Patents

Literature

2014results about How to "Low raw material cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Haptic devices using electroactive polymers

ActiveUS7196688B2Low costEfficiently provideInput/output for user-computer interactionManual control with multiple controlled membersActive polymerHaptic sensing

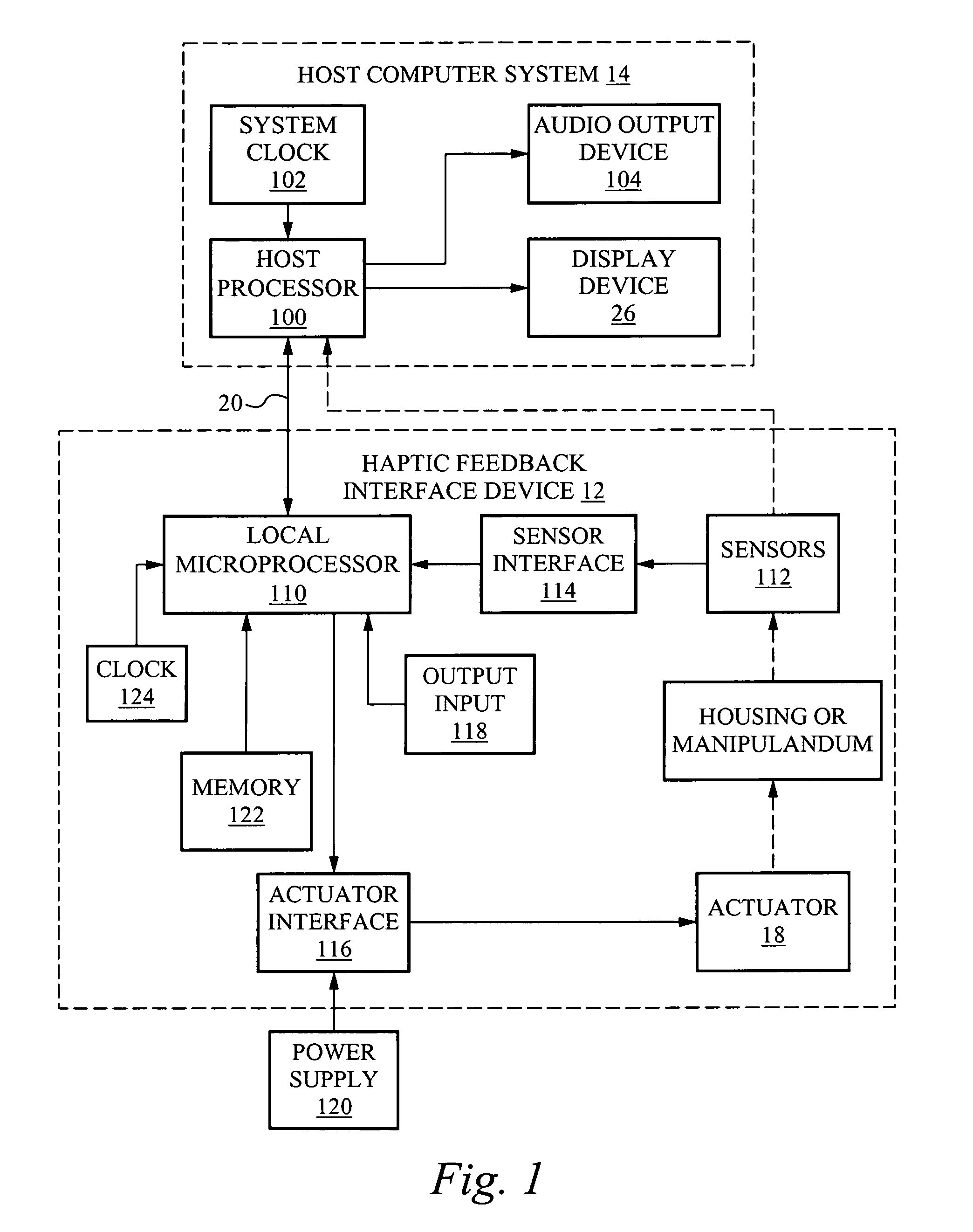

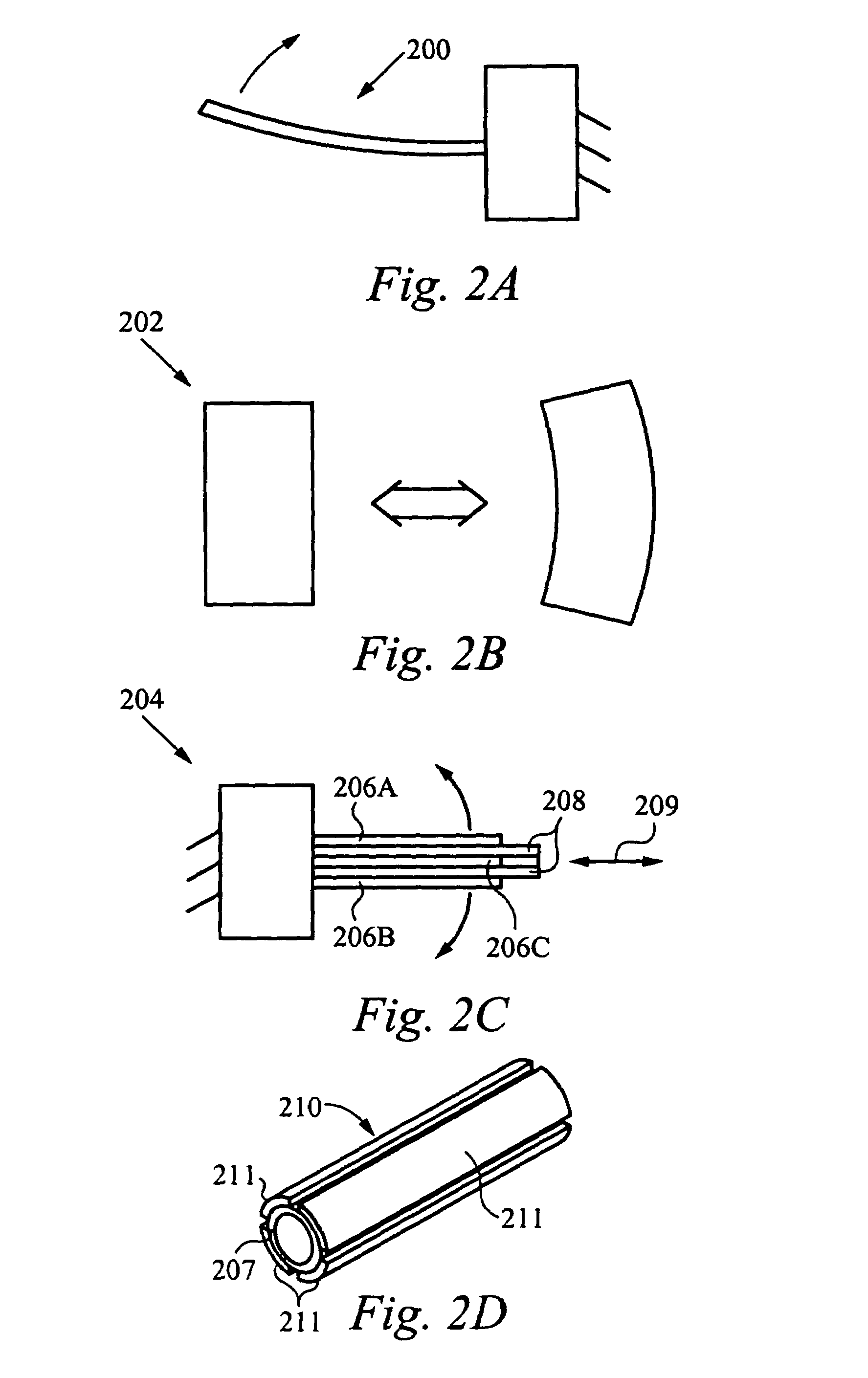

Haptic feedback interface devices using electroactive polymer (EAP) actuators to provide haptic sensations and / or sensing capabilities. A haptic feedback interface device is in communication with a host computer and includes a sensor device that detects the manipulation of the interface device by the user and an electroactive polymer actuator responsive to input signals and operative to output a force to the user caused by motion of the actuator. The output force provides a haptic sensation to the user. Various embodiments of interface devices employing EAP actuators are described, including embodiments providing direct forces, inertial forces, and braking forces.

Owner:IMMERSION CORPORATION

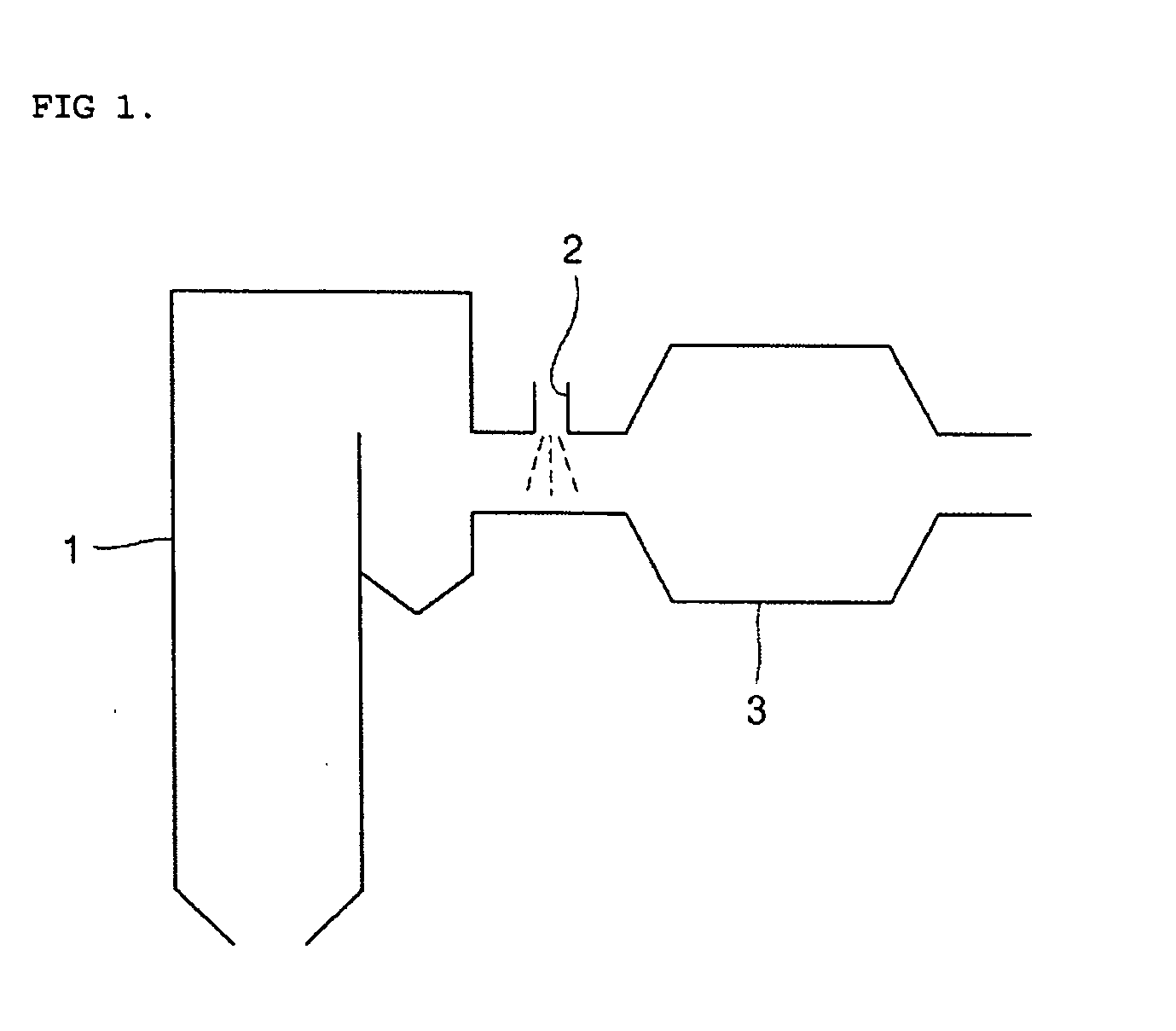

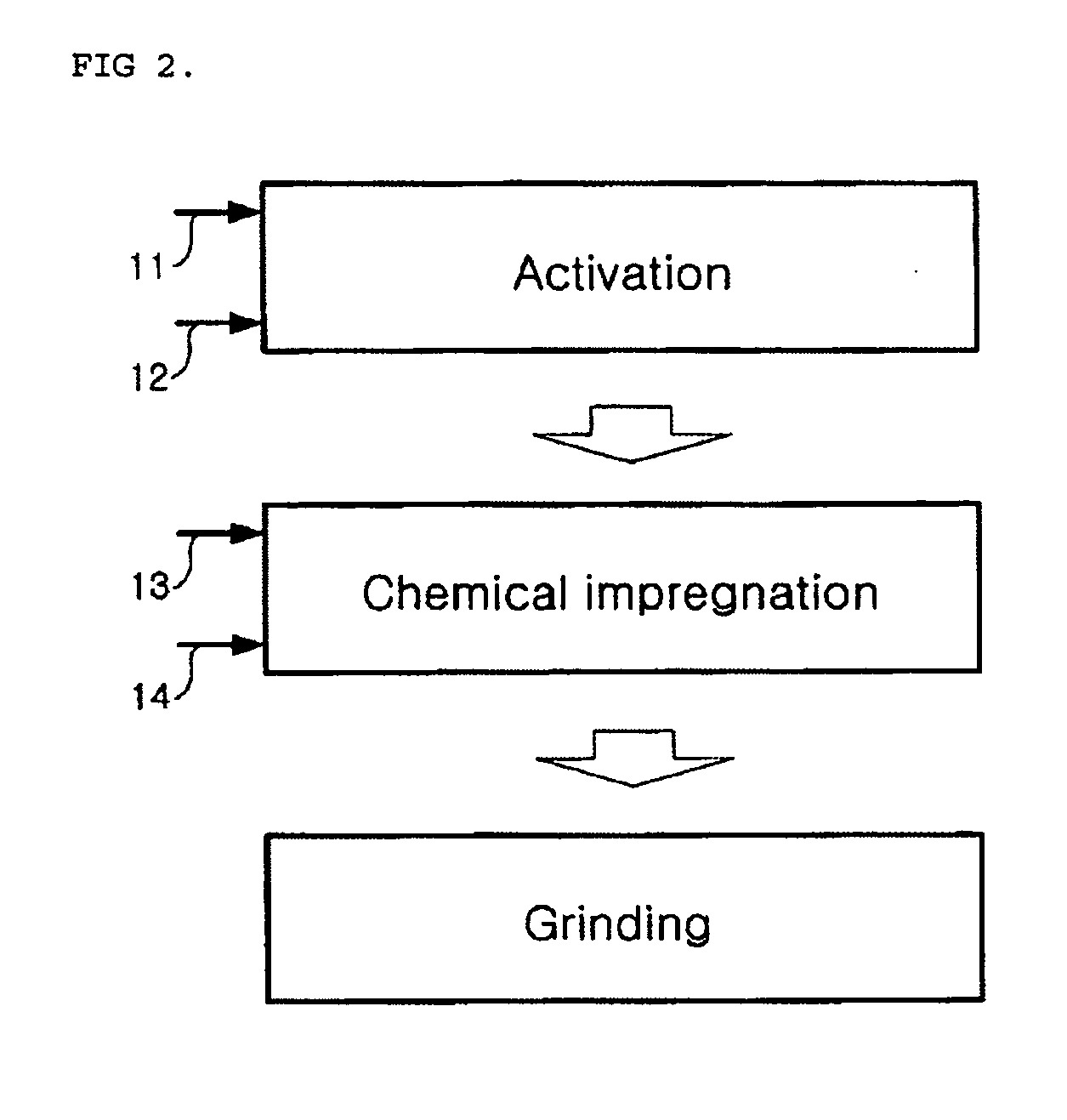

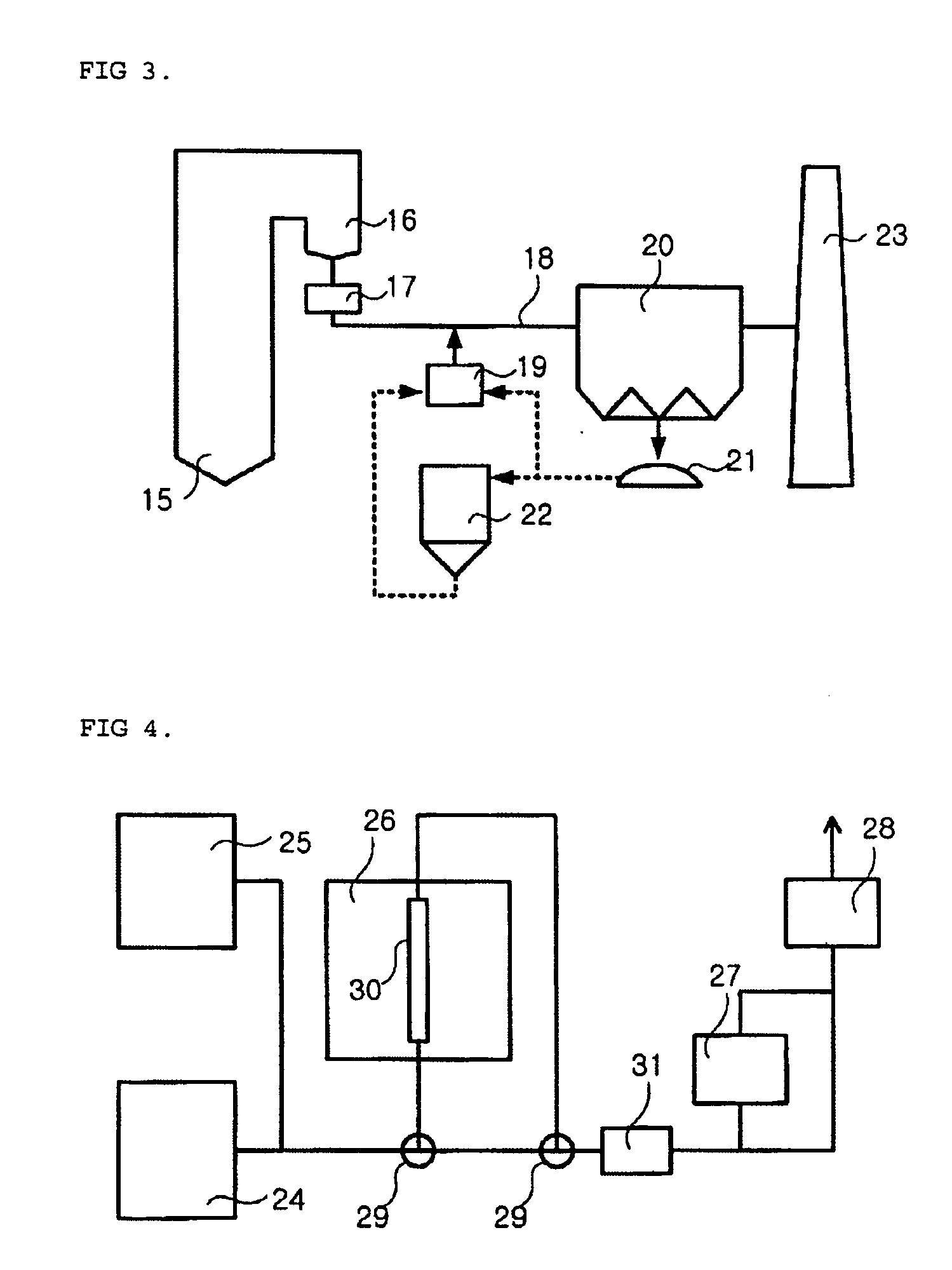

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

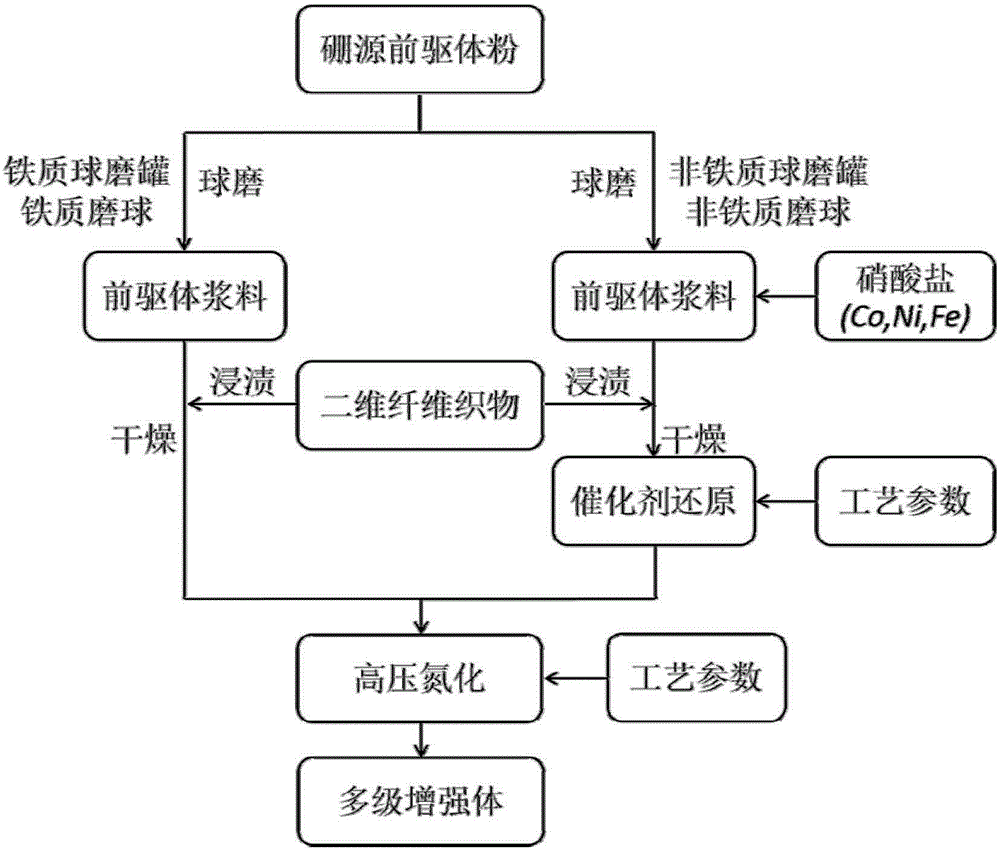

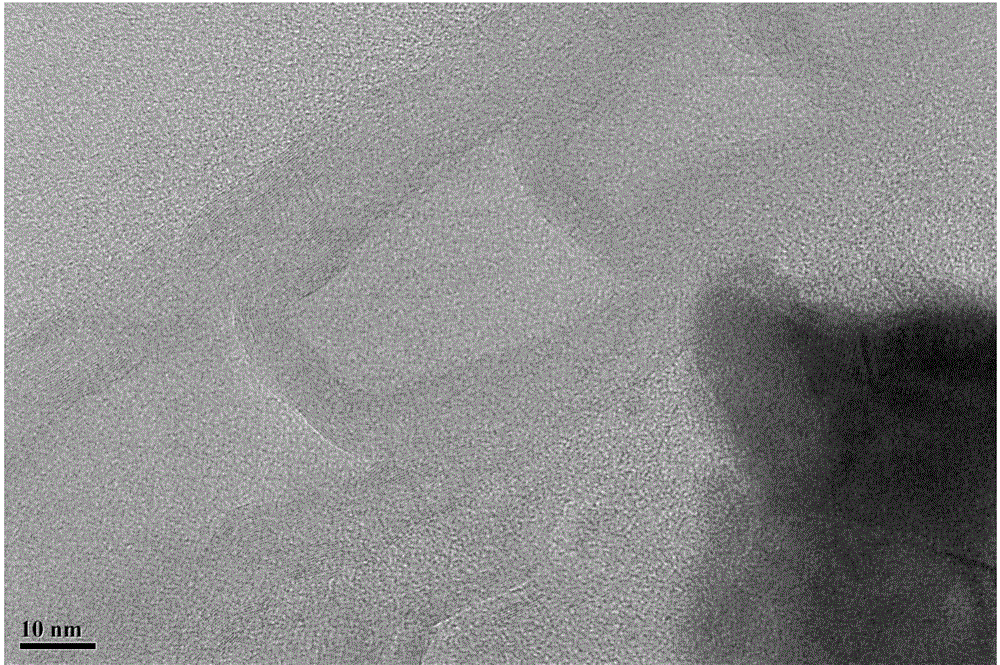

Two-dimensional fiber/boron nitride nanotube multistage reinforcement and preparation method thereof

ActiveCN104909790ASimple preparation processLow raw material costBoron nitride nanotubeBoron nitride

The invention relates to a two-dimensional fiber / boron nitride nanotube multistage reinforcement and a preparation method thereof. In the two-dimensional fiber / boron nitride nanotube multistage reinforcement, boron nitride nanotubes are uniformly distributed on the surface of two-dimensional fibers. The preparation method for the two-dimensional fiber / boron nitride nanotube multistage reinforcement is innovatively explored for the first time, and the desired two-dimensional fiber / boron nitride nanotube multistage reinforcement is prepared. The preparation method is simple; raw materials for the reinforcement are cheap, safe and easily available; and a foundation is laid for subsequent construction of a three-dimensional fiber / boron nitride nanotube multistage reinforcement and research and development of a multistage reinforced composite.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

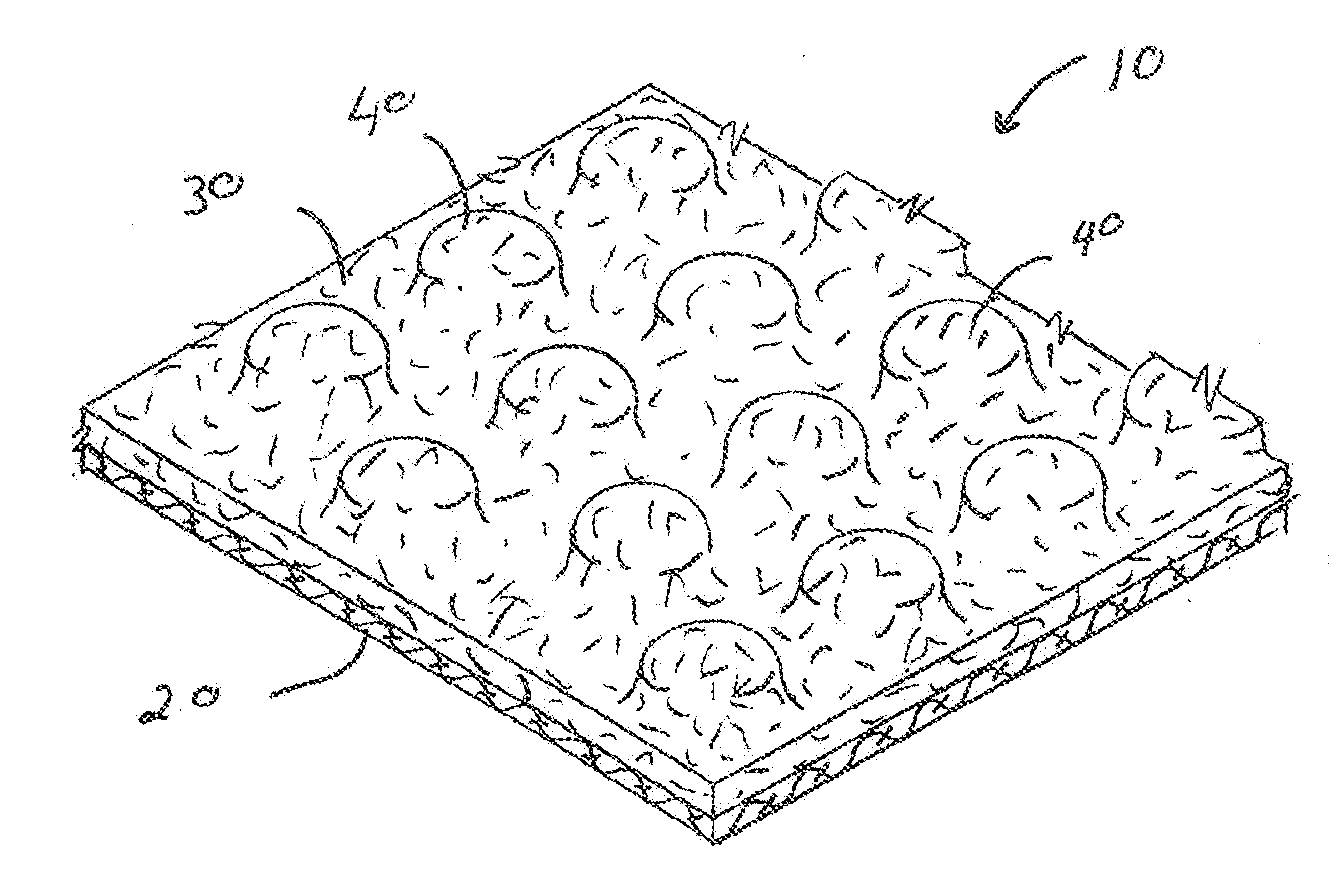

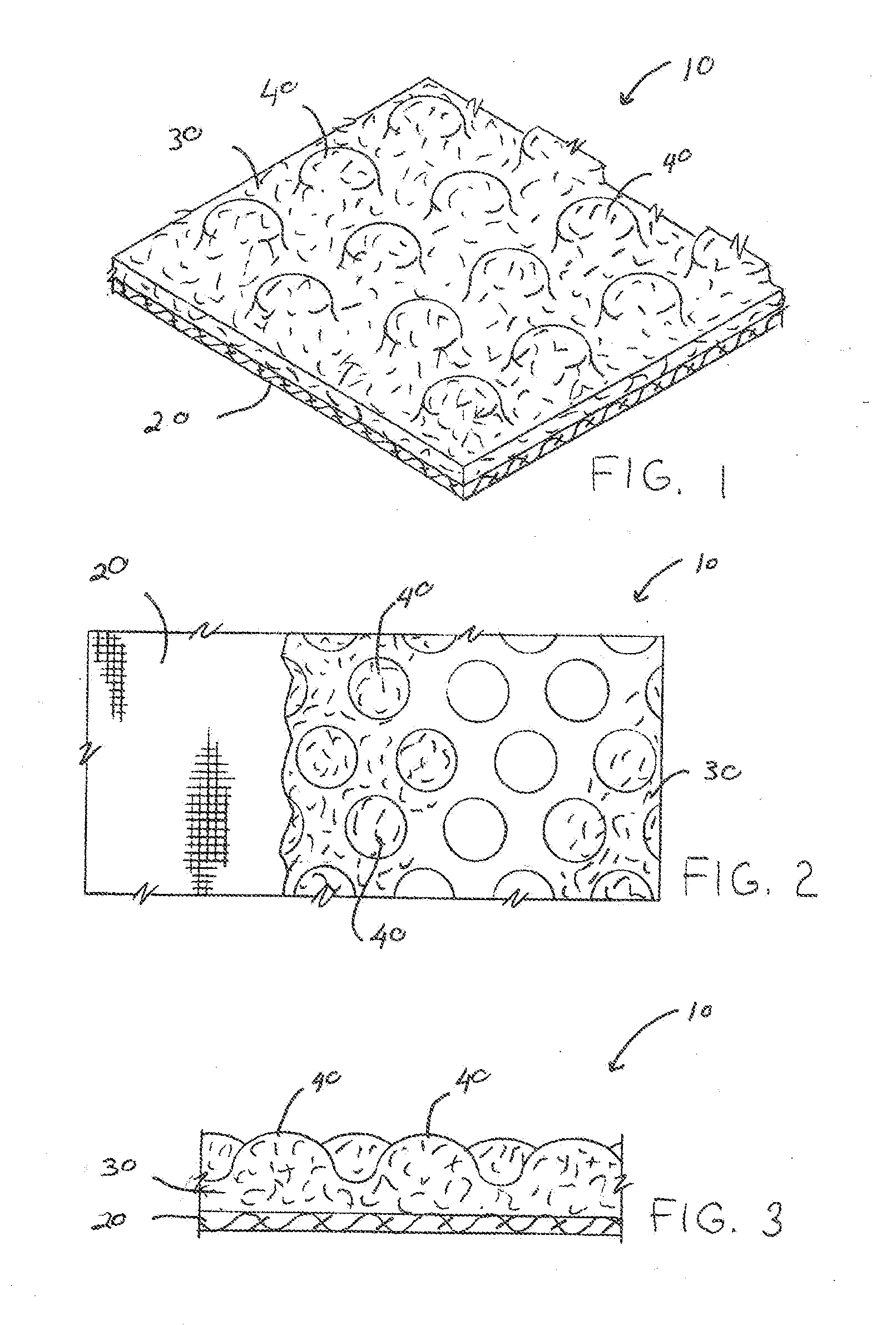

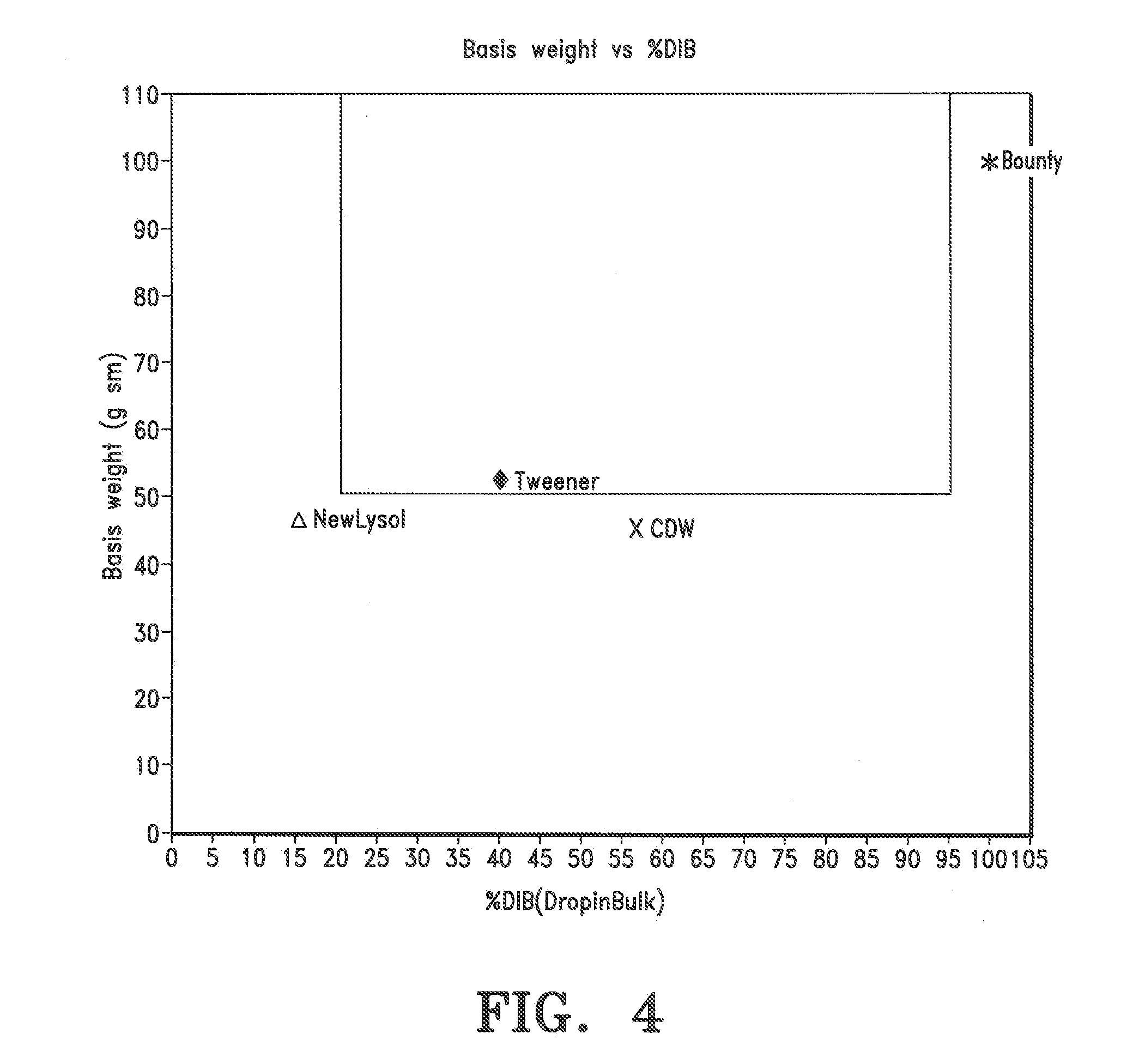

Textured wipes

InactiveUS20120227203A1Reduce material usageHigh strengthBoard cleaning devicesCarpet cleanersEngineeringSecondary layer

A wipe formed of a base layer and a secondary layer. The wipe has an initial caliper of at least about 0.5 mm, a basis weight of less than about 55 gsm and a % DIB of about 20-95%. The base layer is formed of a non-biodegradable material such as thermoplastic polymer and the secondary layer is formed of a biodegradable material such as wood pulp, cellulose and / or regenerated cellulose. The top surface of the secondary layer generally includes a non-uniform distribution of fibers.

Owner:THE CLOROX CO

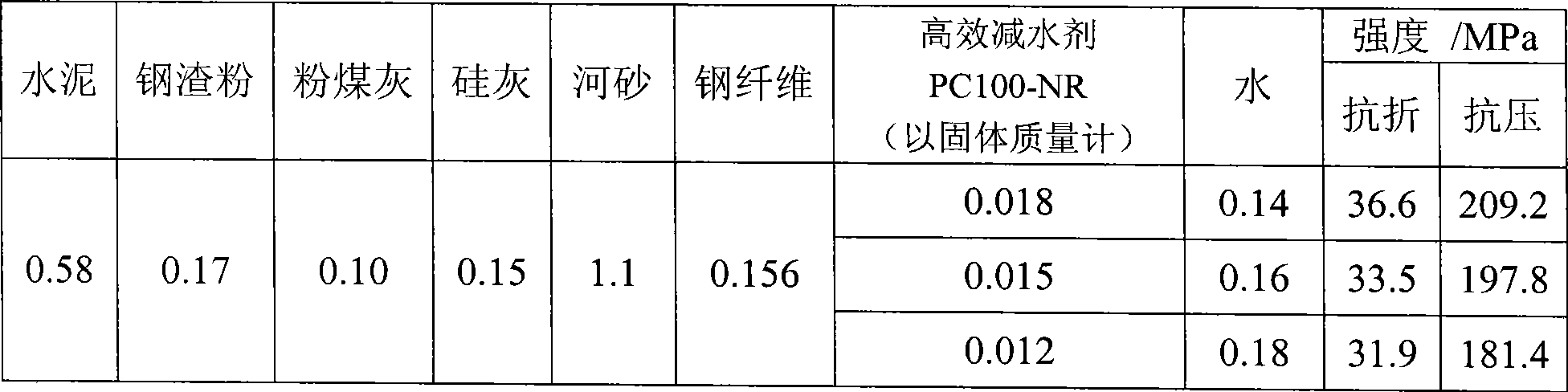

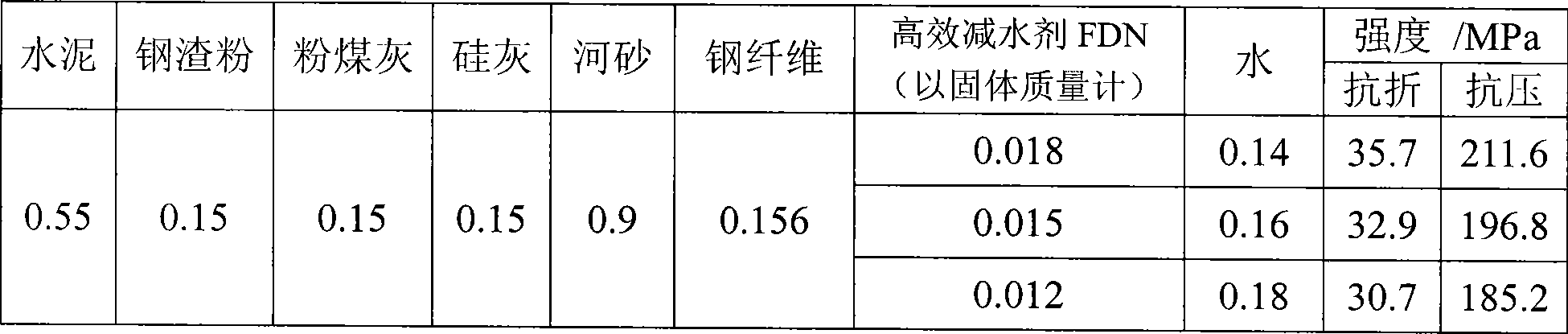

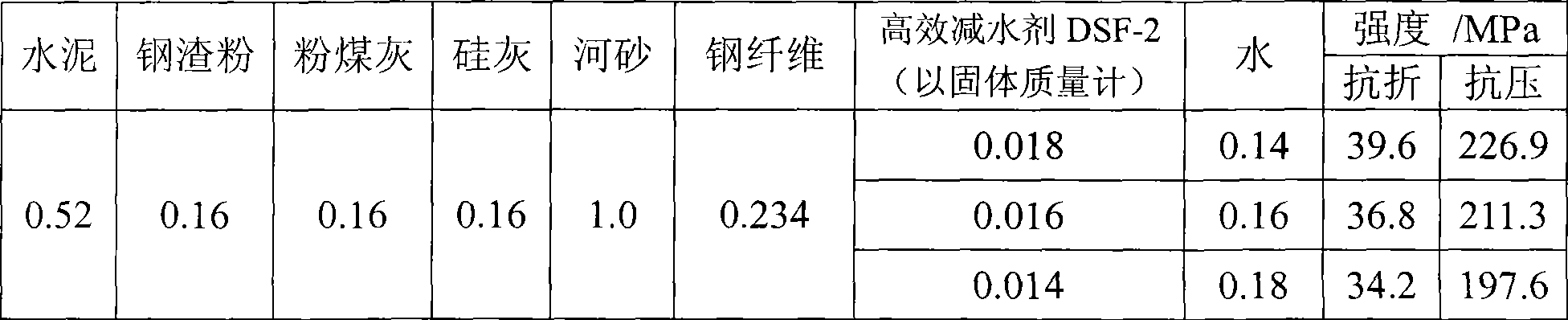

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

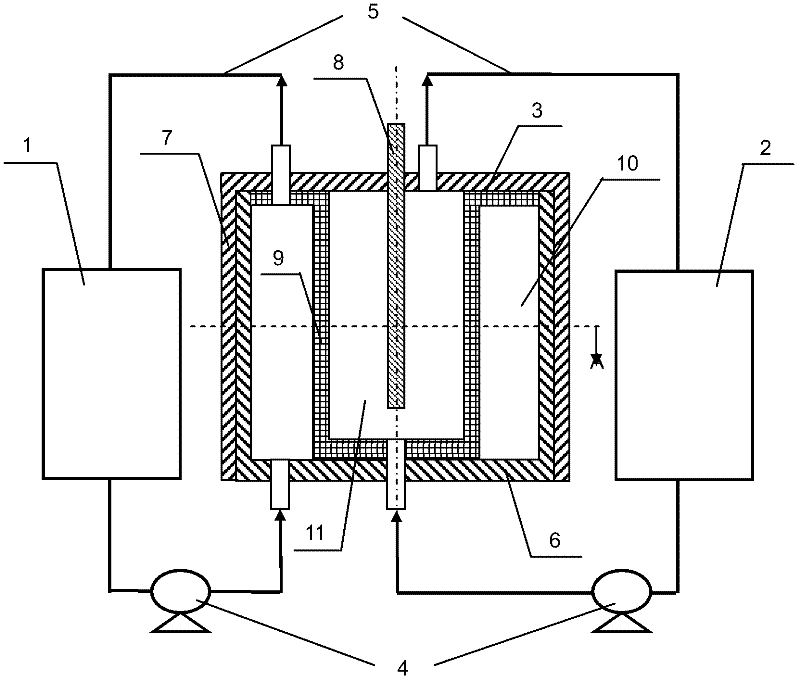

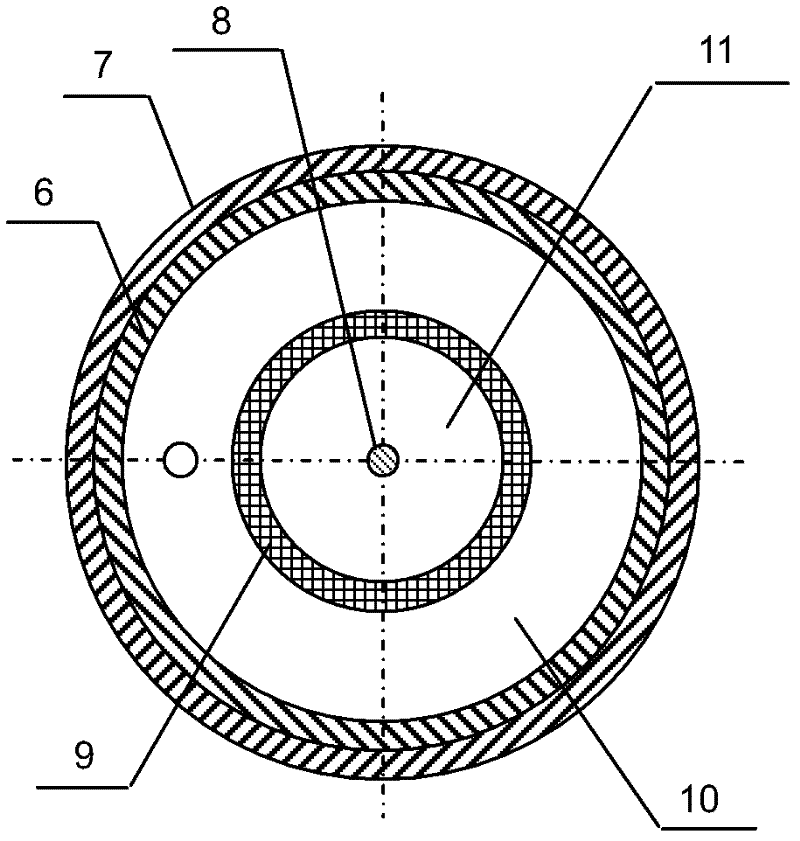

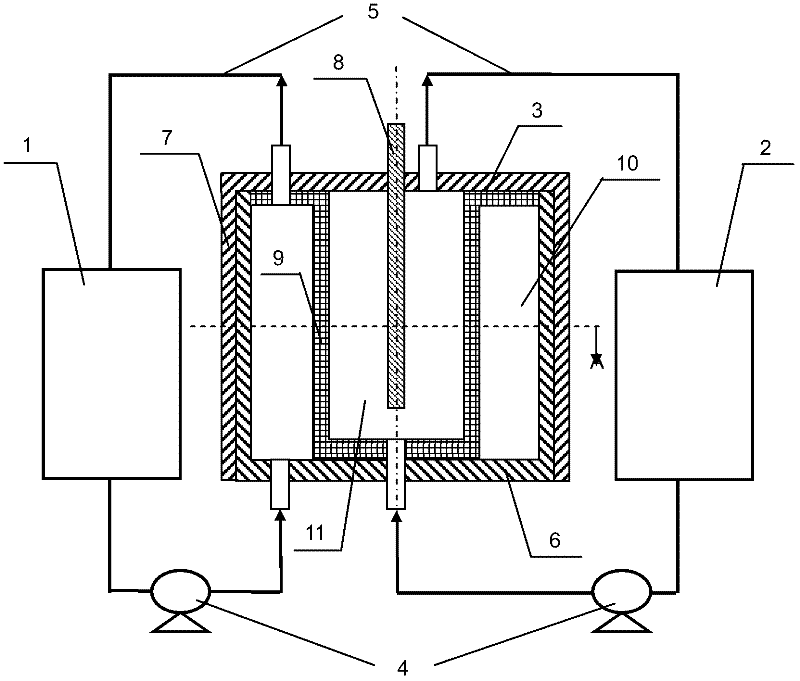

Lithium ion flow redox battery

InactiveCN102315473AScale upSolution to short lifeCell electrodesRegenerative fuel cellsHigh energyRedox

The invention provides a lithium ion flow redox battery, belonging to the technical field of lithium ion batteries. The lithium ion flow redox battery comprises a positive electrode suspension tank, a negative electrode suspension tank and a battery reactor, wherein the positive electrode suspension tank contains the mixture of positive electrode composite material particles and an electrolyte; the negative electrode suspension tank contains negative electrode composite material particles and an electrolyte; the battery reactor comprises a positive electrode current collector, a negative electrode current collector and one layer or a plurality of layers of microporous separators; the microporous separators separate the positive electrode current collector from the negative electrode current collector in an insulation mode so as to respectively form a positive electrode chamber and a negative electrode chamber; the positive electrode chamber is communicated with the positive electrode suspension tank through a seal pipeline; and the negative electrode chamber is communicated with the negative electrode suspension tank through a seal pipeline. Compared with a full vanadium flow redox battery, the lithium ion flow redox battery has the advantage of high energy density, the adoption of the environmentally-friendly and non-toxic electrolyte and low cost, and is applicable to large-scale energy storage of power grids.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

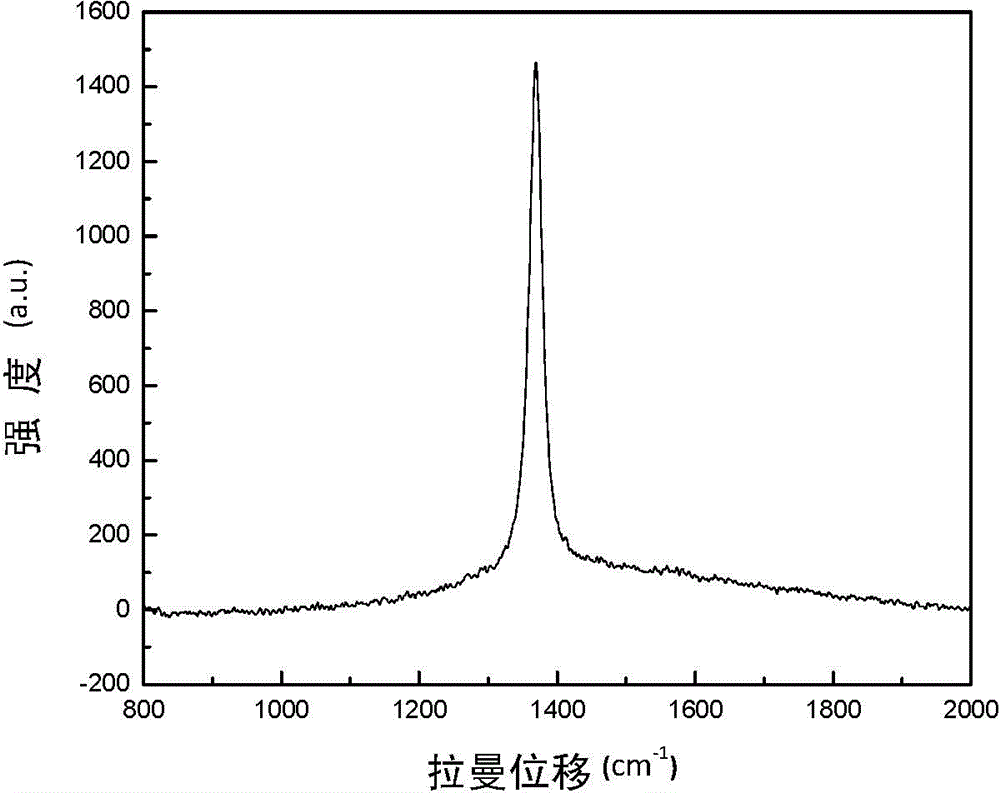

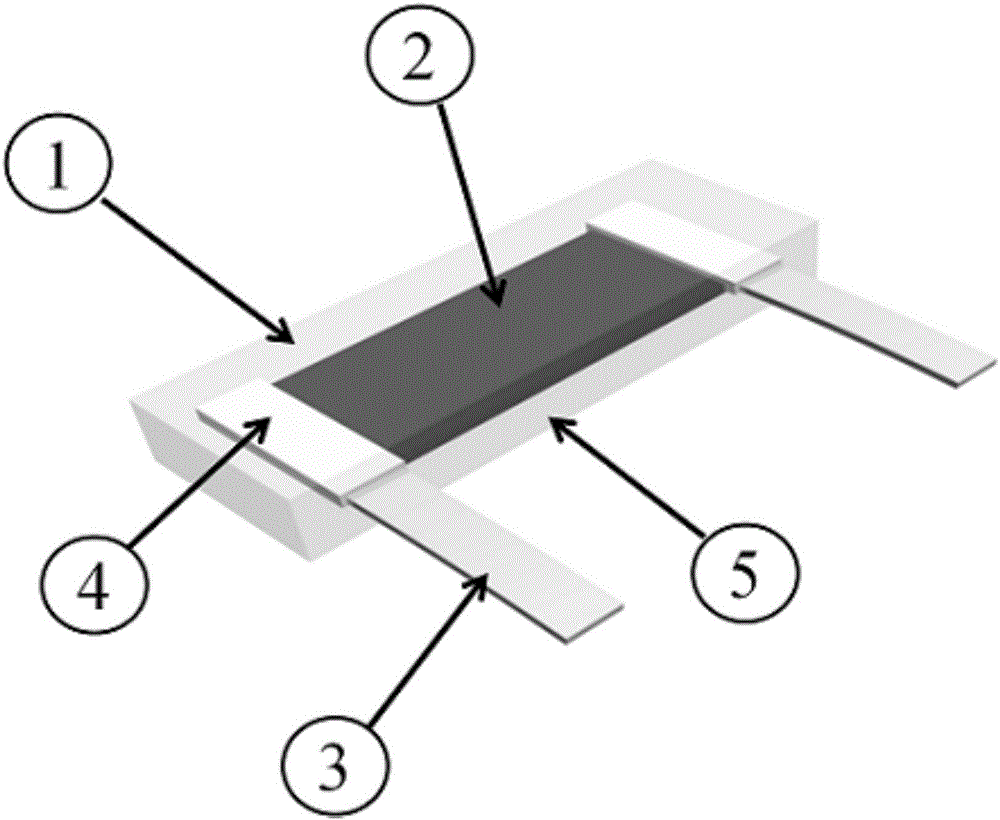

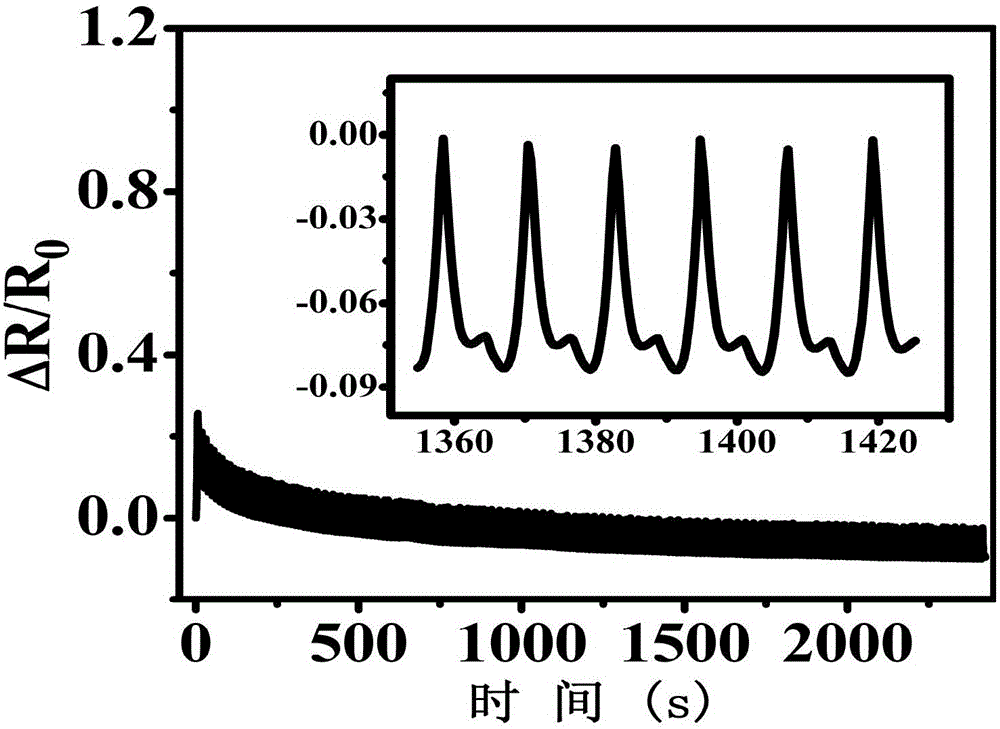

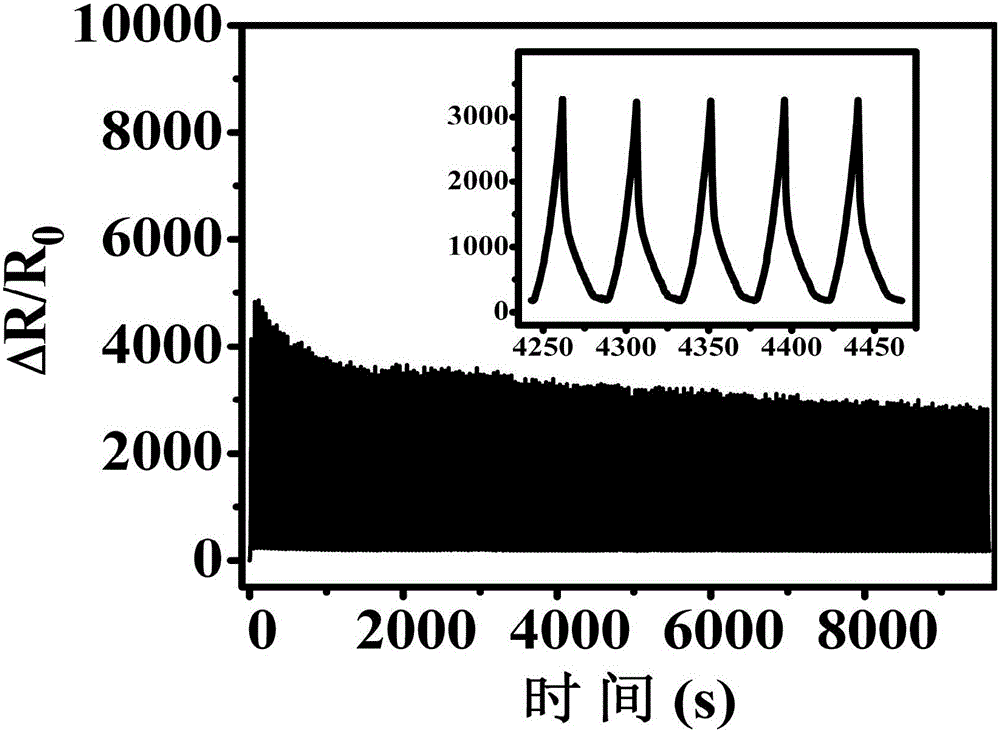

Flexible wearable strain sensor and preparation method thereof

InactiveCN106052544ALow raw material costImprove performanceElectrical/magnetic solid deformation measurementFiberComposite film

The invention relates to the field of strain sensors and in particular to a flexible wearable strain sensor and a preparation method thereof. The invention provides a flexible wearable strain sensor and is characterized in that the flexible wearable strain sensor includes an upper insulating layer, a conductive layer and a lower insulating layer. The conductive layer is arranged between the upper insulating layer and the lower insulating layer. The upper insulating layer and the lower insulating layer are made from a flexible wearable high-molecule material. The conductive layer is a high-molecule fiber / conductive filler composite film having a conductive network structure. According to the invention, the strain sensor is advantaged by low cost of raw materials, excellent product properties, simple technology operations, wide range of strain testing (suitable to response under large strain), and high sensitivity.

Owner:ZHENGZHOU UNIV

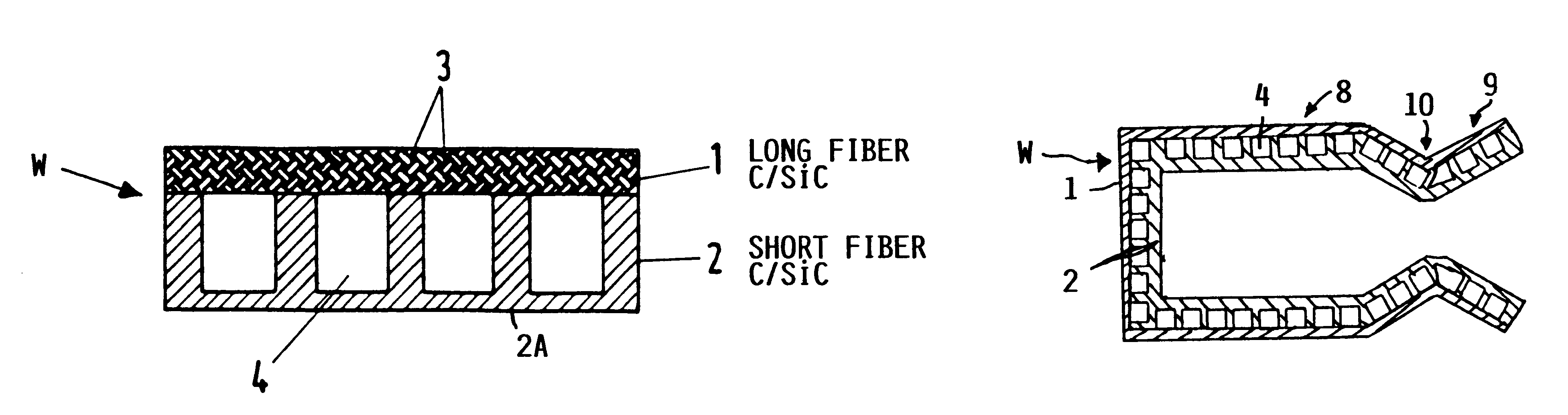

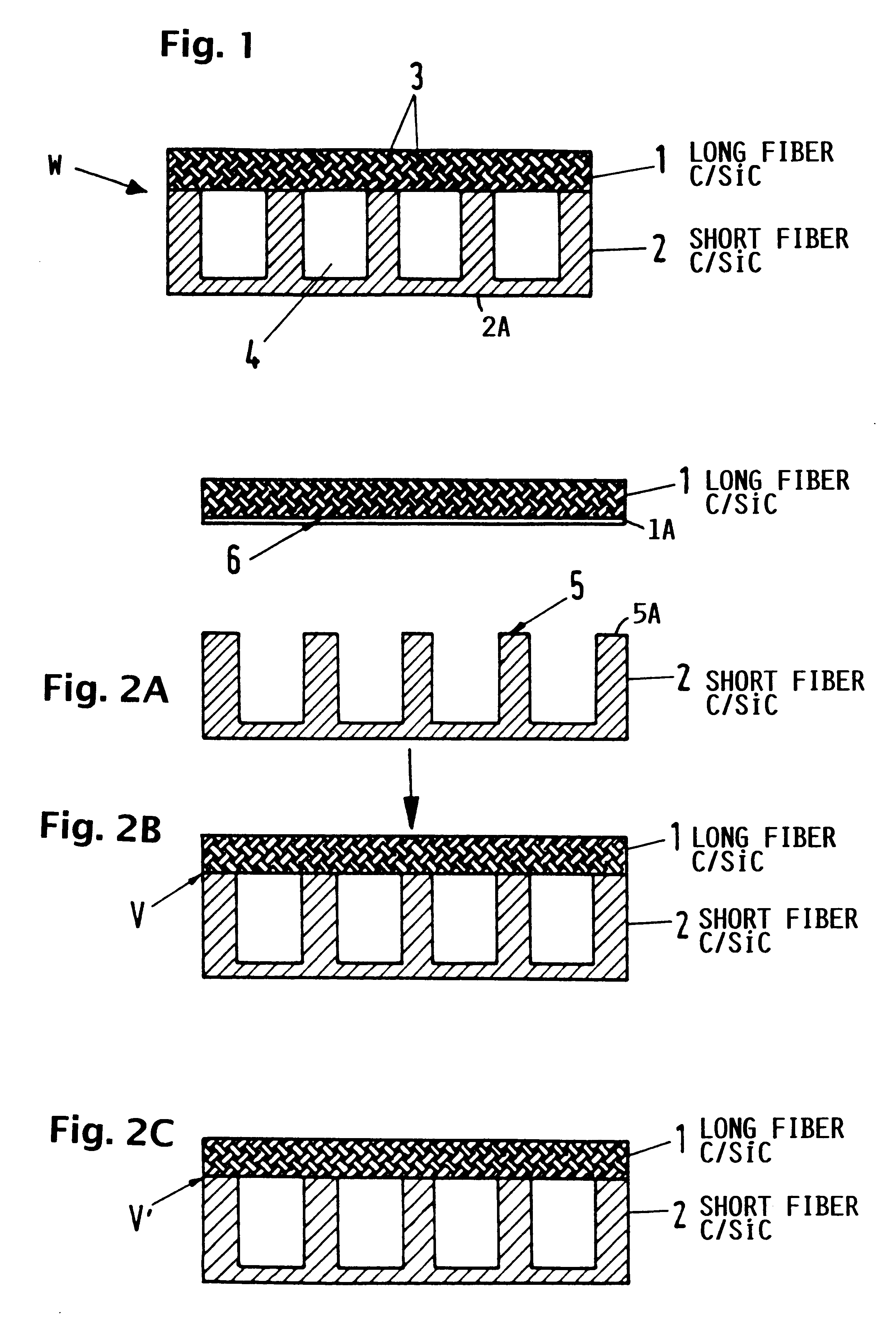

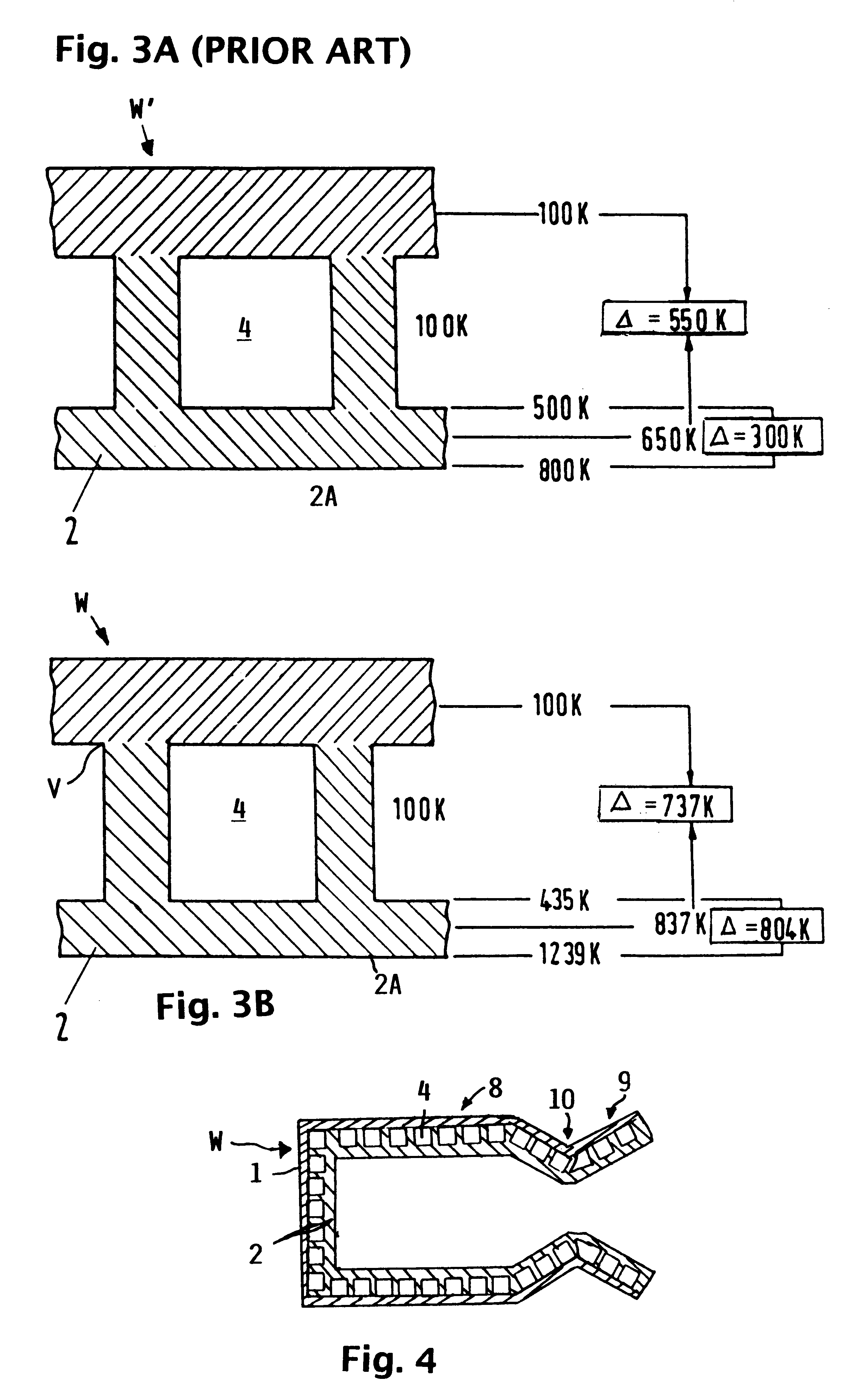

Combustion chamber wall construction for high power engines and thrust nozzles

InactiveUS6182442B1Long lastingReduce quality problemsContinuous combustion chamberPower plant exhaust arrangementsFiberCombustion chamber

A wall construction for a combustion chamber or thrust nozzle of a high power engine of a flying body includes an inner wall body that is subjected to the hot gases within the combustion chamber, and an outer jacket that surrounds the inner wall body and carries the mechanical loads. The inner wall body has a plurality of cooling channels through which a cooling medium may flow. The outer jacket is made of a long-fiber C / SiC composite material, while the inner wall member is made of a short fiber C / SiC composite material. The reduced thermal expansion coefficient of this ceramic composite material in comparison to metal alloys leads to a reduced straining and reduced deformation of the wall construction and therewith an increased operating life.

Owner:DAIMLER AG

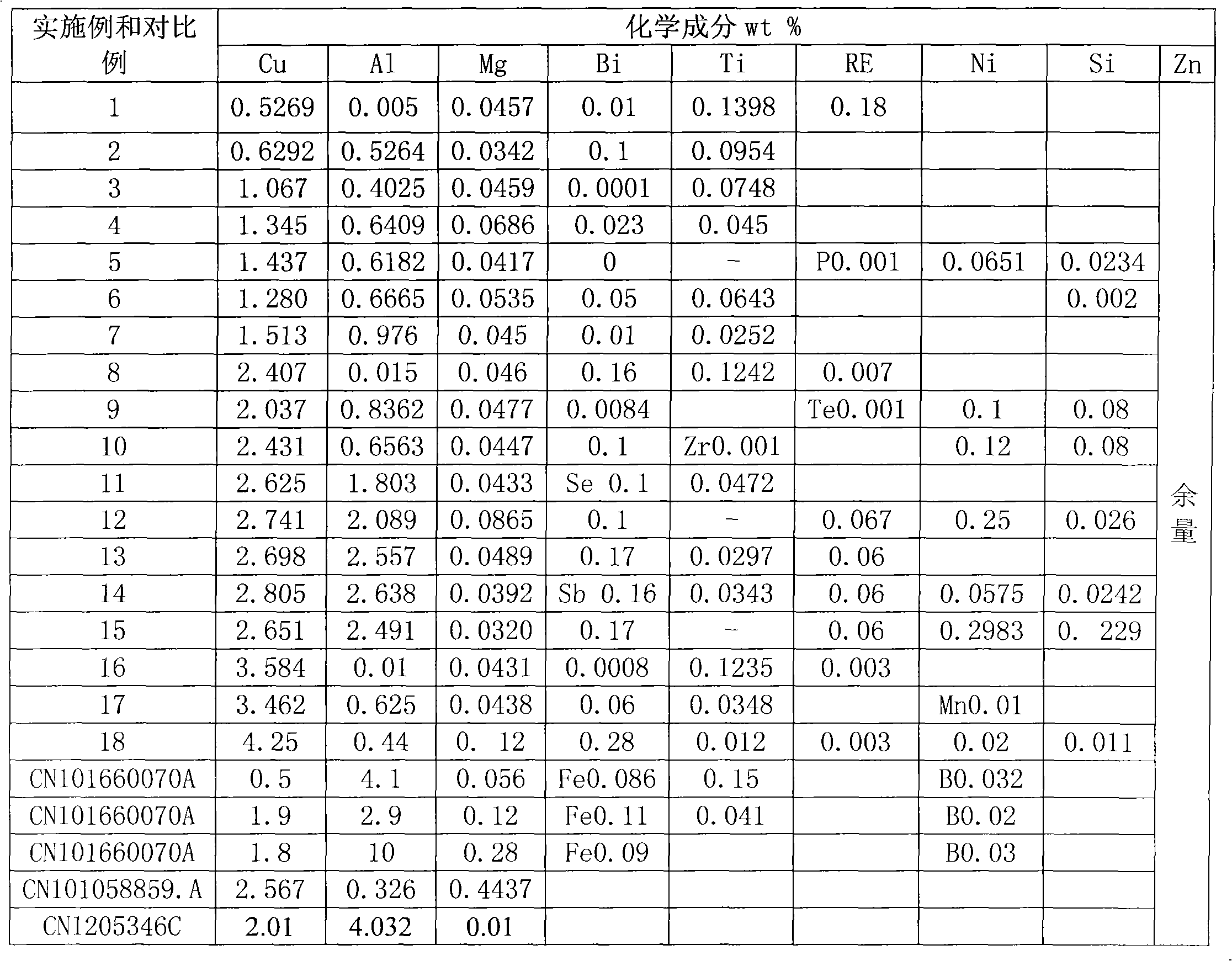

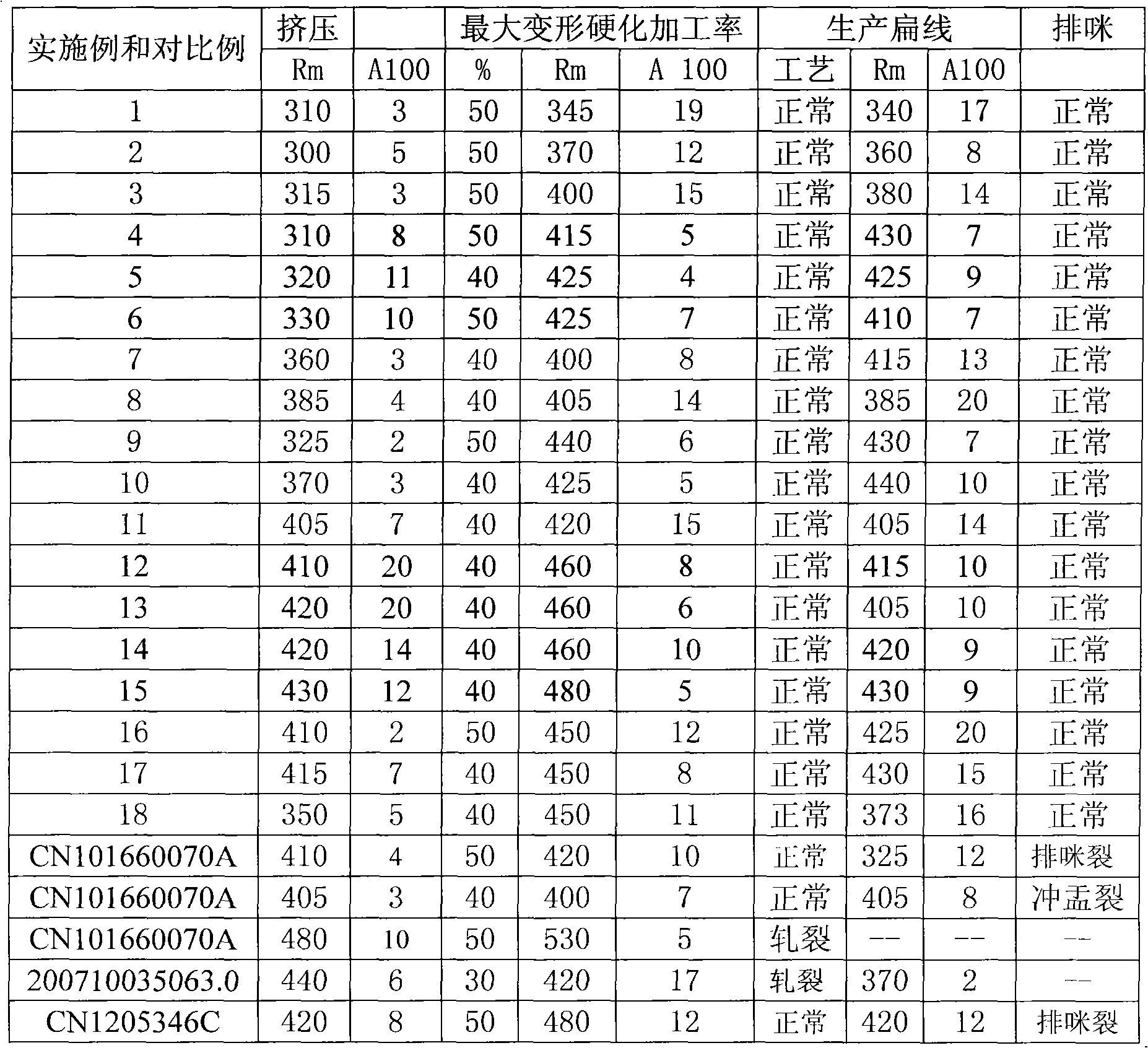

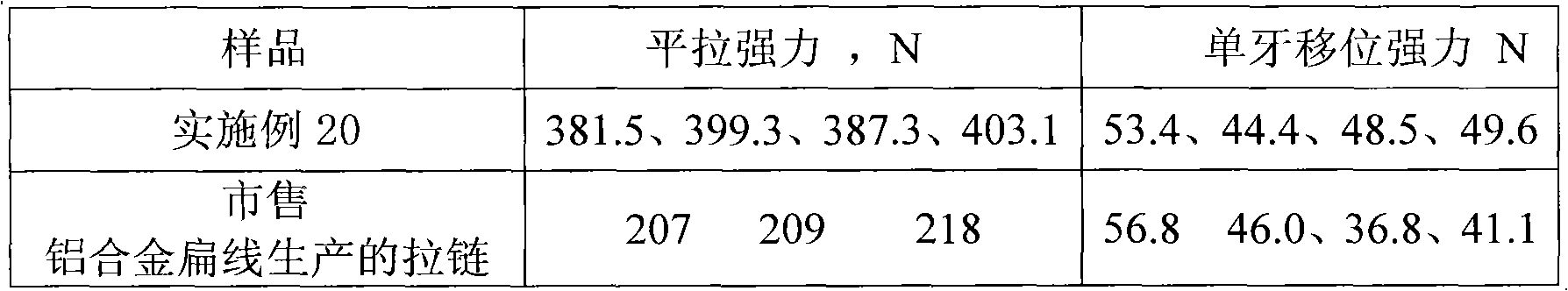

Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

ActiveCN102011029AOvercoming difficult deformationMeet the mechanical performance requirementsSlide fastenersZinc alloysImpurity

The invention discloses a zinc-alloy zipper tooth belt produced by a row microphone method, in particular to zinc alloy for a zipper tooth belt and a preparation method of the zipper tooth belt. The alloy comprises the following components by weight percent: 0.5-5% of Cu, 10-4.5% of Al, 0.01-0.2% of Mg and the balance of X, Y, Zn and unavoidable impurities, wherein the sum of the percentages of the components is 100%; the X is selected from at least one of 0.0001-0.5% of Bi, 0.01-0.19% of Ti, 0.001-0.3% of RE, 0.001-1% of Ni and 0.001-1% of Si; and Y is selected from at least one of Mn, Co, Nb, Zr, Cr, Ca, P, Sb, Te and Se. By adopting the deformed zinc alloy and the alloy producing method disclosed in the invention, the production of the zipper line can be met, and the zipper tooth belt can be produced smoothly by the row microphone method; and the produced zipper can be processed into different colors.

Owner:NINGBO POWERWAY ALLOY MATERIAL

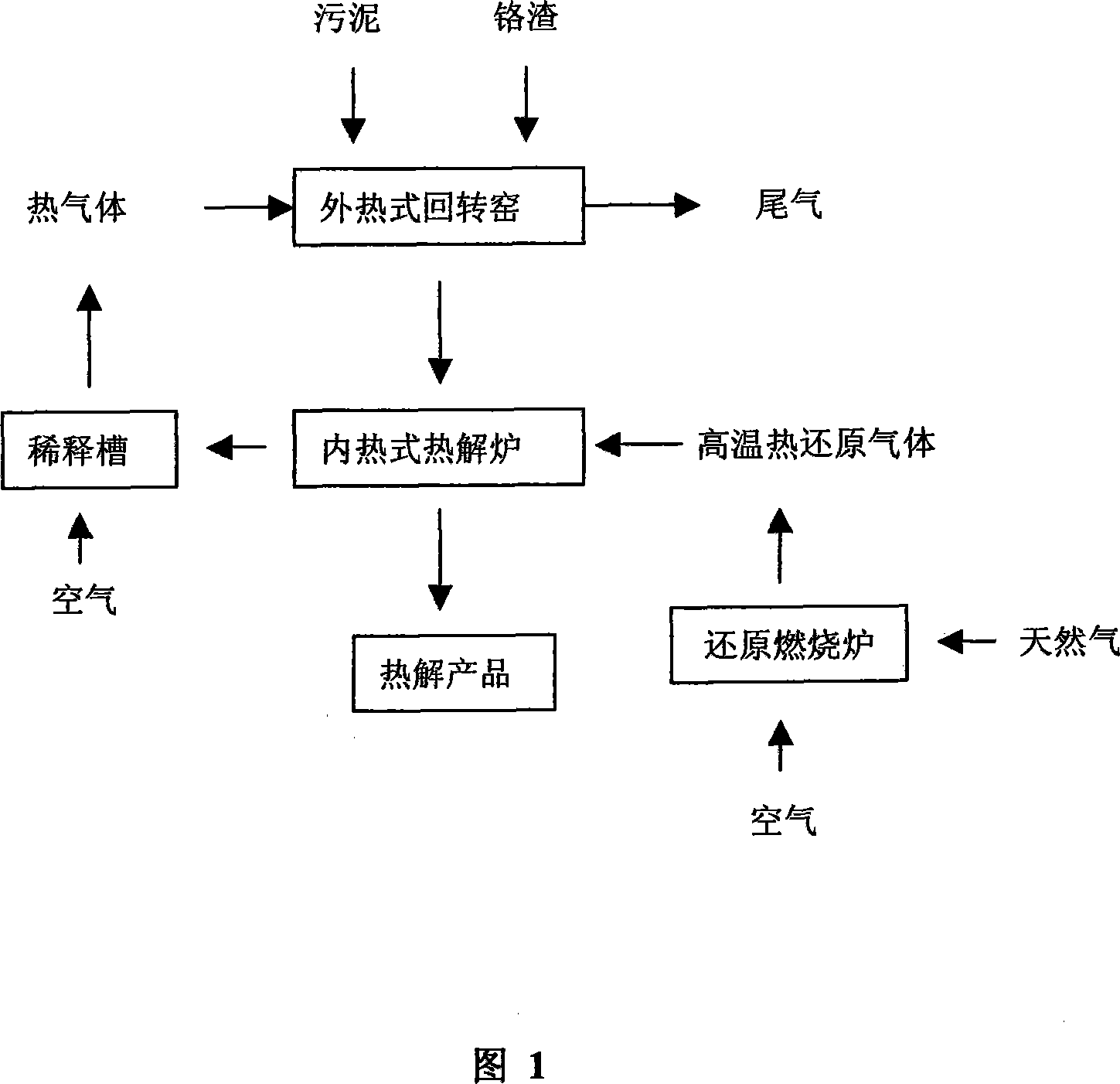

Pyrolytic treatment method for chromium slag

InactiveCN101053908ALow raw material costReduce energy consumptionIncinerator apparatusSlagExhaust gas

The invention relates to a thermolysis processing process of chromium slag, using dehydration mud from municipal sewage plant as an additive. The process comprises: firstly mixing the chromium slag and the mud in proportion and sending the mixture to an external heating type tilting furnace for preheat and dry, then sending the mixture to an interior heating type pyrolyzing furnace to carry out thermolysis reaction, wherein the high temperature hot reduction gas of the interior heating type pyrolyzing furnace enters from a reduction combustion furnace, and the pyrolysis products after being reduction treated are cooled and discharged. Exhaust gas of the interior heating type pyrolyzing furnace enters the external heating type tilting furnace after mixed with air via a dilution trap to dry the mixture of the chromium slag and the mud indirectly. The invention can detoxicate the chromium slag, meanwhile, treat the mud and use energy effectively, thus has obvious economic benefits and environmental benefits.

Owner:SHANGHAI JIAO TONG UNIV

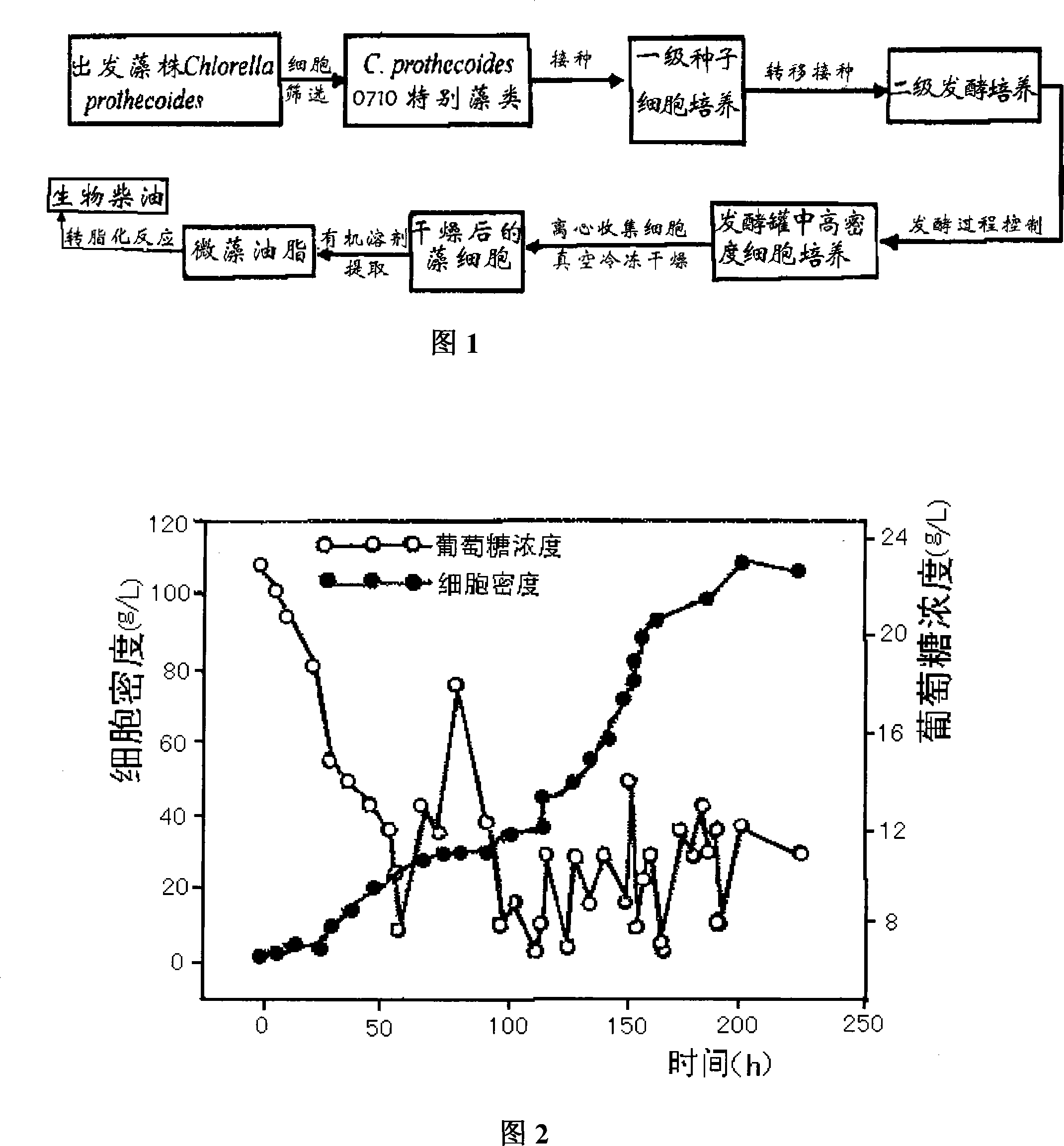

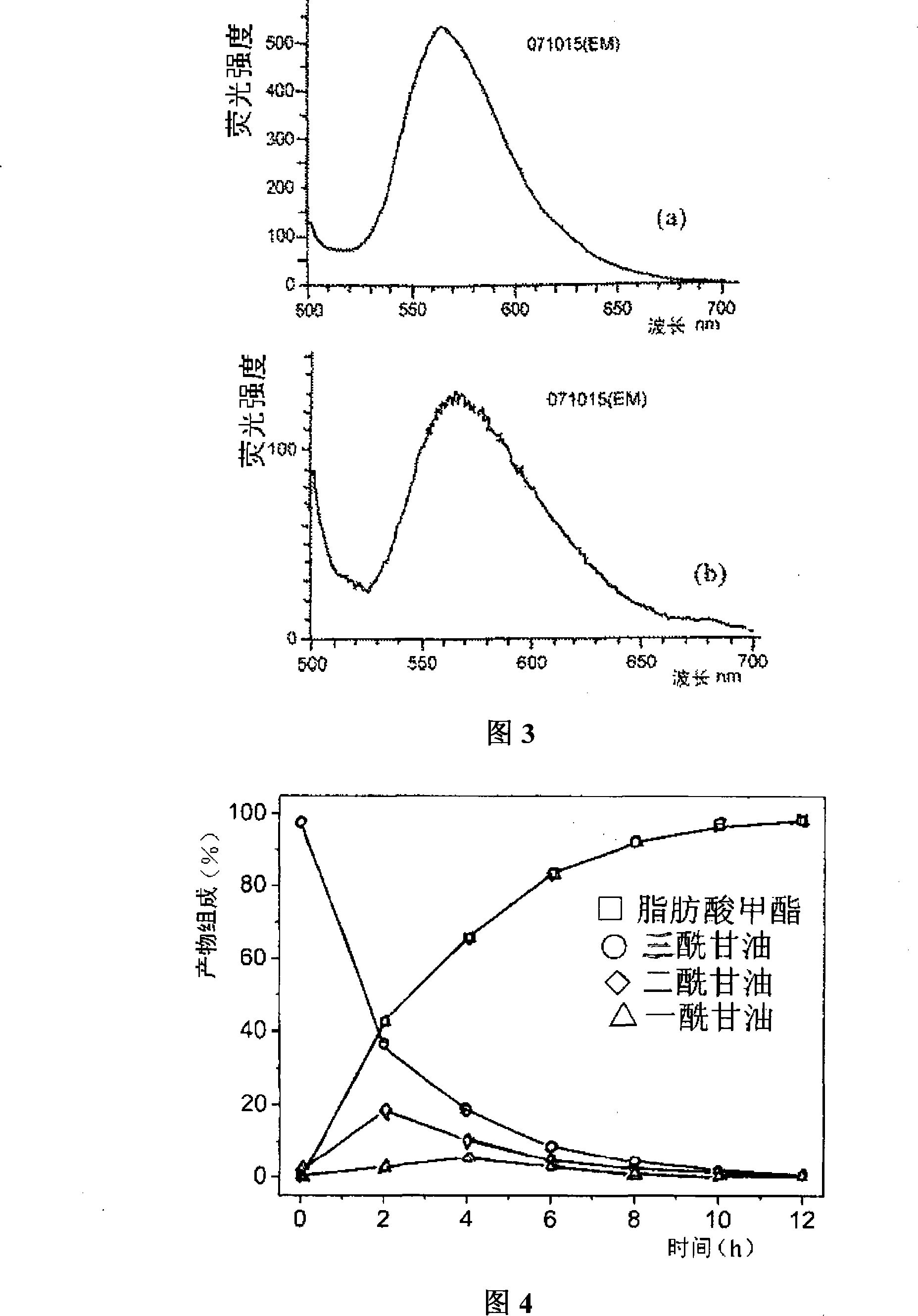

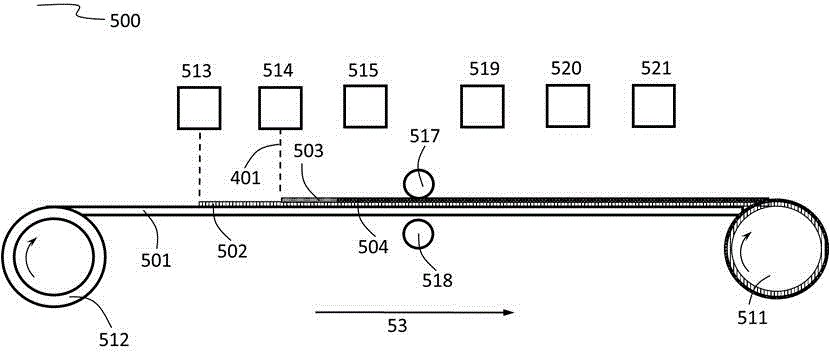

Method for producing biodiesel by high-density fermentation of heterotrophic chlorella

InactiveCN101230364ALow raw material costOptimizing conditions for heterotrophic fermentationFatty acid esterificationUnicellular algaeBiodiesel feedstockBiodiesel

The invention discloses a method of producing bio-diesel by fermenting the heterotrophic chlorella in high density which belongs to the renewable biological energy field. The method uses the heterotrophic chlorella fermented in high density in the bio-reactor as a raw material, which screens the chlorella species having high growth rate and high oil content, directly inoculates into the bottle as the first-class germ to culture then transfers to the fermentation cylinder to undergo the second-glass high density fermentation; the reaction condition is then optimized, and the process is controlled; the culture containing the carbohydrate is dripped to provide the nutrition for the cell growth, therefore the heterotrophic chlorella cells cultured in high density with density of 108g / L and oil content of 61 percent are separated, collected and dried; the algae oil is extracted, and the bio-diesel is produced by transesterification reaction; the invention reduces the cost for the raw material of bio-diesel, and satisfies the demand of industrialized application of producing bio-diesel by heterotrophic chlorella cells, therefore the technique of the invention becomes an economical and effective way of making oils from bio-diesel materials.

Owner:TSINGHUA UNIV

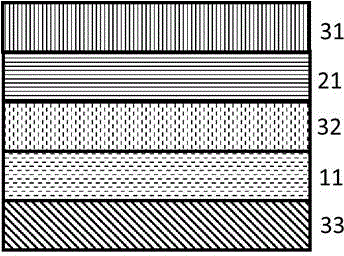

Novel electrode material applicable to intelligent liquid crystal dimming film and preparation method thereof

InactiveCN105761774ALow costLow raw material costCarbon-silicon compound conductorsCable/conductor manufactureThin film electrodeThin membrane

The invention relates to a novel electrode material applicable to an intelligent liquid crystal dimming film and a preparation method thereof. A transparent conductive film is at least composed of a substrate and a graphene conductive layer. The transparent conductive film further comprises a functional layer. Graphene sheets are stacked, tiled and connected with one another on a substrate to form the graphene conductive layer. A flexible liquid crystal dimming film device is prepared through the whole wet coating process of the electrodes of a graphene transparent conductive film. The liquid crystal light adjusting layer of the commercialized flexible liquid crystal dimming film is also prepared through the wet coating process. The above two coating processes can be linked up through the roll-to-roll process. Therefore, the preparation of graphene transparent conductive electrodes and the subsequent preparation of the dimming film are ensured to be continuous, low in cost and large-scale in production.

Owner:江苏天贯碳纳米材料有限公司

Production method for environment-friendly soilless lawn carpet

InactiveCN101606482AAchieve recyclabilityQuality improvementAgriculture gas emission reductionCultivating equipmentsPublic placeNonwoven fabric

The invention relates to a production method for an environment-friendly soilless lawn carpet, which mainly comprises the following steps: laying a waterproof layer, nonwoven fabric, a wadding fiber layer and a nutrition substrate layer in sequence; seeding grass seeds, coating with the nonwoven fabric and then laying vermiculite or zeolite particles; and finally periodically watering and fertilizing during the incubation period. The lawn carpet produced by the invention has short lawn forming time, labor conservation, low labor intensity, low management cost, high lawn purity, no weed, complete root system, good grass quality, uniform thickness, easy survival after transplantation, convenient management, and reeling and cutting property, and overcomes the defects of the prior lawn such as bad applicability and easy rupture. The produced lawn carpet has the advantages of long green period, fresh and green color, strong resistance, light mass, degradability, convenient maintenance convenient transportation and the like, and can be widely applied to the afforestation or the decoration of public places, airports, office buildings, residential building roofs and the like.

Owner:HENAN ACAD OF AGRI SCI +1

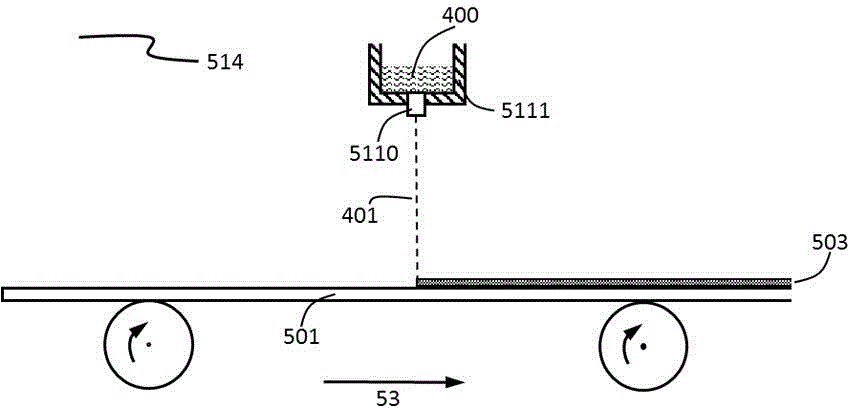

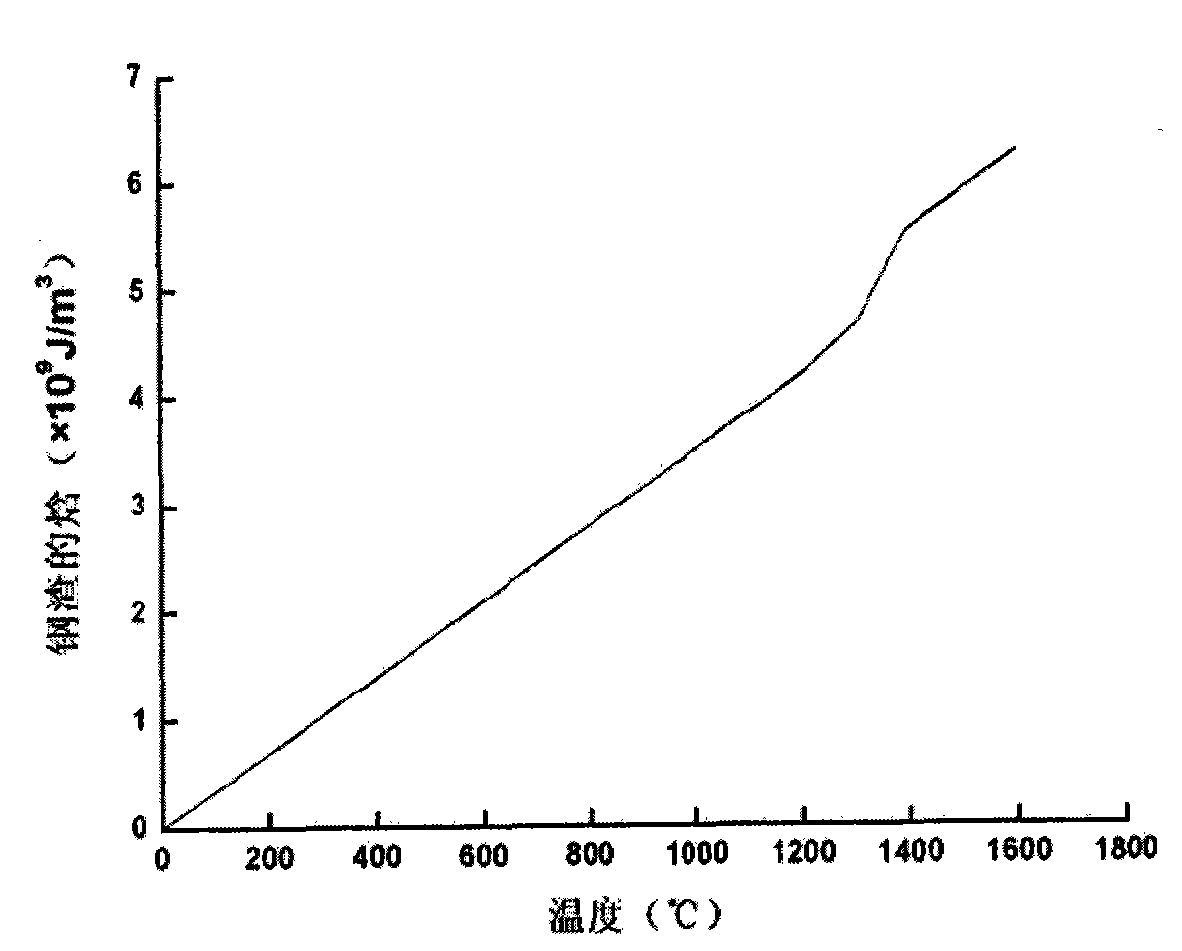

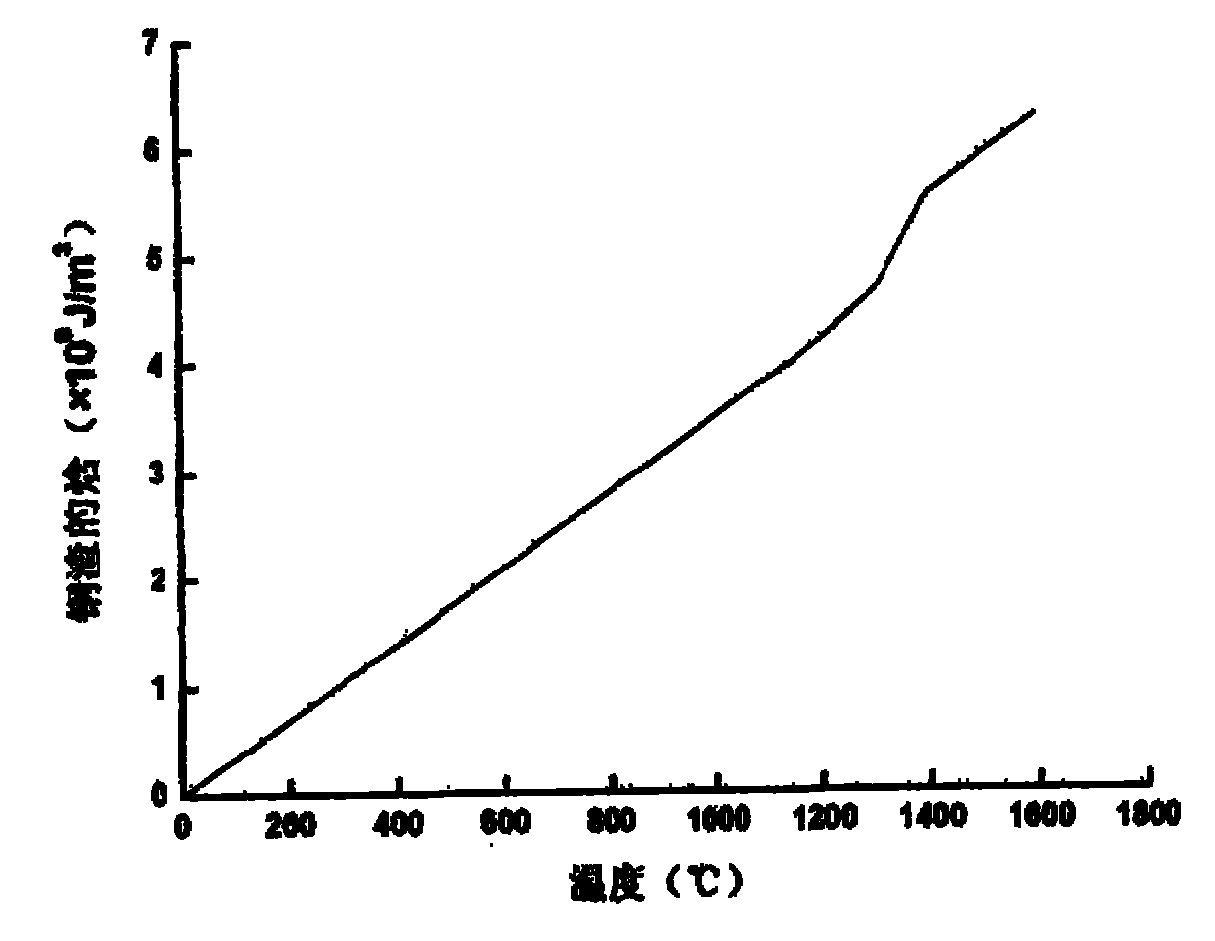

Energy-saving slag thermal insulator

InactiveCN101892332AImprove insulation effectLow raw material costRecycling and recovery technologiesChemical reactionSlag

The invention relates to an energy-saving slag thermal insulator, and belongs to the technical field of energy conservation, emission reduction and comprehensive utilization in the metallurgy industry. The thermal insulator comprises the following main chemical components in percentage by weight: 25 to 70 percent of SiO2, 1 to 25 percent of Al2O3, 1 to 40 percent of CaO, 0 to 20 percent of MgO, 0 to 10 percent of F<->, 0 to 10 percent of R2O (R is a monovalent metal ion), 0 to 10 percent of Fe2O3, 5 to 60 percent of fixed carbon with bulk density of 0.25 to 0.75g / cm<3>. The thermal insulator has high thermal insulation performance and can reduce the thermal loss of high-temperature slag; the thermal insulator contains a certain amount of fixed carbon, so heat generated in the chemical reaction of the fixed carbon can be used for further making up the thermal loss of the slag; meanwhile, the thermal insulator belongs to a silicon-aluminum material, and part or all of the thermal insulator can be dissolved in the slag finally so as to improve the chemical composition of the slag and reduce the melting point of the slag. The thermal insulator has the advantages of simple production process, low cost, and suitability for various processes for utilizing the sensible heat of the slag, increasing the fluidity of the slag or improving the performance of the slag.

Owner:UNIV OF SCI & TECH BEIJING

Glass and use of a glass for glass-metal bonds

ActiveUS20110045960A1Simple processImprove carrying capacitySolar heat devicesPV power plantsKovarMetal binding

The glass of the glass-metal bond contains the following ingredients in the following amounts: SiO2, 72-80 wt %; B2O3, 4-<6 wt %; Al2O3, 2-5 wt %; Na2O, 4-7 wt %; K2O, 0-3 wt %; CaO, 2.5-8 wt %; MgO, 0-2 wt %; BaO, 0-4 wt %; TiO2, 0-5 wt %; CeO2, 0-2 wt %; Fe2O3, 0-0.1 wt %; F, 0-2 wt %; and the ratio of the sum total amount of Al2O3 and B2O3 (in mol %) to the sum total amount of MgO, CaO and BaO (in mol %) in the glass is less than 5. The glass-metal bond advantageously includes a KOVAR® alloy and the glass of the aforesaid composition and connects the glass envelope tube with an inner metal absorber tube in a tube collector.

Owner:SCHOTT AG

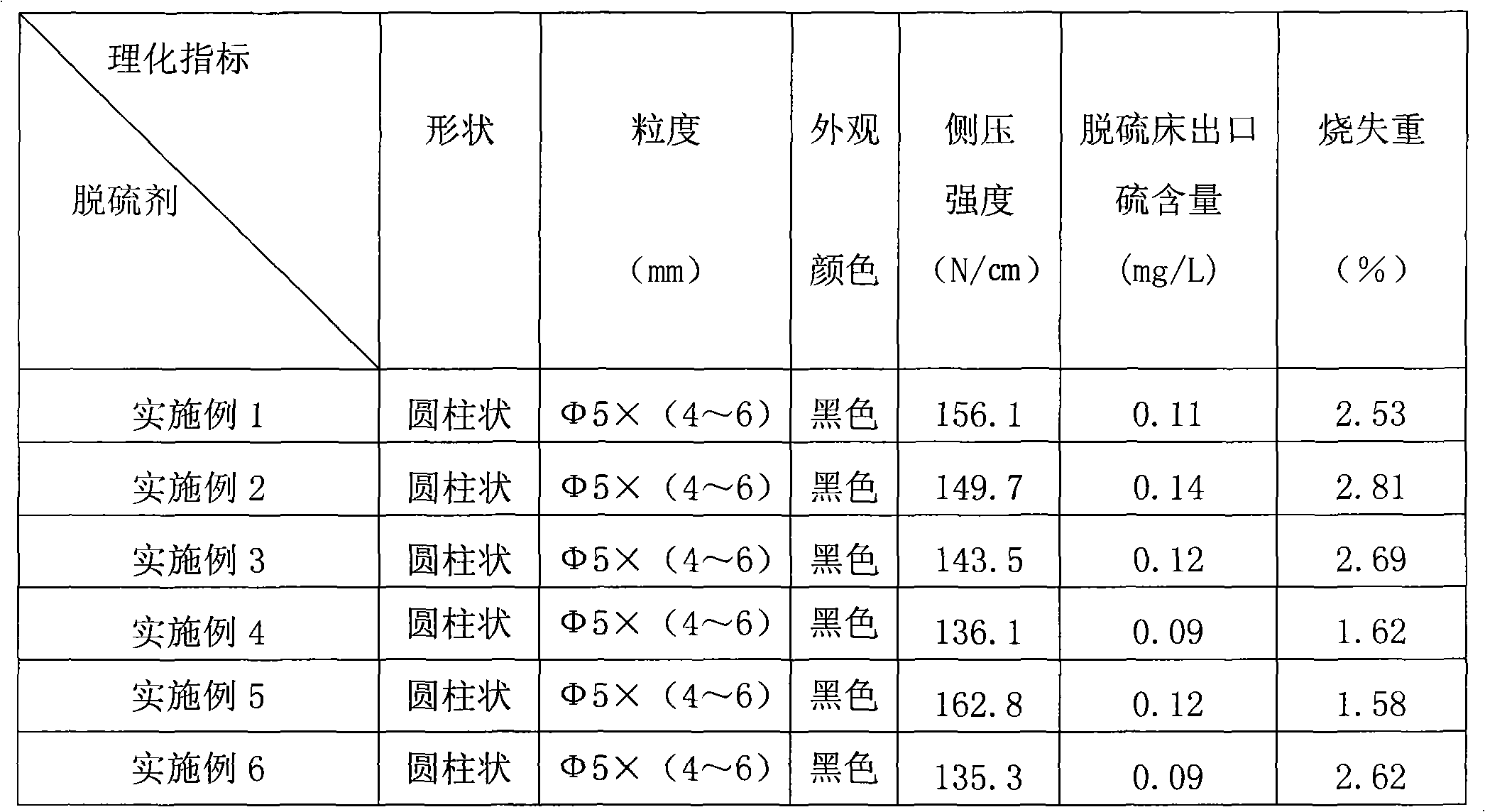

Desulfurizing agent for reforming stock oil and preparation method thereof

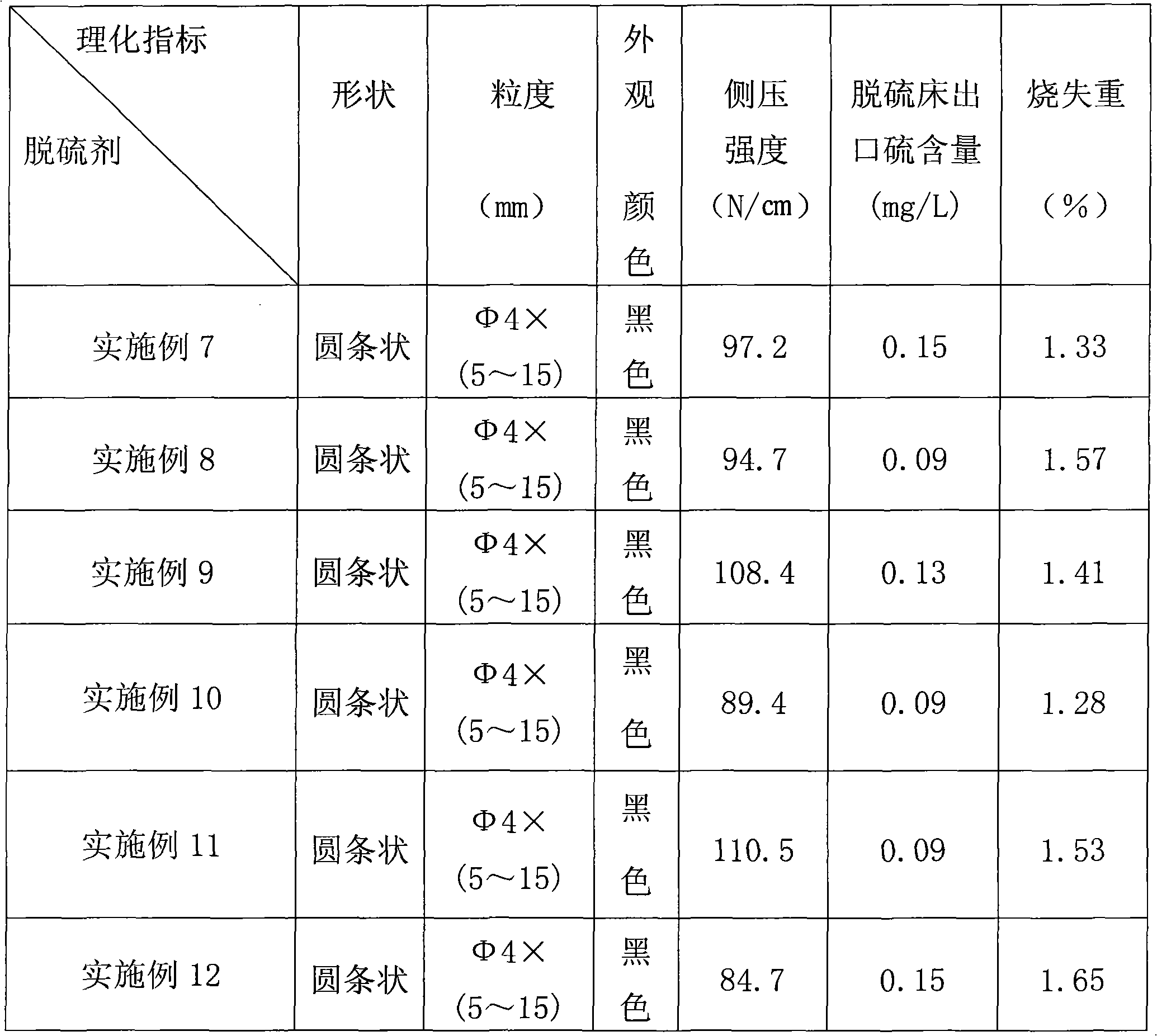

InactiveCN101643664AExpand the range of raw materialsLow raw material costRefining with metal oxidesAluminiumSulfide

The invention relates to a desulfurizing agent for reforming stock oil and a preparation method thereof, in particular to the desulfurizing agent used for desorbing sulfides in the reforming stock oilsuch as H2S and the like. The desulfurizing agent is characterized by consisting of 10%-40% of ZnO, 15%-22% of NiO, 10%-17% of Al2O3, 5%-22% of SiO2 and the balance inevitable impurities. The desulfurizing agent takes zinc and nickel as active components and bentonite (or diatomite, or white clay, or zeolite, or high-alumina cement and or common cement) as a carrier, and active components thereofare directly present in the form of oxides of zinc and nickel or oxides transformed by corresponding carbonate (basic carbonate) and nitrate. In the invention, the desulfurizing agent has enlarged raw material range, thus effectively reducing raw material cost, simplifying production process of the desulfurizing agent, lowering production cost, improving strength to more than twice, and prolonging service life of the desulfurizing agent.

Owner:JINDUICHENG MOLYBDENUM CO LTD

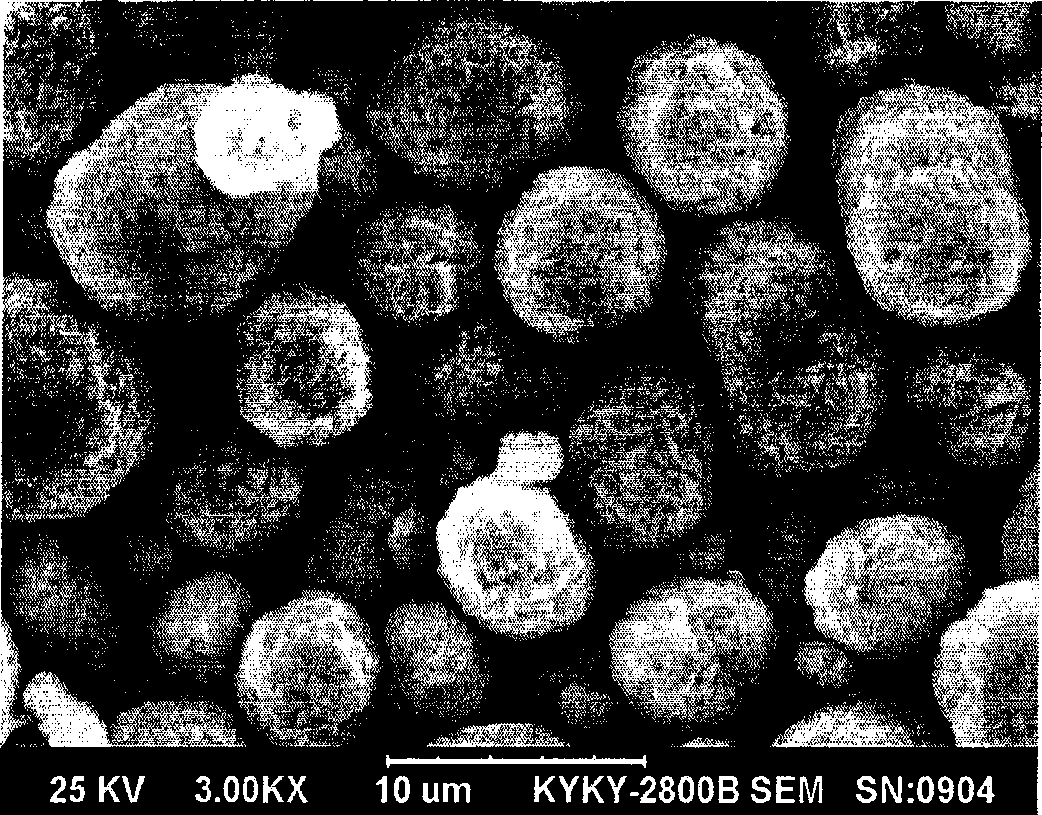

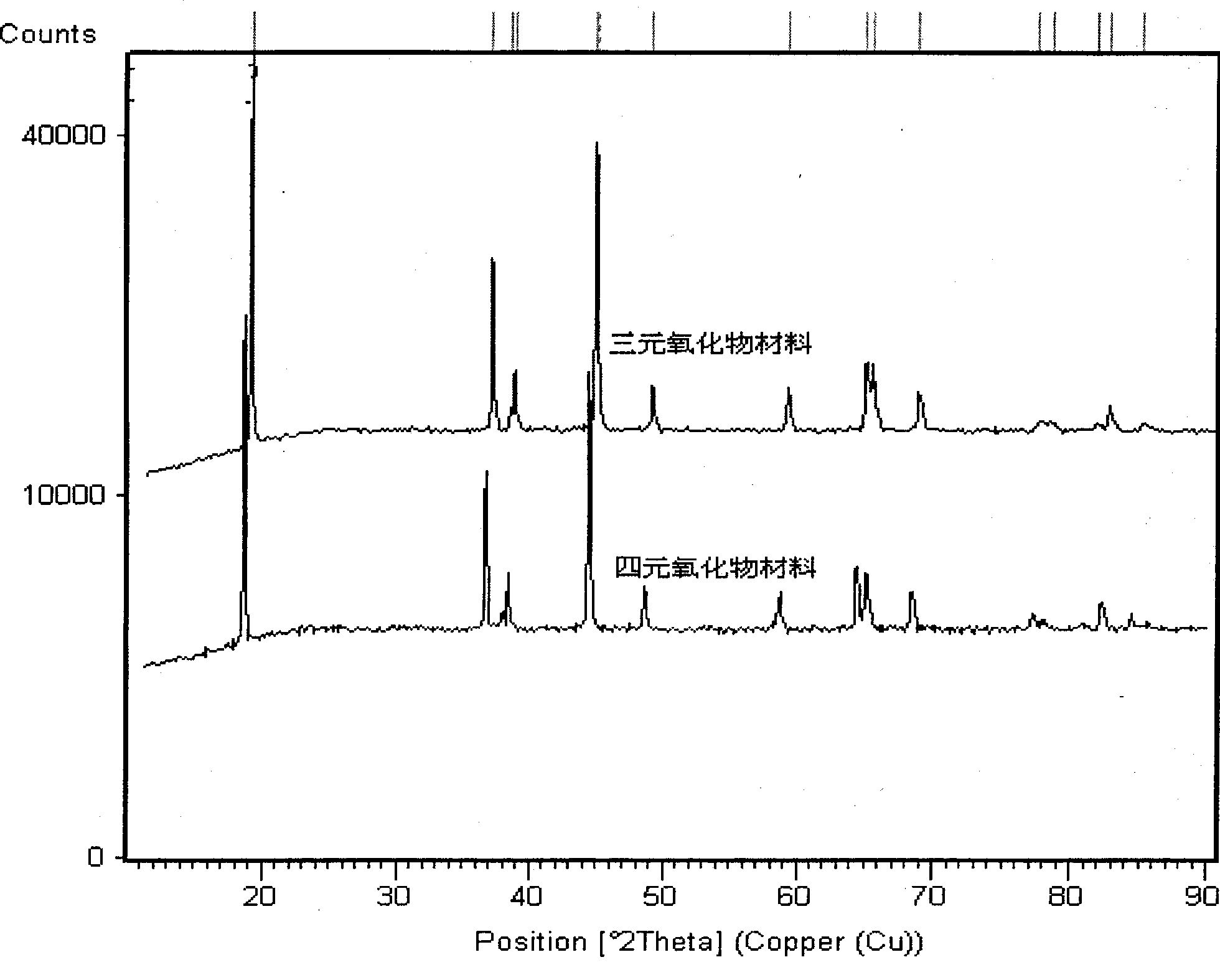

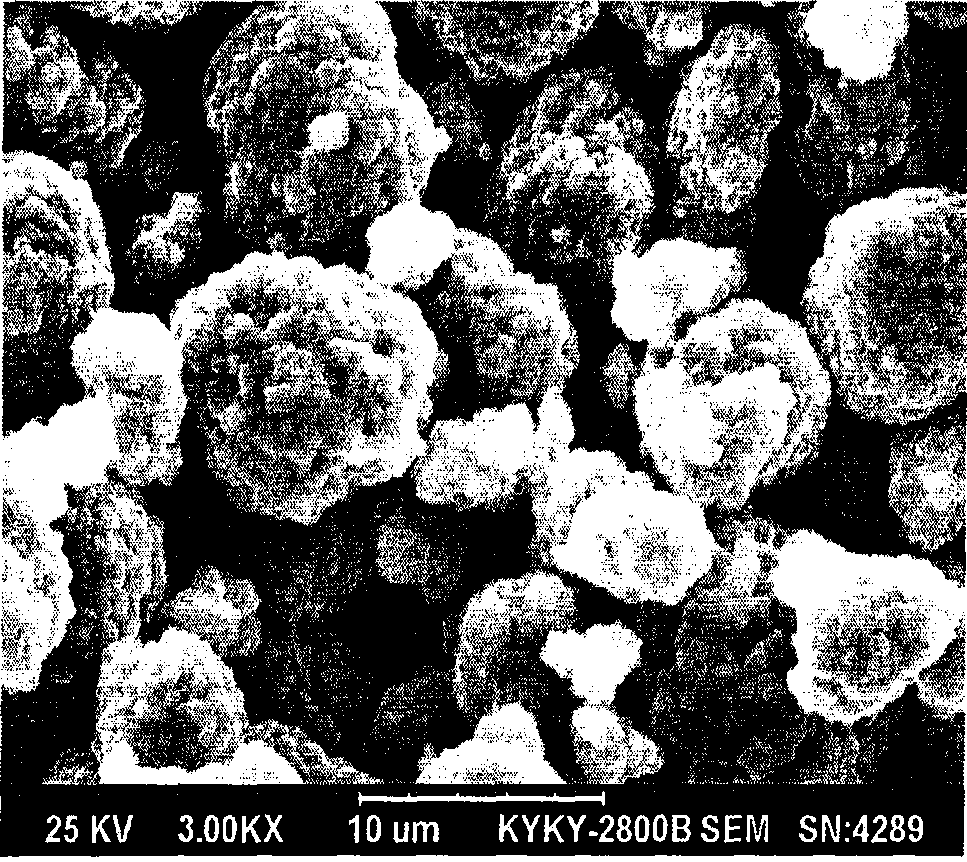

Metal oxide lithium ionic cell positive pole material and preparation thereof

ActiveCN101483265ALow raw material costReduce manufacturing costElectrode manufacturing processesLithium compoundsElectrochemistryLithium-ion battery

The invention discloses a metal oxide lithium ion battery positive material and a preparation method thereof. The problem to be solved is to improve the electrochemistry property of the positive material. The material formula of the invention is LiNi1-x-y-zMnxCoyMzO2, wherein the x+y+z is less than 1, or a quaternary or a quinary metal oxide material of the LiNi1-x-y-z-rMnxCoyMzNrO2, wherein the x+y+z+r is less than 1, and the M and N are selected from one of the Al, Ti, Cr, Mg, V, Zn and Zr, x is equal to 0.01-0.8, y is equal to 0.01-0.8, z is equal to 0.01-0.8 and r is equal to 0.01-0.8. The preparation method comprises: preparing a precursor mixture, mixing and sintering. Comparing with the prior art, the invention prepares the oxide lithium ion battery material by a liquid phase multi-element mixing reaction, a mixing method and a solid state sintering method, the maximum discharging capacity is larger than 150mAh / g, the primary coulomb efficiency is more than 90, the capacity conservation rate after 300 cycles is more than 95 The metal oxide lithium ion battery positive material is suitable for industrial scale production.

Owner:BTR NEW MATERIAL GRP CO LTD

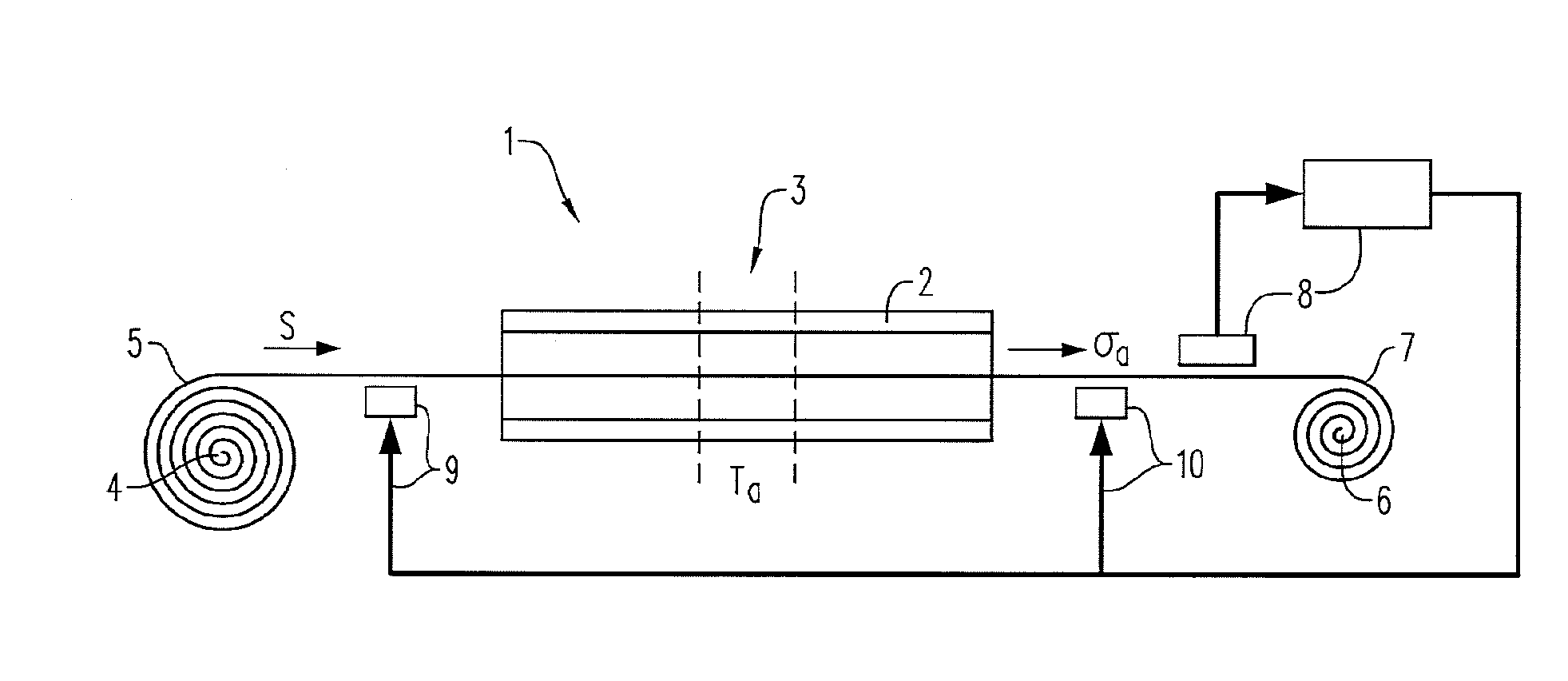

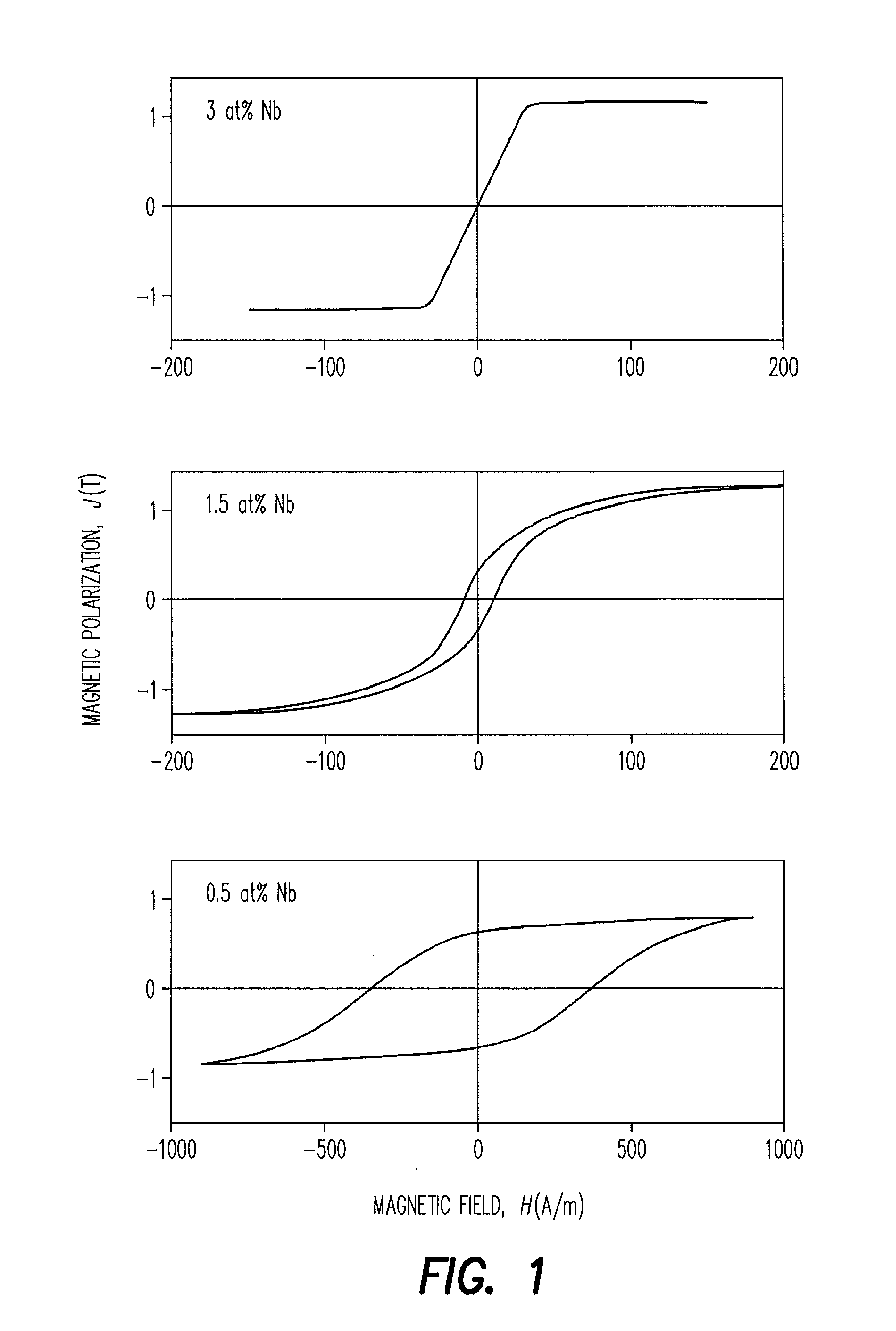

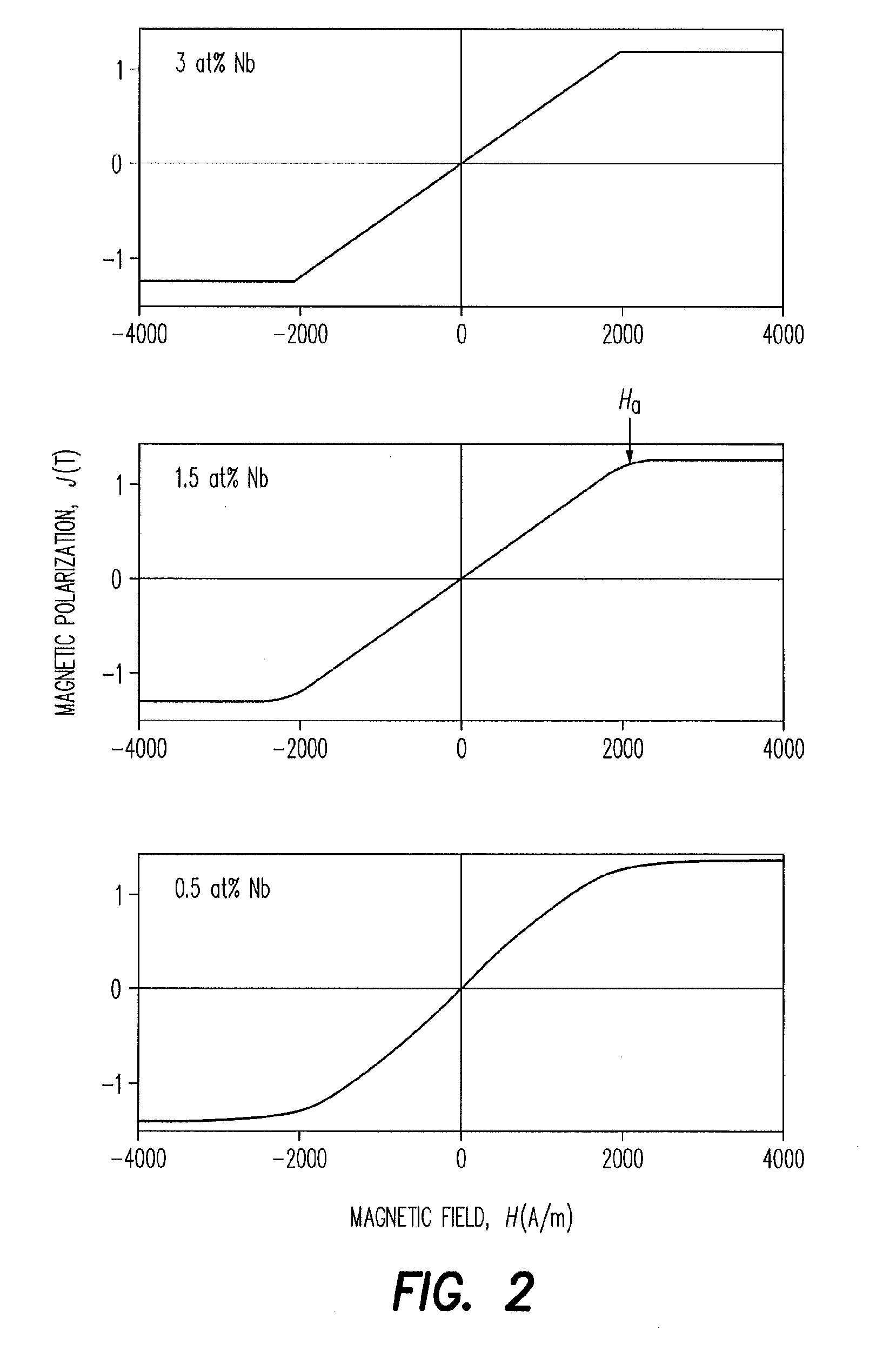

Alloy, magnetic core and process for the production of a tape from an alloy

ActiveUS20120262266A1Degradation of magnetic propertyImprove regularity of soft magnetic property of magneticNanomagnetismIndividual molecule manipulationHysteresisLinear region

An alloy is provided which consists of Fe100-a-b-c-d-x-y-zCuaNbbMcTdSixByZz and up to 1 at % impurities, M being one or more of the elements Mo, Ta and Zr, T being one or more of the elements V, Mn, Cr, Co and Ni, Z being one or more of the elements C, P and Ge, 0 at %≦a<1.5 at %, 0 at %≦b<2 at %, 0 at %≦(b+c)<2 at %, 0 at %≦d<5 at %, 10 at %<x<18 at %, 5 at %<y<11 at % and 0 at %≦z<2 at %. The alloy is configured in tape form and has a nanocrystalline structure in which at least 50 vol % of the grains have an average size of less than 100 nm, a hysteresis loop with a central linear region, a remanence ratio Jr / Js of <0.1 and a coercive field strength Hc to anisotropic field strength Ha ratio of <10%.

Owner:VACUUMSCHMELZE GMBH & CO KG

Method for preparing tobacco maillard reaction spice

ActiveCN103146481ALow raw material costMild reaction conditionsTobacco preparationEssential-oils/perfumesFlavorChemistry

The invention relates to a method for preparing a tobacco maillard reaction spice, a splice prepared by the method, and application of the spice in a cigarette. The preparation method disclosed by the invention has the characteristics of being simple in process, high in yield, free of pollution in the production process, convenient to operate and the like; the sweet smell of a cigarette product is plumper by the obtained tobacco spice; offensive odor is reduced; thrill is reduced; and the comfort is improved.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

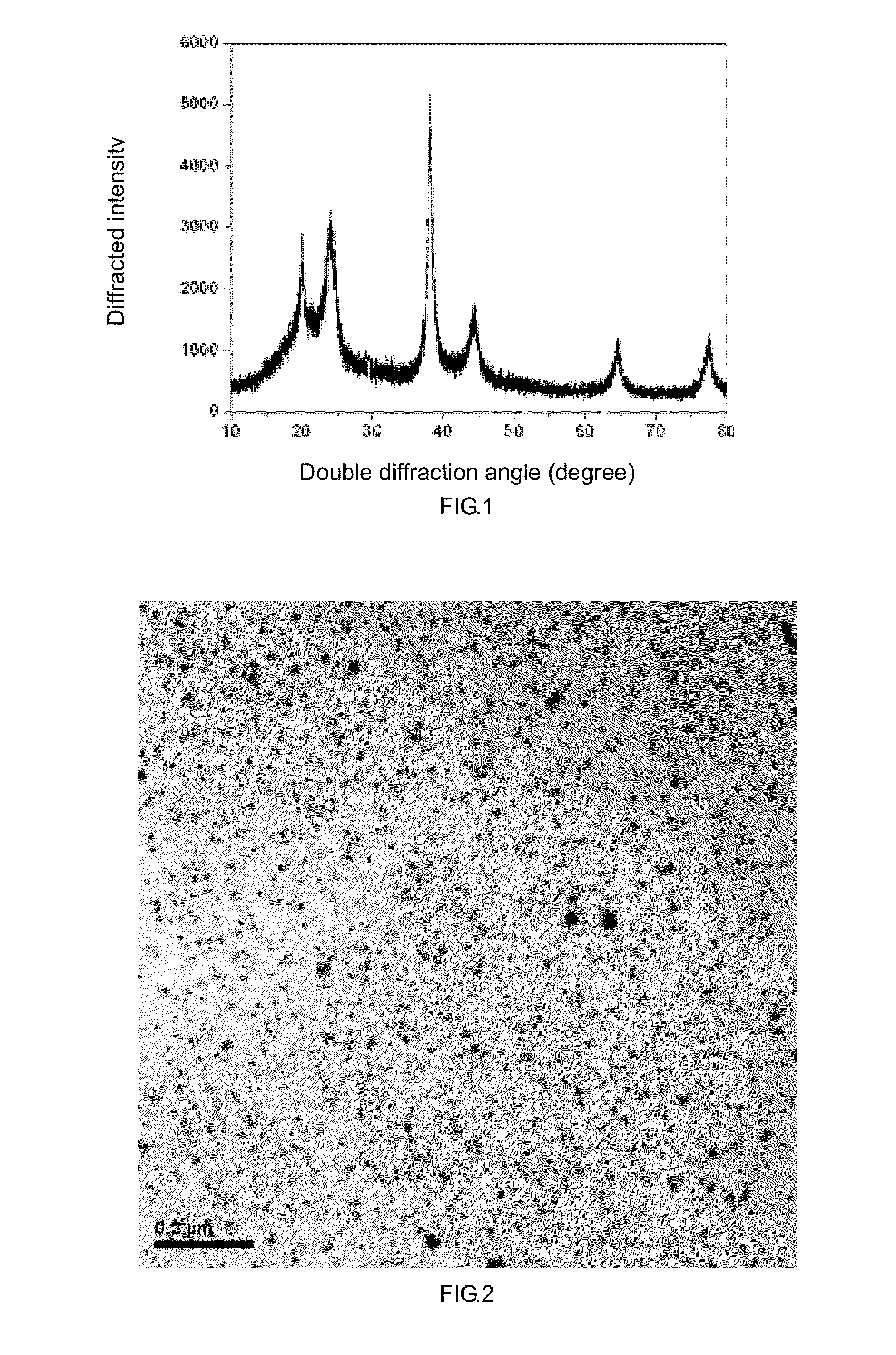

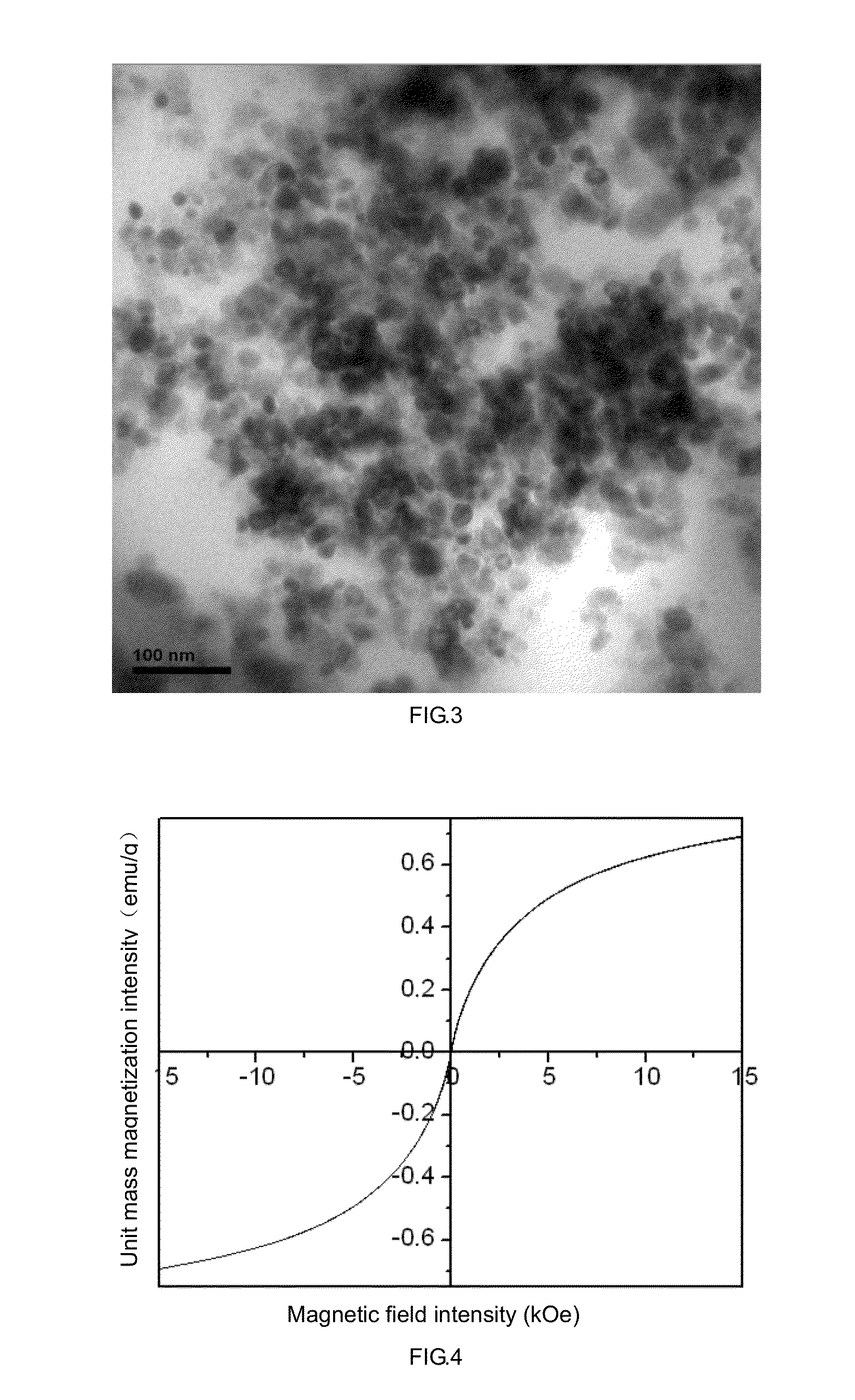

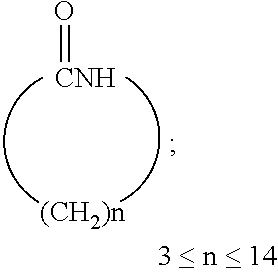

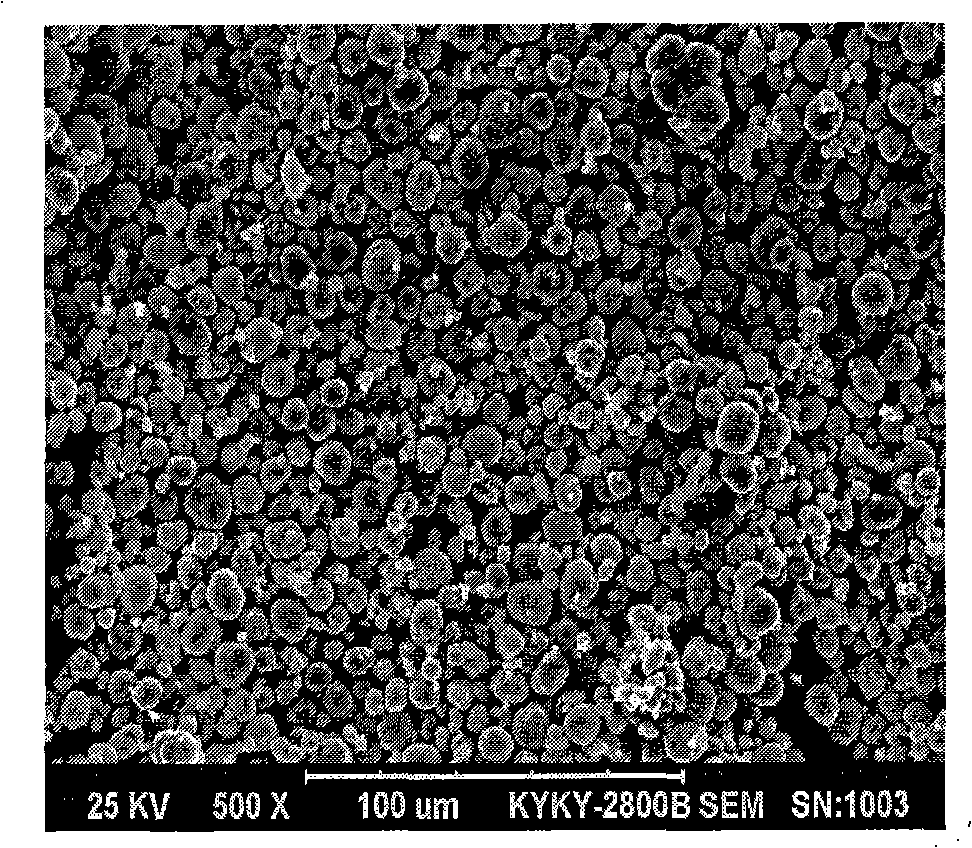

NANO particle/polyamide composite material, preparation method therefor, and use thereof

ActiveUS20140048738A1Improve mechanical propertiesEasy to moldNanotechInorganic material magnetismSynthesis methodsPolyamide

The present invention relates to the technical field of polymer composite material, and a nano particle / polyamide composite material, a preparation method therefor and a use thereof are disclosed. The nano particle / polyamide composite material comprises 0.01-99 parts by weight of inorganic nano particles and 1-99.99 parts by weight of a polyamide matrix. The preparation method for the nano particle / polyamide composite material of the present invention comprises hydrolysis polymerization or anionic polymerization. The nano particle / polyamide composite material of the present invention has the particular functions of nano materials, while having the advantages of the polymer matrix such as good mechanical performance and being easy for processing and molding. The nano particle is well dispersed in the polyamide matrix, is physically stable, and has a strong interaction at an interface between the nano particles and the polymer matrix, thus being useful as a structural material, a functional material and a polymer masterbatch. The cost of raw materials used in the synthesis method is low, the production apparatus is simple, and the route is green and environment friendly. Therefore, the method is applicable to large-scale industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

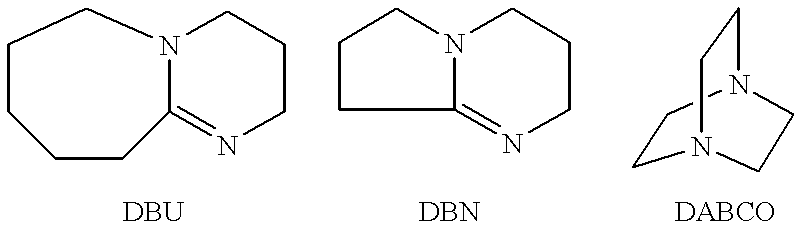

Process for converting an alcohol to the corresponding fluoride

InactiveUS6248889B1Good choiceLow costOrganic compound preparationOrganic halogenationAlcoholOrganic base

A process for preparing a fluoride from its corresponding alcohol comprises the steps of (a) forming a mixture comprising (i) at least one fluorinated, saturated aliphatic or alicyclic sulfonyl fluoride (for example, perfluorobutanesulfonyl fluoride) and (ii) at least one primary or secondary alcohol; and (b) adding a molar excess of at least one strong, aprotic, non-nucleophilic, hindered, double bond-containing, organic base (for example, 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU)) to the mixture.

Owner:3M INNOVATIVE PROPERTIES CO

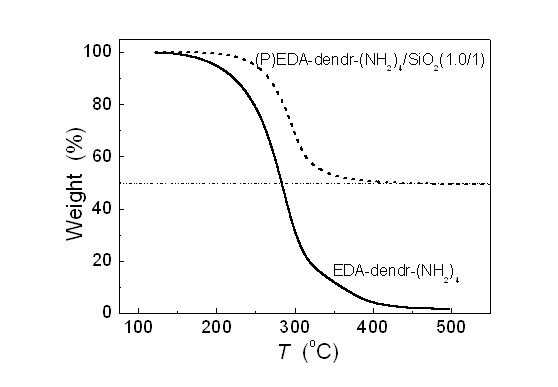

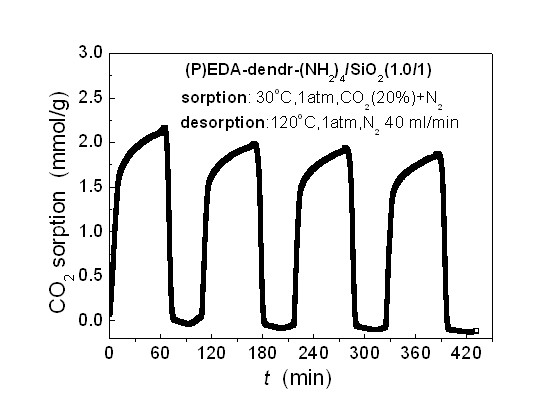

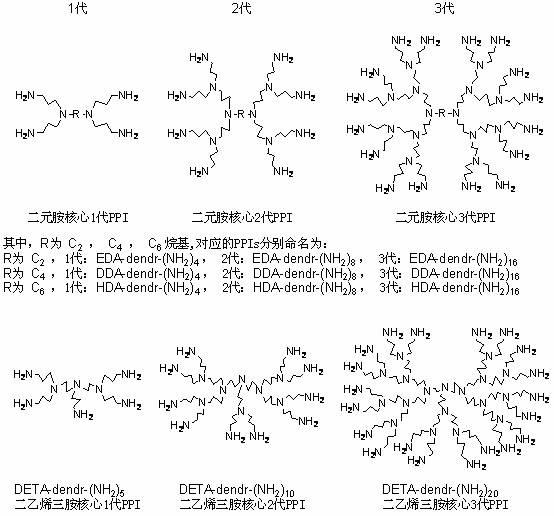

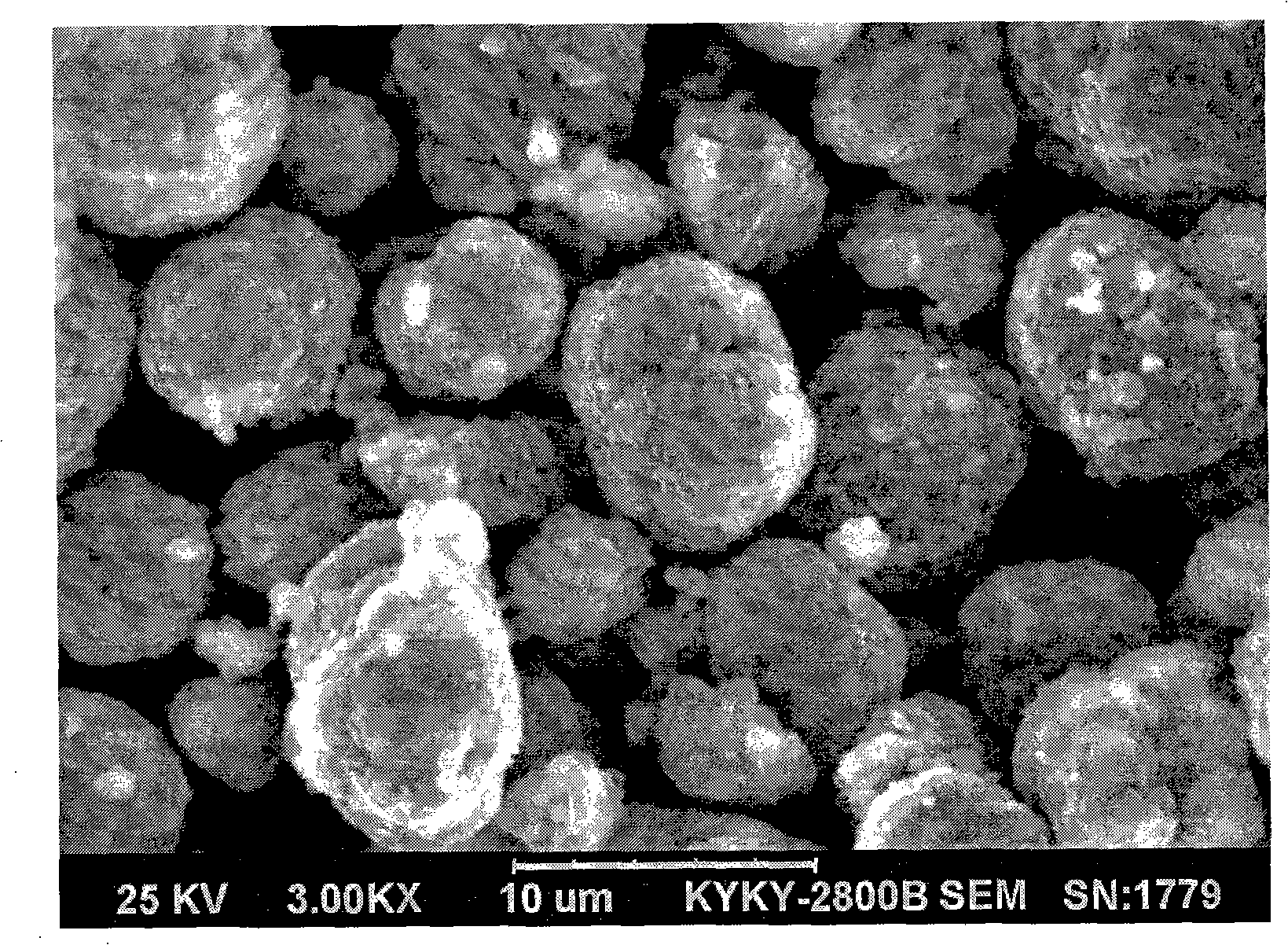

Supported polypropylene imine material and preparation method and application thereof

InactiveCN102068967AImprove thermal stabilityGood chemical stabilityProductsOther chemical processesPolymer scienceSorbent

The invention discloses a supported polypropylene imine material and a preparation method and application thereof. The material is formed by supporting polypropylene imine in a porous carrier material, wherein the mass ratio of the polypropylene imine to the porous carrier material is 0.1-2:1. The polypropylene imine one or random mixture of first generation, second generation or third generationpolypropylene imines taking ethylene dimine, butyl diamine, hexanediamine or diethylenetriamine as a core. The polypropylene imine is supported on the porous carrier material such as porous silica gel, active alumina, silicon-based ordered mesoporous material SBA-15, MCM-41 or active carbon or the like by a physical dipping-solvent evaporation method or a chemical method; and the material can be used as an adsorbent for catching and separating acid gas such as CO2, SO2 or H2S or the like from a gas mixture. The adsorbent has the advantages of quick and efficient adsorption, high adsorption capacity, high selectivity, recycle and the like.

Owner:ZHEJIANG UNIV

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

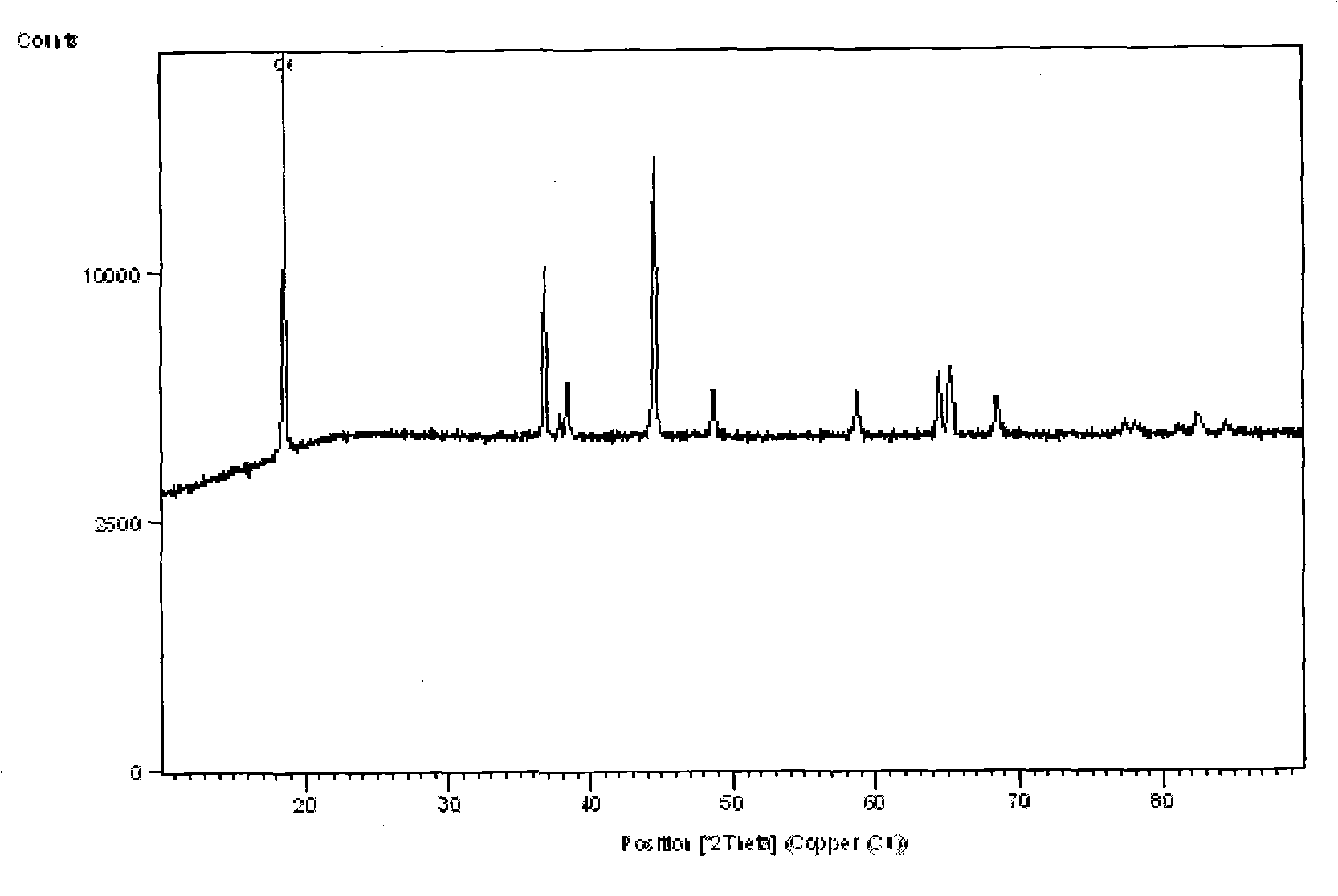

Method for making ZSM-5 zeolites

InactiveUS6261534B1Sufficient amountMinimize wasteAluminium compoundsMolecular sieve catalystsX-rayZSM-5

The invention includes a method for preparing a crystalline zeolite having the X-ray diffraction lines of Table 1. The method includes preparing a template-free reaction mixture including at least one active source of a first oxide selected from the group consisting of an oxide of silicon, germanium or both, optionally at least one active source of a second oxide selected from the group consisting of an oxide of aluminum, boron, gallium, iron or a mixture thereof; and heating the reaction mixture at crystallization conditions for sufficient time to form a crystallized material containing zeolite crystals having the X-ray diffraction lines of Table 1, where said zeolite crystals have a first oxide / second oxide molar ratio greater than 12.

Owner:CHEVROU USA INC

Positive electrode material of multi-component composite lithium ion cell and its preparation method

ActiveCN101320807ALow raw material costReduce manufacturing costElectrode manufacturing processesChemical/physical/physico-chemical processesCapacitanceMetallic lithium

The invention discloses a positive pole material of multiple composite lithium iron battery and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material, the positive pole material of the invention has the general formula: Li0.8-1.2NixCoyzO2, the crystal structure of the positive pole material is hexagonal system; crystal lattice is doped with more than one elements selected from the group consisting of Ti, Al, Mg, Cr, Zn, Ce, La, Lu, Y and F, the production method of the positive pole material comprises the steps of: synthesis of substrate materials, doping of substrate crystal lattices, mixing with lithium source compounds, sintering. As compared with the prior art, the produced positive pole material of multiple composite lithium iron battery of the invention combines into the simulative battery with metallic lithium sheets, and discharges and charges at 0.3C of discharge and charge current density, when the discharge and charge voltage is 2.5-4.2V, the maximum discharge capacitance reaches over 160mAh / g, the first Coulomb efficiency reaches more than 90%, the capacitance retention rate after circulation for 100 weeks is above 92%, the costs of raw materials and production are low, accordingly, the invention is apt for large-scale industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

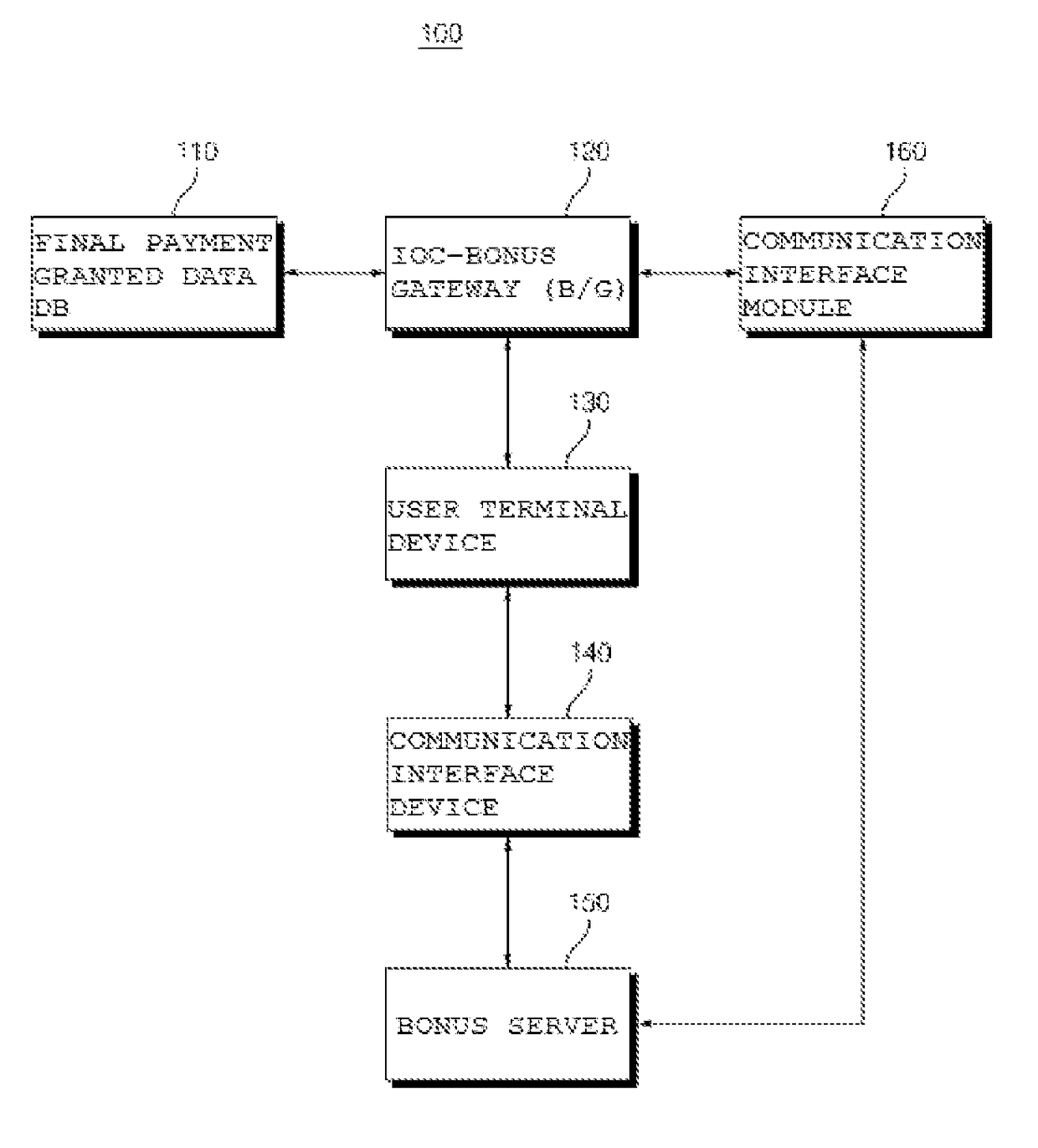

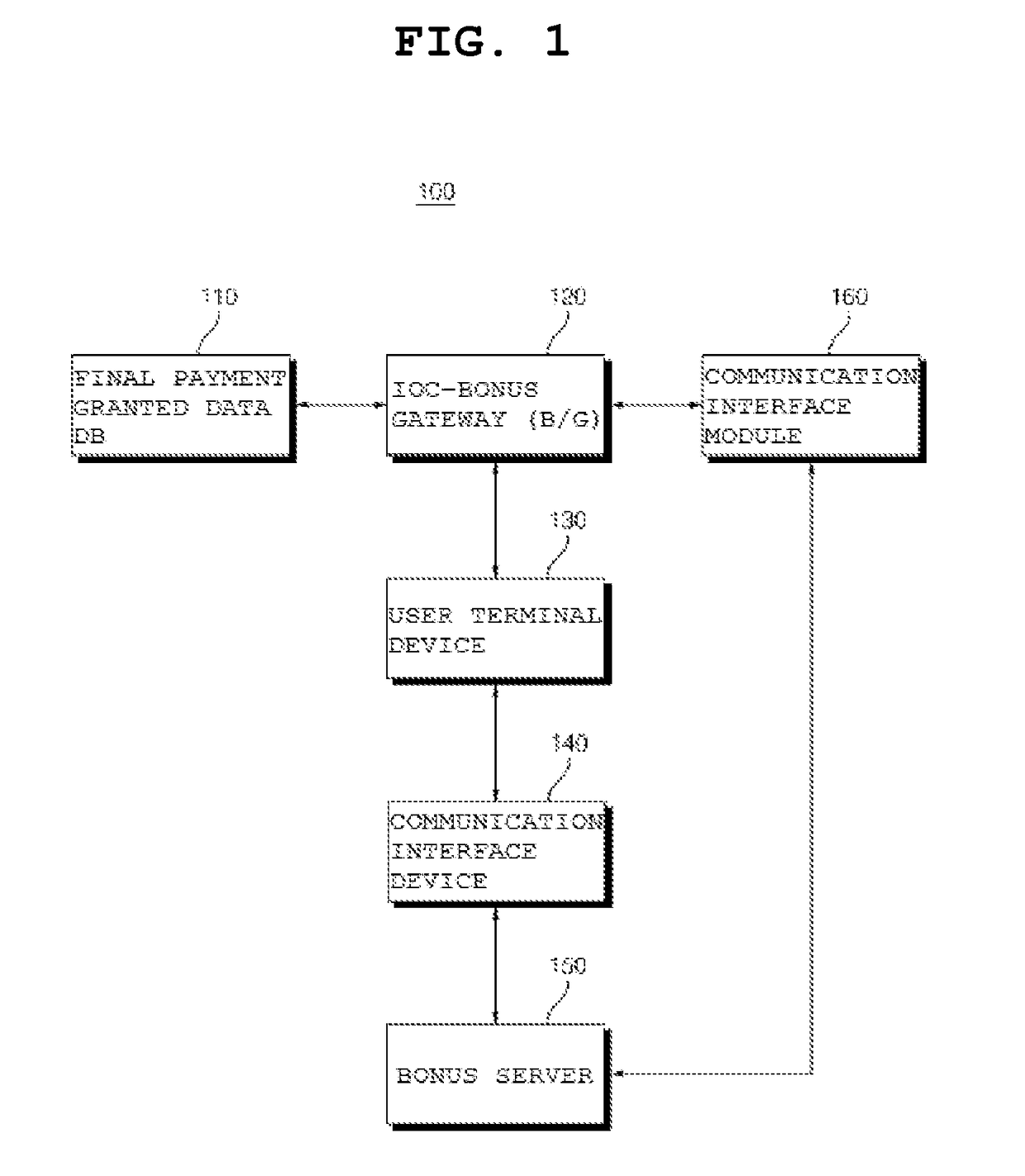

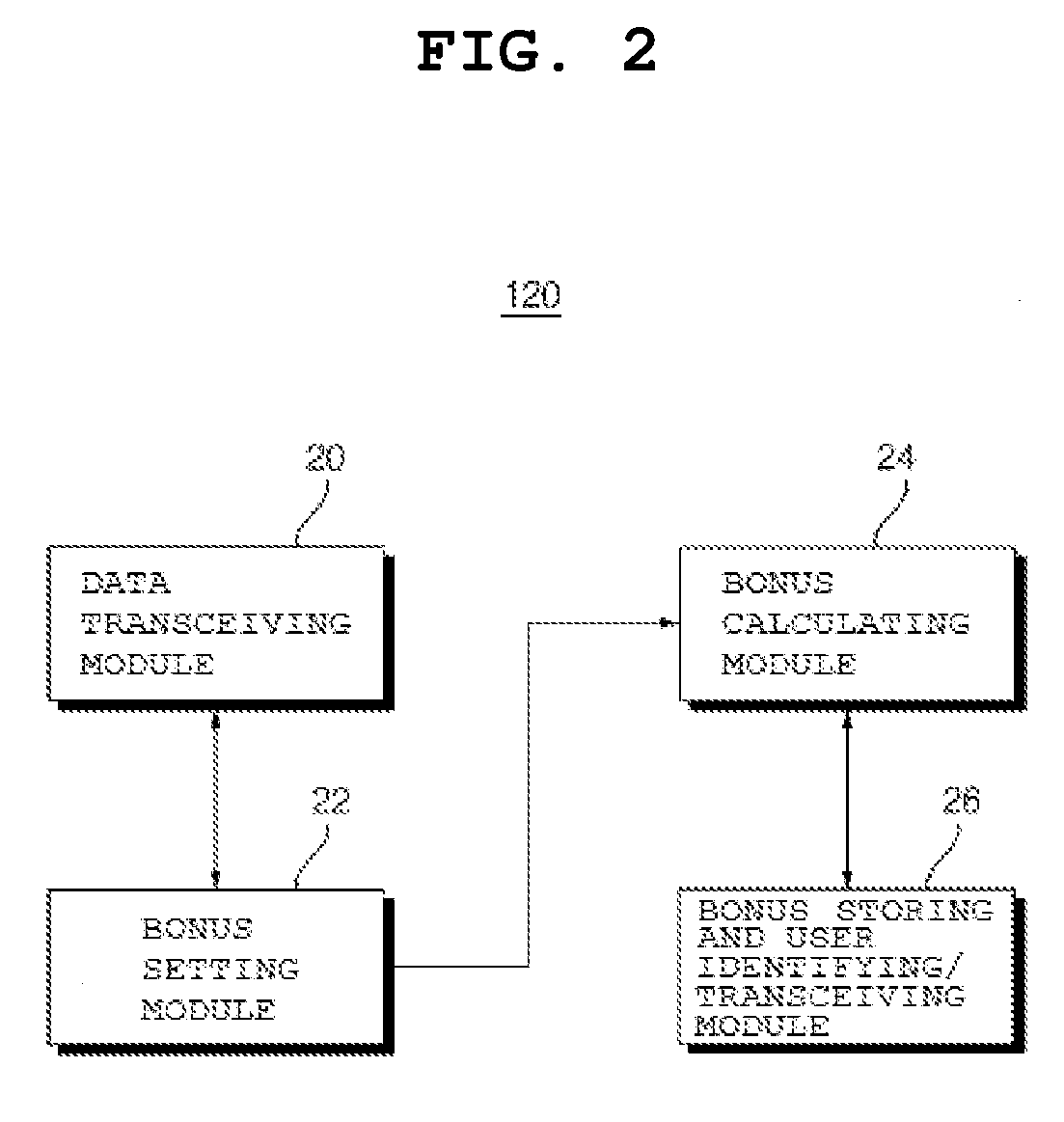

System and method for integrated accumulation and granting of bonus in on-line commercial transaction

InactiveUS20170300953A1Cost saving effectLow raw material costDiscounts/incentivesPayment circuitsPaymentTerminal equipment

The present invention relates to a system and a method of integrally accumulating and granting a bonus in an on-line commercial transaction, in which in order to integrally accumulate an accumulated point according to a wired / wireless on-line site commercial transaction, an Internet of communication (IoC)-bonus gateway automatically calculates various commercial transaction bonuses and transmits the calculated commercial transaction bonuses to a user terminal device, and the commercial transaction bonuses are transmitted from the user terminal device to a bonus server, so that the on-line commercial transaction bonus is granted, accumulated, and integrated, without passing through an on-line electronic payment granting intermediary gateway (payment gateway (P / G)).

Owner:KIM SEONG KIL

Catalyst system and method for the reduction of NOx

ActiveUS20060133976A1Improve efficiencyReduce NOxNitrous oxide captureNitrogen compoundsIndiumCobalt

A catalyst system for the reduction of NOx comprises a catalyst comprising a metal oxide catalyst support, a catalytic metal oxide comprising at least one of gallium oxide or silver oxide, and at least one promoting metal selected from the group consisting of silver, cobalt, molybdenum, tungsten, indium, bismuth and mixtures thereof. The catalyst system further comprises a gas stream comprising an organic reductant, and a compound comprising sulfur. A method for reducing NOx utilizing the said catalyst system is also provided.

Owner:GENERAL ELECTRIC CO

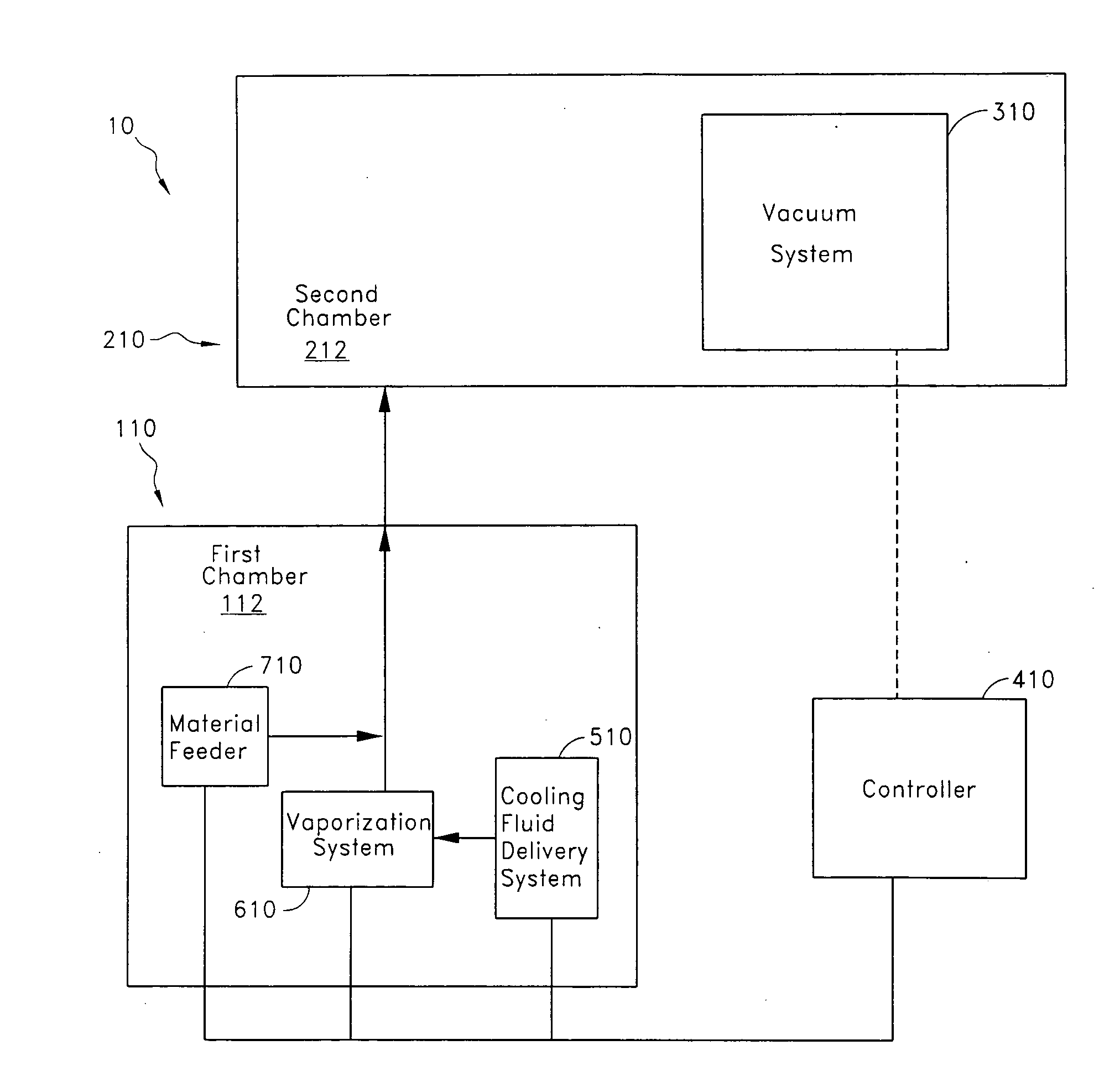

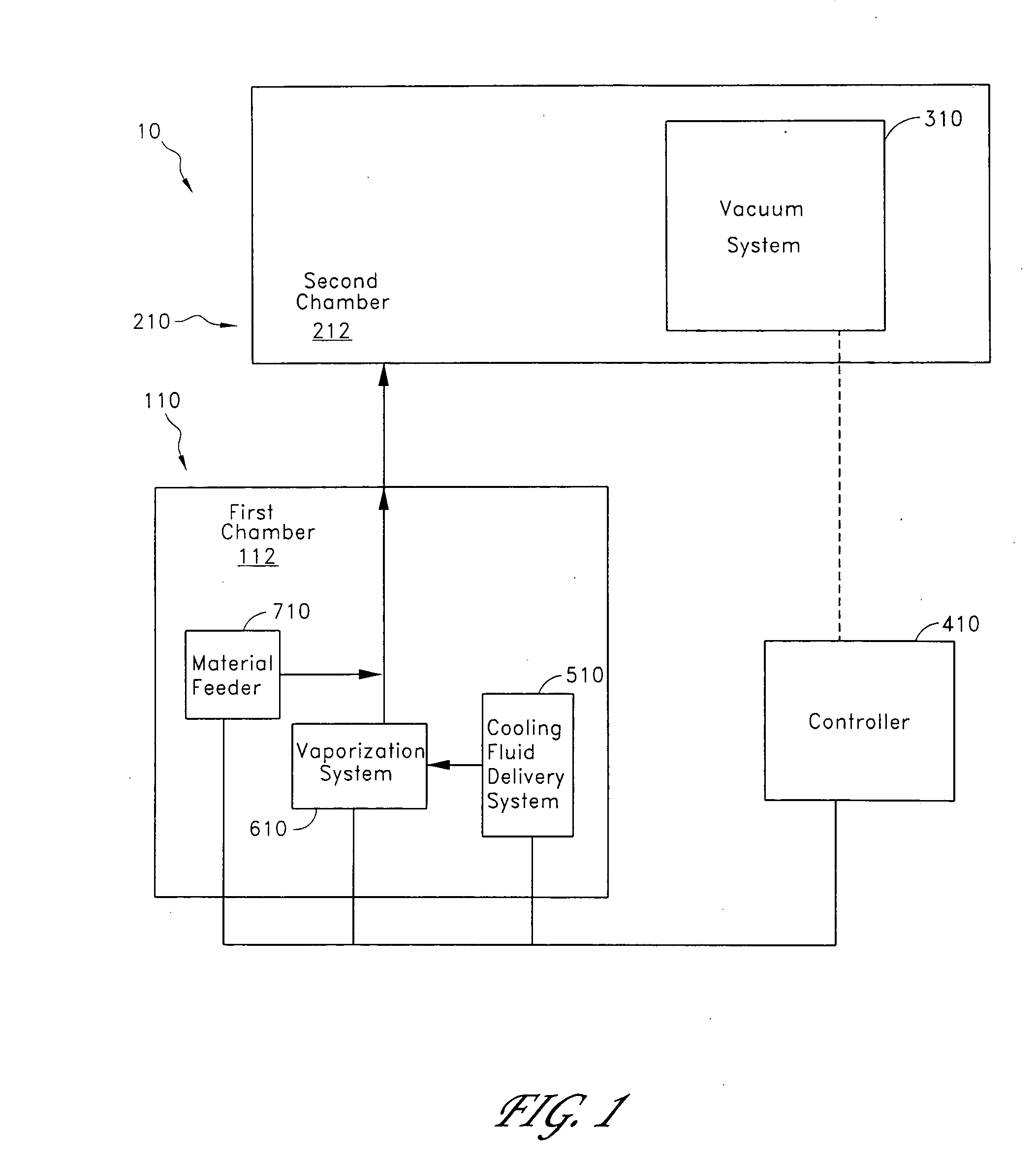

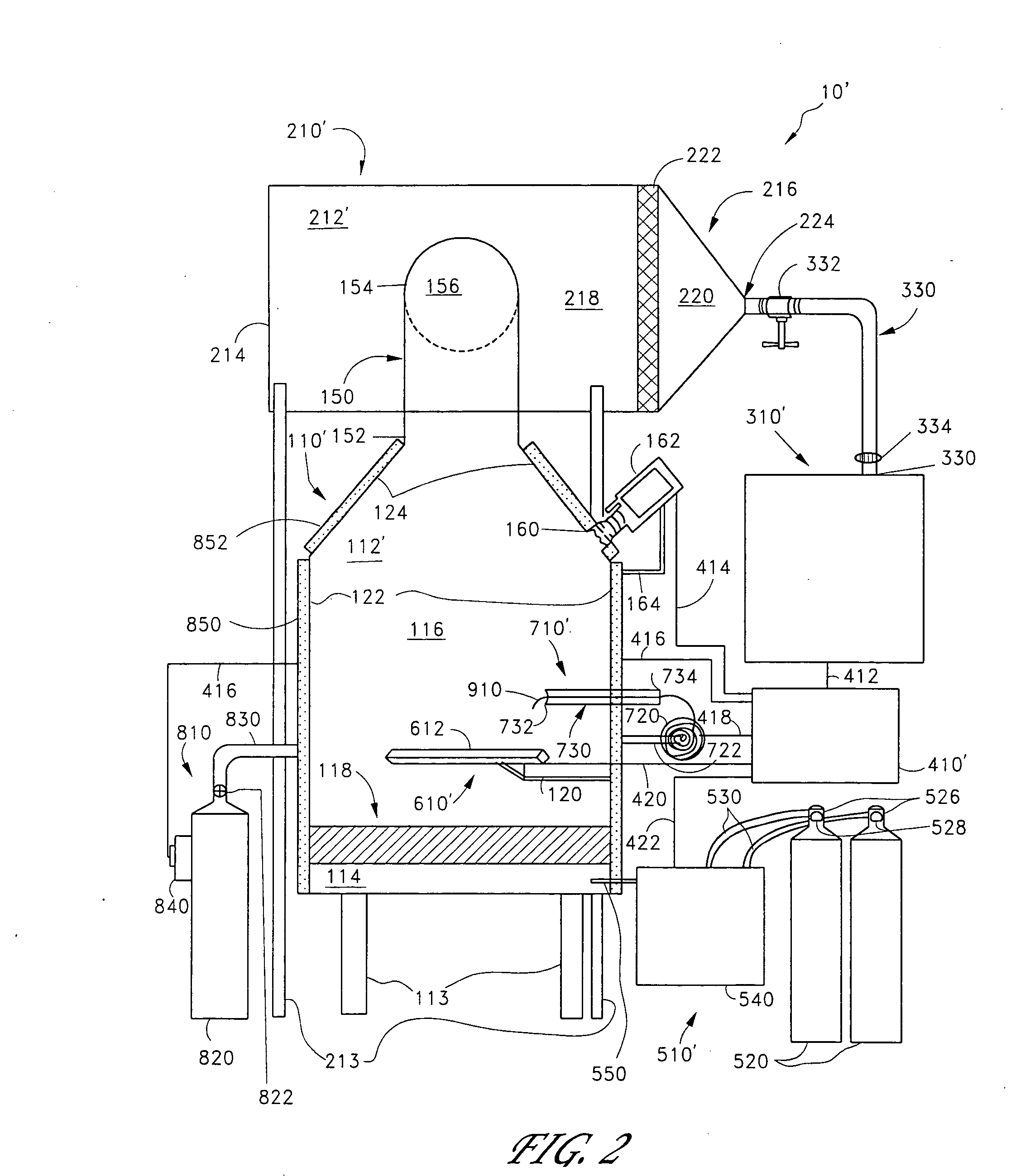

Method and apparatus for forming nano-particles

InactiveUS20080108005A1Low raw material costReduce manufacturing costMuffle furnacesTransportation and packagingProduct gasEngineering

Nano-scale particles of materials can be produced by vaporizing material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range. A raw material feeder can be configured to feed raw material toward a heater which vaporizes the raw material. The feeder can include a metering device for controlling the flow of raw material toward the heater. A gas source can also be used to cause gas to flow through a portion of the raw material feeder along with the raw material.

Owner:BRICOLEUR PARTNERS LP

Method for preparing high-specific-surface-area activated carbon from tobacco stalks

InactiveCN103121682AImprove qualityWide variety of sourcesCarbon compoundsSolid waste disposalActivated carbonSlag

The invention discloses a method for preparing high-specific-surface-area activated carbon from tobacco stalks, which comprises the following steps: pulverizing tobacco stalks into granules, mixing the granules and an activating agent according to a mass ratio of (1:8)-(2:1), adding the obtained mixture into water, evenly stirring, and impregnating for 10-14 hours; after impregnation is finished, filtering, drying the filter residue, placing into an electric furnace having a nitrogen protective atmosphere, and carbonizing at 450-750 DEG C for 1-2 hours; and after carbonization is finished, cooling in a nitrogen atmosphere, washing the obtained furnace slag, and drying. According to the method, high-quality activated carbon can be simply and quickly prepared from wastes in the tobacco industry. Thus, the method changes wastes into valuable substances, fully utilizes resources, avoids environmental pollution, has good economic benefits and is beneficial to industrial production.

Owner:CENT SOUTH UNIV

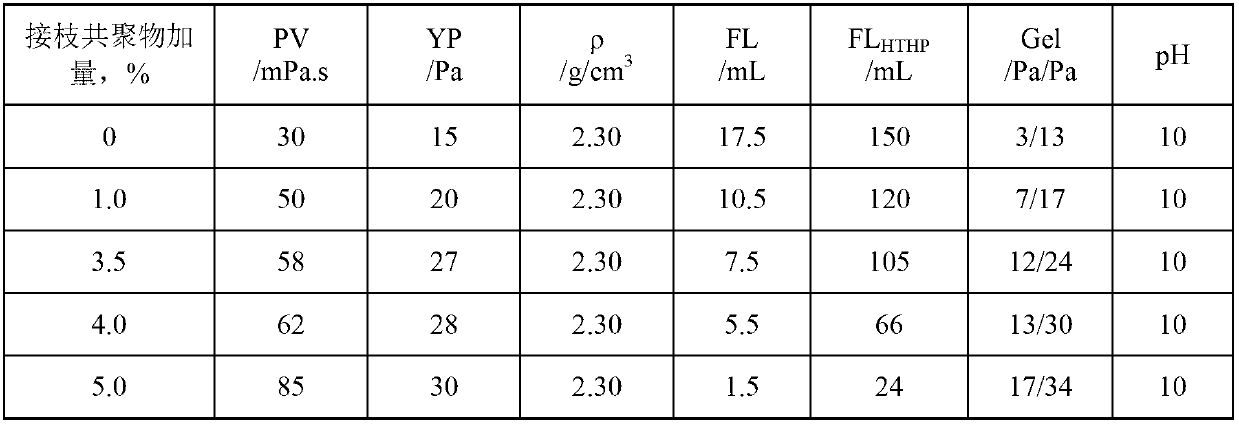

Fluid loss additive for drilling fluid and preparation method thereof

ActiveCN102766240AControl rheologyReduce high temperature and high pressure filtration lossDrilling compositionSide chainWell drilling

The invention discloses a fluid loss additive for drilling fluid and a preparation method thereof, belonging to the technical field of chemical drilling fluid treating agents for oilfields. The method comprises the following steps of: carrying out one-step reaction on phenol, formaldehyde, humate, pyrosulfite and anhydrous sulfite so as to obtain a sulfonated phenolic humic acid resin; in the presence of an initiator, carrying out graft copolymerization on the sulfonated phenolic humic acid resin and a mixture of sodium hydroxide, 2-acrylamide-2-methyl-propyl sulfonate, acrylamide and dodecylacrylamide; and carrying out drying and crushing on the obtained product so as to obtain sulfonated phenolic humic acid resin-alkenyl monomer graft copolymer. The fluid loss additive disclosed by the invention has the functions of controlling the rheological property of drilling fluid and reducing the high-temperature and high-pressure filter loss of drilling fluid, not only enhances the thermal stability of side chains of a chain polymer, but also improves the salt tolerance of a sulfonated phenolic resin, and guarantees that products have good properties under high temperature and high salt conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com