Patents

Literature

643 results about "Short pulse laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As more understanding is gained about the way laser light interacts with materials, more laser materials processing is being undertaken by 'short pulse length' (or 'ultra-fast') pulsed lasers. For a given laser pulse energy, the shorter the pulse, the higher the peak laser power available.

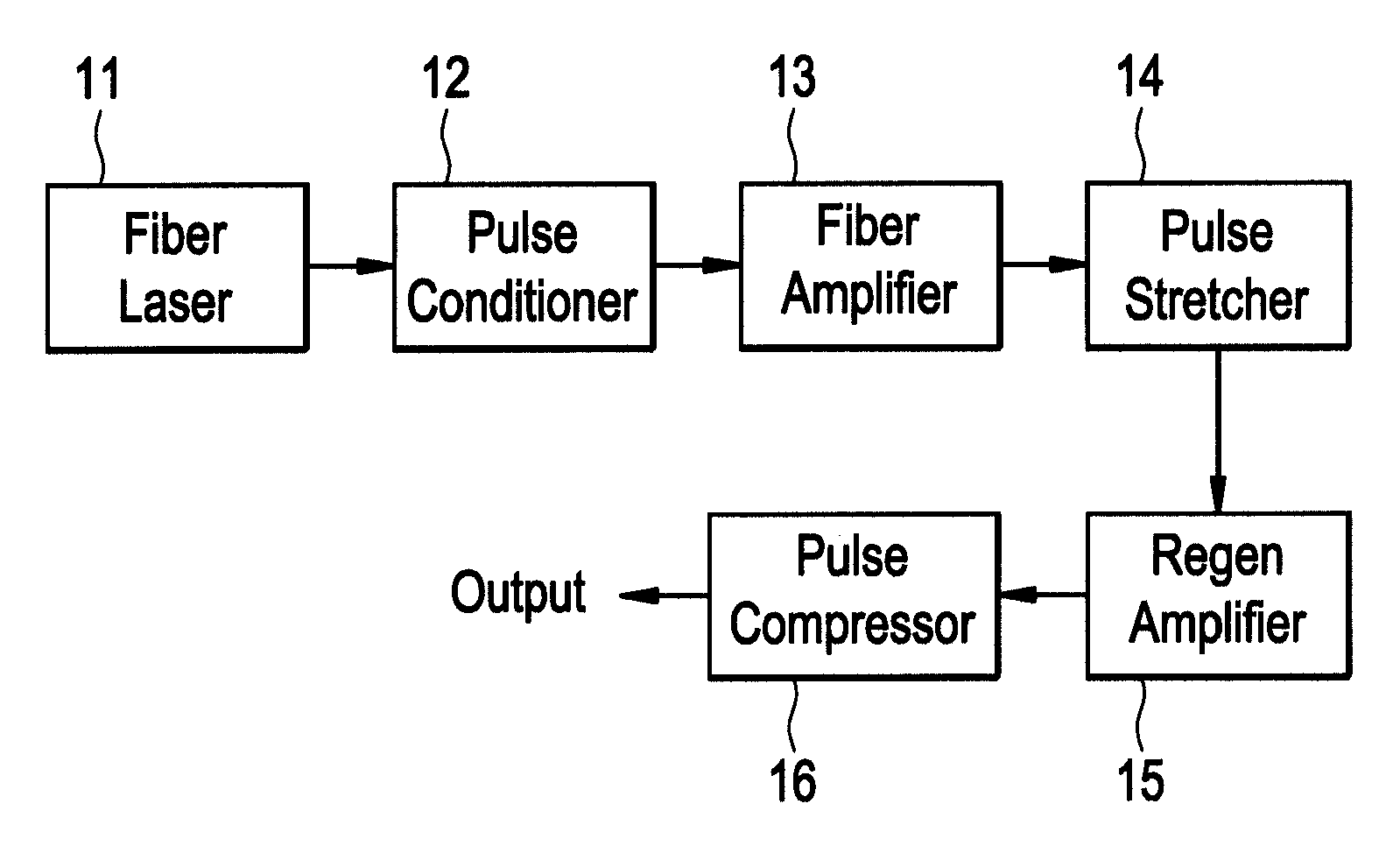

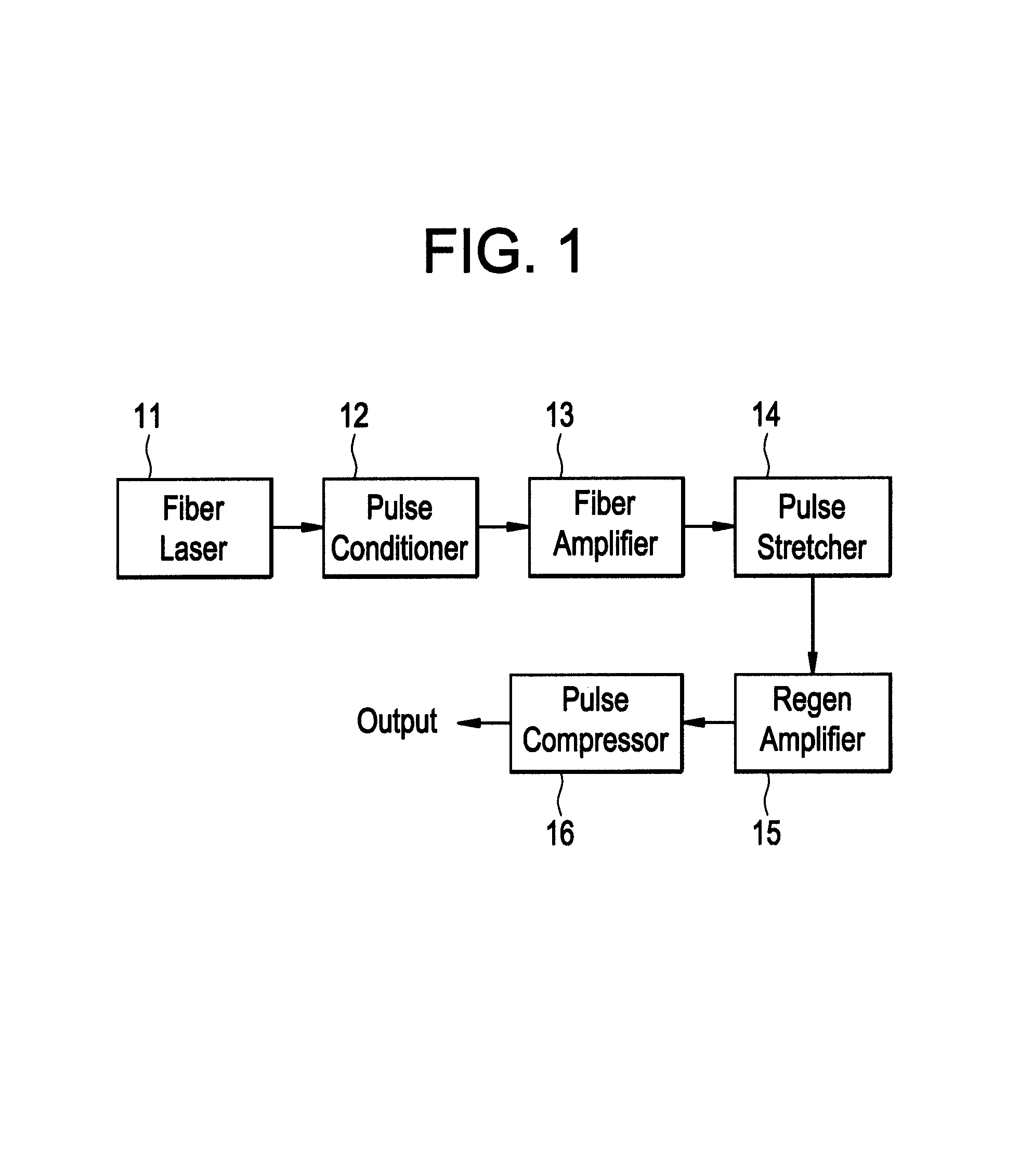

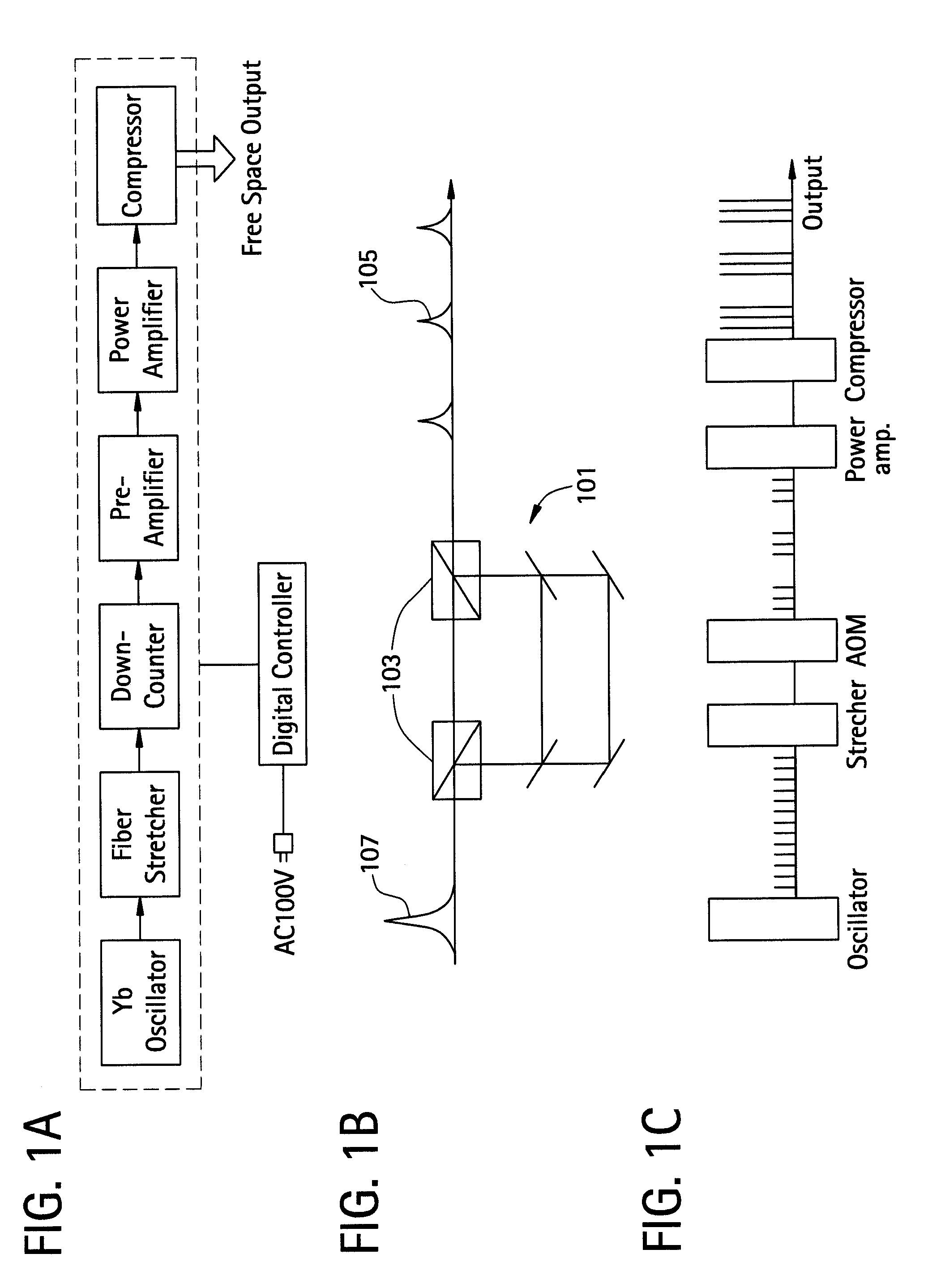

Yb: and Nd: mode-locked oscillators and fiber systems incorporated in solid-state short pulse laser systems

InactiveUS20060120418A1Increase flexibilityMaximize positive effectOptical devices for laserAudio power amplifierEngineering

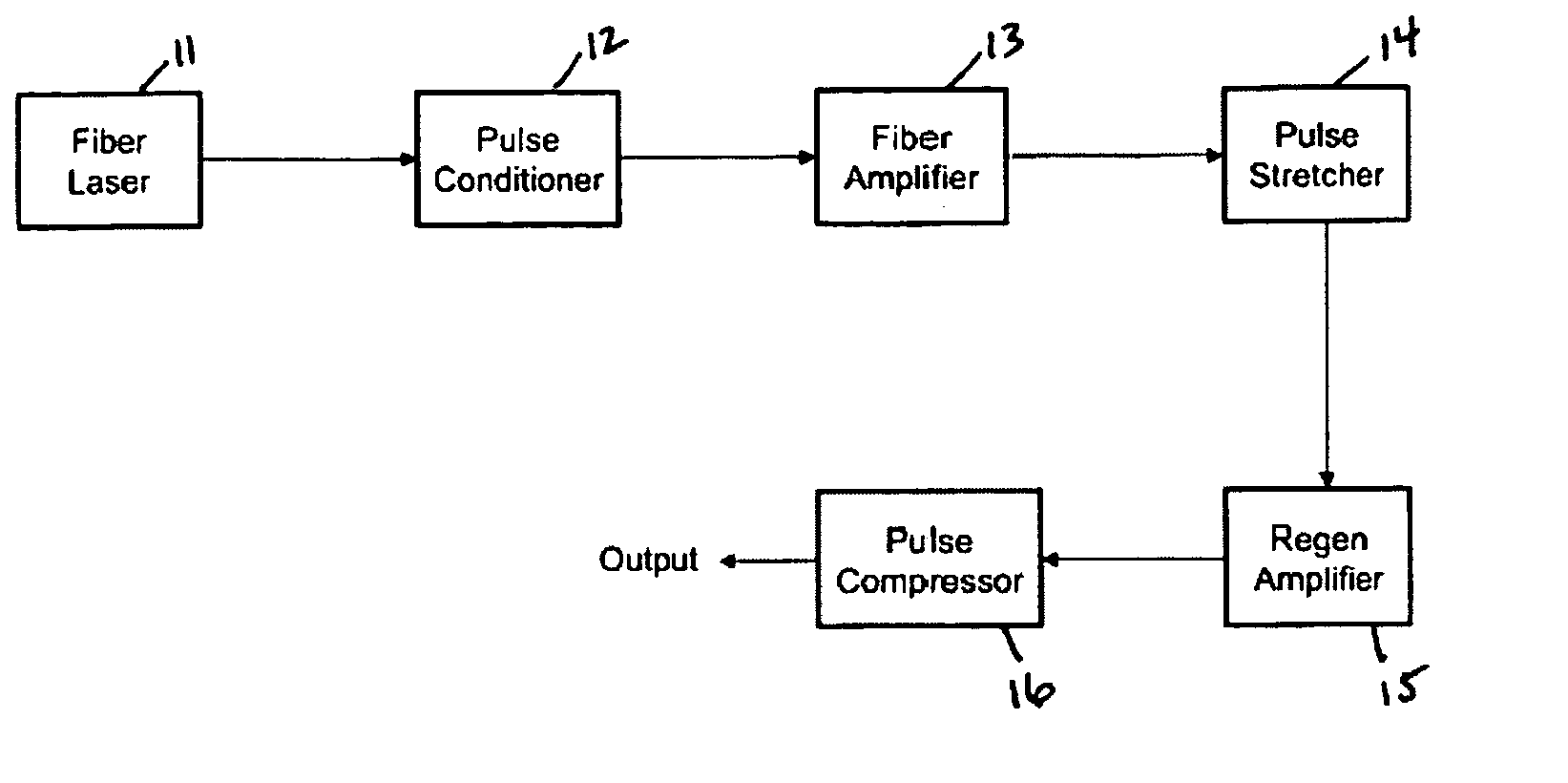

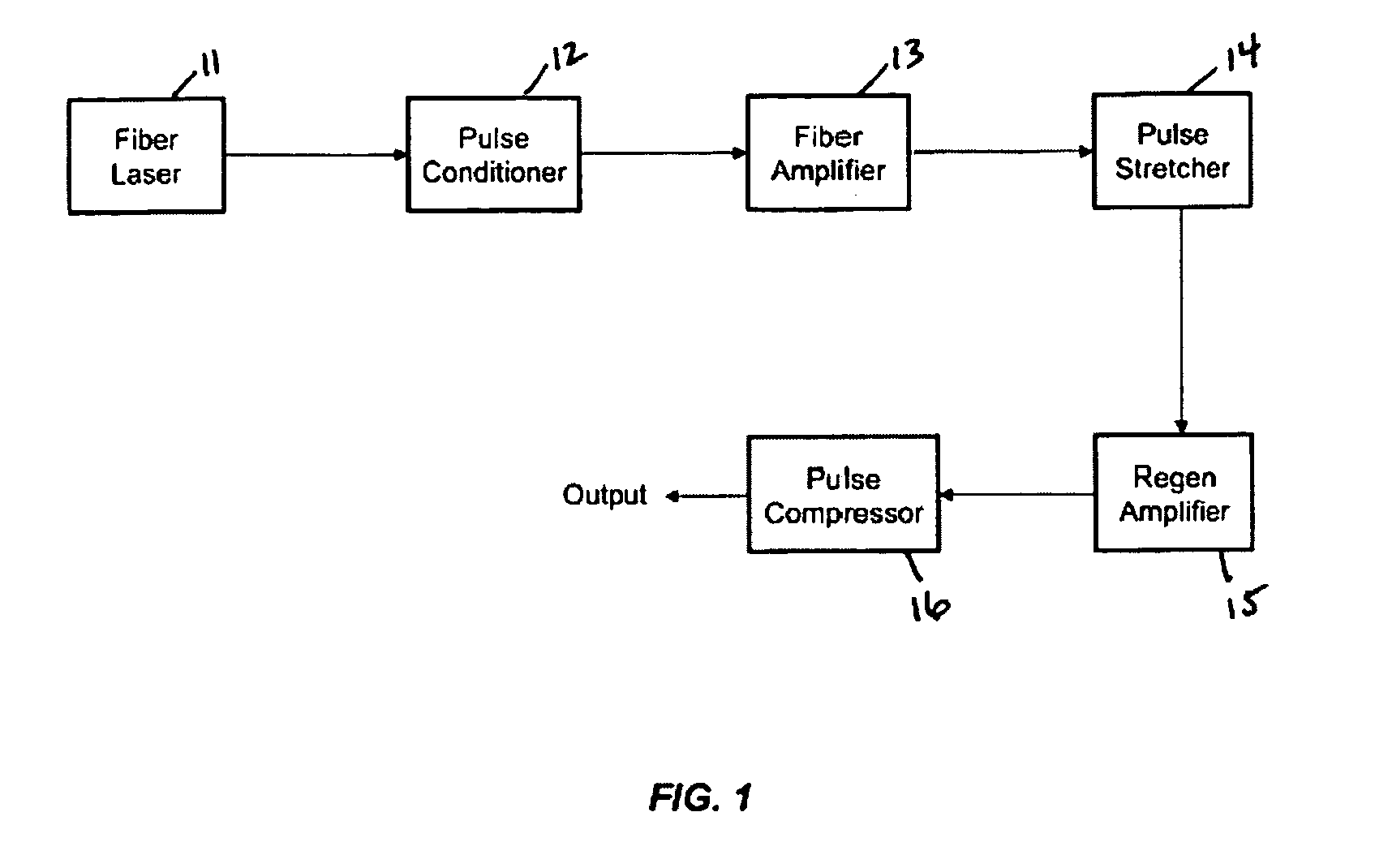

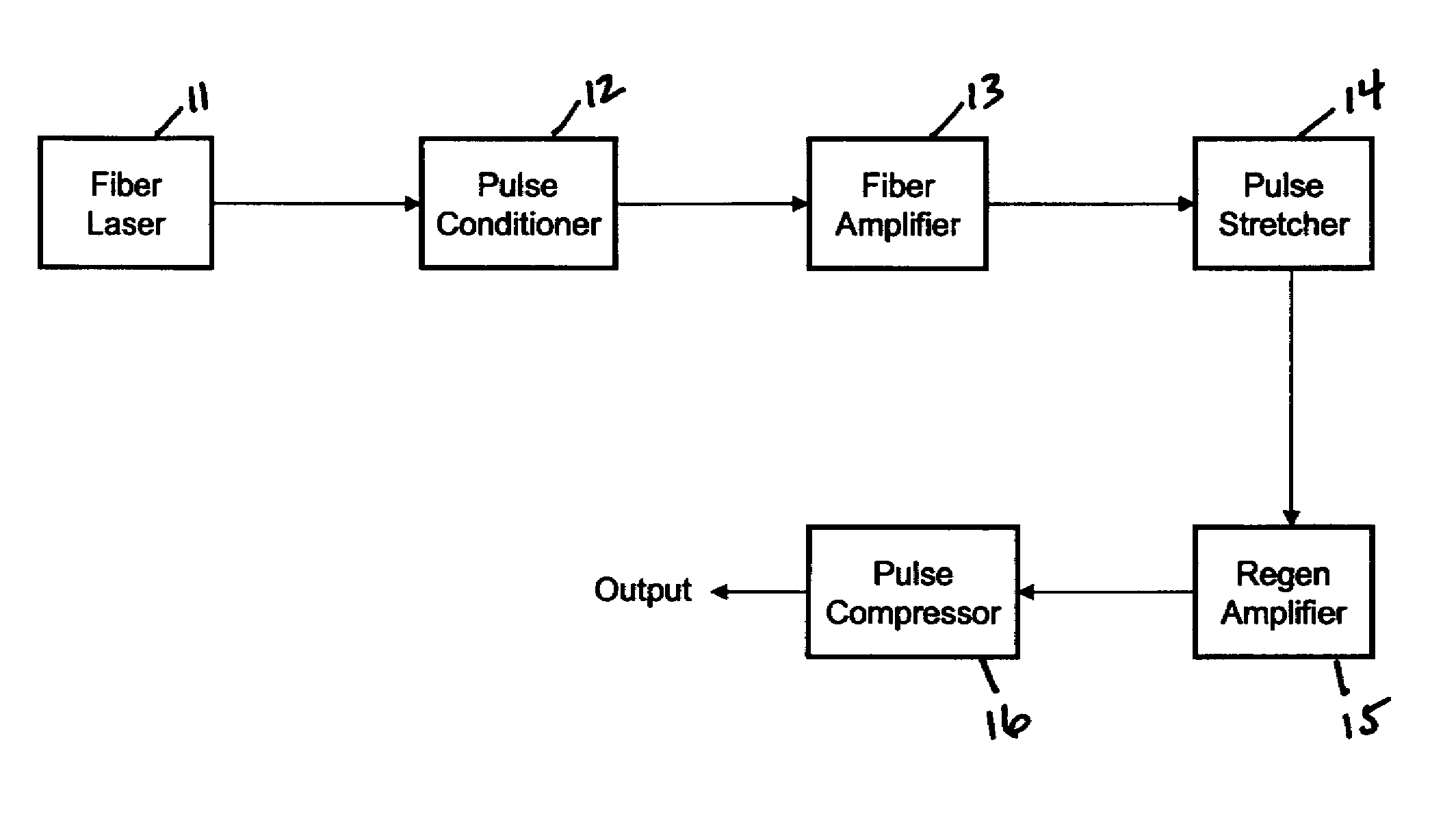

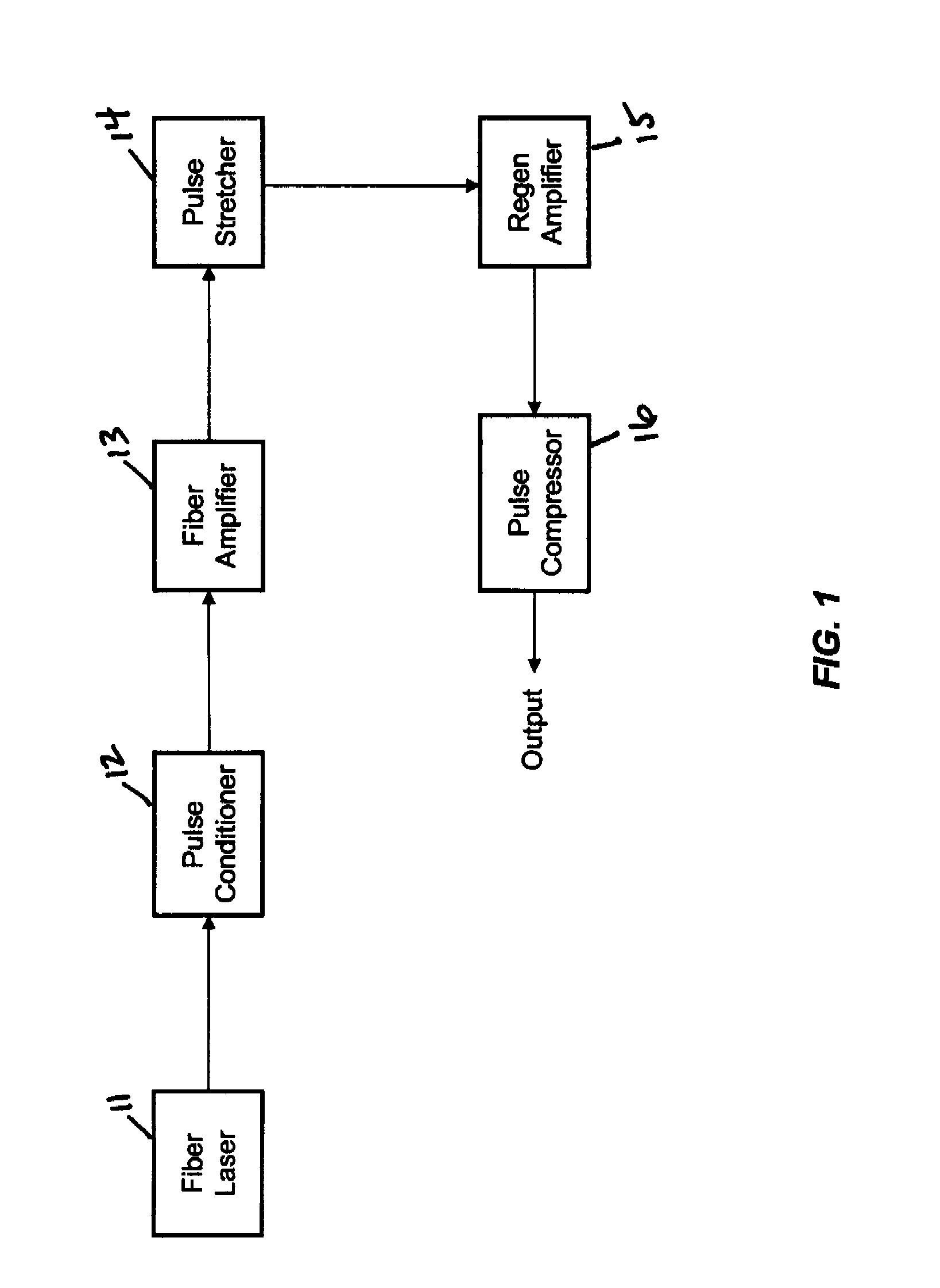

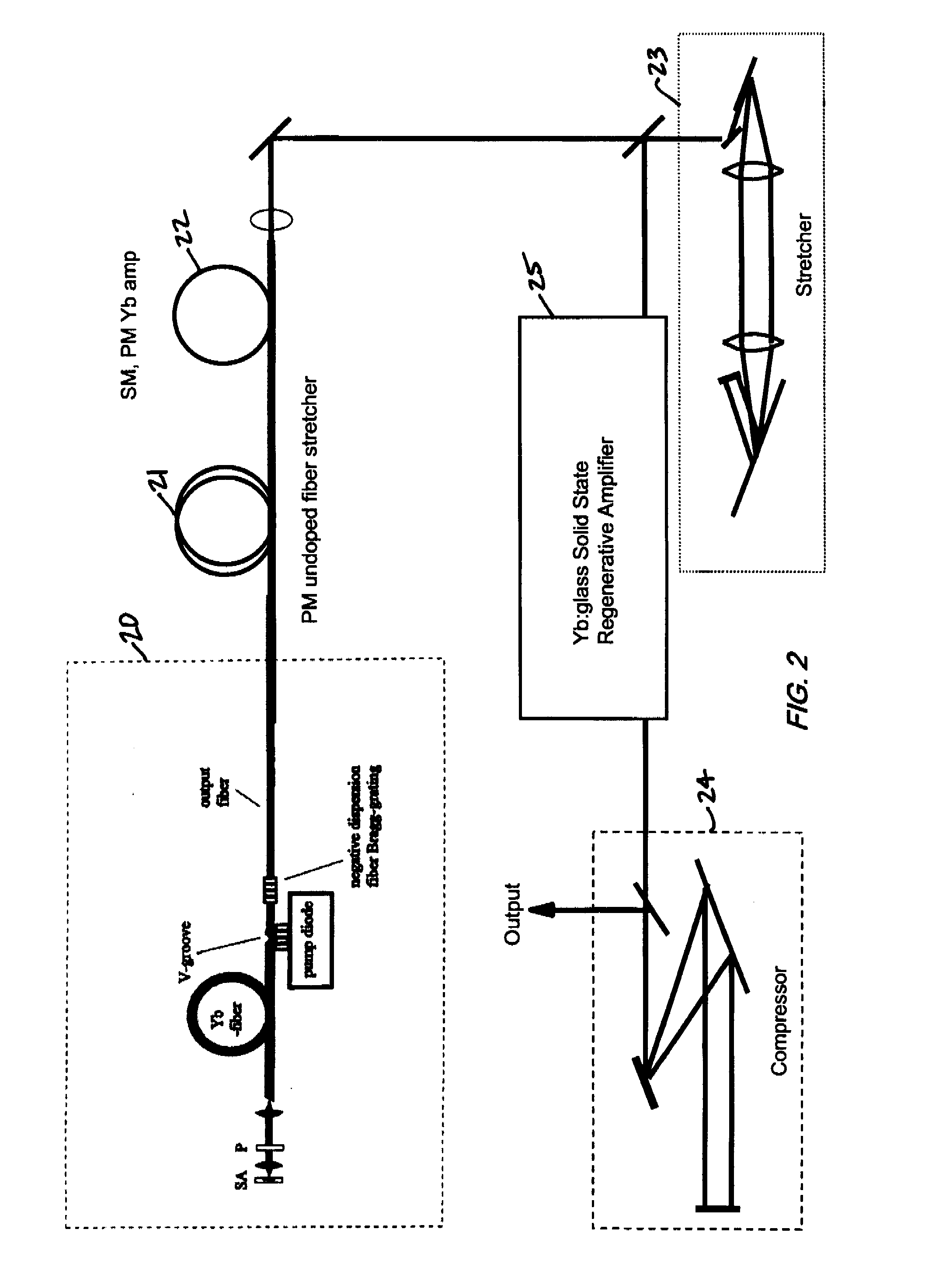

The invention describes classes of robust fiber laser systems usable as pulse sources for Nd: or Yb: based regenerative amplifiers intended for industrial settings. The invention modifies adapts and incorporates several recent advances in FCPA systems to use as the input source for this new class of regenerative amplifier.

Owner:IMRA AMERICA

Multiple-mode device for high-power short-pulse laser ablation and CW cauterization of bodily tissues

InactiveUS8353899B1Easy to carryAvoid spreadingSurgical instrument detailsNon-linear opticsPulse durationBody tissue

Owner:LOCKHEED MARTIN ACULIGHT CORP

Method and multiple-mode device for high-power short-pulse laser ablation and CW cauterization of bodily tissues

InactiveUS8202268B1Easy to carryAvoid spreadingLaser using scattering effectsDiagnosticsPulse durationLaser ablation

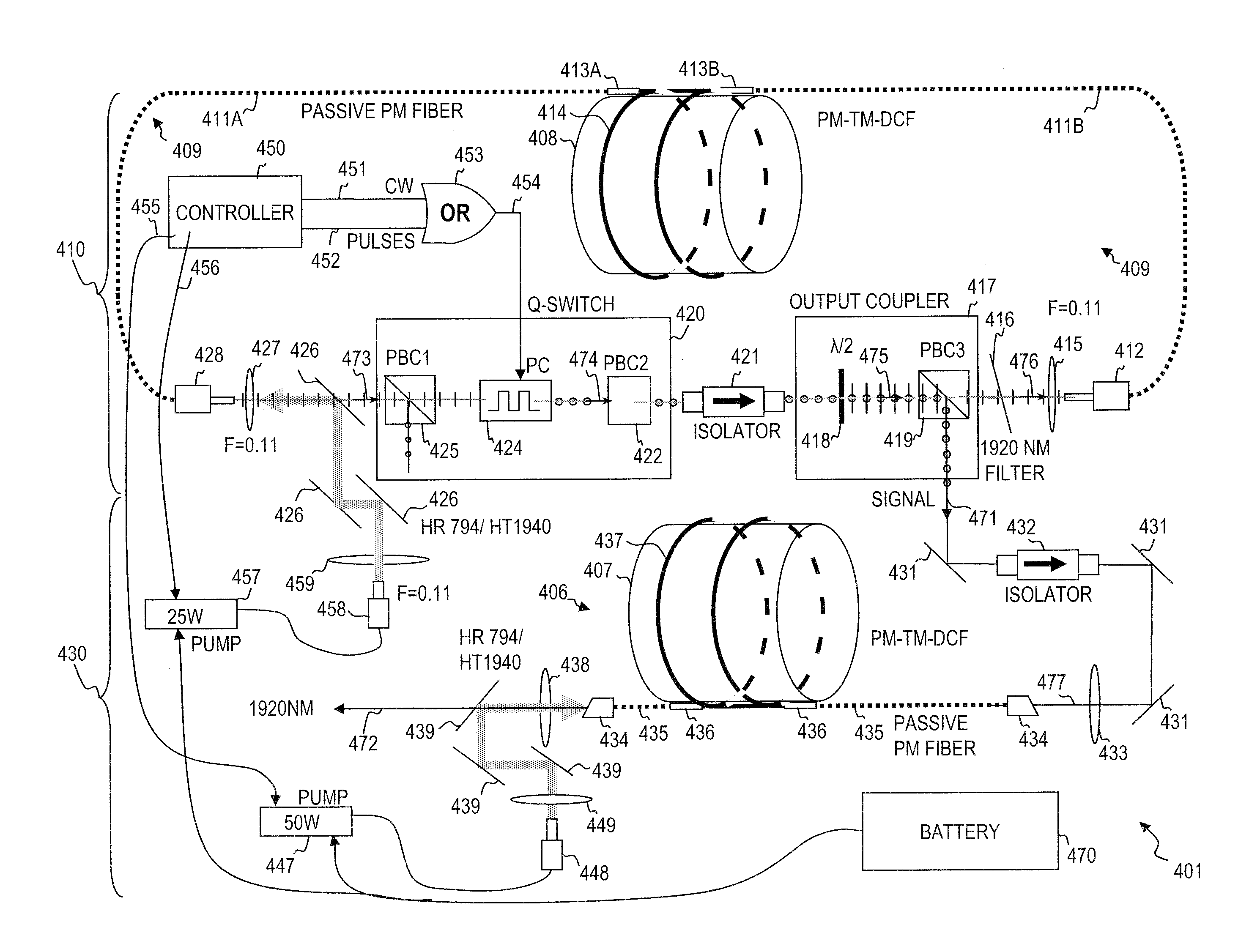

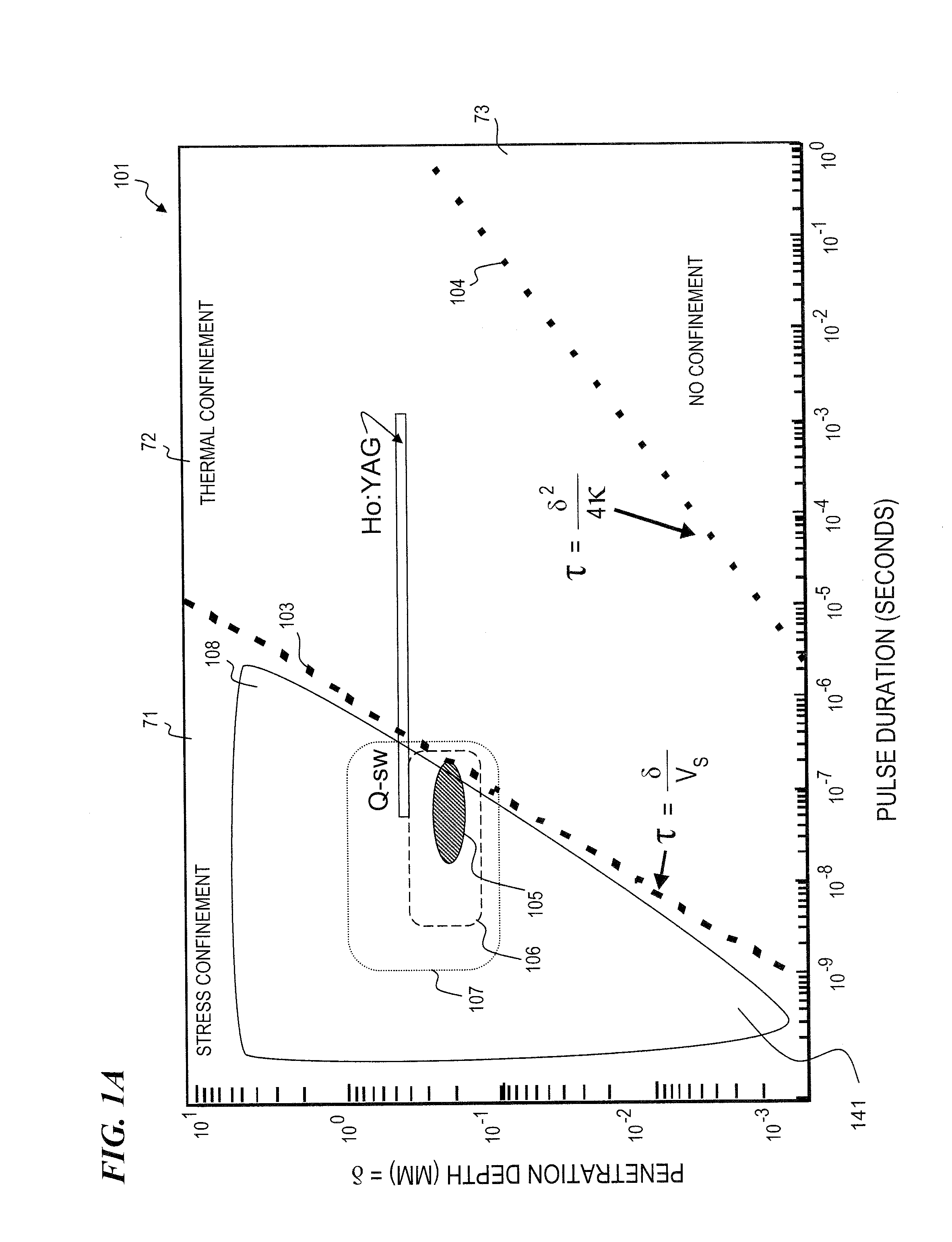

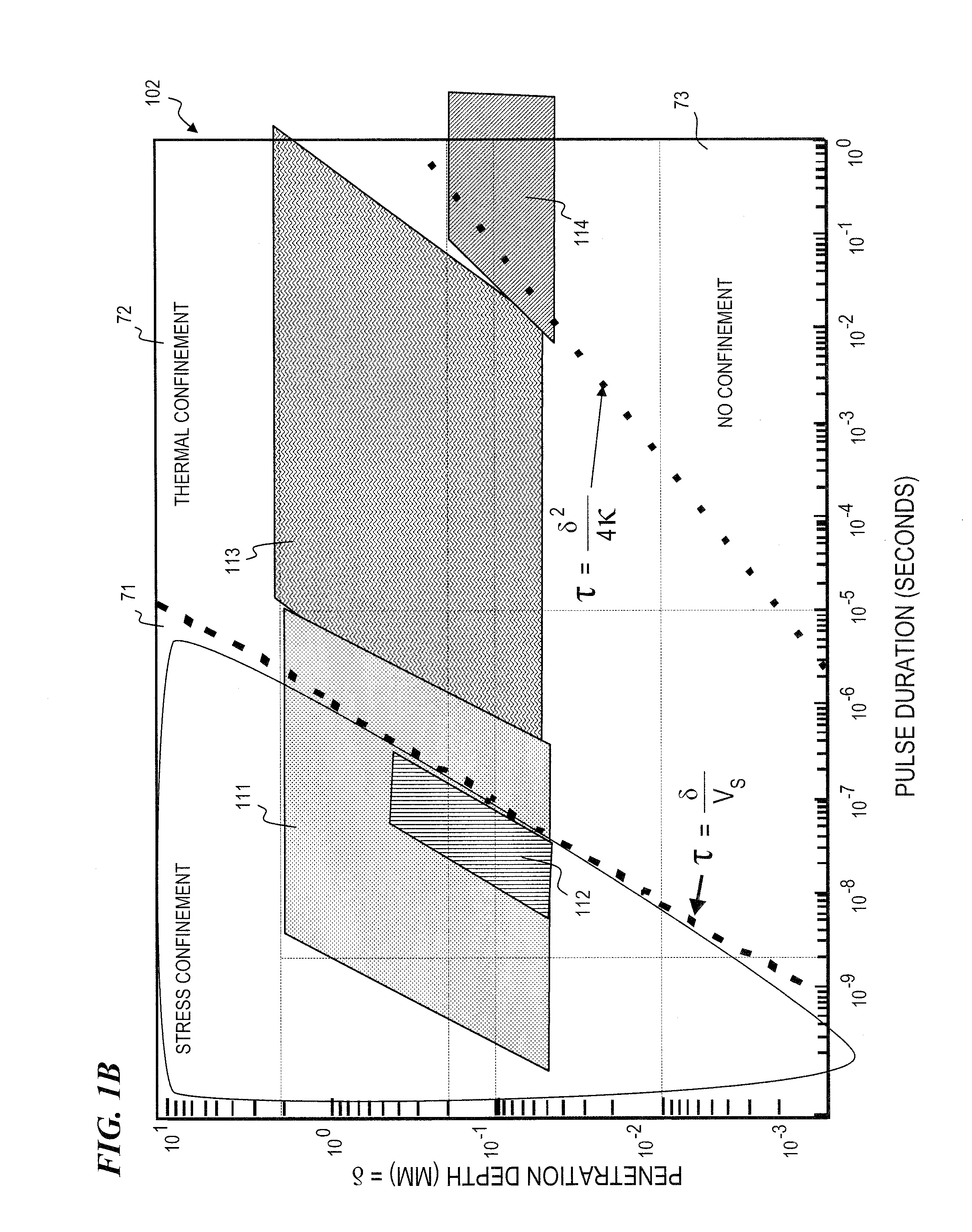

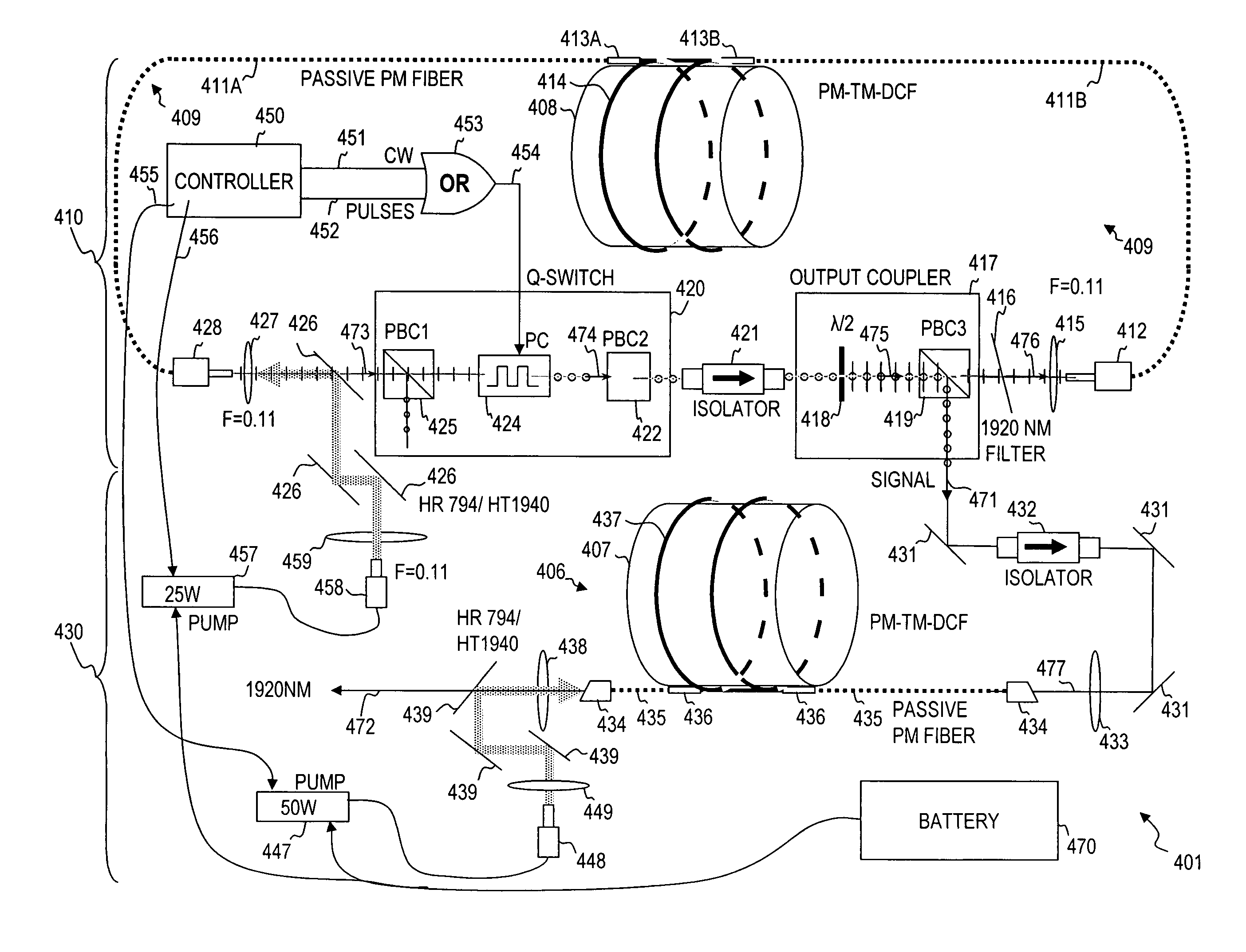

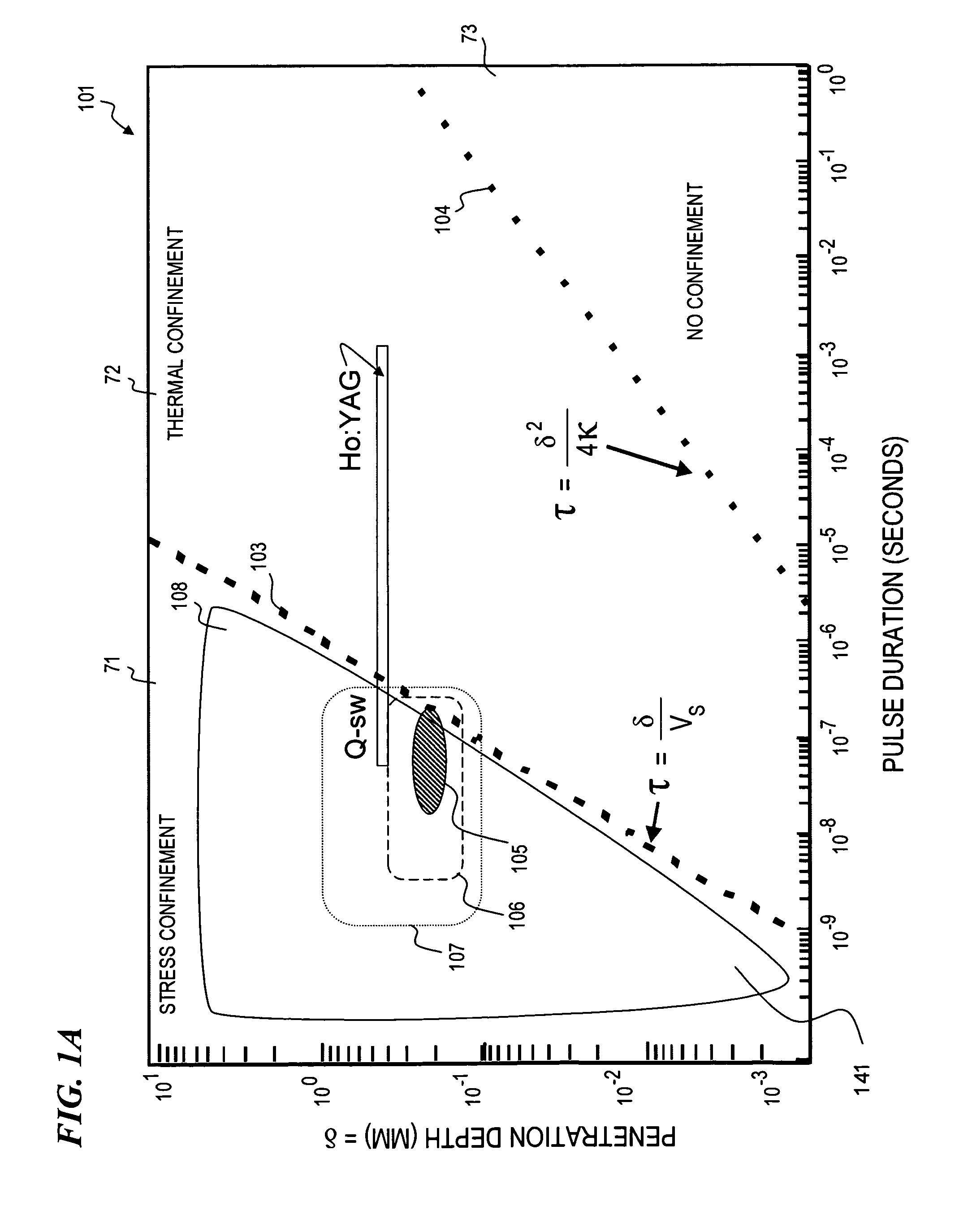

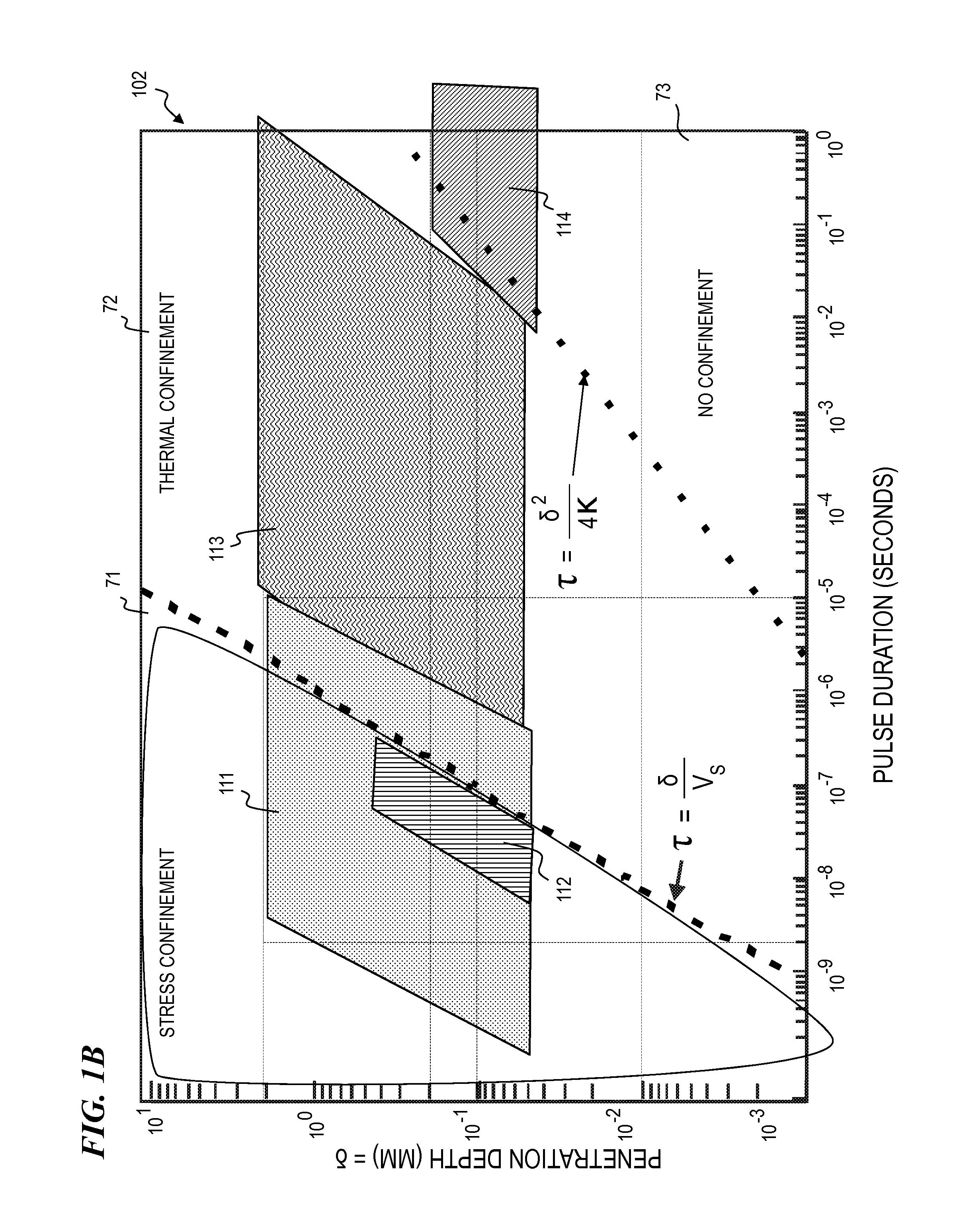

An apparatus and process using a high-power, short-pulsed thulium laser to output infrared laser pulses delivered through an optical fiber, for cutting and ablating biological tissue. In some embodiments, the pulse length is shortened sufficiently to keep inside the stress-confined ablation region of operation. In some embodiments, the pulse is shortened to near the stress-confined ablation region of operation, while being slightly in the thermal-constrained region of operation. In some embodiments, the laser is coupled to a small low —OH optical fiber (˜100 μm diameter). In some embodiments, the device has a pulse duration of about 100 ns for efficient ablation; however in some embodiments, this parameter is adjustable.

Owner:NERVESENSE LTD

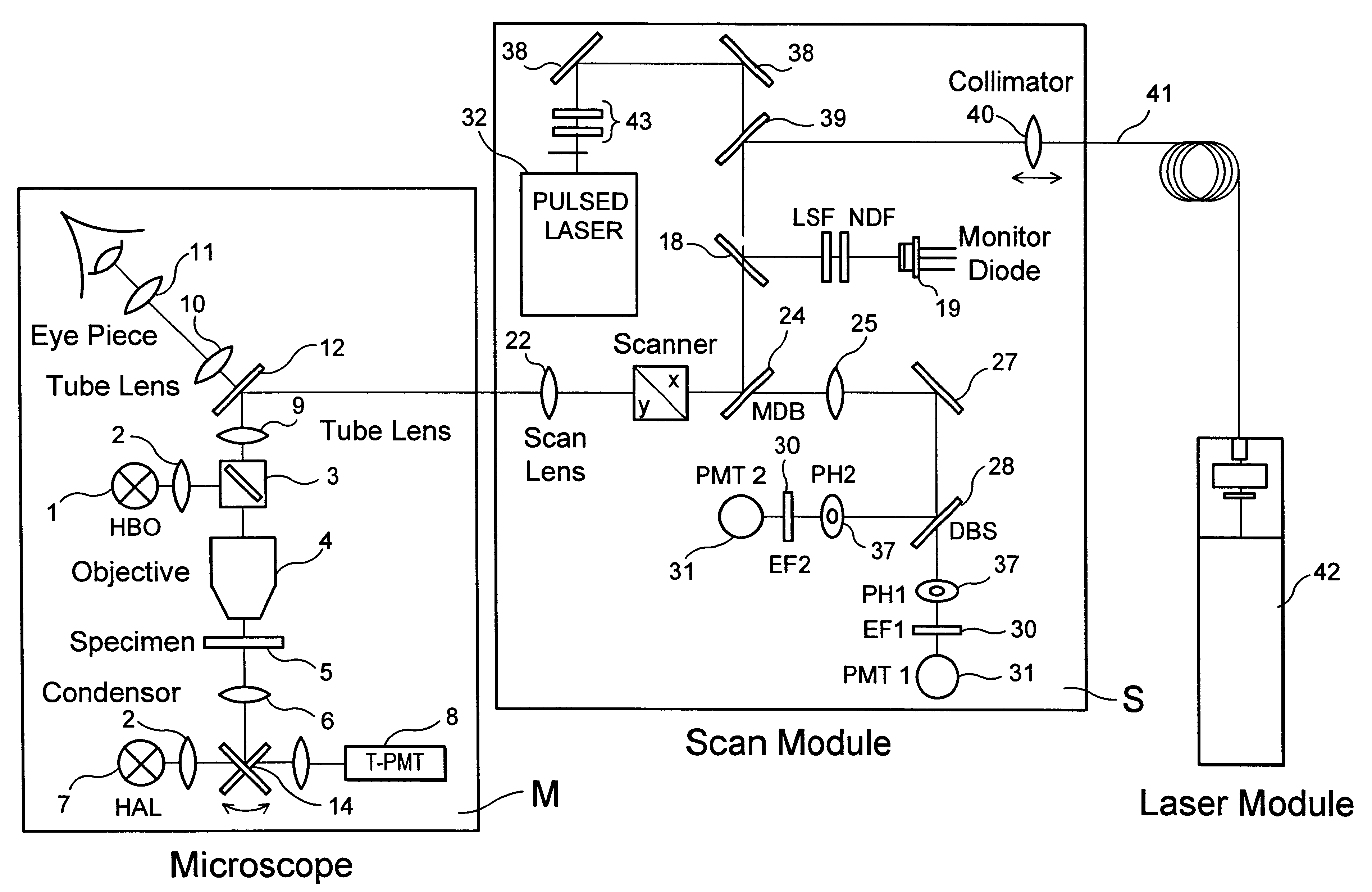

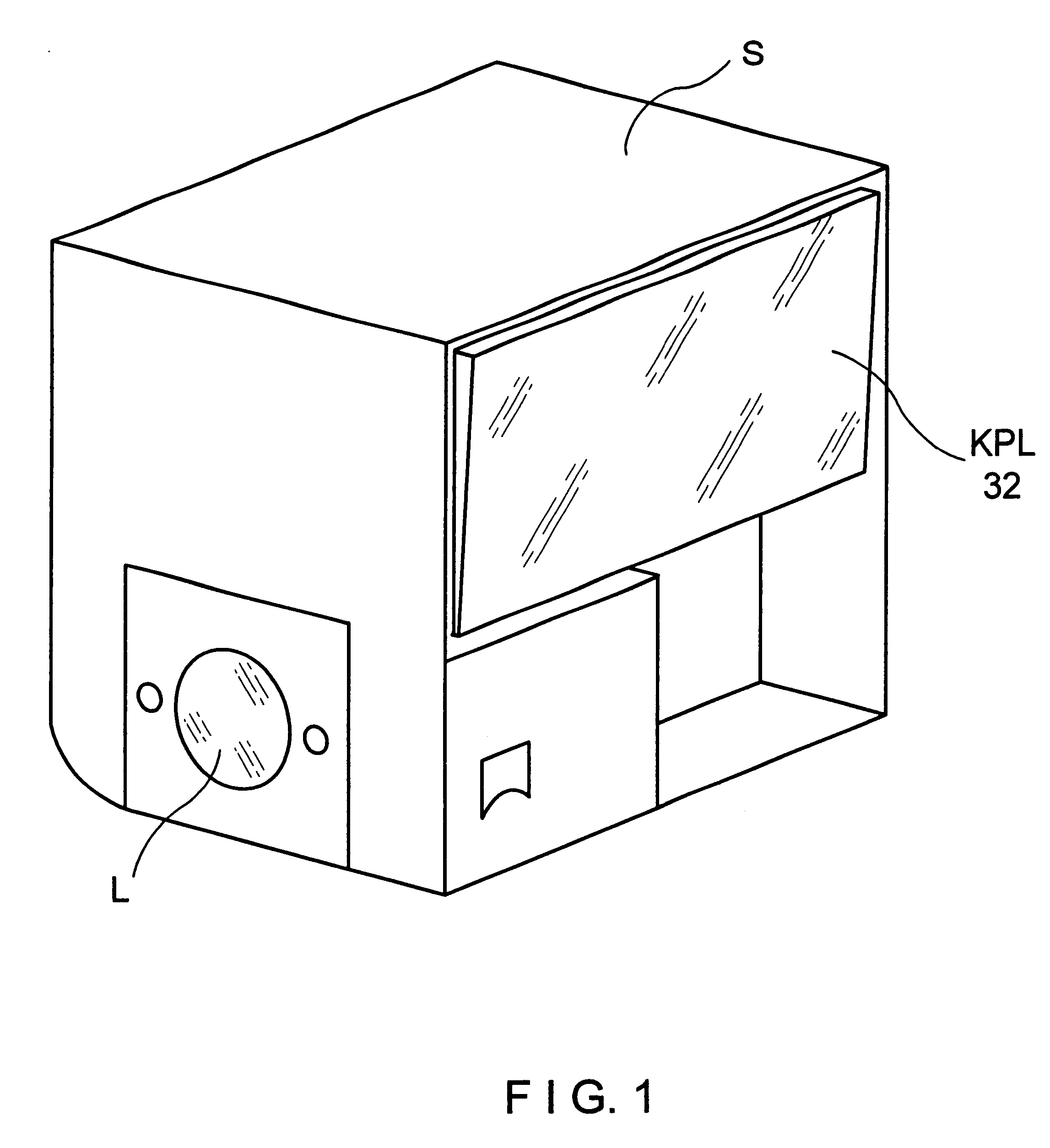

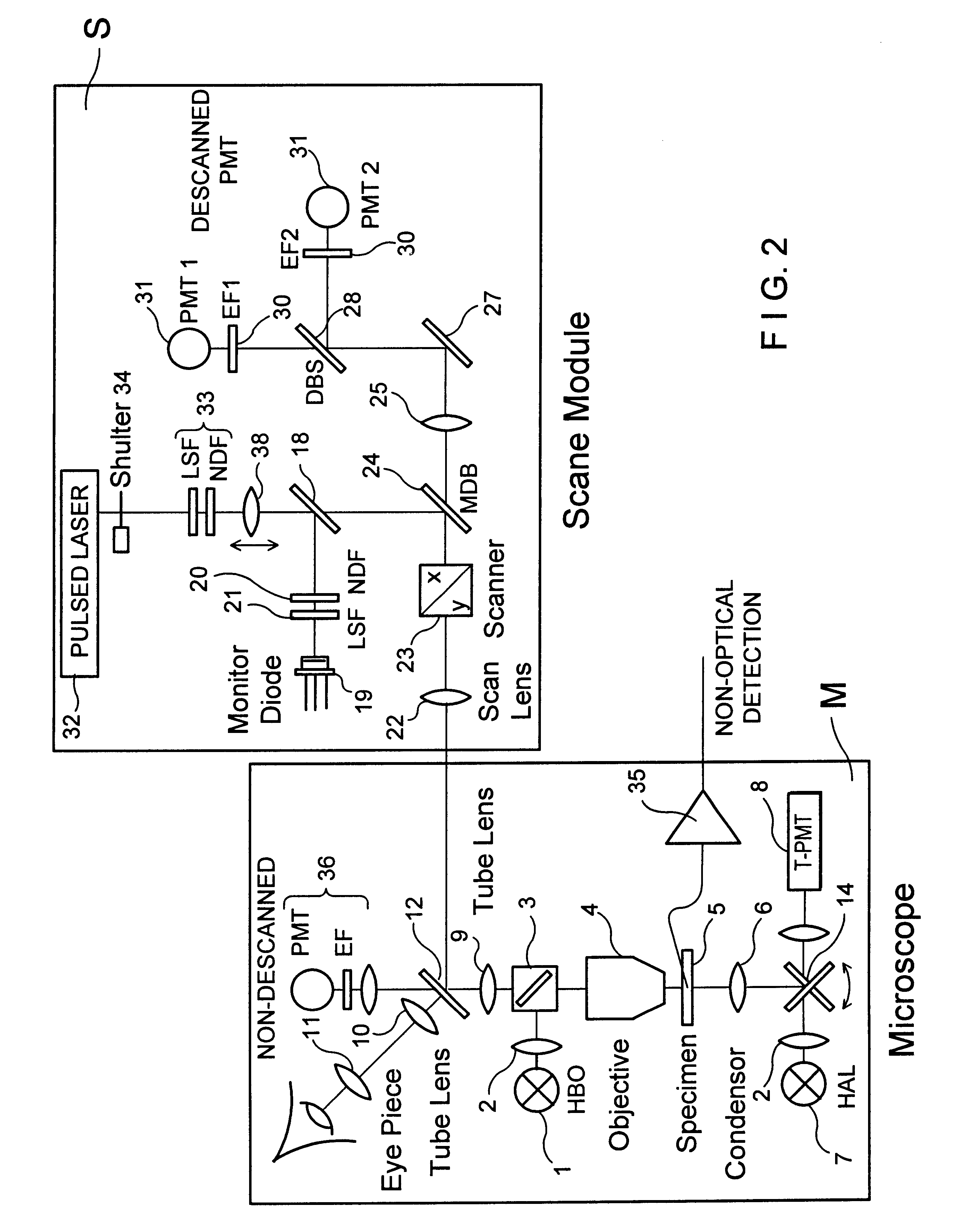

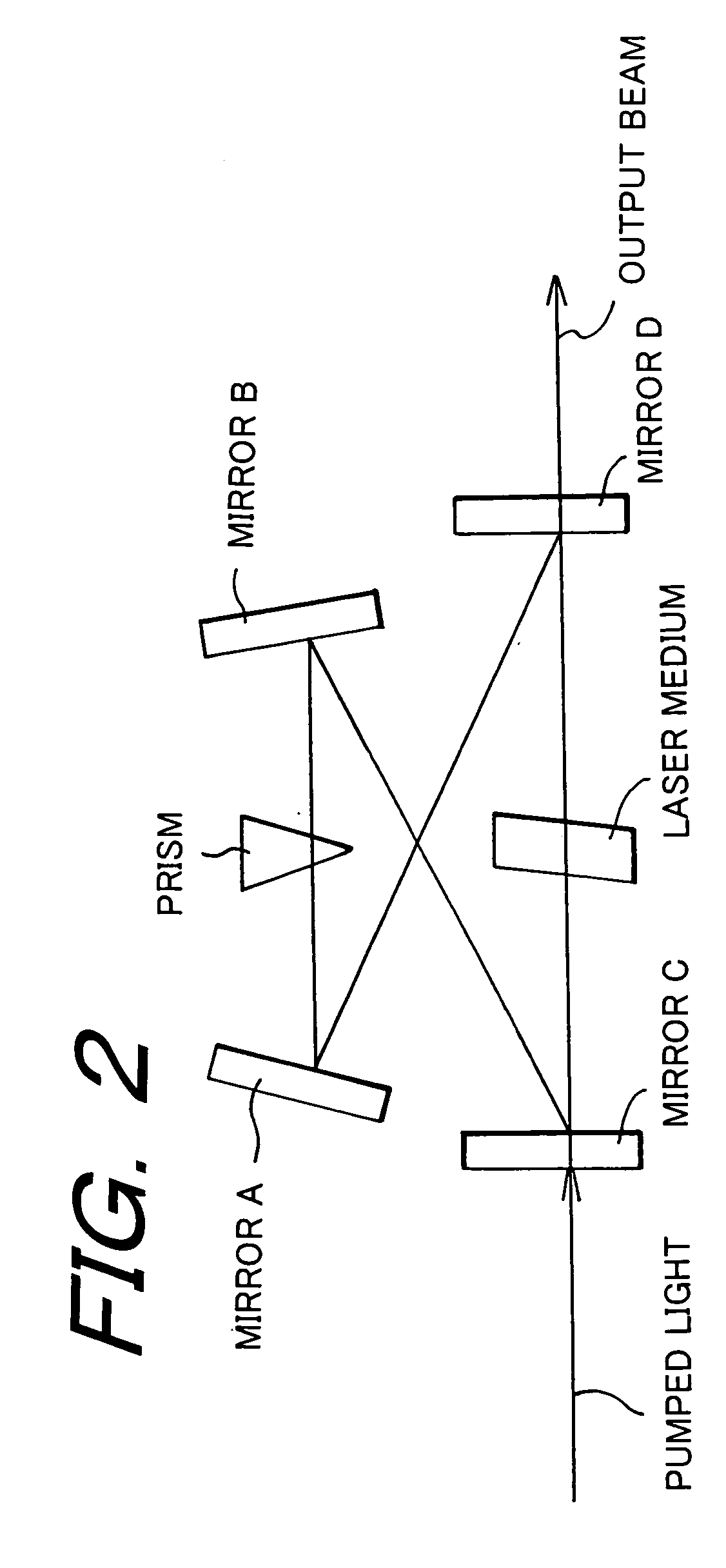

Highly compact laser scanning microscope with integrated short-pulse laser

InactiveUS6356088B1Improve signal-to-noise ratioAttenuation bandwidthMaterial analysis using wave/particle radiationScanning probe techniquesLaser scanning microscopeDirect coupling

The invention describes a highly compact laser scanning microscope with integrated short-pulse laser. Direct coupling or a fiber coupling of the short-pulse laser with the laser scanning microscope is advantageously circumvented with this arrangement. This compact arrangement of the laser in the scan module of the laser scanning microscope can be used in a particularly advantageous manner, for example, in multiphoton microscopy for three-dimensionally resolved microscopic analysis, e.g., of biological specimens. Because of the inherent depth discrimination of the multiphoton technique, confocal pinholes can be entirely omitted in the detection beam path. Accordingly, the microscope system can be realized in a very simple manner with respect to engineering and is particularly simple to handle with respect to application. Through the use of a short-pulse laser system in which a plurality of wavelengths are available simultaneously, diverse applications can be realized in one and the same compact microscope system.

Owner:CARL ZEISS MICROSCOPY GMBH

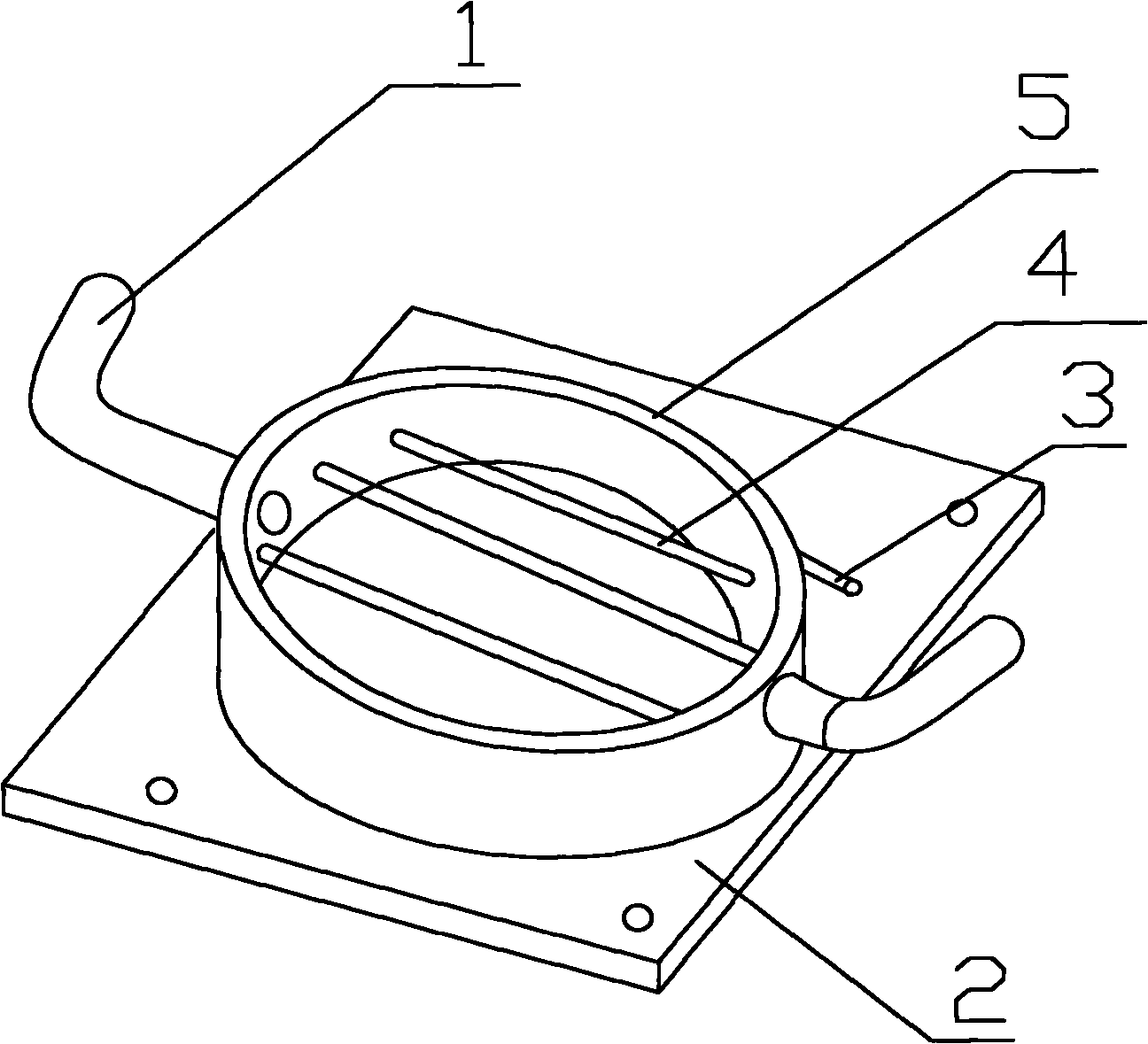

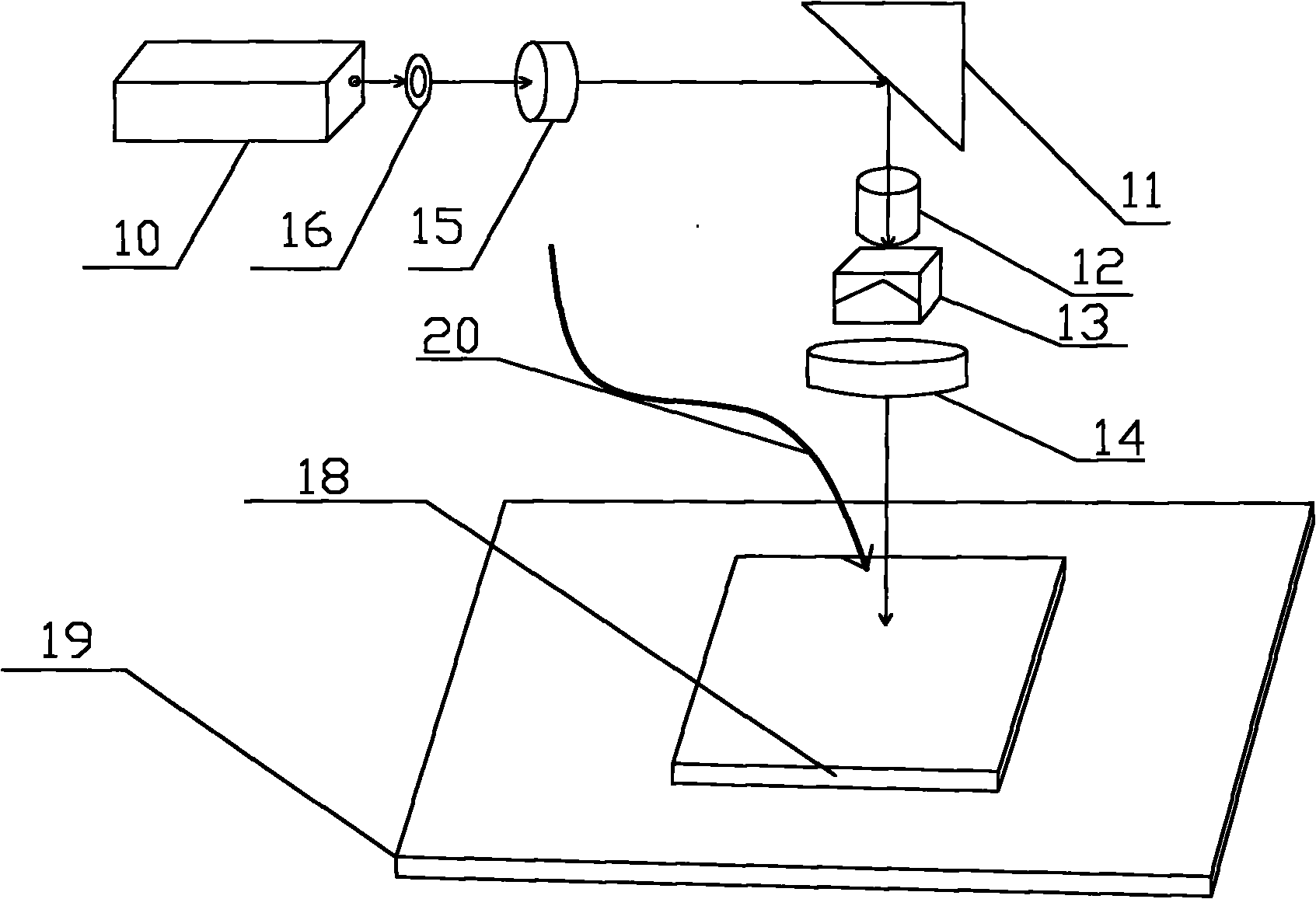

Device and method for abnormally cutting toughened glass by ultra-short pulse laser

InactiveCN102248302AImprove smoothnessImprove cutting efficiencyLaser beam welding apparatusBeam expanderSlag

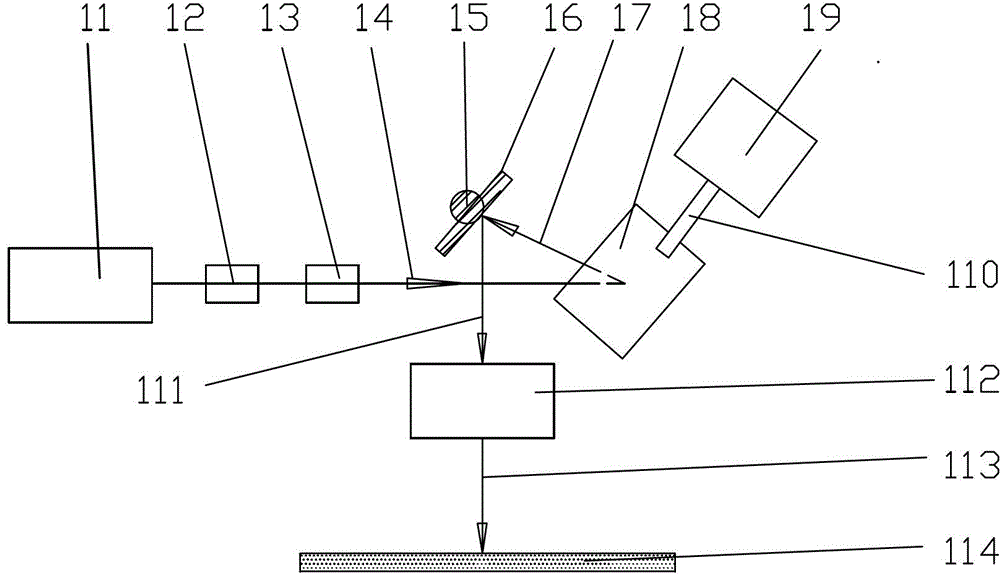

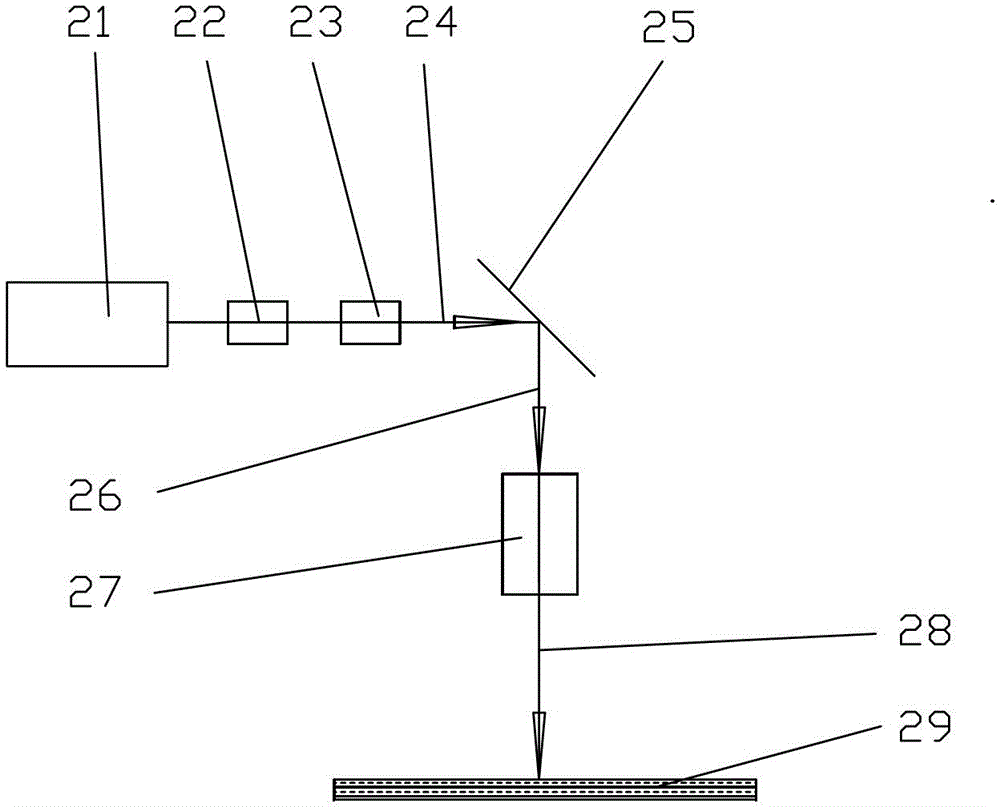

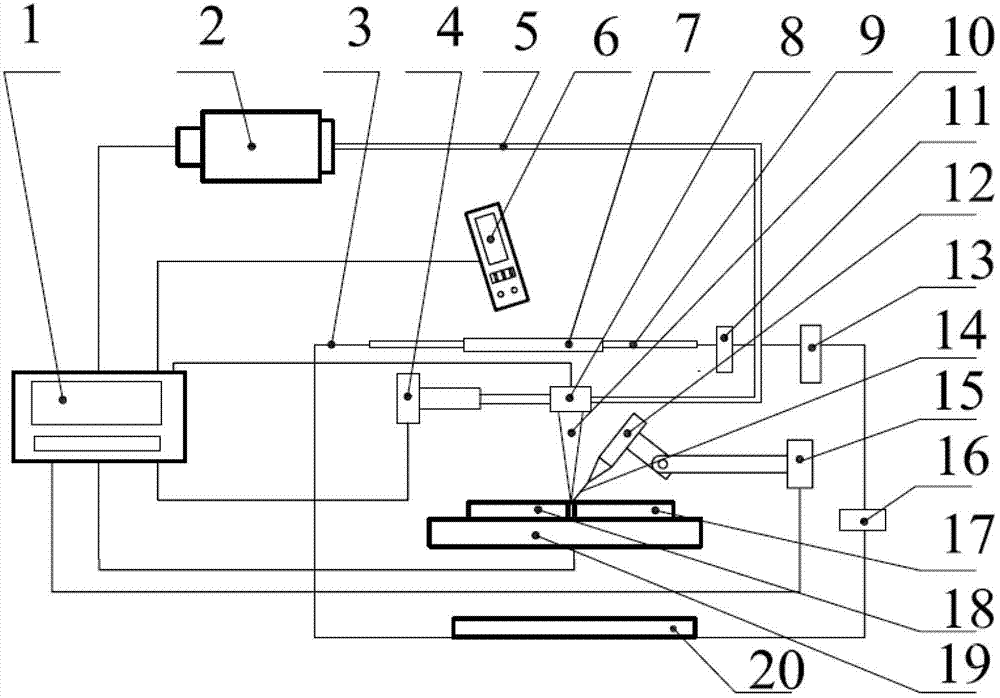

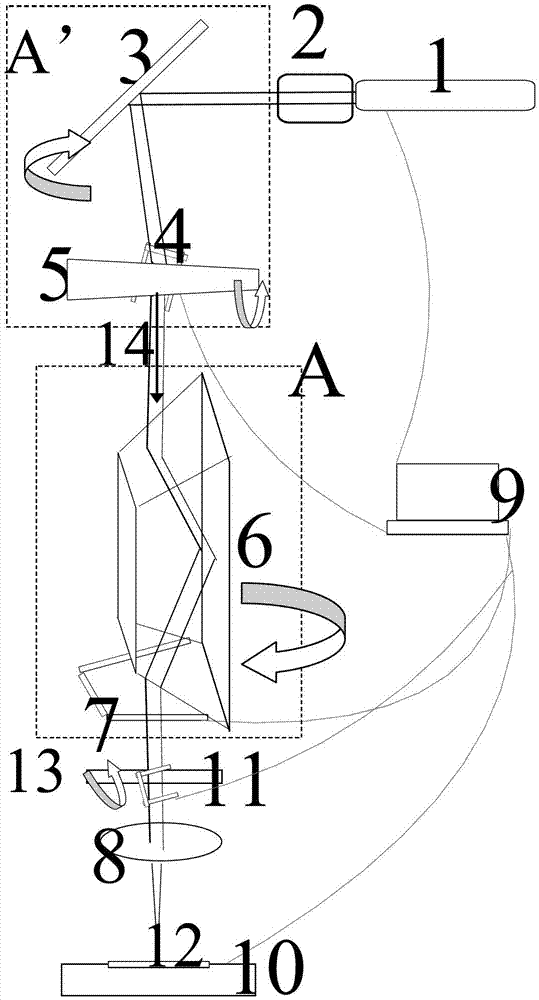

The invention relates to a device and method for abnormally cutting a toughened glass by ultra-short pulse laser. An output end of an ultra-short pulse laser apparatus is provided with an optical gate, an output end of the optical gate is provided with a beam expander, an output end of the beam expander is provided with a 45-degree holophote, an output end of the 45-degree holophote is provided with a three-dimensional (3D) dynamical focusing system, an output end of the 3D dynamical focusing system is provided with a telecentric field lens which is arranged facing to a platform above which a blowing device is arranged. When the ultra-short pulse laser device is used to cut, a heating device is used for heating the glass; the ultra-short pulse laser is focused in the glass by the 3D dynamical focusing system to abnormally scan the glass along with the laser, and the whole processing procedure is in helical processing; a suction dust-collecting device at the bottom of the platform is used for collecting the scanned glass slag; and the blowing device on the platform is used for blowing the slag and dust particles processed on the surface of the glass. The abnormal graph processing to the toughened glass is a processing form with smooth cutting surface and high cutting efficiency.

Owner:SUZHOU DELPHI LASER

High average power ultra-short pulsed laser based on an optical amplification system

The present invention includes an apparatus and the method to scale the average power from high power ultra-short pulsed lasers, while at the same time addressing the issue of effective beam delivery and ablation, by use of an optical amplification system.

Owner:RAYDIANCE

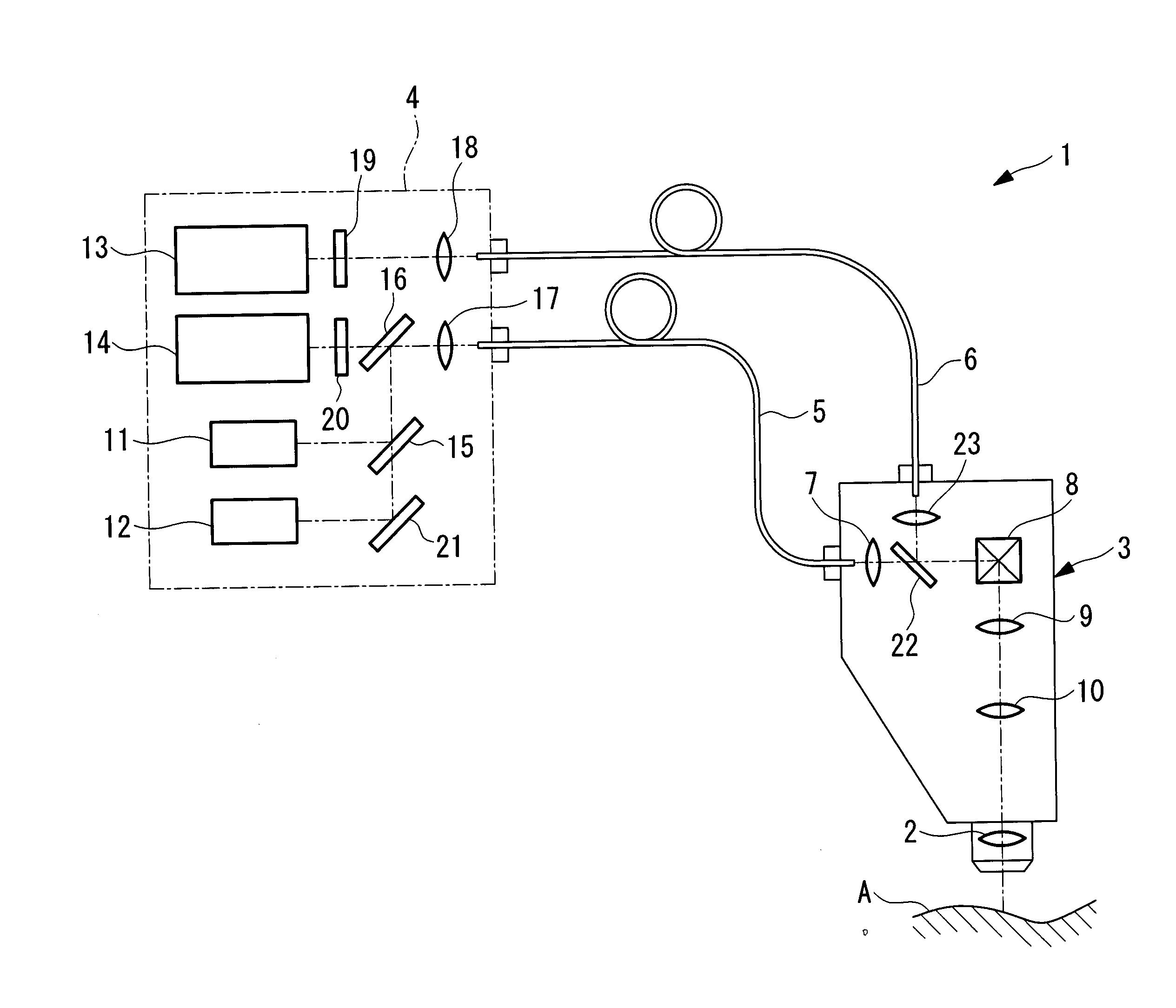

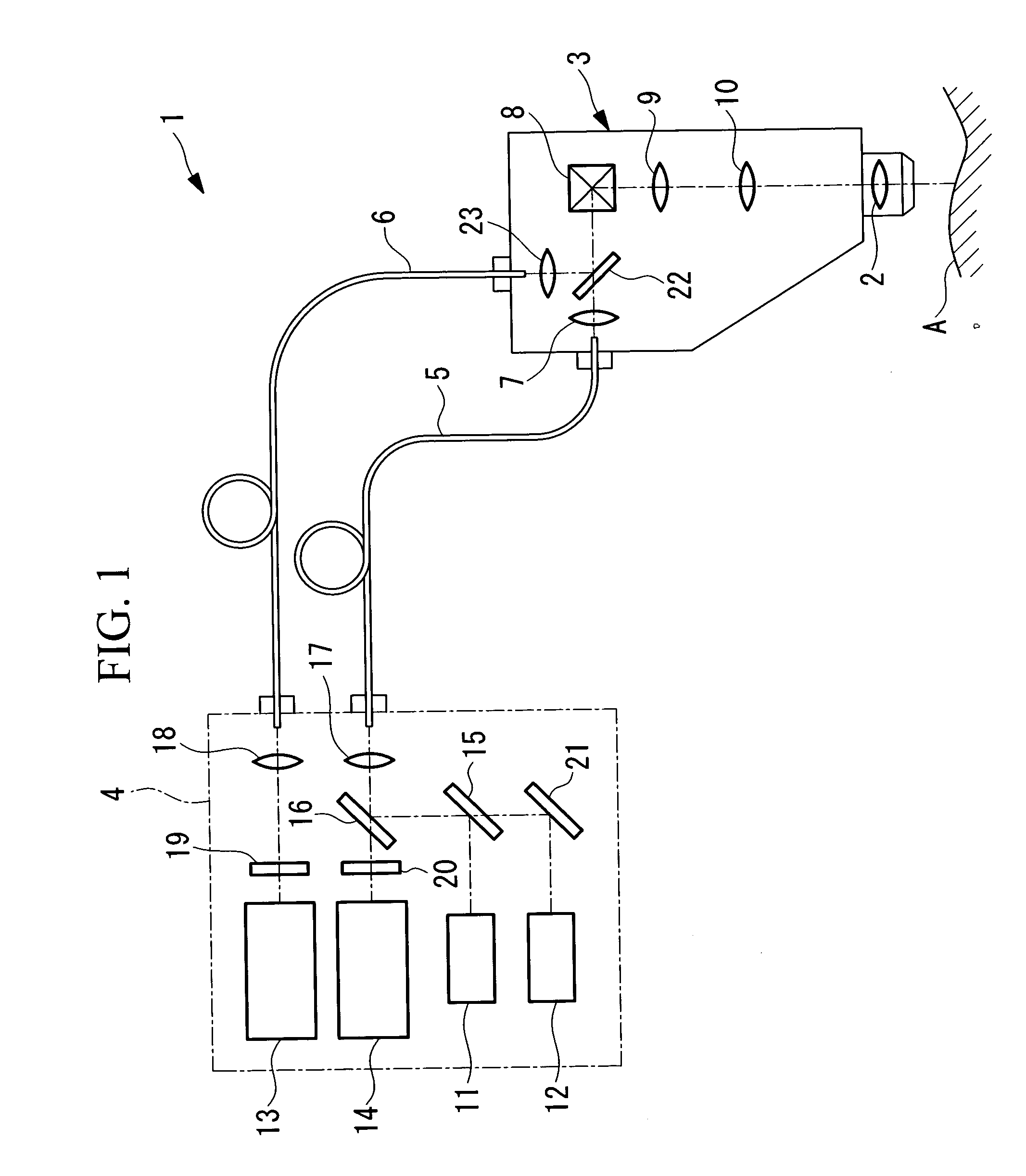

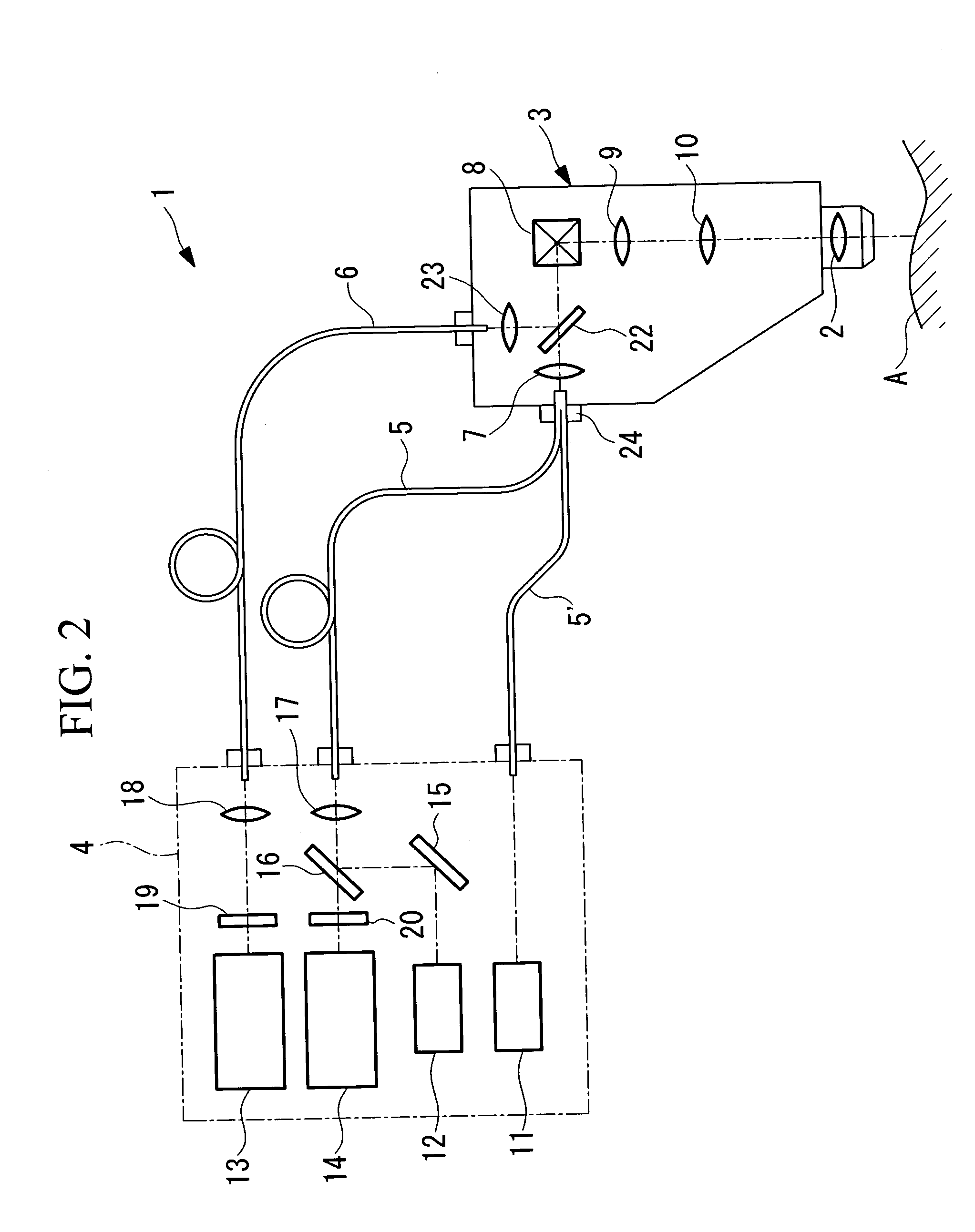

Laser-scanning examination apparatus

InactiveUS20060017920A1Reduce lossesCompact configurationRadiation pyrometrySpectrum investigationLaser scanningLaser light

The invention reduces the loss of fluorescence intensity obtained from a specimen to acquire clear fluorescence images when irradiating the specimen with ultrashort-pulse laser light produced by a laser light source. The invention provides a laser-scanning examination apparatus including a laser light source for producing ultrashort-pulse laser light; a laser light source for producing continuous-wave laser light; a measurement head including an optical scanning unit for scanning the laser light on a specimen and an objective optical system; an imaging unit for detecting return light from the specimen in response to the ultrashort-pulse laser light; and an imaging unit for detecting return light from the specimen in response to the continuous-wave laser light. The laser light sources and one imaging unit are connected to the measurement head by an optical fiber, and the other imaging unit is connected to the measurement head by another optical fiber with a larger core diameter.

Owner:OLYMPUS CORP

Yb: and Nd: mode-locked oscillators and fiber systems incorporated in solid-state short pulse laser systems

InactiveUS7508853B2Increase flexibilityMaximize positive effectLaser using scattering effectsOptical devices for laserAudio power amplifierEngineering

The invention describes classes of robust fiber laser systems usable as pulse sources for Nd: or Yb: based regenerative amplifiers intended for industrial settings. The invention modifies adapts and incorporates several recent advances in FCPA systems to use as the input source for this new class of regenerative amplifier.

Owner:IMRA AMERICA

Edge deletion method for thin-film solar cells

ActiveCN102916081AFast edge cleaningGood edge qualityFinal product manufactureLaser beam welding apparatusNanosecond laserLaser processing

The invention belongs to the field of laser processing, discloses an edge deletion method for thin-film solar cells, and concretely relates to a method for carrying out edge deletion on thin-film solar cells by using ultra-short pulse laser. The method disclosed by the invention is importantly characterized in that high-peak-power ultra-short pulse laser with an extremely high transparent conductive film absorption rate is introduced into an application of carrying out edge deletion on thin-film solar cells. Compared with laser power used by edge deletion implemented by using infrared nanosecond laser, the method can complete high-efficiency and high-quality laser edge deletion by using smaller average laser power; and glass is not easy to be damaged, the compatibility with different kinds of transparent conductive films is extremely strong, and the application cost is reduced.

Owner:张立国

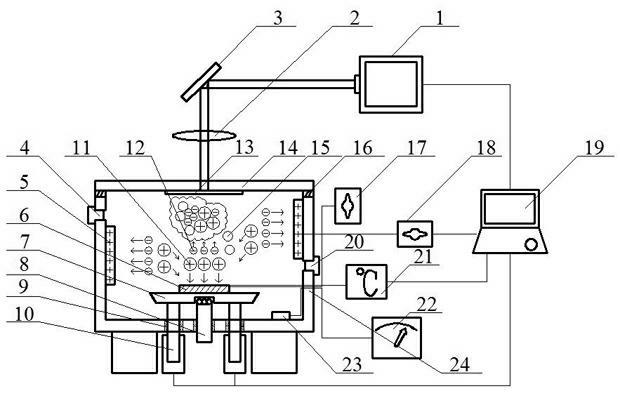

Laser sonic surface wave stress test system

InactiveCN101281172AFast 2D scanningHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationMetallic materials

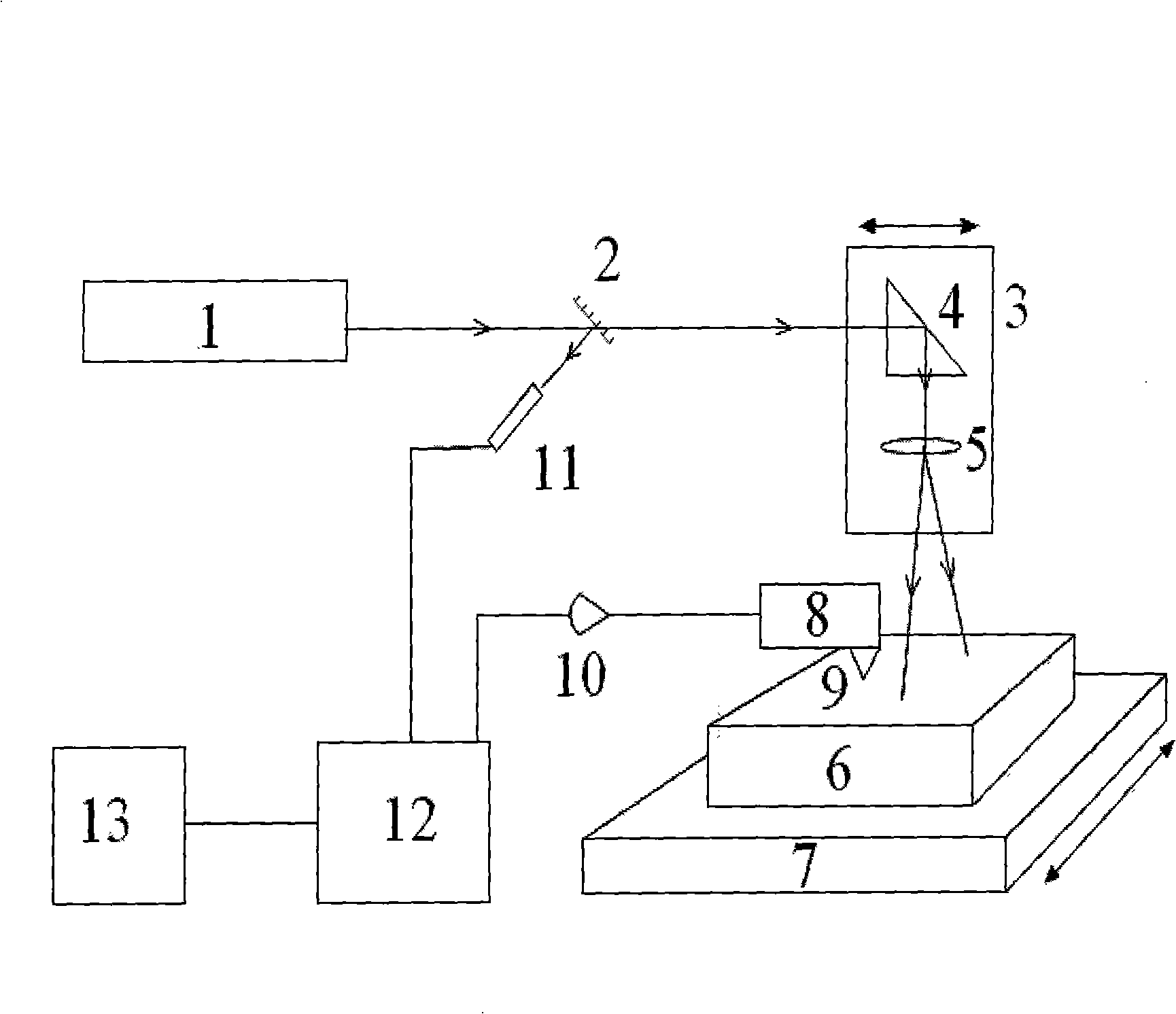

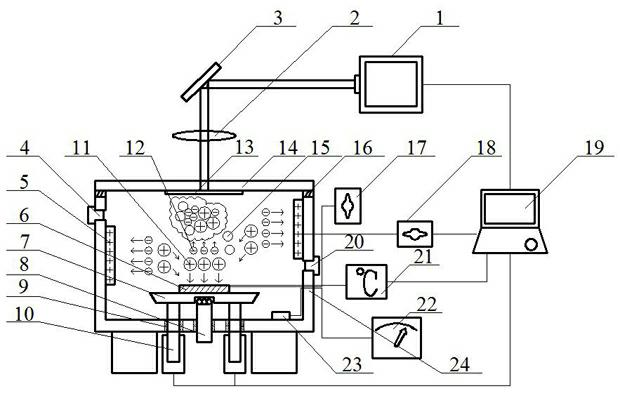

The invention discloses a laser acoustic surface wave stress test system, which is mainly comprises an ultrasound surface wave excitation part composed of a short-pulse laser, a spectroscope, a triple prism and a cylindrical convex lens, and an ultrasound surface wave detection part composed of a PVDF piezoelectric film and a high-frequency pre-amplifier. The invention uses the short-pulse laser to generate a high-frequency ultrasound surface wave on the surface of the samples to be tested, a stress value is obtained according to the principle of acoustic elasticity, the PVDF piezoelectric film is served as the receiver of the ultrasound surface wave, fast two-dimensional scanning is realized on the surface of the samples in the way that the PVDF piezoelectric film is fixed, the excitation source and the samples to be tested are in two-dimensional translation motion, the obtained ultrasound surface wave signals are transmitted to an electronic computer, and the measurement of the stress distribution on the surface and the sun-surface of the samples is realized through fast computing and processing by programming according to the principle of acoustic elasticity. The system has the advantages of simple structure and low cost, which can be widely used in the stress distribution measurement on the surface and the sun-surface of metal materials.

Owner:NANJING UNIV OF SCI & TECH

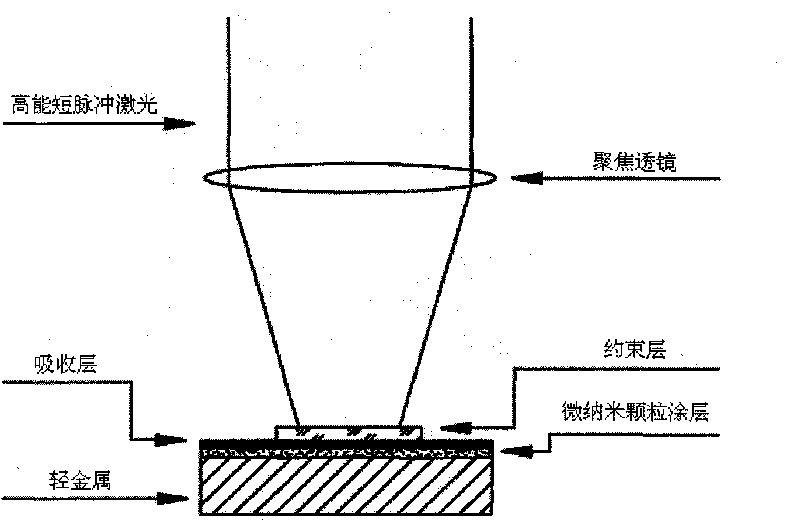

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

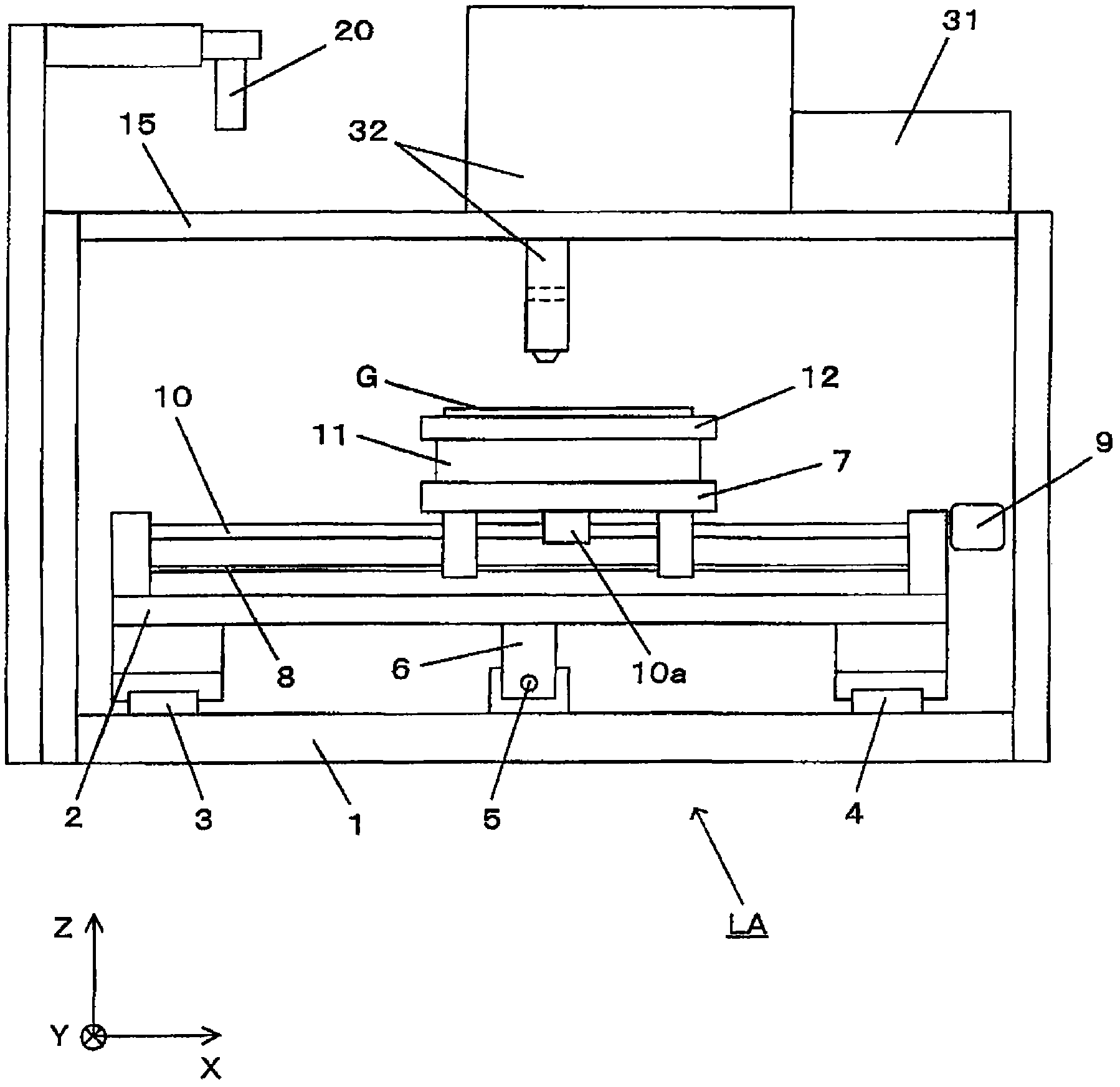

Substrate processing device and substrate processing method

InactiveCN102649199AReduce the number of scansSemiconductor/solid-state device manufacturingLaser beam welding apparatusLight beamOptoelectronics

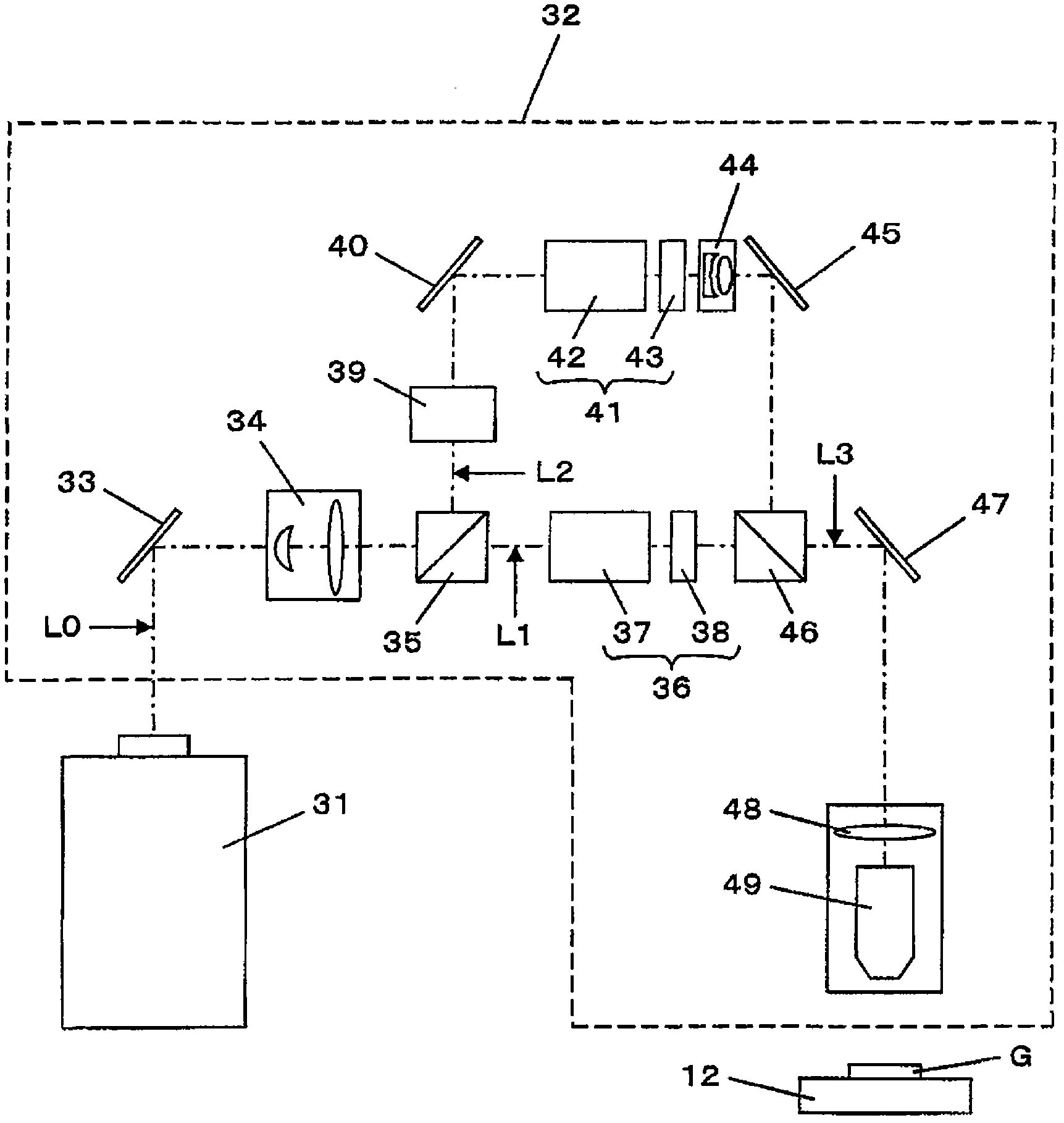

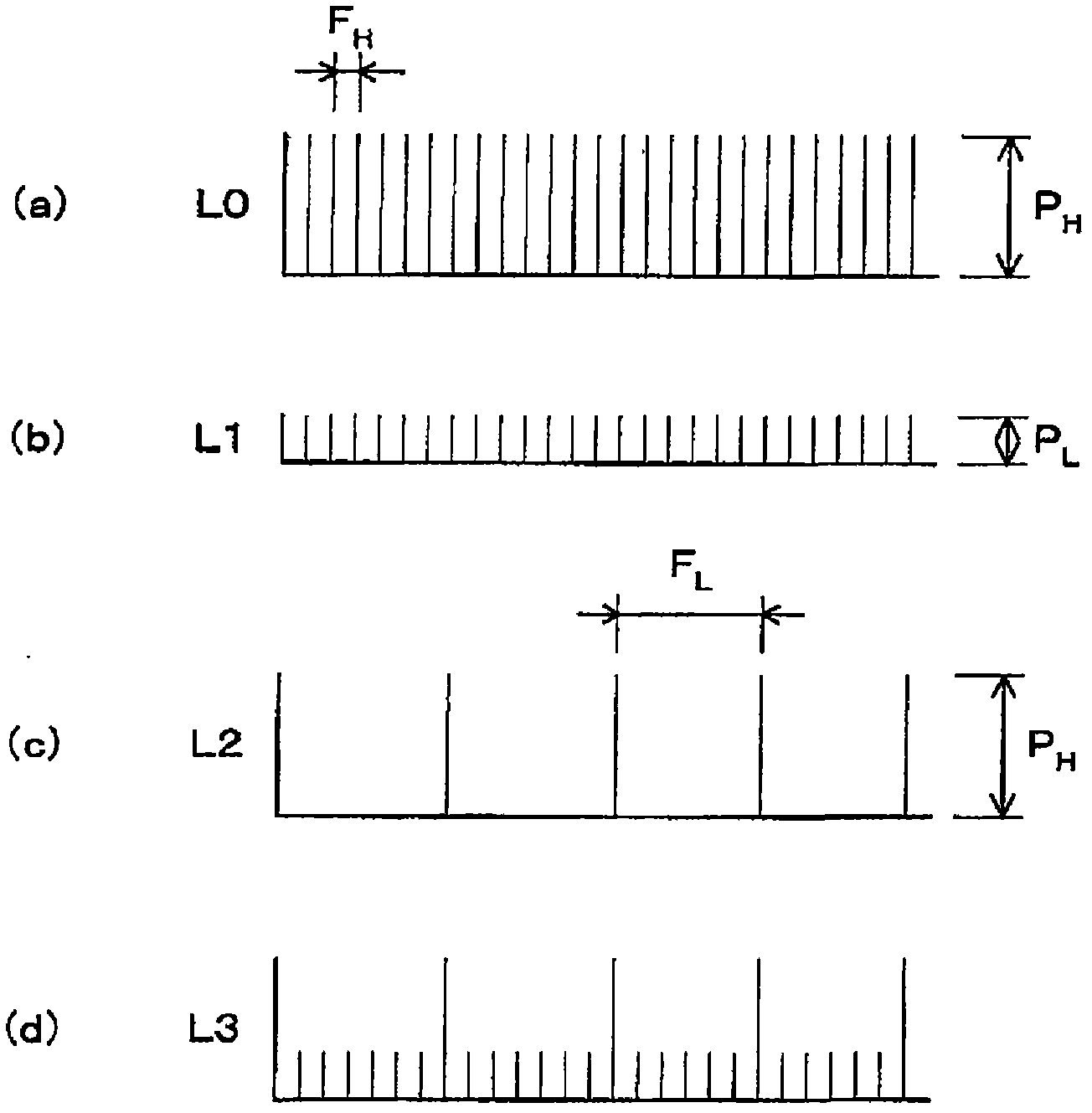

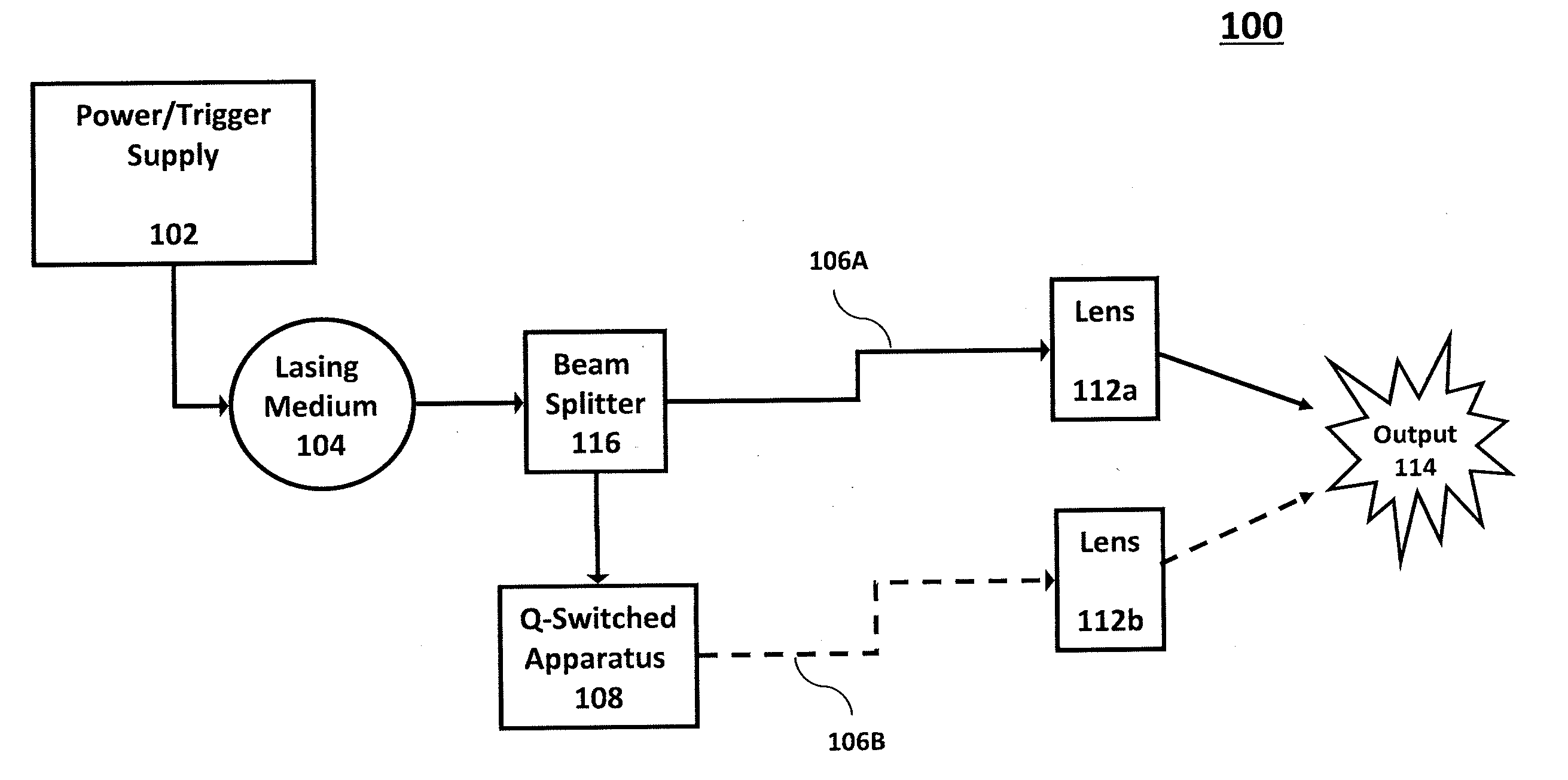

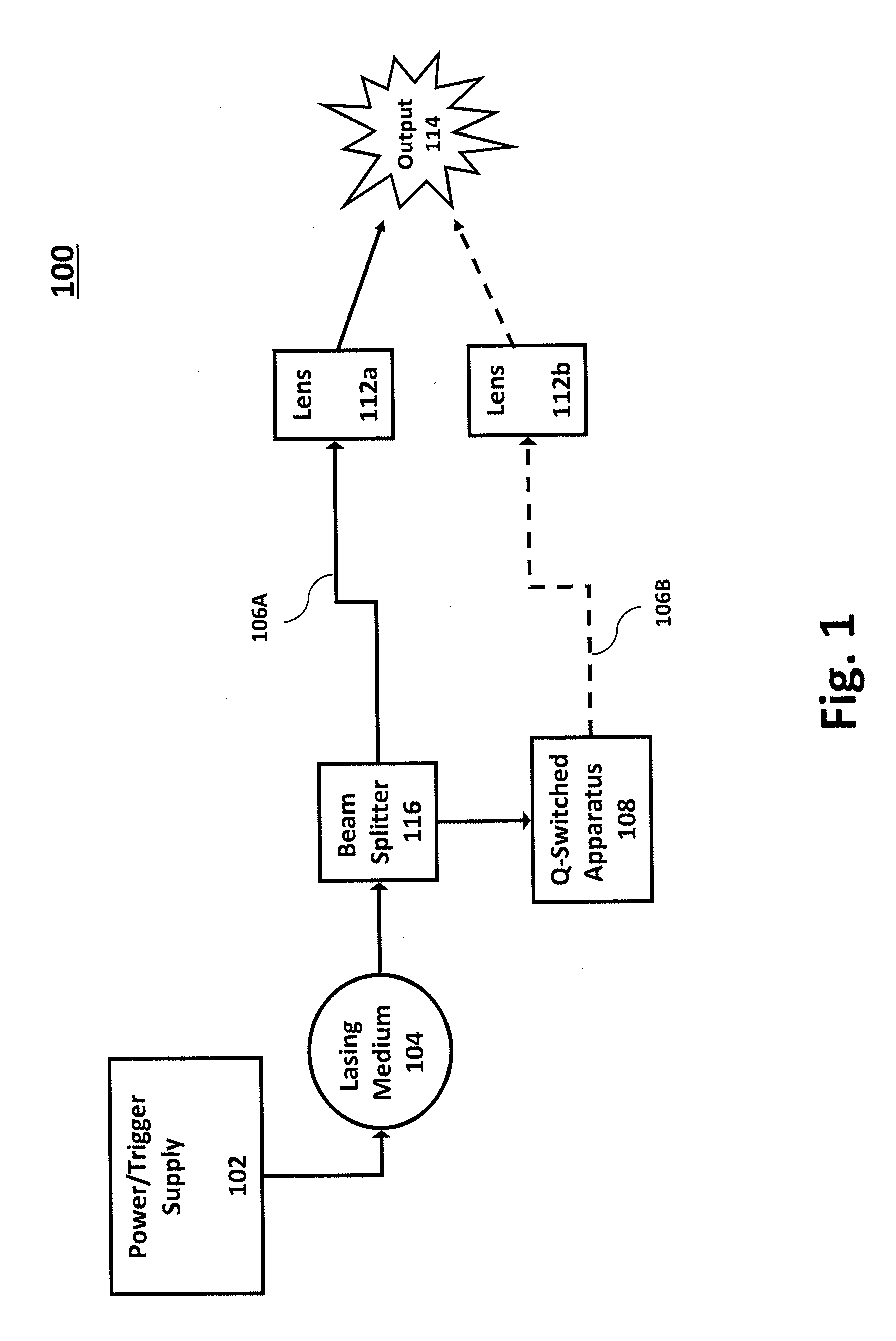

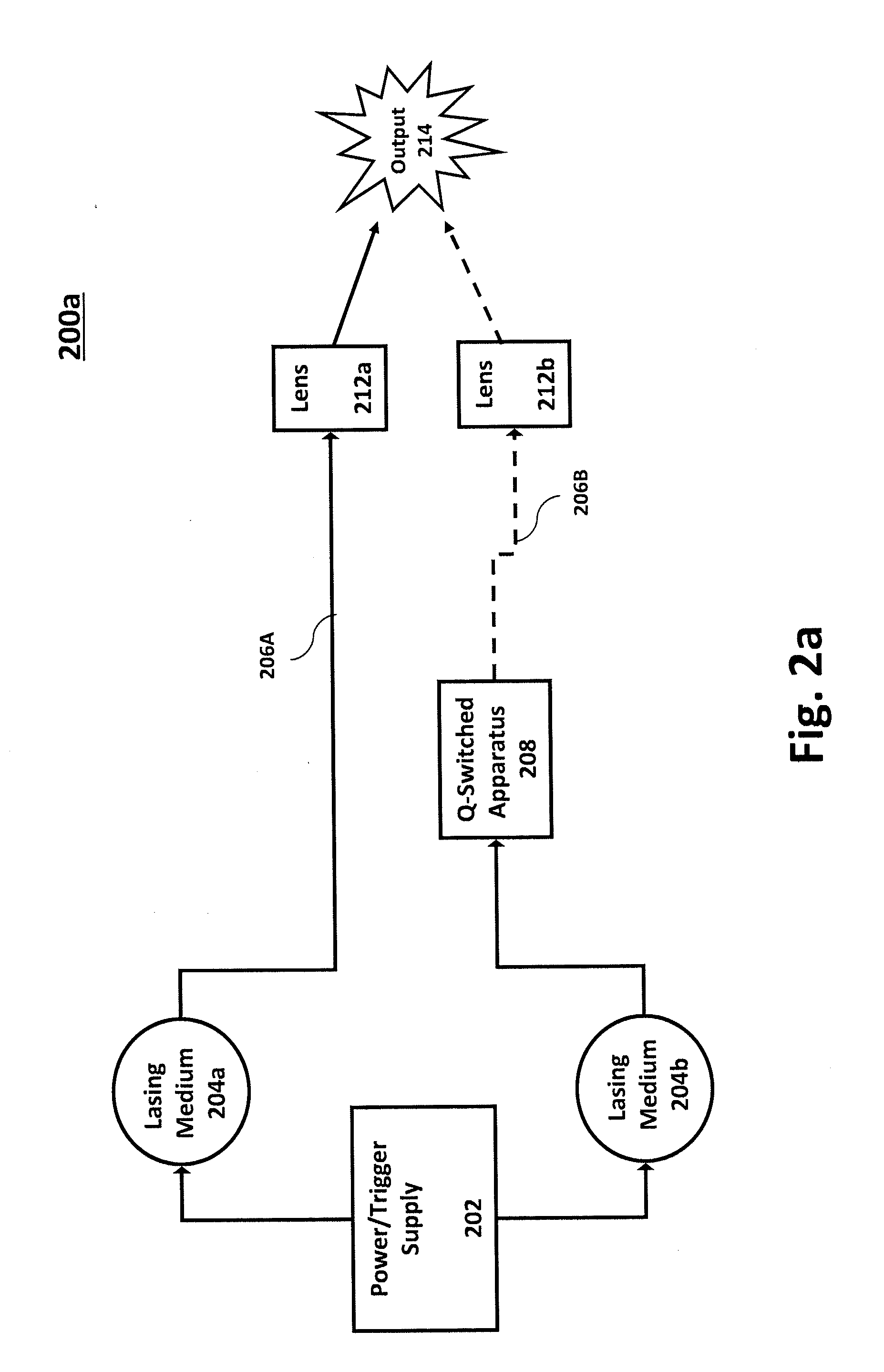

The invention provides a substrate processing device and a substrate processing method, which can conduct short pulse laser processing on the surface of the substrate and the internal part of the substrate without increasing scanning times. The substrate processing device comprises a short pulse laser light source (31), a light path branch part (35) which divide a short pulse laser beam into a first light path side and a second light path side, a pulse selection part (39) which converts repetitive oscillation frequency to make the second light path side to conduct repetitive oscillation of a second frequency smaller than the first frequency, an output adjustment part (36) which adjusts in a manner that the output power of the second light path side is larger than that of the first light path side, a light path synthesis part (46) which forms a synthetic laser beam by overlapping the first and second light path sides, a synthetic laser beam irradiation optical part (48) which comprises an object glass (49) and irradiates the synthetic laser beam towards the substrate, and a scanning mechanism which enables the synthetic laser beam to conduct relative scanning.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Laser welding method for metal sheets applied to ultra low temperature environment

ActiveCN102728950AAccelerate dislocation movementAccelerated particle diffusionLaser beam welding apparatusHigh energyMechanical property

The invention discloses a laser welding method for metal sheets applied to an ultra low temperature environment. The method comprises the following steps of: integrally putting a metal sheet I and a metal sheet II in an inert gas environment, heating to the dynamic strain ageing temperatures of the metal sheet I and the metal sheet II, welding a filler wire in a seam zone by adopting fiber laser, putting the welded metal sheets in a liquid nitrogen environment, and emitting high-energy short pulse laser to carry out double-side laser impact on the metal sheets covered with an aluminum foil. The filler wire is welded for the metal sheets through laser at the dynamic strain ageing temperatures, so that the seam quality of a metal welding joint is greatly improved, and the seam zone is combined tightly with the metal sheets; and by laser impact strengthening treatment of the welding joint and the metal sheets in the same working environment at an ultra low temperature, ultra low temperature corrosion resistance and mechanical property of a metal welding member are remarkably improved.

Owner:ZHANGJIAGANG FURUI HEAVY EQUIP CO LTD

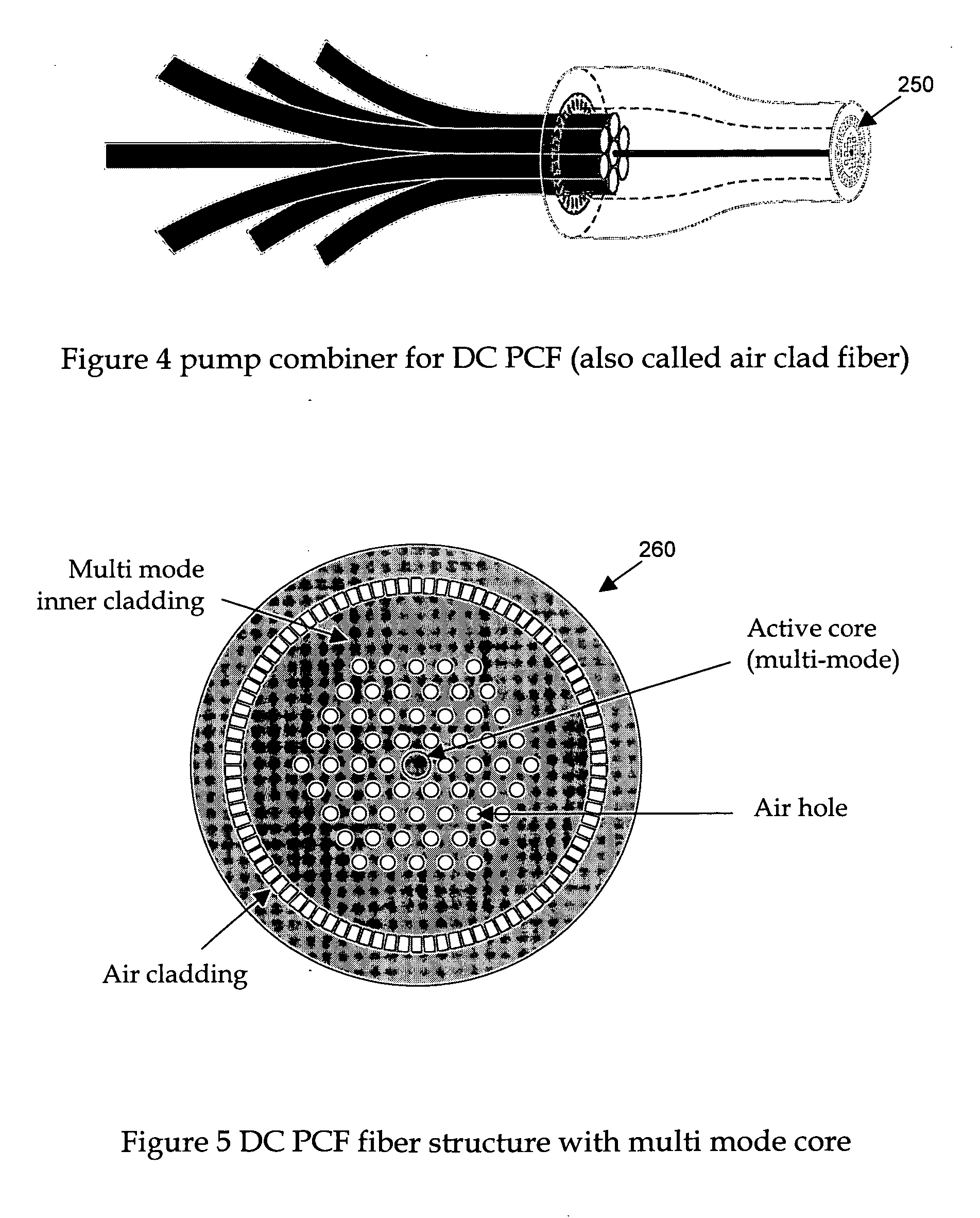

Utilization of yb: and nd: mode-locked oscillators in solid-state short pulse laser system

InactiveUS20080232407A1Improve performanceModifies the spectral gain profileCladded optical fibreLaser using scattering effectsFiberUltrasound attenuation

Owner:IMRA AMERICA

System and method for processing micro conical bore by rotation of laser beam

InactiveCN102950385AControllable taperHigh precisionLaser beam welding apparatusLaser processingOptical axis

The invention discloses a system and a method for processing a micro conical bore by rotation of a laser beam. The system comprises a laser generating unit, a laser deflection unit, a laser rotating unit, a taper control unit and a laser processing unit; the laser generating unit is used for generating a beam of short-pulse laser and sending the short-pulse laser to the incident end of the laser deflection unit; the laser deflection unit is used for sending the short-pulse laser to the incident end of the laser rotating unit by the exit end of the laser deflection unit after carrying out deflection on the short-pulse laser; the laser rotating unit is used for rotating the laser beam and transmitting the laser beam to the incident end of the taper control unit by the exit end of the laser rotating unit; and the taper control unit is used for correcting a horizontal distance between the laser beam and an optical axis and then transmitting the laser beam to a processed workpiece on the laser processing unit by the exit end of the taper control unit. The invention can overcome the technical defects of conventional processing means of processing a fine round hole in a mechanical and electric spark manner and the like and completely avoids the defects of a great number of burrs, difficulty in control on the accuracy, poor reliability and the like of a current fine conical bore.

Owner:CHINA KEHAN LASER FUJIAN

Method for fabricating thin films

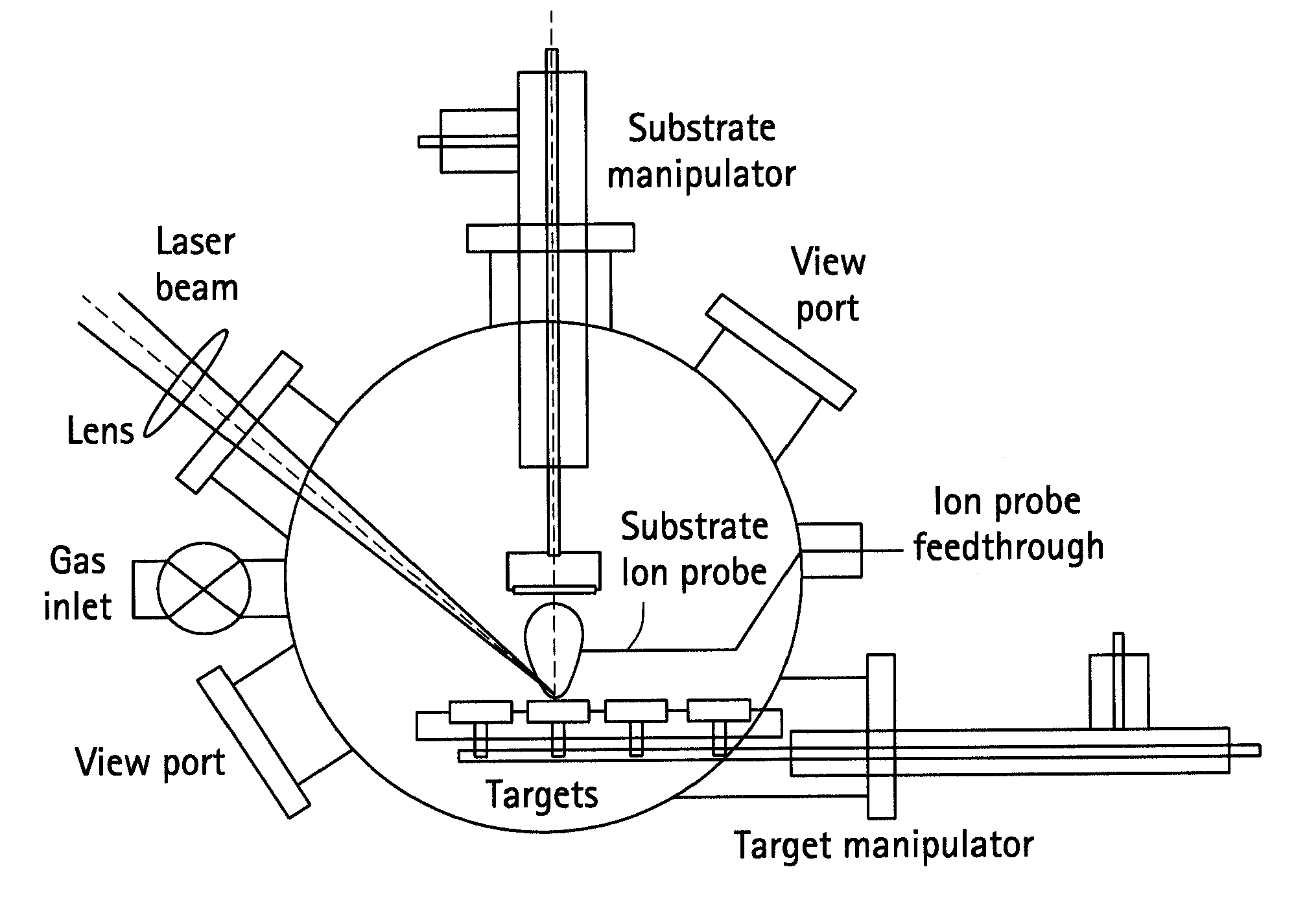

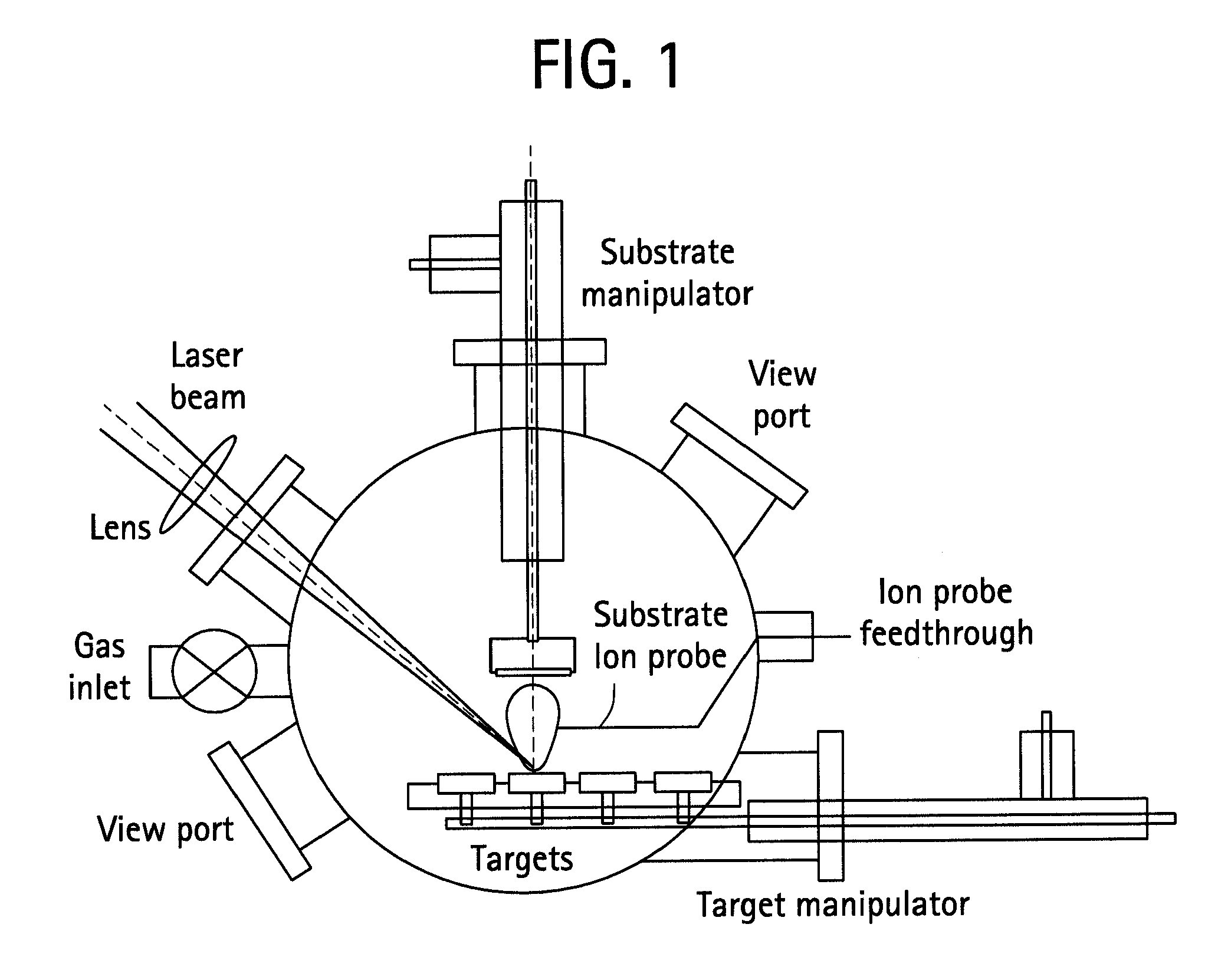

A method of ultrashort pulsed laser deposition (PLD) capable of continuously tuning formed-film morphology from that of a nanoparticle aggregate to a smooth thin film completely free of particles and droplets. The materials that can be synthesized using various embodiments of the invention include, but are not limited to, metals, alloys, metal oxides, and semiconductors. A ‘burst’ mode of ultrashort pulsed laser ablation and deposition is provided, where each ‘burst’ contains a train of laser pulses. Tuning of the film morphology is achieved by controlling the burst-mode parameters such as the number of pulses and the time-spacing between the pulses within each burst, the burst repetition rate, and the laser fluence. The system includes an ultrashort pulsed laser, an optical setup for delivering the laser beam such that the beam is focused onto the target surface with an appropriate average energy density (fluence), and a vacuum chamber in which the target and the substrate are installed and background gases and their pressures are appropriately adjusted.

Owner:IMRA AMERICA

Short burst laser cleaning method of metal surface

The invention provides a method for cleaning a metal surface by short pulsed laser. The method cleans the area to be cleaned on the metal surface in a manner of round lapping irradiated by defocusing facula of laser and is characterized in that: (1) the short pulsed laser is adopted to clean the surface, wherein, the laser pulse width is less than 100ns, and the peak power density is more than 100MW / cm<2>; (2) when processed, the end face, as well as the upper surface and the lower surface near the end face, need to be cleaned, and the laser irradiates the upper surface of a sheet metal at an inclined angle of 45 - 60 degrees, with part of the laser facula being projected on the end face and the other part of the laser facula being projected on the upper surface; mainly aiming at meeting the requirements for cleaning a thin layer of oxide film on the surface of titanium alloy, aluminum alloy and the like before welding, the method can obtain higher surface cleaning quality than the conventional laser cleaning method and faster process flow than acid cleaning method, is suitable for rapid treatment of laser processing, and has good reference value for the fast flow of processing production line and wide applicability.

Owner:BEIJING AVIATION MFG ENG INST CHINA AVIATION NO 1 GRP

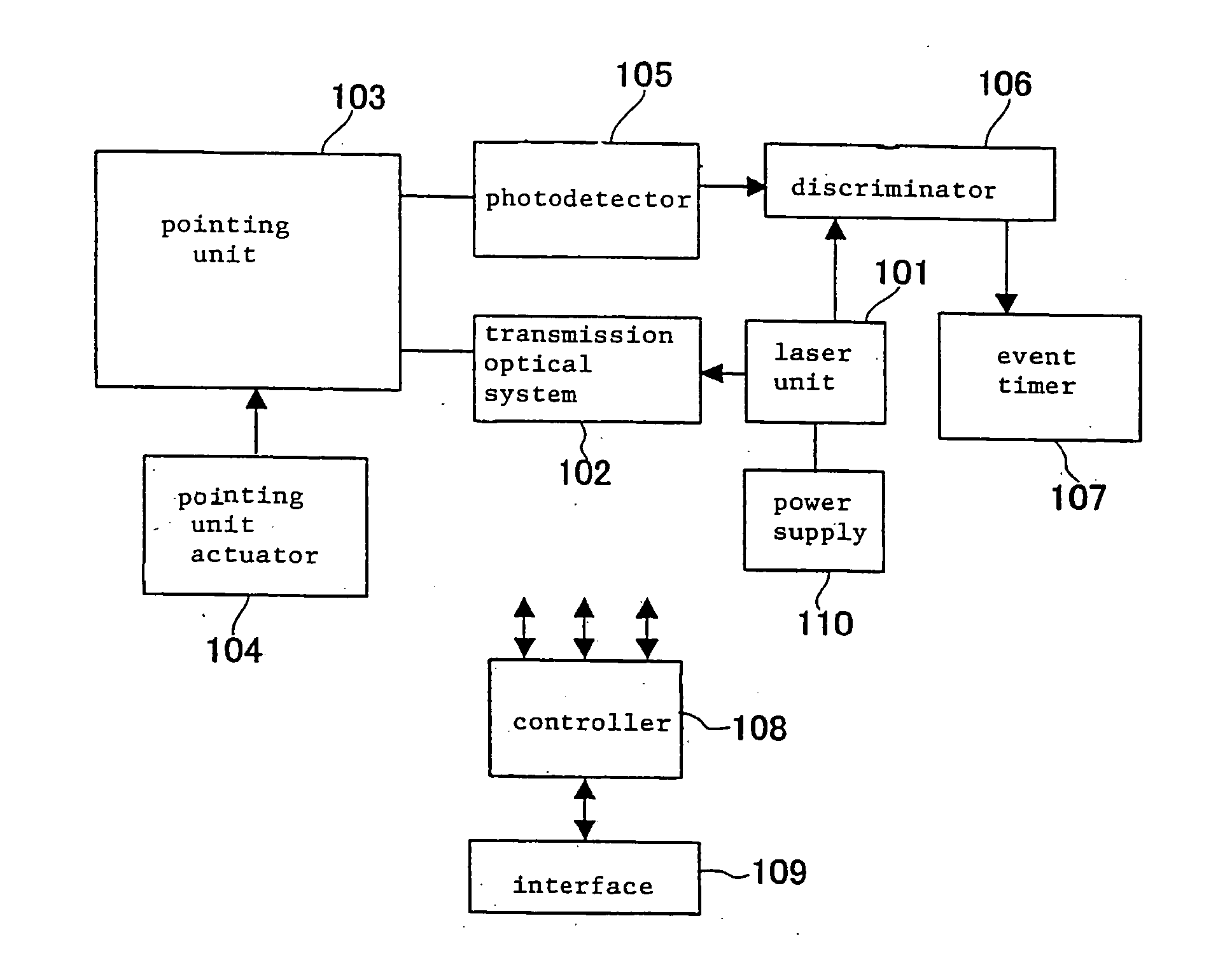

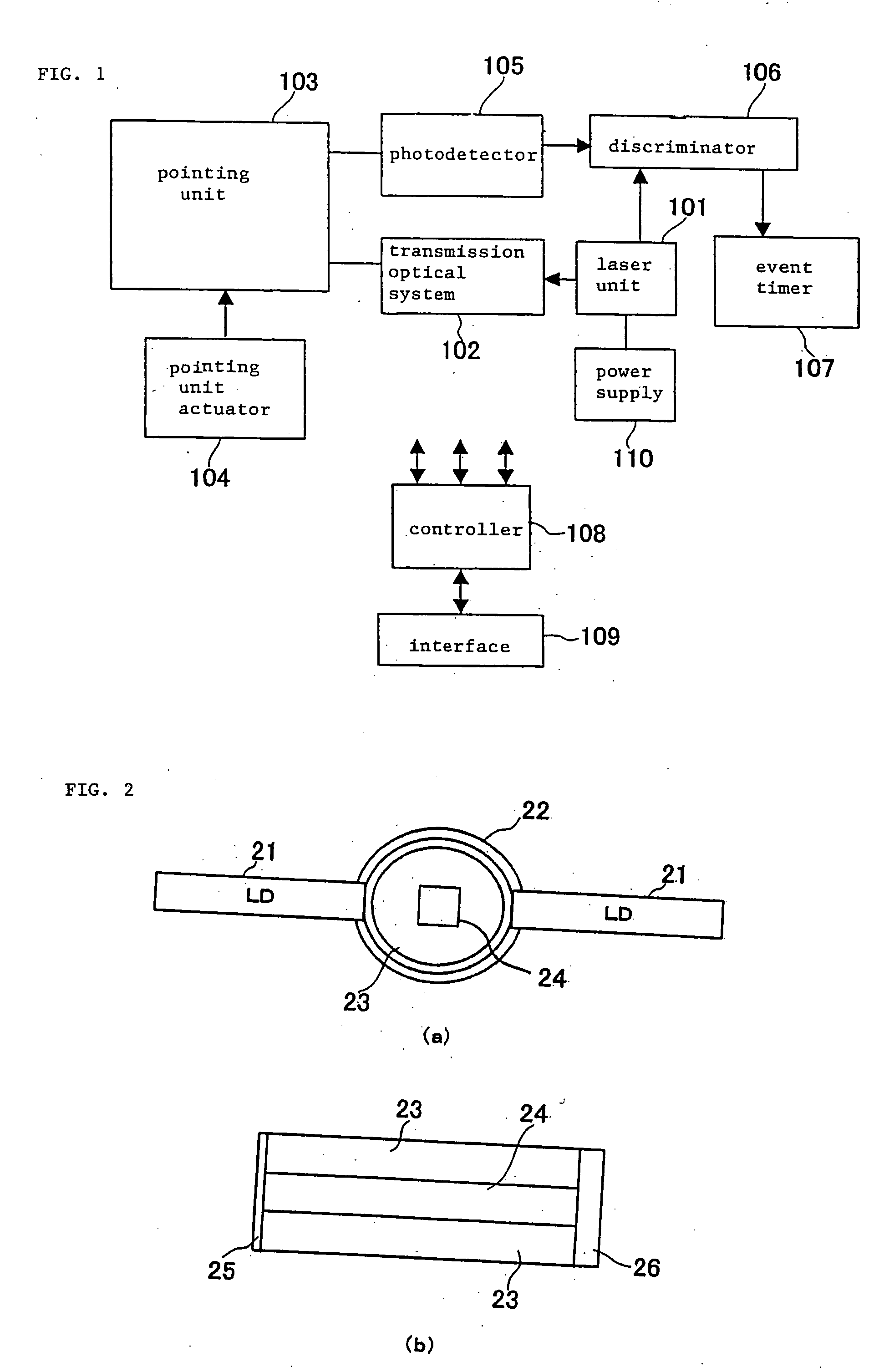

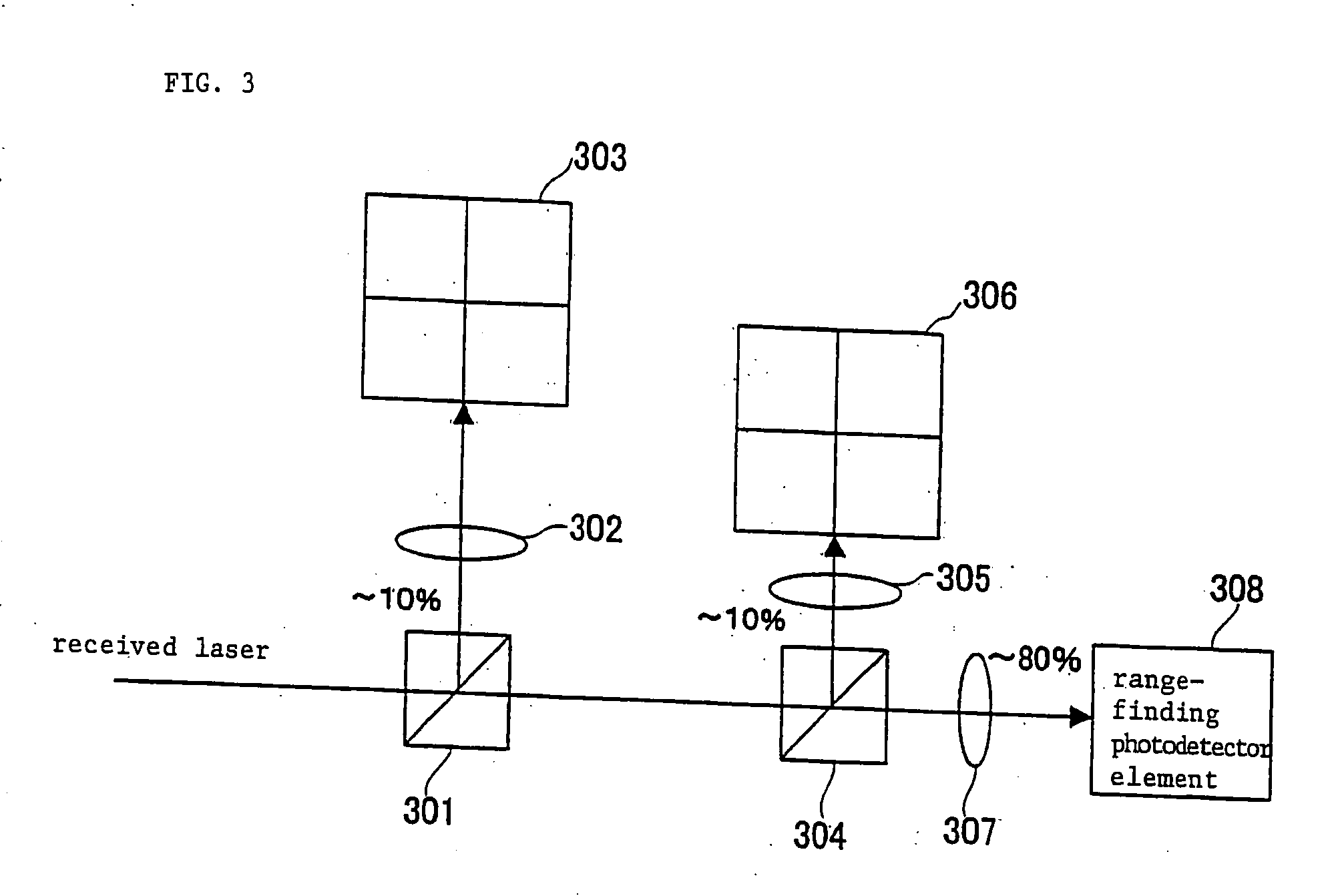

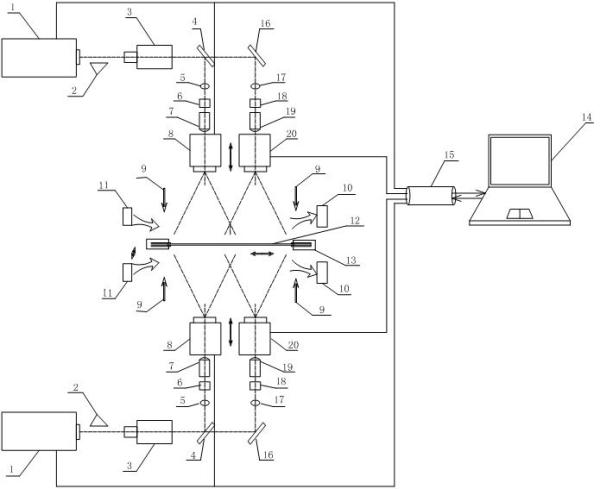

Laser range finder

InactiveUS20050061957A1Accurate measurementCosmonautic vehiclesOptical rangefindersLaser rangingPhotovoltaic detectors

A laser range finder measures the range between itself and another laser range finder by propagating a laser beam only in one way therebetween. A laser unit generates a short-pulse laser beam to be transmitted to the other laser range finder. A photodetector receives a short-pulse laser beam transmitted from the other laser range finder and detects the direction of the other laser range finder. A pointing unit adjusts the direction in which the laser beam generated by the laser unit is to be transmitted, into alignment with the direction of the other laser range finder which is detected by the photodetector. A controller stores in advance a holding time after the other laser range finder receives the short-pulse laser until the other laser range finder transmits the short-pulse laser, and calculates the range between the own laser range finder and the other laser range finder from the time at which the short-pulse laser beam is transmitted, the time at which the short-pulse laser beam is received, and the holding time.

Owner:NEC CORP

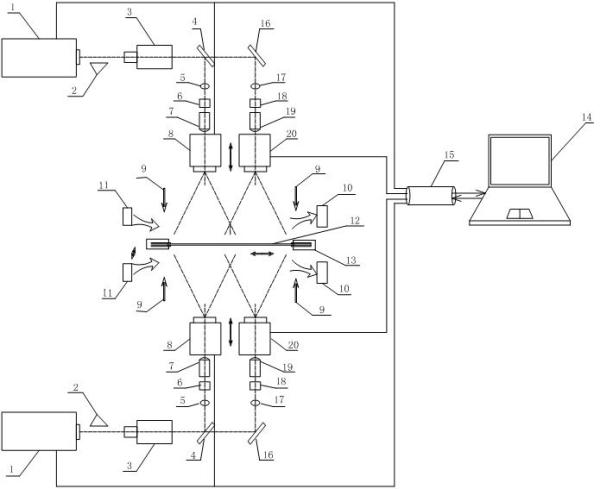

Device and method for pulse laser etching of conducting film layer on double-sided indium tin oxide (ITO) glass

InactiveCN102357736ANo pollution in the processLinear stabilityLaser beam welding apparatusLaser etchingBeam expander

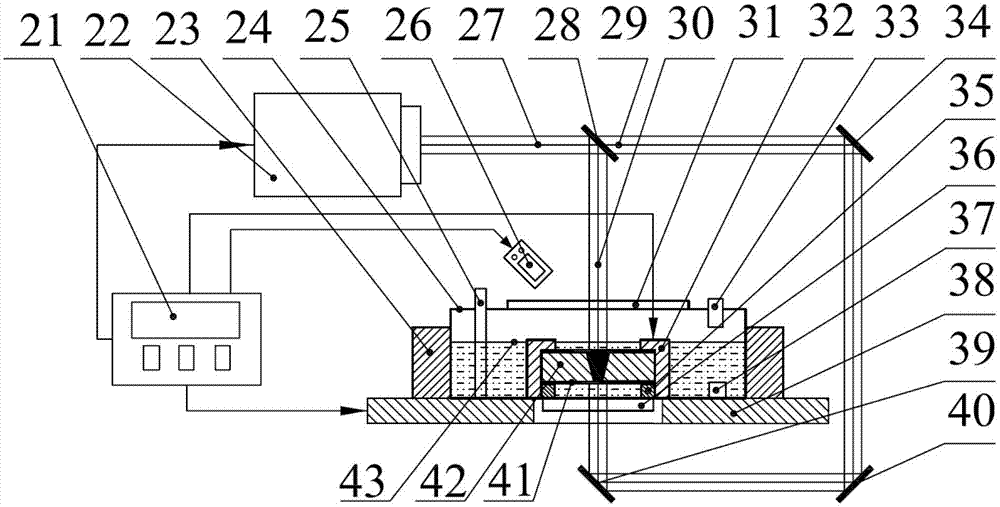

The invention relates to a device and a method for the pulse laser etching of a conducting film layer on double-sided indium tin oxide (ITO) glass. The front and back surfaces of a film material are provided with a set of pulse laser etching device respectively. Each set of pulse laser etching device comprises a high-frequency short-pulse laser, a semi-transmitting semi-reflecting mirror, a Glan prism and a completely reflecting mirror; the output end of the high-frequency short-pulse laser is sequentially provided with an optical gate, a beam expander and the semi-transmitting semi-reflecting mirror; the output end of the semi-transmitting semi-reflecting mirror is provided with a first 1 / 2 wave plate and the completely reflecting mirror; the output end of the first 1 / 2 wave plate is sequentially provided with a first Glan prism and a first three-dimensional (3D) dynamic focusing lens; the output end of the first 3D dynamic focusing lens is provided with a first galvanometer; the output end of the completely reflecting mirror is provided with a second 1 / 2 wave plate; the output end of the second 1 / 2 wave plate is sequentially provided with a second Glan prism and a second 3D dynamic focusing lens; the output end of the second 3D dynamic focusing lens is provided with a second galvanometer; and the output ends of the first and second galvanometers are both dead against the surface of the film material. The device and the method are used for etching double-sided ITO glass in different touch screen products to realize high-efficiency high-accuracy circuit manufacturing.

Owner:SUZHOU DELPHI LASER

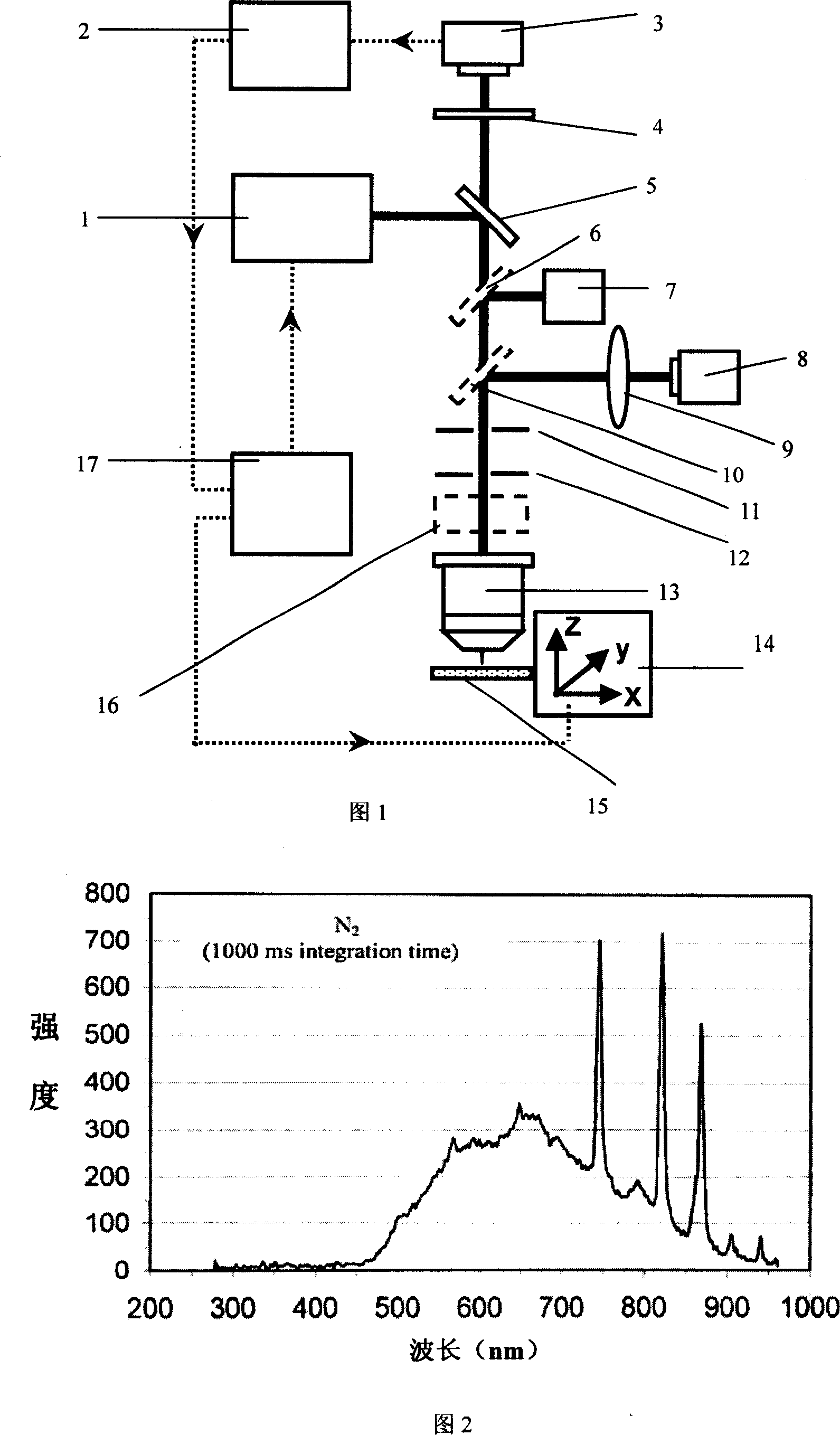

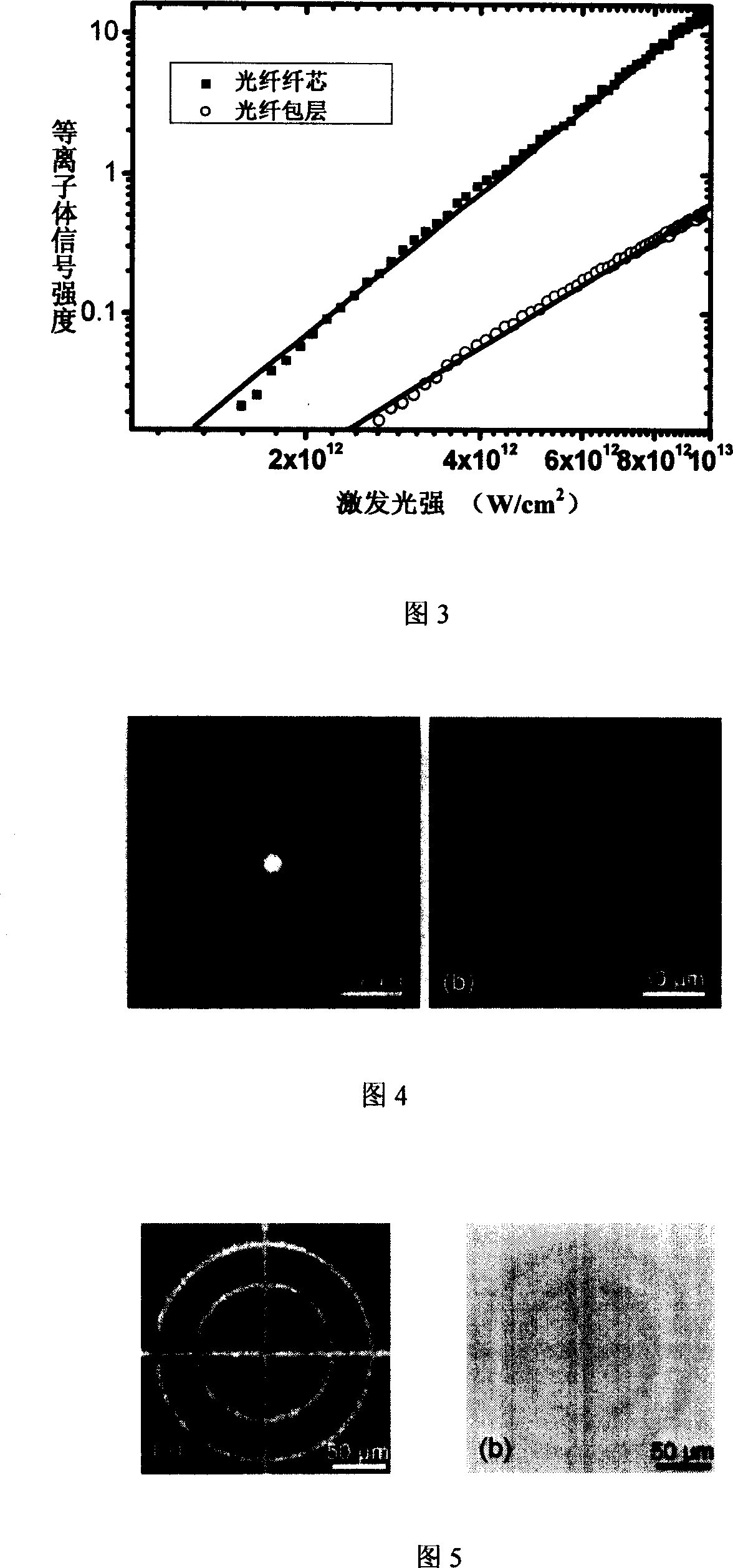

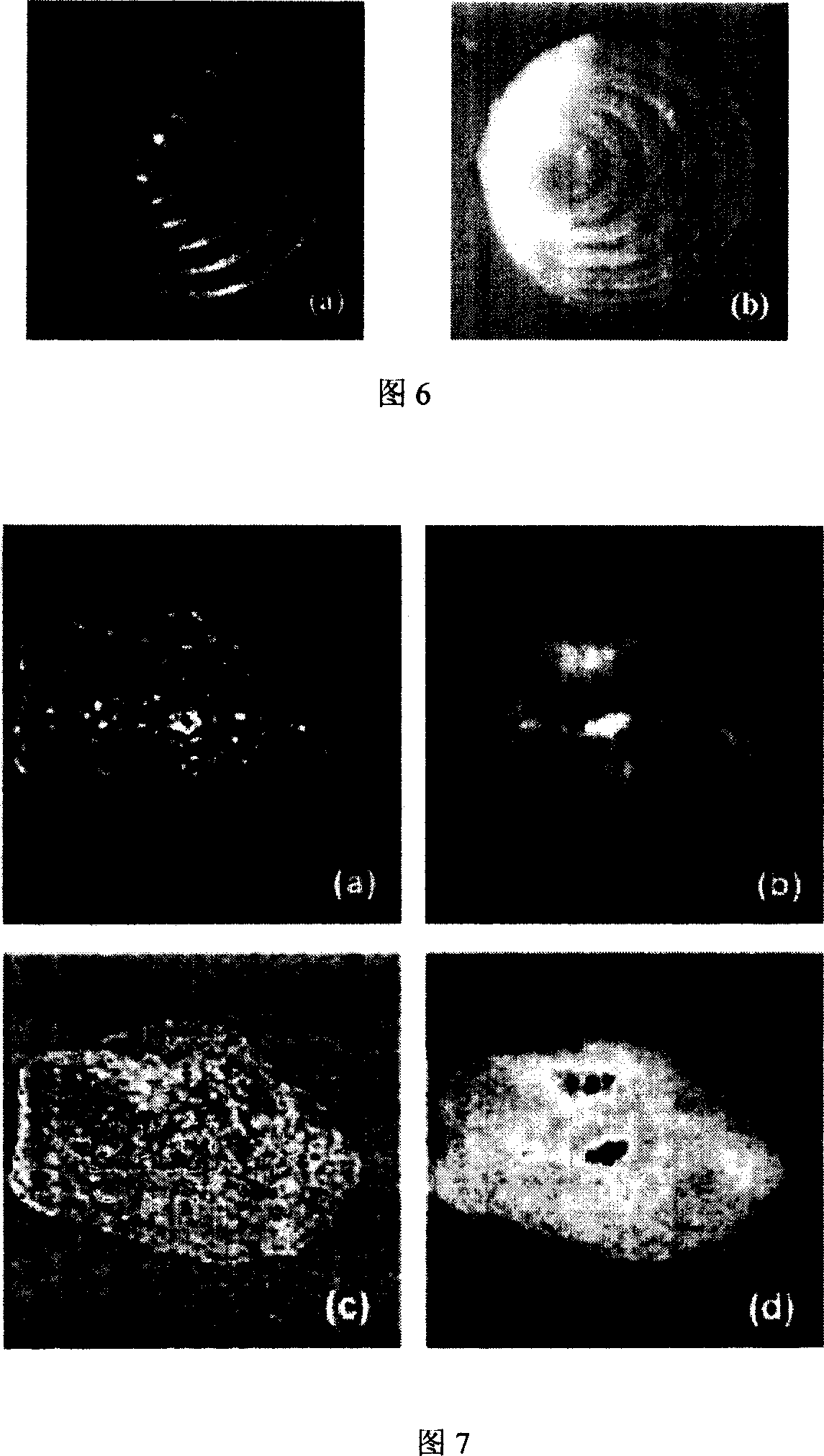

Nonlinear micro imaging method of multiphoton ionization induced by ultrashort pulse laser

InactiveCN1963469AHigh sensitivityAvoid damageAnalysis by material excitationMaterial analysis by transmitting radiationIonizationUltrashort pulse laser

This invention relates to one super short impulse laser guided multiple photon non linear microscopes imaging method and its application, which uses focus super short impulse laser guidance object local surface gas or micro ionize to form micro area plasma, wherein, it adopts photoelectricity detector for plasma electromagnetic irradiation intensity within invisible light wave section; it gets object materials space change microscope images through recording object different position plasma irradiation intensity.

Owner:NANKAI UNIV

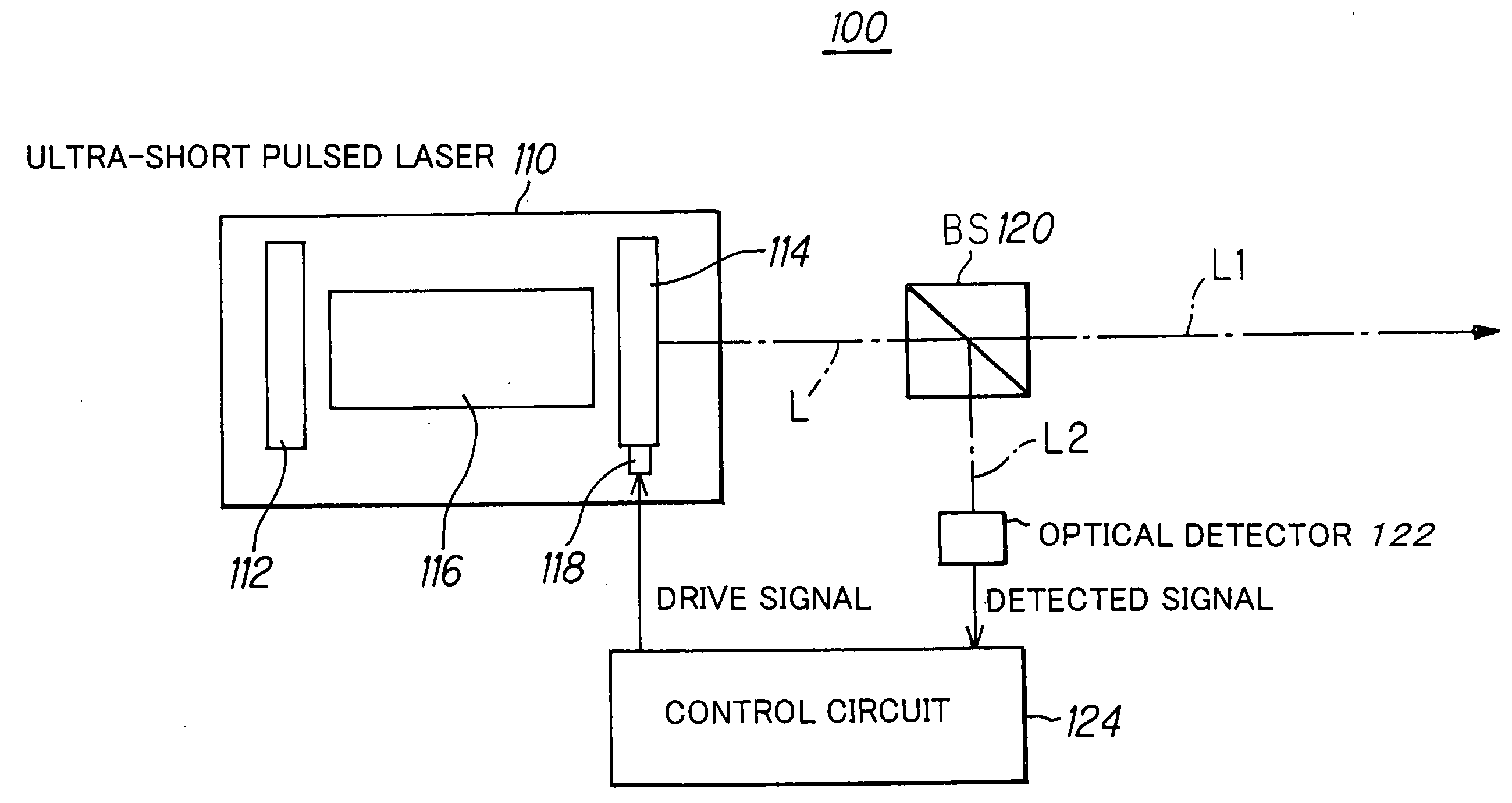

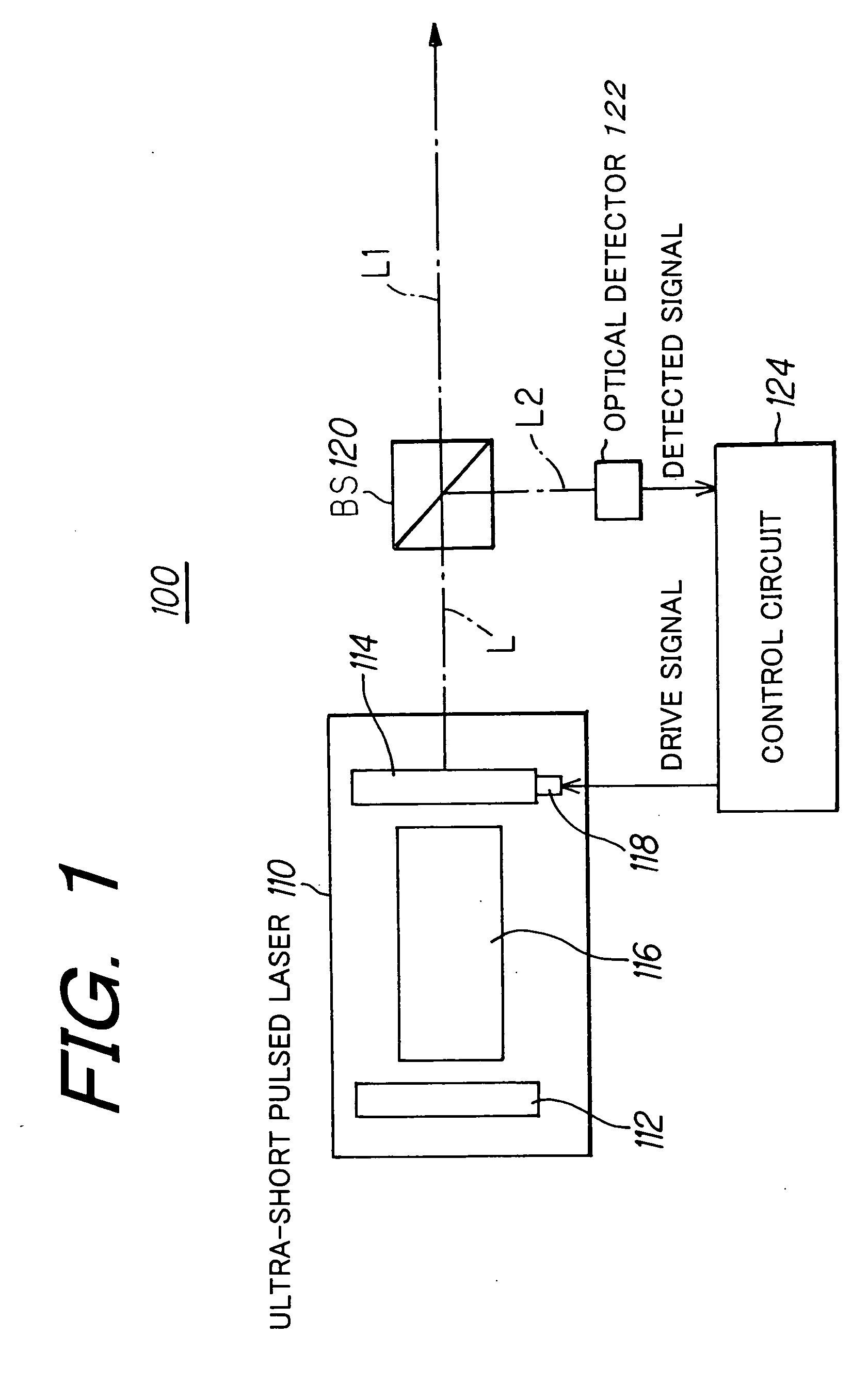

Method of controlling laser oscillation of pulsed laser and pulsed laser system

InactiveUS20060182154A1Improve accuracyGood effectLaser detailsLaser beam welding apparatusPicosecond laserOptical processing

In order to perform positional control of a condensing spot of pulsed laser beam highly accurately when performing optical modeling, optical recording or the like in optical machining technology, optical recording technology or the like which uses various kinds of pulsed laser, which are ultra-short pulsed lasers such as a femtosecond laser and short pulsed laser such as a picosecond laser and a sub-picosecond laser, as a light source, a pulsed laser system detects an output beam from a pulsed laser, controls laser oscillation of the pulsed laser based on the detection result such the output beam contains CW laser beam together with pulsed laser beam, and allows the pulsed laser to output the pulsed laser beam and the CW laser beam simultaneously as the output beam from the pulsed laser.

Owner:RIKEN

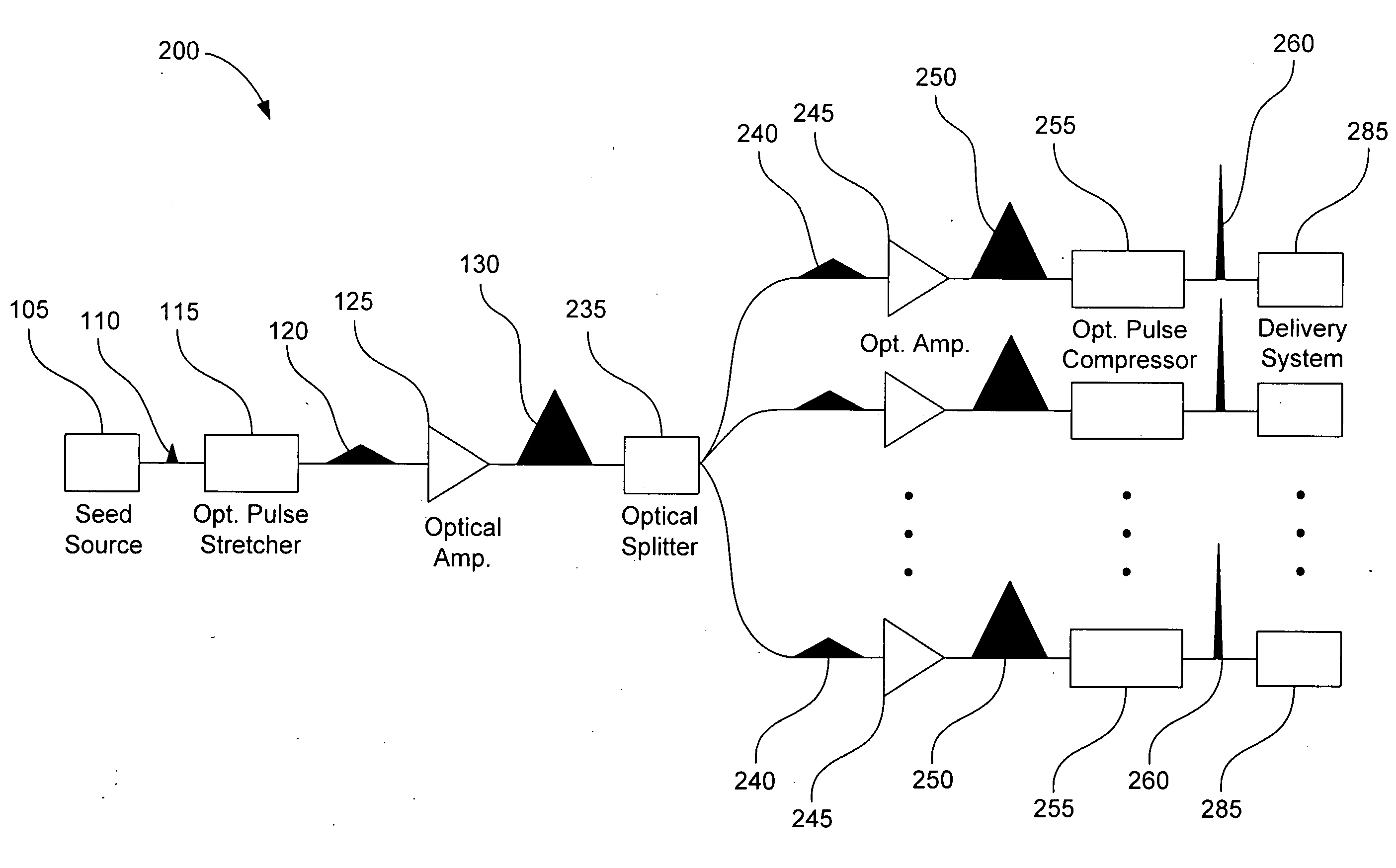

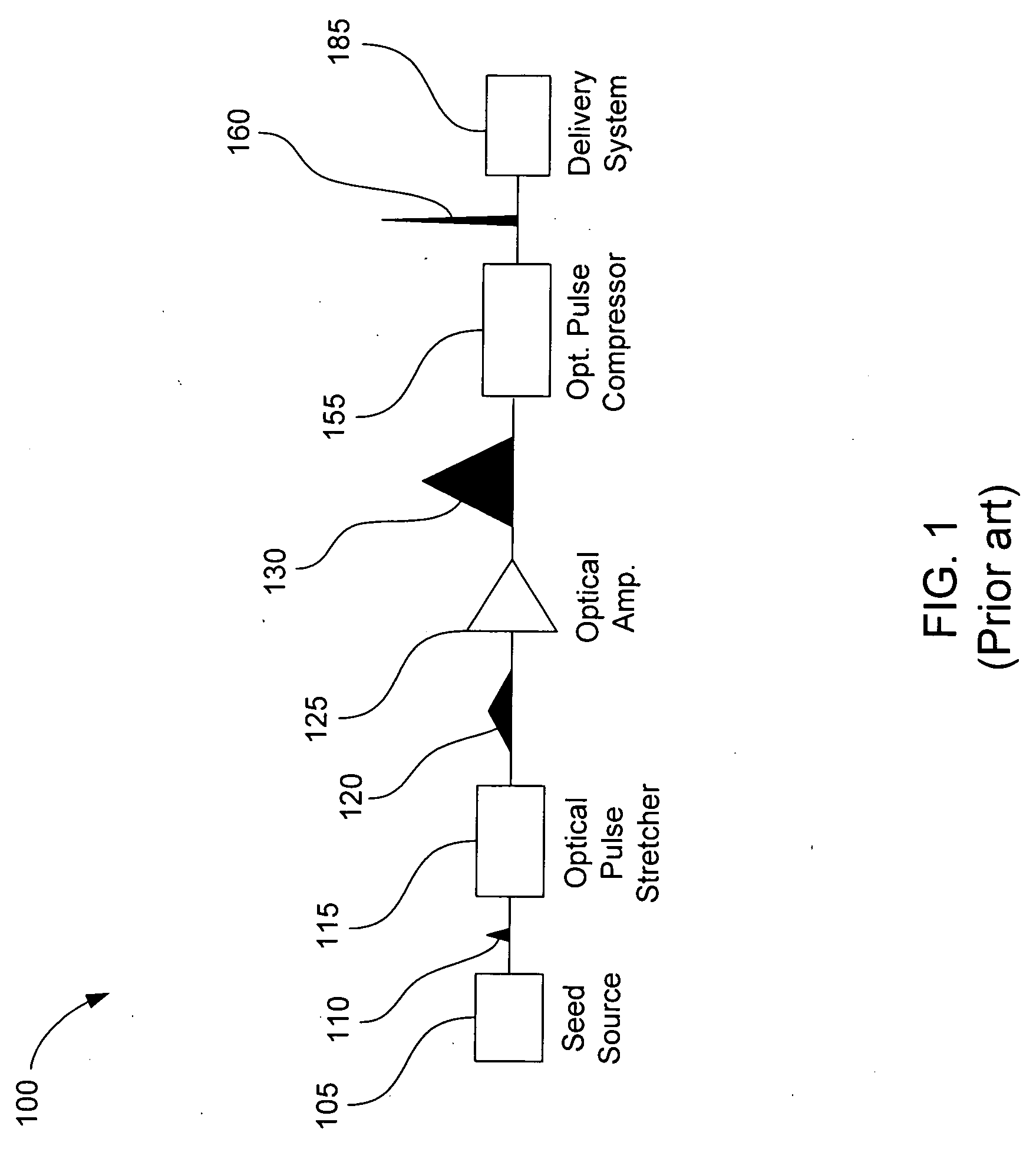

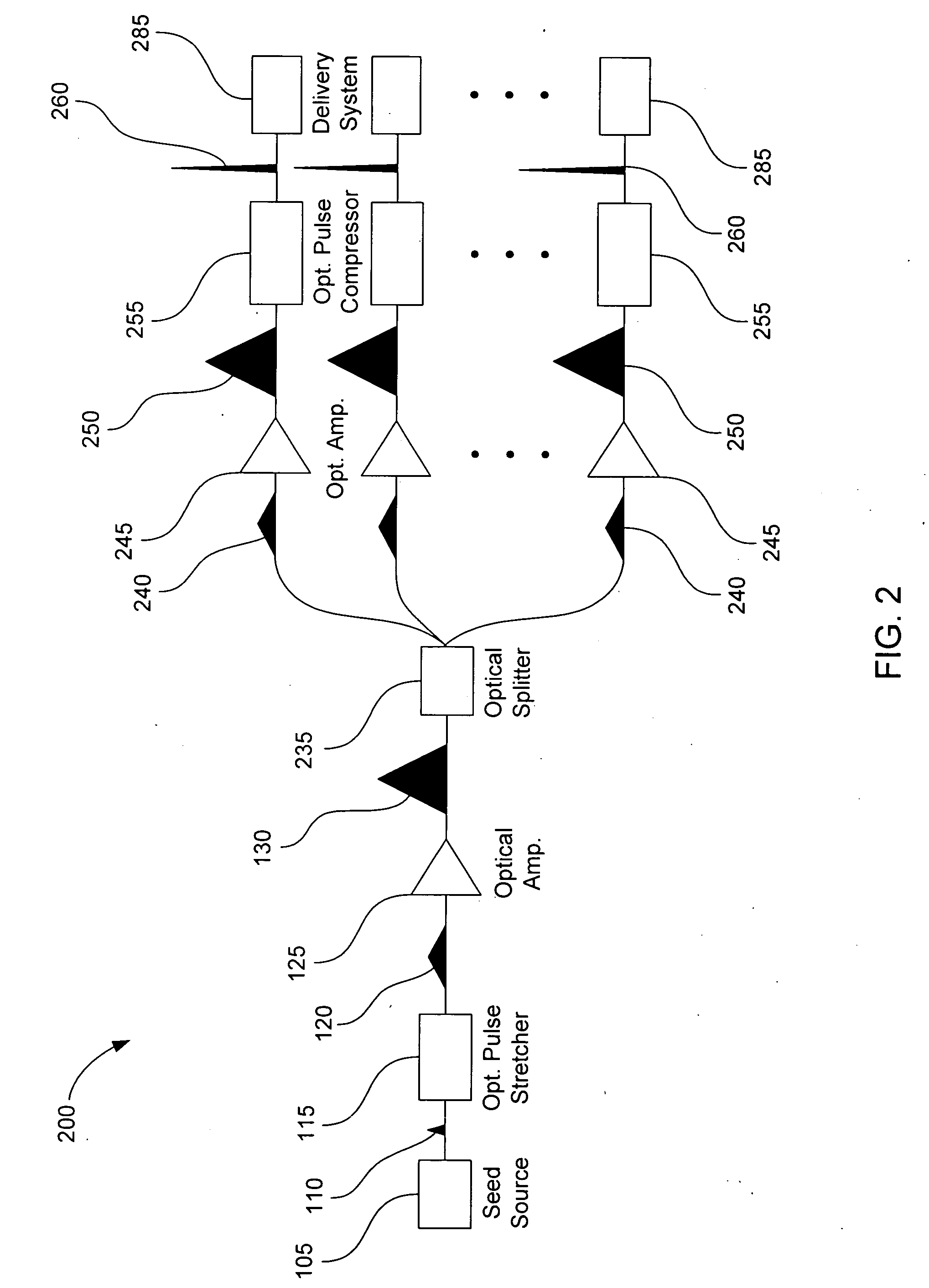

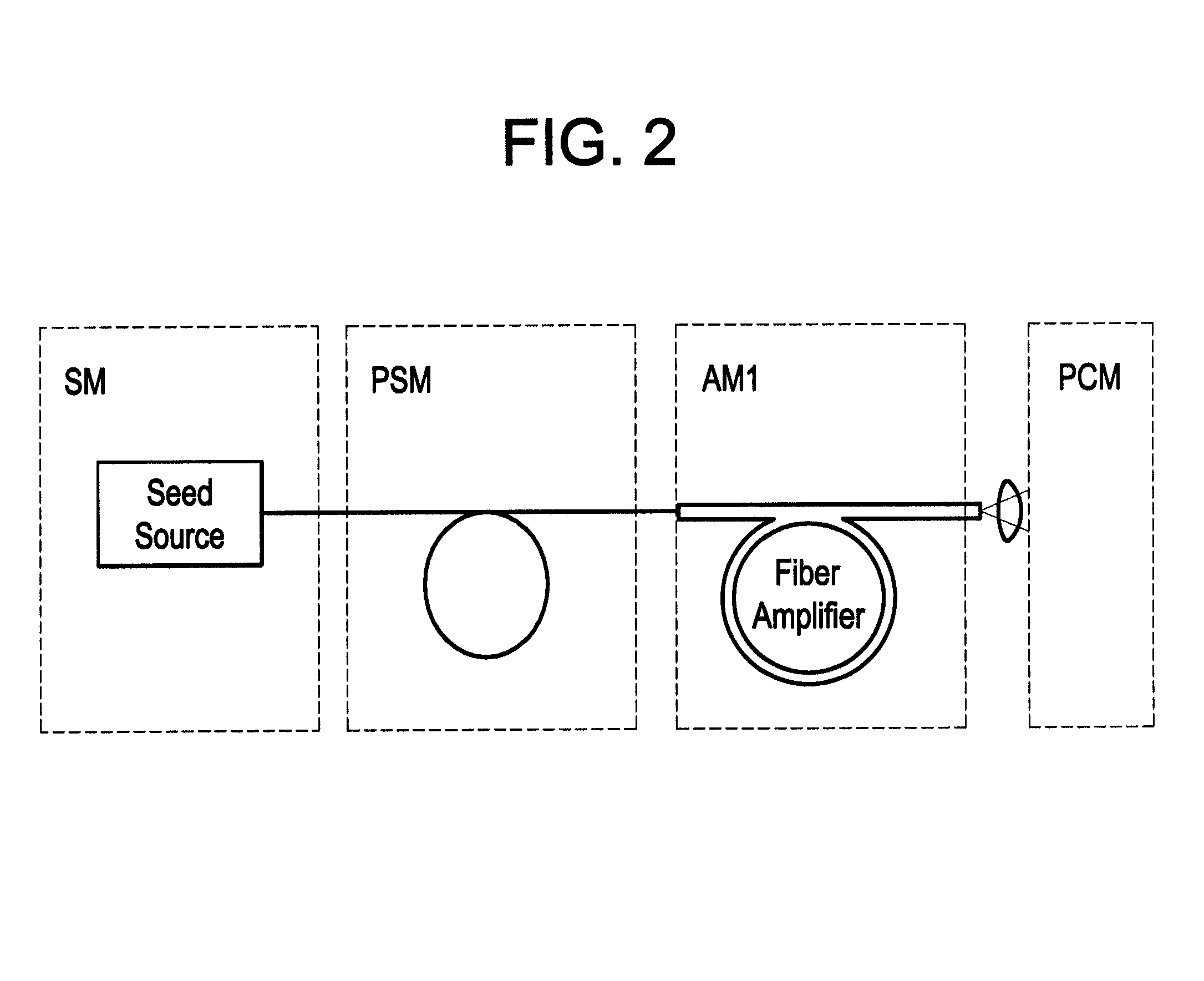

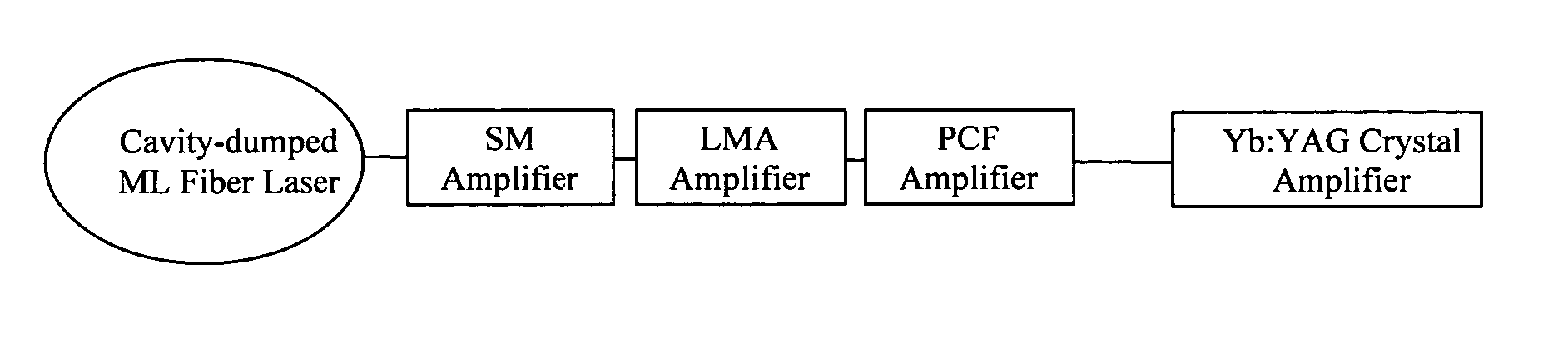

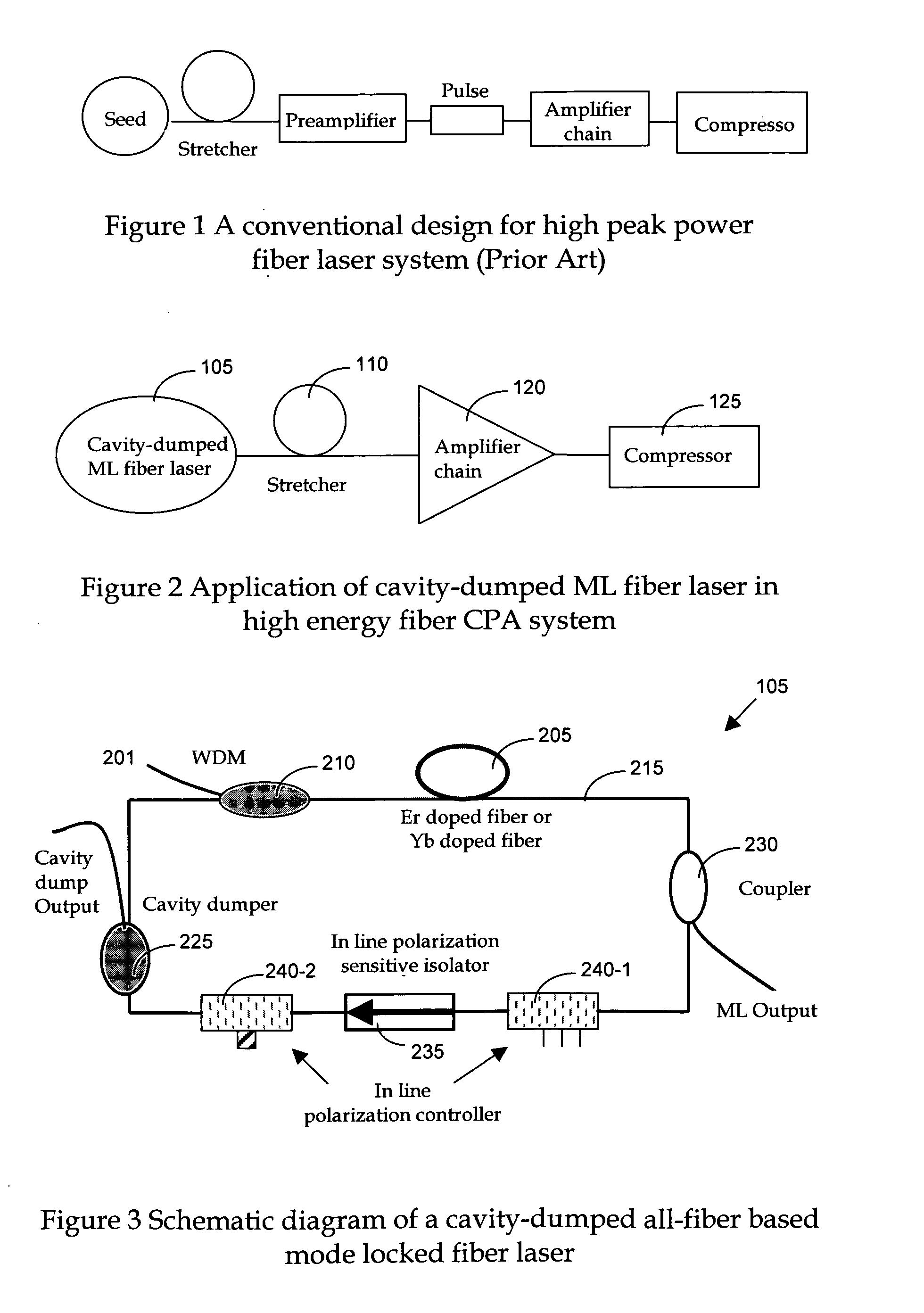

Ultrahigh energy short pulse lasers

ActiveUS20070171945A1Improve reliabilityLaser using scattering effectsAudio power amplifierHybrid amplifier

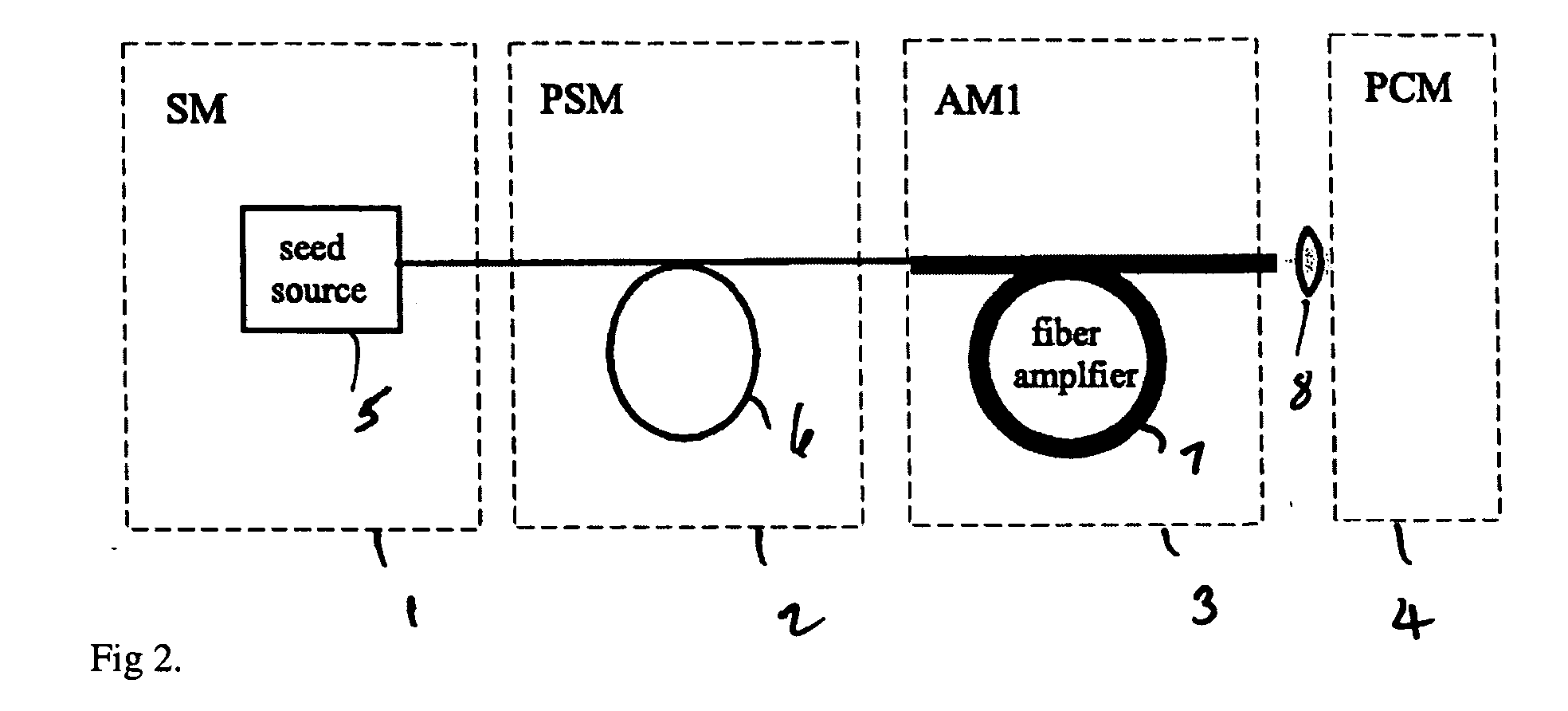

A Chirped pulse amplification (CPA) fiber laser system. The CPA fiber laser system includes a fiber mode-locking (ML) oscillator implemented as a cavity dumped ML oscillator including a cavity dumper for generating a seed laser at a reduced repetition rate to project to a pulse stretcher for stretching a pulse width of the laser. The CPA fiber laser system further includes a multistage amplifier chain for generating an amplified laser to project to a compressor for compressing the amplified laser. The multistage amplifier chain further includes a hybrid amplifier includes a solid-state amplifier to generate a laser of approximately 1˜10 mJ for a 10-100 KHz repetition rate.

Owner:POLARONYX

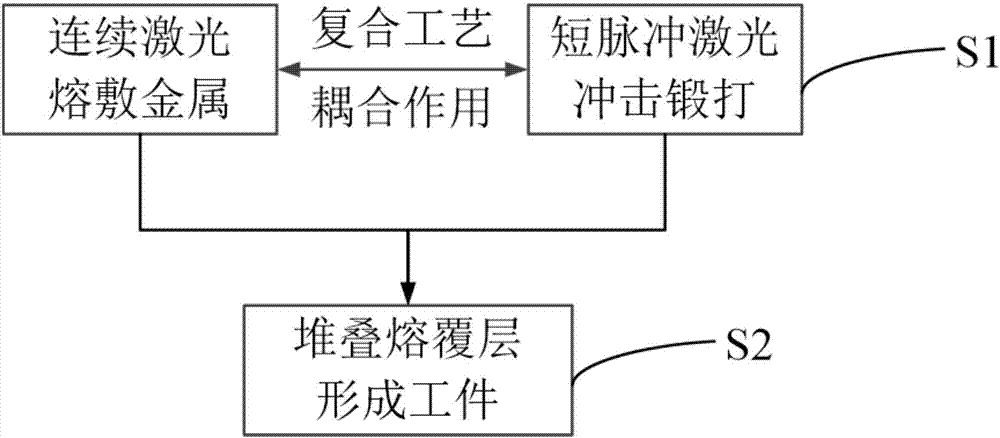

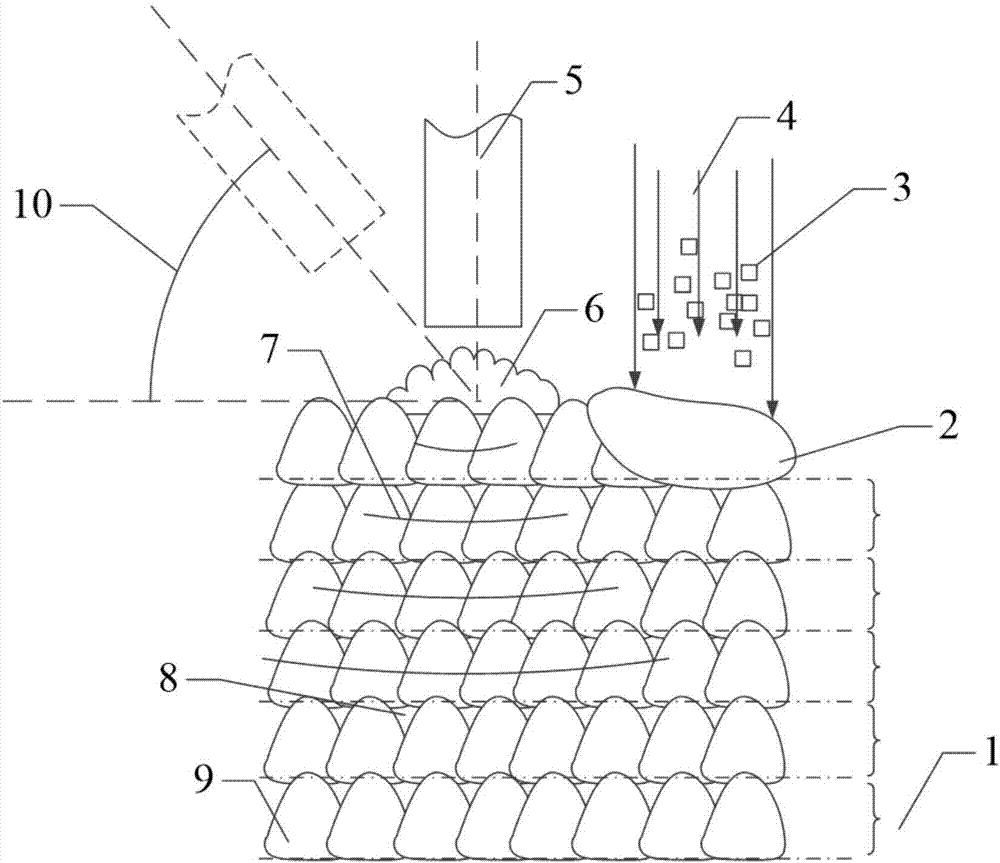

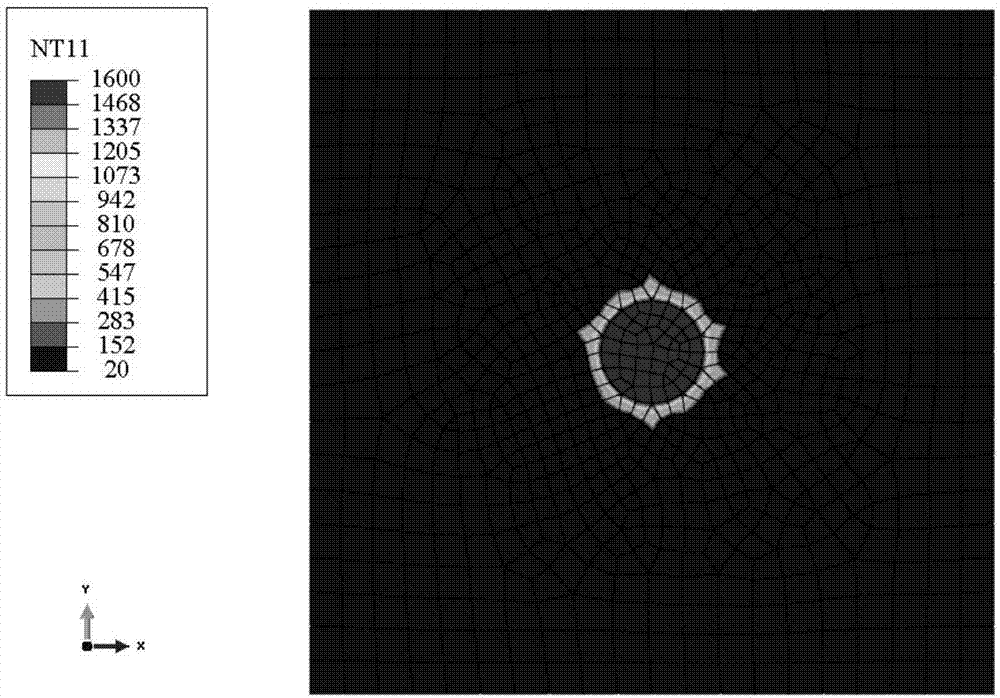

Method for additive manufacturing through depositing, forming, impacting, forging and compositing through double laser beams

InactiveCN107475709AWith laser pulse energyWith laser pulse widthAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsLaser beams

Owner:GUANGDONG UNIV OF TECH

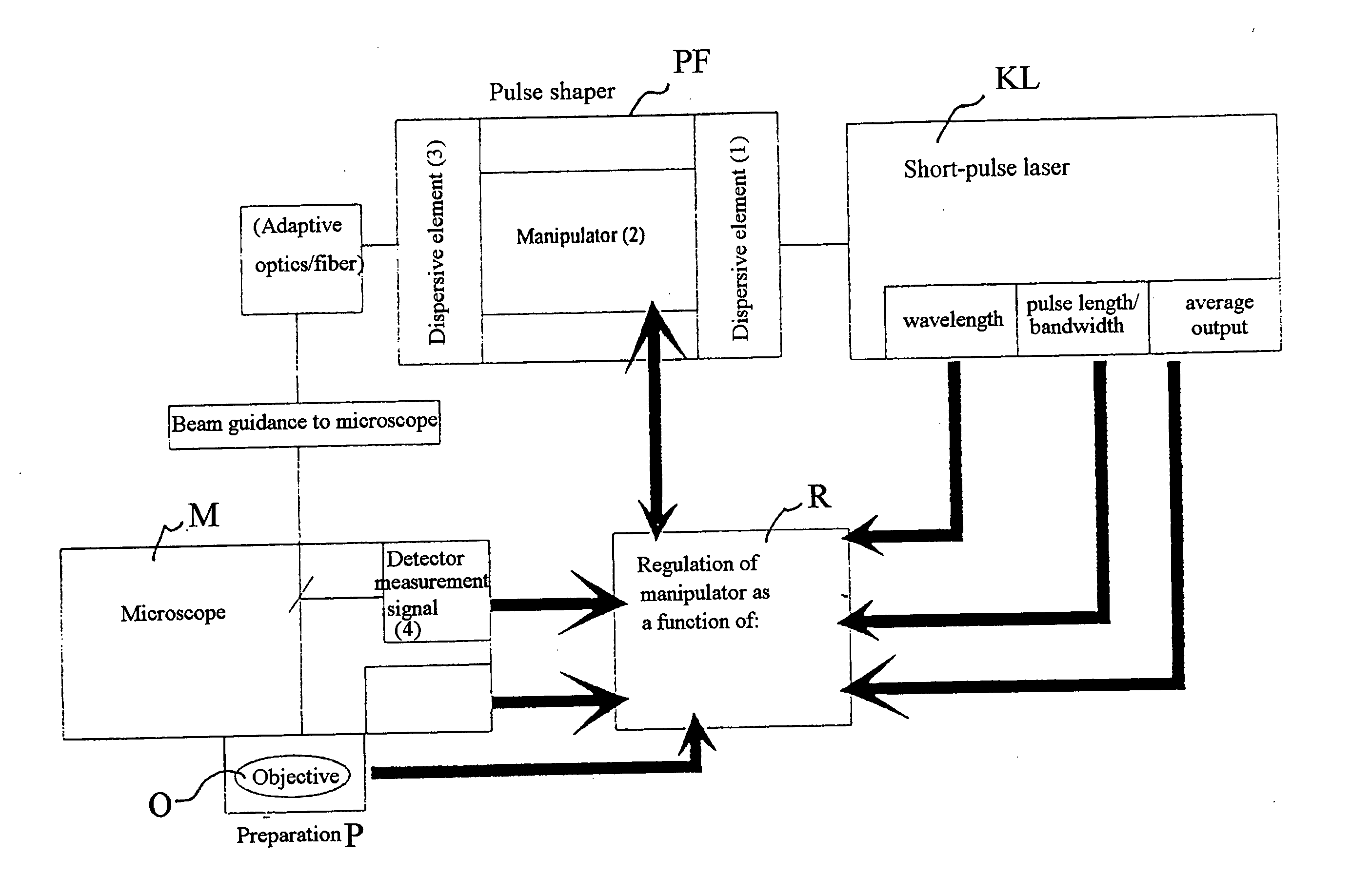

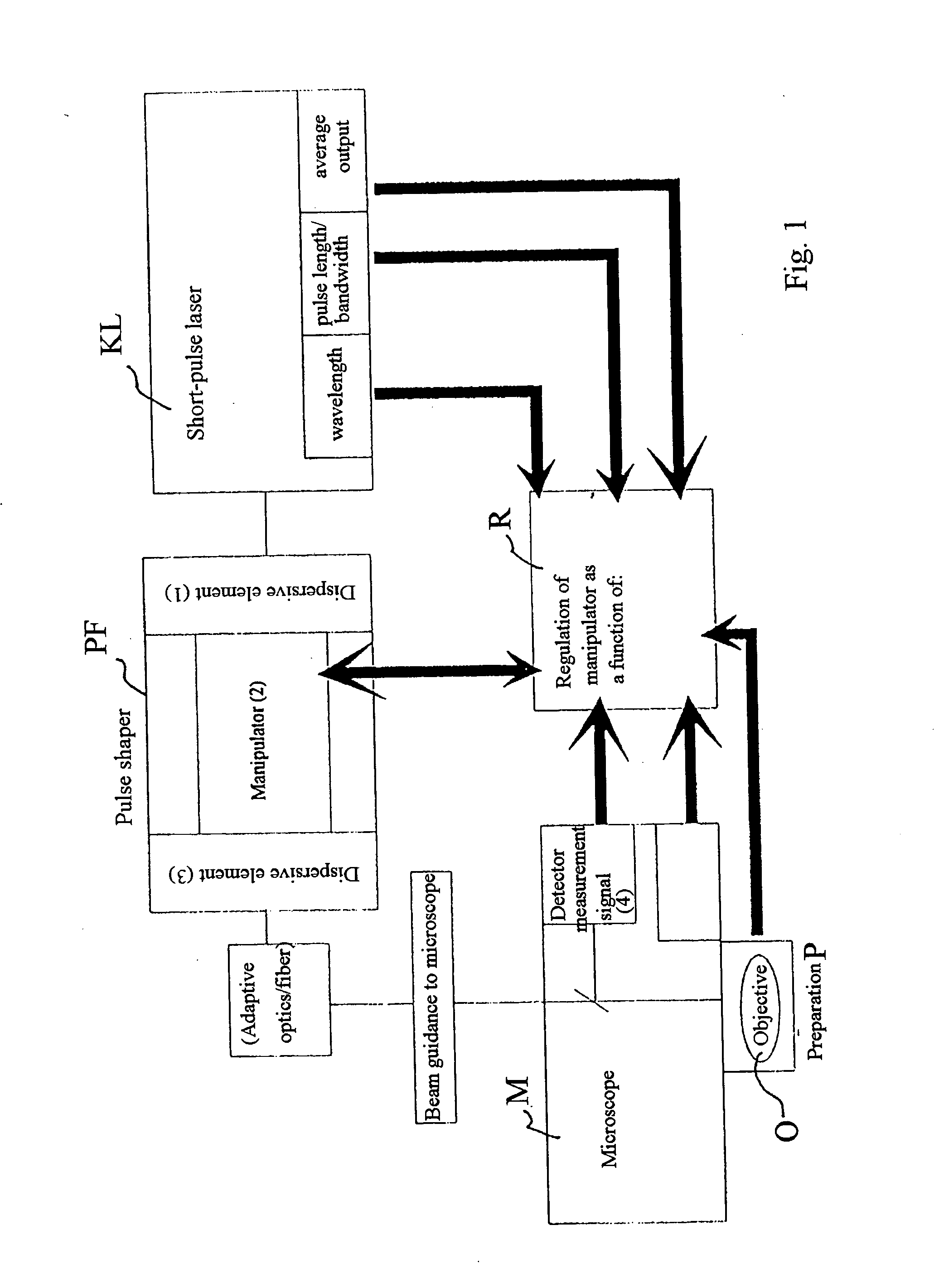

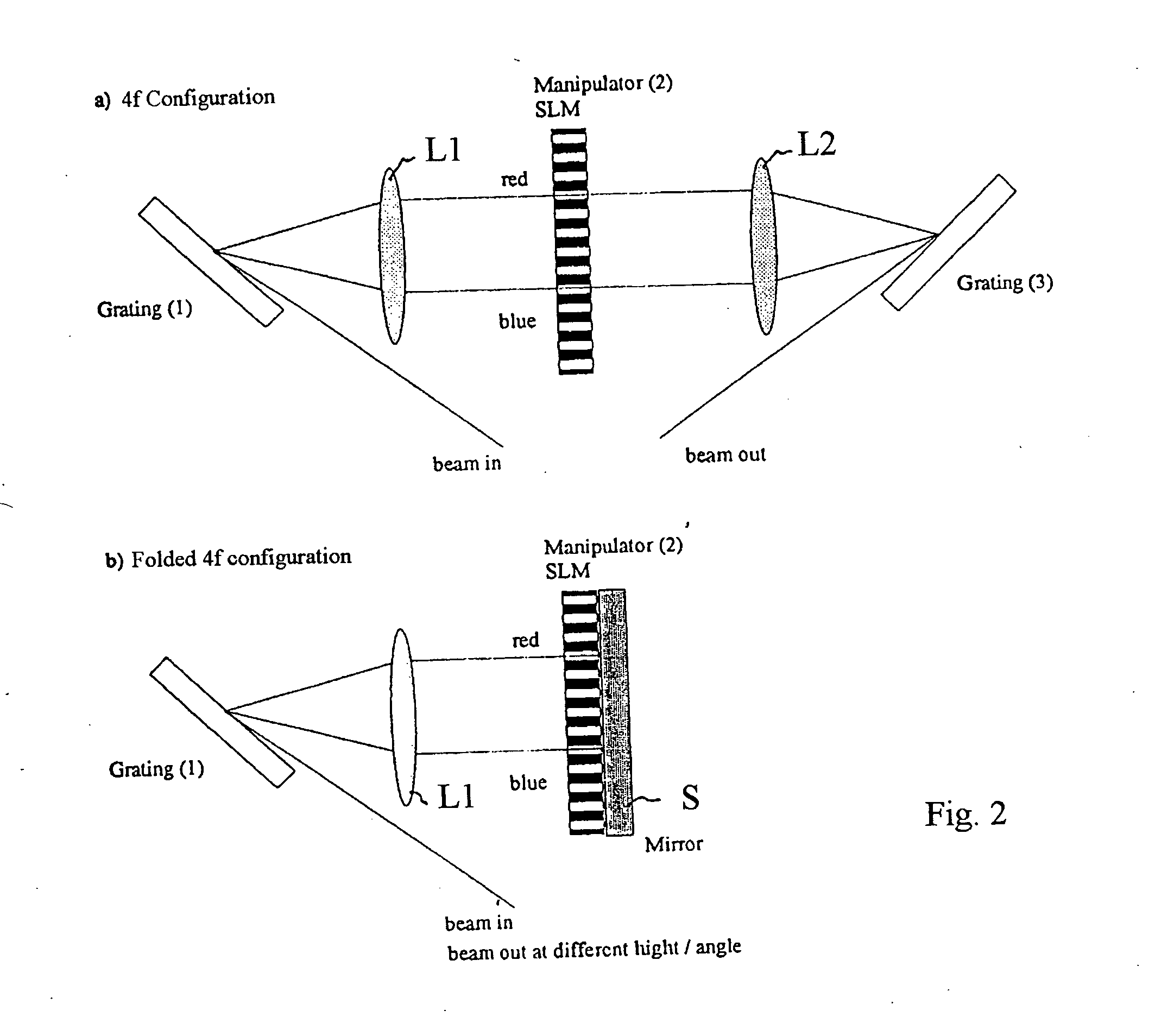

Arrangement for optimizing the pulse shape in a laser scanning microscope

InactiveUS20050017160A1Laser detailsBeam/ray focussing/reflecting arrangementsLaser scanning microscopeLight beam

A Device for coupling a short pulse laser into a microscope beam path, wherein the spectral components of the laser radiation are spatially separated by means of a dispersive element, the individual spectral components are manipulated and are then spatially superimposed again by means of another dispersive element.

Owner:CARL ZEISS MICROSCOPY GMBH

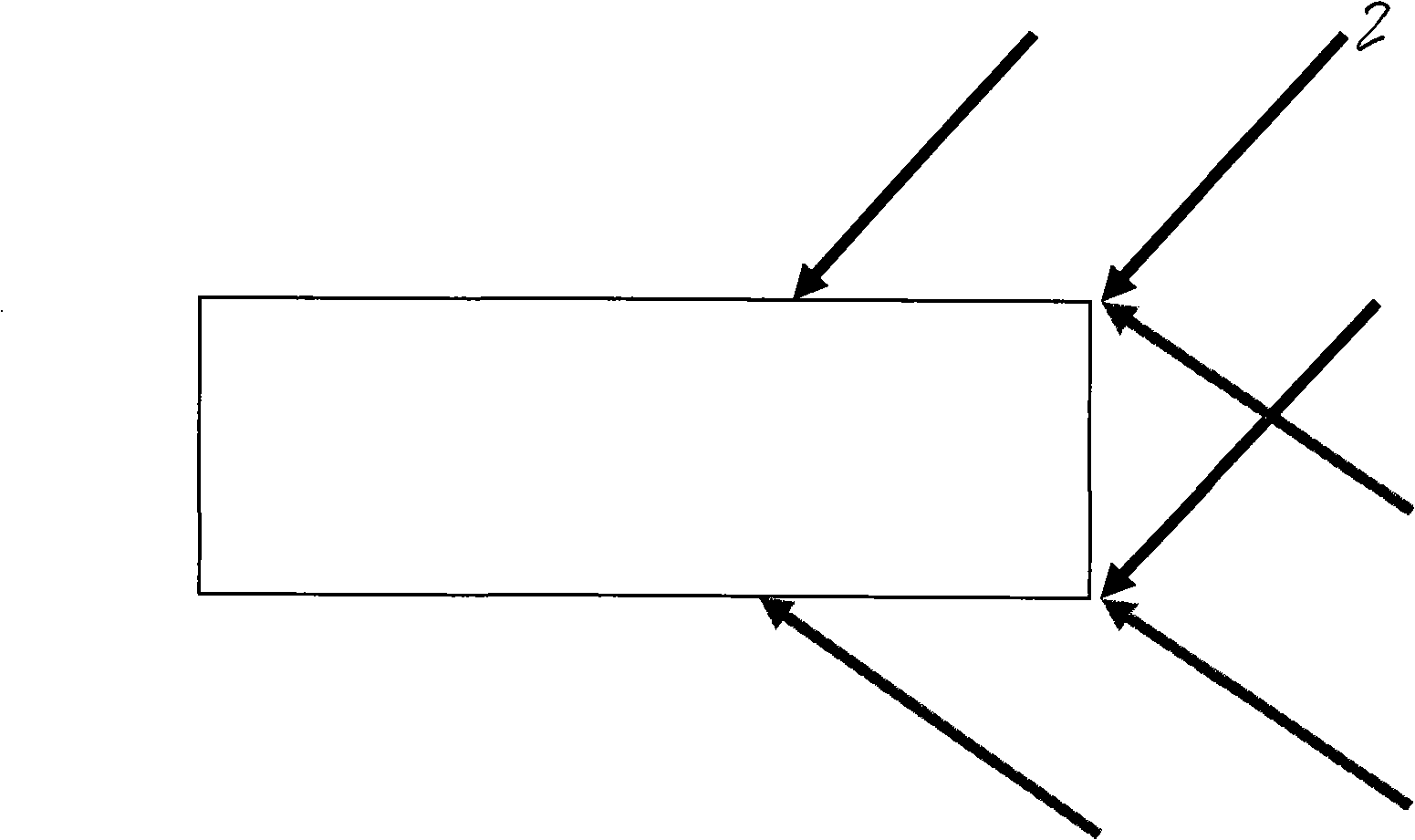

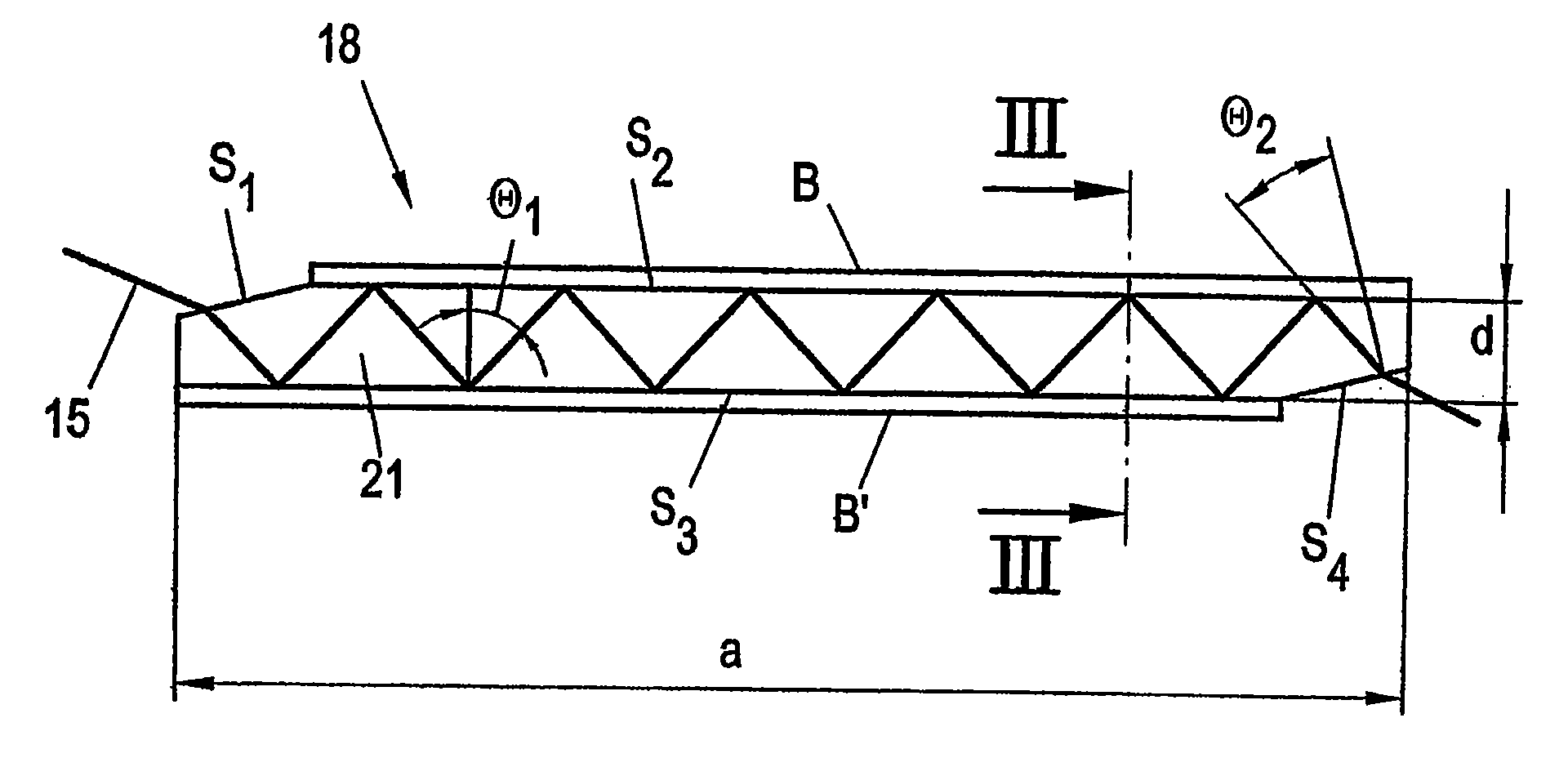

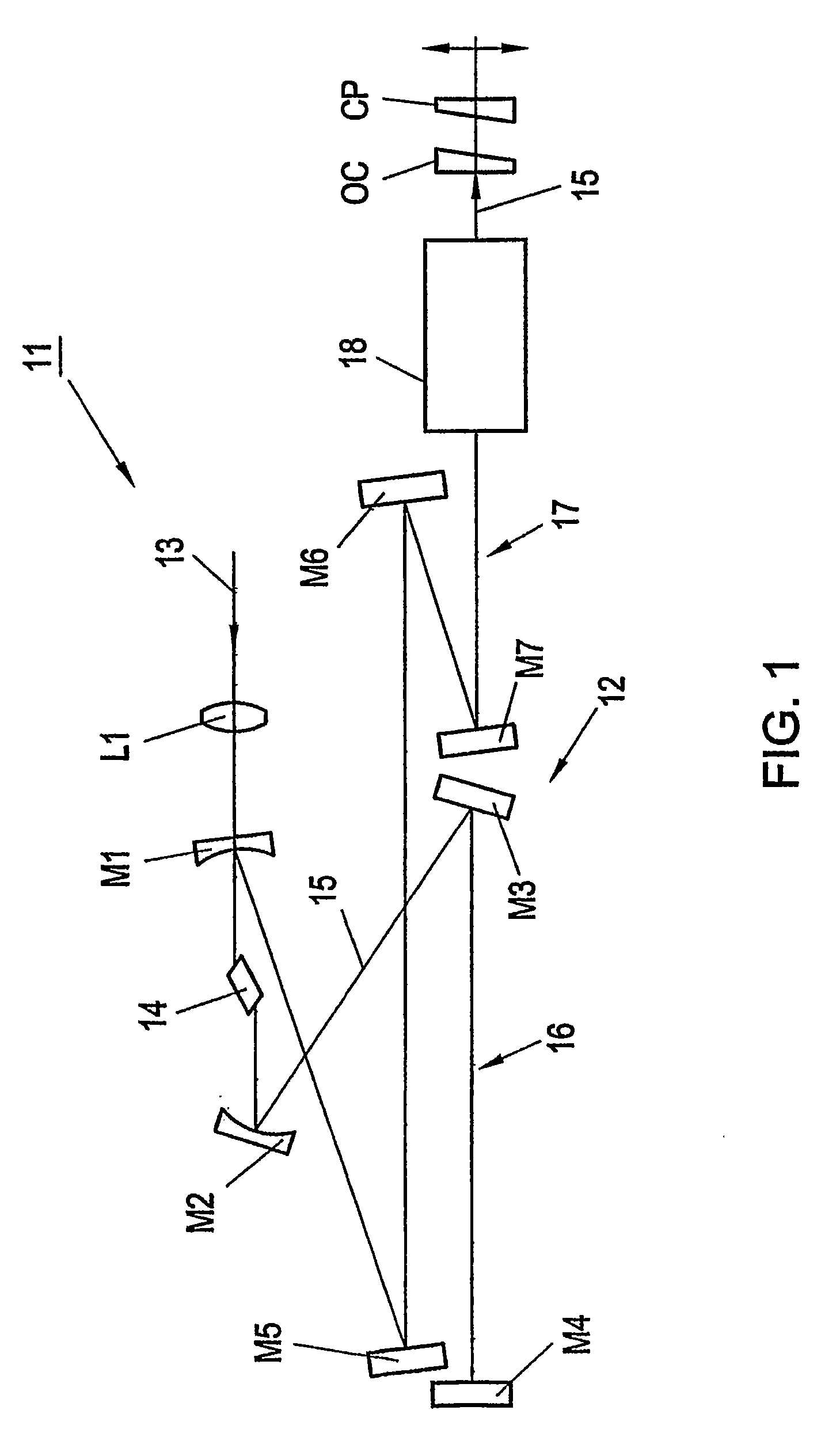

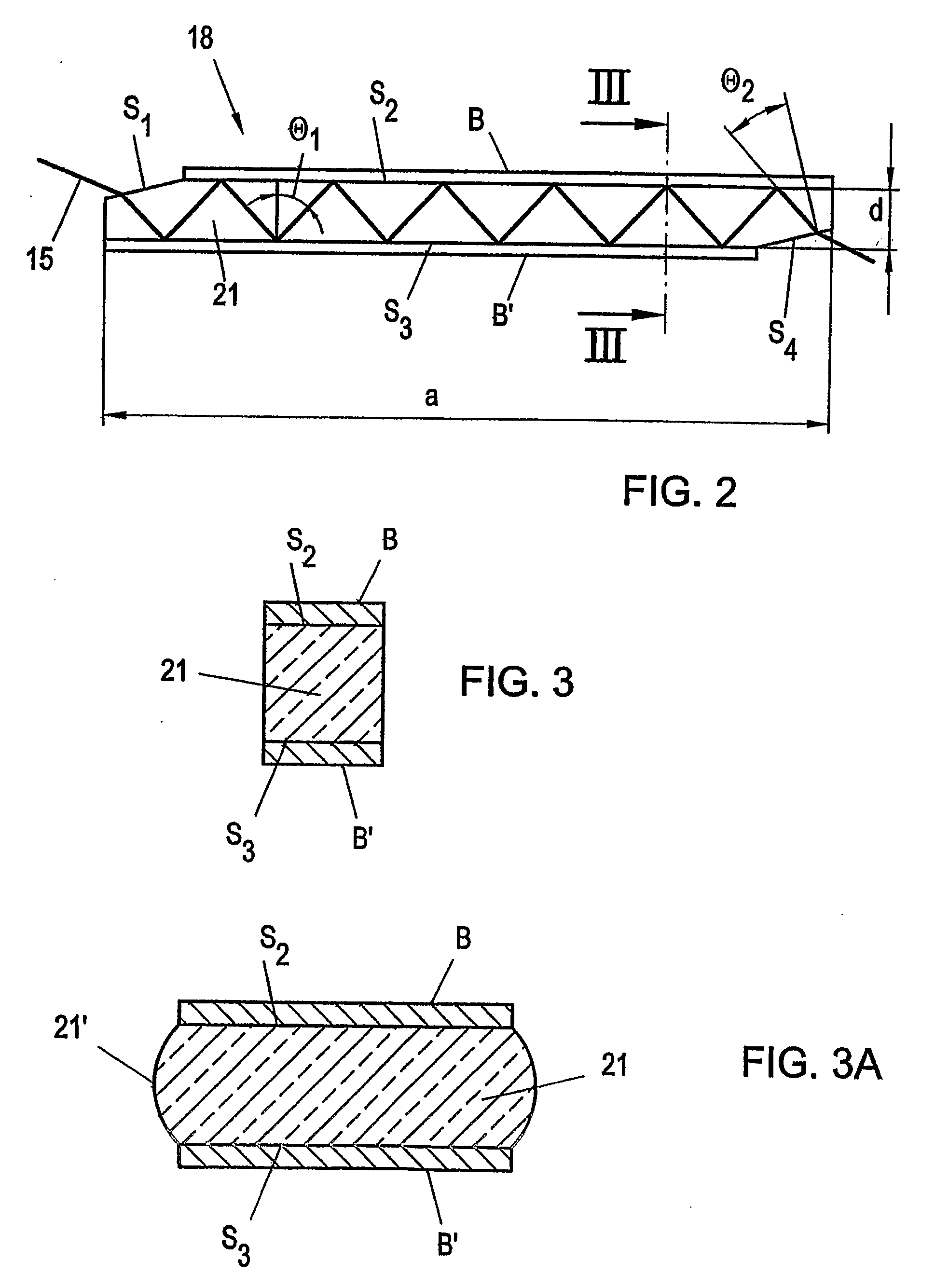

Multiple-Reflection Delay Line For A Laser Beam And Resonator Or Short Pulse Laser Device Comprising A Delay Line Of This Type

InactiveUS20080013587A1Small and compact designDecrease length of resonatorMirrorsActive medium materialExit surfaceLaser beams

A multiple-reflection delay line member for a laser beam, including mirror elements for the multiple reflection of the laser beam to reduce the dimensions of a laser resonator at a predetermined optical length, wherein the mirror elements are comprised of two oppositely arranged, longitudinally extending polished surfaces of a glass element which extends in one direction and which further comprises a polished laser beam entry surface as well as a polished laser beam exit surface, wherein the mirror element surfaces of the glass element are located between the entry surface and the exit surface and, with the laser beam, form an angle that at least equals the critical angle for total reflection, whereas the entry surface and the exit surface with the laser beam of the glass element define an angle that is smaller than the critical angle for total reflection.

Owner:HIGH Q LASER

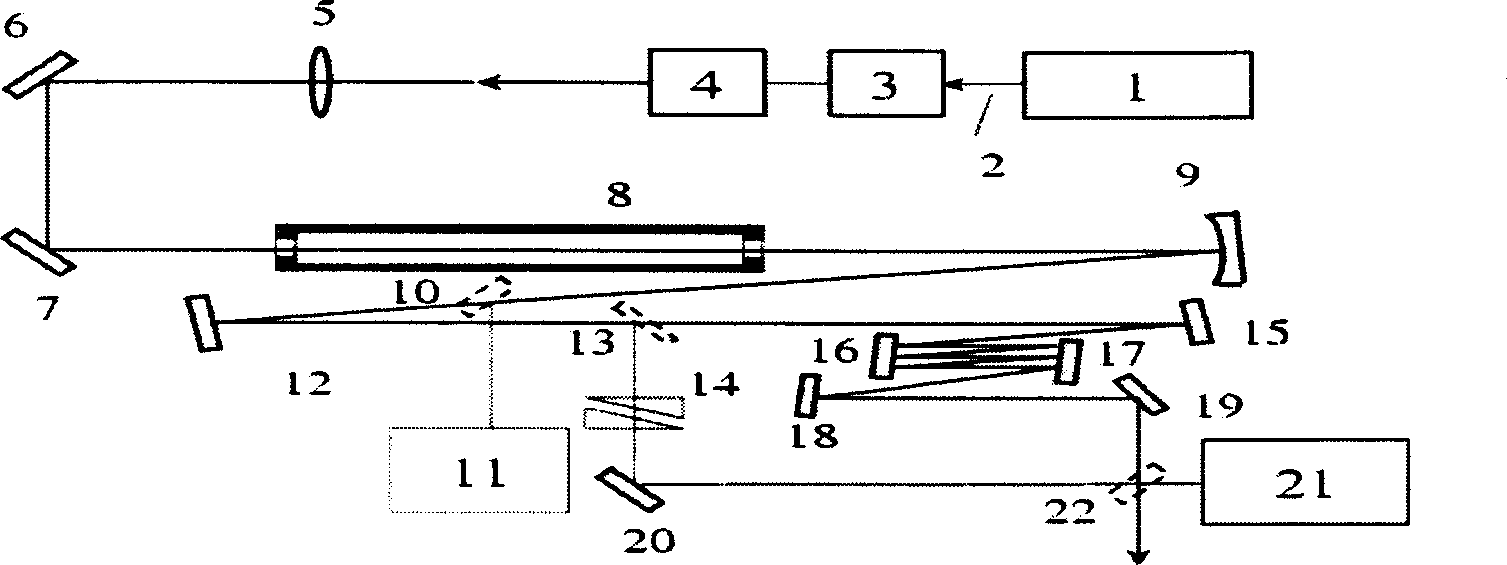

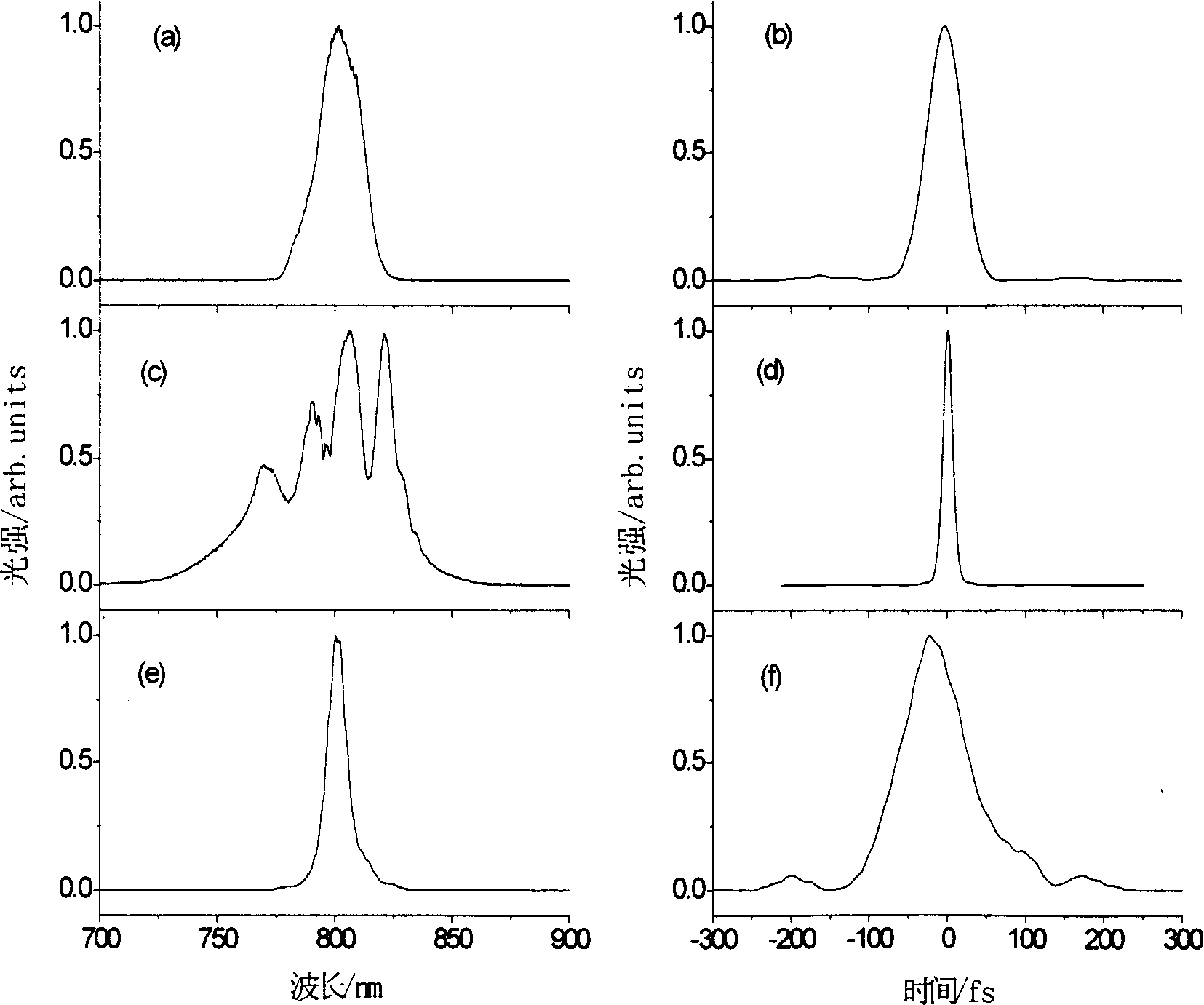

Laser pulse stretching and compression device

InactiveCN1870359ASolve the problems of low conversion efficiency and complex structureSolve the limitation of low incident pulse energyLaser detailsNon-linear opticsControl systemEnergy control

This invention relates to a laser pulse expansion and compression device charactering that it is composed of a super-short pulse laser, a chirp control system, an energy control system, a non-linear action system, a dispersion compensation system and a test system, which can either expand spectrums and compress pulses or compress spectrums and expand pulses.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Compact ultra-short pulsed laser eye surgery workstation

ActiveUS20160374857A1Reduce and eliminate mechanical vibrationLaser surgerySurgical instrument detailsFiberBeam splitter

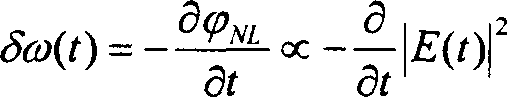

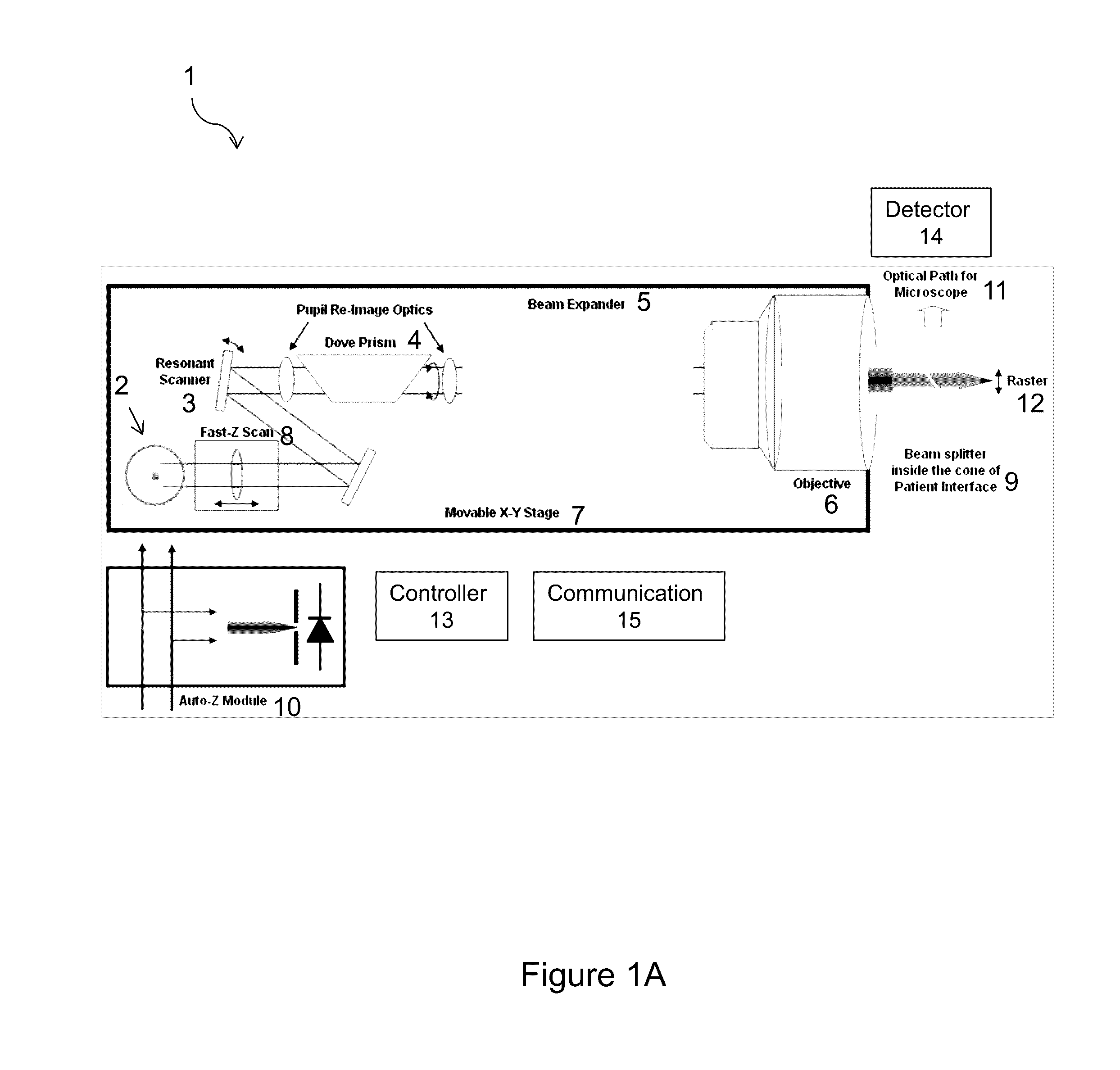

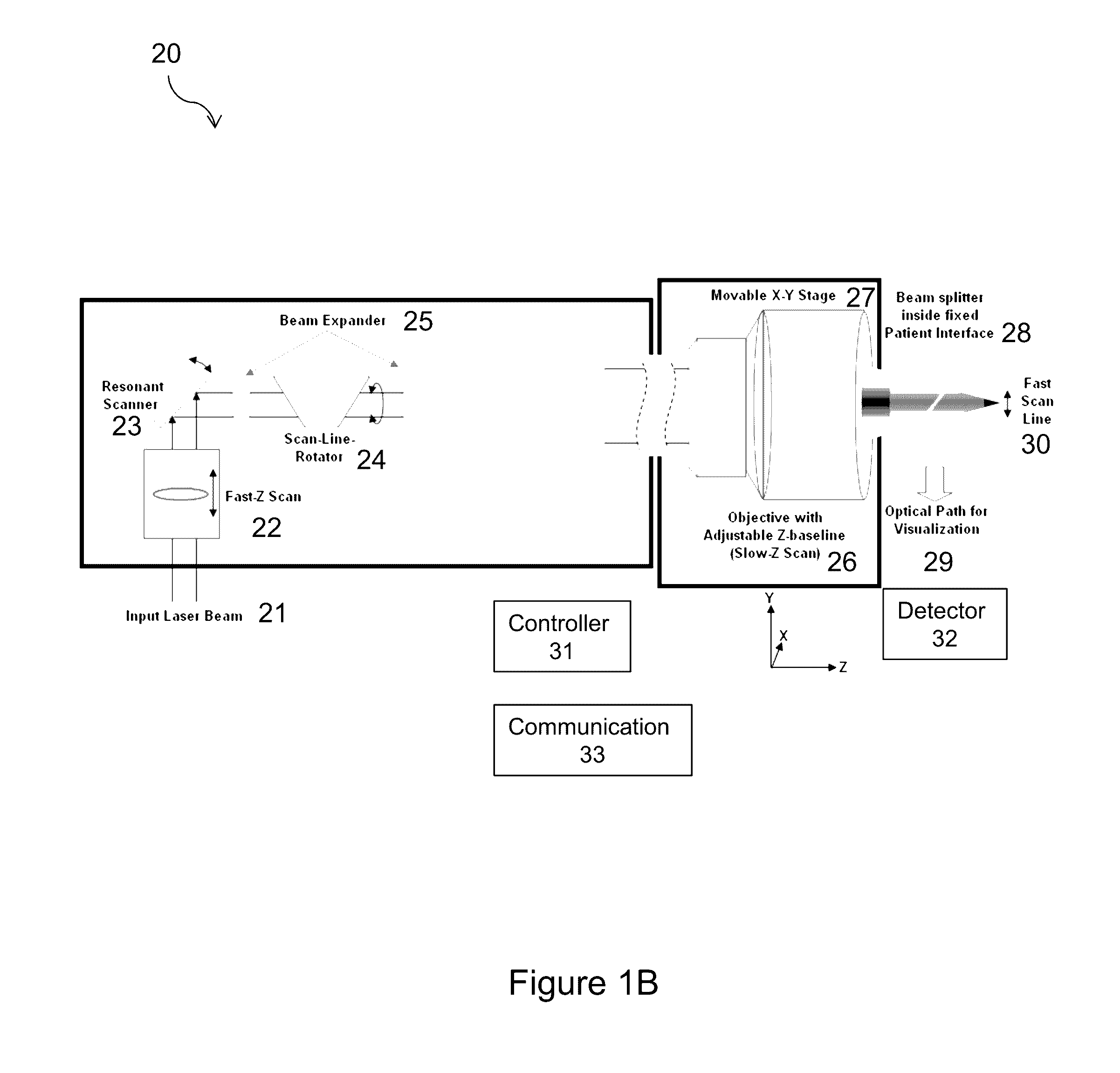

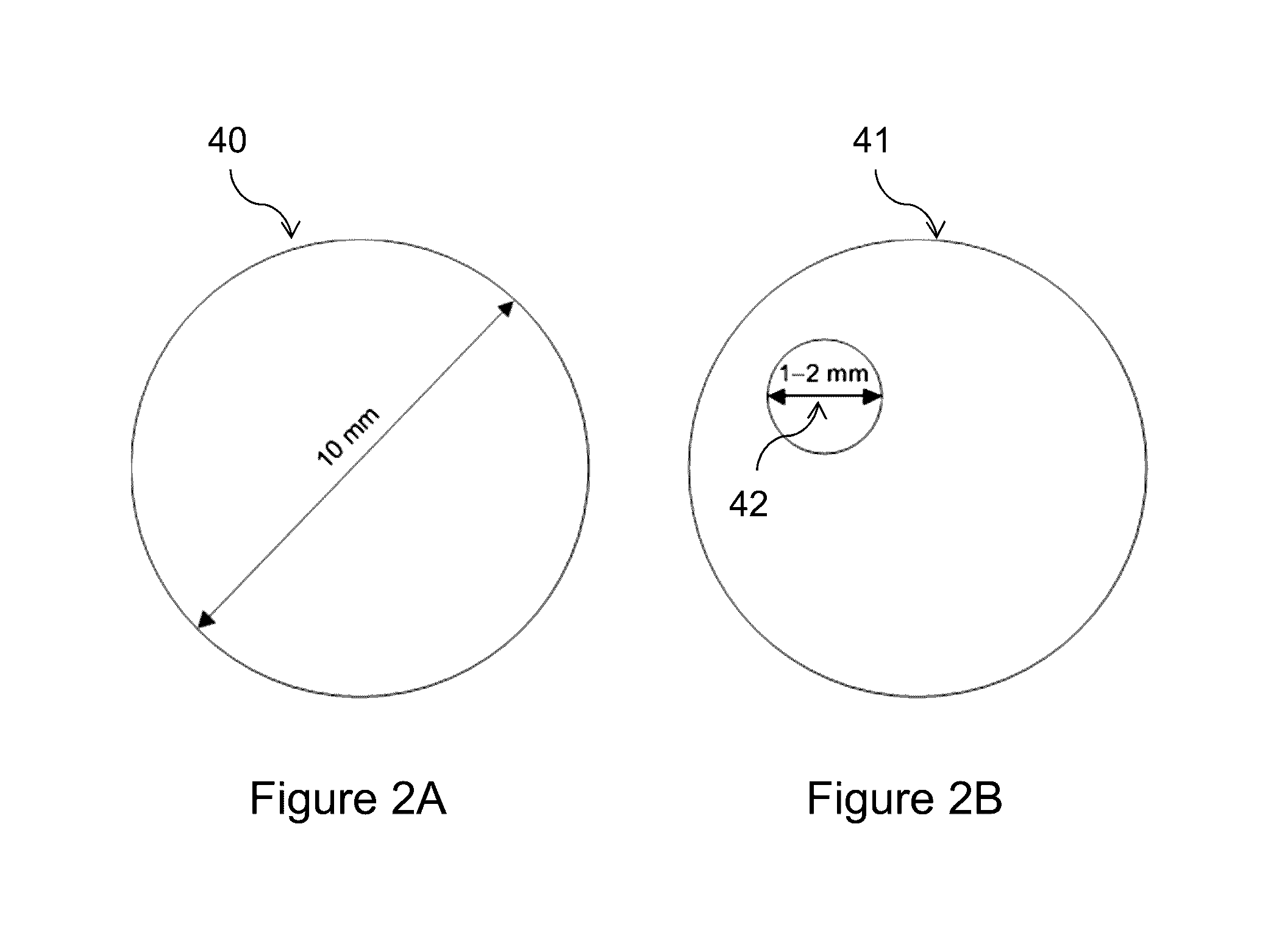

A compact system for performing laser ophthalmic surgery is disclosed. An embodiment of the system includes a mode-locked fiber oscillator-based ultra-short pulsed laser capable of producing laser pulses in the range of 1 nJ to 5 μJ at a pulse repetition rate of between 5 MHz and 25 MHz, a resonant optical scanner oscillating at a frequency of 200 Hz and 21000 Hz, a scan-line rotator, a movable XY-scan device, a z-scan device, and a controller configured to coordinate with the other components of the system to produce one or more desired incision patterns. The system also includes compact visualization optics for in-process monitoring using a beam-splitter inside the cone of a patient interface used to fixate the patient's eye during surgery. The system can be configured such that eye surgery is performed while the patient is either sitting upright, or lying on his or her back.

Owner:AMO DEVMENT

Combination Laser Treatment of Skin Conditions

InactiveUS20120253333A1Reduce and eliminate aging changeReduce and eliminate and permanent defectSurgical instrument detailsHair removalCutaneous condition

A method and apparatus for treatment of health and skin conditions through the use of a combination of laser systems or a laser system capable of delivering different pulse durations. The laser system being capable of producing both Q-switched short pulsed laser energy and millisecond long pulsed laser energies. Multiple skin conditions would be susceptible to this treatment, including acne, skin aging and textural changes, pigmentary changes, scarring, rosacea, striae, redness and hair removal.

Owner:GARDEN JEROME M +2

Method and apparatus for laser to induce plasma to inject into substrate

InactiveCN102208321AAdd depthHigh hardnessElectric discharge tubesVacuum evaporation coatingShock waveHigh energy

The invention relates to a method and apparatus for a laser to induce plasmas to inject into a substrate and is directed to the fields of plasma injection apparatus and plasma injection material processing technology. A high energy burst pulse strong laser initiated by a laser impacts on tinsel which absorbs the high energy burst pulse laser energy. The high energy burst pulse laser energy is instantly gasified and ionized, thereby producing hot plasmas. The hot plasmas are composed of metal ions, electrons and uncharged atoms. The plasmas absorb subsequent laser energy to expand and blast. During the blast process of the plasmas, an expulsive force between the electrons and a workpiece connected to the negative potential drives the electrons to move against the workpiece. A positive charge plate neutralizes a part of the electrons. Suction between positive valency metal ions and the negative potential workpiece drives the metal ions to move towards the workpiece. Under the superposedeffects of a shock wave effect formed in the expansion and blast of the plasmas and an attraction effect of an electric field, the metal ions hit on the workpiece at a great speed; hence the injection of the metal ions is completed.

Owner:JIANGSU UNIV +1

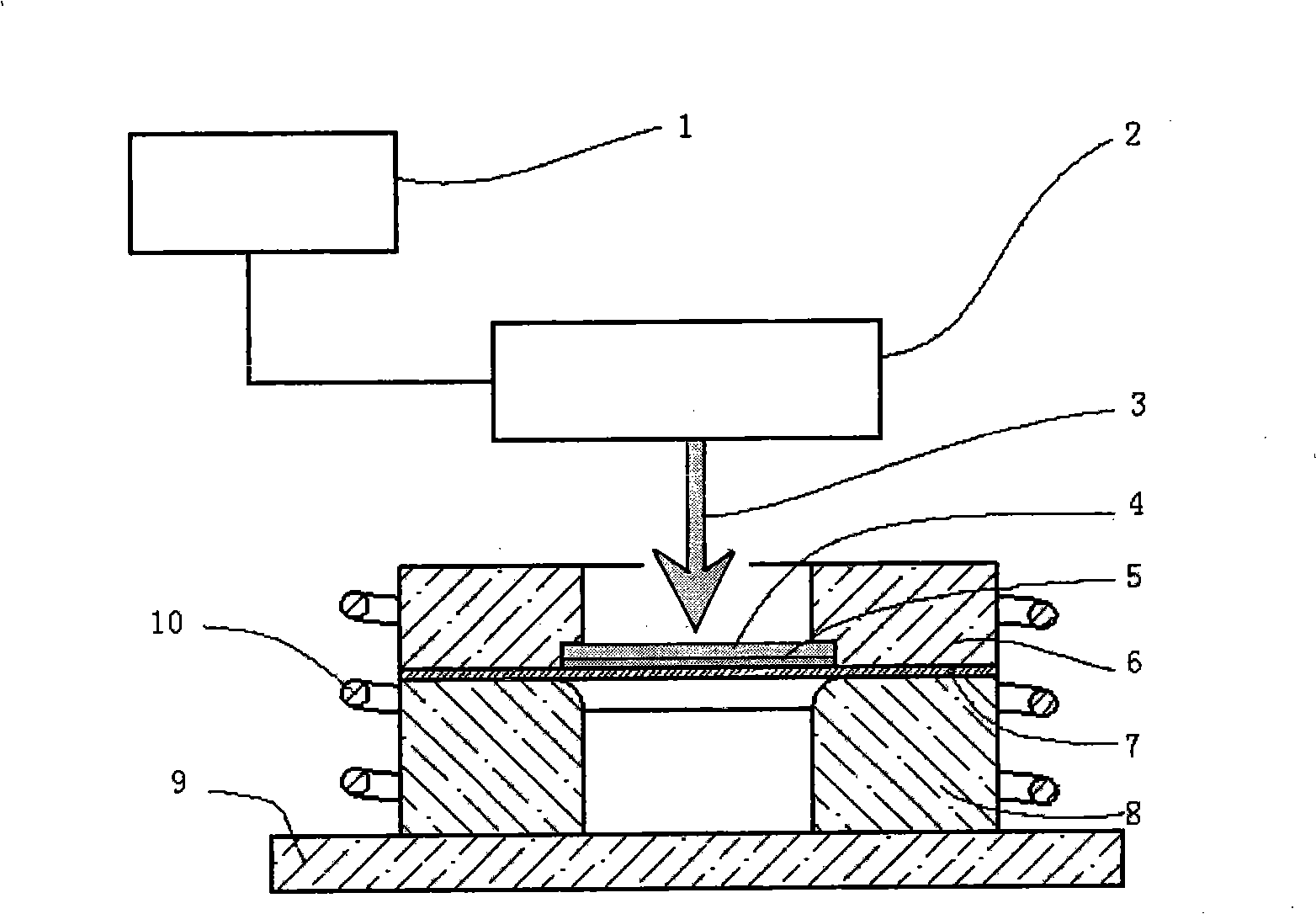

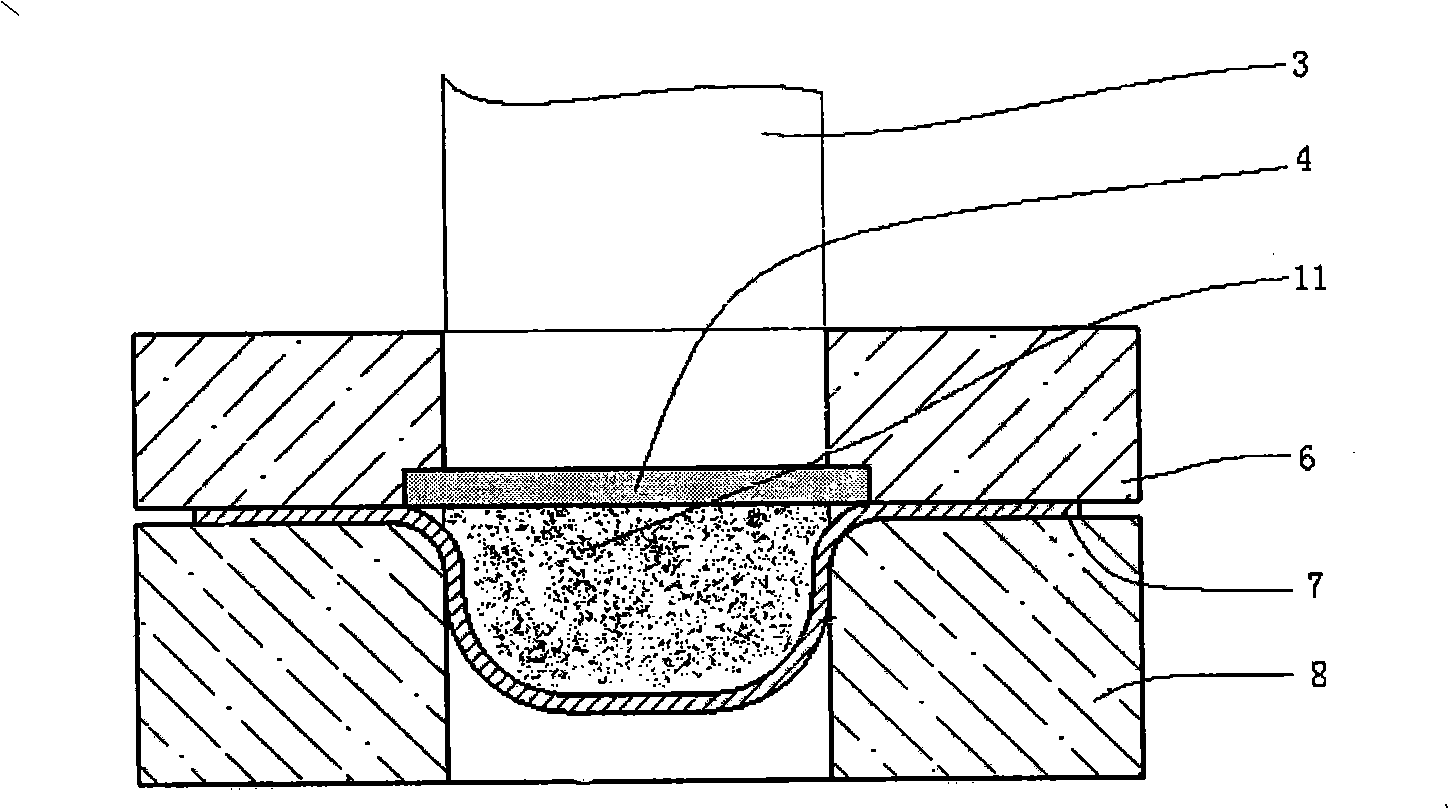

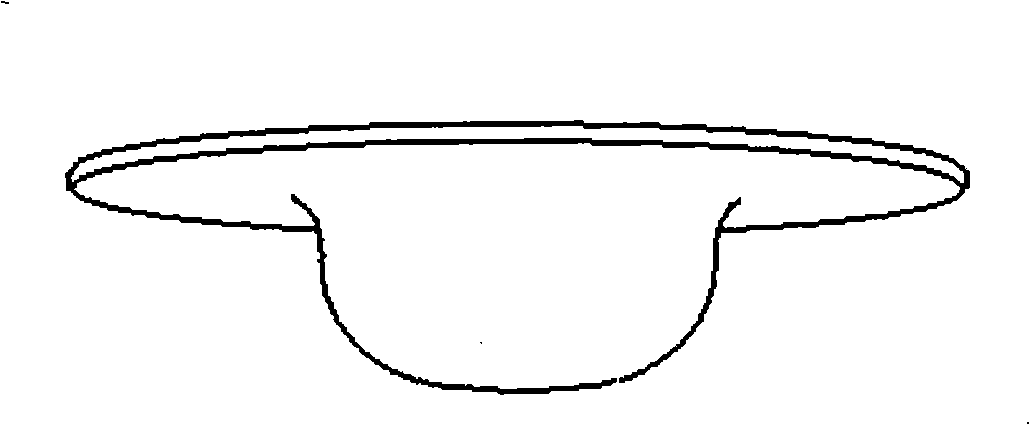

Bulk-heating sheet laser pressing method and device

InactiveCN101332540AGood formabilityFast formingLaser beam welding apparatusDeep drawingMaterials science

The invention relates to a plate laser stamping method with an integral heating function and a special device. In the method, ceramics is taken as a female die and a clamping ring; the female die, the clamping ring and the plate are arranged in an electrifying coil, the forming property of the plate is strengthened by heating, and then the plate is irradiated by short pulsed laser with energy density greater than the ignition threshold of the material and is shocked by the shock force of plasma produced by the interaction between the laser and the material to lead to the plastic deformation of the plate under the combined action of the rigid female die. The method belongs to a high-strain rate forming method of rapid forming speed, and can form materials which are hard to be deformed at a normal temperature; the method is especially suitable for deep drawing and bulging of small parts of thin plates and can be applied to the manufacturing field of the structural parts of micro electromechanical system.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com