Flexible wearable strain sensor and preparation method thereof

A strain sensor and flexible technology, applied in the field of strain sensors, can solve the problems of lack of practical features of strain sensors, poor stretchability of strain sensors, poor flexibility of PMMA, etc., and achieve the effects of wide strain test range, excellent product performance and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

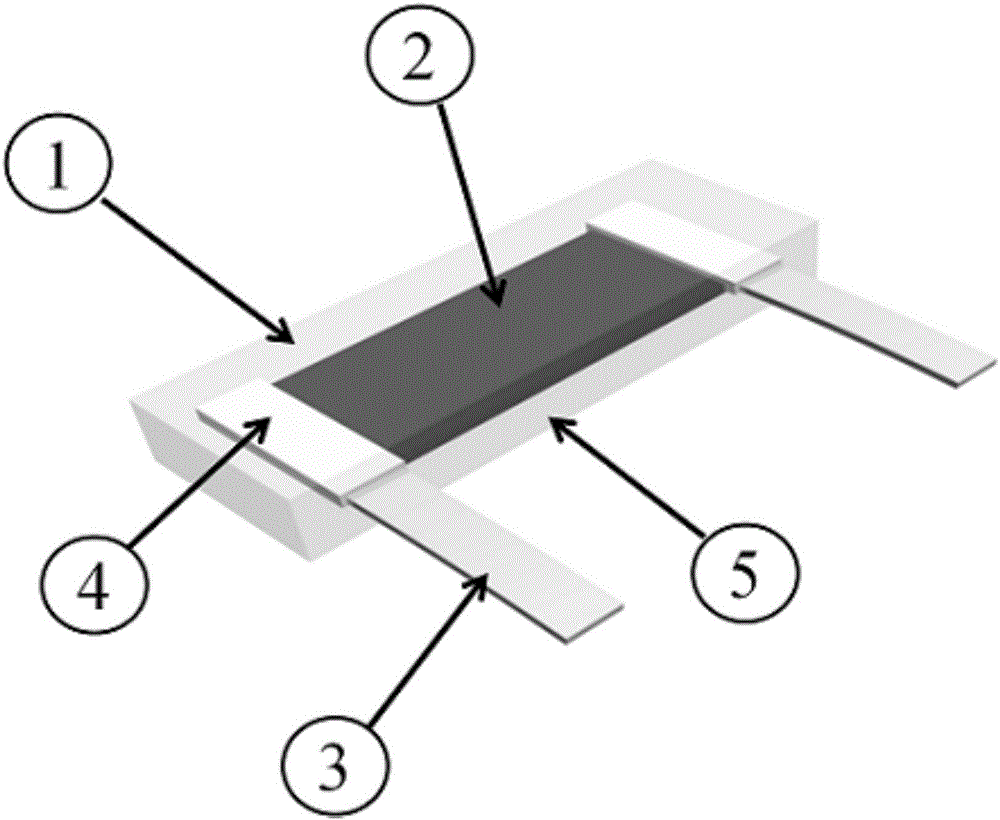

[0030] The invention provides a method for preparing a strain sensor. A specific implementation method is: spin-coat PDMS with a thickness of 10-400 μm on a substrate, place it in an oven at 50-150° C. for 1-60 minutes, and then The electrospun fiber membrane modified by conductive filler is placed on it, and then the wire is introduced through the wire fixing unit, and finally a layer of PDMS with a thickness of 10-400 μm is spin-coated on it, and placed in an oven at 50-150 ° C to make it Complete curing is enough; wherein, the method for modifying the conductive filler on the electrospun fiber membrane is: mixing the conductive filler with deionized water to prepare a conductive filler dispersion with a mass concentration of 0.01 to 5%, and then placing the electrospun fiber membrane on the Sonicate in the dispersion for 1-100 minutes, and then place it in the air to dry.

[0031] In the present invention, the electrospun thermoplastic polyurethane fiber film is used as the...

Embodiment 1

[0032] The preparation of embodiment 1 strain sensor

[0033] The method for preparation, concrete steps are as follows:

[0034]Place the TPU and graphene nanosheets in an oven at 80°C for 8 hours to remove the moisture;

[0035] (1) Electrospinning: Add 5.8g of dried TPU into a mixed solvent of 10ml of N,N-dimethylformamide and 10ml of tetrahydrofuran, stir mechanically at room temperature for 2.5h to fully dissolve it, and prepare Uniform TPU spinning solution;

[0036] The TPU spinning solution is electrospun to form TPU electrospun fibers: Electrospinning parameters: the distance between the spinneret and the collection device is 15cm, the spinning voltage is 21KV, the drum speed is 1200r / min, and the collection device is wrapped with The rotating drum of aluminum foil, when the electric field force generated by the high voltage is greater than the surface tension of the solution, the spinning solution will form a jet at the spinneret, and then go through jet instabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com