Patents

Literature

1158results about How to "Guaranteed surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

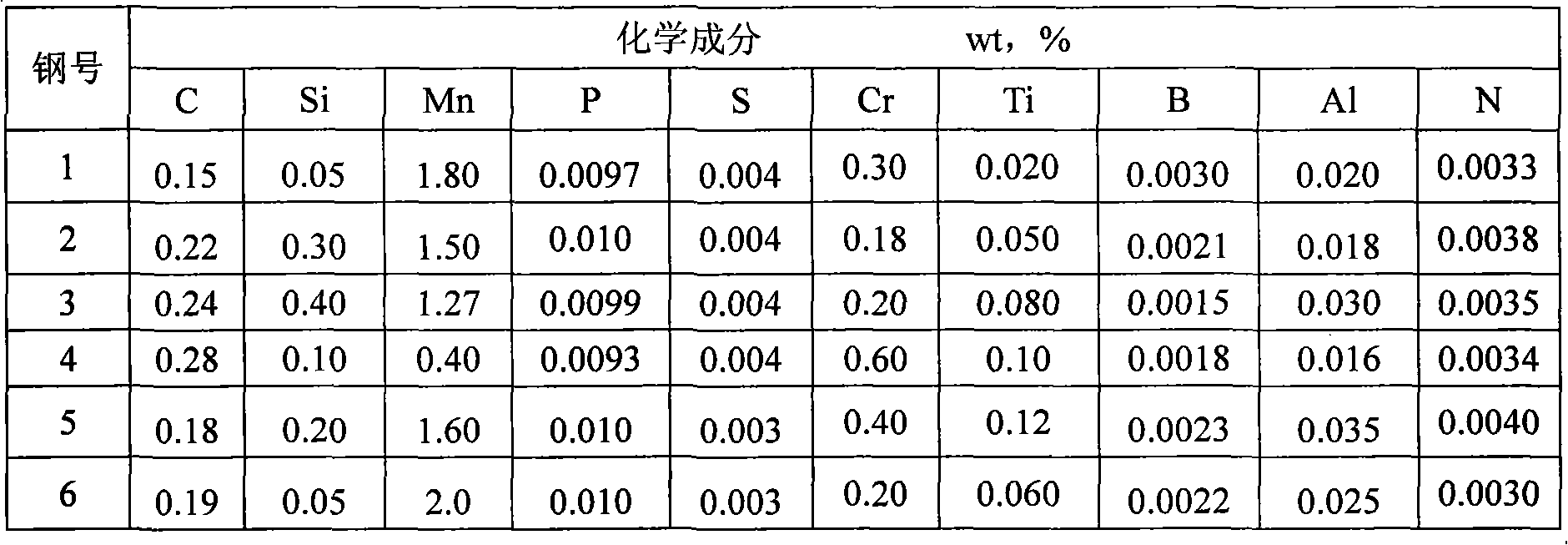

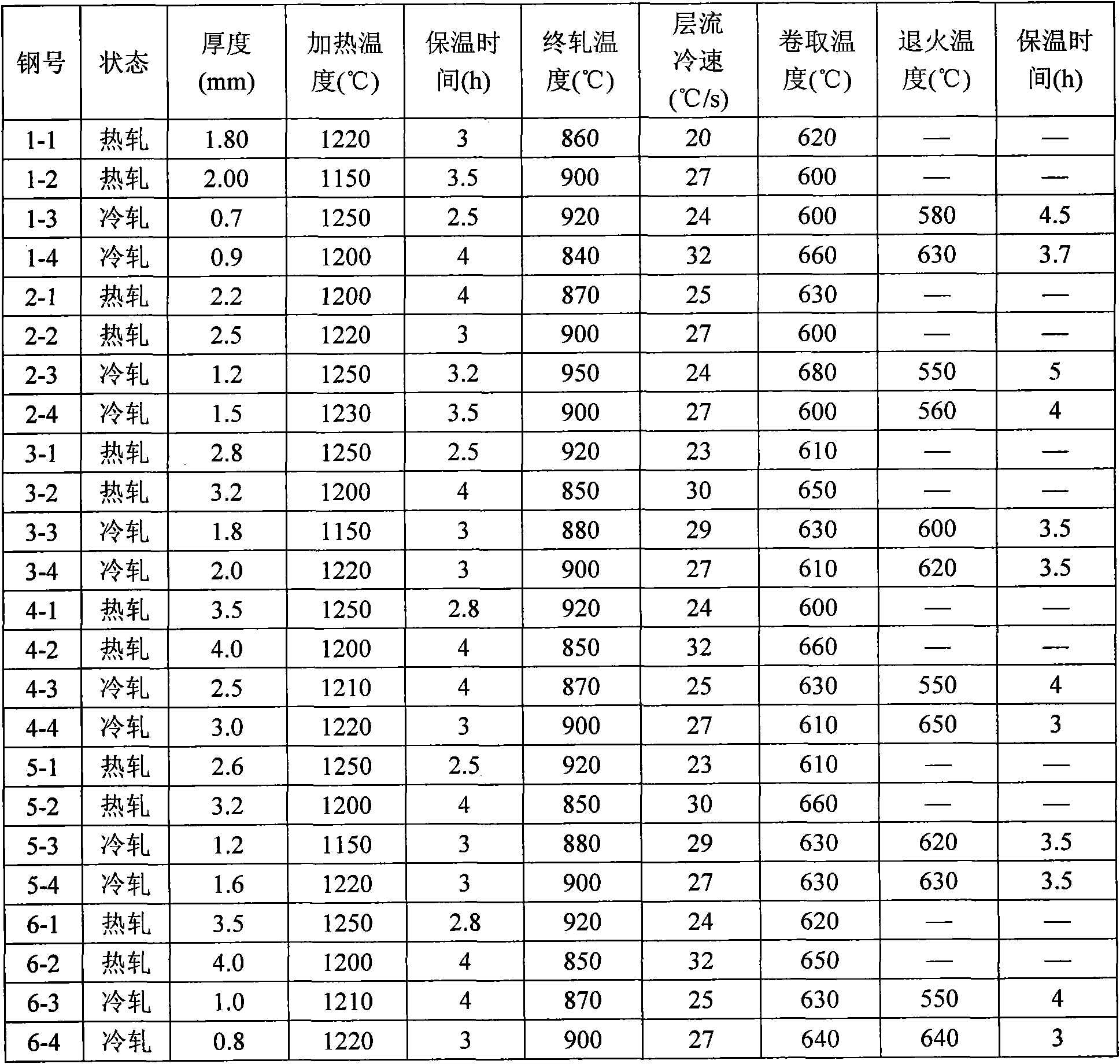

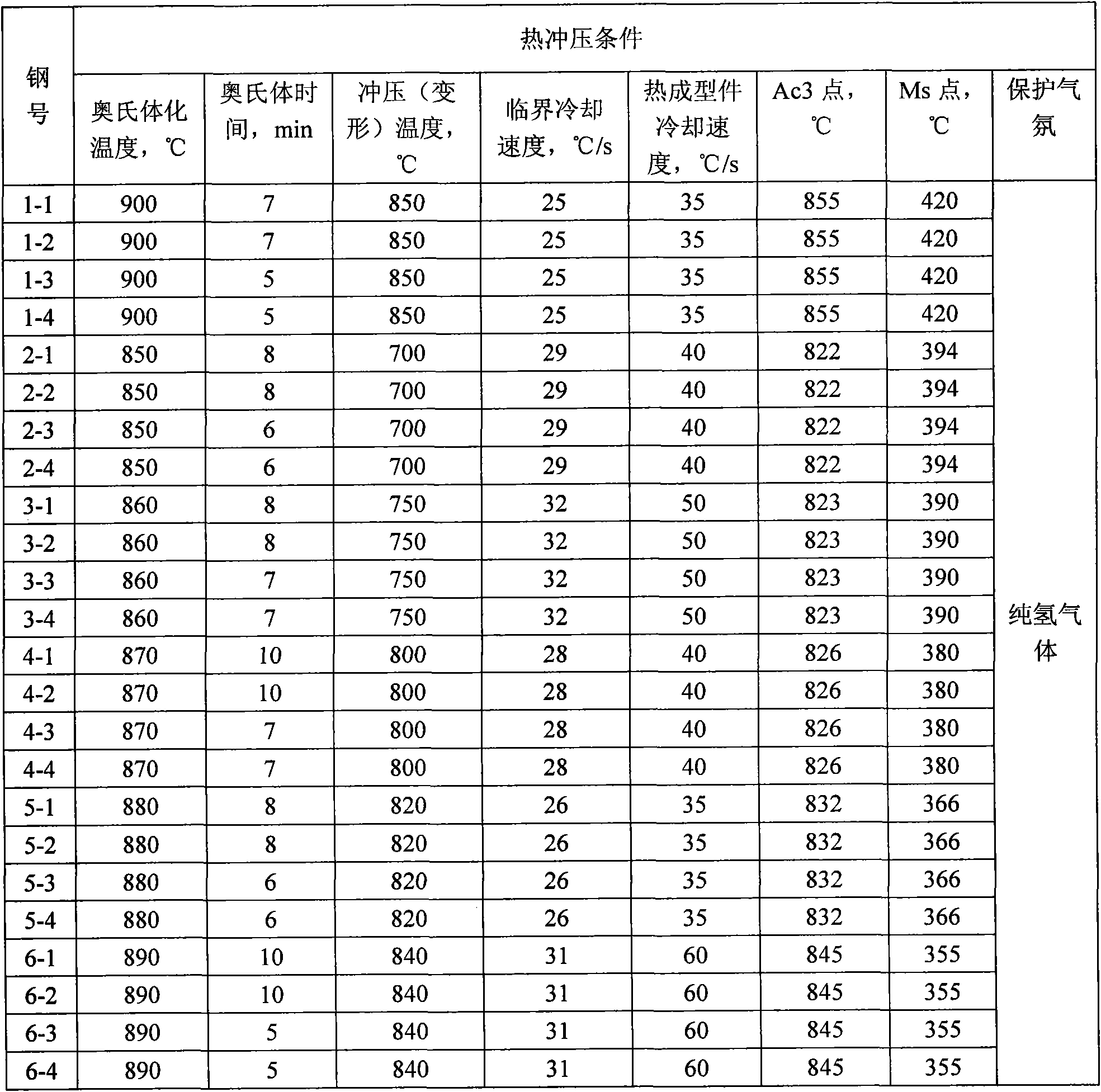

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

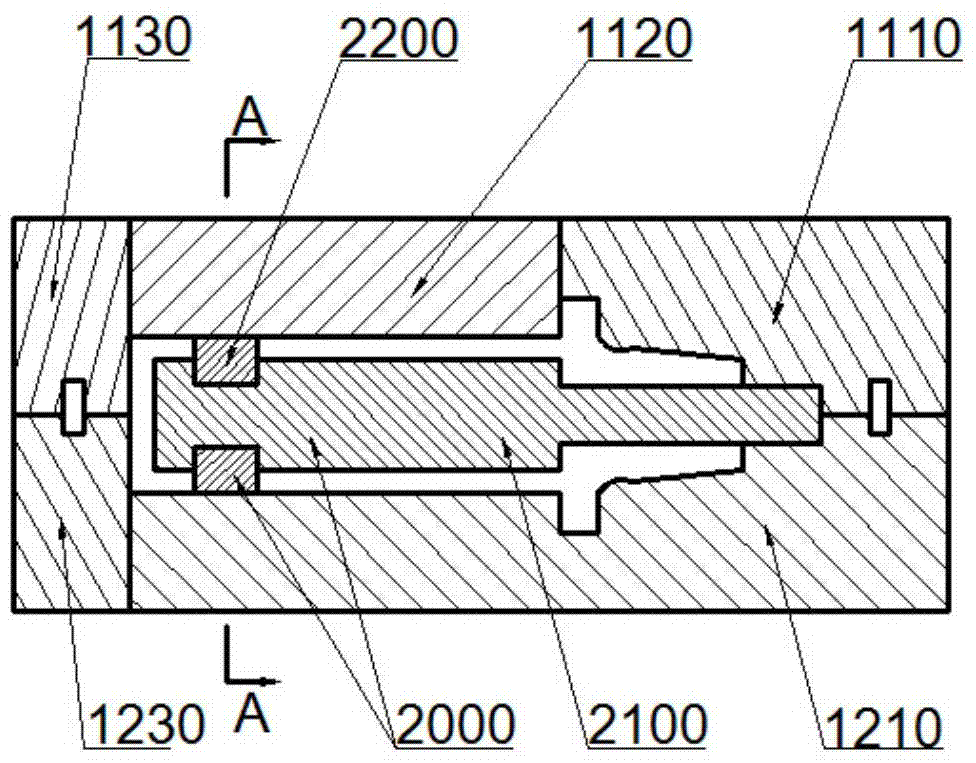

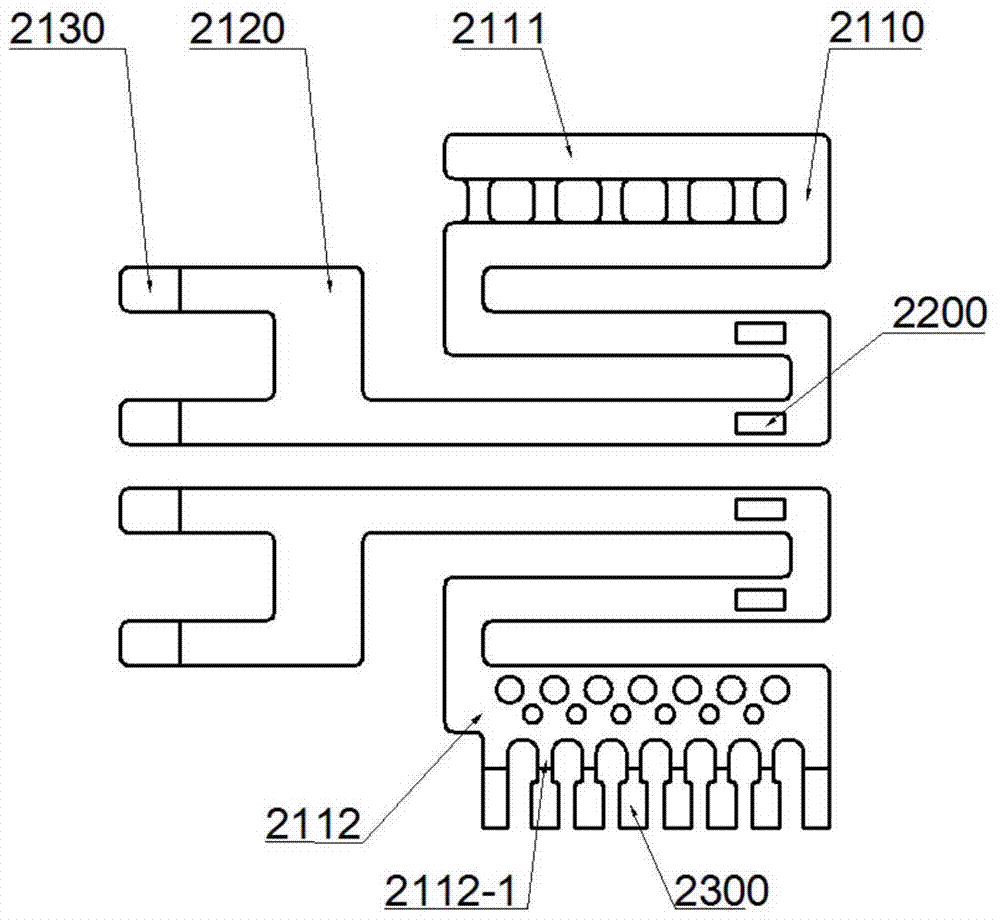

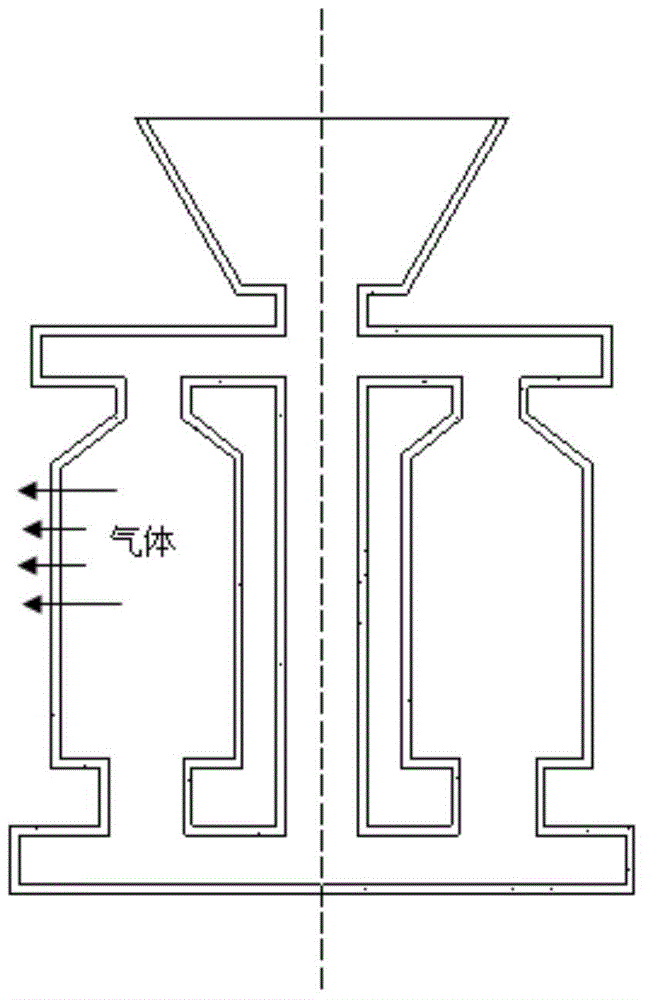

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

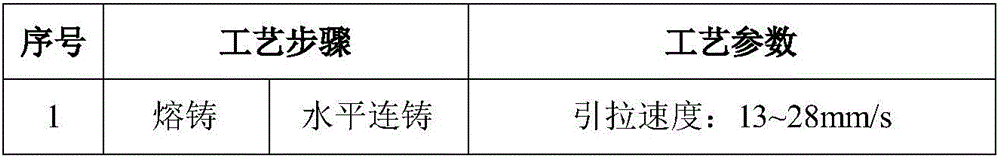

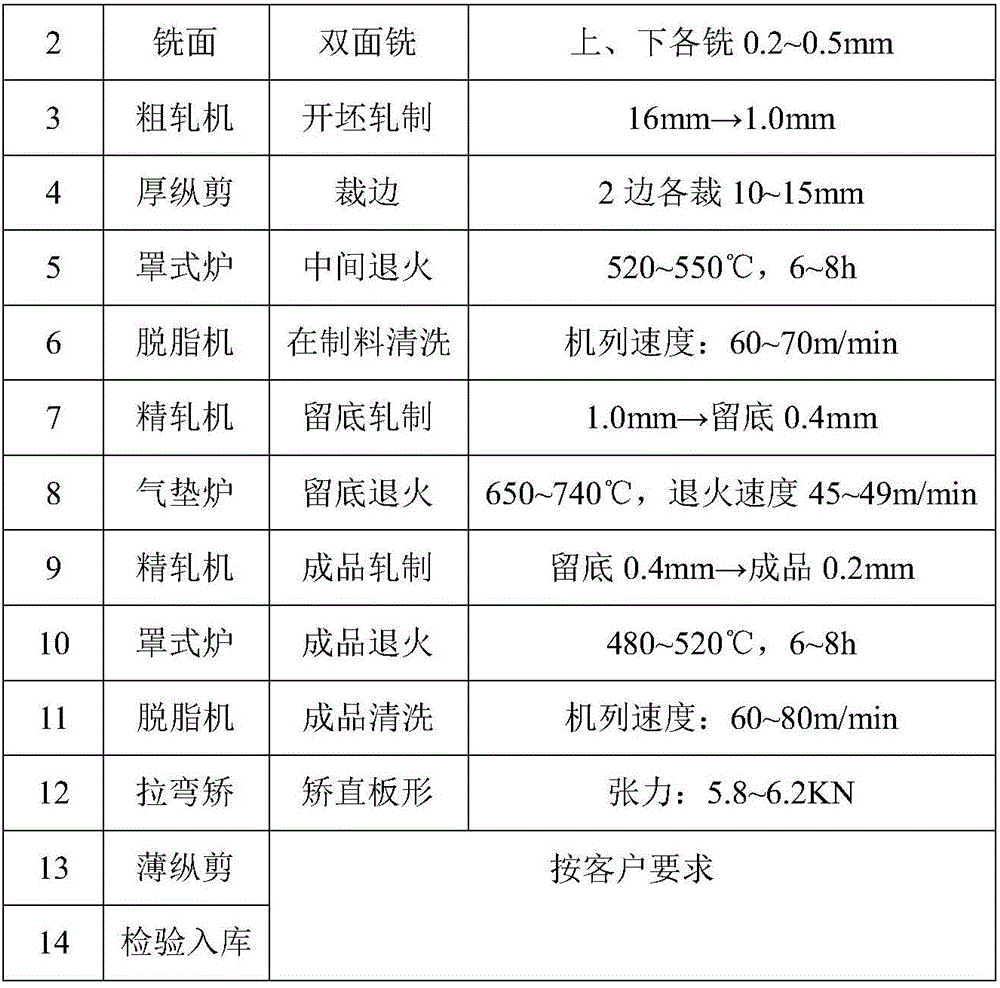

Production method of aluminum and copper composite metal band

ActiveCN101758071ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsCopperUltimate tensile strength

The invention discloses a production method of an aluminum and copper composite metal band. In the method, the aluminum and copper composite metal band is manufactured by anaerobic continuous casting and rolling of semisolid aluminum or aluminum alloy and a solid copper band. In the production method of the invention, the anaerobic metallurgical combination of the solid copper band and molten aluminum is realized, the aluminum oxidization problem is solved, the combined strength is high, and the aluminum and copper bonding strength is more than or equal to 100MPa; the continuous casting and rolling of the copper band and the molten aluminum are adopted to produce the aluminum and copper composite metal band, so the production efficiency is greatly improved by scores of times and the product quality is stable; the produced aluminum and copper composite metal band retains the original surface quality of the copper band, has a uniformly-thick copper layer and can be deeply processed by cold rolling; and the copper band and the molten aluminum, which comprise different components, can be used, and products are diversified and widely applicable. The method has the advantages that: the production process of the copper and aluminum composite band is advanced and comprises a few working procedures; and the energy-saving, material-saving and economic effects are obvious.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

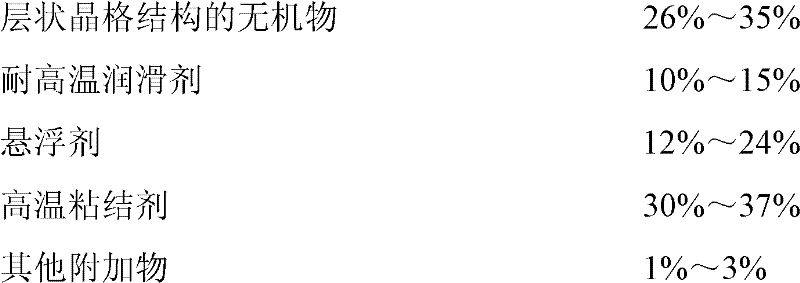

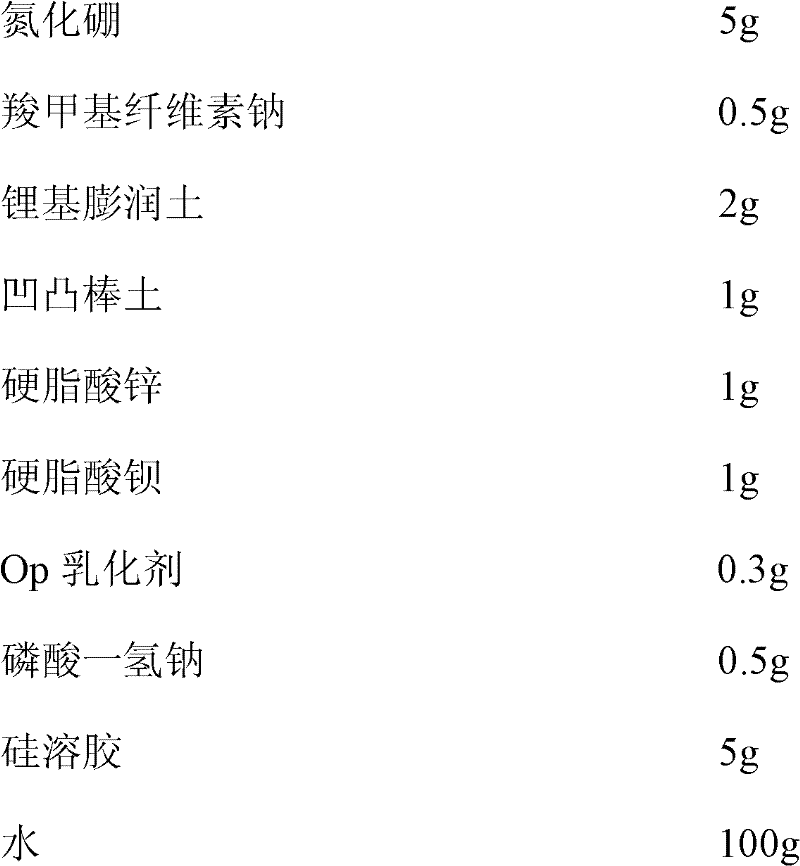

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

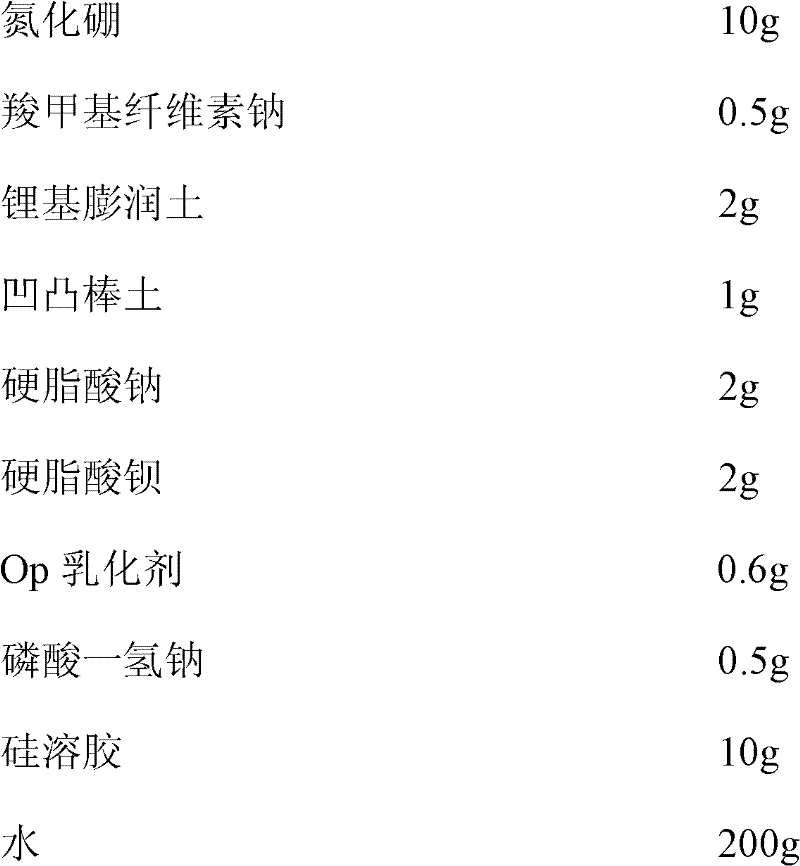

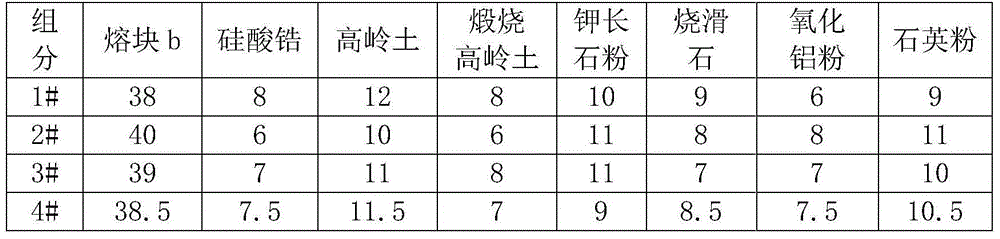

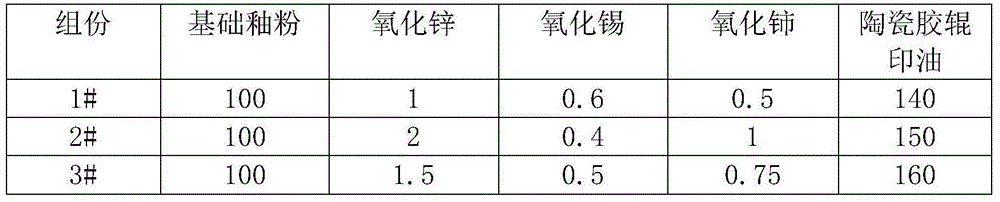

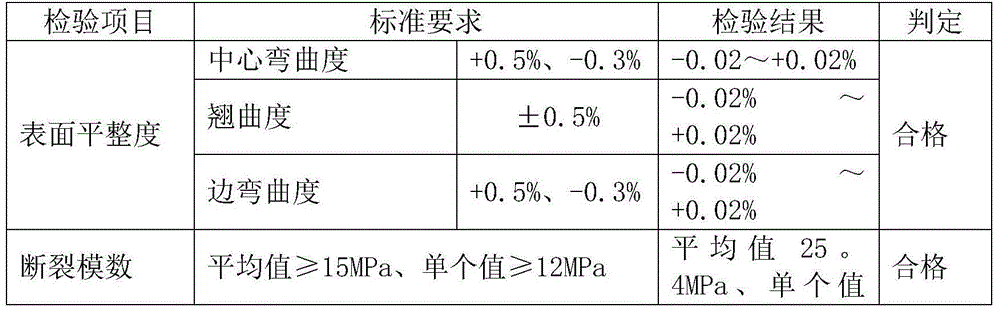

Glaze and preparation of embossment phantom glazed brick

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

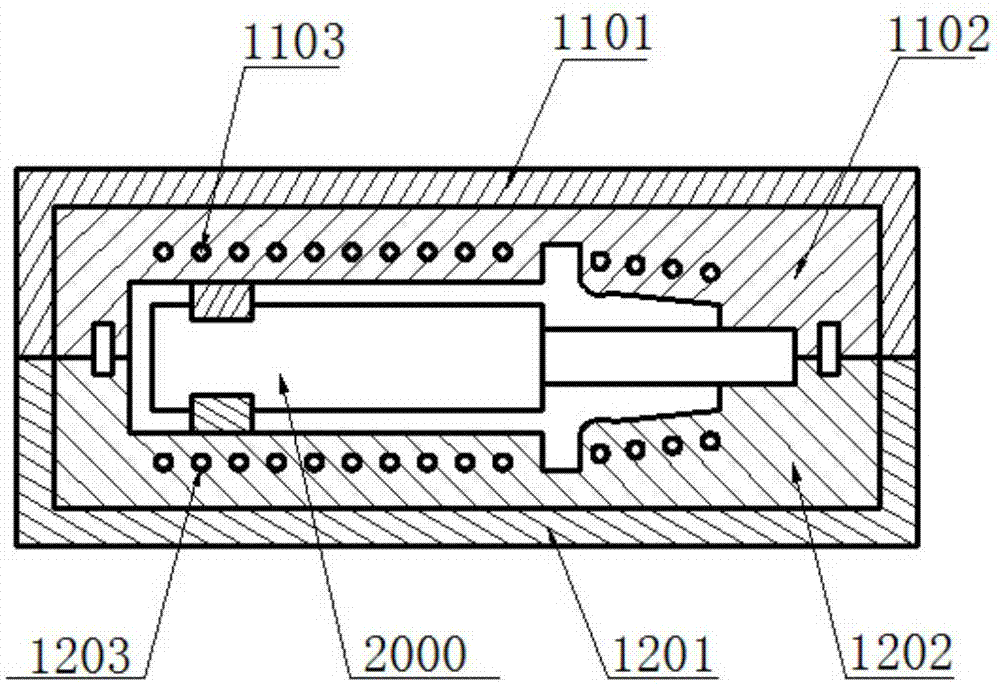

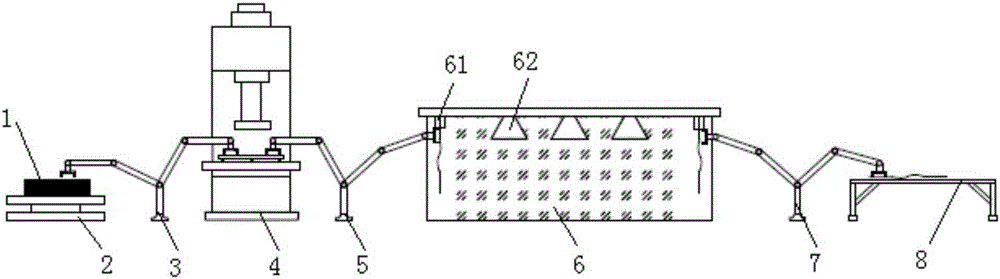

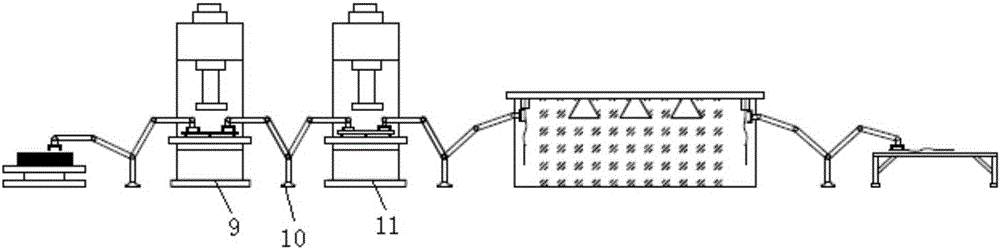

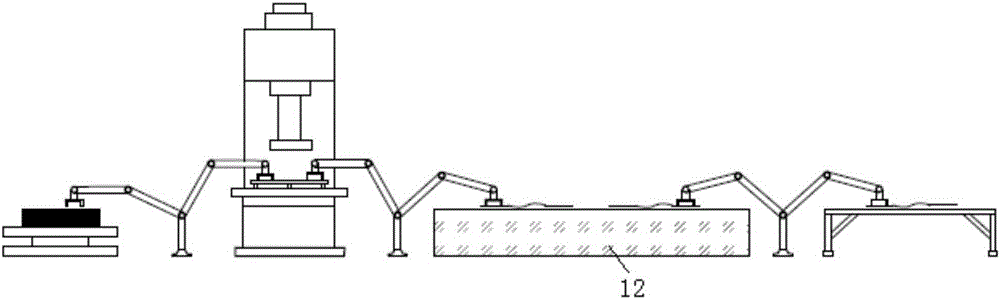

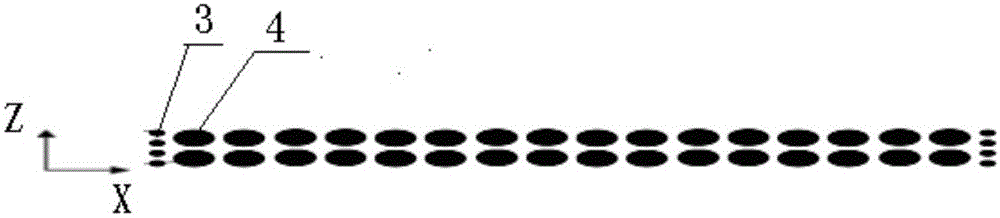

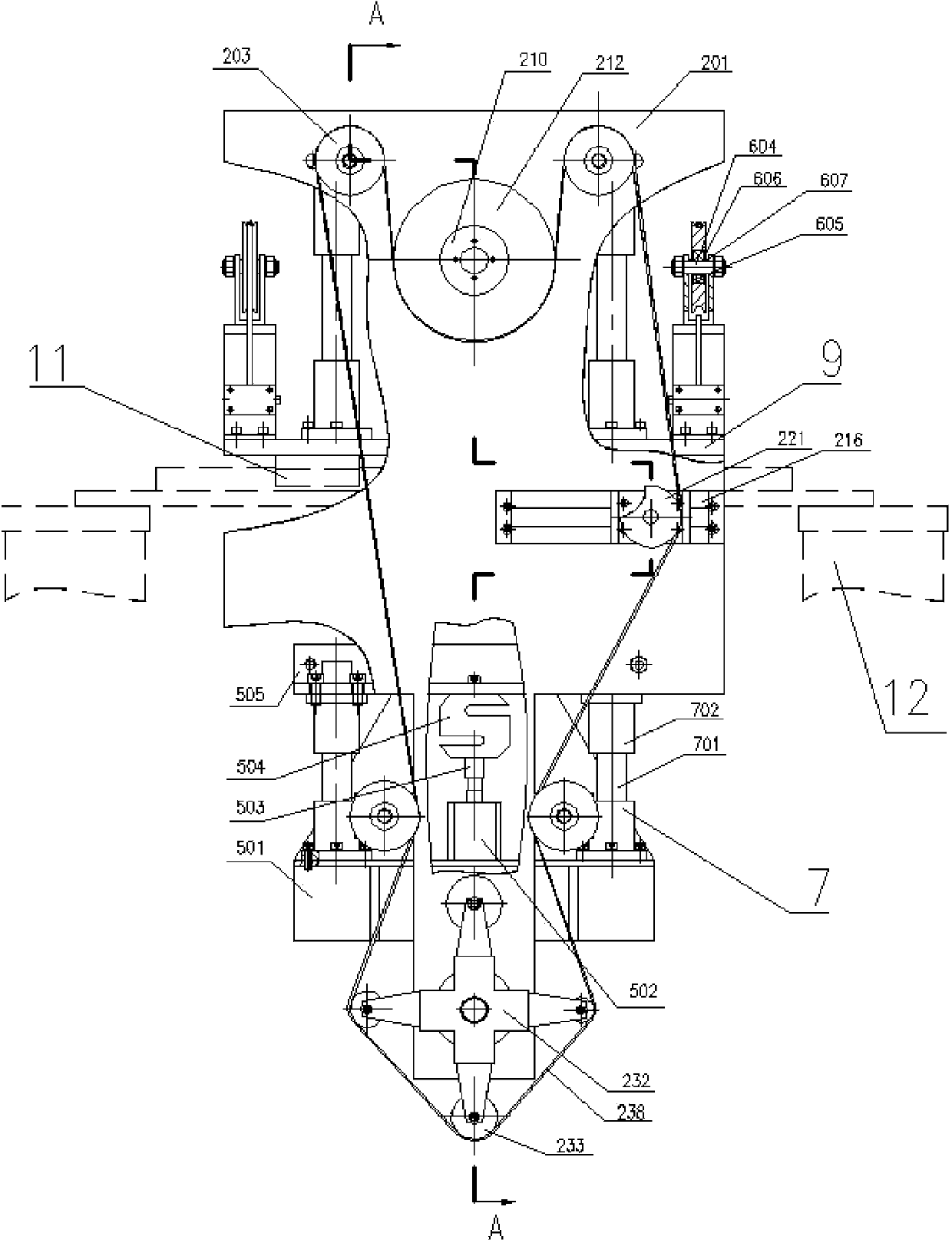

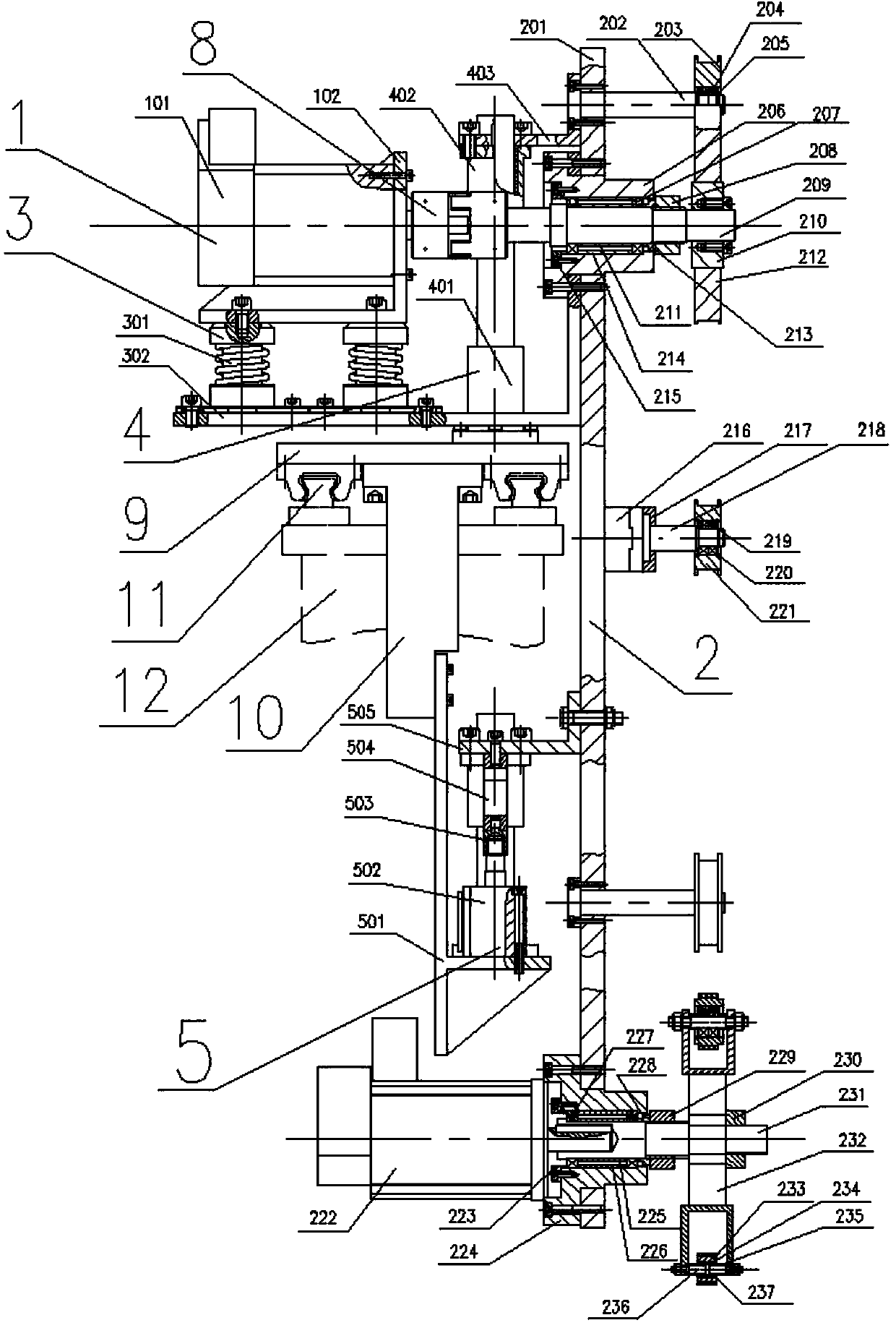

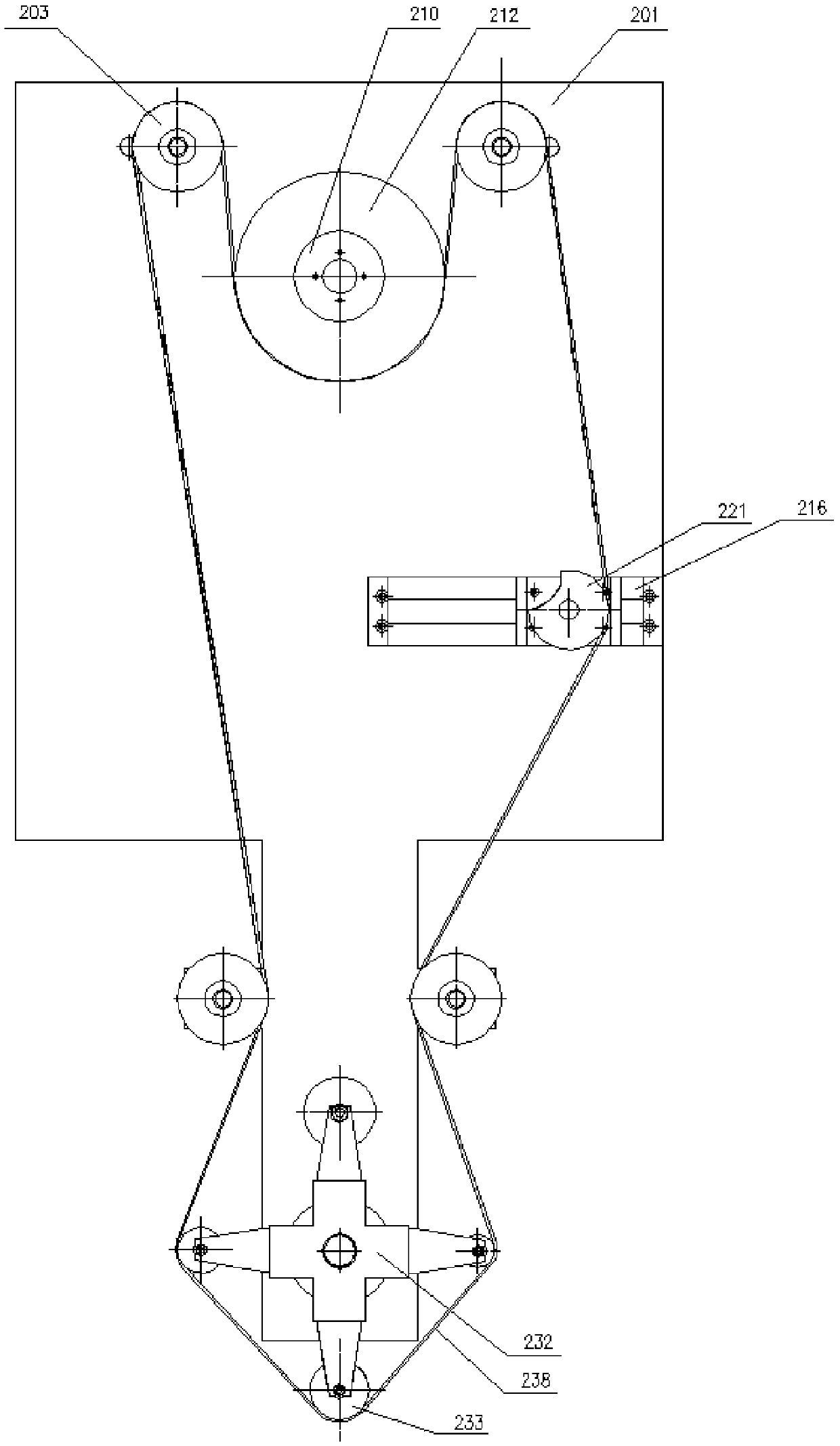

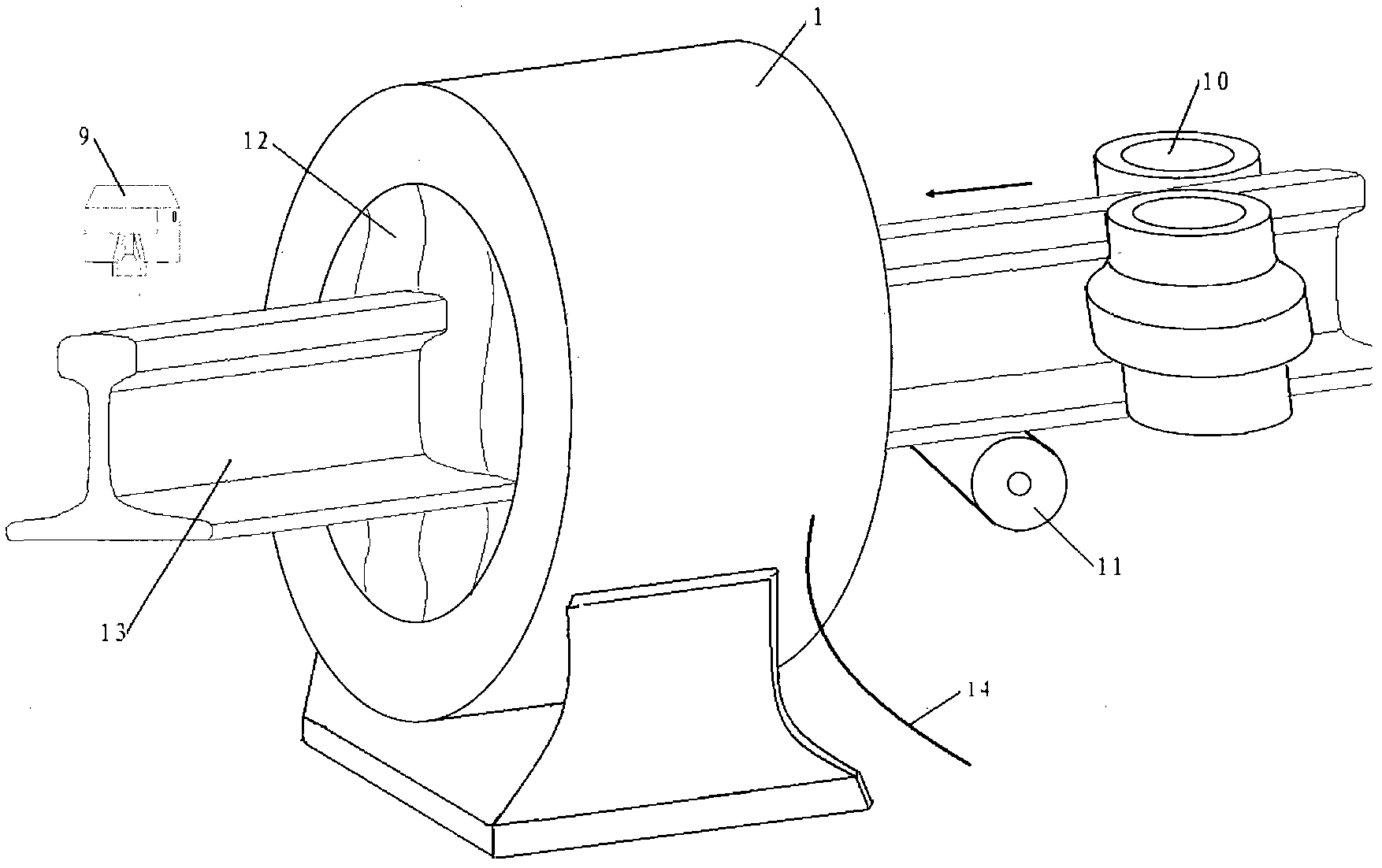

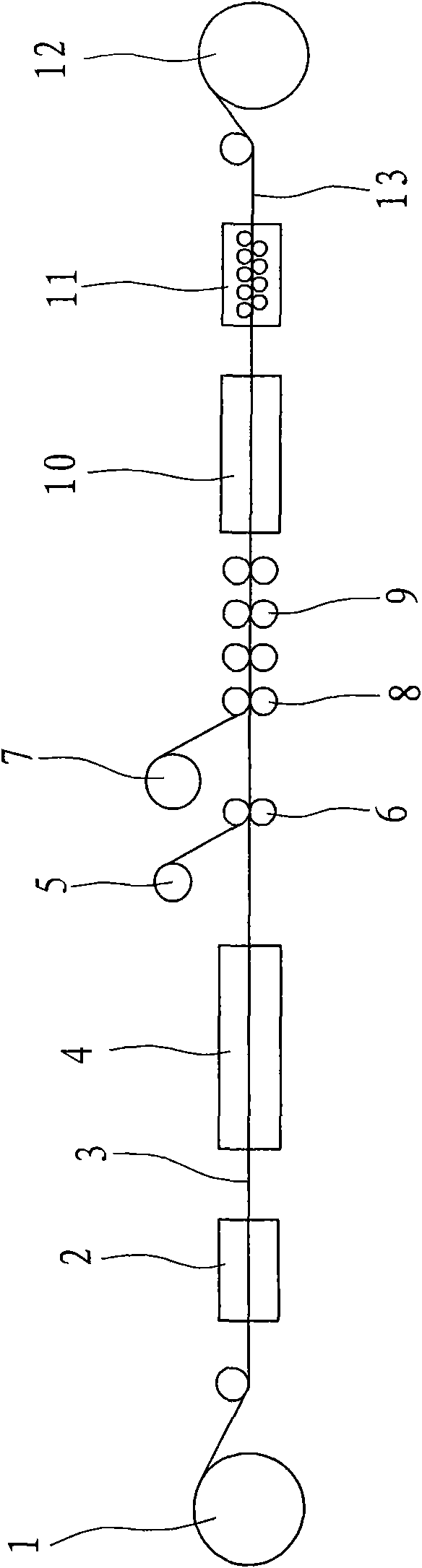

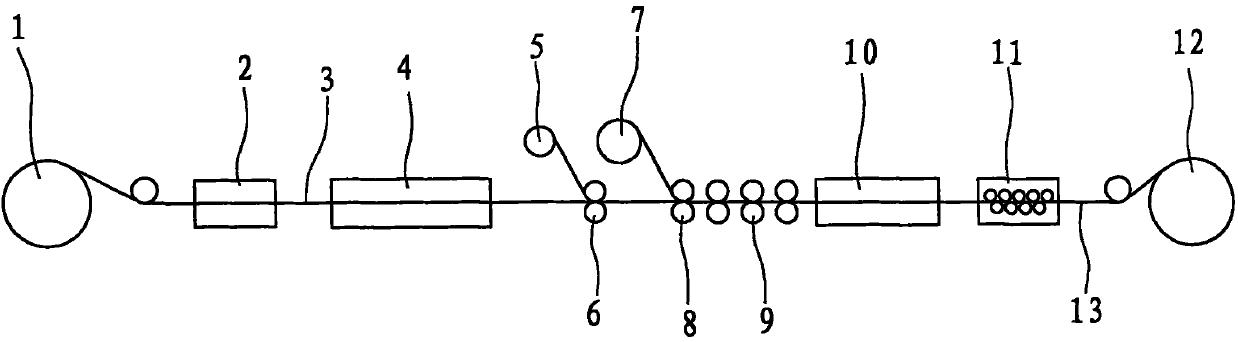

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

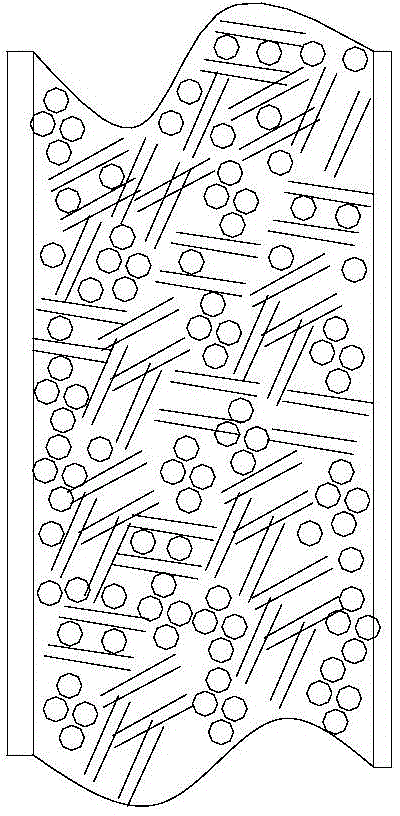

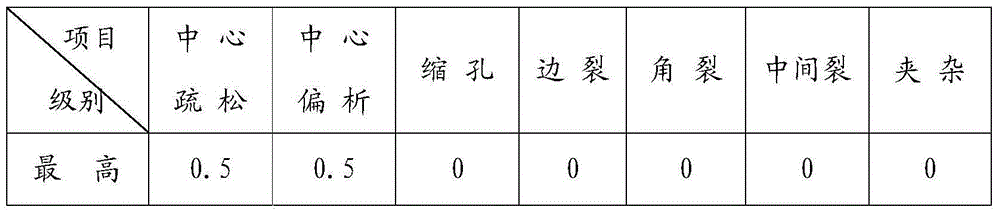

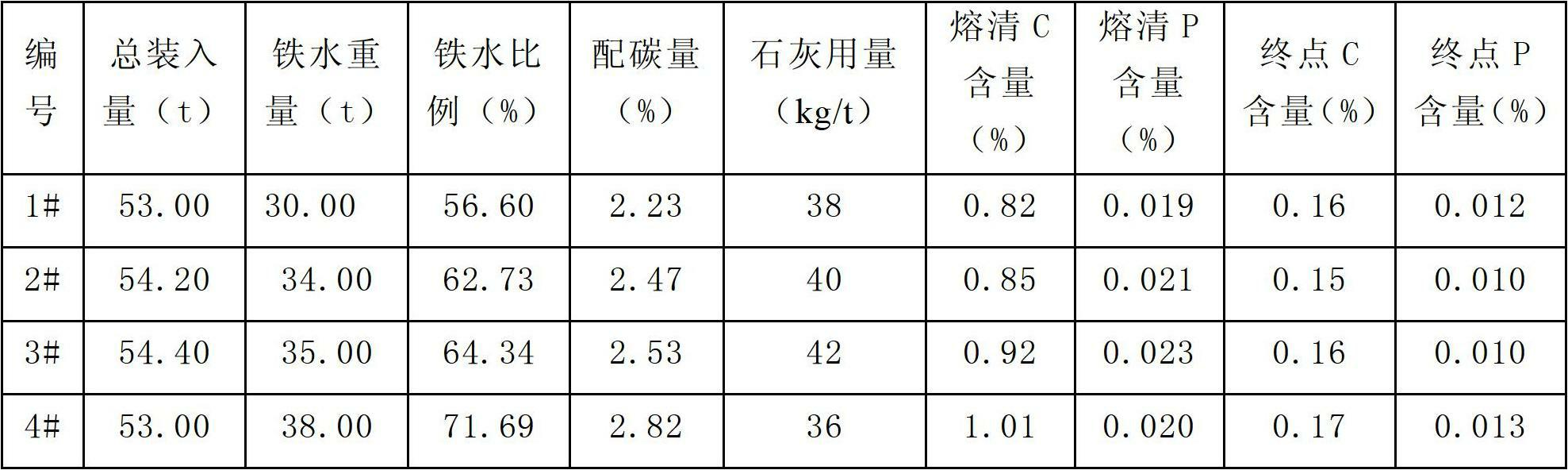

Method for producing tire cord steel wire by converter billet continuous casting process

ActiveCN102534094AGuaranteed surface qualityLow costManufacturing convertersMetal rolling arrangementsSlagSilicon alloy

The invention relates to a method for producing a tire cord steel wire according to a converter billet continuous casting process and belongs to the technical field of production of tire cord steel wires in the field of ferrous metallurgy. The method comprises the following process steps: desulfurizing by pre-treating molten iron, namely desulfurizing by spraying magnesium on a foundry ladle; smelting by using a converter, namely deoxidizing and alloying, modifying steel ladle slag, re-carburizing the molten iron and adding low-alkalinity pre-melted slag into the steel ladle after tapping; adding ferro-silicon alloy, manganese iron alloy and micronitrogen carburant in the tapping process and re-carburizing; and in the refining process and after the refining is finished, rolling the wire at high speed by adopting a two-stage steel ladle bottom blowing argon system and adopting billet continuous casting of 130mm*130mm or 160mm*160mm. The method has the advantages that: the production isreduced; the production efficiency is improved; and the method is particularly suitable for development and production of tire cord steel products in steel enterprises without big billet or rectangular billet continuous casting and without vacuum treatment equipment.

Owner:SHOUGANG CORPORATION

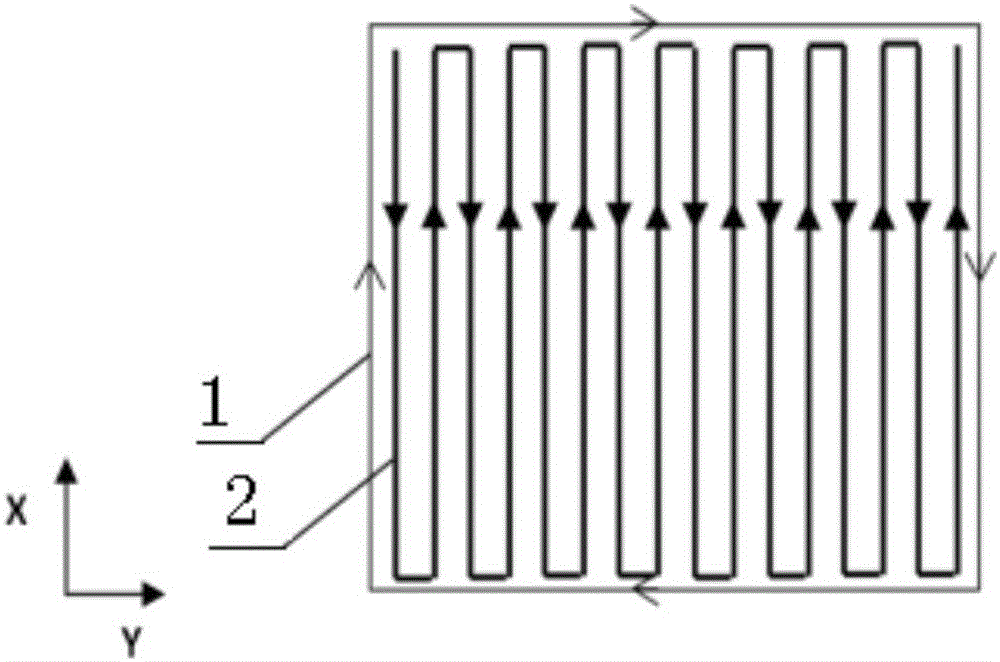

Metal laser selective melting method

InactiveCN105665704AQuick scanEnsure surface refinementAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningMetal powder

The invention provides a metal laser selective melting method. The metal laser selective melting method is characterized in that two kinds of lasers with different powers are adopted for conducting laser melting on metal powder zones needling to be melted; during melting, the lasers with the low power firstly conduct scanning on outline boundaries of the metal powder zones; then the lasers with the high power conduct scanning on internal zones of the metal powder zones; and during scanning, the thickness of a metal powder layer obtained by scanning with the lasers with the high power one time is integral multiples of the thickness of the metal powder layer obtained by scanning with the lasers with the low power one time. According to the metal laser selective melting method, the efficiency of the laser molding process is improved, and meanwhile, the surface quality of a metal part is guaranteed; and in other words, while the stability and the molding quality of the overall process are guaranteed, the building speed of metal laser selective melting equipment is improved as a whole.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

Lathe work method for thin-walled parts of middle-small diameter

ActiveCN101015863AImprove stabilityReduce distortionAutomatic control devicesTurning toolsEngineeringMechanical engineering

The invention discloses a method for turning middle and small thin-wall element, wherein the invention uses auxiliary clamper on general turning machine, first based on the outer diameter of element, produces a slim sheath with same diameter and middle slim as auxiliary clamper, machines the blank of object element, then puts the draw-in gear into the inner hole of slim sheath, puts them together into three-claw positioning clamping disc of turning machine, clamping and machining roughly and finely, and since the invention uses slim sheath as auxiliary clamper, the long-disc claw can obtain uniform dispersed clamping force on the surface of object element, to reduce unit clamping force, reduce vibration and deformation or the like. And the invention improves efficiency via transferring thin-wall element on three-claw automatic positioning clamping disc.

Owner:XIAN SHAANGU POWER

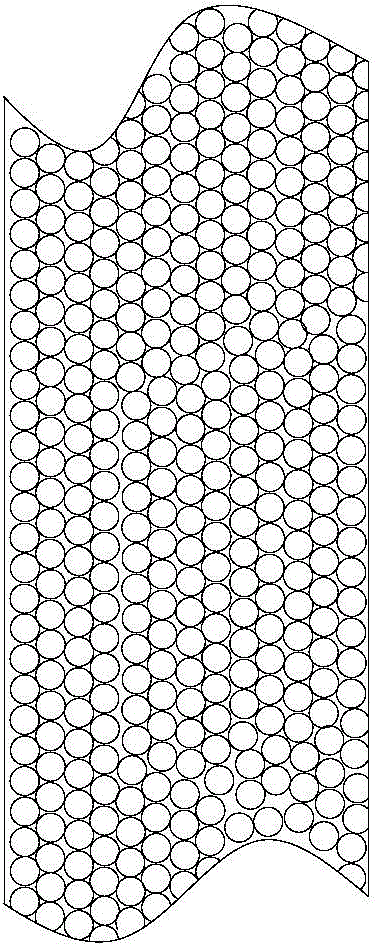

Method for increasing permeability of investment cast ceramic shell

ActiveCN104399885AGuaranteed surface qualityImprove casting pass rateFoundry mouldsFoundry coresFiberCarbon fibers

The invention provides a method for increasing the permeability of an investment cast ceramic shell, and belongs to the field of investment casting. The problem of easy formation of defects of the surface of a cast member in the cast member casting process in the prior art is solved. The method comprises the following steps: adding an adhesive, strengthening layer all-layer powder and carbon-containing fibers into a stirring barrel, adding an antifoaming agent and a wetting agent, and adjusting the viscosity of the obtained coating to a required range by using deionized water to obtain a strengthening layer coating with all layers having the carbon-containing fibers; coating a wax mold with the surface layer coating of the shell according to a routine shell making technology, completing a coating, sanding and drying process by using the all-layer strengthening layer coating, coating a sealing slurry layer without the carbon-containing fibers, and drying to obtain a shell; and dewaxing the shell, and roasting to obtain the net structured ceramic shell with exhaust channels. The method guarantees the strength of the shell, improves the permeability of the shell, eliminates the defects caused by unsmooth exhaust of the surface of the cast member, guarantees the quality of the surface of the cast member, and improves the qualified rate of the cast member.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

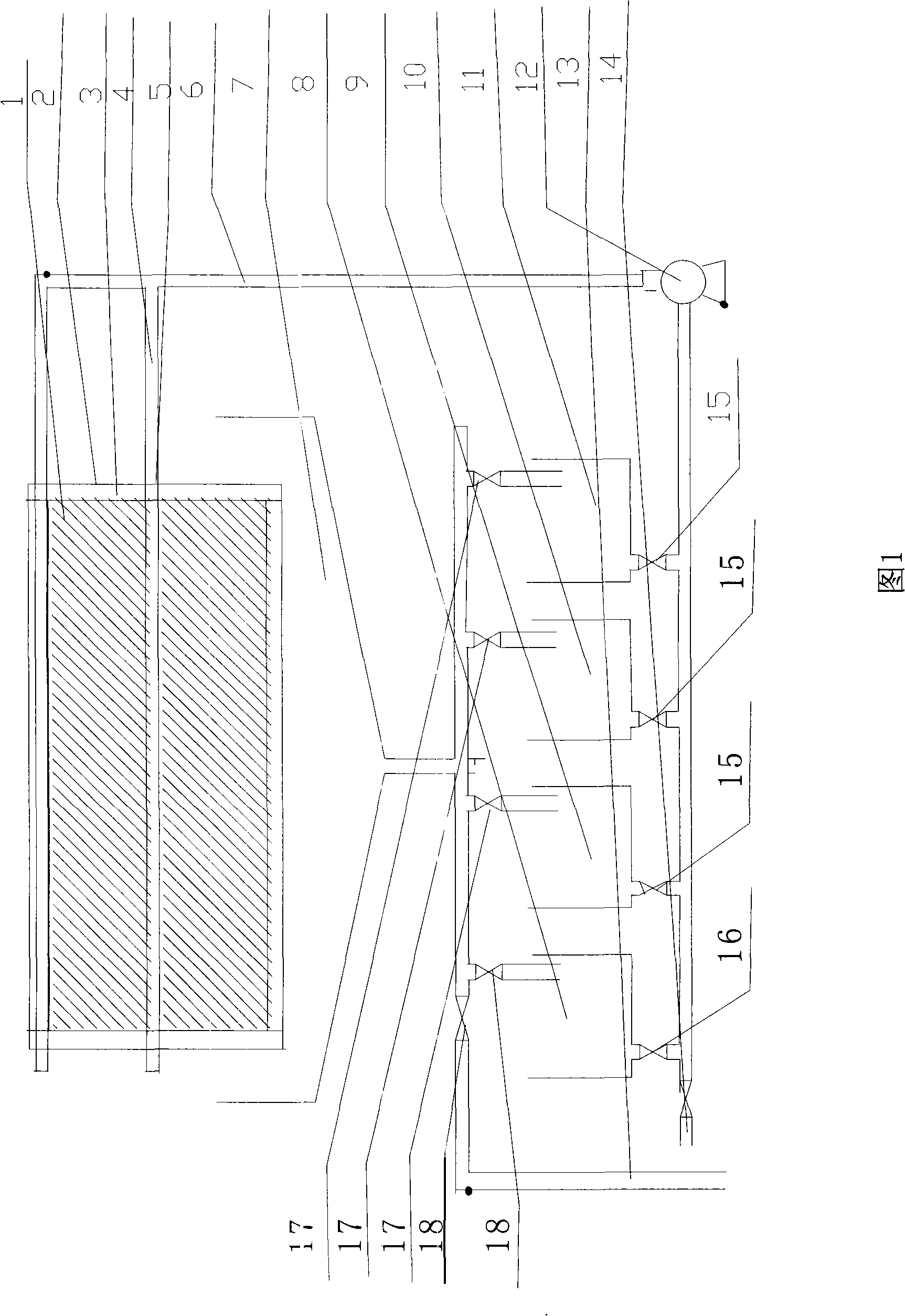

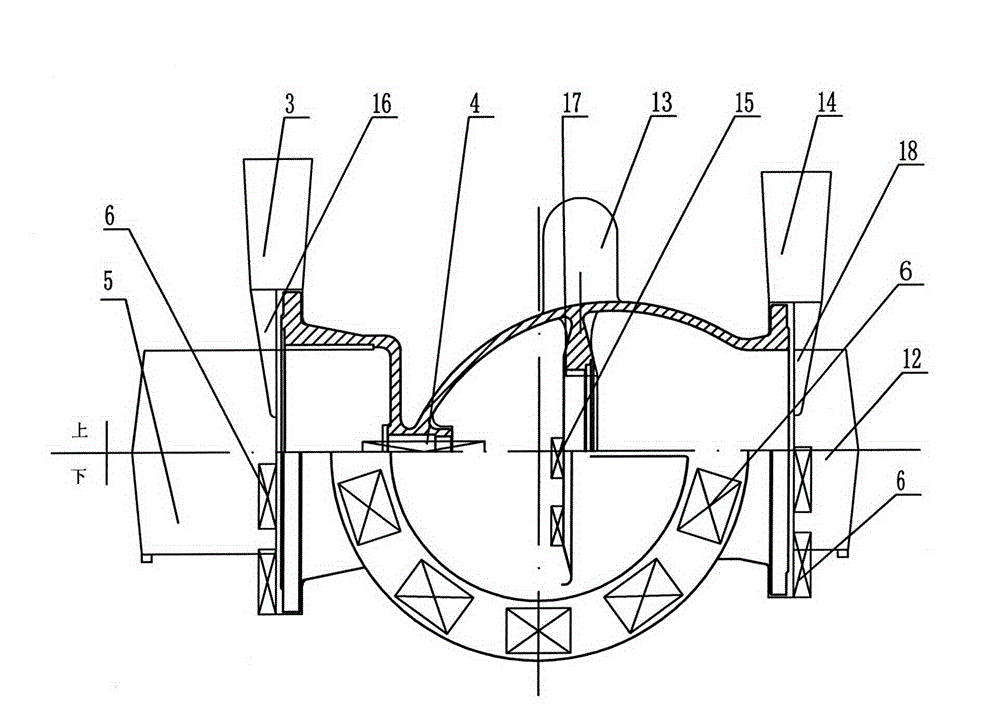

Method for spray pickling, polishing and passivating stainless steel composite board and devices thereof

InactiveCN101275231AGuaranteed surface qualityAdd chemical polishing processMetallic material coating processesDraining tubeEngineering

The invention relates to a method of stainless clad plate spray pickling, polishing and passivating and a device. The device is mainly consisted of a mounting rack (2), a sparge pipe (4), a scaffold (5), a perfusion tube (6), a recovery tank (7), a hot water vat (8), pickling bath (9), a polishing tank (10), a passivating tank (11), a pump (12), a drainage pipe (13), a tap-water pipe (14), an acidproof fluid supply valve (15), a hot water valve (16), an acidproof return liquid valve (17), and a water valve (18). Wherein, the mounting rack is arranged above the recovery tank. The sparge pipe subtended by the scaffold aims at the mounting rack. The sparge pipe is connected with the pump. The hot water valve and three acidproof fluid supply valves are connected in turn in a pipeline connecting the tap-water pipe and the pump. The hot water valve is connected with the hot water vat. Three acidproof fluid supply valves are separately connected with the pickling bath, the polishing tank and the passivating tank. A blind pipeline is arranged above four tanks via the water valve. The water valve is connected with the drainage pipe. One terminal of the blind pipeline is connected with the recovery tank, and the other terminal of the blind pipeline is connected with the hot water vat, the picking bath, the polishing tank and the passivating tank in turn via one water valve and three acidproof return liquid valves.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

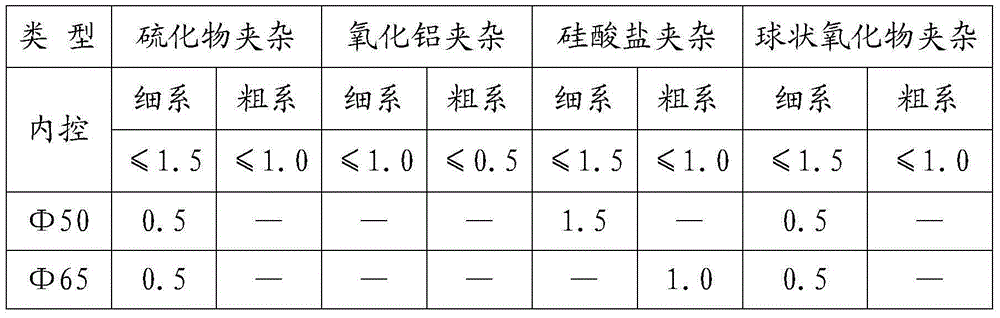

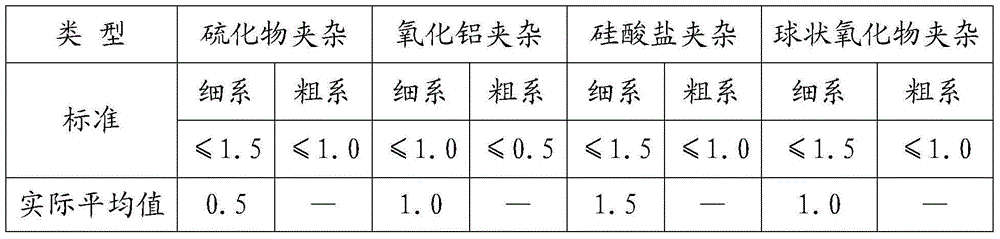

Method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb

InactiveCN105200349AImprove corrosion resistanceReduce hardnessManufacturing convertersProcess efficiency improvementChemical compositionSmelting process

The invention discloses a method for producing sulfuric acid dew-point corrosion-resistant round steel 09CrCuSb, wherein the method comprises the following steps: 1) reasonably determining the chemical composition and the inclusion control level of round steel 09CrCuSb; 2) determining the revolving furnace smelting process and N, H and O gas contents; 3) formulating an appropriate continuous casting secondary cooling schedule to make a casting blank keep away from a cracking temperature in a straightening zone, reasonably adopting crystallizer cooling water parameters and vibration negative slip parameters, and controlling casting blank surface cracks; and 4) determining a reasonable heating schedule and a rolling process, choosing low temperature for fast sintering, and reasonably distributing materials, so as to reduce enrichment of Cu elements on the steel surface and avoid the round steel from generating star-shaped cracks; and by controlling the rhythm of steel rolling, avoiding scratches of the round steel surface. By adding alloy elements such as Cr, Cu and Sb, a passivation film is formed on the steel surface; by formulating reasonable smelting, continuous casting and steel rolling processes, the round steel composition is effectively ensured, corrosion resistance can conform to relevant standards and requirements; and through the process, generation of the cracks of the copper-containing steel is avoided.

Owner:TIANJIN IRON & STEEL GRP

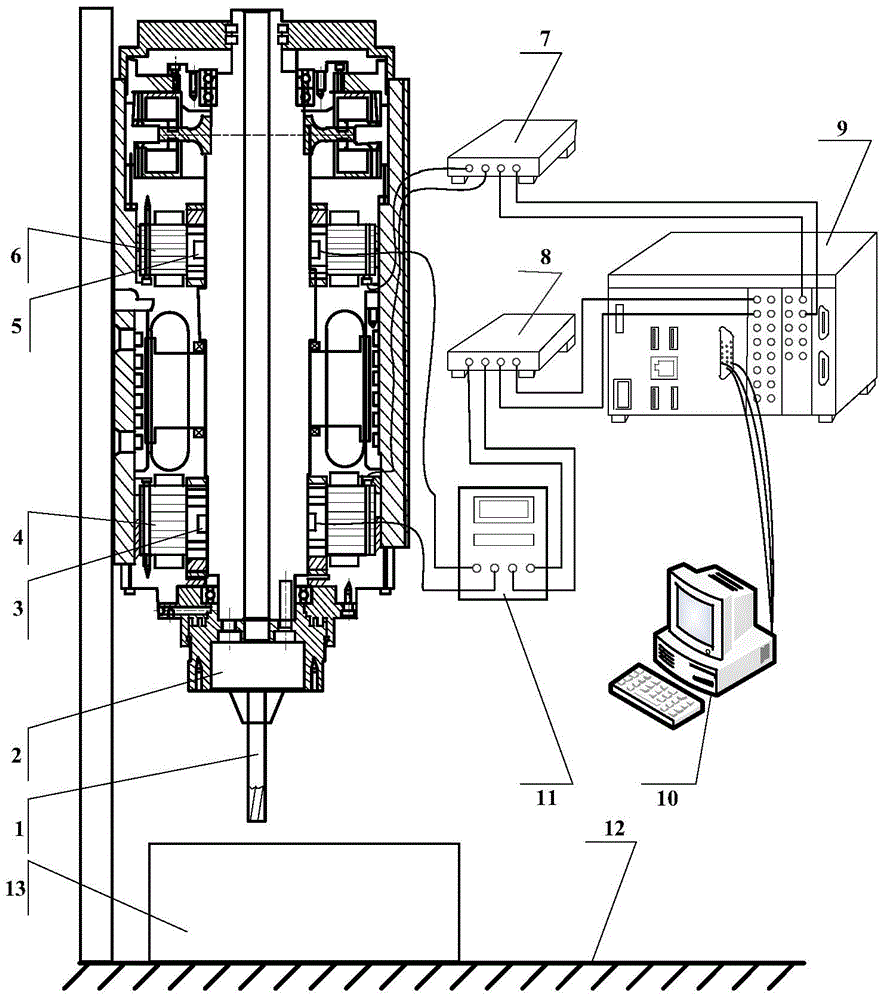

Constant-force grinding and polishing tool system

ActiveCN103786082AReduce the impactSimple structureBelt grinding machinesGrinding feed controlConstant forceMotor vibration

The invention relates to a constant-force grinding and polishing tool system and belongs to grinding and polishing tools. The constant-force grinding and polishing tool system comprises a power device, a gear change grinding tool, a damping device, a guide device, a force compensation and detection device and a counter weight device to realize constant-force grinding. A grinding tool head guarantees the gear change grinding tool to move vertically by the aid of the guide device to form a blade normal grinding and polishing force through total weight resultant force of the tool system and a low-friction countercylinder. A tool head normal force is measured and compared with a set value by an S-type sensor, a final value is fed back to a computer, and the low-friction countercylinder is regulated and controlled for force compensation by an electrical appliance proportional valve. The power device insulates vibration influences of a motor vibration source on the tool system by the aid of the damping device, and high-precision force control is realized through feedback of the S-type sensor. The constant-force grinding and polishing tool system has the advantages that the system is novel in structure, constant-force polishing of blade surfaces with different curvatures is realized, surface uniformity is realized, residual stress is diminished, and polishing efficiency is improved.

Owner:吉林大学重庆研究院

Water-soluble salt core type metal powder injection molding technology

The invention provides a water-soluble salt core type metal powder injection molding technology and relates to the technical field of metal powder injection molding. The technology comprises the steps of mixing, water-soluble salt core preparing, mold core inlaying and mold clamping, injection molding, core-removing drying, degreasing and sintering. According to the technology, a fused and poured water-soluble salt core forms a part cavity and can be dissolved and removed through clean tap water at indoor temperature, the removal time is short, the safety is high, the environmental friendliness is high, and the potential problems of production insecurity, environmental pollution and strength reduction of green bodies caused by polymer core removal can be effectively solved. Part products manufactured through the technology are uniform in internal structure, high in compactness, high in surface smoothness, high in dimensional precision and stable in quality, a great deal of time and cost are saved for volume production of small and precision parts provided with closed or complicated cavity structures and made of various metal materials, the economic benefit is good, and the application prospect is good.

Owner:QILU UNIV OF TECH

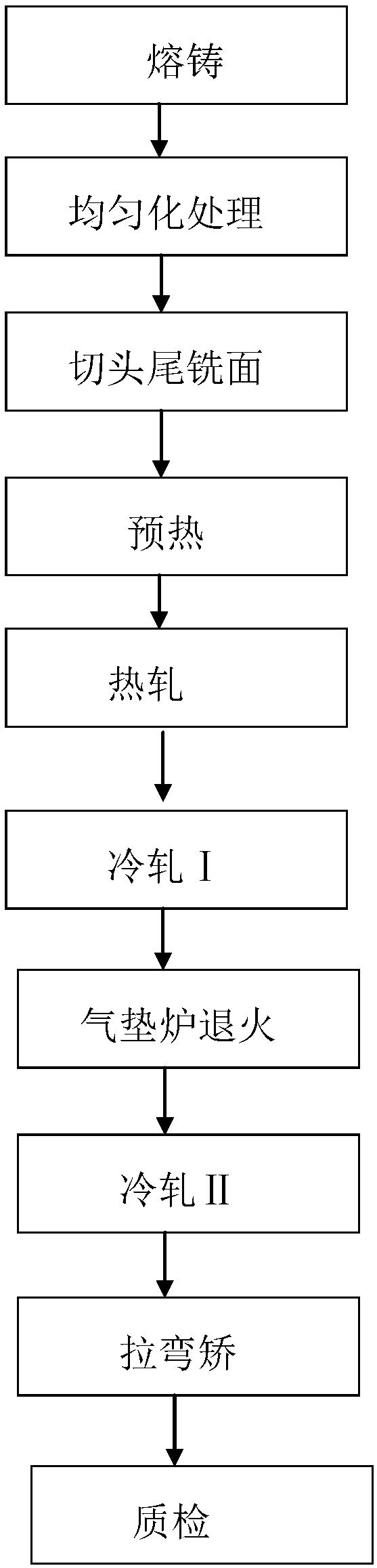

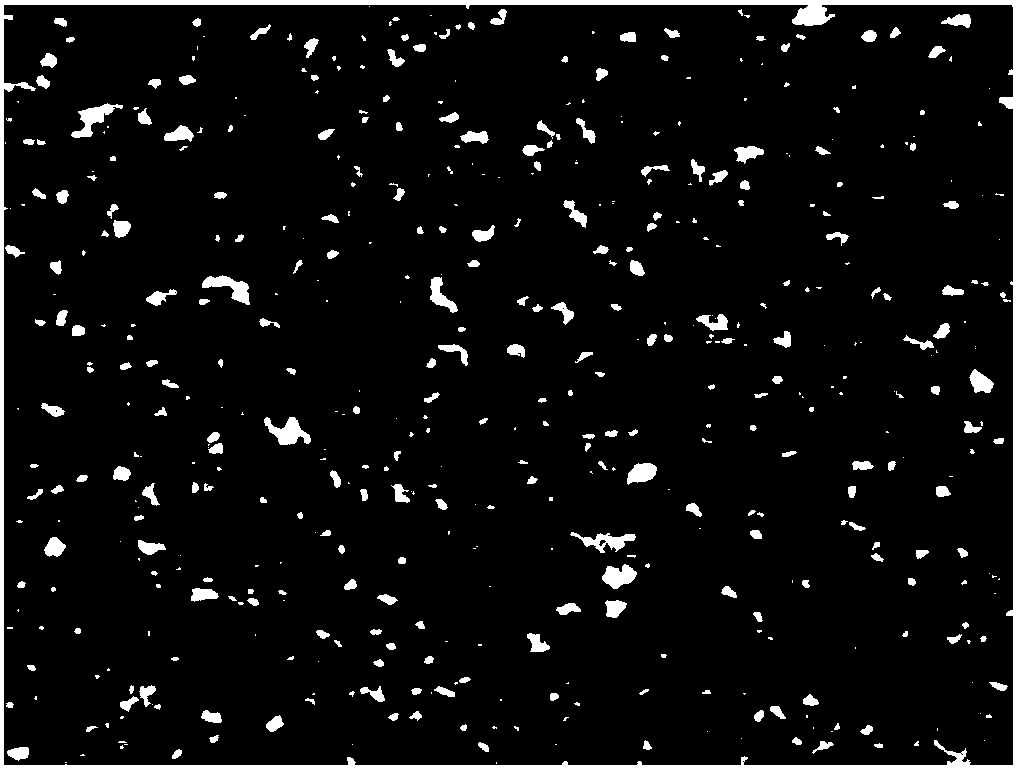

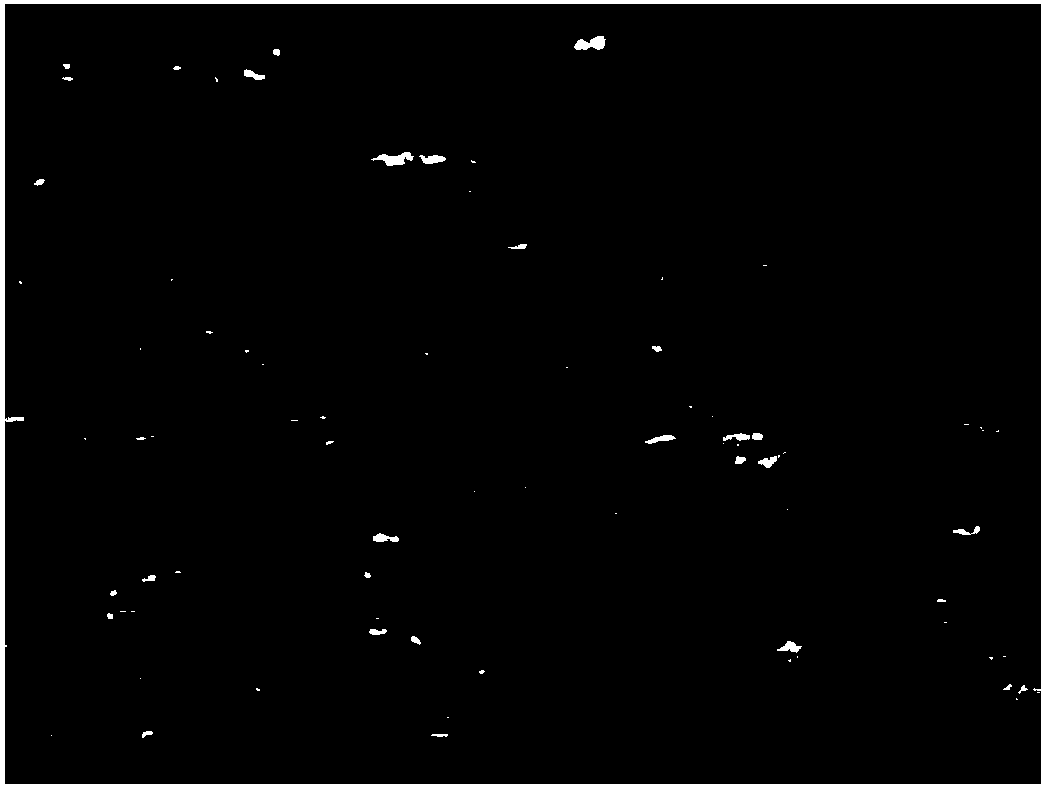

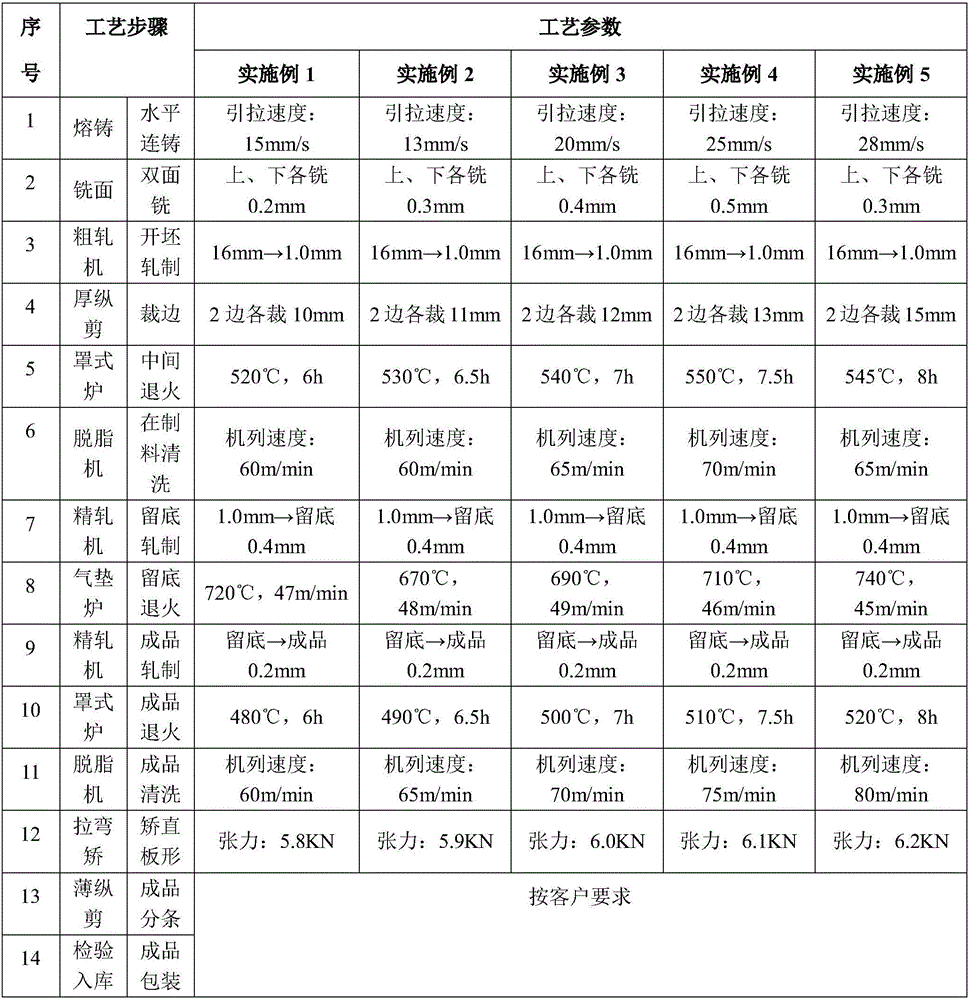

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

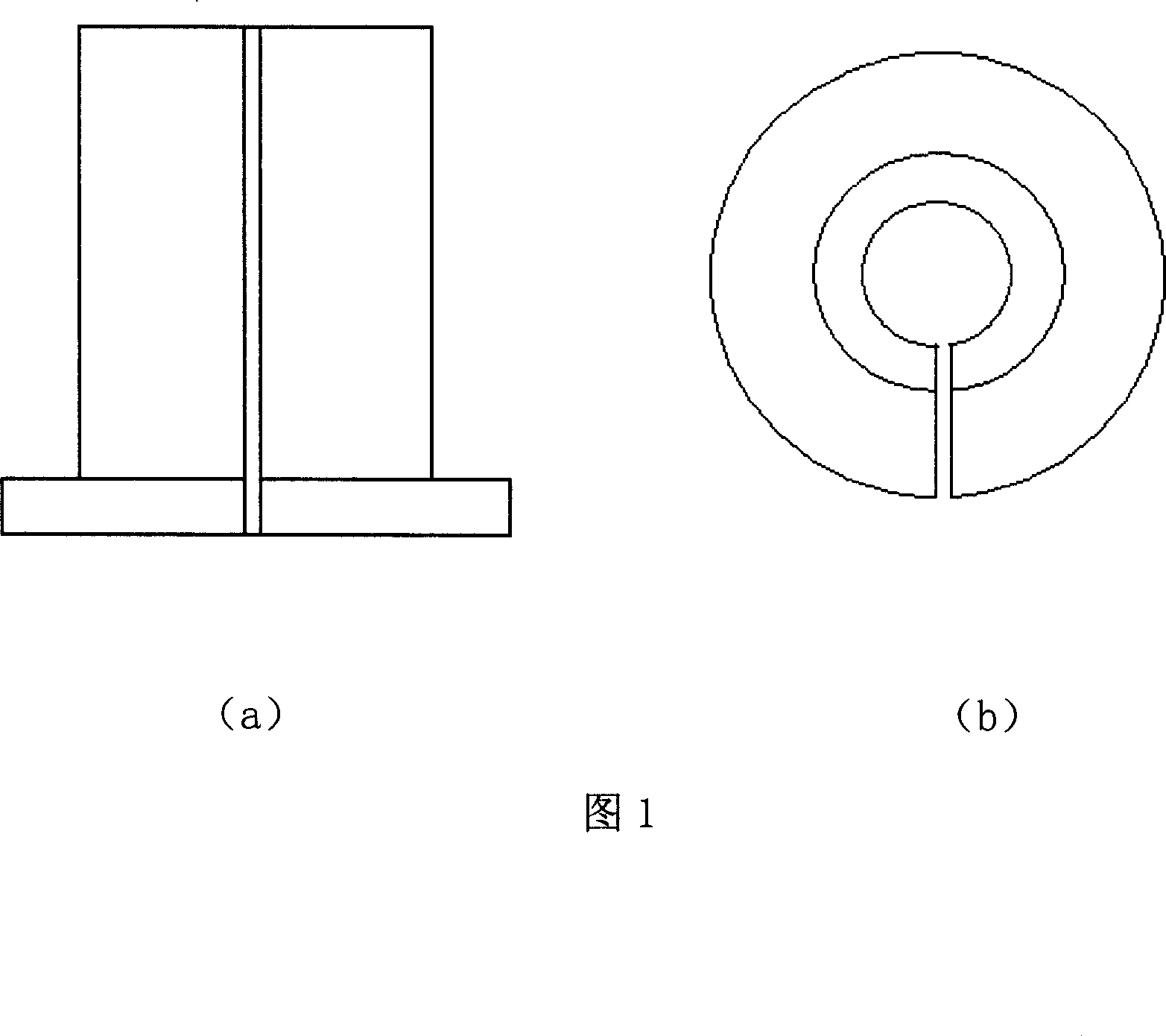

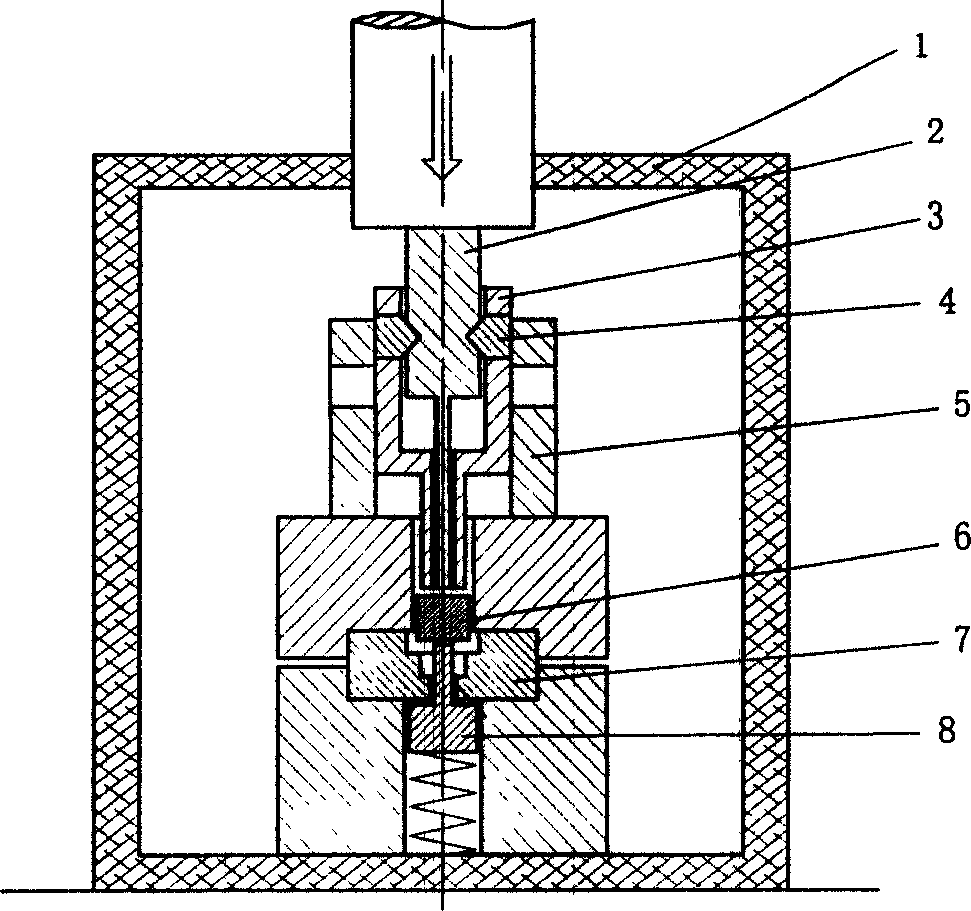

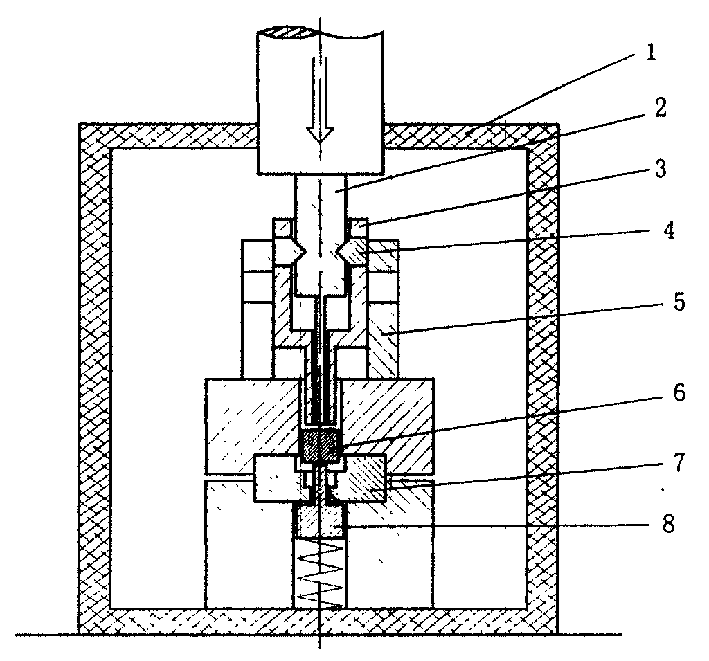

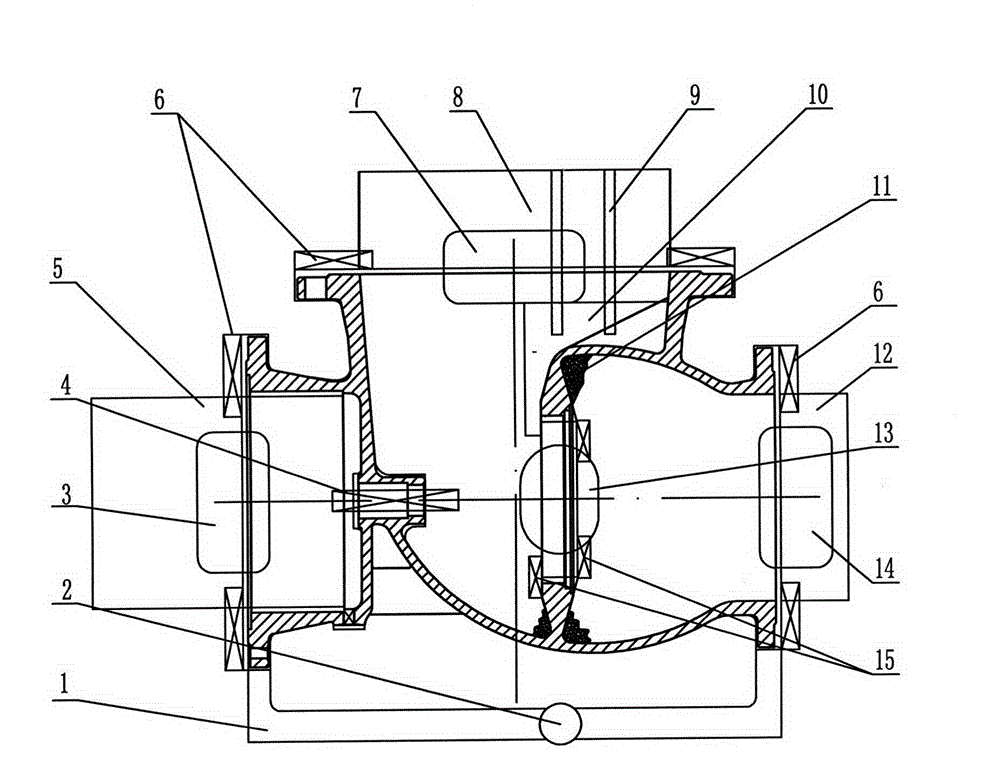

Amorphous alloy precision parts superplastic drop-forging shaper and method thereof

InactiveCN1199747CImprove mechanical propertiesGuaranteed surface qualityMetal-working apparatusSurface roughnessSuperplasticity

The invention provides a superplastic die forging forming device and method for amorphous alloy precision parts. The device is composed of a vacuum furnace (1), a replaceable pressure head and a mold. The replaceable indenter is made up of inner indenter (2), outer indenter (3), slide block (4), connecting seat (5), and mold is made up of mold (7), ejection mechanism (8). The process is to place the blank and the mold in a vacuum furnace, and when the vacuum degree reaches 8×10 -3 Pa, start heating, heating rate 0.5 ~ 3.0 ℃ / s; heating temperature should be between Tg ~ Tx; forming strain rate range of 1 × 10 -2 ~5×10 -4 the s -1 . The advantage is that it is suitable for the forming of bulk amorphous alloy materials with large supercooled regions such as Zr-based, La-based, and Pd-based. The dimensional accuracy of the prepared parts is between ±0.1% and ±0.3%, and the surface is rough. The degree Ra is less than 0.8μm, and it can even reach the nanoscale mirror surface.

Owner:UNIV OF SCI & TECH BEIJING

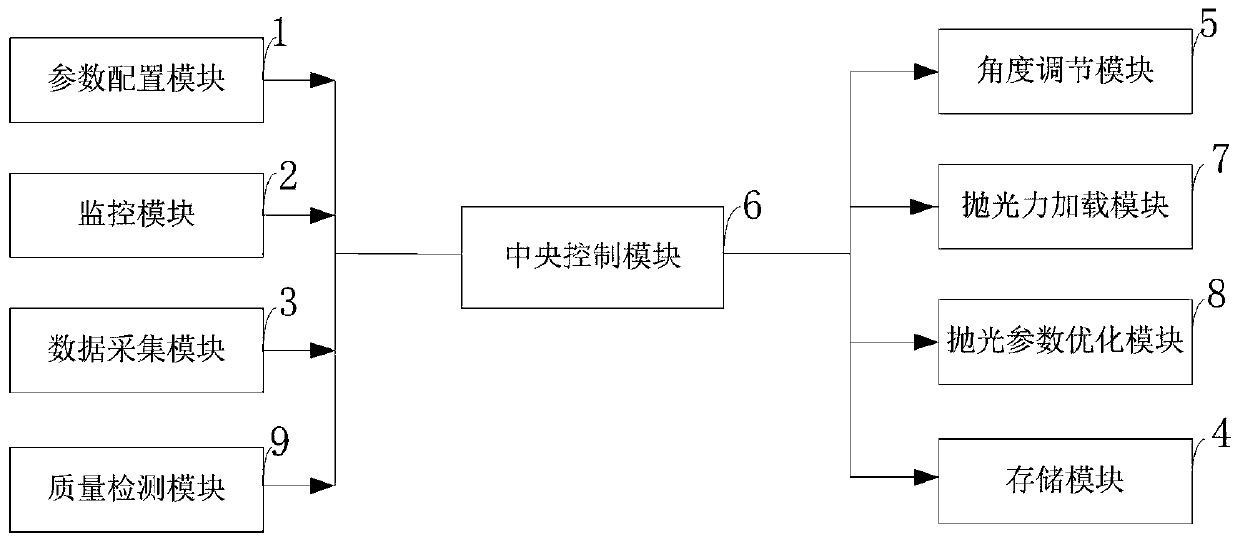

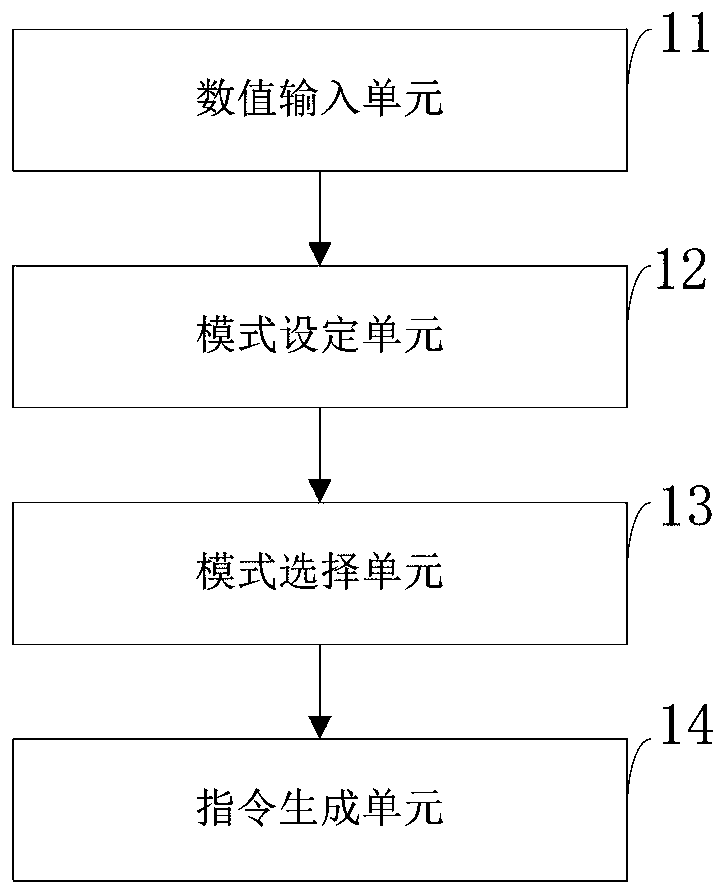

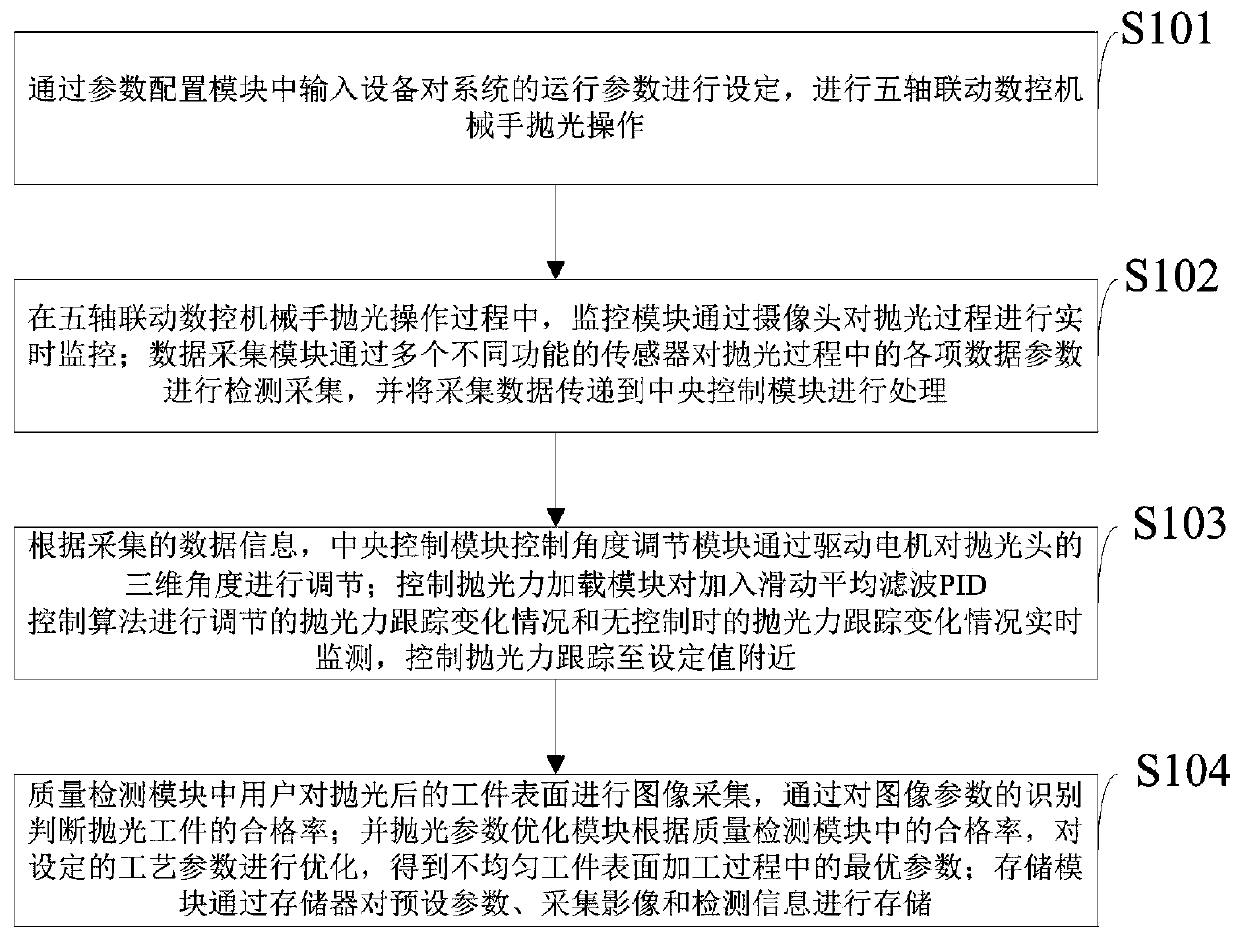

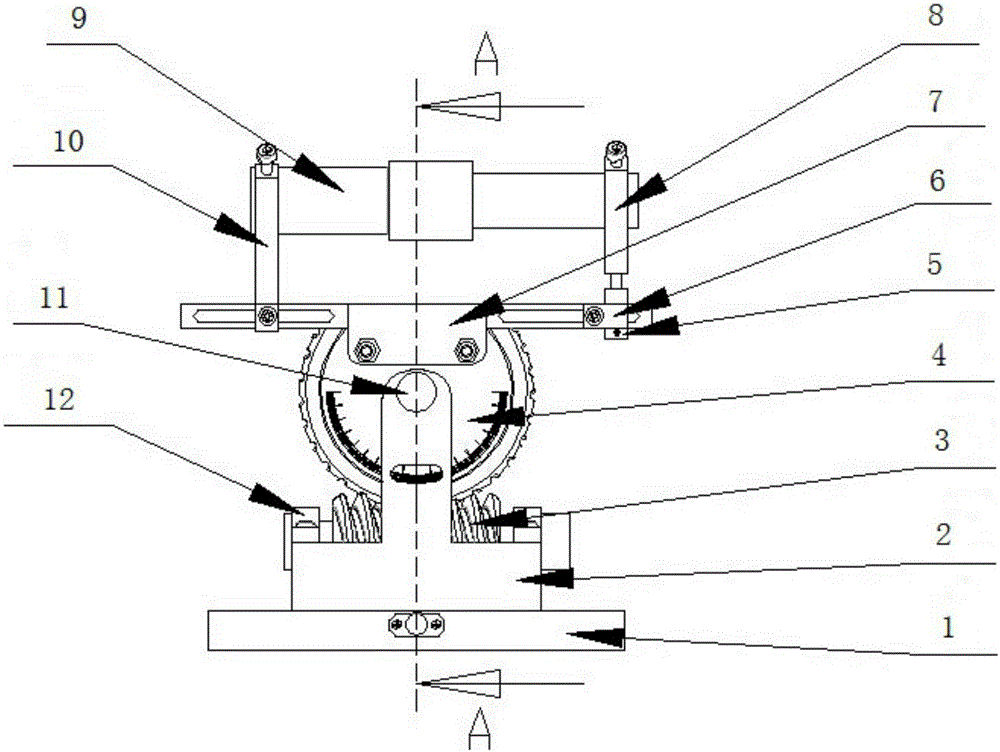

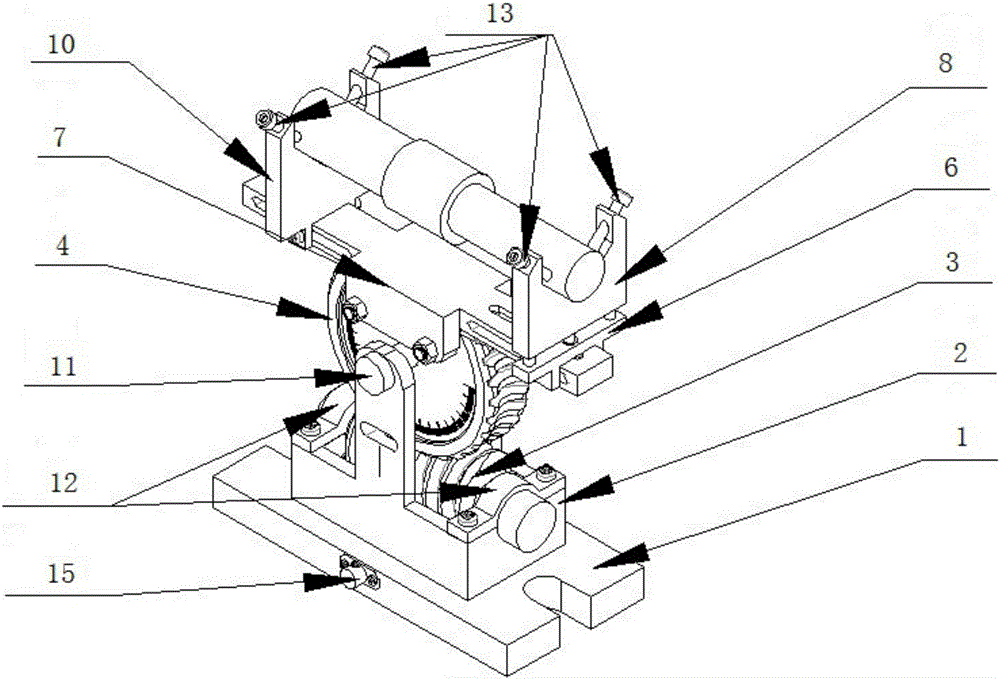

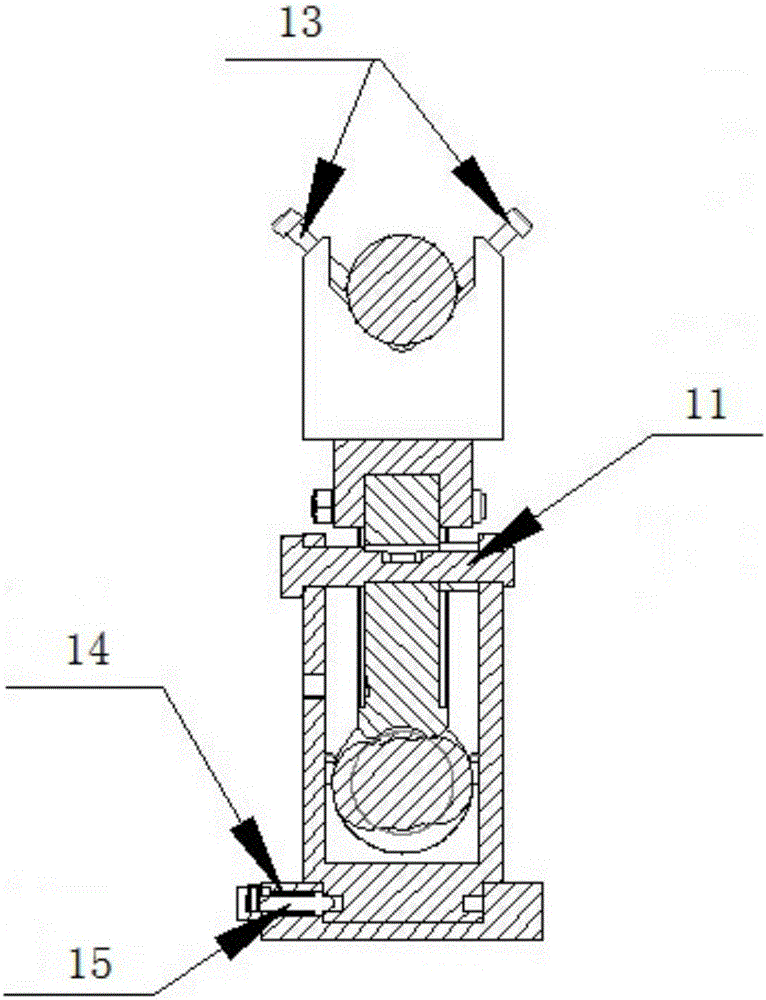

Five-axis linkage numerical control manipulator polishing control system and method

InactiveCN111468989AOptimizing Process ParametersAccurate and fast variable polishing force controlPolishing machinesAutomatic grinding controlNumerical controlControl system

The invention belongs to the technical field of machining, and discloses a five-axis linkage numerical control manipulator polishing control system and method. The five-axis linkage numerical controlmanipulator polishing control system comprises a parameter configuration module, a monitoring module, a data acquisition module, a storage module, an angle adjustment module, a central control module,a polishing force pneumatic loading module, a polishing parameter optimization module and a quality detection module. The parameter configuration module comprises a numerical value input unit, a modesetting unit, a mode selection unit and an instruction generation unit. The monitoring module monitors the polishing process in real time through a camera. The data acquisition module detects and acquires various data and parameters in the polishing process through a plurality of sensors with different functions. According to the five-axis linkage numerical control manipulator polishing control system and method, accurate and rapid tracking variable polishing force control can be achieved in the polishing process, the corresponding polishing force is controlled in real time, and the force control requirement of polishing machining can be effectively met; and on the premise that the polishing quality is guaranteed, the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

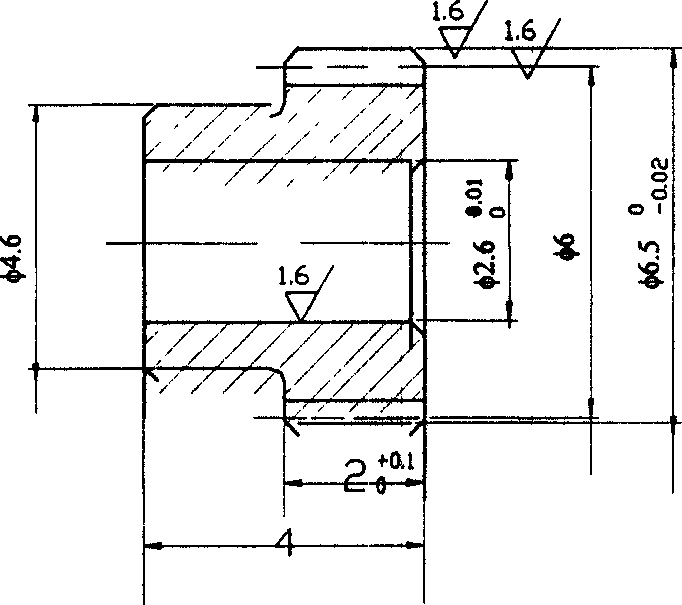

General frock clamp for shaft parts

InactiveCN105855934AConvenient and efficient processingEfficient and convenient detectionPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a universal tooling fixture for shaft parts, which comprises a base fixed on a workbench, a clamping mechanism, an adjusting mechanism and an angle adjusting mechanism. Using the general tooling and fixture for shaft parts described in the present invention, an angle adjustment mechanism is set to realize the placement of shaft parts at any angle and all-round rotation, and the adjustment mechanism is set to adjust different shaft diameters and different lengths. As well as adjusting the clamping position of shaft parts with various shaft diameters on the same shaft, a clamping mechanism with adjustment parts is set up to clamp shaft parts. This device makes shaft parts more accurate during processing, testing and assembly. Efficient and convenient, especially for fast switching when clamping different positions of different shaft parts, which brings great convenience, and can effectively solve the problem of single specification of clamping parts, inflexible placement and troublesome operation of existing shaft parts tooling fixtures, etc. Problem, the device is simple in structure, easy to use, low in cost, and easy to popularize.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

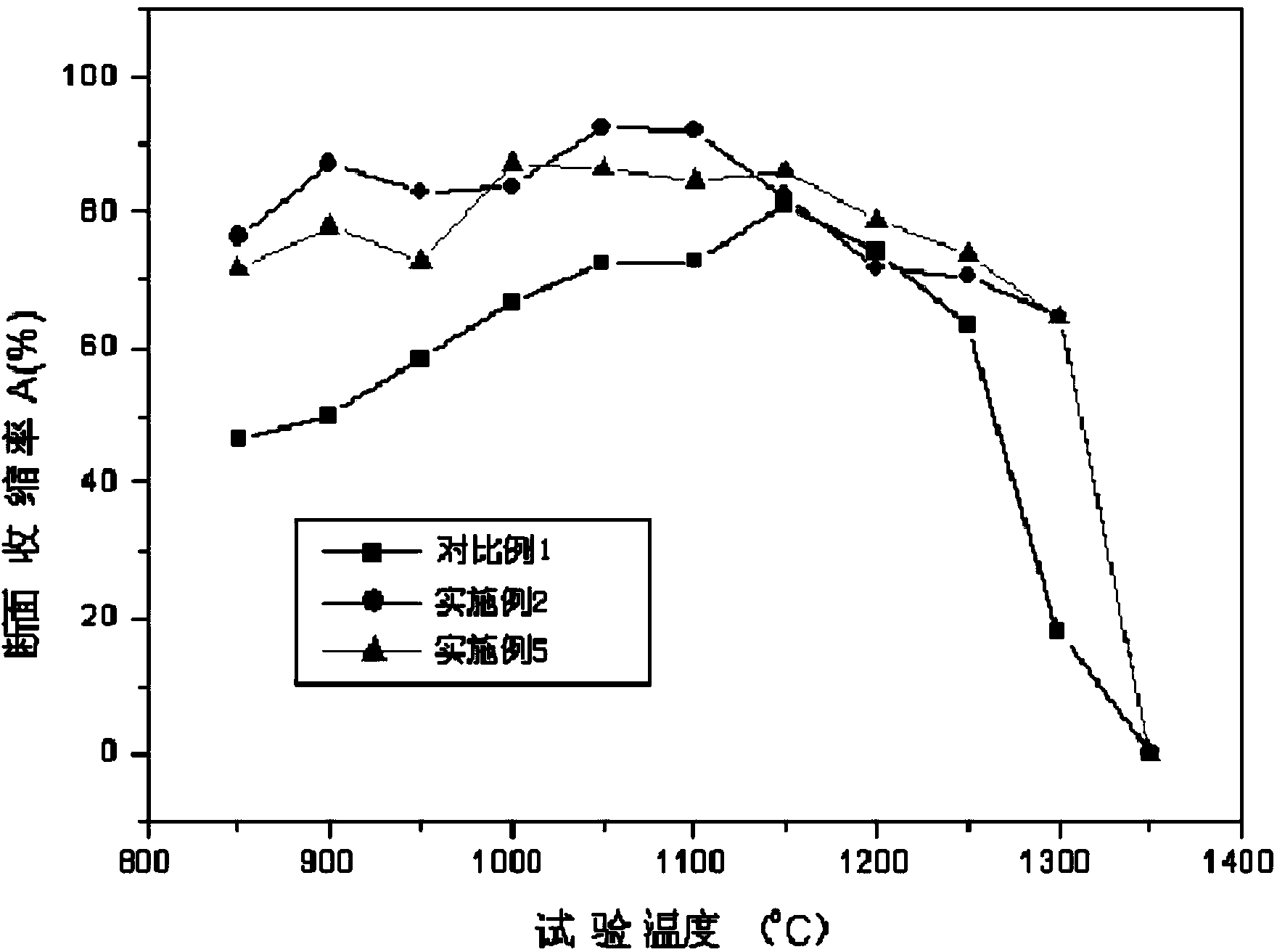

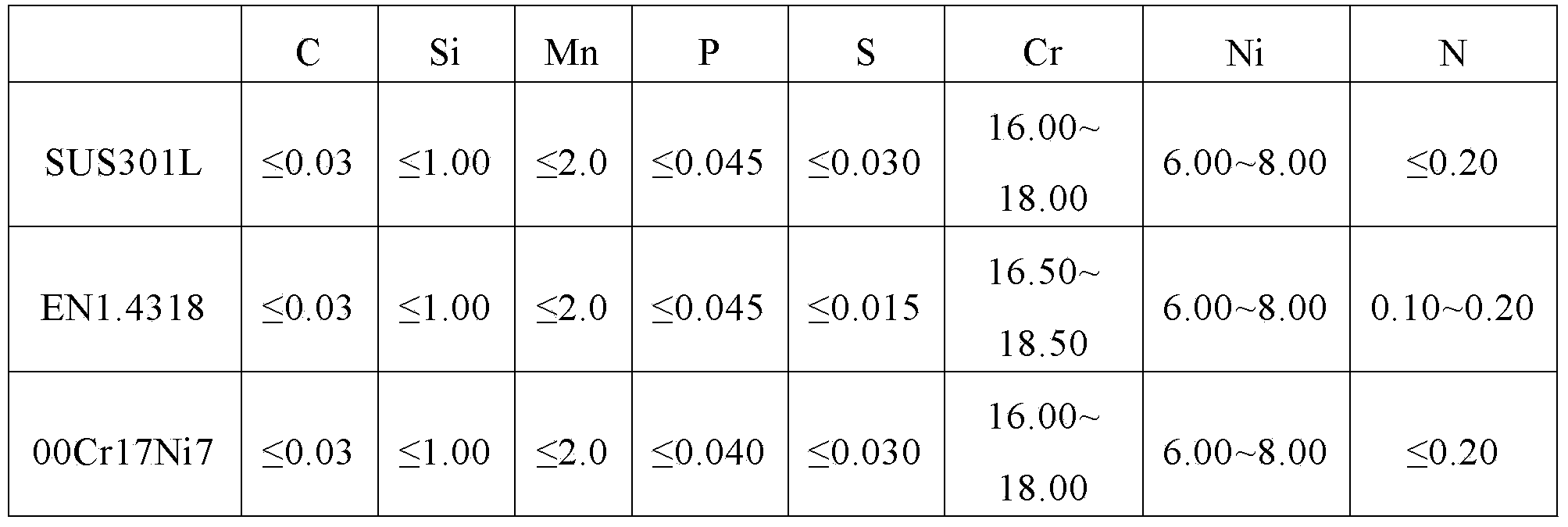

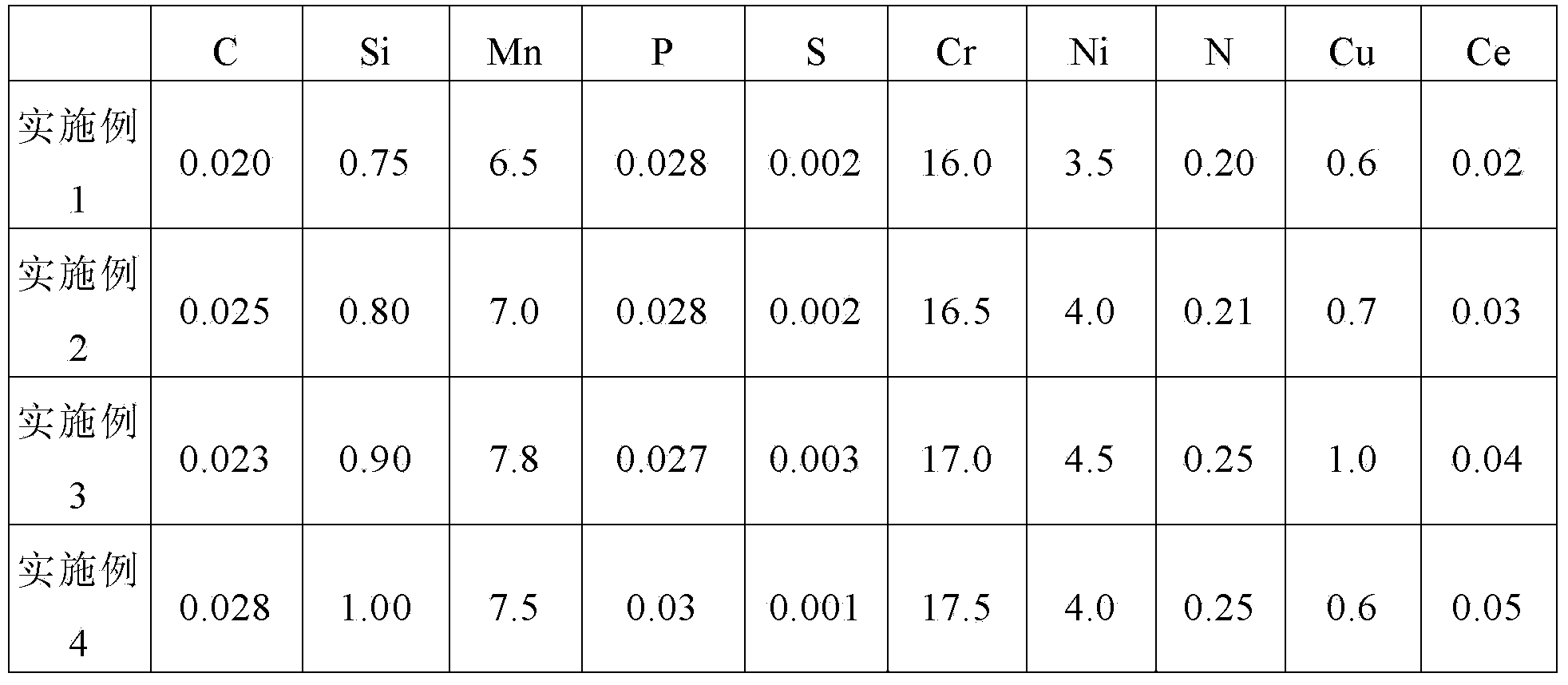

Austenitic stainless steel for urban rail vehicle face plates and manufacturing method of austenitic stainless steel

The invention discloses austenitic stainless steel for urban rail vehicle face plates and a manufacturing method of the austenitic stainless steel. The austenitic stainless steel comprises the following chemical compositions inpercentage by weight: less than 0.03% of C, 0.75-1.0% of Si, 6.5-8.0% of Mn, 16.0-17.5% of Cr, 3.0-4.5% of Ni, 0.15-0.25% of N, 0.5-1.0% of Cu, 0.02-0.05% of Ce, no greater than 0.040% of P, no greater than 0.03% of S, and the balance of Fe and inevitable impurities; the manufacturing method of the austenitic stainless steel comprises the following steps: through the operations of smelting, continuous casting, refining, tombarthite mixture block feeding, and soft stirring, continuous casting slabs are obtained by continuous casting, and the continuous casting slabs are heated; after hot rolling, cooling, reeling, air cooling, solution treating, shot blasting, acid cleaning, cold rolling and annealing acid cleaning are conducted, the finished product austenitic stainless steel is manufactured. According to the austenitic stainless steel for the urban rail vehicle face plates and the manufacturing method of the austenitic stainless steel, the oxidation of the edge part grain boundary caused by overheating of the slab edge part can be avoided; in the process of heating, a layer of dense chromium oxidation film with high adhesion is formed on the surface, the surface quality of the continuous casting slabs is protected, and the guarantee about surface quality control of stainless steel material used for the urban rail vehicle face plates can be provided.

Owner:BAOSTEEL STAINLESS STEEL

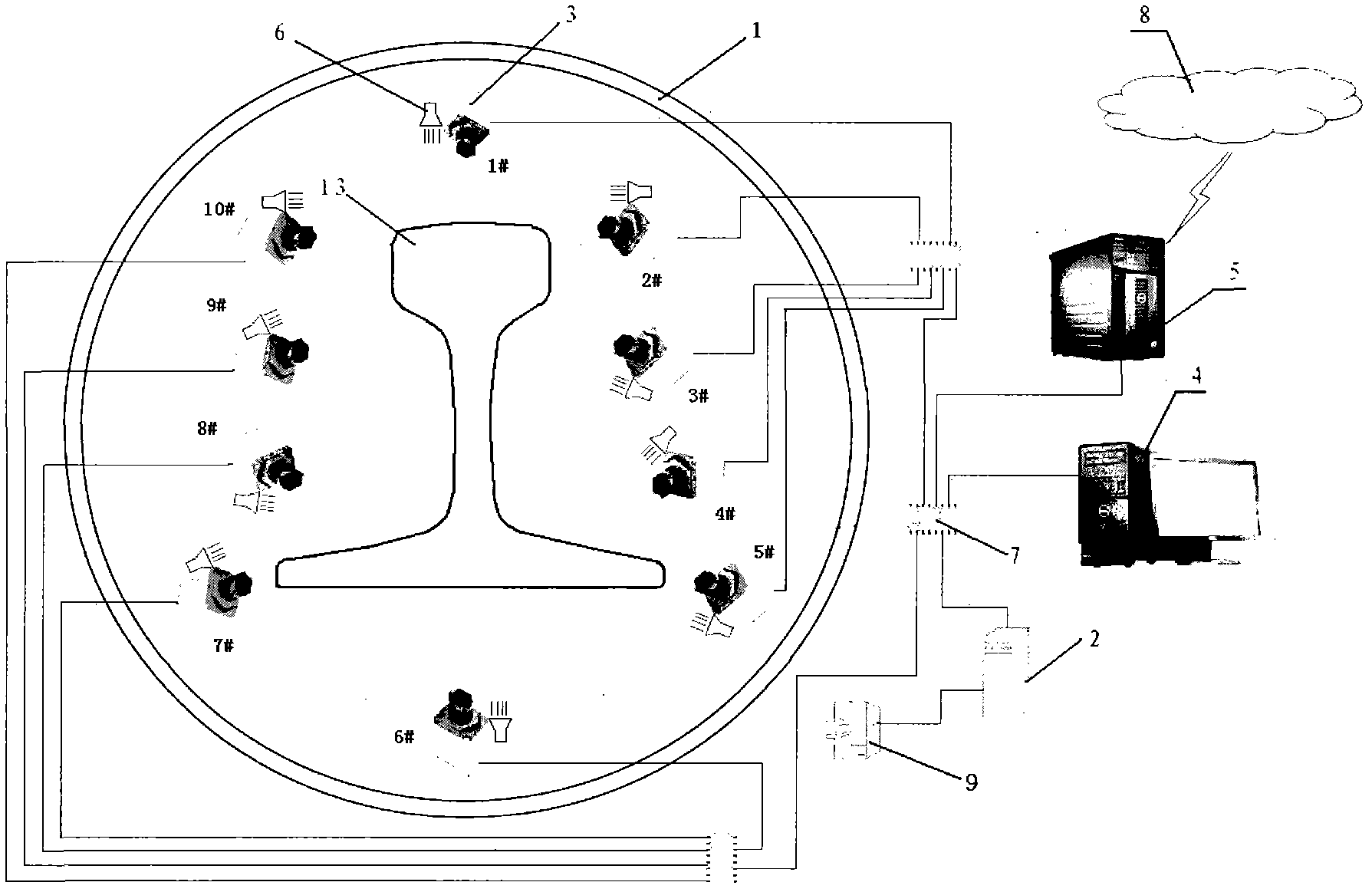

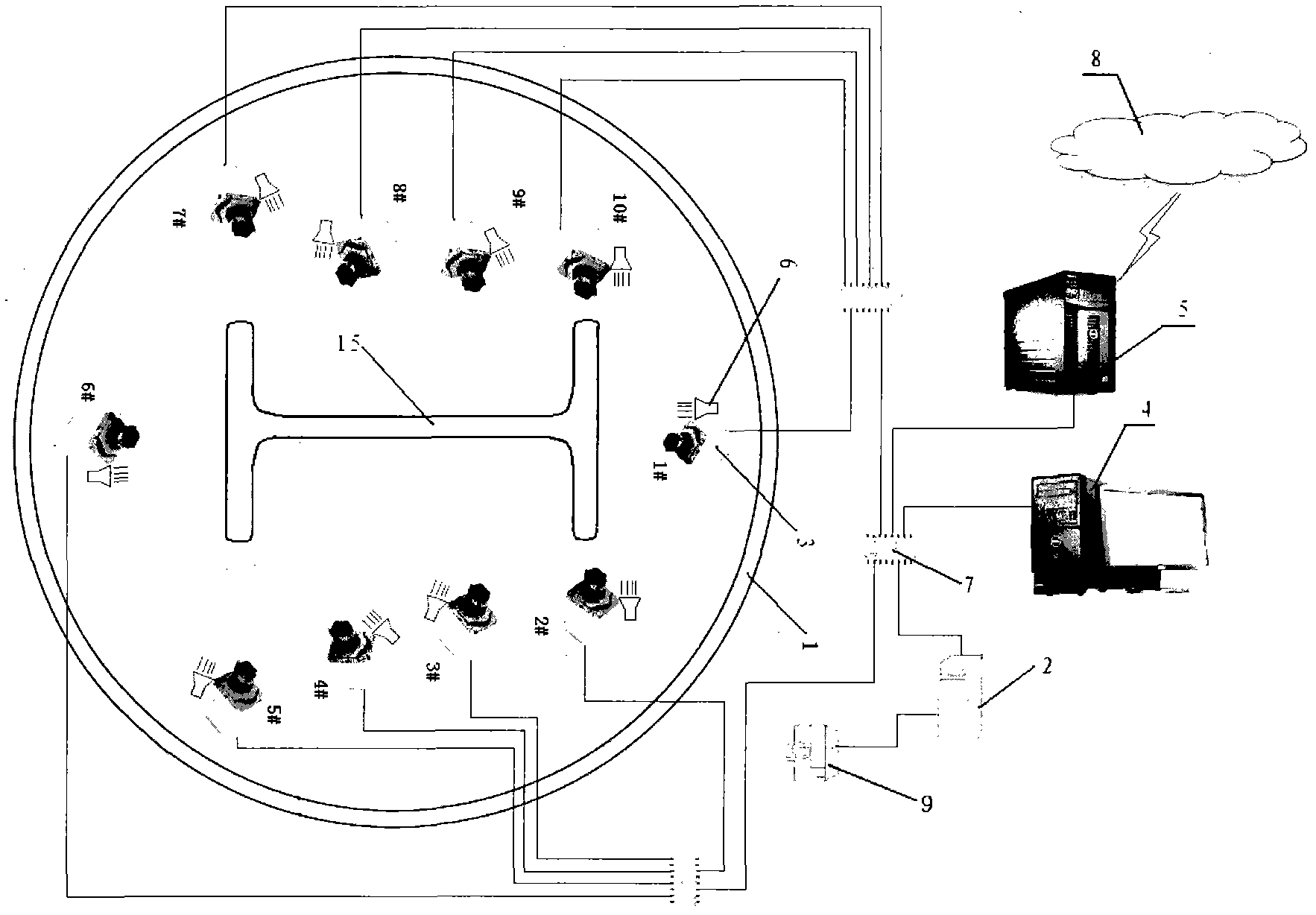

Surface defect automatic detecting device for section bars

InactiveCN102384910ARun at high speedAutomatic identification and strong adaptabilityOptically investigating flaws/contaminationInformation processingEngineering

The invention relates to a surface defect automatic detecting device for production process of a section bar rolling mill production line, which comprises a fixing device, a control device, video cameras, an image collecting computer, an information processing server, a light-emitting diode (LED) light source, a local area network, a process control network system, a spraying device, a pinch roll, a conveying roller way, stripper rubber and compressed air. The surface defect automatic detecting device for production process of the section bar rolling mill production line is characterized in that the number of the video cameras is determined according to the maximum number of the video cameras needed in the most complex surfaces of all varieties of the section bars to be detected. The surface defect automatic detecting device achieves automatic detection of surface defect of section bars (including varieties of heavy rails, H-shaped steel, joint steel, channel steel, steel angle and the like) by controlling and adjusting focal distance and angle of the video camera and the number of the video cameras. The surface defect automatic detecting device for production process of the section bar rolling mill production line is strong in adaptability, the same configuration can be applied to heavy rail processing lines and profile steel finishing lines, and accordingly software, hardware and spare parts of the device are universal, and manufacture and maintenance cost of equipment can be saved.

Owner:魏卿轩

Method for directly casting and rolling aluminum plate base for PS plate with electrolytic aluminium liquid

ActiveCN101318288AQuality assuranceQuality improvementTemperature control deviceMetal rolling arrangementsSocial benefitsFiltration

The invention relates to a method for cast-rolling to produce aluminum substrates used in PS plates directly by electrolytic aluminum liquid; the main steps are as follows: electrolyzing the aluminum liquid under the high temperature, smelter hearth, adjusting element compositions, refining, conducting the furnace, adjusting the temperature to 740 DEG C to 750 DEG C, adding Al-Ti-B refiners to carry out the grain refinement, degassing, filtering, cast-rolling coils of strip, cool rolling, stretch bending and straightening, and producing finished products; various steps of the invention are synthesized to optimize technique parameters; the prepared aluminum substrates used in the PS plates is high in tensile strength and elongation, and the quality of the prepared aluminum substrates are better than that of similar products, thus omitting the remelting process when aluminum ingots are used, saving resources, reducing the production cost and increasing the economic and social benefits.

Owner:登电集团铝加工有限公司

Method for casting air sucking valve steel casting part

ActiveCN103056325AGuaranteed surface qualityGuaranteed compactnessFoundry mouldsFoundry coresMetal moldZircon

The invention relates to a method for casting an air sucking valve steel casting part. The method comprises the steps (1) using central cross sections of flange holes on two sides of the casting part as parting surfaces, manufacturing a metal mold, using water glass quartz sand to manufacture an upper portion and a lower portion, using water glass limestone sand as back sand, using the water glass quartz sand as facing sand to manufacture sand cores and brushing zircon power coatings on the surfaces of the upper portion, the lower portion and the sand cores; (2) placing the sand cores into a cavity of the lower portion, placing outer cold irons on flange end faces of the lower portion, placing open risers and riser pads on the upper portion, placing second outer cold irons on two end faces of an inner flange of the lower portion, correspondingly placing blind risers and riser pads on the upper portion, placing inner cold irons at the valve rod hole positions of a second sand core and a fourth sand core and leading a straight pouring channel and a horizontal pouring channel of a pouring system into flange edges on two sides at the parting surface positions; (3) assembling the mold after the cores fall; (4) smelting furnace burden and pouring the casting part; and (5) performing cooling, mold opening and core falling to clean the casting part. By means of the method for casting the air sucking valve steel casting part, casting part cracks can be decreased, an internal structural of the casting part is compact, and the rate of finished products is high.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Production process for stainless steel damping composite board

InactiveCN101905558AGuaranteed surface qualityImprove the shock and noise reduction effectSynthetic resin layered productsLaminationMetallurgyComposite plate

The invention discloses a production process for a stainless steel damping composite board, which comprises the following steps of: firstly, preheating a hot galvanizing cold-rolled steel sheet; secondly, rolling and adhering a macromolecular damping adhesive film on the preheated hot galvanizing cold-rolled steel sheet by using a film coating roller; thirdly, rolling and combining the stainless steel sheet on the macromolecular damping adhesive film by a sheet coating roller, heating the whole sheet body by a pressing roller at the same time and further performing rolling and adhesion to realize stable solidification; and finally, cooling the whole sheet body by using forced air cooling and rolling the cooled sheet to obtain the stainless steel damping composite board, wherein the stainless steel sheet is a surface plate, the hot galvanizing cold-rolled steel sheet is a base plate and the macromolecular damping adhesive film is a middle layer; the preheating temperature of the hot galvanizing cold-rolled steel sheet is 80 to 120 DEG C; the temperature of the film coating roller is 120 to 150 DEG C; the temperature of the sheet coating roller and the pressing roller is 170 to 220 DEG C; and the composite board is cooled to 20 to 30 DEG C by the forced air cooling. The process has the advantages that: the production is simple; the cost is low; and the product uses few stainless steel, has a high strength, and can damp and reduce noises and be produced continuously with low cost and high production process.

Owner:XUCHANG AUSTAR AUTOMATION EQUIP

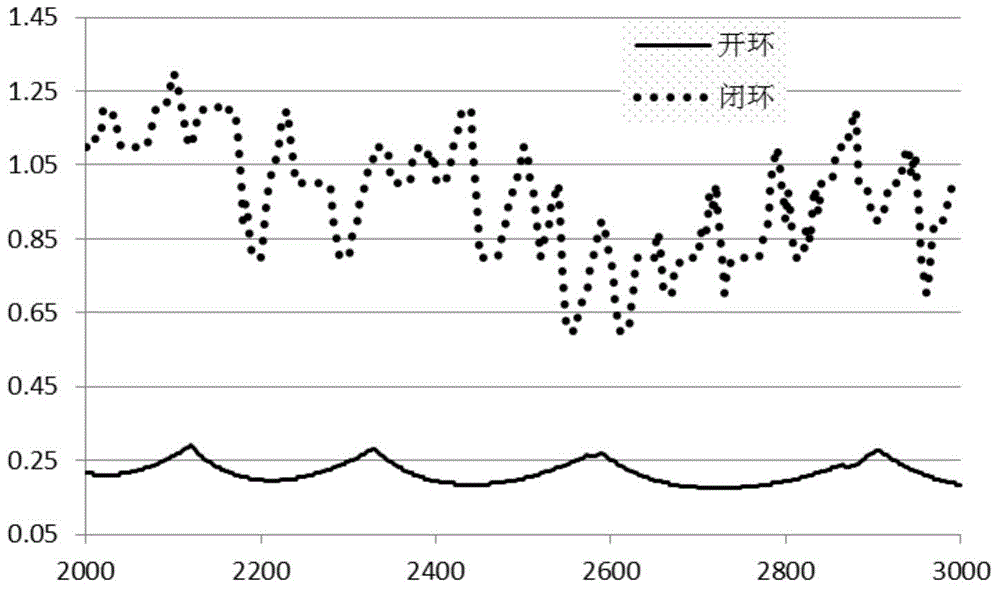

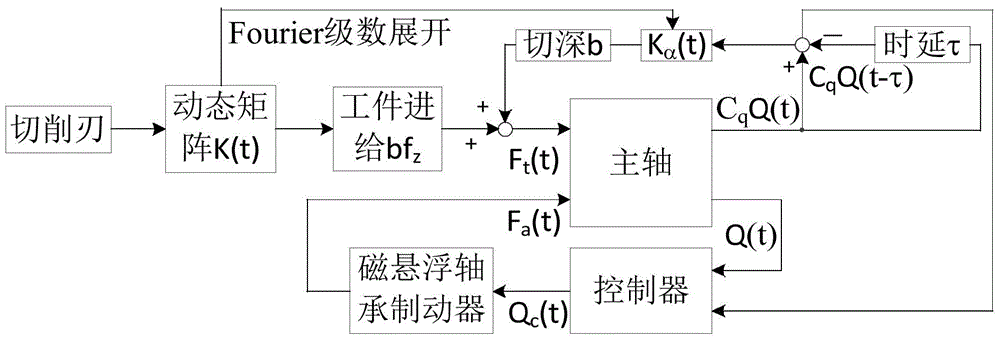

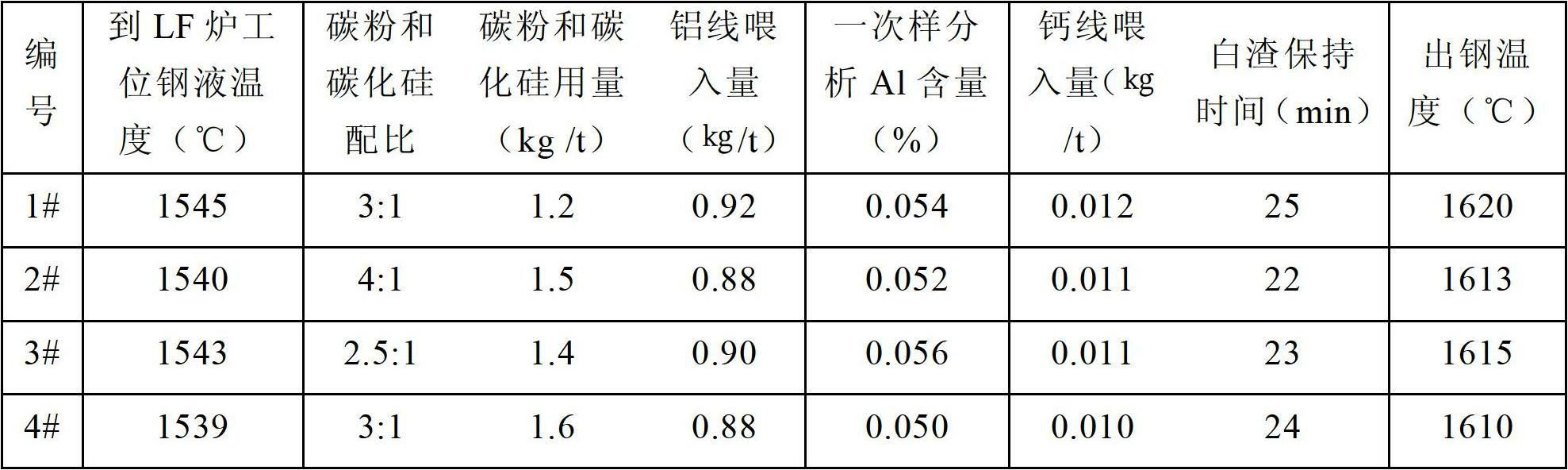

Active control method of milling chatter vibration based on electric spindle of magnetic suspension bearing

ActiveCN104647132AGuaranteed surface qualitySmooth millingAutomatic control devicesFeeding apparatusChatter vibrationWeight coefficient

The invention discloses an active control method of milling chatter vibration based on an electric spindle of a magnetic suspension bearing. The method comprises the following steps: collecting a current displacement signal generated when the electric spindle has the milling chatter vibration; obtaining a state vector Q(t) formed by the displacement of the electric spindle and the speed; obtaining harmonic displacement which is shown as the formula in the description according to the electric spindle displacement [Fx Fy]T and a trigonometric function column vector phi(t); obtaining a first self-adaptive weight coefficient which is shown as the formula in the description and a second self-adaptive weight coefficient which is shown as the formula in the description; obtaining a first self-adaptive rate K1 and a second self-adaptive rate K2 according to the harmonic displacement h(t), the first self-adaptive weight coefficient lambda1 and a second self-adaptive weight coefficient lambda2; obtaining self-adaptive control current which is shown as the formula in the description according to the first self-adaptive rate K1, the second self-adaptive rate K2 and the harmonic displacement h(t); and applying the self-adaptive control current Qc(t) on a radial magnetic suspension bearing and generating corresponding magnetic field force so as to restrain the chatter vibration of the spindle. Through the active control method, the chatter vibration in the milling process is eliminated, thereby ensuring the processing quality and improving the processing efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Steel for petroleum casing connecting piece and manufacturing method thereof

InactiveCN102660711AGuaranteed surface qualityImprove cleanlinessElectric furnaceProcess efficiency improvementChemical compositionSlow cooling

The invention discloses steel for a petroleum casing connecting piece and a manufacturing method thereof, and belongs to the technical field of metallurgy. The steel for the petroleum casing connecting piece comprises the following chemical ingredients in percentage by mass: 0.28 to 0.33 percent of C, 0.20 to 0.35 percent of Si, 0.45 to 0.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.90 to 1.10 percent of Cr, 0.18 to 0.25 percent of Mo, 0.020 to 0.050 percent of alt, less than or equal to 0.25 percent of Cu, less than or equal to 2.0*10<4> percent of H, 40*10<4> to 70*10<4> percent of N, less than or equal to 15*10<4> percent of T.O and the balance of Fe and inevitable impurities. The manufacturing method comprises the following production processes: an initial refining process of an electric furnace, a refining process of a ladle furnace (LF), a vacuum degassing (VD) process, a continuous casting process, a casting blank slow cooling process and an inspection and finishing process. The cleanliness, tissue compactness and uniformity of continuous casting round billets for the petroleum casing connecting piece are improved greatly, and the requirement of the steel for the petroleum casing connecting piece is met.

Owner:LAIWU IRON & STEEL GRP

Manufacturing method of fired mold precision cast aluminum alloy case

InactiveCN102921888AReduce manufacturing costConvenient sourceFoundry mouldsFoundry coresSurface layerMullite

The invention discloses a manufacturing method of a fired mold precision cast aluminum alloy case. The method includes the following steps: 1) blending binder; 2) preparing surface layer slurry; 3) sanding on a surface layer; 4) preparing transition surface layer slurry; 5) sanding on a transition layer; 6) preparing reinforcing layer slurry; 7) sanding on a reinforcing layer; 8) preparing sealing layer slurry; 9) drying a sealing layer. According to the method, mullite sand which is cheap is used, purchasing is convenient, proportioning is easy, and the surface quality and the size accuracy of a mold shell and even a final cast piece can be greatly improved.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

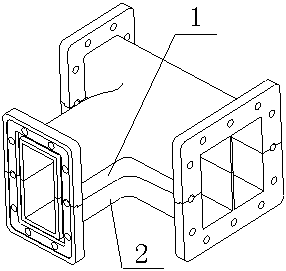

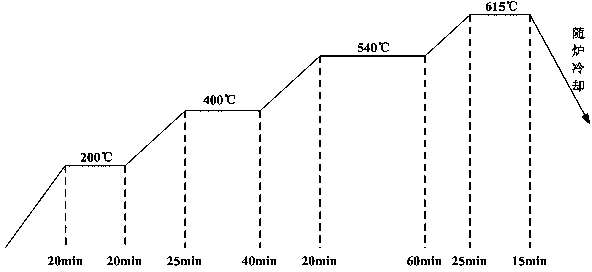

Self-positioning vacuum brazing technique for multi-cavity electrical bridge waveguide

The invention relates to a self-positioning vacuum brazing technique for a multi-cavity electrical bridge waveguide. The self-positioning vacuum brazing technique comprises the following steps of preparing materials and finishing the machining of an upper part and a lower part of the waveguide; respectively carrying out surface treatment on the machined upper and lower parts of the waveguide; producing brazing filler metals according to overall dimensions of the upper part and the lower part of the waveguide and assembling the upper part and the lower part of the waveguide and the brazing filler metals; matching the assembled electrical bridge waveguide with a work fixture and placing the assembled electrical bridge waveguide and the work fixture into a vacuum aluminum brazing furnace; carrying out vacuum brazing on the multi-cavity electrical bridge waveguide according to a vacuum brazing temperature process curve; carrying out numerical control machining on the shape of the waveguide and a ring flange; drilling and carrying out electrochemical treatment. According to the self-positioning vacuum brazing technique disclosed by the invention, the ring flange and a waveguide tube are integrally formed at one time, so that the processing work procedures are simplified, and the production period is short; a groove and a shoulder are arranged, so that self positioning is realized, combined times are reduced, and the assembly precision is high; one-time welding forming is realized by adopting vacuum brazing, and thus the deformation of cavities caused by multiple times of welding is avoided; in addition, no brazing flux is needed, and thus the corrosion of the brazing flux to the cavities is avoided, and the service life of the multi-cavity electrical bridge waveguide is prolonged.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

Method for cold rolling high silicon electric steel

InactiveCN101209459ASolve the problem of welding broken stripsGuaranteed surface qualityRoll force/gap control deviceOther manufacturing equipments/toolsMechanical energyAcid washing

The invention provides a cold rolling method for high-silicon electrical steel. The method comprises conventional processes of a first cold rolling for a hot rolled plate after being treated with acid washing or a second cold rolling with annealing during operation, decarbonization annealing and recrystallization annealing, etc., and is characterized in that the hot rolled plate before being treated with acid washing is done with welding end to end and then continuous endless rolling is done by a mill with multi-stands; a warm rolling is realized by that mechanical energy is transformed into heat energy during the rolling and the temperature of the steel plate raises; the tension among each mill stand is 100-300 N / mm <2> and 30-80 N / mm<2> for the last mill stand; the draft is 15-30 percent and 5-15 percent for the last mill stand and the outlet speed of the rolling mill is no less than 500m / min and the thickness of the finished product is 0.2-0.8mm. By adopting a plurality of mill stands to realize the warm rolling, the invention effectively solves the breakage occurred in edges; the last mill stand is served as the pass mill stand of finished products so as to guarantee the quality of the surface of the steel strip; large tension is adopted during the rolling so as to ensure that a forward slipping area can be reduced and deformation bands are increased. Compared with the method by a single mill stand, the method of the invention prolongs the cycle of roll changing, reduces the labor intensity, shortens the production cycle and improves productivity and quality of steel plates. In addition, the method of welding from head to tail for transition with low-silicon steel can effectively solve the problem of breakage during the welding of the high-silicon electrical steel.

Owner:ANGANG STEEL CO LTD

Construction method of long open-cut tunnel

ActiveCN101725149ASmall sizeImprove binding efficiencyUnderground chambersEmbankmentsWater levelGround water level

The invention discloses a construction method of a long open-cut tunnel, comprising the following steps of: after reducing ground water level by utilizing precipitation of a tube well, carrying out the slope excavation to be the designed height, sequentially constructing a bed course, waterproof roll and inverted arch and filling, carrying out secondary lining by using inner and outer mould trolleys, constructing external coverage and waterproof engineering, back-filling and compacting. The invention has the advantages that: the construction method has strong scene maneuverability, is easy to popularize, ensures the construction safety, and improves the construction quality of the long open-cut tunnel.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

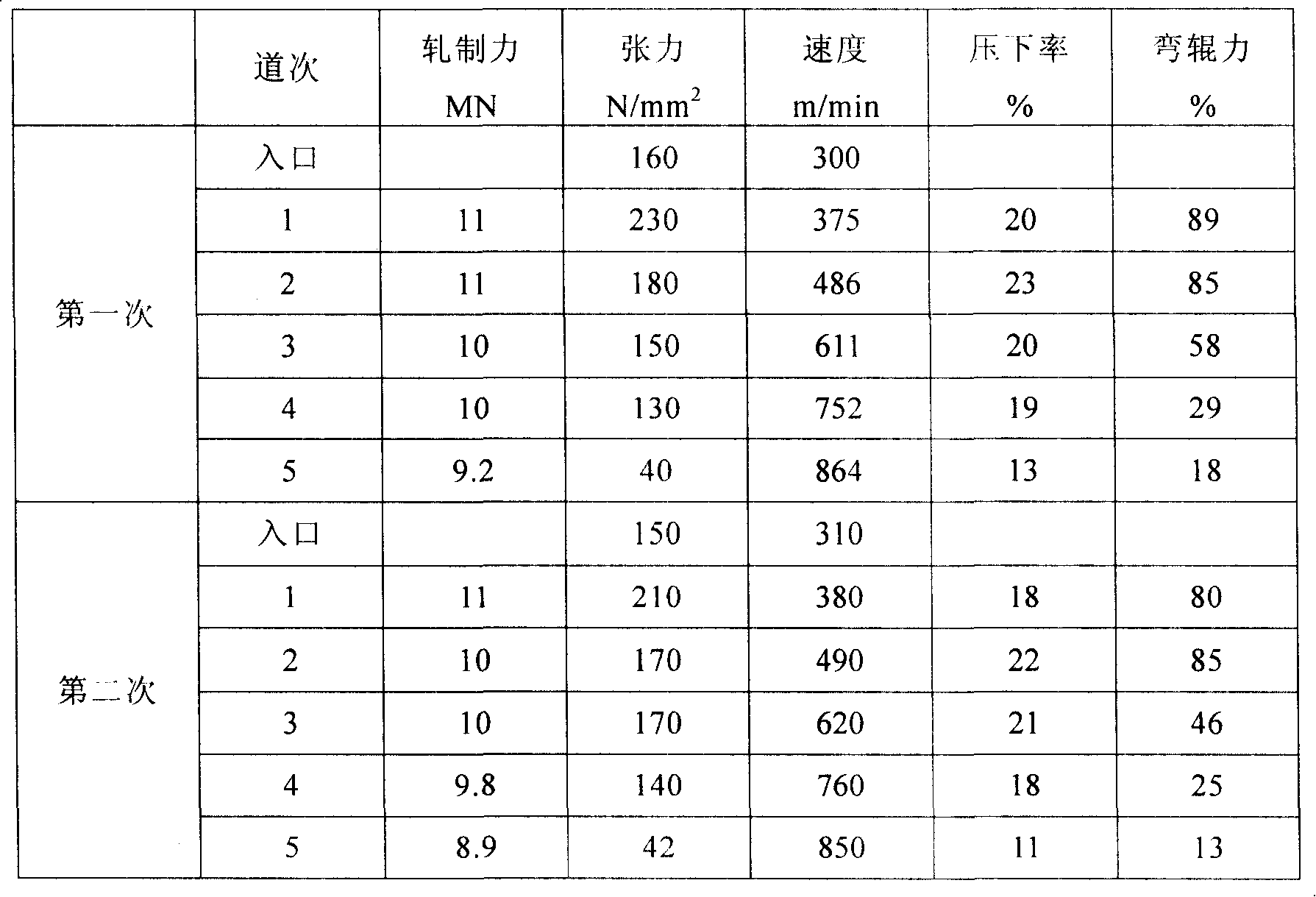

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com