Laser sonic surface wave stress test system

A surface acoustic wave and stress testing technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of high cost, low sensitivity of optical interferometers, and the inability to measure the two-dimensional distribution of surface stress, etc., and achieve simple structure , system cost reduction, and the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

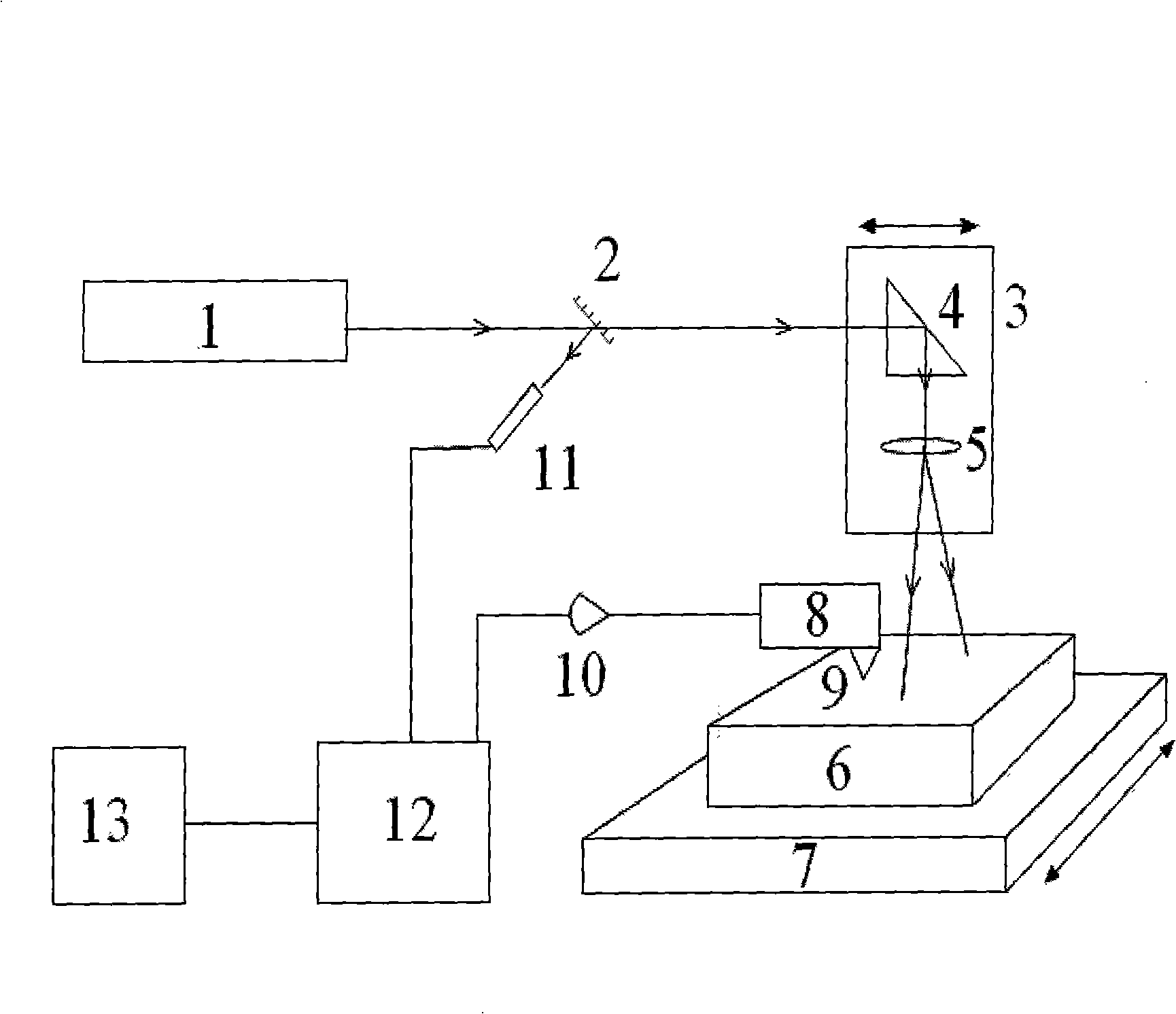

[0009] The specific structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Referring to the accompanying drawings, the laser surface acoustic wave stress testing system made according to the present invention mainly consists of a pulse laser 1, a beam splitter 2, a triangular prism 4 and a cylindrical convex lens 5 to form an ultrasonic surface wave excitation part, and consists of a PVDF piezoelectric film 9 and a high frequency The preamplifier 10 constitutes an ultrasonic surface wave detection section. Pulse laser 1 is a short pulse laser with an output wavelength of 1064 nm, a pulse width of 10 ns, and a single pulse output energy of 70 mJ. The beam splitter 2, the triangular prism 4 and the cylindrical convex lens 5 are sequentially arranged on the same optical path; a photodiode 11 is arranged on the reflection optical path of the beam splitter 2, which receives a small part of the reflected l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com