Construction method for cement gypsum composite stable steel slag base layer

A technology of steel slag and cement, which is applied in the direction of road repair, road, on-site coagulation pavement, etc. It can solve the problems of inaccurate measured data, non-compliance with the setting of transverse joints, and ineffective utilization, etc., to achieve The effects of saving management costs, improving resource utilization efficiency, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Part 1: Engineering Test of Construction Method of Cement-Gypsum Composite Stabilized Base

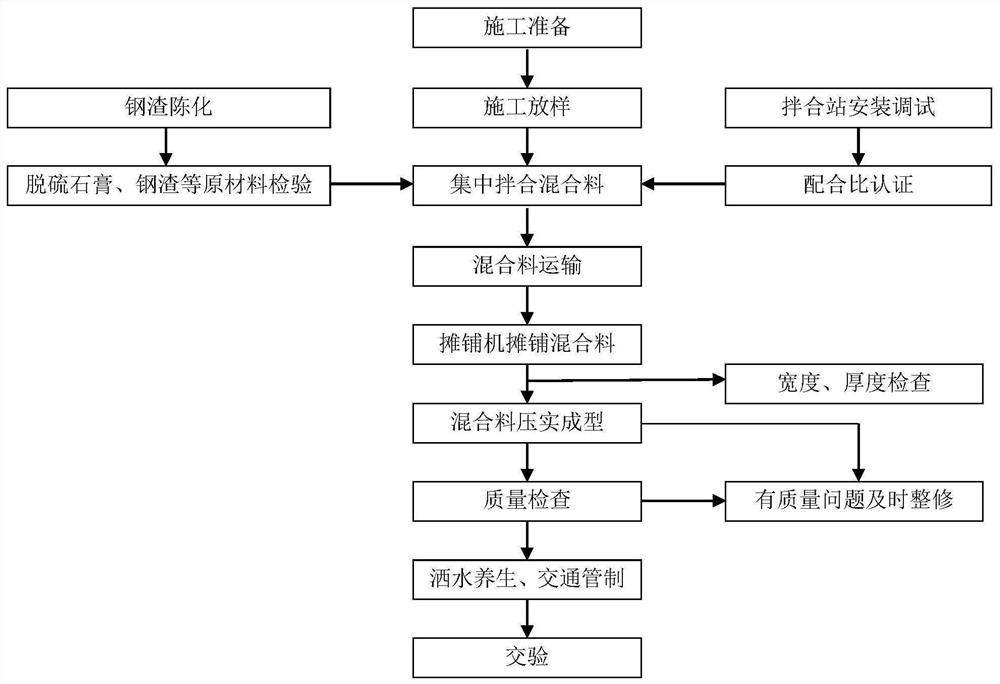

[0056] figure 1 It is a process flow chart of the construction method of the cement desulfurization gypsum composite stabilized steel slag base of the present invention. According to the process flow in Figure 1, the following examples are given to further illustrate the technical solution of the present invention. The test road section of this project is located near Baotou Iron and Steel (Group) Co., Ltd., and the nearby steel slag, desulfurized gypsum and other waste materials of the plant are used as the pavement base material.

[0057] 1.1 Cement, steel slag and desulfurized gypsum used in the engineering test of the present invention

[0058] (1) The cement is PO32.5 retarded cement, the initial setting time is 4 hours, and the final setting time is 6.5 hours; the temperature of the cement entering the tank is 25 ° C; the number of days for the cement to be released from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com