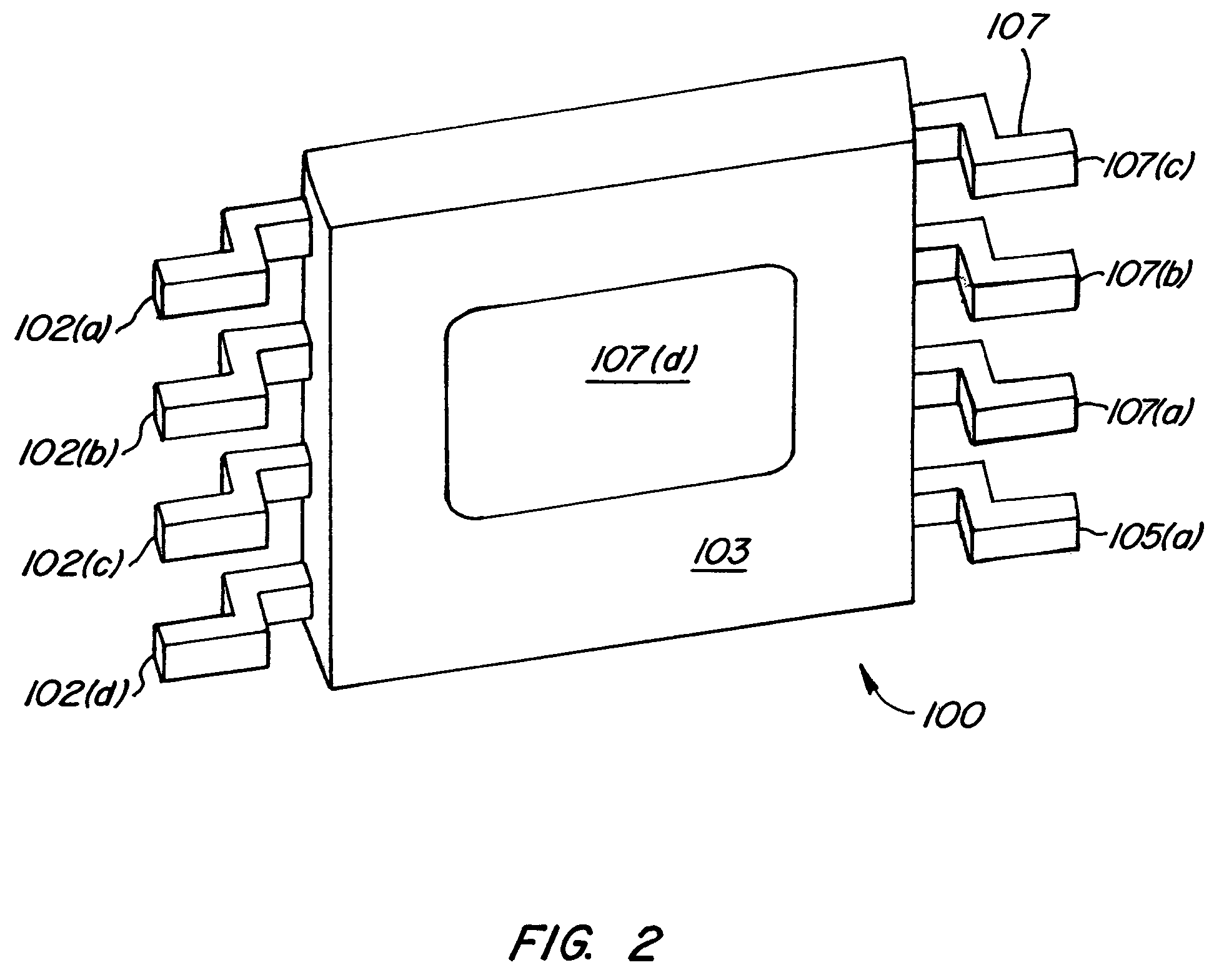

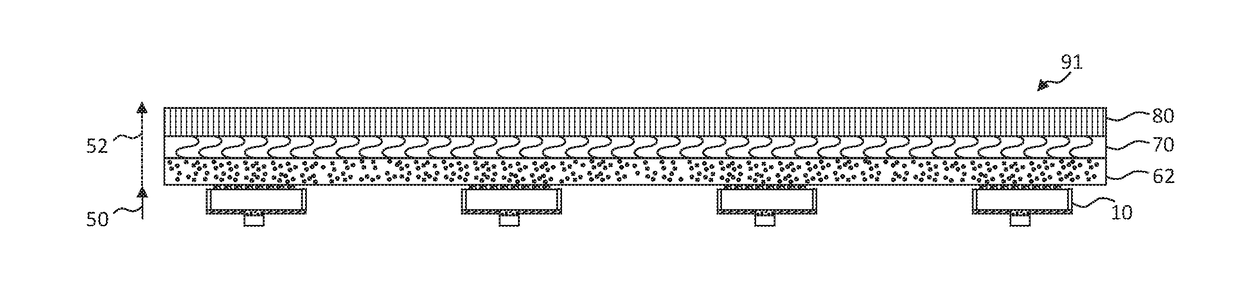

Thin, thermally enhanced flip chip in a leaded molded package

InactiveUS6891256B2Low profileThin profileSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead structure

Embodiments of the invention are directed to semiconductor die packages. One embodiment of the invention is directed to a semiconductor die package including, (a) a semiconductor die including a first surface and a second surface, (b) a source lead structure including protruding region having a major surface, the source lead structure being coupled to the first surface, (c) a gate lead structure being coupled to the first surface, and (d) a molding material around the source lead structure and the semiconductor die, where the molding material exposes the second surface of the semiconductor die and the major surface of the source lead structure.

Owner:SEMICON COMPONENTS IND LLC

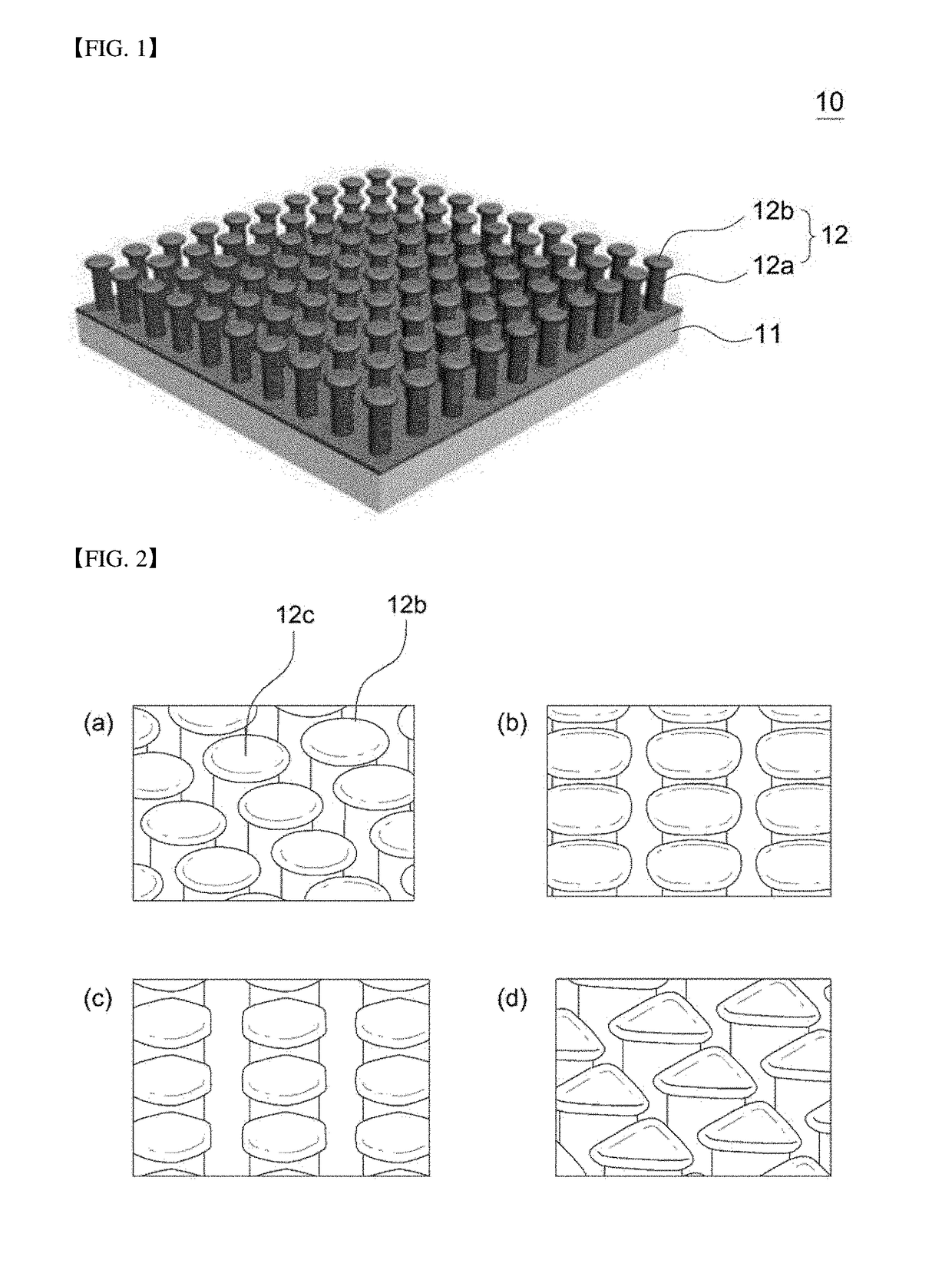

Nanowire LED structure and method for manufacturing the same

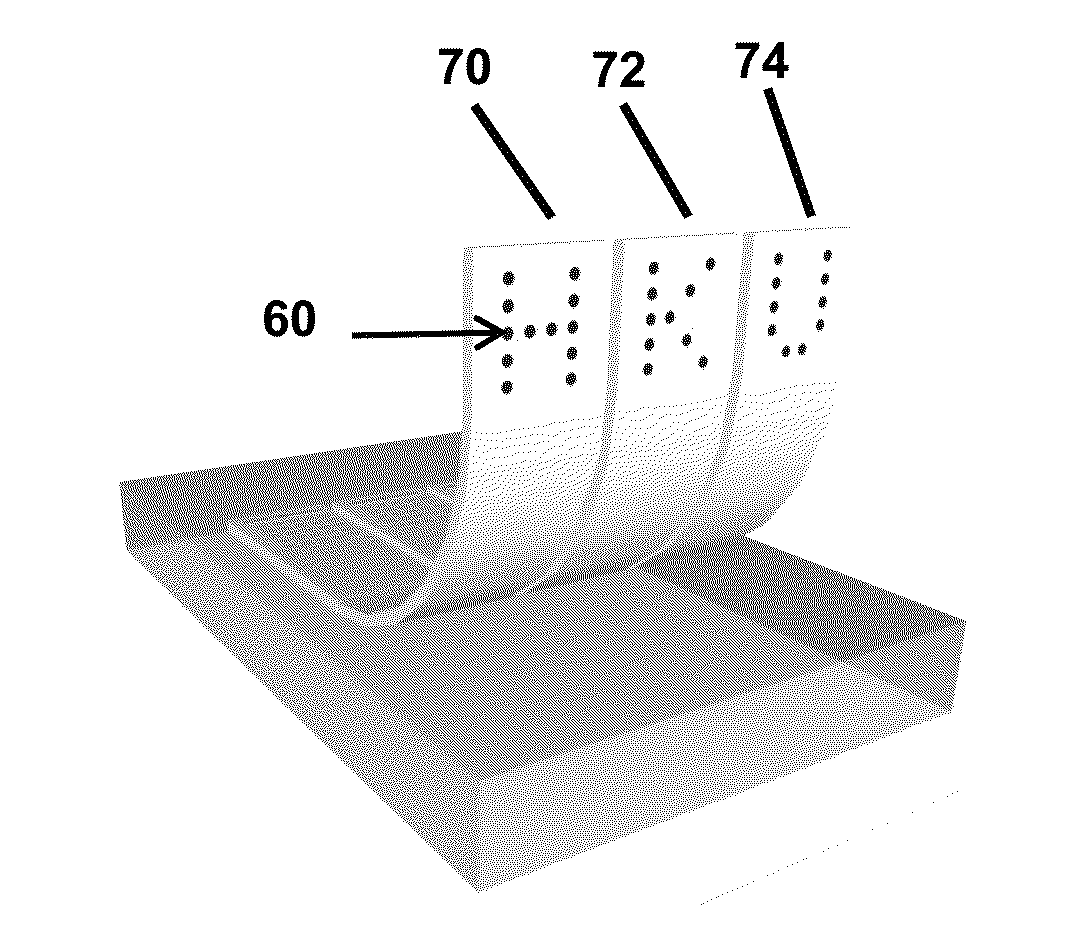

ActiveUS20110309382A1Discontinuity is reduced and eliminatedEasy to spreadSolid-state devicesSemiconductor/solid-state device manufacturingElectricityAir bridge

A light emitting diode (LED) structure includes a plurality of devices arranged side by side on a support layer. Each device includes a first conductivity type semiconductor nanowire core and an enclosing second conductivity type semiconductor shell for forming a pn or pin junction that in operation provides an active region for light generation. A first electrode layer extends over the plurality of devices and is in electrical contact with at least a top portion of the devices to connect to the shell. The first electrode layer is at least partly air-bridged between the devices.

Owner:NANOSYS INC

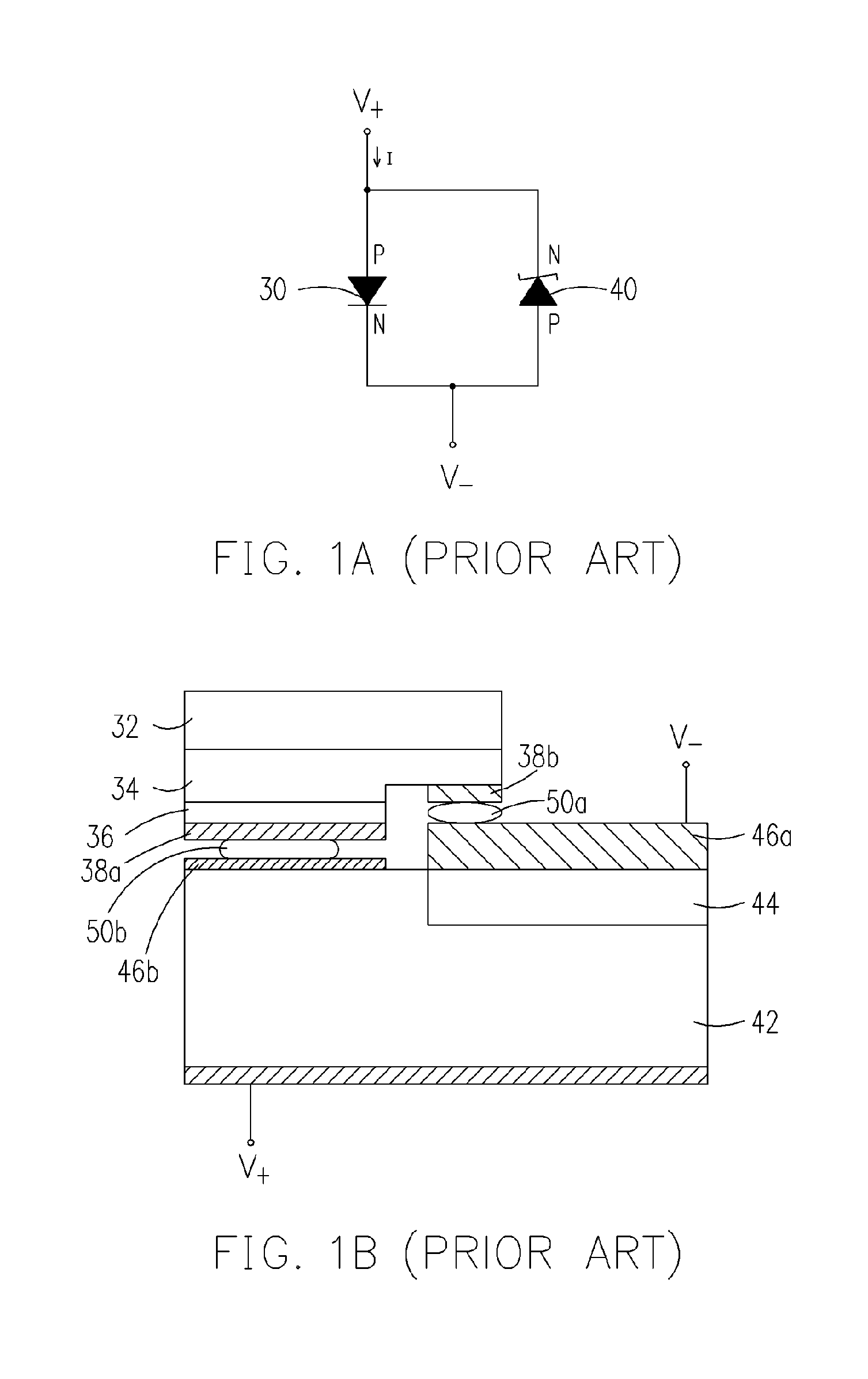

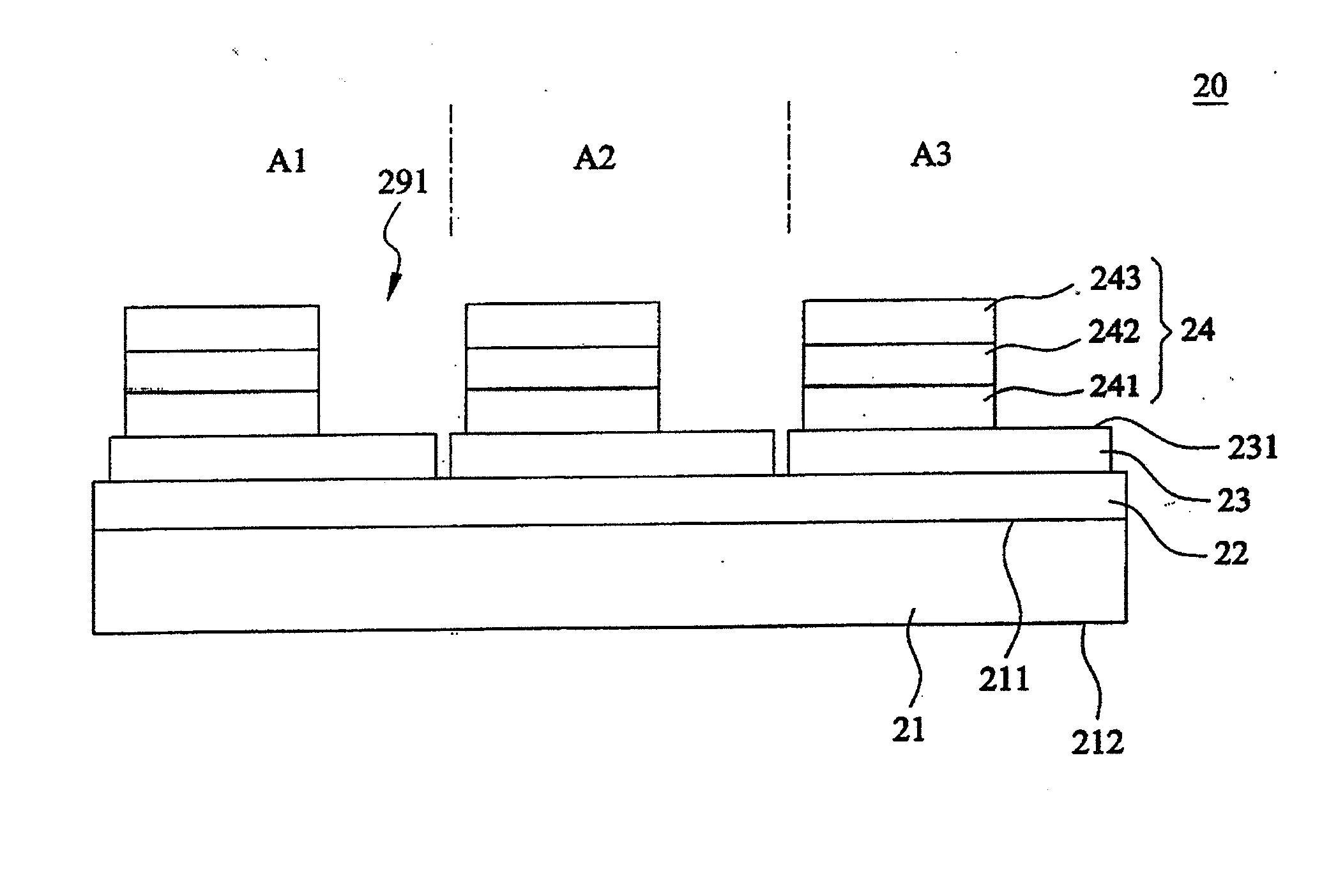

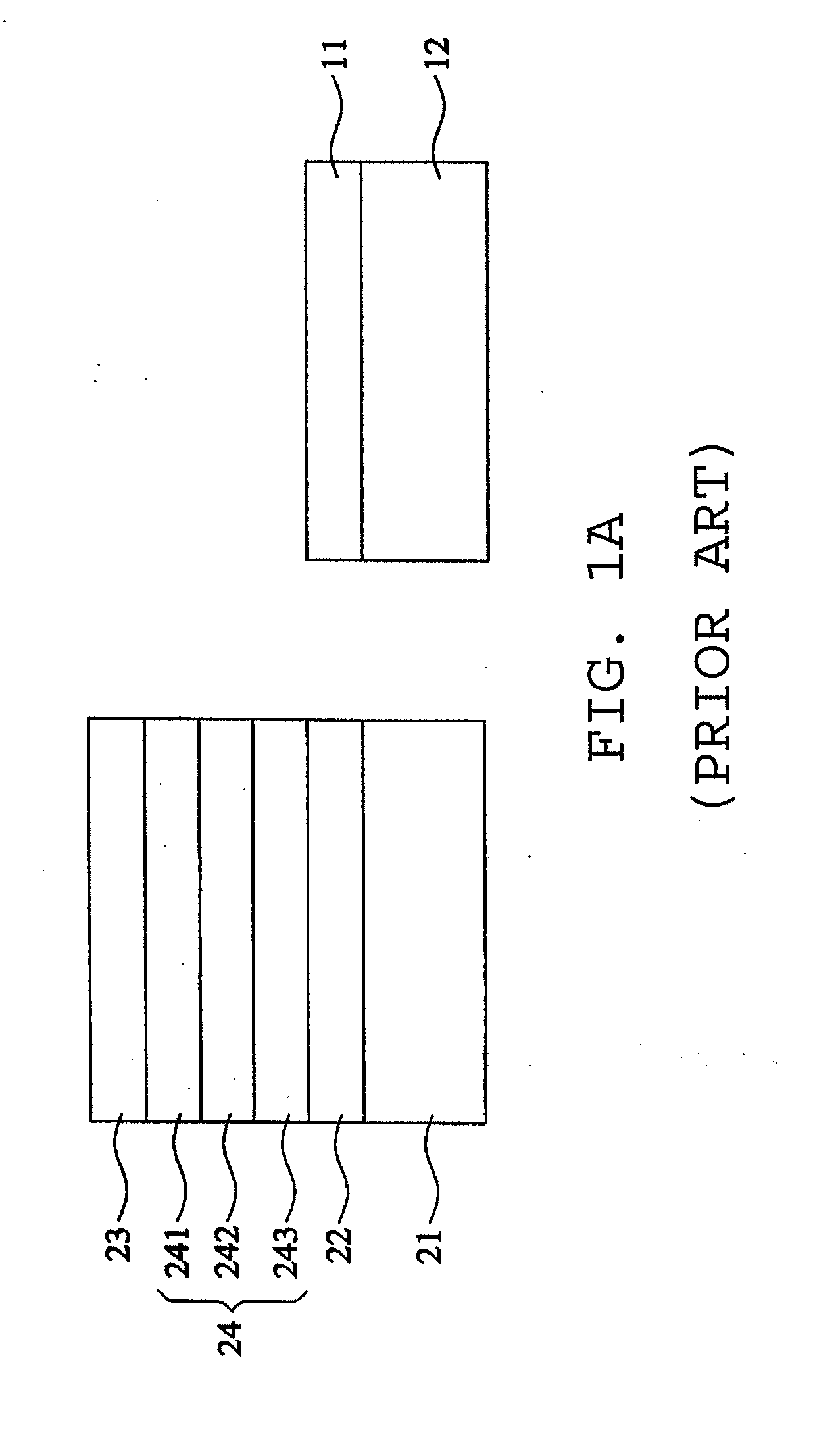

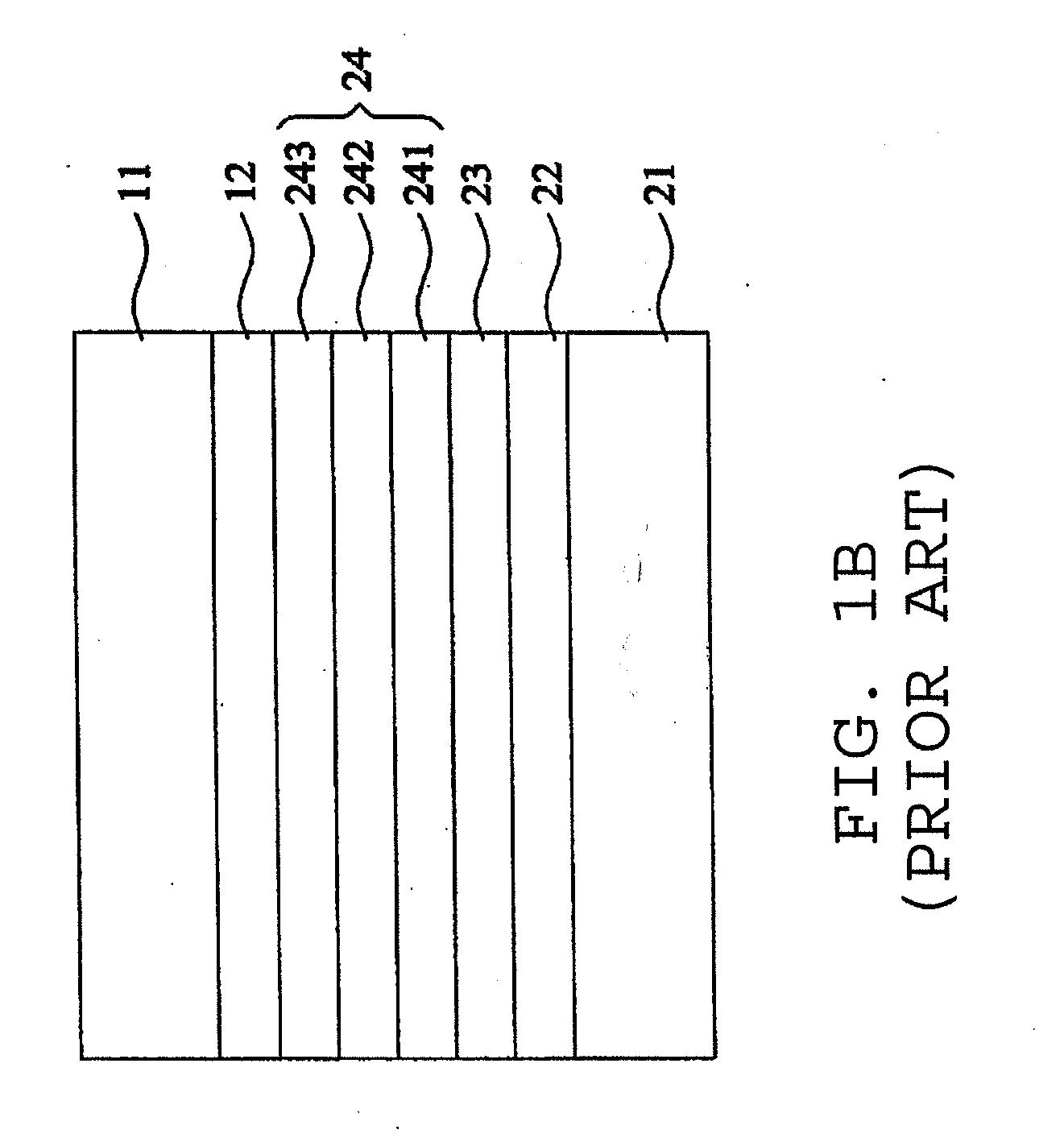

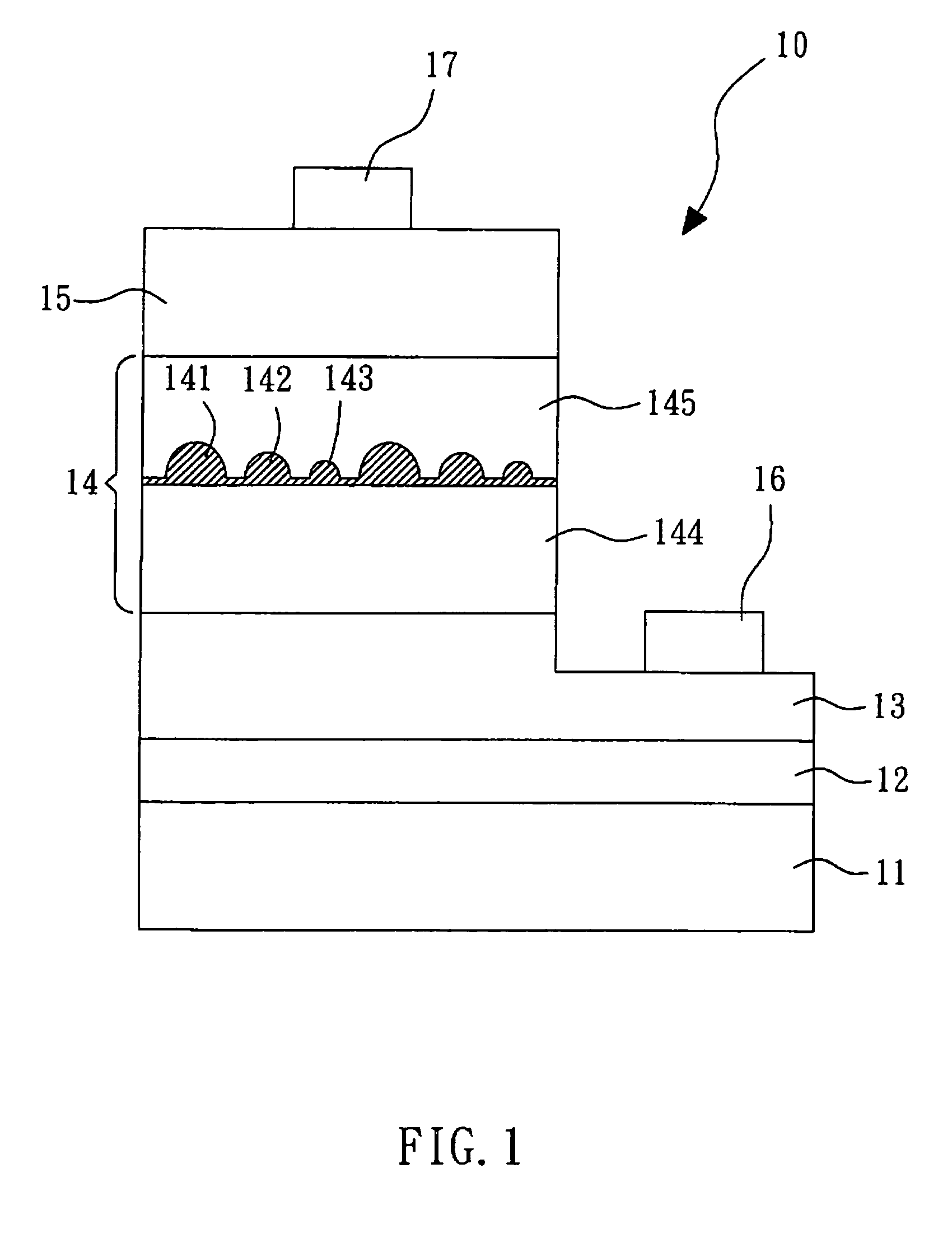

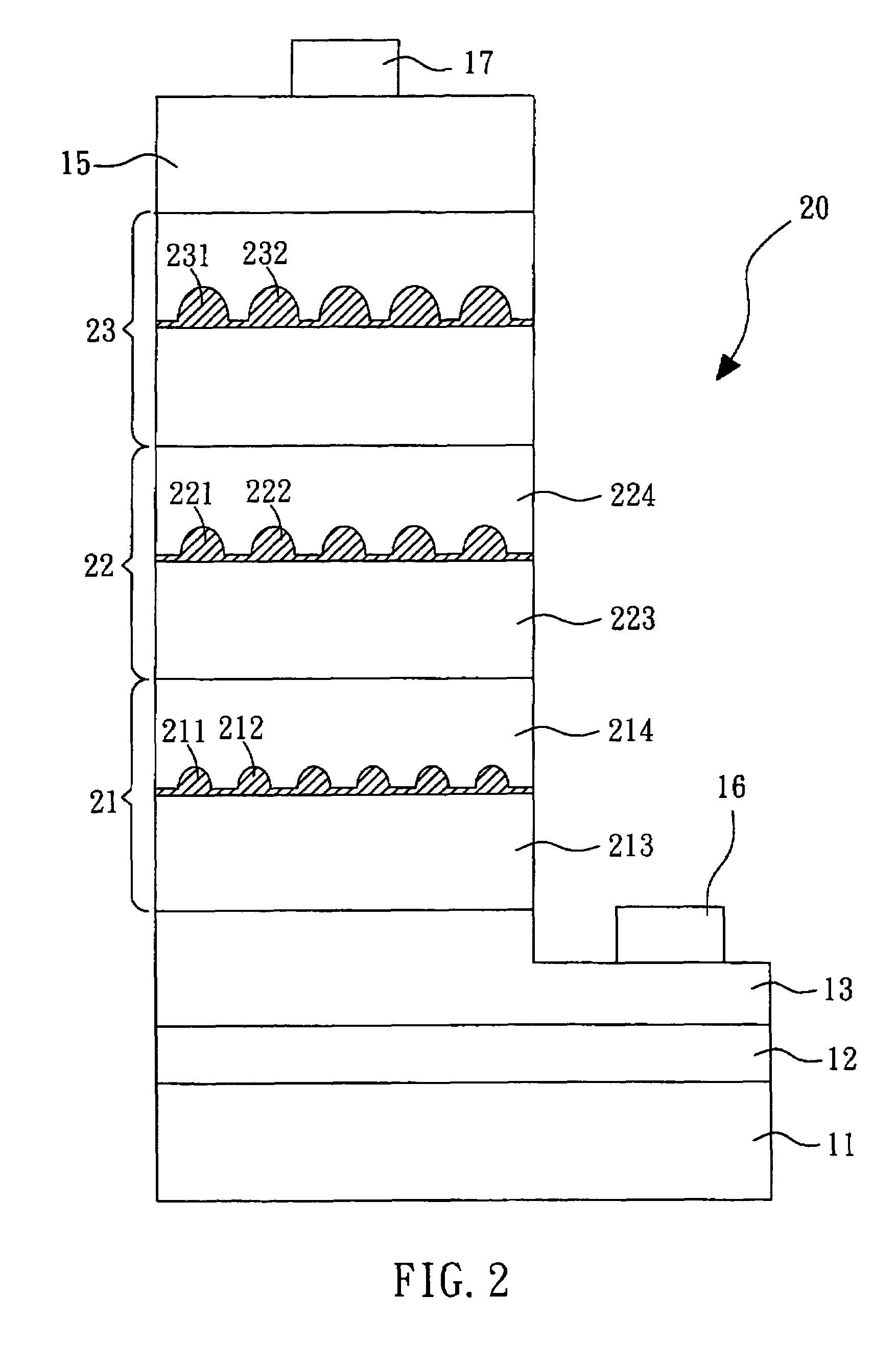

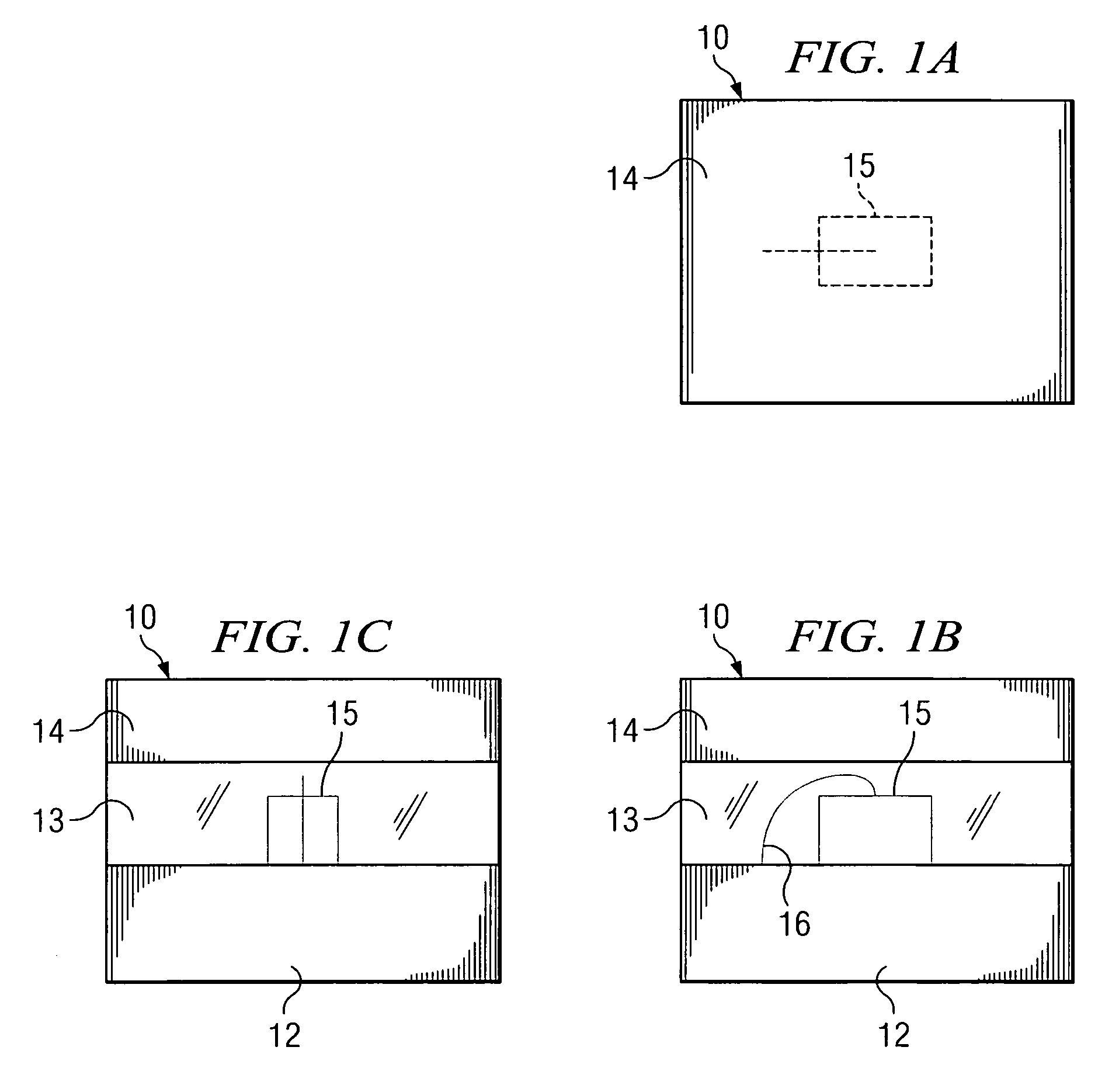

Light-emitting diode structure with electrostatic discharge protection

InactiveUS20050167680A1Protection from damageLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead structure

A light-emitting diode (LED) structure with electrostatic discharge (ESD) protection is described. The LED includes a substrate, a patterned semiconductor layer, a first electrode and a second electrode. The patterned semiconductor layer is disposed over the substrate, and is divided into at least a first island structure and a second island structure. The first electrode and the second electrode are connected between the first island structure and the second island structure. A shunt diode is formed by the first electrode, the second electrode and the second island structure. The shunt diode is connected in parallel to the LED with an inverse voltage compared to the LED. In the LED structure of the invention, the first island structure and the second island structure are manufactured simultaneously by the epitaxy procedure. Therefore, the LED could be protected from damage due to electrostatic discharge (ESD).

Owner:EPISTAR CORP

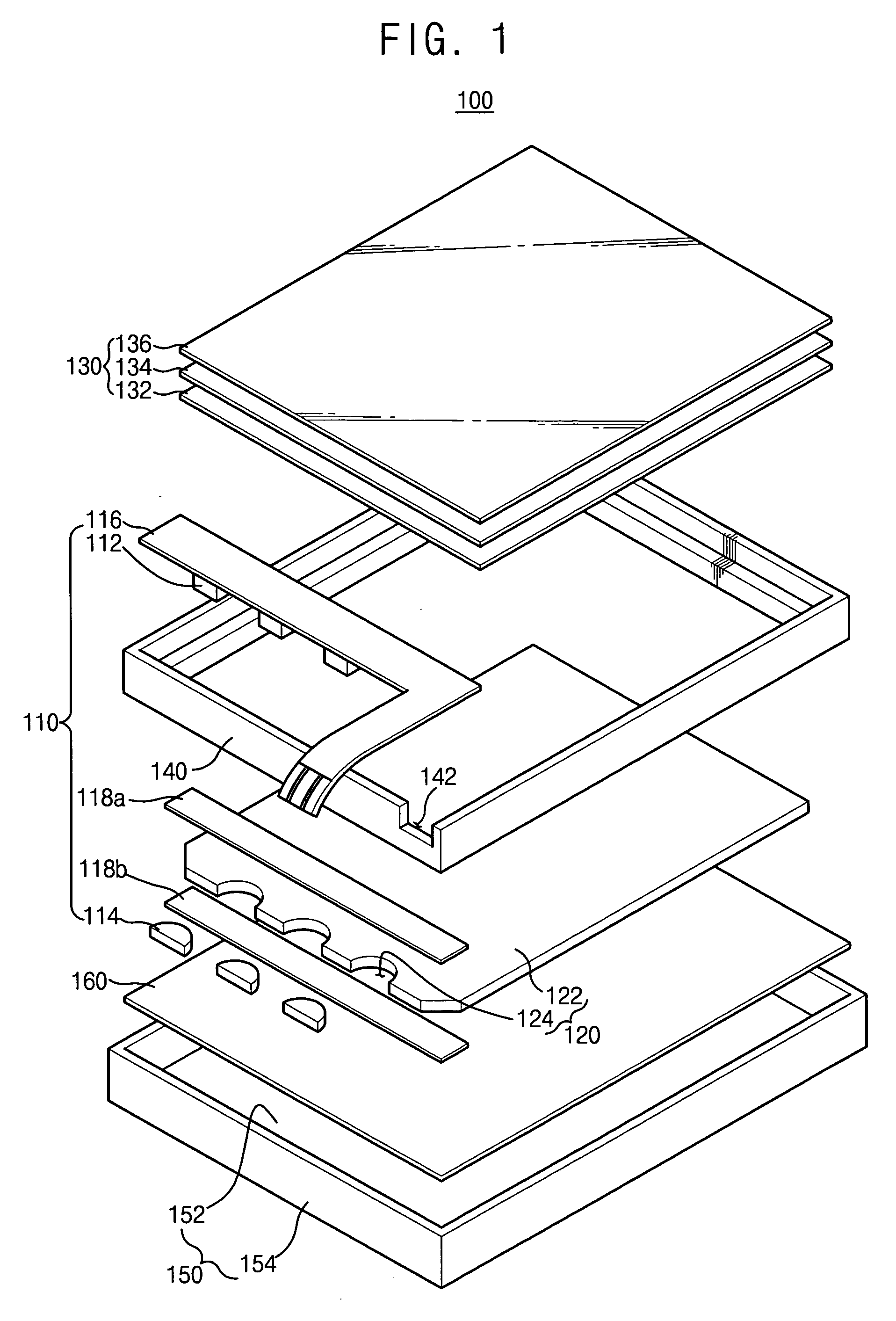

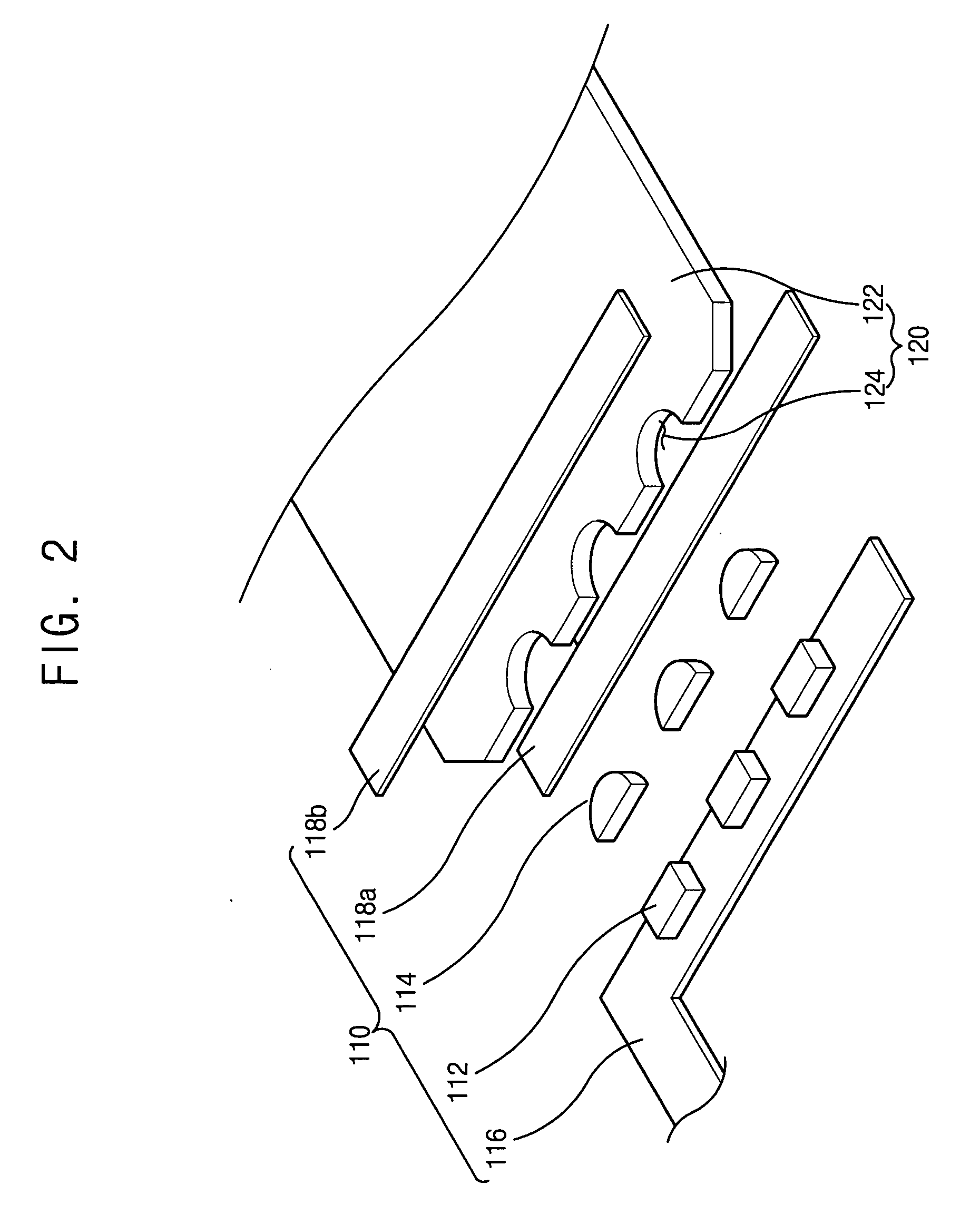

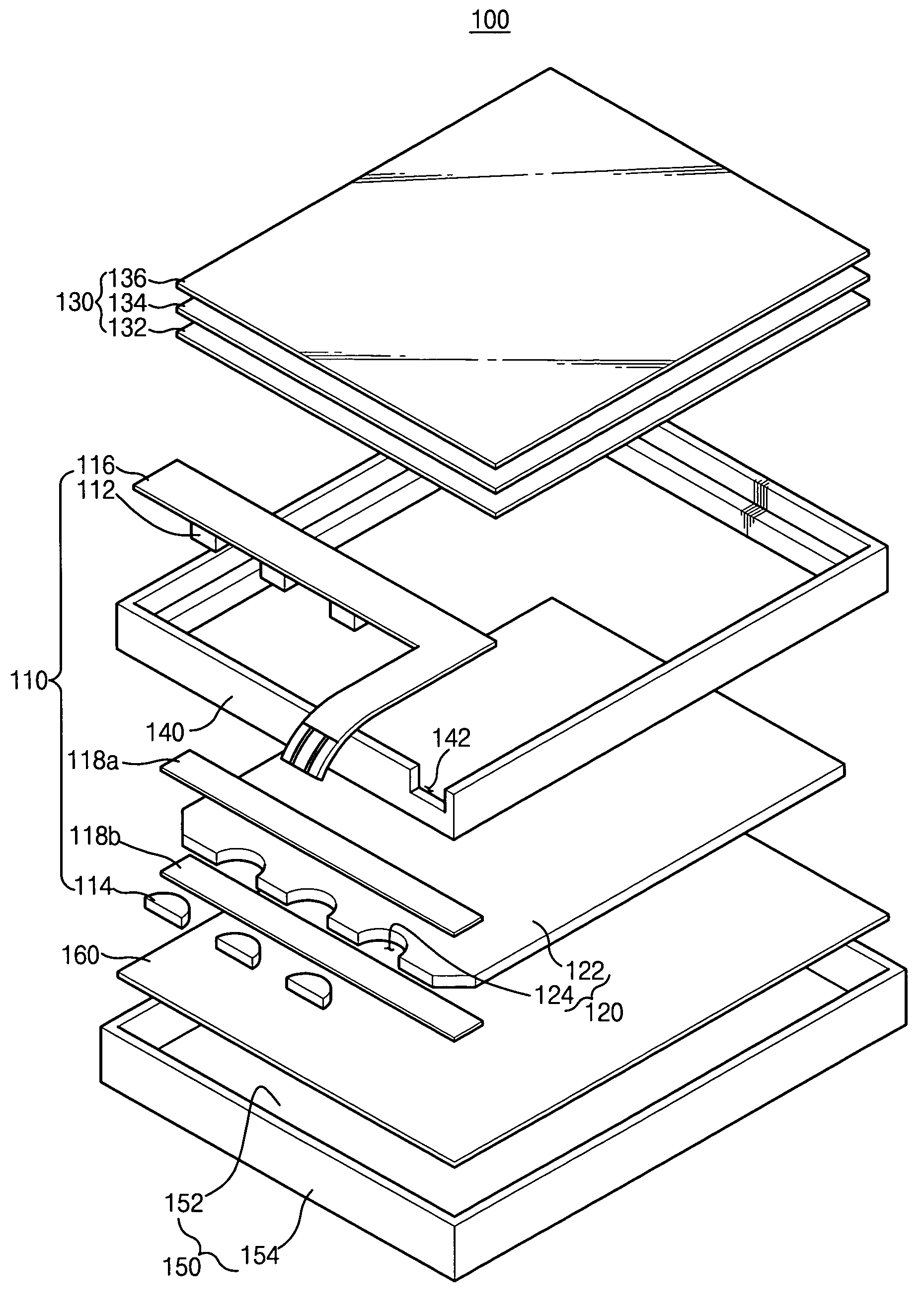

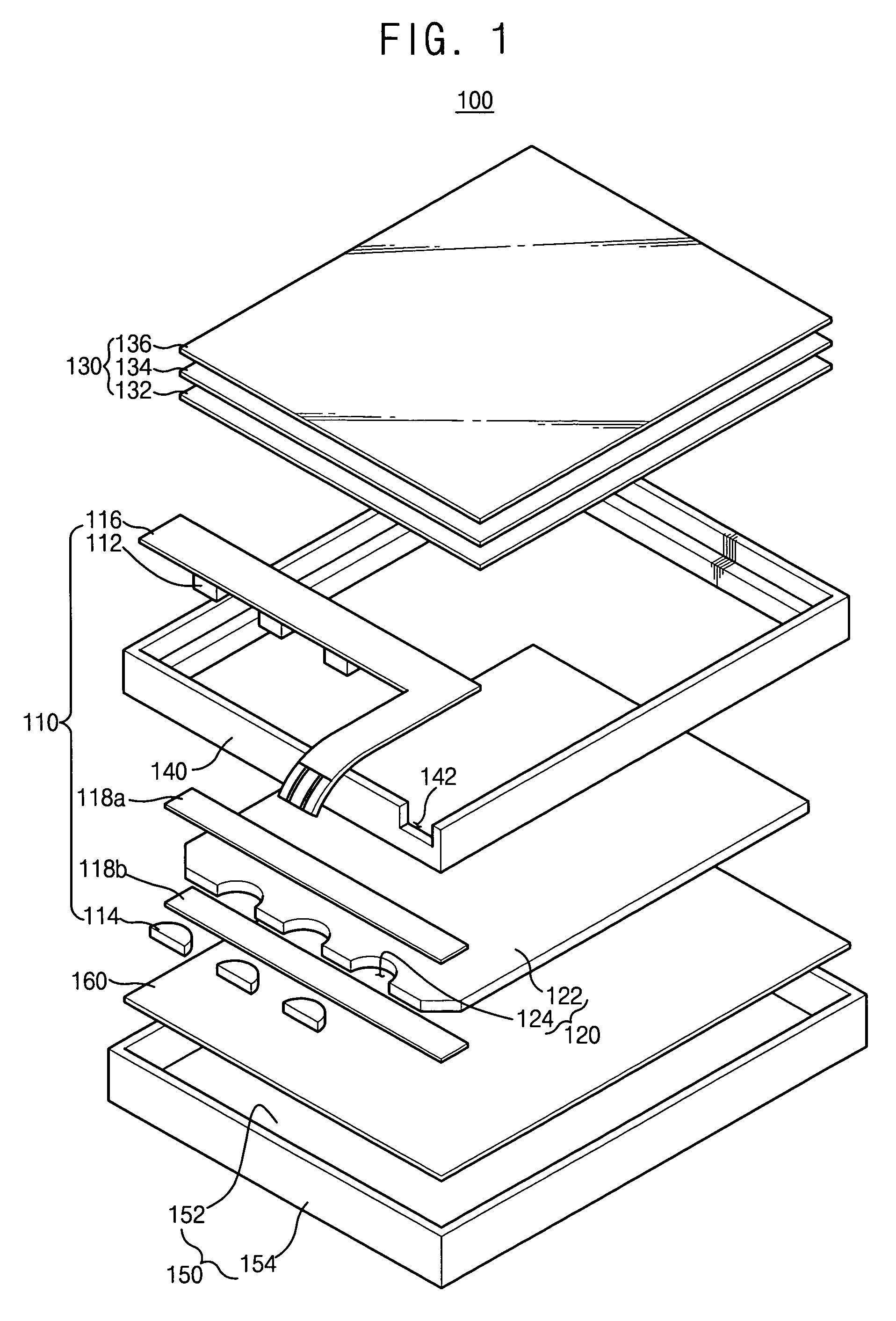

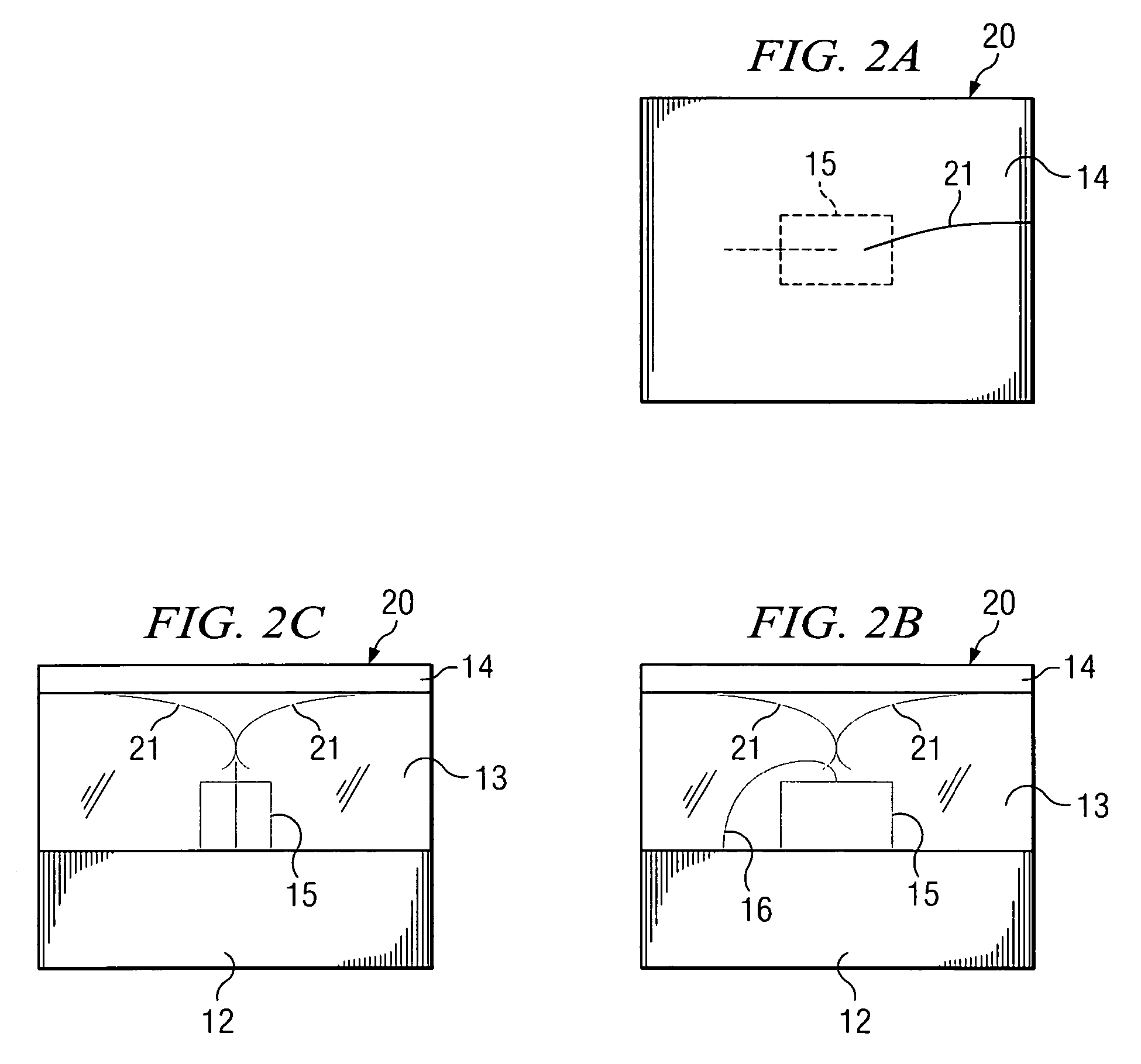

White light generating unit, backlight assembly having the same and liquid crystal display device having the same

ActiveUS20060072315A1Small sizeImprove divergence anglePlanar/plate-like light guidesSpectral modifiersLiquid-crystal displayFluorescence

A white light generating unit includes an LED structure and a lens structure. The LED structure generates a light. The lens structure has a convex lens or a concave lens. The lens structure has a fluorescent member that receives the light from the LED structure to emit a white light.

Owner:SAMSUNG DISPLAY CO LTD

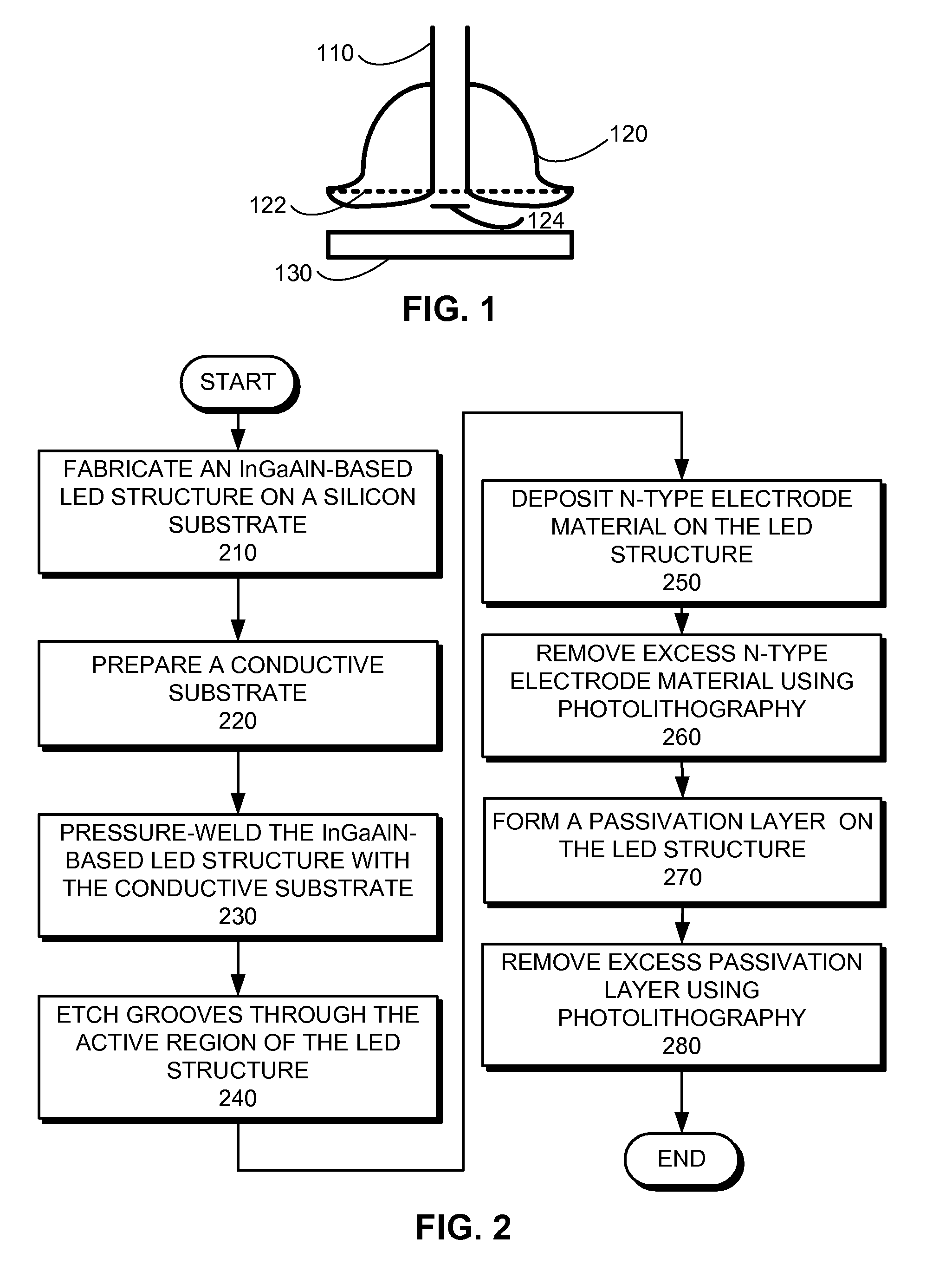

Method for fabricating robust light-emitting diodes

InactiveUS20110049540A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringLead structure

One embodiment of the present invention provides a method for fabricating light-emitting diodes (LEDs). The method includes fabricating an InGaAlN-based multilayer LED structure on a conductive substrate. The method further includes etching grooves of a predetermined pattern through the active region of the multilayer LED structure. The grooves separate a light-emitting region from non-light-emitting regions. In addition, the method includes depositing electrode material on the light-emitting and non-light-emitting regions, thereby creating an electrode. Furthermore, the method includes depositing a passivation layer covering the light-emitting and non-light-emitting regions. Moreover, the method includes removing the passivation layer on the electrode to allow the non-light-emitting regions which are covered with the electrode material and the passivation layer to be higher than the light-emitting region and the electrode, thereby protecting the light-emitting region from contact with test equipment.

Owner:LATTICE POWER (JIANGXI) CORP

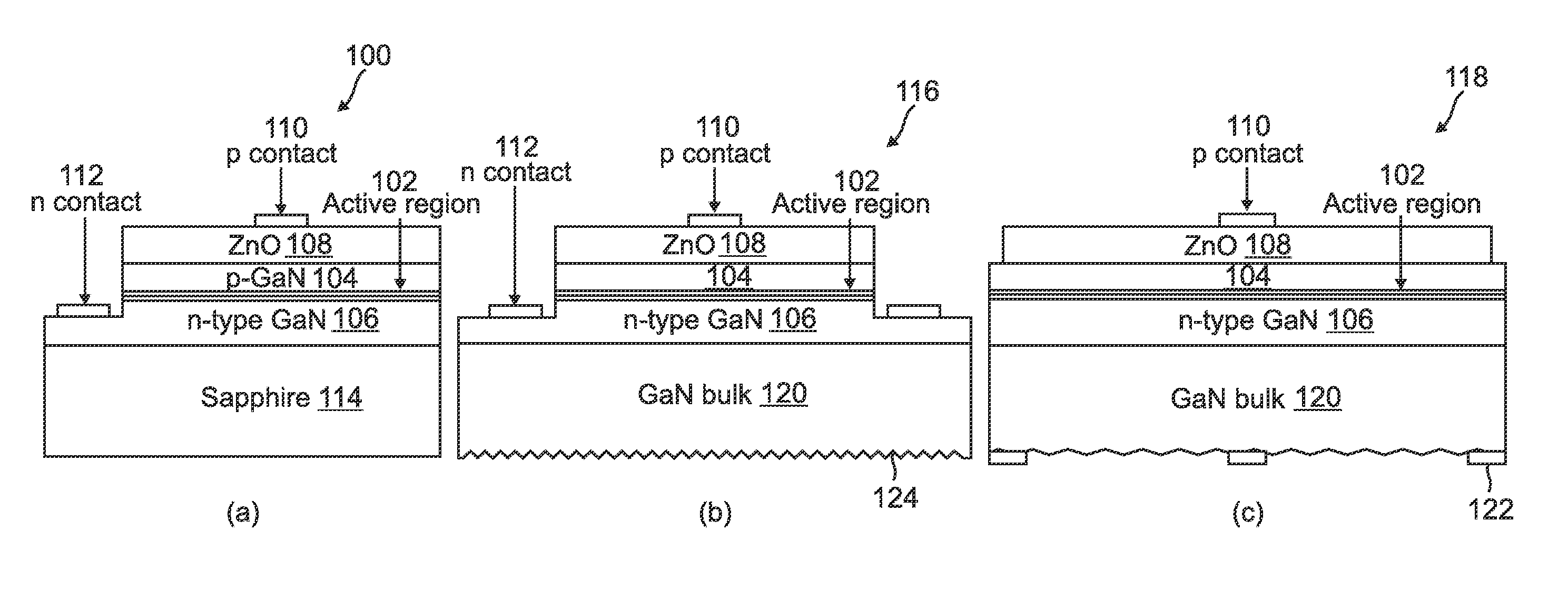

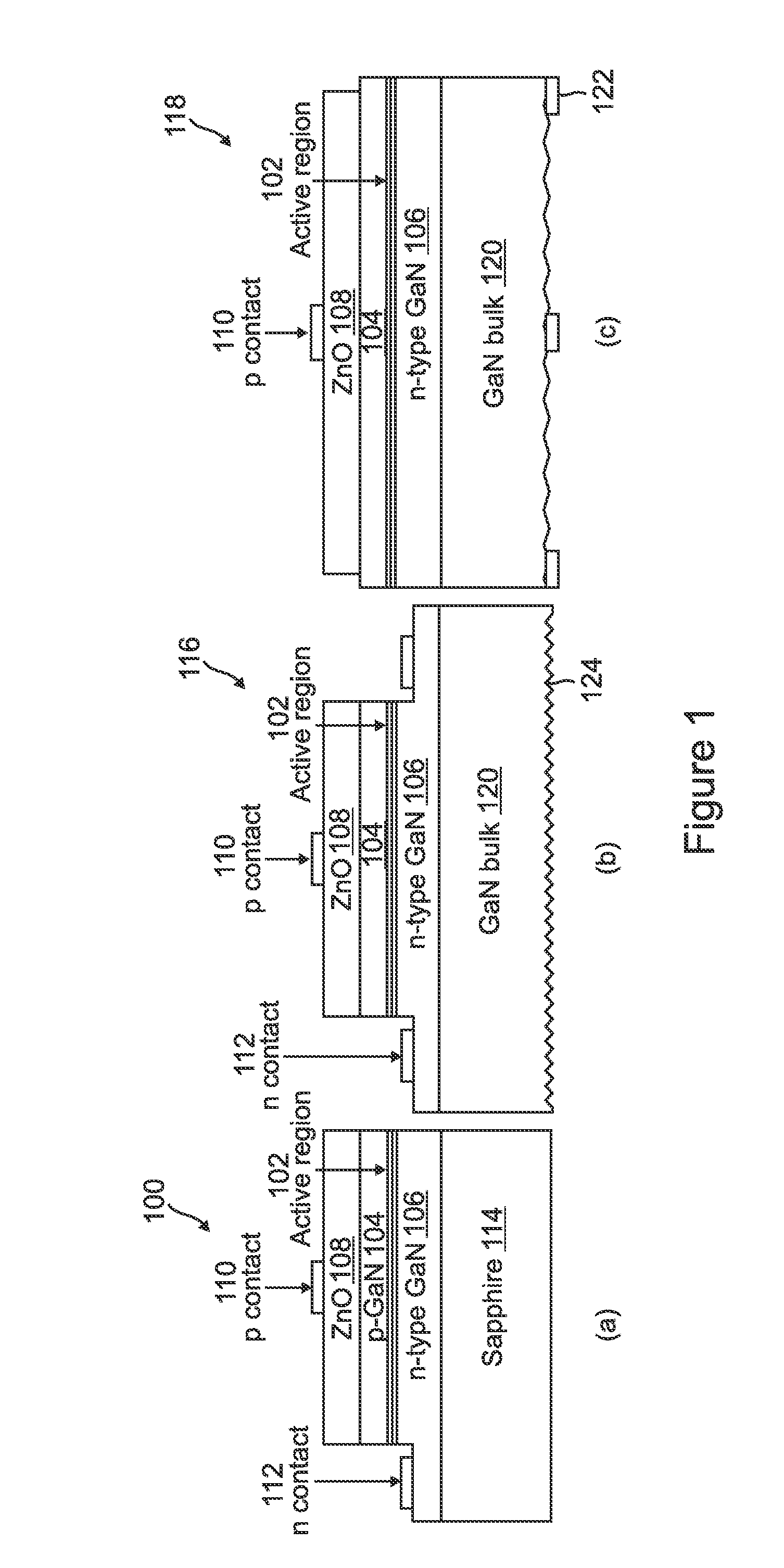

Light emitting diodes with zinc oxide current spreading and light extraction layers deposited from low temperature aqueous solution

ActiveUS20110101414A1Accelerated dissipationEasy extractionLiquid-phase epitaxial-layer growthZinc oxides/hydroxidesPower flowAqueous solution

A method for fabricating a Light Emitting Diode (LED) with increased light extraction efficiency, comprising providing a III-Nitride based LED structure comprising a light emitting active layer between a p-type layer and an n-type layer; growing a Zinc Oxide (ZnO) layer epitaxially on the p-type layer by submerging a surface of the p-type layer in a low temperature aqueous solution, wherein the ZnO layer is a transparent current spreading layer; and depositing a p-type contact on the ZnO layer. The increase in efficiency may be more than 93% with very little or no increase in cost.

Owner:RGT UNIV OF CALIFORNIA

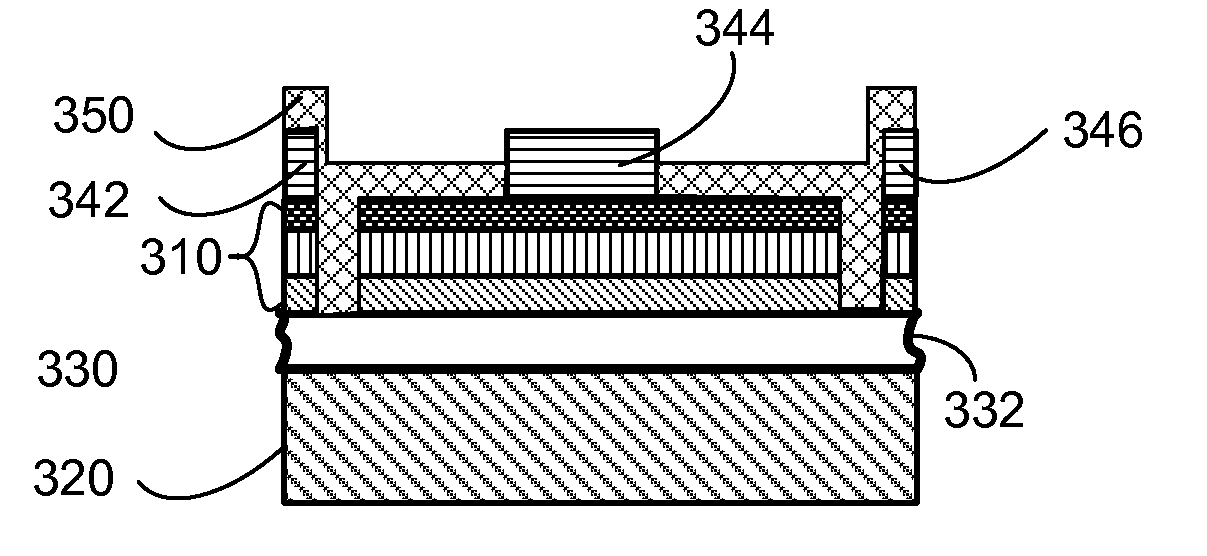

LED Structure

InactiveUS20100059733A1Improve finenessSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactIsolation layer

An LED structure includes a first substrate; an adhering layer formed on the first substrate; first ohmic contact layers formed on the adhering layer; epi-layers formed on the first ohmic contact layers; a first isolation layer covering the first ohmic contact layers and the epi-layers at exposed surfaces thereof; and first electrically conducting plates and second electrically conducting plates, both formed in the first isolation layer and electrically connected to the first ohmic contact layers and the epi-layers, respectively. The first trenches or the second trenches allow the LED structure to facilitate complex serial / parallel connection so as to achieve easy and various applications of the LED structure in the form of single structures under a high-voltage environment.

Owner:HELIO OPTOELECTRONICS

Side-emitting optical coupling device

An LED package includes a LED structure that outputs light in a pattern about an axis and an optical coupling device with a central axis. The coupling device is positioned relative to the LED structure and accepts light from the LED. The coupling device includes a first dielectric interface surface that is substantially cylindrical with respect to the central axis, and a reflecting surface. The first dielectric interface surface accepts a first portion of light from the LED structure and directs it toward the reflecting surface. The reflecting surface accepts the light from the first dielectric interface surface and directs it toward the first dielectric interface surface in a direction substantially perpendicular to the central axis.

Owner:CREELED INC

LED Structure

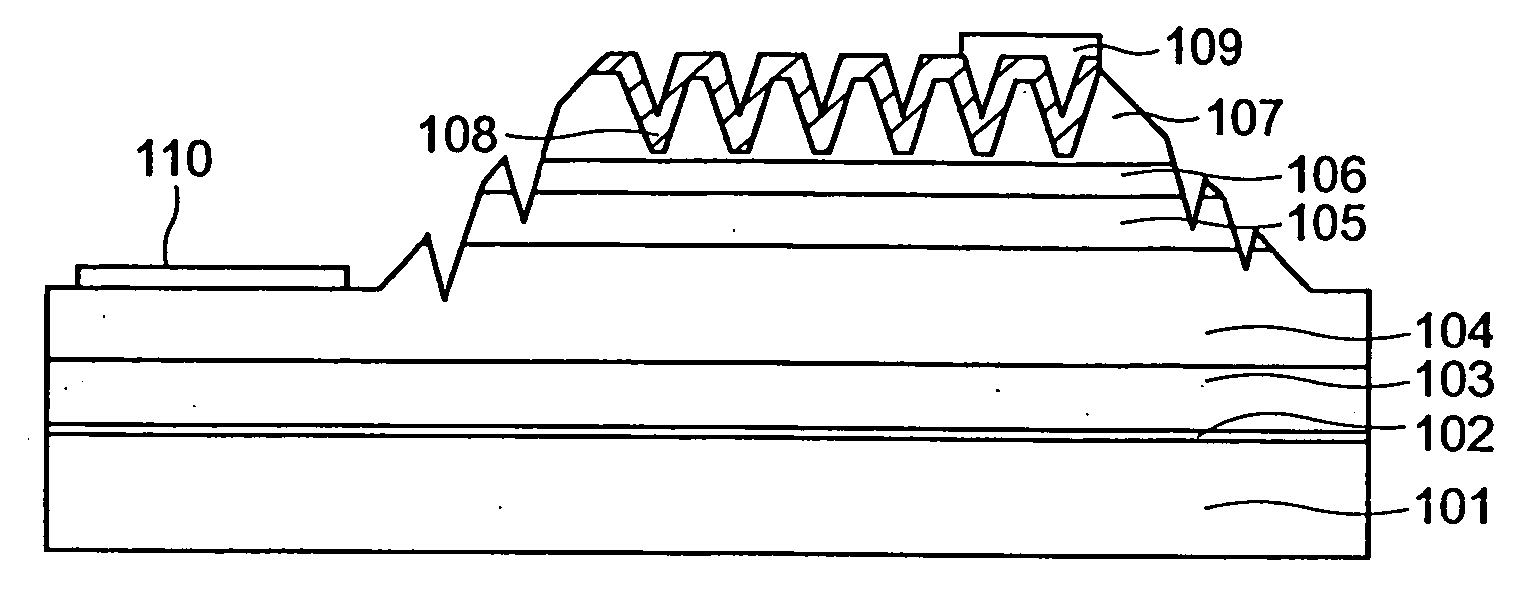

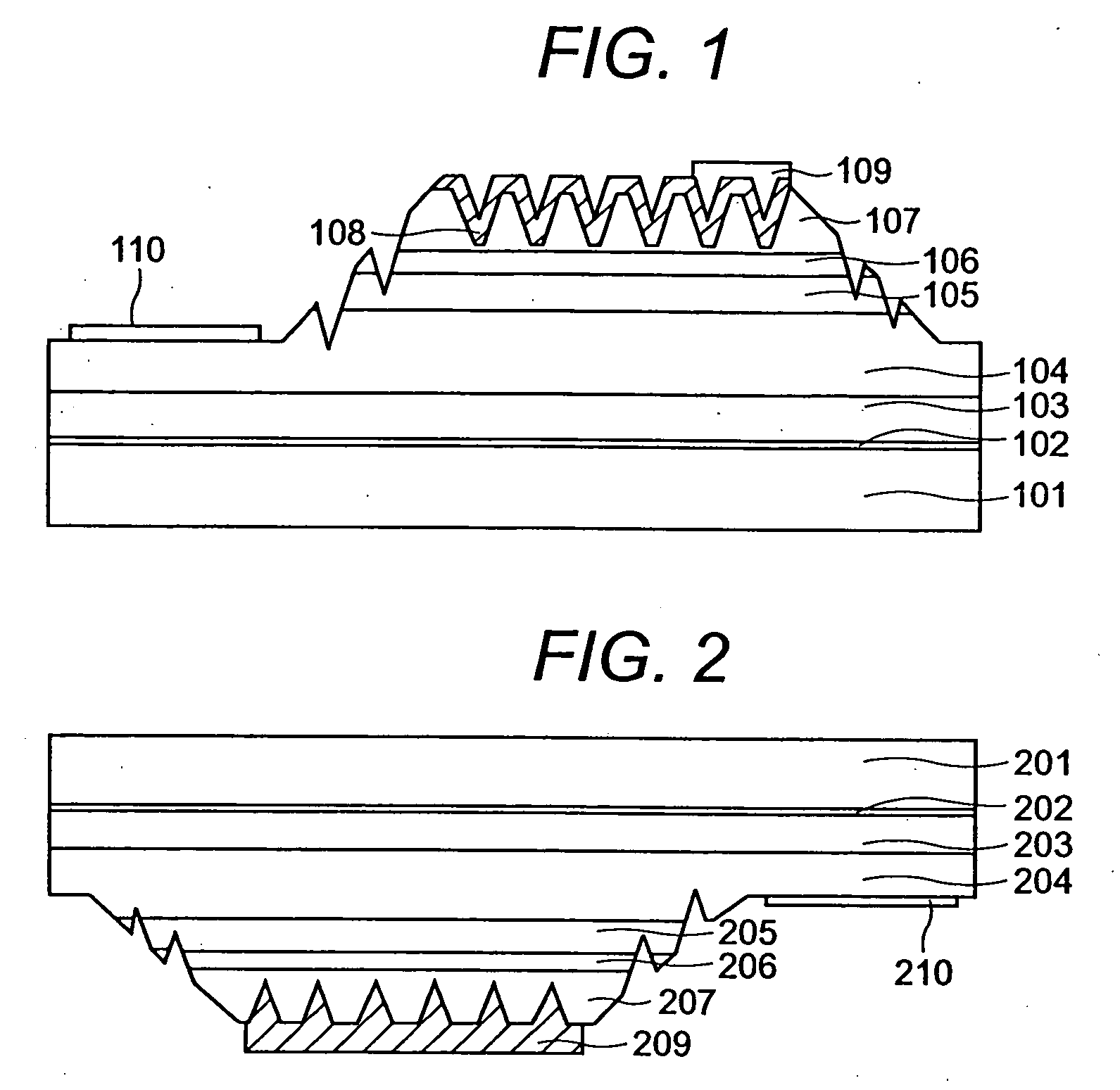

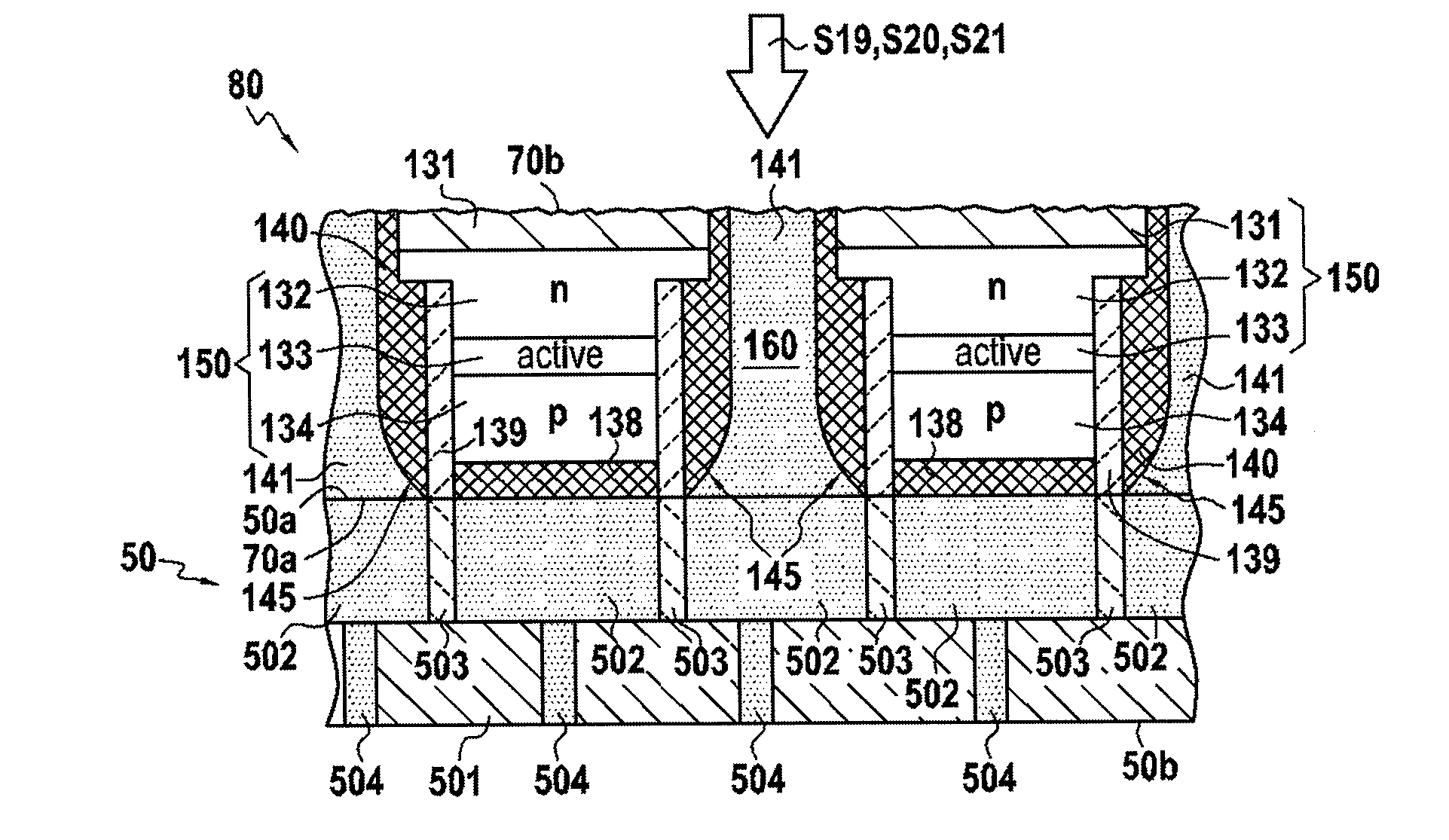

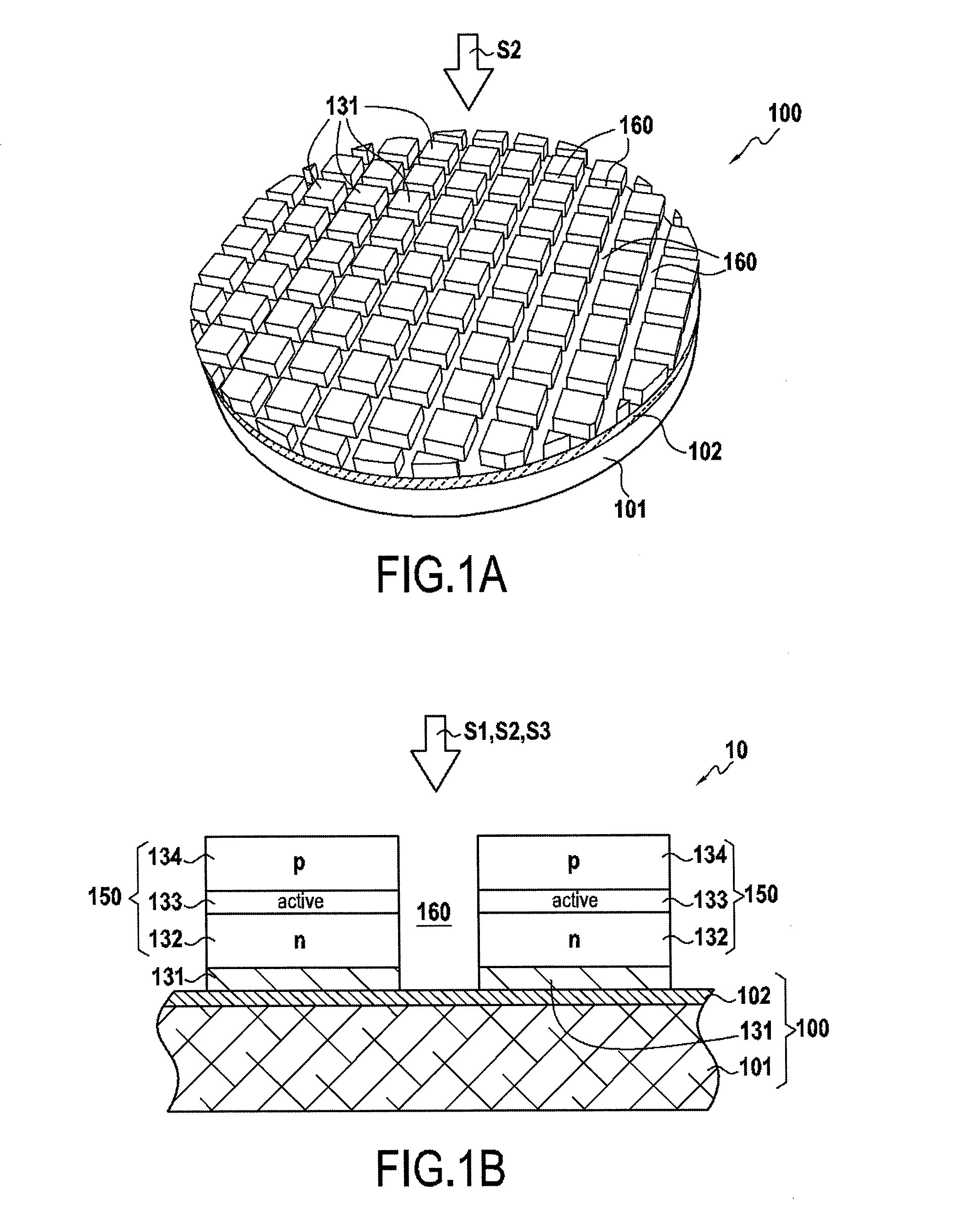

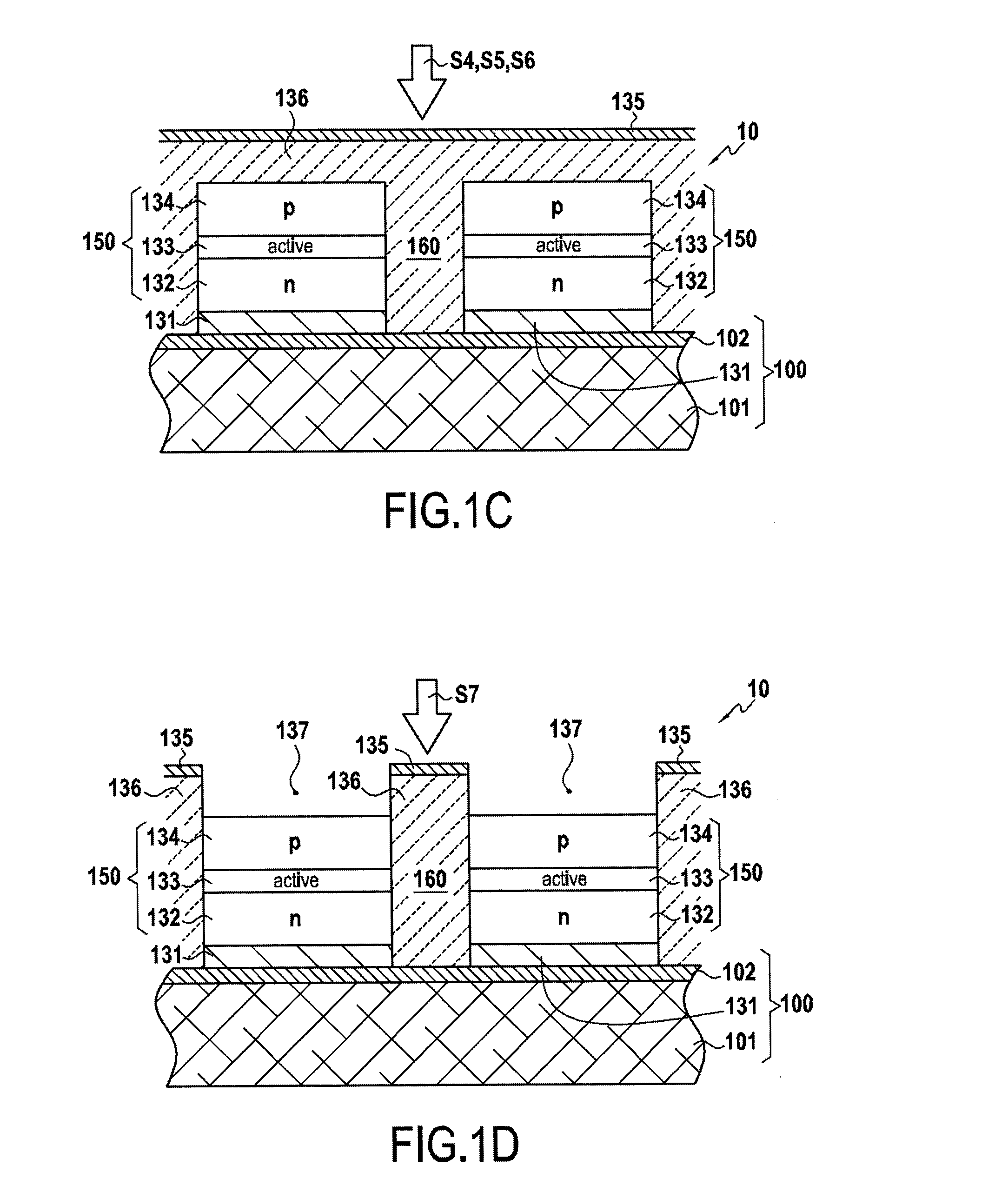

ActiveUS20090146165A1Easy to understandSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerLead structure

A light emitting device, a wafer for making the same, and method for fabricating the same are disclosed. The device and wafer include a first layer of a first conductivity type, an active layer, and a layer of a second conductivity type. The active layer overlies the first layer, the active layer generating light. The second layer overlies the active layer, the second layer having a first surface in contact adjacent to the active layer and a second surface having a surface that includes features that scatter light striking the second surface. A layer of transparent electrically conducing material is adjacent to the second surface and covered by a first layer of a dielectric material that is transparent to the light generated by the active layer. A mirror layer that has a reflectivity greater than 90 percent is deposited on the first layer of dielectric material.

Owner:SEOUL SEMICONDUCTOR

LED structures for reduced non-radiative sidewall recombination

LED structures are disclosed to reduce non-radiative sidewall recombination along sidewalls of vertical LEDs including p-n diode sidewalls that span a top current spreading layer, bottom current spreading layer, and active layer between the top current spreading layer and bottom current spreading layer.

Owner:APPLE INC

White light generating unit, backlight assembly having the same and liquid crystal display device having the same

ActiveUS7360937B2Small sizeImprove divergence angleMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayFluorescence

A white light generating unit includes an LED structure and a lens structure. The LED structure generates a light. The lens structure has a convex lens or a concave lens. The lens structure has a fluorescent member that receives the light from the LED structure to emit a white light.

Owner:SAMSUNG DISPLAY CO LTD

Broad-spectrum A1(1-x-y)InyGaxN light emitting diodes and solid state white light emitting devices

ActiveUS7005667B2High luminous intensityHigh indexSolid-state devicesNanoopticsIndiumLuminous intensity

A broad-spectrum Al(1-x-y)InyGaxN light emitting diode (LED), including: a substrate, a buffer layer, an N-type cladding layer, at least one quantum dot emitting layer, and a P-type cladding layer. The buffer layer is disposed over the substrate. The N-type cladding layer is disposed over the buffer layer to supply electrons. The quantum dot emitting layer is disposed over the N-type cladding layer and includes plural quantum dots. The dimensions and indium content of the quantum dots are manipulated to result in uneven distribution of character distribution of the quantum dots so as to increase the FWHM of the emission wavelength of the quantum dot emitting layer. The P-type cladding layer is disposed over the quantum dot emitting layer to supply holes. A broad-spectrum Al(1-x-y)InyGaxN yellow LED may thus be made from the LED structure of this invention, with an emission wavelength at maximum luminous intensity falling within a range of 530˜600 nm, and FWHM within a range of 20˜150 nm. After packaging an Al(1-x-y)InyGaxN blue LED to form a solid state white light emitting device, the mixing of blue light and yellow light would generate white light with a high CRI index, high luminous intensity and capable of various color temperature modulation.

Owner:GENESIS PHOTONICS

Light emitting diode and manufacturing method thereof

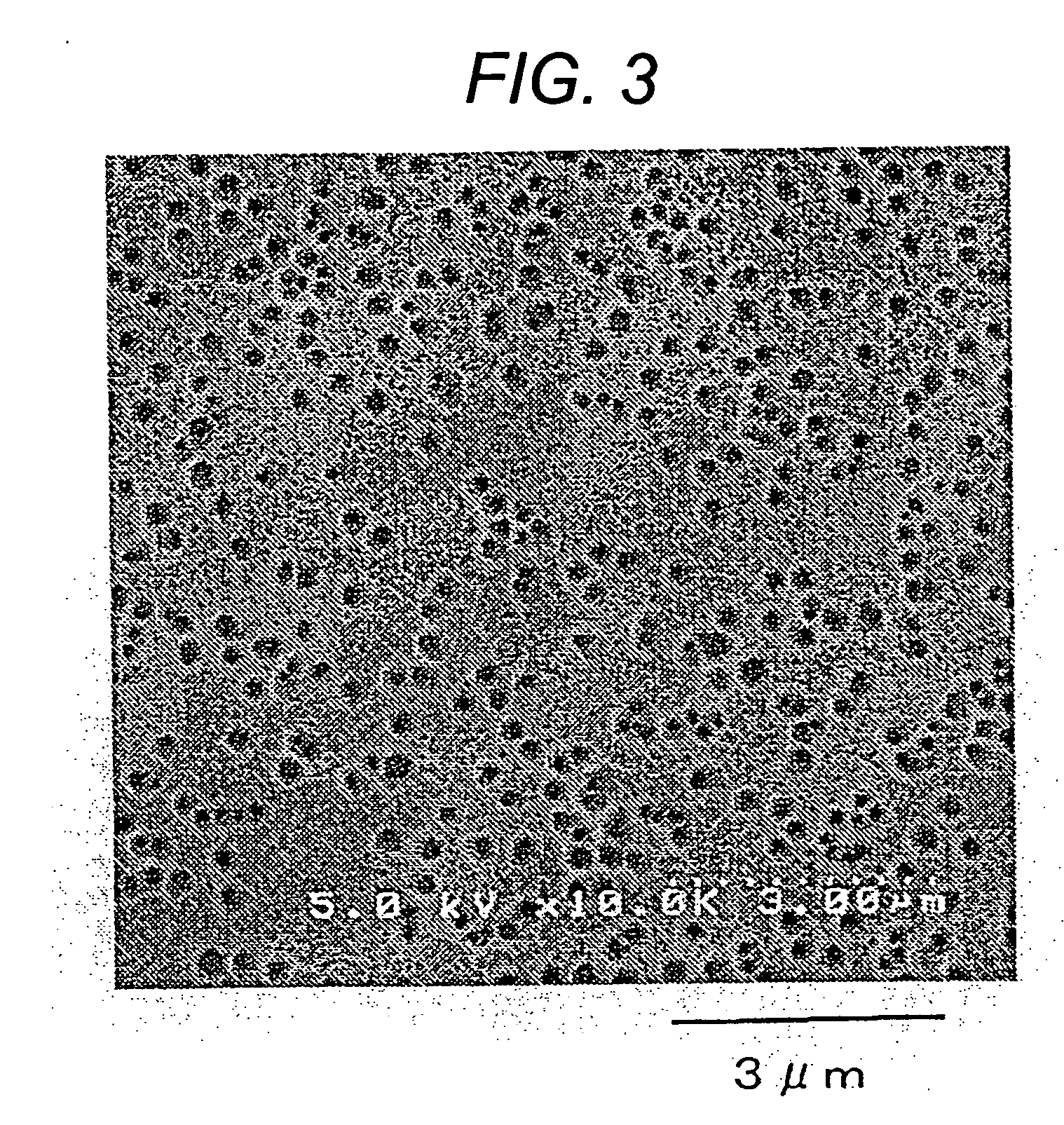

InactiveUS20060273336A1Light extraction efficiencyReduce contact resistanceSemiconductor devicesIn planeVolumetric Mass Density

A technique of ensuring compatibility between the method of improving the light extraction efficiency by roughening the surface of a LED structure, and the method of avoiding the adverse effect of a low-cost electrode pad ((1) forming a current distribution layer by a transparent conductive film made of metal or metal oxide, and (2) forming a flip chip structure). A light emitting diode comprises at least an n-type semiconducting layer, an active layer composed of 30 or less quantum well layers, and a p-type semiconducting layer provided on a substrate, wherein the surface of the semiconductor lamination structure contains a flat portion and a plurality of bores. In this case, the in-plane coverage rate ((the area of the bore opening / surface area)×100) of the plurality of the bores is 10% or more without exceeding 85%; the opening of the bore has a diameter of 100 nm or more without exceeding 4000 nm; the depth of the bore is smaller than the distance between the active layer and the flat portion; and the density of the plurality of the bores expressed in terms of number of bores is 8×105 per / cm2 or more without exceeding 1.08×1010 per / cm2.

Owner:SUMITOMO CHEM CO LTD

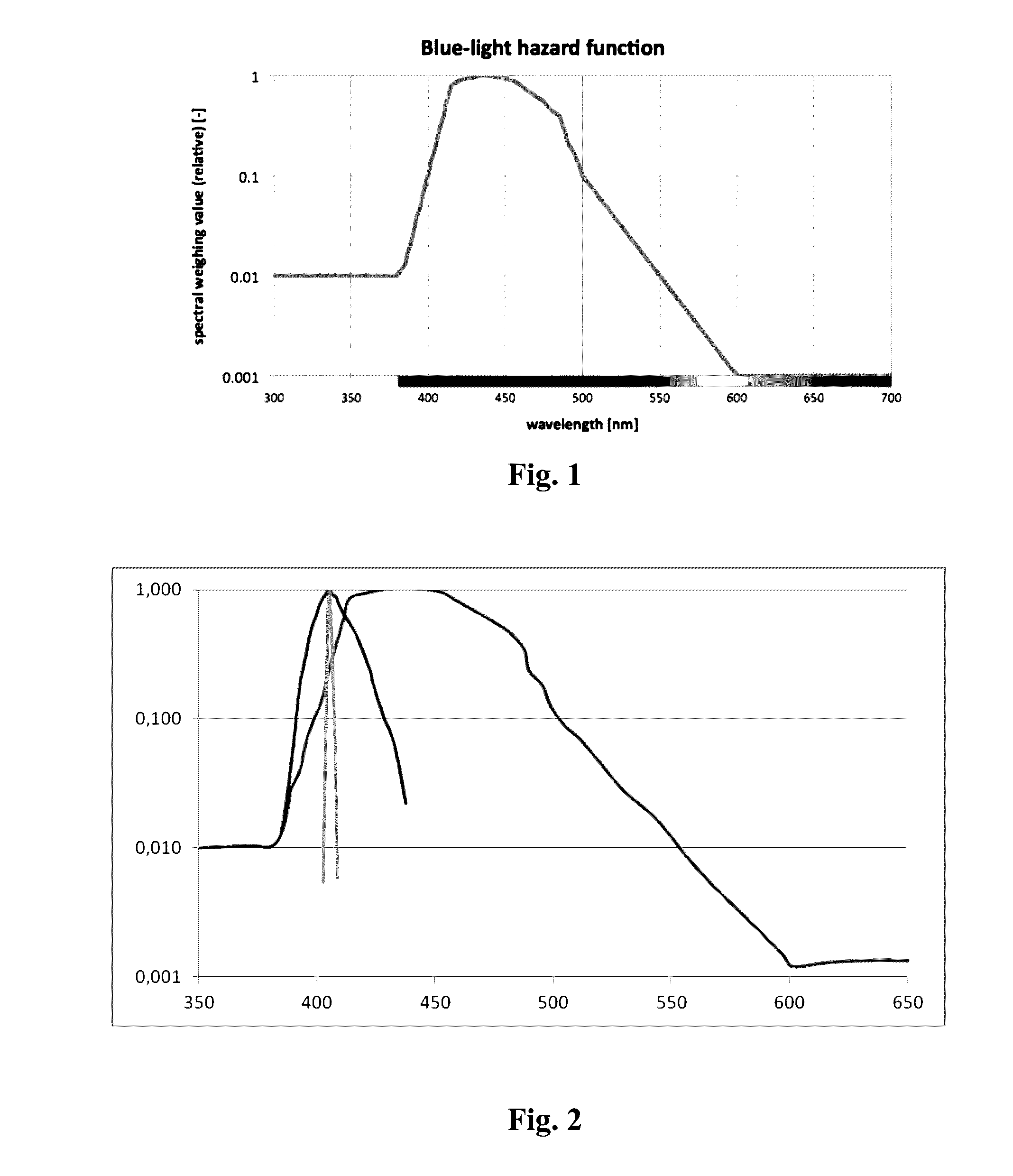

LED structure and luminaire for continuous disinfection

InactiveUS20170014538A1Avoid interferenceEasy to useLight source combinationsLighting elementsEffect lightWavelength conversion

A LED structure, a lighting fixture and a method of providing white light illumination. The LED structure comprises a substrate; a light emitting area defined on the substrate as a cavity; a first type of light emitting semiconductor source with bactericidal characteristics mounted in the cavity; a second type of light emitting semiconductor source mounted in the cavity with ability to excite the wavelength conversion material to generate white light; and a wavelength conversion material layer formed on top of the light emitting semiconductor sources. The invention enables disinfection by a lighting source or a luminaire visibly apparent to human as a white light source that is neither harmful to a human nor creates discomfort.

Owner:CALYXPURE INC

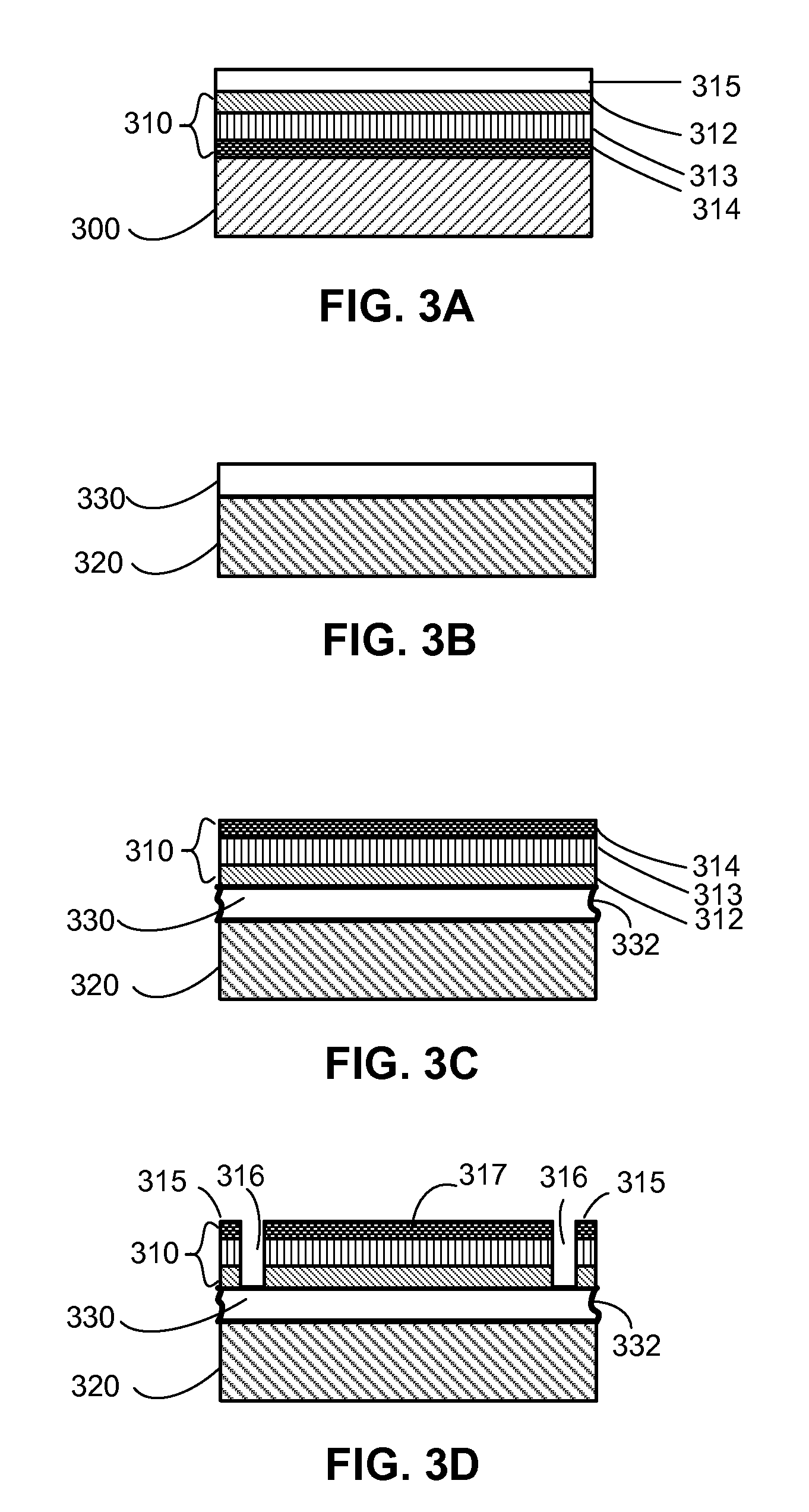

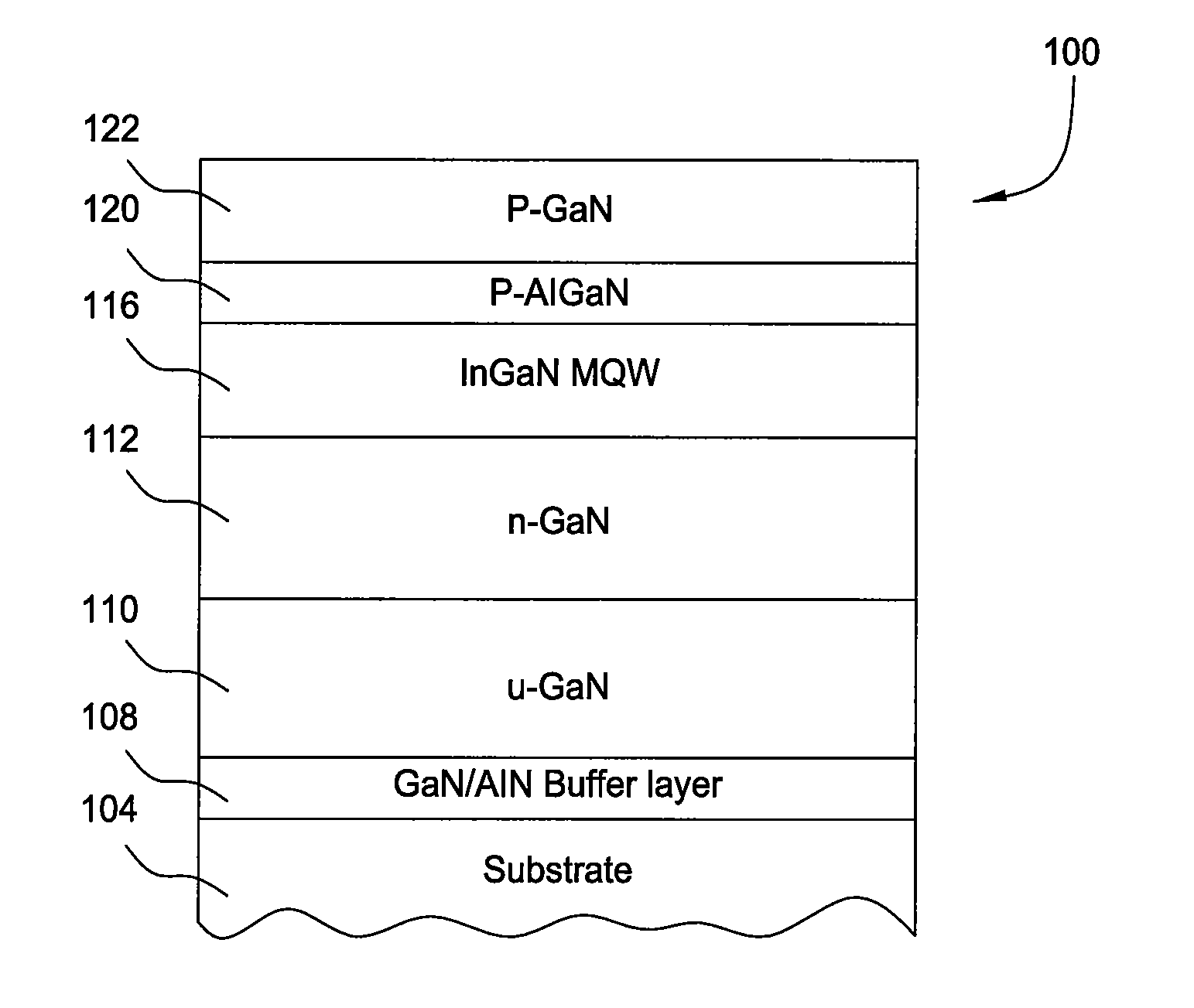

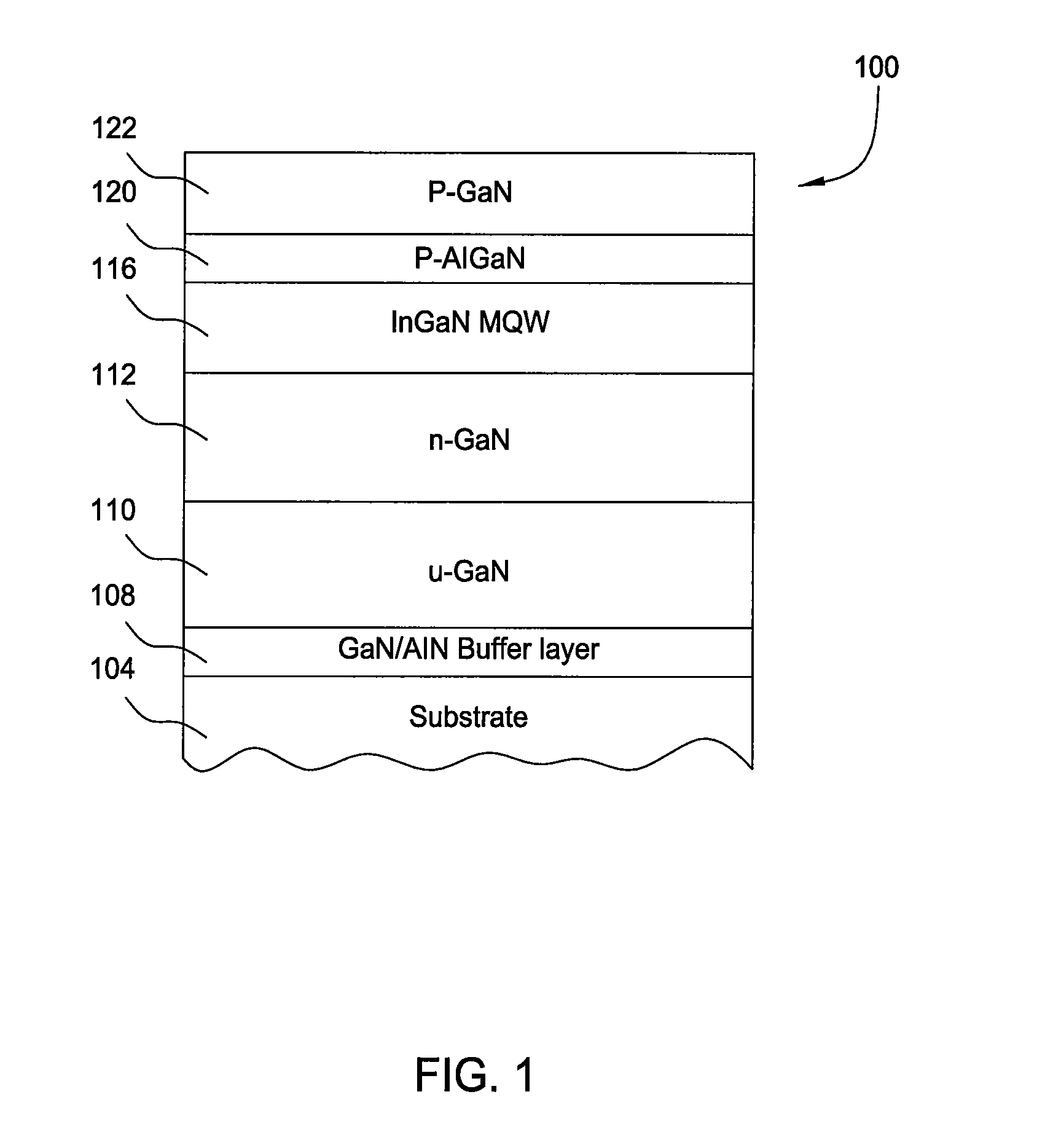

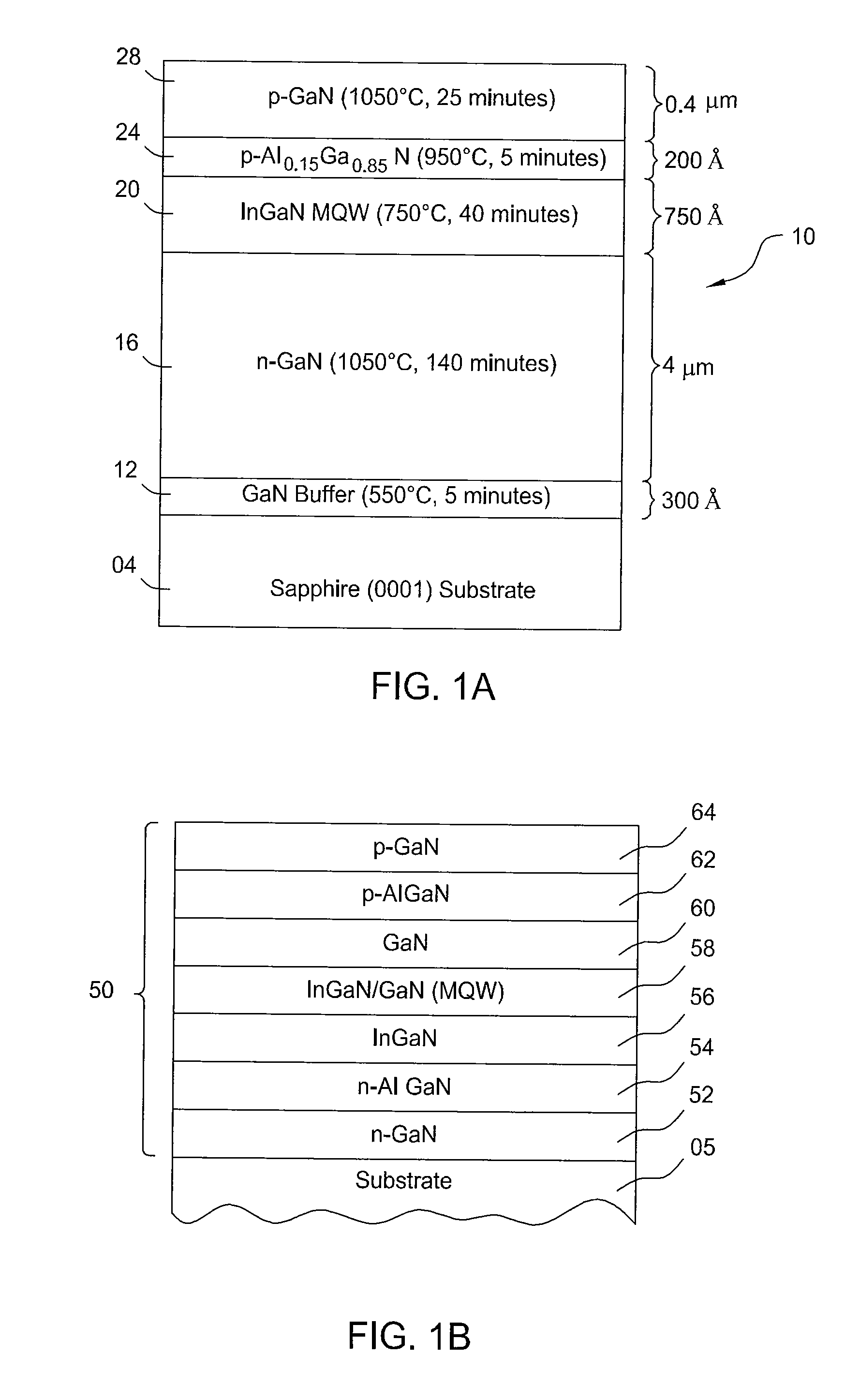

Forming a compound-nitride structure that includes a nucleation layer

InactiveUS20110244663A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductor structureEngineering

The present invention generally provides apparatus and methods for forming LED structures. In one embodiment, a method for fabricating a compound nitride-based semiconductor structure is provided. The method comprises forming a Group III-nitride buffer layer over one or more substrates in a first processing chamber, transferring the one or more substrates having the Group III-nitride buffer layer deposited thereon into a second processing chamber without exposing the one or more substrates to an ambient atmospheric environment, and forming a bulk Group III-V layers over the Group III-nitride buffer layer in the second processing chamber. In one example, the first processing chamber may be a MOCVD, PVD based chamber, CVD based chamber, ALD based chamber, sputtering chamber, or any other vapor deposition chamber. The second processing chamber may be a MOCVD or HVPE chamber.

Owner:APPLIED MATERIALS INC

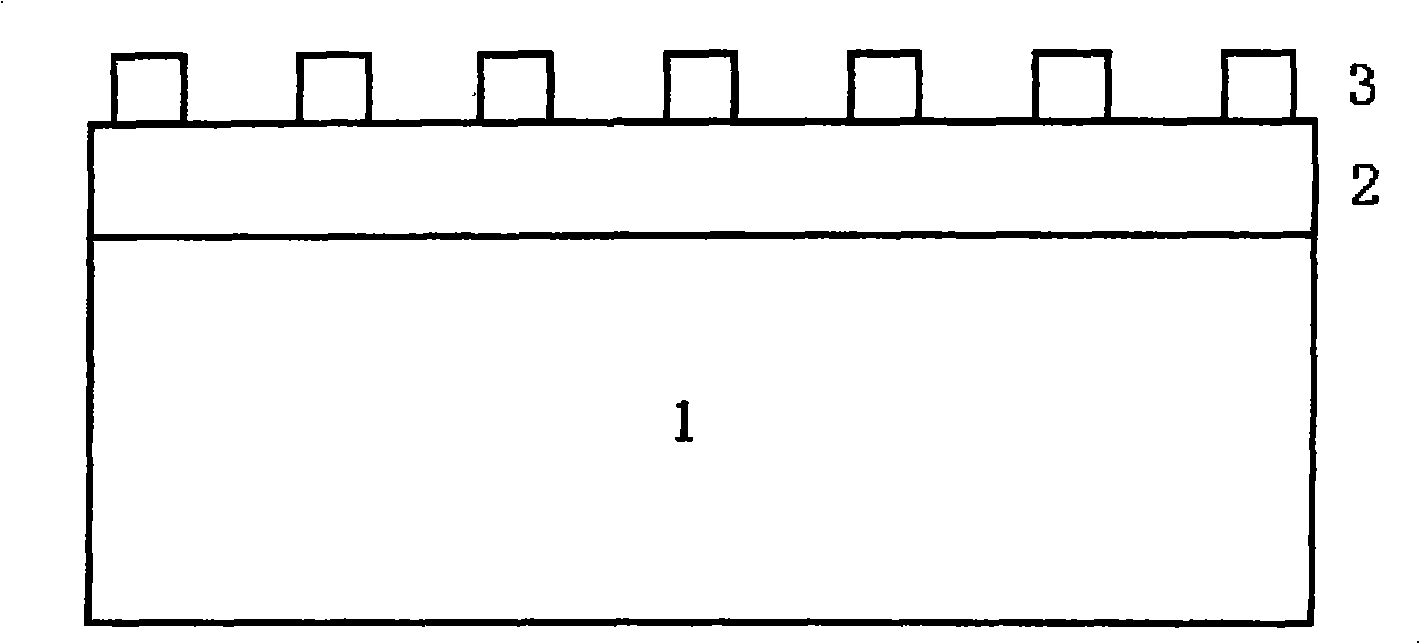

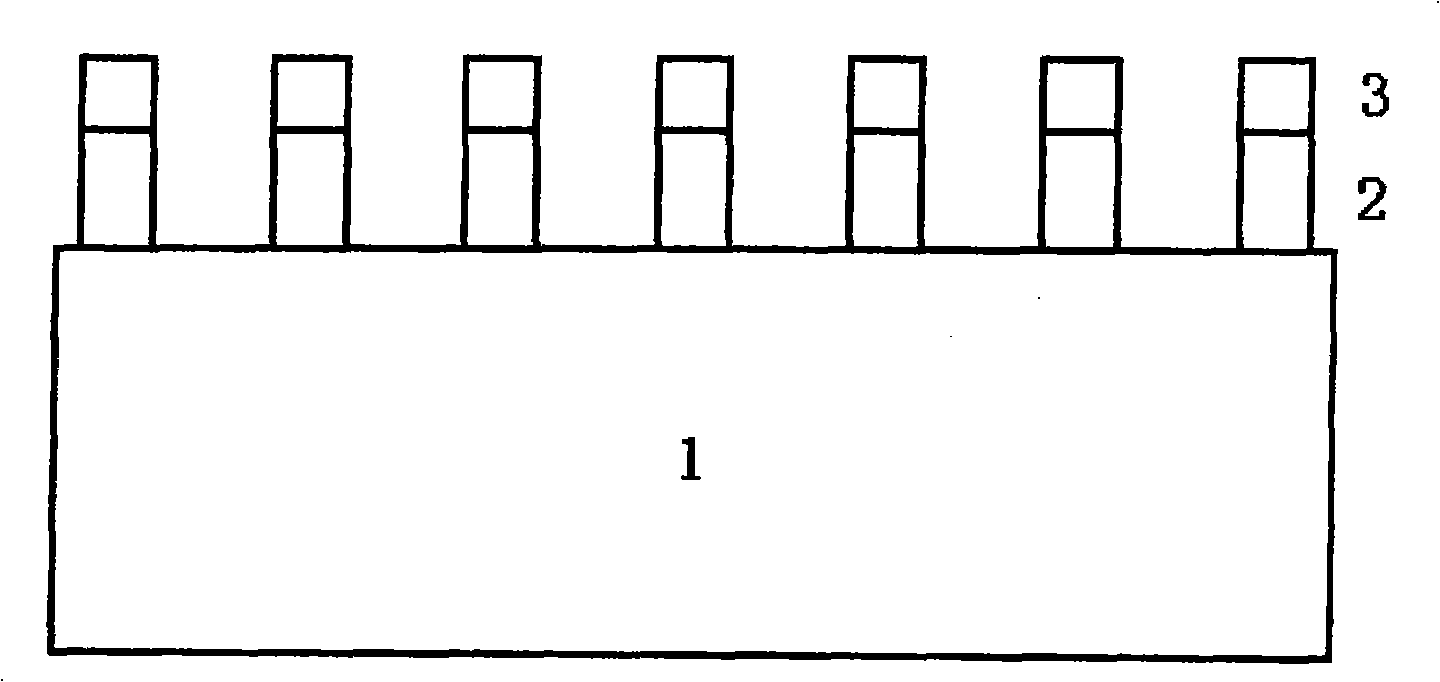

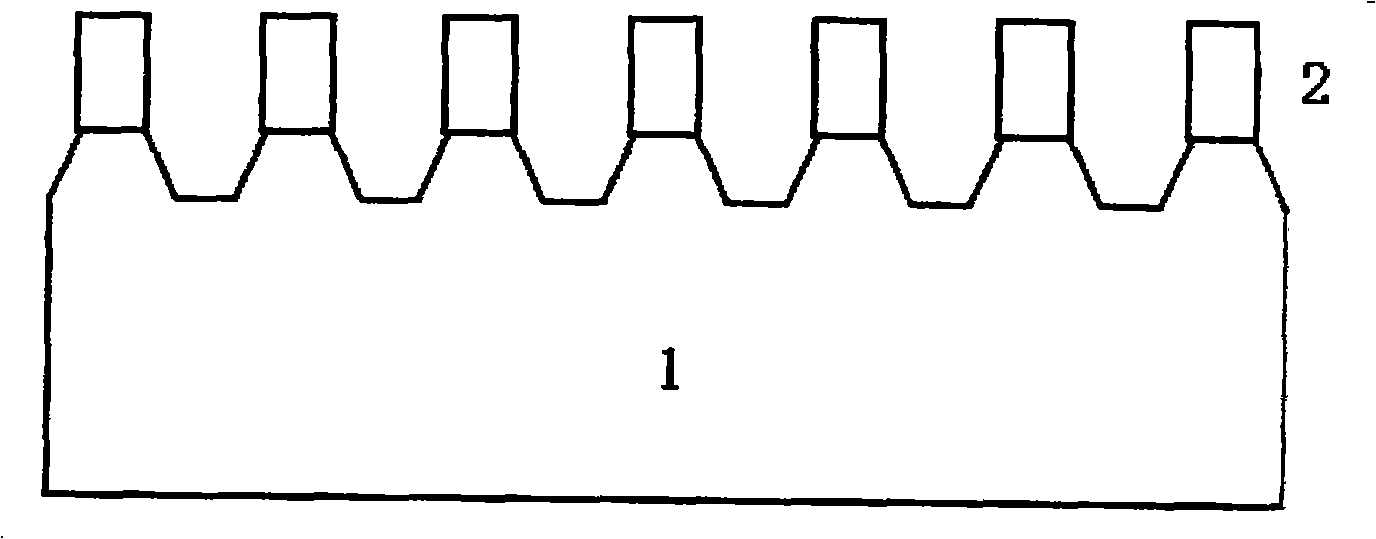

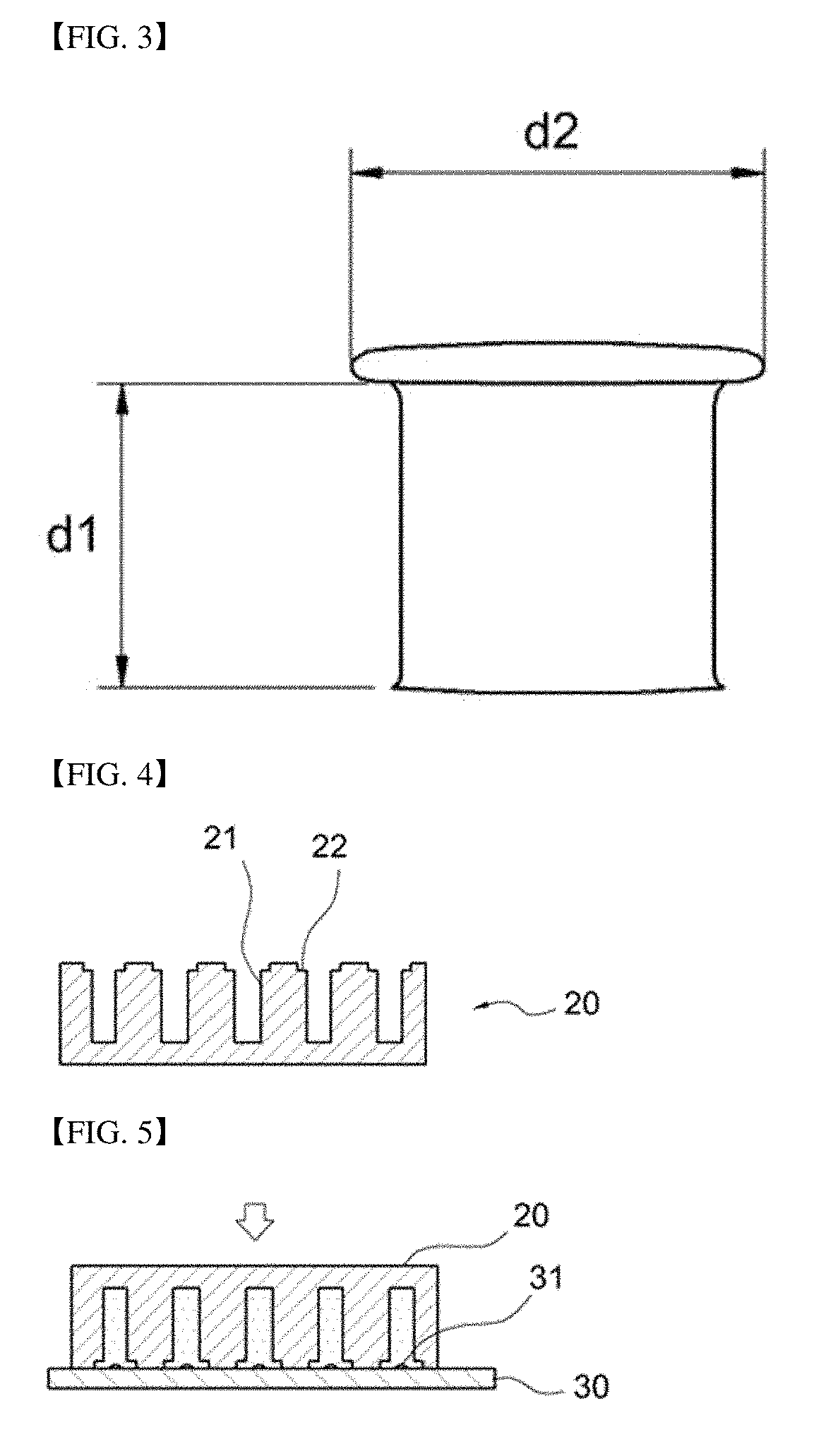

Method for improving luminous efficiency of GaN based LED by using graphic underlay

InactiveCN101345274AImprove luminous efficiencyQuality improvementSemiconductor devicesGraphicsNucleation

The invention provides a method which uses a graphic substrate to improve the illumination efficiency of a GaN-based efficiency, comprising the steps as follows: a silicon dioxide film is deposited on a sapphire substrate; a photoresist graphic array is optically etched; the photoresist graphic array is taken as a mask so as to etch the silicon dioxide film with the graphic structure; the silicon dioxide film with the graphic structure is taken as a mask so as to etch the sapphire substrate and the graphics is etched onto the sapphire substrate; the sapphire substrate is thoroughly cleaned so as to form a pyramid structure with triangular sections; a low-temperature nucleation layer grows on the graphic sapphire substrate; temperature is continuously increased on the low-temperature nucleation layer so as to grow an n-typed mixed GaN layer and an array structure which has low dislocation density and V-shaped holes on the surface; a multiple quantum well layer and a p-typed material layer required when the LED structure material grows continue to grow; furthermore, the final surface is led to still have the array structure with V-shaped holes.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

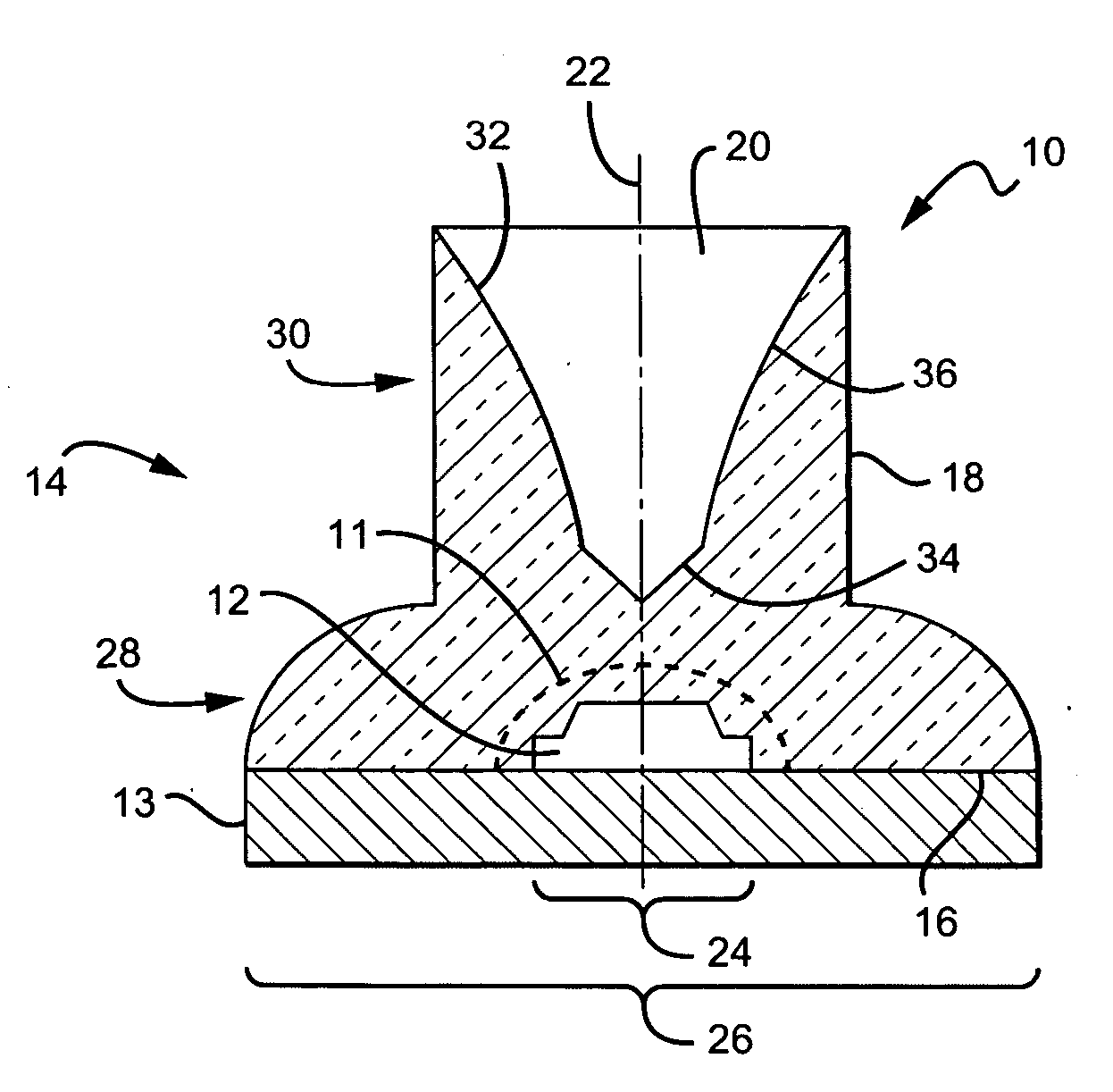

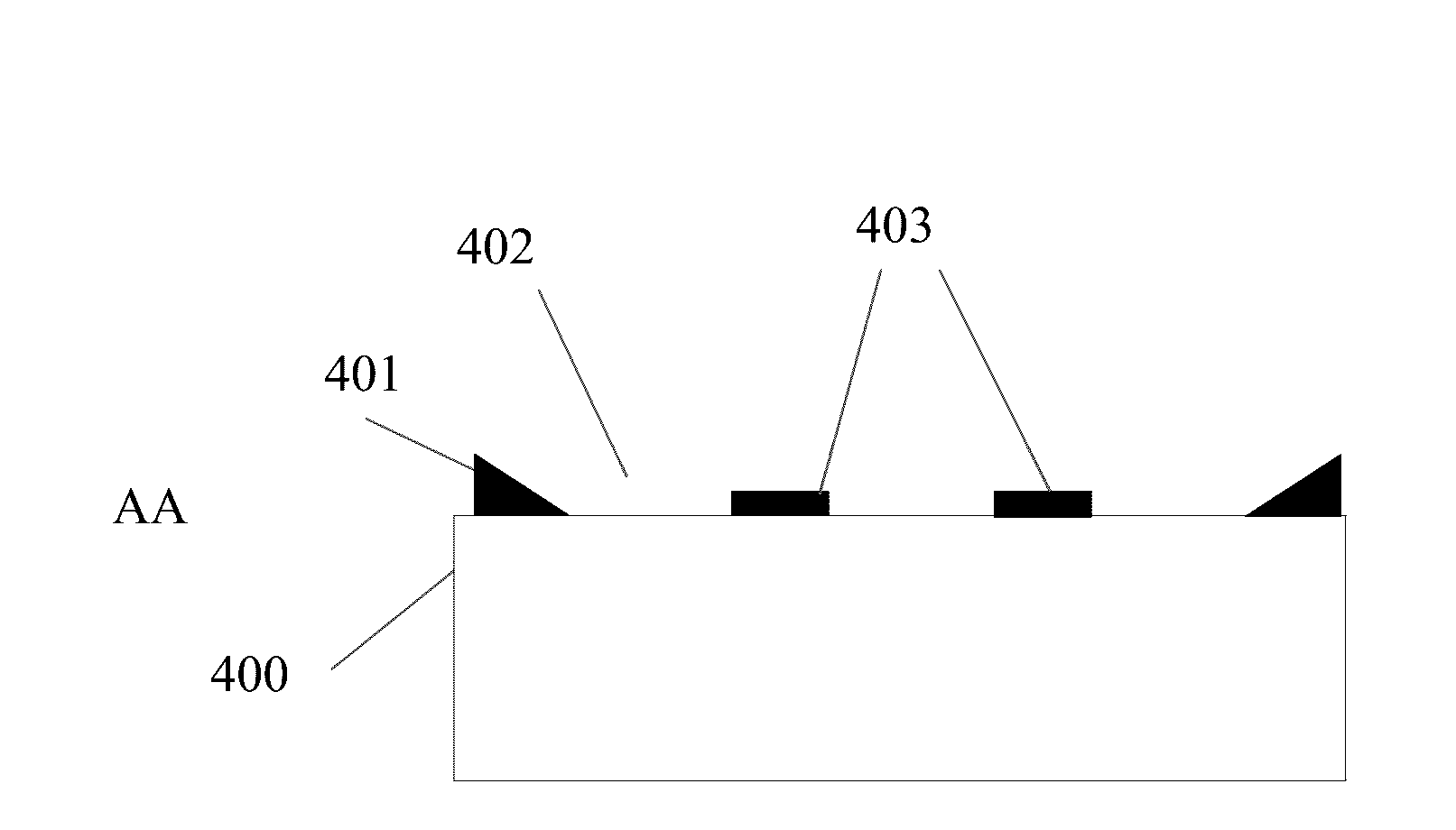

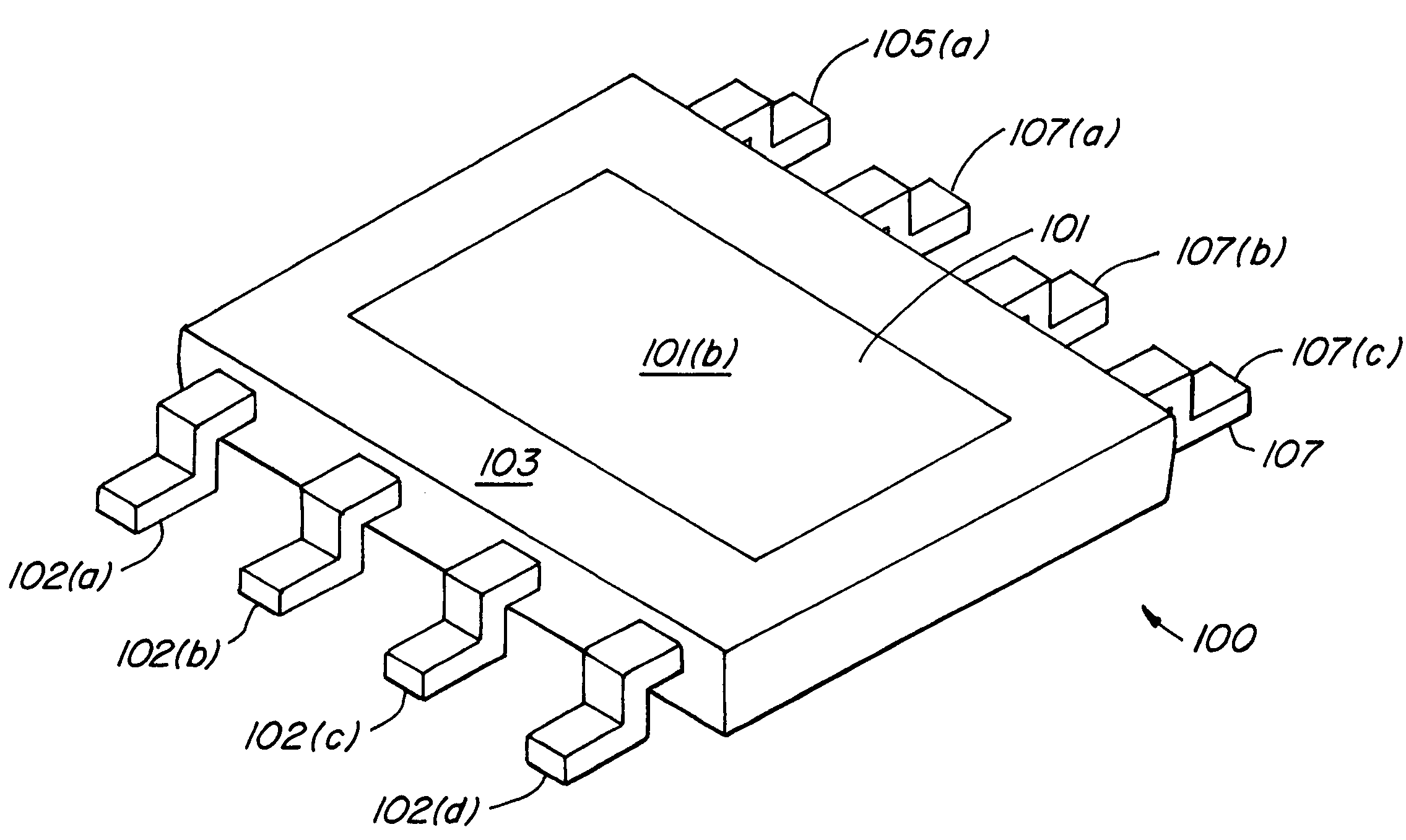

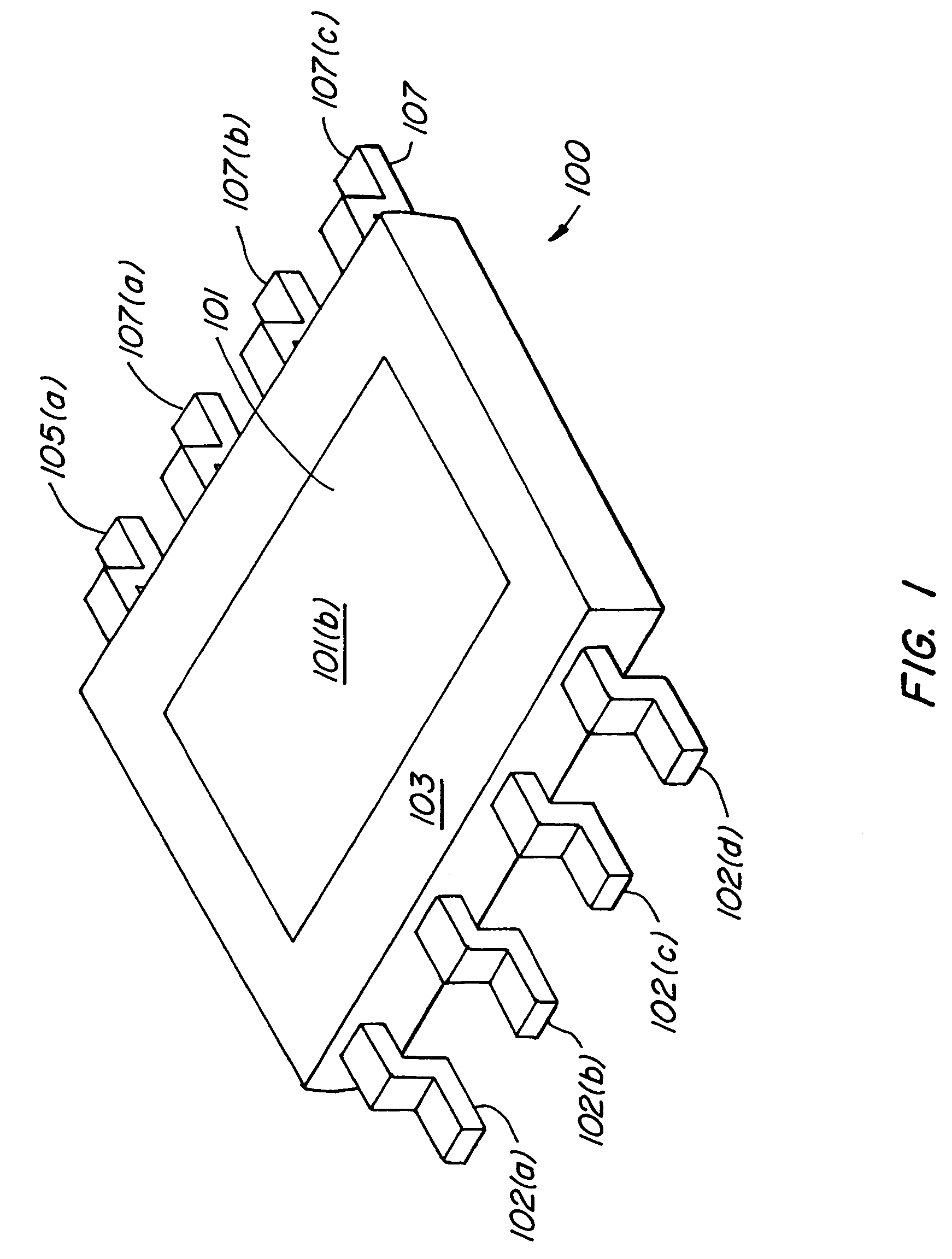

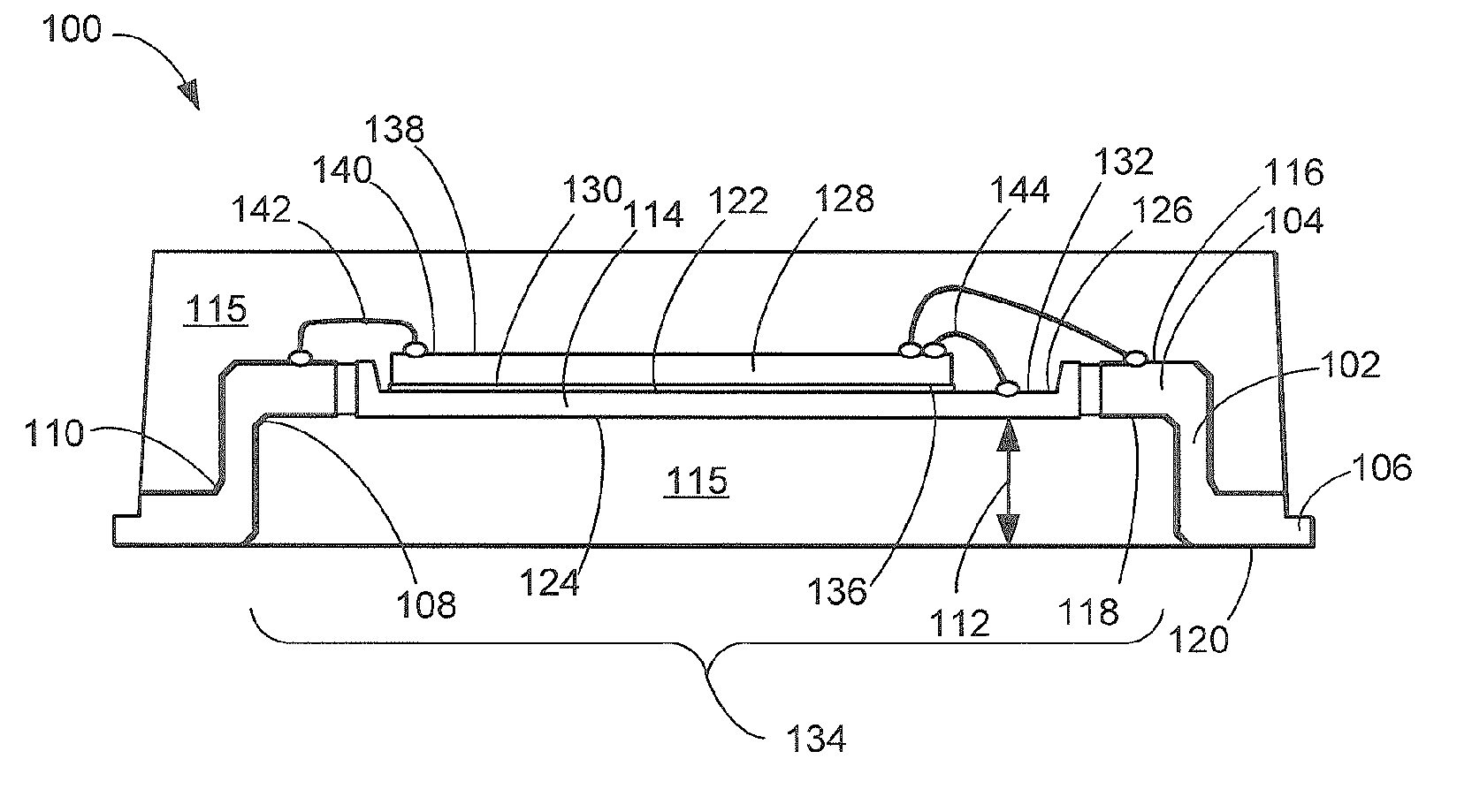

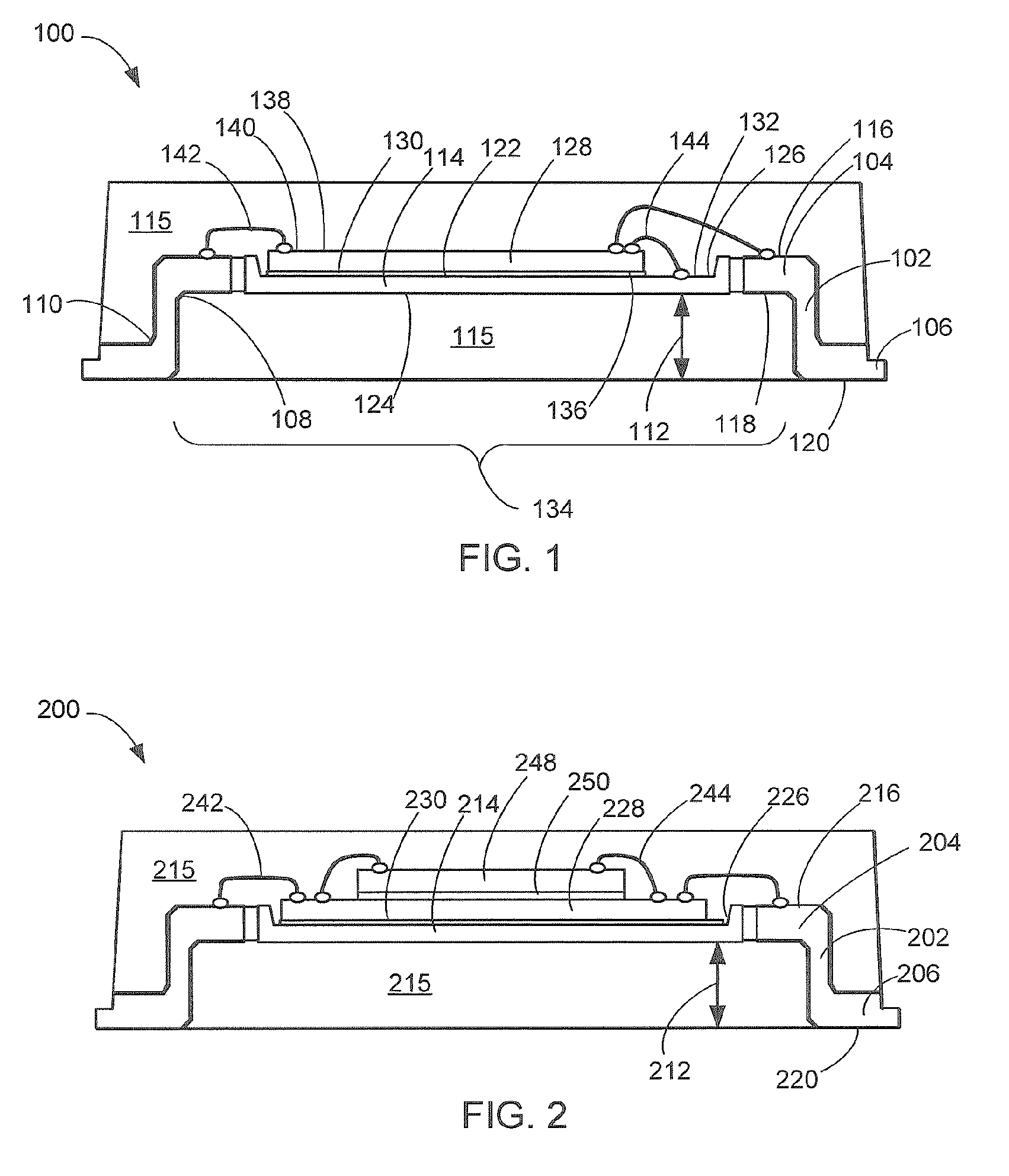

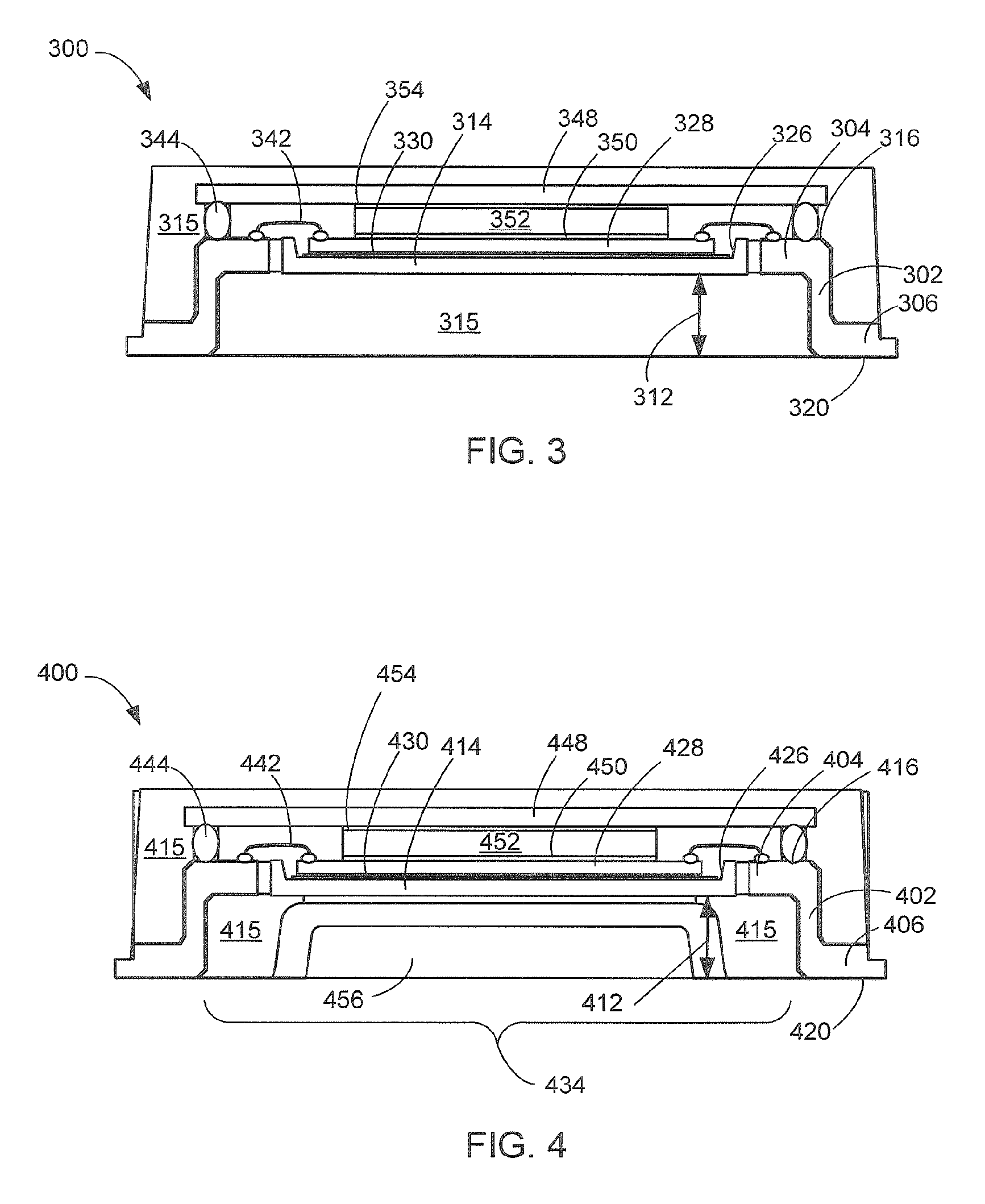

Thin, thermally enhanced molded package with leadframe having protruding region

InactiveUS7332806B2Low profileThin profileTransistorSemiconductor/solid-state device detailsLead structureSemiconductor

A semiconductor die package. It includes (a) a semiconductor die including a first surface and a second surface, (b) a source lead structure including protruding region having a major surface, the source lead structure being coupled to the first surface, (c) a gate lead structure being coupled to the first surface, and (d) a molding material around the source lead structure and the semiconductor die. The molding material exposes the second surface of the semiconductor die and the major surface of the source lead structure.

Owner:SEMICON COMPONENTS IND LLC

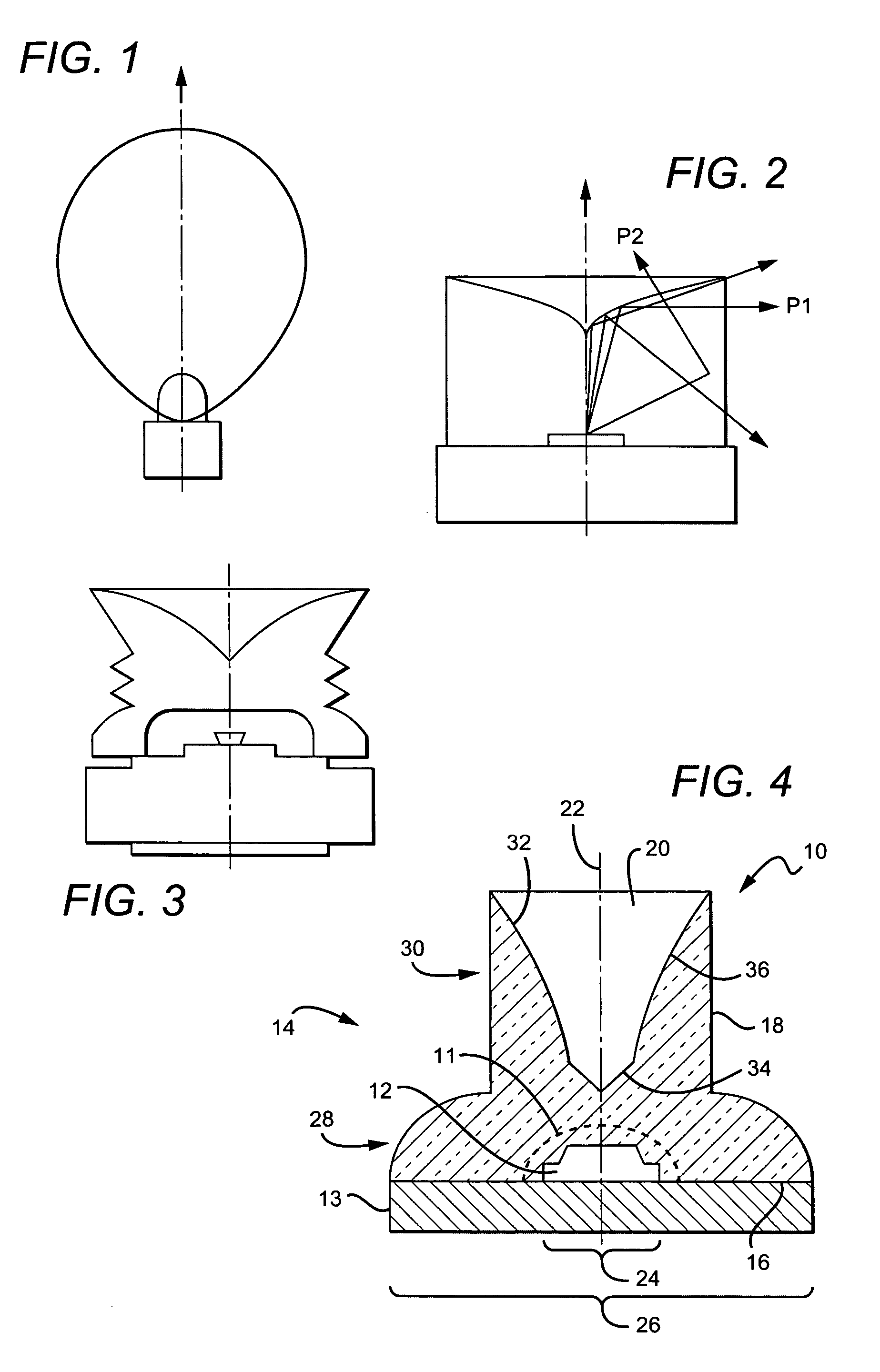

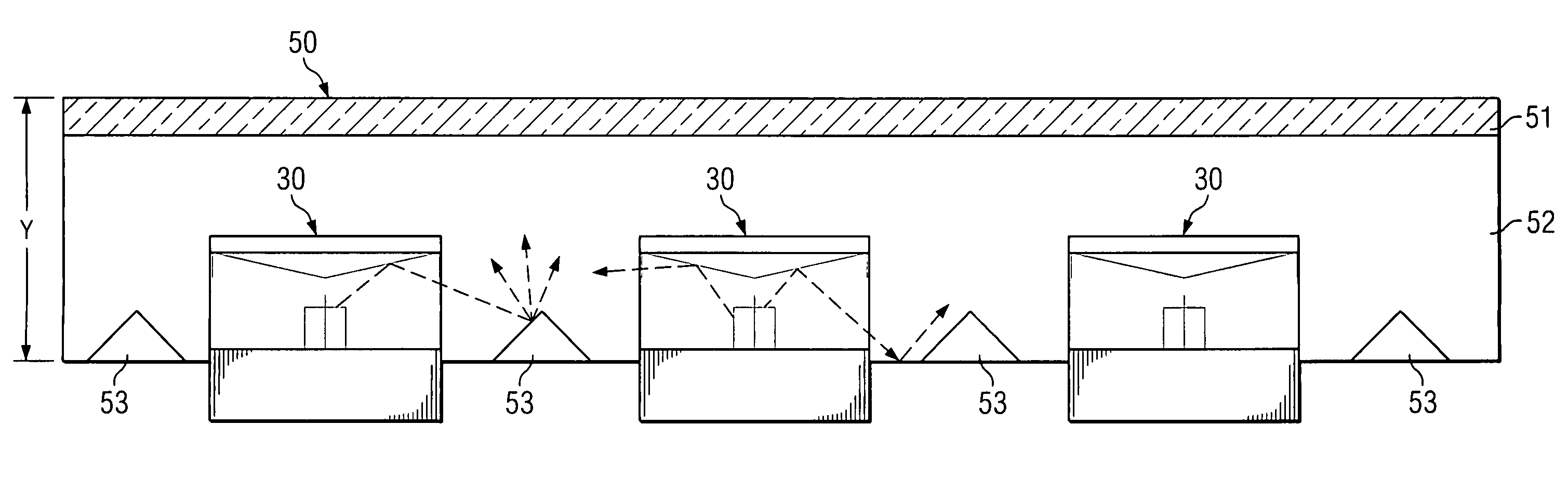

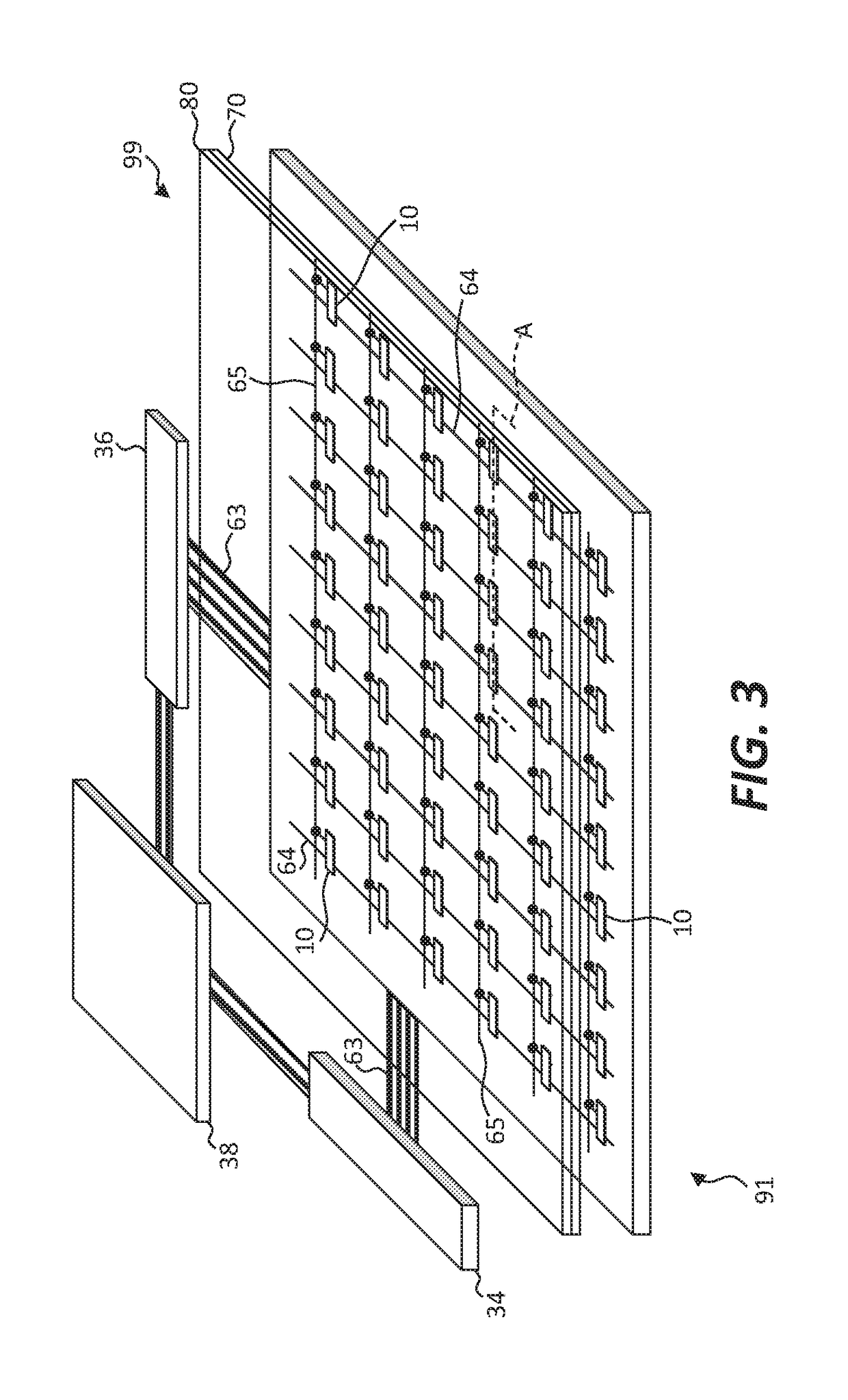

System and method for forming a back-lighted array using an omni-directional light source

ActiveUS7261454B2Increase lumen outputShow cabinetsNon-electric lightingDisplay deviceOptoelectronics

Owner:EPISTAR CORP

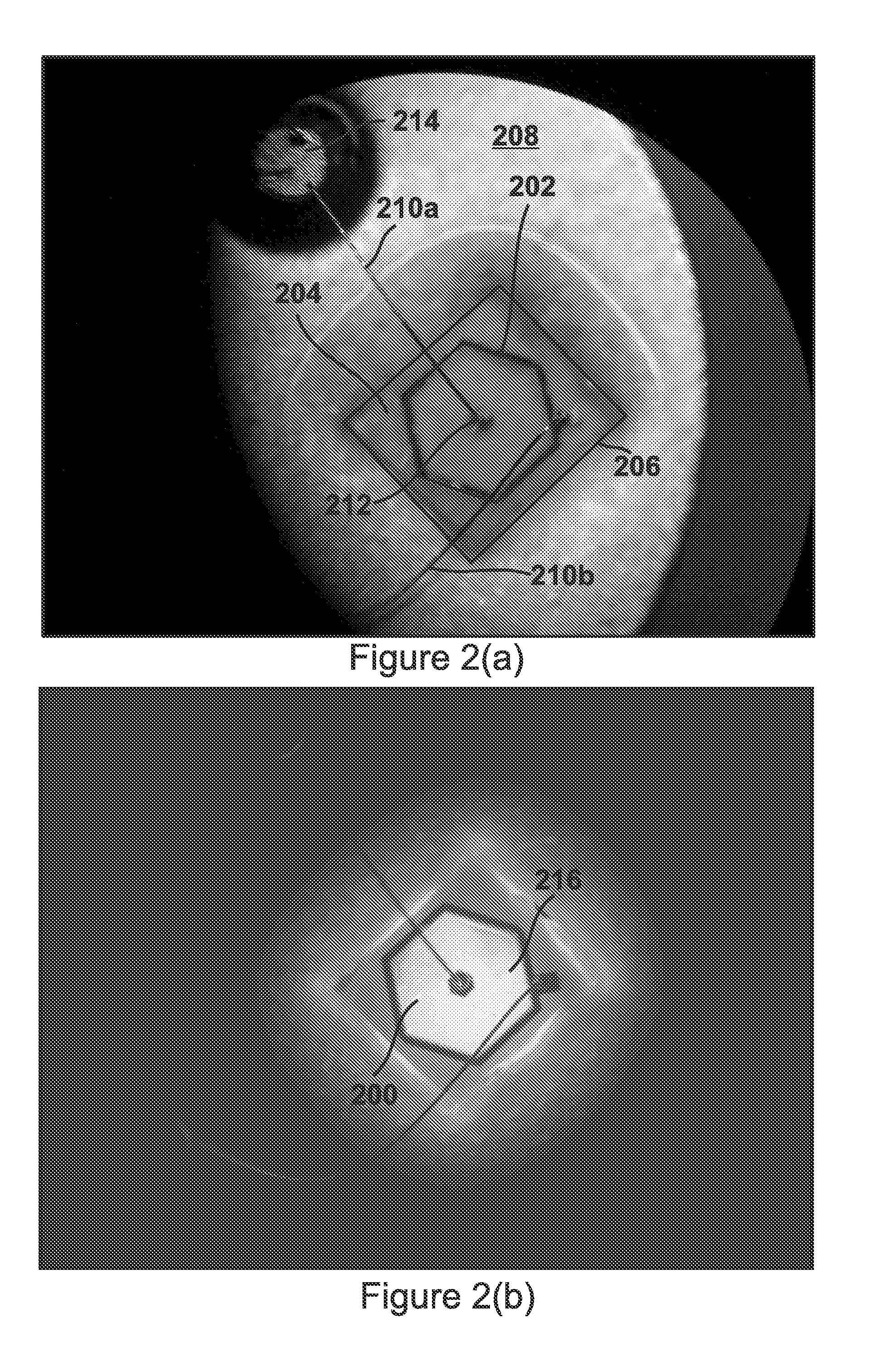

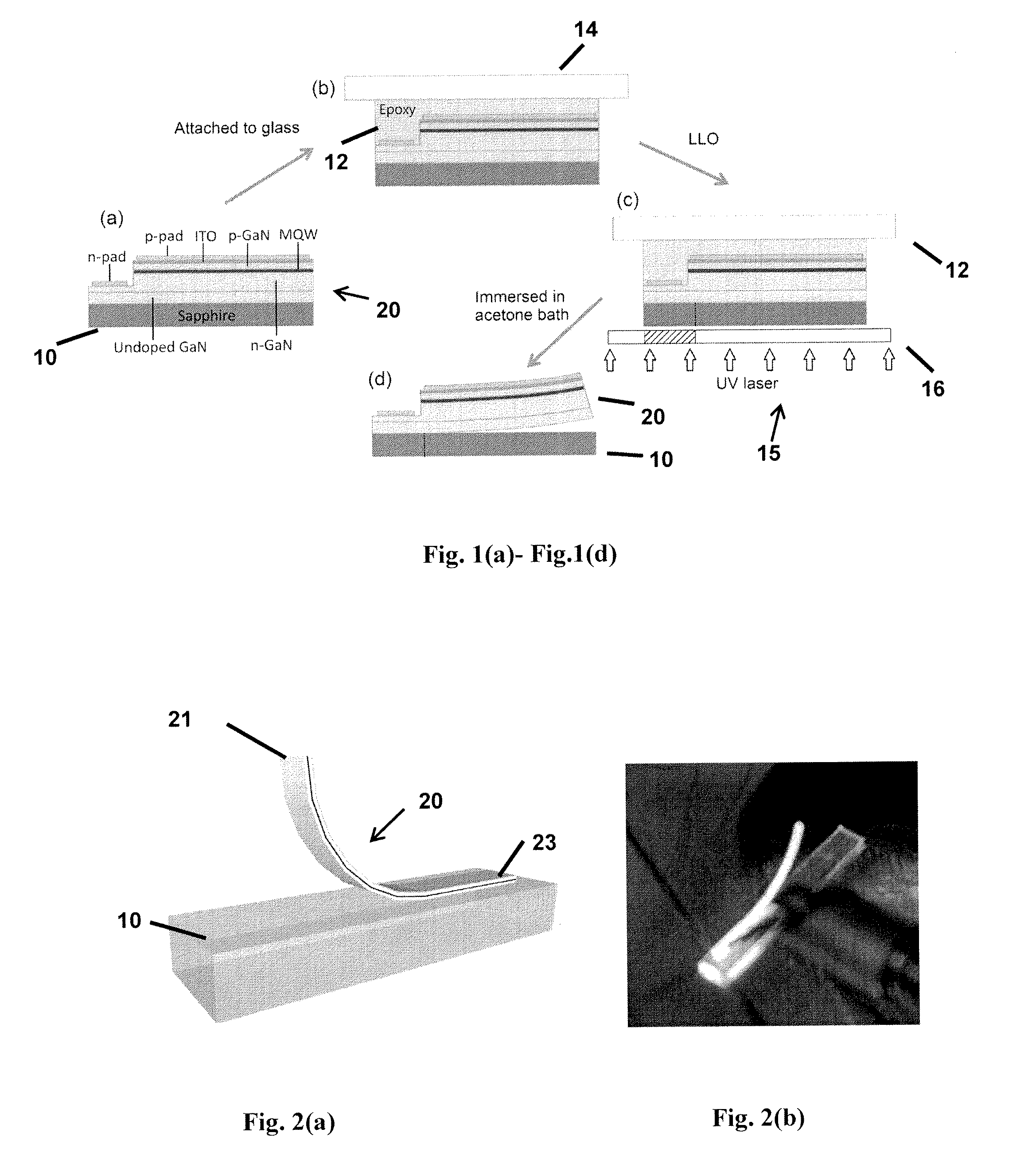

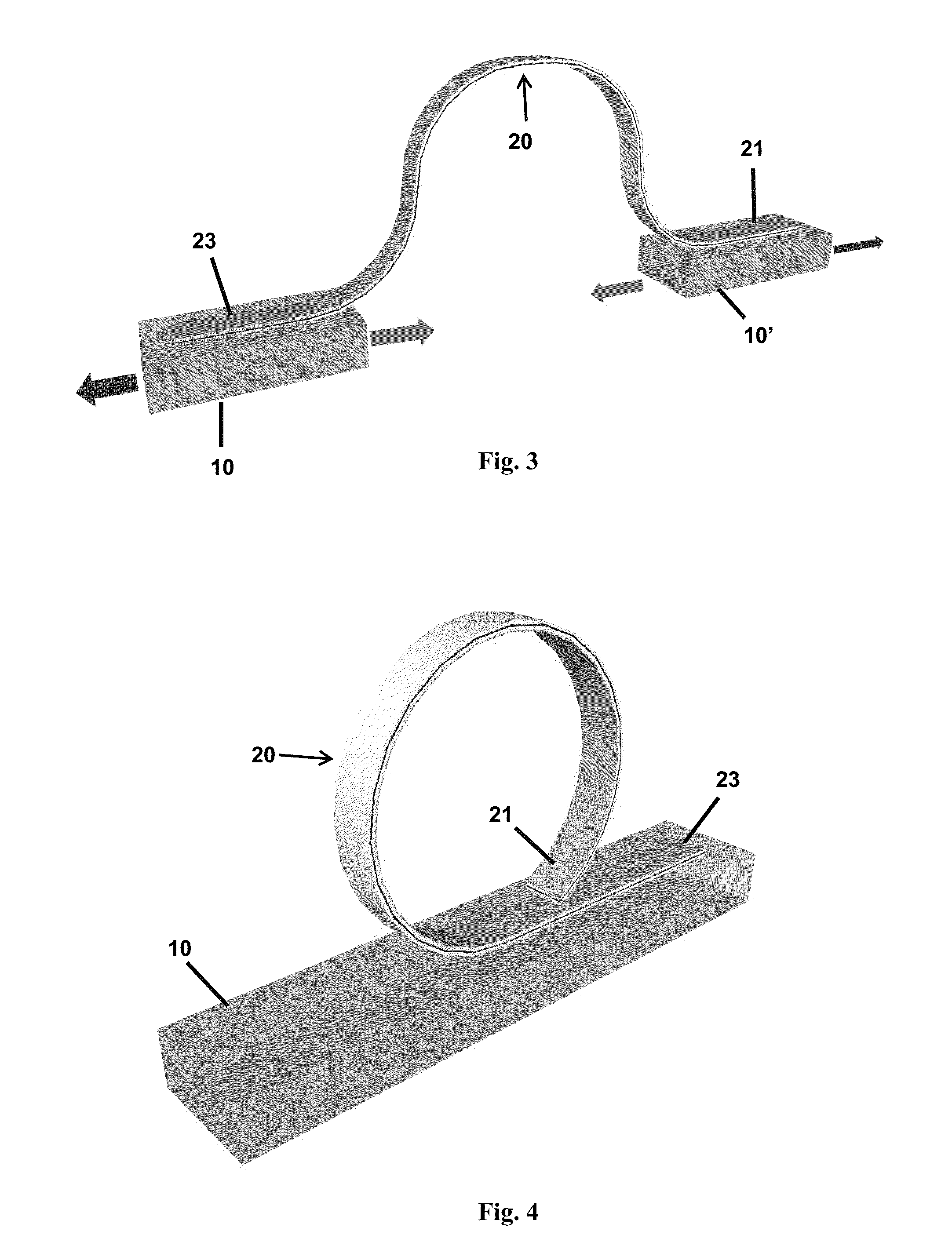

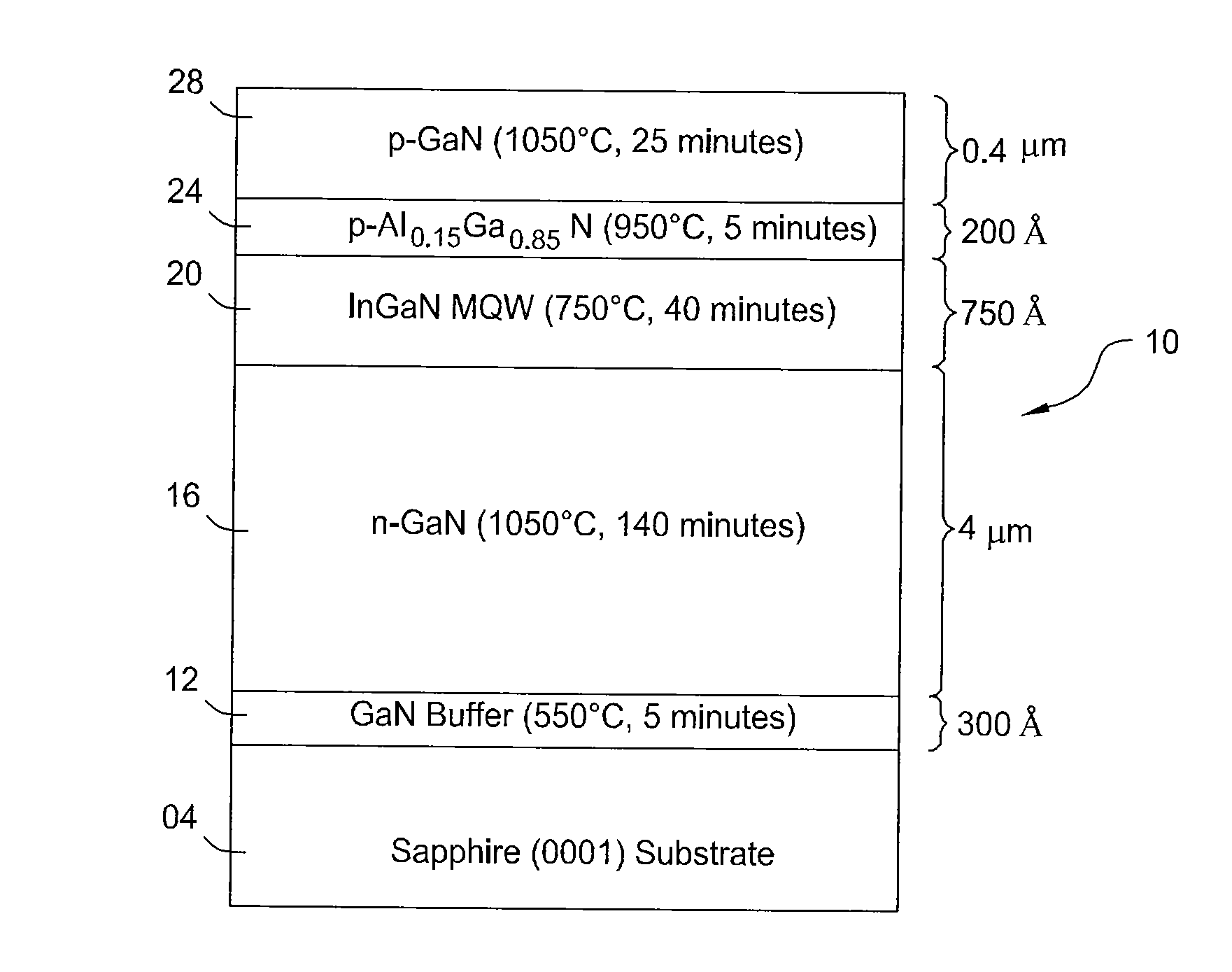

Flexible GAN light-emitting diodes

Methods of fabricating flexible, free-standing LED structures are provided. An LED structure can be formed on a sapphire substrate, and the surface of the LED structure can then be coated with epoxy and attached to a rigid supporting substrate. A laser lift-off process can be performed using an ultraviolent beam from a high-power pulsed-mode laser and a shadow mask, causing at least a portion of the LED structure to separate from the sapphire substrate. The structure can then be immersed in an acetone bath to dissolve the epoxy and separate the structure from the supporting substrate.

Owner:THE UNIVERSITY OF HONG KONG

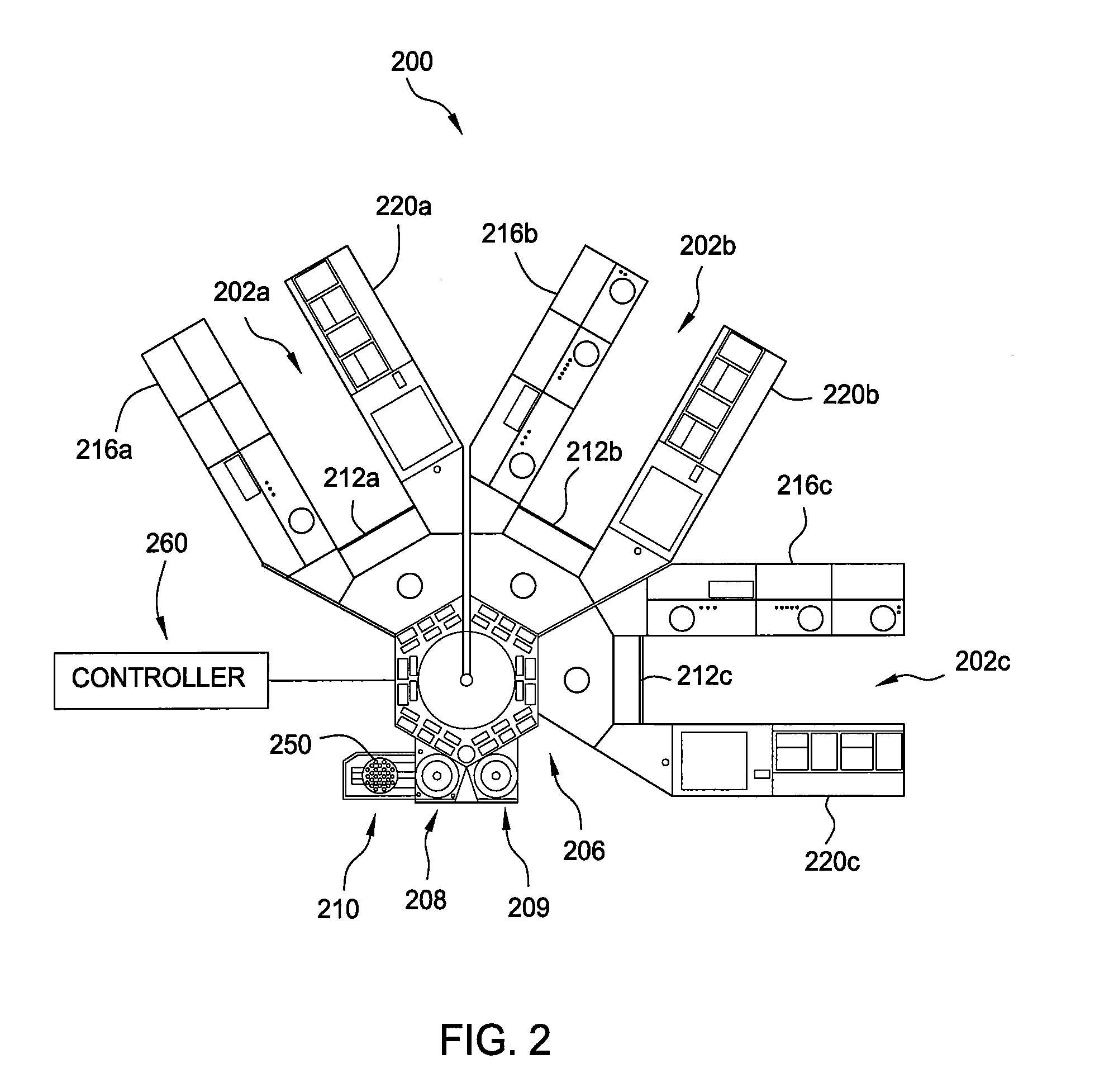

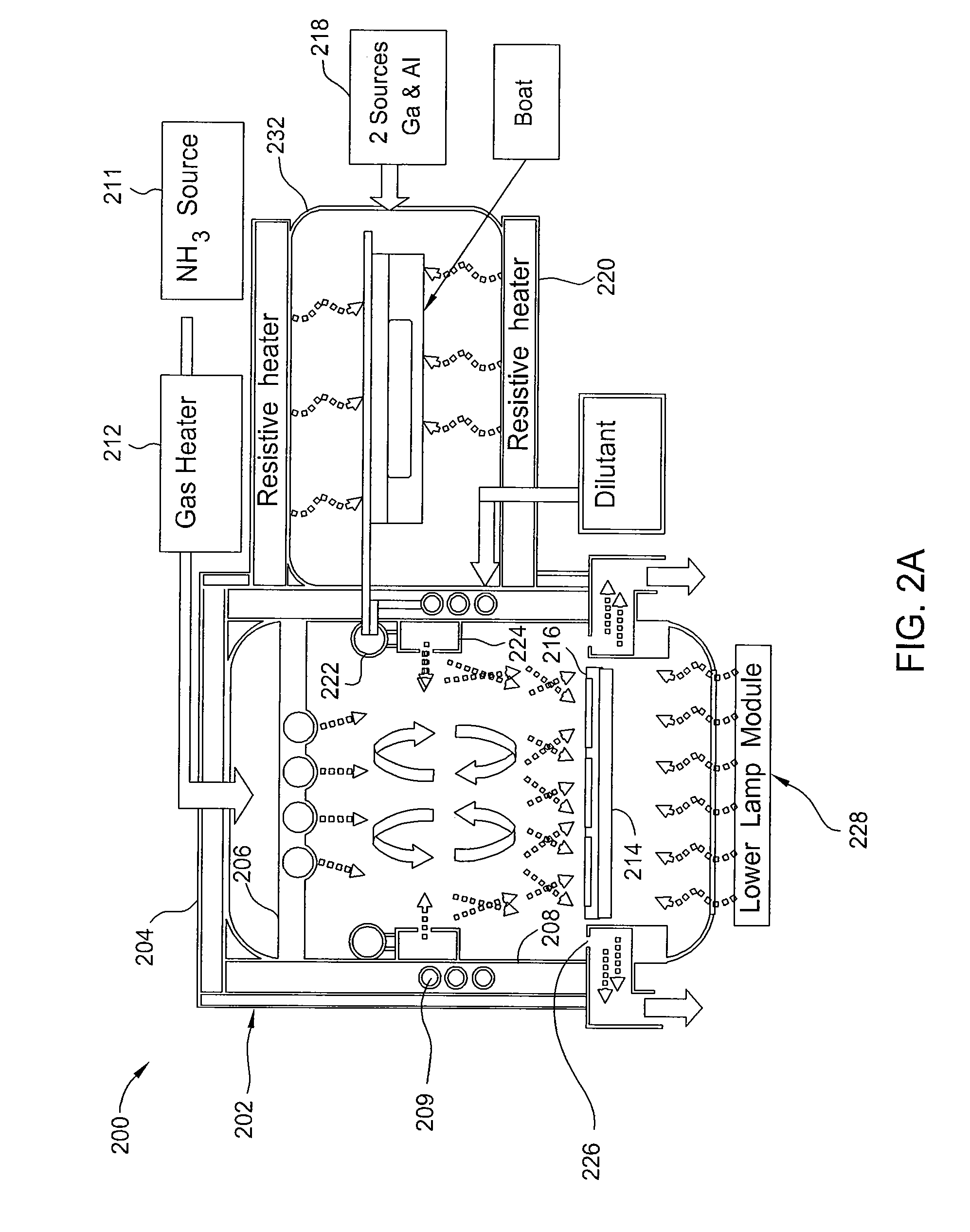

Cluster tool for leds

ActiveUS20100261340A1Polycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenChemical vapor deposition

The present invention generally provides apparatus and methods for forming LED structures. One embodiment of the present invention provides a method for fabricating a compound nitride structure comprising forming a first layer comprising a first group-III element and nitrogen on substrates in a first processing chamber by a hydride vapor phase epitaxial (HVPE) process or a metal organic chemical vapor deposition (MOCVD) process, forming a second layer comprising a second group-III element and nitrogen over the first layer in a second processing chamber by a MOCVD process, and forming a third layer comprising a third group-III element and nitrogen over the second layer by a MOCVD process.

Owner:APPLIED MATERIALS INC

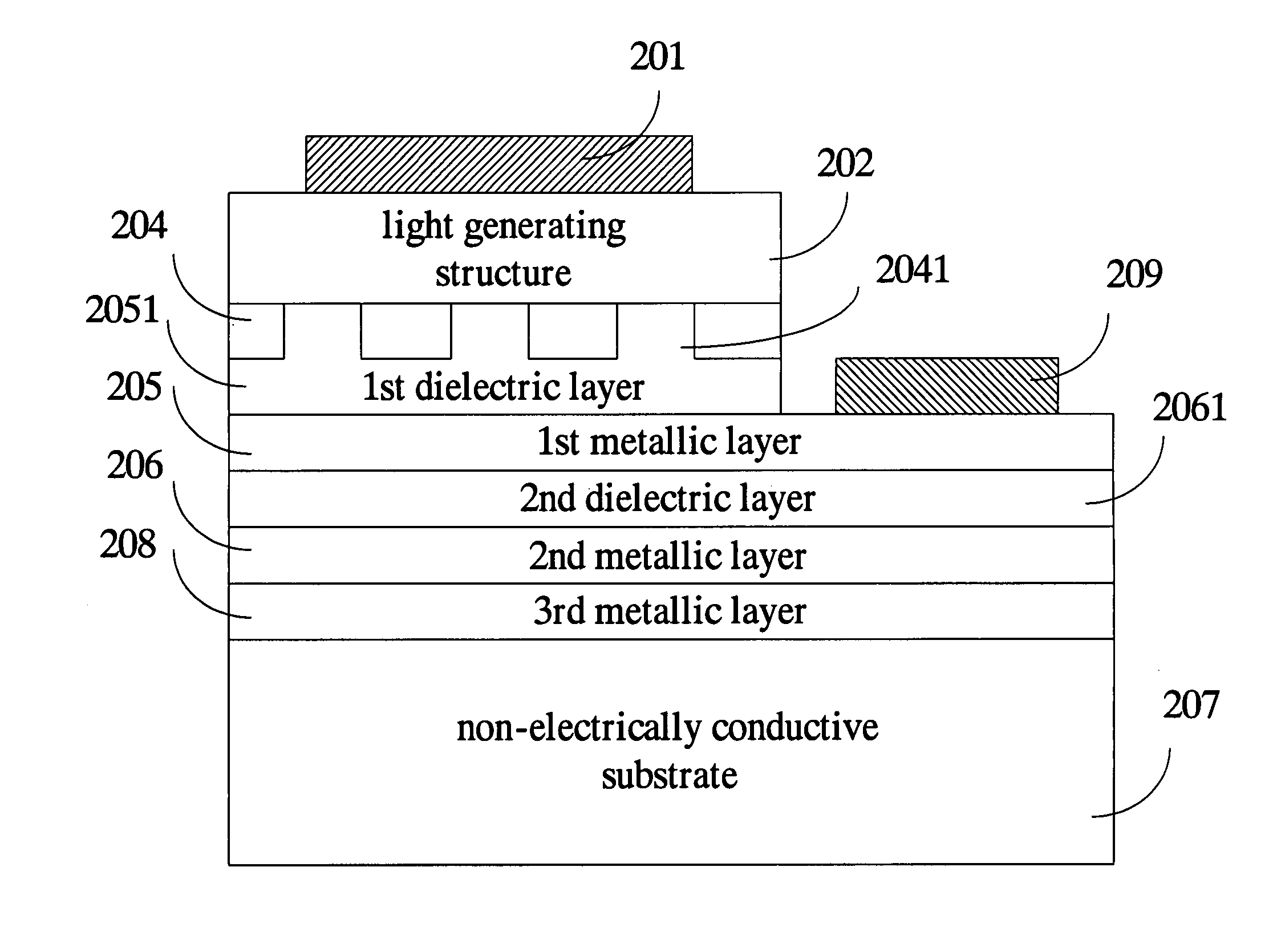

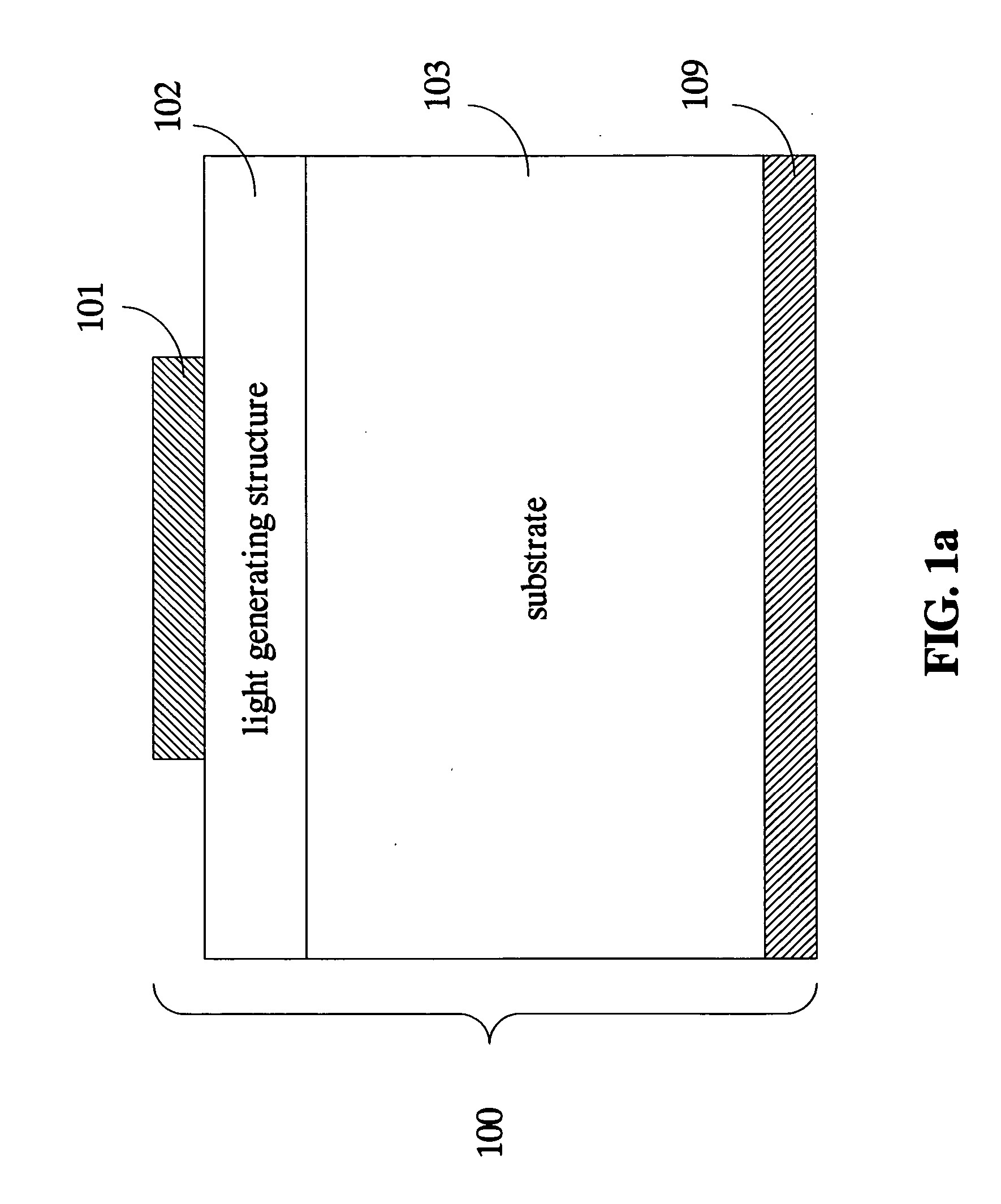

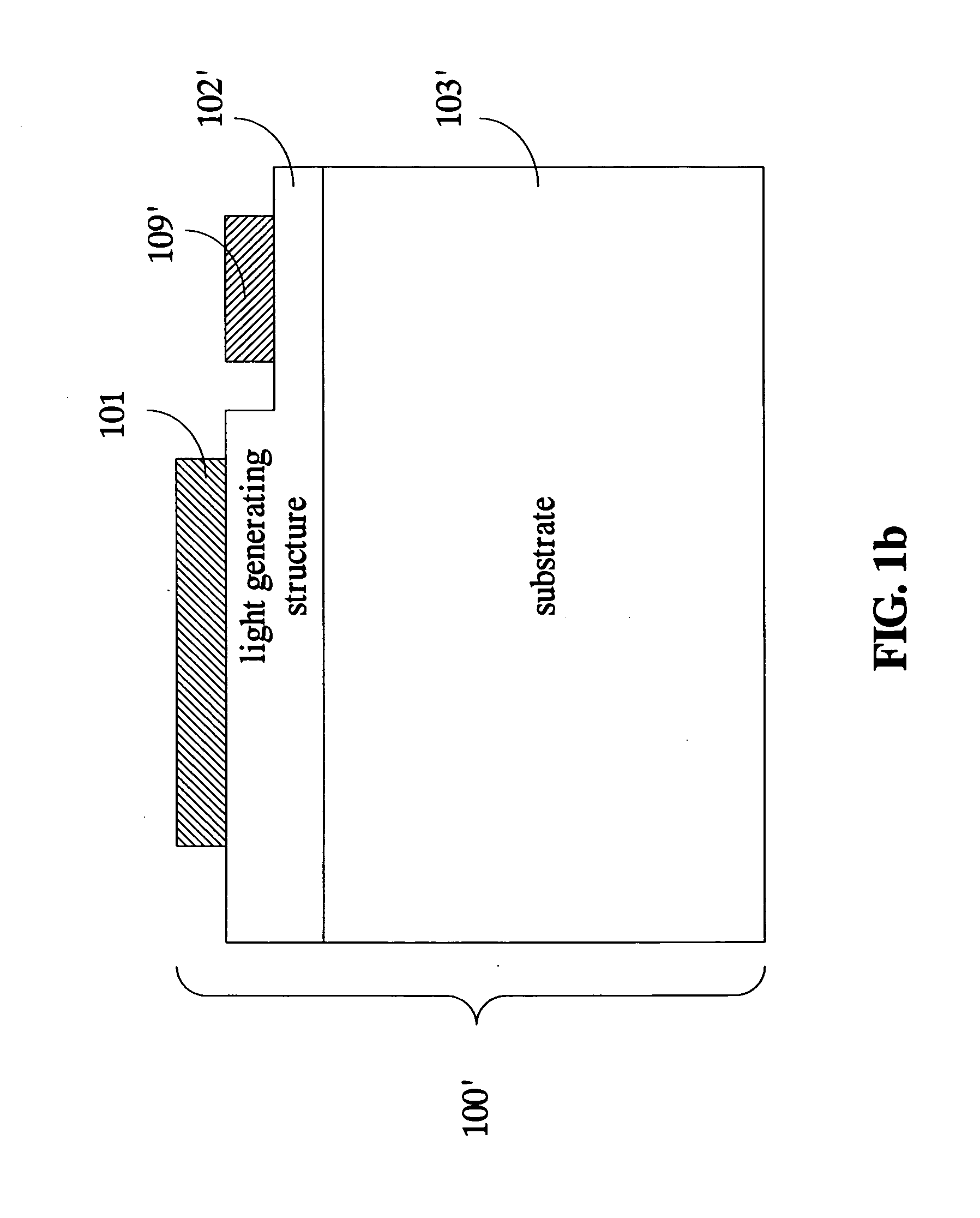

High-brightness light emitting diode having reflective layer

ActiveUS20070012937A1Increase brightnessImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesOhmic contactAlloy

An LED structure is disclosed herein, which comprises, sequentially arranged in the following order, a light generating structure, a non-alloy ohmic contact layer, a metallic layer, and a substrate. As a reflecting mirror, the metallic layer is made of a pure metal or a metal nitride for achieving superior reflectivity. The non-alloy ohmic contact layer is interposed between the metallic layer and the light generating structure so as to achieve the required ohmic contact. To prevent the metallic layer from intermixing with the non-alloy ohmic contact layer and to maintain the flatness of the reflective surface of the first metallic layer, an optional dielectric layer is interposed between the metallic layer and the non-alloy ohmic contact layer.

Owner:EPISTAR CORP

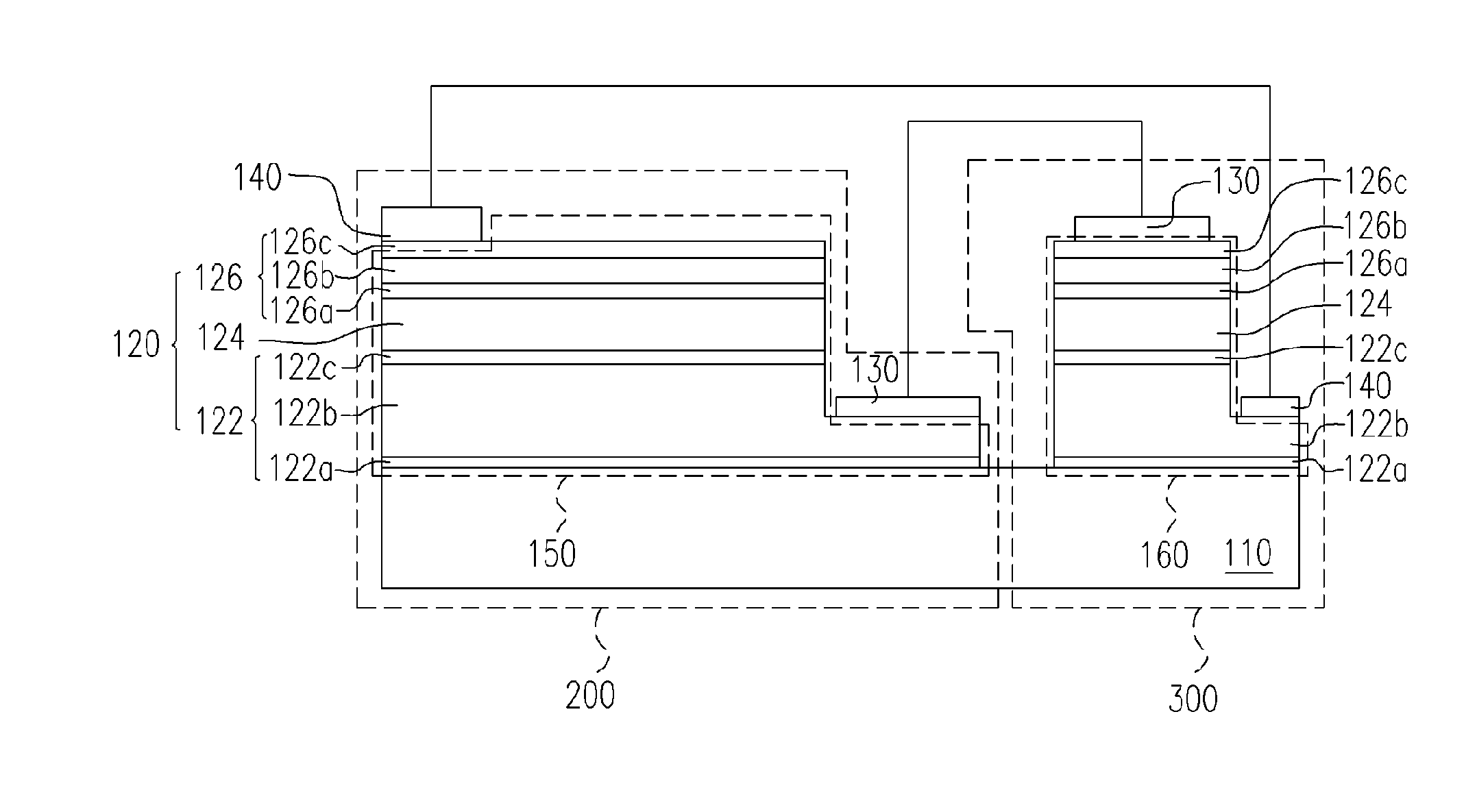

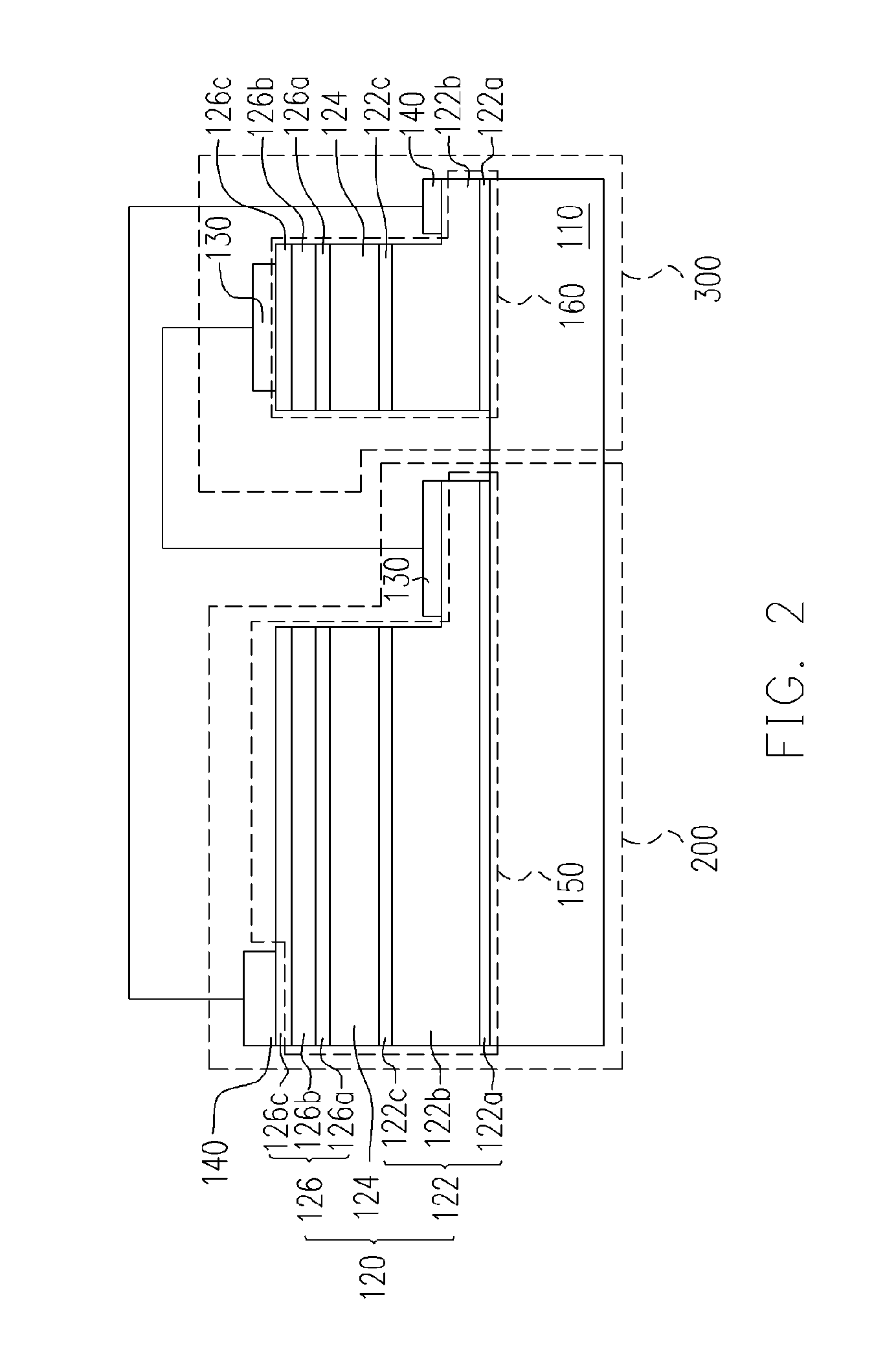

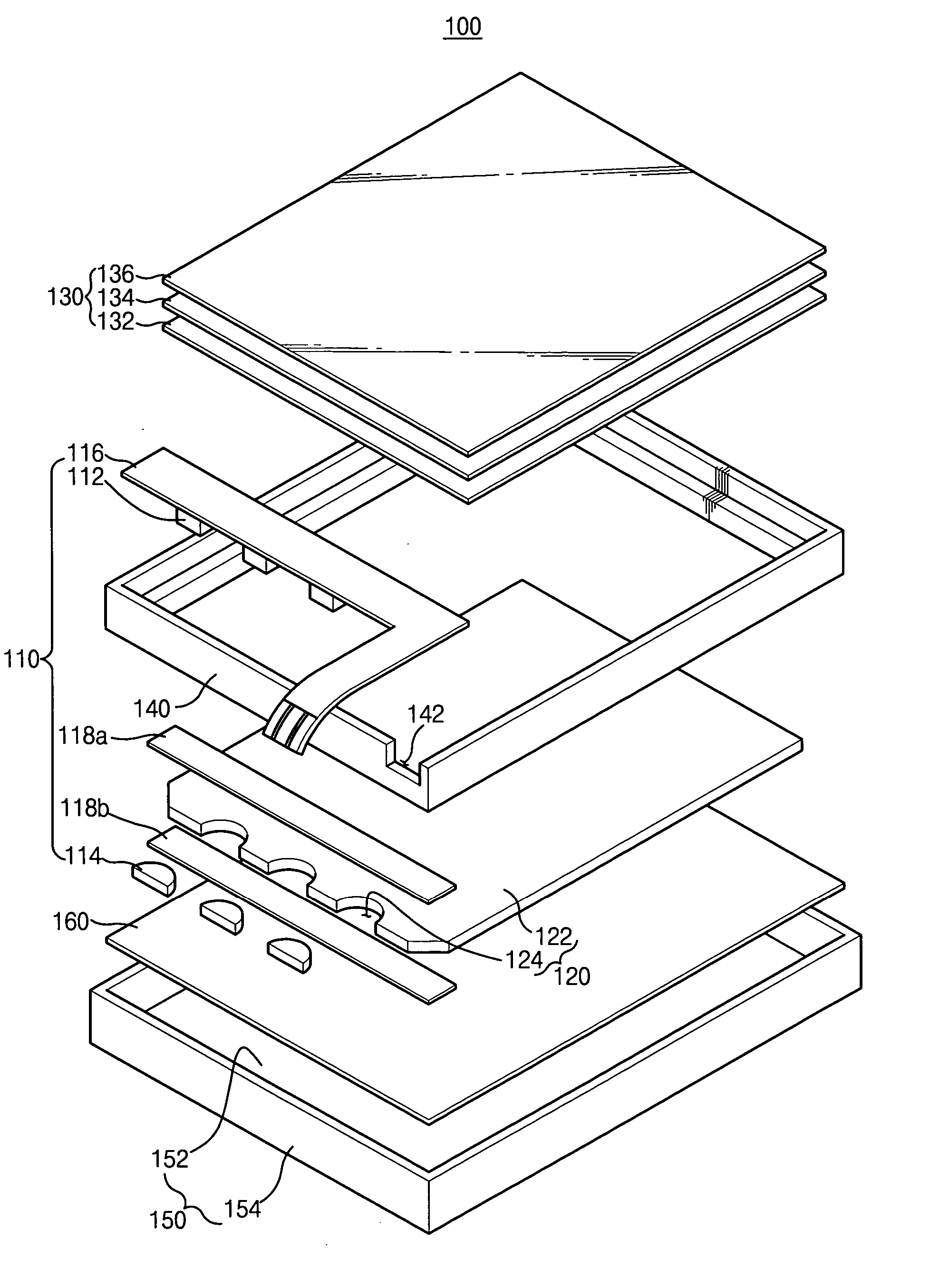

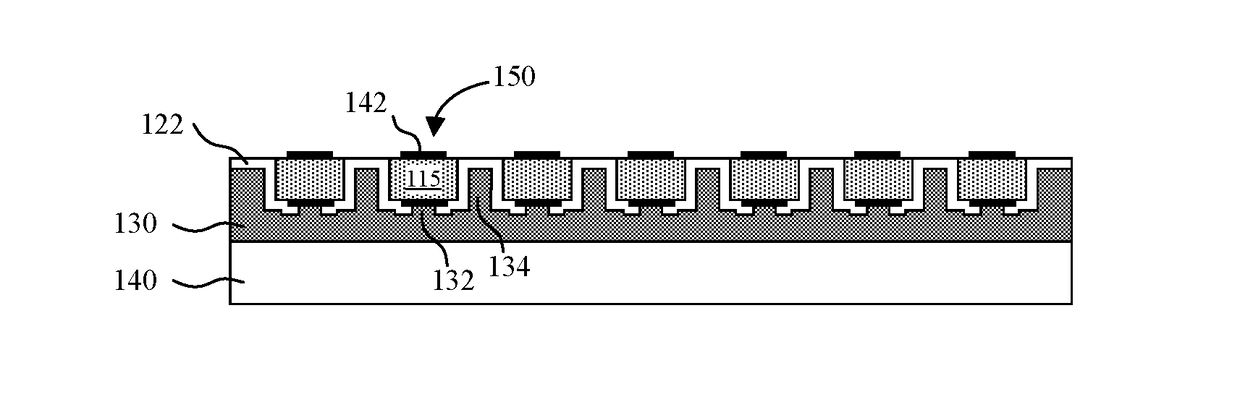

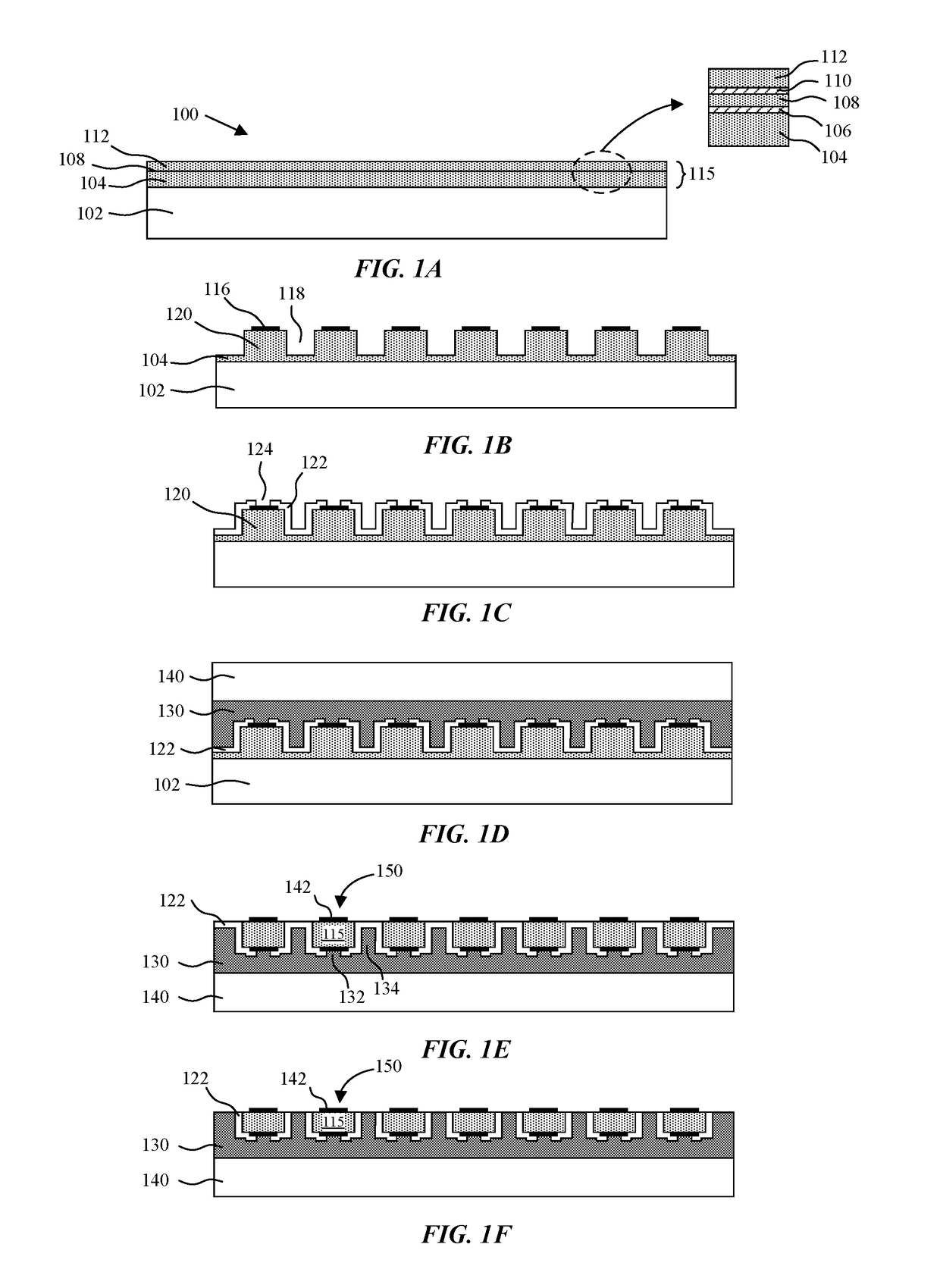

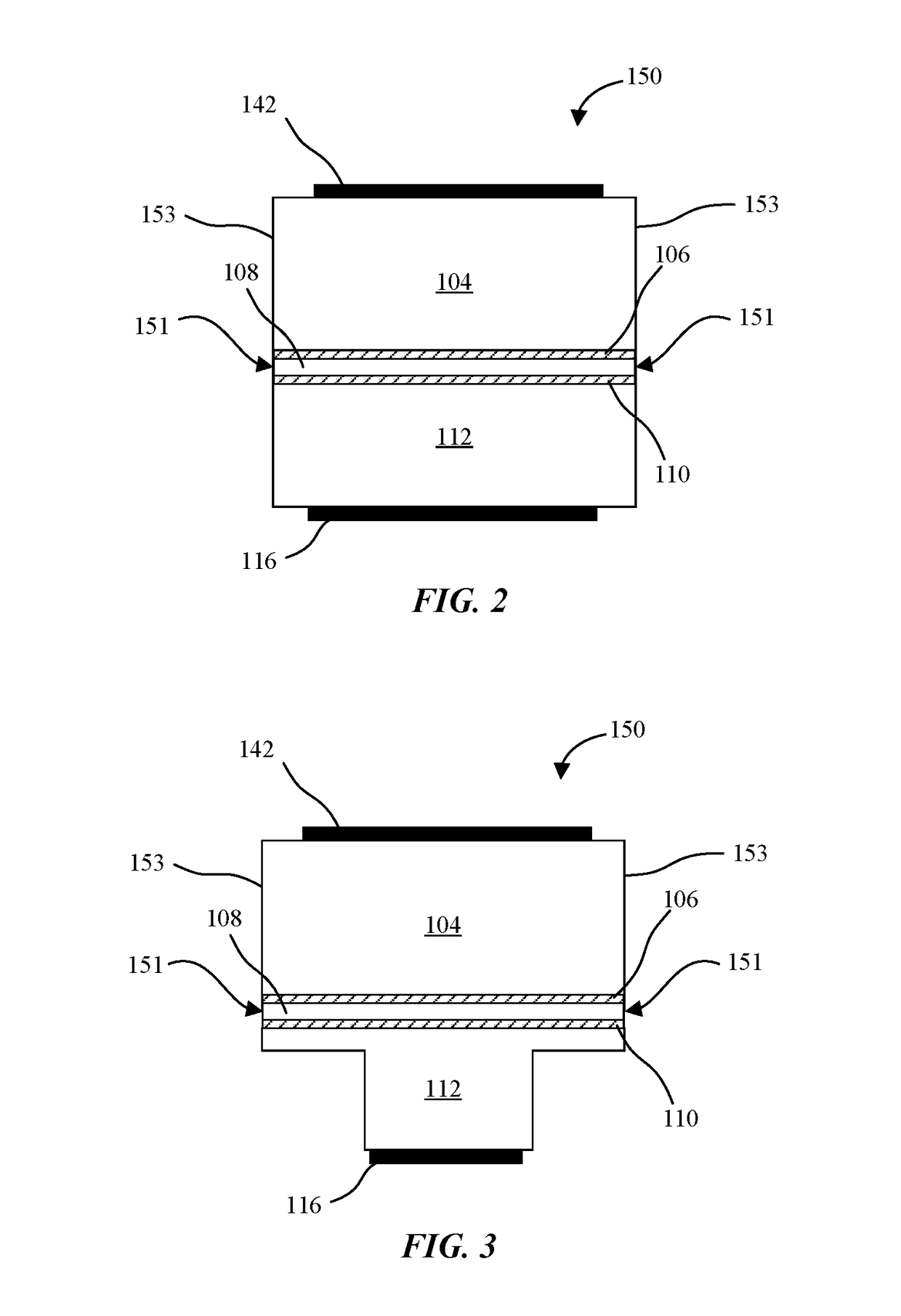

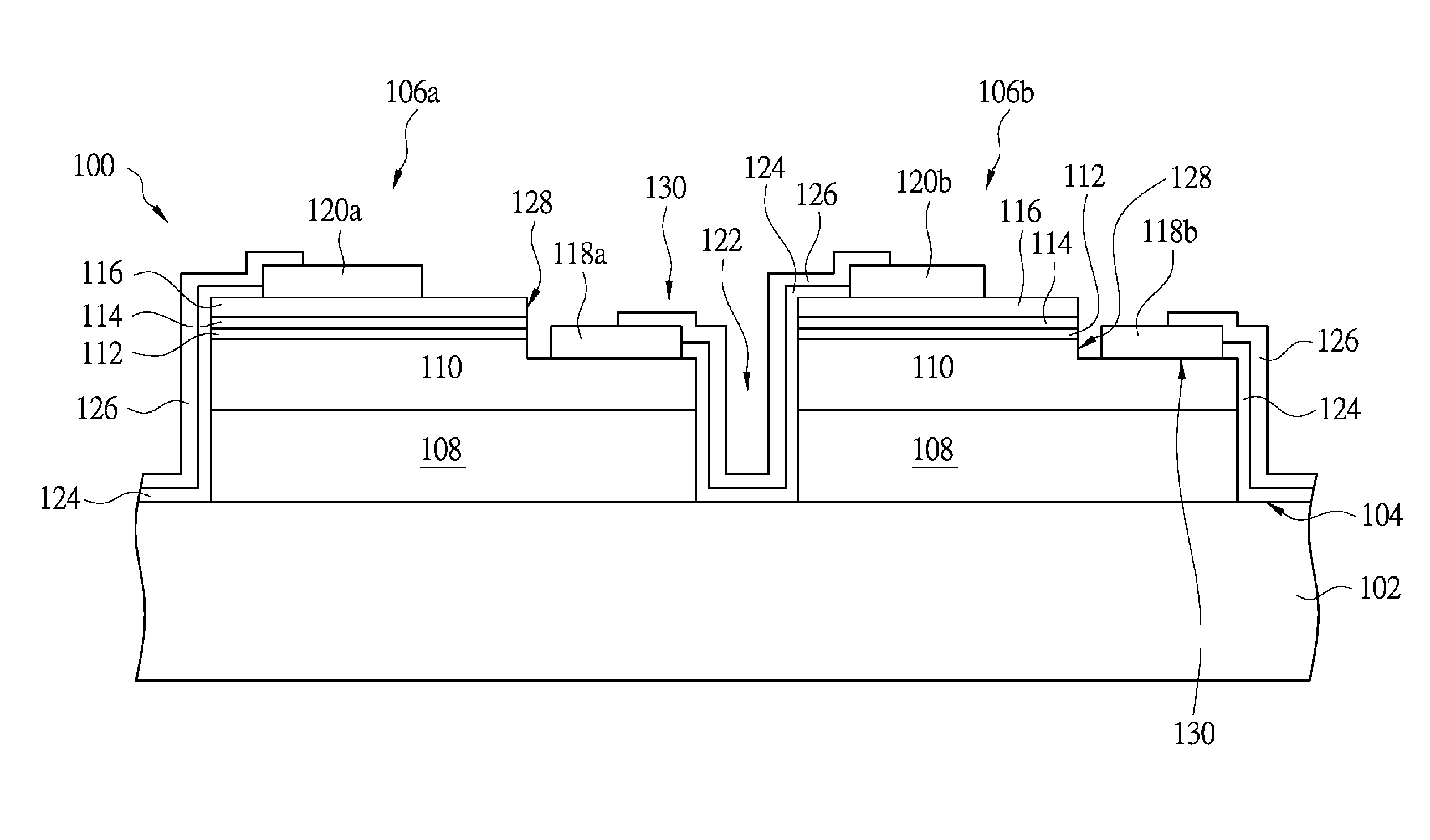

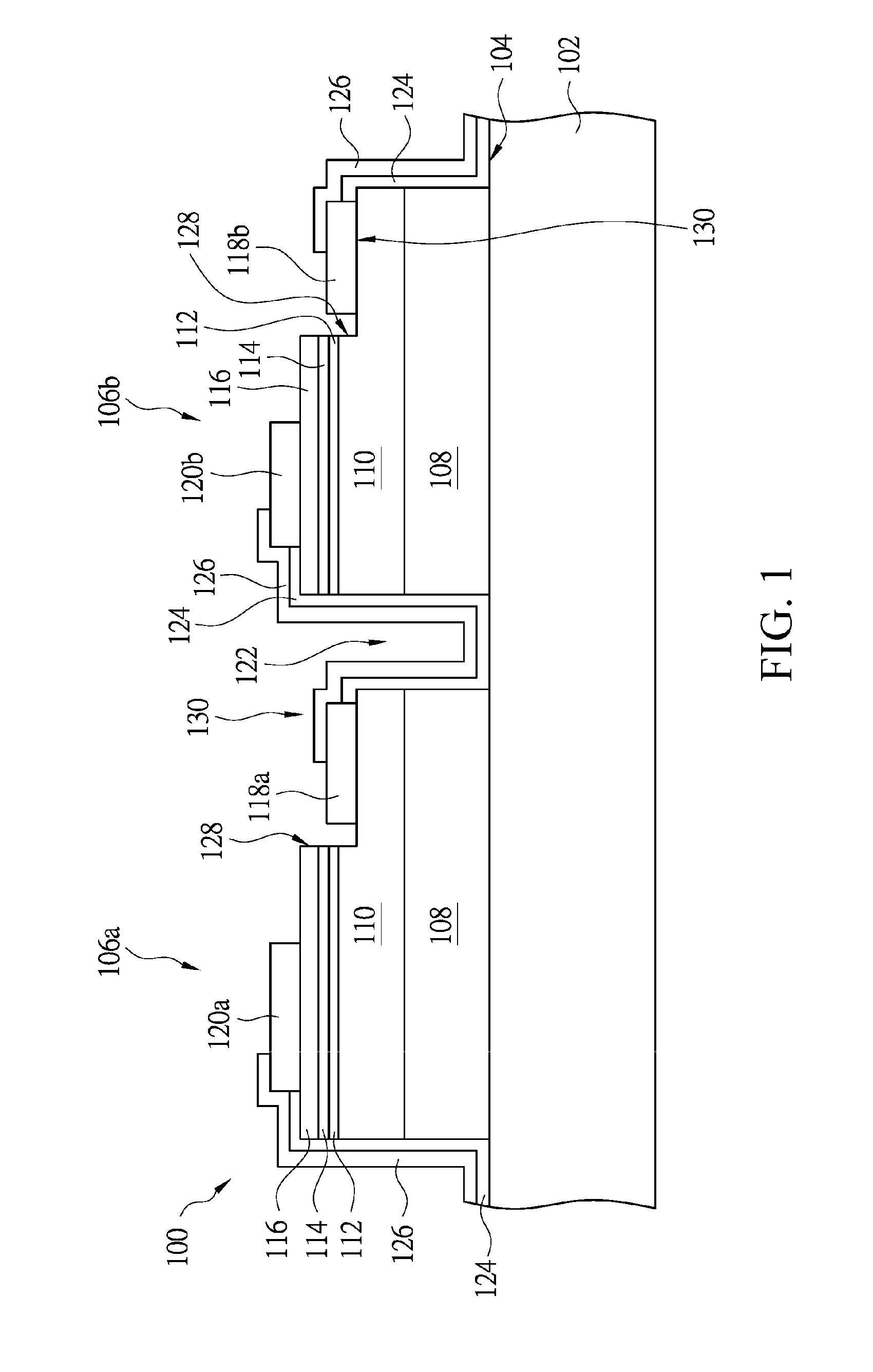

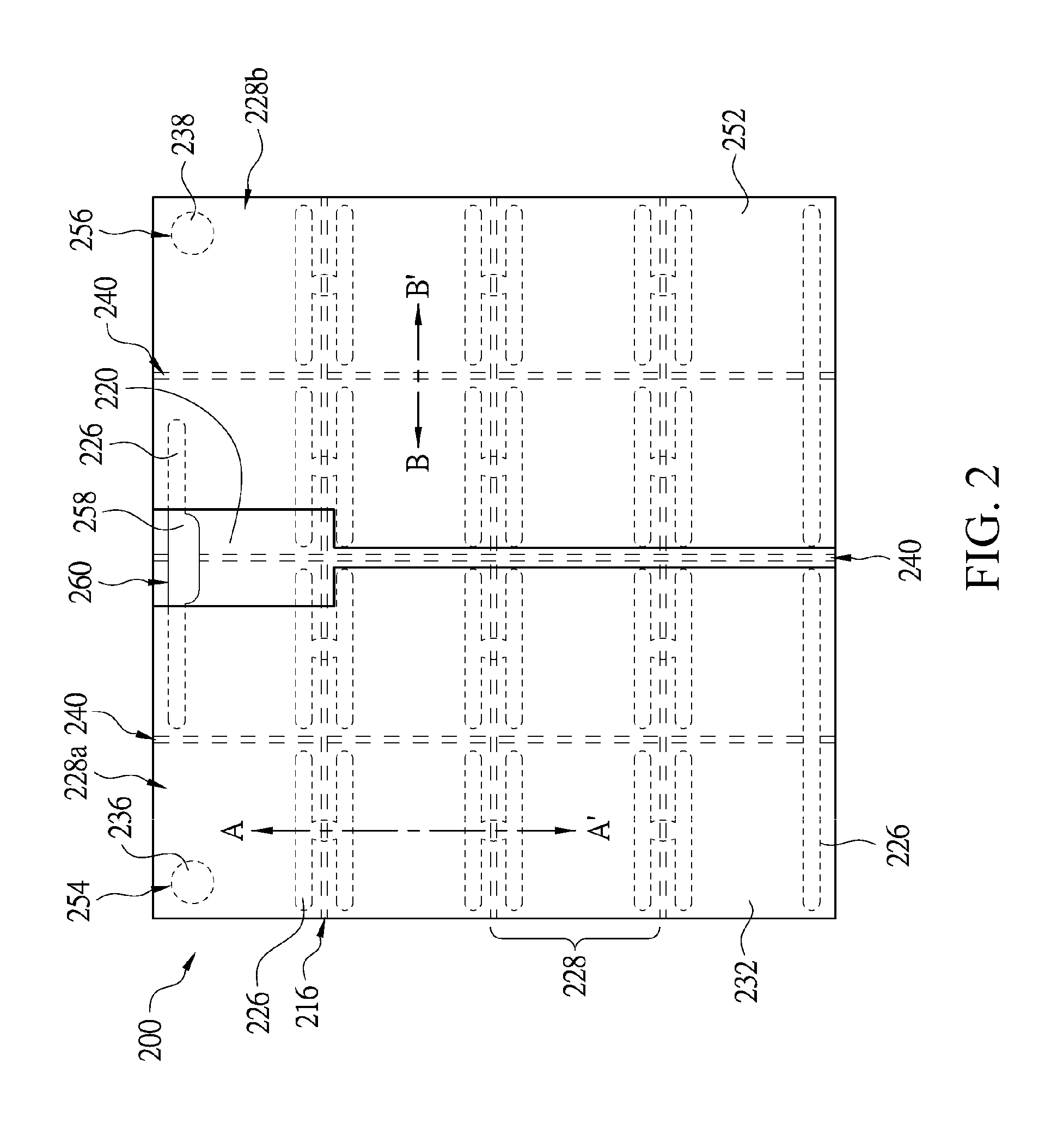

Light-emitting diode structure and method for manufacturing the same

InactiveUS20130292719A1Closely arrangedHigh light efficiencySolid-state devicesSemiconductor/solid-state device manufacturingInterconnectionActive layer

A light-emitting diode (LED) structure includes an insulation substrate; LED chips each includes an epitaxial layer having a first conductivity type semiconductor layer, an active layer, and a second conductivity type semiconductor layer stacked on the insulation substrate, and comprises a mesa structure and an exposed portion of the first conductivity type semiconductor layer adjacent to each other, and a first isolation trench within the mesa structure; interconnection layers connect the LED chips; electrode pads respectively connected to exposed portions of the semiconductor layers; a reflective insulating layer covering the interconnection layers, the mesa structures and the electrode pads, and having penetration holes respectively exposing a portion of the electrode pads; and bonding pads located on a portion of the reflective insulating layer and connected to the electrode pads through the penetrating holes. A method of manufacturing the LED structure.

Owner:CHI MEI LIGHTING TECH

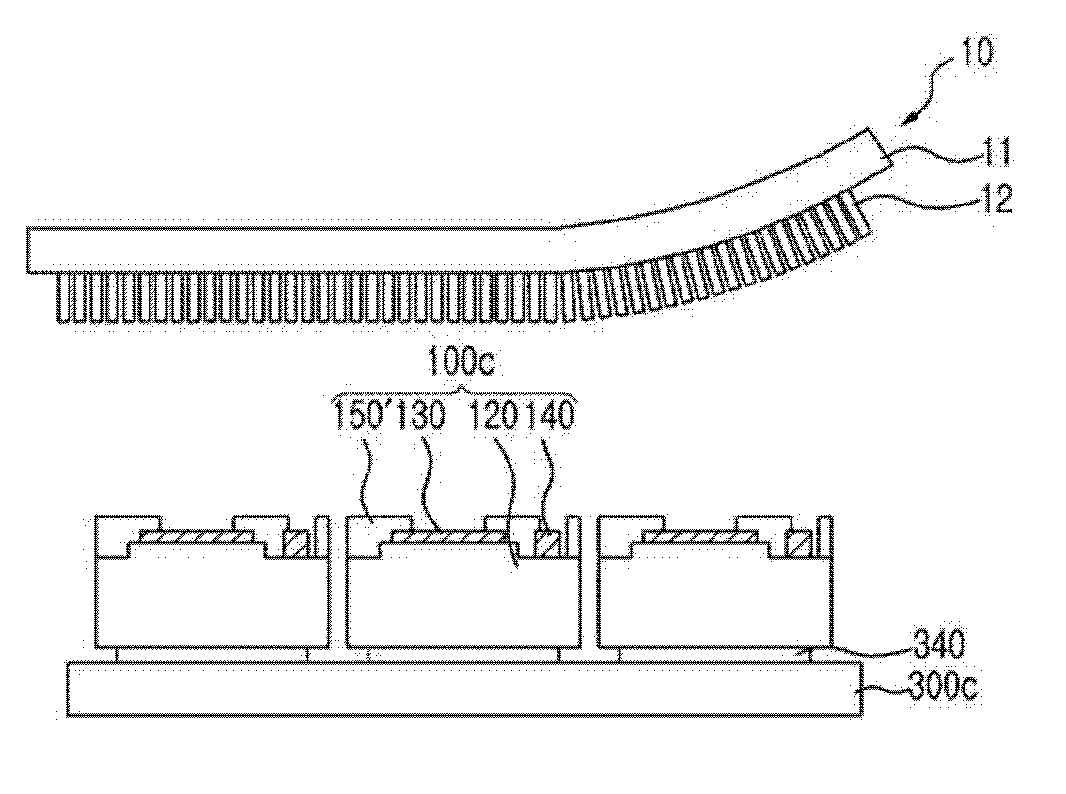

Light-emitting diode structure, transfer assembly, and transfer method using the same

ActiveUS20180204973A1Easy transferMaintain bond strengthSemiconductor/solid-state device testing/measurementSolid-state devicesSpiteEngineering

The present invention is intended to provide a light-emitting diode (LED) structure which can be easily transferred onto another substrate, a transfer assembly whose adhesive strength with LED structures can be maintained in spite of repetitive transfer processes, LED structures and a transfer assembly for selectively transferring the LED structures, and a transfer method using the same.

Owner:KOREA PHOTONICS TECH INST

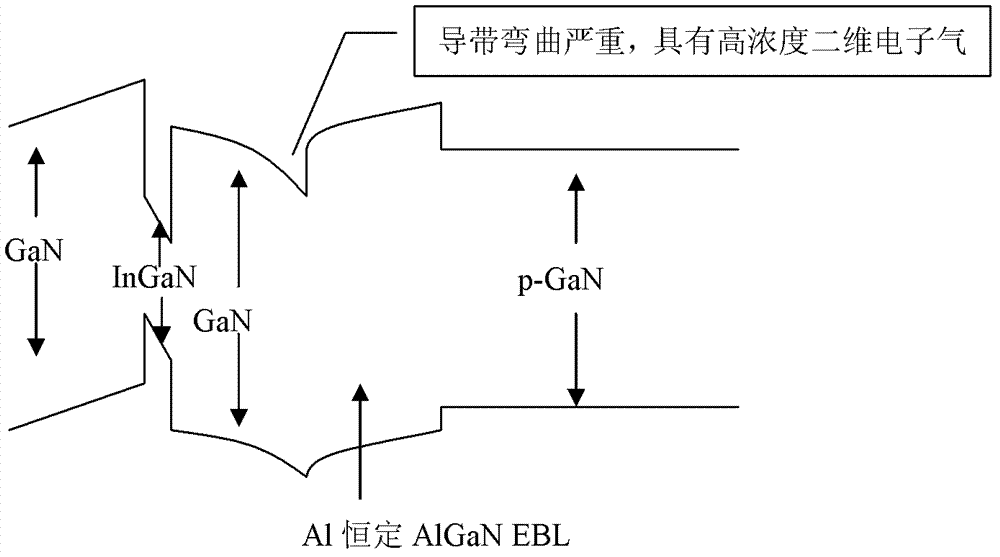

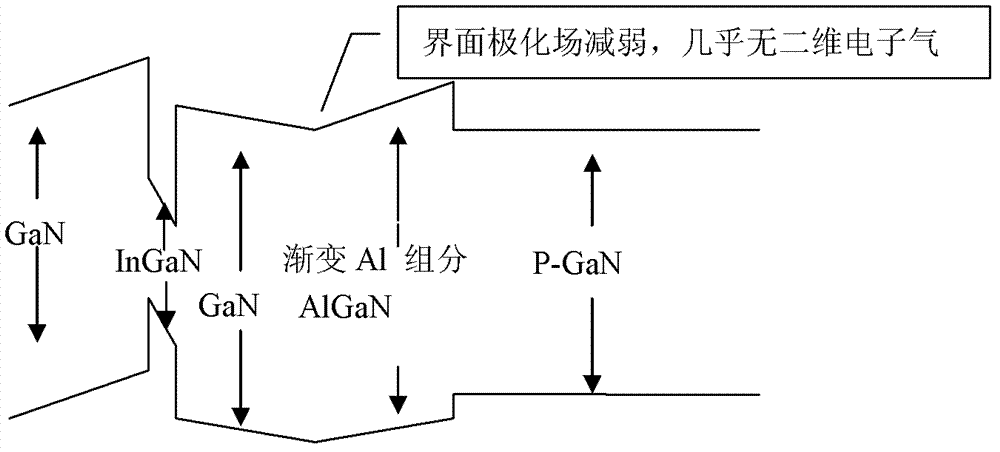

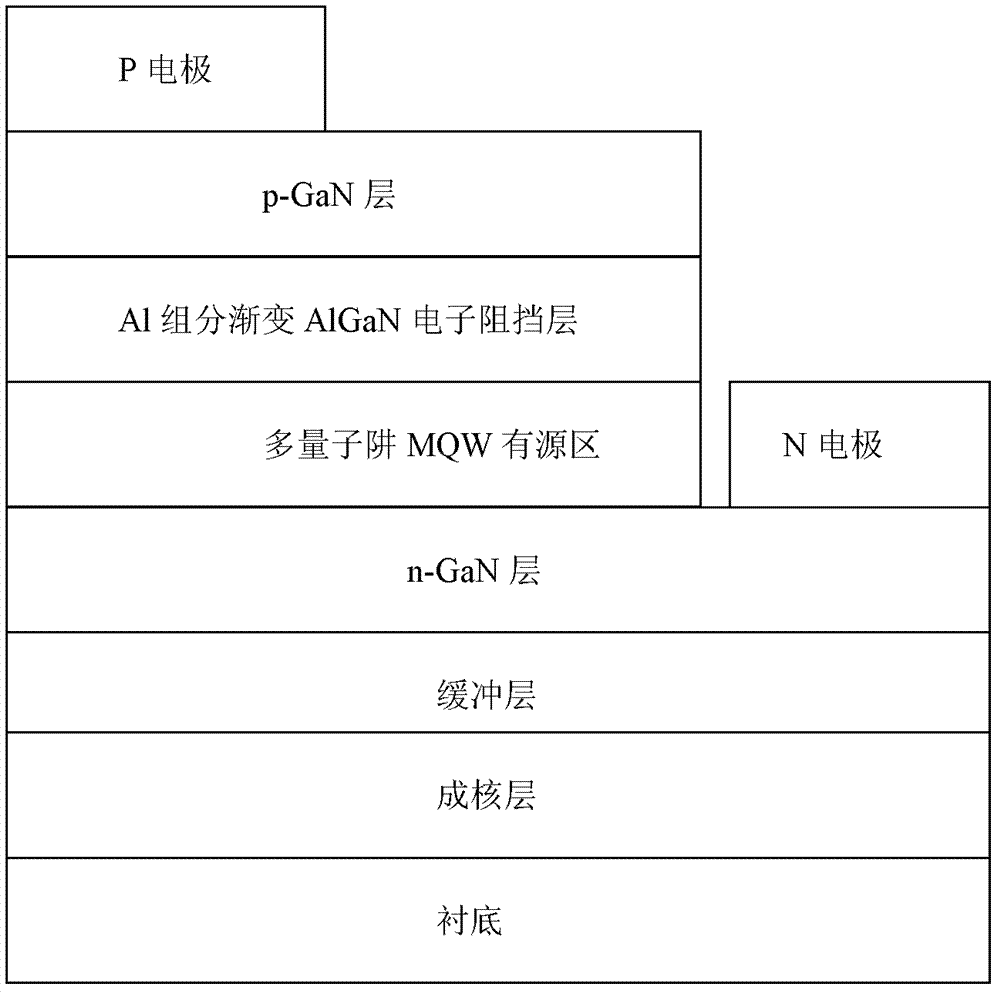

LED structure with aluminum-component-gradient electron blocking layer

InactiveCN102820394AAvoid defectsLess bendingSemiconductor devicesUltrasound attenuationQuantum efficiency

The invention relates to an LED structure with an aluminum-component-gradient electron blocking layer. Low-Al-component AlxGa1-xN is arranged on one side, which is in contract with an outer GaN barrier of a multiple-quantum well layer, of the aluminum-component-gradient electron blocking layer, the x is greater than or equal to 0 and smaller than or equal to 0.1, high-Al-component AlyGa1-yN is arranged on one side, which is in contact with a p-GaN layer, of the aluminum-component-gradient electron blocking layer, the y is greater than 0.1 and is smaller than or equal to 0.4, and the quantity of Al components in the middle of the aluminum-component-gradient electron blocking layer is gradually increased linearly. The low-Al-component AlGaN is arranged on one side, which is in contact with the GaN barrier, of the electron blocking layer, so that the density of polarization charges between interfaces of the electron blocking layer and the GaN barrier are effectively reduced, and a polarization field is weakened. Accordingly, the concentration of two-dimensional electron gas of the interfaces is greatly reduced, leakage current is decreased, the internal quantum efficiency of a device is improved in general, and the problem of attenuation of the quantum efficiency is solved.

Owner:JIANGSU YONGDING COMM

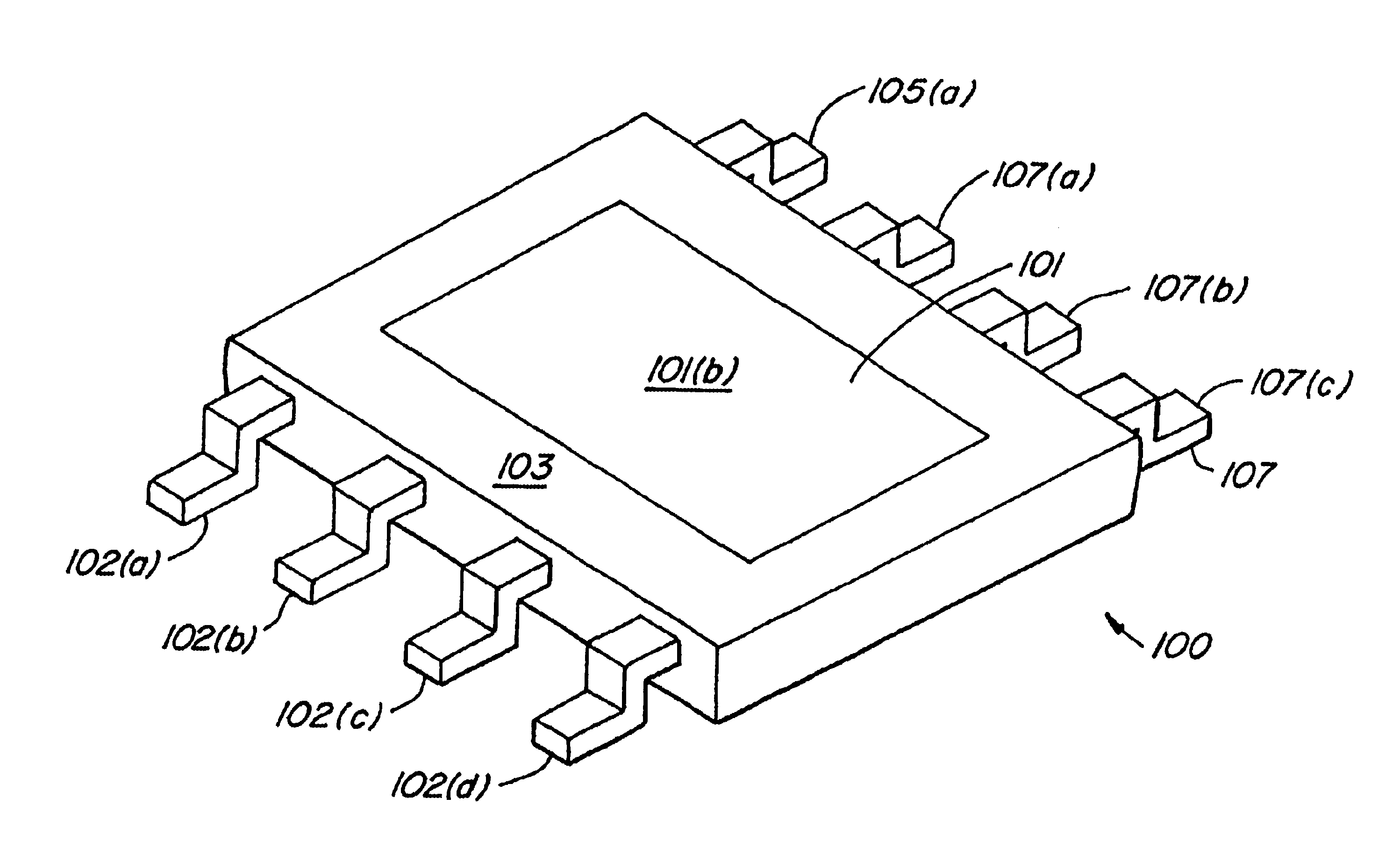

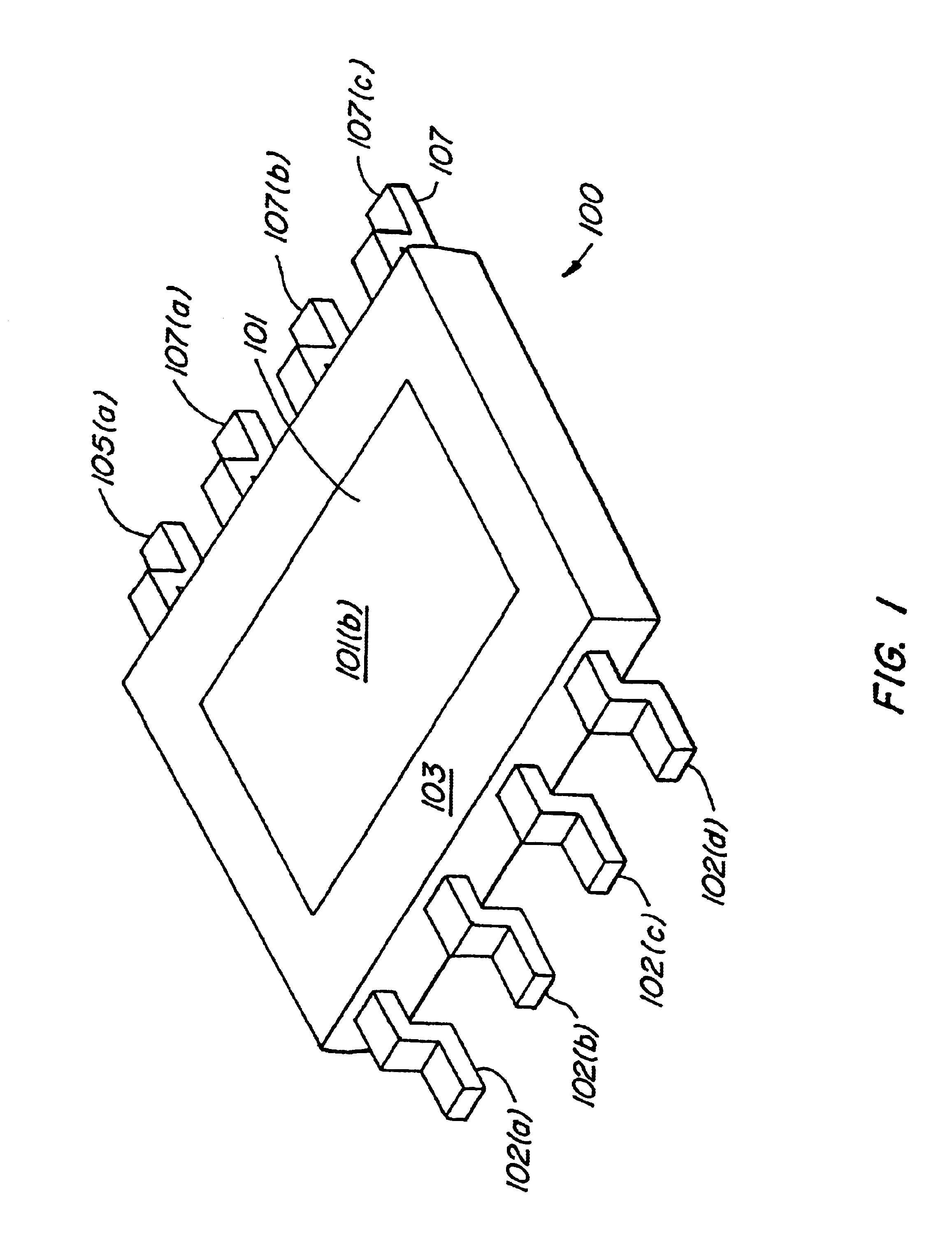

Non-leaded integrated circuit package system

ActiveUS20060180904A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringLead structure

A non-leaded integrated circuits package system is provided including etching differential height lead structures having inner leads at a paddle height, providing mold locks at the bending points of the differential height lead structures, etching an elevated paddle at a same height as the inner leads, mounting a first integrated circuit on the elevated paddle, and electrically connecting first electrical interconnects between the first integrated circuit and the inner leads.

Owner:STATS CHIPPAC LTD

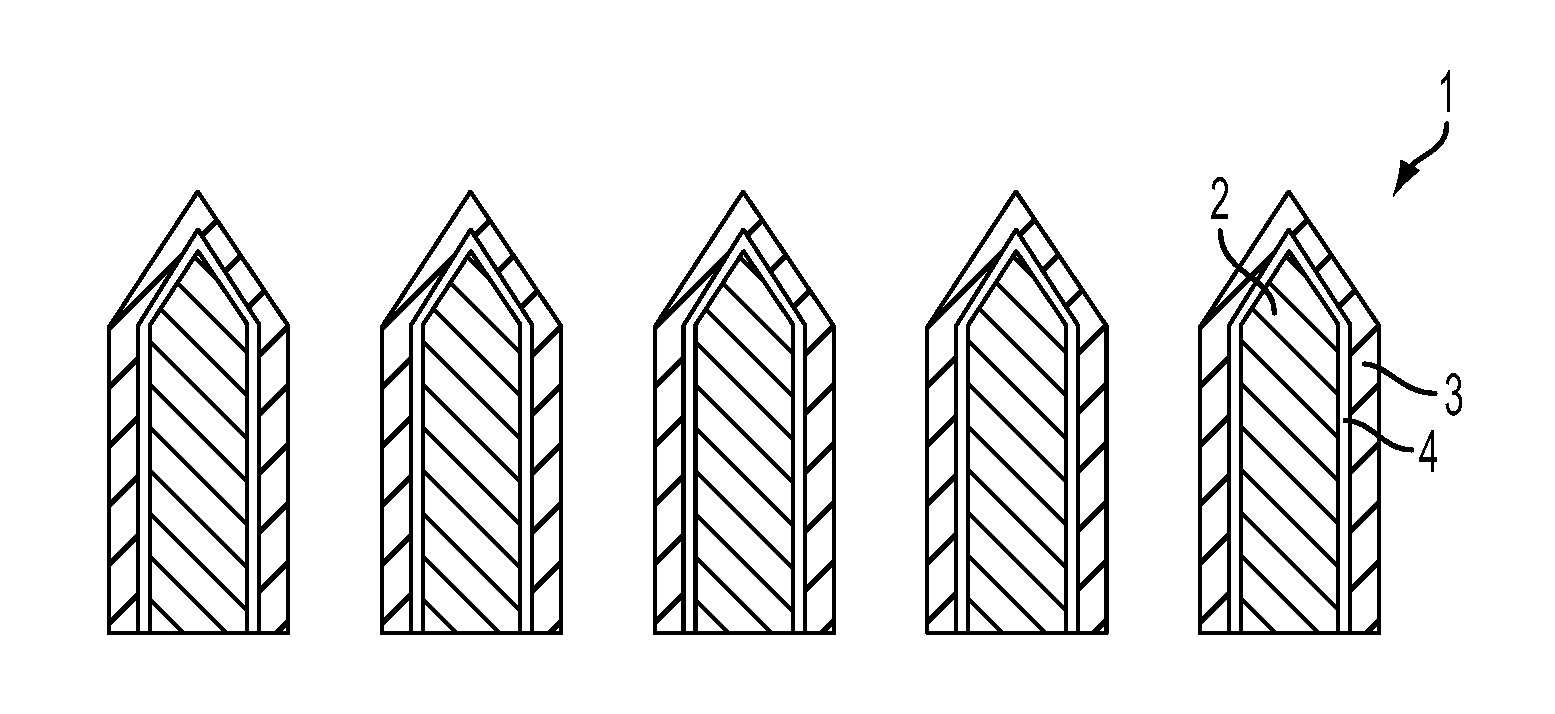

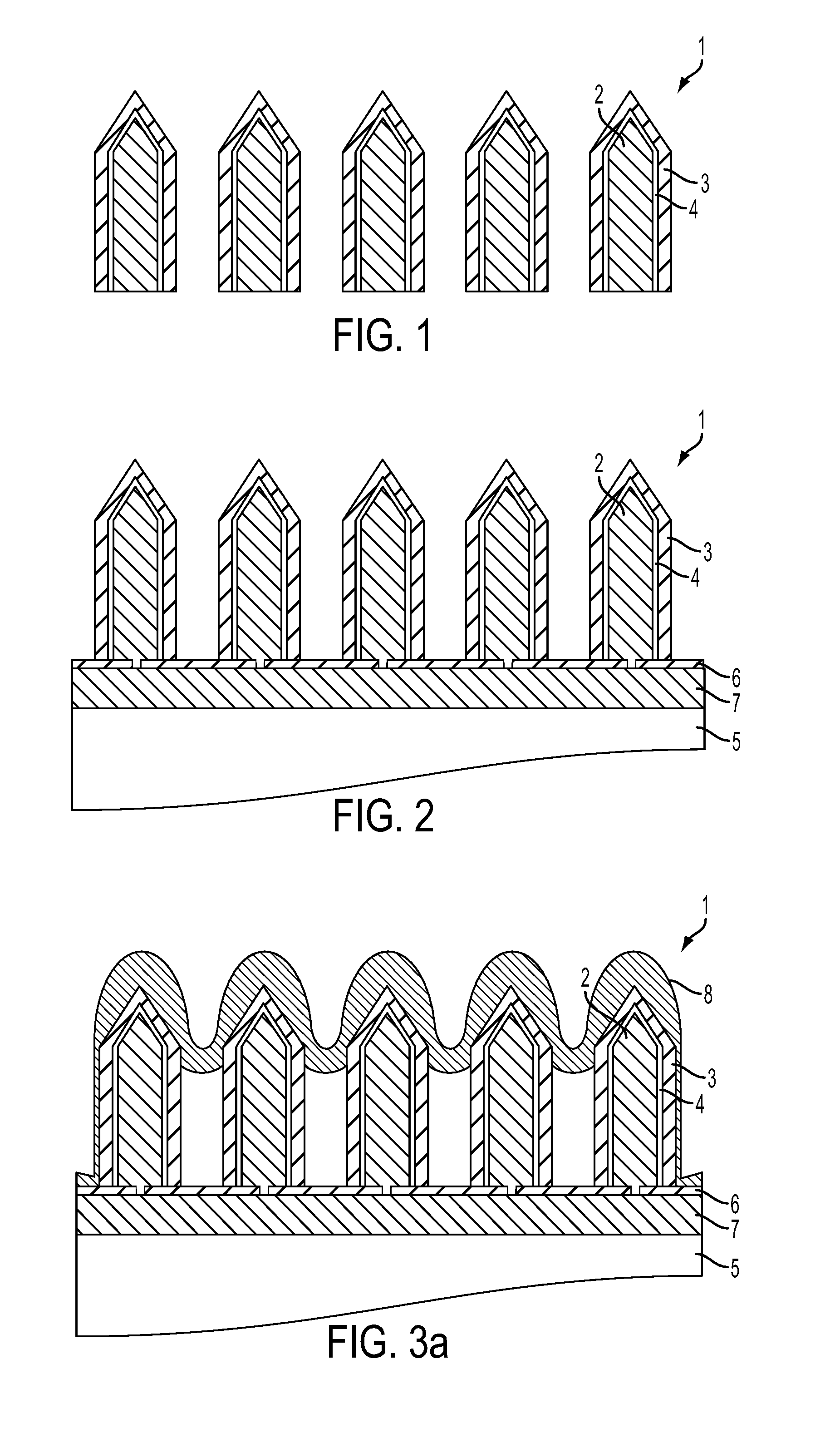

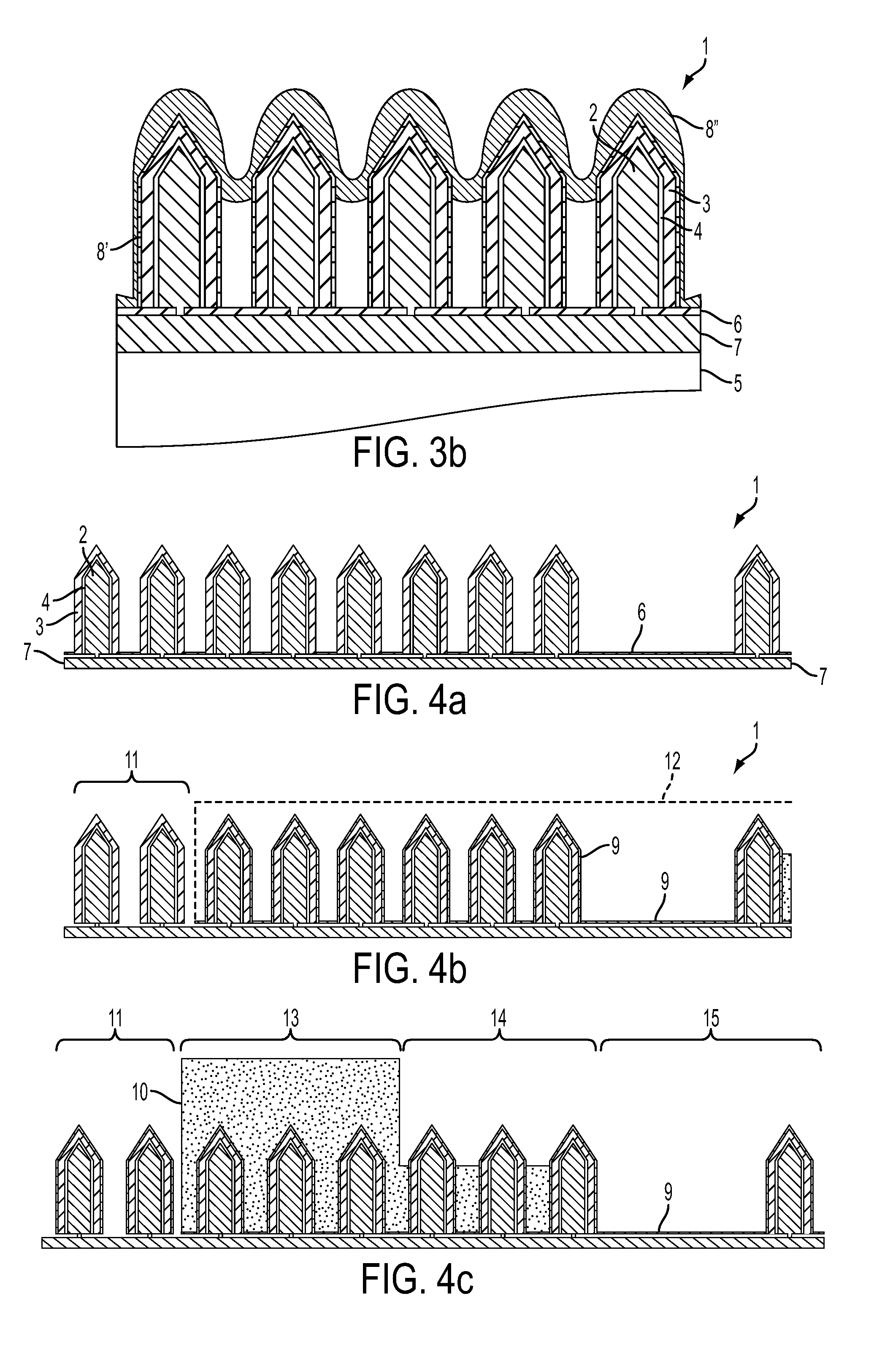

Method of collective manufacture of leds and structure for collective manufacture of leds

InactiveUS20150155331A1Shorten production timeLow costSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsEngineering

The disclosure relates to a method of collective manufacturing of light-emitting diode (LED) devices comprising formation of elemental structures, each comprising an n-type layer, an active layer and a p-type layer, the method comprising: —reduction of the lateral dimensions of part of each elemental LED structure; —formation of a portion of insulating material on the sides of the elemental structures;—formation of n-type electrical contact pads and p-type electrical contact pads; —deposition of a conductive material layer; on the elemental structures and polishing of the conductive material layer; and—bonding by molecular adhesion of a second substrate on the polished surface of the structure.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

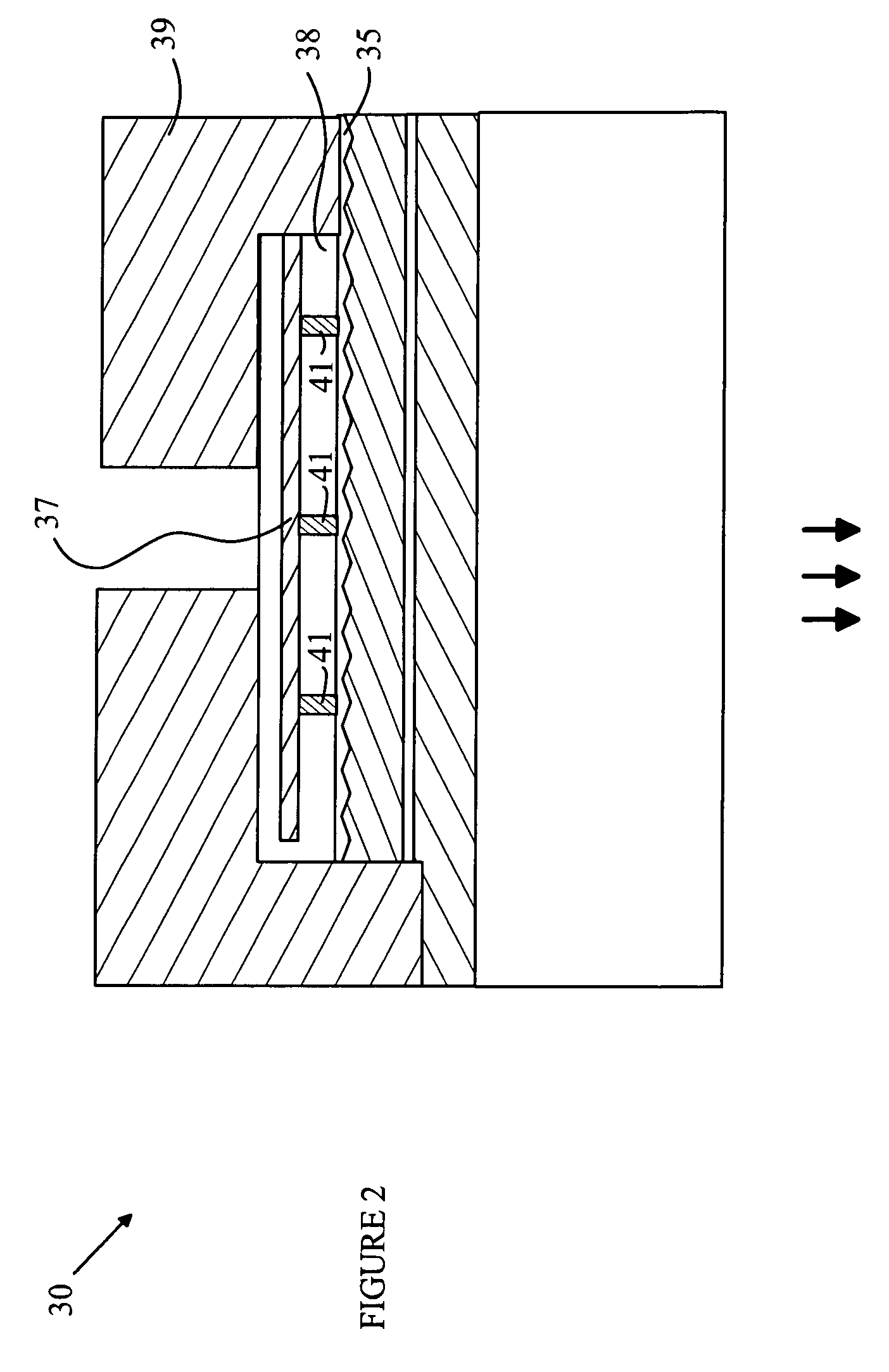

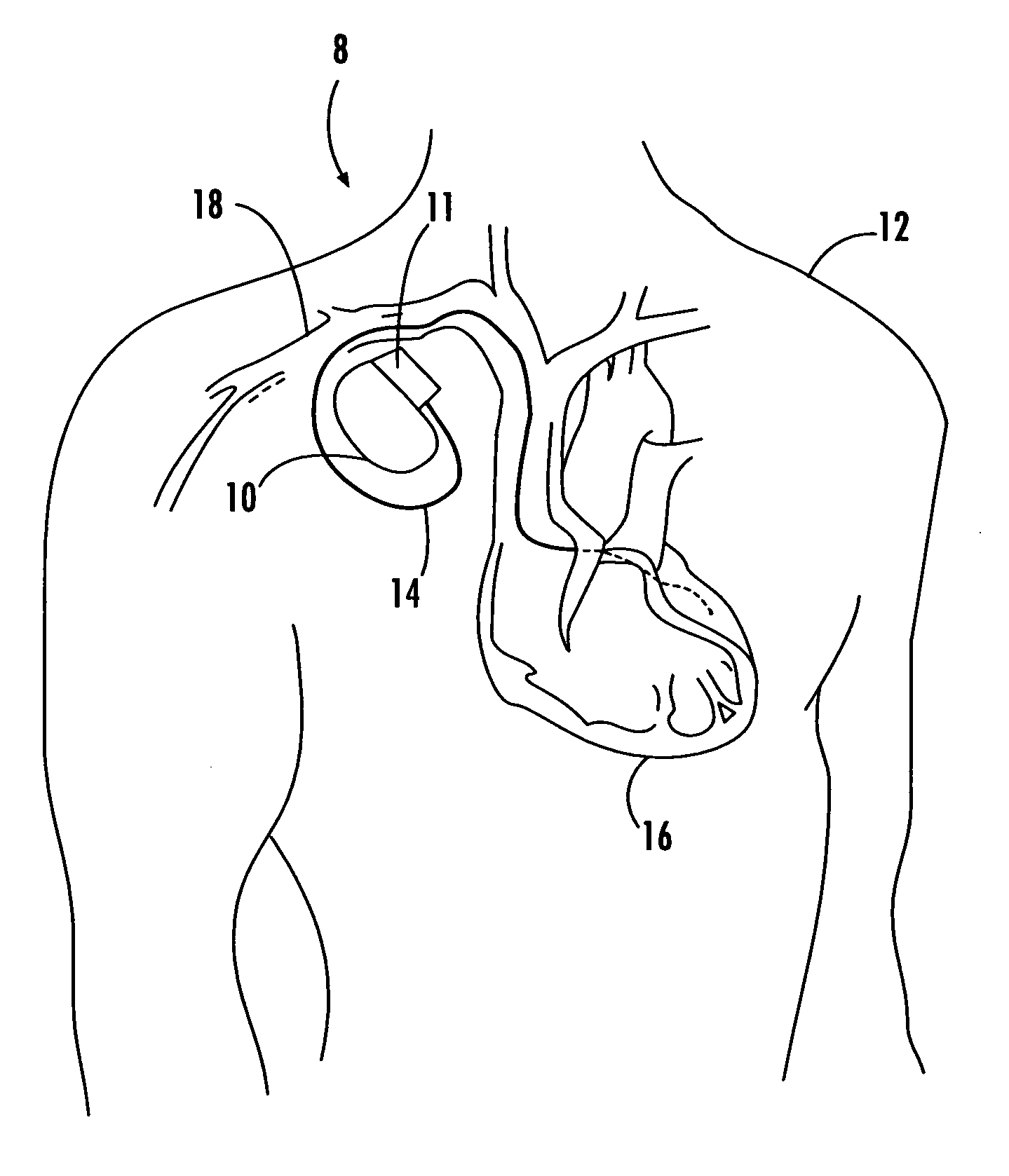

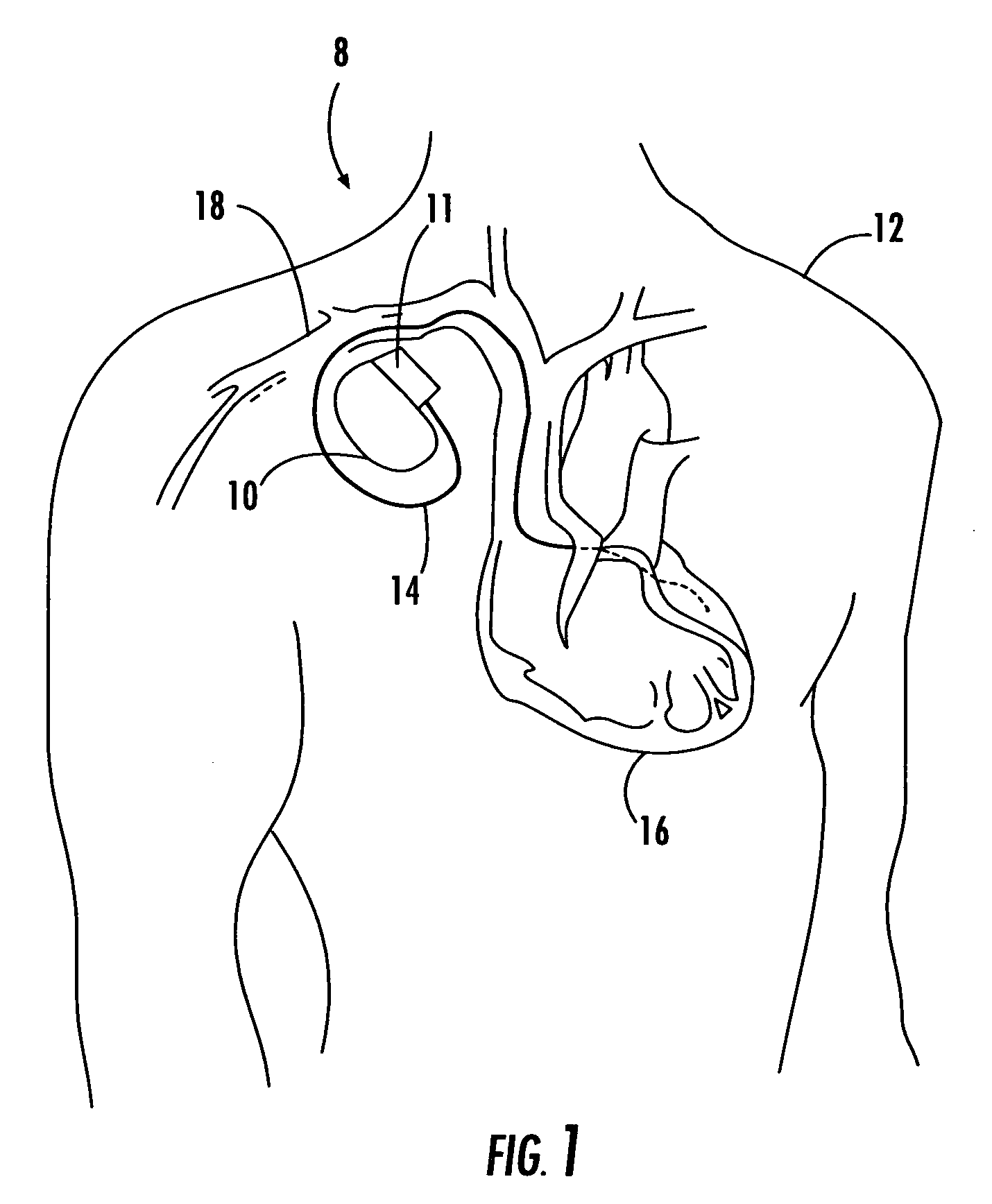

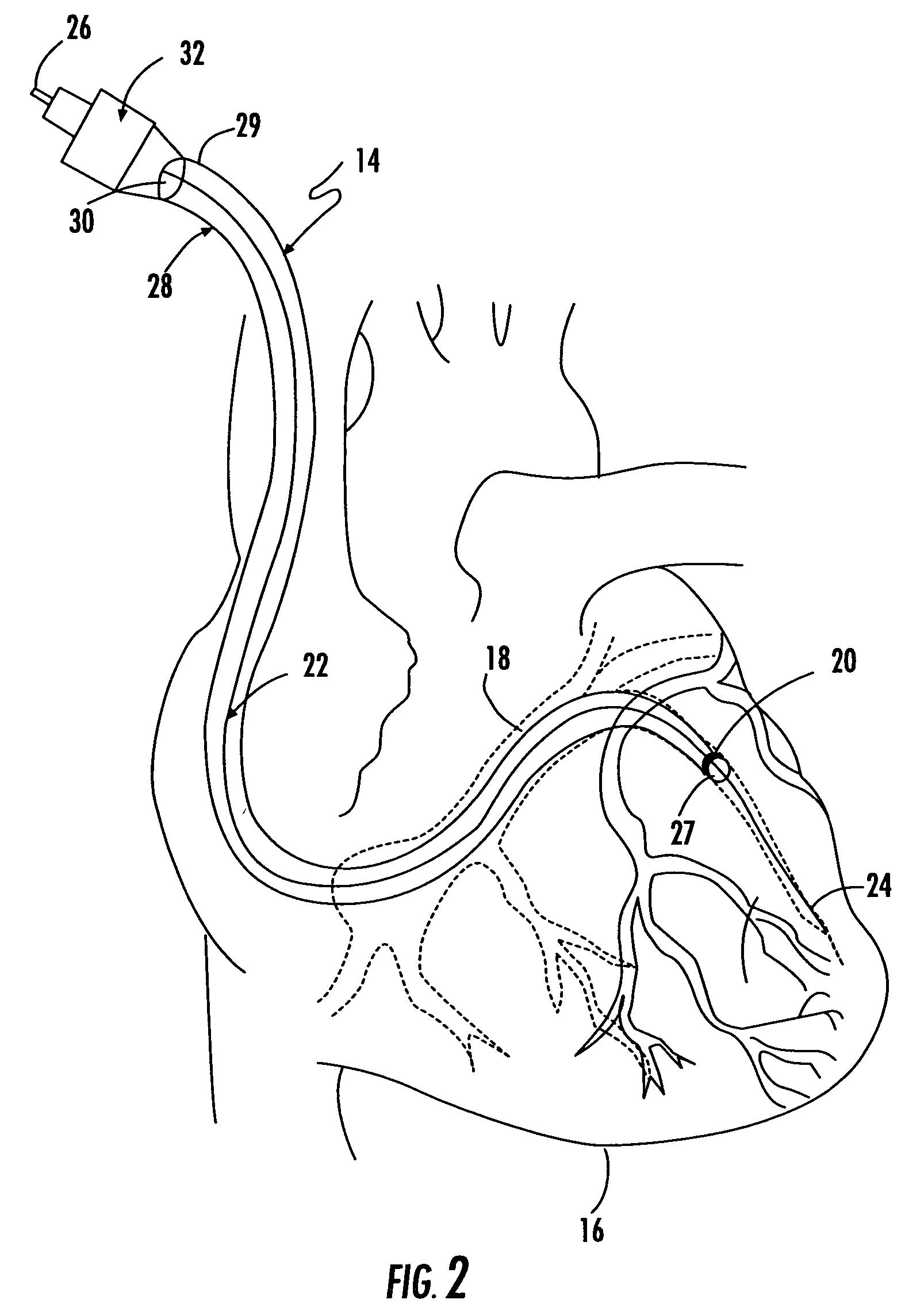

Method and apparatus for reliably placing and adjusting a left ventricular pacemaker lead

InactiveUS20060106445A1Easy to anchorImprove positionTransvascular endocardial electrodesExternal electrodesLocking mechanismLeft ventricular size

A left ventricular stimulation lead construction and a technique for lead placement that provides for improved anchoring and positioning of the electrode located on the distal end of the lead, while also including a method for readjusting the positioning of the lead as necessary. The lead includes a small diameter guide wire wherein the distal end of the guide wire serves as an anchor for the pacing lead. The lead structure includes a central hollow lumen to allow passage of the guide wire and a locking mechanism positioned on the proximal end of the pacing lead to fix the ends of the guide wire and pacing lead relative to one another. The method provides for advancing the guide wire until it is anchored, positioning the pacing lead along the guide wire into the desired position relative to the cardiac tissue, releasably fixing the lead relative to the guide wire, wherein the guide wire is permanently retained to serve as an anchor.

Owner:WOOLLETT IAN

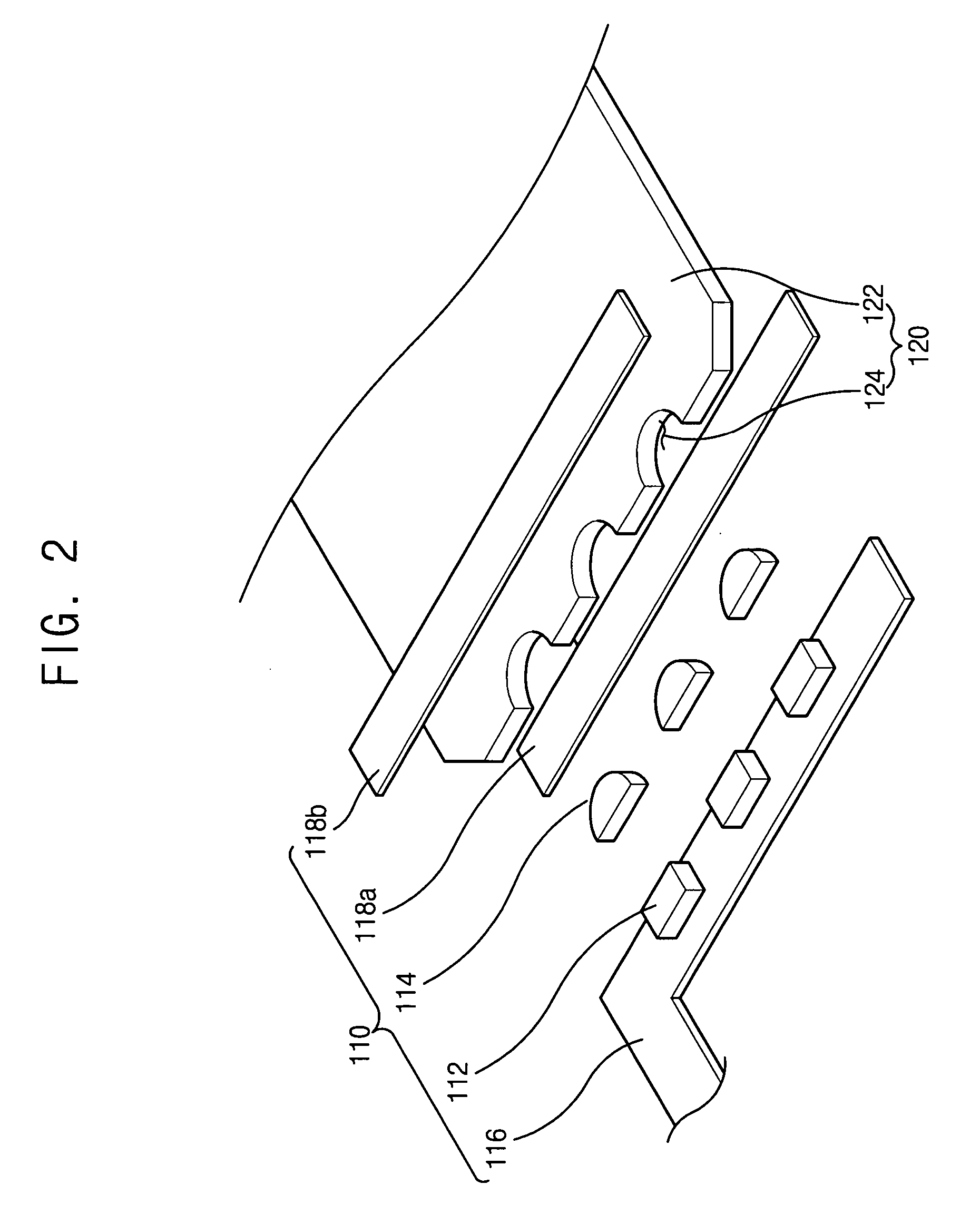

LED structure with polarized light emission

ActiveUS20170357127A1Reduce the numberReduce thicknessSolid-state devicesNon-linear opticsLiquid-crystal displayWire grid

A light-emitting diode (LED) structure includes an LED substrate having a first side and a second side opposing the first side. One or more light-emitting diodes are disposed on the first side and arranged to emit light through the LED substrate. In certain embodiments, a wire-grid polarizer is disposed on the second side and arranged to polarize light emitted from the one or more light-emitting diodes. A plurality of different colored LEDs or an LED with one or more color-conversion materials can be provided on the LED substrate to provide white light. A spatially distributed plurality of the LED structures can be provided in a backlight for a liquid crystal display. A polarization-preserving transmissive diffuser can diffuse light emitted from the LED toward the liquid crystal layer and a polarization-preserving reflective diffuser can diffuse light emitted from the LED away from the liquid crystal layer.

Owner:X DISPLAY CO TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com