Constant-force grinding and polishing tool system

A polishing tool and grinding technology, used in grinding/polishing equipment, manufacturing tools, grinding machine parts, etc., can solve the problems of complex mathematical model, complex mechanical structure, low polishing efficiency, etc., to achieve simple mathematical model, The effect of simplifying the decoupling mode structure and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

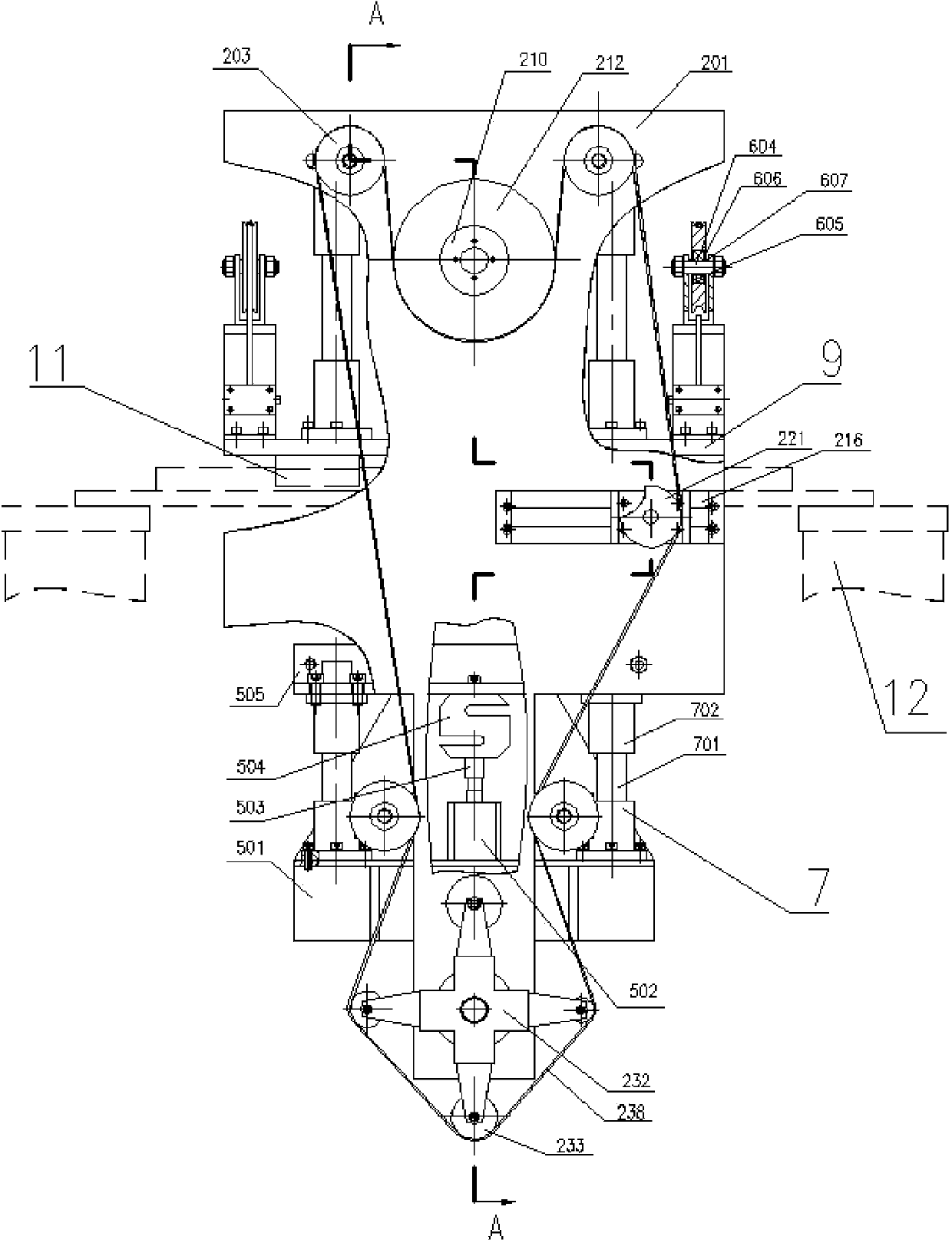

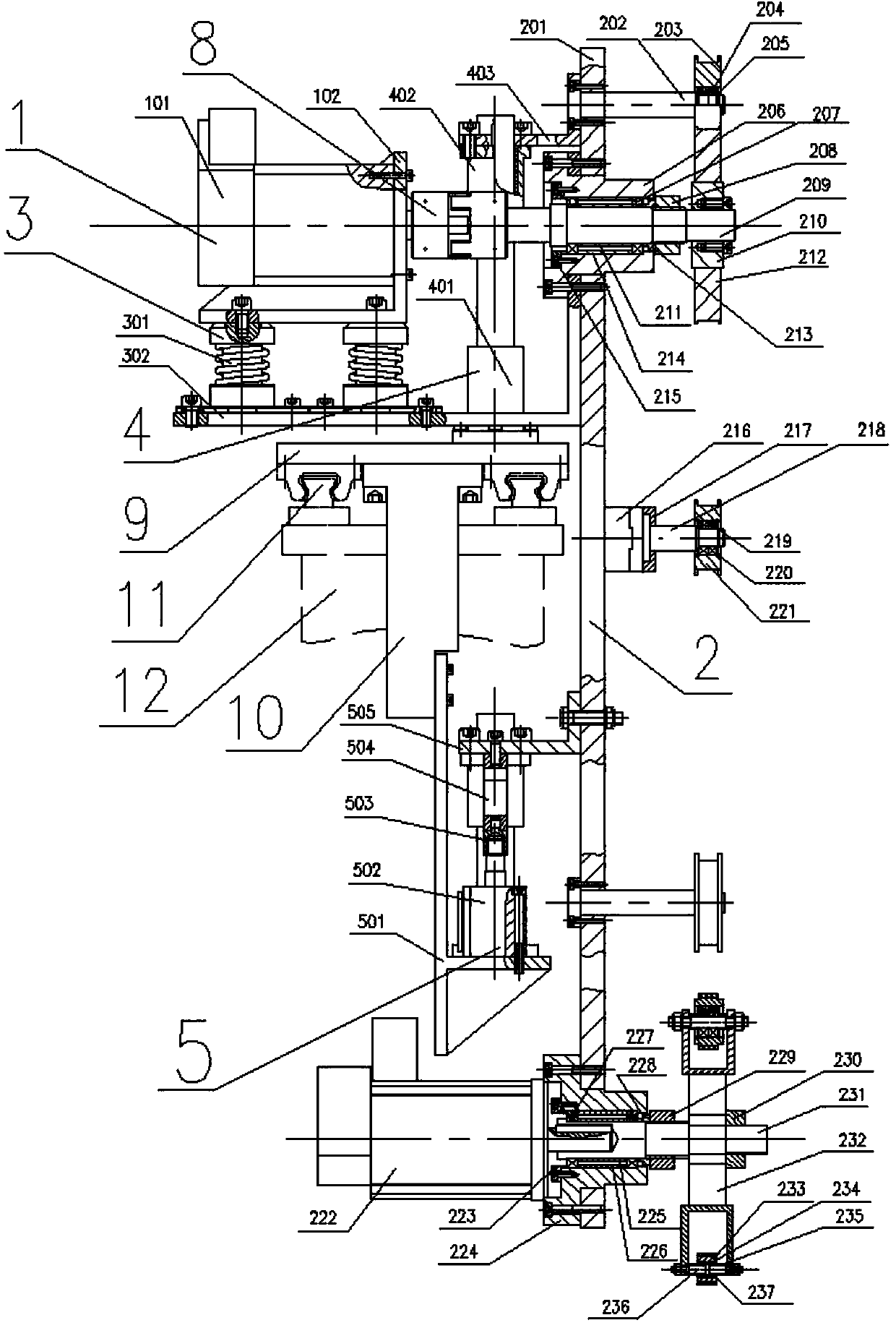

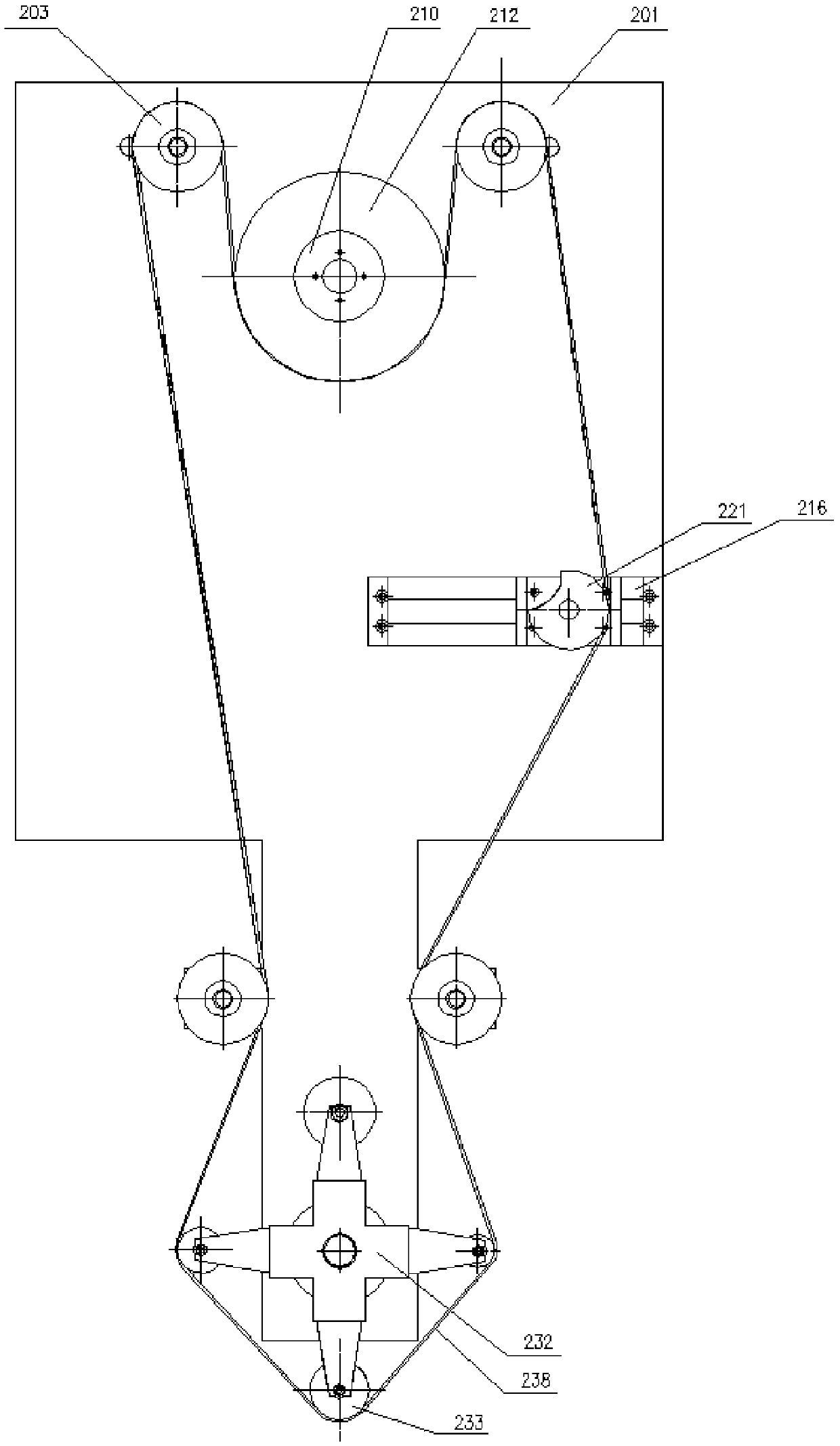

[0023] Including power device 1, wheel changing grinding tool 2, vibration damping device 3, guide device 1 4 and guide device 2 7, force compensation and detection device 5, counterweight device 6, power device 1 is connected with vibration damping device 3 through screws , also link to each other with the power take-off shaft 209 of wheel-changing grinding tool 2 by plum spline coupling 8, and wheel-changing grinding tool 2 is respectively connected with damping device 3, guiding device one 4 and guiding device two 7, force compensation by screw It is fixedly connected with the detection device 5, the counterweight device 6 is fixedly connected with the support plate 9 through screws, and connected with the wheel changing grinding tool 2 through screws, the support plate 9 is fixedly connected with the guide rail slider 11, and the force compensation is connected with the detection device 5 through Part 10 is connected to the support plate.

[0024] The power device is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com