Colored radiation refrigeration film and preparation method thereof

A technology of radiation cooling and film, applied in the field of color radiation cooling film and its preparation, which can solve the problems such as the decline of cooling performance of radiation cooling materials, limitation of radiation cooling materials, complicated preparation process, etc., and achieve long-lasting color, low cost and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

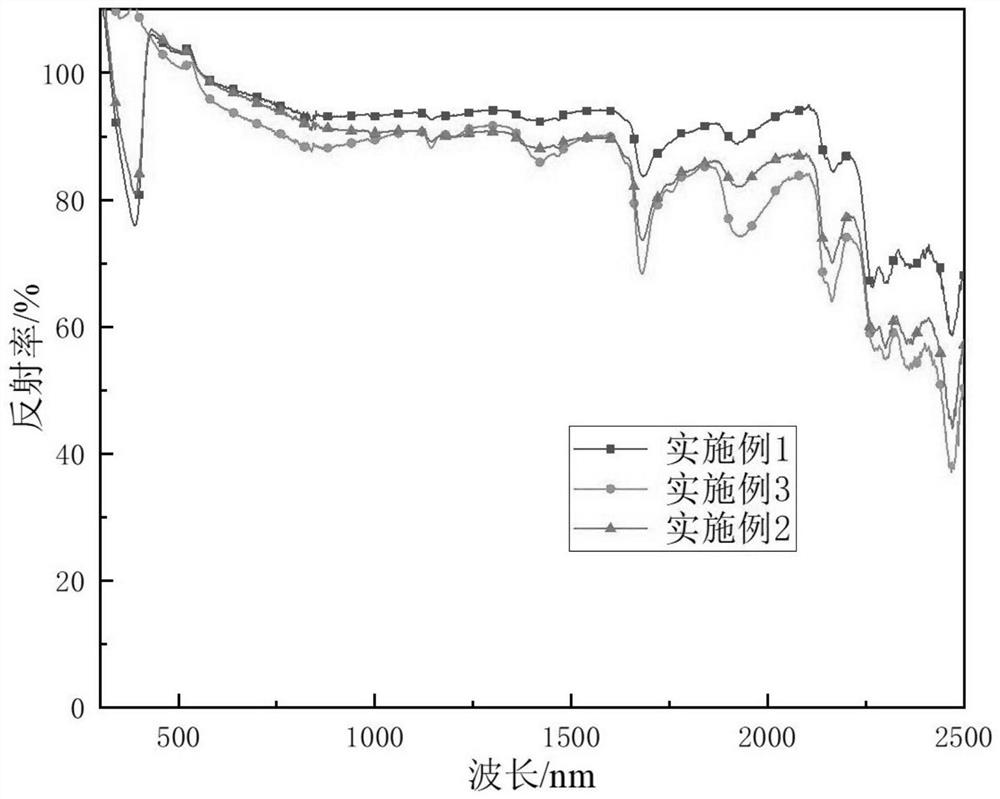

Embodiment 1

[0040] A kind of color radiation cooling film, its preparation method comprises the following steps:

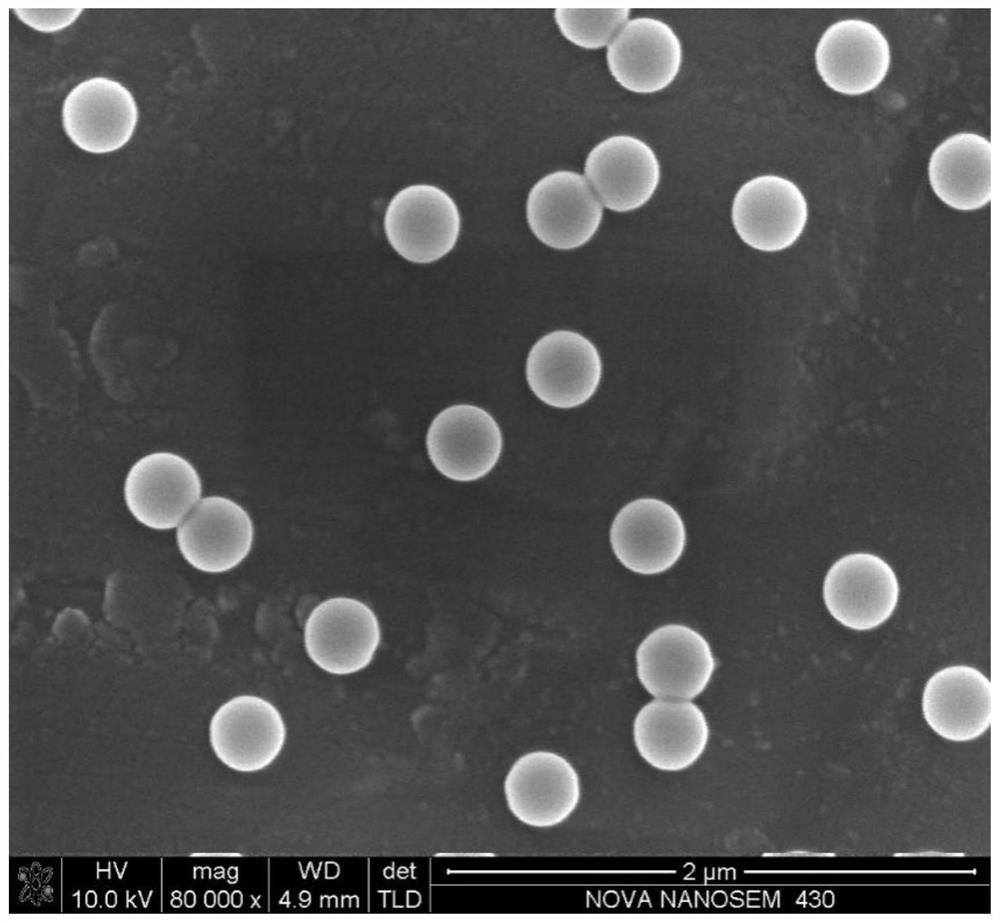

[0041] 1) Add 12g of styrene and 0.03g of sodium lauryl sulfate into 130mL of deionized water, place in a nitrogen atmosphere, adjust the stirring speed to 200rpm, stir for 1h, then add 0.1g of ammonium persulfate, and heat up React at 70°C for 4 hours, centrifuge to obtain polystyrene microspheres;

[0042] 2) Mix 20g of polyacrylate emulsion with a solid content of 50%, 10g of titanium dioxide, 1.5g of dispersant BYK-2015, 0.3g of defoamer Tego-810, 0.3g of leveling agent BYK-348 and 0.9g of Mix the film-forming agent alcohol ester twelve, then add zirconia ball milling beads, conduct ball milling to make a slurry, and then use aluminum foil as the base to coat the film with a film thickness of 50 μm and dry at 30°C to obtain a radiation cooling film layer;

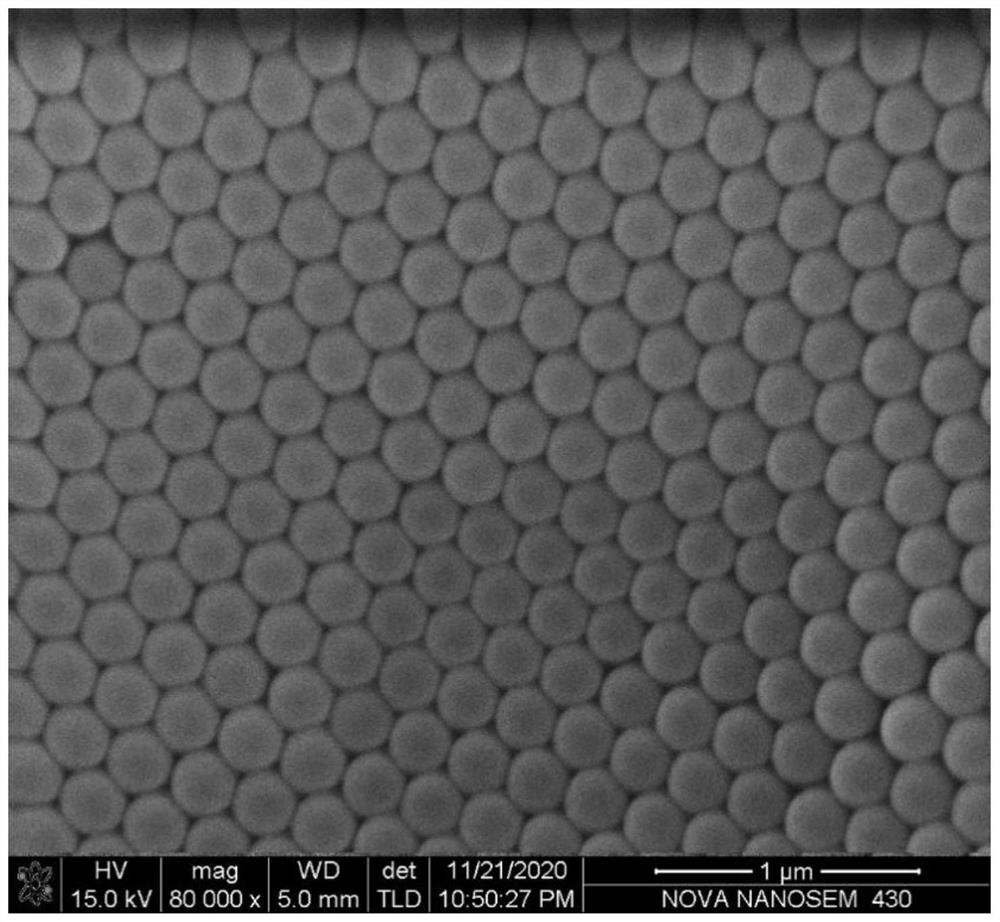

[0043] 3) Add 1g of polystyrene microspheres to 9mL of deionized water, then add 3.3g of polyacrylate emulsion with...

Embodiment 2

[0048] A kind of color radiation cooling film, its preparation method comprises the following steps:

[0049] 1) Add 15g of styrene and 0.05g of sodium lauryl sulfate into 130mL of deionized water, and place in a nitrogen atmosphere, adjust the stirring speed to 350rpm, stir for 1h, then add 0.15g of ammonium persulfate, and heat up React at 80°C for 6 hours, centrifuge to obtain polystyrene microspheres;

[0050] 2) Mix 10g of water-based polyvinylidene fluoride resin with a solid content of 50%, 15g of calcium carbonate, 1.25g of dispersant BYK-2015, 0.5g of defoamer Tego-810, 0.25g of leveling agent BYK-348 and Mix 0.75g of film-forming agent alcohol ester twelve, then add zirconia ball milling beads, carry out ball milling to make a slurry, and then use aluminum foil as a substrate to coat the film with a film thickness of 100 μm and dry at 45°C to obtain a radiation cooling film layer;

[0051] 3) Add 3g of polystyrene microspheres to 7mL of deionized water, then add 0.7...

Embodiment 3

[0053] A kind of color radiation cooling film, its preparation method comprises the following steps:

[0054] 1) Add 18g of styrene and 0.07g of sodium lauryl sulfate into 130mL of deionized water, and place in a nitrogen atmosphere, adjust the stirring speed to 500rpm, stir for 1h, then add 0.22g of ammonium persulfate, and raise the temperature React at 80°C for 8 hours, centrifuge to obtain polystyrene microspheres;

[0055] 2) Mix 8g of water-based polyvinylidene fluoride resin with a solid content of 50%, 20g of magnesium phosphite, 1.4g of dispersant BYK-2015, 0.28g of defoamer Tego-810, and 0.28g of leveling agent BYK-348 Mix with 0.84g of film-forming agent alcohol ester twelve, then add zirconia ball milling beads, conduct ball milling to make a slurry, and then use aluminum foil as the base to coat the film with a film thickness of 150 μm and dry at 60°C to obtain a radiation cooling film layer ;

[0056] 3) Add 5g of polystyrene microspheres to 5mL of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com