Flow control method in large expansion angle channel

A technology of flow control and expansion angle, applied in the direction of engine components, machines/engines, stators, etc., can solve the problems of engine weight increase, achieve the effects of reducing axial size and weight, enhancing stability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

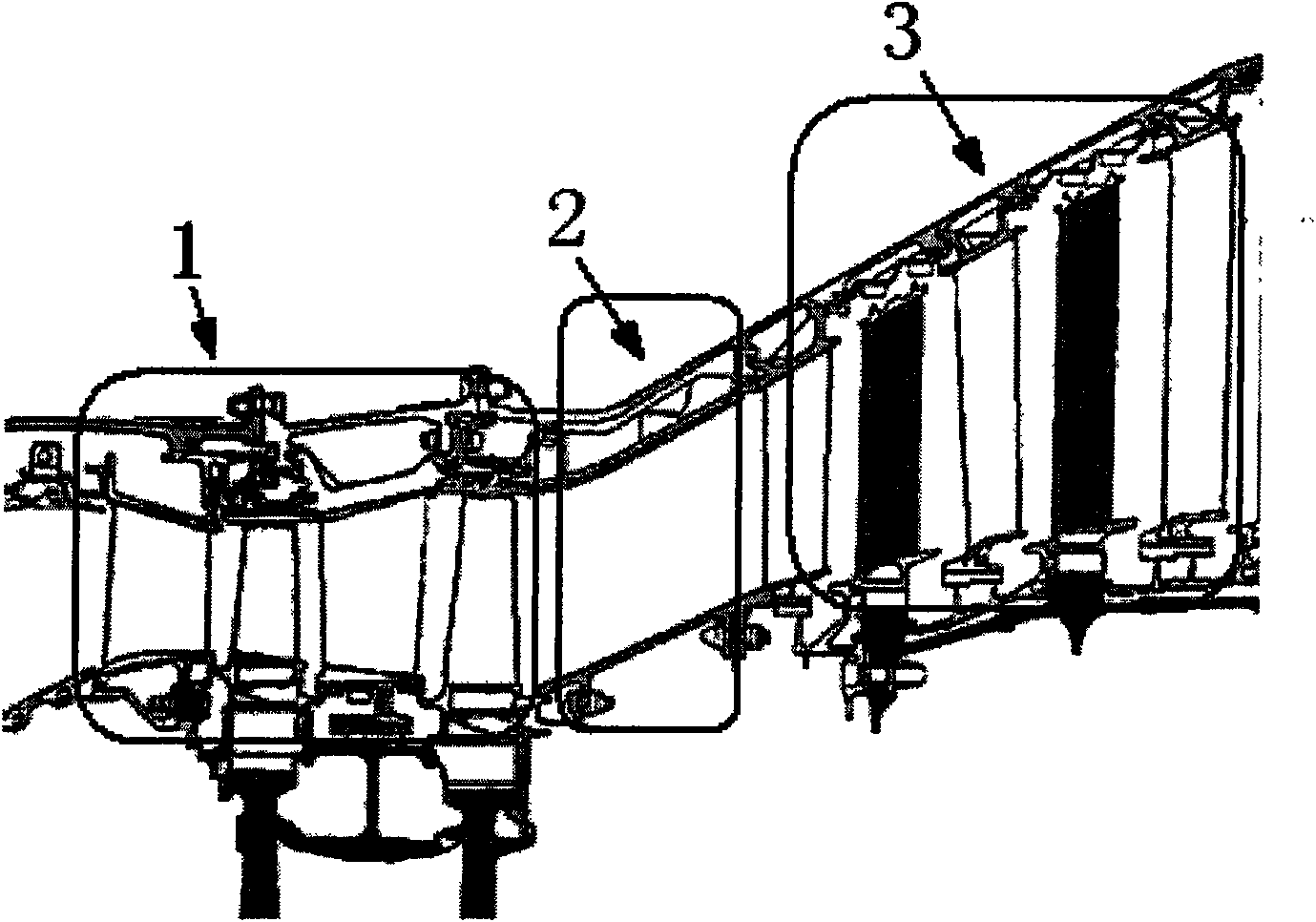

[0020] The control method of the present invention can be used for the flow control of various fluid machines including aeroengines, gas turbines and other impeller machines and expansion passages inside pipelines.

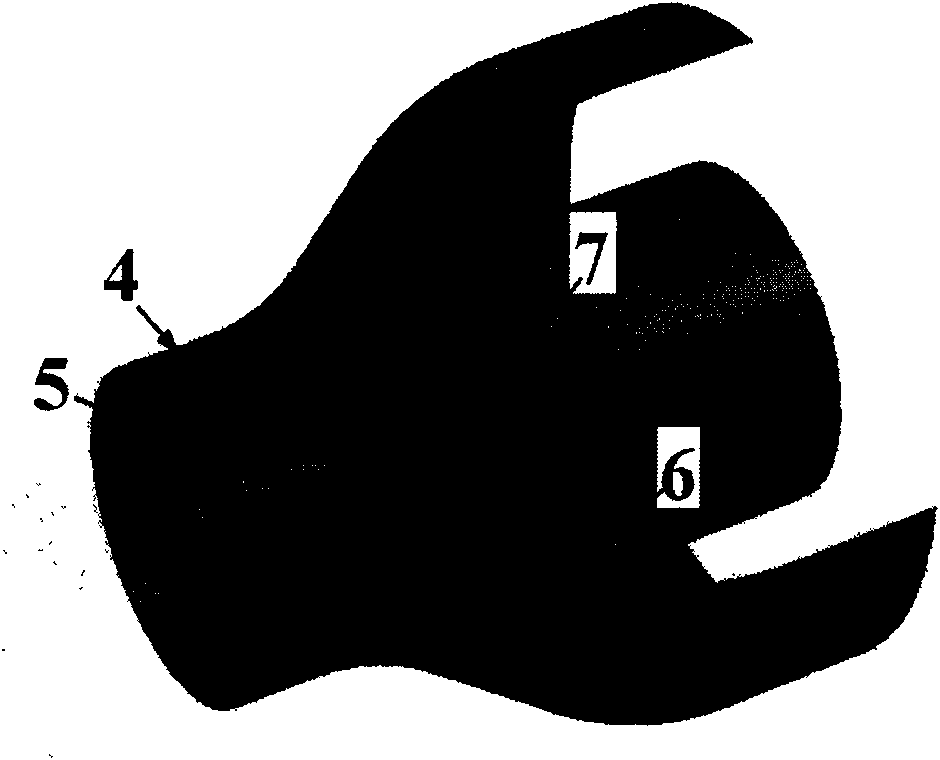

[0021] Such as Figure 2a-2d and image 3 As shown, in the embodiment of the present invention, a flow guide ring 7 or a flow guide plate 8 is arranged in the expansion channel, that is, between the flow channel outer wall 4 and the flow channel inner wall 5, or a flow guide ring 7 and a flow guide plate 8 are arranged at the same time, Divide the deflector ring 7 into a plurality of segments in the circumferential direction, and one or more segments constitute the deflector 8 . The guide ring 7 or the guide plate 8 is fixed by the support plate 6 . When the expansion angle of the channel is not very large, there is obvious secondary flow in the flow channel, but there is no recirculation zone or the size of the recirculation zone is small, then the deflector pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com