Patents

Literature

170 results about "Laser micromachining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser Micromachining. Laser micromachining is the generic term for a process used to make tiny features in parts - measured in micrometers or millimeters. Pulsed lasers effectively complete this work by depositing very small, finite amounts of energy into a material, resulting in extremely precise and reproducible material removal.

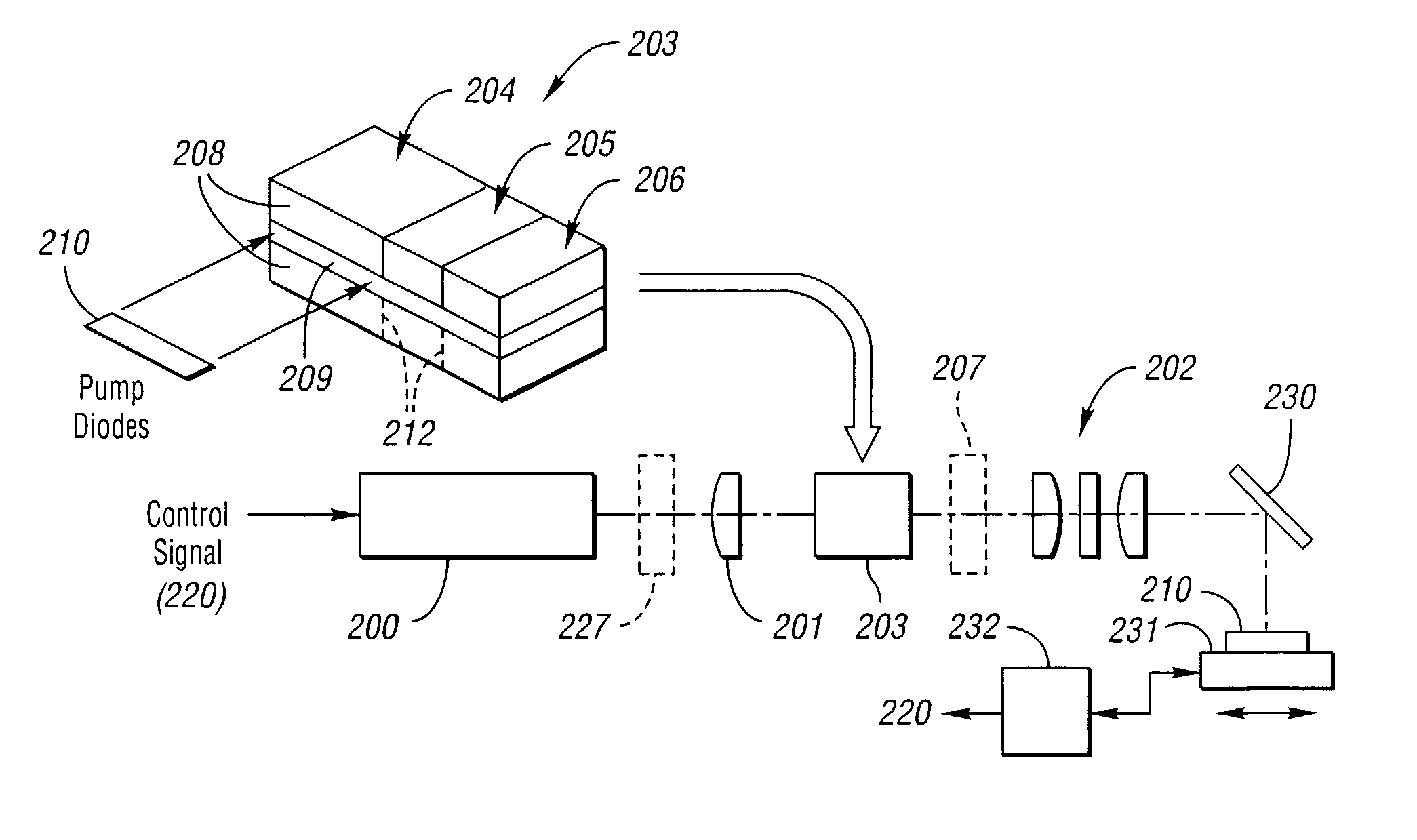

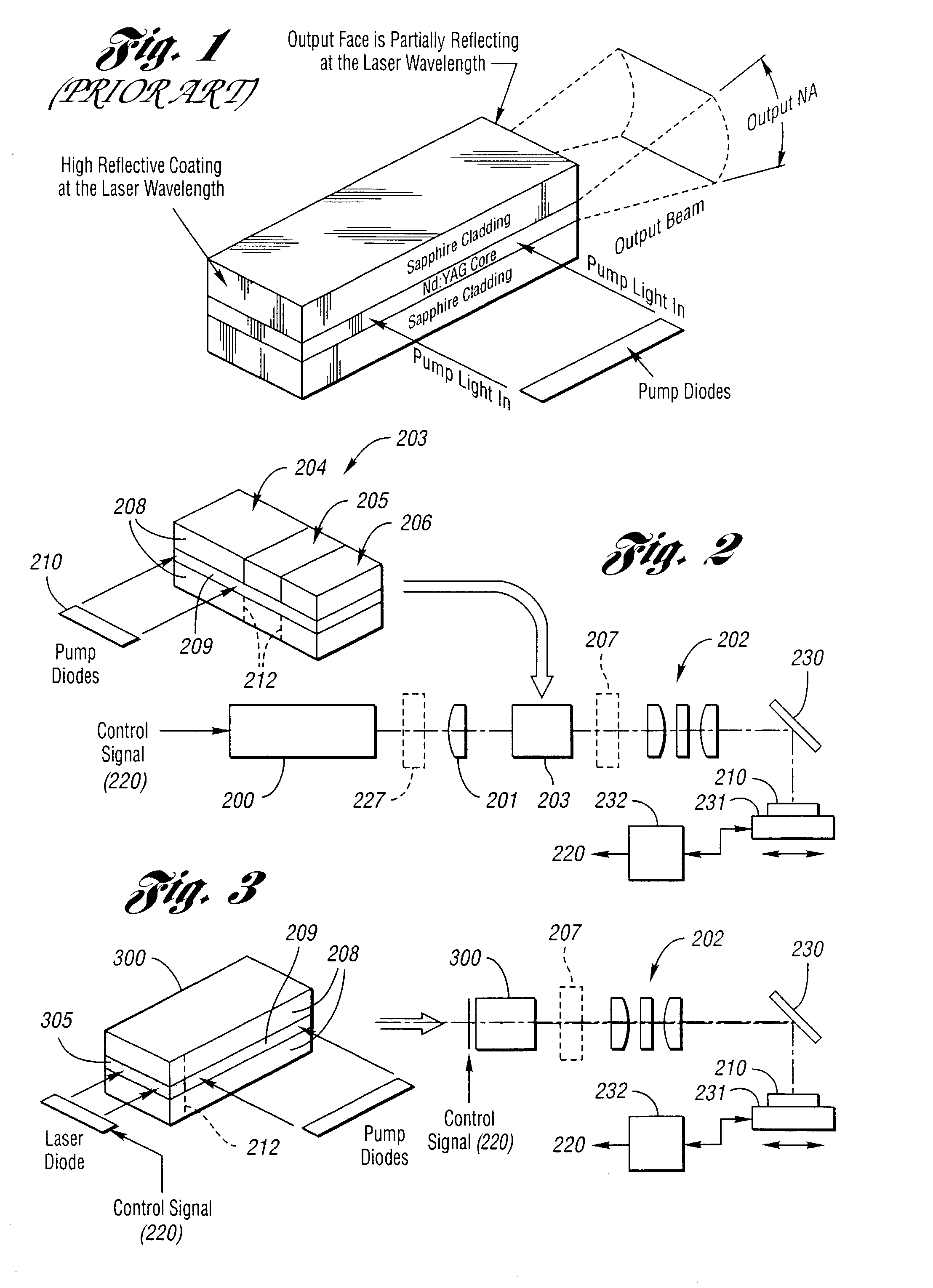

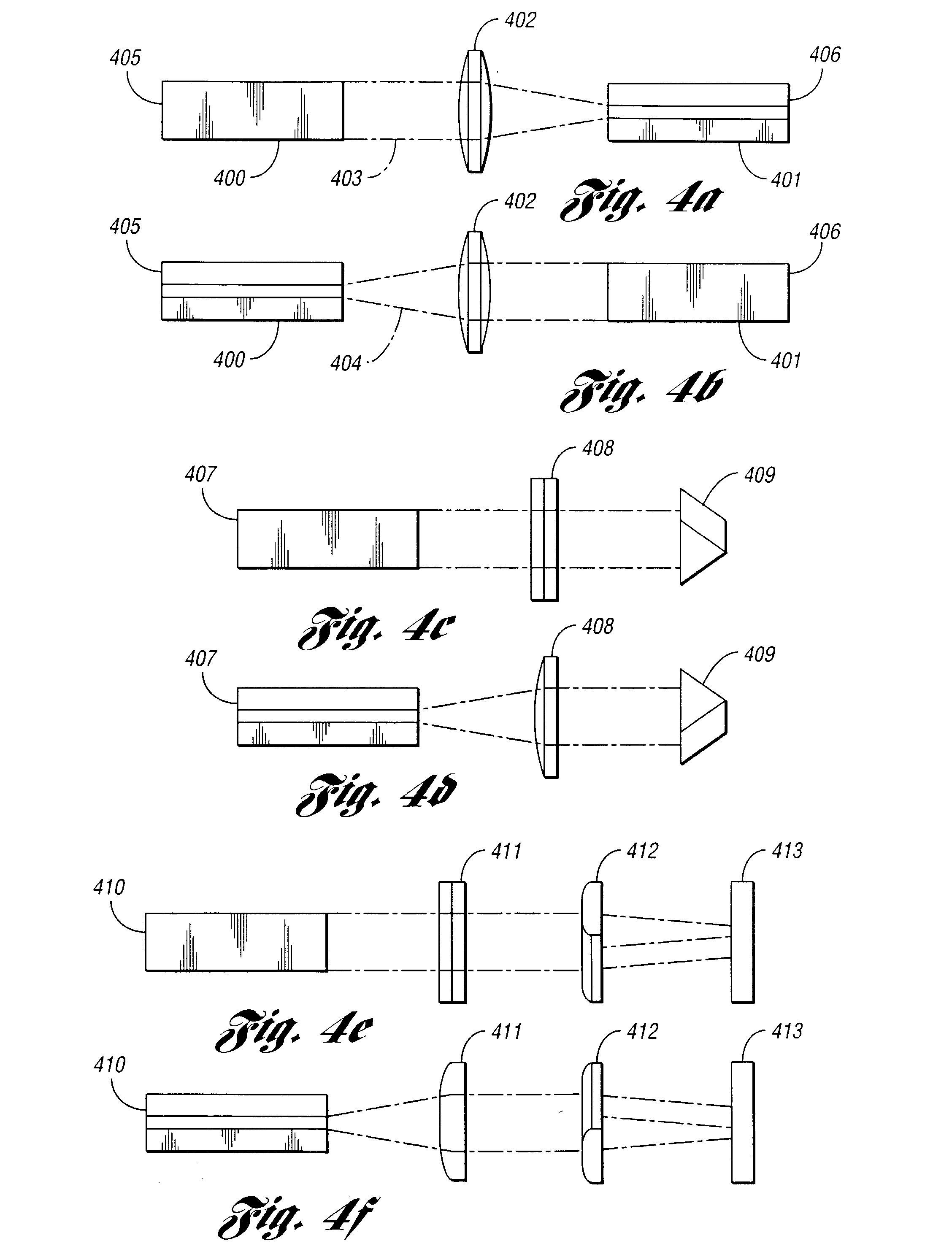

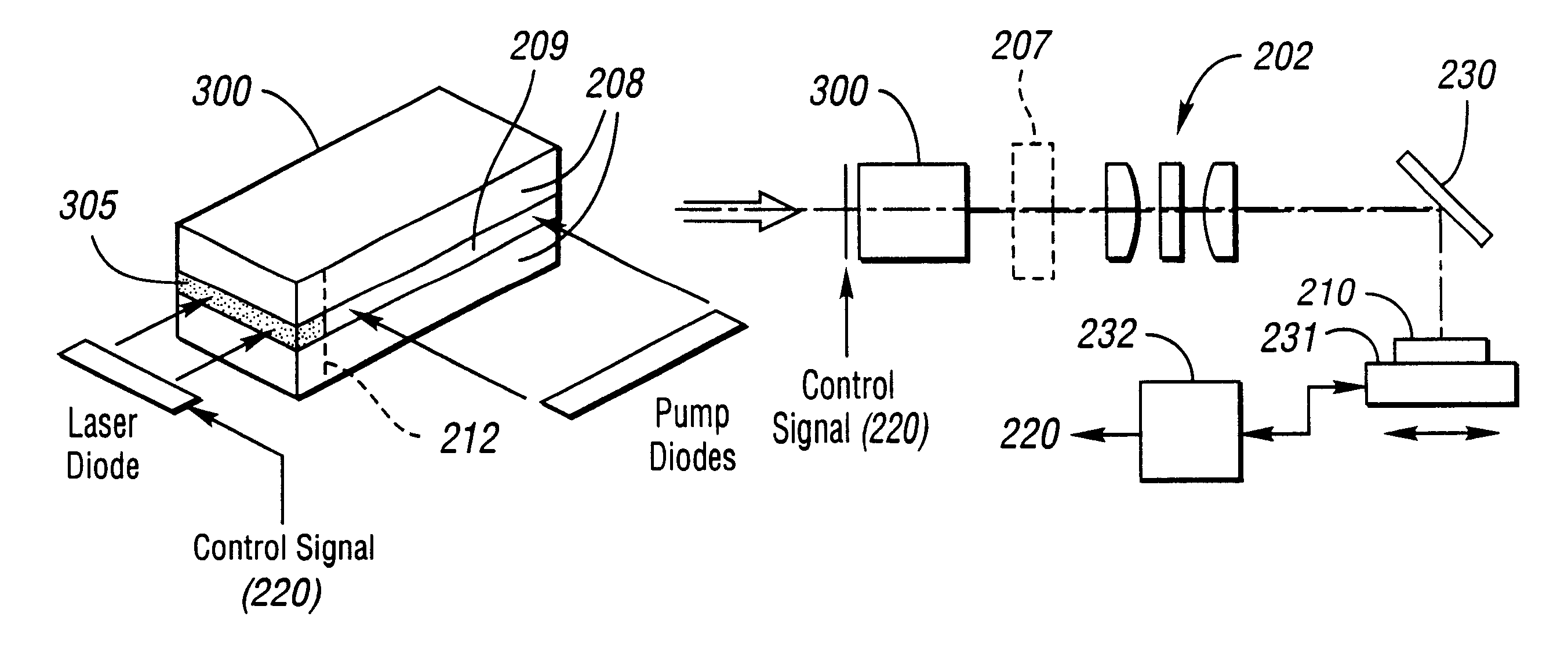

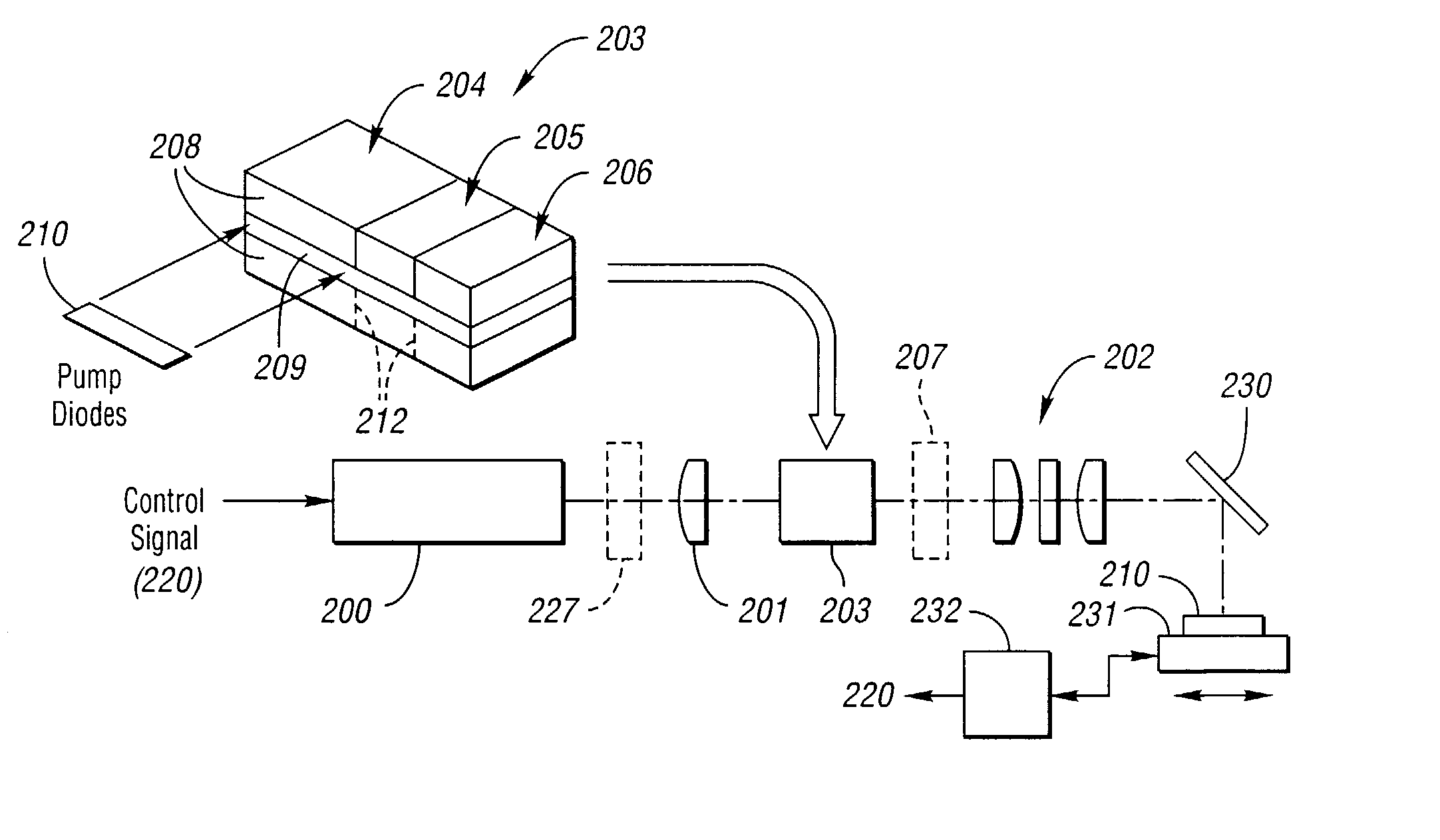

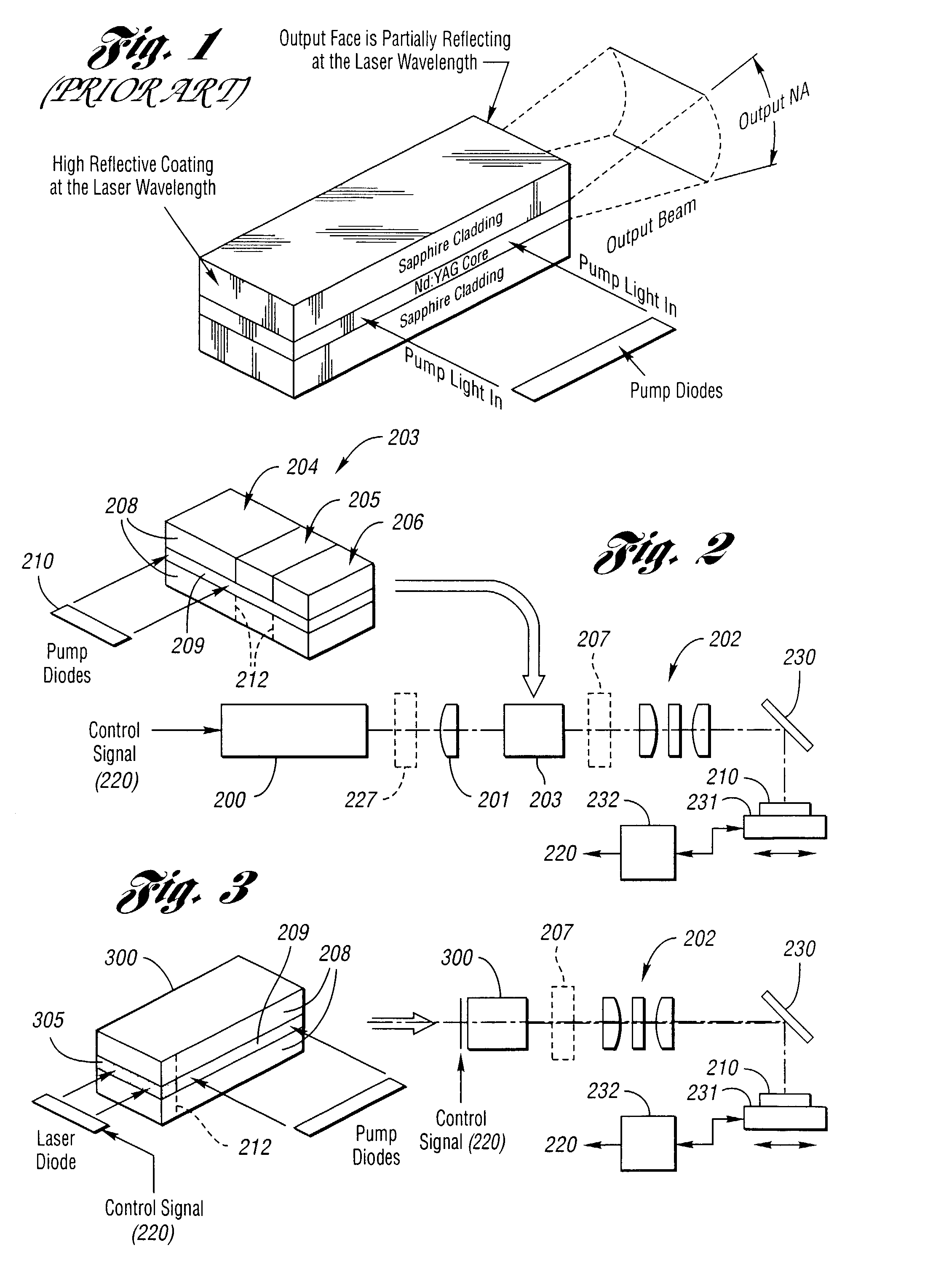

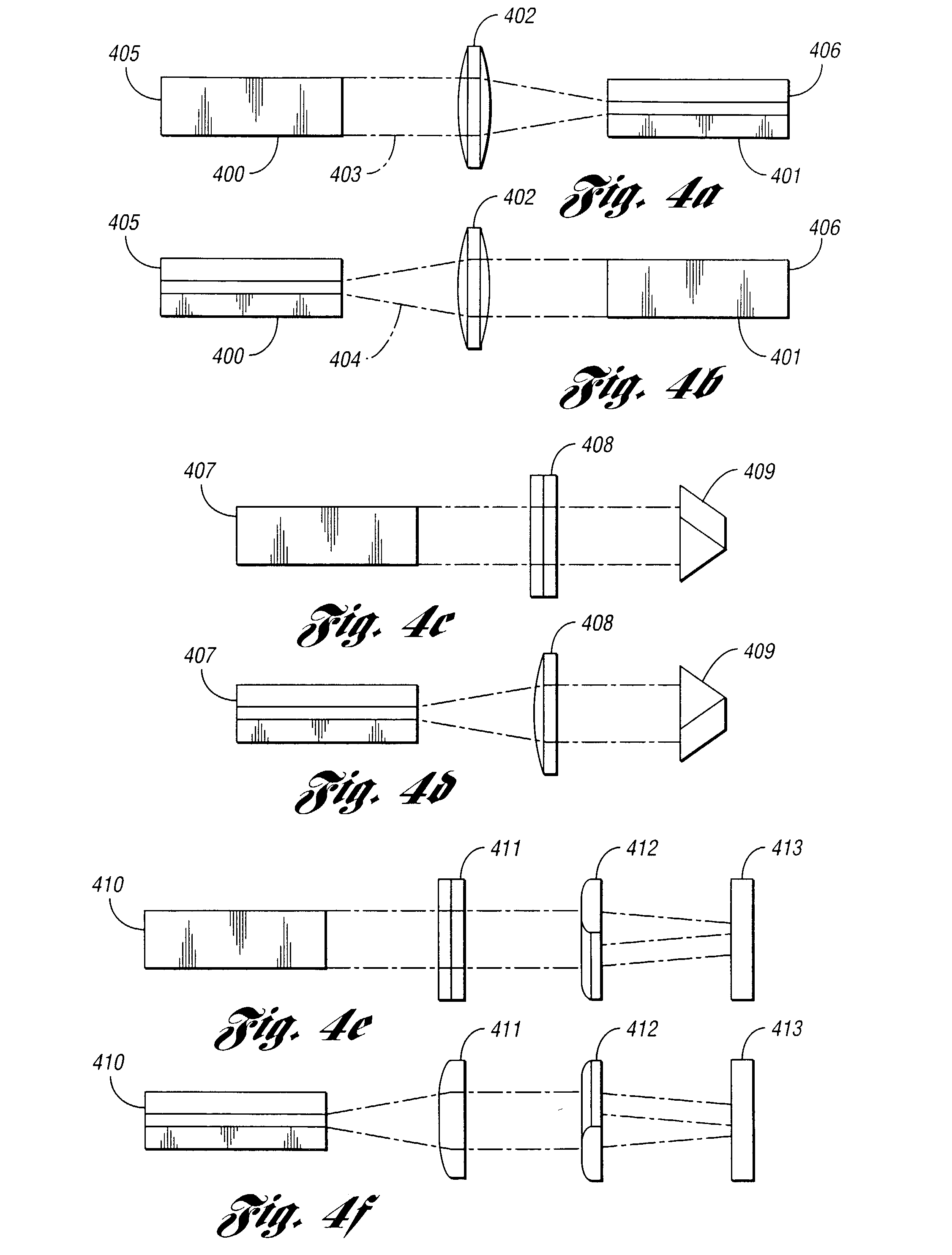

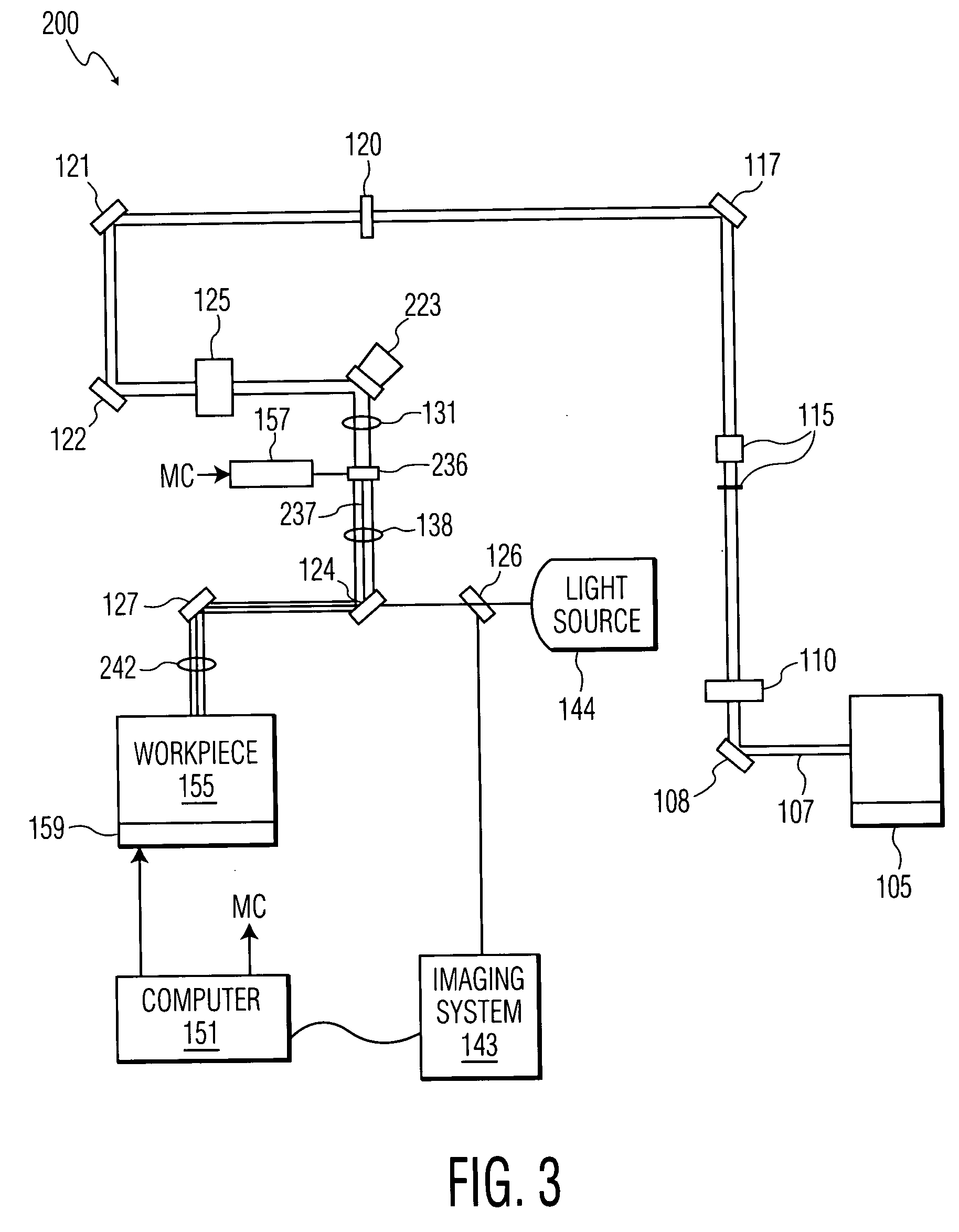

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS20030161375A1Optical resonator shape and constructionActive medium shape and constructionEngineeringWaveguide

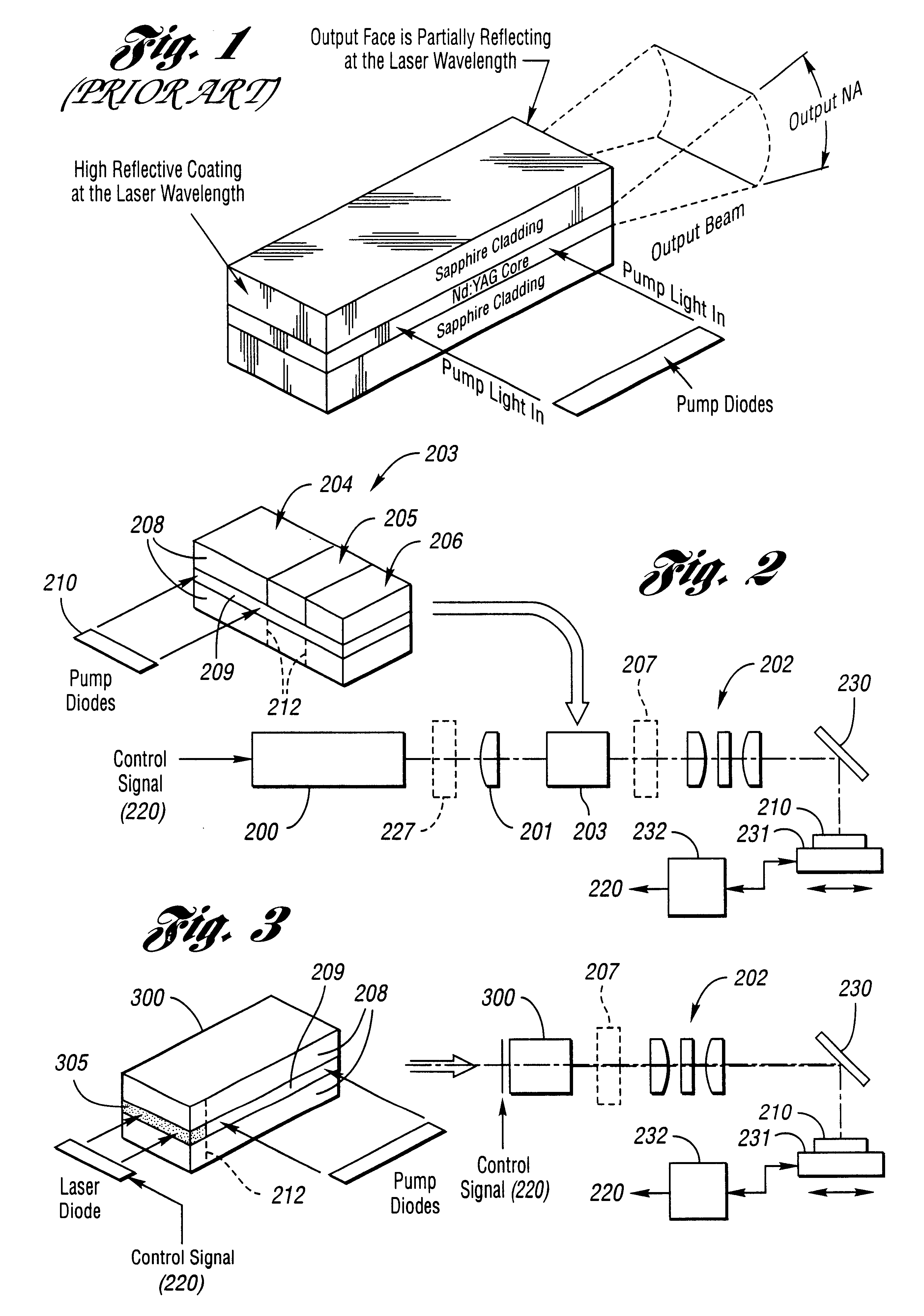

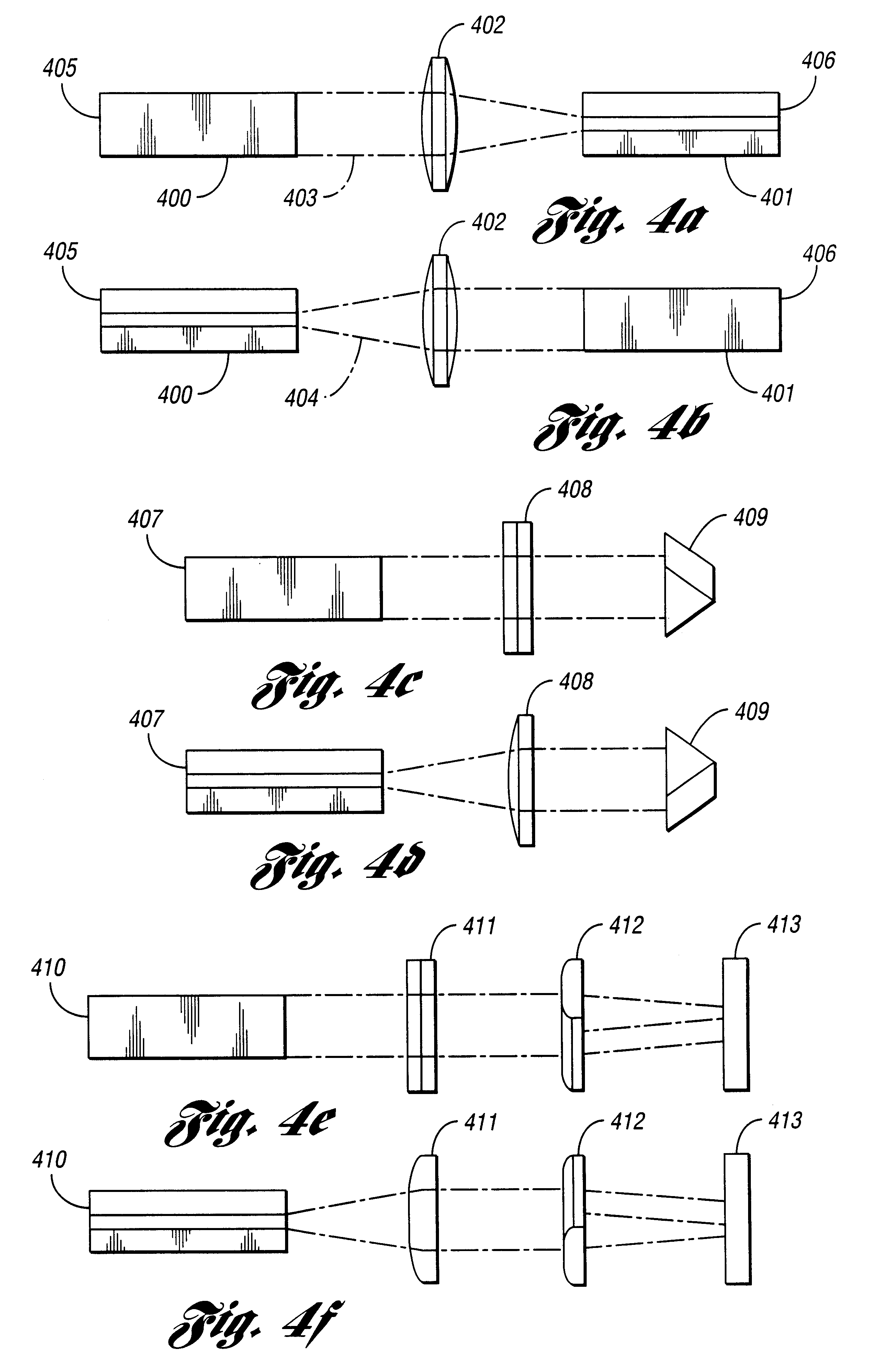

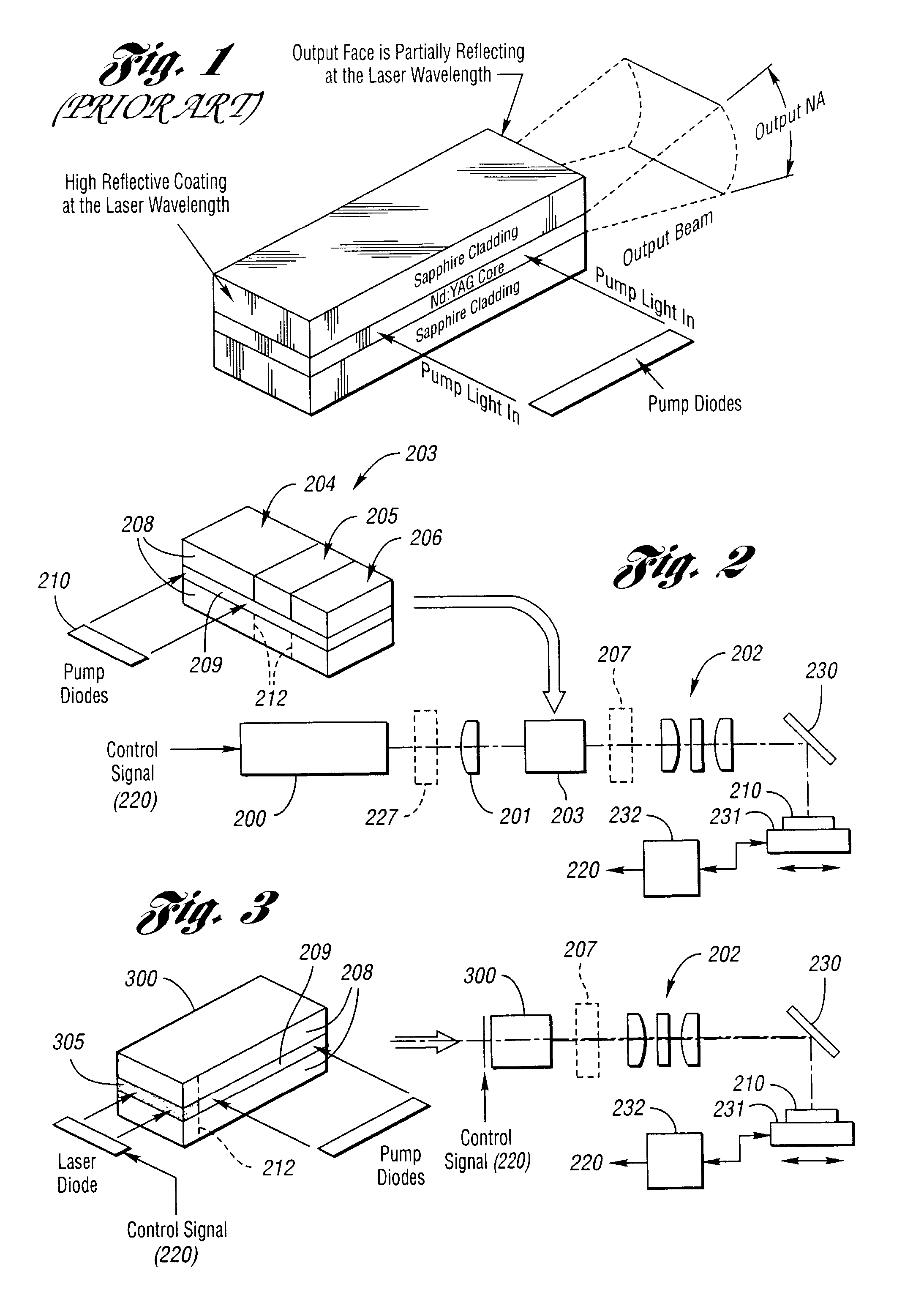

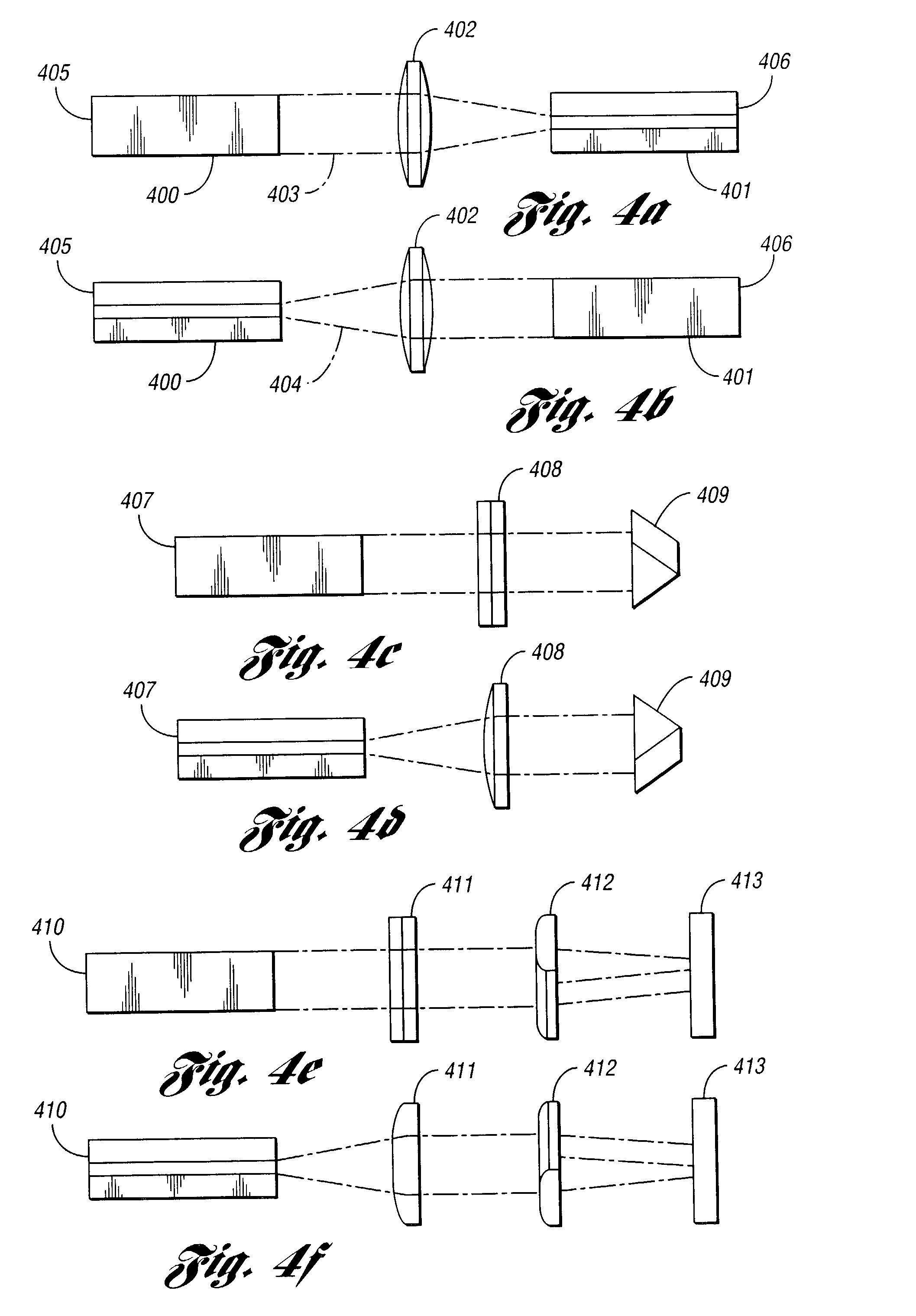

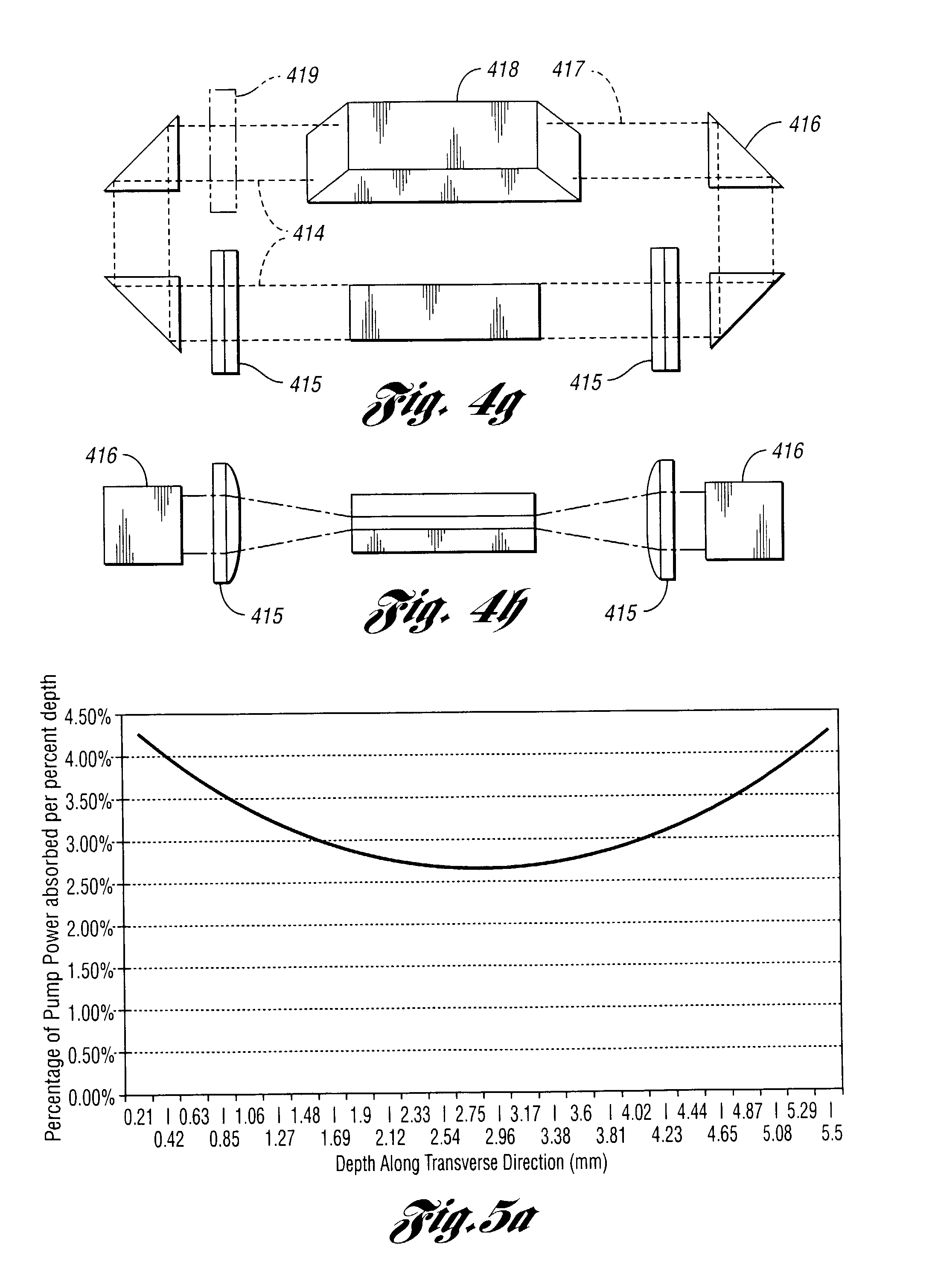

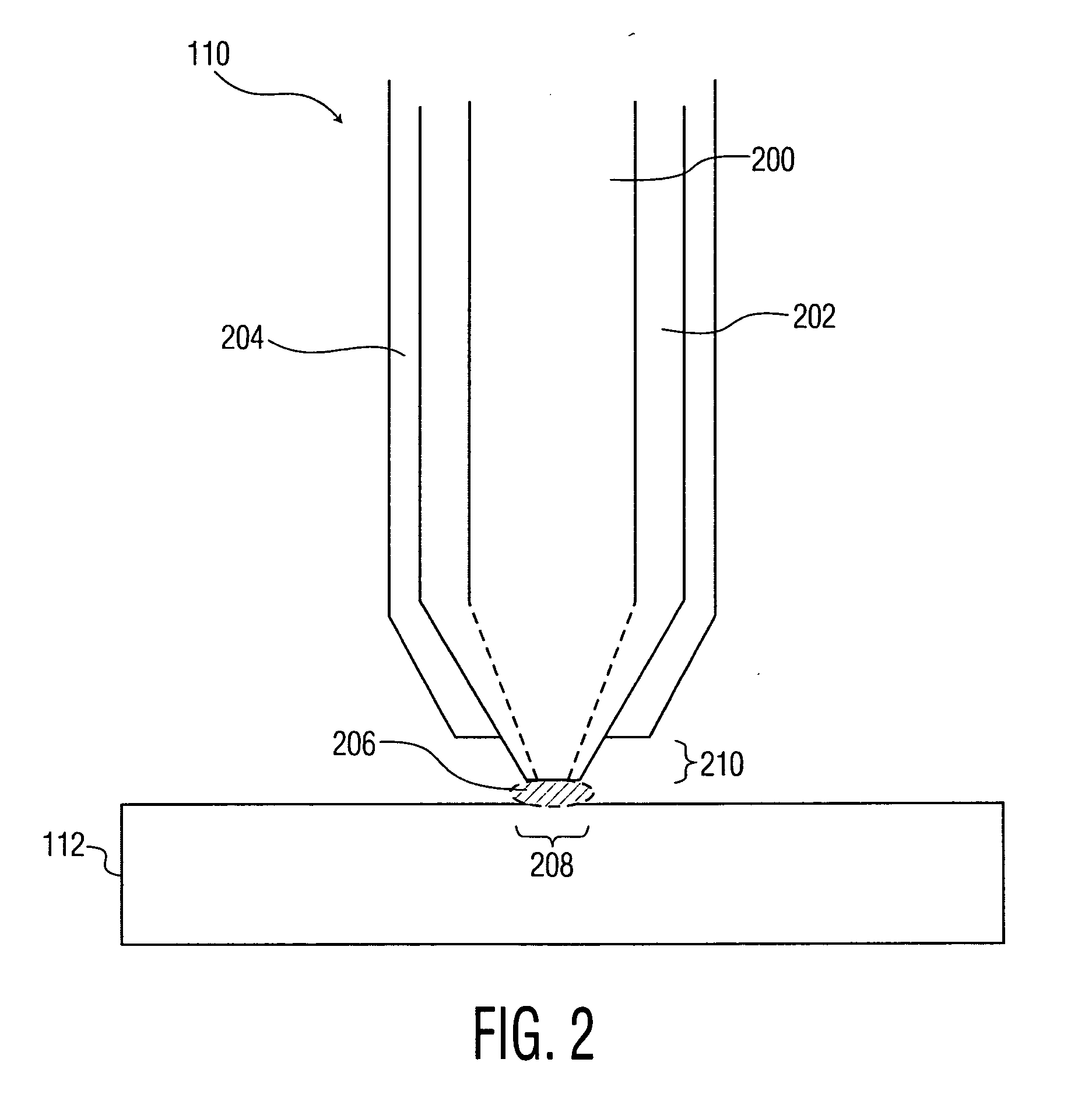

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

Laser based material processing methods and scalable architecture for material processing

InactiveUS6738396B2Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

Laser based material processing methods and scalable architecture for material processing

InactiveUS20030160034A1Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

Articulation Systems, Devices, and Methods for Catheters and Other Uses

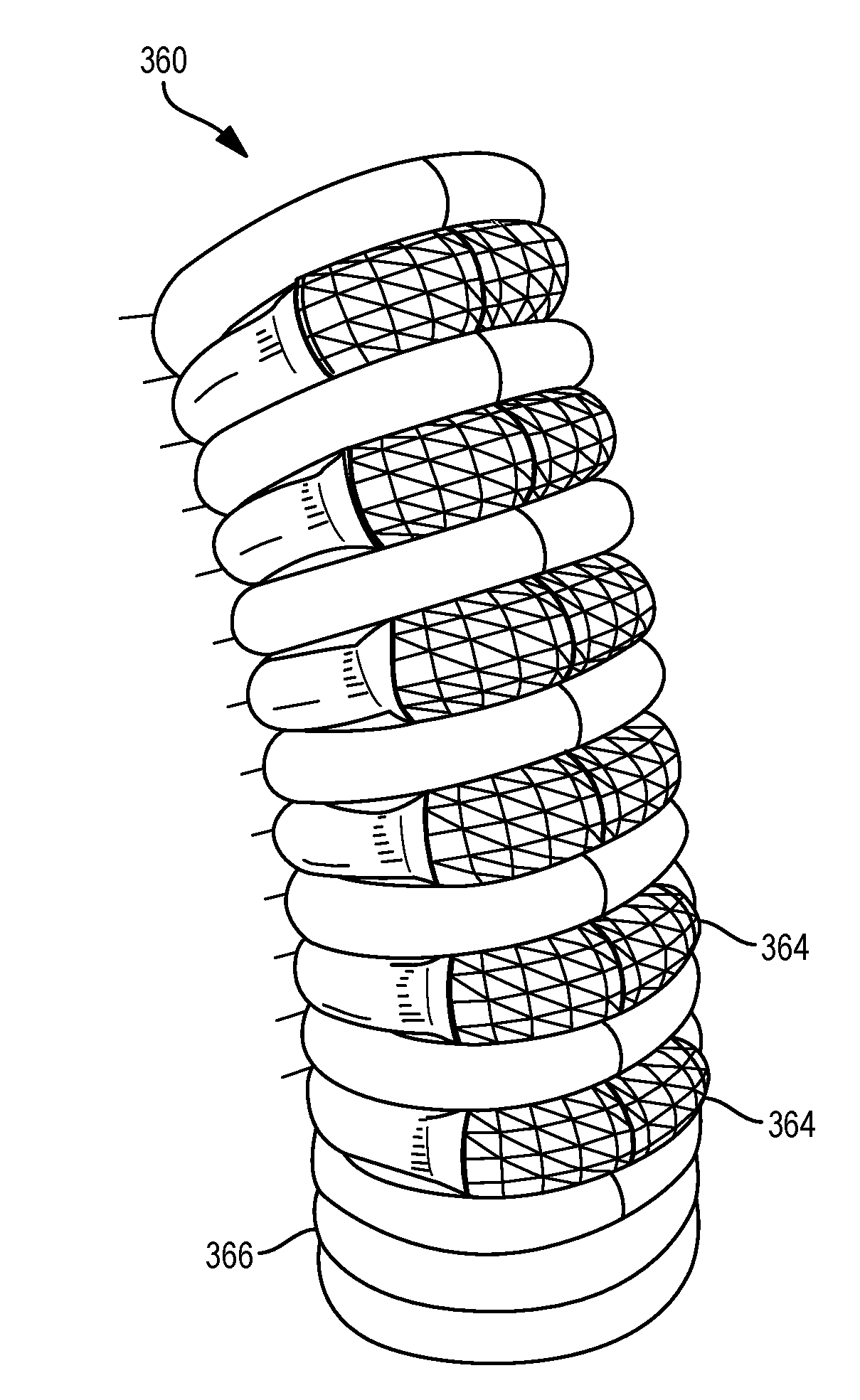

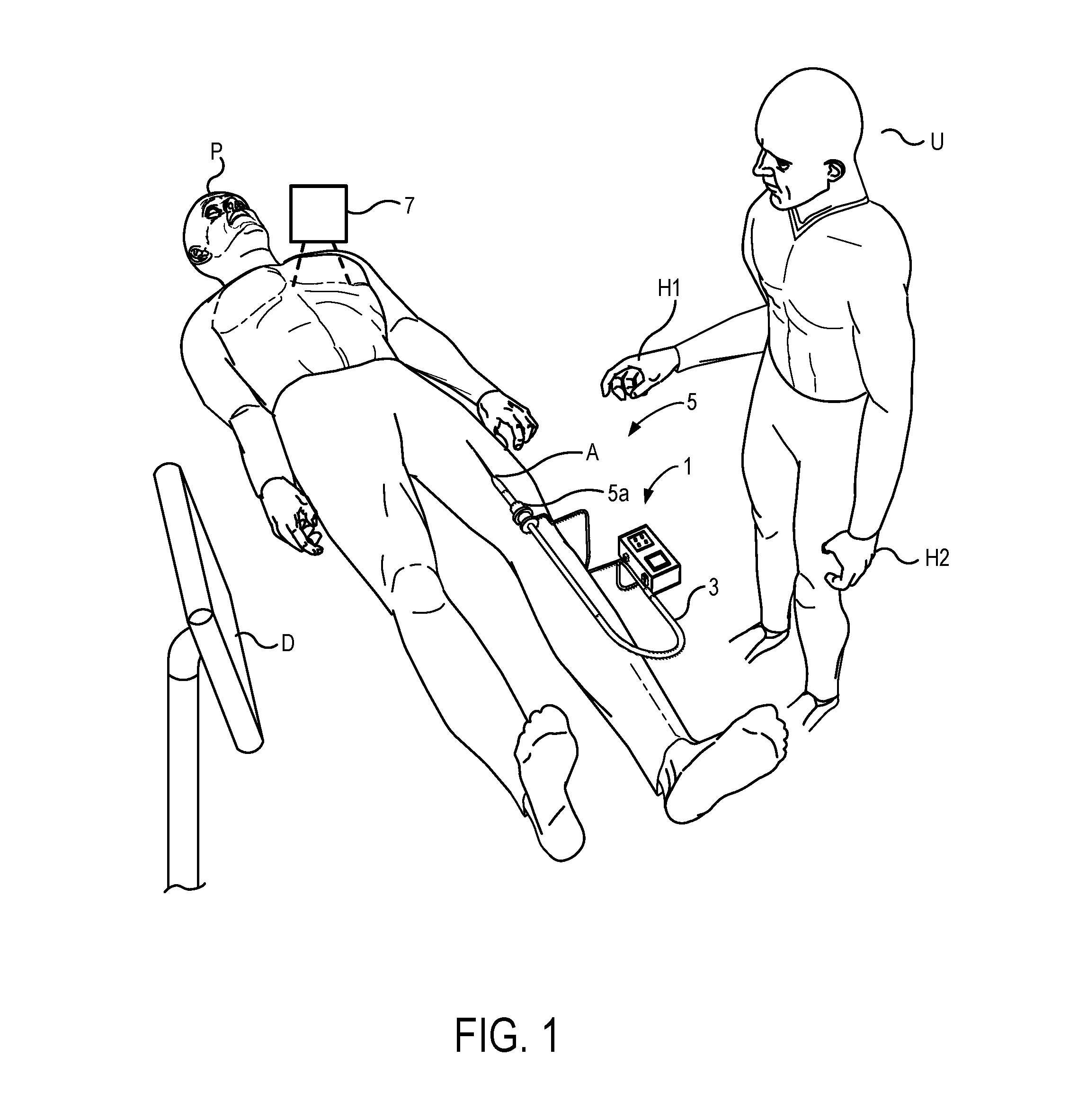

ActiveUS20160279388A1Constant inflation pressureFacilitate independent pressure controlBalloon catheterSurgical navigation systemsLaser micromachiningSacroiliac joint

Articulation devices, systems, methods for articulation, and methods for fabricating articulation structures will often include simple balloon arrays, with inflation of the balloons interacting with elongate skeletal support structures so as to locally alter articulation of the skeleton. The balloons can be mounted to a substrate of the array, with the substrate having channels that can direct inflation fluid to a subset of the balloons. The articulation array structure may be formed using simple planar 3-D printing, extrusion, and / or laser micromachining techniques. The skeleton may comprise a simple helical coil or interlocking helical channels, and the array can be used to locally deflect or elongate an axis of the coil under control of a processor. Liquid inflation fluid may be directed to the balloons from an inflation fluid canister, and may vaporize within the channels or balloons of the articulation system, with the inflation system preferably including valves controlled by the processor. The articulation structures can be employed in minimally invasive medical catheter systems, and also for industrial robotics, for supporting imaging systems, for entertainment and consumer products, and the like.

Owner:PROJECT MORAY INC

Solid polymer electrolyte composite membrane comprising porous ceramic support

ActiveUS20060183011A1Electrolysis componentsElectrolytic capacitorsPolymer electrolytesIn situ polymerization

A solid polymer electrolyte composite membrane and method of manufacturing the same. The composite membrane comprises a porous ceramic support having a top surface and a bottom surface. The porous ceramic support may be formed by laser micromachining a ceramic sheet or may be formed by electrochemically oxidizing a sheet of the base metal. A solid polymer electrolyte fills the pores of the ceramic support and preferably also covers the top and bottom surfaces of the support. Application of the solid polymer electrolyte to the porous support may take place by applying a dispersion to the support followed by a drying off of the solvent, by hot extrusion of the solid polymer electrolyte (or by hot extrusion of a precursor of the solid polymer electrolyte followed by in-situ conversion of the precursor to the solid polymer electrolyte) or by in-situ polymerization of a corresponding monomer of the solid polymer electrolyte.

Owner:PLUG POWER

Method of drilling holes with precision laser micromachining

InactiveUS6951627B2Welding/soldering/cutting articlesLaser beam welding apparatusLight beamOptoelectronics

Owner:PANASONIC CORP

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS7065121B2Optical resonator shape and constructionActive medium shape and constructionWaveguideBeam control

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100 W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

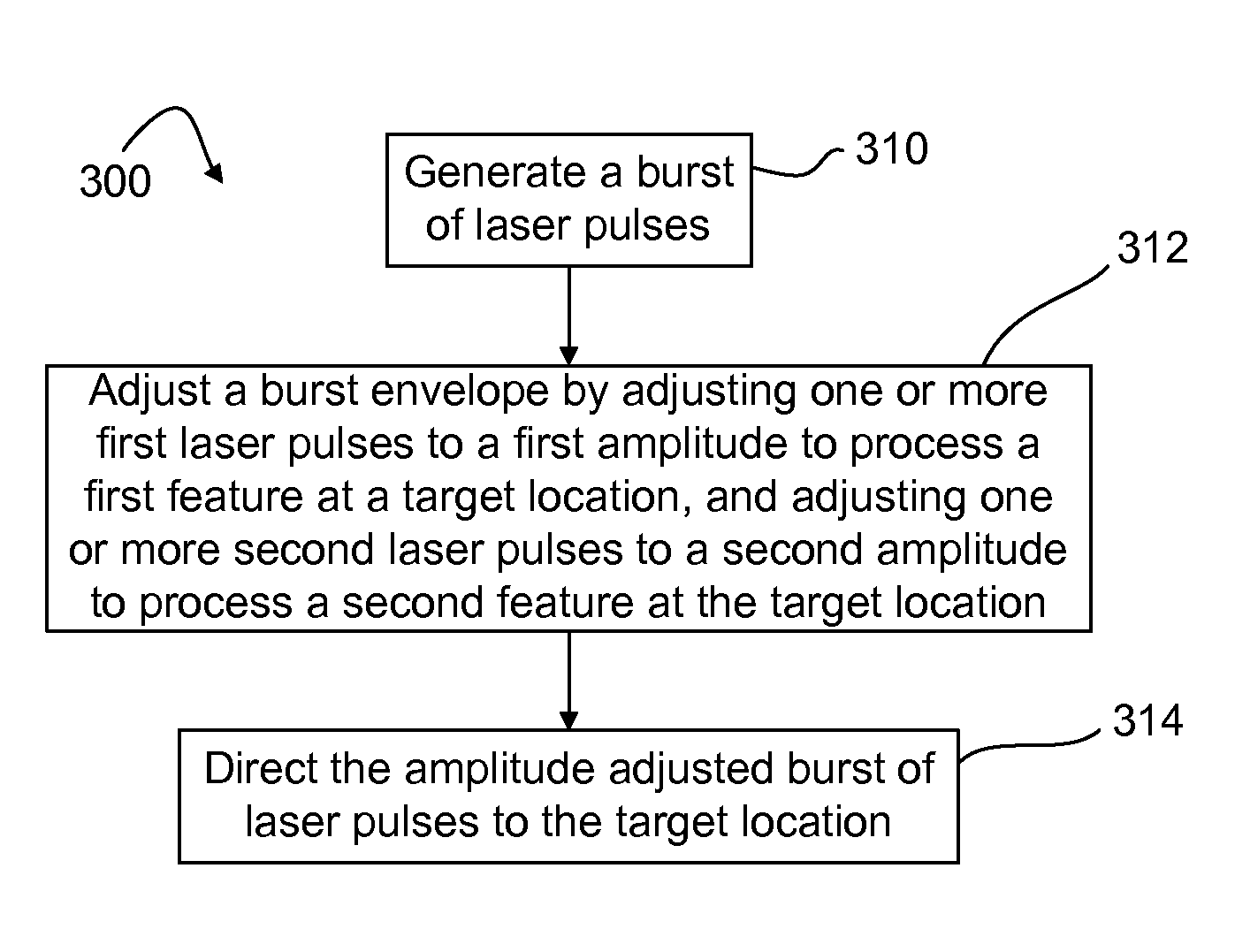

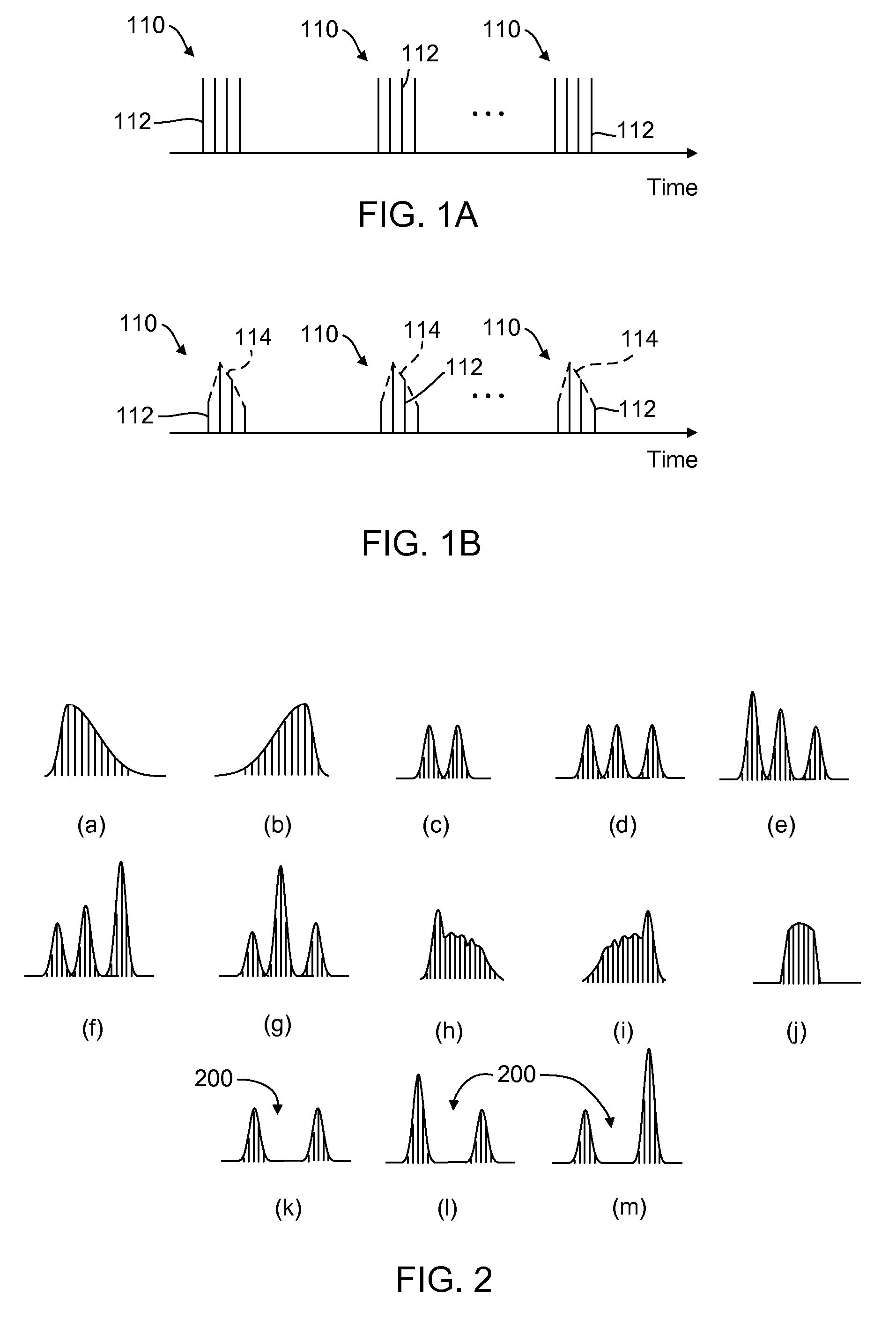

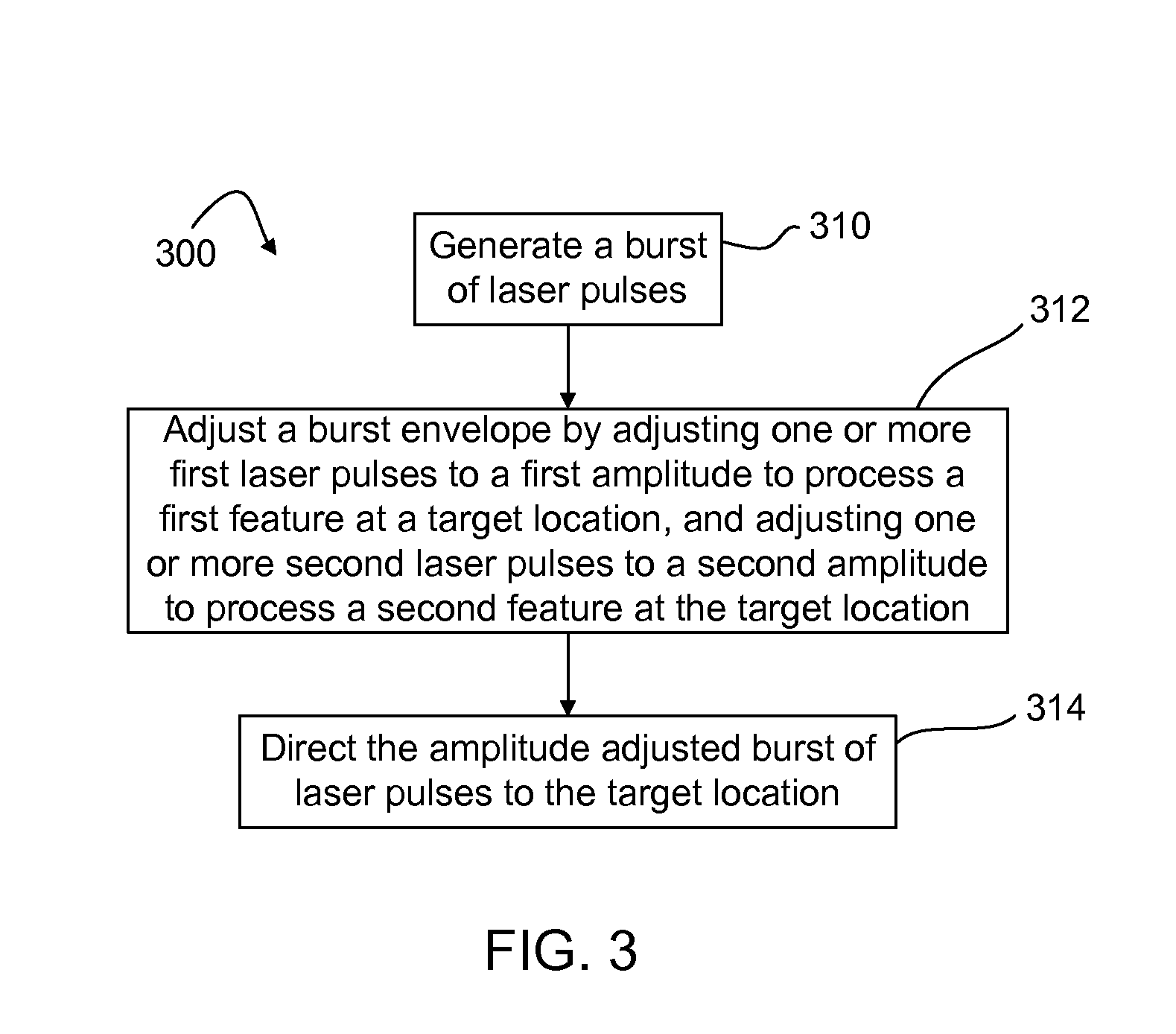

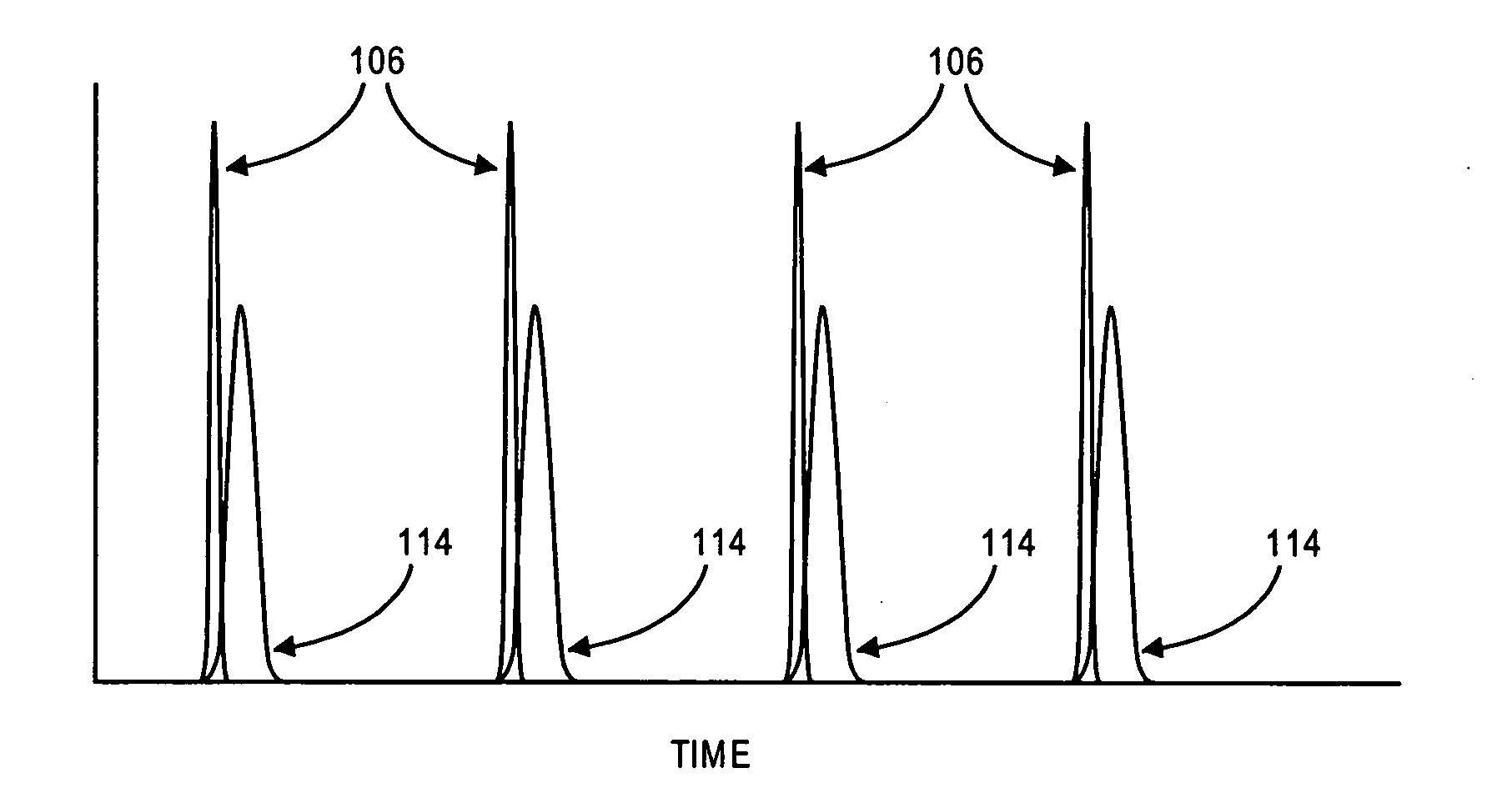

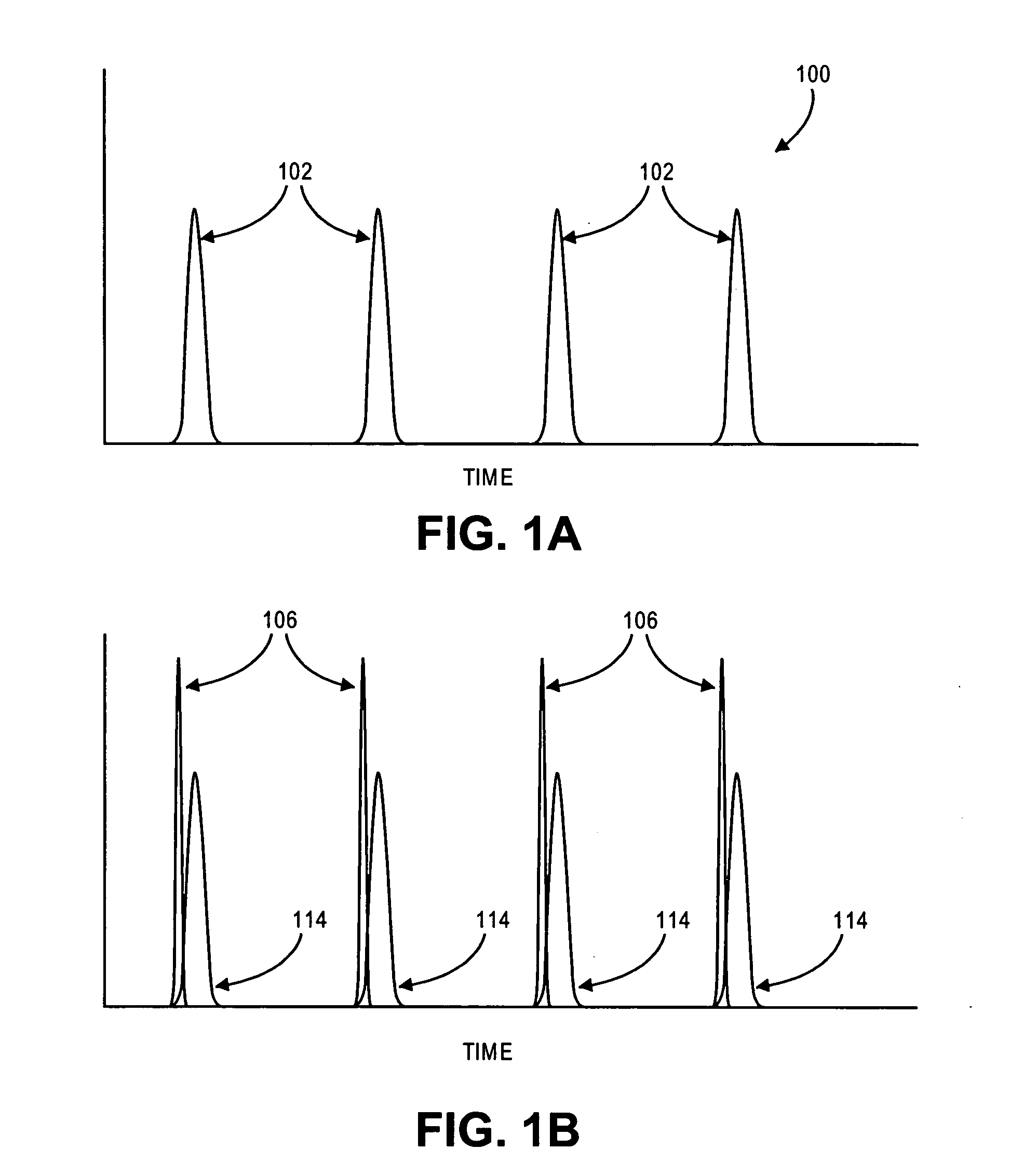

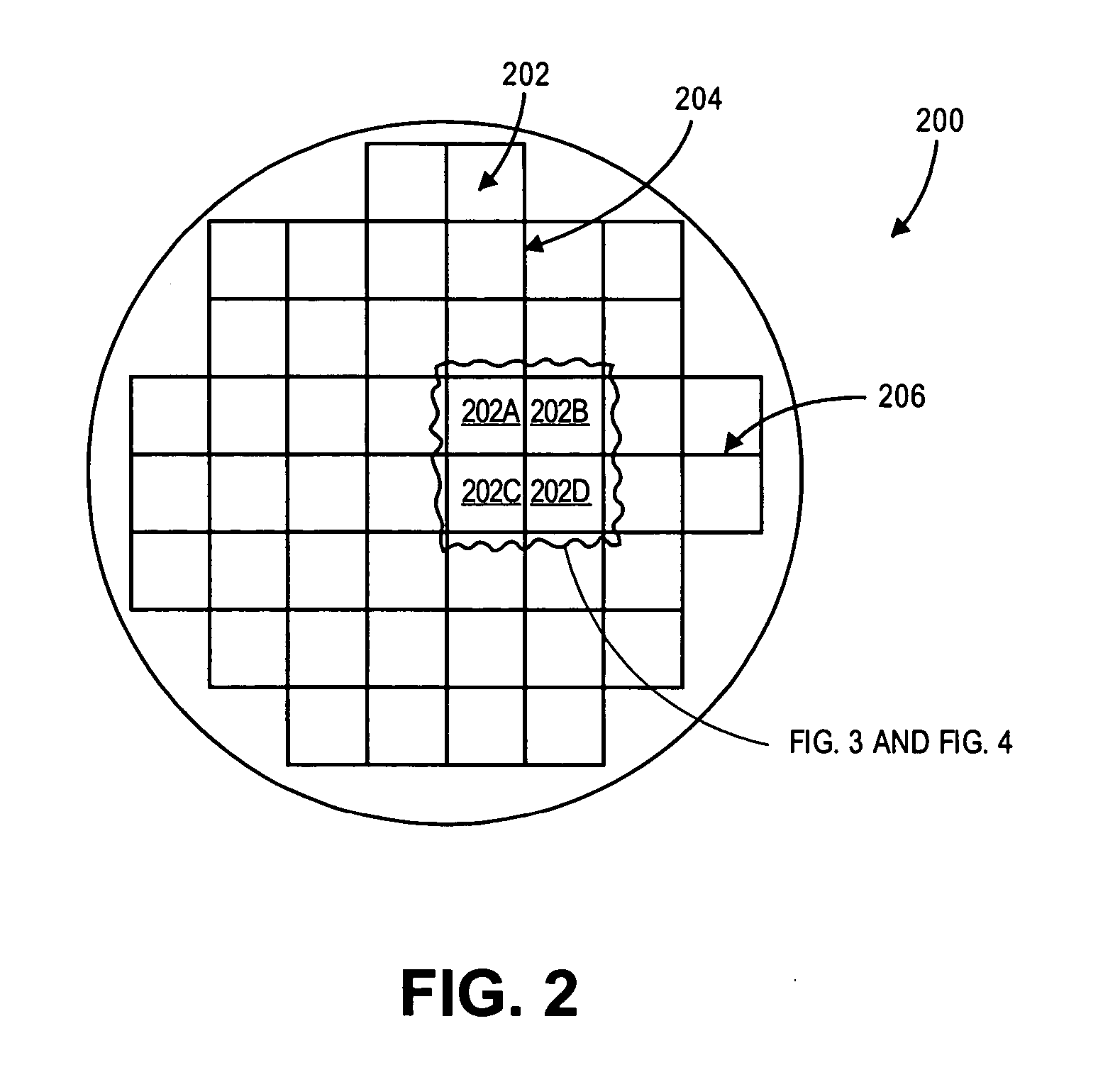

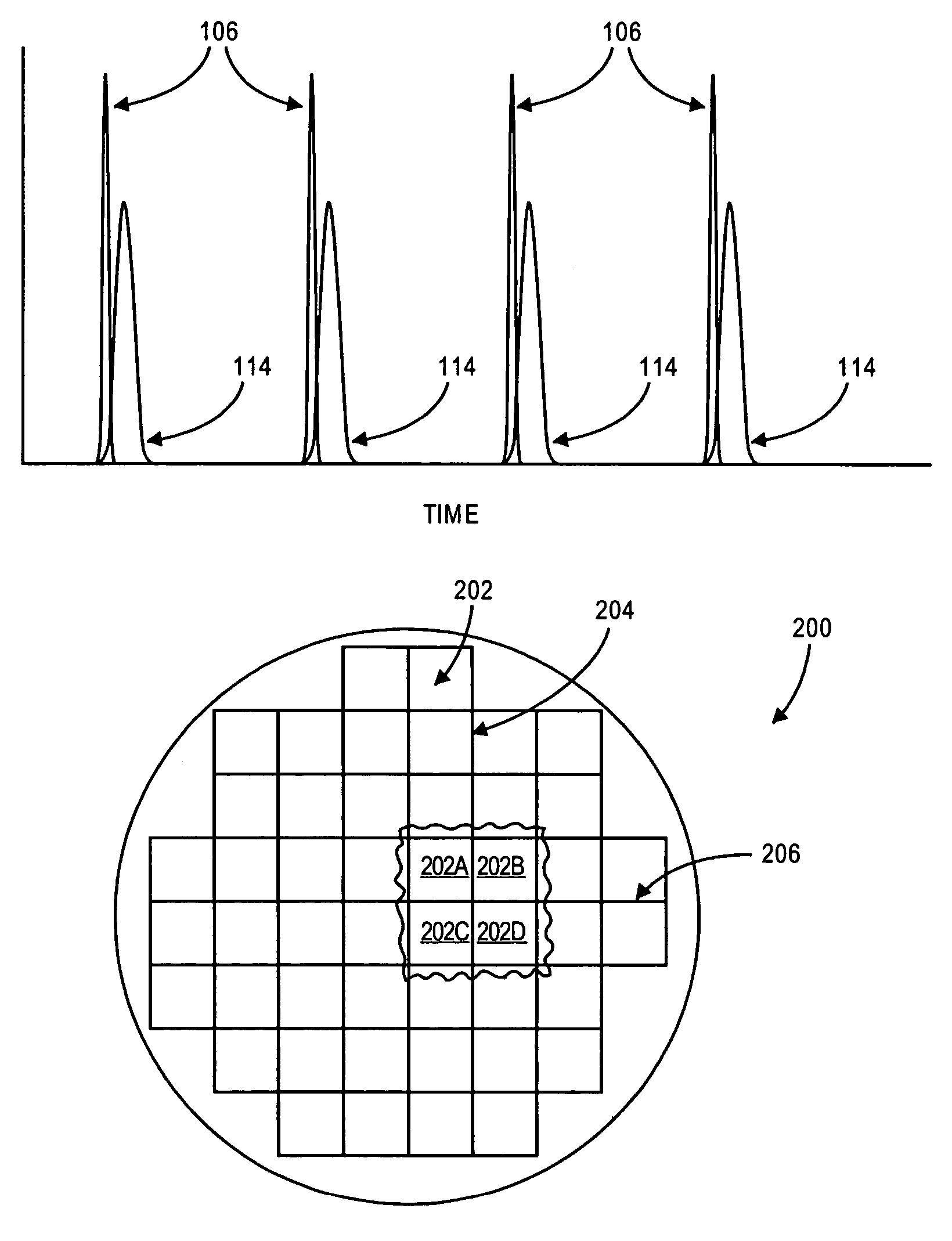

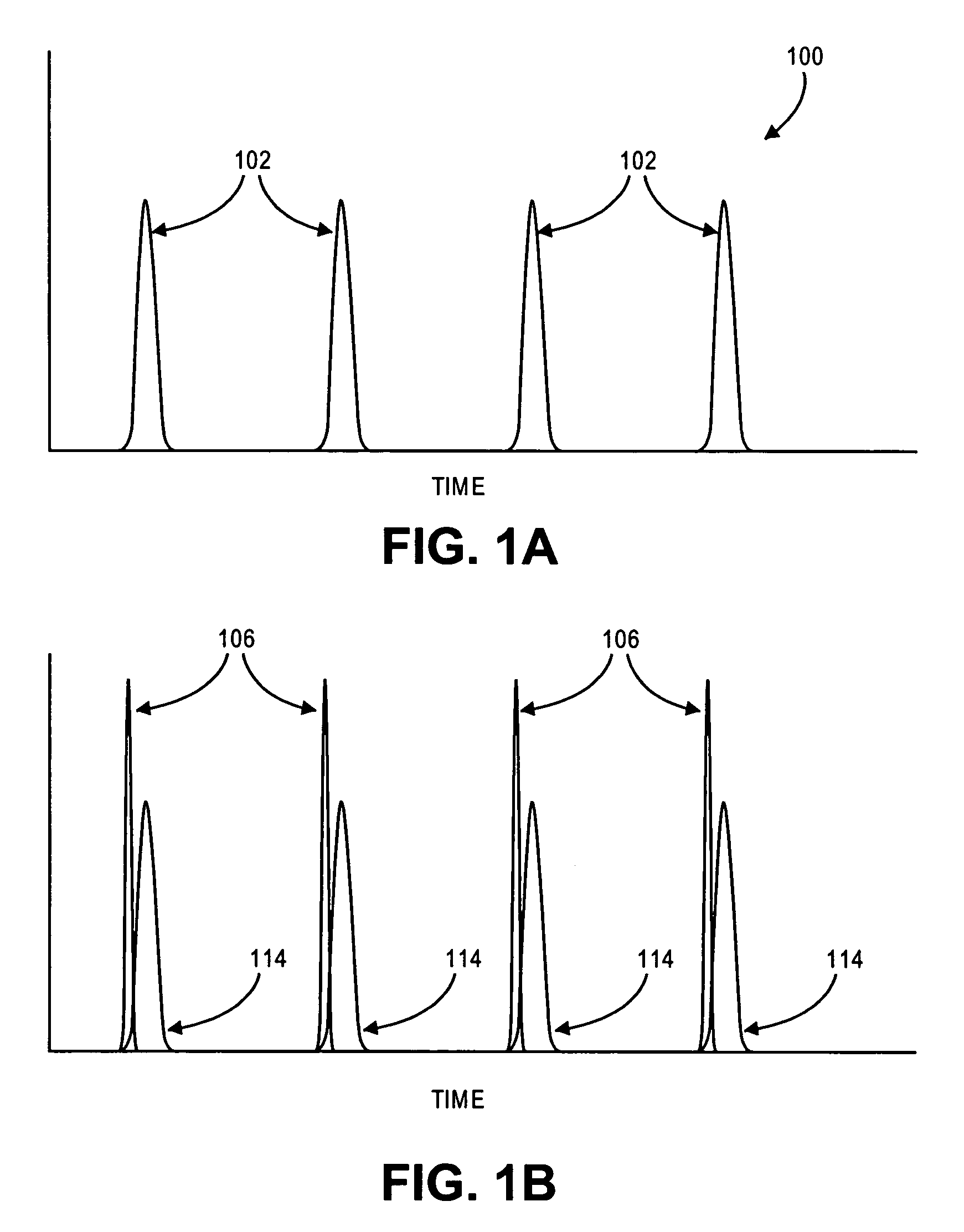

Laser micromachining with tailored bursts of short laser pulses

A series of laser pulse bundles or bursts are used for micromachining target structures. Each burst includes short laser pulses with temporal pulse widths that are less than approximately 1 nanosecond. A laser micromachining method includes generating a burst of laser pulses and adjusting an envelope of the burst of laser pulses for processing target locations. The method includes adjusting the burst envelope by selectively adjusting one or more first laser pulses within the burst to a first amplitude based on processing characteristics of a first feature at a target location, and selectively adjusting one or more second laser pulses within the burst to a second amplitude based on processing characteristics of a second feature at the target location. The method further includes directing the amplitude adjusted burst of laser pulses to the target location.

Owner:ELECTRO SCI IND INC

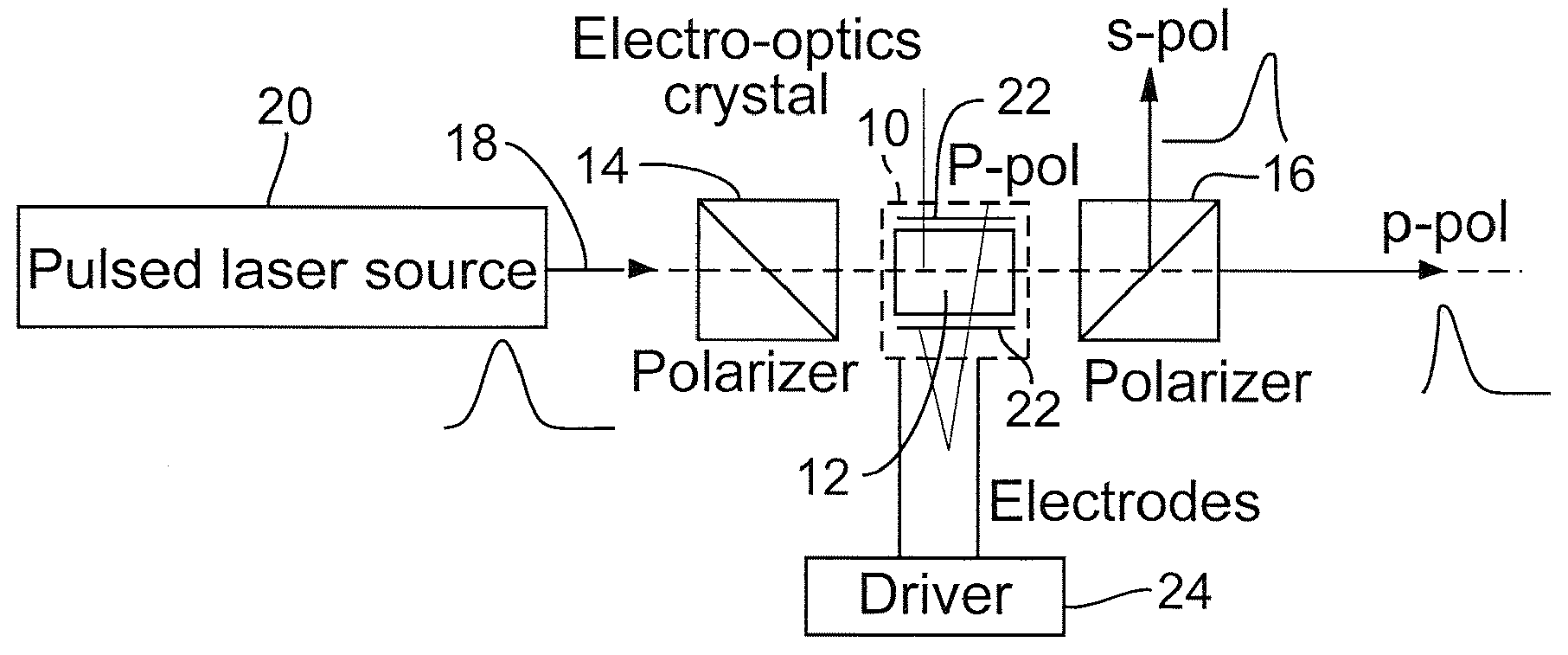

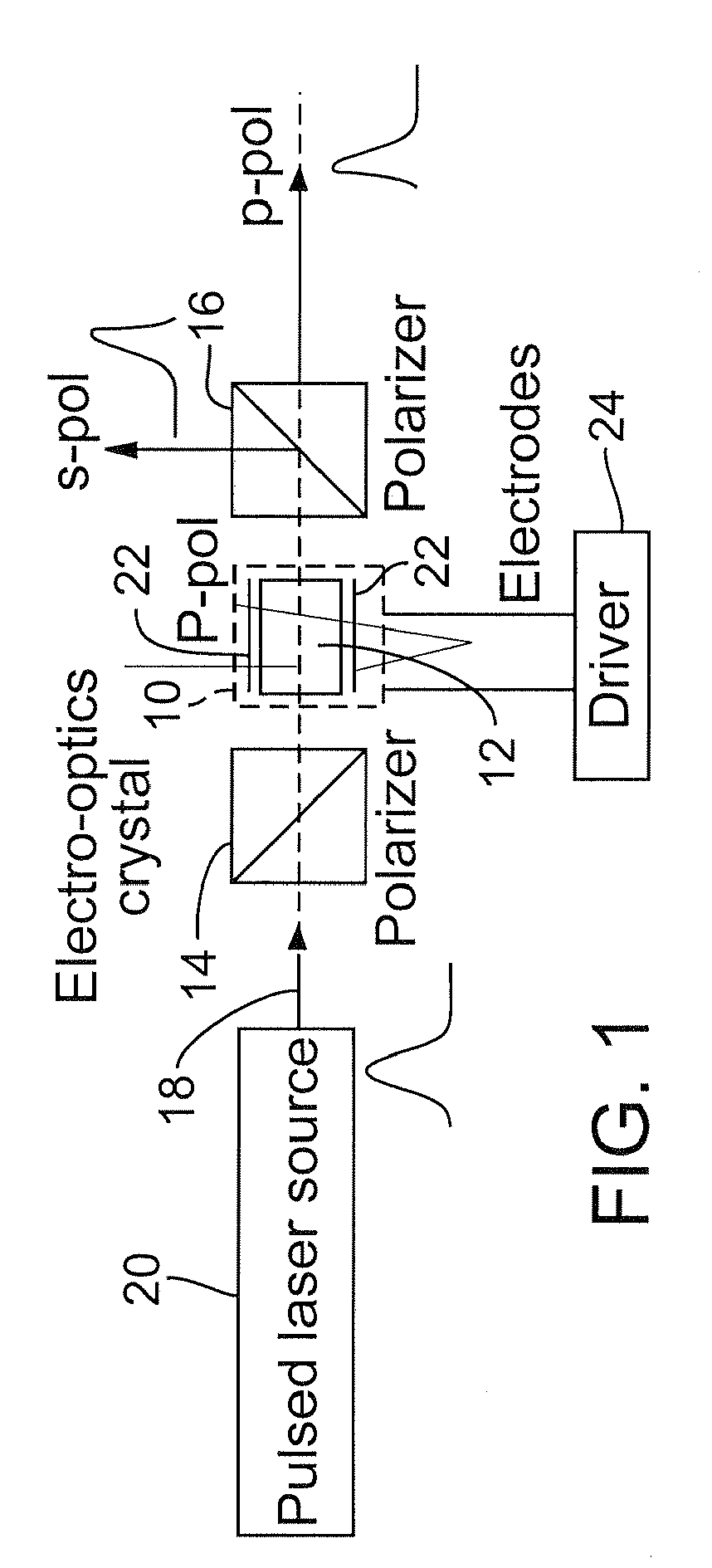

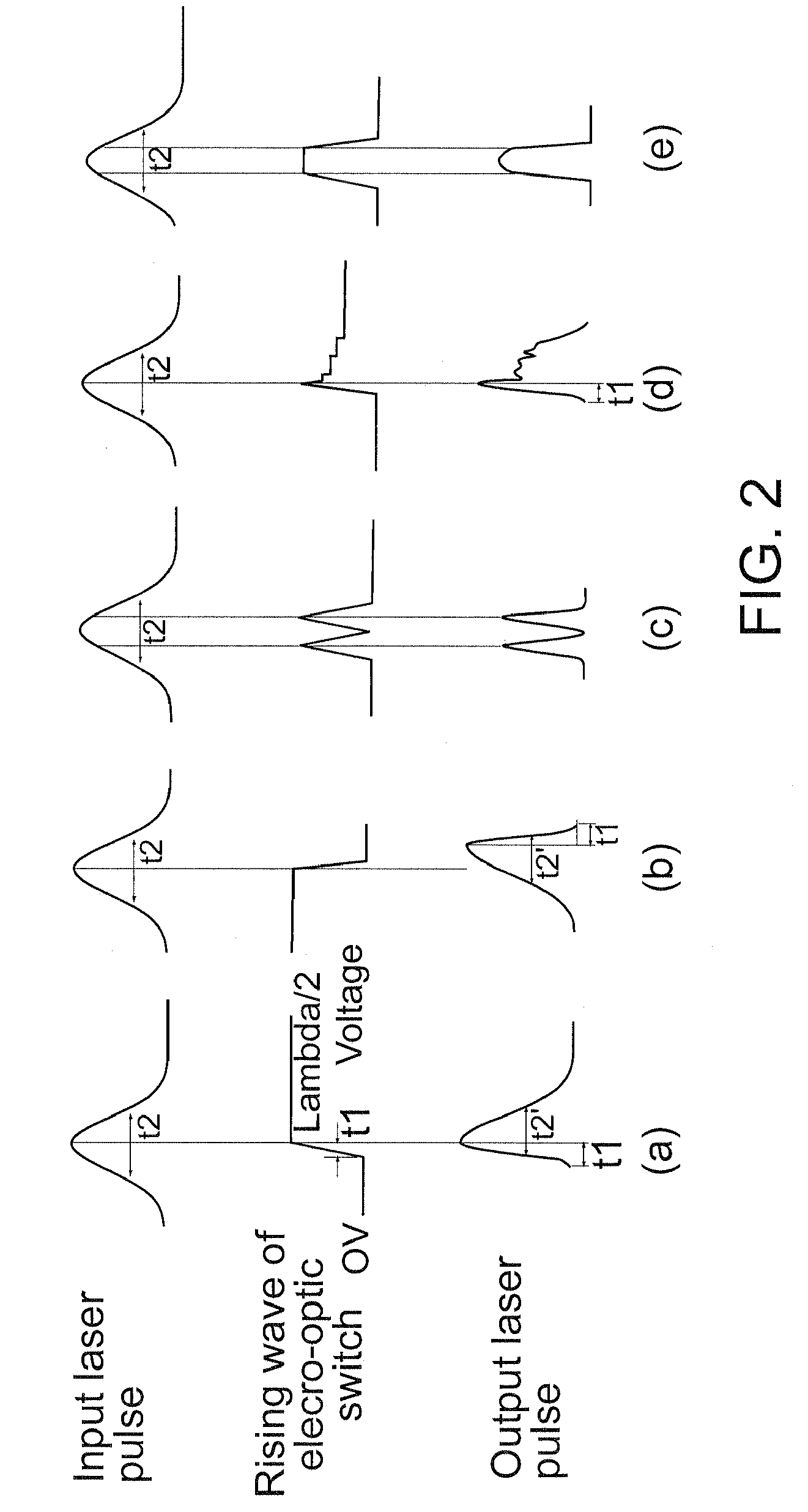

Laser micromachining using programmable pulse shapes

InactiveUS20090245301A1Improve throughputAvoid damageLaser detailsNon-linear opticsLeading edgeNanosecond

Laser pulse shaping techniques produce tailored laser pulse spectral output. The laser pulses can be programmed to have desired pulse widths and pulse shapes (such as sub-nanosecond to 10 ns-20 ns pulse widths with 1 ns to several nanoseconds leading edge rise times). Preferred embodiments are implemented with one or more electro-optical modulators receiving drive signals that selectively change the amount of incident pulsed laser emission to form a tailored pulse output. Triggering the drive signal from the pulsed laser emission suppresses jitter associated with other stages of the link processing system and substantially removes jitter associated with pulsed laser emission build-up time.

Owner:ELECTRO SCI IND INC

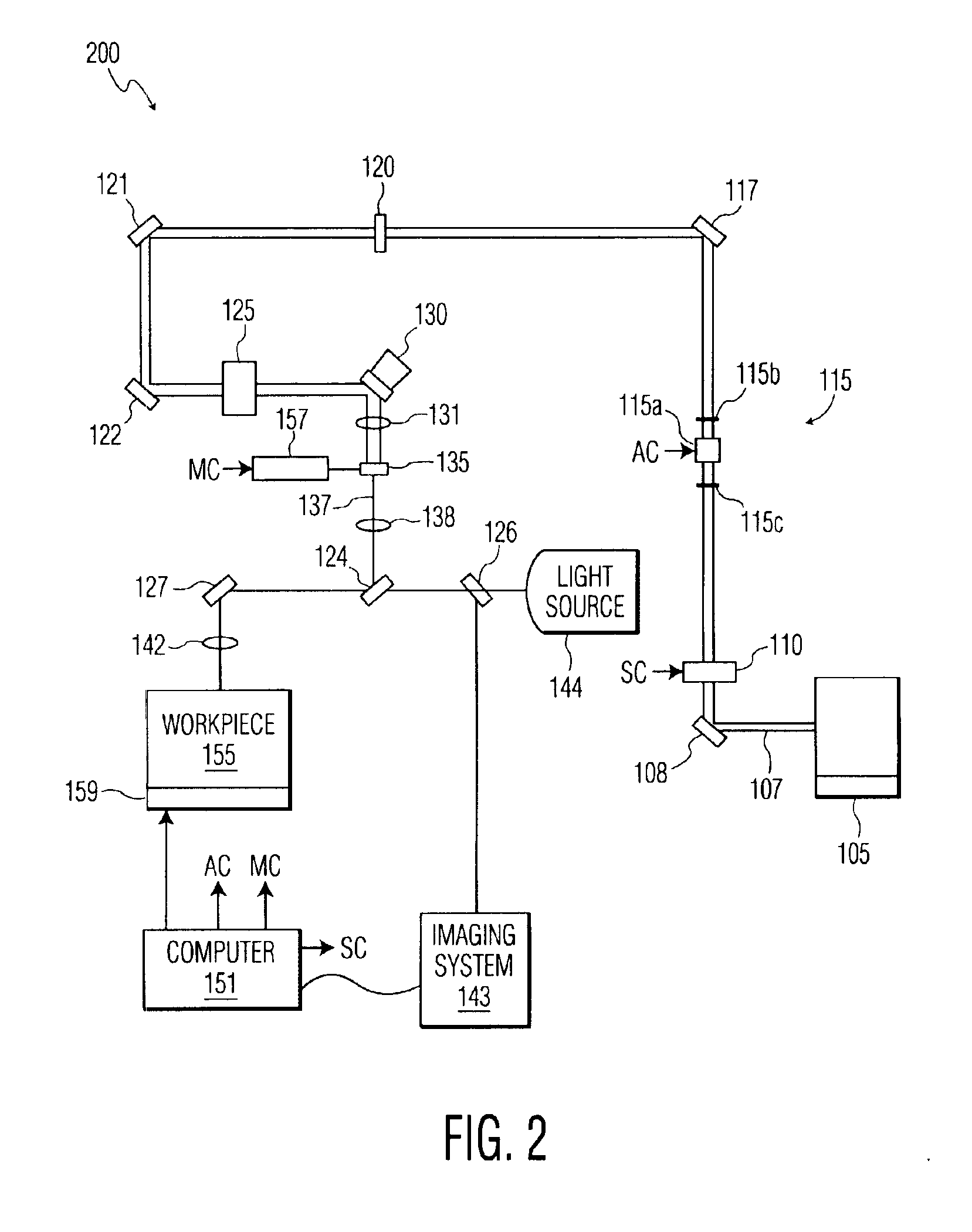

Laser micromachining method

InactiveUS20060091125A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesHigh energyLaser scribing

A method is described for laser scribing or dicing portions of a workpiece using multi-source laser systems. In one embodiment, a first laser uses multiphoton absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece. In an alternative embodiment, a first laser uses high energy single-photon absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece.

Owner:INTEL CORP

Laser micromachining method

InactiveUS7169687B2Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesTwo-photon absorptionHigh energy

A method is described for laser scribing or dicing portions of a workpiece using multi-source laser systems. In one embodiment, a first laser uses multiphoton absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece. In an alternative embodiment, a first laser uses high energy single-photon absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece.

Owner:INTEL CORP

Debris capture and removal for laser micromachining

A method of capturing and removing metallic debris created on a target side of a target metal specimen undergoing laser micromachining entails providing a barrier that encompasses the immediate volume surrounding a laser cutting head output nozzle to contain the ejected debris and extracting the debris through a vacuum outlet. A preferred system implementing this approach to debris management includes a barrier in the form of a flexible fiber brush configured in the shape of a ring and positioned to trap ejected debris within a localized area surrounding a target area where the laser beam is incident on the target metal specimen. The ring brush is made of material that is robust to molten metals. An inert gas directed at a high flow rate along the target surface of the metal specimen carries ejected surface debris trapped in the ring brush toward a vacuum outlet.

Owner:ELECTRO SCI IND INC

Laser micromachining method

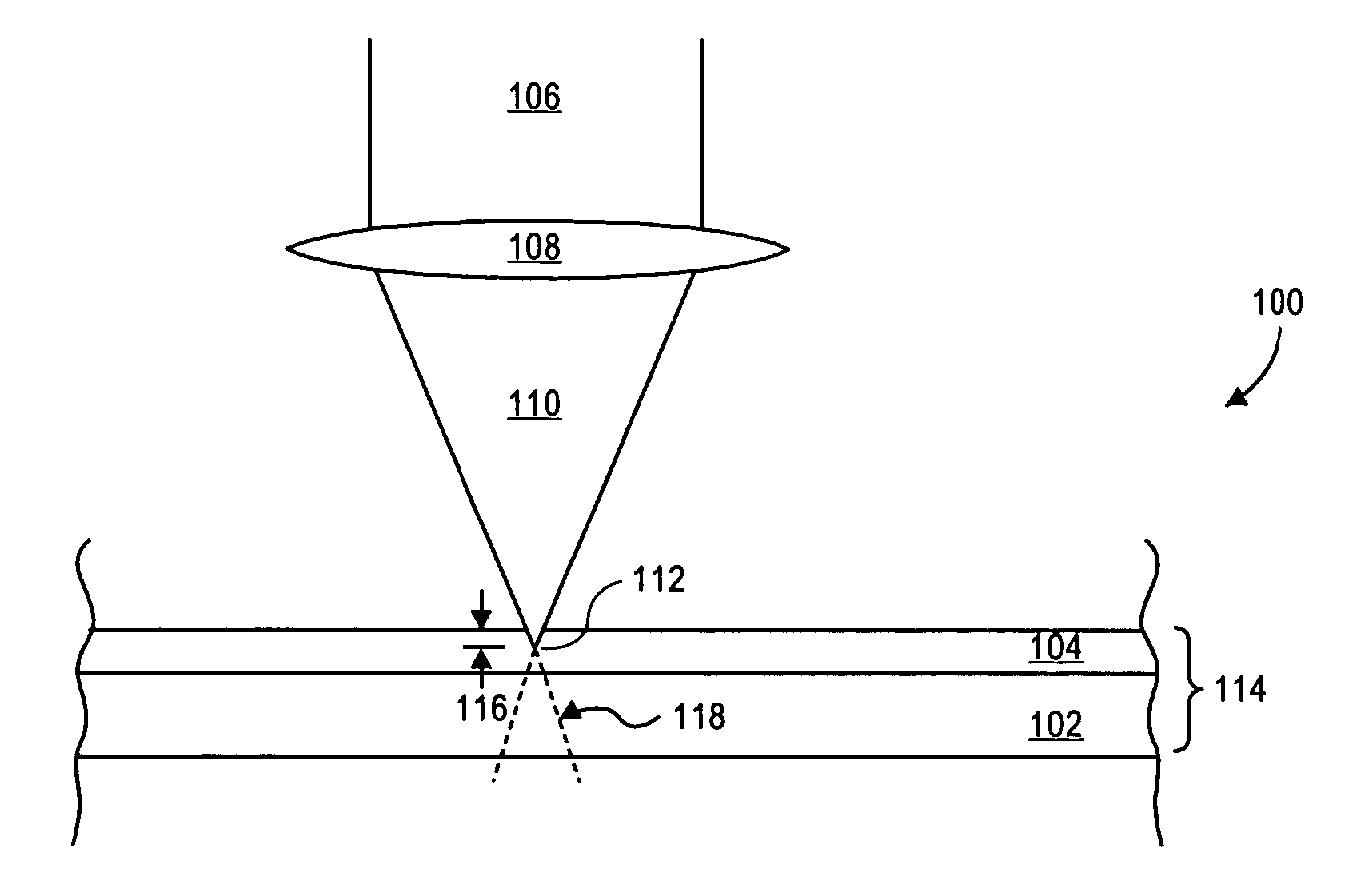

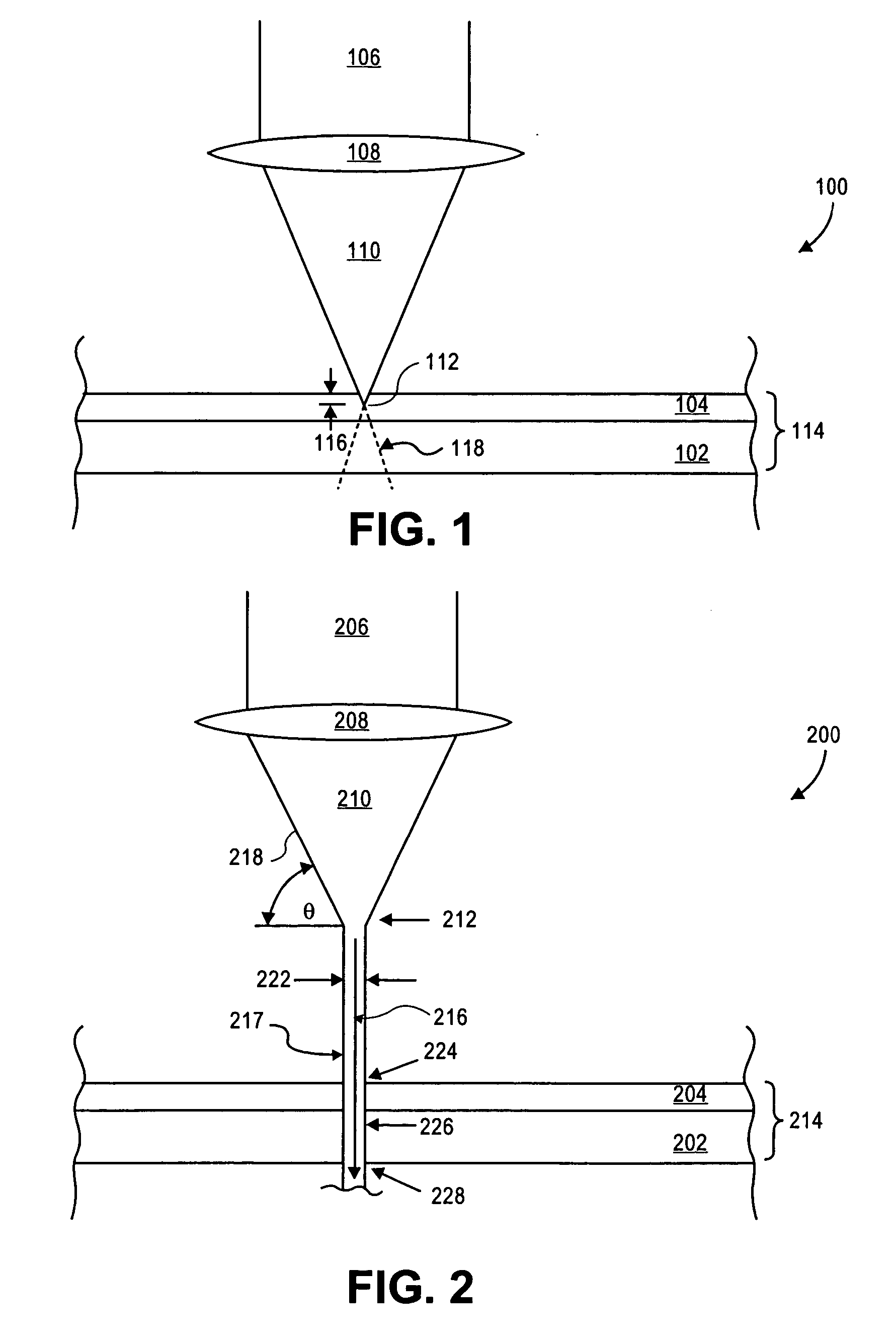

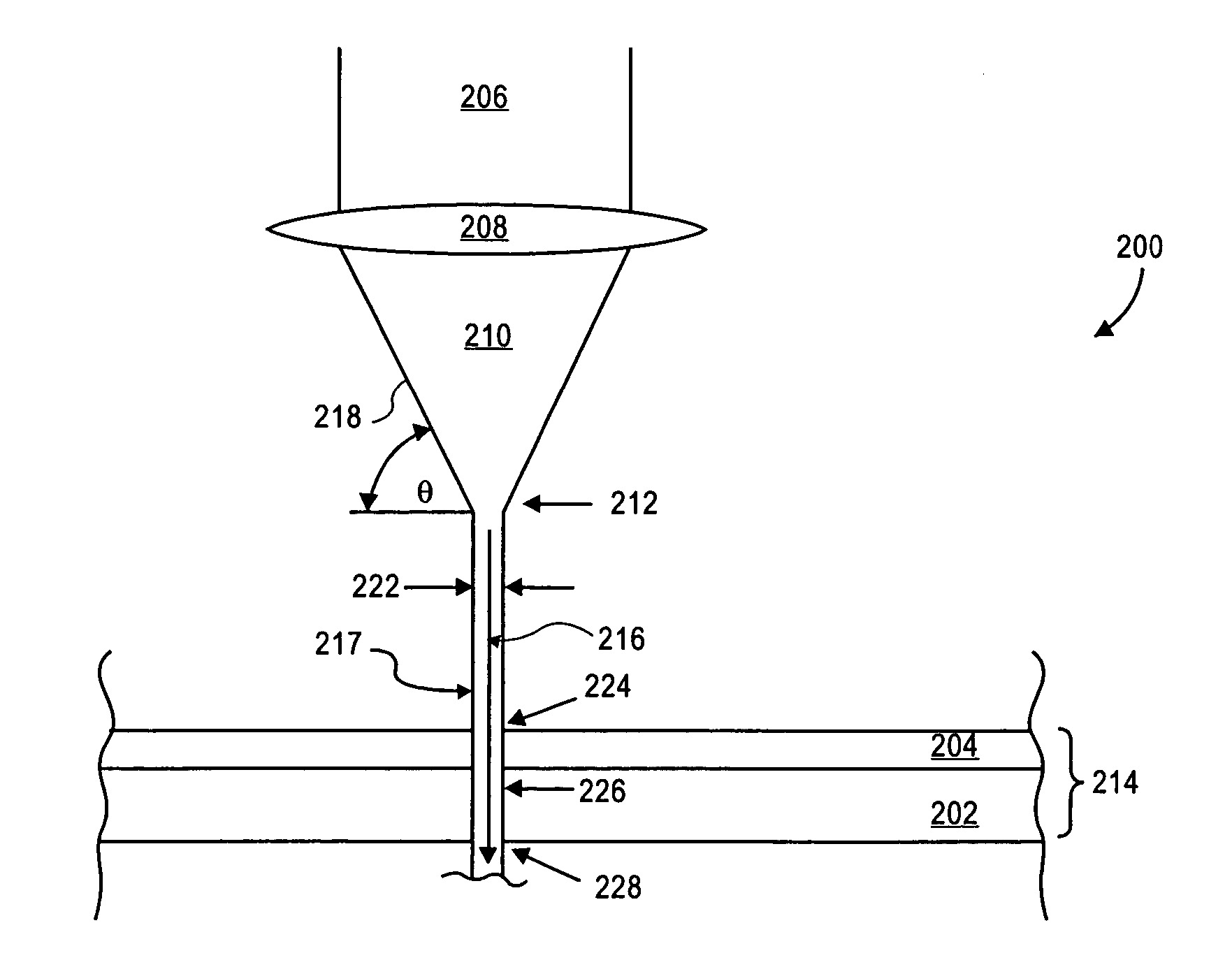

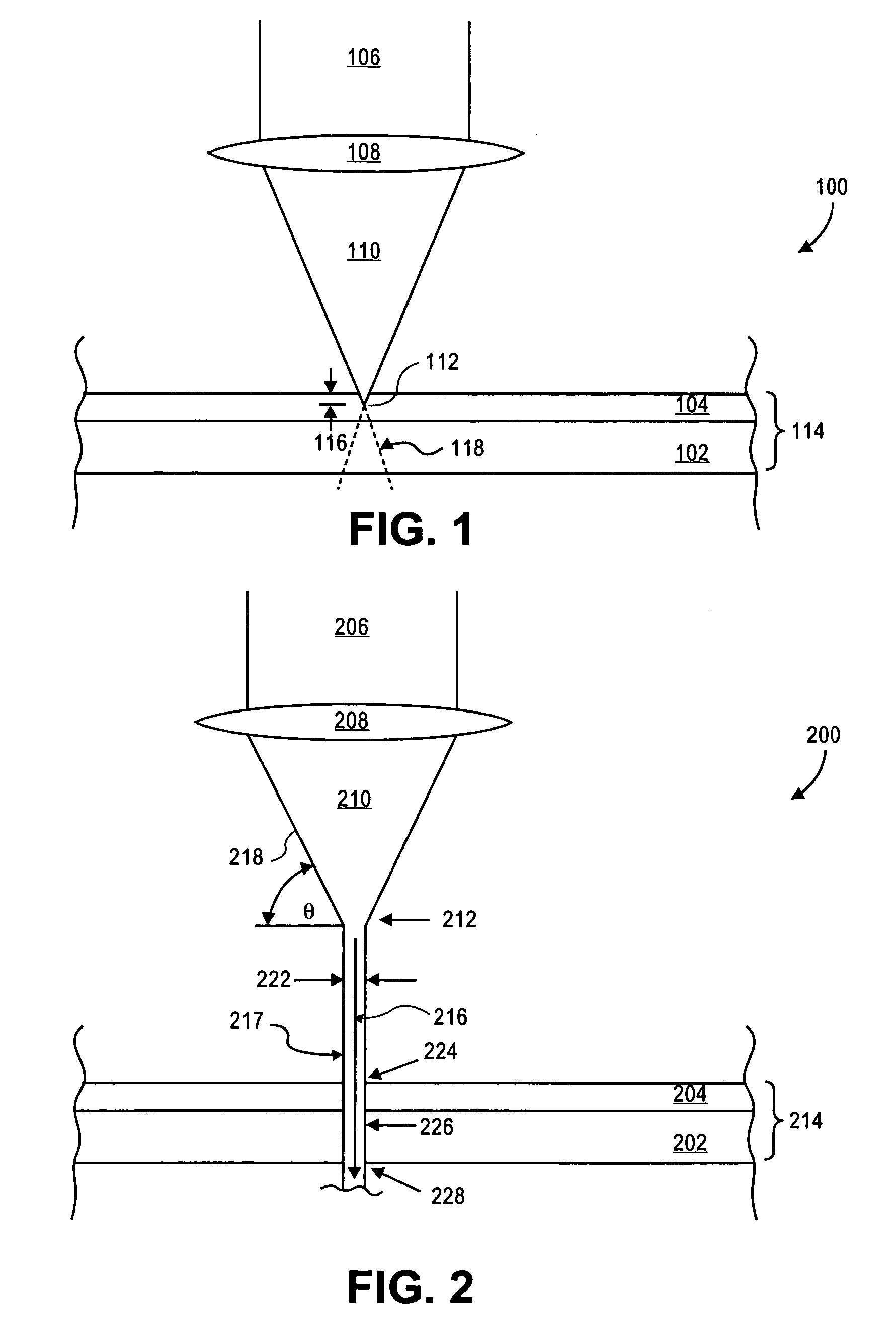

InactiveUS20060099810A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLight beamPlasma channel

A laser micromachining method is disclosed wherein a workpiece is milled using an incident beam from a laser beam focused above the surface of the workpiece. The incident beam is guided by a plasma channel generated by the incident beam. The plasma channel, which has a relatively constant diameter over an extended distance, is generated by continual Kerr effect self-focusing balanced by ionization of air beam defocusing.

Owner:INTEL CORP

Laser micromachining method

InactiveUS7303977B2Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLight beamPlasma channel

A laser micromachining method is disclosed wherein a workpiece is milled using an incident beam from a laser beam focused above the surface of the workpiece. The incident beam is guided by a plasma channel generated by the incident beam. The plasma channel, which has a relatively constant diameter over an extended distance, is generated by continual Kerr effect self-focusing balanced by ionization of air beam defocusing.

Owner:INTEL CORP

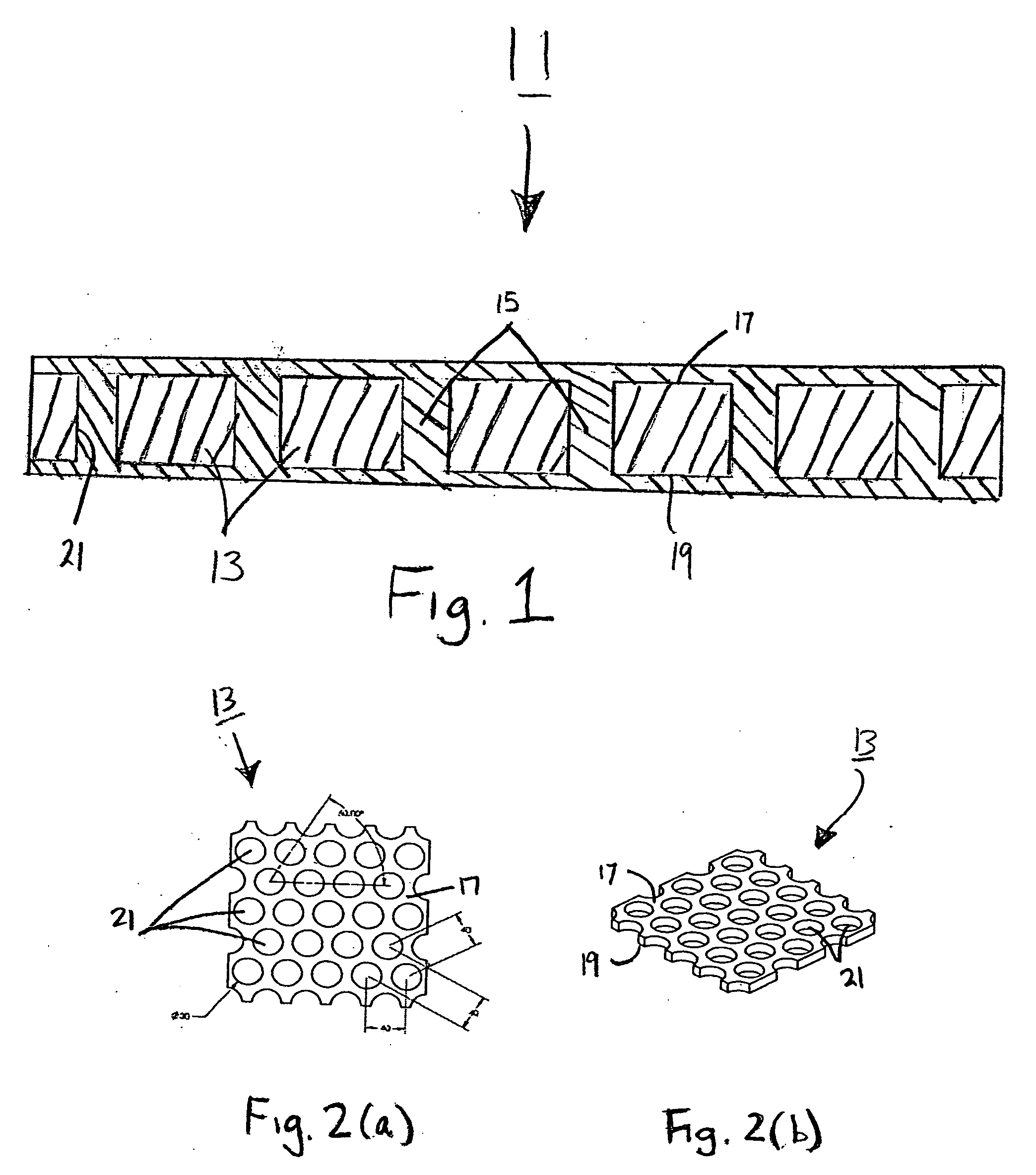

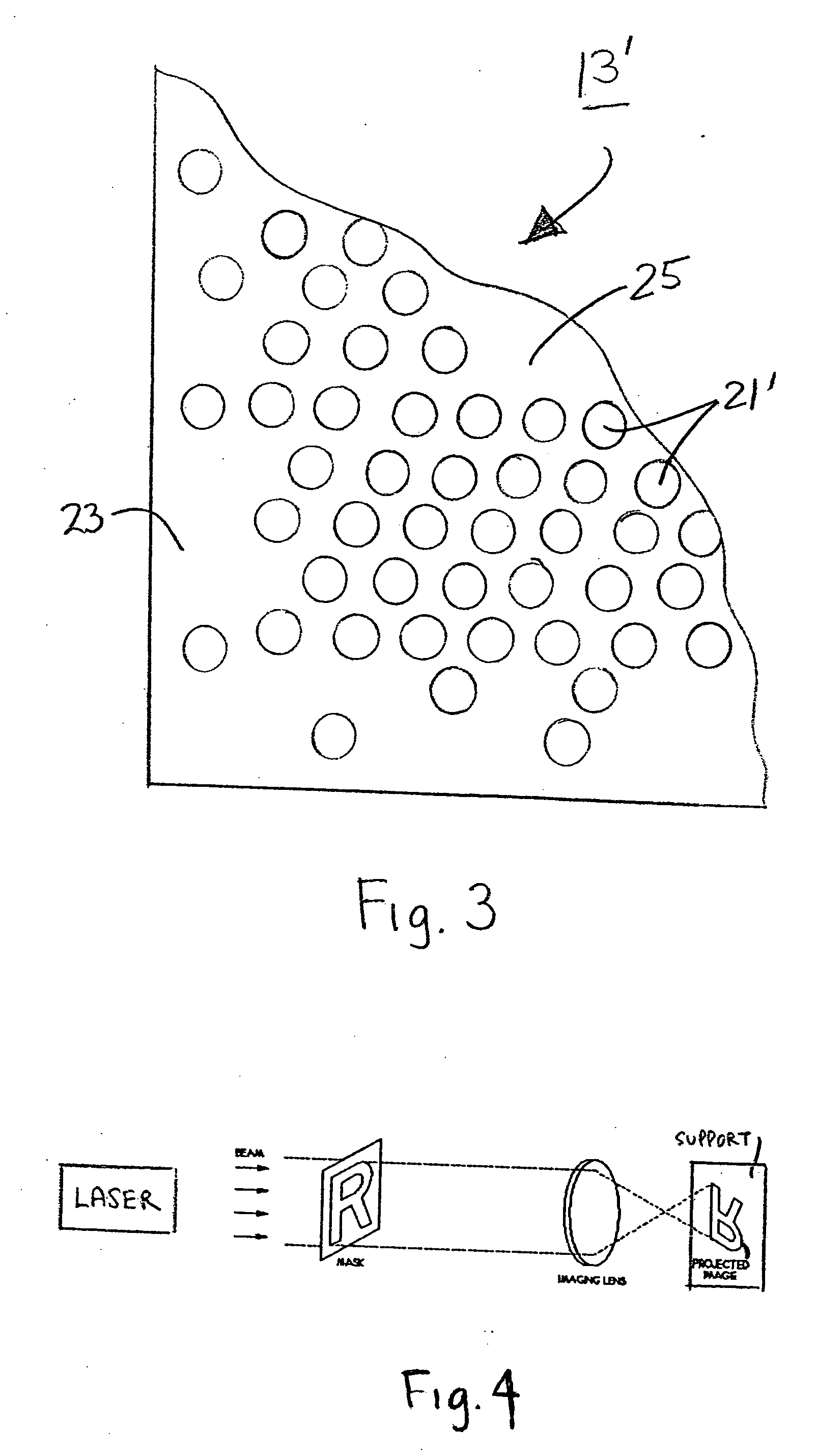

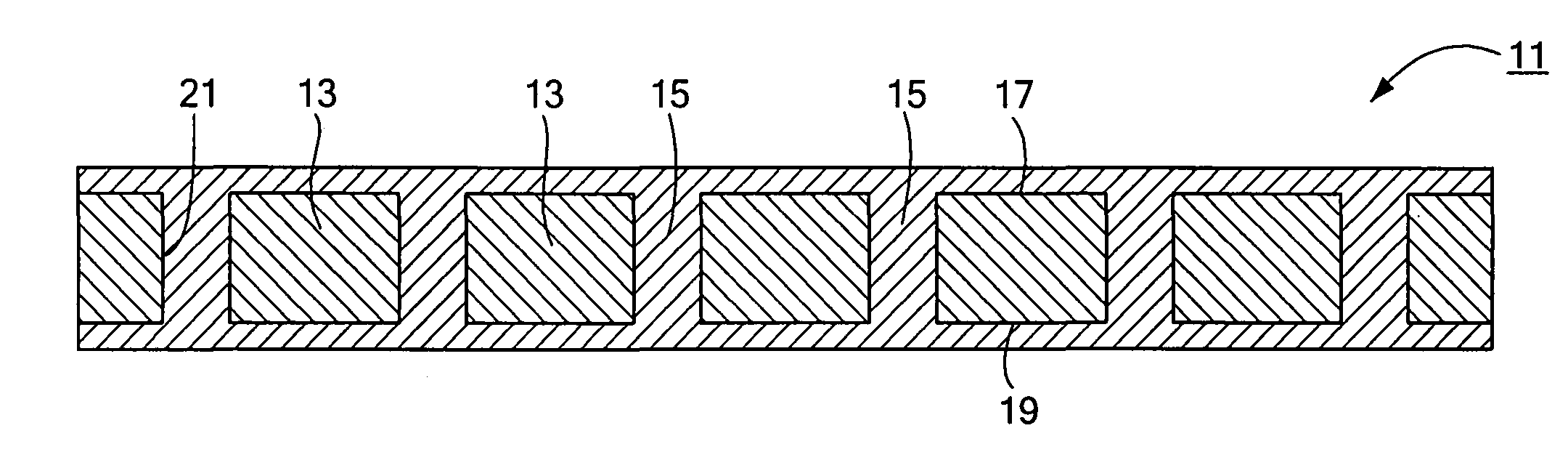

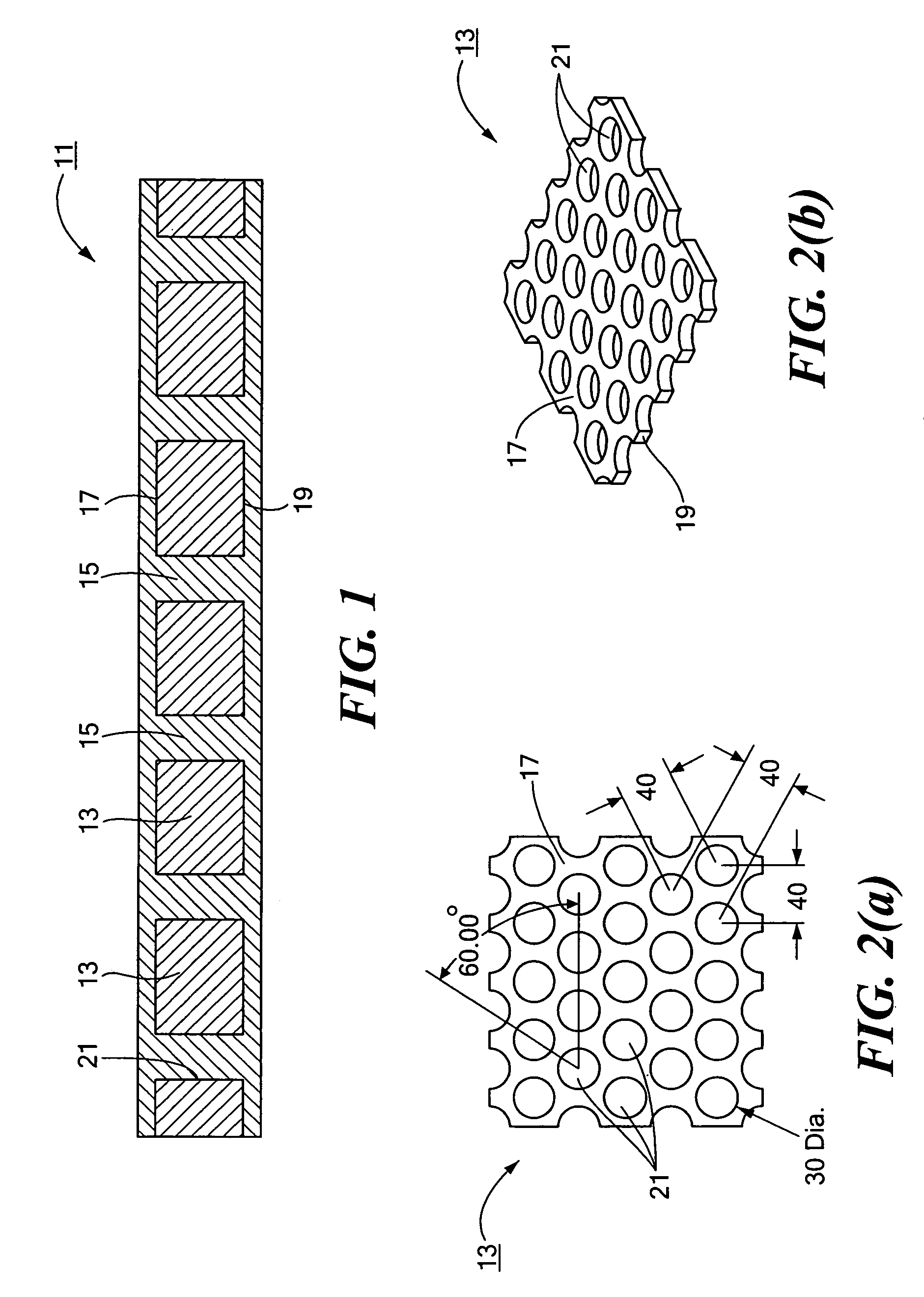

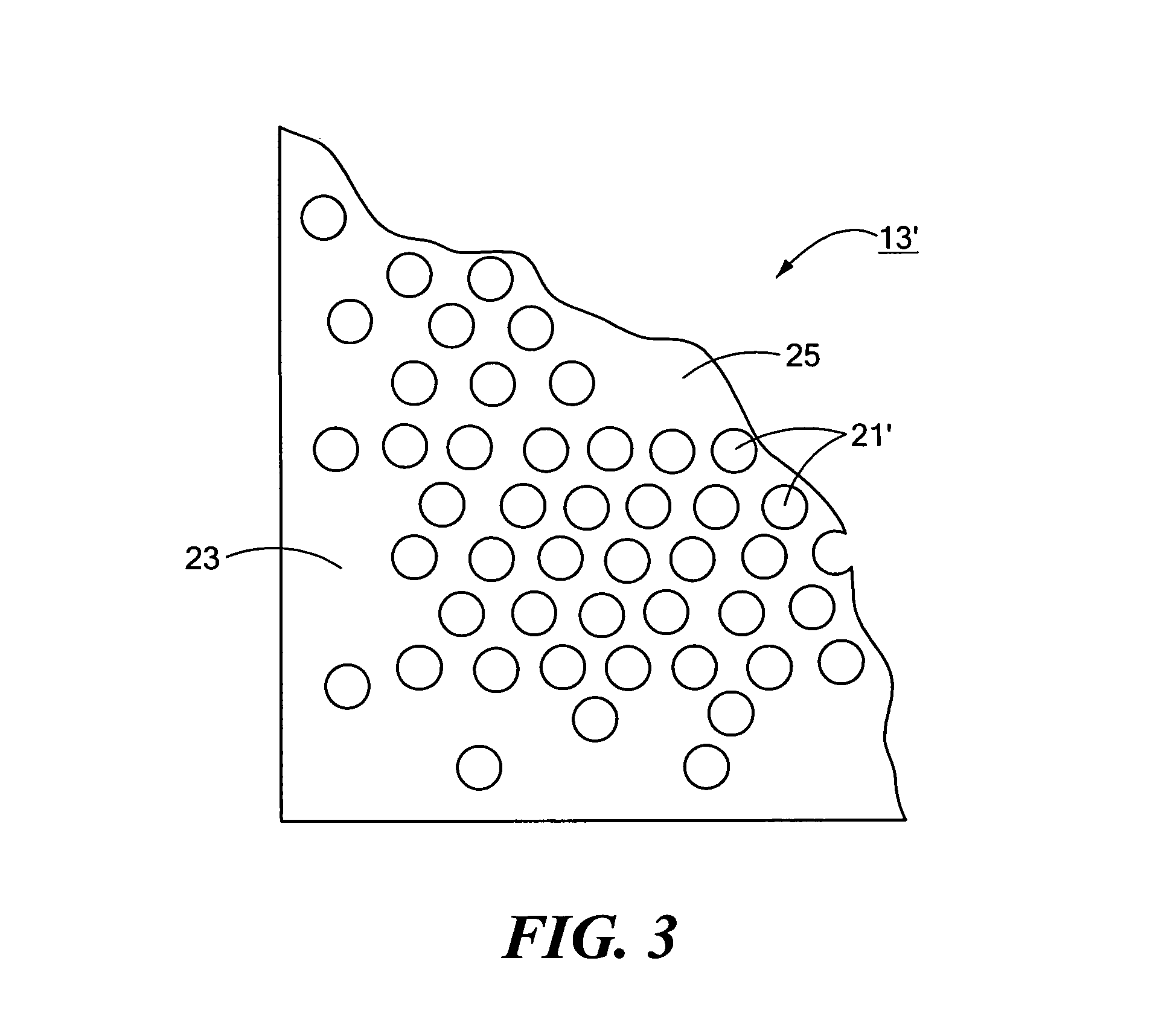

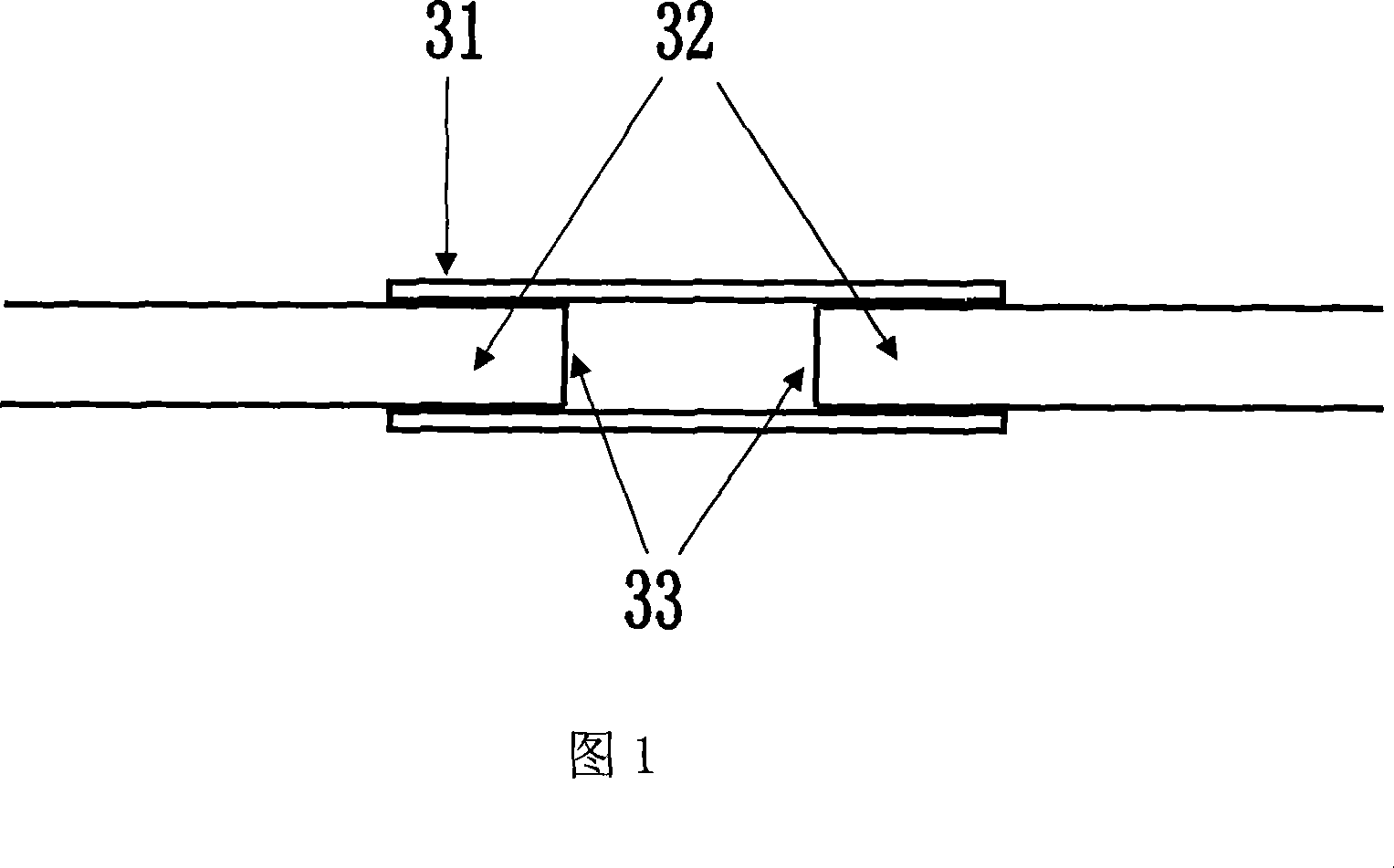

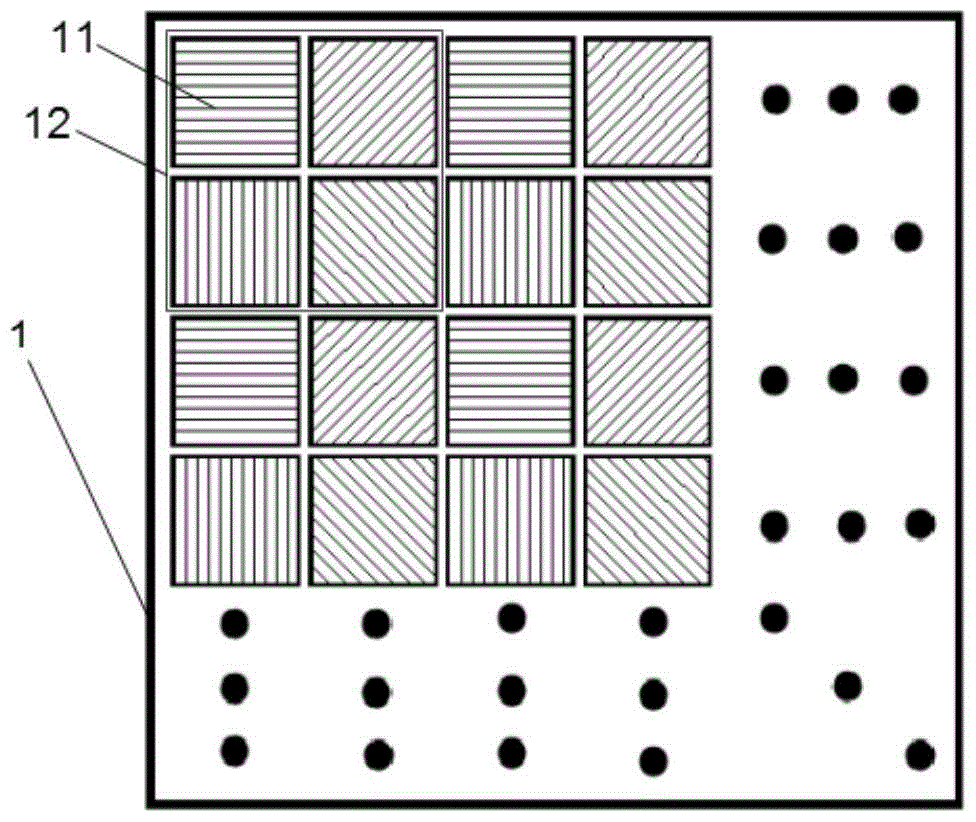

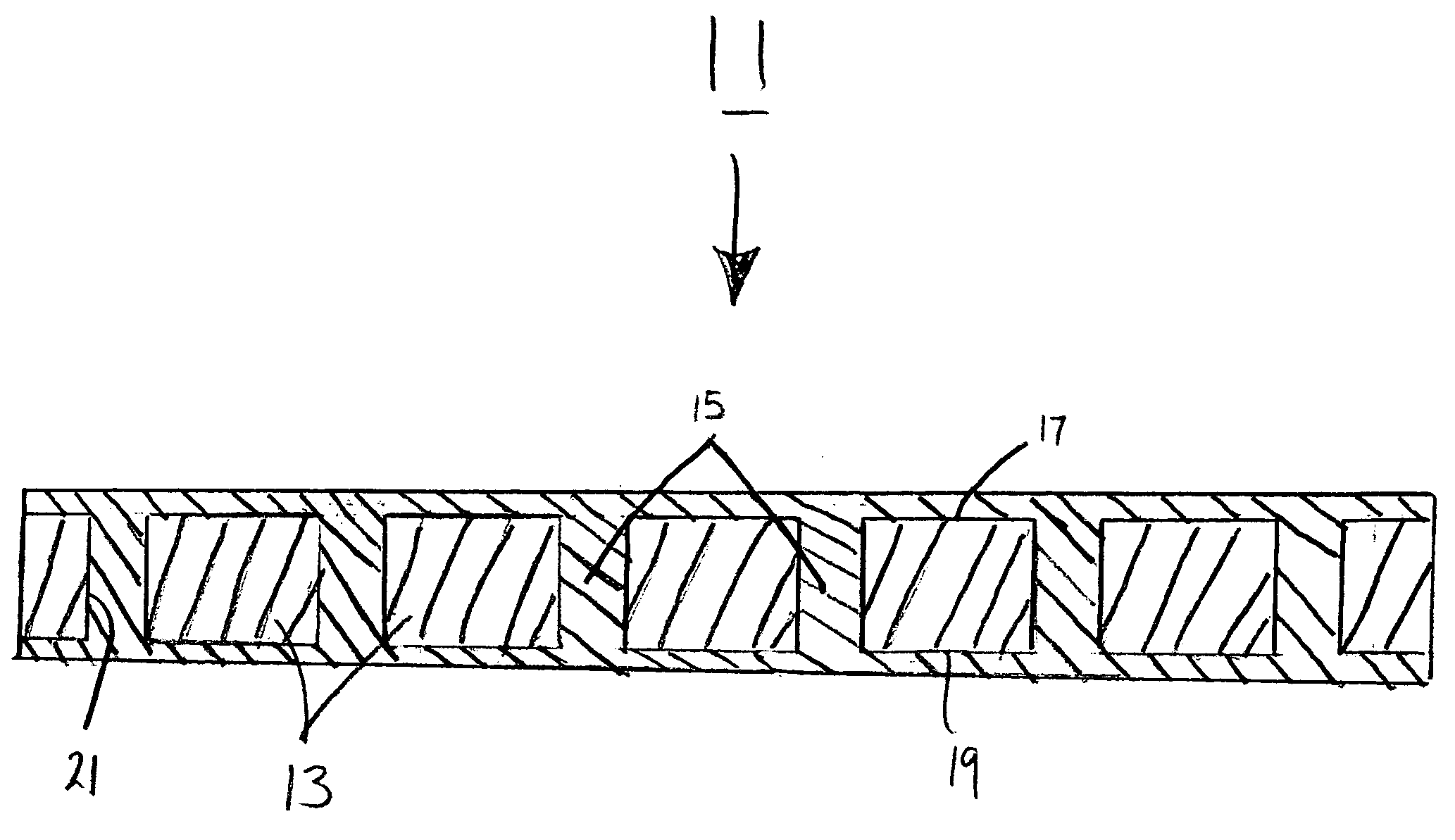

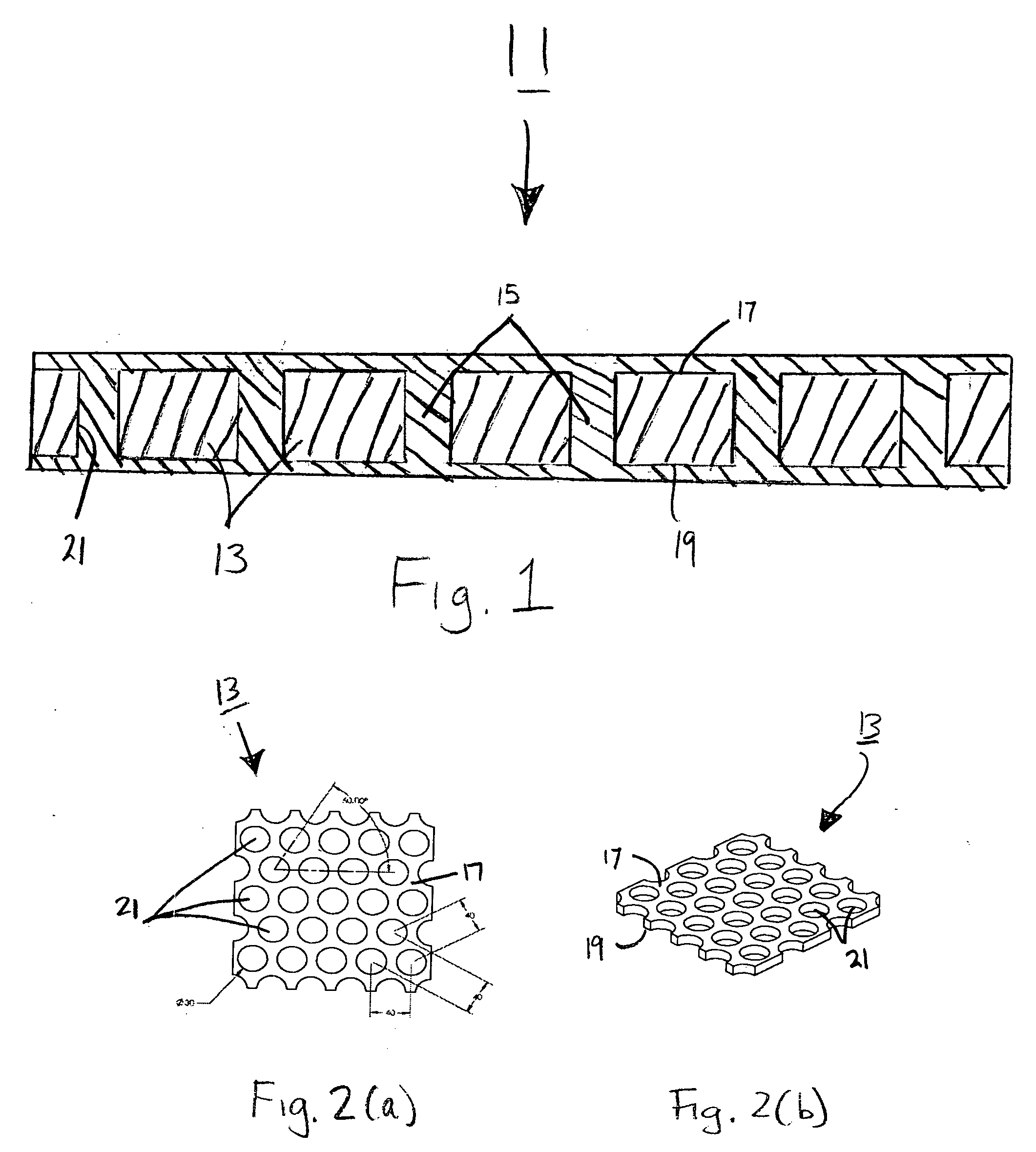

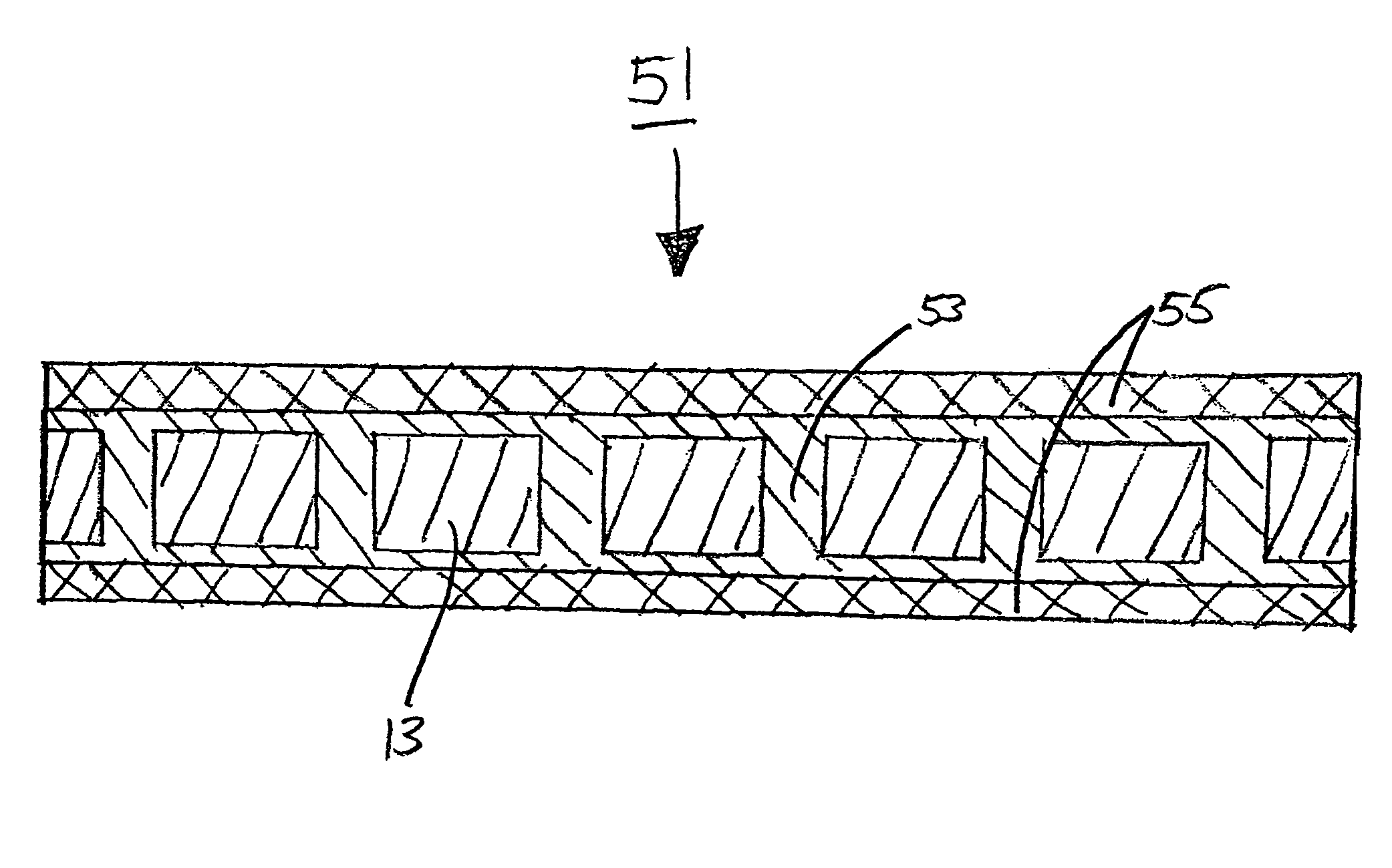

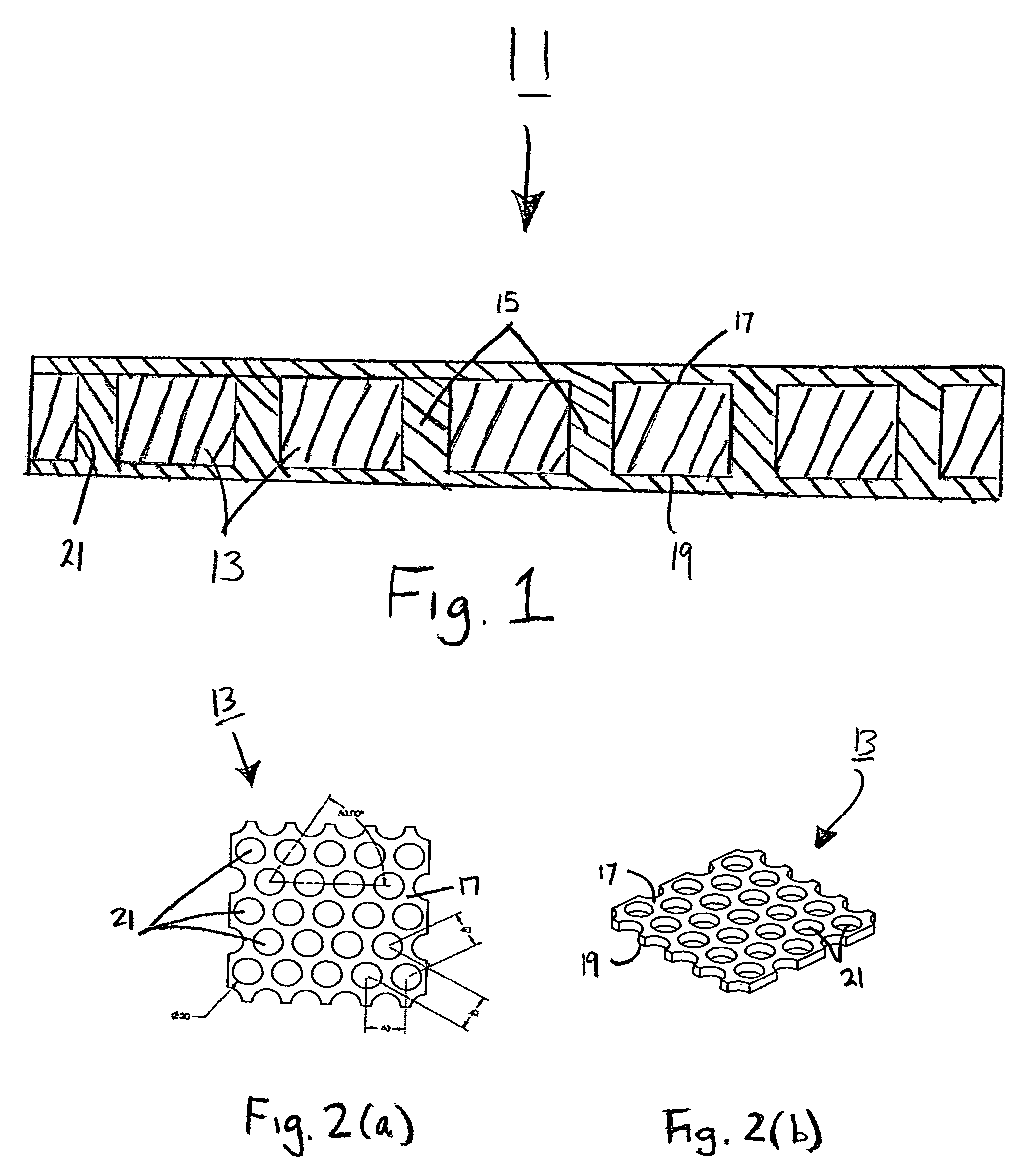

Solid polymer electrolyte composite membrane comprising laser micromachined porous support

A solid polymer electrolyte composite membrane and method of manufacturing the same. According to one embodiment, the composite membrane comprises a rigid, non-electrically-conducting support, the support preferably being a sheet of polyimide having a thickness of about 7.5 to 15 microns. The support has a plurality of cylindrical pores extending perpendicularly between opposing top and bottom surfaces of the support. The pores, which preferably have a diameter of about 5 microns, are made by laser micromachining and preferably are arranged in a defined pattern, for example, with fewer pores located in areas of high membrane stress and more pores located in areas of low membrane stress. The pores are filled with a first solid polymer electrolyte, such as a perfluorosulfonic acid (PFSA) polymer. A second solid polymer electrolyte, which may be the same as or different than the first solid polymer electrolyte, may be deposited over the top and / or bottom of the first solid polymer electrolyte.

Owner:PLUG POWER

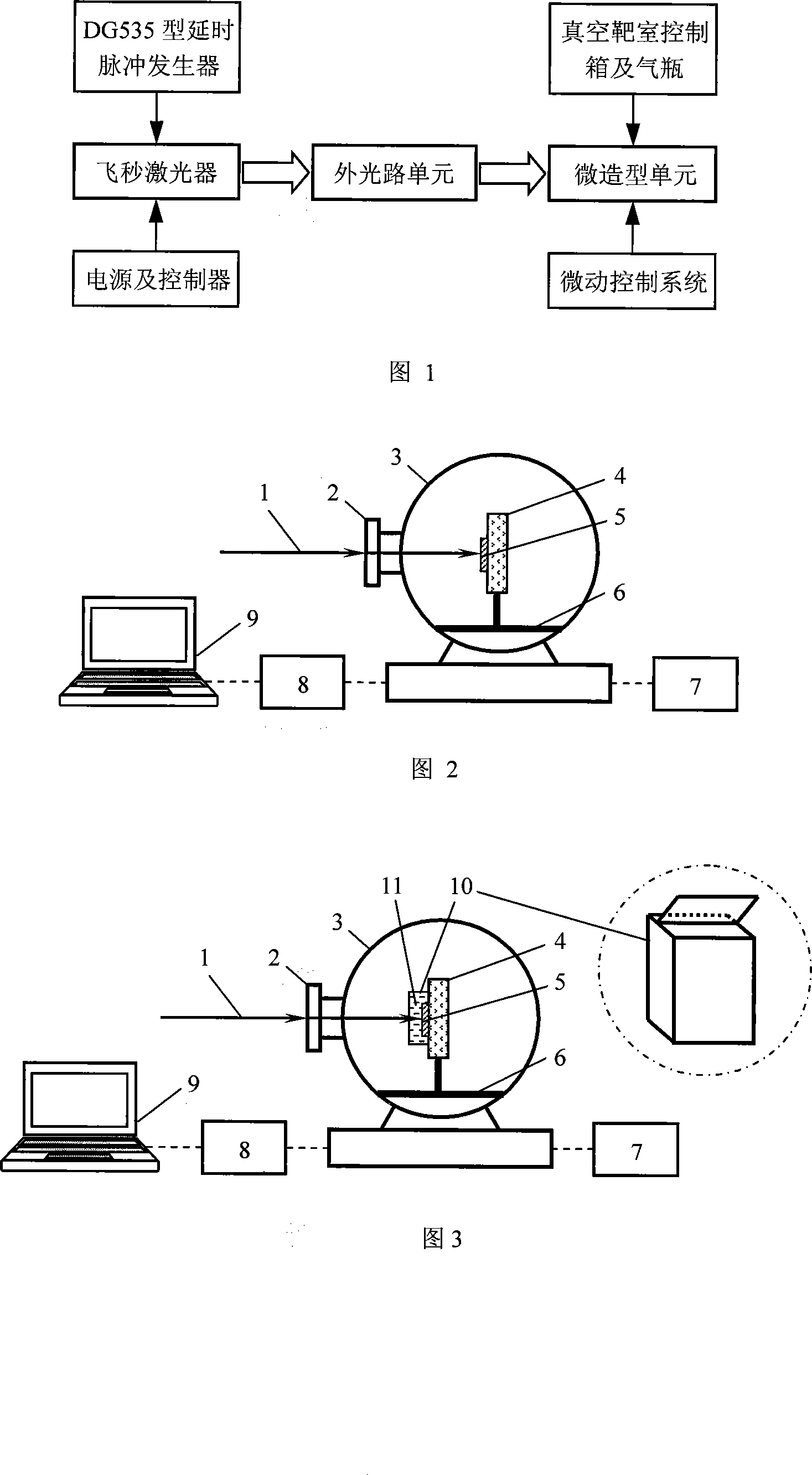

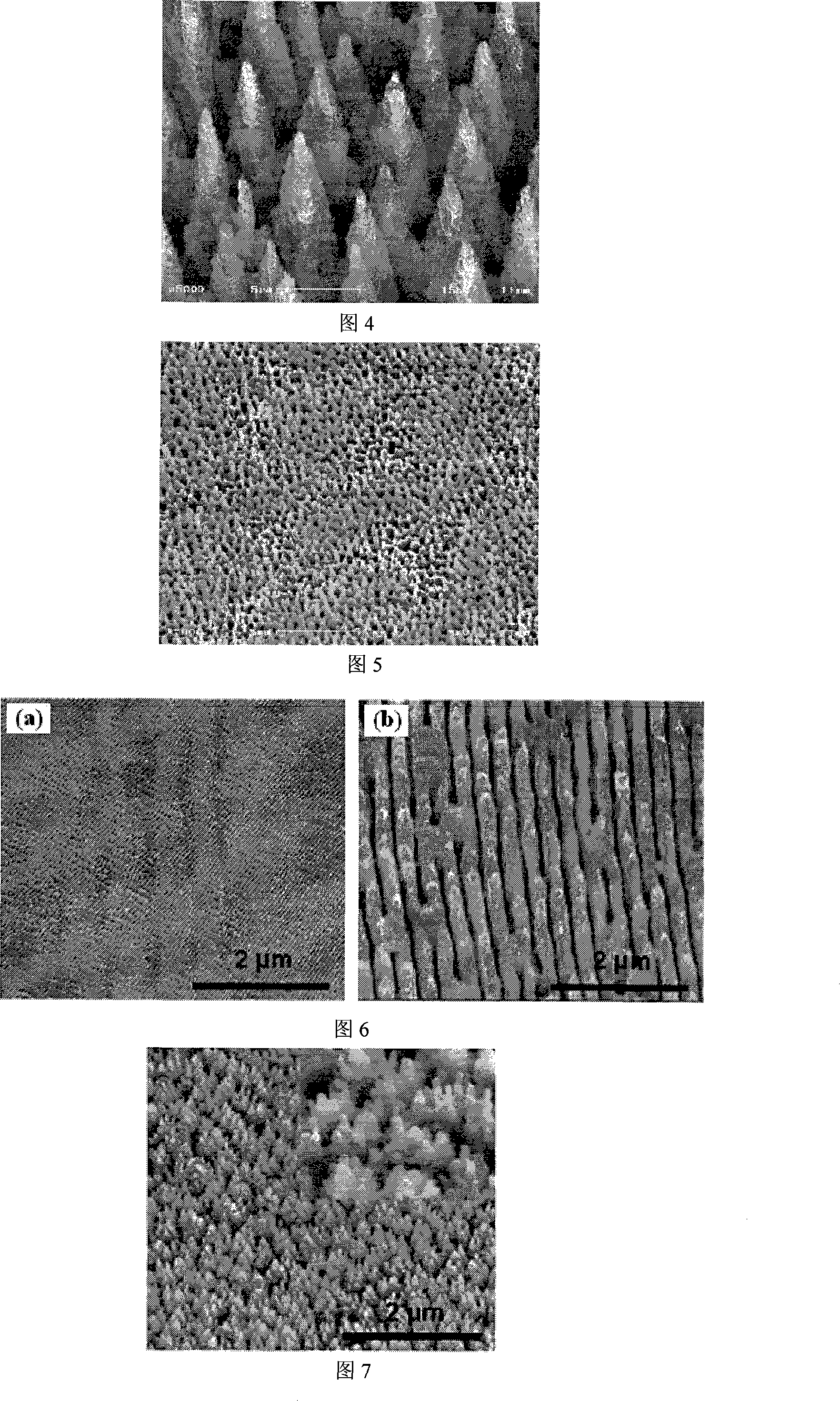

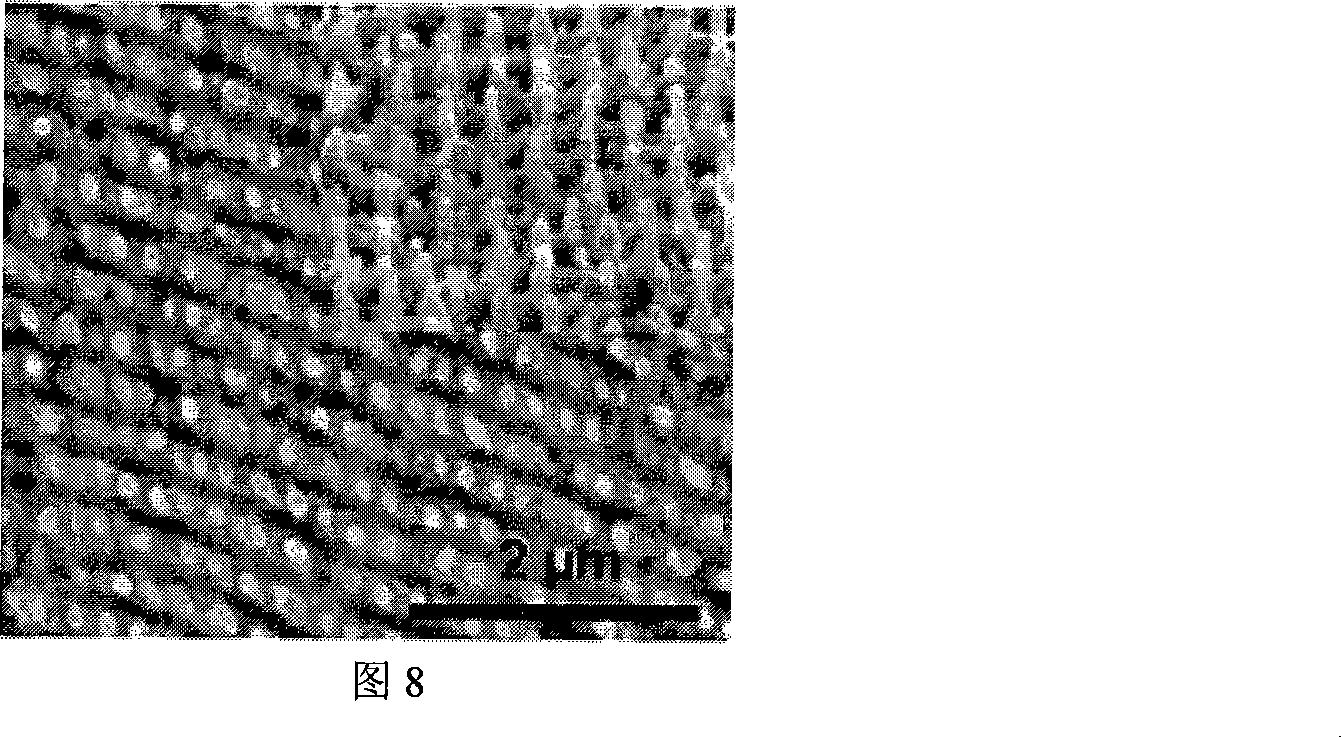

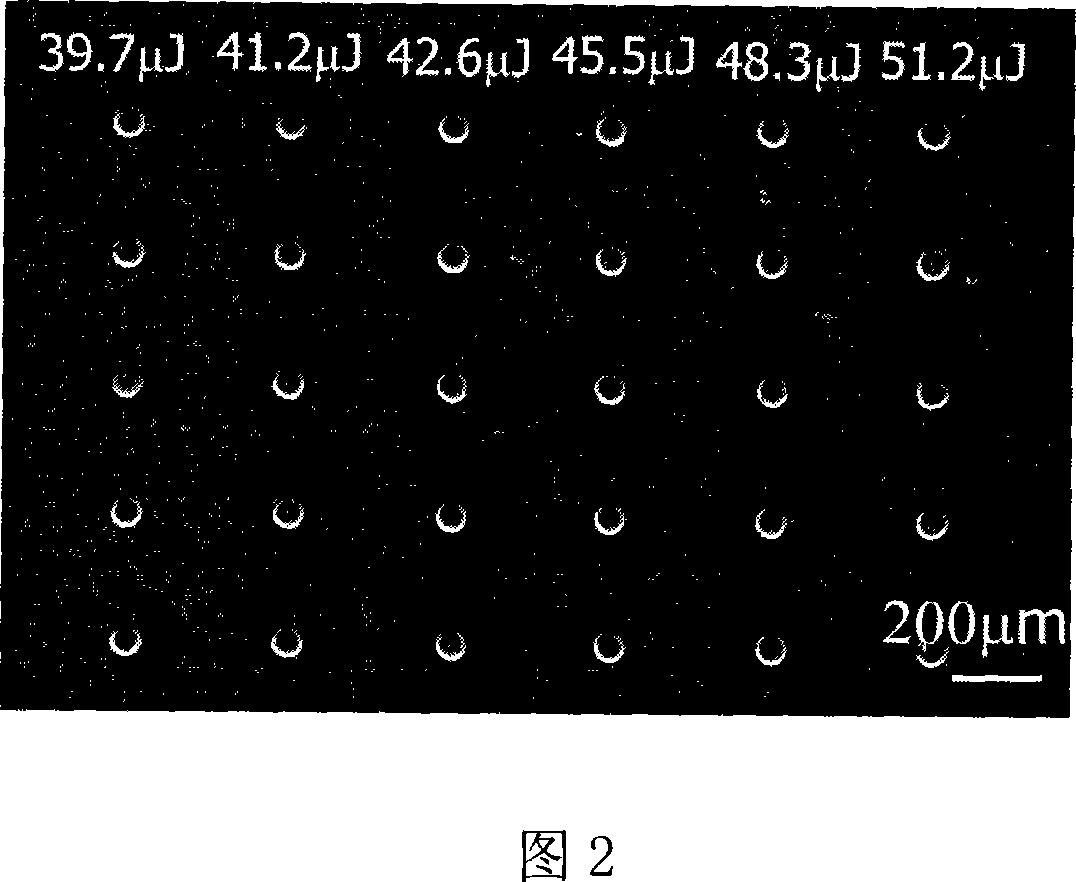

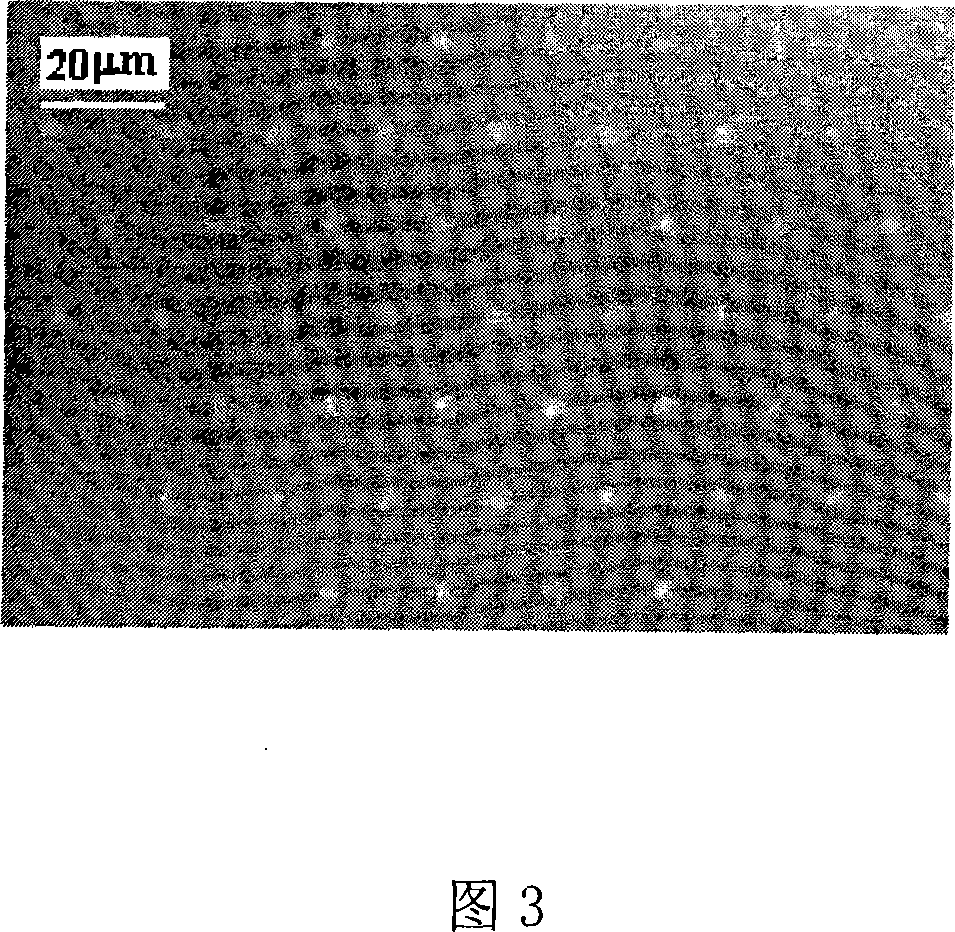

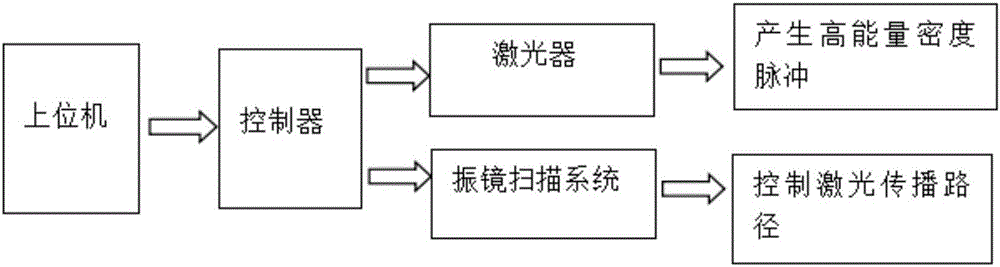

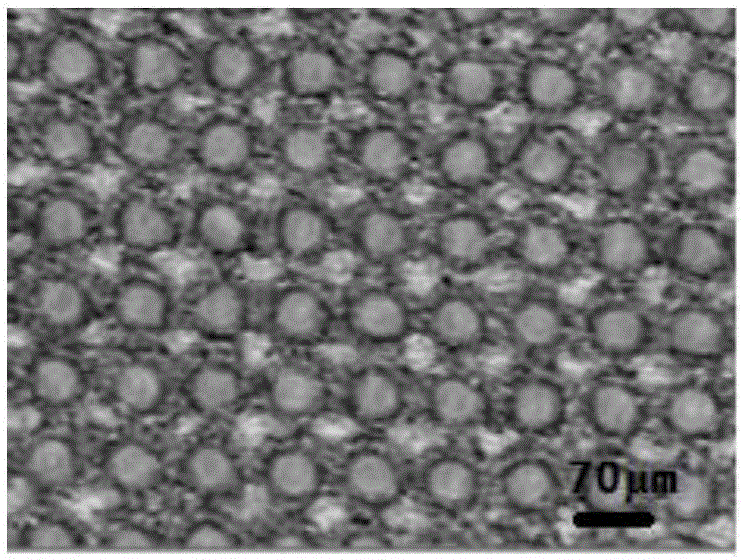

Laser modeling method for semiconductor material micro-nano multi-scale function surface

InactiveCN101219770AEasy to operateLow costNanostructure manufactureDecorative surface effectsMicro nanoMaterials preparation

The invention relates to a laser shaping method of a multi-scale functional surface of micronano for semiconductor material, relating to micronano material preparation and laser micromachining technical field; the invention aims at providing a method and a device for preparing femtosecond laser of super-hydrophobic functionalization for microstructural surface based on the semiconductor material and through the systematically technical design of multi-scale surface micro-shaping and microstructural surface processing, and realizing optional and controllable preparation of semiconductor material surface having multi-scale microstructure such as micron, submicron and nano. The invention solves the technical problems such as high cost, low efficiency and difficult operation in traditional preparation methods of microstructural surface with super-hydrophobic function.

Owner:JIANGSU UNIV

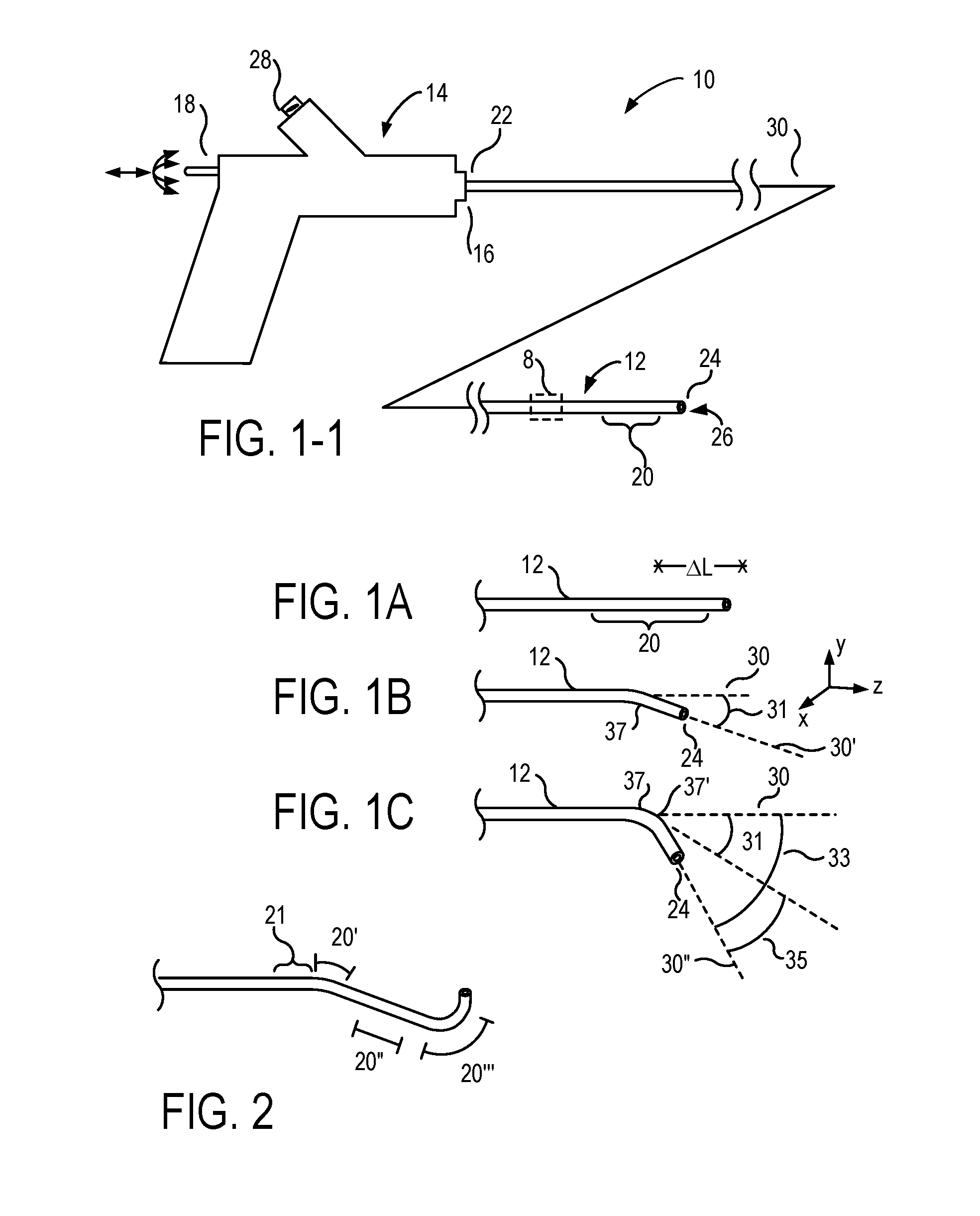

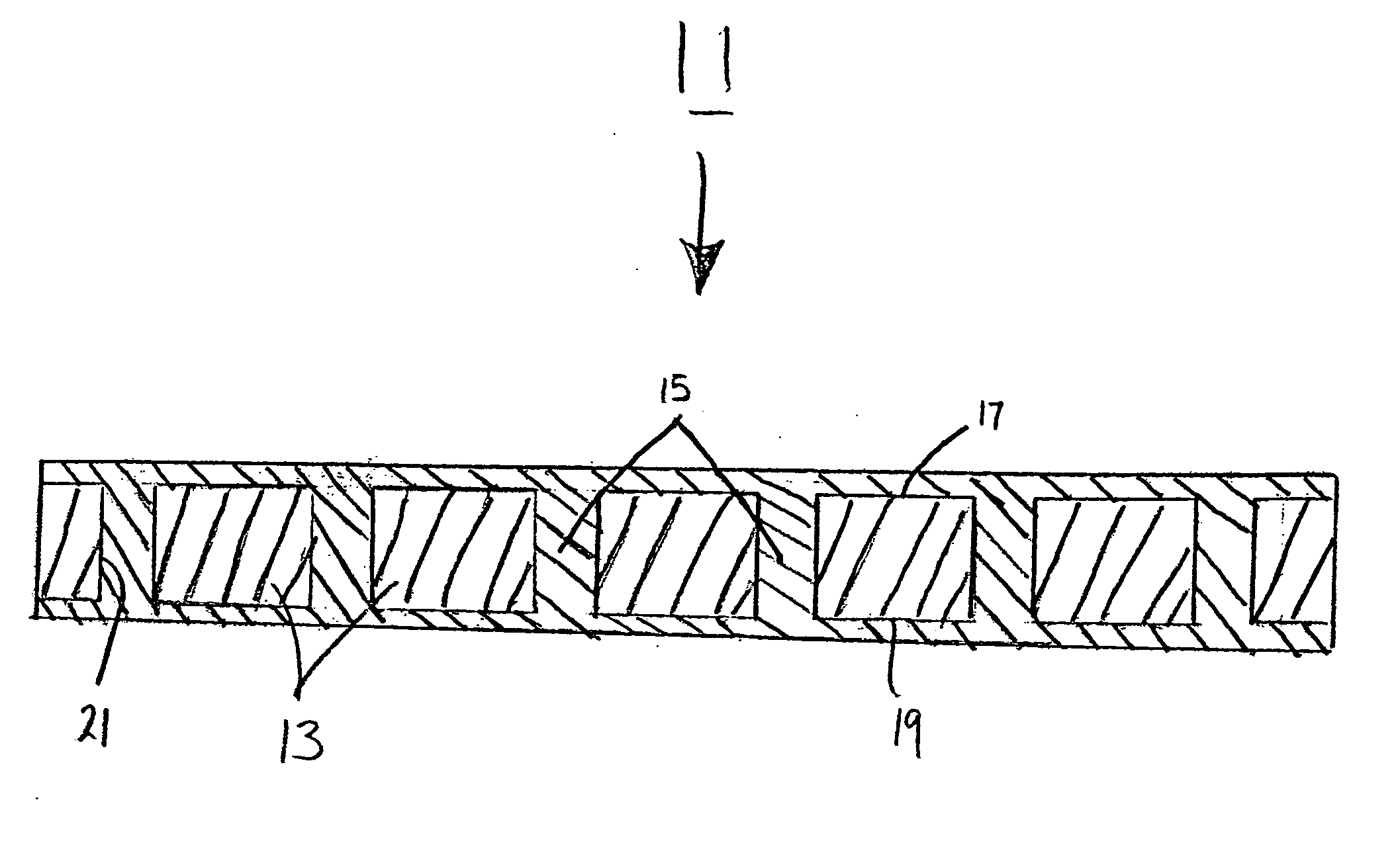

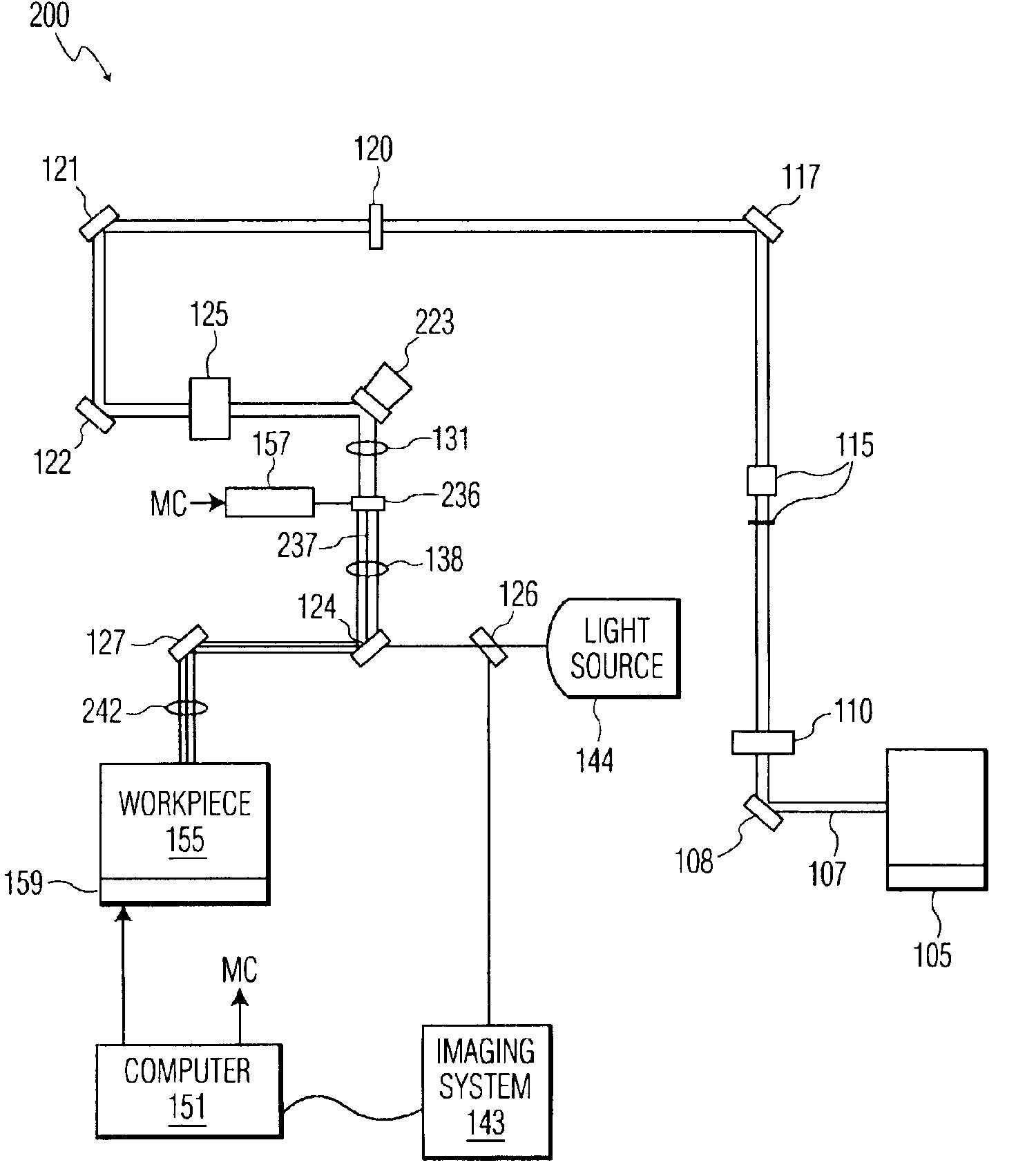

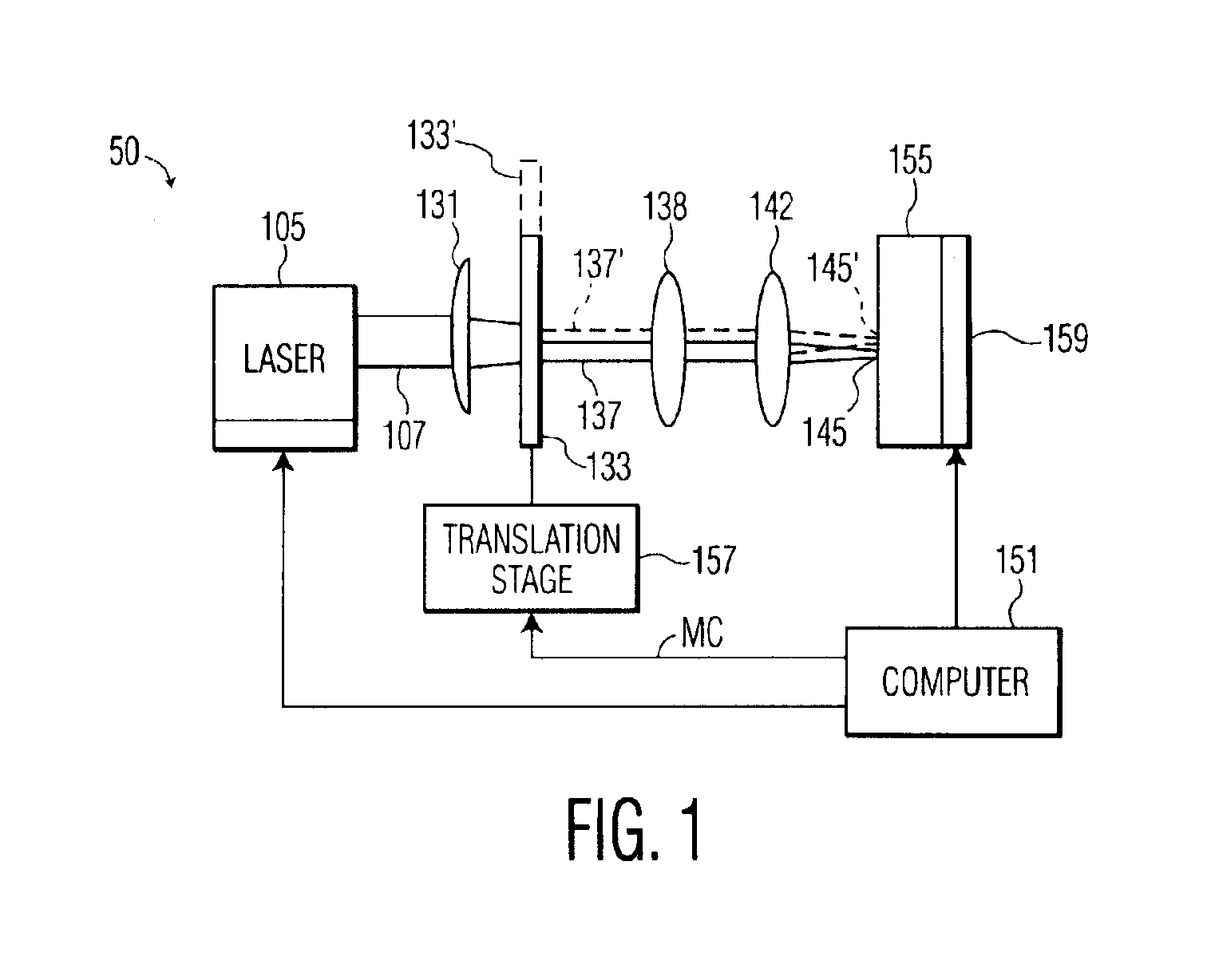

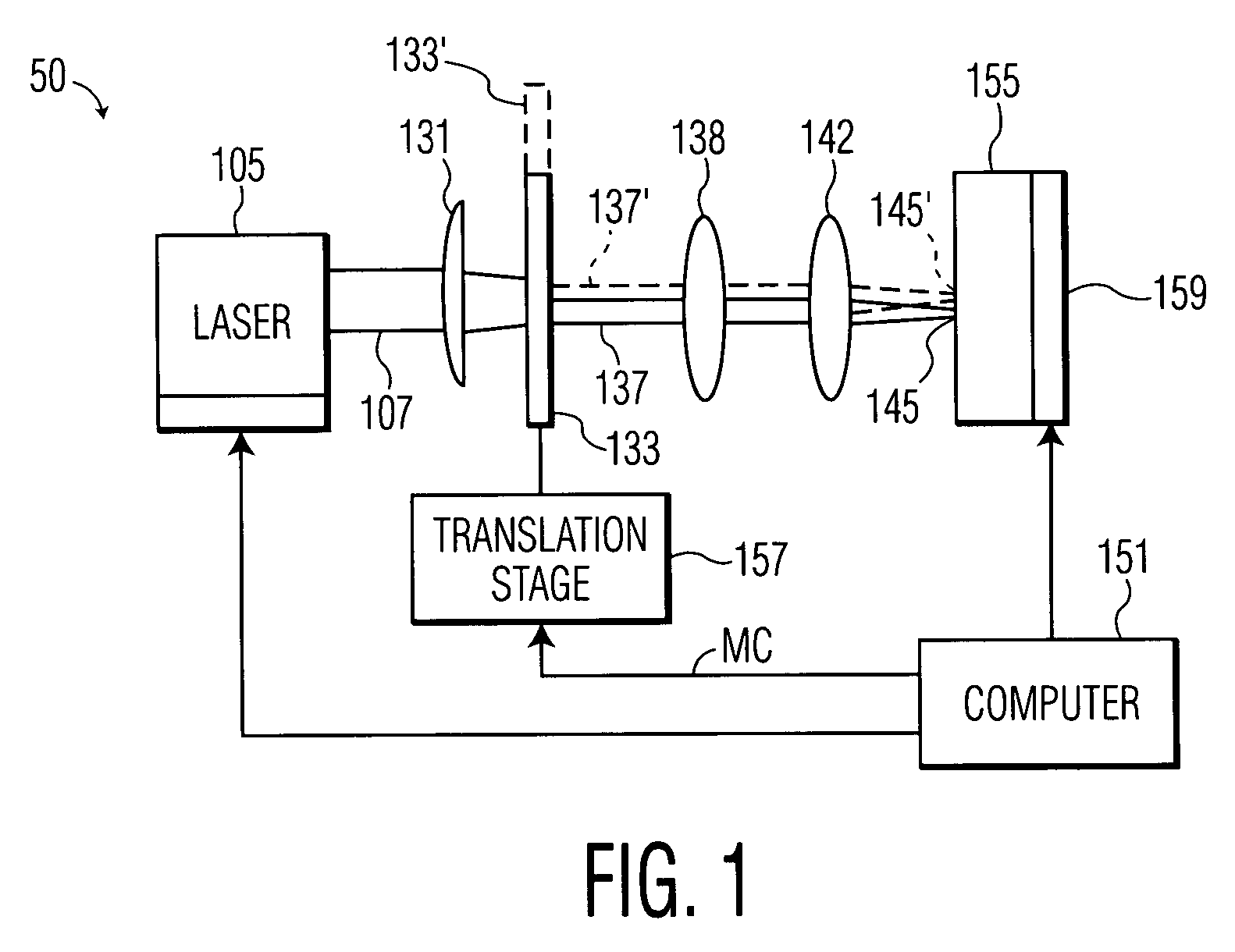

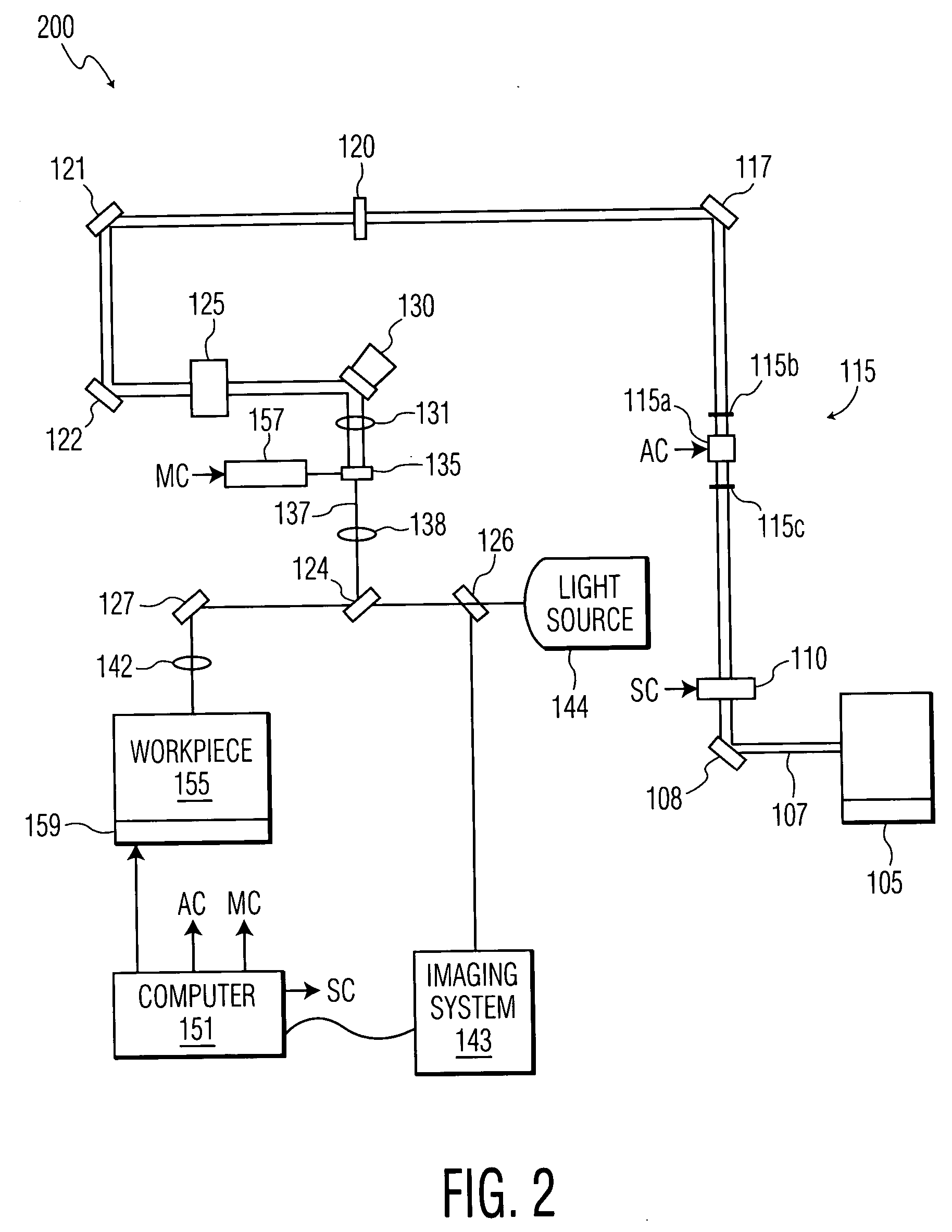

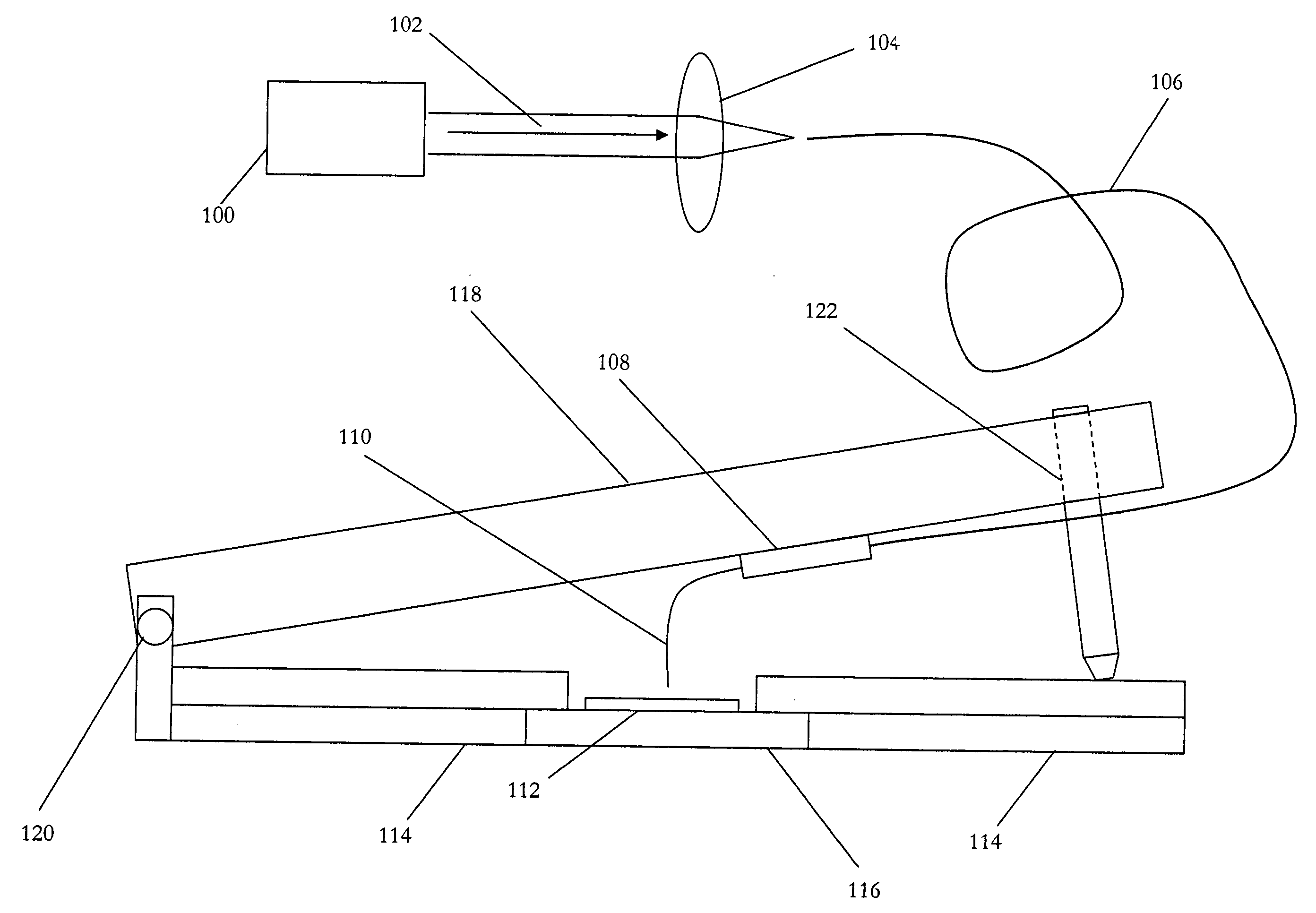

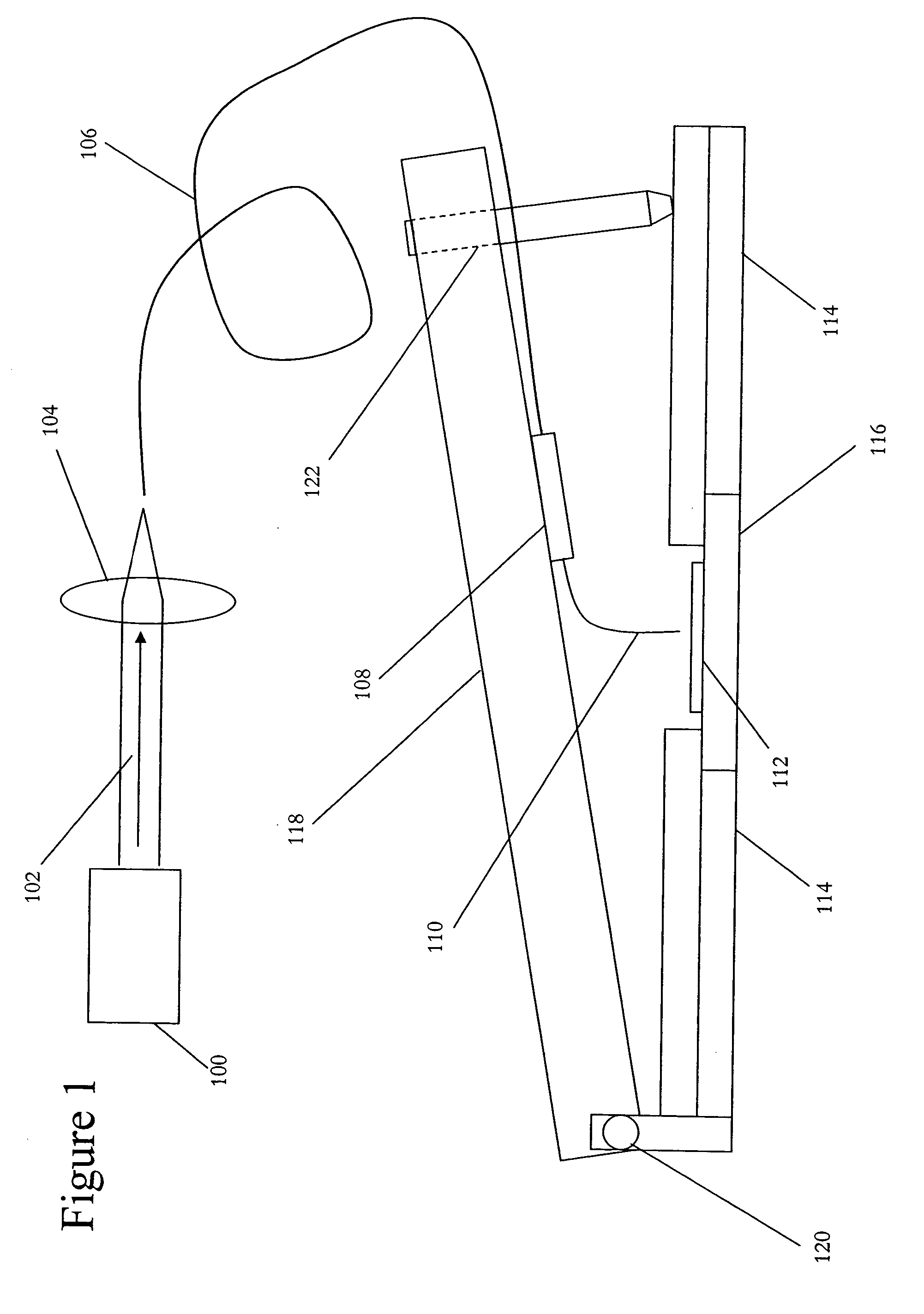

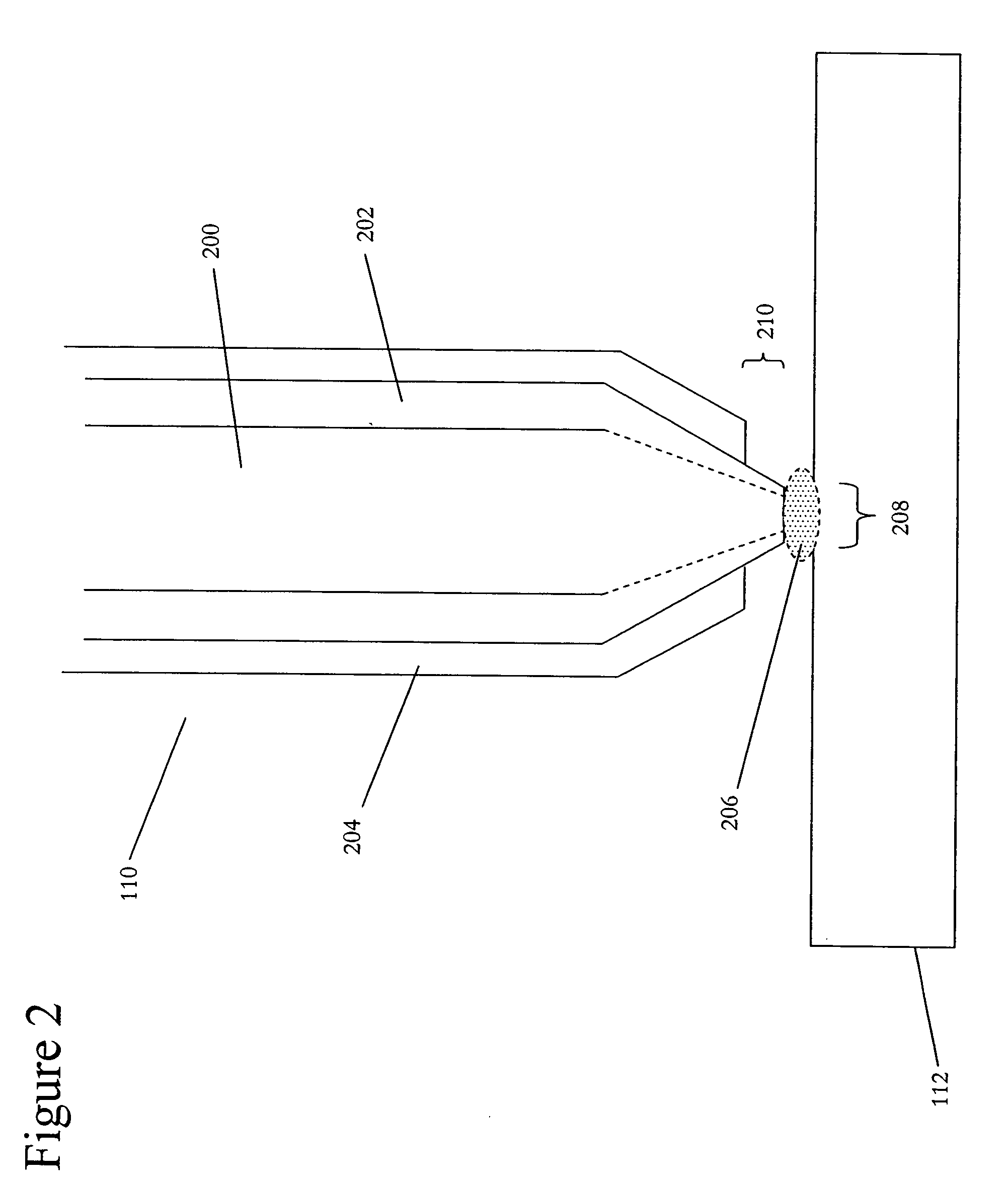

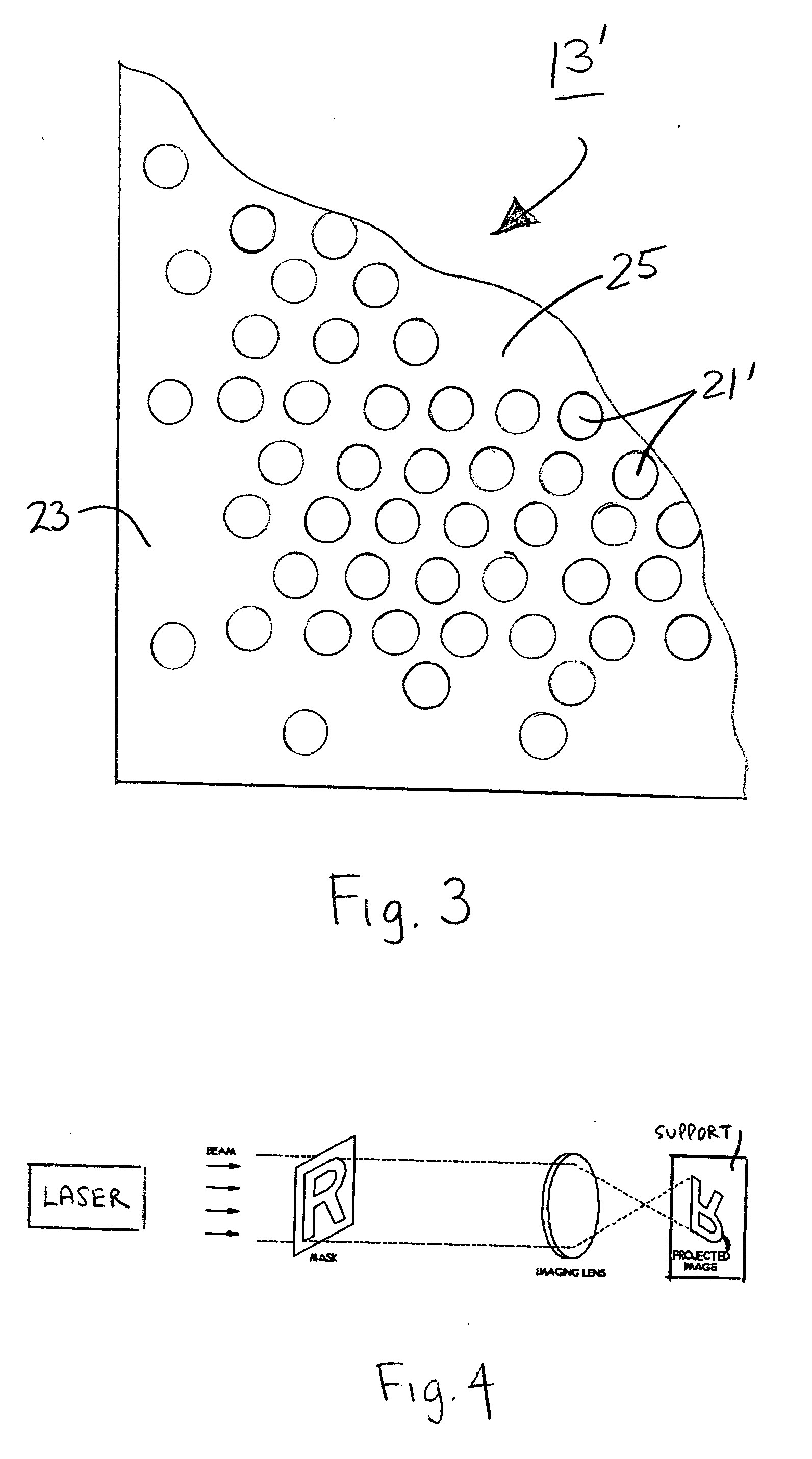

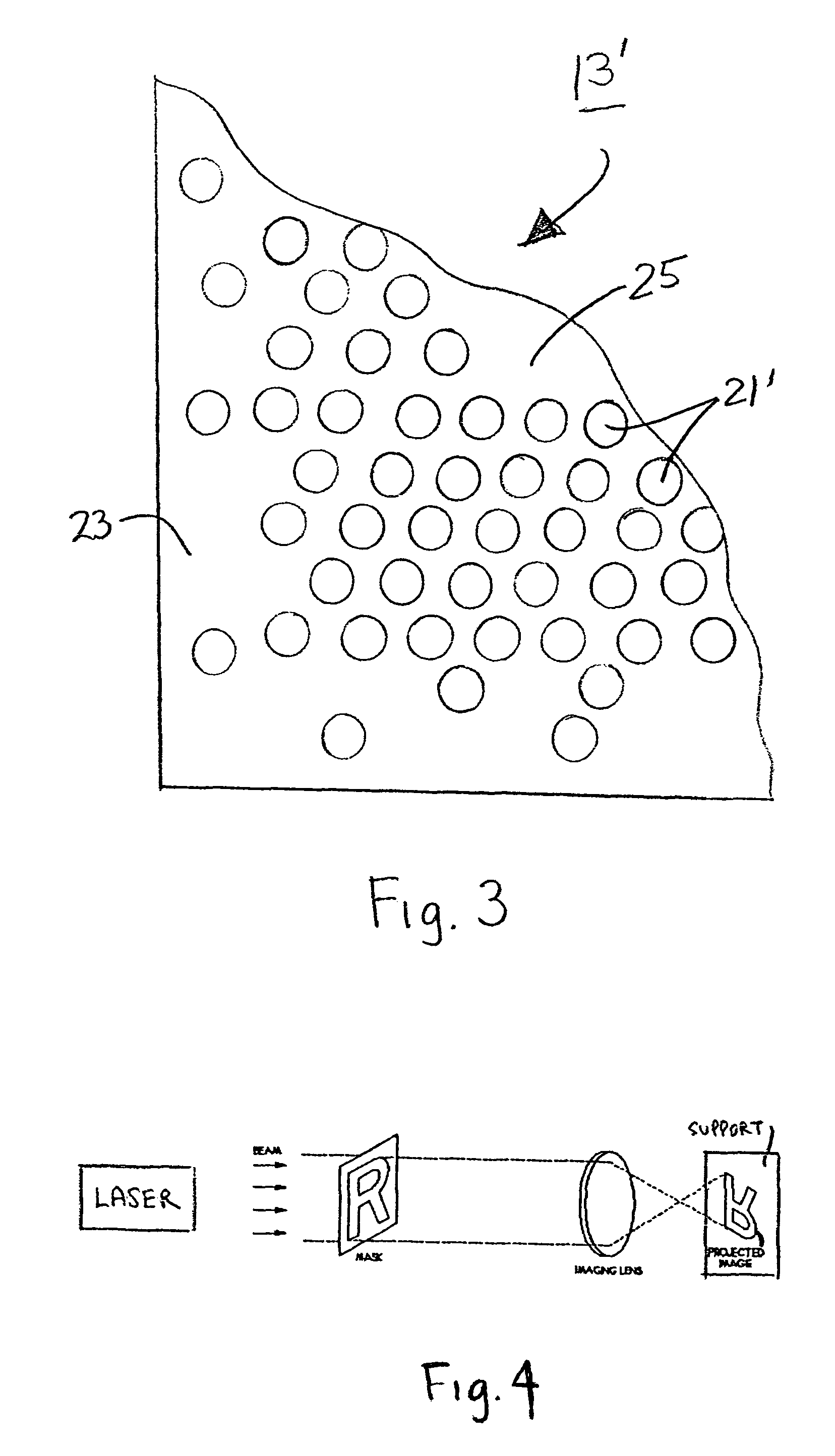

Precision laser micromachining system for drilling holes

InactiveUS20050103759A1Optical resonator shape and constructionWelding/soldering/cutting articlesReduced sizeLight beam

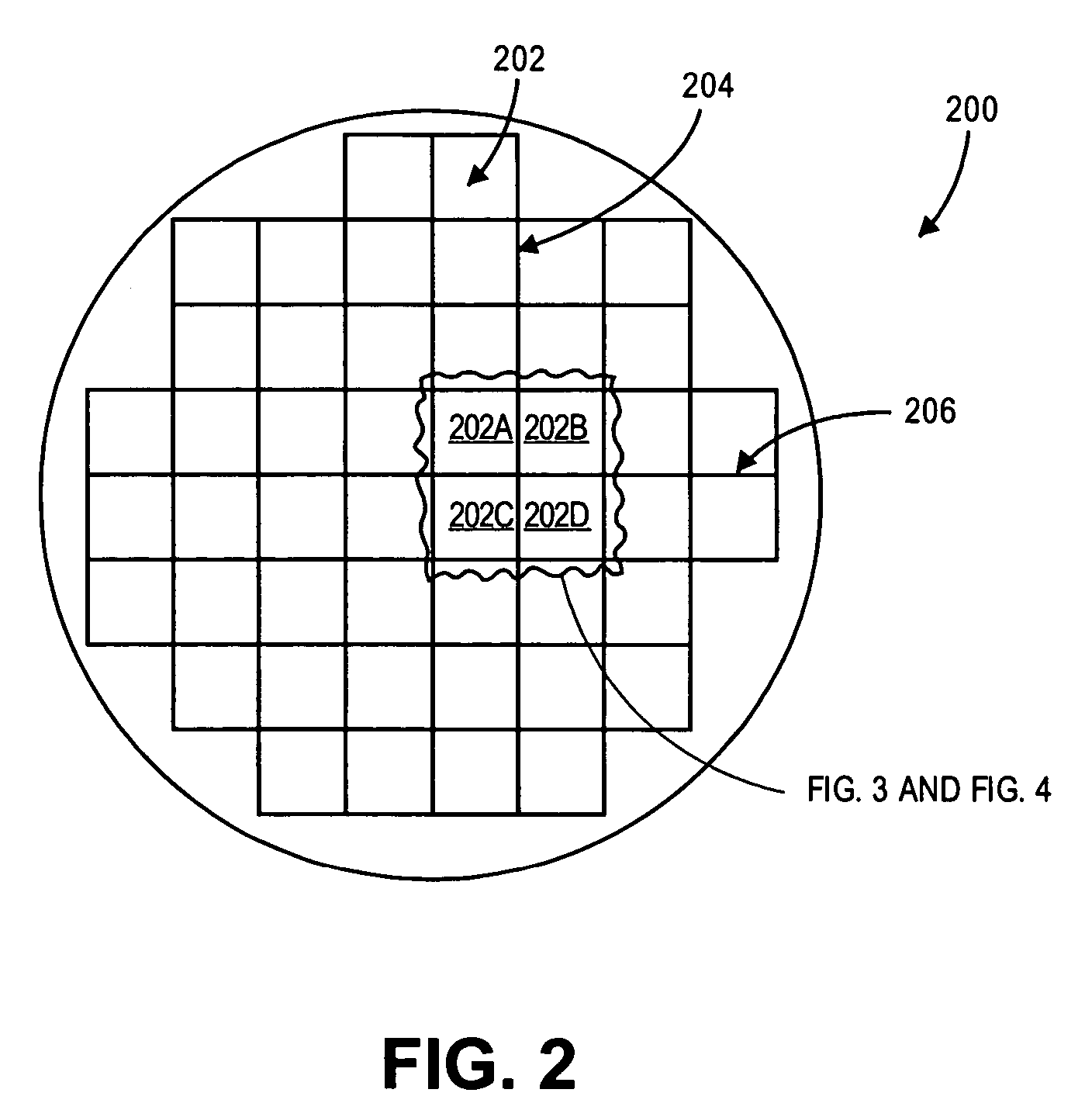

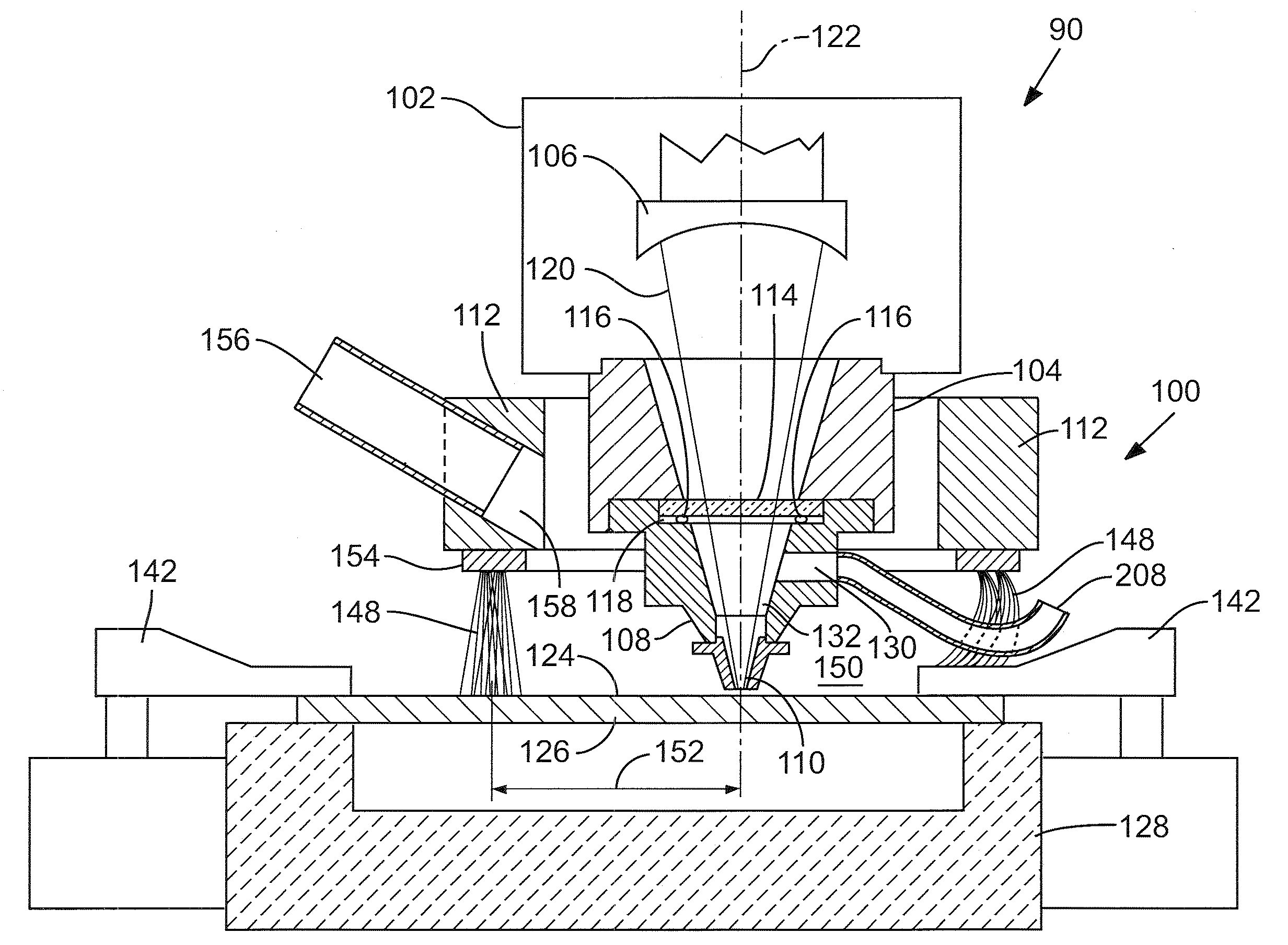

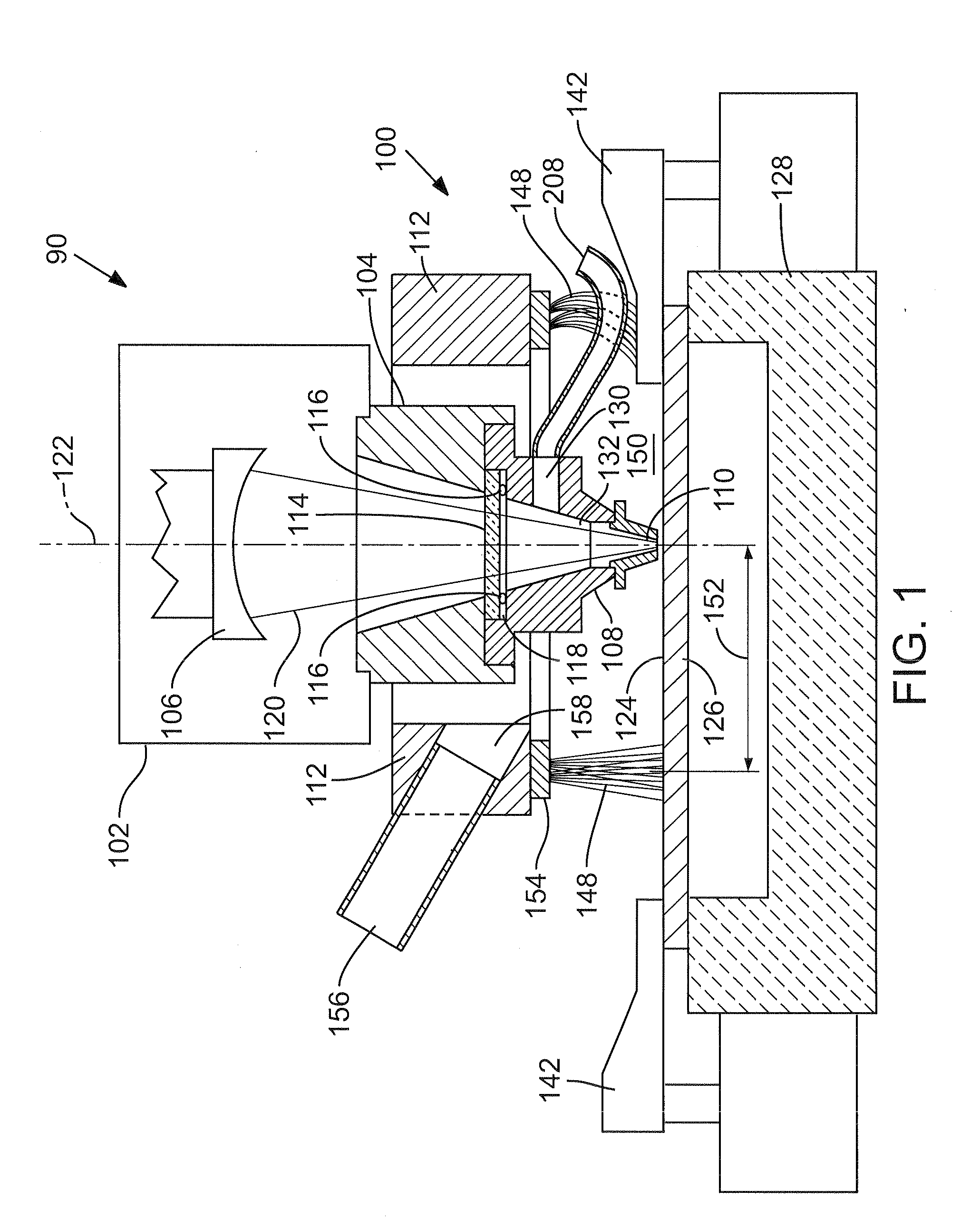

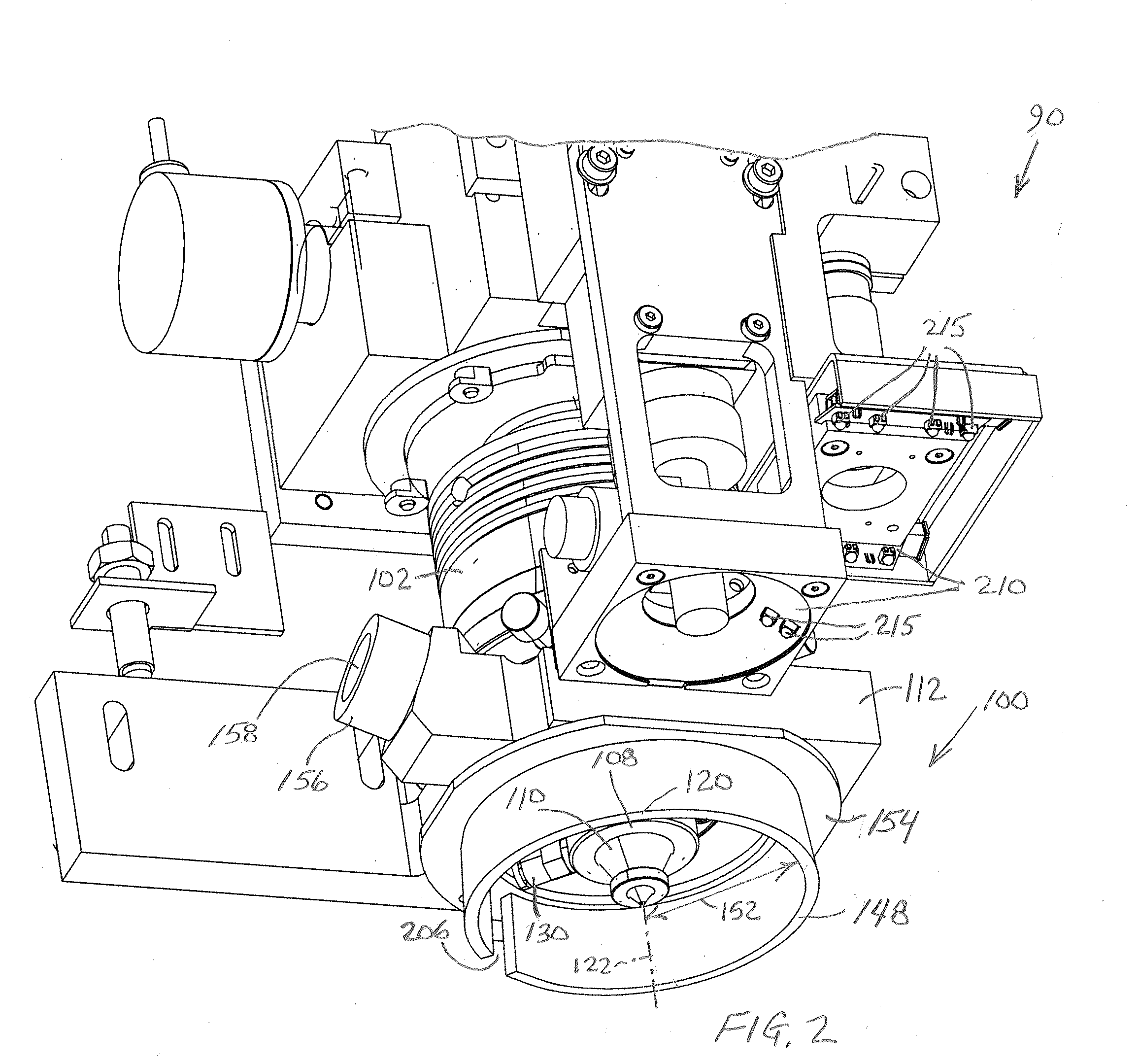

A laser drilling system for drilling holes in a work piece with a laser. The system includes: a laser for creating a laser beam and directing the laser beam along an optical path; a mask having at least one aperture, the mask and the aperture being located in the optical path to cause the creation of a sub-beam; a lens for forming a reduced-size image of the sub-beam onto the work piece and a translation stage for moving the mask to change the position of the sub-beam on the work piece. The laser beam has a wavefront cross-section with an area greater than the size of the aperture and is incident upon the mask and the aperture to create the sub-beam.

Owner:LI MING +2

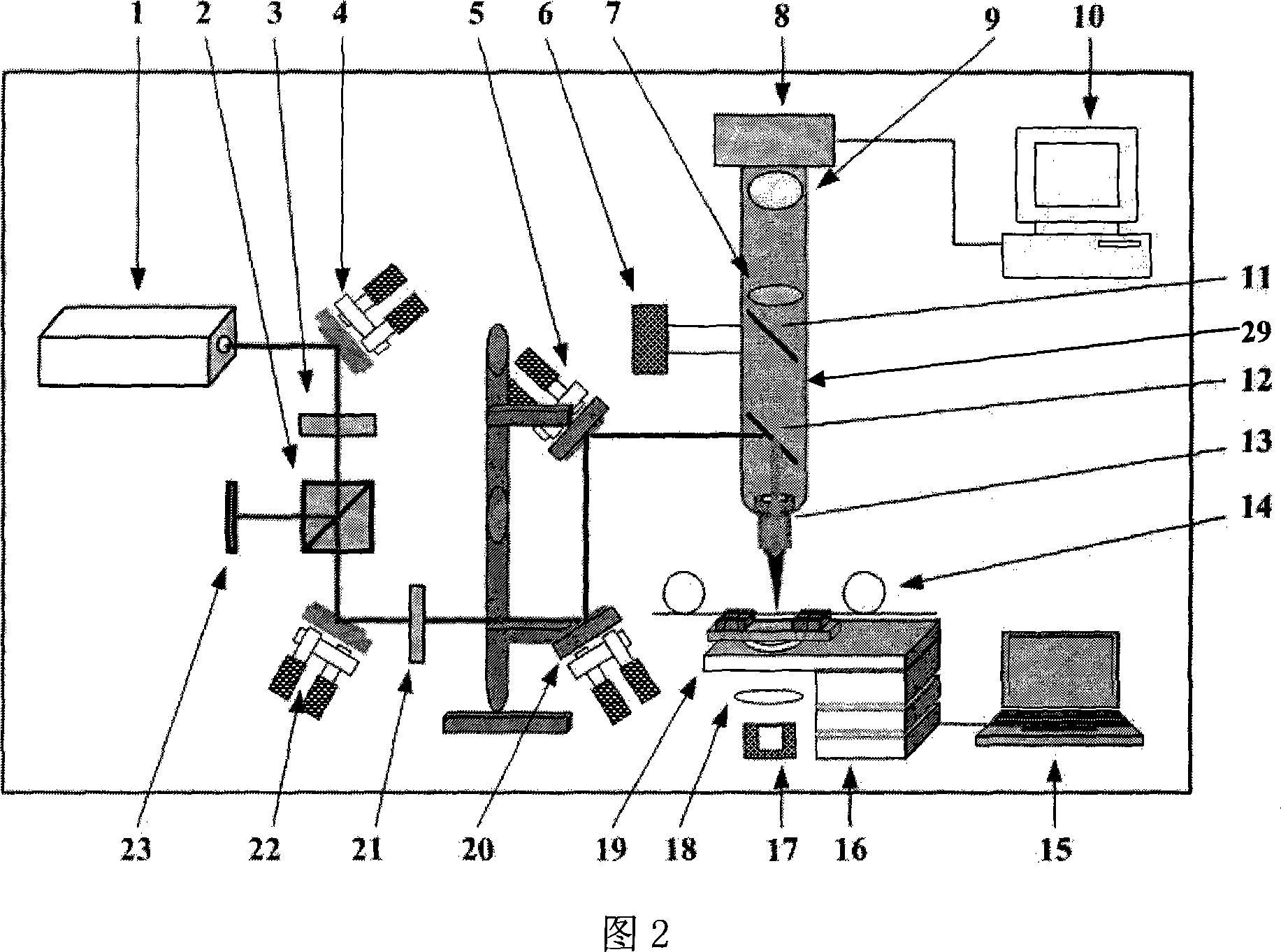

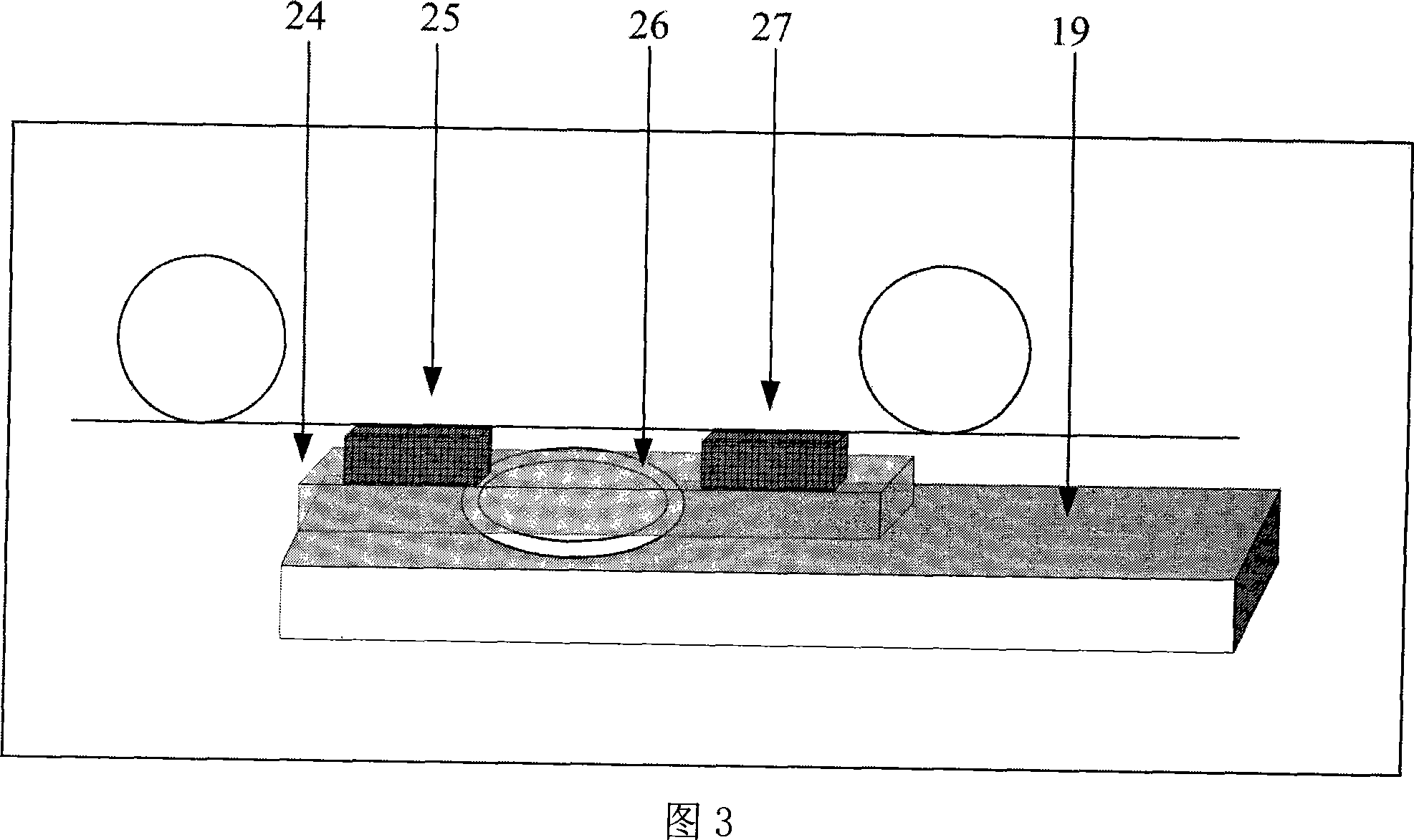

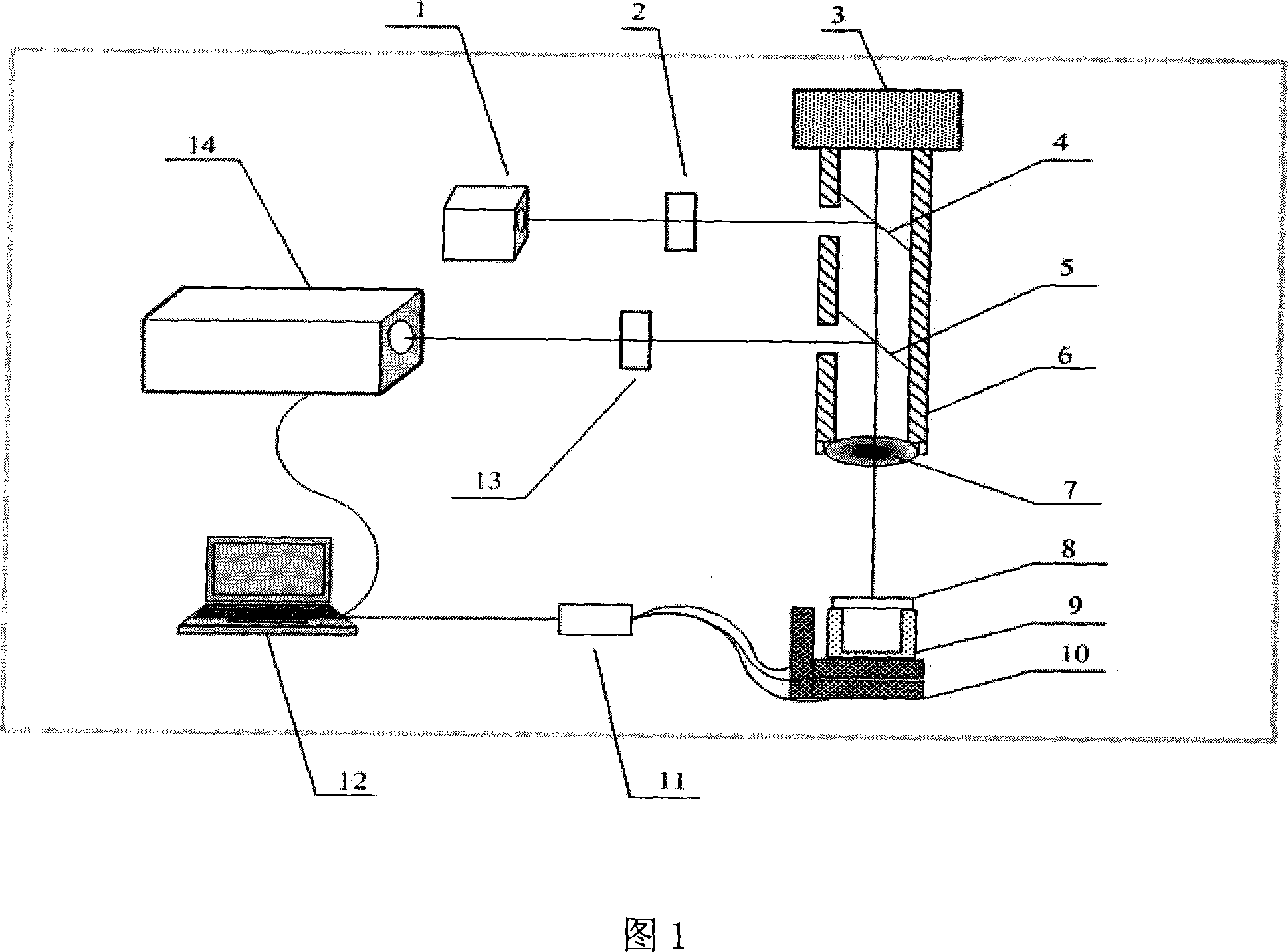

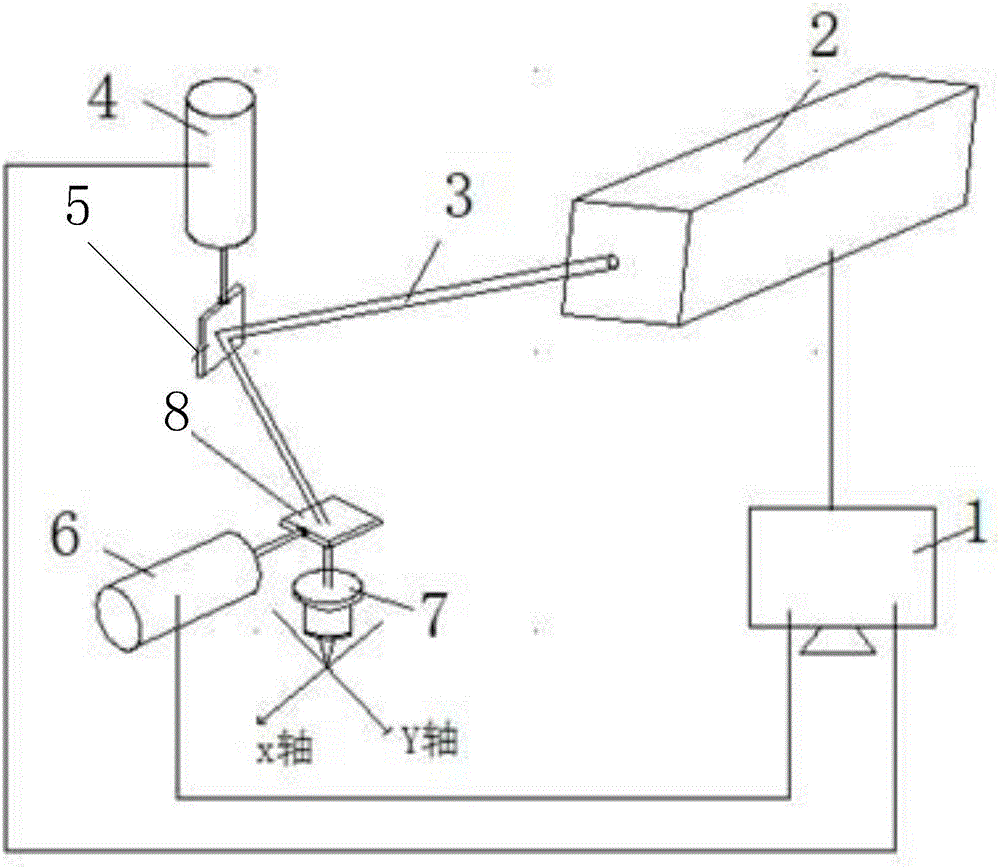

Method and apparatus for producing fibre-optical FP sensor by ultrashort pulse laser fine machining

InactiveCN101028670AImprove sensor sensitivityGood compatibilityLaser beam welding apparatusCcd cameraUltrashort pulse laser

An ultra-short pulse laser micromachining technology for preparing F-P sensor of optical fiber features that the ultra-short pulse laser beam is fully reflected by a full-reflecting mirror, then focused by a focusing system and finally used to machine an F-P cavity on an optical fiber to generate an F-P sensor, and the machined image and it position on optical fiber are reflected via a half-mirror to a CCD camera and then transmitted to a monitor. Its apparatus is also disclosed.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method and apparatus for ultrashort pulse laser parallel fine machining

InactiveCN101028671AImprove processing efficiencyPrevent sputtering and contaminationLaser beam welding apparatusLaser processingOptoelectronics

A parallel ultra-short pulse laser micromachining technology is characterized by that an ultra-short pulse laser beam passes through a microlense array to become multiple divergent ultra-short pulse laser beams, which are then focused onto a focal plane on a workpiece by a focusing system for micromachining on it. Its apparatus is also disclosed.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

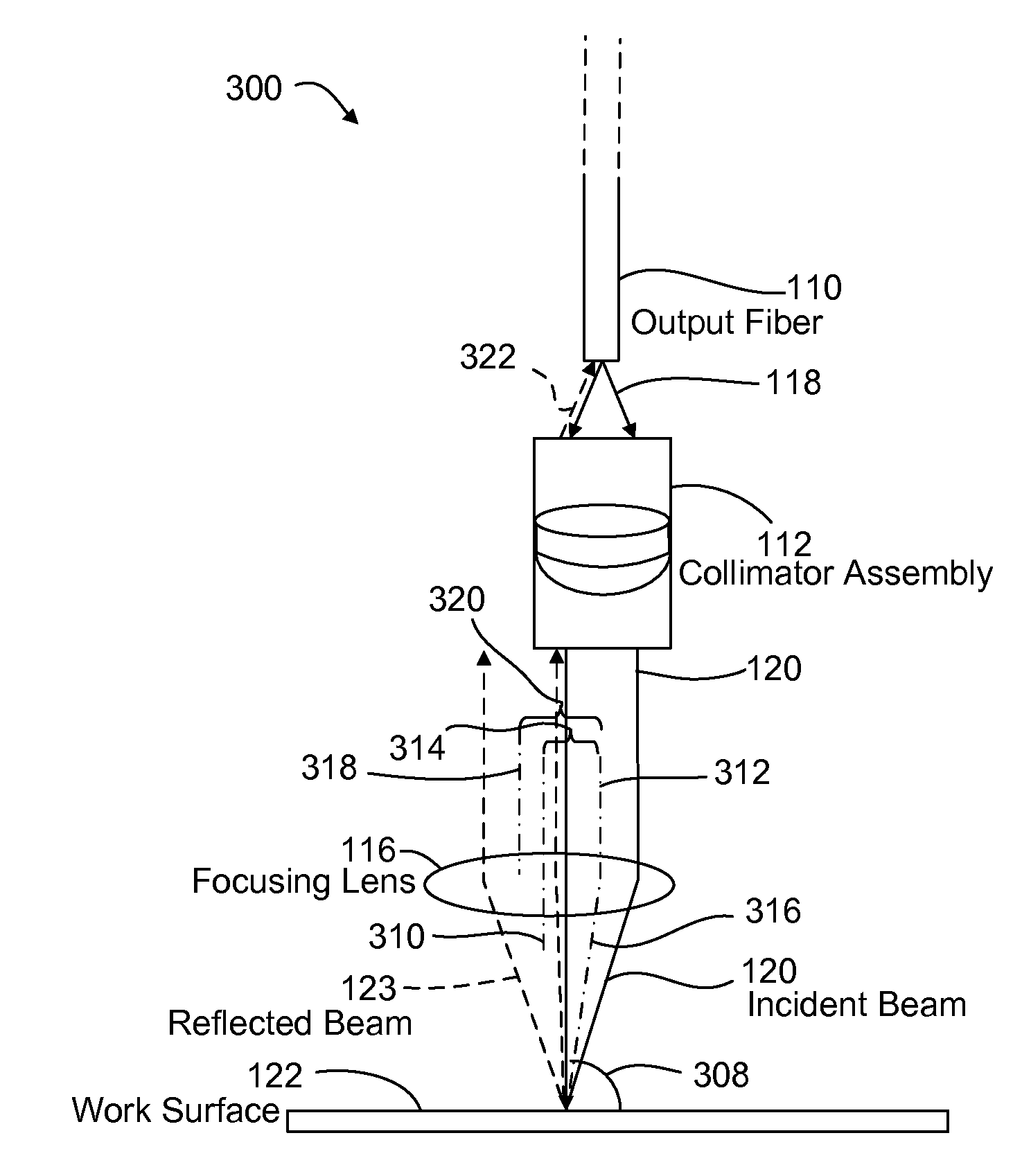

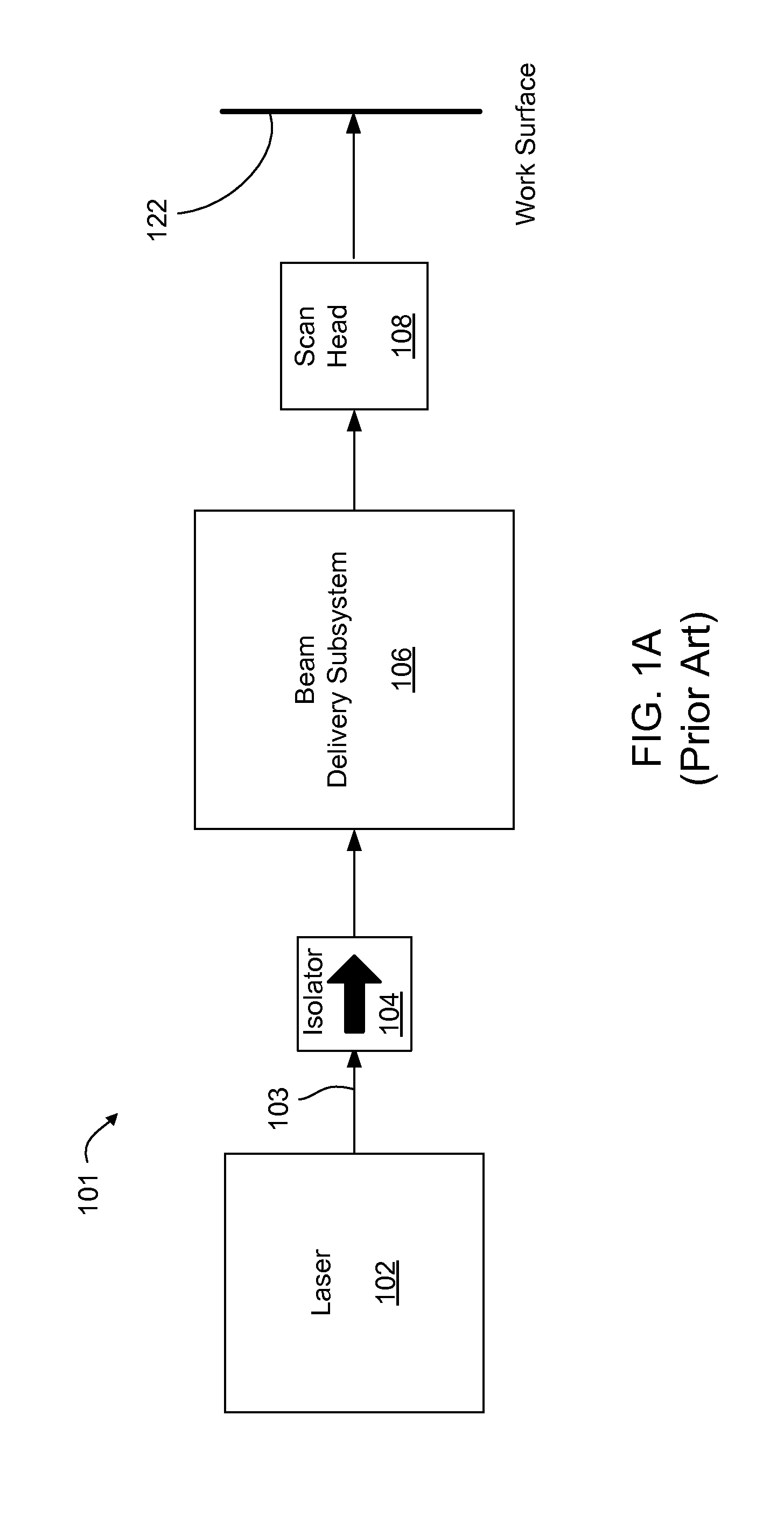

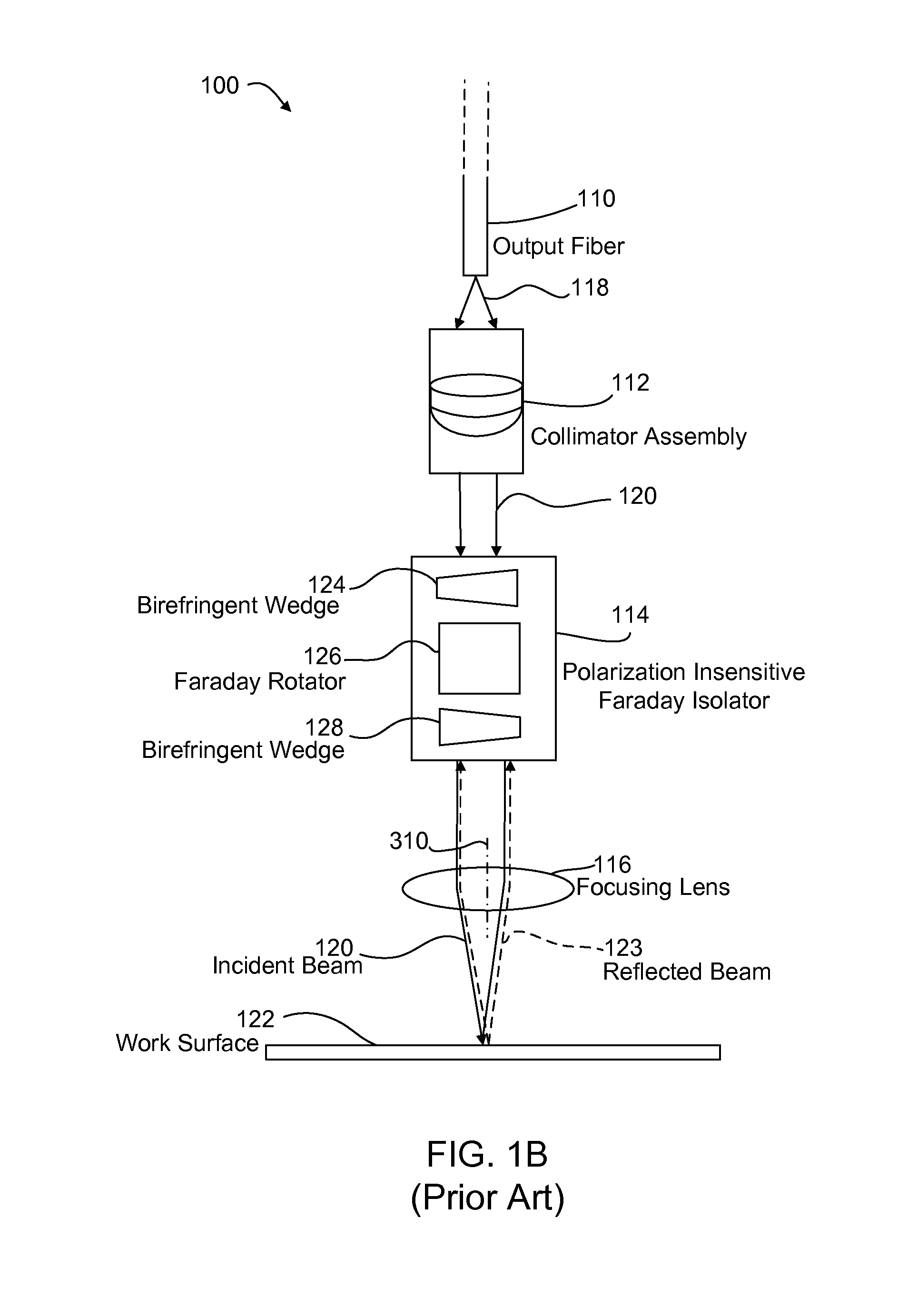

Reducing back-reflection in laser micromachining systems

InactiveUS20120152918A1Reduce and prevent back-reflectionsReduce the overall diameterLaser detailsLaser beam welding apparatusBeam expanderLaser processing

Systems and methods reduce or prevent back-reflections in a laser processing system. A system includes a laser source to generate an incident laser beam, a laser beam output to direct the incident laser beam toward a work surface along a beam path, and a spatial filter. The system further includes a beam expander to expand a diameter of the incident laser beam received through the spatial filter, and a scan lens to focus the expanded incident laser beam at a target location on a work surface. A reflected laser beam from the work surface returns through the scan lens to the beam expander, which reduces a diameter of the reflected beam and increases a divergence angle of the reflected laser beam. The spatial filter blocks a portion of the diverging reflected laser beam from passing through the aperture and returning to the laser beam output.

Owner:ELECTRO SCI IND INC

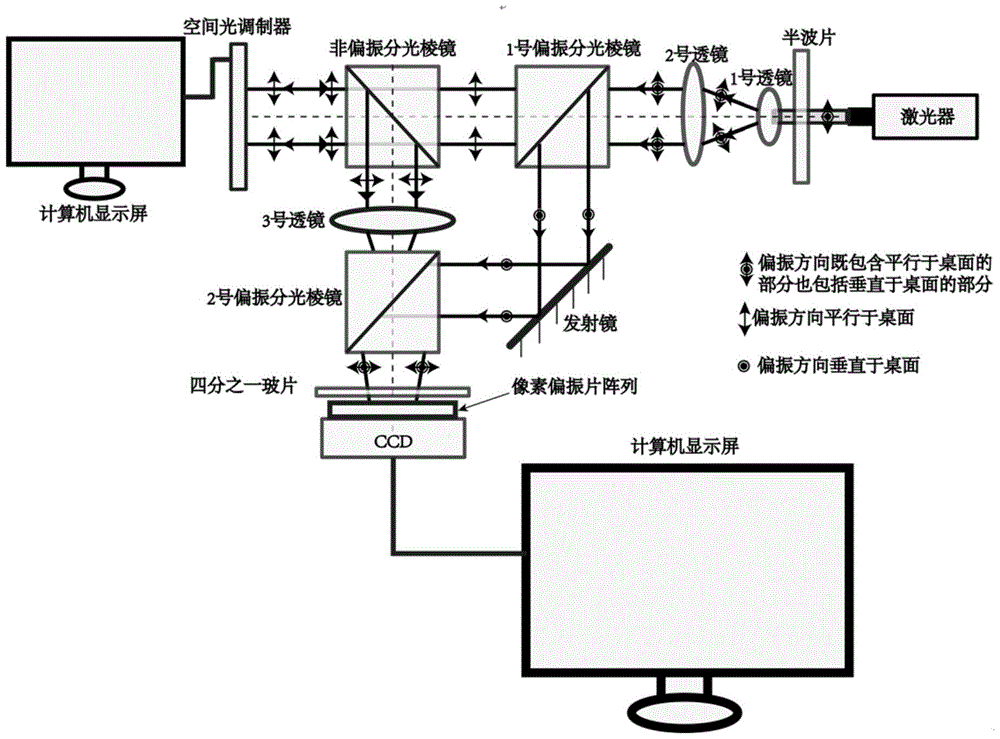

Method for real-time detection of diffraction phase of structure light field

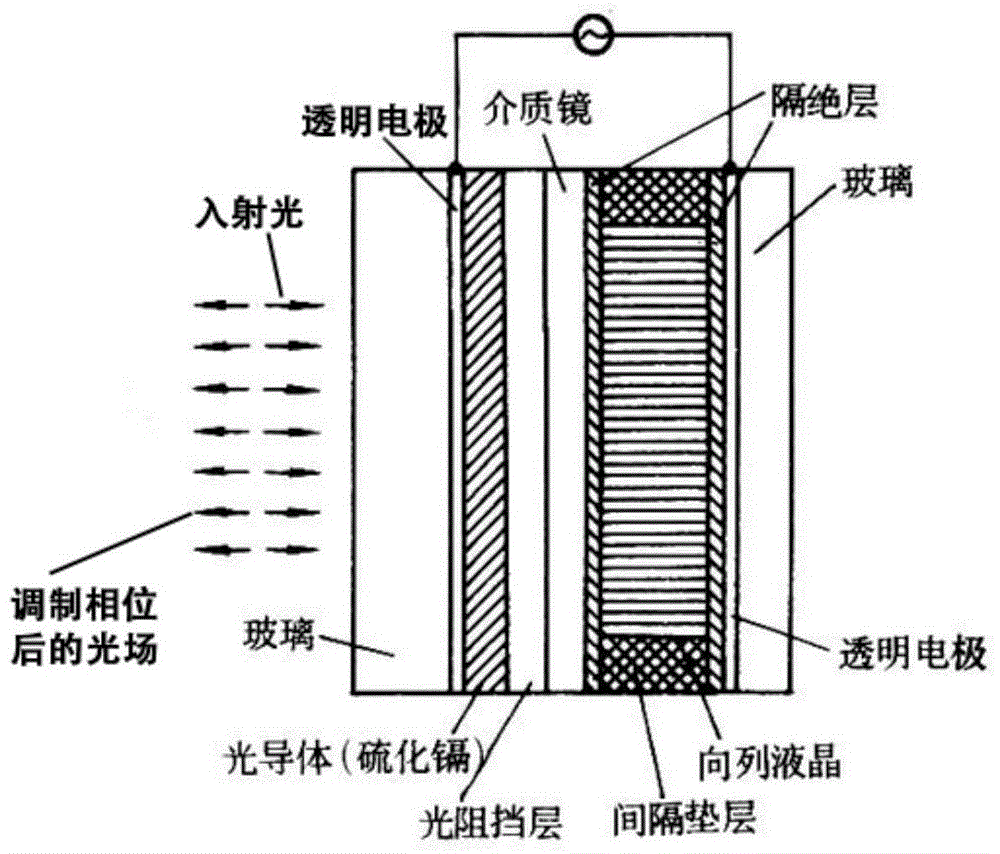

InactiveCN105675150AOvercome the disadvantage of not being able to measure dynamic light fieldsReduce the cumbersomeness of useOptical measurementsPhotometry using electric radiation detectorsSpatial light modulatorPolarizer

The invention discloses a method for real-time detection of the diffraction phase of a structure light field. The method includes the steps of: utilizing a camera integrated with a pixel polarizing film array to collect fringe patterns generated by interference of reference light beam output through a preset optical path and structured light beam generated by adjustment of a spatial light modulator, the dimensions of each polarizing film unit in the pixel polarizing film array and pixel dimensions of a photosensitive element in the camera being consistent and in one-to-one alignment; and extracting four fringe patterns of different polarization directions from the fringe patterns generated by interference of the structured light and the reference light according to the polarization directions of the polarizing film units so as to calculate the diffraction phase of the structure light field. The method disclosed by the invention realizes real-time measurement of light intensity and phase information of the structure light field, enables a user to deeply know physical characteristics of the structure light field, and has a very large driving function for the structure light field in the fields of optical tweezers, laser micromachining and optical signal propagation.

Owner:UNIV OF SCI & TECH OF CHINA

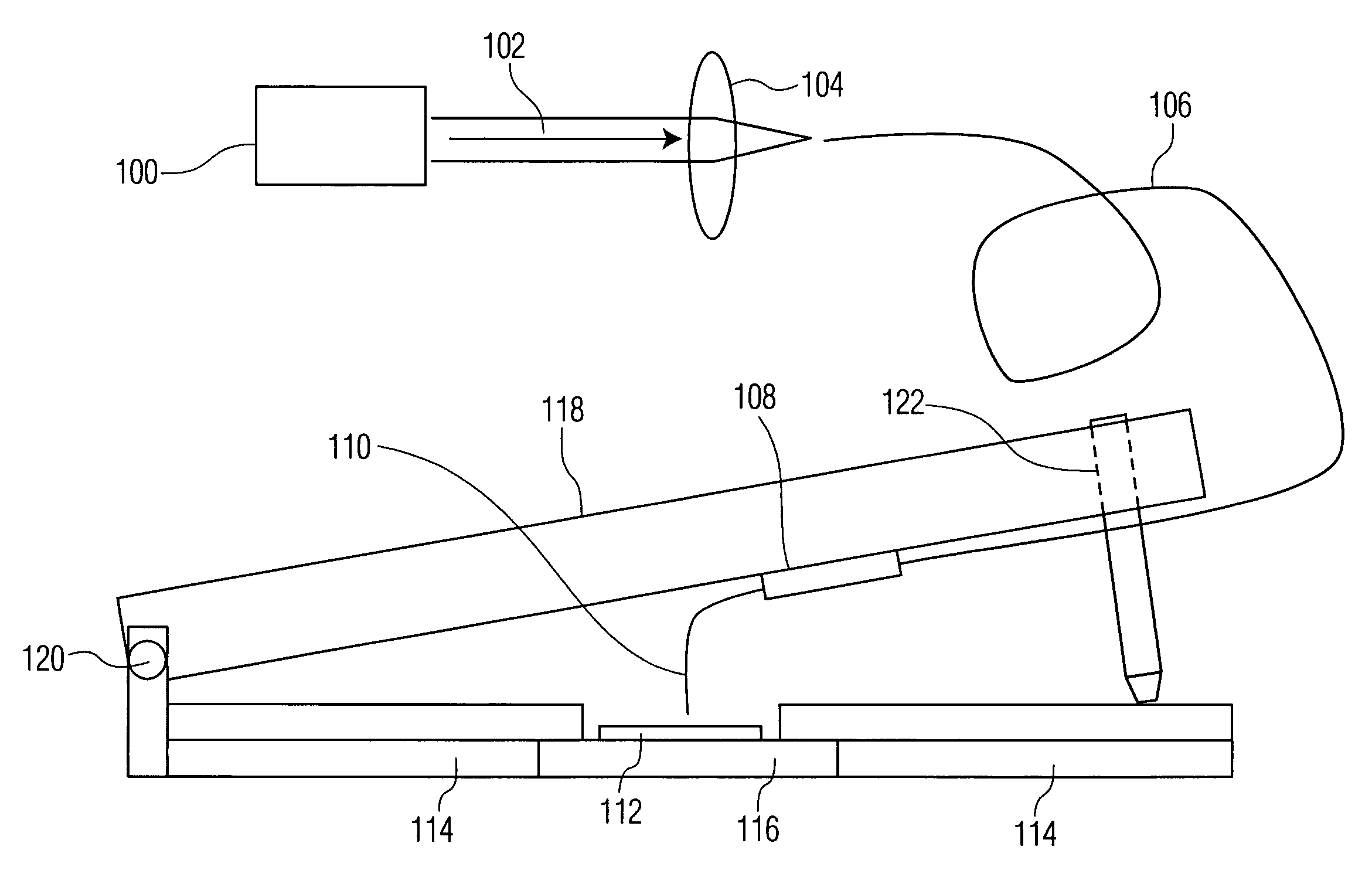

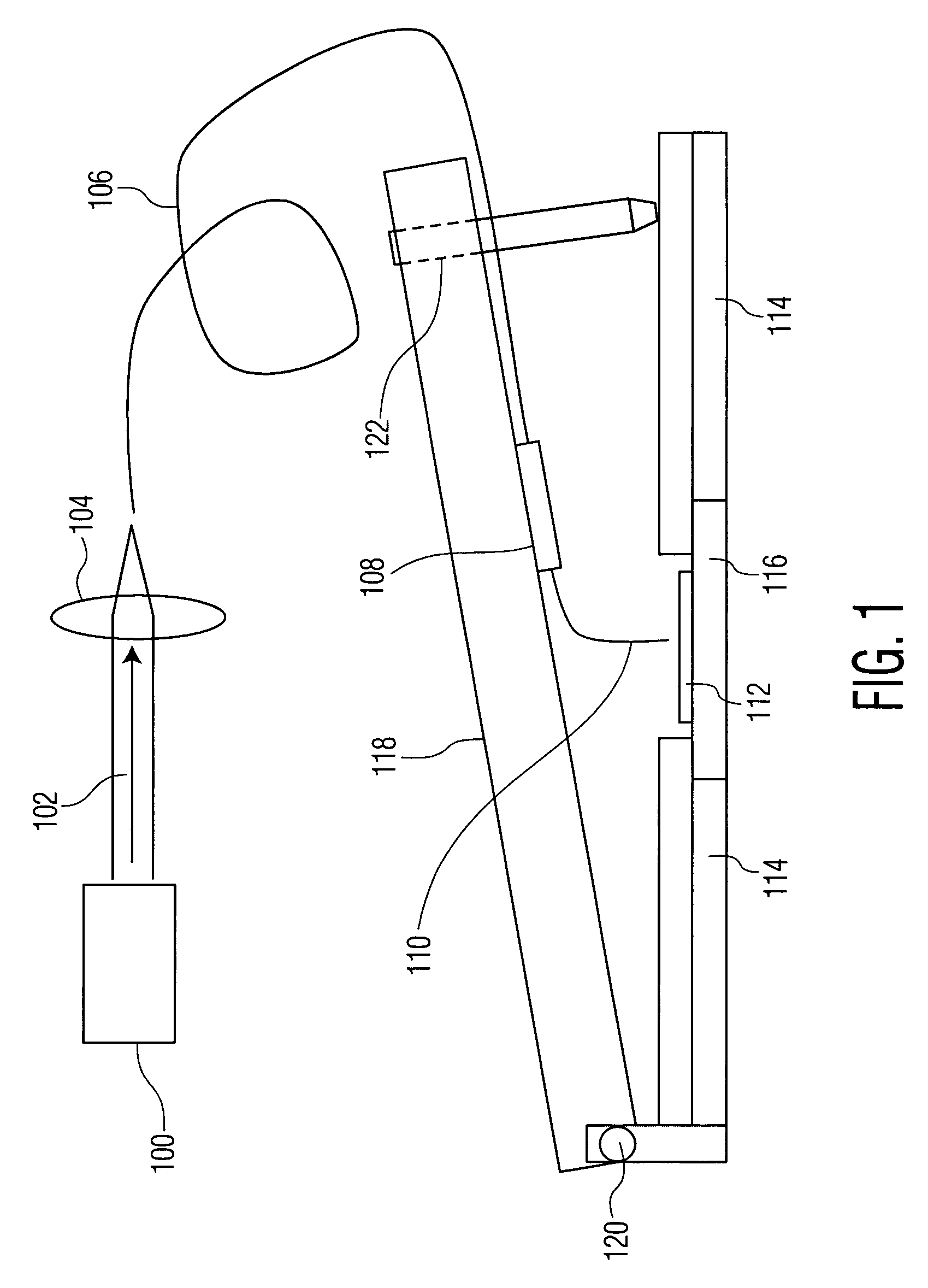

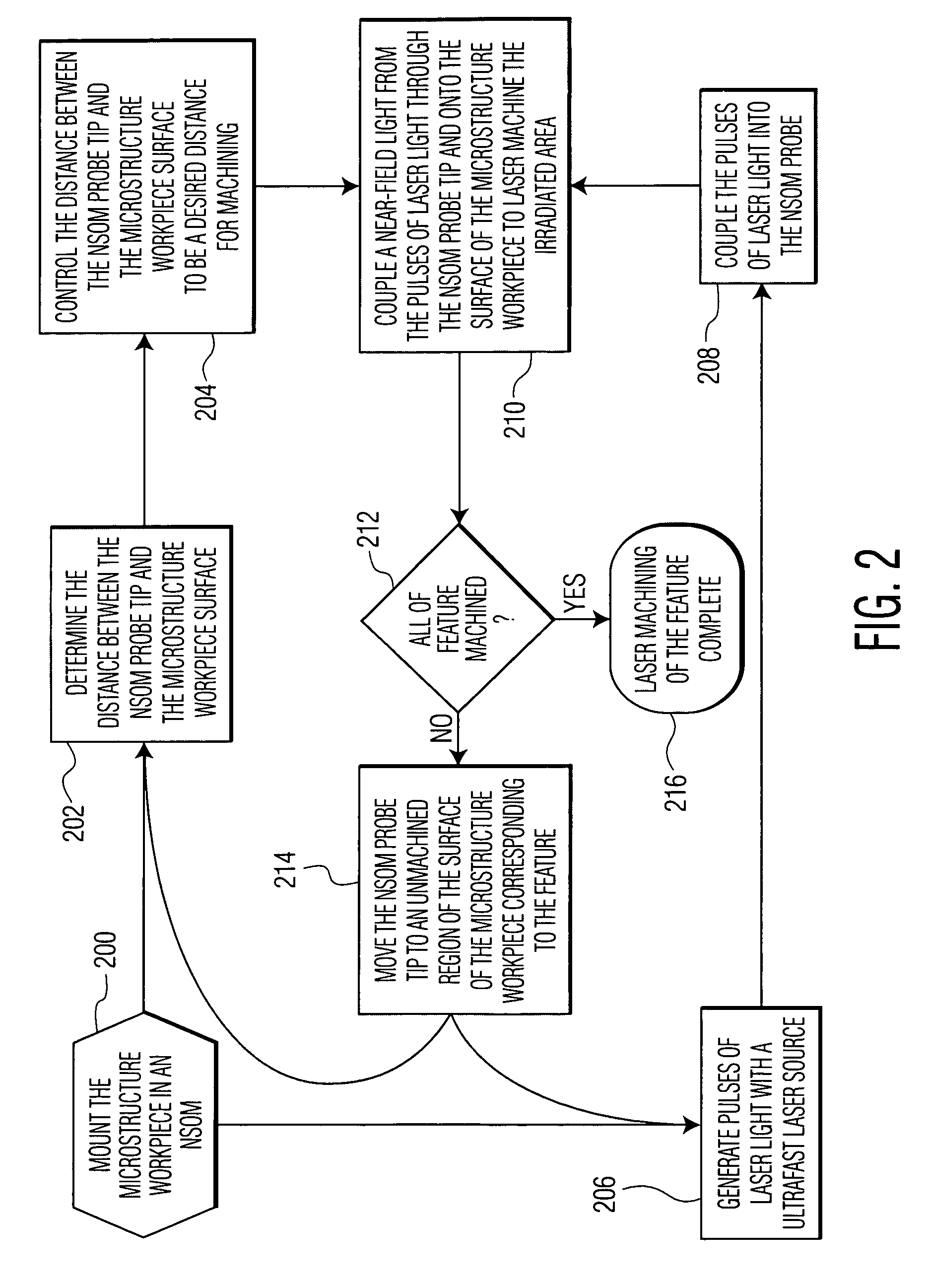

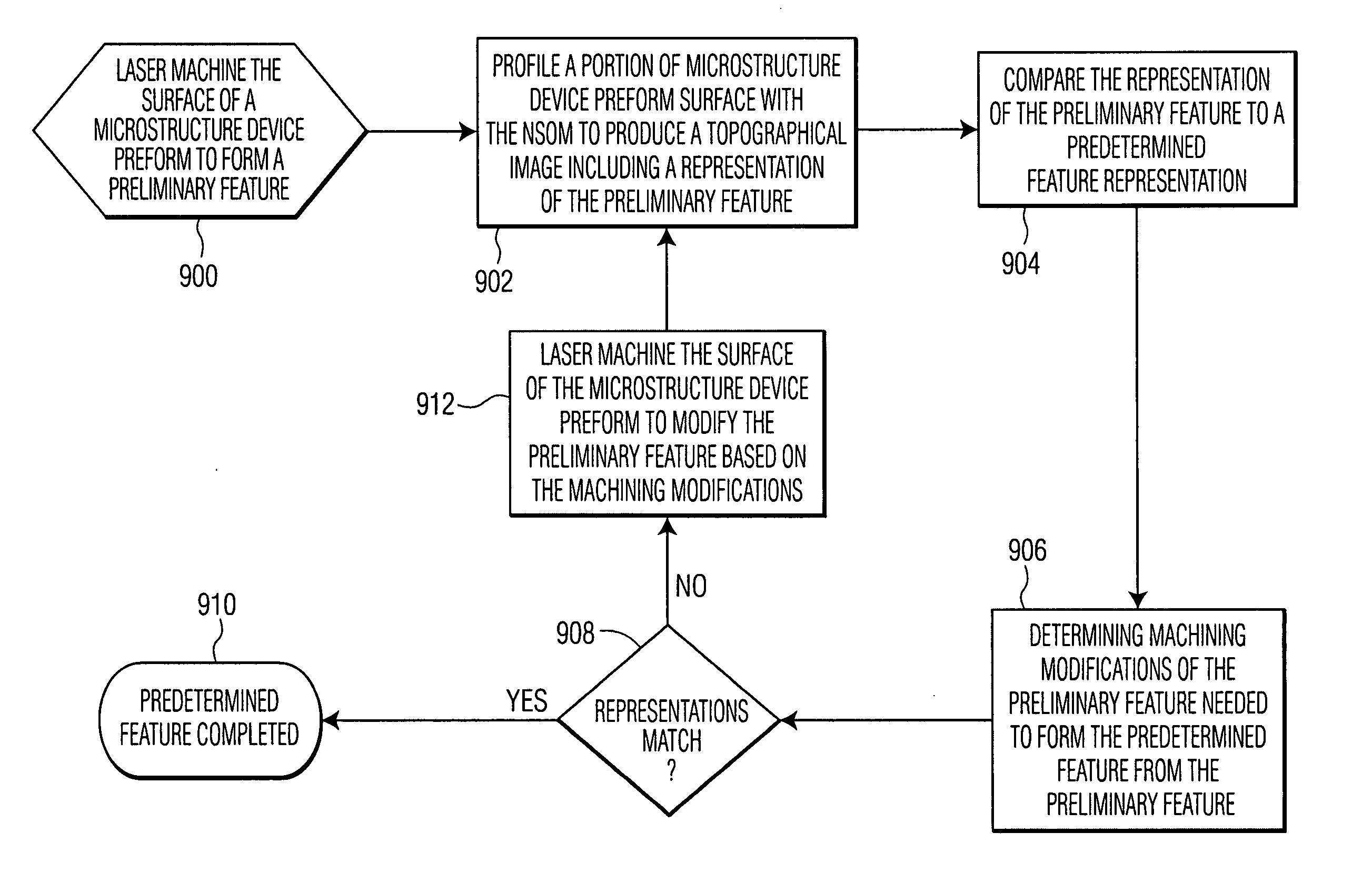

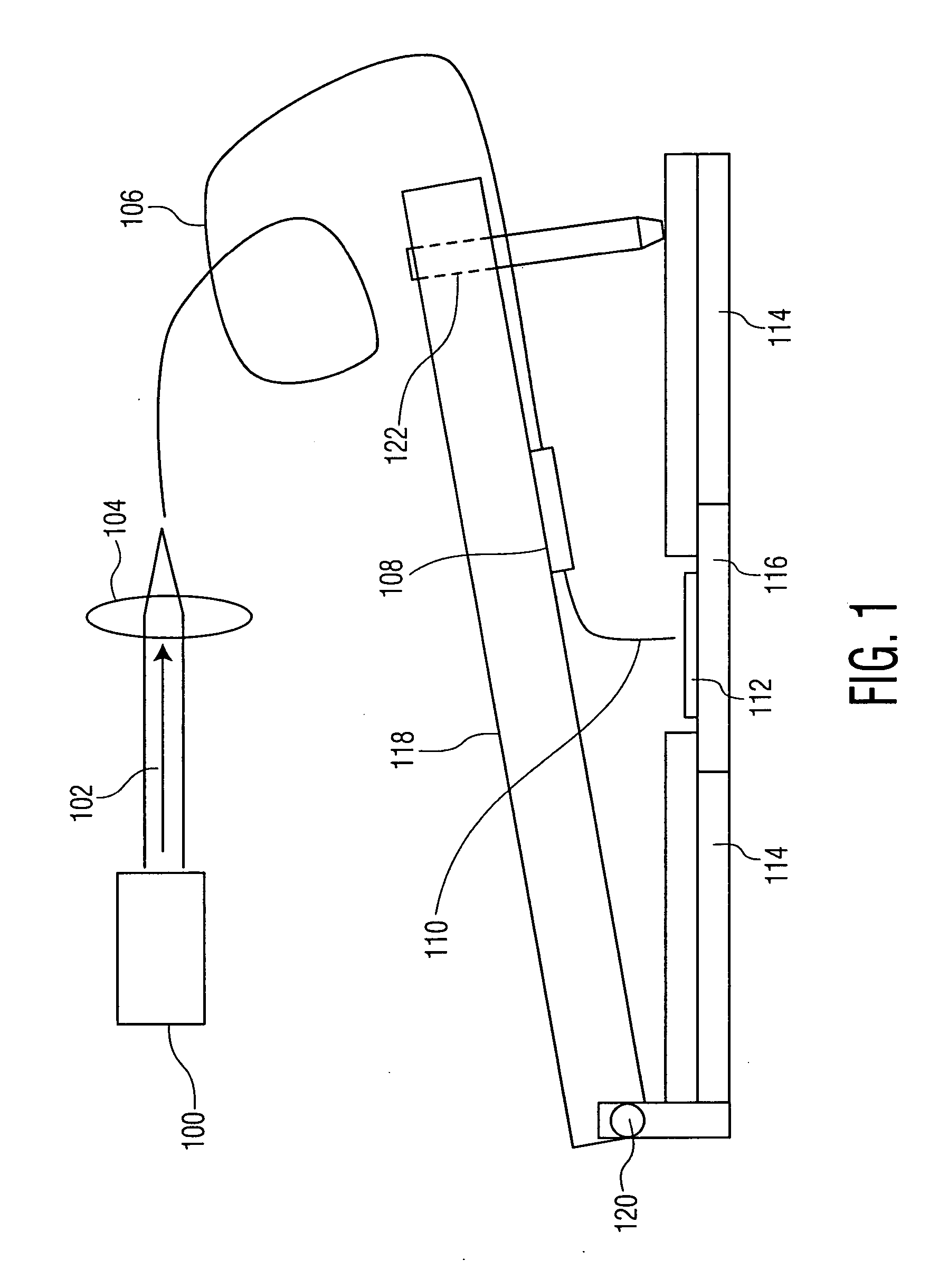

Near-field scanning optical microscope for laser machining of micro- and nano- structures

InactiveUS7053351B2Material analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsLaser lightNear-field scanning optical microscope

A near-field scanning optical microscope (NSOM) laser micromachining system for laser machining features on surfaces using an ultrafast laser source and a method of laser machining such features. The system includes: the ultrafast laser source to generate pulses of laser light having pulse durations less than 1 ns and a peak wavelength; an NSOM probe having a substantially cylindrical shape; an NSOM mount to controllably hold the NSOM probe and the microstructure workpiece to be machined; an NSOM probe monitor coupled to the NSOM mount for determining the distance between the probe tip of the NSOM probe and the surface; and an NSOM controller coupled to the NSOM probe monitor, and motion stages in the NSOM mount. The NSOM mount includes an XY motion stage and a Z motion stage. These motion stages are couple to either the NSOM probe or the microstructure workpiece, or one motion stage to each.

Owner:PANASONIC CORP

Precision machining method using a near-field scanning optical microscope

InactiveUS20060027543A1Material nanotechnologyNanoinformaticsScan lineNear-field scanning optical microscope

A method for manufacturing a microstructure device using a near field scanning optical microscope (NSOM) laser micromachining system. A microstructure device preform, including an existing feature, is provided. The NSOM probe tip is scanned over a portion of the preform selected such that a plurality of scan lines cross the existing feature. Scanned locations of the existing feature in at least two scan lines are determined. The orientation of the existing feature is determined based on the scanned locations and the shape of the existing feature. At least one expected machining location in a subsequent scan line is determined based on the shape and orientation of the existing feature. The micro-machining laser is pulsed as the NSOM probe is scanned through the expected machining location(s) during the subsequent scan lines to form at least one fine feature on the microstructure device preform, thus, completing the microstructure device.

Owner:PANASONIC CORP

Method for preparing aluminum alloy super-hydrophobic functional surface by laser marking machine

InactiveCN106400022ASimple preparation processRaw materials are easy to getMetallic material coating processesRough surfaceAlcohol

The invention belongs to the technical field of preparation of metal-based microstructural functional surfaces. A method for preparing an aluminum alloy super-hydrophobic functional surface by a laser marking machine comprises the following steps: (1) grinding, ultrasonically cleaning and drying an aluminum alloy sample to obtain a clean aluminum alloy sample; (2) performing laser micromachining: performing laser surface scanning treatment on the surface of the sample by adopting an infrared laser marking machine; and (3) performing silanization treatment: performing ultrasonic cleaning on the sample subjected to the laser micromachining, placing the cleaned sample into an ethyl alcohol solution of cetyl trimethyl silane for soaking to form a layer of hydrophobic film on the surface of the sample, and flushing and drying the sample to obtain a product. The product has the characteristics that (1) preparation can be realized under an atmospheric environment by adopting a method for combining the laser micromachining technology and the silanization treatment technology; (2) the machining cost of the method disclosed by the invention is lower than that of a femtosecond laser device, and machining parameters are independently controllable; and (3) the obtained product is of a structure with a rough surface, and the contact angle for water is about 150 degrees.

Owner:JIANGSU UNIV OF TECH

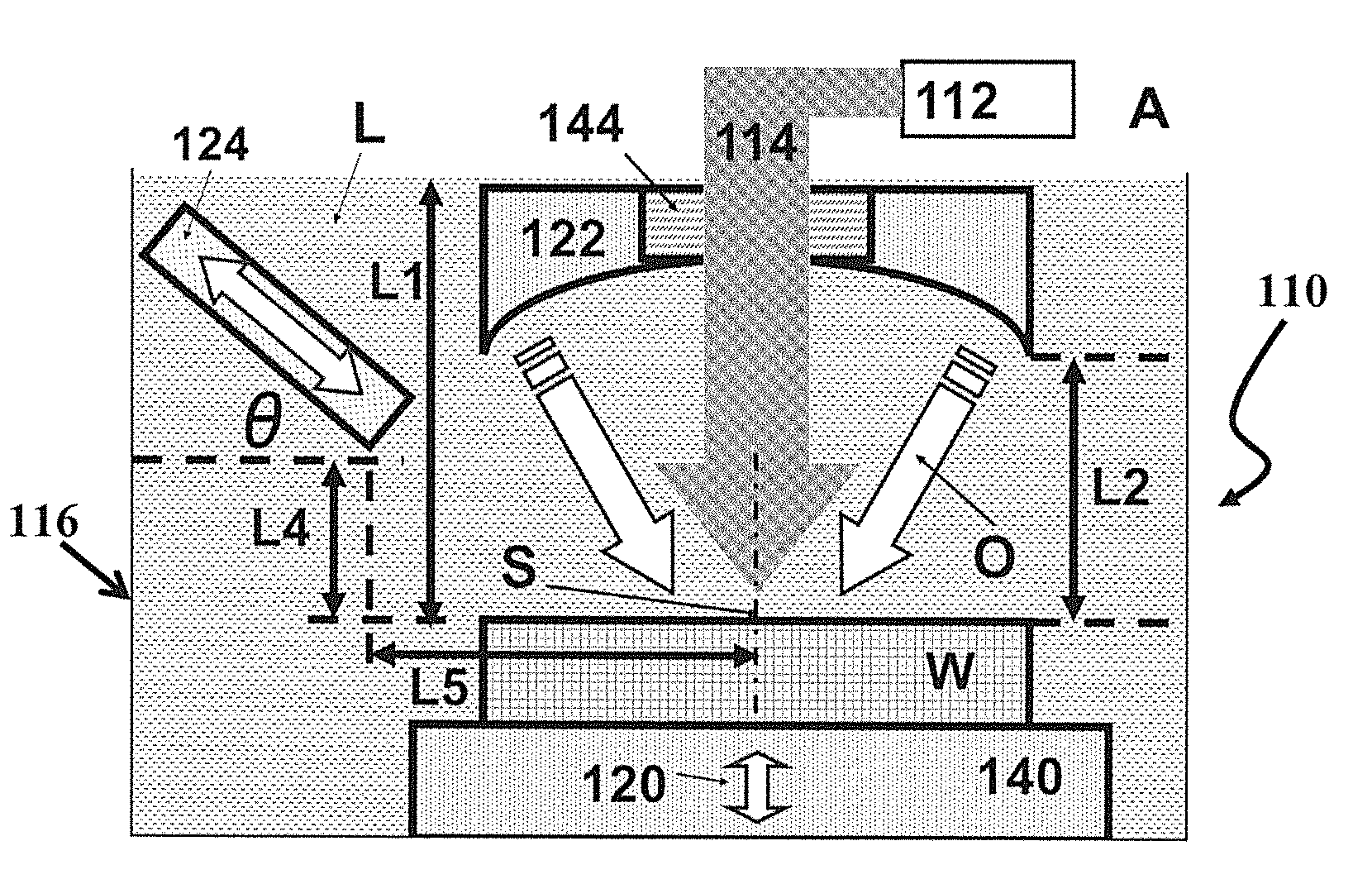

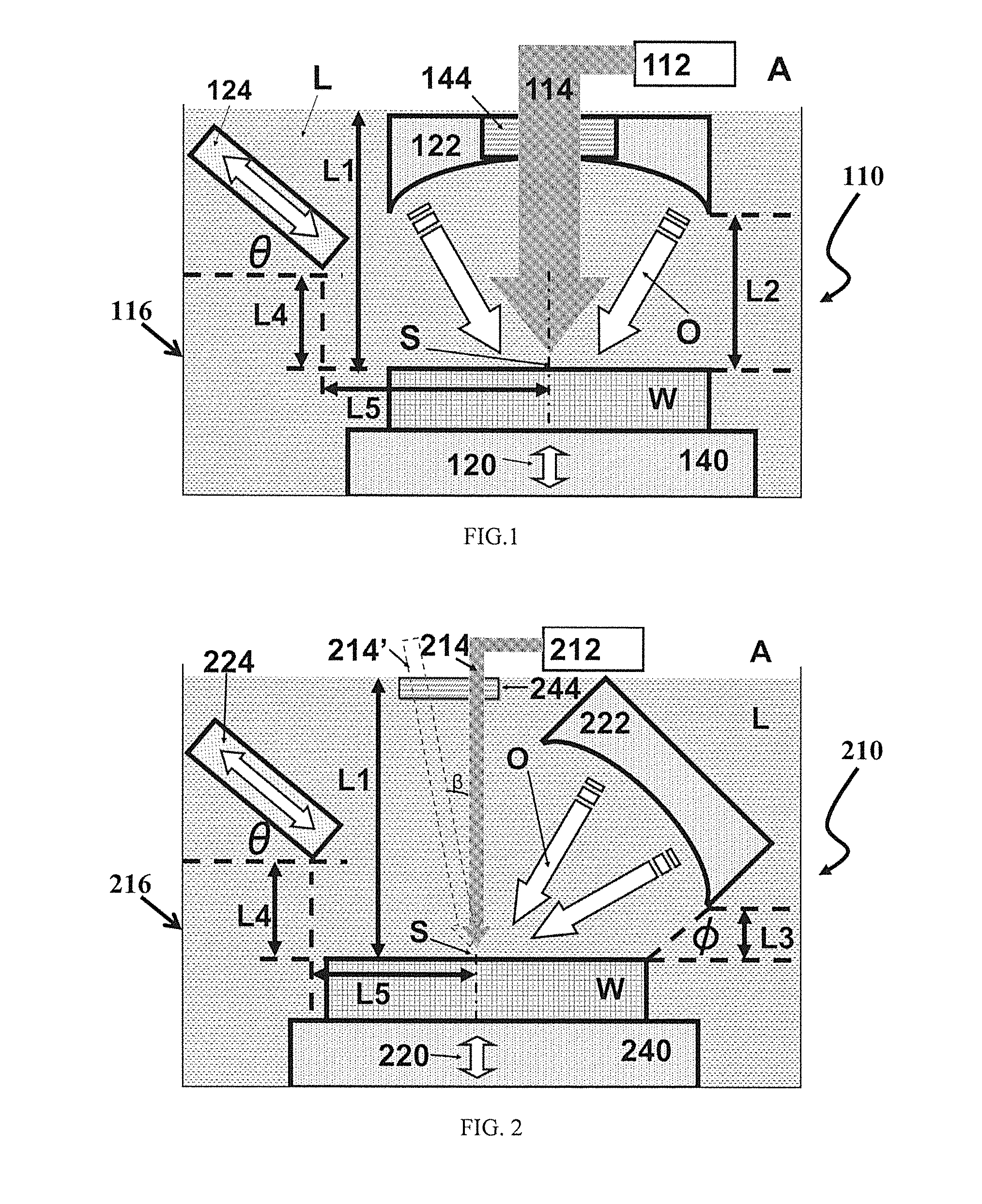

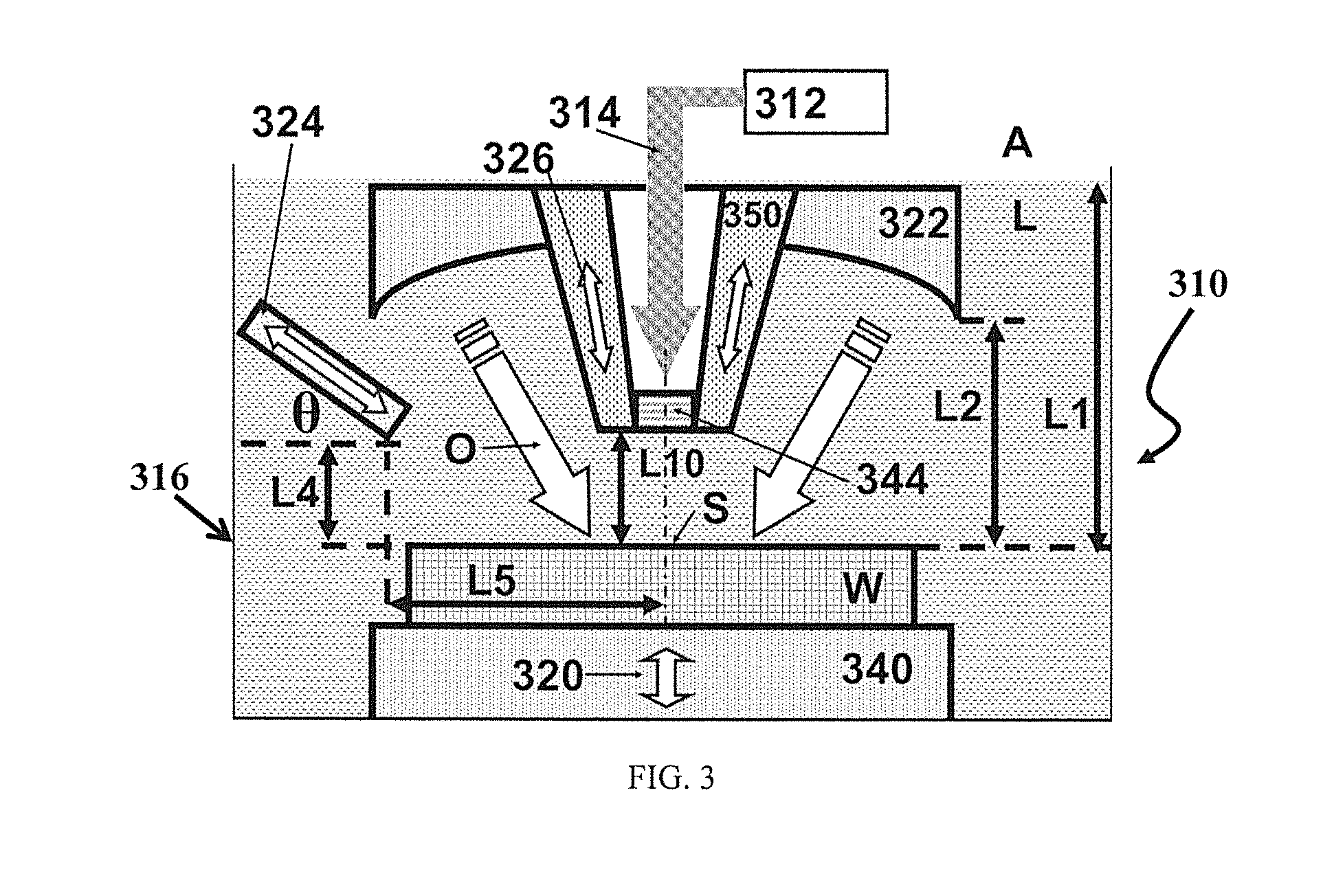

Ultrasound-assisted water-confined laser micromachining

ActiveUS20140263213A1Reduces and minimizesEdge grinding machinesLaser beam welding apparatusUltrasound deviceUltrasound assisted

Systems and processes for improved laser machining, such as micro machining, of a workpiece. Systems and processes involve directing at a first surface of the workpiece a laser beam and wherein at least the laser-irradiated region of the first surface of the workpiece is immersed in a liquid, and delivering to the liquid-immersed and laser-irradiated workpiece surface region at least a first ultrasound output from a first ultrasound device. The ultrasound output and the laser beam desirably impact the workpiece first surface substantially simultaneously.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Solid polymer electrolyte composite membrane comprising laser micromachined porous support

A solid polymer electrolyte composite membrane and method of manufacturing the same. According to one embodiment, the composite membrane comprises a rigid, non-electrically-conducting support, the support preferably being a sheet of polyimide having a thickness of about 7.5 to 15 microns. The support has a plurality of cylindrical pores extending perpendicularly between opposing top and bottom surfaces of the support. The pores, which preferably have a diameter of about 5 microns, are made by laser micromachining and preferably are arranged in a defined pattern, for example, with fewer pores located in areas of high membrane stress and more pores located in areas of low membrane stress. The pores are filled with a first solid polymer electrolyte, such as a perfluorosulfonic acid (PFSA) polymer. A second solid polymer electrolyte, which may be the same as or different than the first solid polymer electrolyte, may be deposited over the top and / or bottom of the first solid polymer electrolyte.

Owner:PLUG POWER

Methods of roughening ceramic surface

InactiveCN1496343AInsulating substrate metal adhesion improvementVacuum evaporation coatingAbrasive blastingEtching

Disclosed herein is a method of roughening a ceramic surface by forming mechanical interlocks in the ceramic surface by a chemical etching process, a thermal etching process, or a laser micromachining process. Also disclosed herein are components for use in semiconductor processing chambers (in particular, a deposition ring for use in a PVD chamber) which have at least one ceramic surface having mechanical interlocks formed therein by chemical etching, thermal etching, or laser micromachining. Ceramic surfaces which have been roughened according to the chemical etching, thermal etching, or laser micromachining process of the invention are less brittle and damaged than ceramic surfaces which are roughened using conventional grit blasting techniques. The method of the invention results in a roughened ceramic surface which provides good adherence to an overlying sacrificial layer (such as aluminum).

Owner:APPLIED MATERIALS INC

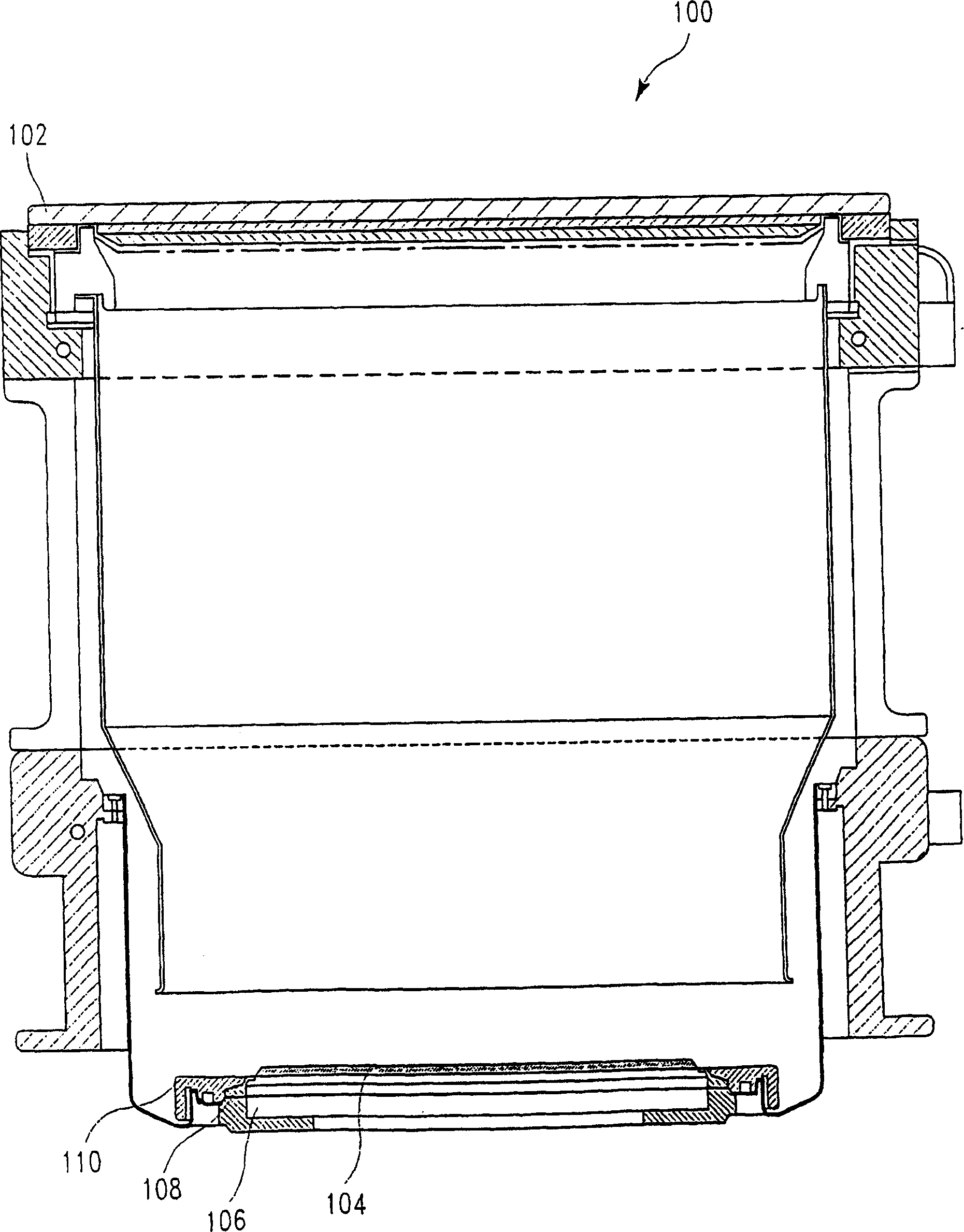

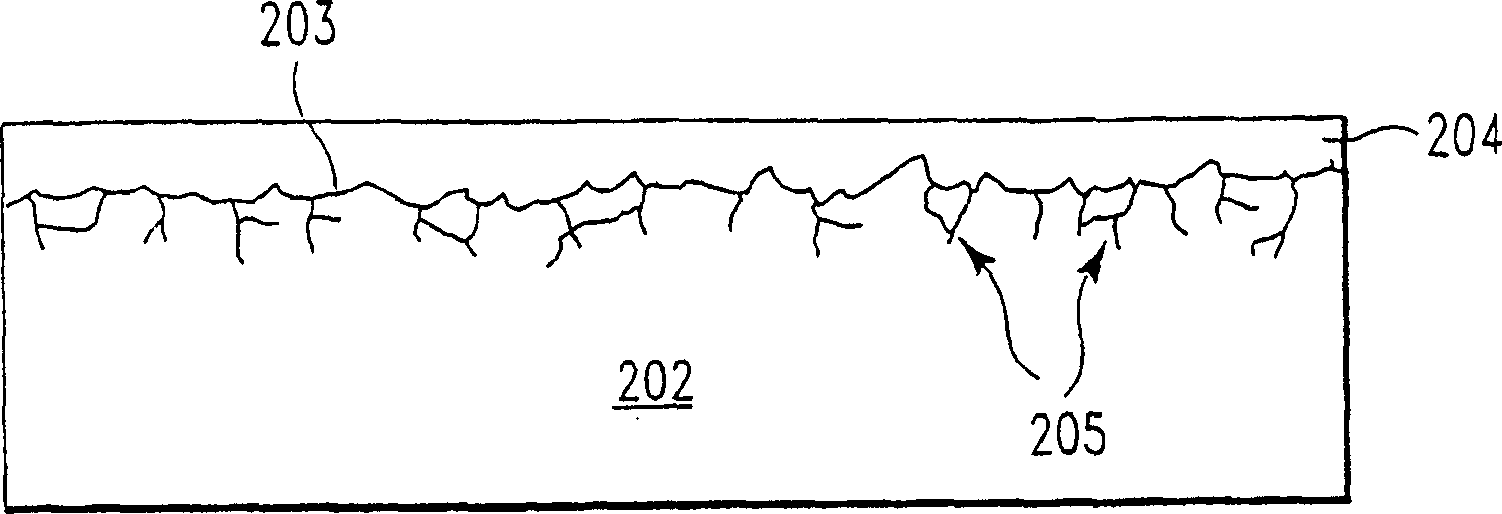

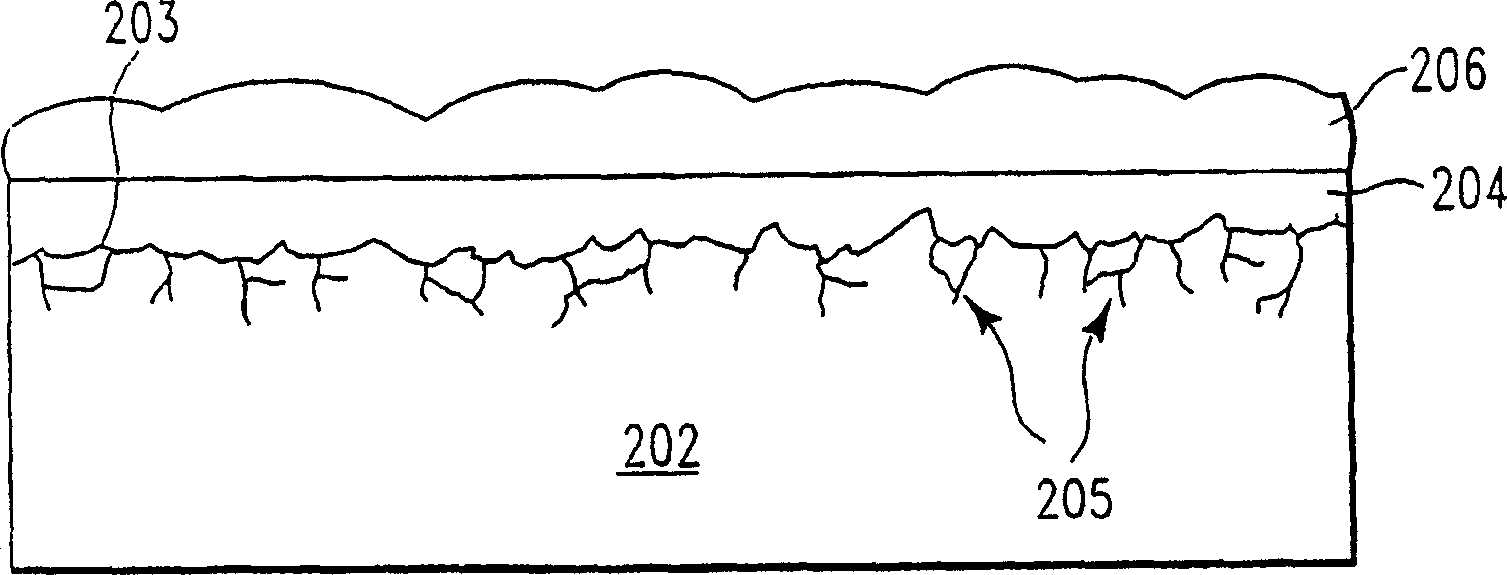

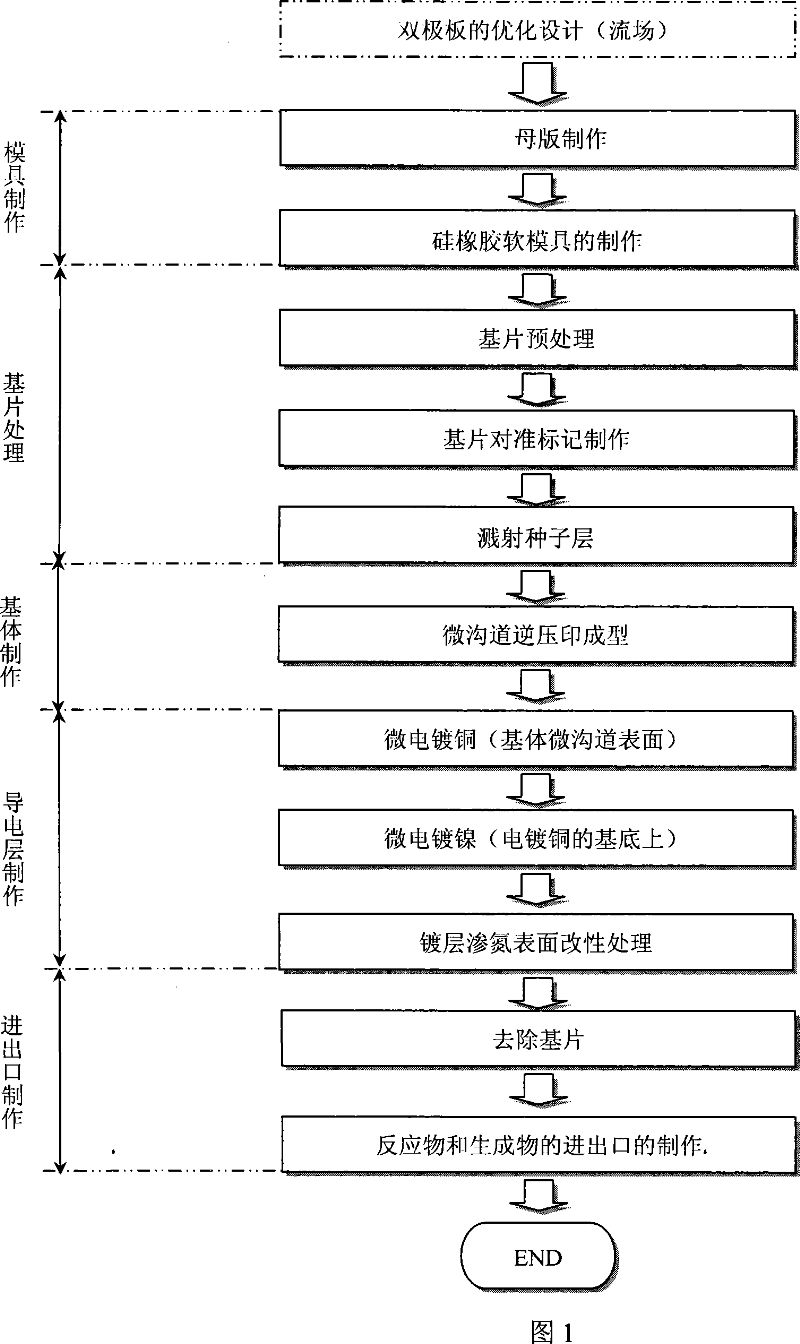

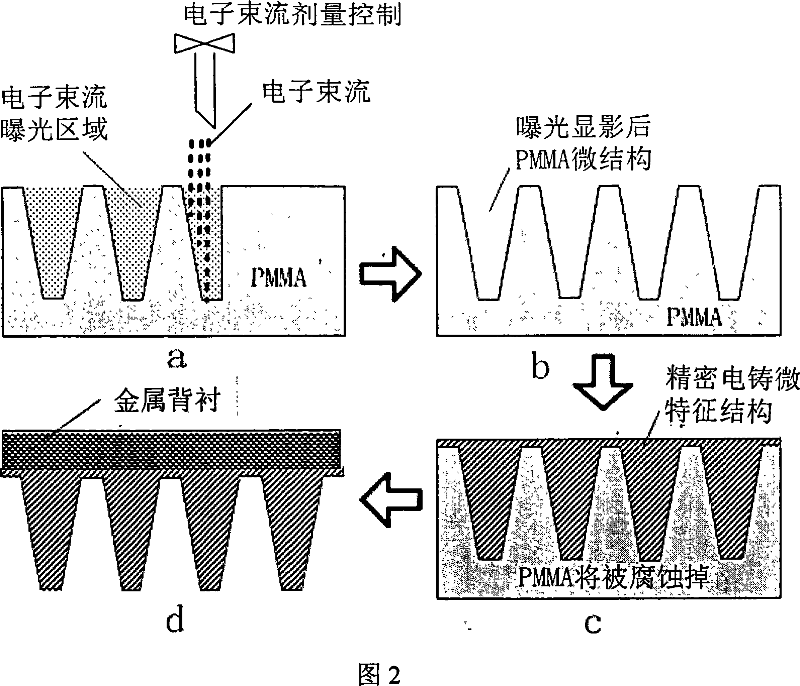

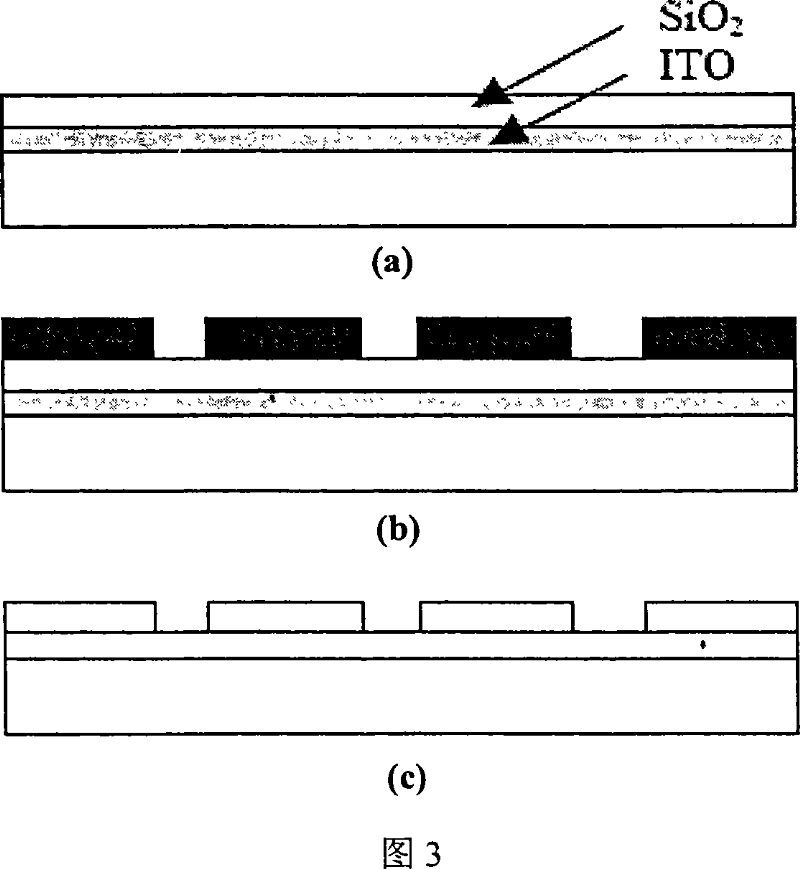

Composite dual-electrode plates preparation method of minisize directly connecting methanol fuel battery

InactiveCN101043078AReduce weightReduce volumeCell electrodesFinal product manufactureNitrationPolymer

The invention discloses a clad plate preparation method of micro methanol battery, the modified polymethyl methacryate is the basis materials, the high conductivity copper is conductive layer, and the nickel is as the anti-corrosion protective material. Adopting non-siliceous composite preparation technology, firstly producing the master mask and silicon rubber soft mould; then adopting the craft of 'inverse autogram' to stamp the micro channel of flow field on the modified polymethyl methacryate whose substrate is glass; then depositing the copper on surface of micro channel with craft of plating, a layer of nickel is plated on the substrate of the copper, then the composite deposite is nitration surface modified treatment; at last, after eliminating the glass substrate, producing the imports and exports of the reactants and resultant by laser micromachining. The polymer / copper nickel base clad plate possesses advantages that the weight is light, the volume is small, performance is well, cost is low, and it fits for batch size production.

Owner:XI AN JIAOTONG UNIV

Method for modifying existing micro-and nano-structures using a near-field scanning optical microscope

InactiveUS20050221577A1Material nanotechnologyDecorative surface effectsNear-field scanning optical microscopeContour analysis

A method for manufacturing a microstructure, which includes at least one fine feature on an existing feature, using an NSOM laser micromachining system. A microstructure device preform is provided. A portion of its top surface is profiled with the NSOM to produce a topographical image. This profiled portion is selected to include the existing feature. An image coordinate system is defined for the profiled portion of top surface based on the topographical image. Coordinates of a reference point and the orientation of the existing feature in the image coordinate system are determined using the topographical image. The probe tip of the NSOM is aligned over a portion of the existing feature using the determined coordinates of the reference point and the orientation of the existing feature. The top surface of the microstructure device preform is machined with the micro-machining laser to form the fine feature(s) on the existing feature.

Owner:PANASONIC CORP

Solid polymer electrolyte composite membrane comprising porous ceramic support

A solid polymer electrolyte composite membrane and method of manufacturing the same. The composite membrane comprises a porous ceramic support having a top surface and a bottom surface. The porous ceramic support may be formed by laser micromachining a ceramic sheet or may be formed by electrochemically oxidizing a sheet of the base metal. A solid polymer electrolyte fills the pores of the ceramic support and preferably also covers the top and bottom surfaces of the support. Application of the solid polymer electrolyte to the porous support may take place by applying a dispersion to the support followed by a drying off of the solvent, by hot extrusion of the solid polymer electrolyte (or by hot extrusion of a precursor of the solid polymer electrolyte followed by in-situ conversion of the precursor to the solid polymer electrolyte) or by in-situ polymerization of a corresponding monomer of the solid polymer electrolyte.

Owner:PLUG POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com