Paint spraying equipment for processing curtain hooks

A painting equipment and technology for curtains, applied in the field of curtain hooks, can solve problems such as damage to body functions, slow spraying of artificial paint, uneven spraying on the surface of curtain hooks, etc., and achieve the effects of improving painting efficiency and improving heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

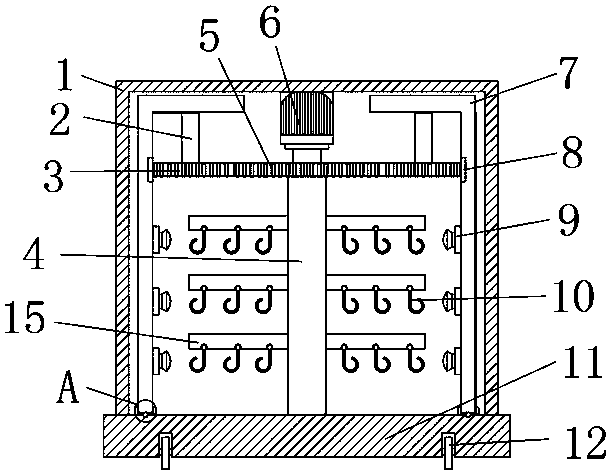

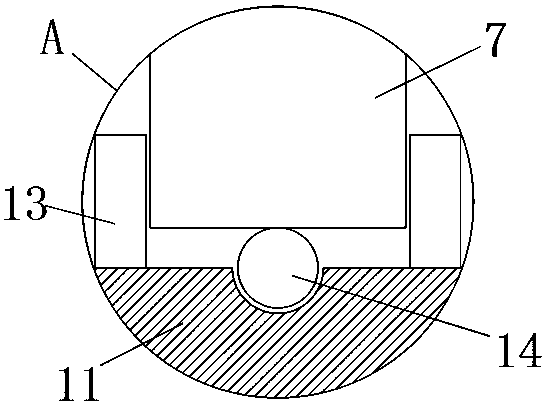

[0016] refer to Figure 1-2 , a kind of painting equipment for curtain hook processing, comprising a base 11, the base 11 is fixedly connected with a housing 1, the base 11 is connected with a rotating shell 7 through a rolling device, the rolling device includes a circular ball groove, the rolling ball The groove is opened on the base 11, and a plurality of rolling balls 14 are arranged in the rolling ball groove, and the rotating shell 7 is placed on the plurality of rolling balls 14, and the base 11 is fixedly connected with two symmetrically arranged limiting plates 13, and the rotating shell 7 The bottom end of 7 is located between two limiting plates 13, and a plurality of rolling balls 14 makes the rotating shell 7 rotate more smoothly by reducing the friction between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com