Distributed high-precision long-gauge-length carbon fiber strain test device and method

A technology of strain testing and long gauge length, applied in the direction of electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of small resistivity, unstable output signal display, small output signal, etc., and reduce the cost of post-processing steps, superior long-term performance, and the effect of saving monitoring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

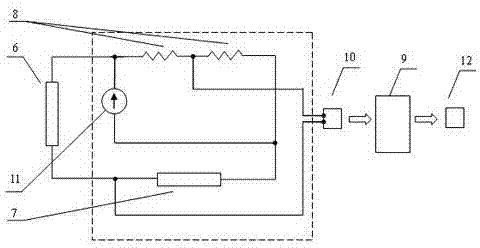

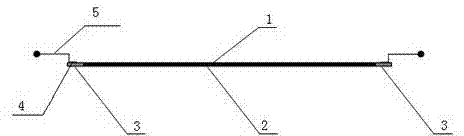

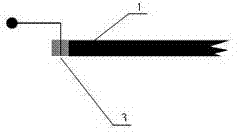

[0031] Such as figure 1 As shown, a distributed high-precision long gauge carbon fiber strain test device includes two long gauge carbon fiber strain sensors, two resistors 8 with the same resistance value as the long gauge carbon fiber strain sensor, the long gauge carbon fiber strain sensor, Resistor 8 and constant current power supply 11 are arranged in the form of a Wheatstone temperature compensation bridge, one of which is a long-gauge carbon fiber strain sensor as the working piece 6, and the other long-gauge carbon fiber strain sensor is used as the temperature compensation piece 7; the Wheatstone temperature compensation The signal output end of the electric bridge is connected with the signal input end of the primary signal 10, and the signal output end of the primary signal 10 is connected with the signal input end of the single-chip microcom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com