Austenitic stainless steel for urban rail vehicle face plates and manufacturing method of austenitic stainless steel

A technology for austenitic stainless steel and urban rail vehicles, which is applied to austenitic stainless steel for urban rail vehicle panels and its manufacture, and the field of manufacturing urban rail vehicles or train passenger car panels, can solve the degradation of product surface quality, chemical composition performance fluctuations, Product performance instability and other problems, to avoid grain boundary oxidation, avoid product performance fluctuations, and protect the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

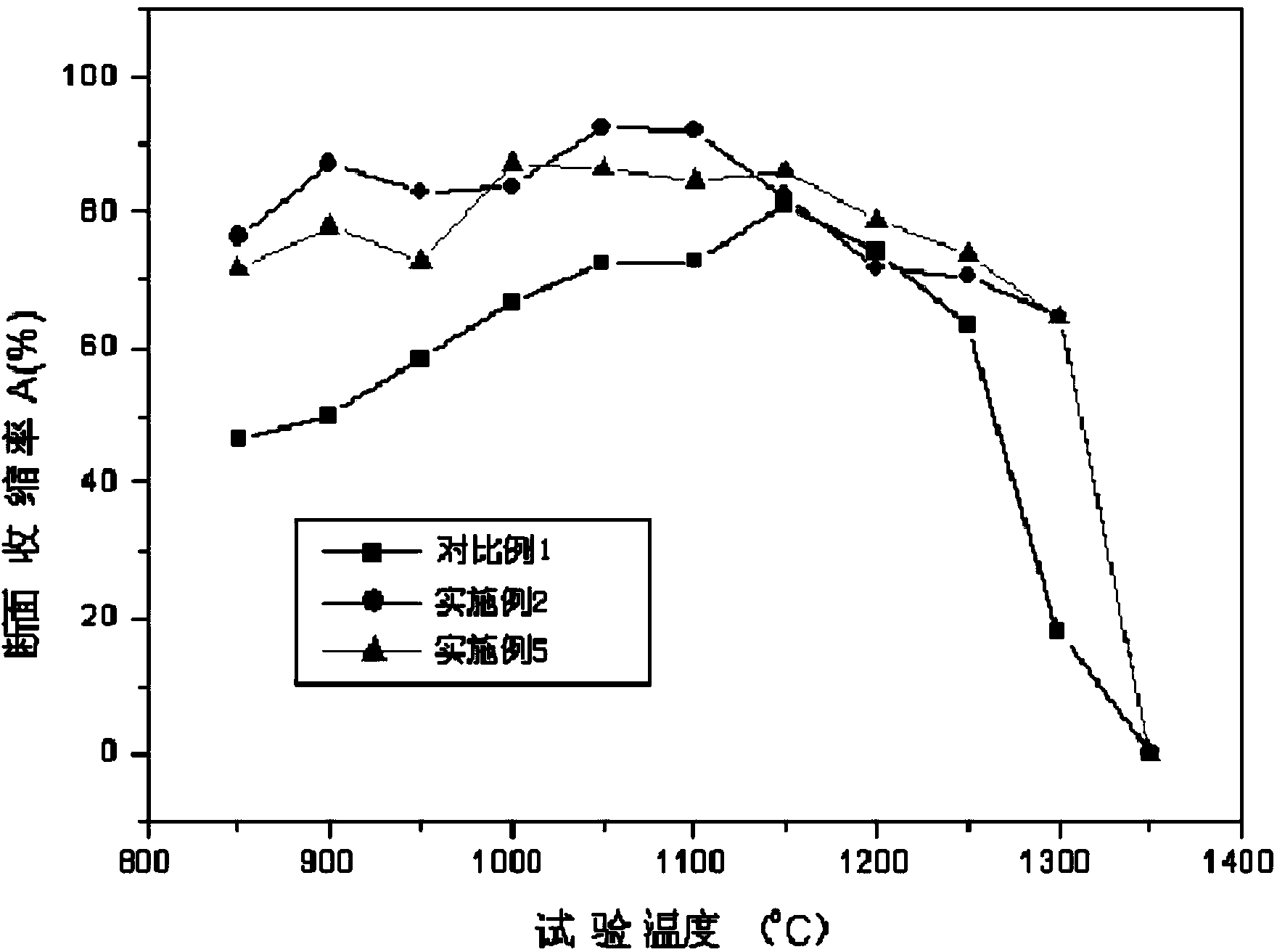

Examples

Embodiment 1

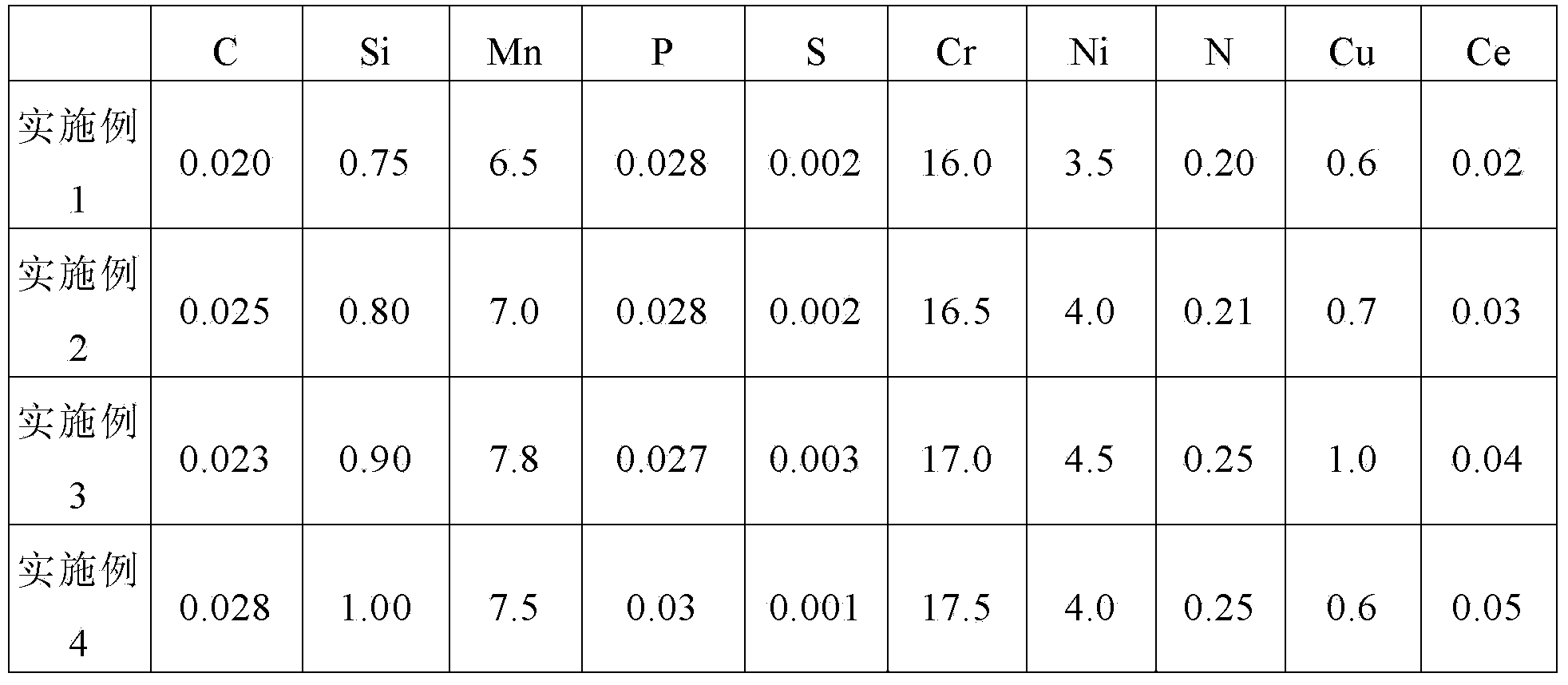

[0061] Pour 120 tons of molten steel smelted in the electric furnace and AOD furnace into the baked ladle, hoist it to the refining station and feed the mixed rare earth block, the oxygen content in the molten steel is 28ppm, add 96kg of the mixed rare earth block, and blow argon at the bottom after feeding the block After soft stirring for 10 minutes, the temperature of the ladle reaches 1525°C, and it is hoisted to the continuous casting platform. The specification of the continuous casting slab is 1250*200mm, and the casting speed is reduced to 0.7m / min in the last 10 minutes. The chemical composition of the continuous casting slab is shown in Table 2. The continuous casting slab is sent to a walking beam heating furnace for heating, the residual oxygen in the furnace is controlled to be 2%, the furnace temperature is controlled at 1280°C, and the time in the furnace is 220 minutes. After 7 passes of rough rolling, the thickness of the intermediate billet is 35mm. After 7 ...

Embodiment 2

[0063] Pour 130 tons of molten steel smelted in the electric furnace and AOD furnace into the baked ladle, hoist it to the refining station and feed the mixed rare earth block, the oxygen content in the molten steel is 27ppm, add 104kg of the mixed rare earth block, and blow argon at the bottom after feeding the block After soft stirring for 12 minutes, the temperature of the ladle reaches 1525°C, and it is hoisted to the continuous casting platform. The chemical composition of the continuous casting slab is shown in Table 2. The specification of the continuous casting slab is 1250*200mm, and the casting speed is reduced to 0.7m / min in the last 10 minutes. The continuous casting slab is sent to a walking beam heating furnace for heating, the residual oxygen in the furnace is controlled to be 3%, the furnace temperature is controlled at 1280°C, and the time in the furnace is 220 minutes. After 7 passes of rough rolling, the thickness of the intermediate billet is 35mm. After 7...

Embodiment 3

[0065] Pour 120 tons of molten steel smelted by the electric furnace and AOD furnace into the baked ladle, hoist it to the refining station and feed the mixed rare earth block, the oxygen content in the molten steel is 28ppm, add 120kg of the mixed rare earth block, and blow argon at the bottom after feeding the block After soft stirring for 15 minutes, the temperature of the ladle reaches 1525°C, and it is hoisted to the continuous casting platform. The specification of the continuous casting slab is 1250*200mm, and the casting speed is reduced to 0.7m / min in the last 10 minutes. The chemical composition of the continuous casting slab is shown in Table 2. The continuous casting slab is sent to a walking beam heating furnace for heating, the residual oxygen in the furnace is controlled to be 2%, the furnace temperature is controlled at 1280°C, and the time in the furnace is 220 minutes. After 7 passes of rough rolling, the thickness of the intermediate billet is 35mm. After 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com