Patents

Literature

566results about How to "Improve waterproof function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

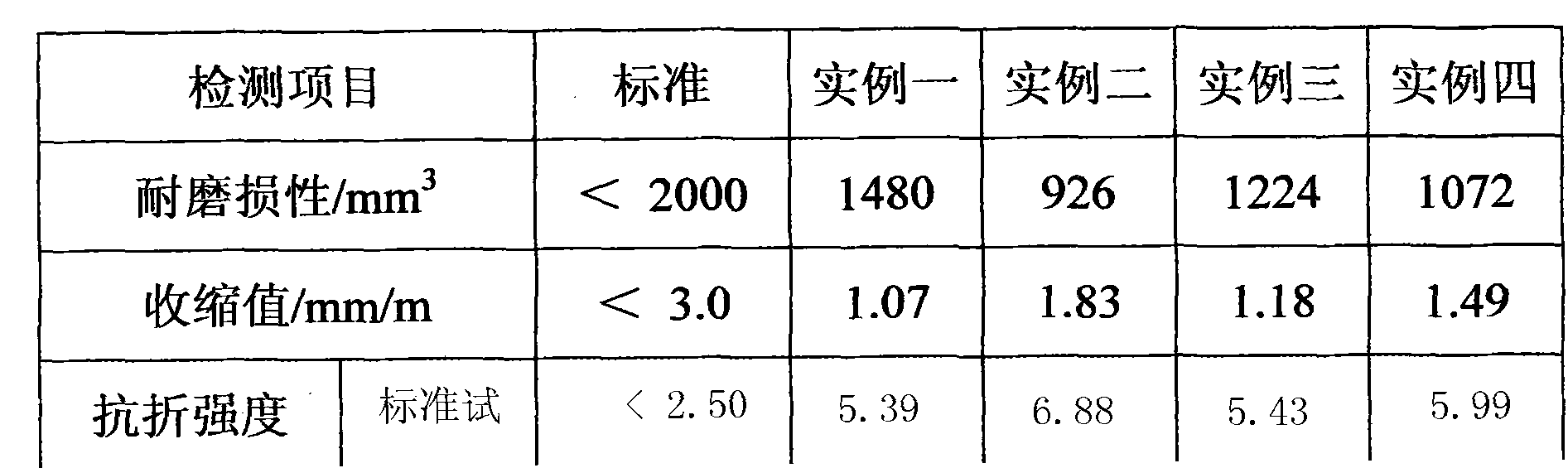

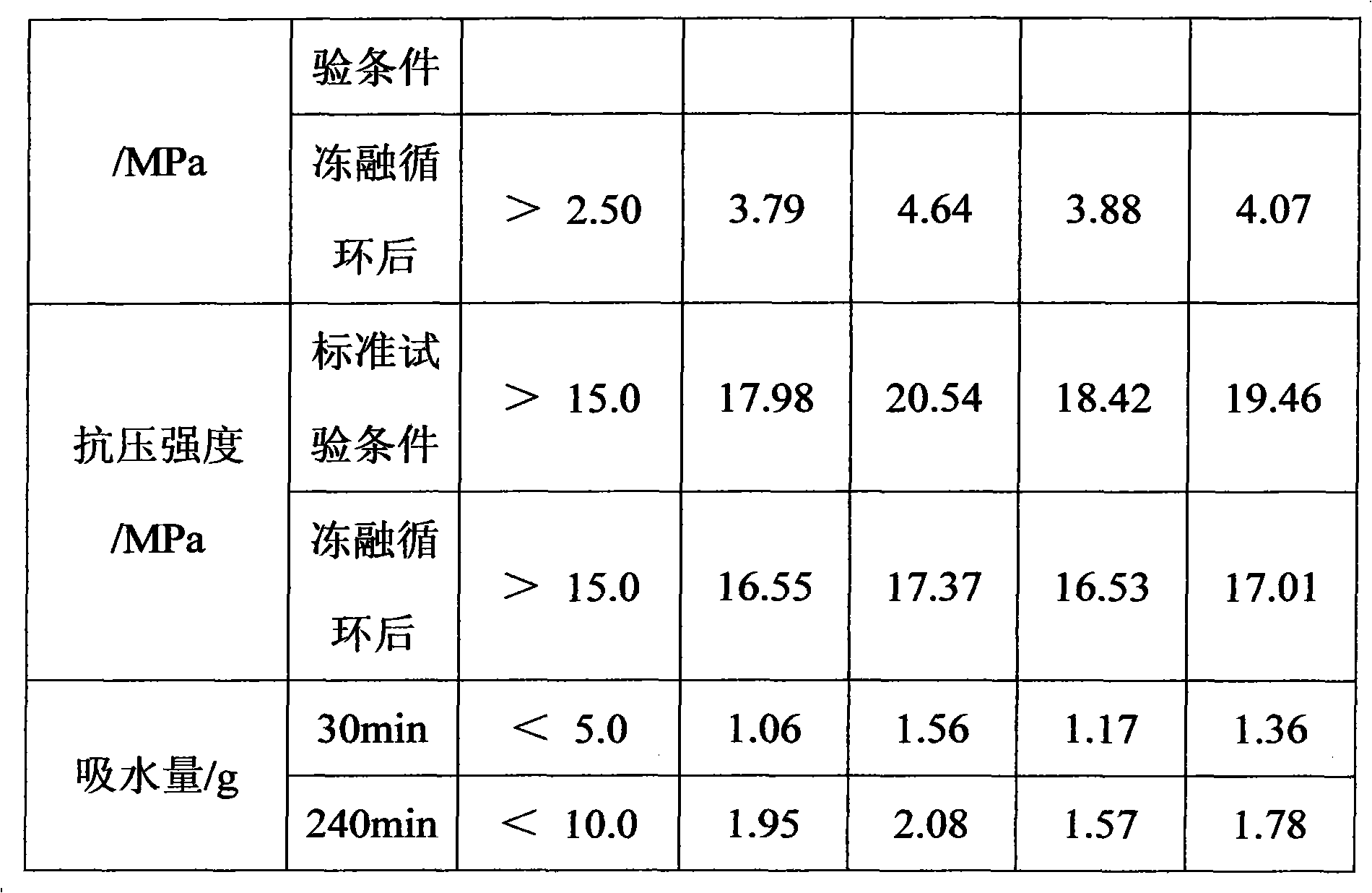

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

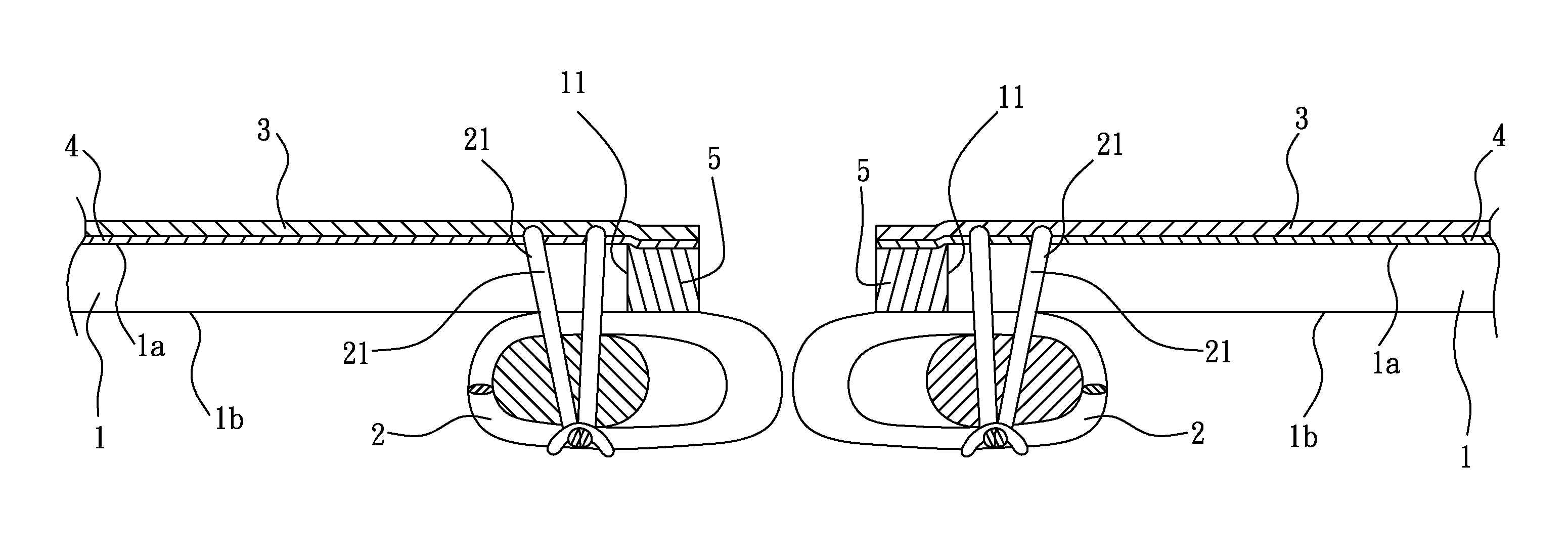

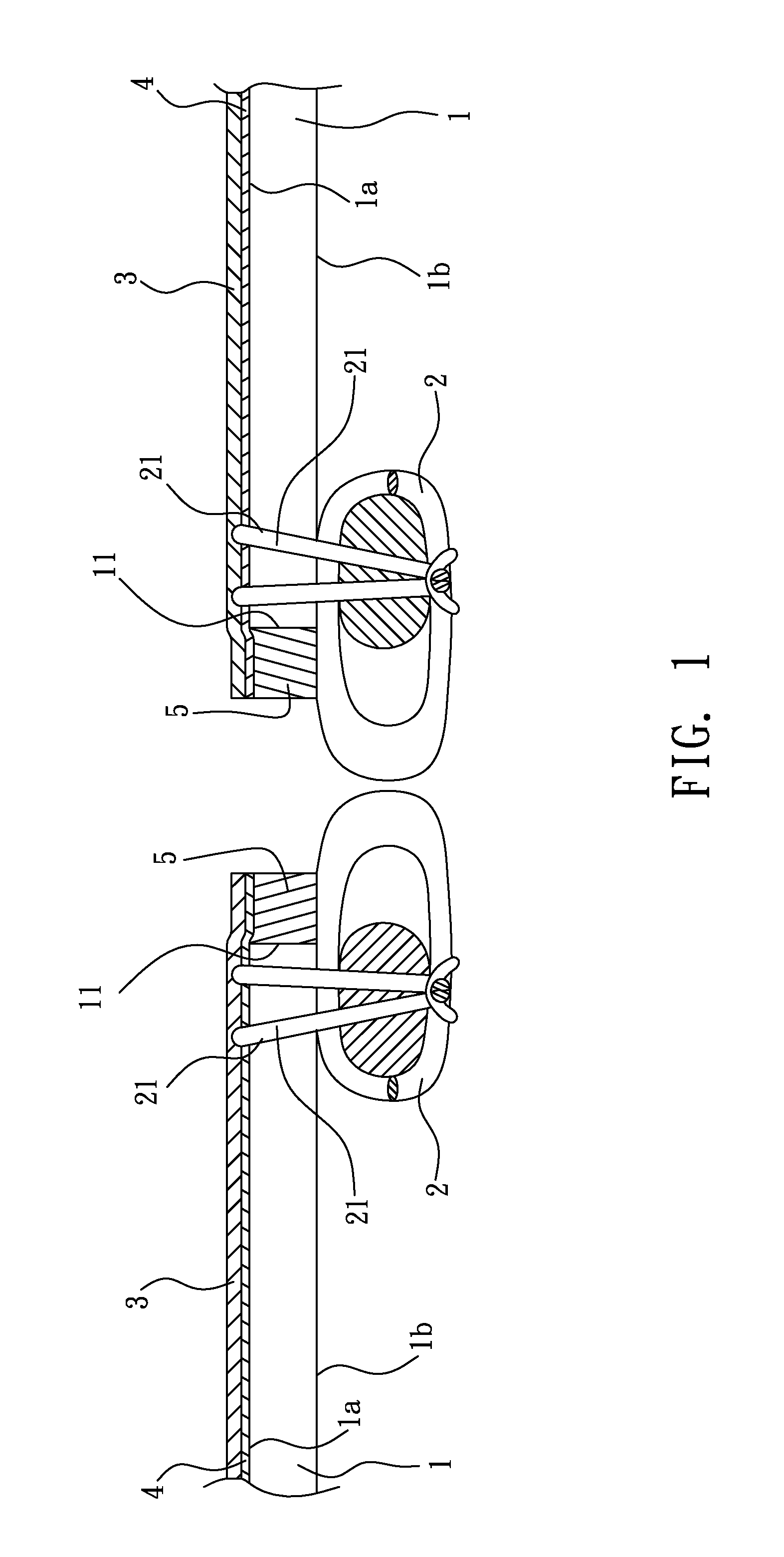

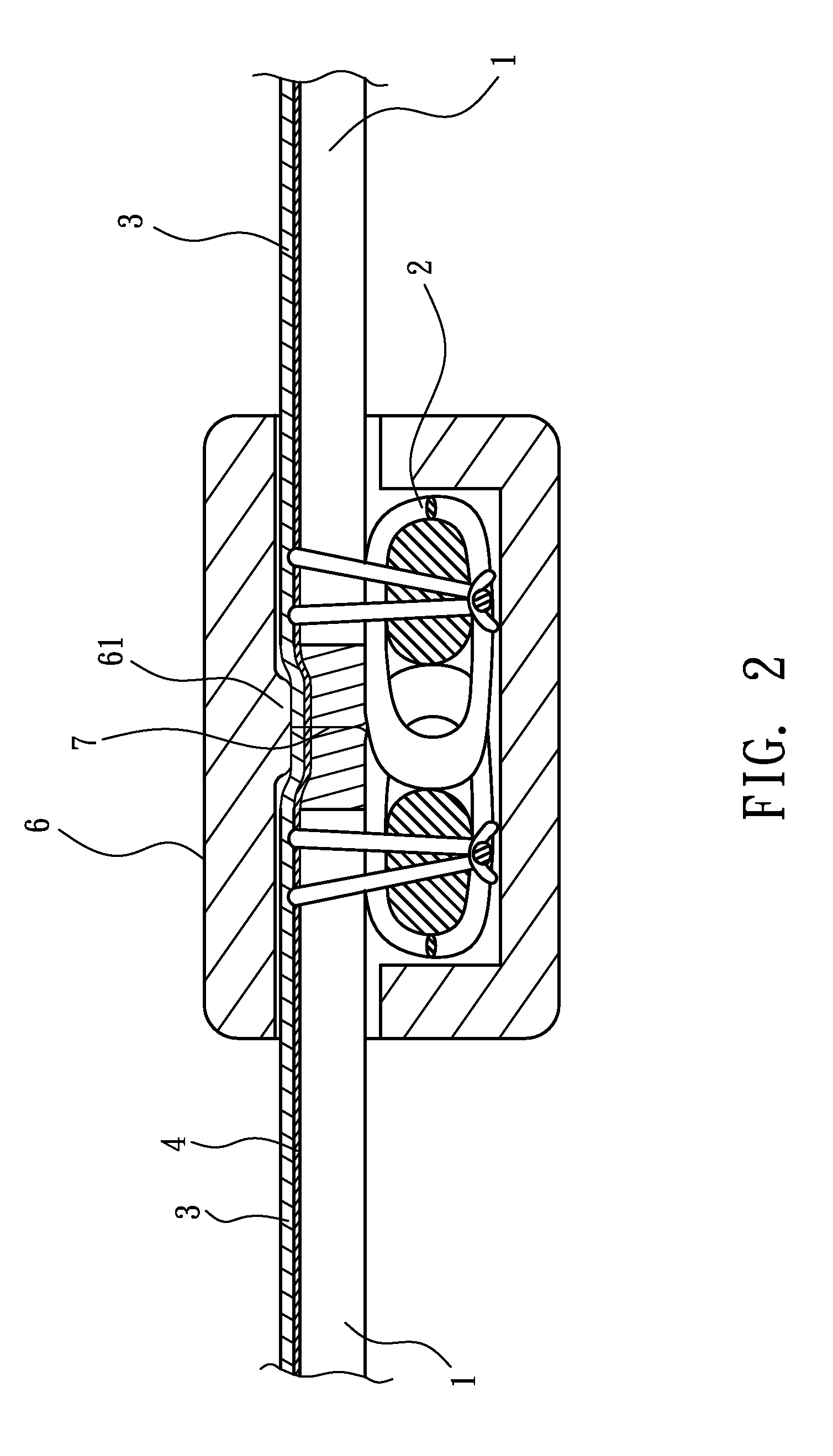

Continuous-coil type waterproof slide fastener and the structure impervious to fluid thereof

ActiveUS20100125982A1Eliminates water permeationAvoid damageSnap fastenersSlide fastenersEngineeringFastener

A continuous-coil type waterproof slide fastener includes two support tapes each having opposing first face and second face, two rows of coupling elements respectively formed of a continuous length of monofilament and respectively secured to along the inner longitudinal edge of the second face of each of the two support tapes, a high polymer elastic member bonded to the vertical wall of the inner longitudinal edge of each support tape and transversely extending from the vertical wall of the inner longitudinal edge to a predetermined distance, each high polymer elastic member further having a covering portion on the inner longitudinal edge of the second face of the associating support tape and a filling portion penetrates into inner chinks in the associating row of coupling elements, and a fluid impervious film covered at least on the first face of each support tape and the associating high polymer elastic member.

Owner:CHOU CHAO MU +1

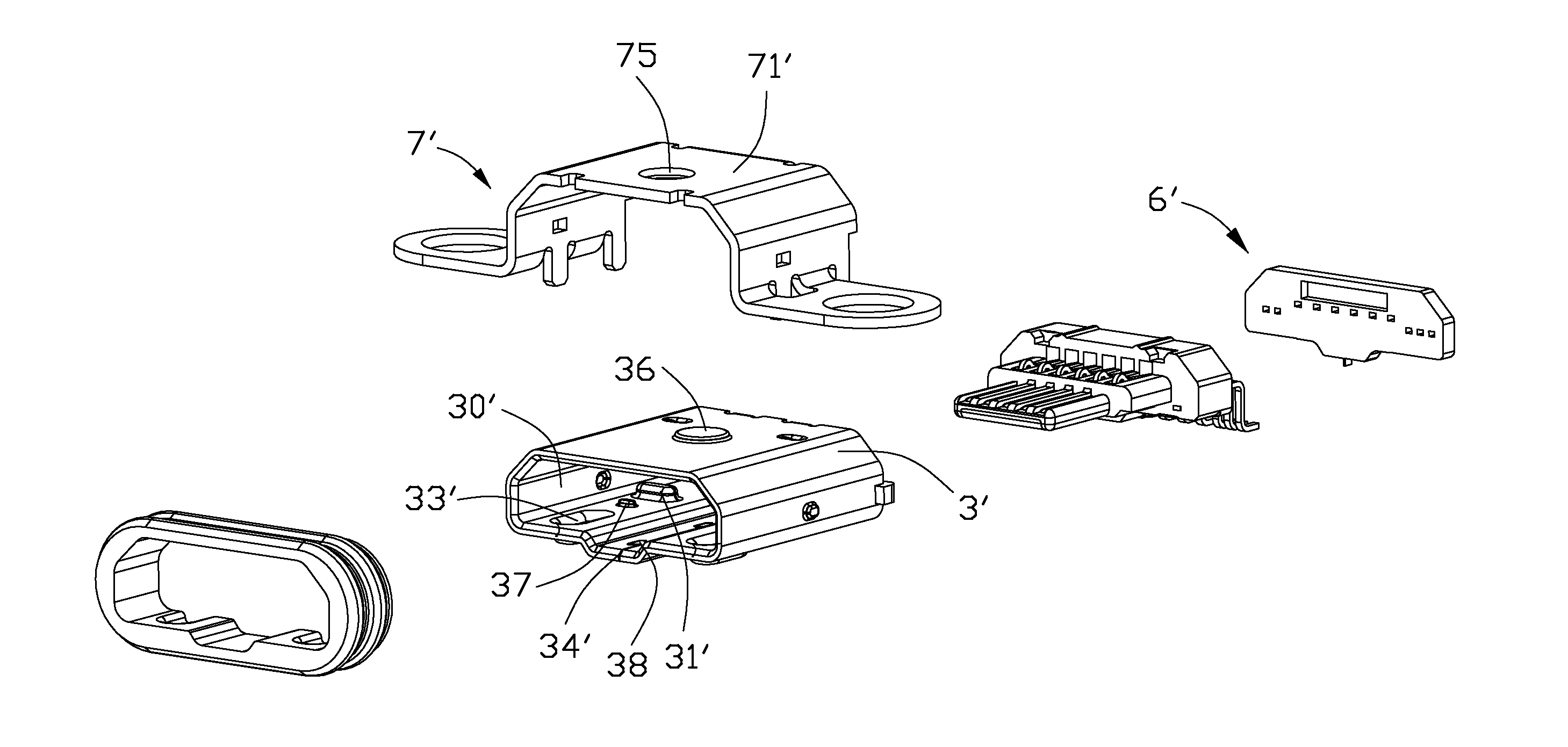

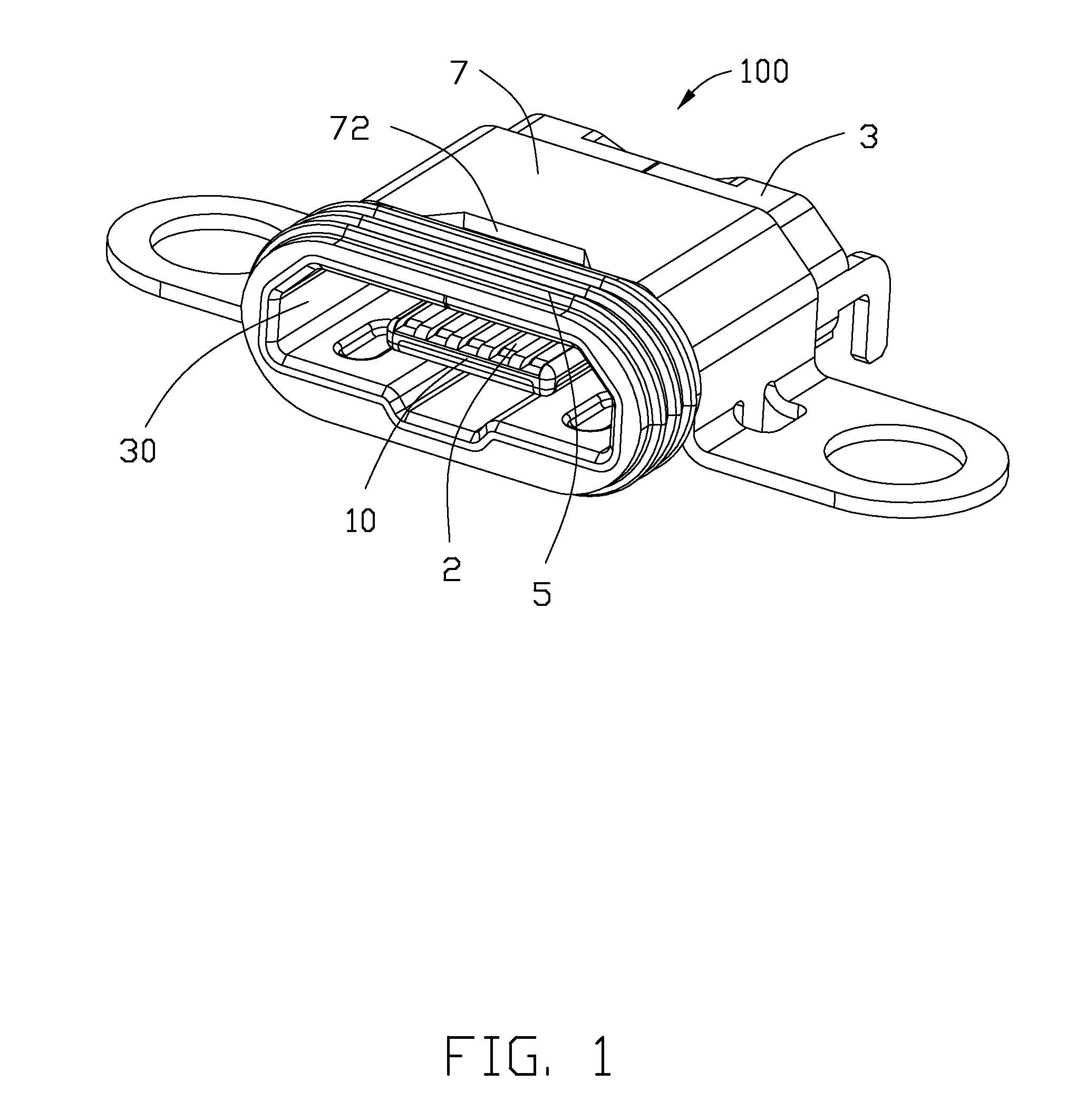

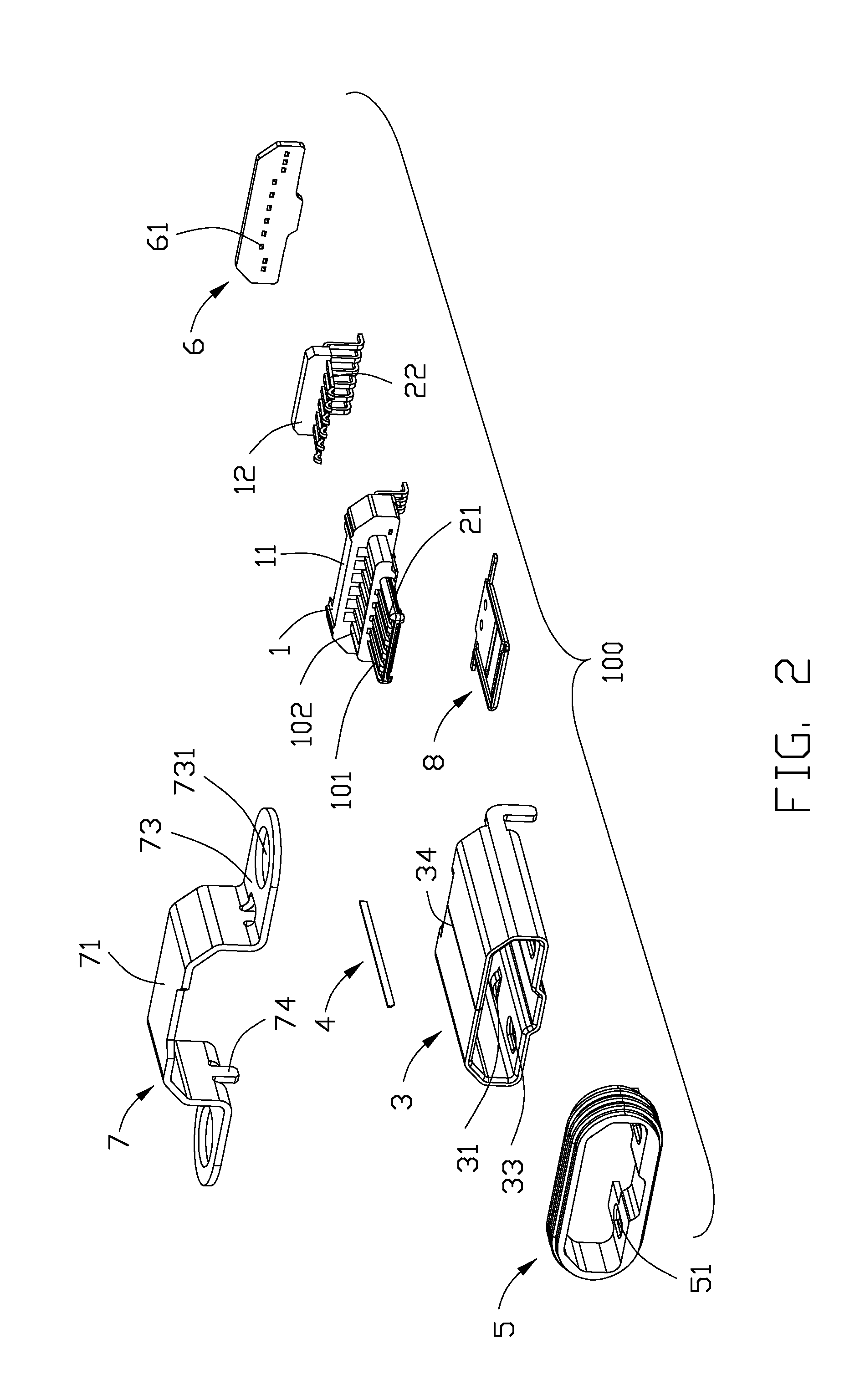

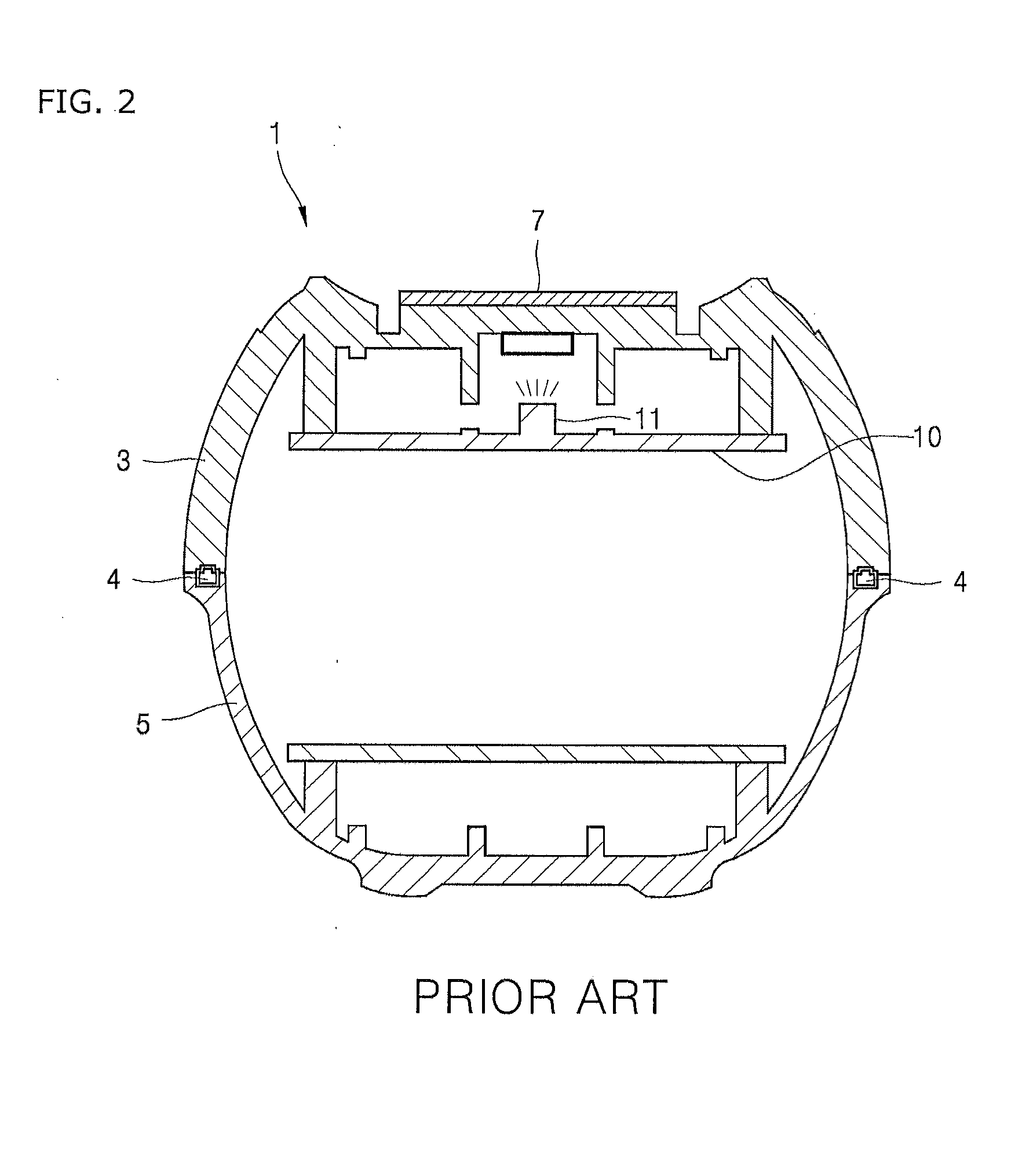

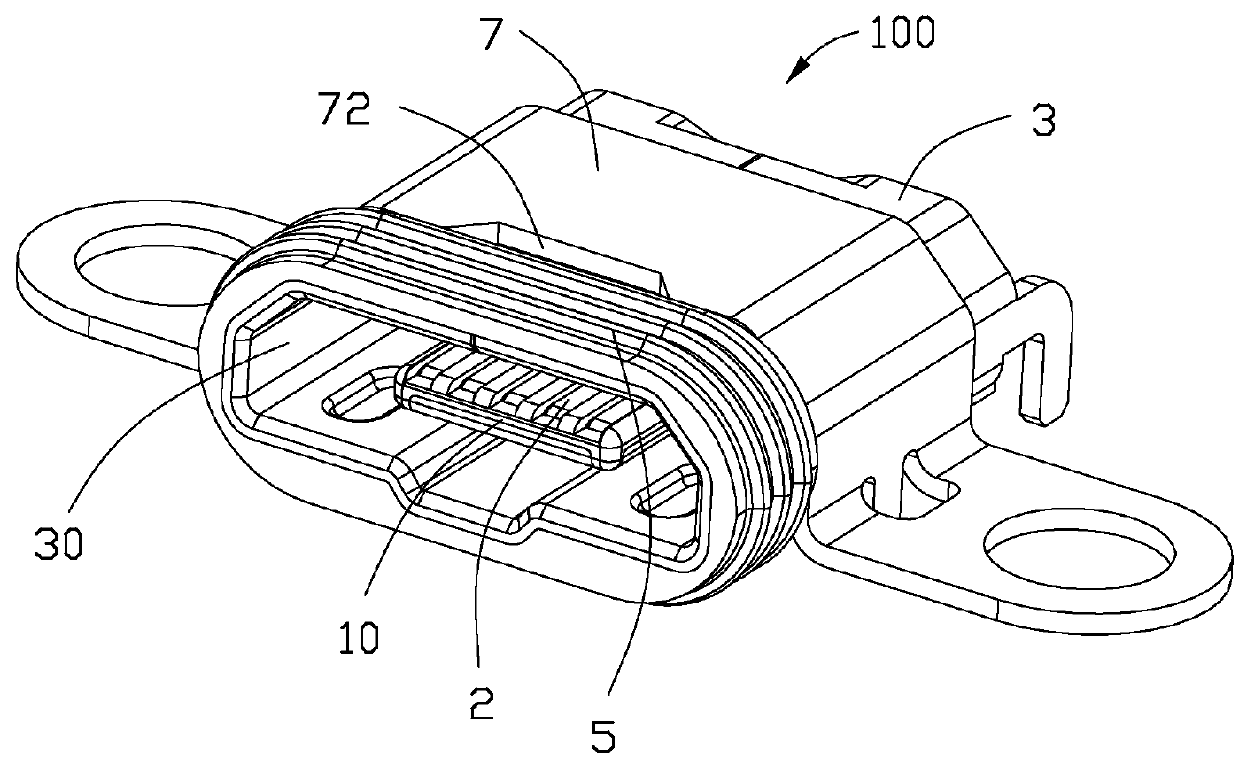

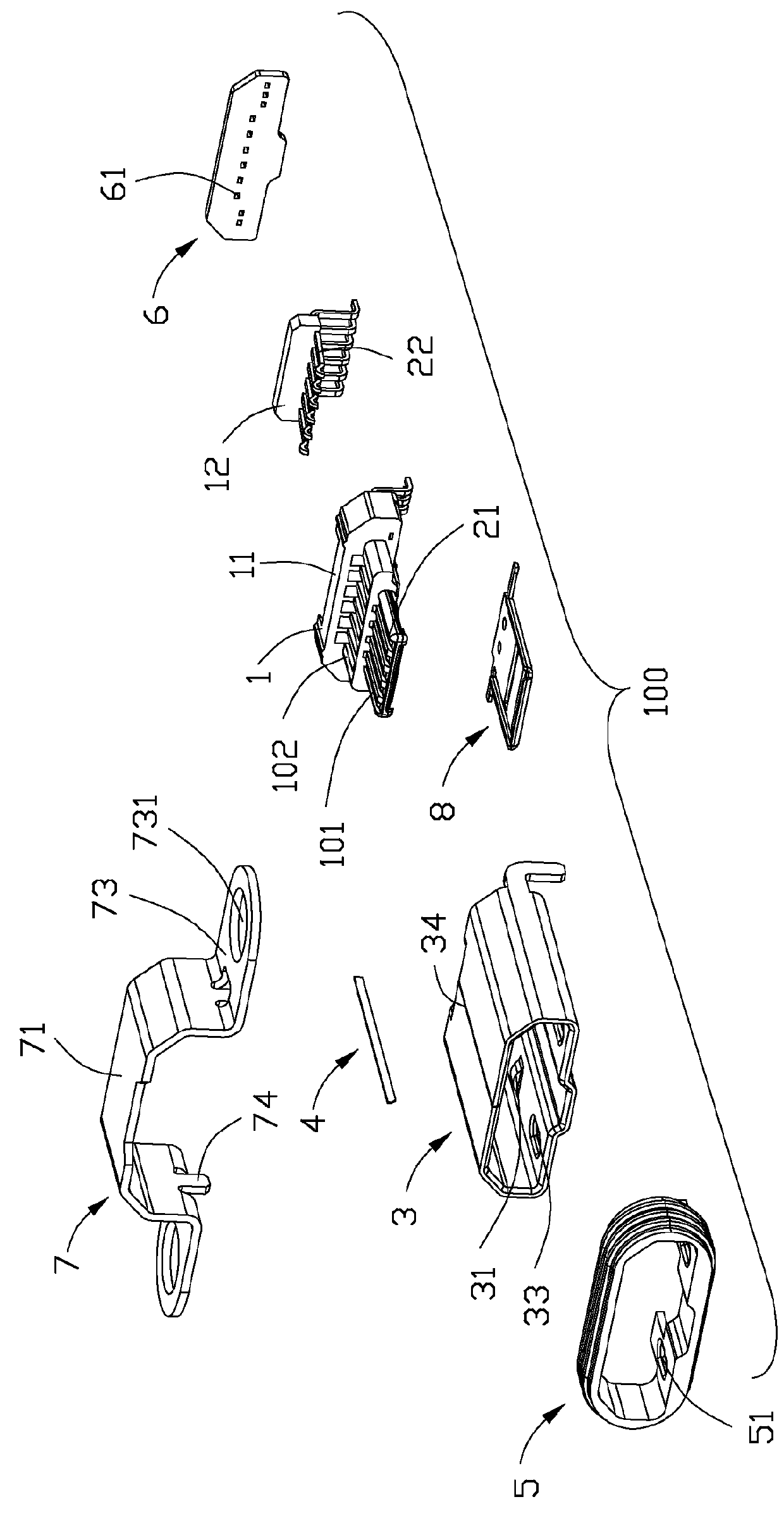

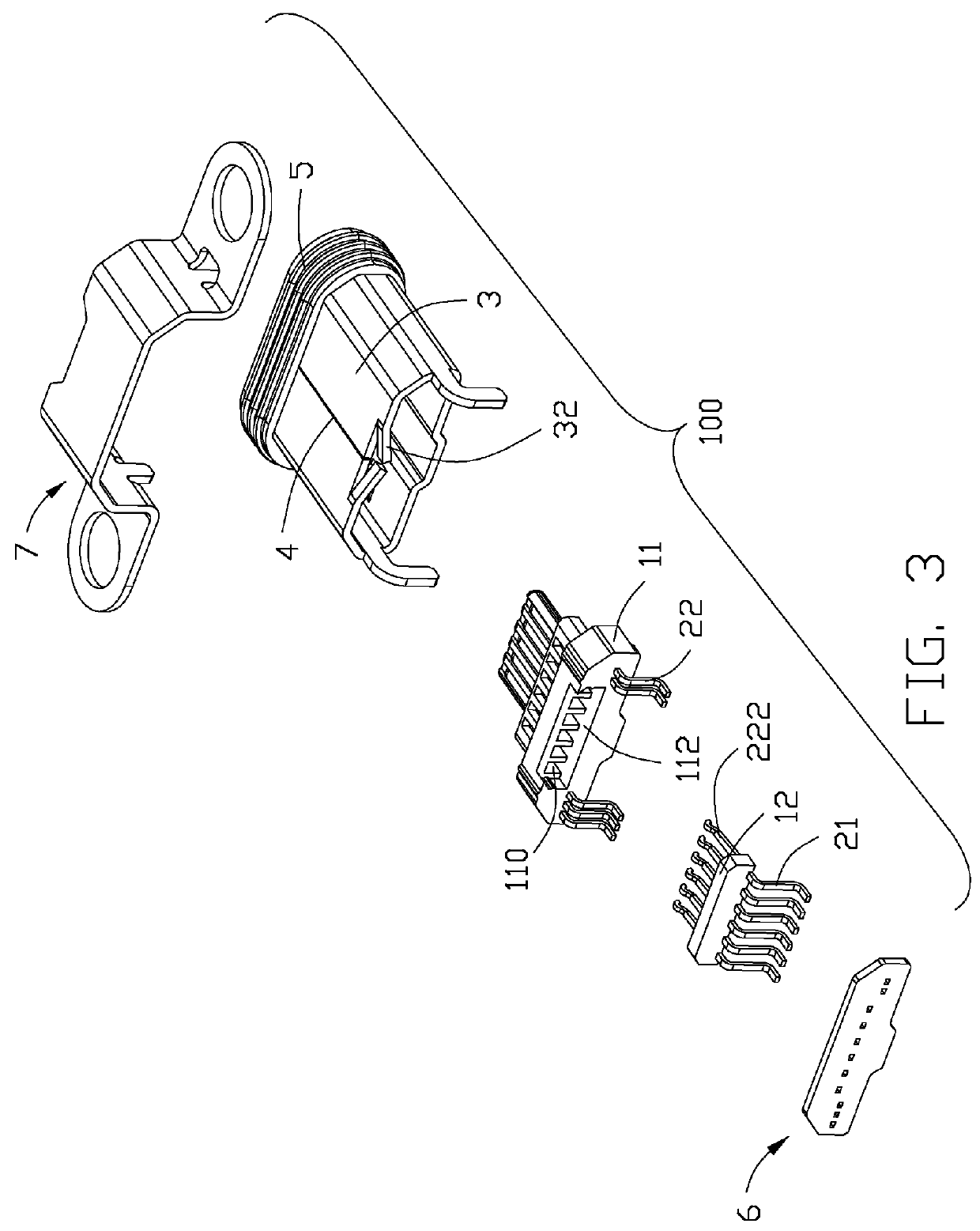

Electrical connector having waterproof function

ActiveUS20150155661A1Improve waterproof functionLow costTwo-part coupling devicesCoupling protective earth/shielding arrangementsSolderingElectrical and Electronics engineering

An electrical connector includes an insulating housing, a plurality of conductive terminals installed in the insulating housing and a metallic shell shielding around the insulating housing. The insulating housing has a mating portion extending forwardly thereof. The metallic shell surrounds to form a mating cavity into which the mating portion extending and a joint communicating with the mating cavity. The conductive terminals are exposed to one face of the mating portion. The joint is filled with soldering material to form a soldering segment. The electrical connector has good waterproof function with the soldering segment in the joint.

Owner:FOXCONN INTERCONNECT TECHNOLOGY LIMITED

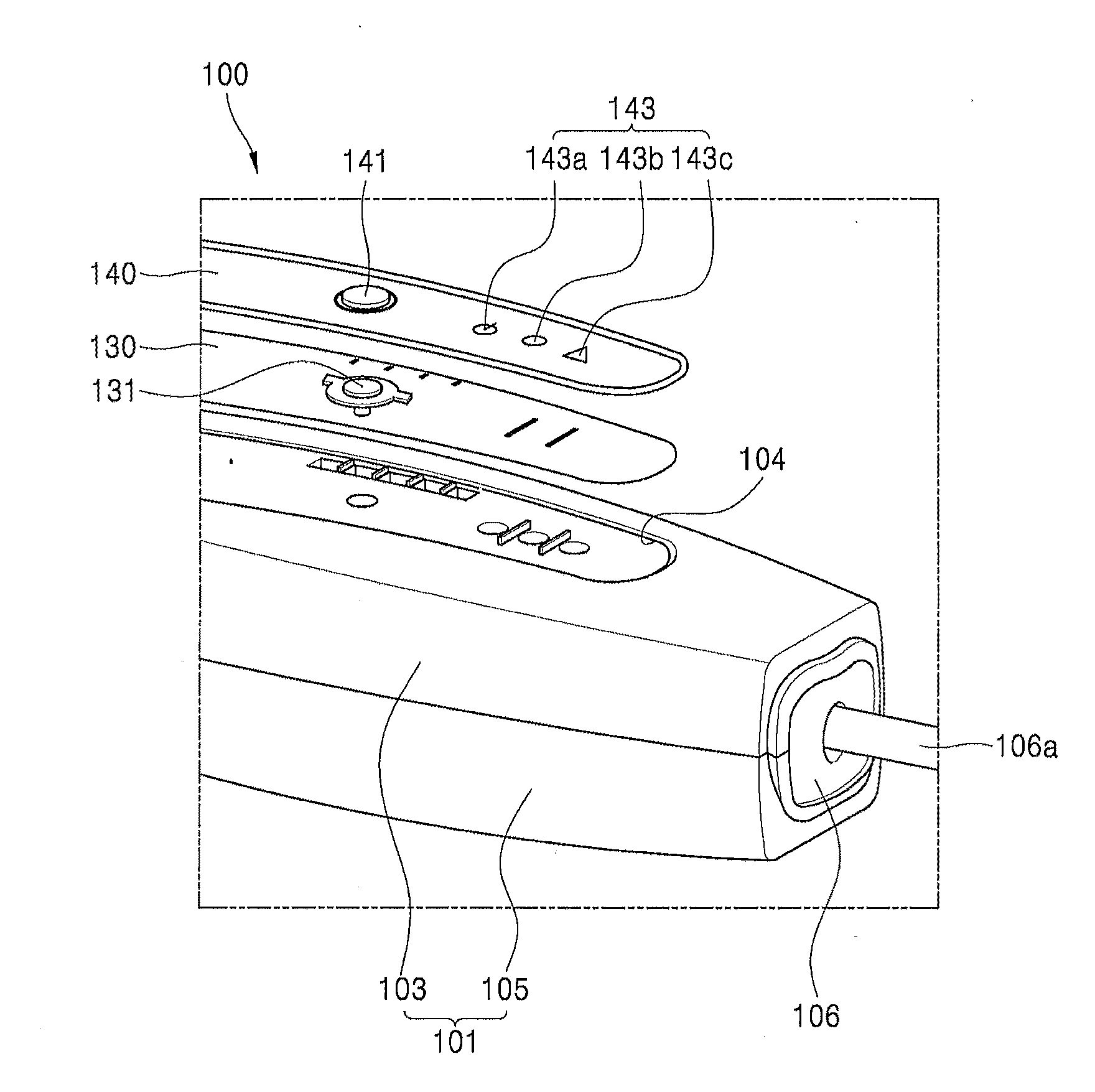

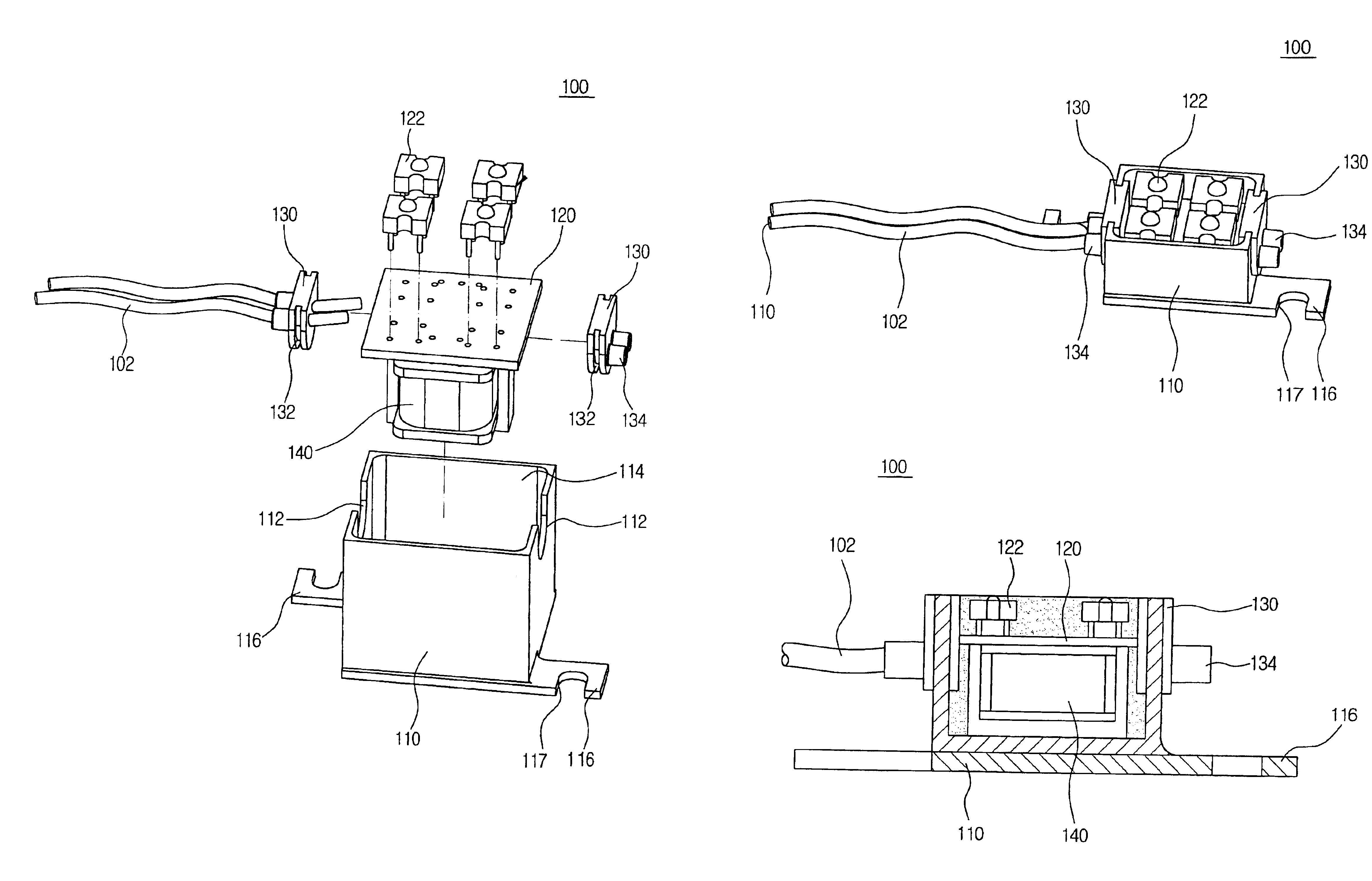

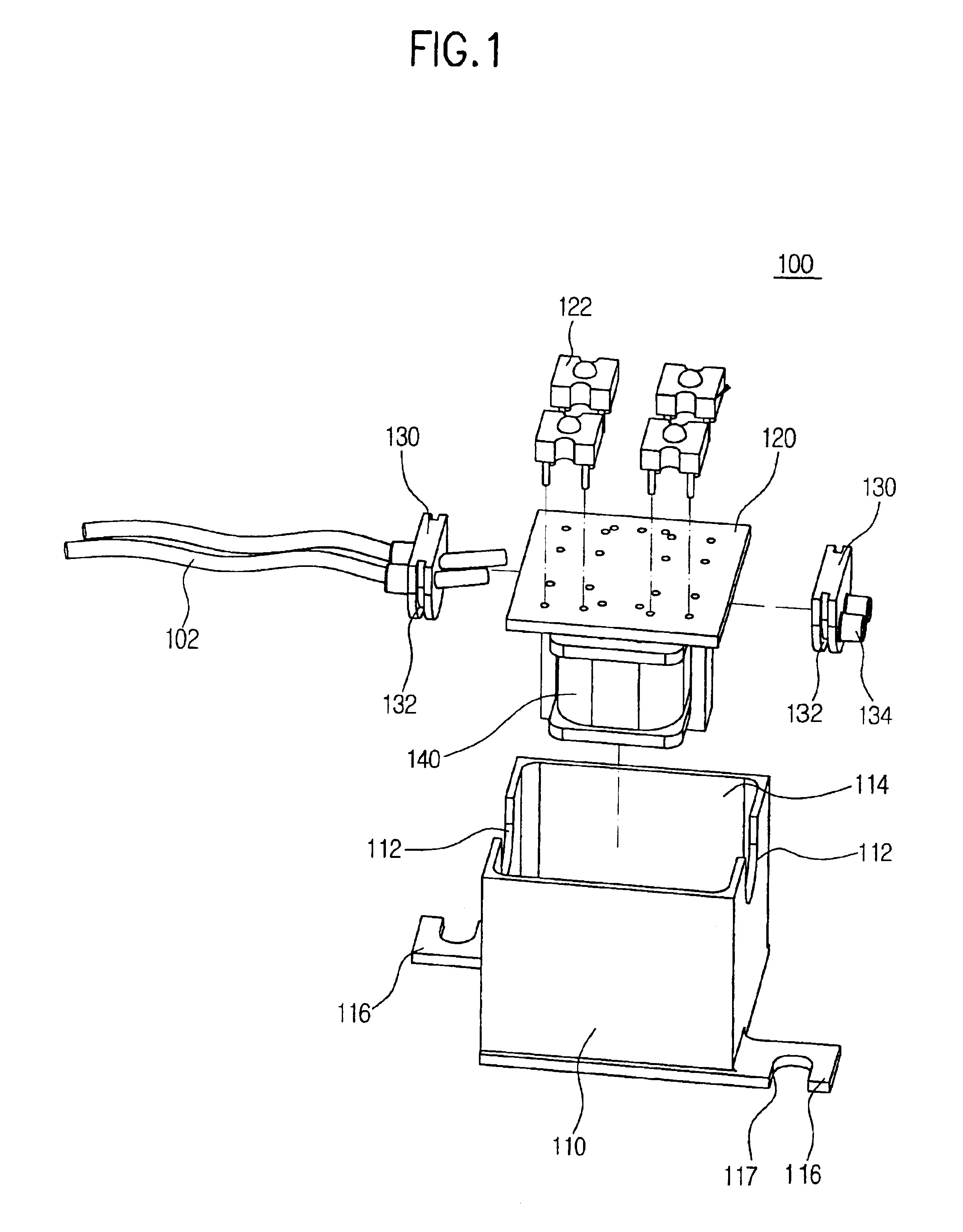

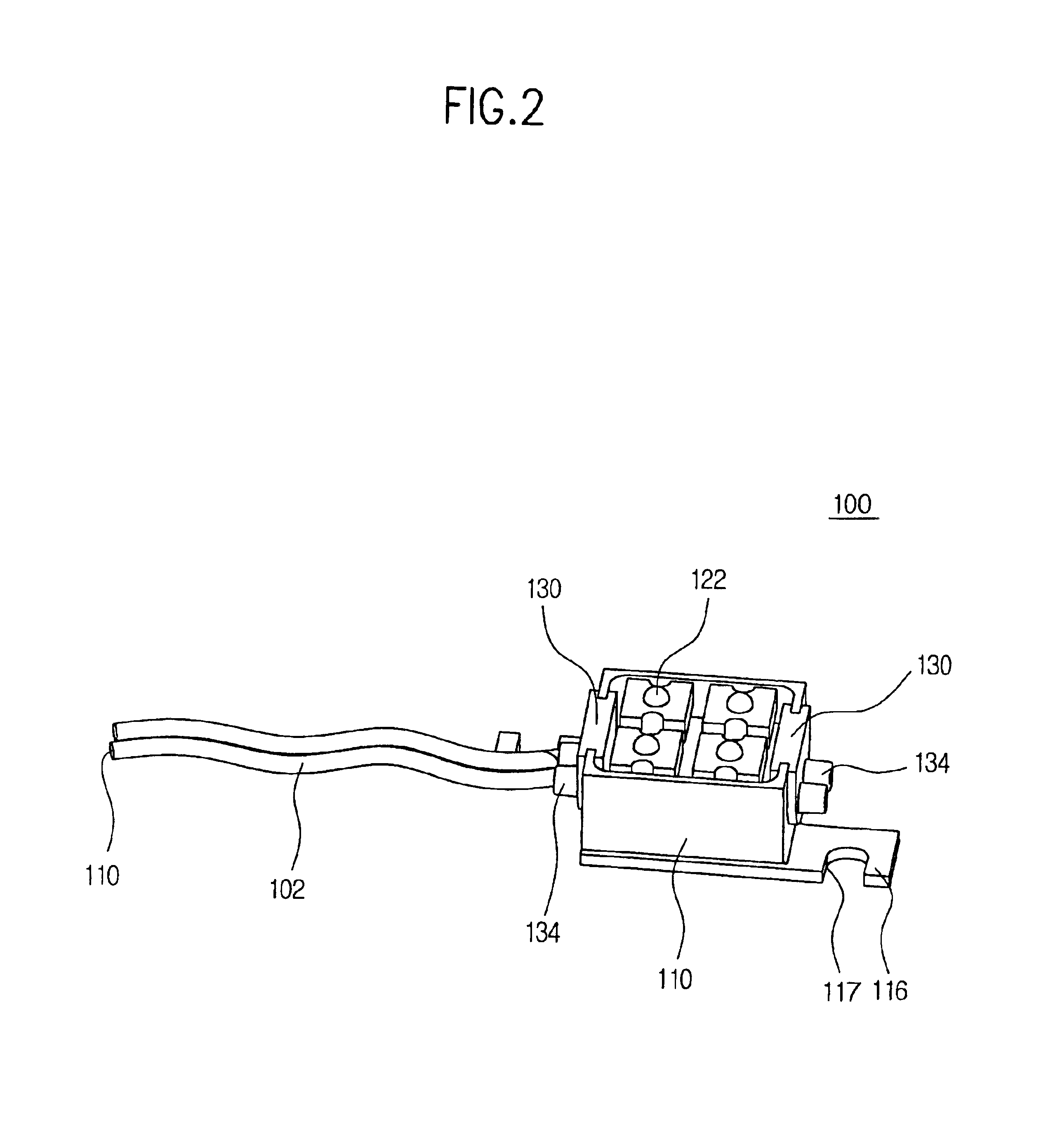

Control box for electric vehicle charger

InactiveUS20160315488A1Easy to operateIncreased durabilityCircuit monitoring/indicationCharging stationsEngineeringElectric vehicle

Some embodiments in the present disclosure relate to a control box for an electric vehicle charger that may provide enhanced manipulation convenience and an improved waterproof function. According to an embodiment, the control box may include a case having a circuit board therein, the circuit board may include a light emitting unit and a switch, a cover member attached to an upper portion of the case and may be configured to allow light emitted from the light emitting unit to be transmitted therethrough, the cover member may include a press protrusion to press the switch, and an exterior member attached to an upper portion of the cover member.

Owner:LSIS CO LTD

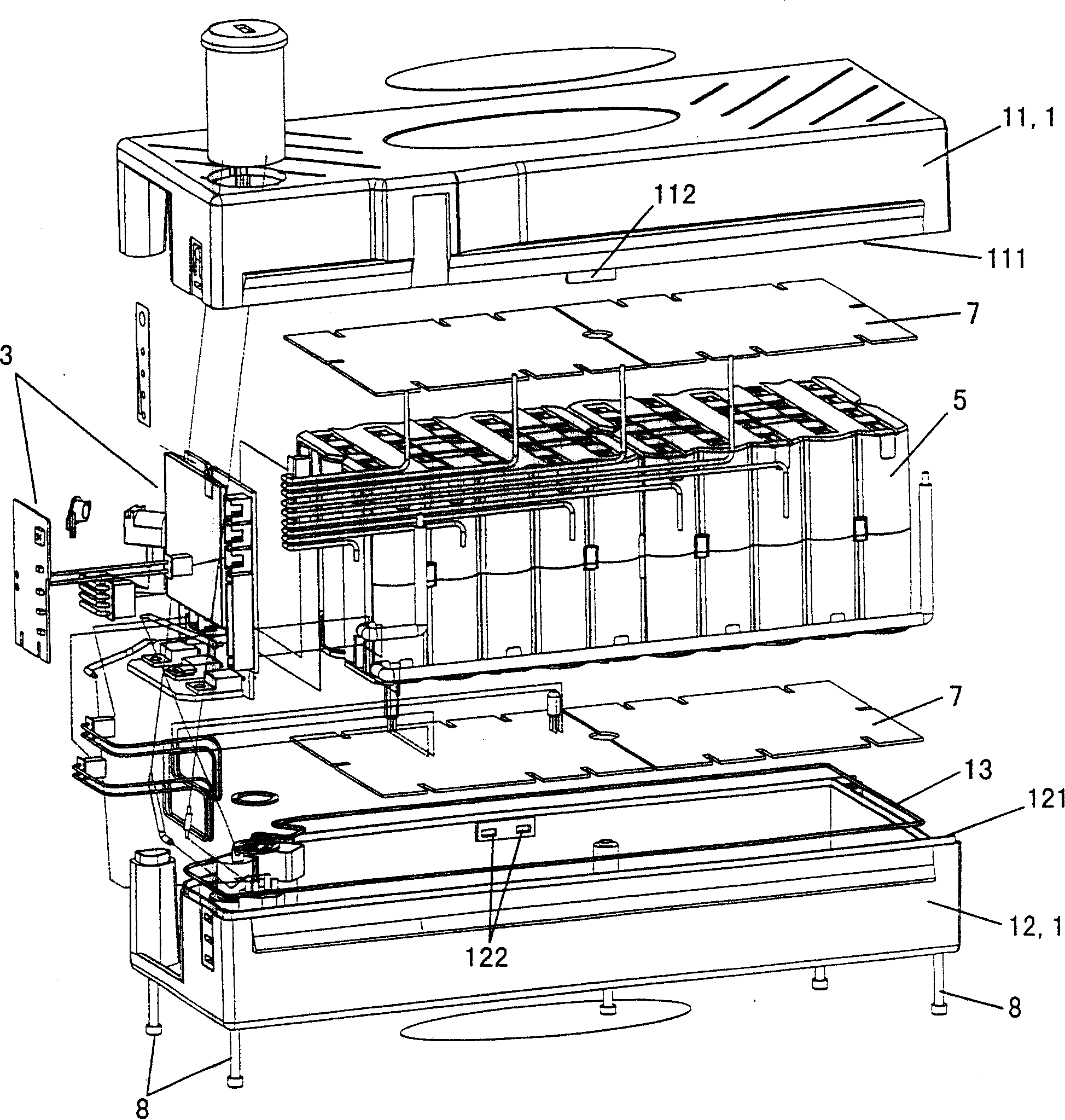

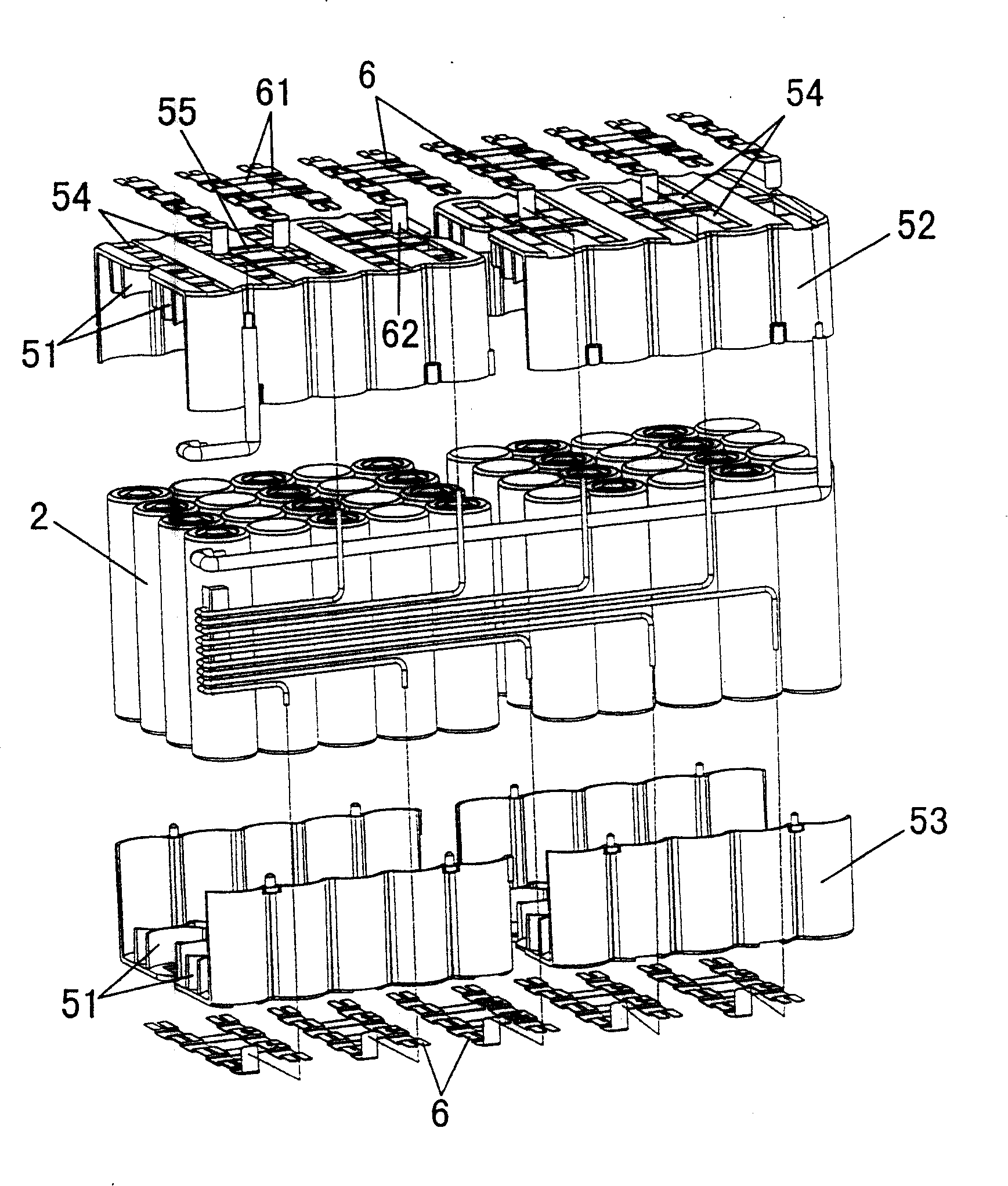

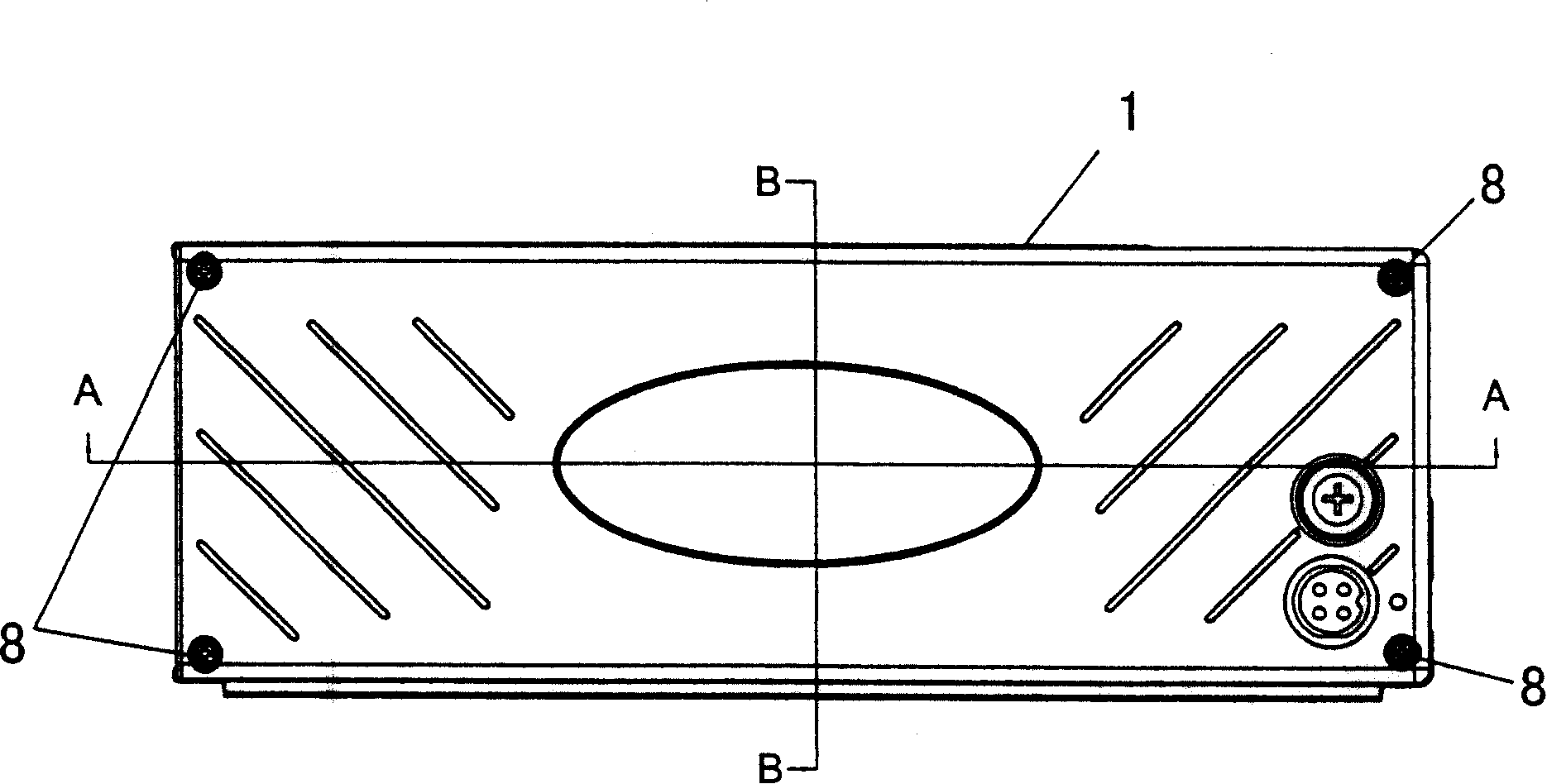

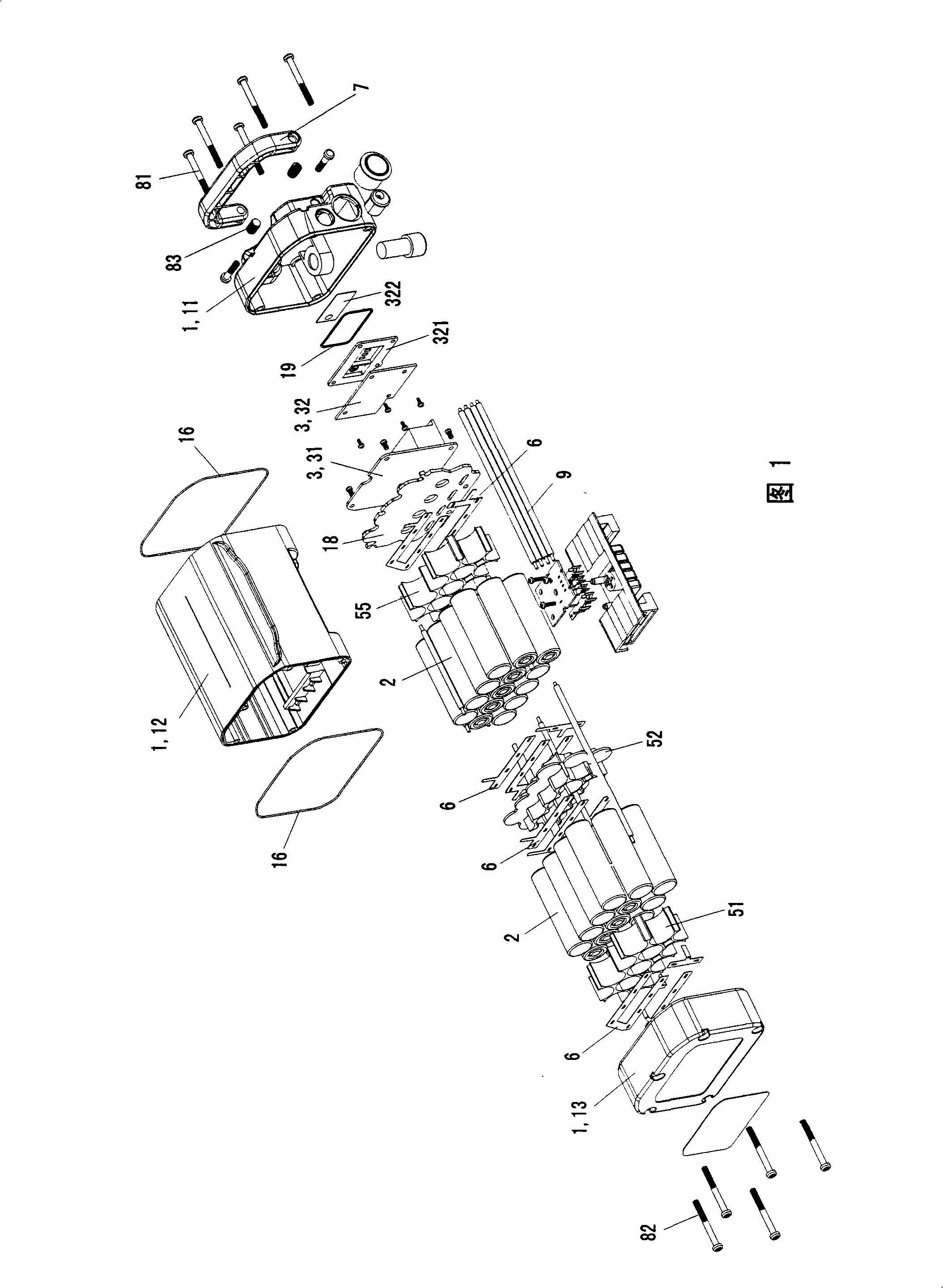

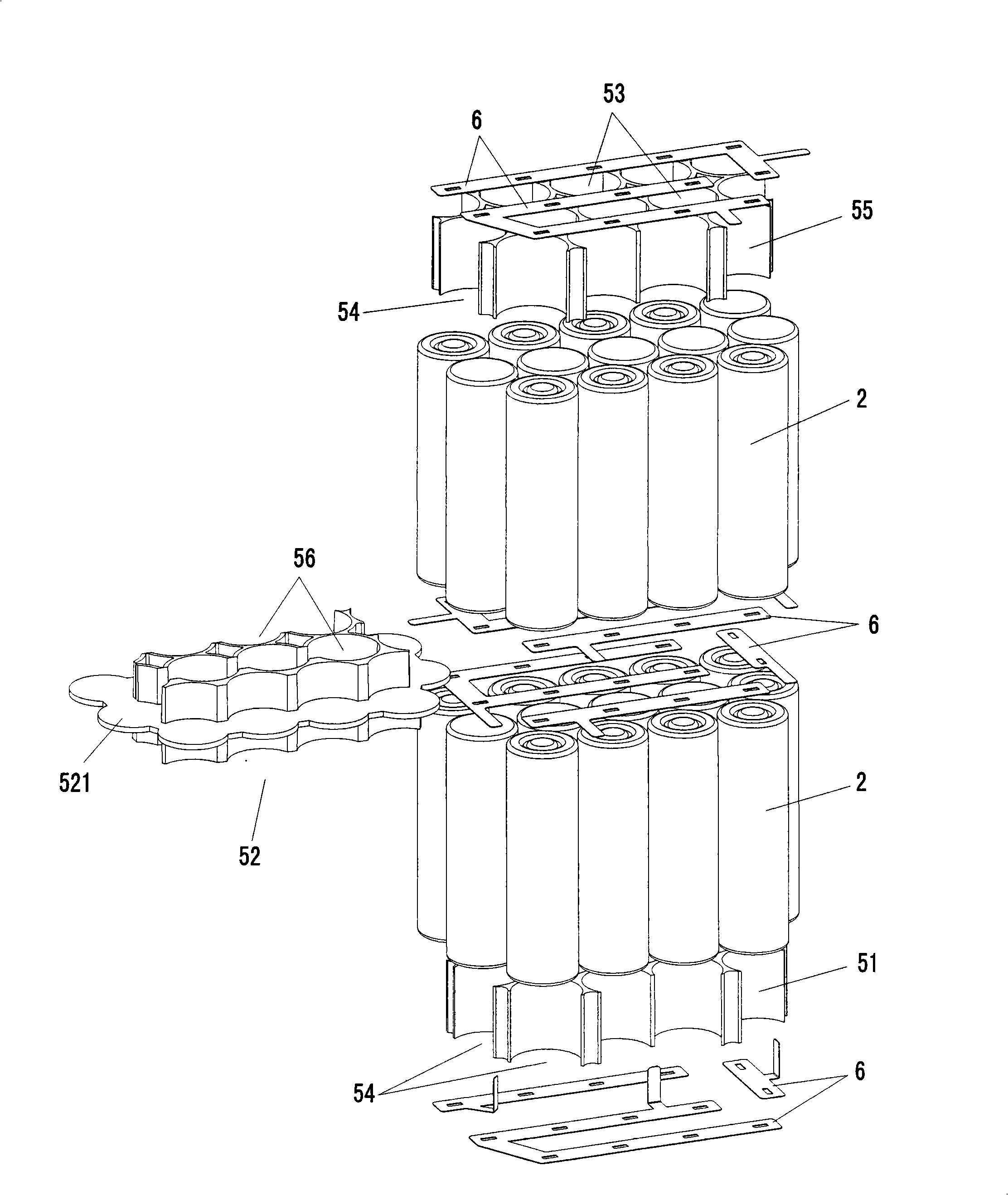

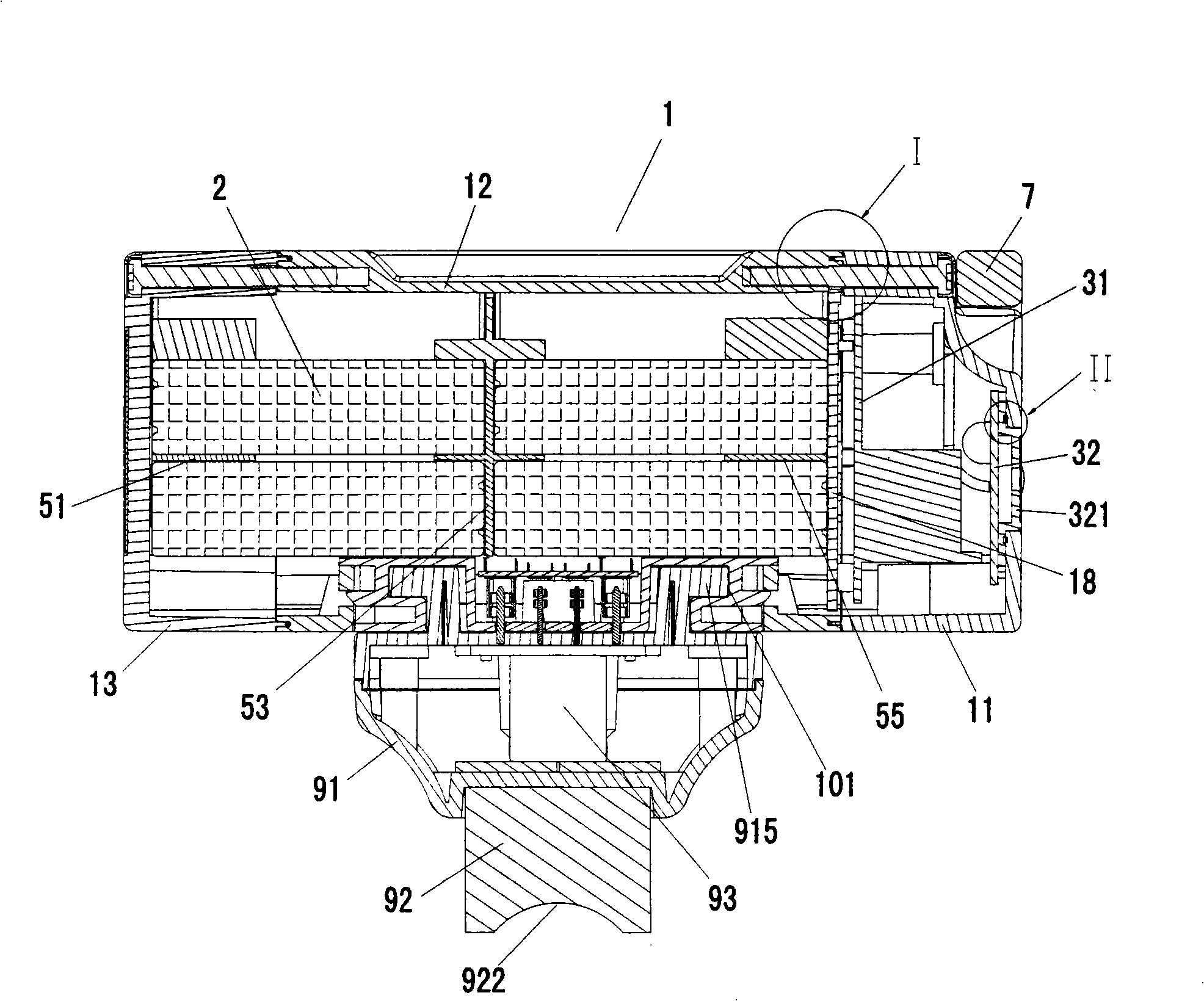

Shakeproof and dampproof dynamic battery unit

InactiveCN101237033AGood shock resistanceGood waterproof functionBattery isolationSecondary cellsEngineeringPower battery

The invention relates to a shock-resistant and damp-proof power battery set which comprises an outer shell (1), a plurality of cells (2) arranged inside the outer shell (1) and a charging / discharging protection circuit board (3) in electric connection with the plurality of cells (2), wherein a support structure (5) constraining the positions of the plurality of cells (2) axially and radically is fixed in the outer shell (1), the plurality of cells (2) constrained in the support structure (5) are arranged with a clearance in between. The cells in the battery set can be positioned reliably to keep a sound electric contact, has very good shock-resistant performance and heat dispersion performance and is very suitable to be used on various power battery sets in shaking circumstances.

Owner:GUANGZHOU ZHANHUI ELECTRONICS

Electrical connector having waterproof function

ActiveUS9385484B2Improve waterproof functionLow costCouplings bases/casesTwo-part coupling devicesElectrical connectorSoldering

An electrical connector includes an insulating housing, a plurality of conductive terminals installed in the insulating housing and a metallic shell shielding around the insulating housing. The insulating housing has a mating portion extending forwardly thereof. The metallic shell surrounds to form a mating cavity into which the mating portion extending and a joint communicating with the mating cavity. The conductive terminals are exposed to one face of the mating portion. The joint is filled with soldering material to form a soldering segment. The electrical connector has good waterproof function with the soldering segment in the joint.

Owner:FOXCONN INTERCONNECT TECH LTD

Light emitting diode assembly for an illuminated sign

InactiveUS6924973B2Avoid damageImprove waterproof functionLighting support devicesPoint-like light sourceTransformerEngineering

The light emitting diode assembly for an illuminated sign is disclosed having an enhanced waterproofs function and an enhanced durability. The light emitting diode assembly includes a case being open upwards, in which a connecting recess is formed on upper portions of both sides of the case. A printed circuit board is installed in the case and being mounted on upper sides of a plurality of light emitting diodes. The hollow cap is coupled in the connecting recess of the case, in which a plurality of wires passes through the cap. A synthetic resin material for covering the printed circuit board, the cap and the light emitting diode, is filled in the case. In this structure, the light emitting diode assembly can prevent the printed circuit board, transformer and the light emitting diode from being damaged by using an epoxy resin.

Owner:ATTO DISPLAY

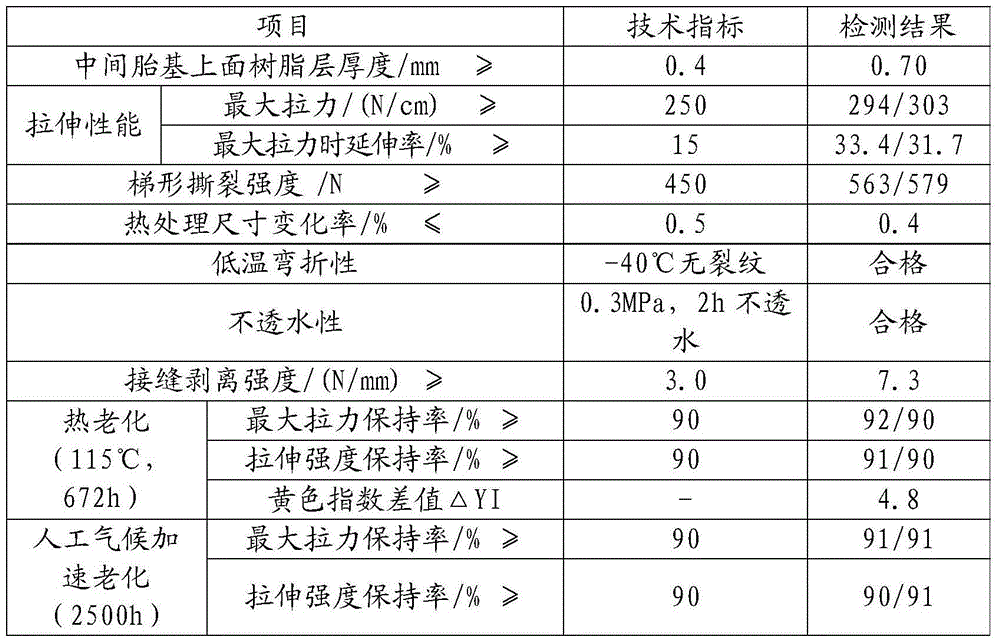

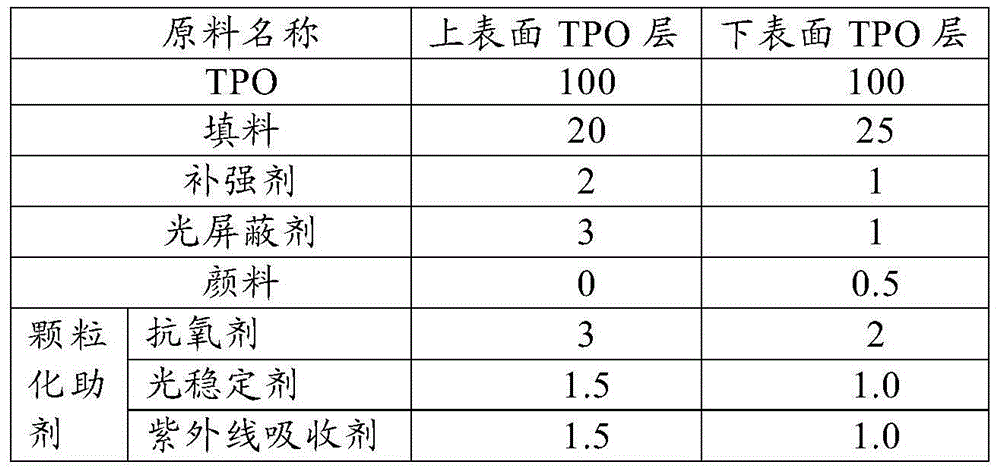

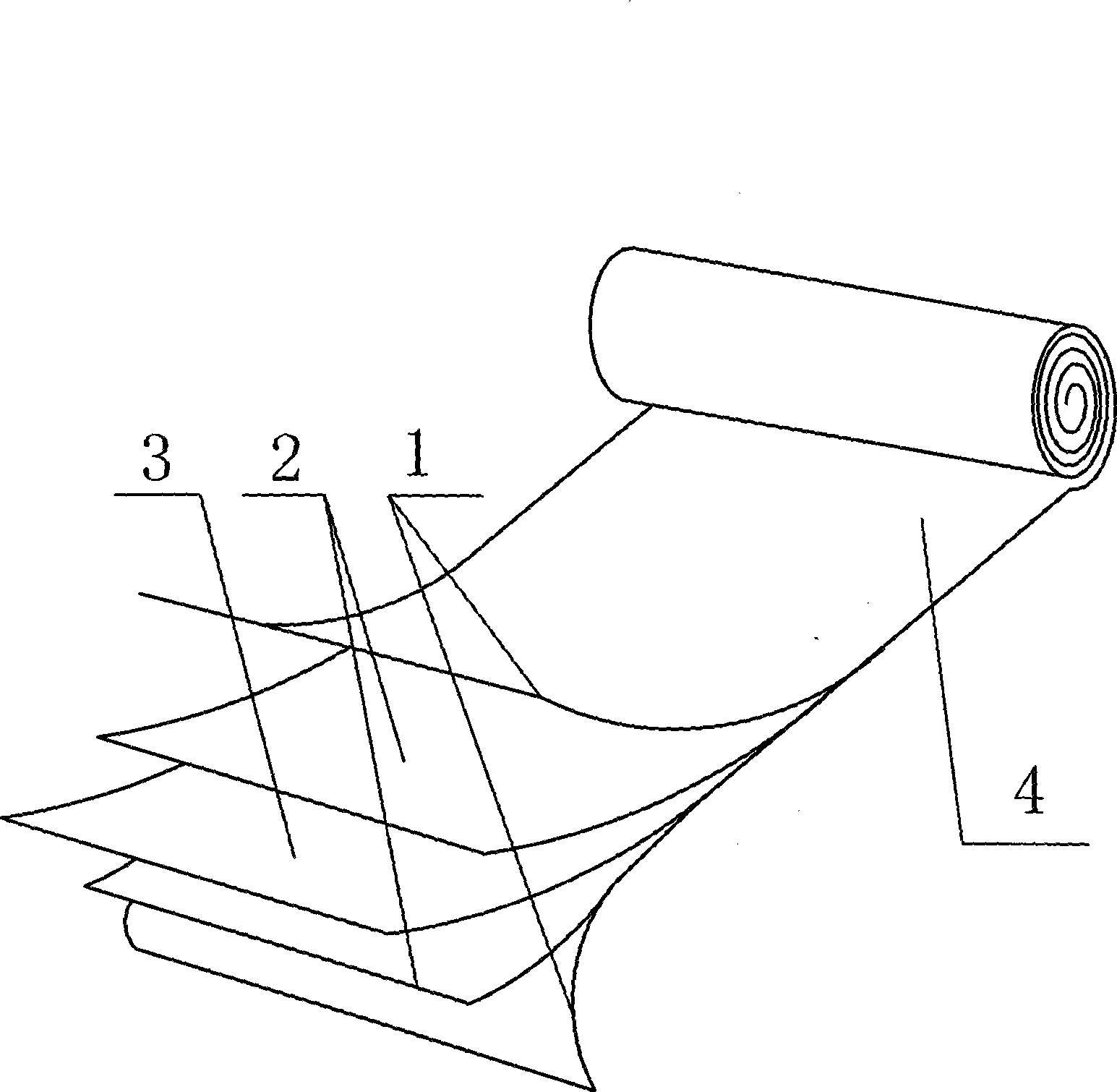

Waterproof roll and preparation method thereof

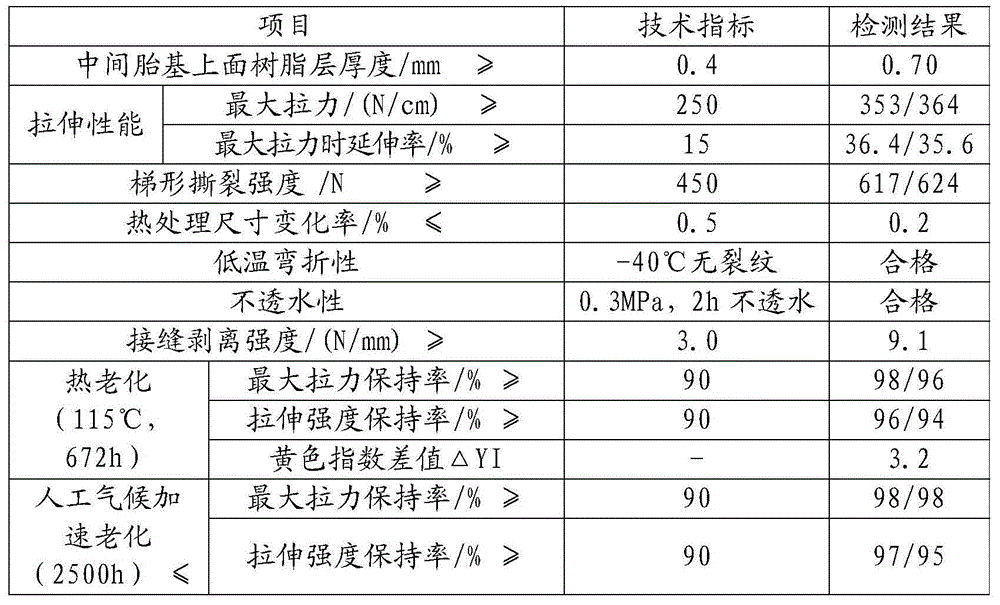

ActiveCN104669747AImprove heat aging resistanceGood weather resistanceSynthetic resin layered productsConstructions elementsThermoplasticCrazing

The invention provides a waterproof roll and a preparation method thereof, belongs to the technical field of polymer waterproof rolls, and can solve the problems of color fading, color changing, surface staining, microcracking, hairline crack and the like of a conventional TPO (thermoplastic polyolefin) roll product in the use process. The waterproof roll comprises a TPO roll layer, wherein raw materials of the TPO roll layer comprise polymeric TPO resin and a granular auxiliary; the granular auxiliary comprises an antioxidant, a light stabilizer and an ultraviolet light absorber, and the grain size of the granular auxiliary is 0.5-1.5 mm. The waterproof roll has excellent weather fastness, ageing resistance, waterproof function and fastness and reliability in construction.

Owner:苏州东方雨虹建筑材料有限公司

Self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and insulated wallboard

ActiveCN102249641ASolve insulation problemsSolve fire resistanceSolid waste managementCement mortarStearate

A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and an insulated wallboard solve technical problem in a prior art that self-leveling cement mortar with weak waterproofness causes weak insulation effect of an insulated wallboard. A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover is employed as a technique. Ingredients of the self-leveling cement mortar dry powder comprise a compound impervious component; and the impervious component is prepared by mixing a redispersible high-molecular polymer and one of an organosilicon waterproof agent and a stearate, or a mixture of the two, and accounts for 0.6-4.3wt% of the self-leveling cement mortar dry powder. A special impervious ingredient is added to enhance compactness, microdilatancy and low dry shrinkage property of the cement based self-leveling mortar, so as to substantially increase waterproof function and endurance of the cement based self-leveling mortar. Therefore, a problem that a cladded super-light foaming cement sheet material loses insulation function due to water penetration and problems of flame resistance and endurance are solved fundamentally.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

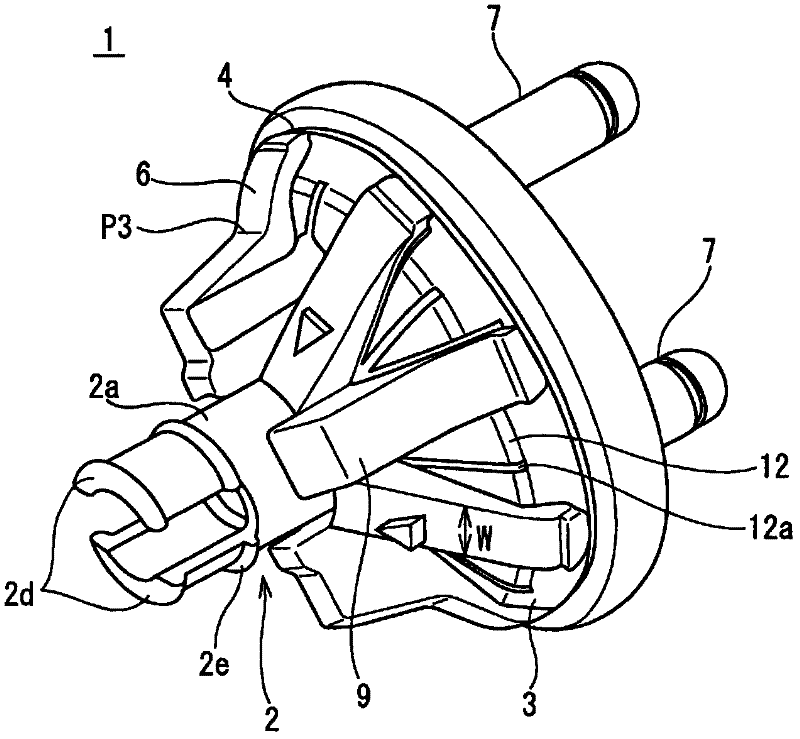

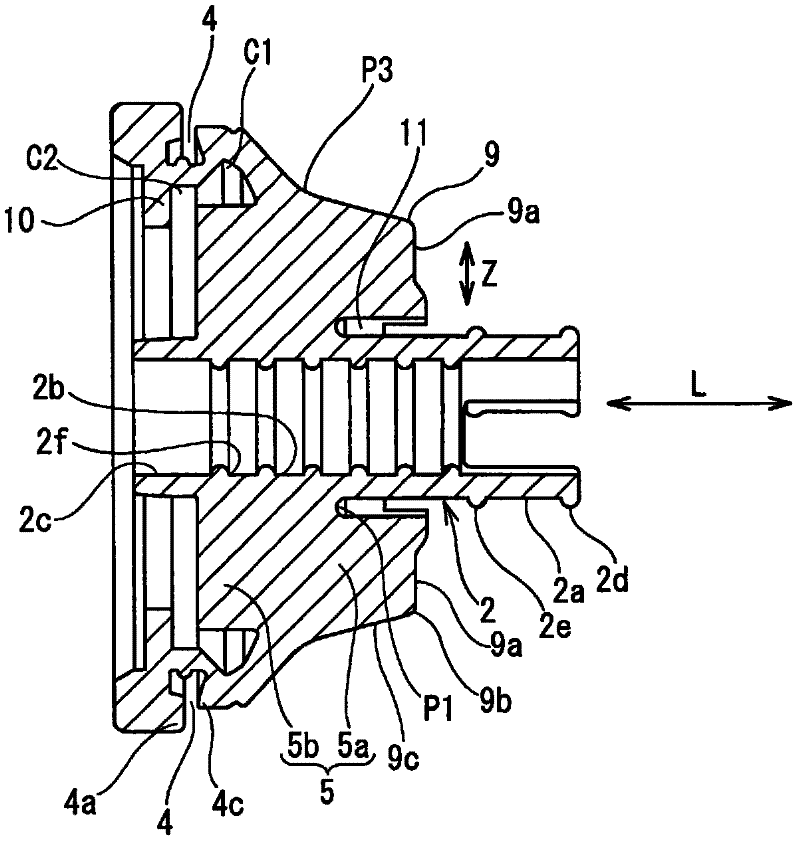

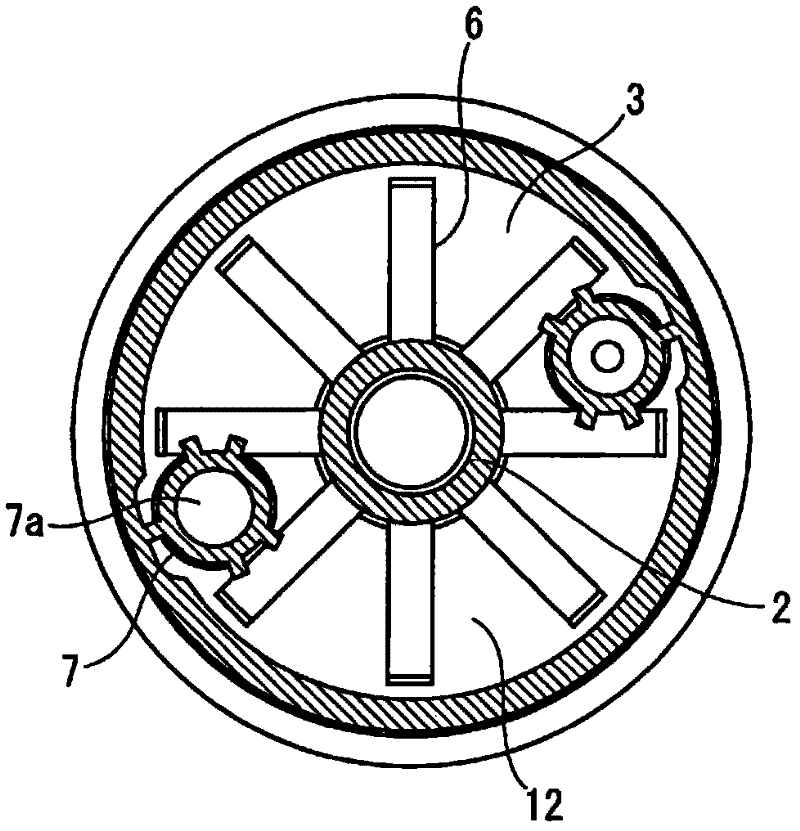

Grommet

InactiveCN102239617AReduce the number of winding operationsGood shape retentionElectric/fluid circuitInsulating bodiesEngineeringGrommet

A grommet mounted in a through-hole in a vehicle body panel and through which a wire harness is passed. Even if taping only one side, the grommet shape is retained and the grommet is prevented from deforming in the direction in which an engaging recess of the grommet separates from the peripheral edge of the through-hole. The grommet comprises: an enlarged-diameter tube which connects to the outer periphery of the longitudinal intermediate section of a small-diameter tube through which wires are tightly passed, and which is enlarged in diameter to surround the other side of the small-diameter tube; an engaging recess which is annularly formed in the outer peripheral surface of the enlarged-diameter tube on the large diameter side thereof; inner ribs provided at intervals in the circumferential direction and connecting between the inner periphery of the enlarged-diameter tube and the outer peripheral surface of the other side of the small-diameter tube; and wire insertion tubes which connect to through-holes for wires formed in the enlarged-diameter tube and which extend through the inside of the enlarged-diameter tube and project from the opening end on the large-diameter side. The inner ribs stick out with a clearance from the inner peripheral surface of the enlarged-diameter tube from the position where the enlarged-diameter tube contacts the inner peripheral surface of the through-hole of the vehicle body panel to a position facing the engaging recess.

Owner:SUMITOMO WIRING SYST LTD

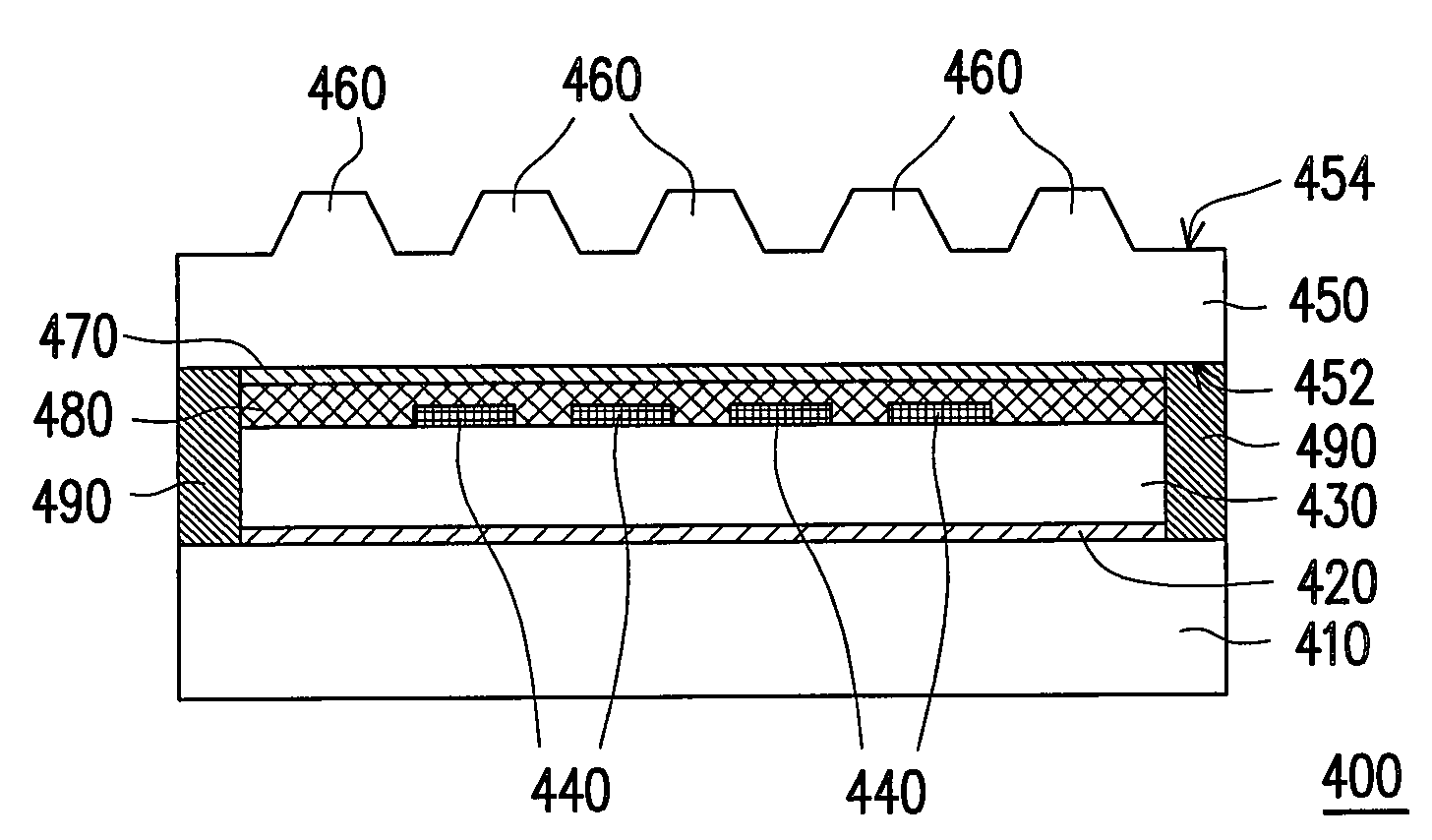

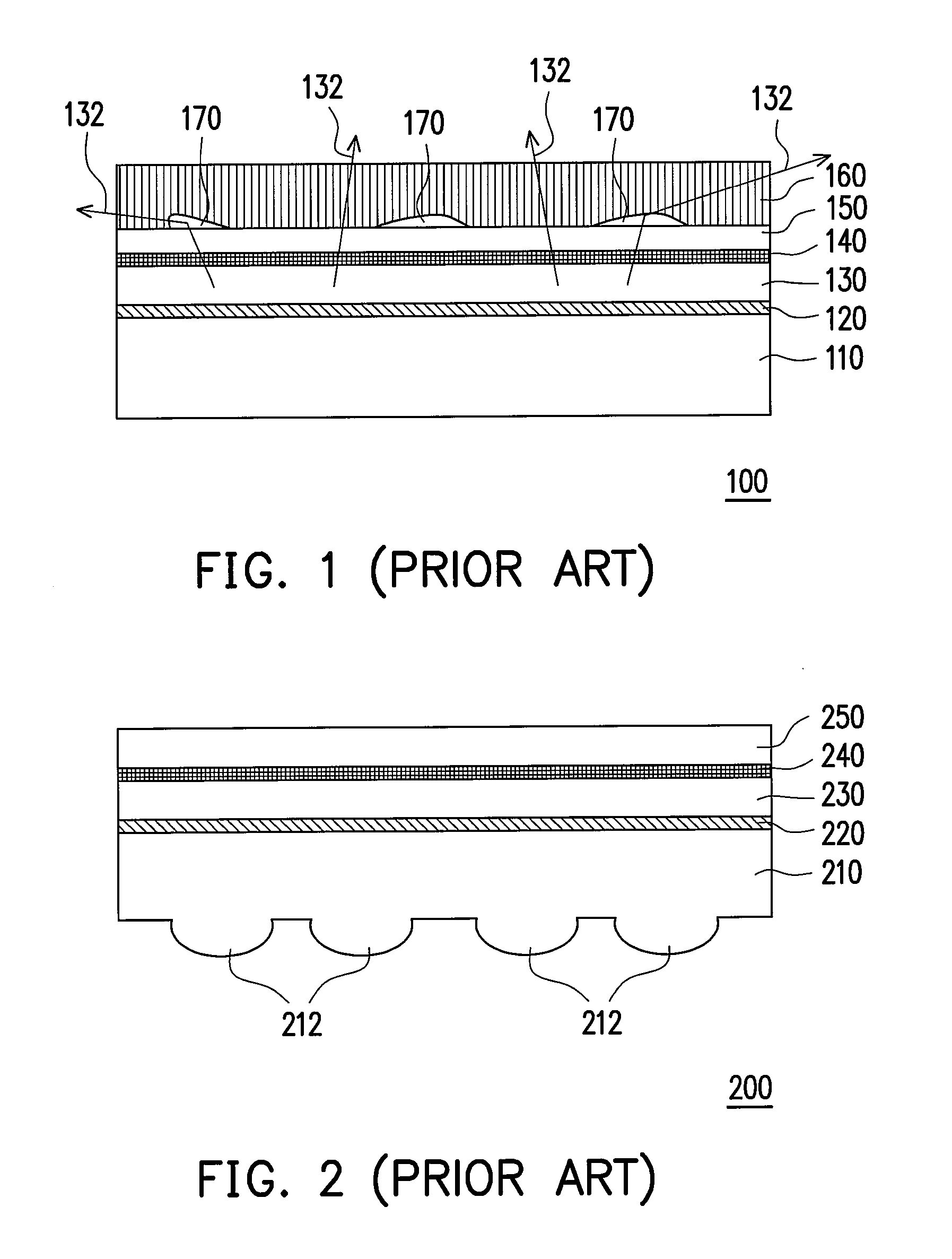

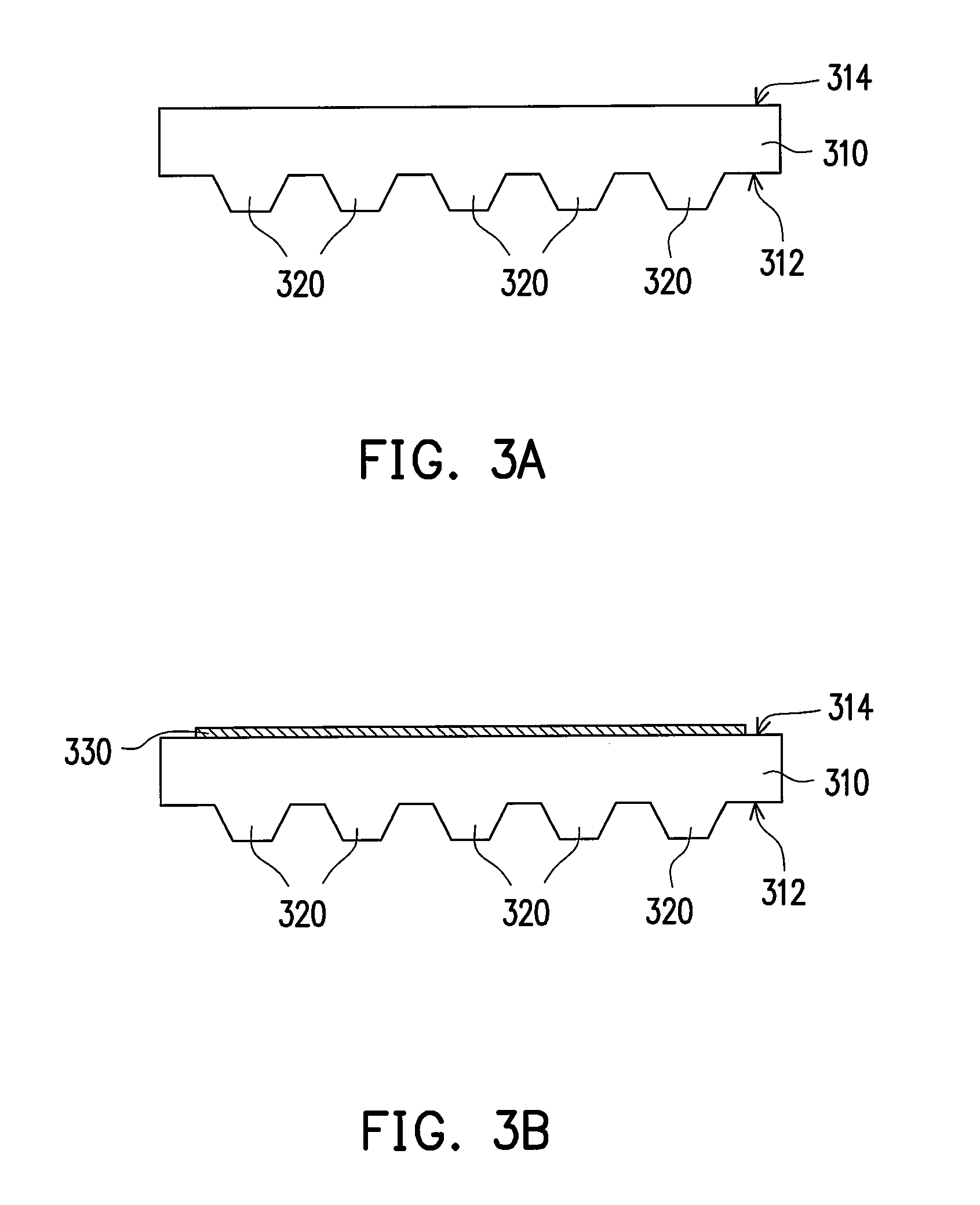

Organic electroluminescence device and fabricating method thereof

InactiveUS20080100201A1Good effectLow production costDischarge tube luminescnet screensFinal product manufacturePolymer substrateOxidation resistant

An organic electroluminescence (OEL) device, having a polymeric substrate, a plurality of light enhanced structures, an anti-oxidation layer, a first electrode, an organic light emitting layer, a second electrode and a protective layer, is provided. The polymeric substrate has a first surface and a second surface. The light enhanced structures are disposed on the first surface. The anti-oxidation layer is disposed on the second surface. The first electrode is disposed on the anti-oxidation layer. The organic light emitting layer is disposed on the first electrode. The second electrode is disposed on the organic light emitting layer. The protective layer is disposed on the second electrode. Since the OEL device has light enhanced structures, not only light efficiency can be improved but also surface scattering is reduced. Moreover, a method of fabricating an OEL device is also provided to make the OEL device in mass production for lowering the production cost.

Owner:CHUNGHWA PICTURE TUBES LTD

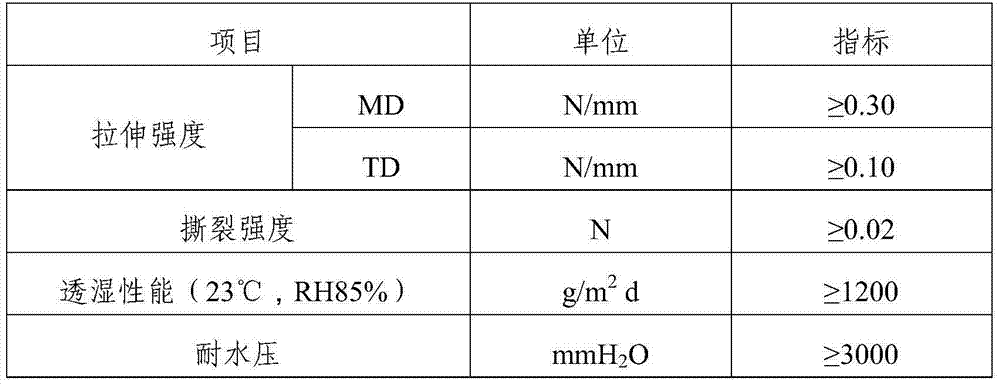

Waterproof air-permeable plastic film, and preparation method and application thereof

ActiveCN103571012AImprove waterproof functionDoes not affect breathabilitySynthetic resin layered productsWaxPolypropylene

The invention provides a novel waterproof air-permeable plastic film which is prepared from the following raw materials in parts by weight: 40-80 parts of high-polymer plastic, 20-60 parts of filler and 1-5 parts of auxiliary material. The high-polymer plastic is selected from at least one of polyethylene, polypropylene, thermoplastic elastomer and the like; the filler is selected from at least one of smectite, bentonite and titanium white; and the auxiliary material is selected from at least one of high-polymer wax, modified poly-terephthaloyl p-phenylenediamine, calcium stearate and the like. Due to the adoption of the plastic film (biaxial or uniaxial) stretching technique, the natural mineral filler with special functions is added to the raw material formula of the waterproof air-permeable plastic film, so that the waterproof function of the air-permeable plastic film is greatly enhanced on the premise of not influencing the air permeability of the material.

Owner:昆山威胜干燥剂研发中心有限公司

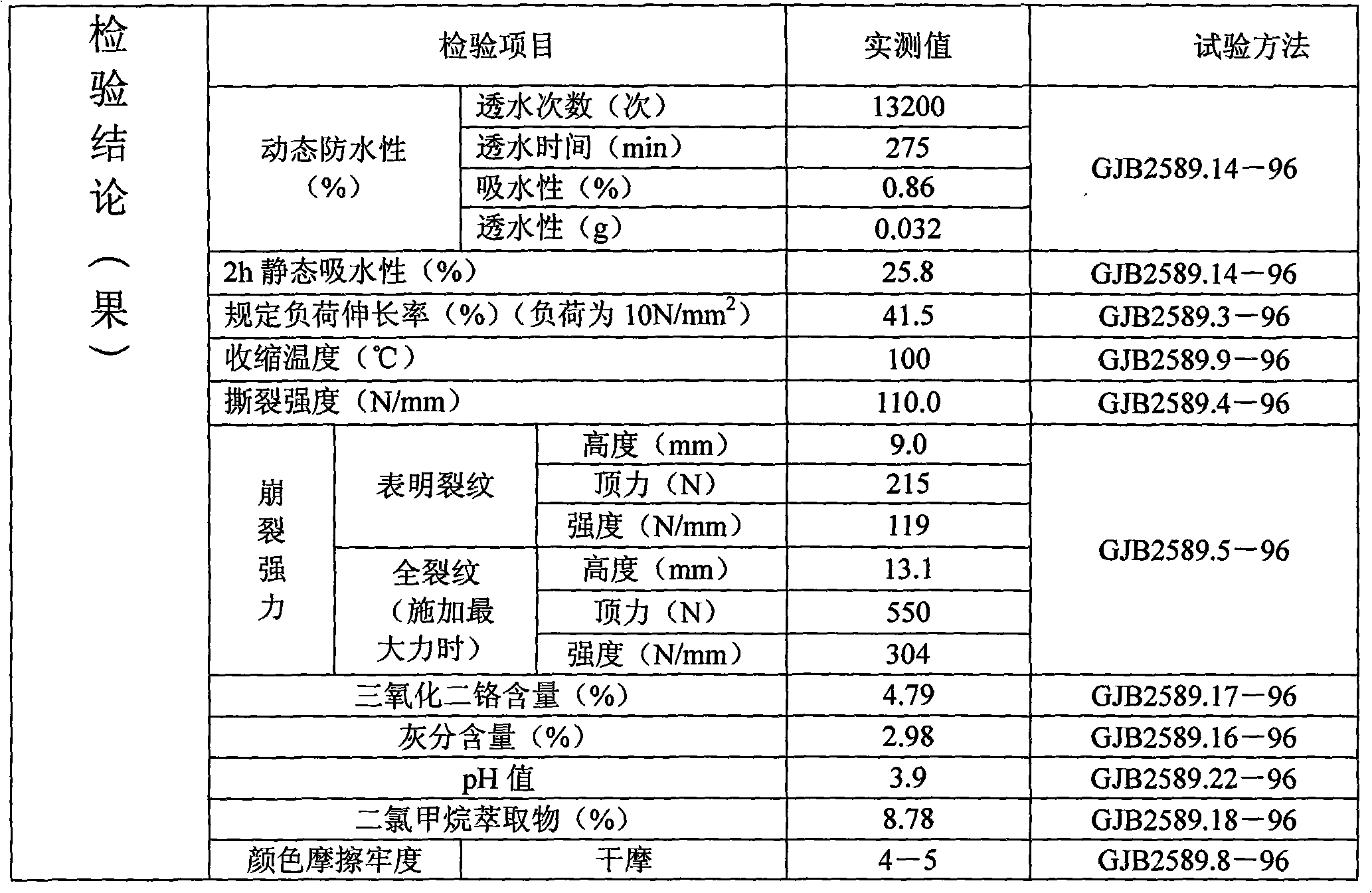

Method for manufacturing waterproof soft-surface leather

InactiveCN101993962AReduce the impactImprove waterproof functionLeather surface finishingLeather impregnationFormic acidMaterials science

The invention relates to a method for manufacturing waterproof soft-surface leather. The method comprises the steps of waterproofing treatment and finishing treatment, wherein the waterproofing treatment is as follows: adding a waterproof material (accounting for 0.1-0.3wt% of leather) and polyacrylic acid derivatives (accounting for 1-2wt% of the leather) into a big drum to regulate the pH value to 4-6, adding waterproof fat liquor (accounting for 8-12wt% of the leather), rotating for 50-90 minutes, adding fluorine waterproofing agent (accounting for 3-4wt% of the leather), adding 1.2-1.5% formic acid to regulate the pH value to 2.5-4.5, washing with water, changing bath, regulating the pH value to 2.5-4.5 by using formic acid, adding trivalent metal salt (accounting for 3wt% of the leather), rotating for 60-90 minutes, washing with water, discharging, squeezing to remove water, spreading, carrying out vacuum-drying, remoistening, and vibrating to soften the leather, thereby obtaining the waterproof leather. The leather manufactured by the method of the invention has the advantages of excellent dynamic waterproofing property, high-temperature yellowing resistance and light resistance, has physical and chemical indices and appearance properties of common vamp leather. The leather is the main material for shoemaking enterprises, especially for novel battle boots for People's Liberation Army and People's Armed Police.

Owner:JIHUA 3515 LEATHER & SHOES

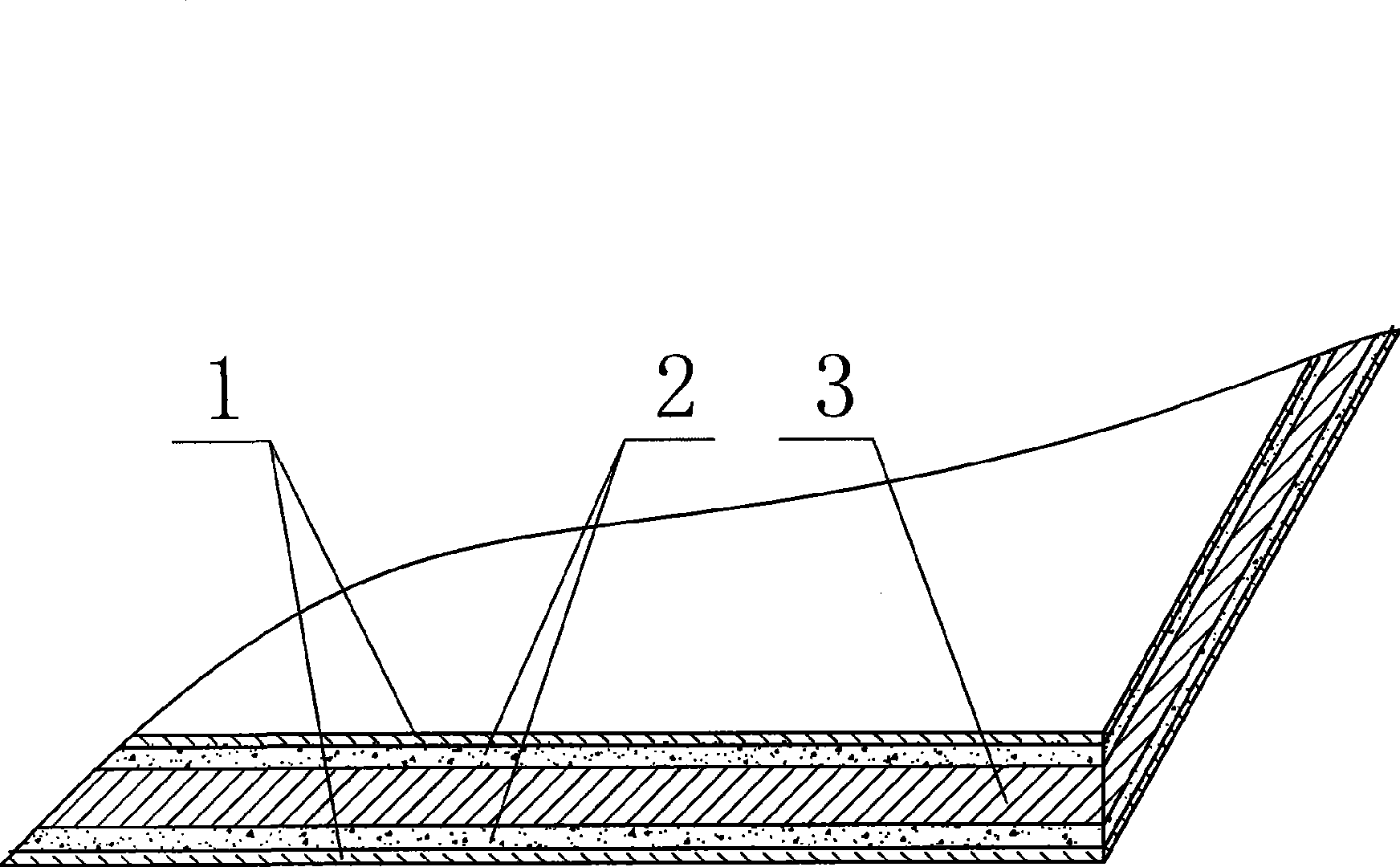

Production method for multifunctional rigid foam polyurethane composite board

InactiveCN101487296AImprove waterproof functionHigh strengthWallsHeat proofingPolymer scienceAdhesive

The invention discloses a preparation method used for preparing a multifunctional polyurethane hard foam composite board. The method comprises the following steps: a polymer cement sheet is prefabricated; a polyurethane foaming machine manufacturing line is adopted to froth the PAPI and conjugate polyether into the polyurethane board and the cement sheet is simultaneously compounded on two surfaces of the polyurethane board to prepare the polyurethane insulation composite board. The preparation method of the polymer cement sheet comprises the following steps: after an adhesive and an inorganic powder are mixed according to the proportion of 1:1.5 to 2, the mixture is pressed with a non-woven cloth by the manufacturing line; the adhesive is prepared by the following materials according to the weight portions: 75 to 85 percent of polymer emulsion, 5 to 10 percent of flame retardant, 1 to 6 percent of film-forming additives, 5 to 10 percent of deionized water and 0 to 1.5 percent of thickener; the inorganic powder is prepared by the following materials according to the weight portions: 40 to 60 percent of stuffing, 10 to 25 percent of solid flame retardant and 25 to 40 percent of cement. The composite board prepared by the method integrates the fireproof, waterproof, high-intensity and insulation functions into a whole and can be used for the outer-wall waterproof, fireproof and insulation engineering of buildings.

Owner:夏良强

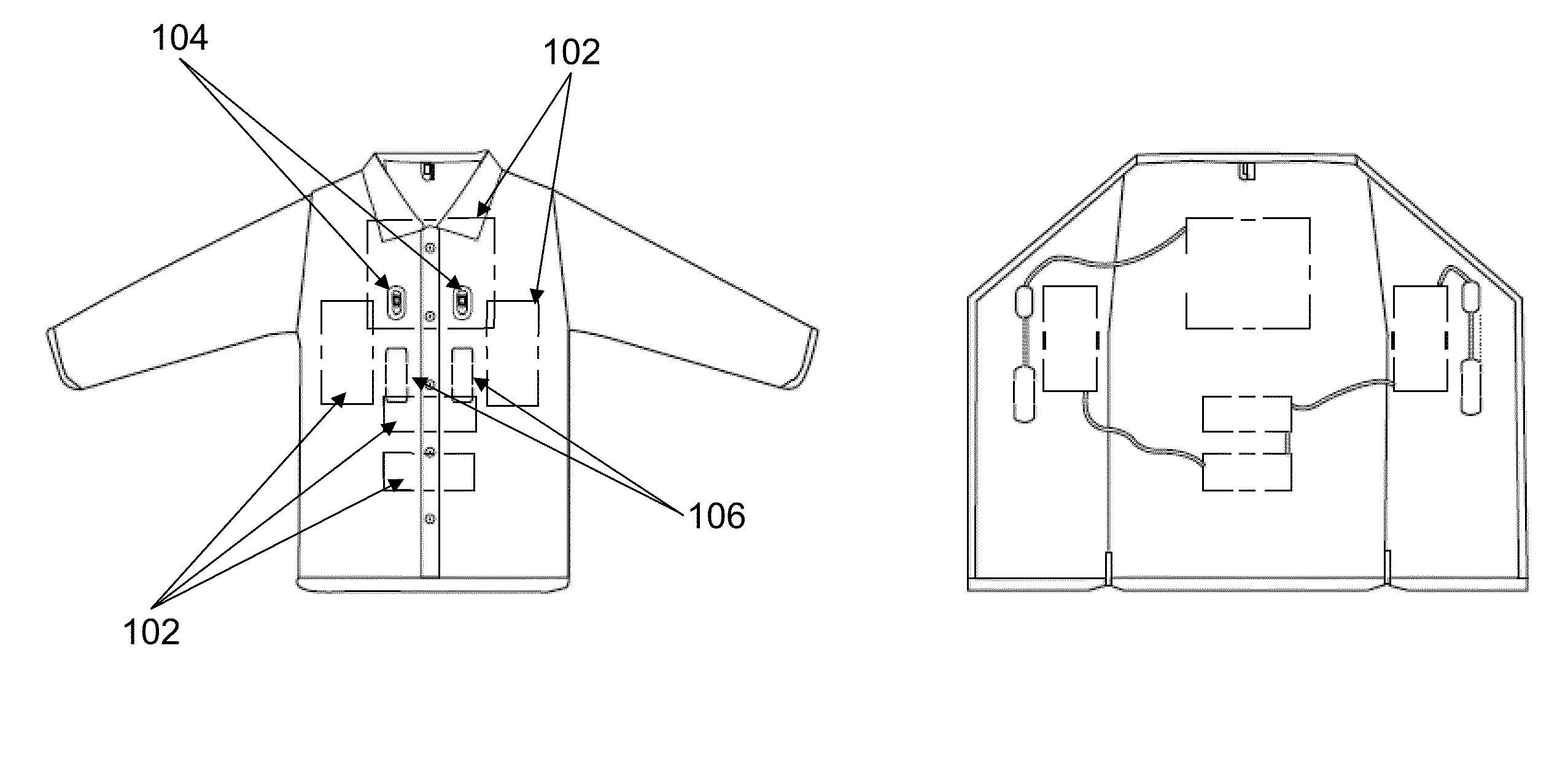

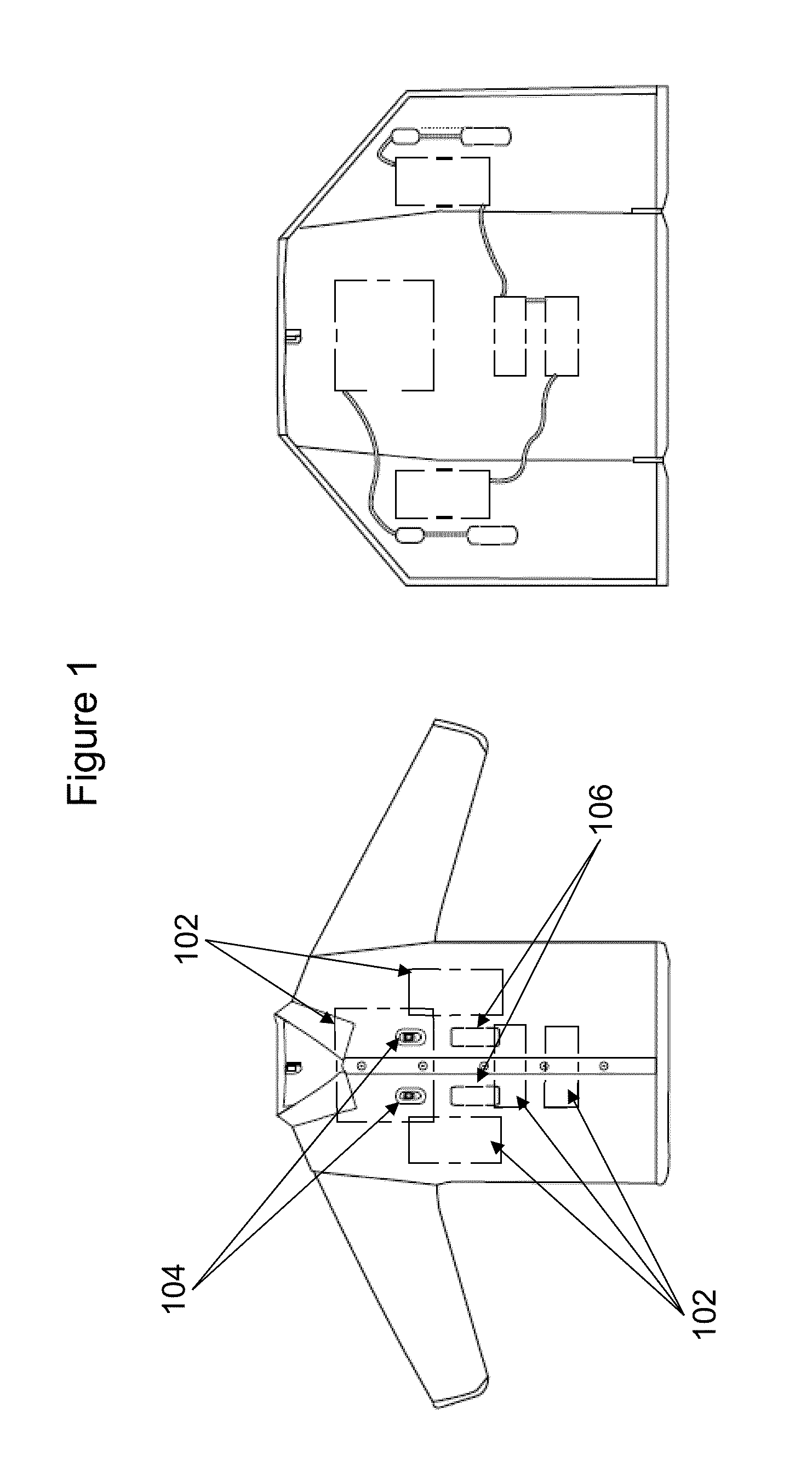

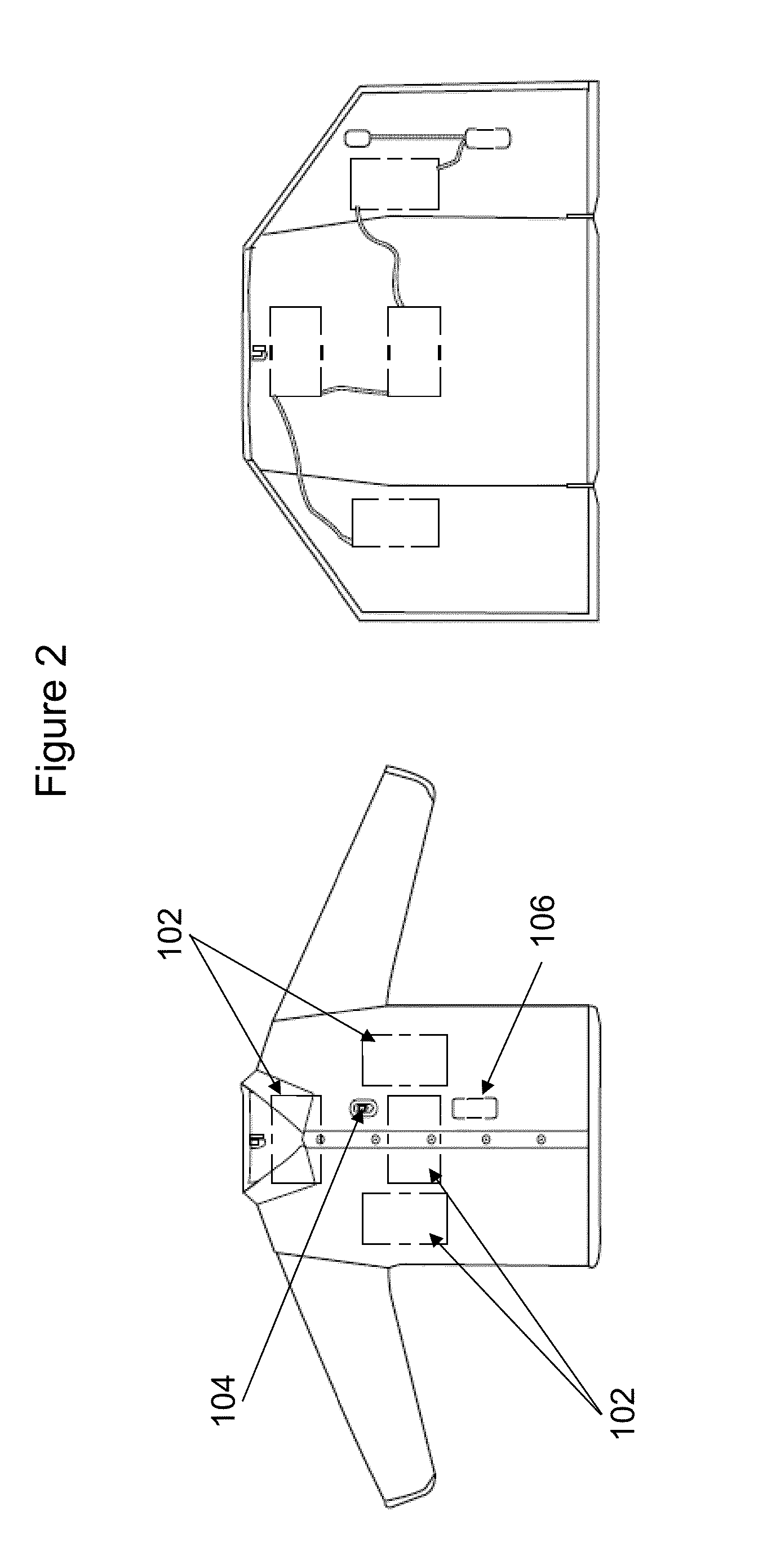

Electrically-Heated Clothing/Pants and Its Accessories

InactiveUS20150272236A1Improve isolationImprove waterproof functionHeating element shapesProtective garmentEngineeringElectric heating

Owner:PHIHONG TECH CO LTD

Mobile terminal and side key structure thereof

InactiveCN103280357ALow costImprove waterproof functionElectric switchesForeign matterComputer terminal

The invention provides a mobile terminal and a side key structure thereof. The side key structure of the mobile terminal comprises a shell, a side key and side key silica gel, wherein the shell is provided with a side key hole; the side key comprises a pressing part and a skirt part arranged at the edge of the pressing part; the pressing part is inserted into the side key hole and is limited through the skirt part; and the side key silica gel is arranged in the shell and is used for isolating the shell into an inner region and a side key acting region, so as to prevent foreign matters from entering the inner region from a gap between the side key and the side key hole when the side key is pressed down. Through the manner, the inner region of the shell can be completely isolated from the outer space; the mobile terminal and the side key structure thereof have good waterproof and dustproof functions; and the side key and the side key silica gel are separately and fixedly arranged, so that the cost of a double-colored injection mould in the prior art is saved and the production cost is reduced.

Owner:盐城市亢声机械有限公司

Water-proof air-permeable polyurethane synthetic leather and preparation method thereof

InactiveCN101982604ABreathableGuarantee throughSynthetic resin layered productsTextiles and paperFoaming agentPolyresin

The invention belongs to water-proof air-permeable polyurethane synthetic leather in the technical field of synthetic leather, comprising the following components by weight percent: 60-70% of polyurethane particles, 3-7% of lubricant, 1-3% of foaming agent, 4-8% of reconcile resin, 10-15% of calcium carbonate, 10-15% of sodium chloride the grain diameter of which is 100-200 meshes, and 1-3% of pigment. The preparation method of the invention comprises the following steps: feeding the materials into a blender, and evenly mixing the raw materials; placing into a banbury mixer, heating, plastifying; placing into a two-roller machine, gelling, homogenizing, filtering by a filter and extruding; placing into a calender, and pulling out into rubber fabric; placing into a laminator, and fitting with base fabric and shell fabric at the condition of heating and pressurizing; and placing into a foaming machine, decomposing and foaming at the high temperature, cooking in water for 10-24 hours at the temperature of 50-60 DEG C, changing water for 2-5 times, knurling and postprocessing. The beneficial effects of the invention are as follows: sodium chloride is added and then removed in preparation process, more extremely fine holes are generated, and the air permeability of the synthetic leather of the invention is enhanced.

Owner:张瑜

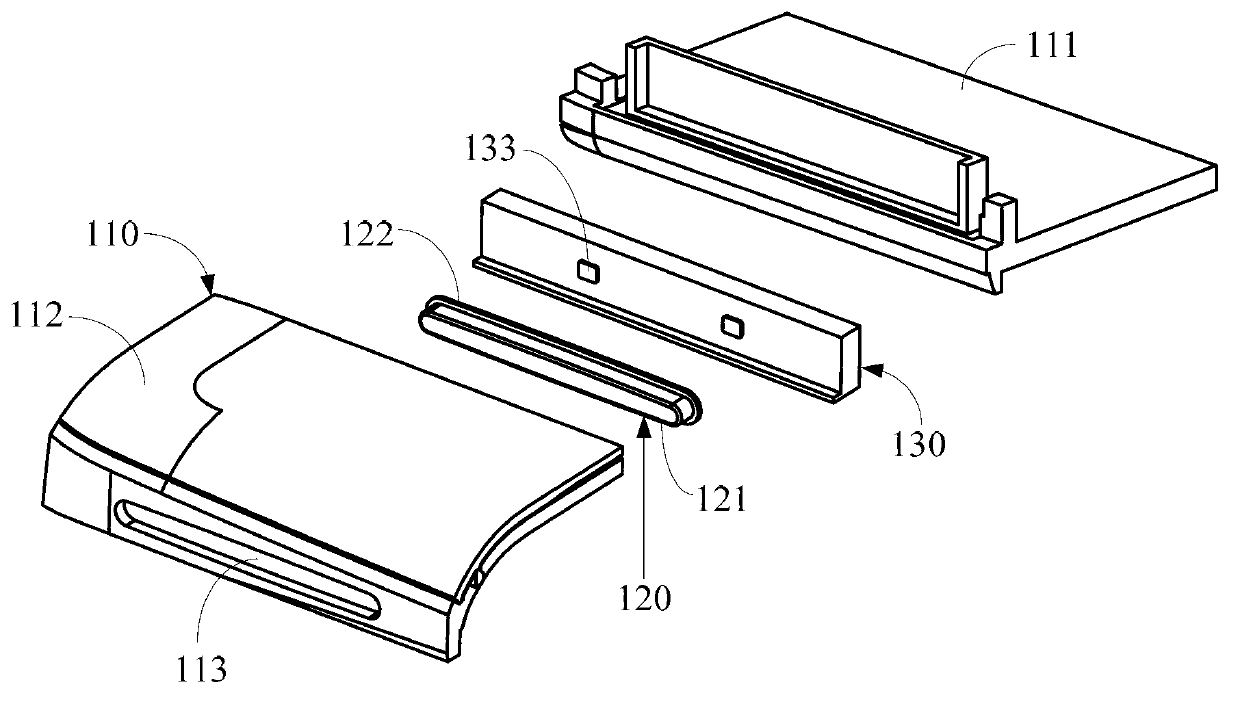

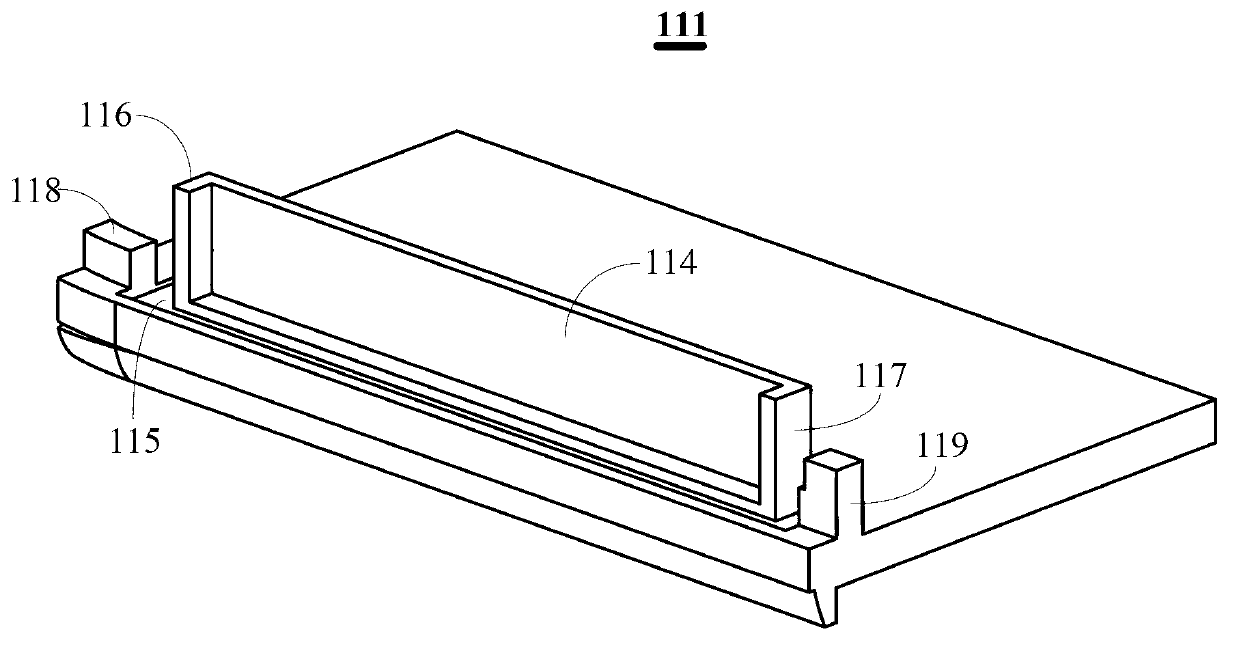

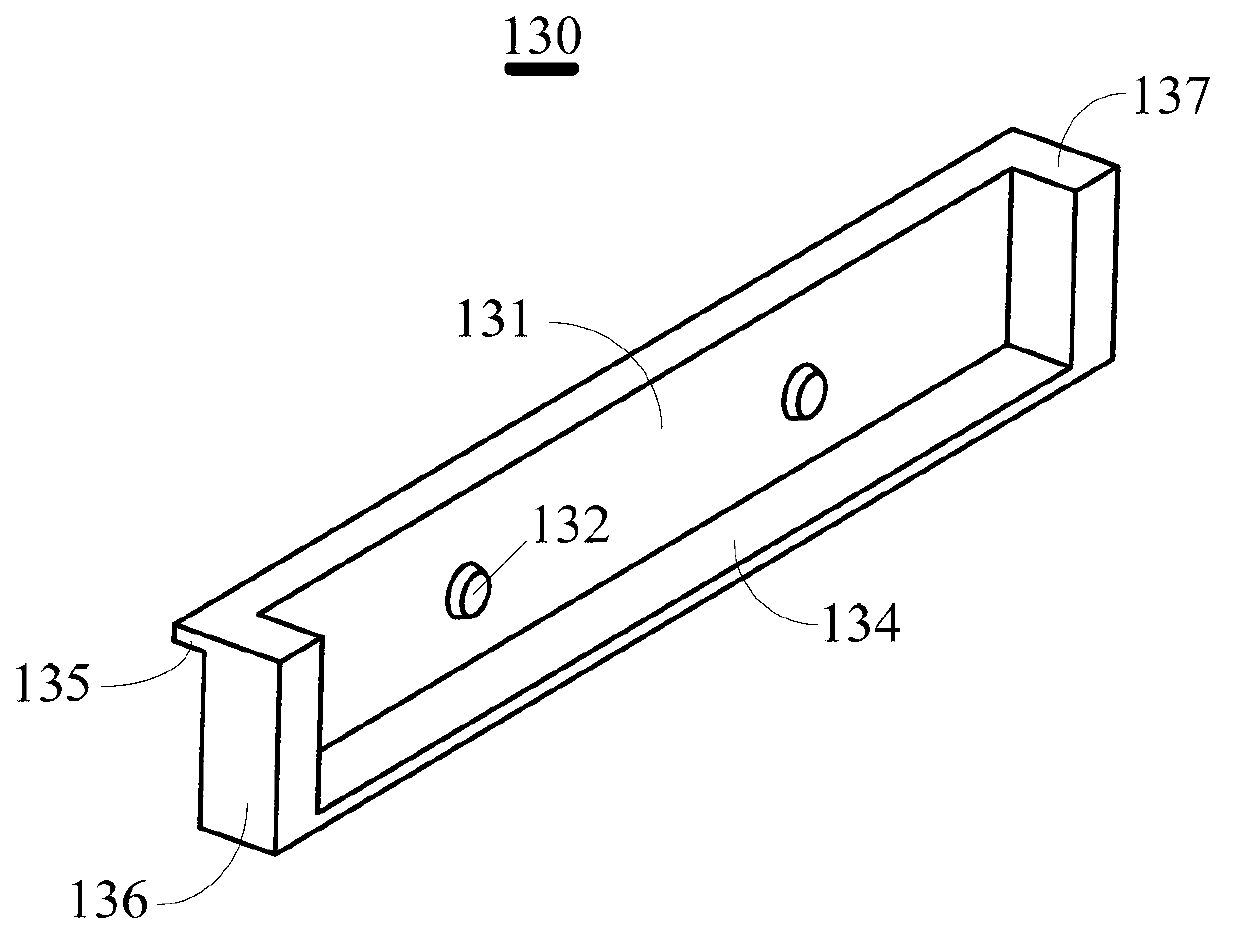

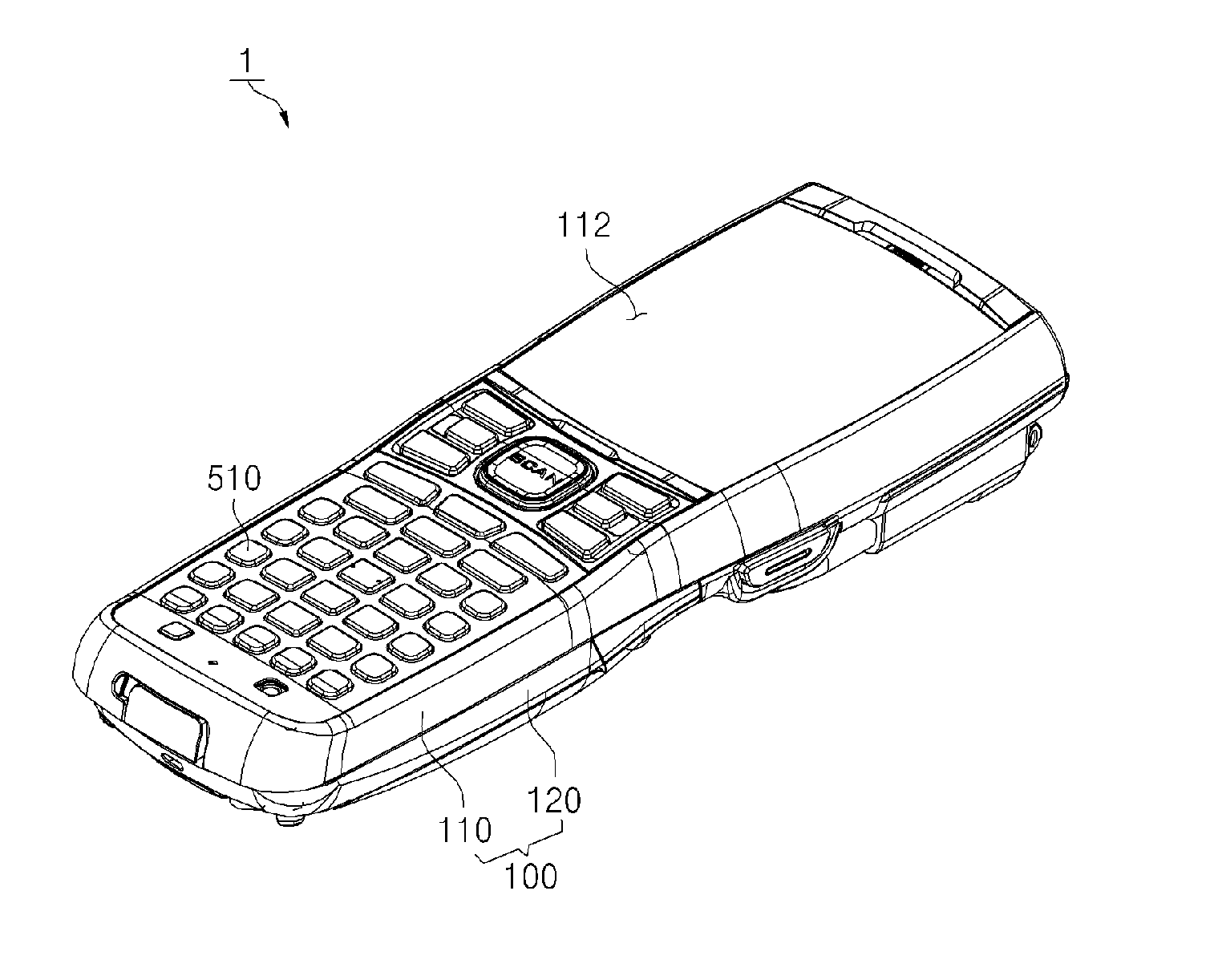

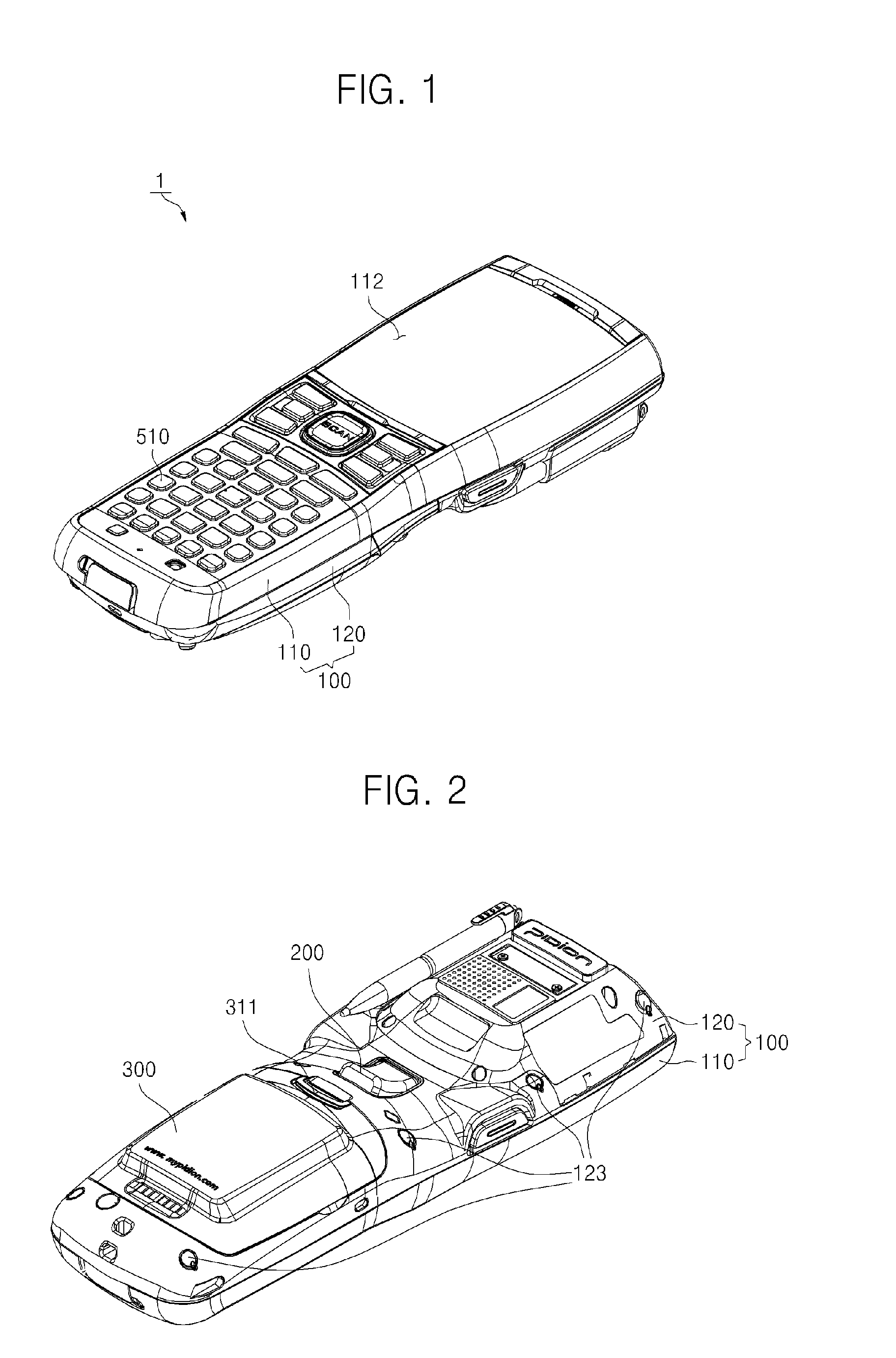

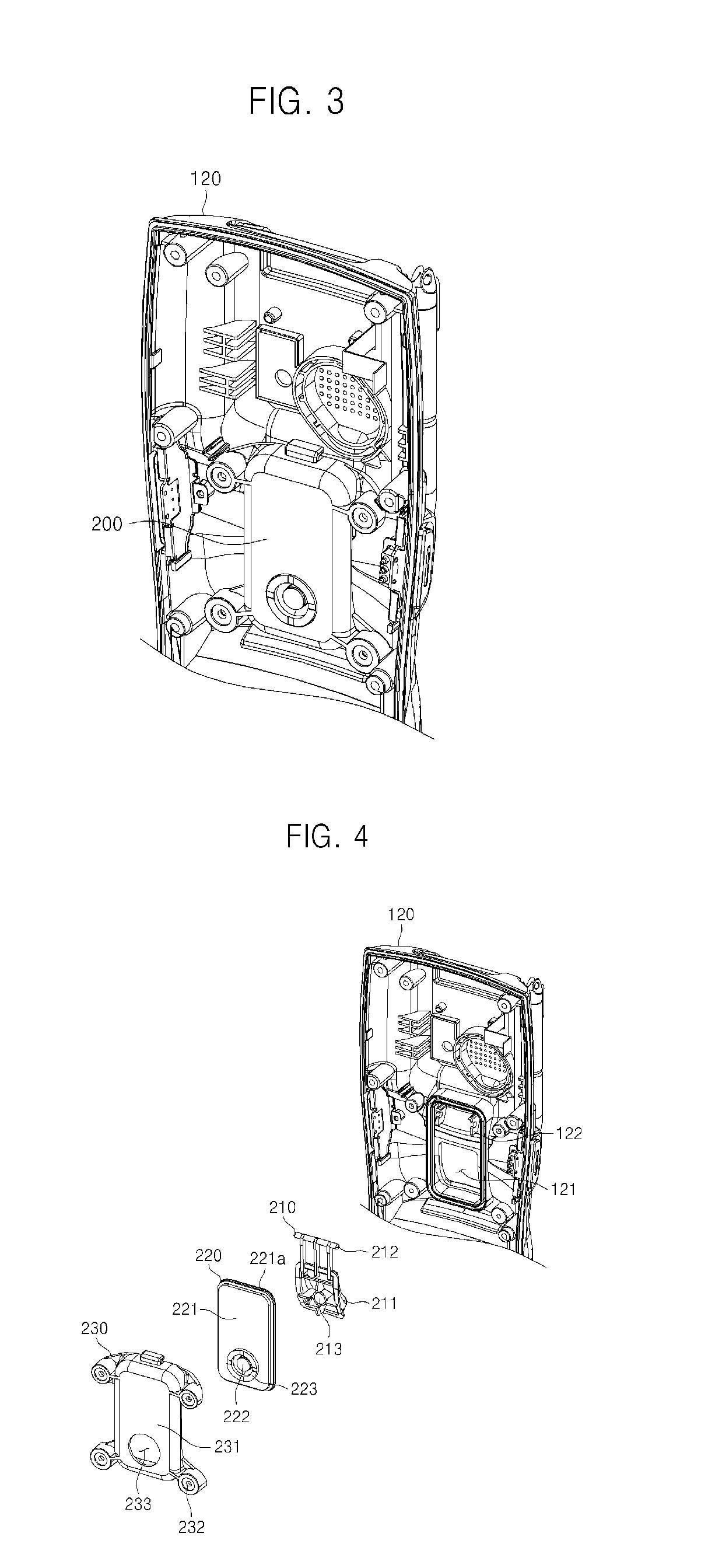

Mobile terminal

ActiveUS20140185234A1Easy to manufactureEasy to assembleDigital data processing detailsElectrical apparatus contructional detailsUser inputEngineering

Disclosed is a mobile terminal. The mobile terminal of the present invention comprises: a terminal case including a front surface case and a rear surface case which are coupled together; and a trigger unit, which is provided so as to be exposed to the exterior of the terminal case for performing user input by means of a pulling movement, wherein the trigger unit further includes a trigger switch which is exposed to the exterior of the terminal case, a trigger rubber which comes into close contact with the inside of the terminal case so as to cover the trigger switch, and a trigger bracket which supports the trigger rubber by means of pressure and which is coupled to the inside of the terminal case. According to the present to invention, provided are the mobile terminal and the method for manufacturing same, the mobile terminal having a superior waterproof function and which is easy to produce and assemble.

Owner:BLUEBIRD

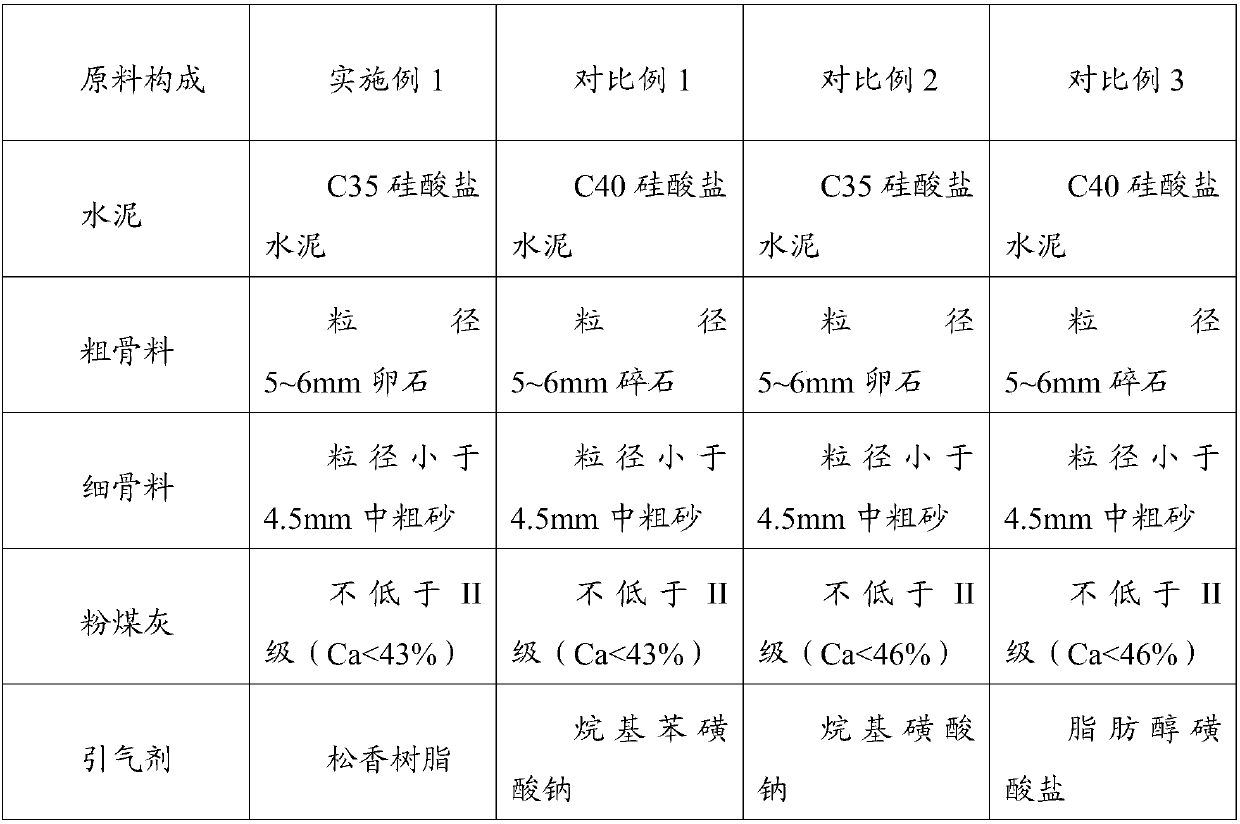

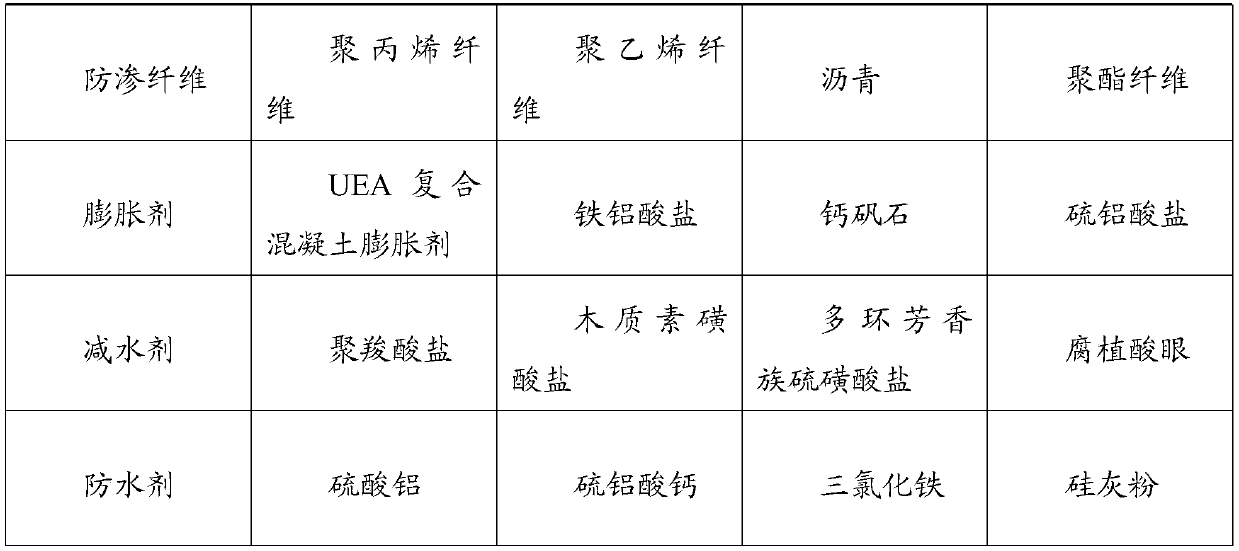

Leaking-resistant concrete and construction method thereof

InactiveCN109574585AImprove waterproof functionImprove structural performanceRoof toolsFiberWater leakage

The invention provides leaking-resistant concrete. A construction raw material of the leaking-resistant concrete comprises, by weight, 90-110 parts of cement, 300-360 parts of coarse aggregates, 230-270 parts of fine aggregates, 50-80 parts of fly ash, 20-40 parts of additives and 50-60 parts of water. The additives comprise air entraining agents, leaking-resistant fibers, expanding agents, waterreducing agents and waterproof agents. The total alkali content of the leaking-resistant concrete is smaller than 2.25kg / m<3>, the raw material is simple, and the concrete is convenient to construct.Inner gap structures of the concrete are changed by the air entraining agents, a capillary channel is cut off, the leaking-resistant fibers have crack-resistant effects on gaps, and the brittleness ofthe concrete is reduced. The leaking-resistant concrete is used for construction of a roof structure, the leaking-resistant strength of the leaking-resistant concrete is far higher than that of common concrete after the leaking-resistant concrete is stirred, poured, vibrated and maintained, water seepage and water leakage of the leaking-resistant concrete are omitted through 14-day testing, and the leaking-resistant concrete is higher in weather resistance and cannot easily crack.

Owner:JILIN PROVINCE JIANYUAN DESIGN GRP

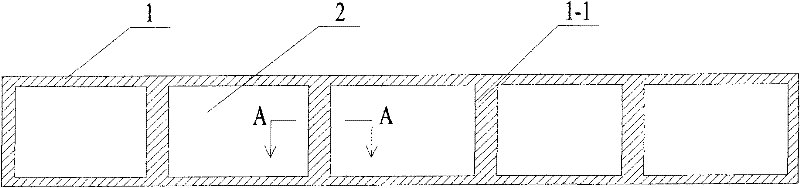

Self-adhering polymer modification bitumen composite anti-root water-proof coiled material and preparing method thereof

ActiveCN101413325AImprove waterproof performanceSo as not to damageRoof covering using flexible materialsSynthetic resin layered productsPolymer modifiedMaterials science

The invention relates to a novel building waterproof material in a building roof engineering technology and a planting roof engineering technology and a preparation method, in particular to a self adhesive polymer and modified bitumen composite root resistance waterproof membrane and a preparation method thereof, wherein the membrane uses a self-adhibiting method for cold construction and has chemical root resistance and physical root resistance and two waterproof barriers. The membrane has a multi-layer laminar structure formed by a covering, a self-adhesive chemical root resistance waterproof layer, and a physical root resistance waterproof layer which are orderly combined; and the method for preparing the membrane comprises the following steps: firstly, a polymer and modified bitumen root resistance composite material of the self-adhesive chemical root resistance waterproof layer is produced, then heavy calcium carbonate powder is added, and finally a chemical root inhibitor is added to produce the polymer and modified bitumen root resistance composite material; then the polymer and modified bitumen root resistance composite material is coated on a polyethylene root penetration resistant waterproof material with thickness control, and is subjected surface coating, cooling, and winding packaging, and thus a finished product of the membrane is obtained. The popularization and application of the membrane on roof gardens play an active role in facilitating the improvement on the dwelling environment of people.

Owner:TANGSHAN DESHENG WATERPROOF

Insulation system with polycrystalline anti-cracking and waterproofing mortar

InactiveCN101851960AImprove the defect of insufficient penetration gripImprove adhesionHeat proofingInsulation systemReducing agent

The invention discloses an insulation system with polycrystalline anti-cracking and waterproofing mortar, which belongs to the technical field of the building material. The insulation system comprises interface mortar, insulation mortar and waterproofing mortar, wherein the waterproofing mortar comprises the following components: cement, sand, redispersable latex powder, hydroxypropyl-methyl cellulose ether, inorganic water reducing agent, organosilicon waterproofing agent, sodium silicate and inorganic retarder. Compared with the prior art, the invention has the following advantages of: 1, solving the problem that the bonding strength of the inorganic cementitious material for penetration is not sufficient, and significantly improving the bonding strength and the compressive strength of the whole insulation system; 2, improving the construction property of the material and the insulation effect of the system; 3, improving the construction property and enhancing the long-term strength of the product; 4, improving the waterproofing function of the system, and changing the rigidity of various kinds of polycrystalline mortar into softness, thereby improving the impact resistance, bending resistance, tensile strength, shrinkage resistance and other strain capacities of the insulation system; and 5. improving the bending resistance and the tensile strength of the material and the physical anti-cracking performance of the system.

Owner:HAIDA CONSTR GRP

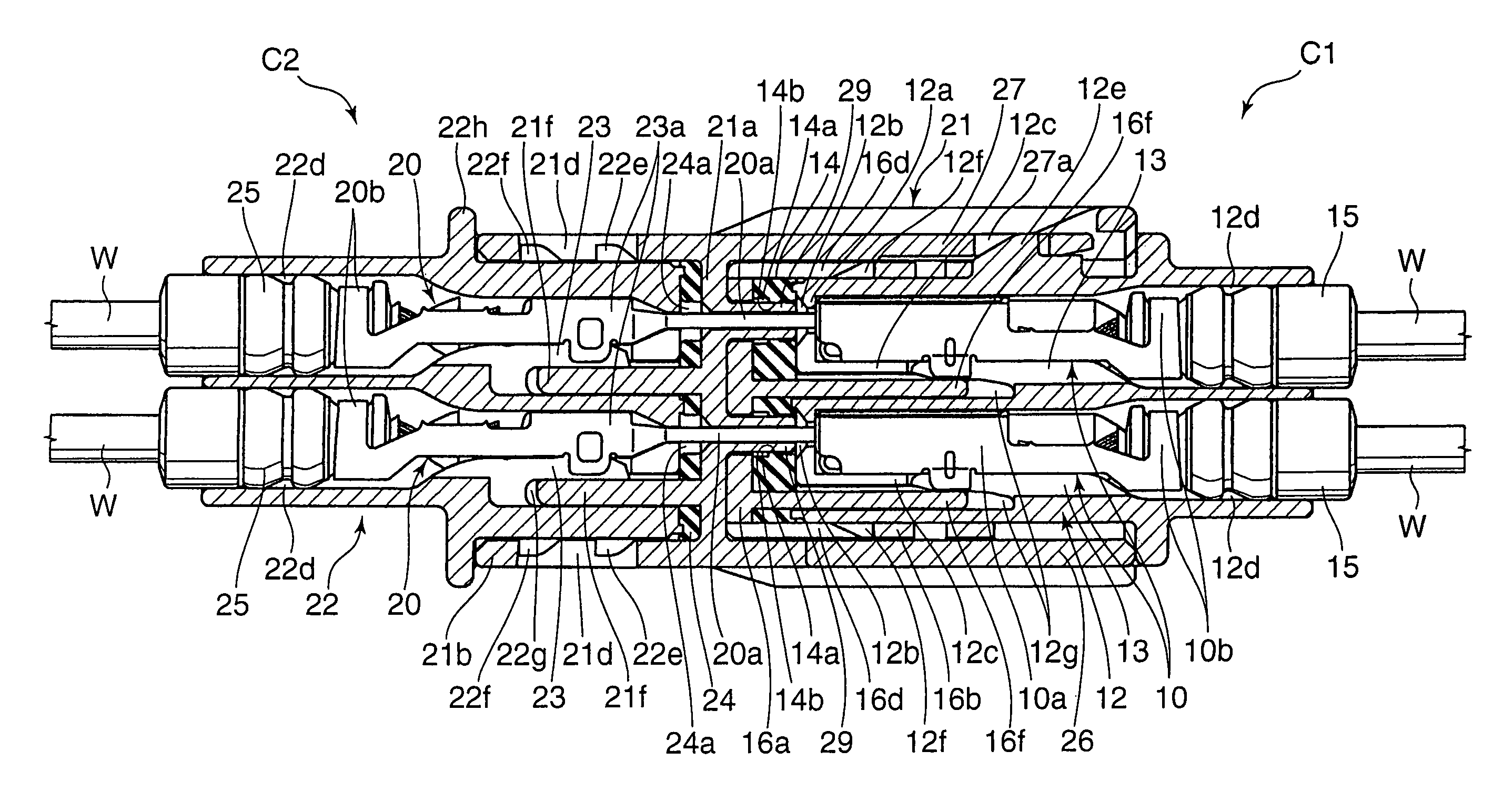

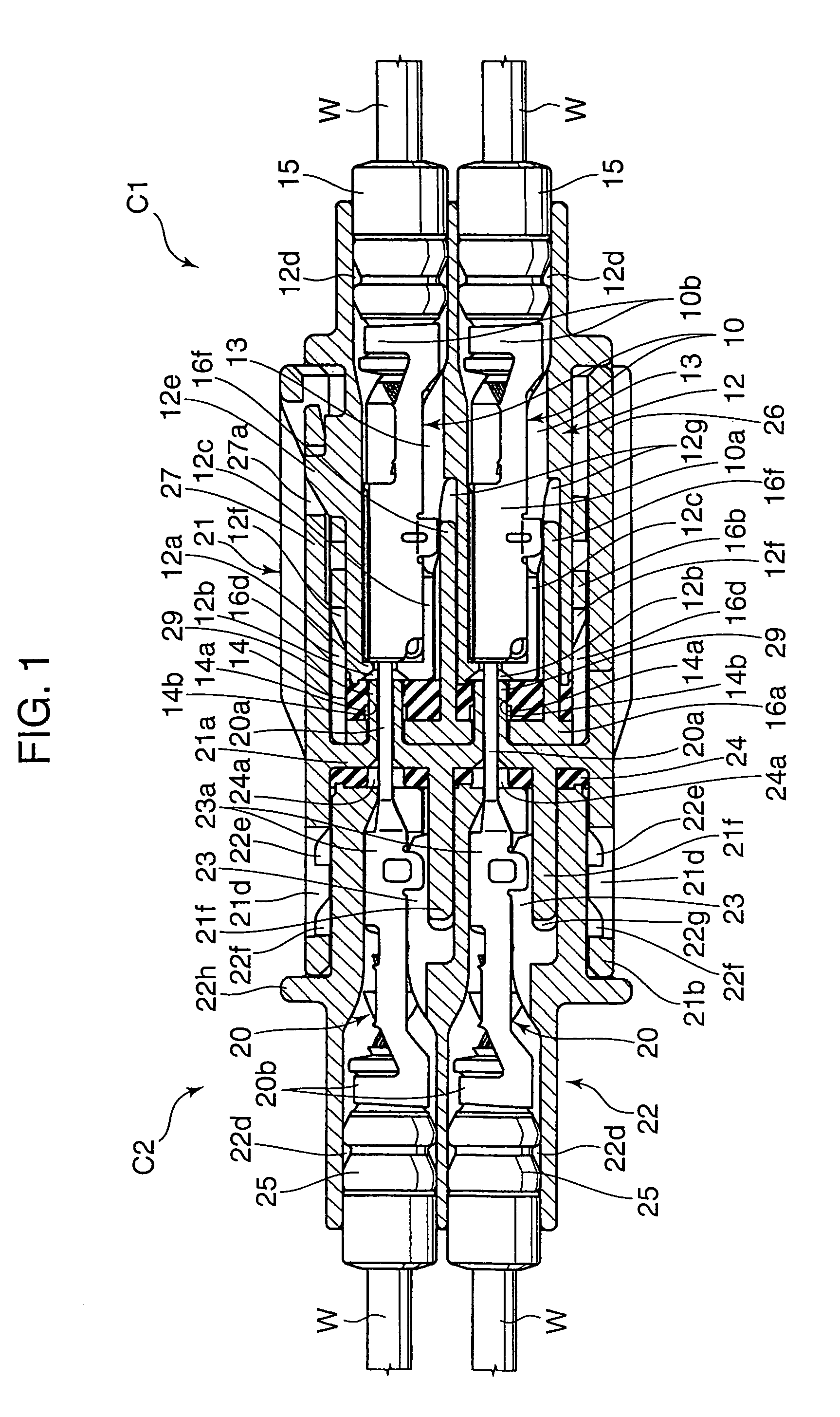

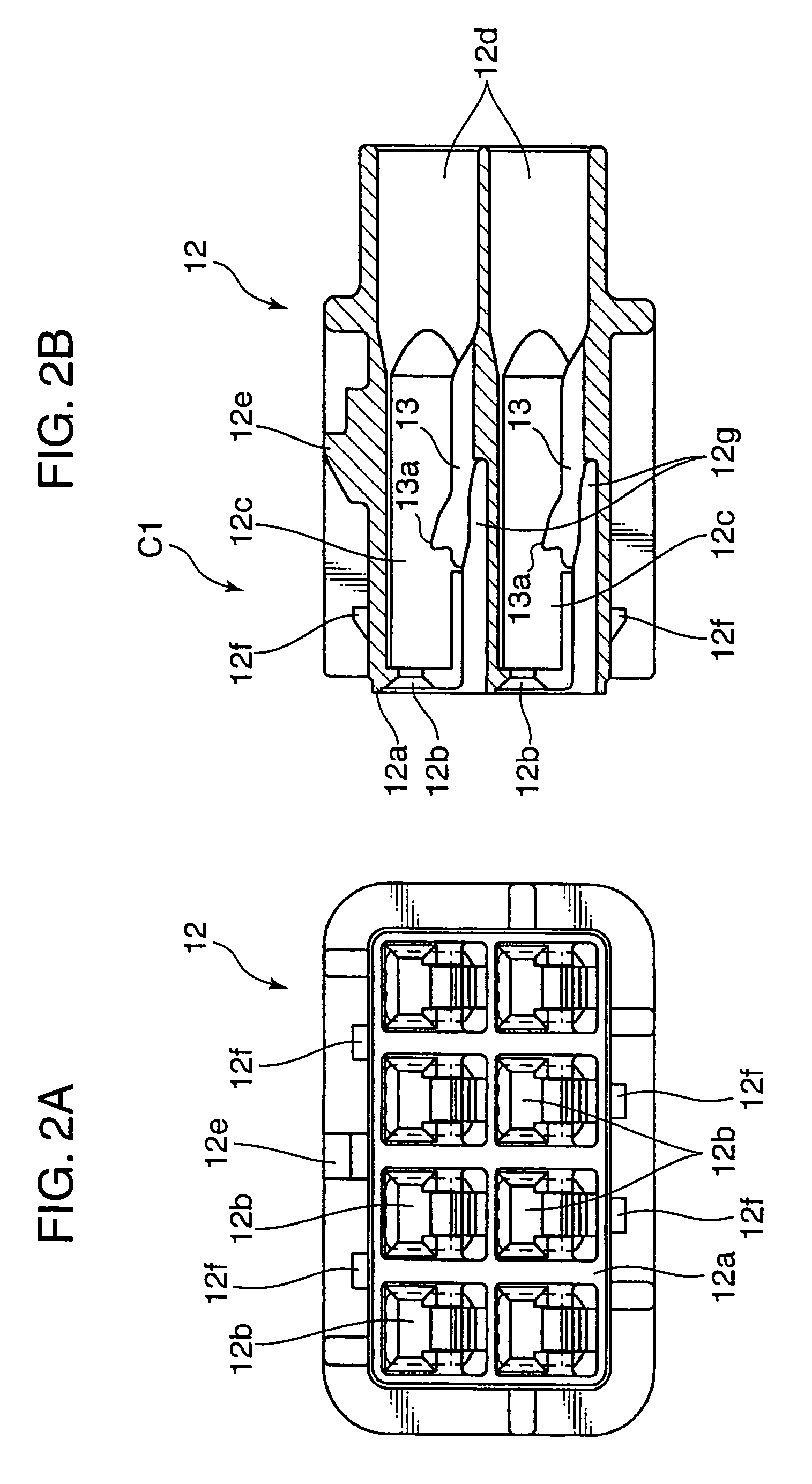

Small double-locking waterproof connector

InactiveUS7419395B2Enlarges and complicates structureImprove waterproof functionSecuring/insulating coupling contact membersCouplings bases/casesEngineeringMechanical engineering

A object of the present invention is to enable a double-locking of female terminals without making a whole connector larger in size or complicating a structure thereof while maintaining fine waterproof function. A female connector includes a female housing for retaining a female terminal and a seal member holder. The seal member holder retains a seal member having through holes. When the seal member holder is completely attached to the female housing, the seal member comes in close contact with a front surface of the female housing. In this state, a male terminal of a male connector fits into the female terminal so that a projecting portion of the female connector comes in close contact with an inner surface of the through hole to make terminals waterproof individually. Further, the seal member holder is provided with a double-locking piece in, which pursues the double locking of the female terminal in the female housing at the time of the complete attachment.

Owner:AUTONETWORKS TECH LTD +2

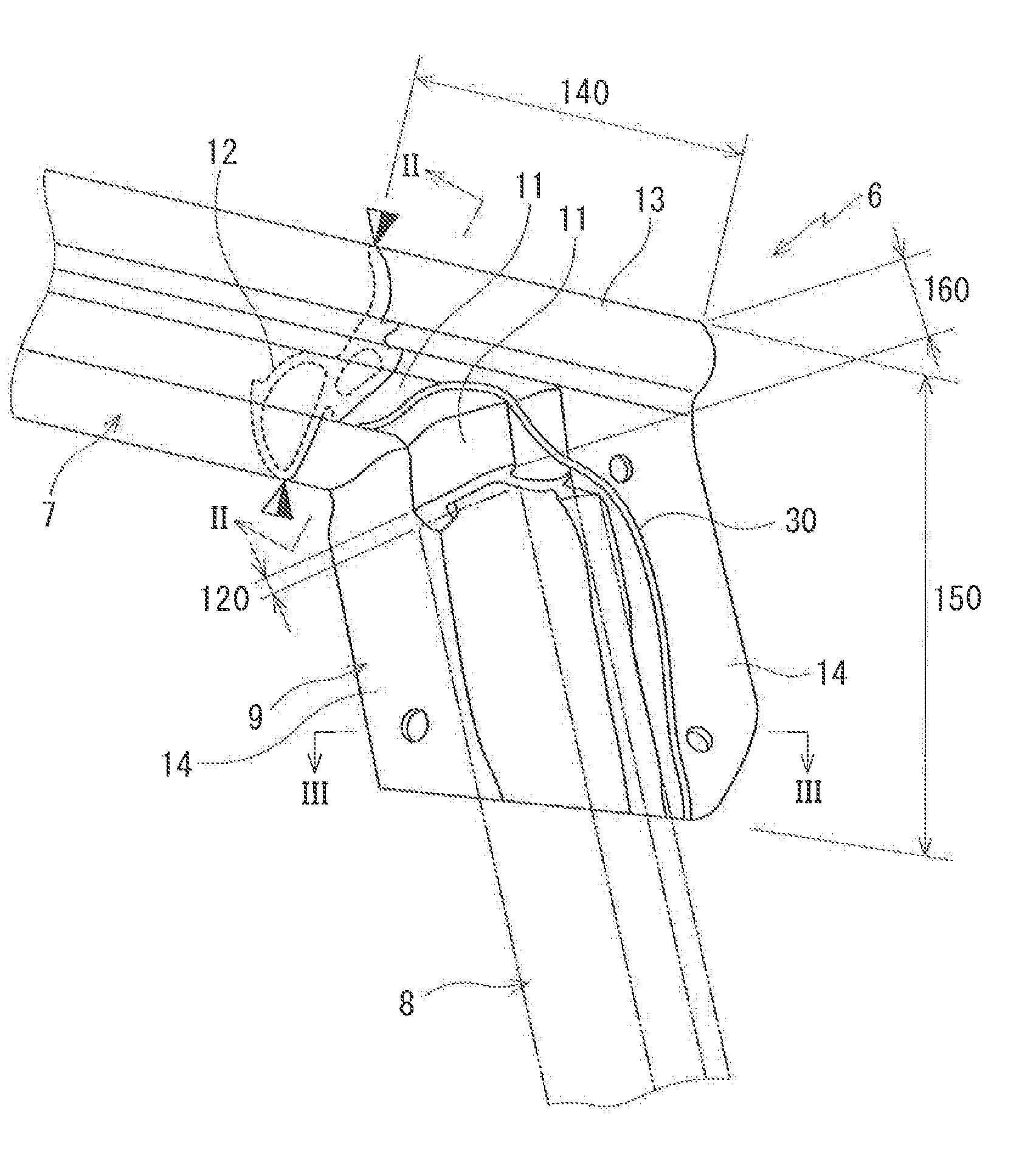

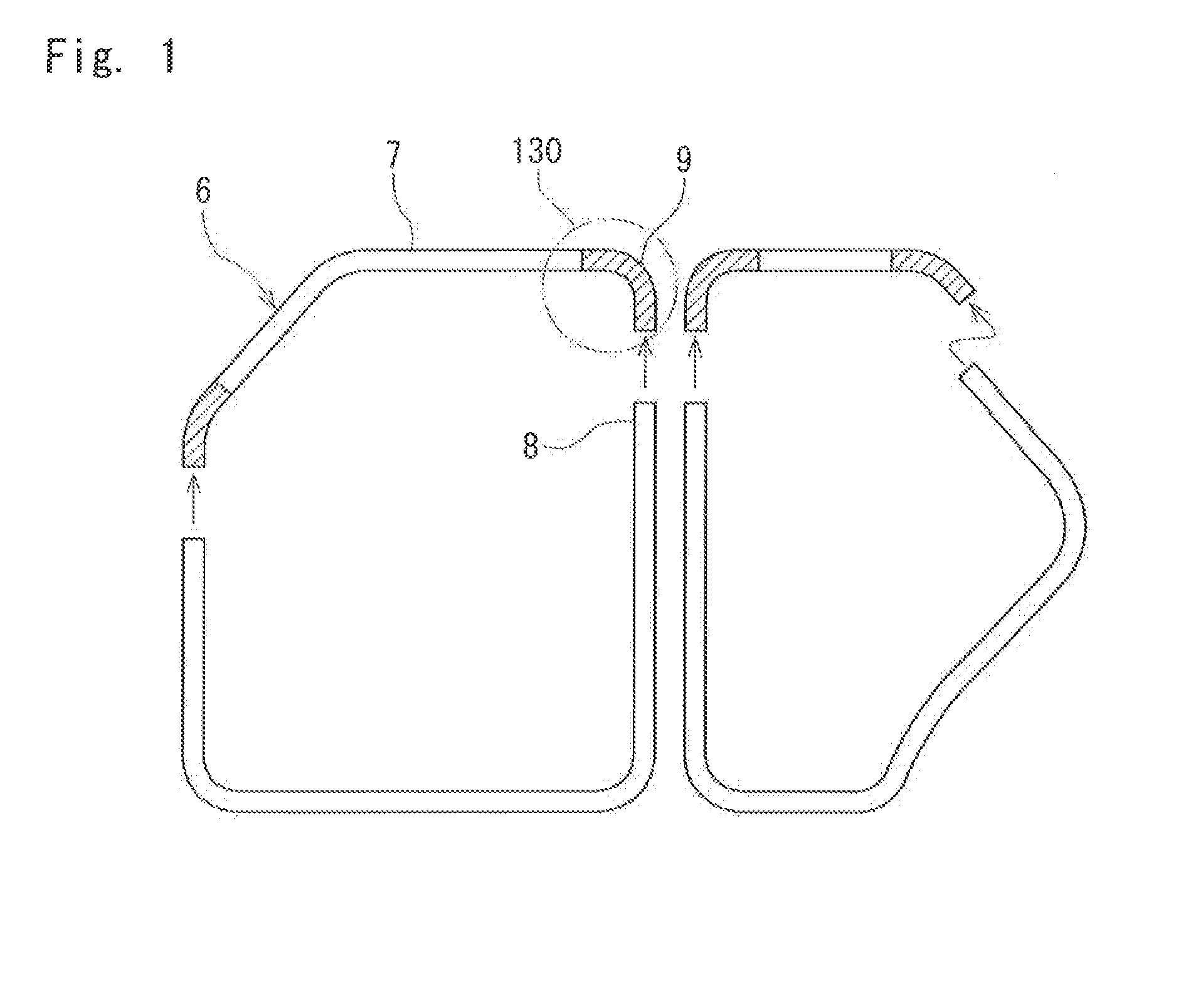

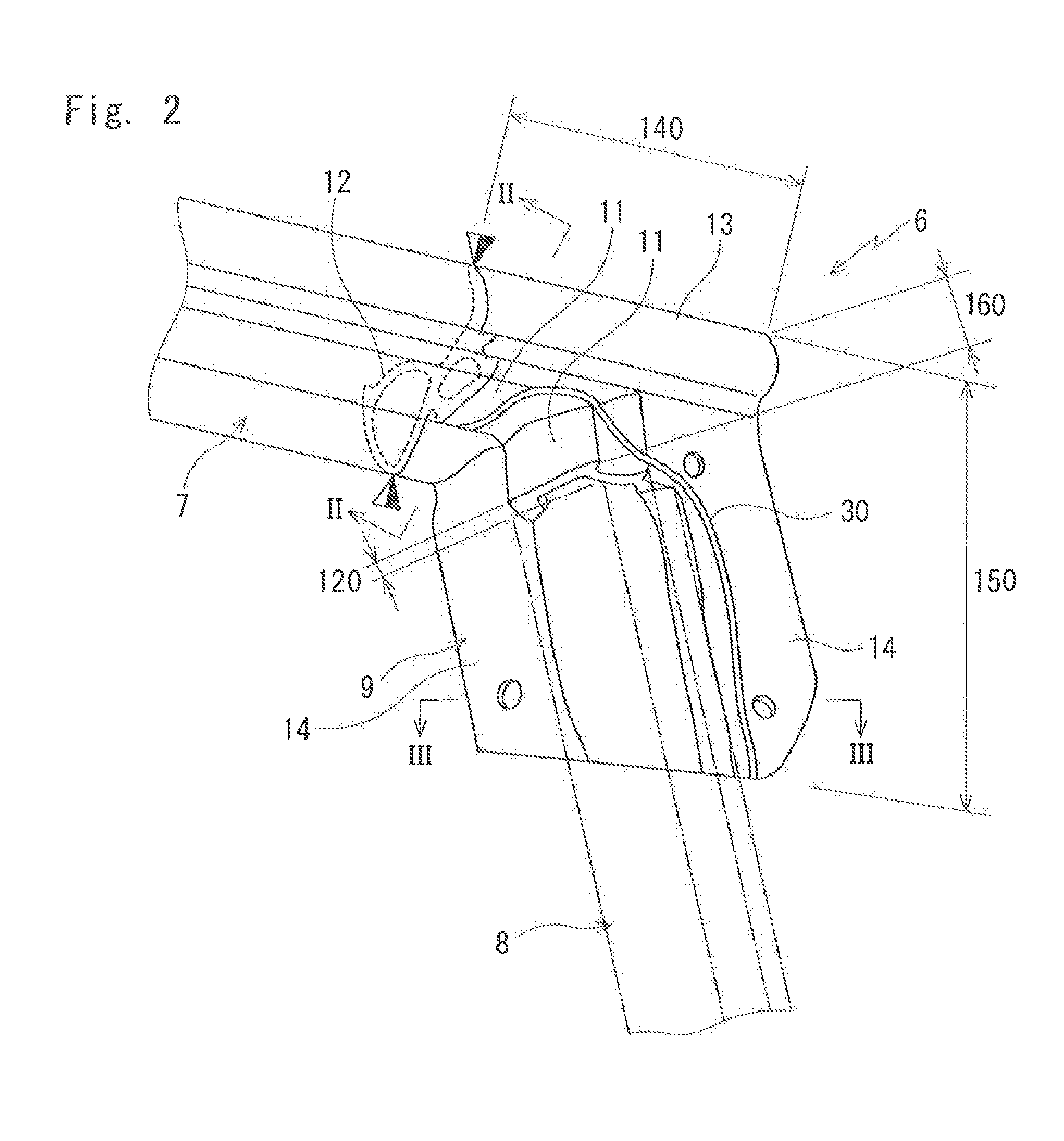

Door weather strip

ActiveUS20140059940A1Increase the number of lapsHold steadyEngine sealsSealing arrangementsEngineeringMechanical engineering

A door weather strip includes an upper extrusion molded part installed on a door sash on a roof side; a molded part without a slit thereon, connected to the upper extrusion molded part on a door corner part; and a lower extrusion molded part installed on a vertical part of the door sash and detachably inserted into the molded part; the upper and lower extrusion molded parts and the molded part having a base bottom part and a hollow seal member formed thereon, in which: a seal bead is formed on the molded part, the seal bead extending from an inner-cabin side toward an outer-cabin side relative to the base bottom part of the molded part on the roof side and descending along an outer-cabin side of a part of the molded part on the vertical part side of the door sash.

Owner:NISHIKAWA RUBBER

Colorful ceramic tile joint mixture and preparation technology thereof

InactiveCN102167554ALong-lasting colorImprove hydrophobicityCrack resistanceHydroxypropylmethyl cellulose

The invention relates to a colorful ceramic tile joint mixture which comprises the raw materials based on weight percentage as follows: 35%-50% of white portland cement, 45%-60% of quartz powder, 0.05%-0.3% of hydroxypropyl carboxymethyl hydroxypropyl cellulose, 0.055-0.25% of water repellent and 1%-3% of pigment. After the colorful ceramic tile joint mixture is used, the constructability is greatly improved, the deformability is improved, the water resistance is realized, the compactedness is increased, the cracking resistance is improved, and the color is more durable and gorgeous.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Anti-knock power battery apparatus

InactiveCN101308938AGood shock resistanceMaintain stability and reliabilityFinal product manufactureBattery isolationPower batteryEngineering

Disclosed is a shakeproof power battery pack device. A bracket structure which limits the positions of a plurality of battery pack units(2) is arranged inside a shell(1); the bracket structure comprises a lower bracket(51), an upper bracket(55) and at least one middle bracket(52) arranged between the upper bracket(51) and the lower bracket(55); a plurality of locating holes(53)or locating semi-holes(56)which are respectively used to clamp the batteries are arranged on the brackets; one battery pack unit(2) is arranged between the lower bracket(51)and the middle bracket(52) and one battery pack unit(2) is arranged between the middle bracket(52)and the upper bracket(55); the battery pack units(2) are vertically stacked into a whole body and are encased in the shell. The batteries of the battery pack are reliably positioned and are of good shake resistance, so the electric cores can have good electric contact and good heat dissipation; therefore the shakeproof power battery pack device is suitable for power battery pack device under vibration conditions.

Owner:GUANGZHOU ZHANHUI ELECTRONICS

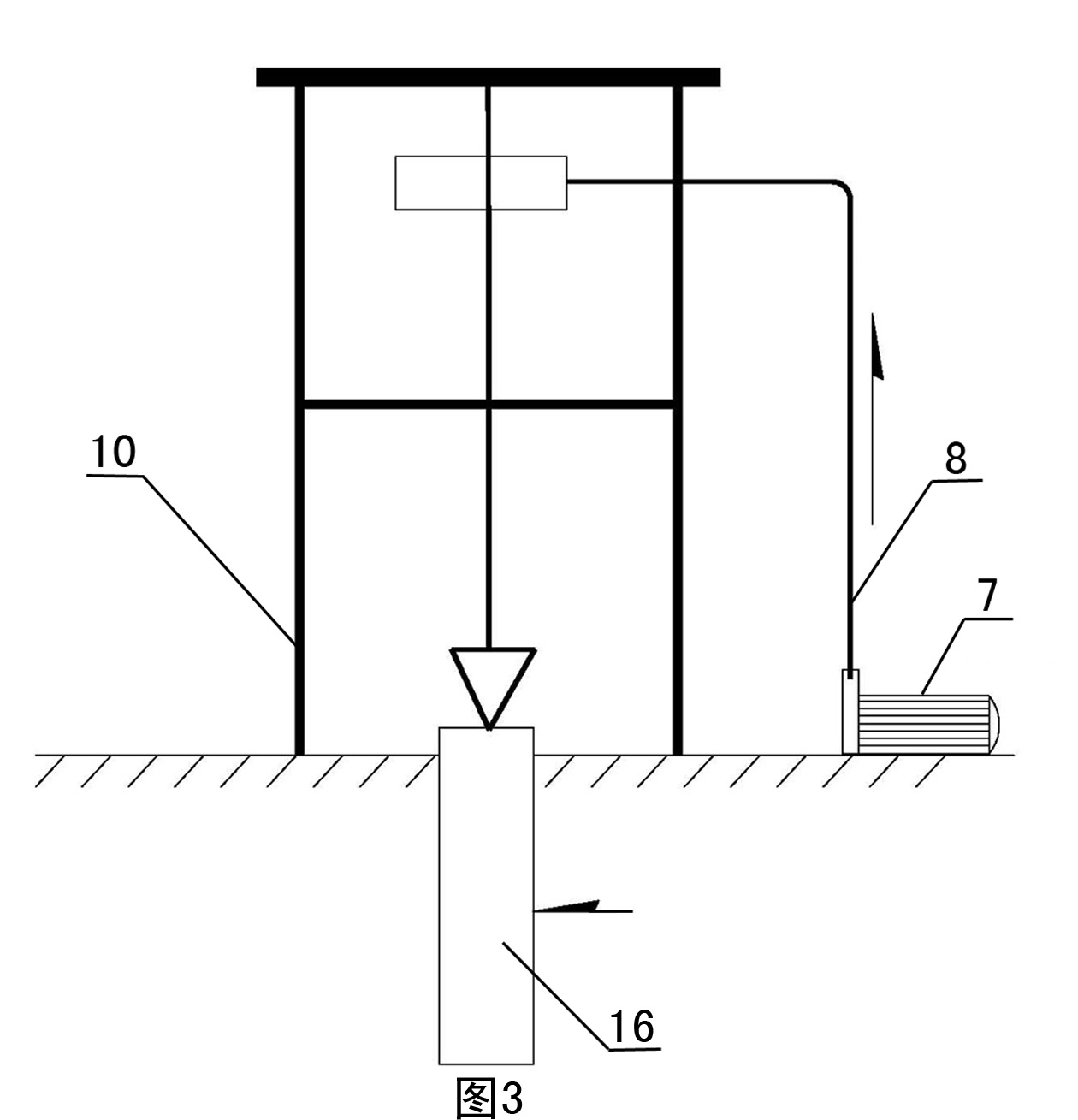

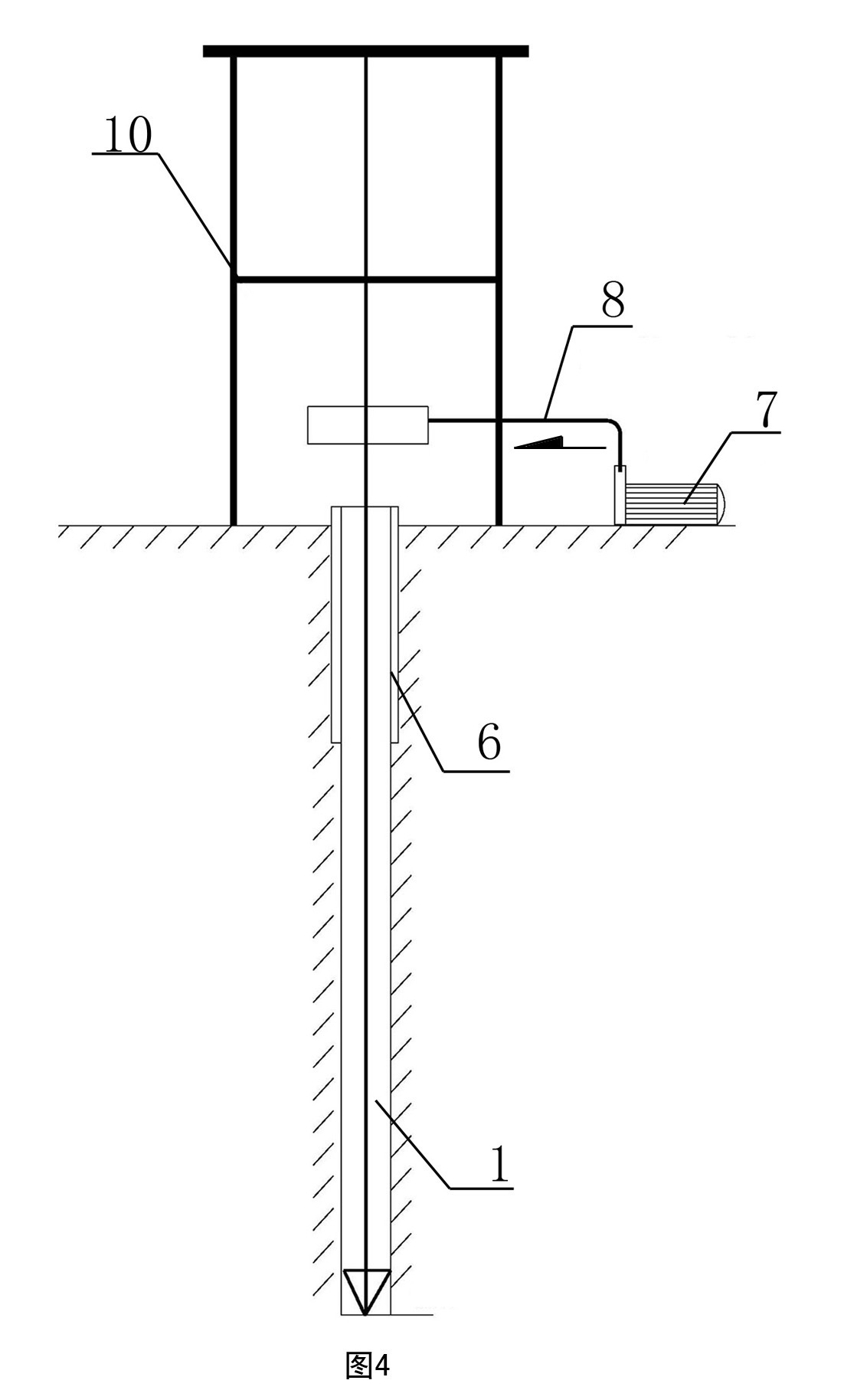

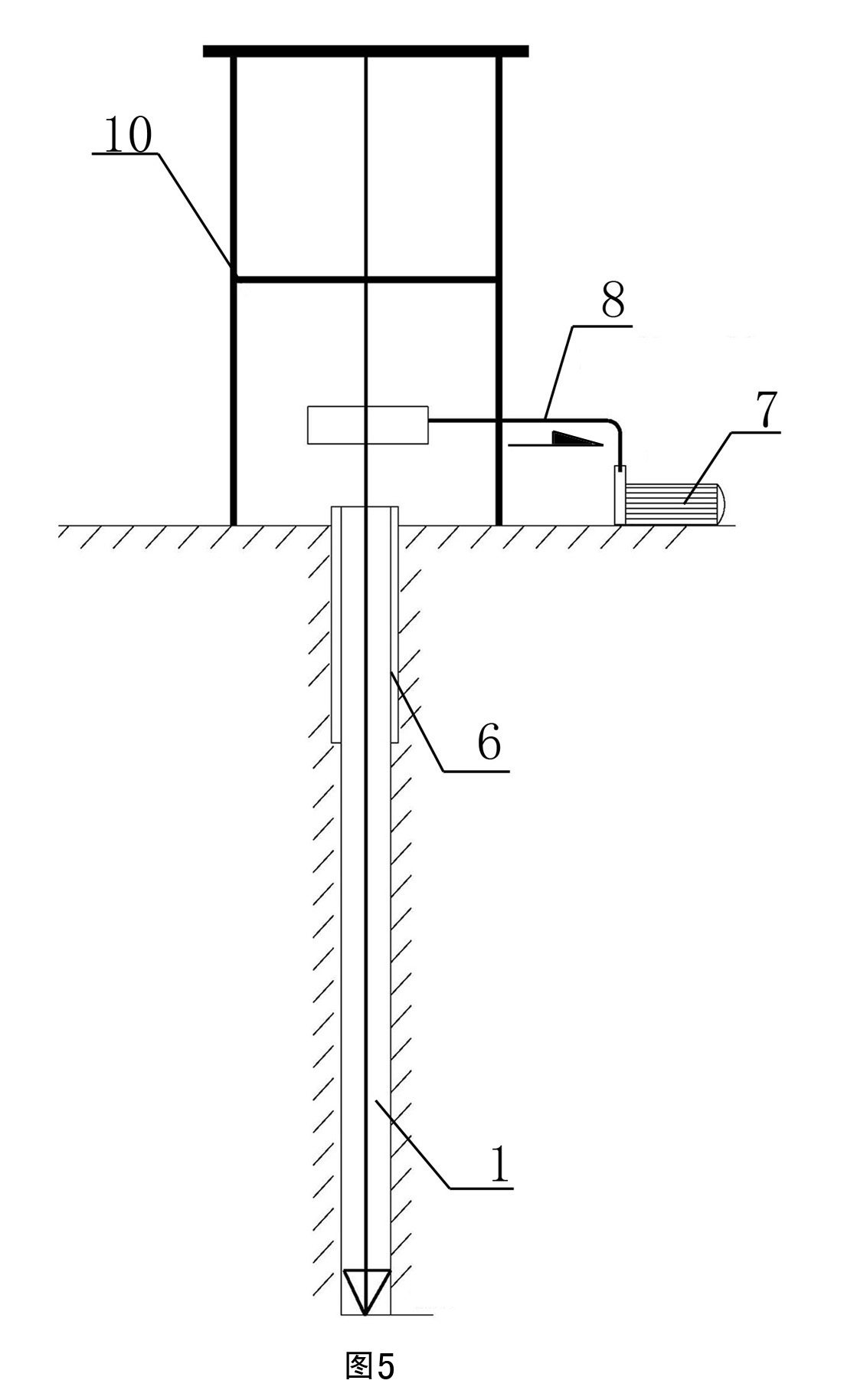

Anti-corrosion inclusion bored concrete pile used for saline soil foundation and construction method thereof

The invention relates to an anti-corrosion inclusion bored concrete pile used for saline soil foundations and a construction method thereof. The bored concrete pile comprises a concrete pile body in structure, wherein the inside of the concrete pile body is provided with a reinforcement cage, a flexible, watertight and anticorrosive protection tube is covered on the bottom and periphery of the concrete pile body; and the watertight and anticorrosive protection tube is formed by hot-pressing or welding n layers of polyethylene geotextile bags and n-1 layers of geomembranes, and n is not less than 2. The construction method comprises the following steps: injecting cement mortar between pile holes and the watertight and anticorrosive protection tube, then injecting water in the watertight and anticorrosive protection tube to ensure that the watertight and anticorrosive protection tube expands to the pile hole wall, then injecting concrete paste in the watertight and anticorrosive protection tube, discharging water from the watertight and anticorrosive protection tube by using the concrete paste, and obtaining the bored concrete pile when concrete is set. The invention solves the anticorrosive problem of the concrete pile in saline soil areas, effectively reduces the production cost of the anti-corrosion bored concrete pile and satisfies the strength requirements of projects. The anti-corrosion inclusion bored concrete pile of the invention is applicable to the concrete pile construction with anticorrosive requirements and is especially used in saline soil foundations.

Owner:陕西长嘉建设工程有限公司

Waterproof breathable organic silicon synthetic leather and manufacturing method thereof

ActiveCN102041688AGuaranteed breathabilityGuaranteed breathability of synthetic leatherSucessive textile treatmentsFiberVulcanization

The invention relates to a waterproof breathable organic silicon synthetic leather and a manufacturing method thereof. The synthetic leather comprises a cloth substrate or a fiber substrate and at least one organic silicon rubber layer compounded on the surface thereof, wherein the organic silicon rubber is prepared from 50-70% of vinyl-containing polydiorgnosiloxane base polymer, 2-5% of silicon-hydrogen bond-containing oligomeric siloxane vulcanization crosslinking agent, 0.5-2% of platinum compound vulcanization catalyst, 0.5-2% of alkynol hydrosilylation addition reaction inhibitor, 5-10% of white carbon black, 5-10% of calcium carbonate and 10-20% of sodium chloride of 100-200 meshes. The manufacturing method of the synthetic leather comprises the following steps: selecting a substrate; gluing; drying and curing; and boiling to leach the sodium chloride. Since the sodium chloride is added and the synthetic leather is boiled in water after being molded, the sodium chloride can be completely dissolved in the water, so that a certain number of air holes can be formed in the synthetic leather, thereby enduing the synthetic leather with certain breathability. Because the formed air holes have small hole diameters, water can not penetrate through the air holes of the synthetic leather, thereby ensuring the favorable waterproof function.

Owner:高文源

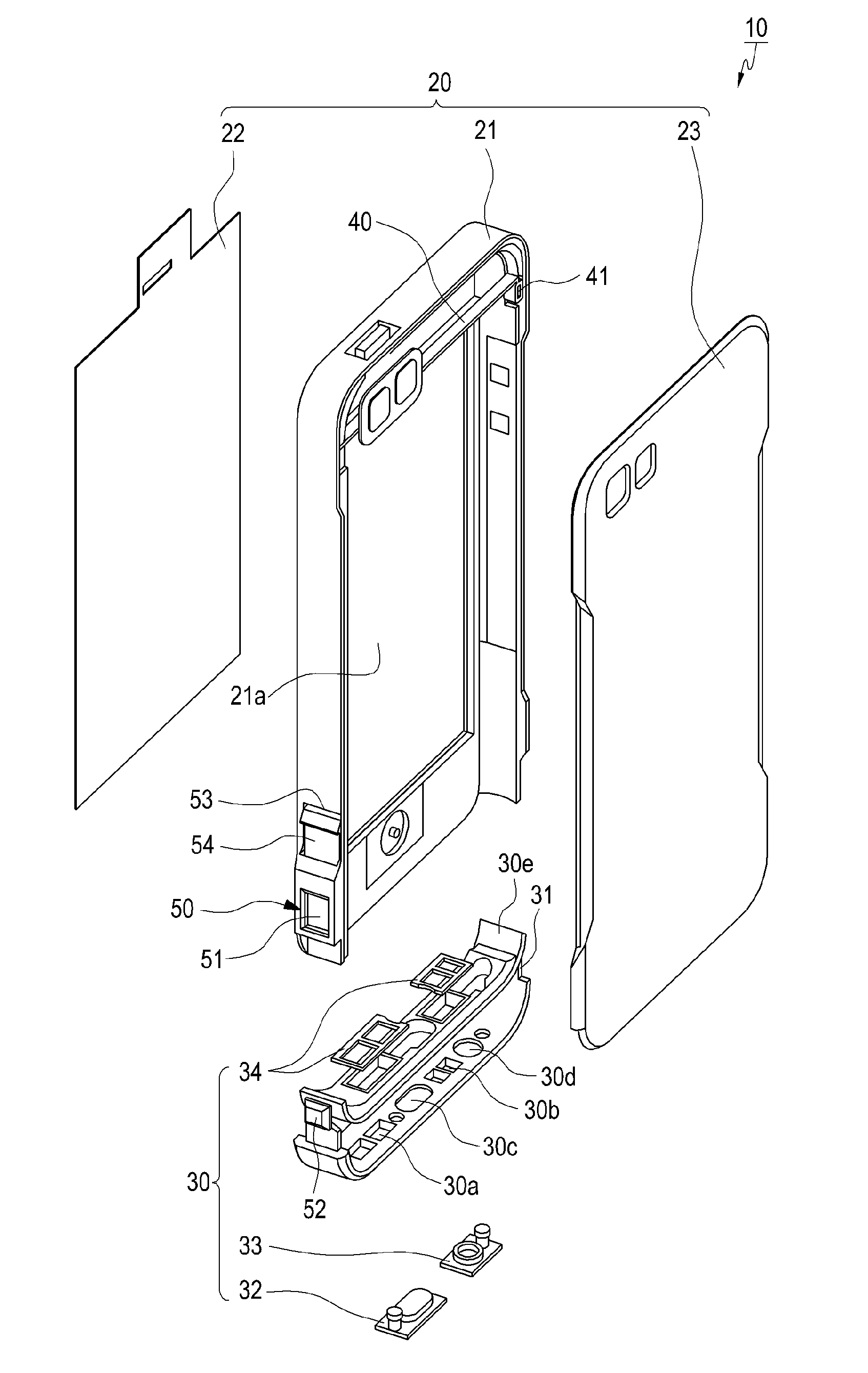

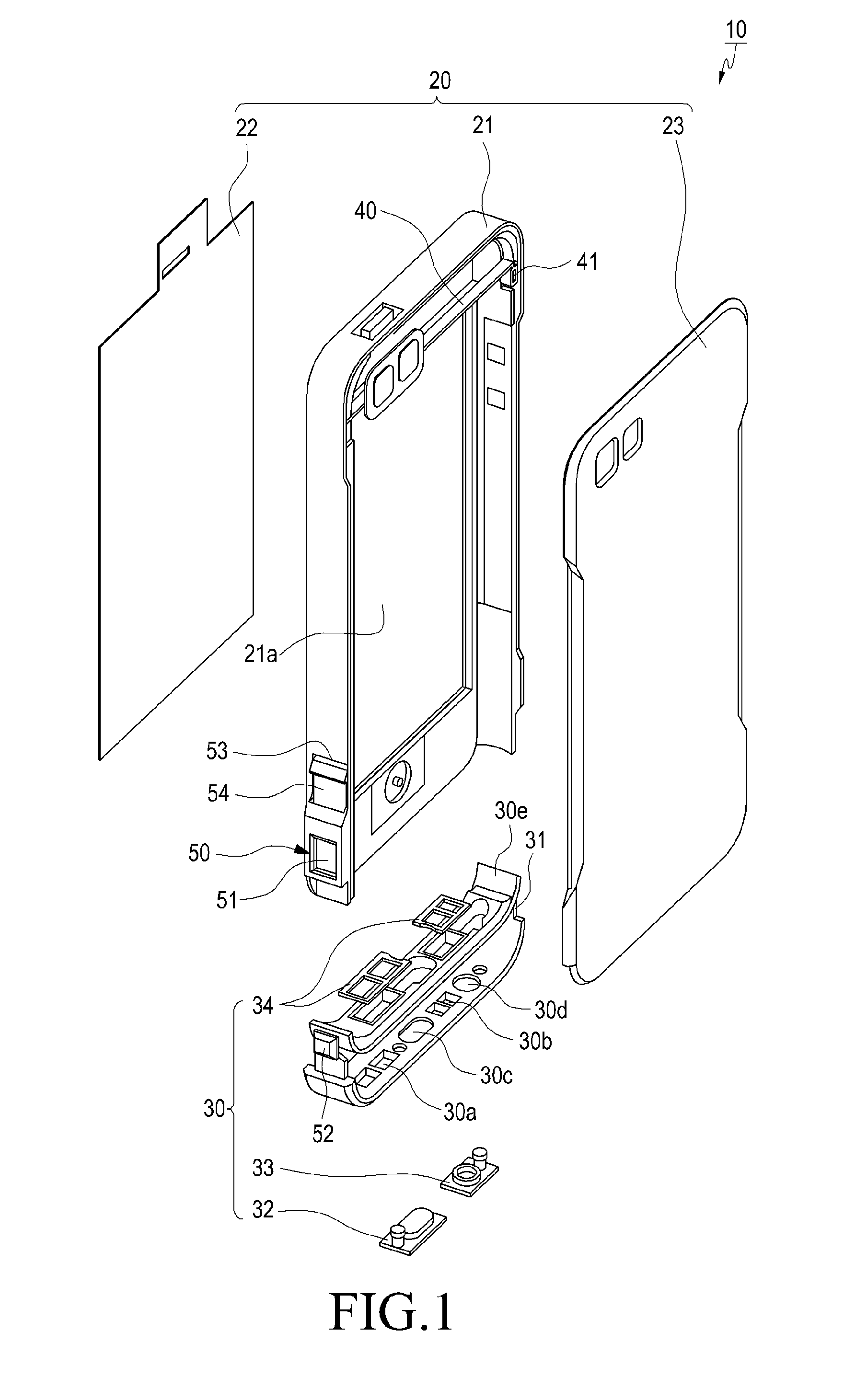

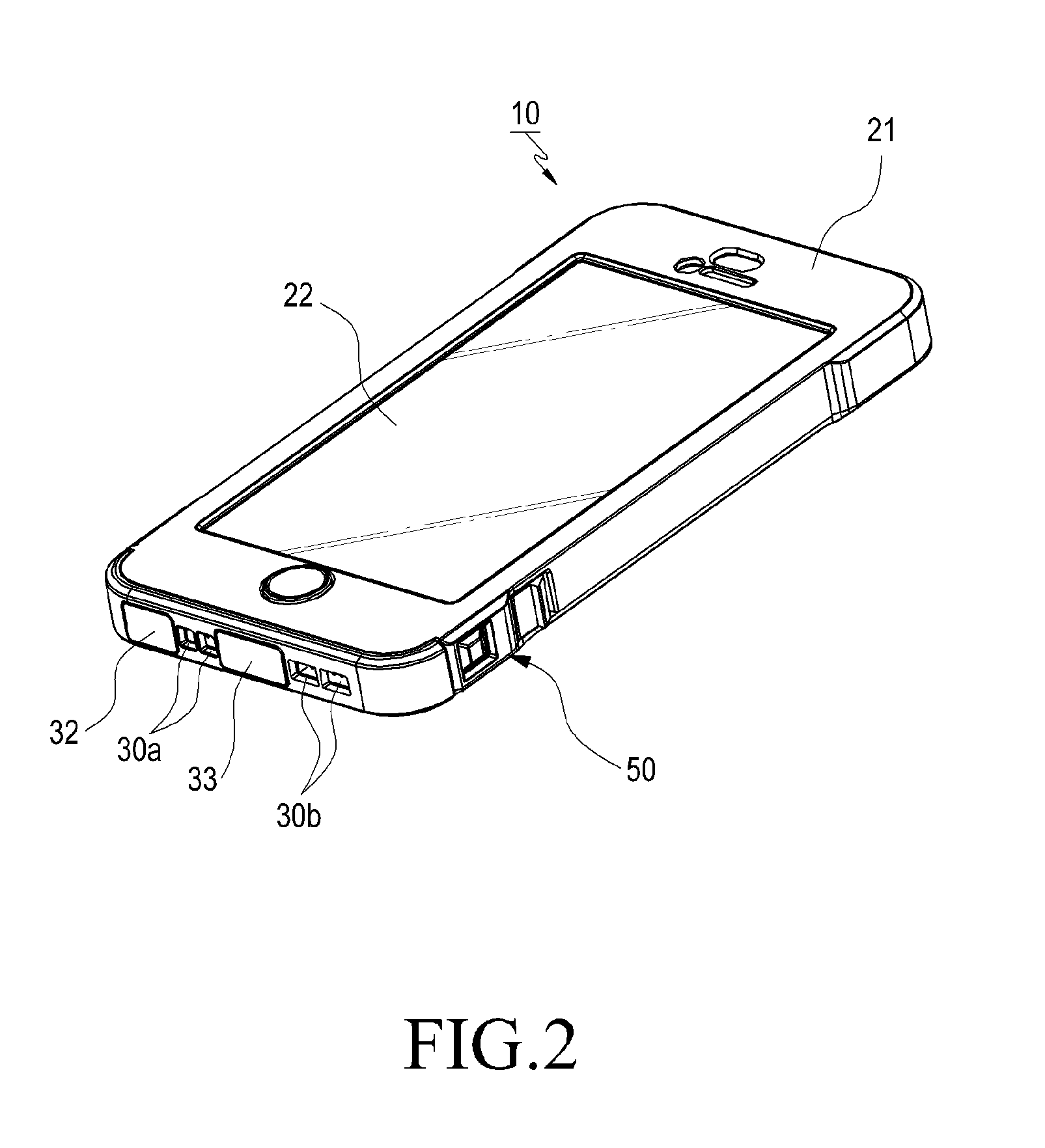

Waterproof case for electronic device

InactiveUS20140353179A1Avoid damageEasily being opened and closedDigital data processing detailsOther accessoriesEngineeringMechanical engineering

Owner:KIM JUSTIN CHIWON

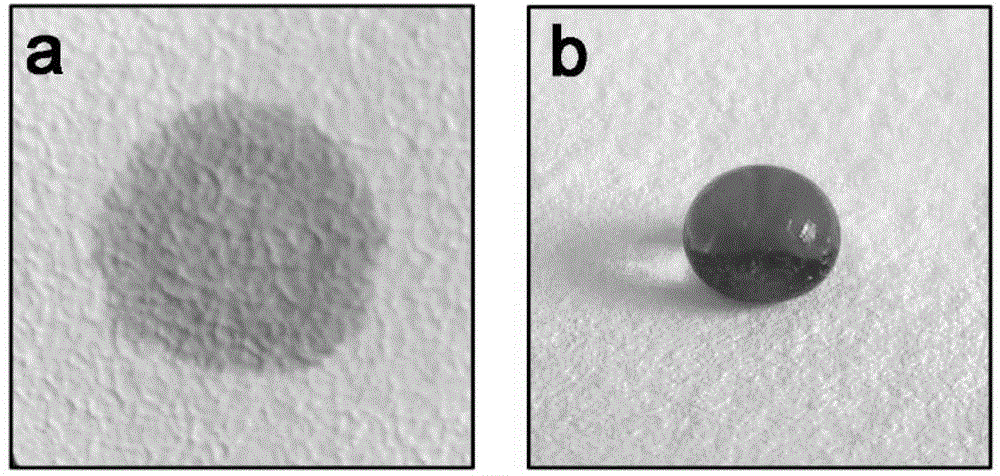

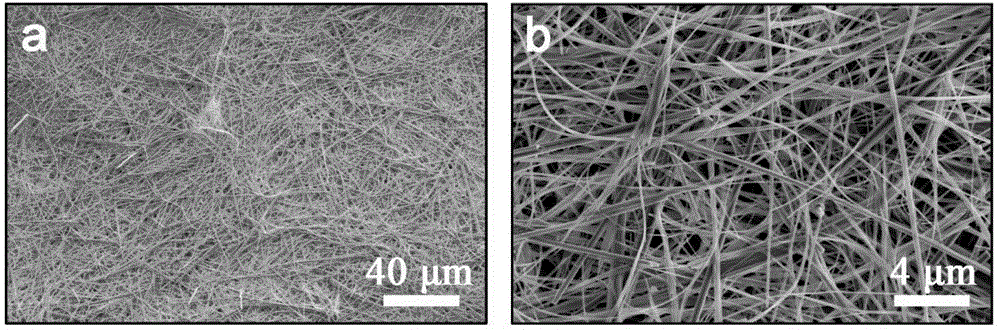

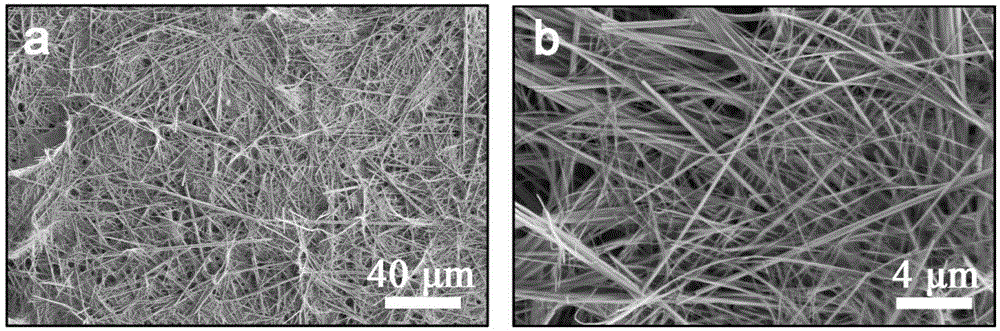

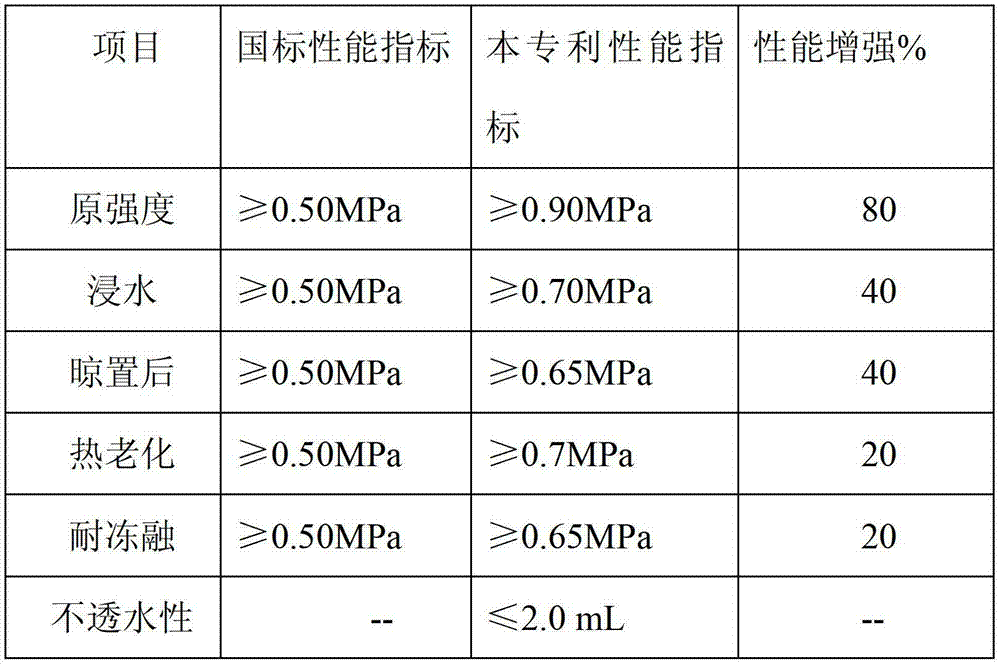

Hydroxyapatite overlength nanowire flameproof paper with waterproof function

ActiveCN106522015AWaterproofWith waterproof functionWater-repelling agents additionPaper/cardboardNanowireApatite

The invention relates to hydroxyapatite overlength nanowire flameproof paper with a waterproof function. The hydroxyapatite overlength nanowire flameproof paper with the waterproof function has super-hydrophobicity and fireproof and flame-retardant functions. The main component of the flameproof paper is hydroxyapatite overlength nanowire. The product also contains fatty acid salt or a perfluorinated compound modified on the hydroxyapatite overlength nanowire. The fatty acid salt or the perfluorinated compound carries out surface modification on the hydroxyapatite overlength nanowire. As hydroxyapatite overlength nanowire has rich surface reactive groups, the hydroxyapatite overlength nanowire is easy to undergo surface modification. Thus, the hydroxyapatite overlength nanowire is easy to combine with the fatty acid salt or the perfluorinated compound such that the hydroxyapatite overlength nanowire flameproof paper is endowed with an excellent waterproof function.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Polycrystal flexible tile binder

The invention discloses a polycrystal flexible tile binder. The polycrystal flexible tile binder comprises cement, quartz sand, redispersible latex powder, organosilicone water repellent, hydroxymethyl propyl cellulose ether, sodium silicate, slag powder and coarse whiting. The polycrystal flexible tile binder has the advantages of small plasticity, good construction performance, ageing resistance, permeability resistance, waterproofness, internal stress resistance, acid and alkaline corrosion resistance and the like.

Owner:HAIDA CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com