Patents

Literature

57results about How to "Improve divergence angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

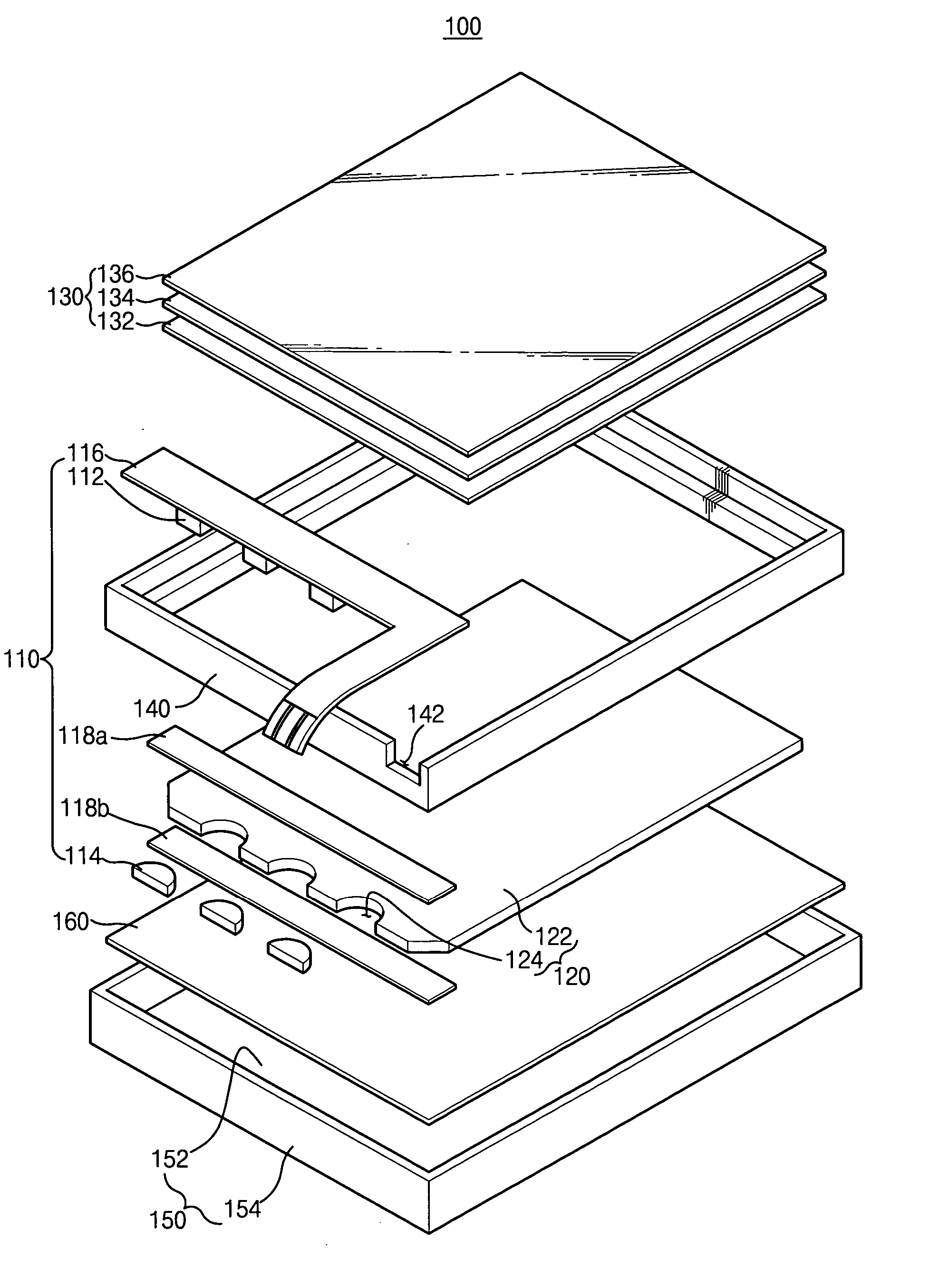

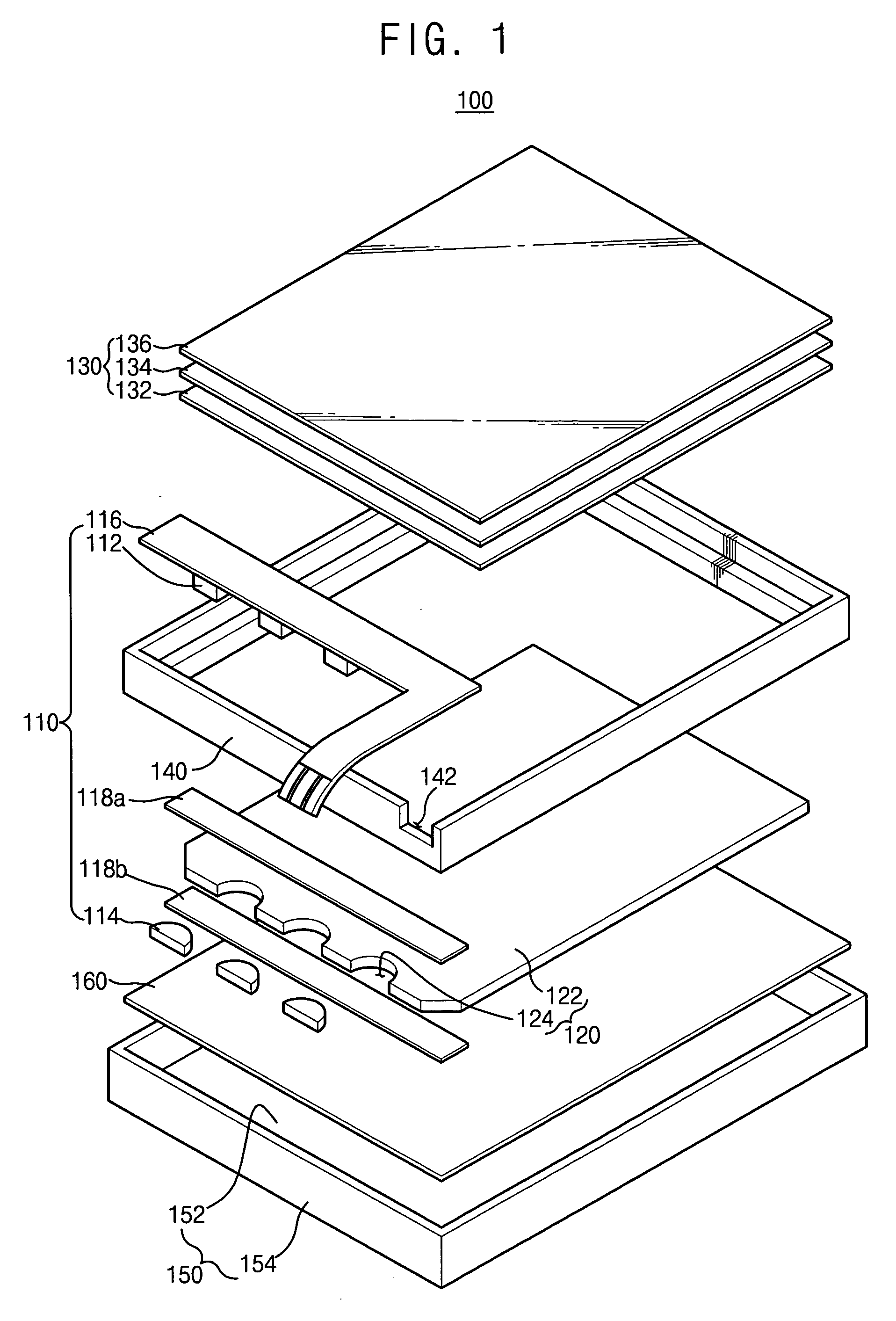

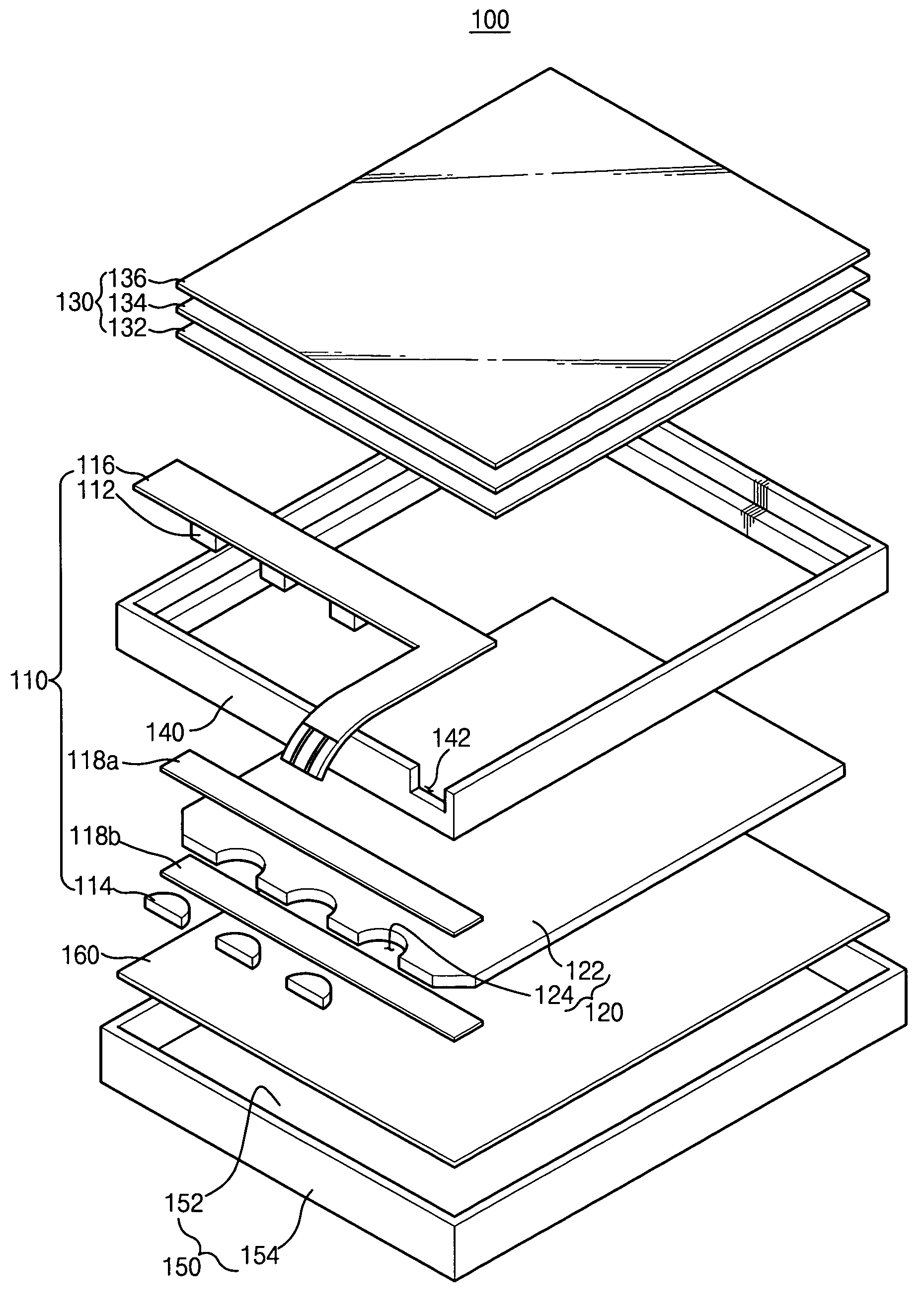

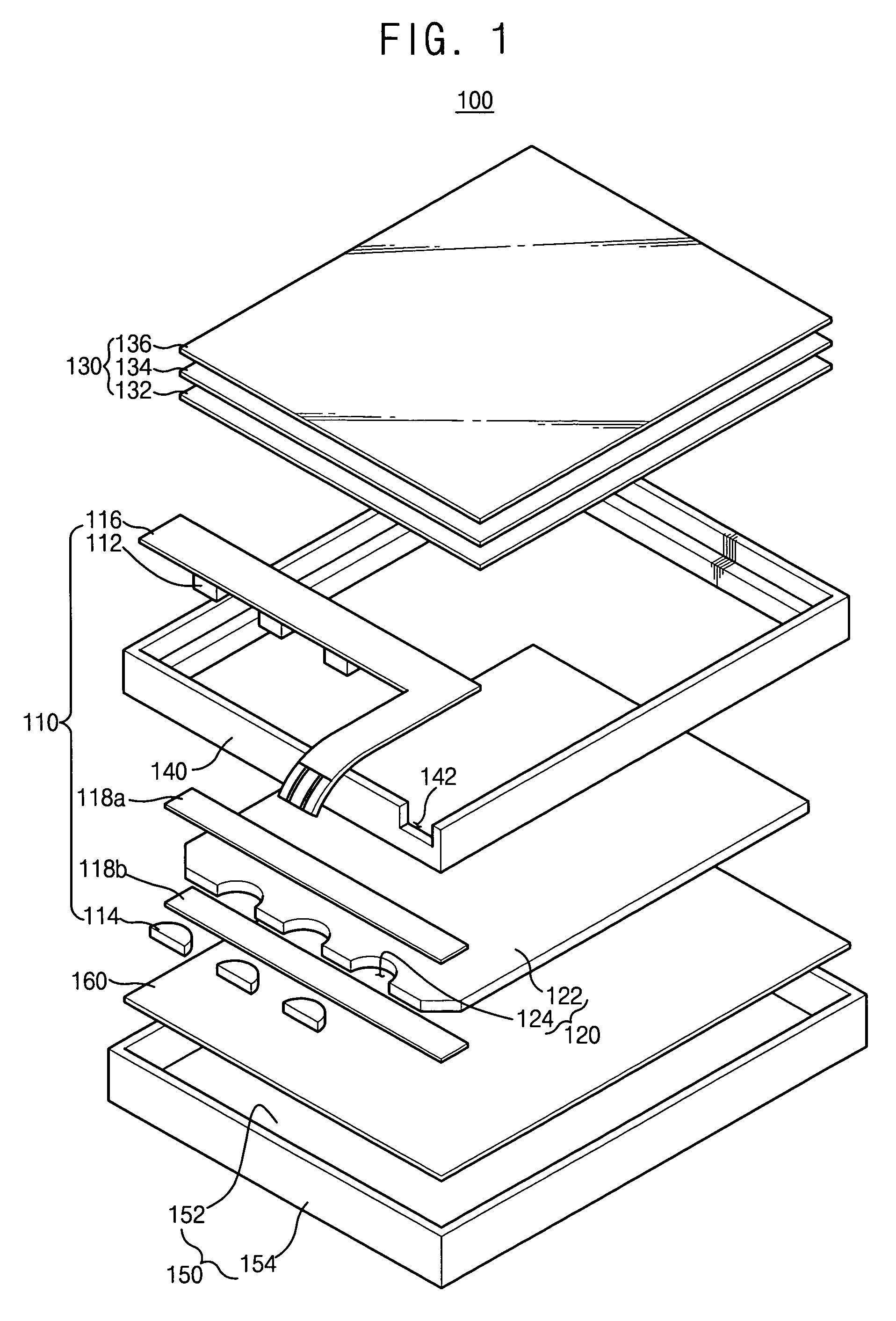

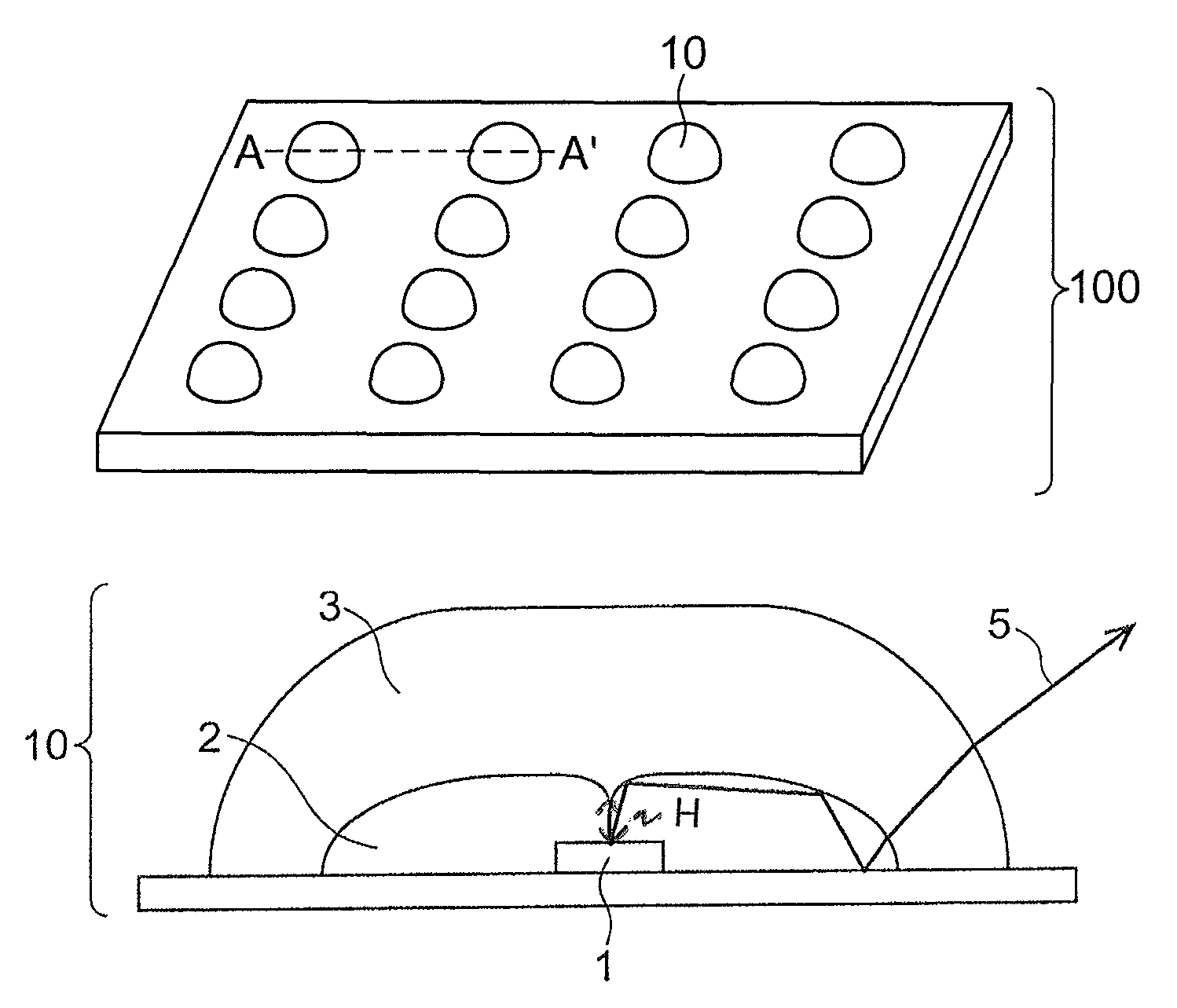

White light generating unit, backlight assembly having the same and liquid crystal display device having the same

ActiveUS20060072315A1Small sizeImprove divergence anglePlanar/plate-like light guidesSpectral modifiersLiquid-crystal displayFluorescence

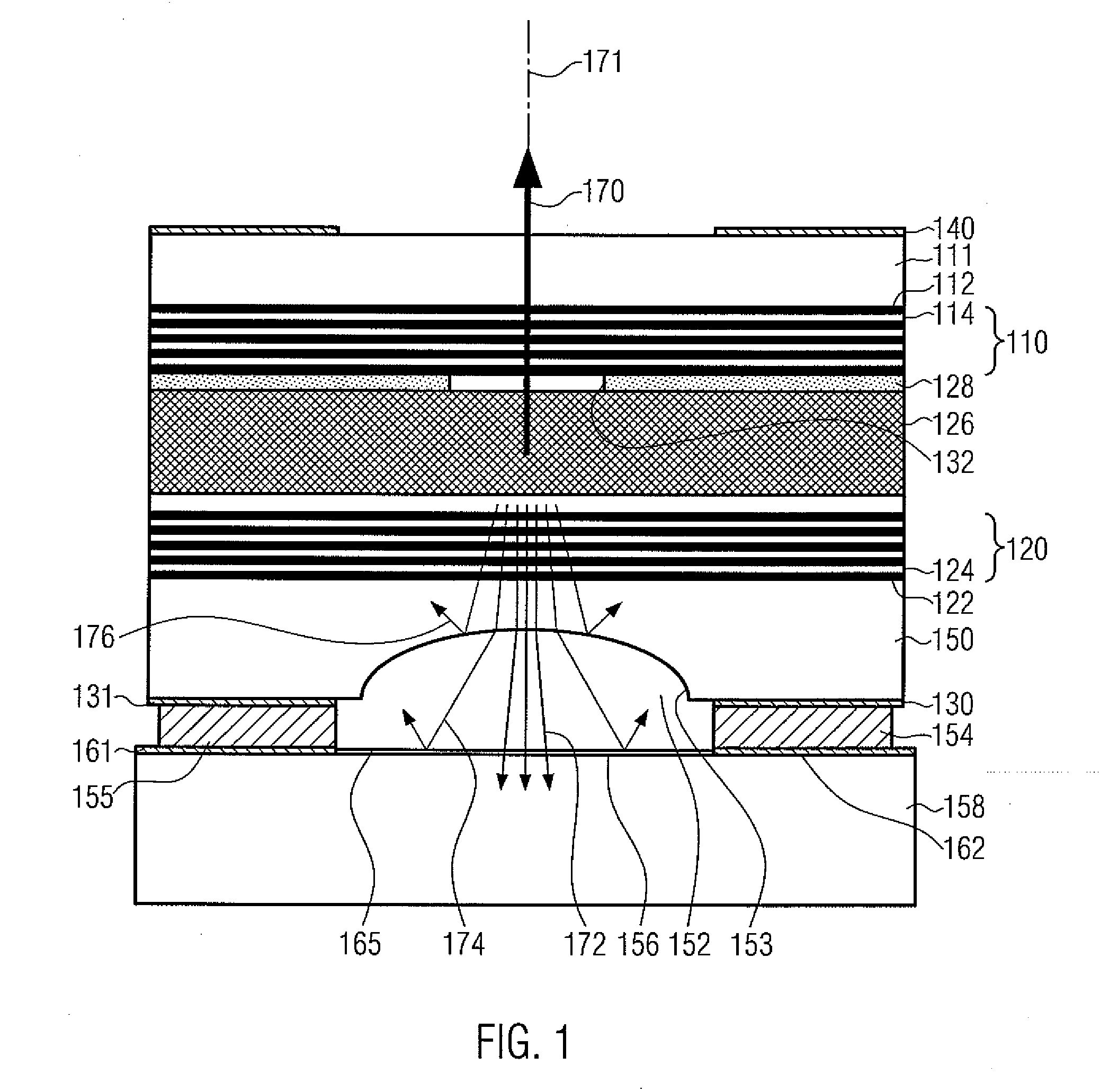

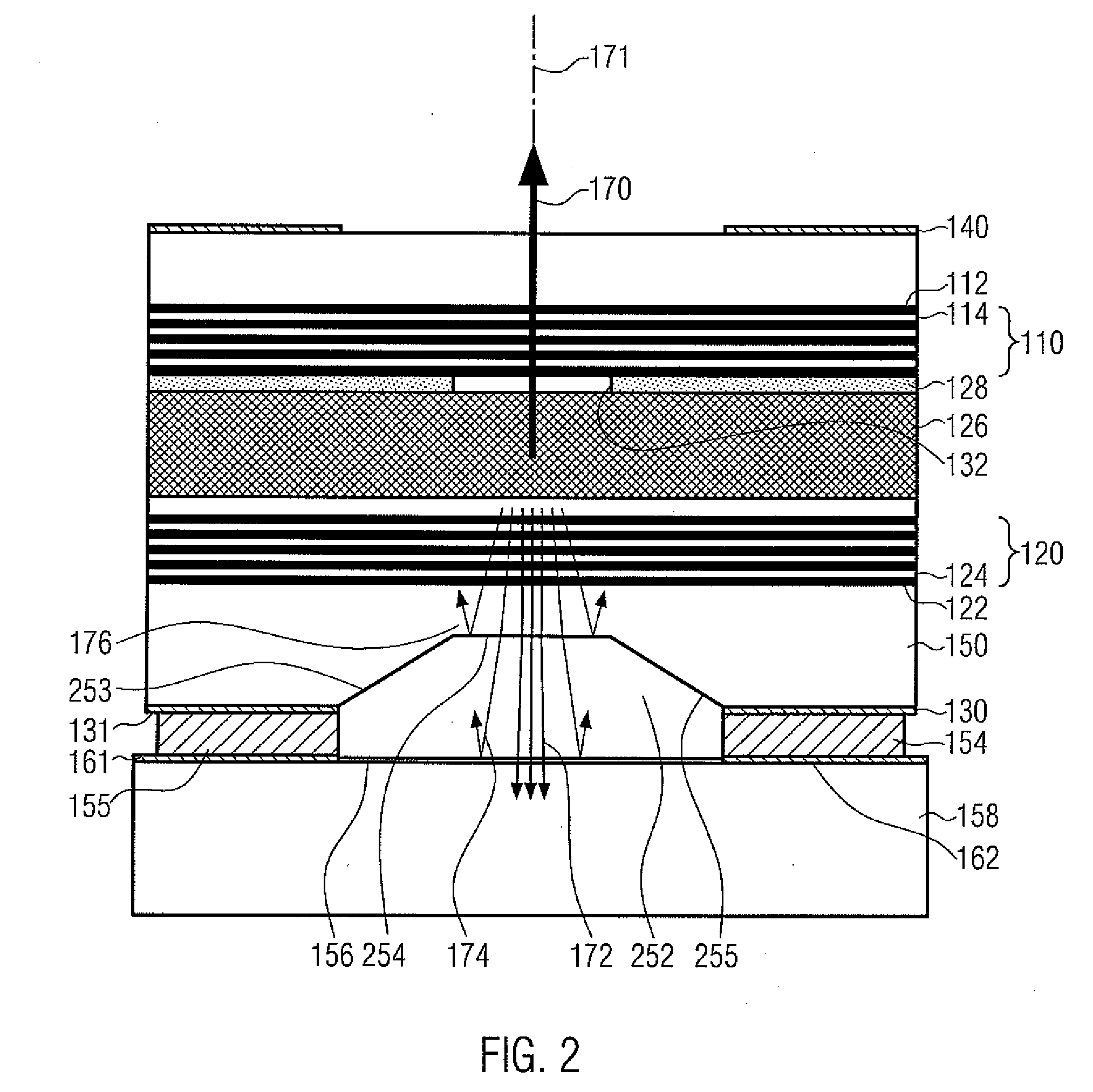

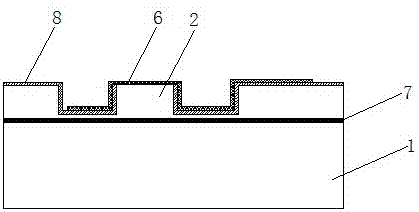

A white light generating unit includes an LED structure and a lens structure. The LED structure generates a light. The lens structure has a convex lens or a concave lens. The lens structure has a fluorescent member that receives the light from the LED structure to emit a white light.

Owner:SAMSUNG DISPLAY CO LTD

White light generating unit, backlight assembly having the same and liquid crystal display device having the same

ActiveUS7360937B2Small sizeImprove divergence angleMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayFluorescence

A white light generating unit includes an LED structure and a lens structure. The LED structure generates a light. The lens structure has a convex lens or a concave lens. The lens structure has a fluorescent member that receives the light from the LED structure to emit a white light.

Owner:SAMSUNG DISPLAY CO LTD

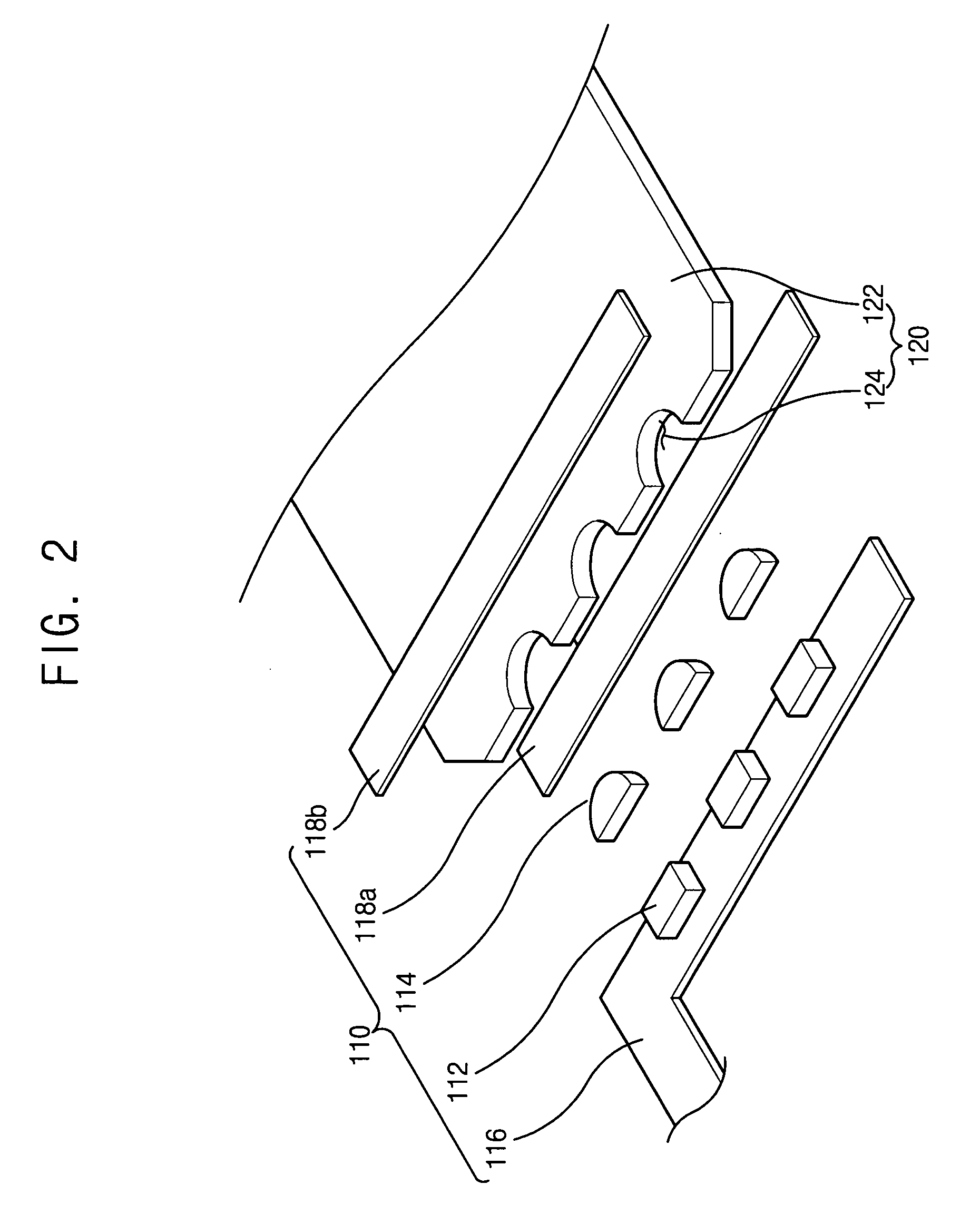

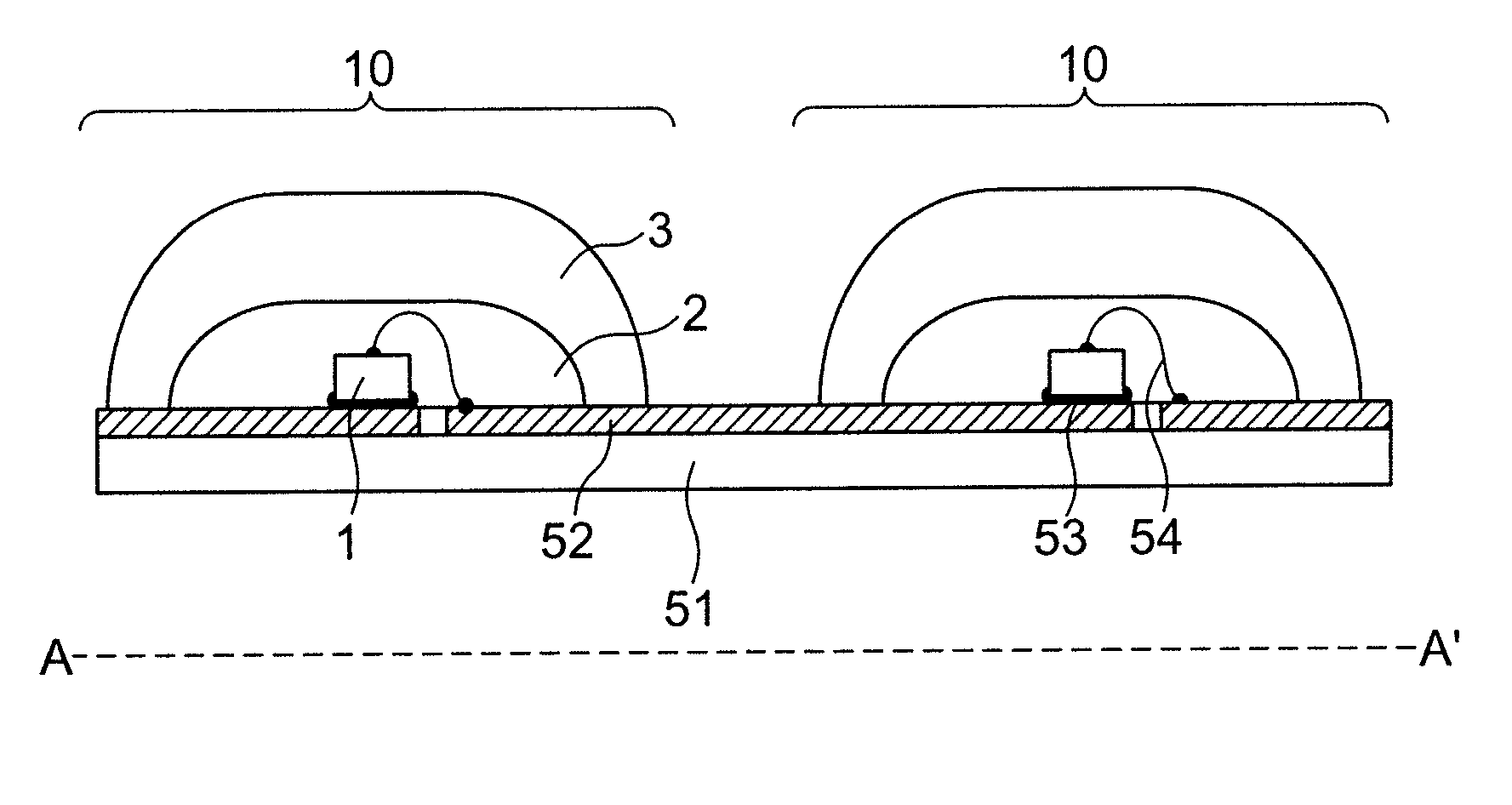

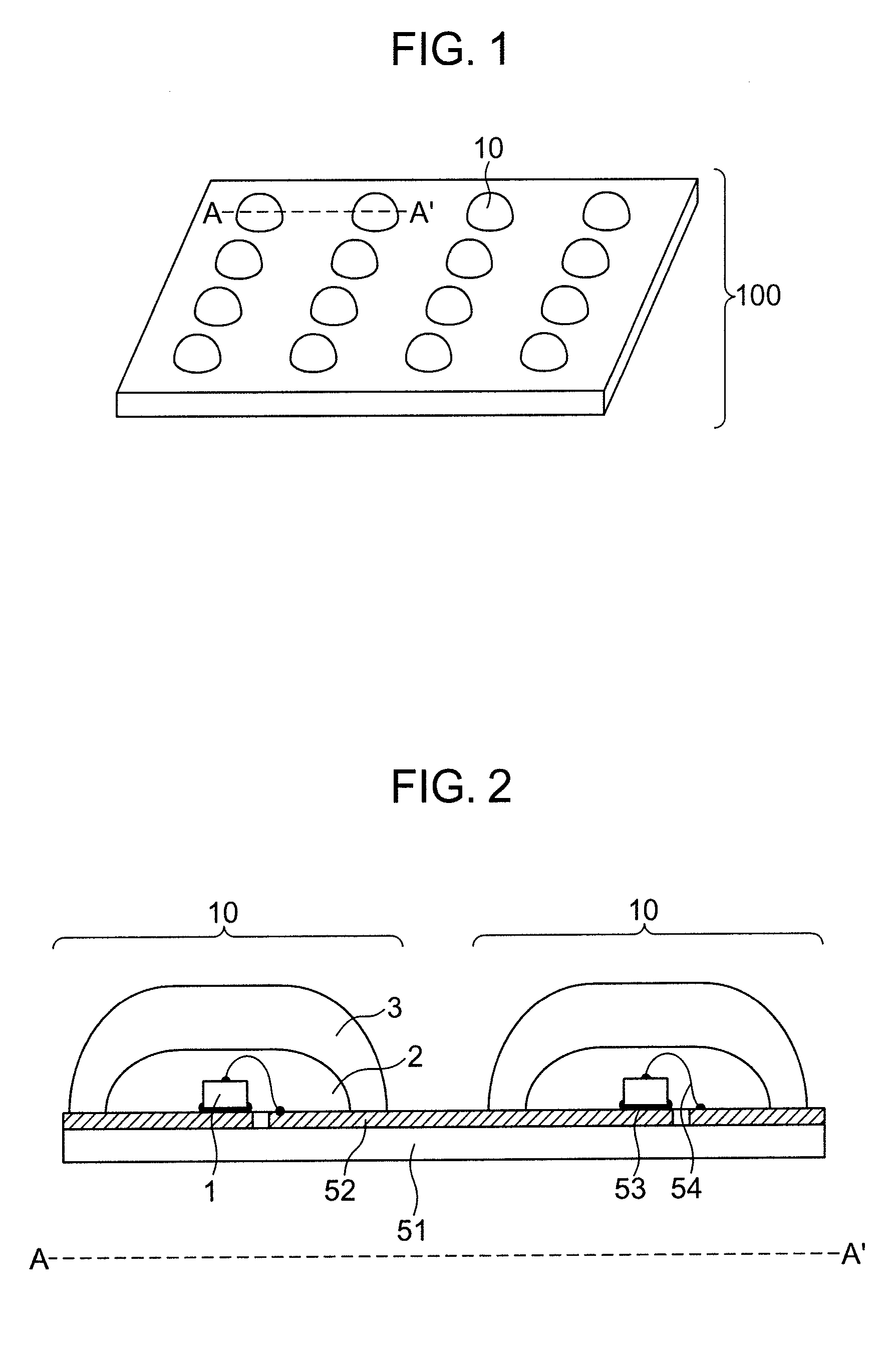

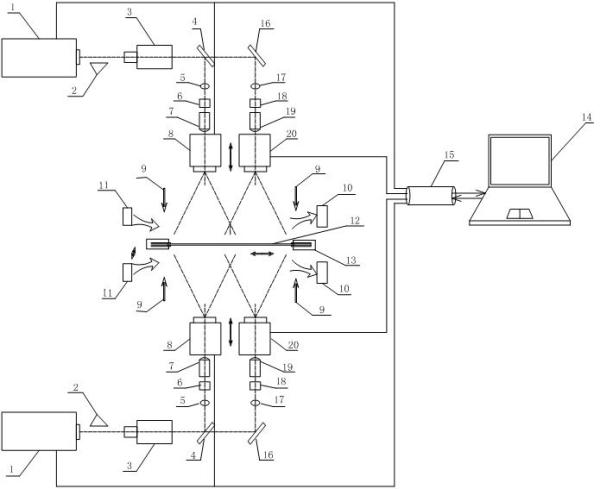

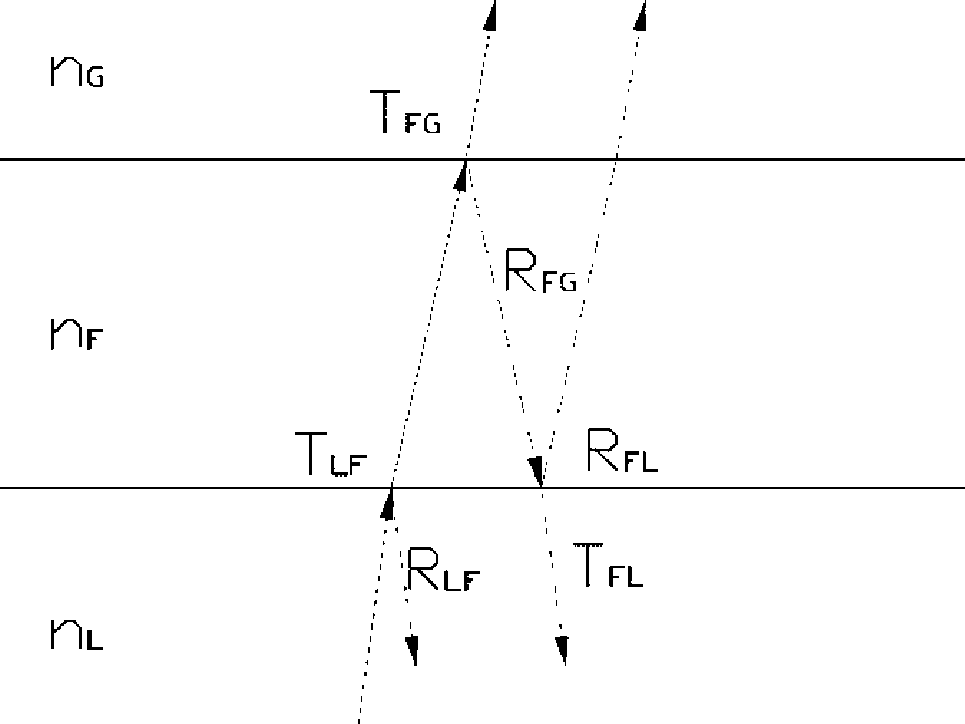

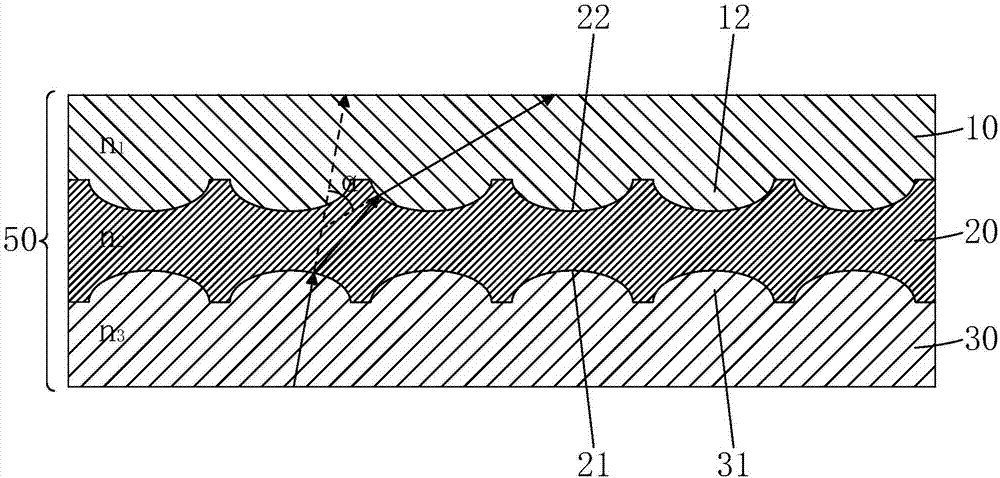

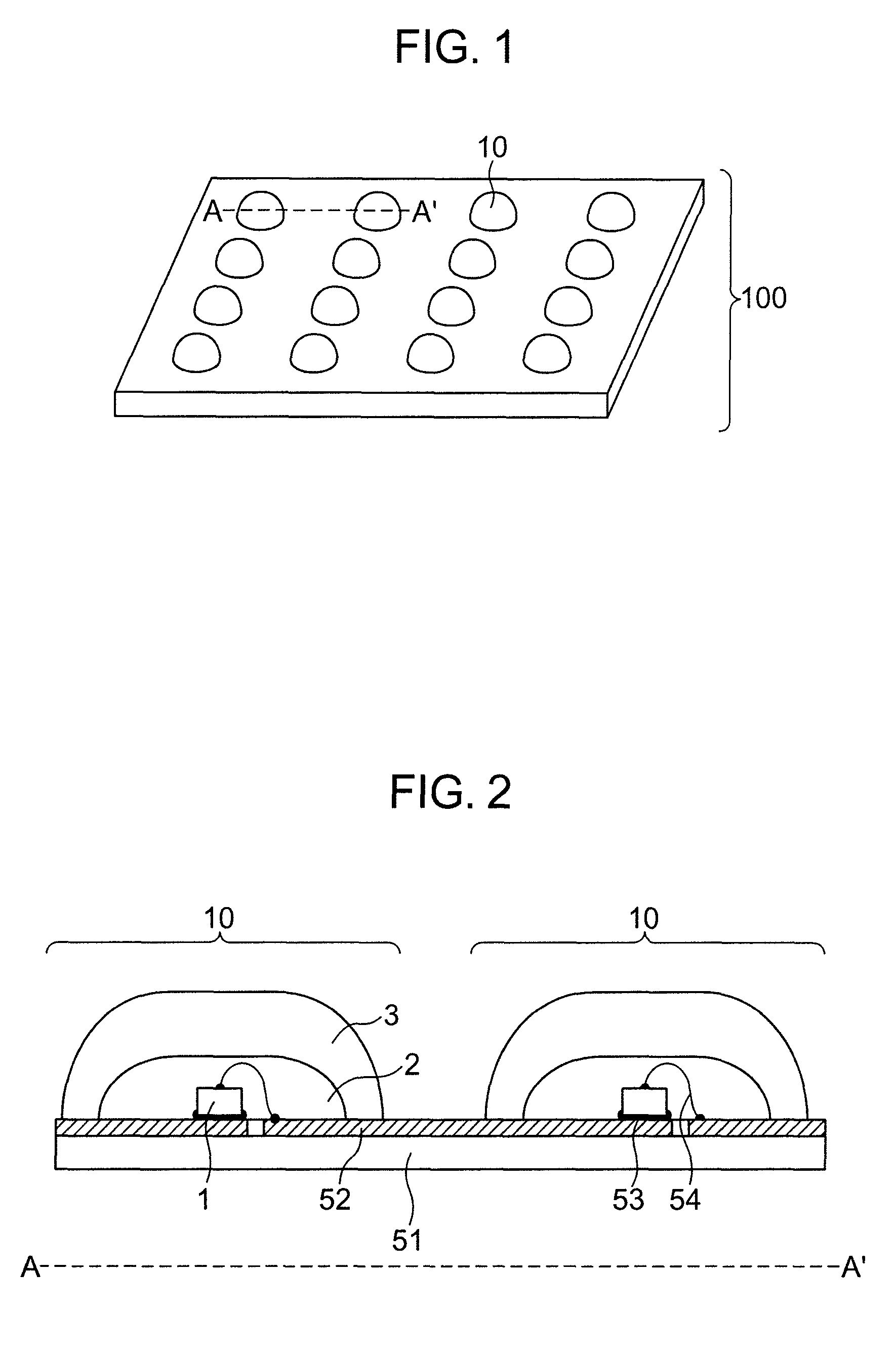

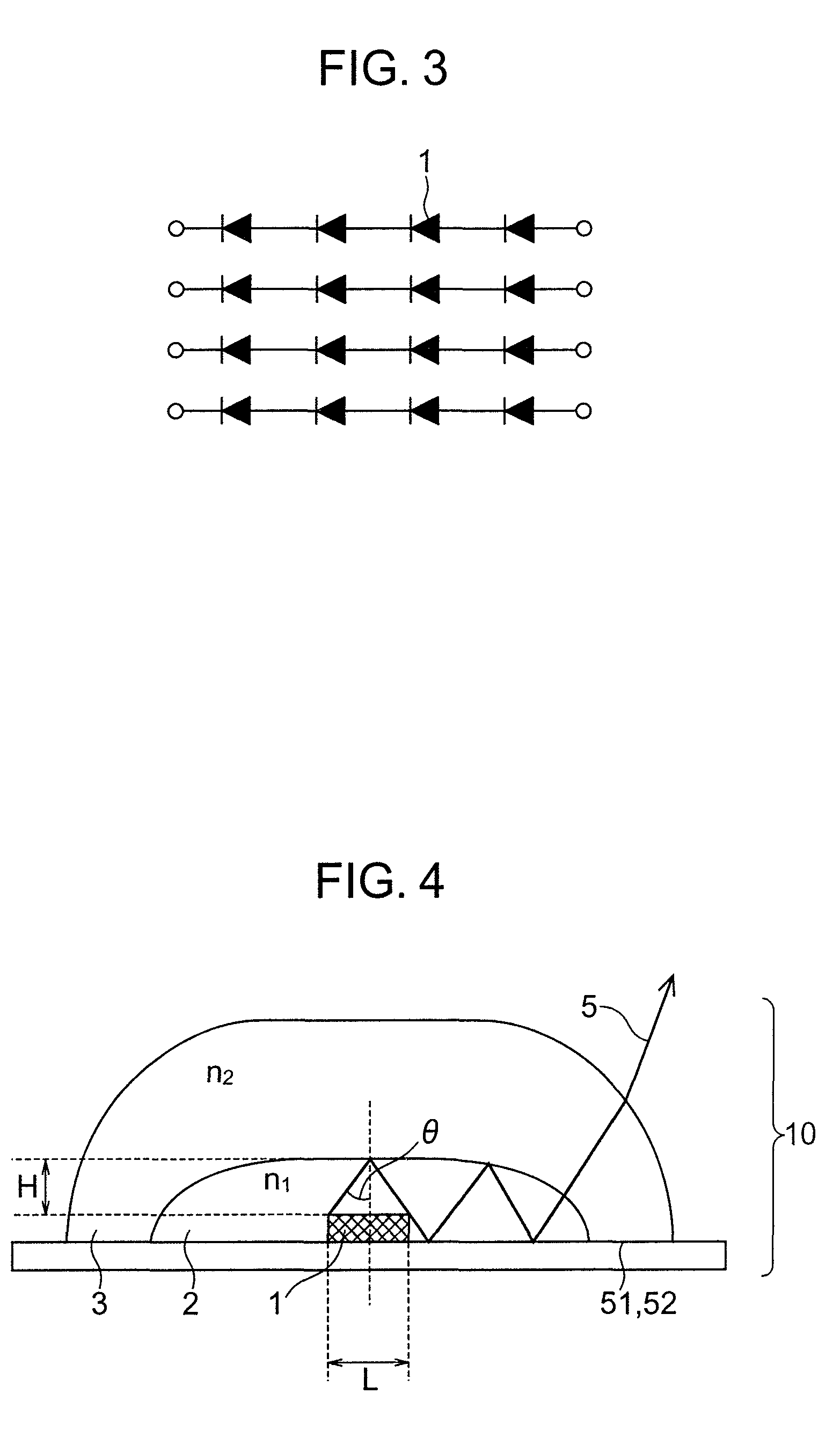

Illumination device and display device incorporating the same

ActiveUS20080137331A1Improve lighting efficiencyImprove light uniformitySolid-state devicesCondensersDivergence angleDisplay device

An illumination device has a plurality of sealing structures each including a light-emitting diode, sealed by a high refractive index transparent material member which is further sealed by a low refractive index transparent material member. To increase a divergence angle of light radiation, the portion of the high refractive index transparent material member which covers an upper surface of the light-emitting diode is structured so as to satisfy a relation H>(L / 2) / tan { sin−1(n1 / n2)}, where H represents a thickness of the high refractive index transparent material member measured at the central portion of the upper surface of the light-emitting diode, L represents the length of one side of the upper surface of the light-emitting diode, n1 represents the refractive index of the high refractive index transparent material member and n2 represents the refractive index of the low refractive index transparent material member.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

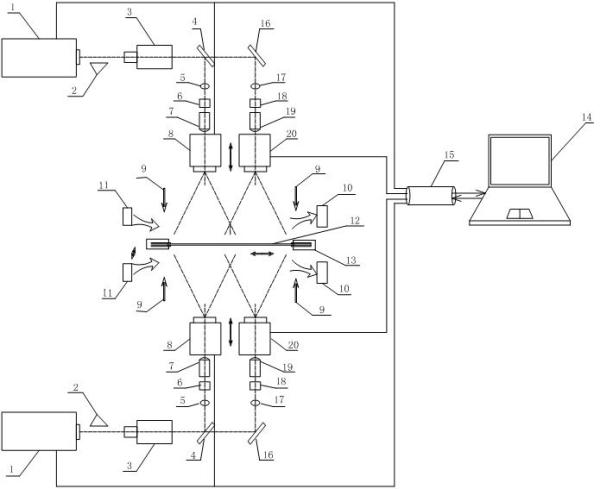

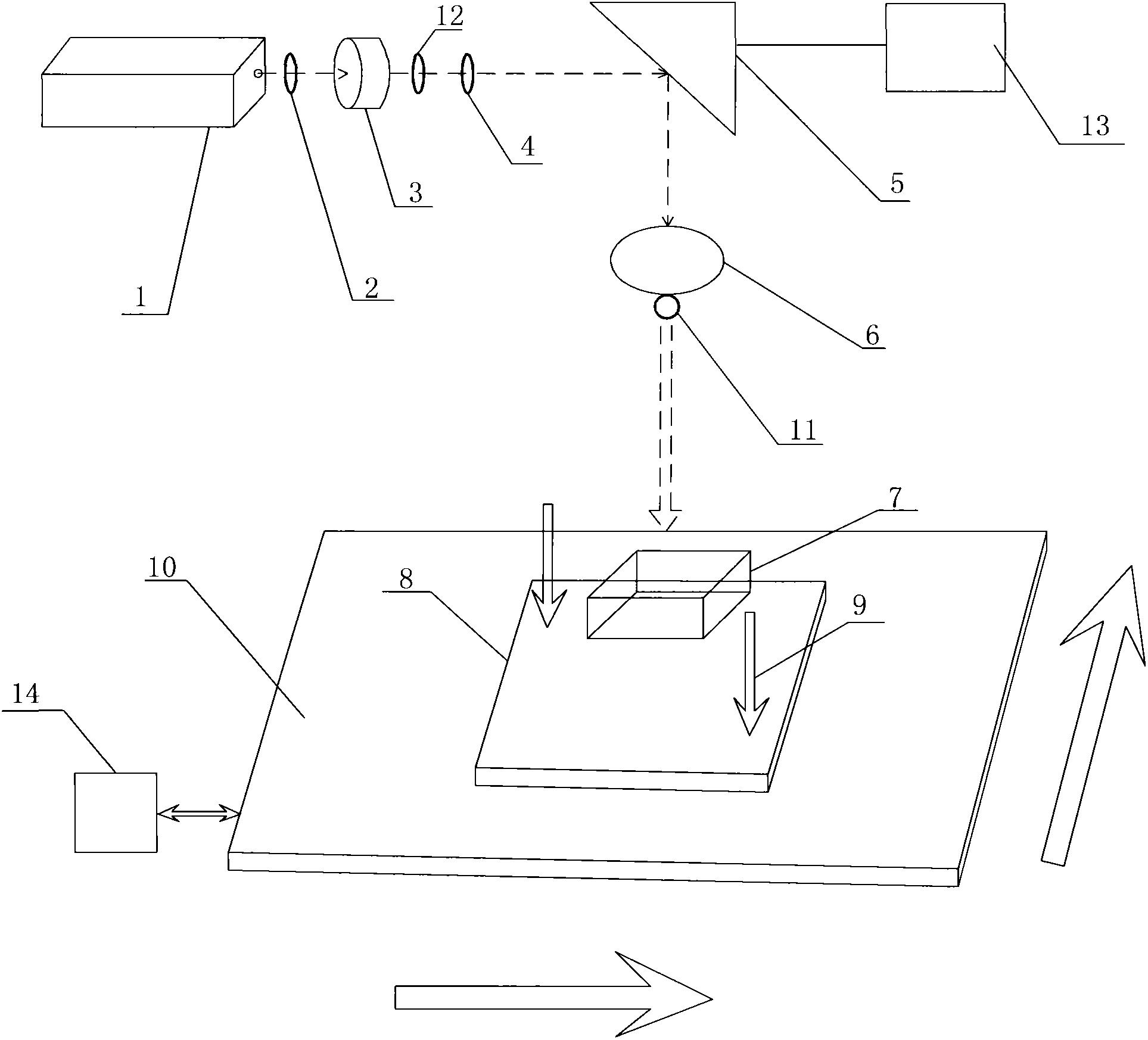

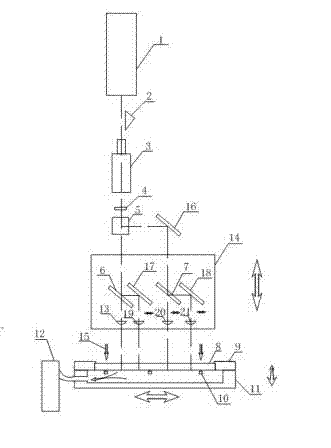

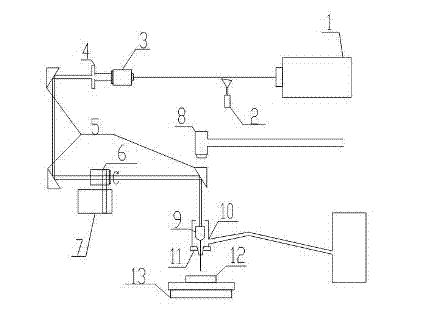

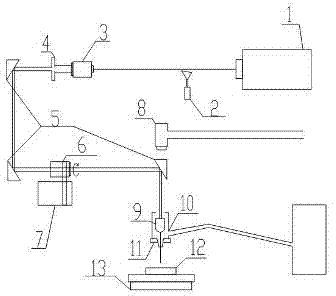

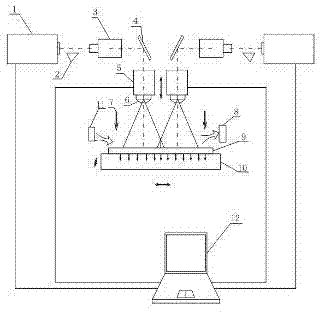

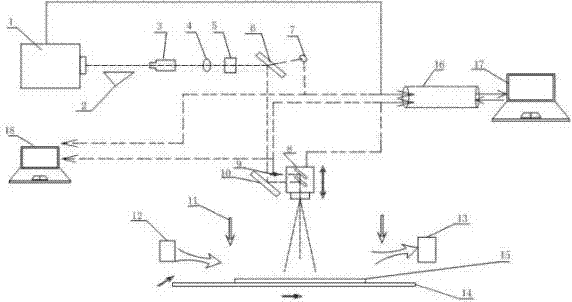

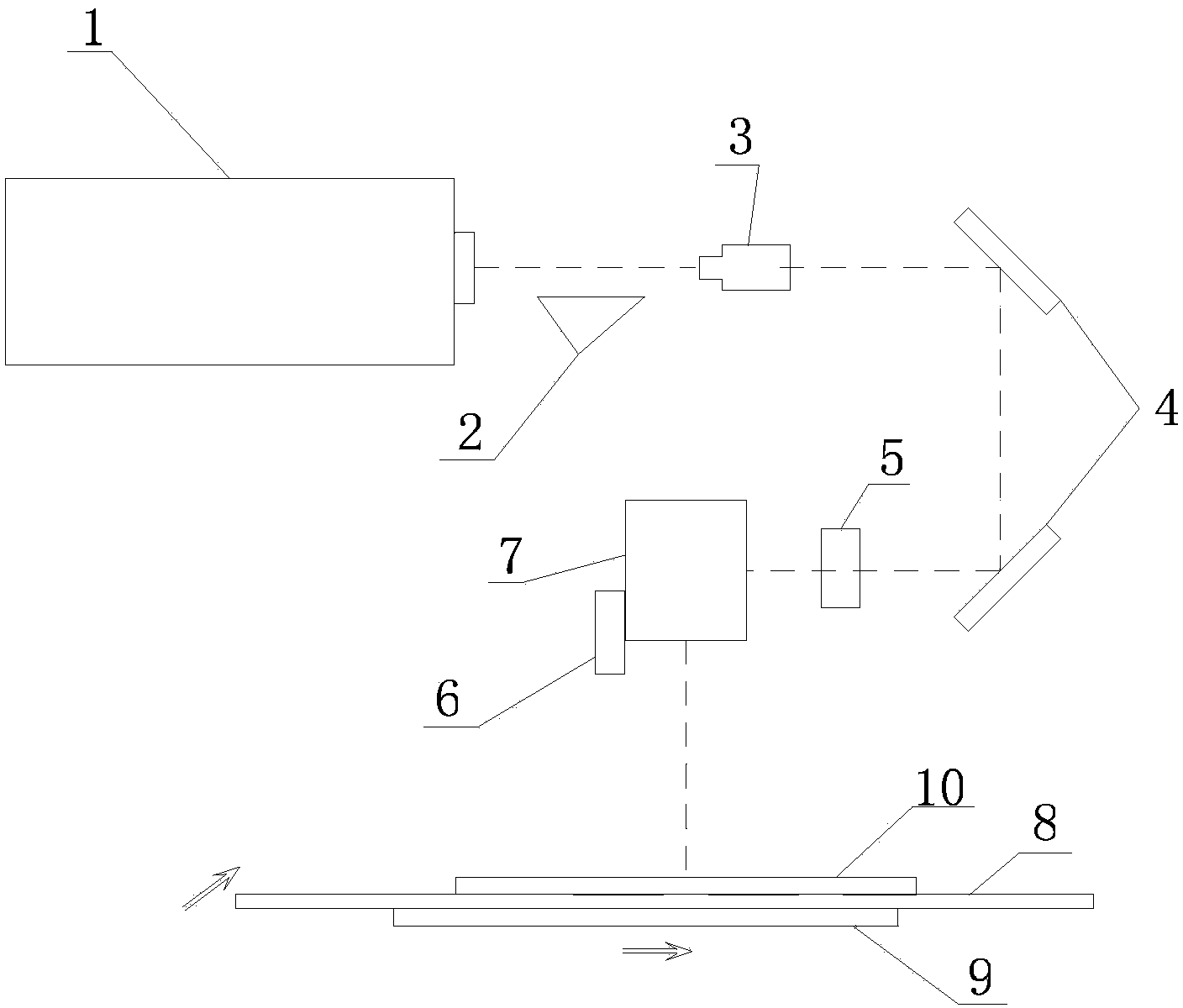

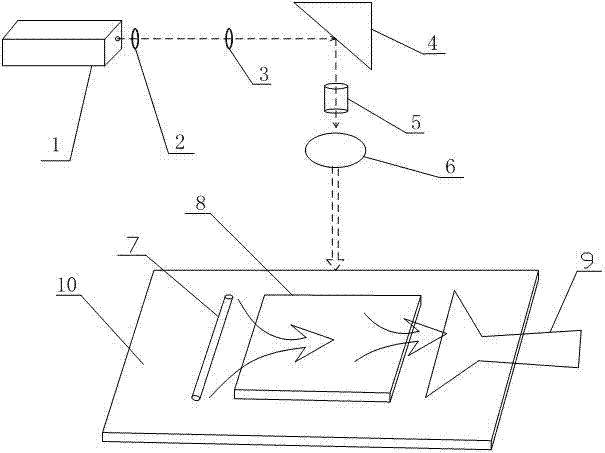

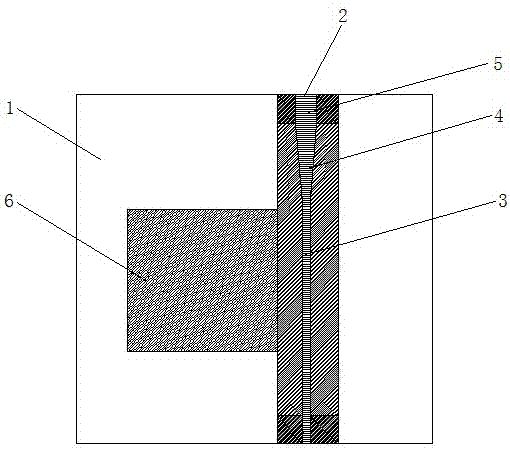

Device and method for pulse laser etching of conducting film layer on double-sided indium tin oxide (ITO) glass

InactiveCN102357736ANo pollution in the processLinear stabilityLaser beam welding apparatusLaser etchingBeam expander

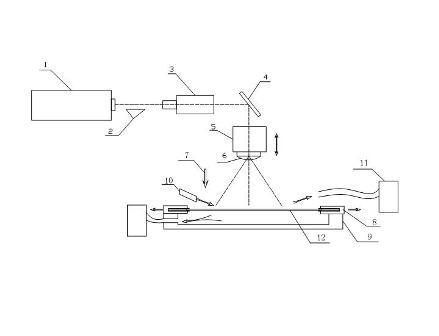

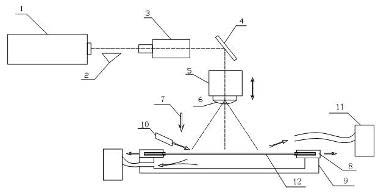

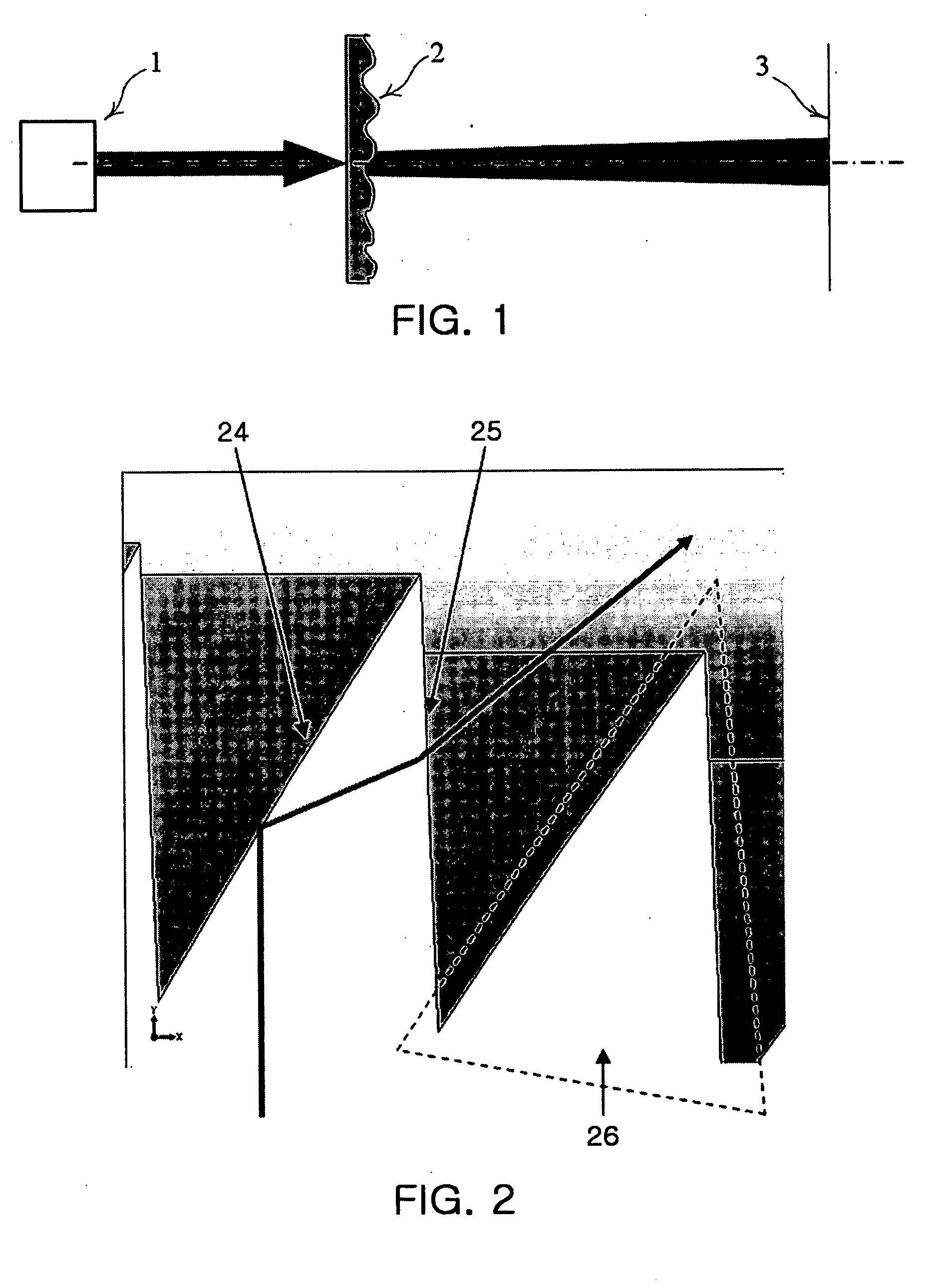

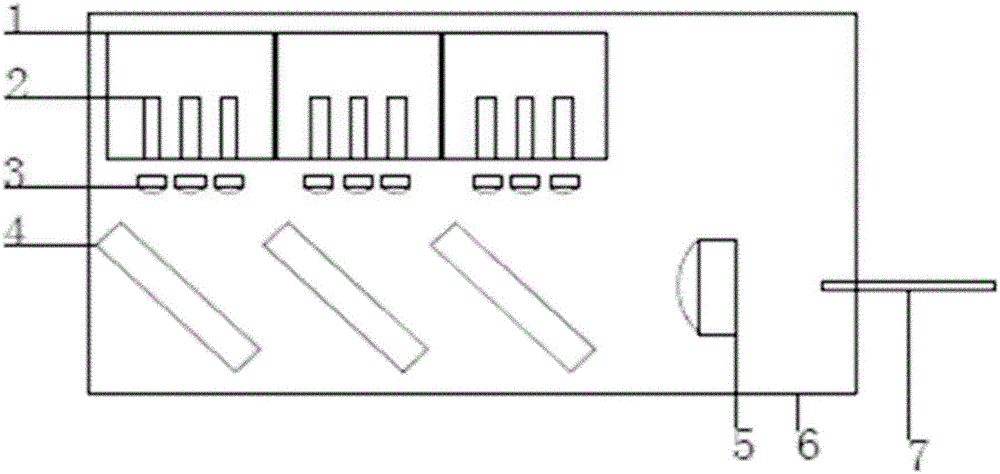

The invention relates to a device and a method for the pulse laser etching of a conducting film layer on double-sided indium tin oxide (ITO) glass. The front and back surfaces of a film material are provided with a set of pulse laser etching device respectively. Each set of pulse laser etching device comprises a high-frequency short-pulse laser, a semi-transmitting semi-reflecting mirror, a Glan prism and a completely reflecting mirror; the output end of the high-frequency short-pulse laser is sequentially provided with an optical gate, a beam expander and the semi-transmitting semi-reflecting mirror; the output end of the semi-transmitting semi-reflecting mirror is provided with a first 1 / 2 wave plate and the completely reflecting mirror; the output end of the first 1 / 2 wave plate is sequentially provided with a first Glan prism and a first three-dimensional (3D) dynamic focusing lens; the output end of the first 3D dynamic focusing lens is provided with a first galvanometer; the output end of the completely reflecting mirror is provided with a second 1 / 2 wave plate; the output end of the second 1 / 2 wave plate is sequentially provided with a second Glan prism and a second 3D dynamic focusing lens; the output end of the second 3D dynamic focusing lens is provided with a second galvanometer; and the output ends of the first and second galvanometers are both dead against the surface of the film material. The device and the method are used for etching double-sided ITO glass in different touch screen products to realize high-efficiency high-accuracy circuit manufacturing.

Owner:SUZHOU DELPHI LASER

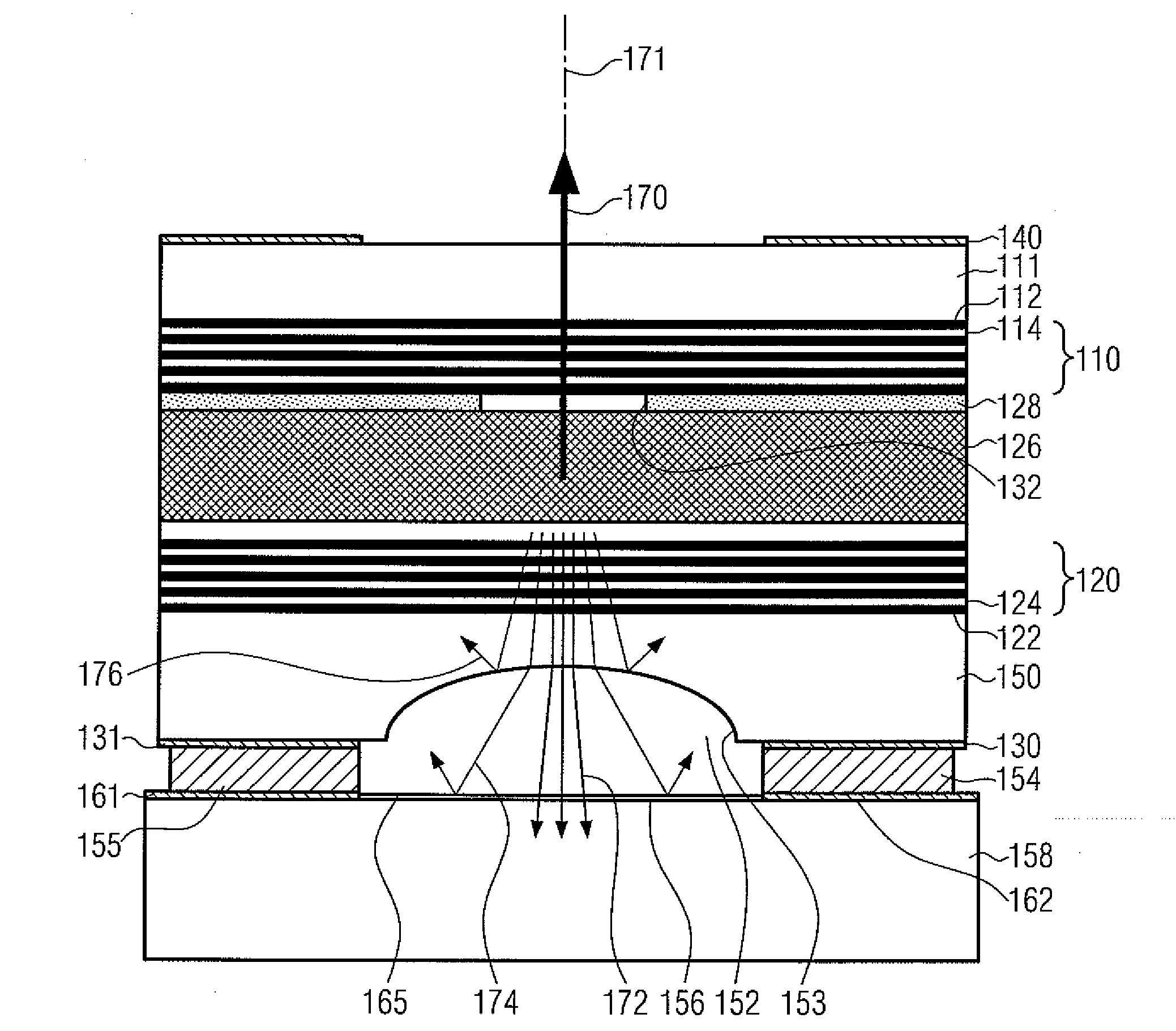

Optoelectronic device and method of operating optoelectronic device

ActiveUS20080247436A1Reduce the amount requiredImprove divergence angleLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserSignal-to-noise ratio (imaging)

The invention provides an optoelectronic device combining a vertical cavity surface emitting laser (VCSEL) and a photodetector for monitoring the output power of the vertical cavity surface emitting laser. To improve the signal-to-noise ratio of the photodetector, a light deflector is interposed between the photodetector and the VCSEL.

Owner:II VI DELAWARE INC

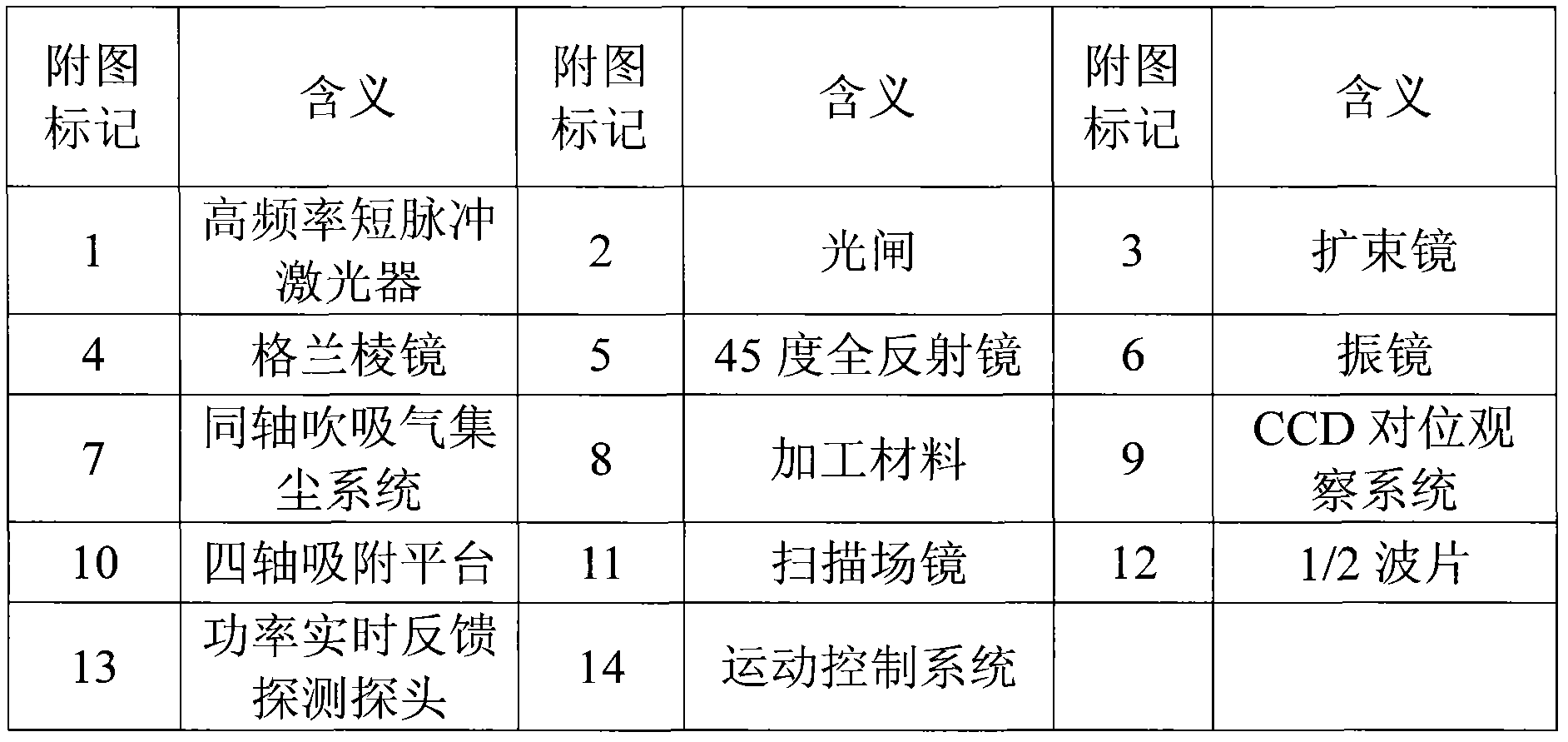

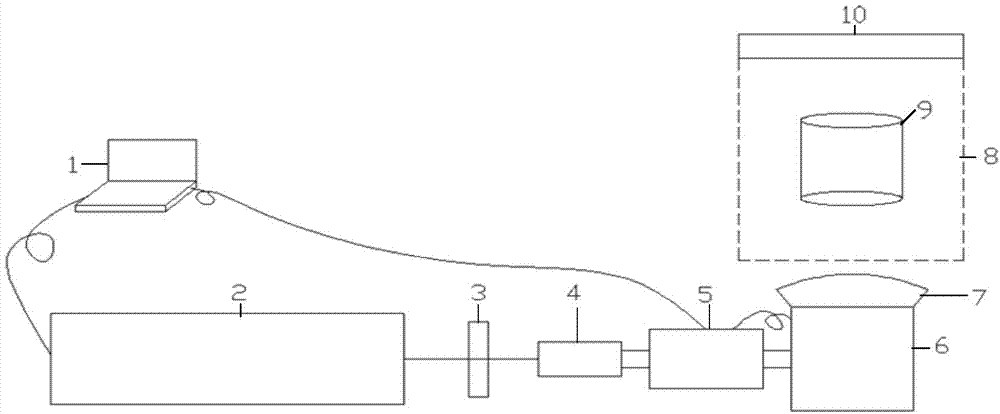

Device and method for making metal film group holes by using ultra-short pulse laser

InactiveCN102319960AEasy to processImprove surface qualityLaser beam welding apparatusOptoelectronicsObservation system

The invention relates to a device and a method for making metal film group holes by using ultra-short pulse laser. An optical shutter is arranged at the output end of a high-frequency ultra-short pulse laser device, a beam expander is arranged at the output end of the optical shutter, a 45-degree total reflector is arranged at the output end of the beam expander, a vibrating mirror and a scanning field mirror are sequentially arranged at the output end of the 45-degree total reflector, the scanning field mirror is opposite to a working platform, a charge coupled device (CCD) alignment observation system is arranged above the working platform, a group of clamping cylinders are arranged on the working platform, an air blowing system is arranged at one side of the working platform, a dust collecting system is arranged at the other side of the working platform, and a dust collecting system is also arranged below the working platform. By optical focusing of the ultra-short pulse laser device, the focal point is positioned on a metal film material, so that energy of the laser device is efficiently utilized; and by controlling the pulse number and the pulse duration of the ultra-short pulse laser device, the pulse number and the pulse time for forming each metal film aperture are modulated, so that required apertures on each metal film are sequentially machined.

Owner:SUZHOU DELPHI LASER

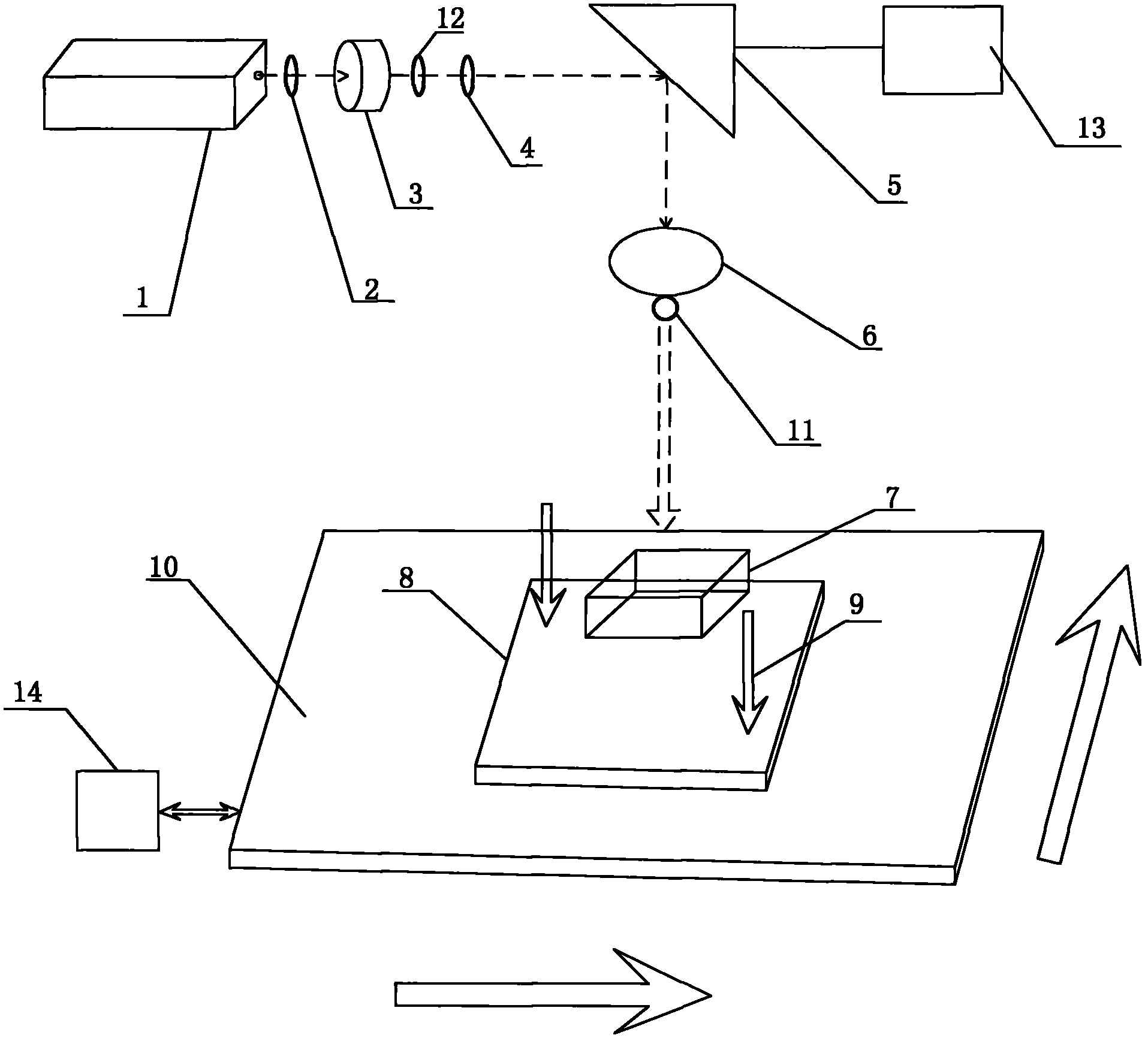

Device and method for etching silver syrup on electronic product

InactiveCN102205468AImprove divergence angleHighlight substantive featuresSemiconductor/solid-state device manufacturingLaser beam welding apparatusPrismCopper

The invention relates to a device and a method for etching silver syrup on an electronic product. The device is characterized in that an optical shutter is arranged at an output end of a high-frequency short pulse laser, wherein a beam expanding lens is arranged at the output end of the optical shutter; a 1 / 2 wave plate and a Glan prism are arranged at the output end of the beam expanding lens in turn; a 45-degree holophote is arranged at the output end of the Glan prism; a vibrating lens and a scanning field lens are arranged at the output end of the 45-degree holophote in turn; the scanning field lens is opposite to a four-shaft absorbing platform; a coaxial blowing and sucking dust-collecting system is arranged on the four-shaft absorbing platform; and CCD (charge coupled device) contraposition systems are respectively arranged at opposite angle positions of the four-shaft absorbing platform. The method is characterized by using a high-frequency infrared pulse laser as a laser source, processing a target position of a material by using a diagonal CCD grabbing target, ensuring a processing chart being one-to-one corresponding to a sample position on a platform, and etching the silver syrup, copper films or molybdenum aluminum layers in invisible areas of different touch screen products, thereby achieving the etching purpose by gasifying film materials in the invisible areas under the action of the high-frequency short pulse infrared laser.

Owner:SUZHOU DELPHI LASER +1

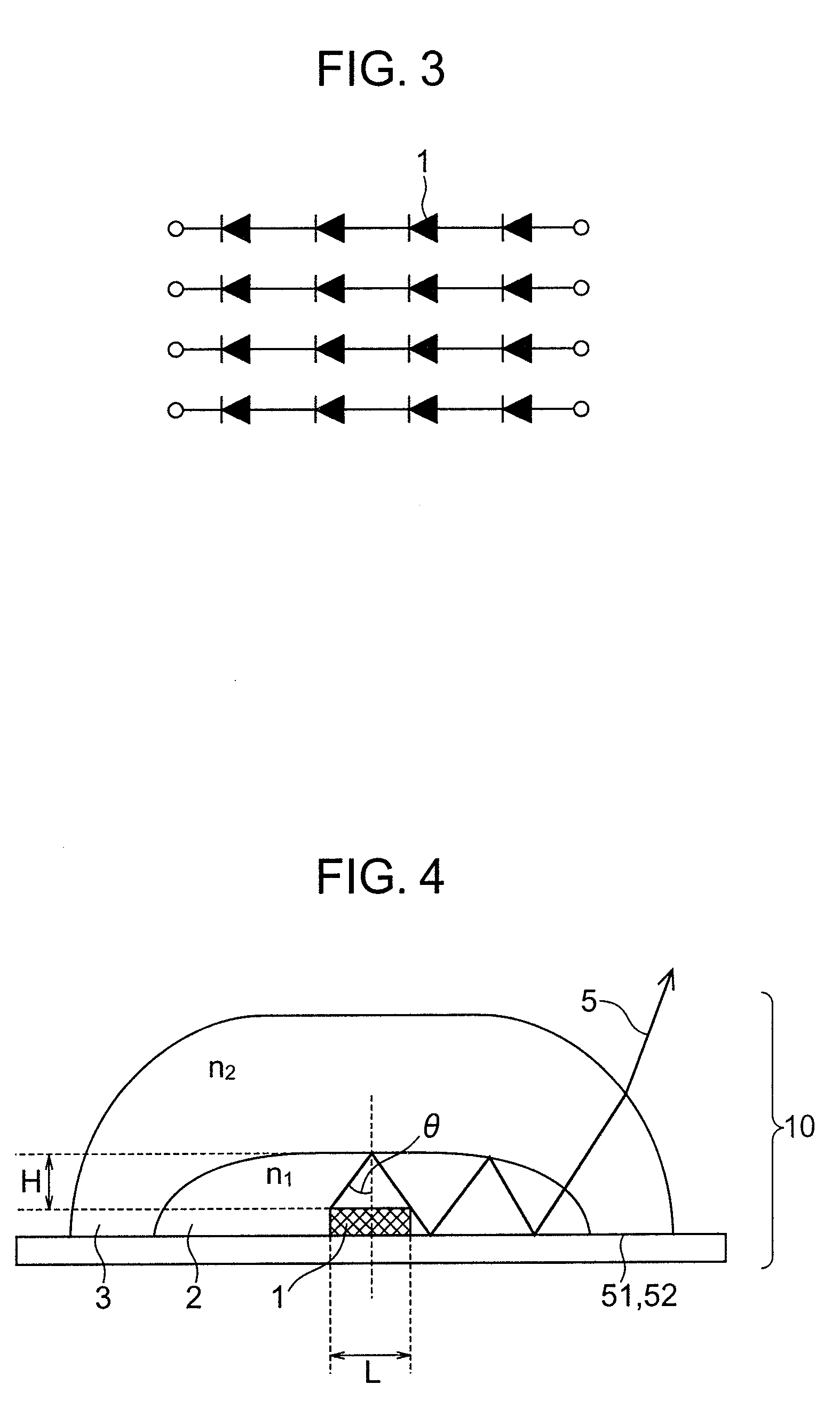

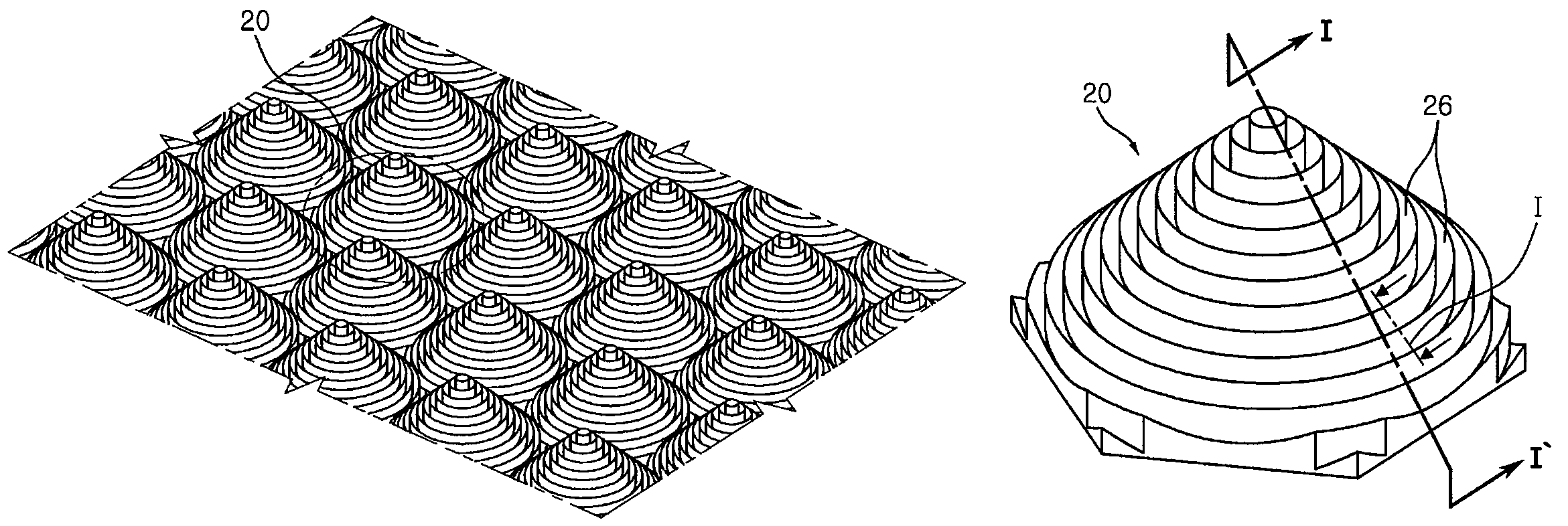

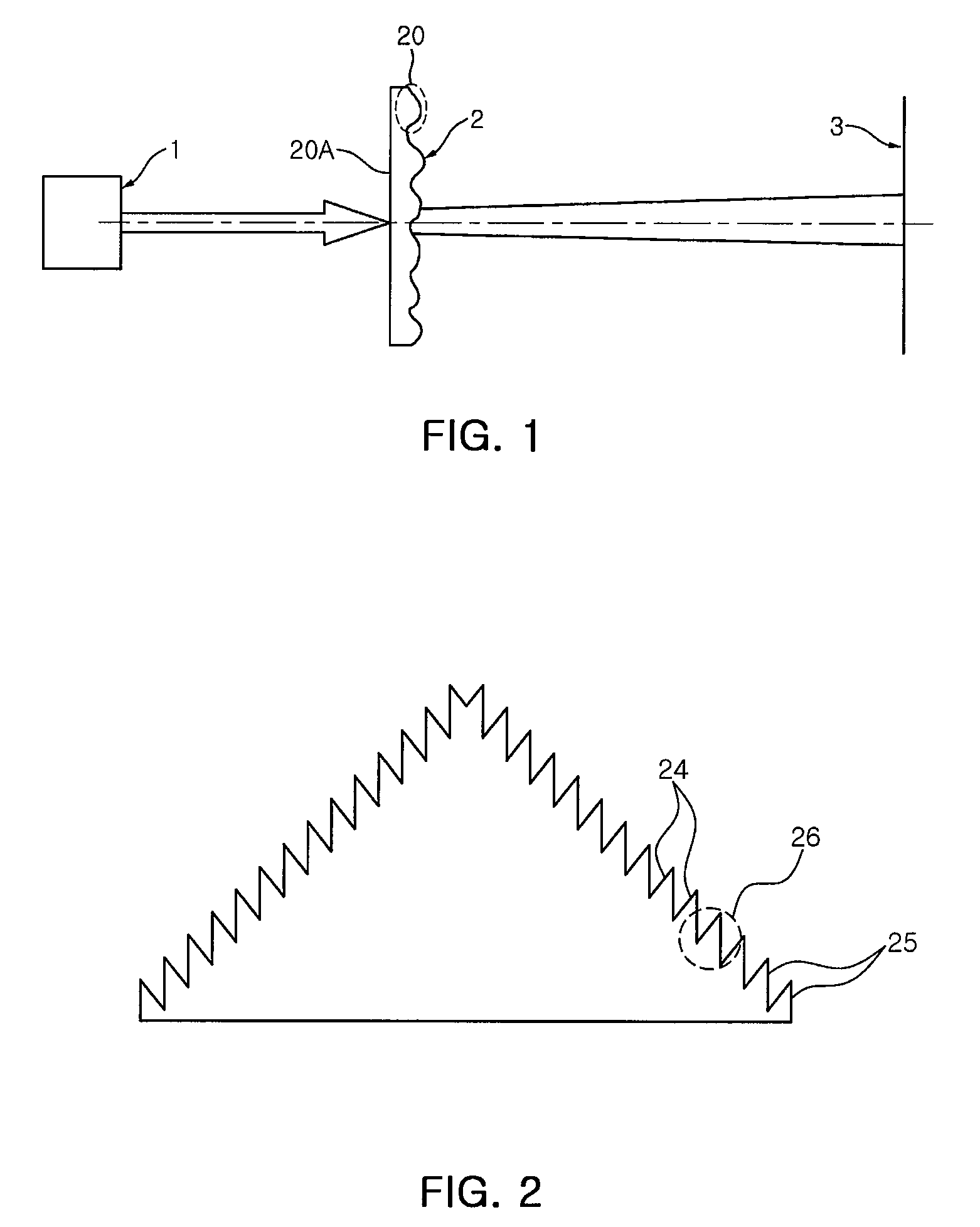

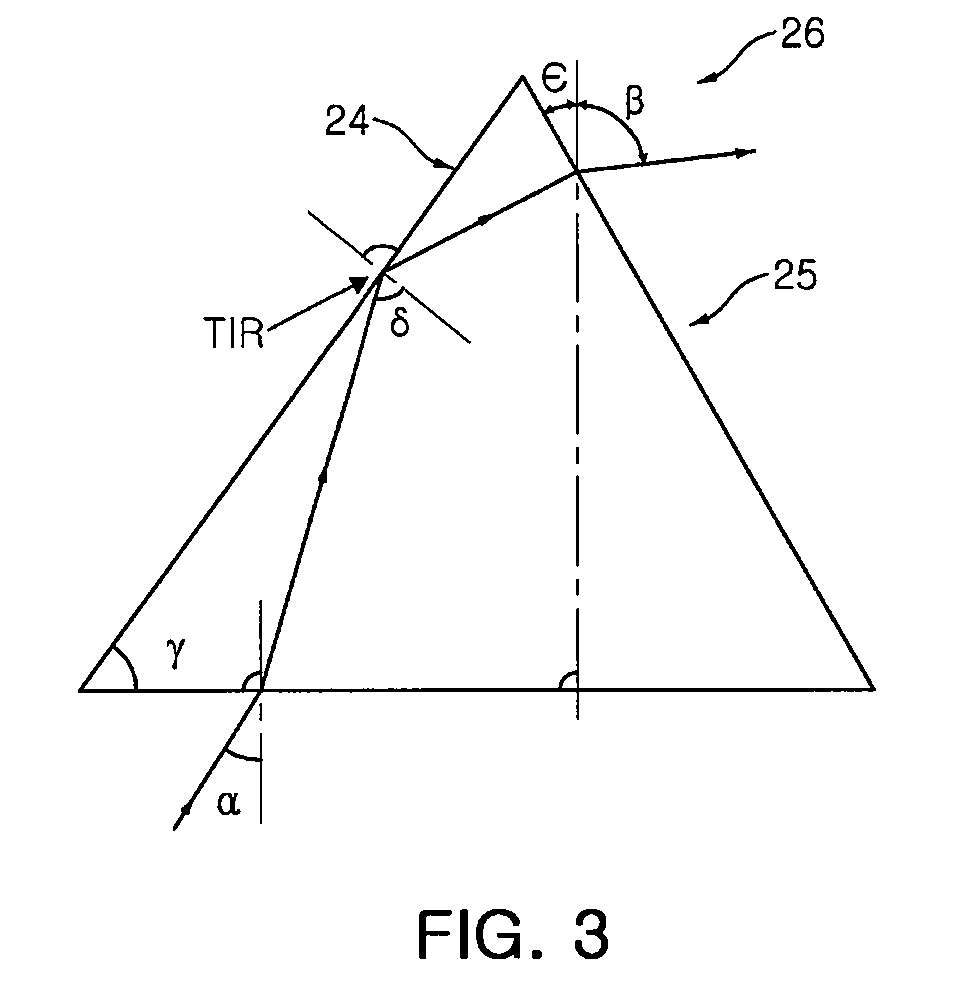

Total internal reflection micro lens array

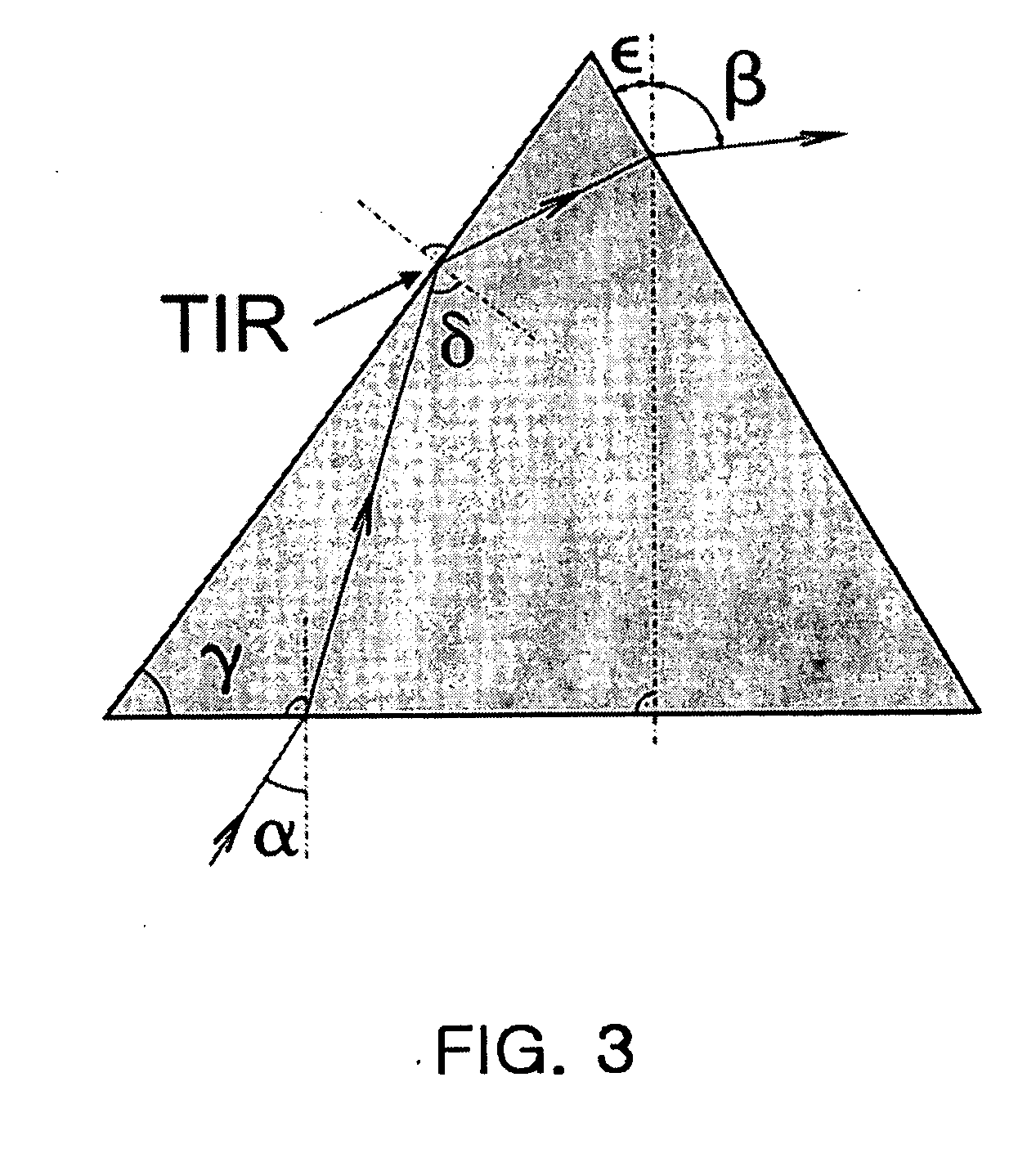

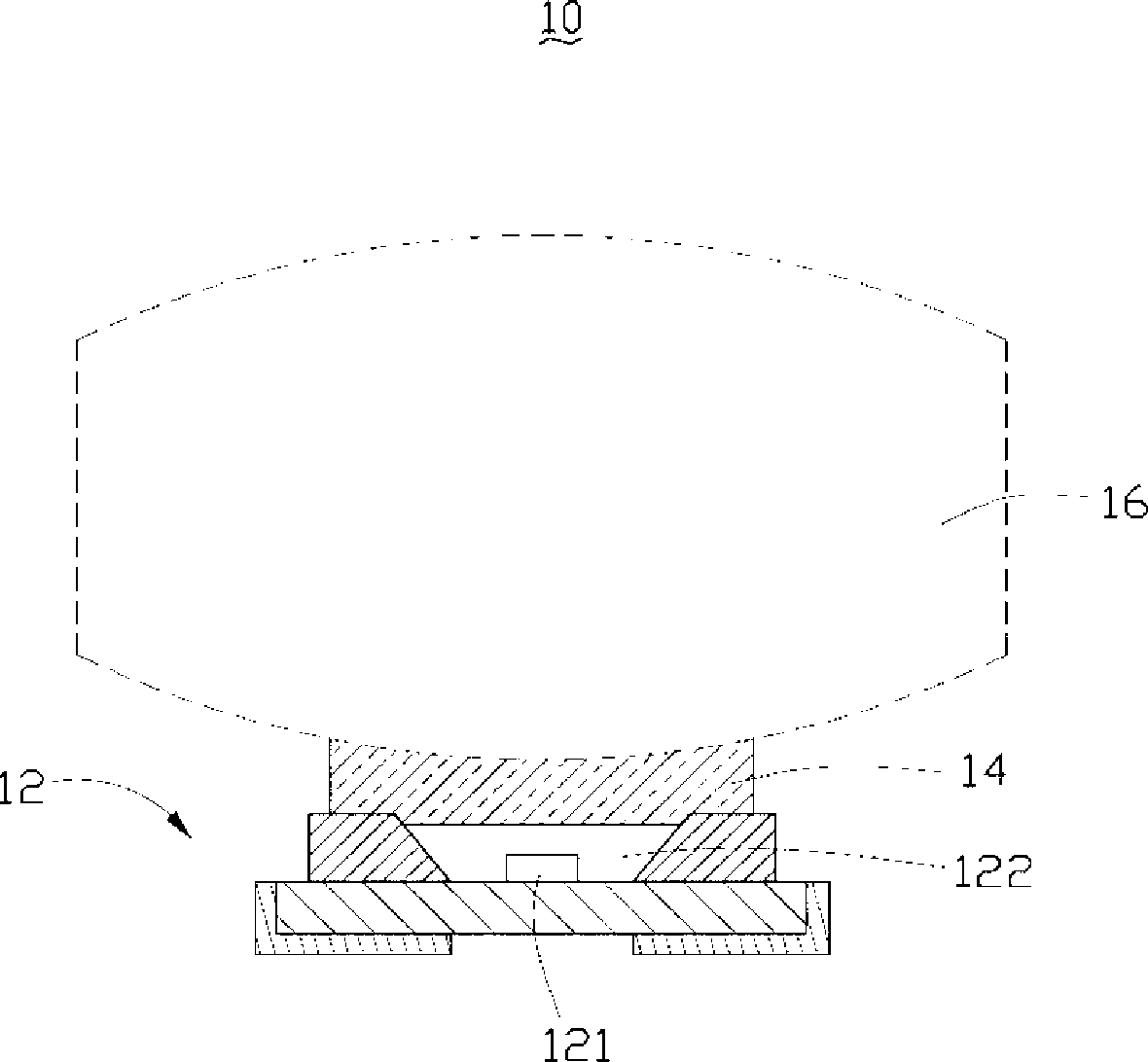

InactiveUS20070091444A1Improve divergence angleShape controllableLensRefractorsFresnel lensTotal internal reflection

The invention relates to a total internal reflection micro lens array for a wide-angle lighting system. The micro lens array includes a plurality of Fresnel lens structures formed on a same optical incidence surface. Each of the Fresnel lens structure comprises a plurality of grooves, each having a reflecting surface and a refractive surface. Incoming radiation incident through the incidence surface of the lens structure is internally totally reflected by the reflecting surface, refracted by the refractive surface and exits the lens structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Light source assembly

InactiveCN101418927AEasy to mix lightImprove light field distributionPoint-like light sourceCondensersOptoelectronicsProcessing element

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

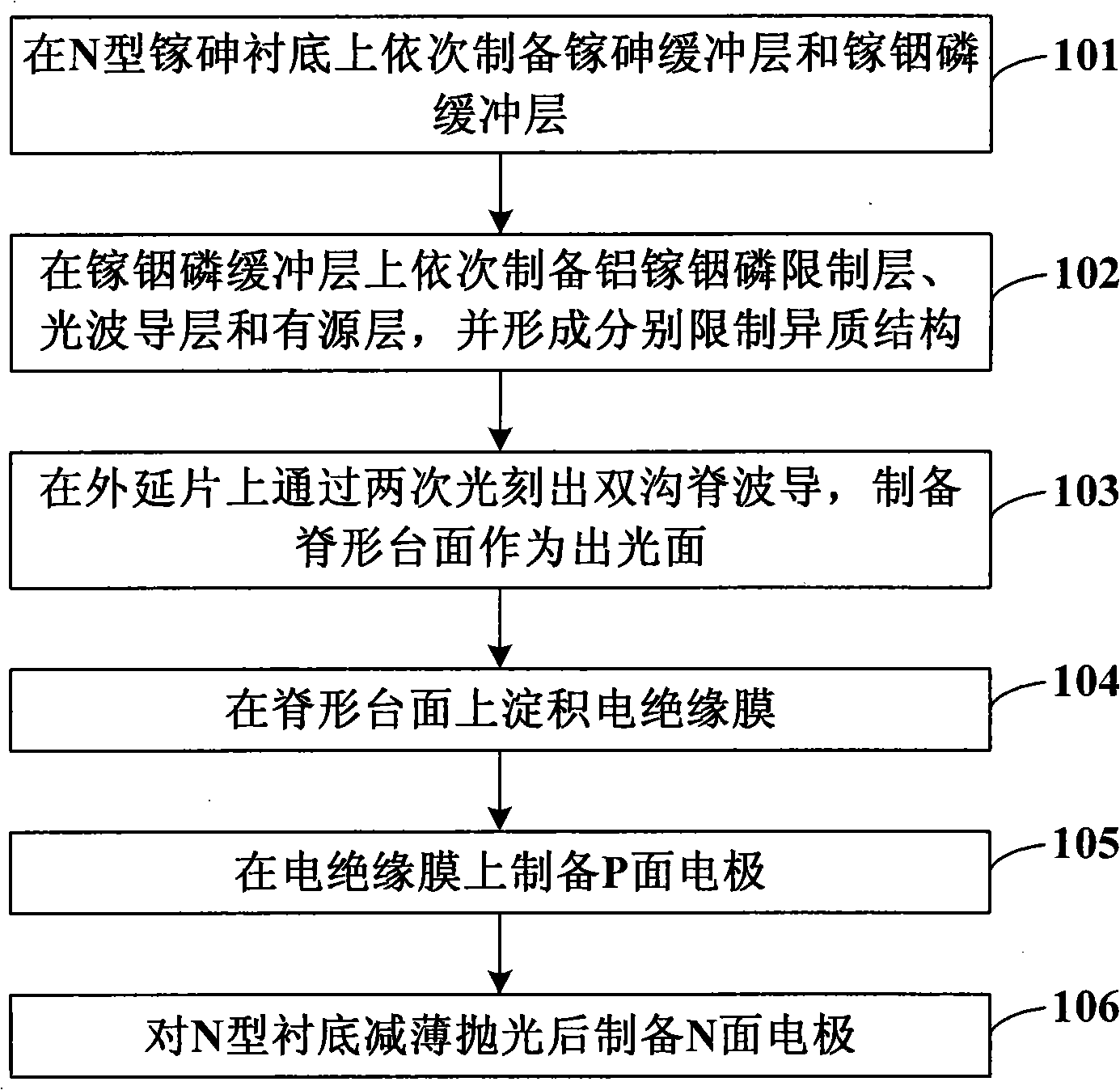

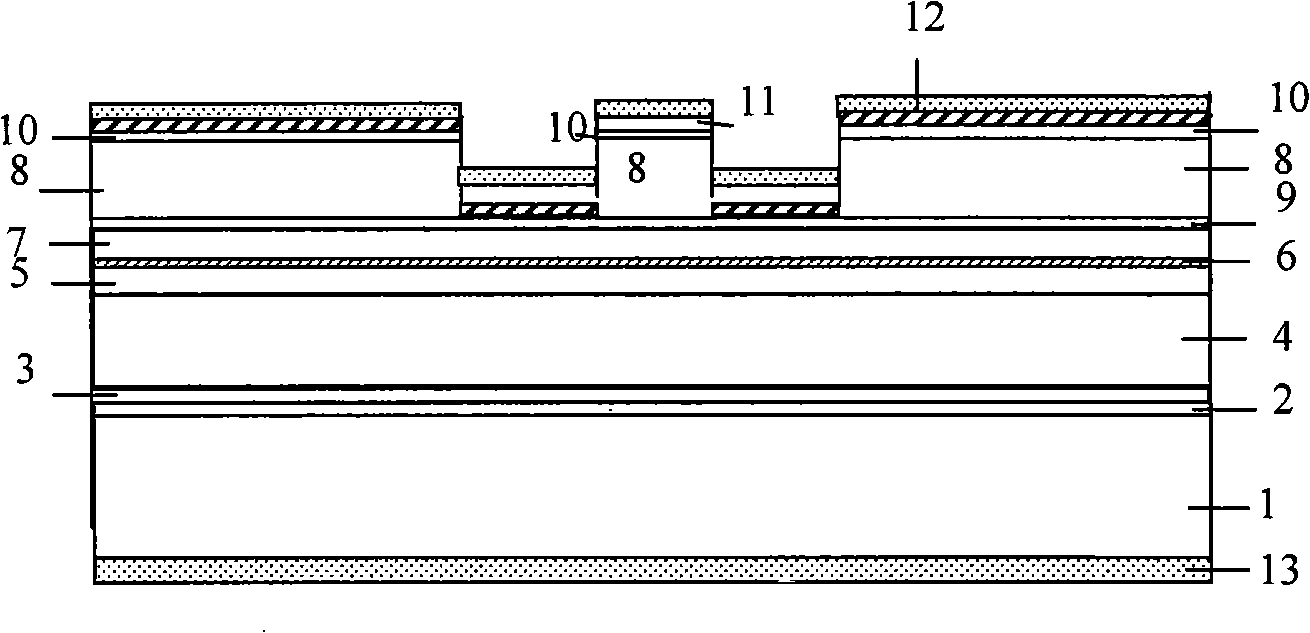

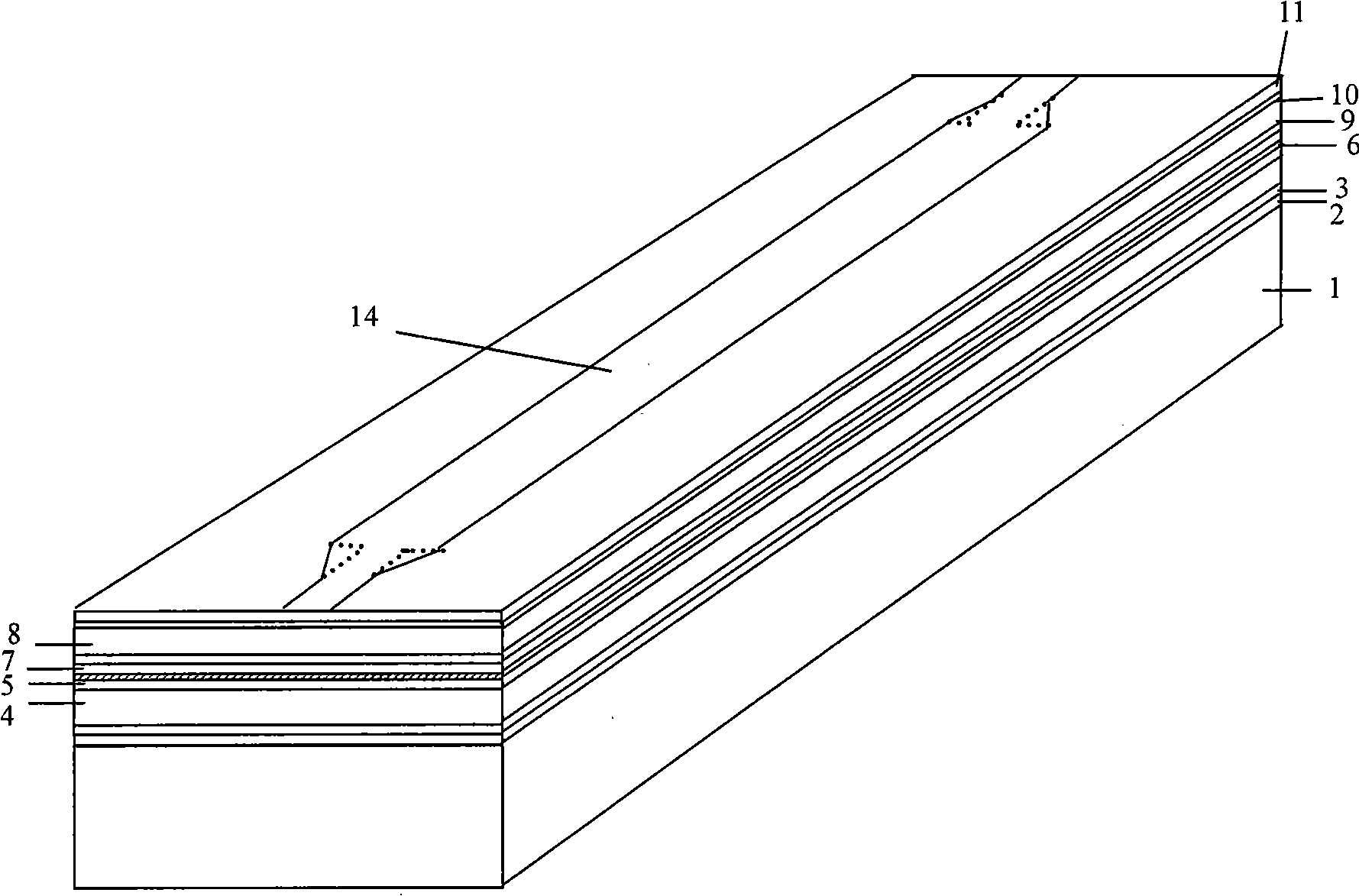

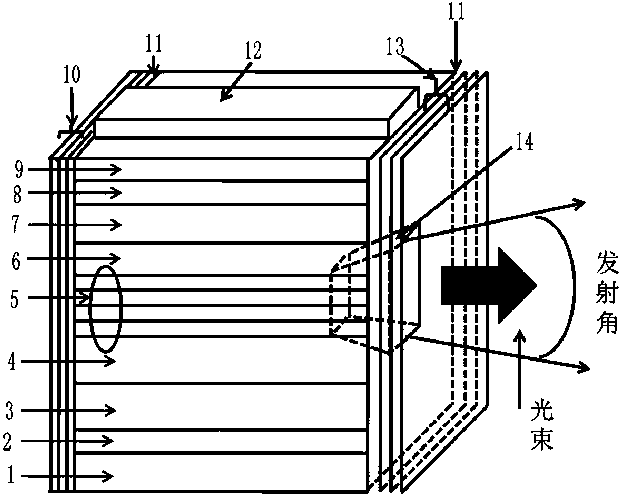

Production method of quantum well edge-emission semiconductor laser

InactiveCN101316027AImprove output spotOutput power is not affectedOptical wave guidanceLaser detailsFiberLight spot

The invention discloses a preparation method of a quantum well emitting semiconductor laser used for improving the output light spot, relating to the technical field of a semiconductor laser. The preparation method comprises the steps as follows: A. a Ga-As damping layer and a Ga-In-P damping layer are sequentially prepared on an N-typed Ga-As underlay; B. an Al-Ga-In-P limiting layer, a fibre waveguide layer and an active layer are sequentially prepared on the Ga-In-P damping layer and a structure which limits heterostructures is respectively formed; C. a dual-ridge waveguide is formed on an external extension sheet by etching twice; a ridge-shaped table is prepared to be taken as a light outlet surface; D. an electric insulation film is deposited on the ridge-shaped table; E. a P-surface electrode is prepared on the electric insulation film; F. an N-surface electrode is prepared after the N-typed underlay is thinned and polished. The preparation method of the invention ensures that the original output power and the photoelectric conversion efficiency of the ridge-shaped fibre wave guide laser are not affected basically, increases the parallel divergence angle and improves the output light spot of the laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Device and method for laser etching cathode film material of OLED display

InactiveCN102284789AImprove luminous efficiencyThin line widthLaser beam welding apparatusErosionCathode

The invention relates to a device and method for laser etching cathode thin film materials of OLED displays. An electric shutter and an electric beam expander are arranged at the output end of the high-frequency short-pulse laser, and a 1 / 2 wave plate is arranged at the output end of the electric beam expander. 1 The output end of the / 2 wave plate is arranged with a polarization beam splitter, the output end of the polarization beam splitter is arranged with a first half-mirror and a first 45-degree reflector, and the output end of the first half-mirror is arranged with a first focusing mirror and a first half-mirror. The second 45-degree reflective mirror, the output end of the second 45-degree reflective mirror is arranged with a second focusing mirror, the output end of the first 45-degree reflective mirror is arranged with a second half mirror, and the output end of the second half mirror is arranged There is a third focusing mirror and a third 45-degree reflecting mirror, and a fourth focusing mirror is arranged at the output end of the third 45-degree reflecting mirror, and the output end of the focusing mirror is facing the two-axis adsorption platform. The cathode material of the OLED display is vaporized under the action of a high-frequency short-pulse laser to achieve the purpose of erosion, and the four beams realize the line etching of the cathode area.

Owner:SUZHOU DELPHI LASER

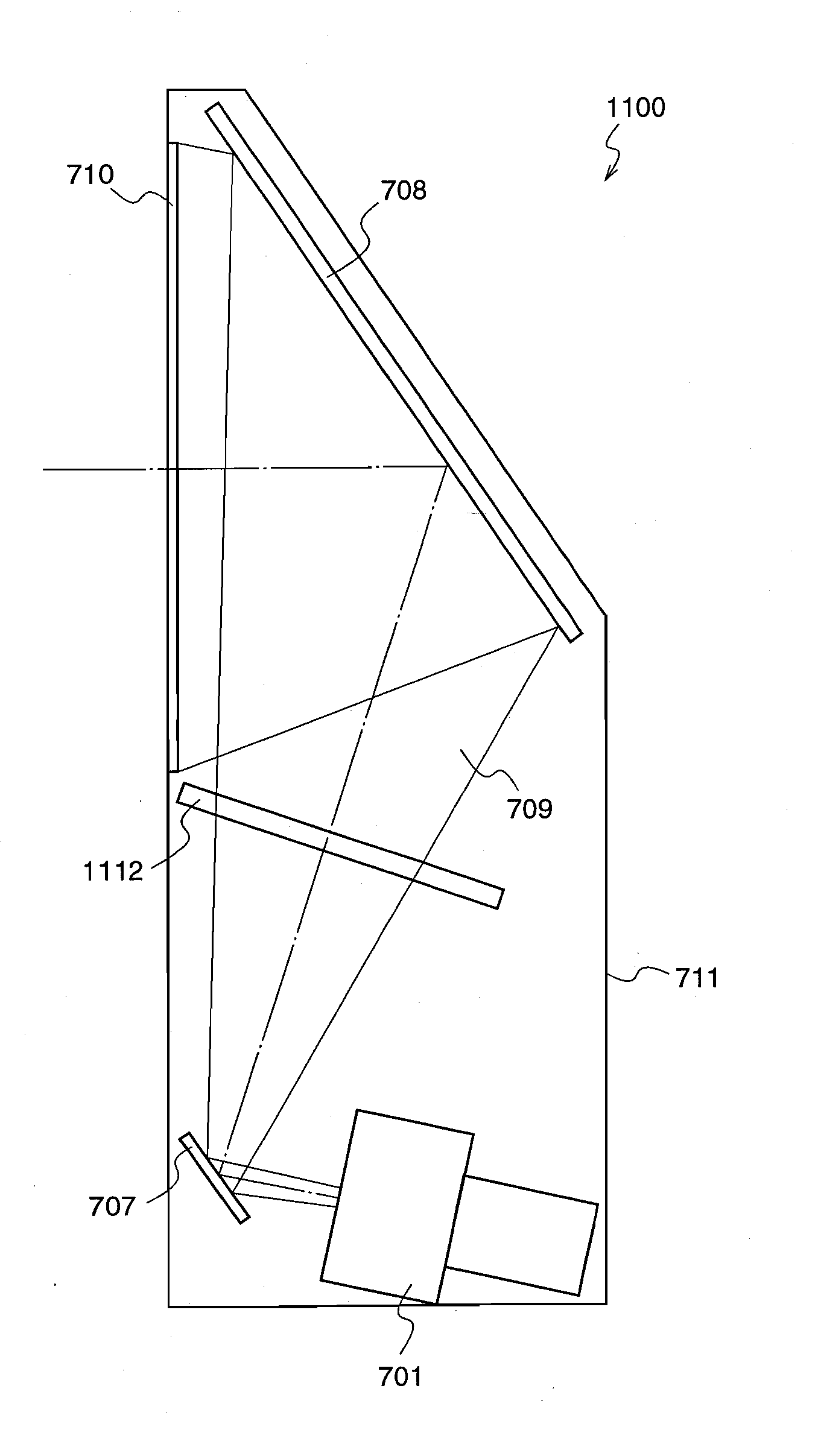

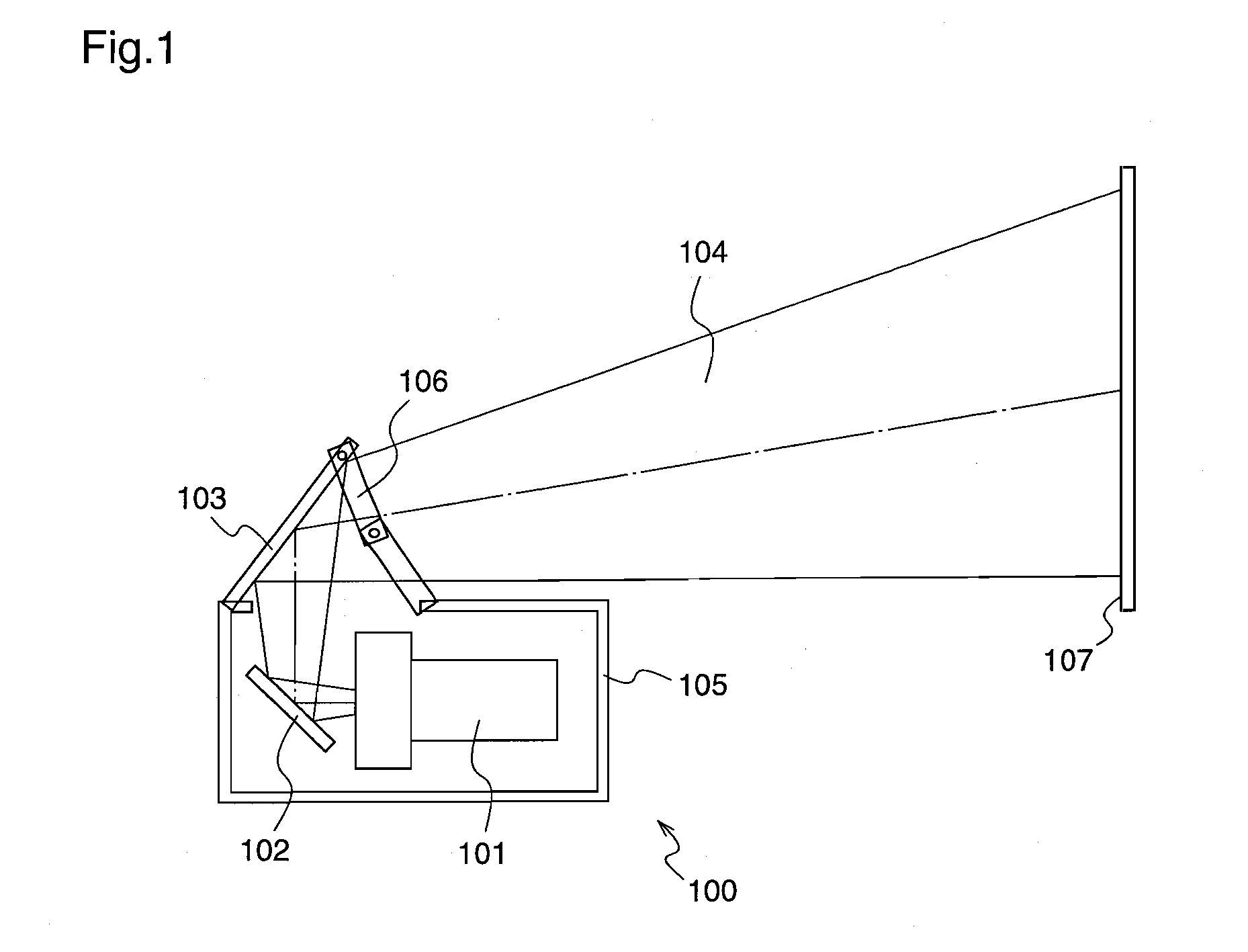

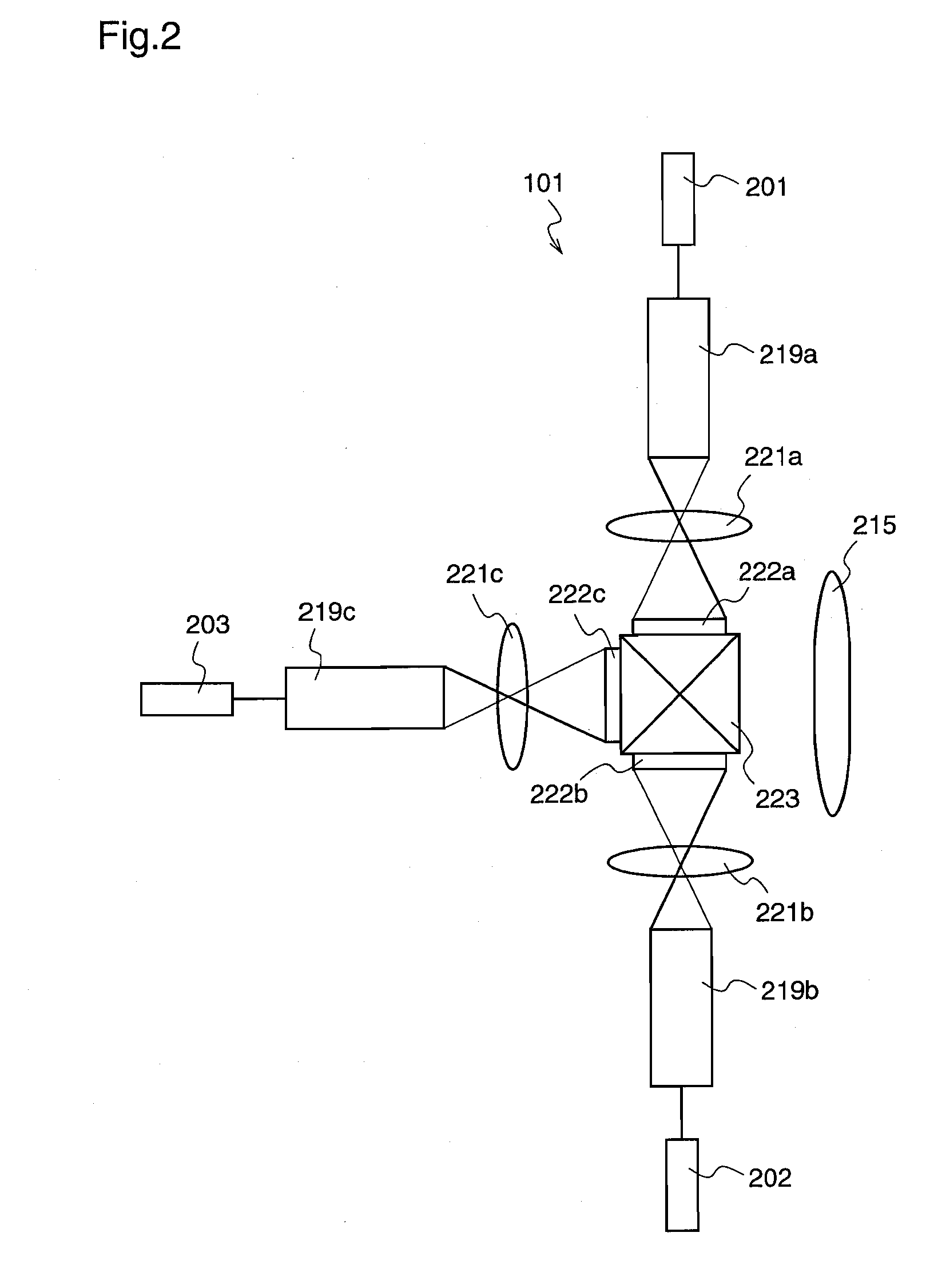

Image projection device and rear projection type display device

InactiveUS20100157256A1Improve securityLong distanceBuilt-on/built-in screen projectorsColor television detailsDisplay deviceLaser light

An image projection device comprising an image projection means (101) for projecting an image by laser light by using a one-dimensional or two-dimensional spatial light modulation element, a first folding mirror (102) for initially folding the laser light emitted from the image projection means (101), and a second folding mirror (103) for reflecting the laser light emitted from the image projection means (101) to a screen (107) through the first folding mirror (102), wherein a distance between the second folding mirror (103) and the image projection means (101) is made larger than a distance L by which a light output power emitted from the projection lens of the image projection means (101) with a solid angle of 38.4 / (L×L) is less than 1 mW. Therefore, even when a person observes the image projection device (100) from a position onto which an image is projected, the person is in an area where safety is ensured, thereby enhancing the safety.

Owner:PANASONIC CORP

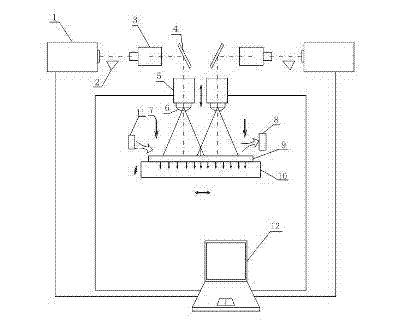

Laser processing device of silicon glass bonding slice and method thereof

ActiveCN102310285AImprove divergence angleReal-time observation of processing progressLaser beam welding apparatusBeam expanderLaser processing

The invention relates to a laser processing device of a silicon glass bonding slice and a method thereof. An output end of an ultraviolet high-frequency ultrashort pulse laser is provided with an optical gate, a beam expander and an aperture diaphragm, an output end of the aperture diaphragm is provided with a pair of 45-degree completely reflecting mirrors, output ends of the 45-degree completely reflecting mirrors are provided with deflection lenses, an output end of the deflection lens is provided with a 45-degree completely reflecting mirror, an output end of the 45-degree completely reflecting mirror is provided with a focus lens, the focus lens is right opposite to a three-dimensional movable platform, a CCD (Charge Coupled Device) illuminating lamp is arranged under the focus lens, and a coaxial CCD (charge coupled device) para-position observation system is distributed above the three-dimensional movable platform. Light beams sent by the ultraviolet high-frequency ultrashort pulse laser chemically focus a focal point on the upper surface of glass material, a spiral deflection lens controls the width of a once-cut cutting track, adjusts the cutting track into the cutting track with proper width, accurately positions the cut cutting track, and controls the focal point to correspondingly descend along with the increase of the cutting depth to orderly cut each cutting track on the silicon glass bonding slice.

Owner:SUZHOU DELPHI LASER

Device and method for laser etching OLED display anode thin film material

InactiveCN102284794AImprove divergence angleHighlight substantive featuresLaser beam welding apparatusObservation systemFilm material

The invention relates to a device and a method for laser etching the anode film material of an OLED display. The output end of the high-frequency short-pulse laser is arranged with an electric shutter, the output end of the electric shutter is provided with an electric beam expander, and the output end of the electric beam expander A 45-degree total reflection mirror is arranged in sequence, and the output end of the 45-degree total reflection mirror is arranged with a vibrating mirror and a scanning field mirror. The scanning field mirror is facing the three-axis adsorption platform, and one side of the three-axis adsorption platform is equipped with an ion wind blower system, the dust collection system is installed on the other side, the CCD alignment observation system is installed at the diagonal positions on the three-axis adsorption platform, and the high-frequency short-pulse laser and the vibrating mirror are connected to the industrial computer. Using high-frequency pulsed lasers of different wavelengths as the laser source, laser etching is performed on the anode material of the OLED display, so that the anode material of the OLED display is vaporized under the action of the high-frequency short-pulse laser to achieve the purpose of erosion, and the processed product is pollution-free. , OLED display products with stable linearity and good functions.

Owner:SUZHOU DELPHI LASER

Total internal reflection micro lens array

InactiveUS7548376B2Improve divergence angleControllable shapeLensRefractorsFresnel lensTotal internal reflection

Owner:SAMSUNG ELECTRONICS CO LTD

Three-dimensional display and imaging device and three-dimensional display and imaging method for laser-excited air ionization

InactiveCN104849868AImprove divergence angleTo achieve the purpose of collimationOptical elementsAir IonizationDirect imaging

The invention relates to a three-dimensional display and imaging device and a three-dimensional display and imaging method for laser-excited air ionization. A beam expanding lens is distributed at the output end of a light path of a laser machine; a 3D dynamic focusing system is arranged at the light path output end of the beam expanding lens; a high-speed scanning system is distributed at the light path output end of the 3D dynamic focusing system; a telecentric scanning field lens is distributed at the light path output end of the high-speed scanning system and is over against an imaging area. Ultra-short pulse laser is focused in air for ionizing air to emit light; the 3D dynamic focusing and scanning field lens is used for quickly scanning for enabling single point to form a three-dimensional appearance outline through a vision persistence principle, so that direct imaging is performed in air and the three-dimensional outline is directly formed in air; during practical application, a plurality of systems can be synthesized for use according to the size; or different colors can be emitted according to different laser-ionized gases, and colorful imaging is performed through laser and gas synthesis.

Owner:SUZHOU DELPHI LASER

Device and method for etching copper conducting film on glass substrate ink by using pulse laser

InactiveCN102416528AImprove divergence angleHighlight substantive featuresLaser beam welding apparatusPrismOptoelectronics

The invention relates to a device and a method for etching a copper conducting film on glass substrate ink by using pulse laser. An optical gate and a beam expander are arranged at the output end of a high-frequency pulse laser in turn; a 1 / 2 wave plate and a Glan prism are arranged at the output end of the beam expander in turn; a high-reflectivity lens is arranged at the output end of the Glan prism; a total reflection mirror is arranged at the output end of the high-reflectivity lens; a vibrating mirror field lens system is arranged at the output end of the total reflection mirror; the output end of the vibrating mirror field lens system is opposite to a four-axis high-accuracy platform; a charge coupled device (CCD) contrapuntal observation system is arranged above the four-axis high-accuracy platform; a plasma air blowing system is arranged on one side of the four-axis high-accuracy platform, and a dust collection system is arranged on the other side of the four-axis high-accuracy platform; a real-time power monitoring probe is also arranged at the output end of the high-reflectivity lens and is connected with the vibrating mirror field lens system through a communication system and a control system; and the high-frequency pulse laser is used for etching lines of a copper conducting film layer in an invisible area of a black ink substrate on glass.

Owner:SUZHOU DELPHI LASER

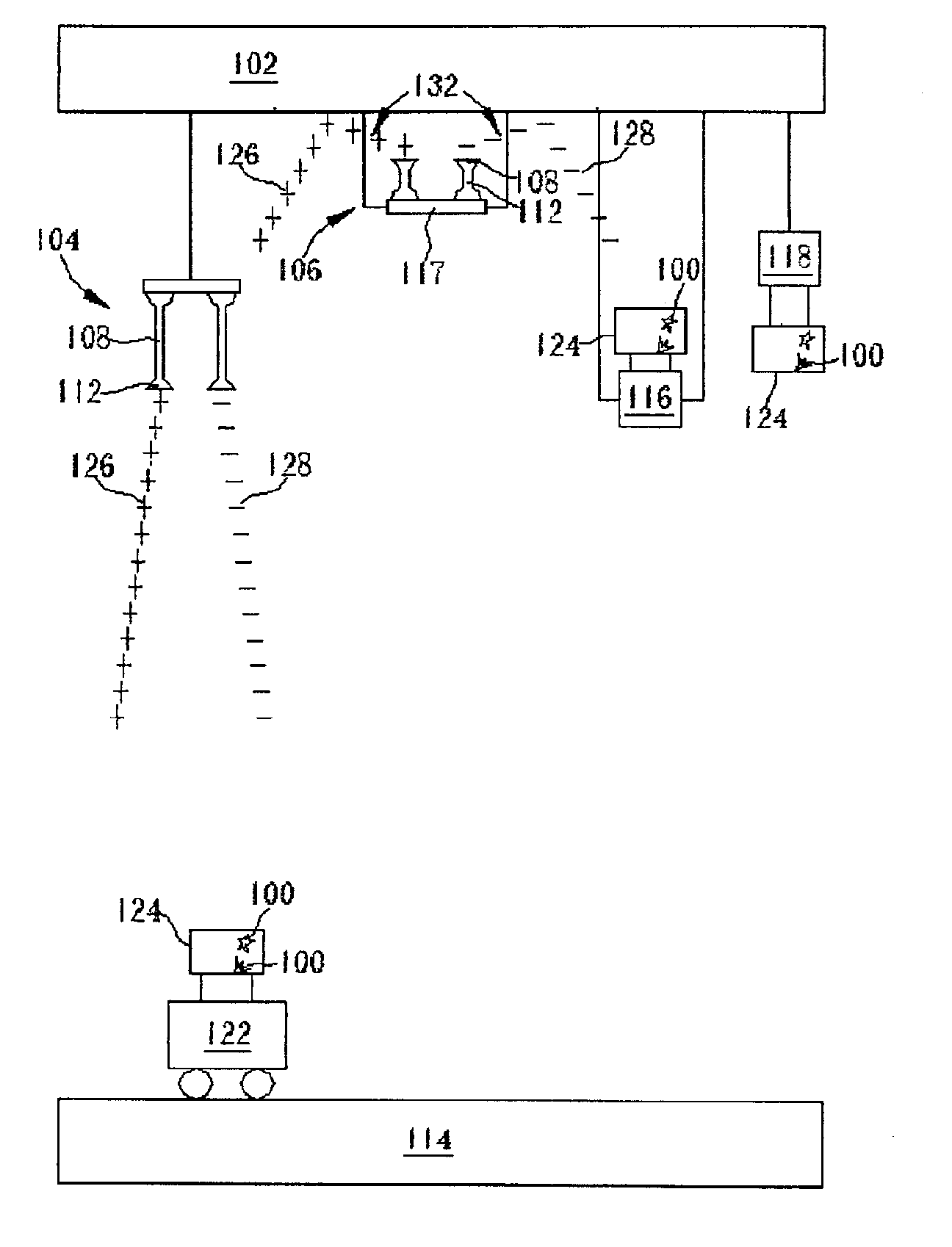

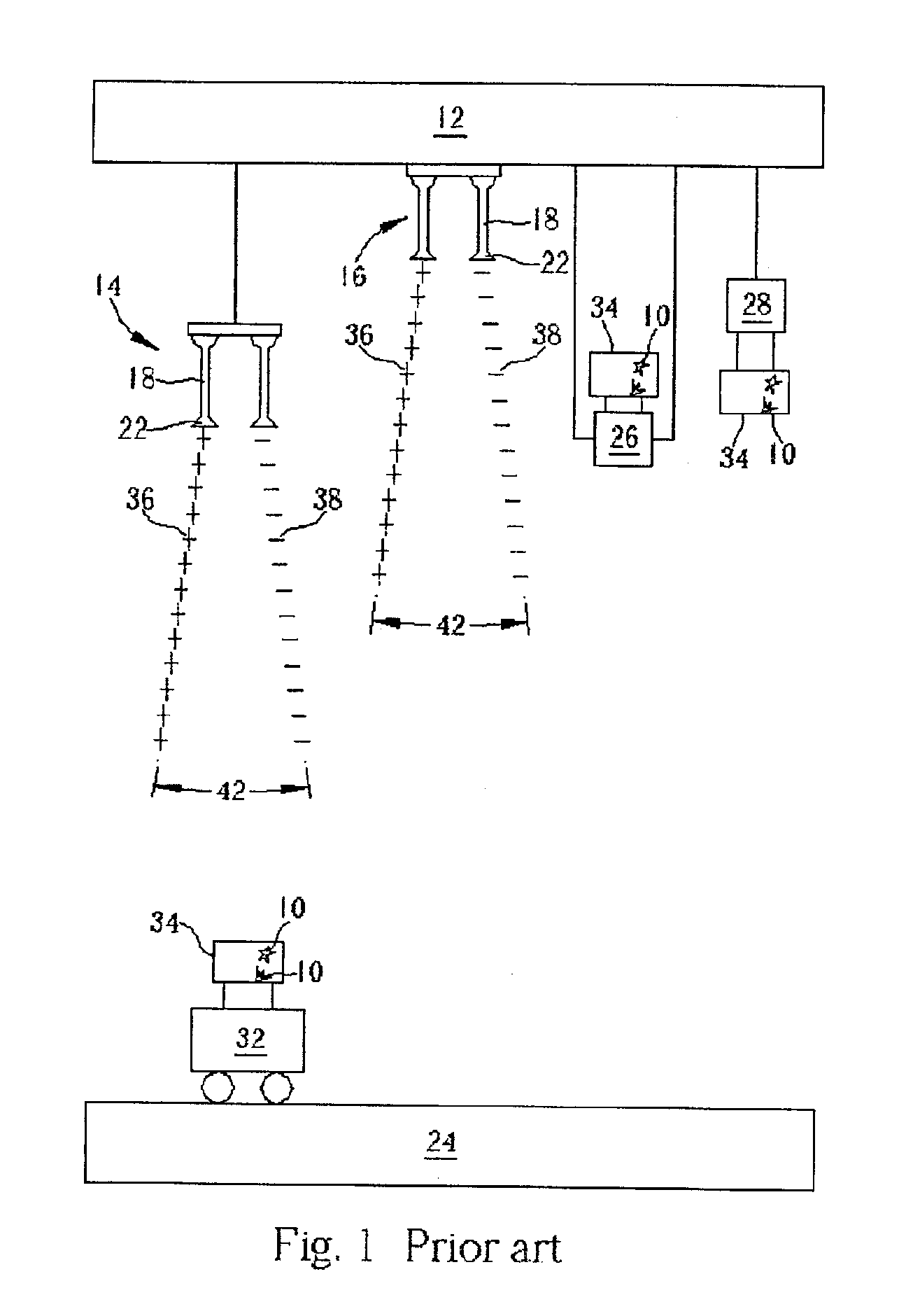

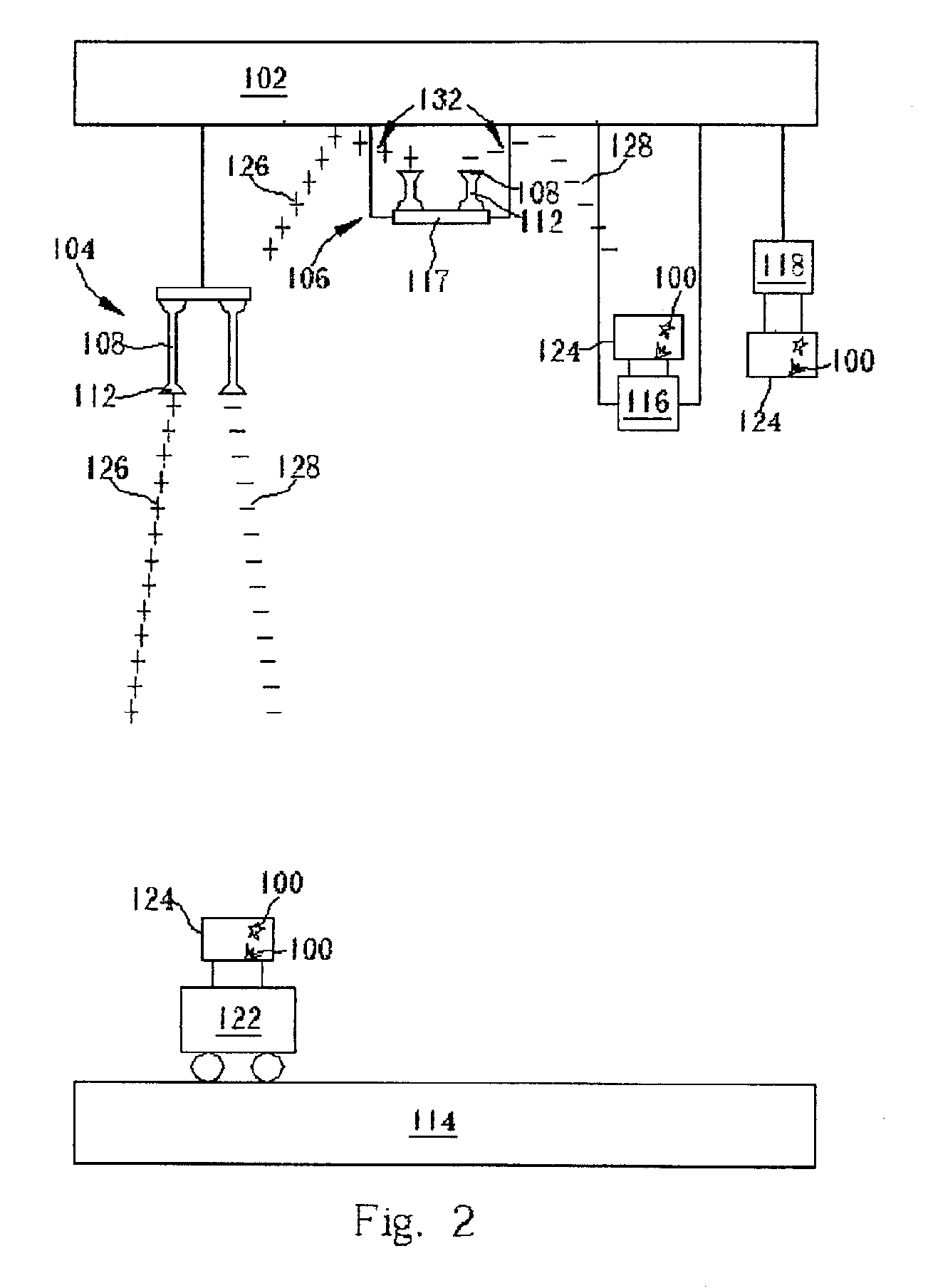

Method for preventing electrostatic discharge in a clean room

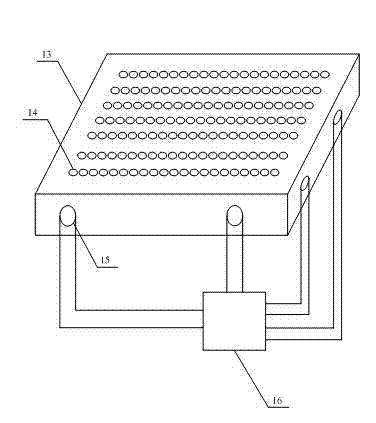

InactiveUS6873515B2Effective preventionImprove divergence angleEnergy based chemical/physical/physico-chemical processesElectrostatic chargesEngineeringDelivery system

The present invention provides a method of removing electrostatic charges from a clean room with a laminar flow apparatus. The laminar flow apparatus is disposed on a ceiling of the clean room. An ion generator at a first height and a transportation system at a second height are disposed in the laminar flow. An output tip of an emitter of the ion generator faces toward the ceiling to enlarge a divergent angle between positive and negative ions, effectively removing the electrostatic charges from the clean room and from a carrier in the transportation system.

Owner:UNITED MICROELECTRONICS CORP

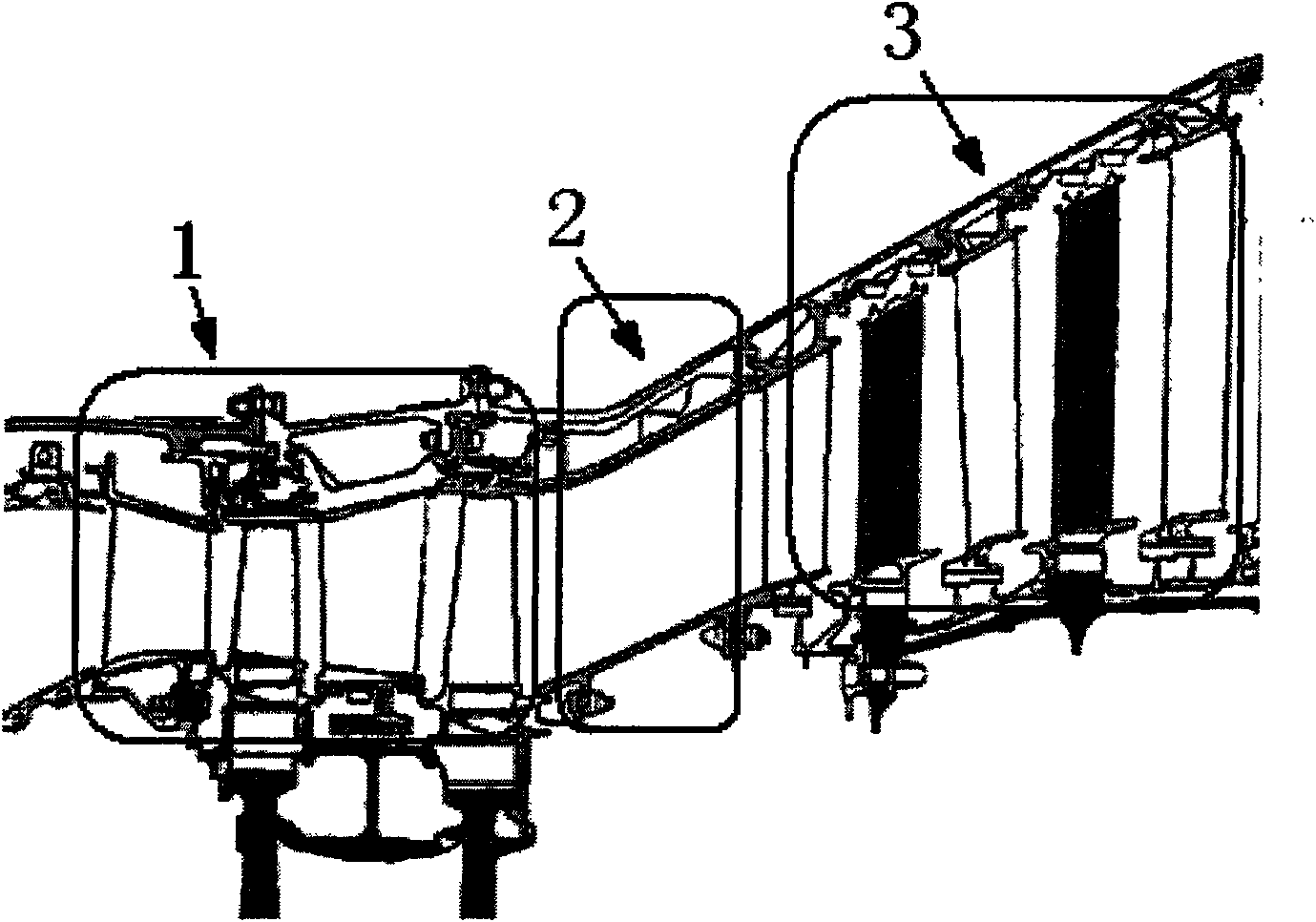

Flow control method in large expansion angle channel

InactiveCN101598036AEasy to controlImprove aerodynamic performanceStatorsMachines/enginesBypass ratioEngineering

A flow control method in a large expansion angle channel comprises that in a divergent channel, a guide ring (7) or a guide plate (8) is arranged between a runner outer wall (4) and a runner inner wall (5) or both are arranged, the guide ring (7) is divided into a plurality of parts in the circumferential direction and the guide plate (8) is composed of one or more parts. The invention can not only increase the expansion angle of a runner but also improve the flow control, thus improving the pneumatic performance of a large bypass ratio turbofan engine and reducing the axial dimension and weight.

Owner:BEIHANG UNIV

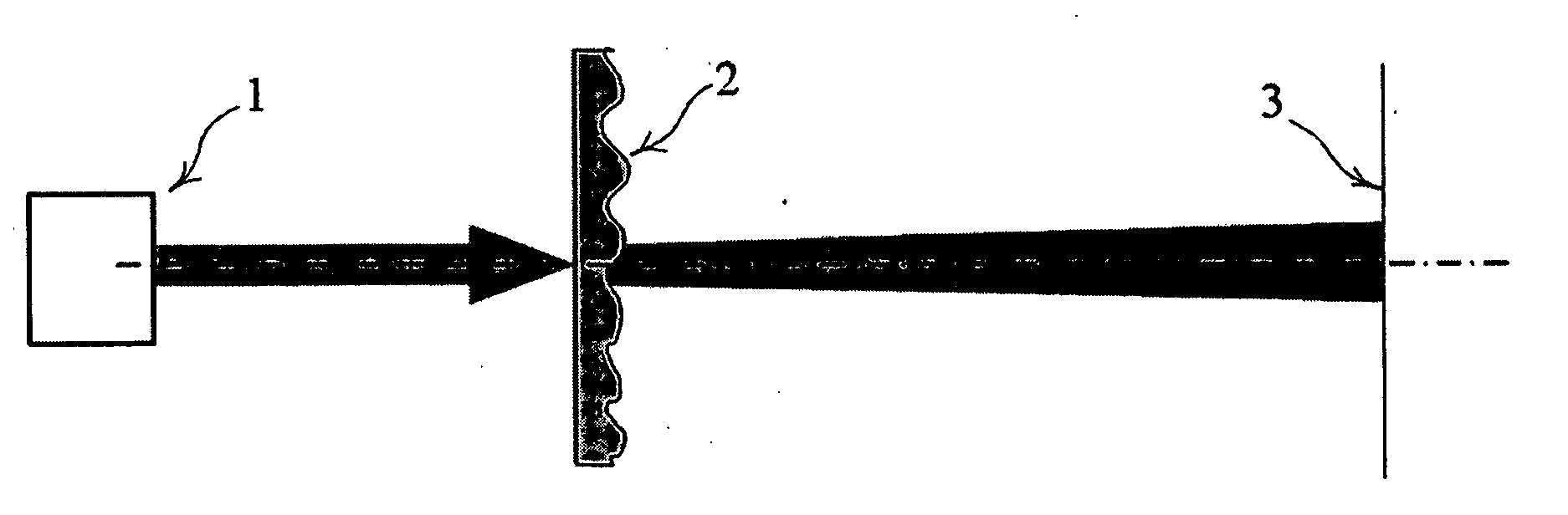

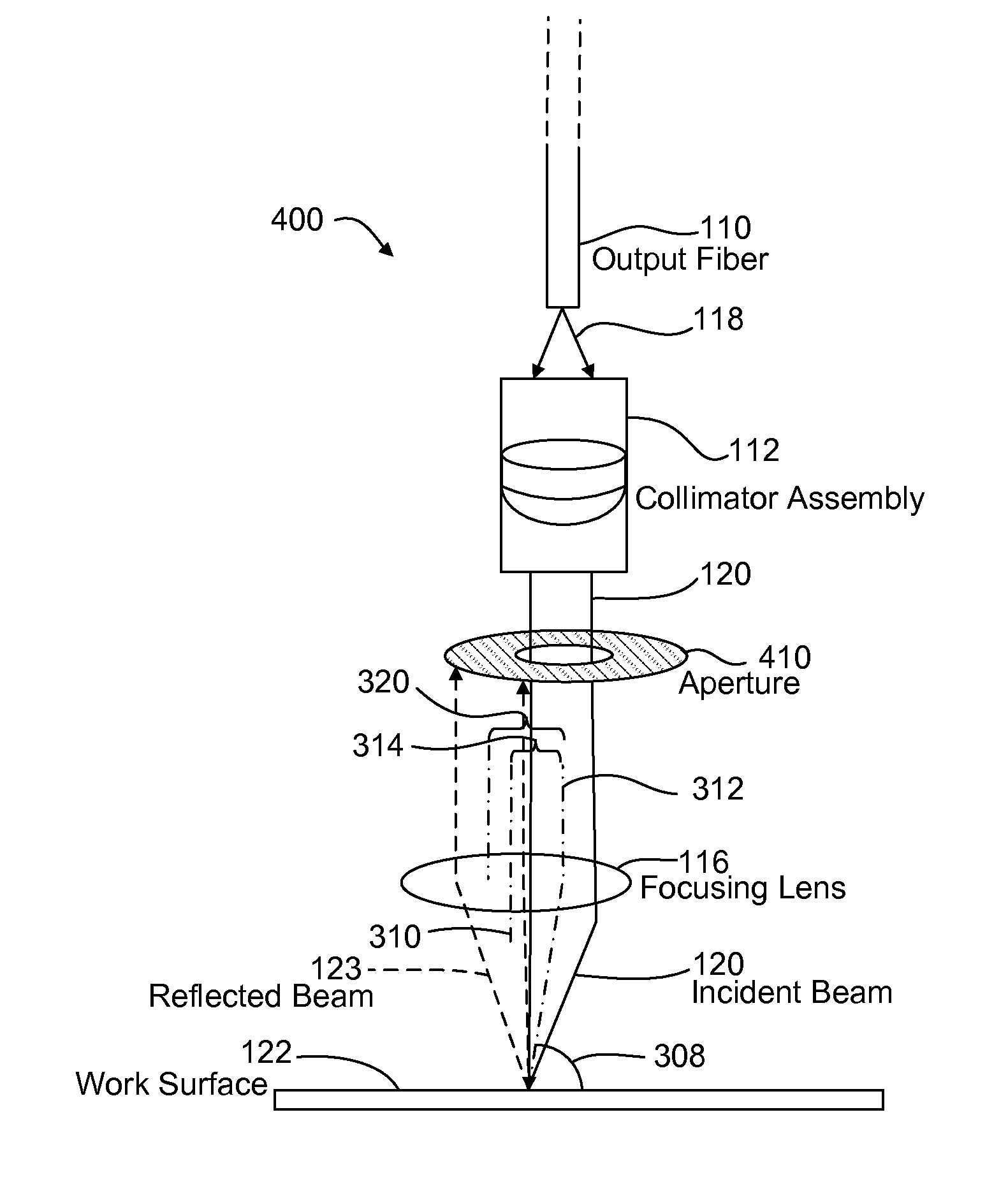

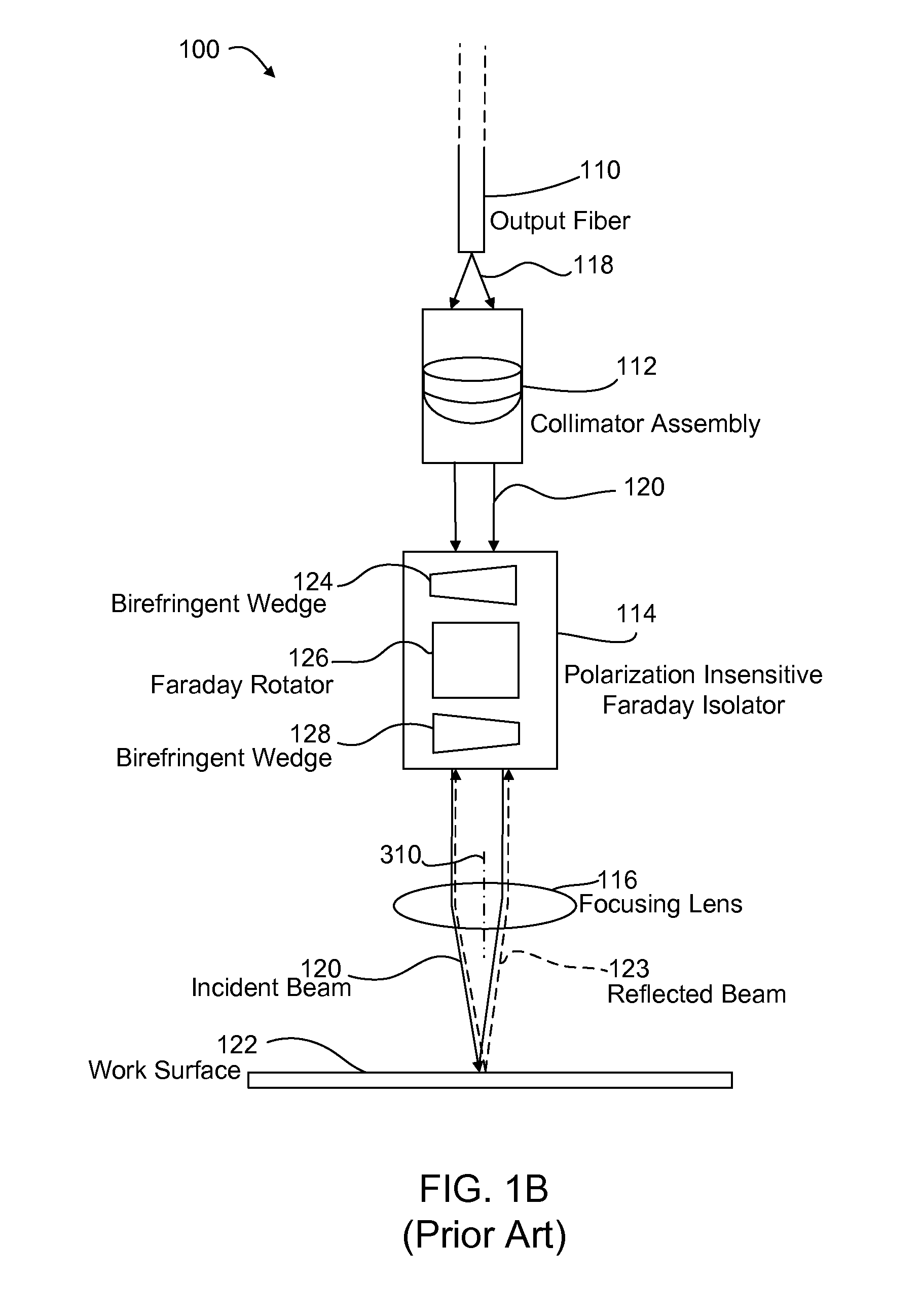

Reducing back-reflection in laser micromachining systems

InactiveUS8878095B2Reduce and prevent back-reflectionsReduce the overall diameterLaser detailsLaser beam welding apparatusBeam expanderLaser processing

Systems and methods reduce or prevent back-reflections in a laser processing system. A system includes a laser source to generate an incident laser beam, a laser beam output to direct the incident laser beam toward a work surface along a beam path, and a spatial filter. The system further includes a beam expander to expand a diameter of the incident laser beam received through the spatial filter, and a scan lens to focus the expanded incident laser beam at a target location on a work surface. A reflected laser beam from the work surface returns through the scan lens to the beam expander, which reduces a diameter of the reflected beam and increases a divergence angle of the reflected laser beam. The spatial filter blocks a portion of the diverging reflected laser beam from passing through the aperture and returning to the laser beam output.

Owner:ELECTRO SCI IND INC

Device and method for carrying out laser machining on light guide board inside glass

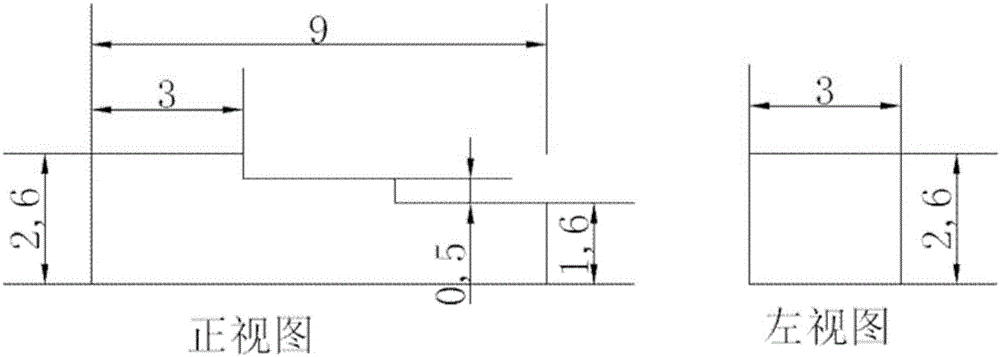

InactiveCN104237997AImprove divergence angleSmall spotGlass shaping apparatusOptical light guidesCamera lensThree dimensional microstructure

The invention relates to a device and method for carrying out laser machining on a light guide board inside glass. A beam expander, a 45-degree total reflection mirror set, a beam shaping unit and a scanning galvanometer are arranged on a light path of the output end of a laser in sequence. The beam output end of the scanning galvanometer right faces a carrier platform. A CCD system is installed on the scanning galvanometer. A lens of the CCD system right faces the carrier platform. Laser beams emitted by the laser are coaxially expanded through the beam expander, the beam transmission divergence angle is improved, the light path is made to be aligned, and the light spot is smaller after focusing is carried out by coaxially expanding the laser beams; the expanded beams reach the 45-degree total reflection mirror set and enter the beam shaping unit, the shaped focusing light spot can be of a three-dimensional microstructure inside the glass, the shaped beams reach the scanning galvanometer, laser beams emitted by the scanning galvanometer are focused inside the glass serving as a workpiece to be machined, and marks are etched inside the glass. The device is high in light transmittance, wide in application range, long in service life, not prone to abrasion and accurate in machining position.

Owner:SUZHOU DELPHI LASER

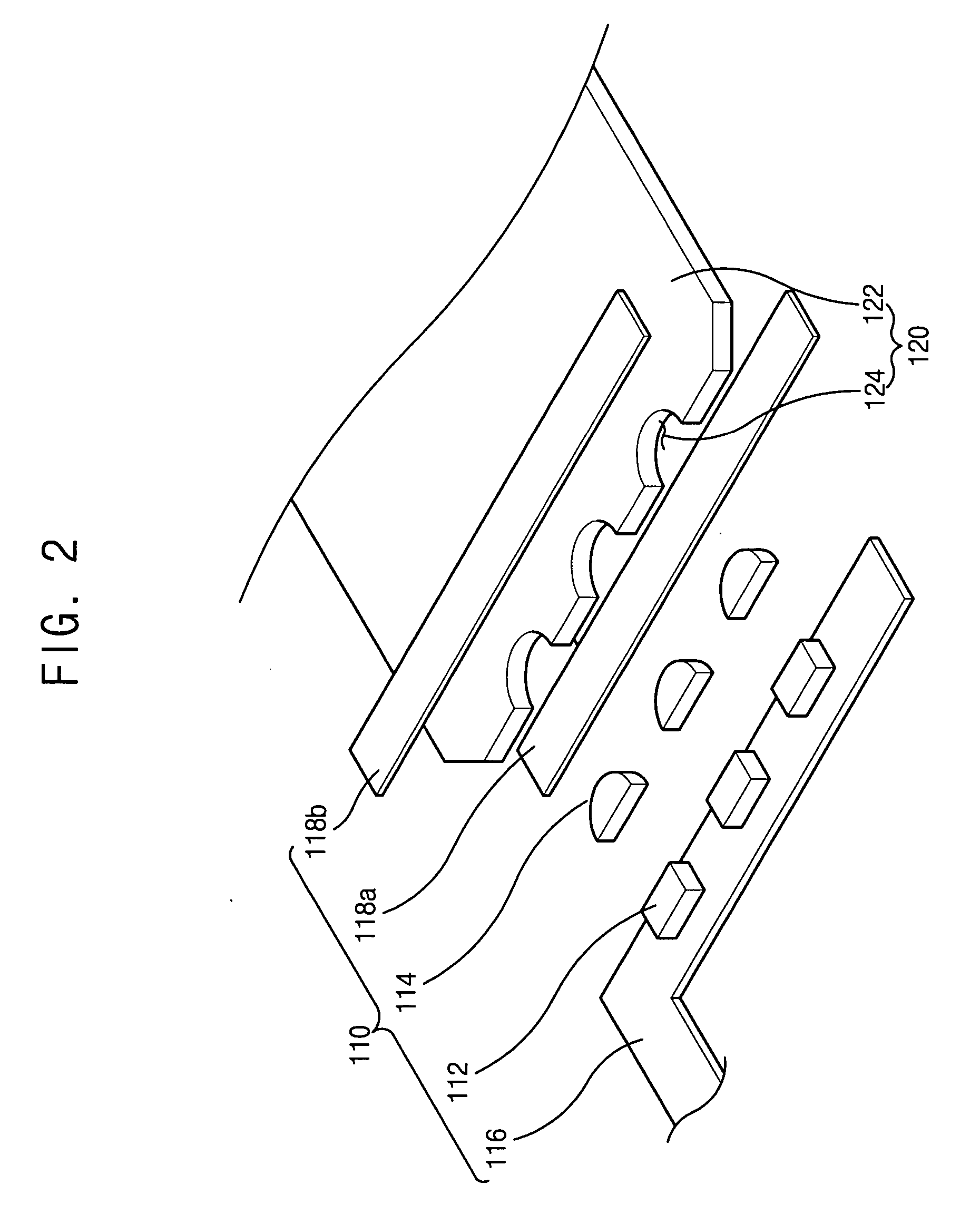

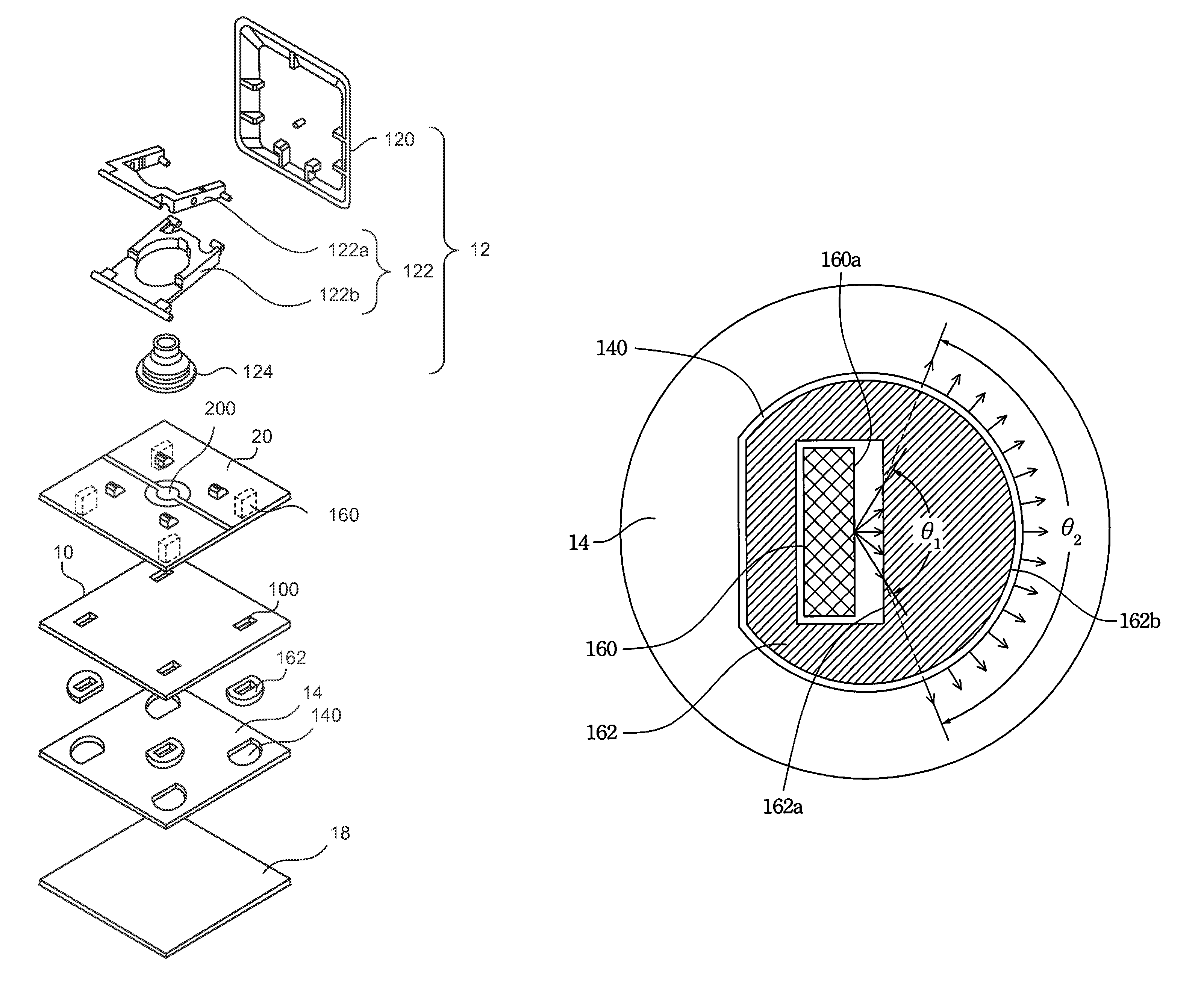

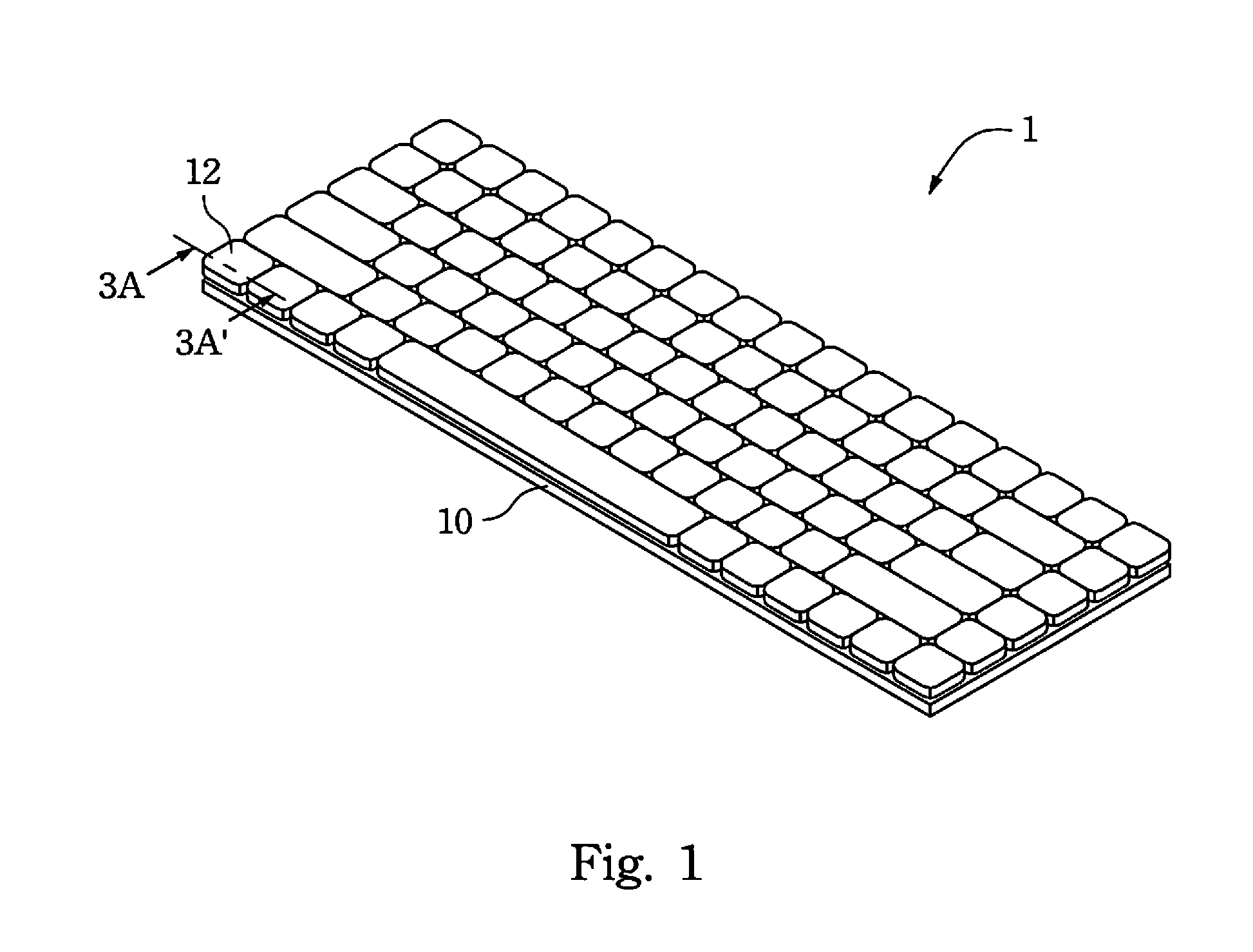

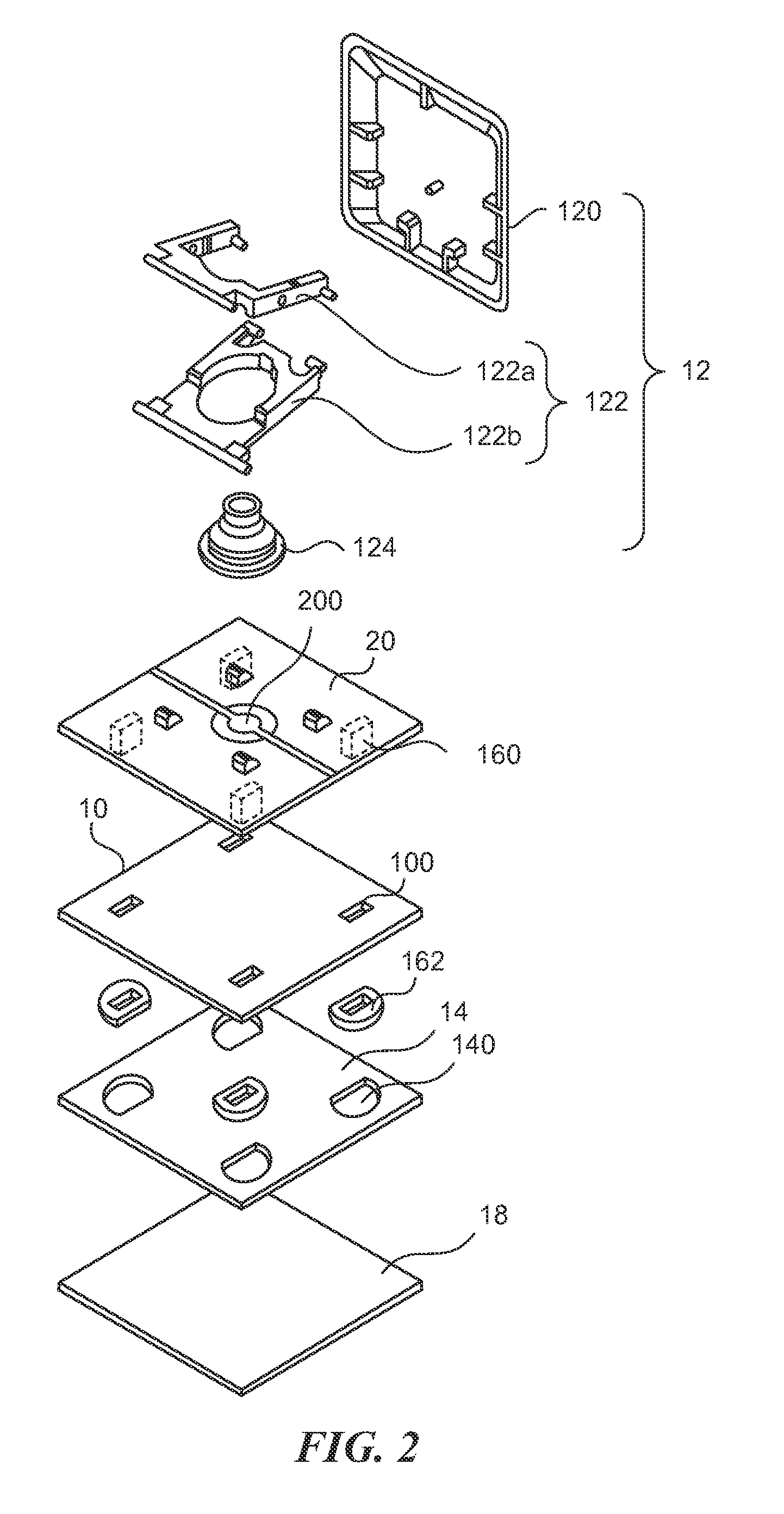

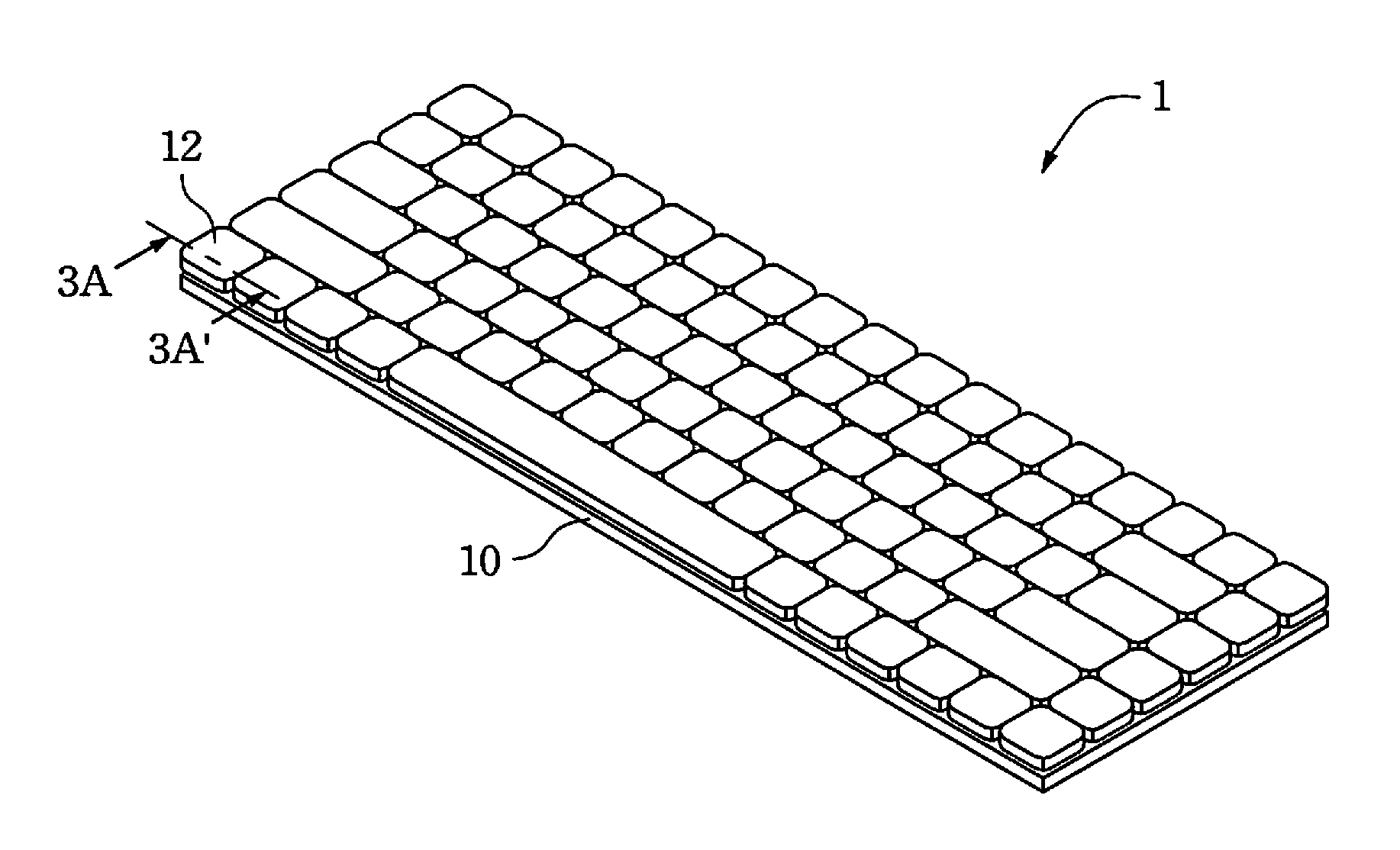

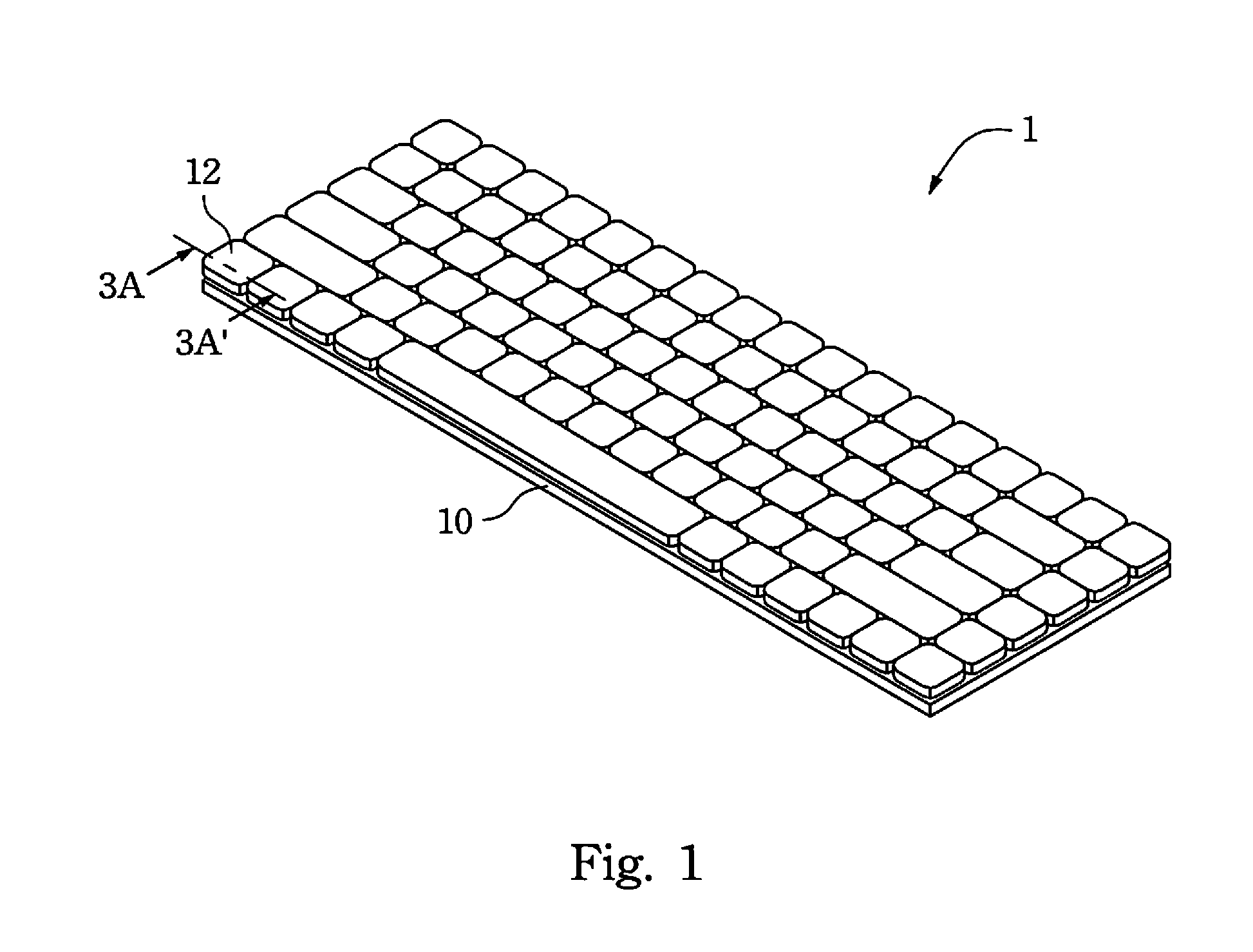

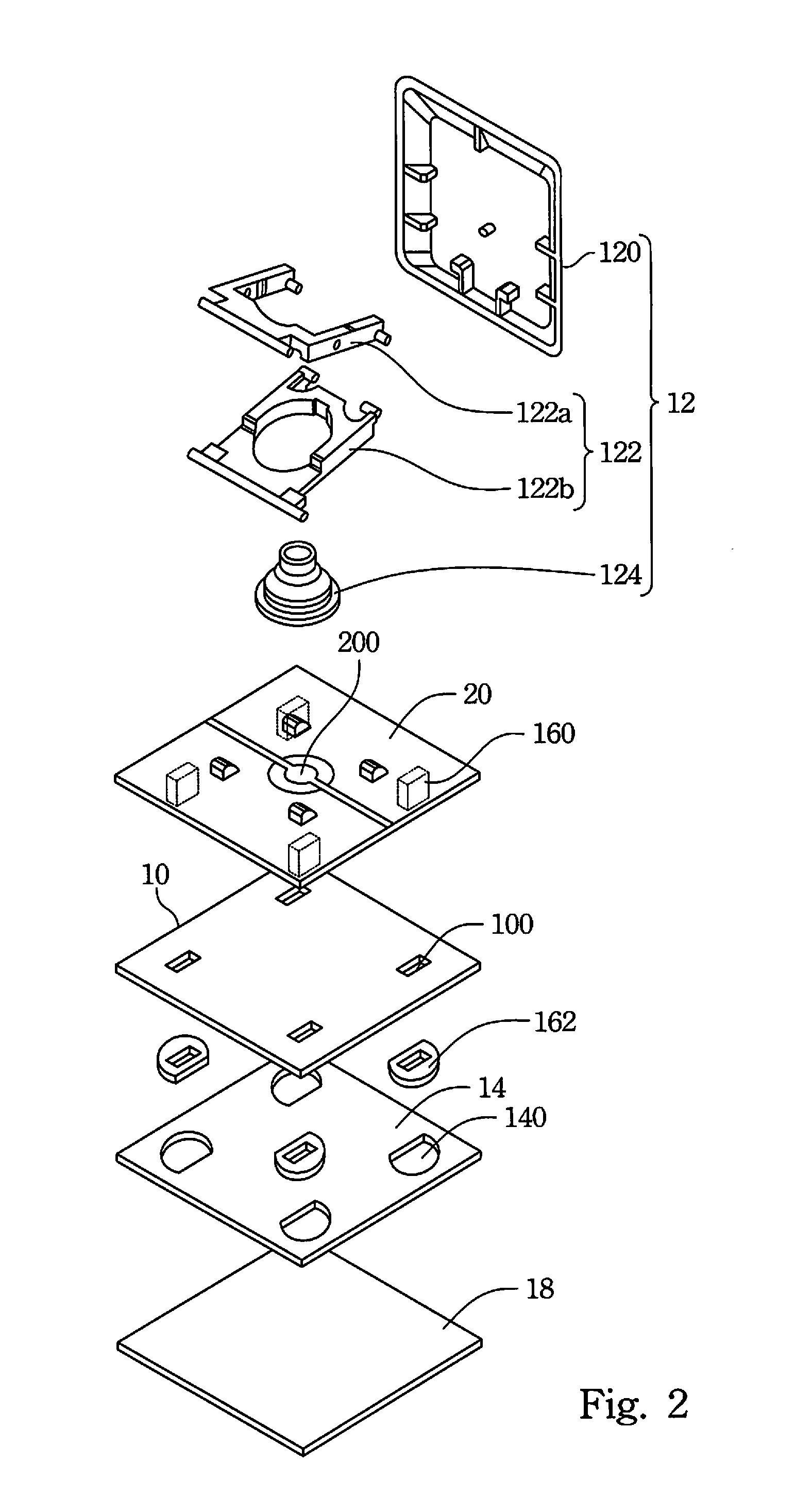

Luminescent keyswitch module and keyboard thereof

ActiveUS9018554B2Increase brightnessImprove divergence angleLegendsContact operating partsLight guideDivergence angle

A luminescent keyswitch module includes a base plate, a keyswitch, a light guide plate, a light source, a diffusion structure, and a reflector. The keyswitch is disposed on the base plate. The light guide plate, disposed under the base plate, has an accommodating space communicated with a through hole of the base plate. The light source passes through the through hole, is accommodated in the accommodating space, and emits light having a first divergence angle. The diffusion structure is accommodated in the accommodating space and located between the light source and the light guide plate. The light passes through the diffusion structure. The light leaving the second light exit surface has a second divergence angle larger than the first divergence angle. The reflector is disposed under the light guide plate, so as to reflect the light to pass through the light guide plate and the base plate to the keyswitch.

Owner:CHICONY ELECTRONICS

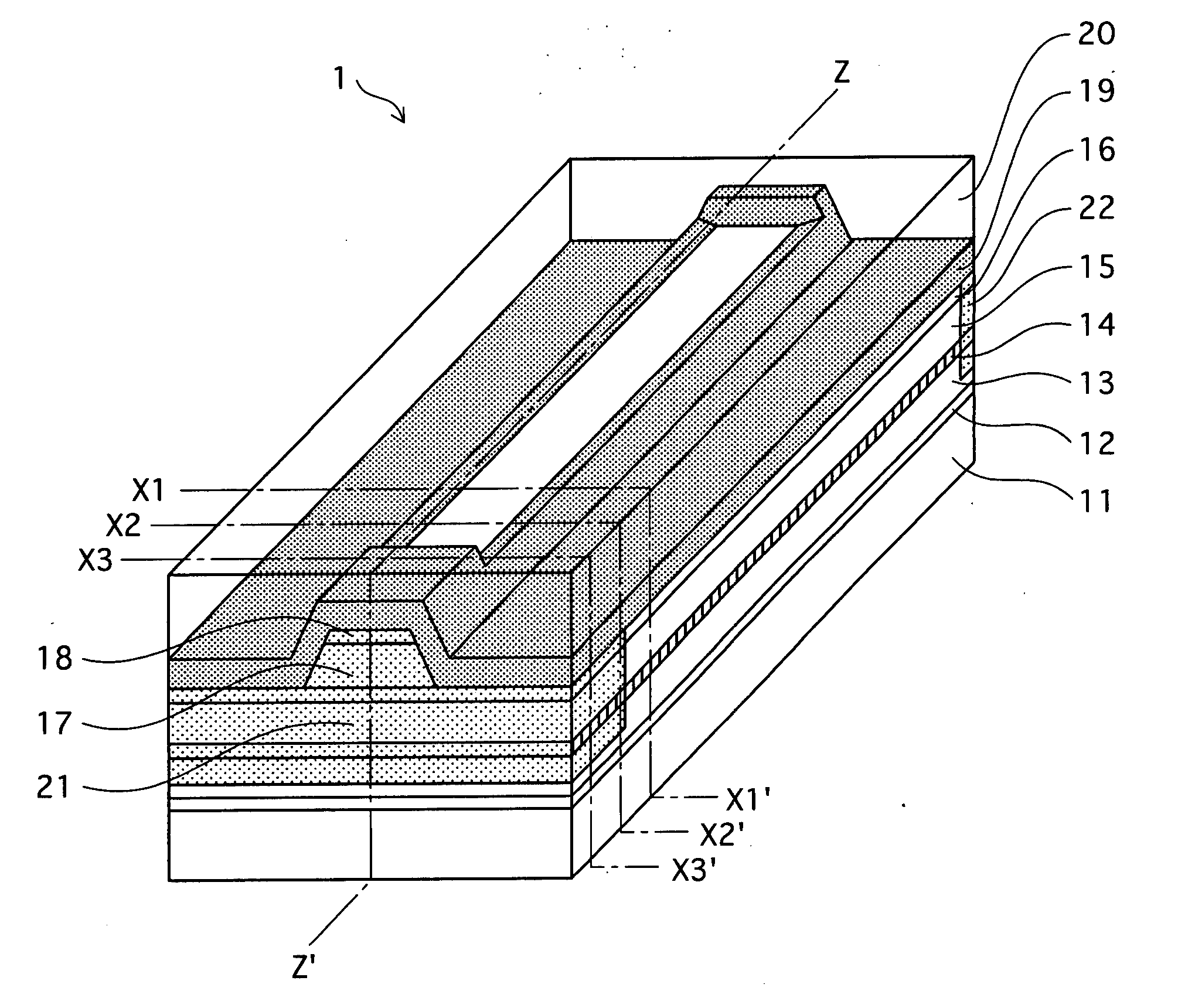

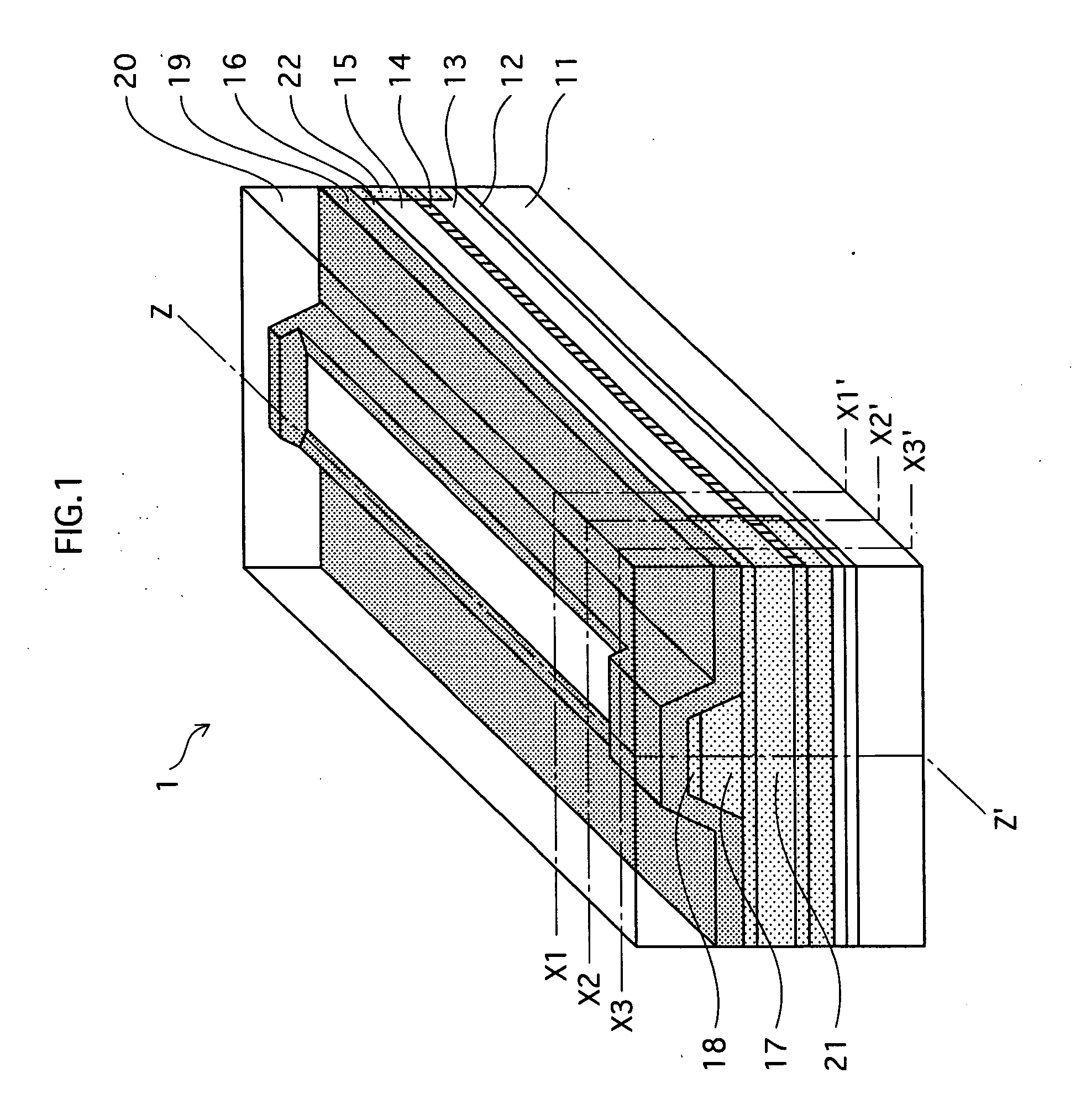

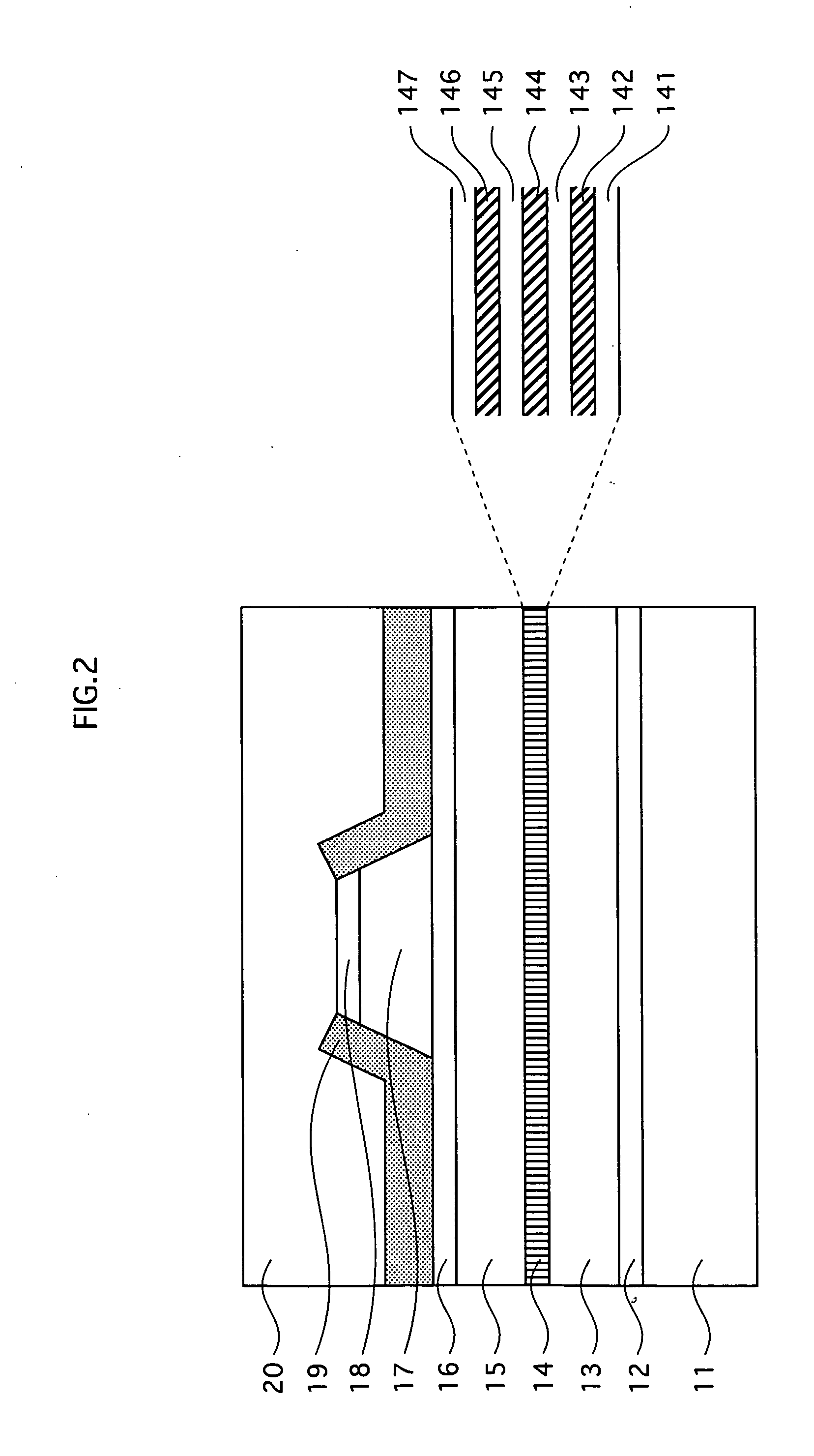

Semiconductor laser

ActiveUS20050232325A1Increase in threshold currentDrop in CODOptical wave guidanceLaser optical resonator constructionDivergence angleCarrier signal

In a semiconductor laser 1, a current blocking layer 19 covers a p-type 2nd cladding layer 17 and a p-type cap layer 18 that extend in a lengthwise direction of an optical resonator, at both a light-emission end and an end opposite the light-emission end, to thus form non-current injection regions in an optical waveguide. By making current blocking layer 19 at the light-emission end large enough that carriers flowing from a current injection region do not reach the light-emission end surface, the light intensity distribution in the near field at the light-emission end surface is strongly concentrated, allowing the horizontal divergence angle of an emerging laser beam to be enlarged. This structure makes it possible to enlarge the horizontal divergence angle independently after having optimized the thickness of cladding layers and the size of the current injection region.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

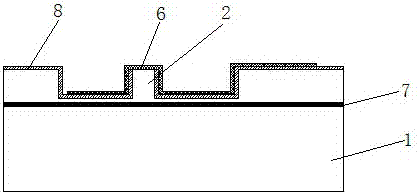

Edge-emitting laser beam shaping structure, laser chip and preparation method of laser chip

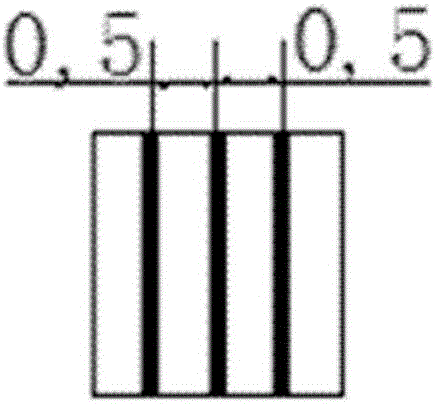

PendingCN109802296AImprove power densityTo achieve the effect of aggregationLaser detailsLaser active region structureSemiconductor materialsLight beam

The invention discloses an edge-emitting laser beam shaping structure, a laser chip and a preparation method of the laser chip, and belongs to the technical field of semiconductor materials. The invention provides the edge-emitting laser beam shaping structure which improves the power density of laser spots and reduces the beam divergence angle, the laser chip and the preparation method of the laser chip. According to the technical scheme, the side-emitting laser beam shaping structure is a trapezoidal platform, wherein the trapezoidal platform is sunken in an N-type doped waveguide layer, anactive layer and a P-type doped waveguide layer in an edge-emitting laser chip. The upper bottom surface of the trapezoidal table is located on the front output cavity surface of the edge-emitting laser chip, and a Si passivation film and an antireflection film are sequentially disposed on the surface defined by the trapezoidal platform in a plated manner.

Owner:TAIYUAN UNIV OF TECH

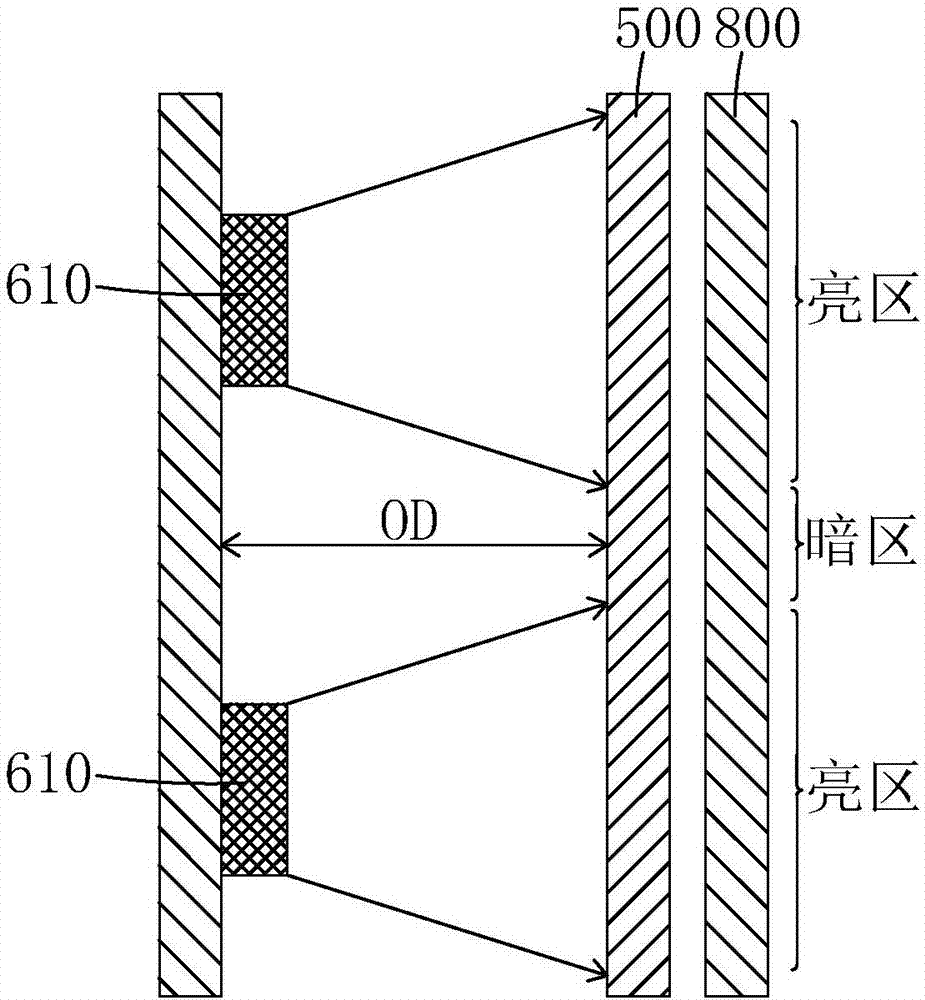

Diffusion plate and direct type backlight module

InactiveCN108008475AEasy to useImprove divergence angleDiffusing elementsSolid-state devicesDivergence angleRefractive index

The invention provides a diffusion plate and a direct type backlight module. The diffusion plate is provided with a first groove at a light incoming side of a second structure layer and a second groove or a third protruding portion at a light outgoing side of the second structure layer and sets a first structure layer, the second structure layer and a third structure layer to be sequentially increased in reflective index, thereby being capable of significantly improving a divergence angle of incident light, and achieving the uniformity of backlight brightness. The direct type backlight modulecontains the diffusion plate. The diffusion plate has excellent diffusion effect for the light, so that a problem of lamp shadow can be solved while the number of LED lamps and the light mixing distance are reduced, thereby realizing low cost and ultrathin design of the direct type backlight module, and being conductive to achieving the application of the direct type backlight module in the fieldof ultrathin TVs.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Illumination device and display device incorporating the same

ActiveUS7824049B2Improve light extractionImprove directivitySolid-state devicesGlobesRefractive indexDisplay device

Owner:JAPAN DISPLAY INC +1

Device and method for etching conducting layer made from graphene on touch screen

InactiveCN103071925AImprove divergence angleSmall spotLaser beam welding apparatusLaser etchingGalvanometer

The invention relates to a device and a method for etching a conducting layer made from graphene on a touch screen. An optical gate is arranged at the output end of a high-frequency short-pulse laser; a beam expanding lens is arranged at the output end the optical gate; a 45-degree full-reflection mirror is arranged at the output end of the beam expanding lens; a dynamic focusing mirror and a scanning field mirror are arranged at the output end of the 45-degree full-reflection mirror; the scanning field mirror is over against a working platform; a blowing device is arranged on one side of the working platform; and a dust collecting device is arranged on the other side of the working platform. High-frequency pulse lasers of different wavelengths are taken as laser sources for performing laser etching on conducting layers made from graphene in different touch screen products, so that the aim of etching graphene conducting layers by gasifying under the action of a high-frequency short-pulse laser is fulfilled; and a high-accuracy dynamic focusing mirror is matched with a galvanometer, so that an etching rang of (500 millimeters)*(500 millimeters) is realized at one time, and a touch screen electronic product having the advantages of no pollution, linear stability and complete functions is processed.

Owner:SUZHOU DELPHI LASER

Luminescent keyswitch module and keyboard thereof

ActiveUS20140061017A1Easy to optimizeImprove divergence angleContact mechanismsLegendsLight guideDivergence angle

A luminescent keyswitch module includes a base plate, a keyswitch, a light guide plate, a light source, a diffusion structure, and a reflector. The keyswitch is disposed on the base plate. The light guide plate, disposed under the base plate, has an accommodating space communicated with a through hole of the base plate. The light source passes through the through hole, is accommodated in the accommodating space, and emits light having a first divergence angle. The diffusion structure is accommodated in the accommodating space and located between the light source and the light guide plate. The light passes through the diffusion structure. The light leaving the second light exit surface has a second divergence angle larger than the first divergence angle. The reflector is disposed under the light guide plate, so as to reflect the light to pass through the light guide plate and the base plate to the keyswitch.

Owner:CHICONY ELECTRONICS

Small divergence angle ridge-type laser device and manufacturing method therefor

InactiveCN106911078AImprove impactDoes not limit output powerOptical wave guidanceDivergence angleWaveguide

The invention provides a small divergence angle ridge-type laser device and manufacturing method therefor. The laser device comprises an epitaxial structure and a ridge waveguide structure formed on the epitaxial structure, wherein the ridge waveguide structure comprises a parallel gain region and a light field mode expanding region that are orderly arranged along a light emitting direction, width of the light field mode expanding region gradually increases along the light emitting direction, a narrow end of the light field mode expanding region is connected with the parallel gain region, width of the narrow end of the light field mode expanding region equals width of the parallel gain region, the parallel gain region is 100 to 300 um in length, and the light field mode expanding region is 10 to 150 um in length. According to the small divergence angle ridge-type laser device and the manufacturing method therefor, no adjustment of the epitaxial structure is needed, no new epitaxial technology or technology process is needed, increase of a threshold current can be controlled in a restrained way, output power of a semiconductor laser device cannot be limited, output power can be improved by more than 10%, and main parameter performance during utilization can be improved to a certain extent.

Owner:WUHAN GUANGANLUN OPTOELECTRONICS TECH CO LTD

Beam combination device based on photonic crystal laser

InactiveCN106785895AIncrease the clear apertureIncrease profitLaser output parameters controlPhotonic crystalLight beam

The present invention discloses a beam combination device based on a photonic crystal laser. The device comprises: a tube; a stepping heat sink configured to dispose photon laser short bars and realize the overlapping of faculas of a fast-axis direction after laser emitted from the photon laser short bars at different heights of steps passes through a reflector; a spherical lens configured to compress angles of divergence of the fast-axis direction and a slow-axis direction; the reflector configured to change a laser propagation direction; and a focusing coupling mirror configured to couple the light beam after the laser is subjected to beam combination (the overlapping of the fast-axis direction) into fibers. The beam combination device based on the photonic crystal laser reduces the usage quantity of lenses and the volume of the tube, reduce the manufacturing cost, the assembling and the regulation of the lenses are easier, and the device is more compact in structure so as to more easily couple into fibers with small core diameters. The beam combination device based on the photonic crystal laser also can realize the coupling output with hectowatt magnitudes through simple extension.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com