Beam combination device based on photonic crystal laser

A photonic crystal and laser technology, which is applied to devices for controlling the output parameters of lasers, etc., can solve the problems of difficult module assembly and adjustment, expensive production costs, and increased optical system complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

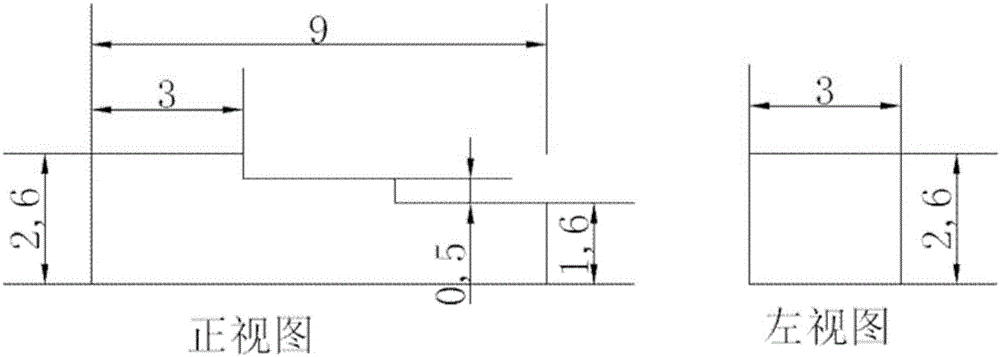

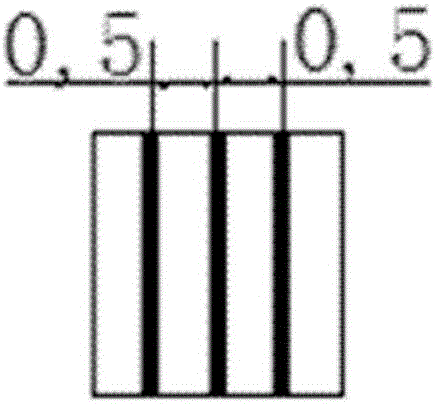

[0028] Various structural schematic diagrams according to disclosed embodiments of the invention are shown in the accompanying drawings. The figures are not drawn to scale, with certain details exaggerated and possibly omitted for purposes of clarity. The various data, shapes and their relative sizes and positional relationship instruments shown in the figure are exemplary. In practice, deviations may be caused by manufacturing tolerances or limited technology, and those skilled in the art may It can be additionally designed to have different shapes, sizes, and relative positions.

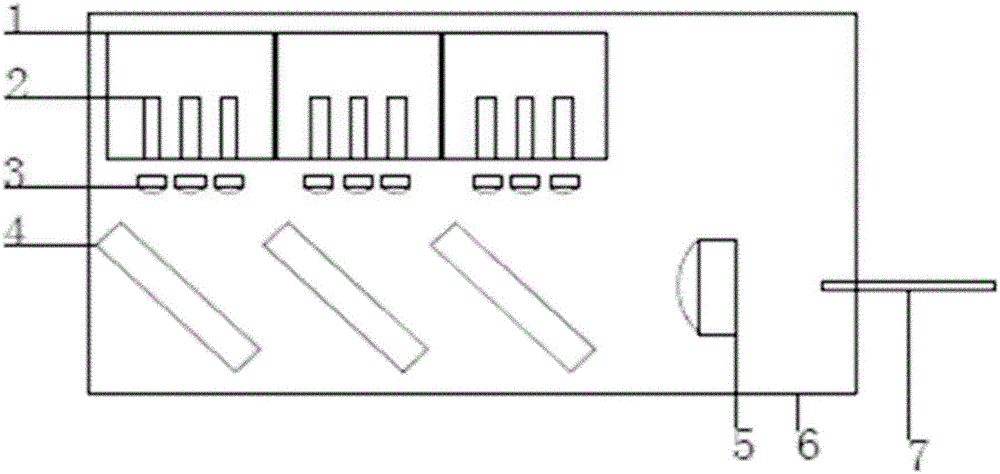

[0029] figure 1 It is a top view of a device based on photonic crystal laser beam combining. As shown in the figure, the device includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com