Mounting method of integral stern shaft tube on naval architecture and ocean engineering

An installation method and marine engineering technology, applied in the directions of ship components, ship construction, transportation and packaging, can solve the problems of bumping the overall stern tube, affecting the progress of the project, affecting the epoxy pouring, etc., saving labor, reducing Workload, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below we will further elaborate on the installation method and auxiliary tools of the integral stern tube on the ship and marine engineering of the present invention in combination with the accompanying drawings and specific embodiments, in order to understand more clearly the structural composition and structure of the special tooling in the present invention. The working principle of the installation method, but it cannot be used to limit the protection scope of the present invention.

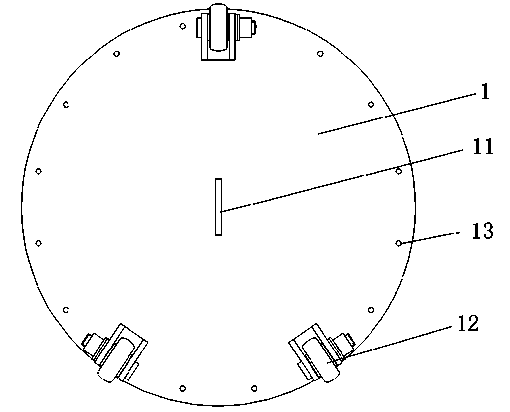

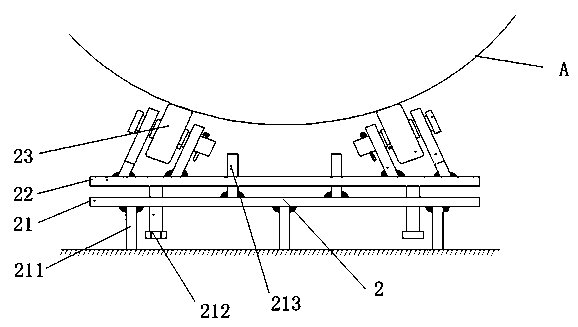

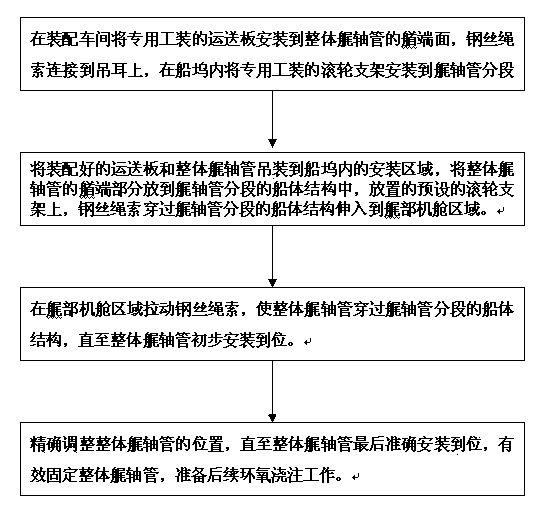

[0026] The installation method of the integral stern tube on ships and marine engineering of the present invention utilizes a new tooling design and a new installation process to minimize the installation workload of the integral stern tube and improve the quality and efficiency of the overall stern tube installation. Wherein, the auxiliary tool used for the installation of the stern tube includes two parts, the delivery plate 1 and the roller bracket 2 . The transport plate 1 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com