Waterproof heat insulation sandwich layer used for waterproof heat insulation surface materials

A interlayer and fabric technology, applied in applications, protective clothing, layered products, etc., can solve the problems of poor air permeability and poor heat preservation ability of waterproof and heat-insulating fabrics, and achieve the effect of soft texture, strong weather resistance, and good waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

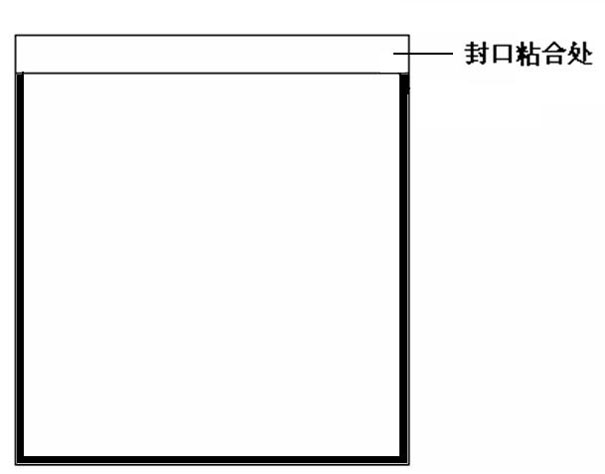

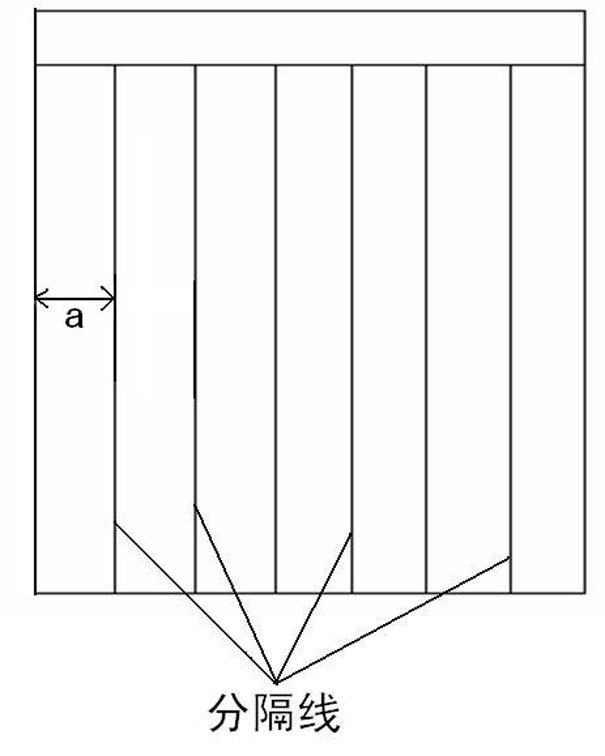

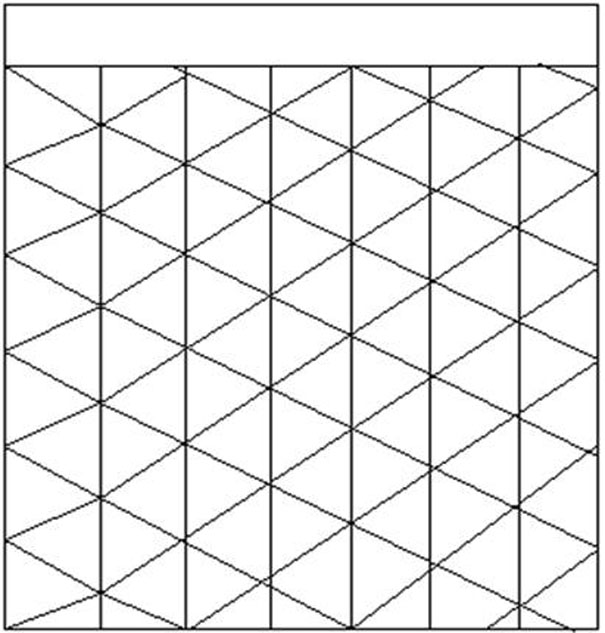

[0023] Specific Embodiment 1: The waterproof and heat-insulating interlayer used for waterproof and heat-insulating fabrics in this embodiment is composed of hydrophobic airgel powder filler 2 and polytetrafluoroethylene sealing outer layer 1 from the inside to the outside, and the hydrophobic airgel powder The bulk filler 2 is evenly spread in the Teflon sealing outer layer 1, and the thickness of the waterproof and heat-insulating interlayer is controlled to be 0.5 mm to 30 mm.

[0024] The structural diagram of the waterproof and heat-insulating interlayer of this embodiment is as follows: figure 1 shown.

[0025] In this embodiment, the waterproof and heat-insulating interlayer is composed of a polytetrafluoroethylene sealing outer layer with waterproof and breathable functions and a loose and breathable hydrophobic airgel powder. The thermal conductivity of the waterproof and heat-insulating interlayer is 0.025-0.05W / m·K.

[0026] The waterproof and heat-insulating int...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the hydrophobic airgel powder filler 2 is one of silica aerogel, zirconia aerogel and alumina aerogel, both A mixture of species or a mixture of all three. Other parameters are the same as in the first embodiment.

[0029] In this embodiment, when the hydrophobic airgel powder filler 2 is a mixture of two or three of silica aerogel, zirconia aerogel and alumina aerogel, the mixing ratio is arbitrary Compare.

[0030] Considering the use environment of the waterproof and breathable interlayer in this embodiment, water vapor is unavoidable, so the hydrophobic airgel is preferred. In order to avoid the influence of acidic environments such as acid rain, airgel that can maintain hydrophobicity for a long time, even in a slightly acidic environment, is particularly preferred, such as silica airgel, ferric oxide aircondensation glue or alumina airgel.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the particle size of the hydrophobic airgel powder filler 2 is 10 μm to 1 mm. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

[0032] In this embodiment, the particle size of the hydrophobic airgel powder filler 2 is larger than the micropore diameter of the waterproof and air-permeable sealing outer layer 1, so as to prevent the leakage of the hydrophobic airgel powder, improve the comfort of use, and prolong the service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com