Patents

Literature

182 results about "Gauge length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term ‘gauge length’ denotes the length of a specimen used for testing purposes. The latter is usually taken as the length between the grips for the test.

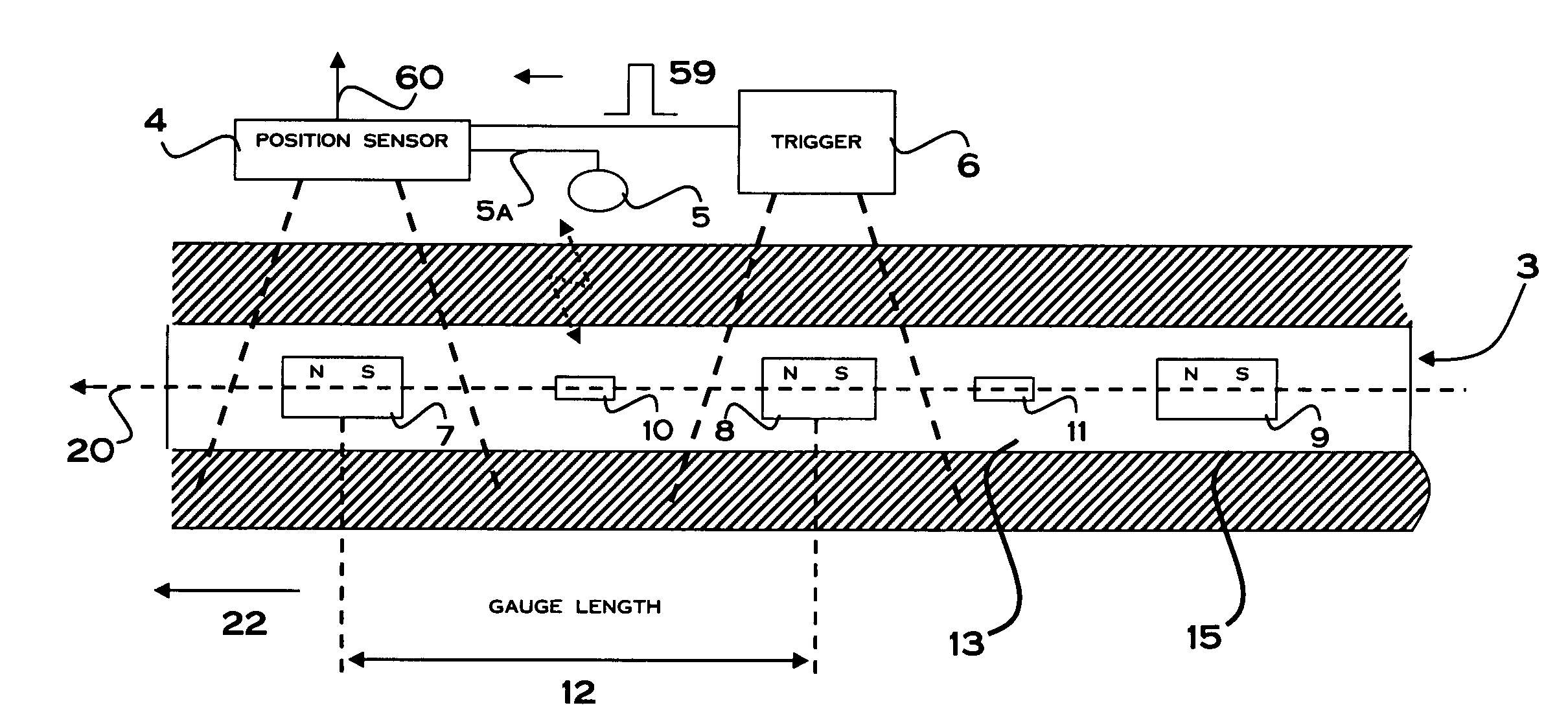

Strain gauge sensor system and method

InactiveUS7441464B2Unlimited measurement rangeGood strain measurement resolution and reliabilityForce measurement by measuring magnetic property varationUsing electrical meansFiberStrain gauge

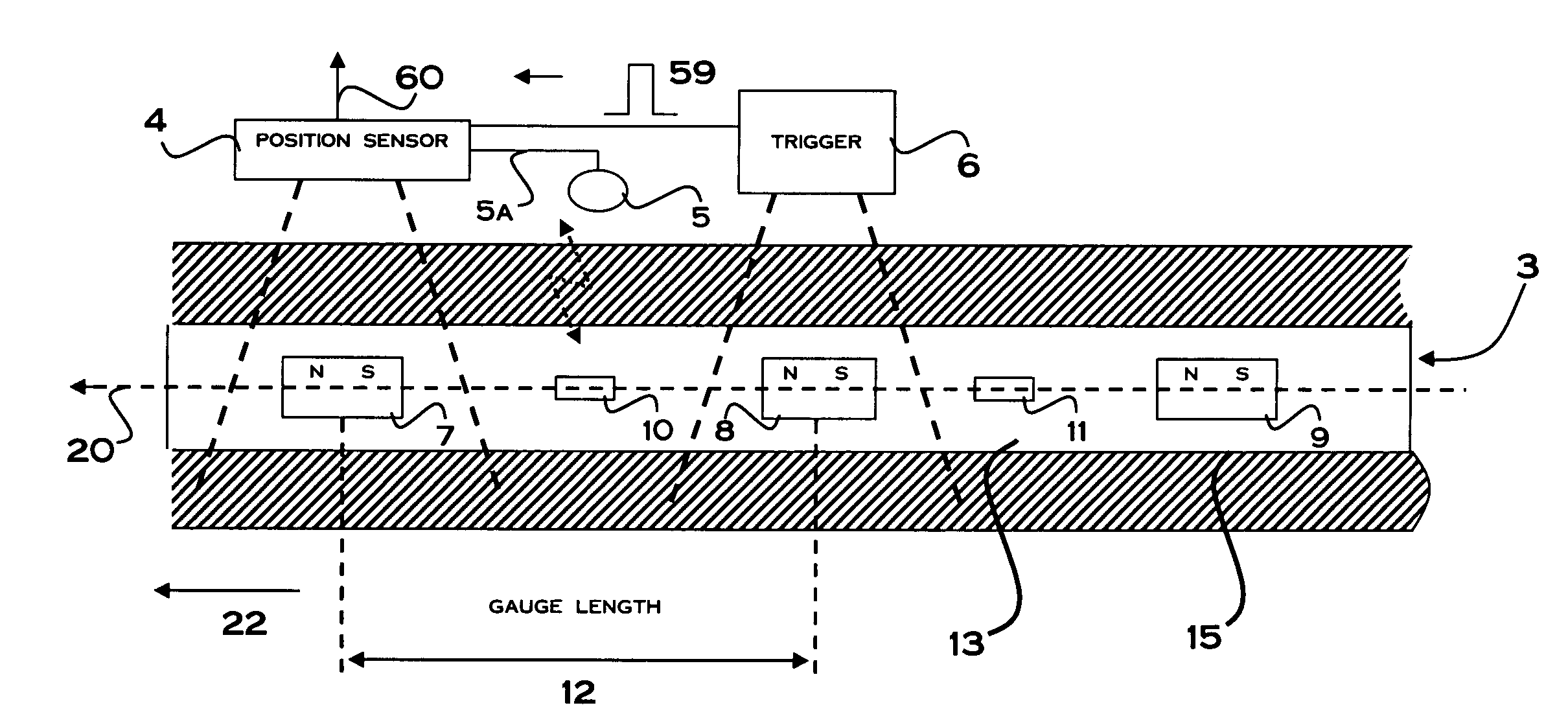

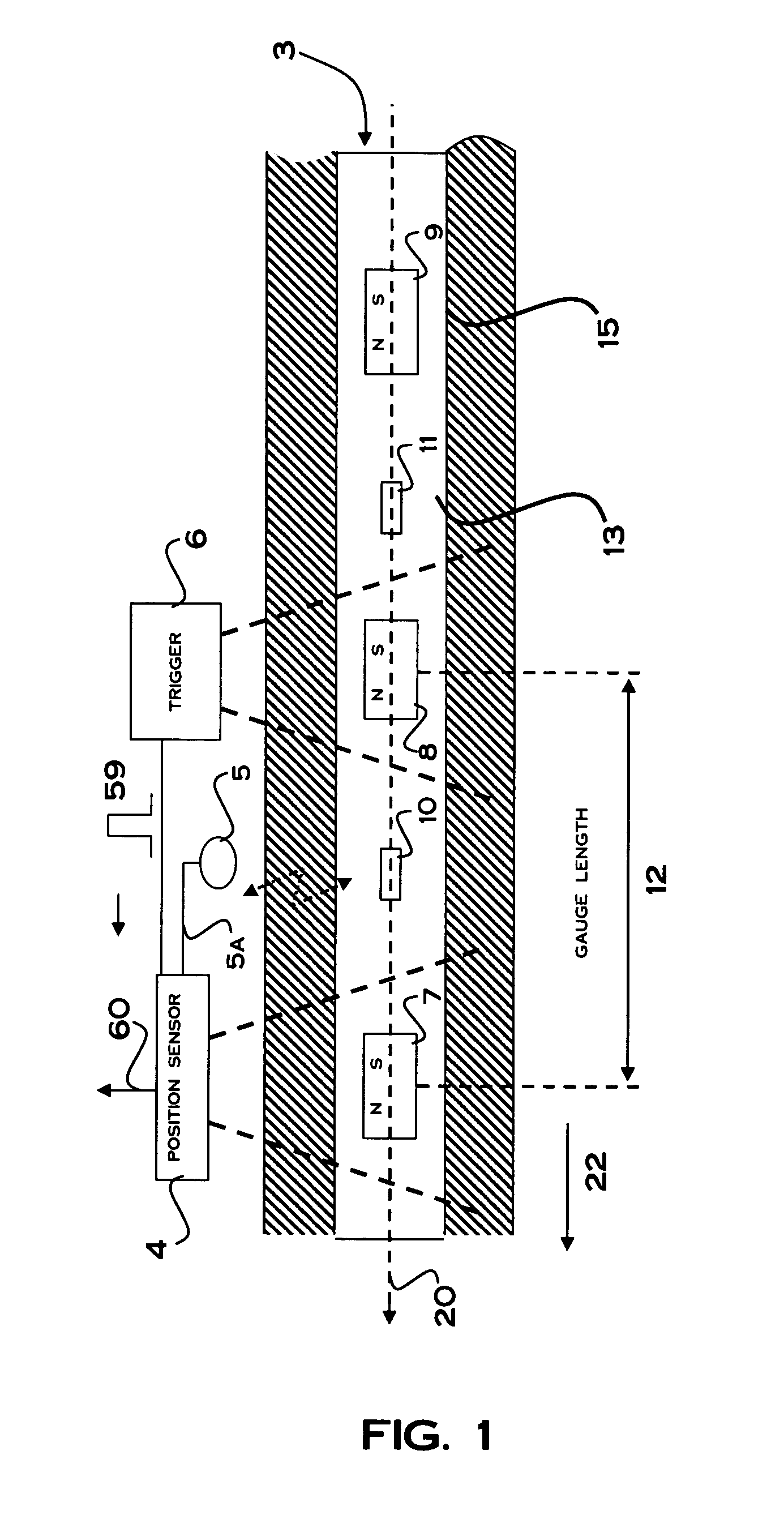

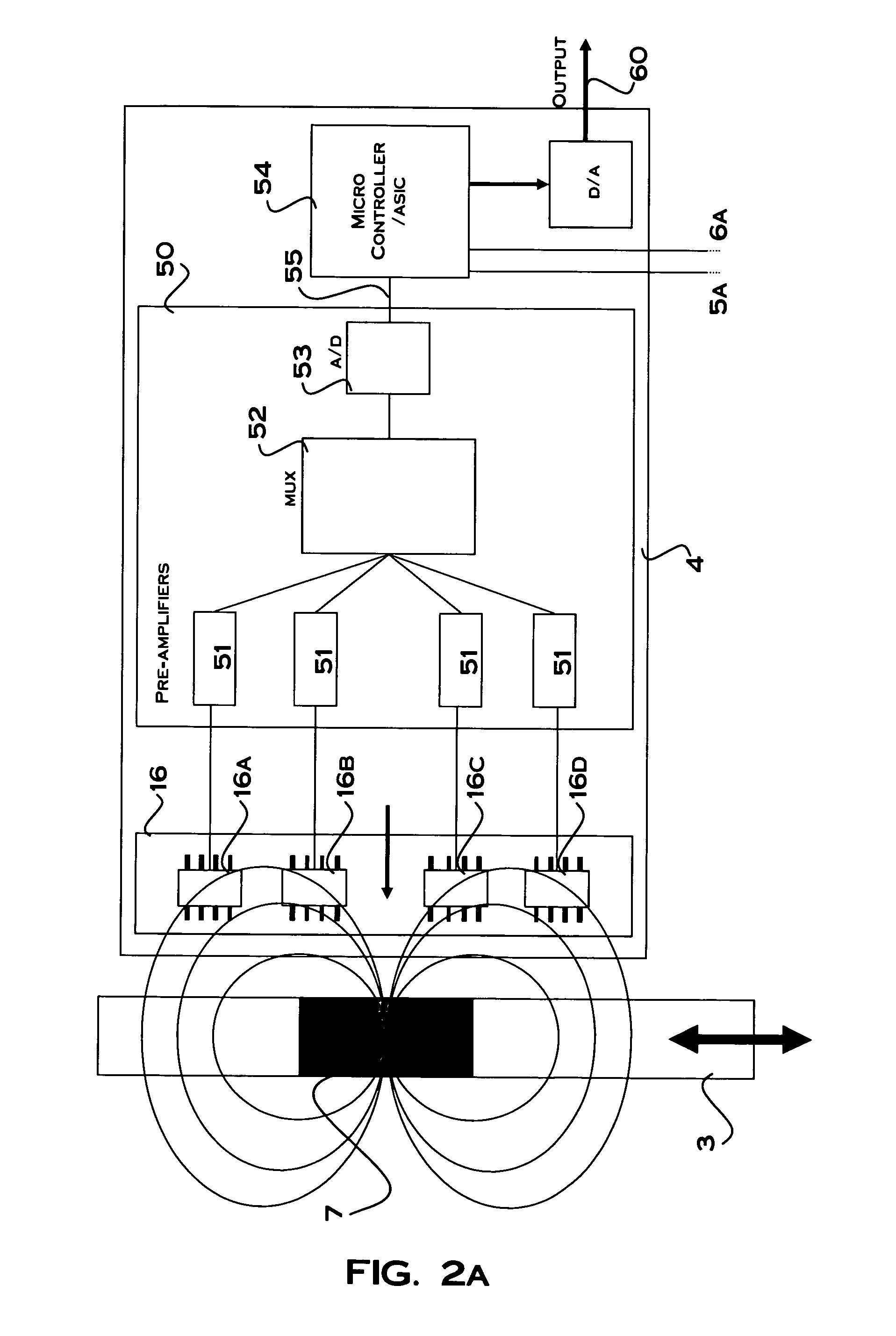

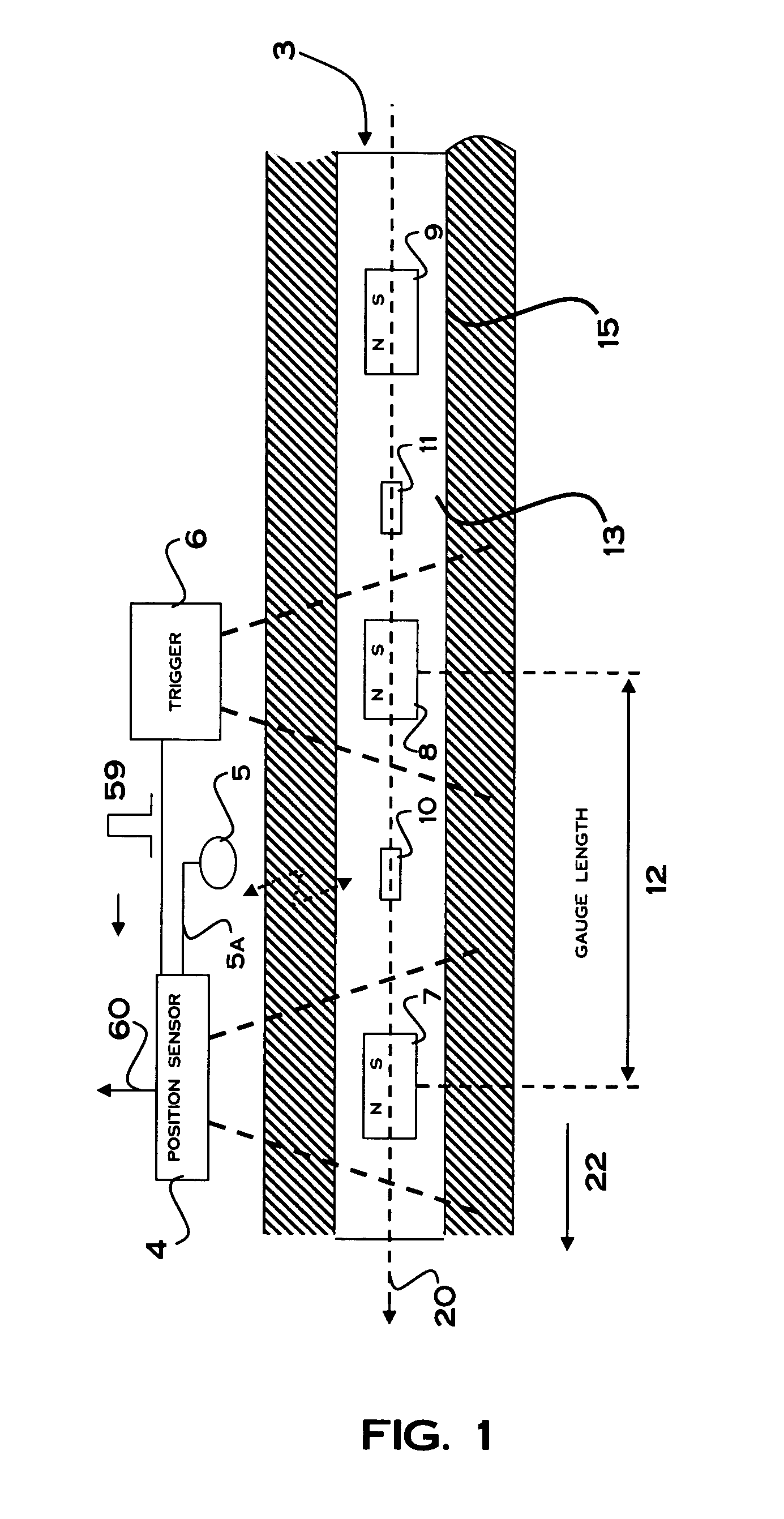

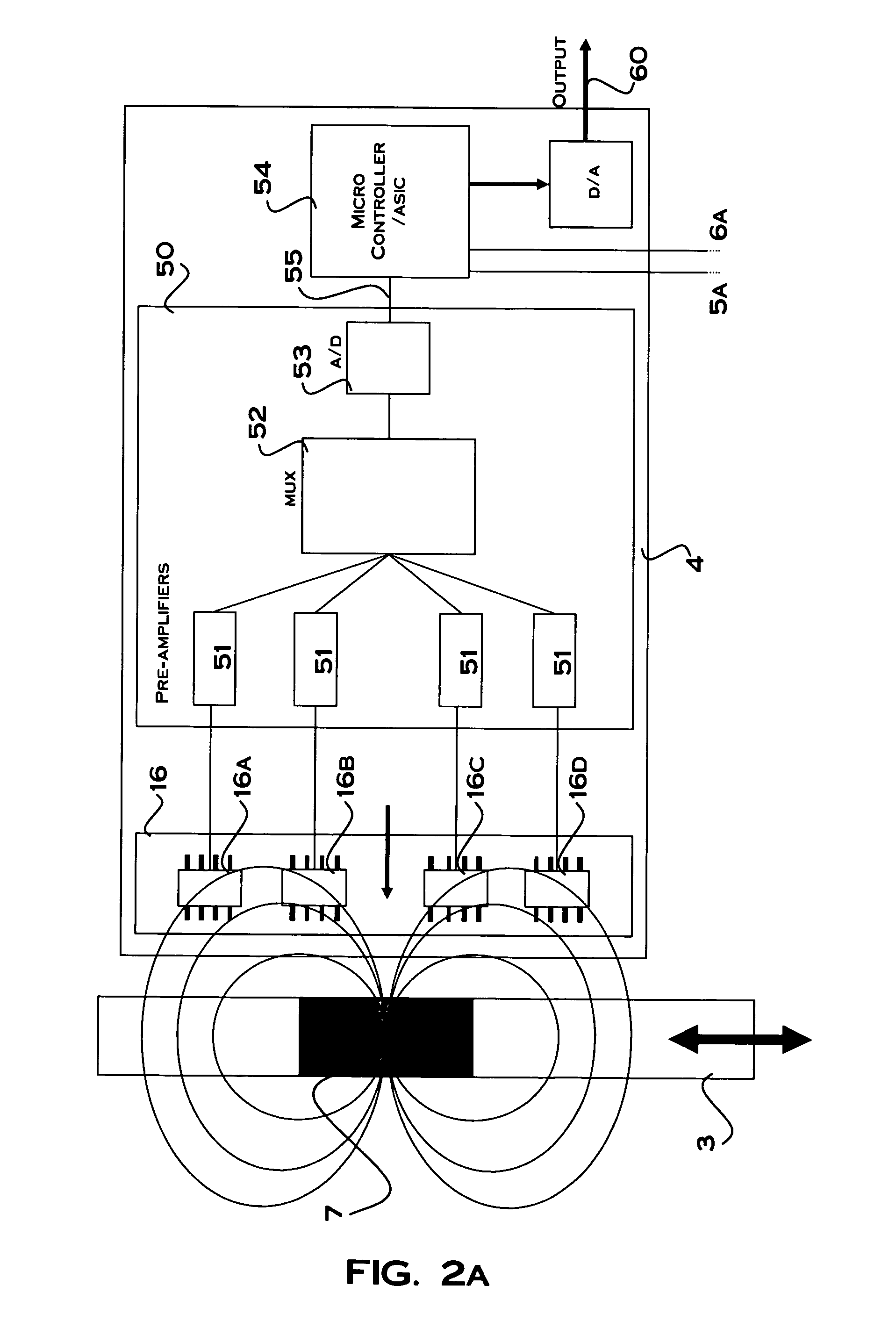

A strain gauge sensor system and method for measuring the strain in a member, such as a fiber rope, has a sensor target assembly having a plurality of magnets carried spaced apart by individual gauge lengths along the member. Position and trigger sensor devices are configured spaced apart along side a desired path of travel of the member. When the member is fed along the desired path of travel, the trigger sensor device, in response to magnetically sensing a passing magnet, triggers the position sensor device to read the position of an adjacent passing magnet. The strain in the gauge length is determined from the read position. RFID tags placed on the member between the magnets can be identified by an RF reader to identify a particular gauge length being measured. The system can include a deployment device for feeding the member along the desired path.

Owner:HONEYWELL INT INC

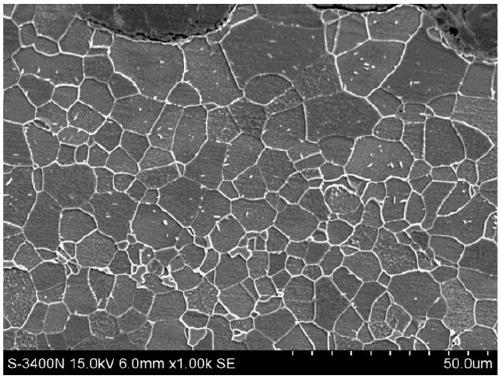

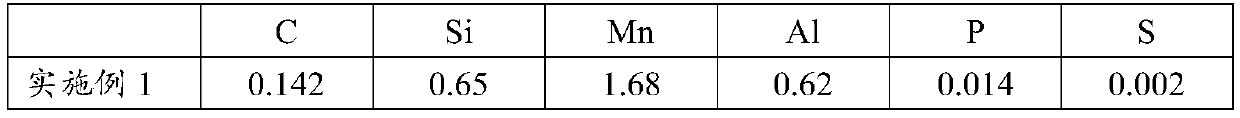

High-strength cold-rolled hot-galvanized precipitation reinforced steel and manufacturing method thereof

ActiveCN102199723AGood welding performancePremium surface qualityTemperature control deviceMetal rolling arrangementsSheet steelImpurity

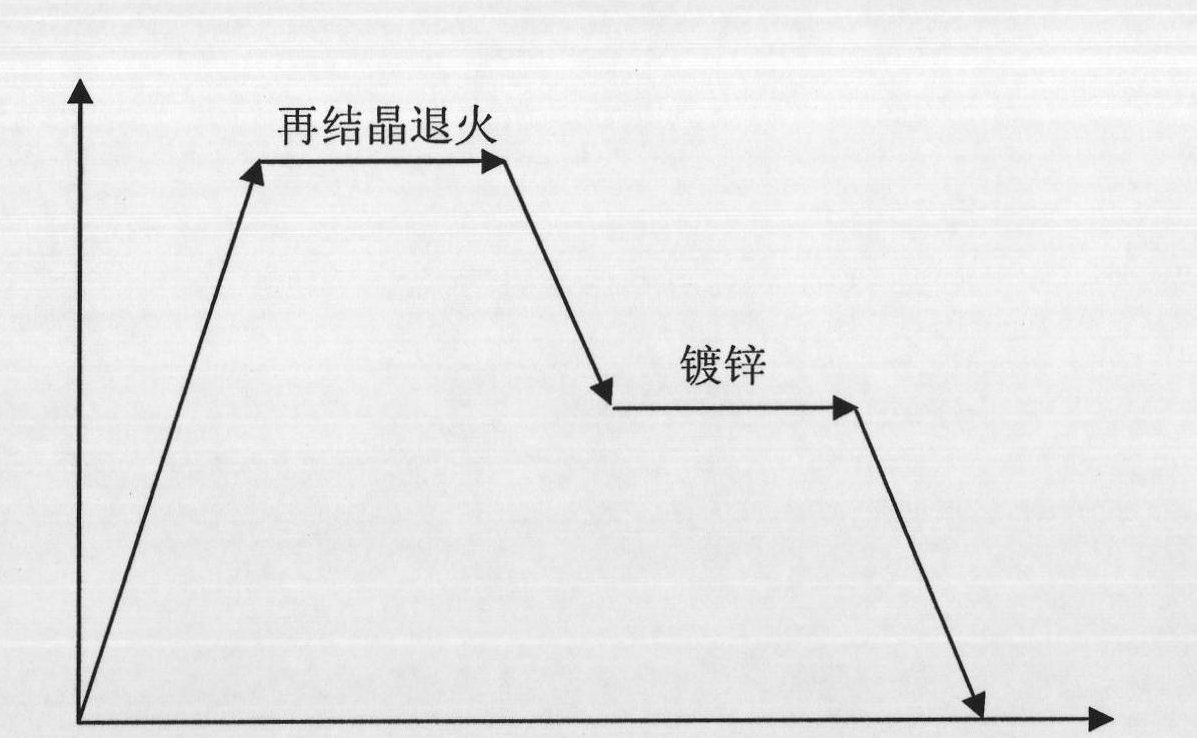

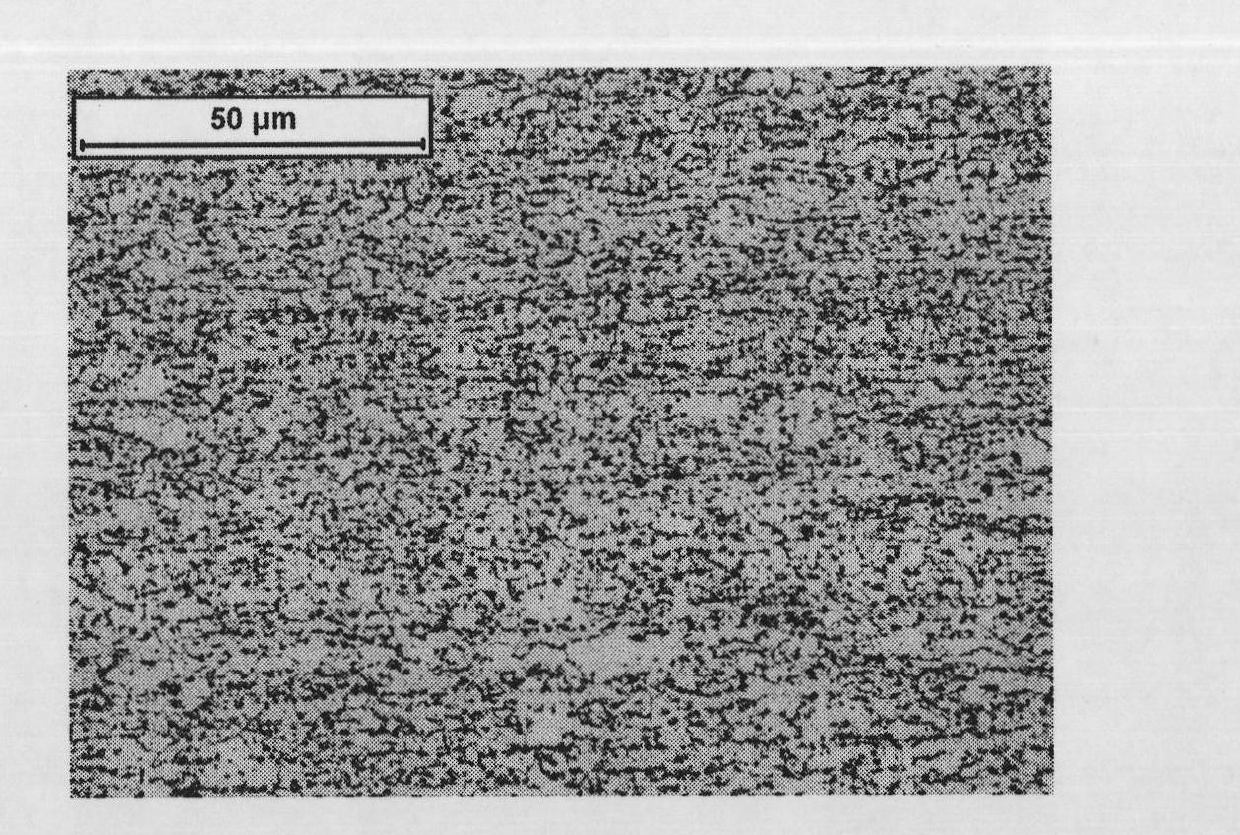

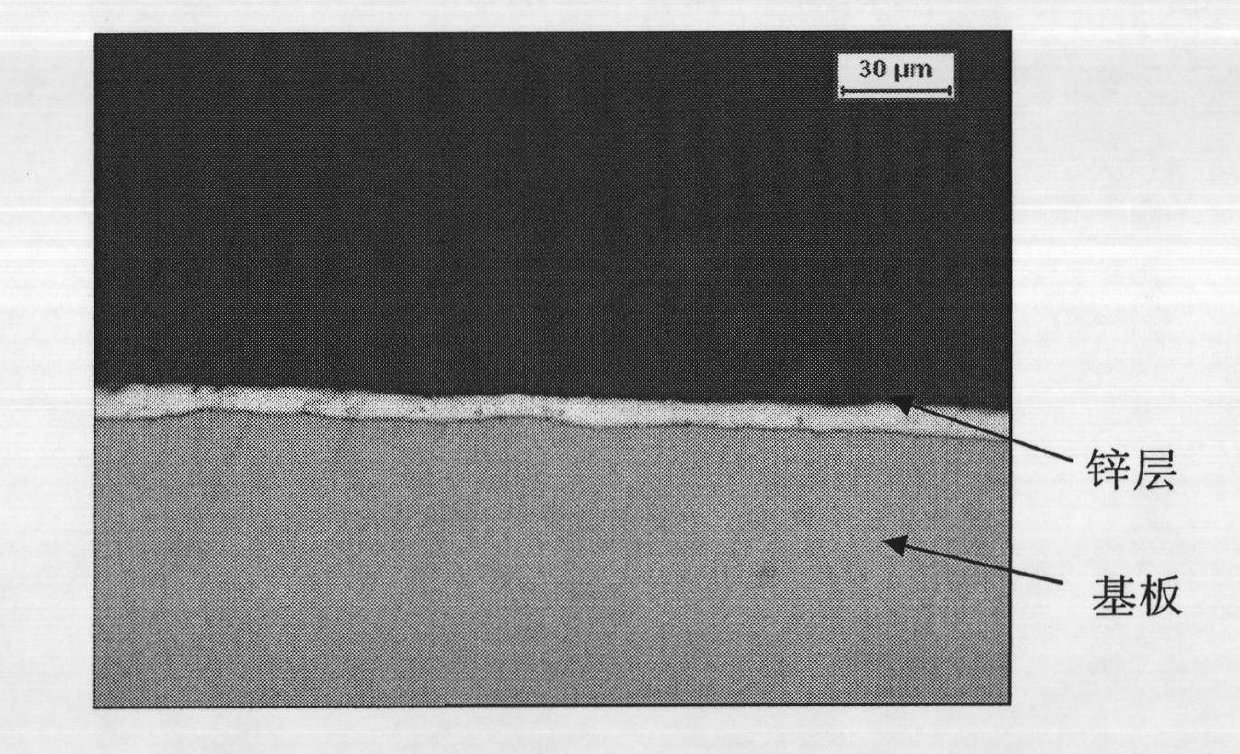

The invention discloses a high-strength cold-rolled hot-galvanized precipitation reinforced steel plate and a manufacturing method thereof. The steel plate comprises the following components: 0.09 to 0.12 weight percent of C, less than or equal to 0.05 weight percent of Si, 0.8 to 1.8 weight percent of Mn, less than or equal to 0.02 weight percent of P, less than or equal to 0.01 weight percent of S, less than or equal to 0.008 weight percent of N, 0.02 to 0.06 weight percent of Al, 0.05 to 0.08 weight percent of Nb and Ti and the balance of Fe and inevitable impurities. The microstructure ofthe steel plate is ferrite and second phase particles, wherein the diameter of the second phase particles is about less than 6 mu m, the yield strength is 500 to 600MPa, the tensile strength is 570 to 710MPa, and the total coefficient of elongation is over 14 percent (80 gauge length and transverse stretching). The hot-galvanized steel plate has high welding performance and surface quality and can be widely used in automotive structural membranes.

Owner:BAOSHAN IRON & STEEL CO LTD

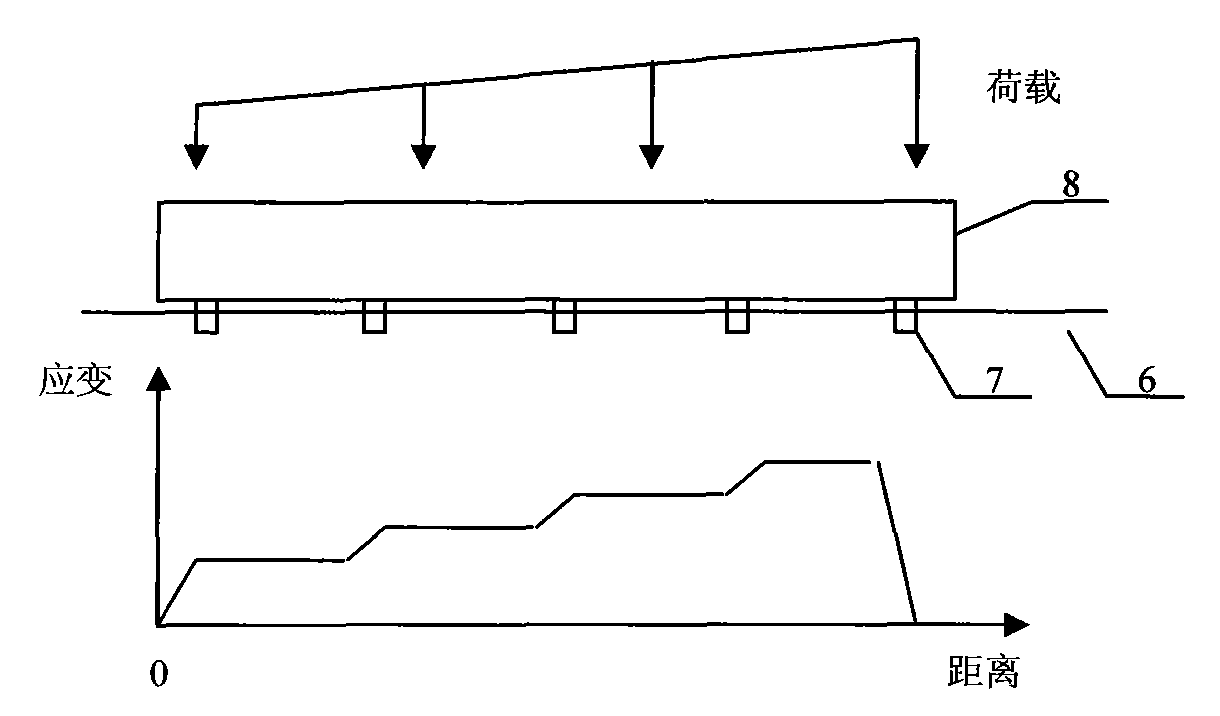

Long-gauge-length-strain-influence-envelope-based bridge damage identification method

InactiveCN105973627AQuick detection of stiffness distributionStructural/machines measurementData acquisitionMonitoring system

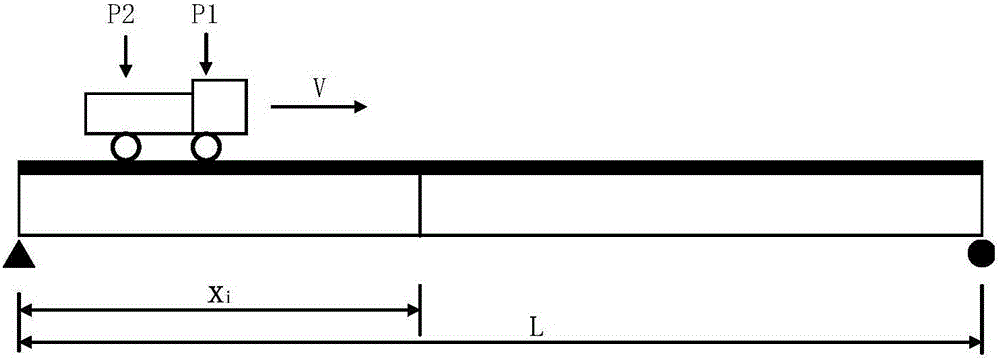

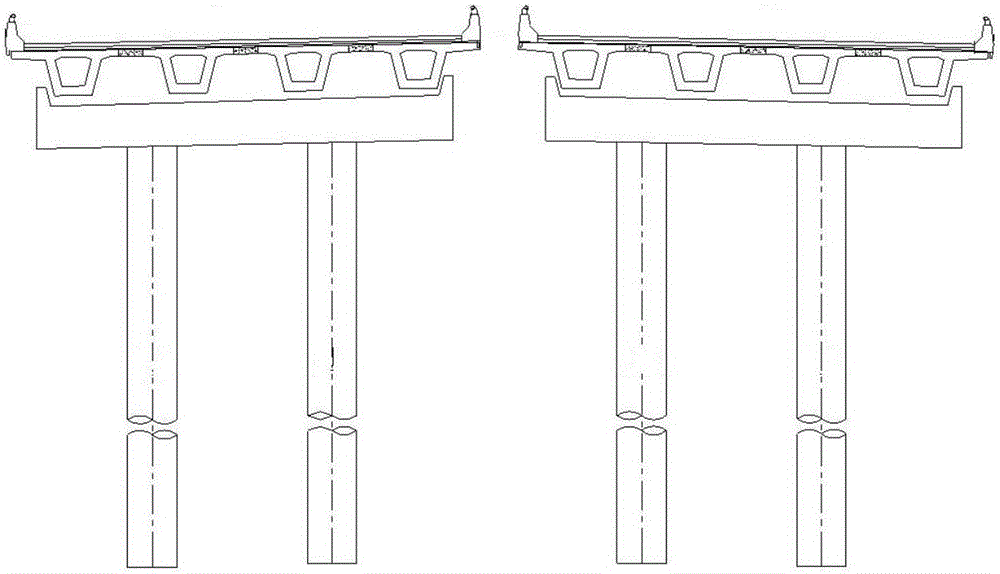

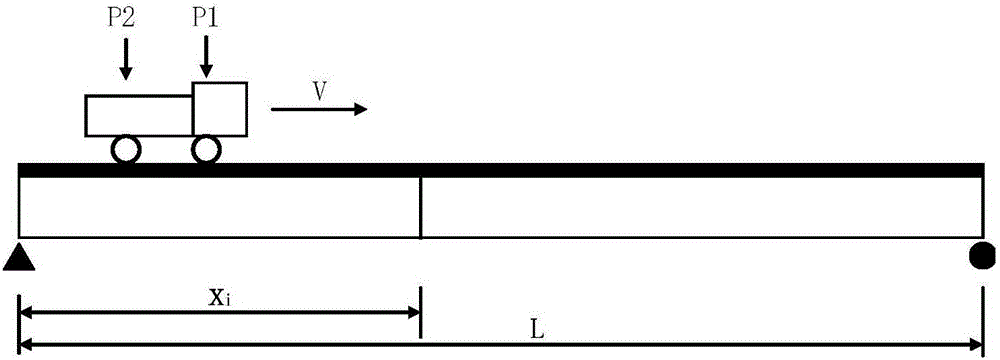

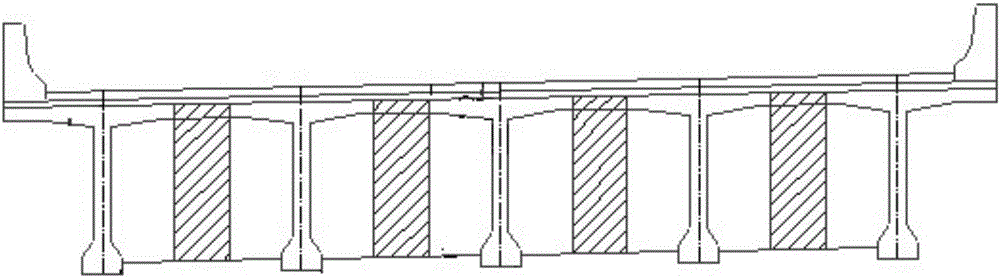

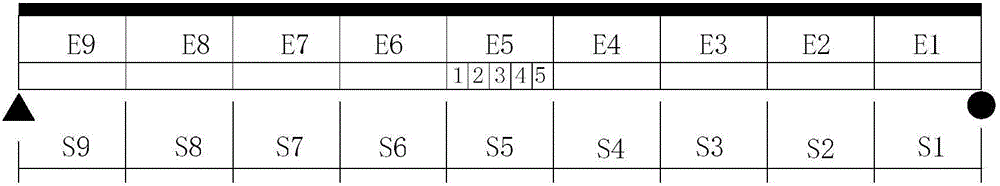

The invention discloses a long-gauge-length-strain-influence-envelope-based bridge damage identification method. The method comprises: a distributed long-gauge-length strain sensing monitoring system is constructed; when a vehicle crosses a bridge, data acquisition is carried out; the collected data are decomposed; a long-gauge-length strain influence envelope of the bridge is extracted; and then bridge damage identification and bearing state estimation are carried out. Long-gauge-length strain sensors are used for measuring strain information of the bridge when the vehicle is crossing the bridge; and with an empirical mode decomposition method, a long-gauge-length strain time history is decomposed, a static strain component extraction criterion is put forward, and a strain influence envelope of the bridge is formed based on the extracted maximum static strain value, thereby determining a bearing force state of the bridge. During implementation, closing of the traffic is avoided; and on the basis of the long-gauge-length strain time history under vehicle driving, the rigidity distribution situation of the bridge can be detected rapidly.

Owner:SOUTHEAST UNIV

Method and Apparatus for Optical Sensing

ActiveUS20180045543A1High sensitivityReduce reflectivityConstructionsSubsonic/sonic/ultrasonic wave measurementFiberGrating

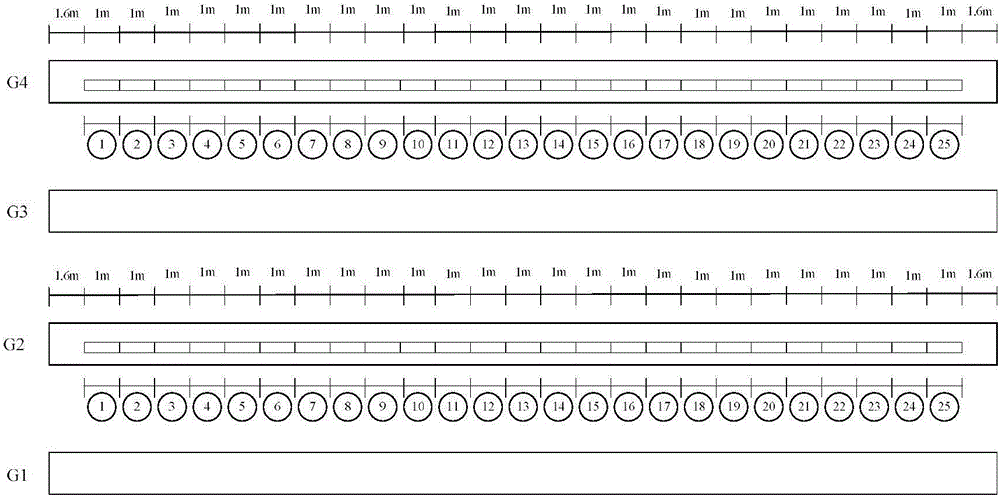

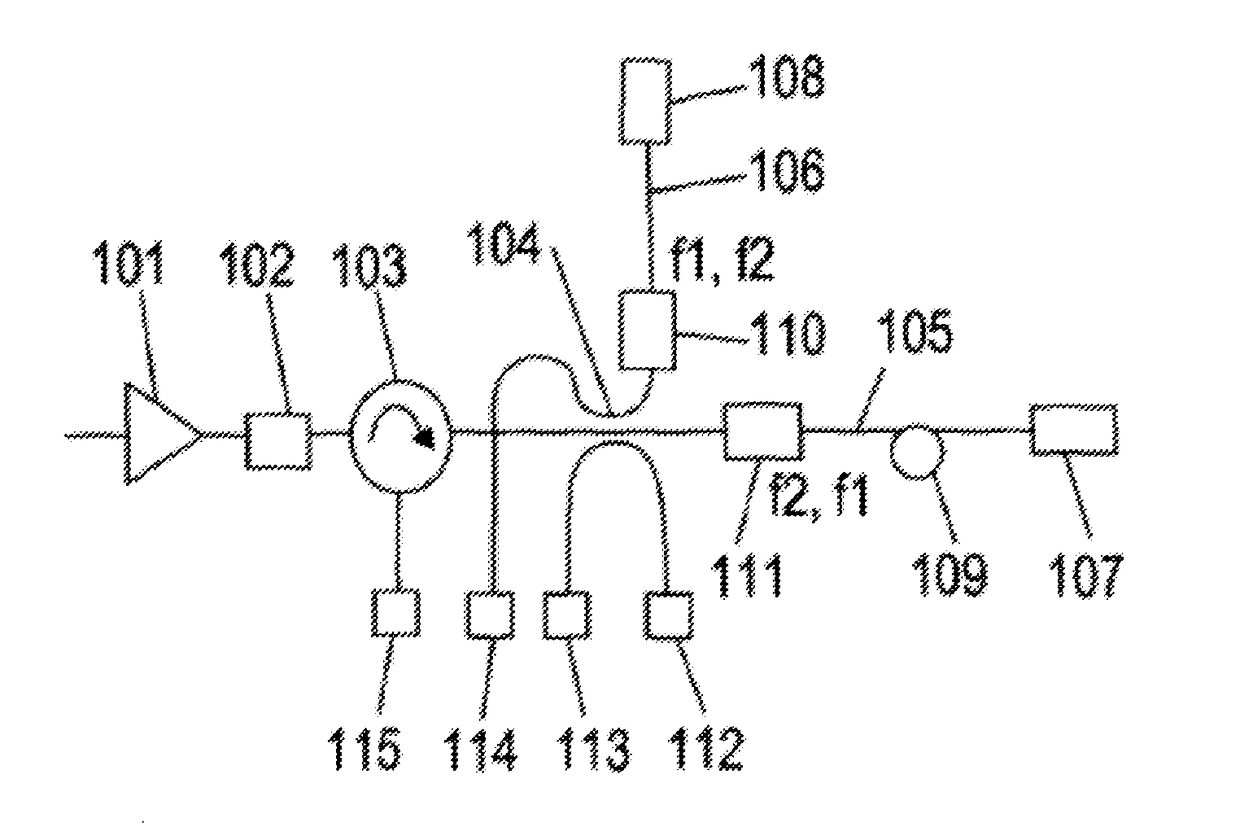

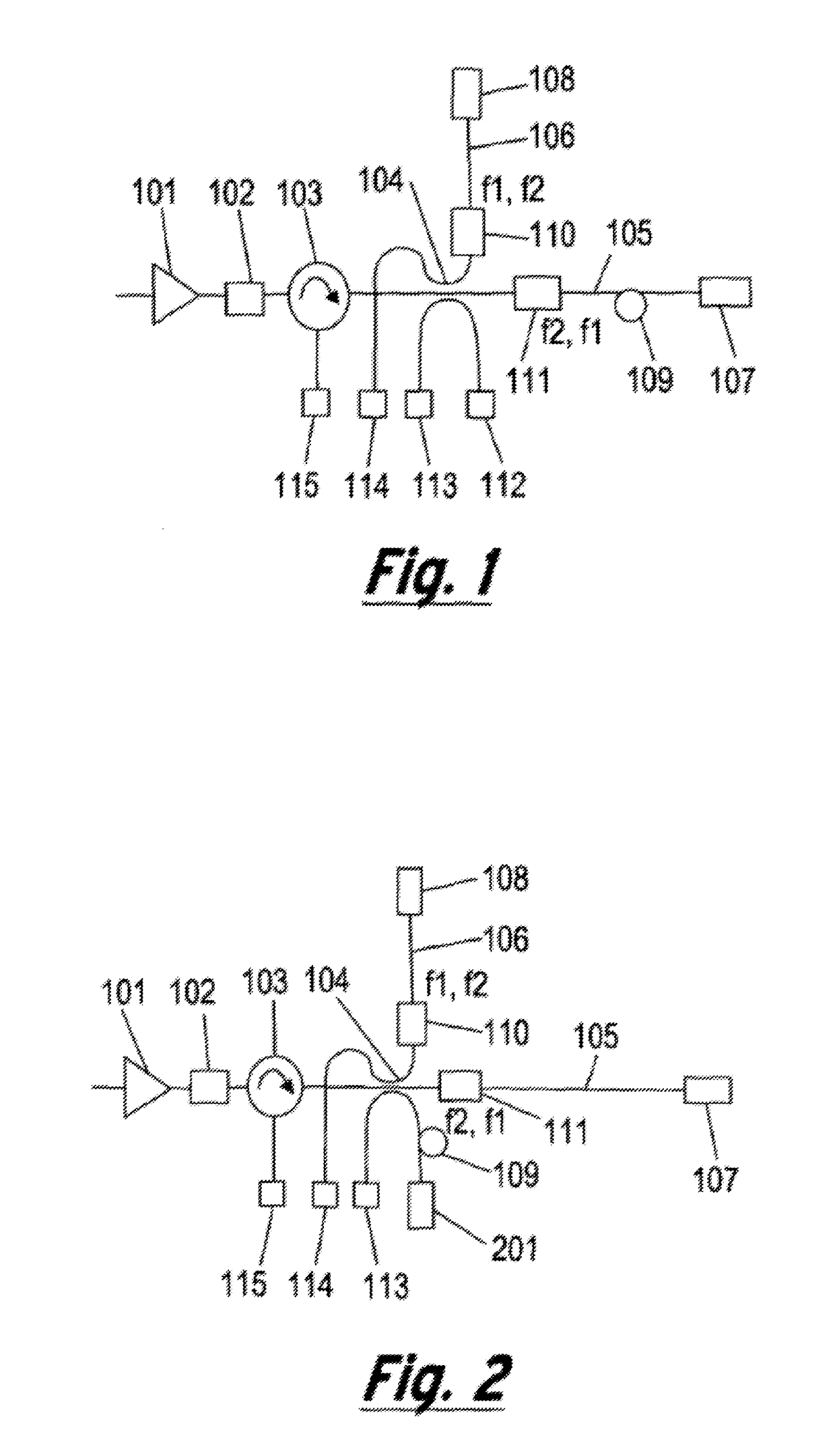

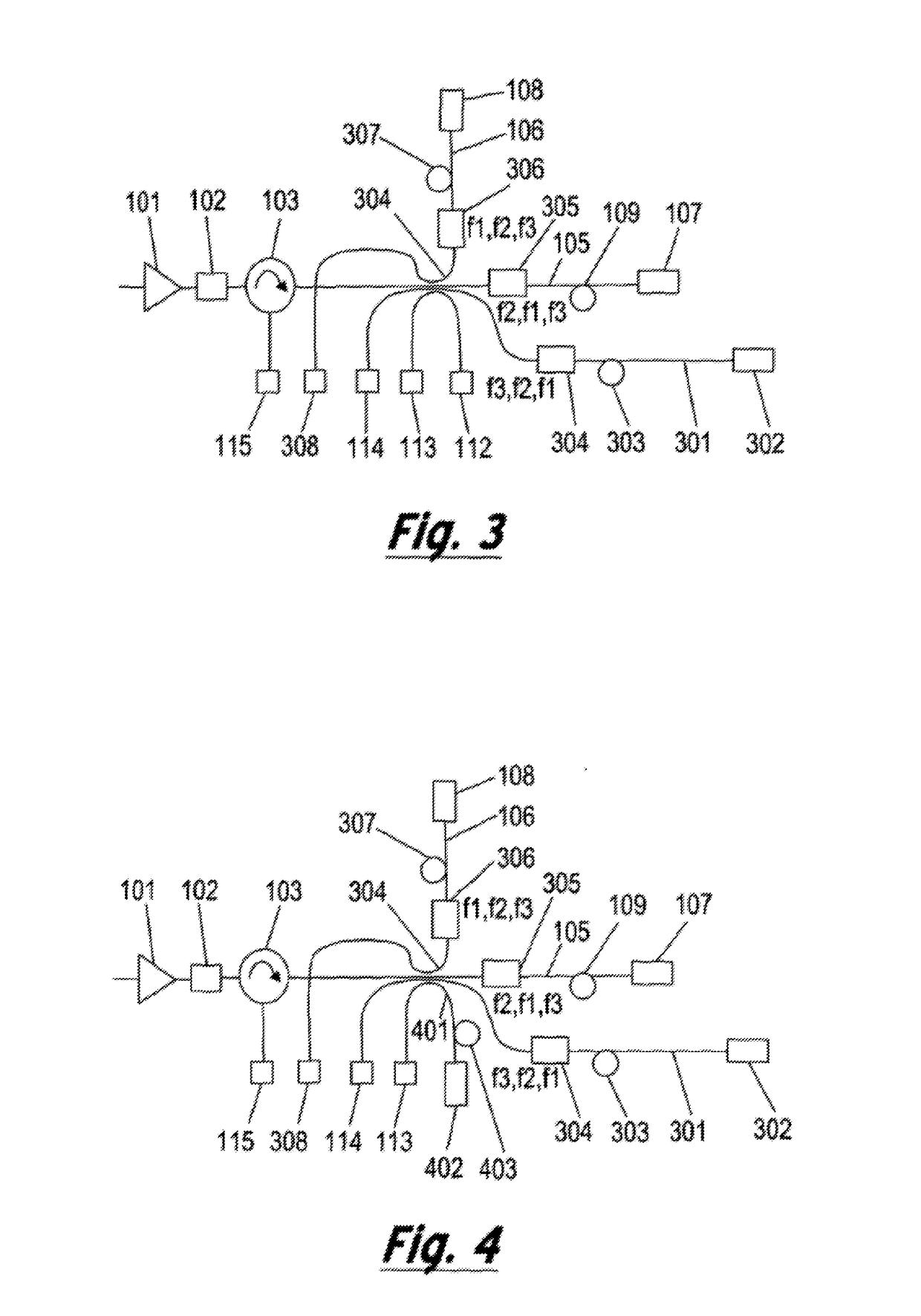

An optical fiber distributed acoustic sensor system includes weak broadband reflectors inserted periodically along the fiber. The reflectors reflect only a small proportion of the light from the DAS incident thereon back along the fiber, typically in the region of 0.001% to 0.1%, but preferably around 0.01% reflectivity per reflector. In addition, to allow for temperate compensation to ensure that the same reflectivity is obtained if the temperature changes, the reflection bandwidth is relatively broadband. In some embodiments the reflectors are formed from a series of fiber Bragg gratings, each with a different center reflecting frequency, the reflecting frequencies and bandwidths of the gratings being selected to provide the broadband reflection. A chirped grating may also be used to provide the same effect. In preferred embodiments, the reflectors are spaced at half the gauge length i.e. the desired spatial resolution of the optical fiber DAS.

Owner:SILIXA

High strength tape articles from ultra-high molecular weight polyethylene

Owner:HONEYWELL INT INC

Strain gauge sensor system and method

InactiveUS20080105059A1Unlimited measurement rangeGood strain measurement resolution and reliabilityForce measurement by measuring magnetic property varationUsing electrical meansFiberStrain gauge

A strain gauge sensor system and method for measuring the strain in a member, such as a fiber rope, has a sensor target assembly having a plurality of magnets carried spaced apart by individual gauge lengths along the member. Position and trigger sensor devices are configured spaced apart along side a desired path of travel of the member. When the member is fed along the desired path of travel, the trigger sensor device, in response to magnetically sensing a passing magnet, triggers the position sensor device to read the position of an adjacent passing magnet. The strain in the gauge length is determined from the read position. RFID tags placed on the member between the magnets can be identified by an RF reader to identify a particular gauge length being measured. The system can include a deployment device for feeding the member along the desired path.

Owner:HONEYWELL INT INC

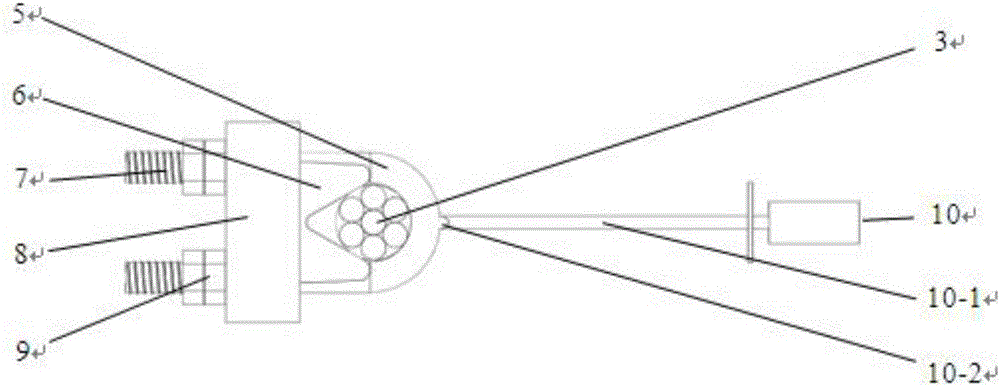

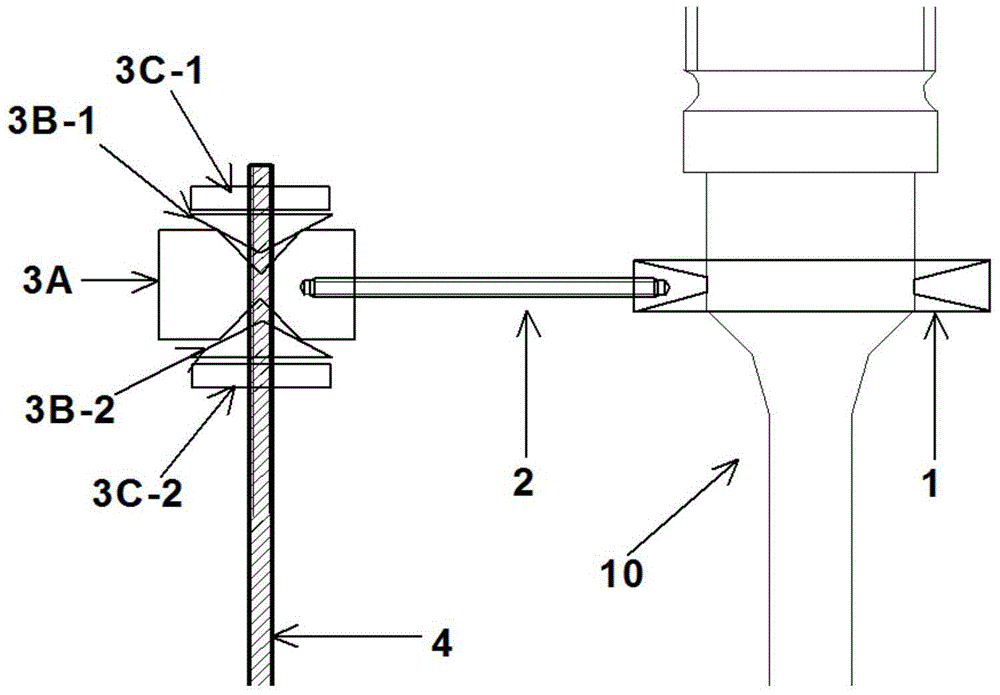

High temperature resistant spring-type device for measuring metallic material deformation

InactiveCN102721611ASolving deformation measurement problemsSimple structureMaterial strength using tensile/compressive forcesMetallic materialsMaterials science

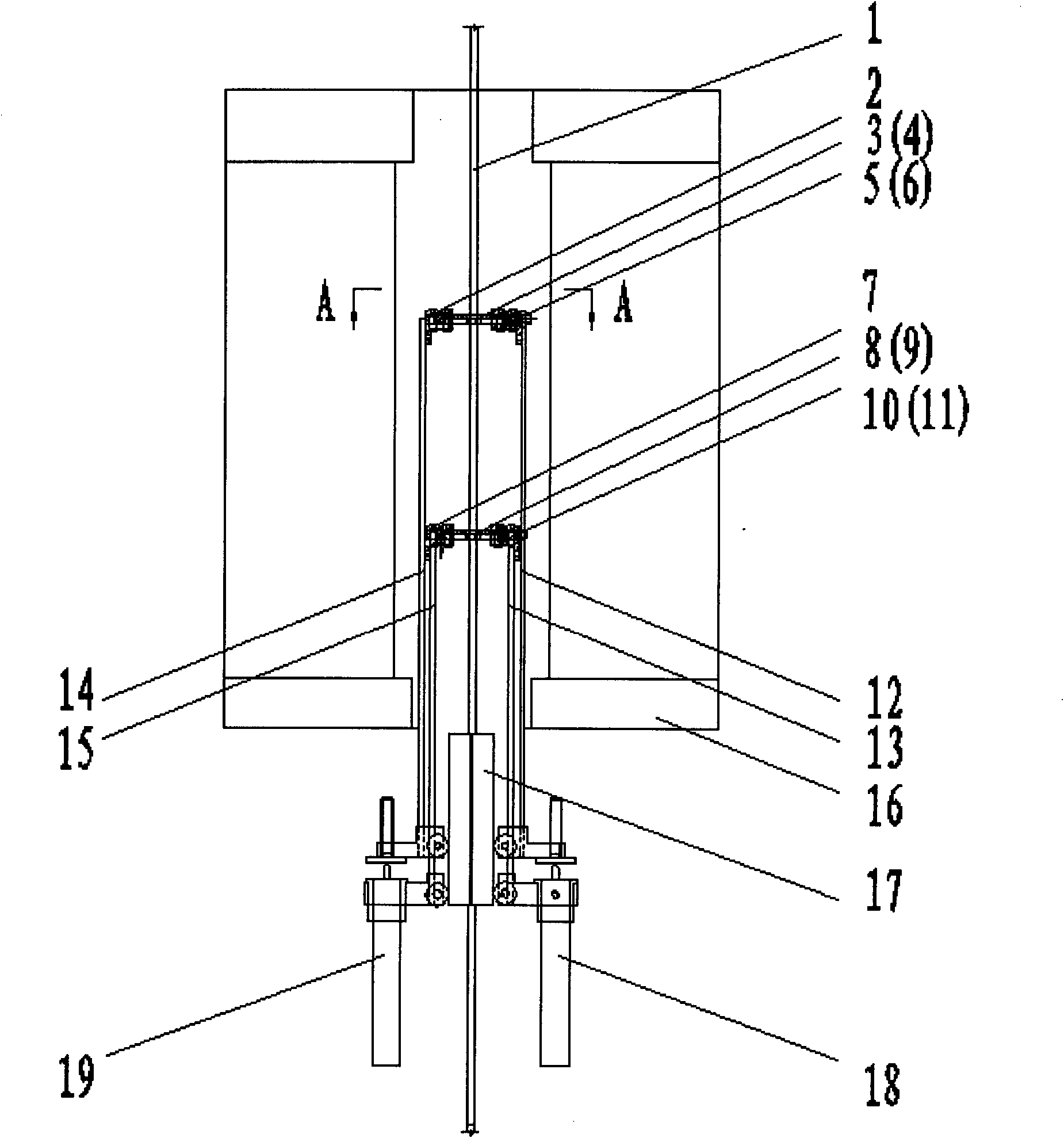

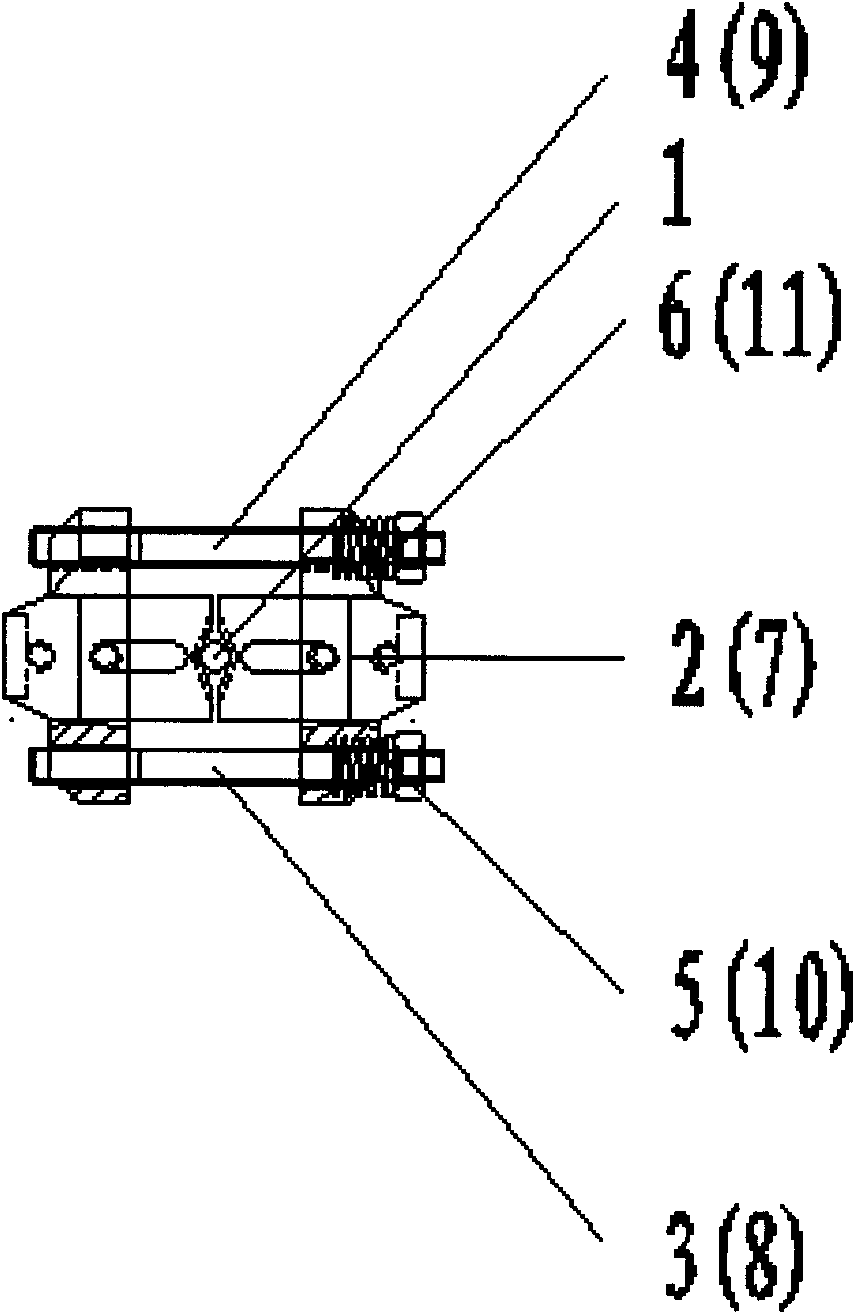

The invention relates to a high temperature resistant spring-type device for measuring metallic material deformation, which comprises high temperature resistant springs, an upper clamp splice, a lower clamp splice, extension rods, deformation sensors, and a high temperature furnace. The upper clamp splice and the lower clamp splice are both arranged in the high temperature furnace, and end portions thereof are provided with the high temperature resistant springs and are fixedly provided with the extension rods. Due to compacting forces of the high temperature resistant springs, in the process of the sample being extended longer and thinner by high temperature, edges of the upper clamp splice and the lower clamp splice are driven to move inwardly with even, and the sample is always clamped firmly. The lower ends of the extension rods extend from a lower opening of the high temperature furnace, and are connected with the deformation sensors at two symmetrical sides of the sample, such that a two-side measuring system is formed for measuring a deformation value of the sample. Compared with the prior art, the device, simple in structure and convenient in installation, can both measure the deformation values within a gauge length of common and special non-boss metallic material samples in a high temperature extension test, wherein the common non-boss metallic materials are wire materials, bar materials, tube materials, etc., while the special non-boss metallic materials are multi-ply type such as steel wire cables, etc.

Owner:TONGJI UNIV

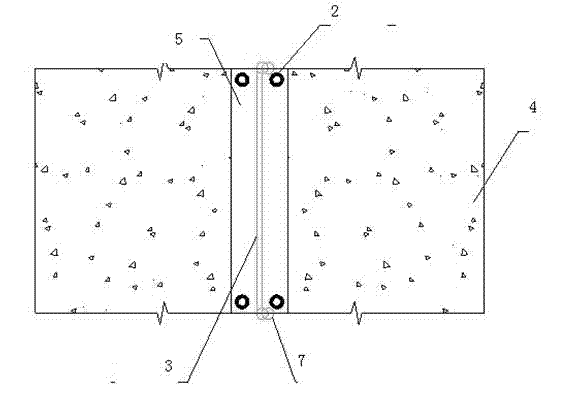

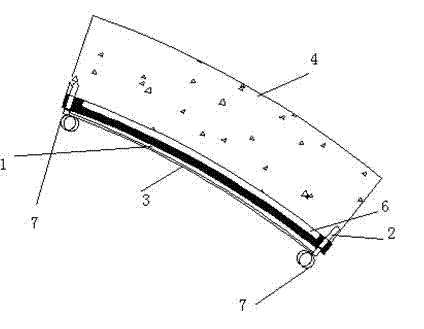

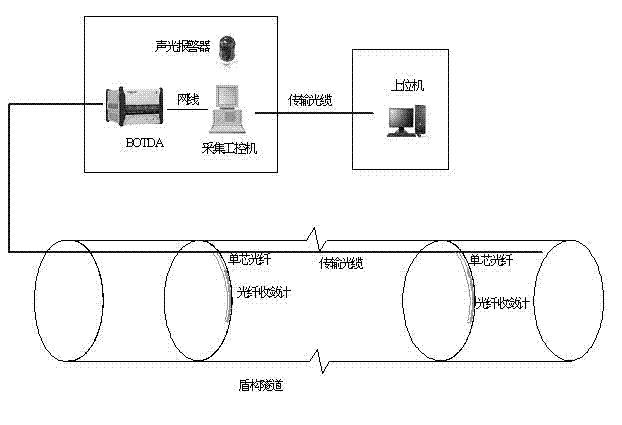

Tunnel convergence deformation distribution fiber monitoring method and system thereof

InactiveCN102384725ARapidly converges on deformed dataObtain converged deformation data quicklyThermometers using physical/chemical changesUsing optical meansTime domainSEMI-CIRCLE

A tunnel convergence deformation distribution fiber monitoring method is disclosed. A setting method of a distributed fiber convergence deformation monitoring sensor is adopted. The method is characterized in that: a sensing fiber is arranged on a matrix sheet material surface which has a same shape with an inner-side curved surface of a shield tunnel concrete segment so as to form a distributed fiber convergence deformation sensor and two ends of the sensor are respectively fixed on the inner side of the concrete segment; a cross section is in shapes of a rectangle, a U shape, a semi-circle or an arc or a circular ring; the sensing fiber has two parallel paths; one path is tight buffer fiber, which is used to measure strain alonga radial direction of the sensor; the sensing fiber is arranged on the surface of the sheet material sensor; using Brillouin optical time domain analysis (BOTDA) method, through calibrating correlation between a sensor gauge length convergence value and sensing fiber strain variation, convergence state change information of the tunnel section can be converted and measurement of the tunnel section convergence value can be performed. By using the invention,monitoring and measuring precision of the convergence state of the any representative section of the tunnel is high.

Owner:NANJING UNIV

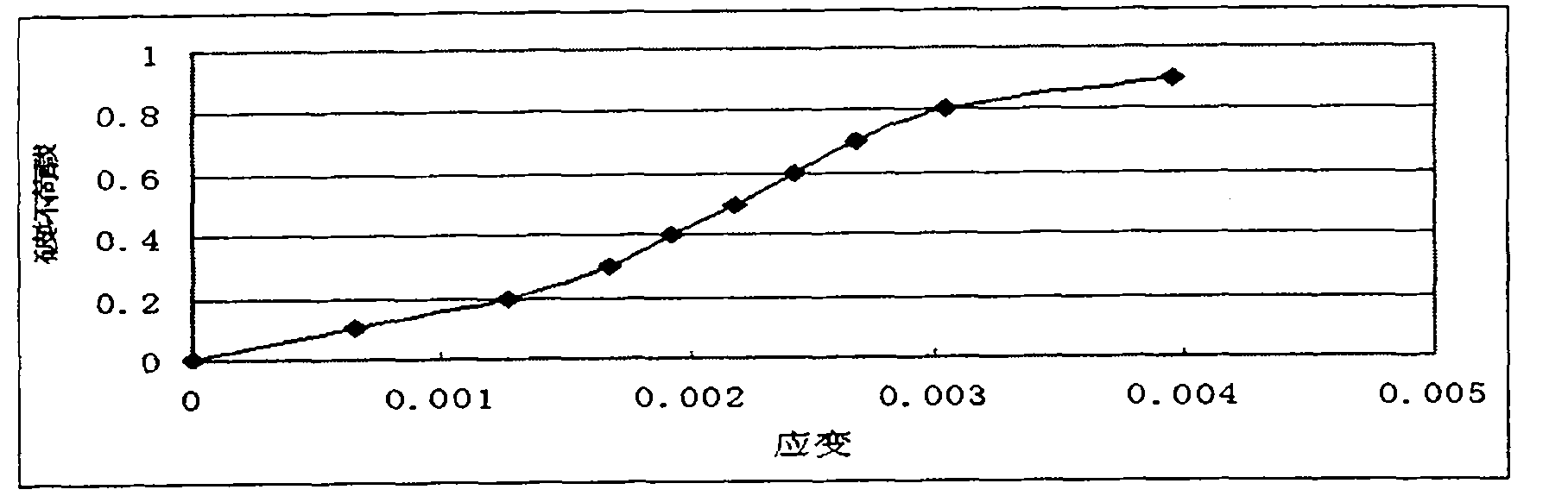

Method for determining modulus of elasticity of plastic concrete

InactiveCN102116716AAvoiding the Pitfalls of Experimental ErrorReflect deformabilityStrength propertiesPrismEngineering

The invention discloses a method for determining modulus of elasticity of plastic concrete. 3 150x150x300mm prism testing pieces are manufactured under industrial standards, the testing pieces to be measured are placed on a testing machine and starting reading is recorded, the testing machine is started, deformation values under various loads are recorded, and static compressive modulus of elasticity of the testing pieces are calculated in accordance with the following equation Ec = (P1 / A) x (L / deltaL), wherein L is the full length of the testing pieces. The average value of the static compressive modulus of elasticity of the three testing pieces is regarded as the testing result. The method fills in the blank in the aspect of plastic concrete testing method, is characterized by adopting full gauge length for measuring the testing pieces, avoiding pre-pressing procedure and taking the slope of 40% secant as the elastic modulus value of the plastic concrete, and simultaneously eliminates 0.5MPa of stress and the calculation of stress items thereof from the calculation of the testing result, thereby overcoming the defect of large error in the prior method, achieving simpler and faster testing process and being advantageous for the popularization of the method.

Owner:SINOHYDRO BUREAU 14 CO LTD

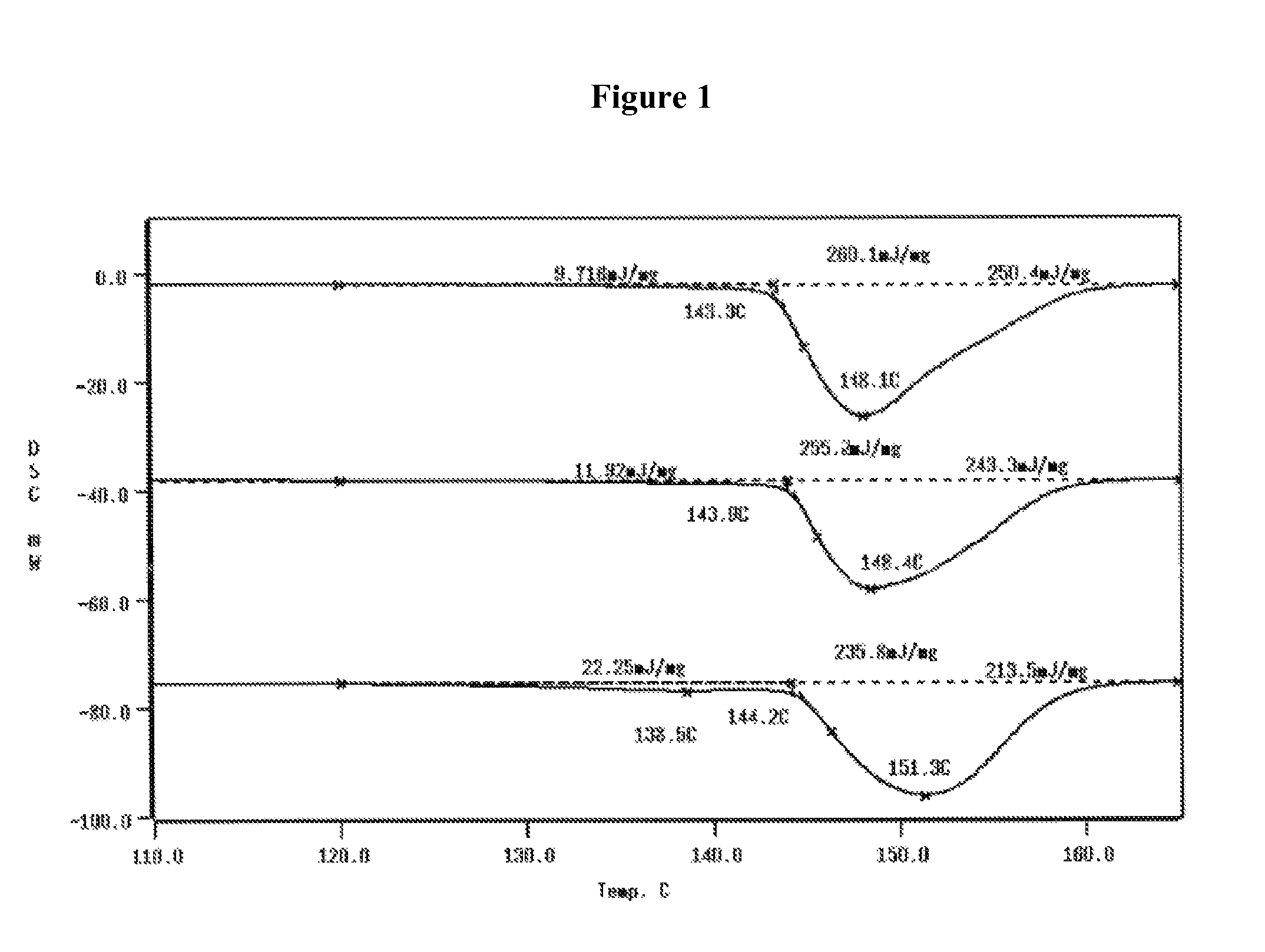

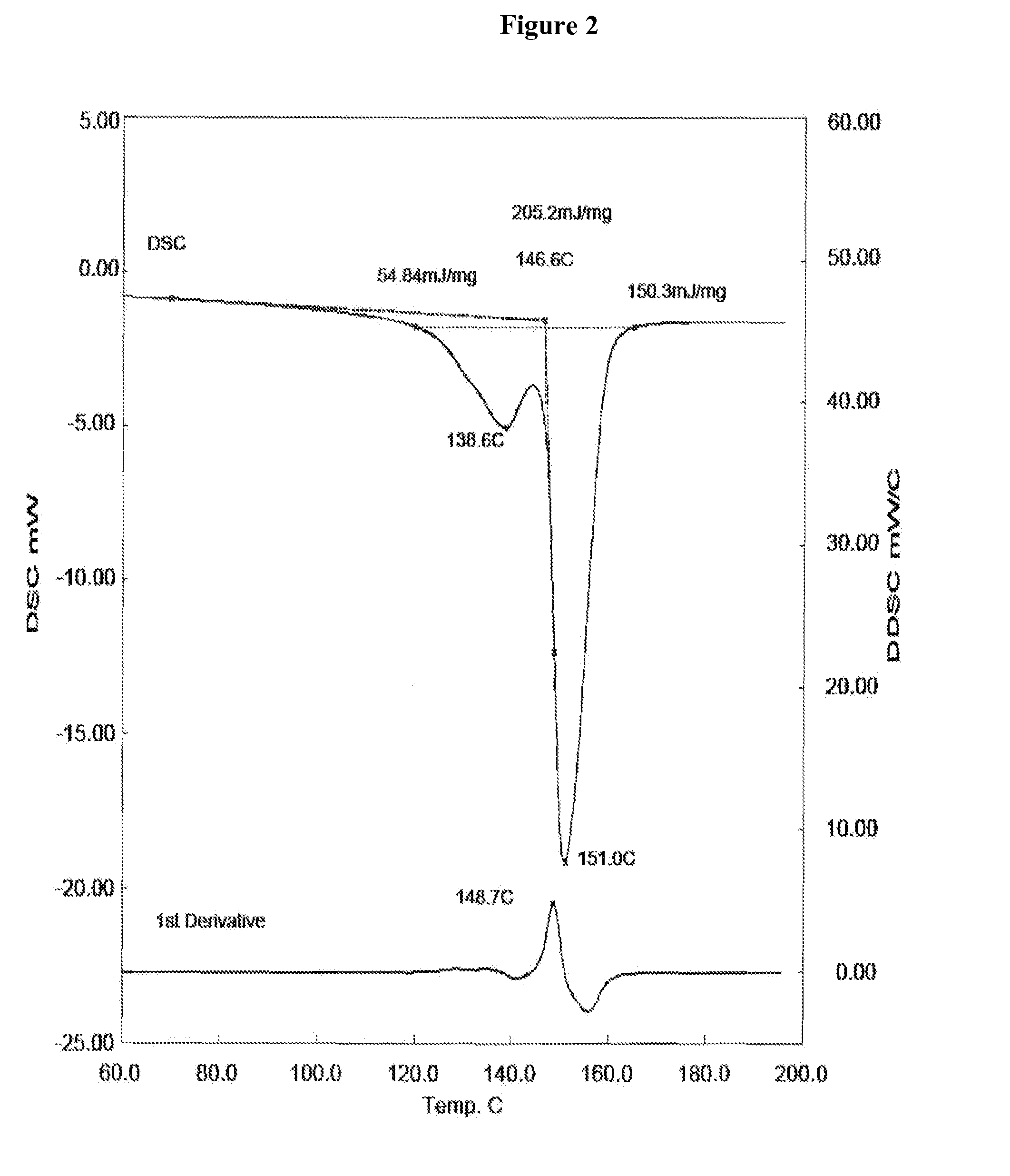

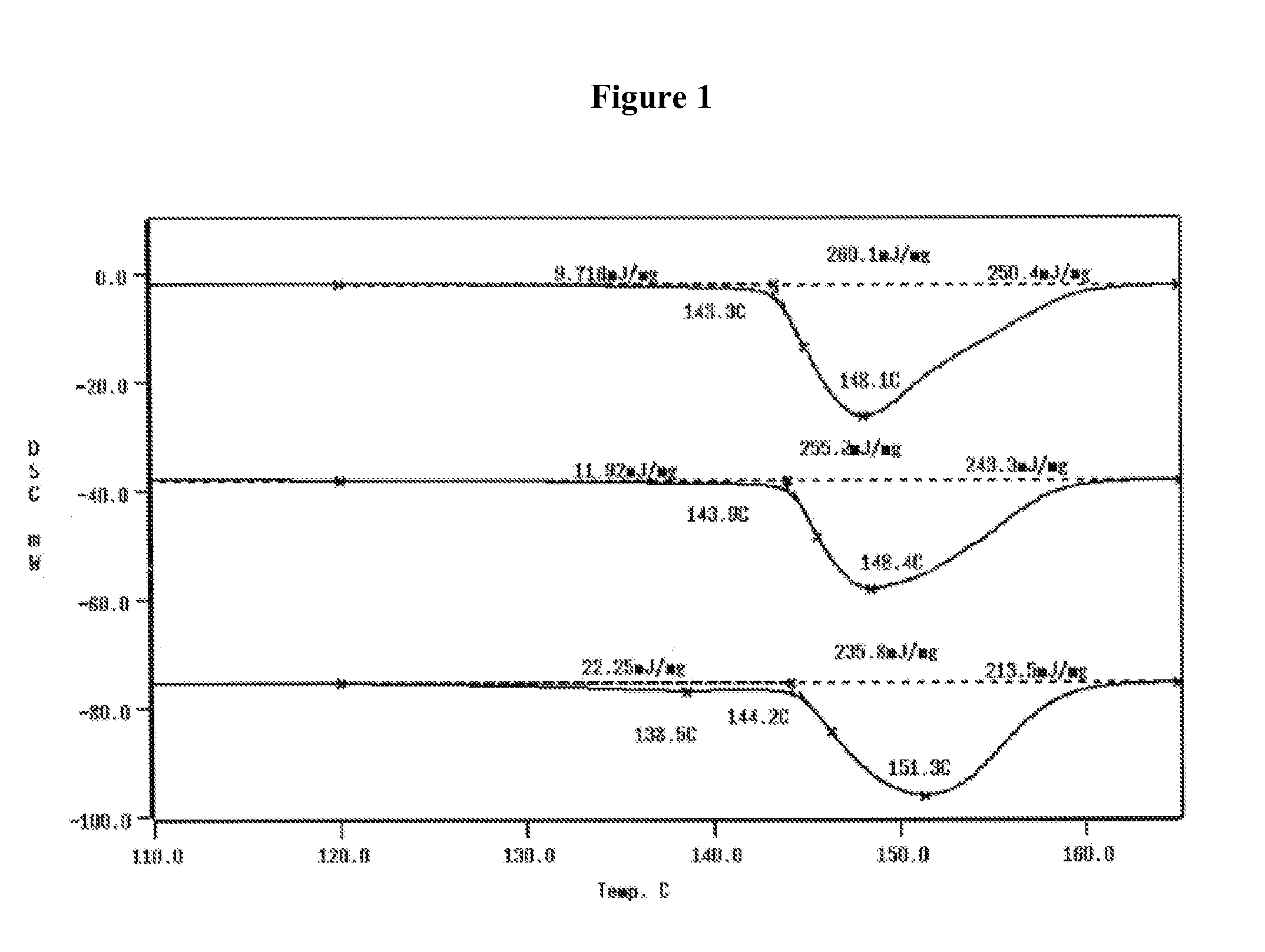

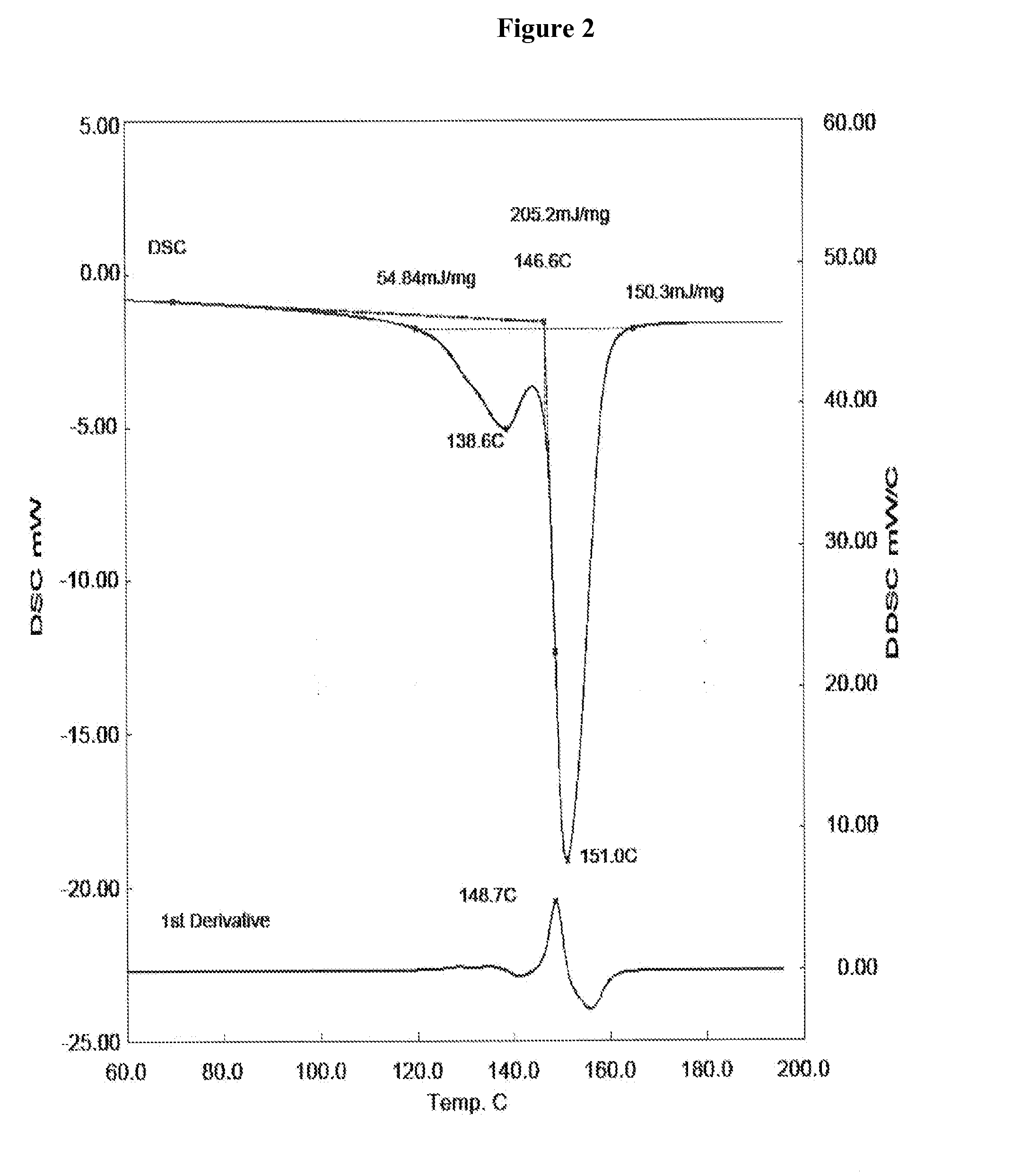

High strength tape articles from ultra-high molecular weight polyethylene

ActiveUS20120121852A1High yarn strengthHigh strengthArmourOrnamental textile articlesYarnPolymer science

Tape articles having improved properties are made from ultra-high molecular weight (UHMW) multi-filament yarns. The tape articles can have a ratio of the low temperature area under the curve (120° C. to Tm-onset) to the total area under the curve (120° C. to 165° C.) of less than about 0.15 as calculated from an increasing temperature DSC scan from a temperature of 30° C. to a temperature of 200° C. at a constant rate of 10° C. per minute. Additionally, in some examples the tape articles can also have a tenacity at least about 24 g / d (2.06 GPa) when measured by ASTM D882-09 at a 10 inch (25.4 cm) gauge length and at an extension rate of 100% / min. Further, the tape articles can have no long period of less than 450 Angstroms (Å) when measured by small angle x-ray analysis.

Owner:HONEYWELL INT INC

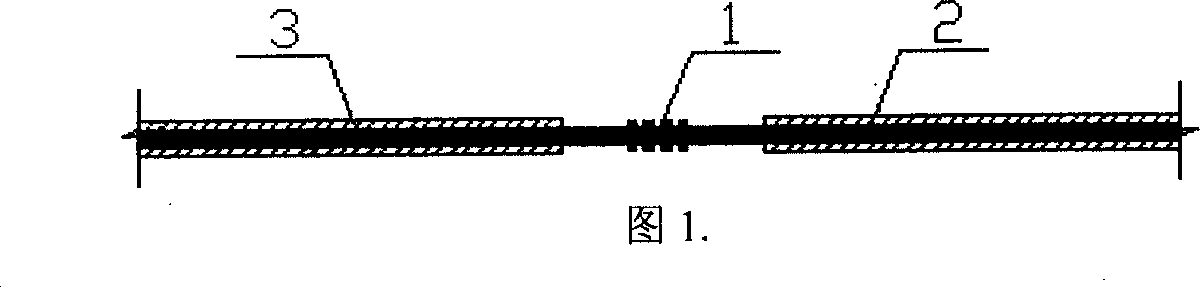

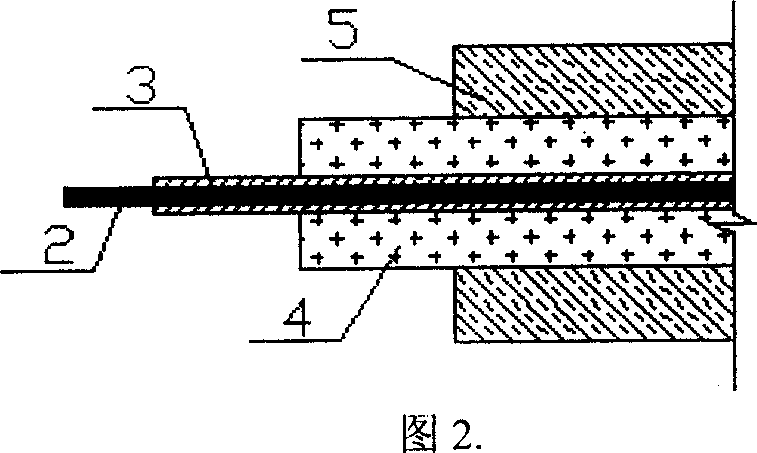

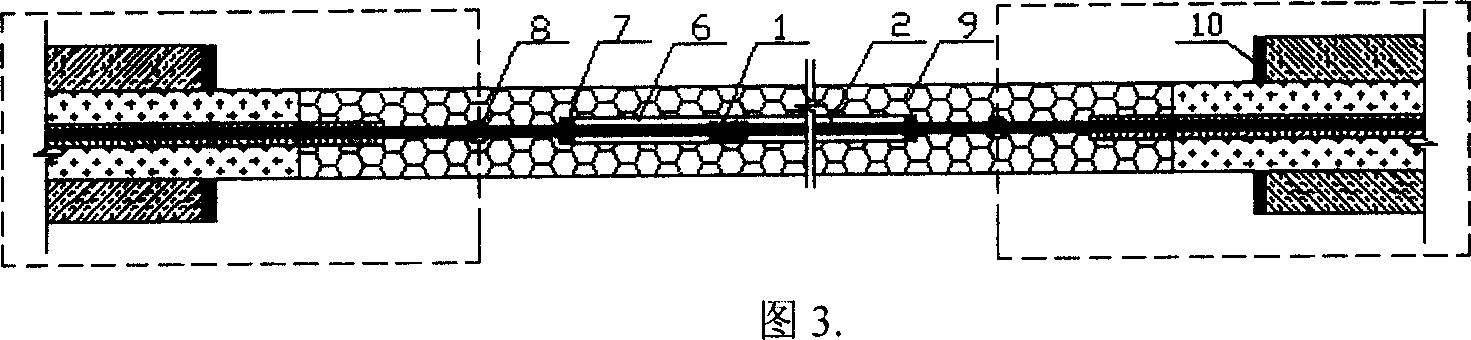

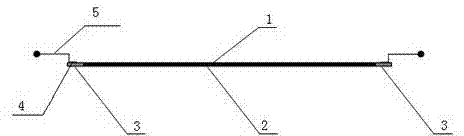

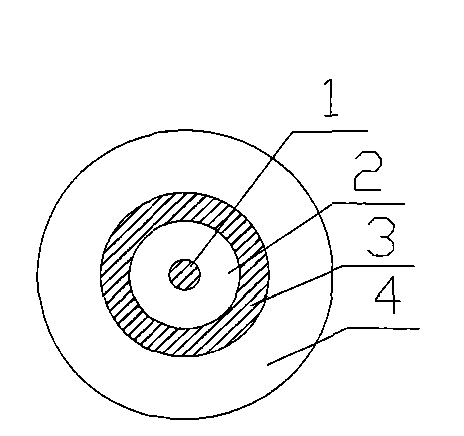

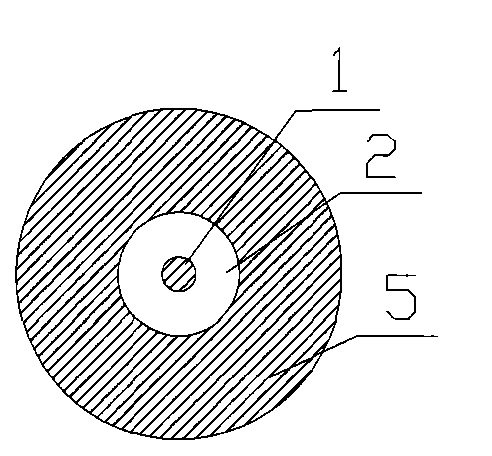

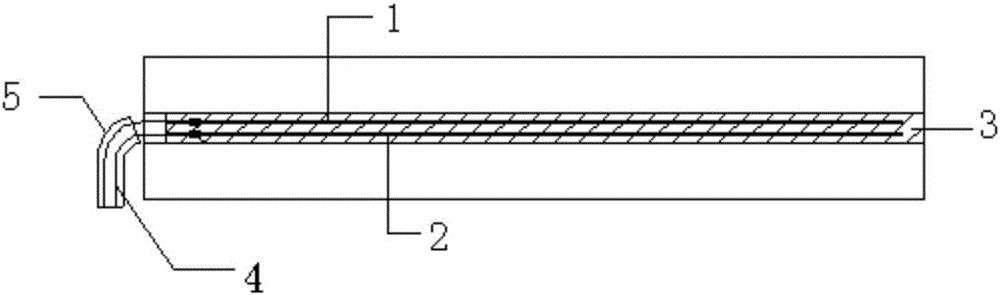

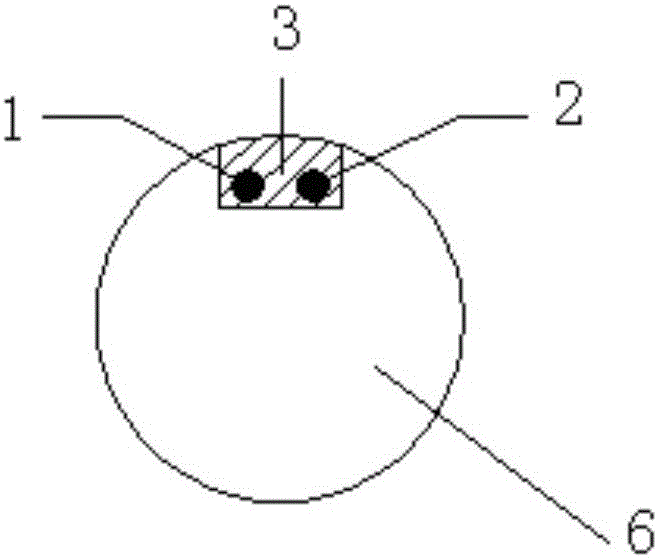

Distributed long gauge length optical fibre Bragg optical grating strain sensor and mfg. process thereof

The invention relates to distributivity long gauge length optical fiber Prague grating strain gage and its manufacturing method. It is formed by many long gauge length optical fiber Prague grating strain gages with series connection. The two ends of the each long gauge length optical fiber Prague grating are respectively connected with mono-mode fiber without coating. Their outer is hitched by annular tube of which two ends are fixed on the mono-mode fiber respectively by optical fiber and annular tube, which two ends are connected with outer mono-mode fiber optical cable by welding point. Composite material packaging layer is covered at the outside of the above structure.

Owner:江苏绿材谷新材料科技发展有限公司

Bridge damage identification and assessment method based on long gauge length rigidity coefficient

ActiveCN106092623AQuick checkQuick monitoringStructural/machines measurementData acquisitionEngineering

The invention discloses a bridge damage identification and assessment method based on a long gauge length rigidity coefficient. The method comprises the following steps of establishing a distributed long gauge length strain sensing monitoring system, wherein a plurality of long gauge length strain sensors are arranged in key areas of a monitored bridge structure; collecting data when a single vehicle crosses a bridge; calculating the rigidity coefficient of each unit based on a distributed long gauge length strain time history and the central coordinates of each sensor; forming the long gauge length unit rigidity coefficient of each unit into a matrix, and forming a long gauge length unit rigidity coefficient matrix of a bridge; performing bridge damage identification and carrying capacity state assessment; and identifying the damage degree using the change condition of long gauge length rigidity coefficients, and improving the reliability of an identification result by repeated sample data analysis. The invention can rapidly detect and monitor a bridge without influencing normal traffic operation, can extract the rigidity distribution condition of a bridge structure, and can provide a reliable basis for bridge management and maintenance.

Owner:SOUTHEAST UNIV

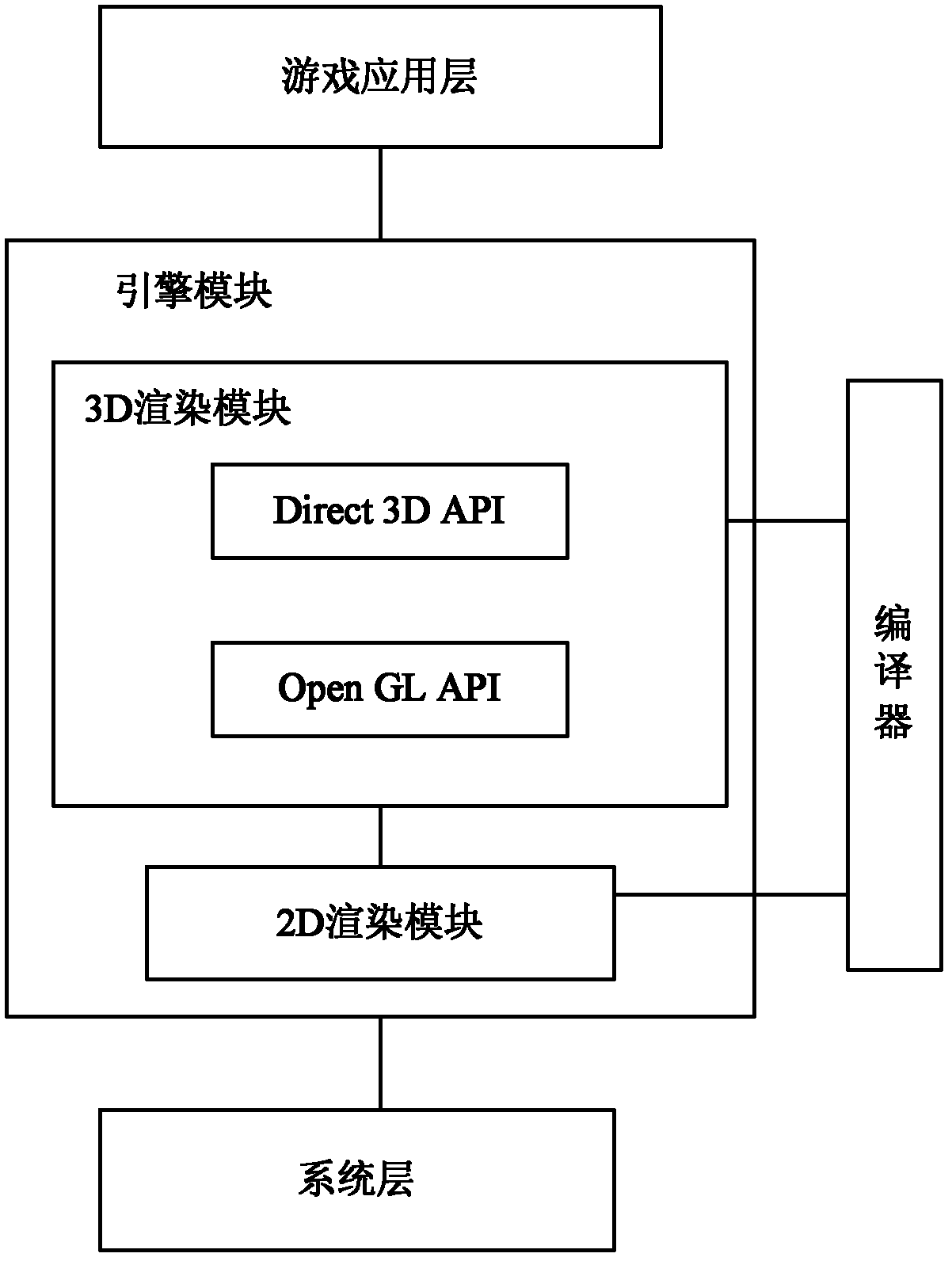

Geart three-dimensional (3D) game engine

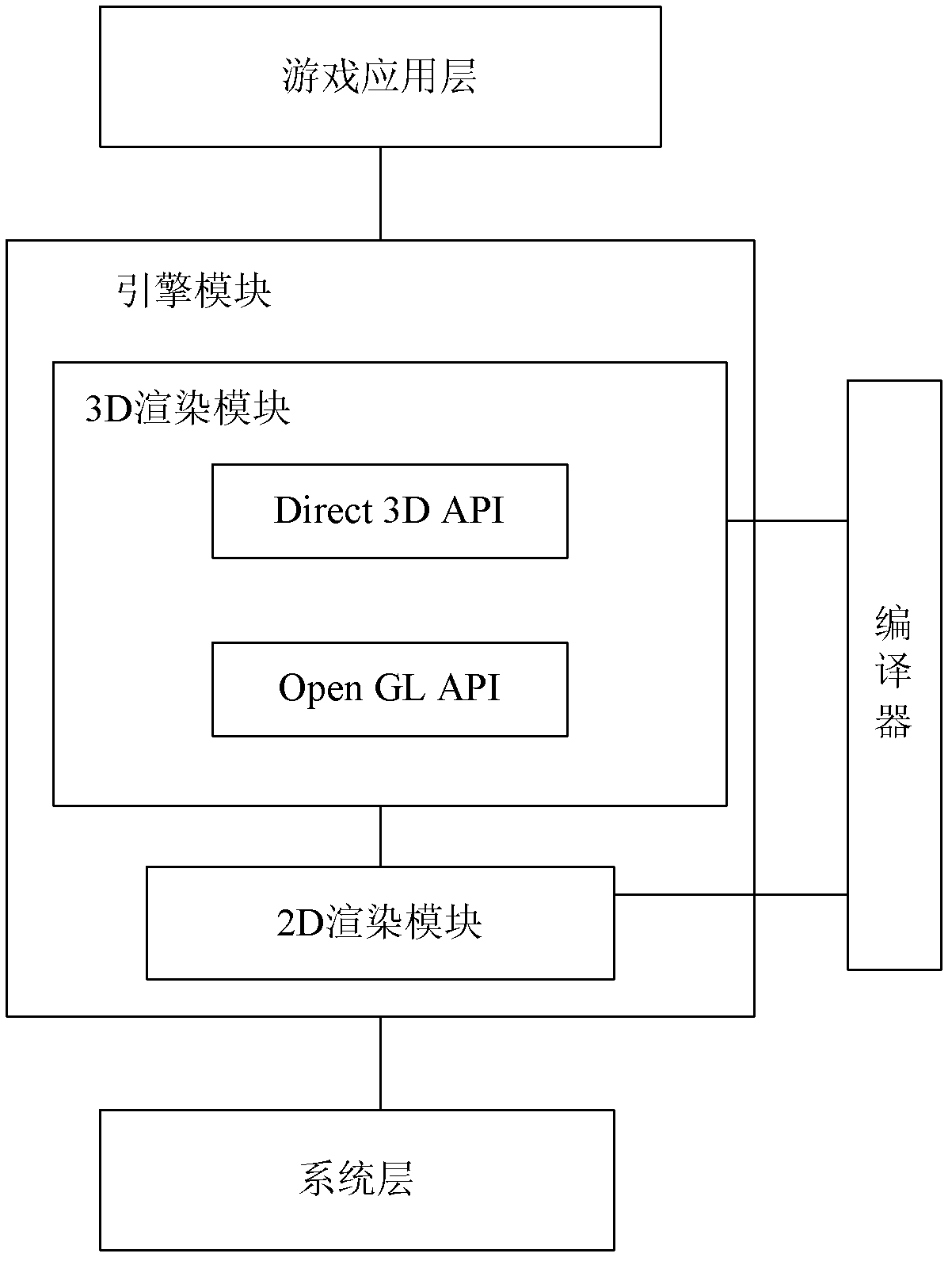

The invention discloses a Geart three-dimensional (3D) game engine which comprises a game application layer, an engine module, a system layer and a compiler, wherein the engine module is arranged between the game application layer and the system layer, and the compiler is connected with the engine module; the engine module comprises a 3D rendering module and a 2D (two-dimensional) rendering module, which are connected with each other, and the 3D rendering module comprises a Direct 3D application program interface (API) and an Open gauge length application program interface (GL API); the compiler is used for compiling a code input by a user into a program, detecting the compiling environment of the user in the process of compiling, and selecting the API according to the compiling environment of the user; and the two-dimensional (2D) rendering module is used for forming a plane figure by putting each peak point in a 3D figure rendered by the 3D rendering module into a plane when a compiling program is received, and gluing textures on the plane figure. The game engine provided by the invention is compatible with different operation platforms, and is higher in flexibility, so that the 2D game and the 3D game can be simultaneously developed.

Owner:深圳市天拓立方通讯科技有限公司

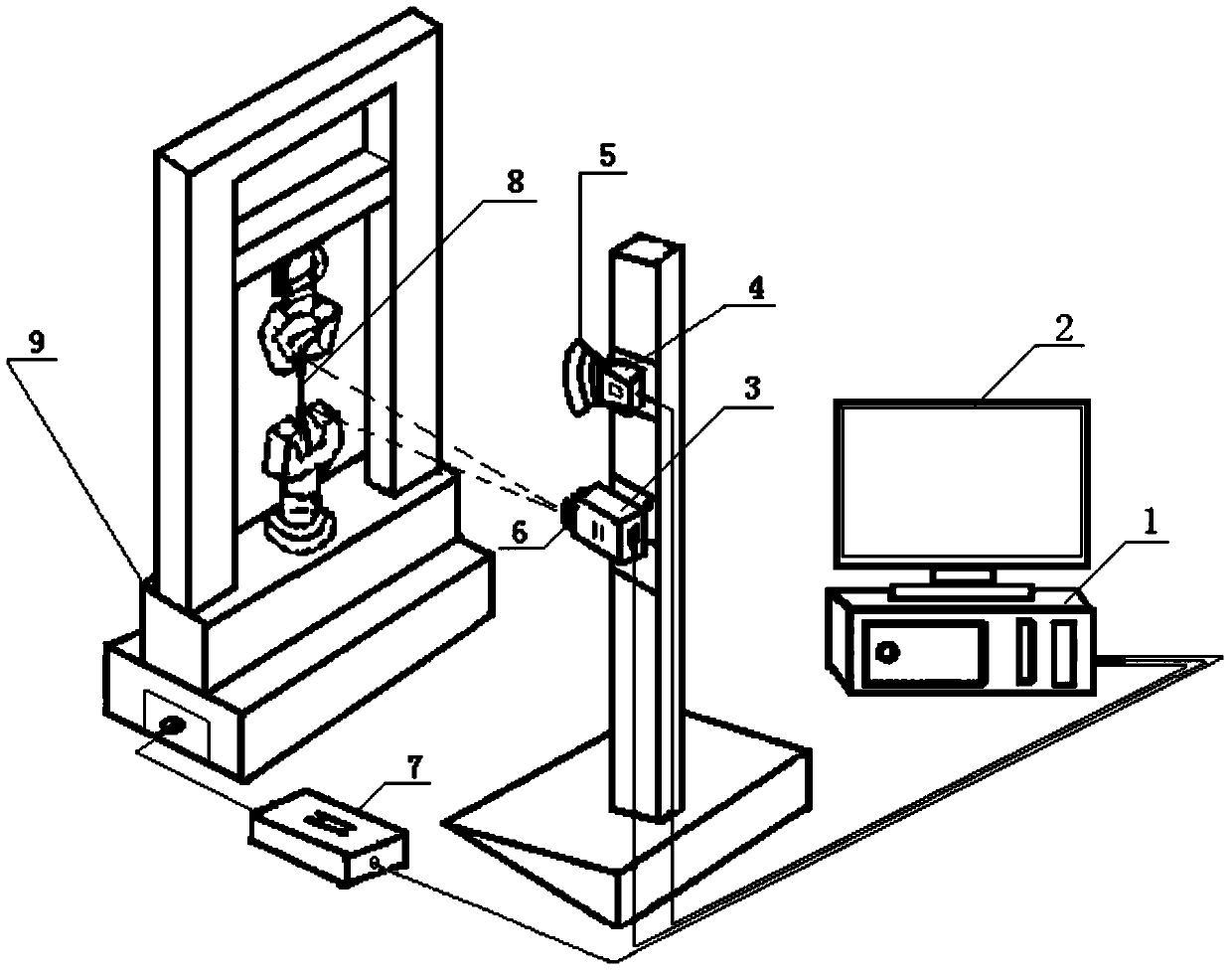

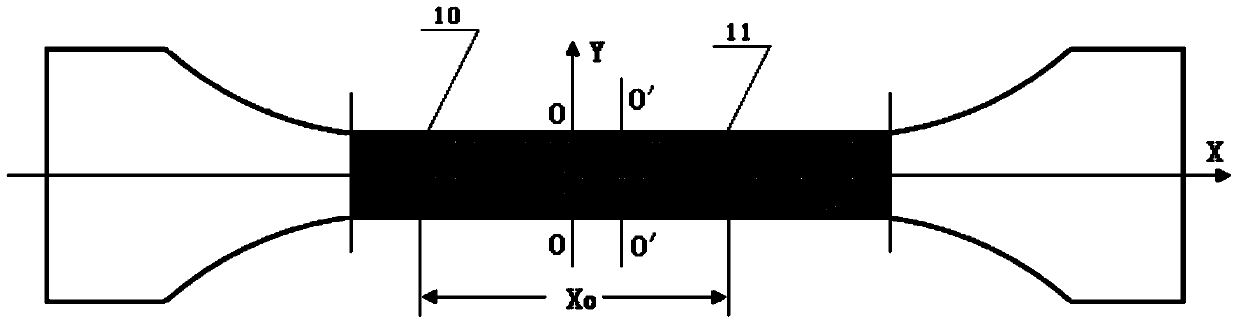

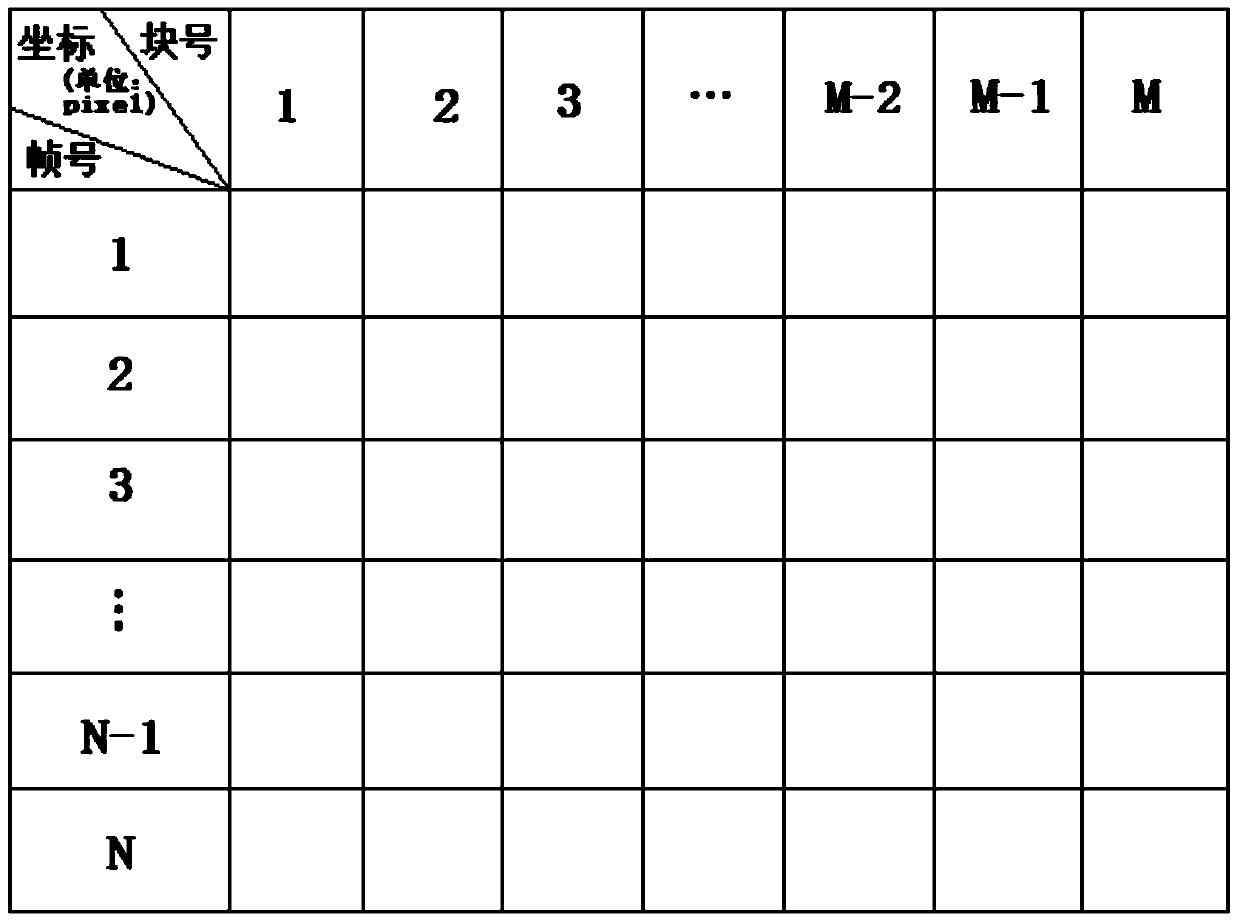

Intelligent breaking elongation test method of metal material based on random point tracking

InactiveCN103471910AReduce mistakesRealize intelligenceMaterial strength using tensile/compressive forcesInvestigating material ductilityMetallic materialsComputer science

The invention relates to an intelligent breaking elongation test method of a metal material based on random point tracking. Before test, random points in irregular sizes and shapes are sprayed on the surface of the detected metal material by paint spraying equipment as marks. The method comprises the steps of: during the test, acquiring an image sequence of surface deformation of the detected material with a machine vision system, automatically selecting a best original gauge length and a final gauge length for calculating breaking elongation of the metal material according to a breaking position and preset local elongation, and accurately working out the breaking elongation of the metal material. With the adoption of the method, the detection precision of the breaking elongation of the metal material can be improved, different local elongations and a deformation trend of the material during tension can be automatically analyzed and calculated, and the method provides scientific bases for material detection and product design.

Owner:DONGHUA UNIV

Distributed high-precision long-gauge-length carbon fiber strain test device and method

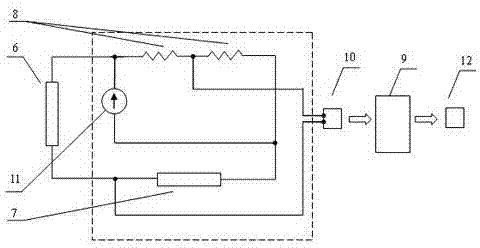

InactiveCN102494603AFewer post-processing stepsImprove linearityElectrical/magnetic solid deformation measurementMicrocontrollerCarbon fibers

The utility model discloses a distributed high-precision long-gauge-length carbon fiber strain test device and a method, and relates to the technical field of health detecting and monitoring in a civil engineering traffic structure. One of long-gauge-length carbon fiber strain sensors is taken as a working piece, the other long-gauge-length carbon fiber strain sensor is taken as a temperature compensating piece; a signal output end of a Wheastone temperature compensating bridge is connected with a signal input end of a primary signal, a signal output end of the primary signal is connected with a signal input end of a singlechip, and a signal output end of the singlechip is connected with a signal input end of a high-credibility approximate truth value. The invention aims at providing the distributed high-precision long-gauge-length carbon fiber strain test device for sensing performance of the comprehensive carbon fiber materials in the small strain range, which realizes the sensing of small strain of structures in large range under the condition of long-term unstable temperature so as to achieve the continuous detecting and monitoring on the stress (strain) of the structure.

Owner:SOUTHEAST UNIV

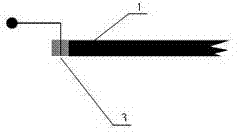

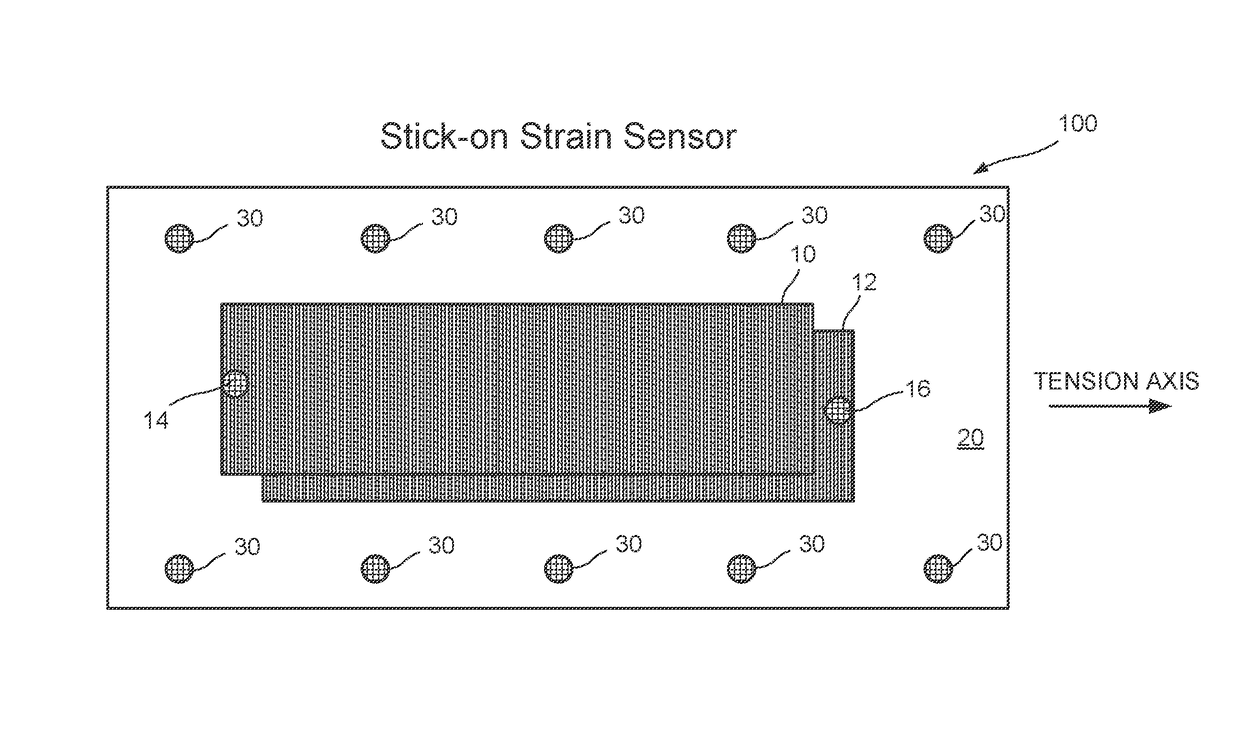

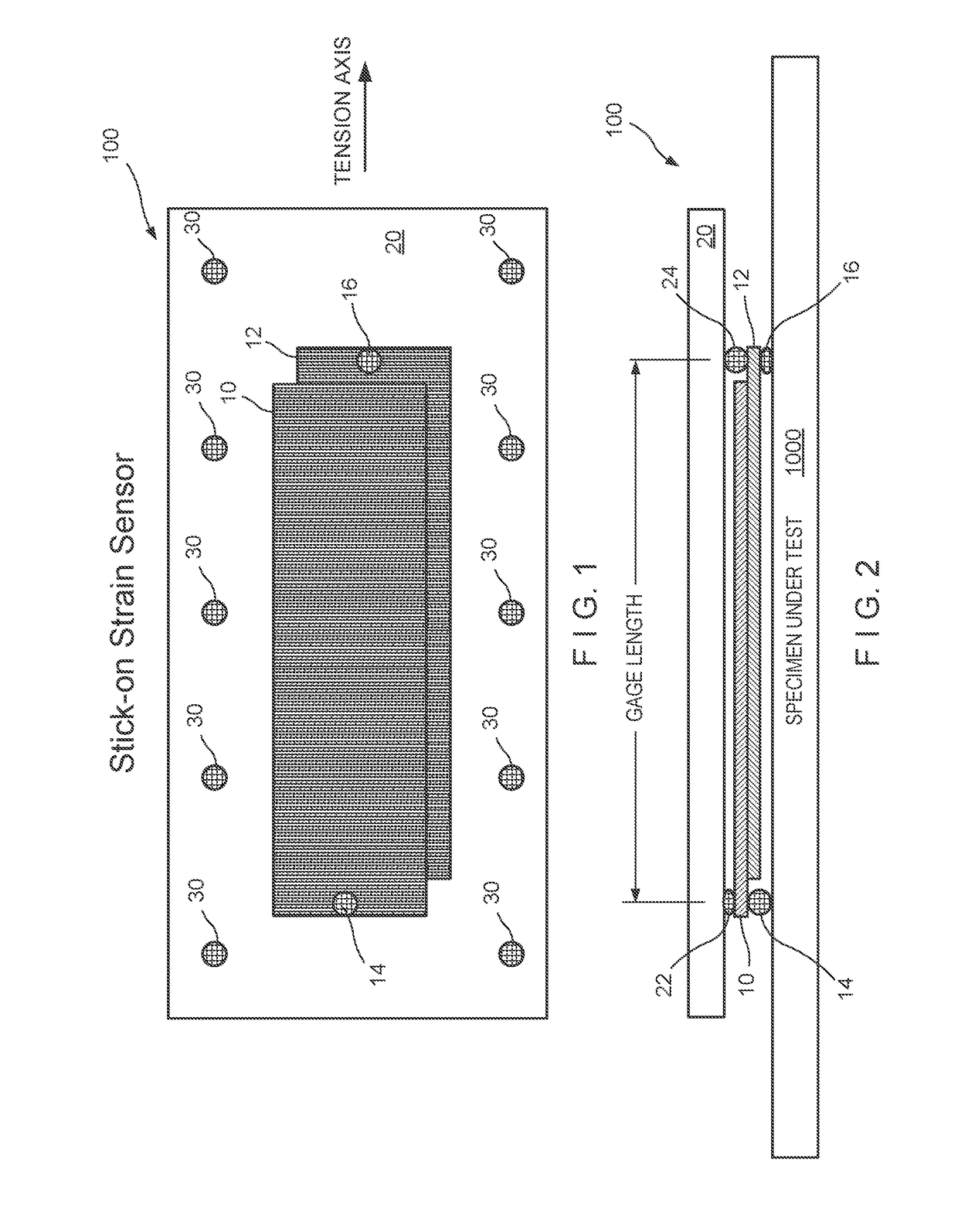

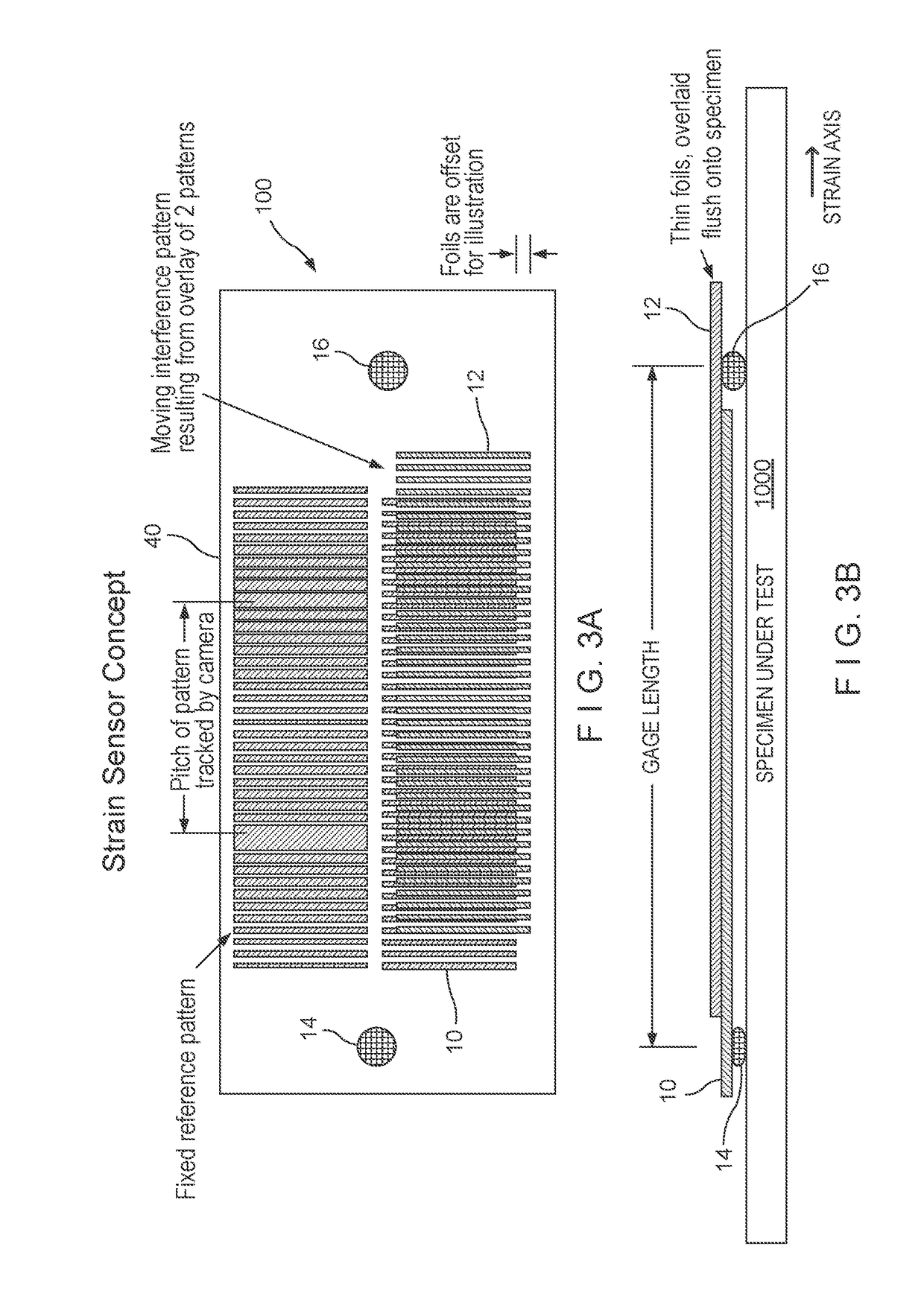

Optical strain gauge

This disclosure presents a method of measuring the strain response of a test material remotely by optical devices using a thin multi-layer assembly, called an optical strain gauge, which is attached directly to the test specimen by pair of adhesive patches built into the assembly. The optical strain gauge assembly attaches quickly and easily by just pressing it onto the specimen by virtue of the two pressure-activated adhesive patches. There is typically no surface preparation necessary for the test specimen. The spatial separation between the two patches adhered to the specimen surface serves to establish an initial gauge length for calculating strain by measuring the stress induced changes to this separation when a load is applied to the test specimen.

Owner:ILLINOIS TOOL WORKS INC

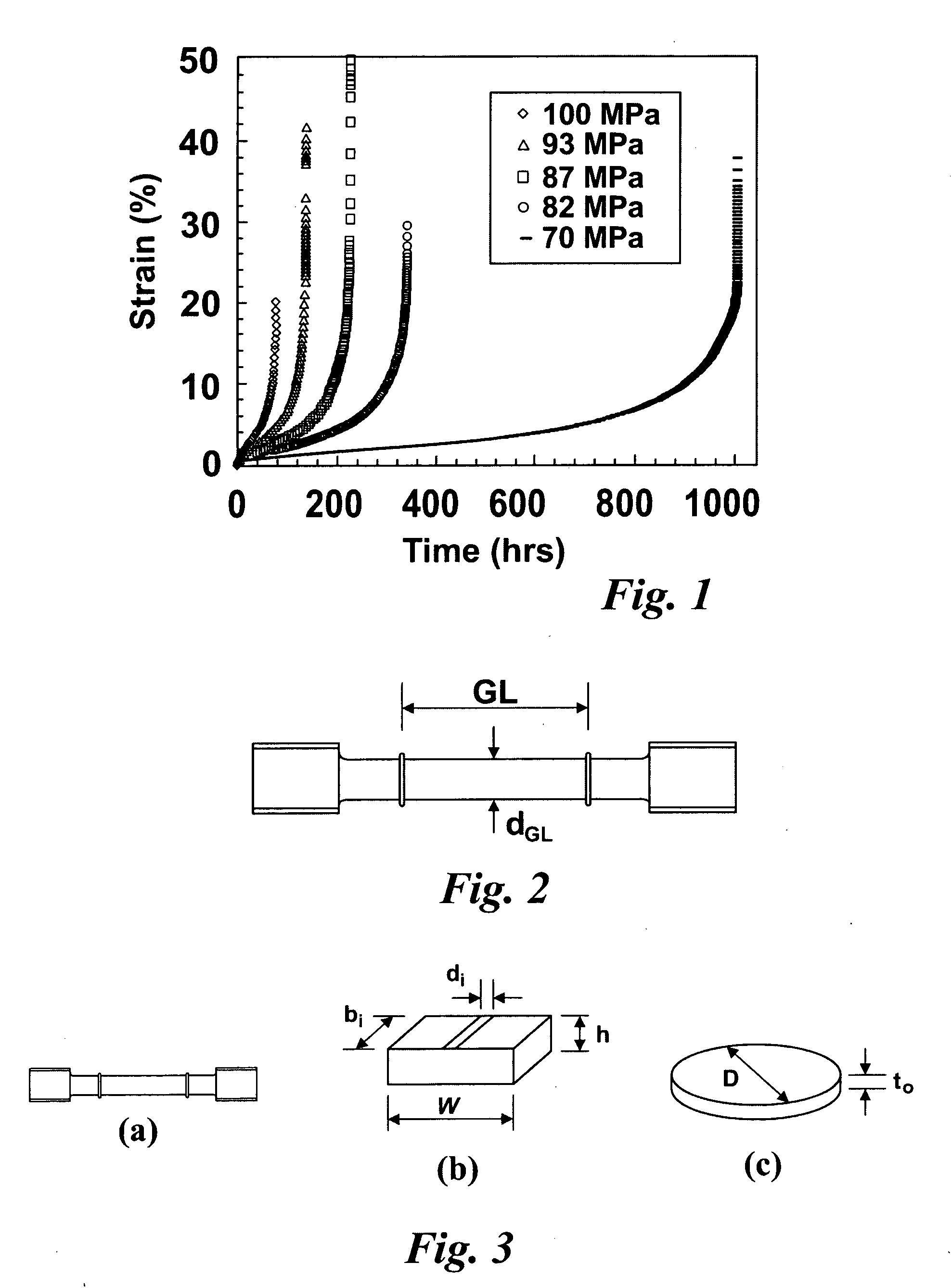

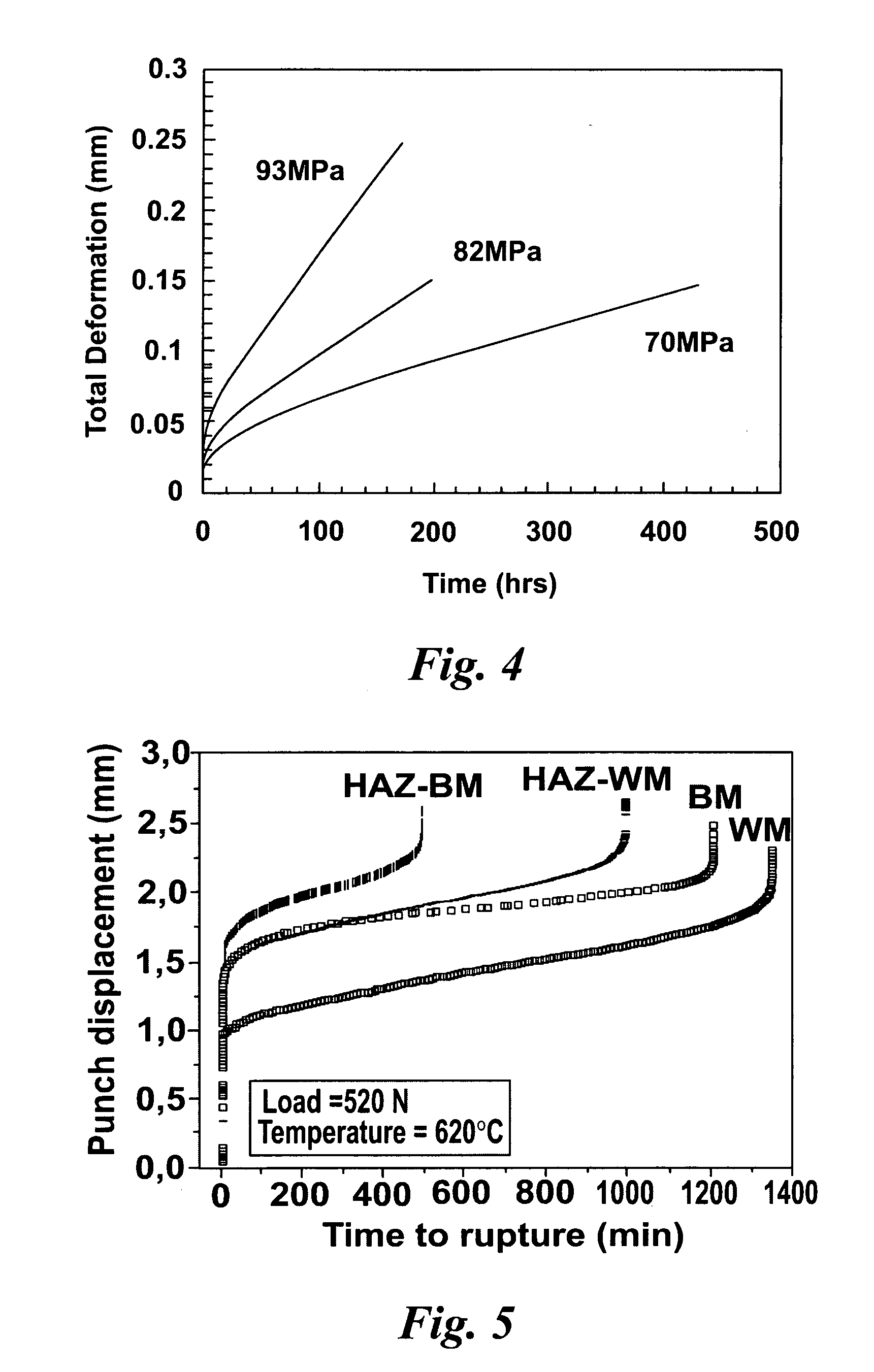

Specimen creep test and methods of using such tests

InactiveUS20110277553A1Easy to measureLarge deformationSynthetic resin layered productsForce measurementTest sampleEngineering

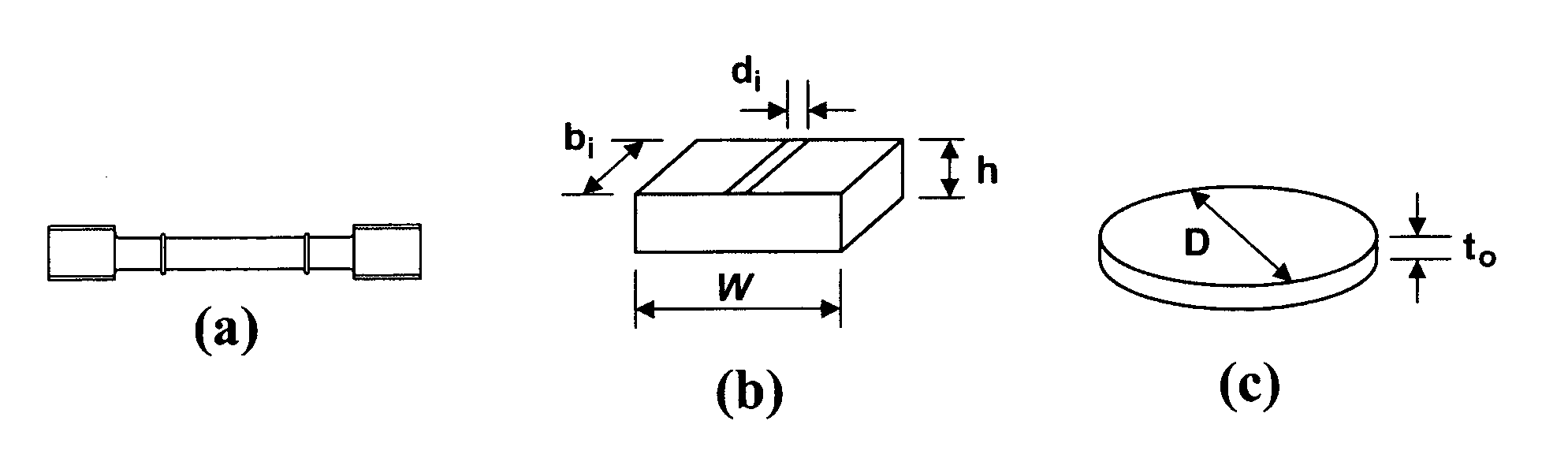

A method for testing the mechanical properties of a specimen having a first contact surface and a second contact surface spaced apart and opposing the first contact surface, the method comprising: applying forces to the contact surfaces of the specimen to deform the specimen over a period of time and determining the response of the specimen to the forces over time; and defining a spatial distance between the contact surfaces such that the equivalent gauge length of the specimen is greater than the distance between the contact surfaces.

Owner:UNIVERSITY OF NOTTINGHAM

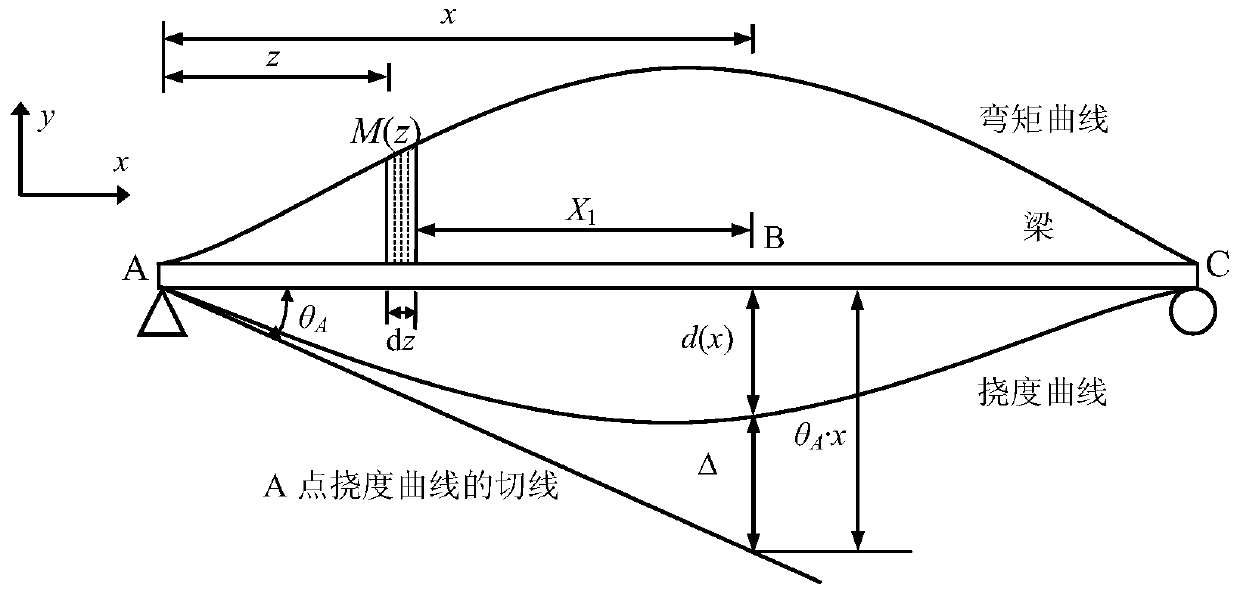

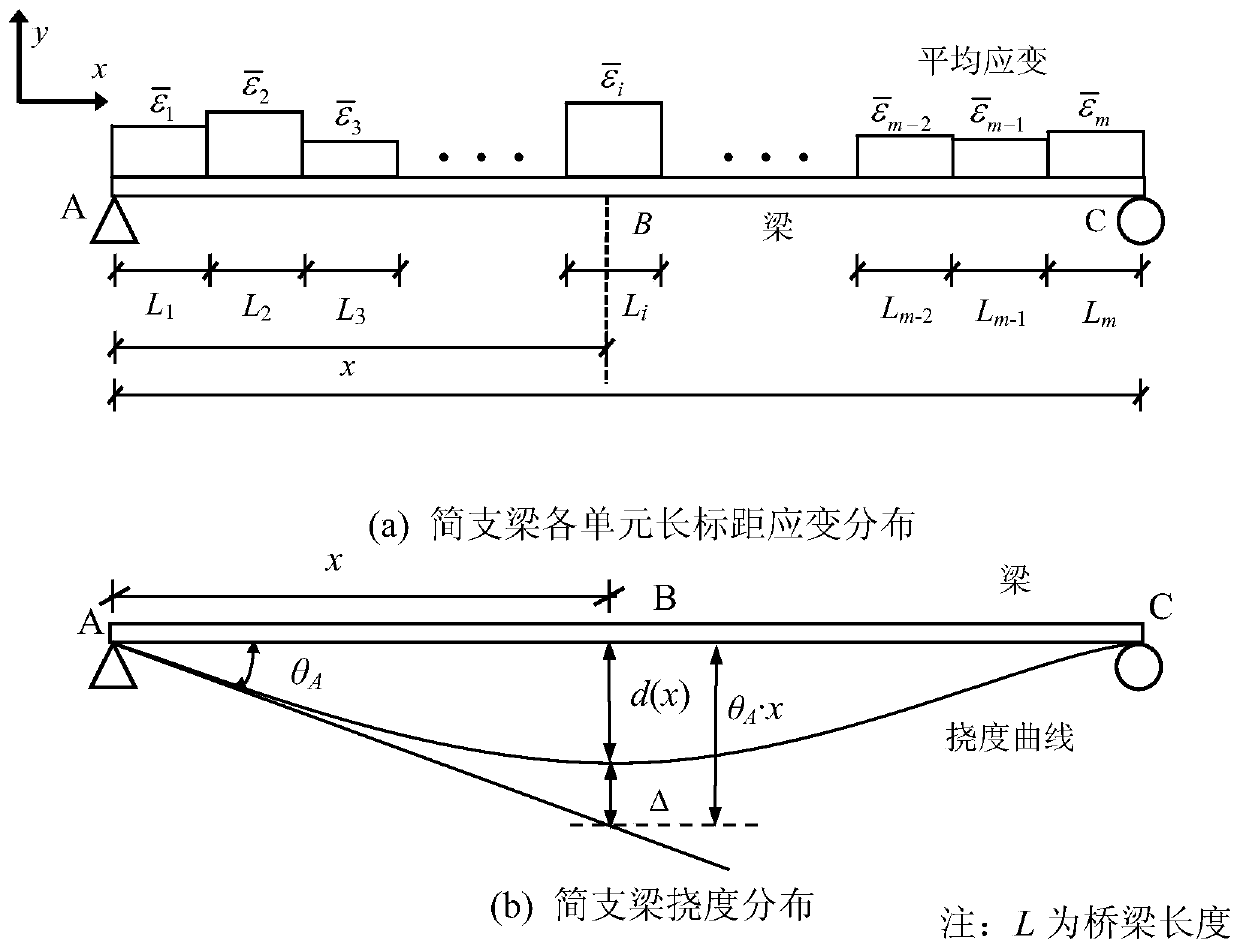

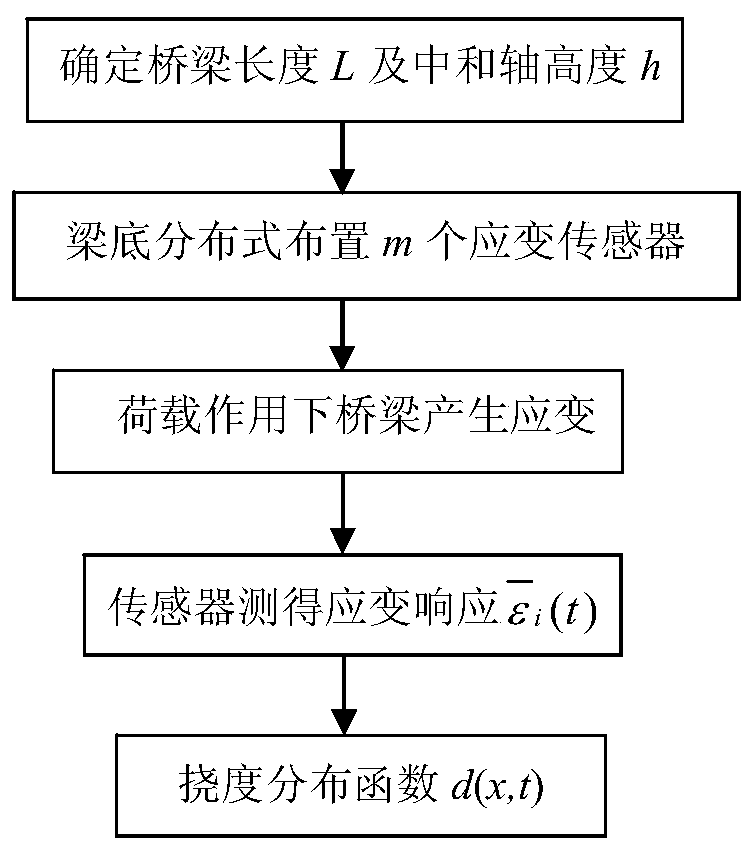

Method for identifying bridge deflection based on long gauge length strain improved bending moment area method

ActiveCN110487496AHigh measurement accuracyImprove stabilityElasticity measurementTime changesEngineering

The invention discloses a method for identifying bridge deflection based on a long gauge length strain improved bending moment area method. The method comprises the following steps of: S1, determininga bridge length L and a bridge cross section neutral axis height h; S2, continuously arranging m long-gauge-length strain sensors on the bridge in the length direction, and testing long-gauge-lengthstrain measured by each long-gauge-length strain sensor under the action of any load; S3, obtaining a function relationship between deflection and strain by adopting an improved bending moment area method; and S4, calculating the deflection of a point x at the moment t on the bridge according to the function relationship between the deflection and the strain. Based on an improved bending moment area method, the function relationship between the deflection and the strain can be deduced. Deflection distribution of any point on the structure along with time change and deflection distribution of the structure at any moment can be obtained through a formula in combination with the measured strain. The method is not affected by external loads, is suitable for static loads and dynamic loads, andis high in measurement precision, good in stability and convenient to use.

Owner:扬州市市政建设处 +1

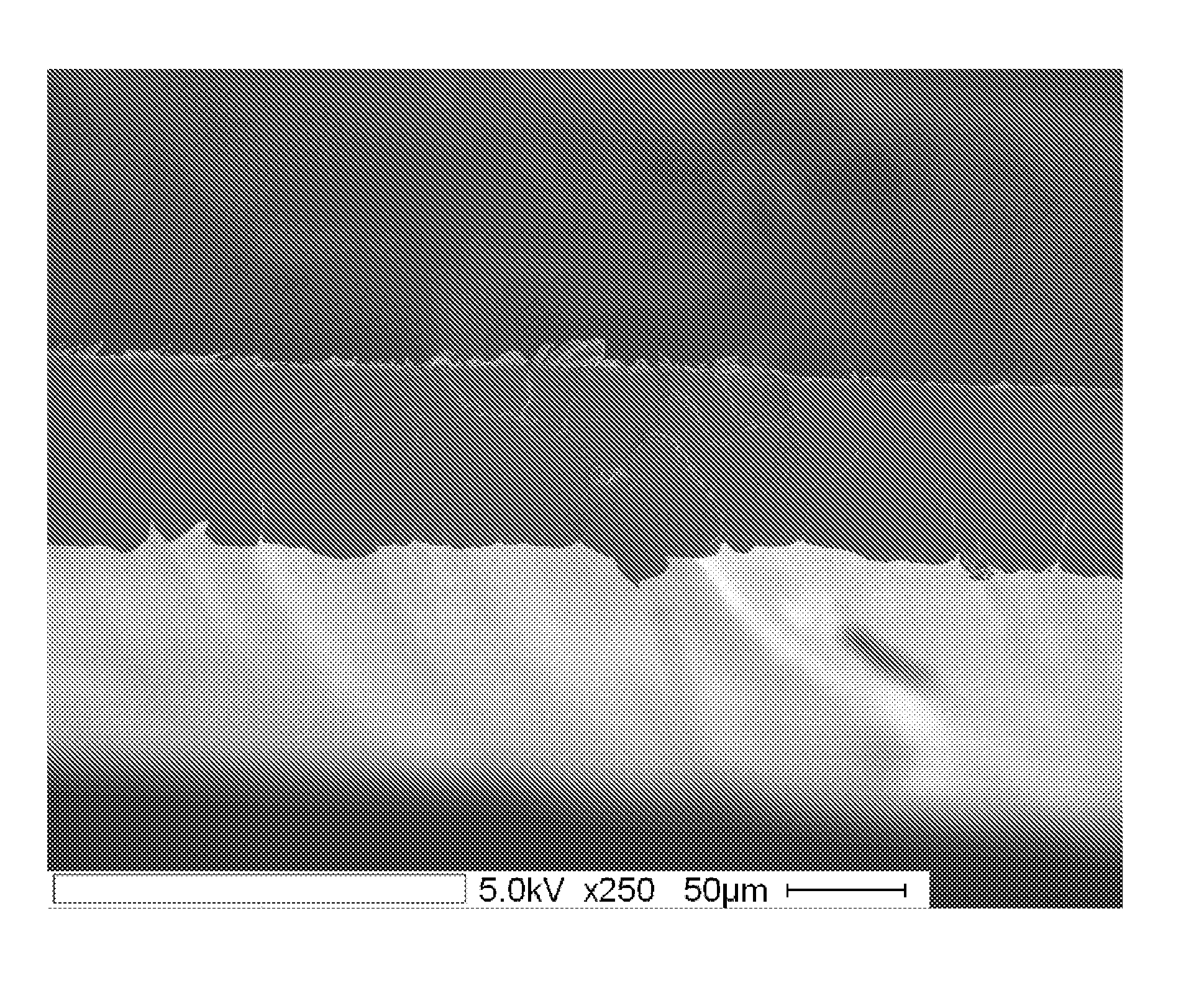

Scale manufacturing technique of distributed high-precision self-monitoring FRP bar/rope based on optical fiber sensing

InactiveCN101624790AComposite AccurateComposite uniformCladded optical fibreMaterial analysis by optical meansResin coatingOptical fiber cable

The invention discloses a scale manufacturing technique of a distributed high-precision self-monitoring FRP bar / rope based on optical fiber sensing. The technique mainly comprises the two procedures of: (1) preparation and packaging of a high-precision long gauge length optical fiber sensor, namely coating a resin coating layer with larger rigidity and thickness directly at the periphery of an optical fiber light-transmitting element, manufacturing non-slip optical fiber, then weaving / winding fiber at the periphery thereof in an unbonded manner and finally, coating an insulating gum with gauge length at the interval section of the surface to form a packaging product of long gauge length optical fiber; (2) using a long gauge length insulating method to manufacture the self-monitoring FRP bar / rope, namely leading the packaging product of long gauge length optical fiber into the scale production process of the FRP bar / rope, mainly comprising main techniques of control of optical fiber composite state, control of the shape of the self-monitoring FRP bar / rope and the like, and leading out the optical fiber in the insulating gum so as to be used for connecting other optical fiber by stripping the curved FRP. The product manufactured by the method can be cut randomly according to requirements and is a universal type product.

Owner:SOUTHEAST UNIV +2

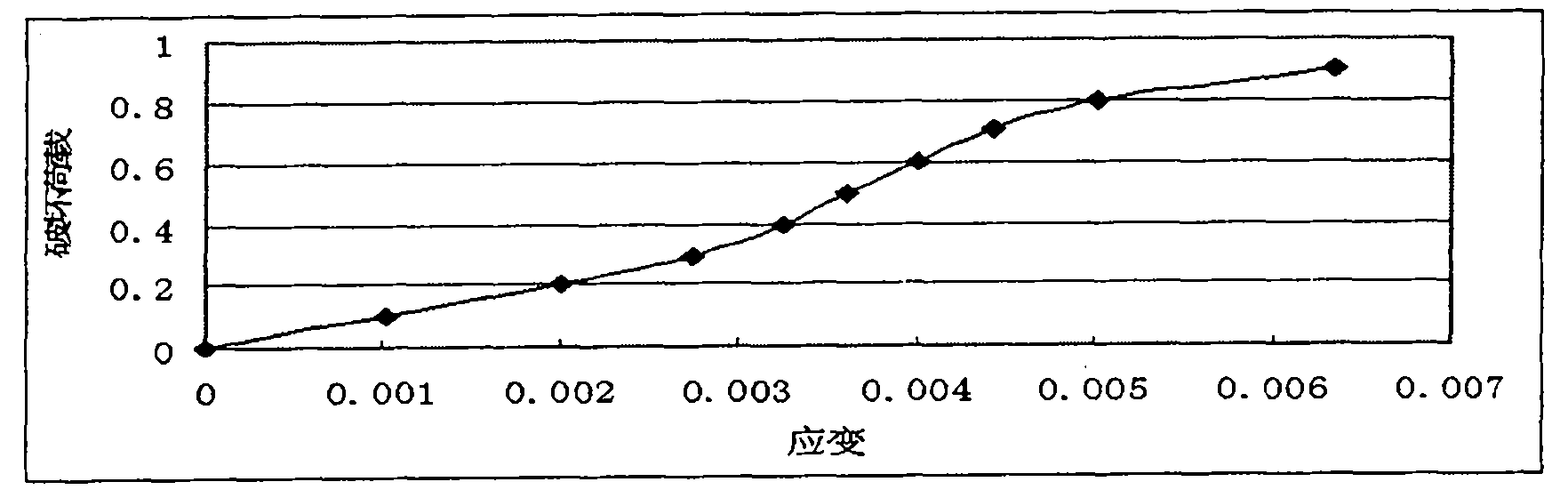

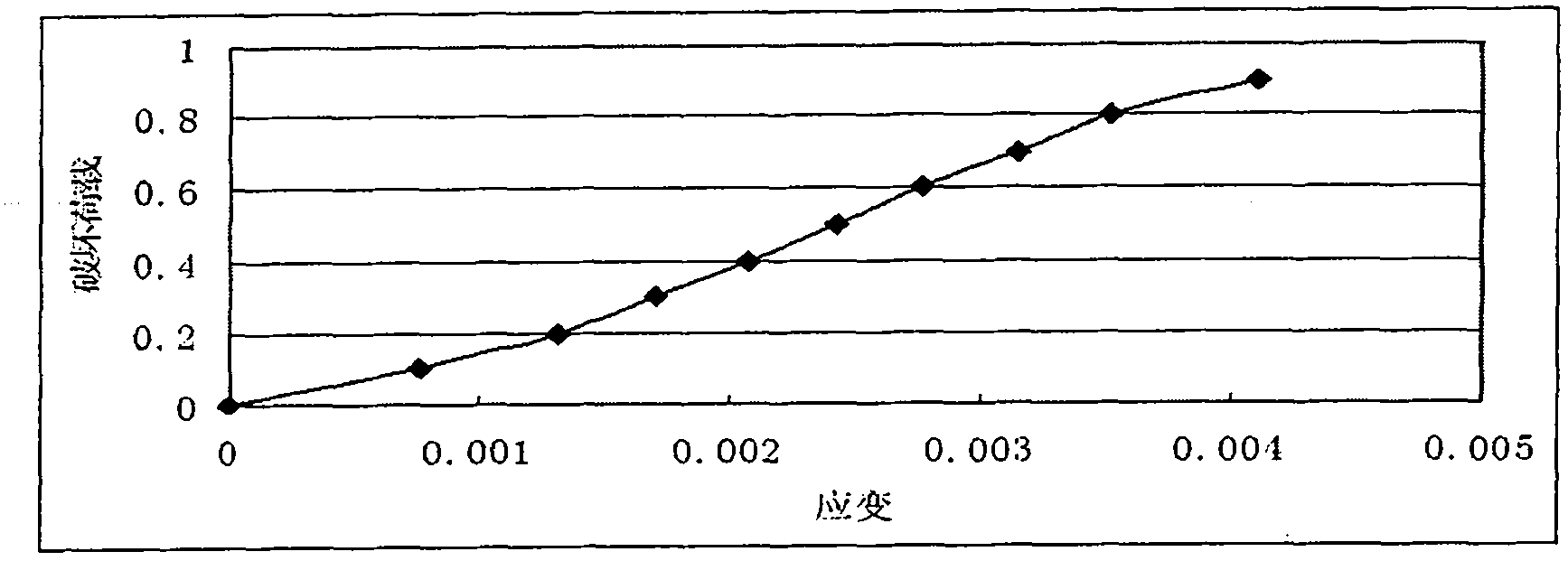

700MPa-level hot-rolled TRIP auxiliary dual-phase steel and preparation method thereof

The invention provides 700MPa-level hot-rolled TRIP auxiliary dual-phase steel and a preparation method thereof. The tissue of the 700MPa-level hot-rolled TRIP auxiliary dual-phase steel is residual austenite, martensite and ferrite, wherein the surface-layer tissue comprises 3-6% of the residual austenite, 16-25% of martensite and the balance of ferrite; point-like carbide is provided in the ferrite; the steel main body tissue comprises 2-5% of the residual austenite, 26-40% of martensite and the balance of ferrite; and no carbide is separated out from the ferrite. The steel has specified plastic extension strength of 384-406 MPa, has tensile strength of 692-707 MPa, and has percentage elongation after fracture (80mm gauge length) of 22.5-24.5%. The steel provided by the invention can beapplied to a complex automobile structure part and a chassis part, and has relatively good economical efficiency and a relatively good application prospect.

Owner:SHOUGANG CORPORATION

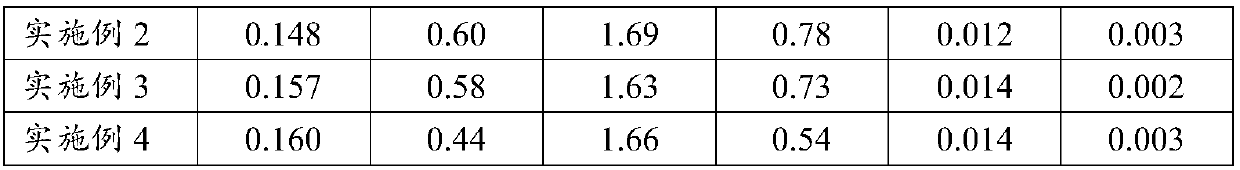

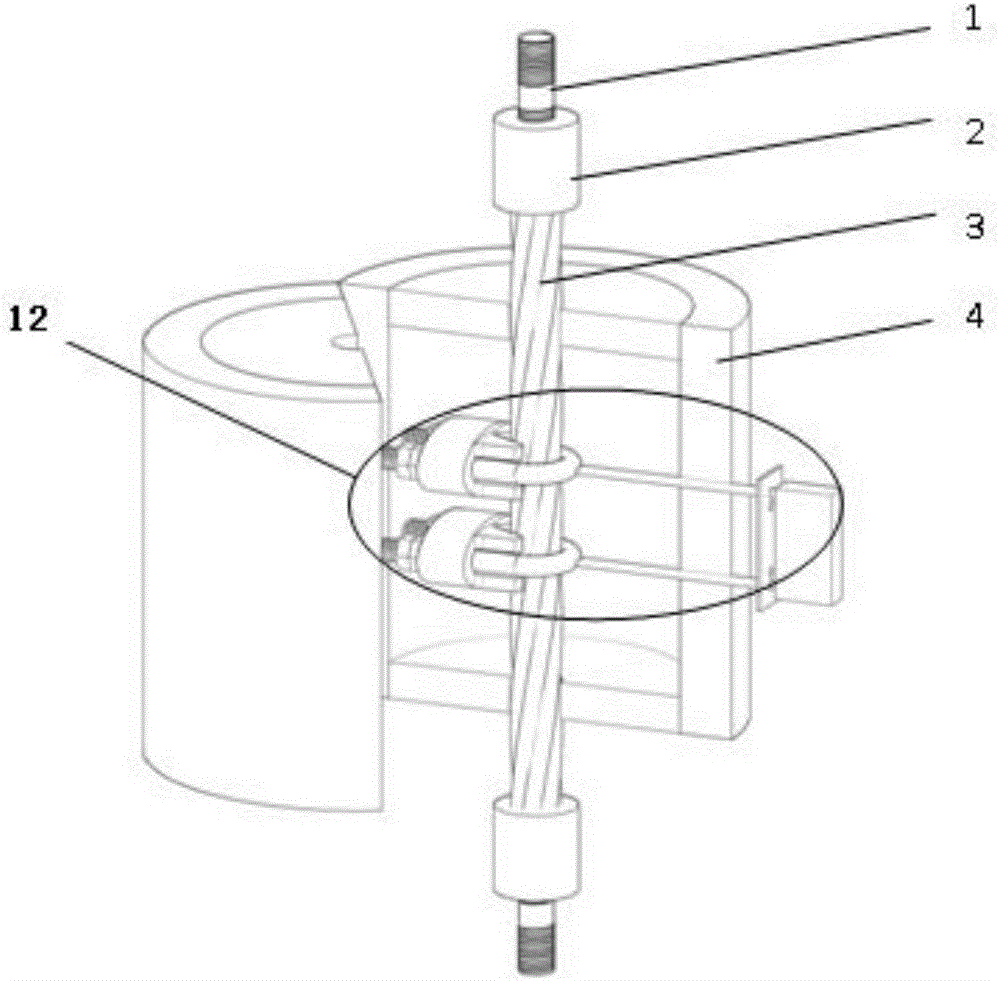

Bidirectional long-gauge-length fiber grating strain sensor

The invention discloses a bidirectional long-gauge-length fiber grating strain sensor. The bidirectional long-gauge-length fiber grating strain sensor comprises two measuring devices, wherein the two measuring devices are connected into a whole through an elbow and perpendicular to each other, each measuring device comprises a stress and deformation portion, a fiber grating sensor and a fiber grating adjusting instrument which is connected with the fiber grating sensor, each stress and deformation portion comprises two stainless steel disks and a stainless steel tube which is arranged between the stainless steel disks, the fiber grating sensors penetrate the stainless steel tubes, one ends of the fiber grating sensors are connected with the fiber grating adjusting instruments, the other ends of the fiber grating sensors are connected with each other through a connecting optical fiber which is arranged inside the elbow, and the fiber grating sensors are connected with inner walls of the stainless steel tubes through two bonding points. According to the bidirectional long-gauge-length fiber grating strain sensor, the two measuring devices are arranged, so that strain data in two directions can be read in one time, and sensors are prevented from being embedded repeatedly; and the stainless steel tubes are arranged, so that the sensors are fully protected, and the normal working of the sensors is prevented from being affected during foundation rolling compaction.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

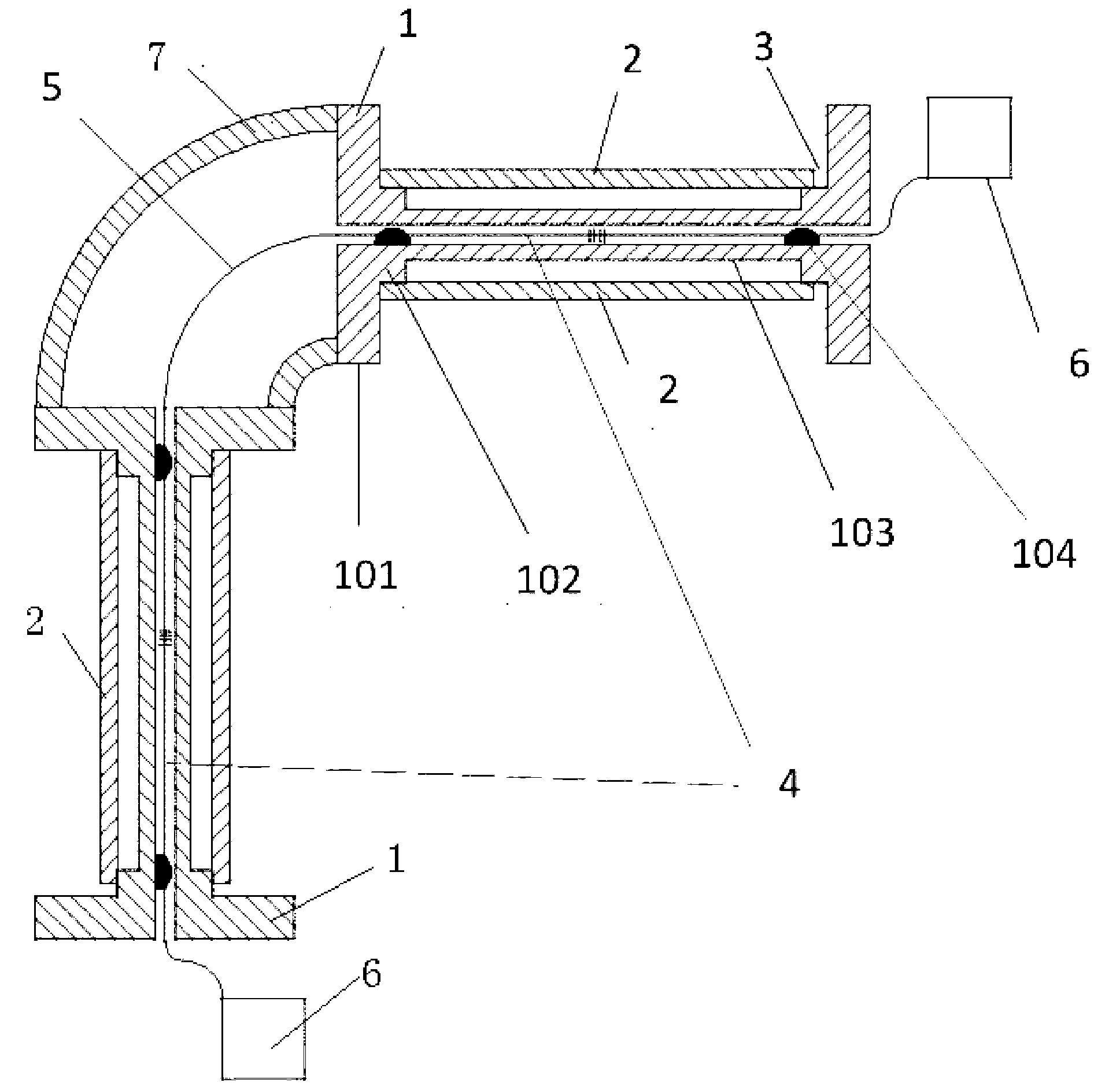

Method for measuring yield strength of non-planar structure material

InactiveCN102841013AAccurate measurementEliminate the effects ofStrength propertiesTensile testingBiomedical engineering

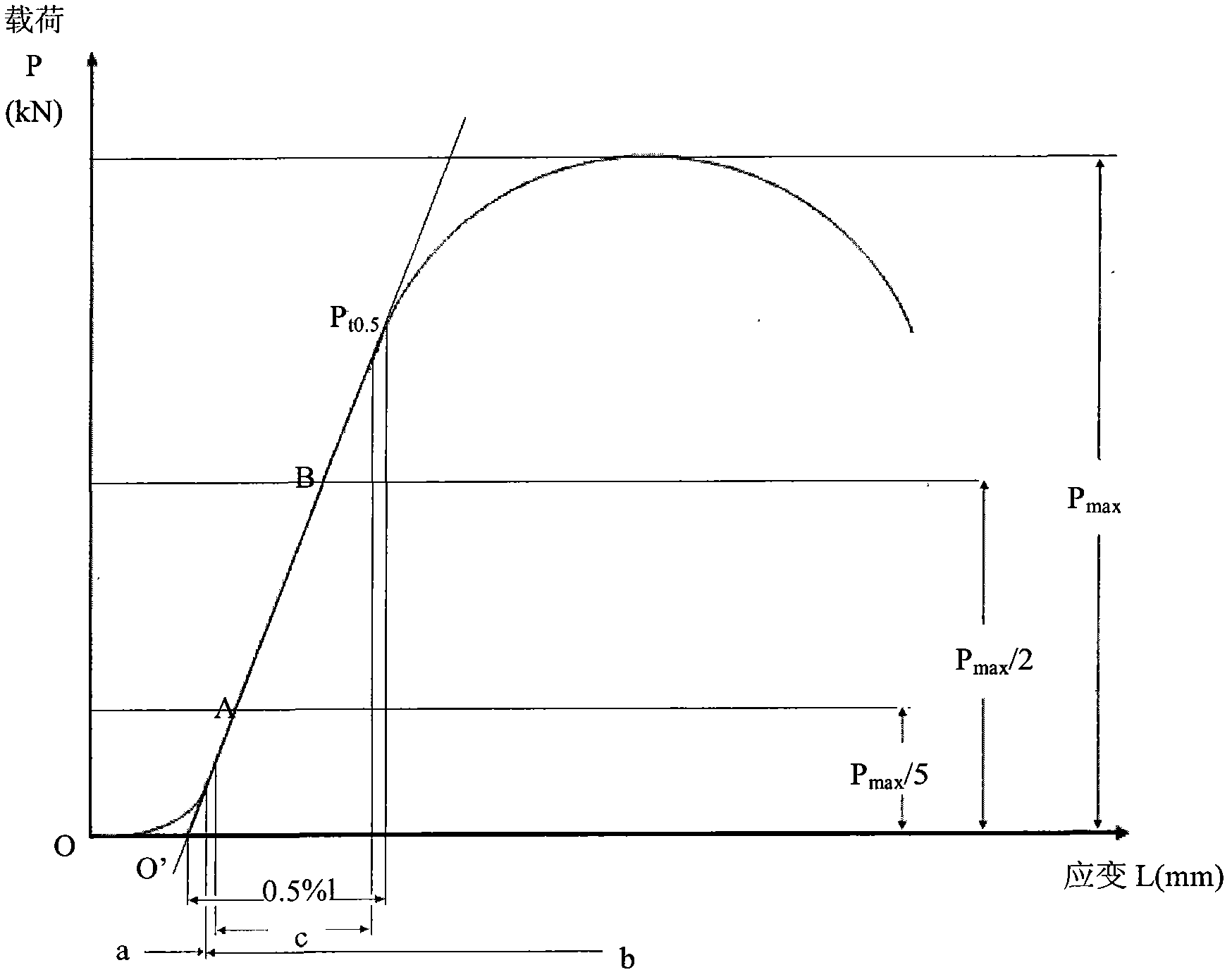

The invention relates to a method for measuring yield strength of a non-planar structure material. The method comprises: 1, manufacturing a tension specimen, clamping the specimen in a tension testing machine, clamping an extensometer on the tension specimen, and setting the extensometer to zero; 2, directly loading on the tension specimen to carry out a tension test to obtain a complete tension test curve; and 3, selecting two points from a proportion extension section as base points, adopting the two points to obtain a straight line, adopting an intersection point of the straight line and a abscissa as an origin, adopting the origin as a benchmark to rightward find a strain point of 0.5% specimen gauge length on a strain shaft, wherein a load value corresponding to the strain point is a conditional yield load corresponding to 0.5% strain, and the yield strength of the material can be measured according to the yield load and the specimen size. With the method of the present invention, influence on measurement of the yield strength Rt0.5 of the material by roughness of the specimen can be eliminated, and the unique yield strength Rt0.5 value can be accurately, reliably and repeatedly measured.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH

Intelligent photoelectric composite cable for monitoring local large deformation of structure and monitoring method

InactiveCN105788749ALower deployment costsEasy to operateCommunication cablesInsulated cablesCoaxial cableMonitoring system

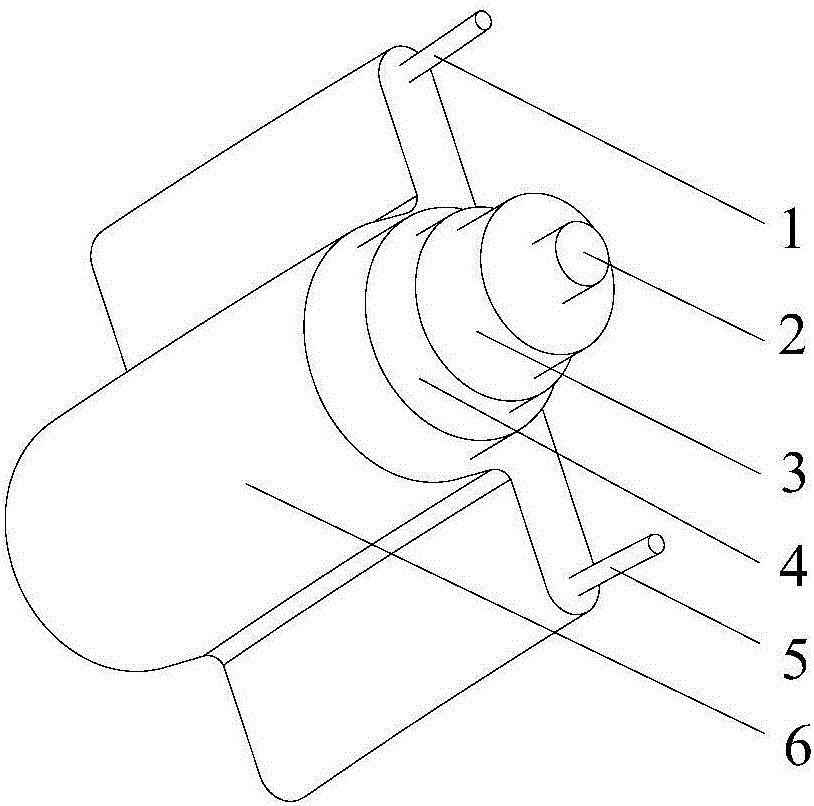

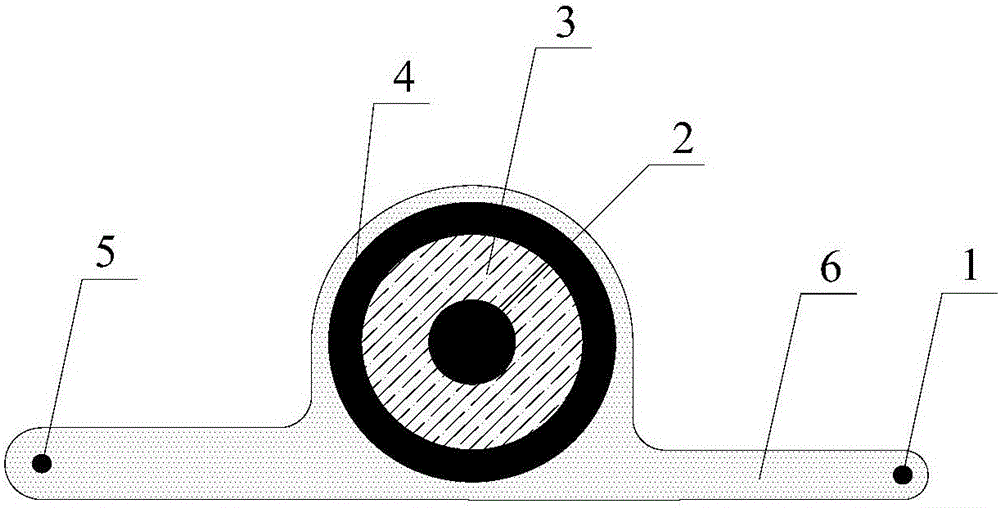

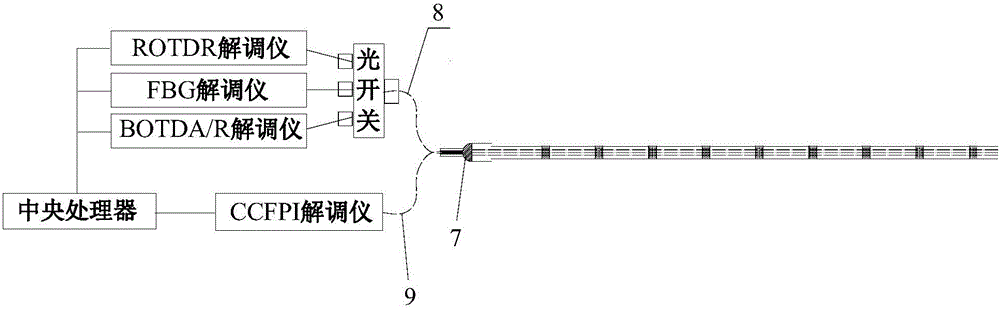

The invention discloses an intelligent photoelectric composite cable for monitoring local large deformation of a structure and a monitoring method. The intelligent photoelectric composite cable comprises distributed sensing devices capable of working together, wherein the distributed sensing devices are formed by compounding two sensing probes of an optical fiber and a coaxial cable employing silicone rubber as a cohering and filling medium and customizing a strain measurement gauge length in advance; various strains and temperature sensing probes are connected to an ROTOR demodulator, an FBG demodulator, a BOTDA / Rdemodulator and a CCFPI demodulator through transmission cables respectively; and strain data of a strain sensing array after temperature compensation correction is obtained, so that whole-process monitoring of the local large deformation of the structure is achieved. Aiming at the condition that an existing test method cannot easily track damage information of the local large deformation process of the structure, the bottleneck problem of combination of micro high precision and a macro large strain test is solved by the intelligent photoelectric composite cable; and a distributed optical fiber sensing technology and a distributed coaxial cable sensing technology are merged for the first time to construct an intelligent monitoring system.

Owner:DALIAN UNIV OF TECH

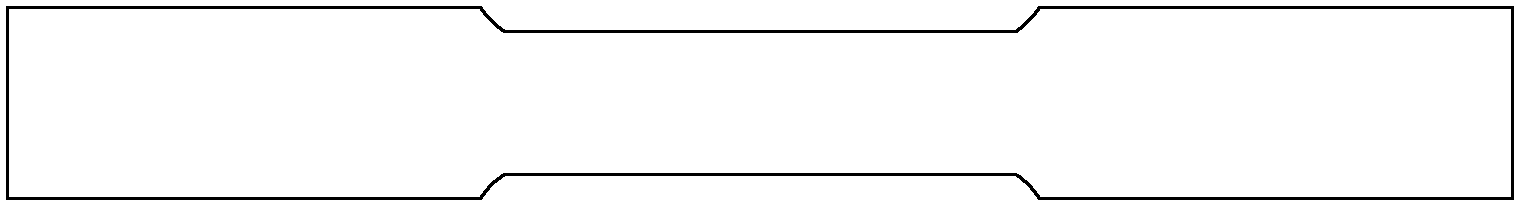

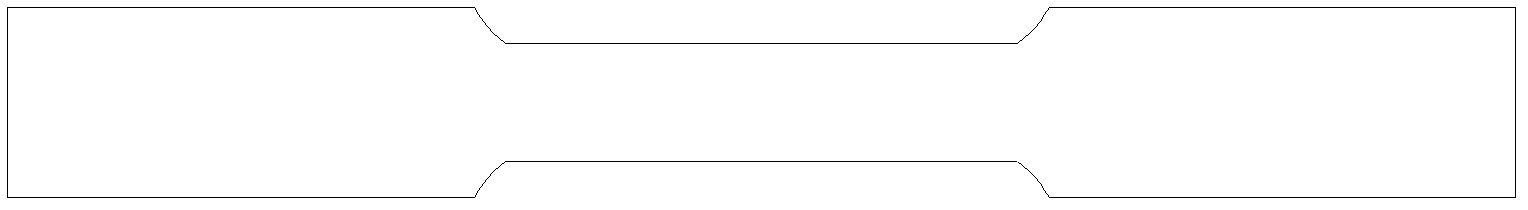

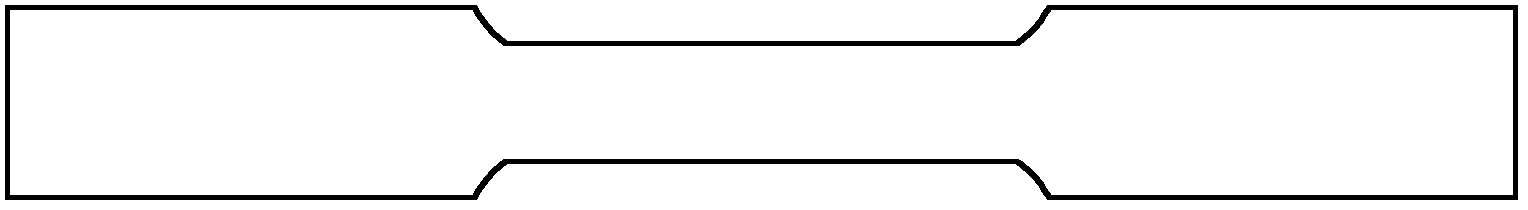

Manufacturing method of material tensile sample

InactiveCN102426120AFast preparationEfficient preparationPreparing sample for investigationNumerical controlPunching

The invention provides a manufacturing method of a material tensile sample. The method comprises steps that: A, according to the dimension of a standard tensile sample, a punching die of a punching machine is manufactured, wherein the gauge length section width of the punching die is larger than that of the standard tensile sample; B, according to the quality and the thickness of a material requiring punching, a punching machine with a corresponding tonnage is selected; with the punching by using the punching machine and the punching die, a crude sample is obtained; C, the crude sample obtained through punching is subject to finish machining in a numerical control milling machine, such that a standard sample is obtained. The method provided by the invention is advantaged in that: with the method, a thin material standard sample for mechanical property testing can be manufactured with high speed and high efficiency; with the method, numerical control milling machine processing of a plurality of thin materials can be simultaneously carried out, such that processing speed is improved; with the method, the precision of the obtained standard sample is high, and the accuracy of testing results can be ensured.

Owner:SHANGHAI FALAB TEST

Multifunctional intelligent anchor pole and installation arrangement method thereof

InactiveCN105973285AThe principle is simple and reliableNovel test methodForce measurement by measuring optical property variationUsing optical meansFiberEpoxy

The invention discloses a multi-functional intelligent anchor rod and its installation and layout method, which comprises non-fusion long gauge distance multi-grating sensor, optical fiber grating multi-point temperature compensation auxiliary sensor, epoxy resin or planting glue, armored optical cable and soft plastic Sleeve; the non-welded long-gauge-length multi-grating sensor and fiber-optic grating temperature-compensated auxiliary sensor are installed in the small groove opened along the longitudinal direction of the anchor rod, and are encapsulated by epoxy resin or planting glue; The grating sensor includes a plurality of long-gauge fiber grating sensing units connected in series. The long-gauge fiber grating sensing unit includes a sleeve, an optical fiber packaged in the sleeve, and a grating written on the optical fiber. The two ends of the optical fiber are respectively fixed on the Anchor section of casing. The invention can be used not only for anchorage and reinforcement in related projects such as civil engineering, tunnels, and mining, but also for monitoring the bearing capacity, stress-strain, and damage of anchor rods, and can be used for surrounding rock support and surrounding rock convergence deformation and stability monitoring.

Owner:SOUTHEAST UNIV

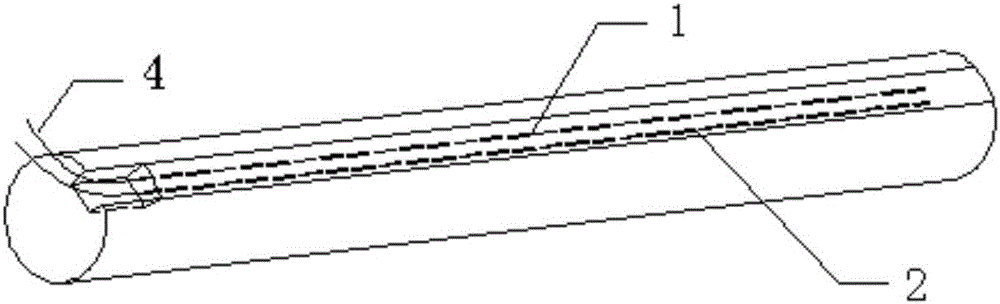

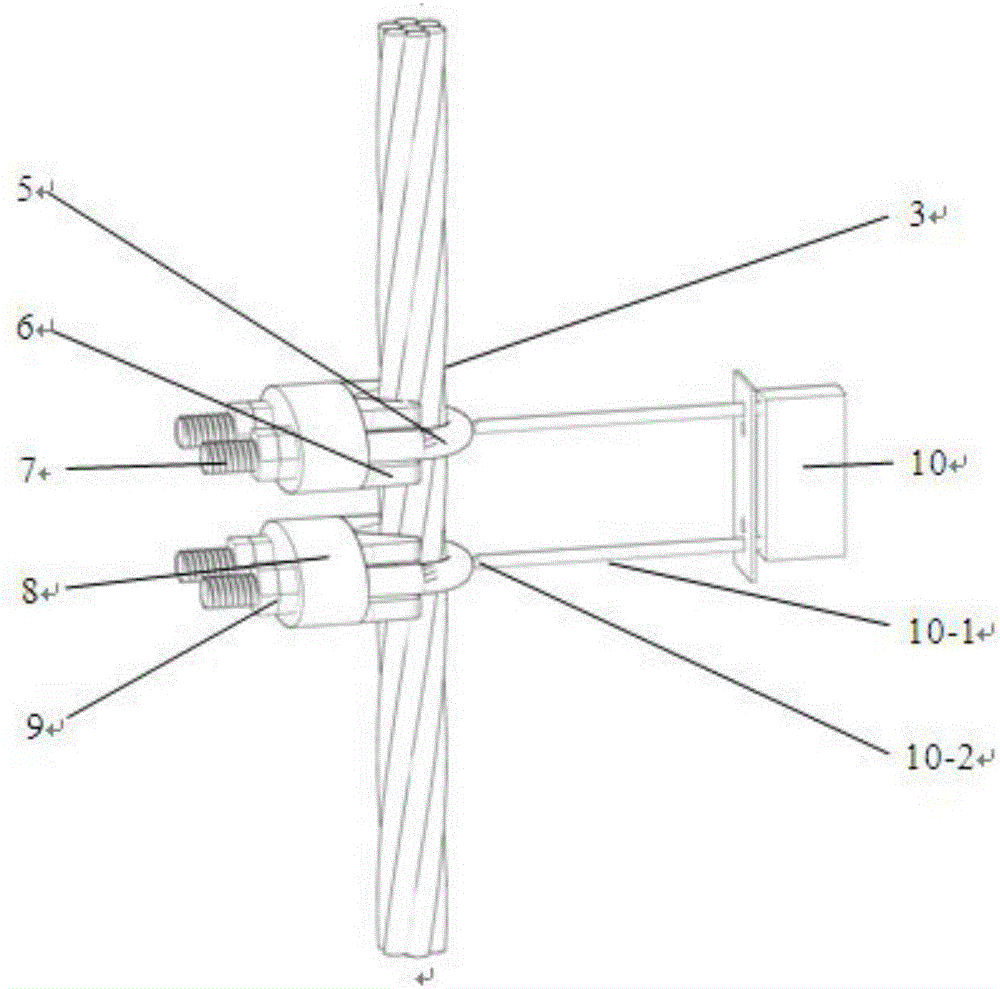

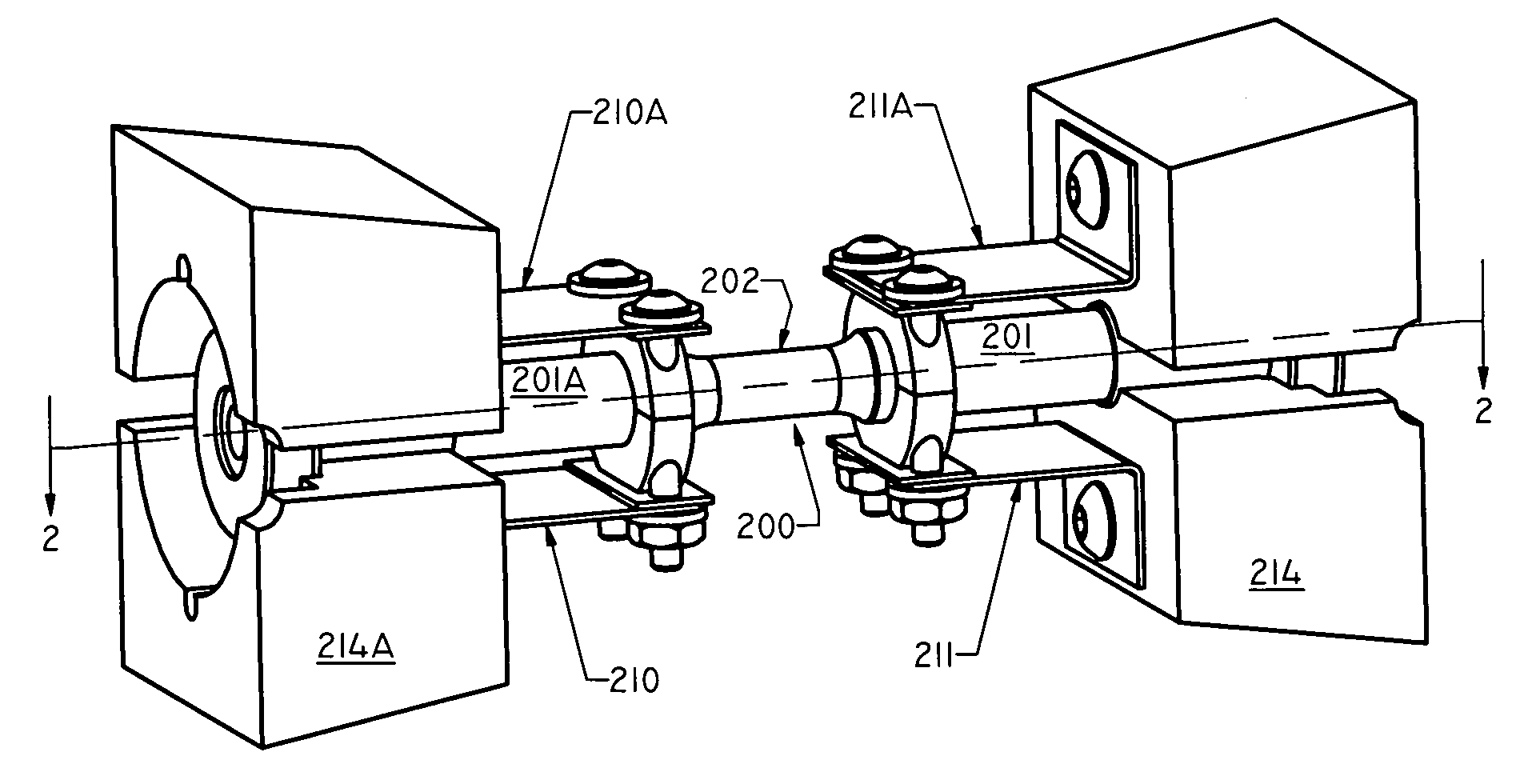

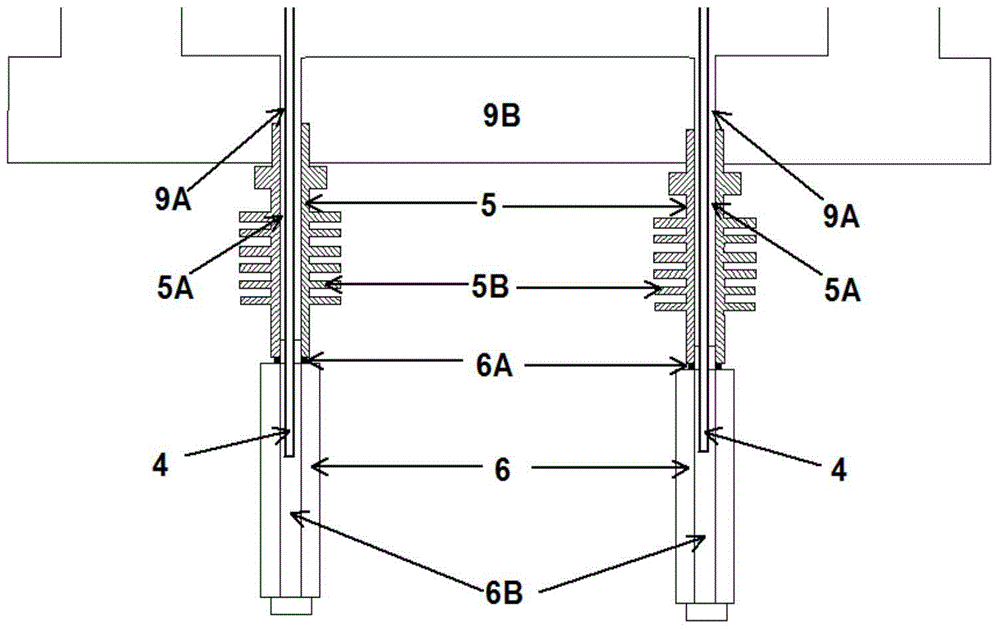

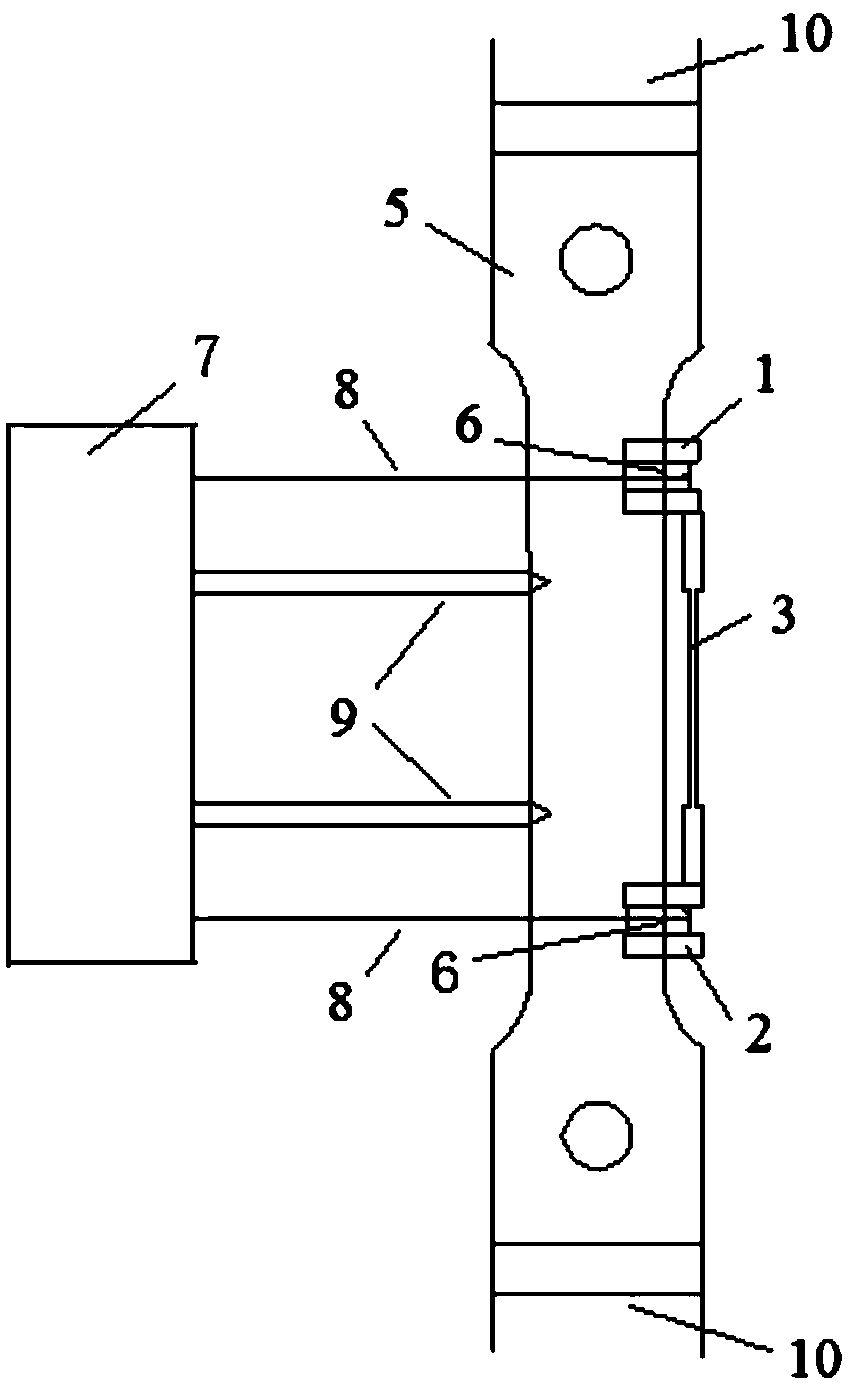

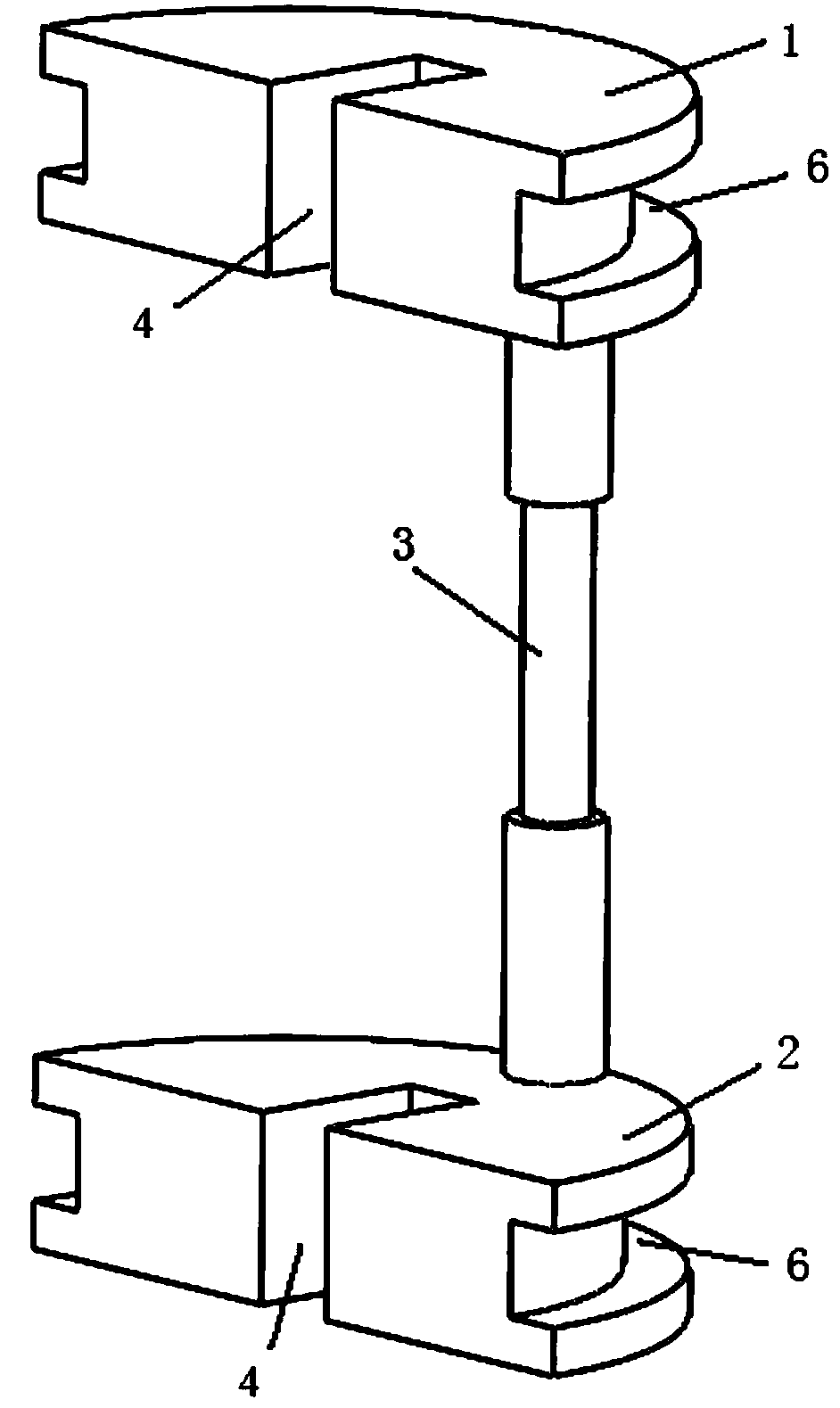

Displacement extension clamping device for measuring axial tensile deformation of steel cable at high temperature and using method of displacement extension clamping device

InactiveCN106018078ANo slippageEnsure synchronous displacementStrength propertiesEngineeringMechanical engineering

The invention discloses a displacement extension clamping device for measuring axial tensile deformation of a steel cable at high temperature and a using method of the displacement extension clamping device. The displacement extension clamping device for measuring the axial tensile deformation of the steel cable at high temperature comprises an upper clamp, a lower clamp and a high-temperature extensometer, wherein each of the upper clamp and the lower clamp comprises a U-shaped tube clamp, a V-shaped claw, bolts, a base and high-temperature nuts; U-shaped tube clamps sleeve a sample; two ends of each U-shaped tube clamp are respectively connected with the two corresponding bolts; each V-shaped claw is further arranged on the corresponding base; the U-shaped tube clamps and the V-shaped claws oppositely fasten to clamp the sample; the high-temperature nuts are tightened through the bolts, so that the sample, the U-shaped tube clamps and the V-shaped claws cannot slide relatively; the high-temperature extensometer is provided with two extension rods; a blade contact is arranged at the top end of each extension rod; the extension rods are adjusted so that the two blade contacts can be respectively inlaid in wedge-shaped grooves formed in the surfaces of the top ends of the two U-shaped tube clamps; high-temperature deformation in a gauge length section of the sample is transmitted to the extension rods; and test data are recorded by the high-temperature extensometer.

Owner:NANJING TECH UNIV

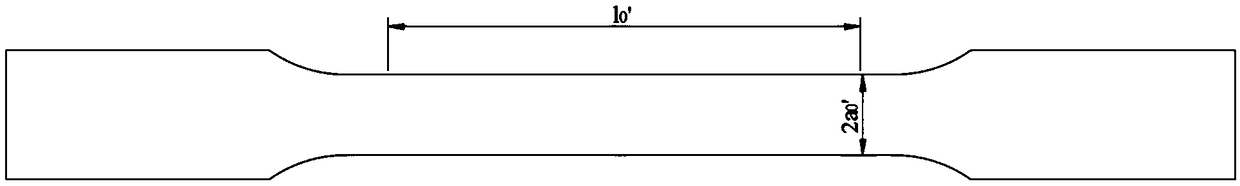

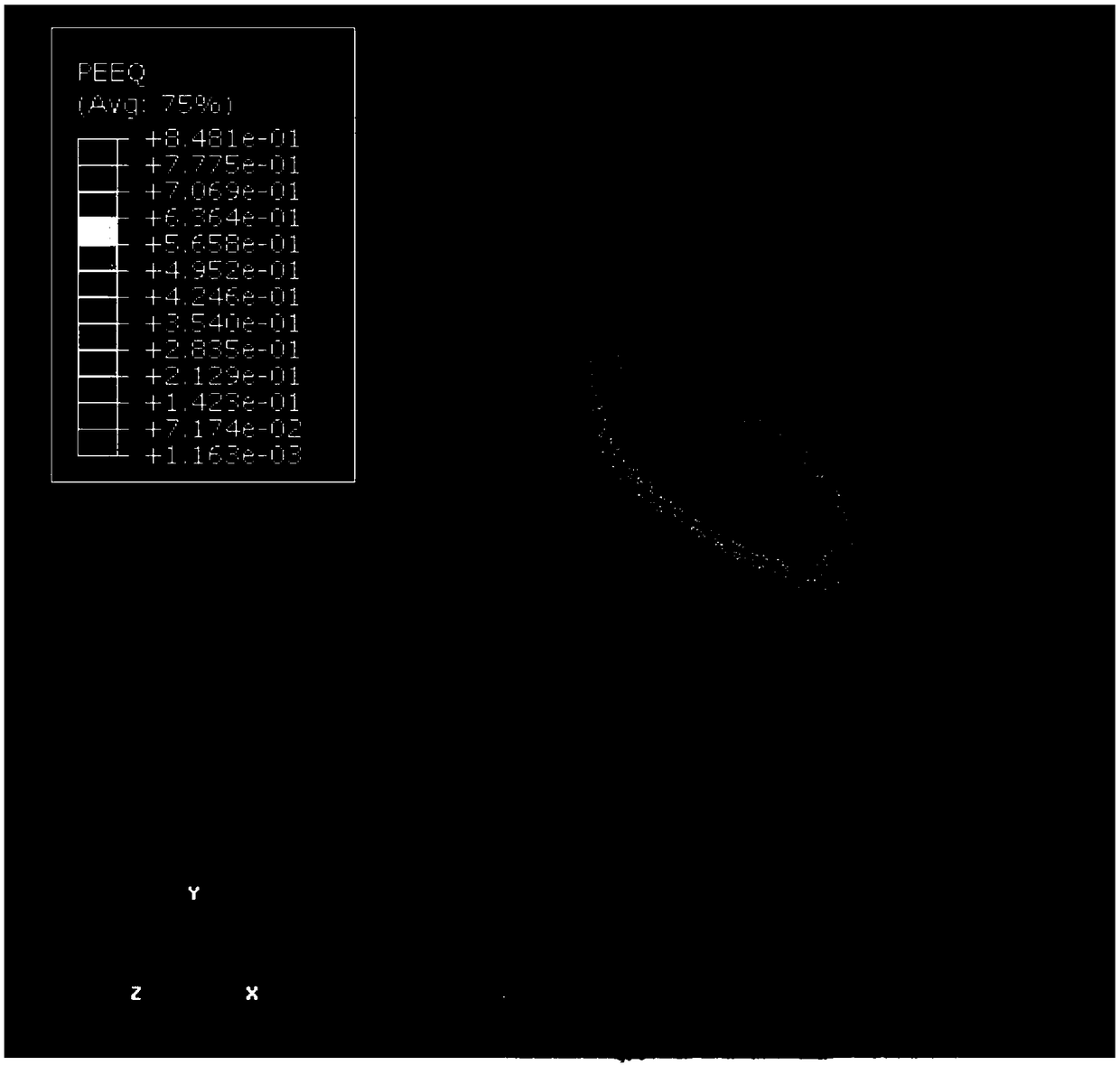

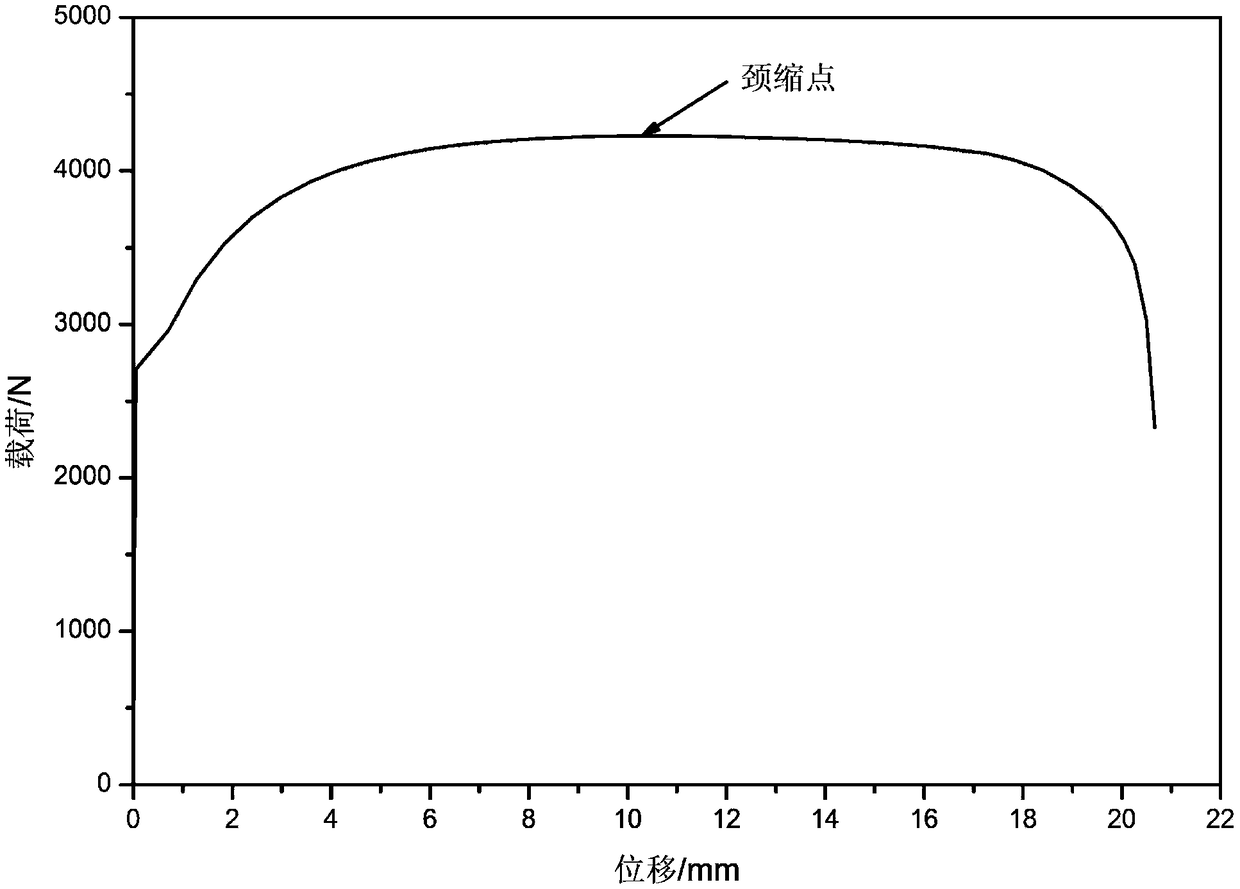

Method for measuring large-stress range stress strain in uniaxial tensile test of metal plate sample

InactiveCN108982222AEliminate cumbersome measurement linksSave time and costMaterial strength using tensile/compressive forcesBridgman methodStress–strain curve

The invention relates to a method for measuring the large-stress range stress strain in a uniaxial tensile test of a metal plate sample. The method comprises the following steps: building a step modelfor gradual expansion of unstable necking of uniaxial tension of the metal plate sample; measuring the instant gauge length and the minimum sectional width at a necking position of the plate sample after extension instability; building an interpolation curve expression of the necking profile on the basis of necking step coordinates of the necking step model at each moment; solving the parametersof the necking step model according to the mechanical relationship of necking in the width direction and the thickness direction and the principle of volume conservation; finally calculating the actual stress and actual strain at the moment through a Bridgman method. By adopting the method, the test measuring link for the necking outer profile curvature radius in the existing method is omitted, and the measuring accuracy of a large-strain range stress-strain curve is improved, so that the method has important significance to the mechanical performance test of metal materials.

Owner:JILIN UNIV

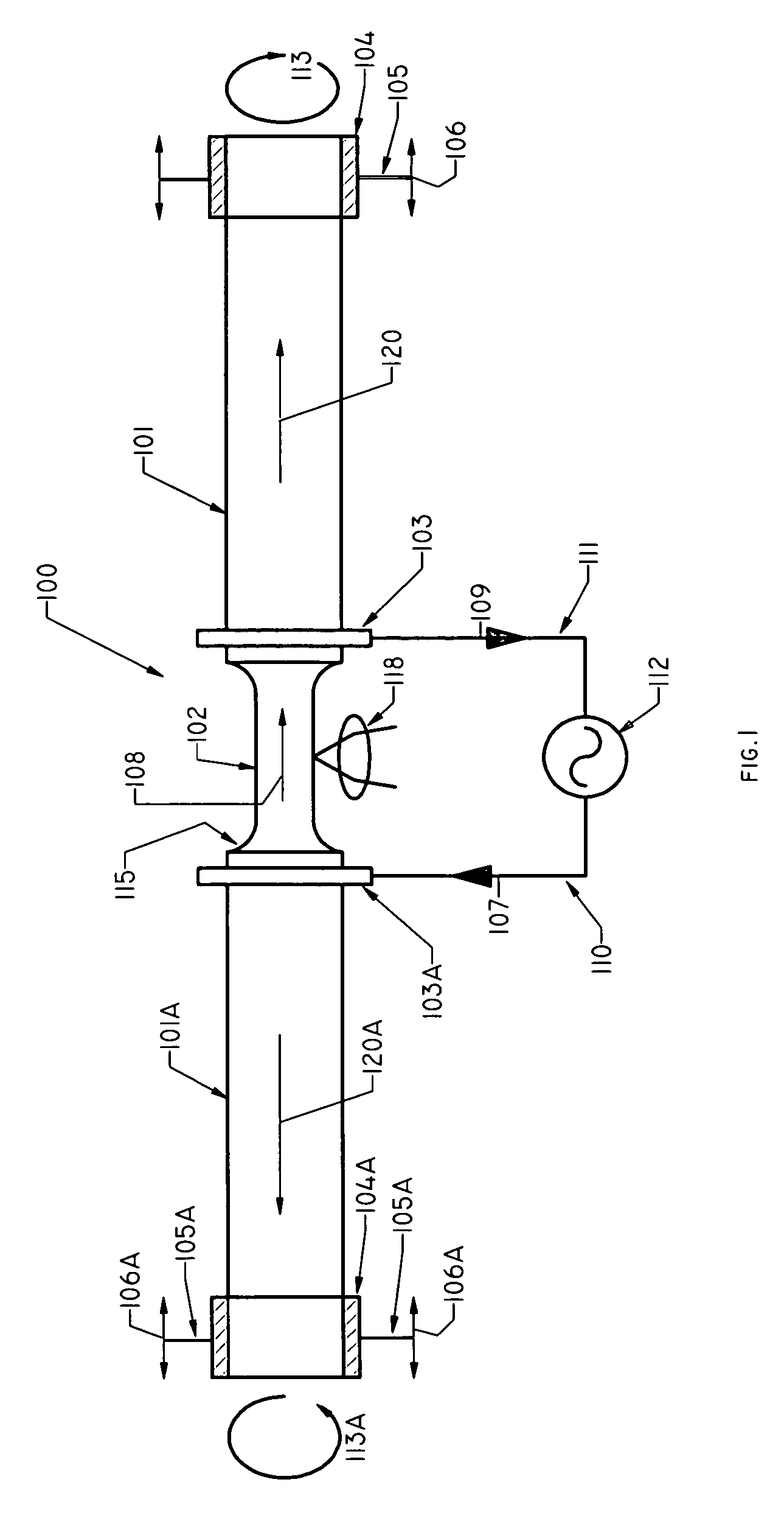

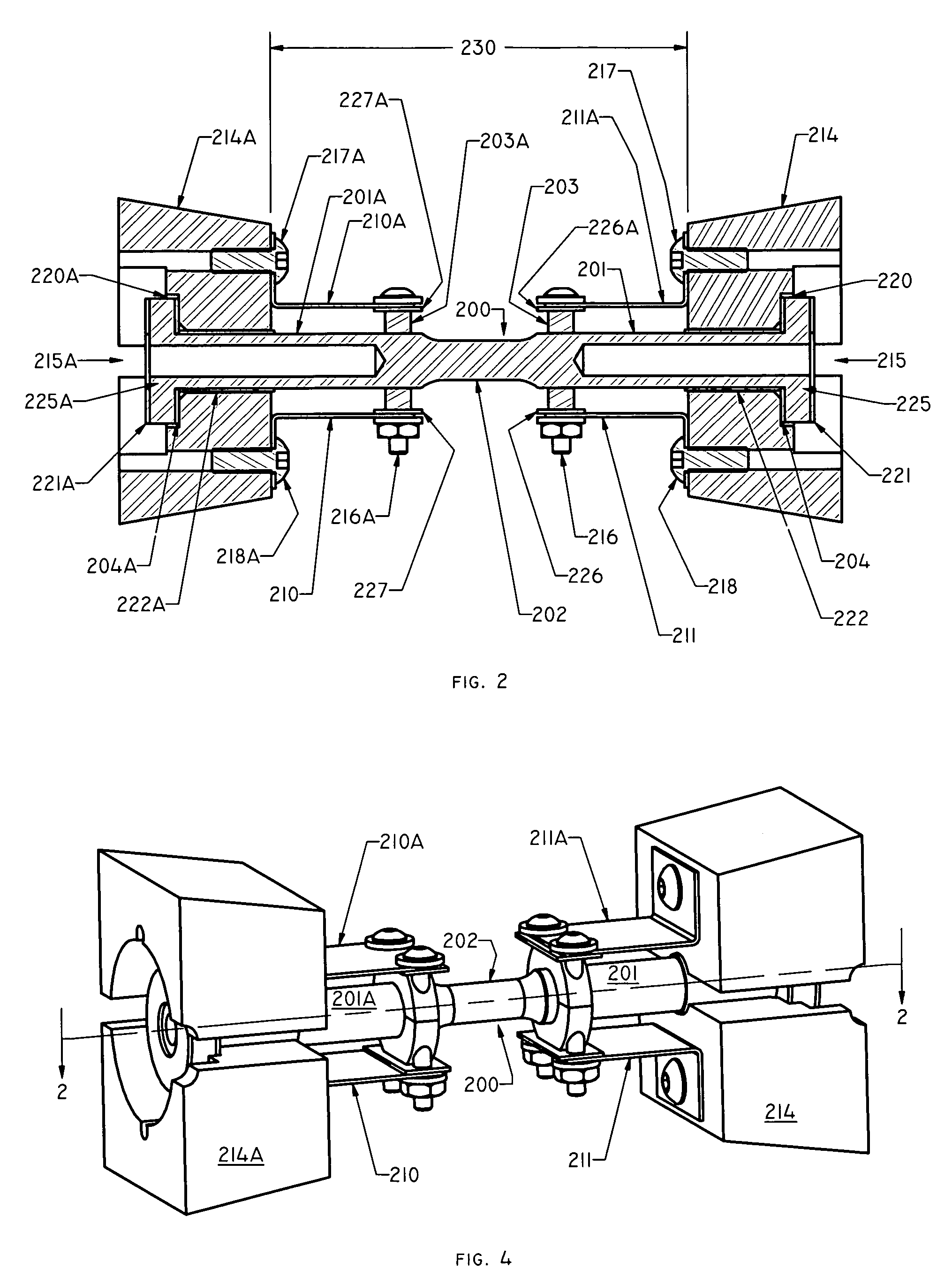

Technique for applying direct resistance heating current to a specific location in a specimen under test while substantially reducing thermal gradients in the specimen gauge length

ActiveUS7363822B2Increase resistanceExcessive heatingMaterial strength using tensile/compressive forcesOhmic-resistance heatingElectrical resistance and conductanceEngineering

A technique for imparting direct resistance heating to a gauge length of a conductive metallic specimen under test and which can be used to add an independent dynamic thermal capability to a mechanical material test system. Specifically, a pair of, e.g., conductive collars, each of which encircles and abuts against a corresponding portion of the external surface of the specimen near an opposing end of its gauge length and inward of a corresponding grip. Each collar imparts additional self-resistive heat to the specimen along a circumferential collar / specimen interface. This additional heat appreciably reduces or cancels thermal gradients otherwise arising from self-resistive heating across the gauge length as well as compensates for thermal losses in each specimen end section. Through this arrangement, each specimen end section and the grips are not appreciably heated as the gauge length heats. The amount of additional heat is set by selecting a collar material to have a desired resistivity and also by appropriately dimensioning each collar.

Owner:DYNAMIC SYST INC

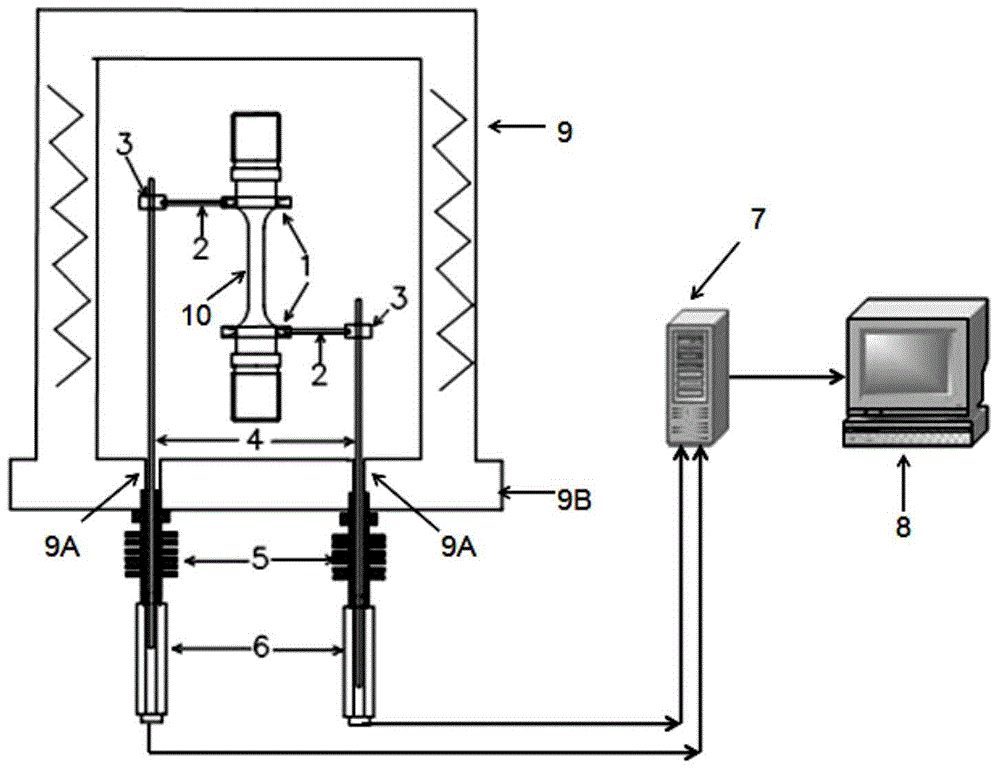

System and method for monitoring metal sample stress in high-temperature and high-pressure environment in real time

InactiveCN105092372AReal-time monitoring of strainOvercoming the conundrum of strainStrength propertiesData acquisitionEngineering

The invention provides a system and method for monitoring metal sample stress in a high-temperature and high-pressure environment in real time. The system comprises two connection assembly systems, two displacement sensing systems and a data acquisition system. The method includes the steps that when metal sample stress is monitored in real time and a metal sample bears axial force in the high-temperature and high-pressure environment in a high-pressure kettle, metal within the gauge length deforms in a stretch-out or draw-back mode, the deformation amount of the metal is transmitted to induction iron cores through the connection assembly systems fixed to the metal sample, inductance type extensometers can sense displacement of the induction iron cores and send out electric signals, a signal amplifier can amplify the electric signals, the data acquisition device acquires the amplified electric signals and calculates the displacement difference of the two connection assembly systems, and the metal sample stress is obtained by dividing the displacement difference by the original gauge length. The system and the method solve the problem that in the prior art, the stress can not be measured in real time in the high-temperature and high-pressure environment, high measurement accuracy is achieved, and the test requirements for mechanical and chemical interaction in various high-temperature and high-pressure environments can be met.

Owner:XIAN THERMAL POWER RES INST CO LTD

Fixing device for metal sheet high temperature tensile extensometer

ActiveCN108956281AAchieve fixationRealize measurementMaterial strength using tensile/compressive forcesMetal sheetEngineering

The invention relates to a fixing device for a metal sheet high temperature tensile extensometer, the fixing device fixes the high-temperature extensometer by upper and lower clamping blocks, whereinthe two clamping blocks in the form of a semicircular block are provided with through grooves at sample contact portions to fix a sample, and are provided with annular grooves at curved parts to facilitate connecting with the high-temperature extensometer by a fixing line. A guide rod of the fixing device is provided with a telescopic sleeve which is convenient for use of samples of different gauge lengths. The fixing device has the advantages of simple structure, convenient and easy operation AND low manufacturing cost, is suitable for high-temperature tensile tests of metal sheets of variousthicknesses and lengths, and effectively avoids the breakage of the fixing line, falling off of the extensometer and failed testing caused by direct contact with a thin plate sample at high temperature.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com