Patents

Literature

64 results about "Long pulsed laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for measuring sub-static laser scratch of interface jointing strength

InactiveCN1405553AThe mechanism of laser action is obviousThe mechanism of laser action is simpleUsing mechanical meansColor/spectral properties measurementsCoated surfaceThin layer

This invention relates to laser and material performance test using continuous loading long-pulse laser to load a coating or film test subject surface in quasi-stationary state and heat its thin layer (only dozens of nm thick) with laser thermal action and thermal conduction thereafter, to form a temperature field in the subject. When the thermal stress reaches to a certain value on the coating abbesion will heppen to the subject or even warping or scaling due to the difference between coefficient of thermal expansion and the temperature and the feed system makes the subject to do feed movement to form mars on the surfaces. The related laser energy at scaling position at the interface can express the binding strength of the interface to get the binding strength by theory analysis and digital calculation.

Owner:JIANGSU UNIV

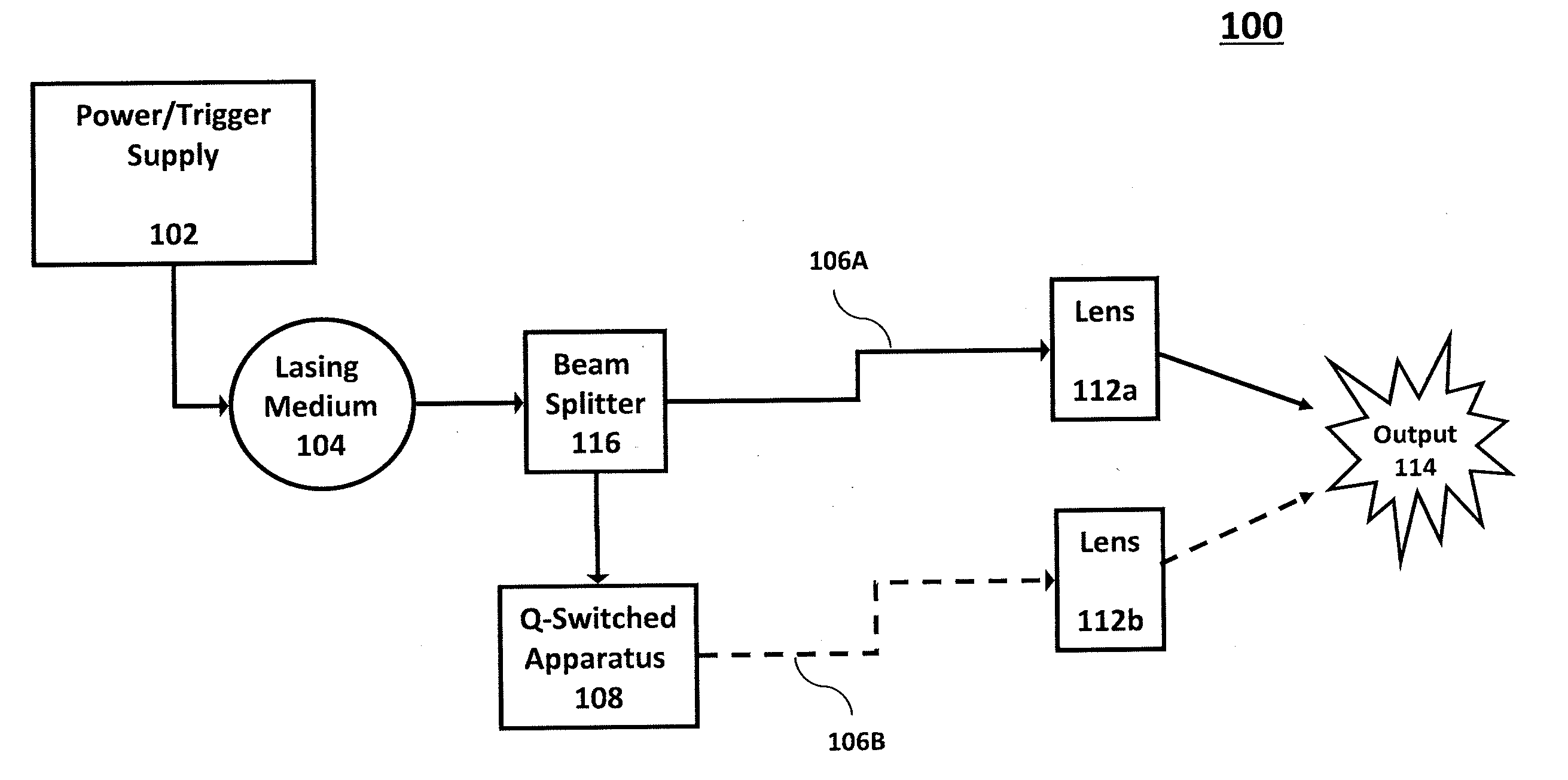

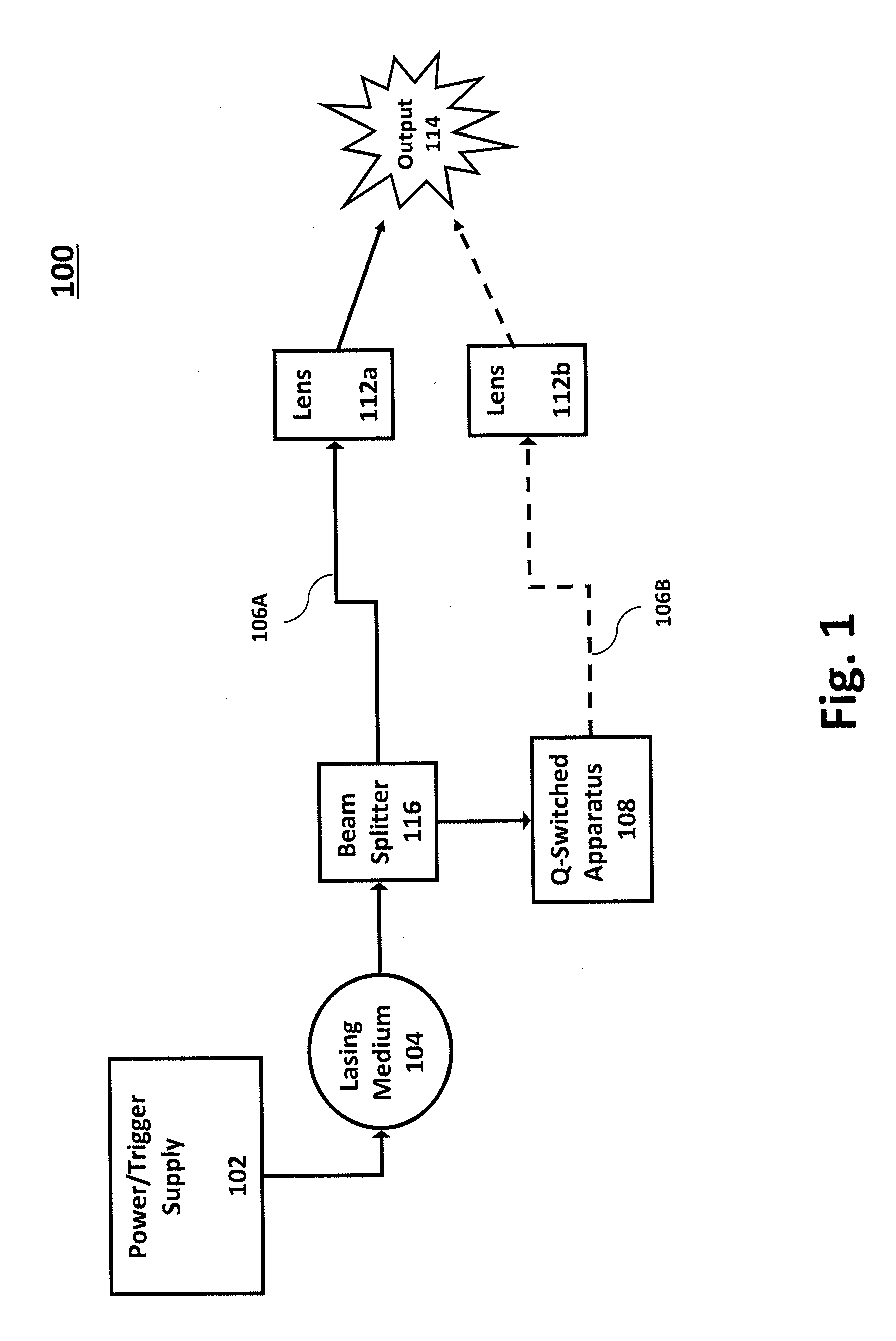

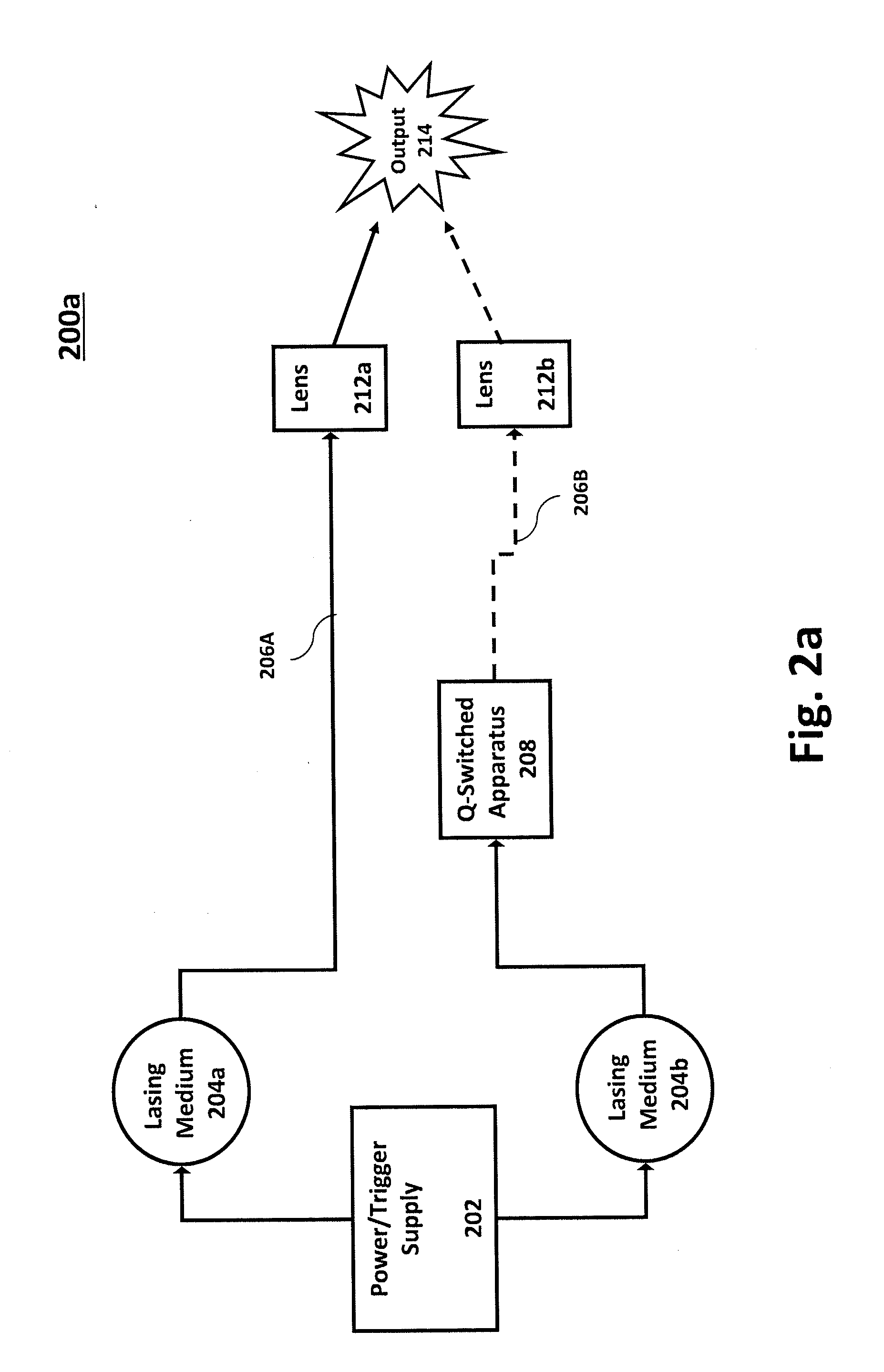

Combination Laser Treatment of Skin Conditions

InactiveUS20120253333A1Reduce and eliminate aging changeReduce and eliminate and permanent defectSurgical instrument detailsHair removalCutaneous condition

A method and apparatus for treatment of health and skin conditions through the use of a combination of laser systems or a laser system capable of delivering different pulse durations. The laser system being capable of producing both Q-switched short pulsed laser energy and millisecond long pulsed laser energies. Multiple skin conditions would be susceptible to this treatment, including acne, skin aging and textural changes, pigmentary changes, scarring, rosacea, striae, redness and hair removal.

Owner:GARDEN JEROME M +2

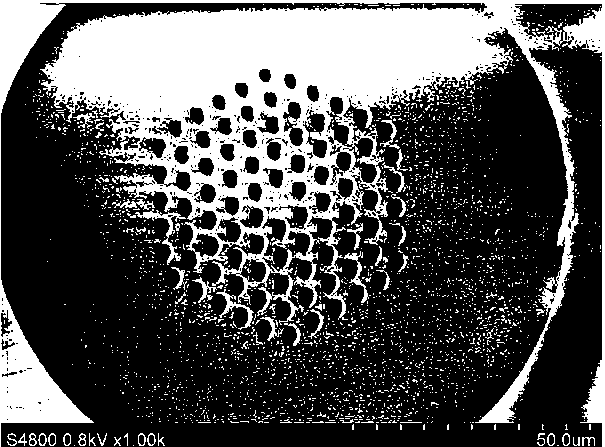

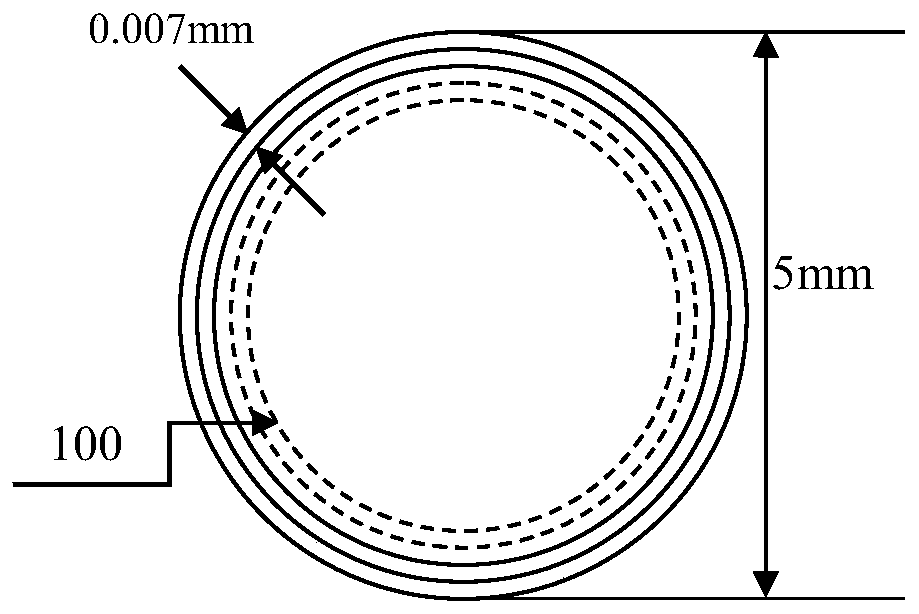

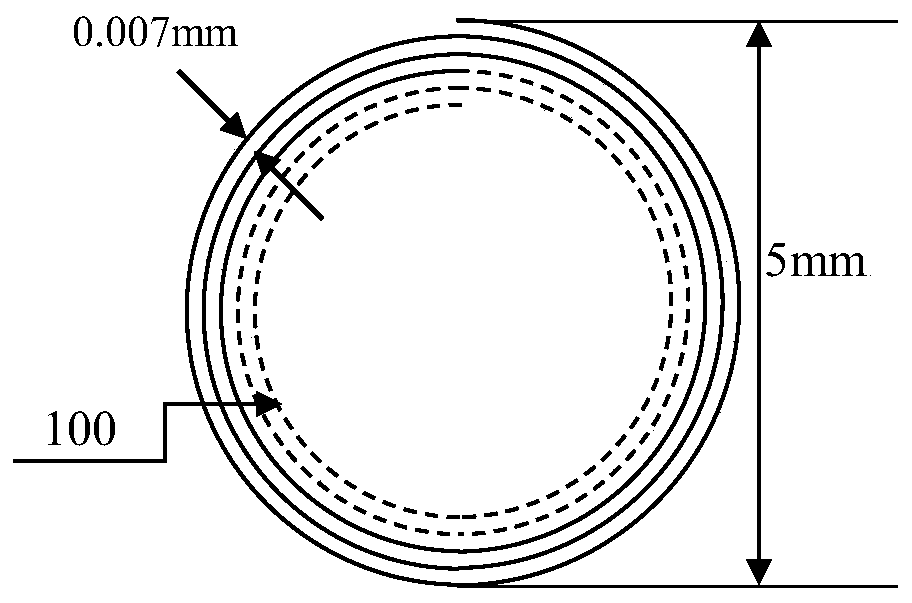

Microporous array processing device and microporous array processing method

InactiveCN109570781AReduced impact strengthQuality improvementMicrostructural devicesLaser beam welding apparatusRotary stageLight beam

The invention discloses a microporous array processing device and a microporous array processing method. The microporous array processing method comprises the following steps of S1, converting a laserbeam into Bessel spots by means of an axicon principle, and focusing the spots to the surface of a to-be-processed component; S2, adjusting the axicon according to a microporous array needed by the to-be-processed component to obtain quantity and distribution of the needed spots; and S3, processing the spots to the to-be-processed component by means of laser pulse to form the microporous array. The microporous array processing device comprises a laser light source, a light source adjusting assembly, the axicon and a moving table successively arranged along the direction of propagation of light, wherein the axicon is mounted on a five-axis precision rotary table and is driven by the five-axis precision rotary table to adjust the angle the axicon and an incident beam. The microporous arrayprocessing device and the microporous array processing method process multiple micropores at single time, so that the work efficiency is improved. The heat effect is relatively long, the action of pulse laser is small, and the quality of a processed material is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

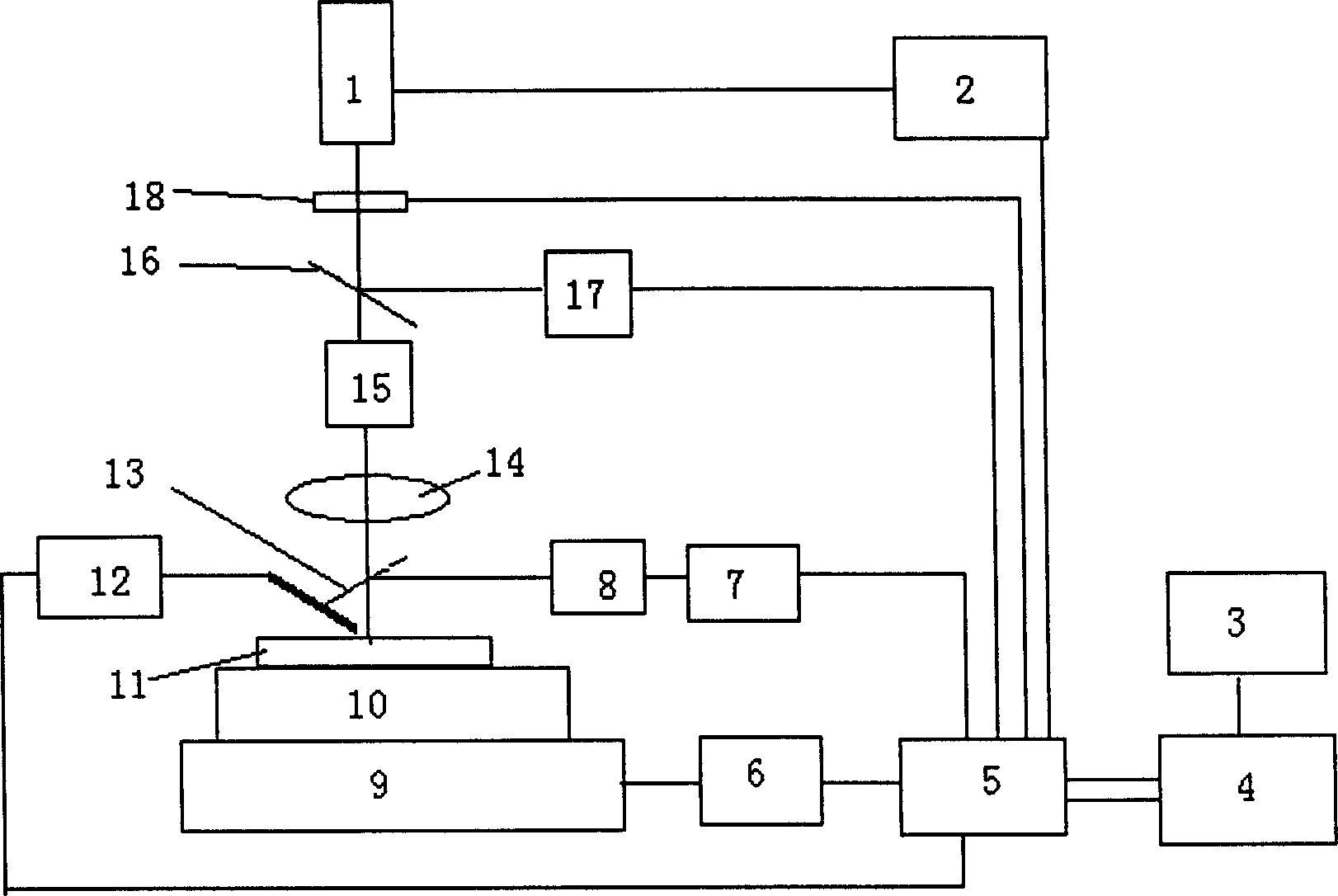

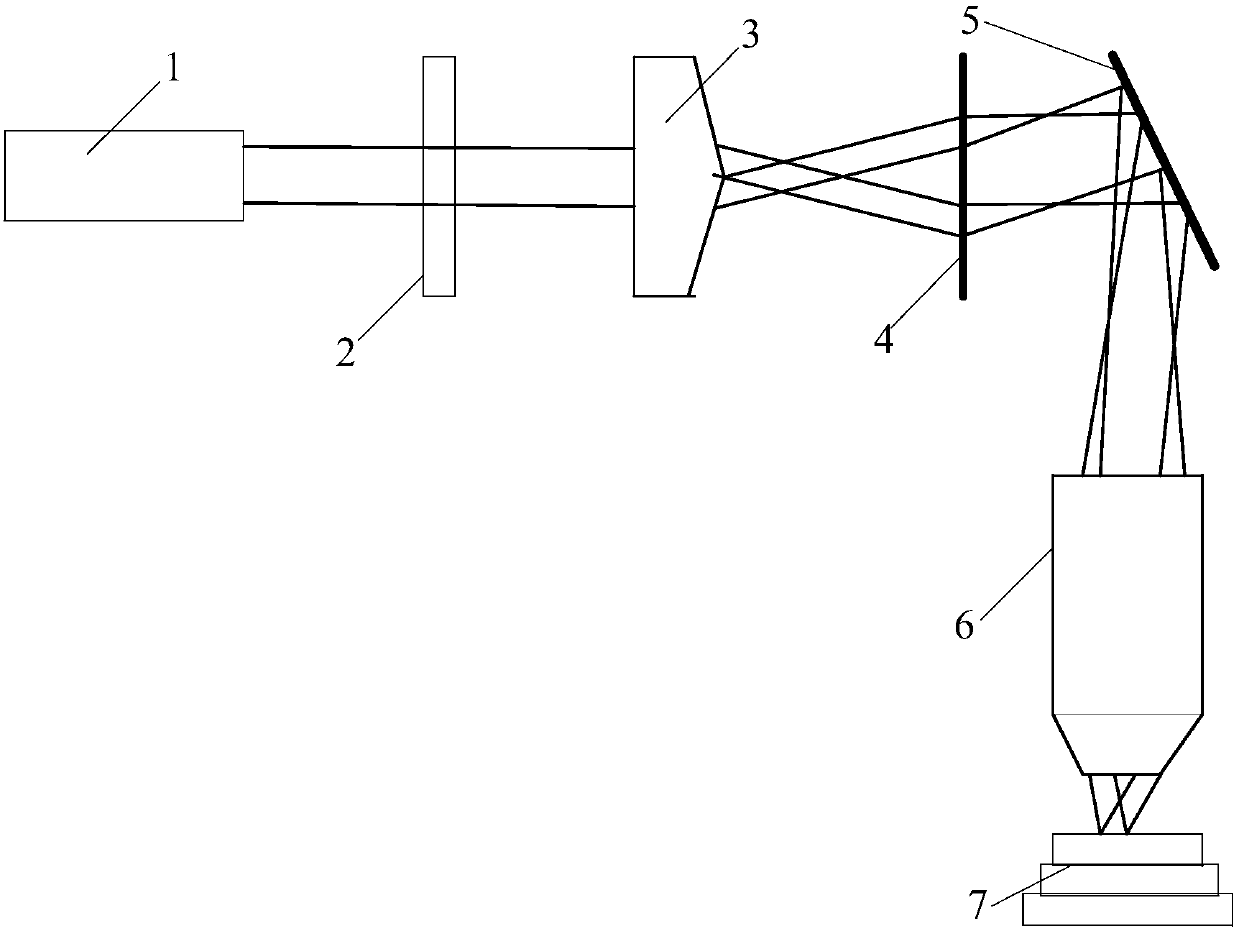

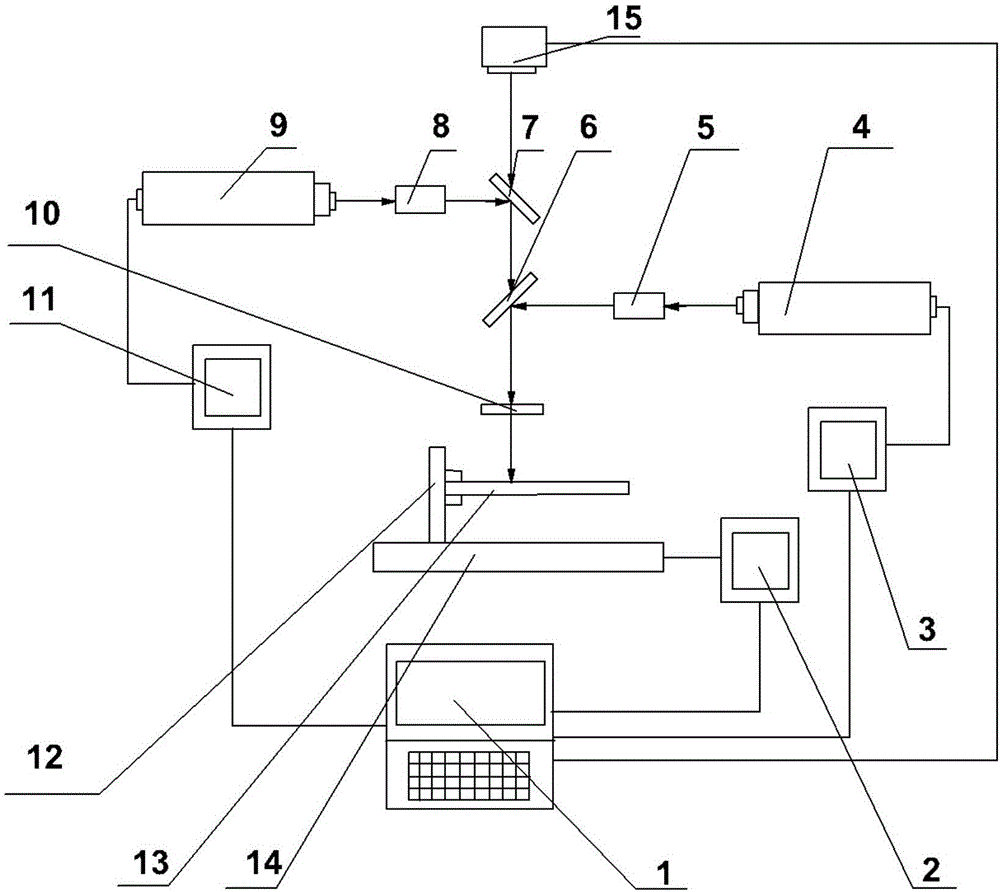

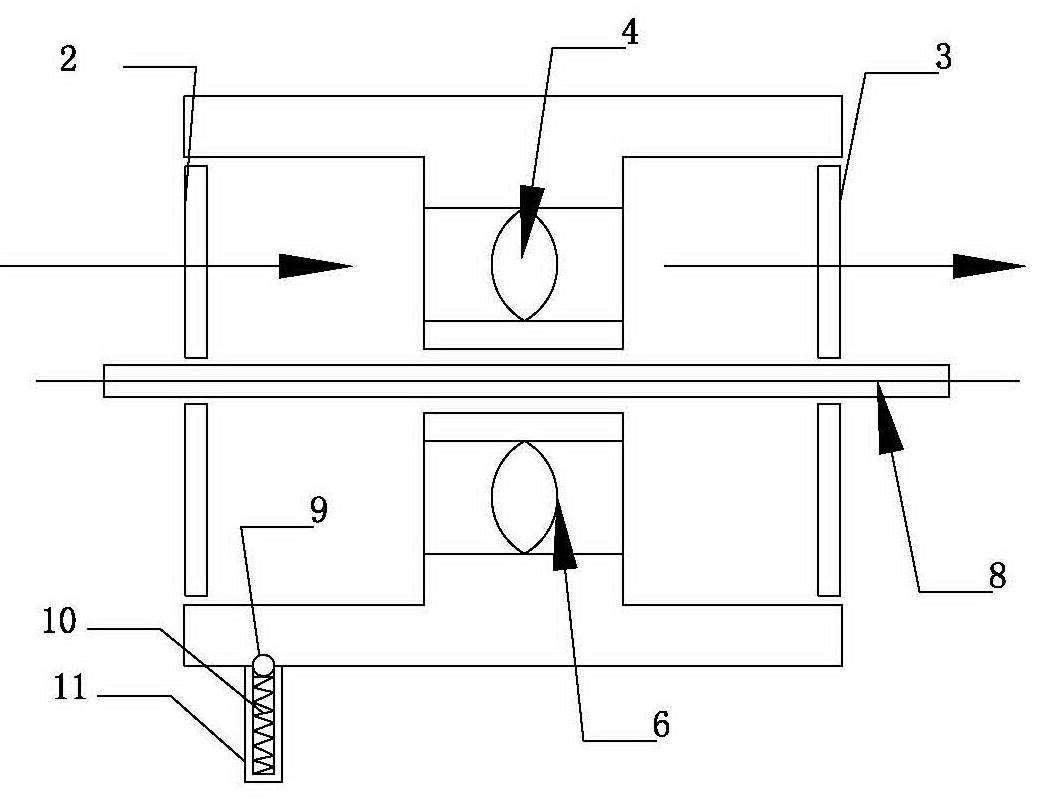

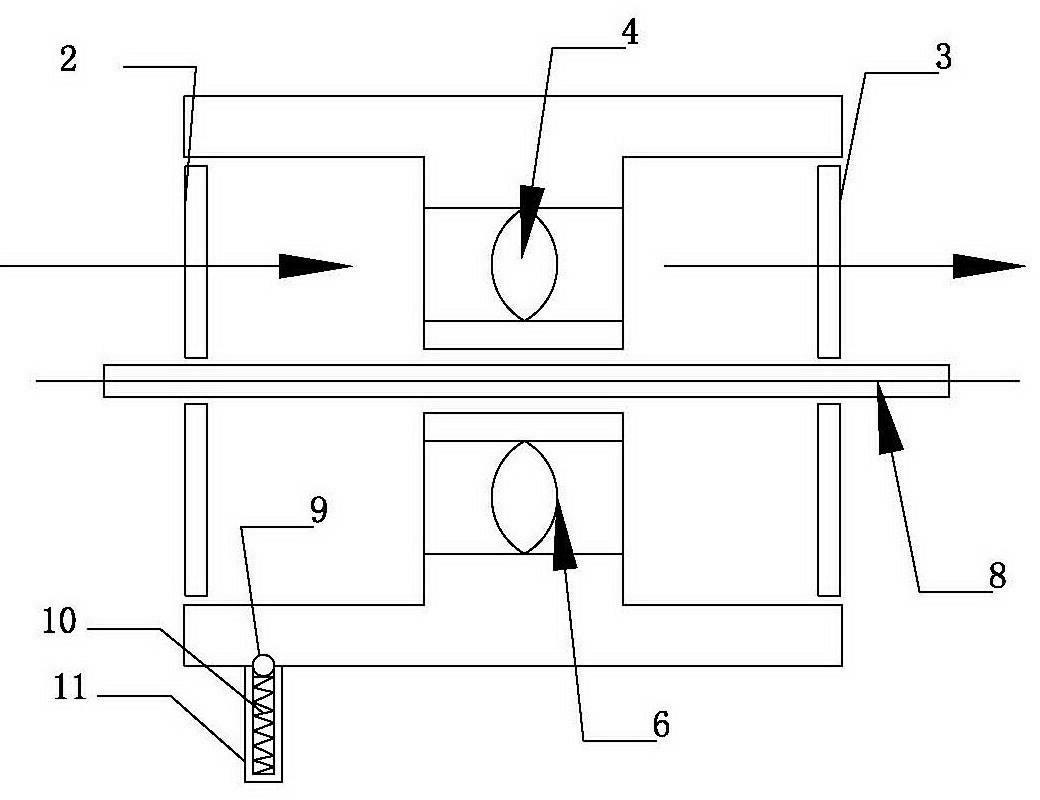

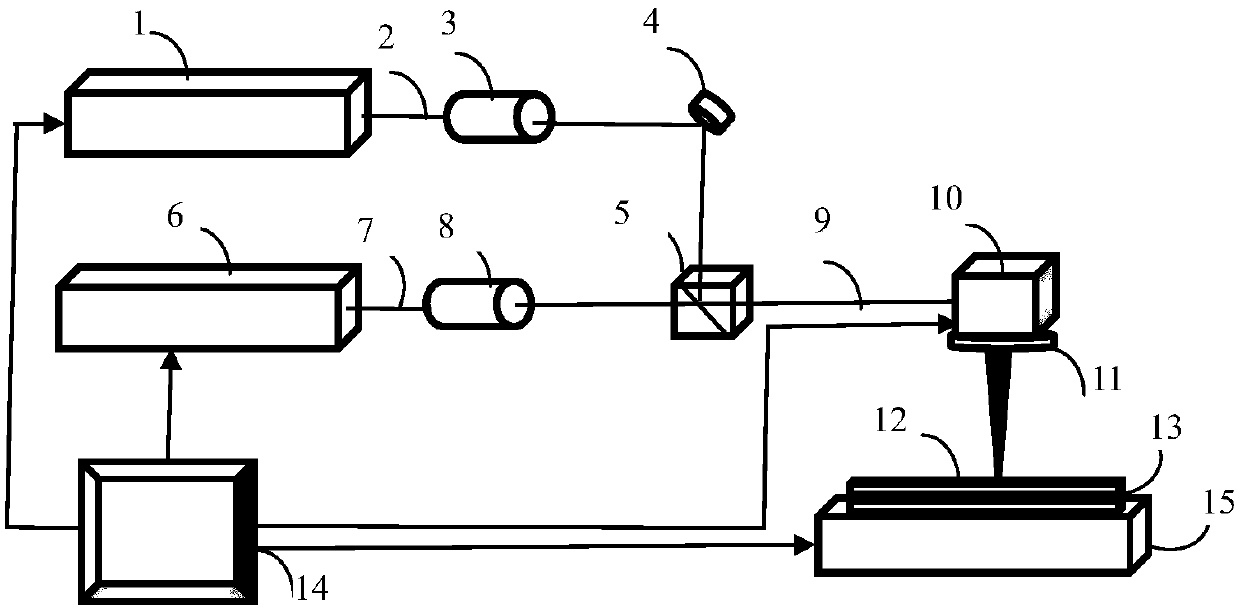

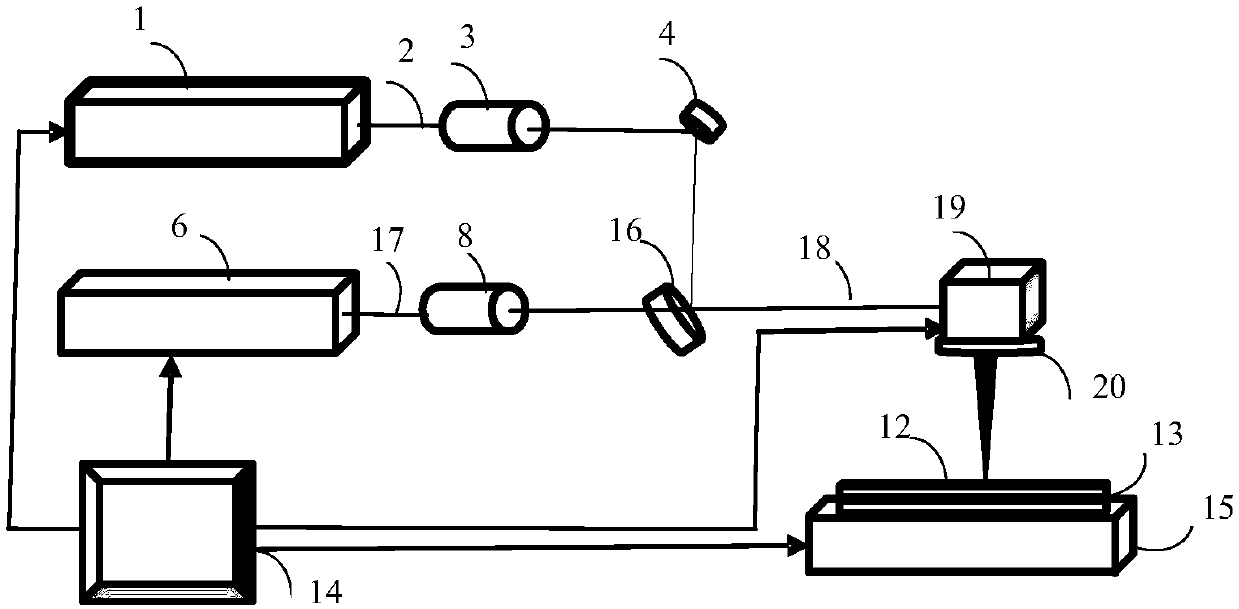

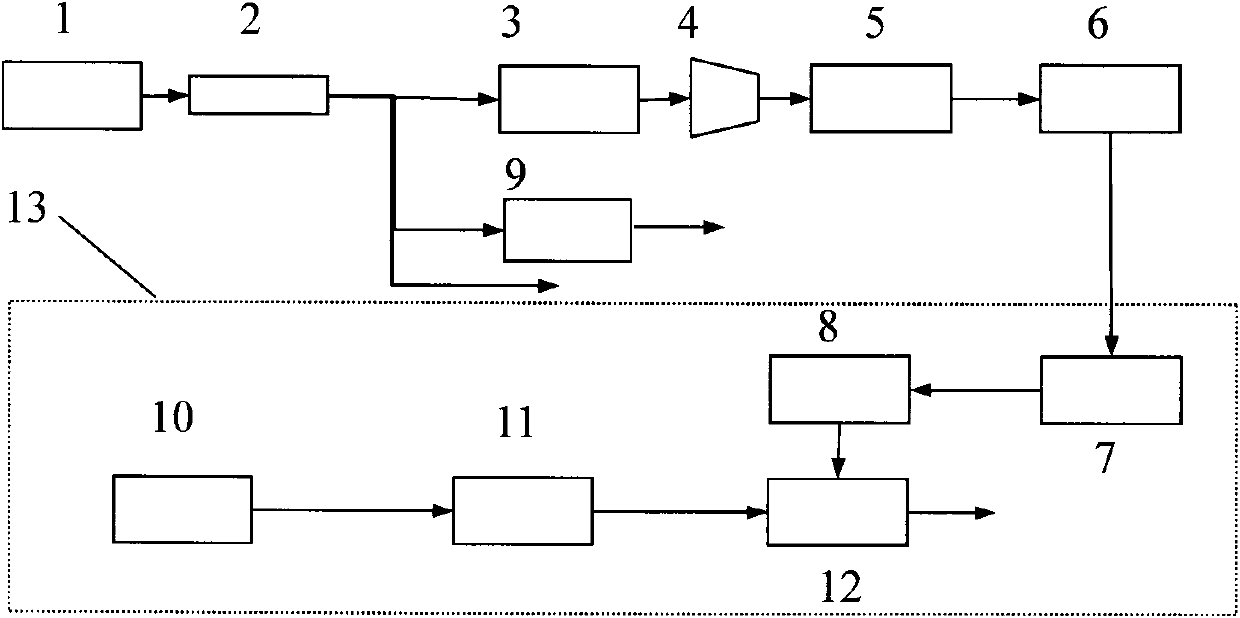

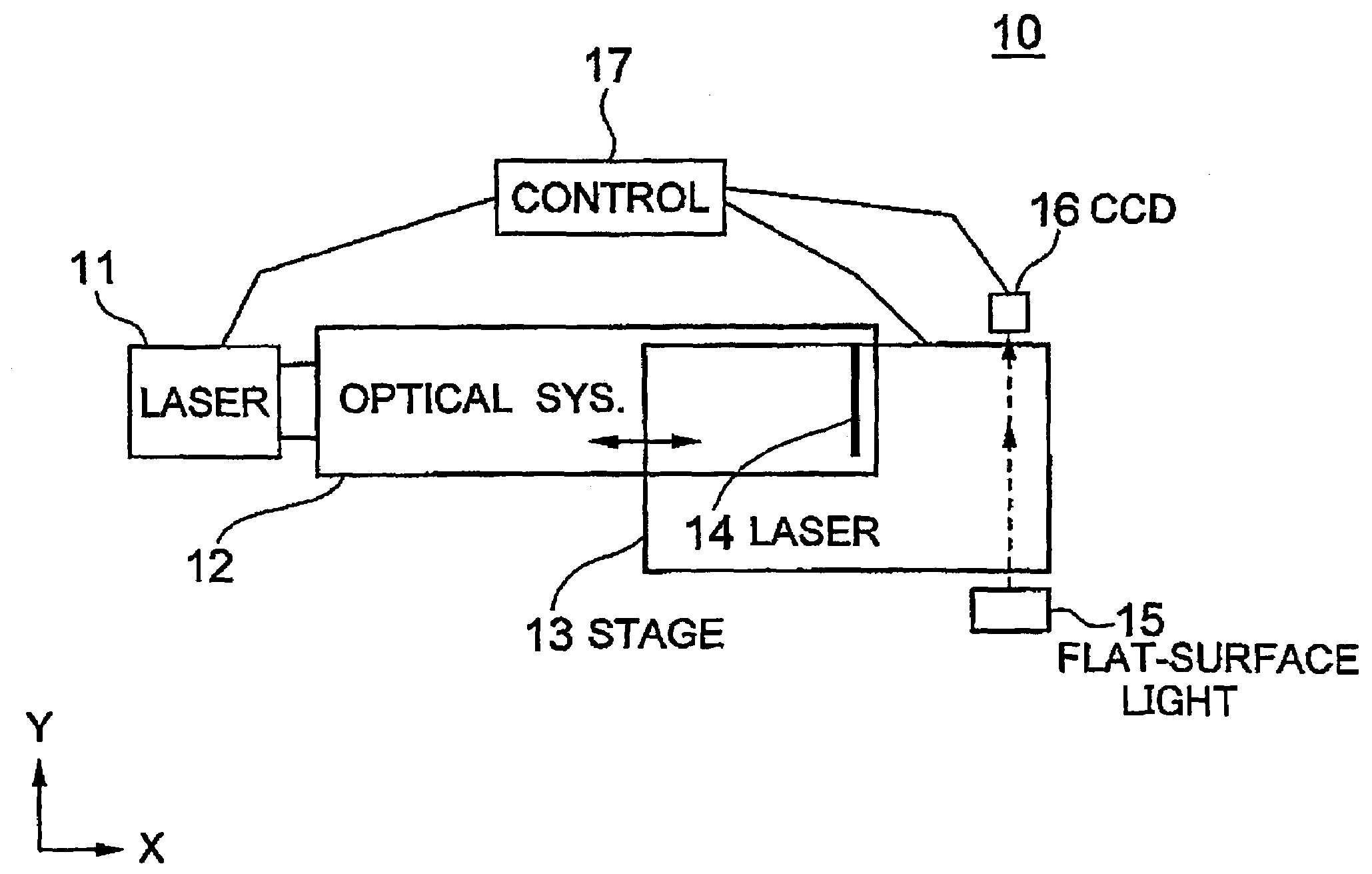

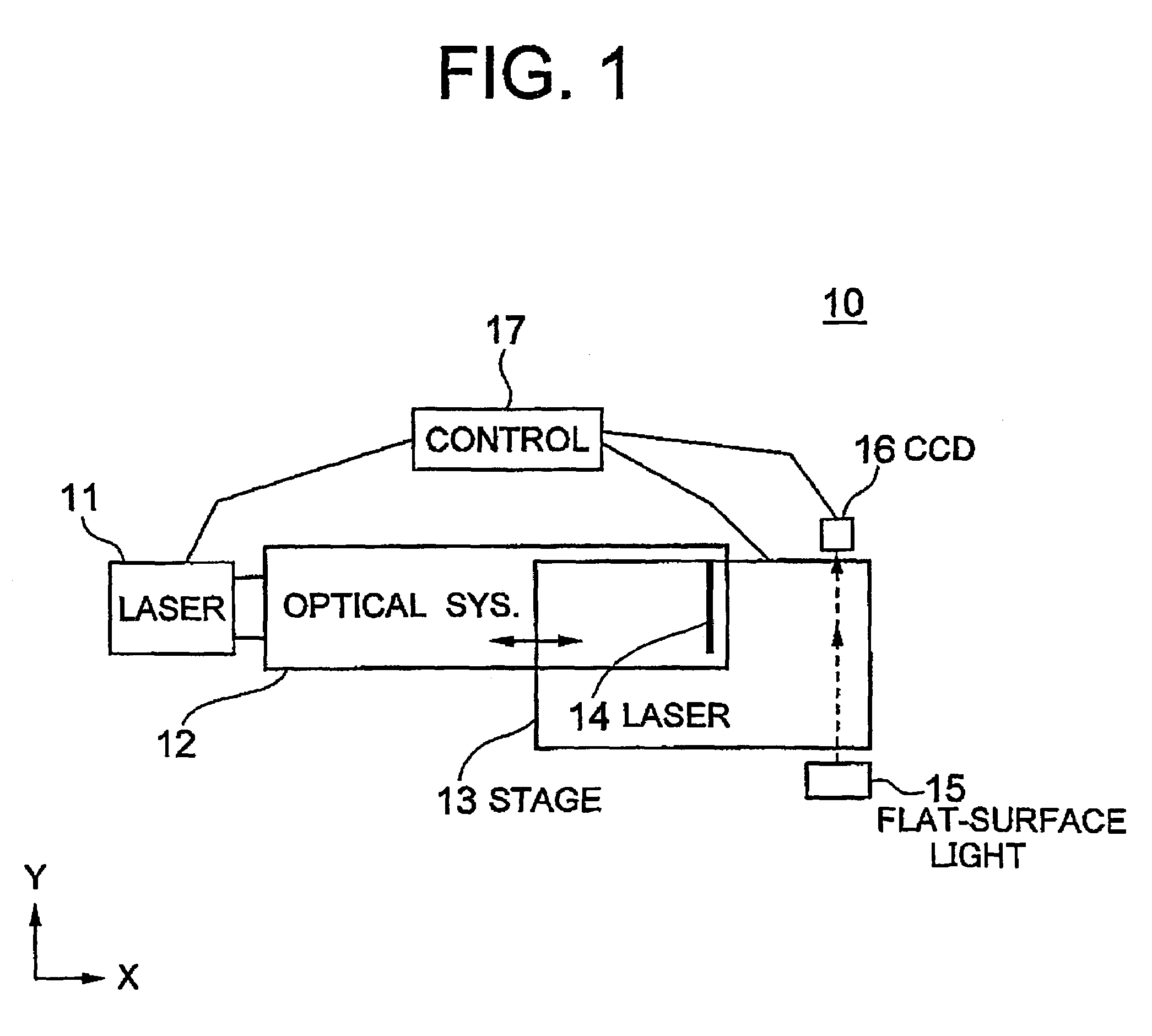

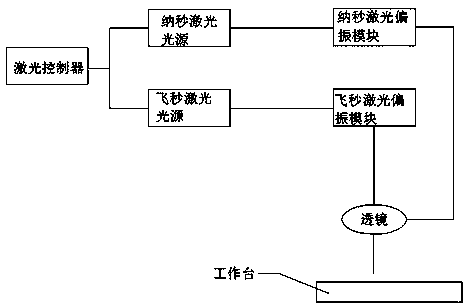

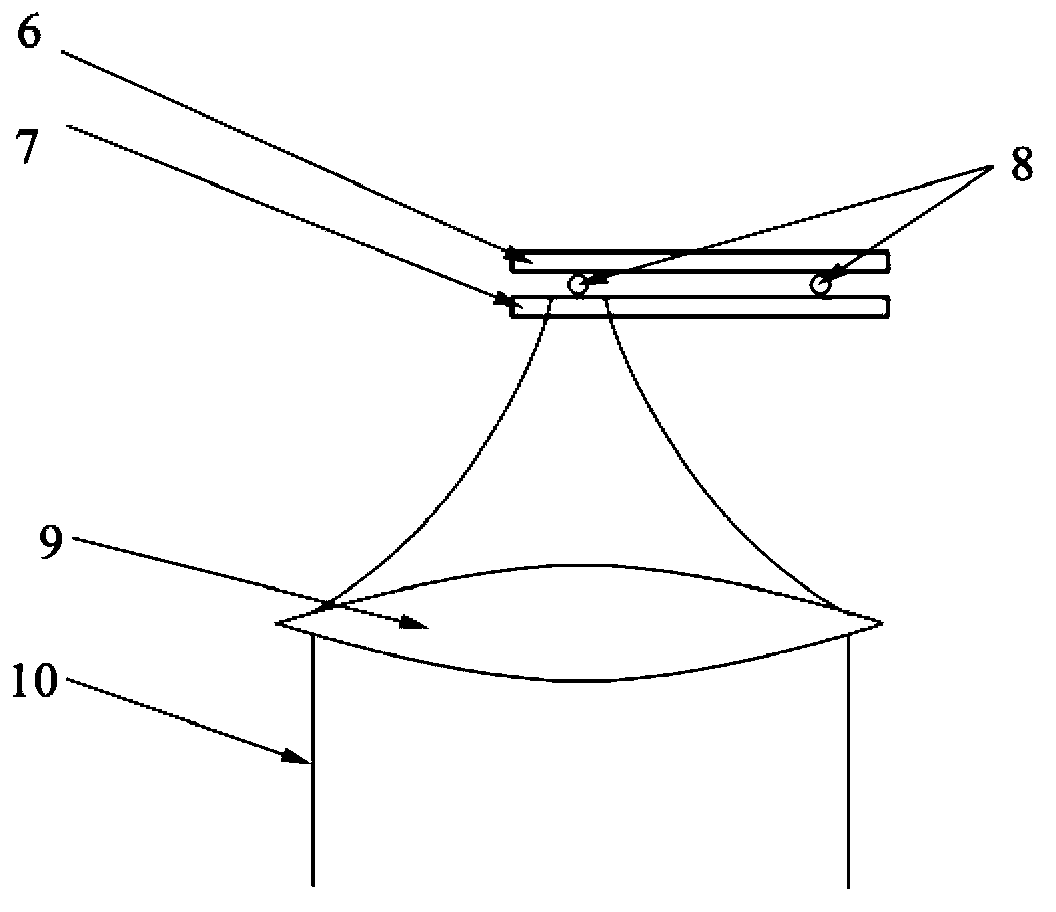

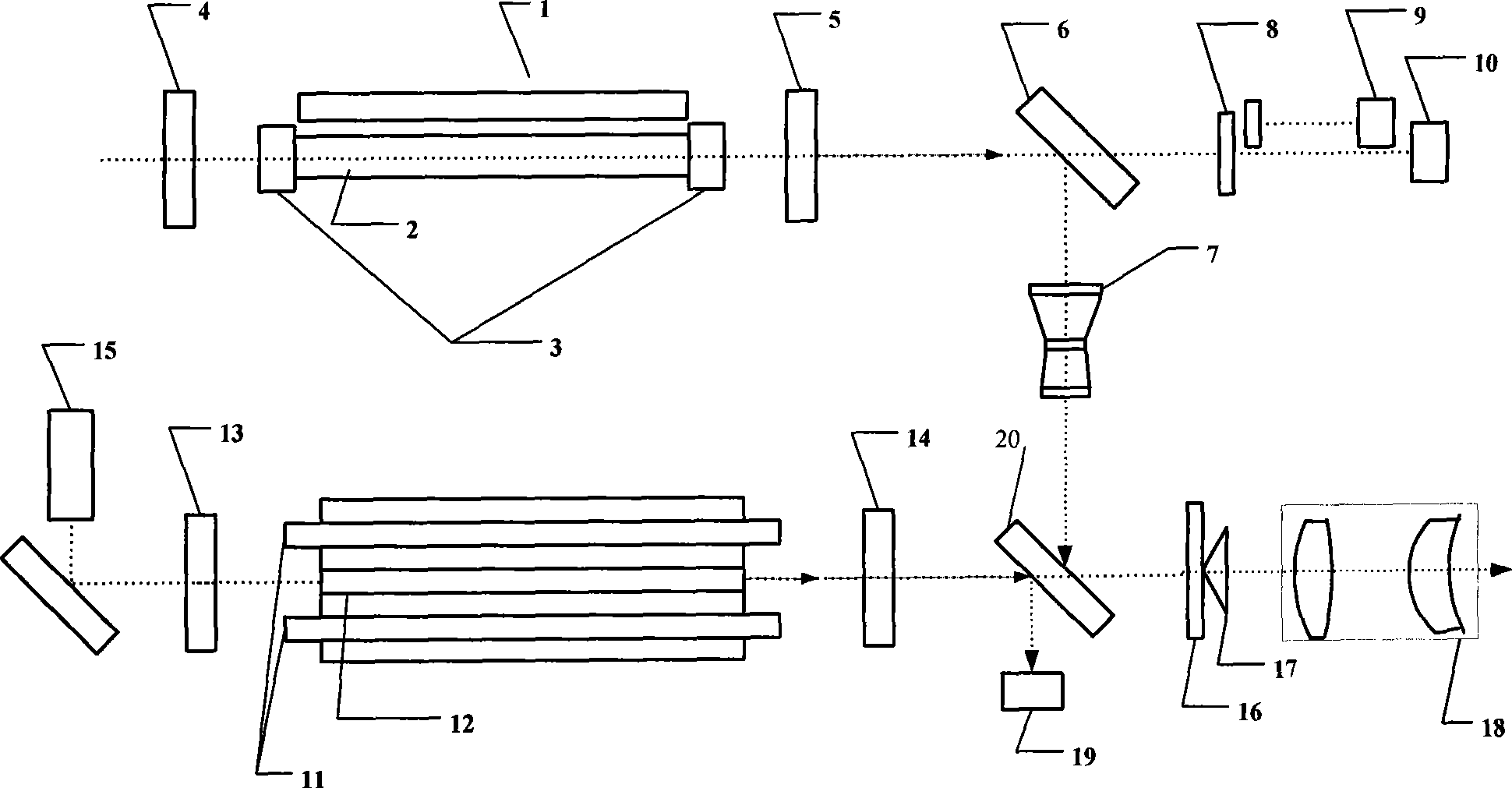

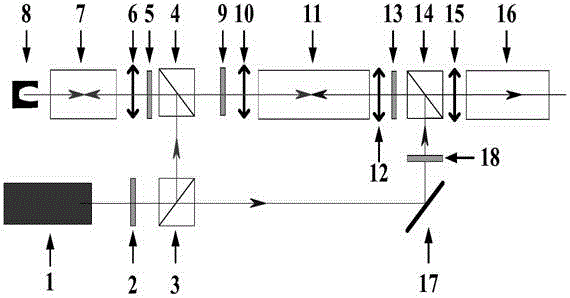

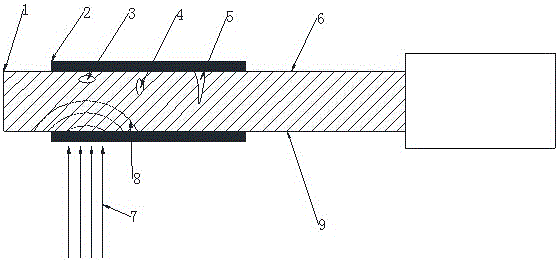

Laser-aided-heating long-pulse-laser perforating device and method

ActiveCN106735943AImprove removal efficiencyImprove absorption rateLaser beam welding apparatusPlane mirrorLaser assisted

The invention discloses a laser-aided-heating long-pulse-laser perforating device and method. The laser-aided-heating long-pulse-laser perforating device comprises a long-pulse laser device, a first beam expanding device, a CCD camera, a reflection plane mirror, a transmission / reflection plane mirror, a convex lens, a second beam expanding device, a continuous laser device, a long-pulse-laser controller, a continuous-laser controller, a workpiece, a clamp, a movable workbench, a workbench controller and a computer. The method using the laser-aided-heating long-pulse-laser perforating device is mainly characterized in that the continuous laser device is used to heat the to-be-processed area of the upper surface of the workpiece before the long-pulse laser device is used to process the workpiece, during the processing and after the workpiece is processed for a certain period of time, that is to say, effects of preheating and slow cooling are achieved during laser perforation. By the laser-aided-heating long-pulse-laser perforating device and method, the problem that micro-cracks easily appear on the wall of a hole perforated by a current long-pulse-laser perforating method is alleviate effectively, and high processing quality of the workpiece is achieved.

Owner:JIANGSU UNIV

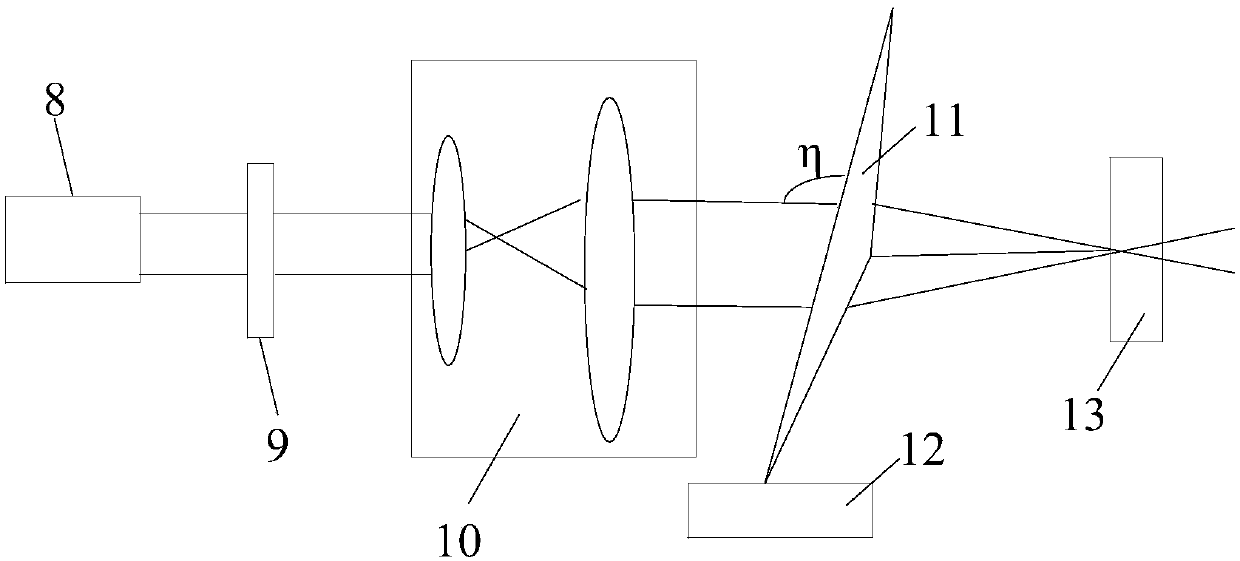

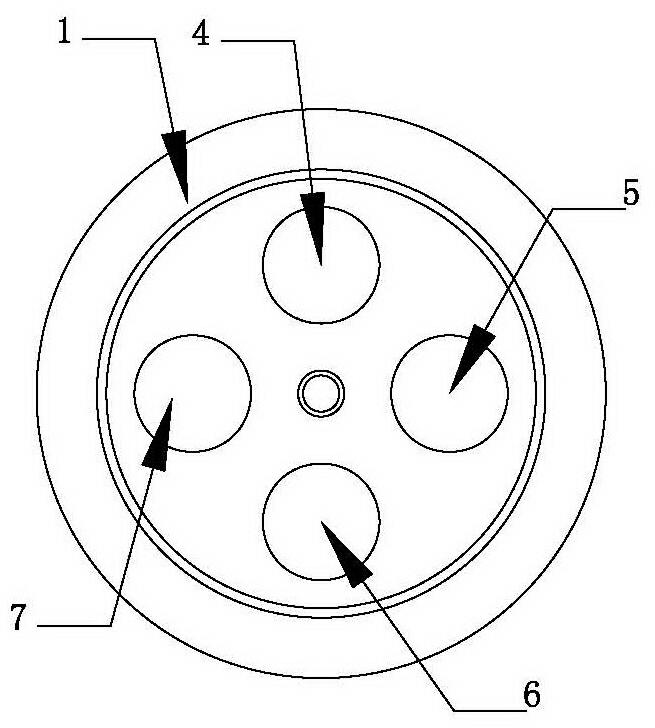

Method and device for regulating spot size of long-pulse laser

ActiveCN102670304APrecision therapyLittle side effectsSurgical instrument detailsProper treatmentEngineering

The invention discloses a device for regulating the spot size of a long-pulse laser. The device comprises a lens switching rotary drum, wherein a plurality of lens through holes are formed in the lens switching rotary drum, and the lens through holes are internally fixedly provided with lenses with different focuses; and an angle location device is arranged on the outer circumferential surface of the lens switching rotary drum to ensure that the axial line of one lens through hole is coincident with the axial line of a laser main light path during every rotating location. During the use, the lens switching rotary drum is rotated, a plurality of matching grooves are formed on the periphery of the drum wall of the switching rotary drum, and the corresponding lens is turned into the laser main light path when rotating to a certain angle, therefore, the most proper treatment spot is selected according to the shape and area of the skin to be treated, the accurate treatment is realized and the side effects are reduced.

Owner:上海奥通激光技术有限公司

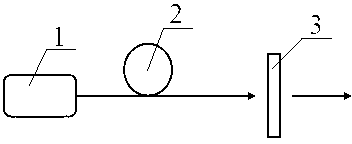

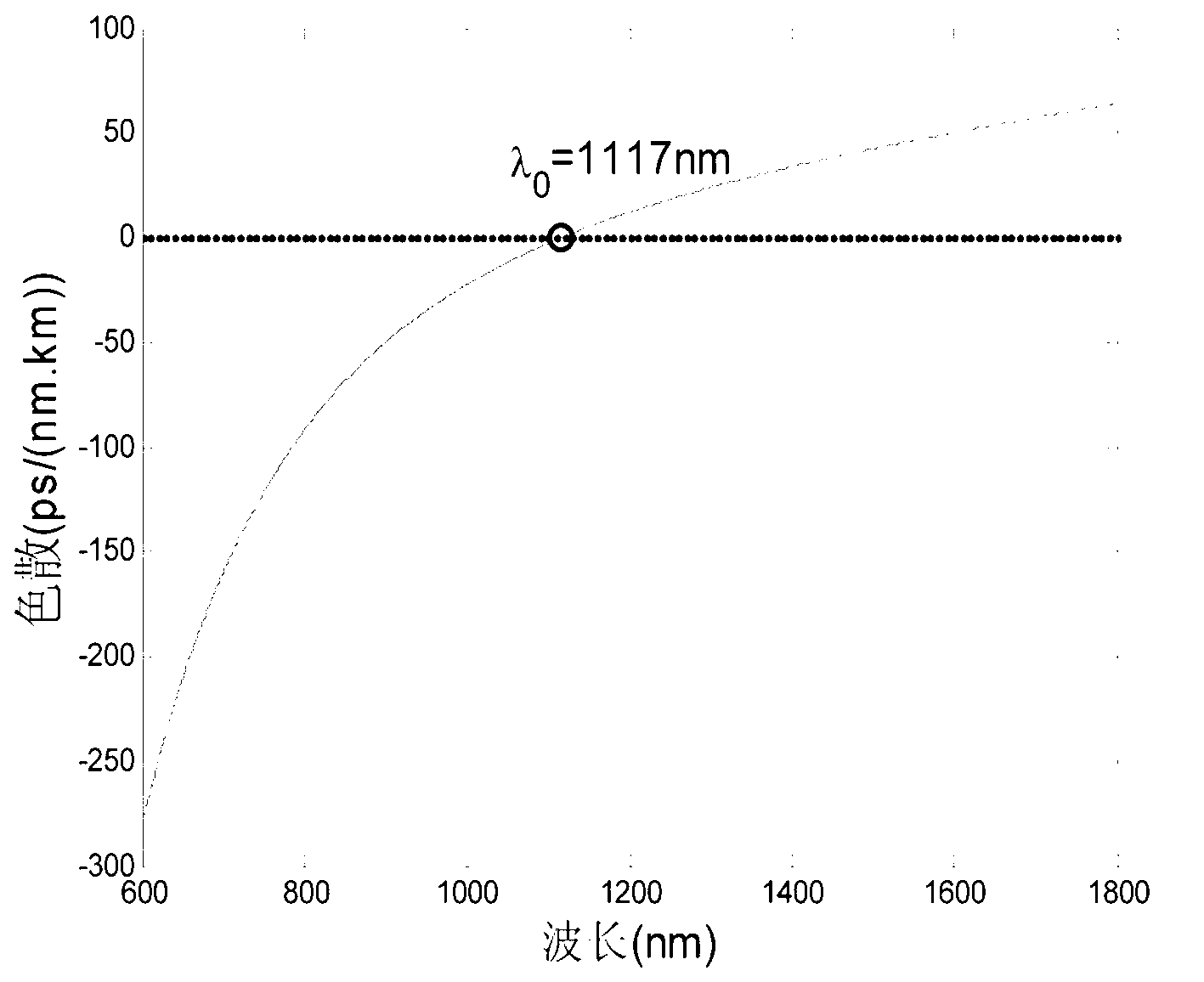

All-optical wavelength converter based on photonic crystal optical fiber four-wave frequency mixing effect

InactiveCN102841480ASimple structureLow costCladded optical fibreOptical waveguide light guidePicosecondLaser beams

The invention provides an all-optical wavelength converter based on a photonic crystal optical fiber four-wave frequency mixing effect. The all-optical wavelength converter comprises a laser, an optical crystal optical fiber and an optical filter, wherein the laser is a long pulse laser or a continuous laser with a pulse width more than tens of picoseconds, and the laser is used for outputting a pump light and providing a converting wavelength; the photonic crystal optical fiber is used for receiving and transmitting an output light of the laser; a laser beam can generate a degenerated four-wave frequency mixing effect during being transmitted in the photonic crystal optical fiber; and the laser beam output from the photonic crystal optical fiber passes through a narrow-band optical filter with a central wavelength of lambda and a proper bandwidth, thus, the laser beam with the wavelength of lambda can be obtained. According to the all-optical wavelength converter, one laser is adopted to synchronously provide the pump source and the converting wavelength, so that the all-optical wavelength converter has the advantages of simple structure, low cost and the like; and moreover, structural parameters of the photonic crystal optical fiber are designed, so that wavelength converting within a larger range can be achieved.

Owner:NAT UNIV OF DEFENSE TECH

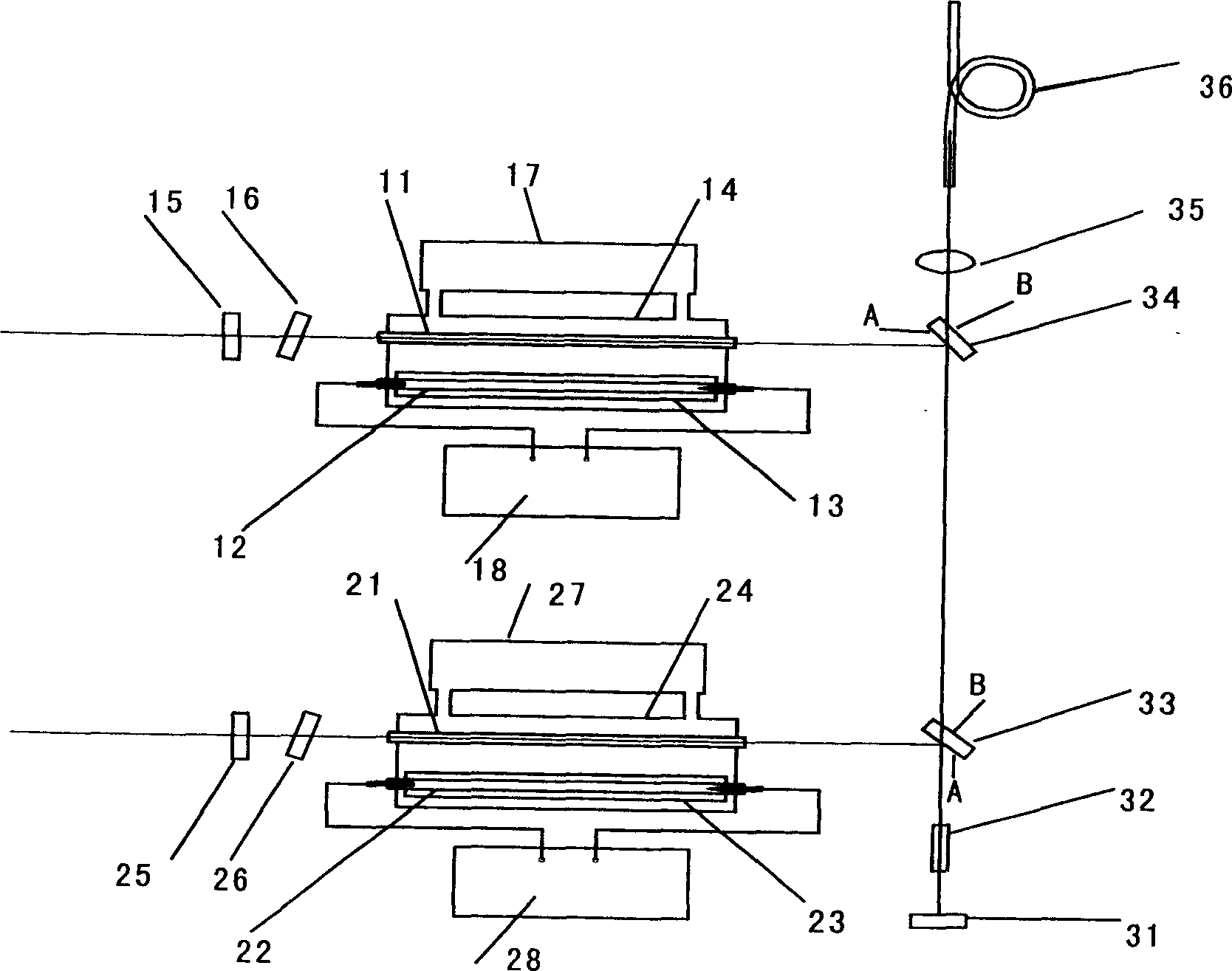

Laser-ultrasonic testing system

InactiveUS6813951B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationLight beam

Owner:NAT RES COUNCIL OF CANADA

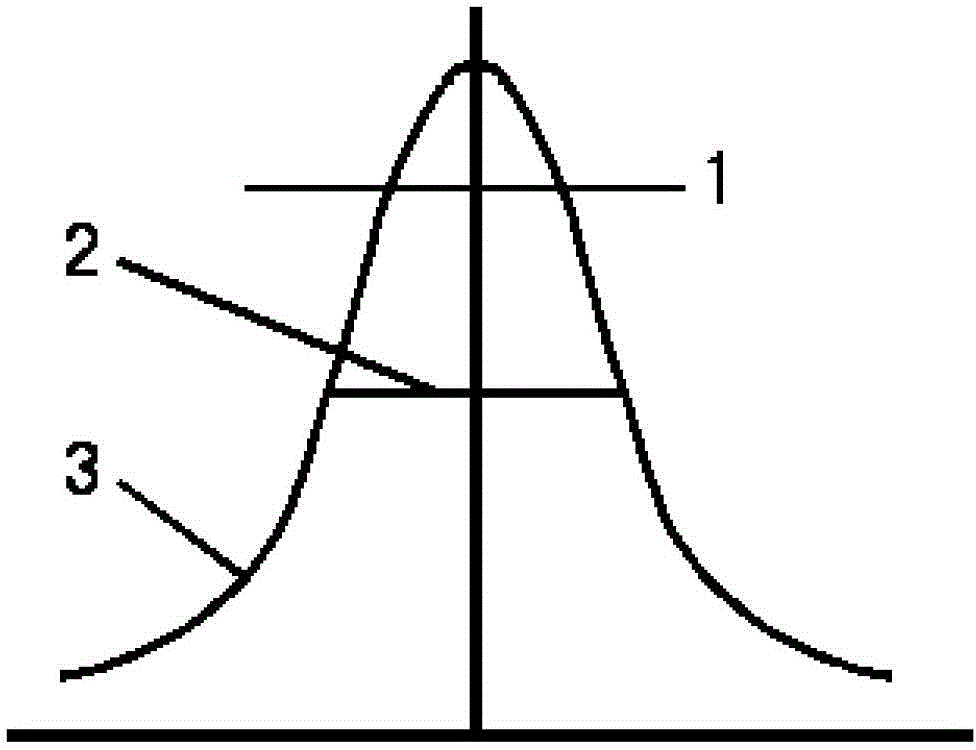

Method and apparatus for multi-laser-beam-combined welding of glass material

The invention discloses a method and apparatus for multi-laser-beam-combined welding of a glass material. According to the invention, laser beams emitted by an ultrafast pulsed laser and including glass-transmitting light and laser beams emitted by a continuous laser or long-pulse laser and including glass-transmitting light are combined onto a same optical axis and are then focused on the contact-making part of two pieces of glass by a scanning galvanometer and a field-scanning focusing mirror; the ultrafast pulsed laser beams produce non-linear absorption effect in the two pieces so as to allow the glass material in areas beside a focal point to be fused; the fused glass material has substantially improved absorptivity on continuous or long-pulse laser due to changes in absorptivity; more fused glass materials are produced through further inputting of energy so as to fill welding gaps and to eradicate etching effect, so welding of the area where the focal point is located is finished; and the glass material is scanned and welded until welding operation is finished. The method and apparatus provided by the invention can improve laser beam welding efficiency and can be applied through engineering approaches.

Owner:HUAZHONG UNIV OF SCI & TECH

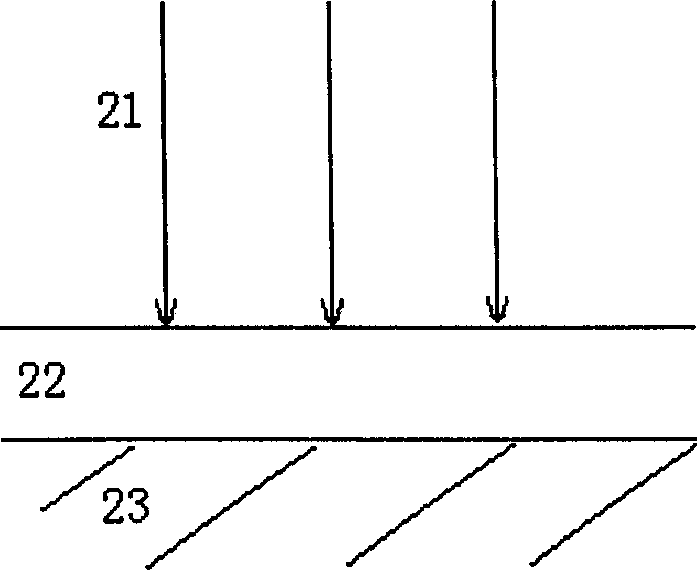

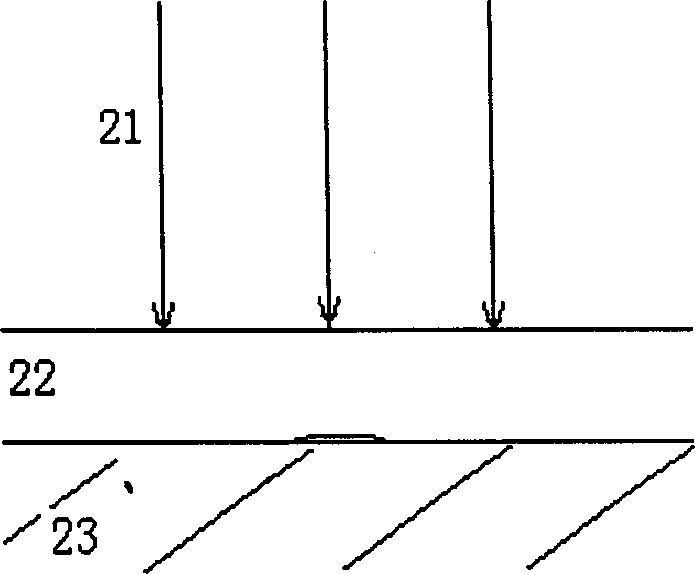

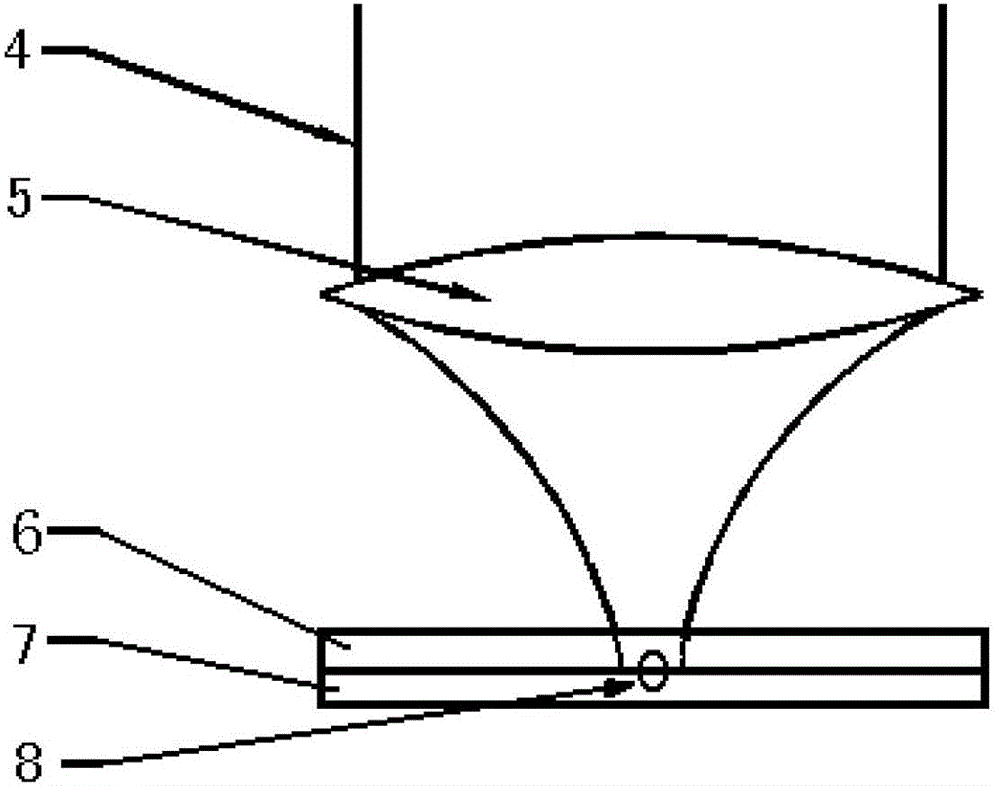

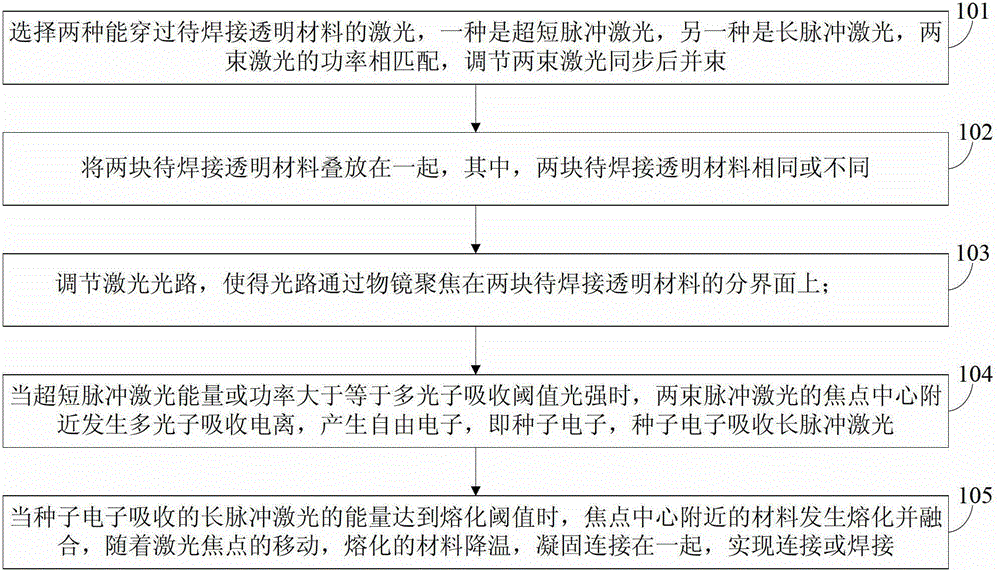

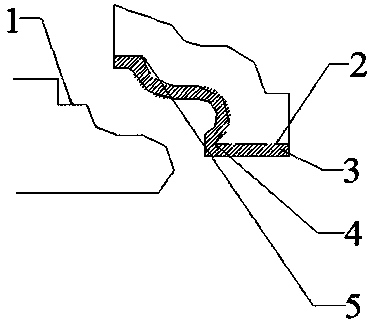

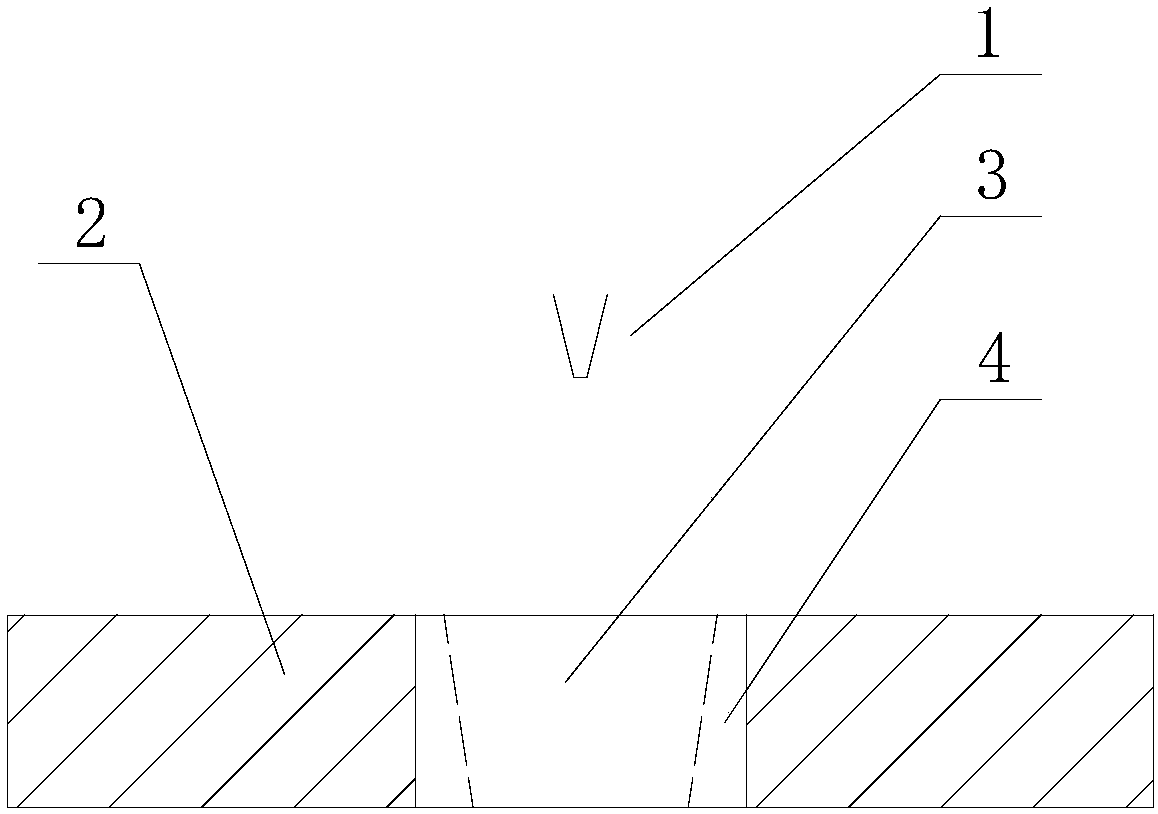

Method for welding transparent material

InactiveCN102909474ALow costAchieve weldingLaser beam welding apparatusOptoelectronicsUltrashort pulse laser

A method for welding transparent material includes: selecting two types of laser capable of transmitting the transparent material to be welded, one being ultrashort pulse laser and the other being long pulse laser, and synchronizing the two laser beams and combining the beams; stacking two blocks of transparent material to be welded; allowing the laser beams to focus on an interface of the two blocks of transparent material to be welded through an objective lens; when the energy (or power) of the ultrashort pulse laser is larger than or equal to multiphoton absorption threshold intensity, allowing occurrence of multiphoton absorption (ionization) near the focus center (of the two pulse laser beams) to generate free electrons which are seed electrons capable of absorbing the long pulse laser; and when the energy of the long pulse laser (absorbed by the seed electrons) reaches a melting threshold of the material to be welded, and allowing the material near the focus center to melt and fuse and connect together so as to achieve connecting or welding. Compared with the welding method using the ultrashort pulse laser only, the method has lowered cost and improved welding efficiency. Welding of the transparent material is achieved.

Owner:TIANJIN UNIV

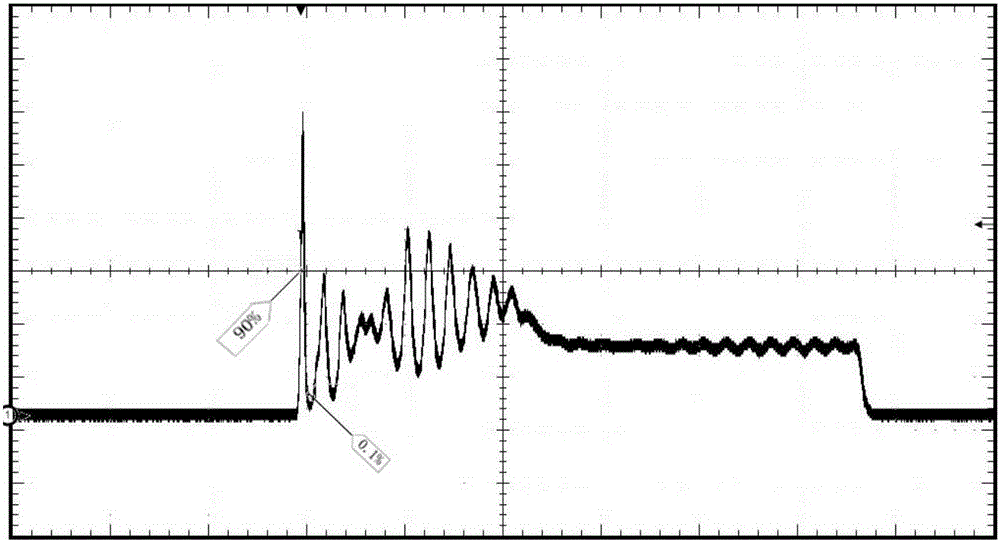

Laser pulse synchronous triggering device

InactiveCN101908712AAchieve stable synchronizationRelative time jitter reductionLaser detailsFiberPulse shaping

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Laser drilling method

InactiveCN103056520AIncrease evaporation rateReduced shieldingLaser beam welding apparatusFluid layerOptoelectronics

The invention provides a laser drilling method. The laser drilling method includes steps of (1), enabling a supercharging device to spray high-pressure gas or liquid to the surface of a workpiece to be drilled and forming a high-speed fluid layer on the surface of the workpiece; and (2), starting a laser device to emit laser beams to drill a hole on the surface of the workpiece. The flowing direction of fluid of the high-speed fluid layer is parallel to the surface of the workpiece. The laser drilling method has the advantages that the pressure on the surface of the machined hole is reduced by the high-speed fluid, so that molten materials in the machined hole and steam of the materials are quickly discharged; a plasma shielding effect is relieved by the high-speed fluid, accordingly, the laser drilling machining speed is increased, and the laser drilling machining quality is improved; and long-pulse laser can be used for drilling operation owing to the high-speed fluid layer, and the control cost is lowered.

Owner:WENZHOU UNIVERSITY +3

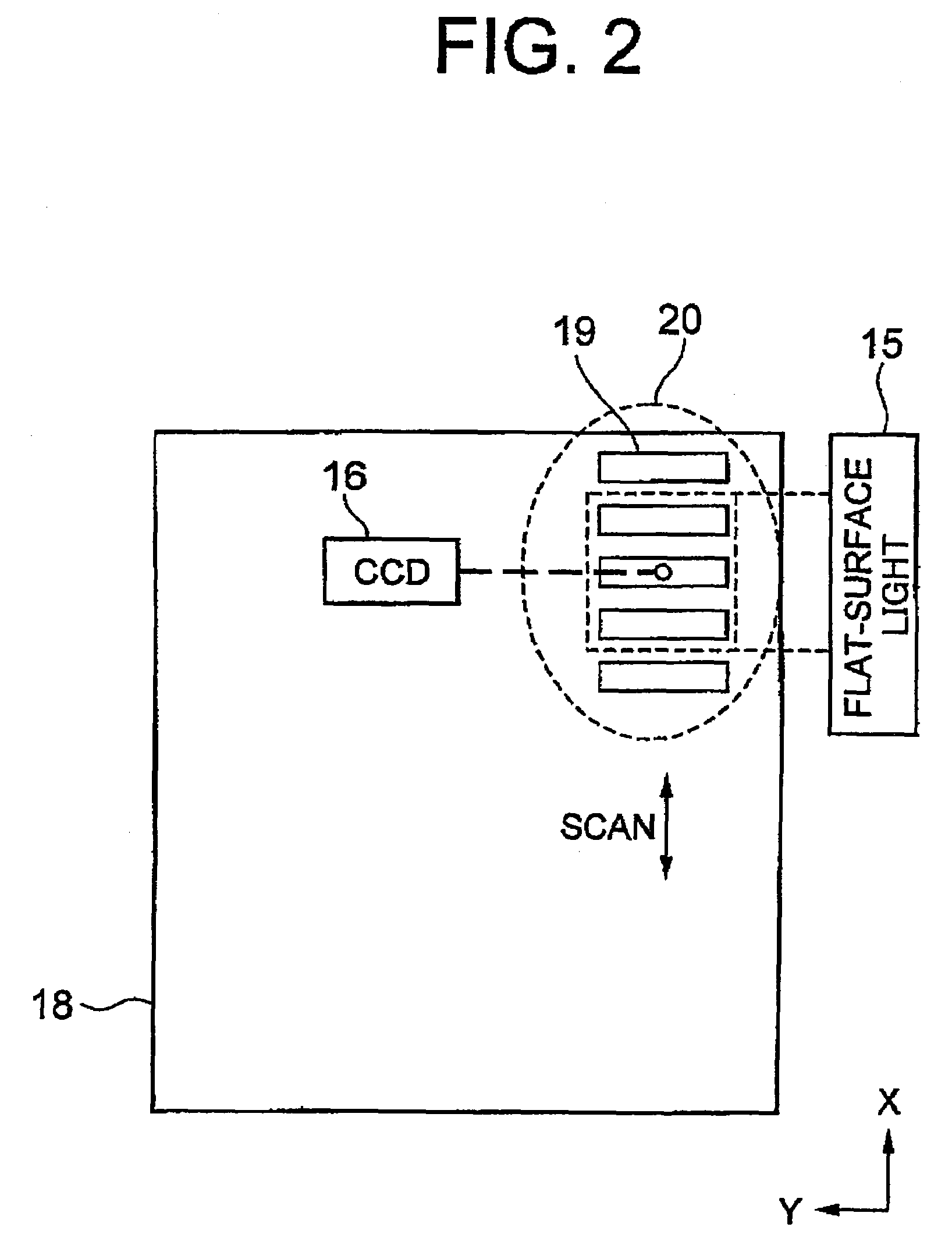

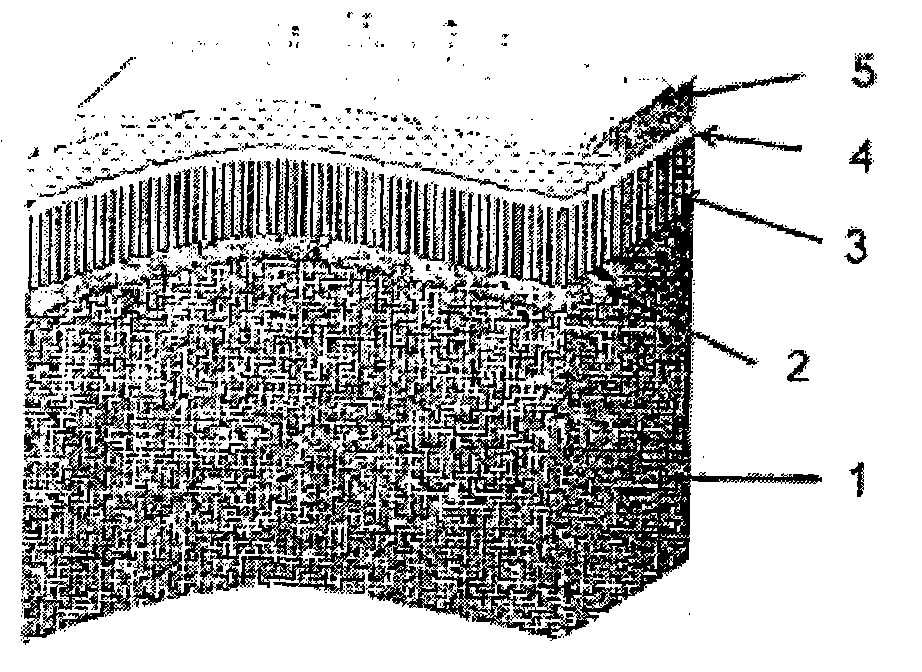

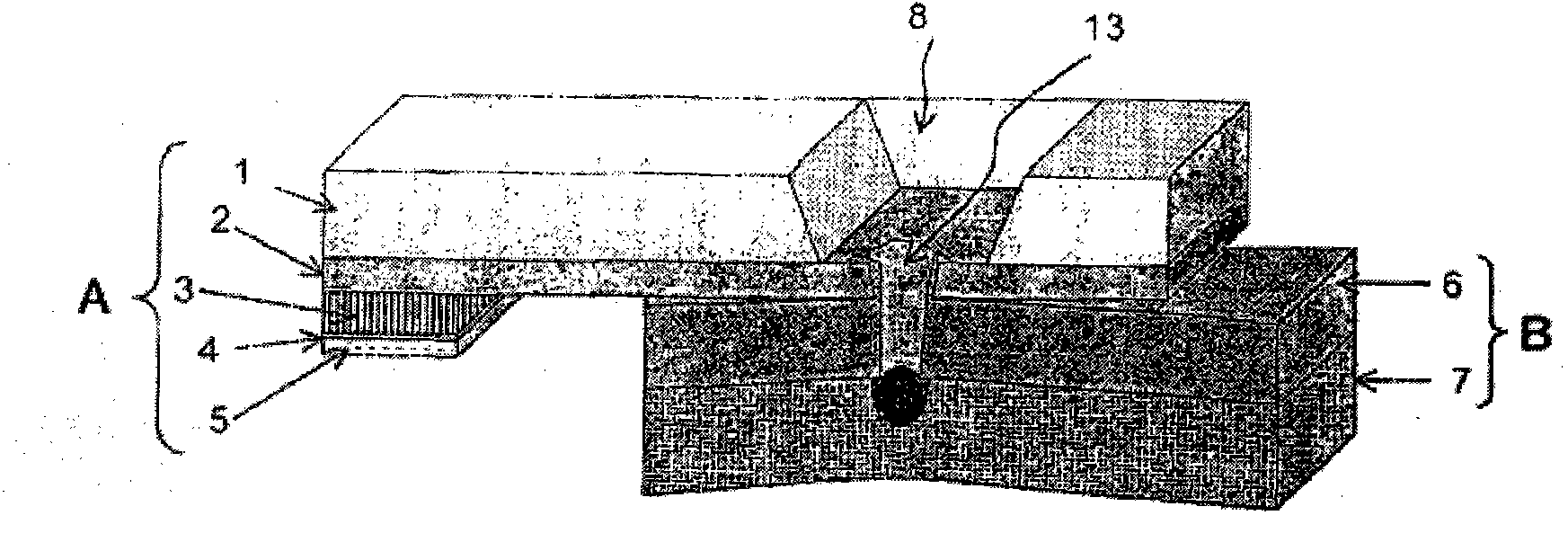

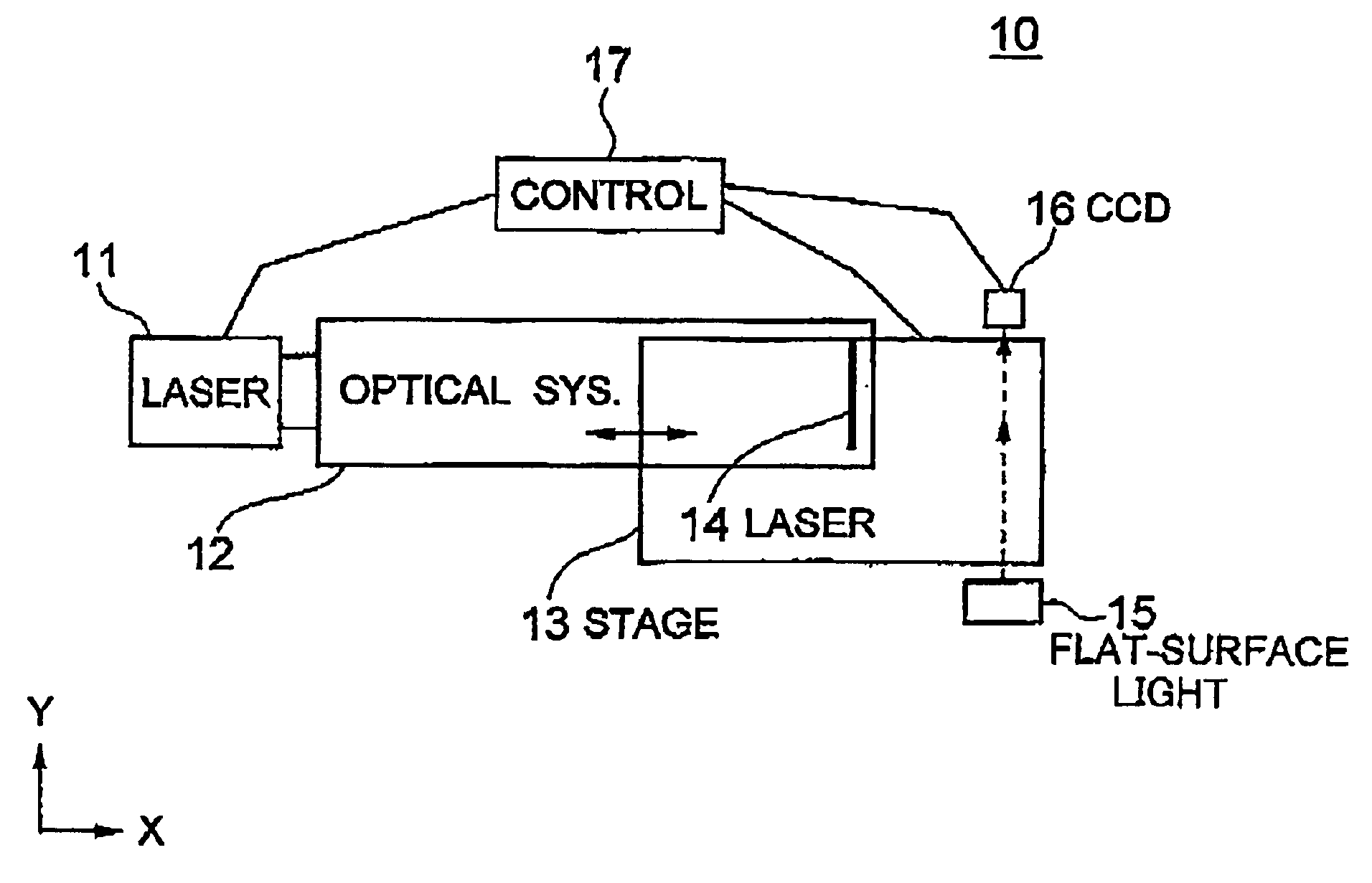

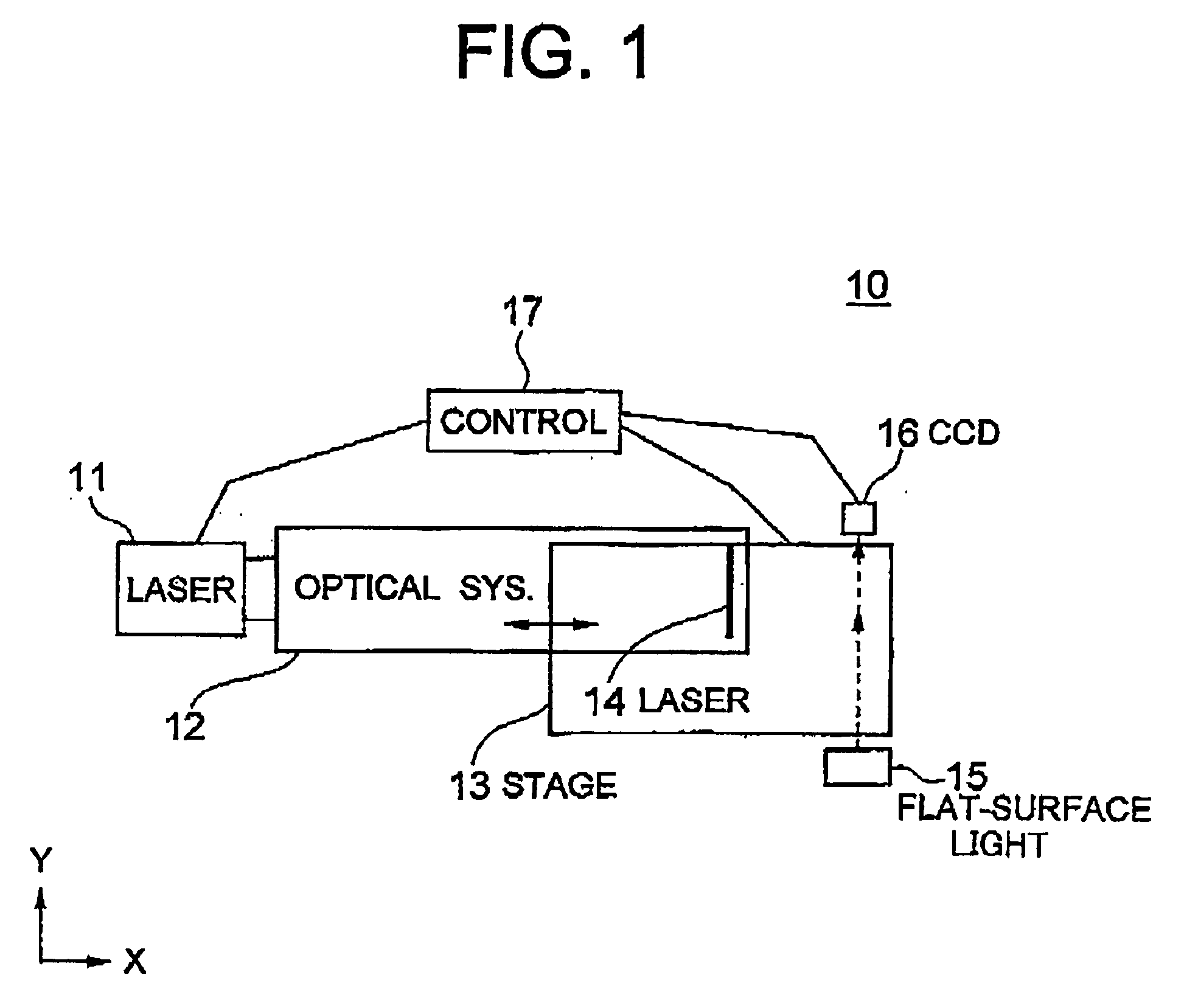

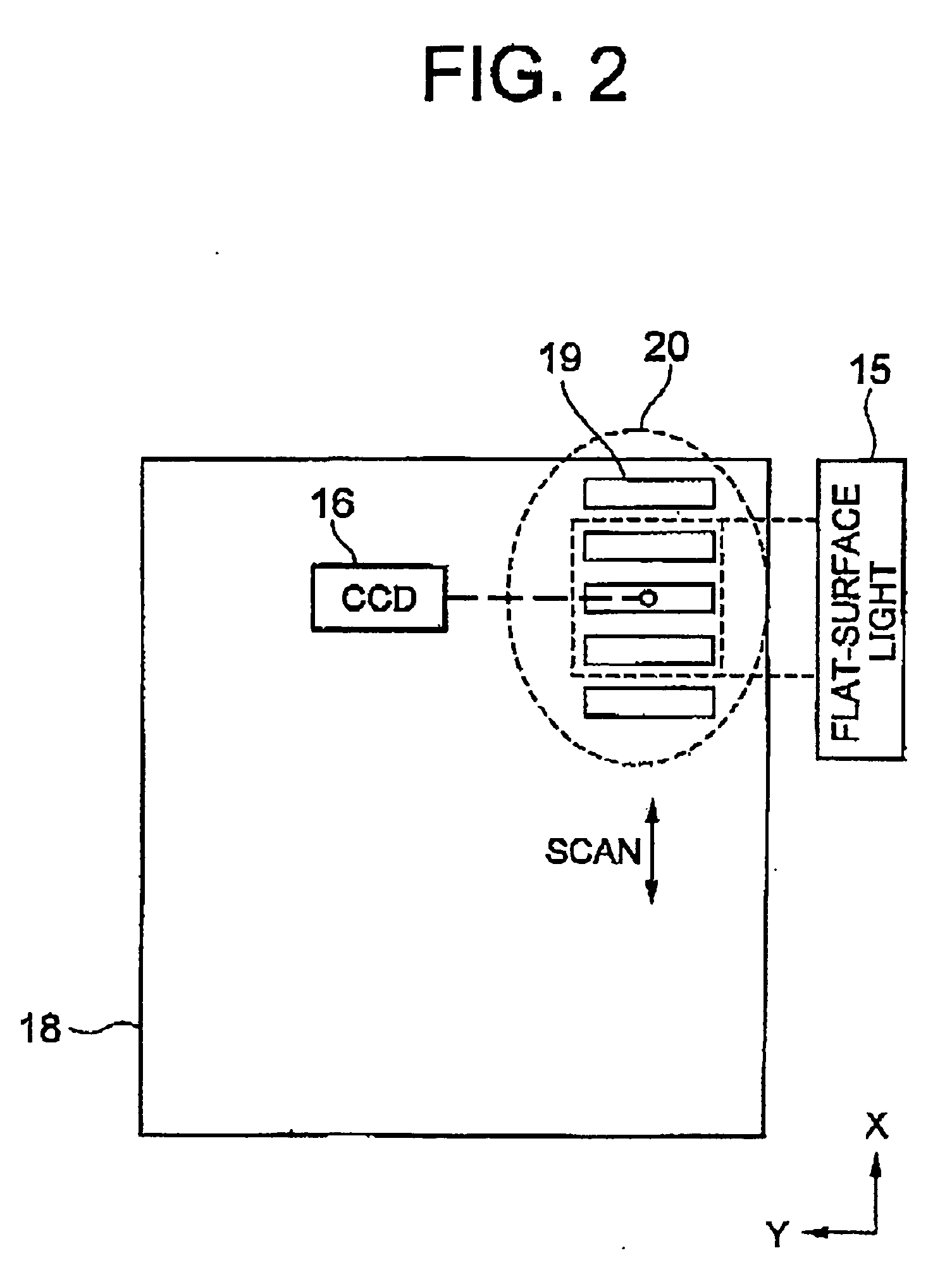

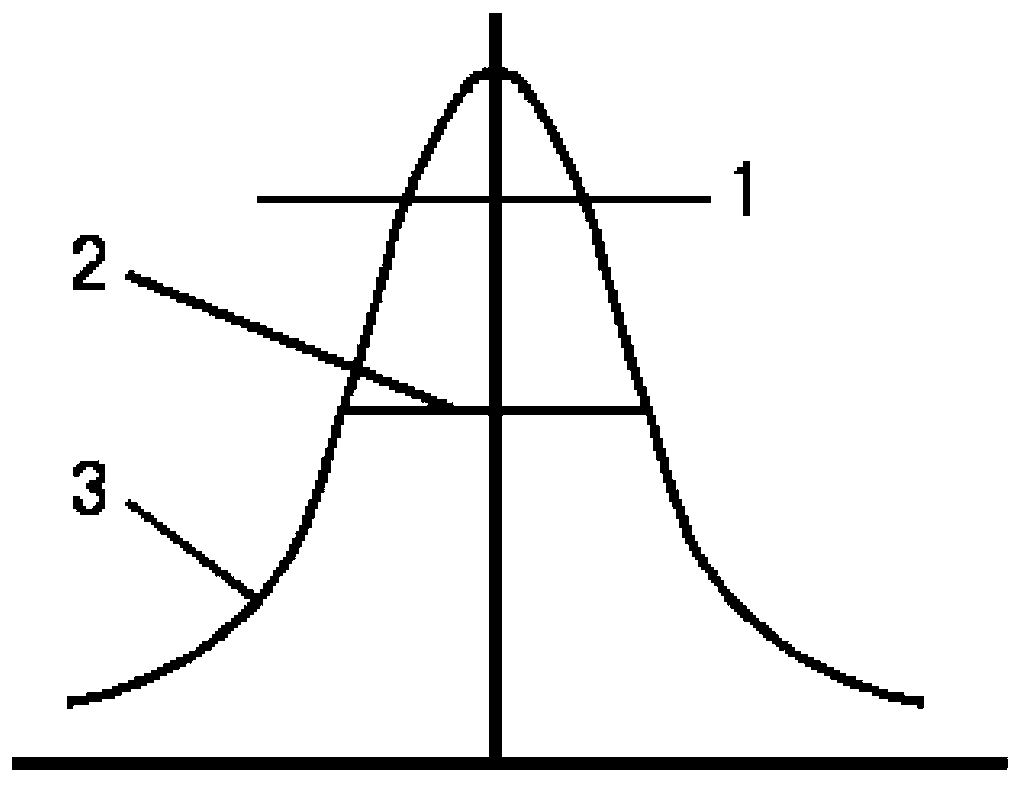

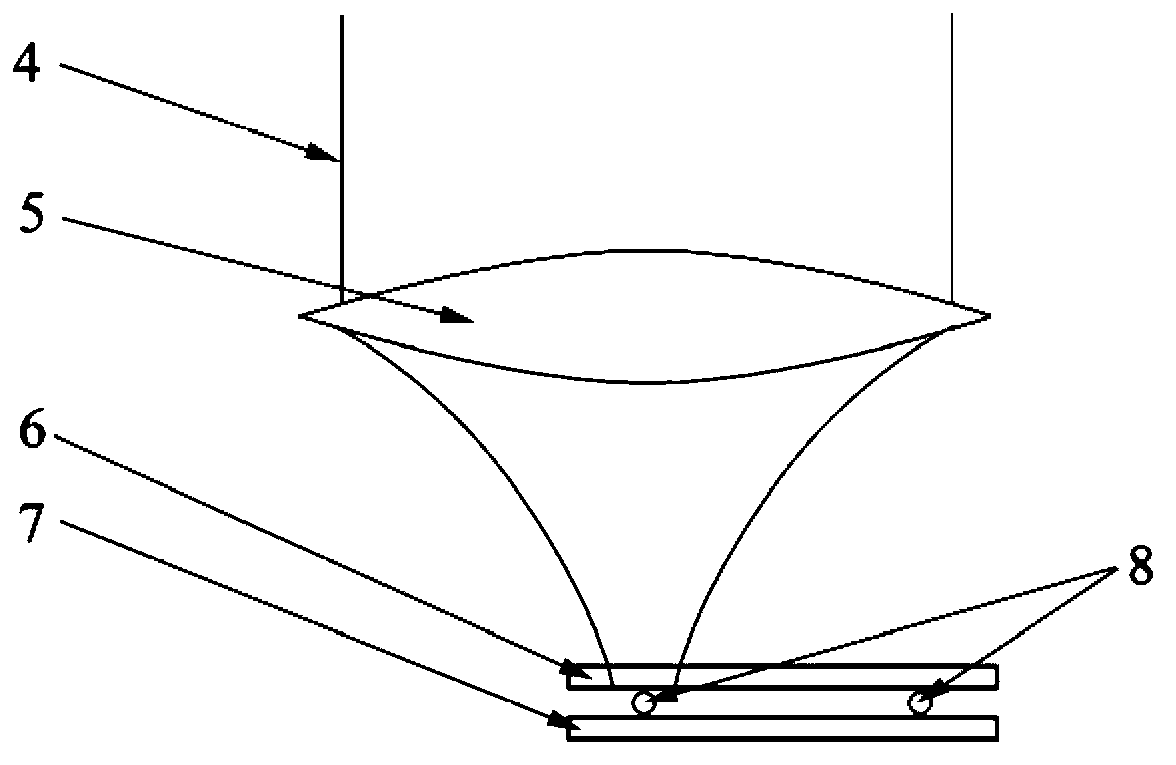

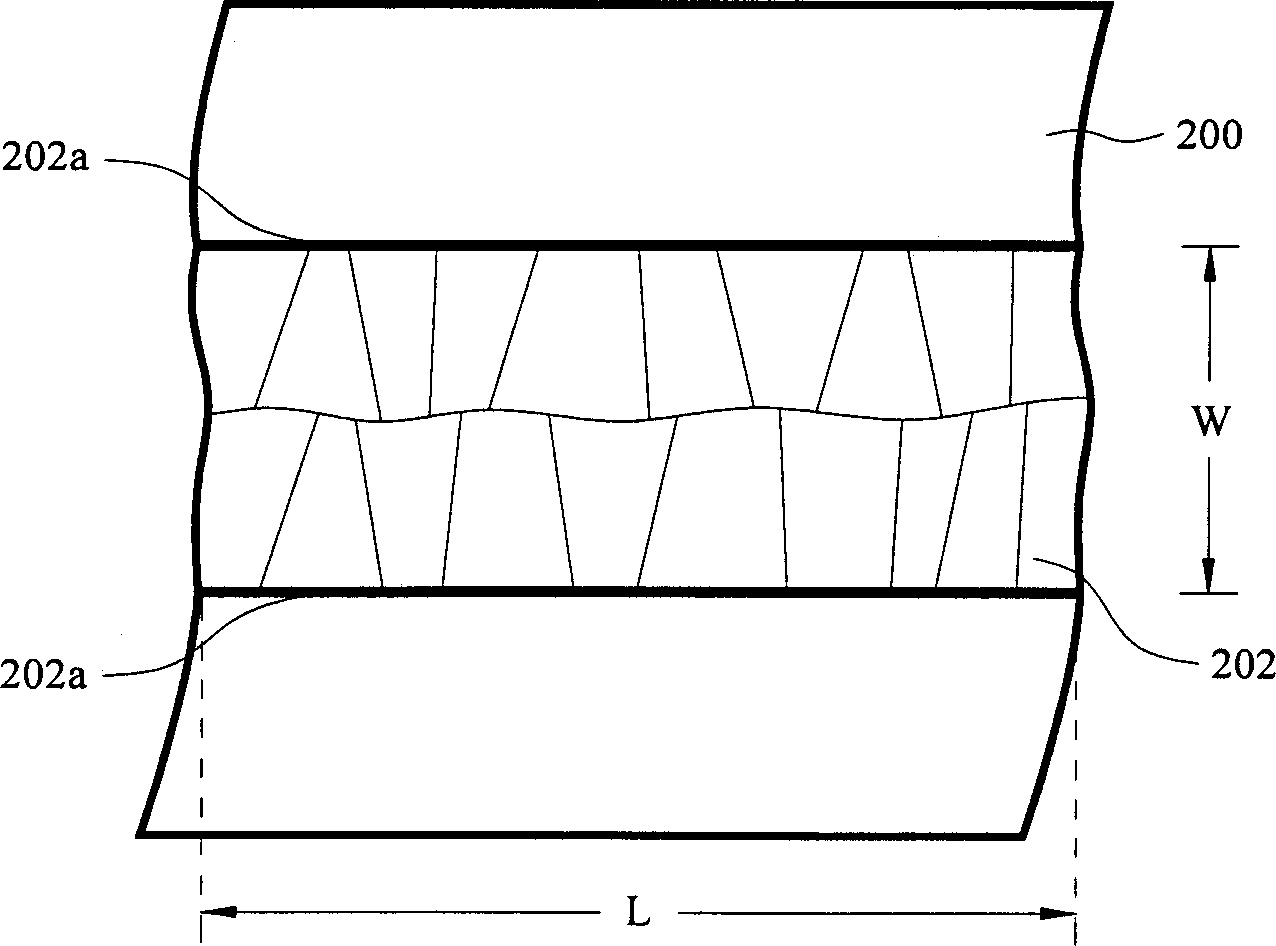

Laser irradiation method and apparatus for forming a polycrystalline silicon film

InactiveUS7473657B2Good reproducibility and reliabilityImprove accuracyTyre partsSemiconductor/solid-state device testing/measurementLong axisAmorphous silicon

A method for changing an amorphous silicon film to a poly-crystalline silicon film includes the steps of irradiating an elongate pulse laser beam onto the silicon film while scanning in the direction normal to the major axis of the elongate pulse laser beam, to form a plurality of irradiated areas, irradiating flat-surface light onto the irradiated areas in the direction parallel to the major axis, and analyzing distribution of the reflected light from the irradiated areas to determine the threshold value of micro-crystallization. The threshold value is used to further determine an energy density of the elongate pulse laser beam for the phase change process.

Owner:VISTA PEAK VENTURES LLC

Non-graphitization complex profile PCD forming tool cutting edge laser processing method

InactiveCN108213735AGuaranteed one-time moldingGuaranteed chippingLaser beam welding apparatusLaser processingGraphite

The invention provides a non-graphitization complex profile PCD forming tool cutting edge laser processing method. The method comprises following specific steps that S1, according to the machining face profile, a PCD blade profile shape is designed, and machining allowance is reserved; S2, long pulse lasers are used for cutting a PCD composite piece into a needed PCD blade; S3, the PCD blade is subject to vacuum welding to a hard alloy base body, and a needed PCD tool is obtained; S4, the welded PCD tool is clamped on a laser machine tool; S5, a short pulse laser device in an integrated optical fiber laser device is used for refining a roughly-machined PCD tool, a graphite layer after rough machining is removed, and the machining precision is further improved. The machining efficiency andthe machining precision of a PCD forming tool cutting edge can be improved, the machining period is shortened, the front tool face oxidation effect of the PCD tool is reduced, and the non-graphitization aim is achieved.

Owner:GUANGDONG UNIV OF TECH

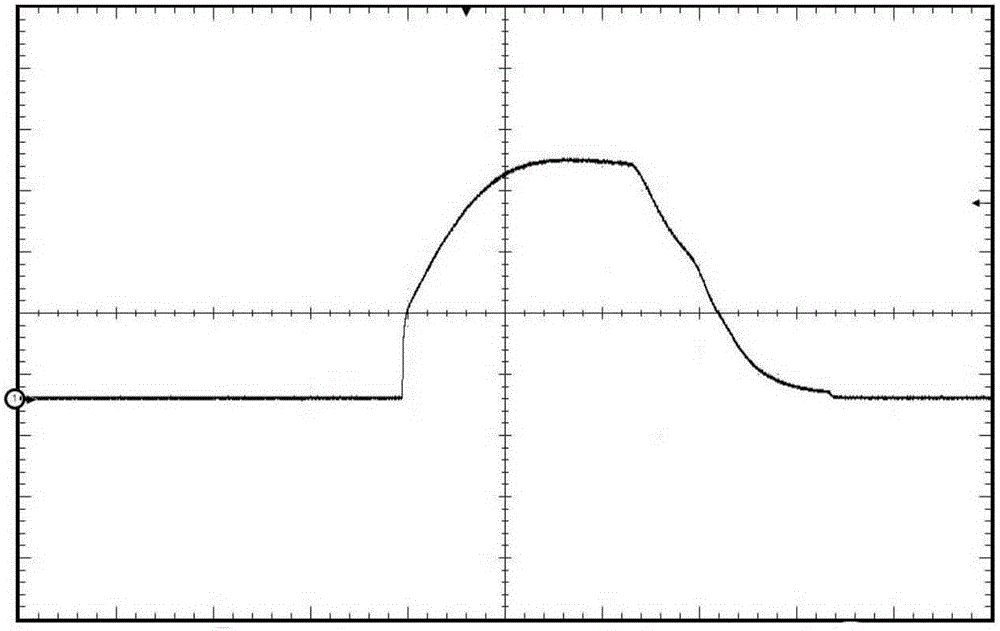

High-energy long pulse laser obtaining device, method and application

The invention discloses a high-energy long pulse laser obtaining device, method and application. The high-energy long pulse laser obtaining device sequentially comprises a continuous laser source, an isolator, an electro-optic modulator, a polarizing plate and a laser amplifier in a laser transmission direction. According to the high-energy long pulse laser obtaining device, a continuous narrow-linewidth tunable single-frequency laser device is adopted as a seed source; the amplified laser is still tunable single-frequency narrow-linewidth laser when having relatively high energy; the center wavelength is the same as that of the seed source; the pulse width is determined by the pulse width of a modulation signal; and an output pulse waveform is determined by a modulation signal waveform, a modulation laser pulse and a time sequence of an amplifier-stage pump pulse, and is a smooth waveform.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

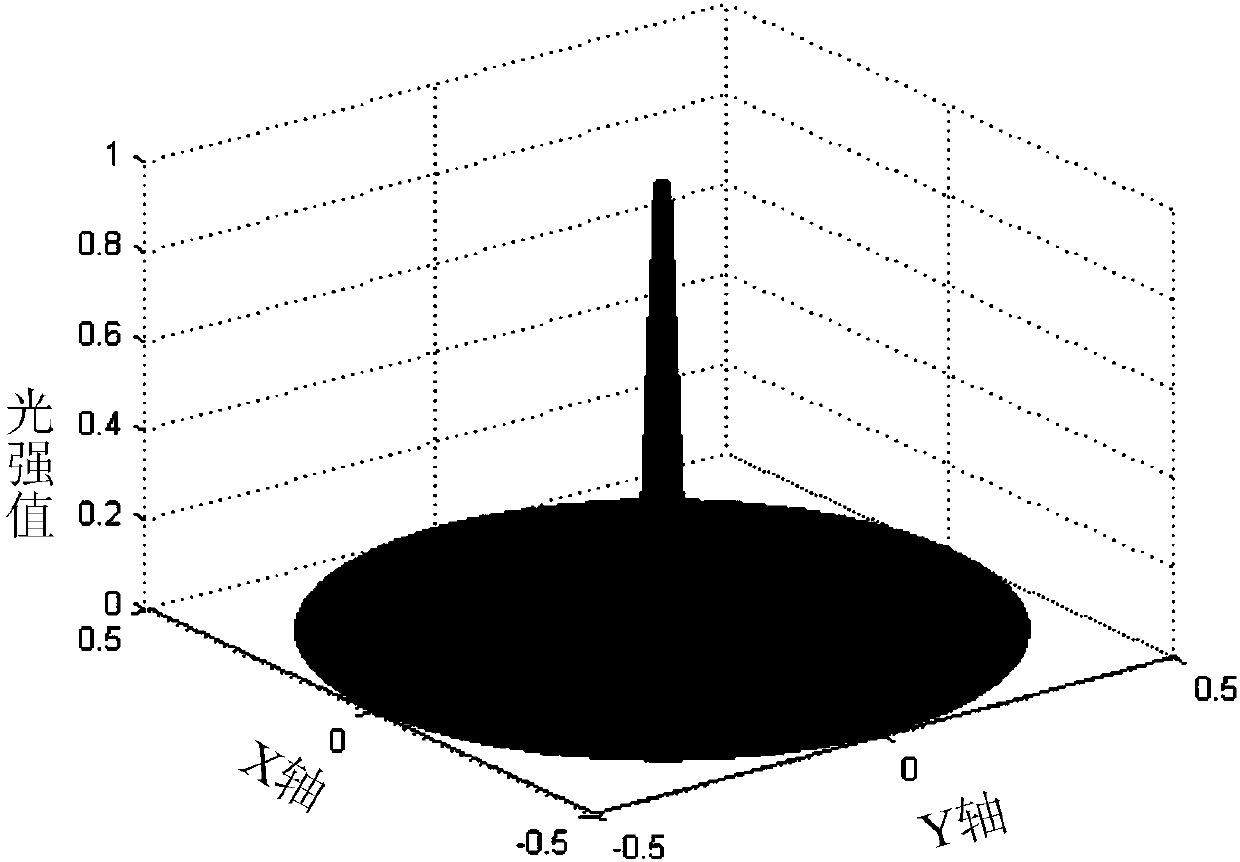

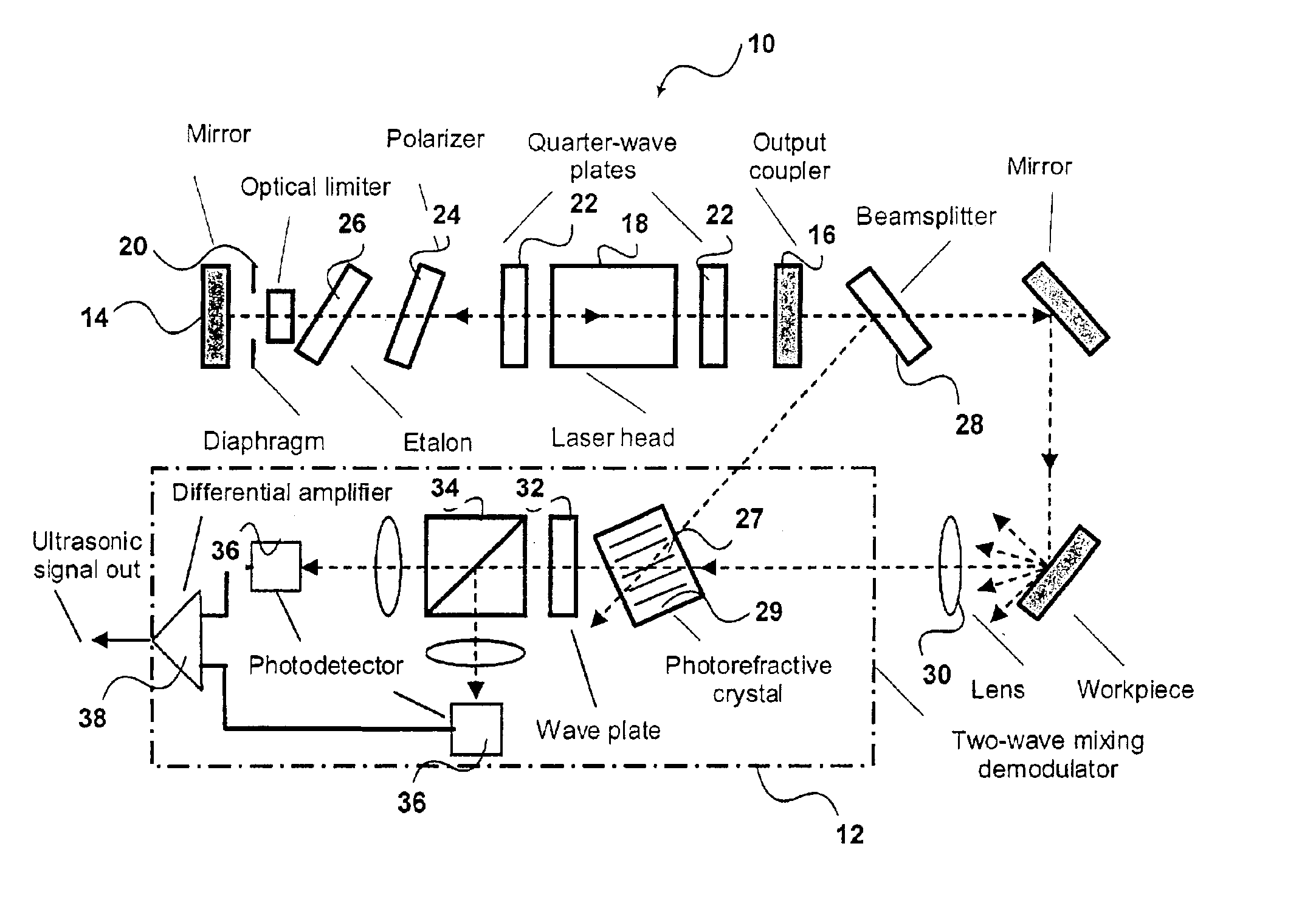

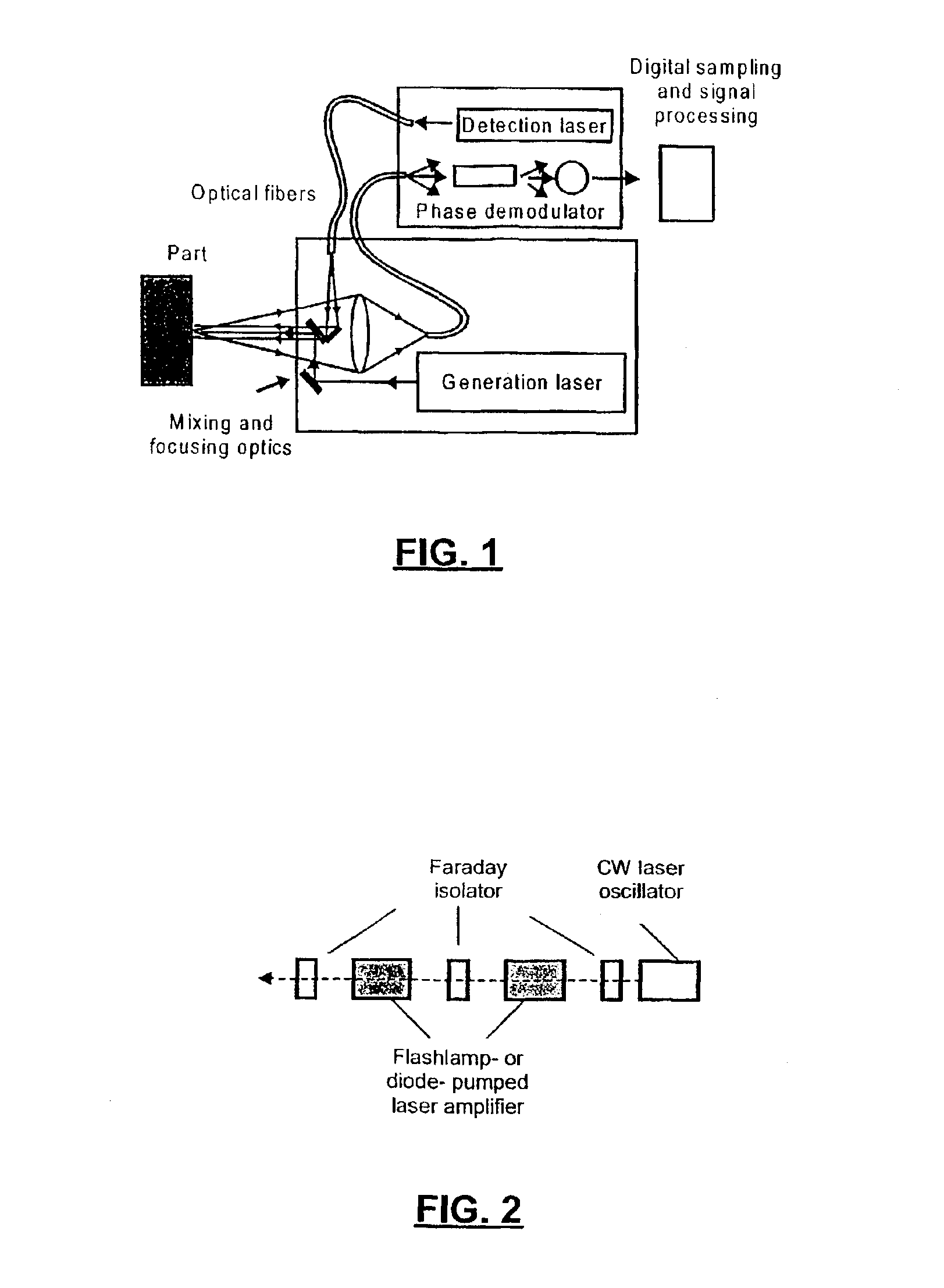

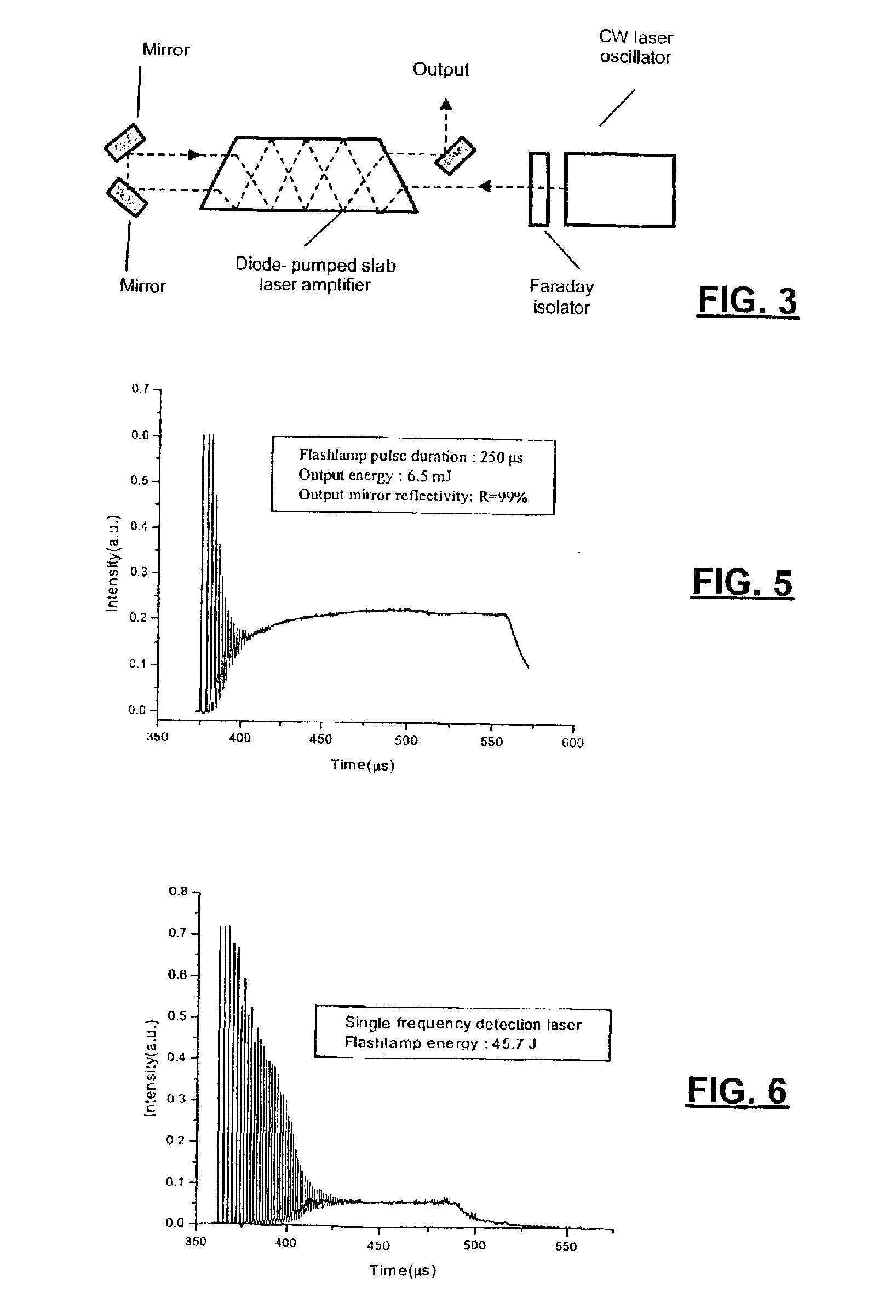

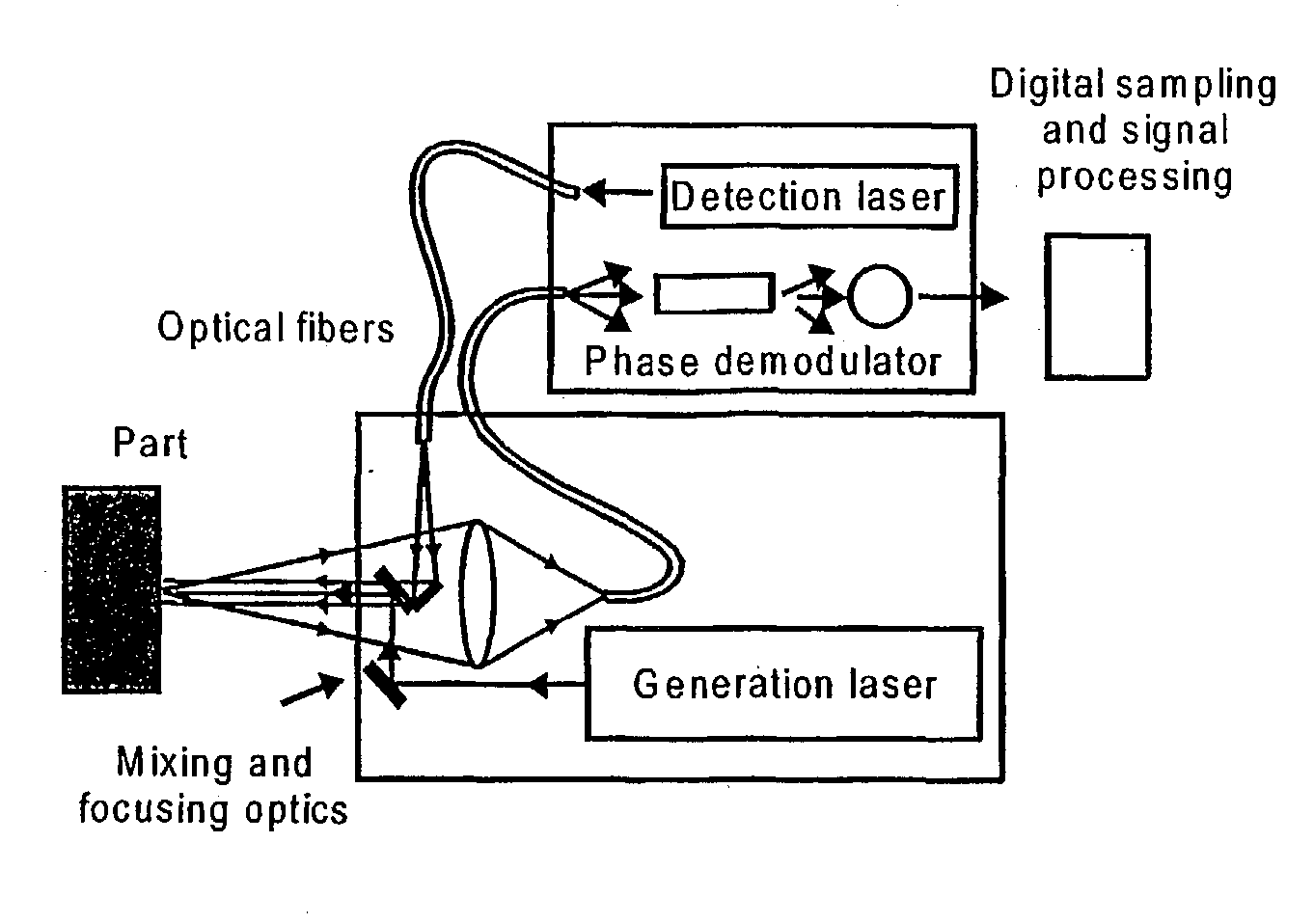

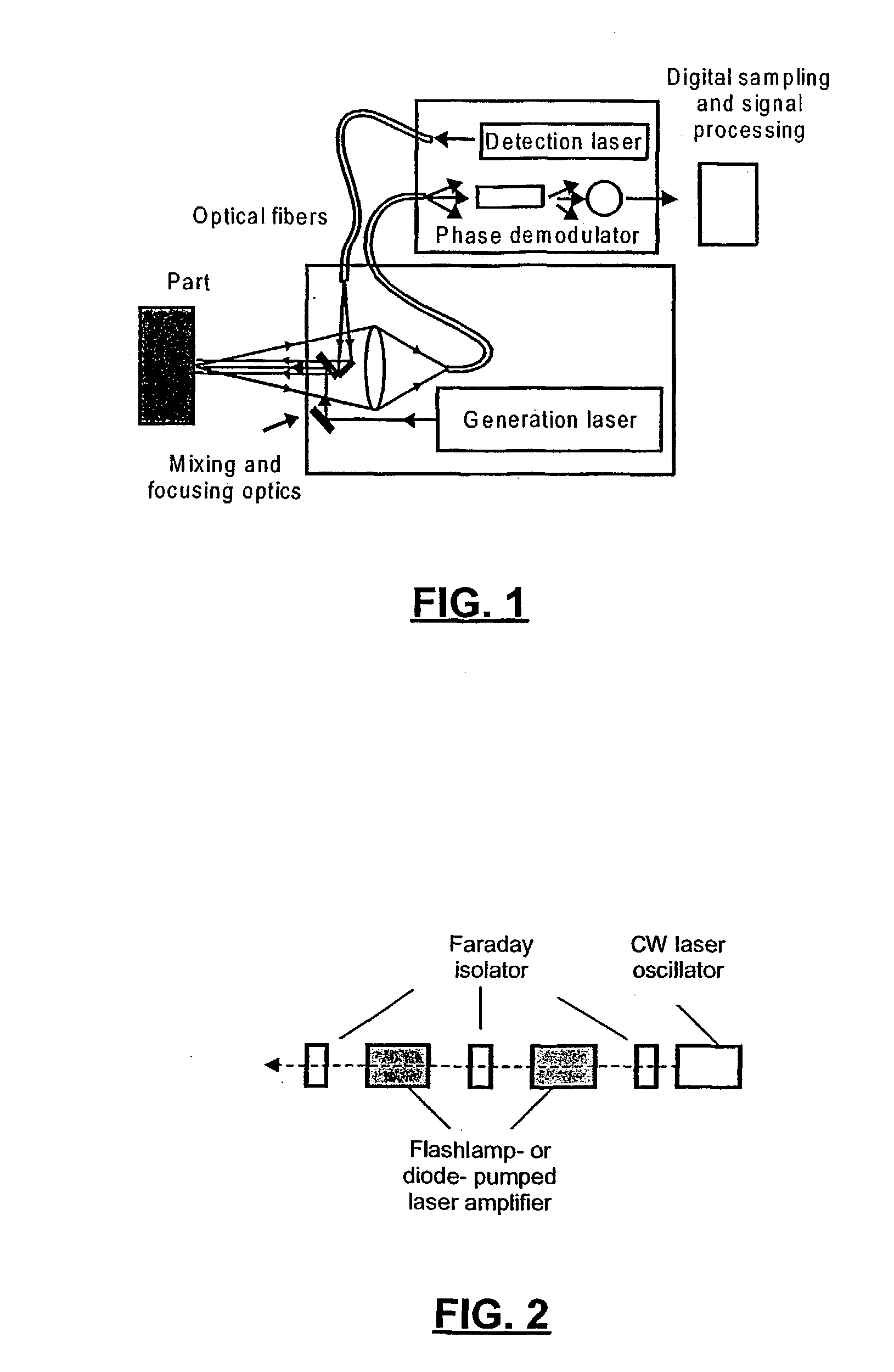

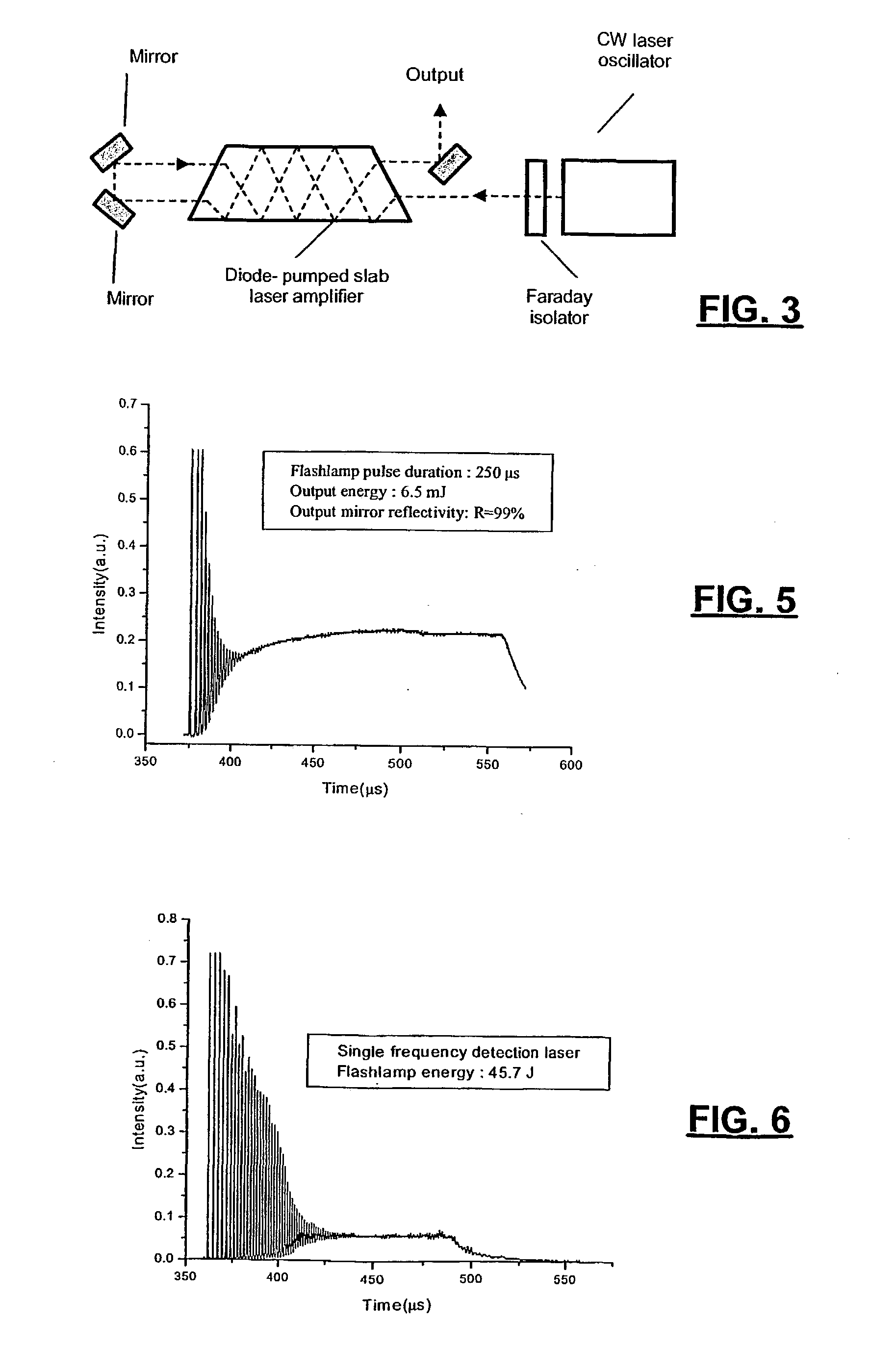

Laser -ultrasonic testing system

InactiveUS20030172736A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesLight beamUltrasonic testing

In a method for ultrasonic testing of objects, ultrasound is generated inside or at the surface of the object. The surface of the object is illuminated with a beam from a long-pulse laser oscillator, typically in the range 1 mus to a few 100 mus, that is substantially free of intensity fluctuations. The light from the incident beam that is scattered or reflected by the surface of the object is collected and demodulated to obtain a signal representative of the ultrasonic motion. The method allows for the use of a compact and efficient arrangement.

Owner:NAT RES COUNCIL OF CANADA

Means and method for connecting thin metal layers

InactiveCN101971351APhotovoltaic energy generationLaser beam welding apparatusEngineeringThin film solar cell

Disclosed are a configuration for bonding a thin metal layer to two workpieces {B} and {A}, e.g. solar cells and film-backed / reinforced small contact strips as well as a method for the stable production of such a connection, comprising the following steps: (i) the backing film is removed from the solar cell; (ii) the two films / layers are pressed together; and (iii) the two parts are irradiated from the side of the rear contact {} of the thin-film solar cell. According to the invention, preferably two or three laser treatment steps are used for removing the backing film of the thin-film solar cell in an ablation process by means of a short-pulse laser and riveting the first metal layer, e.g. the rear contact of the solar cell, to the second metal layer, e.g. the small contact strip, by irradiating the same by means of a long-pulse laser. The energy density, pulse duration and temporary pulse form, pulse frequency, and wavelength for the ablation process and the welding / riveting processare selected according to the specific materials used. Such a laser riveting process can be used for electrically contacting thin-film solar cells with small flexible contact strips.

Owner:EUROPEAN SPACE AGENCY

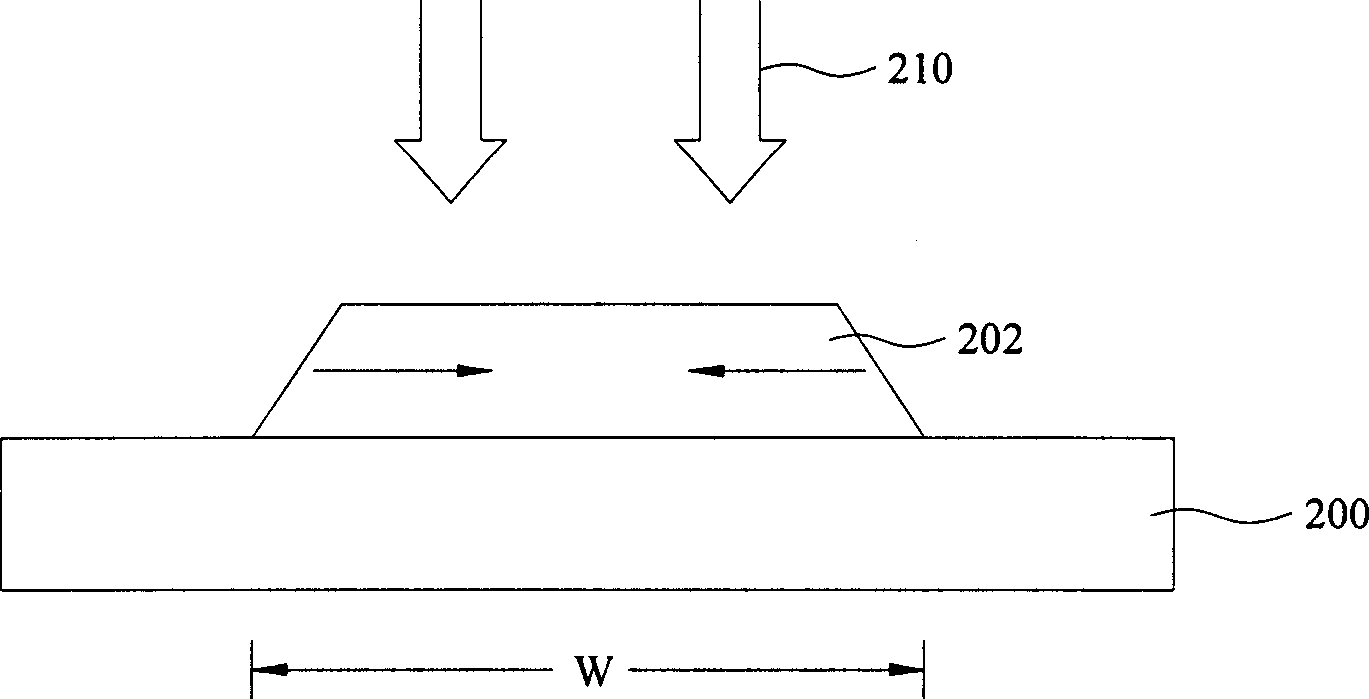

Laser irradiation method and apparatus for forming a polycrystalline silicon film

InactiveUS20060194354A1Good reproducibility and reliabilityImprove accuracyTyre partsSemiconductor/solid-state device testing/measurementAmorphous siliconLight beam

A method for changing an amorphous silicon film to a poly-crystalline silicon film includes the steps of irradiating an elongate pulse laser beam onto the silicon film while scanning in the direction normal to the major axis of the elongate pulse laser beam, to form a plurality of irradiated areas, irradiating flat-surface light onto the irradiated areas in the direction parallel to the major axis, and analyzing distribution of the reflected light from the irradiated areas to determine the threshold value of micro-crystallization. The threshold value is used to further determine an energy density of the elongate pulse laser beam for the phase change process.

Owner:VISTA PEAK VENTURES LLC

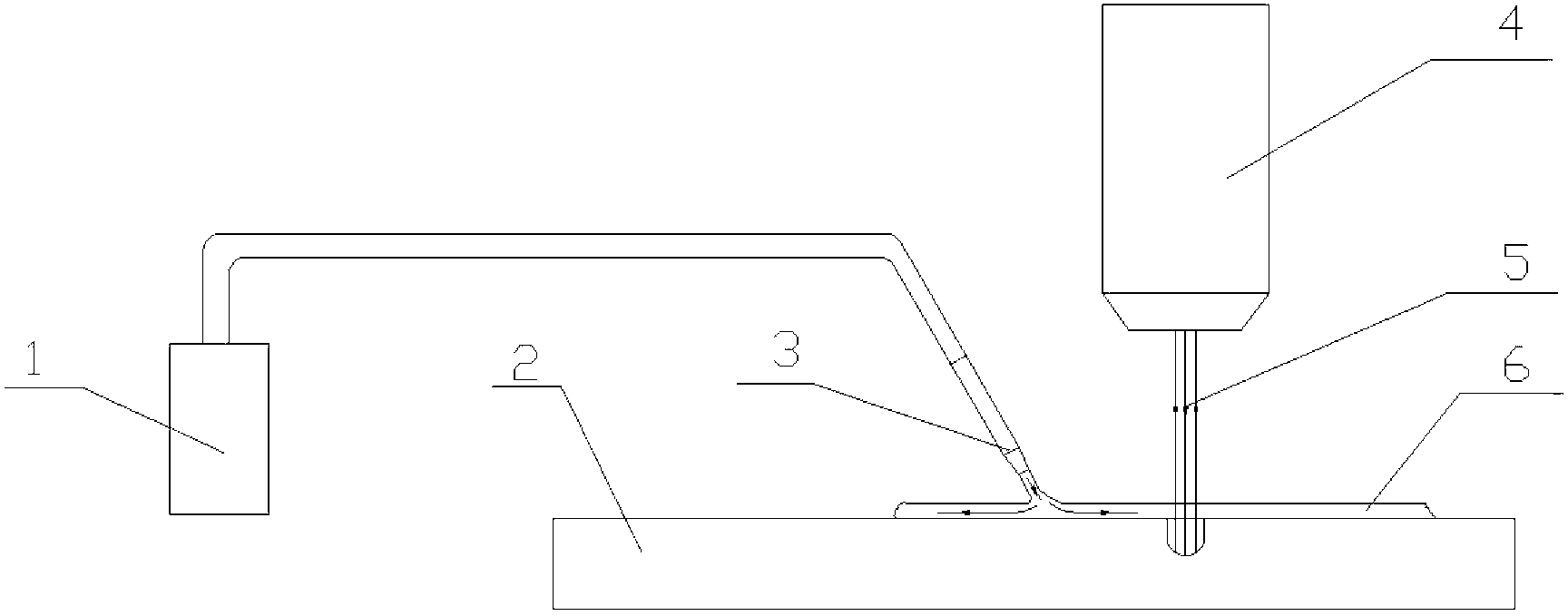

Aero-engine film hole laser high-efficiency combined machining method

InactiveCN108067739AImprove processing efficiencyGuarantee processing qualityLaser beam welding apparatusNanosecond laserOptoelectronics

The invention discloses an aero-engine film hole laser high-efficiency combined machining method. A long-pulse laser and ultrafast laser combined hole forming method is adopted. According to the method, firstly, a preformed hole is formed through nanosecond laser; secondly, the preformed hole is processed into the hole meeting the requirement through the ultrafast laser; the machining efficiency and machining quality are both considered, and the film hole machining efficiency is improved. As the preformed hole of a film hole is machined through long-pulse laser (rough machining), the next stepof the machining amount of ultrafast laser (finish machining) is greatly reduced. The machining efficiency is improved. The requirements for the machining efficiency during engineering machining aremet. Through the combined hole forming method, the film hole can be free of a remelting layer, burrs and splashes, and high-quality and high-efficiency machining of a low-heat influence area can be achieved.

Owner:AECC AVIATION POWER CO LTD

Method for welding panel glass of display

InactiveCN103011571ARealize solder packageLow costGlass reforming apparatusGlass fiberDisplay device

The invention discloses a method for welding panel glass of a display. Ultrashort pulse laser is utilized to generate an optical near-field enhancement effect near contact points of the inner surfaces of the panel glass of the display and a glass fiber (or glass bead) spacer (which is positioned between the panel glass of the display), so as to generate multiphoton absorption (ionization) and provide seed electrons, and long pulse laser can be absorbed by the seed electrons; and when melting threshold values of the glass fiber (or glass bead) spacer and the panel glass of the display are reached, two pieces of panel glass of the display are fused and connected together. Along with movement of a laser focus according to a predesigned route, welding and packaging of the panel glass of the integral display are implemented. The method reduces cost of only using the ultrashort pulse laser to weld the glass, improves welding efficiency and implements welding and packaging of the panel glass of the display.

Owner:TIANJIN UNIV

Method for repairing metal surface micro-cracks based on laser micro-fusion

InactiveCN106956079ALow costNo significant change in shape accuracyLaser beam welding apparatusLaser processingMaterials science

The invention provides a method for repairing metal surface micro-cracks based on laser micro-fusion and belongs to the field of laser processing. The surface of a metal workpiece is scanned by using long-pulse laser or continuous laser beams, micro-melting is carried out on a micro-crack zone by utilizing the heat effect of the laser, and micro-molten metal liquid flows and is condensed after flowing across the micro-crack zone, so that an effect of repairing the metal surface micro-cracks is realized. The method for repairing the metal surface micro-cracks based on laser micro-fusion does not require extra materials, and is simple in technology, convenient to operate, high in production efficiency, free of environmental pollution, easy for the realization of automatic production and favorable for massive popularization in the industry.

Owner:JIANGSU UNIV

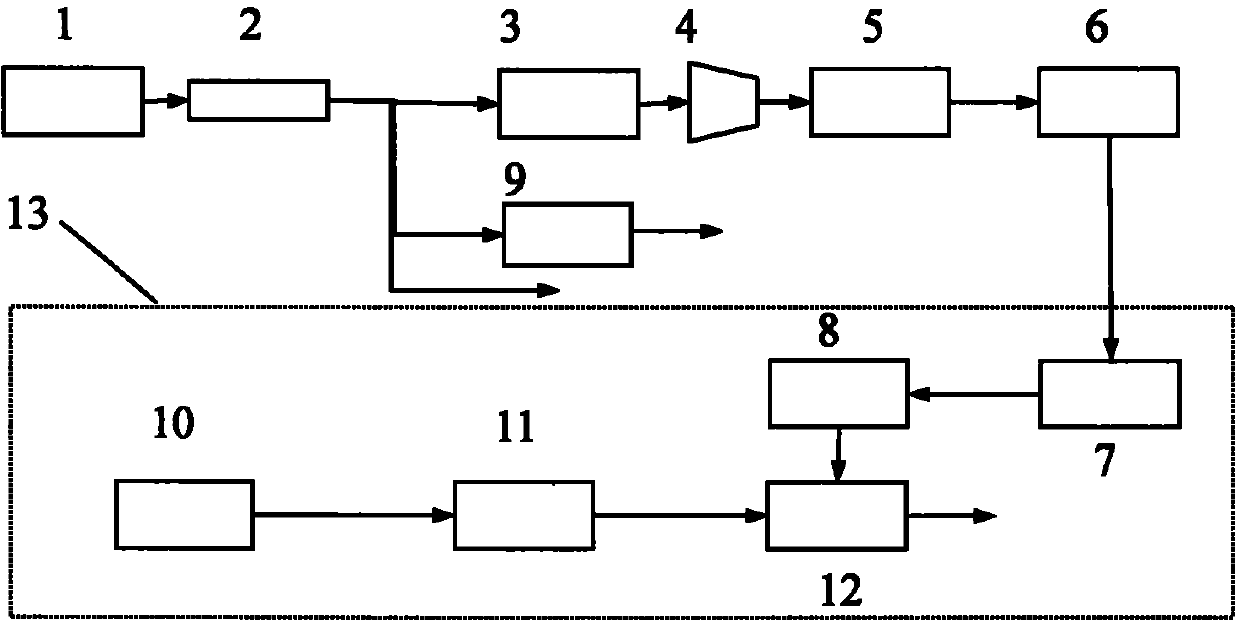

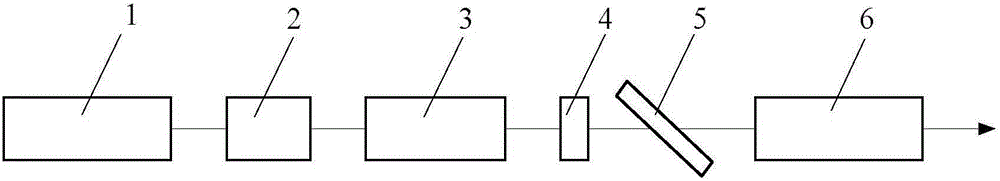

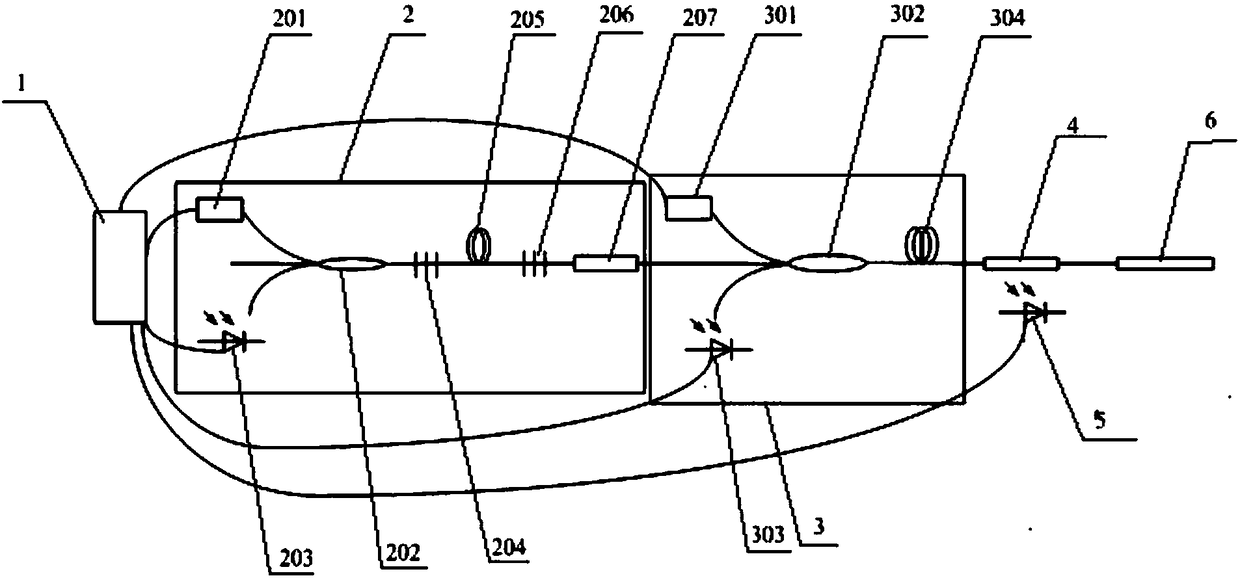

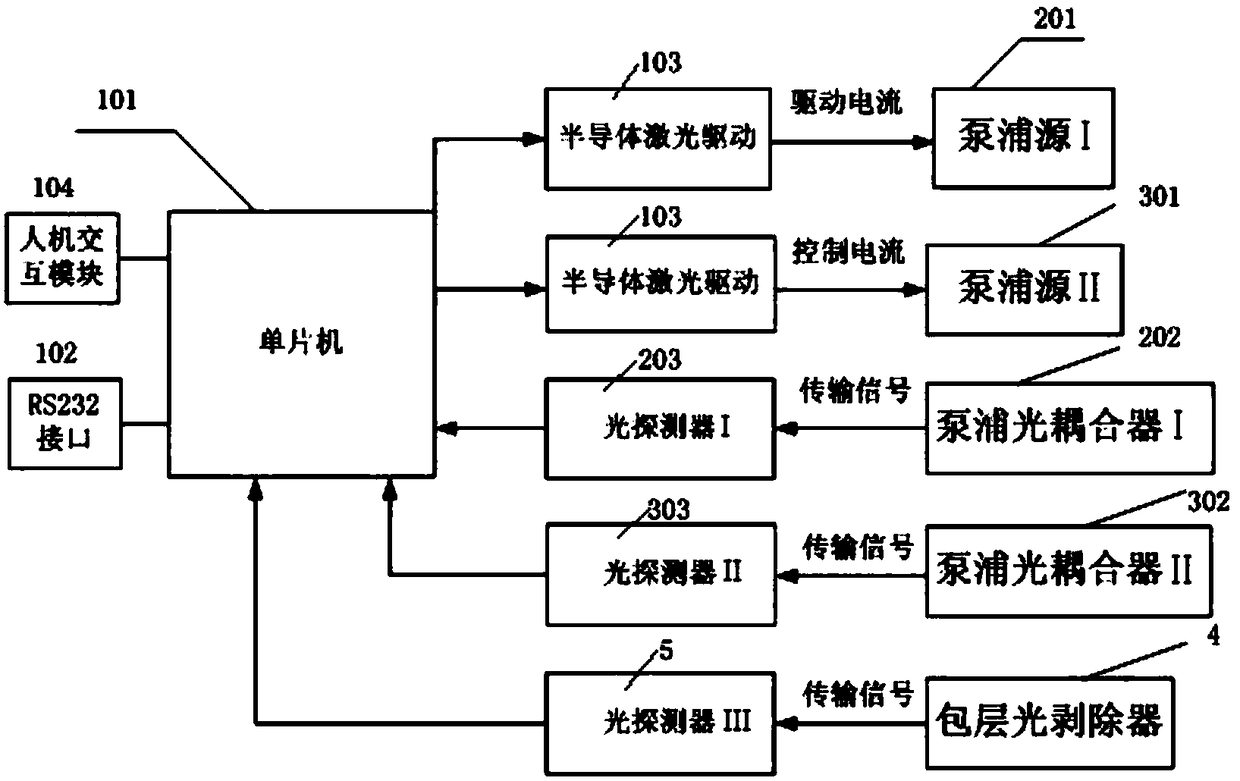

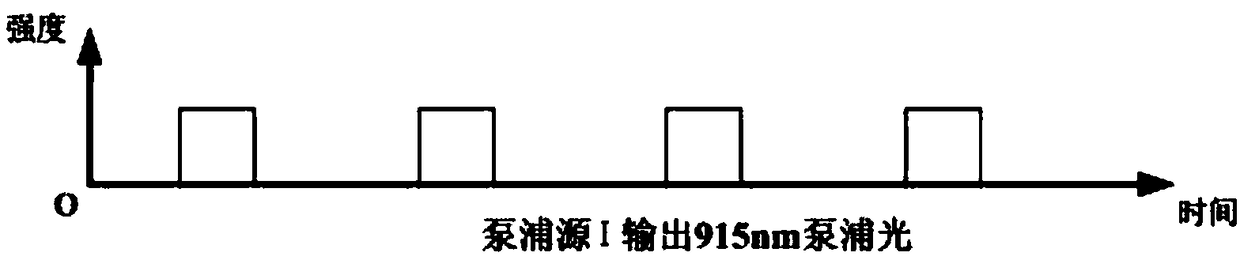

Large energy long pulse fiber laser

PendingCN108574198AQuality improvementImprove machining accuracyLaser detailsHigh energyFiber disk laser

A large energy long pulse fiber laser belongs to the technical field of fiber laser. The large energy long pulse fiber laser includes a laser driver, a seed source, a laser amplifier, a cladding optical stripper, an optical detector III, and a laser output head. A main oscillation power amplifying structure MOPA is adopted in the long pulse fiber laser, and a continuous or long pulse laser driveris used to drive a semiconductor laser as a pump source, long pulse fiber laser seed light with high beam quality is acquired, and then the seed light source is amplified through the laser amplifier,and a continuous or long pulse high energy long pulse laser with the desired parameters can be acquired. The laser amplifier also uses the long pulse laser driver to drive the semiconductor laser as apump source; and through the photoelectric detection and synchronous driving technology, the laser amplifier pump source pulse and the seed light pulse operate synchronously. In the above manner, a continuous or long pulse fiber laser with high beam quality can be obtained, and the large energy long pulse fiber laser is used for applications such as laser welding.

Owner:长春德信光电技术有限公司

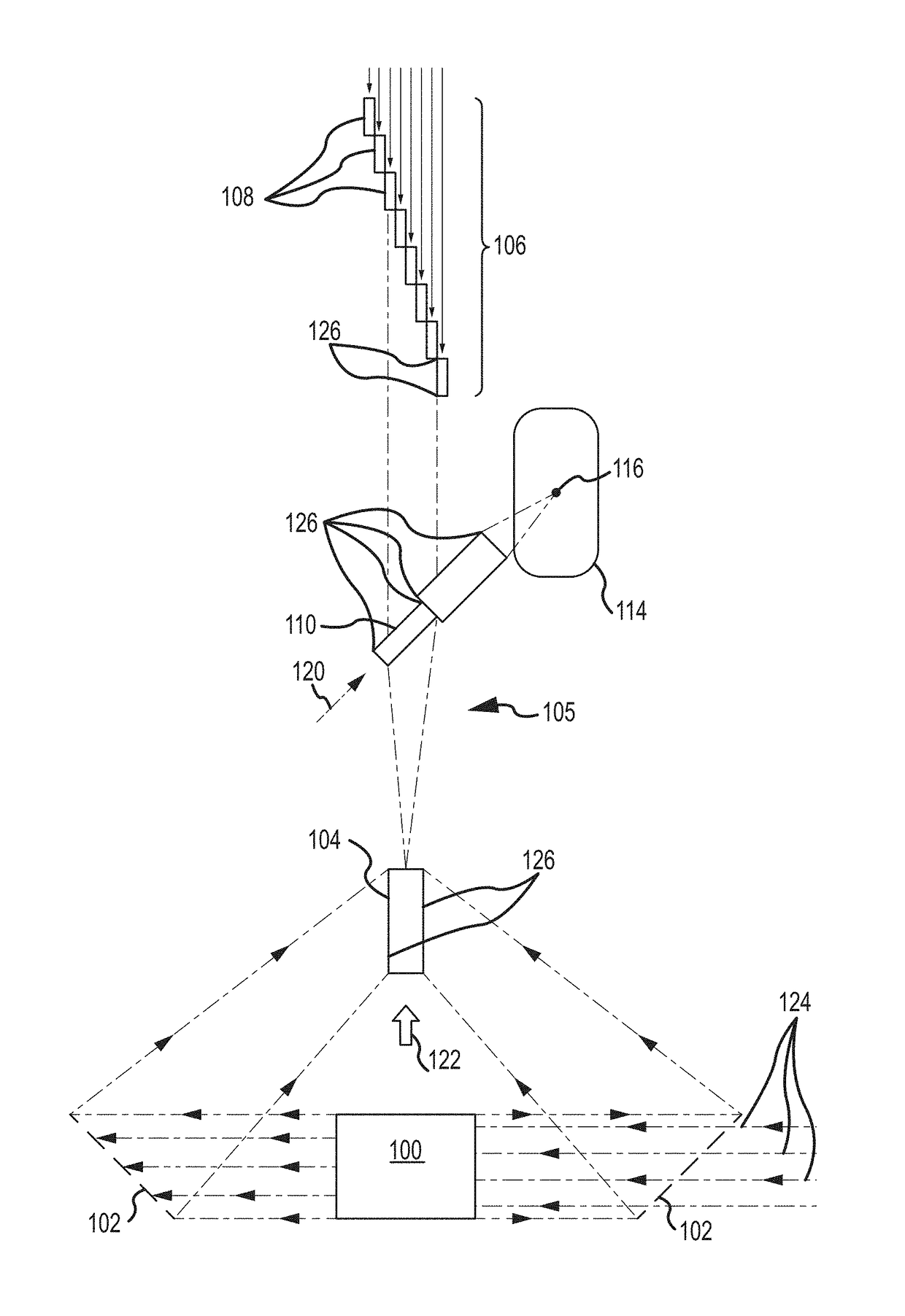

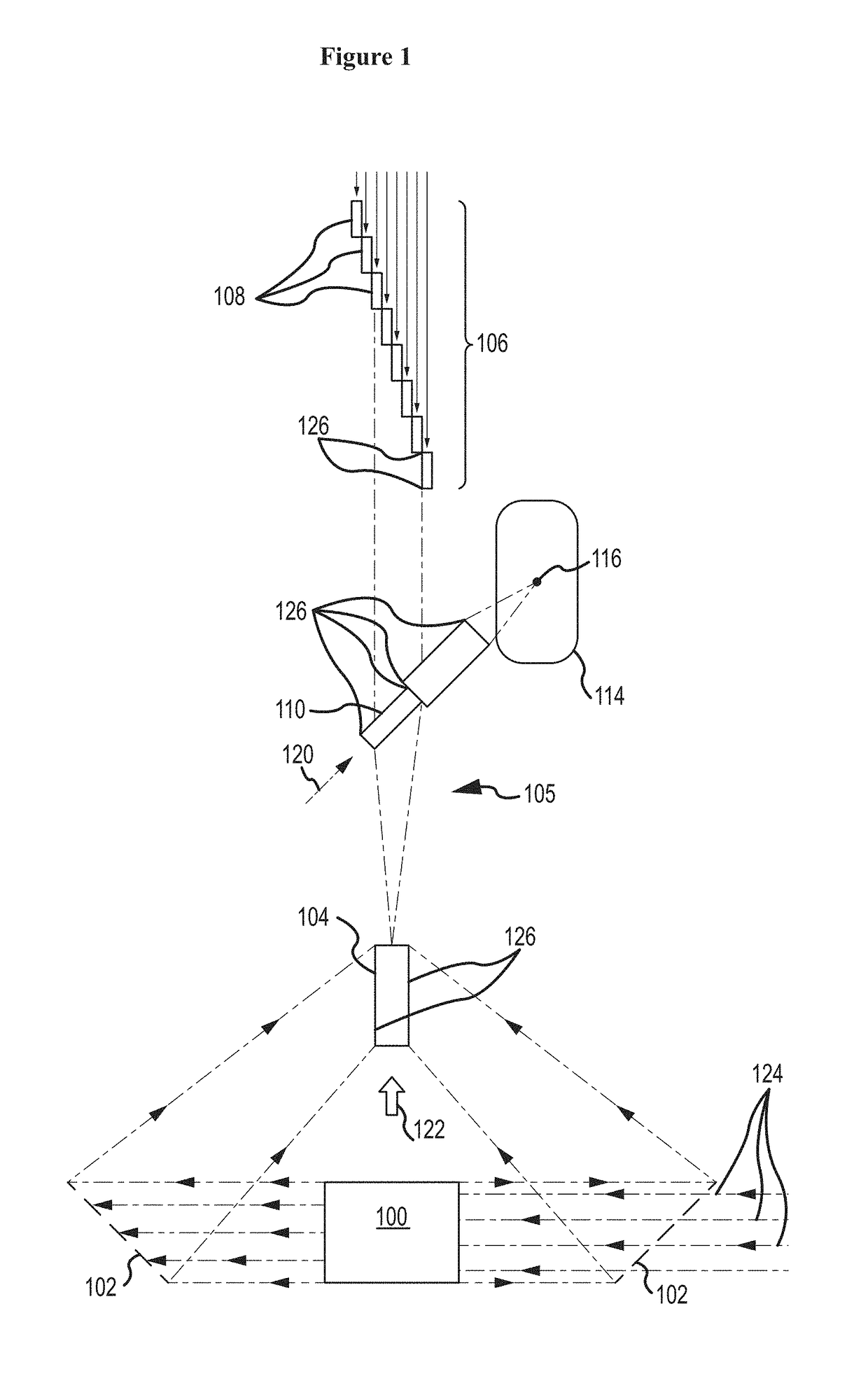

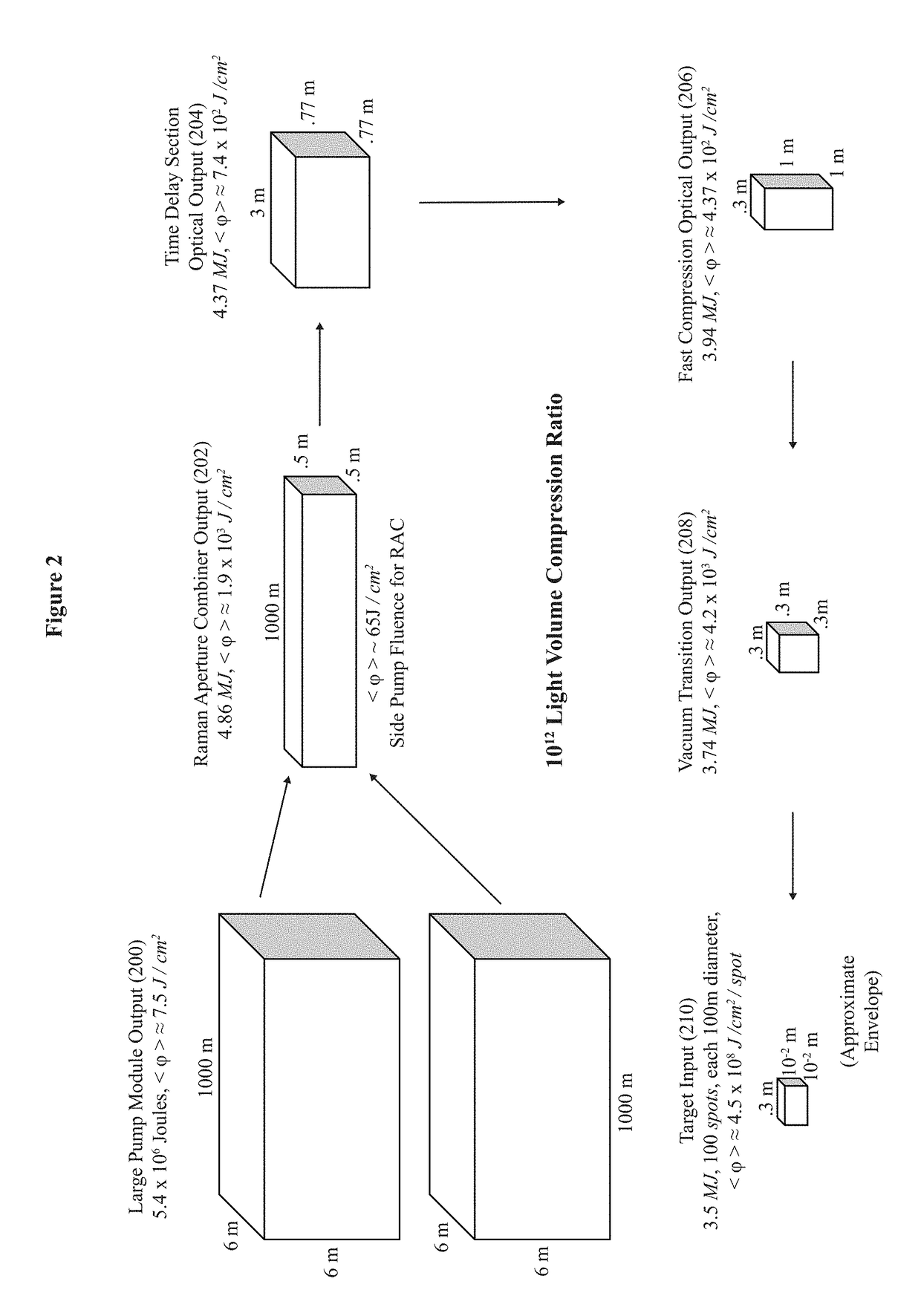

Optical Configurations for Fusion Laser

ActiveUS20180159290A1Low costControl damageLaser using scattering effectsNuclear energy generationLeg lengthLight beam

Embodiments include an optical configuration of a laser for driving an inertial confinement target that may include a section configured to generate long pulse laser light (Primary Laser Source) and then to compress the long pulse with multiple compression stages to a desired pulse length, energy, and beam quality (Compression Section). These configurations can utilize compression stages that do not include any material optics operating near damage fluence, and that do not require material optics exposed to high fluences to couple compression stages to each other.

Owner:INNOVEN ENERGY

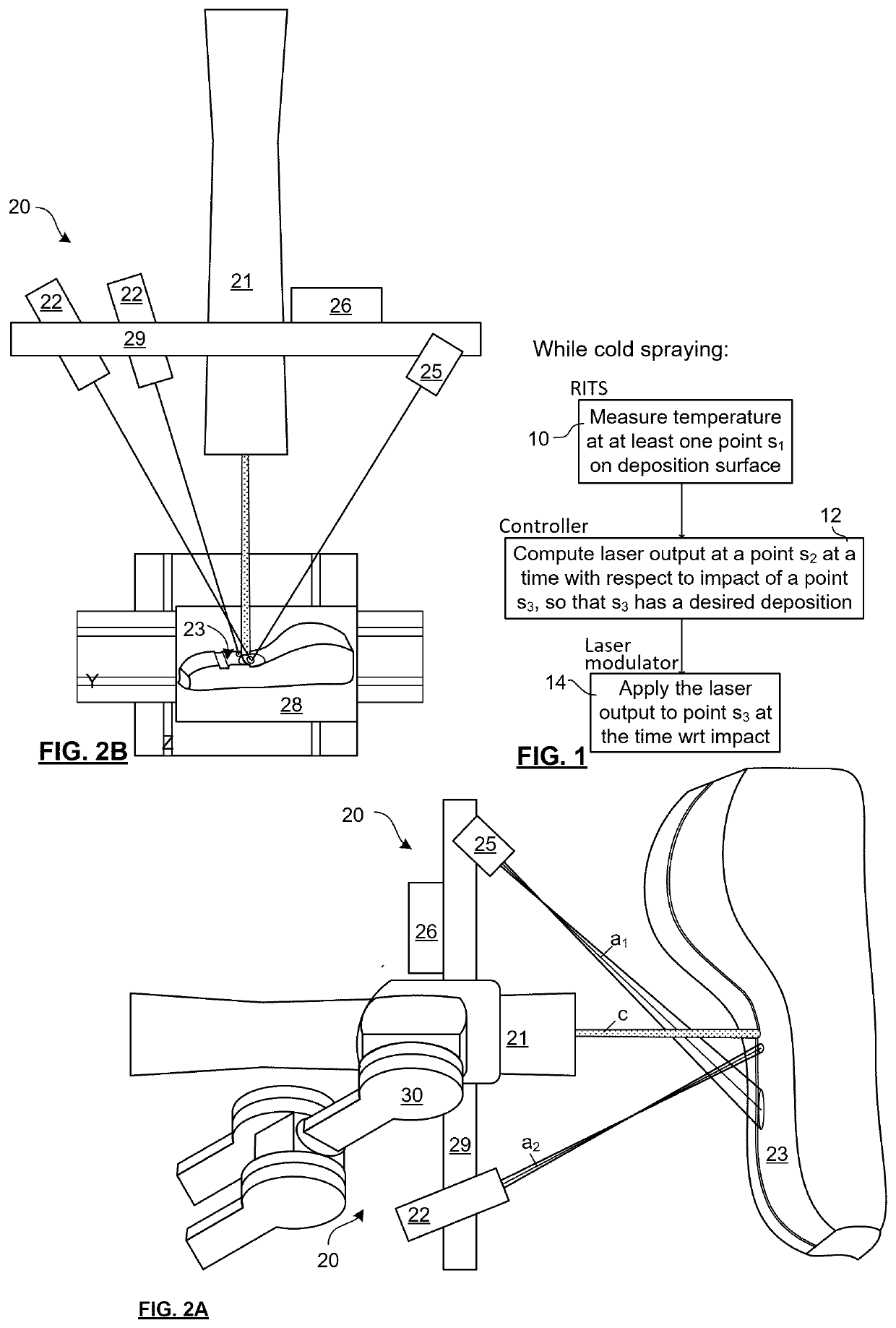

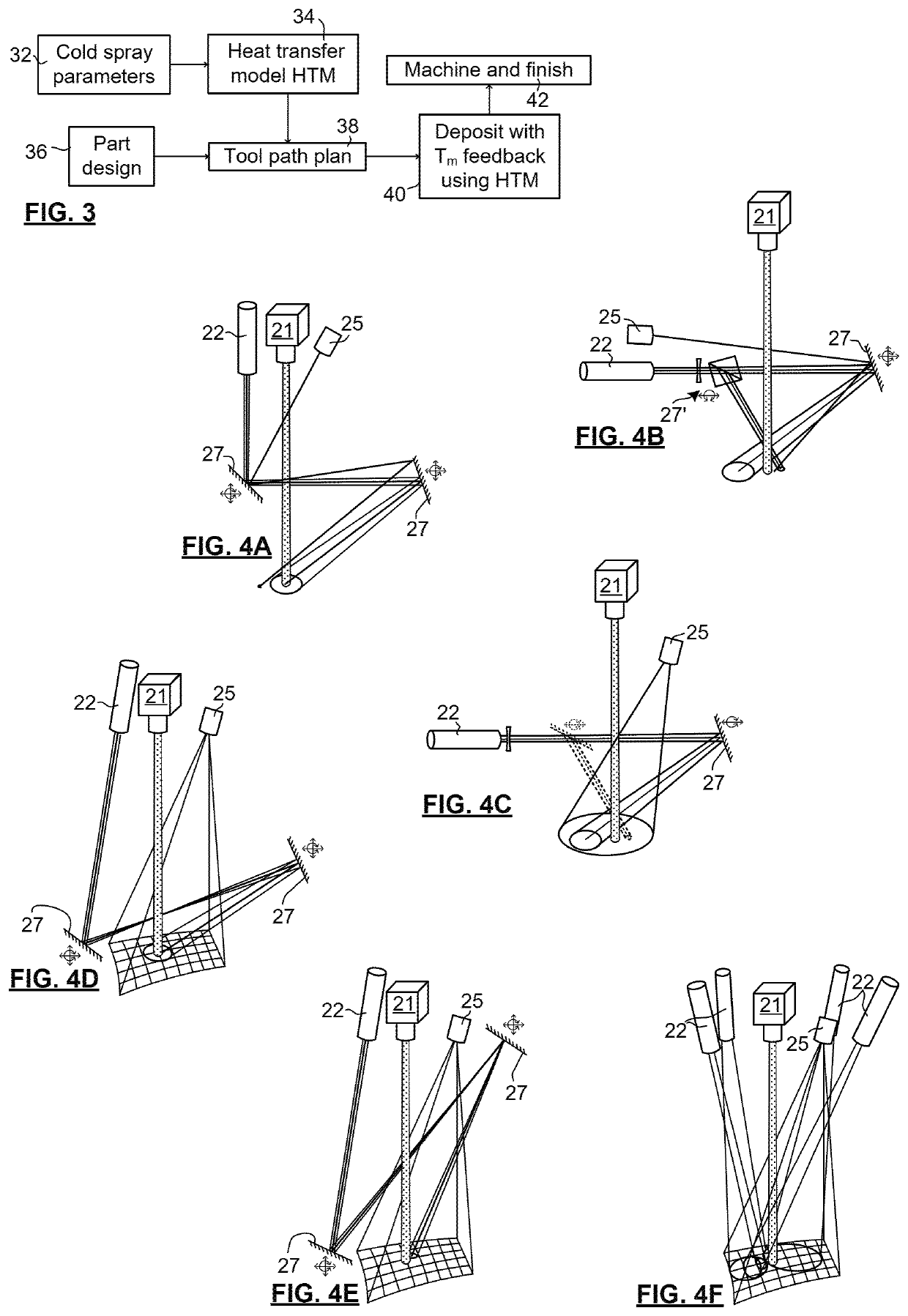

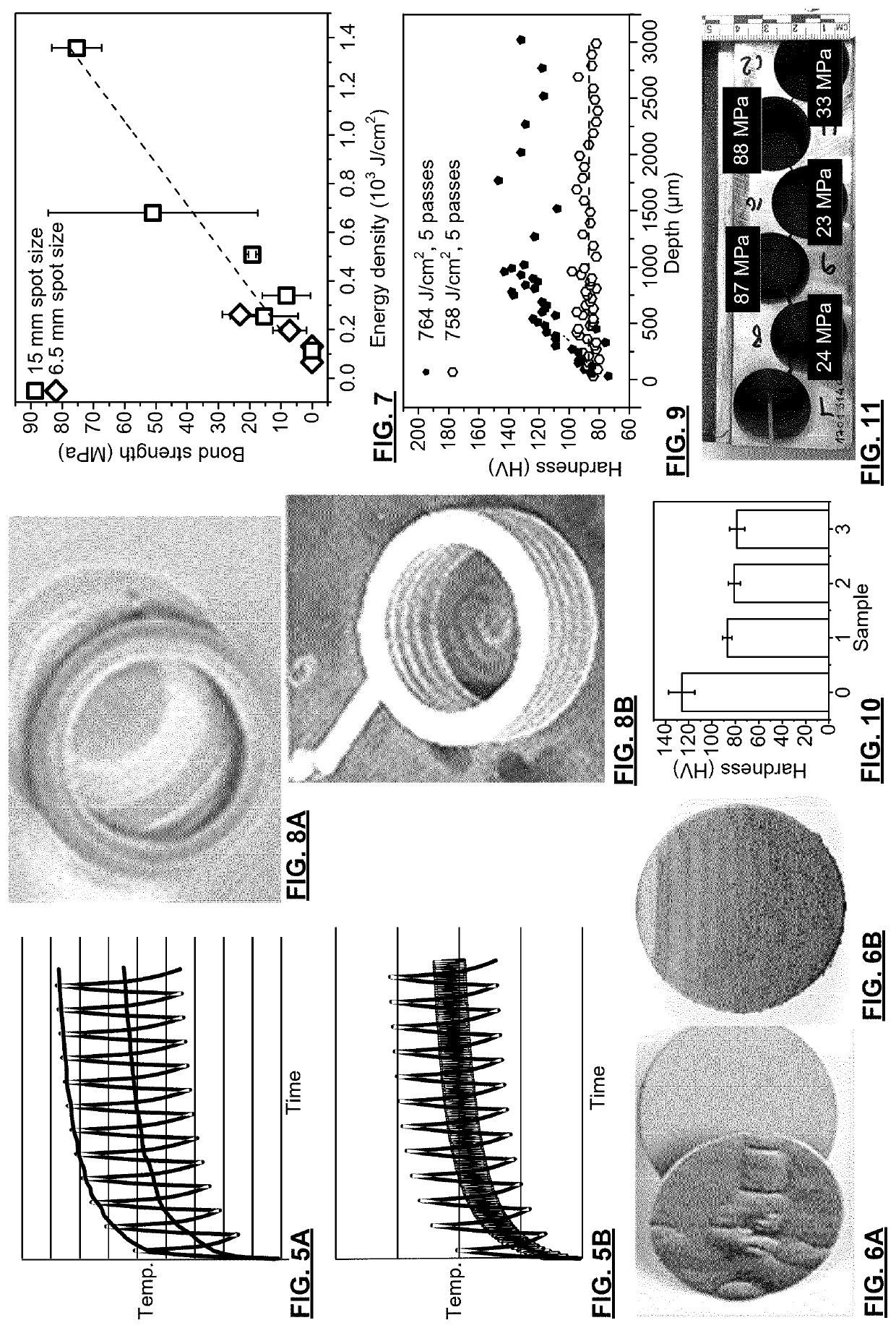

Apparatus and method for temperature controlled cold spray

PendingUS20210187618A1Good control over deposition propertyEasy temperature controlAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlFeedback controller

A technique for improving cold spray deposition conditions for cold spray additive manufacture of parts involves providing an in-situ temperature feedback controller with a remote instantaneous temperature sensor supplying surface temperature measurements of the deposition surface, and a (preferably long pulse) laser for heating. Temperature feedback allows for control over deposition conditions yielding predictable deposition properties.

Owner:NAT RES COUNCIL OF CANADA

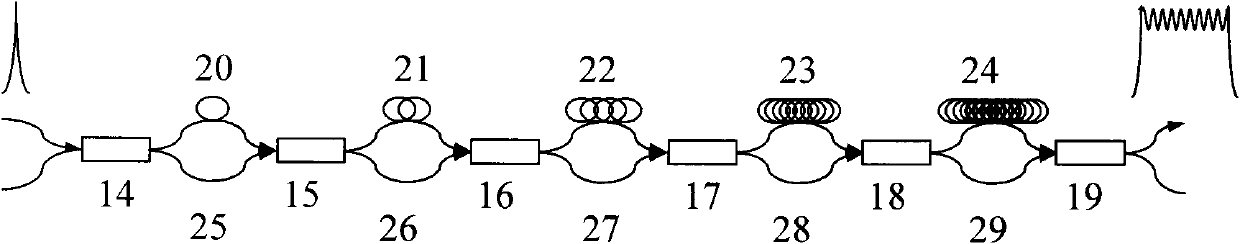

Dual wavelength laser therapeutic method and equipment

The invention discloses a therapy method and a therapeutic instrument thereof of double-wavelength laser. Long pulse laser of 1064 nm and dye pulse laser of 595 nm are coaxially coupled and guided into optical fiber for therapy through an optical apparatus. The therapeutic instrument comprises a 1064nm long pulse laser generating device of and a 595 nm dye pulse laser generating device arranged on the other light path; the therapeutic instrument also comprises a holophote, an airproof lens, a dye case and a second pumping lamp, another airproof lens, a second part of reflector and light splitting sheet, wherein a facula diameter regulating apparatus is arranged on a main emitting light path of the light spitting sheet; the emitting light path of the facula diameter regulating apparatus is paired with the generating light path of the long pulse laser of 1064 nm, and a light paring sheet is arranged at the paired part. The invention skillfully combines and uses the main wavelength of 595 nm and 1064 nm for the therapy of blood vessel diseases, and the two wavelength coaxially enter the light fiber to be used for the therapy of diseases, thereby the required energy density is greatly reduced while improving the therapy effect of blood vessel diseases, and the occurrence of side effect is reduced.

Owner:上海奥通激光技术有限公司

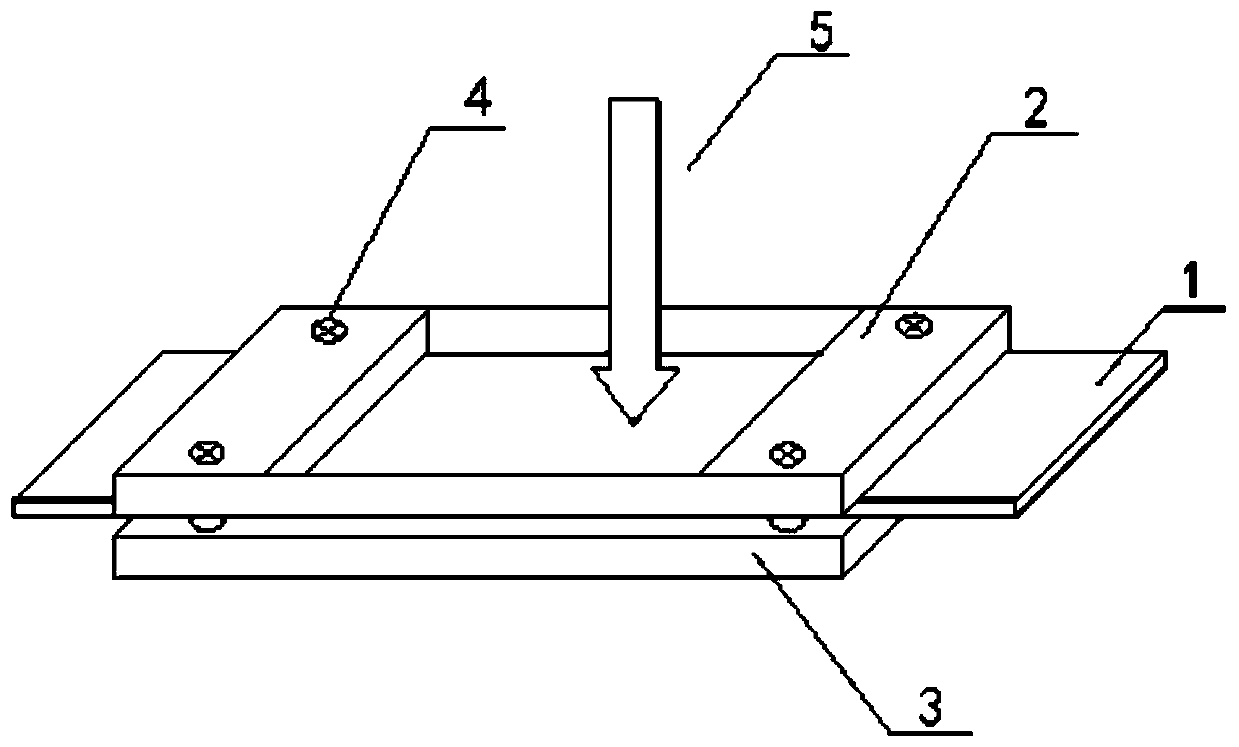

Laser hole making method for carbon fiber composite material and tooling fixture thereof

PendingCN111069798ATypical ultra-short pulse widthTypical Ultra High Peak Power CharacteristicsLaser beam welding apparatusPicosecond laserErbium lasers

The invention discloses a laser hole making method for a carbon fiber composite material. The method comprises the following steps that 1, surface wiping is performed on the carbon fiber composite material to be treated with alcohol cotton, surface pollutants are removed, the carbon fiber composite material is aired and then the carbon fiber composite material is used for later use; and 2, the carbon fiber composite material obtained in the step 1 is subjected to laser scanning machining treatment according to a designed scanning track by adopting an ultrashort pulse laser machining system, and machining holes with different apertures are prepared; and an ultrashort pulse laser adopts a picosecond laser, so that the defects such as thermal effect caused by long pulse laser machining can beavoided. The hole surfaces prepared by the laser hole making method is good in morphology, neat in edge and free of obvious defects, and compared with a mechanical hole making mode, the heat radiation area can be remarkably reduced, the roughness of the inner walls of the round holes is reduced, and the hole making precision is improved. The invention further discloses a tooling fixture suitablefor the laser hole making method of the carbon fiber composite material, the tooling fixture suitable for the laser hole making method of the carbon fiber composite material can effectively reduce thetemperature of the machining area and can reduce the heat radiation area.

Owner:SHANGHAI INST OF LASER TECH

Raman laser device for optimizing pumping laser by means of two-stage stimulated Brillouin scattering method

InactiveCN105024274ANarrowed pulse widthAchieving Stimulated Raman Wavelength ConversionLaser using scattering effectsPeak valueLength wave

The invention provides a Raman laser device for optimizing pumping laser by means of a two-stage stimulated Brillouin scattering method. The stimulated Raman has an extremely high requirement for pulse peak power, which is out of capacity of a common long-pulse laser device and diversification of wavelength is difficult to realize by utilizing SRS wavelength conversion so that a device of combination of compressed pulse and stimulated Raman is designed. According to the device, stimulated Brillouin scattering is performed on pumping laser firstly so as to compress pulse width of pulse laser, during which two times of pulse width compression is performed on laser so that great rising of pulse laser peak power is realized. Then the compressed pulse laser is utilized to act as pumping laser to realize stimulated Raman scattering wavelength conversion. The raman laser device for optimizing pumping laser by means of the two-stage stimulated Brillouin scattering method is a novel Raman laser device that the Brillouin pulse width compression method is firstly applied to stimulated Raman wavelength conversion.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

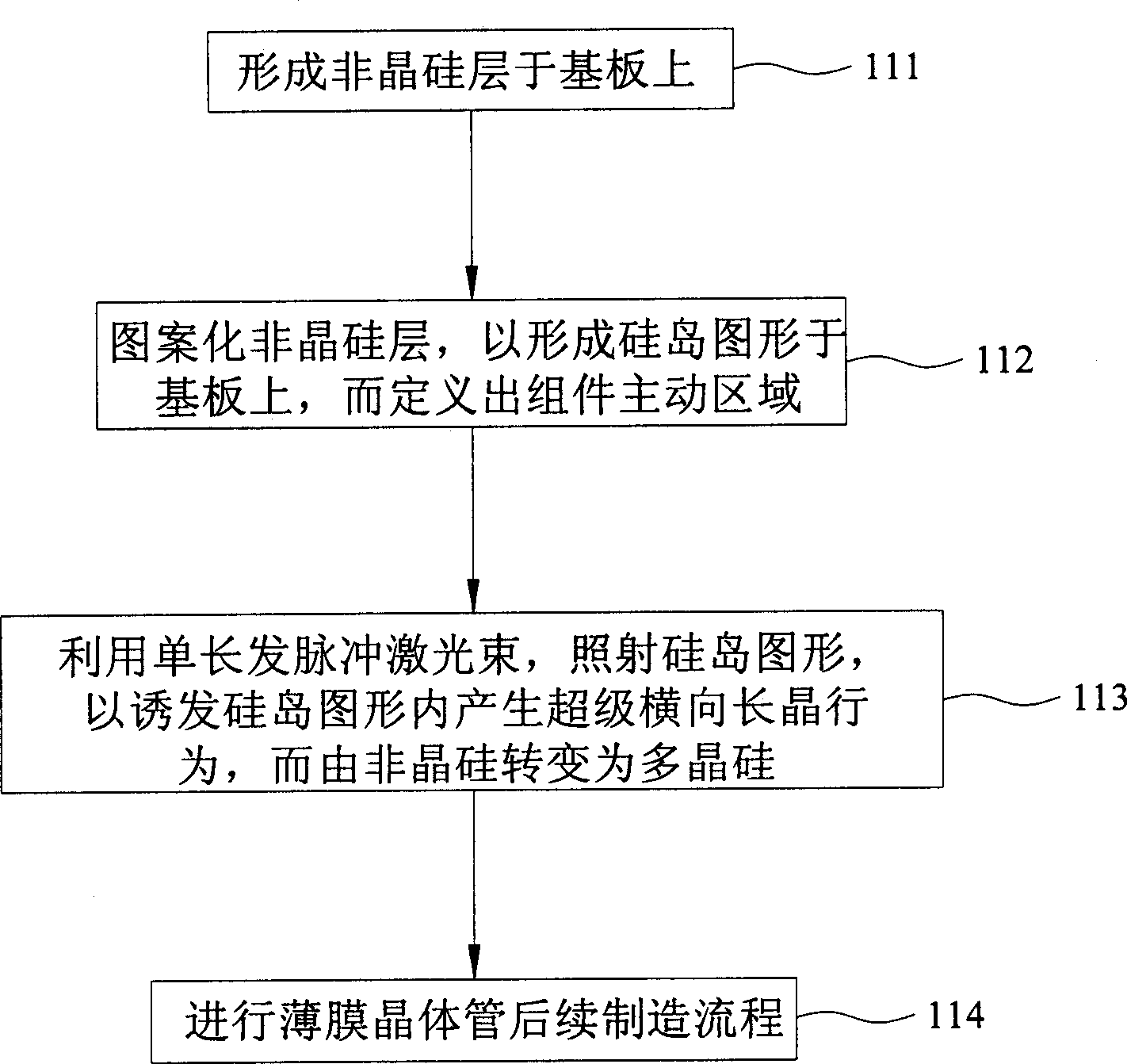

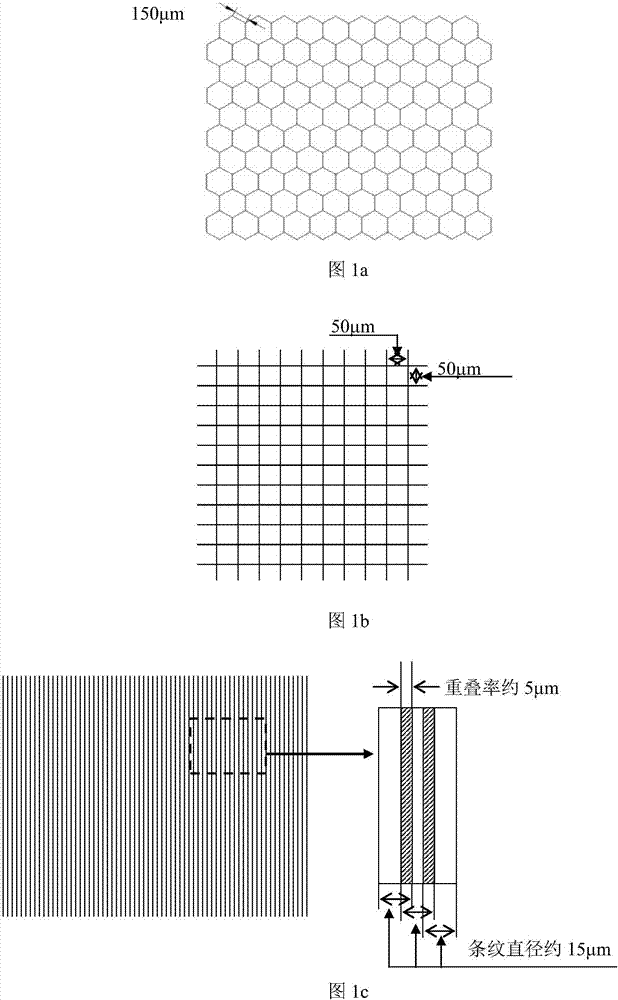

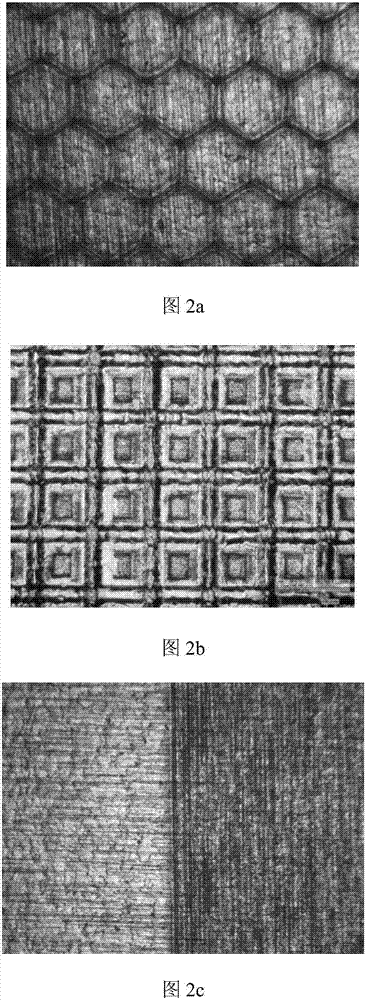

Method for producing polycrystalline thin film transistor

InactiveCN1822334AExtended growth timeImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesAmorphous siliconOptoelectronics

Said polysilicon thin film transistor making method makes patterning to non-crystalline silicon layer after forming non-crystalline silicon layer on substrate to form silicon island graphic, advance defining out assembly active area. Then said method utilizes single shot long pulse laser bean to radiate silicon island graphic, to induce silicon island generating super transverse direction long glittering acting, converting non-crystalline silicon to polysilicon, finally according to sequence to proceed follow-up thin film transistor making process to complete polysilicon thin film transistor manufacture.

Owner:IND TECH RES INST

Laser therapeutic machine

InactiveCN1768715AHigh single pulse energyImprove frequency doubling efficiencySurgical instrument detailsActive medium materialDye laserLeg length

The invention relates to a laser treating equipment whose emission wavelength is 593nm, 594nm, or 589nm which is near to ideal the absorption peak 577nm of oxidized hemoglobin, and since it is the full-solid laser treating equipment, compared to dyestuff laser, said treating equipment can significantly reduce the cost. The pulse length of output laser is 3-100ms which is continuously adjustable and each pulse can be divided into two or more 0.2-3ms long-pulse laser. Said long pulse laser treating equipment can replace present dyestuff laser treating equipment to treat the erythema lesion.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

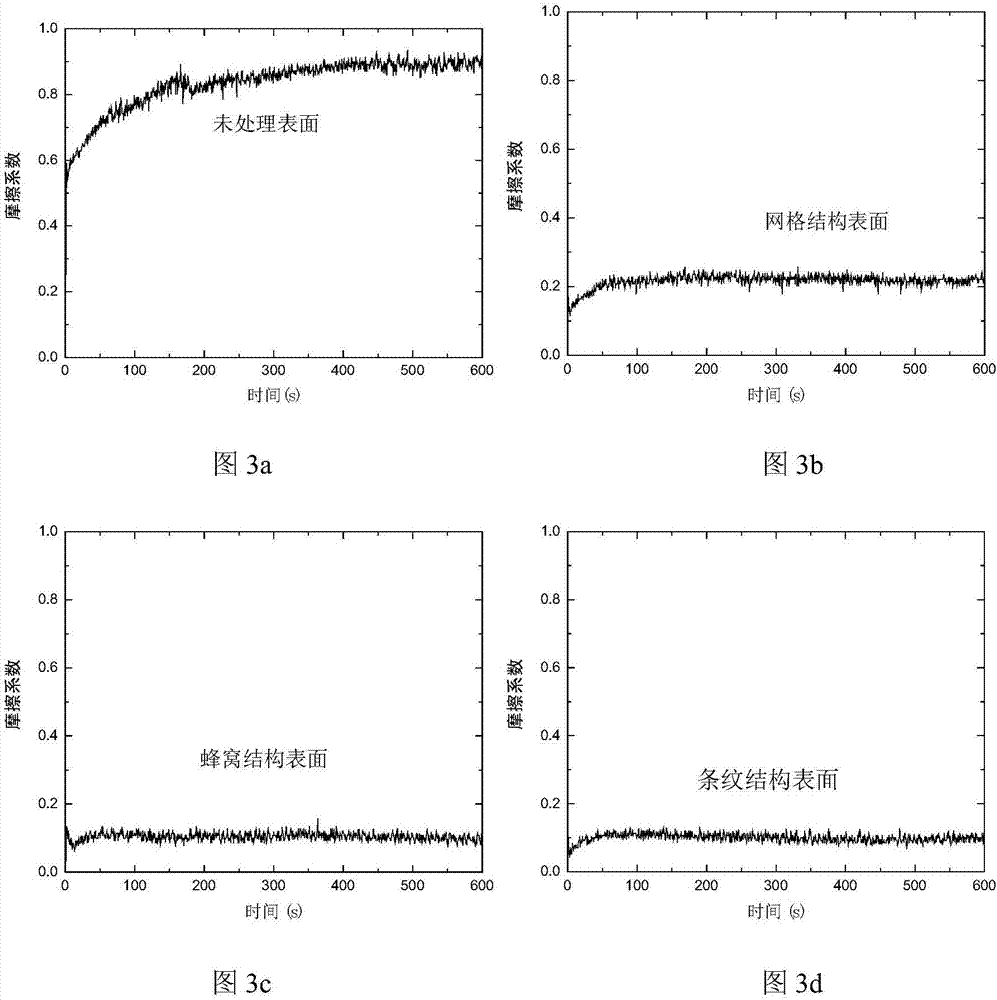

Preparation method of metal surface microstructure with abrasion resistance and hydrophobicity

InactiveCN107999976ATypical ultra-short pulse widthTypical Ultra High Peak Power CharacteristicsLaser beam welding apparatusPicosecond laserPicosecond pulsed laser

The invention discloses a preparation method of a metal surface microstructure with abrasion resistance and hydrophobicity. The method comprises the steps that 1, stainless steel to be treated is subjected to ultrasonic cleaning, surface pollutants are removed, drying is carried out, and the clean stainless steel surface is obtained; 2, mapping software is used for doing microstructure two-dimension design drawing, and a graphic file is guided into picosecond laser machining system galvanometer control software; and 3, a picosecond laser machining system is adopted for carrying out laser scanning machining treatment on the stainless steel surface obtained in the step 1 according to the machining graph guided in the step 2, and the stainless steel surface with the specific form microstructure is prepared. Picosecond pulse laser adopted in the method has typical ultra-short pulse width and ultra-high peak power characteristic, the defects of heat effects and the like caused easily by long pulse laser machining can be avoided, compared with femtosecond laser, the machining cost is low, the machining efficiency is high, the surface friction coefficient of the prepared stainless steel microstructure is reduced remarkably, the abrasion resistance is improved, the contact angle to water is increased remarkably, and hydrophobicity is improved.

Owner:SHANGHAI INST OF LASER TECH

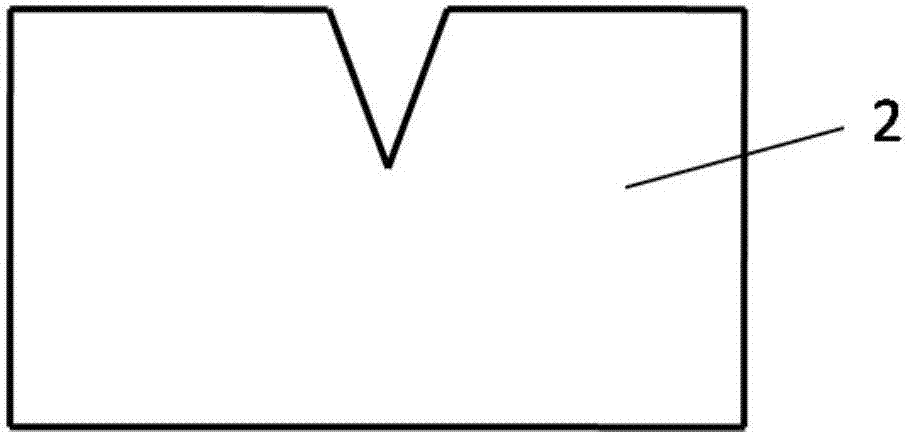

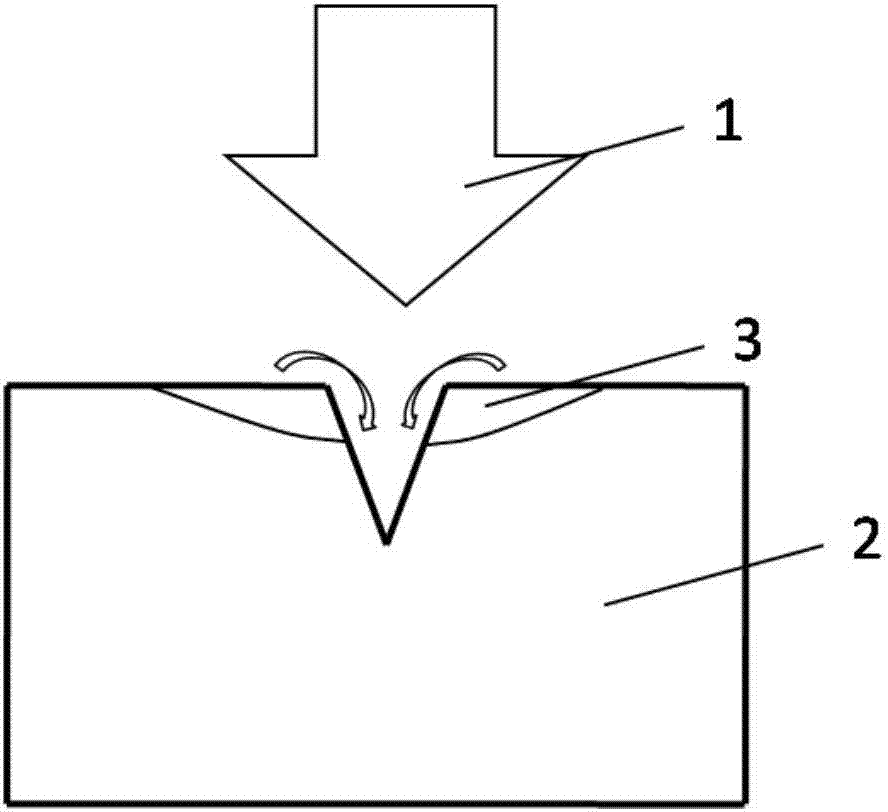

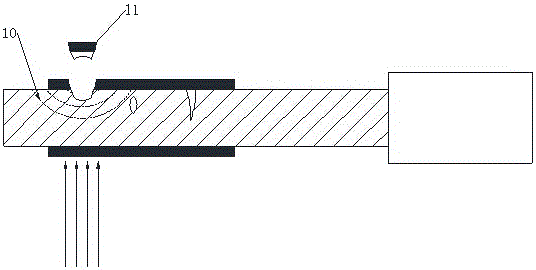

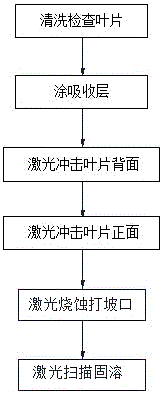

Laser preprocessing method for remanufacturing of blade part

The invention discloses a laser preprocessing method for remanufacturing of a blade part. The laser preprocessing method comprises the steps that firstly, a blade is washed and the surface of the blade is coated with an absorption material layer, then the back side of the blade is impacted by means of a high-power short pulse laser, materials in a transverse invisible crack position on the front side break into flying pieces under the effect of impact waves, and then the invisible cracks become visible; secondly, the front side of the blade is impacted, small-scale invisible cracks are pressed under the effect of laser impact waves, a visible crack area is ablated by means of a long pulse laser, and a welding groove is formed; and finally, the crack area is scanned repeatedly by means of a long pulse laser, so the temperature of the materials in the area is increased and solid is molten, and meanwhile the small-scale invisible cracks are eliminated. By the adoption of the laser preprocessing method, the transverse invisible cracks can be made visible, and the small-scale invisible cracks can be eliminated; in this way, the invisible cracks can be repaired while the visible cracks are repaired, and accordingly the service life of the repaired blade is prolonged, and the maintenance cost is reduced.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com