Method and apparatus for producing fibre-optical FP sensor by ultrashort pulse laser fine machining

An ultra-short pulse laser and sensor technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low-sensitivity sensors and incompatibility of materials to be tested, and achieve high sensing sensitivity and compatibility Good, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

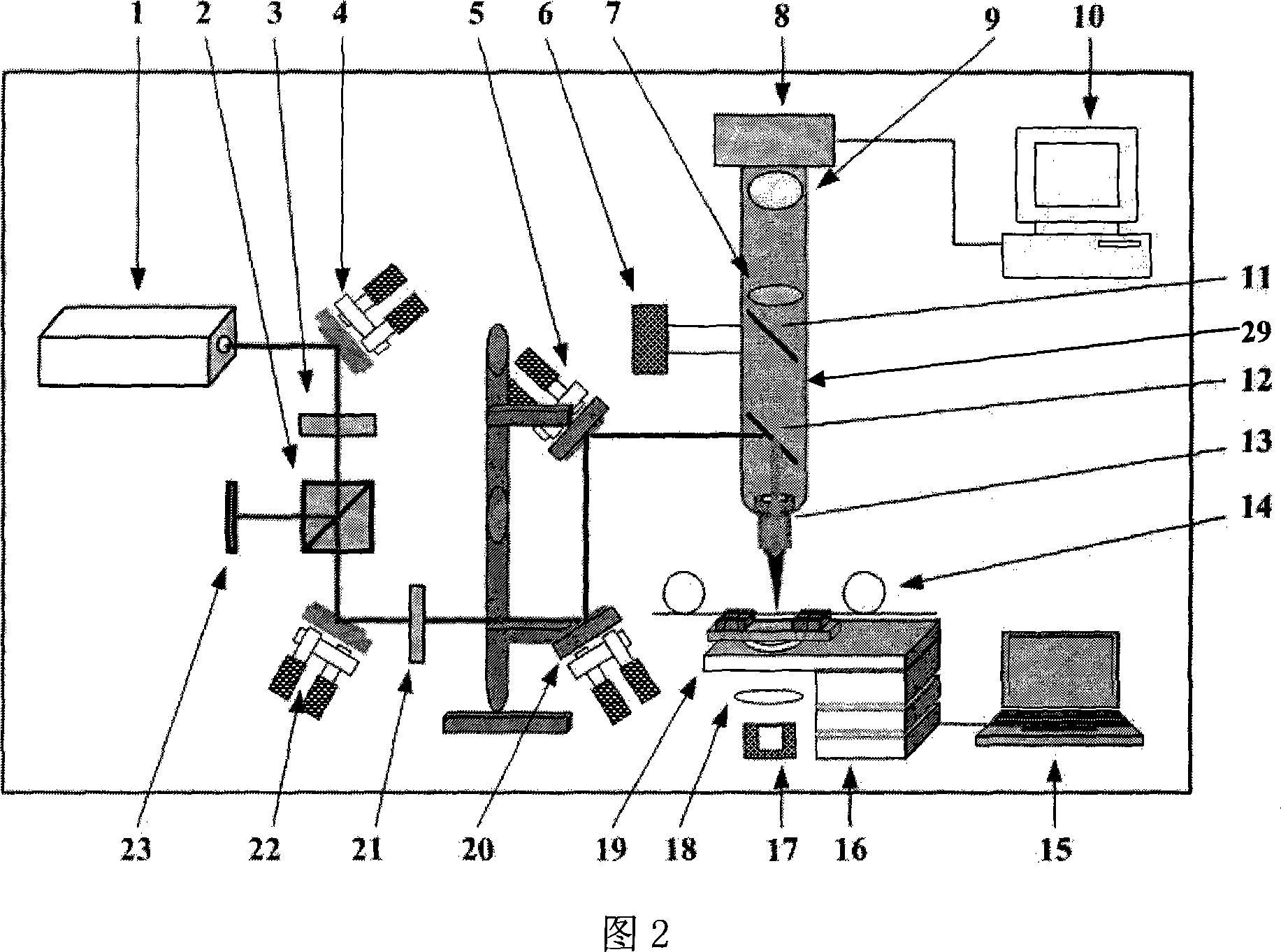

[0035]The schematic diagram of processing equipment for ultrashort pulse laser micromachining optical fiber F-P sensor is shown in Figure 2, mainly including femtosecond laser system, beam control system, real-time monitoring system and focusing system 13 (that is, writing optical head), three-dimensional mobile platform 16, shutter 21 and Computer 15 and CAD control software. In the experiment, the MAITAI self-mode-locked Ti:sapphire femtosecond pulse laser of the American Spectrophysics Corporation was used as the ultrashort pulse laser seed source, and the output single pulse energy was about 10nJ, and the pulse width was 80fs. The amplifier is Spitfire from Spectraphysics, and the pump source is evolution Q-switched-YLF frequency-doubled laser from Spectraphysics. Under 1KHz, 5mJ laser pumping, the output energy is 800uJ, and the laser output pulse width is less than 120fs. The beam control system includes an energy adjustment element combined by a polarizer 2 and a half w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com