Patents

Literature

260results about How to "Improve insulation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

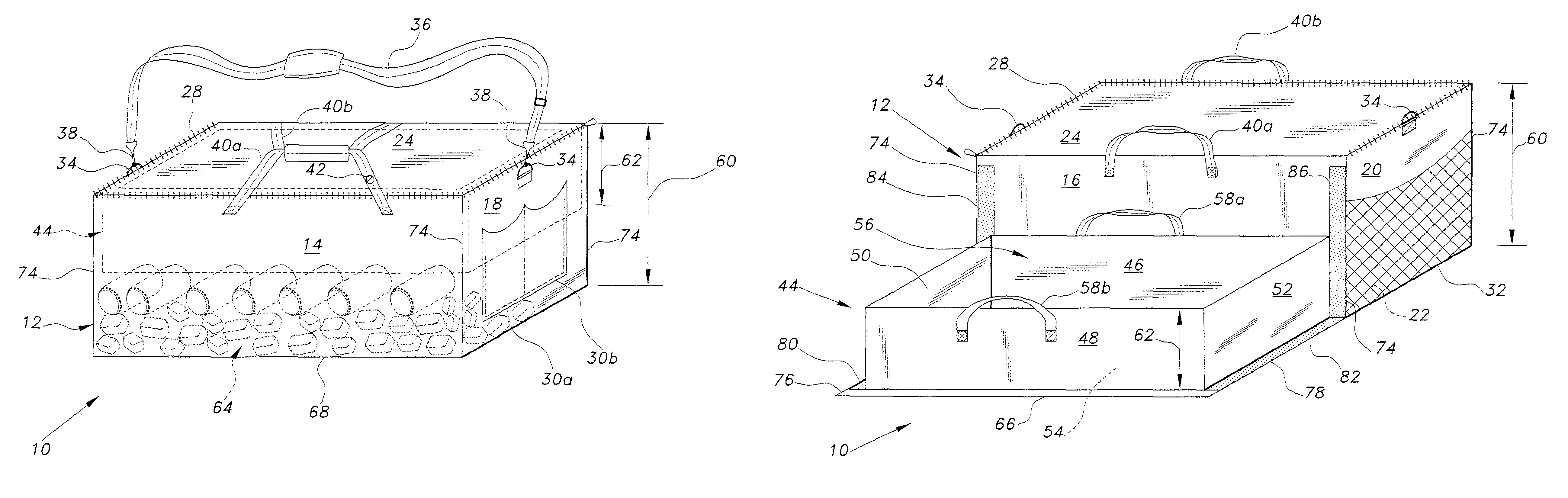

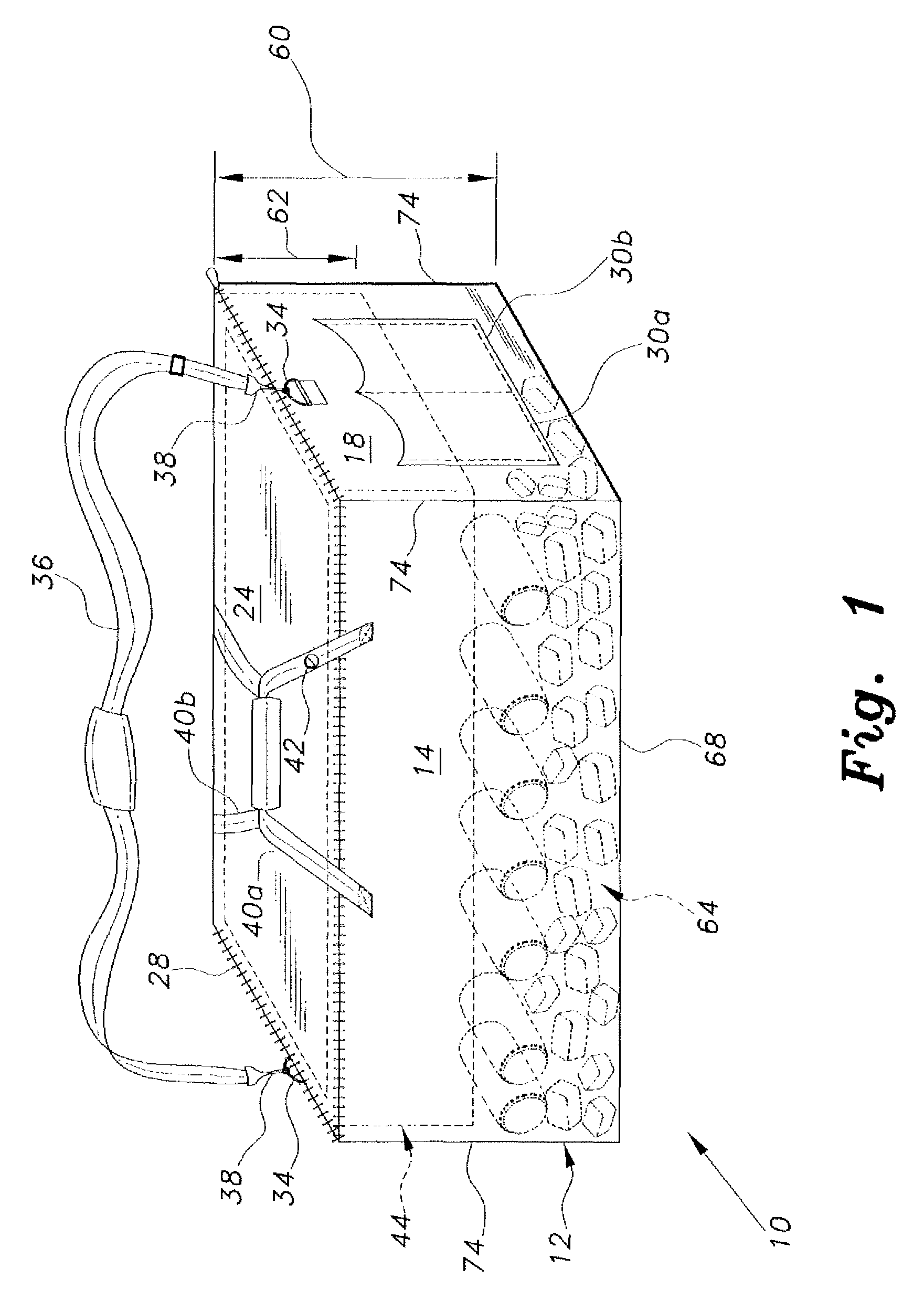

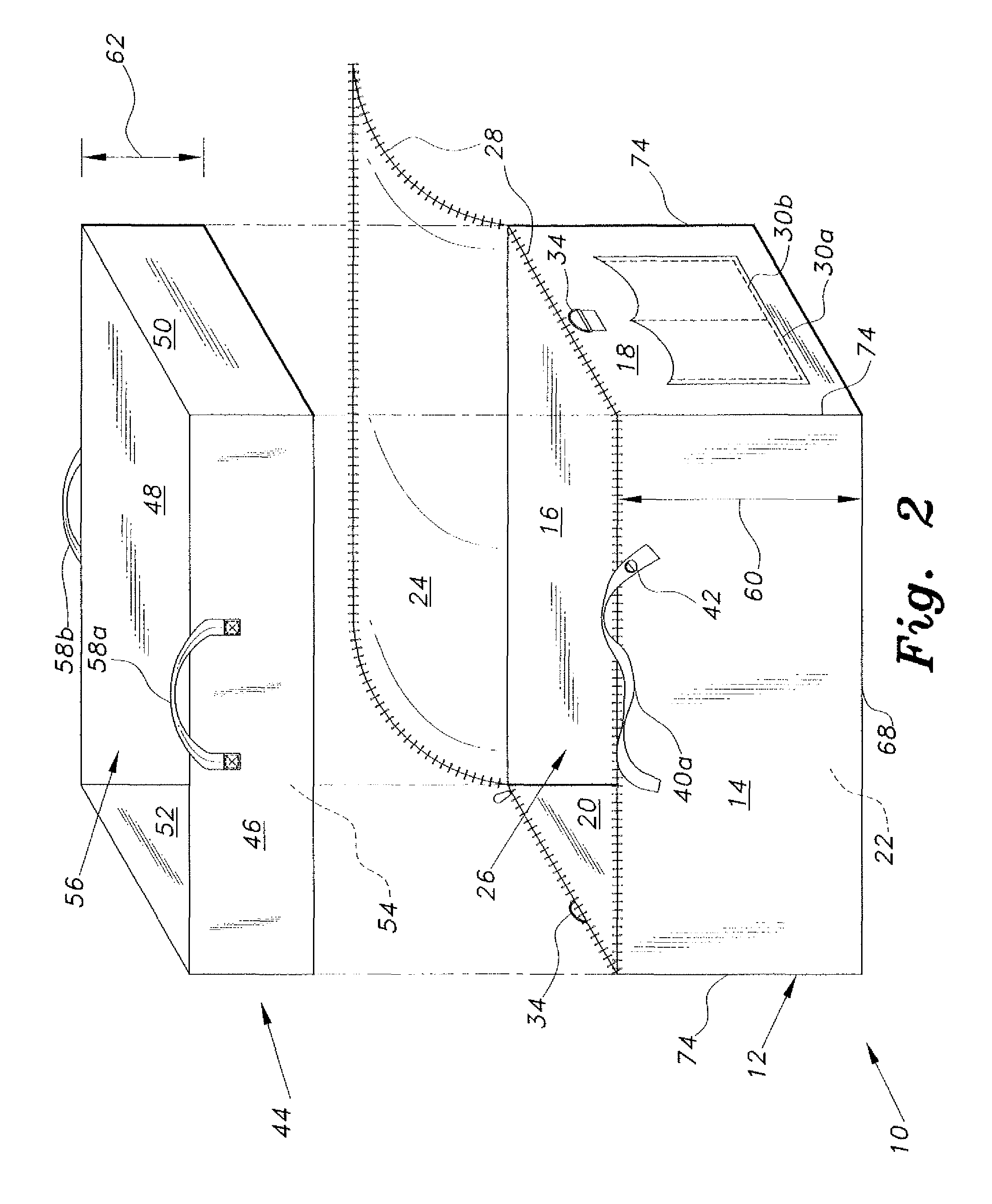

Insulated container and insert

ActiveUS8622235B2Improve insulation efficiencyImprove sealingLighting and heating apparatusClimate change adaptationThermal insulationEngineering

The insulated container and insert are formed of relatively soft and flexible panels having relatively thick cores of thermal insulation captured between thin impervious sheets. The outer container has a closable top, and the insert has an open top. The insert is about half the height of the outer container, allowing ice or other cooling material, beverage cans and / or bottles, etc., to be placed in the bottom of the outer container with the insert resting thereon for the carriage of food therein. As the outer bottom surface of the insert will be moist from contact with ice or the like therebelow, the outer container includes a drop down panel that may be lowered for placement of the insert thereon to preclude contamination of the bottom of the insert with loose sand or the like. Additional carrying handles and straps are provided, as well as outer pockets on the outer container.

Owner:SUCHECKI GLEN R

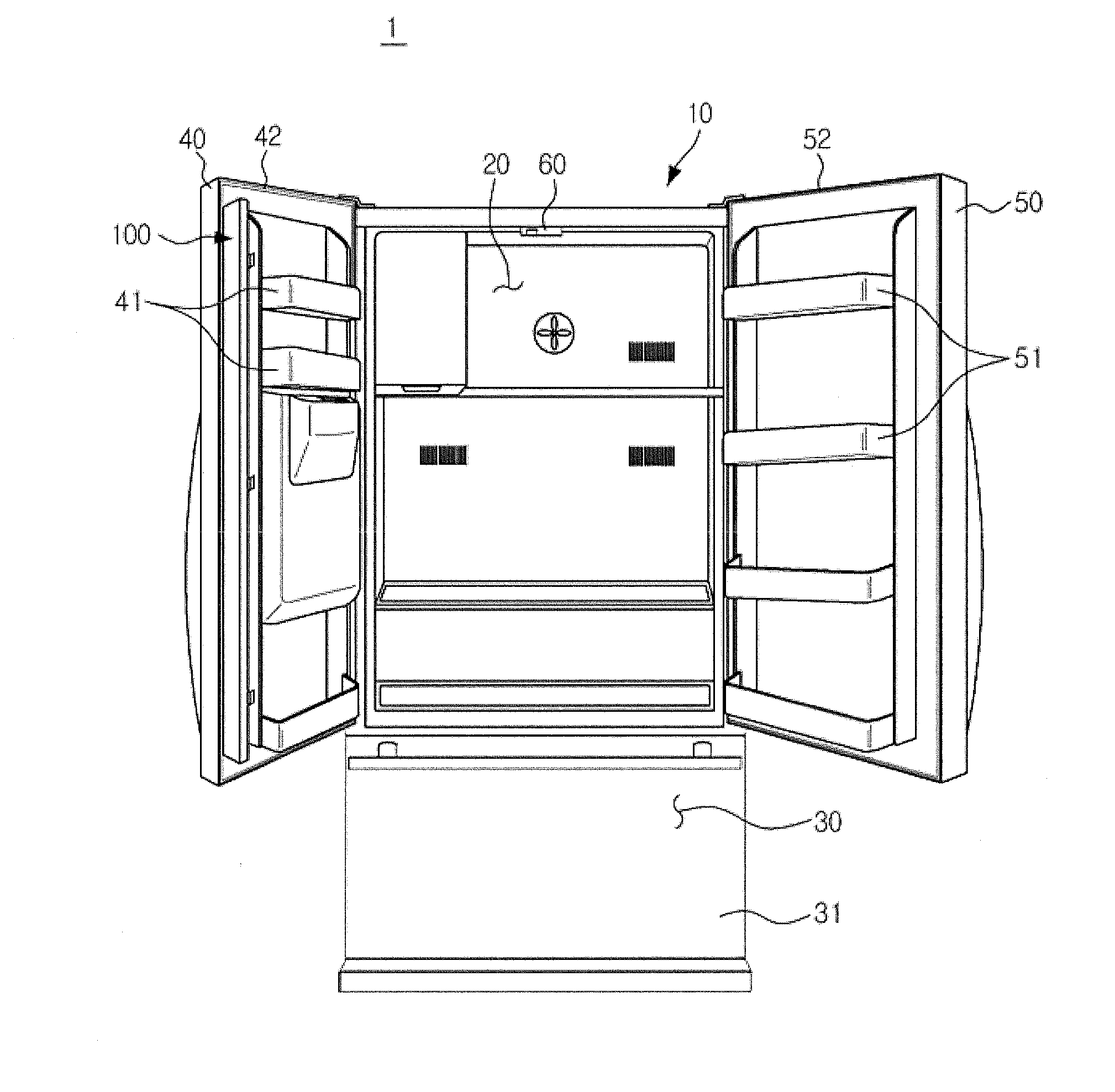

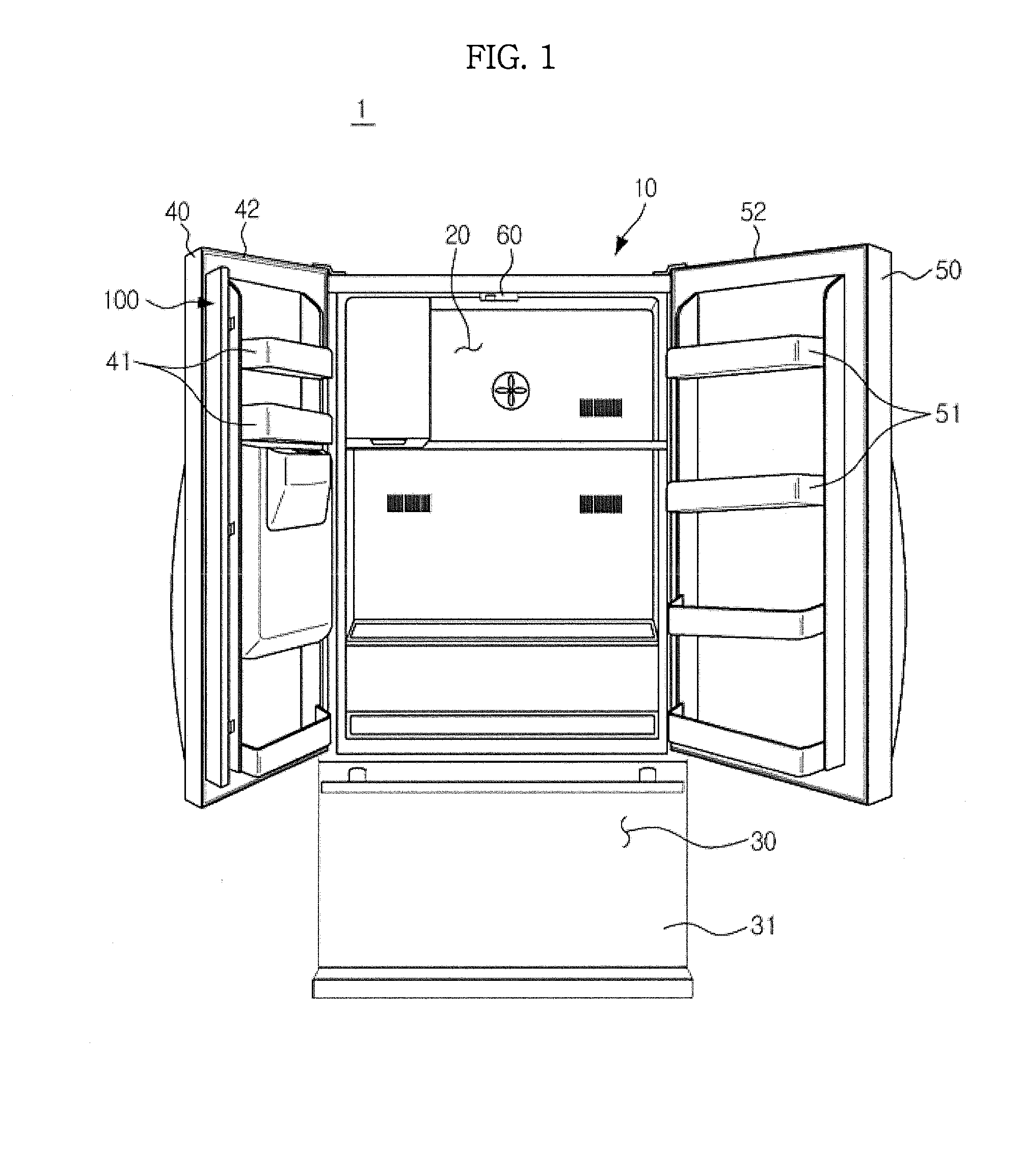

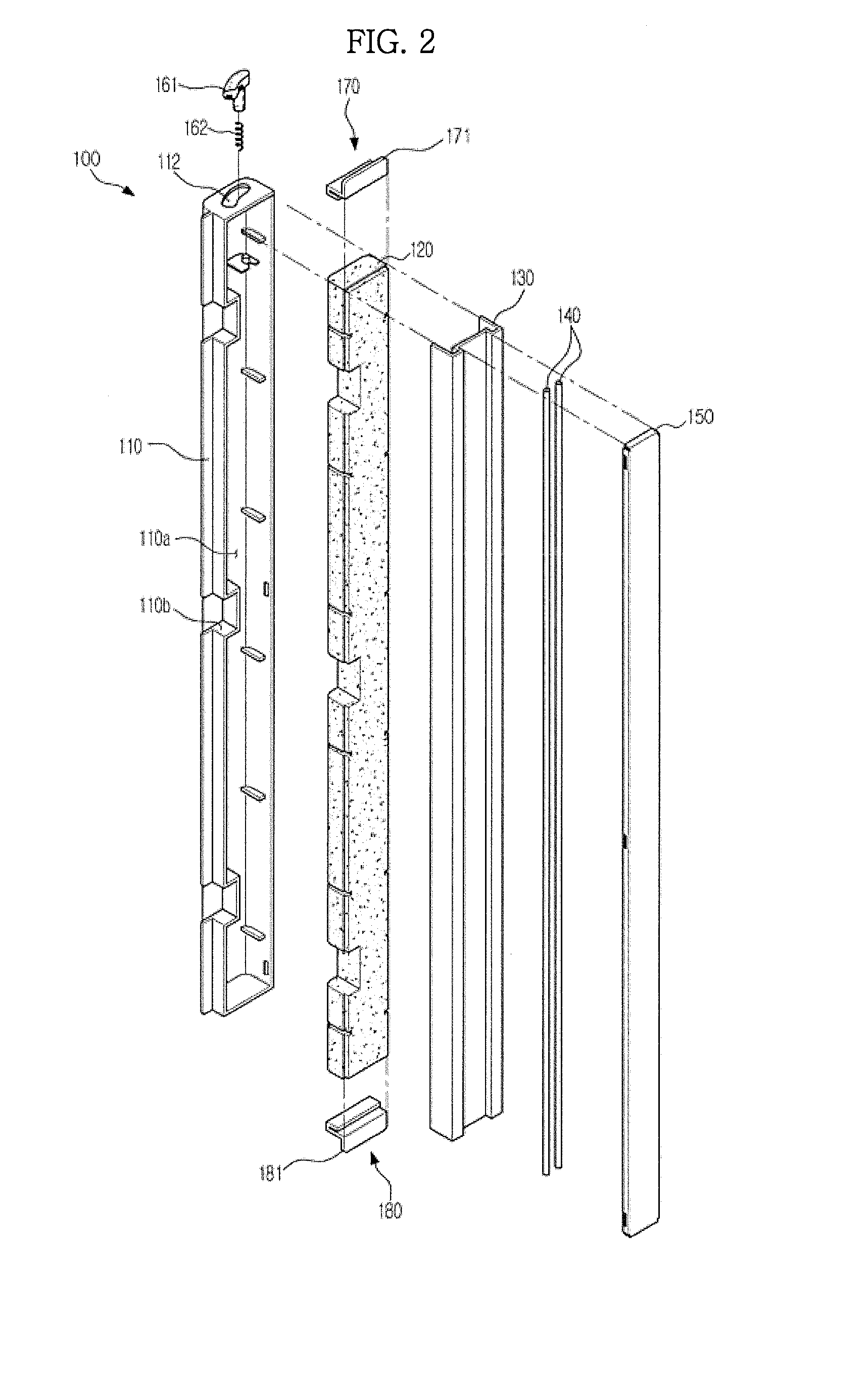

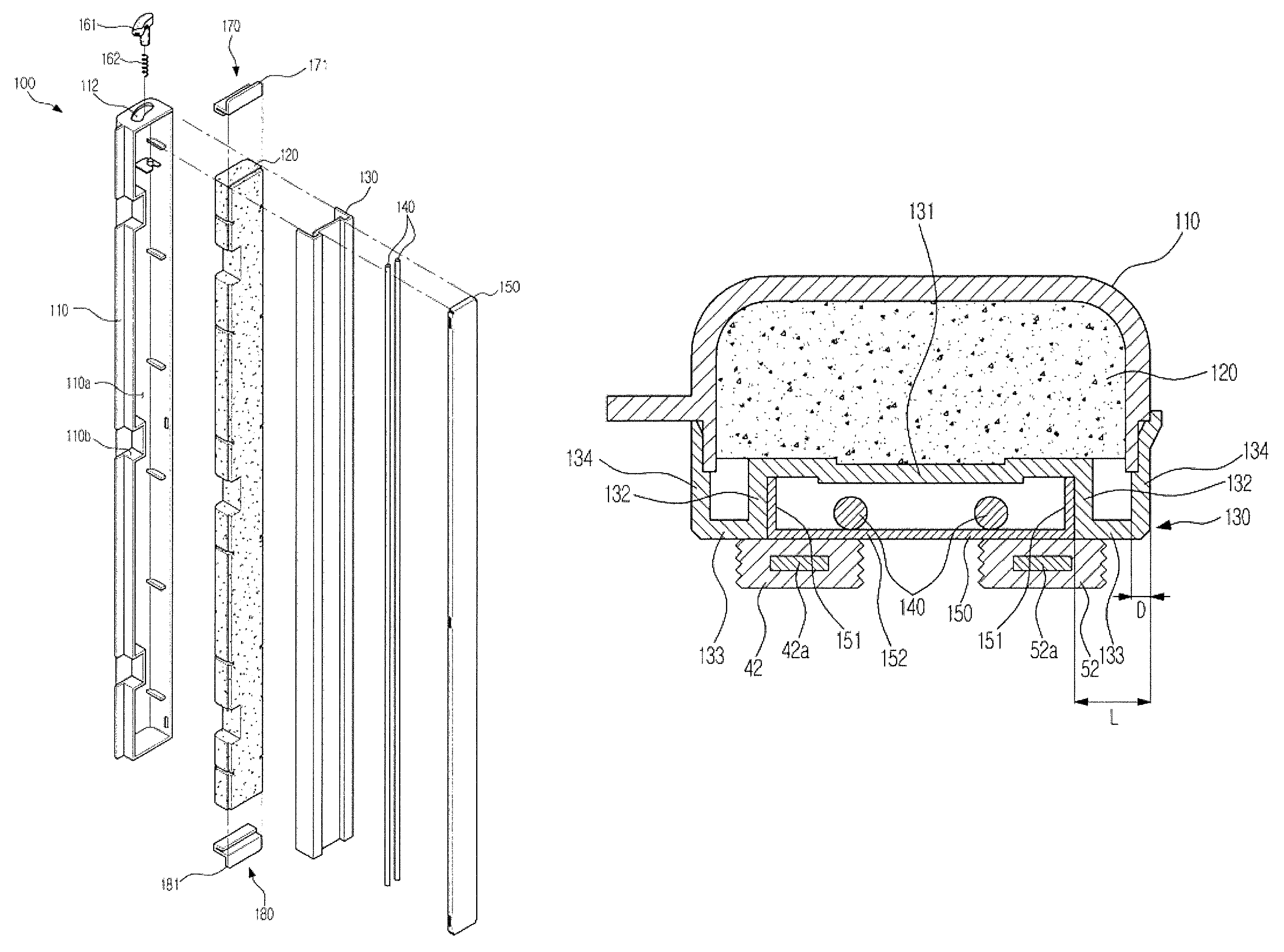

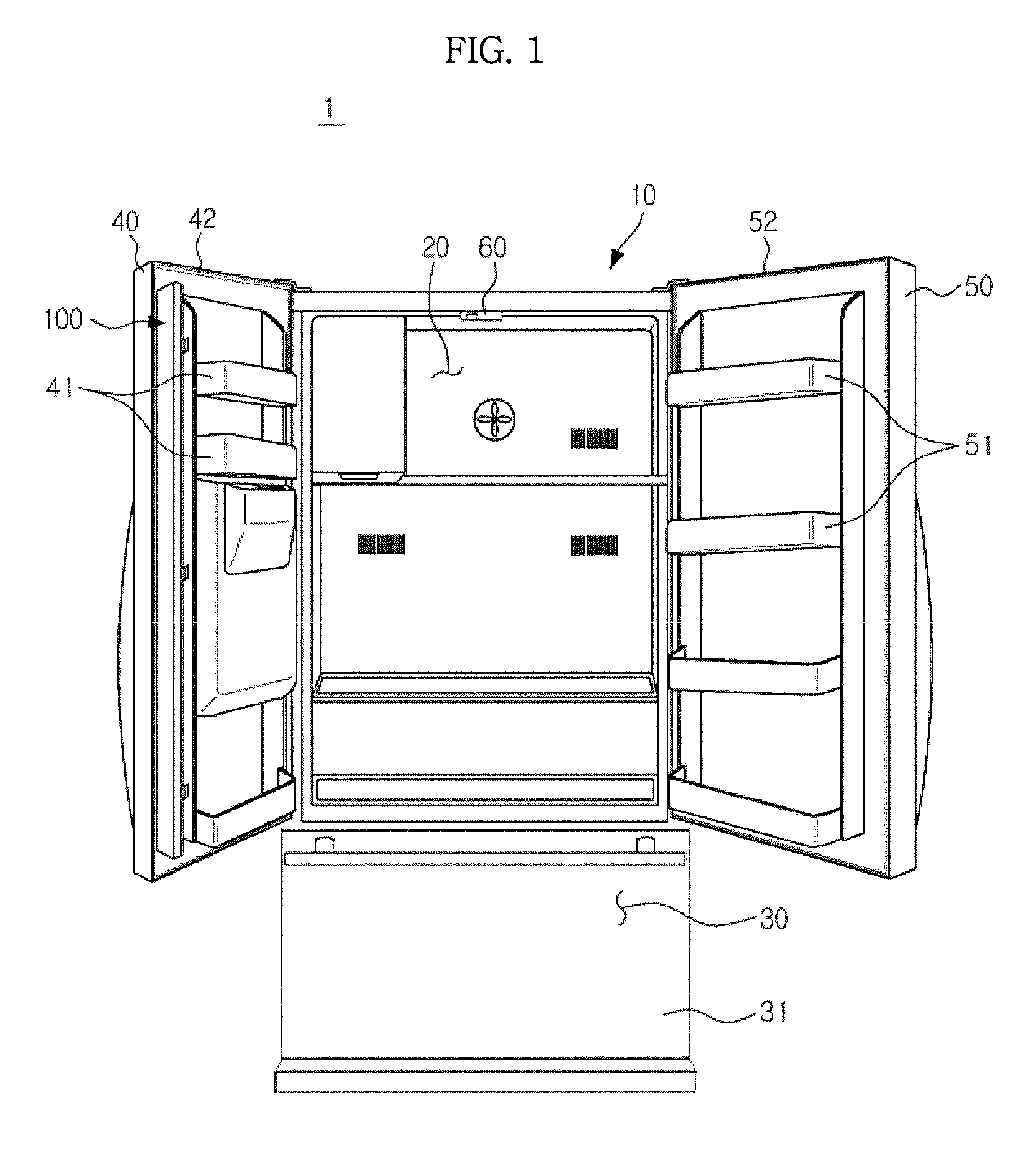

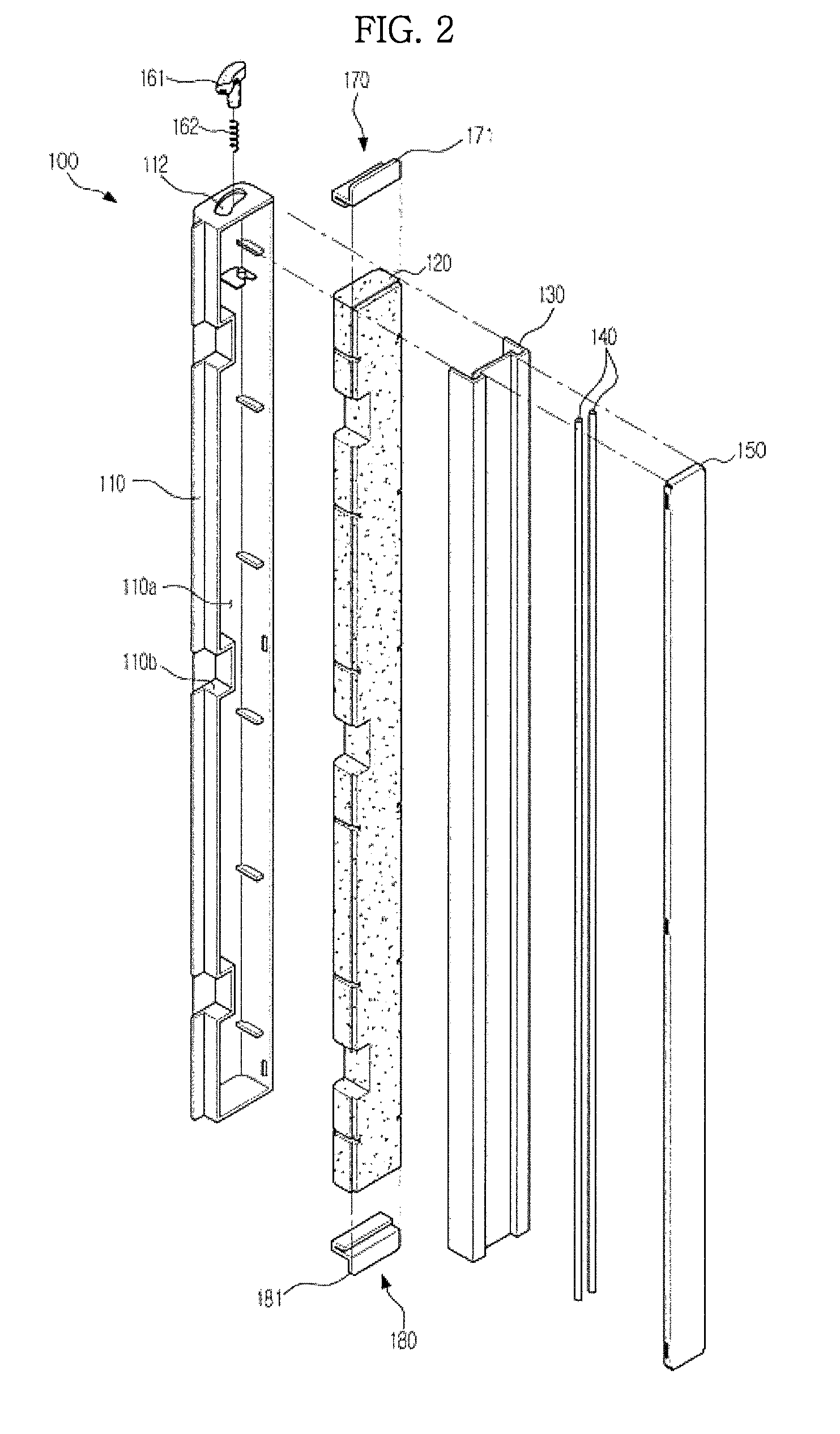

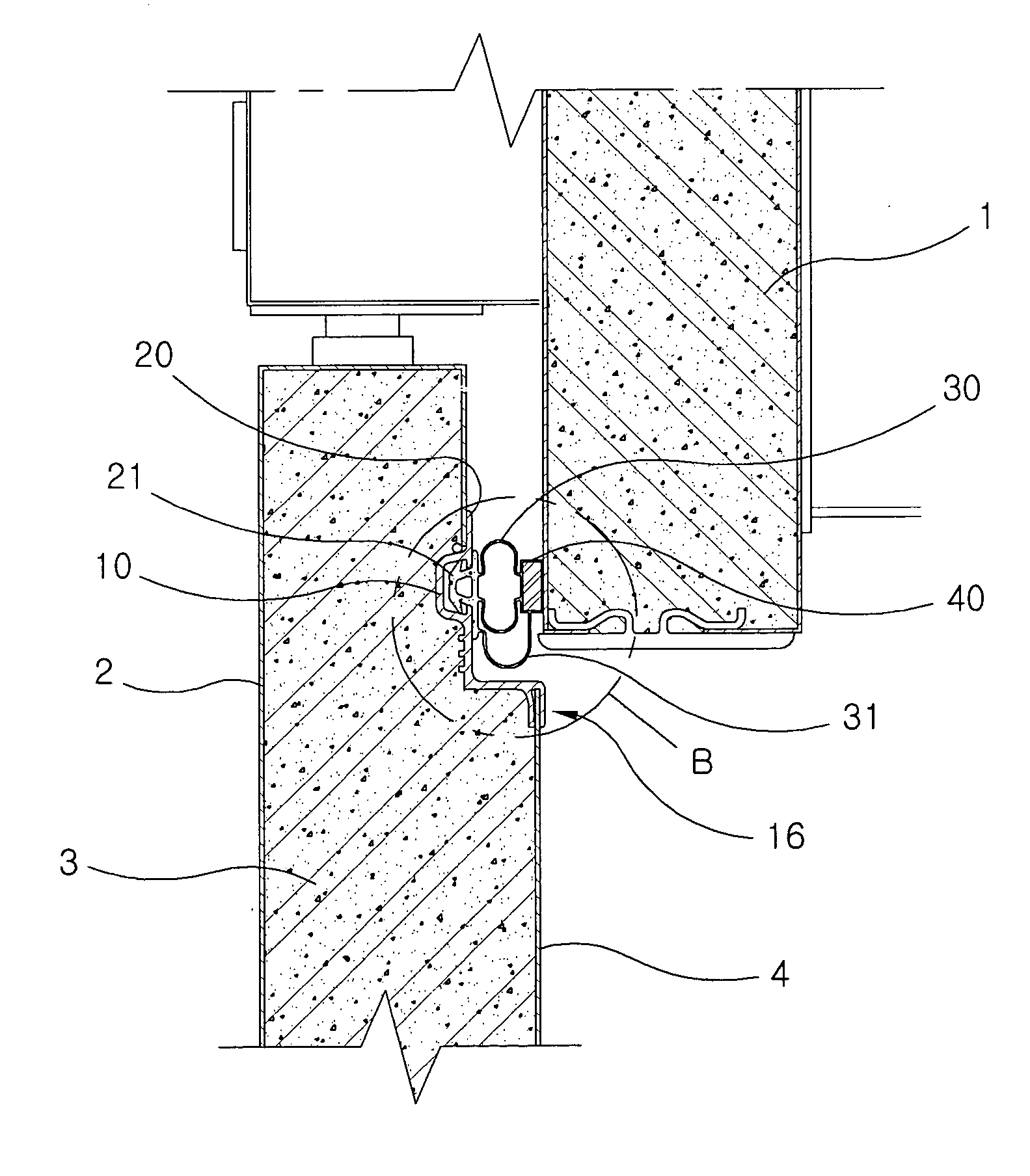

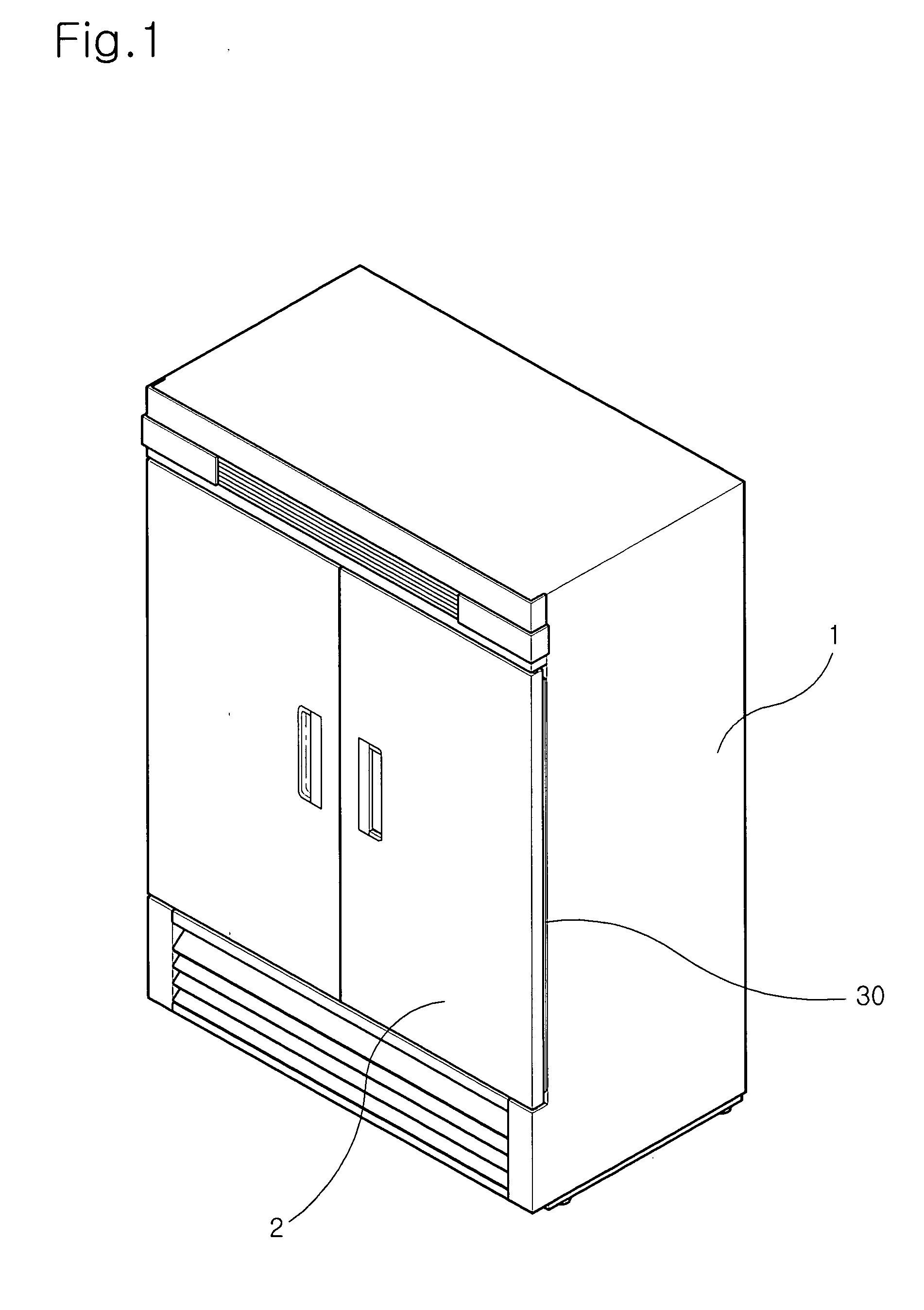

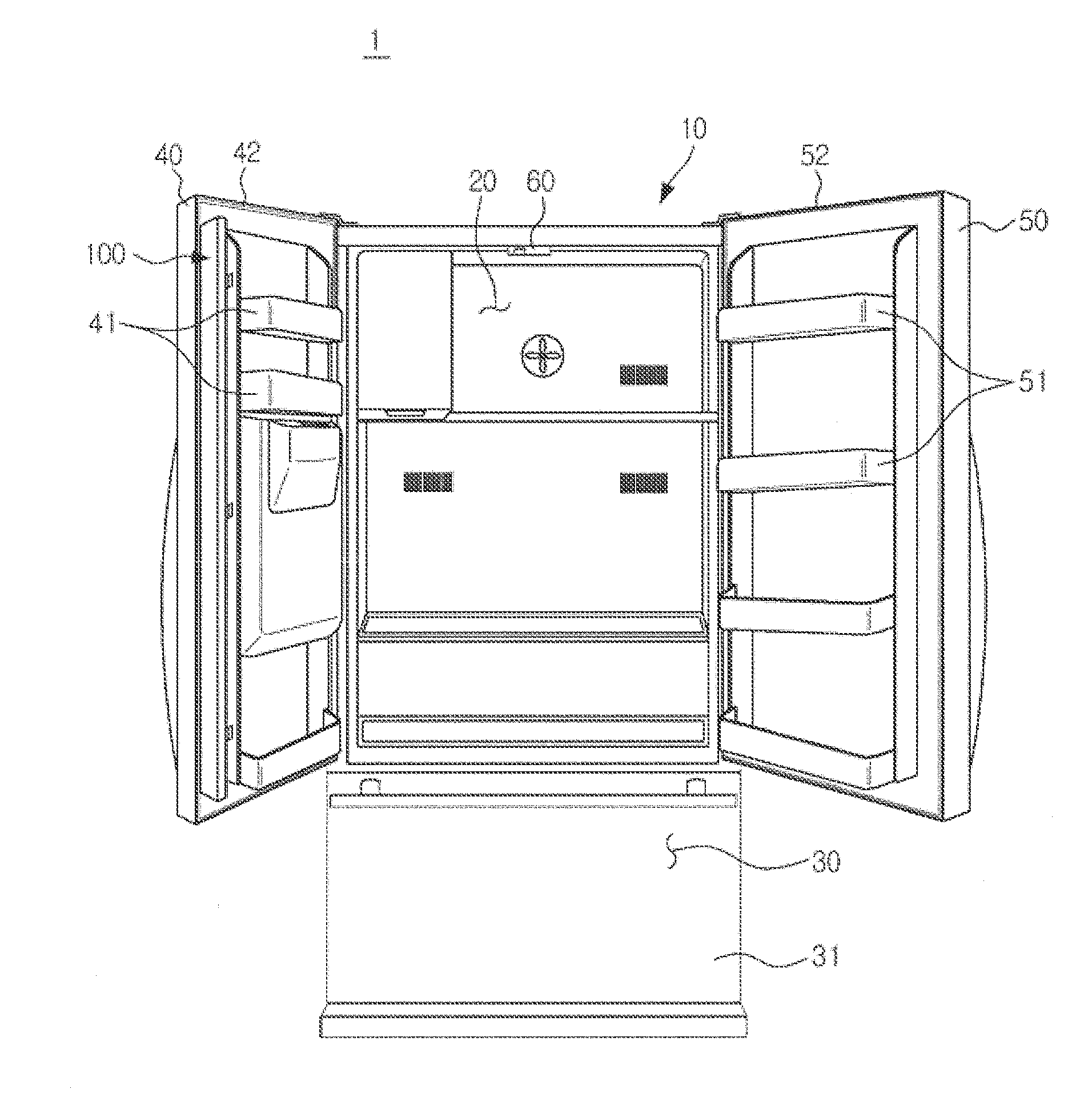

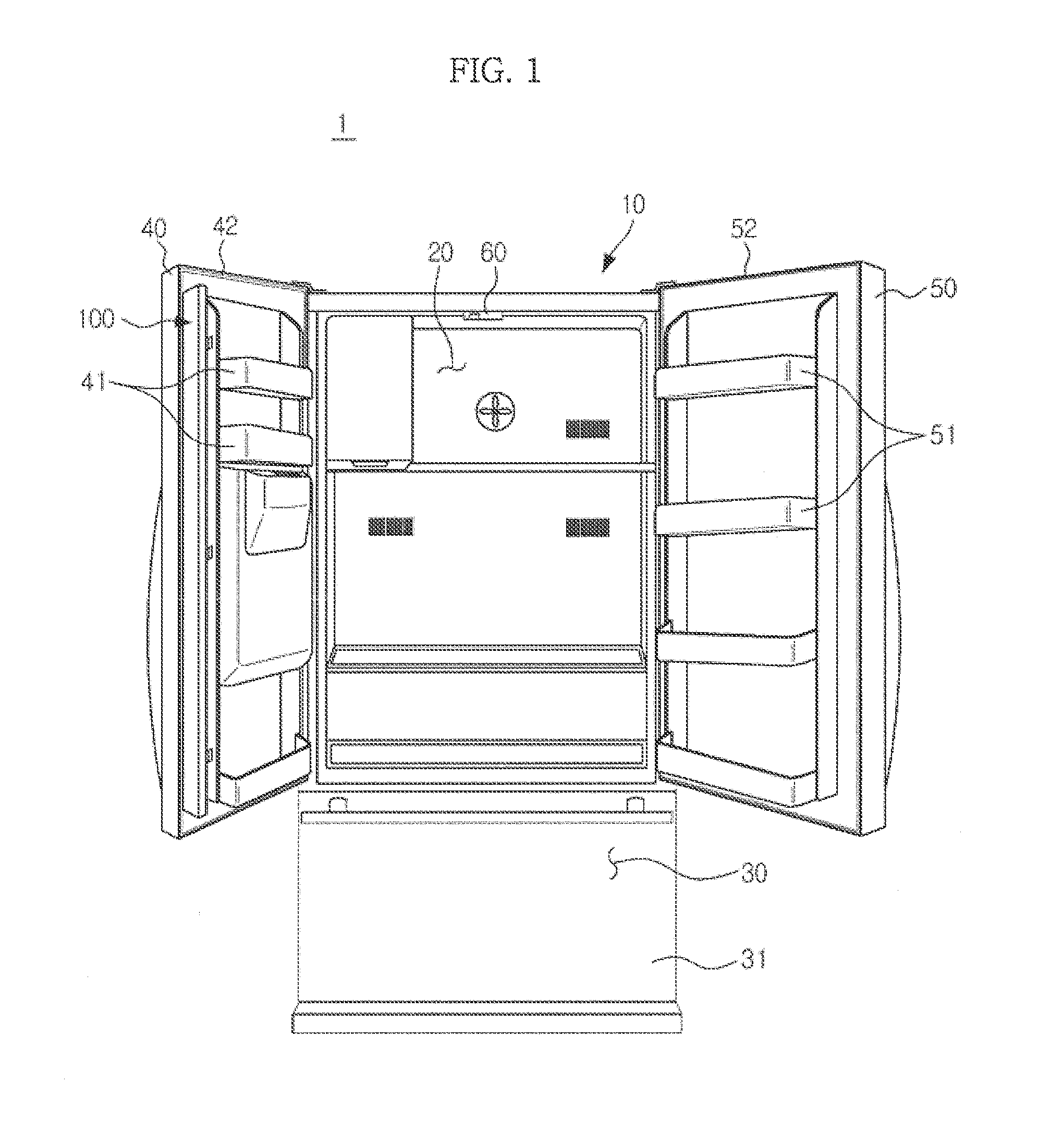

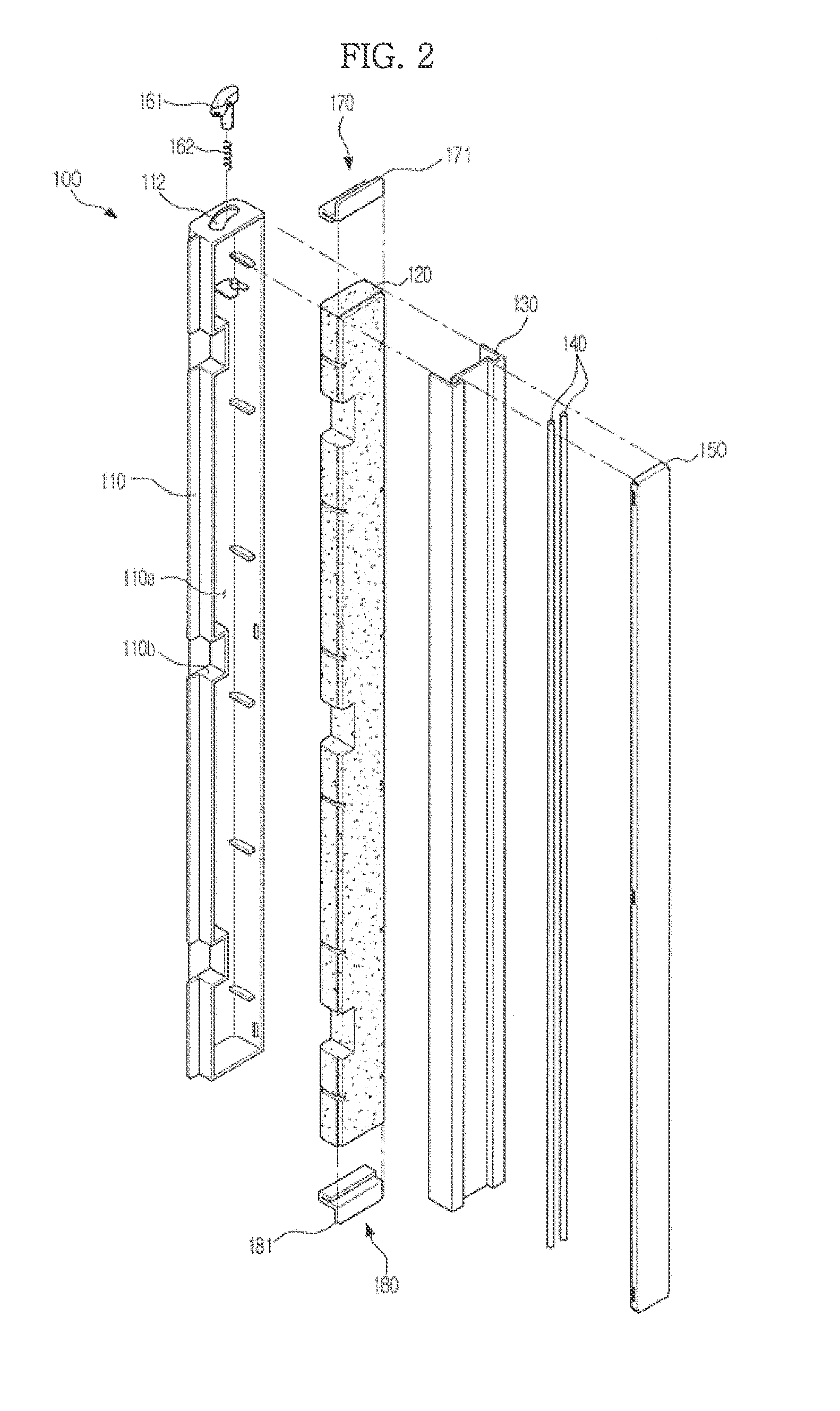

Refrigerator

ActiveUS20130241385A1Improve insulation performanceSealing gapShow cabinetsEngine sealsEngineeringMechanical engineering

A refrigerator provided with a rotating bar configured to seal a gap between one pair of doors, capable of preventing the door from being incompletely closed due to an erroneous operation of the rotating bar, the rotating bar capable of sealing a gap formed between the rotating bar and a body as well as a gap formed between one pair of doors, the rotating bar being elastically supported by an elastic member so as to move by receiving an external force from a guide part provided on the body, the rotating bar including a sealing member protruding from the rotating bar so as to seal a gap between the rotating bar and the body.

Owner:SAMSUNG ELECTRONICS CO LTD

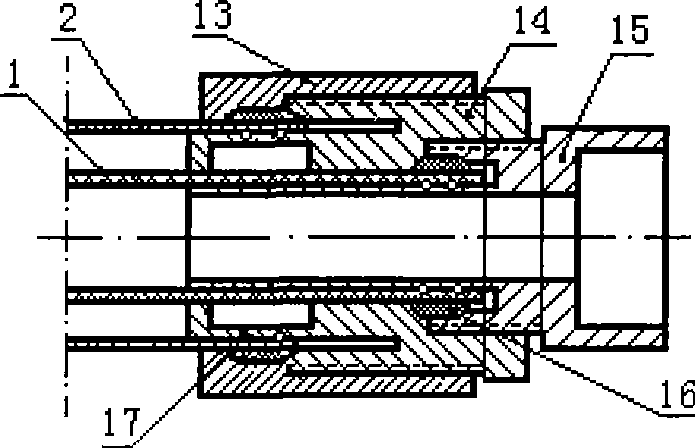

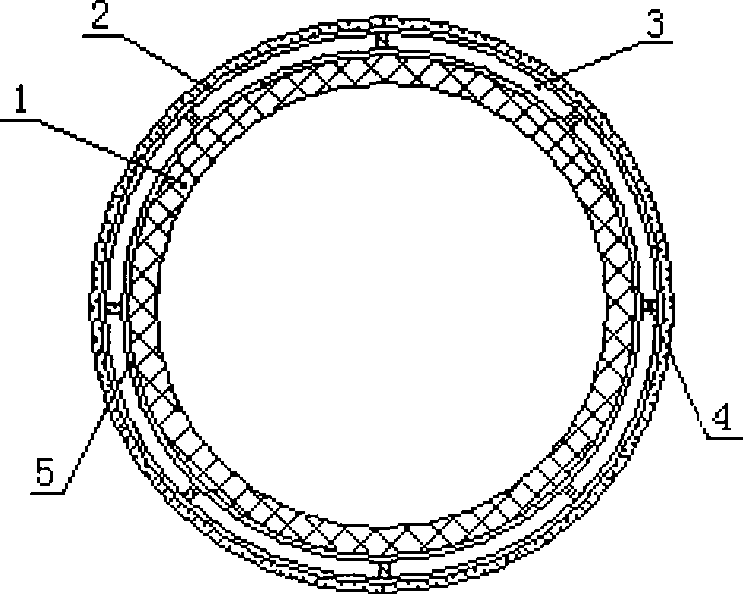

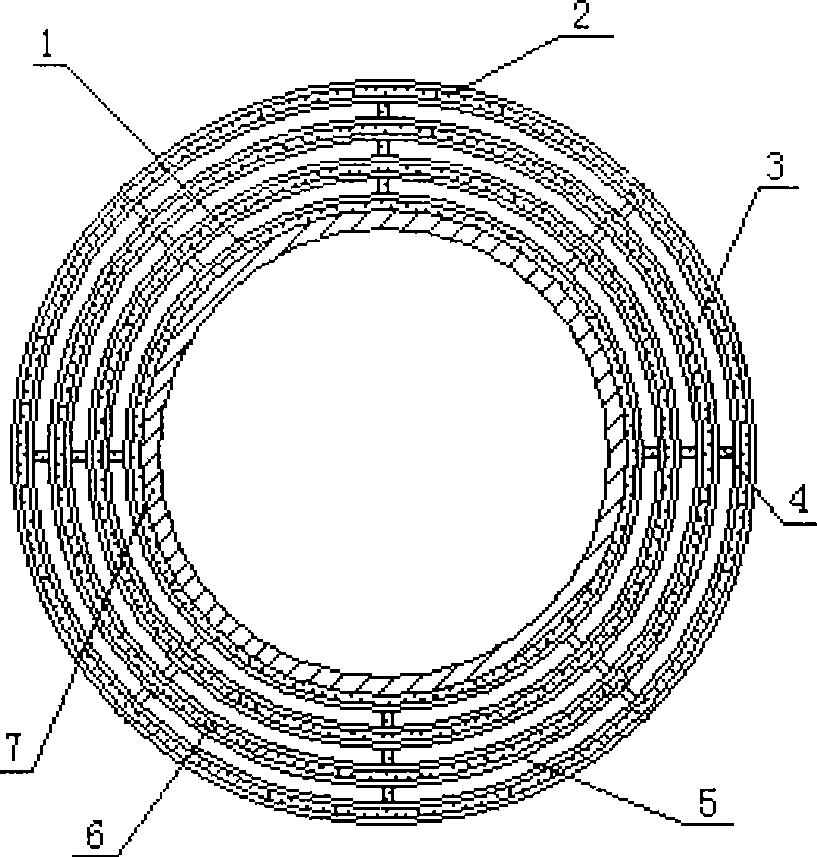

Multi-wall interlayer hollow plastic heat preserving and cold insulating pipeline

InactiveCN101469793AImprove technical effectShorten the production cycleThermal insulationPipe protection by thermal insulationInsulation layerLow emissivity

The invention discloses a multi-wall interlayer hollow plastic heat-insulation, cold insulation pipeline, which is composed of an inner pipe wall, a hollow pipe wall, an outer pipe wall which are connected through embedded rebars, and hollow heat-insulation layer arranged between the inner pipe wall, the hollow pipe wall and the outer pipe wall, characterized in that in the hollow heat-insulation layer, atmospheric pressure or negative pressure gases are used or heat-insulation material is filled as heat insulator; each pipe wall and the embedded rebars can be dipped, sprayed, or coated with low-emissivity mixing layer or a functional layer with low emissivity is extrudedly sticked to the inner pipe wall surface of the hollow heat-insulation layer; the outer pipe wall, the hollow pipe wall and the embedded rebars can be manufactured into rebars and walls mixed by plastics, aluminum powder and adsorption getter according to proportion; metal pipes can be embedded into the plastic inner pipe wall, linear expansion difference of which is melt by a compensator or a corrugated pipe; the cross section of the pipelines can be various shapes by using multi-wall composite pipe head extrusion processing or other molding technology; the pipeline is hot-melt by a using a hot-melt clamp, or secured by using a metal pipe outer wall nut and an inner wall nut and a connector, or uses connection method such as flange, cementation, welding or the like.

Owner:张征年

Cast-in-situ fireproof material of fireproof door and manufacturing method of fireproof door

InactiveCN101519312APrevent agingAvoid problems with reduced fire performanceSolid waste managementFireproof doorsFiberAdhesive

The invention relates to a cast-in-situ fireproof material of a fireproof door and a manufacturing method of the fireproof door, in particular to a cast-in-situ inorganic gelled material of a fireproof door leaf and a fireproof door frame, comprising the following components by weight percent: 30-60 of magnesia; 17-50 of magnesium chloride solution; 0.5-3 of modifier; 0.1-1 of flock and 5-30 of fly ash, which are mixed to be a liquid inorganic gelled material. The invention has the advantages that the inorganic gelled material is manufactured by a cast-in-situ mode, and no adhesive or no prefabricated inner is needed, thereby the conditions of cracks, filling and uneven material mix in the prior art are avoided, and materials which can evaporate noxious gas after heating are completely cancelled; the inorganic gelled material containing a large amount of foam is filled in a framework, thereby the weight of the whole fireproof door is reduced, and the transportation and the installation efficiencies are greatly enhanced; the foam has good insulation effect, and the solidified foam in the fireproof material can further shrink after pressure processing so as to have complete filling, thereby enhancing the density of the fireproof door and greatly strengthening the fireproof performance.

Owner:HUNAN BDF ENERGY SAVING TECH

High temperature-resistant flame-retardant insulating paint and preparation thereof

The invention relates to high-temperature resistant flame-retarding insulating coating and a method for preparing the same, which belong to the material technical field and are used for heat insulation in an aircraft. The compositions by weight percentage of the compositions of the high-temperature resistant flame-retarding insulating coating are: 60 to 70 percent of organic silicone resins, 15 to 20 percent of hollow microballoon filling insulant, 10 to 15 percent of composite fire retardant and 1 to 3 percent of auxiliary agent. The high-temperature resistant flame-retarding insulating coating has low density, high adhesion, good fire resistance and high heat insulation efficiency. The preparation method is to prepare the product with a mesopore structure through addition of the composite fire retardant, coupling agent and the auxiliary agent into the organic silicone resins, uniform mixture of the compositions through high-speed ball milling, addition of the hollow microballoon filling insulant, and low-speed stirring and uniform dispersion.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Coffee cashmere fabric and manufacturing method thereof

The invention discloses a coffee cashmere fabric and a manufacturing method of the coffee cashmere fabric, and aims to provide the warming, comfortable, light and thin coffee cashmere fabric and the manufacturing method thereof. The technical key points of the fabric are that: the fabric consists of the following raw materials in percentage by weight: 13.3 percent of carbon fiber, 29.1 percent of terylene, 19.8 percent of lenzing viscose fiber, 3 percent of spandex and 34.8 percent of normal viscose fiber; and the manufacturing method comprises the following steps of: feeding pure viscose yarn in a first path, terylene in a second path and coffee carbon fiber and lenzing viscose fiber blended yarn in a third path; sequentially and circularly arranging weft yarns; forming two loops by using different thread lengths to form approximate loops on one side of a texture; forming an air retaining layer; and finally dyeing and tidying. The fabric and the method belong to the technical field of textile.

Owner:上海缀菱纺织品有限公司

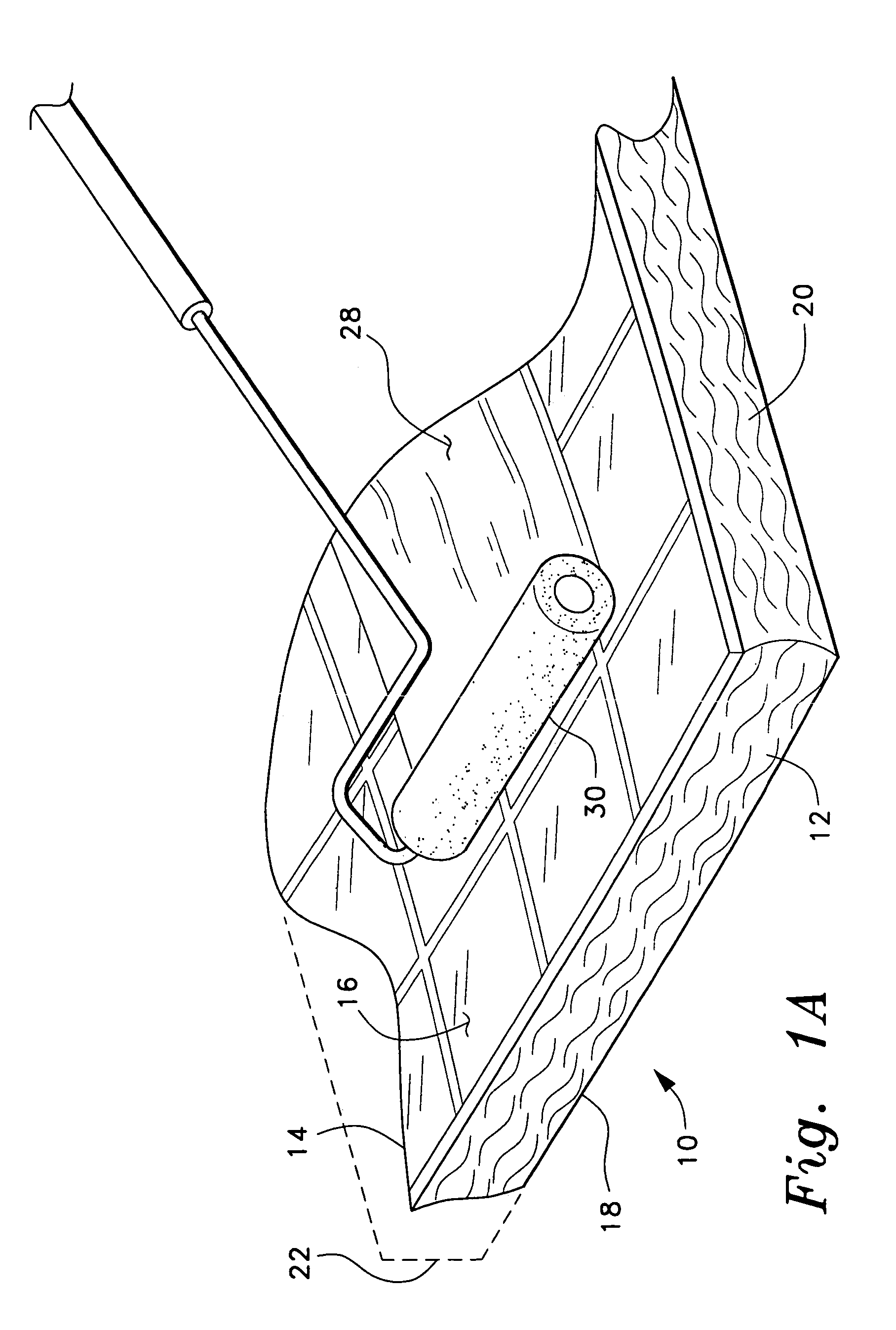

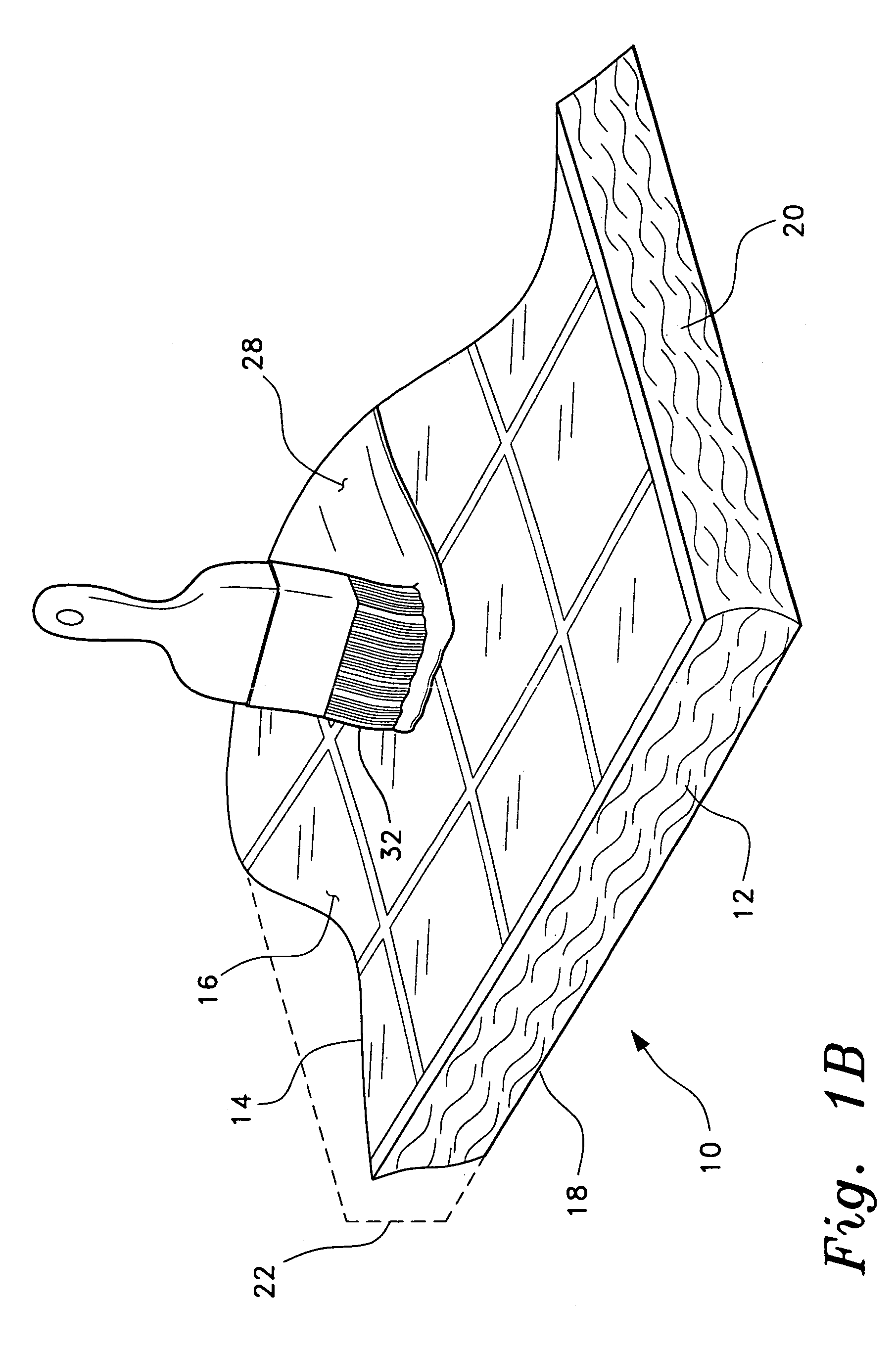

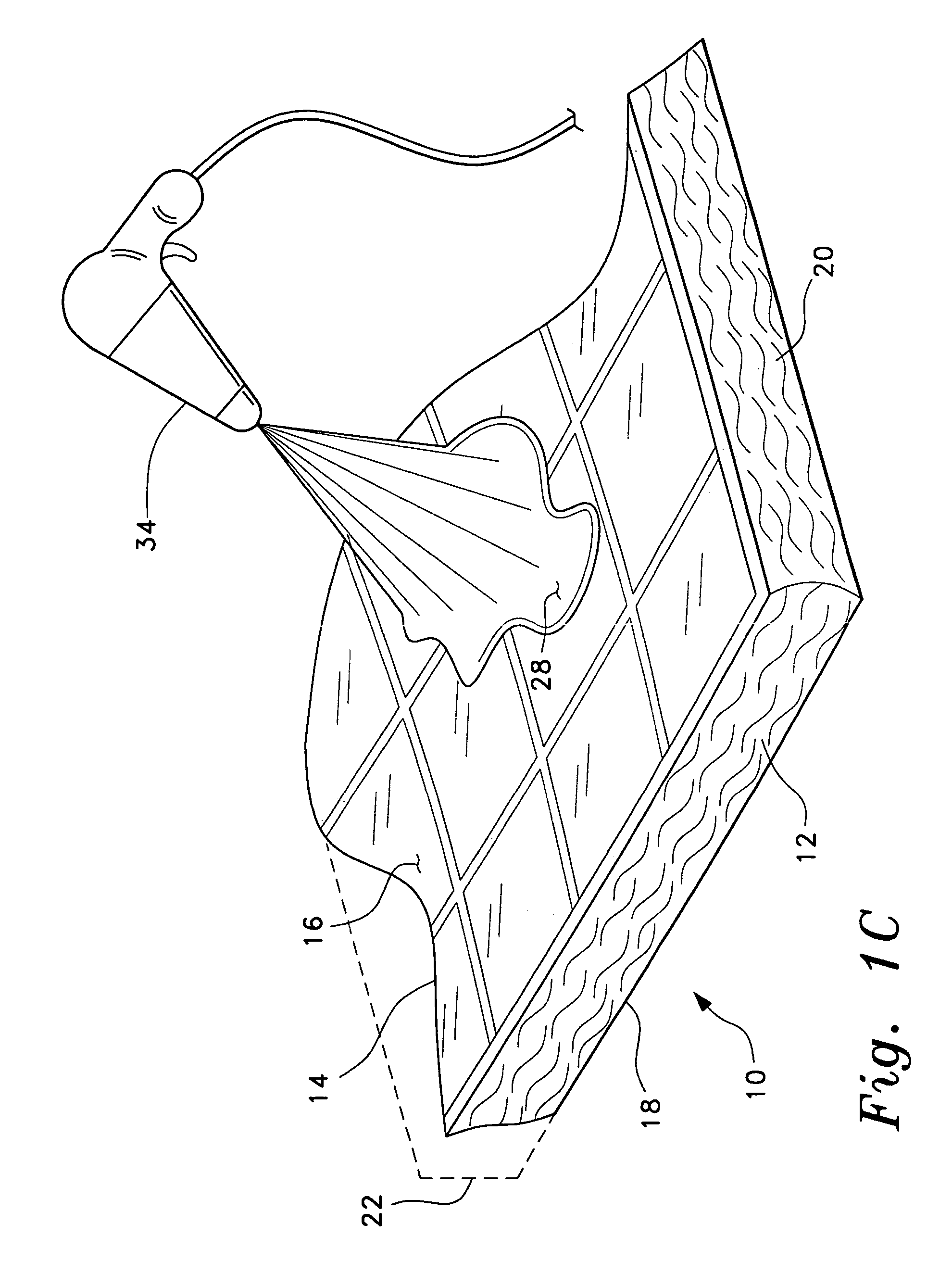

Method of applying a heat reflective coating to a substrate sheet

The method includes applying a heat reflective coating to a substrate sheet of construction material and air drying the heat reflective coating on the construction material. The method is directed particularly to the coating of insulation material, such as fiberglass batts, at the time of manufacture, but may be applied to virtually any sheet of material in order to improve the insulation properties and structural value of the material. By completely encapsulating fibrous insulation material with the impervious heat reflective coating, the emission of irritant fiber particles and corresponding health hazards are eliminated. Also, the efficiency of the insulation material is improved by sealing out moisture when completely encapsulated by the coating.

Owner:PRITCHETT JOSEPH E

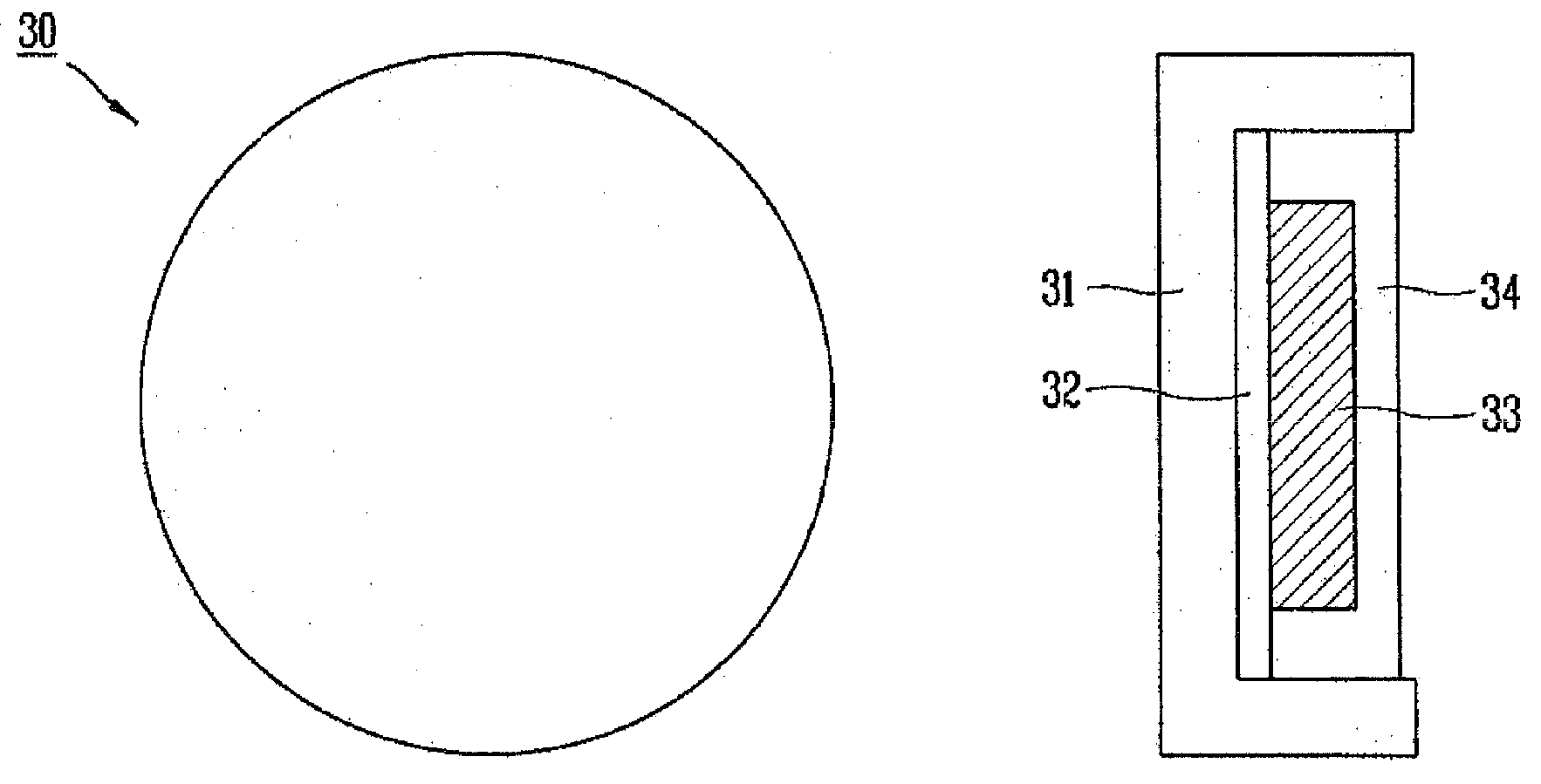

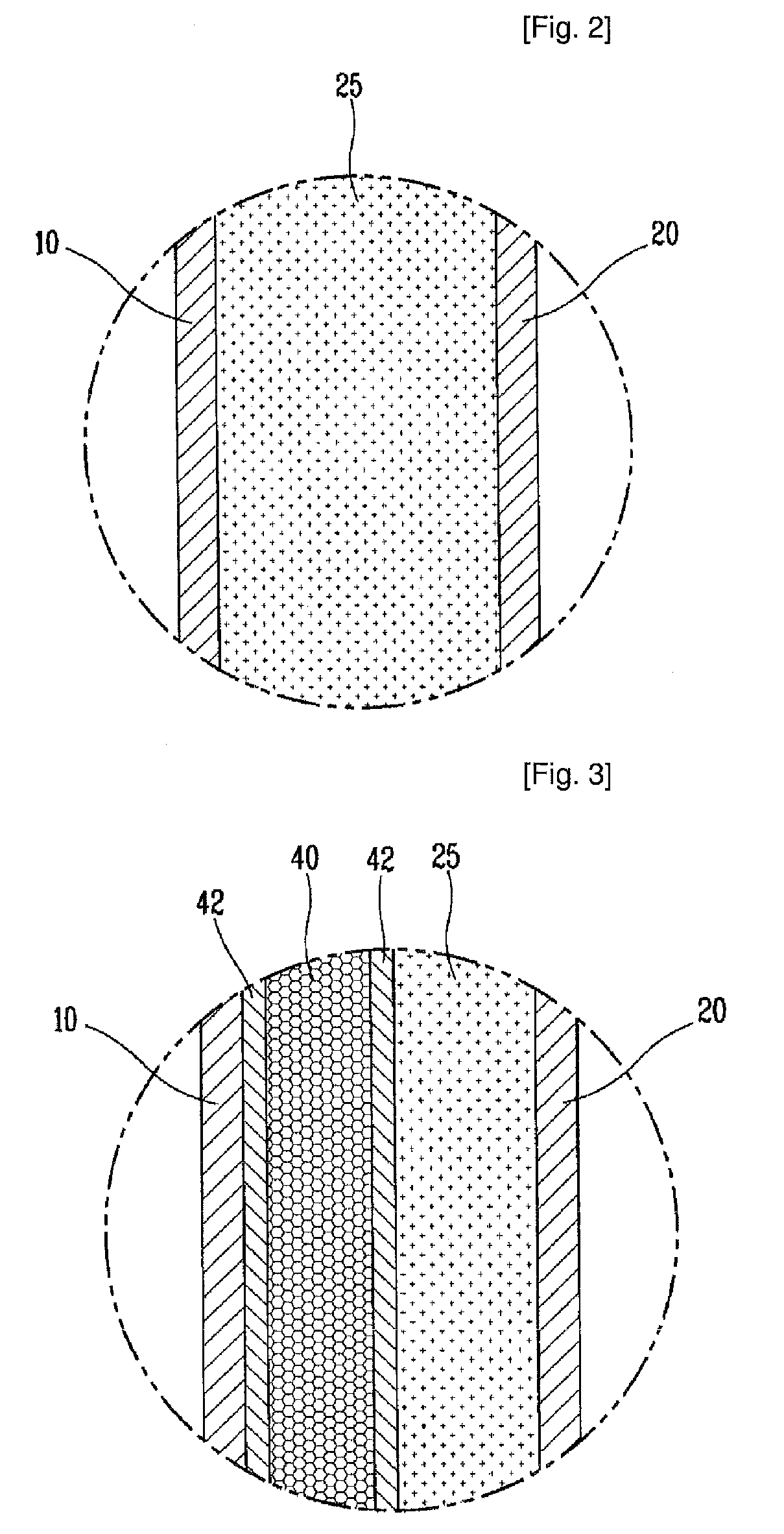

Vaccum Insulation Panal And Insulation Structure Of Refrigerator Using The Same

InactiveUS20080280090A1Low costImprove insulation efficiencyShow cabinetsLighting and heating apparatusGlass fiberEngineering

Disclosed are a vacuum insulation panel and an insulation structure of a refrigerator using the same. The vacuum insulation panel comprises a core material formed by gather glass fiber, a getter having a container to receive an absorbent having quicklime of 90 wt % or greater as a main component, and a sealing cover formed to surround the core material and the getter. The core material can be formed at low cost in such a manner that glass fiber is tangled and gathered by penetrating glass wool having glass fiber using a needle. Since the getter is made of quicklime that can first remove water corresponding to a main component of the absorbent, the getter can be manufactured at low cost and has improved insulation efficiency.

Owner:LG ELECTRONICS INC

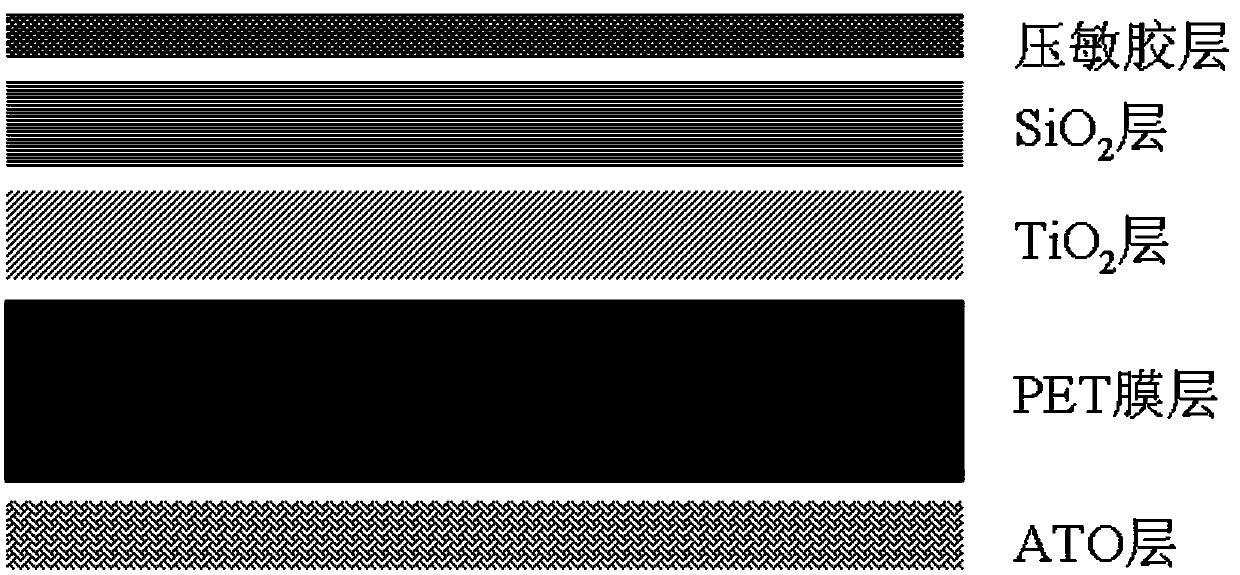

Flexible transparent nano heat-insulation film and preparation method thereof

ActiveCN104178047AImprove insulation efficiencyImprove transmittanceFilm/foil adhesivesRadiation-absorbing paintsInsulation layerThermal break

The invention discloses a flexible transparent nano heat-insulation film which comprises an organic flexible substrate, a nano antimony tin oxide layer coated on one side of the organic flexible substrate, a TiO2 layer coated on the other side of the organic flexible substrate, a SiO2 layer coated on the other side of the TiO2 layer, and a pressure-sensitive adhesive coated on the other side of the SiO2 layer. The invention also discloses a preparation method of the flexible transparent nano heat-insulation film, which comprises the following steps: 1) preparing a TiO2 coating slurry; 2) preparing a SiO2 coating slurry; 3) preparing a nano antimony tin oxide slurry; 4) coating a nano antimony tin oxide absorptive heat-insulation layer; 5) coating a SiO2 / TiO2 reflective heat-insulation layer; and 6) coating the pressure-sensitive adhesive. The method enhances the heat-insulation efficiency of the heat-insulation film, so that the indoor / outdoor temperature difference can reach 10 DEG C; the visible light transmittance of the heat-insulation film is up to 80%; the adhesive force of the coating on the flexible substrate surface reaches Grade 1; the heat-insulation layer can not easily absorb dust, and thus, can not be easily polluted; and the heat-insulation film can be easily attached to or peeled from the surface of the glass, ceramic or any other substrate.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

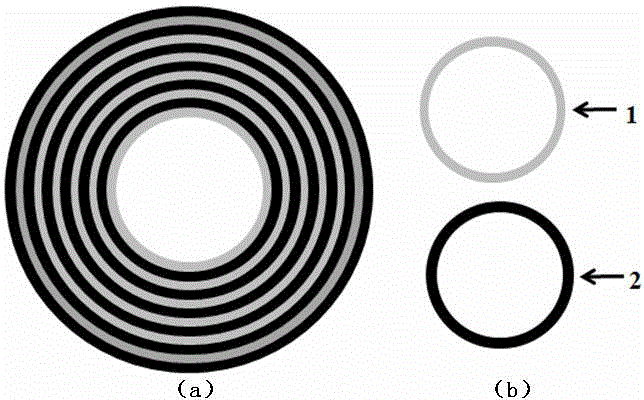

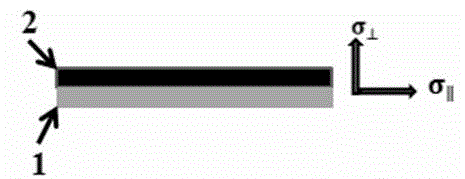

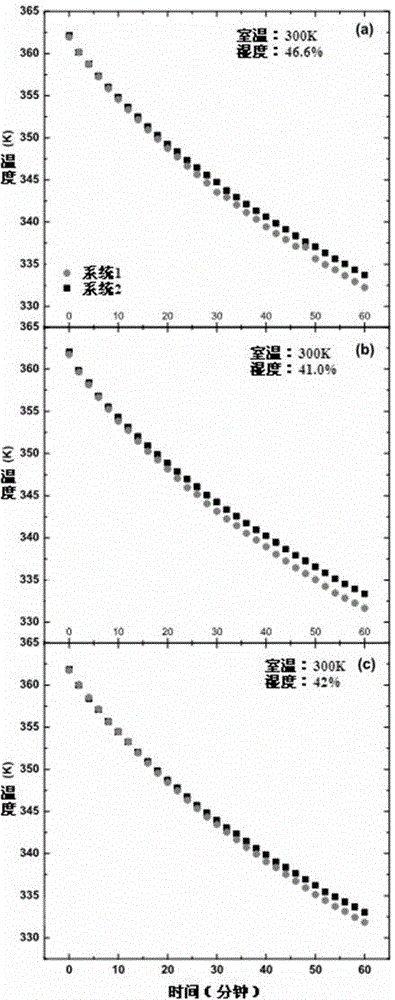

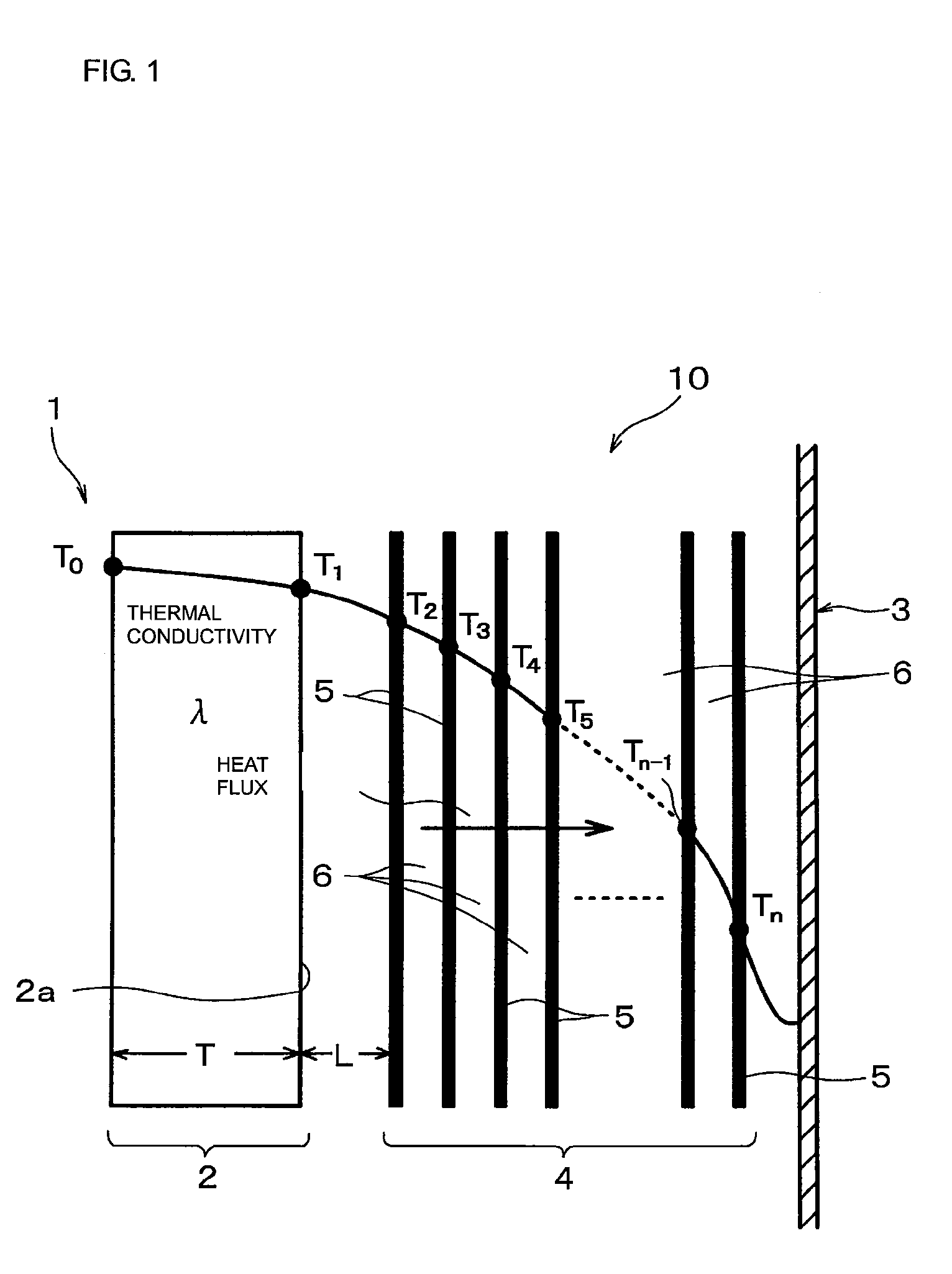

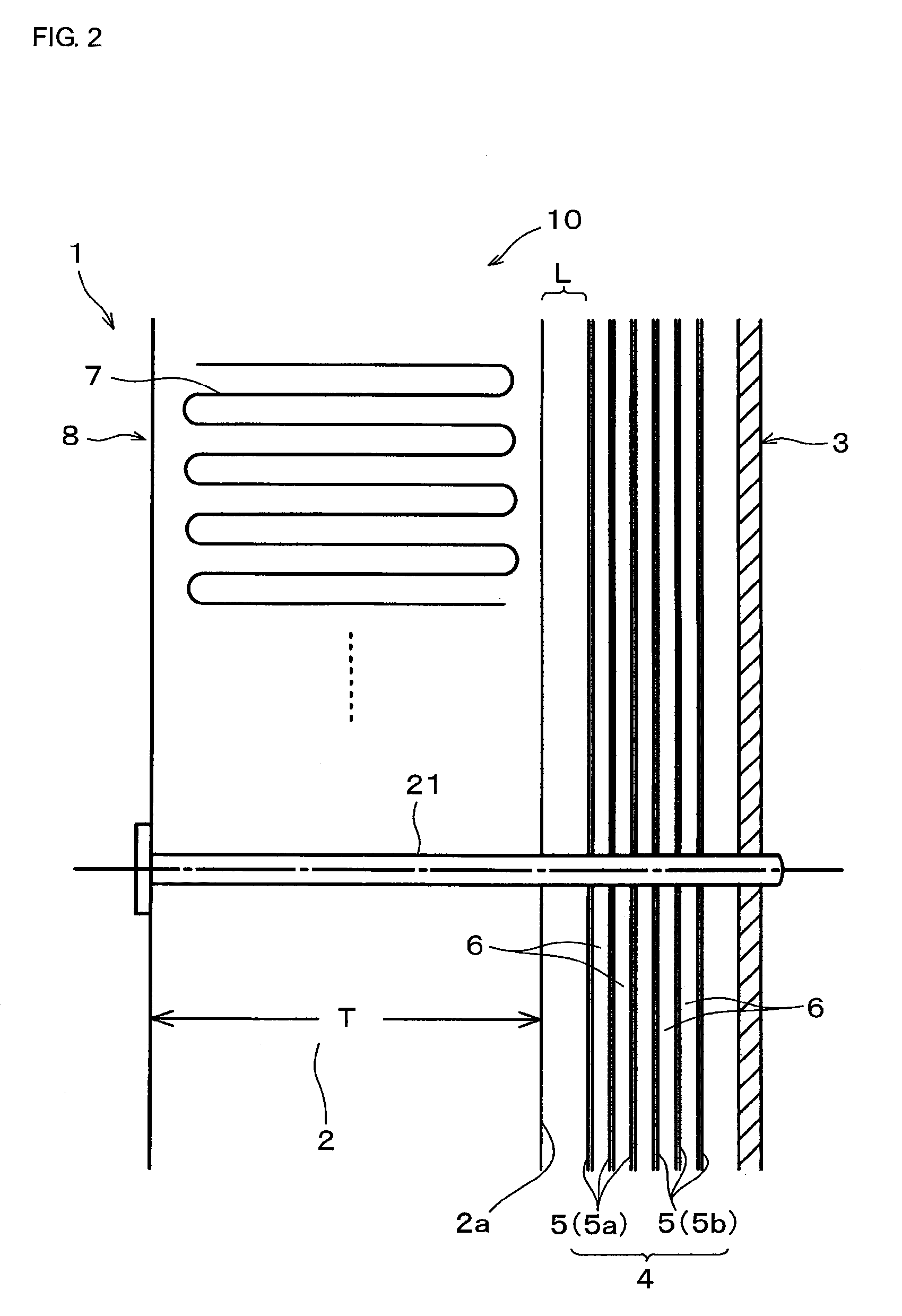

Composite layered structure thermal insulation material high in thermal insulation efficiency

InactiveCN104153471AImprove insulation efficiencyDifficult to distributeClimate change adaptationHeat proofingThermal insulationHigh reflectivity

The invention belongs to the technical field of composite materials, and particularly provides a composite layered structure thermal insulation material high in thermal insulation efficiency. The thermal insulation material is formed by arranging and combining heat high-reflectivity materials and low-thermal-conductivity materials alternately. The thermal insulation material is different from an existing thermal insulation material which achieves the thermal insulation effect on the basis of heat conduction limit. The composite layer structure thermal insulation material high in the thermal insulation efficiency is based on material layered combination, can limit heat conduction, and can also effectively limit heat convection and heat radiation, thereby obtaining the efficient thermal insulation effect. The thermal insulation material can be used for petroleum conveying pipelines, buildings, equipment and the like.

Owner:FUDAN UNIV

Heat-treating furnace

ActiveUS20090029307A1Avoid breakingEfficient preparationFurnace typesCeramic layered productsCeramic moldingComputer module

A heat treating furnace capable of continuously performing binder removal and subsequent firing without requiring a complicated configuration and increasing the equipment size and cost, for example, for degreasing a ceramic molding which is to be fired in a process for manufacturing a ceramic electronic component. A heat insulator is disposed to surround a heat treatment region in a case, and a reflector is disposed between the inner wall of the case and the insulator in order to reflect heat transferred from the heat treatment region through the heat insulator. A module heater including a heater embedded in the insulator is used. As the reflector, there is used a reflector having a structure in which a plurality of thin plates is arranged so that the main surfaces are arranged in parallel to each other with a predetermined space between the adjacent main surfaces.

Owner:MURATA MFG CO LTD

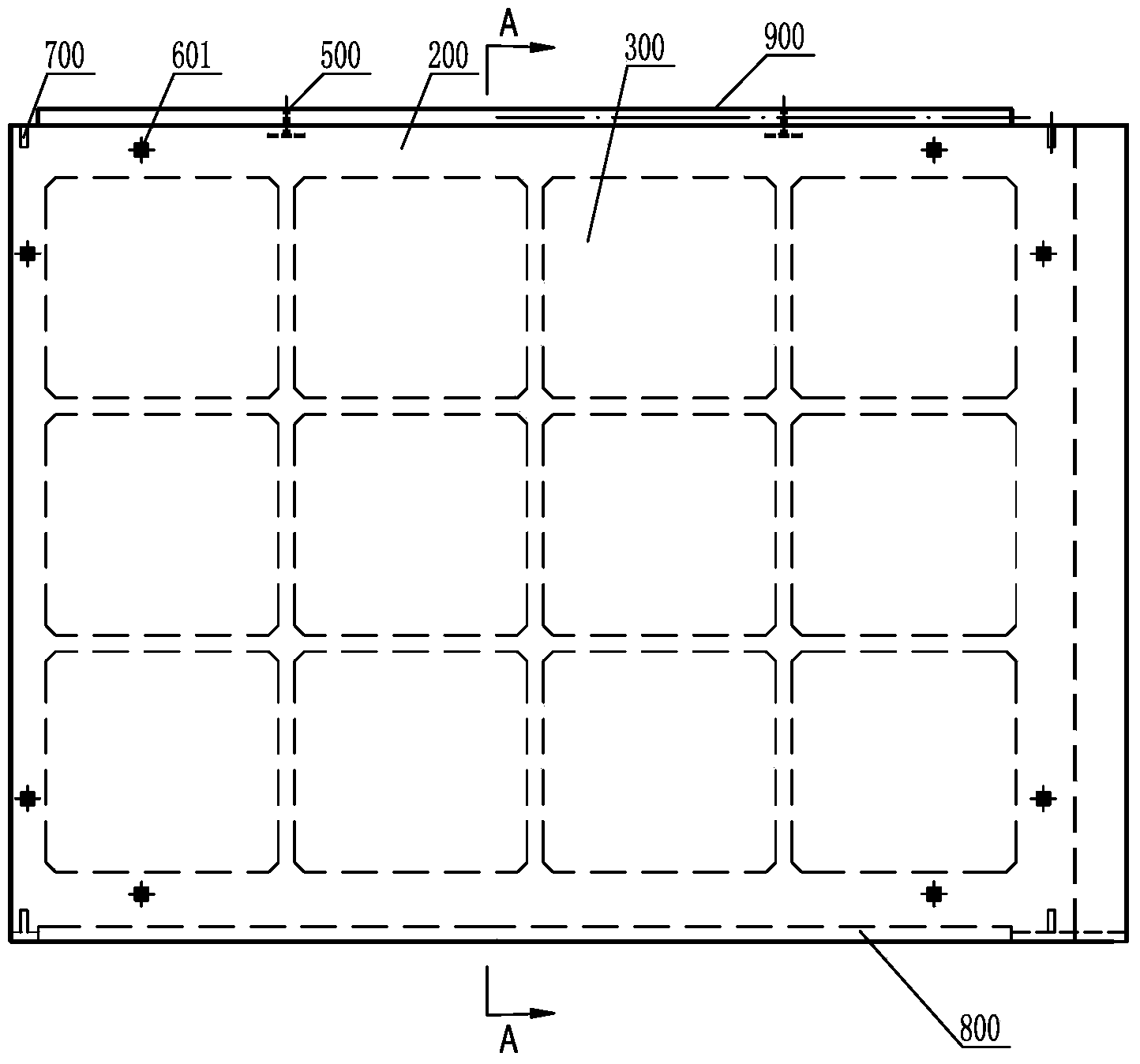

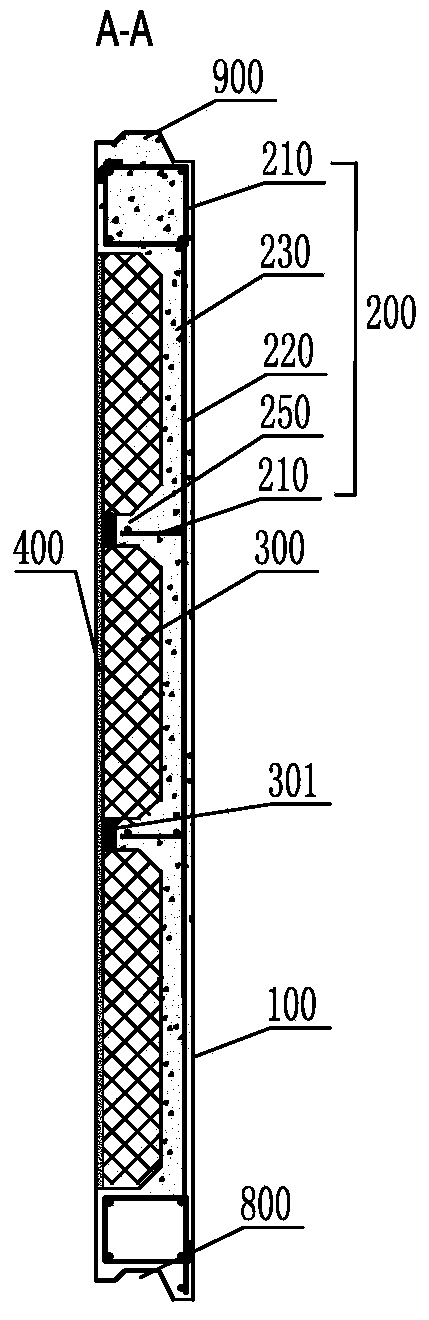

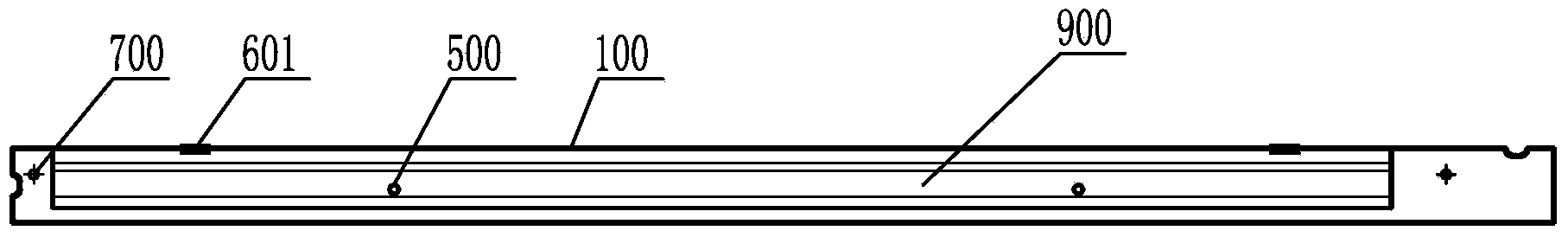

Invisible intelligent full-automatic outer sun-shading system

InactiveCN101994478AReduce air conditioning loadGood energy saving effectLight dependant control systemsClimate change adaptationAutomatic controlElectricity

The invention discloses an invisible intelligent full-automatic outer sun-shading system, comprising a roller shade box, wherein two ends of the roller shade box are connected to the wall by a head installing seat and a trail installing seat. The invisible intelligent full-automatic outer sun-shading system also comprises a plurality of roller shade pieces, wherein one end sof the roller shade pieces are connected to the roller shade box and the other ends are vertically arranged. The invisible intelligent full-automatic outer sun-shading system also comprises a temperature / light sensor, a controller, a clock controller, an electric rotating motor, an unrolling and rolling electric motor and a turning wheel which are sequentially electrically connected, wherein the clock controller, the electric rotating motor, the unrolling and rolling electric motor and the turning wheel are arranged in the roller shade box; and a leading cable is connected with the electric rotating motor, and one ends of the roller shade pieces are connected to the leading cable. The three-dimensional full-weather automatic control of the outer sun-shading system is realized, the heat-proof quality of the sun-shading system is effectively improved, most of sunlight heat can be reflected and shaded; the outer sun-shading system can avoid that the solar radiation directly enter into the indoor room, is beneficial to the prevention of the fluctuation of the indoor temperature, reduces the cold and hot load loss of the air-condition, greatly improves the heat insulation and daylighting performance of the common sun-shading system and the performance of the air-condition system, and achieves better energy saving effect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

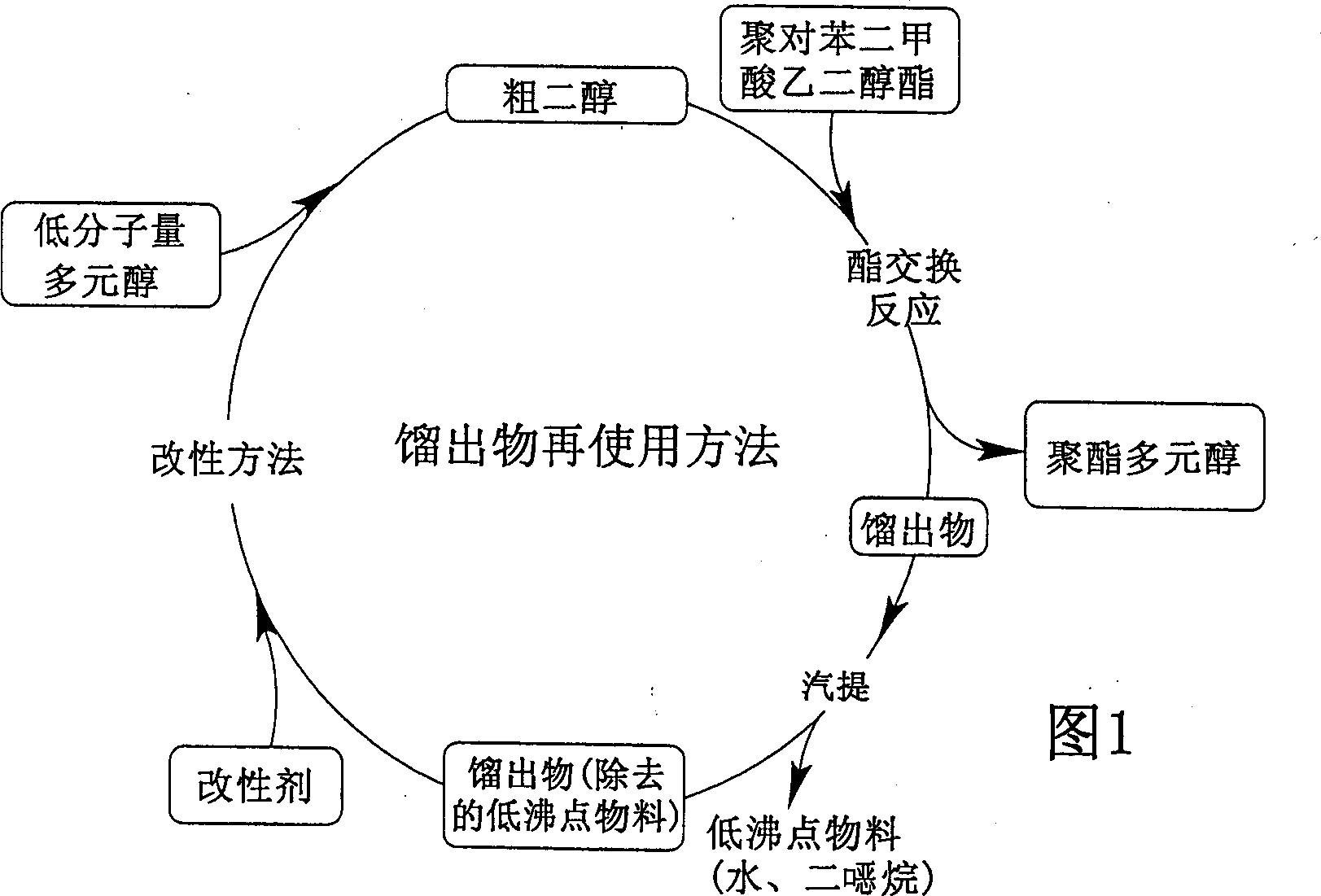

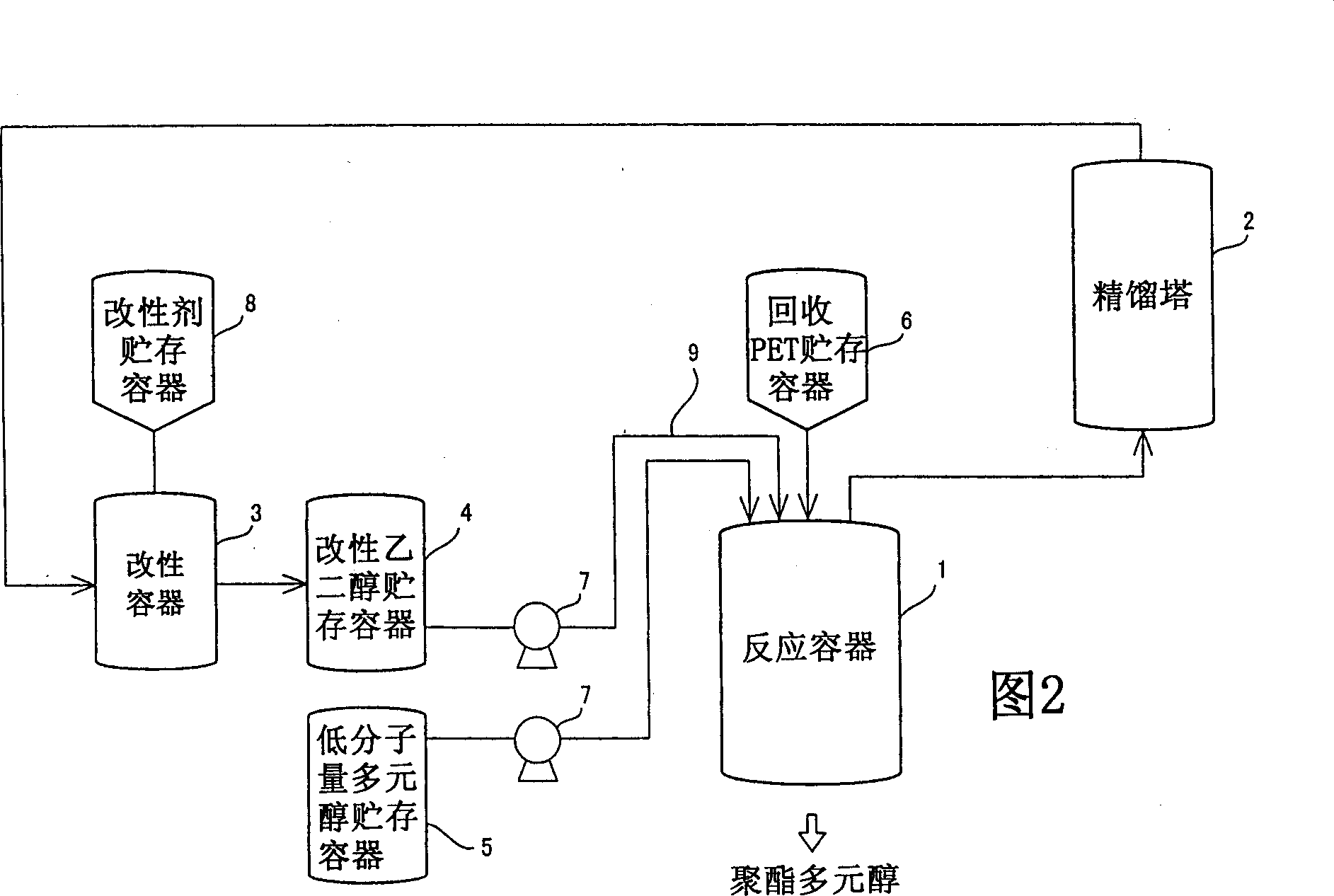

Method and device for producing polyester polyol, polyester polyol and polurethane foam

To provide a method for producing polyester polyol that can provide a simple process to produce extensively improved production efficiencies and also produce the polyester polyol of stable in quality, an apparatus for producing the polyester polyol produced by the method, a polyester polyol produced by the method, and a polyurethane foam obtained by use of the polyester polyol produced by the method, polyethylene terephthalate and raw polyol are allowed to react in a reaction vessel to produce polyester polyol and also ethylene glycol which is a by-product of the reaction is distilled off and the distillate is modified, for example by reaction with an alkylene oxide, in a modifying vessel so that it can have a predetermined hydroxyl value and then is fed to the reaction vessel again as the raw glycol, to thereby produce the polyester polyol.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

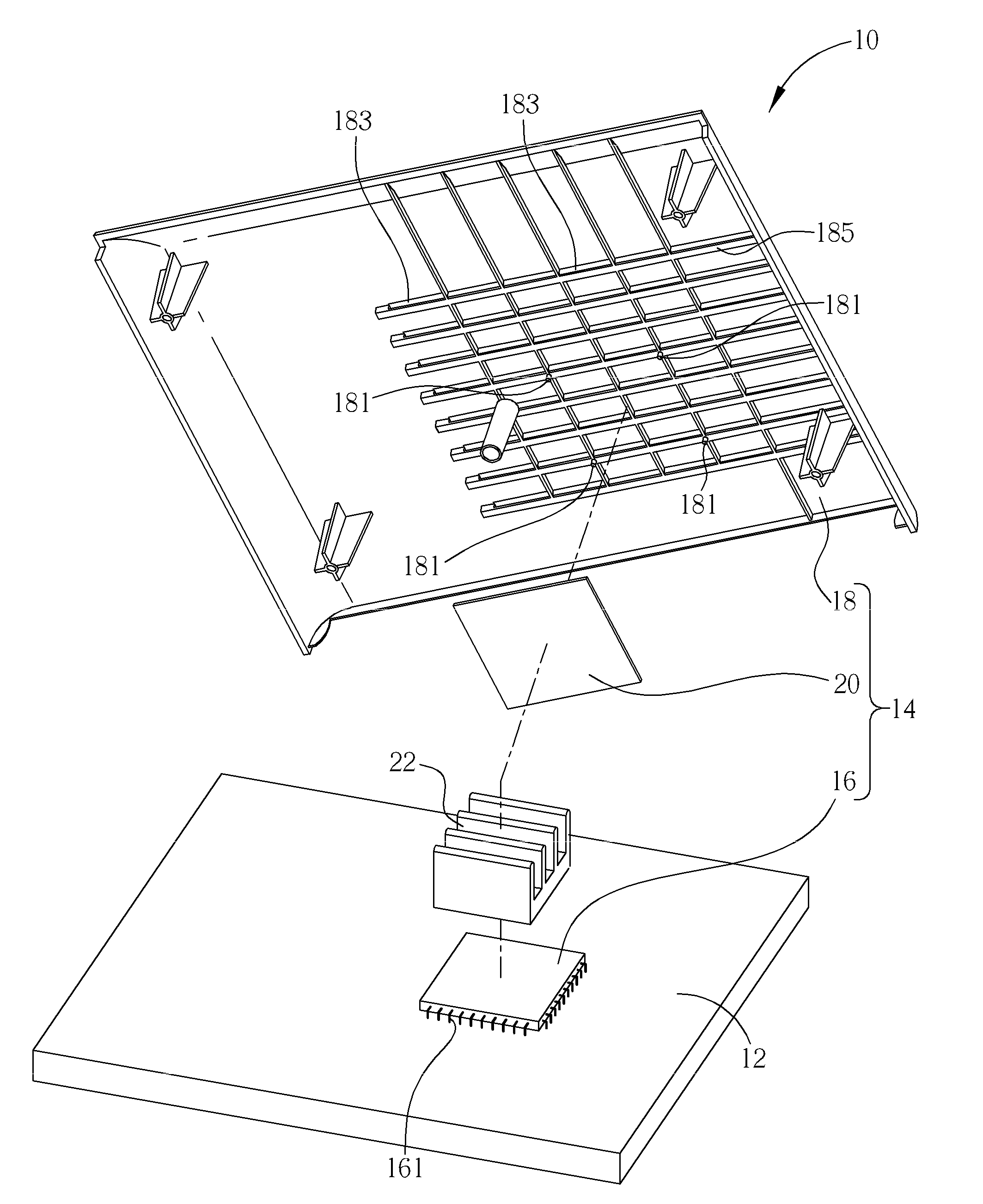

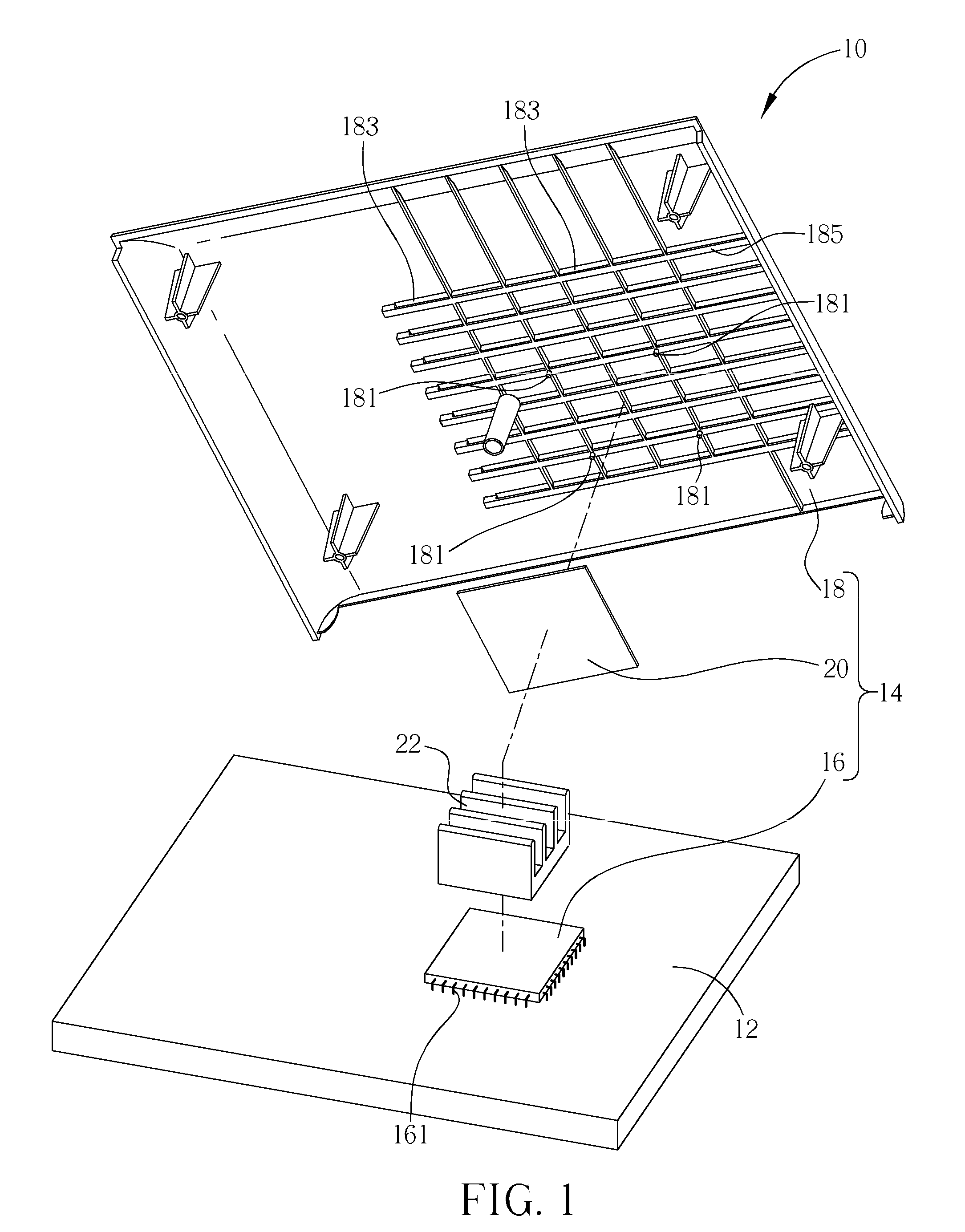

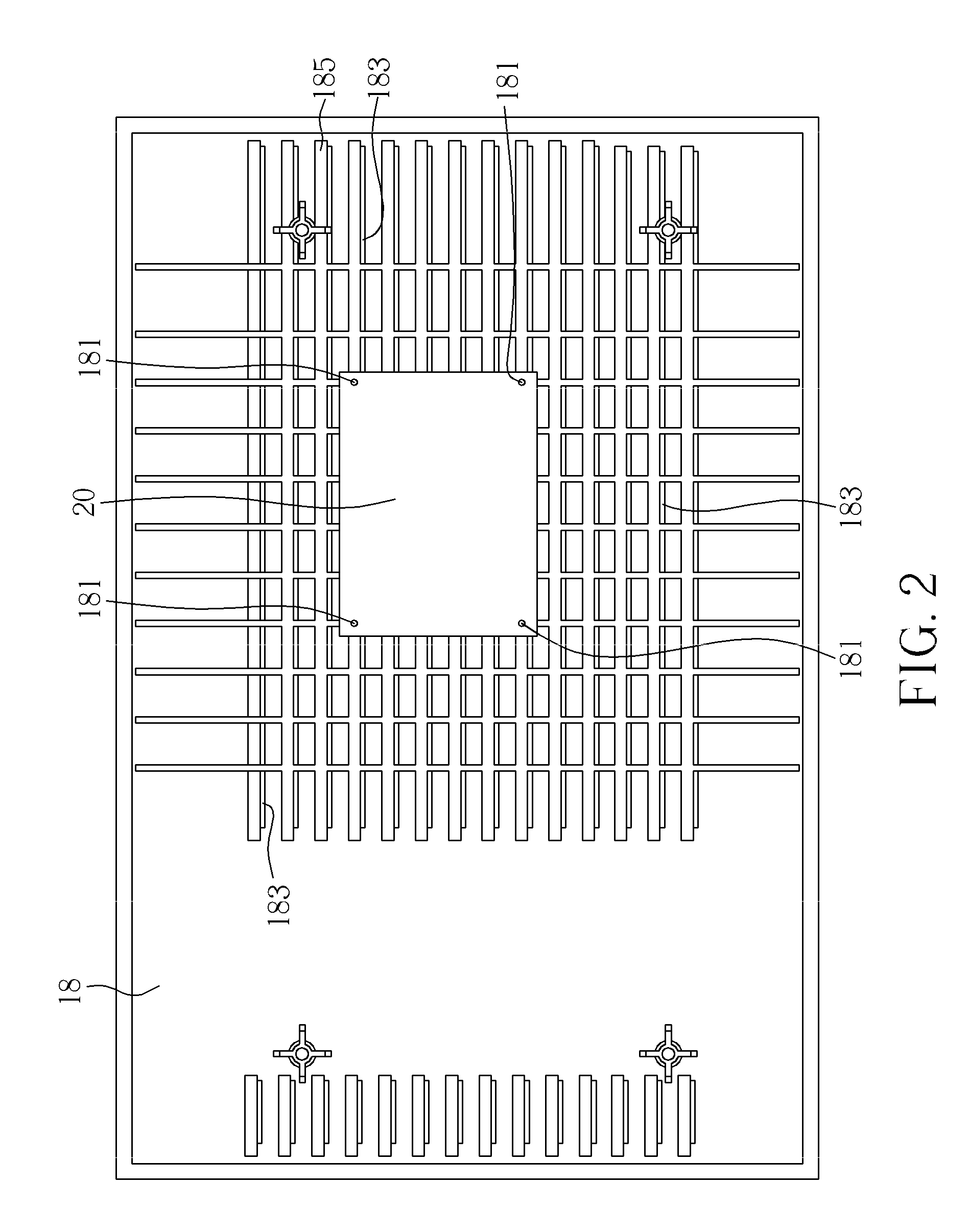

Electronic device with a heat insulating structure

InactiveUS20110063801A1Improve insulation efficiencyAssist in heat dissipationCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersHeat currentEngineering

An electronic device includes a circuit board and a heat insulating structure. The heat insulating structure includes a heat source, an enclosure for covering the heat source, and a heat insulating plate disposed on a side of the enclosure facing to the heat source for preventing heat generated by the heat source from directly transmitting toward the enclosure, and a space being formed between the heat insulating plate and the enclosure. The heat insulating structure further includes a thermal conductive layer disposed on a side of the heat insulating plate facing to the heat source. The heat insulating structure further includes the thermal conductive layer disposed on a side of the heat insulating plate facing to the enclosure. Therefore, the heat insulating plate can be for altering heat current generated by the heat source so as to dissipate the heat current via holes on the enclosure uniformly.

Owner:GEMTEK TECH CO LTD

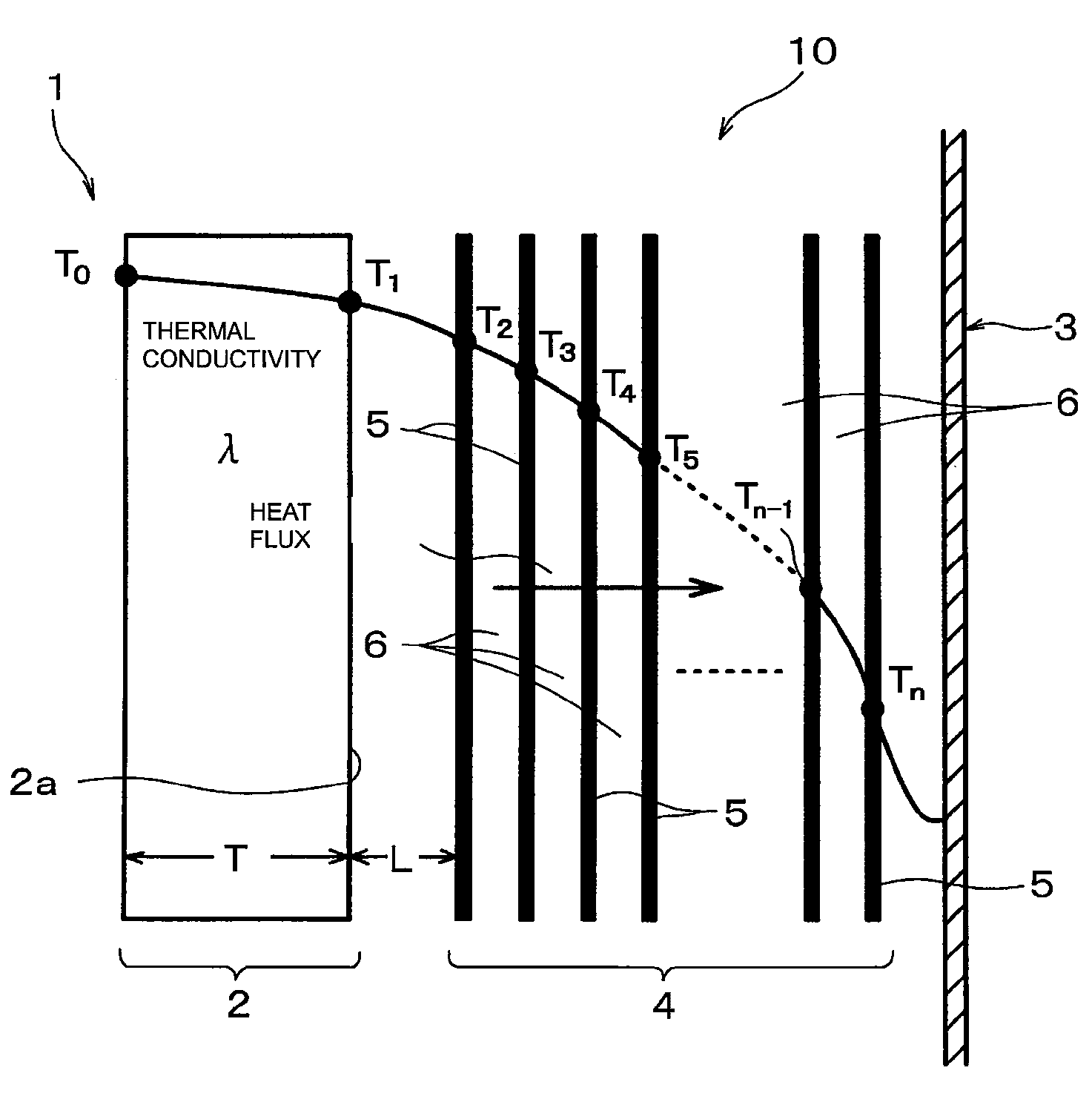

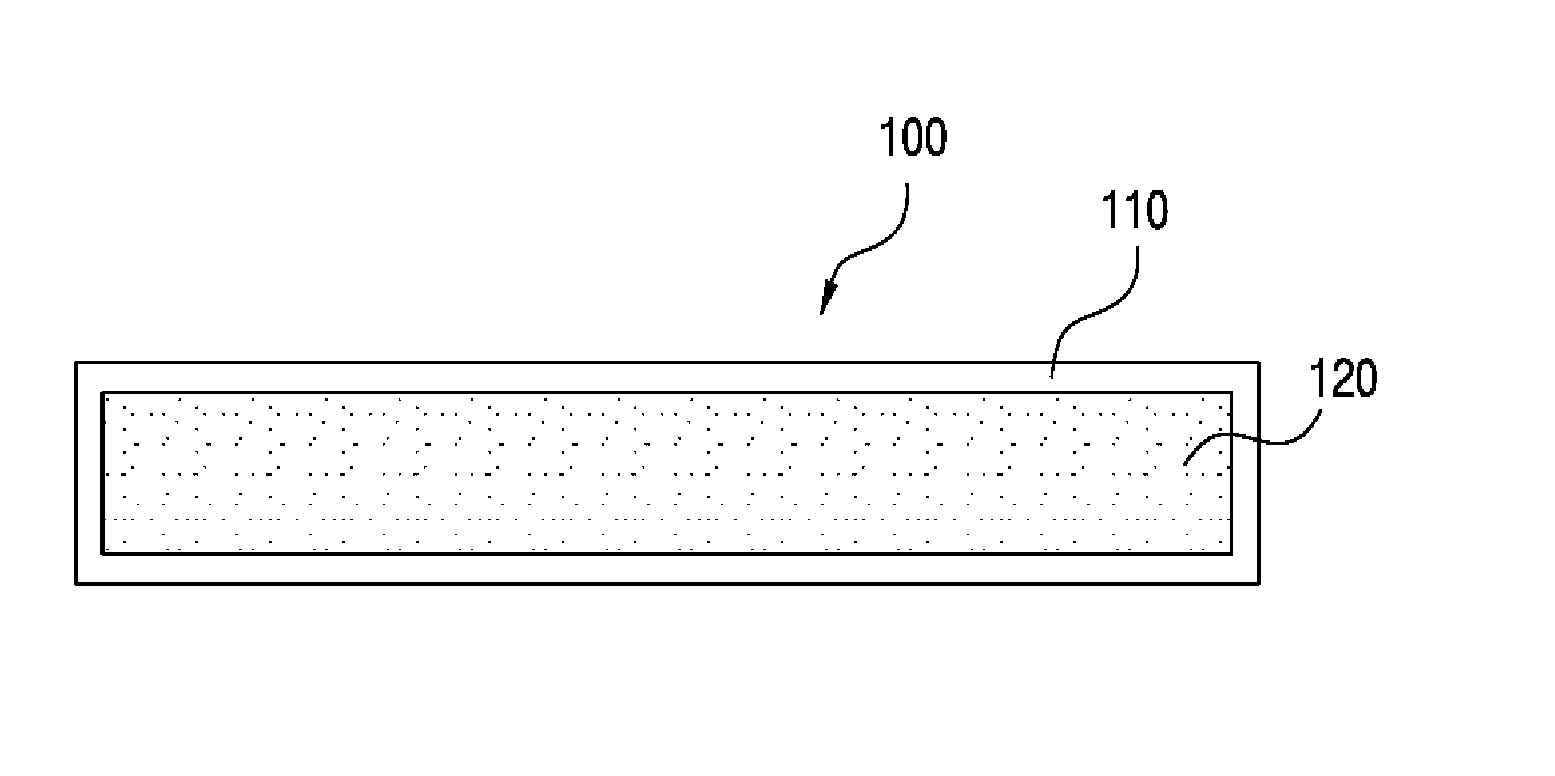

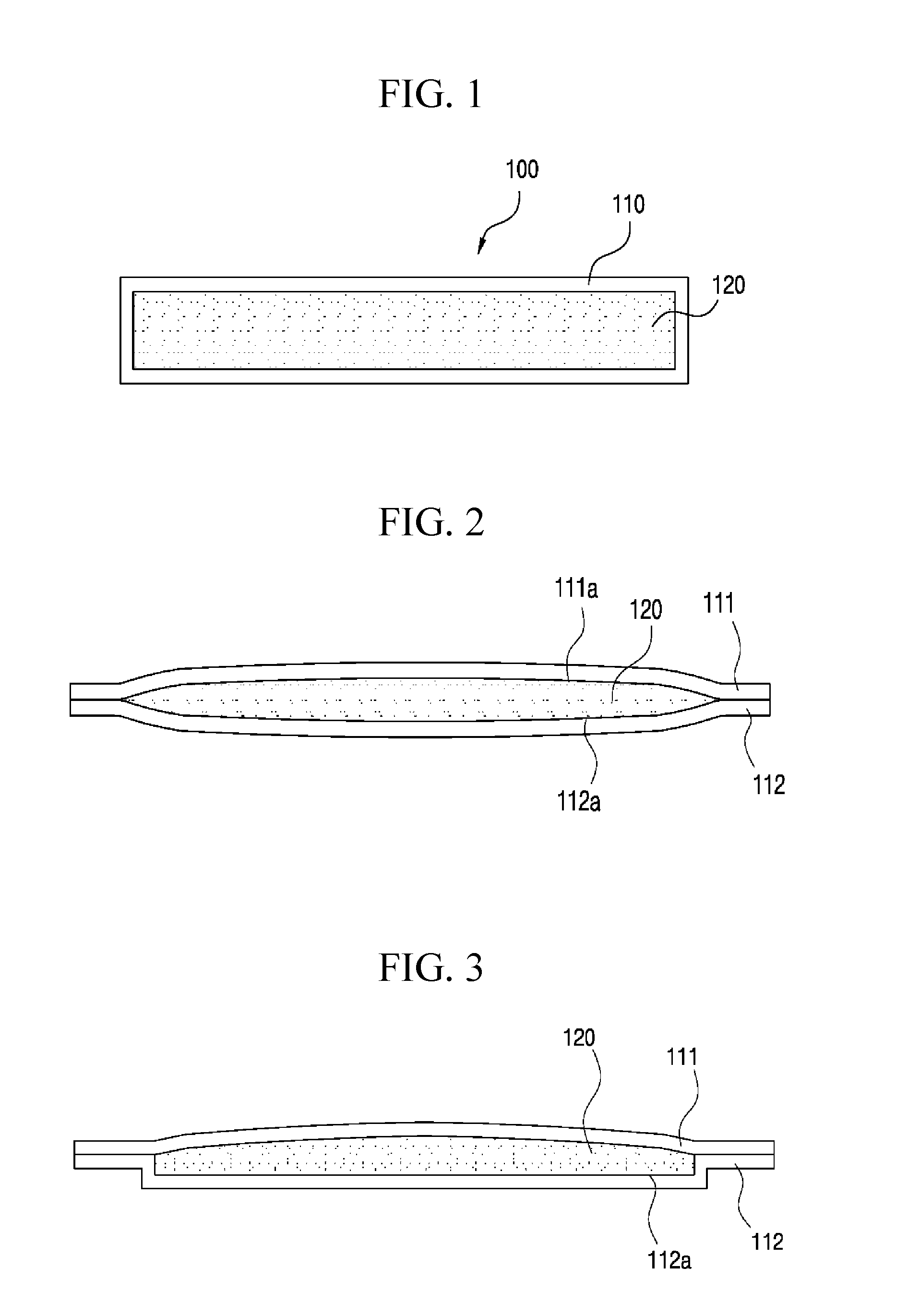

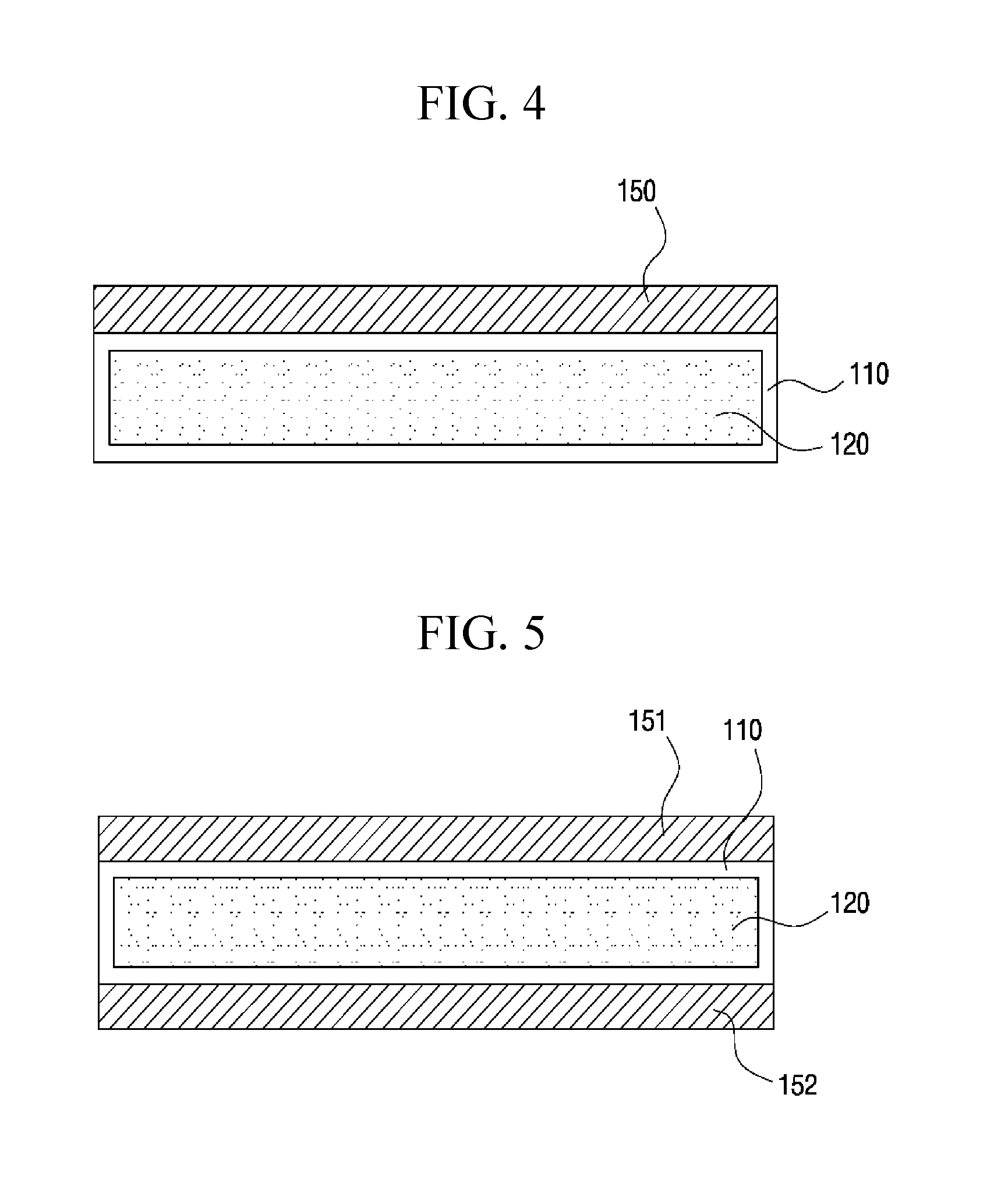

Thermal insulation sheet, hybrid thermal insulation sheet, and thermal insulation panel

ActiveUS20160369936A1Increase efficiencyHigh heat capacityThermal insulationSynthetic resin layered productsThermal insulationEngineering

Owner:AMOGREENTECH CO LTD

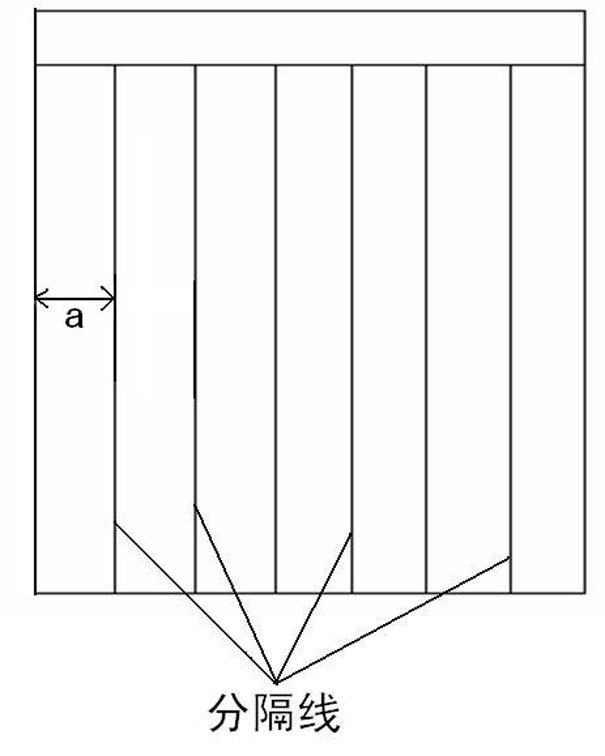

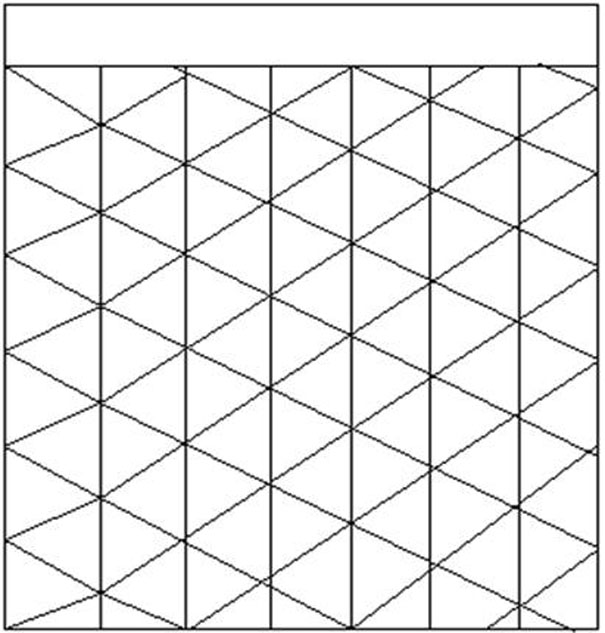

Waterproof heat insulation sandwich layer used for waterproof heat insulation surface materials

ActiveCN101791881AImprove insulation efficiencyStrong weather resistanceSynthetic resin layered productsProtective garmentFilling materialsPolytetrafluoroethylene

The invention provides a waterproof heat insulation sandwich layer used for waterproof heat insulation surface materials, which relates to a waterproof heat insulation sandwich layer. The invention solves the problems of poor ventilation performance and poor heat insulation capability of the existing waterproof heat insulation surface materials. The waterproof heat insulation sandwich layer of the invention consists of hydrophobic aerogel powder body filling materials and a polyfluortetraethylene sealing outer layer from inside to outside, wherein the hydrophobic aerogel powder body filling materials are uniformly paved and spread in the polyfluortetraethylene sealing outer layer, and the thickness of the waterproof heat insulation sandwich layer is controlled in a range between 0.5 and 30 mm. The waterproof heat insulation sandwich layer has the heat conductivity coefficient between 0.025 and 0.05 W / m*K, and has good heat insulation and thermal isolation effect. The polyfluortetraethylene used as the outer layer has good waterproof function. Because of a polyfluortetraethylene microcellular structure and the flowability of the aerogel powder body, the waterproof heat insulation sandwich layer has good ventilation performance. Compared with the existing heat insulation waterproof materials, the invention has the advantages that when the same heat insulation effect is reached, the waterproof heat insulation sandwich layer of the invention has small thickness, light weight, flexible texture, convenient application and wide application field.

Owner:黑龙江德明科技开发有限公司

Integrally prefabricated multifunctional composite external wall panel and industrial building external wall

The invention discloses an integrally prefabricated multifunctional composite external wall panel and an industrial building external wall. The external wall panel comprises an outer decoration layer, a reinforcing bar fine aggregate concrete structural layer, a light-weight heat insulation layer and an indoor decoration layer which are fixedly connected from the outside to the inside, wherein the reinforcing bar fine aggregate concrete structural layer is filled into the light-weight heat insulation layer for forming plate ribs; heat insulation pads are arranged on the end surfaces of the plate ribs; first connecting elements are arranged on the periphery of the external wall panel; the top and the bottom of the external wall panel are respectively provided with positioning mechanisms; the top of the external wall panel is provided with hanging rings; and pre-buried accessories are arranged in the external wall panel. The external wall is formed by the external wall panels through vertical and horizontal distribution, surrounding and shielding, the periphery of each external wall panel is provided with a connecting mechanism connected with a main body stress component; the back part of the connecting mechanism is pre-buried in the reinforcing bar fine aggregate concrete structural layer of the external wall panel; and the adjacent external wall panels are sealed and connected through telescopic sealing elements. The integrally prefabricated multifunctional composite external wall panel and the industrial building external wall have the advantages that the industrial production can be realized; the weight is light; the transportation and the construction are convenient; the heat insulation performance and the sound isolation performance are good; the intensity and the weatherability are good; the internal and external decoration construction is not needed; and the installation is convenient.

Owner:黄涛 +1

Fire-resistant flame-retardant composite thermal insulation mortar and preparation method thereof

The invention discloses fire-resistant flame-retardant composite thermal insulation mortar which is characterized by comprising the following raw materials in parts by weight: 300 to 350 parts of cement, 40 to 45 parts of clay powder, 23 to 26 parts of quartz powder, 12 to 15 parts of hydroxy propyl methyl cellulose ether, 40 to 45 parts of polypropylene short fiber, 30 to 35 parts of building crushed brick powder, 8 to 10 parts of antimony trioxide, 5 to 6 parts of sodium metasilicate, 4 to 5 parts of bentonite powder, 40 to 45 parts of oxidized starch, 24 to 28 parts of calcium propionate, 10 to 12 parts of borax, 30 to 35 parts of expanded pearlite powder, 5 to 10 parts of silica sol, 4 to 6 parts of modified nano-carbon powder, and 600 to 650 parts of water. The fire-resistant flame-retardant composite thermal insulation mortar mainly has the advantages that the workability, water-retaining property and heat insulating efficiency can be improved; common problems such as flaking, cracking and the like are solved; the anti-freezing, water-reducing, impermeable, durable, anti-crack, heat-insulating and heat-proof functions are realized after hardening.

Owner:BENGBU TIANWANG FISHING NEED SUPPLIES

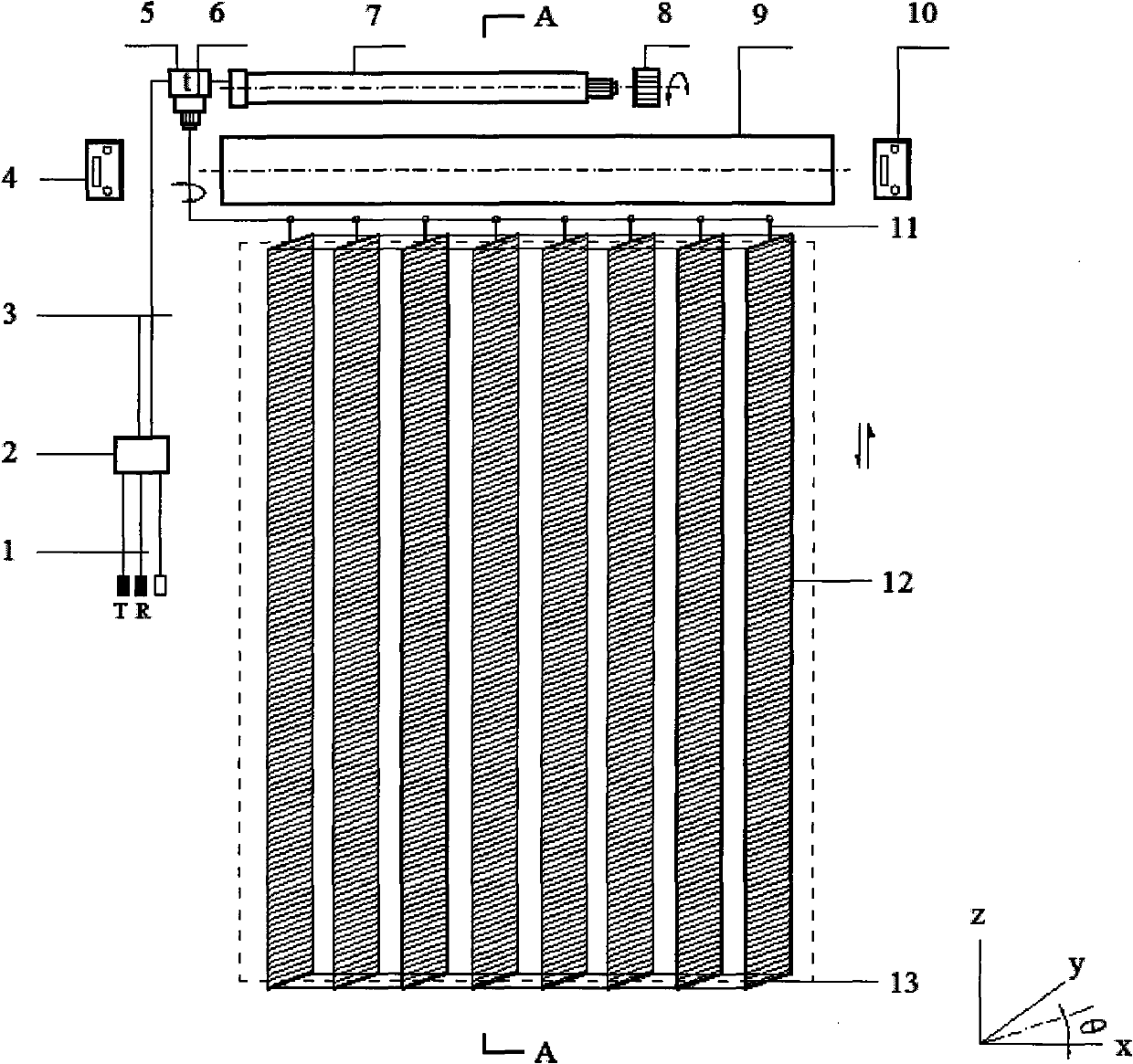

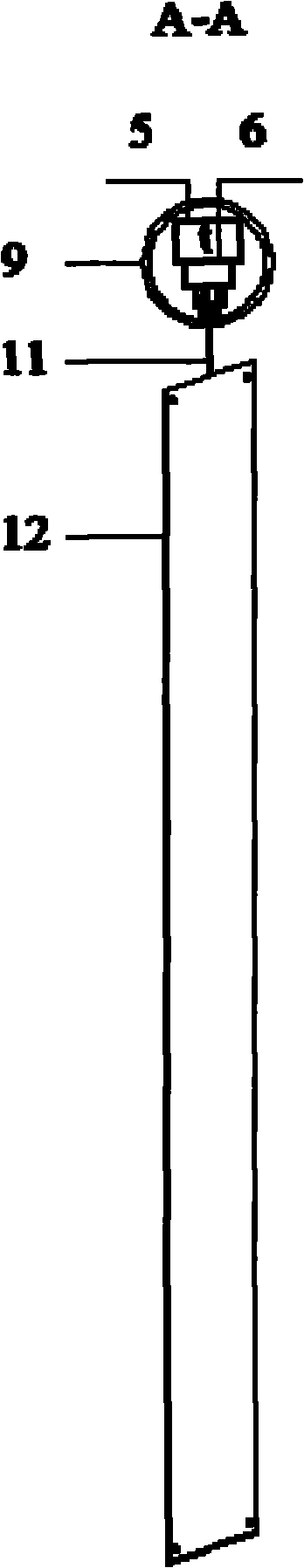

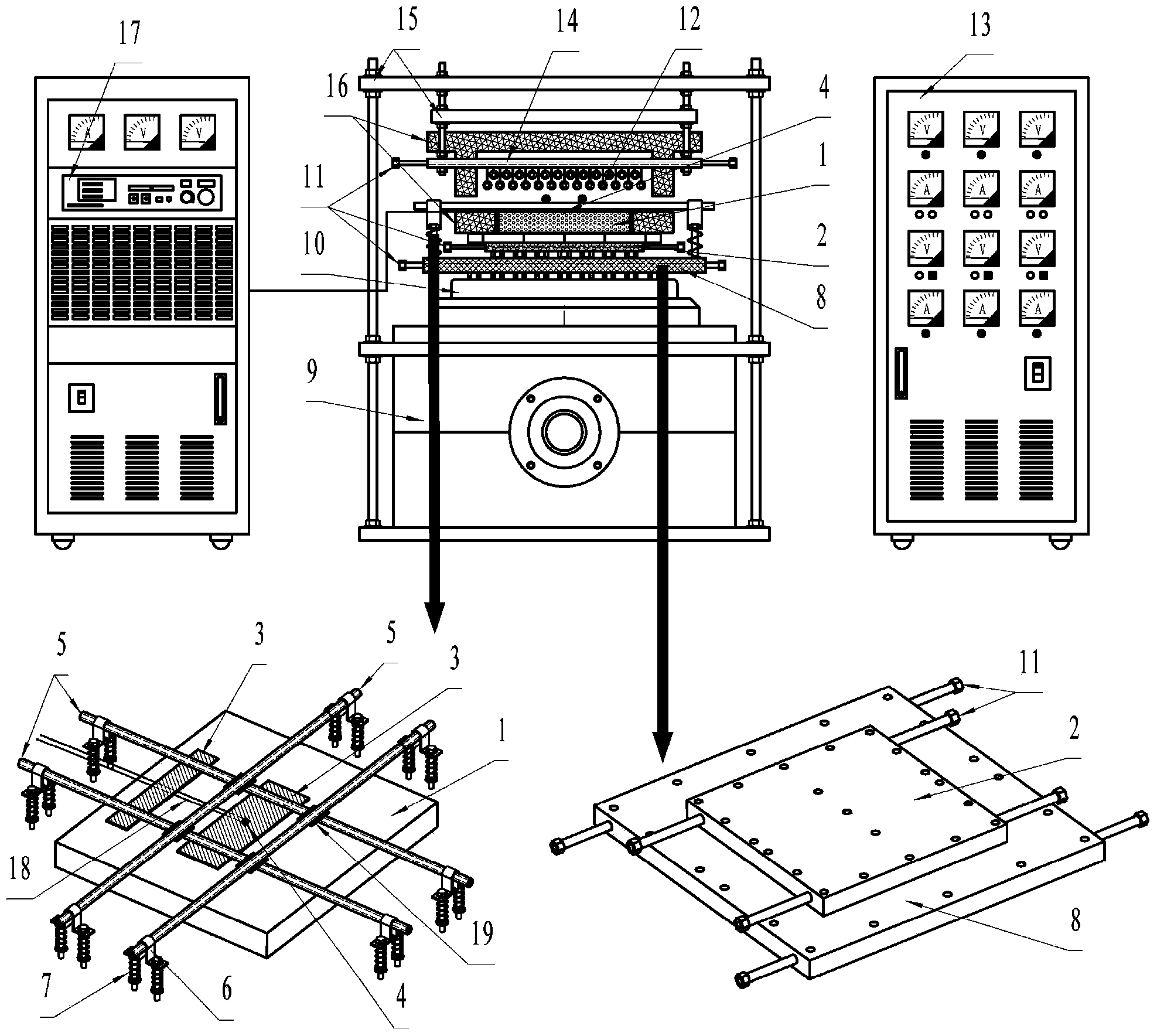

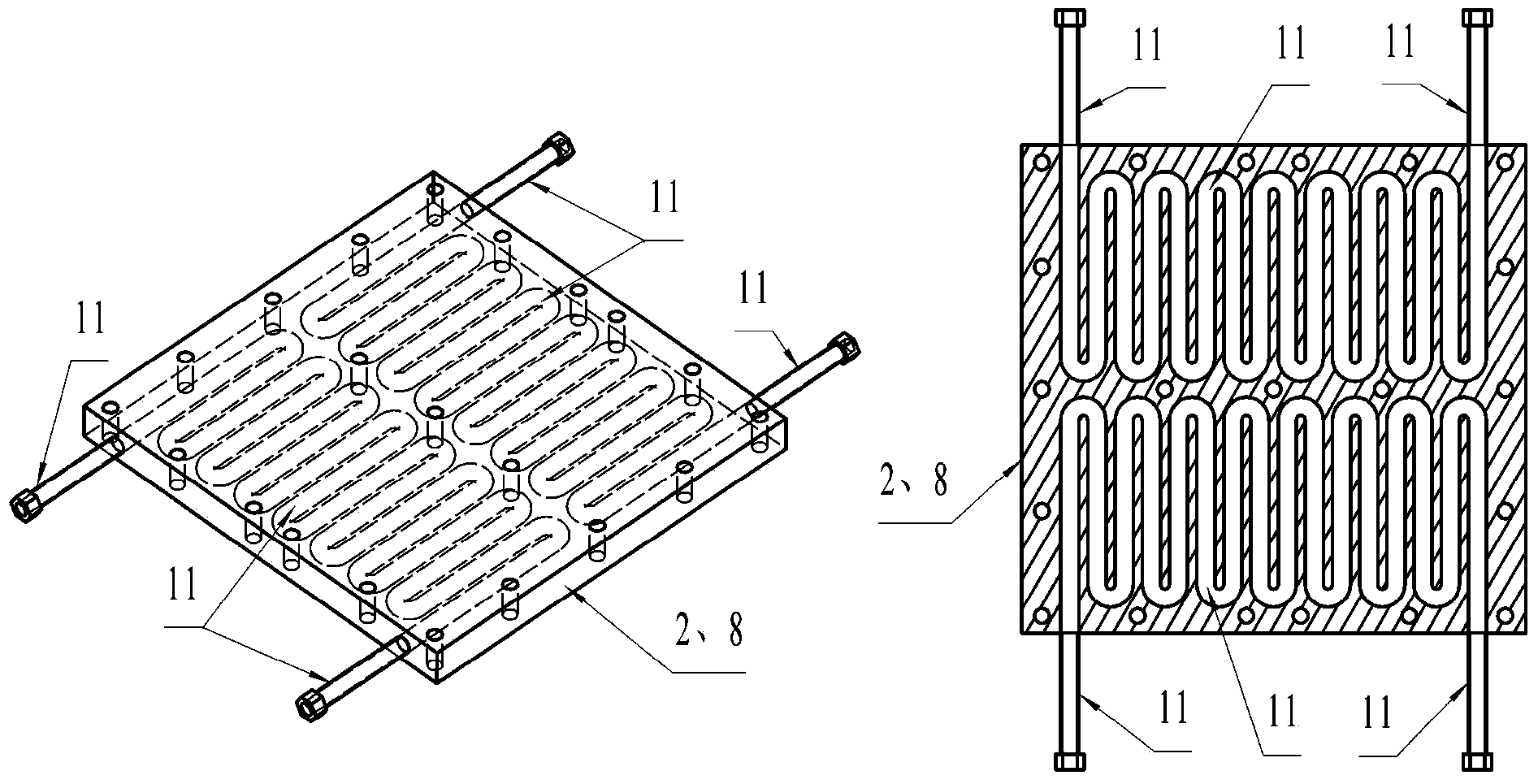

Thermal shock joint experiment device for nanometer thermal insulation material in extreme high-temperature environment

InactiveCN103969137AAvoid it happening againGuaranteed reliabilityMaterial strength using repeated/pulsating forcesThermal insulationReliability design

The invention provides a thermal shock joint experiment device for a nanometer thermal insulation material in extreme high-temperature environment. The thermal shock joint experiment device comprises a nanometer thermal insulation material test piece of a hypersonic flight vehicle, a primary thermal insulation platform, a precious-metal platinum rhodium pressing sheet, a double platinum rhodium temperature sensor, a hollow ceramic rod, a semicircular clamp, a stretched spring, a secondary-stage thermal insulation platform, a shock table body, an excitation platform, a water cooling channel, an infrared radiation heat source array, a high-power regulator, a fixed electrode, a connecting support, a light thermal insulation material, a shock table drive controller, a ceramic tube and a high-temperature-resistant soft mat. The experiment device can realize the experimental measurement for the anti-shock performance of the nanometer thermal insulation material of the hypersonic flight vehicle in the extreme high-temperature environment being 1500 DEG C, provides important experimental bases for the bearing capability, the thermal insulation performance and the safe and reliable design of the novel nanometer thermal insulation material used by hypersonic remote motor flight vehicles in the extreme high-temperature environment, and has an important engineering application value for development of the hypersonic flight vehicle.

Owner:BEIHANG UNIV

Light-weight high-temperature mullite refractory brick prepared from pulverized fuel ash

The invention discloses a light-weight high-temperature mullite refractory brick prepared from pulverized fuel ash. The light-weight high-temperature mullite refractory brick comprises the following raw materials: 40-50% of pulverized fuel ash, 25-35% of clay, 10-20% of aluminite powder, 7-8% of coal gangue, 1-2% of polystyrene, and 0.5-1.5% of saw dust. The light-weight high-temperature mullite refractory brick is prepared through the following steps: (1) weighing pulverized fuel ash, clay, aluminite powder, coal gangue, polystyrene and saw dust according to the proportion of the raw materials formulations; (2) grinding weighed coal gangue into powder, and mixing, adding water into, stirring the raw materials formulations into slurry, wherein the water addition is 23-25%; (3) placing the slurry as a product into a die to be subjected to compression moulding; (4) sending the compressed green body to a dry kiln to be dried, wherein the temperature is 100-150 DEG C, and the water content is 2-7%; (5) sending the dried green body in a tunnel kiln, and calcining for 38-42 minutes at the high temperature of 1,200-1,400 DEG C; and (6) cutting the calcined green body to form a finished product. The mullite refractory brick is energy-saving and is high in heat preservation efficiency.

Owner:SHUOZHOU SHUOXIANG CERAMICS

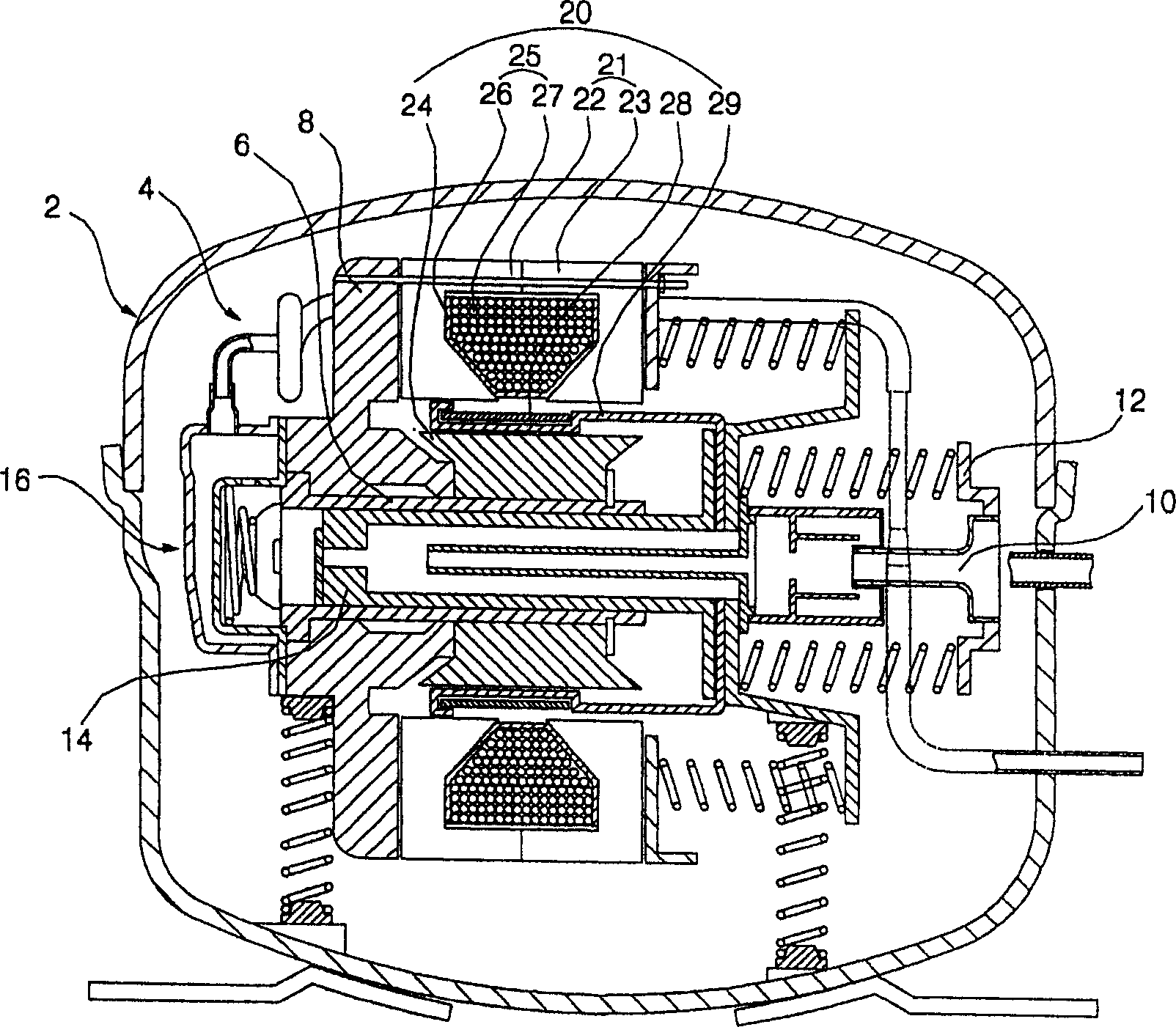

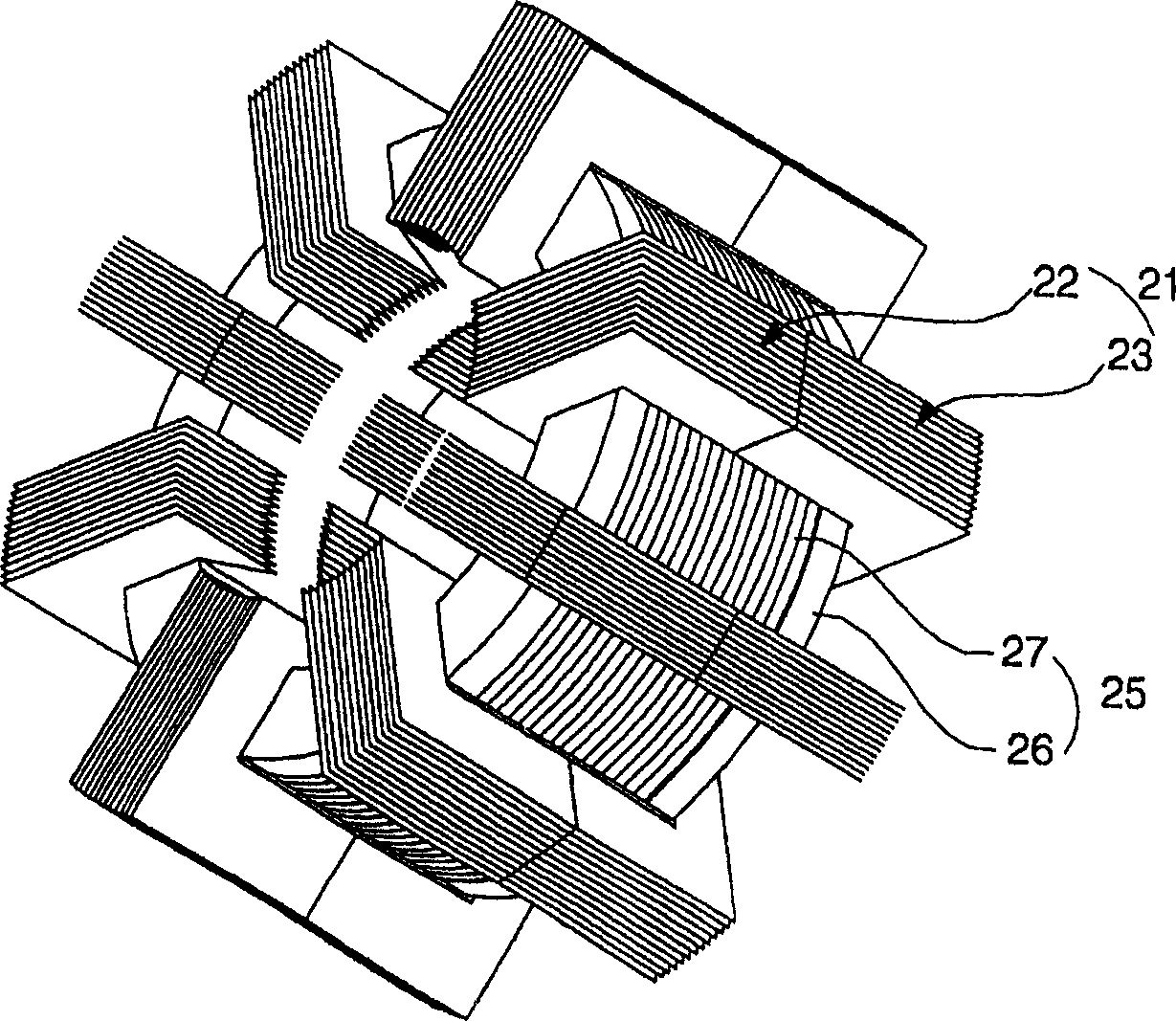

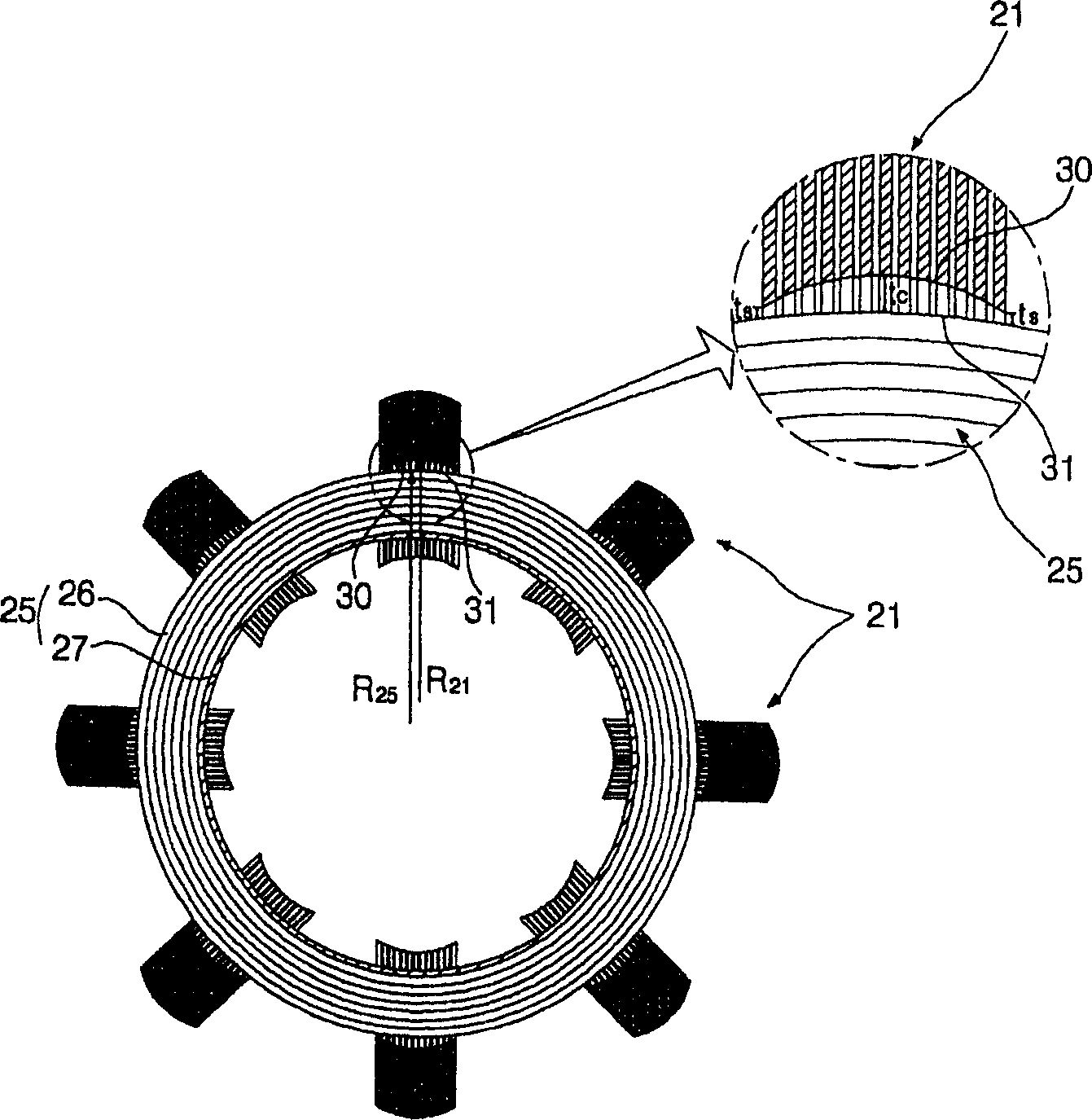

Stator of linear motor

InactiveCN1866696AReduce volumeReduce insulation distanceWindings insulation shape/form/constructionMagnetic circuit rotating partsHeat transfer efficiencyEngineering

In a stator of a linear motor having a plurality of outer core blocks, each of the outer core blocks comprises first and second side core blocks and a center core block. The center core block has an inner diameter equal to an outer diameter of a coil block. Consequently, insulation and heat transfer efficiencies are improved, and the size of the linear motor is minimized. Furthermore, the center core block is provided with a heat sink part, which is inserted in a coil block for dissipating heat from the coil block. Consequently, heat generated from the coil block is effectively dissipated.

Owner:LG ELECTRONICS INC

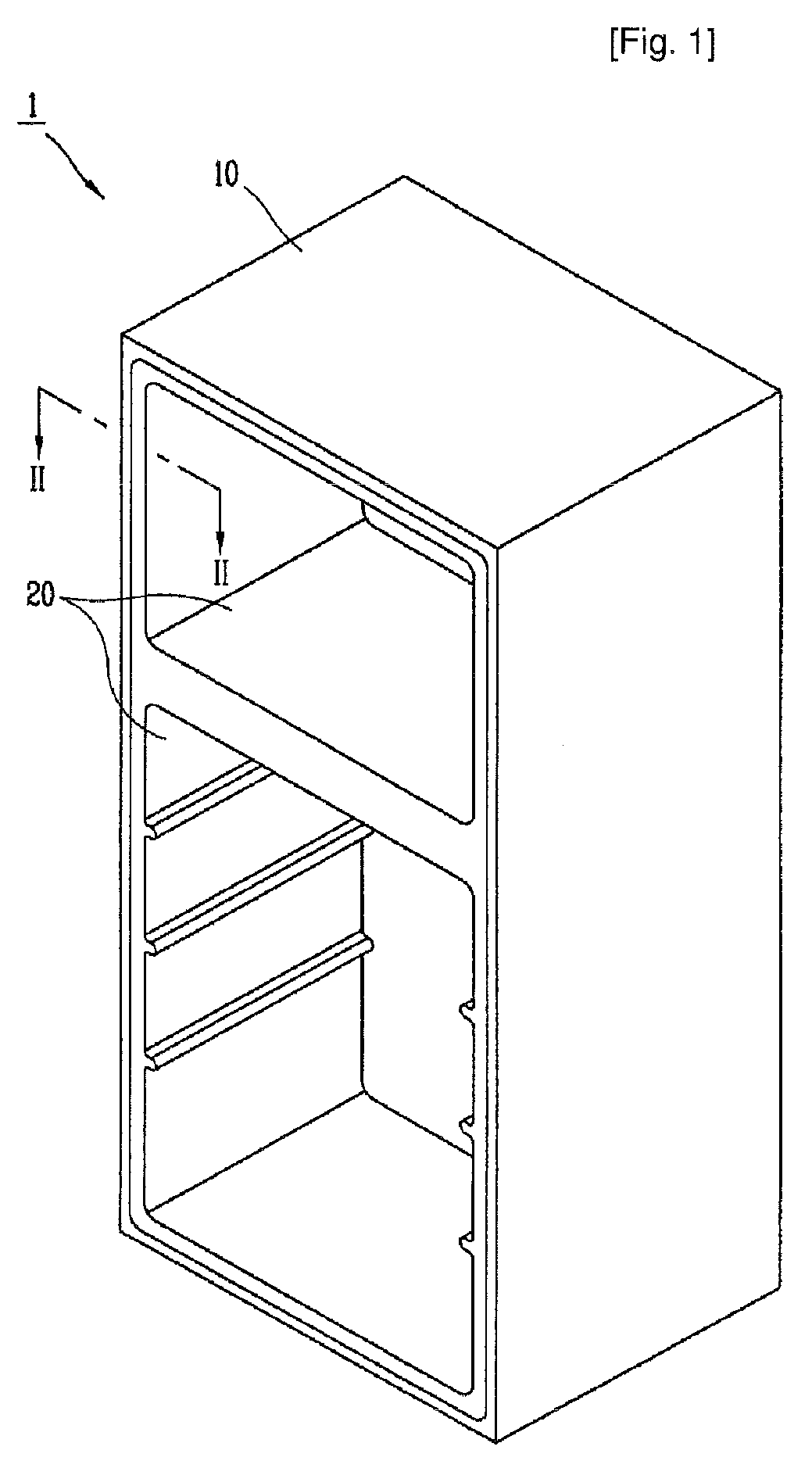

Refrigerator

ActiveUS9157676B2Improve insulation performanceSealing gapShow cabinetsEngine sealsEngineeringRefrigerated temperature

A refrigerator provided with a rotating bar configured to seal a gap between one pair of doors, capable of preventing the door from being incompletely closed due to an erroneous operation of the rotating bar, the rotating bar capable of sealing a gap formed between the rotating bar and a body as well as a gap formed between one pair of doors, the rotating bar being elastically supported by an elastic member so as to move by receiving an external force from a guide part provided on the body, the rotating bar including a sealing member protruding from the rotating bar so as to seal a gap between the rotating bar and the body.

Owner:SAMSUNG ELECTRONICS CO LTD

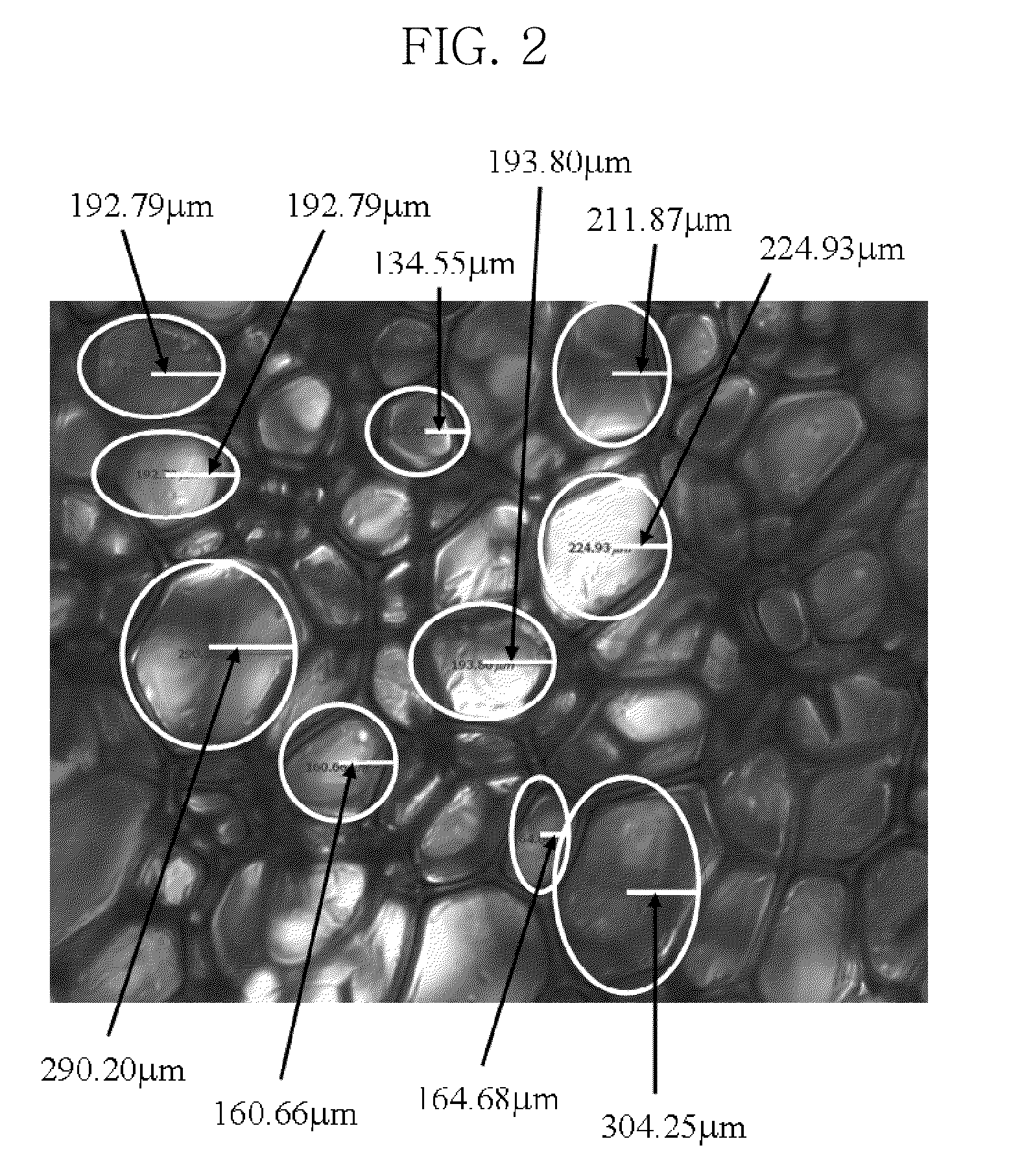

Composition for rigid polyurethane foam and rigid polyurethane foam produced using the same

InactiveUS20100159232A1Improve insulation efficiencySmall sizeOther chemical processesLayered productsPolyolBlowing agent

A composition for a rigid polyurethane foam with reduced cell sizes contains a polyol, water, a catalyst, a blowing agent; and an ionic liquid. The rigid polyurethane foam is produced by adding an ionic liquid as an eco-friendly additive to a polyol composition so as to improve insulation efficiency thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

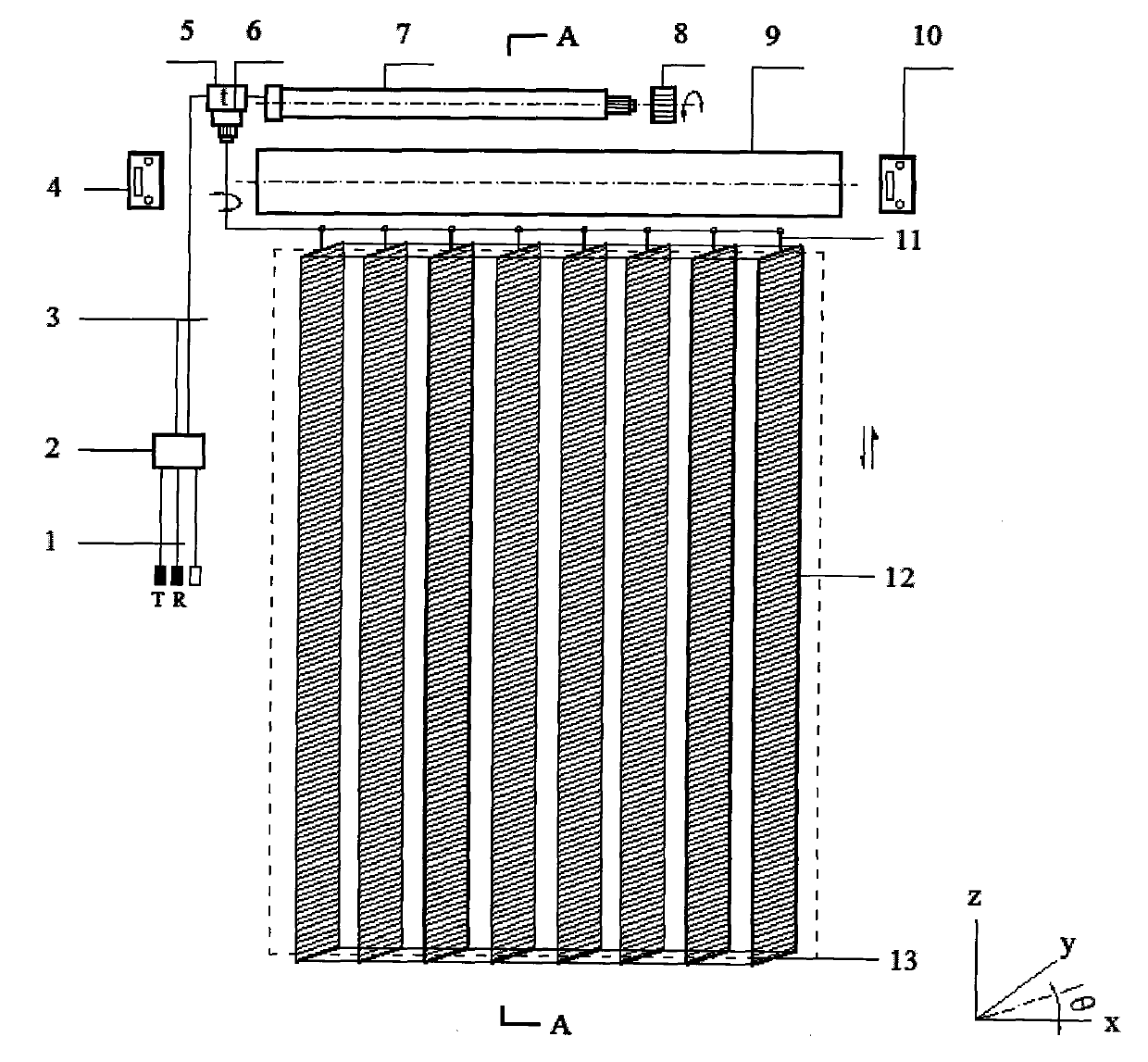

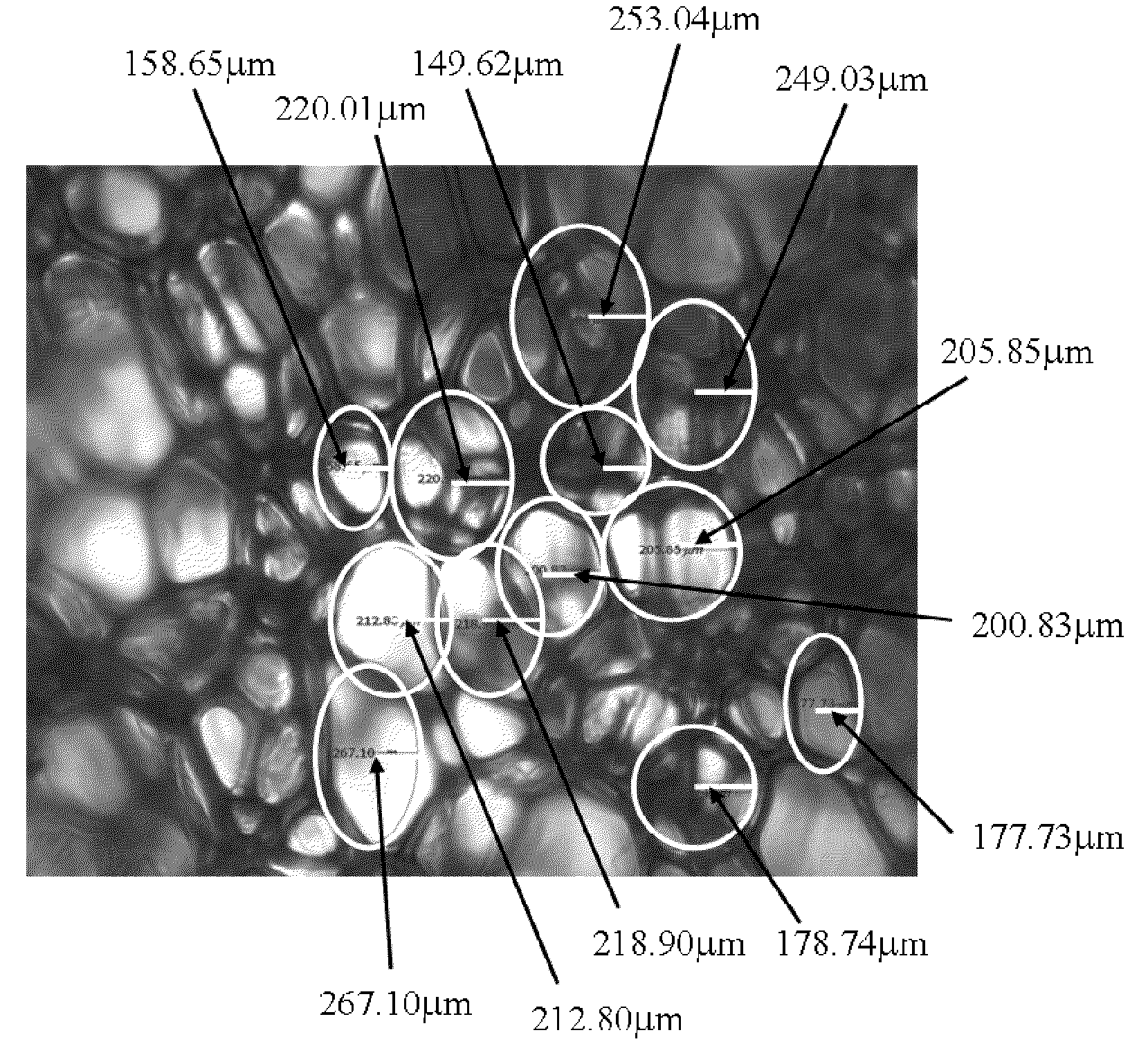

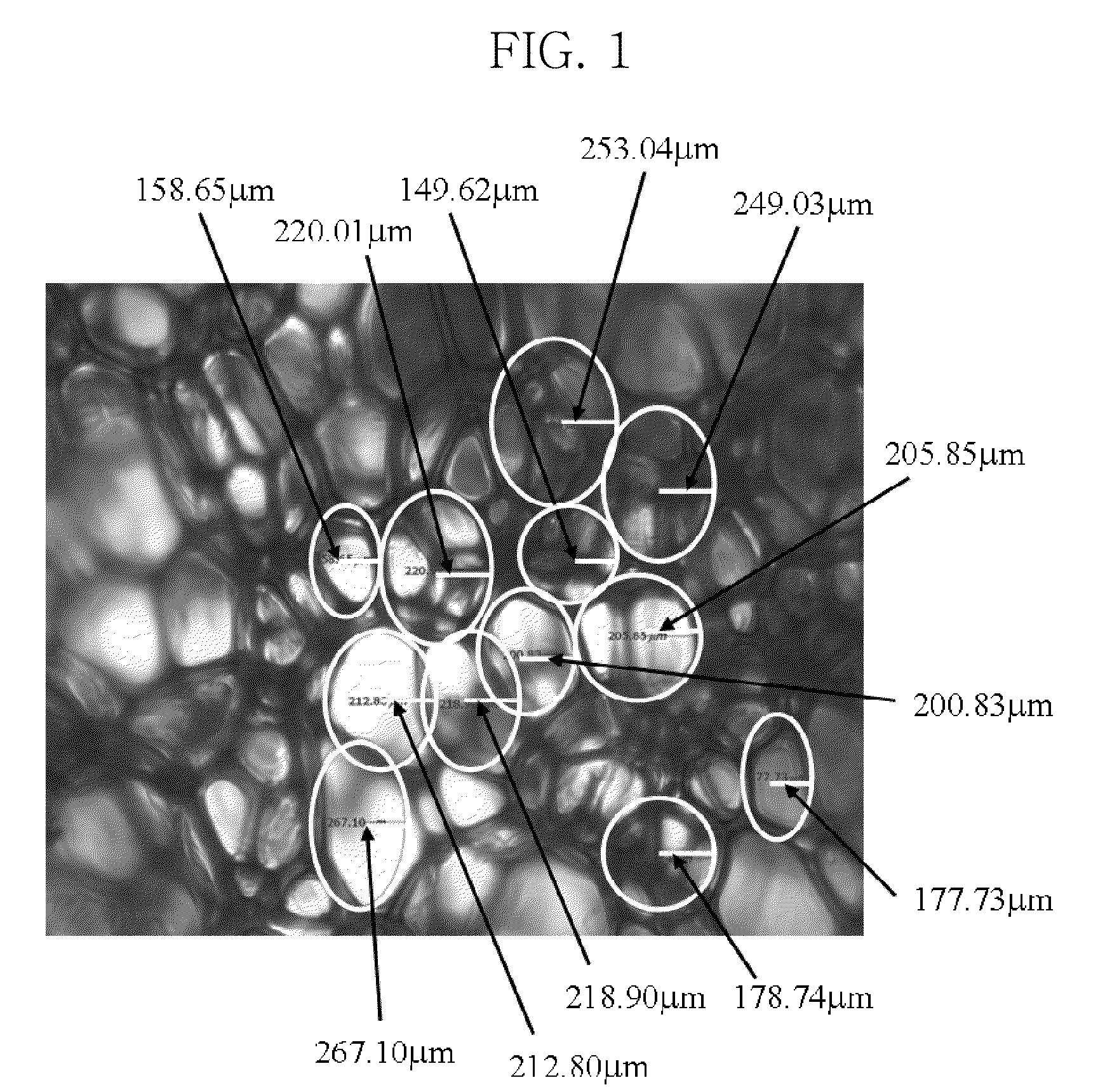

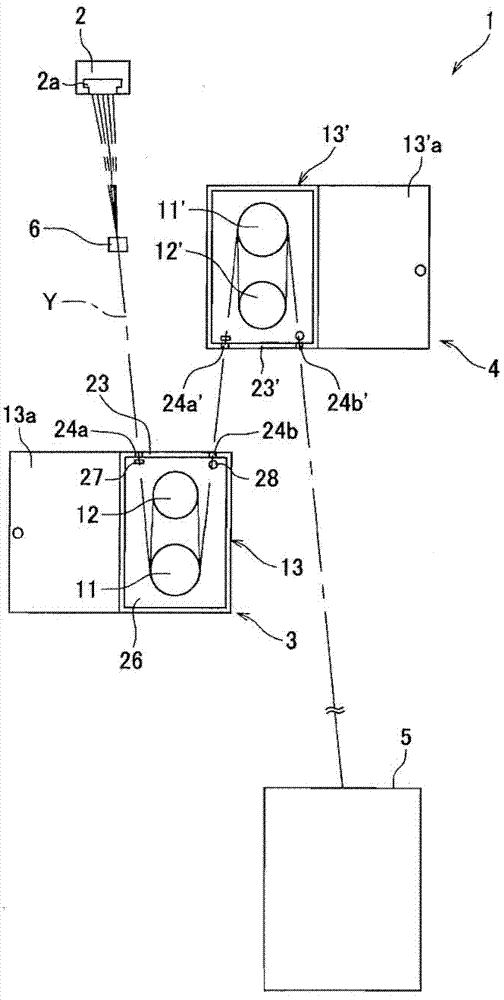

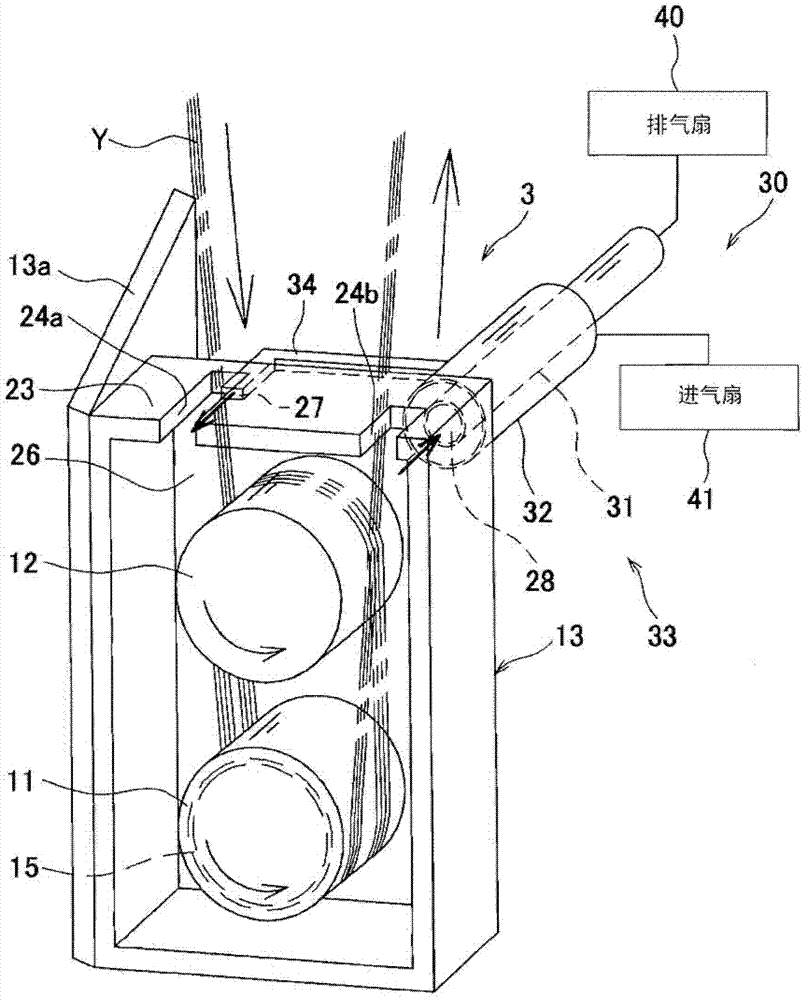

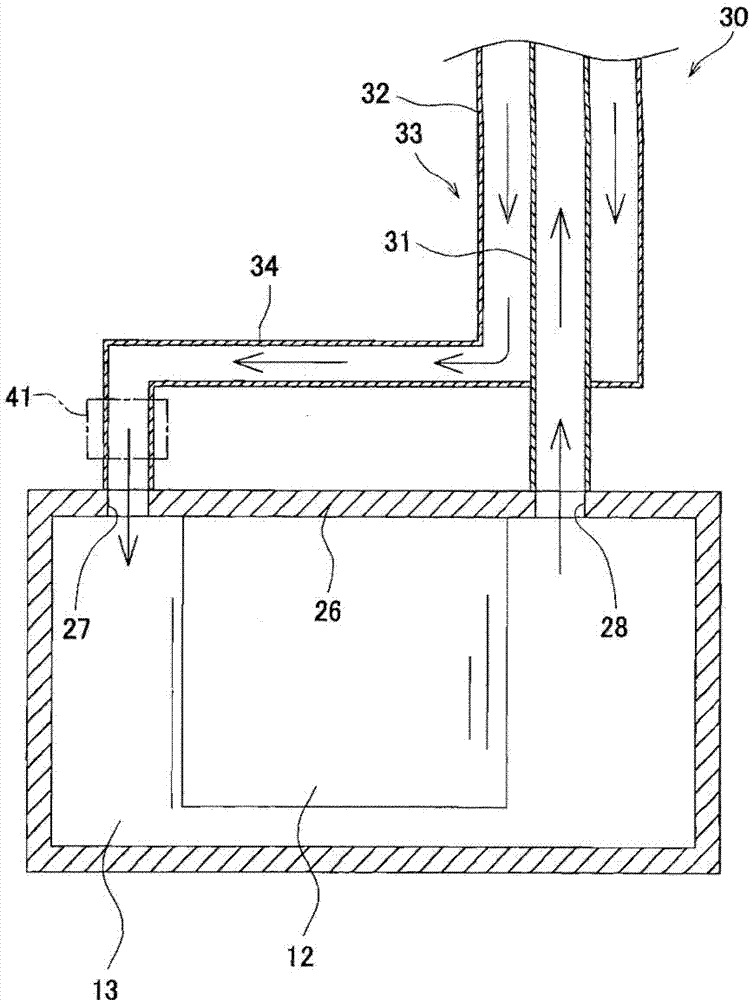

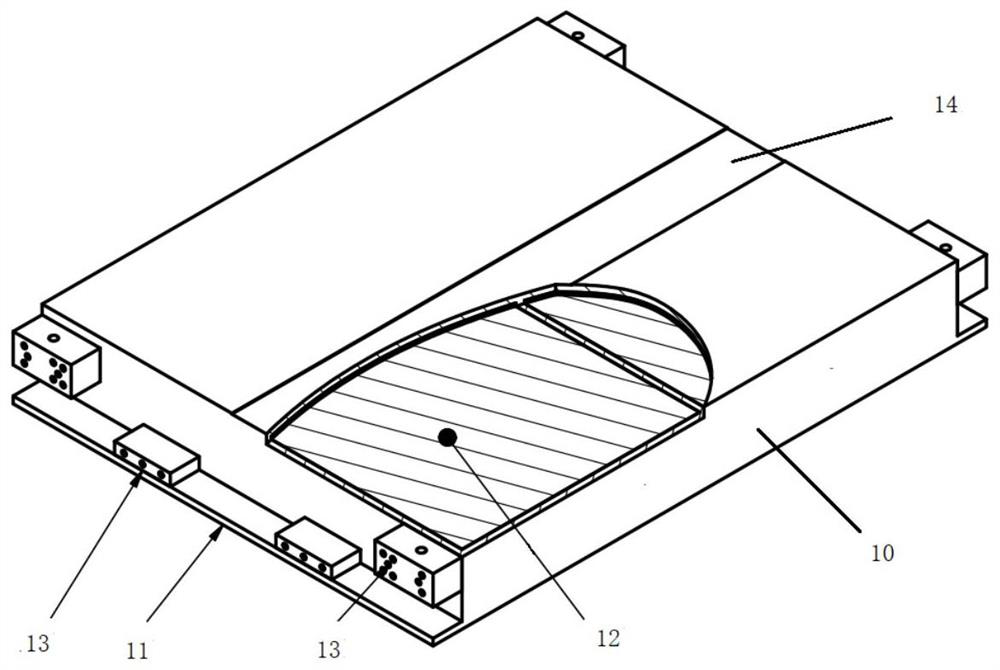

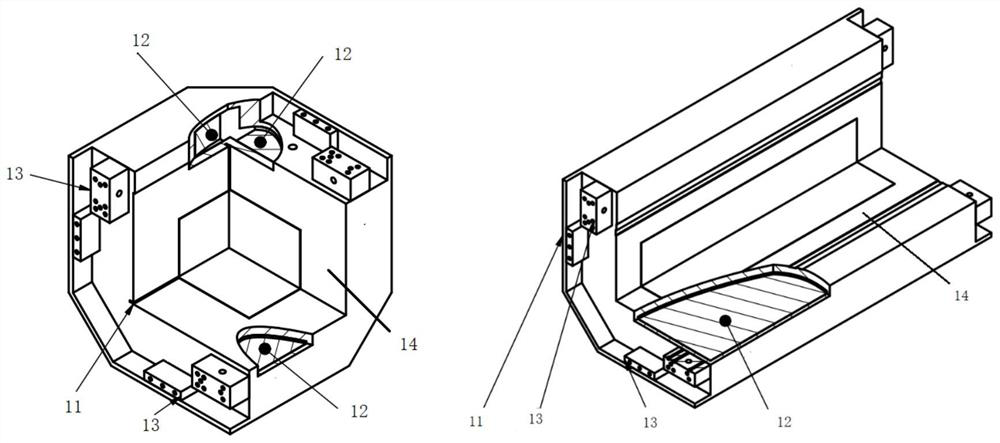

Yarn heater

ActiveCN102733021AAvoid temperature dropImprove insulation efficiencyArtificial filament heat treatmentYarnPlate heat exchanger

By improving the heat insulating efficiency in thermal insulation box, the power consumption of a heater for heating yarns fed from the yarn feeding roller is decreased. A roller unit 3 includes a godet roller 11, a separate roller 12, a thermal insulation box 13 housing the rollers 11 and 12, and a heat exchanger 30 provided outside the thermal insulation box 13. The heat exchanger 30 operates such that, as an exhaust fan 40 is driven, the air in the thermal insulation box 13 is exhausted through an inner tube 31. As an intake fan 41 is driven, the outside air passes through an outer tube 32 and then flows into the thermal insulation box 13 through a branched tube 34. At this stage, the heat exchanger 30 conducts heat exchange between the air running in the inner tube 31 and the air running in the outer tube 32.

Owner:TMT MACHINERY INC

Door gasket structure for refrigerator

InactiveUS20050189726A1Easy to assembleEasy to installBarrages/weirsEngine sealsInterference fitEngineering

Disclosed herein is a door gasket structure for a refrigerator. The door gasket structure comprises a recessed groove member embedded in a thermal insulating material in a correspondingly-recessed inner surface region of a refrigerator door, and having an insertion groove, a coupling member in close contact with the groove member, the coupling member having Wan anchor integrally formed at one surface thereof so as to be inserted in the insertion groove by interference fit, a pair of gaskets integrally formed at the other surface of the coupling member, the pair of upper and lower gaskets having vertically-symmetrical U-shaped forms so as to define an air layer therebetween, and a magnet receptacle integrally formed at ends of the pair of gaskets, and containing a magnet.

Owner:LOTTE ENG & MACHINERY MFG

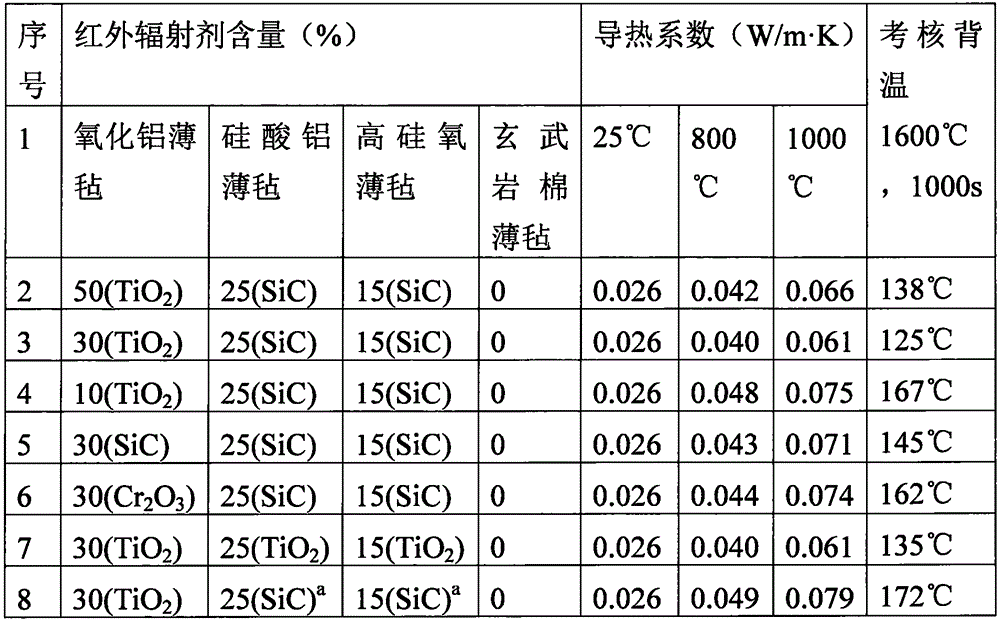

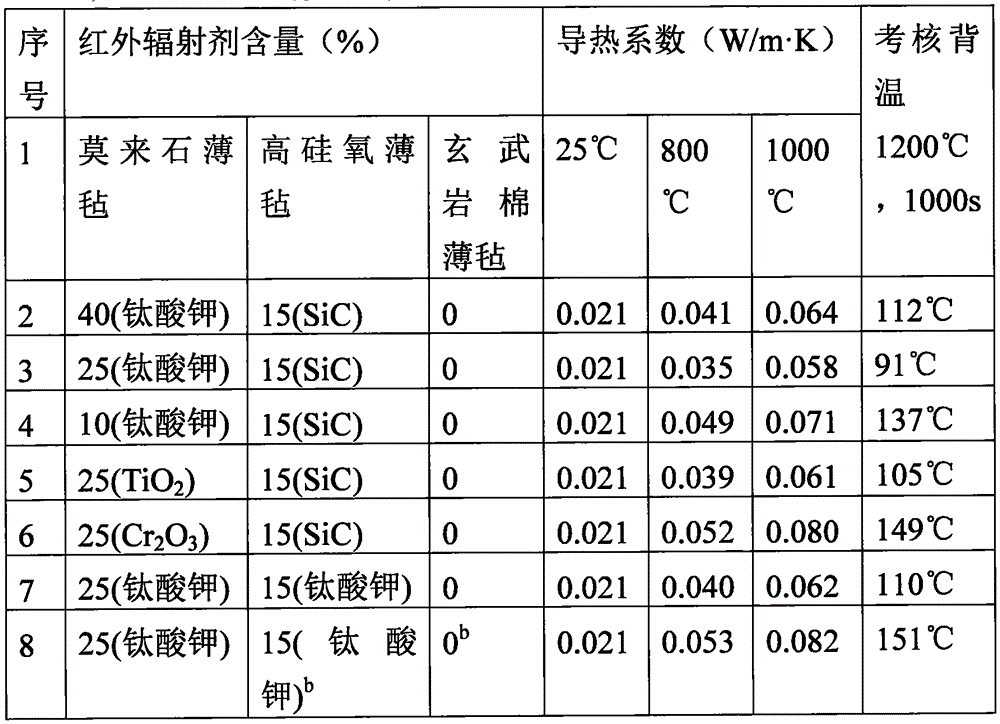

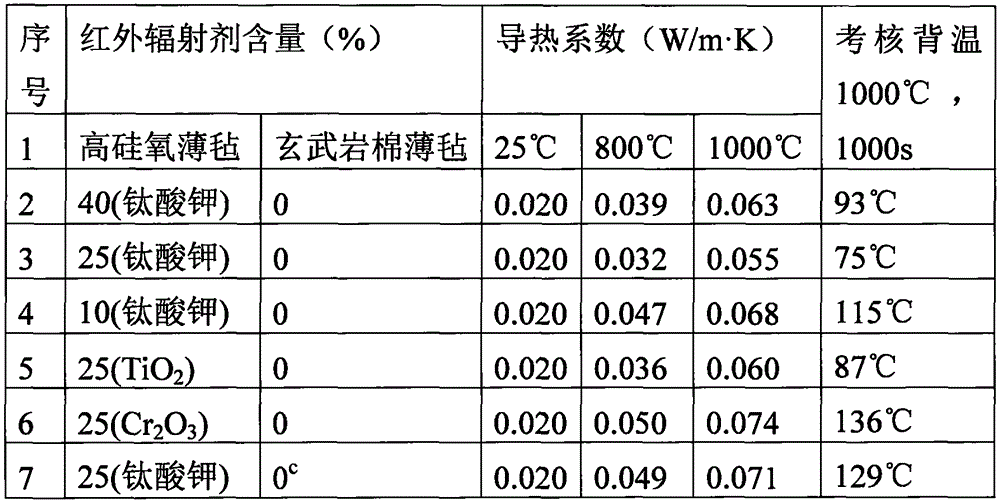

Multilayer-arranged heat insulating material and preparation method thereof

The invention discloses a multilayer-arranged heat insulating material and a preparation method thereof. The method comprises the following steps: preparing fiber slurry; preparing wet blank and de-molding; drying to obtain thin felts; laying up and putting the thin felts into aerogel forming equipment; forming aerogel by soaking laid-up thin felts by virtue of a supercritical drying method, thereby obtaining the multilayer-arranged heat insulating material, wherein the multiple layers of thin felts are selected from a group consisting of a high-temperature region thin felt, a medium-temperature region thin felt, a low-temperature region thin felt, a lower-temperature region thin felt and an extremely-low temperature region thin felt, the thin felts are laid up in a decreasing mode according to the temperature regions, and the thin felts made of different fibers are combined. According to the method, fiber types, infrared blocker types and infrared block content can be regulated according to difference of applied temperature regions, so that a material combination with the best heat insulating property is obtained, and the material has better forming property, is convenient for the preparation of products with different mould surfaces and dimensions, and can be used in a temperature environment with a temperature of 400-1600 DEG C or higher according to the usage environment requirements.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

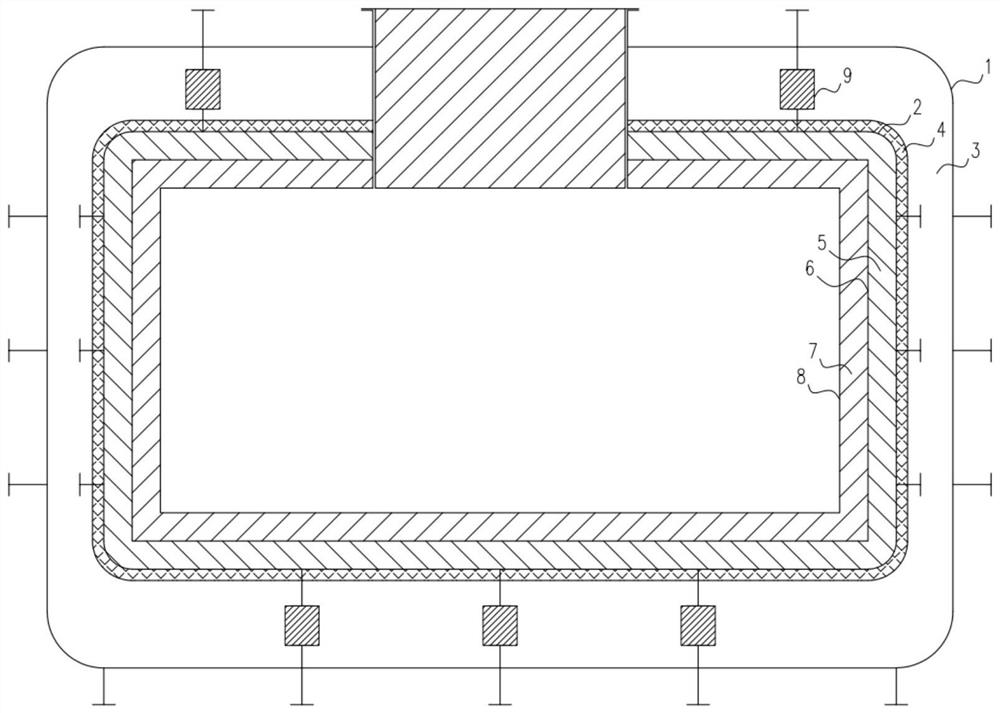

Metal low-temperature film storage tank for liquid hydrogen storage

PendingCN113739061AImprove insulation performanceExtended storage timeVessel mounting detailsVessel manufacturingInsulation layerThin membrane

The invention discloses a metal low-temperature film storage tank for liquid hydrogen storage. The storage tank comprises an outer tank (1), an inner tank (2), an inner and outer tank high-vacuum interlayer (3), a multi-layer winding layer (4), a secondary insulation cold insulation layer (5), a secondary shielding layer (6), a main insulation cold insulation layer (7) and a main shielding layer (8). An insulating support block (9) is arranged between the storage tank outer tank (1) and the storage tank inner tank (2). Two layers of metal films and a high-vacuum heat insulation tank are used as the design basis, an independent film shielding layer liquid containing system is achieved, the insulation and cold insulation performance of a traditional film type storage tank is improved in a high-vacuum heat insulation mode, the evaporation rate is further reduced, and the storage time of liquid cargo hydrogen in the storage tank is prolonged; the film shielding layer is used for containing liquid, so that requirements on materials of the inner tank and the outer tank and construction requirements are further reduced; and the safety performance of hydrogen storage is improved through double-layer shielding and three-layer protection of the inner tank, the shielding completeness under sudden accidents is guaranteed through the flexibility of the thin film, and the accident risk of leakage of a large amount of liquid hydrogen caused by breakage of the inner tank and the outer tank is reduced. The storage tank can be used for storage and transportation of a vehicle-mounted container type liquid hydrogen storage tank, can also be used for a land large vertical liquid hydrogen storage tank, can also be used for storage and transportation of a liquid hydrogen ship fuel cabin and a liquid hydrogen transport ship liquid cargo cabin, and is a brand-new liquid hydrogen film type storage tank which is wider in application, safer and more environmentally friendly.

Owner:SINOTECH MARINE CO LTD

Refrigerator

InactiveUS20150377542A1Improve insulation performanceSealing gapEngine sealsThermal insulationEngineeringMechanical engineering

A refrigerator provided with a rotating bar configured to seal a gap between one pair of doors, capable of preventing the door from being incompletely closed due to an erroneous operation of the rotating bar, the rotating bar capable of sealing a gap formed between the rotating bar and a body as well as a gap formed between one pair of doors, the rotating bar being elastically supported by an elastic member so as to move by receiving an external force from a guide part provided on the body, the rotating bar including a sealing member protruding from the rotating bar so as to seal a gap between the rotating bar and the body.

Owner:SAMSUNG ELECTRONICS CO LTD

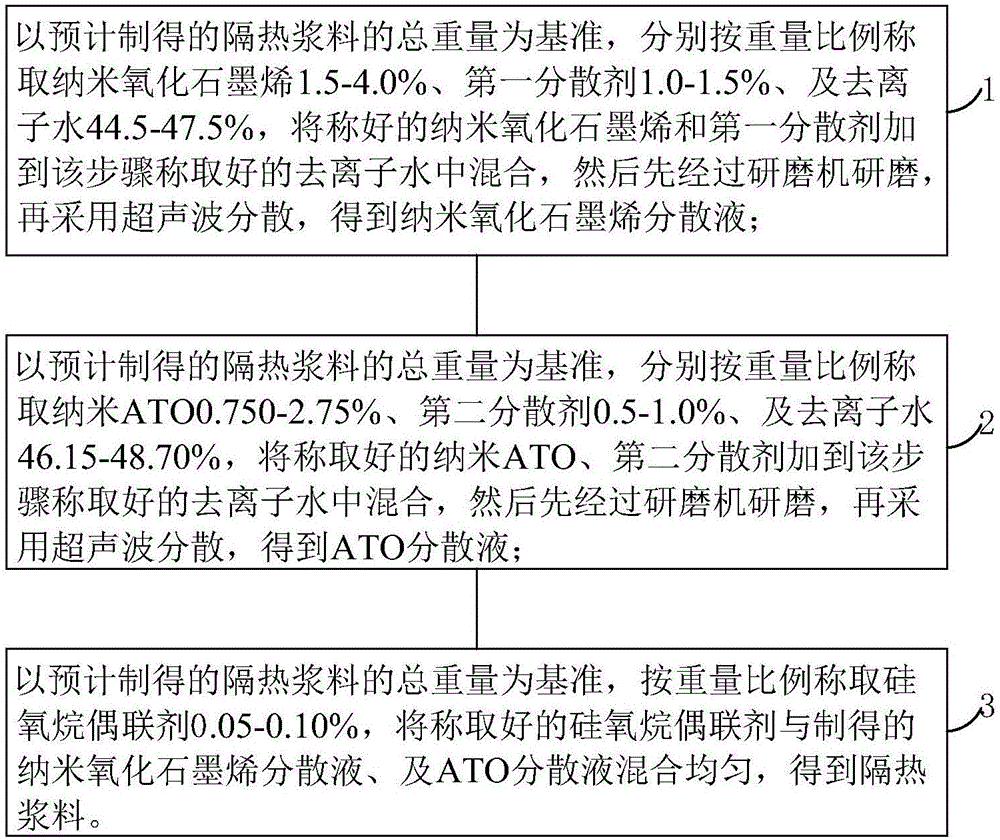

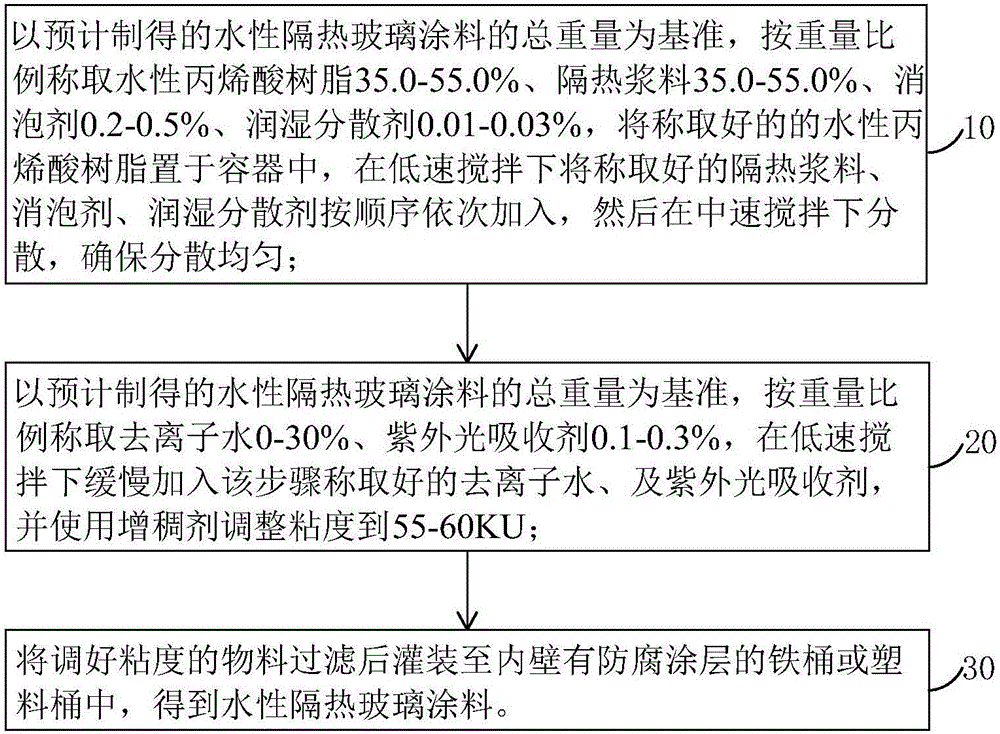

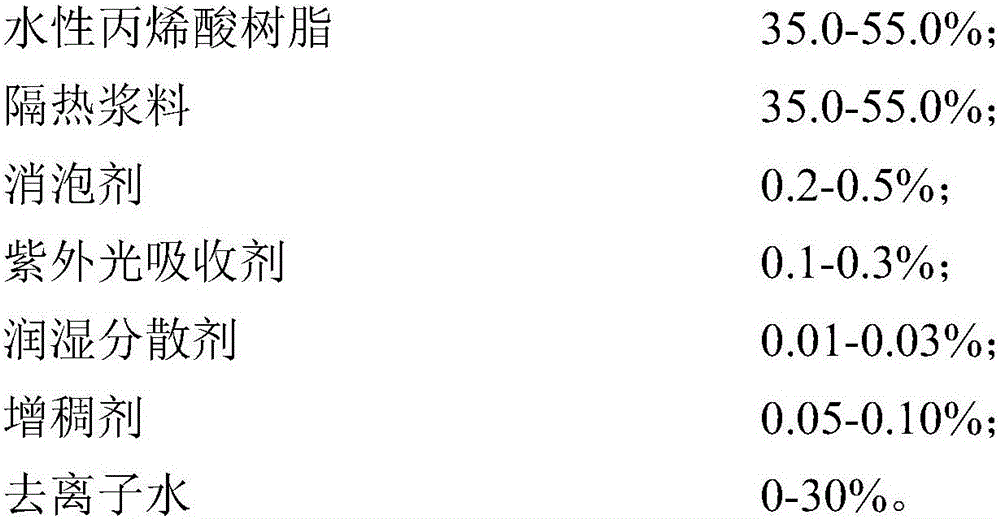

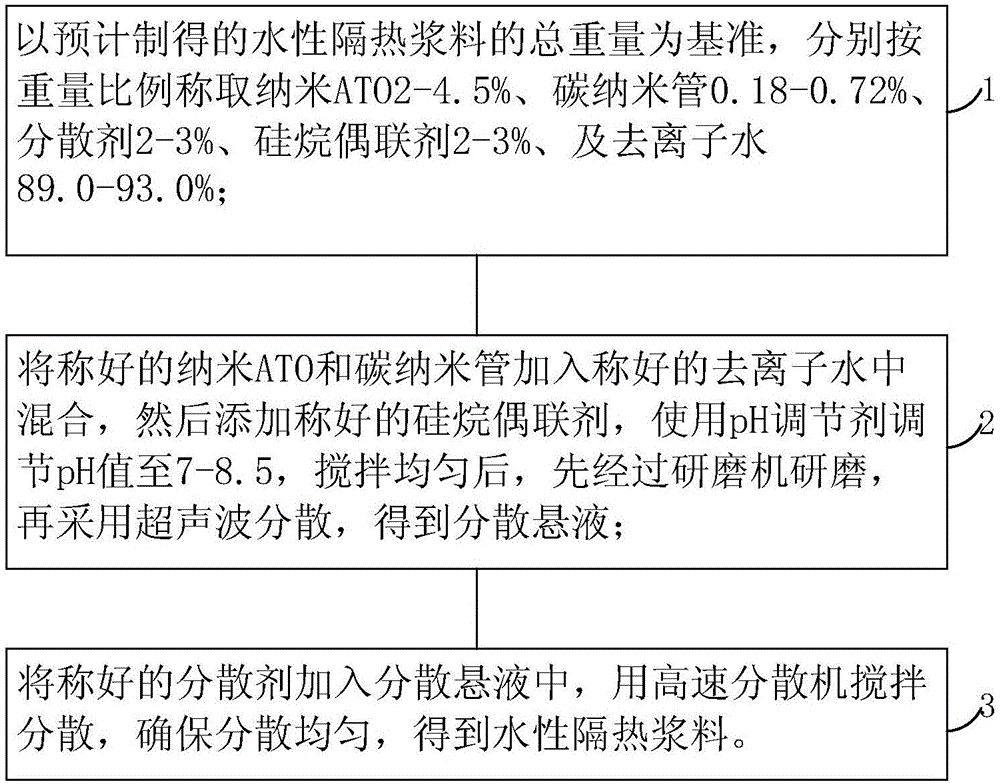

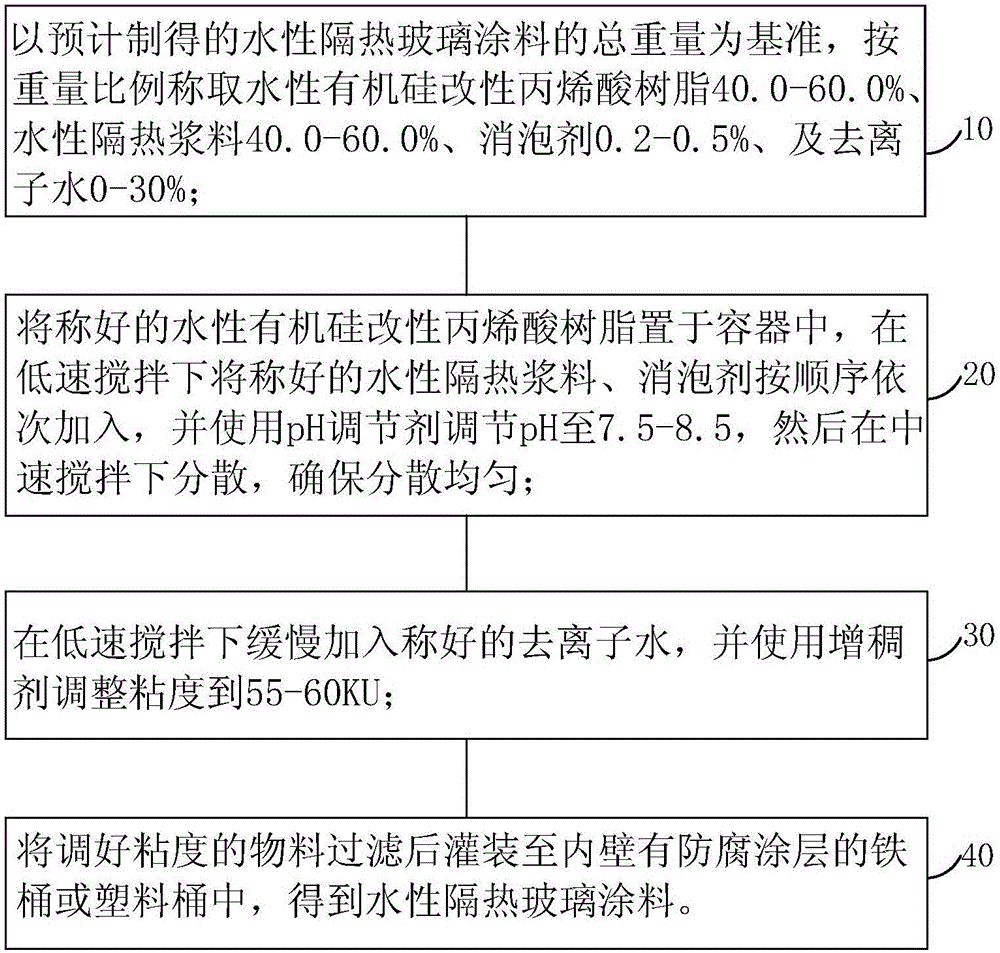

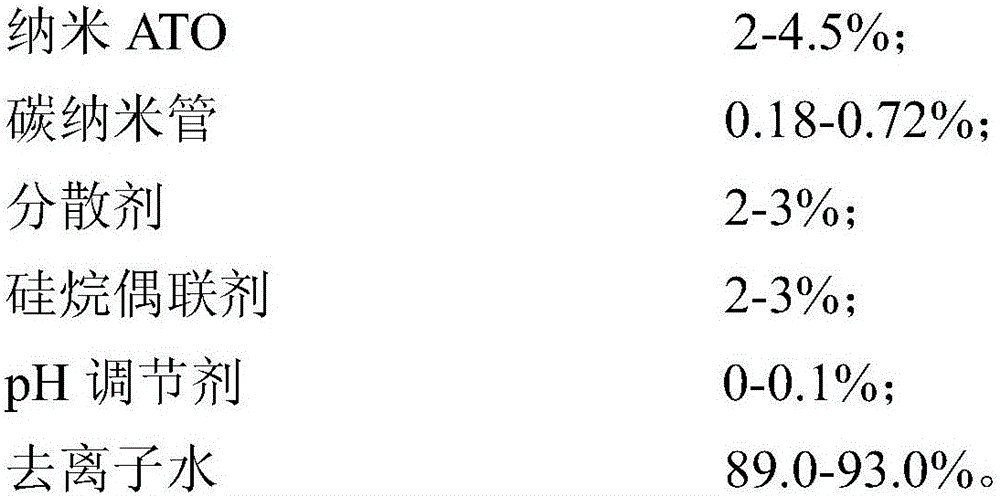

Thermal-insulation slurry and preparation method thereof, water-based insulating glass coating and preparation method thereof

InactiveCN106497200AImprove insulation efficiencyIncrease reflectionReflecting/signal paintsWater solubleOxide

The invention provides thermal-insulation slurry and a preparation method thereof, and water-based insulating glass coating and a preparation method thereof. The thermal-insulation slurry is made from nano-scale graphene oxide and nano-ATO mainly; as the nano-ATO has special optical property, in other words, the nano-ATO has high rejection rate in both the long-wave part of an infrared region and an ultraviolet light region, has high transmittance in a visible region, and meanwhile, as the nano-scale graphene oxide has high thermal insulation efficiency, reflection of radiation of the infrared region can be enhanced effectively, and the defect of poor thermal insulation property of the nano-ATO to the near-infrared short-wave region is overcome. The water-based insulating glass coating is prepared from the thermal-insulation slurry and high-transparency high-adhesion water-soluble polyacrylic resin, so that defects of low transparency and poor thermal insulation effect of the prior art are overcome, the problem about poor thermal-insulation property to the near-infrared short-wave region is solved, and the water-based insulating glass coating keeps stable and uniform for a long time.

Owner:SHENZHEN SUNRISE NEW ENERGY CO LTD

Waterborne heat-insulating slurry and preparation method thereof, as well as waterborne heat-insulating glass coating and preparation method thereof

ActiveCN106752237AImprove insulation efficiencyEasy to operateReflecting/signal paintsWeather resistanceAcrylic resin

The invention provides waterborne heat-insulating slurry and a preparation method thereof, as well as a waterborne heat-insulating glass coating and a preparation method thereof. The waterborne heat-insulating slurry is prepared by selecting nano-ATO and carbon nano-tubes as main heat-insulating materials, the specific optical performance of the nano-ATO is utilized, the long-wave part of an infrared region and an ultraviolet region have a high rejection rate, and a visible region has high transmittance; the carbon nano-tubes with specific carbon atomic arrangement structure have durable high heat-insulating efficiency and ultraviolet aging resistance under near-infrared and ultraviolet irradiation, so that irradiation reflection of the infrared region can be effective reinforced, the defects that the nano-ATO has insufficient partial heat insulating performance and insufficient ultraviolet aging resistance for the near-infrared short-wave part can be overcome. The waterborne heat-insulating glass coating prepared from the heat-insulating slurry and waterborne organic silicone modified acrylic resin can be used for solving the problems of insufficient transparency, poor heat-insulating performance and weak weather resistance of existing coating, and can be kept durable, stable and uniform.

Owner:SHENZHEN SUNRISE NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com