Short burst laser cleaning method of metal surface

A short-pulse laser, metal surface technology, used in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problem of difficulty in cleaning repair parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

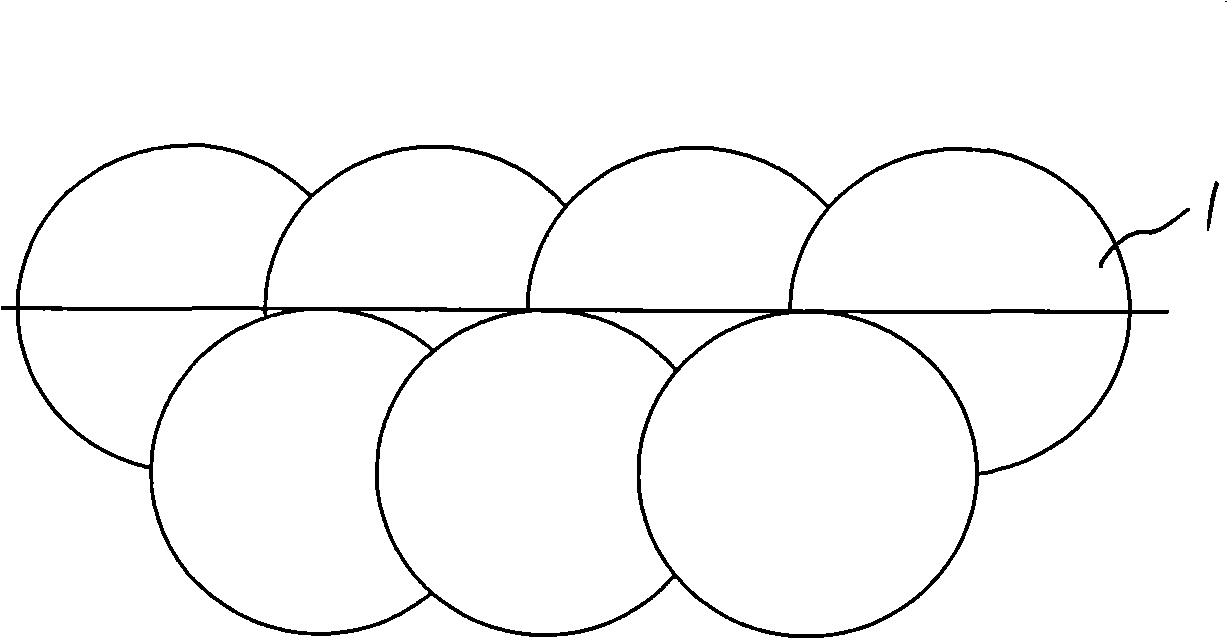

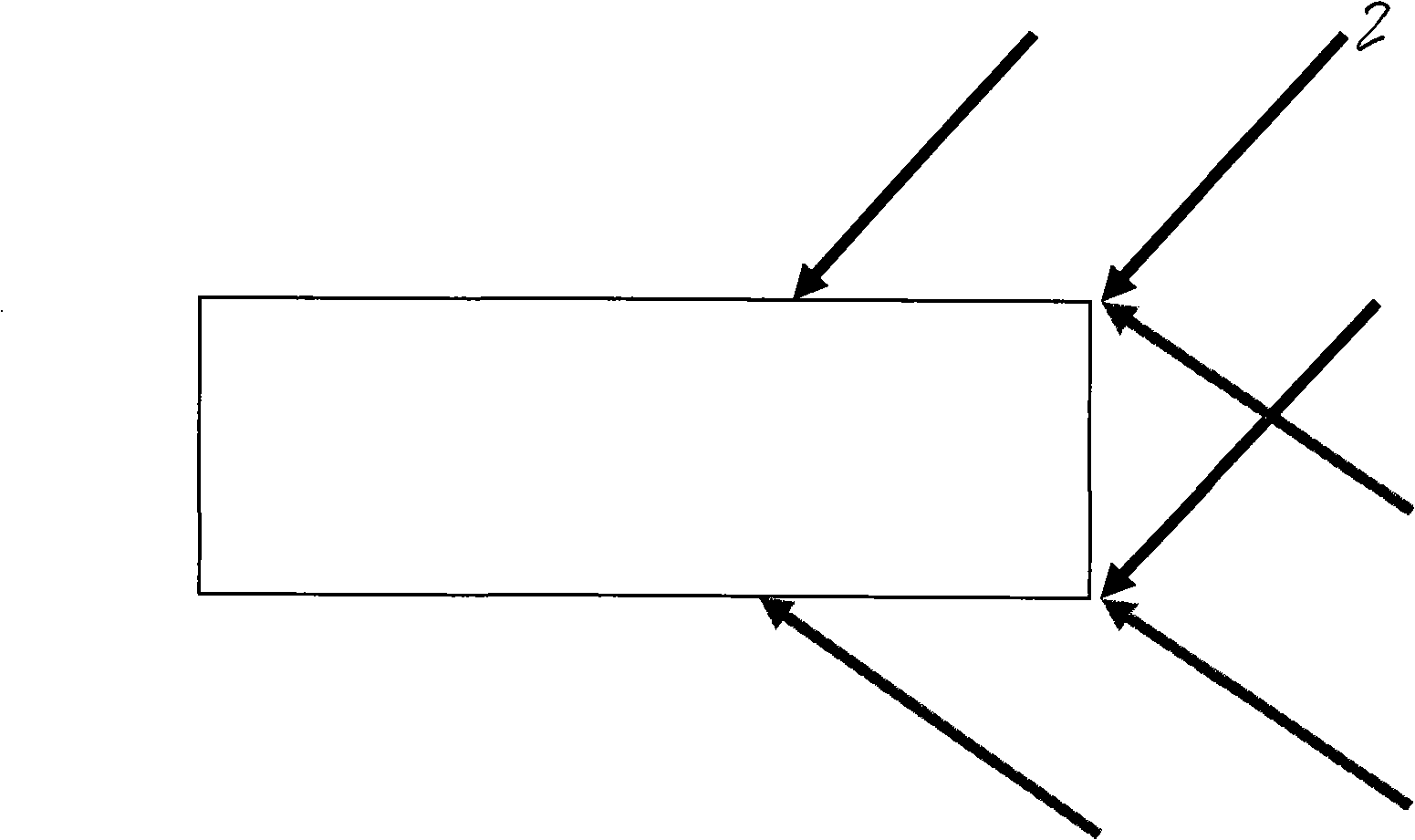

[0012] See attached Figure 1~2 As shown, on the surface of titanium alloy and aluminum alloy, the defocused spot 1 of short-pulse laser is used to irradiate the position to be cleaned. When interacting with materials, in order to prevent a small amount of oxidation of the metal surface in the air environment, the metal surface can be placed in a vacuum environment or under a protective atmosphere such as argon, which is characterized in that,

[0013] (1) Use a short pulse laser and use a protective atmosphere for laser cleaning: the laser pulse is less than 20ns, specifically 20-30ns, 8-15ns, and the peak power density is above 100MW / cm2. When the short-pulse laser acts on the metal surface, The laser and the material mainly produce a vaporization effect, and the oxide film is more likely to absorb laser energy when the laser is acting. Select the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com