Colorful ceramic tile joint mixture and preparation technology thereof

A technology for colored ceramic tiles and caulking agent, applied in the field of colored ceramic tile caulking agent, can solve the problems of easy cracking and poor waterproofness, and achieve the effects of increasing compactness, improving workability, and increasing waterproof function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

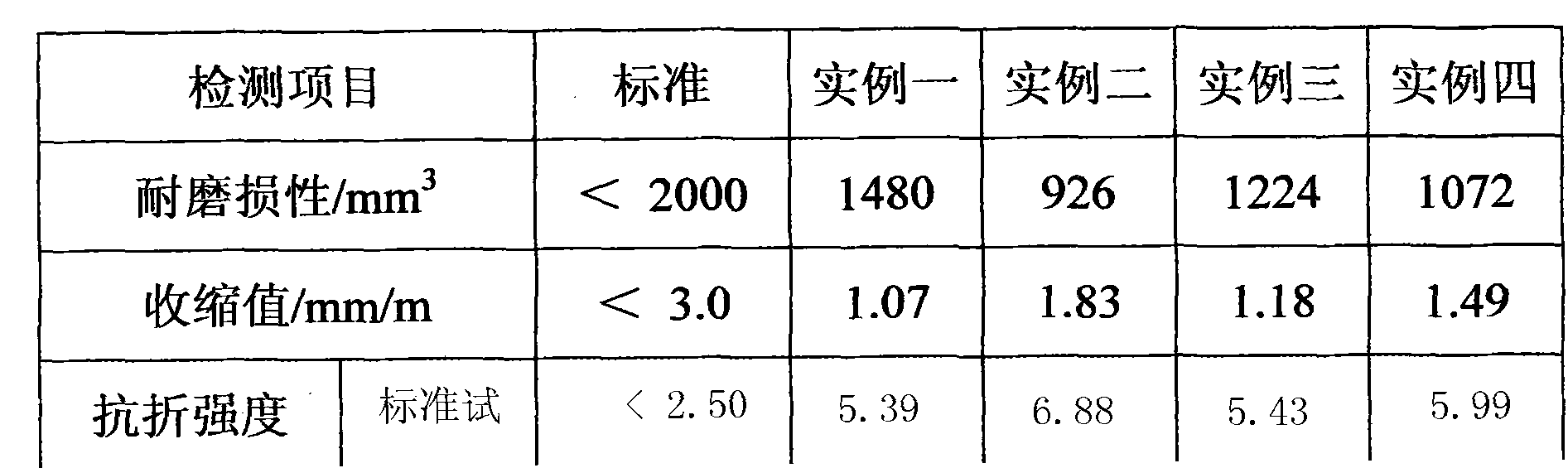

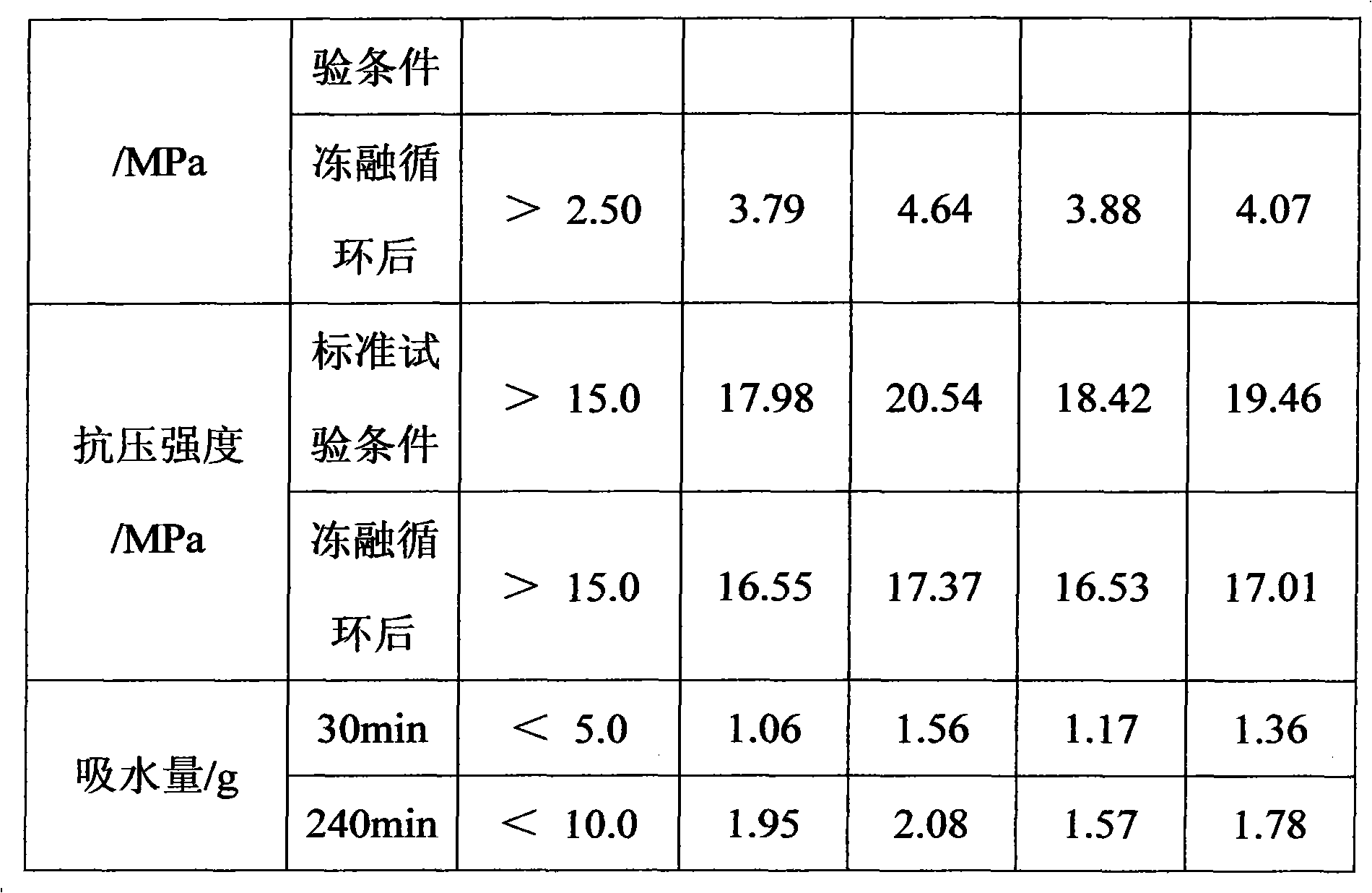

Examples

no. 1 example

[0037] Based on the above range, the present invention provides the first embodiment, and the specific weight ratio of each component is as follows:

[0038] 32.5# white Portland cement 350.0

[0039] 200 mesh quartz powder 600.0

[0040] HPMC 75HD 40000 1.5

[0041] 8031H 15.0

[0042] PWC500 2.0

[0043] Polypropylene fiber 3mm 0.5

[0044] 602 2.0

[0045] F10 2.0

[0046] P750 2.0

[0047] S306 25.0

[0048] Based on the above range, the present invention provides a second embodiment, and the specific weight ratio of each component is as follows:

[0049] 32.53# Ordinary Portland cement 500.0

[0050] 200 mesh quartz powder 450.0

[0051] HPMC 75HD 75000 0.5

[0052] 8031H 30.0

[0053] PWC500 3.0

[0054] Polypropylene fiber 5mm 0.5

[0055] 602 1.0

[0056] 1641F 1.0

[0057] P750 1.0

[0058] S370 13.0

[0059] Based on the above range, the present invention provides a third embodiment, and the specific weight ratio of each component is as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com