Patents

Literature

170 results about "Strain response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strain is the response of a system to an applied stress. When a material is loaded with a force, it produces a stress, which then causes a material to deform. Engineering strain is defined as the amount of deformation in the direction of the applied force divided by the initial length of the material.

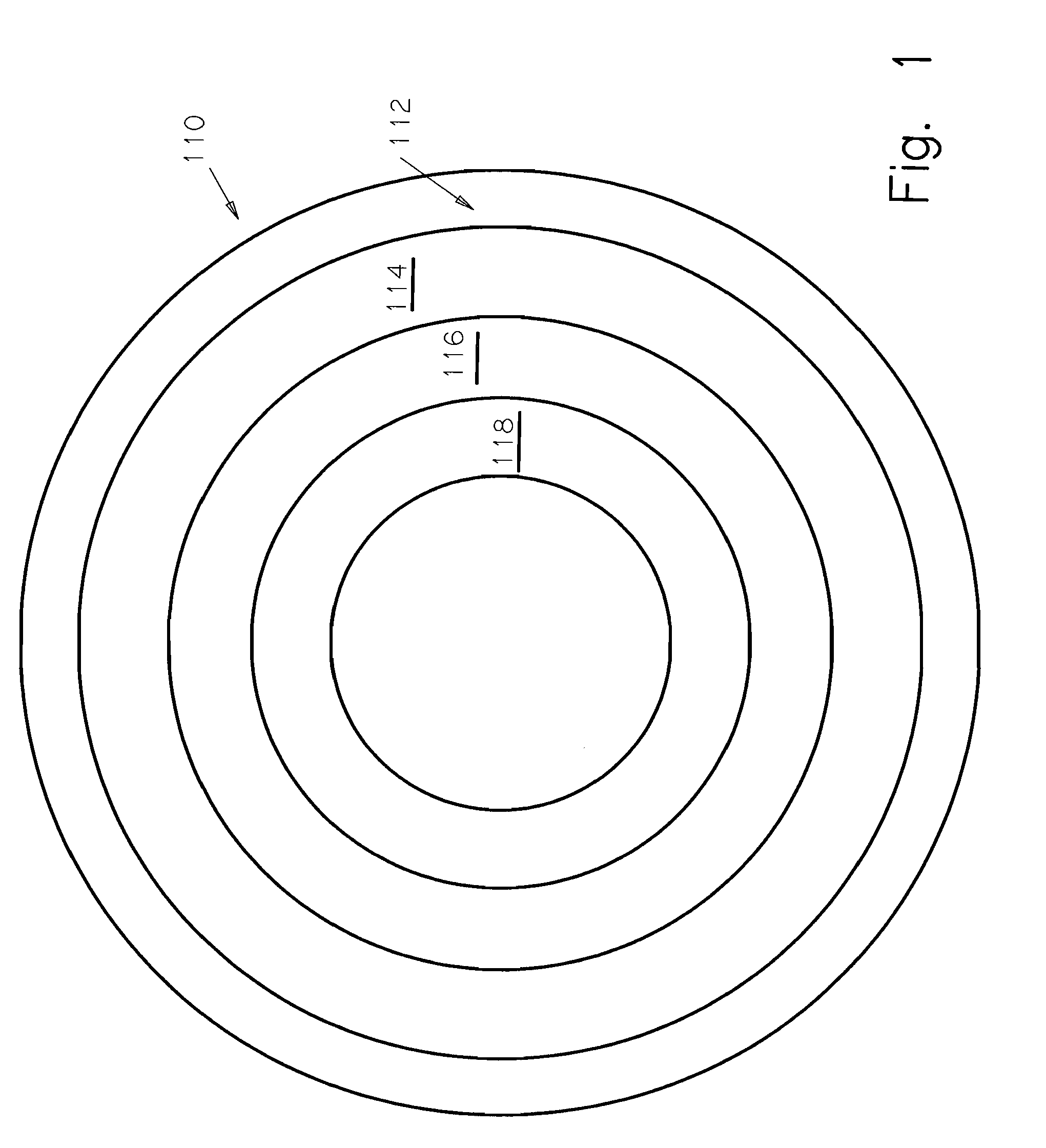

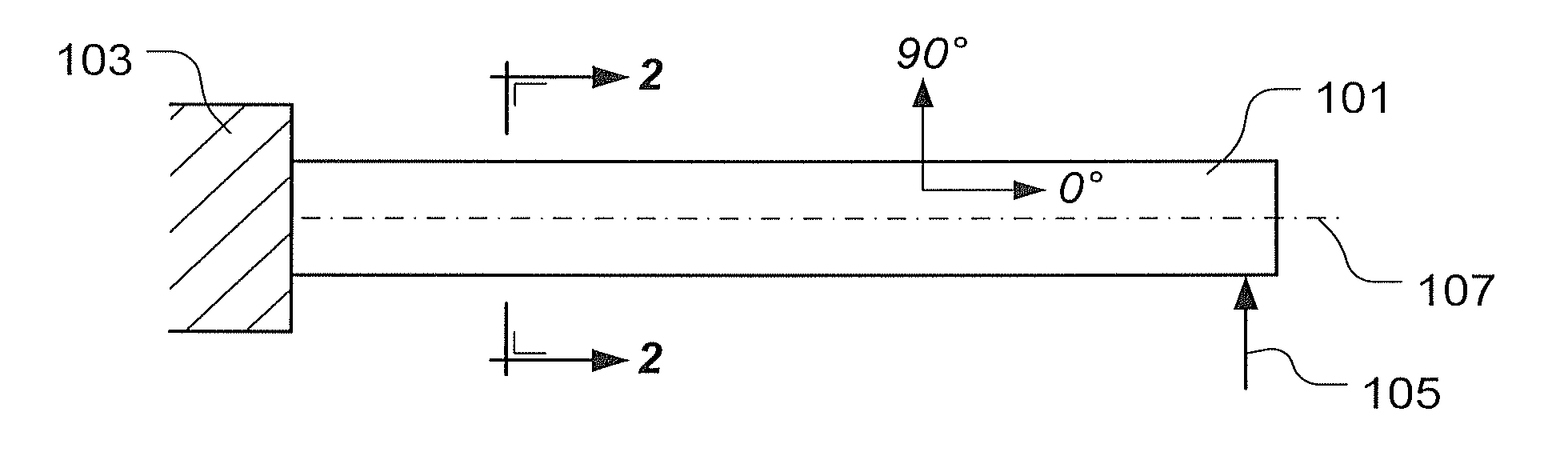

Circumferential strain attenuator

InactiveUS6868737B2Reduce gainWide rangeSubsonic/sonic/ultrasonic wave measurementForce measurement by measuring optical property variationCircumferential strainEngineering

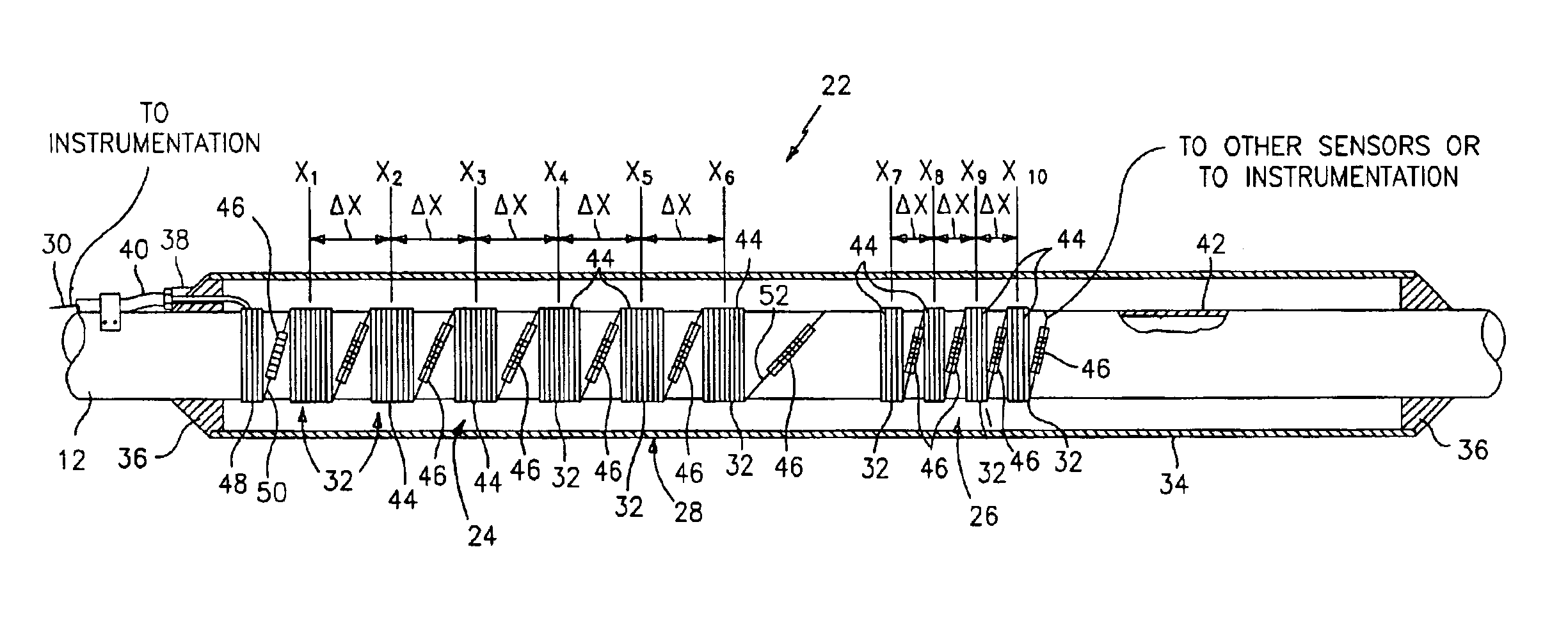

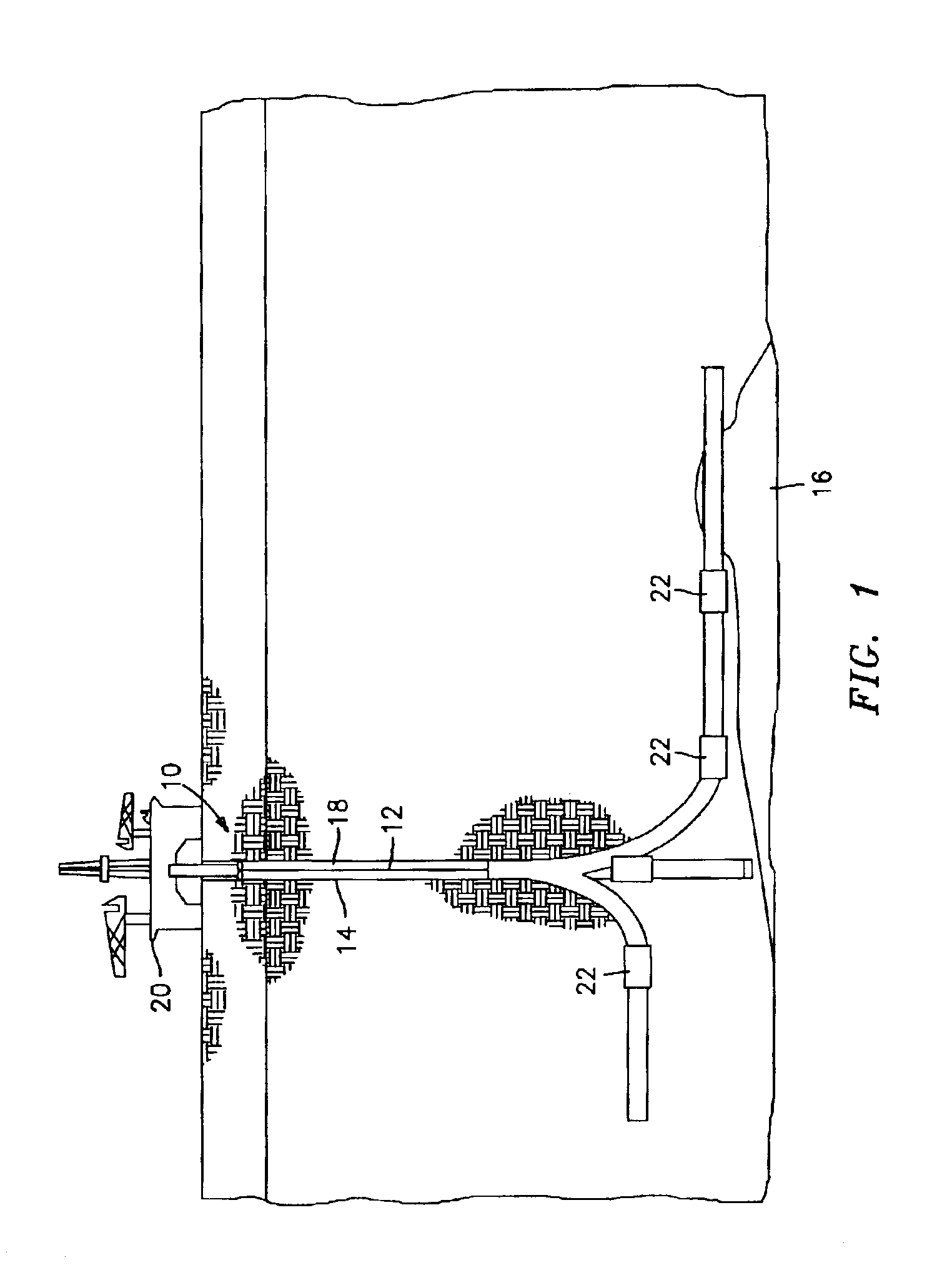

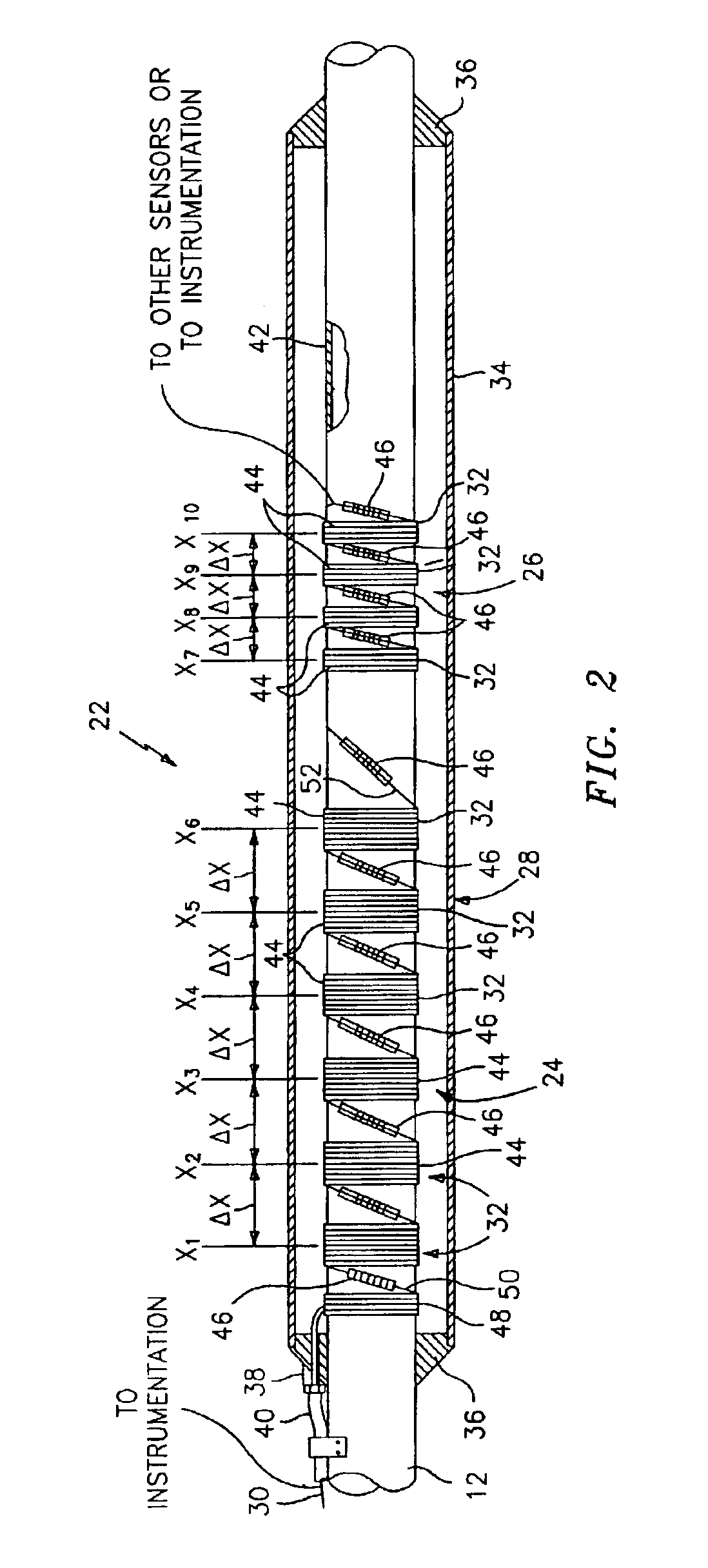

An apparatus for varying the gain of a fiber optic sensor that non-intrusively senses the strain response of a pipe is provided. The apparatus includes a circumferential strain attenuator that has an annular land portion that mechanically couples the attenuator to the pipe. An annular web extends coaxially from the land portion and has a reduced cross sectional area relative to the land, and an annular mandrel portion extends coaxially from the web portion and forms a gap between the pipe and the mandrel. The fiber optic sensor is wound on the circumferential strain attenuator. The web and mandrel cooperate to reduce the strain response of the fiber optic sensor relative to the strain response of the pipe.

Owner:WEATHERFORD TECH HLDG LLC

Model updating method based on strain modal shape correlation

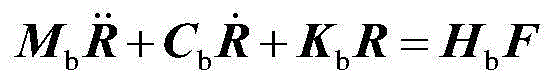

InactiveCN106529055ASimple structureDesign optimisation/simulationSpecial data processing applicationsElement modelStructural dynamics

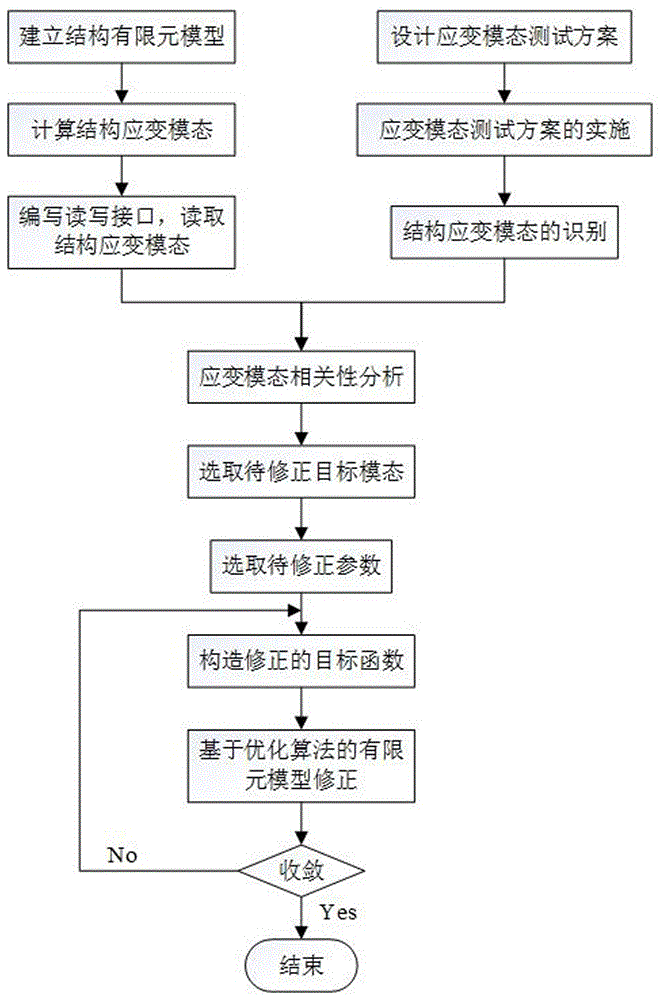

The invention discloses a model updating method based on strain modal shape correlation. The specific steps are as follows: step 1), establishing a finite element model of a structure and analyzing the finite element model; step 2), performing experimental design and analysis; step 3), extracting a finite element simulation strain mode; step 4), performing correlation analysis: adopting a model confidence factor, and analyzing the correlation between the finite element model and the strain modal shape of an experimental test; step 5), selecting a mode to be modified; step 6), selecting a parameter to be identified; step 7), constructing a modification target; and step 8), performing modified iteration. According to the model updating method based on the strain modal shape correlation provided by the invention, by selecting an appropriate unit type, the obtained finite element model of the structure provides a reference model for strain response calculation; by selecting an appropriate strain mode to be modified, parameters to be modified and an optimum design method, the modified finite element model can better reflect the strain response of the structure; and the accurate finite element model is beneficial to the subsequent structural dynamic optimization design based on the finite element model, and the development of structural health monitoring and structural response prediction and so on.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

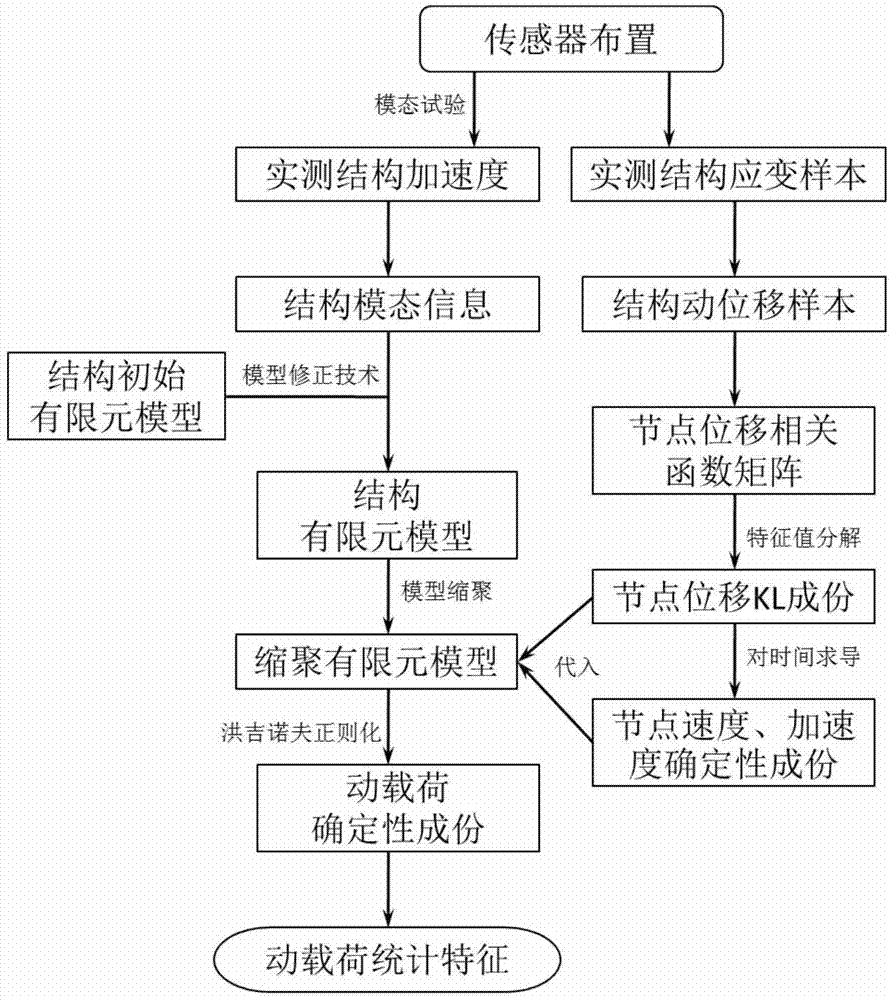

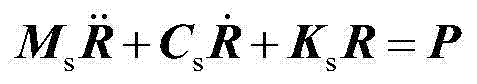

Random recognition method for bridge floor moving vehicle loads

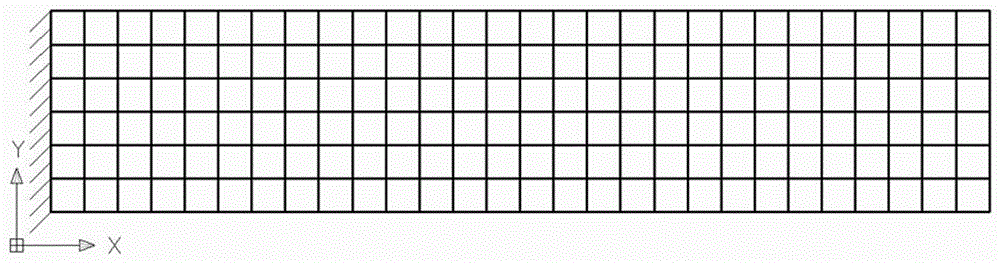

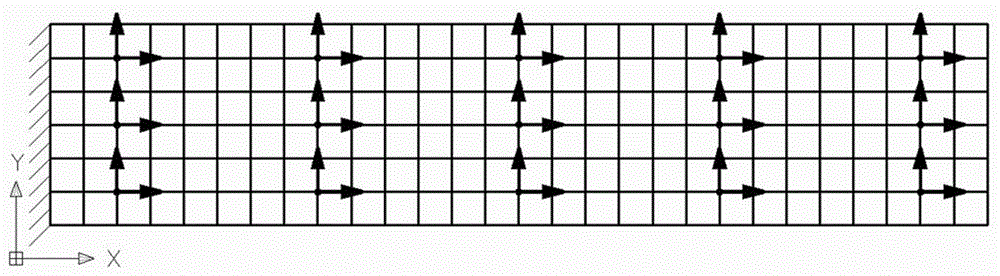

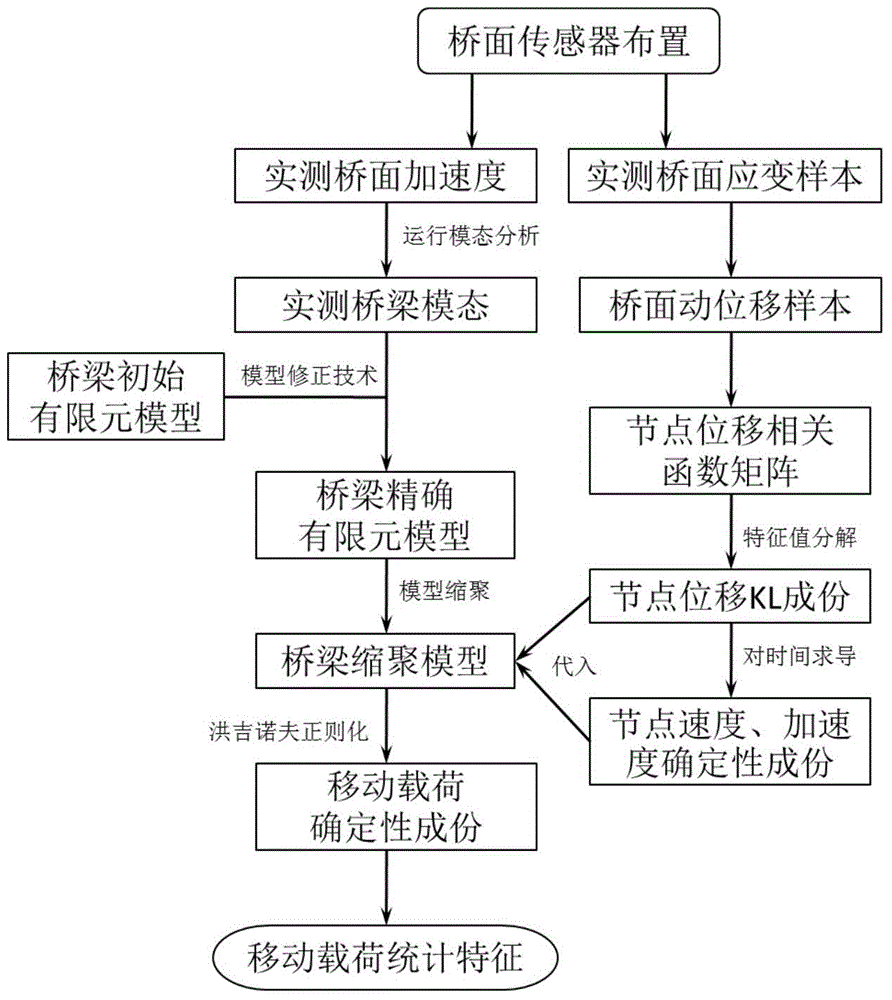

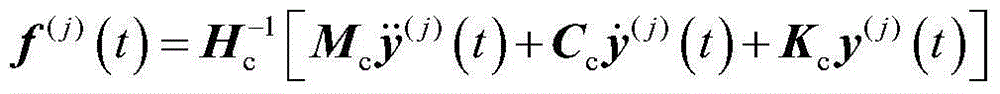

InactiveCN104090977AImprove recognition efficiencyAvoid anti-problem identificationDesign optimisation/simulationSpecial data processing applicationsElement modelDecomposition

The invention discloses a random recognition method for bridge floor moving vehicle loads. The method comprises the following steps that (1) raster sensors, strain sensors and acceleration sensors are arranged on a bridge floor to obtain running speeds of moving vehicles and the dynamic strain and acceleration responses of a bridge under the action of the moving vehicle loads; (2) an accurate structural finite element model is established for a bridge structure, model condensation is carried out, and the freedom degree of the bridge model after the model condensation is made to be matched with dynamic strain signal measuring positions; (3) the deterministic components of bridge random dynamic displacement, speed and acceleration are obtained by utilizing a KL decomposition technique on the basis of actual measurement dynamic strain response samples; (4) the deterministic components random moving vehicle loads on the bridge floor are recognized by directly adopting a sample matrix inversion and a Tikhonov regularization method; (5) the statistical properties, average time history and variance, of the random moving vehicle loads are obtained.

Owner:SOUTHEAST UNIV

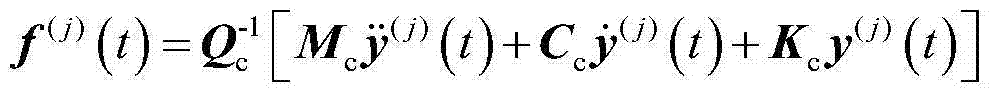

Time domain identification method of random dynamic loads

InactiveCN104123463AOvercome structureOvercoming the drawbacks of randomness in excitation loadsSpecial data processing applicationsTime domainElement model

The invention discloses a time domain identification method of random dynamic loads. The time domain identification method is characterized by comprising the following steps that (1) a strain sensor and an acceleration sensor are arranged on an engineering structure, and dynamic strain samples and acceleration response samples of the structure are obtained through measurement; (2) an accurate structure finite element model is established for the engineering structure, model condensation is conducted, and a condensed finite element model matched with the freedom degree of a dynamic strain response signal obtained through actual measurement is obtained; (3) on the basis of a dynamic strain sample set obtained through actual measurement, the deterministic component of structure random dynamic response is obtained through the KL decomposition technology; (4) deterministic components of the random dynamic loads are identified by the adoption of the direct inversion method and the Tikhonov regularization method; (5) the statistic characteristics, namely, the average time history and the variance, of the random dynamic loads are obtained.

Owner:SOUTHEAST UNIV

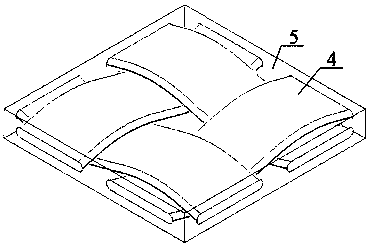

Method for determining laser peening forming process parameter of complex curved-surface-shaped workpiece

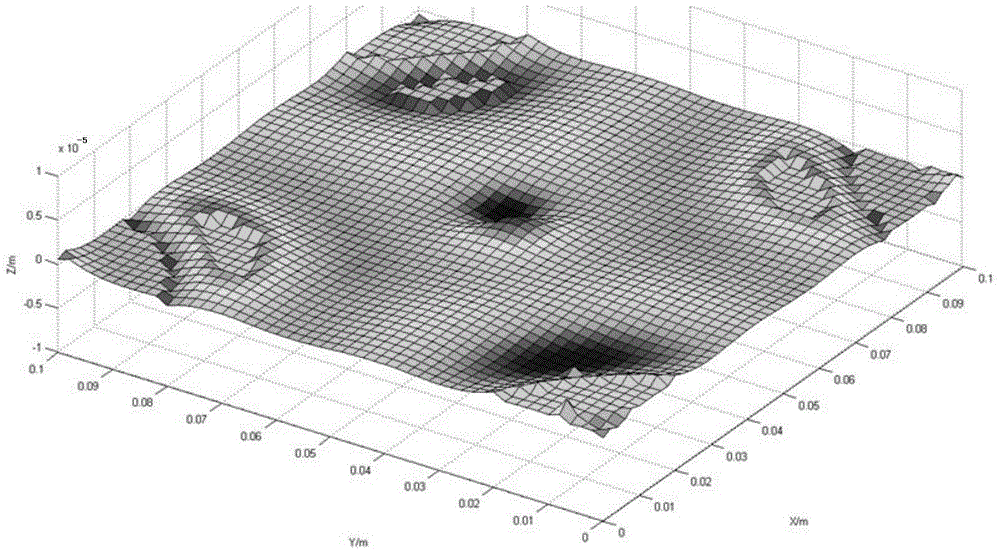

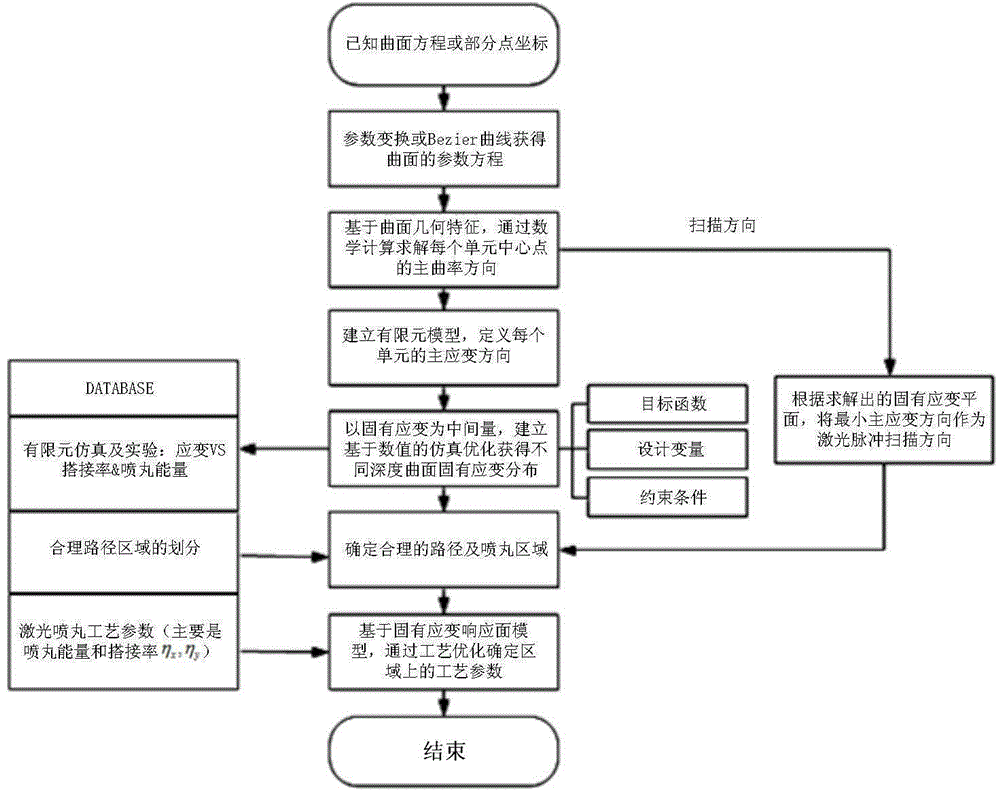

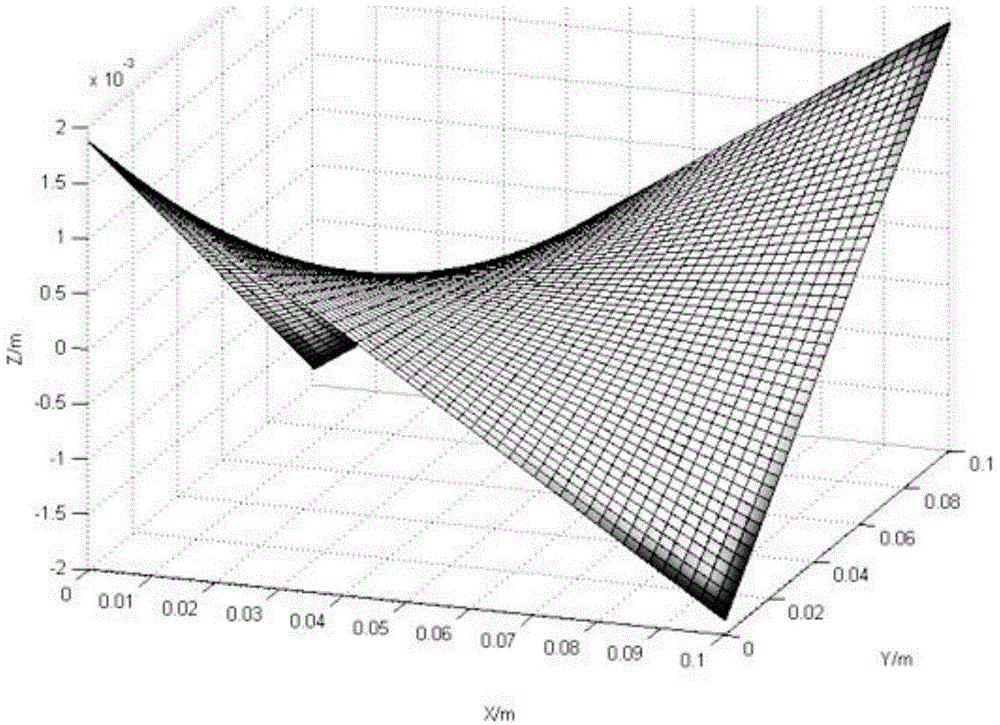

ActiveCN104899345AImprove fatigue resistanceAccelerated corrosionSpecial data processing applicationsElement modelStrain response

The invention provides a method for determining a laser peening forming process parameter of a complex curved-surface-shaped workpiece. The method comprises the following steps: according to a curved surface parameter equation of the workpiece, carrying out geometrical characteristic analysis on the curved surface of the workpiece to calculate a main strain direction so as to obtain a laser pulse scanning direction in laser peening forming; establishing a workpiece bending deformation finite element model which takes depth-direction inherent strain distribution as a deformation source, and optimizing an inherent strain field to obtain the inherent strain distribution of different positions of the workpiece along the depth direction, wherein an inherent strain direction is the main strain direction; and according to inherent strain response surface models under different laser peening forming process parameters and the inherent strain of different positions of the workpiece along the depth direction, optimizing the laser peening forming process parameters, and obtaining an optimal laser peening forming process parameter corresponding to different inherent strain fields on the surface of the workpiece. A non-elastic deformation problem can be converted into an elastic deformation problem to improve the efficiency and the precision of finite element simulation.

Owner:SHANGHAI JIAO TONG UNIV

Weld seam fatigue life calculation method based on total strain energy density

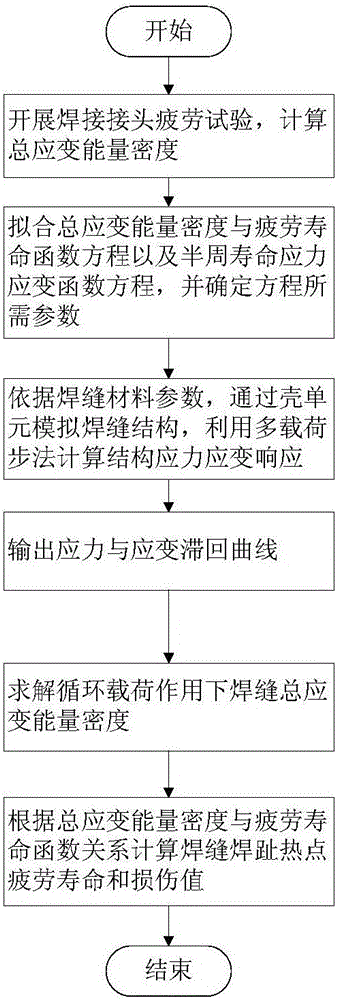

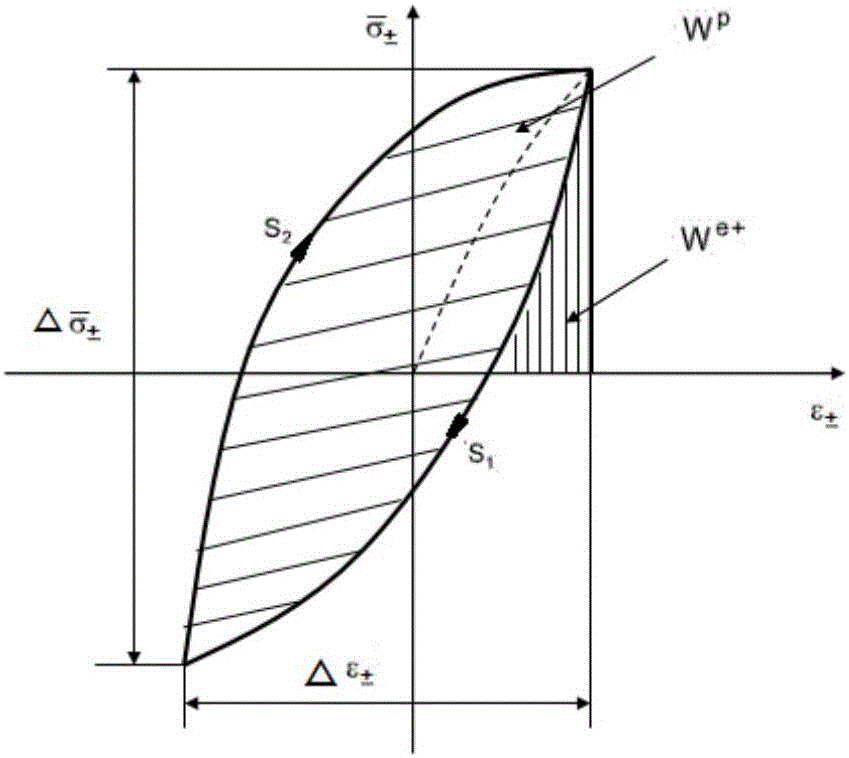

ActiveCN106354898AImprove the accuracy of fatigue life calculationAvoid sureDesign optimisation/simulationSpecial data processing applicationsFatigue IntensityFatigue damage

The invention discloses a weld seam fatigue life calculation method based on total strain energy density. The method mainly comprises the steps that 1, the weld-seam total strain energy density, a life function equation and a fatigue strength coefficient, a fatigue strength index, a cyclic strengthening coefficient and a cyclic strain hardening index which are needed by half-cycle life stress and a strain function equation are acquired through a welded joint fatigue test; 2, the weld seam structure is simulated through a shell unit module, the stress-strain response of the weld seam structure under the cyclic load action is calculated through a multi-load step method, and a stress-strain hysteretic curve is output; 3, the total strain energy density is calculated according to the stress-strain response, and the hot point fatigue life and a damage value of a weld toe of the weld seam are calculated by combining the energy density with the life function equation. According to the method, contribution of elastic-plastic stress and strain to the fatigue damage is comprehensively taken into account, scalar quantities are taken as damage parameters, the position and direction problems related to vectors are effectively avoided, the calculation precision is improved, and the time is saved.

Owner:HUNAN UNIV OF TECH

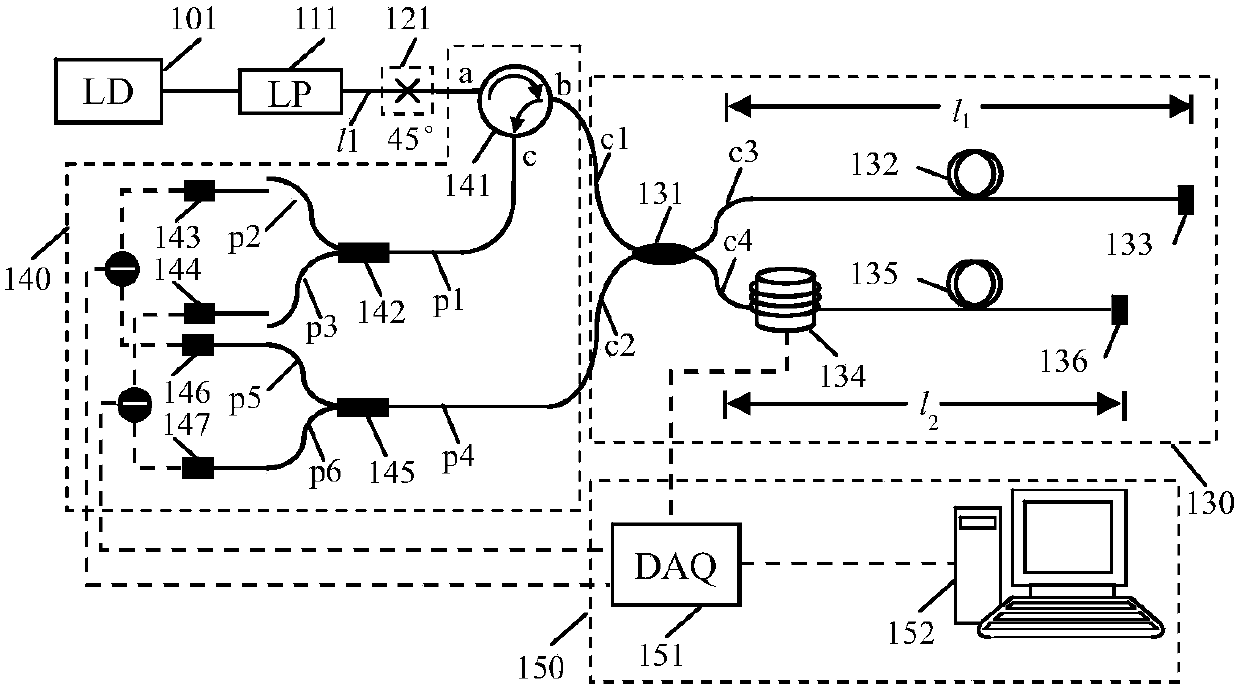

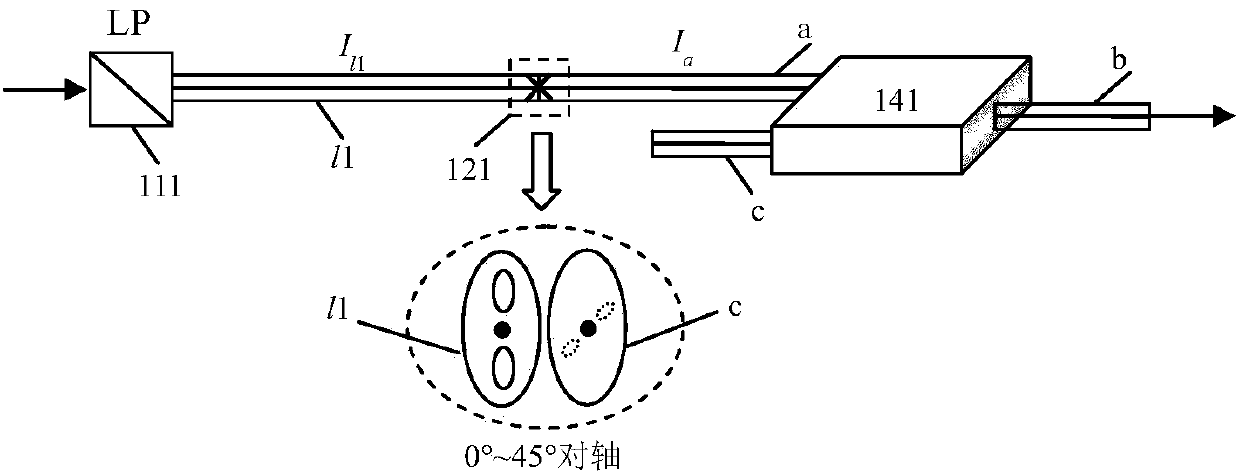

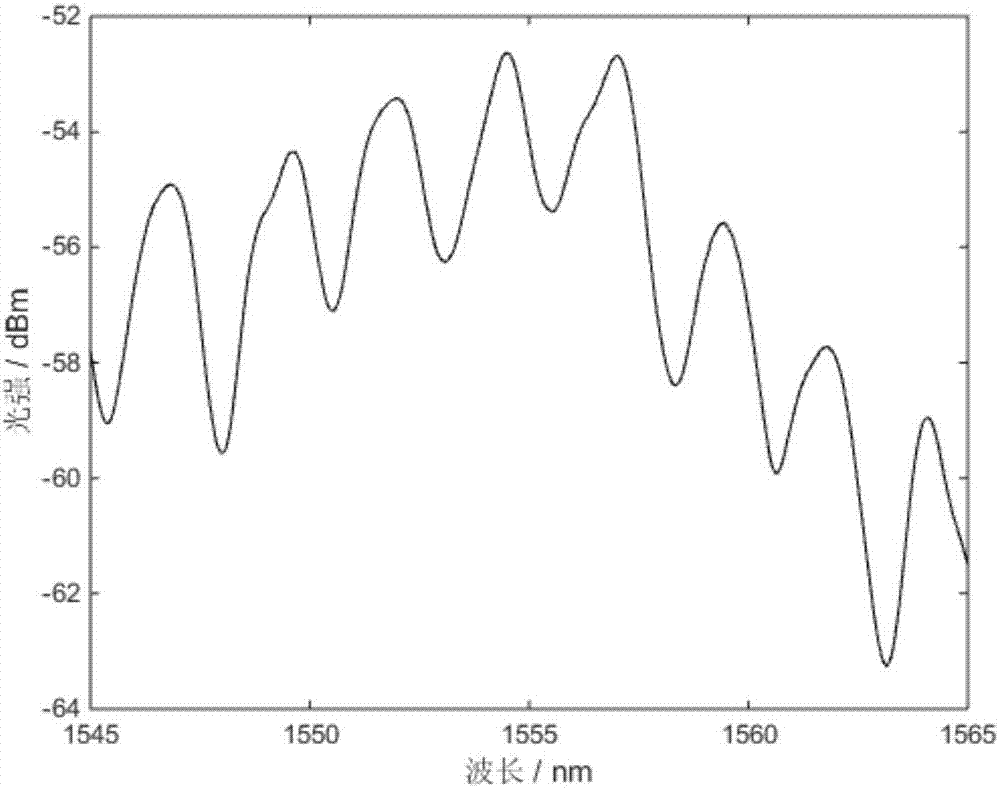

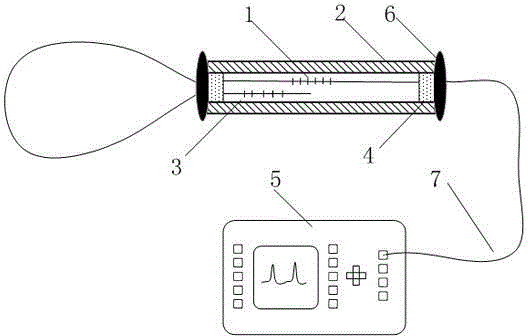

Unbalanced polarization maintaining fiber dual-interferometer temperature strain simultaneous measurement device and method

ActiveCN108168728ASolve temperature problemsGuaranteed accuracyThermometers using physical/chemical changesUsing optical meansFiber couplerTemperature response

The present invention provides an unbalanced polarization maintaining fiber dual-interferometer temperature strain simultaneous measurement device and method. A polarization-maintaining fiber coupler,a phase modulator, a polarization-maintaining fiber and a polarization-maintaining fiber reflector form an unbalanced polarization-maintaining fiber interferometer. A light source injects light intoa fast axis and a slow axis through a polarizer at the same time for transmission, coaxial transmission signal interference is achieved in the interferometer, interference signals are detected by a polarization beam splitting difference detection device formed by a polarization-maintaining circulator, a polarization beam splitter and a photoelectric detector, and finally, a signal collection and demodulation and record device processes the interference signals. Parameters of the fast axis and the slow axis of the polarization maintaining fiber are different to allow fast-axis signals and slow-axis signals to have different responses for the same temperature and the same strain, and an unbalanced interferometer structure is employed to construct an orthogonal response matrix and measure temperature response coefficients and strain response coefficients of two paths of interference signals to achieve simultaneous measurement of temperatures and strains. The unbalanced polarization maintaining fiber dual-interferometer temperature strain simultaneous measurement device and method solve the intersection sensitivity problem, the measurement result is accurate and stable, and the sensitivity is high.

Owner:HARBIN ENG UNIV

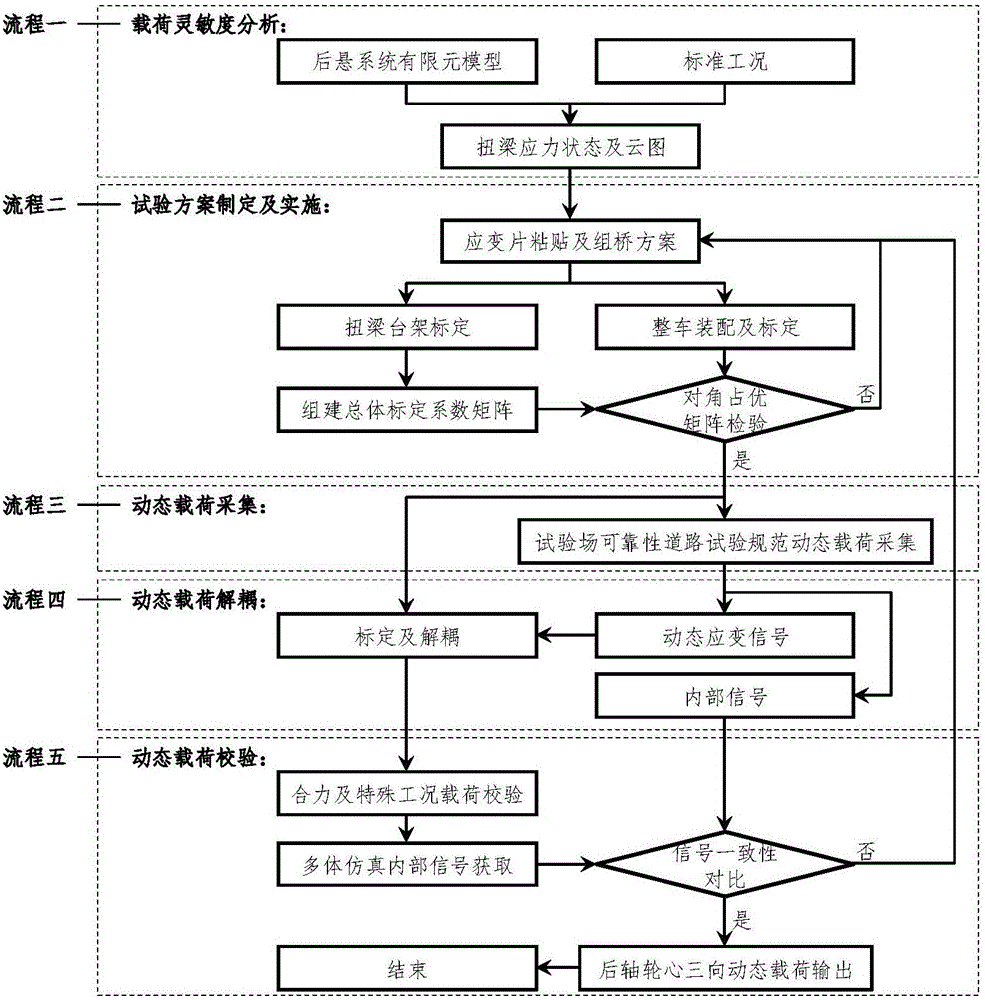

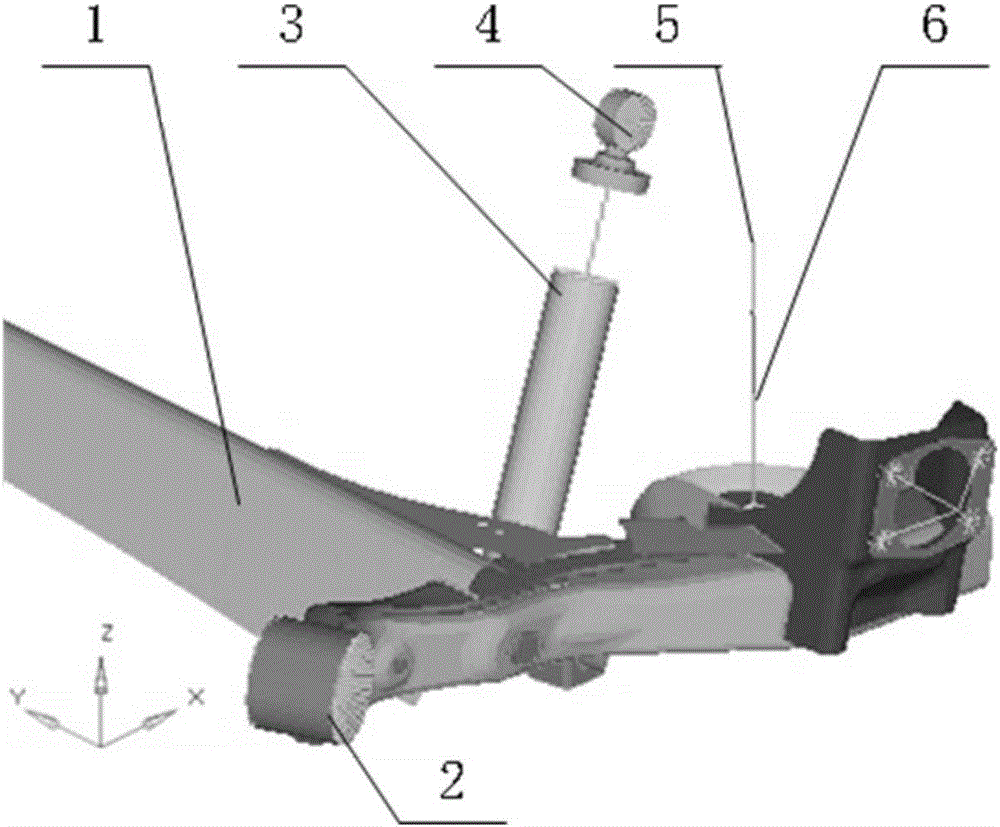

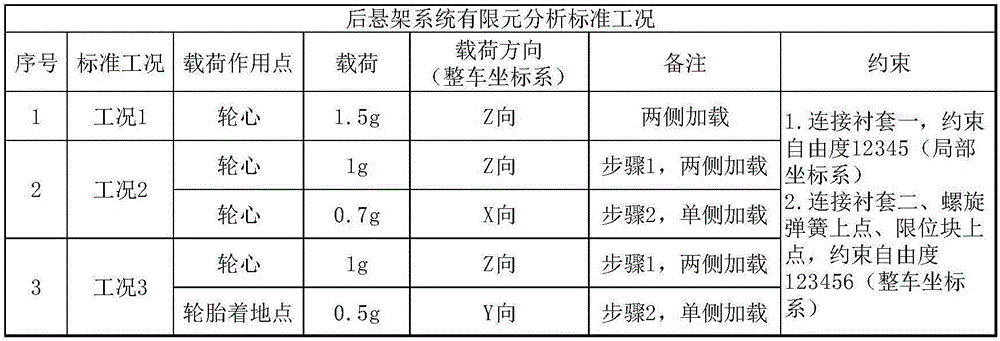

Acquisition method for dynamic wheel center loads of torsion beam type suspension

ActiveCN106840338ALow costAcquisition period is shortApparatus for force/torque/work measurementSpecial purpose weighing apparatusTime domainLoad time

The invention relates to an acquisition method for dynamic wheel center loads of a torsion beam type suspension. The acquisition method particularly comprises the steps of load sensitivity analysis, 2 test scheme making and implementation, 3 dynamic load acquisition, 4 dynamic load decoupling and 5 dynamic load verification. According to the acquisition method, a strain gauge measurement scheme is determined through CAE simulation, wheel center load and strain calibration tests are conducted through loading equipment and a load sensor respectively, calibration coefficients of strain and loads are obtained, participation factors of the loads are acquired through a total calibration coefficient matrix, and then a test strain signal is converted to obtain a torsion beam type suspension wheel center dynamic load time domain signal. Compared with a six-component instrument, the acquisition method has the advantages that by sticking a strain gauge to measure a strain response, the wheel center loads of the torsion beam type suspension are indirectly obtained, the cost is low, the acquisition cycle is short, and the consistence between the wheel center loads and wheel center loads acquired by the six-component instrument is high.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

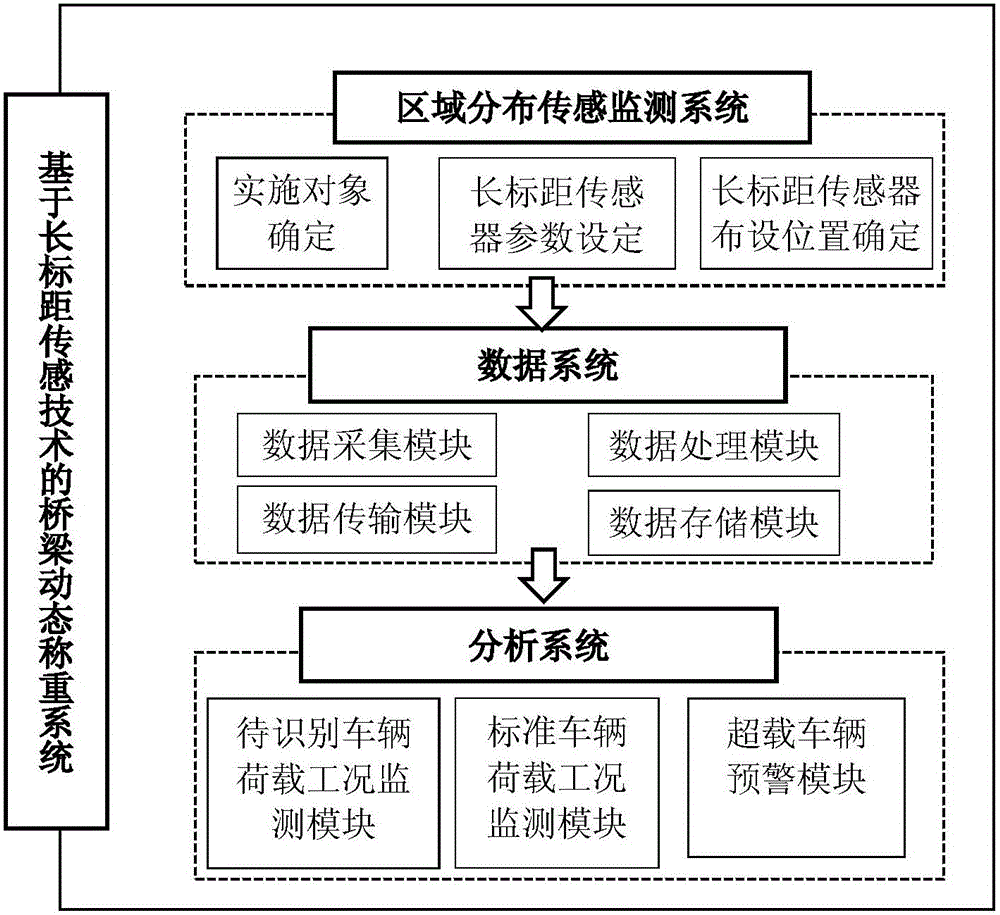

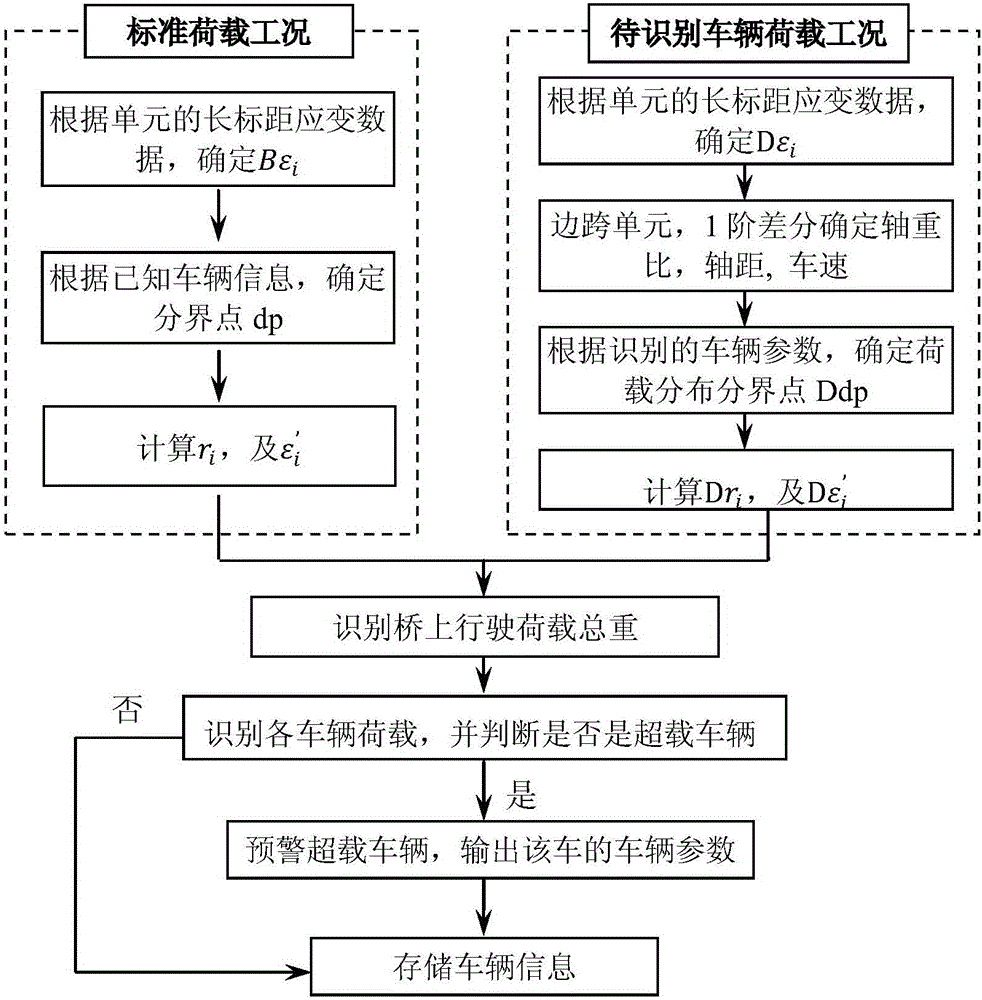

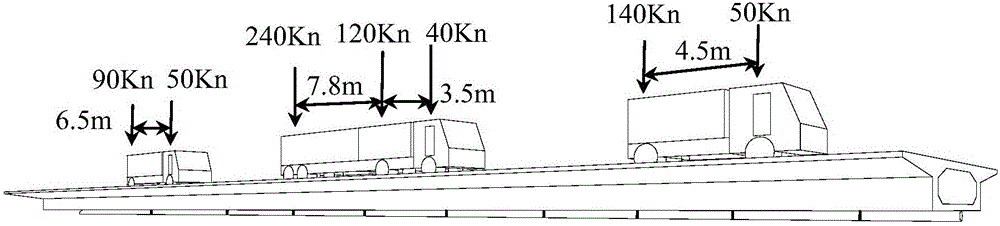

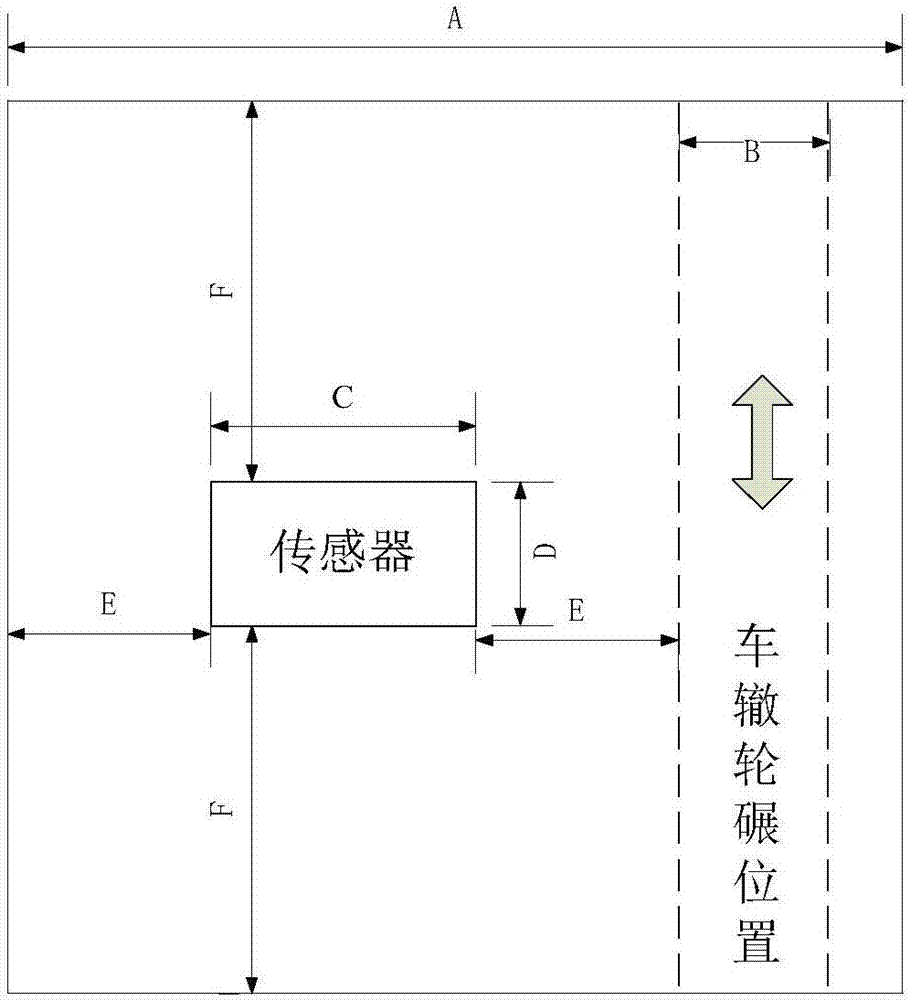

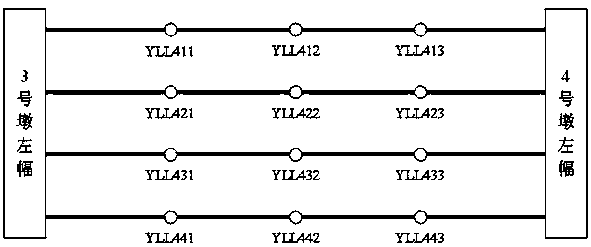

Bridge dynamic weighing method based on long-gauge fiber grating sensing technology and dynamic weighing system thereof

ActiveCN106441530AAvoid damageReduce maintenance costsWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusFiberGrating

The invention discloses a bridge dynamic weighing method based on the long-gauge fiber grating sensing technology and a bridge dynamic weighing system thereof. The dynamic weighing method comprises the steps that long-gauge sensors are arranged: the long-gauge sensors are arranged on the initial entering and final exiting side span units of a vehicle and the part between the two side span units along the length direction of the bridge; load condition monitoring of a vehicle to be identified and load condition monitoring of a standard vehicle are performed: the vehicle of which various parameters are known acts as the standard vehicle, the strain response data of each sensing unit under the load condition of the standard vehicle are acquired, and the maximum strain of each sensing unit only caused by the axle load is calculated; and vehicle load identification under the load condition of the vehicle to be identified is performed. The maximum bending strain value only caused by the axle load under the load condition of the standard vehicle is analyzed and compared with the corresponding value under the load condition of the standard value so that the total weight of the driving load on the bridge and the load of each vehicle can be identified, the overload vehicle can be effectively pre-warned and thus damage to the big long-span bridges can be avoided.

Owner:SOUTHEAST UNIV

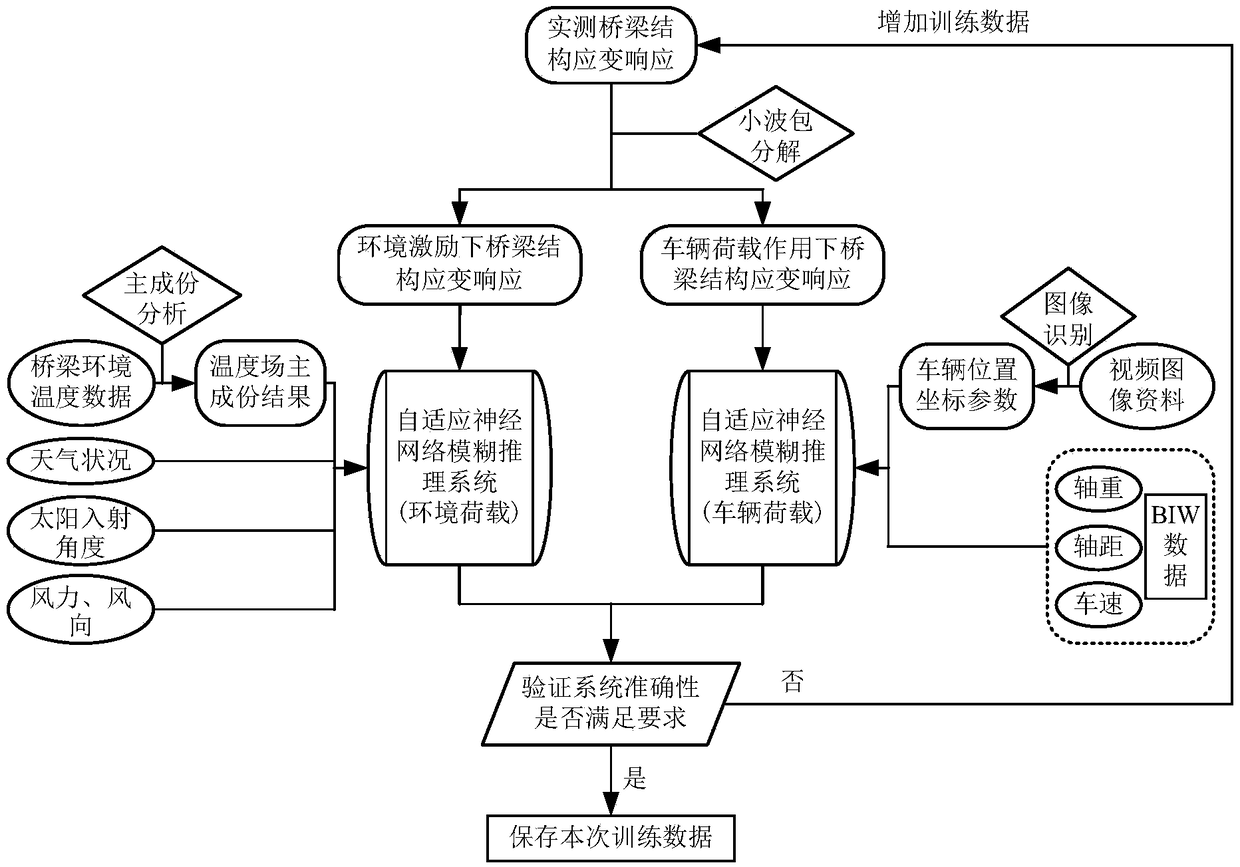

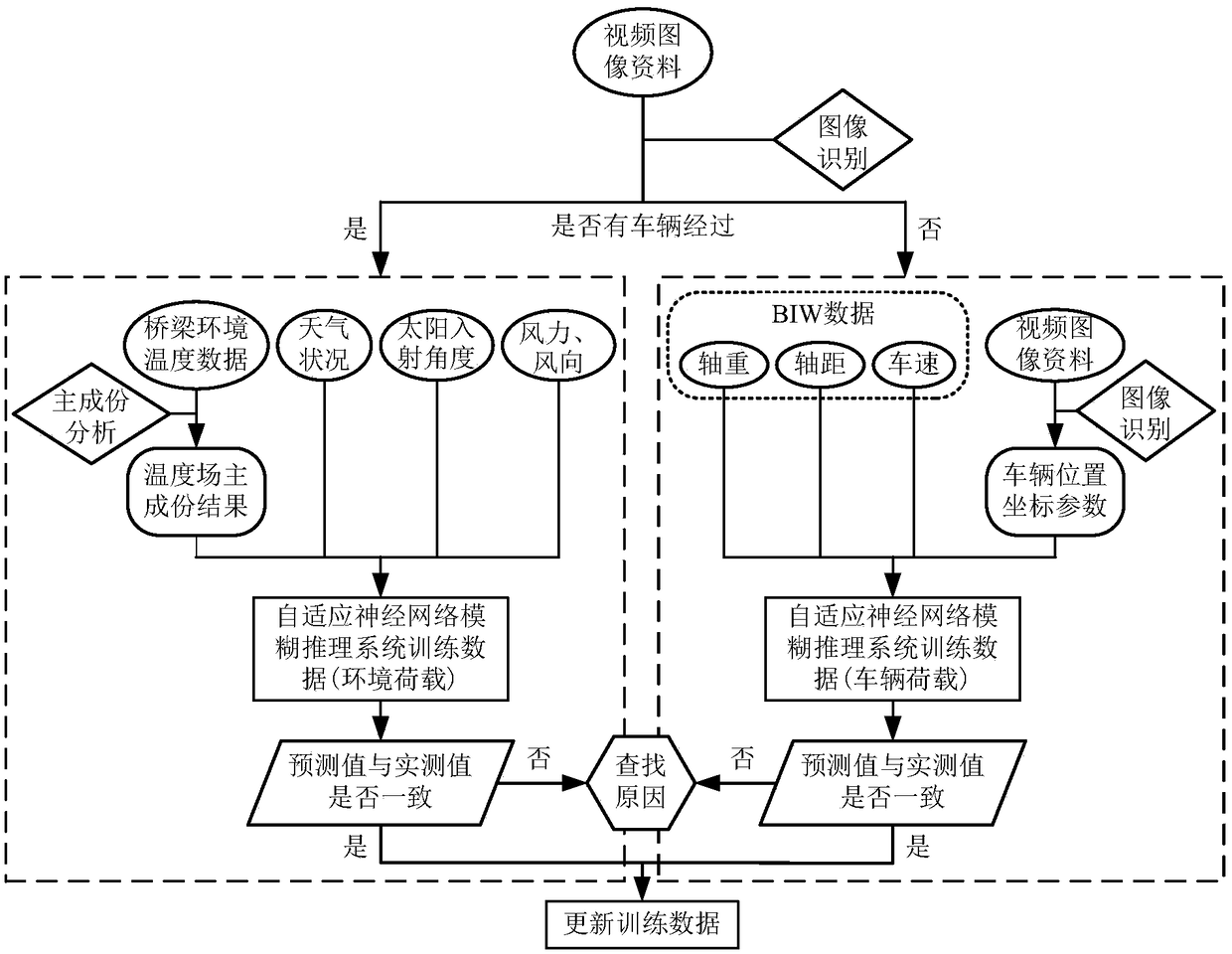

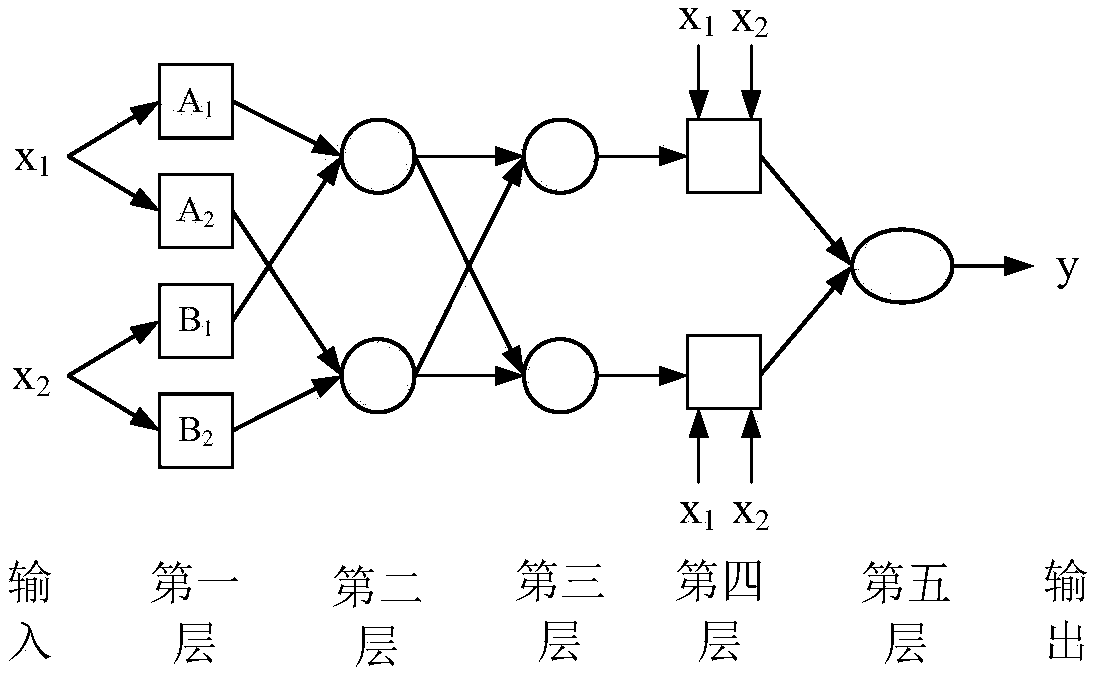

Early warning method for bridge structure strain response exception

ActiveCN108763763ASmall amount of calculationImprove forecasting efficiencyGeometric CADDesign optimisation/simulationKernel principal component analysisAlgorithm

The invention discloses an early warning method for a bridge structure strain response exception. The method comprises the following steps that: utilizing a wavelet packet decomposition method to separate a bridge structure strain response; (2) utilizing a principal component analysis method to extract the principal component of a bridge ambient temperature field; (3) on the basis of an adaptive neural network fuzzy inference system, establishing a complex nonlinear relationship between an actual measurement load factor and corresponding strain data; (4) identifying the position information ofa vehicle on a bridge; (5) identifying the geometric parameter and the axle load of the vehicle; (6) on the basis of the adaptive neural network fuzzy inference system, establishing a complex nonlinear relationship between an actual measurement vehicle load parameter and corresponding strain data; (7) solving a bridge structure strain response theoretical value; and (8) comparing a theoretical solving result of the bridge structure strain response and the actual measurement result of the theoretical solving result, and updating the adaptive neural network fuzzy inference system. By use of themethod, effectively according to the actual measurement load parameter, the bridge structure strain response can be accurately predicted.

Owner:SOUTHEAST UNIV

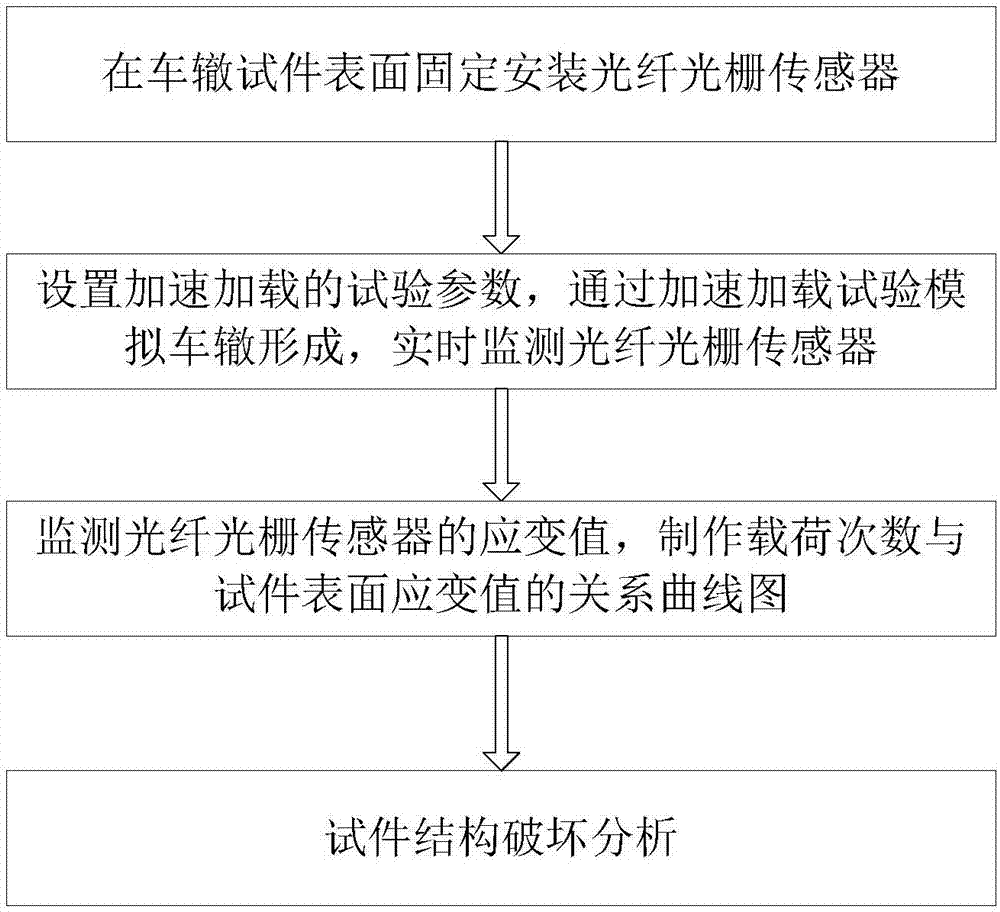

Method of detecting asphalt pavement structure damage based on fiber grating sensors

ActiveCN106894316AExtended service lifeReduce consumptionMaterial strength using tensile/compressive forcesUsing optical meansFiberGrating

The invention discloses a method of detecting the asphalt pavement structure damage based on fiber grating sensors. The method comprises the following steps: 1) fixedly installing one or more fiber grating sensors on the surface of a rut sample; 2) setting test parameters for accelerating loading, simulating the formation of a rut trough accelerating loading tests and monitoring the fiber grating sensors in real time; 3) monitor strain values of the fiber grating sensors and making the relation curve graph between the number of load and the surface strain values of the sample; and 4) performing the sample structure damage analysis, that is, analyzing the deformation and damage degree of the sample through the surface strain values. The method for detecting the asphalt pavement structure damage is simple in operation and high in feasibility, and is of great theoretical significance on the design and maintenance of pavement structures. The surface fiber grating strain sensors are adopted to monitor the asphalt pavement strain response. The process is simple, implementation is easy, and recycling is realized.

Owner:WUHAN UNIV OF TECH

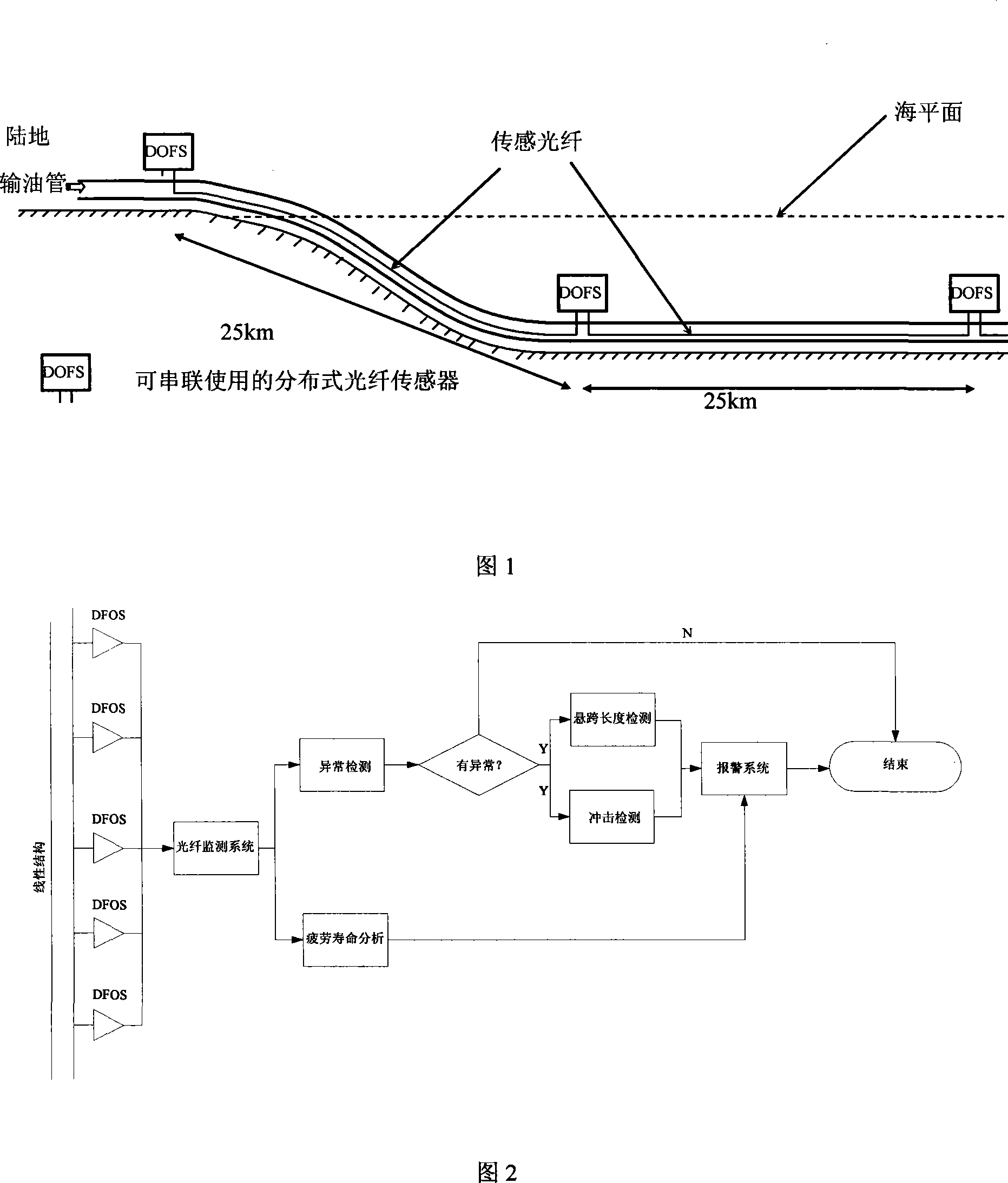

Method for detecting long-distance linear organization abnormal vibration based on distributed optical fibre sensor

InactiveCN101226078ASubsonic/sonic/ultrasonic wave measurementStructural/machines measurementEngineeringAnalysis method

The invention is characterized in that: Brillouin distribution type optical fiber sensor is arranged on linear structure, and the strain signal of optical fiber is detected, and then the strain signal is calibrated so as to obtain linear structural strain curve, moreover by adopting mode identification method based on time sequence analysis method, data processing is made, so as to extract abnormal data in the linear structure strain time sequence and judge the state of linear structure. EMD method is adopted to extract potential simulation component in linear structure span random strain response, random decrement method RDT is applied to extract self-vibration frequency of each stage from the linear structure span random strain response, according to the self-vibration frequency experimental formula given by related standard, the span length of linear structure is calculated. The invention adopts the multi-shaft fatigue strain life model (Shangdeguang model) based on rain flow count method to predict fatigue life of linear structure.

Owner:GUANGSHA CONSTR GROUP +1

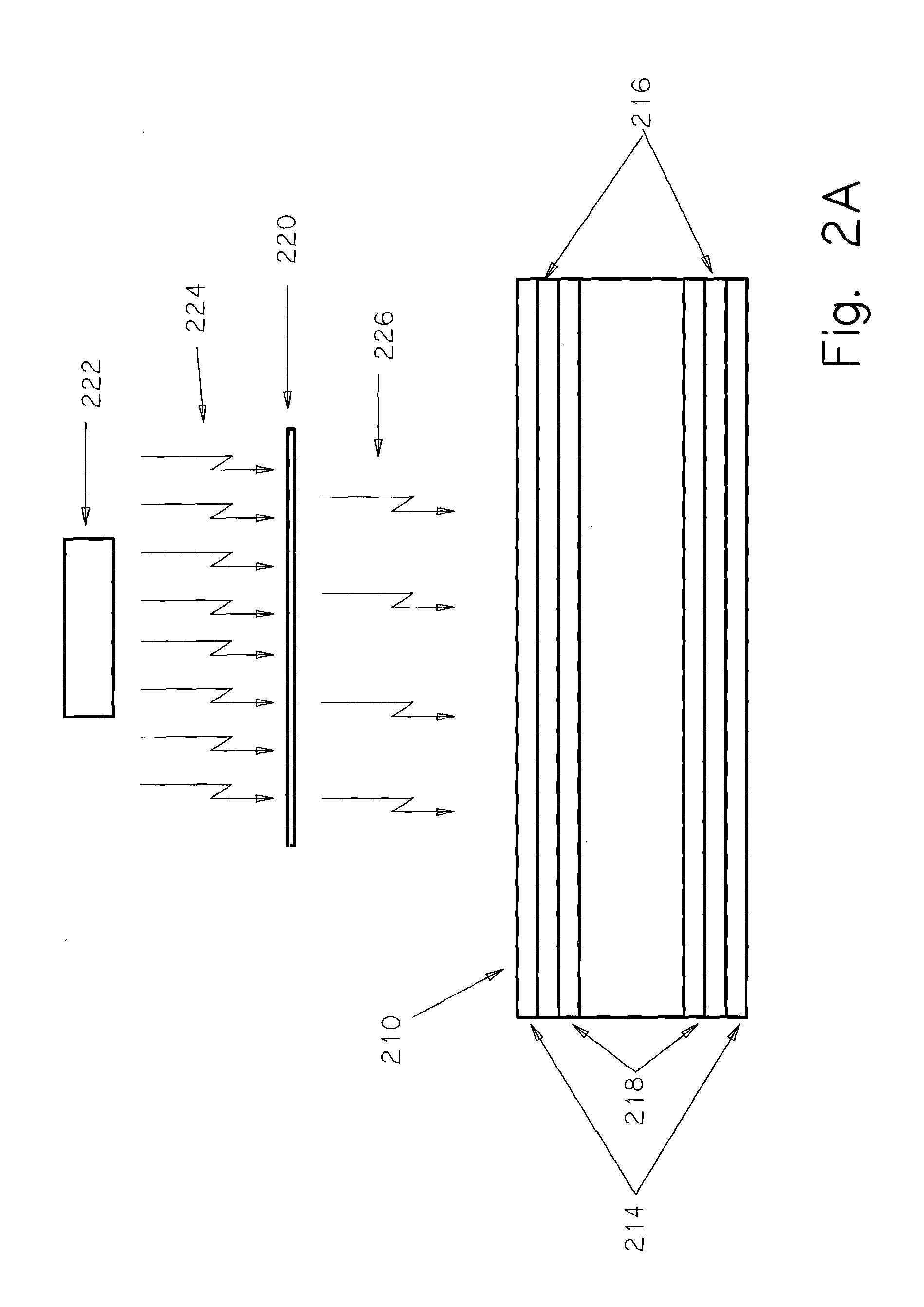

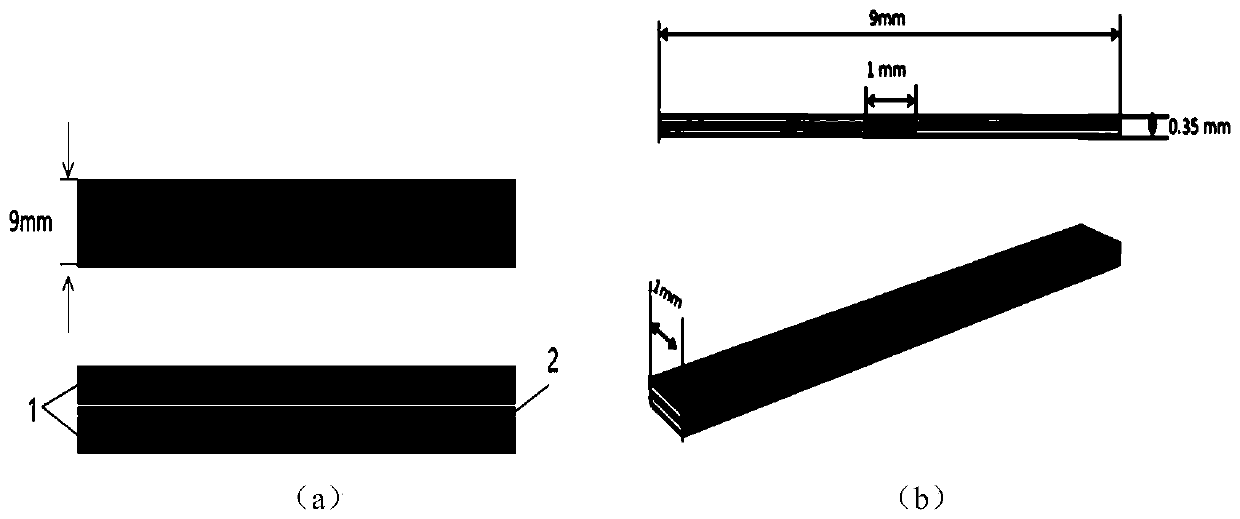

Optical strain gauge

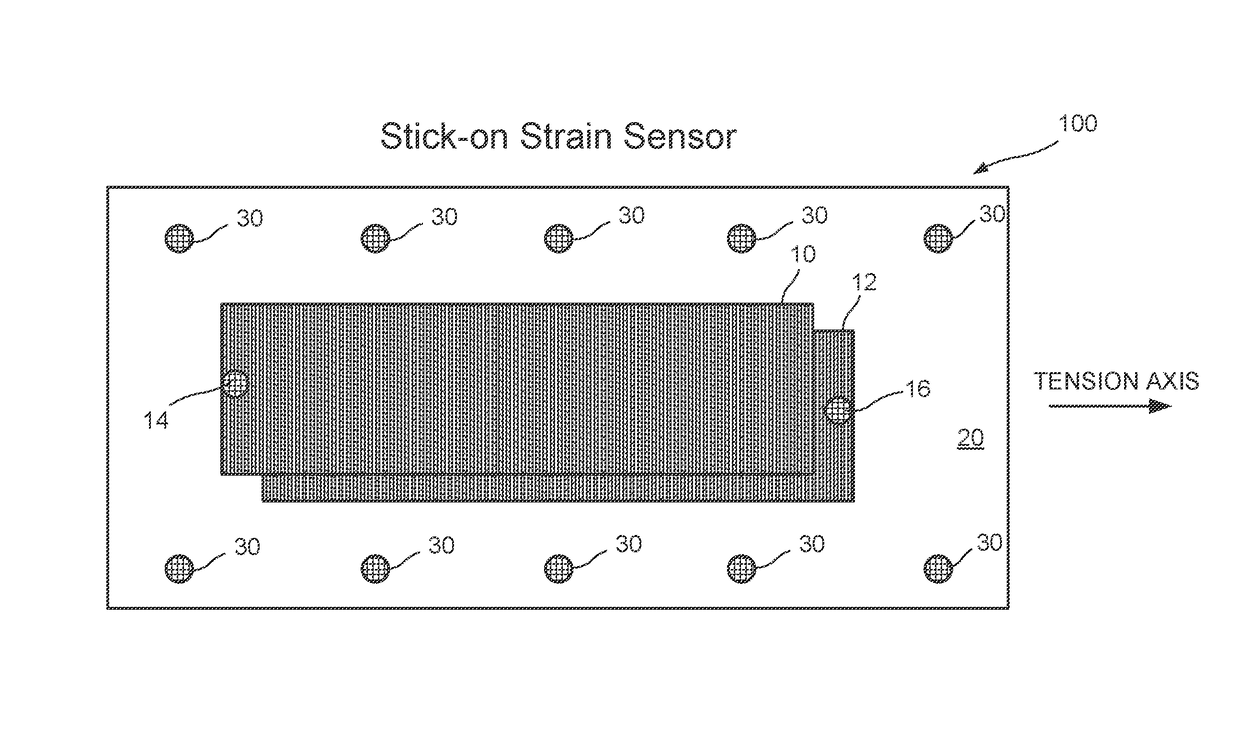

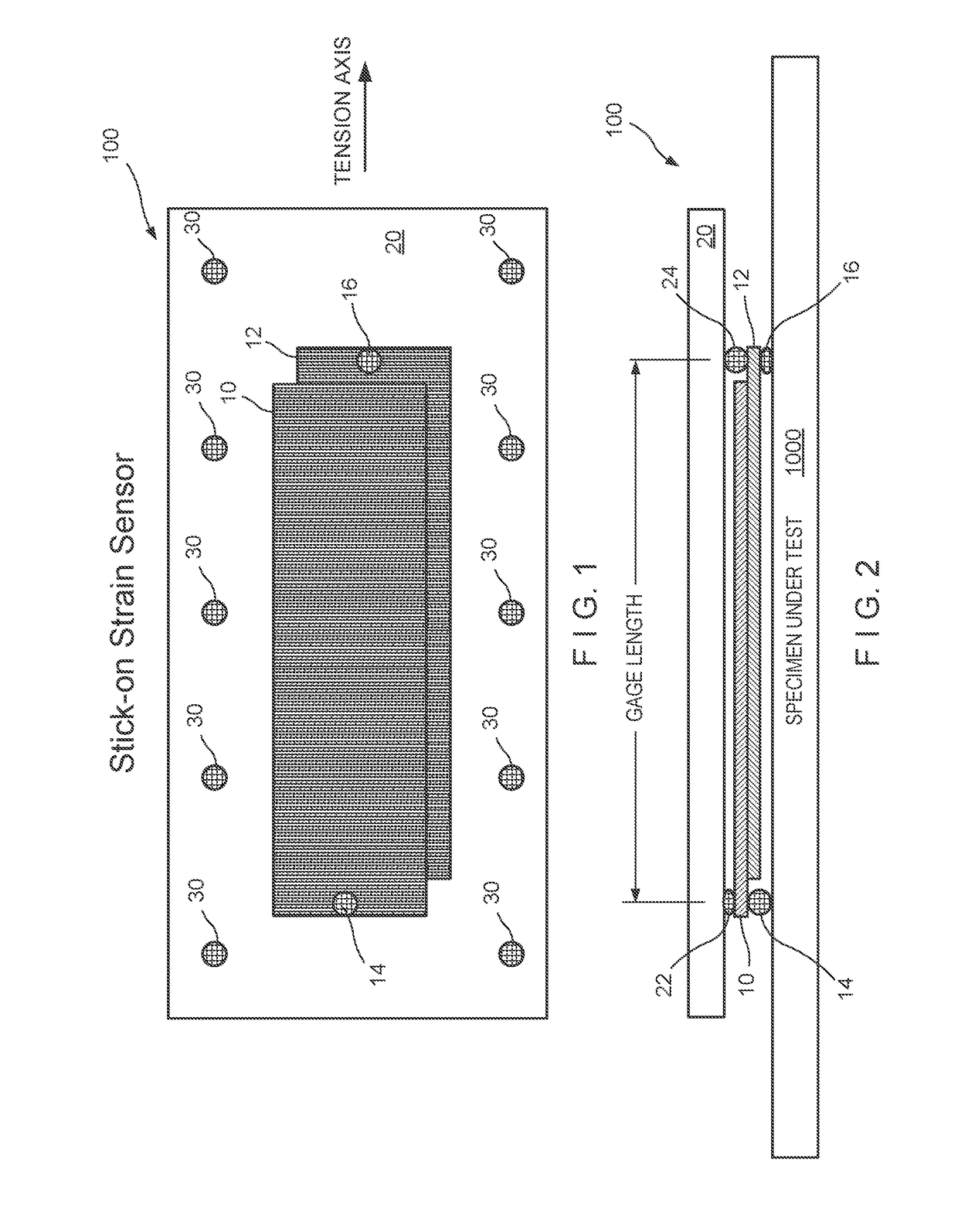

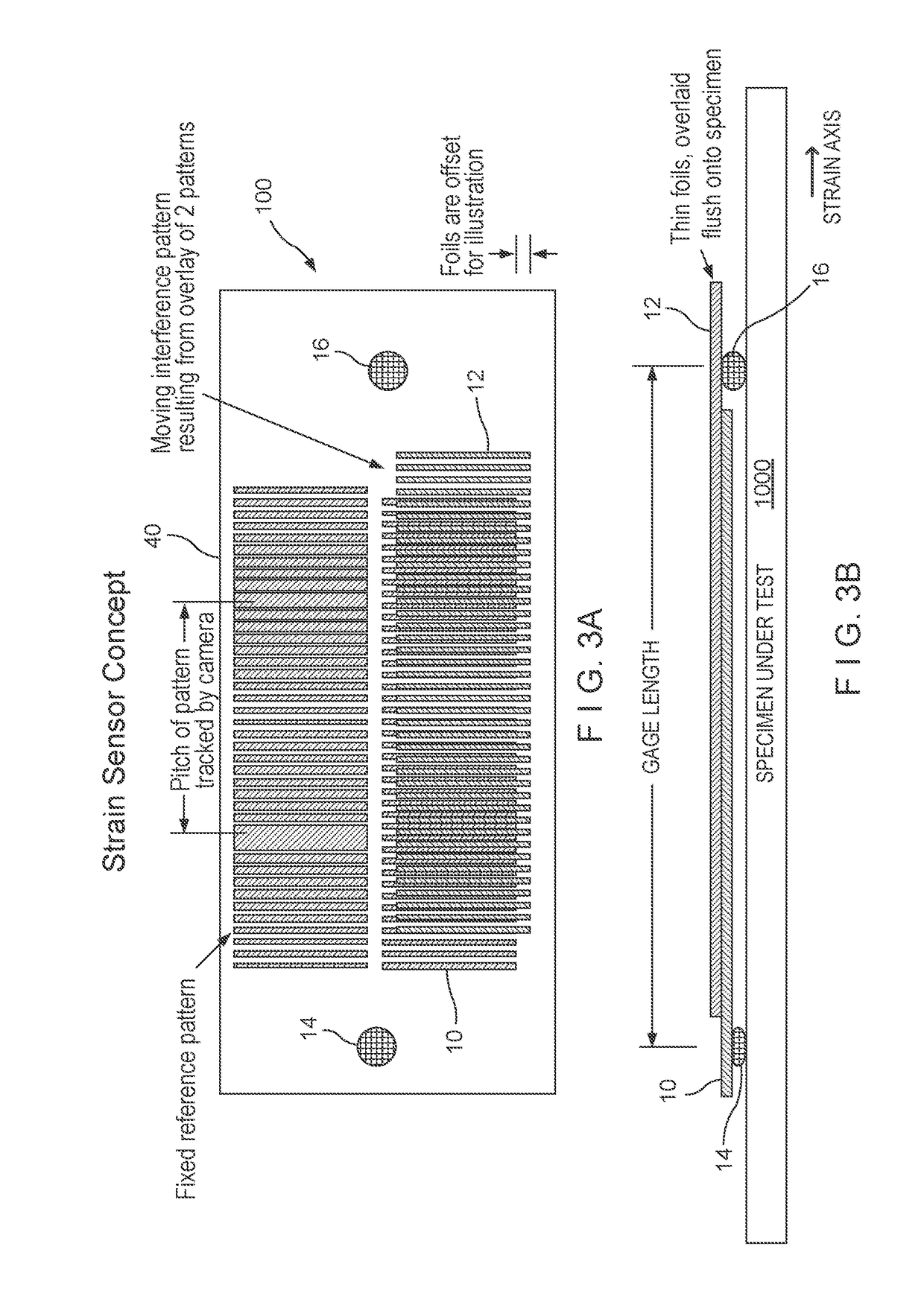

This disclosure presents a method of measuring the strain response of a test material remotely by optical devices using a thin multi-layer assembly, called an optical strain gauge, which is attached directly to the test specimen by pair of adhesive patches built into the assembly. The optical strain gauge assembly attaches quickly and easily by just pressing it onto the specimen by virtue of the two pressure-activated adhesive patches. There is typically no surface preparation necessary for the test specimen. The spatial separation between the two patches adhered to the specimen surface serves to establish an initial gauge length for calculating strain by measuring the stress induced changes to this separation when a load is applied to the test specimen.

Owner:ILLINOIS TOOL WORKS INC

Dual Fiber Grating and Methods of Making and Using Same

A multiple-layer fiber-optic sensor is described with dual Bragg gratings in layers of different materials, so that the known temperature and strain response properties of each material may be utilized to simultaneously correct the sensor output for temperature and strain effects.

Owner:BAKER HUGHES INC

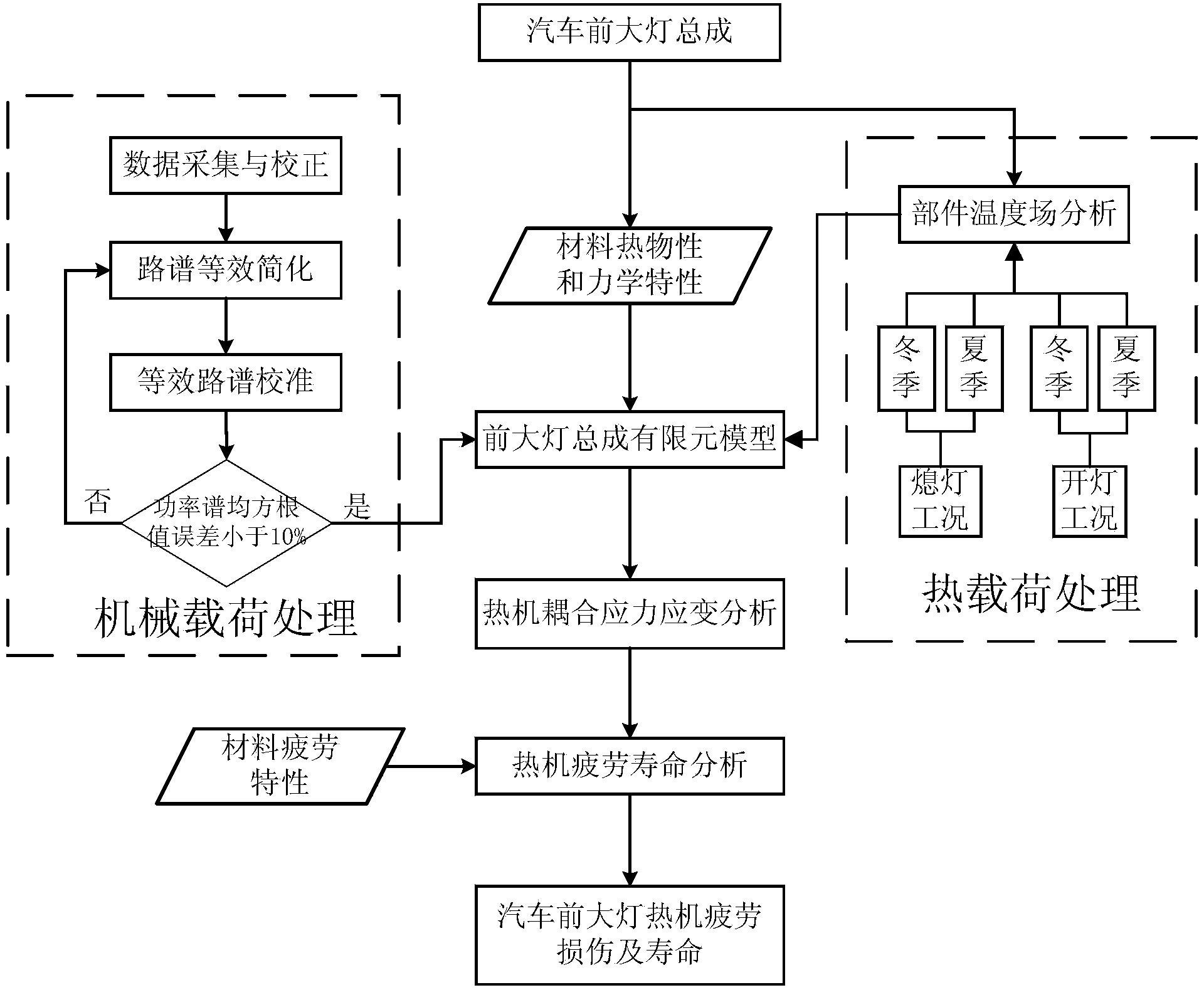

Automobile headlamp structure fatigue life analysis method

ActiveCN104296974ALow costShorten the development cycleOptical apparatus testingStructural fatigueElement model

The invention discloses an automobile headlamp structure fatigue life analysis method. The method comprises the steps that 1a, road spectrum data are collected and corrected; 1b, corrected road spectrums are simplified and calibrated; 2, environment temperatures in winter and summer are simulated respectively, and internal temperatures on the turn-on condition and the turn-off condition of a headlamp are simulated to obtain headlamp temperature field data on four conditions; the time scale between turn-on condition and turn-off condition of the headlamp is determined according to a market survey result, and temperature field combination data are established; 3, a headlamp assembly finite element model is established, thermo-physical properties and mechanical properties of all parts are input into the headlamp assembly finite element model, contact relations and assembly relations between all structures are defined, the temperature field combination data are imported, road spectrum simulation is applied, the thermo-mechanical coupling stress strain response of an automobile headlamp assembly structure within one cycle is calculated, and the thermo-mechanical fatigue life of the headlamp is calculated through fatigue analysis software. By means of the method, the fatigue life of the headlamp can be predicted at the design stage.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

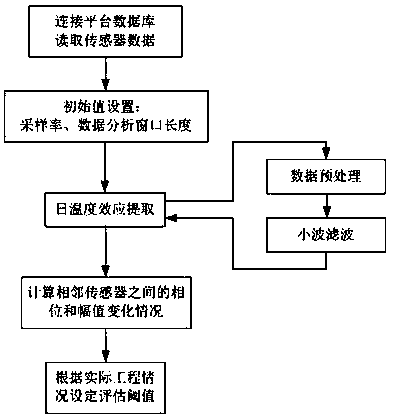

Bridge damage online monitoring method based on daily temperature effect

ActiveCN108444662AEasy to collectEasy to handleElasticity measurementTemperature responsePhase difference

The invention discloses a bridge damage online monitoring method based on a daily temperature effect. The method includes the following steps: processing strain measurement data of a bridge online monitoring system to obtain a daily temperature strain response; and calculating phase differences of daily temperature responses among different sensors, and judging damage positions and the damage degree of a bridge according to amplitude changes of the daily temperature responses. According to the invention, day temperature is used as a forced excitation source, that is to say, the bridge floor issubjected to expand with heat and contract with cold under the effect of the daily temperature, and since a daily temperature change period is slow, the sampling frequency of the monitoring system can be greatly reduced and therefore the software and hardware cost of the system is reduced. In addition, and damage is judged through the phase differences of the daily temperature responses, therebyeffectively overcoming the defect that the measuring range of a strain sensor is limited and improving the accuracy of damage judgment. Based on the above two characteristics, the method is close to engineering and is quite suitable for being applied to an online bridge detection system.

Owner:SHANXI HEXINJIYE TECH

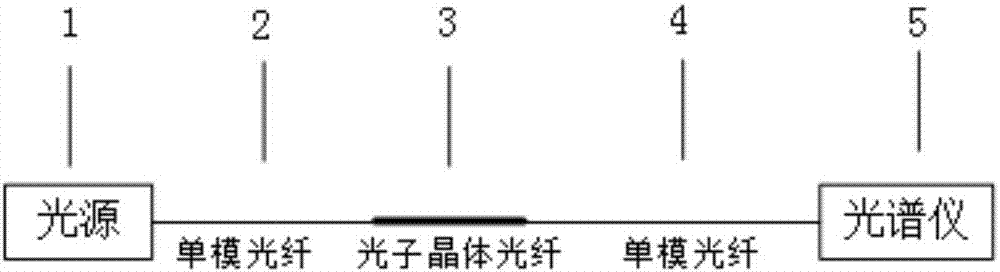

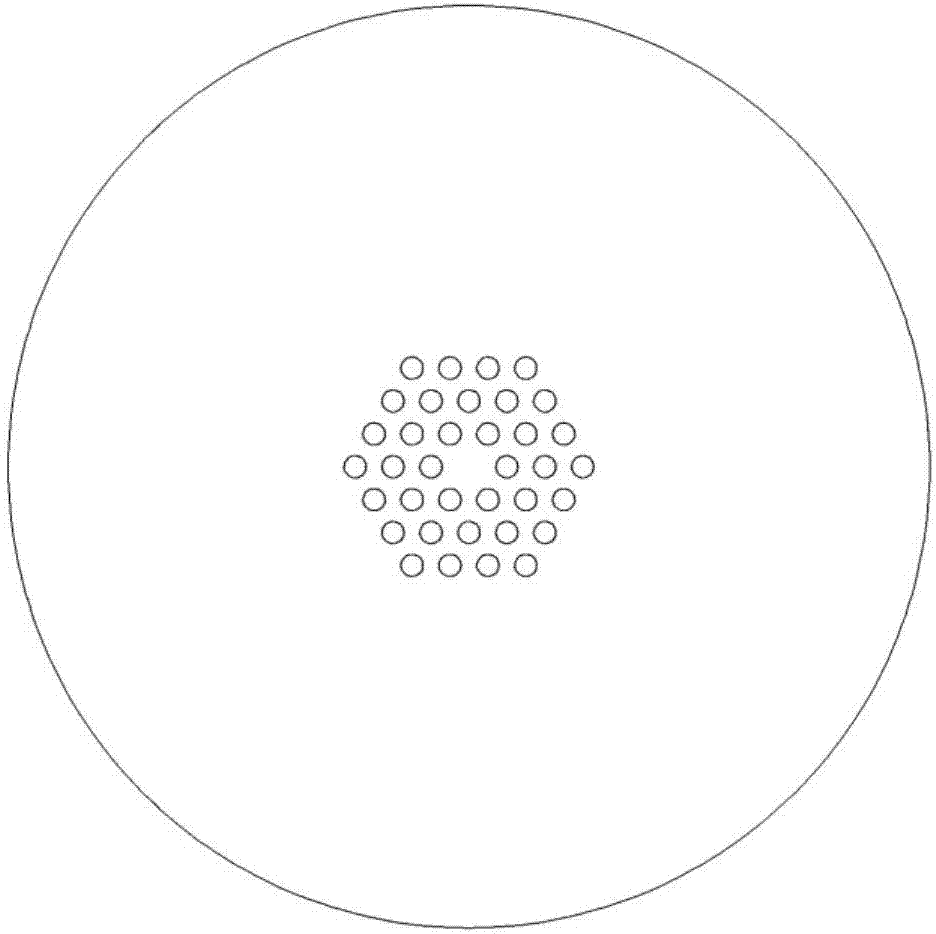

Temperature and strain sensing system and measurement method thereof

ActiveCN107270949ASensitivity measurement is accurateConverting sensor output opticallySpectrographEngineering

The invention discloses a temperature and strain sensing system and a measurement method thereof. A broadband light source, an input single-mode optical fiber, a photonic crystal fiber, an output single-mode fiber and a spectrograph are connected sequentially, wherein the photonic crystal fiber supports a basic mode and a high-order mode. The system can measure the temperature and strain at the same time through the interference between the fiber core basic mode and the fiber core high-order mode. The system employs the Fourier transform, and selects a specific stable mode to carry out the inverse Fourier transform through programming, thereby obtaining the temperature and strain response transmission spectrum in different modes. The system combines with a sensitivity matrix, selects the same peak or valley, measures the drift quantities under different temperatures and strains and obtains the temperature and strain response curve of a sensor.

Owner:WUHAN UNIV OF TECH

A method for predicting the fatigue life of a bonding layer of a bonding structure under high-temperature and low-temperature cold and hot circulation conditions

InactiveCN109766624AGuaranteed reliabilityImprove test efficiencySpecial data processing applicationsElement modelElement analysis

The invention discloses a method for testing the fatigue life of a bonding layer of a bonding structure under high-temperature and low-temperature cold and hot circulation conditions. The method is characterized by establishing a finite element thermal analysis model of a bonding layer of a bonding structure by utilizing a finite element analysis method; and simulating and calculating the strain response of the bonding layer in the cold and hot circulation process within the temperature interval of-120 DEG C to 120 DEG C, obtaining the maximum strain under the cold and hot circulation condition through an in-situ strain test, and verifying the finite element model result of the bonding layer. On the basis of the finite element analysis and the in-situ test results, the maximum thermal stress of the bonding layer of the bonding structure in a given temperature range is determined, so that the temperature load of the test piece in the cold and hot circulation process is converted into the mechanical stress load. And finally, through a fatigue performance test under an equivalent mechanical load, the fatigue life of the structural part bonding layer under high and low temperature coldand hot circulation is predicted quickly with low cost and high accuracy.

Owner:BEIHANG UNIV

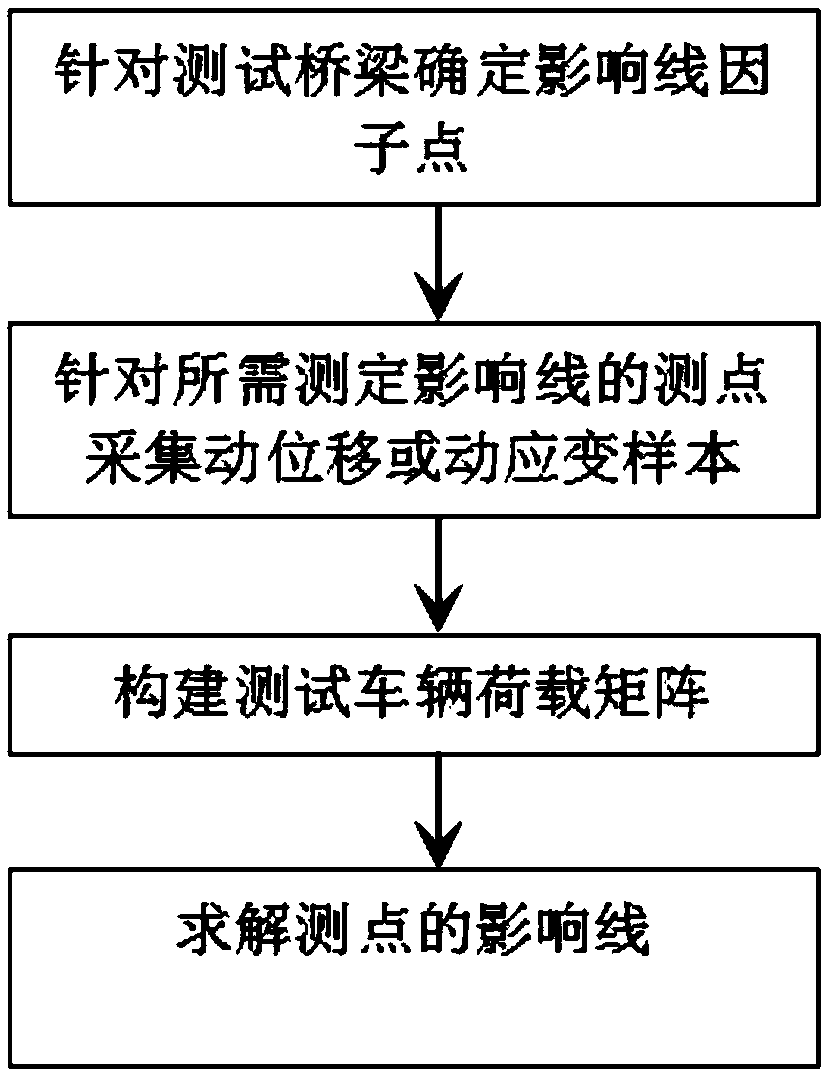

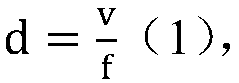

Method for measuring bridge influence line in uniform-speed passing of vehicle

The invention discloses a method for measuring a bridge influence line in uniform-speed passing of a vehicle. Firstly, according to the passing speed of a tested vehicle and sampling frequency of a sensor, influence line factor points of the tested bridge are determined. Then, dynamic displacement or dynamic strain response is acquired for aiming at the measuring point of the to-be-measured influence line. Finally, a vehicle load matrix is constructed and the bridge influence line is solved. The method settles a problem of incapability of realizing well-posed state in a bridge influence line solving equation, thereby obtaining a more accurate bridge influence line.

Owner:NANJING SOUTHEAST BUILD ELECTROMECHANICAL SEISMIC RES INST

Method for dynamically recognizing overweight vehicle in bridge monitoring system

ActiveCN107766877AReduce operating costsThe identification principle is simple and efficientDetection of traffic movementCharacter and pattern recognitionFeature vectorSupport vector machine

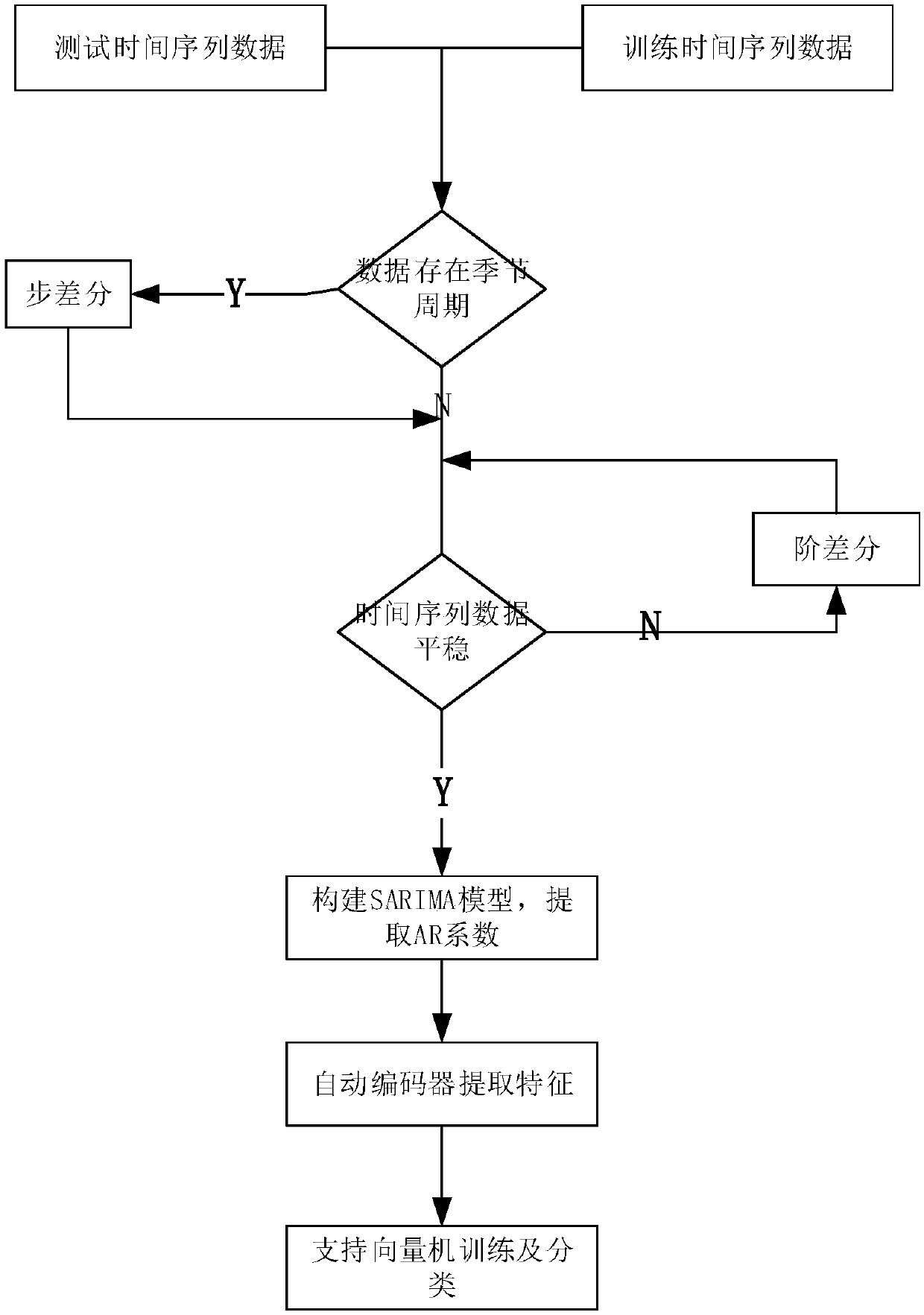

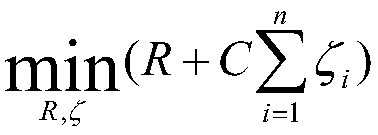

The invention discloses a method for dynamically recognizing an overweight vehicle in a bridge monitoring system. The method comprises the steps of 1) ensuring a strain response time sequence to be astationary sequence and if not, transforming time sequence data into a stationary time sequence through step difference and order difference; 2) modeling the time sequence data using an SARIMA model,taking an AR coefficient of the model as a key feature to identify an abnormality, and then connecting the coefficients of different sensors in the same section in series to obtain a feature vector; 3) inputting the AR coefficient feature vector into a noise reduction automatic encoder for training, after the training is completed, obtaining a middle layer dimension in a network structure of the automatic encoder, that is, the required key feature, and taking the middle layer dimension as a final training feature; and 4) inputting the training feature into a one-class support vector machine with a kernel function for unsupervised training, with a training result being a hypersphere in a high-dimensional space, and then, using the hypersphere to determine whether the test data is overweightabnormal data. The method in the invention is simple and efficient in identification principle and has strong robustness.

Owner:SOUTH CHINA UNIV OF TECH

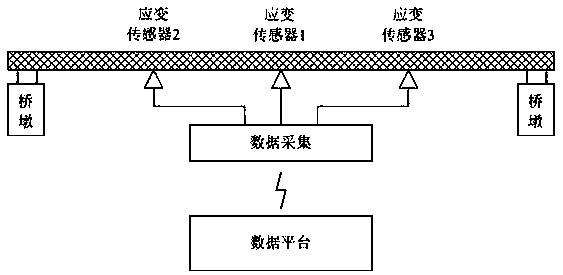

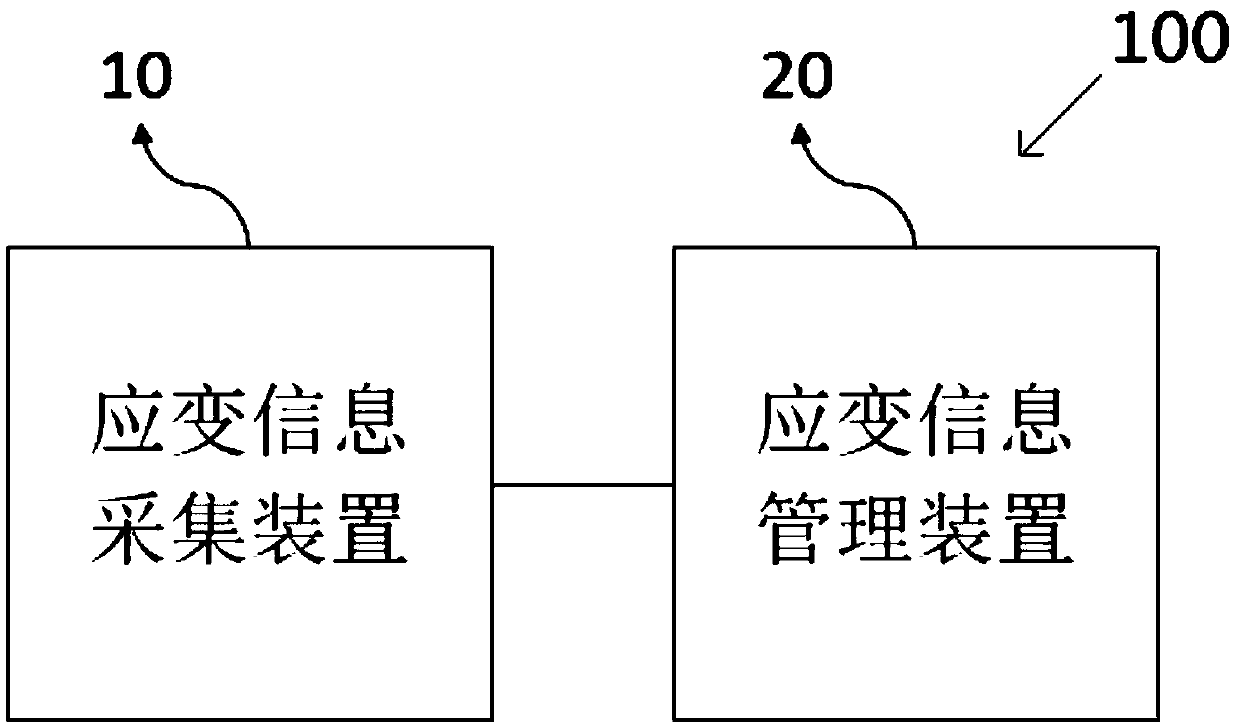

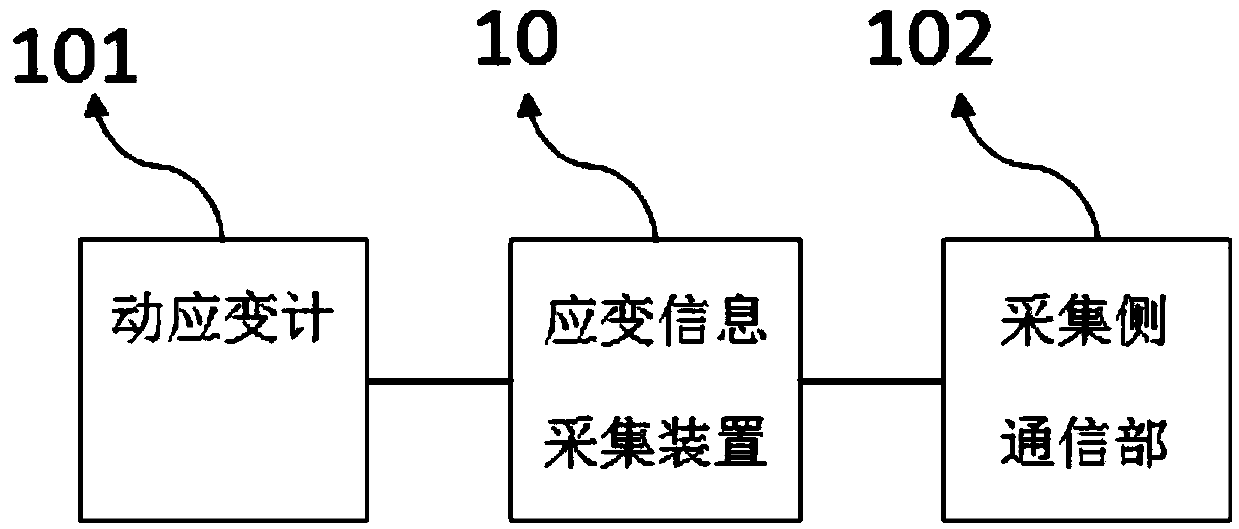

A beam bridge safety monitoring and evaluating device

ActiveCN109684774ALong-term evaluation programStability Assessment ProgramGeometric CADMeasurement devicesInformation processingEngineering

The invention provides a beam bridge safety monitoring and evaluation system, which is used for monitoring dynamic strain information on a plurality of monitoring sections of a bridge and evaluating whether the structure of the bridge is safe or not, and is characterized by comprising a strain information acquisition device havingdynamic strain gauge for acquiring the dynamic strain information; astrain information acquisition device which comprises an acquisition side communication part used for sending dynamic strain information to the strain information management device, and the strain information management device comprises a strain information processing part used for obtaining a strain response curve of the dynamic strain information; A threshold value storage unit in which a threshold value interval is stored; The response amplitude acquisition part is used for acquiring the strain response amplitude of the acquisition channel; The strain distribution calculation part is usedfor calculating to obtain strain distribution on the monitored cross section; The safety index calculation part is used for calculating a neutral axis index; And the structure safety judgment part isused for judging whether the structure of the bridge is safe.

Owner:TONGJI UNIV

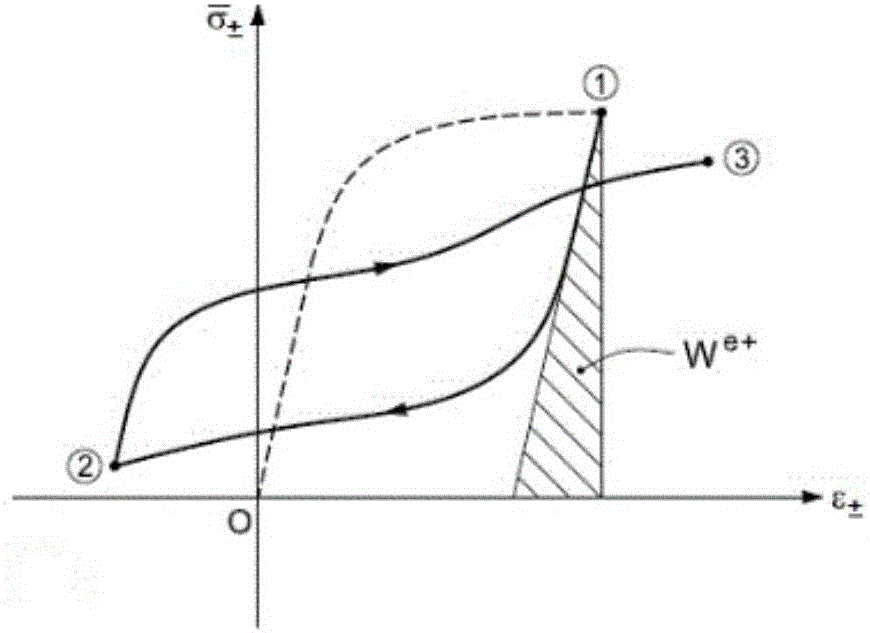

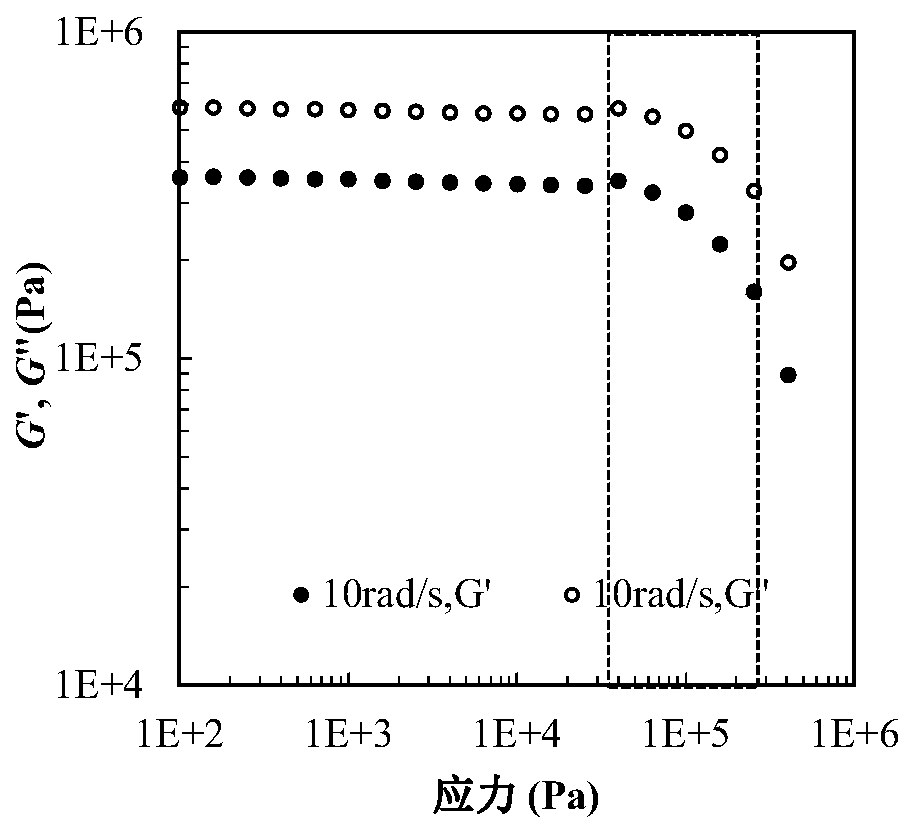

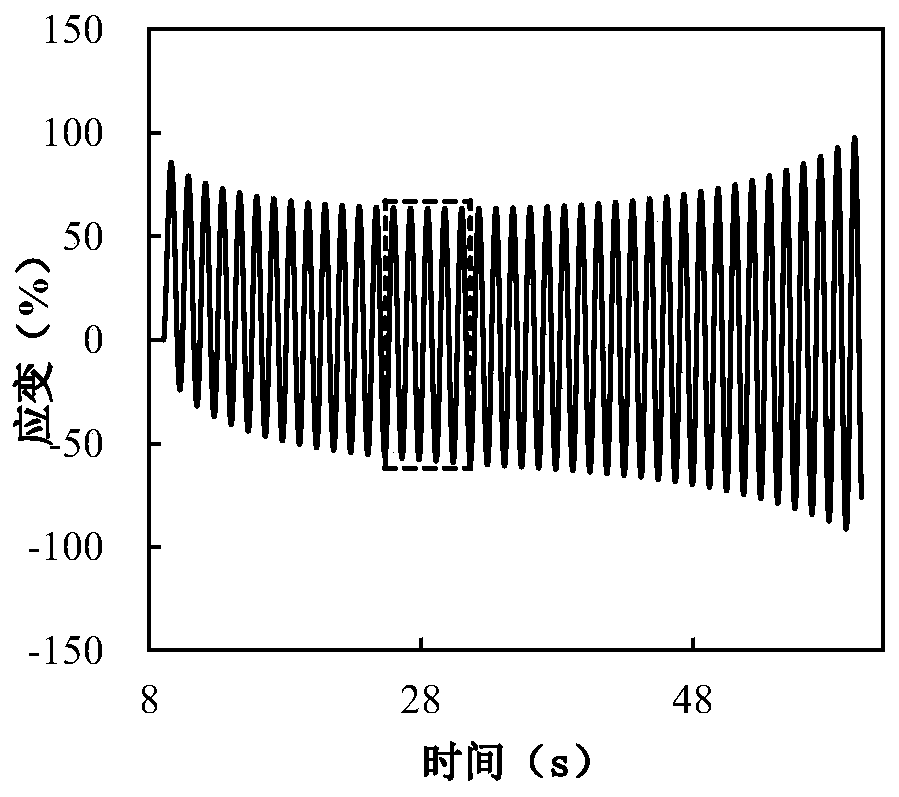

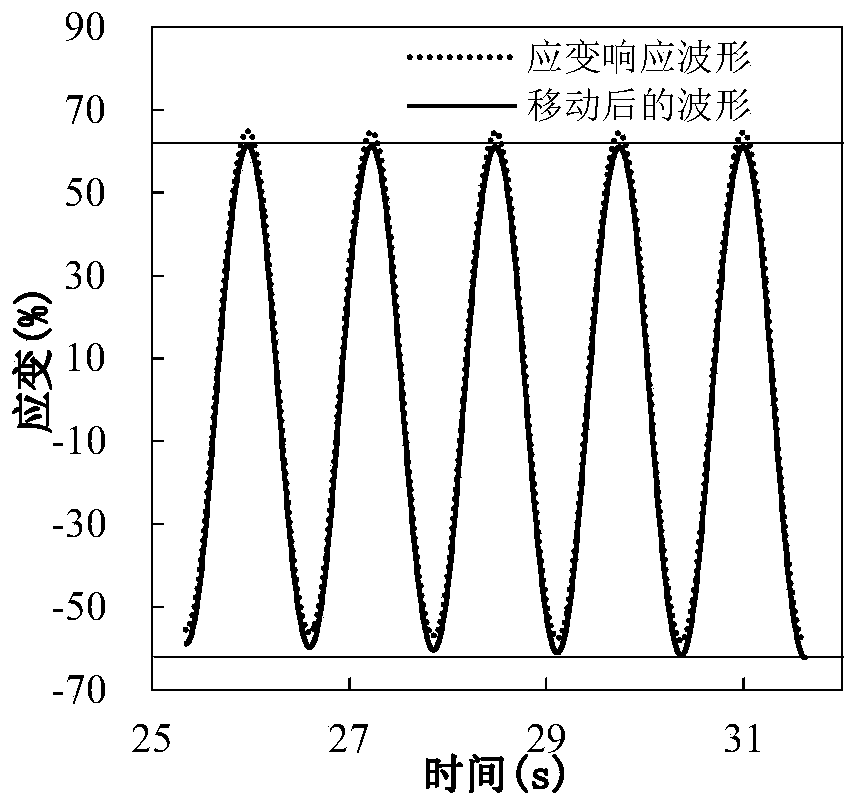

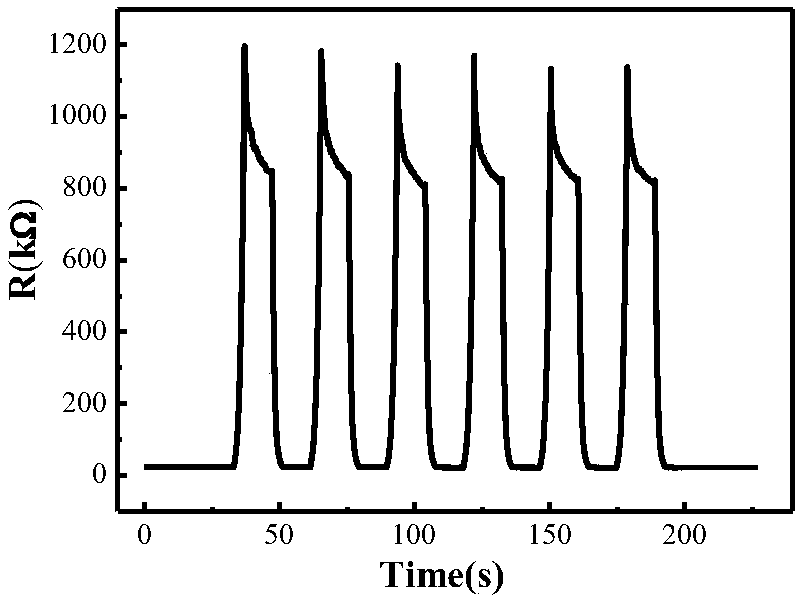

Method for testing nonlinear rheological property of asphalt by Large amplitude oscillatory shear stress

InactiveCN110186810ANonlinear rheological properties facilitate analysisFlow propertiesEngineeringOscillatory shear

The invention provides a method for testing nonlinear rheological property of asphalt by Large amplitude oscillatory shear stress (LAOS stress), belonging to the field of asphalt rheological propertytesting methods. The method comprises the steps of: utilizing a rheometer to perform stress scanning test for asphalt to determine the nonlinear rheological region of the asphalt; selecting a stress level of a time scanning test in a non-linear region; performing the time scanning test, and selecting a stable strain response waveform period for test analysis; preprocessing the strain response waveform to enable the absolute value of the wave crest to be equal to the absolute value of the wave trough; and finally, obtaining a change rule of parameters reflecting the nonlinear rheological behavior of the asphalt by utilizing the preprocessed waveform data. The method for testing nonlinear rheological property of asphalt by Large amplitude oscillatory shear stress facilitates analysis of thenonlinear rheological property of the asphalt and opens up a new way to accurately represent the complex viscoelastic mechanical behavior of the asphalt under the conditions of high temperature and large stress.

Owner:HARBIN INST OF TECH

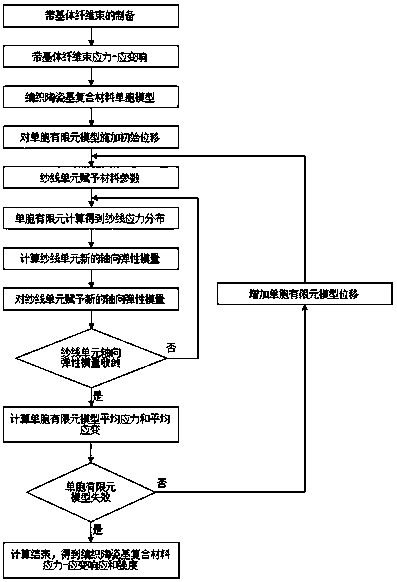

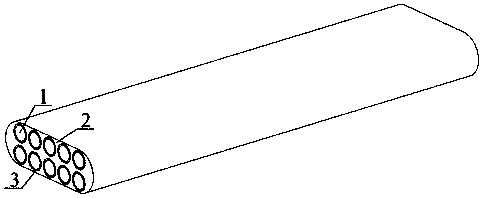

Prediction method for stress-strain response and strength of braided ceramic matrix composite

ActiveCN109858171AImprove accuracyEliminate the component material performance test testSpecial data processing applicationsDispersityYarn

The invention discloses a prediction method for stress-strain response and strength of braided ceramic matrix composite. The method is characterized by comprising the following steps: preparing a beltmatrix fiber bundle with the same in-situ performance as woven CMCs, establishing a unit cell finite element model for the belt matrix fiber bundle, and performing finite element calculation on the unit cell finite element model to obtain the stress-strain response with matrix fiber bundles, and the maximum value of stress on stress-strain curve is strength of woven CMCs.. According to the prediction method for stress-strain response and strength of braided ceramic matrix composite, mechanical properties of fibers, a matrix and a fiber / matrix interface do not need to be used as input quantities; only the mechanical property of the yarn needs to be measured, a large number of component material performance test experiments can be omitted, prediction errors caused by component material performance test dispersity can be avoided, and therefore the efficiency of the prediction process and the accuracy of the prediction result can be greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

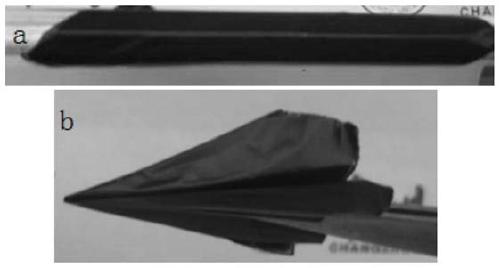

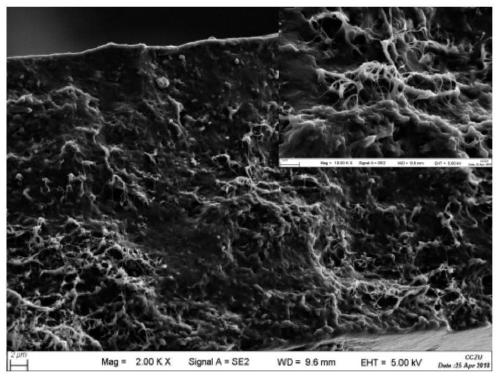

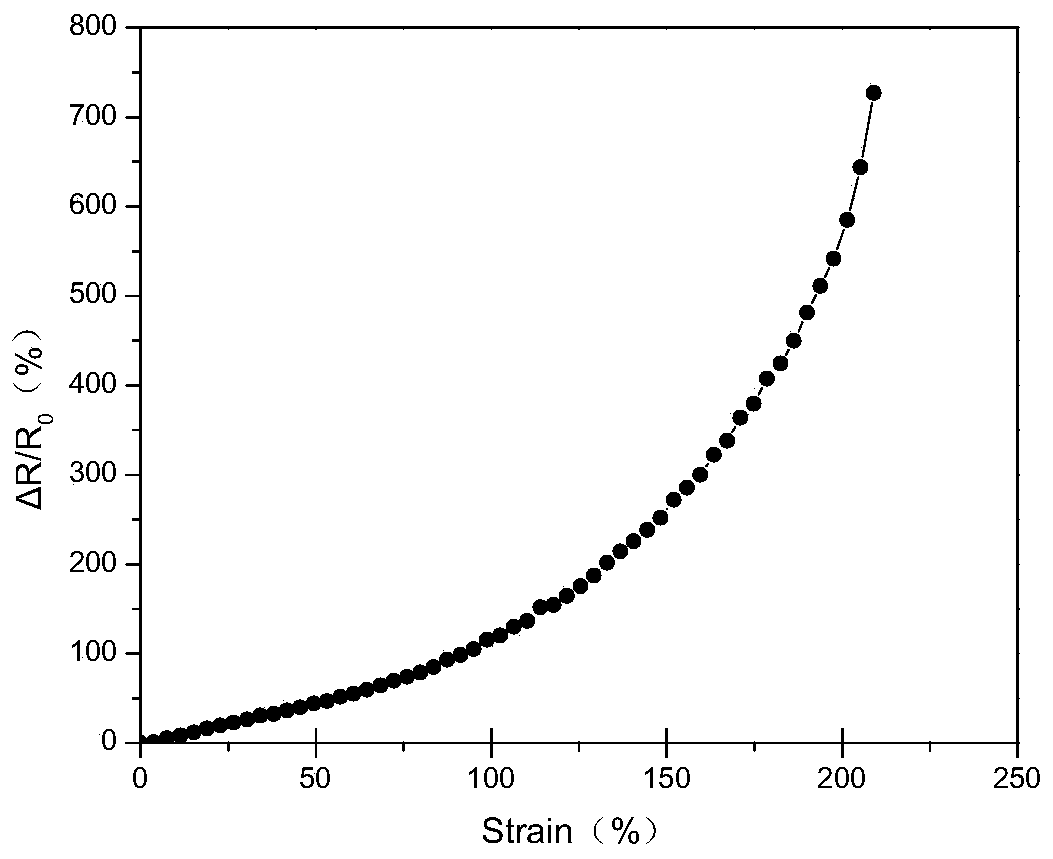

Preparation method of high-conductivity tensile strain response material

The invention discloses a preparation method of a high-conductivity tensile strain response material, and belongs to the technical field of semiconductor sensor materials. The preparation method comprises steps as follows: firstly, a CNT(carbon nano tube) / graphene hybrid material is prepared, then CNT / graphene is uniformly dispersed in a solution of a high polymer material by a homogenizer throughultrasonic oscillation, and finally, a CNT@graphene / polymeric nanocomposite, namely, the high-conductivity tensile strain response material, can be prepared with a solution pouring film formation ordip-coating method. The prepared material has high conductivity, better flexibility and good strain response capacity. The preparation method is simple, low in cost and high in applicability, can be applied to large-scale production and can be widely applied in industries such as smart skin, pressure-sensitive sensors and the like.

Owner:CHANGZHOU UNIV

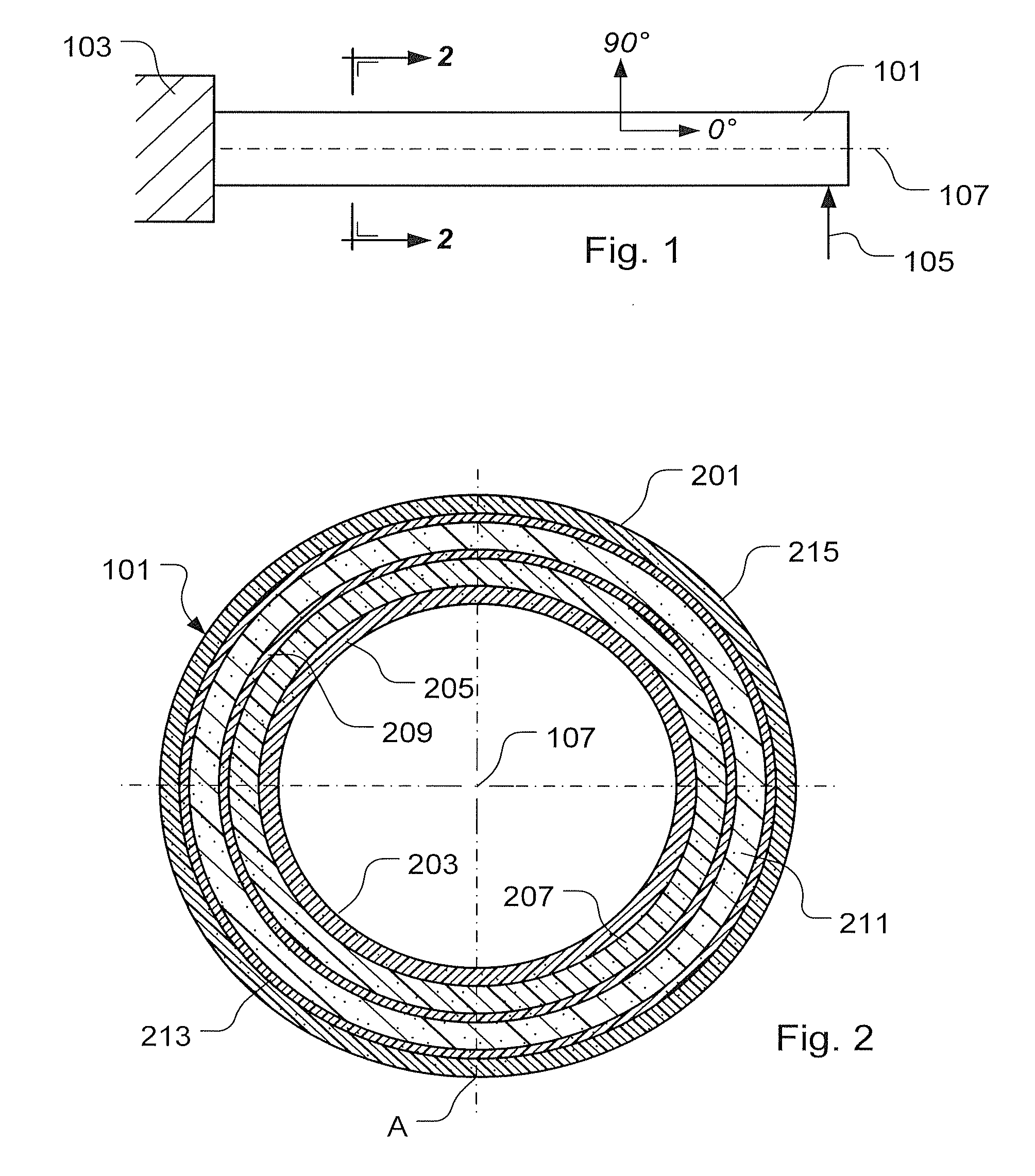

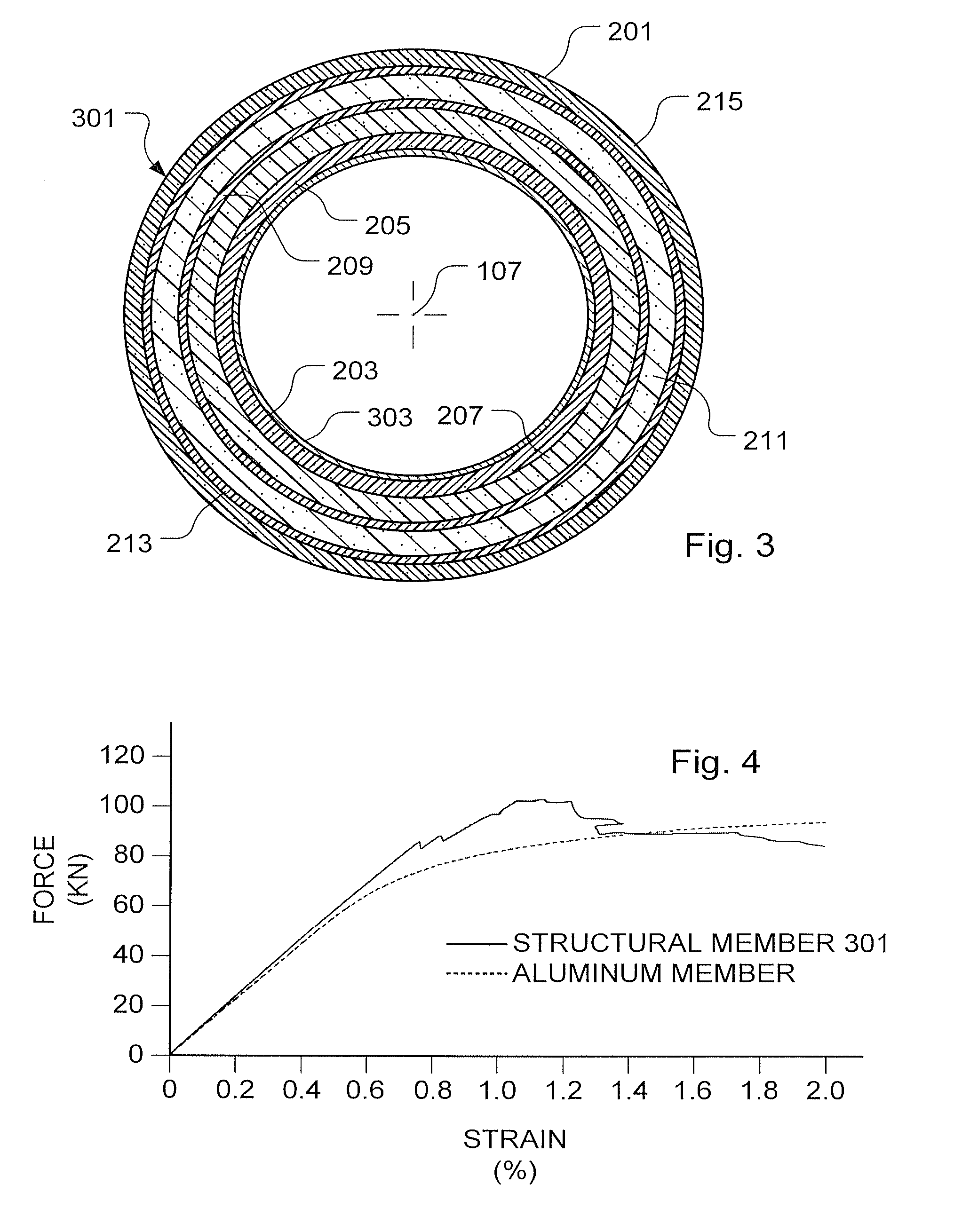

Fiber-Reinforced, Composite, Structural Member Exhibiting Non-Linear Strain-to-Failure and Method of Making Same

ActiveUS20110210201A1Synthetic resin layered productsWeight reductionLoad to failureFiber-reinforced composite

A fiber-reinforced, organic matrix, composite structural member includes a plurality of layers of fiber-reinforced, organic matrix, composite material in which adjacent layers are bonded to one another, wherein the structural member exhibits a non-linear stress-strain response when mechanically loaded to failure. A helicopter landing gear includes a pair of skids and one or more cross members extending between the pair of skids. The one or more cross members includes a plurality of layers of fiber-reinforced, organic matrix, composite material in which adjacent layers are bonded to one another, wherein the cross members exhibit non-linear stress-strain responses when mechanically loaded to failure.

Owner:TEXTRON INNOVATIONS

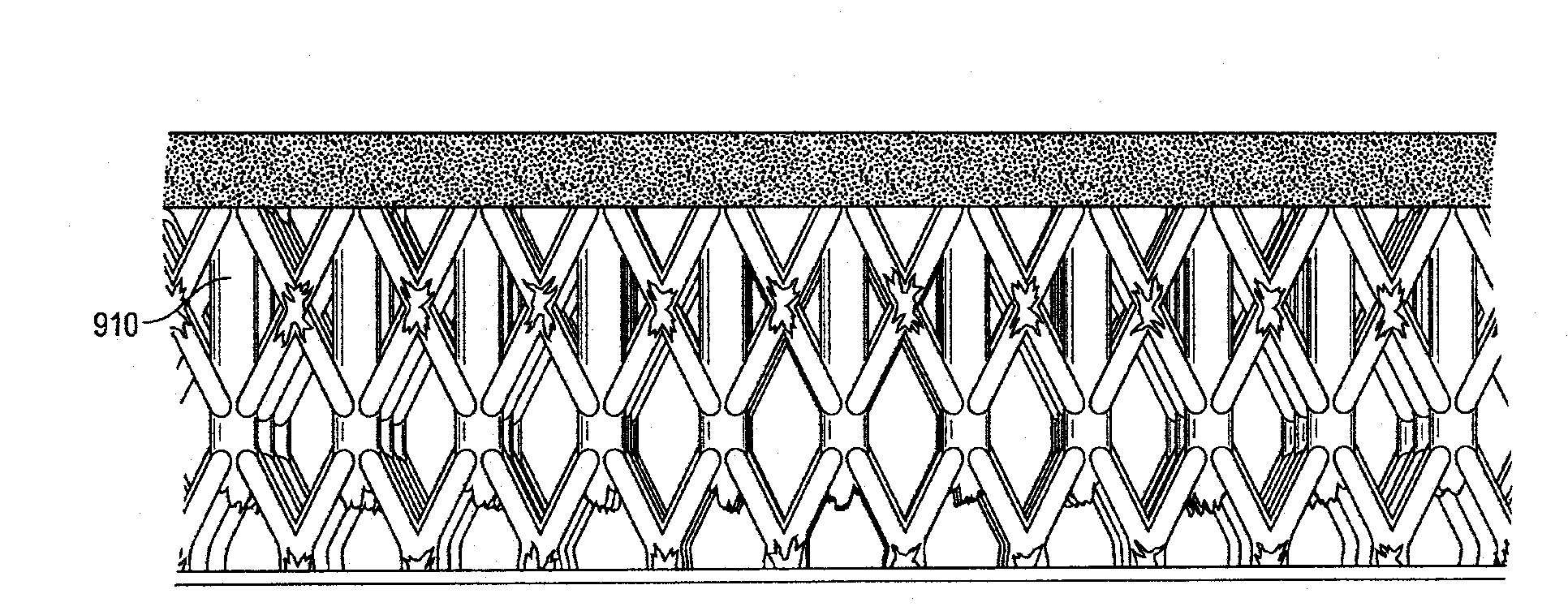

Energy absorbing truss structures for mitigation of injuries from blasts and impacts

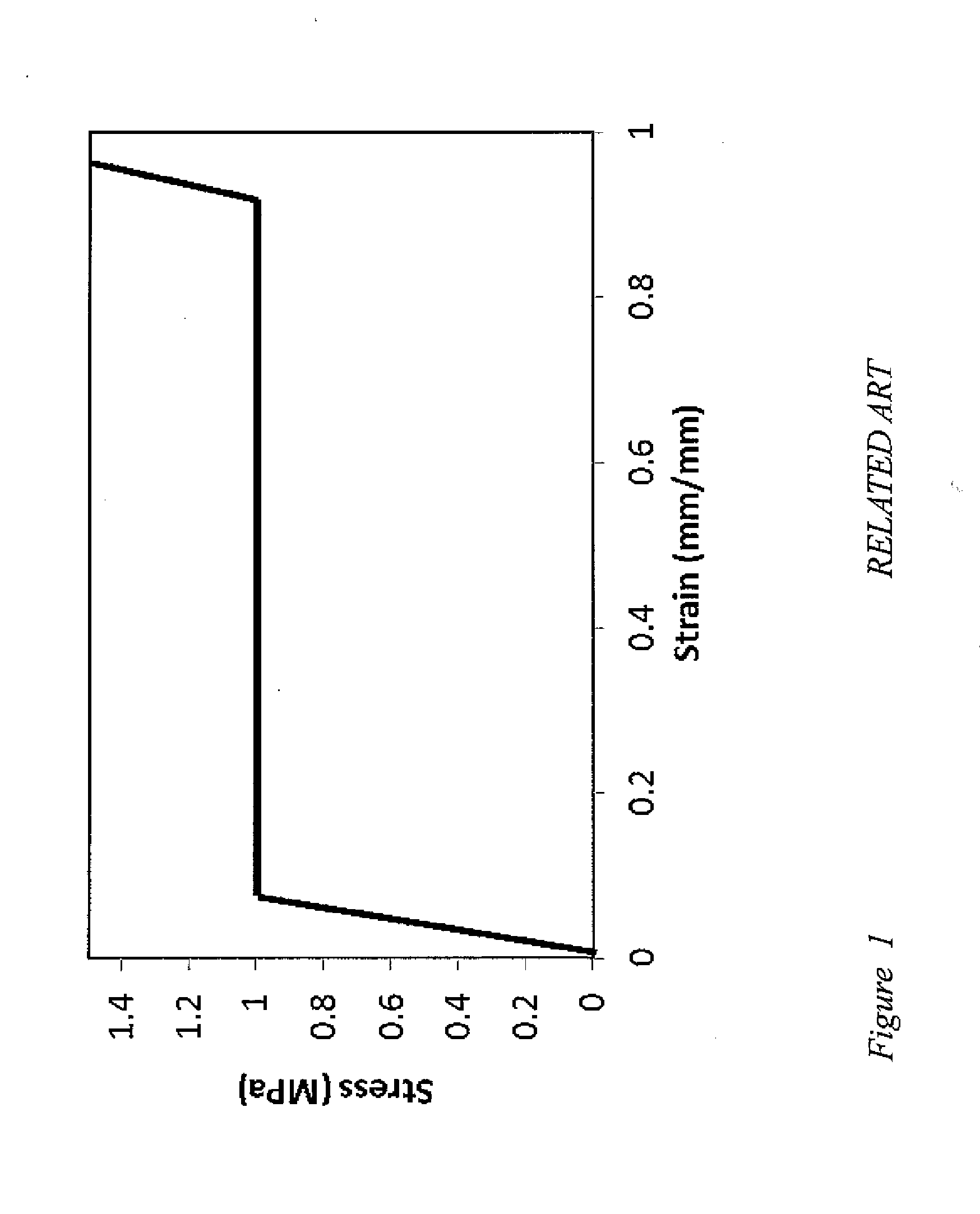

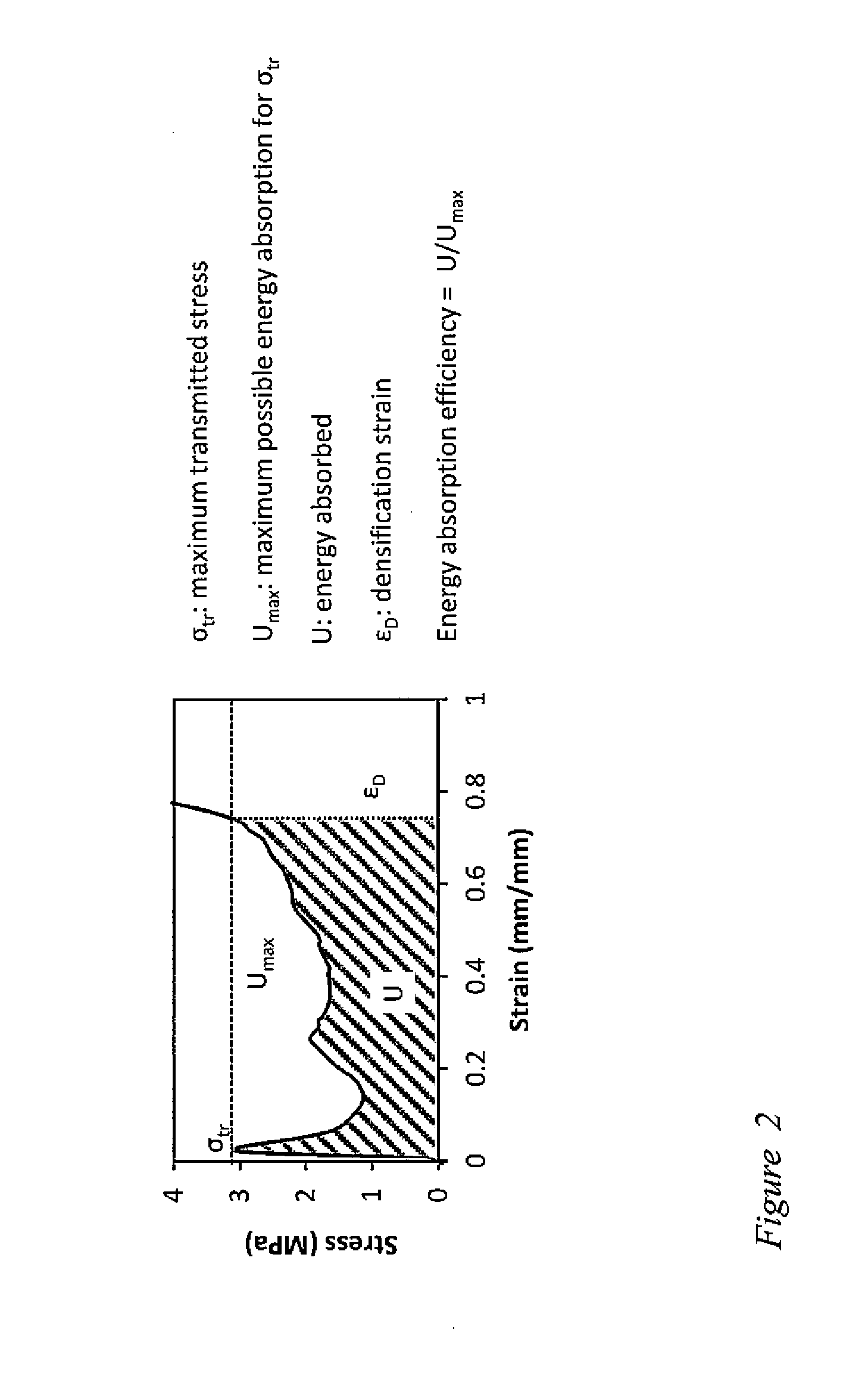

InactiveUS20160160952A1Shock absorptionLower the volumeVehicle arrangementsArmoured vehiclesEnergy absorptionEngineering

Architected materials with superior energy absorption properties when loaded in compression. In several embodiments such materials are formed from micro-truss structures composed of interpenetrating tubes in a volume between a first surface and a second surface. The stress-strain response of these structures, for compressive loads applied to the two surfaces, is tailored by arranging for some but not all of the tubes to extend to both surfaces, adjusting the number of layers of repeated unit cells in the structure, arranging for the nodes to be offset from alignment along lines normal to the surfaces, or including multiple interlocking micro-truss structures.

Owner:HRL LAB

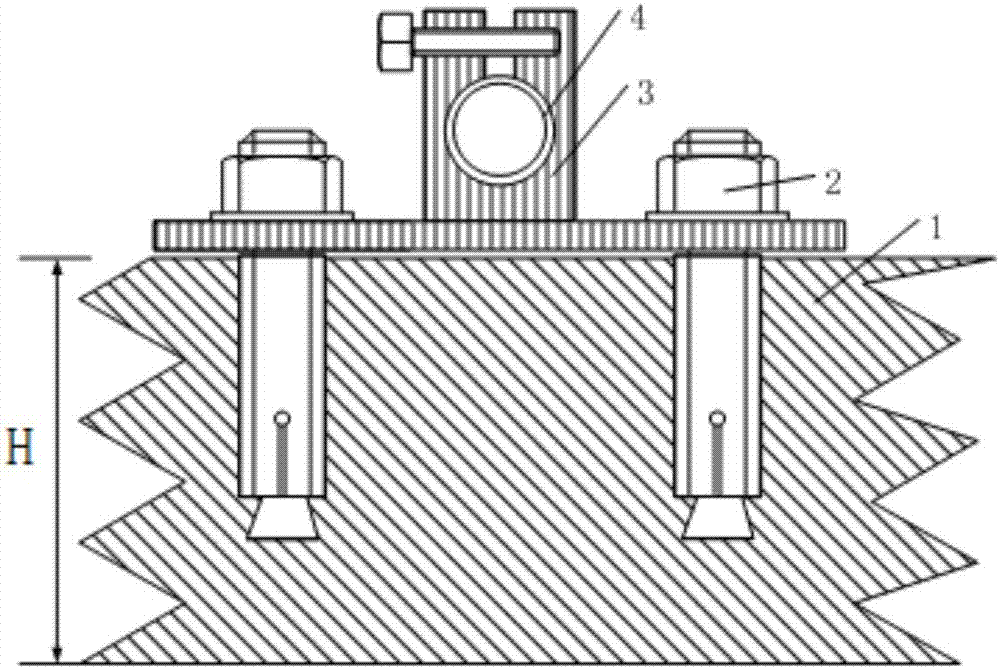

Metal tube structure-based fiber grating corrosion sensor and monitoring method thereof

InactiveCN104406900AEliminate the influence of temperature factorsTemperature factors affect isolationWeather/light/corrosion resistanceFiberGrating

The invention relates to a metal tube structure-based fiber grating corrosion sensor and a monitoring method thereof, and belongs to the technical field of measurement. The sensor is used for monitoring the corrosion condition of a metal structure in acidic and alkaline environment. A making method of the sensor comprises the following steps: a sensing fiber grating penetrates through the inside of a metal tube, a certain size of pre-tension is applied to the sensing fiber grating, and two ends of the sensing fiber grating are respectively fixed to two ends of the metal tube; and one side of the sensing fiber grating is serially connected to a temperature compensating fiber grating, and the temperature compensating fiber grating is freely disposed in the metal tube to be in an unweighted state, and is positioned in a same temperature field together with the sensing fiber grating. The wall of the metal tube gradually becomes thin with the depth of the corrosion degree of the metal tube, so the compressed degree of the metal tube gradually increases, and the grating period of the fiber grating gradually decreases, thereby the center wavelength of the fiber grating gradually deflects. The strain response characteristic of the fiber grating sensor is combined to monitor the corrosion degree of the metal material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

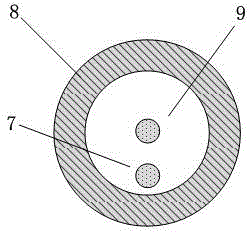

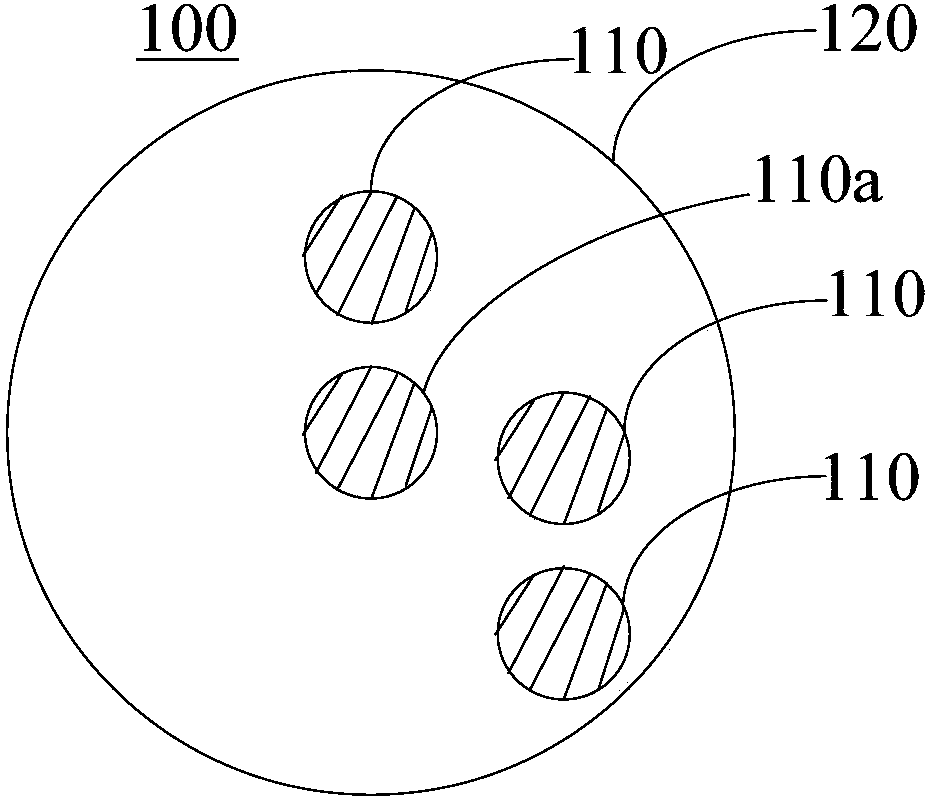

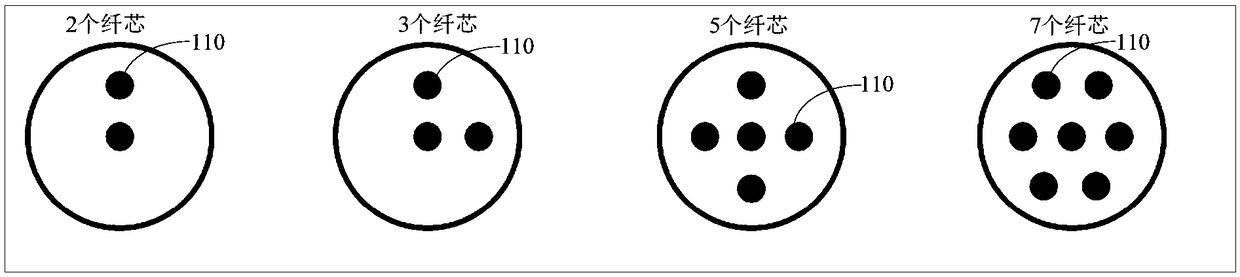

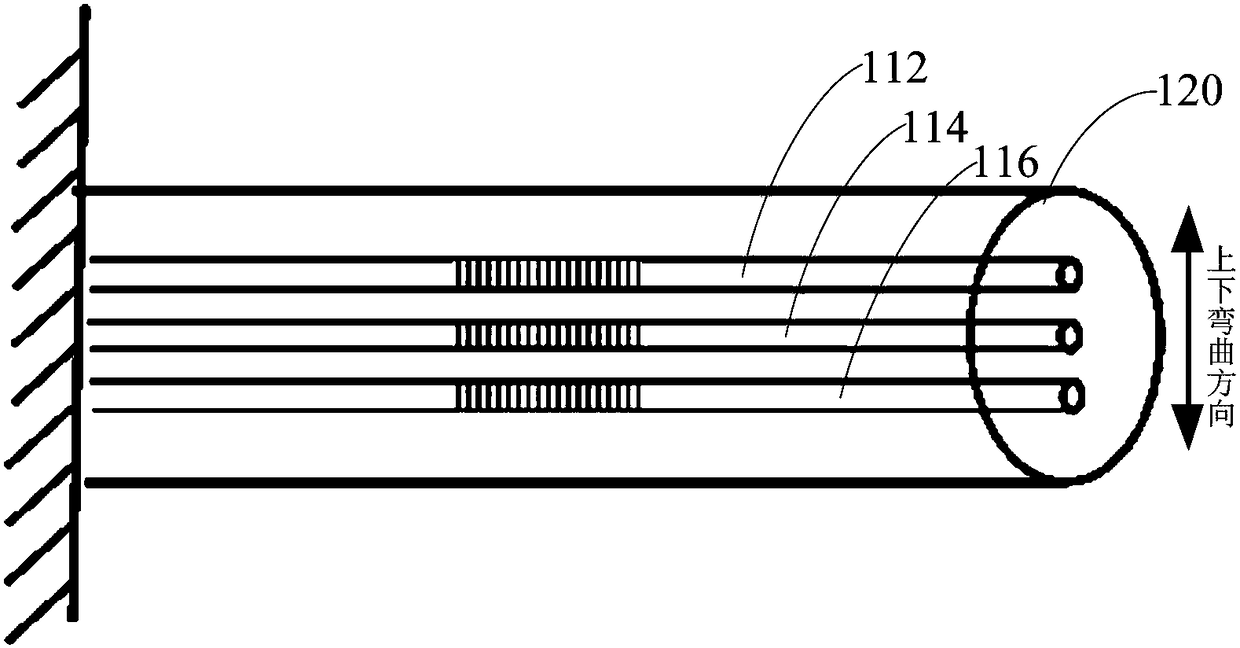

Multi-core fiber grating, fiber sensor, and manufacturing method of multi-core fiber grating

The embodiments of the invention provide a multi-core fiber grating, a fiber sensor, and a manufacturing method of the multi-core fiber grating, and relate to the technical field of fiber sensors. Themulti-core fiber grating comprises a plurality of fiber cores and a cladding, wherein the cladding is wrapped by the plurality of fiber cores; the target fiber core among the plurality of fiber coresis arranged at the center of the cladding; and when the plurality of fiber cores generate bending strain, the wavelength of each fiber core is provided with different strain response rules so as to measure the amplitude and the direction of the bending strain generated from the plurality of fiber cores. The multi-core fiber grating is simple in structure.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

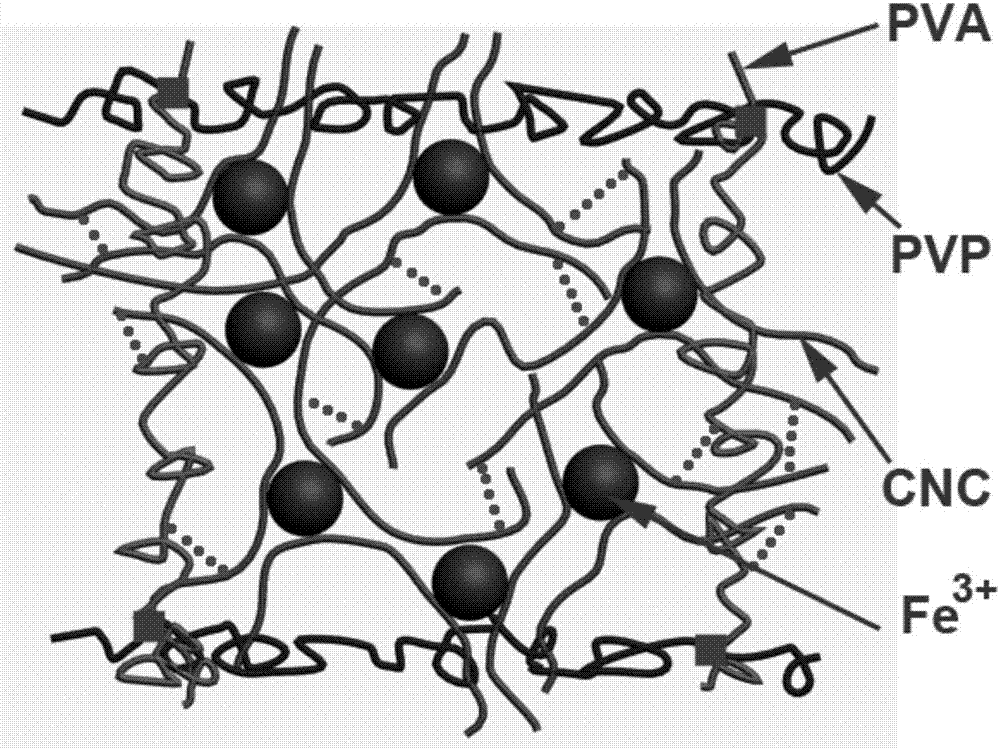

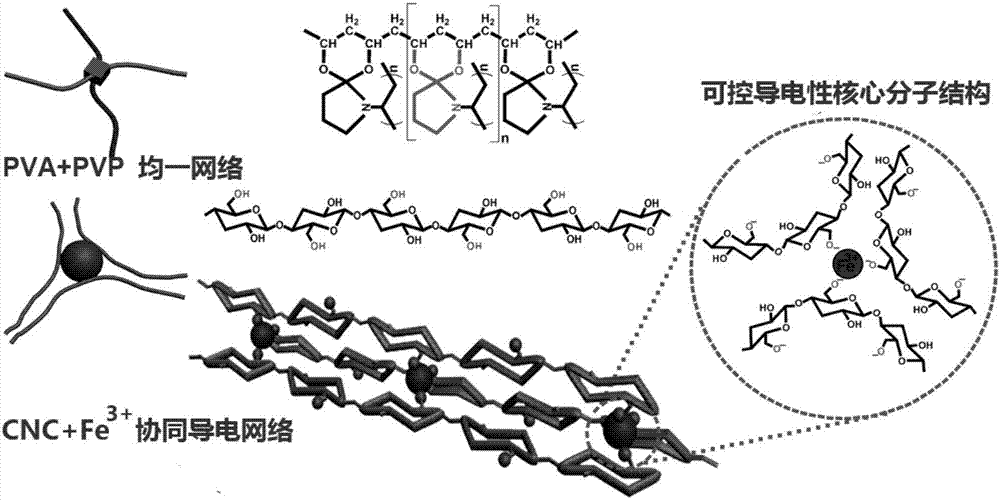

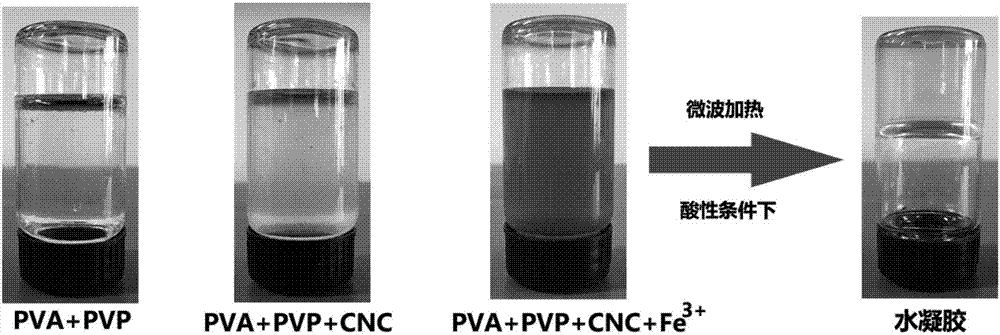

Preparation method of strain-response conductivehydrogel

The invention discloses a method for preparing strain-response conductivehydrogelbased on microwave assisting. The method uses polyvinyl alcohol and polyvinylpyrrolidone as base materials, Fe<3+>is added, a uniform polymer network can be formed through microwave-assisted heating and self-assembly, and the obtained hydrogel has good strain-response conductive properties and can also keep high fatigue resistance strength while having high mechanical strength. In addition, according to a preparation method of the strain-response conductivehydrogel, the operation is simple, the raw materials are wide in source and cheap, the production cost of the product is reduced, and the hydrogel is suitable for large-scale industrial production.

Owner:乌鲁木齐诺西辰环境工程有限公司

Low-cost high-performance human motion sensor and preparation method thereof

InactiveCN108020157ALow costSimple preparation processElectrical/magnetic solid deformation measurementHuman skinHuman motion

The invention belonging to the technical field of sensors provides a low-cost high-performance human motion sensor and a preparation method thereof. The sensor comprises a stretchable flexible substrate, a strain sensitive material arraigned on the stretchable flexible substrate and wires arranged at two ends of the strain sensitive material. The motion sensor has the advantages of simple operation, simple process, low cost and good performance and can be worn on the surface of human skin; the motion situation of the body can be detected based on the strain response; and application needs of human body motion detection and intelligent auxiliary medical service and the like can be met.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com