Method for improving luminous efficiency of GaN based LED by using graphic underlay

A patterned substrate, luminous efficiency technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that affect the quality of material crystals, limit the photoelectric performance of devices, reduce the efficiency of light extraction, etc., to improve the quality and uniformity of crystals , Improving the internal quantum luminous efficiency and enhancing the effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] see Figure 1-Figure 7 As shown, the present invention uses a patterned substrate to improve the method of GaN-based LED luminous efficiency, comprising the following steps:

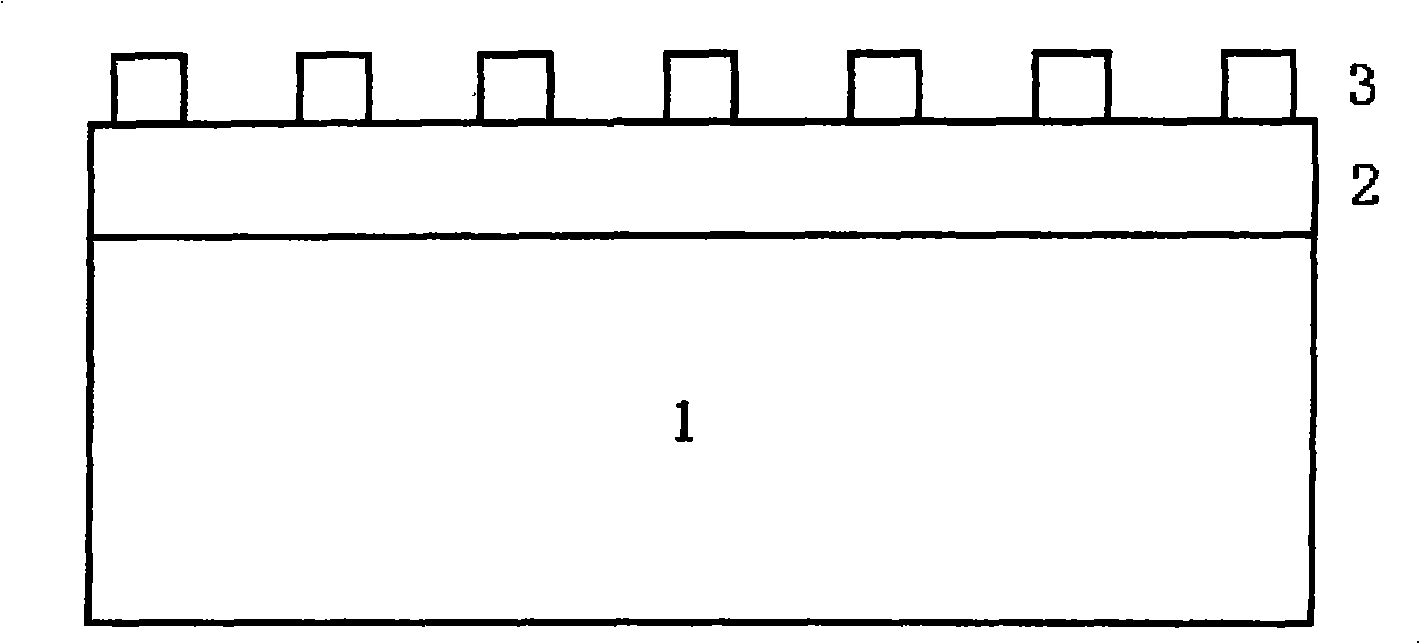

[0033] Step 1: deposit one layer of silicon dioxide film 2 on sapphire substrate 1 (see figure 1 ), the thickness of the silicon dioxide film 2 is 20 nanometers-2 microns;

[0034] Step 2: using photolithography technology to prepare a photoresist pattern array 3, the pattern unit of which is circular, and the size and pitch of the pattern unit of the circular photoresist pattern array 3 are 0.5 μm-10 μm;

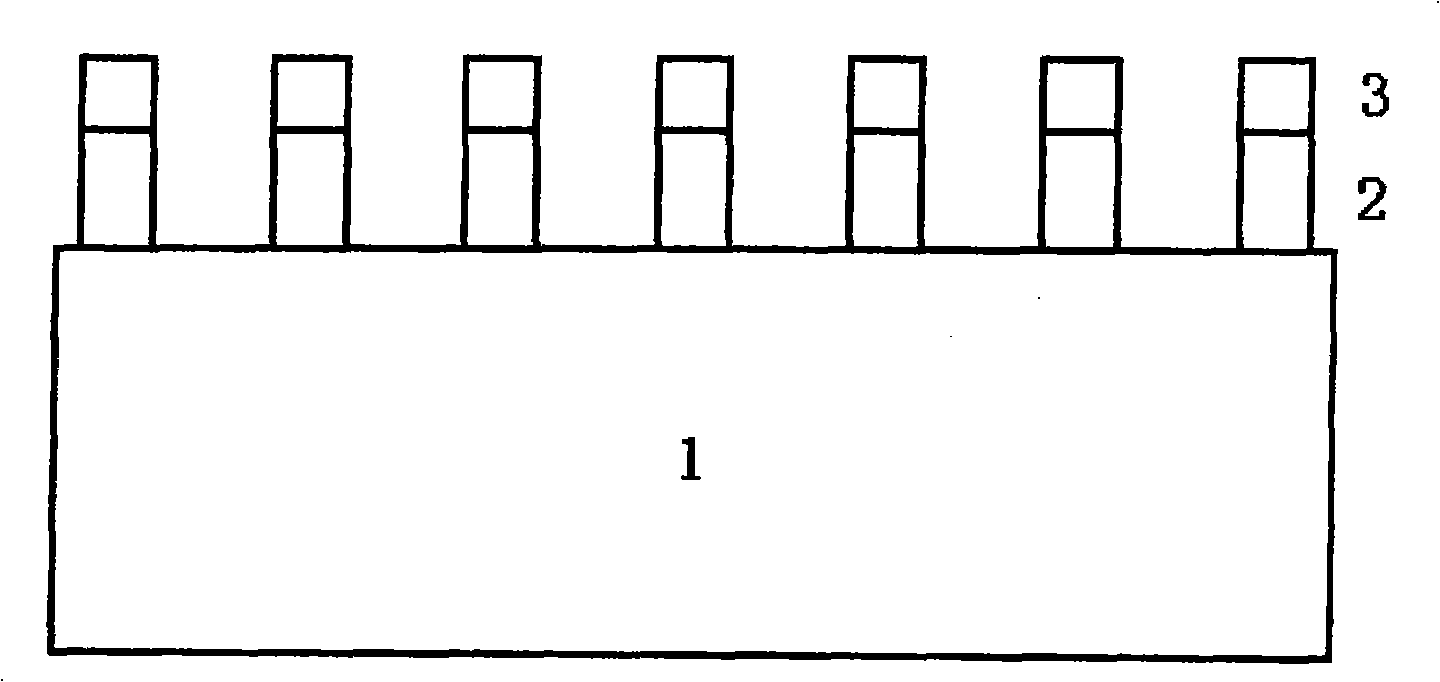

[0035] Step 3: Using the photoresist pattern array 3 as a mask, use hydrofluoric acid + ammonium fluoride + H 2 O mixed solution, etch out the silicon dioxide film 2 with figure structure (referring to figure 2 );

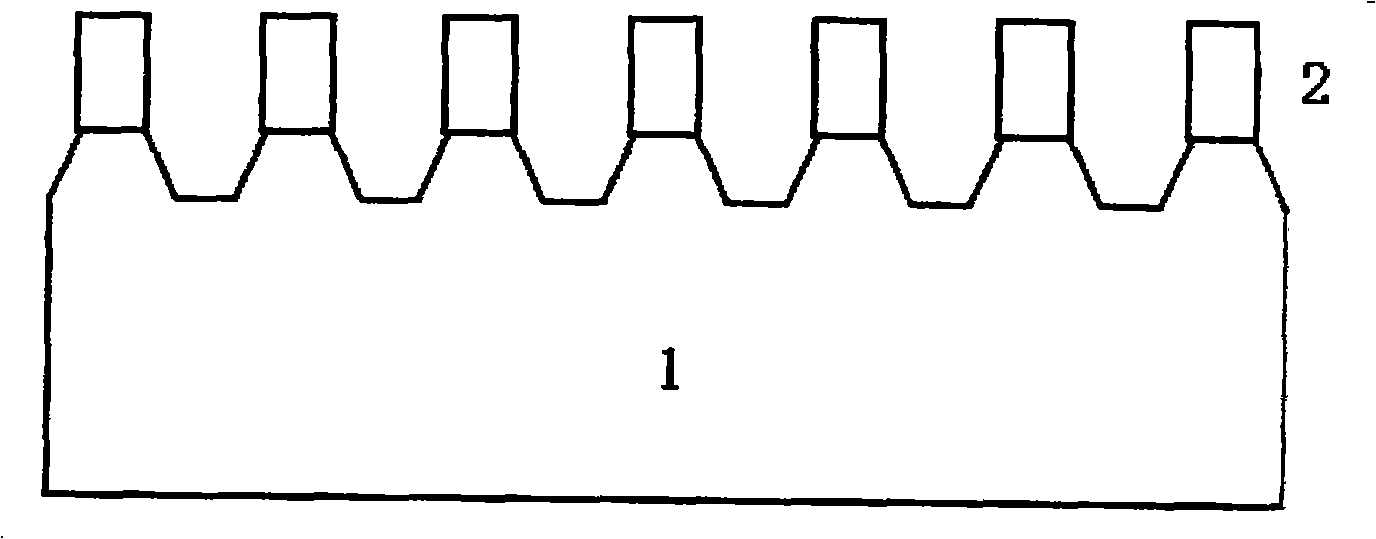

[0036] Step 4: use the silicon dioxide film 2 with pattern structure as a mask, utilize the mixed solution of sulfuric acid and phosphoric acid to etch the sapphire substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com