Painting device for processing of electronic product shell

A technology for electronic products and casings, which is applied in the field of painting devices for processing electronic product casings, can solve problems such as efficiency constraints, and achieve the effects of improved painting efficiency, reasonable design, and uniform painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

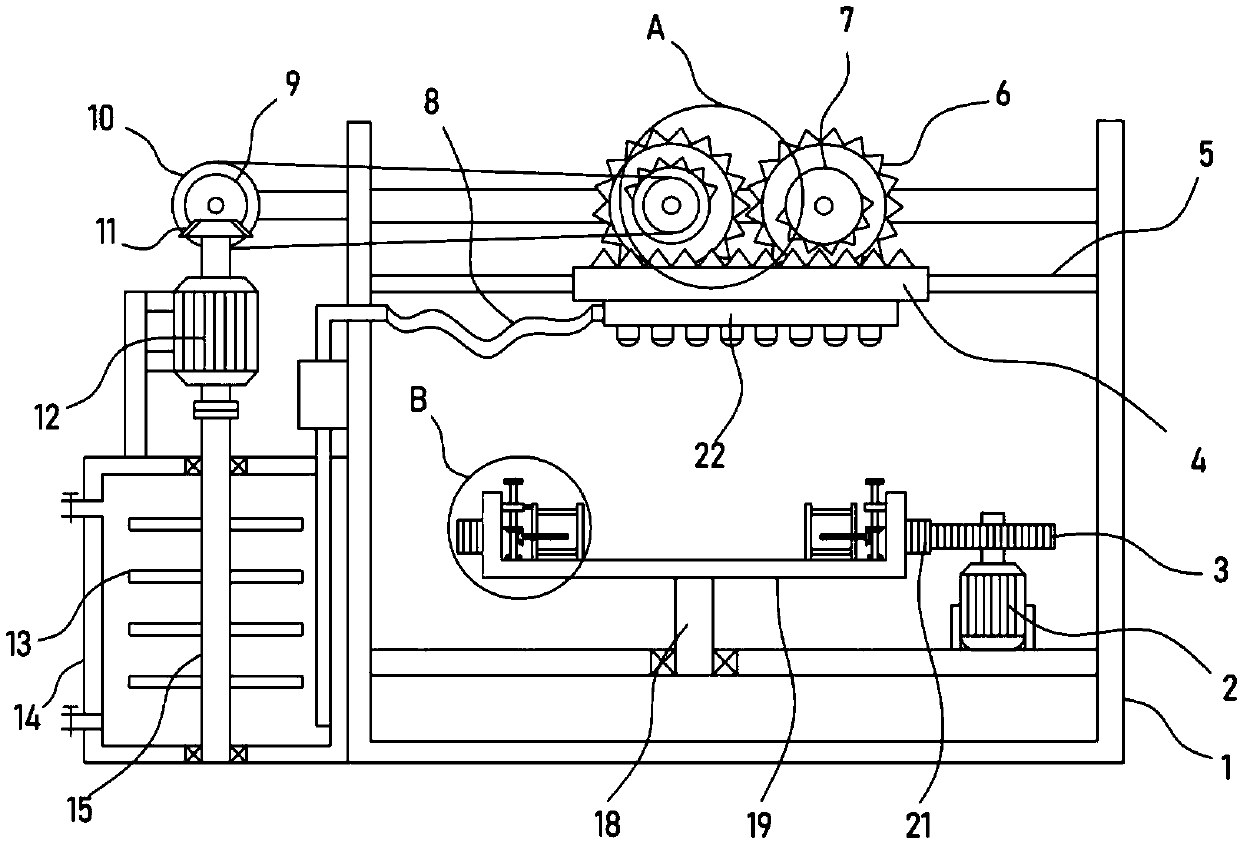

[0021] see Figure 1-3 , a paint spraying device for electronic product shell processing, including a support frame 1 and a paint bucket 14 fixed on the left side of the support frame 1, the paint bucket 14 is used to store the paint to be sprayed. The supporting frame 1 is rotatably provided with a supporting platform 19, and a clamping device for fixing the shell of the electronic product is installed on the supporting platform 19, and the shell of the electronic product is clamped and fixed by the clamping device provided, so as to avoid any damage during the painting process. Cause shaking and affect the painting effect.

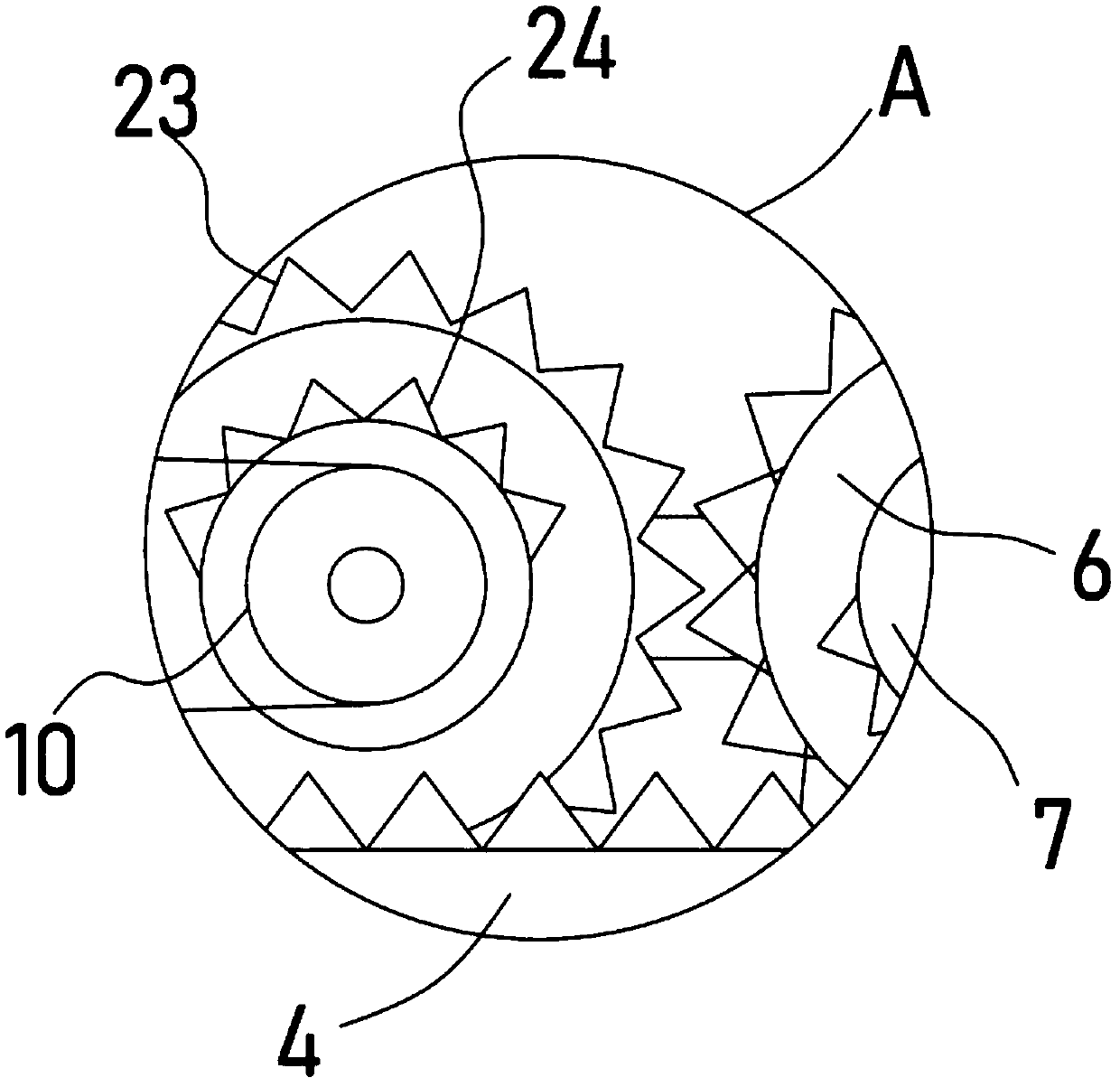

[0022] A guide rod 5 is fixed horizontally on the support frame 1, and a rack 4 is installed slidingly on the guide rod 5. The bottom of the rack 4 is fixedly installed with a paint spraying plate 22, which is connected to the delivery pump through a hose 8, and the delivery pump It communicates with the interior of the paint bucket 14. The gear I6 and ...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, another output shaft of the biaxial motor 12 is coaxially fixed with a stirring shaft 15 extending into the paint bucket 14, and the surface of the stirring shaft 15 is vertically and equidistantly fixed with several stirring rods 13 . The double-axis motor 12 can drive the stirring shaft 15 through another output shaft, and the stirring shaft 15 drives the stirring rod 13 to rotate to realize the rotating and stirring effect on the paint inside the paint bucket 14, which greatly improves the mixing uniformity of the paint and improves the efficiency of spraying paint. The degree of refinement of the paint sprayed out by the disc 22 ensures the spraying quality of the paint.

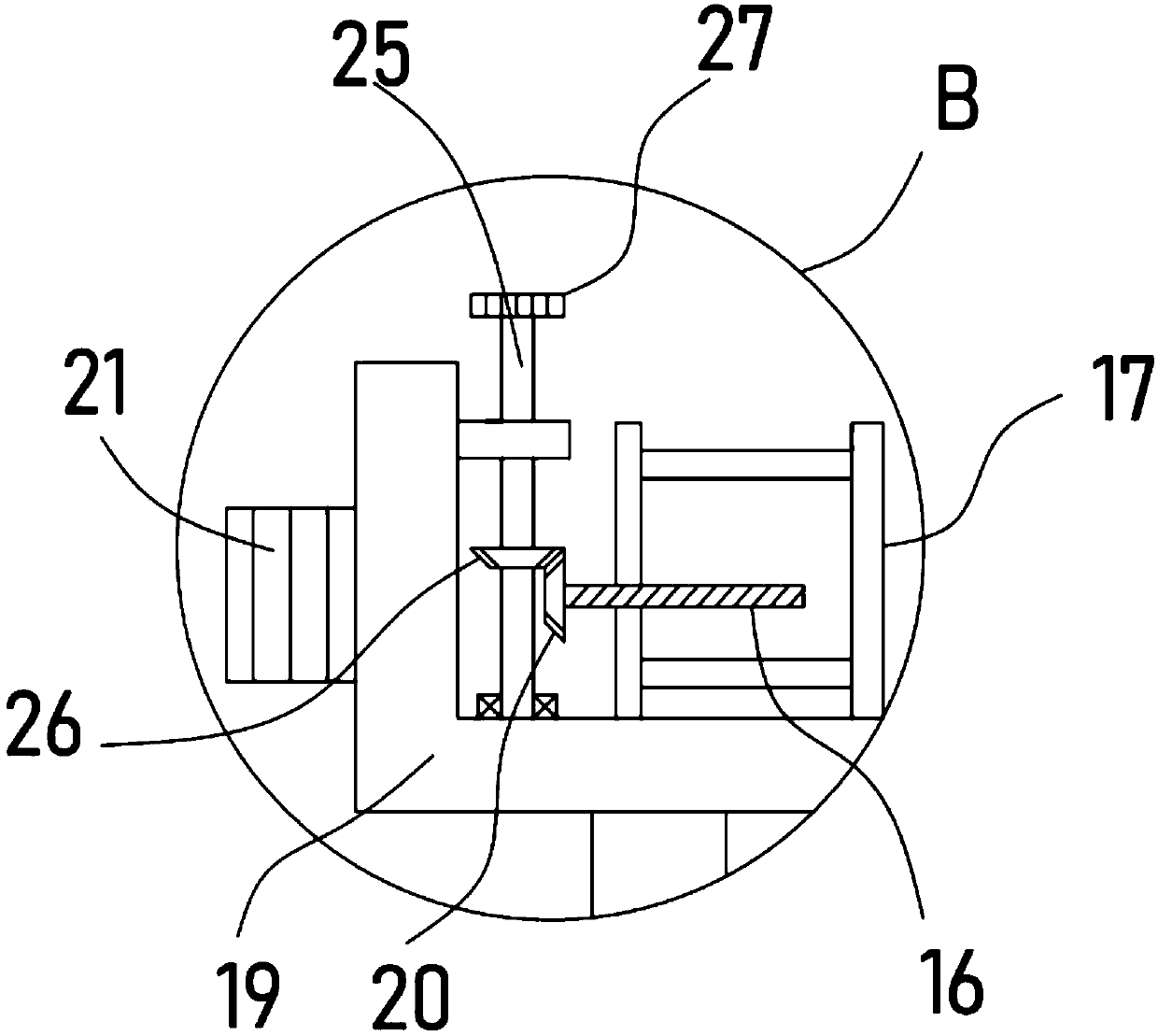

[0029] Further, the clamping device includes a pair of oppositely arranged clamping frames 17, the clamping frames 17 and the inner bottom of the support table 19 are horizontally slidably installed, and the clamping frames 17 can slide toward each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com