Device and method for etching copper conducting film on glass substrate ink by using pulse laser

A glass substrate, pulsed laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low processing efficiency, poor selectivity, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

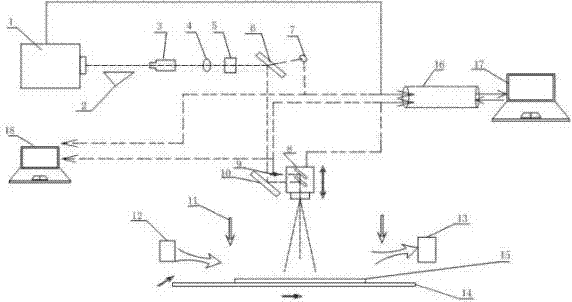

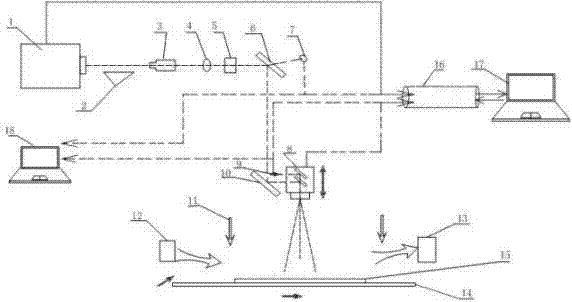

[0014] The invention uses laser etching copper conductive film and ITO thin film material of electronic products, adopts high-frequency pulse laser, the processed material is copper film and ITO material with high conductivity, and the laser is focused on the copper film and ITO thin film material, so as to achieve etching Effect.

[0015] The processing material film layers are glass substrate, black ink, total reflection dielectric film, ITO and copper conductive film from bottom to top. When the high-frequency pulsed laser is focused on the upper surface of the copper film and the device is etching, after reaching the removal energy threshold of the material, the copper film and ITO thin film materials are vaporized under the action of the high-frequency pulsed laser to achieve the etching process. Purpose, when the copper film and ITO are etched completely, when the high-frequency pulsed laser acts on the total reflection dielectric film of the laser wavelength, according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com