Semi-submersible offshore multifunctional engineering ship

A semi-submersible, multi-functional technology, applied in the direction of floating buildings, etc., can solve the problem of single function mode of engineering ships, can not meet the needs of various working conditions of marine engineering, etc., to achieve increased operational flexibility, large benefits, and multiple functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

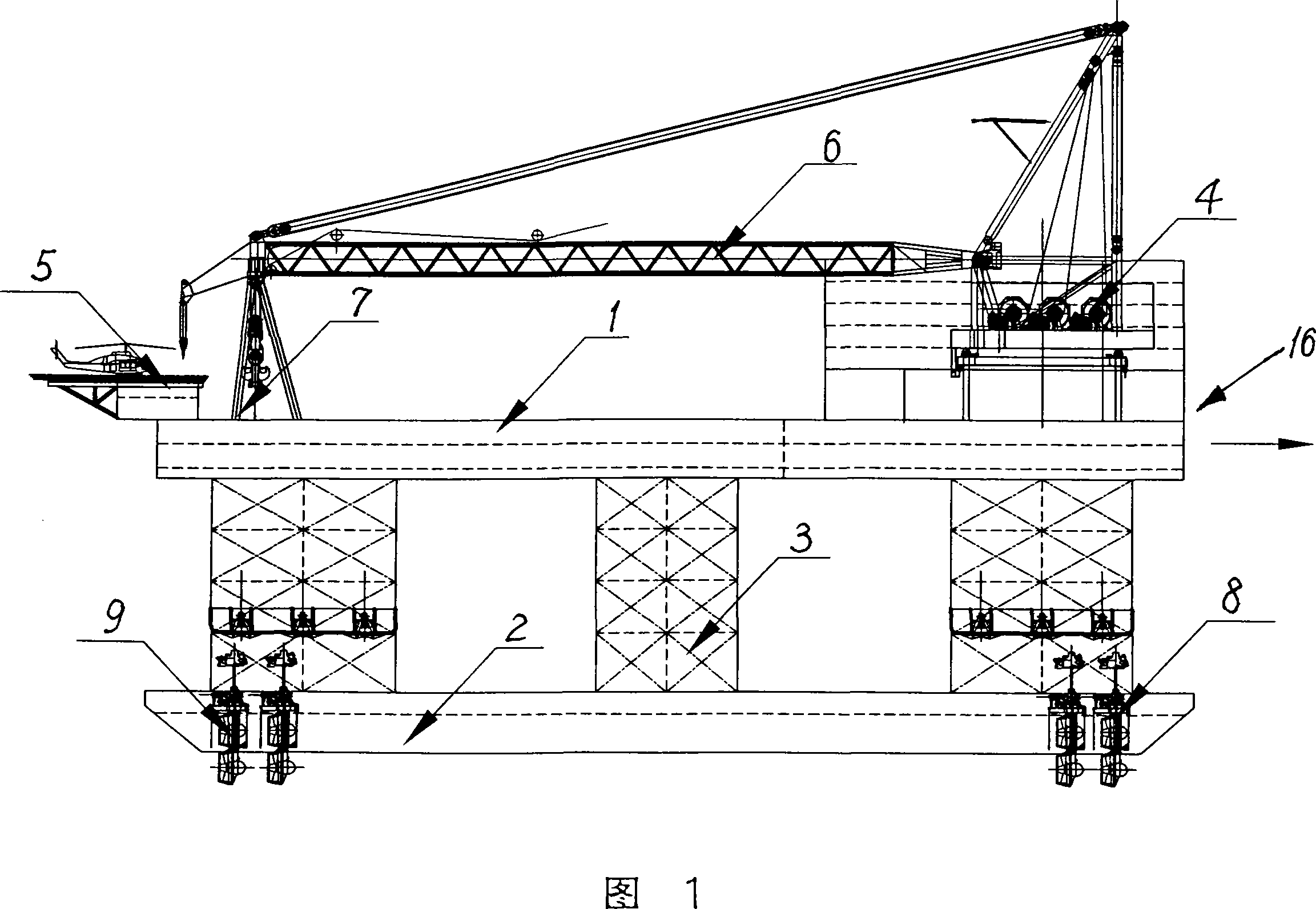

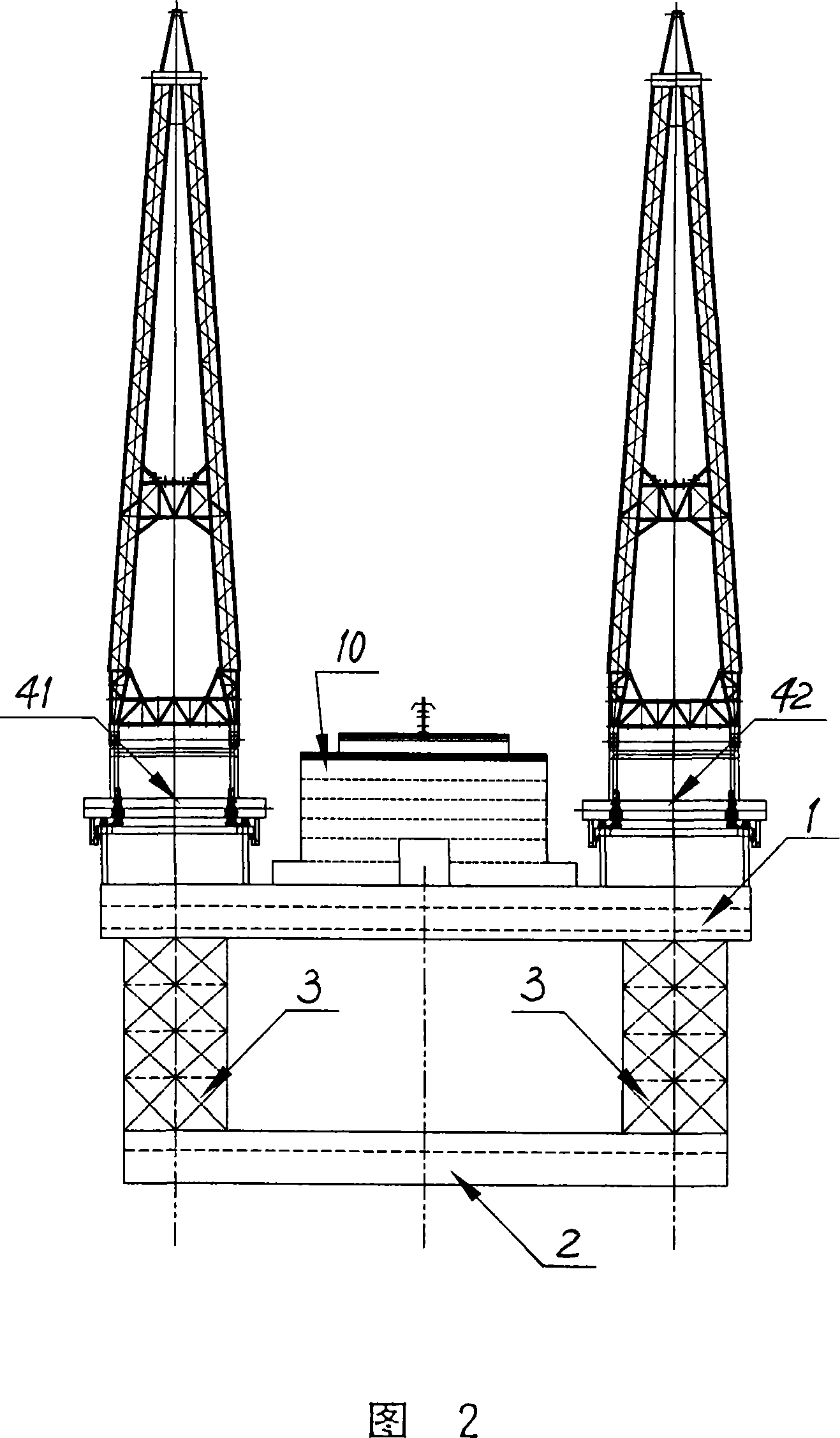

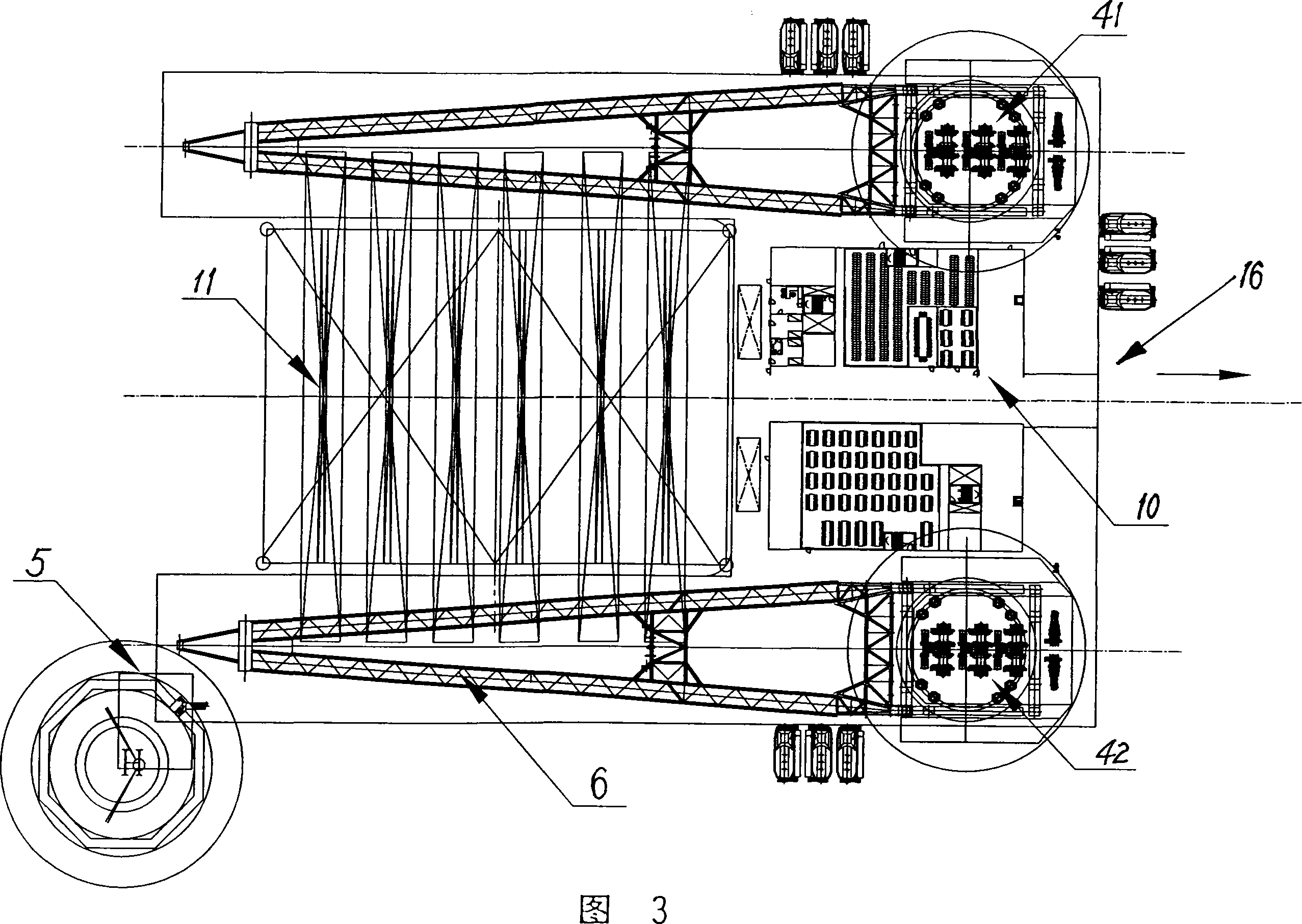

[0026] Referring to Figures 1 to 6, the present invention is a semi-submersible marine multifunctional engineering ship, which includes a hull and a crane installed on the hull.

[0027] The hull is a U-shaped semi-submersible hull structure, which is different from the hull of a general engineering ship. The U-shaped opening size of the U-shaped hull is determined after comprehensively considering the dimensions of different types of offshore drilling platforms. The water part of the U-shaped hull is the upper box 1, and the underwater part of the U-shaped hull is equipped with a streamlined underwater cushion 2. The underwater mat 2 is composed of a port side mat 21, a starboard side mat 22 and a horizontal mat 23 arranged longitudinally. The port side mat 21 and the starboard side mat 22 are connected by the transverse mat 23. A number of uprights 3 are installed between the upper box 1 and the underwater cushion 2. As shown in Figure 1, three uprights 3 are placed on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com