Patents

Literature

80results about How to "Guaranteed one-time molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

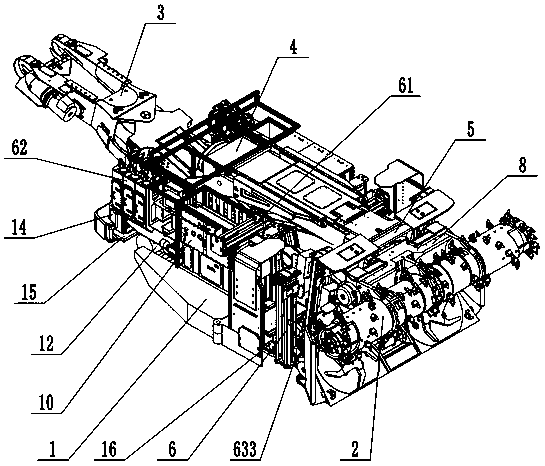

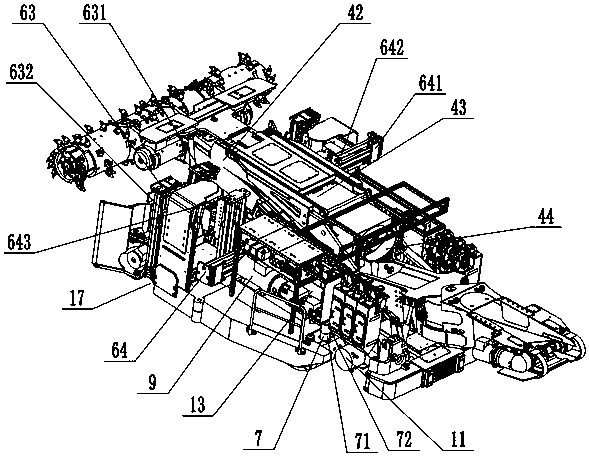

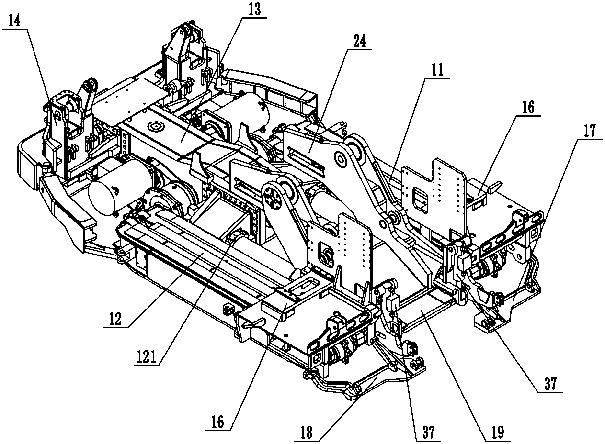

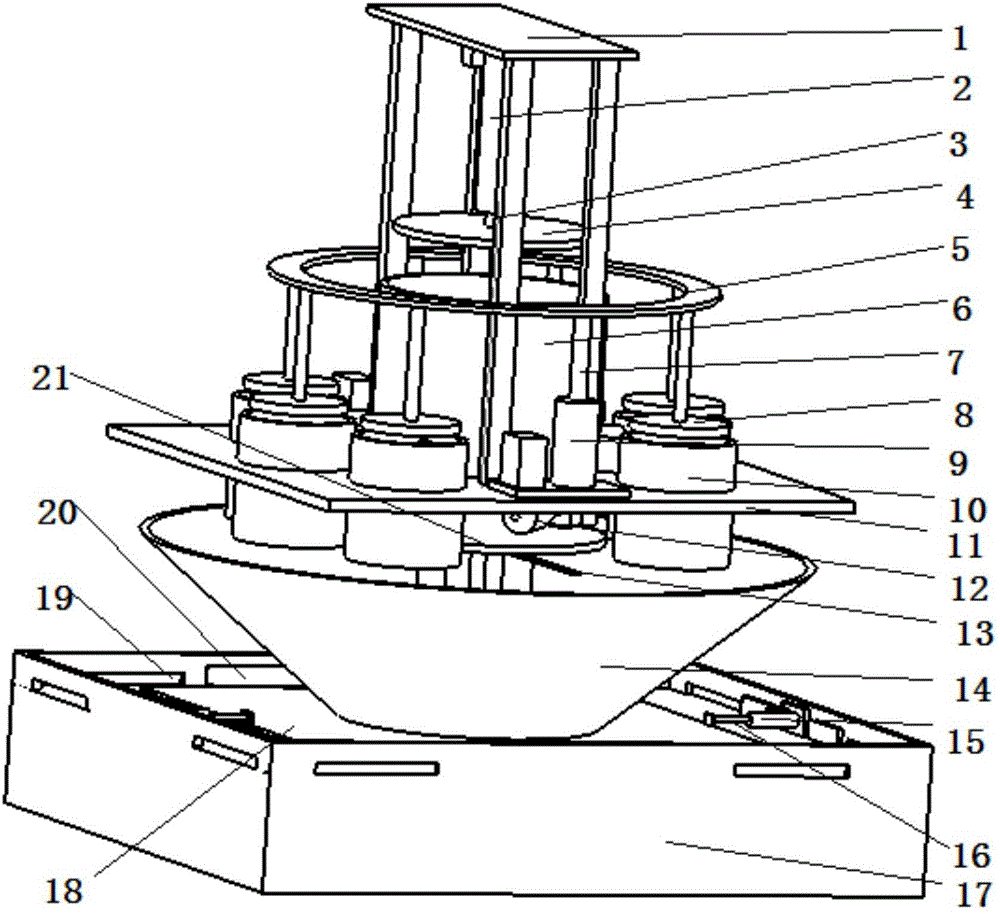

High-adaptability digging and anchoring integrated machine with dual-mode anchor drilling system

PendingCN111075444AAchieving parallel operation of anchor diggingFully automatedPropulsionAnchoring boltsSupporting systemElectric control

The invention provides a high-adaptability digging and anchoring integrated machine with a dual-mode anchor drilling system, and belongs to the technical field of underground coal mining equipment. The high-adaptability digging and anchoring integrated machine comprises a frame main body, a cutting system, a conveying system, a dust removing system, a multifunctional temporary supporting system, the dry-wet dual-mode anchor drilling system, an automatic lubricating system, a water-cooling spraying system, a hydraulic system and an electric control system, wherein a traveling mechanism adopts awide crawler design, so that the adaptability of the digging and anchoring integrated machine to a muddy bottom plate is improved; and the dry-wet dual-mode anchor drilling system has two functions of dry dust removal and wet dust removal, and real-time switching selection is carried out according to the geological conditions of the roadway bottom plate without replacing a drill box. By means ofthe high-adaptability digging and anchoring integrated machine, the problems of muddy of the bottom plate, poor stability of a top side wall and low tunneling efficiency in the rapid coal roadway tunneling under the complex geological conditions are solved; the integrated parallel operation of tunneling, anchor protection, transportation, dust removal and the like of a roadway tunneling working surface is realized; and the efficiency and safety of coal mining and transportation are improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

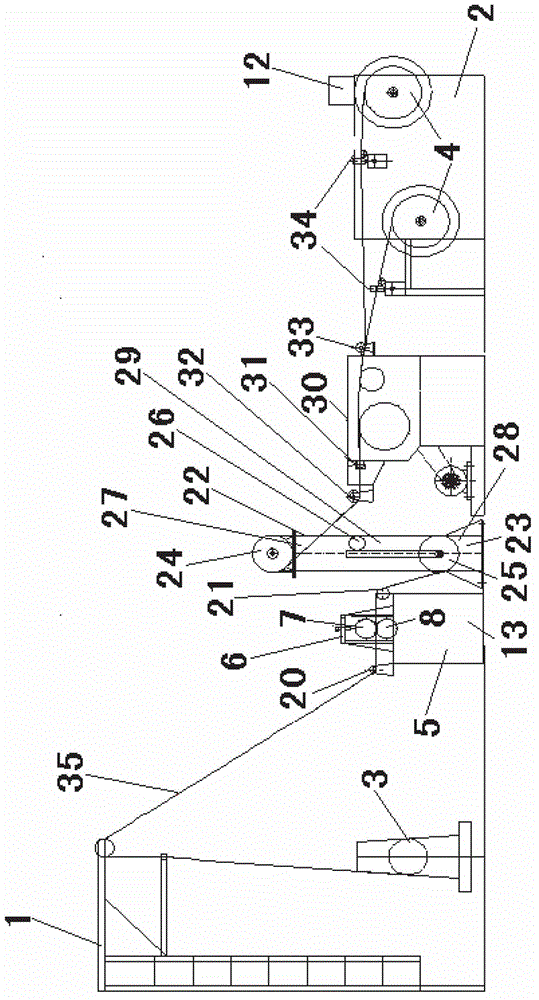

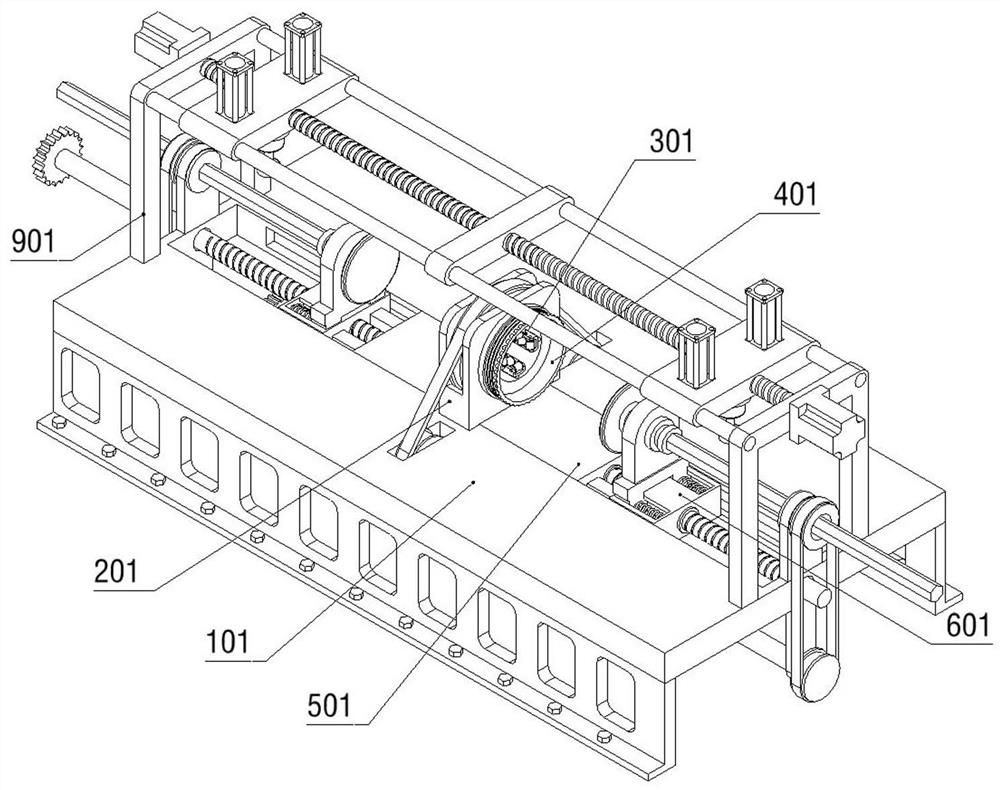

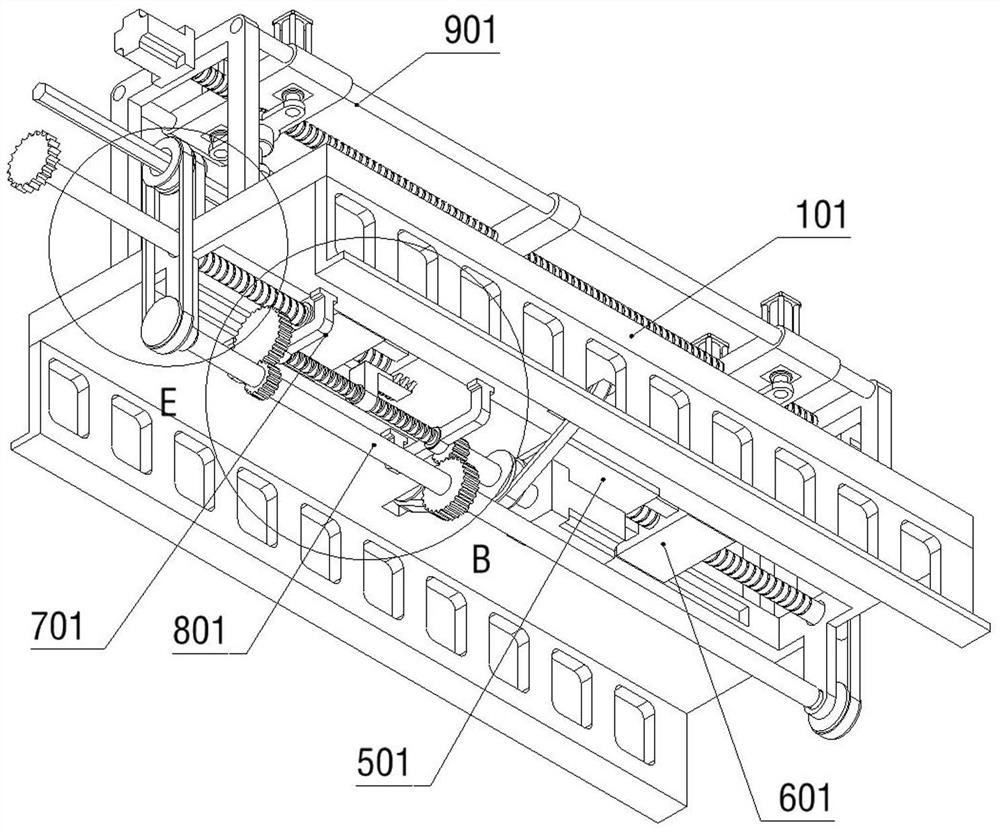

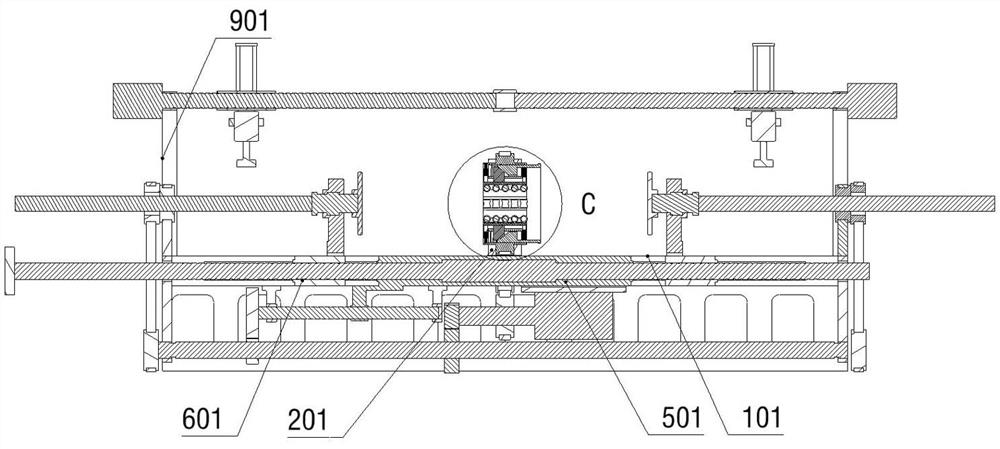

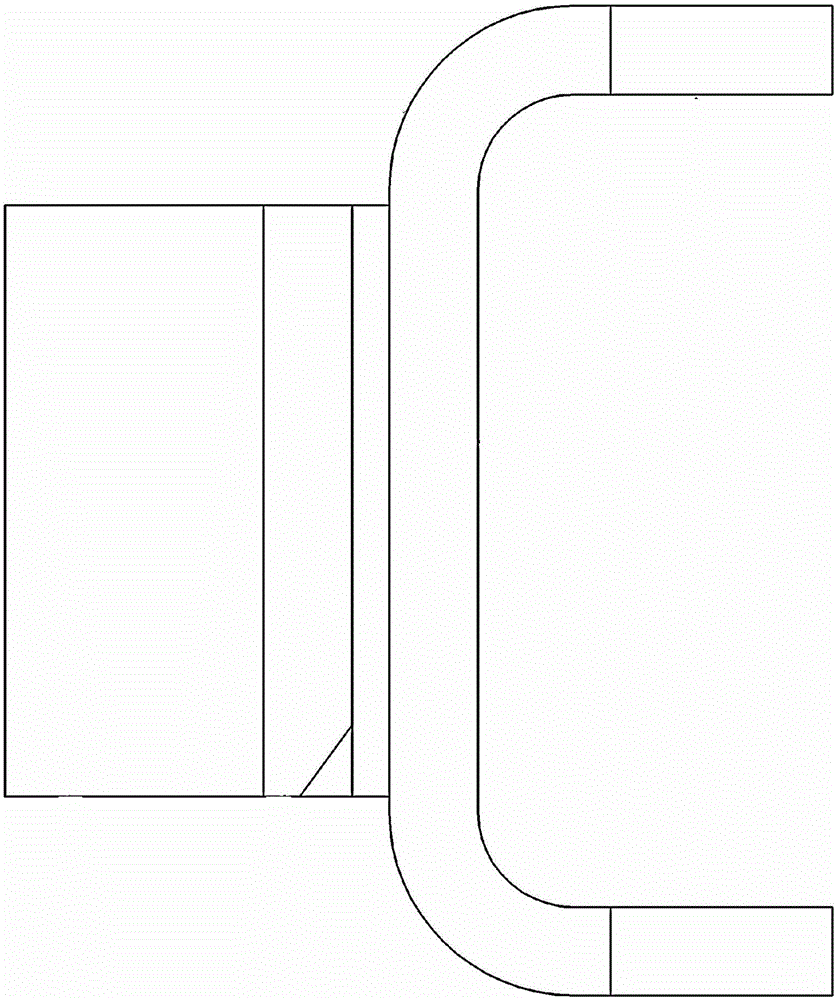

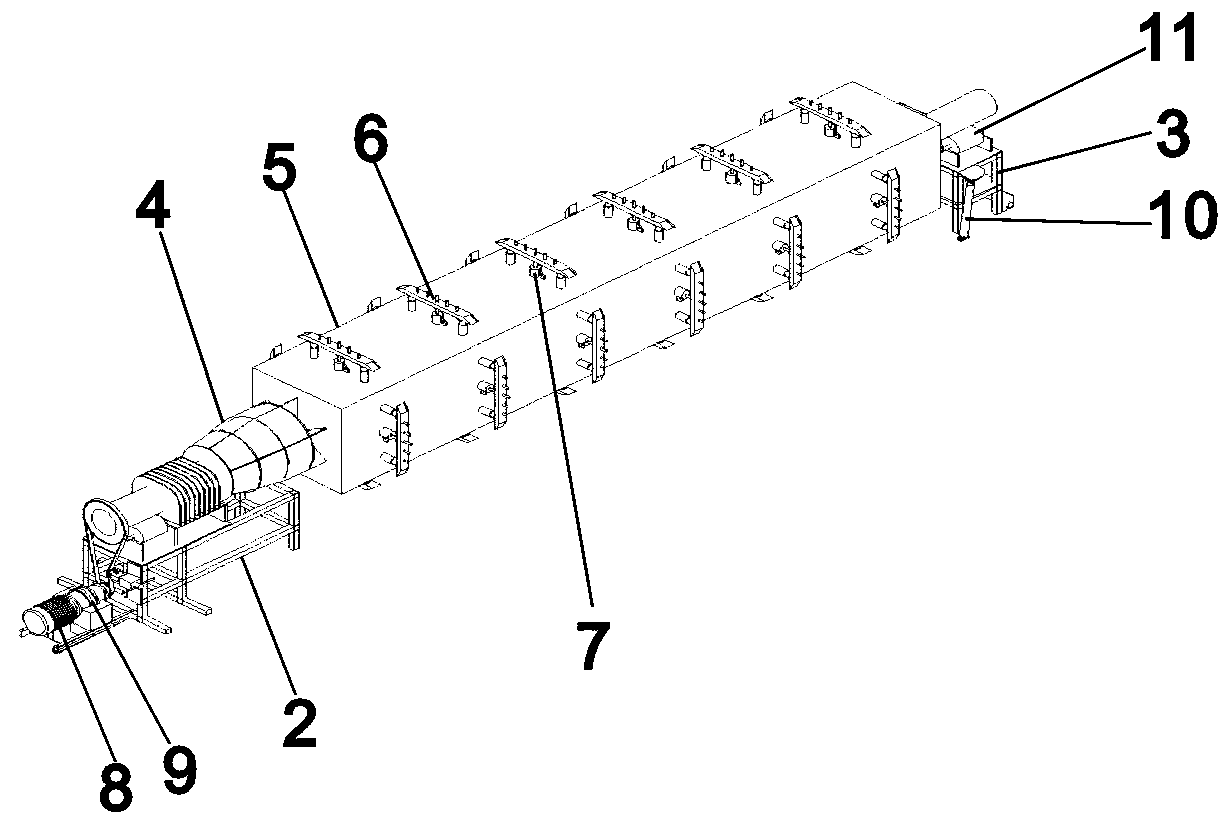

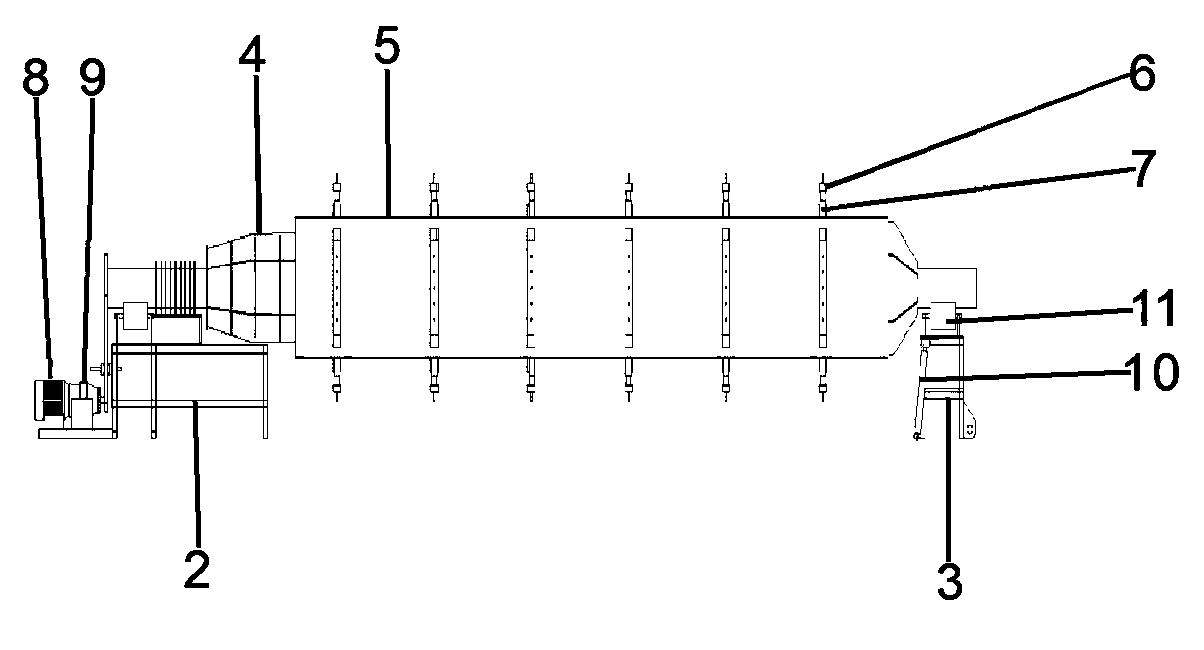

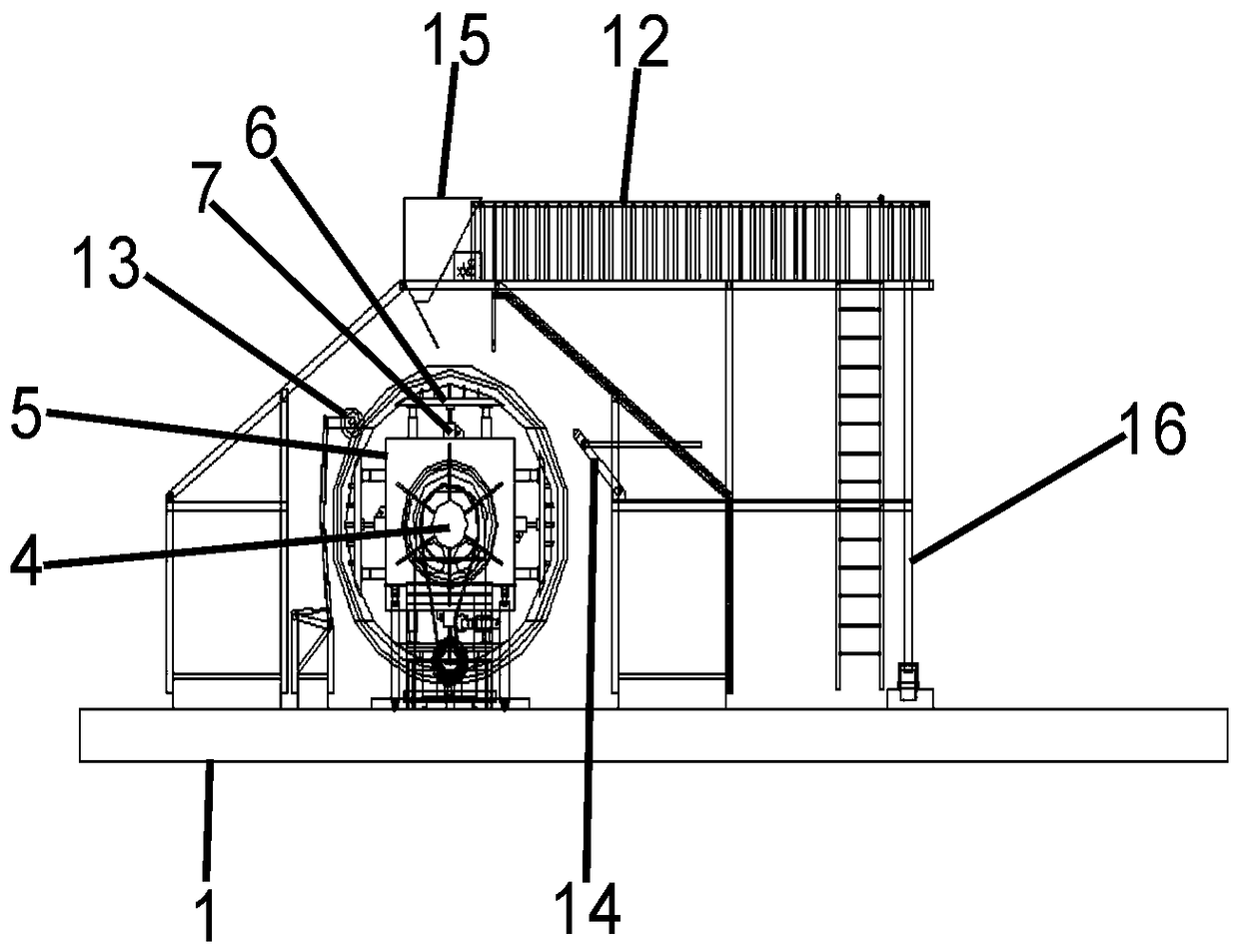

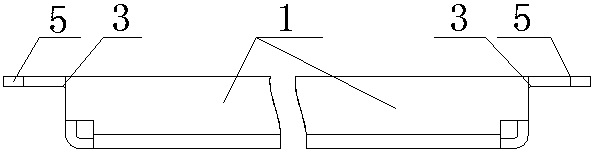

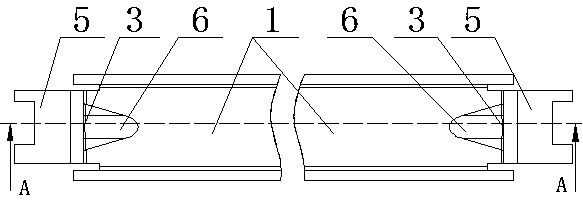

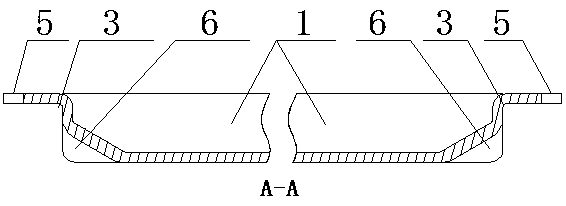

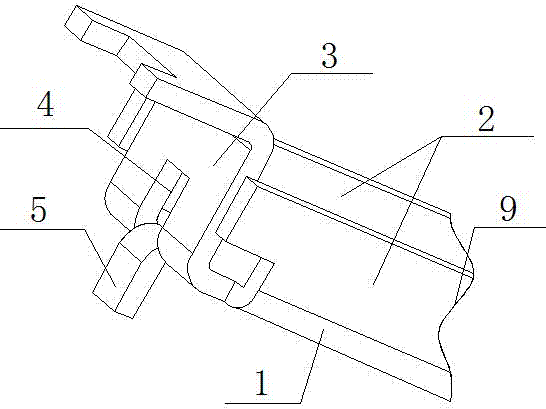

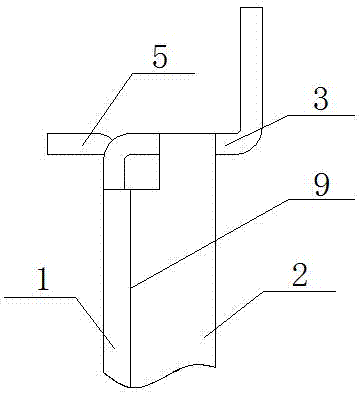

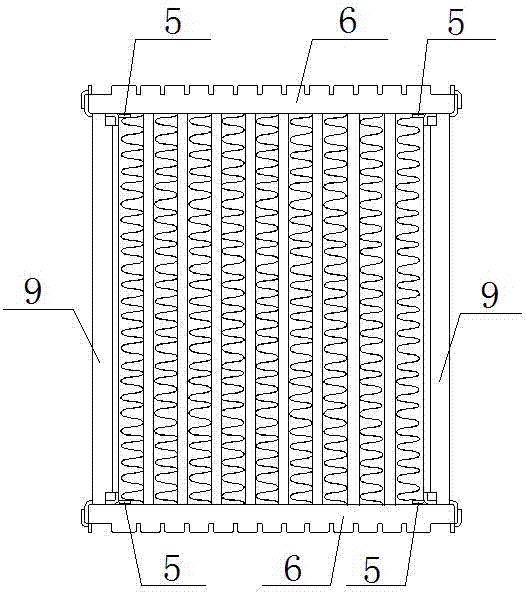

Alloy flat wire processing and forming device and method for rolling wires by using same

InactiveCN102861781AReduce labor intensityIncrease productivityMetal rolling stand detailsMetal rolling arrangementsForming processesAlloy

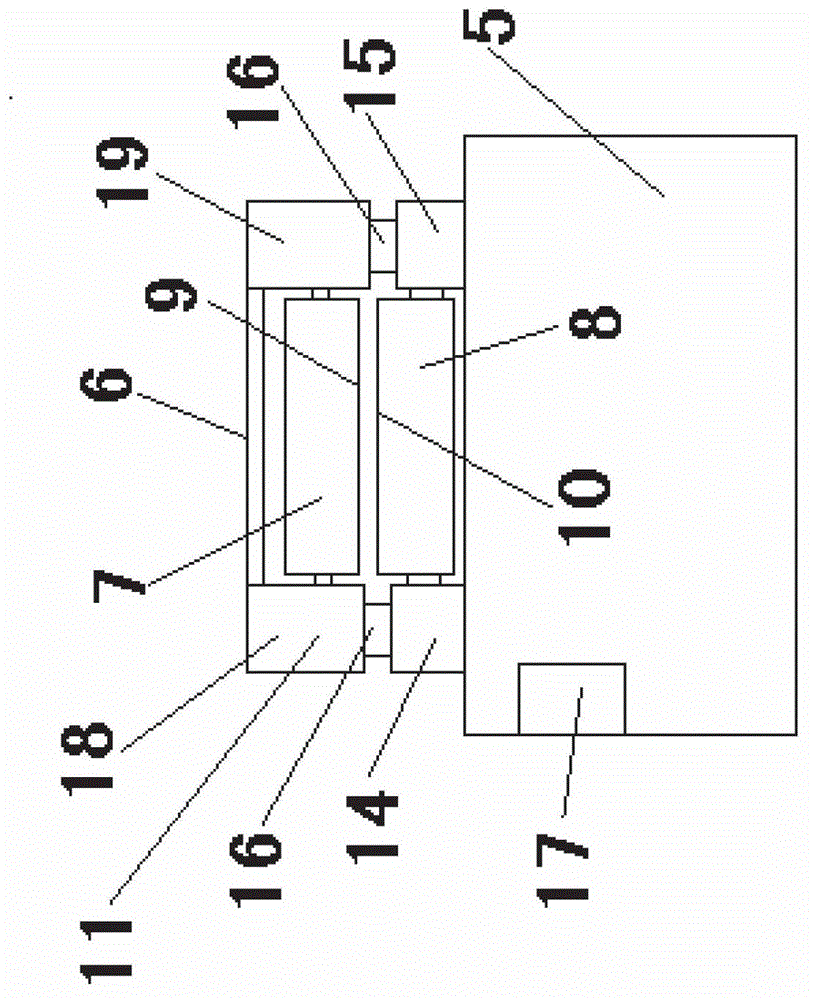

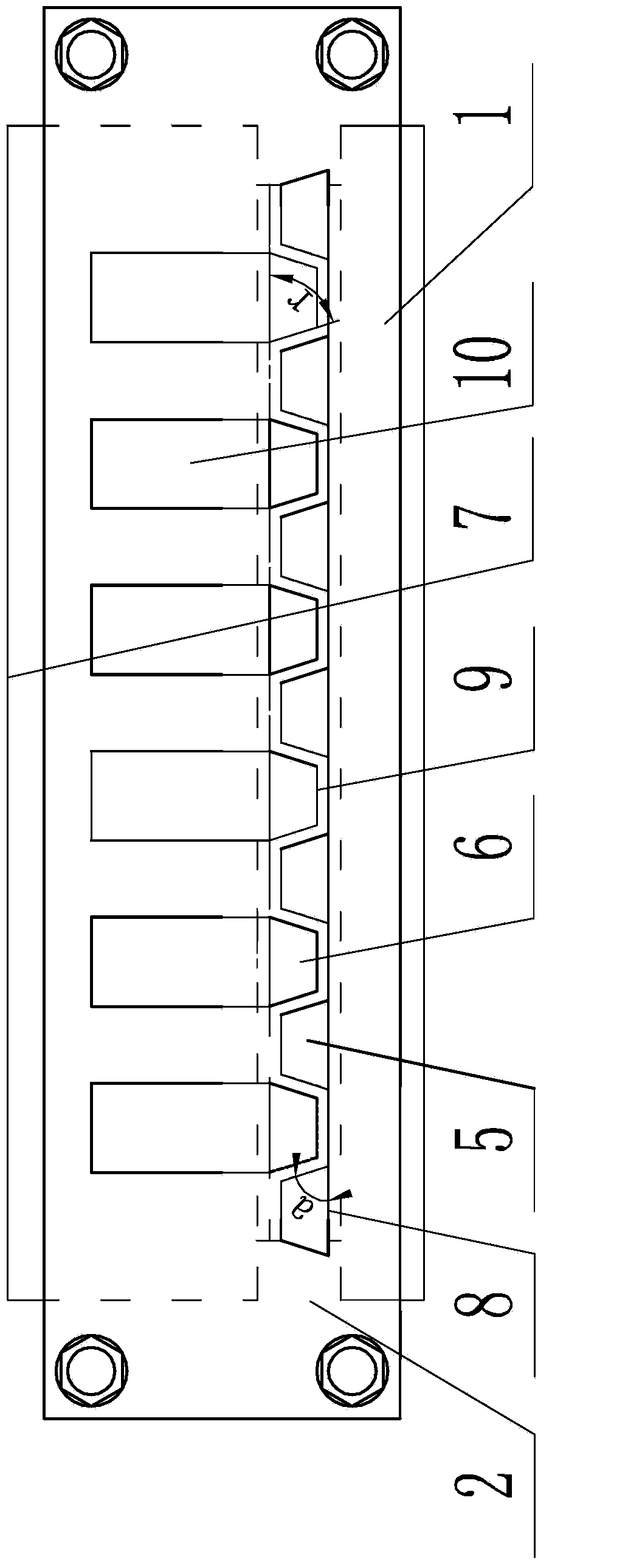

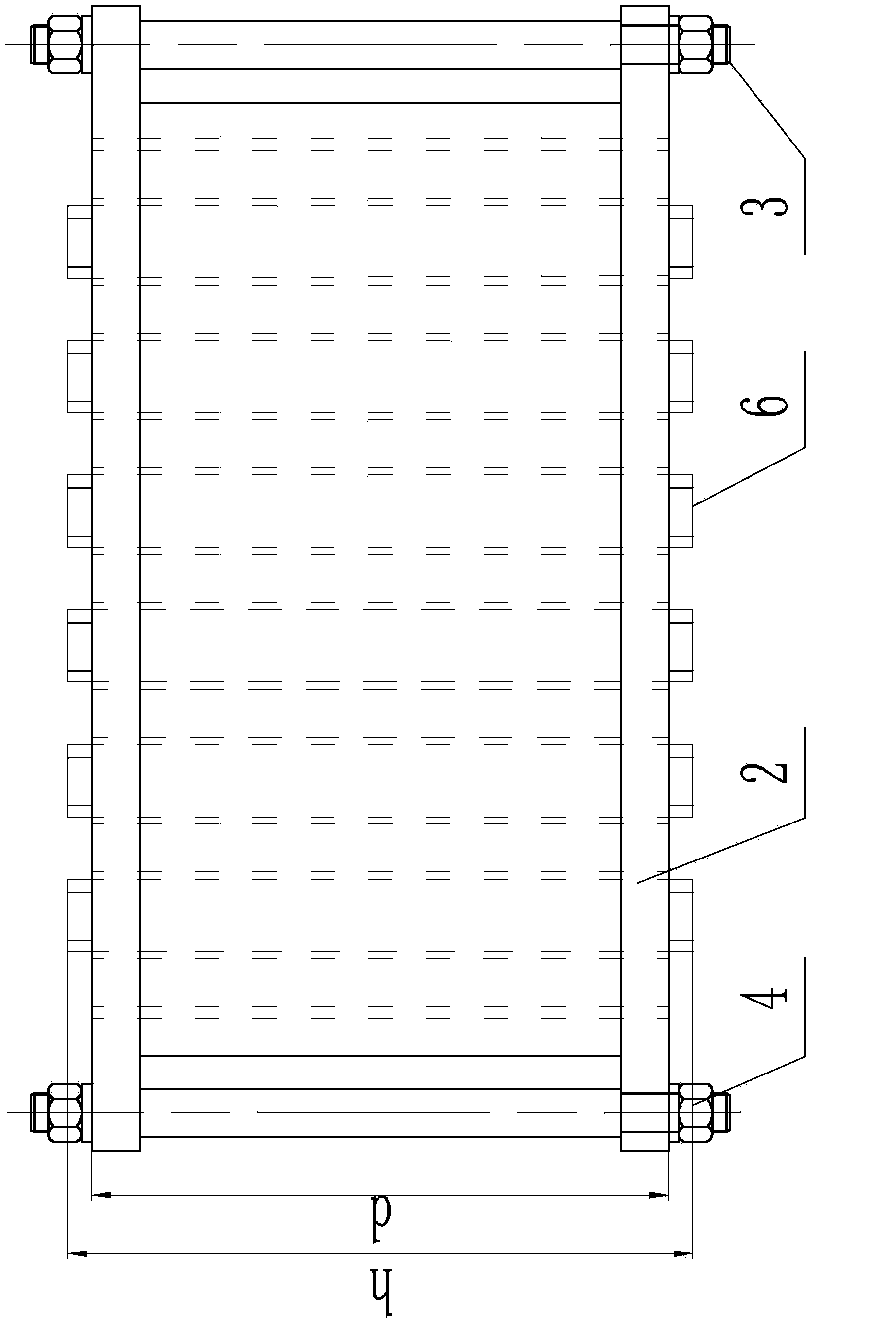

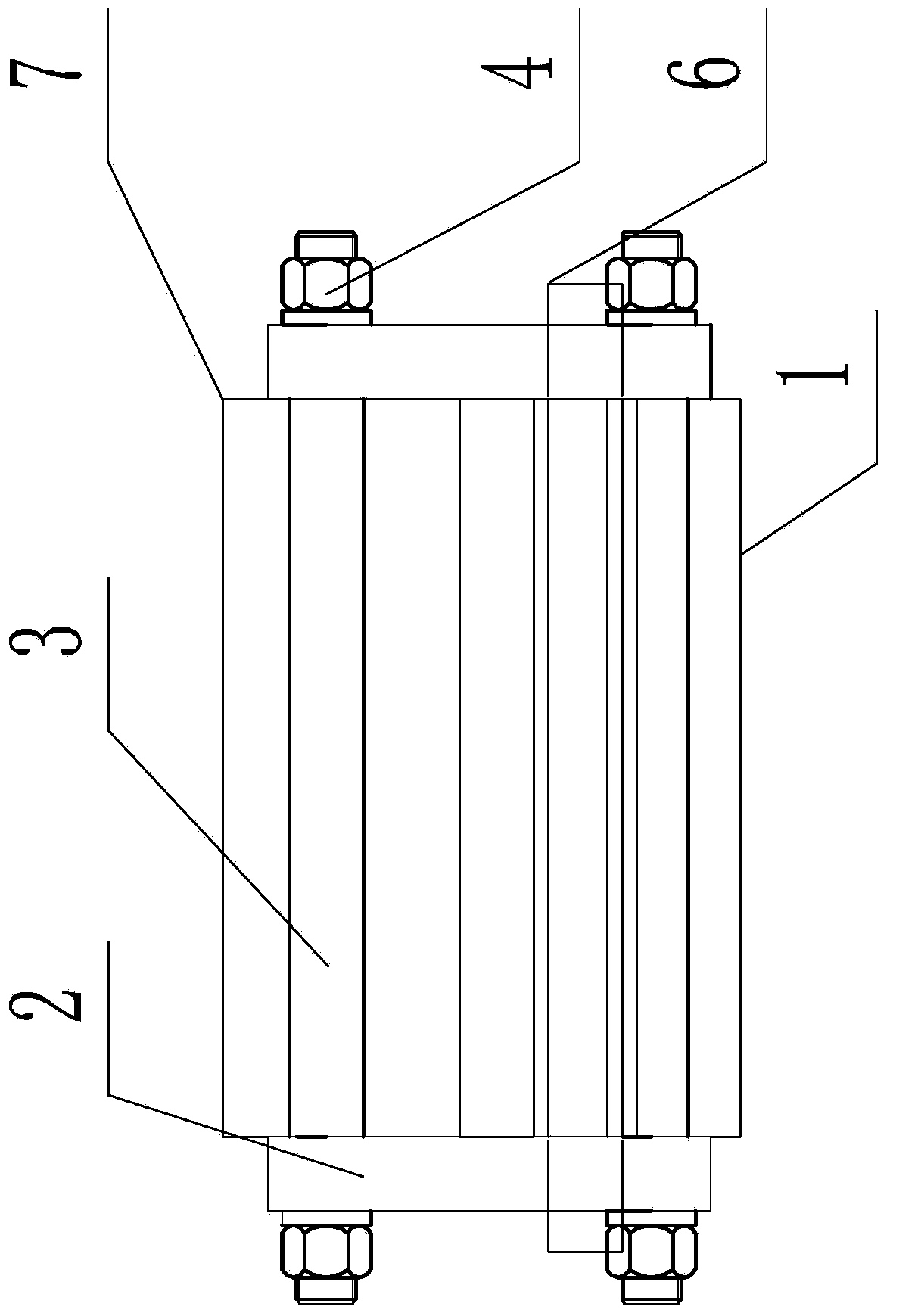

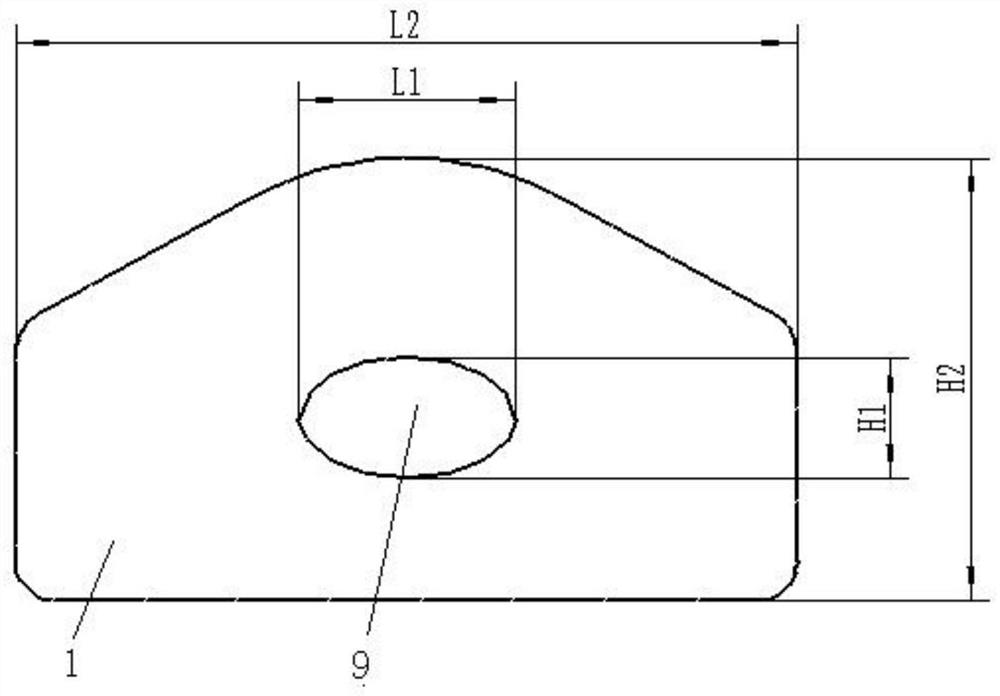

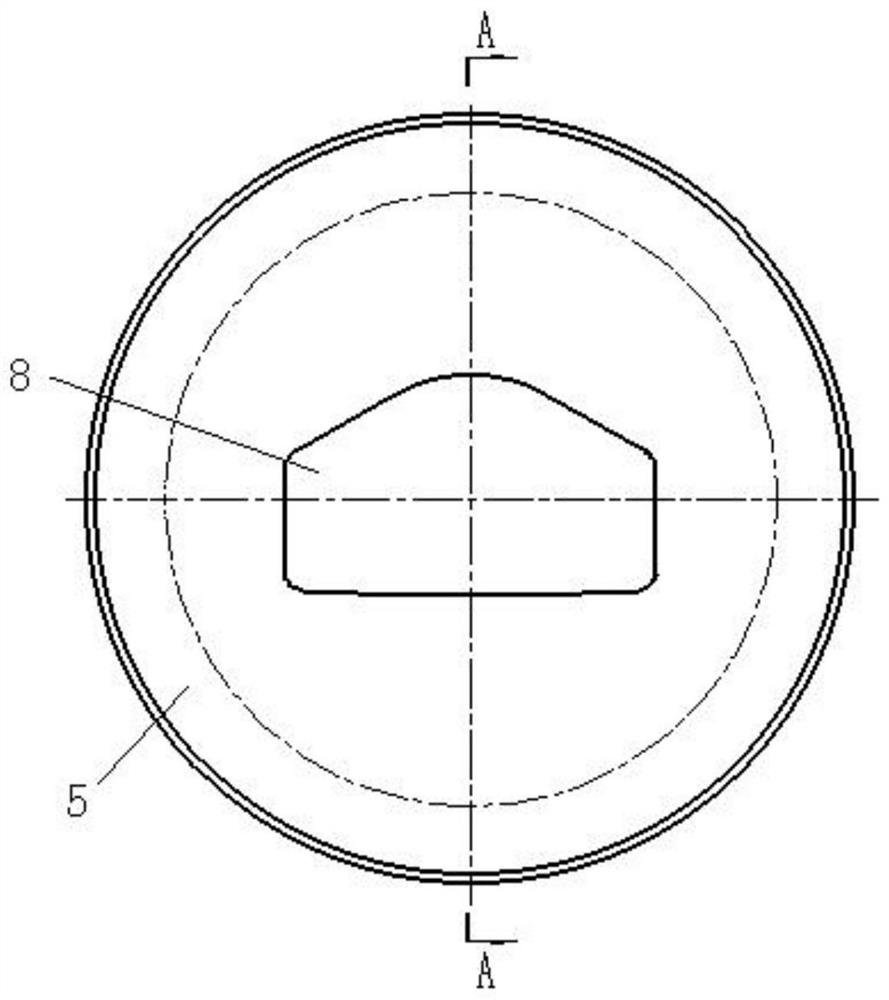

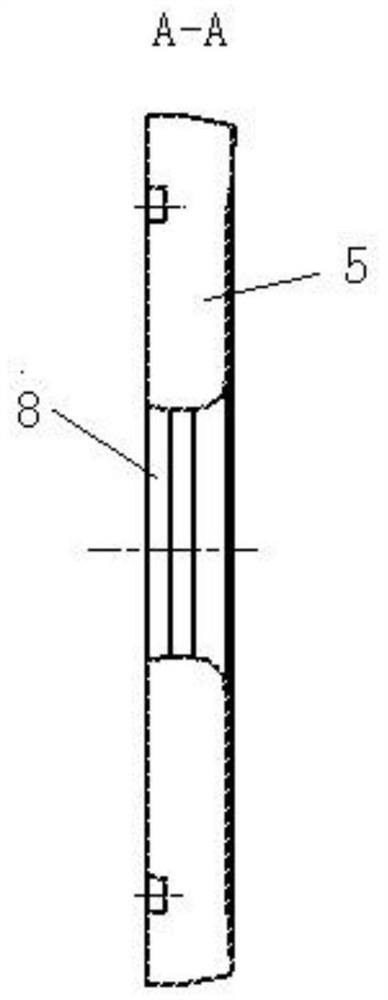

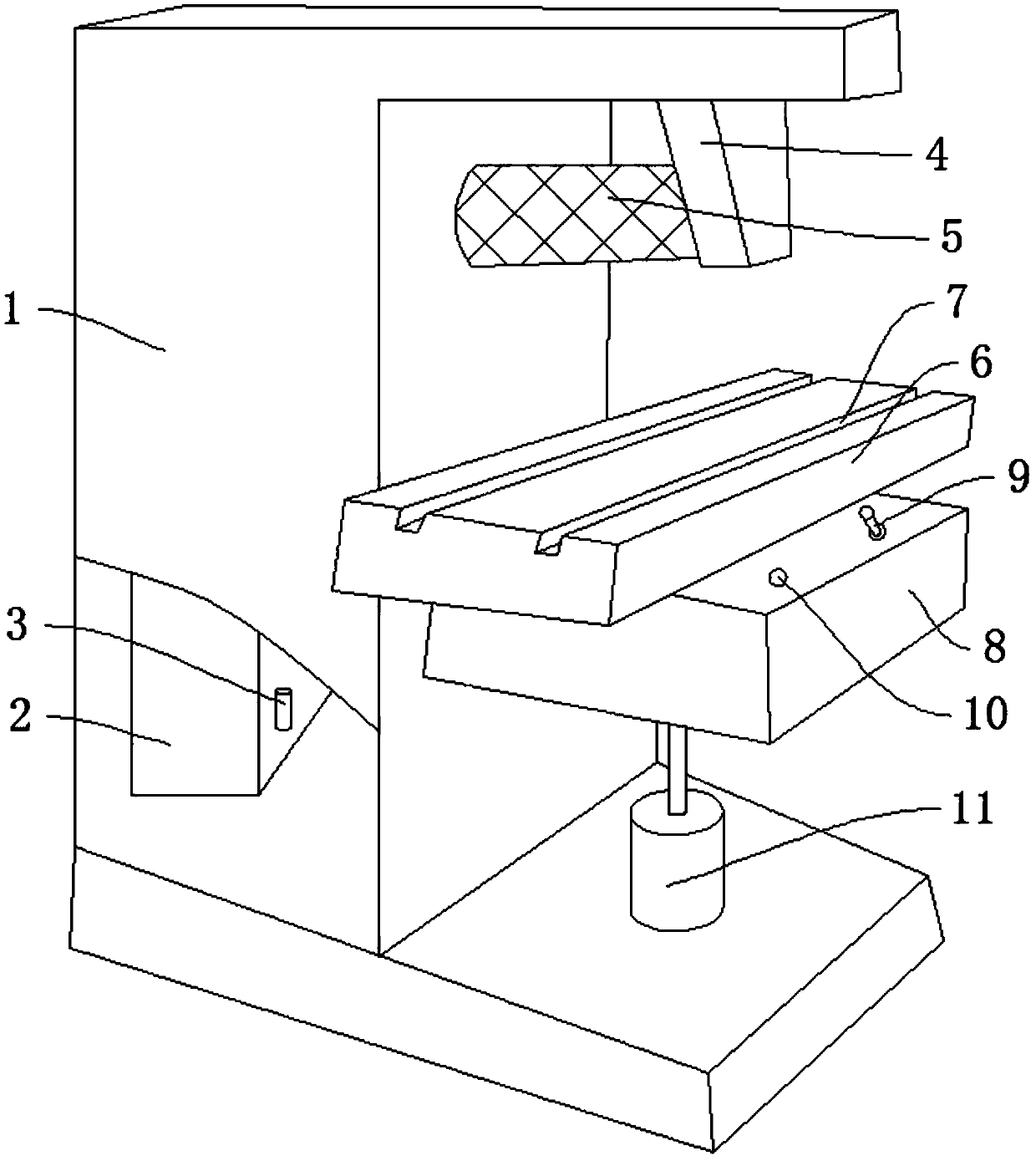

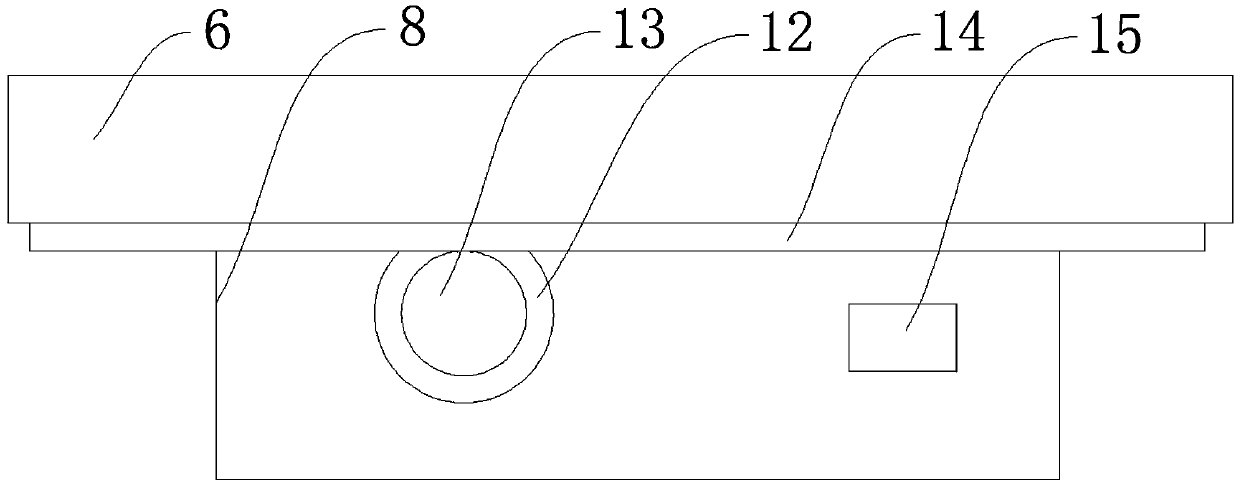

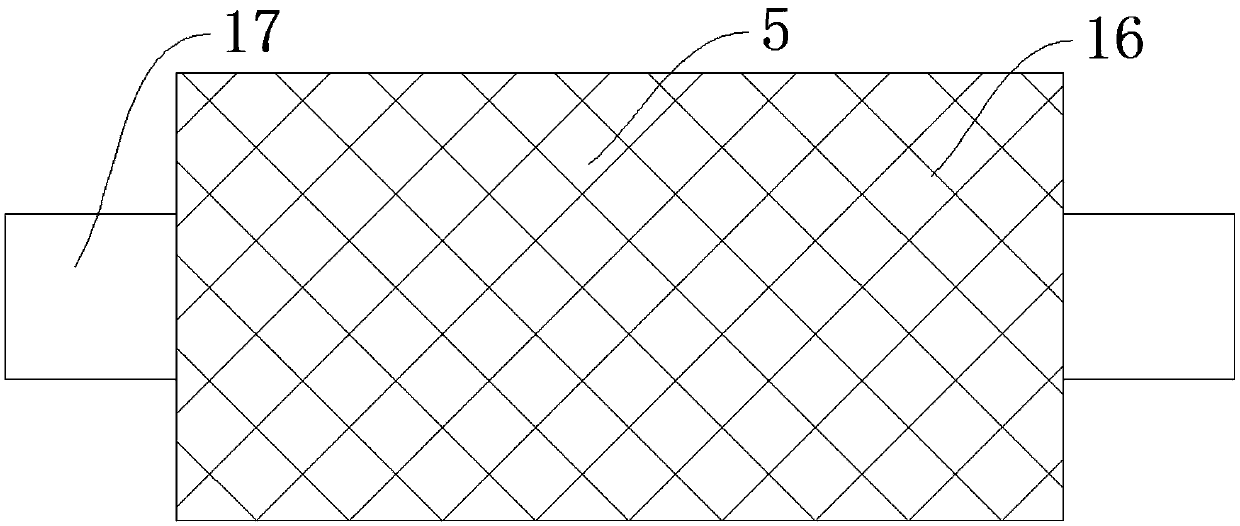

The invention provides an alloy flat wire processing and forming device applied to the technical field of alloy flat wire production and processing and further relates to a method for rolling wires by using same. A wire rolling mechanism (5) is arranged between a wire paying-off mechanism (1) and a wire winding-up mechanism (2) of the alloy flat wire processing and forming device, and an upper roller (7) and a lower roller (8) of the wire rolling mechanism (5) are installed on a rolling mechanism support (6). The wire rolling mechanism (5) further comprises an adjusting part (11) for adjusting a gap between the upper roller end face (9) and the lower roller end face (10), and the wire winding-up mechanism (2) is connected with an electric control mechanism (12) for controlling winding-up. By means of the device and the method, the wires can be ensured to be formed in the processing and forming process in one time, accordingly the labor intensity of operators is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:WUHU CHUJIANG ALLOY COPPER

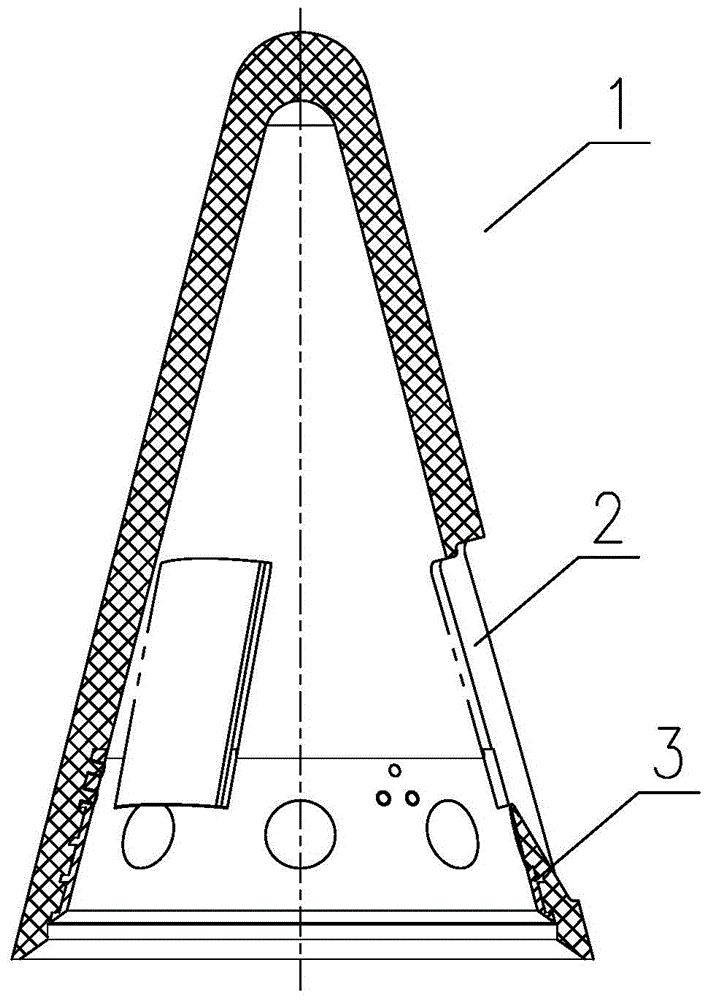

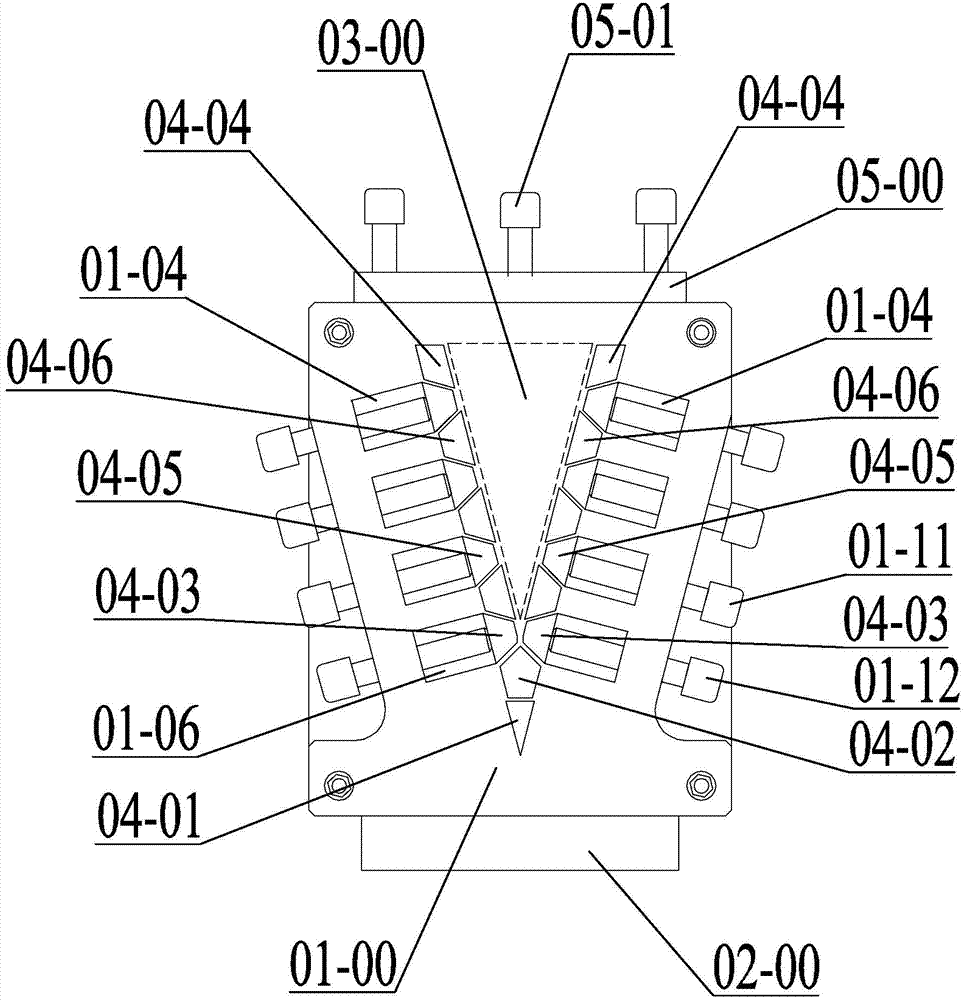

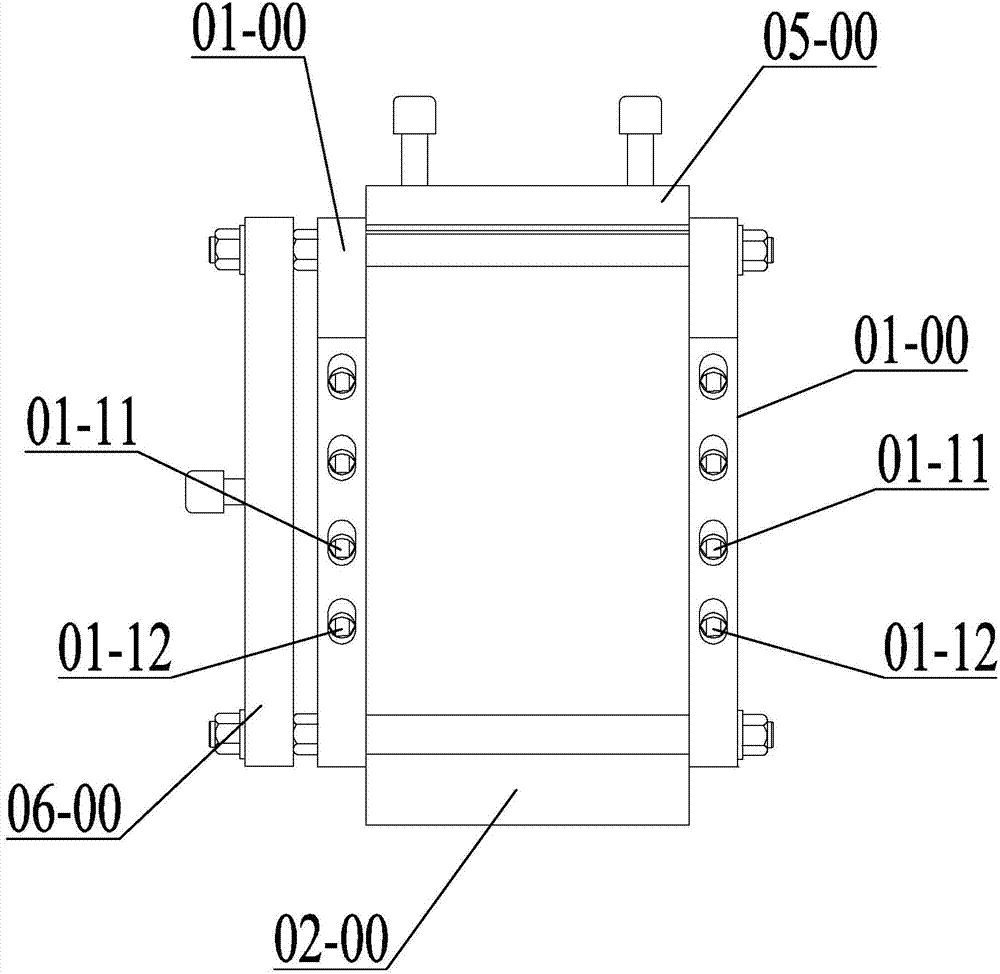

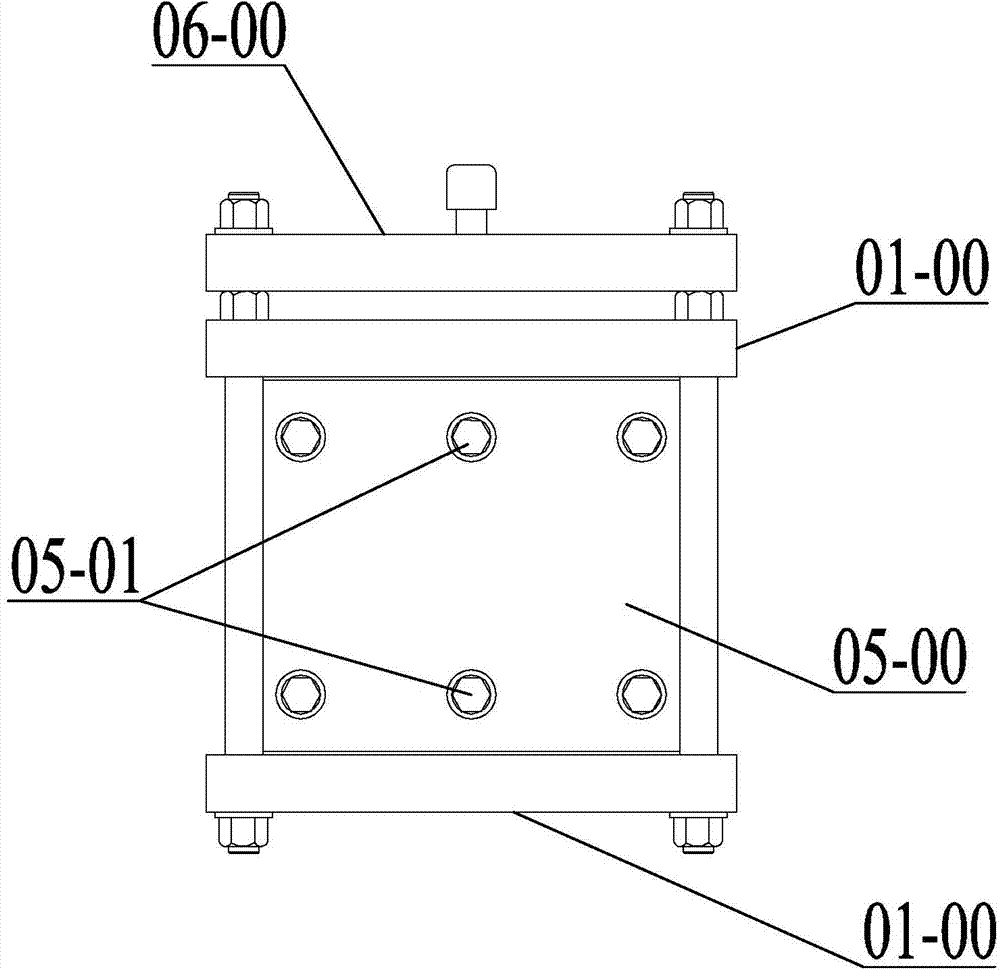

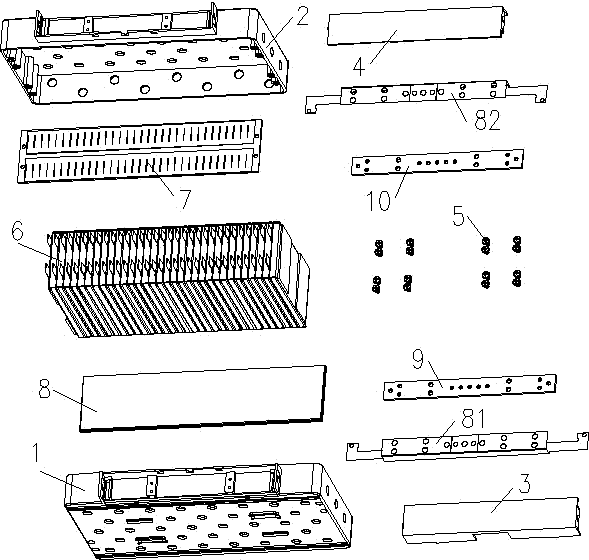

Preparation mold of composite material in ceramic-base corrugated sandwich structure

ActiveCN103831979AGuaranteed dimensional accuracyGuaranteed one-time moldingIsosceles trapezoidState of art

The invention relates to a preparation mold of a composite material in a ceramic-base corrugated sandwich structure and solves the problems that as the borne temperature of the preparation mold of the corrugated sandwich structure is low in a machining process of a component in the corrugated sandwich structure in the prior art, the preparation mold cannot bear sufficient stress, is easy to deform, cannot guarantee the dimensional precision of a test piece and needs to carry out secondary machining. The preparation mold comprises a base plate, a pressing plate, two slide rail plates, four cylindrical connecting pieces, N+1 trapezoidal fixed sliding blocks and N trapezoidal movable sliding blocks, wherein the slide rail plates are rectangular slide rail plates, N+1 erected isosceles-trapezoid-like through holes are uniformly formed in the bottom of each slide rail plate along the horizontal direction, and N inverted isosceles-trapezoid-like through holes are uniformly formed close to each erected isosceles-trapezoid-like through hole along the horizontal direction. The preparation mold is used for manufacturing the ceramic-base corrugated sandwich structure.

Owner:HARBIN UNIV OF SCI & TECH

Shaping method of sealing gasket between windows and covering cap of cone-cylinder-shaped thermal shield

ActiveCN104875316AMeet molding requirementsSolve the sealing problemEngine sealsNumerical controlEngineering

The invention discloses a shaping method of a sealing gasket between windows and a covering cap of a cone-cylinder-shaped thermal shield. The shaping method of the sealing gasket between the windows and the covering cap of the cone-cylinder-shaped thermal shield includes following steps: using a numerical control machining method to process three windows on the thermal shield shaped through mould pressing, and using a near-net-shape forming method to shape the covering cap with a complex molding surface through mould pressing; performing repair so as to obtain matched intervals between the covering cap and the thermal shield windows so as to leave a space for manufacture of the sealing gasket; smearing the windows with prepared sealant, swearing the covering cap with a releasing agent, guaranteeing separation between the covering cap and the sealant, adhering the sealant to the thermal shield windows, and using a special shaping clamp matched with the thermal shield to tightly press the covering cap. The shaping method of the sealing gasket between the windows and the covering cap of the cone-cylinder-shaped thermal shield can guarantee seal performance of the thermal shield windows of a shield throwing system, and simultaneously can meet a downstream / upstream step increment between an external cone of the covering cap and an external cone of the thermal shield.

Owner:湖北三江航天江北机械工程有限公司

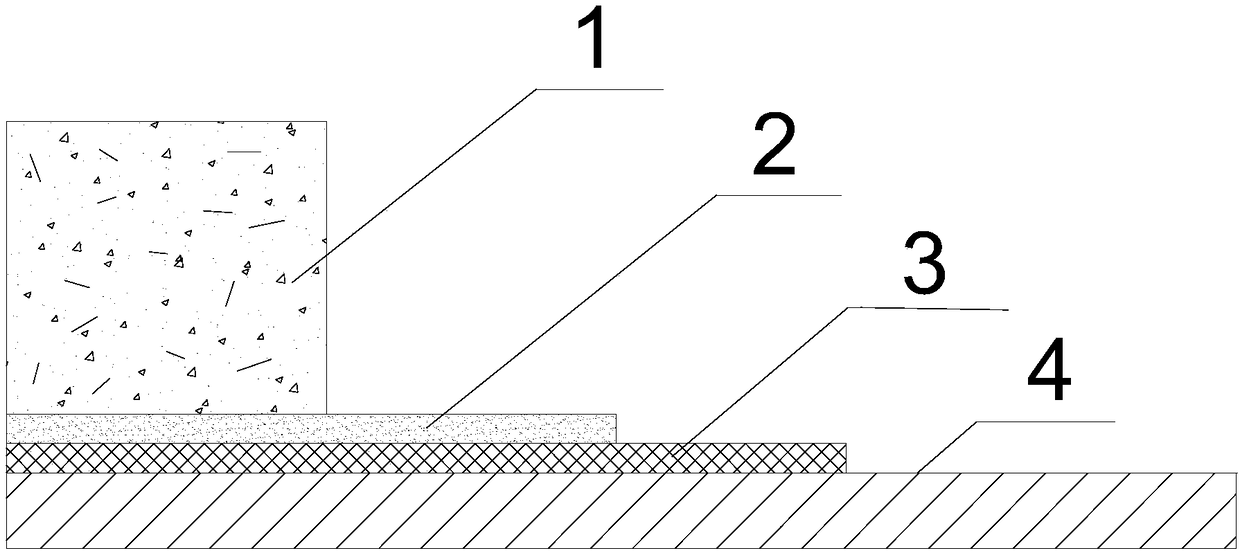

Waterproof sealing system for high-speed railway bridge deck in severe cold area and construction method of waterproof sealing system

InactiveCN108149569AImprove crack resistanceImprove frost resistanceBridge structural detailsBridge erection/assemblyCold areaBridge deck

The invention discloses a waterproof sealing system for a high-speed railway bridge deck in a severe cold area and a construction method of waterproof sealing system. The waterproof sealing system comprises a protecting wall outside cable duct waterproof system and a between-cable waterproof system and is characterized in that the protecting wall outside cable duct waterproof system comprises a waterproof coating layer and a fiber reinforced concrete protecting layer; the between-cable waterproof system comprises a waterproof coil layer and a fiber reinforced concrete protecting layer. The waterproof sealing system has the advantages that the waterproof coil and C40 fine-stone fiber reinforced concrete are composited to serve as the structure waterproof sealing layer, and the crack resistance and freezing resistance of the concrete are increased; a self-made paving machine is used to perform coil paving to guarantee coil adhering density and increase the effect; a vibration platform isused to perform deck ultrathin glass fiber waterproof concrete pouring, a drainage slope is formed in one step, and cracking after construction is prevented effectively.

Owner:中铁二十二局集团第一工程有限公司 +1

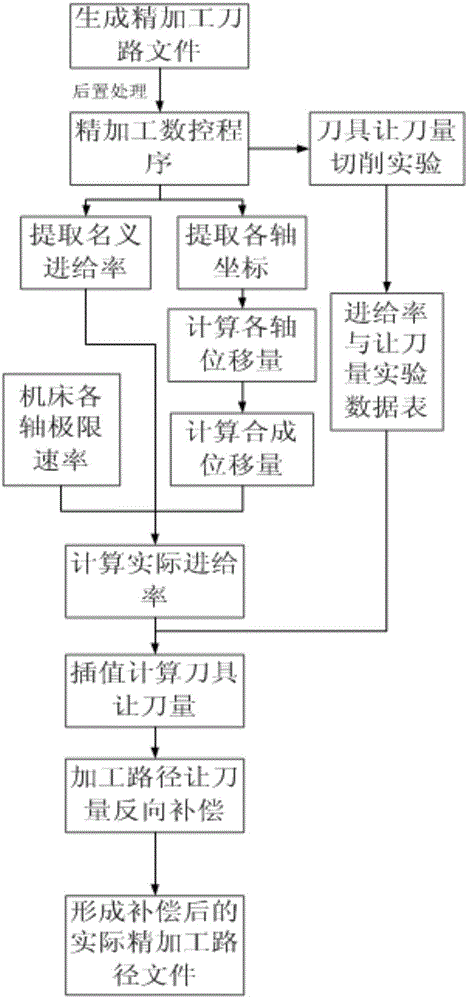

Method for carrying out cutter back-off compensation on multi-shaft processing path of weak-rigidity cutter

ActiveCN104317246ASuppress part size out-of-toleranceGuaranteed one-time moldingProgramme controlComputer controlReverse modeEngineering

The invention discloses a method for carrying out cutter back-off compensation on a multi-shaft processing path of a weak-rigidity cutter. According to the method, a relation between all cutter spacing multi-shaft processing actual speeds and cutter back-off amounts is taken into consideration to generate an overcut path in a reverse mode; and a weak-rigidity tool is used for carrying out cutter back-off deformation processing. The part dimension difference exceeding is effectively reduced or inhibited; the one-time moulding is ensured; multi-times repeated cutting is not required; and the processing efficiency and processing precision are guaranteed.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

Wire bending method of free lead wire of voice coil

InactiveCN101651921AControl outlet positionGuaranteed one-time moldingElectrical transducersEngineeringVoice coil

The invention relates to a wire bending method of a free lead wire of a voice coil, comprising the following steps: providing a vibrating diaphragm which is adhered with the voice coil with the free lead wire; providing a press ring which is provided with a positioning part, wherein the positioning part is provided with a first lateral surface, a second lateral surface opposite to the first lateral surface and a connection surface connected with the first lateral surface and the second lateral surface; providing a support device which is provided with a support column supporting the positioning part of the press ring and a pair of grooves containing the free lead wire of the voice coil, wherein the inner diameter of the support column is shorter than the distance between the first lateralsurface and the second lateral surface; placing a vibrating diaphragm device adhered with the voice coil on the support device, enabling the free lead wire of the voice coil to be respectively contained into the pair of grooves of the support device, then covering the press ring on the support device and connecting the press ring with the support device so that the positioning part of the press ring is inserted into the support column of the support device and the first lateral surface of the positioning part supports against the support column; rotating the press ring, and bending the free lead wire of the voice coil. The invention can ensure the one-step molding of the wire bending angle of the free lead wire of the voice coil.

Owner:AAC TECH PTE LTD +1

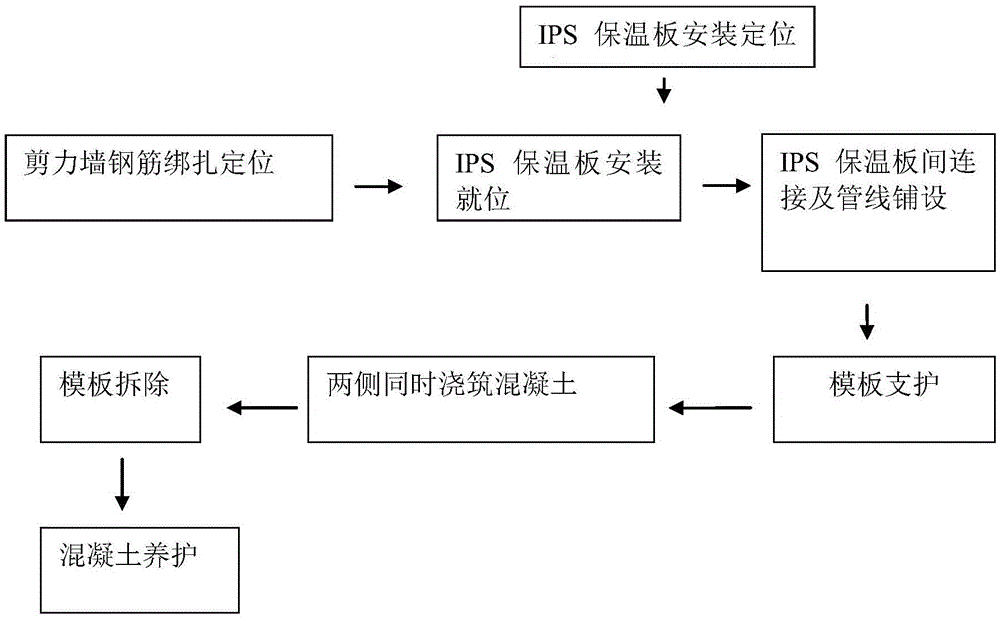

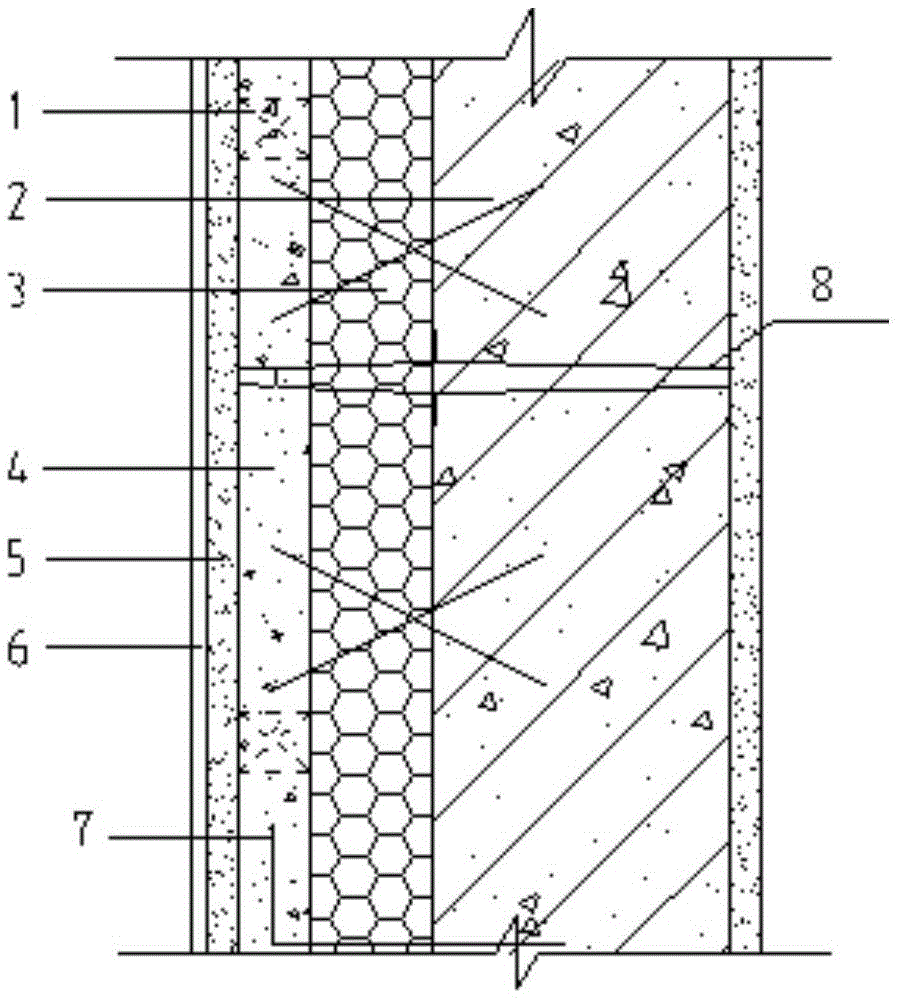

Self-insulation construction scheme for IPS cast-in-place concrete shear wall

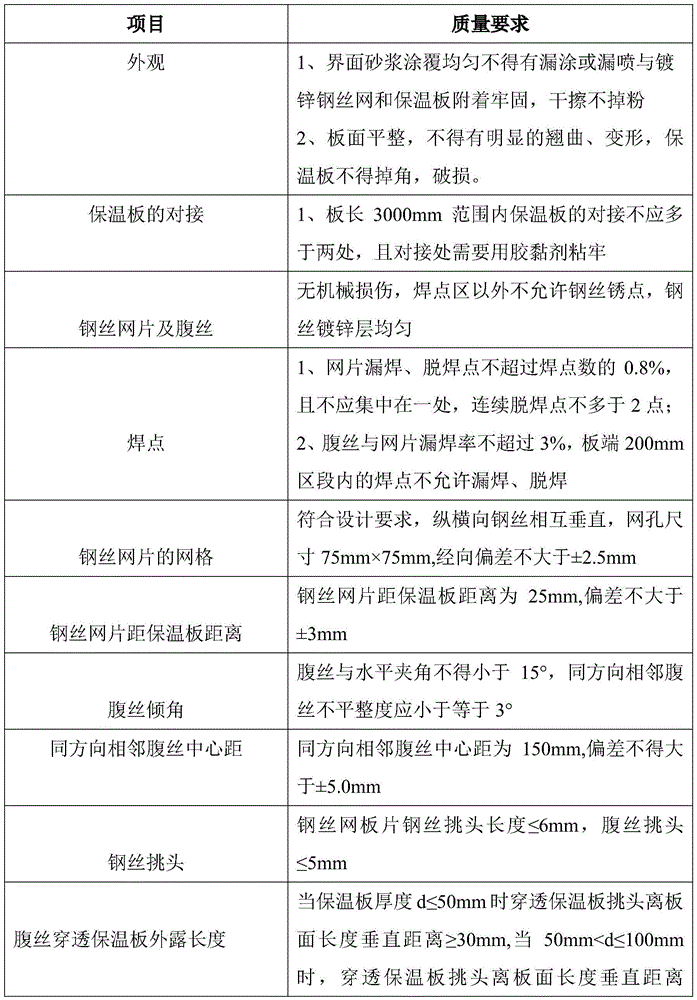

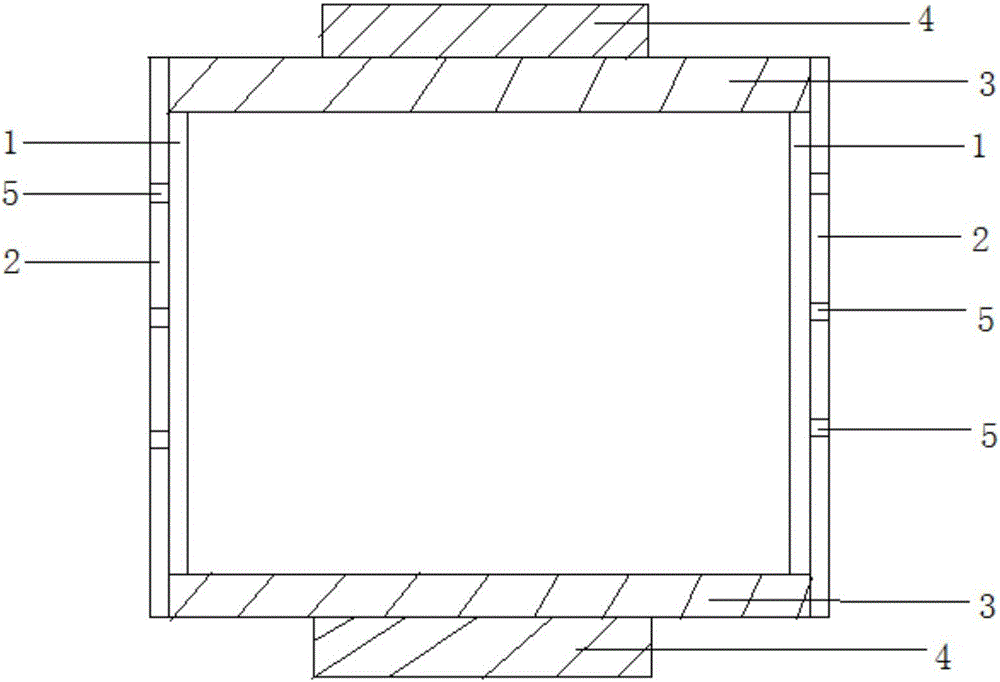

InactiveCN105649232AAchieve energy saving and heat preservation effectGuaranteed firmnessWallsHeat proofingInsulation layerThermal insulation

The invention discloses a self-insulation construction scheme for an IPS cast-in-place concrete shear wall. The self-insulation construction scheme comprises the steps of 1, binding locating steel bars on the shear wall and installing insulation boards on the external sides of the locating steel bars; 2, arranging formworks on the inner sides of the insulation boards in a supporting mode, installing locating blocks on the inner sides and the external sides of the insulation boards, connecting and fixing every two adjacent insulation boards and laying pipelines; 3, binding steel bar stay bars on the insulation boards in a penetrating and inserting mode; 4, arranging formworks on the outer sides of the insulation boards in a supporting mode; 5, pouring concrete on the inner sides and the outer sides of the insulation boards simultaneously; and 6, after the concrete is solidified, removing the formworks and curing the concrete. A material high in thermal resistance value is adopted as a surface insulation layer of an external wall for the integral cast-in-place external wall external insulation system; when the concrete of the external wall is poured, thermal insulation materials are placed on the outer sides of cast-in-place concrete wallboards and are poured with the concrete wallboards of the external wall together, an external thermal insulation layer and a wall body are integrated, and therefore the effect of energy conservation and thermal insulation is realized.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

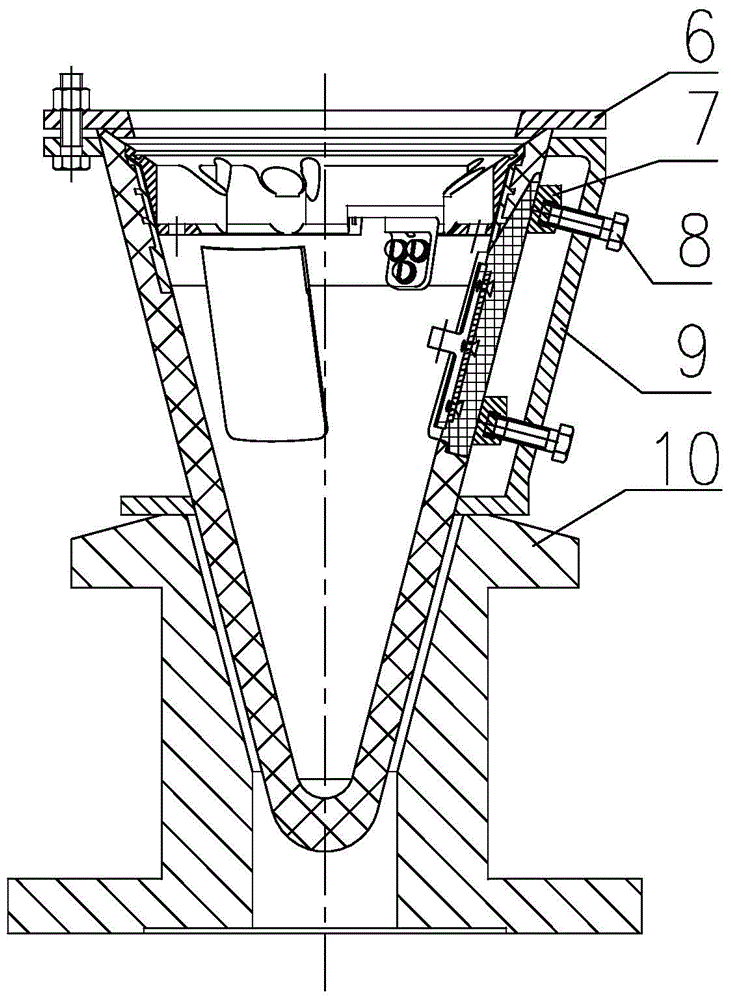

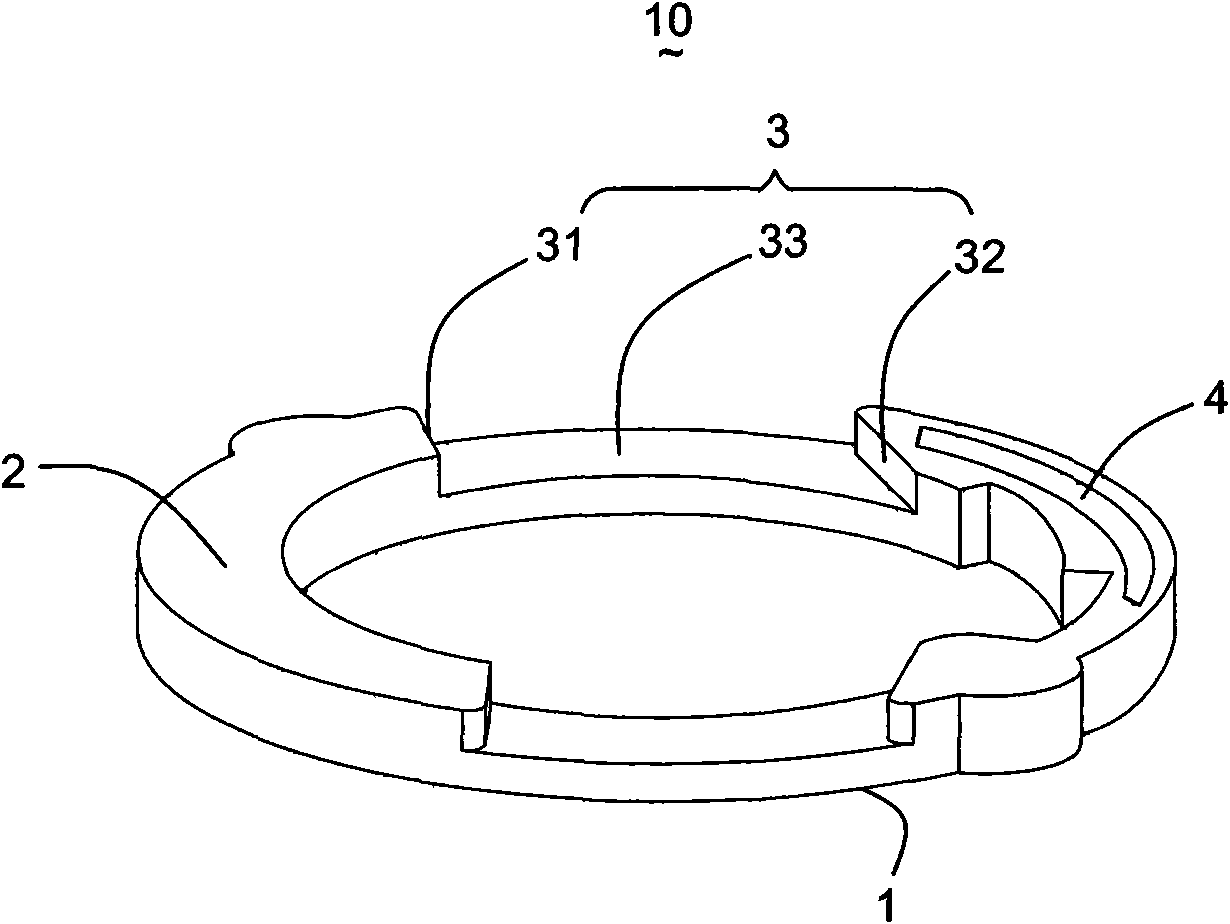

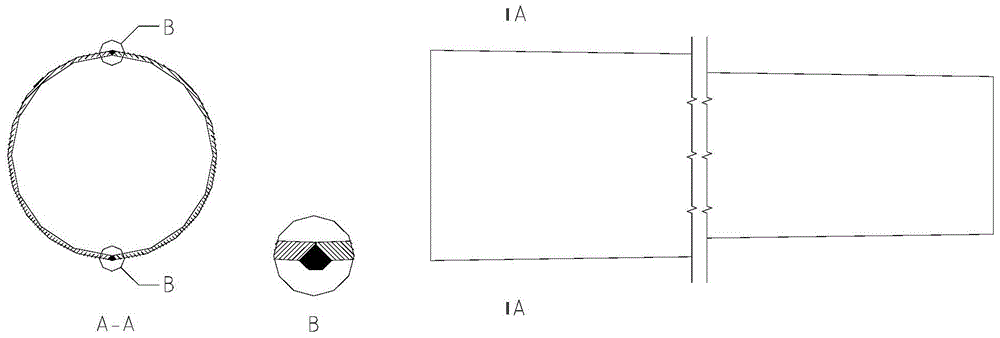

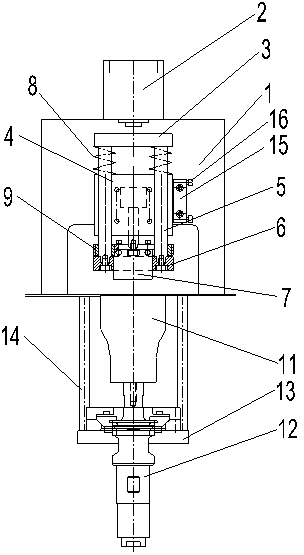

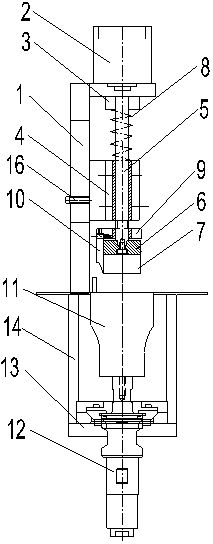

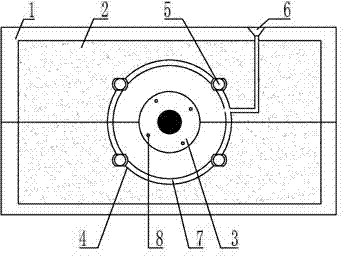

Wet type isostatic cool pressing die

The invention provides a wet-type cold isostatic pressing mold, which includes a mold body and a mold cover plate. During operation, a sealing device is used to seal and fix the mold cover plate on the mold body. It is characterized in that the mold body is composed of a soft inner sleeve and a control The outer part of the soft inner sleeve is the control mold, the soft inner sleeve is attached to the inner wall of the control mold, and there are several diversion holes distributed on the control mold. The holes conduct pressure uniformly to the soft inner sleeve. The wet cold isostatic pressing mold of the present invention has a reasonable structure and is easy to operate, and can withstand the wet cold isostatic pressing forming with a production pressure of 60‑220Mpa, protects the materials inside the mold from erosion, and most importantly can make the cold isostatic pressing The molding technology achieves one-time molding of near-net size, which ensures the accuracy of one-time molding of the green body to the greatest extent, improves production efficiency and reduces manufacturing costs.

Owner:HUBEI XITIAN TECH CO LTD

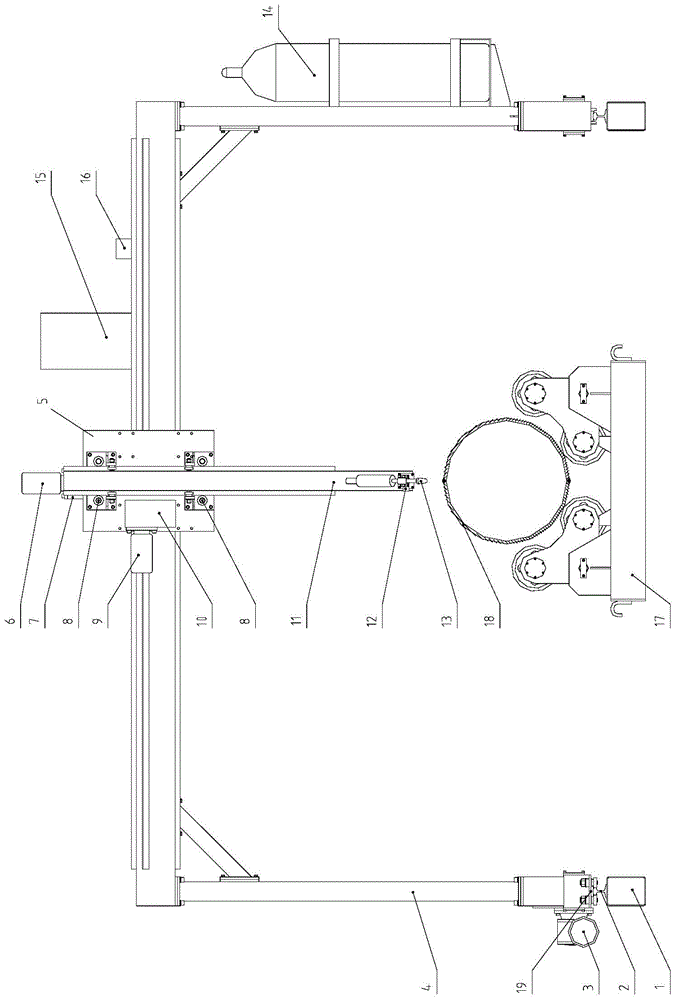

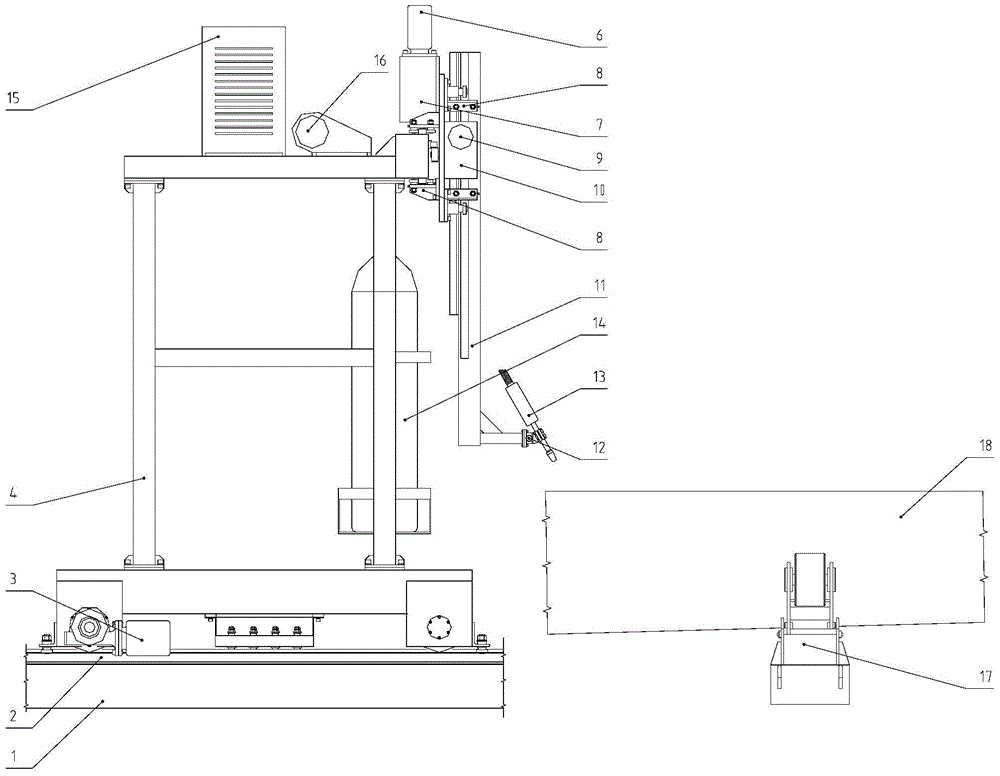

Gantry-type automatic welding and gouging integrated machine for welding steel pipe rods

ActiveCN104475918ALower skill requirementsReduce labor costsWelding/cutting auxillary devicesArc welding apparatusEngineeringReducer

The invention discloses a gantry-type automatic welding and gouging integrated machine for welding steel pipe rods, wherein the gantry frame is a door frame type rack formed by two vertical posts and one cross beam; the cross beam of the gantry frame is provided with a welding machine and a solder wire feeding machine. A crosswise cast iron convex guide rail on a crosswise dragging plate is in sliding match connection with a protruded grooved track on lateral side of the cross beam of the gantry frame; and the cross beam of the gantry frame is provided with a welding arm crosswise walking motor and a welding arm crosswise reducer, so as to provide power for the crosswise movement of the welding arm. Supporting guide rails on bilateral sides of the welding arm are in sliding match connection with vertical sliding chutes on the crosswise dragging plate; and the crosswise dragging plate is provided with a welding arm vertical walking motor and a welding arm vertical reducer, so as to provide power for the vertical movement of the welding arm. Compared with the prior art, the provided gantry-type automatic welding and gouging integrated machine for welding steel pipe rods is able to increase the comprehensive welding efficiency, quality and aesthetic measure of the product, and reduce the cost thereof.

Owner:ANHUI JIXI JIADE STEEL STRUCTURE

Preparation method of three-dimensional soft bracket

ActiveCN103120808AReduce the chance of contaminationAvoid exclusionProsthesisTomographic imageArtificial organ

The invention discloses a preparation method of an artificial organ soft bracket for replacing intracorporeal organs, and belongs to the technical field of bioengineering. The method comprises the steps of firstly, carrying out CT or MRI scanning on an individual organ of a patient, obtaining a group of N layers of faultage images related to organs and tissue parts from bottom to top; leading the obtained model data into a biological molding machine; then taking the organ tissue cells of the individual patient to cultivate, so as to obtain the tissue cell suspension solution with specific cell density; evenly mixing the cultivated tissue cell suspension with specific cell density and hydrogel according to a certain volume ratio; and finally printing the mixture of the tissue cell suspension solution and gel by a homemade biological molding machine, so as to finish preparation of the organ soft bracket. The soft bracket is prepared by a living tissue cell and the gel; meanwhile, the micro-structure and appearance prepared from the soft bracket are effectively controlled; and the requirements of individual difference of the patients and different parts on the organ soft bracket are met.

Owner:西安博恩生物科技有限公司

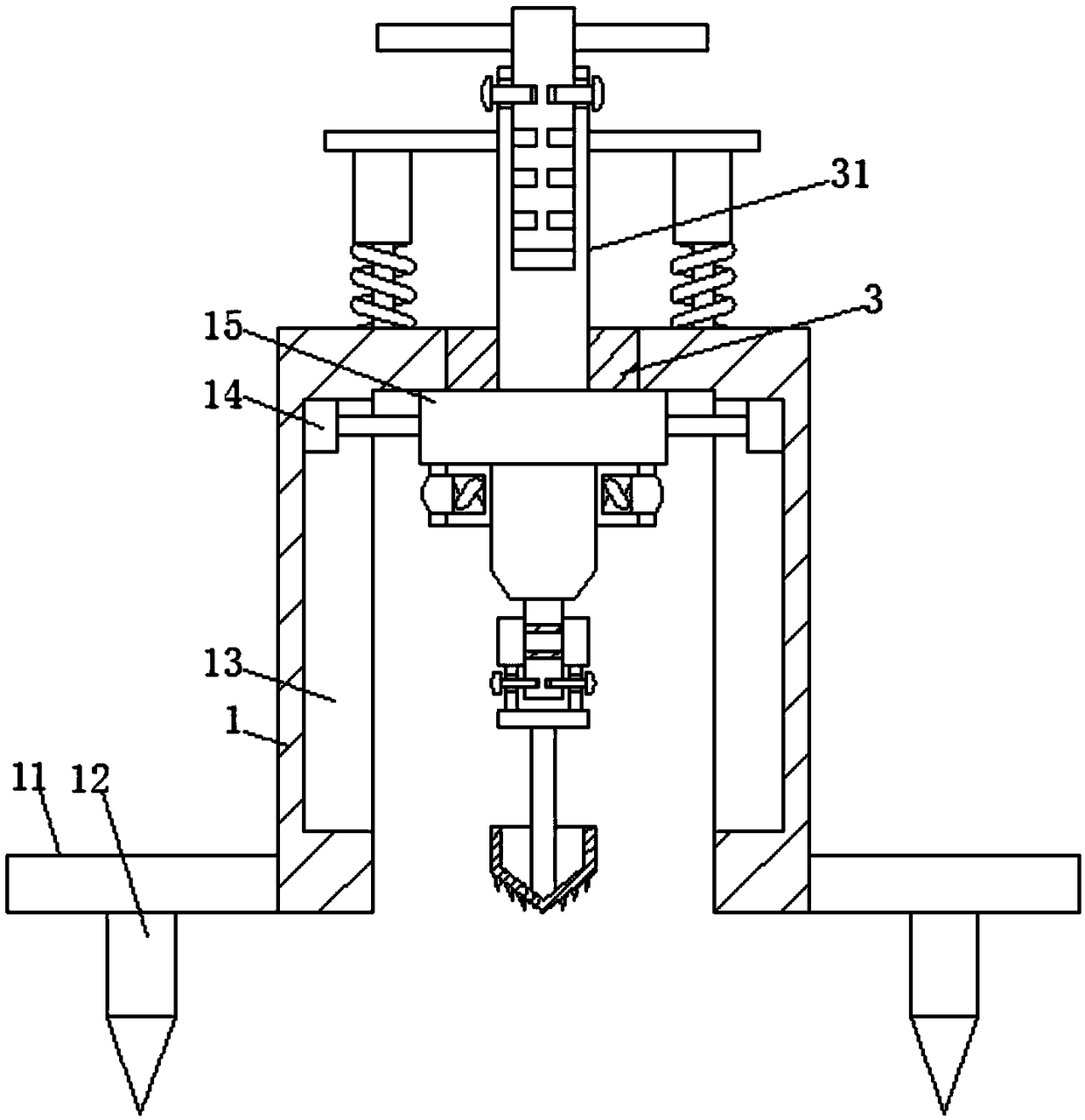

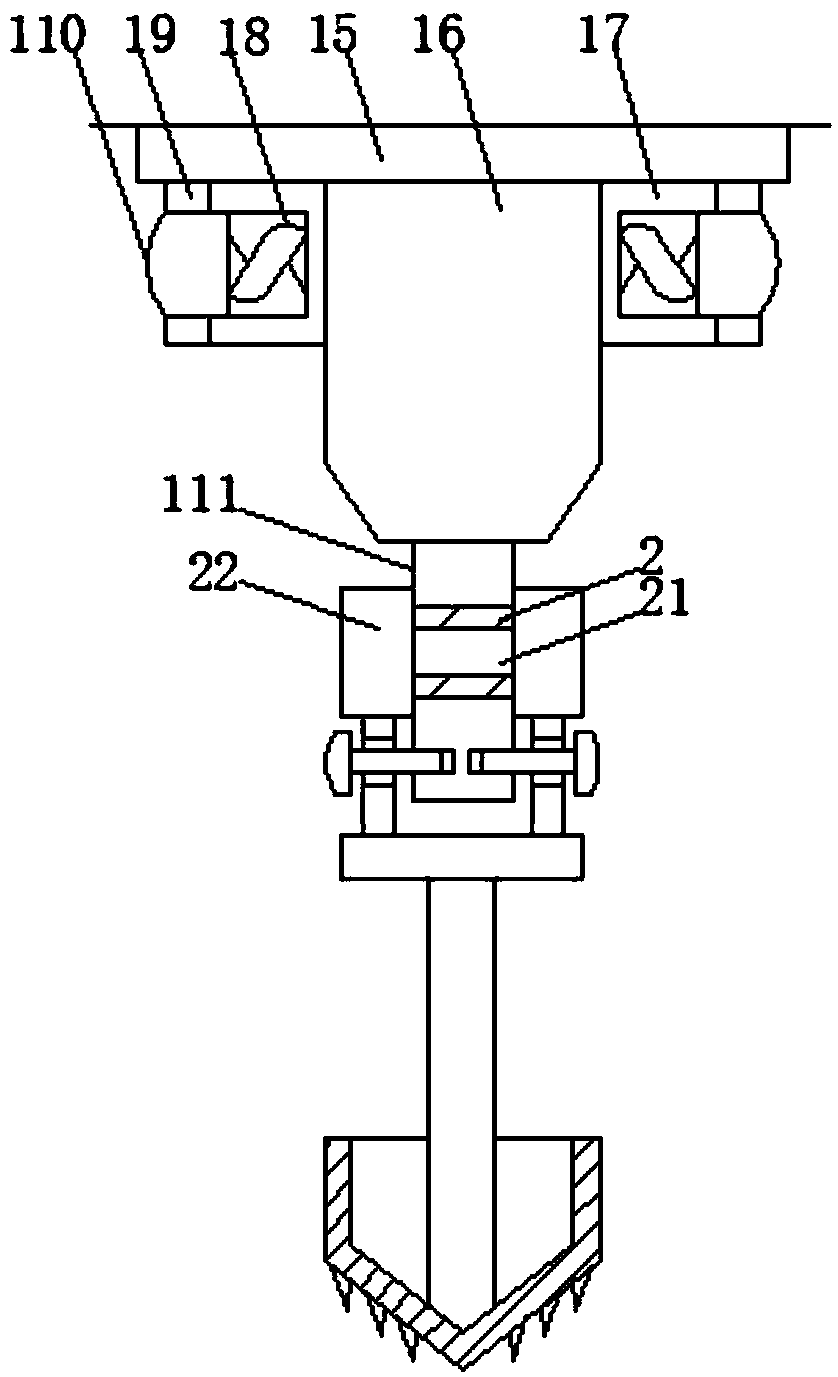

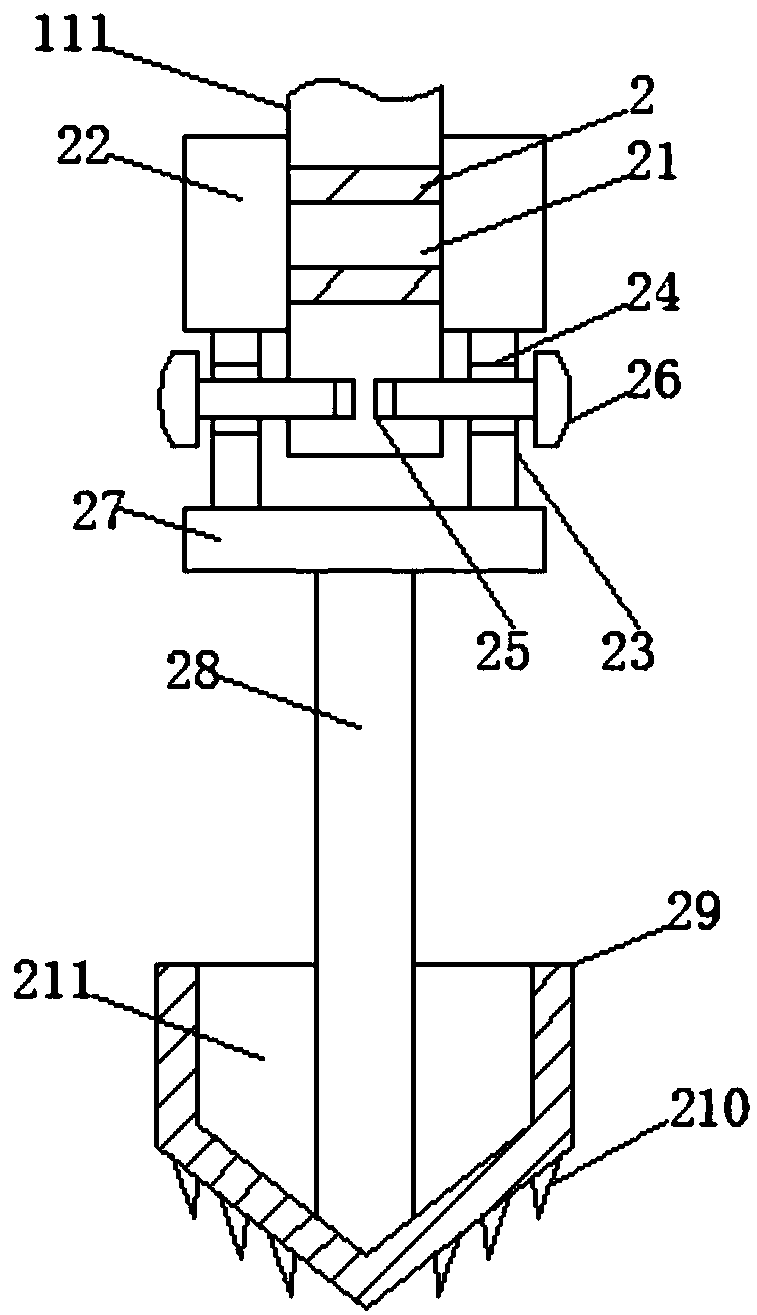

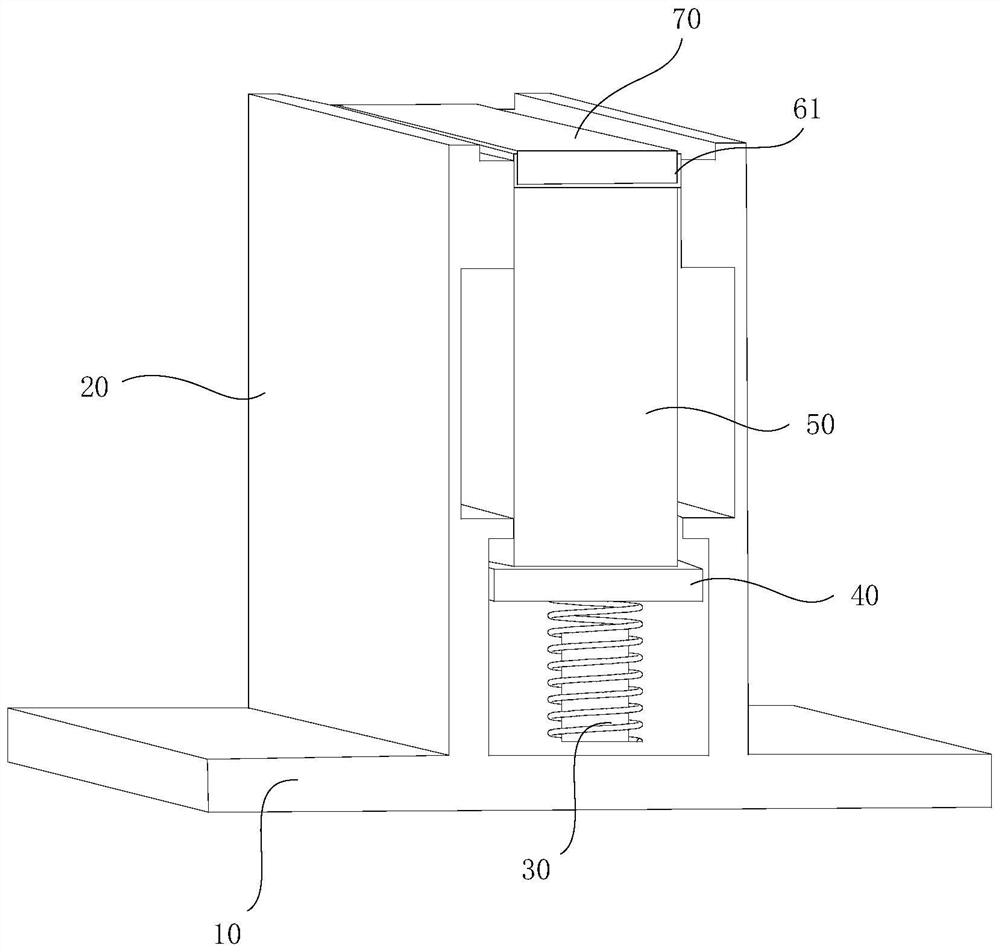

Pit digging device for tangerine seedling plantation

The invention discloses a pit digging device for tangerine seedling plantation. The device comprises a positioning frame, two ends of the outer side of the positioning frame are both fixedly connectedwith pedals, conical bulges are welded at the lower ends of the pedals, two sides of the positioning frame are both internally provided with limiting grooves, the inner sides of the limiting groovesare in sliding connection with limiting blocks, the surfaces of the limiting blocks are fixedly connected with a mounting plate, the surface of the mounting plate cling to a motor, two ends of the outer side of the motor are both fixedly connected with clamping seats, the inner sides of the clamping seats are fixedly connected with first springs, and the other ends of the first springs are fixedlyconnected with clamping pins. According to the pit digging device for tangerine seedling plantation, the positioning frame can be inserted into soil to perform positioning on the whole through the conical bulges, then a drill bit is driven by a telescopic rod to stretch out and draw back up and down so as to carry out pit digging on soil, and a built-in groove can be used for collecting slipped soil, thereby guaranteeing that the pit is formed once during digging.

Owner:寻乌县友华农业科技发展有限公司

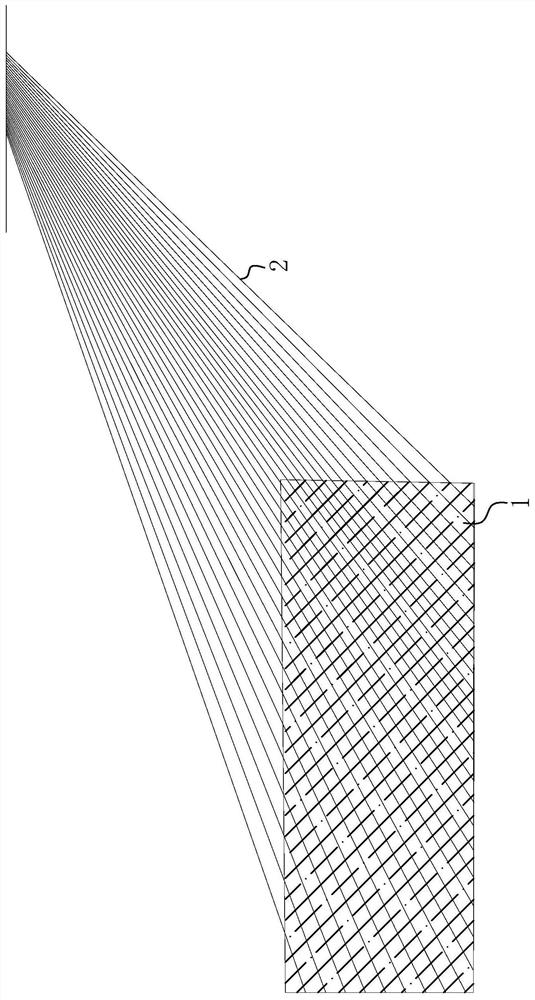

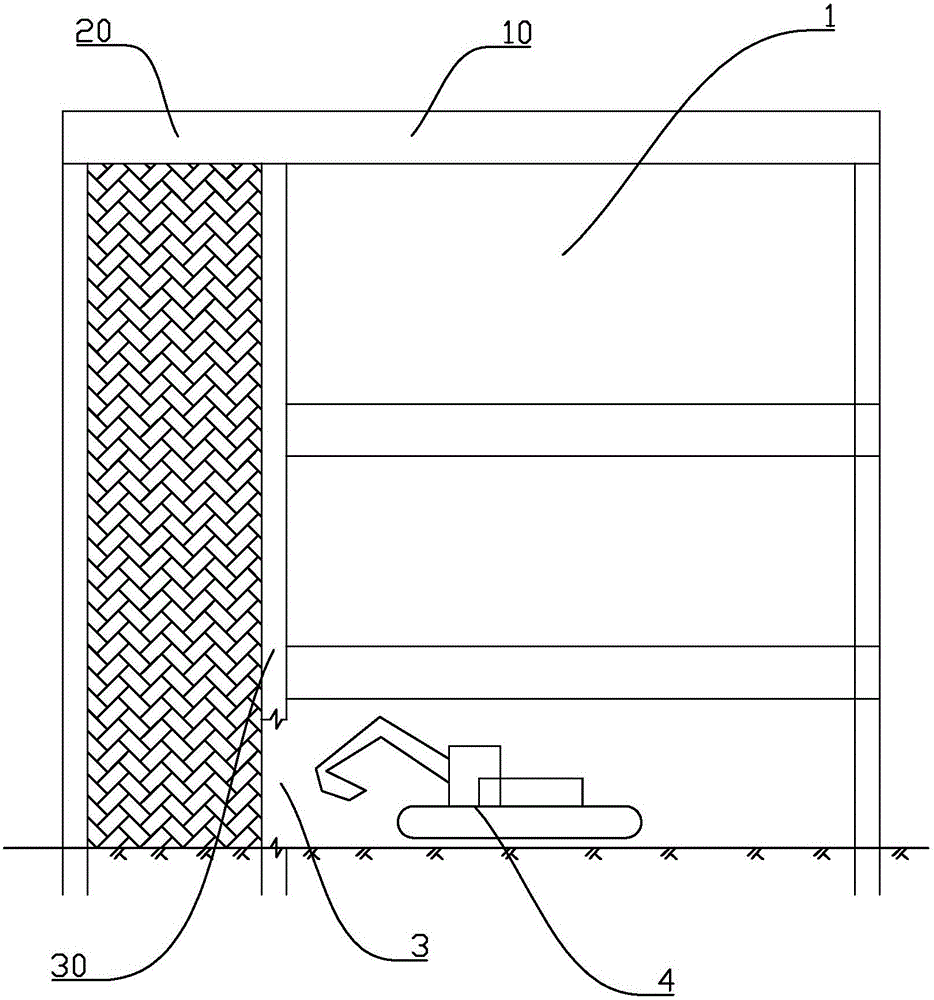

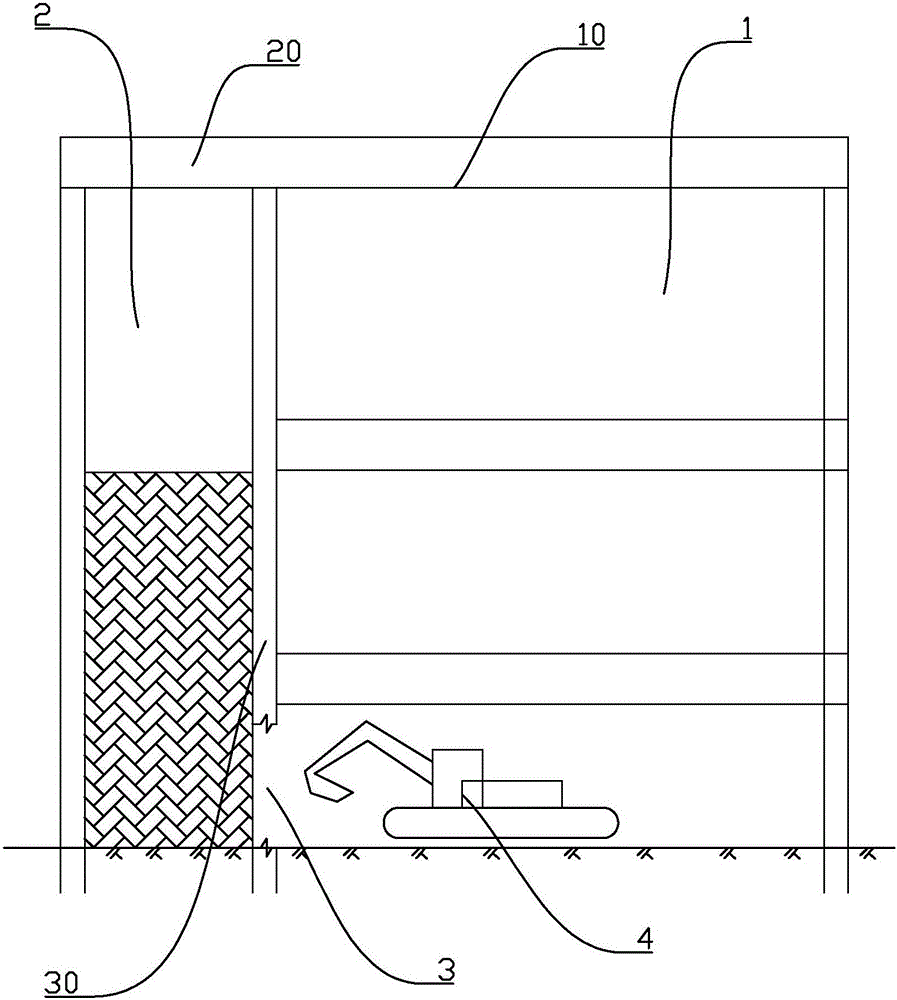

Reinforcing method for side-penetrating of a high-speed rail viaduct pile foundation by shield tunnel

InactiveCN112228081APlay the role of reinforced isolationReduce disturbanceTunnelsStructural engineeringShield tunneling

The invention relates to a reinforcing method for side-penetrating of a high-speed rail viaduct pile foundation by a shield tunnel. The reinforcing method comprises the following steps that S1, paying-off and positioning are carried out, and specifically, the hole positions of drill holes are determined outside a protection area and marked; S2, a drilling machine is in place and drills the holes,specifically, the drilling machine is in place outside the protection area, a drill rod drills the holes by adopting an oblique accurate positioning mode to enable the drill holes to extend to an areato be reinforced, different inclination angles are adopted for the drill holes to form a sector shape between the drill holes and the area to be reinforced, and meanwhile a grouting pipe and a sleevevalve pipe are installed; S3, grouting is carried out, specifically, after a soil body is recovered, grouting is carried out by adopting a single-hole grouting mode, and after a second peak value appears on a pressure gauge, grouting is ended; and S4, hole sealing is carried out, specifically, hole openings are sealed after grouting is ended, and then the next hole operation is carried out. The reinforcing method has the effect of solving the problem of soil body isolation and reinforcement operation between a shield tunnel and an existing high-speed rail viaduct pile foundation.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

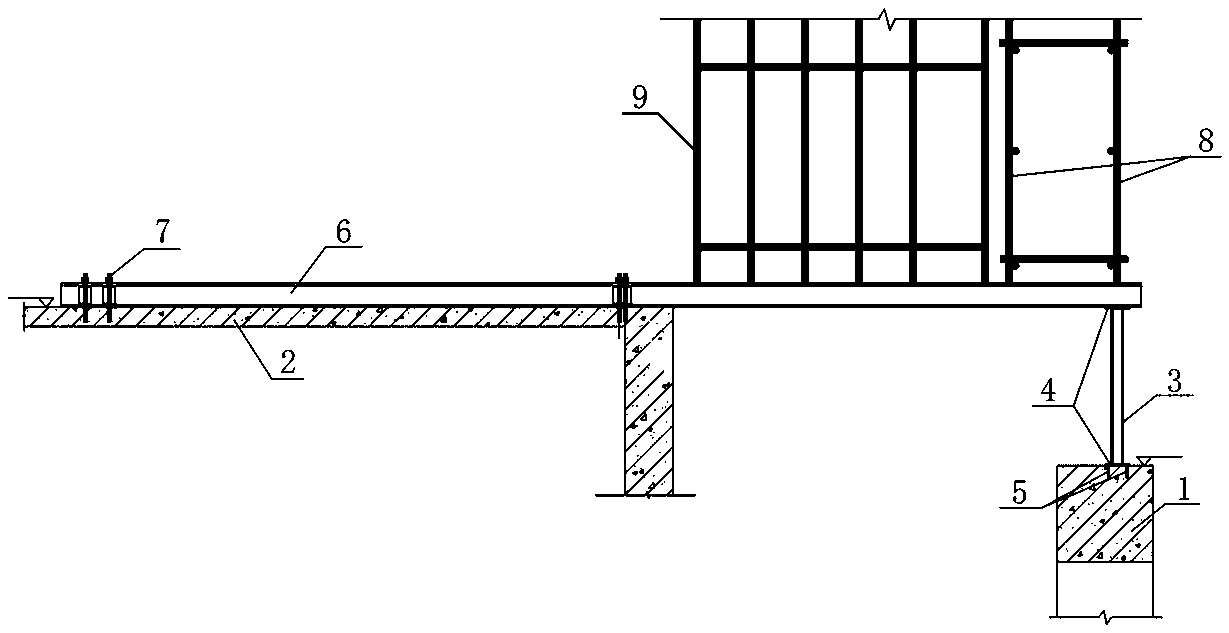

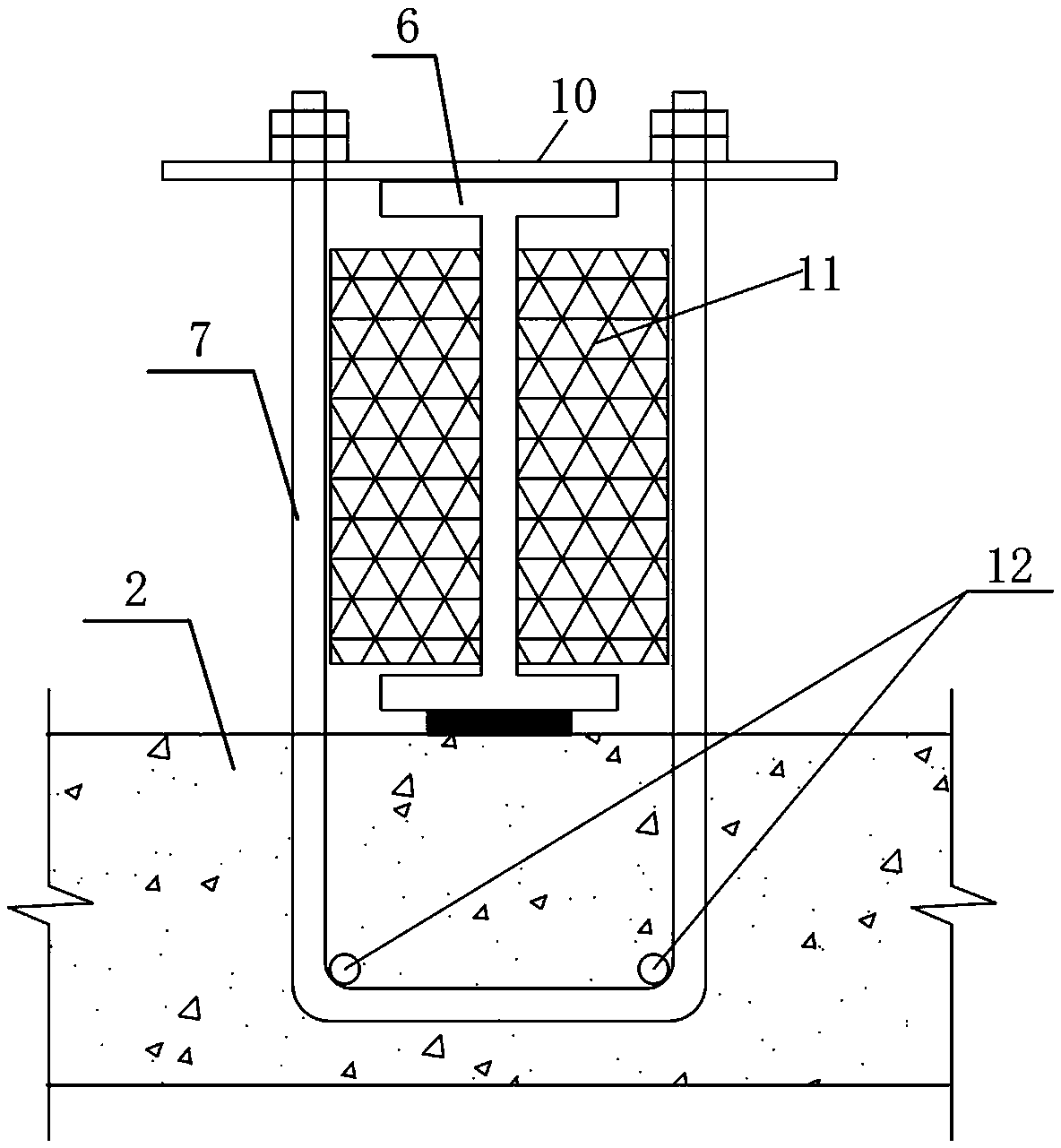

Large-span suspended member construction system and construction method thereof

ActiveCN111335611ASimple form of forceSave construction materialsForms/shuttering/falseworksScaffold accessoriesRebarSteel tube

The invention discloses a large-span suspended member construction system and a construction method thereof. The construction system comprises a foundation pit supporting crown beam, a structural floor slab, a profile steel foundation, a round steel pipe, a template bracket and an outer scaffold. The foundation pit supporting crown beam is a reinforced concrete continuous beam. The arranging position of the structural floor slab is higher than the foundation pit supporting crown beam. A U-shaped connecting device is pre-buried in the structural floor slab; the first end part of the profile steel foundation is connected to the structural floor slab through the U-shaped connecting device. The lower end of the round steel pipe is fixedly connected to the foundation pit supporting crown beam,and the upper end of the round steel pipe is connected to a second end part of the profile steel foundation. The template bracket is arranged on the profile steel foundation. The outer scaffold is arranged on the profile steel foundation and the outer scaffold and the template bracket are arranged in a spaced manner. The scheme solves the problem that it is hard to construct a supporting rack bodyand the outer scaffold of a large-span suspended member at the same time effectively, it is ensured that the large-span suspended member is formed primarily, facilitates insertion of follow-up stepsin advance favorably and shortens the integral construction period.

Owner:中国建筑土木建设有限公司

Particle-forming disk pelleting machine

InactiveCN106378059ANot easy to stickImprove molding rateDrying solid materials with heatGranulation by material expressionHydraulic cylinderInfrared lamp

The invention provides a particle-forming disk pelleting machine. The particle-forming disk pelleting machine comprises a base, a pelleting device and a spheroidizing device, wherein the pelleting device is rotationally connected with the base; the base is also provided with a high energy accumulation infrared lamp; the pelleting device comprises a main material pressing barrel and a side material pressing barrel; the main material pressing barrel and the side material pressing barrel are communicated through a pipeline; a main material pressing mechanism is arranged above the main material pressing barrel; a side material pressing disk is arranged above the side material pressing barrel; multiple small holes which are uniformly distributed are formed in the bottom part of the side material pressing barrel; a cutter is also arranged at the bottom part of a first support; the spheroidizing device comprises a spheroidizing plate and a material retaining plate; first hydraulic cylinders are arranged at two symmetric sides of the spheroidizing plate. According to the particle-forming disk pelleting machine provided by the invention, the granulation rate of a water quality improver is increased through a simple device, the processing cost is reduced, the processing efficiency is increased to the same degree, and the benefit is increased.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

Combined grinding device for rotating surface and adjacent surface of metal workpiece

InactiveCN114603409ARealize comprehensive combined grindingEfficient processingGrinding wheel securing apparatusRevolution surface grinding machinesMetal machiningEngineering

The invention provides a combined grinding device for a rotating surface and an adjacent surface of a metal workpiece, and relates to the technical field of metal processing. Four sliding positioning devices are connected to the operation mounting part in a sliding manner; the four sliding positioning devices are mounted on the inner side of the operation mounting part in an annular array; the operation mounting part is in threaded connection with a positioning driving piece; a movable expansion device is slidably connected to the supporting device; adjacent surface grinding devices are mounted on the two sides of the movable expansion device respectively; the bottom of the supporting device is fixedly connected with a reciprocating driving device; comprehensive combined grinding can be achieved, the machining precision is improved, one-time positioning forming can be achieved, and errors are smaller; the problems that according to an existing metal workpiece grinding device, multi-working-face linkage grinding cannot be achieved, a slidable grinding device is not arranged, the machining cost is greatly increased, the structure is complex, and the manufacturing cost is high are solved.

Owner:艾芦精密机械(江苏)有限公司

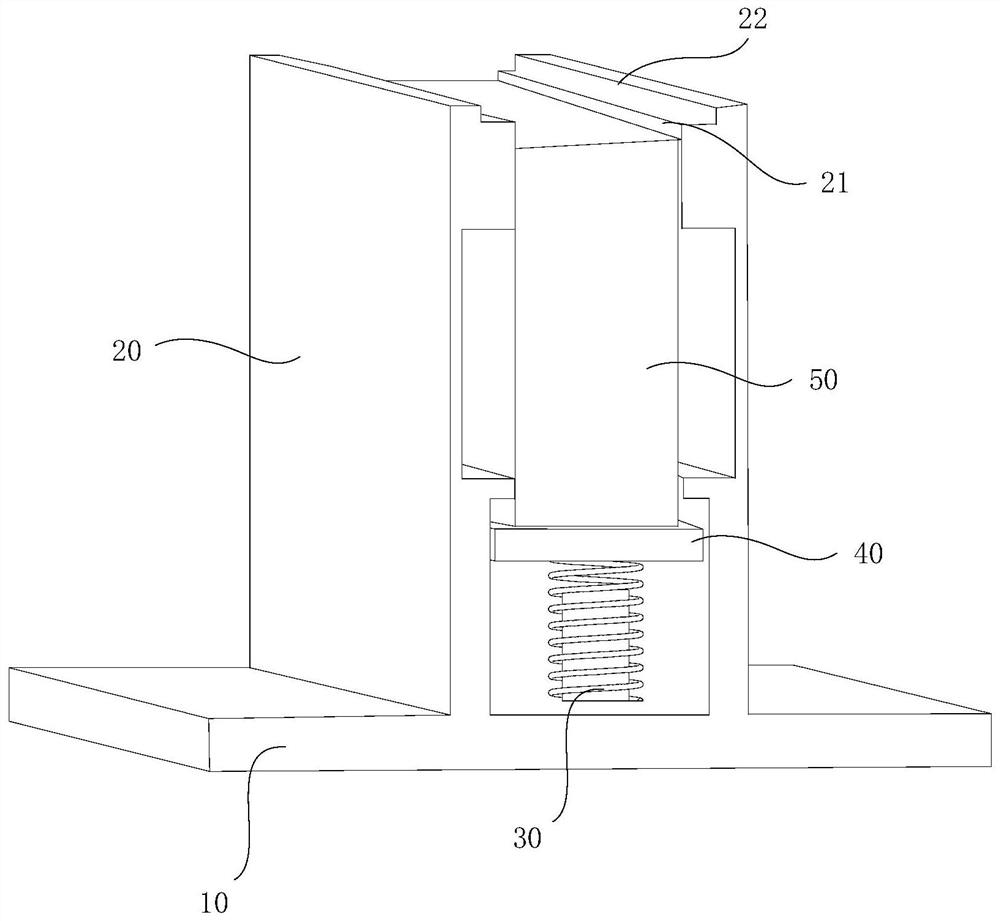

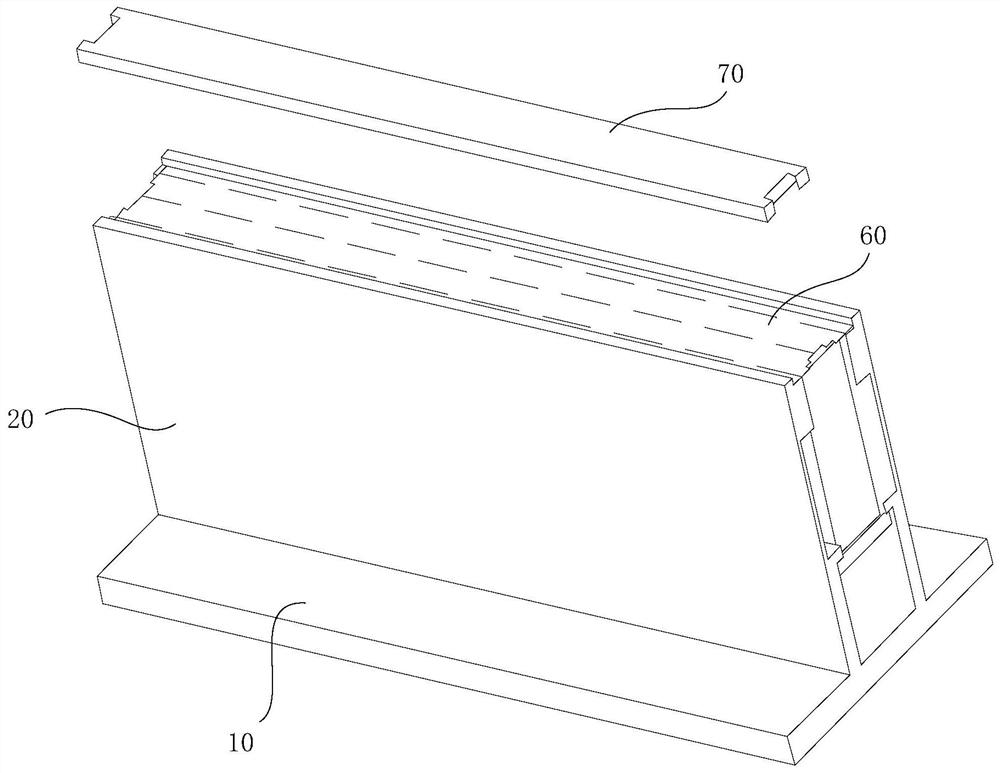

Lateral adhesion cutoff mechanism for adhesive tape

PendingCN108789643AGuaranteed parallelismGuaranteed one-time moldingMetal working apparatusEngineeringFlange

The invention discloses a lateral adhesion cutoff mechanism for an adhesive tape. The lateral adhesion cutoff mechanism comprises a bracket plate; the upper end of the bracket plate is fixedly connected with a cylinder; the lower end of the cylinder is sequentially provided with an upward-pressing plate and a guide cylinder; the guide cylinder is fixed to the bracket plate; the upward-pressing plate is connected with a pressing plate flange through a guide shaft; the lower end of the pressing plate flange is connected with an ultrasonic embossing upper die; a spring is arranged between the upward-pressing plate and the guide cylinder; a downward-pressing plate is arranged between the guide cylinder and the pressing plate flange; the downward-pressing plate is fixedly connected with a piston rod of the guide cylinder; the side of the downward-pressing plate is fixedly connected with an adhesive tape cutoff upper die; and an ultrasonic embossing lower die is correspondingly arranged below the ultrasonic embossing upper die. Compared with the prior art, the lateral adhesion cutoff mechanism for the adhesive tape disclosed by the invention adopts the downward-pressing plate of the cylinder to drive the ultrasonic embossing upper die to laminate an adhesive buckle tape and adopts the guide cylinder to press downwards and drive the adhesive tape cutoff upper die to cut off the adhesive buckle tape, the two downward-pressing actions guarantee one-tome molding of a product, all mechanisms work independently, and the product quality is guaranteed.

Owner:南通国派纺织品有限责任公司

Valve sand casting mold

InactiveCN104226918AGuaranteed one-time moldingHigh precisionFoundry mouldsFoundry coresSand castingCasting mold

The invention discloses a valve sand casting mold, belongs to the field of casting molding, and in particular relates to a sand casting mold. The mold comprises a sand box, a sand mold, a mold core and an anti-adhering coating, wherein the mold core is of a structure with one main core and four auxiliary cores; the auxiliary cores are arranged around the main core; the four auxiliary cores are connected together through an annular pouring gate; an opening is formed in the annular pouring gate and is connected with a main pouring gate; a plurality of exhaust holes are formed in the upper side of the body of the main core; the anti-adhering coating is arranged on one surface, on which a cavity is formed by the sand mold and the mold core, of the sand mold, and coats the outer side of the sand mold. By adopting the valve sand casting mold, the defects that a cast piece is relatively poor in size precision after being processed for multiple times, and the probability of sand washing, sand inclusion and pores is high, are effectively overcome.

Owner:CHENGDU FANXINJIA TECH

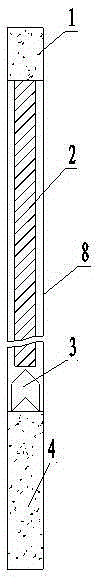

Explosive column for smooth blasting excavation of foundation surface and excavation technology

The invention discloses an explosive column for smooth blasting excavation of a foundation surface and an excavation technology. The explosive column is characterized by comprising blast holes, a buffering layer, a rigid cushion layer, an explosive and a plugging segment, wherein the buffering layer, the rigid cushion layer, the explosive and the plugging segment are arranged at the bottoms of the blast holes; and the buffering layer, the rigid cushion layer, the explosive and the plugging segment are sequentially stacked from bottom to top. The buffering layer is a cylinder; the diameter of the buffering layer is smaller than the diameter of each blasting hole by 0.5 cm-1 cm, and the upper surface and the lower surface of the rigid cushion layer are both conical; and the upper surface and the lower surface of the rigid cushion layer are parallel to each other, and therefore the two-way energy gathering effect can improved. When the explosive column is used, the vertical blast holes, with the circle centers collinear, in rows are drilled in a rock body, and the buffering layer, the rigid cushion layer, the explosive and the plugging segment are sequentially stacked from bottom to top. The technology is simple and convenient, cost is low, operation is easy, adverse effects are reduced because of the two-way energy gathering effect of the rigid cushion layer, the excavation effect is reliable, it can be guaranteed that the dam foundation surface and a slope packway protective layer are formed at a time through excavation, and the explosive column is widely used for excavation engineering of foundation surfaces and slope protective layers of the industries of water conservancy and hydropower engineering, transportation and mines.

Owner:SINOHYDRO BUREAU 16 CO LTD +1

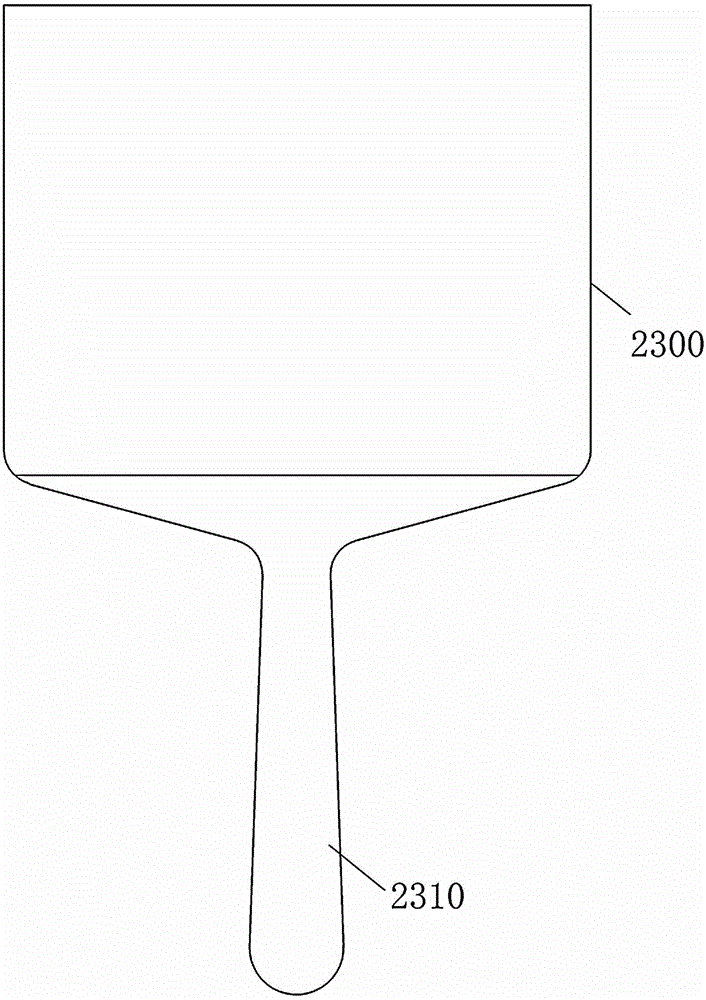

Attaching jig and attaching method for light guide plate and reflector plate, and backlight module

PendingCN112505822AGuaranteed full attachmentImprove reliabilityOptical light guidesLight guideEngineering

The invention discloses an attaching jig and an attaching method for a light guide plate and a reflector plate, and a backlight module. The attaching jig comprises a jig body, the jig body is providedwith a forming part and a supporting part, the supporting part is arranged above the forming part, the size of the supporting part is larger than that of the forming part, the size of the forming part is matched with that of a light guide plate, and the size of the supporting part is matched with the size of a preformed reflector plate. When the light guide plate and the preformed reflector plateare stacked on the supporting part, the light guide plate and the preformed reflector plate are pressed to the forming part from the supporting part by pressing the light guide plate or the preformedreflector plate, and the preformed reflector plate is formed into a formed reflector plate and attached to the light guide plate. The attaching jig is adopted for attaching the light guide plate andthe reflector plate, accurate attaching can be achieved, it is guaranteed that the light guide plate and the reflector plate are completely attached, the reliability of the backlight module is improved, the attaching speed is high, the production efficiency is improved, and manpower waste is reduced.

Owner:深圳市隆利光电科技发展有限公司

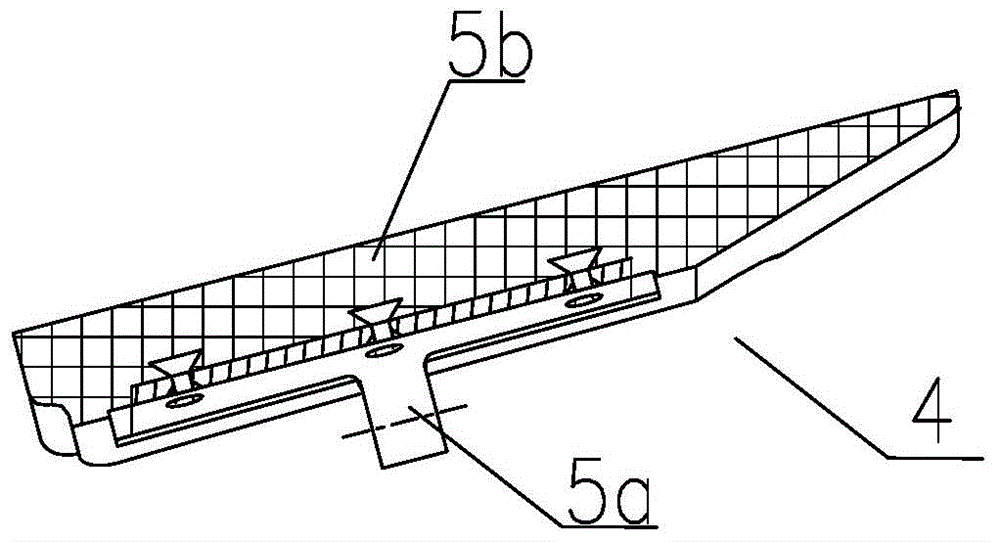

Preparation mould and method of ceramic-based corrugated wing air inlet leading-edge panel

ActiveCN104723578AImprove overall performancePlay the role of heat insulationThermal insulationAirplane

The invention relates to a preparation mould and a method of a ceramic-based corrugated wing air inlet leading-edge panel, and aims at solving the problem that the existing air inlet leading-edge panels of the existing airplanes are V-shaped solid panels so that the weight of the air inlet leading edges is increased, the thermal insulation effect of the solid panels is relatively bad and the available space is small. Triangular long strip blocks and a triangular through slot are arranged at intervals; pentagonal long strip blocks and the triangular through slot are arranged at intervals; the triangular long strip blocks and the pentagonal long strip blocks are arranged at intervals; two corner unfilled trapezoidal long strip blocks, two trapezoidal long strip blocks and two tail trapezoidal long strip blocks are arranged in parallel and in sequence from the bottom to top and symmetrically placed in the triangular through slot about a lug; each trapezoidal long strip block consists of a plurality of movable trapezoidal long strip blocks and a plurality of fixed trapezoidal long strip blocks; and the quantity of the movable trapezoidal long strip blocks is consistent to the quantity of the fixed trapezoidal long strip blocks. The preparation mould and the method are applied to the manufacturing of the wing air inlet leading-edge panels.

Owner:HARBIN UNIV OF SCI & TECH

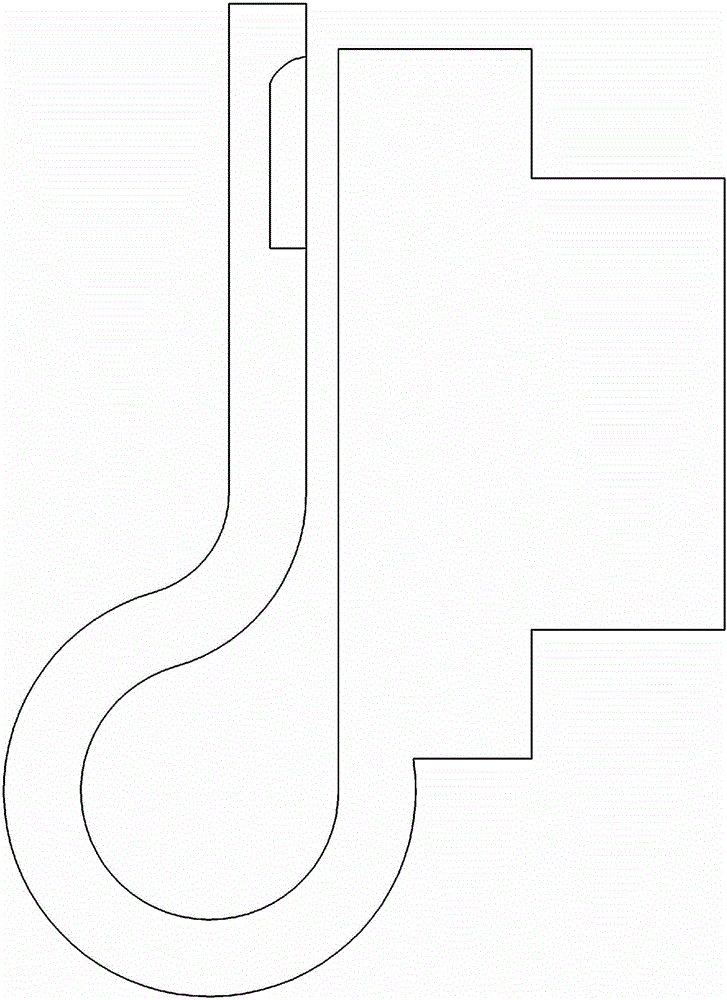

Clamping hoop curved tooling and clamping hoop U-shaped forming mold

InactiveCN104384339AGuaranteed positioning accuracyGuaranteed machining accuracyShaping toolsMetal-working feeding devicesEngineeringProcessing accuracy

The invention provides a clamping hoop curved tooling and a clamping hoop U-shaped forming mold. The U-shaped forming mold comprises a second upper pressing mold and a second lower pressing mold; the second lower pressing mold is provided with a second forming groove which is used for matching with a curving radius of a neck part of a clamping hoop and extends leftwards and rightwards; the second lower pressing mold is also provided with a limiting structure which is used for stopping and limiting a first blank body in the front-and-back direction to determine a pressing and forming position of the neck part of the clamping hoop; the second upper pressing mold is provided with a second pressing head which is as same as the curving radius of the neck part of the clamping hoop and matches with the second forming groove. The limiting structure and the second forming groove of the clamping hoop U-shaped forming mold and the can determine the curving position of the neck part of the clamping hoop on the basis of ensuring the curving radius of the neck part of the clamping hoop, so that the position precision and processing precision of the clamping hoop are ensured, and the processing efficiency and the processing quality are increased greatly.

Owner:河南航天精工制造有限公司

Excavation construction method of small foundation pit near excavated deep foundation pit

ActiveCN105804084ASolve the problem that cannot be constructed synchronouslySolve hidden dangers of waterproofingExcavationsRebarBuilding construction

The invention discloses an excavation construction method of a small foundation pit near an excavated deep foundation pit. An excavation door is formed after a temporary pile, near the small foundation pit, at the bottom of the deep foundation pit is drilled off; soil in the small foundation pit is excavated through the excavation door, so that the soil in the small foundation pit falls down to the elevation of a waist beam support of the deep foundation pit; a corresponding waist beam support is constructed in the small foundation pit; a reinforcement in the corresponding waist beam support in the small foundation pit is connected with a reserved reinforcement of the corresponding waist beam support in the deep foundation pit; and the operation is circulated until the small foundation pit and the deep foundation pit are excavated to the corresponding elevations, so that the difficulty of incapability of synchronously constructing adjacent foundation pits is solved, the construction period is shortened, the projection cost is saved, the once formation of the main structure is guaranteed, the structure stress stability is guaranteed, and the waterproof hidden trouble of the main structure is solved. The safety in the excavation period of two foundation pits is guaranteed.

Owner:GUANGDONG CONSTR CO LTD OF CHINA RAILWAY NO 3 ENG GRP CO LTD +1

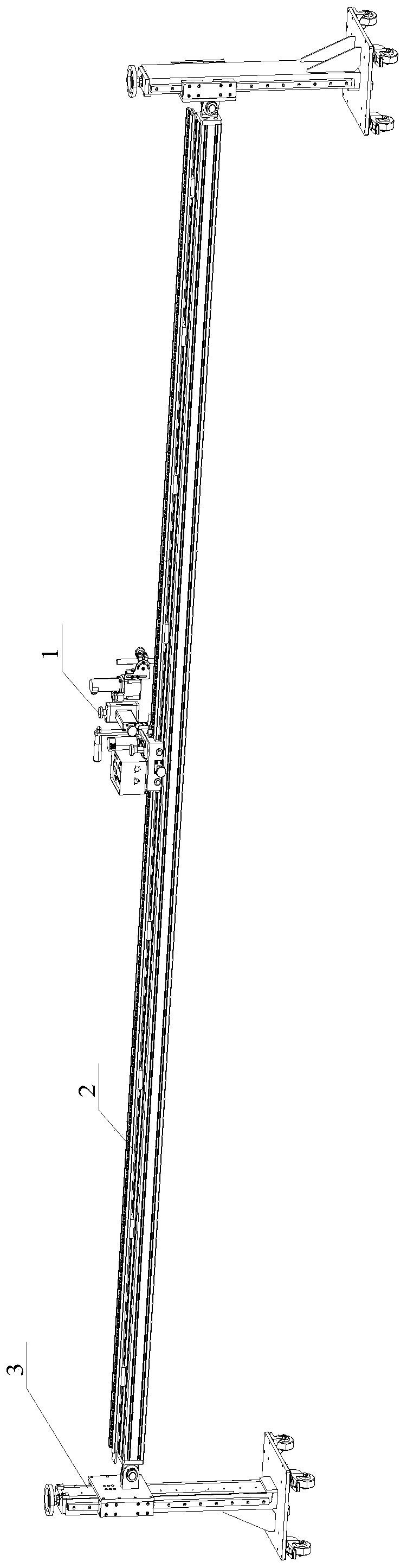

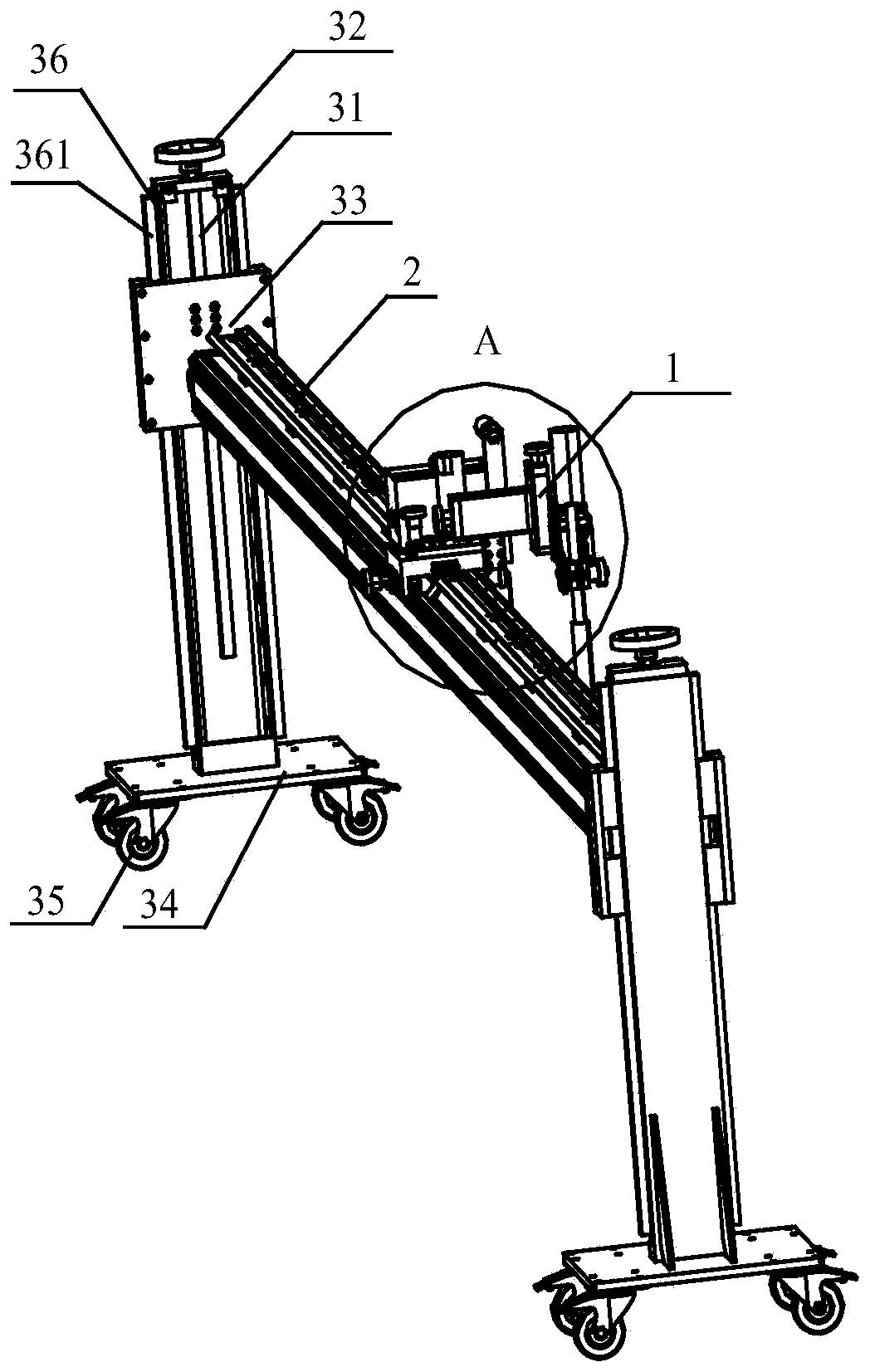

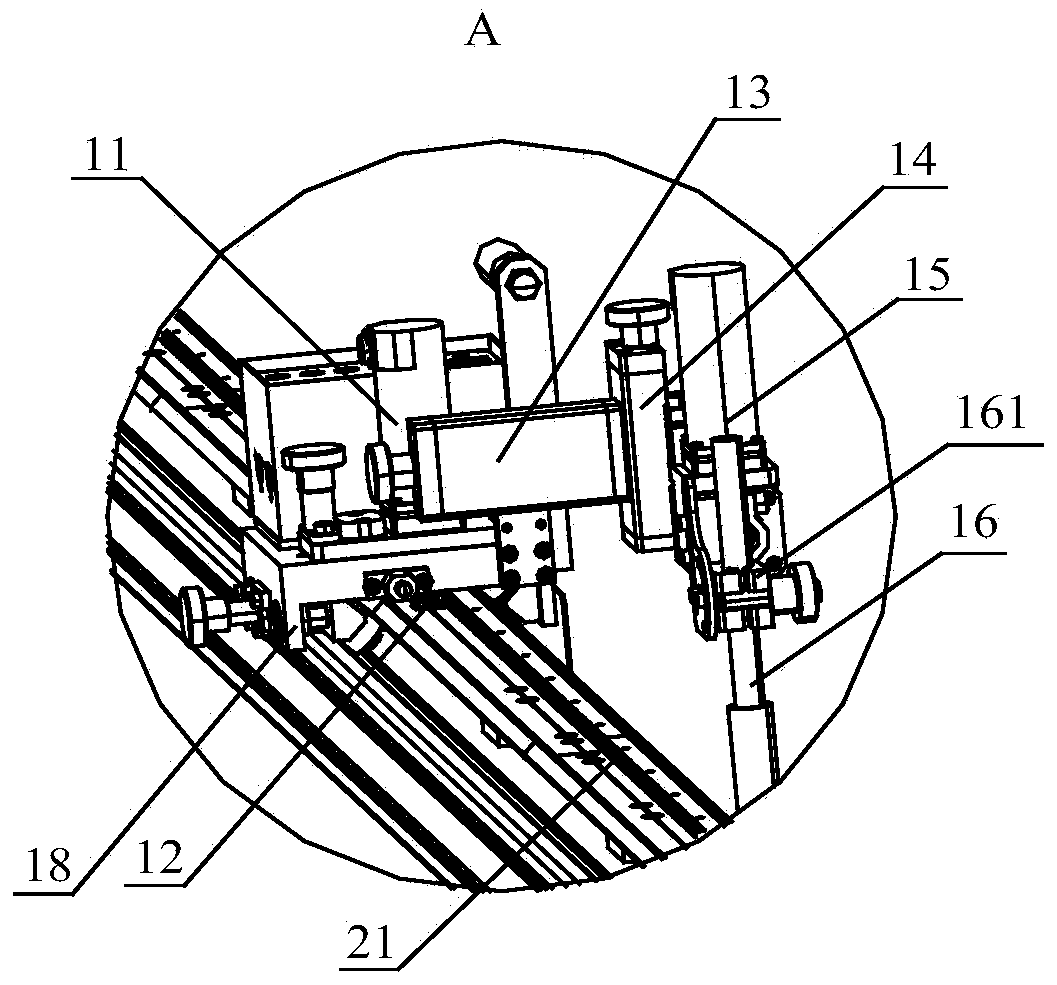

Cutting and welding device used for replacement of cutting edge blade of grab bucket of ship unloader and application method of cutting and welding device

InactiveCN111421201AGuaranteed one-time moldingSolve the problem of stomataWelding/cutting auxillary devicesElectrode supporting devicesElectric machineStructural engineering

The invention provides a cutting and welding device used for replacement of a cutting edge blade of a grab bucket of a ship unloader. The cutting and welding device comprises a rail, manual lifting portals and movable cutting and welding equipment. The manual lifting portals comprise portal bodies, lead screws and nuts, the lead screws extend in the Z-axis direction and penetrate through the topsof the portal bodies, handles are arranged at the top ends of the lead screws, and the ends of the rail are connected with the nuts through mounting portions. The movable cutting and welding equipmentcomprises a rack arranged on the rail, a Y-axis walking motor mounted on the rack and cutting and welding equipment, the Y-axis walking motor drives the rack to move along the rail, an X-axis walkingmotor, a Z-axis walking motor and a rotating motor which are connected sequentially are further arranged on the rack, and an output shaft of the rotating motor is connected with the cutting and welding equipment. The cutting and welding device has the beneficial effects that heat source moving in the cutting and welding processes of the cutting edge plate is completed by a mechanical device, cutting and welding angles are adjusted through cooperation of operation personnel, and linear parts can be cut and welded rapidly and stably. The whole work process is simple and convenient, the construction period is short, and the cost is low.

Owner:MCC BAOSTEEL TECH SERVICE

Hot extrusion forming method of copper alloy rail

PendingCN112170523AReduce oxidationReduce extrusion resistanceExtrusion diesUltimate tensile strengthLubrication

The invention relates to a hot extrusion forming method of a copper alloy rail. The method includes the following steps that 1, blank processing is performed, specifically, (1) forged polished blank round steel is sawn; (2) the center of the blank is drilled; (3) turning machining and polishing of the outer surface and the head are performed; 2, blank heating is performed, specifically, the heating temperature ranges from 900 DEG C to 950 DEG C; 3, tool and mold preparation is performed, specifically, extrusion molds with the same shapes are adopted; 4, lubrication is performed, specifically,the extrusion molds, manipulators and extrusion cylinders are coated with lubricants; 5, hot extrusion is performed, specifically, hot extrusion forming is performed on the blank; 6, cooling is performed, specifically, the copper alloy rail is cooled to the room temperature; 7, solid solution heat treatment is performed, specifically, the heating temperature ranges from 930 DEG C to 950 DEG C; 8,inspection is performed, specifically, the hardness and the conductivity are inspected; 9, straightening is performed, specifically, the copper alloy rail is straightened; 10, cold drawing is performed, specifically, cold drawing is performed on the copper alloy rail; 11, aging heat treatment is performed; 12, the section hardness, conductivity and room-temperature tensile strength are inspected;and 13, straightening is performed. According to the method, one-time forming of the workpiece is guaranteed through optimization of the mold design and the extrusion forming process, the surface quality of the manufactured copper alloy rail is good, and the physical, chemical and mechanical properties of the product are improved.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Prestressed concrete steel bar platform processing equipment

The invention discloses prestressed concrete steel bar platform processing equipment which comprises a support frame, a support tank and a support table. A hydraulic tank is arranged in the support frame; a hydraulic pump is arranged on one side of the hydraulic tank; a support seat is arranged on the top part of the support frame; an extrusion roller is arranged on one side of the support seat; knurling patterns are arranged above the extrusion roller; the support table is arranged under the extrusion roller; a straight rack is arranged under the support table; the support tank is arranged under the support table; an electromotor is arranged in the support tank; and a pinion is arranged in front of the electromotor. The prestressed concrete steel bar platform processing equipment providedby the invention has the beneficial effects that the fixed extrusion roller is utilized for continuously extruding a steel bar platform so as to produce patterns, so that a friction force of the steel bar platform is increased; meanwhile, the gear and rack drive drives the steel bar platform to move in a straight line, so that the continuity of rolling is ensured, and one-time molding is ensured;and in addition, by utilizing hydraulic lifting and descending, a rolling force and cushion are increased, and blockage is avoided.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

Lithium ion battery for automobile

ActiveCN104505481AEasy to carryPrevent displacementCell component detailsBatteriesElectrical batteryEngineering

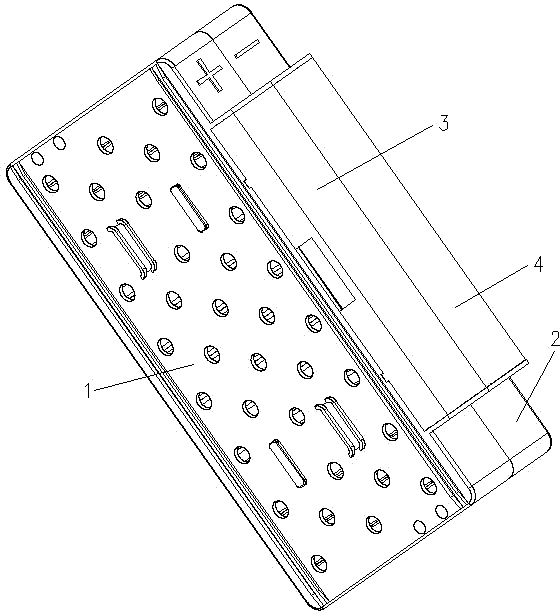

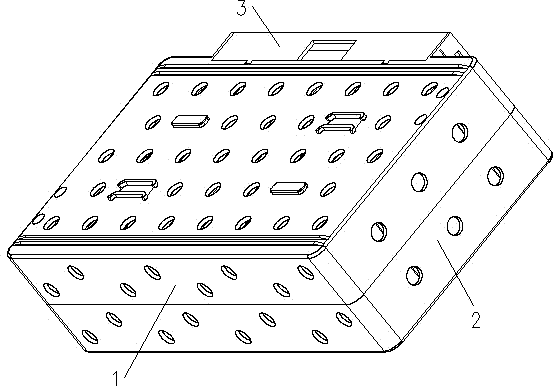

The invention relates to a lithium ion battery for an automobile, and aims at solving the problem that a lithium ion battery for an automobile, which is good in conductivity and has no shifting is not available in the prior art. The lithium ion battery for the automobile, provided by the invention, comprises a cell group and an adaptor board, and is characterized by further comprising a left half shell, a right half shell, a left electric conduction bar, a right electric conduction bar, a left terminal connecting sheet and a right terminal connecting sheet, wherein the cell group and the adaptor board are positioned in a shell formed by the left half shell and the right half shell, the left electric conduction bar is fixed on the top of the left half shell, a preformed groove for the left terminal connecting sheet is formed in the left half shell, the left terminal connecting sheet is connected in the preformed groove for the left terminal connecting sheet in a penetrating manner, the upper part of the left terminal connecting sheet is fixed on the left electric conduction bar, the right half shell is provided with a preformed groove for the right terminal connecting sheet, the right terminal connecting sheet is connected in the preformed groove for the right terminal connecting sheet in a penetrating manner, the upper part of the right terminal connecting sheet is fixed on the right electric conduction bar, and anti-shifting structures are arranged on the left half shell and the right half shell. The lithium ion battery is good in conductivity, and convenient to assemble, and the shifting phenomenon can be avoided.

Owner:湖州天丰电源有限公司

Equipment and method for manufacturing corrugated type glass fiber reinforced plastics integrally-formed cylinder

The invention provides equipment and method for manufacturing a corrugated type glass fiber reinforced plastics integrally-formed cylinder. According to the equipment and method, multiple hydraulic extending-and-contracting guide mechanisms and extending-and-contracting branch blocks are arranged on the surface of a rotary beam, the hydraulic extending-and-contracting guide mechanisms extend and contract to form a corrugated type formed cylinder, the extending-and-contracting guide mechanisms are controlled to extend and contract, the extending-and-contracting branch blocks axially extend andcontract to the designed position along the rotary beam, and a mold is separated from the product; and through synchronous matching use of a resin jet device, a fiber cutting device, a movable fiber cloth laying device and a movable corrugated tightening adapting rolling wheel, precise metering is achieved according to the content and strength of resin in different layers, the production cost is lowered greatly, one-time forming of the whole corrugated type cylinder is guaranteed, the airtightness is good, meanwhile the mechanical strength is number times higher than that of an assembled corrugated tank body, the production efficiency is high, and meanwhile large-scale batch production can be guaranteed. The equipment and method for manufacturing the corrugated glass fiber reinforced plastics integrally-formed cylinder are ingenious in conception and extremely suitable for large-area application and population.

Owner:HUBEI DINGYU ENVIRONMENTAL PROTECTION TECH

Vehicle-mounted radiator protective plate and radiator core body

PendingCN107917636AImprove stabilityGuaranteed root strengthStationary conduit assembliesHeat exchanger casingsStructural stabilityHeat pipe

The invention discloses a vehicle-mounted radiator protective plate and a radiator core body, belongs to the technical field of radiator parts, and solves the problems that the four corners of a radiator protective plate are deformed because the central part is expanded externally by extruding when the radiator is assembled in the prior art, and the stability of a radiator structure cannot be effectively improved by a conventional method of additionally arranging reinforcing ribs at the two ends of the radiator protective plate. The adopted technical scheme is that two limiting clamping grooves are respectively positioned at the bending parts of the two ends of the radiator protective plate and are perpendicularly connected with the radiator protective plate; at least one convex hull is also formed in the surface which is perpendicular to the bending part of the radiator protective plate; the radiator core body comprises a main radiator piece, radiating strips and radiating pipes; theradiator protective plate is the vehicle-mounted radiator protective plate; and the vehicle-mounted radiator protective plate and the radiator core body reinforces the firmness and the stability of the radiator structure.

Owner:SHANDONG HAILI HUACHENG AUTOMOBILE AIR CONDITIONING CO LTD

Belt disengagement prevention radiator guard board and radiator core

PendingCN107976104AAvoid stretchingOptimize the overall structureHeat exchanger casingsHeat exchanger fasteningEngineeringHeat spreader

The invention discloses a belt disengagement prevention radiator guard board and a radiator core and belongs to the technical field of radiator parts. The belt disengagement prevention radiator guardboard solves the problems that heat dissipation belts extend when stressed and bundled or welded and heated, and consequently gaps between the heat dissipation belts and the guard board become large,and welding or belt disengagement is influenced in the prior art. According to the technical scheme, the belt disengagement prevention radiator guard board comprises a body portion, flanging portionsand bending portions; the flanging portions are arranged on the two sides of the body portion, and the bending portions are arranged at the two ends of the body portion; through holes are formed in the connected bending centers of the body portion and the bending portions, a clamping jaw is fixedly arranged at one end of each through hole, and the clamping jaws and the bending portions are of an integrated structure; and the radiator core comprises two radiator main slices, the heat dissipation belts and heat dissipation pipes and further comprises the radiator guard board, and the radiator guard board is the belt disengagement prevention radiator guard board. The belt disengagement prevention radiator guard board is convenient and fast to mount and easy to mold, and the stability of the radiator core can be improved.

Owner:SHANDONG TONGCHUANG AUTO COOLING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com