Patents

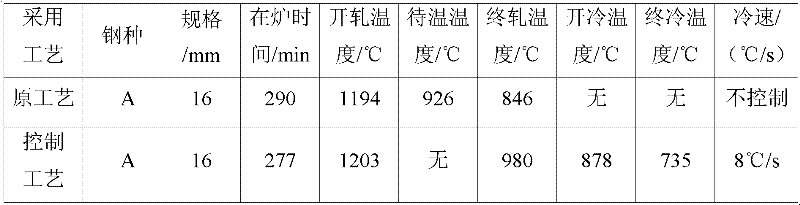

Literature

452 results about "Residual oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residual Oxygen Analysis. In recent times there has been a large increase in the type and number of products packaged using Modified Atmosphere Packaging (MAP) procedures. The majority of these processes concern the removal of oxygen from packaging systems in order to reduce oxidative degradation of the product and increase shelf life.

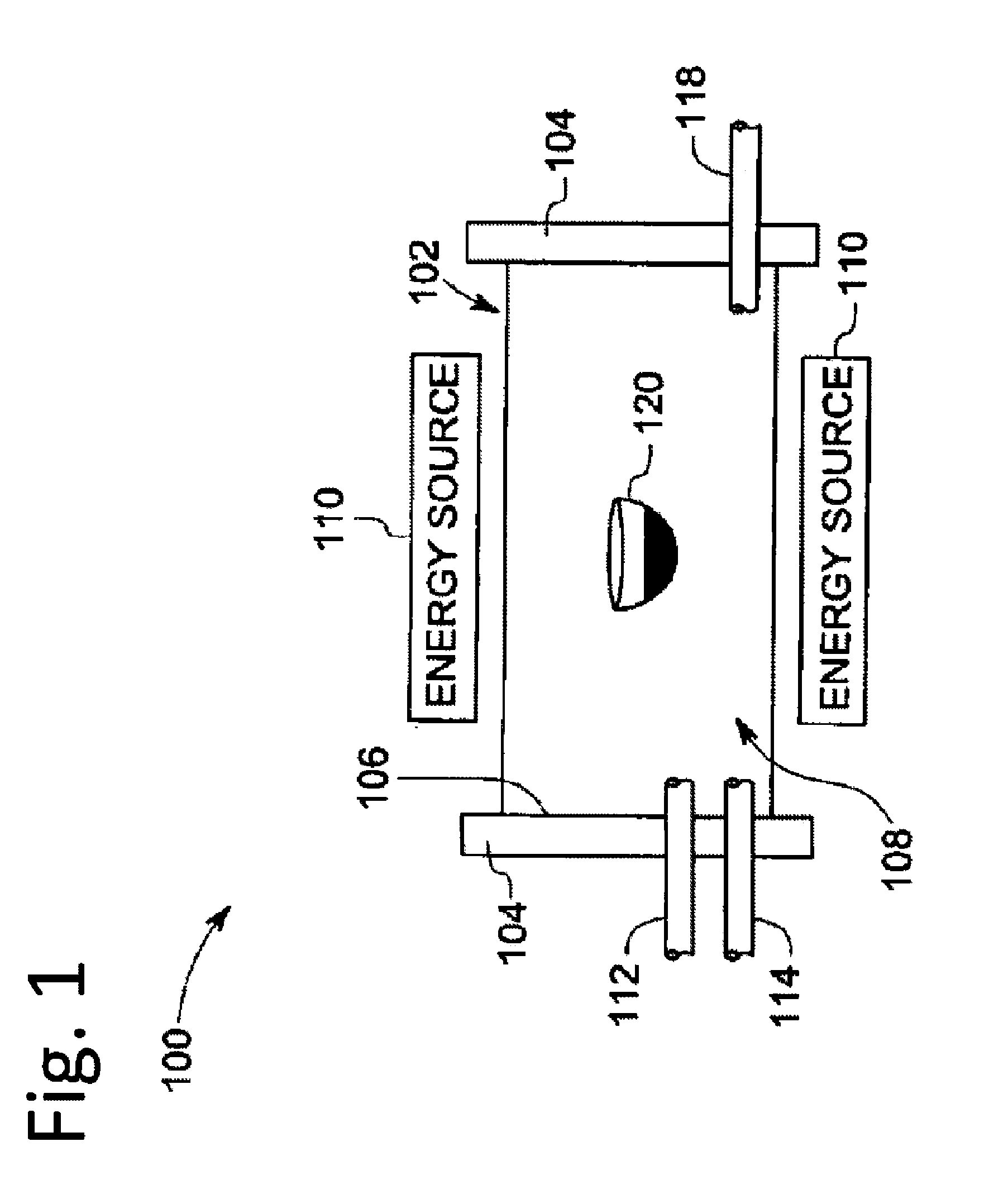

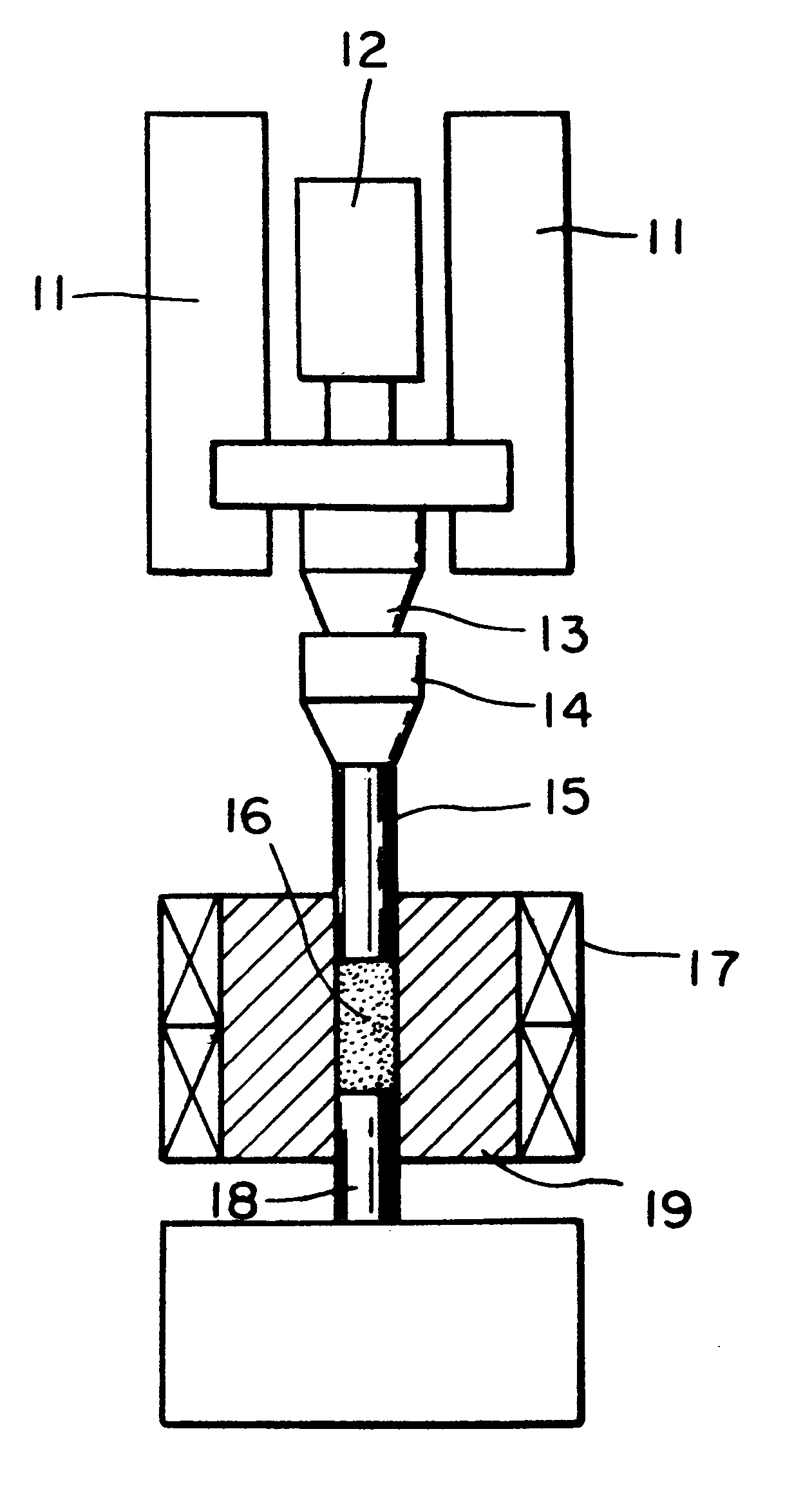

Polycrystalline group iii metal nitride with getter and method of making

ActiveUS20100151194A1Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

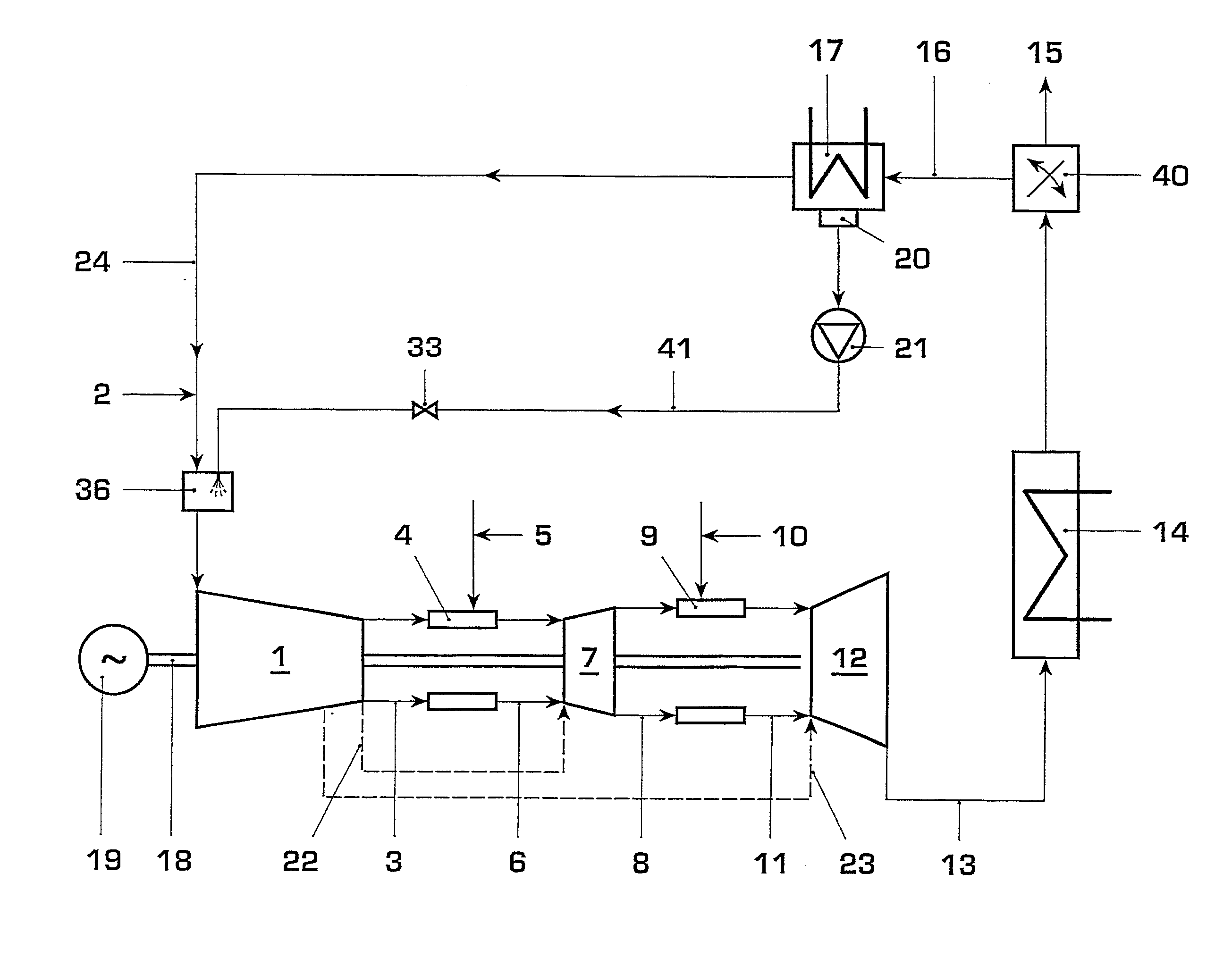

Gas Turbine Installation with Flue Gas Recirculation

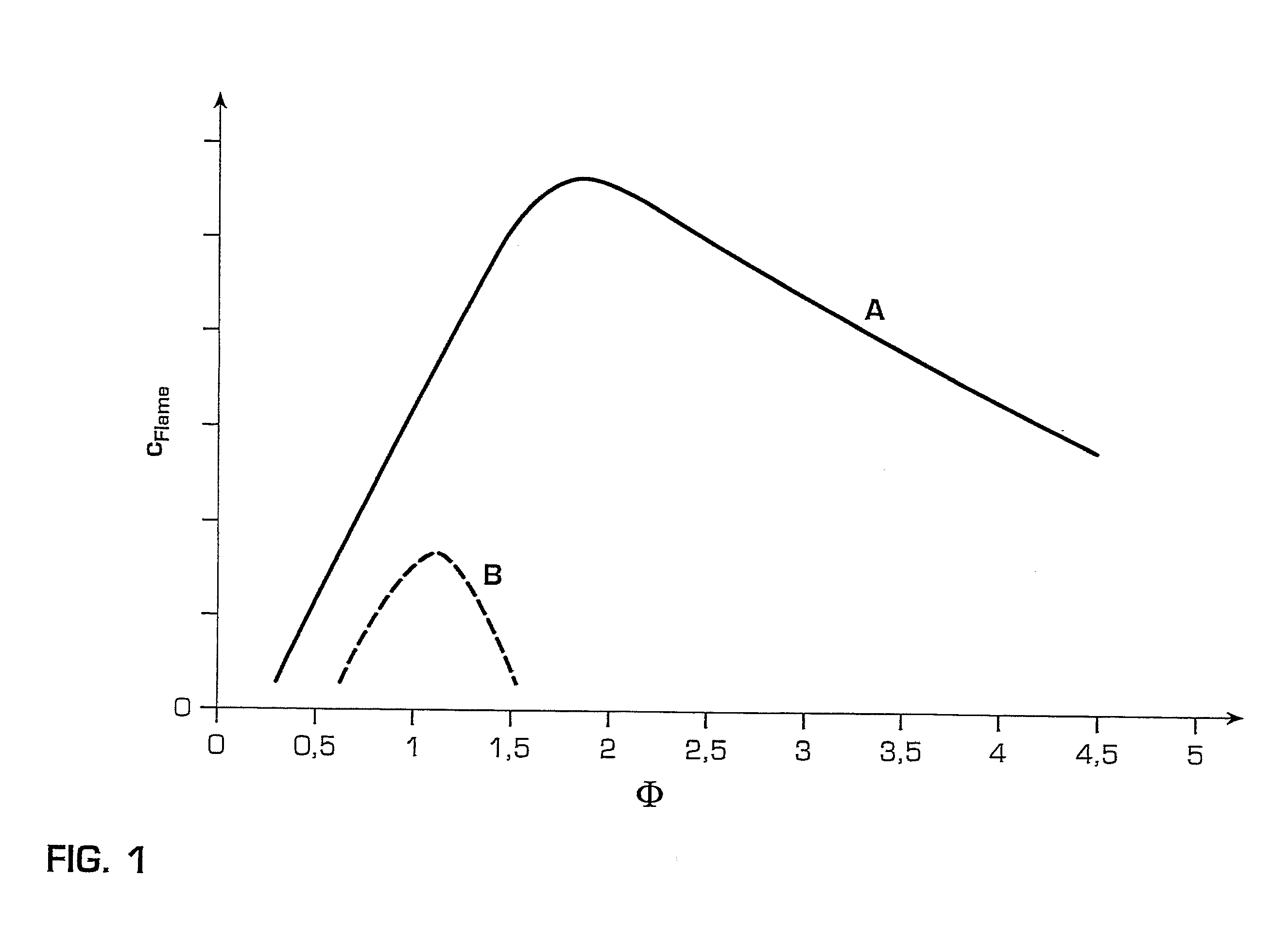

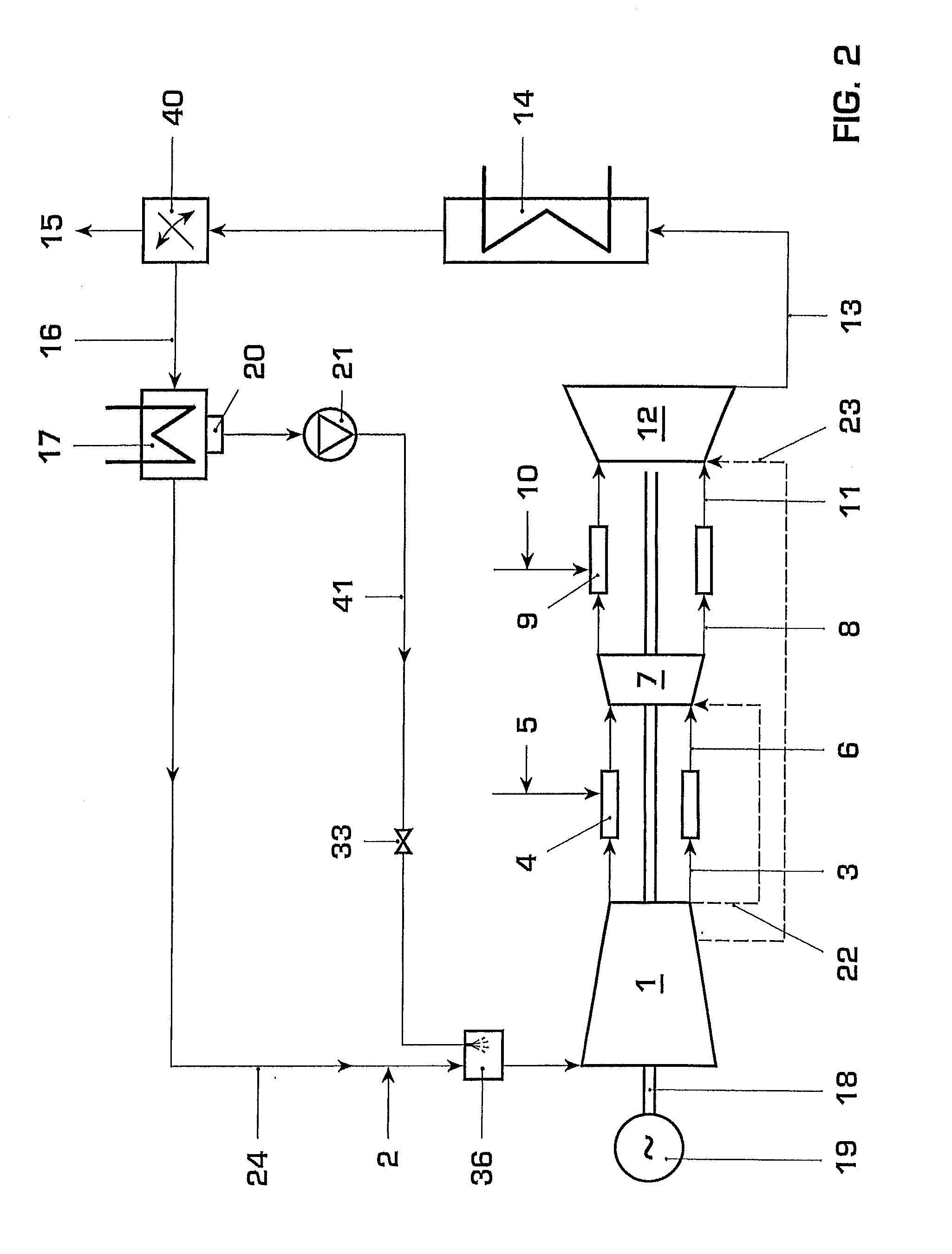

A method and installation are disclosed which can, for example, provide for reliable, low-Nox-emission operation of a gas turbine installation with hydrogen-rich fuel gas. An exemplary gas turbine installation includes an arrangement for flue gas recirculation into a compressor inlet and for fuel gas dilution. Oxygen content in combustion air can be reduced by recirculation of recooled flue gas, and the fuel gas can be diluted with compressed flue gas. The oxygen reduction in the combustion air can lead to minimum residual oxygen in the flue gas which can be used for fuel gas dilution. As a result of the flue gas recirculation, water content in the combustion air can be increased by feedback of the water which results as a combustion product. The oxygen reduction, increased water content, and fuel dilution can reduce the flame velocity of hydrogen-rich fuel gases and enable a robust, reliable and low-emission combustion.

Owner:GENERAL ELECTRIC TECH GMBH

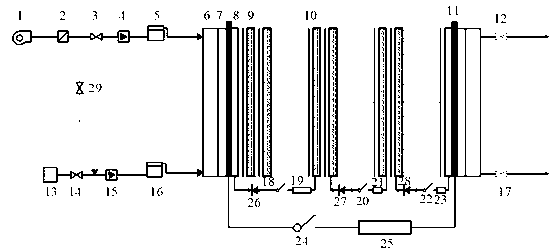

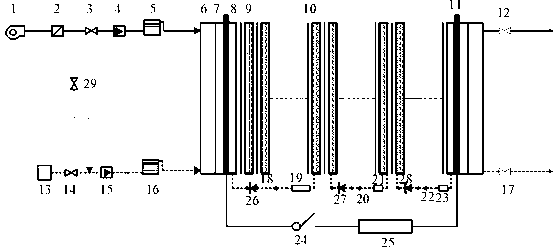

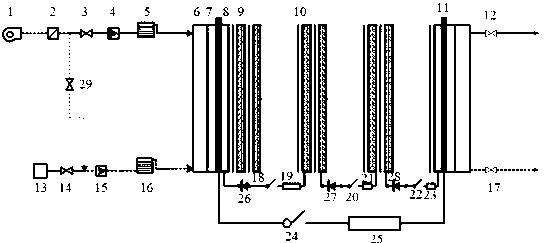

Gas separation by combined pressure swing and displacement purge

InactiveUS6902602B2Improve efficiencyAvoid pollutionGas treatmentIsotope separationSyngasAtmospheric air

Owner:AIR PROD & CHEM INC

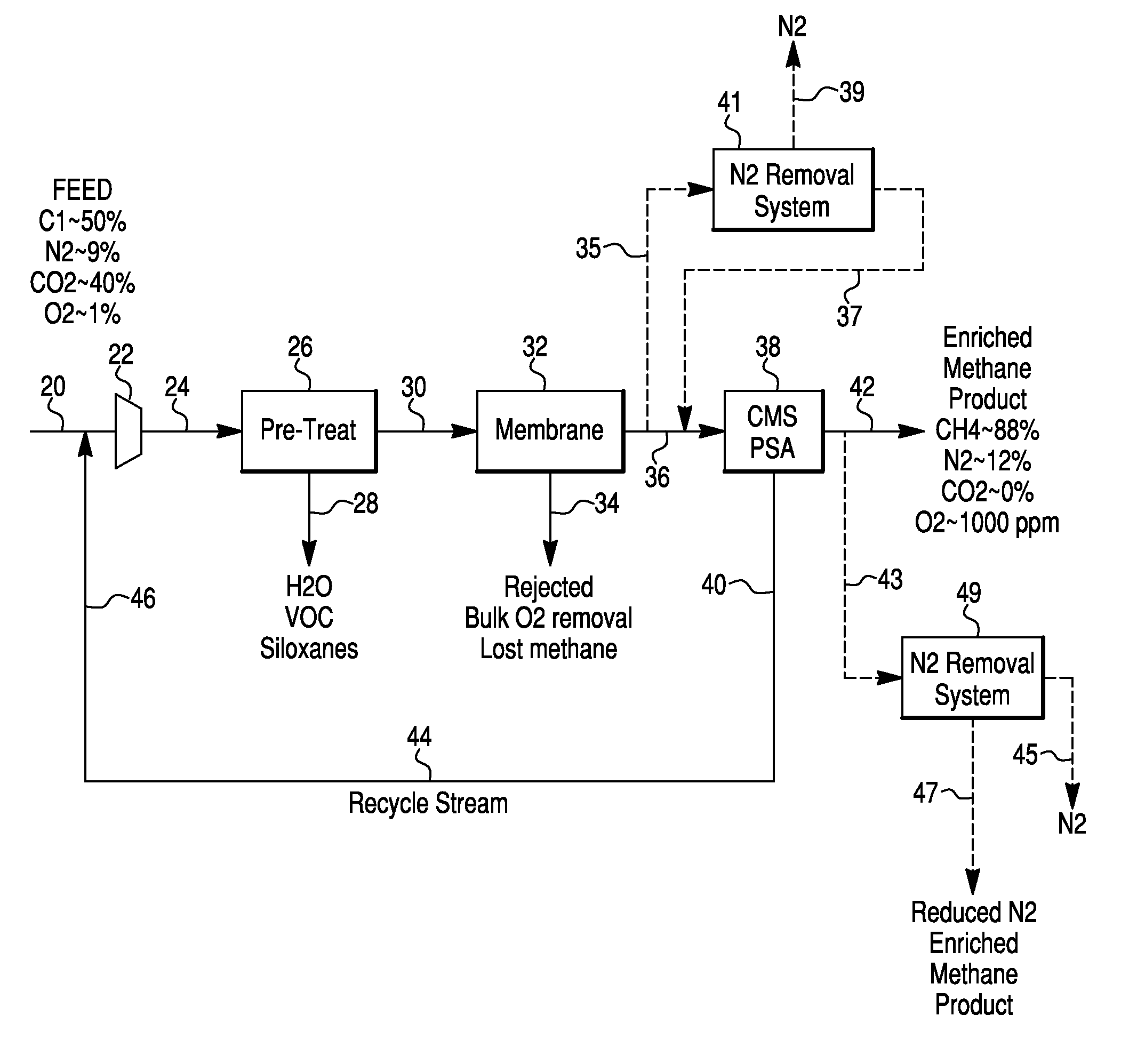

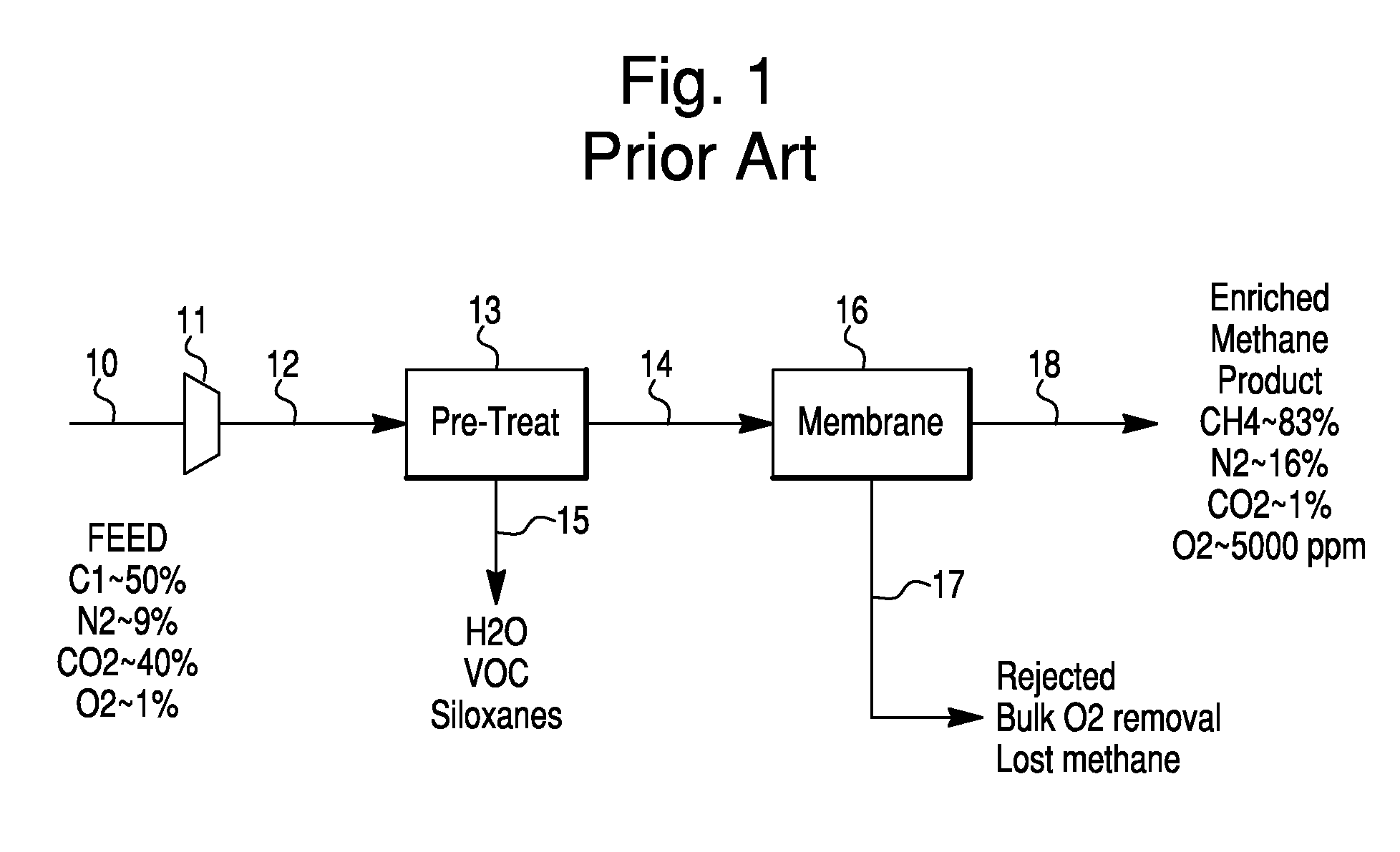

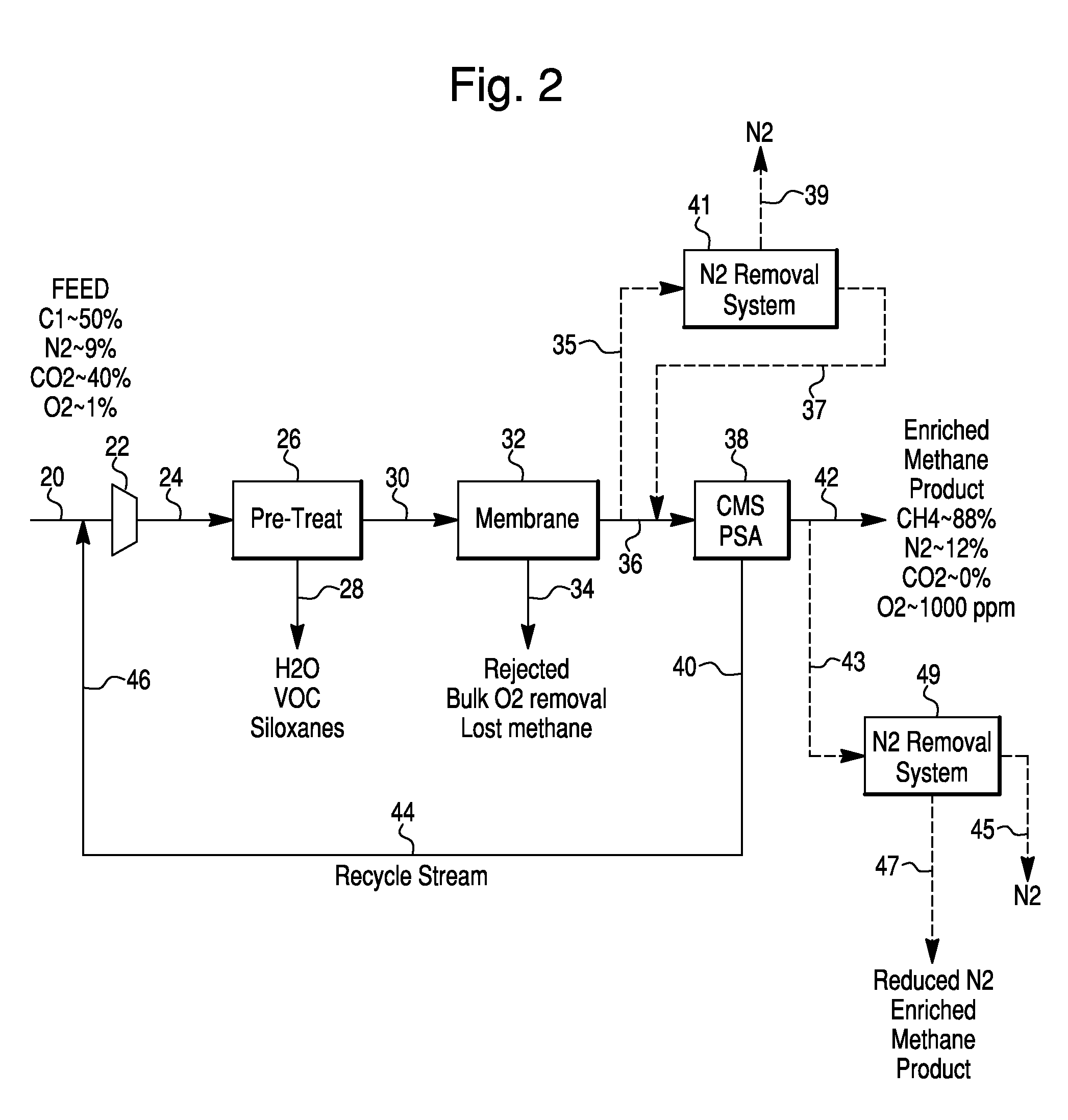

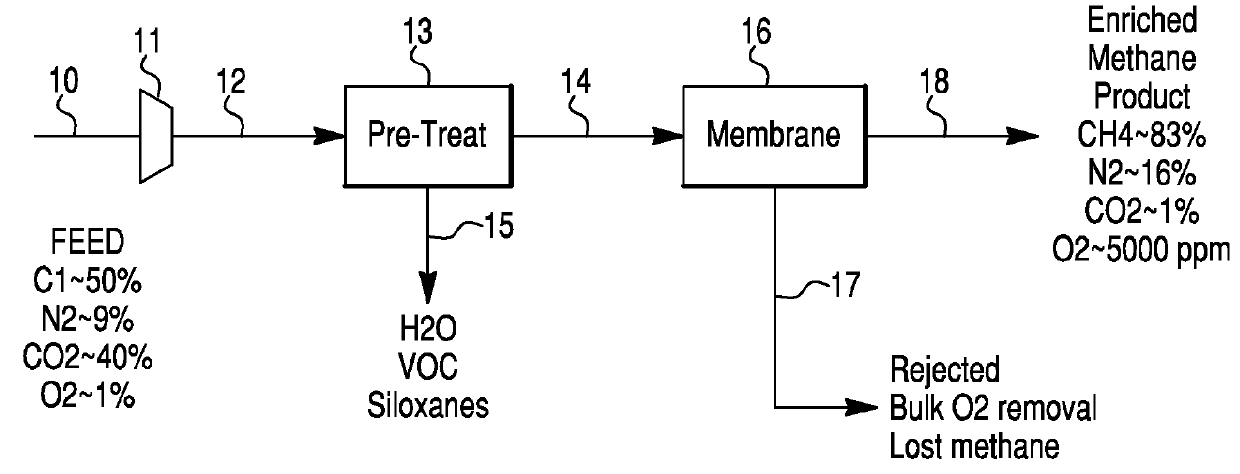

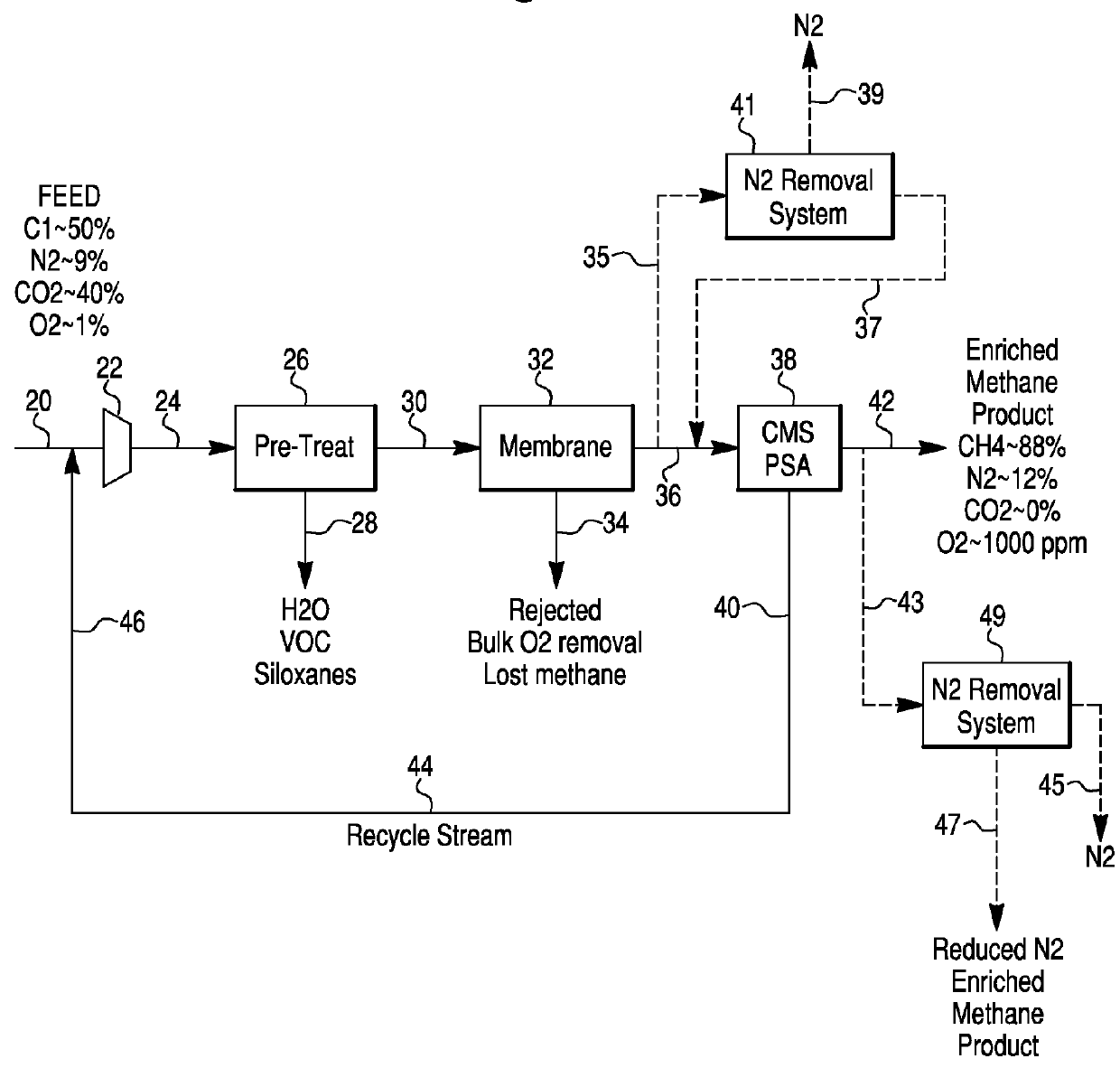

Oxygen Removal From Contaminated Gases

The invention relates to a method for achieving low oxygen levels in a natural gas stream without the use of a catalytic system. In one embodiment, the method comprises: membrane treatment for the removal of the bulk of CO2 and oxygen in the natural gas feed and the addition of a PSA system using a carbon molecular sieve adsorbent for the adsorption of residual oxygen.

Owner:GUILD ASSOCS

Polycrystalline group III metal nitride with getter and method of making

ActiveUS8461071B2Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

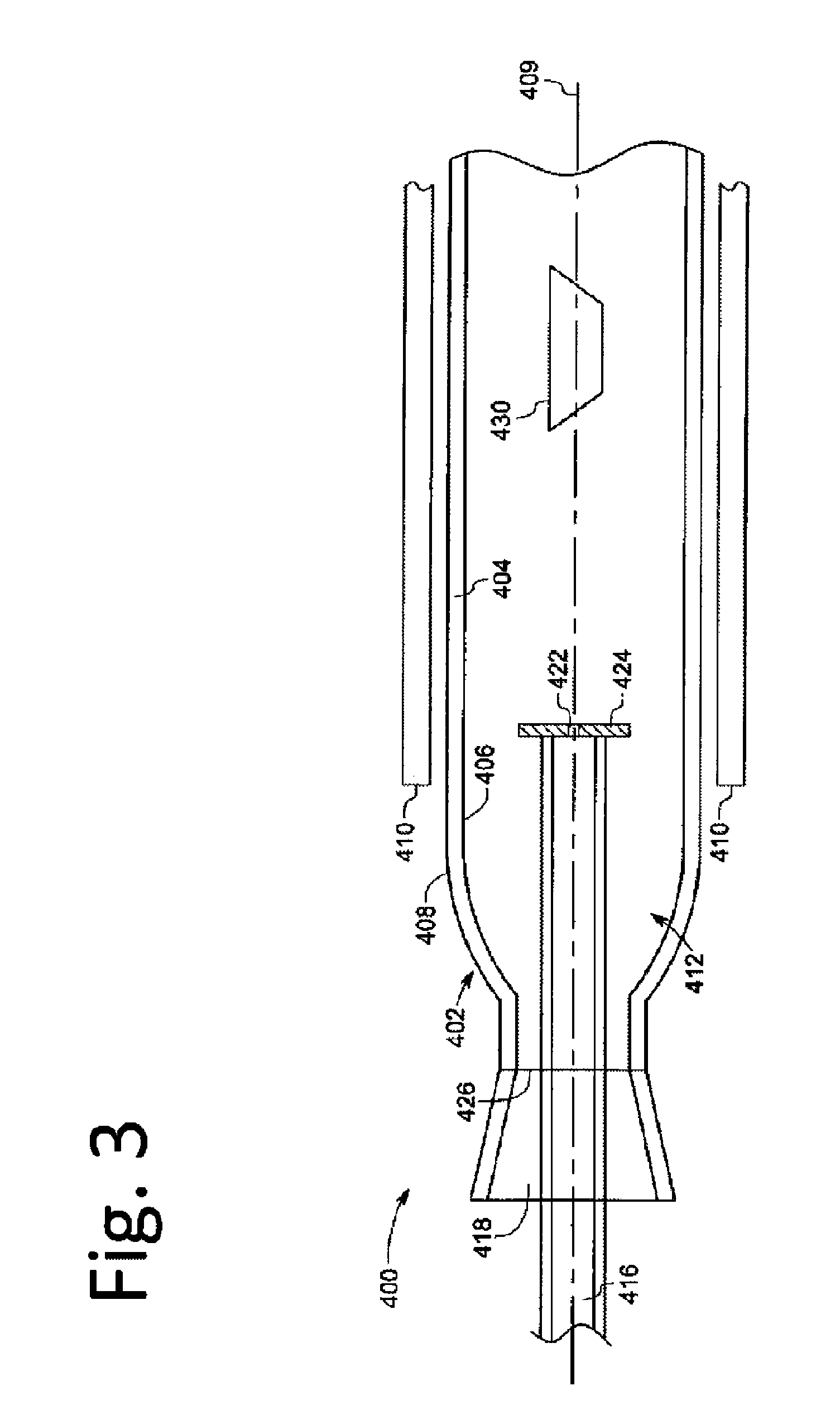

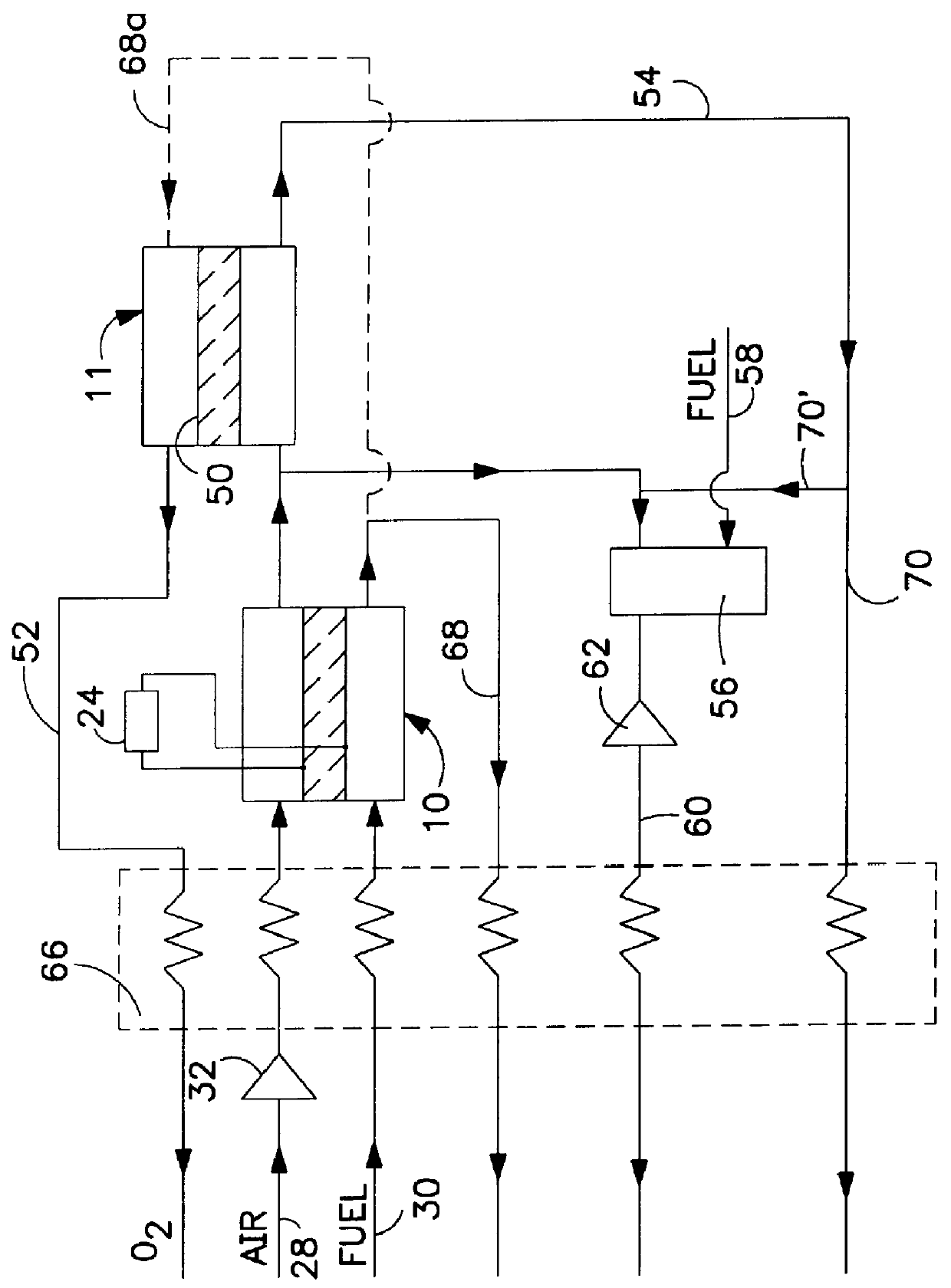

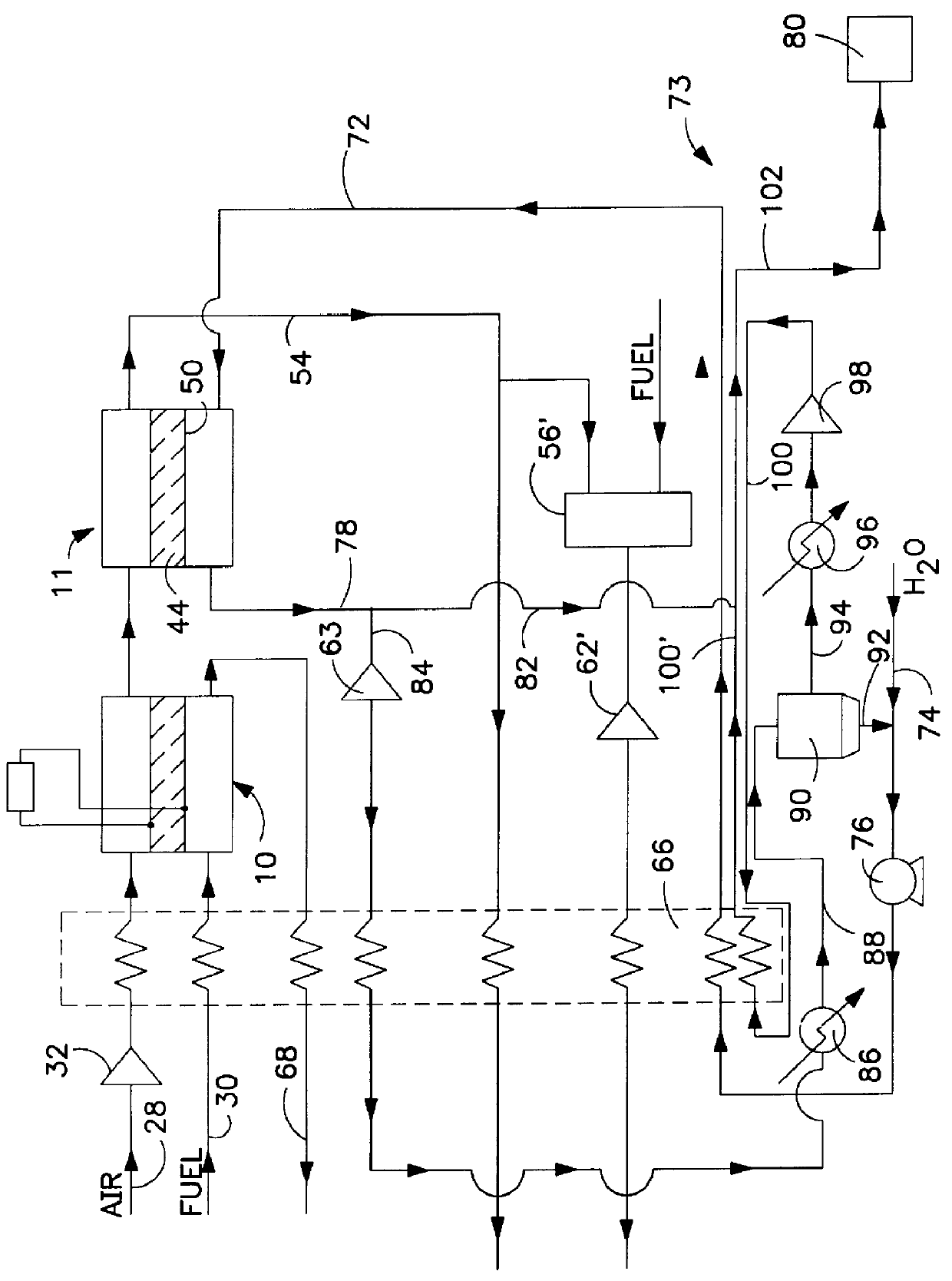

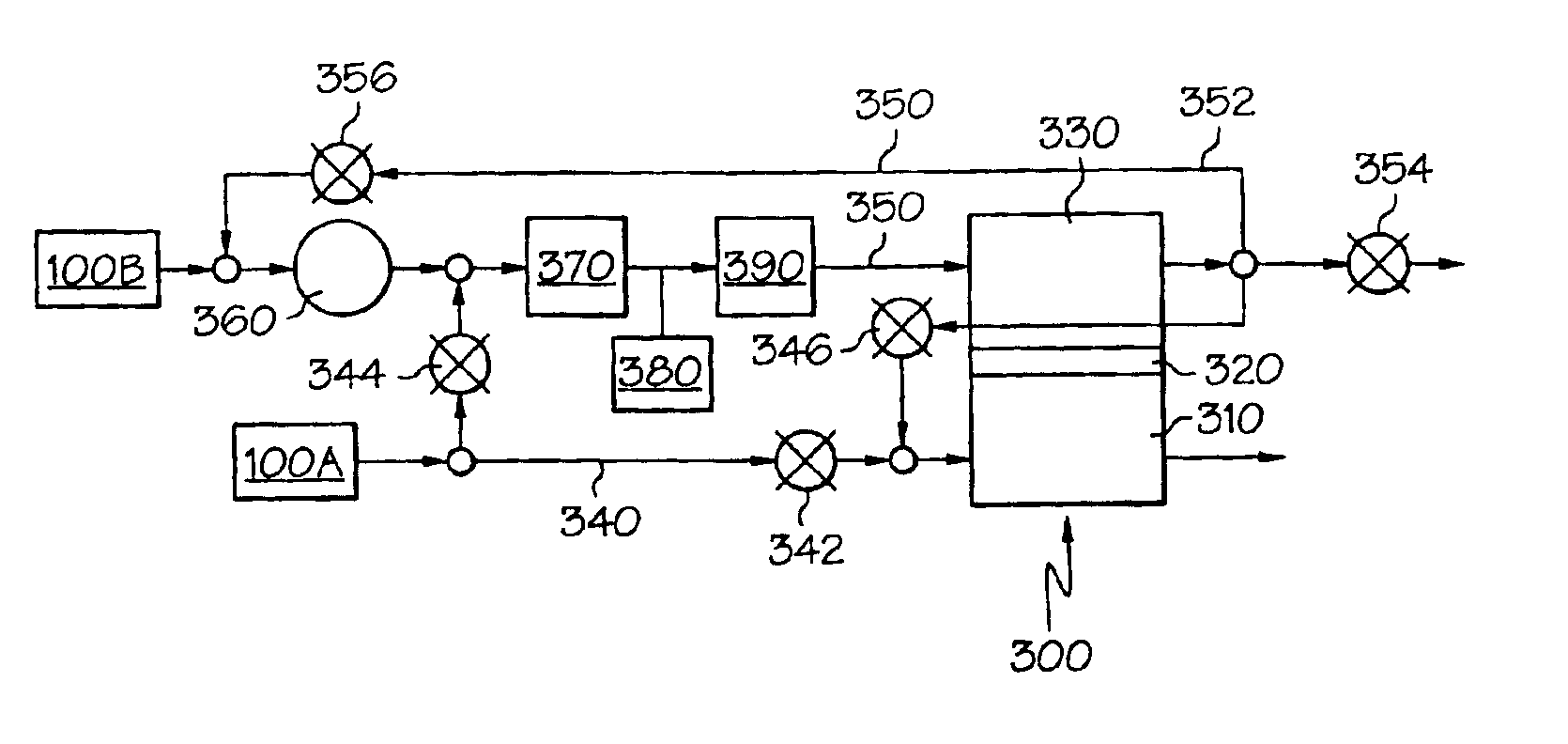

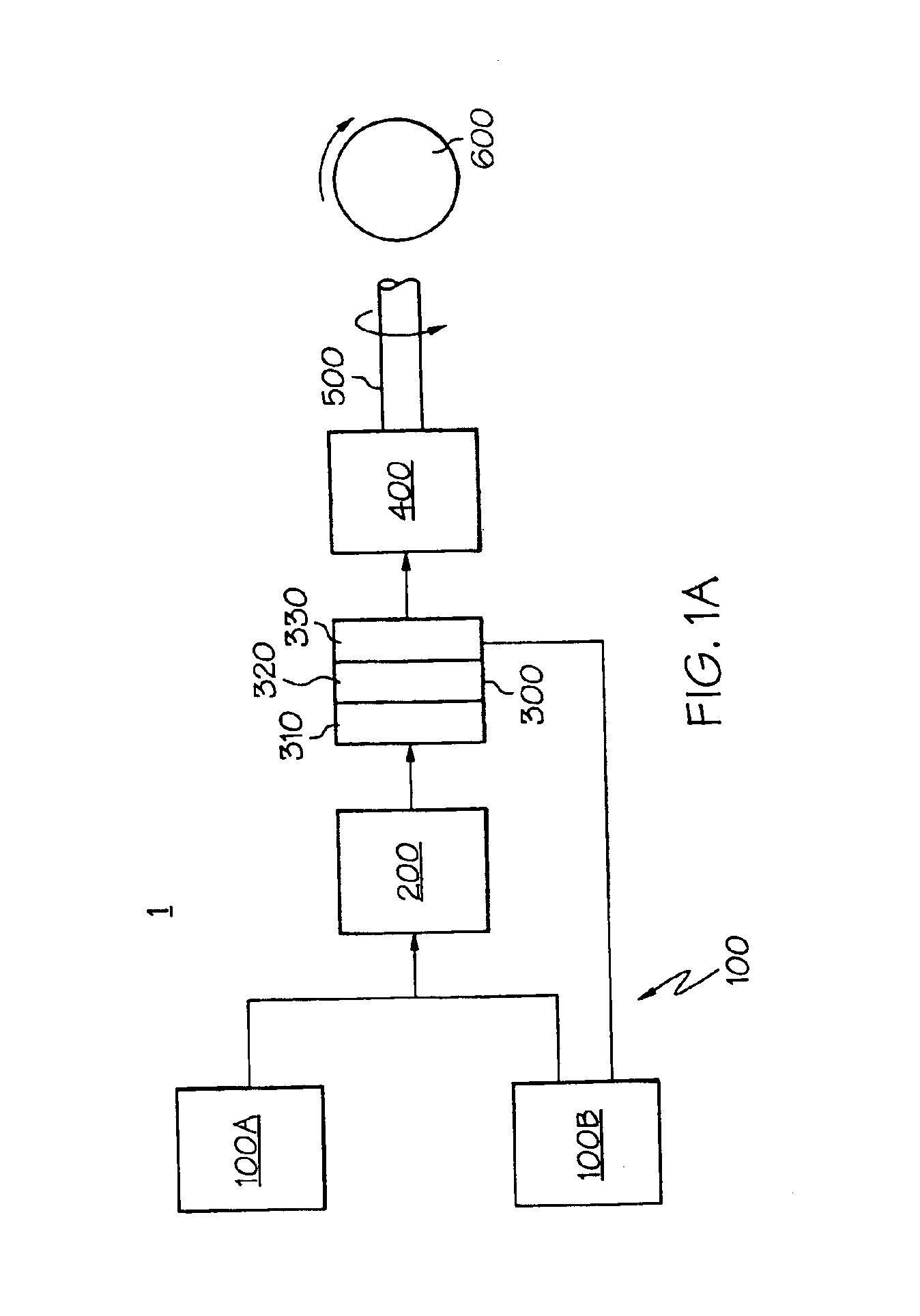

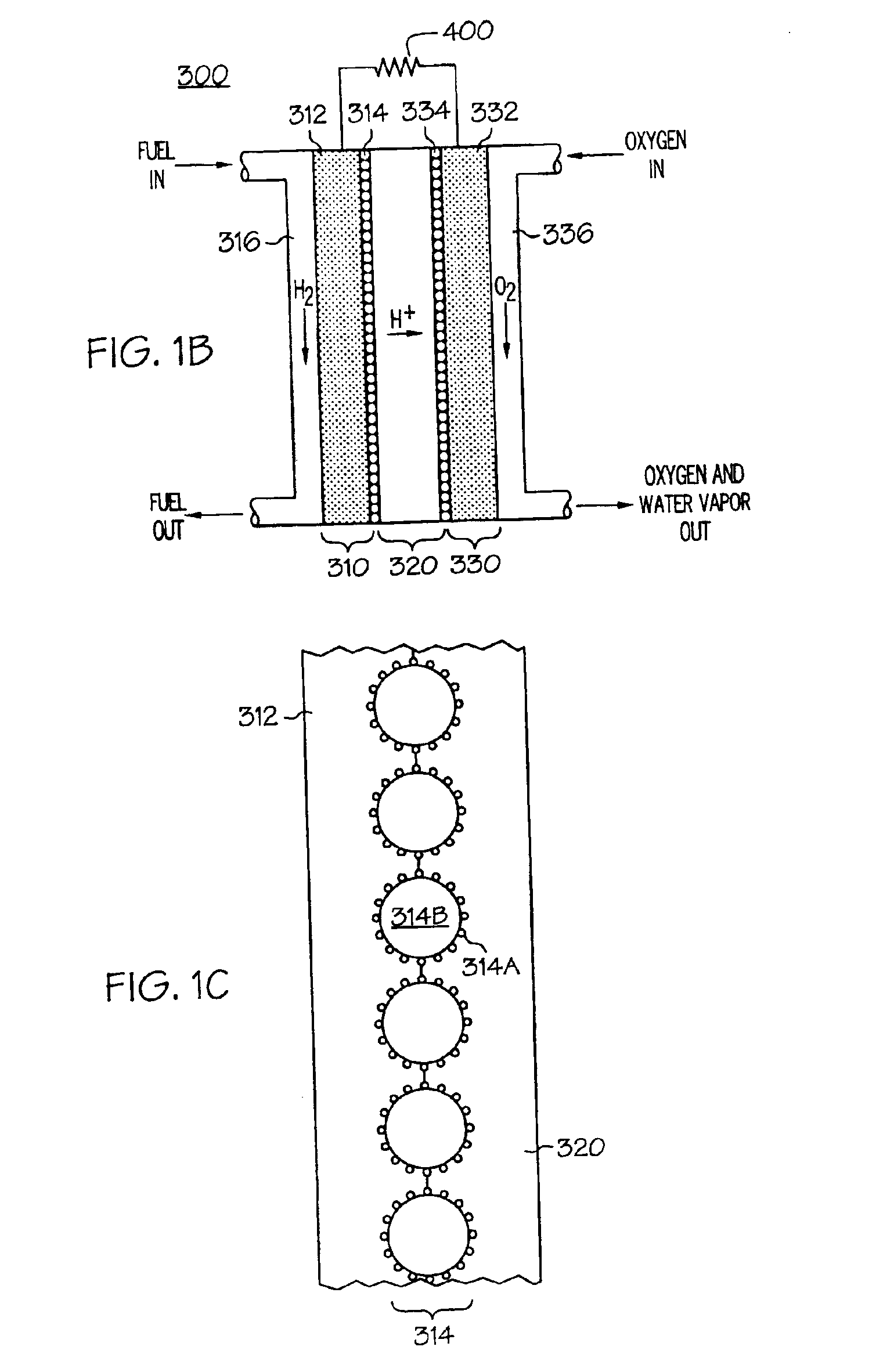

Process integrating a solid oxide fuel cell and an ion transport reactor

InactiveUS6017646AImprove efficiencyMaximize efficiencyHydrogenFuel cell heat exchangeNuclear engineeringOxygen ions

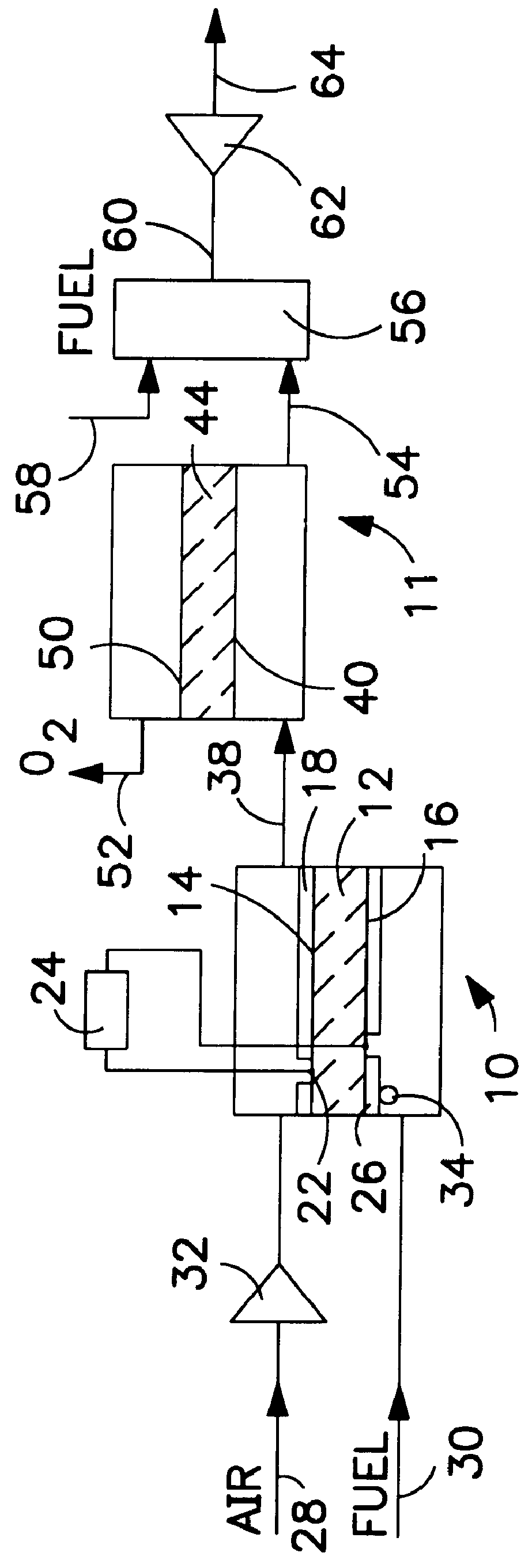

An integrated system utilizing a solid oxide fuel cell and at least one ion transport reactor to generate electric power and a product gas by delivering an oxygen-containing gas, typically air, to a first cathode side of the solid oxide fuel cell and delivering a gaseous fuel to a first anode side. Oxygen ions are transported through a membrane in the fuel cell to the first anode side and exothermally react with the gaseous fuel to generate electric power and heat. The heat and oxygen transport produces a higher-temperature, reduced-oxygen-content gaseous retentate stream exiting the cathode side of the solid oxide fuel cell which is delivered to a first ion transport reactor where a substantial portion of the residual oxygen is transported through an oxygen selective ion transport membrane. A product gas stream is then recovered.

Owner:PRAXAIR TECH INC

Method for preparing rare-earth system sintered magnet

InactiveUS6187259B1Improve magnetic propertiesEasy to produceInorganic material magnetismInductances/transformers/magnets manufactureChemical reactionSintered magnets

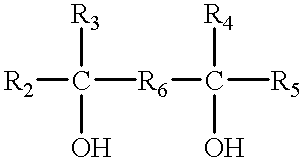

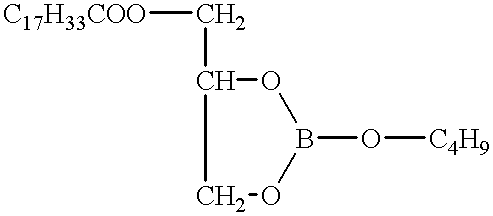

The object of the present invention is to provide rare-earth system sintered magnets such as R-Fe-B system or R-Co system having excellent magnetic properties, unique configuration of a small size, thin wall thickness and intricate geometry. With the method for preparing the present invention, a granulation of alloy powders can be achieved easily, a chemical reaction between rare-earth system and binder substances can be suppressed, so that the residual oxygen and carbon levels in the sintered products can be reduced. Moreover, by this production method, the flowability and lubricant capability during the forming process can be improved. The dimension accuracy and productivity are also enhanced. A certain type of binder is added to rare-earth alloy powders and kneaded into a slurry state. The slurry is then formed into granulated powders by spray-dryer equipment. The thus granulated powders are molded, and sintered through a powder metallurgy technique.

Owner:HITACHI METALS LTD

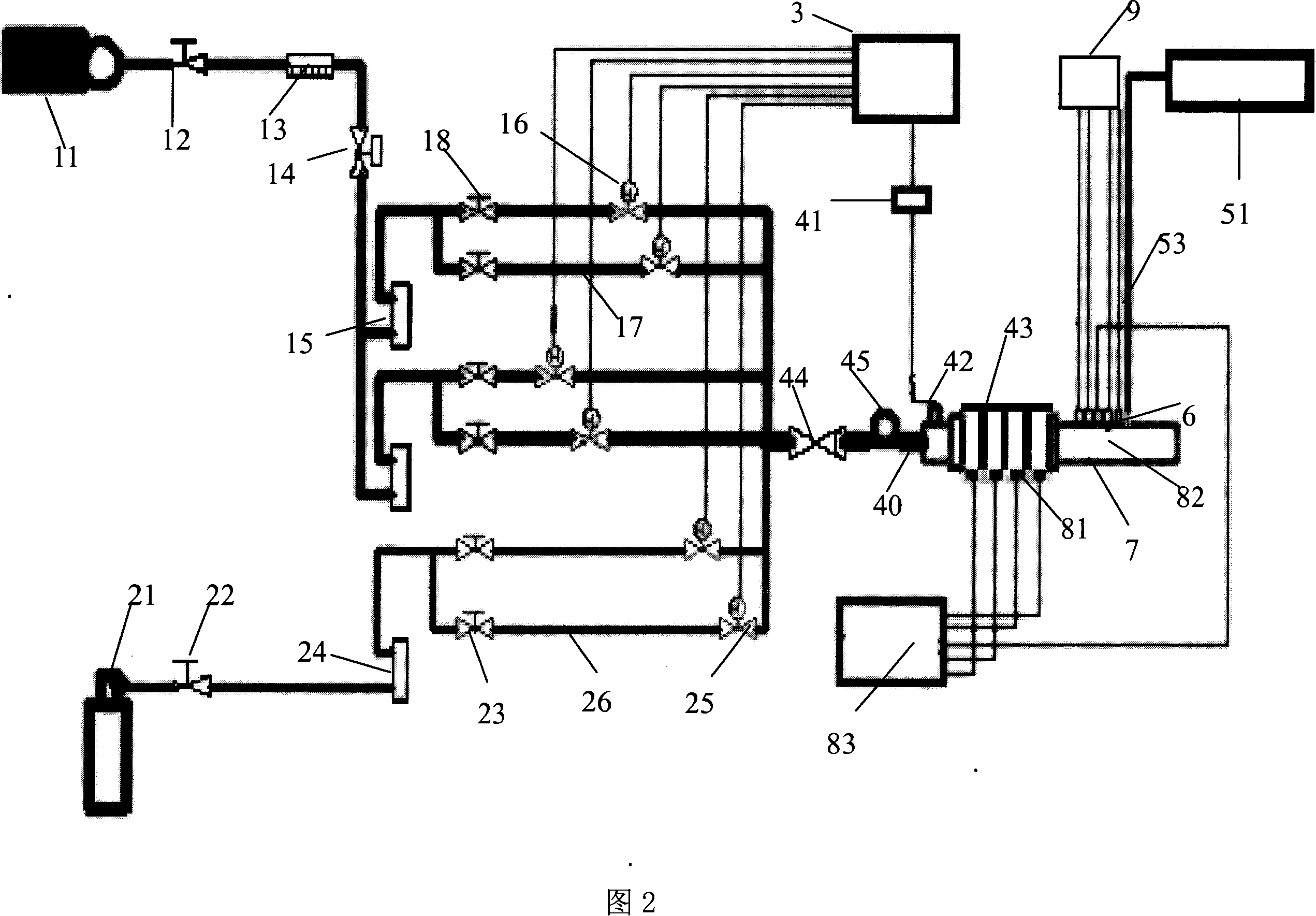

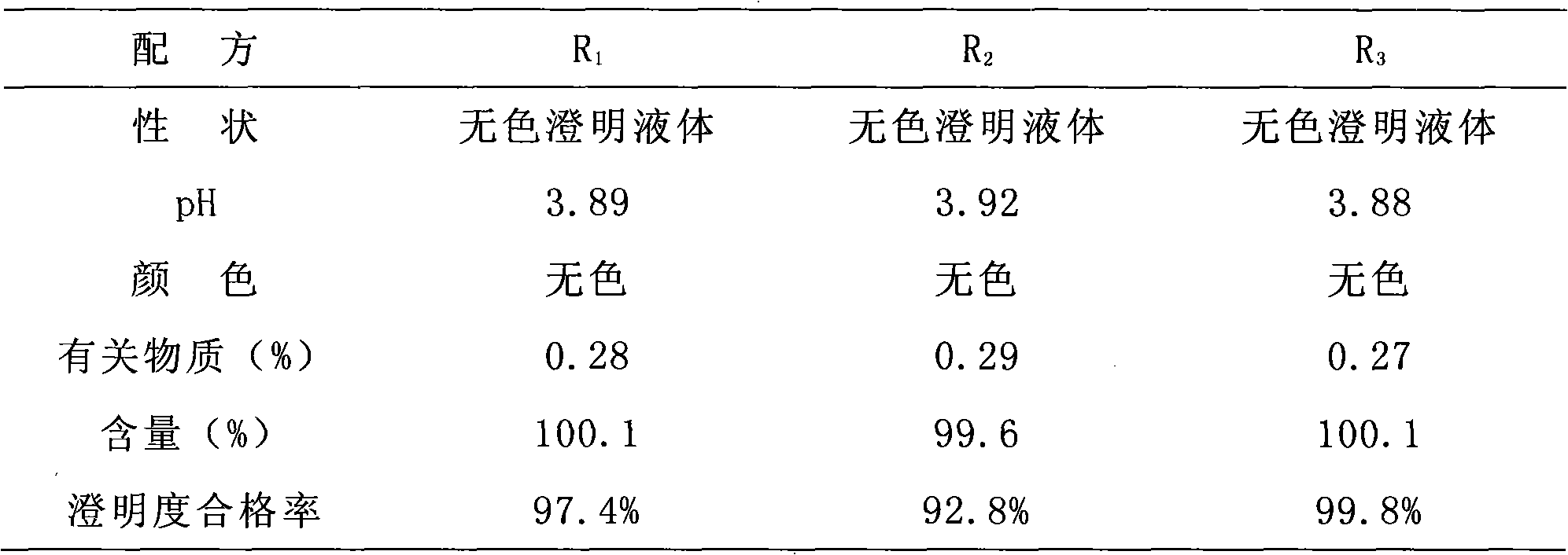

Starting and shutdown control method for proton exchange membrane fuel cell

InactiveCN103259031AReduce voltageReduce time consumptionFuel cell auxillariesLoad circuitElectrical battery

The invention provides a starting and shutdown control method for a proton exchange membrane fuel cell. According to the method, a whole fuel cell stack is divided into a plurality of cell modules; each cell module is connected with a modularized discharging circuit which is composed of a control switch, an auxiliary load and a crystal diode in mutual series connection; each modularized discharging circuit and a main load circuit are in series connection and are respectively connected with the cathode end and the anode end of the fuel cell; an air source is connected with the anode end of the fuel cell through an air blow-down valve; and air is used to purge residual hydrogen at the anode. During starting control, hydrogen is used to purge the anode, and the auxiliary load is used to control the voltage of the cell; and during shutdown control, introduction of air and introduction of hydrogen are successively stopped, a closed system of the auxiliary load is used for discharging, and introduction of air is cooperatively used for purging of the anode. The invention has the following advantages: consumption of time during shutdown of the fuel cell is reduced; the concentration of residual oxygen at the cathode is lowered down; reversal of poles of a single cell in the modules is prevented, and the phenomenon of reversal of poles of the fuel cell in the processes of shutdown discharging and air purging is prevented; and the system of the fuel cell is more simplified and is convenient to operate.

Owner:WUHAN UNIV OF TECH

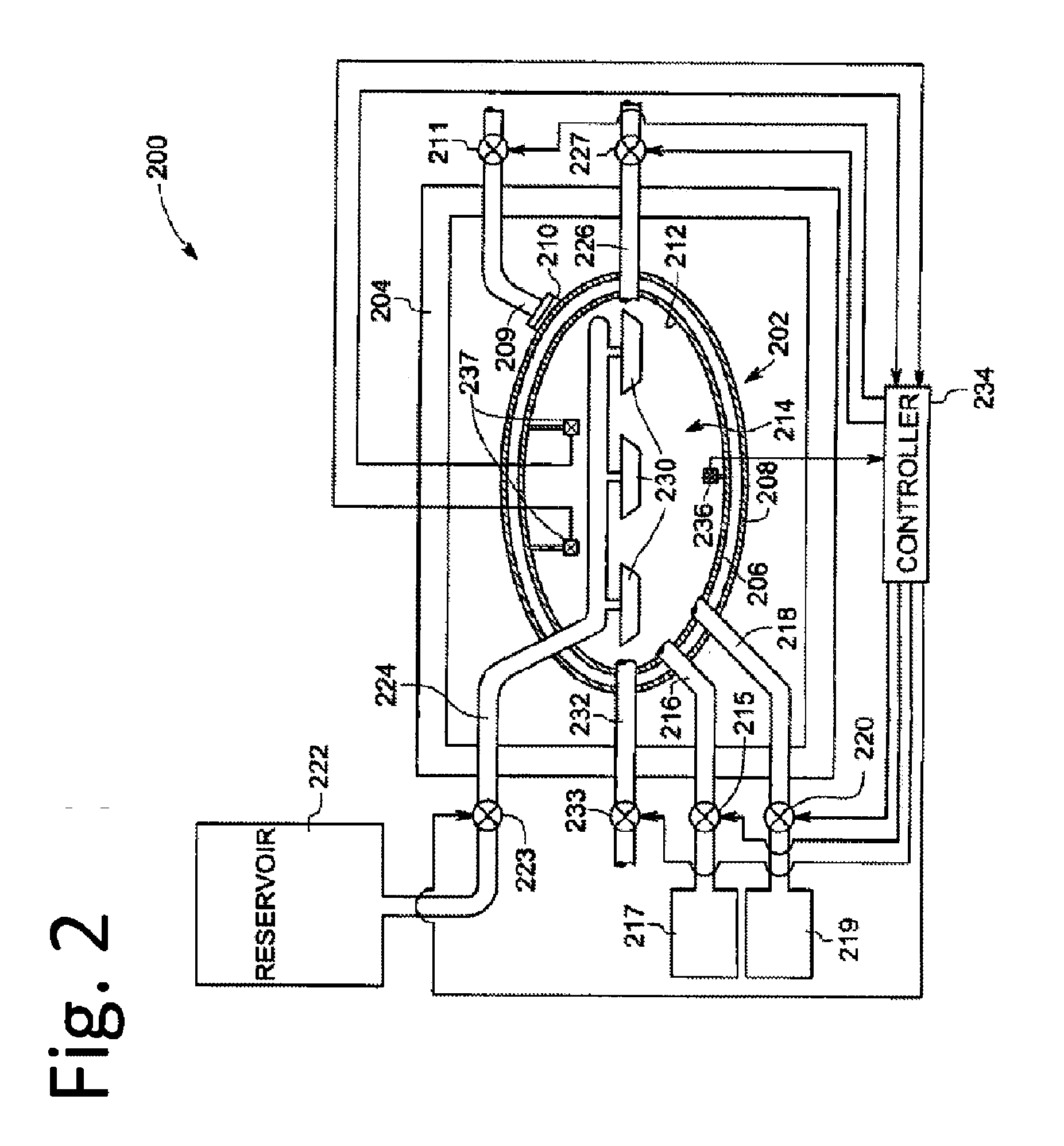

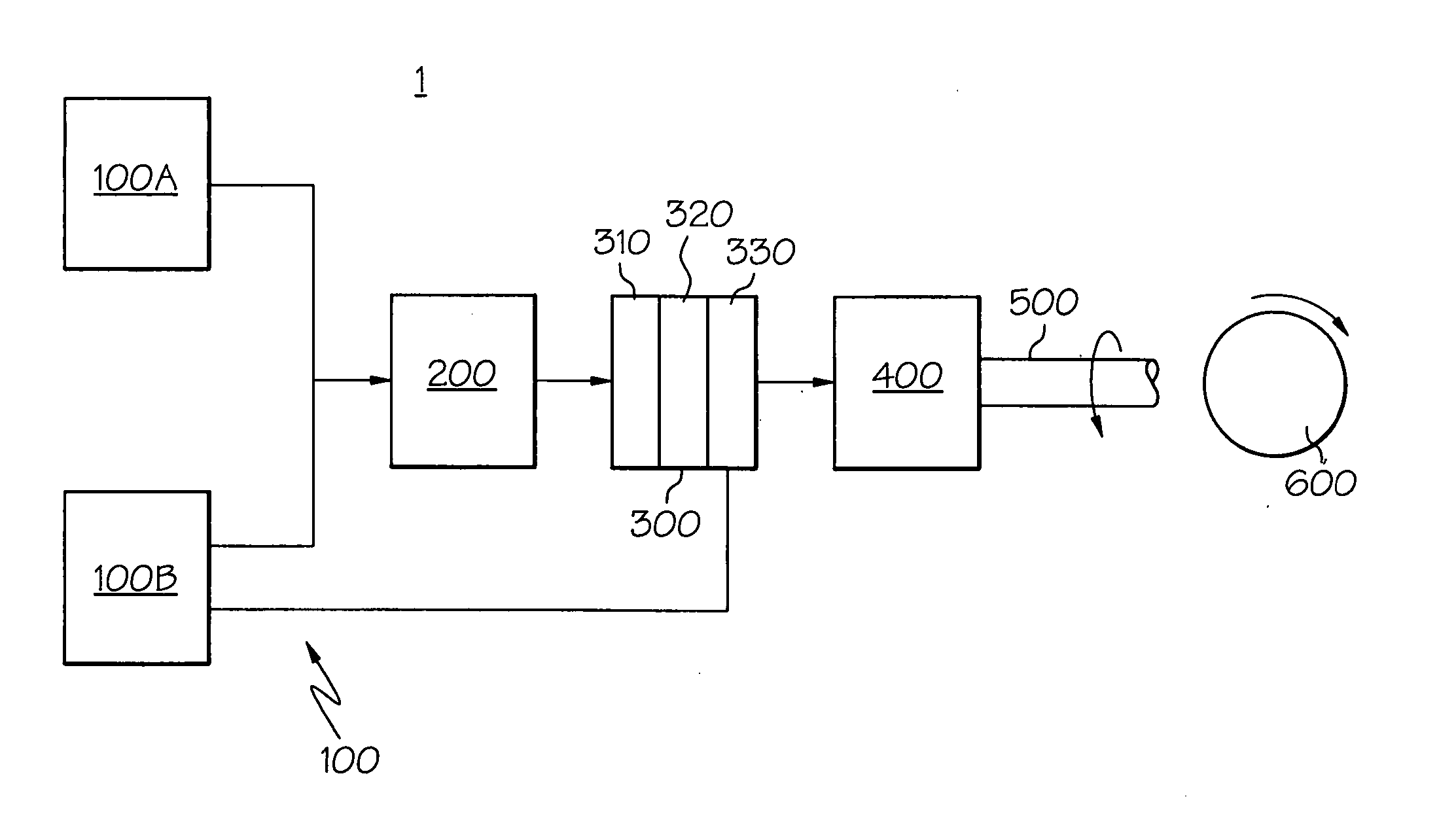

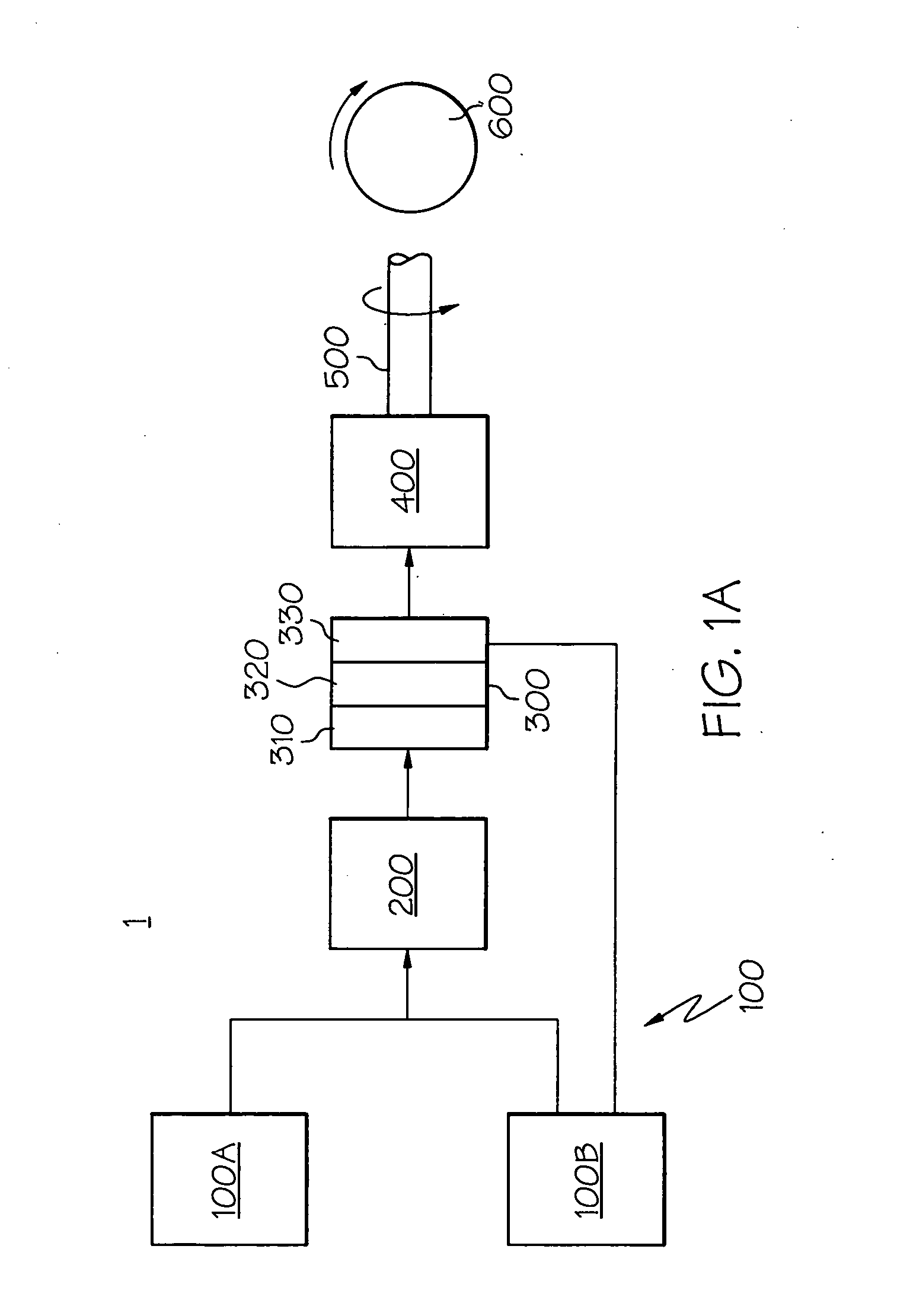

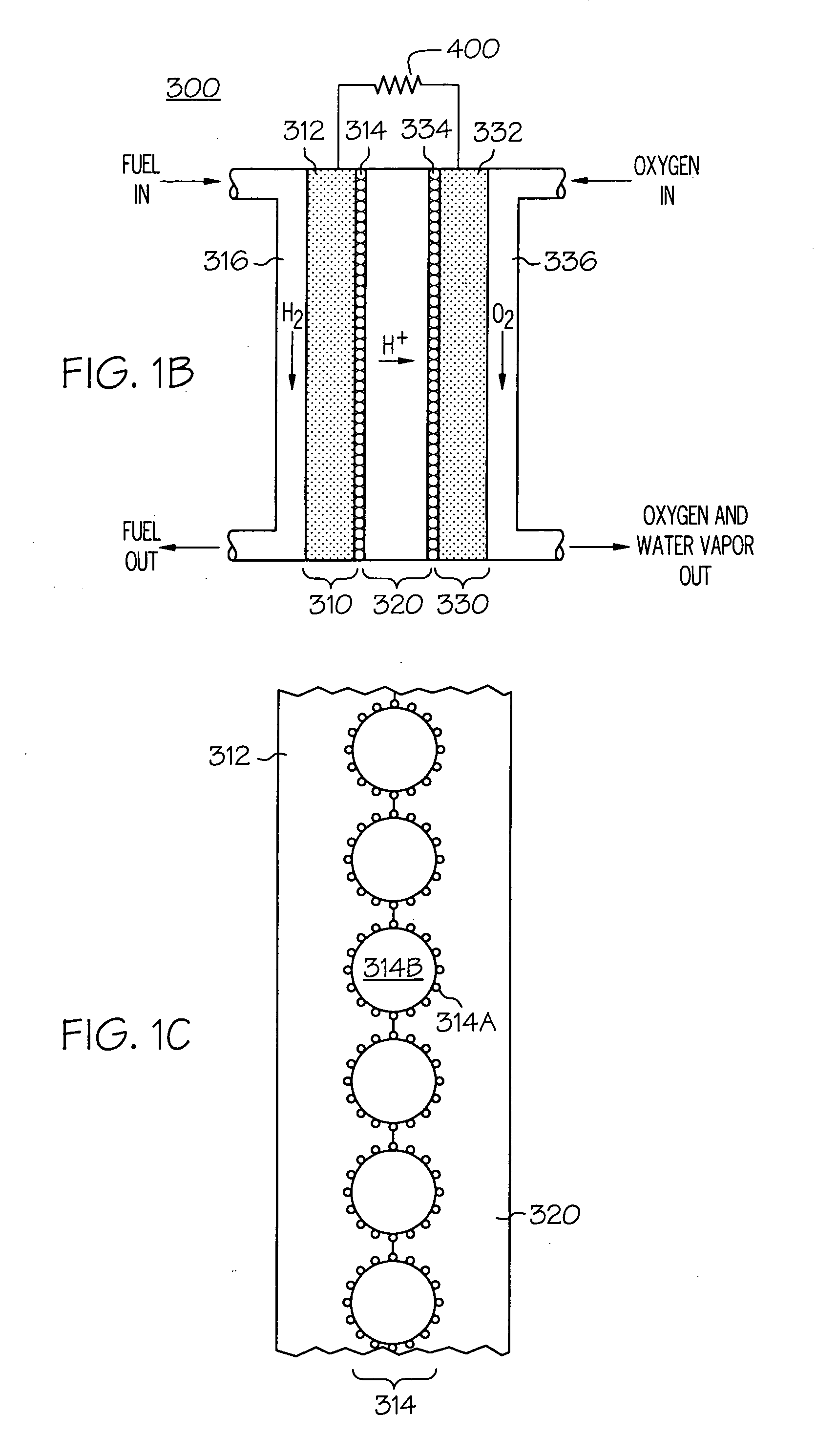

Fuel cell shutdown and startup using a cathode recycle loop

InactiveUS6939633B2Good low temperatureFuel cell heat exchangeSolid electrolyte fuel cellsHydrogenFuel cells

A method and device for operating a fuel cell system. A recirculation loop coupled to a fuel cell cathode ensures that fluids passing through the cathode are recycled, thereby enabling reaction between residual oxygen in the recycled fluid and fuel that has been introduced into the recirculation loop until substantially all of the oxygen is reacted, leaving a substantially oxygen-free, predominantly nitrogen compound in the cathode and related flowpath. Thereafter, this compound can be redirected to purge the remaining residual hydrogen resident in the fuel cell's anode and related flowpath. While the present invention is usable during any period of system operation, it is especially valuable for operational conditions associated with starting up and shutting down a fuel cell system to inhibit the formation of high voltage potentials that could otherwise damage fuel cell catalysts or catalysts supports.

Owner:GM GLOBAL TECH OPERATIONS LLC

Oxygen removal from contaminated gases

The invention relates to a method for achieving low oxygen levels in a natural gas stream without the use of a catalytic system. In one embodiment, the method comprises: membrane treatment for the removal of the bulk of CO2 and oxygen in the natural gas feed and the addition of a PSA system using a carbon molecular sieve adsorbent for the adsorption of residual oxygen.

Owner:GUILD ASSOCS

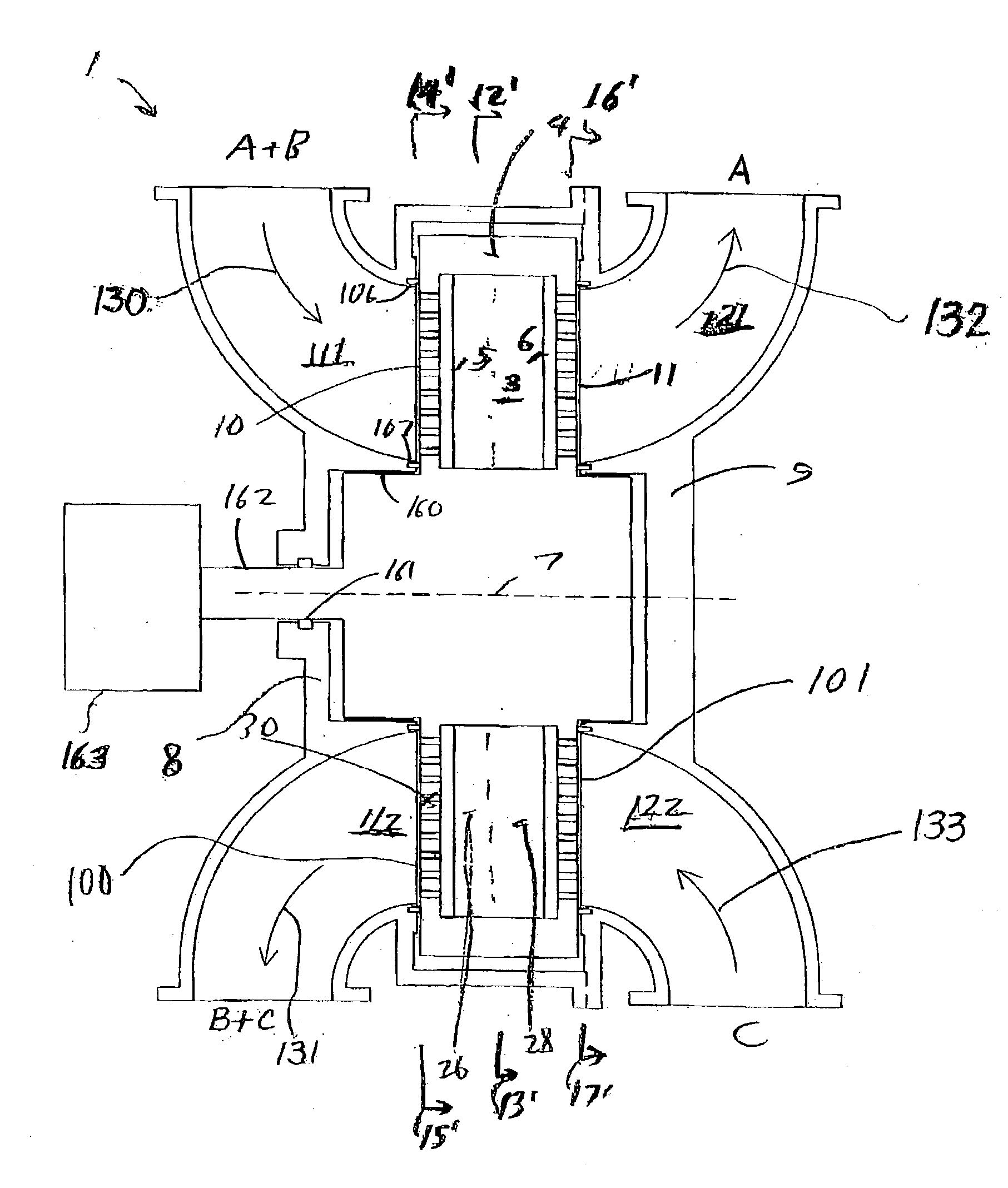

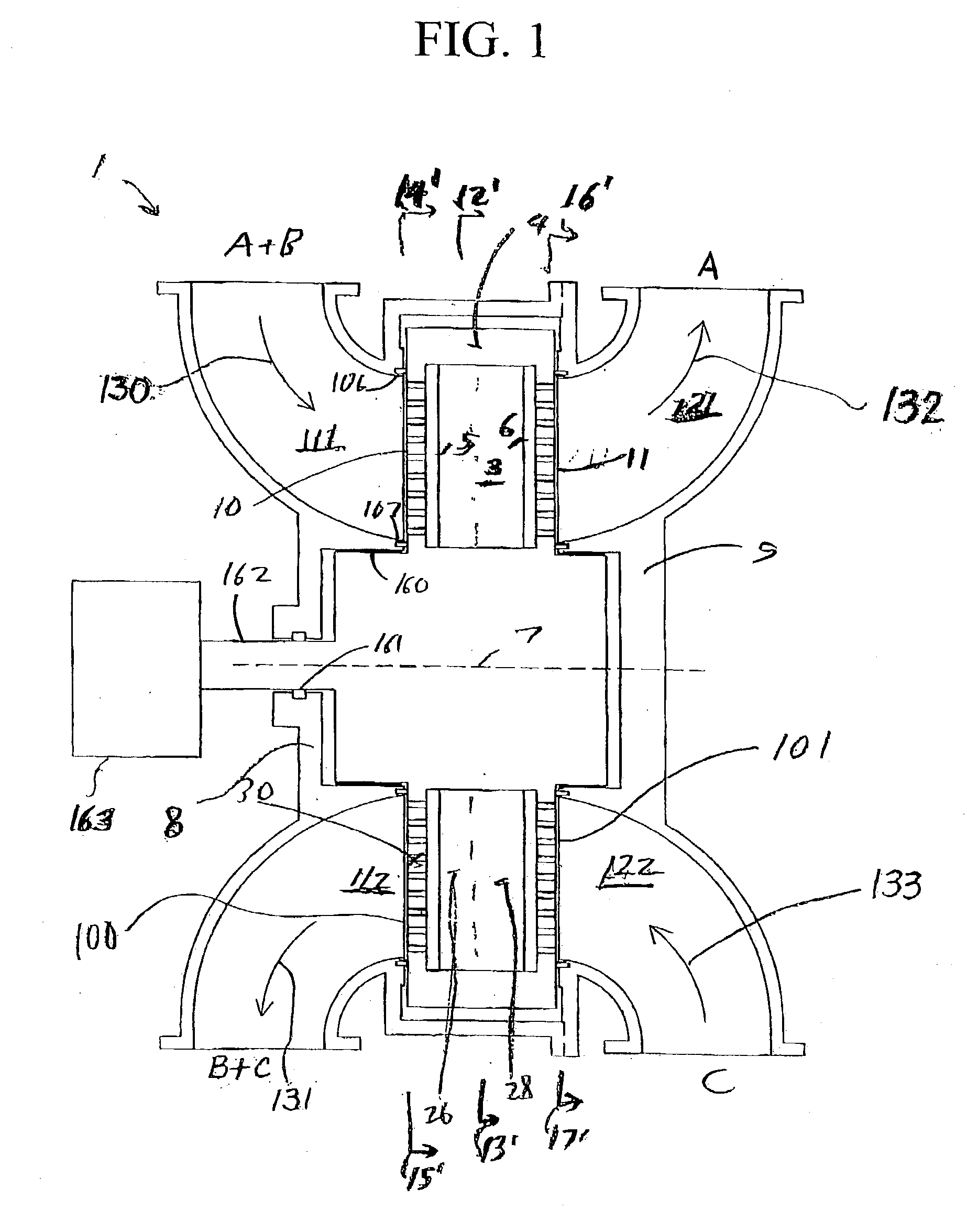

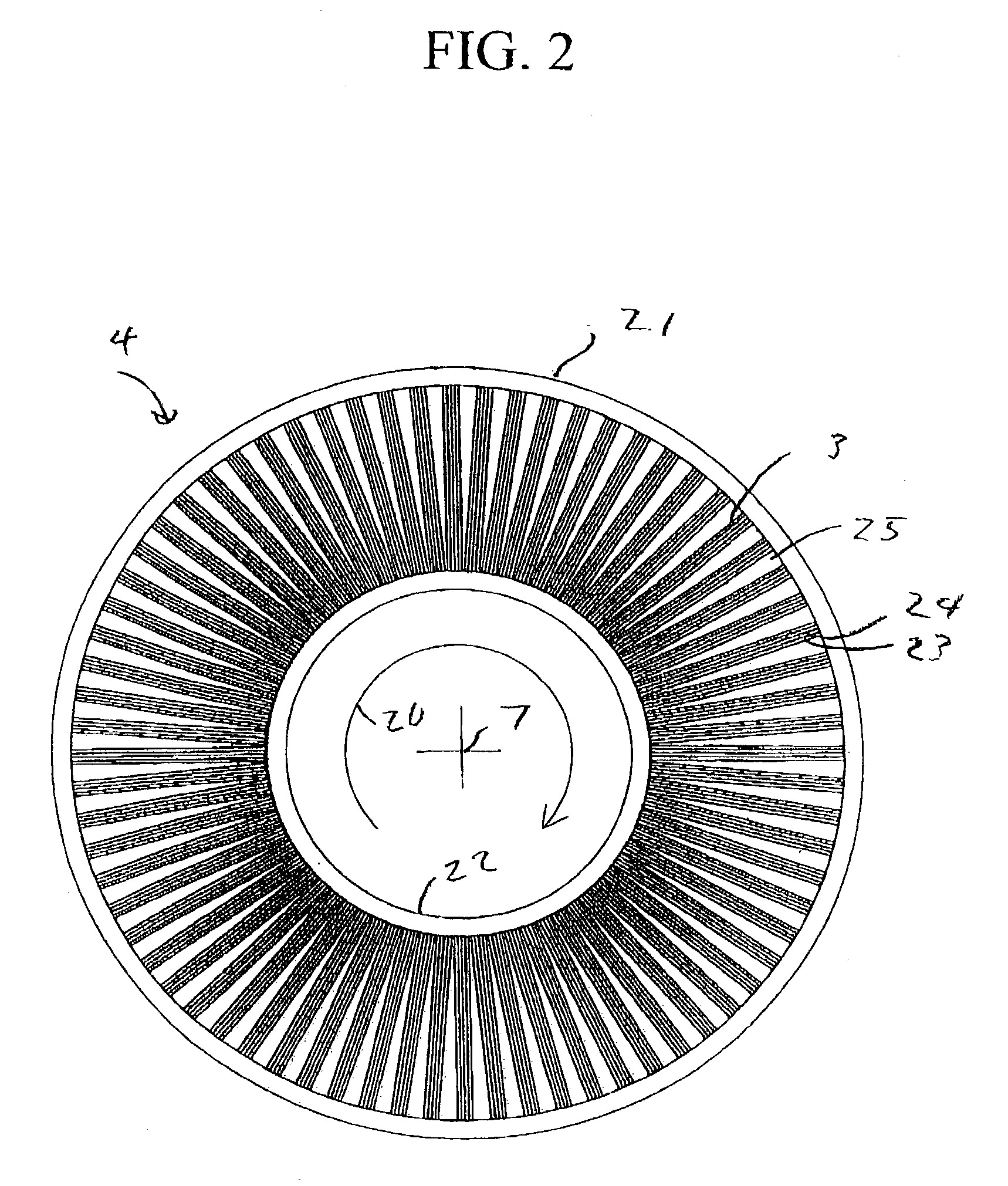

Gas separation by combined pressure swing and displacement purge

InactiveUS20040011198A1Inhibitory responseFacilitate rapid changeGas treatmentIsotope separationSyngasAtmospheric air

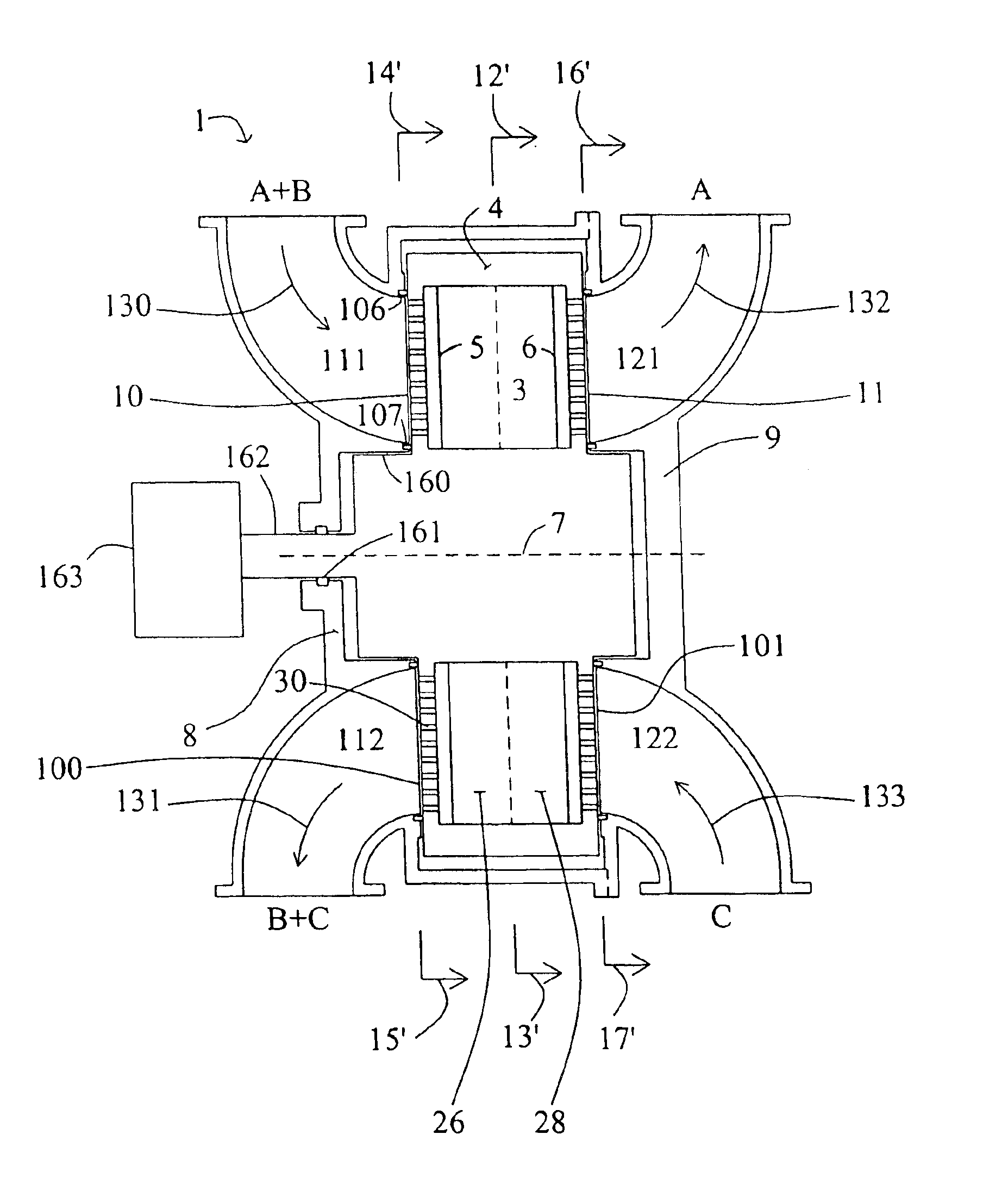

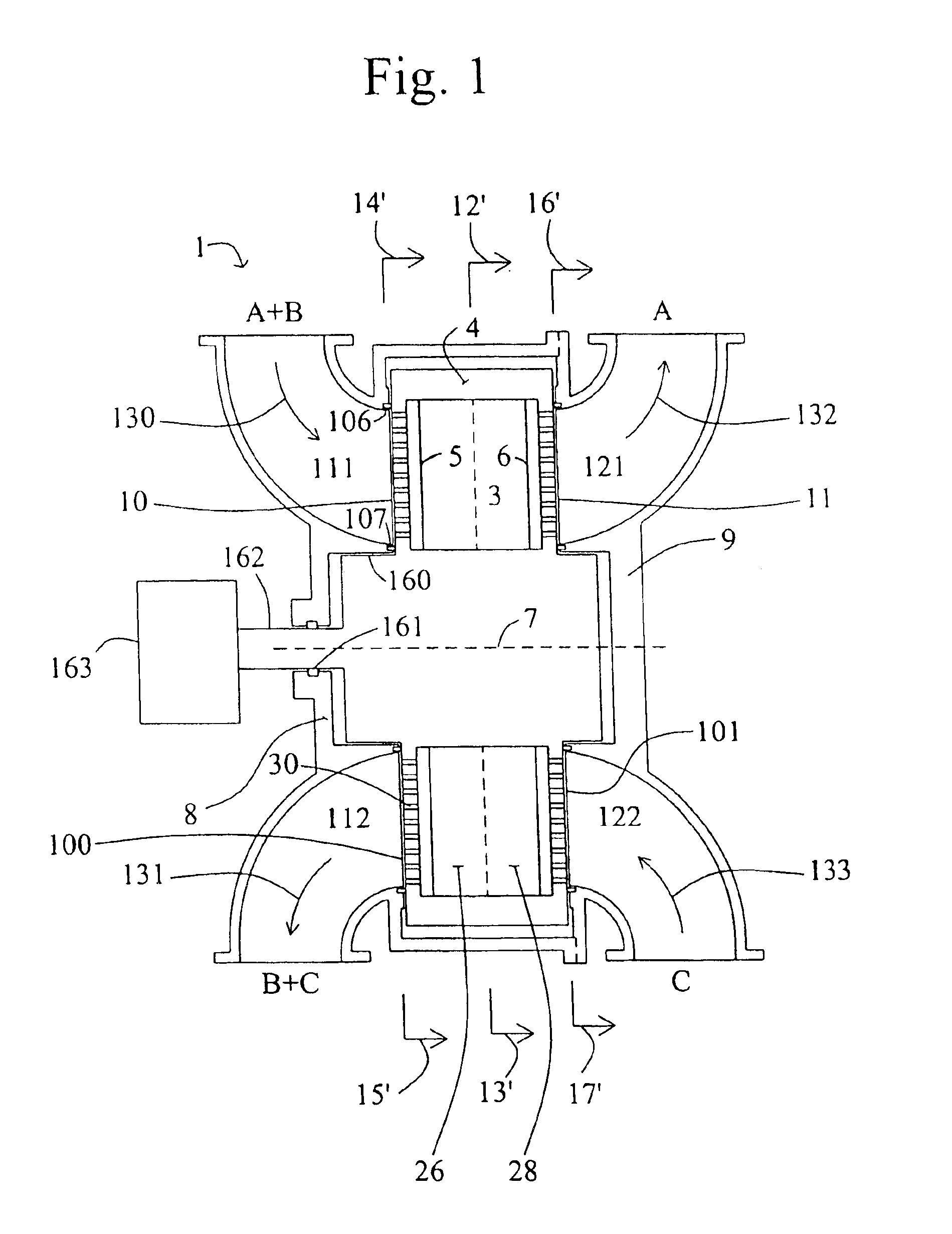

The present disclosure relates to systems and processes for adsorptive gas separations where a first gas mixture including components A and B is to be separated so that a first product of the separation is enriched in component A, while component B is mixed with a third gas component C contained in a displacement purge stream to form a second gas mixture including components B and C, and with provision to prevent cross contamination of component C into the first product containing component A, or of component A into the second gas mixture containing component C. The invention may be applied to hydrogen (component A) enrichment from syngas mixtures, where dilute carbon dioxide (component B) is to be rejected such as directly to the atmosphere, and with preferably nitrogen-enriched air as the displacement purge stream containing residual oxygen (component C).

Owner:AIR PROD & CHEM INC

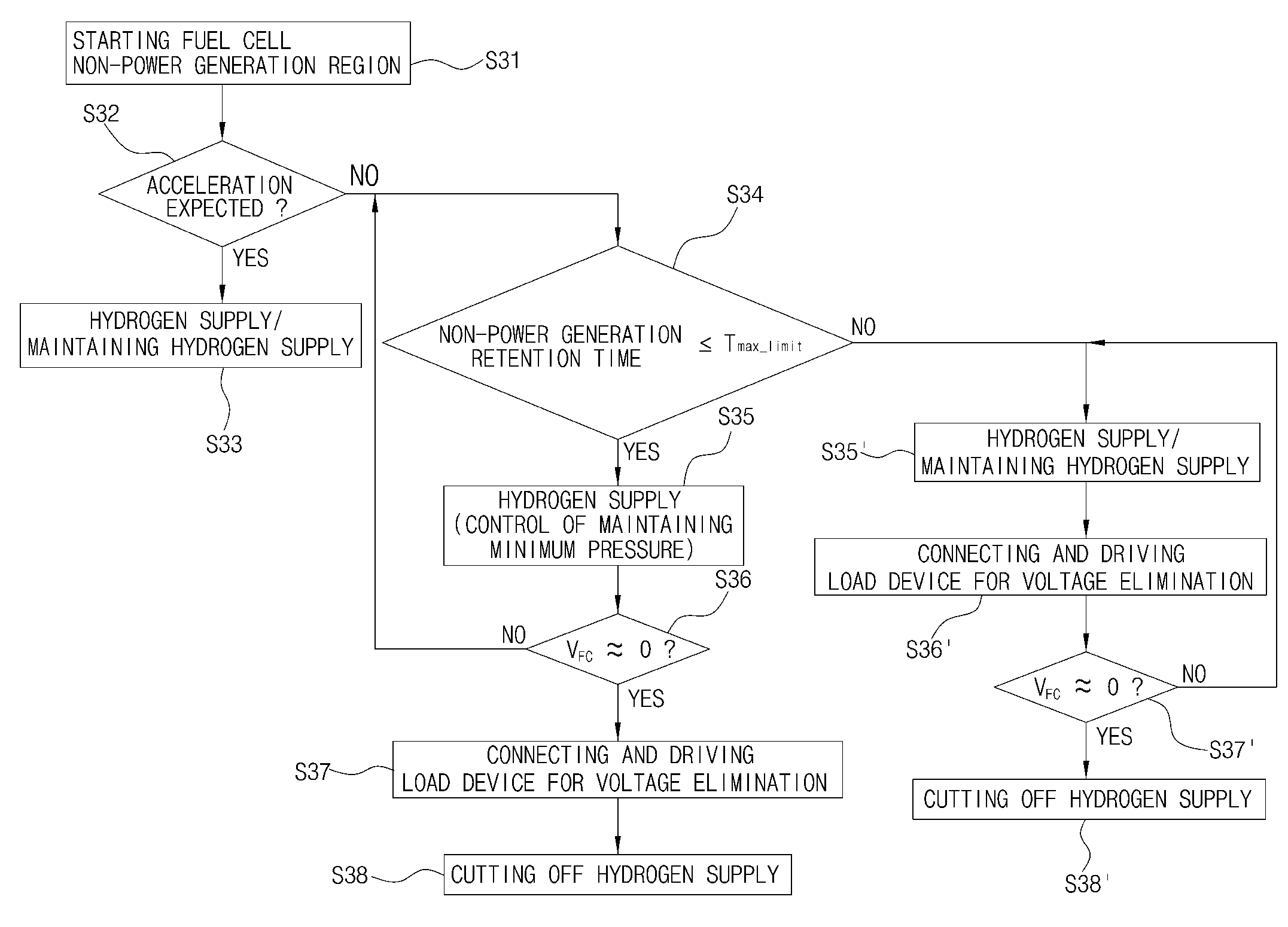

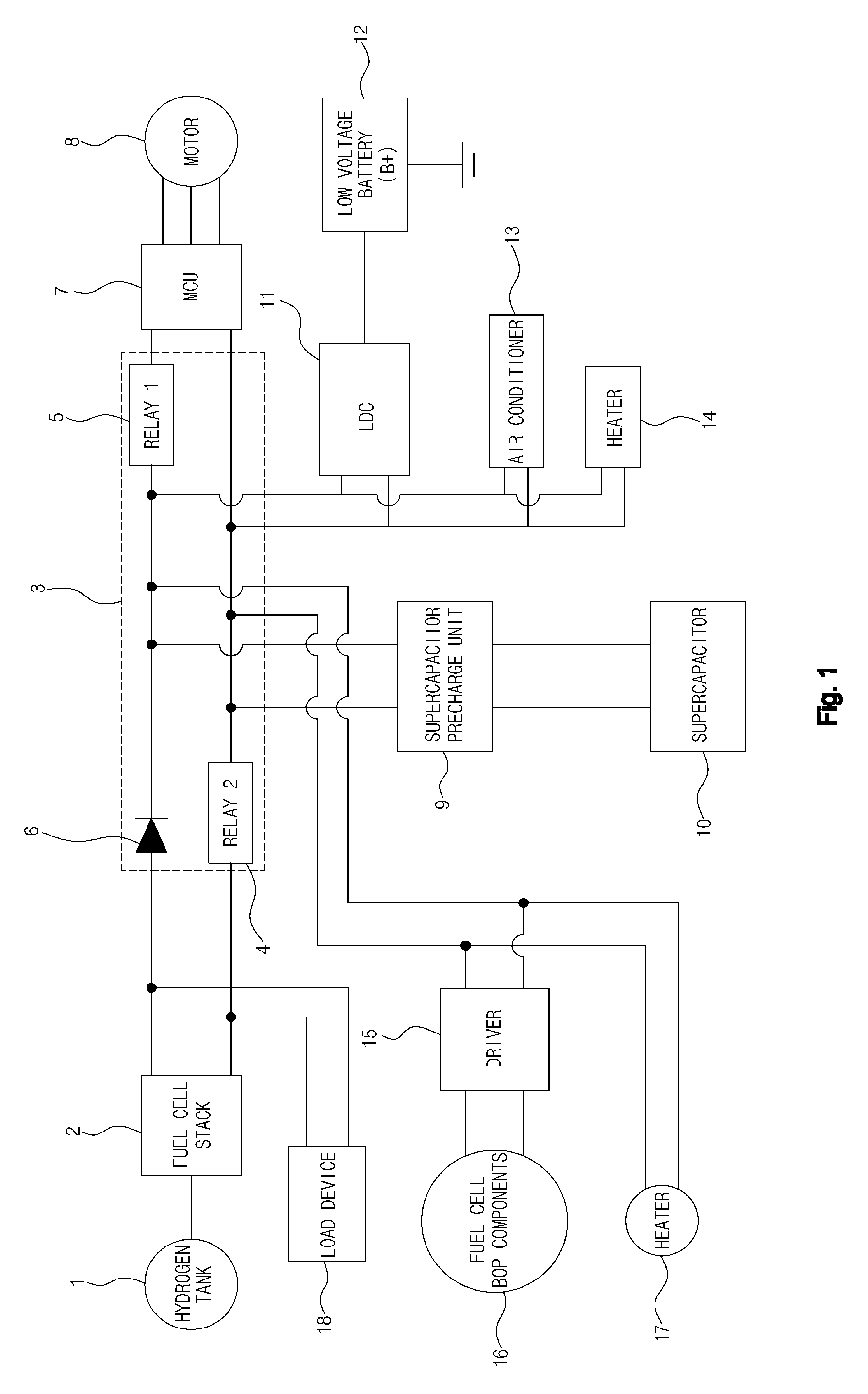

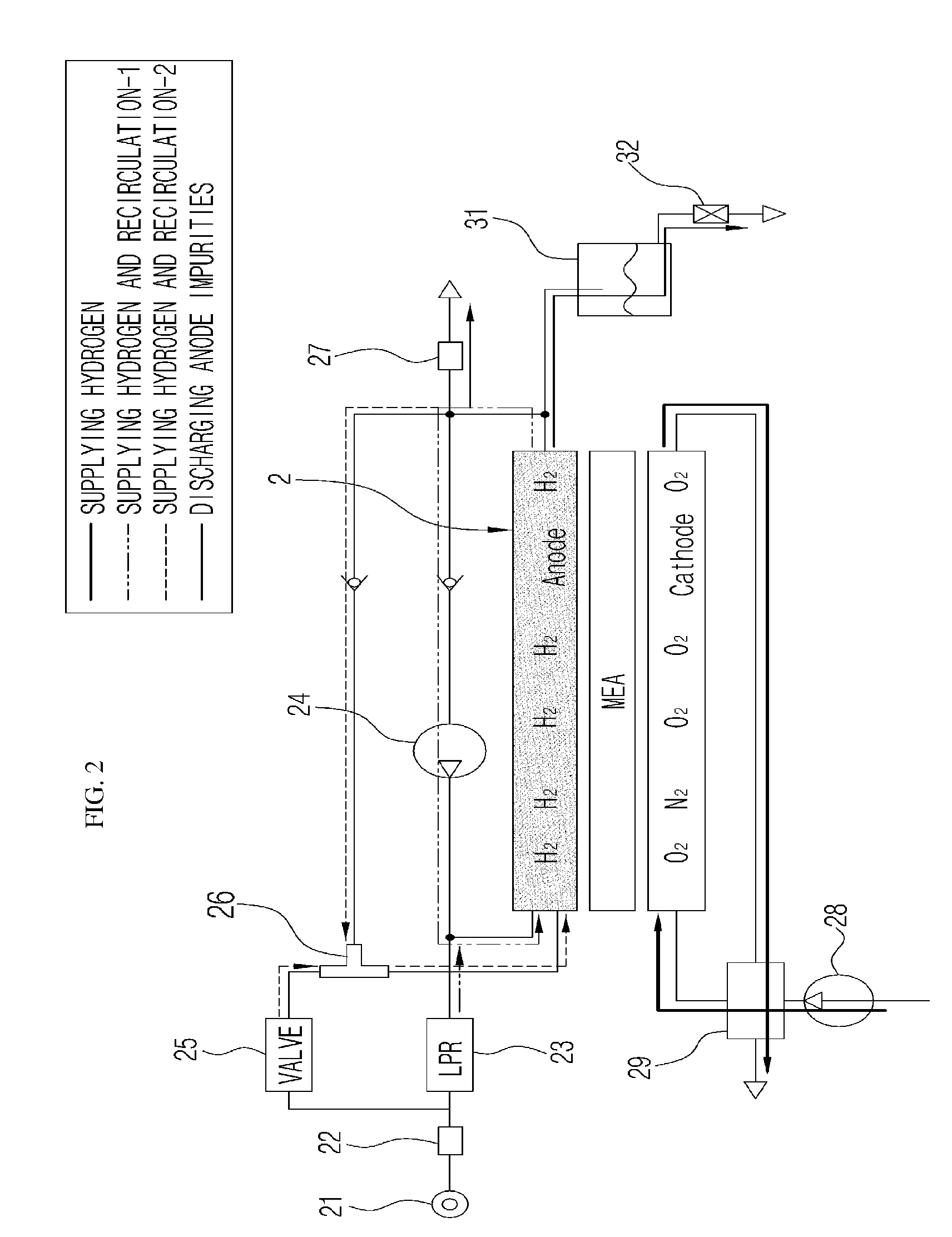

Idle stop-start control method of fuel cell hybrid vehicle

ActiveUS20100009219A1Improve fuel efficiencyIncrease volumeElectrical controlFuel cell auxillariesRegenerative brakeIdle speed

The present invention provides an idle stop-start control method of a fuel cell hybrid vehicle including a fuel cell as a main power source and a storage means as an auxiliary power source, in which air and hydrogen supply is cut off during low power operation where the efficiency of the fuel cell is low and during regenerative braking such that residual oxygen and hydrogen are consumed to drop the voltage of a fuel cell stack, thus stopping the operation of the fuel cell.

Owner:HYUNDAI MOTOR CO LTD

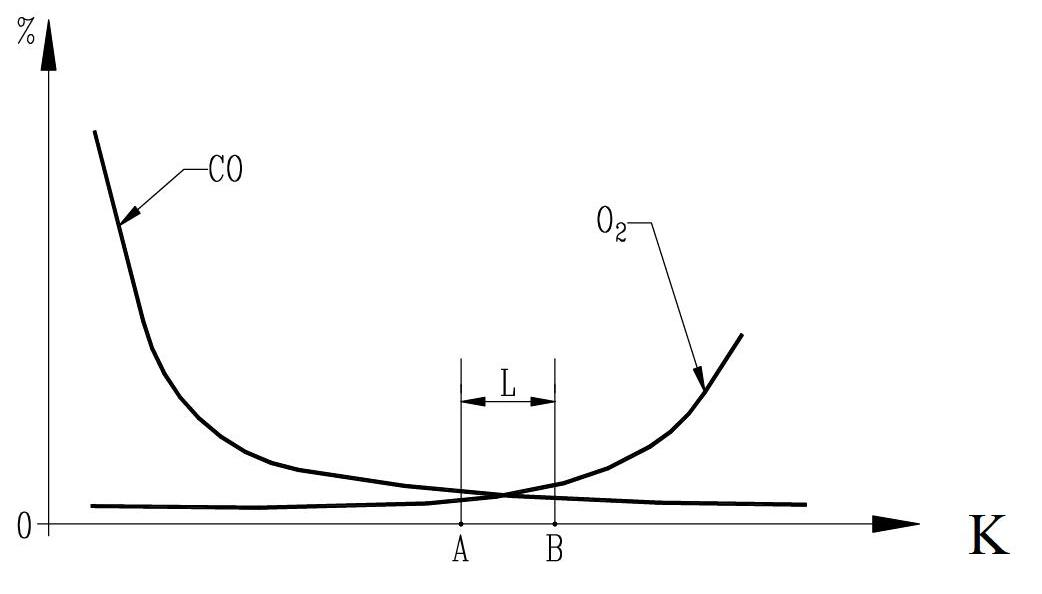

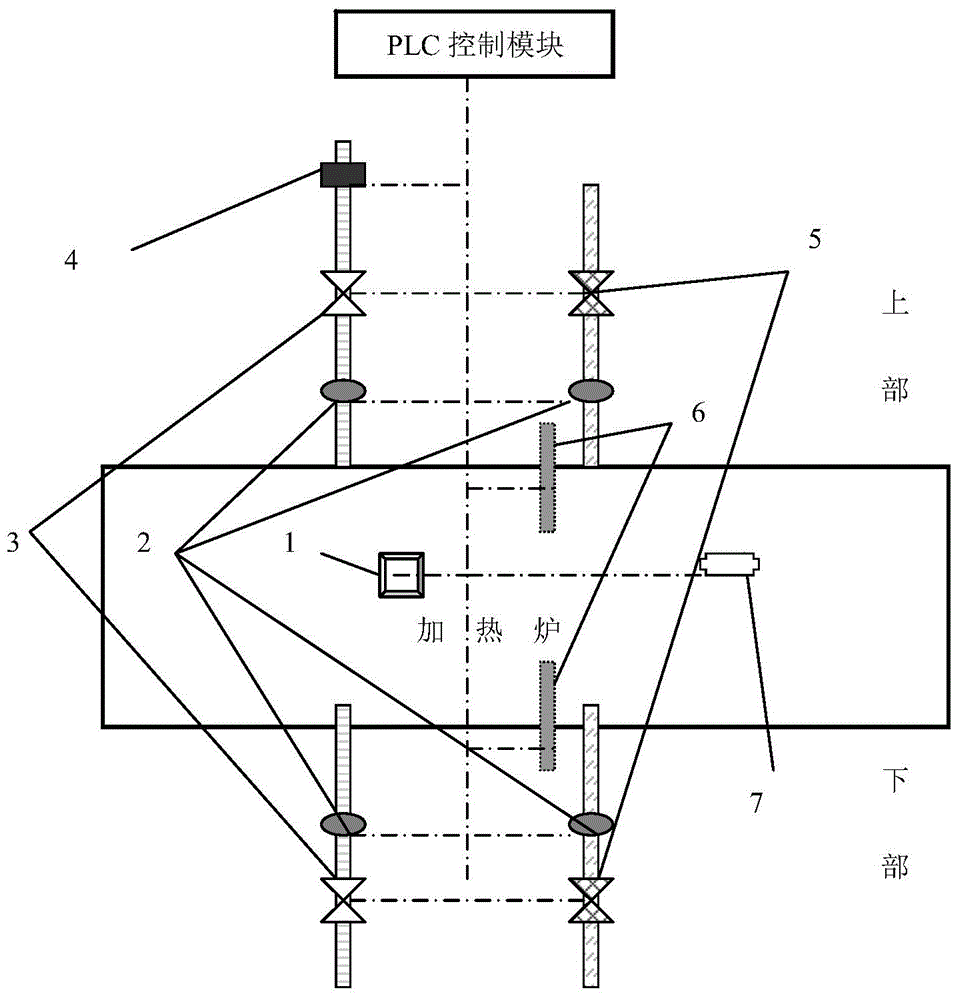

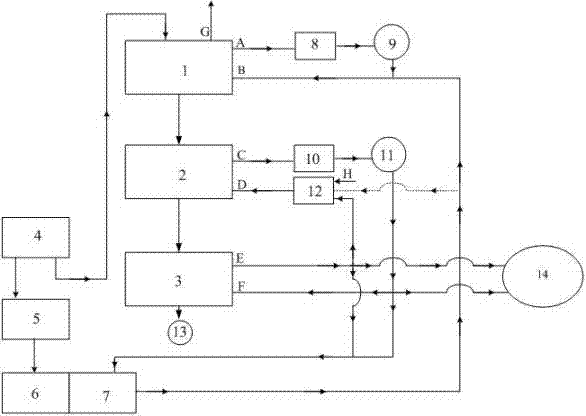

Intelligent dynamic combustion atmosphere controller

ActiveCN102654286AOvercoming calorific valueOvercoming distractionsFuel supply regulationProcess engineeringHeating furnace

The invention provides an intelligent dynamic combustion atmosphere controller, comprising a combustible matter content detector, a residual oxygen amount analyzer, a smoke temperature detector, a PLC (pogrammable logic controller), and a touch screen, wherein an input end of the PLC is connected with the combustible matter content detector, the residual oxygen amount analyzer and the smoke temperature detector; an output end of the PLC is connected with an air flow adjusting valve; combustible matter content, residual oxygen amount and smoke temperature signals, which are collected in smoke in real time, are sent to the PLC; the PLC prompts a combustion atmosphere state by calculating, comparing and analyzing according to set parameters, and controls the air flow adjusting valve to automatically adjust an air-fuel ratio, so as to accurately control combustion atmosphere; and a combustion type, a control mode, a control parameter and an alarming parameter can be set through the touch screen. The intelligent dynamic combustion atmosphere controller has the advantages as follows: the combustible matter content, the residual oxygen amount and the smoke temperature in the smoke in combustion equipment, such as a heating furnace, a boiler and the like, are measured and analyzed, so that the flow of the combustion air is intelligently adjusted; the air-fuel ratio can be automatically adjusted in real time; and the combustion atmosphere can be accurately controlled.

Owner:WUXI LONGSHAN TECH

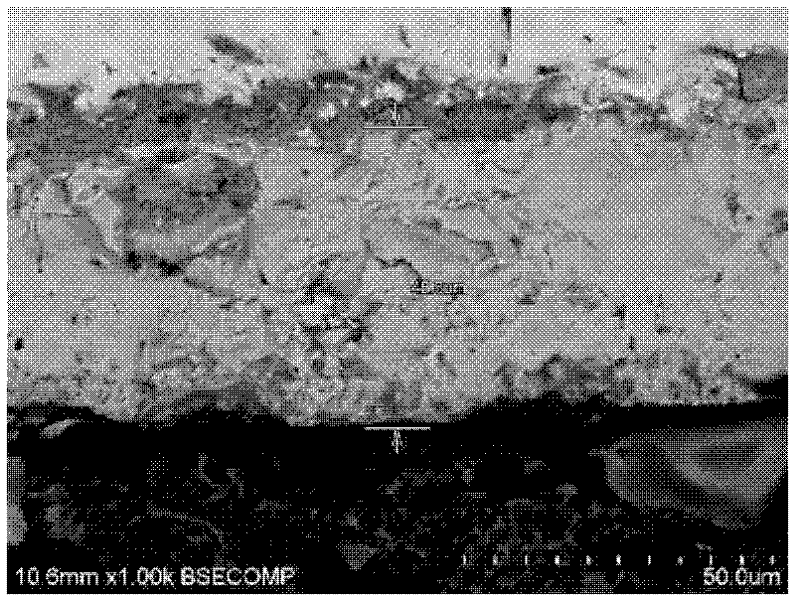

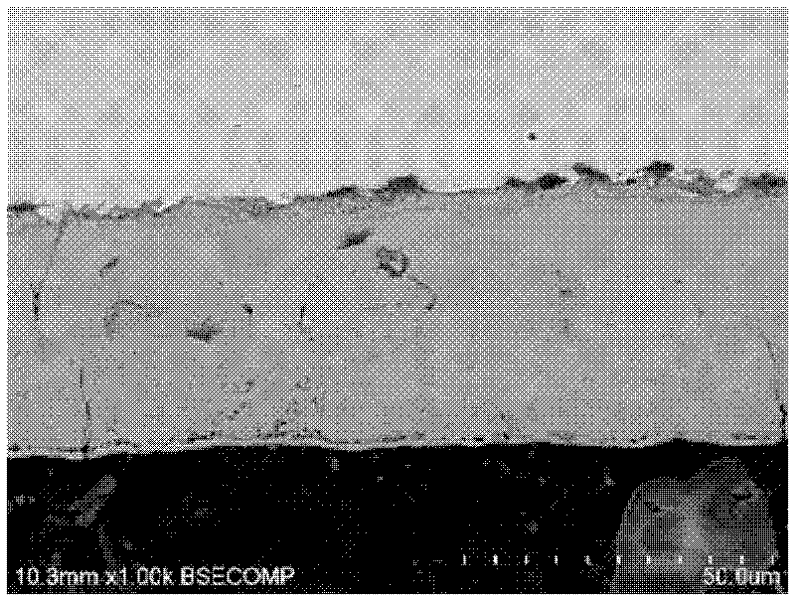

Control method for coast atmospheric corrosion resistant scale on surface of boat deck

ActiveCN102367546AImprove surface qualityIncrease productivityTemperature control deviceWork treatment devicesHull structureStructural composition

The invention discloses a control method for coast atmospheric corrosion resistant scale on the surface of a boat deck, which belongs to the field of steel for hull structures. According to the invention, the structure and thickness of scale on the surface of a boat deck is controlled by optimizing production processes for boat decks. The method comprises the following key points: controlling parameters of heating temperature, time, residual oxygen and the like for continuous casting billets and reinforcing a de-scaling effect once; controlling the index of chloride ion in water for production, reducing the content of deposited chloride ions in scale and inhibiting corrosive pitting; controlling initial rolling temperature and finishing rolling temperature in the stage of finish rolling, reasonably utilizing a weak water cooling system, increasing the content of Fe3O4 in scale, reducing the content of Fe2O3, retaining a small amount of FeO and enabling the scale to have good plasticity, a bonding force and corrosion resistance. The advantages of the invention are as follows: it does not need to reconstruct existing equipment, and the surface quality and production efficiency of the boat deck can be enhanced through technological optimization; structural composition of the scale is reasonably controlled, which enables the surface of the boat deck to have excellent coast atmospheric corrosion resistance, especially enables corrosive pitting caused by chloride ions to be inhibited, and enables the storage duration of the boat deck in coast environment to be prolonged.

Owner:SHOUGANG CORPORATION

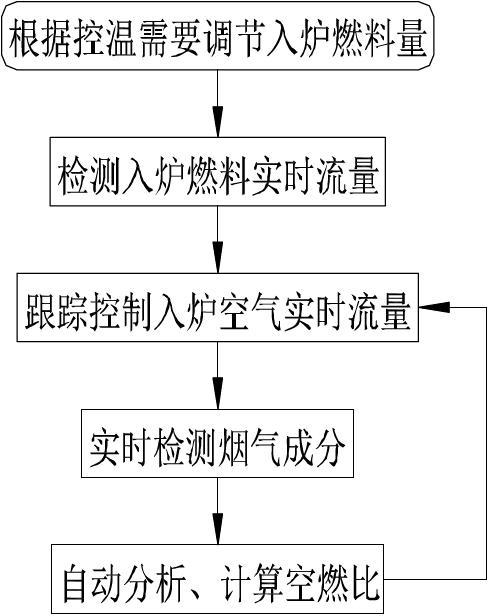

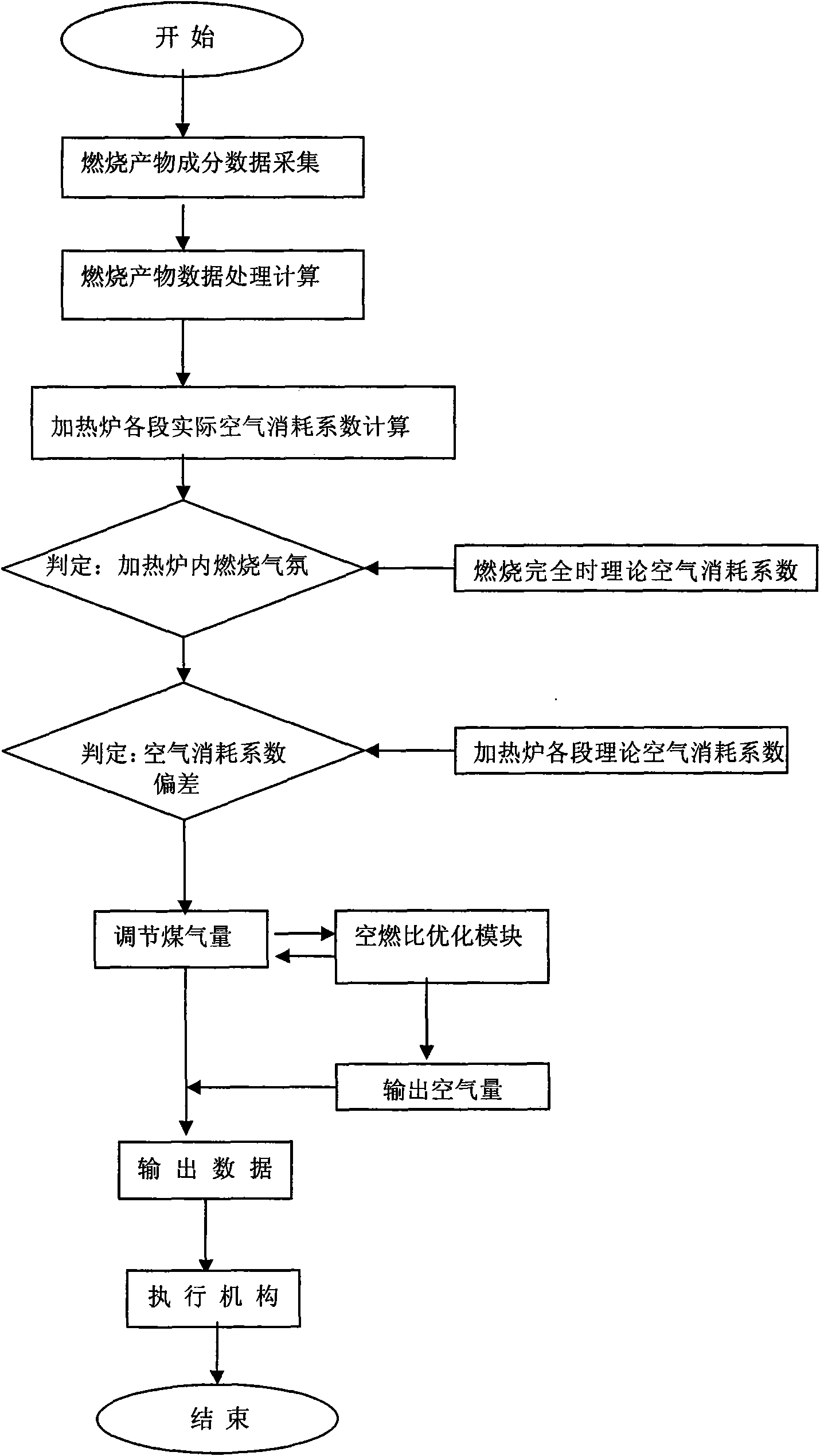

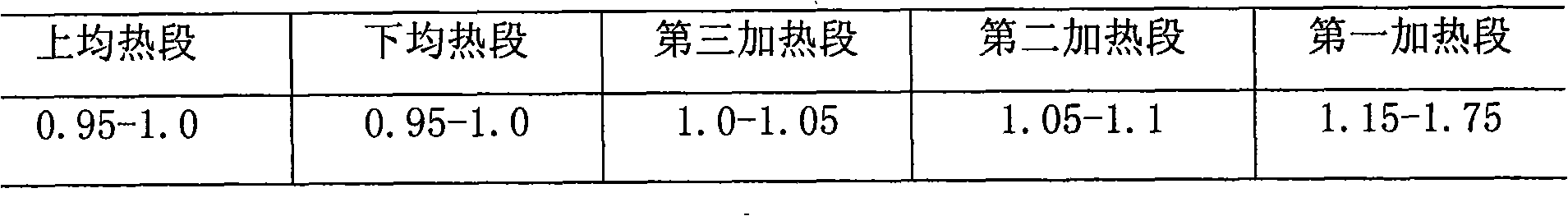

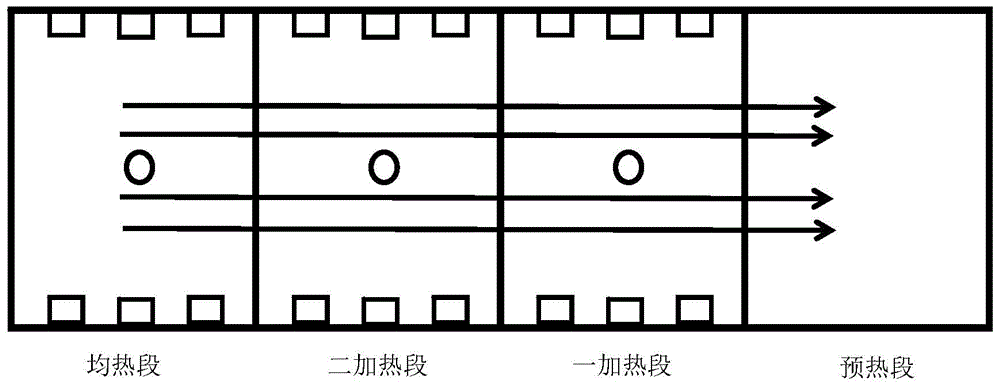

Method for controlling combustion atmosphere in large-scale walking beam type plate blank heating furnace

ActiveCN101561224AReduce burning rateReduce heat lossMaintainance of heating chambersFurnace typesFurnace temperatureComputer control system

The invention relates to a method for controlling combustion atmosphere in a large-scale walking beam type plate blank heating furnace, which belongs to the technical field of fuel combustion of industrial furnaces. A plate blank is heated through a preheating section, each heating section and a soaking section to finish the process of heating and temperature equilibrium; and in the process, a first-level computer control system and a second-level computer control system automatically generate a heating process and automatically set and control the furnace temperature in each section according to original data of the plate blank called from a database; and on the basis of an output control value of a residual oxygen analyzer, the computer control systems calculate the air consumption coefficient of each combustion area, perform dynamic track on the combustion atmosphere in the whole furnace along with the changes of thermal loads, correct the combustion atmosphere according to the actual air-fuel ratio of six combustion areas, adjust the proportion of combustion air and gas, and determine the reasonable air and gas flow to achieve the furnace temperature required by the heating process. The method has the advantages that the condition of furnace gas component changes in the furnace is quantificationally provided for a heating furnace operator in time, so that the combustion in the heating furnace reaches good state; and simultaneously, the energy-saving and environmental protection effects are remarkable.

Owner:SHOUGANG CORPORATION

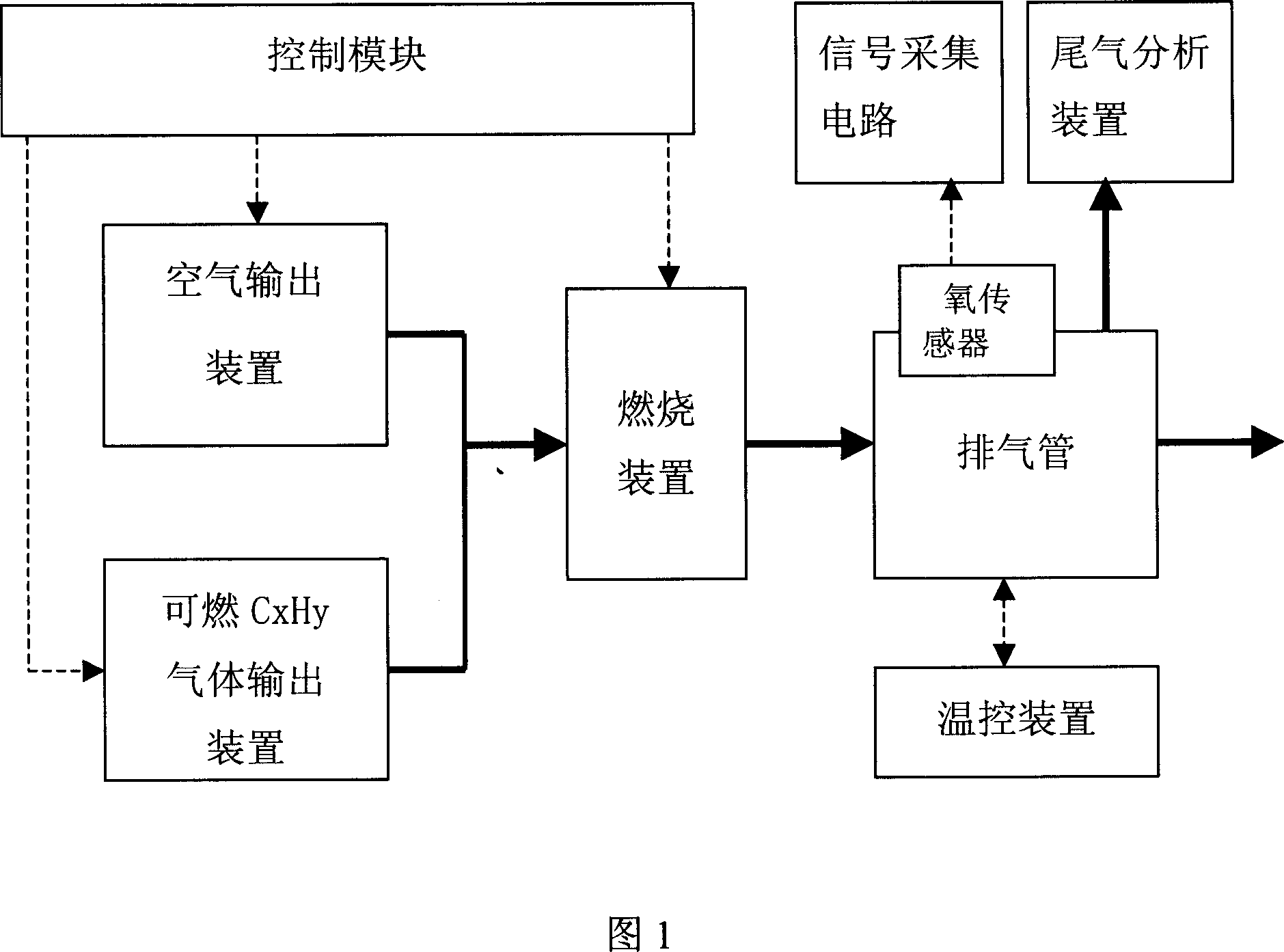

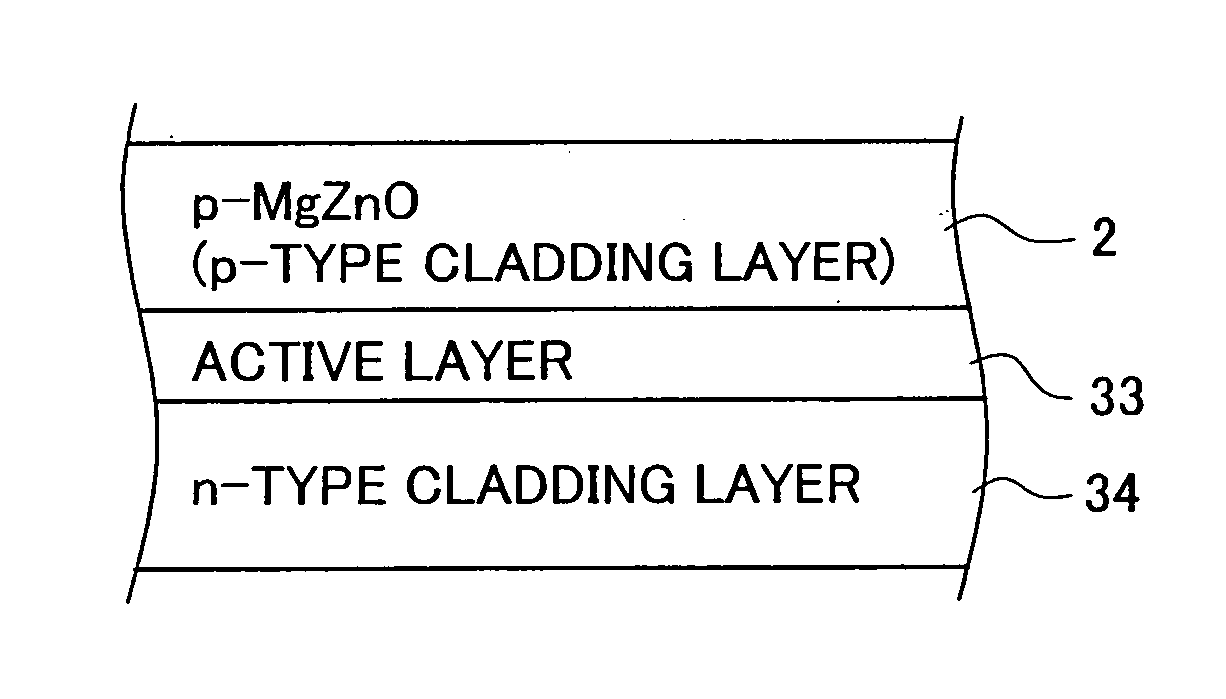

System for testing performance of oxygen sensor in use for car

ActiveCN1959399AEasy to testImplement mutation switchingFuel testingMaterial analysis by electric/magnetic meansTest performanceCombustion chamber

A test system of oxygen transducer used on automobile comprises fuel output unit for mixing fuel with air to generate mixture, combustion unit including ignition element and combustion chamber with air exhaust pipe, oxygen transducer set on air exhaust pipe with its head being inserted into said pipe to sense residual oxygen concentration in tail gas, signal collection unit for receiving signal outputted by oxygen transducer.

Owner:BYD CO LTD

Fuel cell shutdown and startup using a cathode recycle loop

InactiveUS20050058860A1Simple configurationEasy to operateFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsHydrogen

A method and device for operating a fuel cell system. A recirculation loop coupled to a fuel cell cathode ensures that fluids passing through the cathode are recycled, thereby enabling reaction between residual oxygen in the recycled fluid and fuel that has been introduced into the recirculation loop until a reduced voltage level across the fuel cell is achieved. Attainment of the reduced voltage level indicates that the recycled fluid is substantially oxygen-free, yielding an inerting fluid. Thereafter, this compound, followed by air, or air directly can be used to purge the fuel cell's anode and related flowpath during system shutdown. Similarly during system startup, hydrogen can then be introduced into the fuel cell's anode and then air into the cathode and related flowpath for normal operation. The placement of a purge valve allows the anode to be purged with air without re-introducing air into the cathode.

Owner:GM GLOBAL TECH OPERATIONS LLC

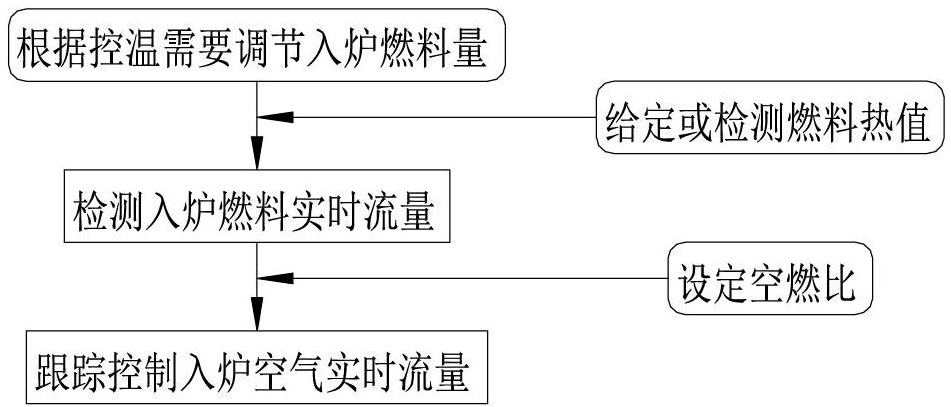

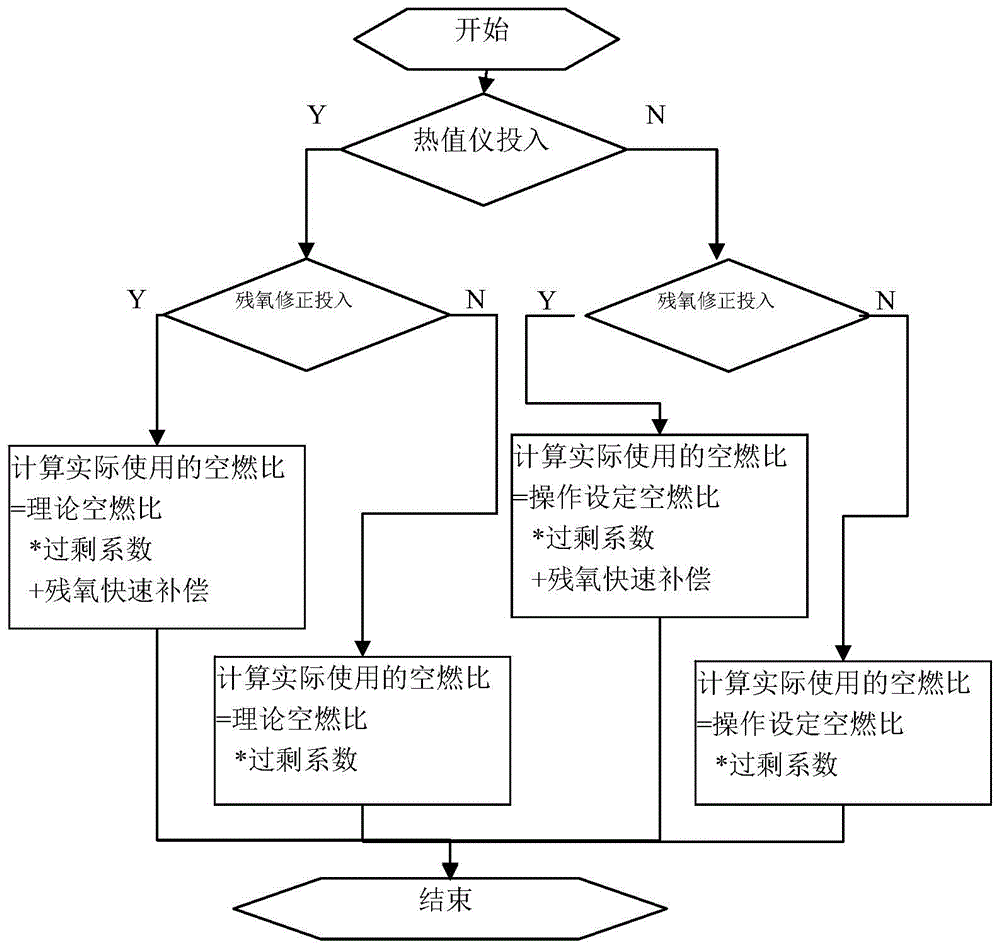

System and method for automatically controlling content of residual oxygen in regenerative heating furnace

The invention discloses a system and method for automatically controlling the content of residual oxygen in a regenerative heating furnace and belongs to the technical field of control over combustion of heating furnaces. The system comprises a computer terminal, a programmable controller, a regulating valve, zirconium oxide analysis meters and a heat value analysis meter. A combustion section of the heating furnace comprises a first heating section, a second heating section and a soaking section, the zirconium oxide analysis meters are installed in the middle portions of the tops of all the sections, and the heat value analysis meter is installed in front of an inlet of a gas main. During combustion of the heating furnace, the actual air-fuel ratios are obtained through calculation according to the theoretical air-fuel ratios of the three sections, and optimal control over the content of the residual oxygen in a hearth is achieved by combining the zirconium oxide analysis meters with the heat value analysis meter for control. The system and method for automatically controlling the content of the residual oxygen in the regenerative heating furnace have the advantages that a gas and an air flow control valve is controlled reasonably, accurately and rapidly, the adjustment function of the regulating valve is effectively utilized, optimal control over the content of the residual oxygen in the hearth of the heating furnace is achieved, fuel is saved, and pollution is reduced.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

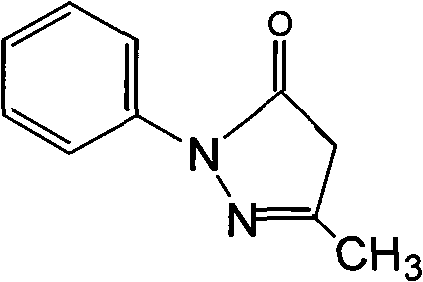

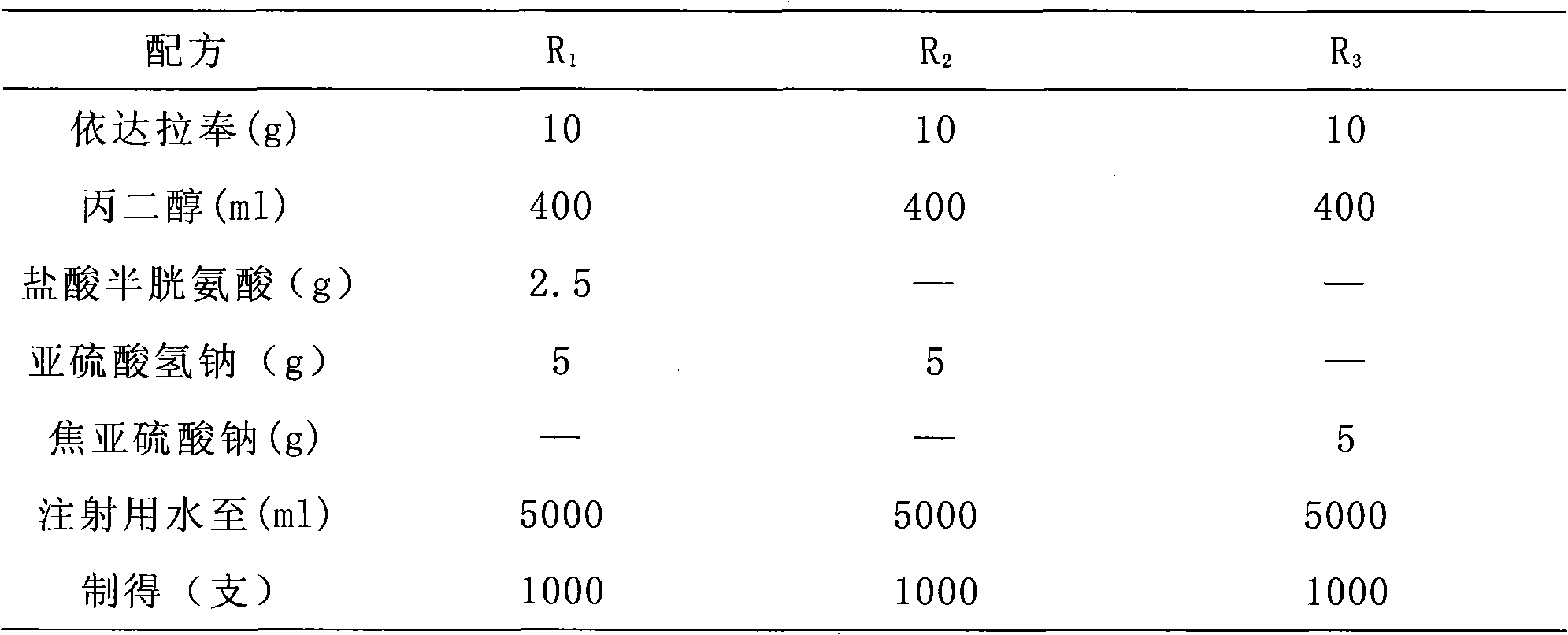

Edaravone injection and preparation method thereof

InactiveCN101933899AImprove stabilityLong validity periodOrganic active ingredientsNervous disorderEdaravone InjectionNitrogen

The invention discloses edaravone injection and a preparation method thereof. The injection contains edaravone serving as an active material, sodium pyrosulfite serving as antioxygen and propylene glycol serving as cosolvent. In the invention, in an edaravone injection production process, the sodium pyrosulfite antioxygen is added and high-purity nitrogen is charged into an ampoule bottle before and after liquid medicine canning and sealing to ensure the residual oxygen in the air above the liquid medicine in the ampoule bottle is less than 3 percent, so the edaravone is kept in a low-oxygen environment all the time. In the invention, the stability of the edaravone injection is improved, the period of validity of the edaravone injection is prolonged, and the safety and effectiveness of the edaravone injection in clinical use are ensured.

Owner:NANJING SIMCERE DONGYUAN PHARM CO LTD

Combustion type gas heat value measuring method and heat value meter thereof

InactiveCN1800848AHigh sensitivityGuaranteed uptimeFuel testingMaterial thermal analysisChemical reactionCoupling

The disclosed combustion-type measurement method for gas heat value comprises: with gas coupling device and combustion-supporting air transmission device, conveying some gas and combustion-supporting air into combustion furnace for complete combustion to produce smoke; measuring the residual oxygen content in smoke to calculate the gas heat value. This invention can not be affected by environmental temperature, has no hysteretic phenomenon, needs small maintenance labor and low cost, and runs stably.

Owner:天津艾尔博特冶金自动化技术有限公司

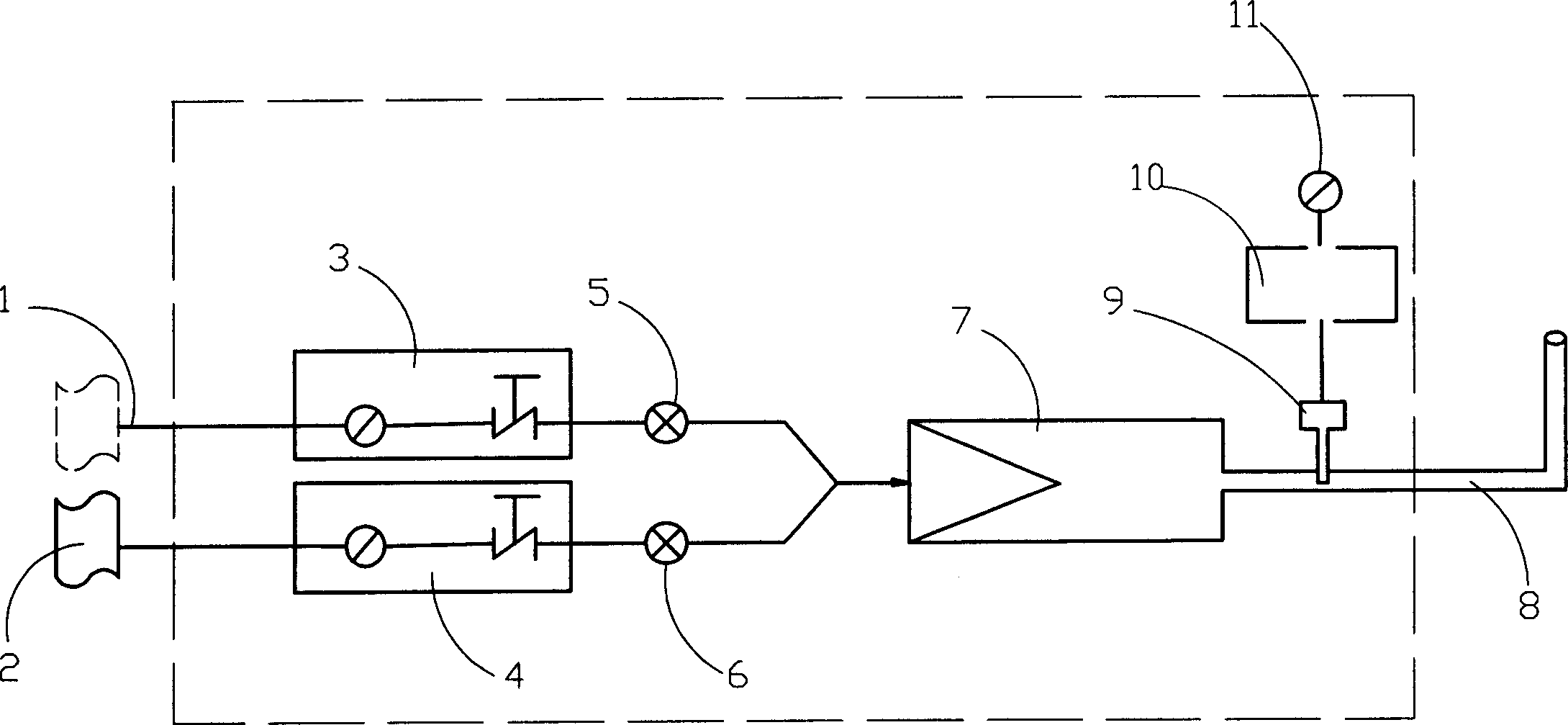

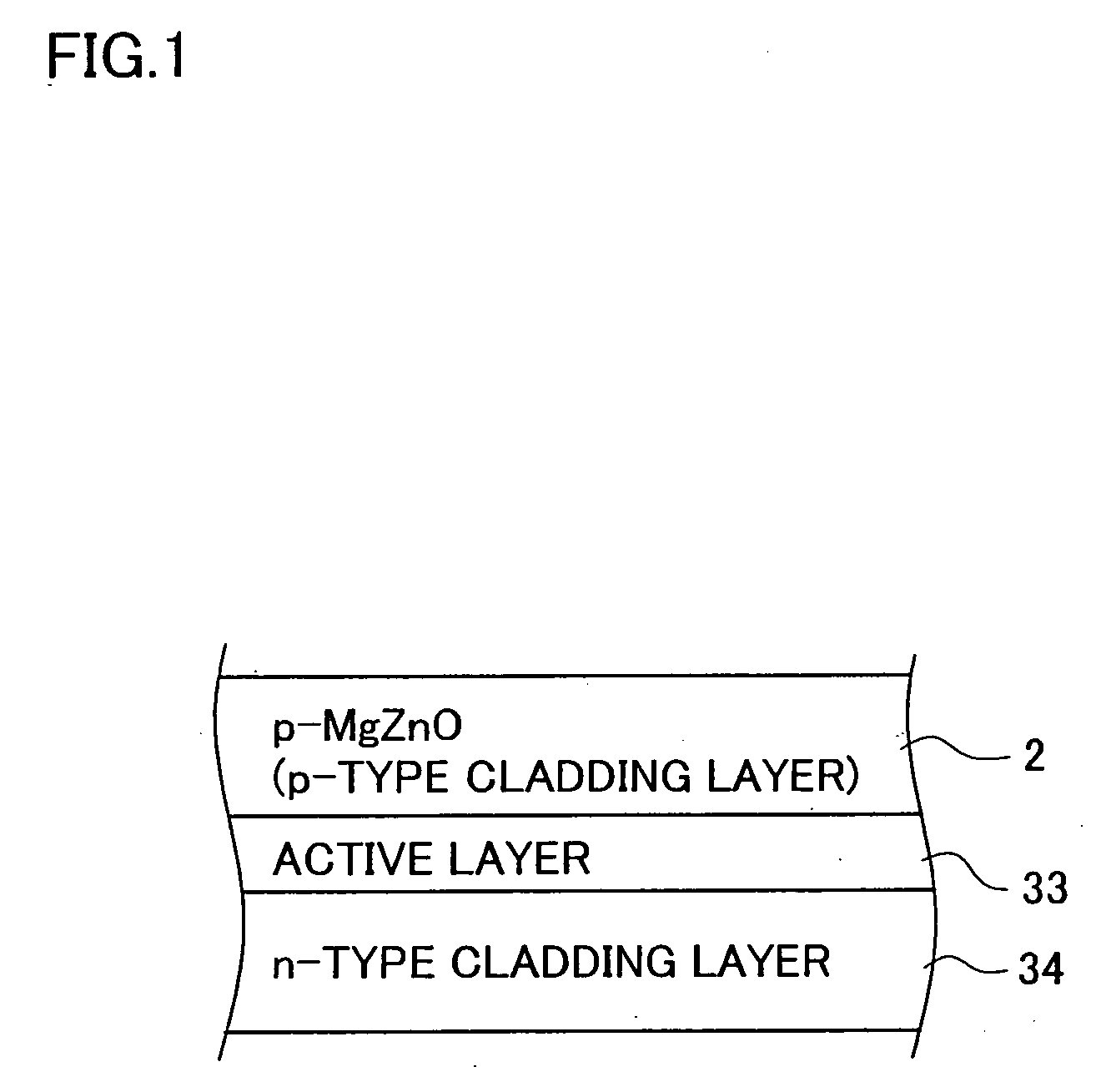

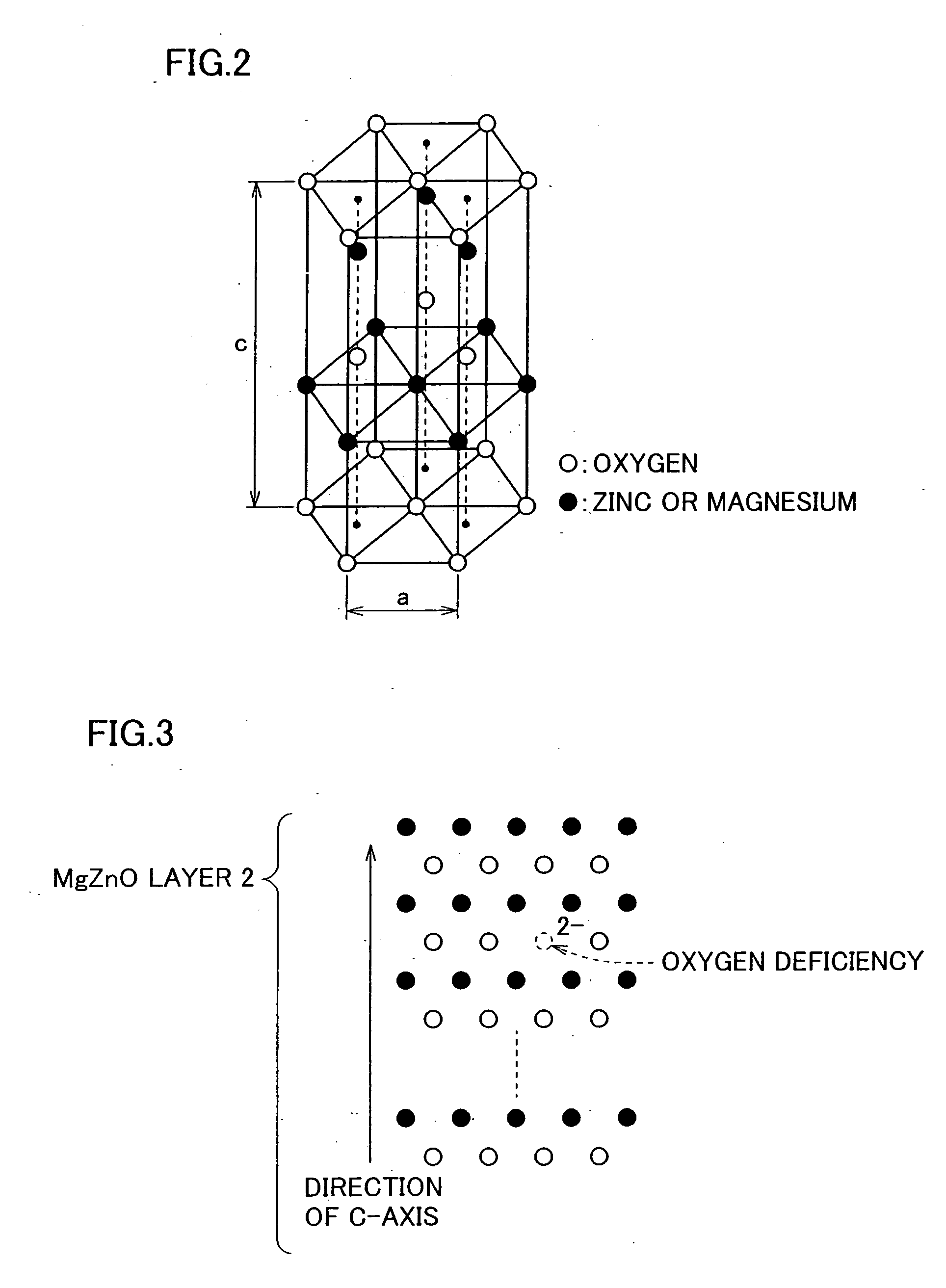

Production method for light emitting element

InactiveUS20050224825A1Improve stabilityGood reproducibilityPolycrystalline material growthSemiconductor/solid-state device manufacturingChemical reactionSemiconductor materials

In a first invention, a p-type MgxZn1-xO-type layer is grown based on a metal organic vapor-phase epitaxy process by supplying organometallic gases which serves as a metal source, an oxygen component source gas and a p-type dopant gas into a reaction vessel. During and / or after completion of the growth of the p-type MgxZn1-xO-type layer, the MgxZn1-xO-type thereof is annealed in an oxygen-containing atmosphere. This is successful in forming the layer of p-type oxide in a highly reproducible and stable manner for use in light emitting device having the layer of p-type oxide of Zn and Mg. In a second invention, a semiconductor layer which composes the light emitting layer portion is grown by introducing source gases in a reaction vessel having the substrate housed therein, and by depositing a semiconductor material produced by chemical reactions of the source gas on the main surface of the substrate. A vapor-phase epitaxy process of the semiconductor layer is proceed while irradiating ultraviolet light to the main surface of the substrate and the source gases. This is successful in sharply enhancing reaction efficiency of the source gases when the semiconductor layer for composing the light emitting layer portion is formed by a vapor-phase epitaxy process, and in readily obtaining the semiconductor layer having only a less amount of crystal defects. In a third invention, a buffer layer having at least an MgaZn1-aO-type oxide layer on the contact side with the light emitting layer portion is grown on the substrate, and the light emitting layer portion is grown on the buffer layer. The buffer layer is oriented so as to align the c-axis thereof to the thickness-wise direction, and is obtained by forming a metal monoatomic layer on the substrate based on the atomic layer epitaxy, and then by growing residual oxygen atom layers and the metal atom layers. This is successful in obtaining the light emitting portion with an excellent quality. In a fourth invention, a ZnO-base semiconductor active layer included in a double heterostructured, light emitting layer portion is formed using a ZnO-base semiconductor mainly composed of ZnO containing Se or Te, so as to introduce Se or Te, the elements in the same Group with oxygen, into oxygen deficiency sites in the ZnO crystal possibly produced during the formation process of the active layer, to thereby improve crystallinity of the active layer. Introduction of Se or Te shifts the emission wavelength obtainable from the active layer towards longer wavelength regions as compared with the active layer composed of ZnO having a band gap energy causative of shorter wavelength light than blue light. This is contributive to realization of blue-light emitting devices.

Owner:SHIN-ETSU HANDOTAI CO LTD

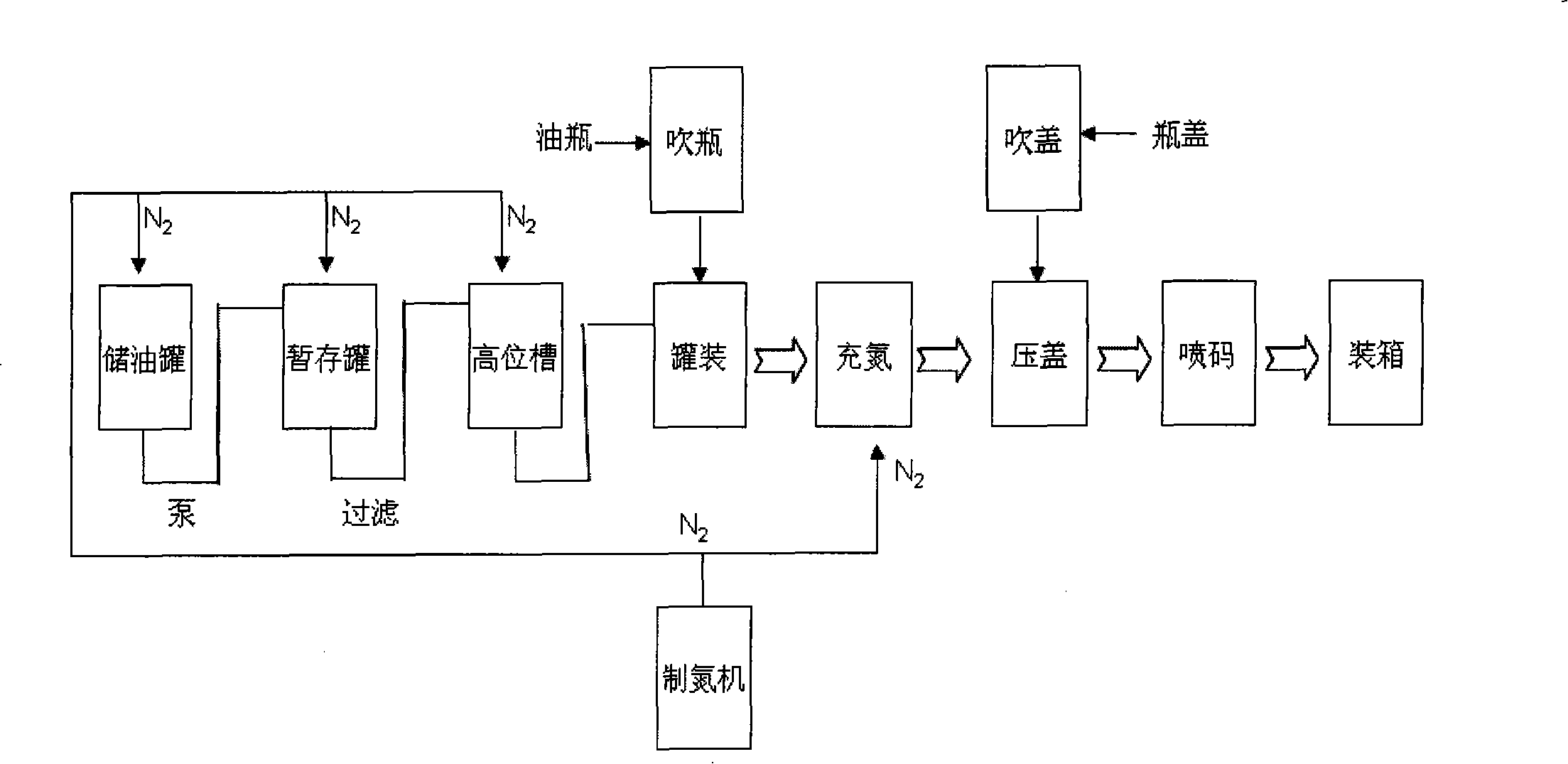

Nitrogen-charging fresh-keeping method for edible oil

InactiveCN101209072AExtended shelf lifePrevent oxidationFinished edible oils/fats preservationAntioxidantNitrogen

The invention relates to a method for preserving edible oil by charging nitrogen. After the edible oil is filled in a tank, nitrogen is charged into a bottle to lead the air in the bottle and the oxygen in the edible oil to be replaced and lead the residual oxygen in the head space of the bottle to be less than 3 percent and then a pressure pad is sealed, thus leading the residual oxygen of the edible oil in the bottle to be very low and the edible oil has no oxygen source that can supply reaction on one hand; and on the other hand, the nitrogen in the head space of the bottle forms a nitrogen sealing which obstructs the oxygen to be contacted with the edible oil, thus achieving the effects of protecting the edible oil and preventing the edible oil from oxygenation; simultaneously, the invention can avoid the hidden troubles to the health of the human body caused by using artificial antioxidant.

Owner:上海佳格食品有限公司

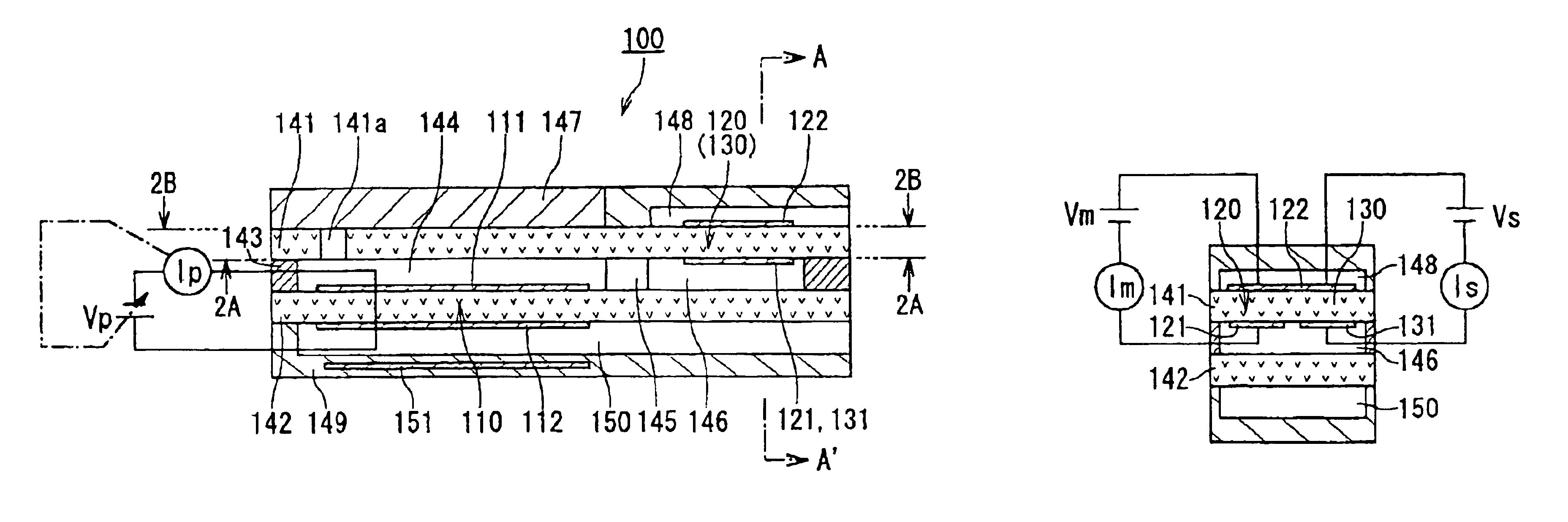

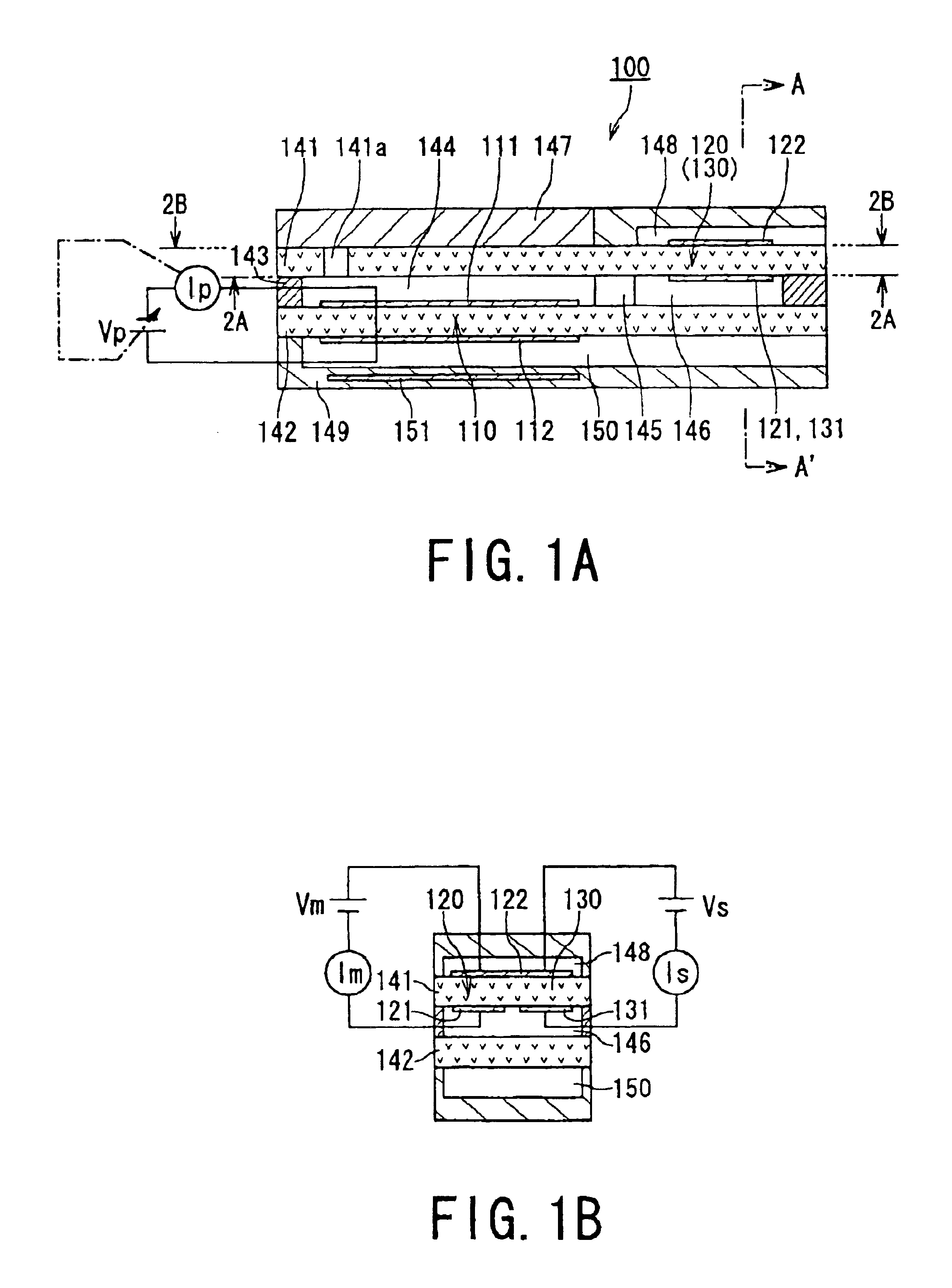

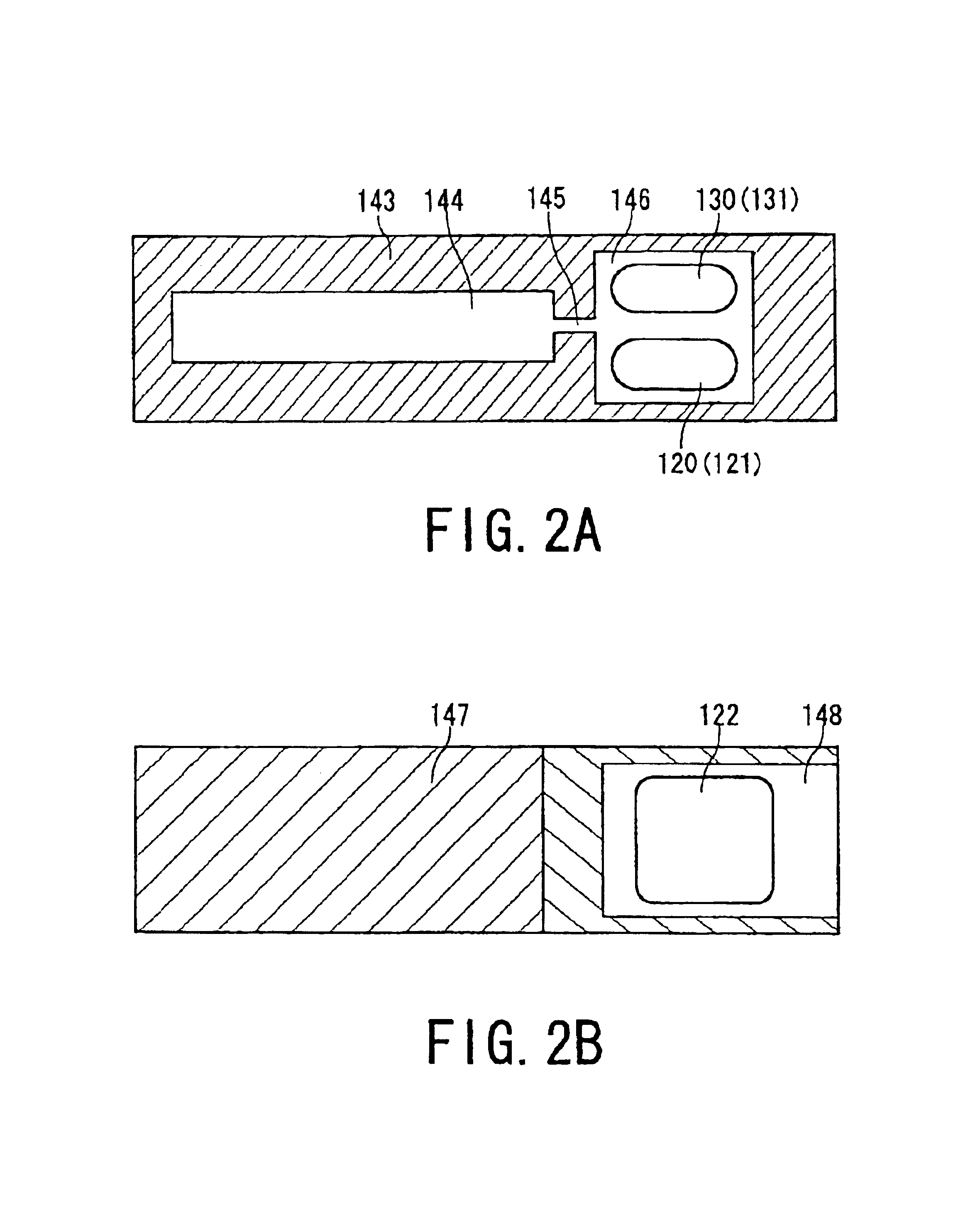

Gas concentration detecting apparatus

ActiveUS6922639B2High precisionSmall resolutionWeather/light/corrosion resistanceVolume/mass flow measurementGas compositionProduct gas

A gas concentration detecting apparatus comprises a gas concentration sensor and a gas concentration calculator. The sensor has first to third cells. A gas to be detected is introduced in a chamber and the first cell is responsible for discharging and changing oxygen from and into the chamber. The second cell detects a concentration of a specific gas component of the gas that has passed along the first cell. The third cell detects a concentration of residual oxygen in the gas that remains after discharge of the oxygen through the first cell. The calculator takes in a current acquired from the second cell measured with a voltage applied thereto and calculates the specific gas component concentration based on the current. The calculator includes plural concentration calculating means whose concentration detecting ranges are mutually different in a scale. The specific gas component concentration is calculated every concentration calculating means.

Owner:DENSO CORP

Brown coal dry-distillation method using coal hot air furnace to supply heat

InactiveCN102732274AReduce sulfur contentFinal emissions are environmentally friendlyDirect heating destructive distillationSpecial form destructive distillationDry heatQuenching

The invention relates to a brown coal dry-distillation method using a coal hot air furnace to supply heat. The brown coal dry-distillation method comprises the following steps of: adding brown coal in a drying furnace to be heated and dried, sending the heated coal into a dry-distillation furnace to be heated and dry-distilled to obtain thermal carbocoal, cooling and quenching the thermal carbocoal in a quenching furnace to obtain a carbocoal product; purifying high-temperature smoke produced by the coal hot air furnace in a purifying room, making dry-distilled coal gas enter into the purifying room, consuming residual oxygen in the high-temperature smoke to produce high-temperature hot air with a low oxygen content as all or partial heating sources of the drying furnace used for coal drying, wherein the dry-distilled heat source in the dry-distillation furnace partially or all comes from the high-temperature smoke produced by burning the dry-distilled coal gas in a burner, and obtaining crude tar and clean dry-distilled normal-temperature coal gas after the following treatments: de-dusting and cooling the dry-distilled coal gas and tar steam, and separating tar and on the like. Compared with the method taking the dry-distilled coal gas as the heat source drying heat source, the high-temperature smoke of the coal hot air furnace is used as the brown coal drying heat source, a lot of dry-distilled coal gas is surplus, such that the saved plenty of dry-distilled coal gas can be for other uses and thus the economic value is high.

Owner:SUZHOU JINLUN ENERGY TECH

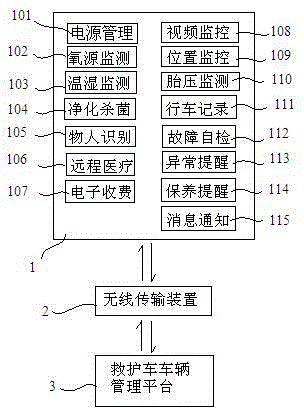

Internet of things intelligent ambulance system

InactiveCN104688446AReal-time understanding of vehicle conditionsControllable securityTotal factory controlAmbulance serviceElectricityWireless transmission

The invention provides an internet of things intelligent ambulance system. The internet of things intelligent ambulance system comprises a vehicle-mounted embedded host and an ambulance vehicle management platform, wherein the vehicle-mounted embedded host is installed in an ambulance, the ambulance vehicle management platform is installed in a hospital, and the vehicle-mounted embedded host is connected with the ambulance vehicle management platform through a wireless transmission device so that data interaction can be achieved. The all-direction intelligent vehicle management is achieved through the internet of things, intelligent sensing and other technologies, and position information, the amount of residual oxygen, the amount of electricity of a storage battery, oil consumption, tire pressure, stretcher states, fault codes and other related information of vehicles are monitored in real time. The vehicle conditions of ambulances can be known in real time through the system, whether the ambulances can be normally driven out for operation is judged or whether the ambulances need to be repaired, maintained and the like is judged, the safety of the ambulances becomes controllable, and guarantees are provided for the smooth and safe development of the first-aid service.

Owner:JIANGXI JIANGLING MOTORS GRP REFITTED VEHICLES CO LTD

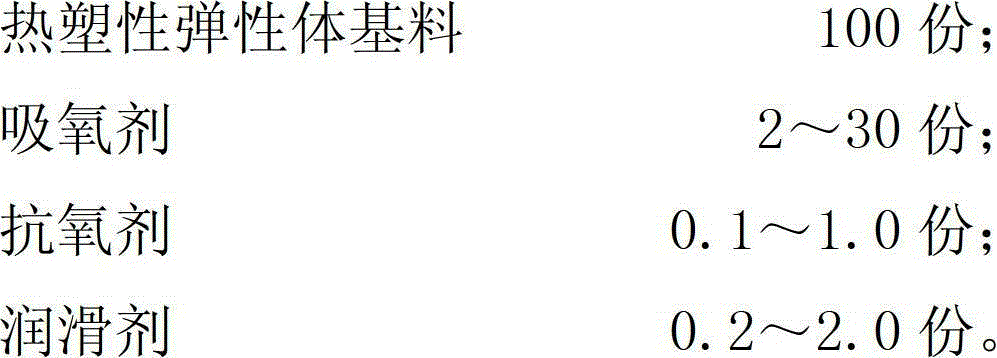

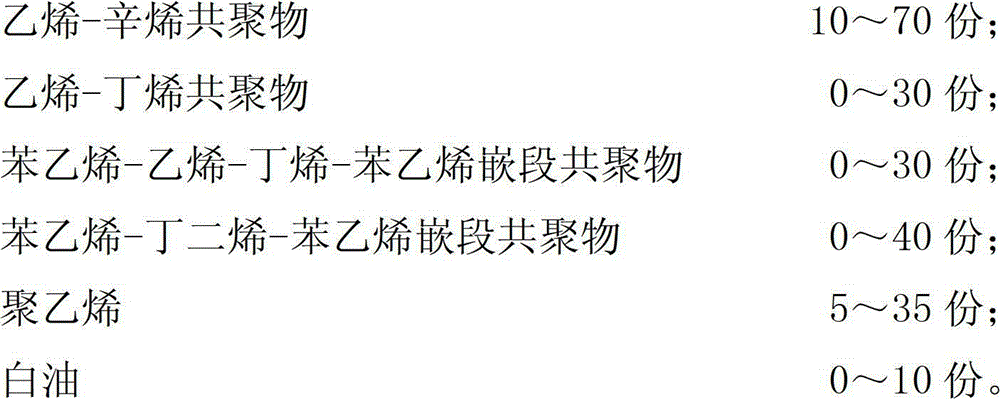

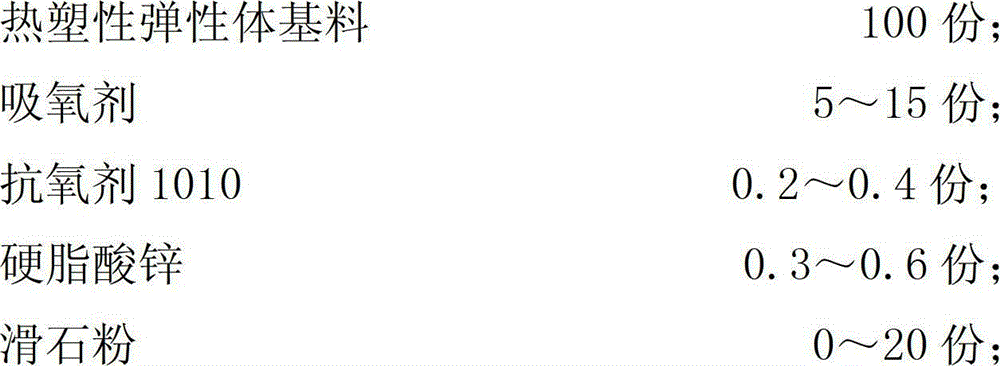

Metal crown lid internal gasket sealing material with oxygen absorbing function

The invention relates to a metal crown lid internal gasket sealing material with an oxygen absorbing function. The metal crown lid internal gasket sealing material is prepared by respectively adding 2-30 parts by weight of single-components of different types or an oxygen absorbent of a compound component by taking a thermoplastic elastomer as a base material. The metal crown lid internal gasket sealing material can be processed into a metal crown lid gasket by adopting an existing non-oxygen absorbing gasket machining process, can absorb residual oxygen of a headspace in an absorbing bottle while keeping the original machining and sealing property of the gasket, and ensures that the oxygen concentration is reduced to a limit oxygen concentration of 0.5ml / l from 210ml / l, thereby prolonging the quality guarantee period.

Owner:SHANGHAI FRONTIER ELASTOMER

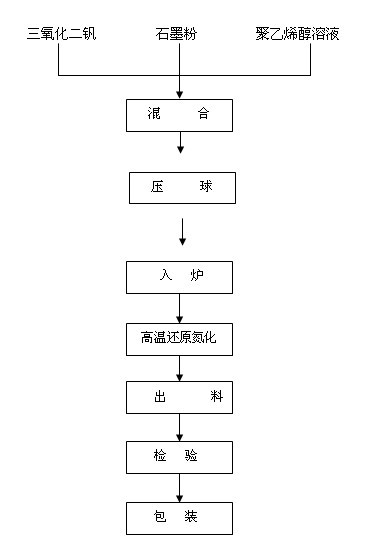

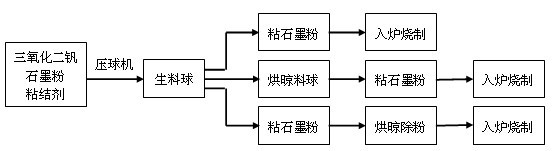

Method for anti-adhesion nitrogen increase in the process of producing vanadium nitride

ActiveCN102140587APrevents sinter sticking problemsHigh nitrogen contentPretreatment methodVanadium nitride

The invention relates to a method for anti-adhesion nitrogen increase in the process of producing vanadium nitride, and belongs to the technical field of vanadium nitride alloy production. The technical scheme comprises the following steps of: pretreating raw pellets before the vanadium nitride raw pellets enters a furnace to be fired, and putting the raw pellets into graphite powder, wherein a pretreatment method of sticking and coating the graphite powder on the surface is adopted, and the graphite powder is taken as an anti-adhesion material; and putting the raw pallets uniformly stuck with the graphite powder into a reaction furnace for firing. By the method, the problem of adhesion among products in the process of producing vanadium nitride can be effectively solved, the appearance quality of the products and the finished product ratio are improved, the surface area of nitriding reaction can be increased by 1 / 8 to 1 / 2 when the vanadium nitride pellets are fired, and the graphite powder on the surfaces of the pellets can consume partial residual oxygen and protect vanadium carbide / vanadium nitride in the pellets so as to prevent the vanadium carbide / vanadium nitride from being oxidized, improve the nitrogen content in the products and improve the grade and yield of the products. The method is suitable for all vanadium nitride production modes, particularly production of vanadium nitride by the most mature horizontal pusher kiln method at present.

Owner:HEBEI IRON AND STEEL

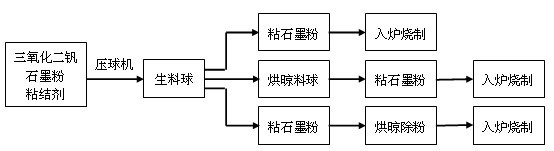

Catalyst with methane catalytic combustion and conversion functions and preparation method thereof

InactiveCN102266768AReduce temperature riseIncrease the outer surface areaGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsManganeseCobalt

The invention discloses a catalyst with functions of methane catalytic combustion and conversion, and a preparation method thereof. The catalyst is an integer honeycomb catalyst, comprising one or a plurality of active components selected from manganese, nickel and cobalt, and one or a plurality of auxiliary agents selected from MgO, La2O3, CeO2 and BaO, wherein the active components are in a form of oxide and account for 5%-20%, and the auxiliary agents account for 1-10%, and the balance is carrier. The catalyst has double functions of methane catalytic combustion and methane steam conversion and can be used in reactions of gas preparation for power generation from low-quality coalbed methane. After reaction, residual oxygen in the gas is little, and a decrease of a feed gas gross calorific value is low; besides the catalyst has high strength, good thermal stability and good low-temperature light-off temperature.

Owner:HAO HUA CHENGDU TECH

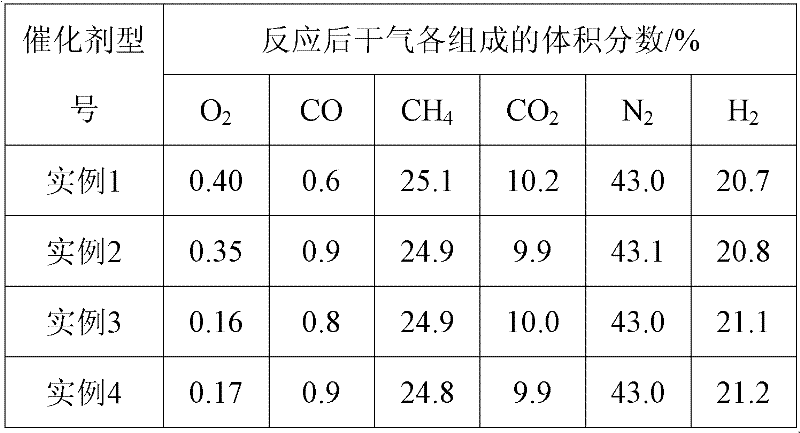

Intelligent combustion control method based on online optimization of air-fuel ratio and used for heating furnace

InactiveCN106322429AReal-time intelligent combustion controlStable intelligent combustion controlFuel supply regulationOptimal controlFeedback control

The invention provides an intelligent combustion control method based on online optimization of the air-fuel ratio and used for a heating furnace. The intelligent combustion control method comprises the following steps that S1, the optimal air-fuel ratio is determined intelligently; S2, the optimal air-fuel ratio is adjusted automatically; S3, the air-fuel ratio is fed back and controlled automatically; and S4, the temperature PID control parameter of the heating furnace is adjusted intelligently. According to the intelligent combustion control method based on online optimization of the air-fuel ratio and used for the heating furnace, the combustion atmosphere is determined according to the rolling specification of a blank and the target temperature, and adjustment of the air-fuel ratio is conducted with the combustion atmosphere as feedforward; and meanwhile, optimal control over the air-fuel ratio is conducted with residual oxygen contents, collected by a patrolling type smoke analysis system, of combustion products of all combustion sections of the heating furnace as feedback, parameters in the combustion process are dynamically adjusted according to the changing condition of the temperature in the control process, and real-time stable intelligent combustion control over the heating furnace is achieved.

Owner:上海策立工程技术有限公司

Production of photoluminescent silicon nanoparticles having surfaces that are essentially free of residual oxygen

InactiveUS20070196297A1Low toxicityExpand coverageCosmetic preparationsNanotechOrganic solventHydrogen

The present invention relates to a method for preparing photoluminescent silicon nanoparticles having uniformly hydrogen-terminated surfaces that are essentially free of residual oxygen. The present invention also relates to a method of preparing a blue-emitting photoluminescent silicon nanoparticle. The present invention further relates to a composition that includes a photoluminescent silicon nanoparticle having a surface that is uniformly hydrogen-terminated and essentially free of residual oxygen. The present invention also relates to a composition including a photoluminescent silicon nanoparticle having a surface that is uniformly coated with an organic layer and essentially free of residual oxygen. The present invention additionally relates to a composition including a photoluminescent silicon nanoparticle stably dispersed in an organic solvent and having a surface that is uniformly coated with an organic layer and essentially free of residual oxygen.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com