Patents

Literature

681 results about "Hull structure" patented technology

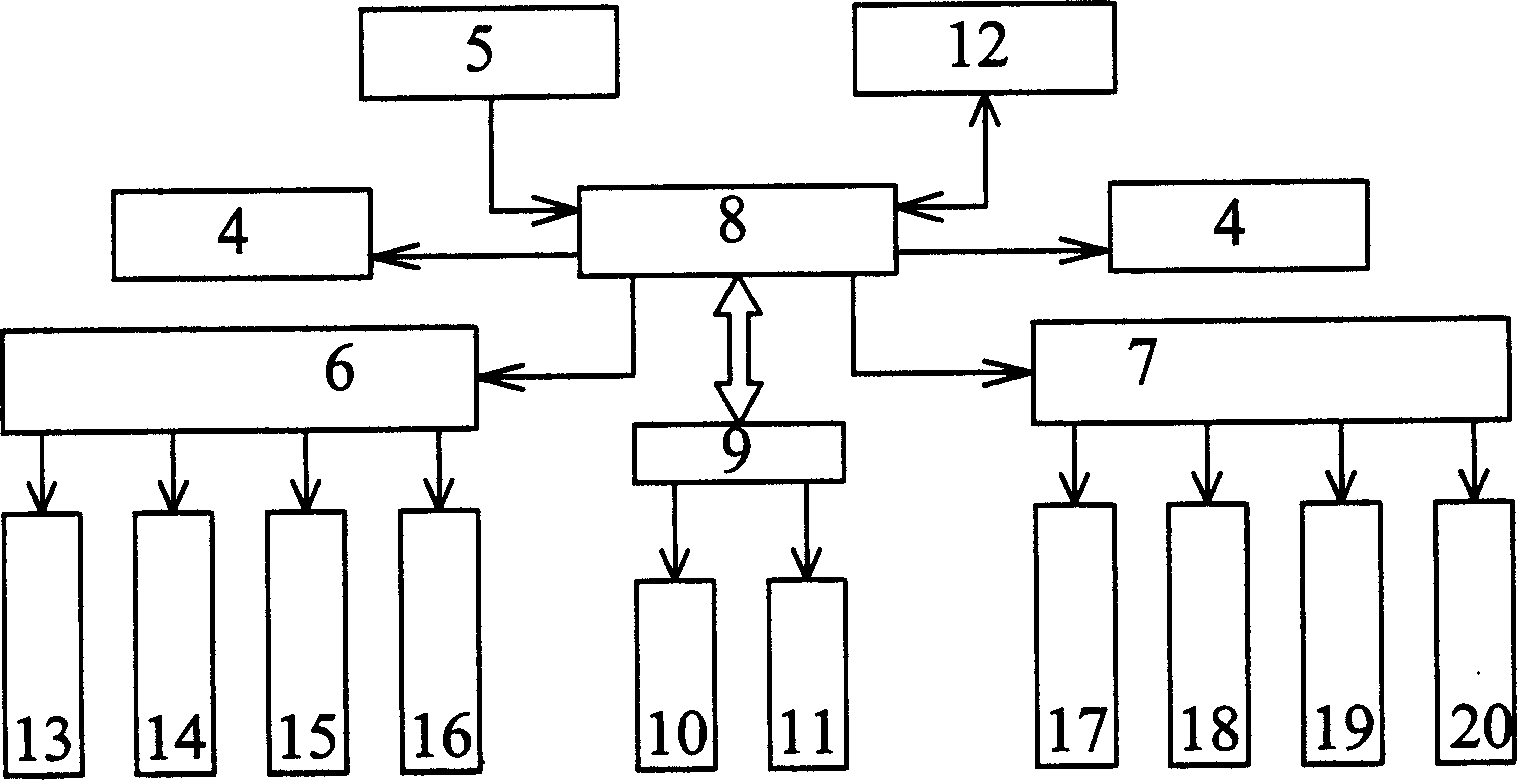

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The hull is the basic structure of a boat, not including the masts (if any), rigging, above board constructions, or attachments of any kind.

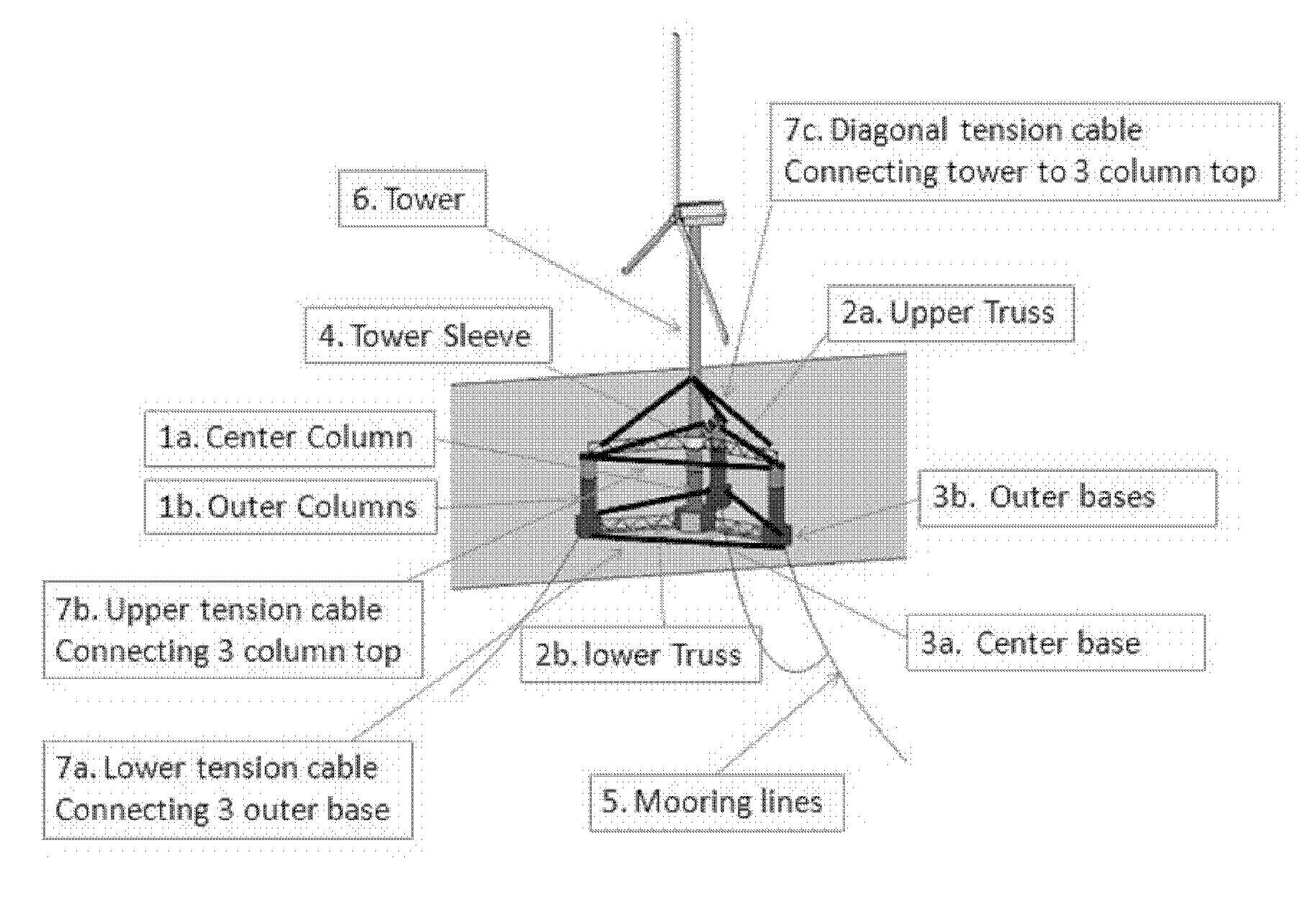

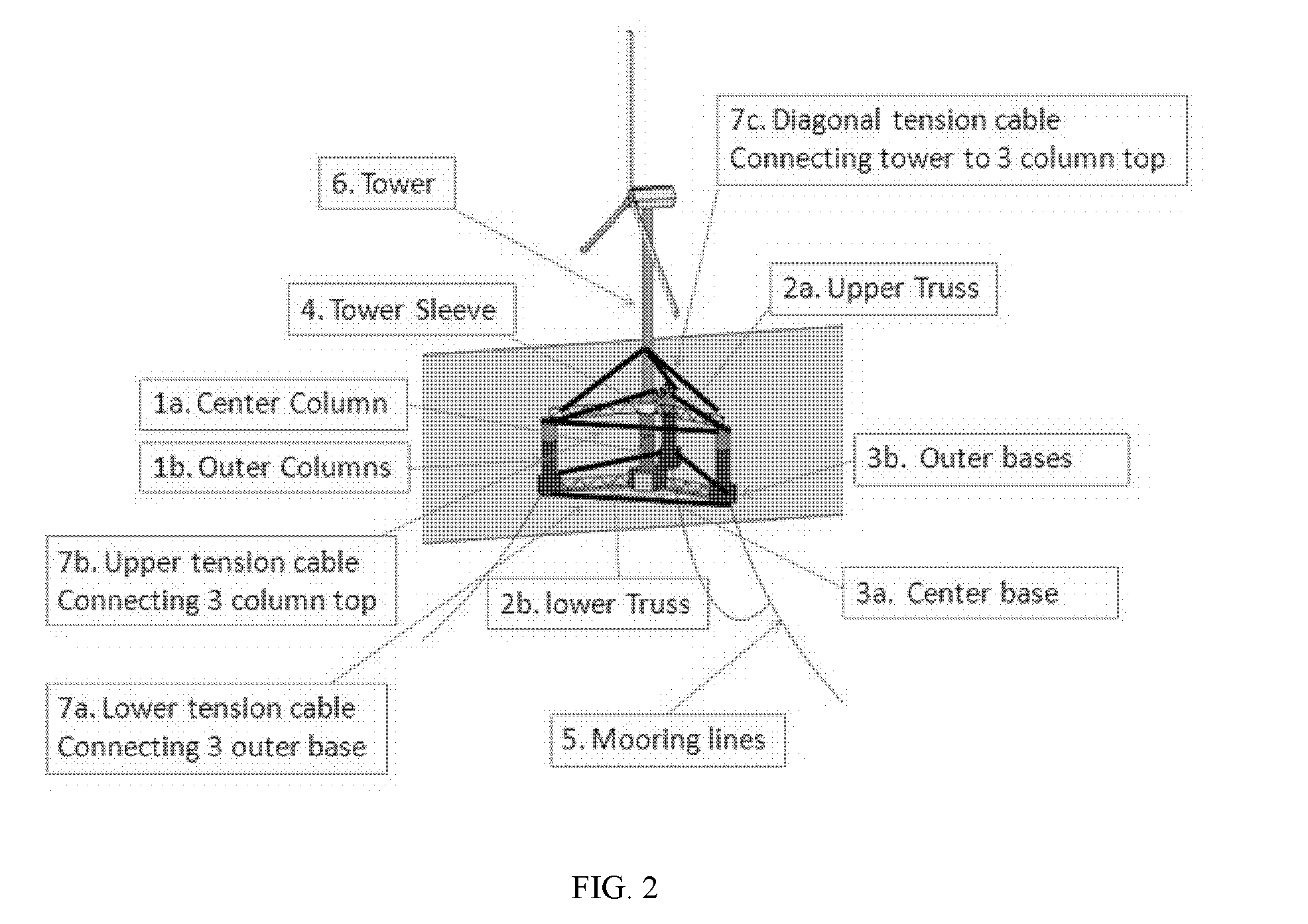

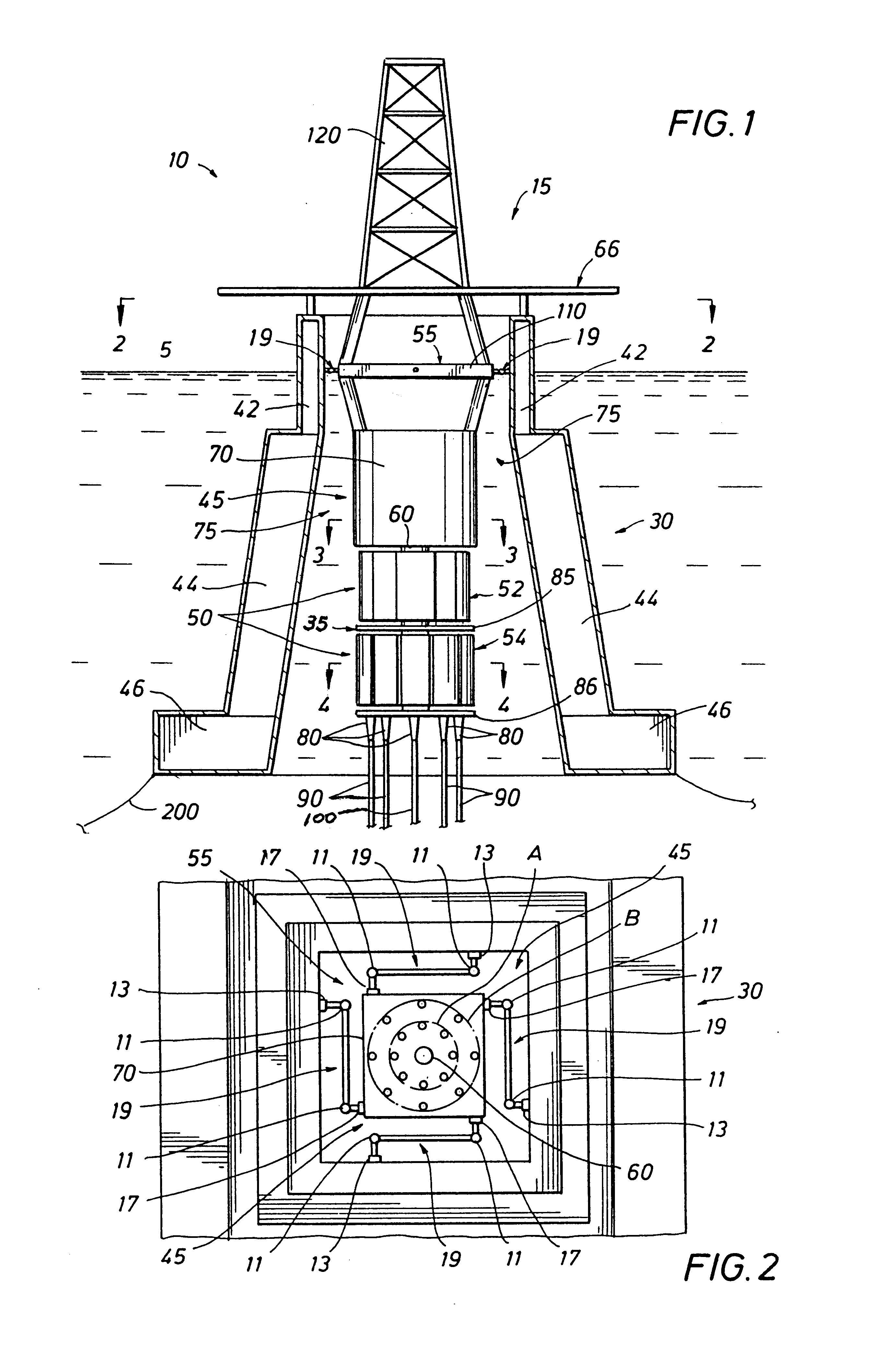

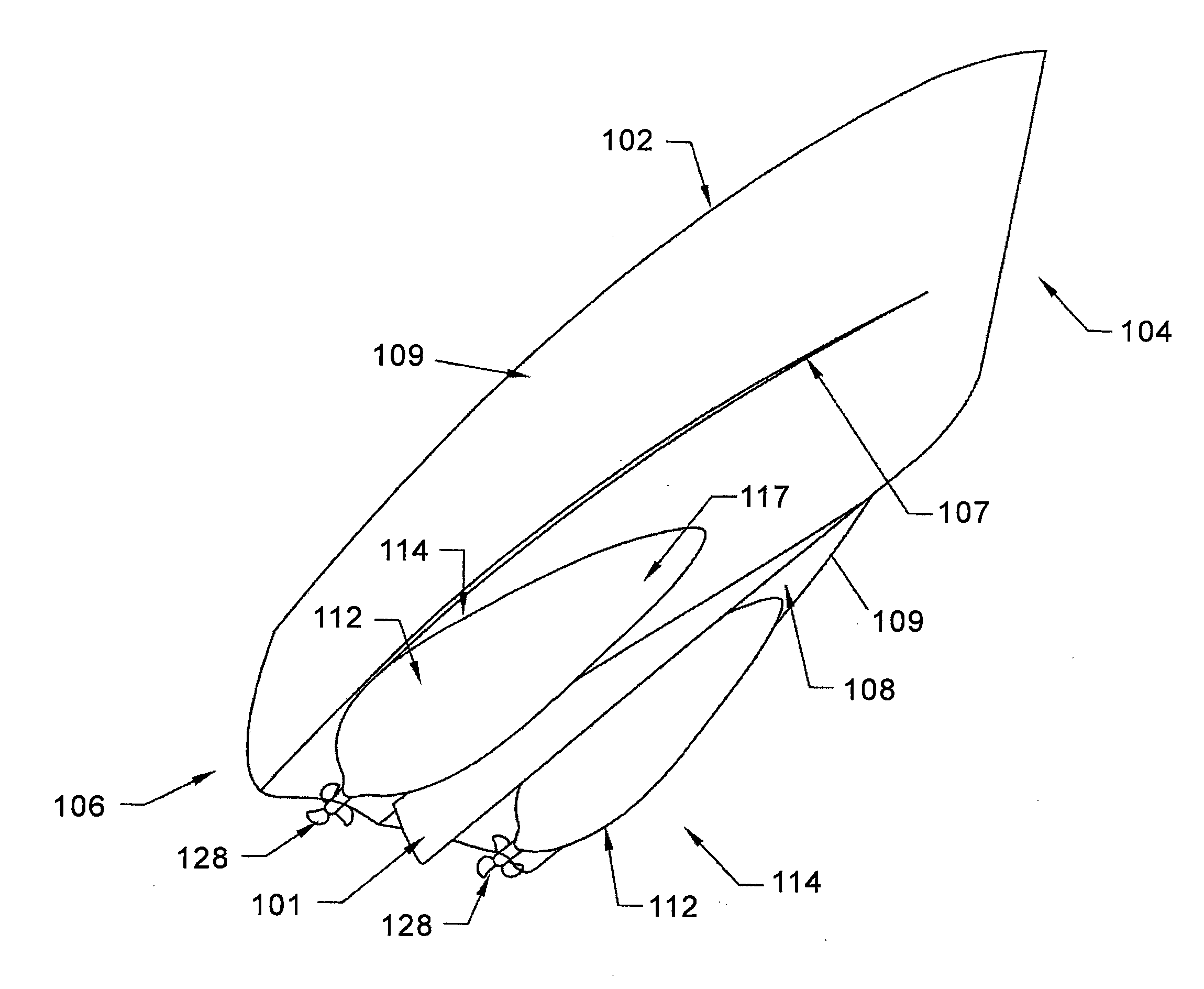

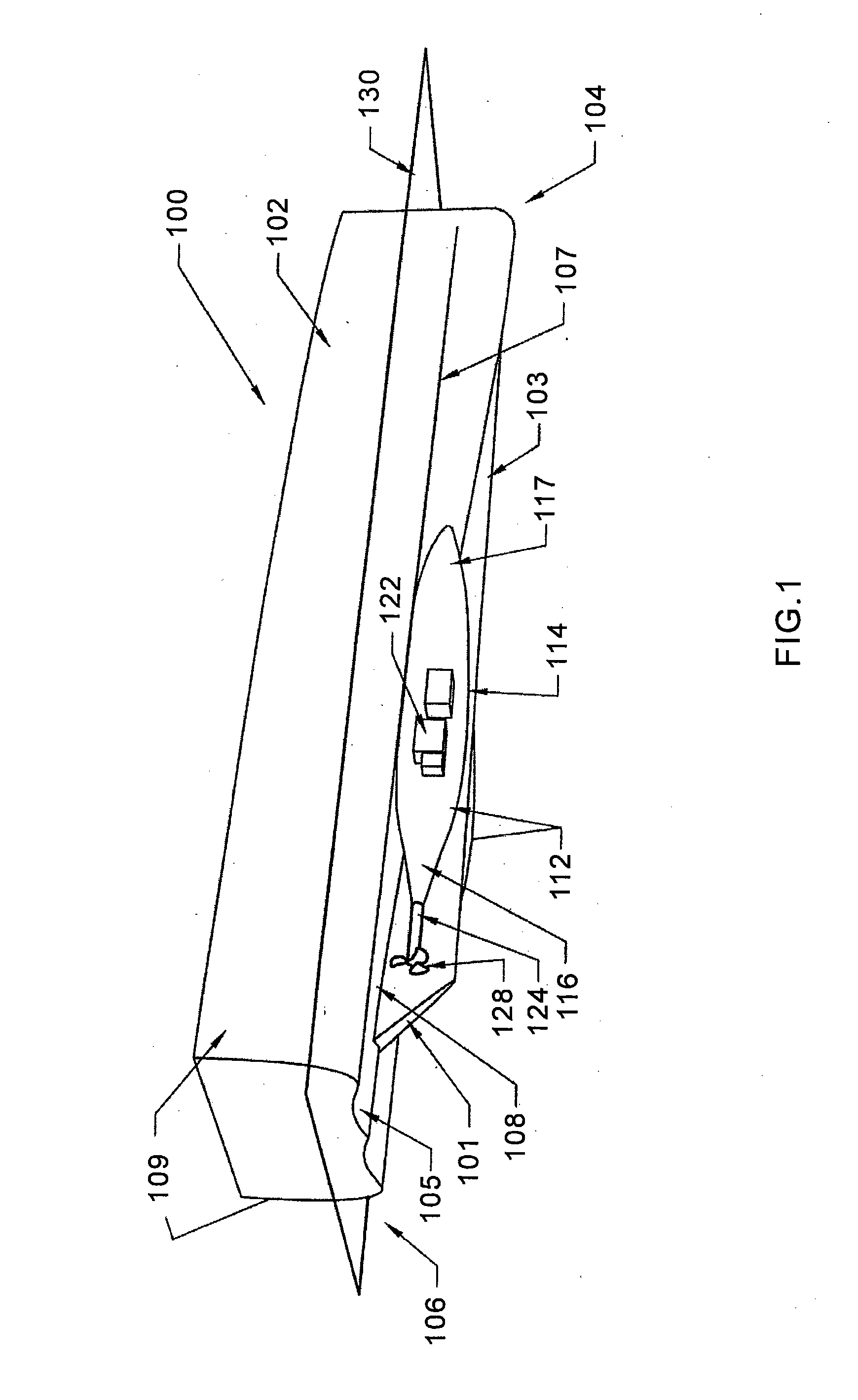

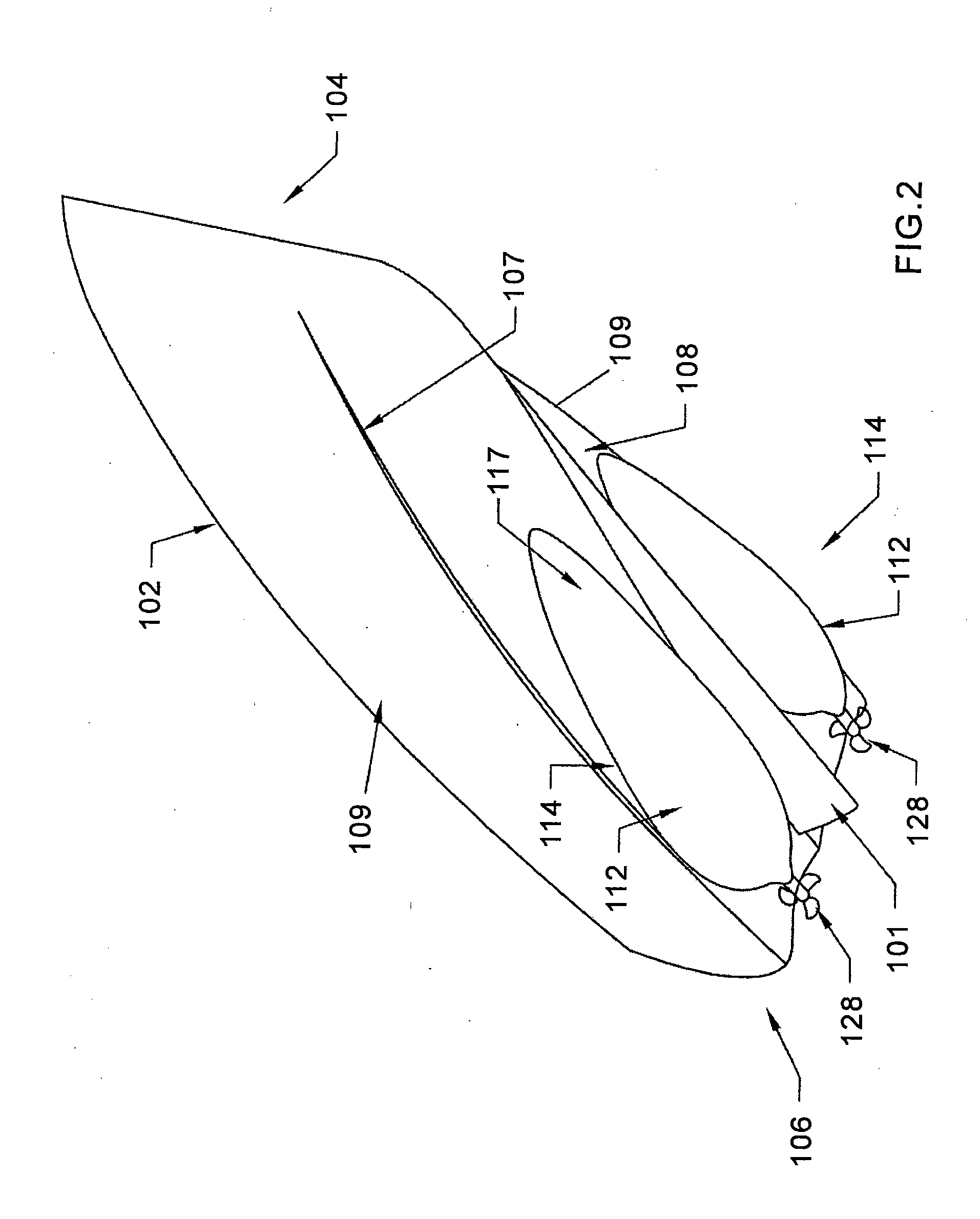

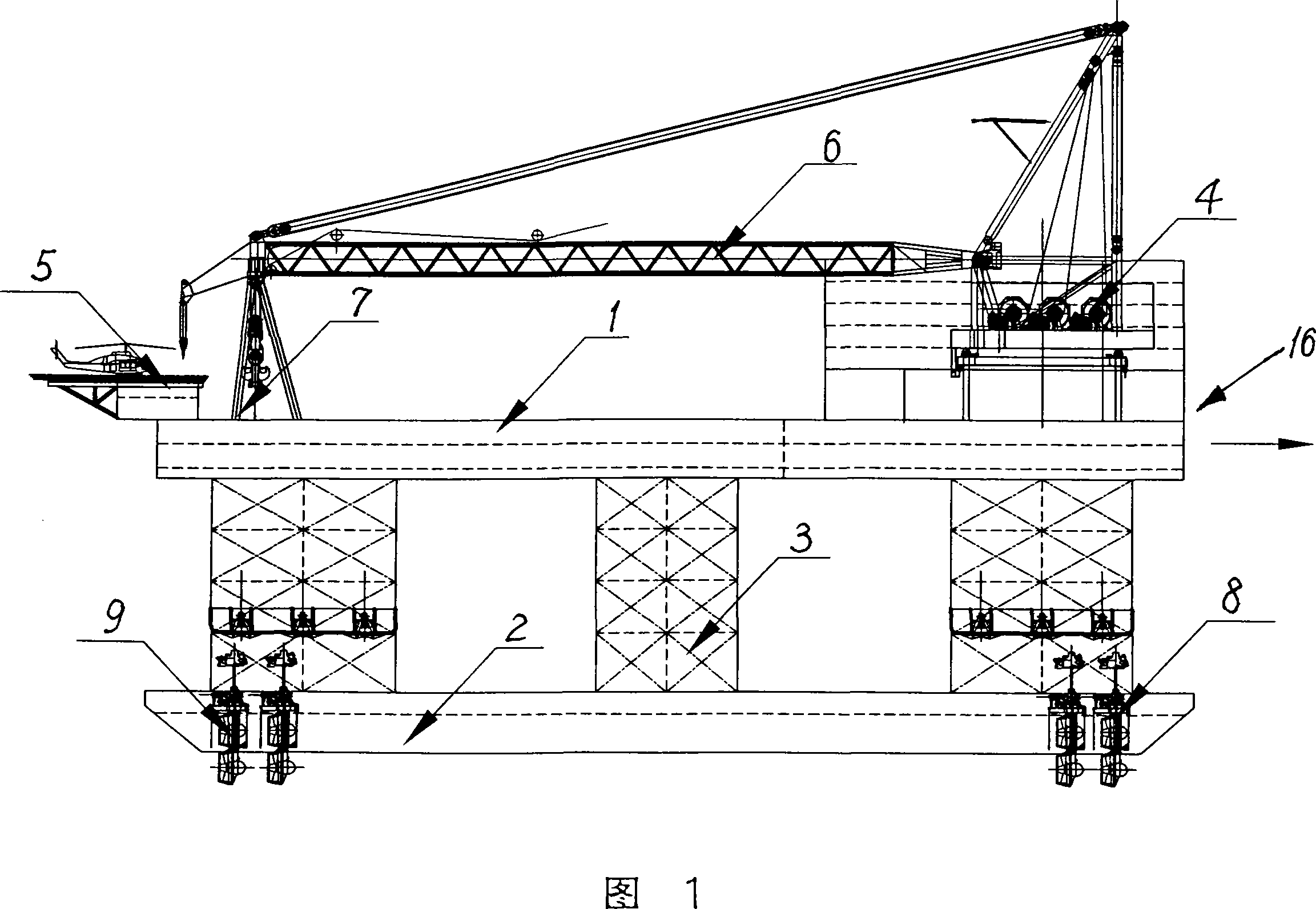

Truss Cable Semi-submersible Floater for Offshore Wind Turbines and Construction Methods

InactiveUS20120103244A1Improve dynamic performanceImprove stabilityWind energy generationFloating buildingsHull structureHybrid material

Truss cable semi-submersible floater for offshore wind turbines and construction methods are provided. A floating system includes a hull, a tensioned cable system, and a tower. The hull includes vertical buoyant columns with one column at the center of the pattern, larger size column base tanks, and a truss system, all of which are coupled to each other for supporting the tower and wind turbines. The column can be made of hybrid materials, including steel and composite-concrete. The steel section and the composite-concrete section of the column can be connected by grouting. The tensioned cable system including upper, lower, and diagonal tensioned cables to connect the column, the column base, and the tower to reduce the bending moments and improve stability, strength and dynamic performance of the hull structure.

Owner:WANG JIN +1

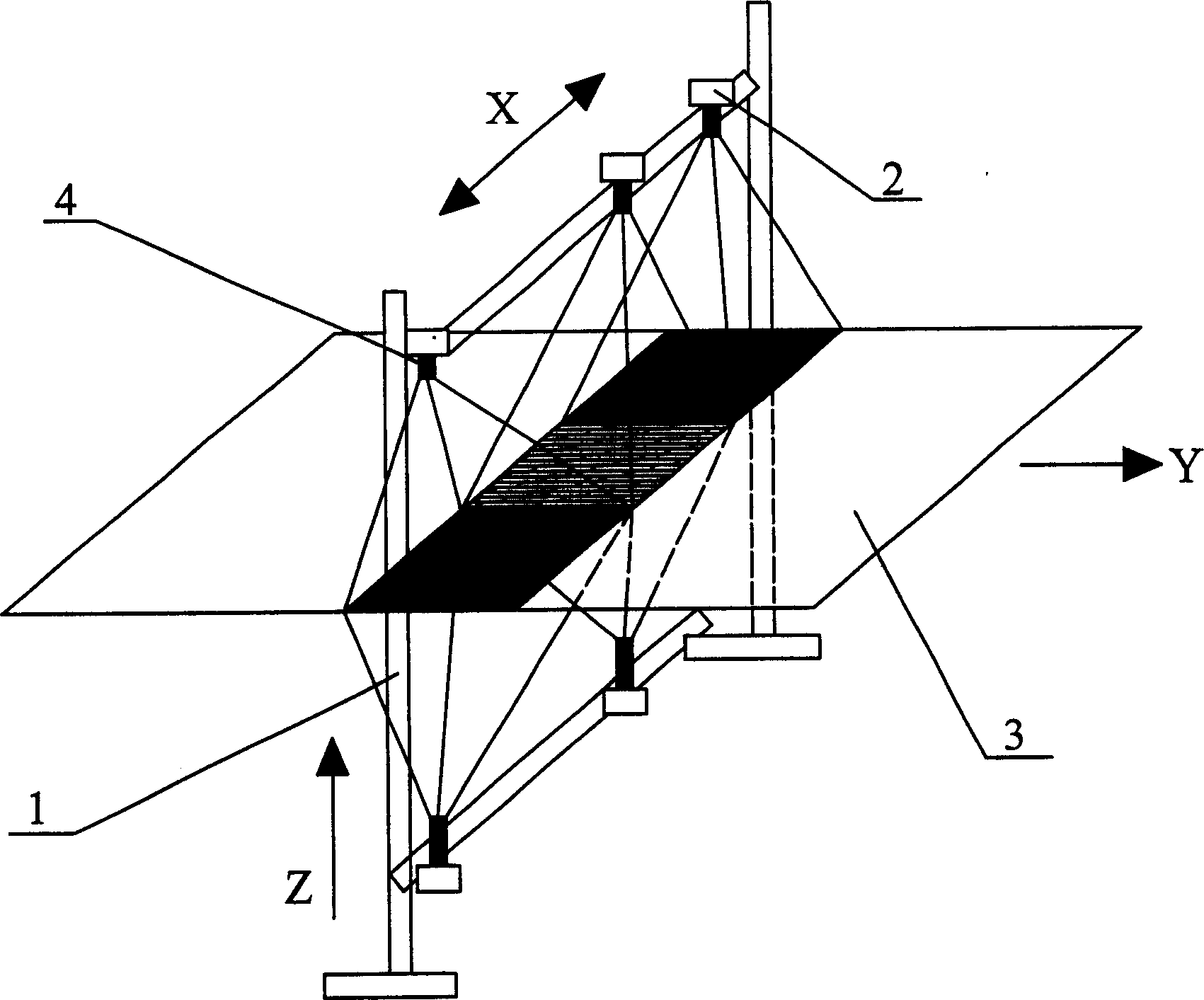

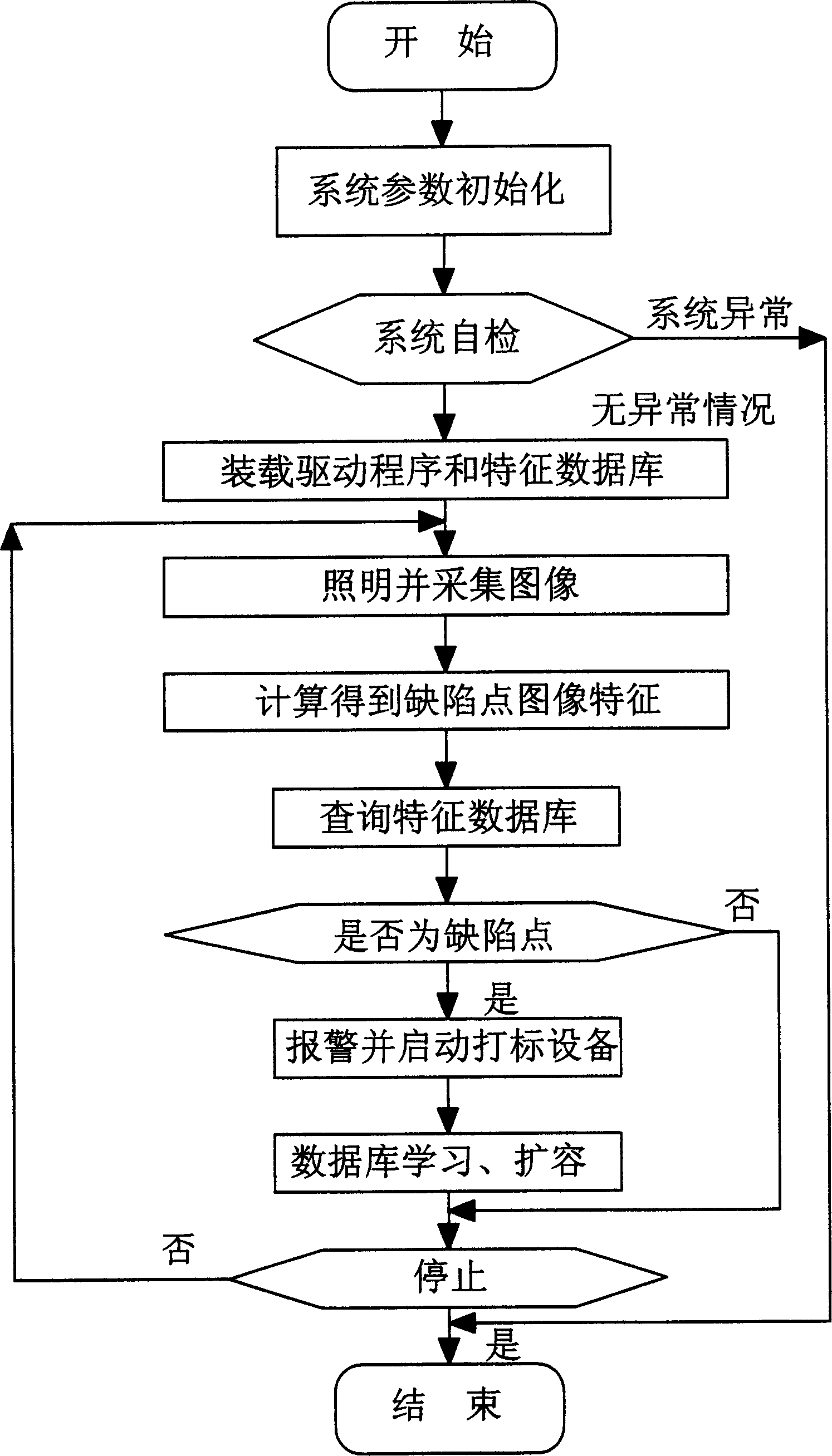

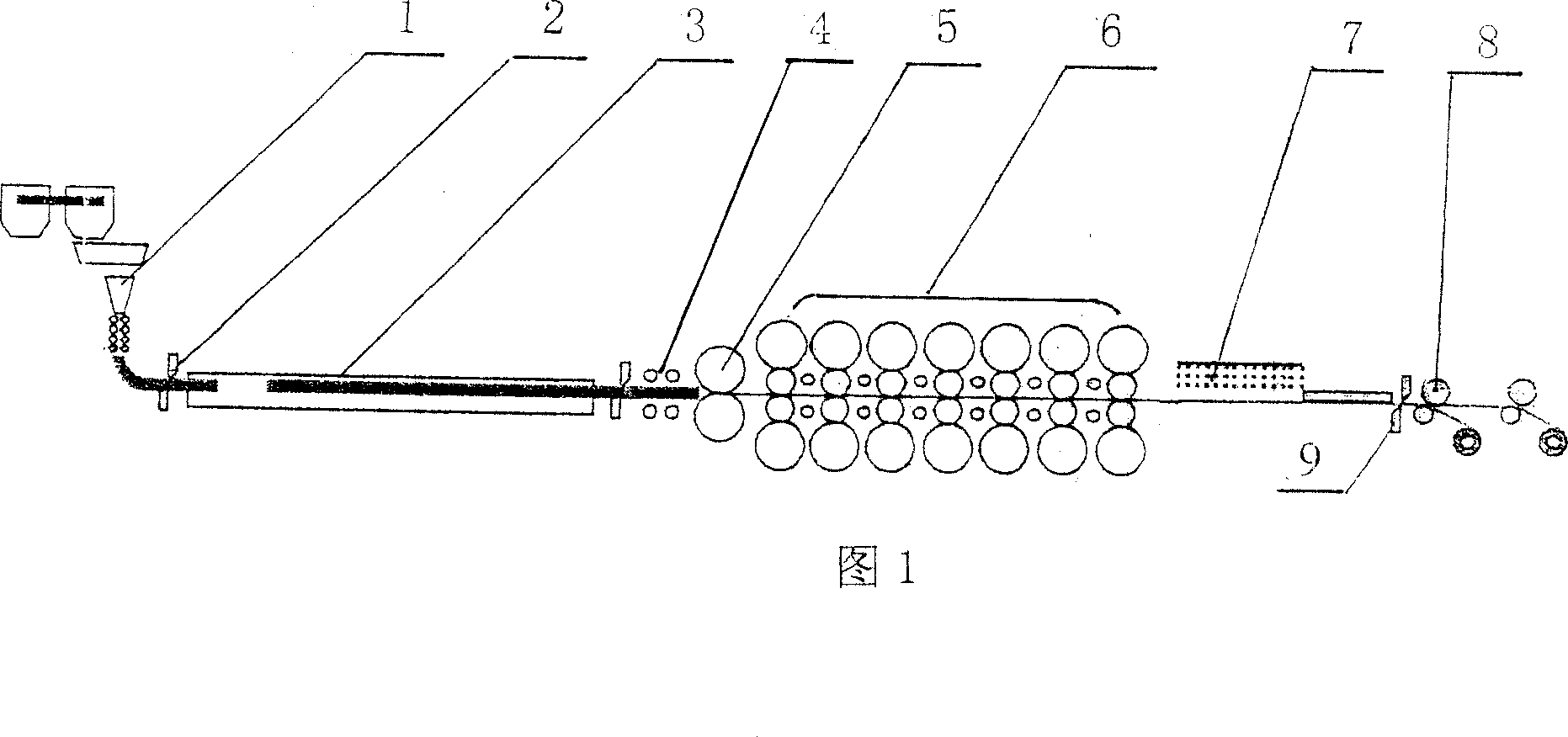

Automatic online detection method for defects on upper and lower surfaces during steel plate pretreatment process

InactiveCN1789990ASafe and reliable workIncrease productivityImage enhancementImage analysisMeasurement deviceEngineering

The invention discloses an on-line self-detecting method of surface defect in the ship formation steel predisposing course, which comprises the following steps: allocating the steel surface luminous equipment to form light field on two faces of on-line steel; setting several cases of independent imaging measuring device corresponding to each light field; proceeding real-time image of two faces of steel simultaneously when the steel moves along horizontal direction; disposing the image and marking the defect point; gathering the image grey scale and colority information separately through grey scale image information collector and colority image signal collector; analyzing and disposing the gathered grey scale and colority information through industrial computer software; adapting image grey scale character to identify and classify the defect point; starting the marking device to mark the defect point when the defect point is detected. The invention shortens the ship formation period greatly, which improves the ship body structure quality and detecting precision.

Owner:BOHAI SHIP HEAVY IND CO LTD

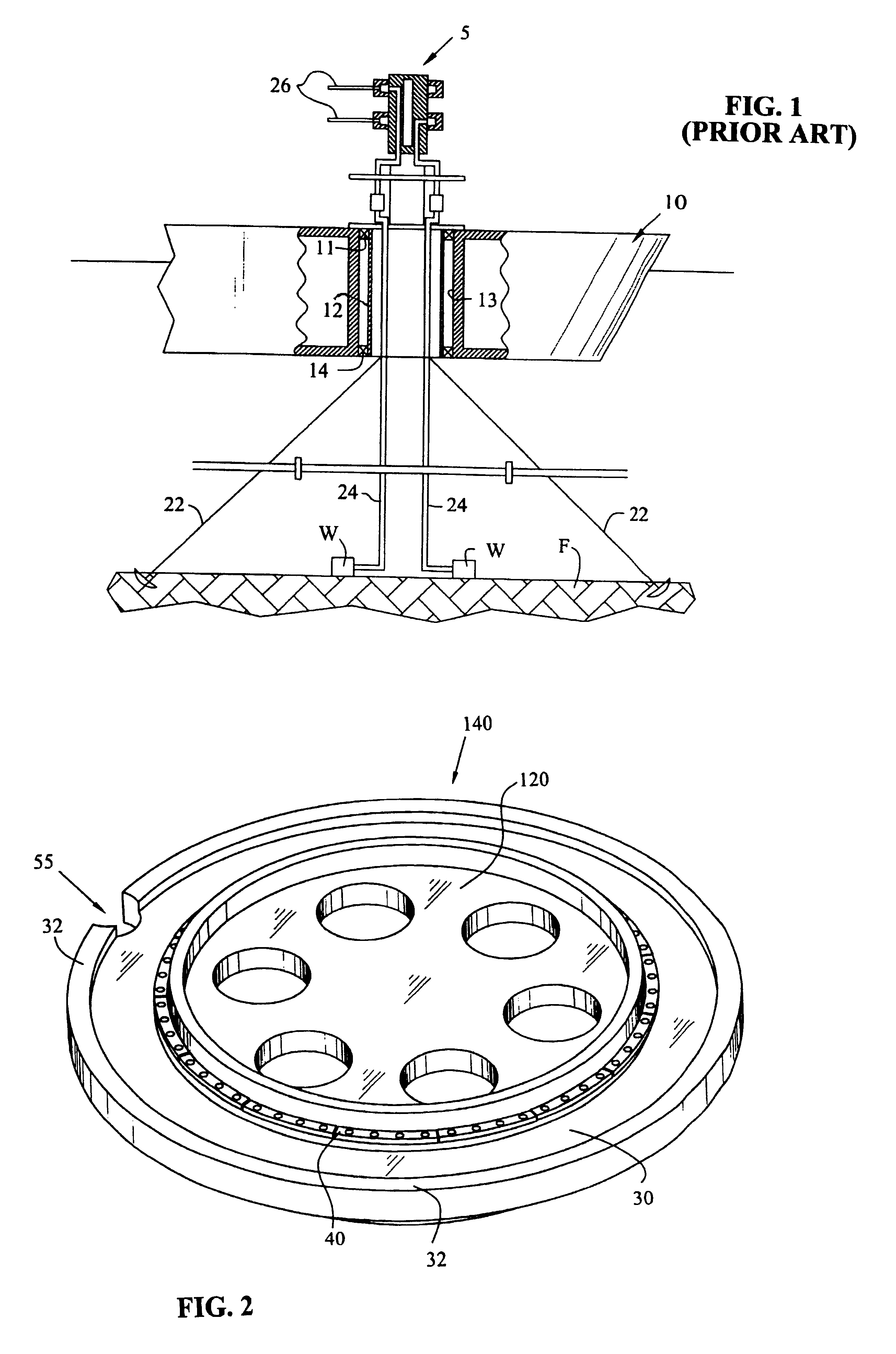

Spar disconnect system

ActiveUS7197999B2Provide structural strengthPrecise alignmentCaissonsFloating buildingsHull structureBuoyancy

A spar-type offshore platform includes a buoyant upper hull structure supporting a deck and having lower end in which is received a buoyant lower mooring module. The upper hull structure is connected to the mooring module by connection lines. The upper hull structure is removed from the mooring module by disconnecting the connection lines from the upper hull structure while leaving the connection lines attached to the mooring module and while the mooring module remains moored to the seabed. The mooring module is lowered relative to the upper hull structure, allowing the latter to be moved away. The upper hull structure may be re-positioned over the mooring module, and the mooring module may be hauled upward into engagement with the lower end of the upper hull structure, so that the connection lines can be recovered and re-attached to the upper hull structure.

Owner:TECH FRANCE SA

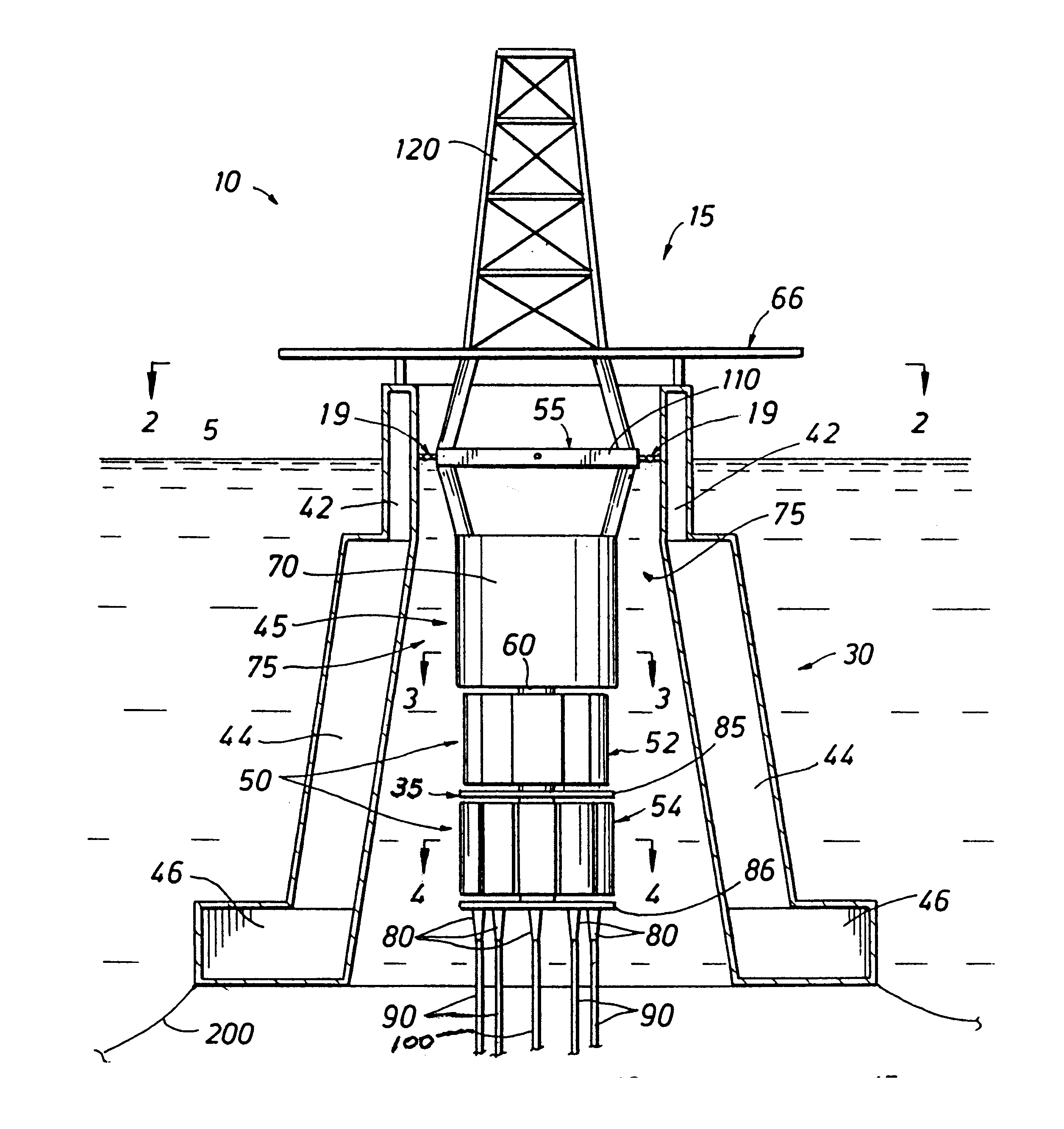

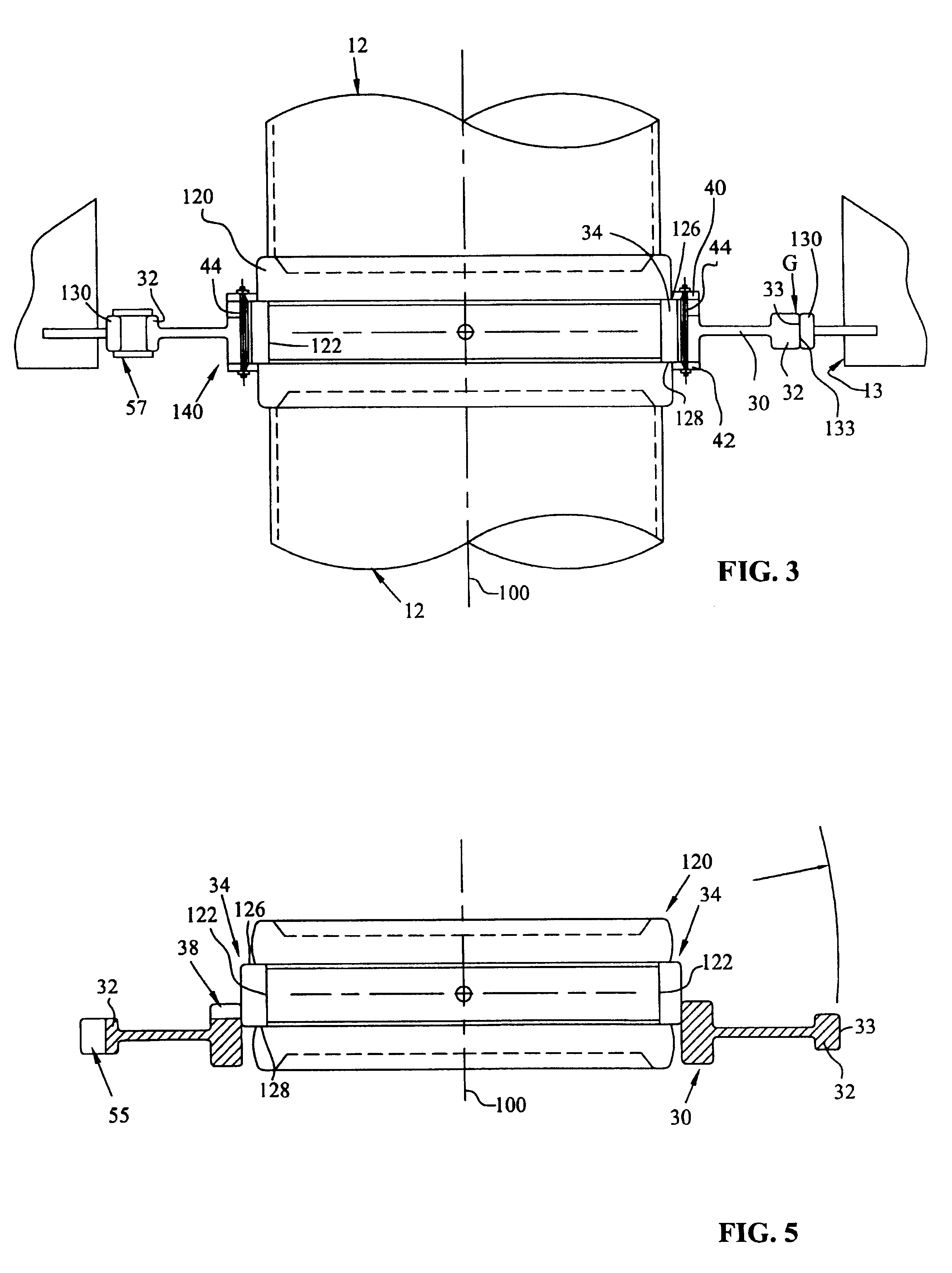

Riser support for floating offshore structure

InactiveUS6712560B1Eliminate cyclical bendingDrilling rodsDerricks/mastsHull structureMarine engineering

A floating offshore platform configuration is provided, which decouples pitch, roll, and heave motions from acting on tensioned risers and accommodates the angular displacement induced by floating offshore platform surge and / or sway excursion without inducing bending in the riser at its entrance to the floating offshore platform. The risers are guided by an inner structure that is tethered from the sea floor and centered inside an outer hull structure. Outer hull structure heave, pitch and roll motions are substantially isolated from acting on the inner structure through a connection mechanism, and each riser is allowed to individually expand or contract.

Owner:SOFEC

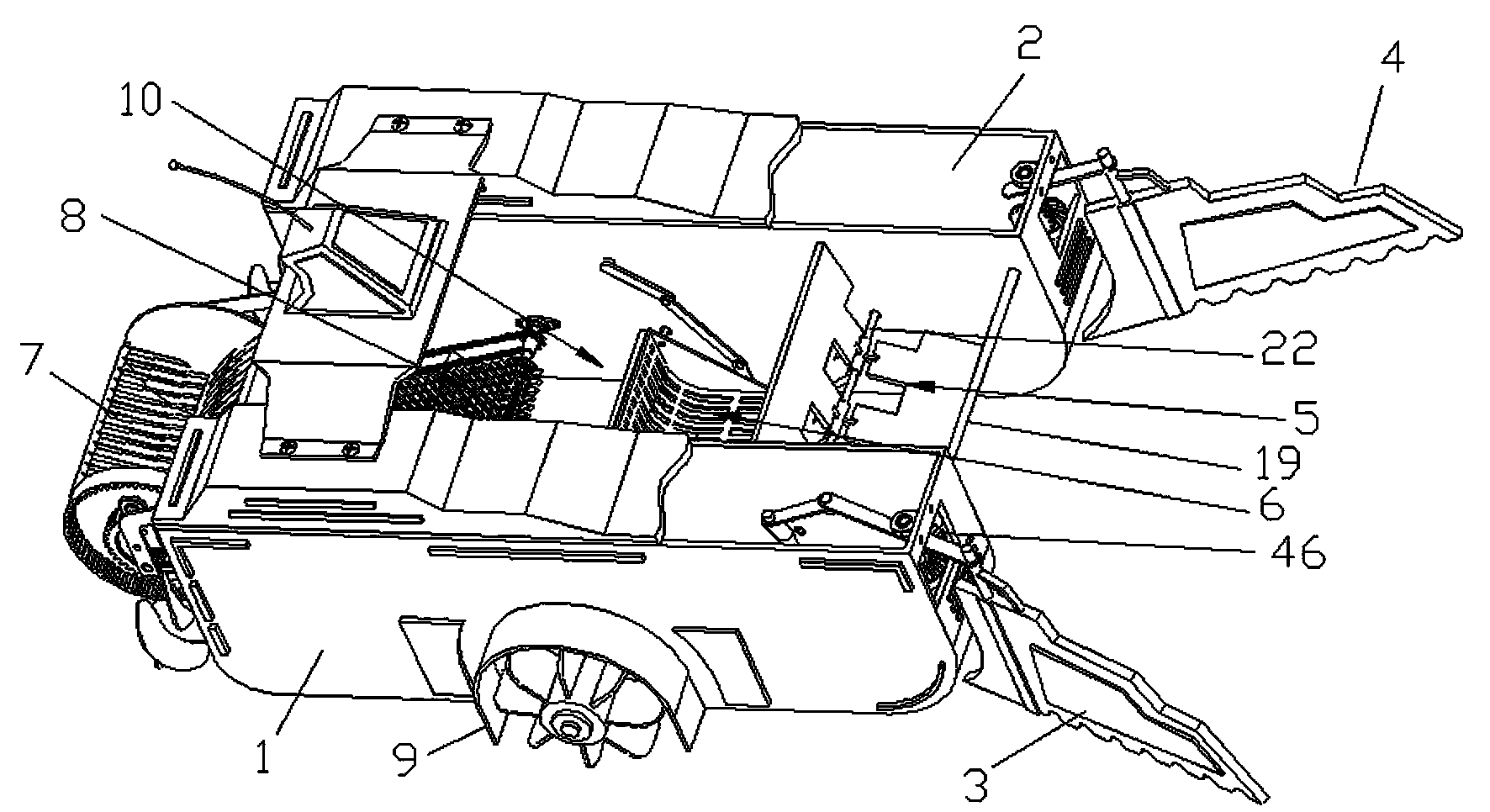

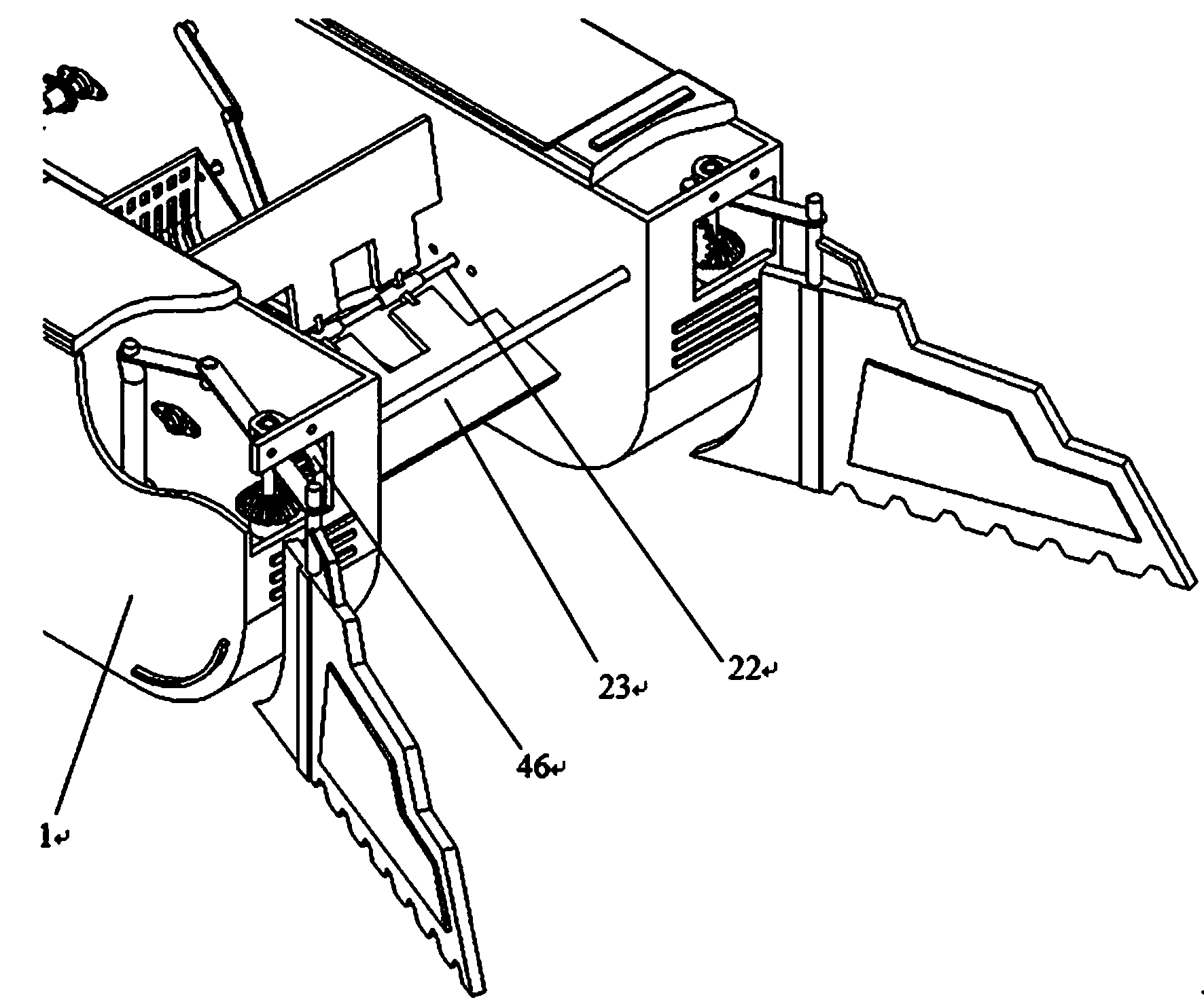

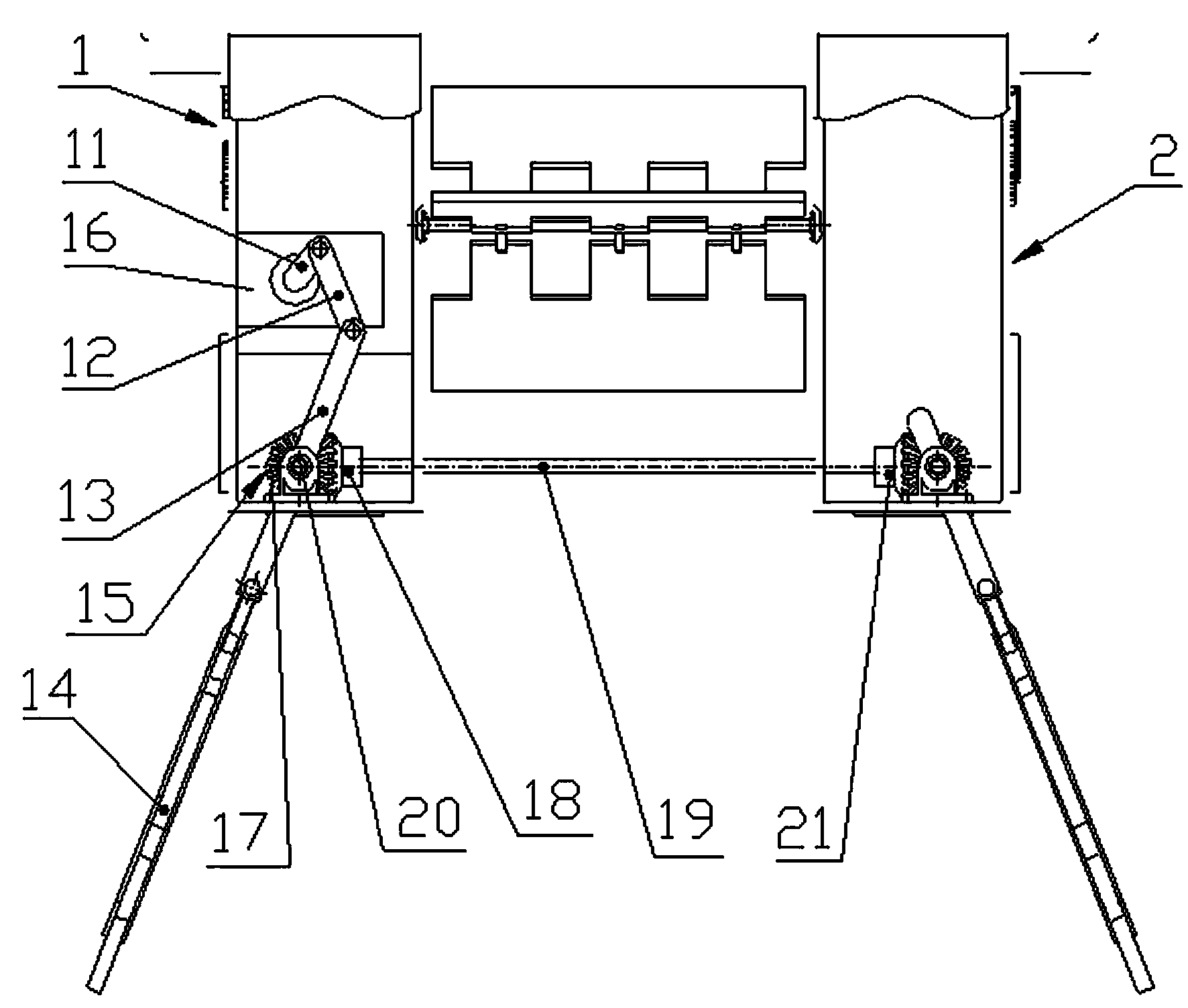

Refuse on water surface and cleaning ship for phytoplankton

InactiveCN104071309AOvercoming the disadvantage of being difficult to synchronizeAvoid knife entanglementWater cleaningWaterborne vesselsHull structureRefuse collection

The invention discloses a cleaning ship for phytoplankton. The cleaning ship is in a double ship structure and is composed of a driving wheel, a refuse guide mechanism, an impeller water distributor, a refuse tipping mechanism, a refuse cabin, a water plant cutting and collecting mechanism, a drive control system and other parts. When the ship works, the refuse in front of the ship is sucked into a tipping bucket refuse collecting area through a refuse guide mechanism and an impeller distributor, and then the refuse collected by the refuse tipping mechanism is poured into the refuse cabin on the ship; meanwhile, the phytoplankton and macrophyte are cut by an aquatic plant cutting mechanism, and then are transported to the refuse cabin through a water plant collecting mechanism (i.e. a rake type conveying crawler), after the refuse is full of the refuse cabin, a ship body docks, and the refuse is hung to a transfer trolley through a hoist. The cleaning ship is fast in speed of clearing away the refuse and phytoplankton on the water surface, and is capable of preventing the phenomenon that a cutter is twisted by the water plants.

Owner:SHENYANG LIGONG UNIV

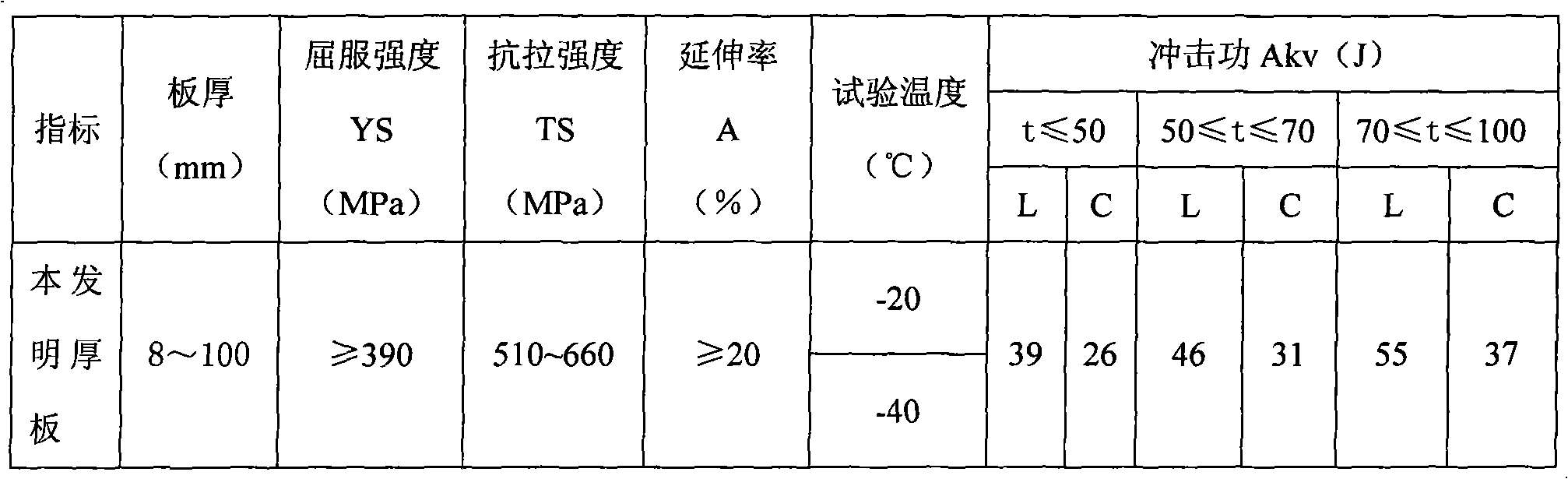

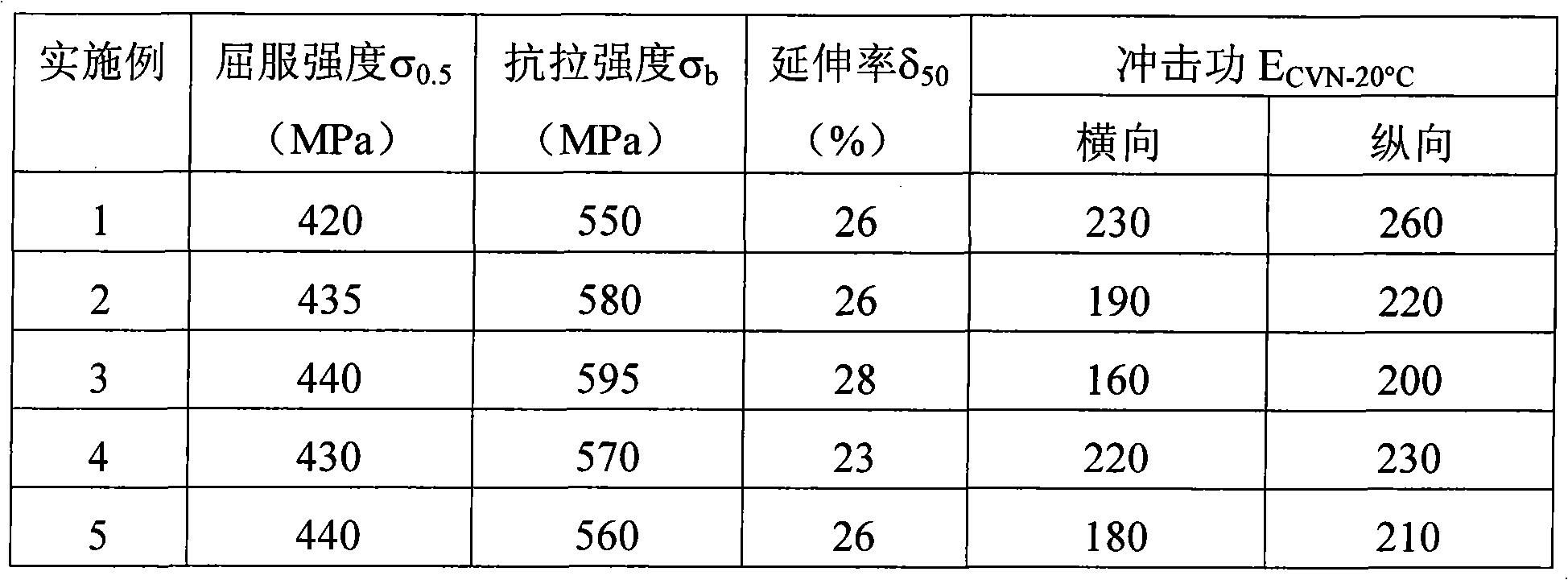

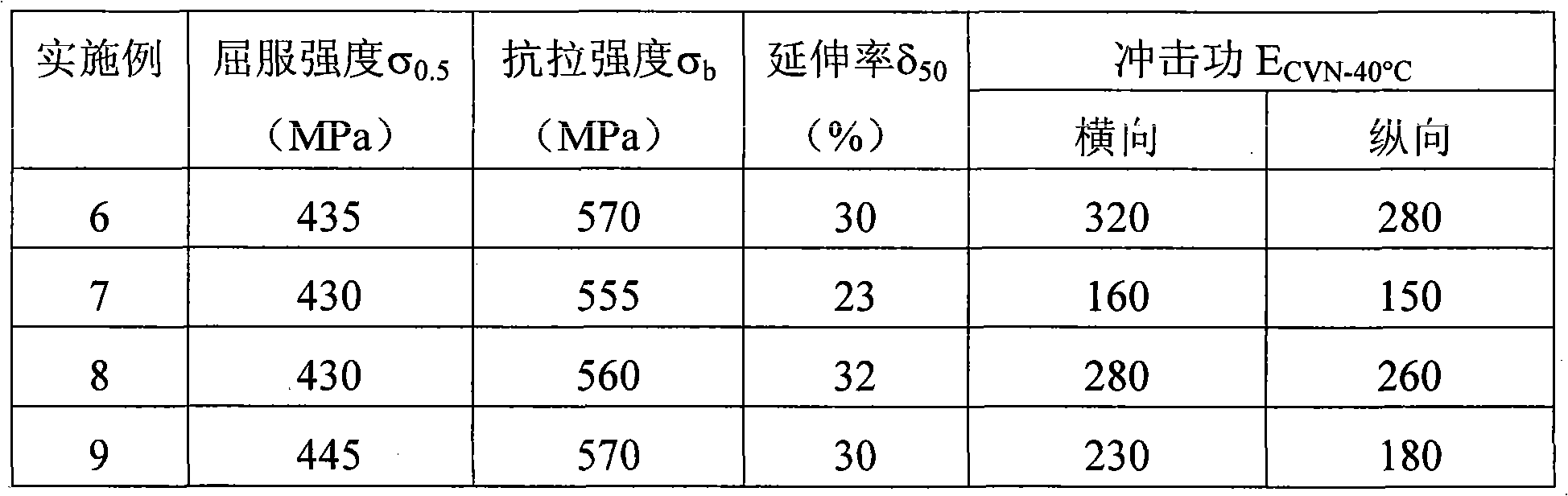

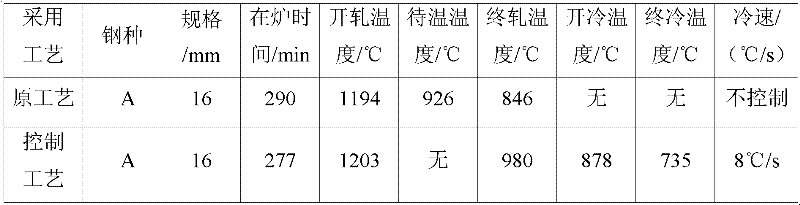

TMCP ocean structure thick plate and method for manufacturing same

InactiveCN101514424ASimple ingredientsReduce manufacturing costMetal rolling arrangementsHull structureChemical composition

Owner:BAOSHAN IRON & STEEL CO LTD

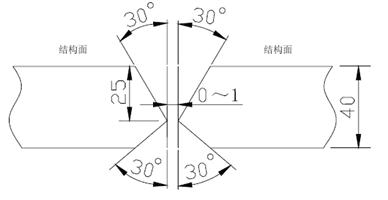

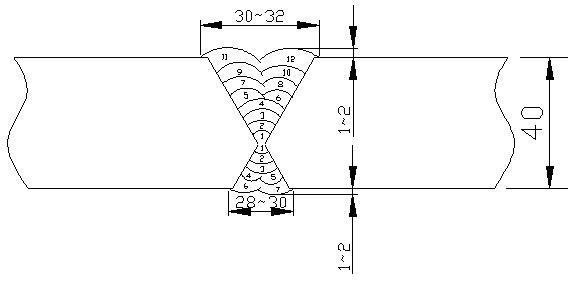

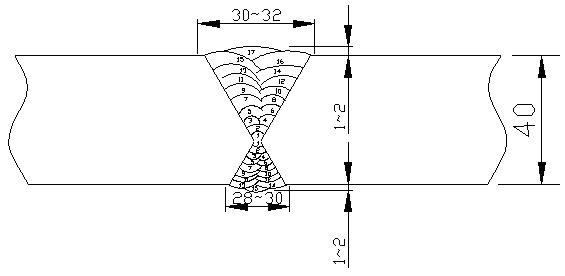

Plain butt welding process for high-strength hull structural steel

ActiveCN102019481AShorten the construction periodImprove labor efficiencyArc welding apparatusWorkpiece edge portionsHull structureCold treatment

The invention relates to a process for welding a high-strength hull structure steel, in particular to a plain butt welding process for a high strength hull structural steel plate (CCSE69040mm). The butt welding process is characterized in that effective specifications for bevel for welding, weld preheating, welding temperature, welding sequence, welding variables and after-welding cold treatment are provided. The plain butt welding process has the advantages of enabling the process of welding a super-thin high strength steel plate to be implemented smoothly, improving the operating efficiency, saving the raw materials, reducing the production cost, reducing the shipbuilding period, and filling a domestic technical blank on the welding of a high strength thick hull structural steel (CCSE69040mm).

Owner:WUCHANG SHIPBUILDING IND

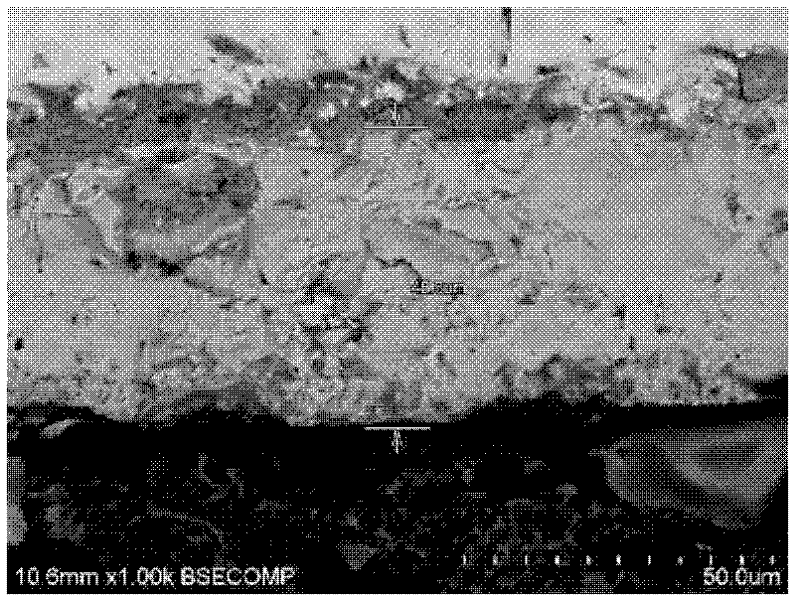

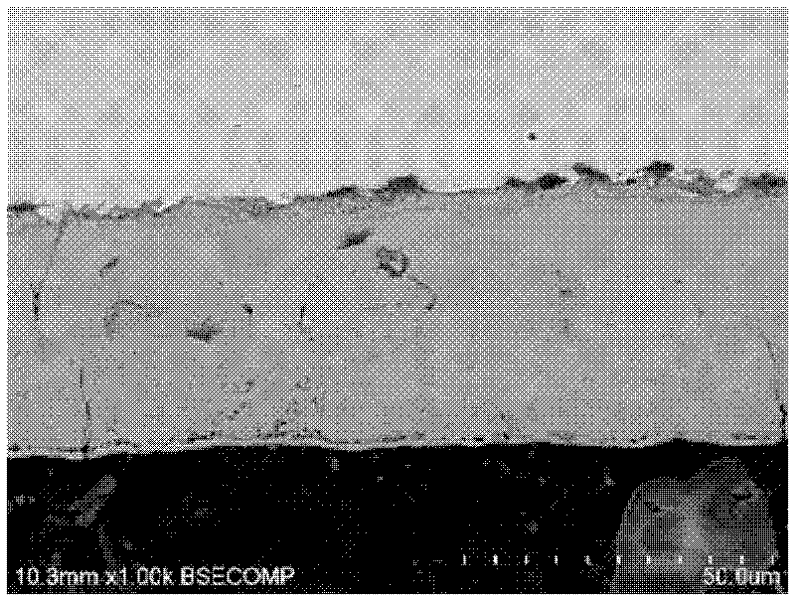

Control method for coast atmospheric corrosion resistant scale on surface of boat deck

ActiveCN102367546AImprove surface qualityIncrease productivityTemperature control deviceWork treatment devicesHull structureStructural composition

The invention discloses a control method for coast atmospheric corrosion resistant scale on the surface of a boat deck, which belongs to the field of steel for hull structures. According to the invention, the structure and thickness of scale on the surface of a boat deck is controlled by optimizing production processes for boat decks. The method comprises the following key points: controlling parameters of heating temperature, time, residual oxygen and the like for continuous casting billets and reinforcing a de-scaling effect once; controlling the index of chloride ion in water for production, reducing the content of deposited chloride ions in scale and inhibiting corrosive pitting; controlling initial rolling temperature and finishing rolling temperature in the stage of finish rolling, reasonably utilizing a weak water cooling system, increasing the content of Fe3O4 in scale, reducing the content of Fe2O3, retaining a small amount of FeO and enabling the scale to have good plasticity, a bonding force and corrosion resistance. The advantages of the invention are as follows: it does not need to reconstruct existing equipment, and the surface quality and production efficiency of the boat deck can be enhanced through technological optimization; structural composition of the scale is reasonably controlled, which enables the surface of the boat deck to have excellent coast atmospheric corrosion resistance, especially enables corrosive pitting caused by chloride ions to be inhibited, and enables the storage duration of the boat deck in coast environment to be prolonged.

Owner:SHOUGANG CORPORATION

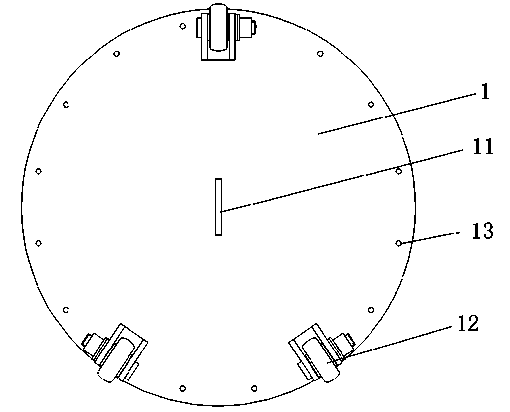

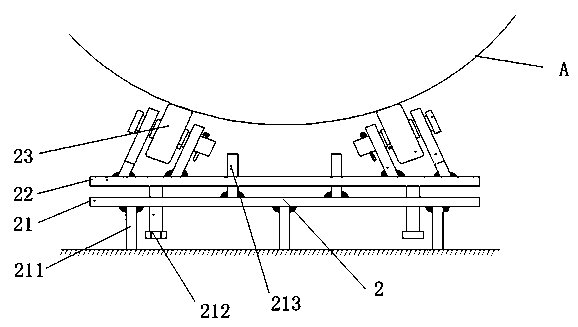

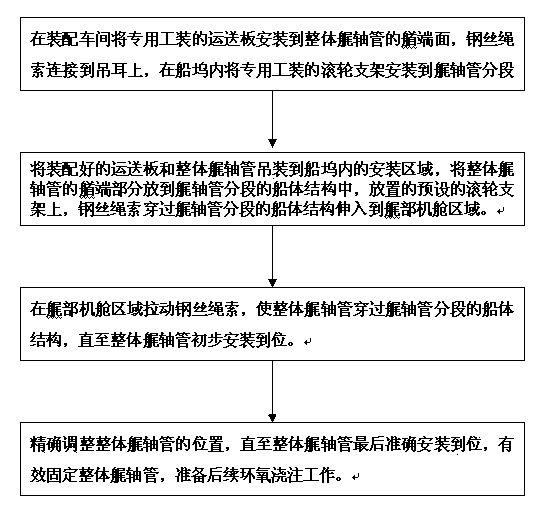

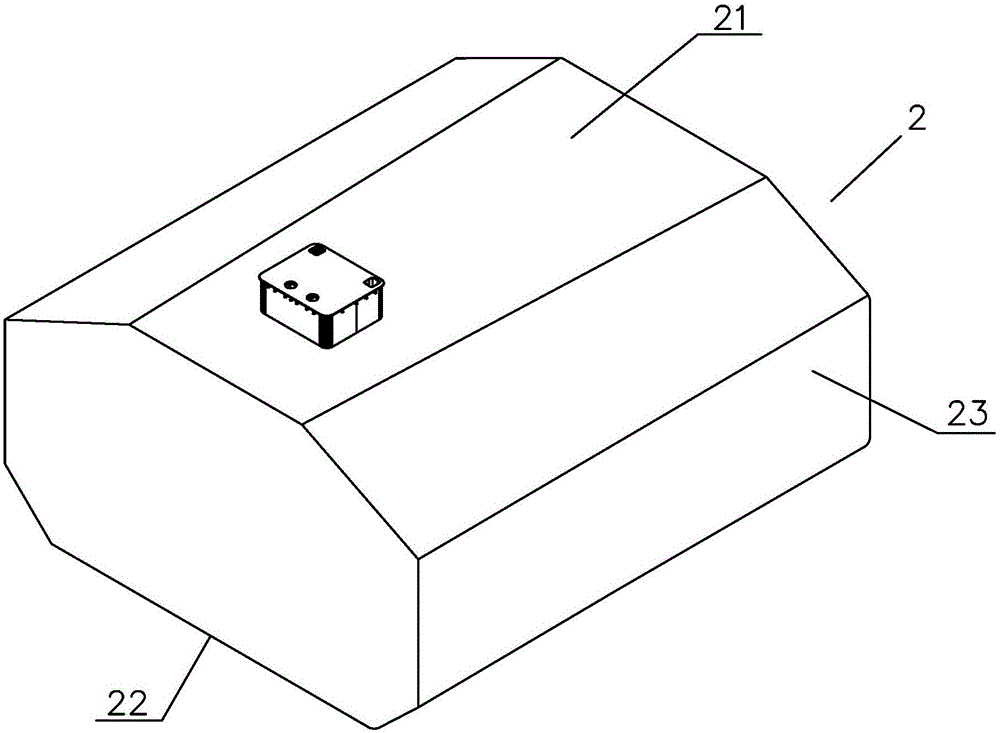

Mounting method of integral stern shaft tube on naval architecture and ocean engineering

The invention relates to a mounting method of an integral stern shaft tube on naval architecture and ocean engineering. The mounting method is used for special tools, and the special tools comprise a conveying plate and an idler wheel support. The mounting method specifically comprises the following steps: firstly, assembling the integral stern shaft tube with the conveying plate integrally, and connecting a steel wire rope with the conveying plate; secondly, mounting the idler wheel support on a ship structure in the subsection of the stern shaft tube in advance; thirdly, lifting the assembled conveying plate and integral stern shaft tube in a dock, and putting the bow end part of the integral stern shaft tube in the ship structure at the subsection of the stern shaft tube; stretching the steel wire rope to a stern engine room area; fourthly, pulling the steel wire rope until the integral stern shaft tube is in place primarily; fifthly, accurately adjusting the position of the integral stern shaft tube in exact place, and effectively fixing the integral stern shaft tube. According to the mounting method disclosed by the invention, the integral stern shaft tube can be effectively prevented from colliding, so that the mounting workload of stern tube assembly is reduced, and the mounting quality and efficiency of the integral stern shaft tube are improved.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

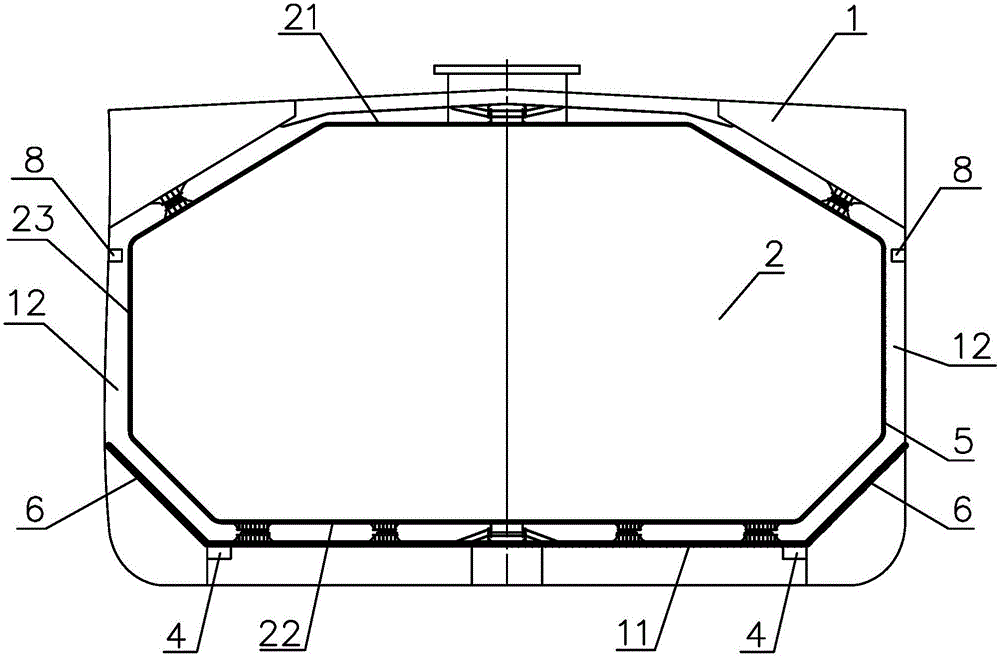

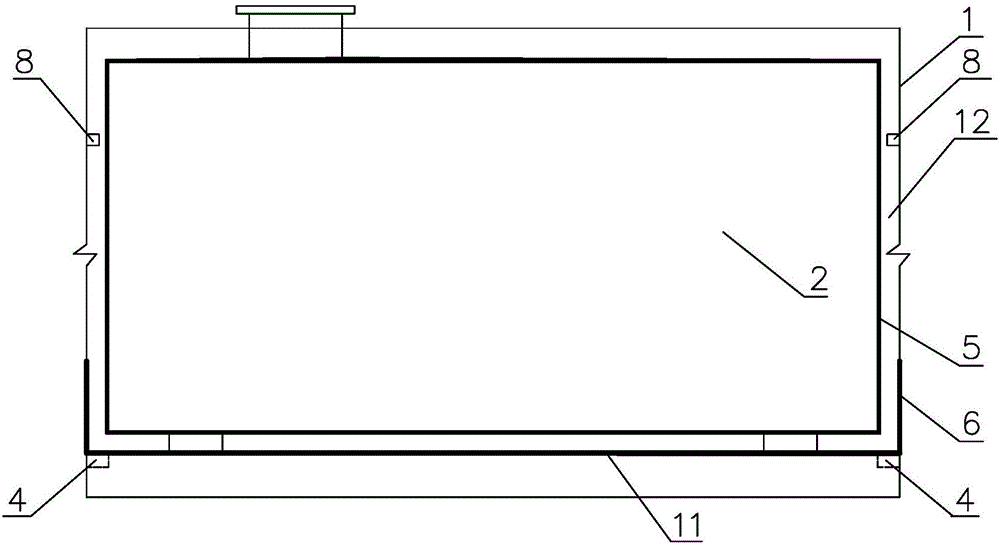

Containment system for type B independent liquid cargo tank

ActiveCN106516016AEffective collection and processingEnsure safetyFor bulk goodsHull structureEngineering

The invention provides a containment system for type B independent liquid cargo tank. The liquid cargo tank comprises a top surface, a bottom surface and a side wall, wherein the top surface, the bottom surface and the side wall are formed by welding a plurality of outer plates; the containment system comprises leakage slots and liquid collecting wells; the leakage slots respectively cover all the weld seams among the outer plates on the top surface and the side wall; the liquid leaking from the weld seams can flow down along the leakage slots to an inner bottom plate of a hull; one or more liquid collecting wells are respectively arranged at both ends of the inner bottom plate in the length direction of the hull; insulating layers are laid on the top surface, the bottom surface and the side wall; the containment system also comprises a baffle plate; the baffle plate is arranged around the liquid cargo tank; and the upper end of the baffle plate is connected with the wall plate of the hull, and the lower end of the baffle plate is connected with the inner bottom plate. According to the containment system disclosed by the invention, the cost is reduced in the aspect of materials by reasonable design of the containment system, and the containment system can guarantee the safety of the hull structure in the case of liquid cargo leakage in the liquid cargo tank.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Integrated marine vessel hull for energy storage

InactiveUS20060228960A1Reduce spacingPropulsion power plantsRegenerative fuel cellsHull structureMarine engineering

A hull structure is provided for a marine vessel having an inner hull and an outer hull. An energy storage device is provided between the inner hull and outer hull. The energy storage device has one or more hollow tubes, or has a honeycomb structure. Hydrogen or oxygen can be stored and placed within the hollow tubes or honeycomb structure. A metal hydride, or liquid hydrogen or compressed hydrogen gas, as well as liquid oxygen or compressed oxygen gas can also be stored inside the hollow tubes or honeycomb structure. The dual use of the hull structure provides for an energy storage apparatus and propulsion generation system that conserves space within the marine vessel, and adds less weight to the marine vessel.

Owner:LOCKHEED MARTIN CORP

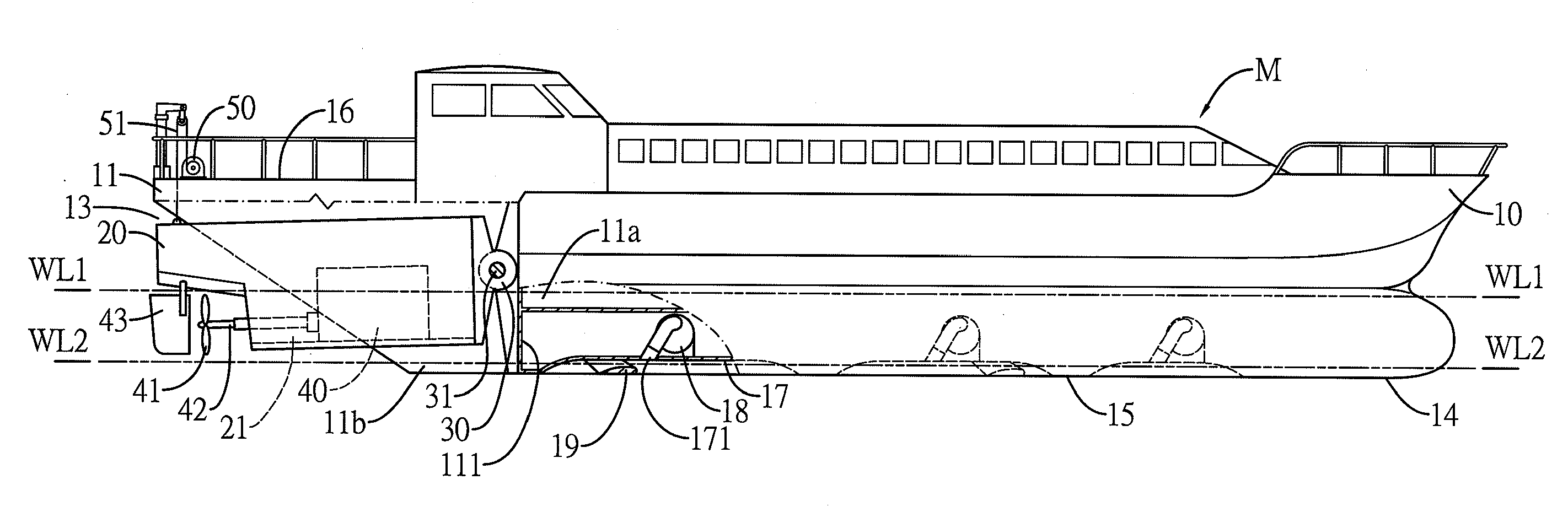

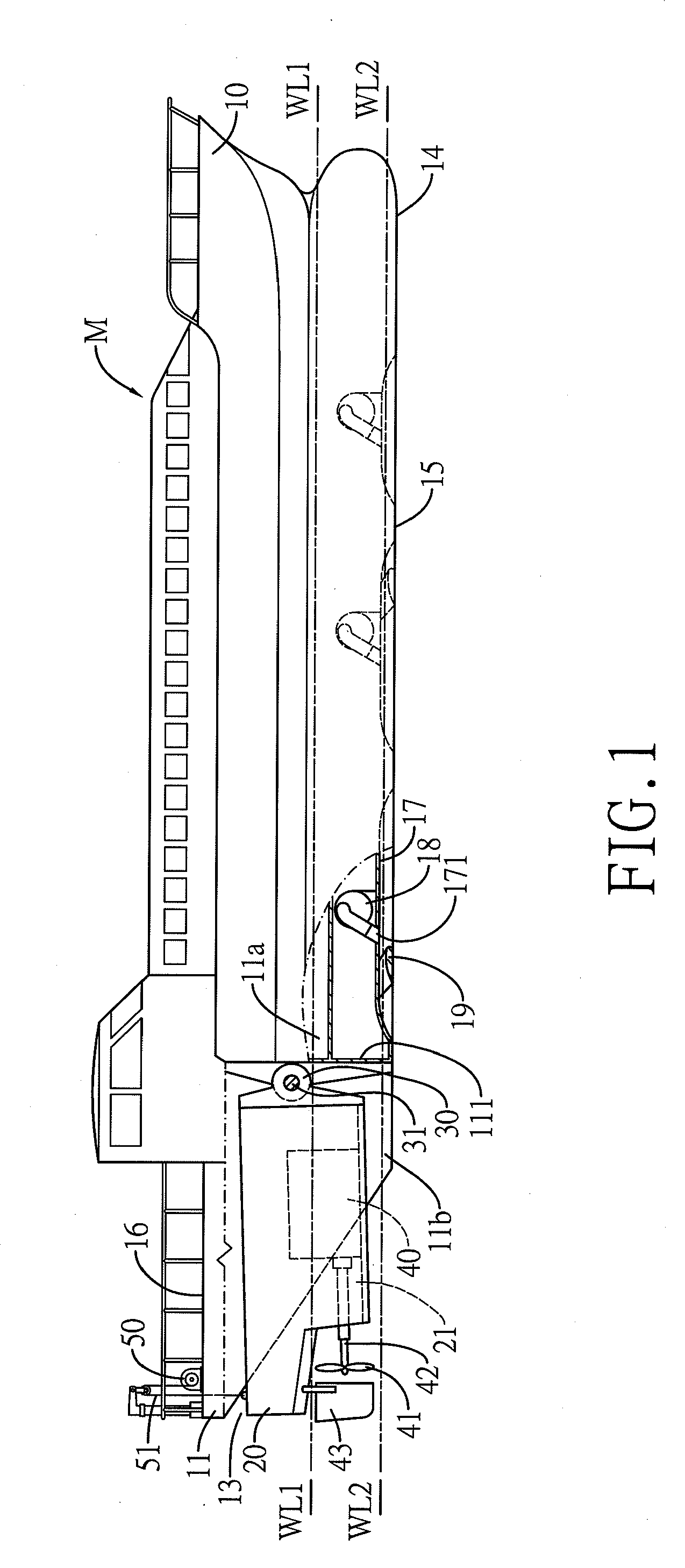

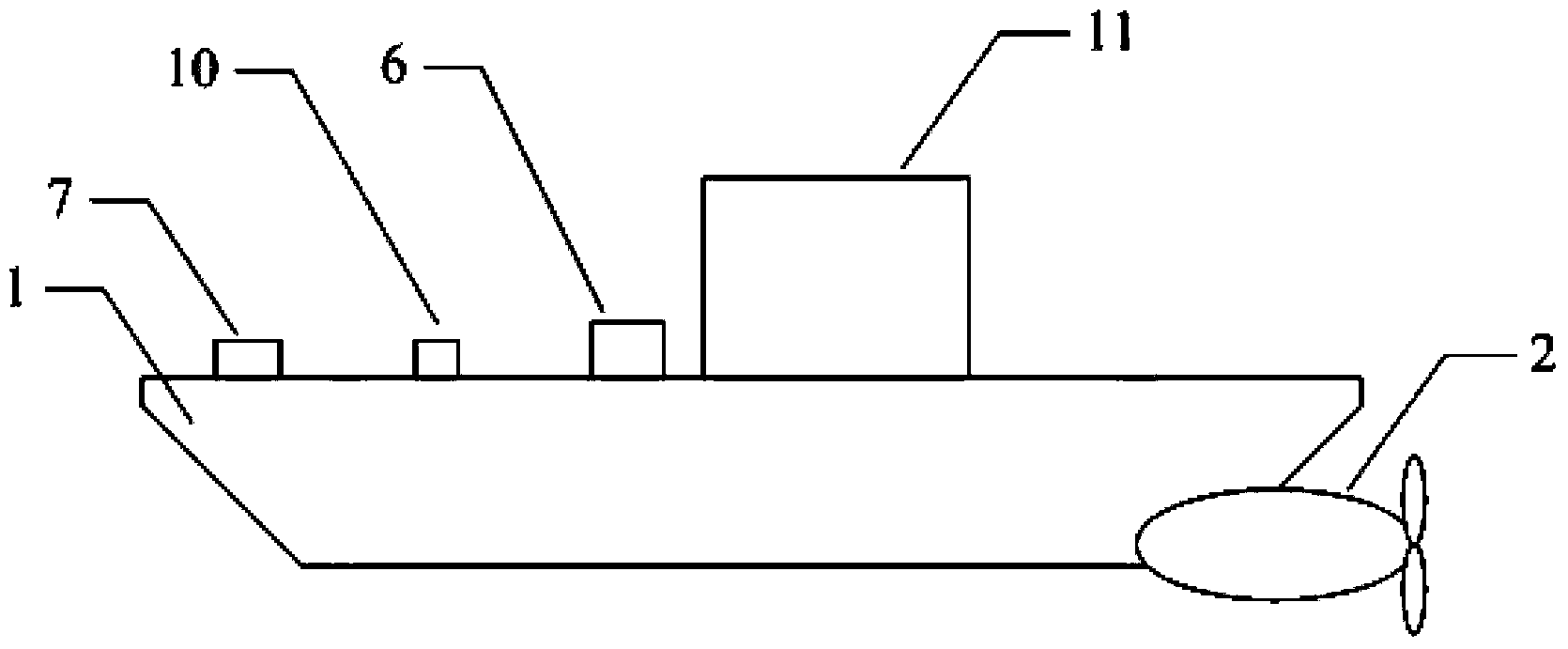

Ship hull structure and a method of operating the ship

ActiveUS20100064959A1Reduce viscous forceIncrease propulsionWatercraft hull designPropulsive elementsHull structureWind wave

A ship hull structure includes a main hull and a movable rearbody having an engine and a propeller. The movable rearbody is located at a lower side of a stern of the main hull, connected with an aft of the main hull to form an integral unit by a hinge linking device allowing the rearbody to pivot up and down. By a block, a crane or a winch and through a chain or a hanging wire, a pivoting angle of the movable rearbody with respect to the main hull can be adjusted and controlled. A bottom of the hull can be provided with at least one, usually plural, air cushion recess, which is filled with pressurized air to reduce a viscous force between a bottom of the ship and water. When a ship of this kind of structure is sailing, the rearbody can be lifted up by the block or the winch, allowing part of the propeller to be separated from a water surface to reduce resistance in the water that the engine can achieve a required rotational speed (RPM) in a short time. Next, the rearbody is laid down slowly, allowing the propeller to be put into the water, thereby increasing propulsion and quickly achieving a cruising speed. When the ship is sailing and encounters with wind wave, the stern will ascend by longitudinal pitching; at this time, the rearbody can descend by its own weight, with a hinge axis as a center, preventing the propeller to leave the water surface to rotate idly. On the other hand, when a bow ascends (that is, the stern descends), the rearbody will maintain a normal draught height by buoyancy of the water and the force between the water and running propeller Therefore, for the entire ship, a wetted surface area of the propeller can be adjusted automatically to keep at a best sailing condition, which can further save fuel consumption significantly. In another embodiment that the bottom of the ship is formed with the air cushion recesses, a friction force of the water can be reduced to increase a ship speed by the air cushion effect formed at the bottom of the ship.

Owner:HUANG BILL WEN CHANG

Radial bearing arrangement and method for installation

A lower bearing arrangement between a turret of an FPU and a moonpool. The outer housing of the bearing is mounted about the turret instead of the FPU's hull structure. Bearing segments are captured between an outer ring of the turret and an inner ring of the outer housing. The outer housing of the bearing assembly is coupled to a reaction ring of the moonpool so that rotation forces of the vessel are transferred to the outer housing of the bearing. The coupling also includes an arrangement by which the outer housing contacts said reaction ring in the nature of a spherical joint.

Owner:FMC TECH INC

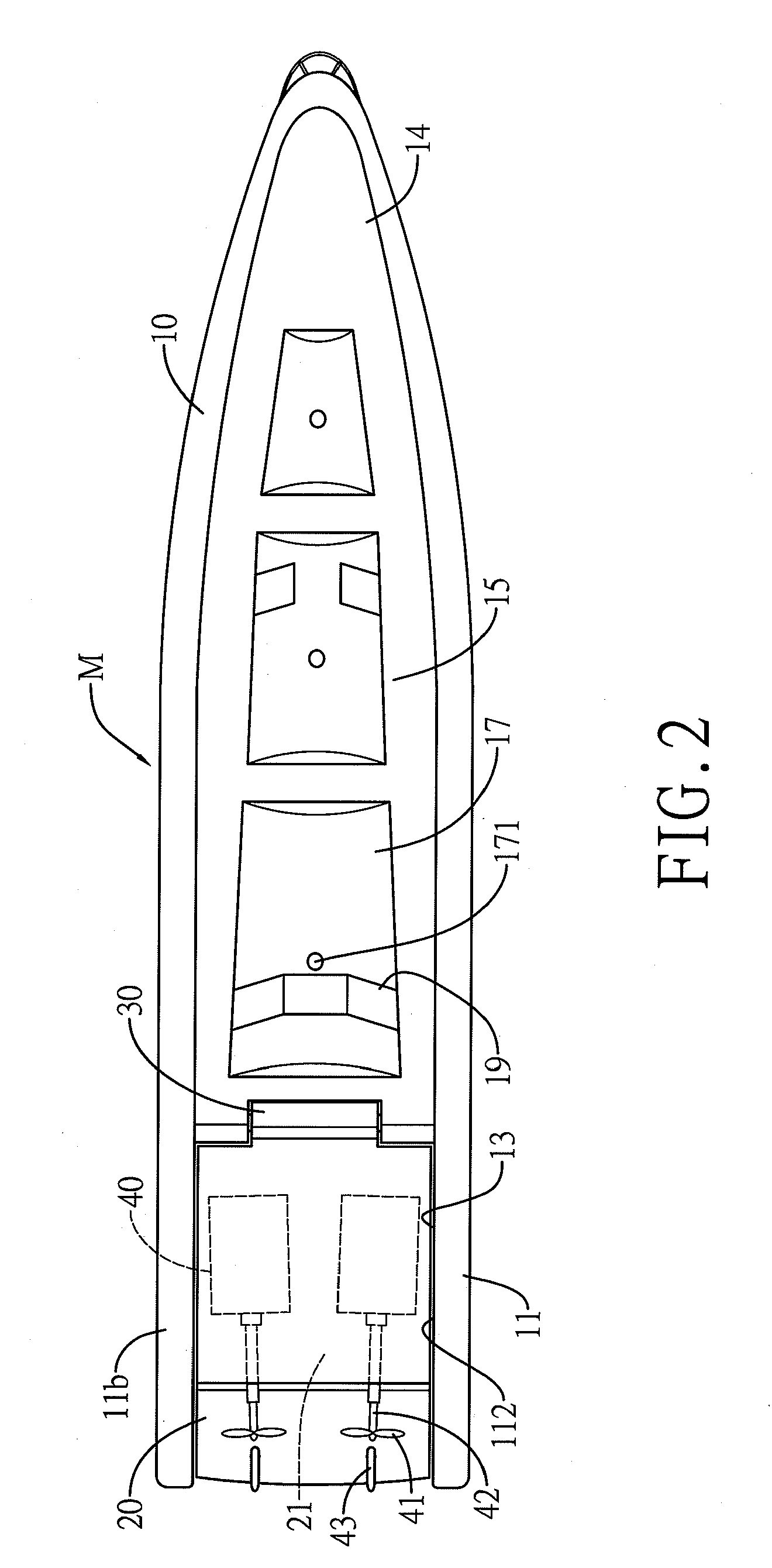

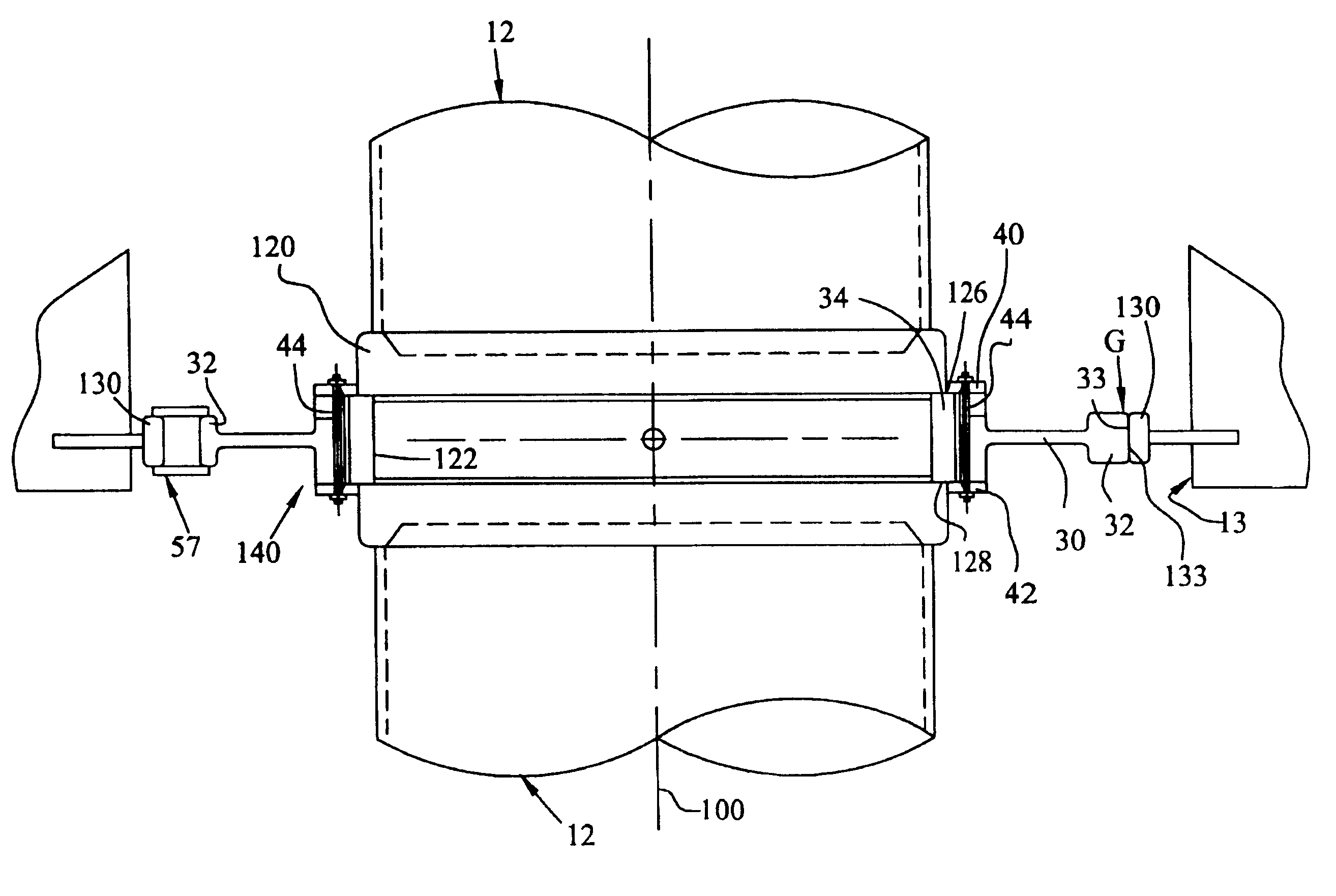

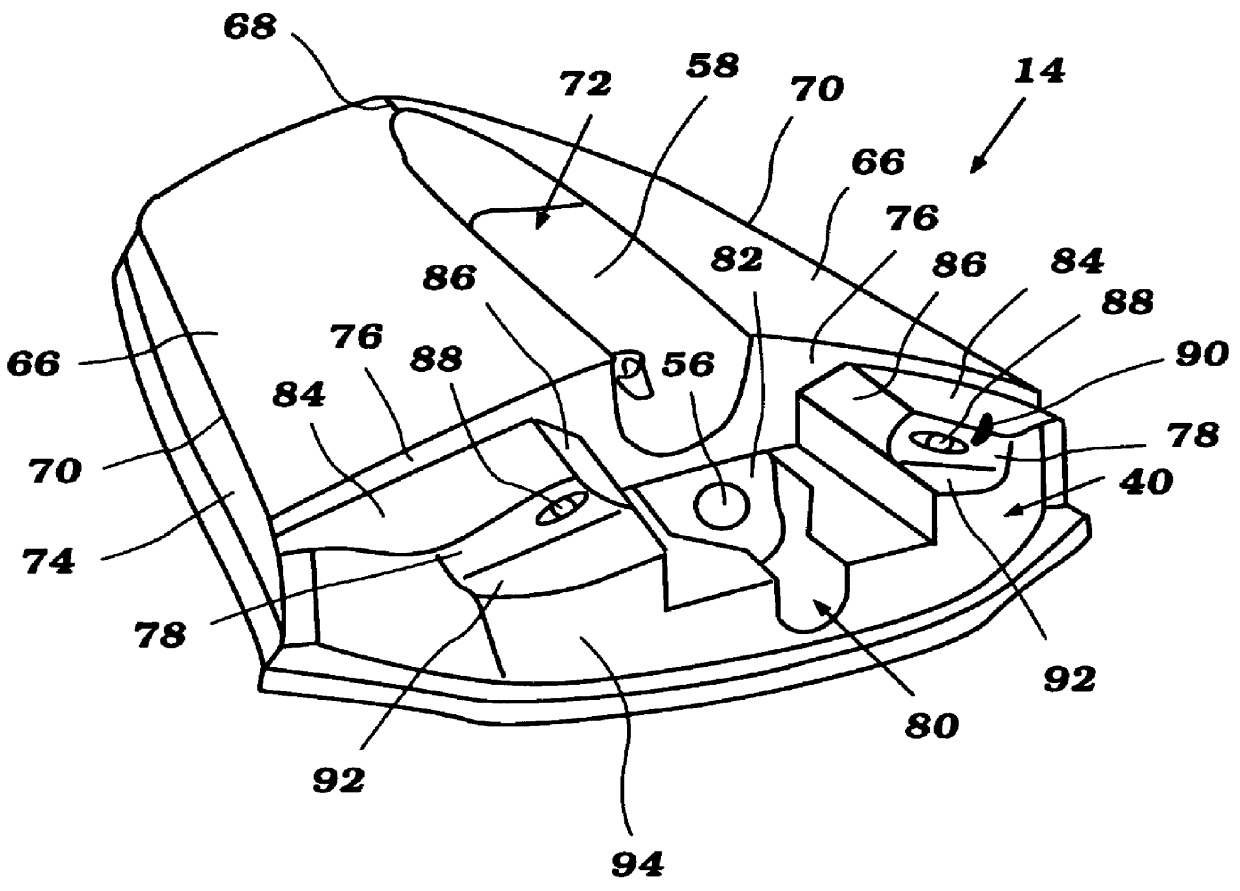

Boat hull structure

InactiveUS20080070455A1Improve stabilityLess fuel consumptionRotary propellersFloating buildingsHull structureMarine engineering

A boat hull comprises a hull body having two lateral flanks linked by a bottom surface, and at least two propulsion compartments provided in two bulges protruding below the bottom surface of the hull body. Each propulsion compartment lodges a propulsion engine located below the bottom surface of the hull body. The propulsion engines are located at the deepest position in the hull and below the water plane.

Owner:TA CHIAO CHOU YACHT BUILDING

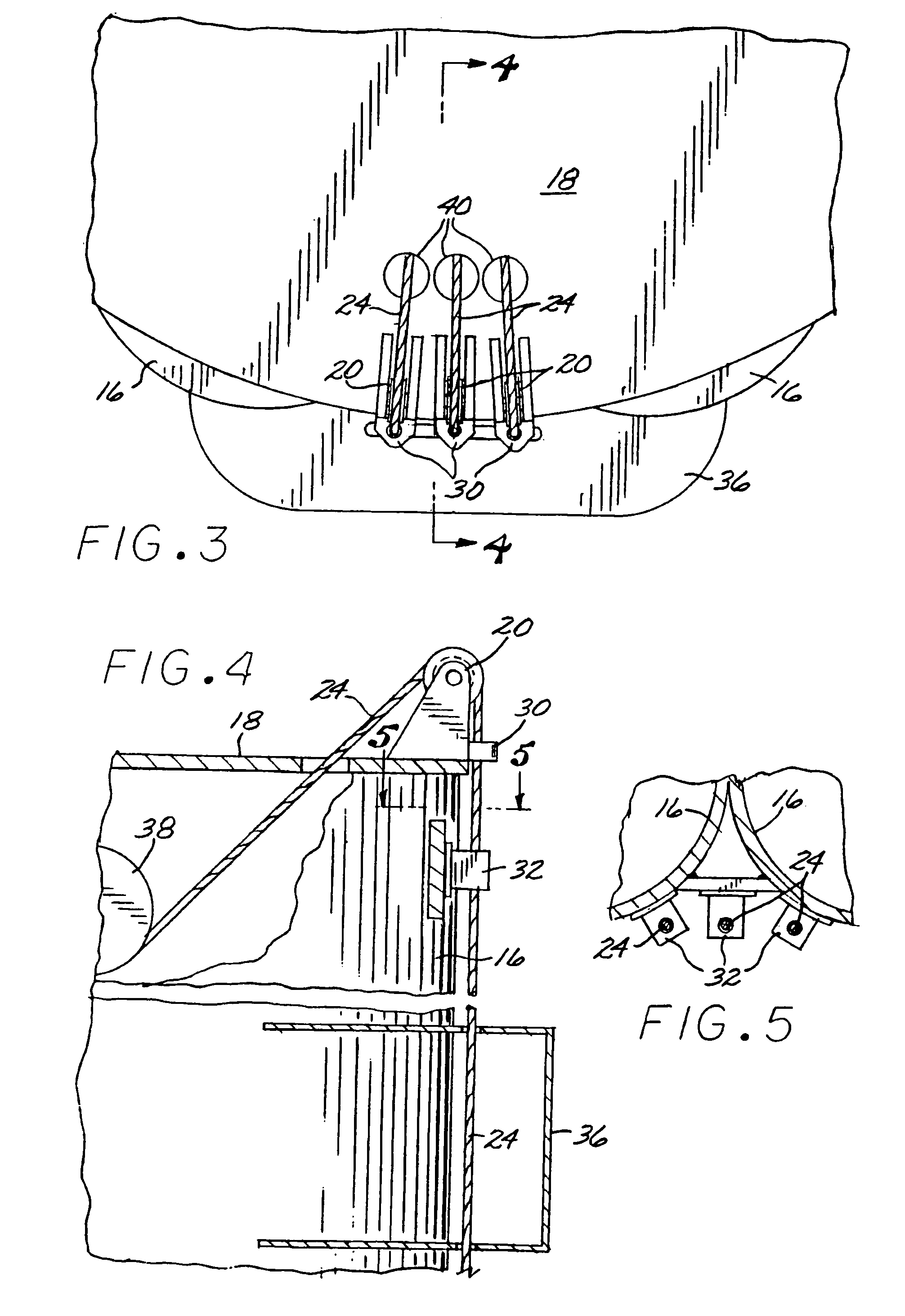

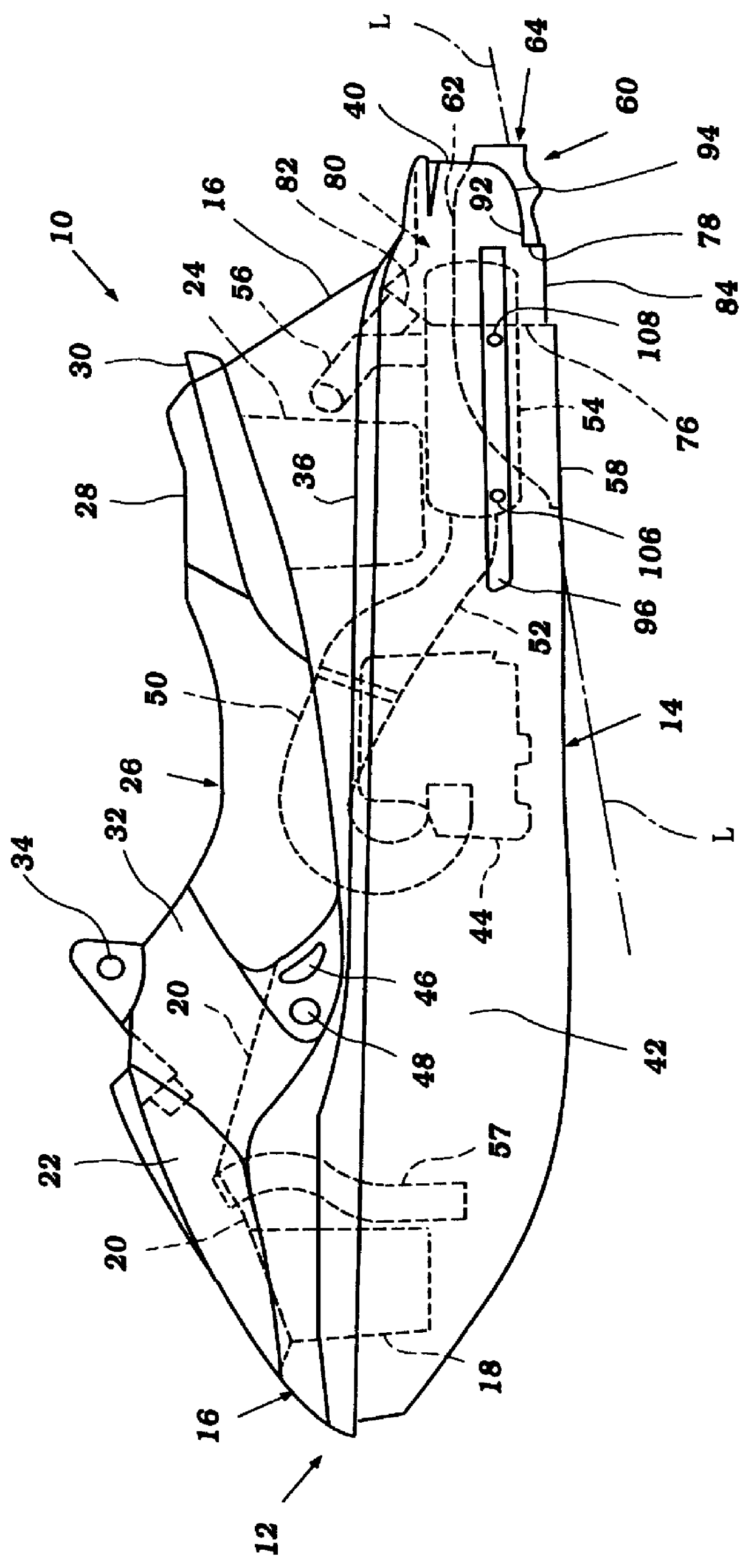

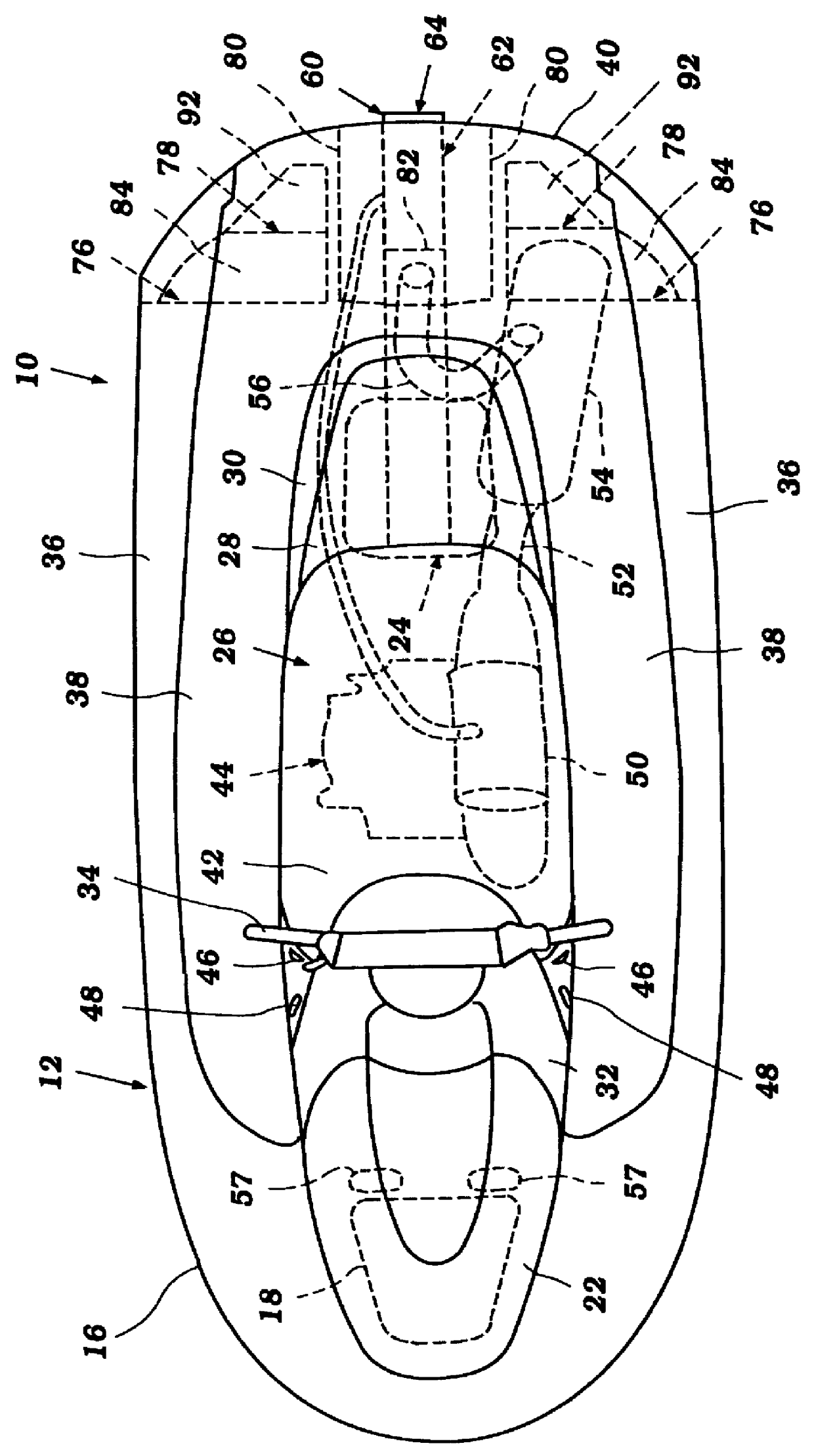

Hull construction for small watercraft

InactiveUS6058873ASelf-bailing equipments/scuppersVessel movement reduction by foilsHull structureWetted area

A personal watercraft includes an improved hull design which reduces drag on the watercraft and inhibits porpoising of the watercraft at high speeds, while providing adequate buoyancy when the watercraft is at rest. The watercraft hull includes a pair of steppers positioned toward the aft end of the watercraft hull. The rear stepper has a greater height than the front stepper. This design reduces the wetted area of the hull when the watercraft is up on plane. The second stepper, however, provides additional surface contact should the watercraft to porpoise in order to stabilize the watercraft. The hull design also includes improved foot steps and adjustable sponsons. The foot steps are sloped upwardly in order to provide greater control of the watercraft when leaning the watercraft in a turn.

Owner:YAMAHA MOTOR CO LTD

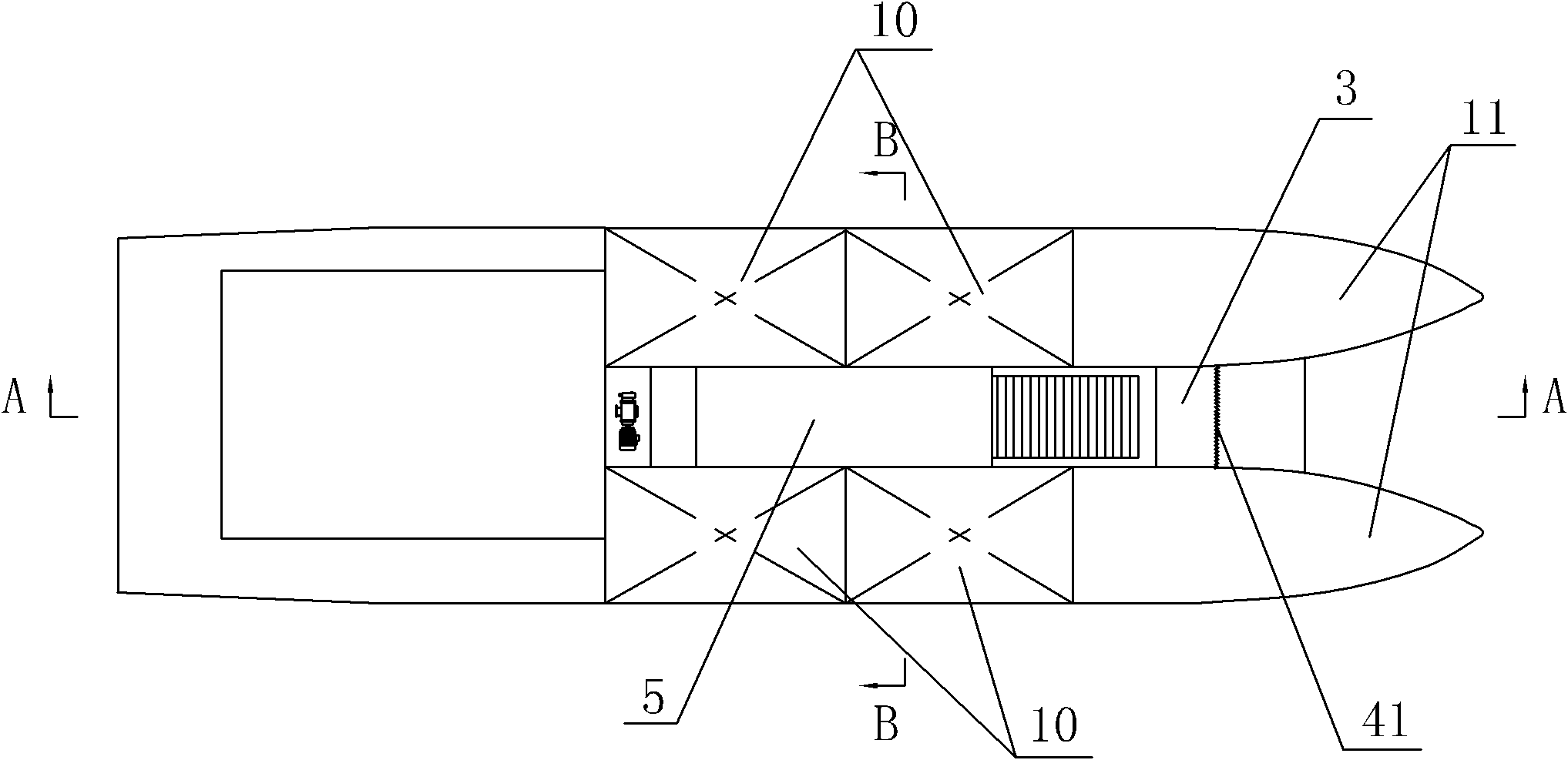

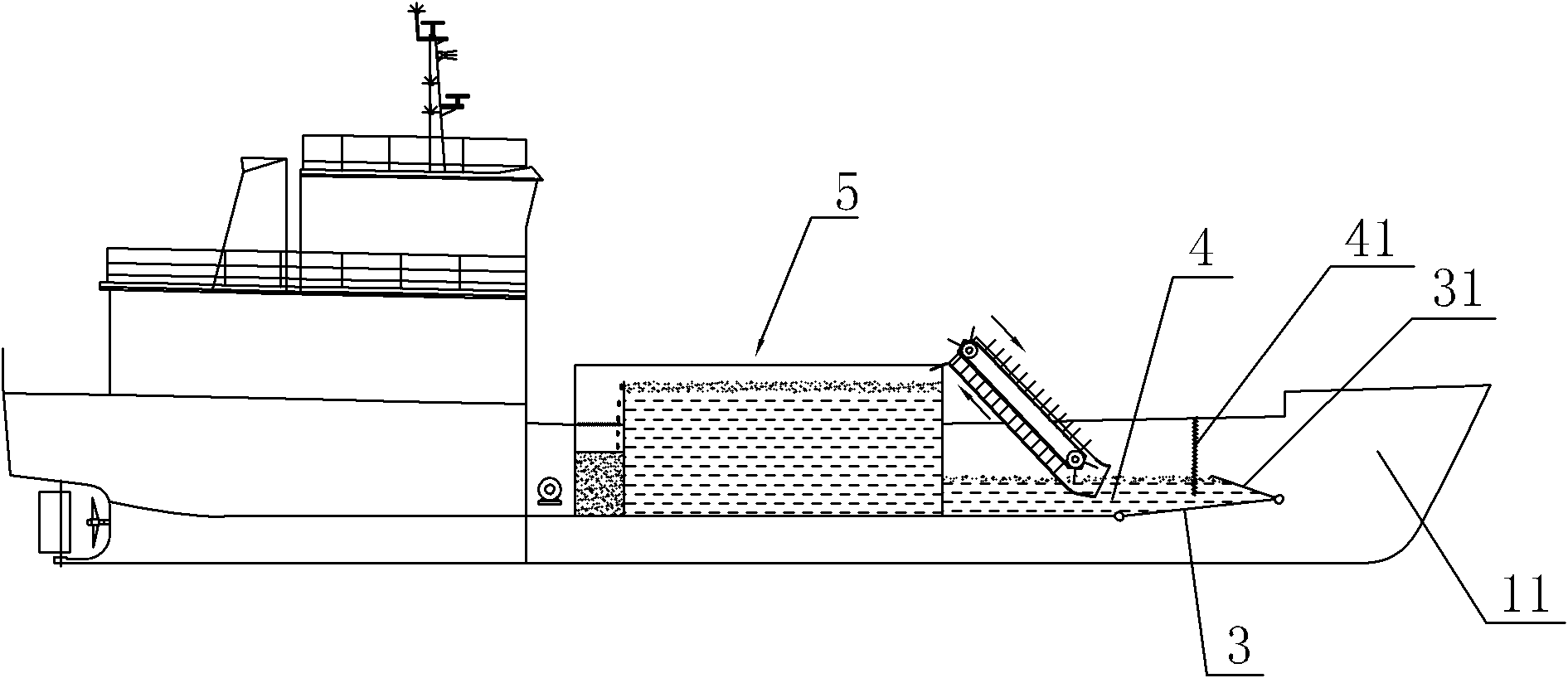

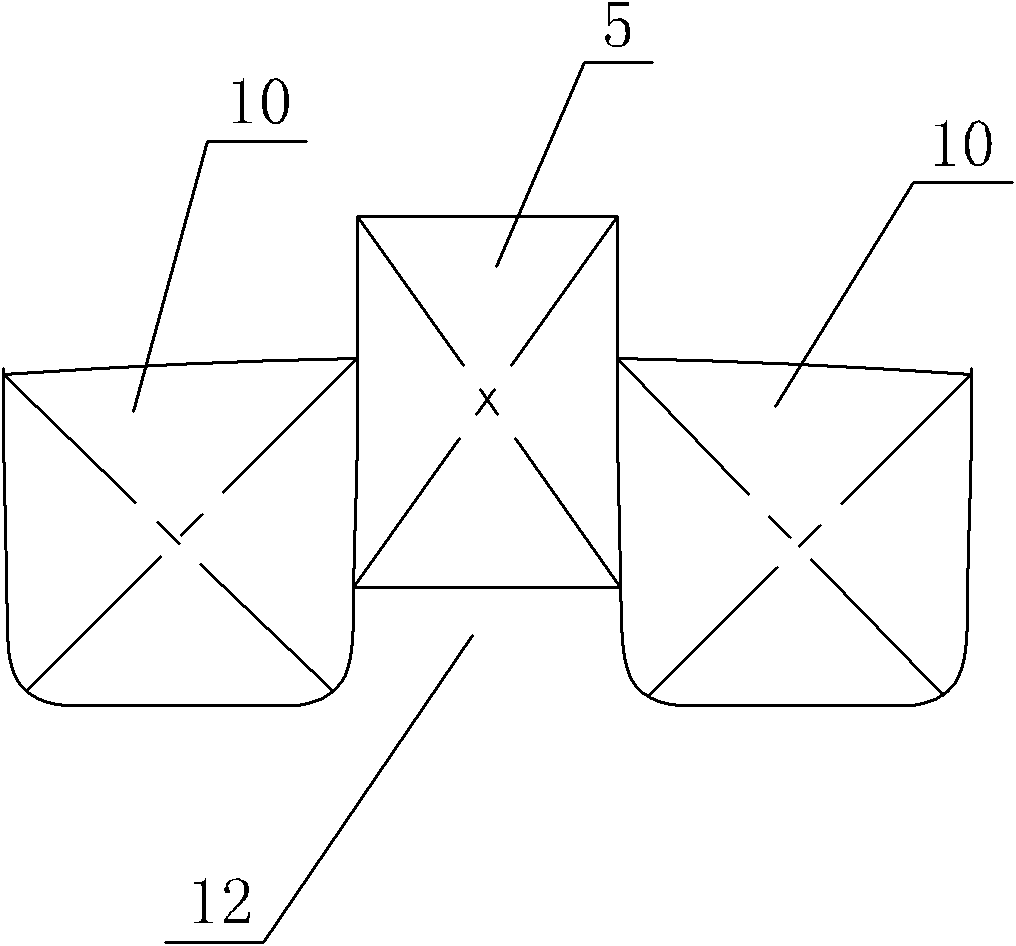

Water surface floating oil recovery ship

InactiveCN101962067AReduce oil inlet resistanceSmooth entryWaterborne vesselsSpecial purpose vesselsHull structureMarine engineering

The invention discloses a water surface floating oil recovery ship. The water surface floating oil recovery ship comprises a hull, a floating oil collecting device and an oil and water separating device, and is characterized in that: the stem of the hull has a catamaran structure and is in a pointed cone form; the middle part to the tail part of the hull has a single hull structure; and a flow guiding channel which is recessed inward and is through in the longitudinal direction is formed in the middle of the bottom of the part which has the single hull structure. The water surface floating oil recovery ship has the advantages that: because the stem of the hull has the catamaran structure, and the flow guiding channel which is recessed inward and is through in the longitudinal direction isformed in the middle of the bottom of the part which has the single hull structure, the oil intake resistance generated in the driving process of the ship can be greatly reduced, floating oil can smoothly enter an oil and water pool, and the oil sweeping area of the ship is increased; and due to a chain type floating oil lifting device, a floating oil heating device in an oil and water separatingcabin, and two garbage filtering grids which are additionally arranged, the overall floating oil recovery ship can be applied to the floating oil with any viscosity and any thickness and has low requirements on a water surface environment, and the applicable water area is wide.

Owner:宁波市科技园区海星船舶设计所

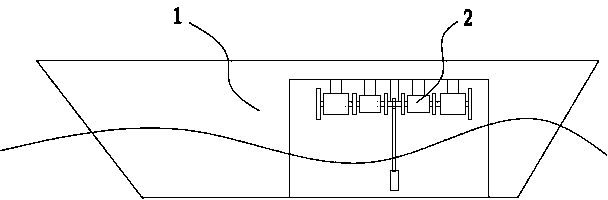

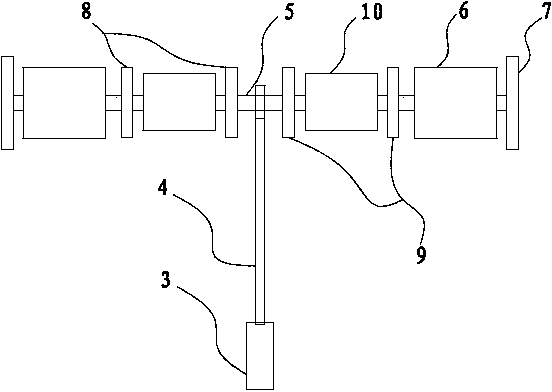

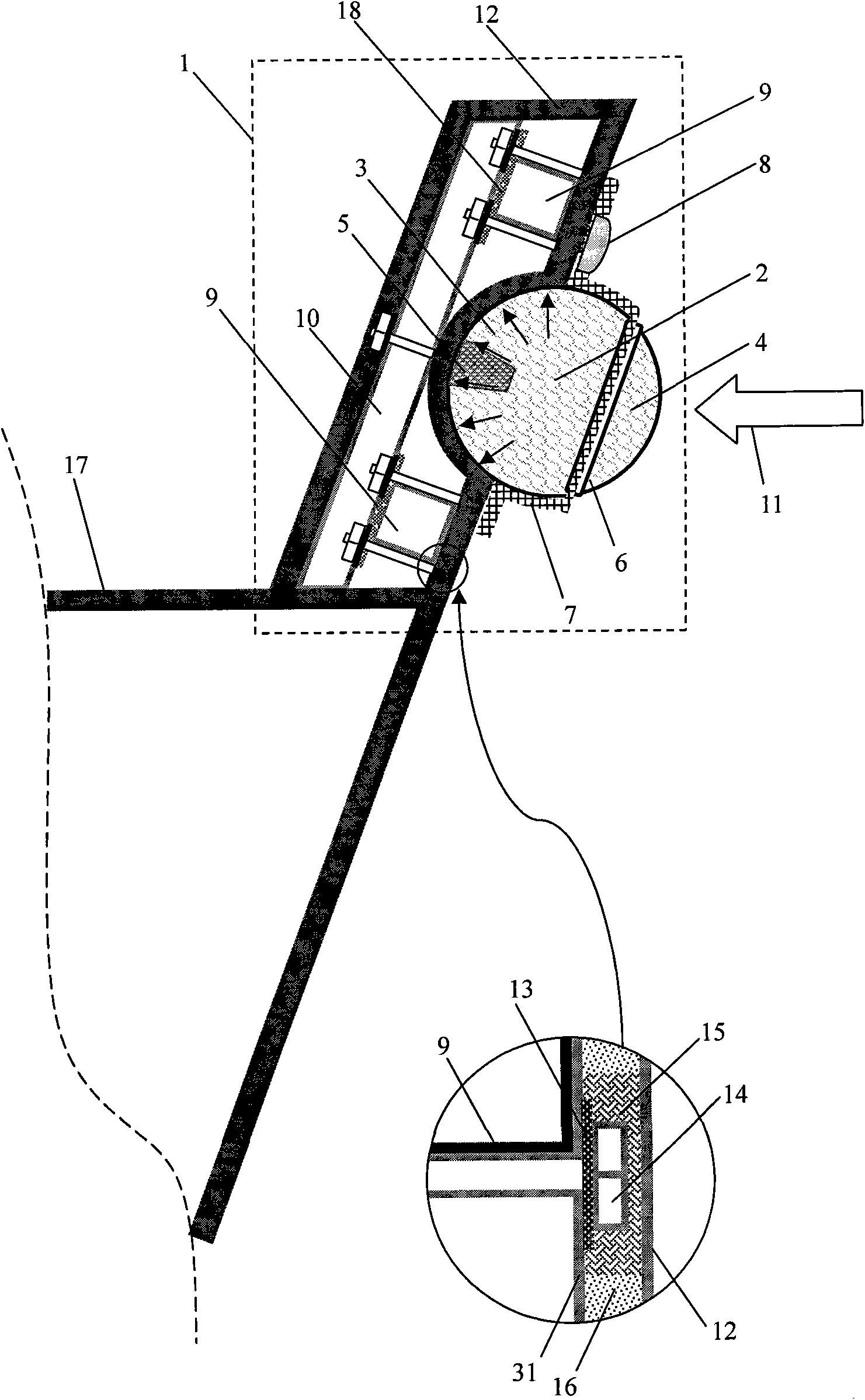

Pendulum electricity generation device using hull swing

The invention relates to a pendulum electricity generation device using hull swing. The problems that according to an existing wave electricity generation device, a hull structure needs to be improved to be suitable for different depths of immersion of a hull are solved. The device comprises a pendulum arranged in a hull, a pendulum bob is arranged at the bottom of the pendulum and connected to a pendulum shaft through a rigid connecting rod, the pendulum shaft is arranged on a hull bearing, the two ends of the pendulum shaft are connected with electricity generators through a forward-direction ratchet wheel and a reverse-direction ratchet wheel respectively. According to ceaseless and changing swing of the hull on the sea, the pendulum is arranged in the hull, unsynchronized swing of the pendulum and the hull is used for driving the electricity generators to generate electricity, electricity generation energy sources are clean, and the generated electricity effectively supplements electricity utilization of ships on the sea.

Owner:ZHEJIANG OCEAN UNIV

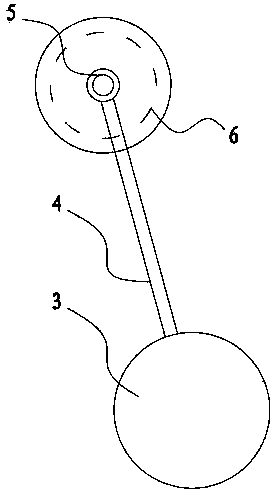

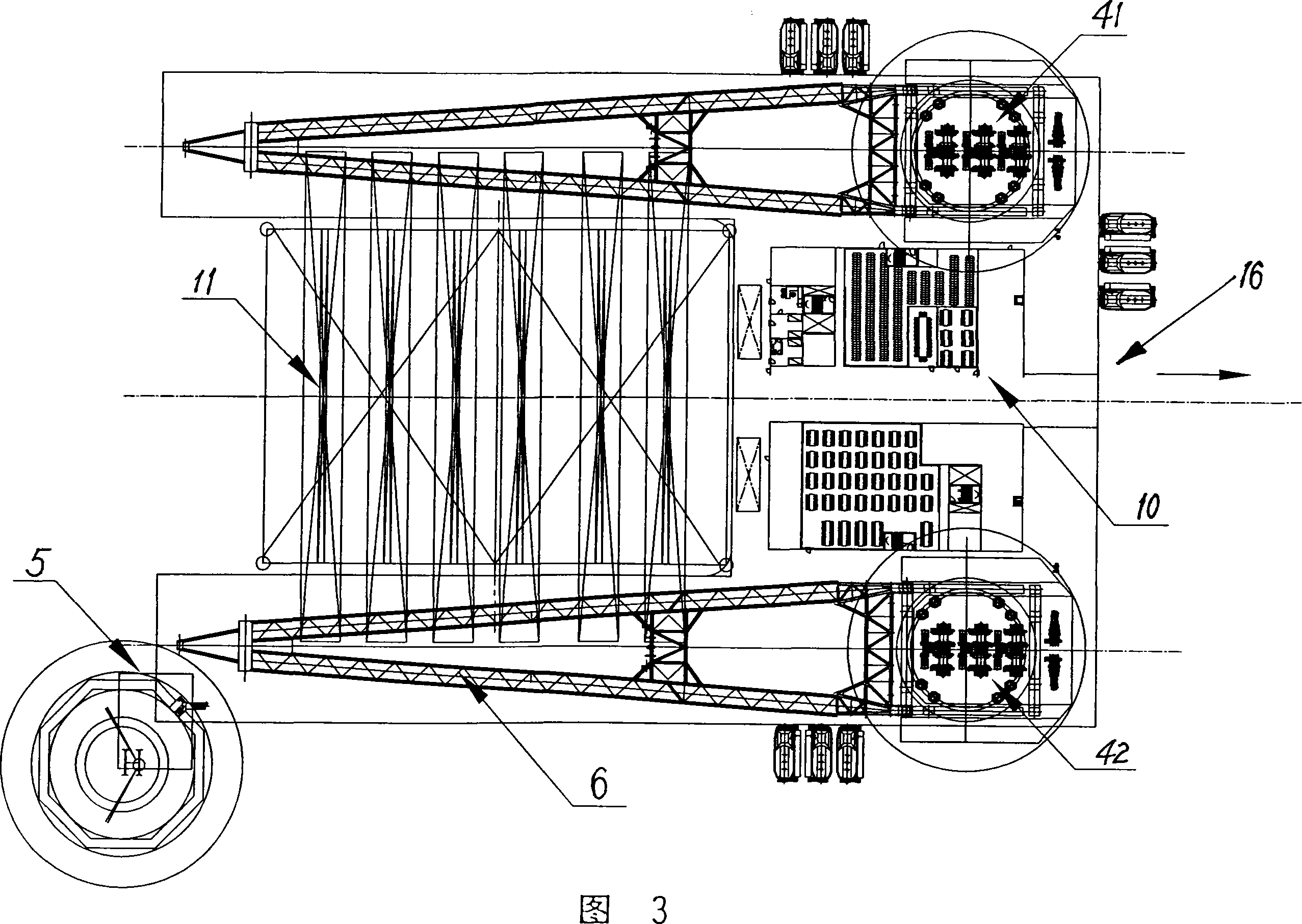

Semi-submersible offshore multifunctional engineering ship

ActiveCN101181927ASolve the contradiction between supply and demandSatisfy the market demand for new ship typesFloating buildingsHull structureMarine engineering

The invention relates to a semi-submersible sea multifunctional engineering ship, comprising a hull, a crane, an underwater mat, a stanchion, an upper box body, a lifting beam, and pipe paving operation line arranged in module type. The hull is in U-shaped semi-submersible hull structure; the above-water part is the upper tank body and the under-water part is provided with a larboard mat and a starboard mat which are connected by a transverse mat; a plurality of stanchions are arranged between the upper tank body and the underwater mat. The cranes are two large full rotary cranes which can work independently, which are respectively arranged at the left side and the right side of an upper deck of the ship head of the U-shaped hull. The plurality of lifting beams is arranged at the opening of the U-shaped hull. The pipe paving operation line is arranged on the module of a main deck in the U-shaped hull trough. The invention has the advantages of implementing a plurality of operation working conditions of sea engineering with smart operation and strong adaptability and improving the application efficiency of the ship, generating great benefit, thus being first-choice equipment with wide application prospect in sea engineering ship field.

Owner:SHANGHAI ZHENHUA HEAVY IND

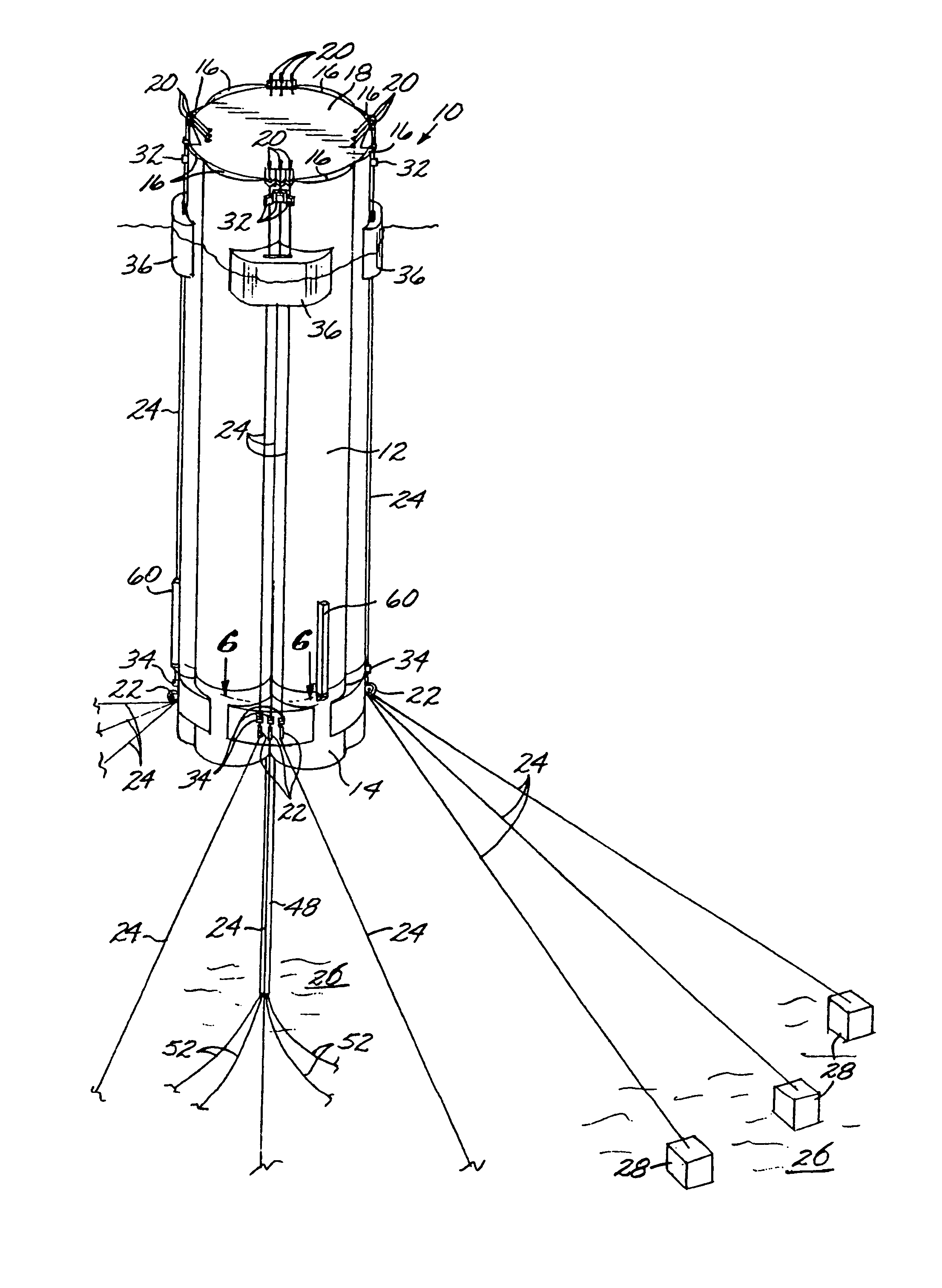

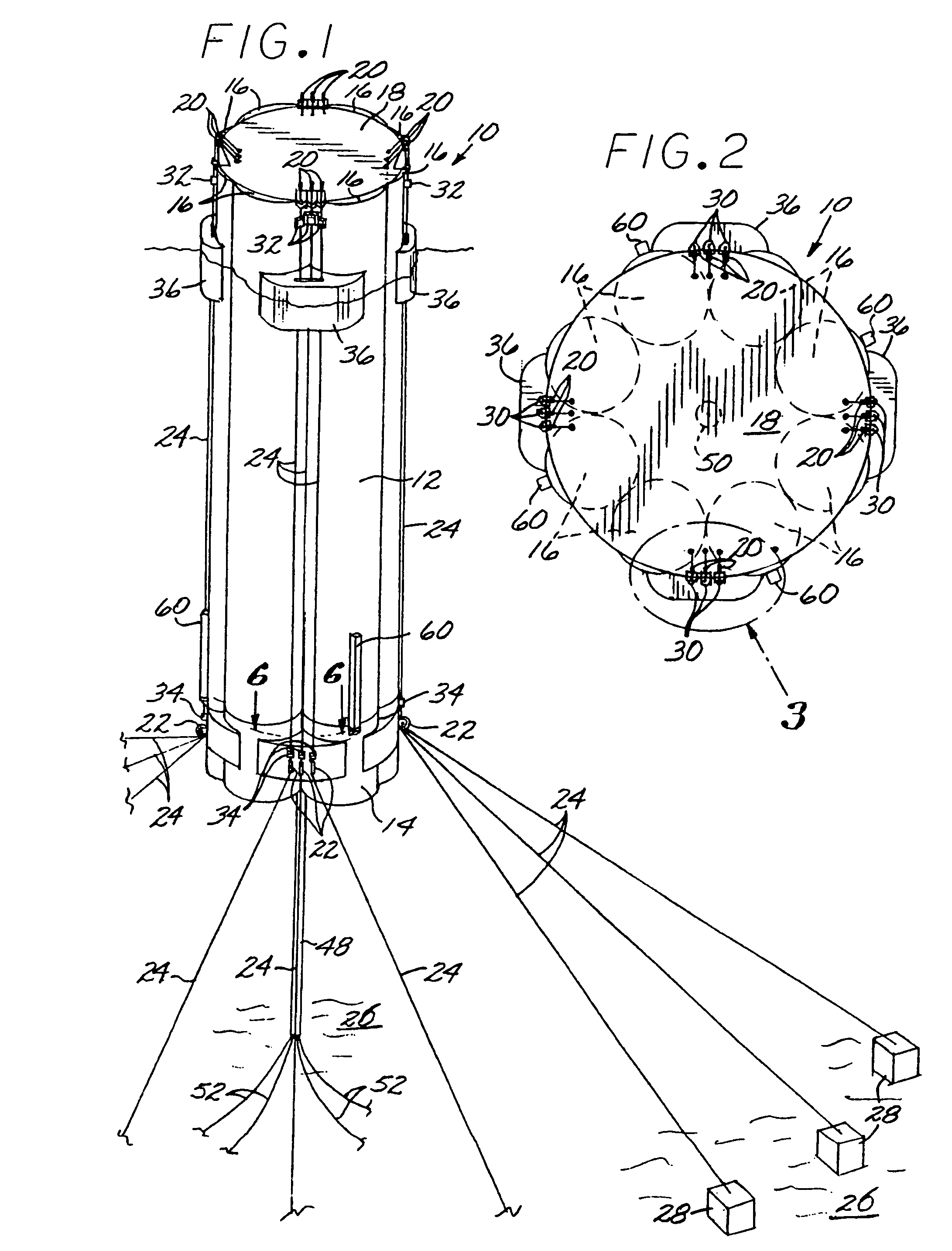

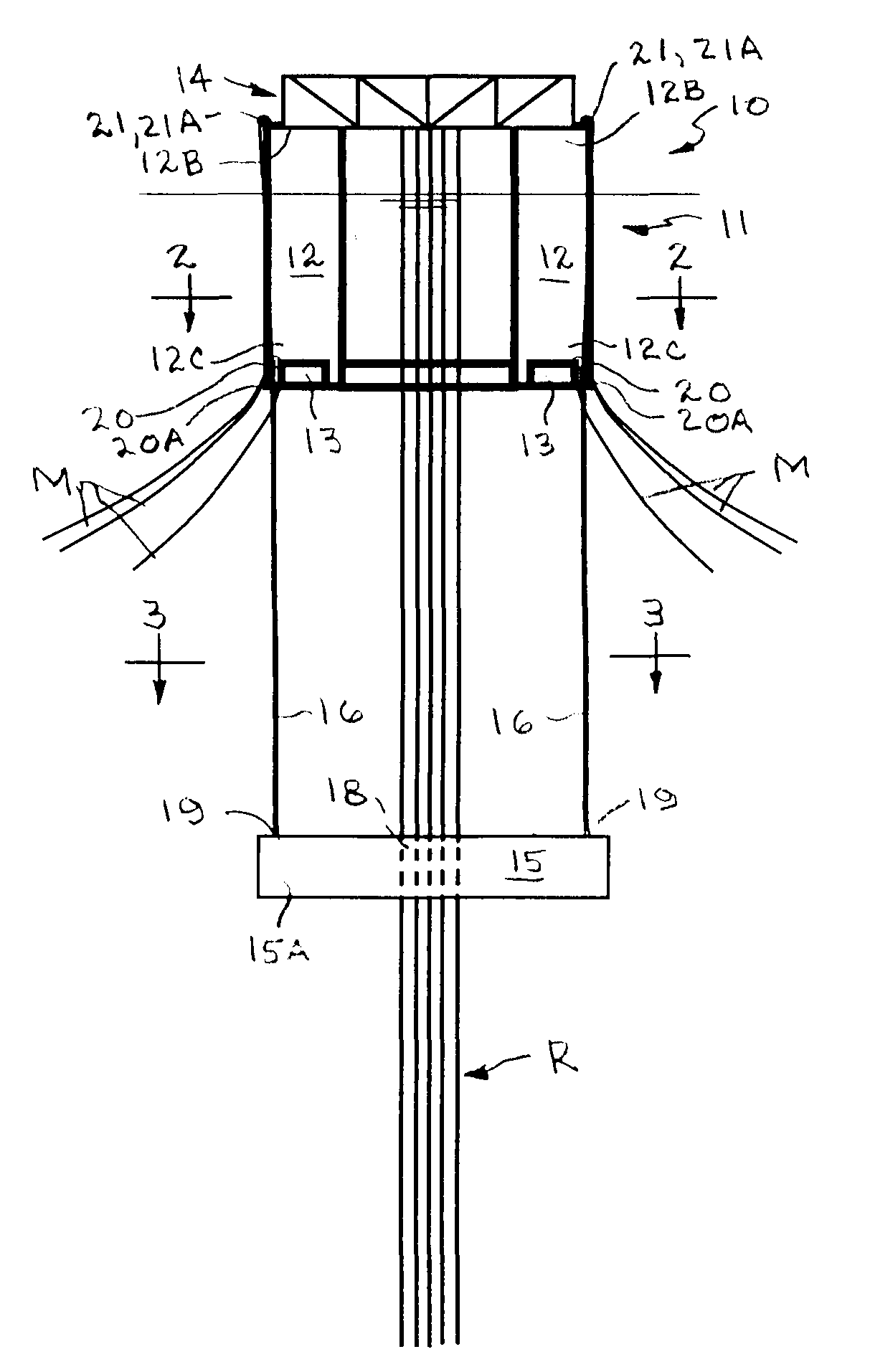

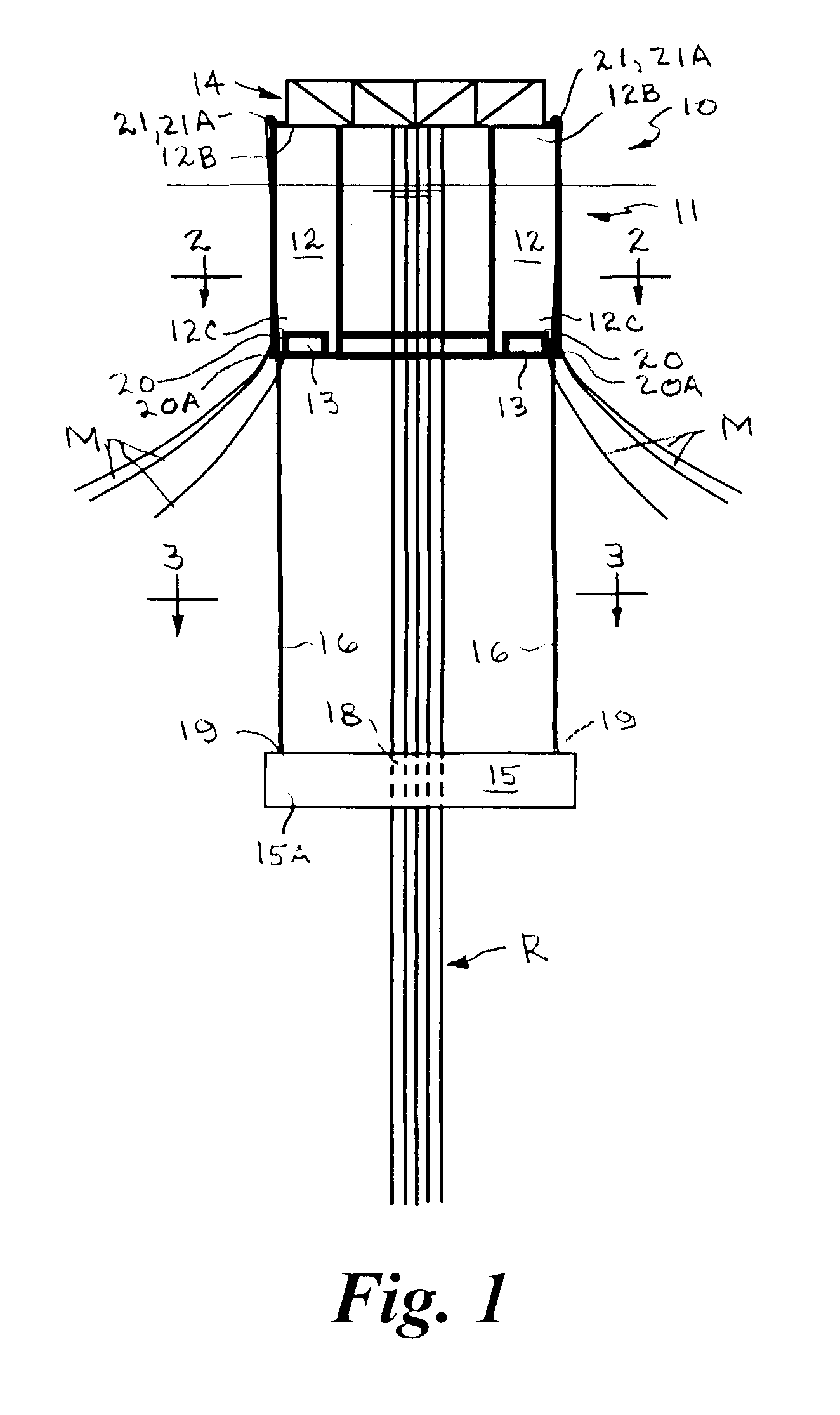

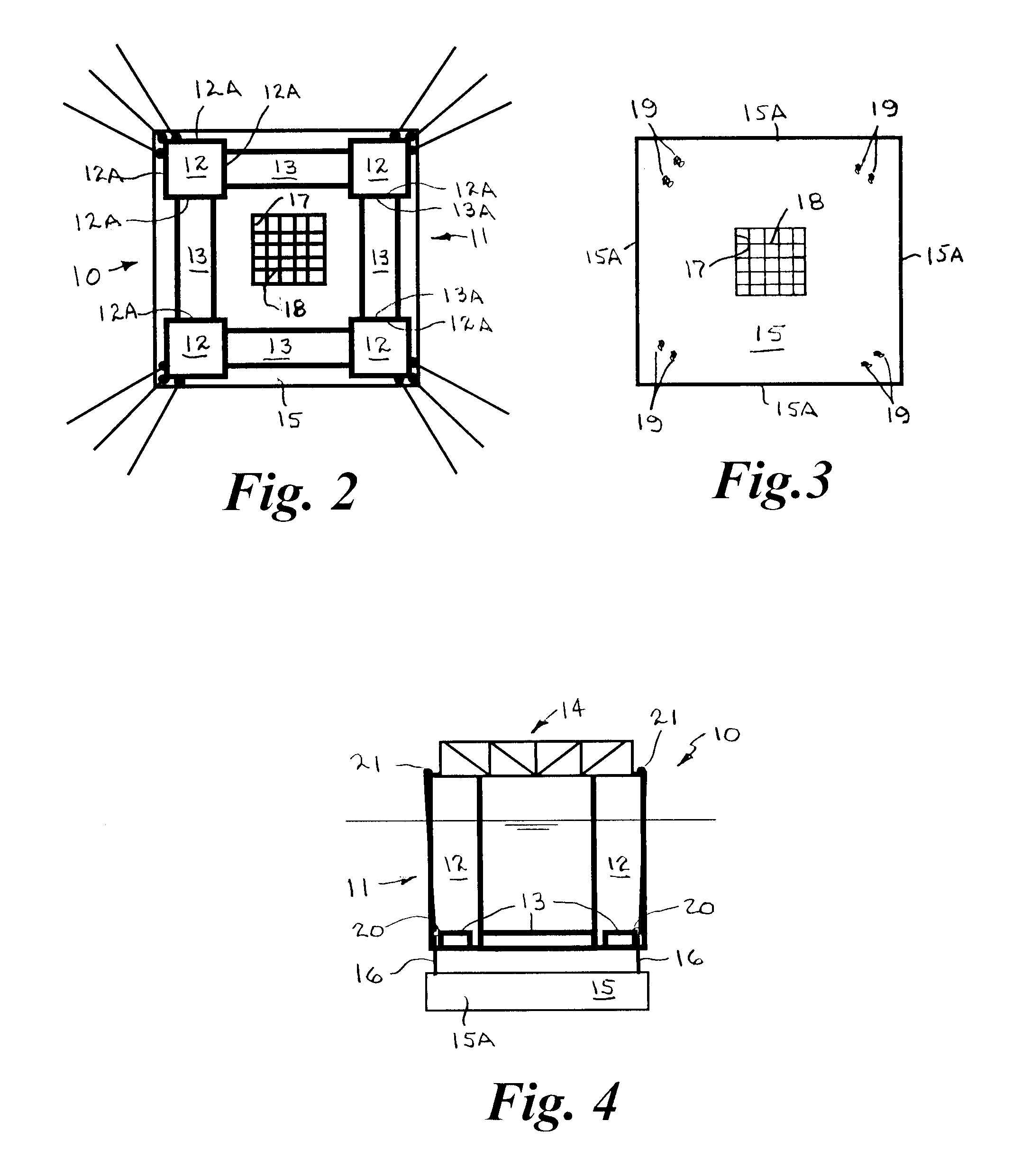

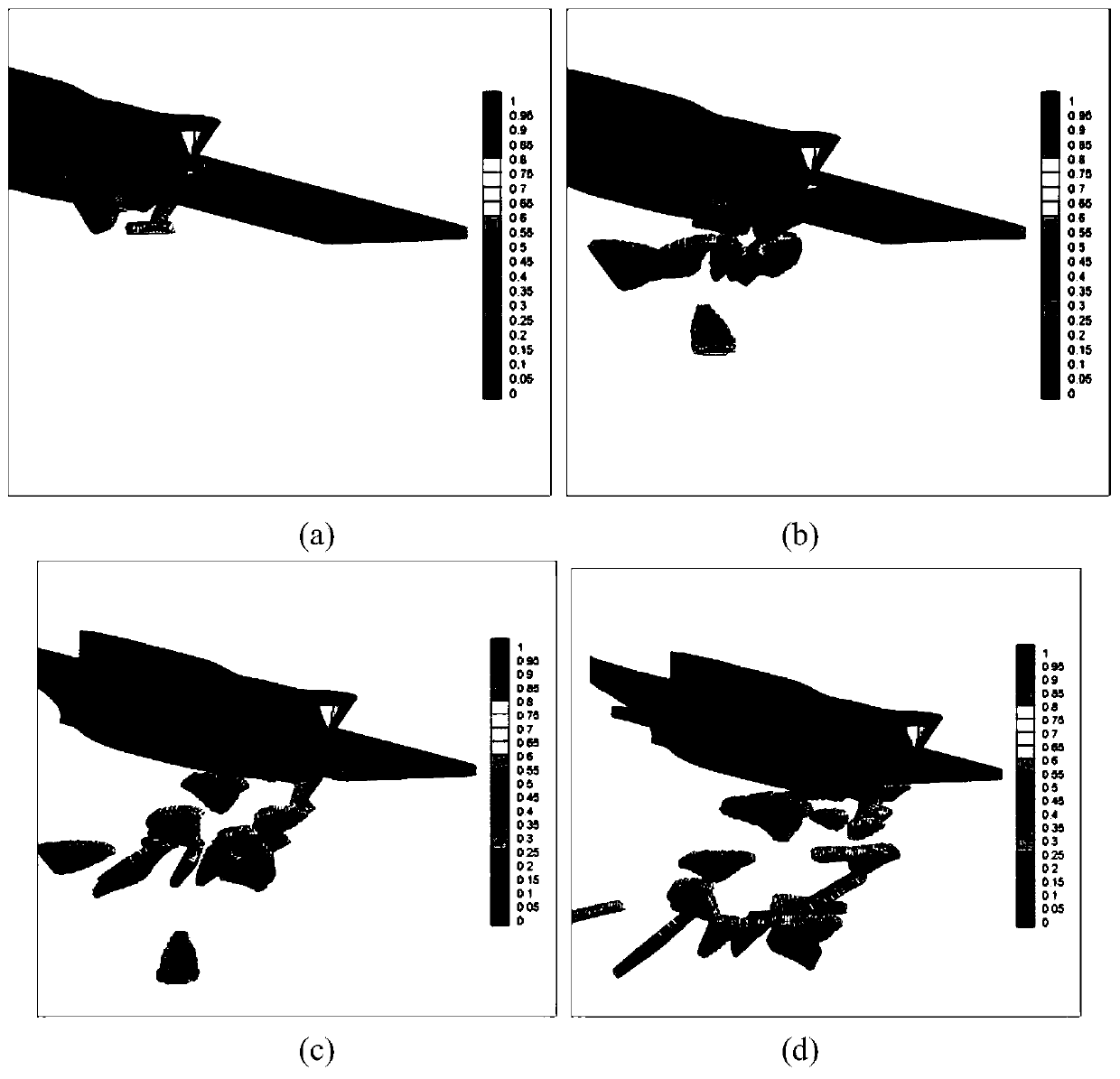

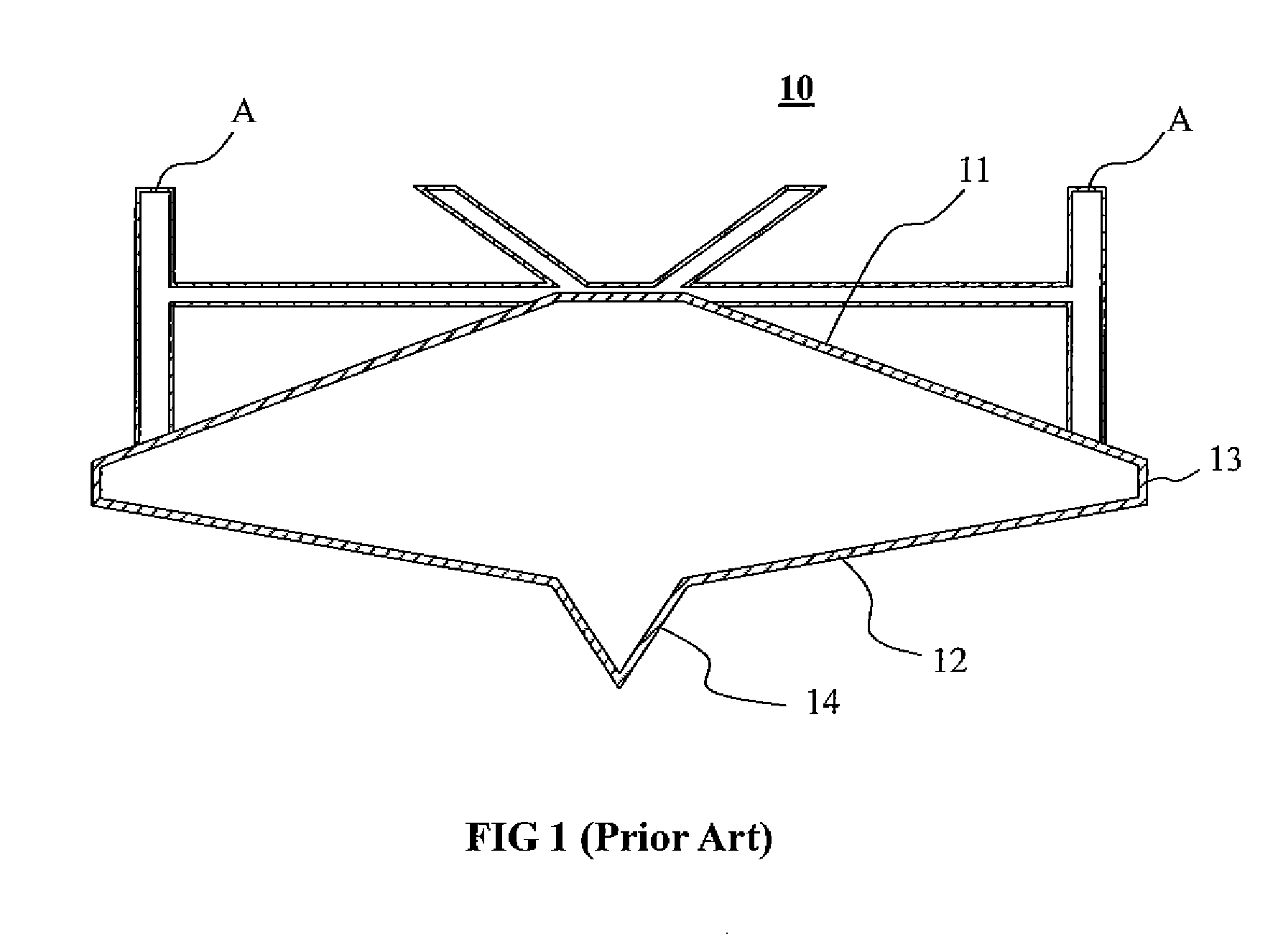

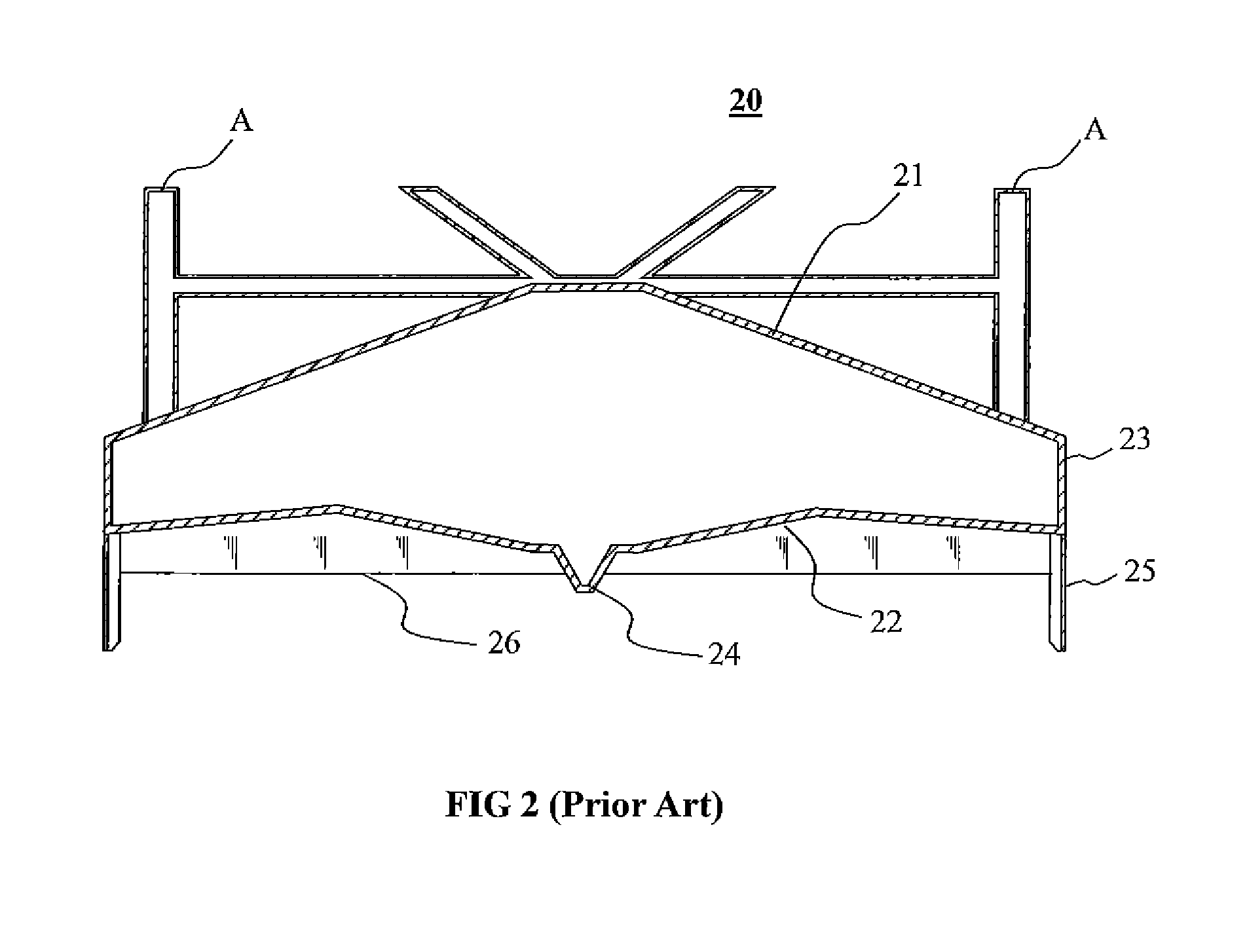

Offshore floating structure with motion dampers

InactiveUS20090235856A1Facilitates expenseFacilitates installation timeVessel safetyVessel stability improvementHull structureSnubber

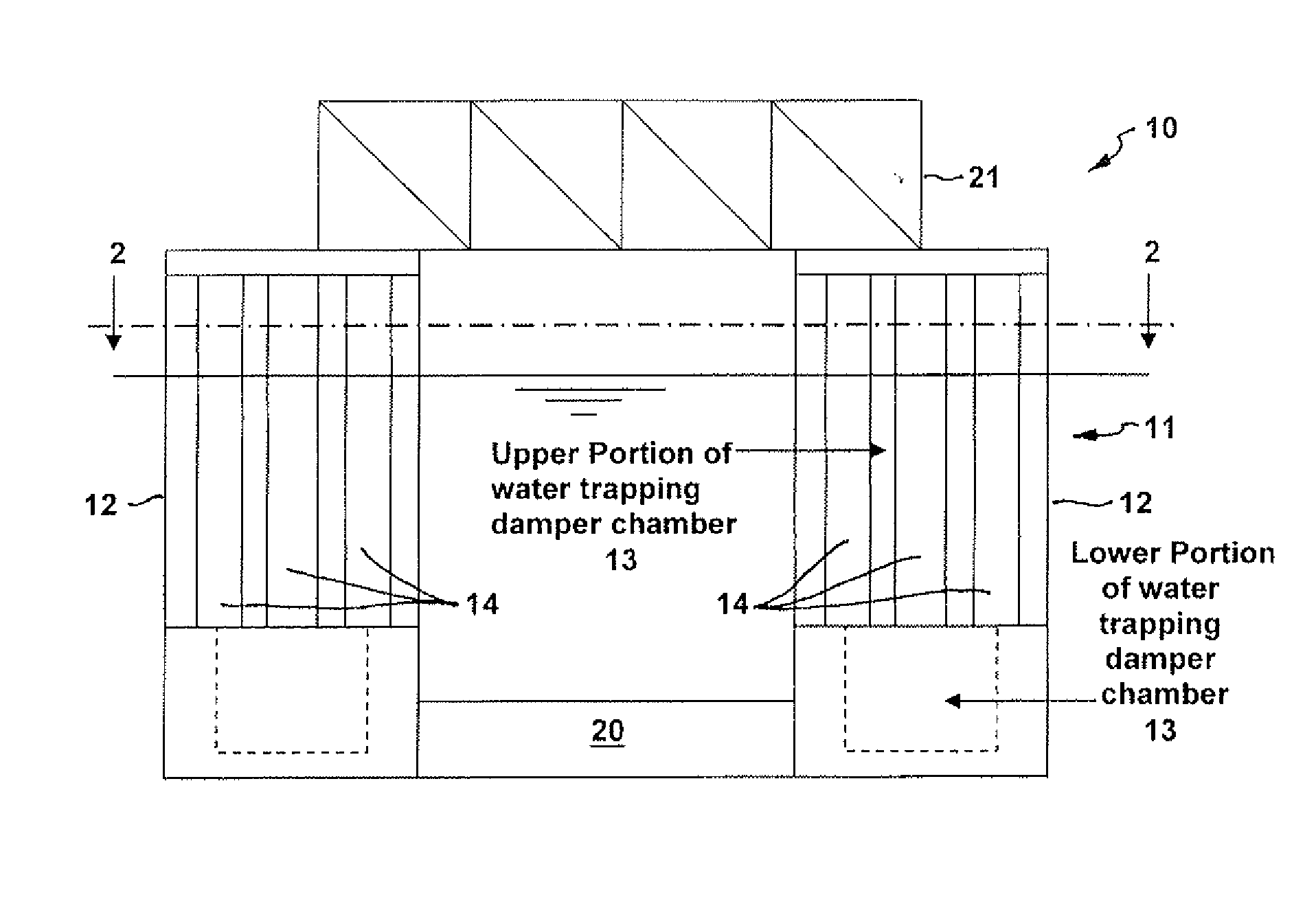

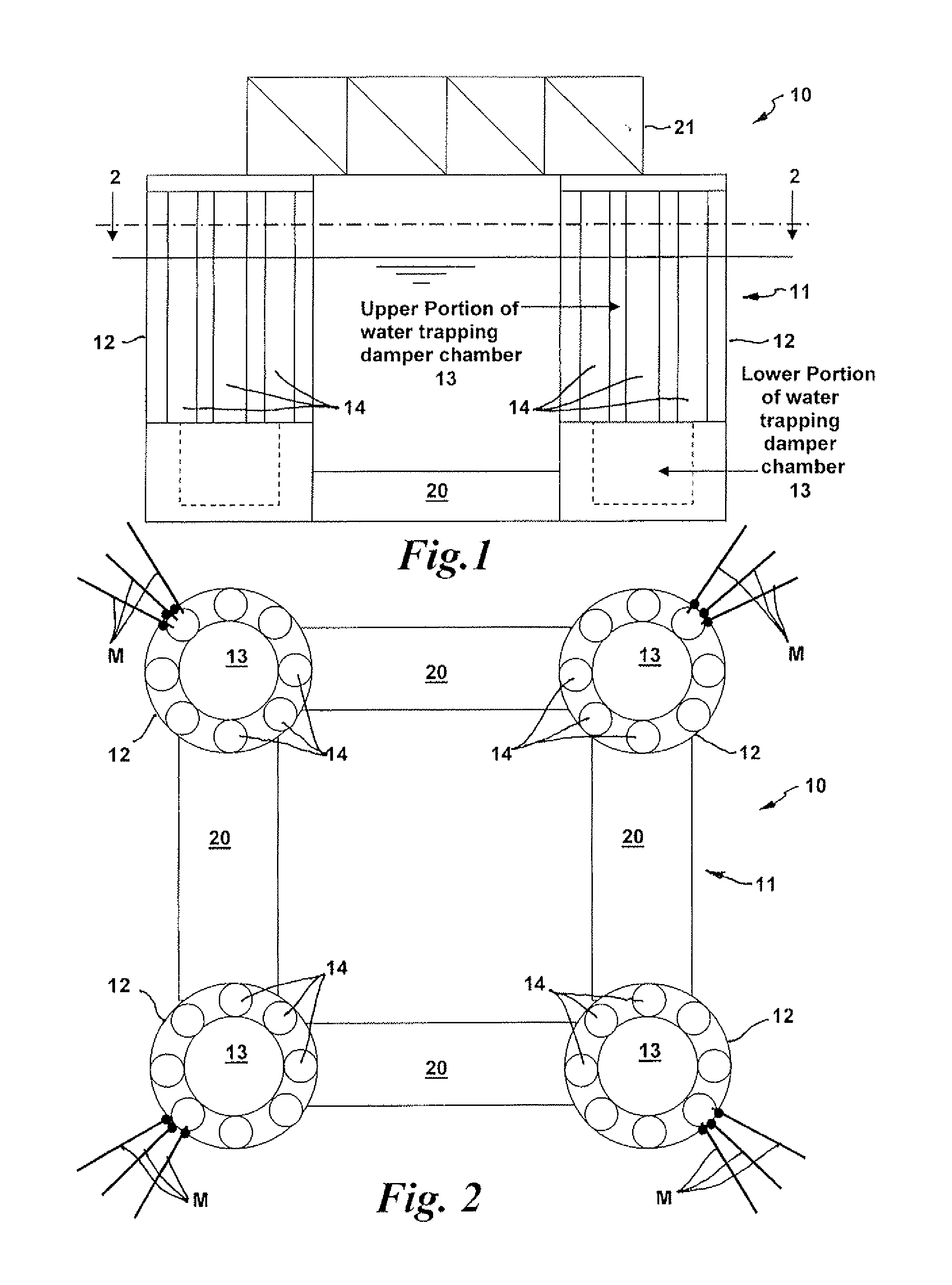

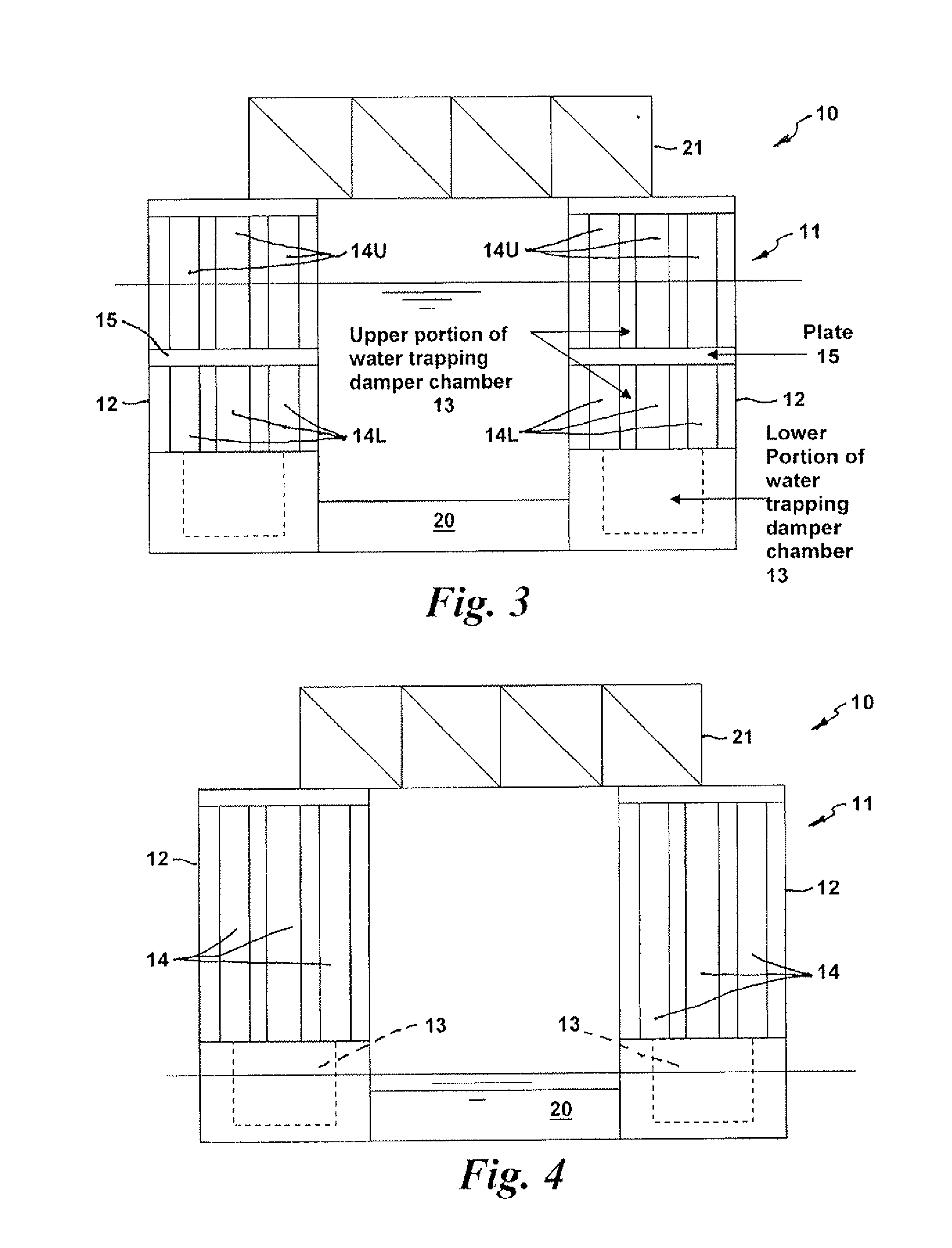

A semi-submersible floating platform (10, 10A) for use in offshore applications has a semi-submersible hull structure (11) including support columns (12), a pontoon structure (13) adjoined to the lower ends thereof, and a deck structure (14) supported at an upper end of the columns for supporting the deck and equipment mounted thereon above the water surface. One or more passive damper weight members (15) are suspended below the hull by flexible connection members (16) at variable distances to provide hydrodynamic mass, damping, and in-water weight to the platform during operation, and the flexible connection members are maintained in tension by the damper weight(s) during operation.

Owner:MANSOUR ALAA M

Offshore Floating Platform with Motion Damper Columns

InactiveUS20100288178A1Significant motionVessel safetyVessel movement reduction by mass displacementHull structureWater trap

Owner:MANSOUR ALAA

High-strength ship hull structural steel and production method of plate roll

ActiveCN101082102AReduce smelting costSmelting operation is simpleRoll mill control devicesFurnace typesProduction lineHull structure

The present invention relates to low alloy steel and is especially steel for hull structure and its production process. The steel for hull structure consists of C 0.03-0.075 wt%, Si 0.01-0.35 wt%, Mn 1.40-1.60 wt%, Als 0.015-0.100 wt%, V 0.020-0.080 wt% and Fe and impurity elements for the rest. It is produced in a CSP production line with special temperature system, reduction schedule and cooling system, and through casting blank, hydraulically shearing, heating and descaling, rolling into strip steel, stream cooling and finally winding. It has the advantages of less alloy elements, simple production process, high production efficiency, low power consumption, high product performance, etc.

Owner:MAANSHAN IRON & STEEL CO LTD

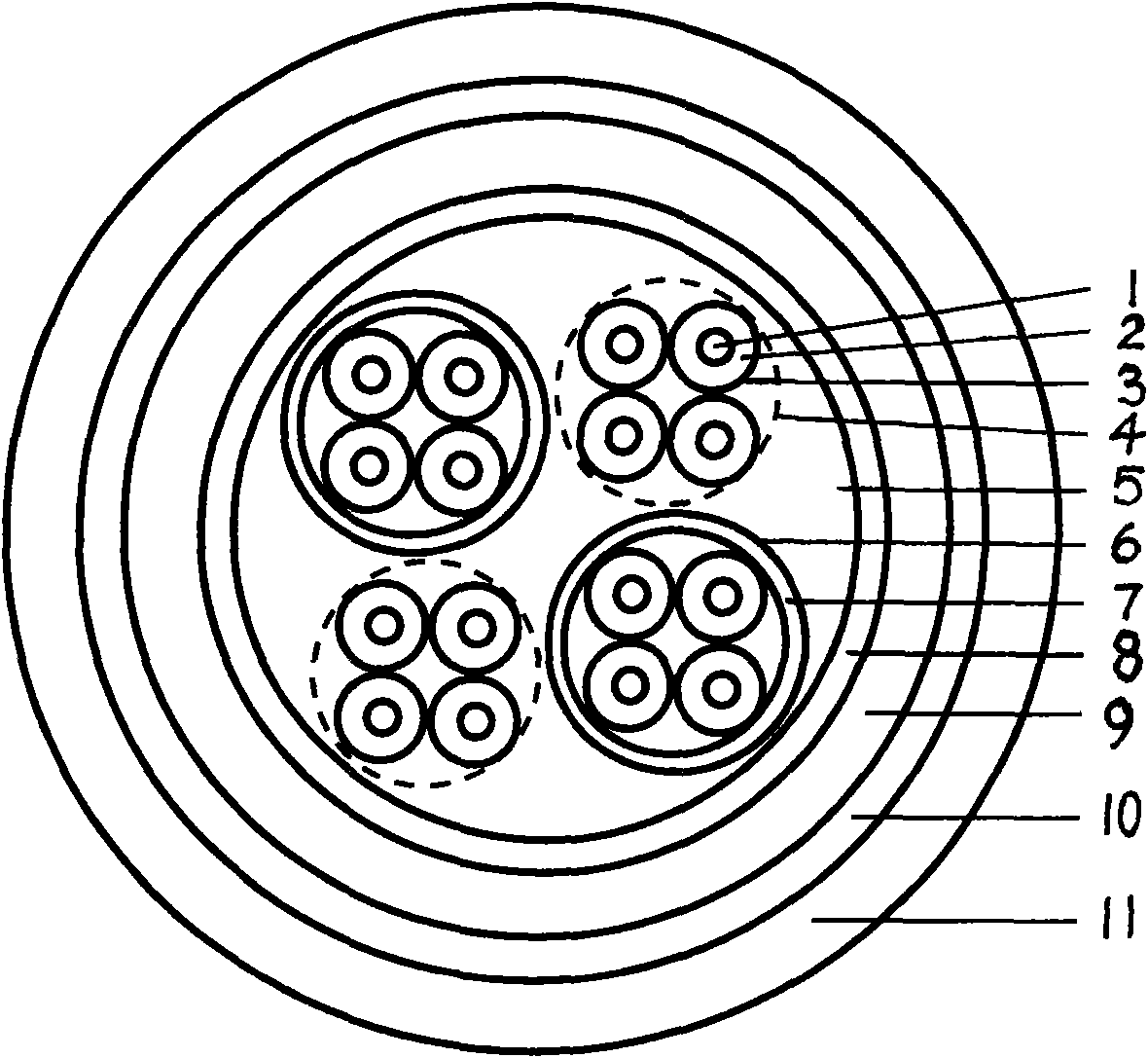

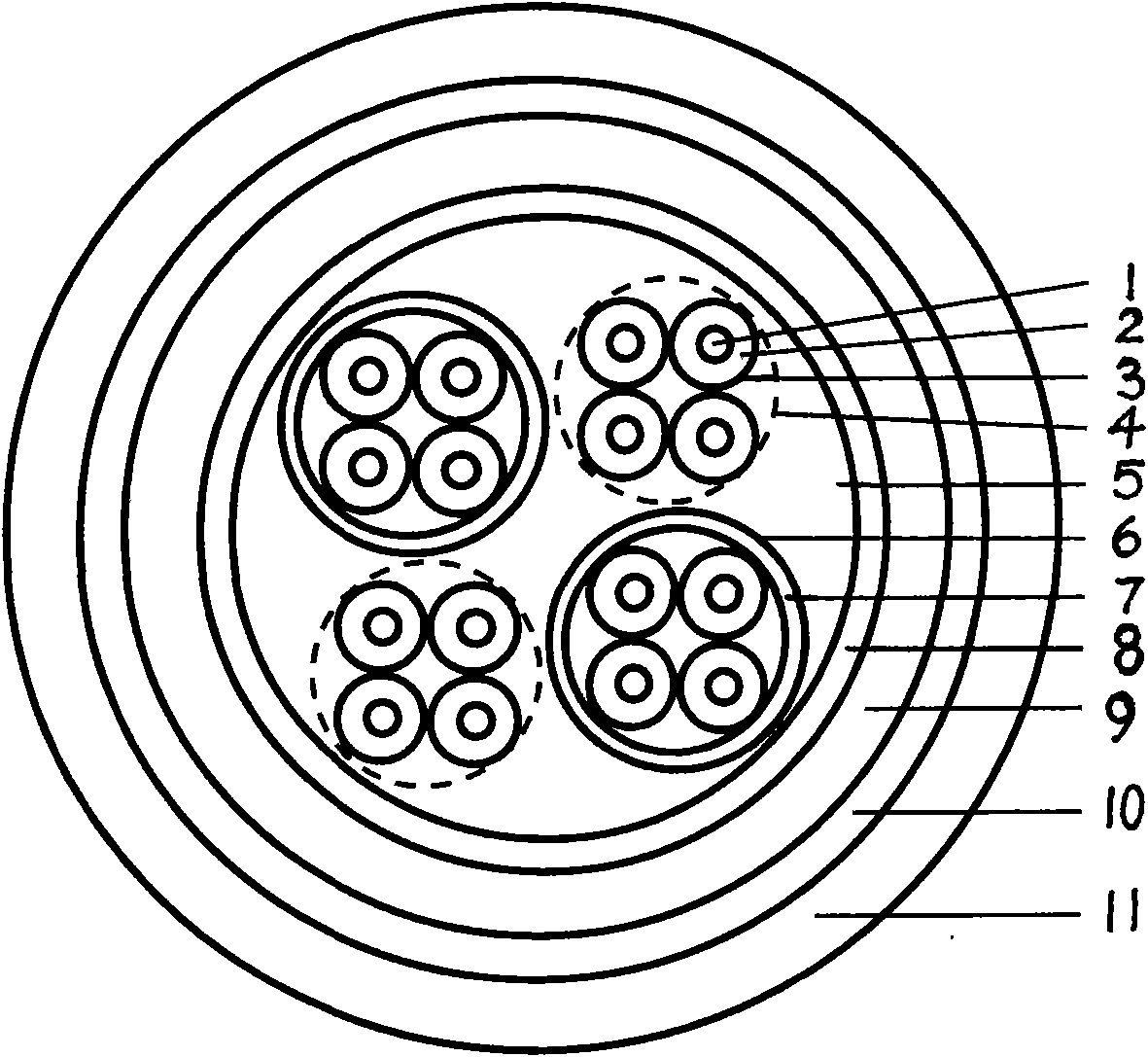

Low-smoke halogen-free flame-retardant comprehensive shielded subway light rail signal cable

InactiveCN101901644AReduce mutual interferenceReduce distractionsInsulated cablesInsulated conductorsHull structureMetal strips

The invention relates to a low-smoke halogen-free flame-retardant comprehensive shielded subway light rail signal cable comprising a cable core and an outer jacket. A plurality of lead groups are arranged in the cable core, a cable core taping layer and a metal strip armored shielding layer are sequentially coated between the cable core and the outer jacket, shielding layers are arranged outside half or more of the lead groups in the plurality of lead groups, and a cable core shielding layer is arranged between the cable core taping layer and the metal strip armored shielding layer. In the invention, a conductor of each lead has the diameter of 0.40-1.53 mm, and each lead has an insulation layer in a hull-foam-hull structure or a foam-hull structure. The shielding layer of the lead group is in the structure of wrapping a bilayer or single-layer copper strip or longitudinally wrapping a single-layer corrugated copper strip or weaving copper wire or tinned copper wire, and the cable core shielding layer is formed by longitudinally wrapping an aluminum-plastic composite strip or a pure aluminum strip or a pure copper strip. The invention has favorable shielding function, can lessen the mutual interference between cable lead groups and the interference of an external electromagnetic field with the cable, has enhanced mechanical and physical performance and flame-retardant performance, and can satisfy the signal cable use requirement of a traditional subway light rail system.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Anti-collision method of ship made of composite materials and hull structure

ActiveCN101898621AImprove protectionImprove rigidityVessel cleaningHull partsHull structureMarine engineering

The invention discloses an anti-collision method of a ship made of composite materials and a hull structure. The invention is mainly characterized in that sandwich plates (12) made of the composite materials are used as the outer walls of the hull, an integrated anti-collision bulwark (1) is adopted, the hull is in a 'cage type' structure, annular reinforced ribs are arranged on the side surfaces of the hull, and an energy-absorbing bow is adopted. The hull structure has the characteristics of light weight and high strength, and simultaneously, the overall anti-collision performance of the ship made of the composite materials is effectively improved through the comprehensive anti-collision structure design. When the ship has a collision on a front surface or a side surface, the comprehensive passive safety protection hull structure provided by the invention can effectively buffer an impact force caused by the collision of the ship, has good energy-absorbing effect and strong anti-deformation capacity, and is favorable for preventing or reducing casualties and property loss caused by the collision of the ship. The invention is especially suitable for the anti-collision design of the ship made of composite materials and has better application and popularization prospects.

Owner:SHENZHEN HISPEED BOATS TECH

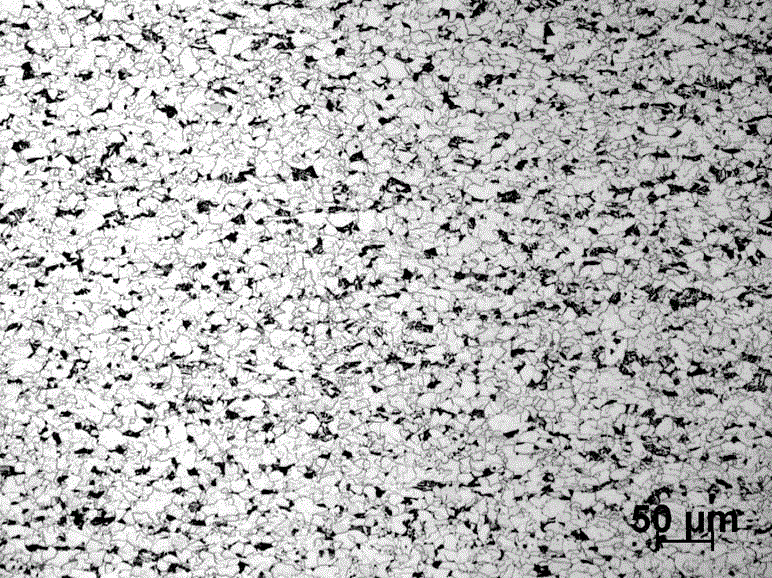

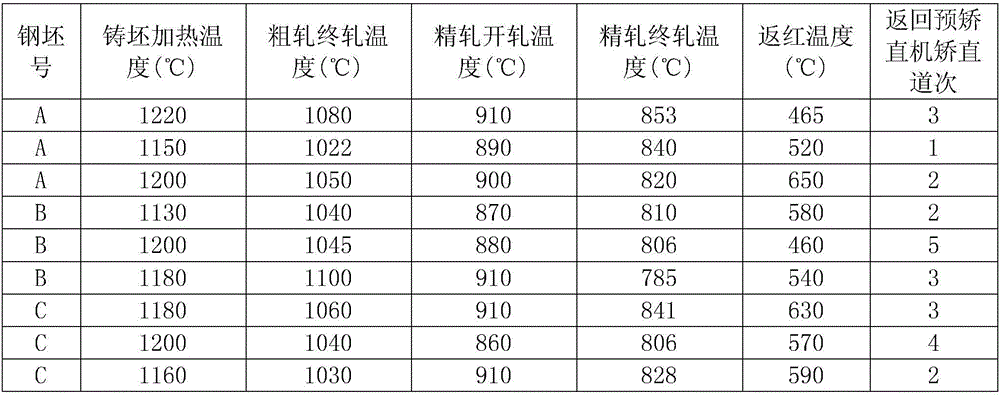

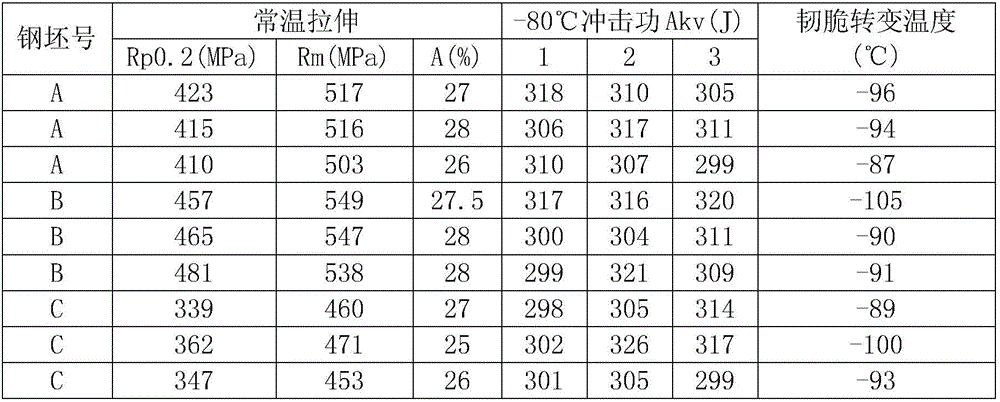

Carbon manganese low-temperature steel for liquefied gas boat and manufacturing method of carbon manganese low-temperature steel

The invention discloses carbon manganese low-temperature steel for a liquefied gas boat and a manufacturing method of the carbon manganese low-temperature steel. The carbon manganese low-temperature steel comprises, by weight, 0.03%-0.08% of C, 0.10%-0.30% of Si, 0.60%-1.30% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.010%-0.080% of Nb, 0.010%-0.060% of Al and the balance Fe and inevitable impurities. The clean steel smelting-continuous casting process is adopted in the method, and a high-purity homogenous continuous casting slab is manufactured; and through two-stage control rolling and control cooling, a wee ferrite and pearlitic structure is obtained. The carbon manganese low-temperature steel for the liquefied gas boat has the beneficial effects that the steel is pure, the texture is even, the grain size is in the 10.0 level to 13.5 level, and the ductile-brittle transition temperature is lower than -80 DEG C; building requirements of a cargo tank and a boat body structure of the liquefied gas boat are met; and meanwhile, the carbon manganese low-temperature steel has the beneficial effects of being simple in chemical component and low in cost.

Owner:NANJING IRON & STEEL CO LTD

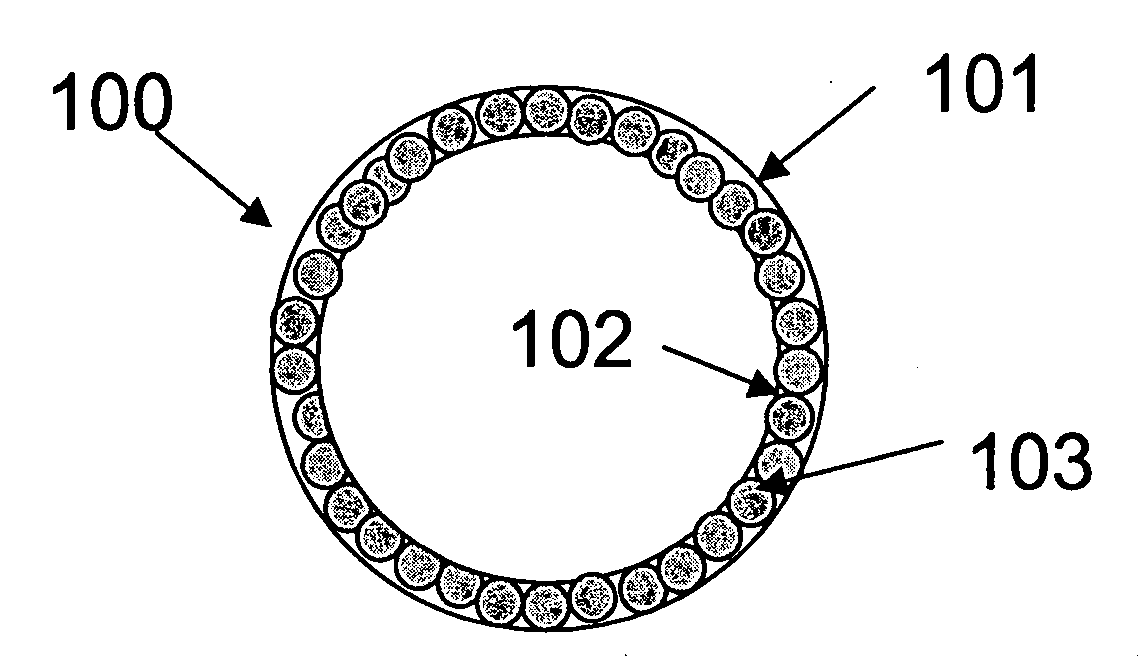

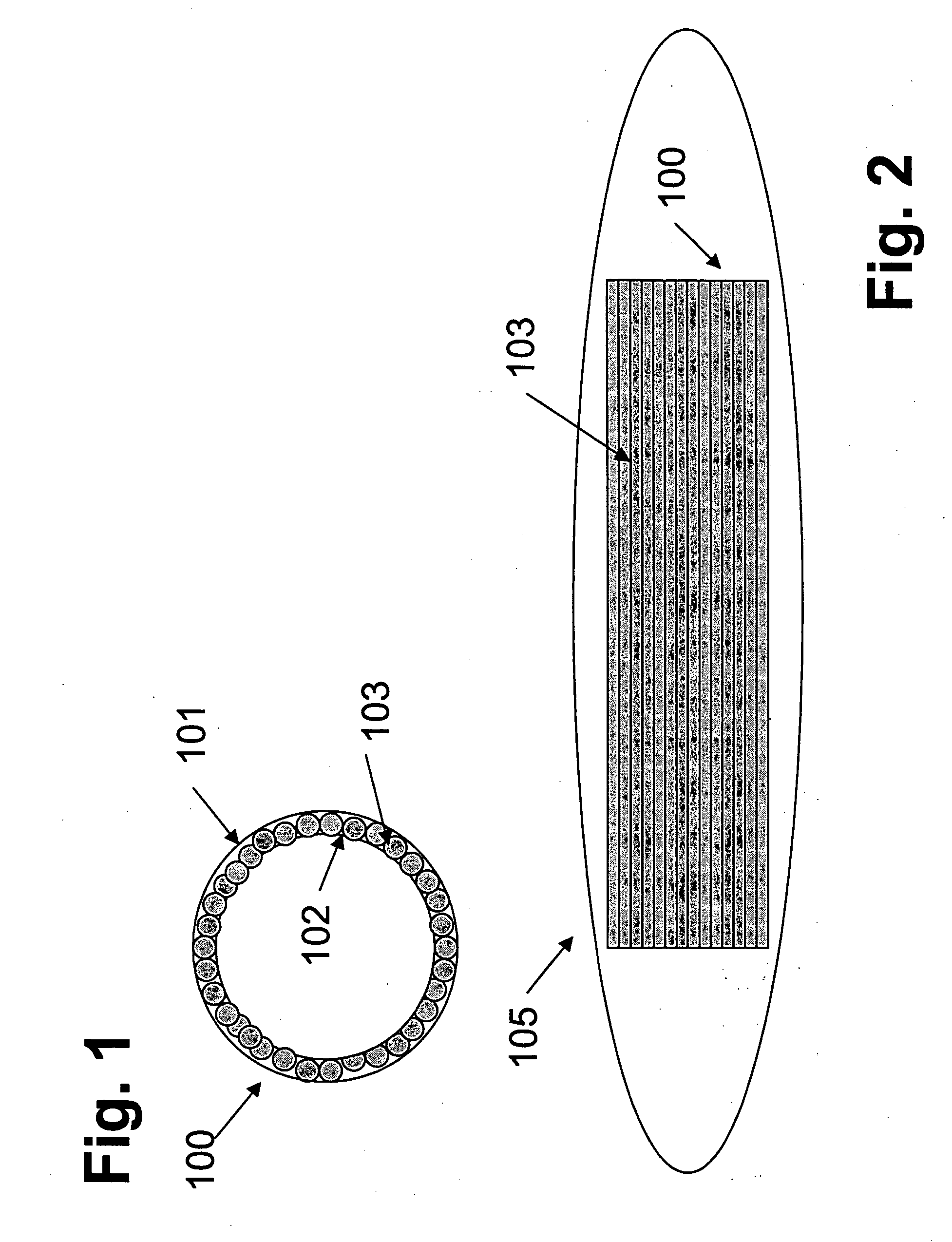

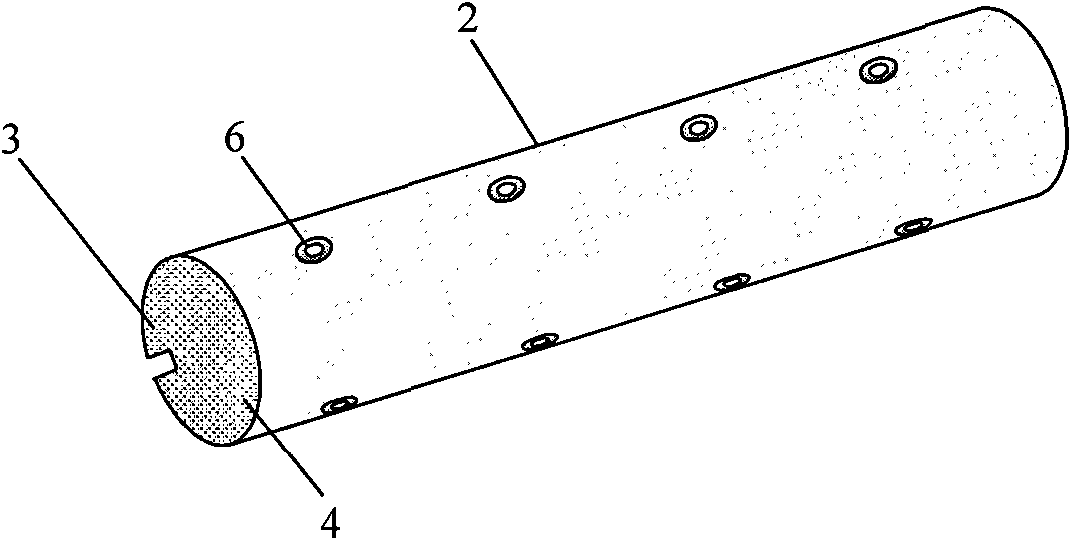

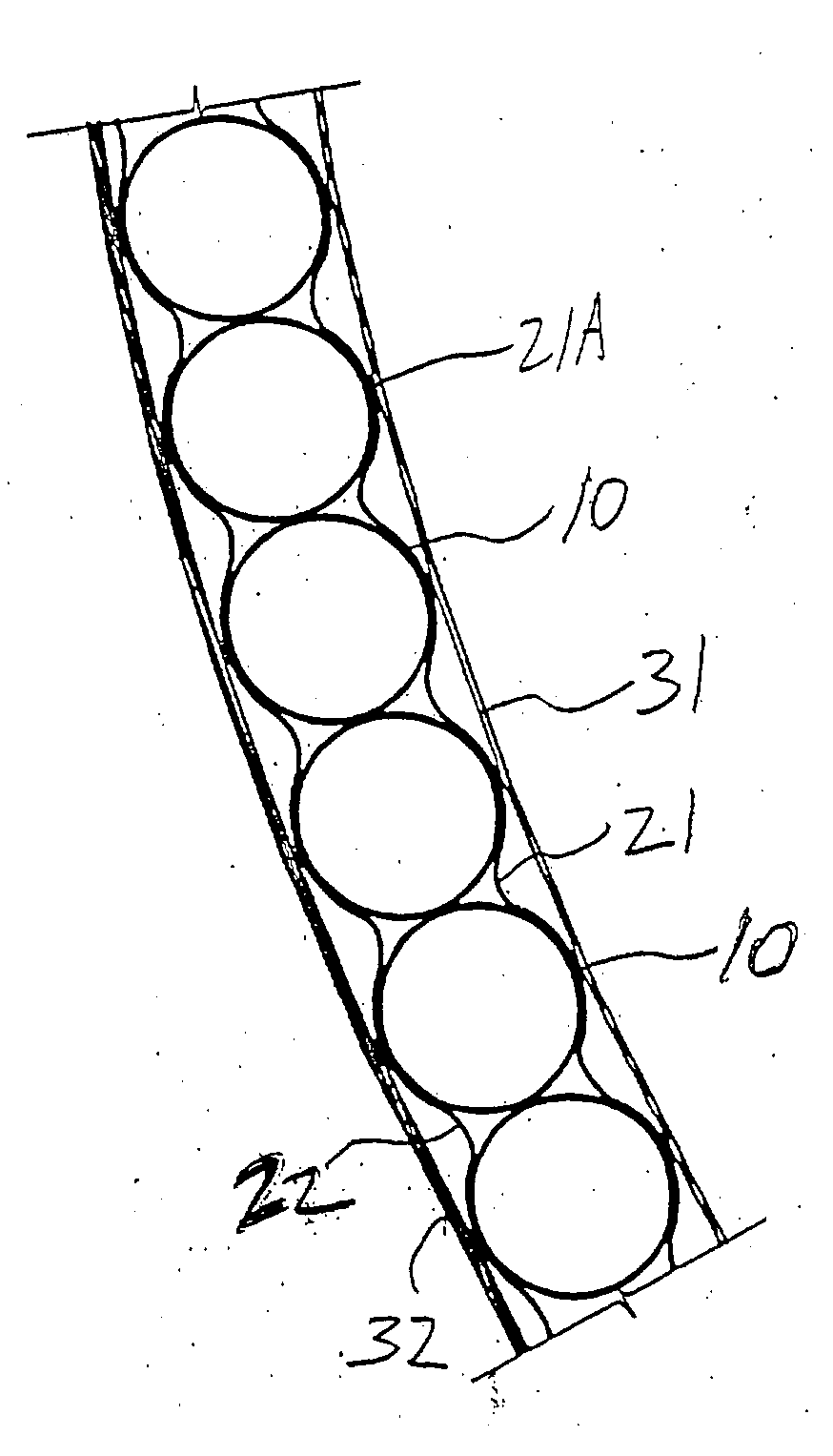

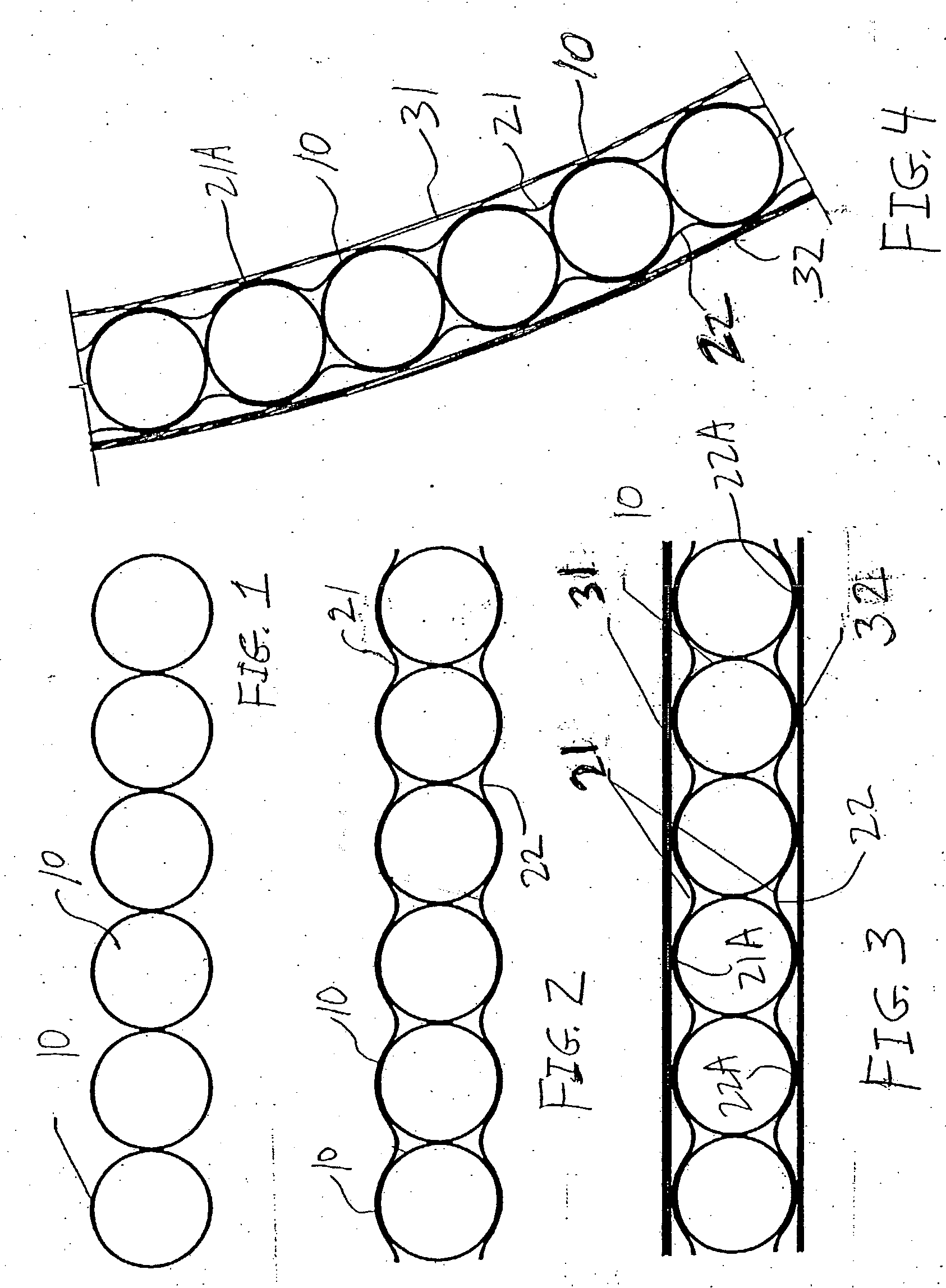

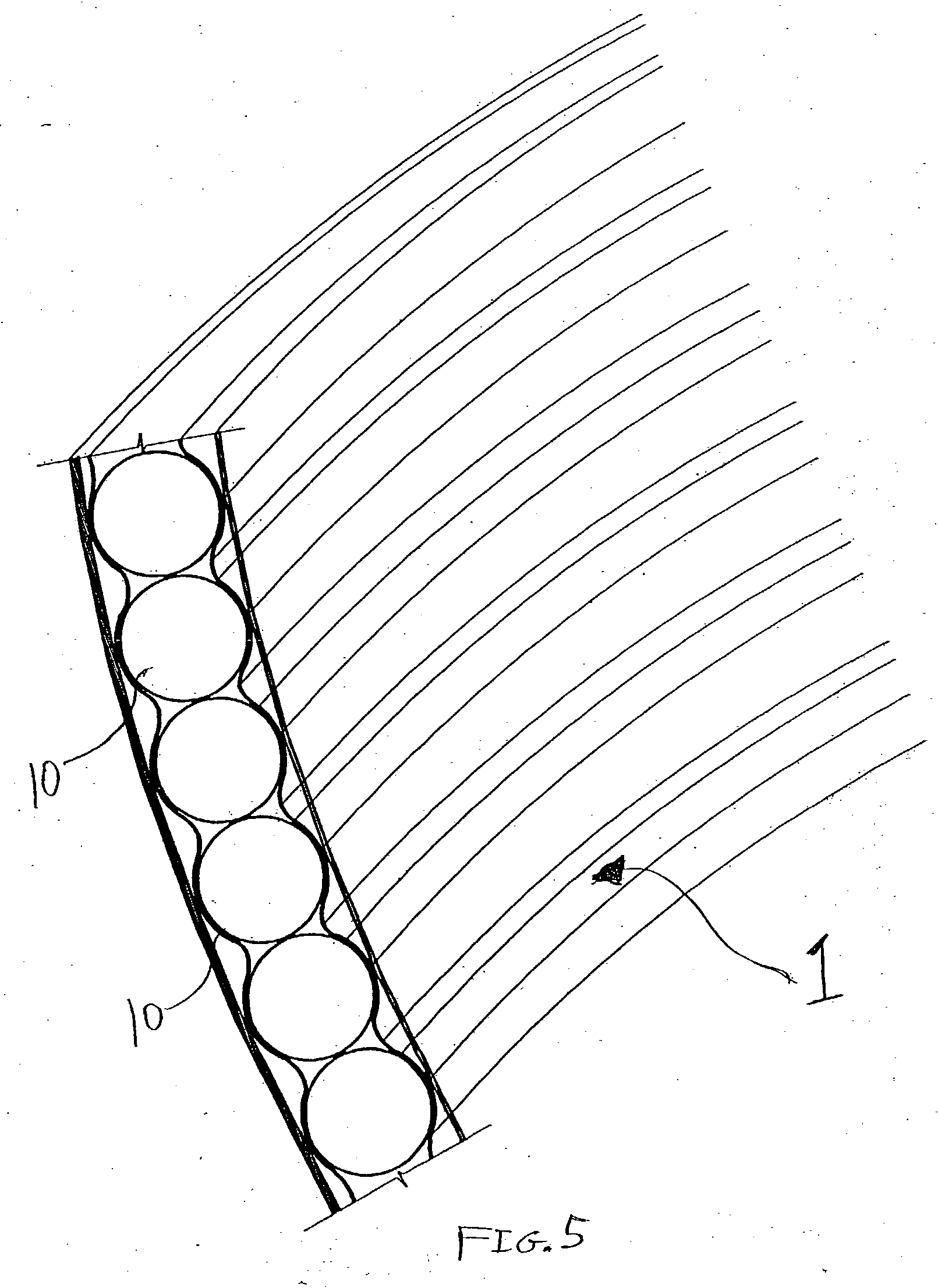

Tubular compartmentalized integrated hull construction

InactiveUS20040149197A1High strengthReduce manufacturing costNon-magnetic metal hullsVessel safetyHull structureBiomedical engineering

An integrated, compartmentalized, water impermeable hull that is constructed of a plurality of lengthwise tubes. The tubes are arranged in a generally parallel relation to one another such that an outer surface of each tube abuts an outer surface of at least one other of the tubes. The tubes are sandwiched between a first inner support layer and a second inner support layer. Each inner support layer undulates along and fixedly adheres to the tubes to thereby hold the tubes in a fixed relation to one another. First and second outer support layers are positioned over the first and second inner support layer, respectively, and are fixed to a plurality of peaks of the first inner support layers to thereby reinforce the first inner support layers.

Owner:MAKLEZOW VIKTOR

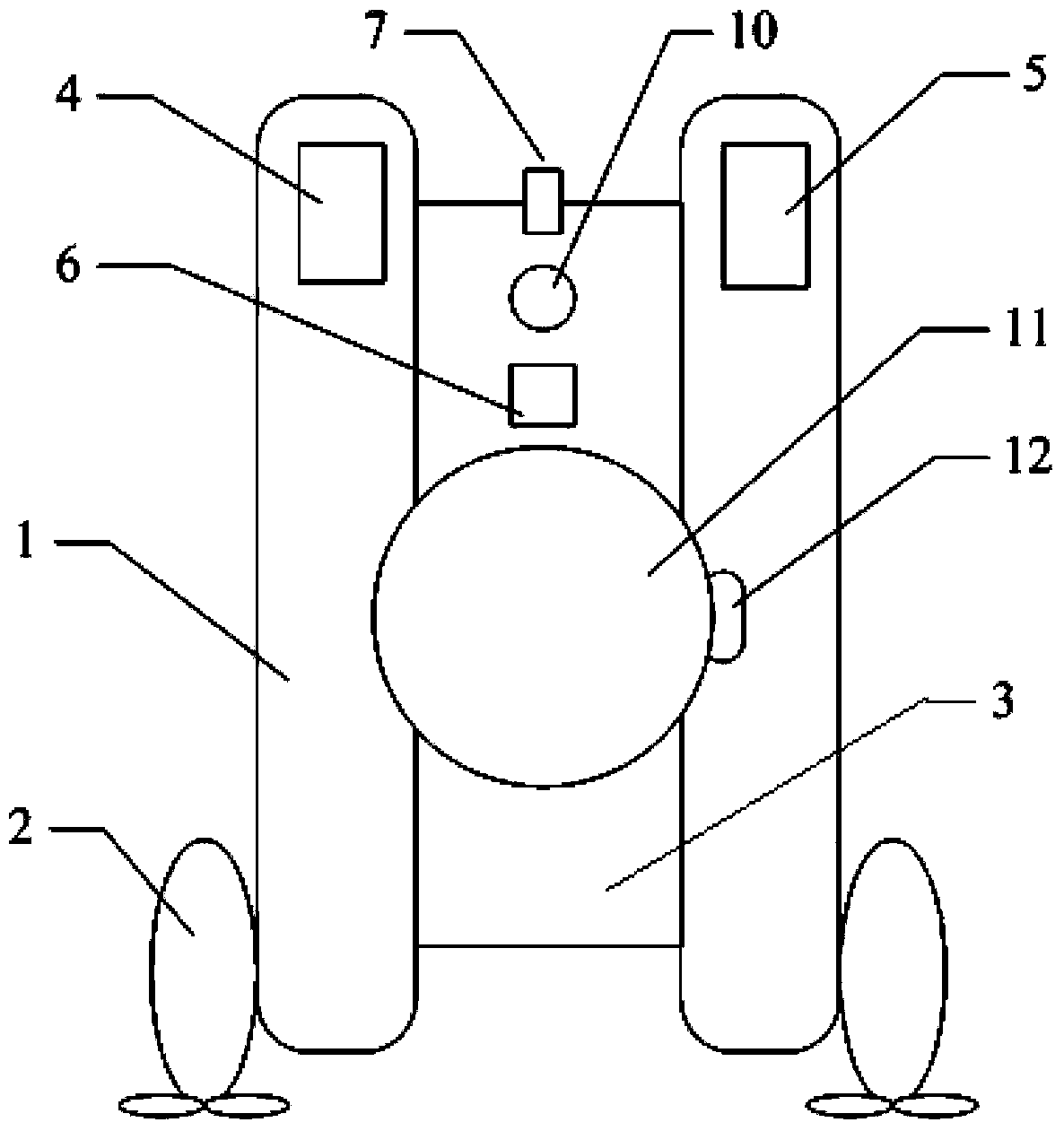

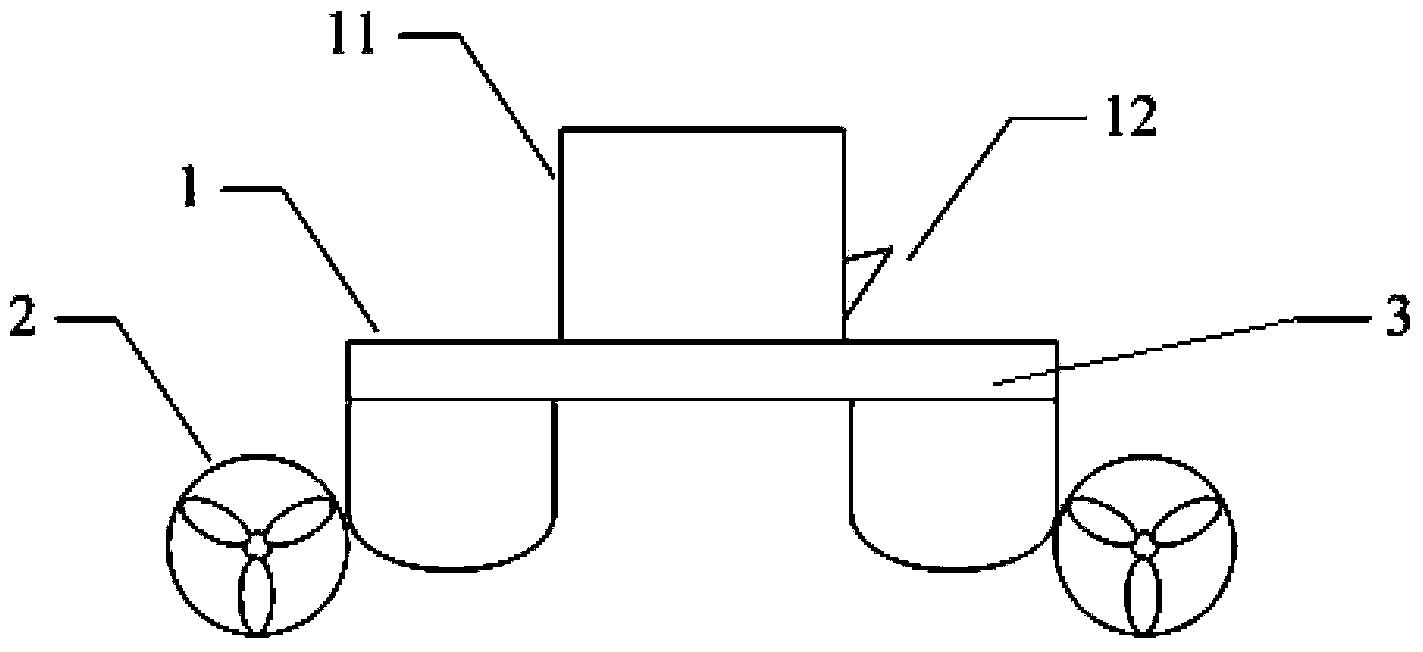

Automatic feeding system for aquaculture pond

ActiveCN103461257AReduce side to side swingImprove stabilityPisciculture and aquariaPosition/course control in two dimensionsButtressHull structure

Disclosed is an automatic feeding system for an aquaculture pond. The aquaculture pond is rectangular, the system comprises a feeding hull, a controller and a feeder, the feeding hull is of a twin-hull structure and comprises two parallel boat-shaped buoys and a deck, the two parallel boat-shaped buoys float on the water and are covered and connected into a whole by the deck, an electronic compass, a wireless signal receiver, the controller and the feeder are mounted on the deck, two wireless signal transmitters are mounted on a buttress of the pond at intervals, two screw propellers are symmetrically mounted on the left side and the right side of a stern of the feeding hull, one screw propeller is arranged on each boat-shaped buoy, the electronic compass monitors the instant course of the feeding hull and feeds the instant course back to the controller, the wireless signal receiver receives wireless signals transmitted by the wireless signal transmitters and feeds the wireless signals back to the controller, and the controller controls running of the two screw propellers. Positioning and orienting of the feeding hull in the patrolling process are not affected by the buttress of the pond and weather factors, and sailing and steering stability is better.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

High-strength and low-temperature-resistant hull-structure steel plate and preparation method thereof

ActiveCN109136738AGuaranteed uniformityHigh strengthFurnace typesProcess efficiency improvementHull structureRoom temperature

The invention relates to a high-strength and low-temperature-resistant hull-structure steel plate and a preparation method thereof. The high-strength and low-temperature-resistant hull-structure steelis at least composed of C, Si, Mn, P, S, Nb, Ti, Al, Cr, Cu, Ni, Mo, Sb, N, Mg, Ca, B and the balance Fe and inevitable impurities. After smelting, refining, continuous casting, rough rolling, finishing rolling, cooling and leveling to the room temperature, the microstructure of the hull-structure steel includes, by volume, 50-55% of polygonal ferrite, 20-25% of quasi-polygonal ferrite, 15-20% ofgranular bainites, 1-13% of martensites and the balance austenites and strip martensites, the yield strength is 520-580 MPa, the tensile strength is 650-750 MPa and the elongation is 20-30% and the absorption energy of transverse V-shaped impact at -40 DEG C is more than 120 J.

Owner:JINGYE STEEL CO LTD

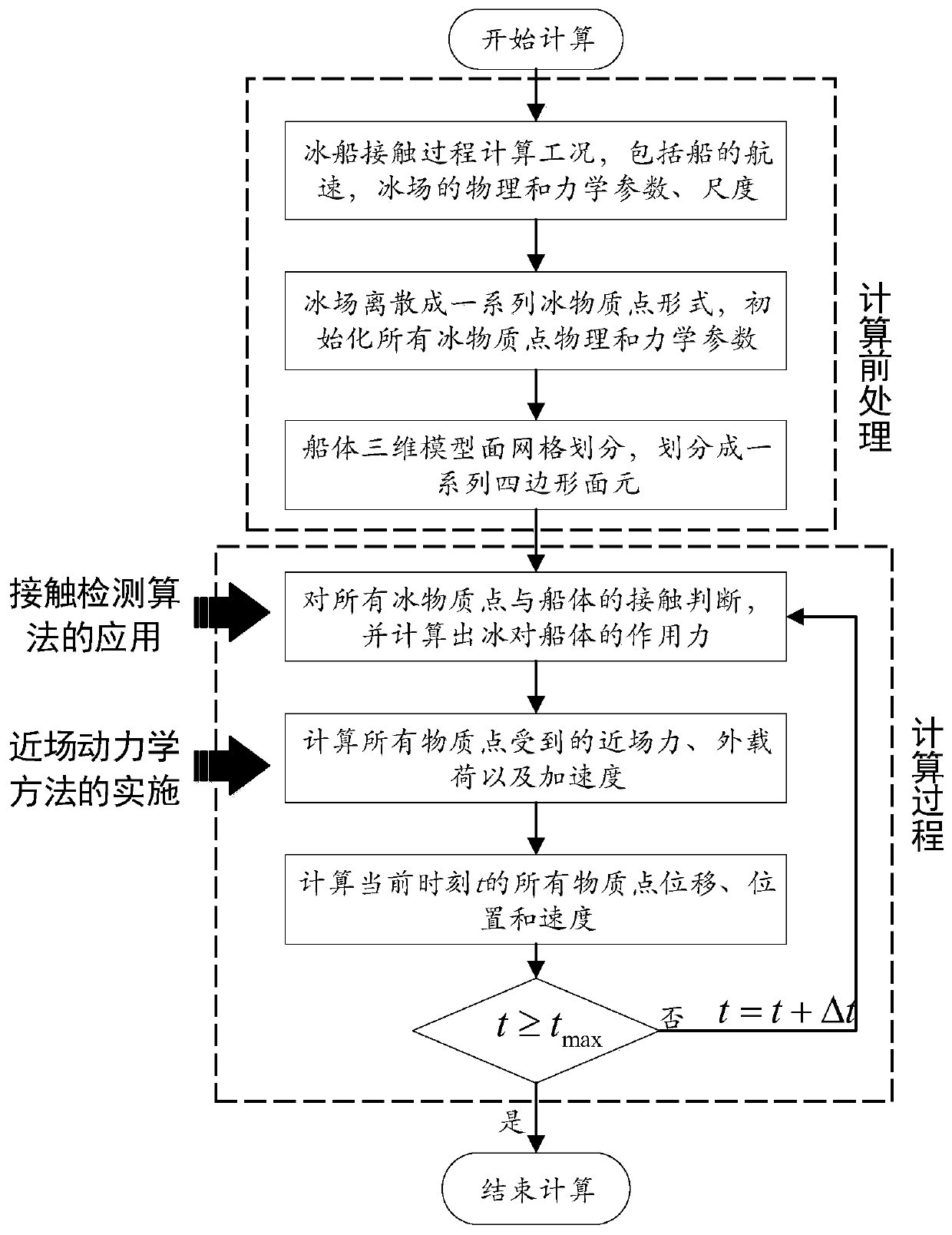

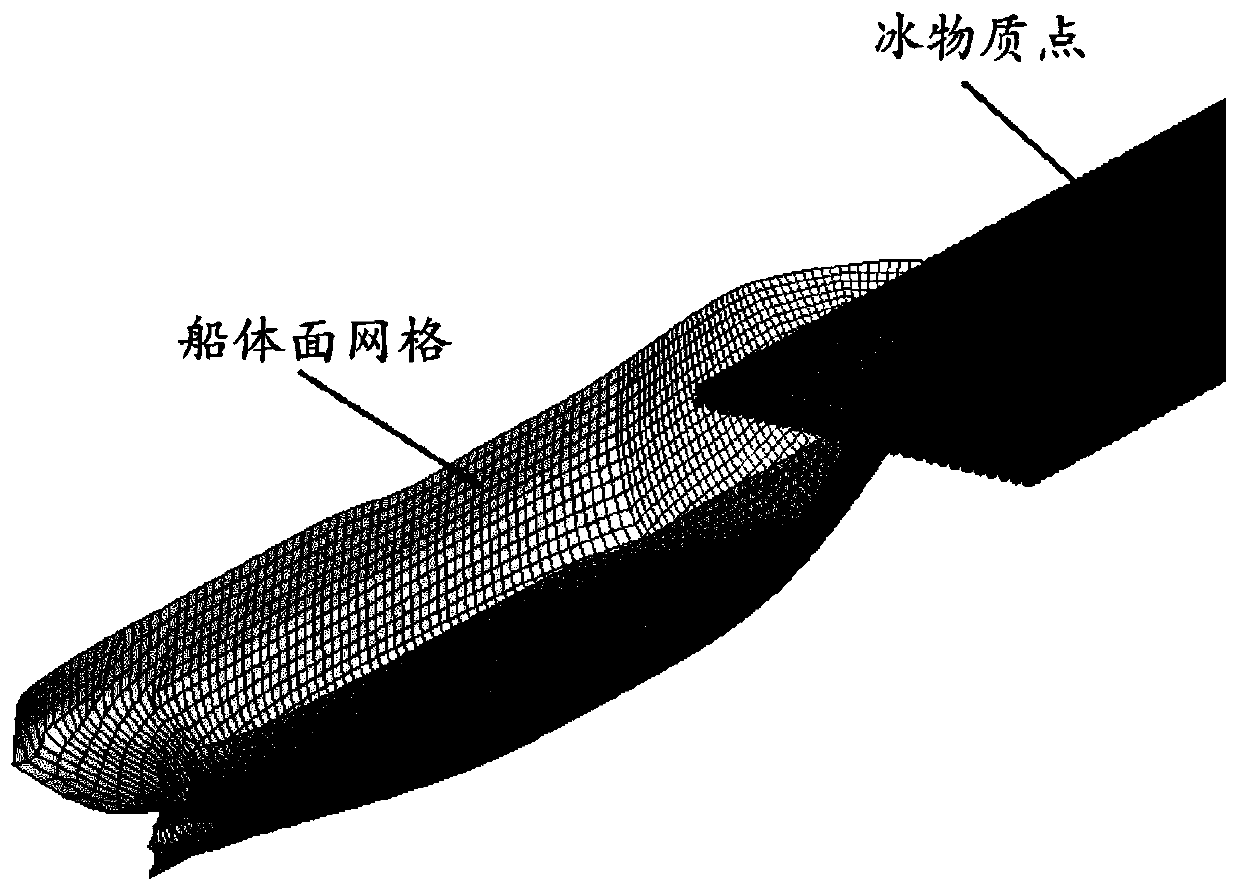

An ice boat contact process numerical calculation method

ActiveCN109766603AEffective contact identificationSustainable transportationSpecial data processing applicationsDynamic methodSolid structure

The invention discloses an ice boat contact process numerical calculation method, and belongs to the field of ice region ship navigation performance calculation. The method is characterized by carrying out the numerical simulation and calculation of the ice boat contact process by combining a near-field dynamics method and an ice boat contact area recognition method, firstly, dispersing an ice field solid structure into a series of ice substance points, and initializing the density, volume, speed and acceleration parameters of all the ice substance points; dispersing the ship body three-dimensional model needing to be calculated into a series of quadrilateral surface element forms; adopting an ice-boat contact area recognition algorithm to carry out the contact judgment on all ice materialpoints and a ship body structure at the current moment and the calculation of an ice load; calculating the crushing condition of the sea ice particles under the contact action at the current moment based on a near-field dynamics method; and calculating sea ice breaking by using an ice boat contact area and a near-field dynamics method in each time step until the maximum time step is reached. Theice boat contact detection method can effectively carry out the contact identification on the ice particles and the boat body and calculate the transient ice load.

Owner:HARBIN ENG UNIV

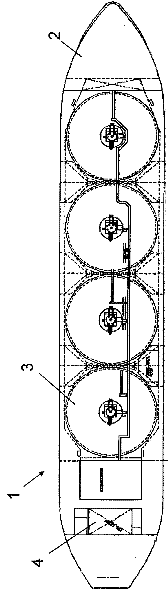

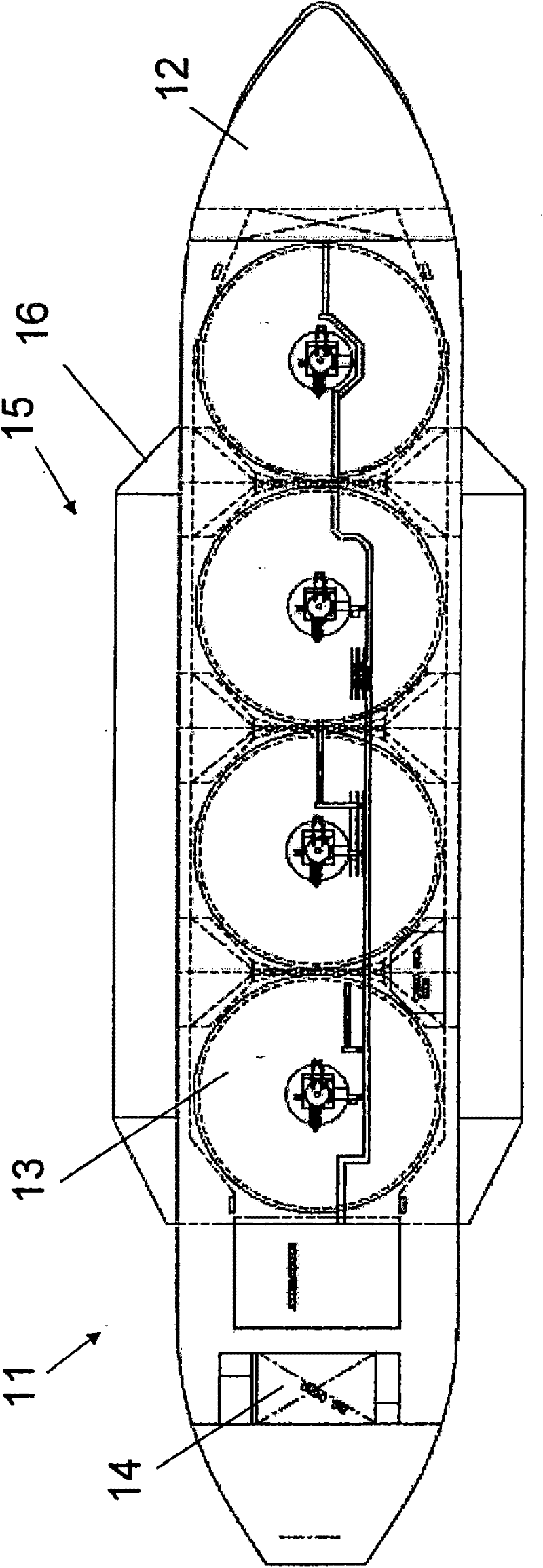

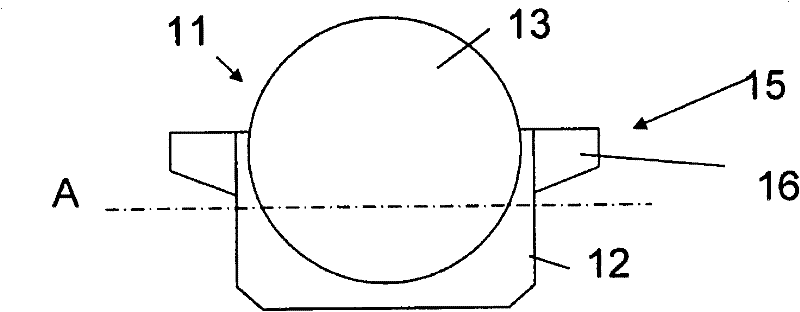

Device for floating production of lng and method for converting a lng-carrier to such a device

The invention relates to a device for floating production of LNG. The device comprises a LNG carrier comprising a ship hull (12) and at least one spherical LNG storage tank (13) for storing LNG, a projecting hull structure (16) fixed to the ship hull (12), a LNG production system (17) for converting natural gas to LNG, where the LNG production system is arranged in the projecting hull structure (16) and means for transferring LNG from the LNG production system (17) to the at lest one spherical LNG storage tank (13). The invention also relates to a method for converting an LNG-carrier to a device for floating production of LNG.

Owner:MOSS MARITIME

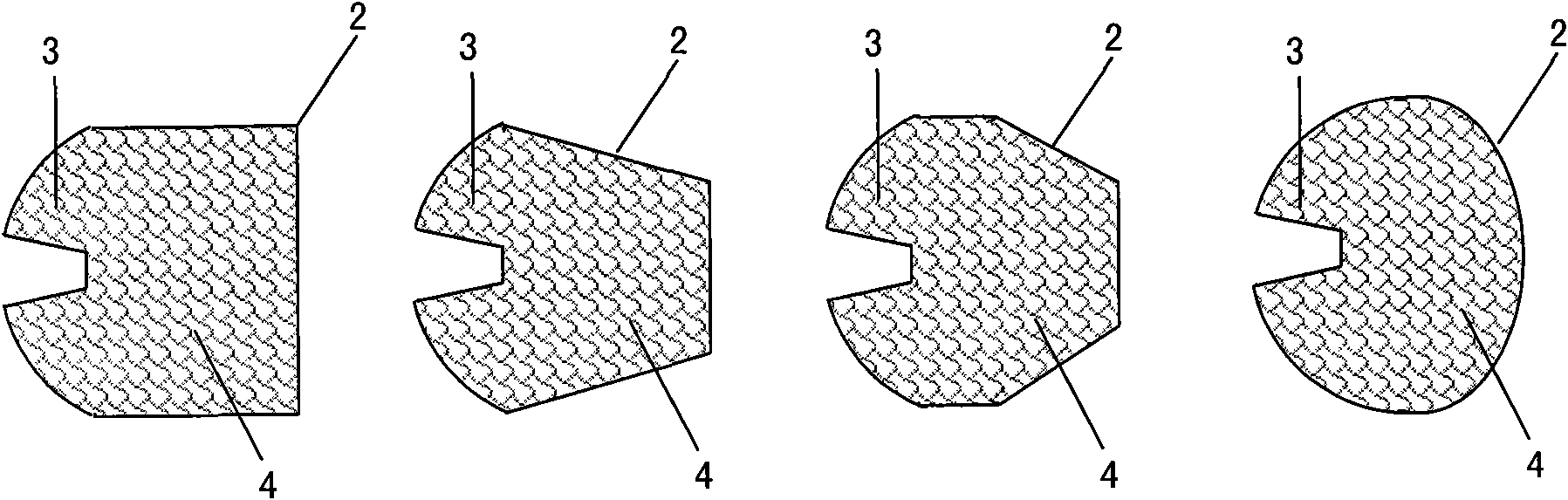

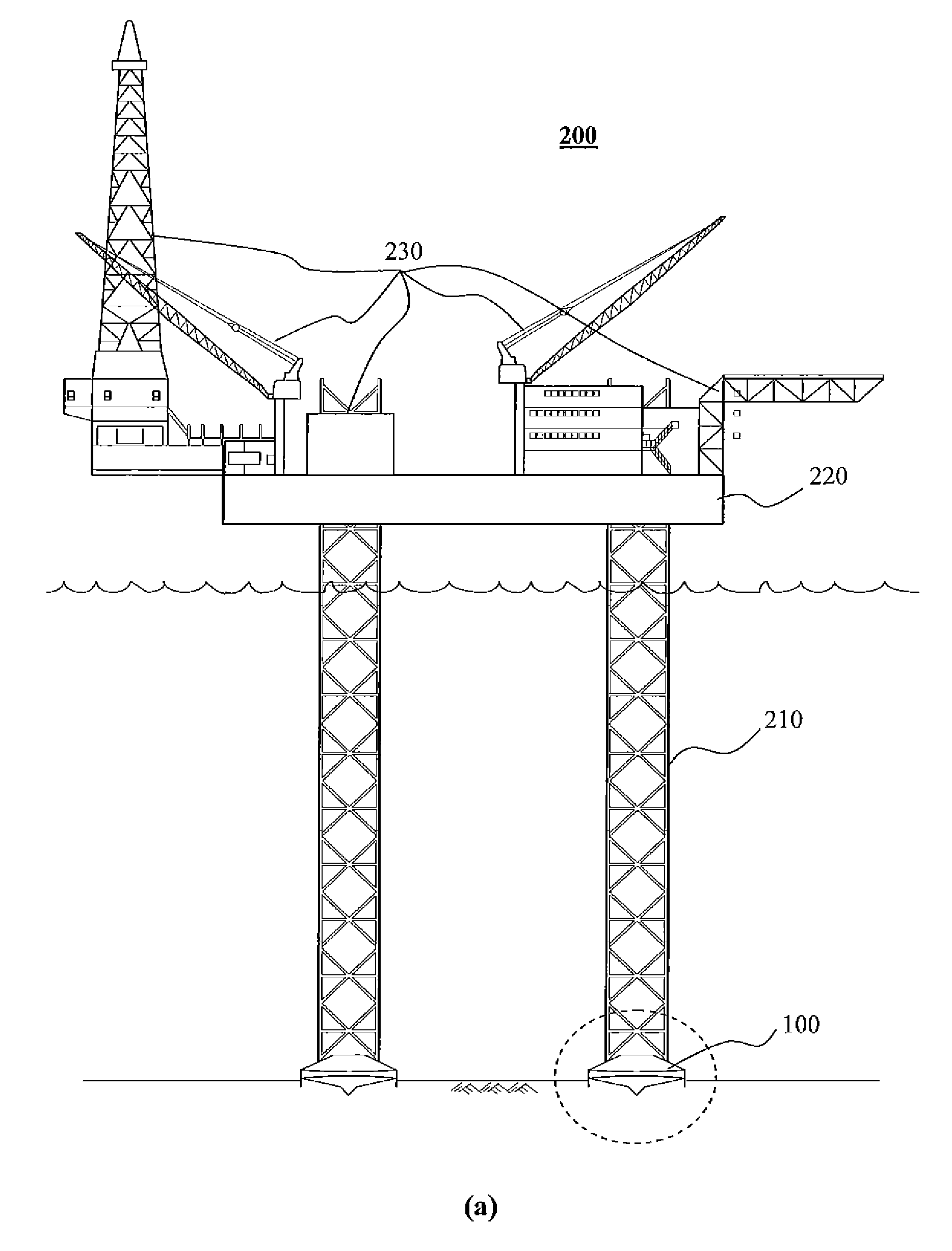

Modified Spudcan With Optimal Peripheral Skirt For Enhanced Performance Of Jackup Operations

ActiveUS20150354164A1Improve performanceArtificial islandsUnderwater structuresHull structureEngineering

A modified spudcan with optimal peripheral skirt for enhanced performance of jackup operations comprises a spudcan top part, a spudcan bottom part, wherein the spudcan bottom has a central tip protruding from the central part of the spudcan bottom; wherein the top and bottom parts are coupled at their peripherals or through a spudcan side wall to form a hull structure, and a peripheral skirt having an upper end being coupled to the spudcan bottom part and a lower end extending downwardly, wherein the tip of the lower end of the peripheral skirt is higher than the distal end of the central tip.

Owner:OFFSHORE TECH DEVMENT PTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com