Patents

Literature

861results about How to "Improve painting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

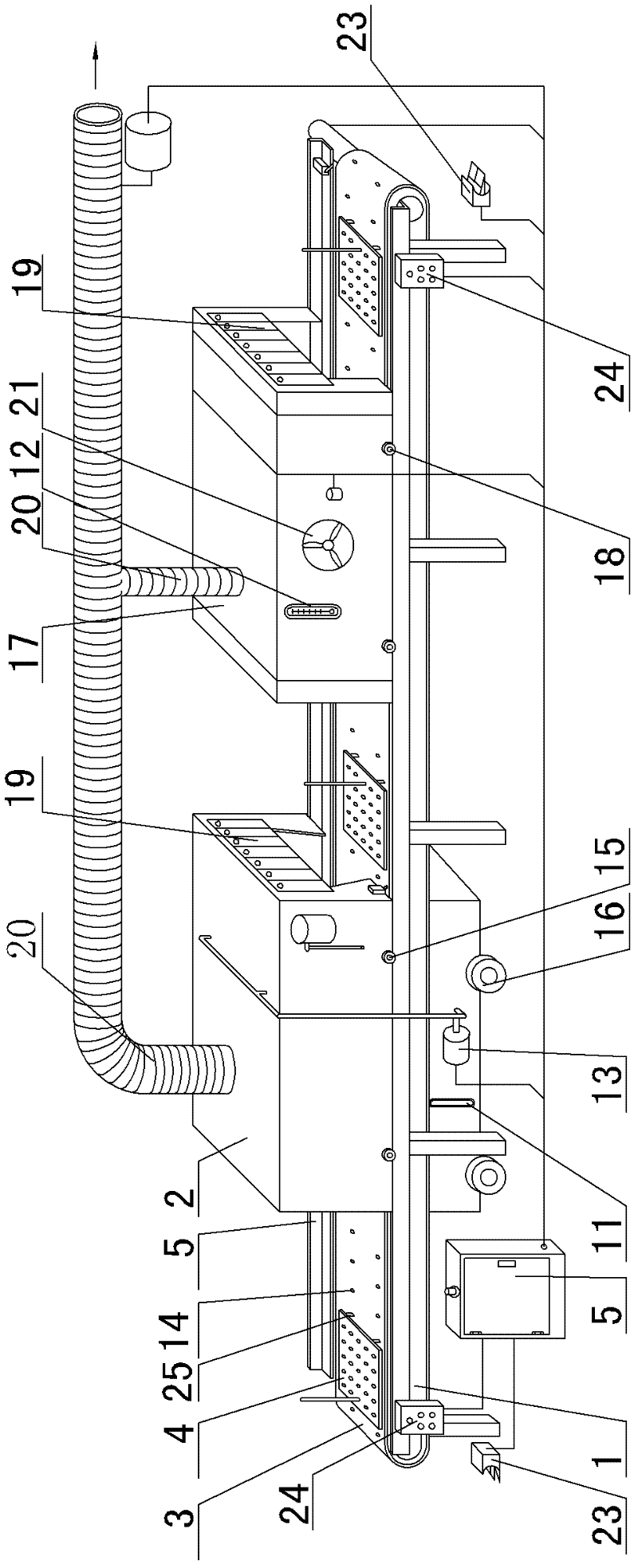

Chopstick spray-paint equipment and chopstick spray-paint method

InactiveCN102335645AHigh degree of automationEasy to operateSpraying apparatusPretreated surfacesProduction rateEngineering

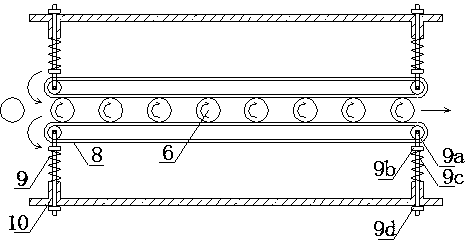

The invention relates to chopstick spray-paint equipment, which comprises a rack, a spray-paint box, a conveyer belt and a chopstick dish, wherein the spray-paint box is arranged on the rack, and the conveyer belt penetrates through the spray-paint box; the chopstick dish is arranged on the conveyer belt; and inserting holes for fixing chopsticks are arranged on the chopstick dish. An electric cabinet for electrically controlling the chopstick spray-paint equipment is also arranged on the spray-paint equipment. The spray-paint box is provided with a front door A and a back door A along the conveying direction of the conveyer belt, and a spray gun for spraying paint is arranged in the spray-paint box. The degree of automation is high, and the chopstick spray-paint equipment replaces manually pulling paint operation and the long-time drying process. The chopstick spray-paint equipment is also provided with a drying box, so that the carrying back and forth among each working procedure and drying and putting area in the paint spraying and drying processes are saved, the labor strength is reduced, the manpower resource is greatly saved, the production rate is increased, the length of a chopstick mold is shortened, and the use ratio of raw materials of chopsticks is increased. Benzene volatile matters and others in the equipment are effectively removed. The spray-paint equipment has simple operation, compact structure and wide practical meaning and marketable value.

Owner:侯唯敏

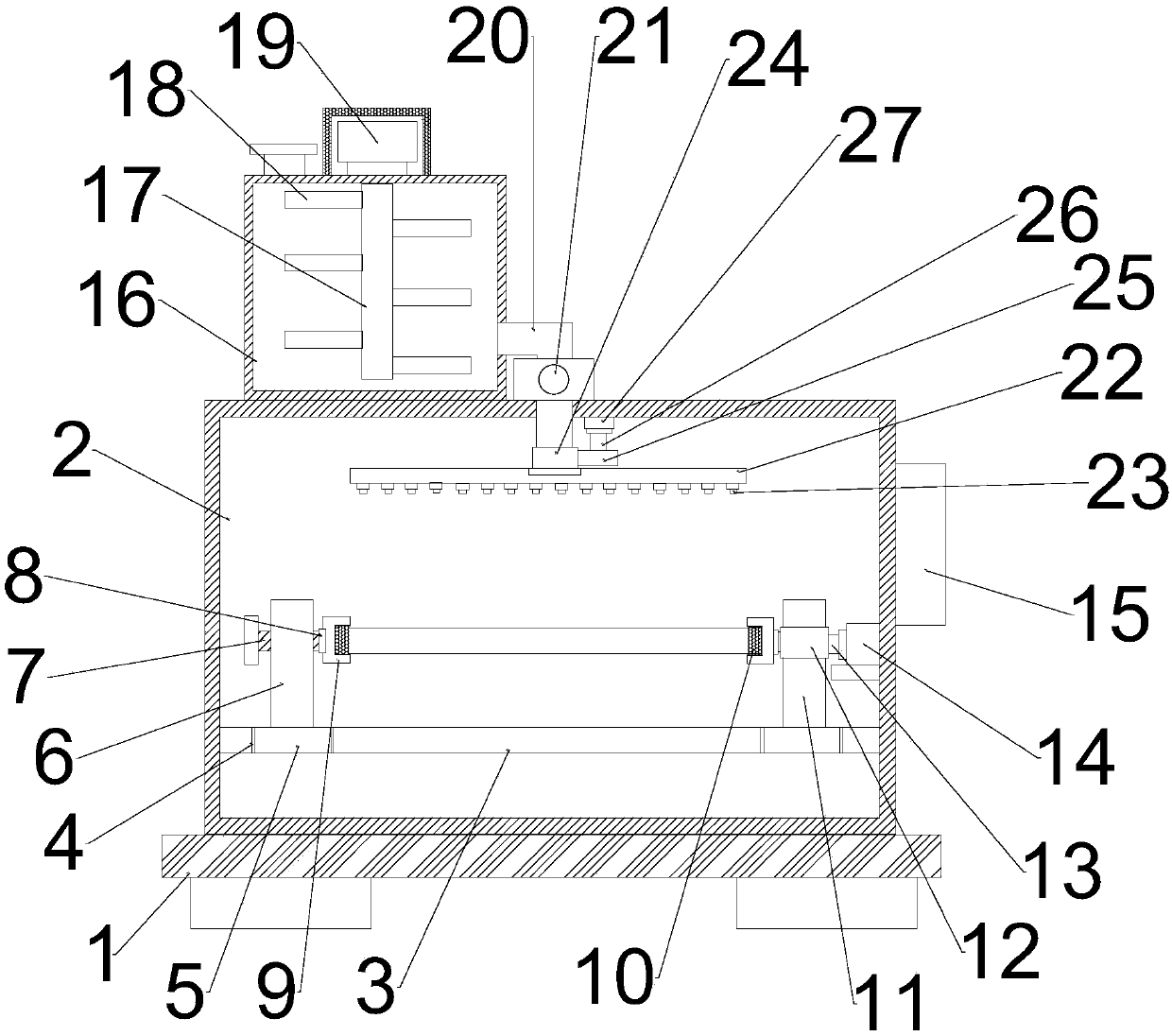

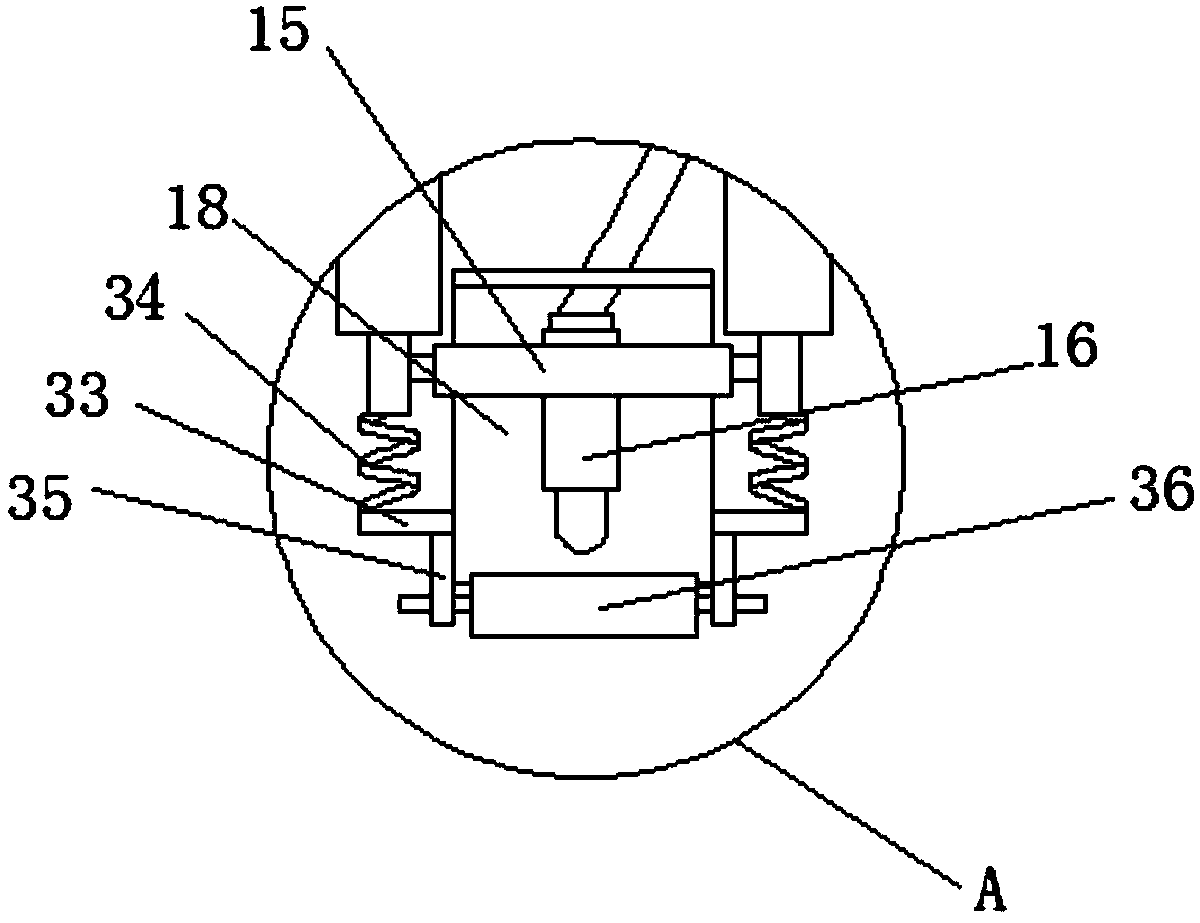

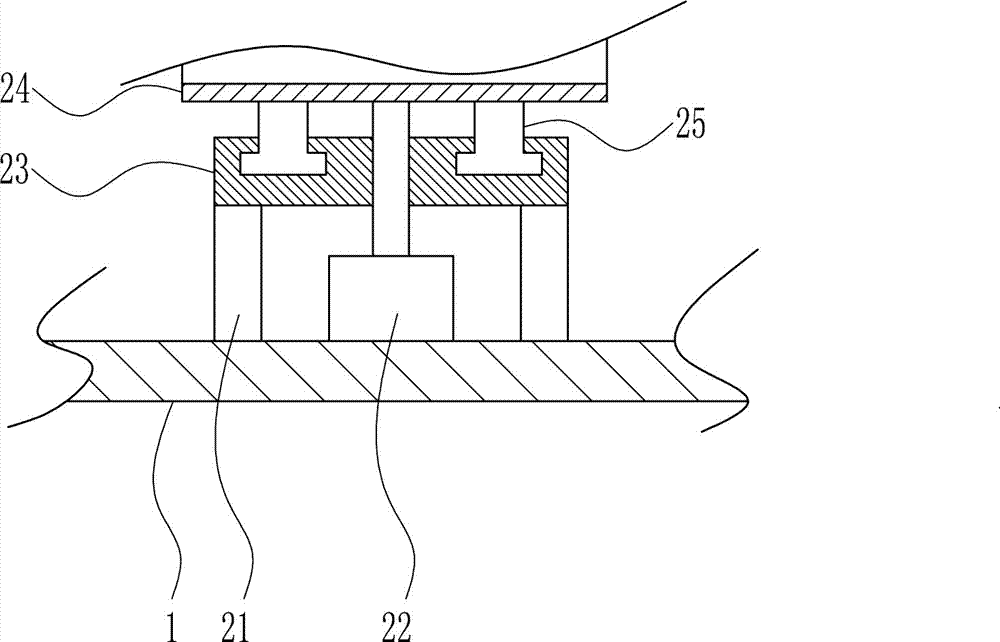

Continuous building wall painting device

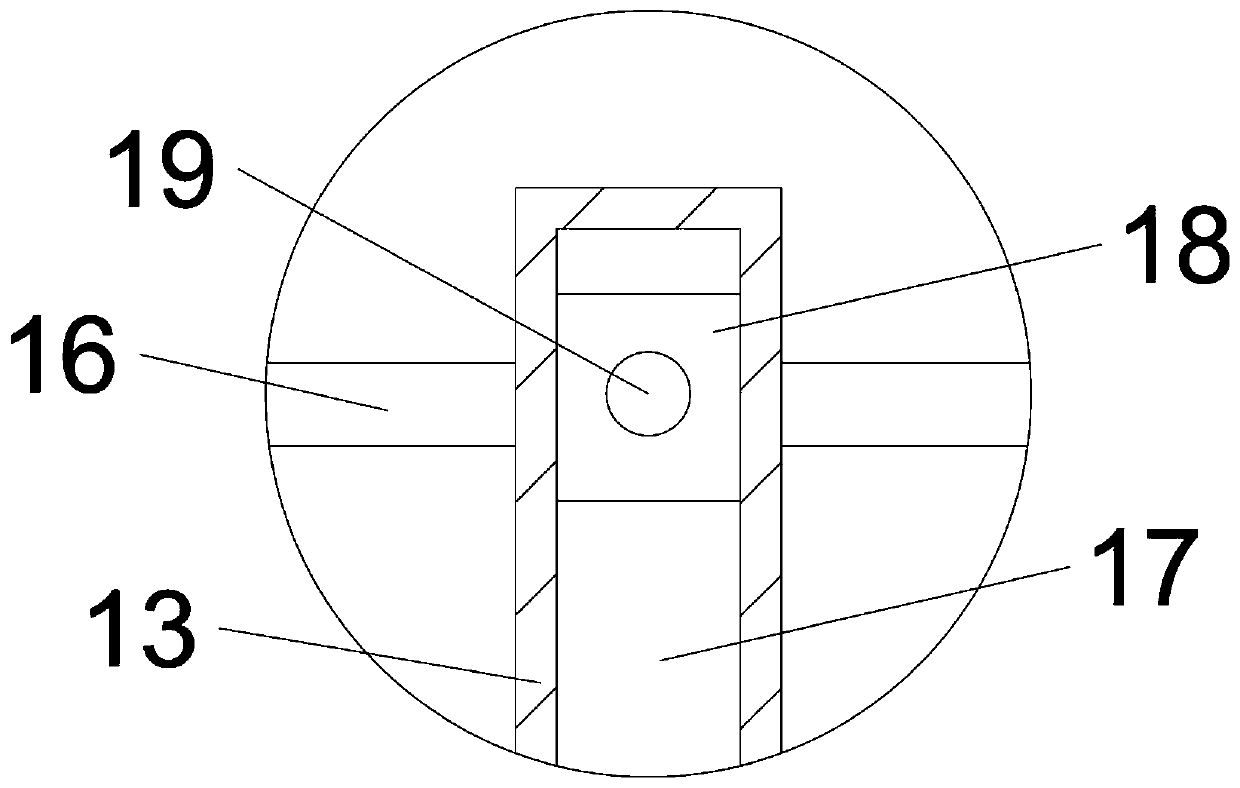

InactiveCN107288320ASimple structureImprove painting efficiencyBuilding constructionsArchitectural engineeringPiston rod

The invention discloses a continuous building wall painting device. The continuous building wall painting device comprises a transverse plate. A vertical supporting plate, a paint box and a cylinder body are arranged on the transverse plate. Both the upper end and the lower end of the cylinder body communicate with the paint box through feed pipes. Two opposite lifting sliding grooves are further formed in the inner wall of the vertical supporting plate. A moving rod is arranged between the two lifting sliding grooves. The two ends of the moving rod are slidably connected with the lifting sliding grooves. A baffle is arranged on the right side of the moving rod. A mounting frame is arranged at the right end of the baffle. A piston is arranged in the cylinder body. A piston rod is arranged at the upper end of the piston, and the top end of the piston rod is fixedly connected with the baffle. A feed cylinder is mounted on the mounting frame. A painting cylinder is arranged on the outer side wall of the feed cylinder. One end of the feed cylinder is connected with the upper end and the lower end of the cylinder body through discharging pipes. The continuous building wall painting device is simple in structure, capable of achieving continuous spraying and painting, high in painting efficiency, uniform in painting, easy and convenient to operate, and high in practicability.

Owner:吴秀女

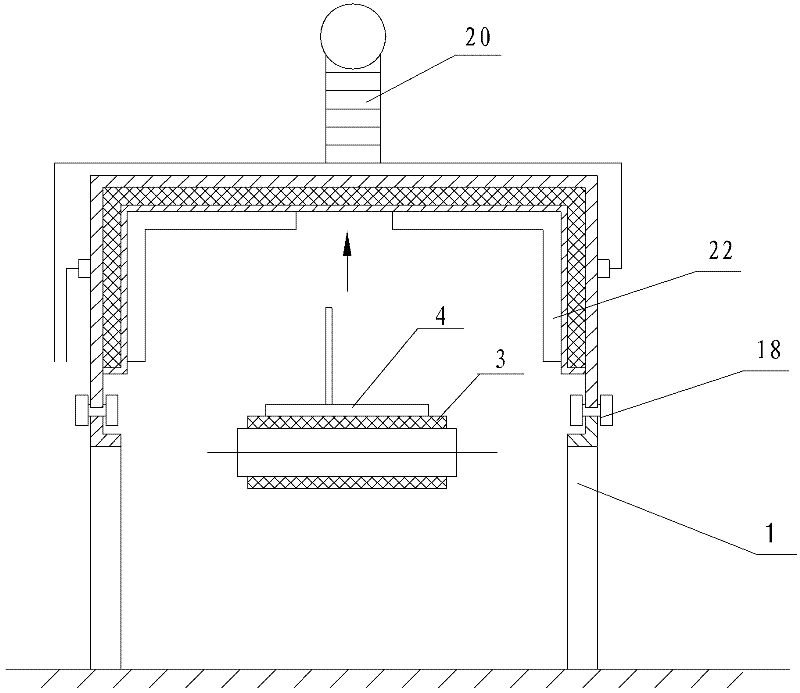

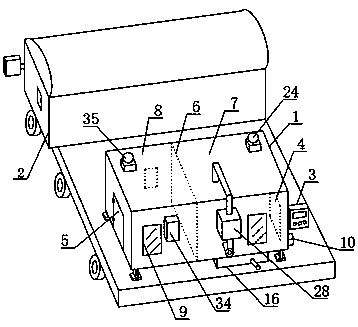

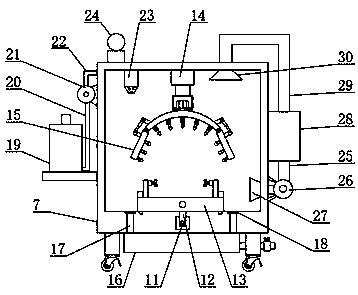

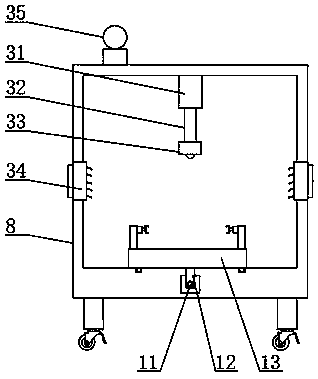

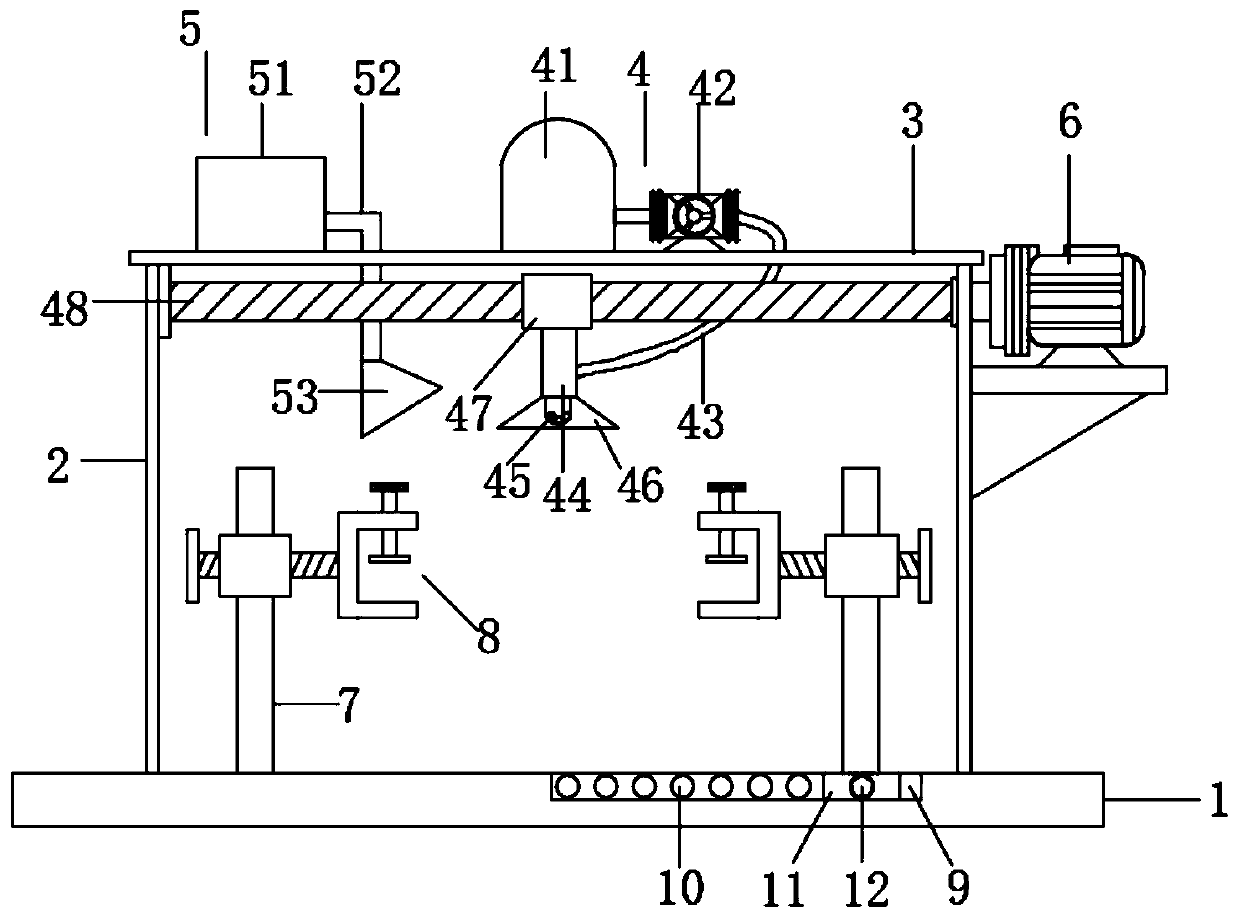

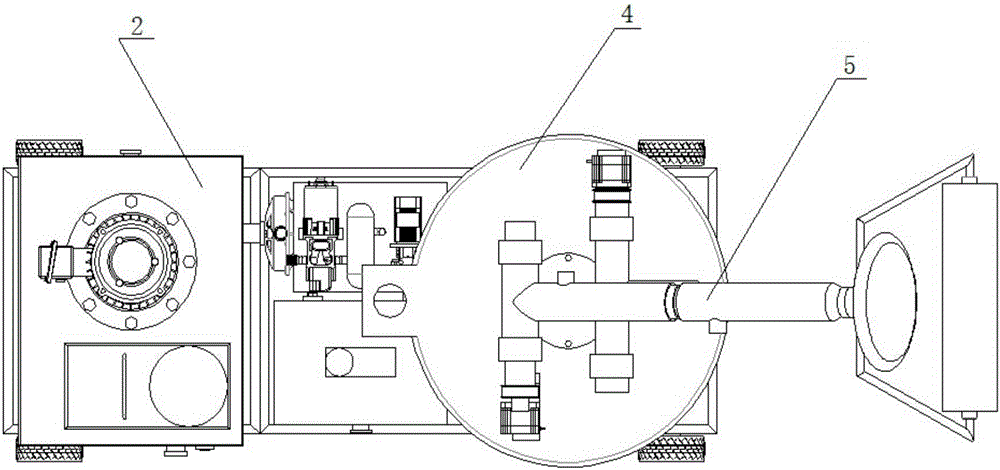

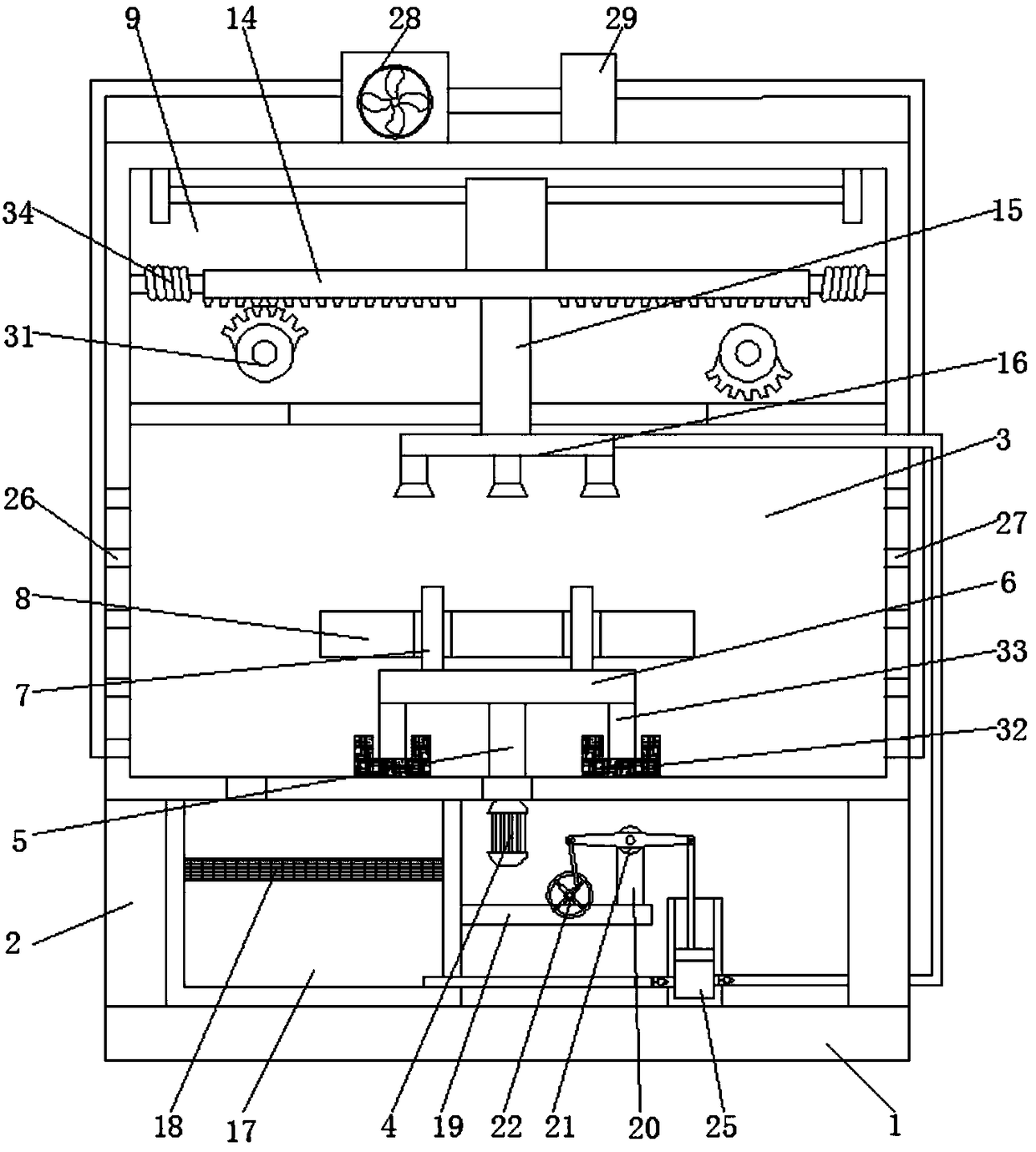

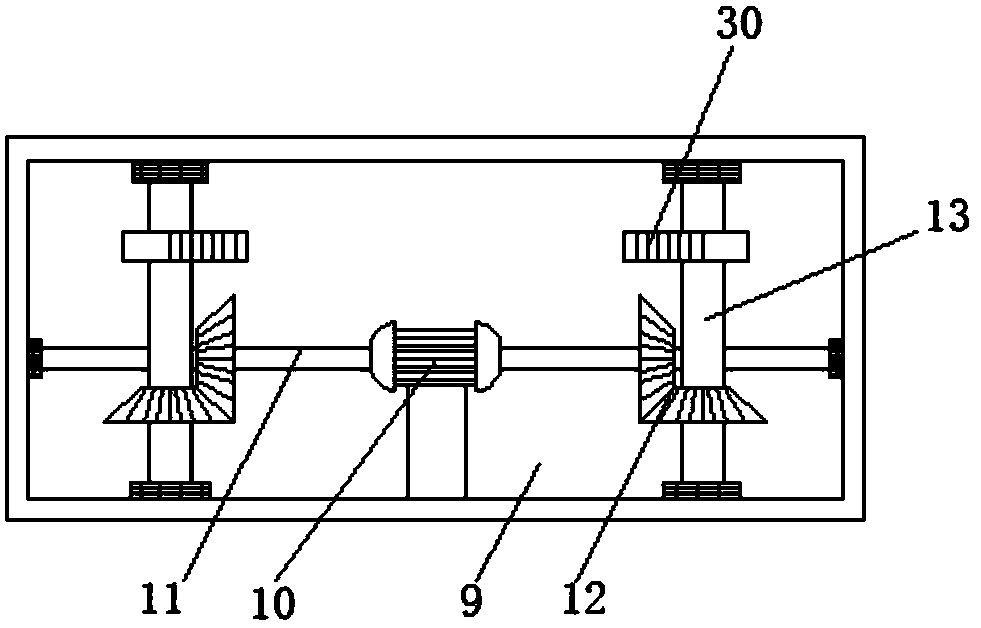

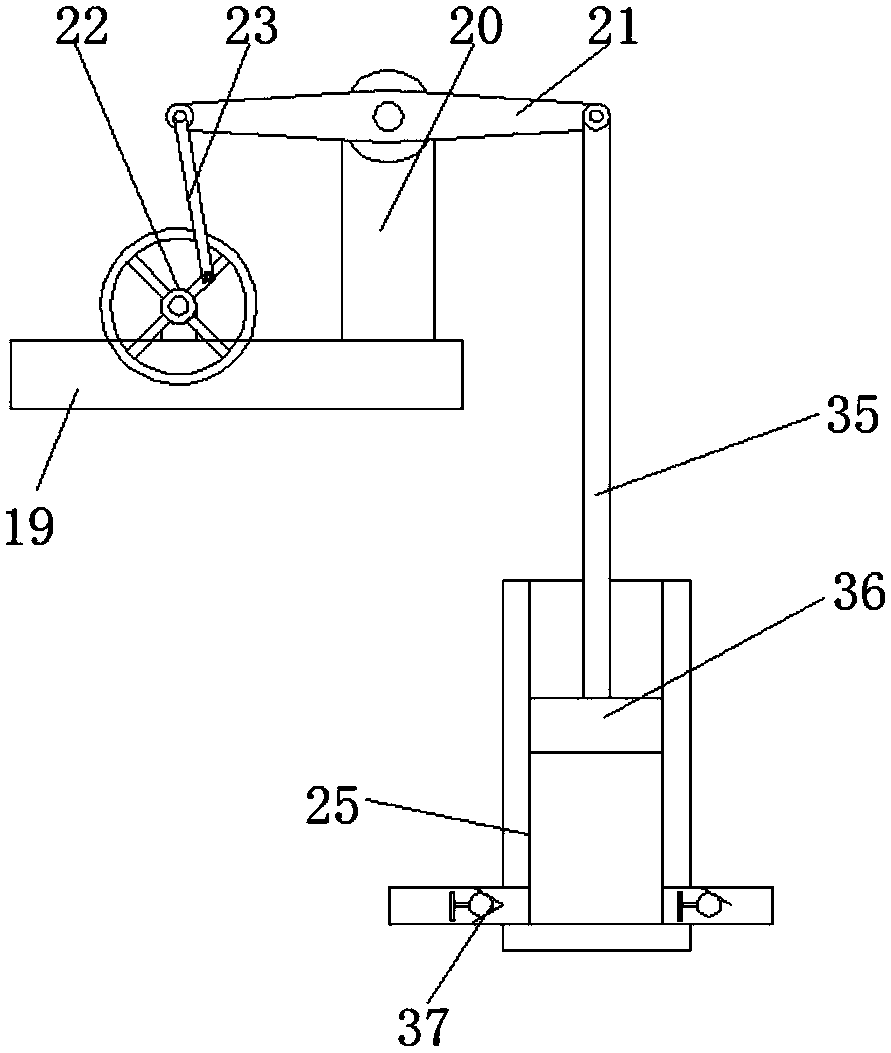

Mobile environment-friendly paint spraying booth

InactiveCN109604101AEasy to paintImprove painting efficiencyPretreated surfacesCoatingsHydraulic cylinderInternal cavity

The invention discloses a mobile environment-friendly paint spraying booth in the technical field of paint spraying. The paint spraying booth comprises a paint spraying booth body and a transport vehicle; an inner cavity of the paint spraying booth body is divided by a dividing plate into a paint spraying chamber located on the right side and a drying chamber located on the left side; a driving mechanism is mounted in the center of the inner wall of the top of the paint spraying chamber; a dust sensor is mounted on the back side of the inner wall of the top of the paint spraying chamber; the top end of a filtering box is connected with the bottom end of an air inlet pipe; the top end of the air inlet pipe extends to the top of an inner cavity of the paint spraying chamber; an air inlet cover is mounted at the top end of the air inlet pipe; and the bottom of a hydraulic cylinder I is connected with a detecting mechanism through a telescopic rod I. According to the paint spraying booth,an upper paint spraying pipe cooperates with side paint spraying devices on two sides, clamped workpieces are rotated by 180 degrees by two rotation motors, and two-side paint spraying is performed onthe workpieces, so that the paint spraying efficiency for the workpieces is improved effectively; and the workpieces after paint spraying are dried by the aid of a fan with heat produced by a heatingresistance wire II during working, so that environmental pollution caused by waste gas and waste liquids which are produced during paint spraying is avoided.

Owner:袁大力

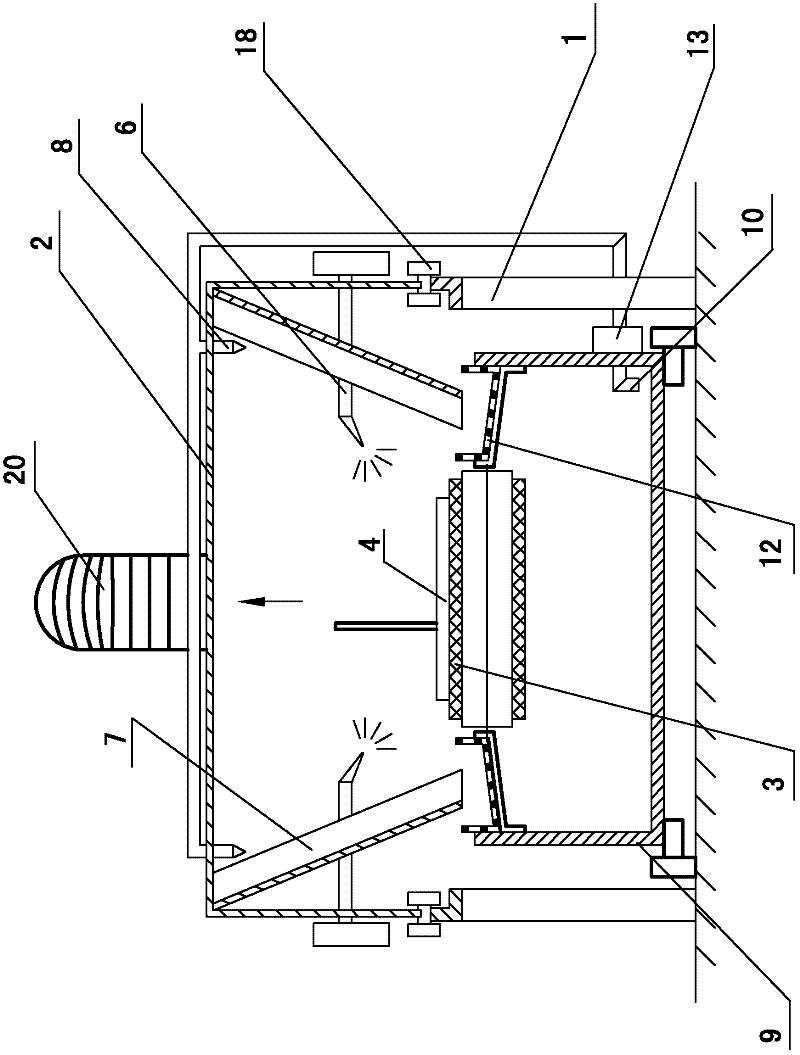

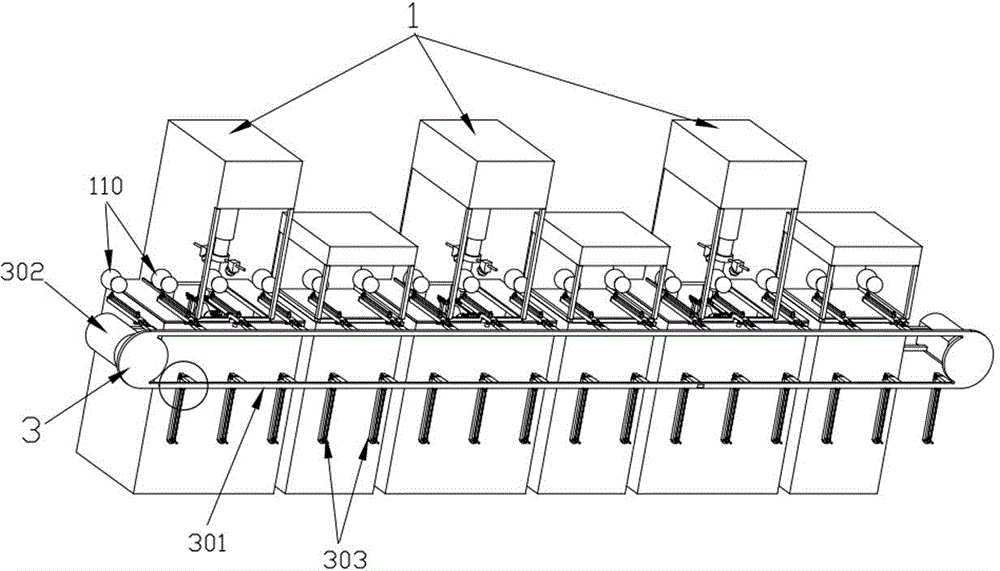

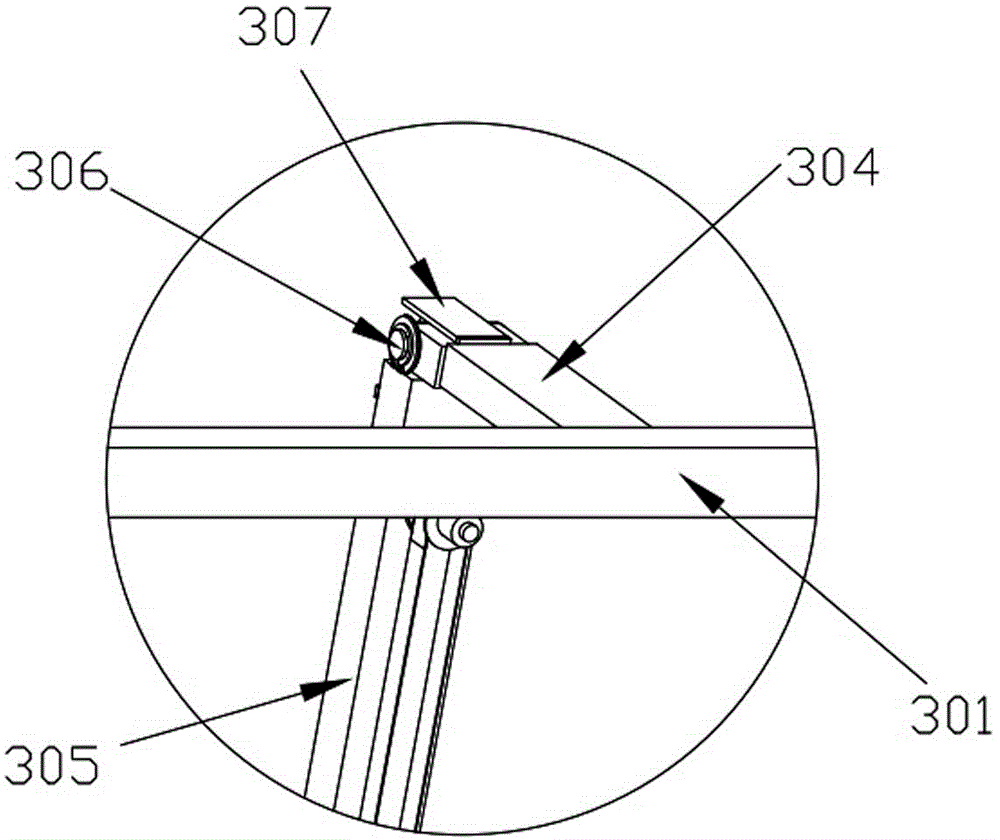

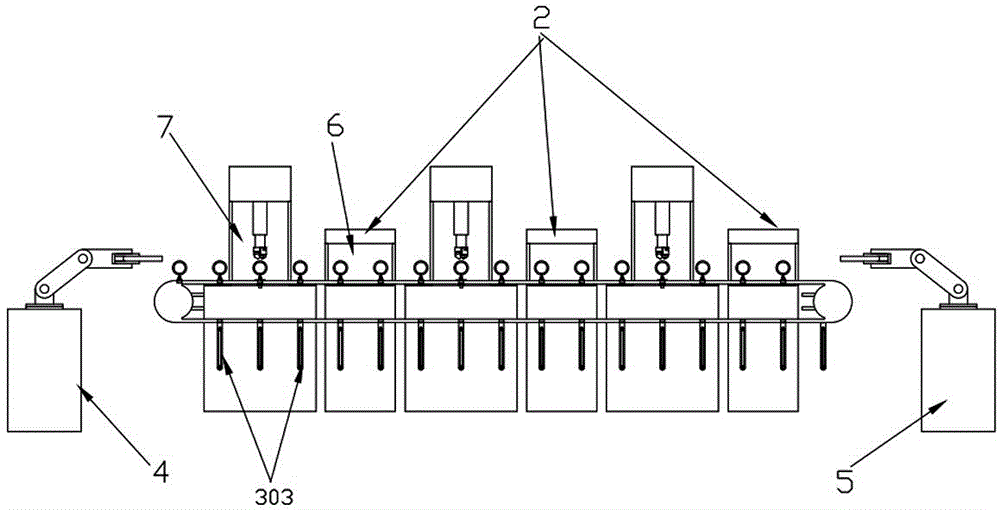

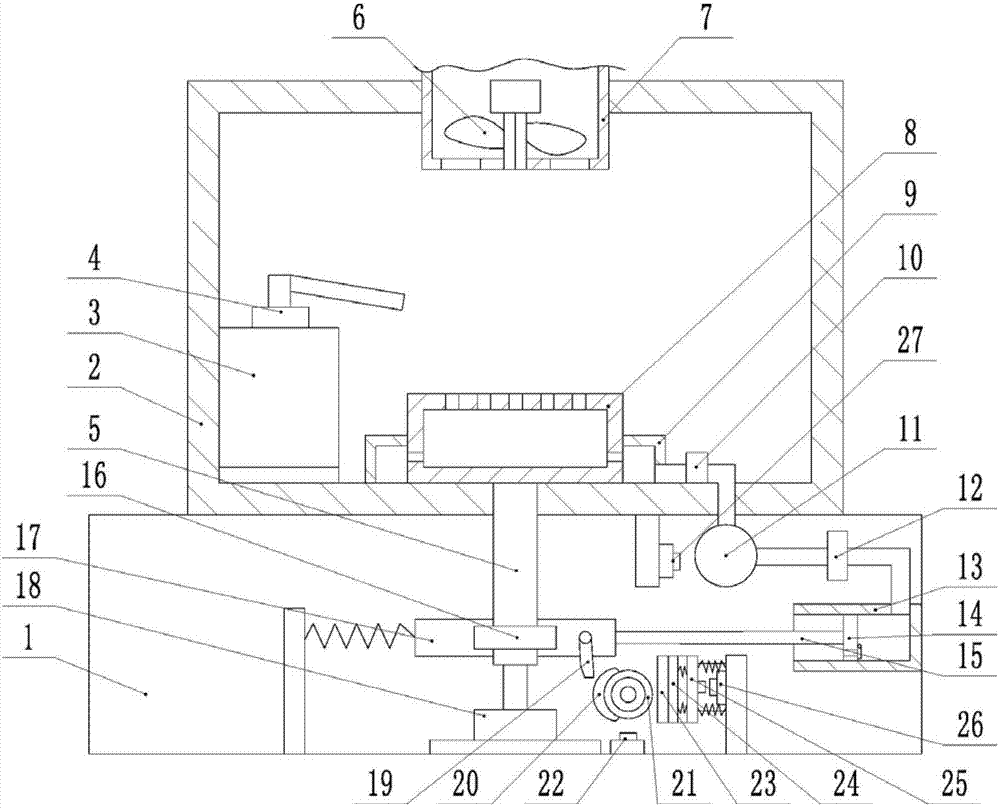

Full-automatic paint spraying assembly line

InactiveCN104056749AHigh degree of intelligenceReduce labor costsLiquid surface applicatorsCoatingsEngineeringAssembly line

The invention discloses a full-automatic paint spraying assembly line of the technical field of automatic machinery. The full-automatic paint spraying assembly line comprises automatic sprayers, automatic dryers, an automatic assembly line, a feeding mechanical hand, an unloading mechanical hand and a touch screen control platform, wherein more than two automatic sprayers are arranged, and a die cleaning mechanism, a spray operating room and a spray mechanism capable of moving triaxially are respectively mounted at the bottom, at the middle and at the top of each automatic sprayer; a die cleaning room used for storing die cleaning water is arranged at the bottom of each die cleaning mechanism; each die cleaning mechanism is composed of two die assembly components which have the same structure and are respectively arranged at the top and at the bottom of each die cleaning mechanism, more than two telescopic air cylinders used for connecting the two die assembly components, and an overturn component used for overturning the two die assembly components, so as to switch positions of the two die assembly components. The assembly line type paint spraying is highly efficient in that various paint spraying procedures can be implemented simultaneously along with synchronous paint drying, the paint with various colors can be sprayed at the same time, and various areas can be simultaneously coated, so that space and cost can be saved, the efficiency is improved, and time consumed for cleaning dies is shortened.

Owner:东莞市贾氏机械制造有限公司

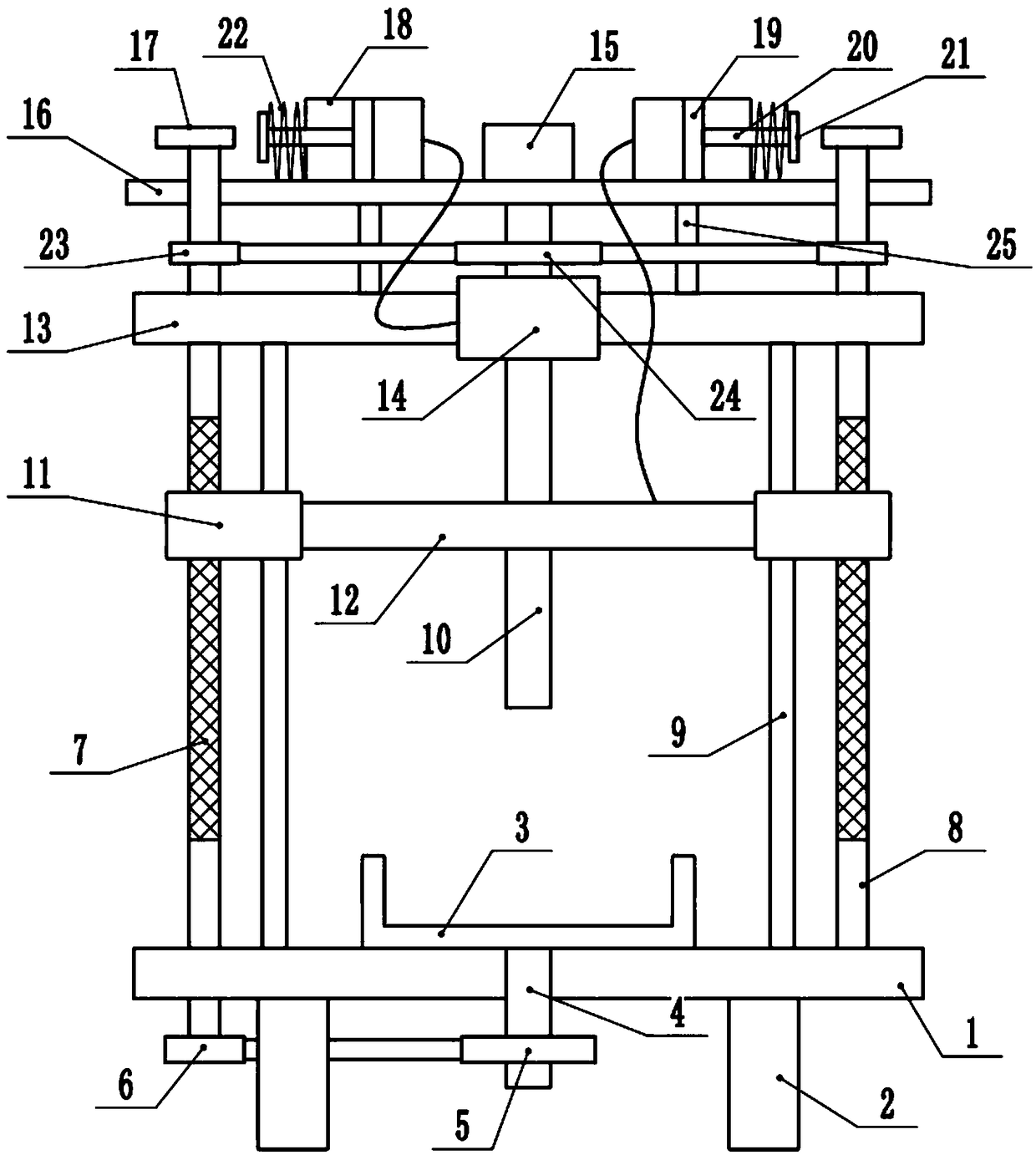

Wooden door processing device with rotational double-side paint spraying function

The invention discloses a wooden door processing device with a rotational double-side paint spraying function. The wooden door processing device comprises a fixing base, a paint spraying chamber and aworking support plate, wherein two chutes are formed in the working support plate; sliding blocks are arranged inside the chutes; a left fixing plate is arranged on the sliding block on the left side; a right fixing plate is arranged on the sliding block on the right side; a lifting threaded column is arranged on the left fixing plate; a rotating fixing device is arranged on the limiting threadedcolumn; a plate clamping block is arranged on the rotating fixing device. The wooden door processing device is applied to pain spraying processing on a wooden door, paint is spayed to the wooden doorthrough a nozzle, in the pain spraying process, a paint spraying tube is rotated slowly under driving of a second rotating motor, then paint spraying uniformity is ensured, and the paint spraying quality of the wooden door is improved; when double sides of the wooden door need to be painted, a first rotating shaft is driven to rotate through a first rotating motor, the wooden door is driven to rotate through the first rotating shaft, the wooden door is rotated for a certain angle, then the double sides of the wooden door can be painted, and the device is convenient and rapid to operate and high in automation degree.

Owner:蚌埠抒阳自动化设备制造有限公司

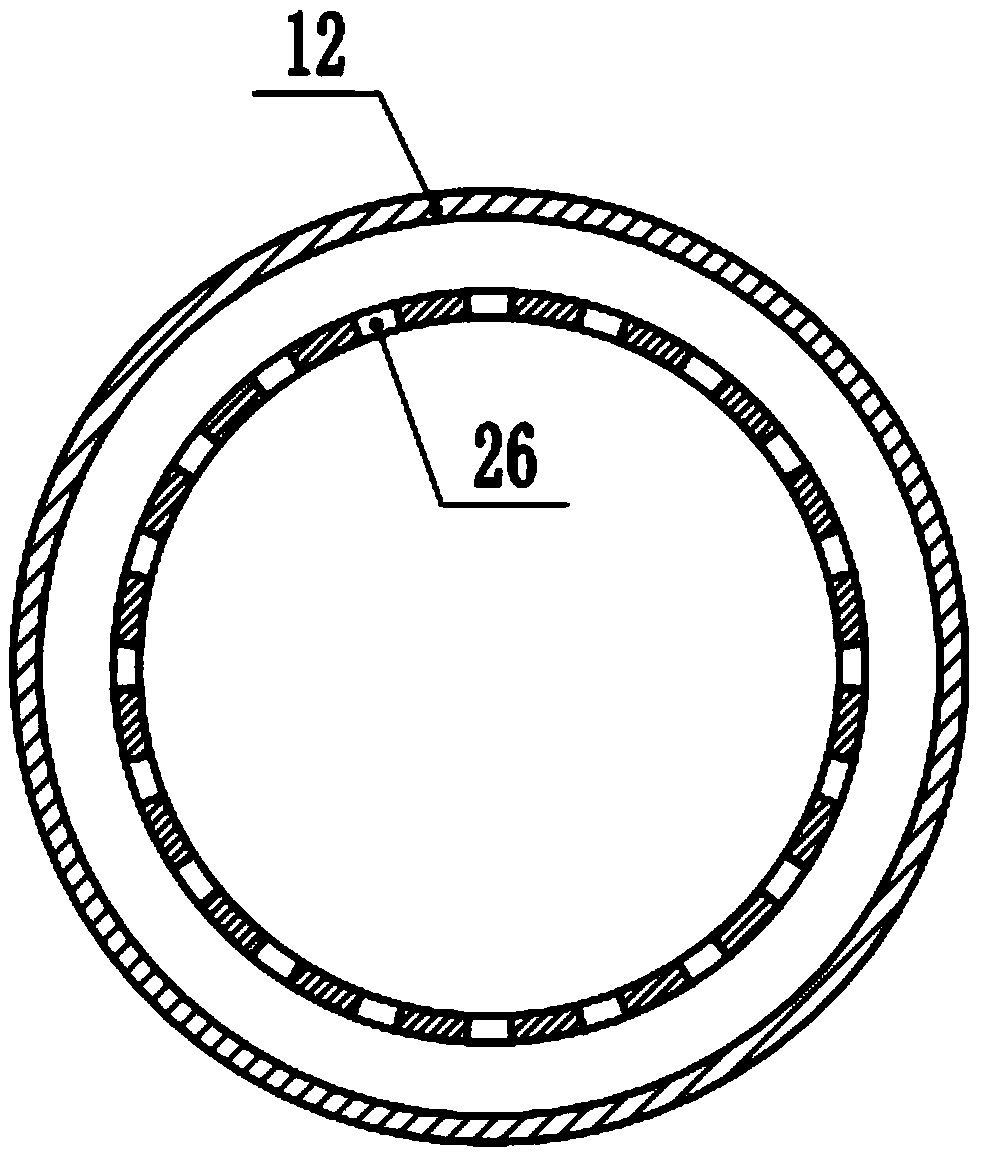

Plastic part surface paint spraying device

InactiveCN107952615AEvenly paintedReduce labor intensitySpray boothsEngineeringMechanical engineering

The invention relates to a plastic part surface paint spraying device, comprises a rack and a spray gun. The rack is fixedly provided with a paint spraying box. The paint spraying box is internally rotatably connected with a rotating shaft. The rotating shaft is fixedly connected with a rotating disk. The rotating shaft is fixedly provided with a fan gear. The fan gear is meshed with a rack. The rack is pivoted with a pawl. The rack is rotatably connected with a ratchet wheel. The pawl is meshed with the ratchet wheel. The rack is provided with a first button. The ratchet wheel is coaxially connected with a cam. The rack is fixedly provided with an inflator. The inflator is internally slidably connected with a piston. The inflator is communicated with an air outlet pipe. The rack is fixedly provided with an air bag. The air outlet pipe is communicated with the air bag. The air outlet pipe is provided with a one-way valve. The paint spraying box is internally fixedly provided with an annular pipe. The rotating disk is rotatably connected in the annular pipe. The rotating disk is communicated with the annular pipe. The rotating disk is provided with an air outlet. Compared with the prior art, the scheme can ensure uniform paint spaying on each position of a plastic product. The device is arranged in a full mechanization manner, and labor intensity is reduced. The plastic productis not needed to be dried again. The device is simpler to operate.

Owner:宁波得晴电器科技有限公司

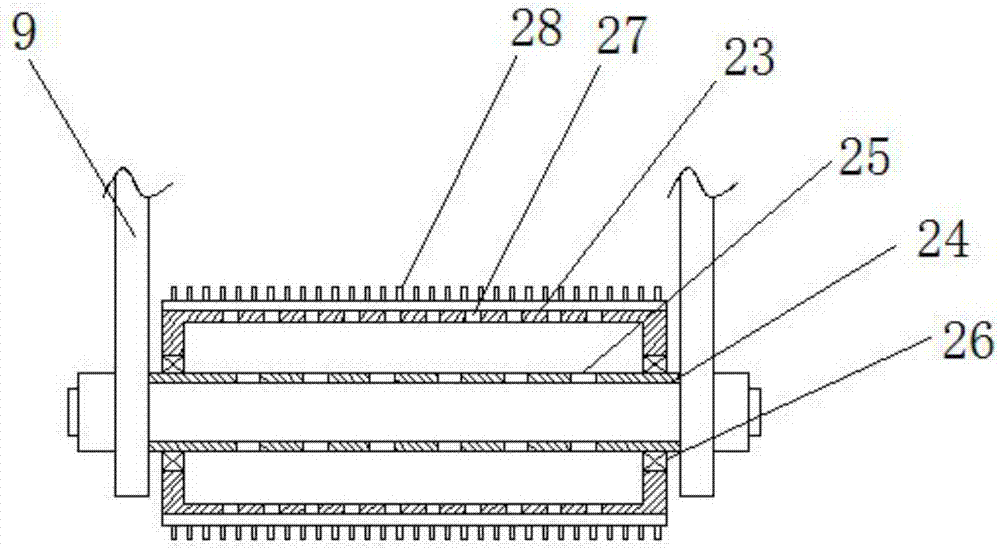

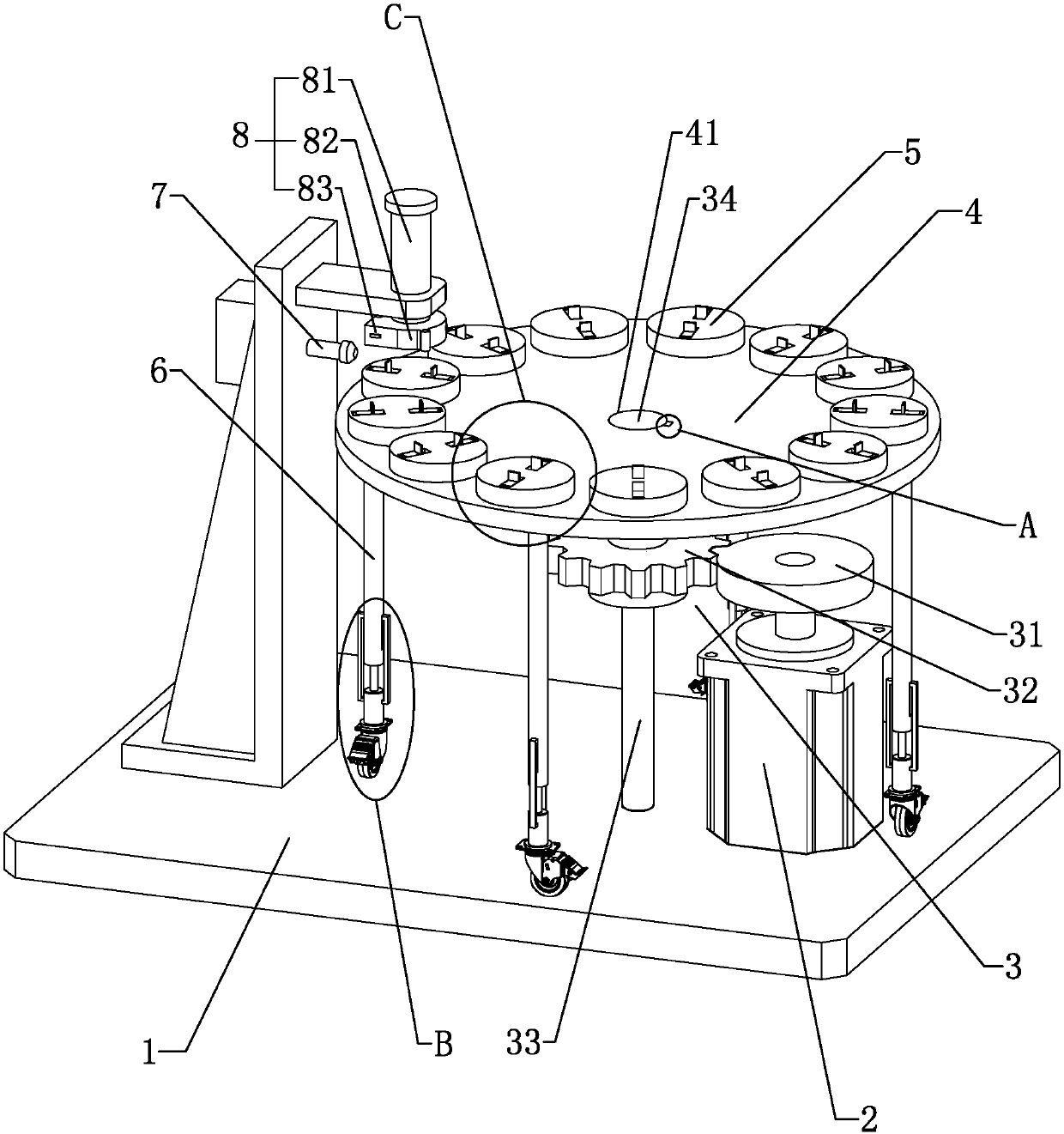

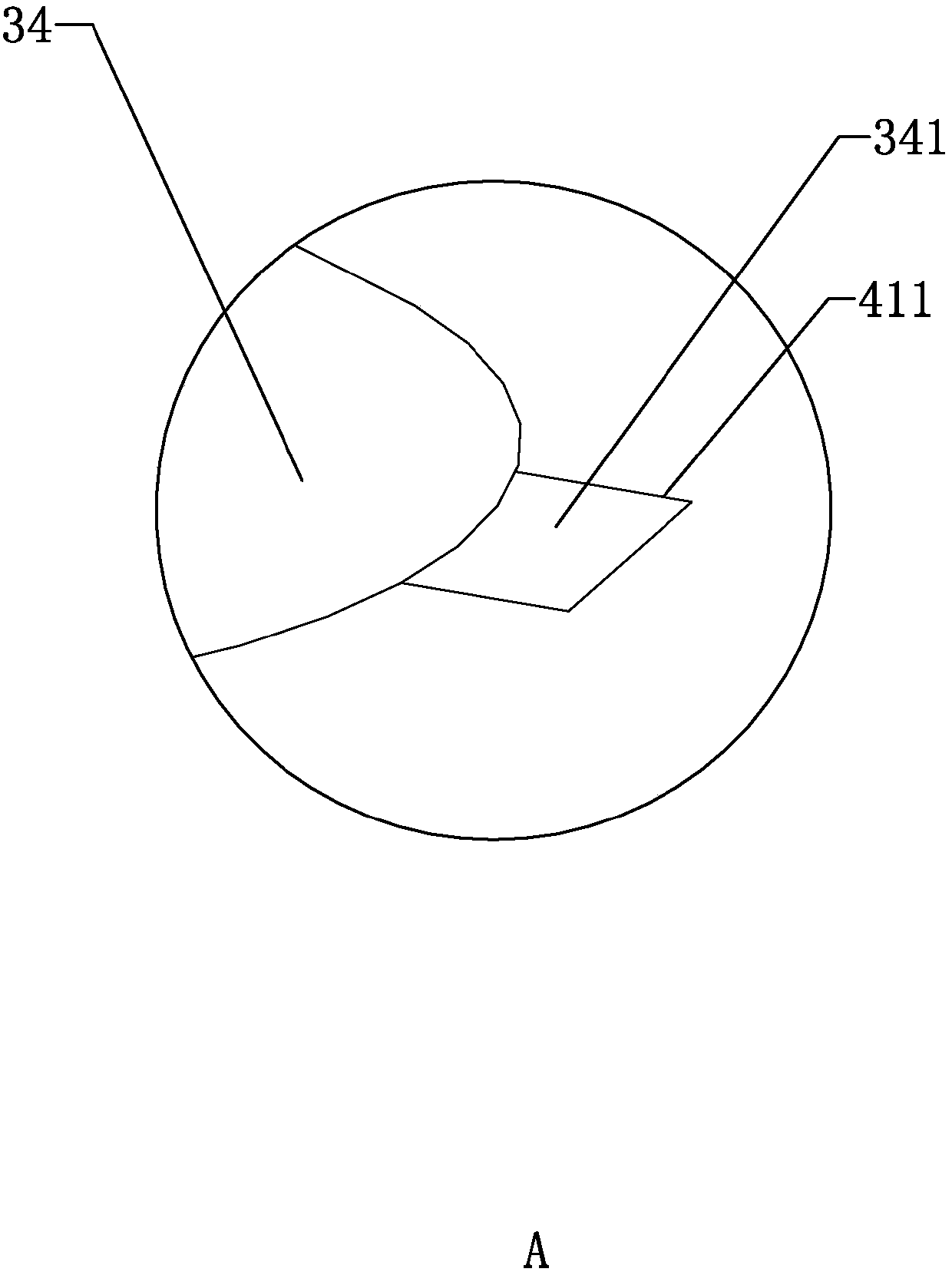

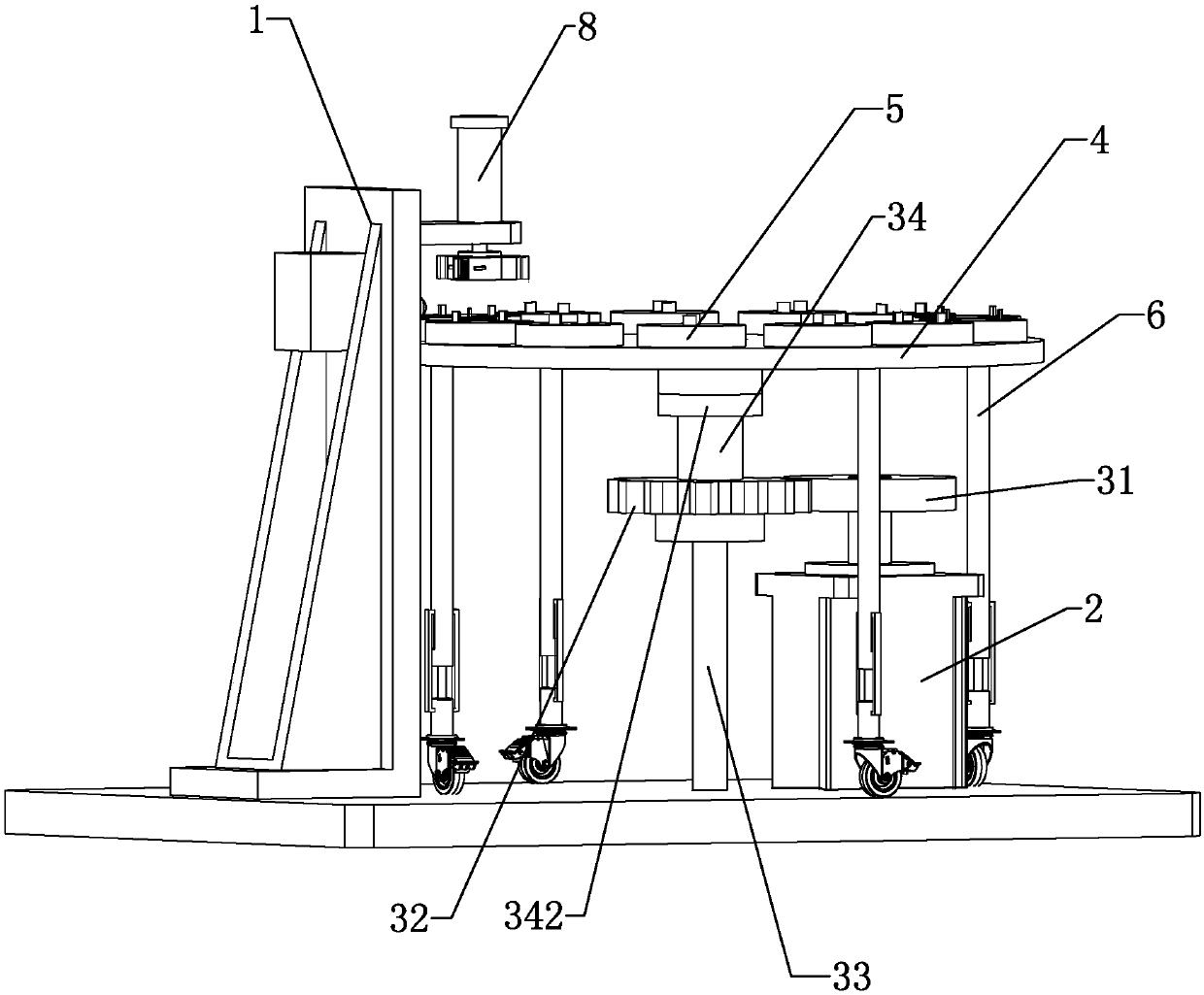

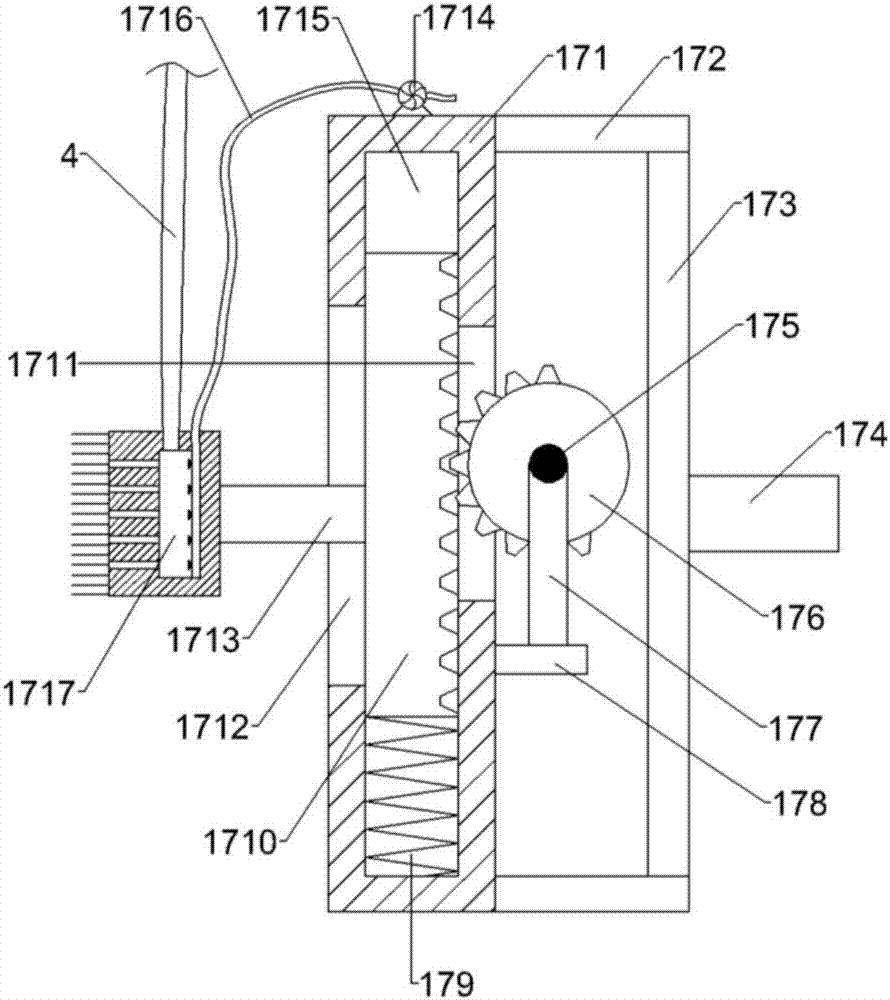

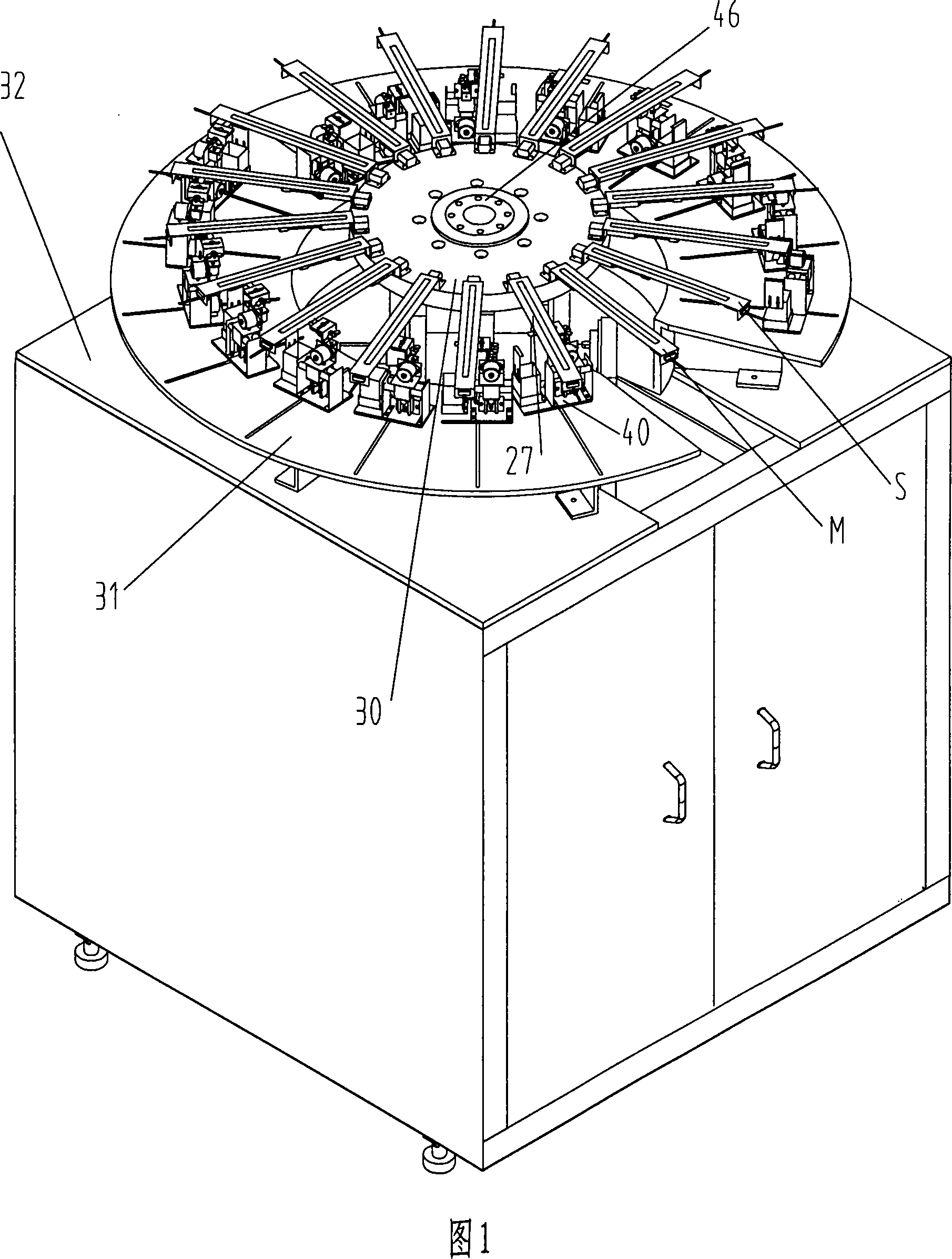

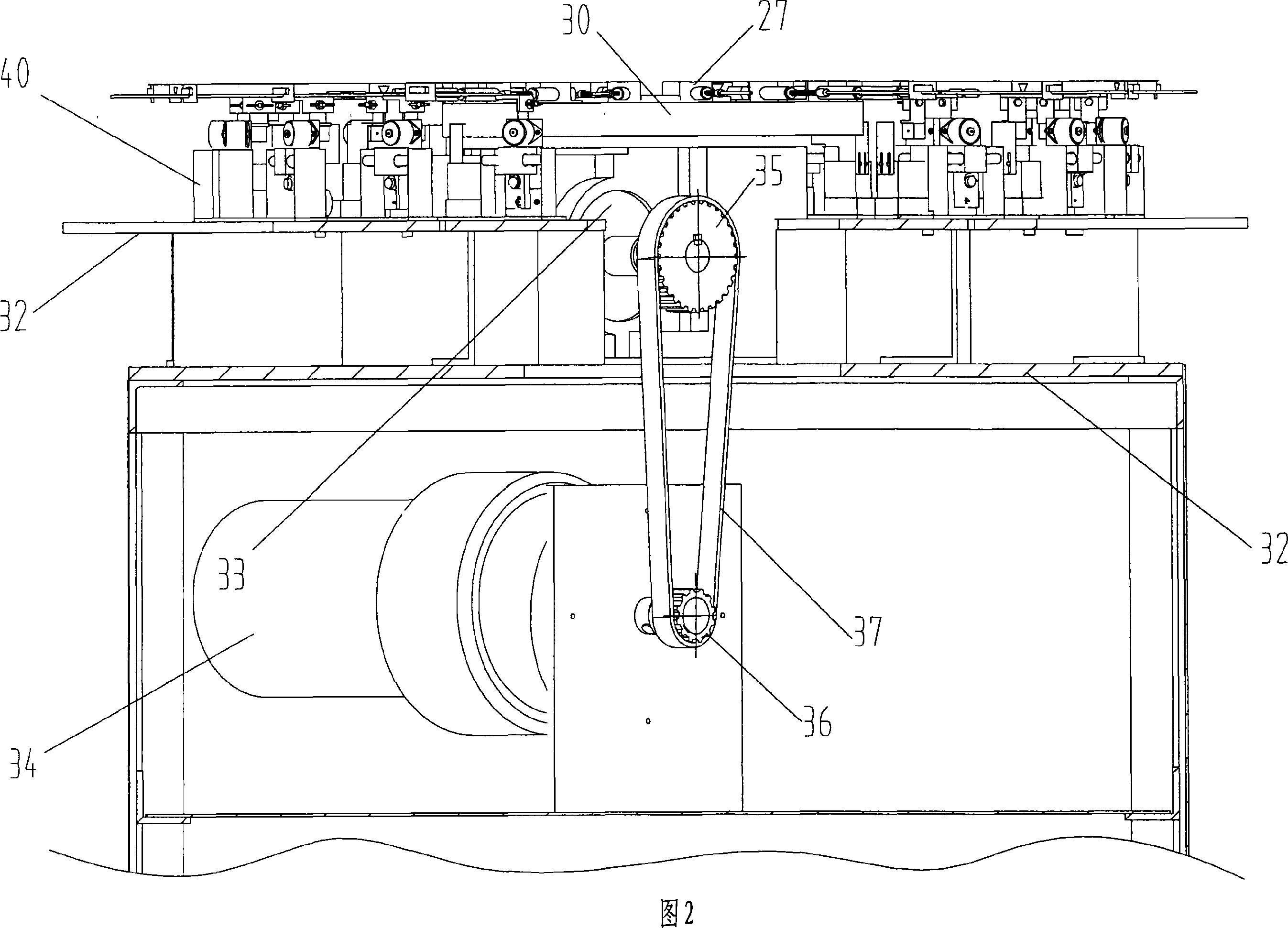

Paint spraying equipment for luminous word shell

ActiveCN107899783AReduced failure rateImprove painting efficiencySpraying apparatusEngineeringSpray method

The invention discloses paint spraying equipment for a luminous word shell and provides a paint spraying method for the luminous word shell. According to the technical scheme, the paint spraying equipment is characterized by comprising a rack, a first motor, an intermittent drive mechanism connected to an output shaft of the first motor, a rotating shaft driven by the intermittent drive mechanismto rotate, a supporting rotary disk sleeving the rotating shaft, a plurality of article supporting rotary tables rotationally connected to the top face of the supporting rotary table, a second motor which is fixed into the supporting rotary table and drives the article supporting rotary tables to rotate, a paint spraying head fixed to the rack, and a shielding mechanism located above the article supporting rotary tables. The shielding mechanism comprises a pressing air cylinder fixed to the rack and a shielding block connected to a drive rod of the pressing air cylinder, the shielding block isinternally provided with a draught fan, and a draught fan works in the direction where the paint spraying head is located. According to the paint spraying equipment for the luminous world shell, thetop face of the luminous word shell is shielded by the shielding mechanism, the draught fan and the paint spraying head work at the same time, the sprayed paint on the top face of the luminous word shell is blown away, and therefore dirt paint traces cannot appear on the top face of the luminous word shell.

Owner:浙江威克环境艺术工程有限公司

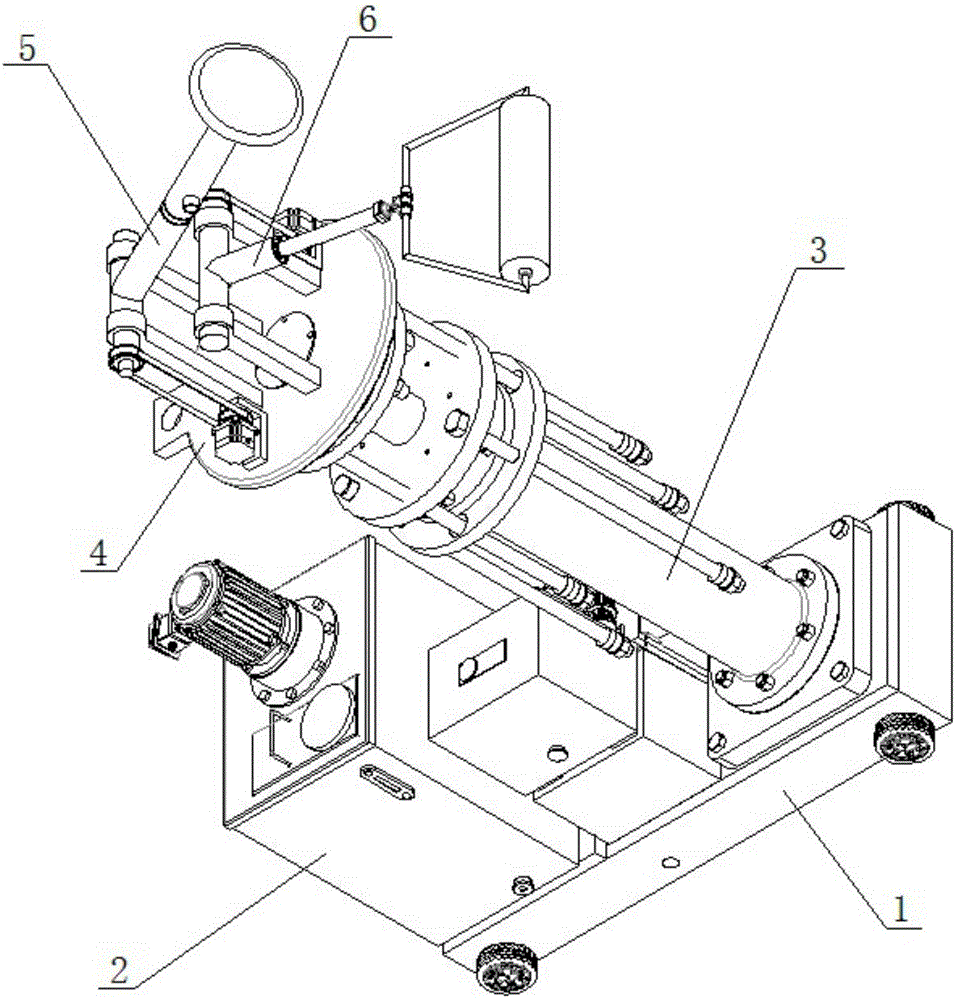

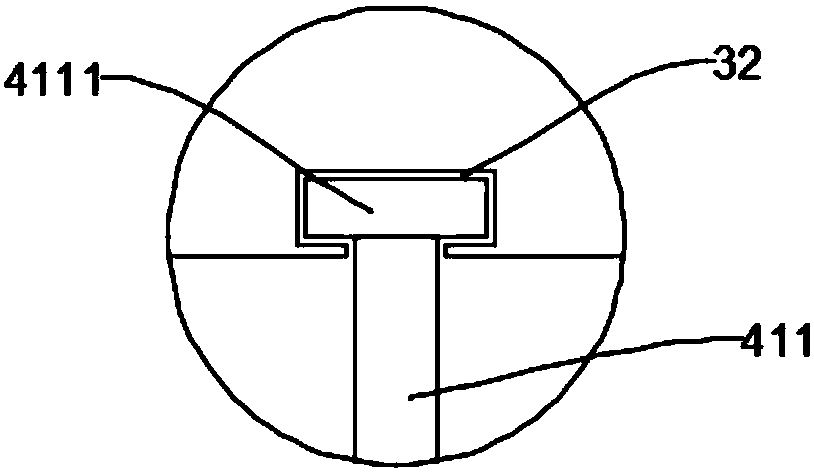

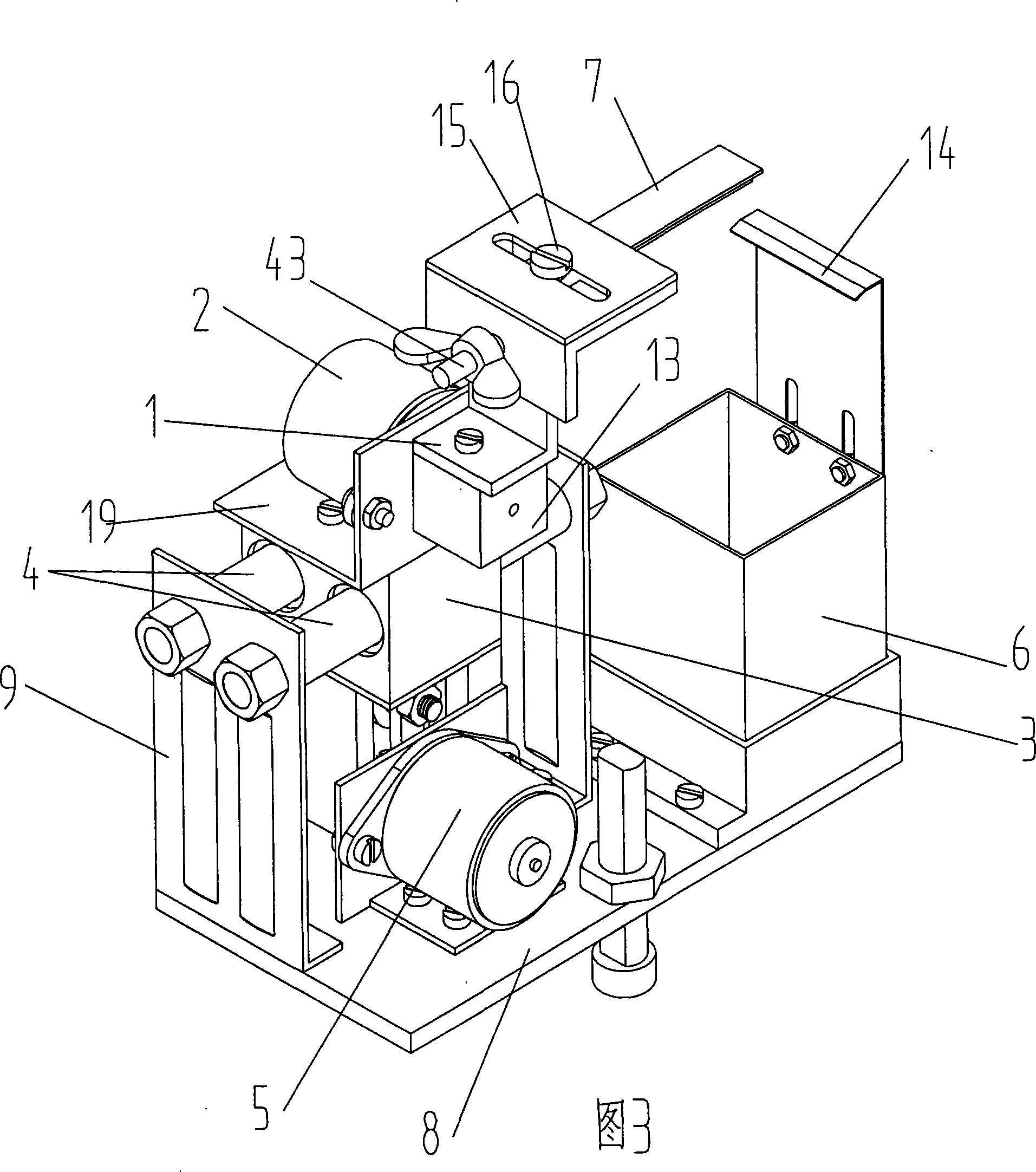

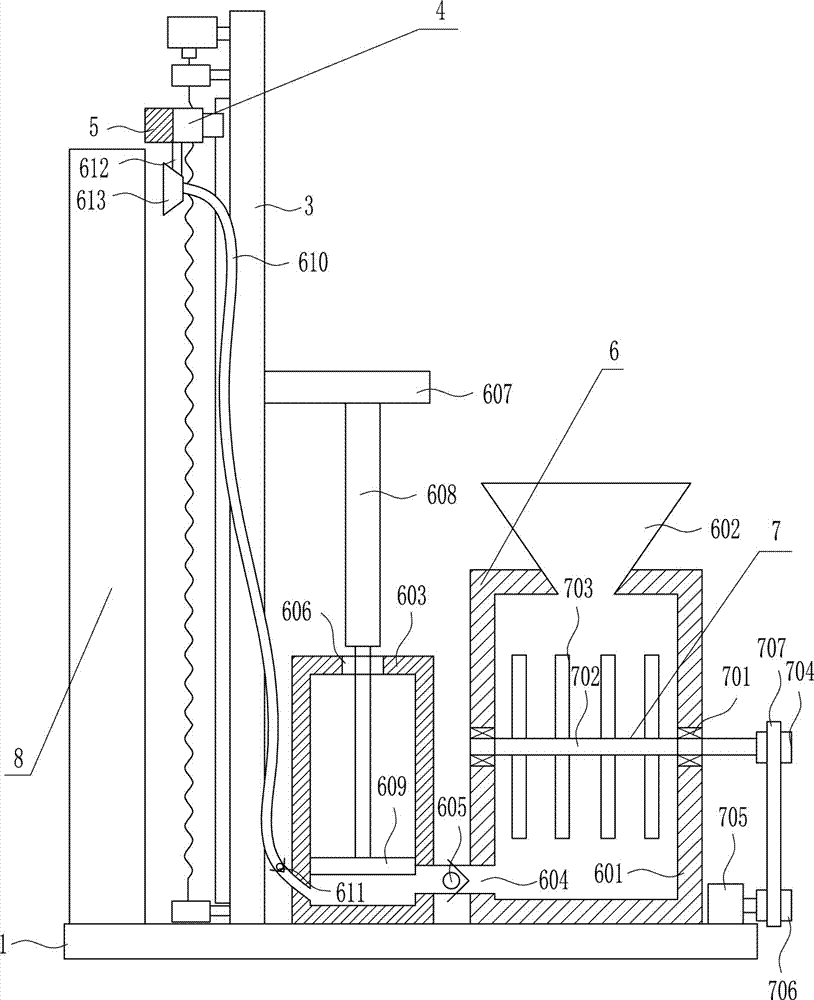

Pipeline spraying device

ActiveCN108787218AEasy to moveStable output speedLiquid surface applicatorsLiquid spraying apparatusUniversal jointSpray nozzle

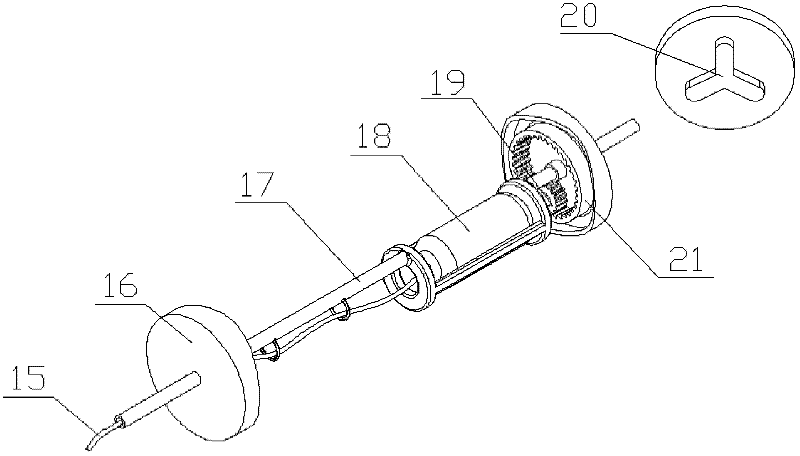

The invention discloses a pipeline spraying device comprising a feeding module and a clamping module. The feeding module comprises a machine frame, a spraying cavity formed in the upper portion of themachine frame, a drive motor arranged on the upper portion of the spraying cavity, a two-way lead screw movably connected with the lower portion of the drive motor, spray nozzles connected to the left side and the right side of the two-way lead screw correspondingly, and a liquid guide pipe arranged on the lower portion of the spraying cavity and communicating with each other. The lower portion of the liquid guide pipe is connected with the spray nozzles. The clamping module comprises a universal joint connected to the left side of the two-way lead screw in a rolling manner, a triangle clamping column used for clamping a pipeline and arranged on the universal joint, a regulation wheel arranged on the right side of the machine frame, and a triangle clamping column used for clamping the pipeline and arranged on the regulation wheel. Paint vehicle on the surface of the pipeline is comprehensively sprayed, and the paint vehicle is evenly sprayed.

Owner:邵勤俏

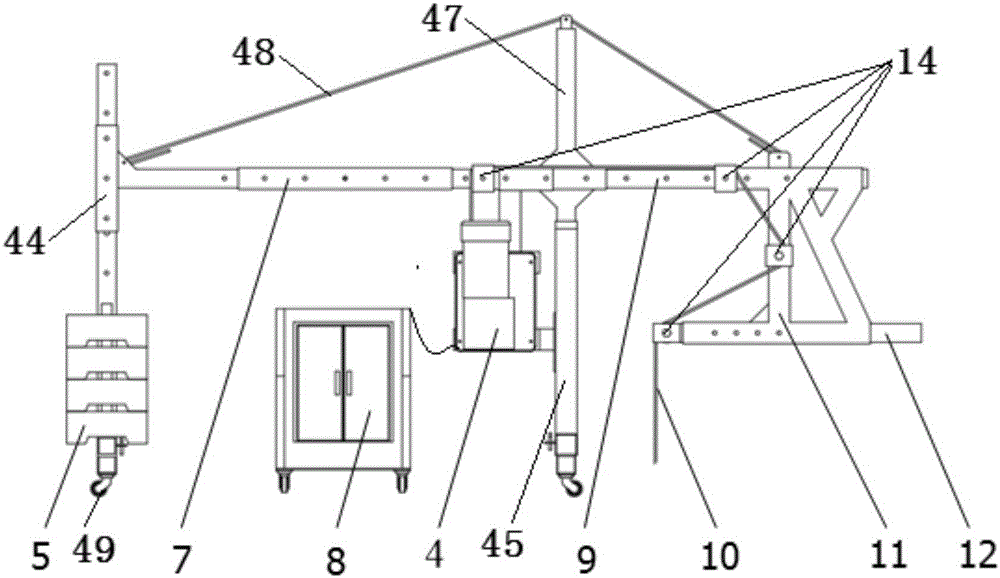

Color steel tile face paint spraying device

A color steel tile face paint spraying device is used for color steel composite plate paint spraying and comprises a base, stand columns and a transverse plate. The stand columns are fixedly arrangedon the two sides of the upper surface of the base, the transverse plate is fixedly arranged between the top ends of the two stand columns, and a drying mechanism is arranged on one side of the top endof the transverse plate. The side, away from the drying mechanism, of the top end of the transverse plate is provided with a paint spraying mechanism. A motor is fixedly arranged above the stand column on one side through a supporting plate. The upper surface of the part, between the two stand columns, of the base is fixedly provided with two fixing columns. Fixing mechanisms are arranged on thetwo fixing columns. A protection cover is arranged outside a paint sprayer and completely wraps the sprayer, so that when the sprayer sprays out paint, the protection cover keeps off the splashed paint, the paint is retained on the protection cover, paint waste is reduced, and the problem that when an existing paint spraying device sprays paint, the paint spraying-out speed is too high, consequently, a coating is scattered and flies, the paint is wasted, and meanwhile the surrounding air environment is polluted are solved.

Owner:ZHONGXIANG DINGMAO TECH

Environment-friendly panel paint spraying device

InactiveCN108580091AAvoid wastingAvoid pollutionLiquid surface applicatorsSpraying apparatusEngineeringCoating

The invention relates to the field of panel machining equipment, and discloses an environment-friendly panel paint spraying device. The environment-friendly panel paint spraying device comprises a base. Supporting plates are fixedly arranged on the two sides of the top of the base, and the top ends of the two supporting plates are fixedly connected with the same support plate. A paint storage boxis fixedly arranged at the middle portion of the top end of the support plate, and a pump body located on one side of the paint storage box is fixedly arranged on the top of the support plate. According to the environment-friendly panel paint spraying device, a sprayer is fixed to the middle portion of a fixing circular plate, a protection cover on the fixing circular plate is utilized for completely wrapping the sprayer, so that when the sprayer sprays out paint, the protection cover stops splashing paint, the paint is reserved on the protection cover and a panel, and the problems that when acommon panel paint spraying device sprays paint, the paint spraying-out speed is too high, bounce is caused, a large number of paint molecules are brought back, consequently, the coating flies all around, the paint is wasted, and meanwhile the surrounding air environment is polluted are solved.

Owner:王雪芬

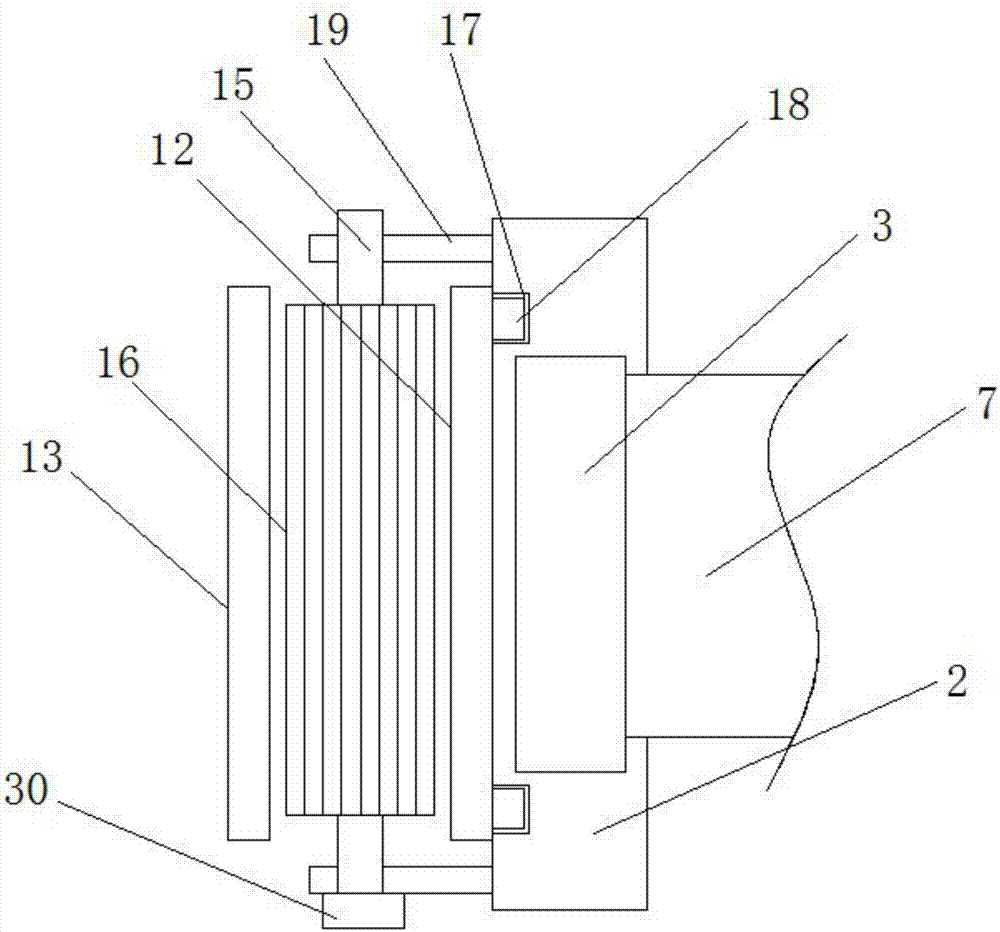

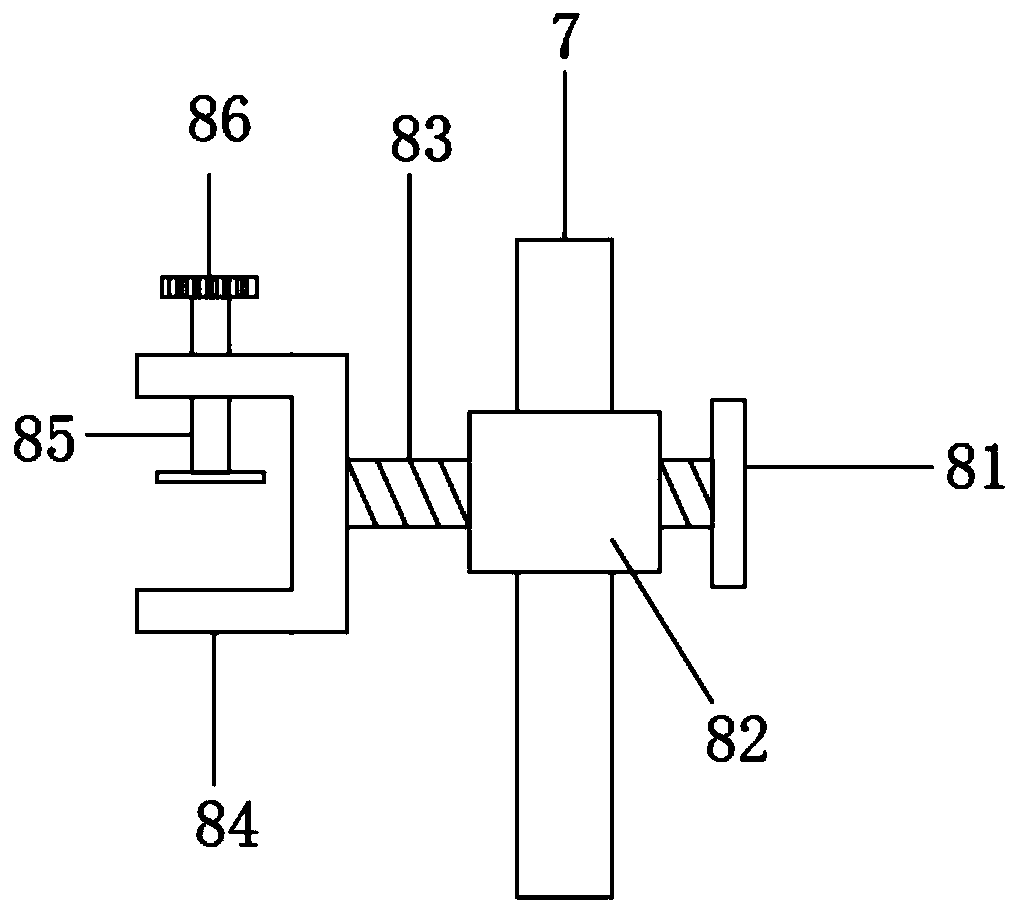

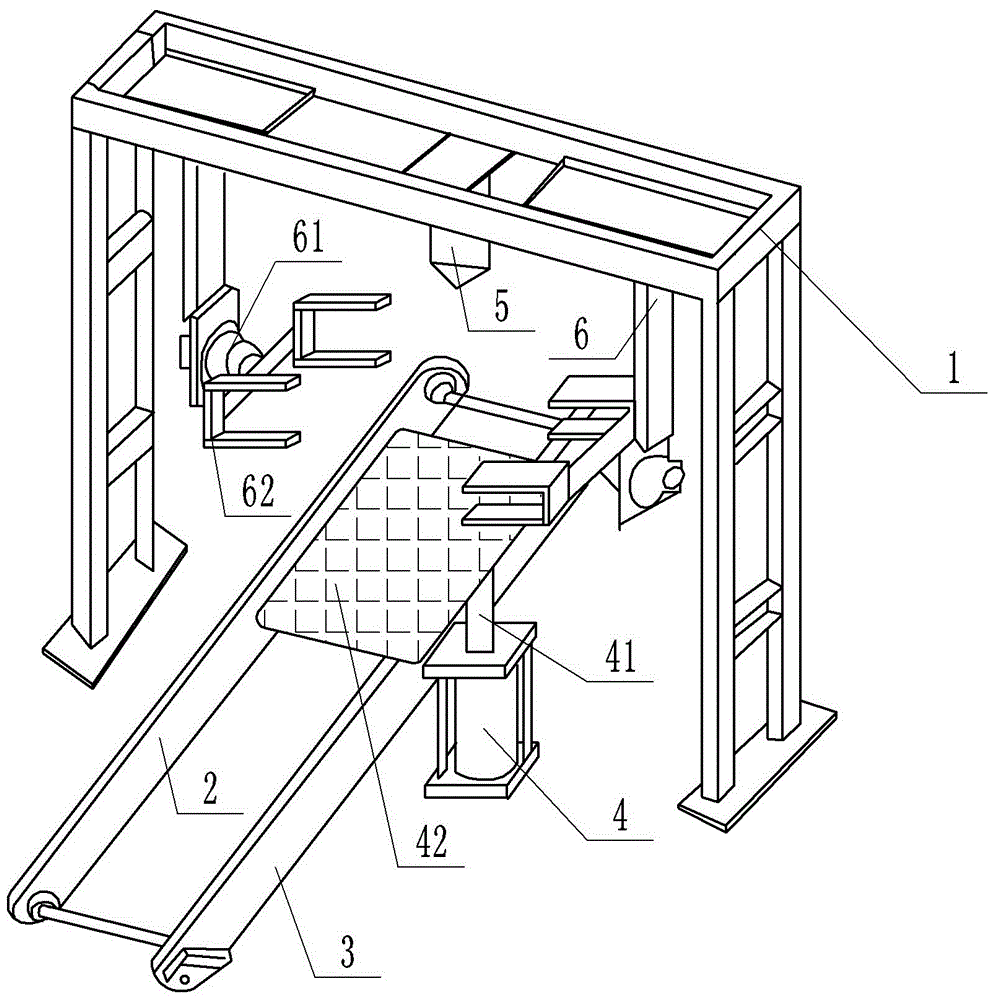

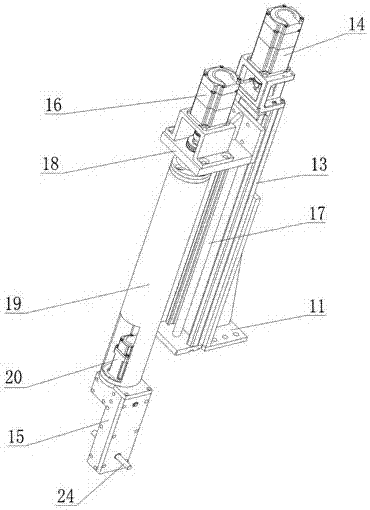

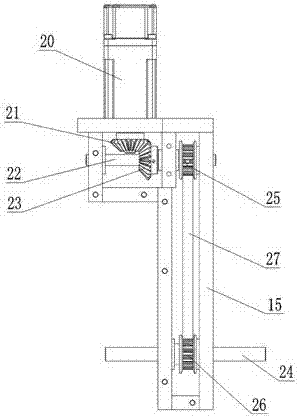

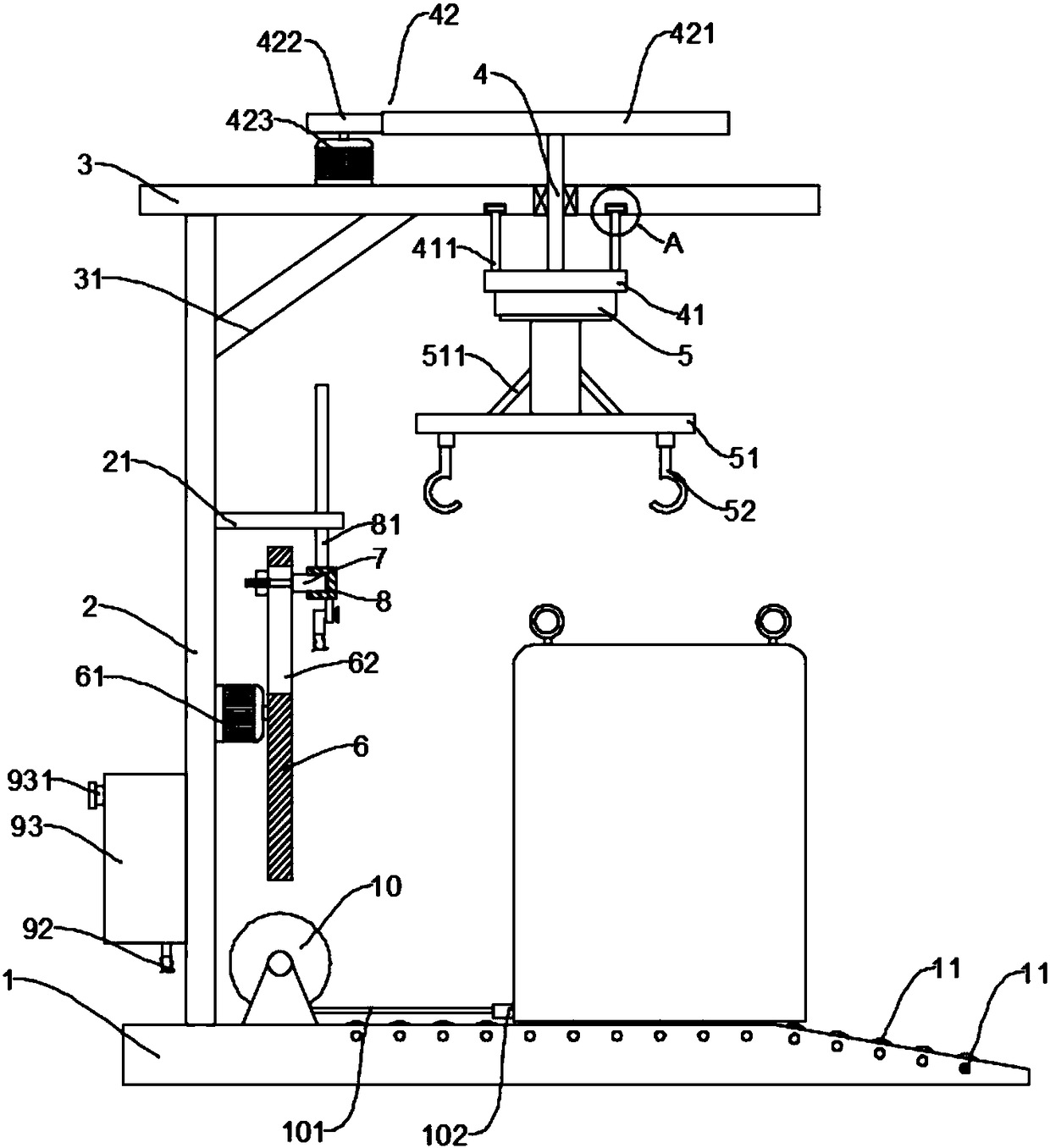

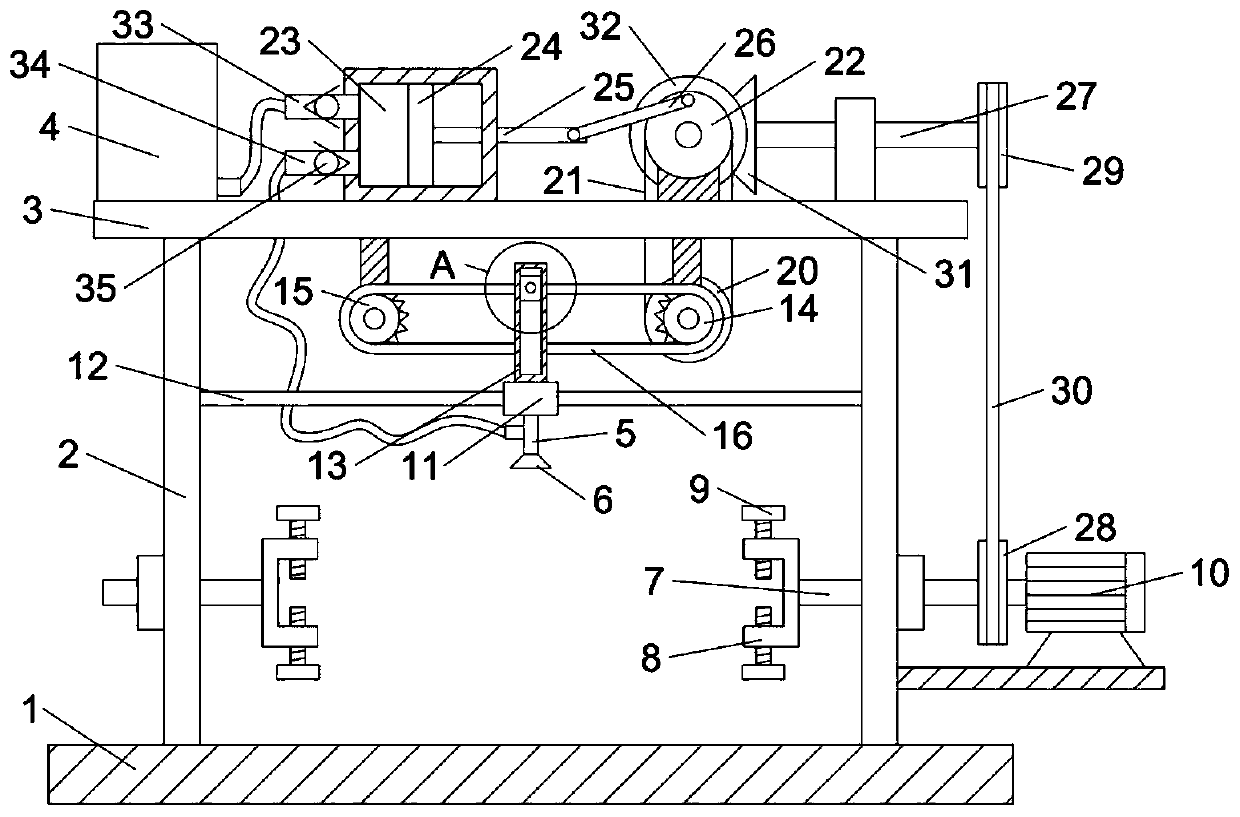

Automatic device for paint spraying of wood door

InactiveCN106423652ARealize all-round paintingReduce labor intensitySpraying apparatusUltimate tensile strengthAutomation

The invention relates to the technical field of paint spraying equipment, in particular to an automatic device for the paint spraying of a wood door. The automatic device comprises a bracket, a conveying device, a lifting device and an automatic paint spraying device, wherein the bracket is located at one side of the transporting direction of the conveying device; the conveying device comprises a left conveying chain and a right conveying chain; the lifting device is located between the left conveying chain and the right conveying chain; a clamping rotating device is arranged above the lifting device, and the clamping rotating device is fixed to the bracket; and the automatic paint spraying device is fixed to the bracket and located above the lifting device. By adopting the technical scheme, the all-dimensional paint spraying of the wood door can be realized, the automation degree is high, the labor intensity of workers is reduced, and the paint spraying efficiency is increased; and as paint spraying is carried out by the machine without depending on the experience of the workers, paint spraying is even, and the spraying effect is great.

Owner:遵义市美呈美居工贸有限公司

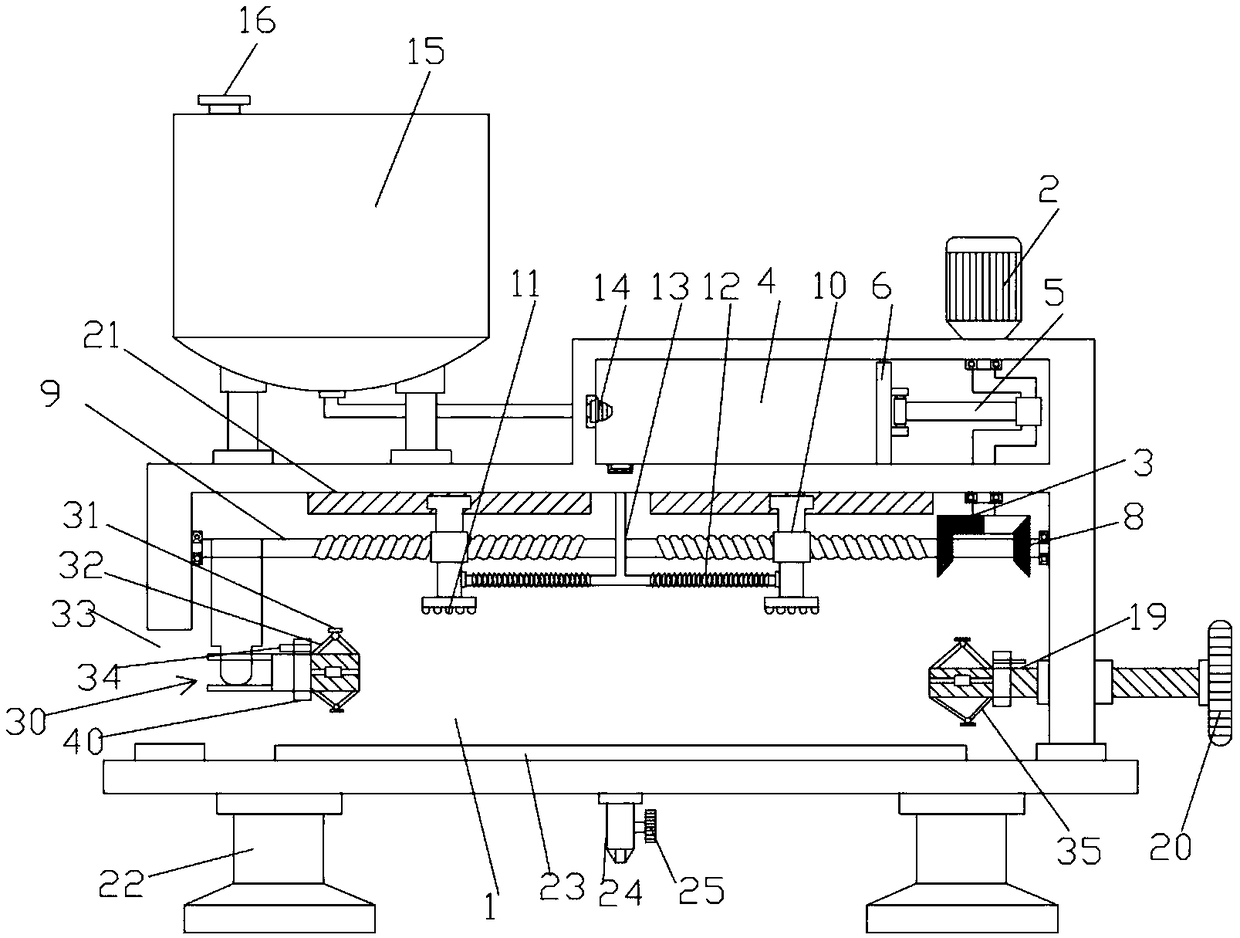

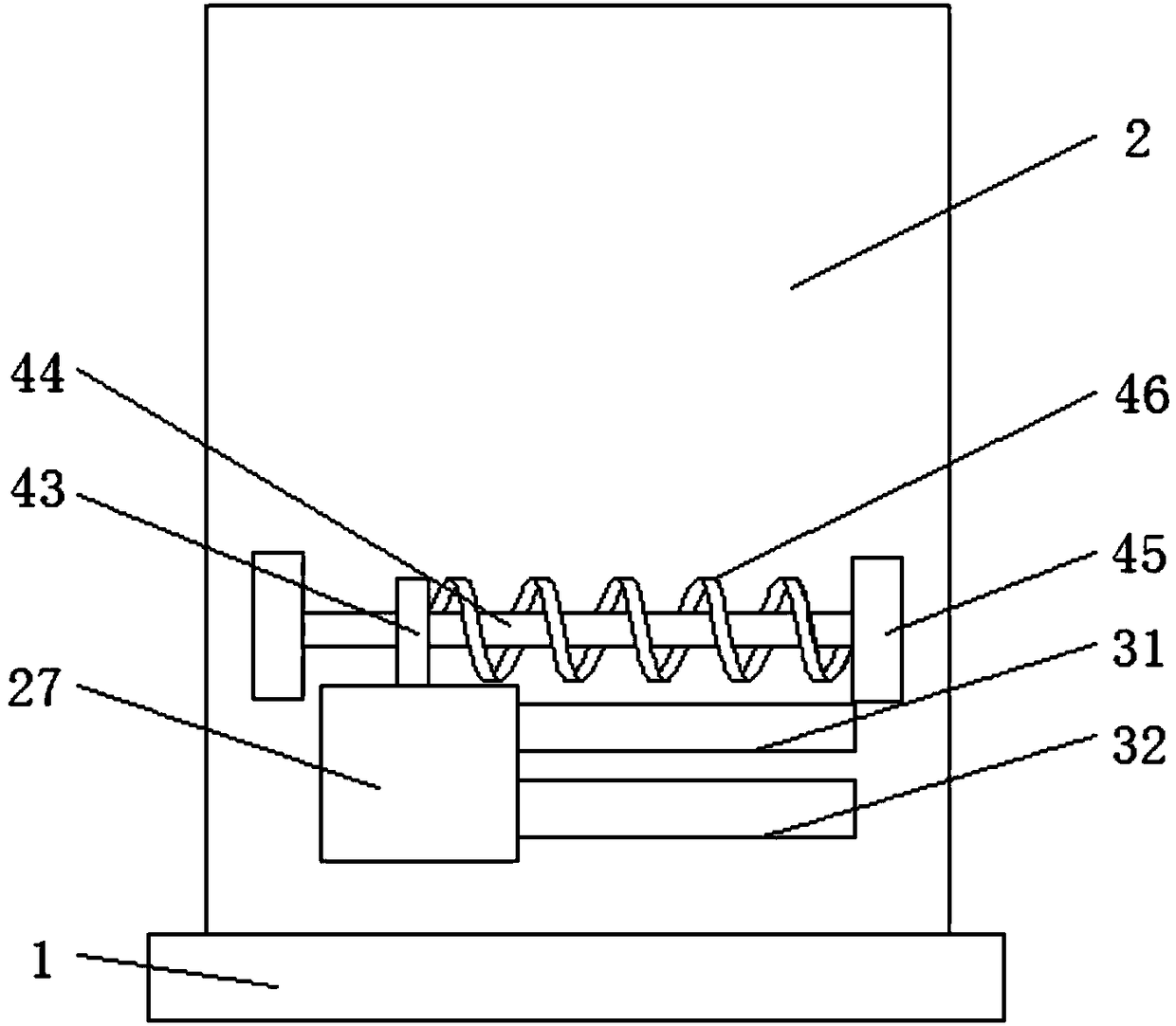

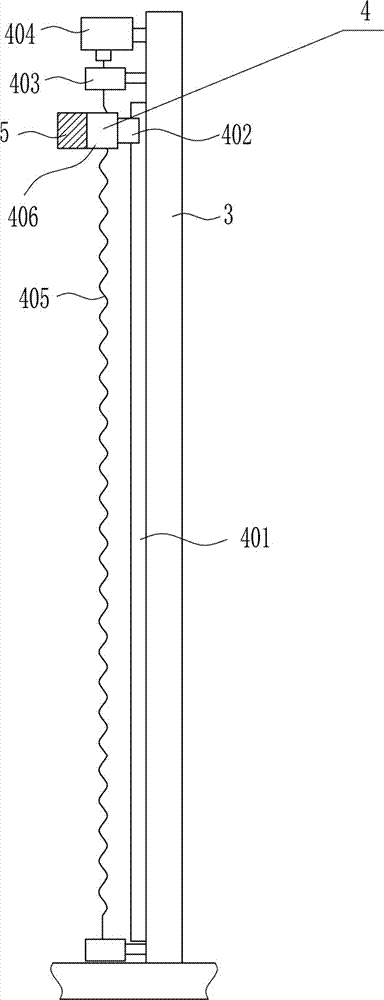

Building construction wall plastering equipment with reciprocating plastering function

InactiveCN107035116ARealize up and down repeated movementApply evenlyBuilding constructionsArchitectural engineeringThreaded rod

A wall painting equipment for building construction with a reciprocating painting function, including a base plate, four rollers are fixedly connected to the lower side of the base plate, a support column is fixedly connected to the upper side of the base plate, and an opening is opened on the support column to move toward the left. groove, a moving block is arranged in the moving groove, and a vertical threaded through hole is provided on the moving block, and a threaded rod is connected to the internal thread of the vertical threaded through hole, and the two ends of the threaded rod are connected to the support column in rotation, and the lower part of the threaded rod A first bevel gear is fixedly connected, a second bevel gear meshes on the right side of the first bevel gear, and a first rotating shaft is fixedly connected to the right end of the second bevel gear, and the first rotating shaft extends rightward through the support column, and the first rotating shaft The right end of the right end is connected with the first motor output end fixedly arranged on the side wall of the support column. The invention has the advantages of reasonable structural design and good painting effect, effectively liberates manpower, ensures the painting effect, improves the painting efficiency, and has wide application value.

Owner:六安市我罗生工业设计有限公司

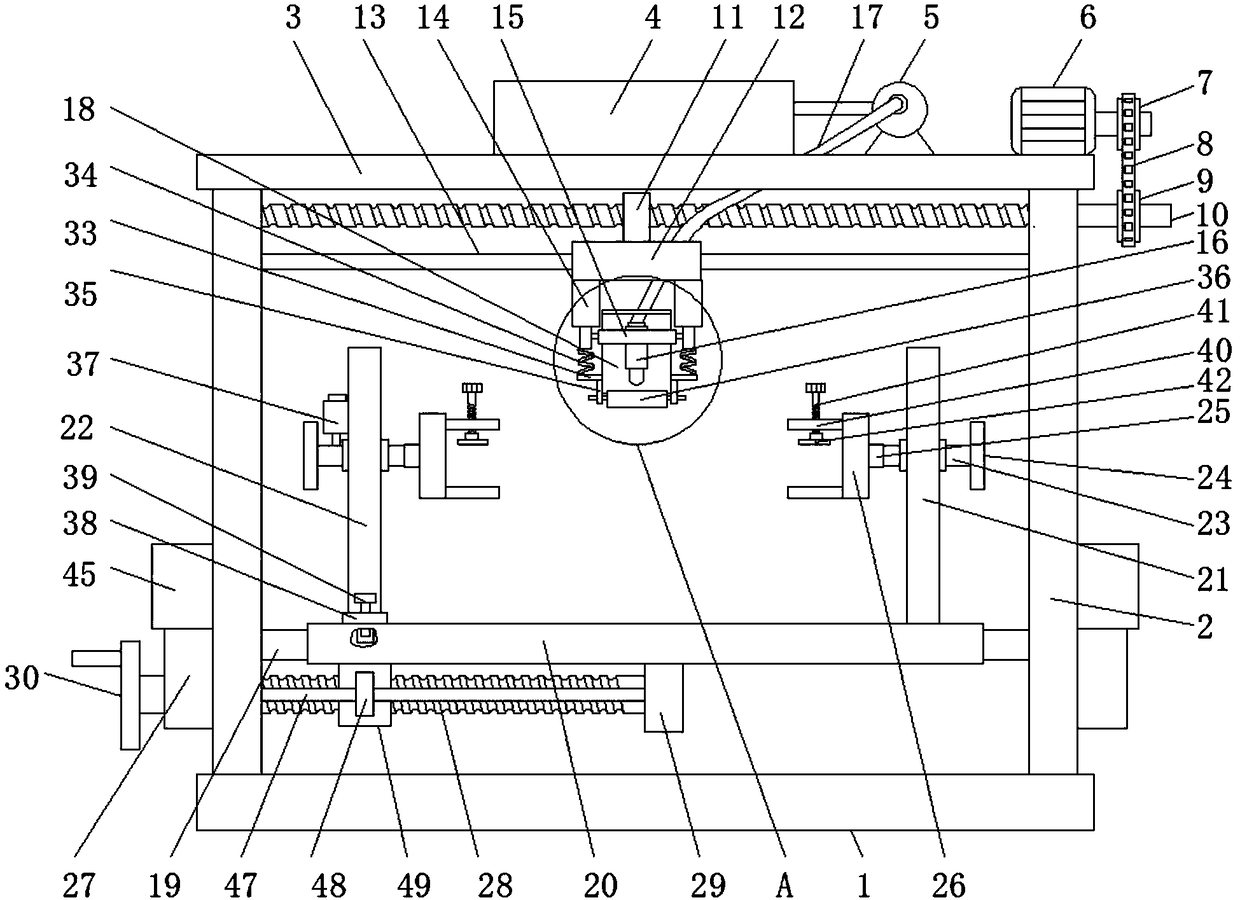

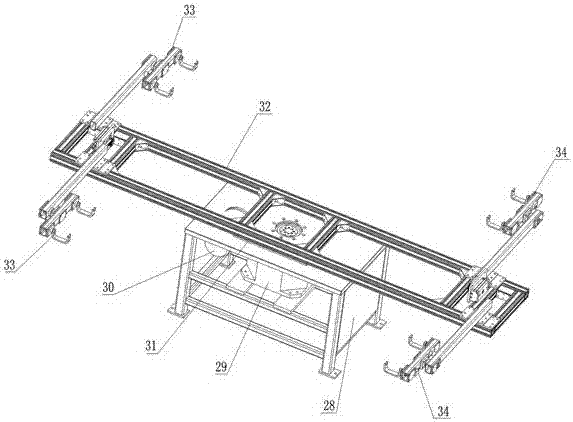

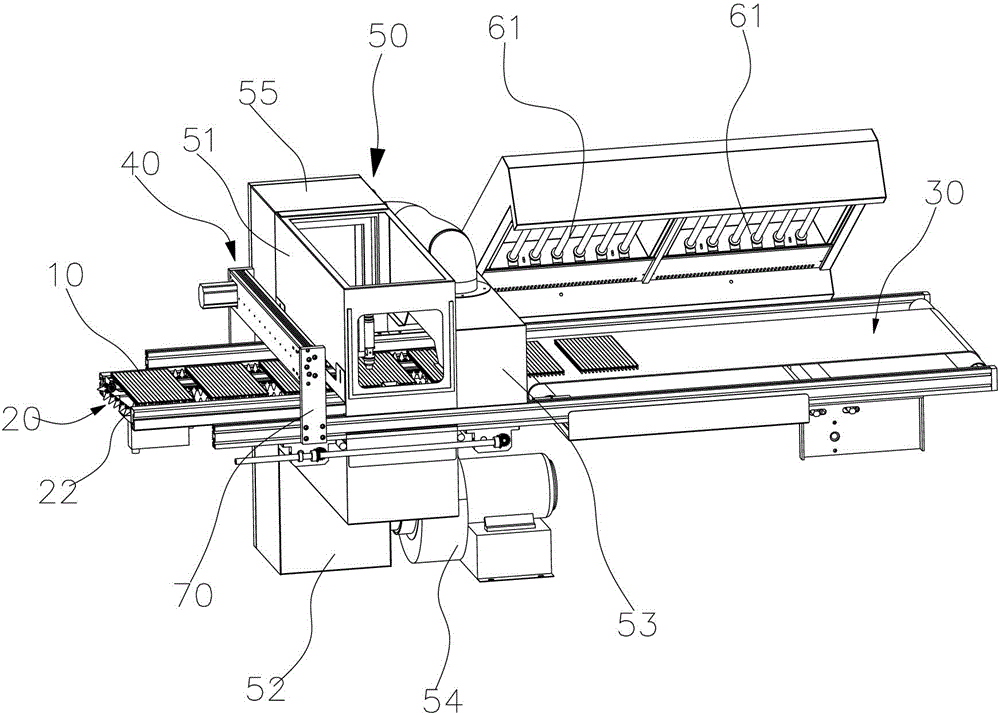

Intelligent door sheet spraying paint spraying production line

ActiveCN107199147AReduce labor intensityCompact structureLiquid surface applicatorsSpraying apparatusManufacturing lineIndustrial engineering

The invention discloses an intelligent door sheet spraying paint spraying production line. The intelligent door sheet spraying paint spraying production line comprises a paint spraying room (101), a rotary table (102), a feeding device (103) and a door sheet containing support (104) which are sequentially arranged from left to right. The intelligent door sheet spraying paint spraying production line has the beneficial effects that the intelligent degree is high, spraying is even, the labor intensity of workers is greatly reduced, the paint spraying efficiency is greatly improved, and paint spraying is even.

Owner:四川科立达智能系统有限公司

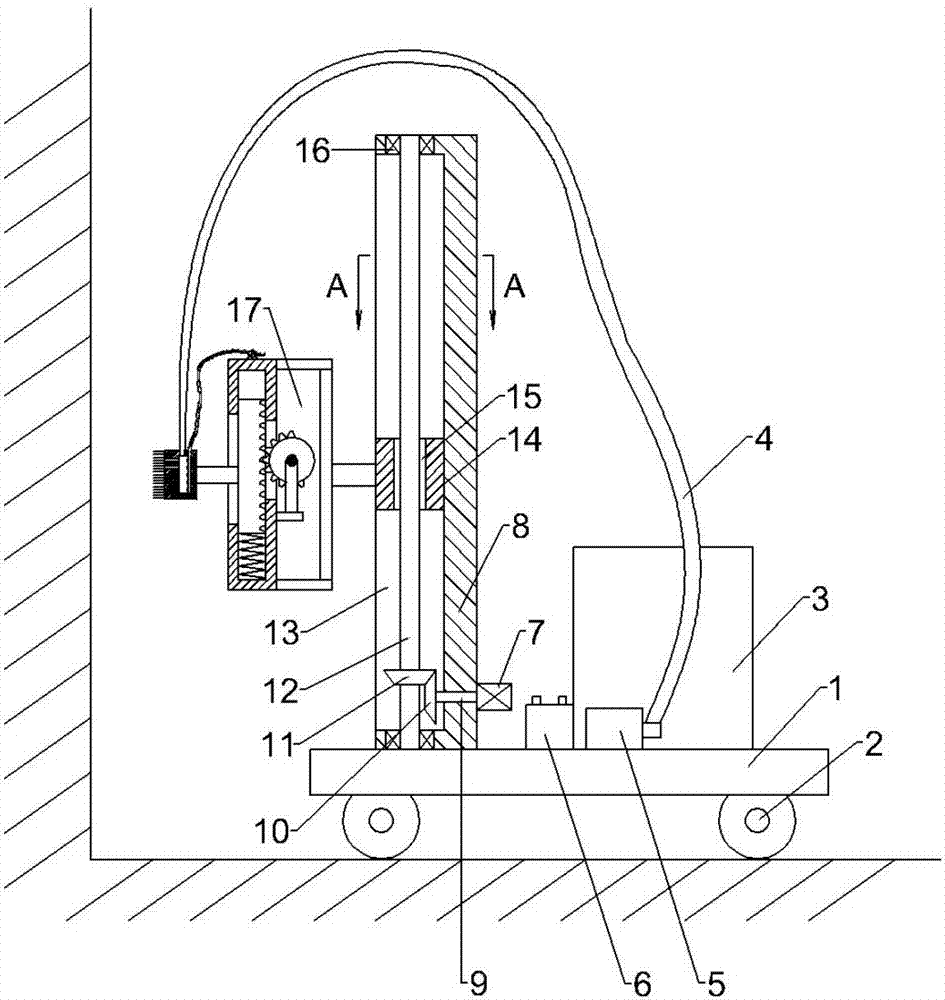

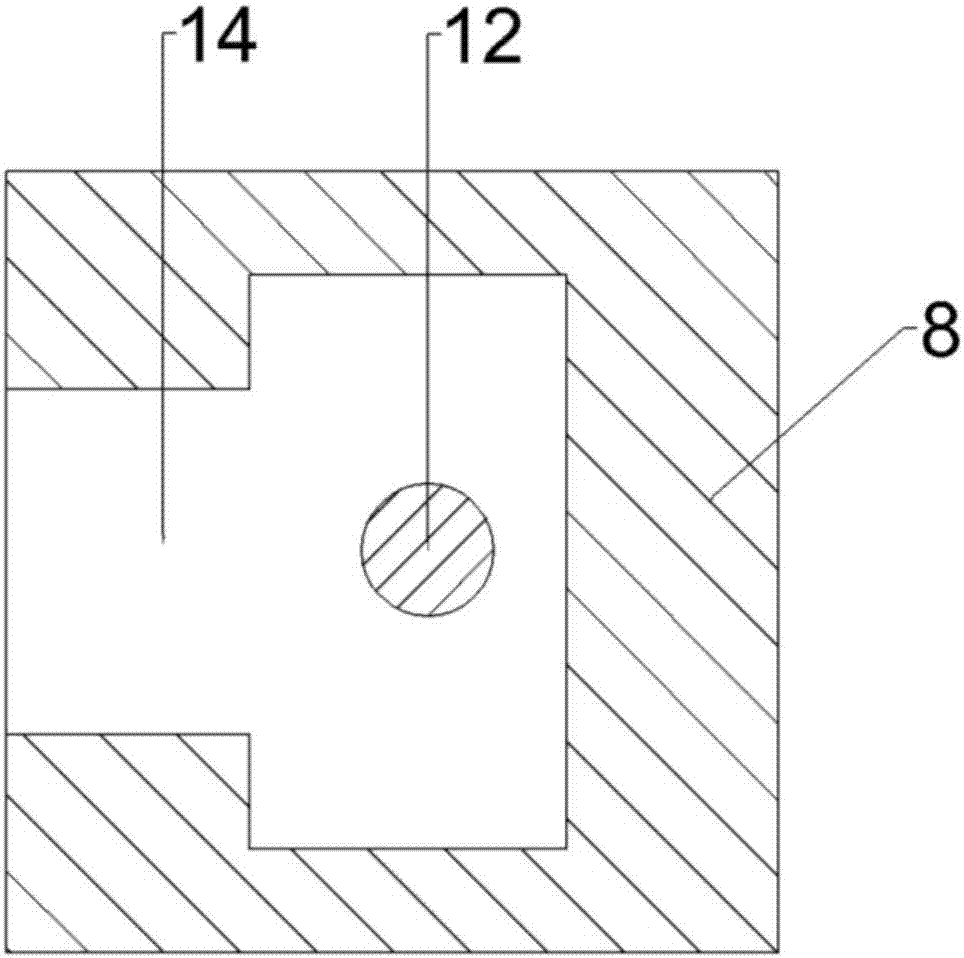

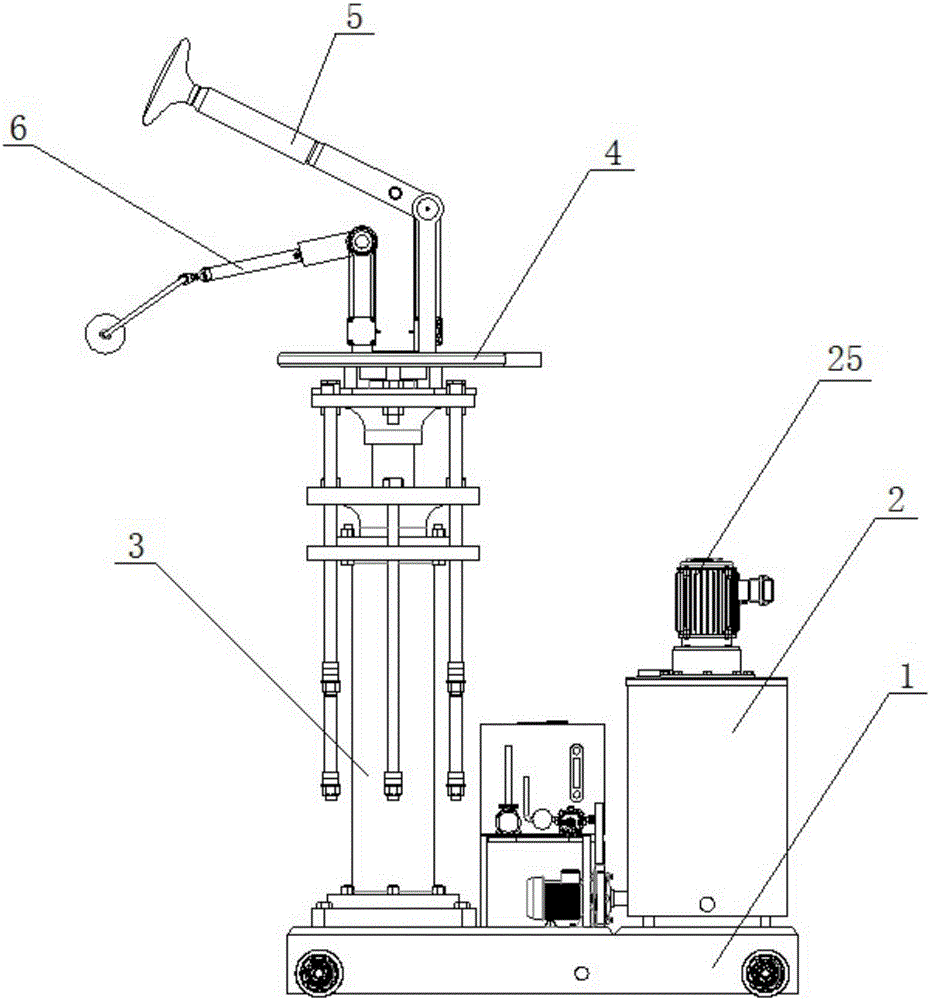

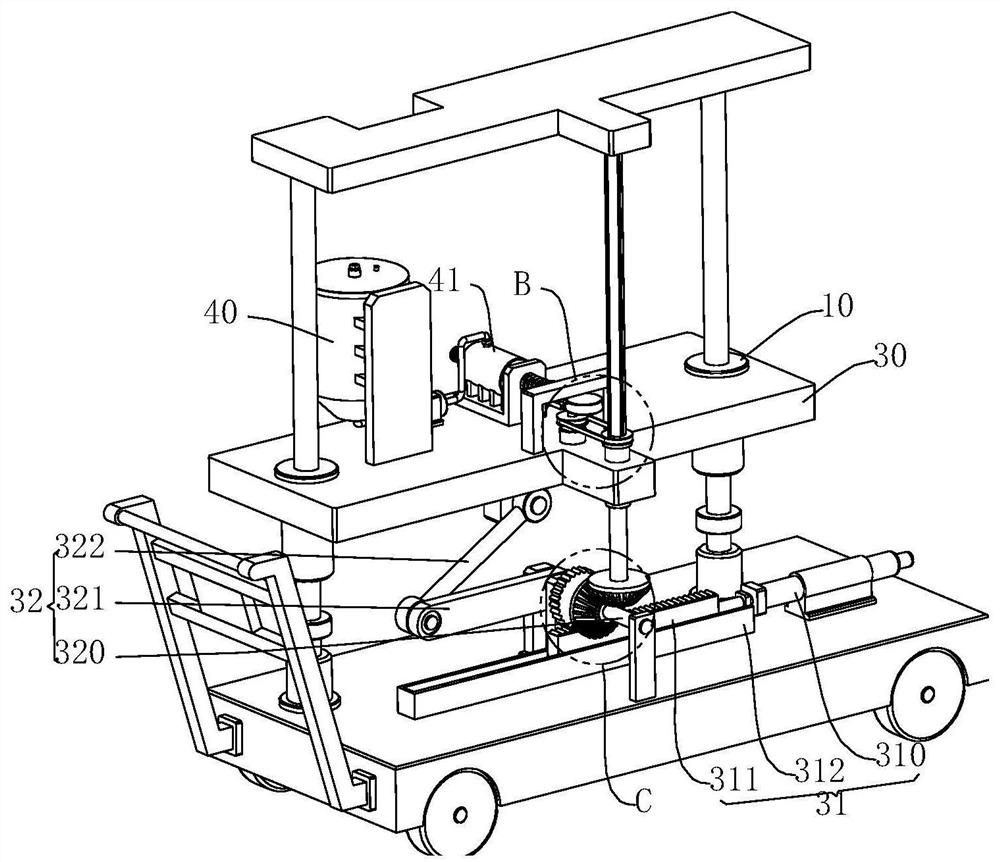

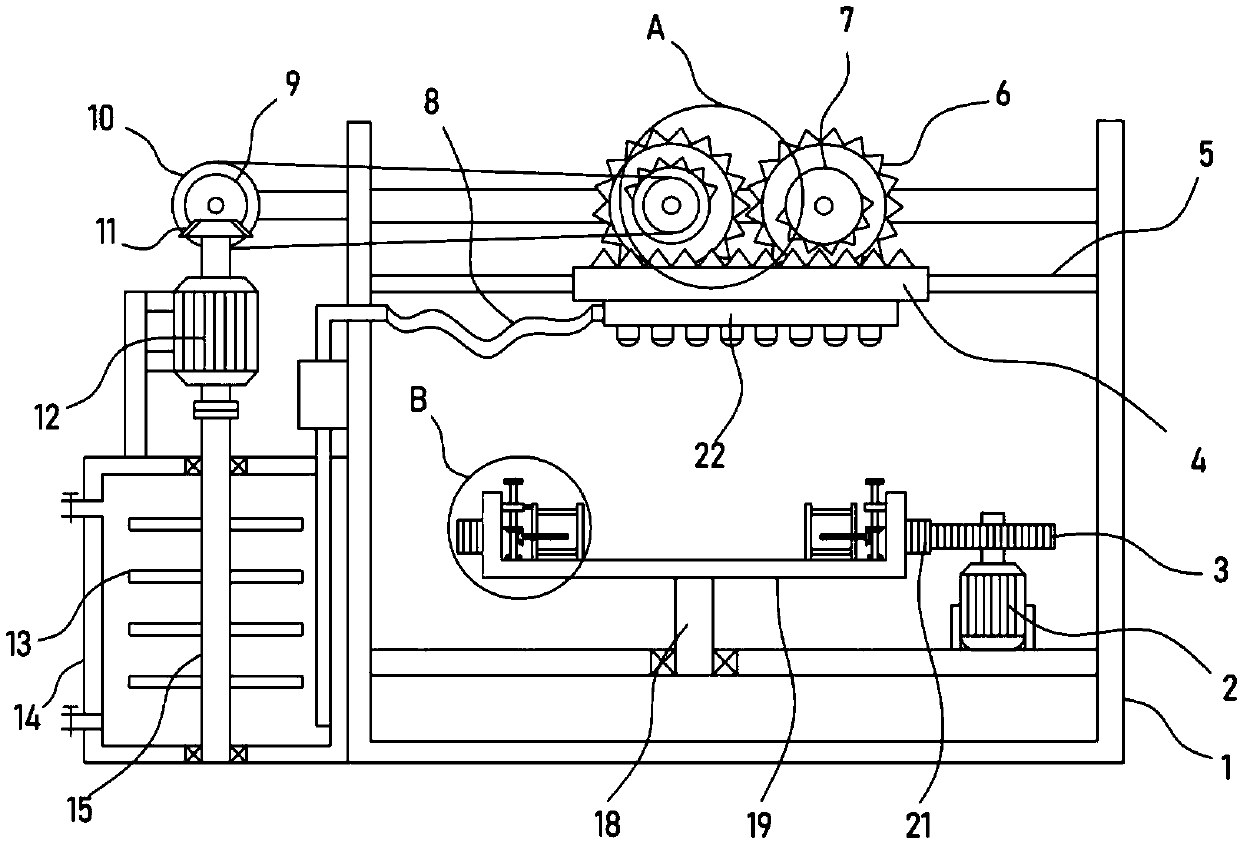

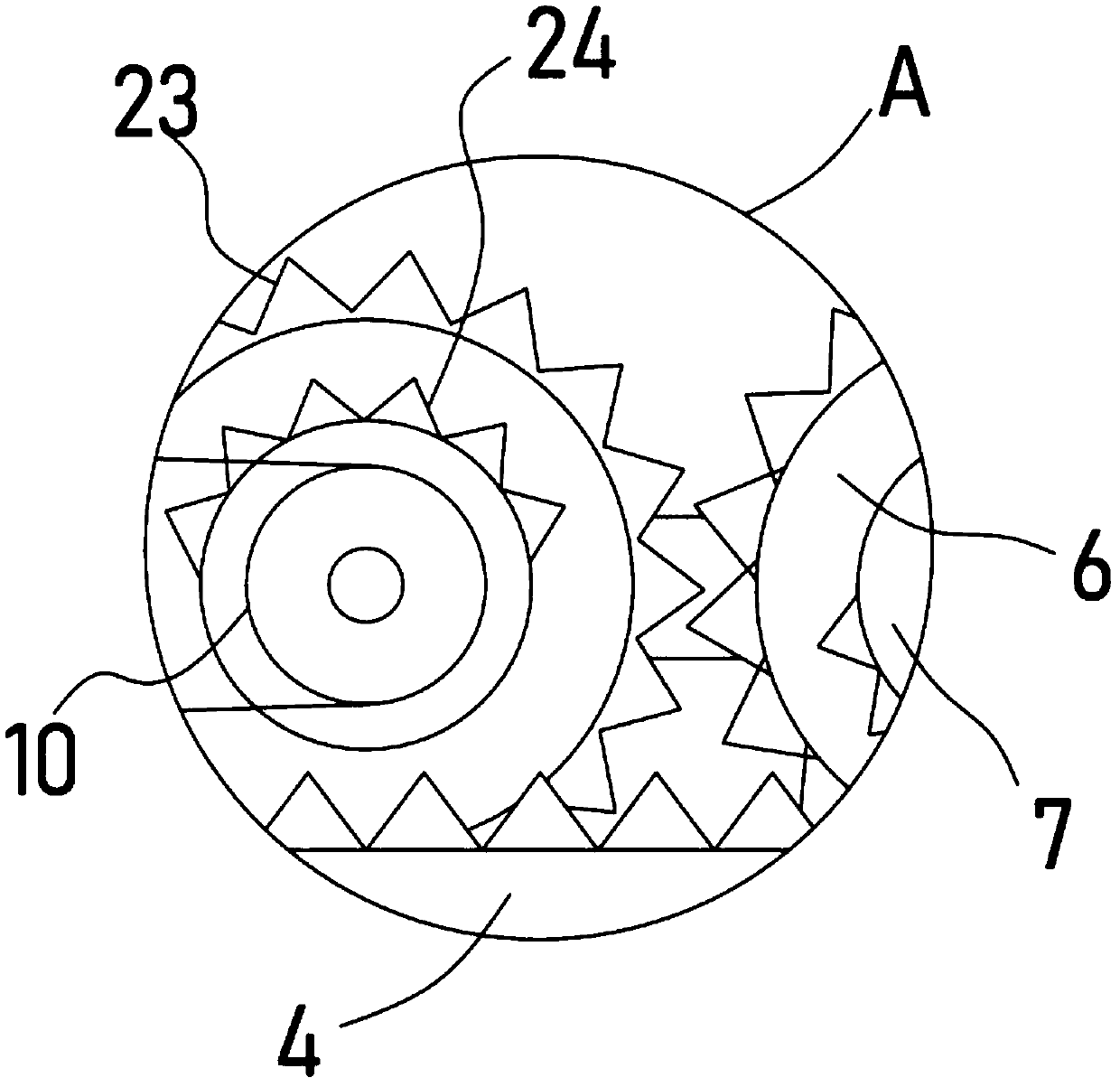

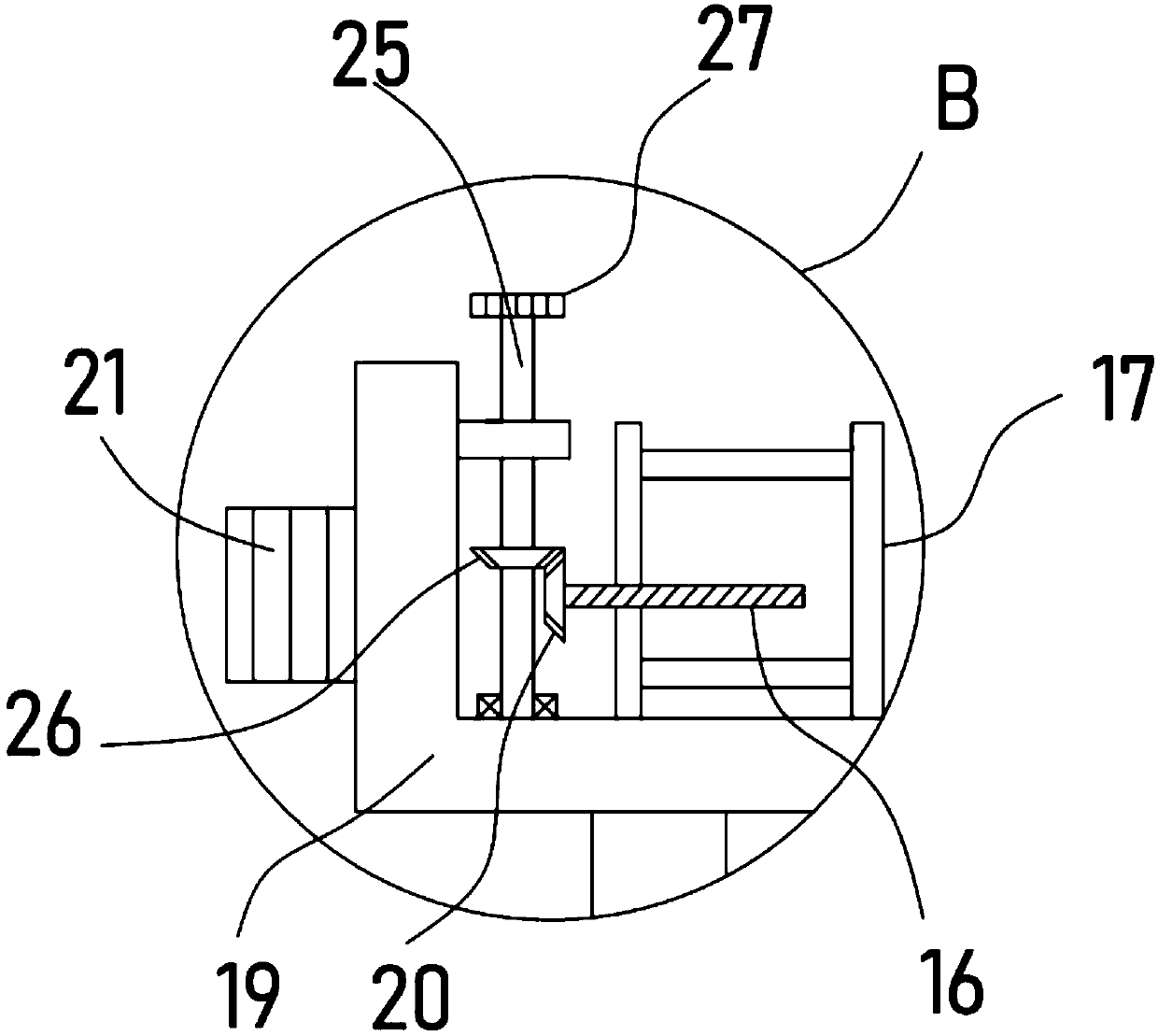

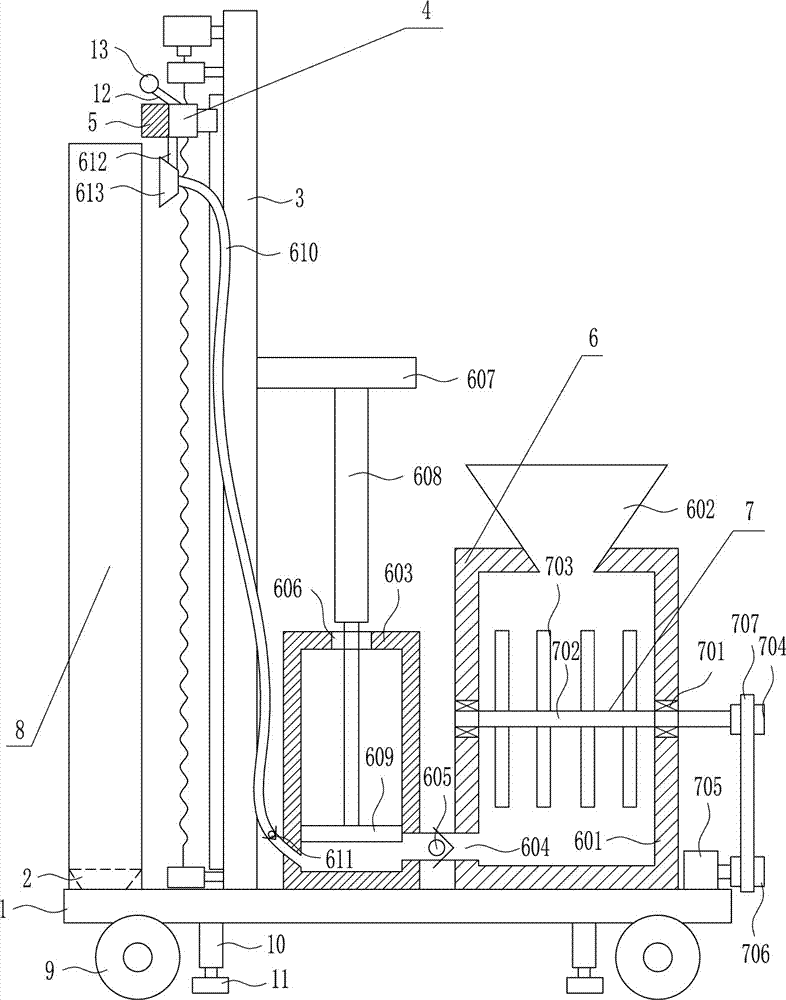

Intelligent whitewashing wall painting machine and application thereof

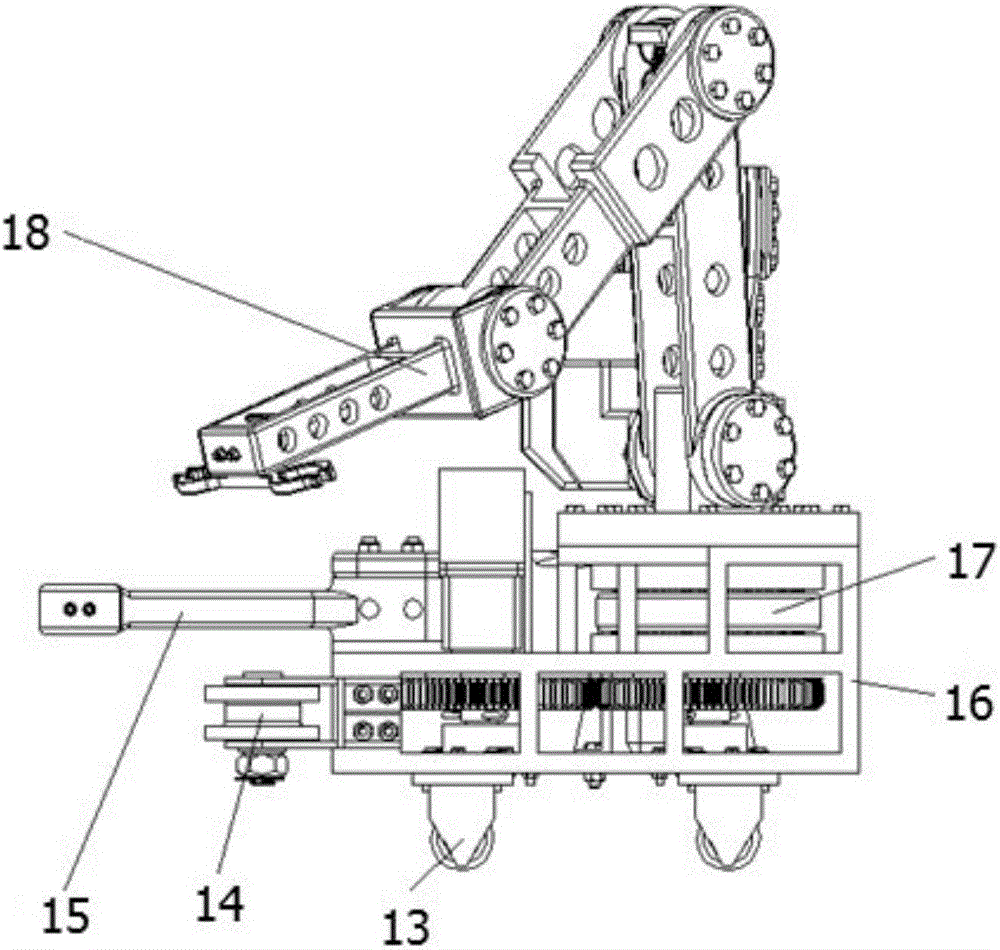

ActiveCN106245892ARealize small rotation in situRealize location movementBuilding constructionsEngineeringSlurry

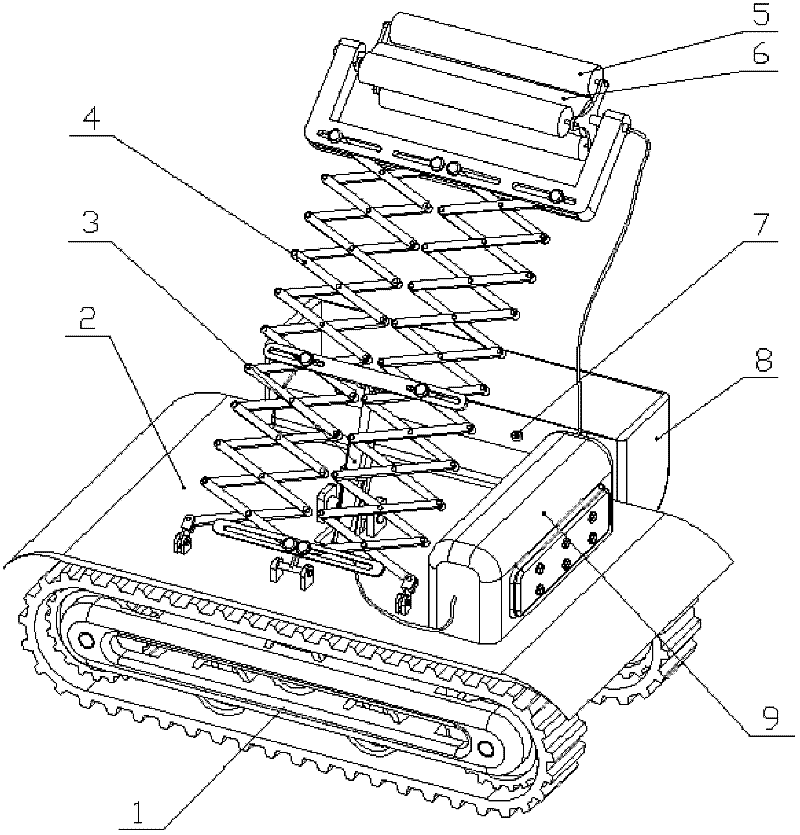

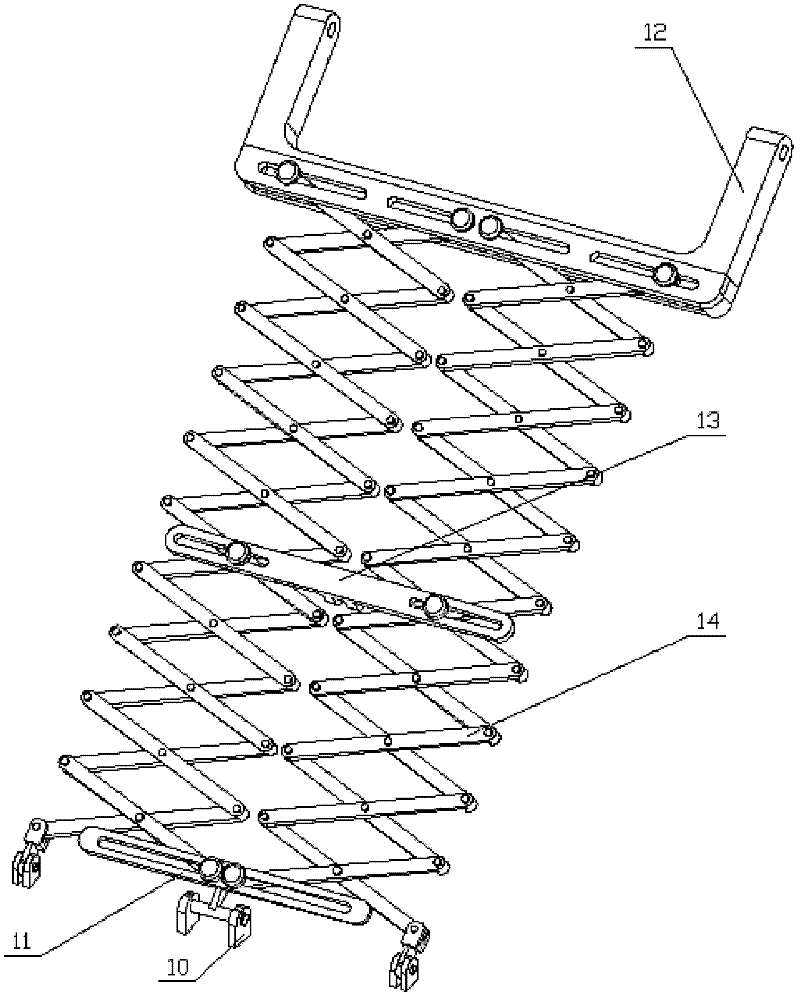

The invention relates to an intelligent whitewashing wall painting machine and application thereof. The intelligent whitewashing wall painting machine comprises a traveling mechanism, a slurry storage mechanism, a lifting mechanism, a rotation mechanism, a whitewashing mechanism and a painting mechanism, wherein the slurry storage mechanism and the lifting mechanism are arranged on the travelling mechanism; the rotation mechanism is arranged at the top end of the lifting mechanism; the whitewashing mechanism and the painting mechanism are arranged on the rotation mechanism; the traveling mechanism is used for driving the painting machine to move; the whitewashing mechanism is used for whitewashing; the painting mechanism is used for painting; the lifting mechanism is used for adjusting the up-down positions of the whitewashing mechanism and the painting mechanism; and the rotation mechanism is used for adjusting the angle positions of the whitewashing mechanism and the painting mechanism. Automatic operation of the painting machine can be realized through program control, the whole painting process is unattended, and intelligent whitewashing and painting operation is truly realized. The painting efficiency is improved, labor cost is reduced, good economical benefits and market value are achieved, and the intelligent whitewashing wall painting machine is worthy of application and popularization.

Owner:SHANDONG UNIV OF SCI & TECH

Motor shell paint spaying device with controllable spraying range

InactiveCN108480087AUniform coatingGuaranteed paint effectSpraying apparatusManufacturing dynamo-electric machinesCircular discEngineering

The invention discloses a motor shell paint spraying device with the controllable spraying range. The motor shell paint spraying device comprises a work table, a vertical frame, a rotary shaft, a lifting device, a circular disc, a convex column, a slipping rod and a spraying pipe. The vertical frame is fixed to the left side of the top of the work table, and a top plate is connected to the top ofthe vertical frame. A rotary shaft is arranged on the top plate in a penetrating mode, the upper end of the rotary shaft is provided with a driving mechanism for driving the rotary shaft to rotate, and a base plate is fixed to the bottom of the rotary shaft. The circular disc is arranged on the position below the right side of the vertical frame, the convex column is connected to the right end face of the circular disc in a matched mode, and the slipping rod is longitudinally arranged on the right side of the circular disc. A fixing ring is connected to the center position of the bottom of theslipping rod, and the spraying pipe is arranged in the fixing ring in a penetrating mode. According to the motor shell paint spraying device, efficient paint spaying can be conducted on a motor shell, the paint spraying effect is good, meanwhile the spraying range can further be adjusted correspondingly according to the size of the motor shell, and the applicability of the motor shell paint spraying device is improved.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

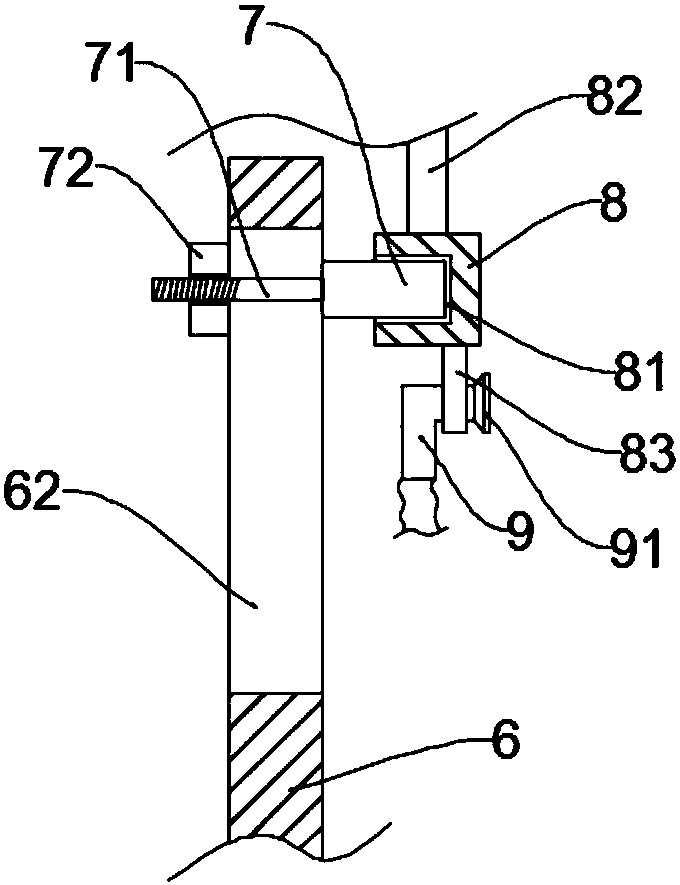

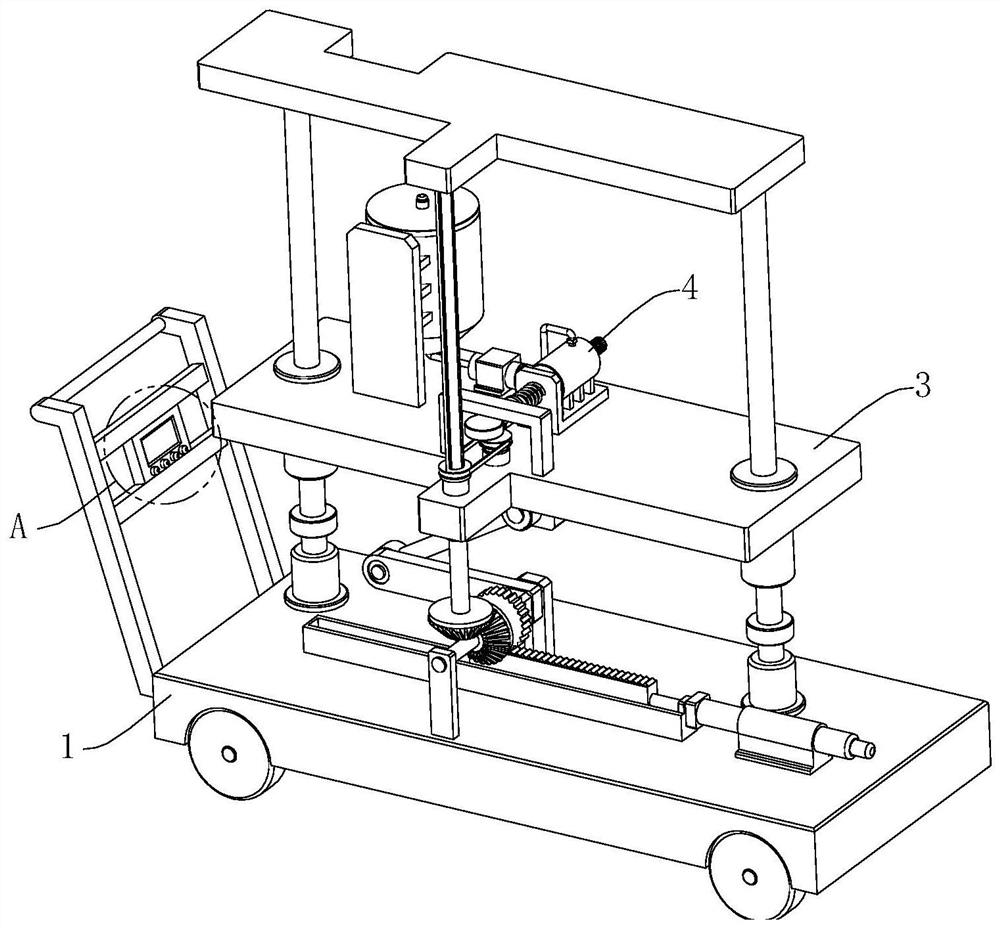

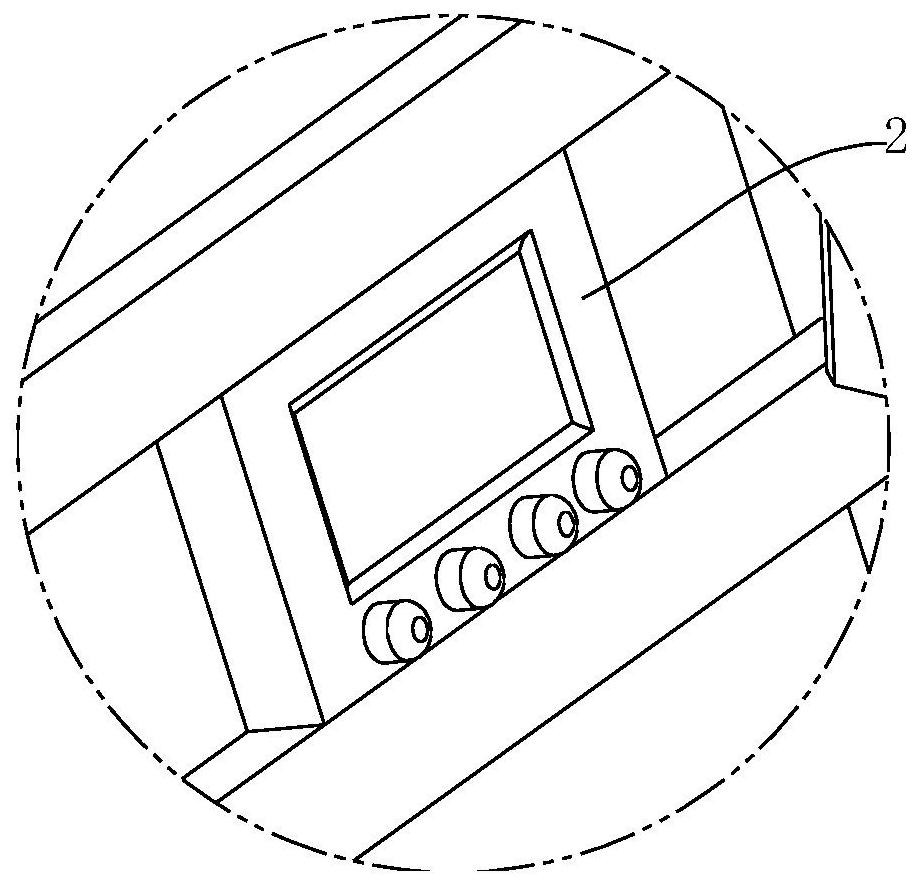

Painting device and method with lifting and spraying-adaptive for indoor decoration

ActiveCN111841927ASpray evenlyAvoid wastingBuilding constructionsLiquid spraying apparatusStructural engineeringAerosolization

The invention relates to the field of decoration devices, in particular to a painting device and method with lifting and spraying-adaptive for indoor decoration. The device comprises a platform cart,and further comprises a controller, a lifting mechanism and a spraying mechanism, wherein the lifting mechanism is arranged at the top of the platform cart to support lifting of the spraying mechanism; the lifting mechanism comprises a lifting plate, a pushing assembly and a jacking assembly; the spraying mechanism is arranged at the top of the lifting plate for painting the indoor wall surface; and the spraying mechanism comprises a storage barrel, a material receiving pipe, an atomizing nozzle, an extrusion assembly and a conveying assembly, wherein the pushing assembly and the conveying assembly are electrically connected with the controller. According to the painting device and method with lifting and spraying-adaptive for the indoor decoration, the wall surface can be synchronously sprayed when the atomizing nozzle rises, so that the power consumption is small, and in the lifting interval, spraying is in an on-off state, and waste of paint materials is effectively avoided; and meanwhile, when the air temperature is low, the anti-curing function is achieved, and thus the paint spraying efficiency is improved.

Owner:银丰工程有限公司

Painting device for processing of electronic product shell

InactiveCN109622263AThe surface is painted evenlyIngenious structureLiquid spraying apparatusReciprocating motionEngineering

The invention discloses a painting device for the processing of an electronic product shell, and relates to the technical field of electronic processing. The painting device includes a supporting frame and a paint bucket fixed on the left side of the supporting frame, a clamping device for fixing the electronic product shell is mounted on a supporting table, a first incomplete gear and a second incomplete gear are fixedly arranged in a first gear and a second gear coaxially and respectively, and a rack is meshed with the first incomplete gear or the second incomplete gear. According to the painting device, the paint is sprayed downwards through a painting disc, the surface painting treatment of the electronic product shell on the supporting table is achieved, the first incomplete gear andthe second incomplete gear rotating oppositely are meshed and connected with the rack alternately so as to achieve the transverse reciprocating motion of the painting disc driven by the rack, so thatthe surface painting of the electronic product shell can be more comprehensive and uniform, a driving gear is in meshed transmission with an outer gear ring so as to achieve the fact that the supporting table drives the electronic product shell to rotate, a full range of surface painting treatment is conducted on the electronic product shell, and the painting efficiency is greatly improved

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS +1

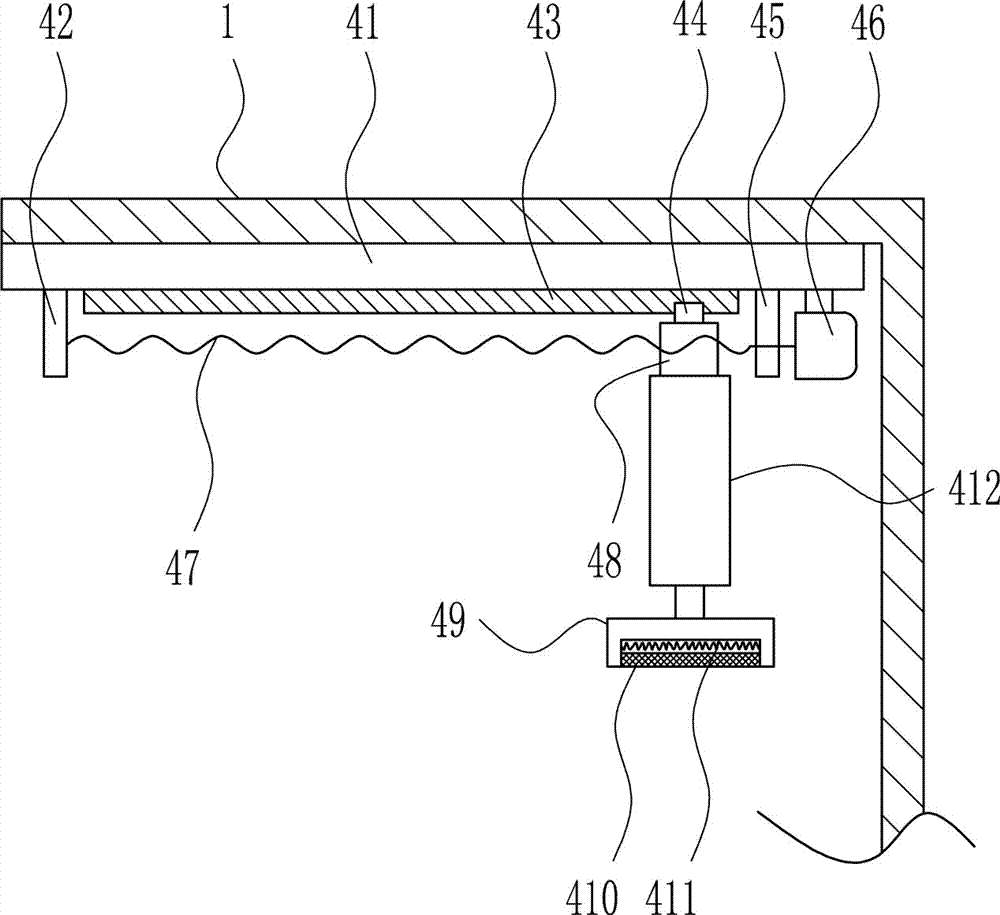

Self-loading type building wall paint coating device

InactiveCN107859296AImprove painting efficiencyEvenly paintedBuilding constructionsMotor shaftLacquer

The invention discloses a self-loading type building wall paint coating device comprising a base seat, and the top of the base seat is fixedly provided with a fixing plate which is in an L shape; theright side wall of the fixing plate is fixedly provided with a slide rail, and a lifting plate is connected to the right side of the slide rail in a slide mode; a paint box is fixedly arranged on thetop portion of the lifting plate, a brush roller is connected with the right side of the paint box in a rotation mode, and the right end of a discharging pipe is connected to the interior of the paintbox by a telescopic hose. A second deceleration motor is also fixed on the bottom of the right side wall of the slide rail; a motor shaft at the top of the second deceleration motor is connected witha screw, and the screw is left handed; and the screw passes through the lifting plate and is connected with the lifting plate in a threaded mode. The device drives the lifting plate to move up and down through the rotation of the screw, thereby driving the brush roller to rotate and move up and down to perform paint brushing; the paint brushing height can be freely adjusted, the safety of the personnel is ensured, the painting efficiency is high, the paint brushing is uniform, and the labor quantity is effectively reduced.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

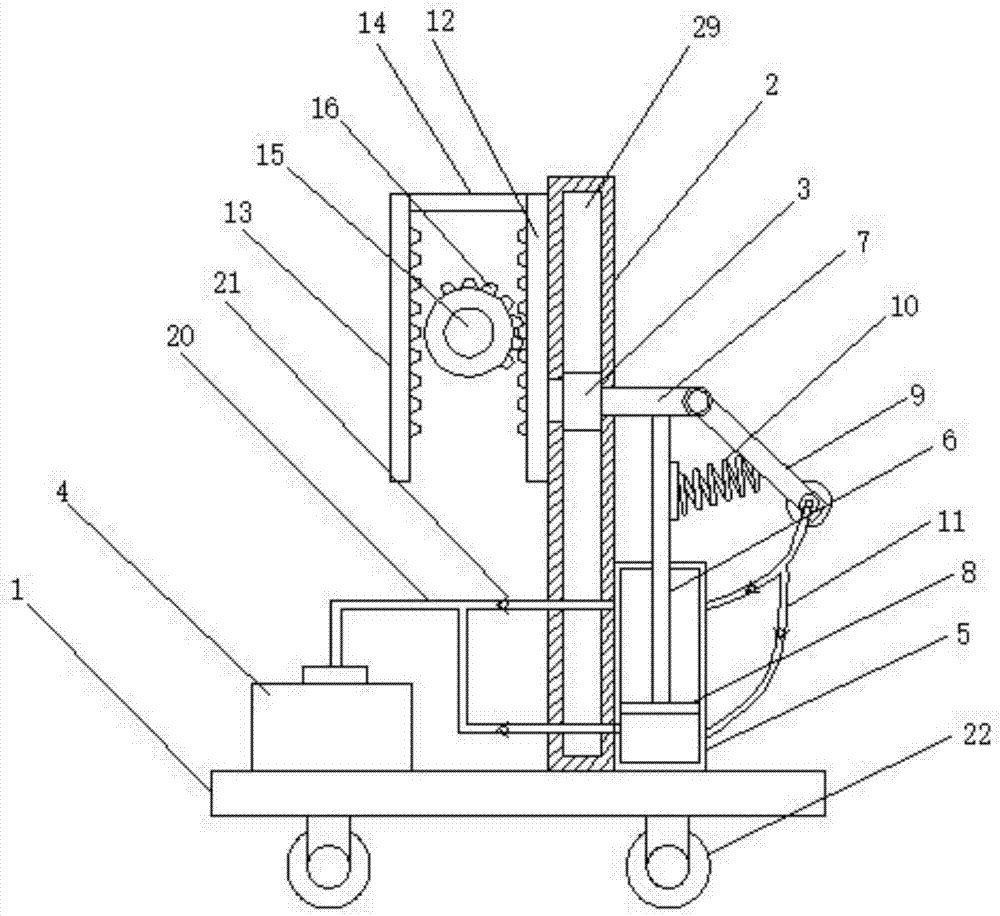

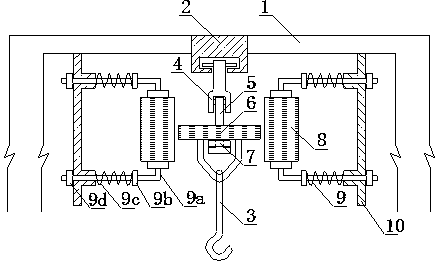

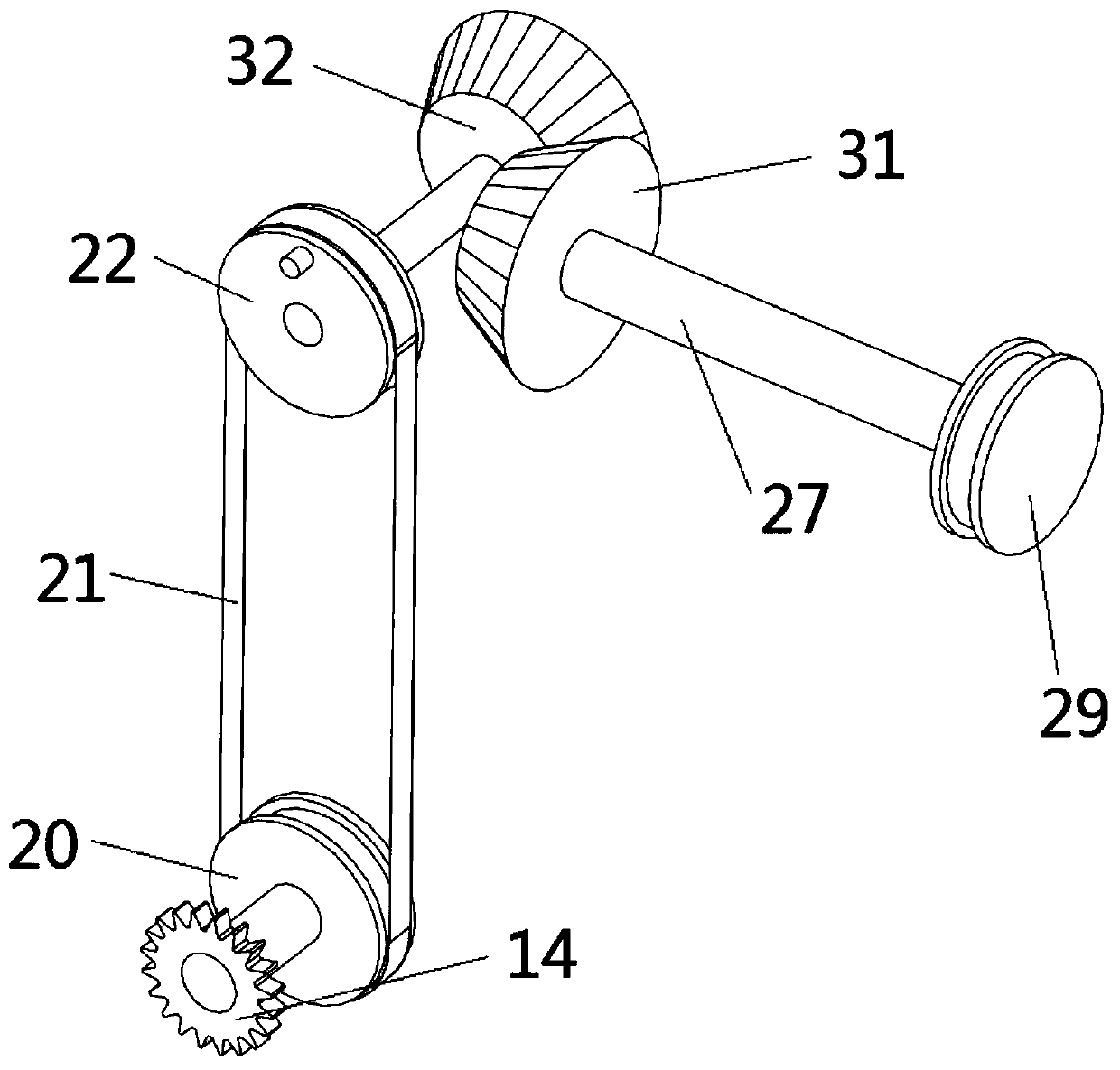

Automatic rotating paint-spraying suspension device

InactiveCN104209210ASmooth rotationHarm reductionSpraying apparatusClassical mechanicsStructural engineering

The invention discloses an automatic rotating paint-spraying suspension device and belongs to the field of paint spraying. The device comprises a bracket, a guide rail and a pothook, wherein the guide rail is connected with the pothook through a rotating mechanism; a driving belt, a spring adjusting rod and a lateral plate are arranged on each of two sides of the rotating mechanism; the driving belts are fixed on the lateral plates through the spring adjusting rods; the lateral plates are fixed on the bracket. The rotating mechanism is connected between the pothook and the guide rail and the driving belts are used for rubbing the rotating mechanism to rotate, so that the paint-spraying pothook is rotated at a uniform speed, the paint-spraying efficiency and the paint-spraying quality are increased, and the harm to a human body caused by near-distance paint-spraying is reduced.

Owner:ANQING TIANRUN ENG MACHINERY

Multi-functional automatic wall plastering machine

InactiveCN102418413AAchieve large-scale movementReduce labor intensityBuilding constructionsElectrical controlAtmospheric pressure

The invention provides a multi-functional automatic wall plastering machine. The multi-functional automatic wall plastering machine consists of a travelling support mechanism, a lifting mechanism and a working device, wherein the lifting mechanism consists of a pneumatic cylinder and a cantilever crane and realizes the movement of the working device; and the working device consists of a main hopper, a rotating beam barrel, a plastering hopper, a scrapping plate, a whitewashing roller and an electrical control part, and realizes full automatic plastering, scrapping and coating whitewashing actions.

Owner:杨岳

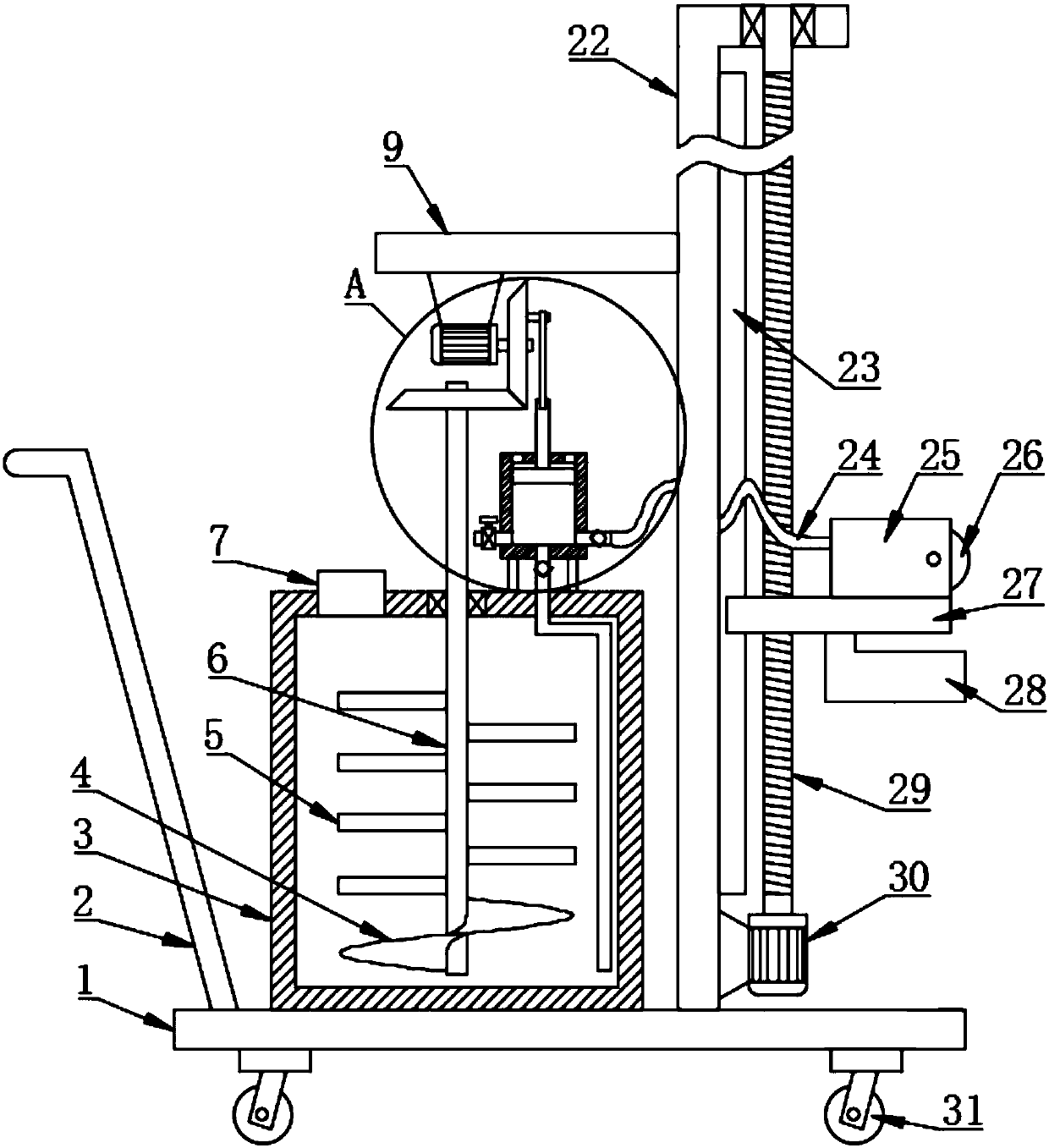

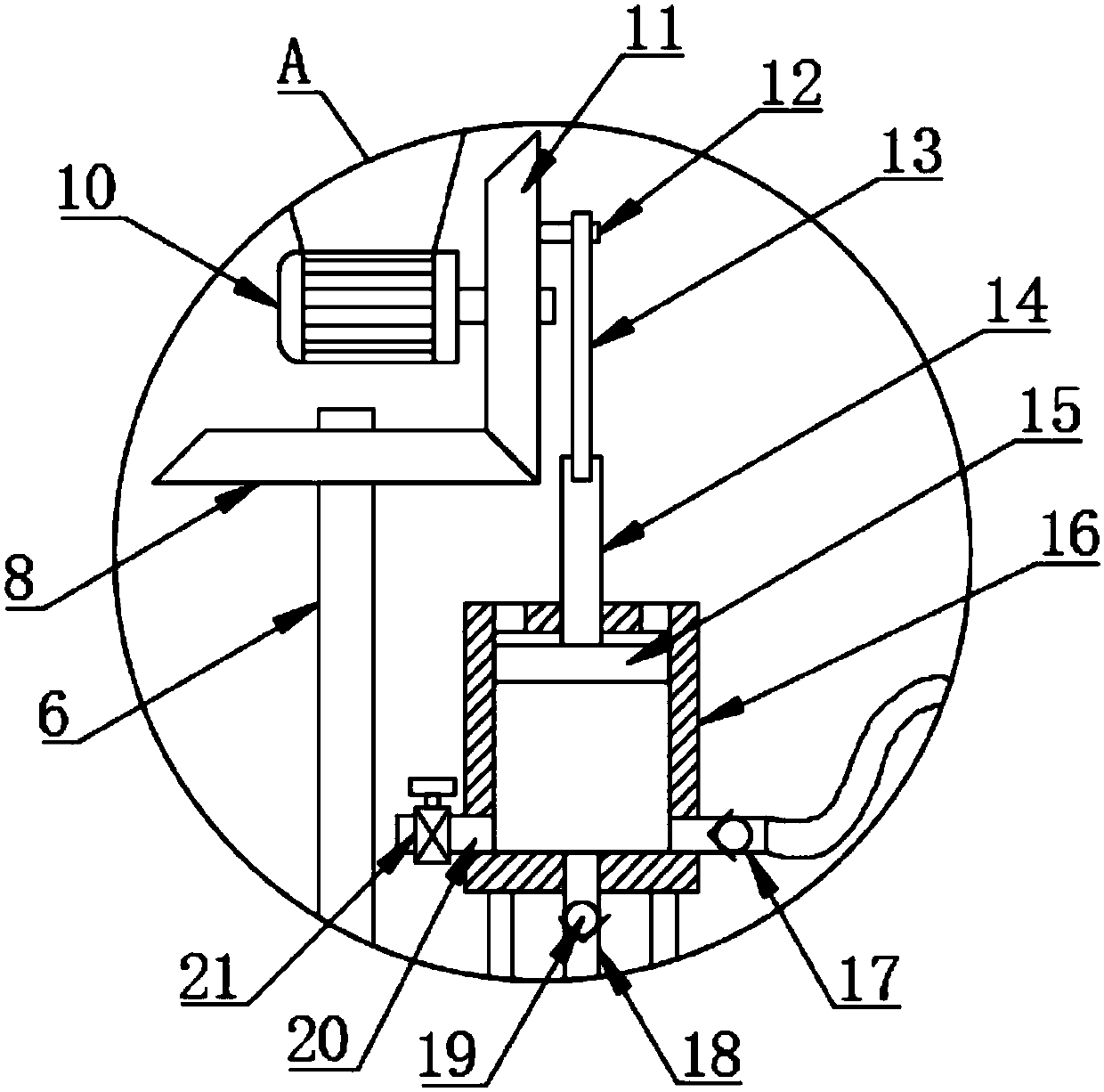

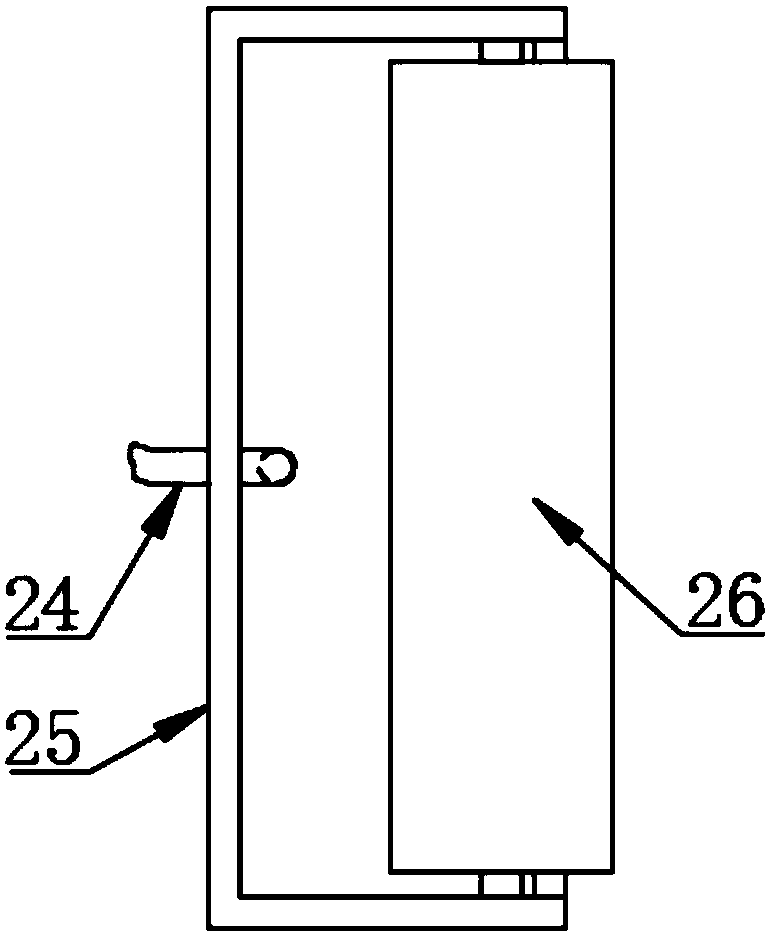

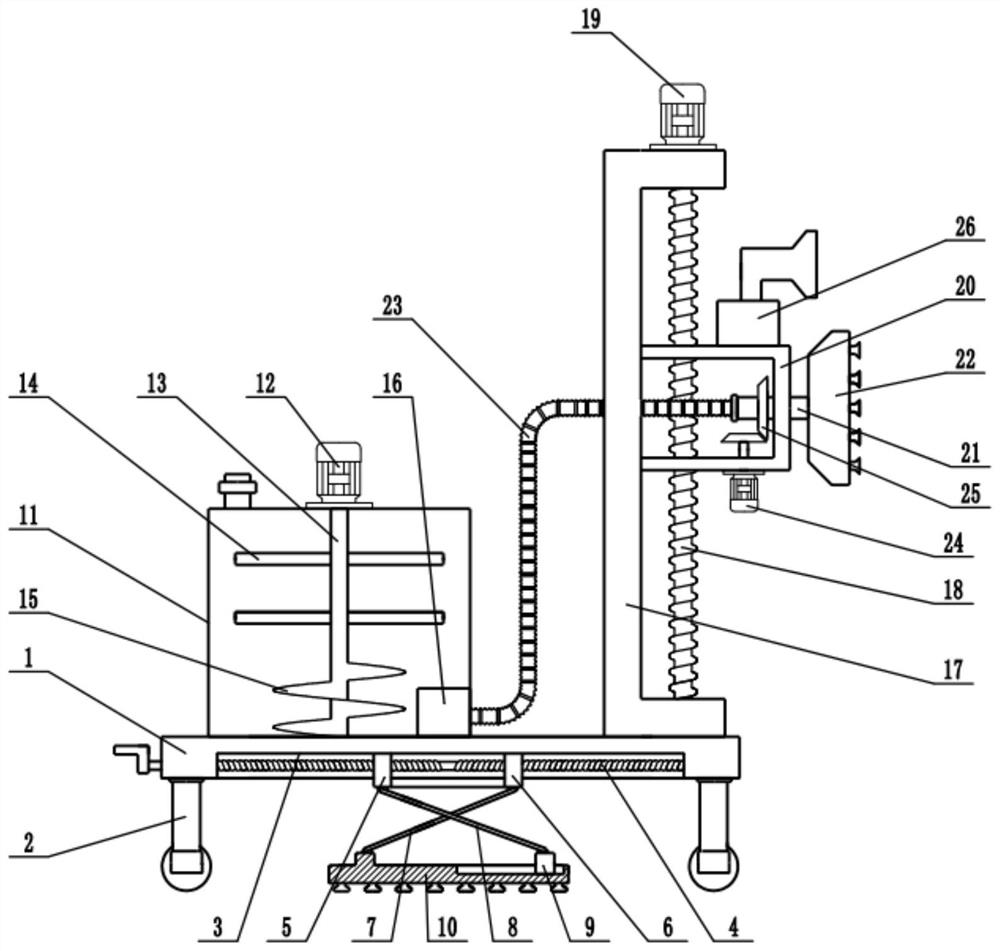

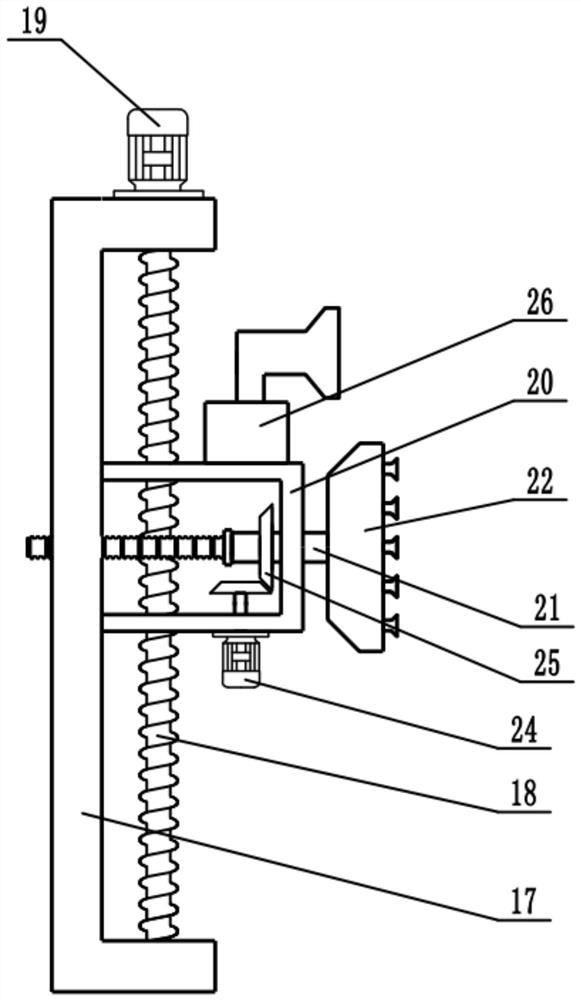

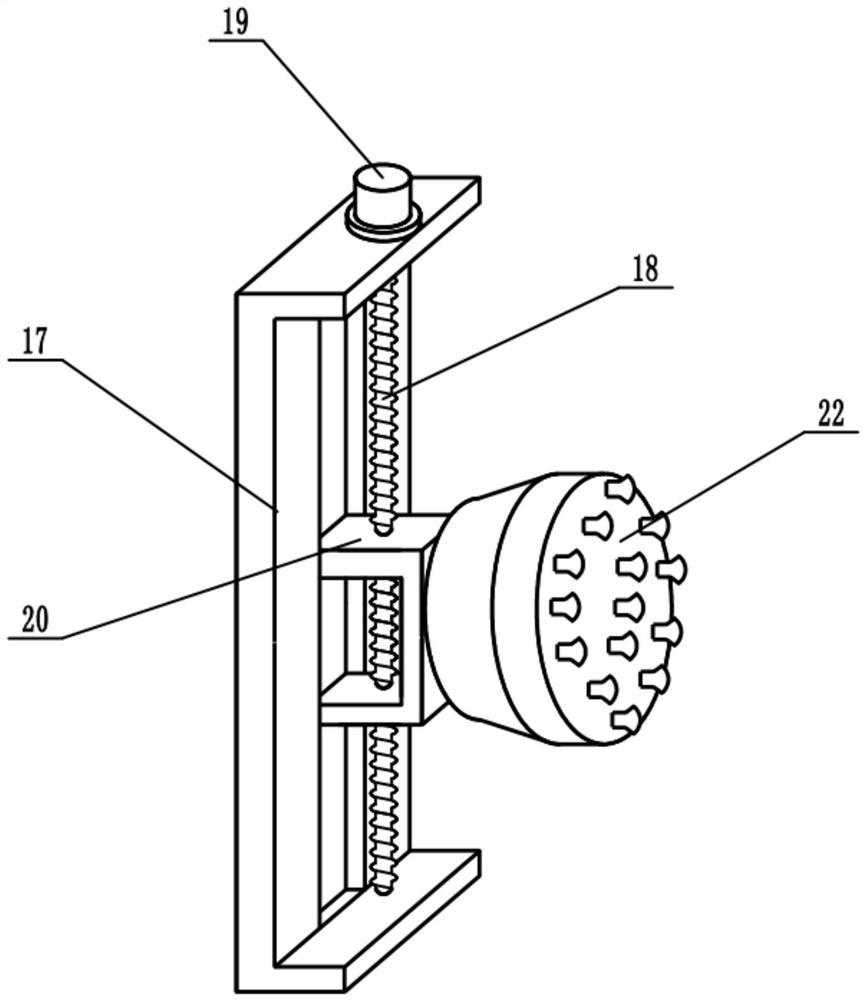

Convenient-to-move wall paint spraying device

InactiveCN111715431AWell mixedPrevent precipitationPretreated surfacesBuilding constructionsSprayerElectric machinery

The invention relates to the field of building equipment, in particular to a convenient-to-move wall paint spraying device. The device comprises a rack, a storage box, a booster pump, a mounting frameand a sprayer. The upper surface of the rack is fixedly connected with the storage box, a stirring mechanism is installed in the storage tank, the bottom of the storage box is also provided with thebooster pump, the upper surface of the rack is fixedly connected with the mounting frame, a lifting lead screw is mounted inside the mounting frame, the interior of the mounting frame is slidably connected with a lifting frame, a hollow rotating shaft penetrates through the lifting frame, and the sprayer is installed at the right end of the hollow rotating shaft. A stabilizing mechanism is mountedat the bottom of the rack. By means of the stabilizing mechanism, the stability of the device is greatly improved, and wall paint spraying is facilitated. Paint is stirred through the stirring mechanism, so that the paint is evenly mixed, and the paint is prevented from being precipitated. The paint in the storage box is conveyed to the sprayer through the booster pump for wall paint spraying. The sprayer is driven by a third motor to rotate, so that the spraying process is more uniform, and the paint spraying efficiency is improved.

Owner:胡海军

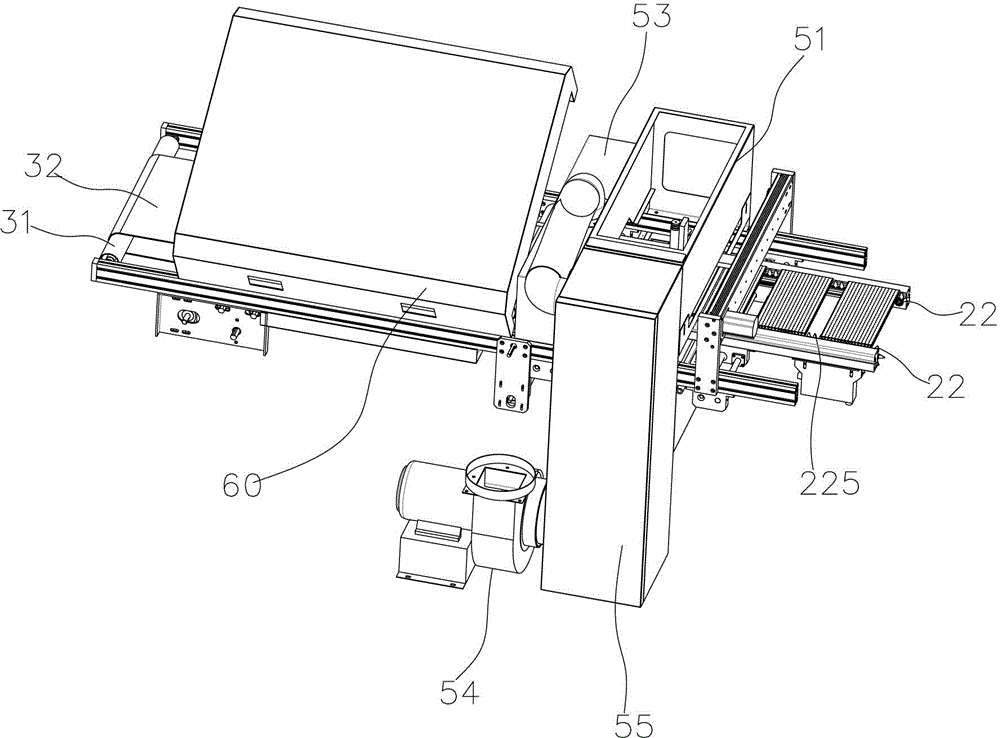

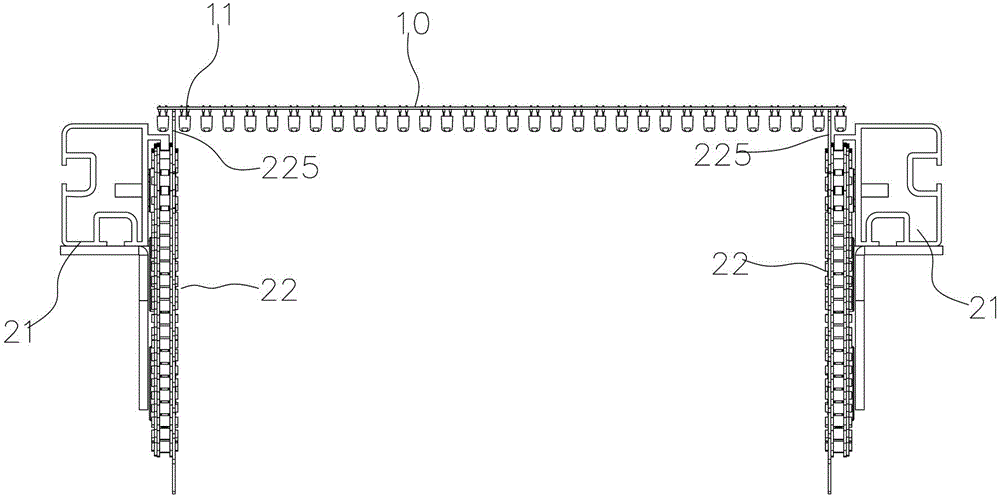

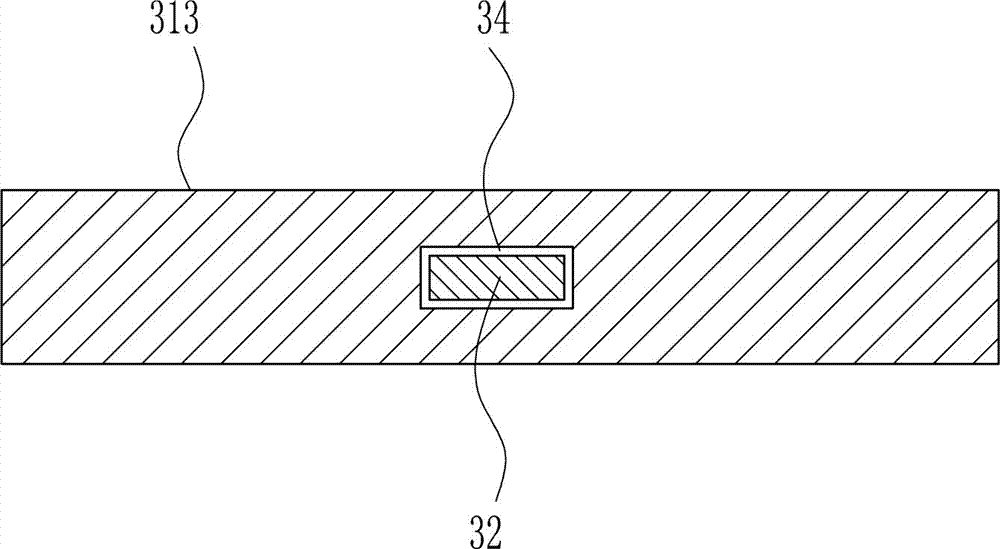

Spraying equipment for LED display screens without board edges

InactiveCN104549845AImprove paint qualityExtended service lifeSpraying apparatusPretreated surfacesLED displayControl system

The invention belongs to spraying equipment, and provides spraying equipment for LED display screens without board edges. The spraying equipment comprises a transmission gear, a conveying device, a spraying device, an air draft device, a drying device and a control system. The transmission gear and the various devices can harmoniously run under the control of the control system, the transmission gear comprises two parallel transmission chains, each transmission chain comprises a plurality of inner chain sheets, outer chain sheets, hinge pins and rolling shafts, chain teeth are arranged on the outer sides, which are close to the to-be-painted LED display screens without the board edges, of the outer chain sheets of the various transmission chains, and two ends of each to-be-painted LED display screen without the board edges are respectively supported by the various corresponding chain teeth on the two transmission chains. The spraying equipment has the advantages that circuit boards can be ejected and transported by the aid of the chain teeth, and accordingly the painting efficiency can be improved by 30%; the LED display screens can be painted by the aid of the spraying device, accordingly, the painting quality can be greatly improved, and damp-proof, mildew-proof and dustproof paint can be saved by 20%; the paint can be sprayed on the LED display screens without auxiliary jigs, and accordingly the spraying equipment is low in production and material costs.

Owner:SHENZHEN ZHONGTUO AUTOMATION EQUIP CO LTD

Thin plastic pipe machine for brushing

InactiveCN101041147AImprove efficiencyGood painting qualitySpecial surfacesCoatingsLacquerEngineering

The invention relates to a brushing machine of thin plastic pipe, belonging to the brushing mechanical technology field, for solving problems of low brushing efficiency in handwork, heavy labor intensity and no assurance for brushing quality. The invention comprises manipulator, clamping device and worktable. The manipulator can simulate human hand to dip lacquer, lift, brush and draw back. It can accomplish the brush of paint layer on the surface of thin plastic pipe mechanically and automatically. By adding intermittent rotator, the manipulator and the clamping device can be allocated according to the brushing work station to form the intermittent automatic brushing machine with multiple work stations. The brush to multiple thin and long plastic pipes with multiple purposes can be accomplished. It is provided with regular brushing work, even brushing layer, good brushing quality and high efficiency. It can be used as brushing equipments for thin plastic pipe, maw pipe and so on.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient paint spraying device for leather shoe manufactory

ActiveCN107138313APlay a supporting rolePlay a guiding rolePretreated surfacesLiquid spraying apparatusEngineeringMechanical engineering

The invention relates to a paint spraying device, in particular to an efficient paint spraying device for a leather shoe manufactory. The efficient paint spraying device for the leather shoe manufactory aims to achieve the effects of being high in paint spraying work efficiency and full and uniform in paint spraying. The efficient paint spraying device for the leather shoe manufactory comprises an installation frame and the like. A paint spraying mechanism used for leather shoe paint spraying treatment, a swinging mechanism used for swinging a paint spraying component and a rotating mechanism used for rotating a fixing component and a leather shoe are all fixed to the top of the installation frame. The swinging mechanism is located between the paint spraying mechanism and the rotating mechanism. A fixing mechanism used for fixing the leather shoe is fixed to the rotating mechanism. A drying mechanism used for drying the leather shoe is fixed to the inner top of the installation frame. The efficient paint spraying device for the leather shoe manufactory achieves the effects of high paint spraying work efficiency and full and complete paint spraying. The rotating mechanism can drive the fixing mechanism to rotate, so that the leather shoe is driven to rotate.

Owner:嘉兴久珥科技有限公司

Hardware product paint spraying device

InactiveCN108525903AEvenly paintedImprove painting efficiencyLiquid spraying apparatusSpray nozzleMechanical engineering

The invention provides a hardware product paint spraying device. The hardware product paint spraying device comprises a base, supporting columns are fixedly mounted on the left and right sides of thetop of the base, and a spraying box is fixedly installed at the tops of the supporting columns. A rotating disc motor is fixedly installed at the middle of the bottom of the spraying box, and a rotating shaft is arranged at the top of the rotating disc motor. The rotating shaft penetrates through the spraying box and extends into the spraying box. A rotating disc is fixedly installed at the top ofthe rotating shaft, and plug pins are fixedly installed on both sides of the top of the rotating disc. According to the hardware product paint spraying device, a plate is firmly fixed to the turntable by arranging the plug pins; by arranging the turntable motor to be matched with the rotating shaft, the rotating disc can drive the plate to rotate, so that paint spraying is more uniform and the paint spraying efficiency is improved; by arranging a moving box, spray nozzles can move left and right to expand the range of rotation; and by arranging a rack to be matched with driving of two half gears, a connecting rod can move left and right to drive the spray nozzles to move left and right.

Owner:新昌县盛南建材有限公司

Paint spraying device for wood processing

ActiveCN110404714AImprove painting efficiencyFull painting processSpraying apparatusReciprocating motionEngineering

The invention discloses a paint spraying device for wood processing, and belongs to the field of wood processing. The paint spraying device comprises a paint spraying pipe, the paint spraying pipe communicates with a paint storage box through a paint conveying chamber, a paint conveying assembly is arranged in the paint conveying chamber, a clamping assembly is rotationally arranged below the paint spraying pipe, the paint spraying pipe is arranged at the bottom of the sliding block, the sliding block is connected with a reciprocating assembly, and the reciprocating assembly, the paint conveying assembly and the clamping assembly are connected with a driving mechanism. According to the paint spraying device for wood processing, the paint spraying pipe is connected with the sliding block, and the sliding block is connected with the reciprocating assembly so that the paint spraying pipe can be driven to do reciprocating motion on the horizontal plane through the driving mechanism and a transmission assembly, and then the paint spraying efficiency of wood can be improved. In addition, the rotatable clamping assembly is connected with the driving mechanism so that the wood can be overturned while the paint spraying pipe performs paint spraying, and then the wood can undergo spraying processing in a more comprehensive and uniform mode.

Owner:阜南县猛发工艺品有限公司

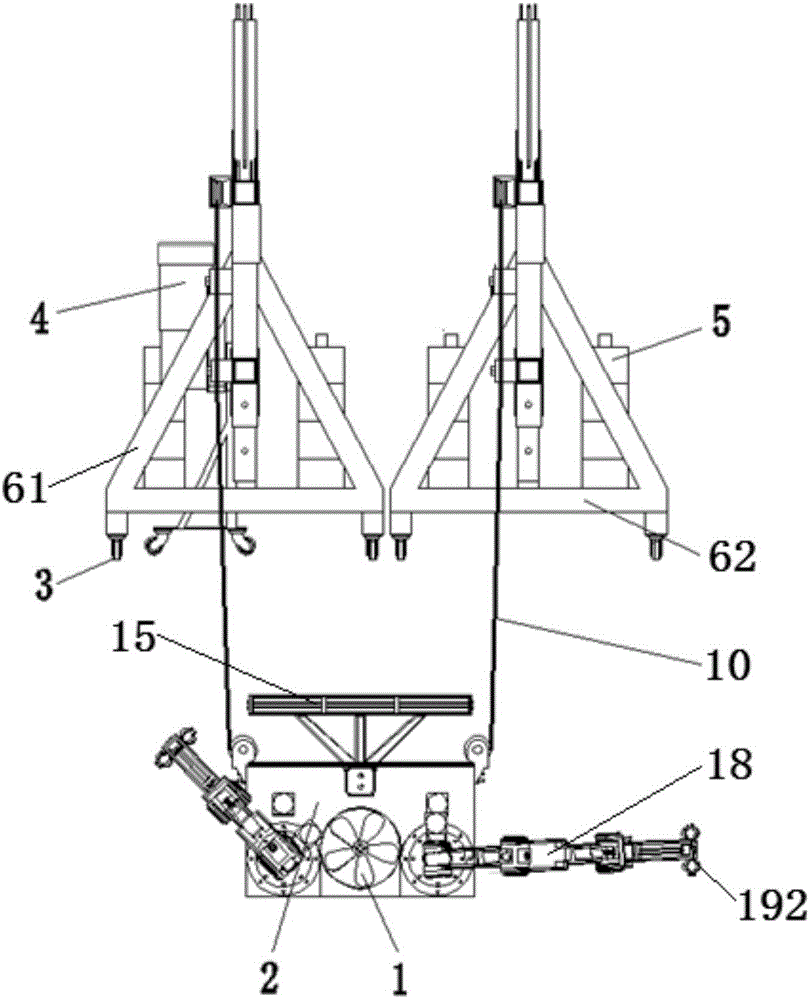

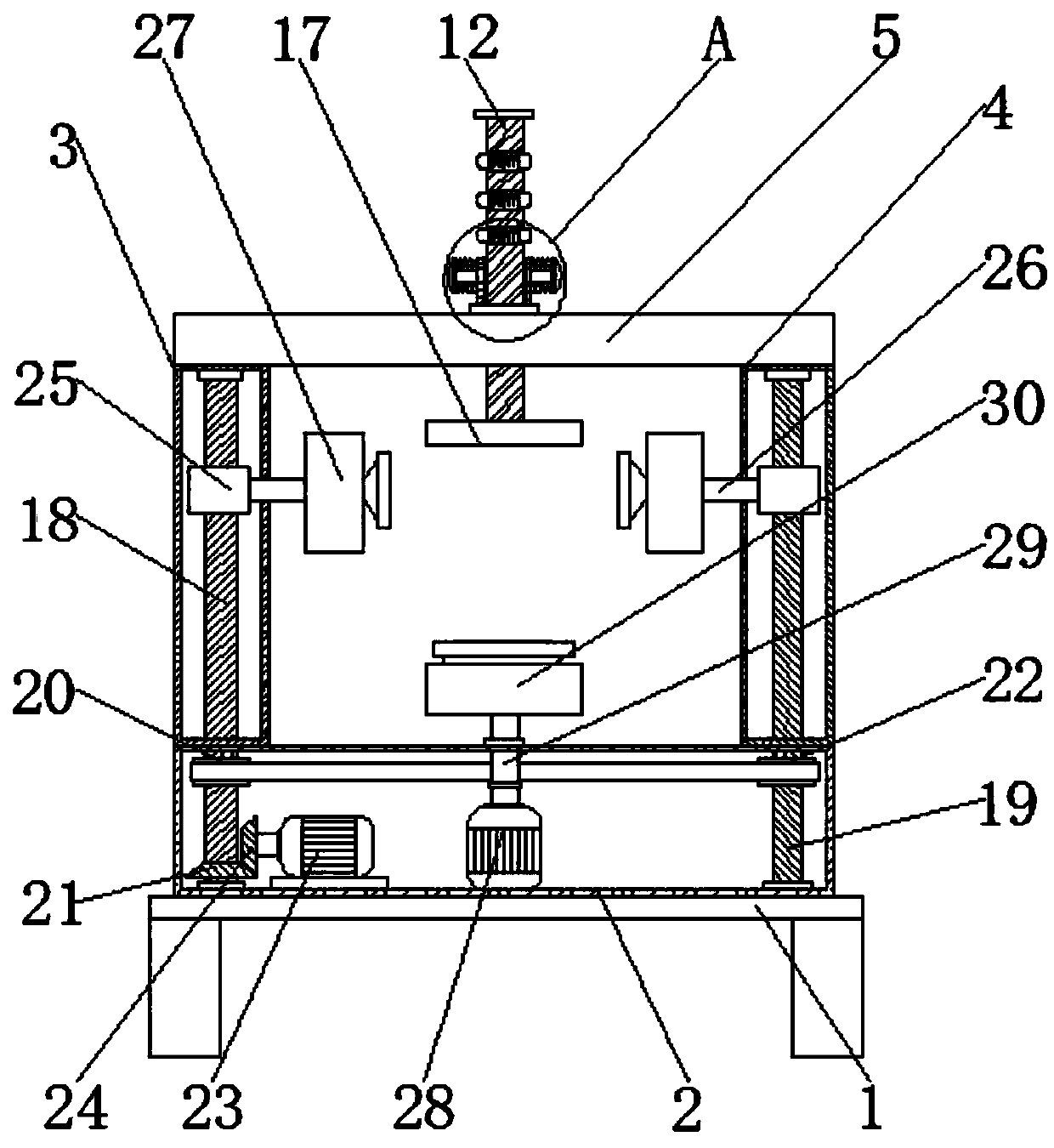

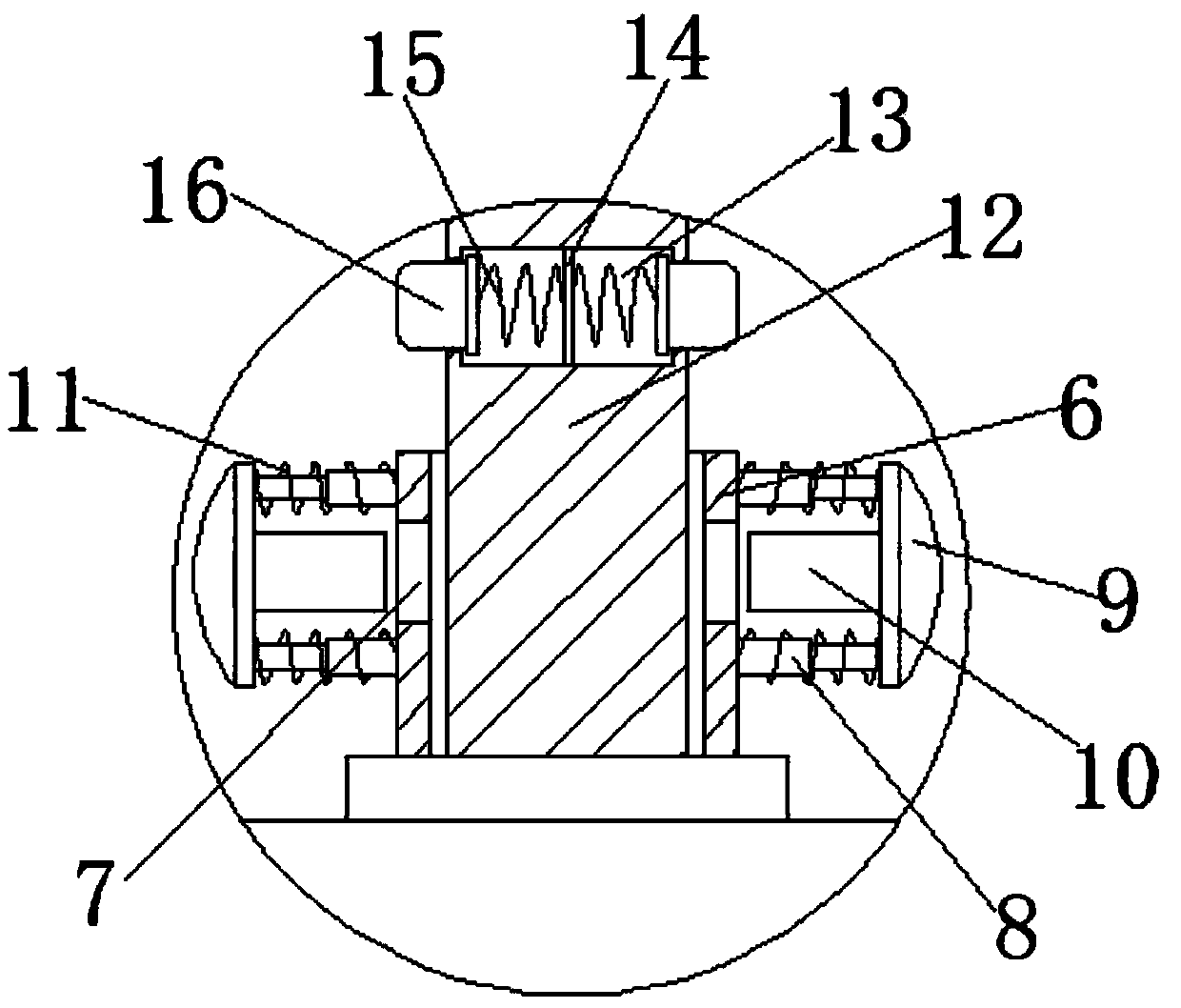

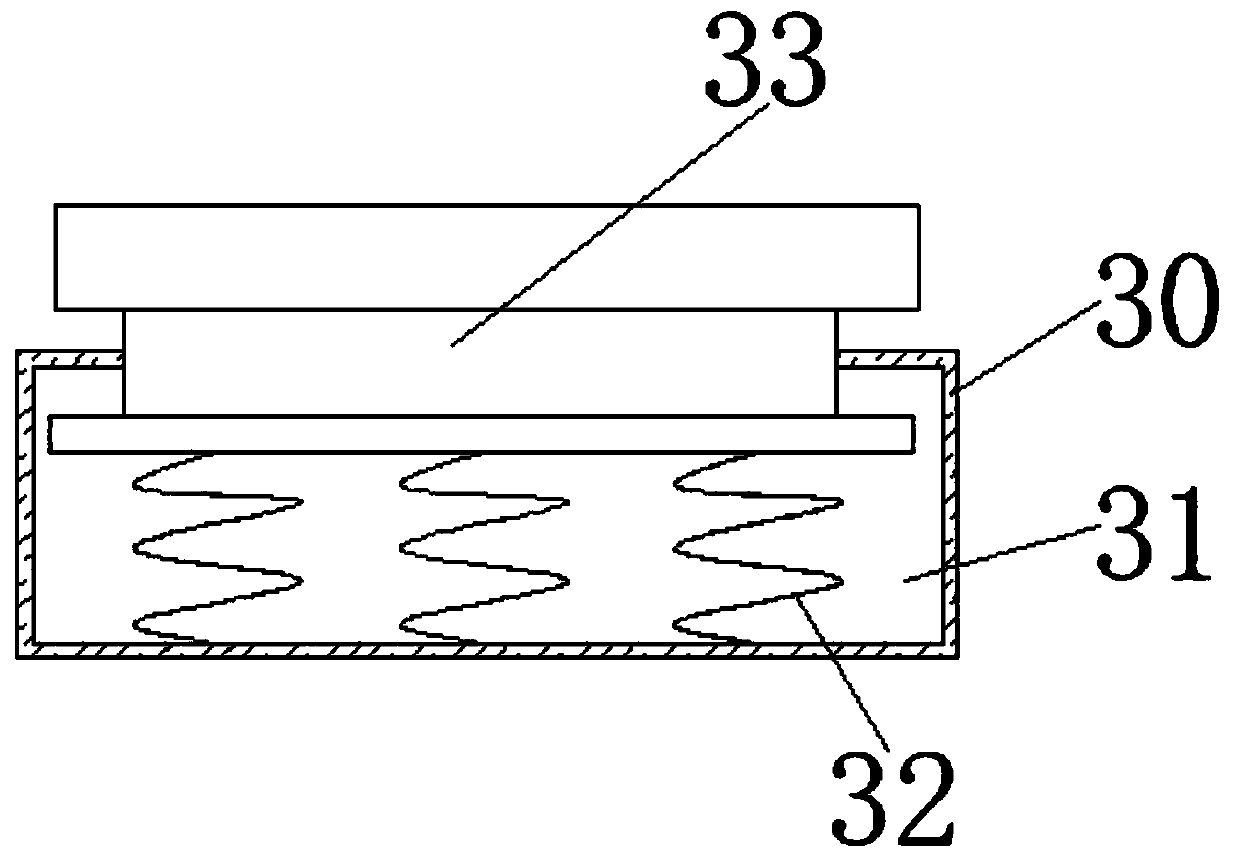

Suspended multi-degree of freedom painting machine for high-rise building exterior walls

InactiveCN106437105AEasy to fixStable supportBuilding constructionsMulti degree of freedomEngineering

A suspended multi-degree of freedom painting machine for high-rise building exterior walls comprises a painting machine body, a first suspension frame and a second suspension frame. For achieving the purpose, the suspended multi-degree of freedom painting machine is characterized in that the first suspension frame is provided with an elevator, a steel wire rope is connected to the elevator, and one end of the steel wire rope sequentially bypasses pulleys which are arranged on the first suspension frame and the painting machine body respectively and then is fixed to pulleys arranged on the second suspension frame; the painting machine body is provided with a front painting device and mechanical painting arms, spray gun claws for fixing spray guns are arranged on the top of the front painting device and the tops of the mechanical painting arms respectively, and the bottom ends of the mechanical painting arms are fixed to the surface of the painting machine body through mechanical arm rotating mechanisms. Regular and even wall surfaces are painted through the front painting device, irregular and uneven wall surfaces are painted through the mechanical painting arms, therefore, the painting machine not only can paint the even and regular wall surfaces, but also can paint the irregular and uneven complex wall surfaces, the painting difficulty of the paining machine is reduced, and the painting efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

High-efficiency auto spare part paint spraying device

The invention discloses a high-efficiency auto spare part paint spraying device which comprises a base plate. A box is fixedly connected to the top of the base plate, a first installing box and a second installing box are fixedly connected to the two sides of the top of the box, an installing plate is fixedly connected between the top of the first installing box and the top of the second installing box, a hollow rod is rotationally connected to the top of the installing plate through a bearing, groove holes are formed in the two sides of the hollow rod, stretchable rods are fixedly connected to the tops and the bottoms of the two sides of the hollow rod, a button is fixedly connected between the ends, far away from the hollow rod, of the two stretchable rods, an ejection rod is fixedly connected to the position on one side of the button and located between the two stretchable rods. The high-efficiency auto spare part paint spraying device relates to the technical field of auto spare part paint spraying equipment. According to the high-efficiency auto spare part paint spraying device, manual paint spraying is not needed, auto spare part paint spraying can be achieved in an all-around manner, the paint spraying efficiency is improved, and the equipment practicability is achieved.

Owner:山西中德智达新能源装备科技有限公司

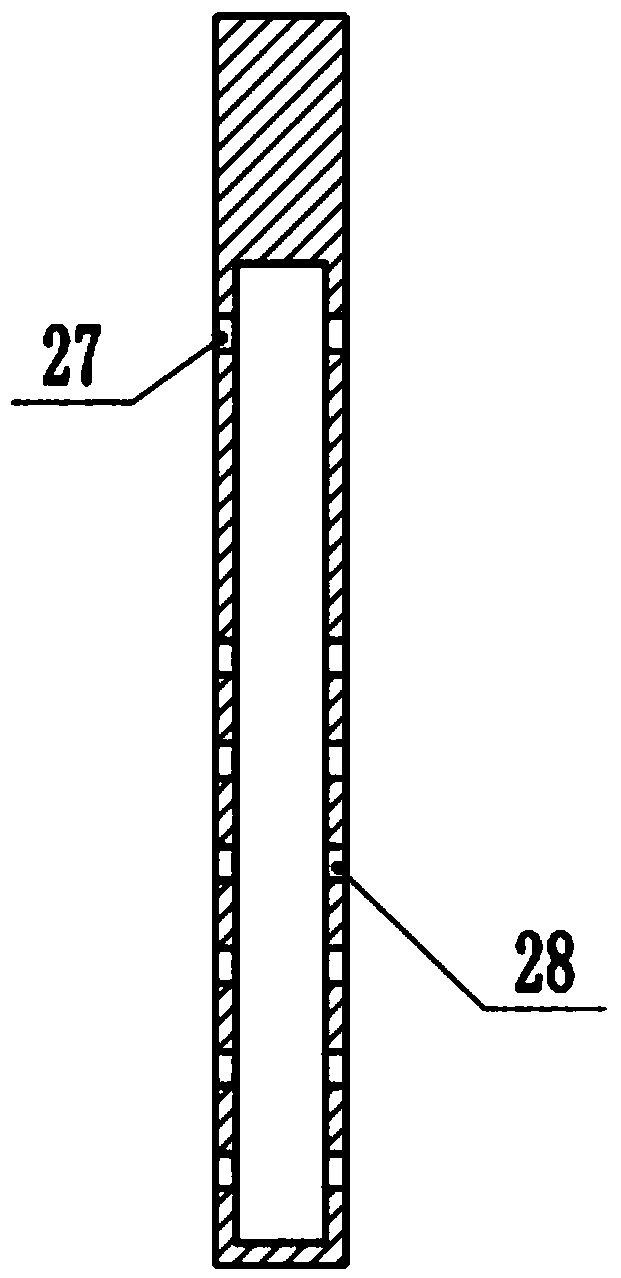

Synchronously and uniformly automated painting device for inner and outer walls of tubular member

The invention discloses a synchronously and uniformly automated painting device for inner and outer walls of a tubular member, and belongs to the technical field of automation equipment. The synchronously and uniformly automated painting device includes a fixing base, wherein guide frames are arranged on both sides of the upper end of the fixing base; a top plate is arranged on the upper ends of the guide frames; a paint feeding tank is arranged in the middle of the top plate; the upper end of the top plate is connected with a fixing plate through top frames; the middle of the upper end of thefixing plate is provided with a rotating motor; an output shaft at the lower end of the rotating motor is connected with a rotating shaft; a driving belt pulley is arranged at the middle of the upperend of the rotating shaft; both ends of the driving belt pulley are connected with driven belt pulleys through belts; rotating rods are arranged at the middles of the driven belt pulleys; the upper ends of the rotating rods pass through the fixing plate and are connected with rotating cams; the middles of the rotating rods pass through the top plate and are connected with reciprocating blocks through reciprocating thread areas; the bottom end of one rotating rod pass through the fixing base and is connected with a rotating belt pulley; and the right end of the rotating belt pulley is connected with a drive belt pulley through a belt. According to the synchronously and uniformly automated painting device, the synchronous painting of the inner and outer walls of the tubular member is ensured, the painting efficiency and the painting quality are improved, and the practicability is high.

Owner:宁波众创智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com