Self-insulation construction scheme for IPS cast-in-place concrete shear wall

A shear wall and self-insulation technology, applied in thermal insulation, walls, building components, etc., can solve the problems of insufficient ash, easy water seepage at joints, and weak fixing of insulation boards, so as to ensure one-time forming, overcome the The effect of easy water seepage and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the drawings and specific embodiments.

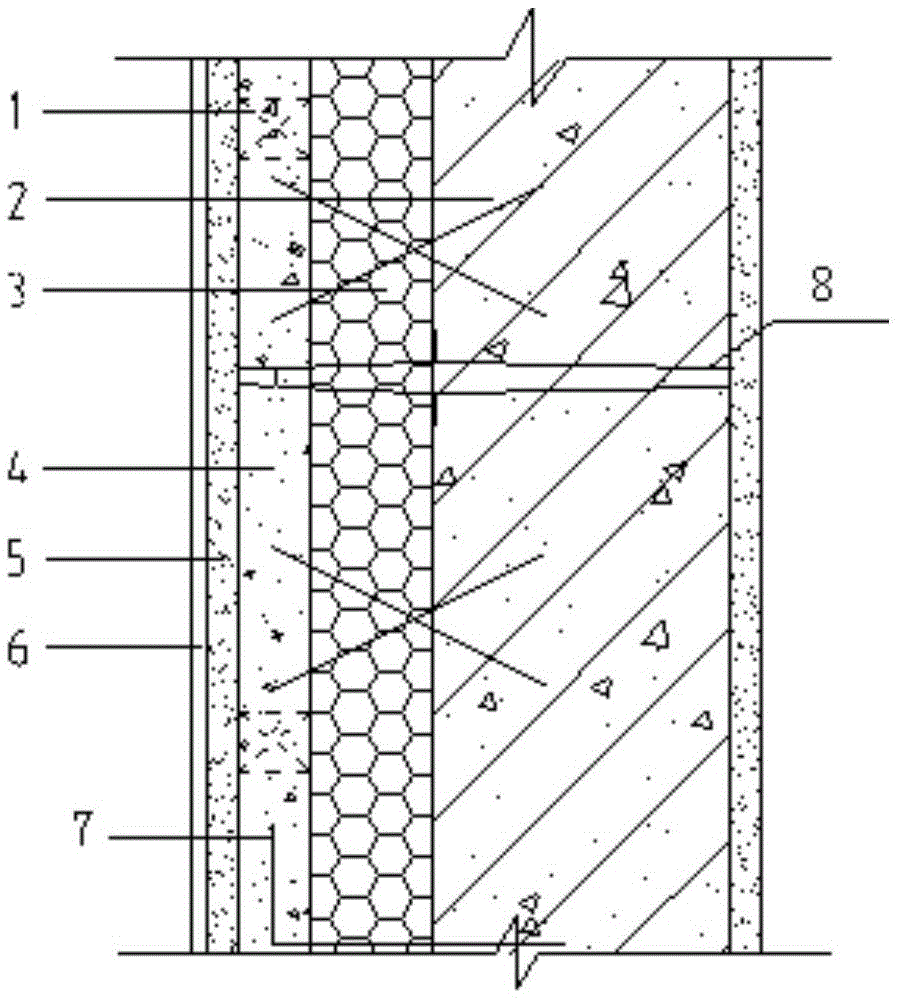

[0040] The residential building project of Yijuyuan District is a shear wall structure with a pile foundation. The structural design safety level of the building is level two, and the seismic level of the shear wall is level 3. The outer wall of this project is an IPS cast-in-place concrete shear wall self-insulation system. The self-insulation system of IPS cast-in-place concrete shear wall is a cast-in-place concrete composite wall composed of inner ordinary shear wall, IPS insulation board, outer concrete protective layer and other parts, which integrates load-bearing, heat preservation and enclosure.

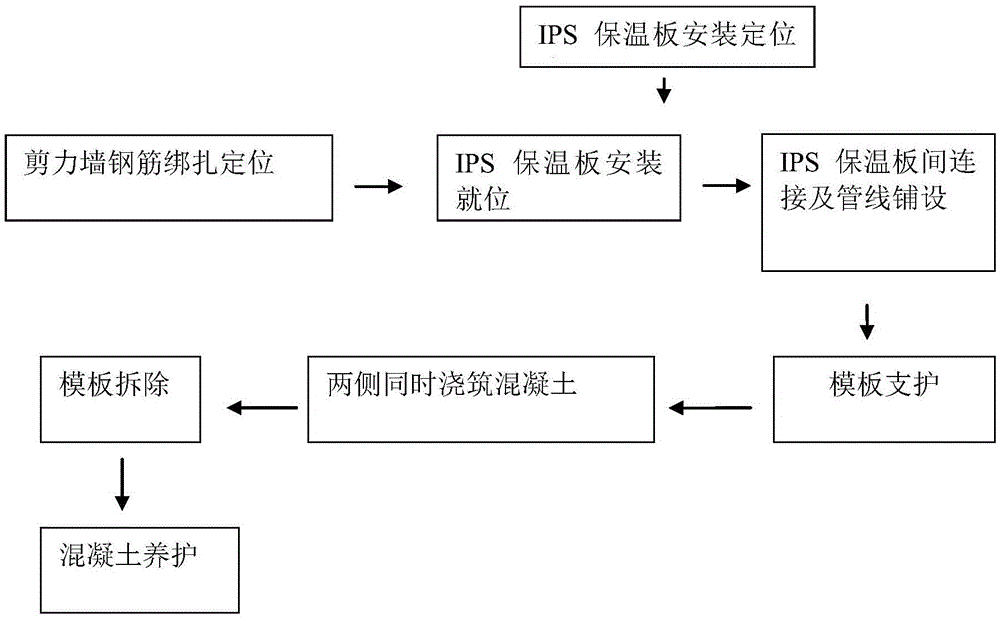

[0041] Such as figure 1 As shown, the construction process is: binding and positioning of shear wall reinforcement → IPS board installation → installation of plastic brace → installation of positioning block inside IPS board → mesh connection between IPS boards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com