Patents

Literature

114 results about "Fiber strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strain, is where the fiber and cable experience length and optical attenuation changes when the cable which is designed to protect the fiber is stressed in some way.

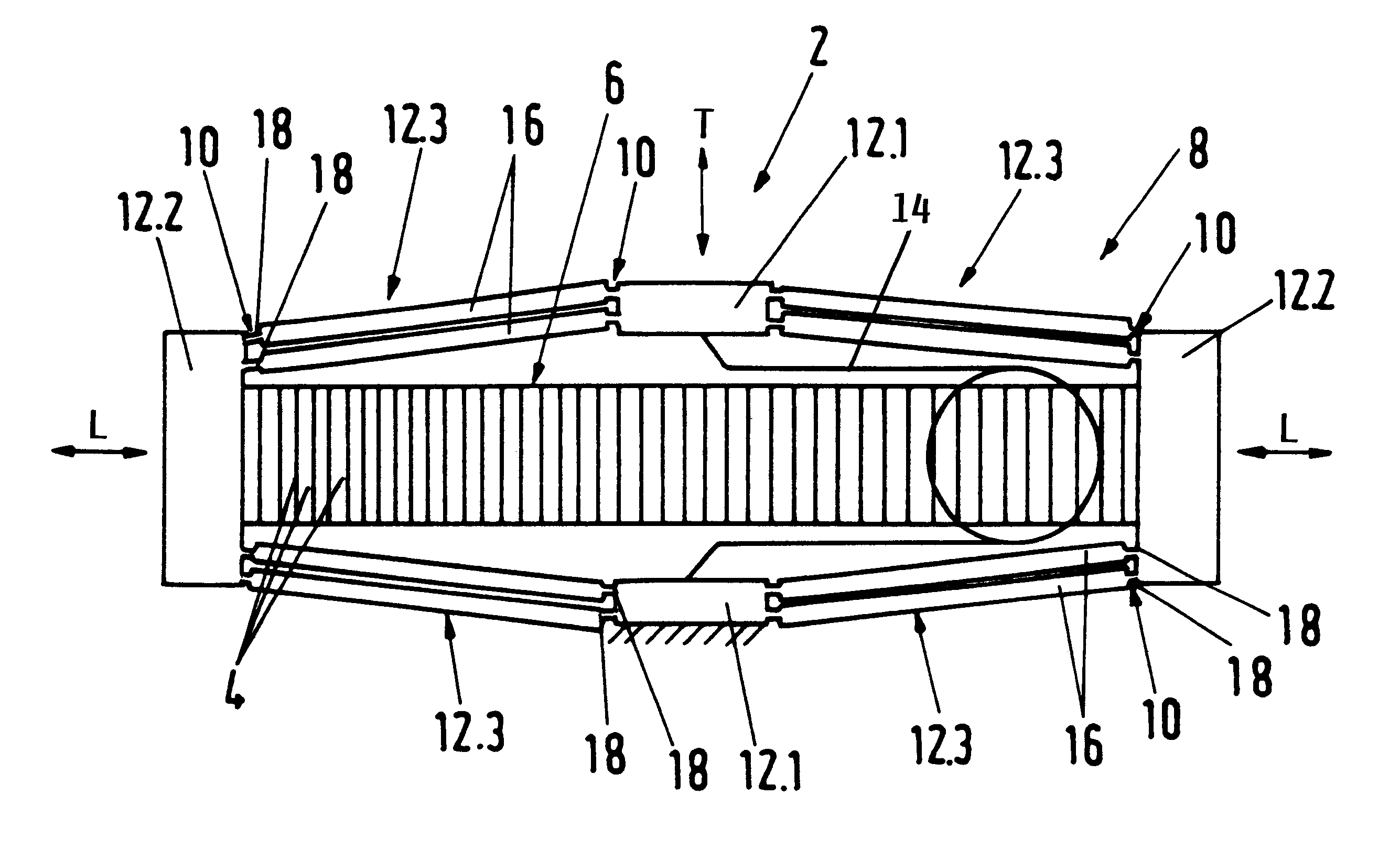

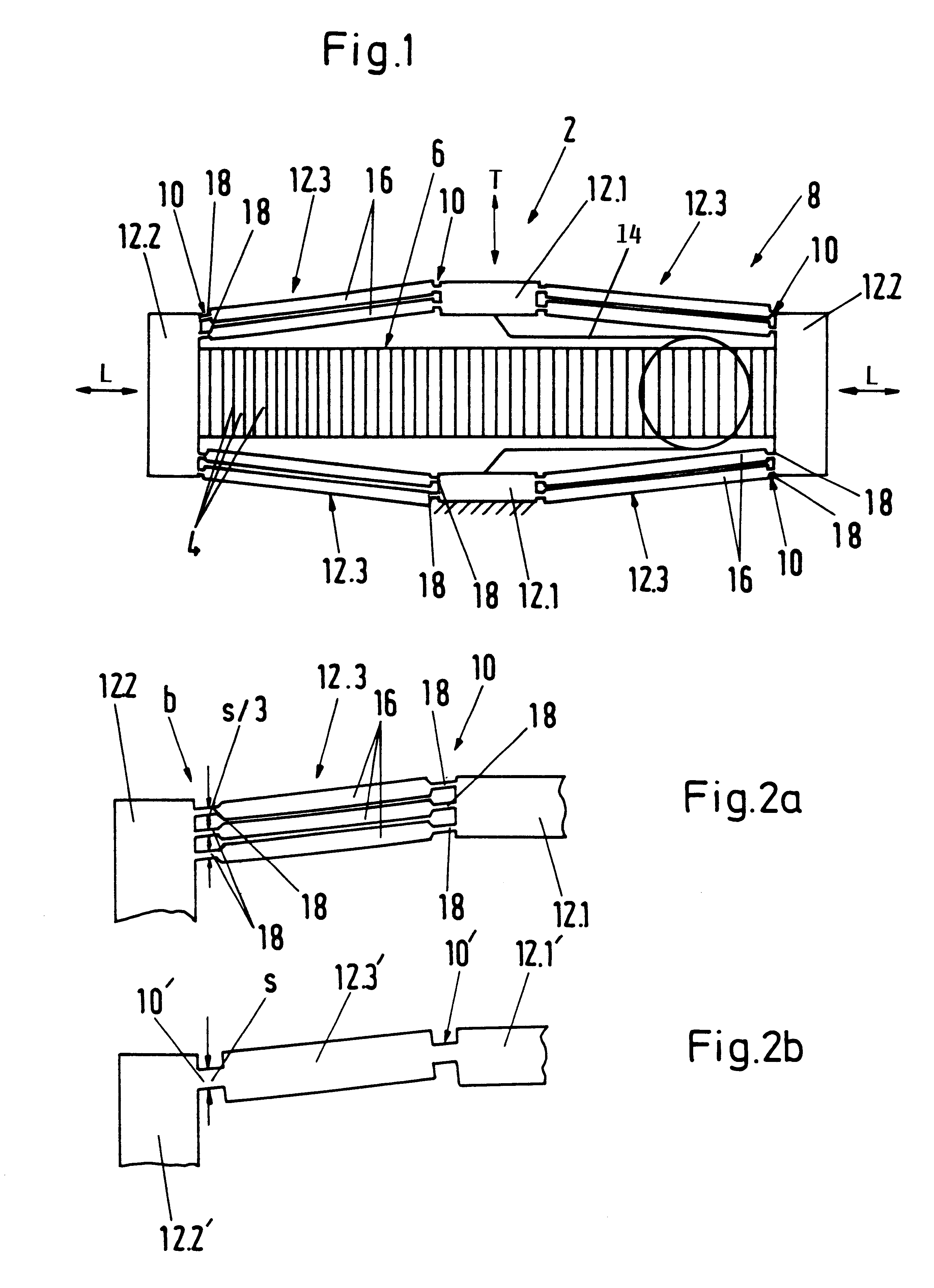

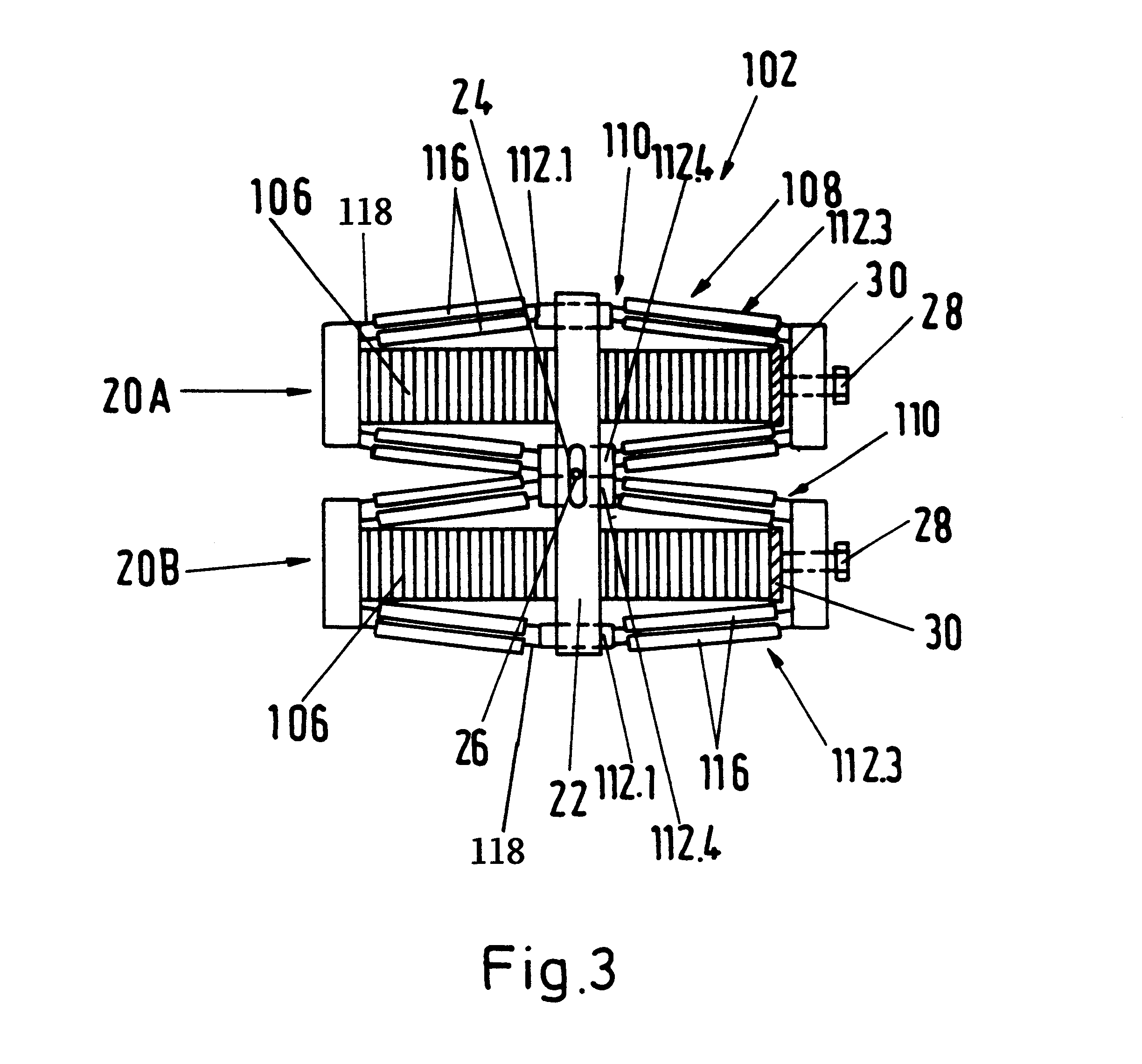

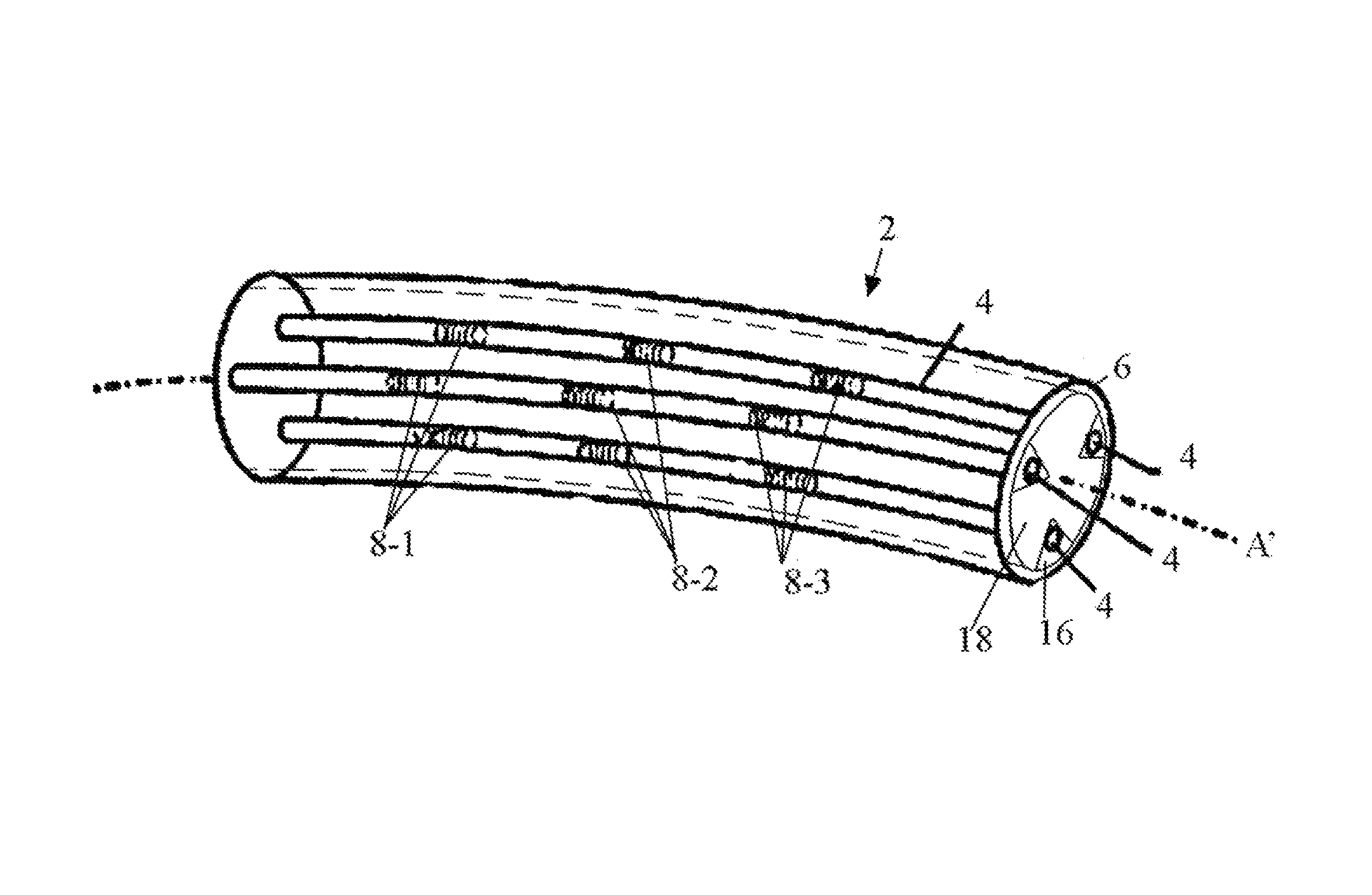

Electrostrictive or piezoelectric actuator device with a stroke amplifying transmission mechanism

InactiveUS6294859B1Low bending stiffnessReduce joint stiffnessPiezoelectric/electrostriction/magnetostriction machinesGearingFiber strainPiezoelectric actuators

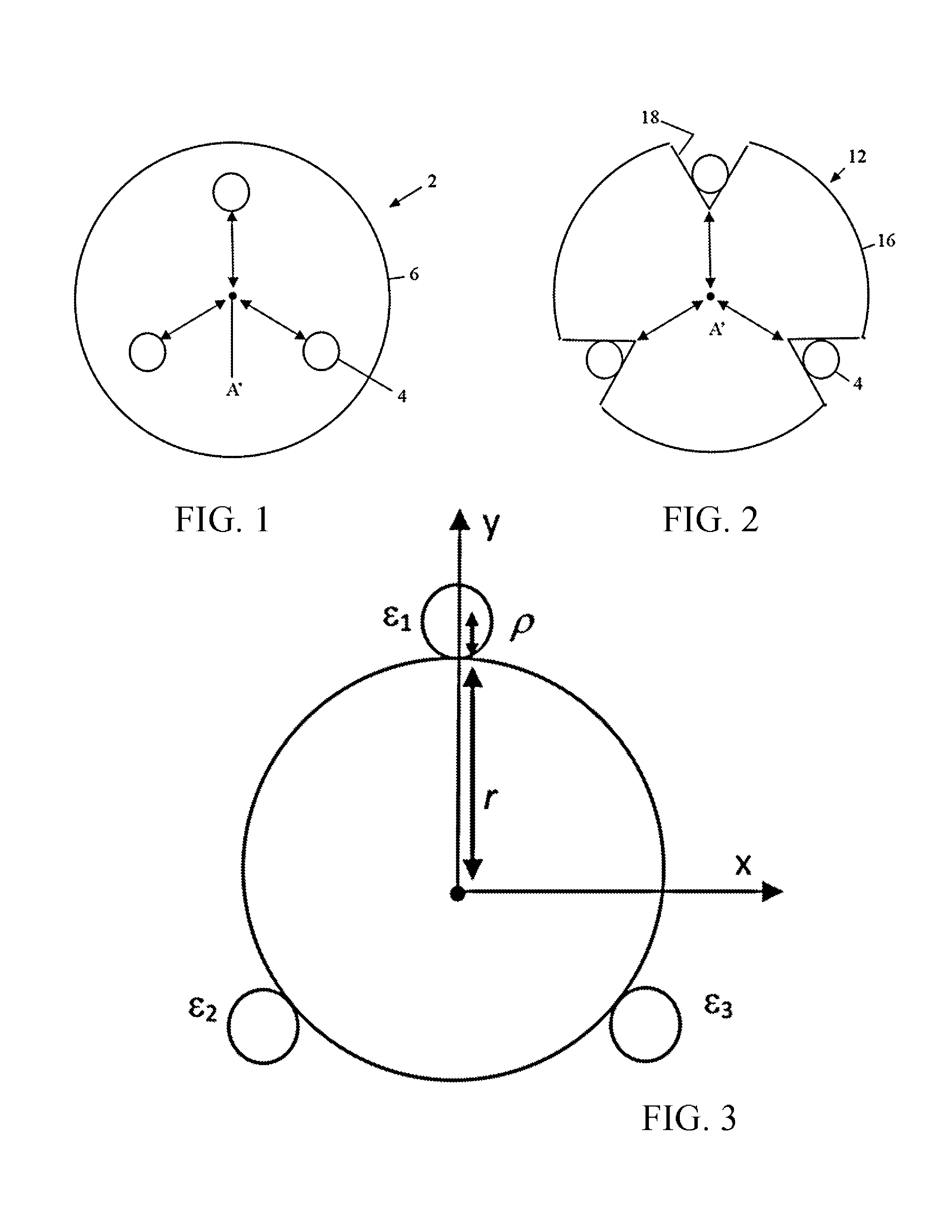

An actuator device (2) includes a piezoelectric or electro-strictive solid state actuator element (6) that is elongated upon application of an electric voltage thereto, and a transmission mechanism (8) that amplifies the stroke displacement of the actuator element. The transmission mechanism (8) includes a plurality of rigid frame members (12), including unitary frame members (12.1, 12.2) and divided frame members (12.3), and elastically flexible joints (10) that respectively interconnect the frame members. Each one of the divided frame members (12.3) is made up of a plurality of separate parallel link rods (16). Each flexible joint (10) is made up of a plurality of individual parallel hinge members (18) that respectively connect an end of each one of the link rods (16) to the adjacent unitary frame member (12.1, 12.2). By this division of the flexible joints and of the divided frame members into parallel sub-components, the cross-sectional thickness of each individual hinge member is reduced, and thereby the bending stiffness and the outer fiber strain of the material of the hinge members is significantly reduced while providing the same total tensile strength and tensile stiffness. The link rods of each divided frame member effectively form a parallelogram linkage for moving and guiding the output members (12.1) in a parallel manner.

Owner:EADS DEUT GMBH

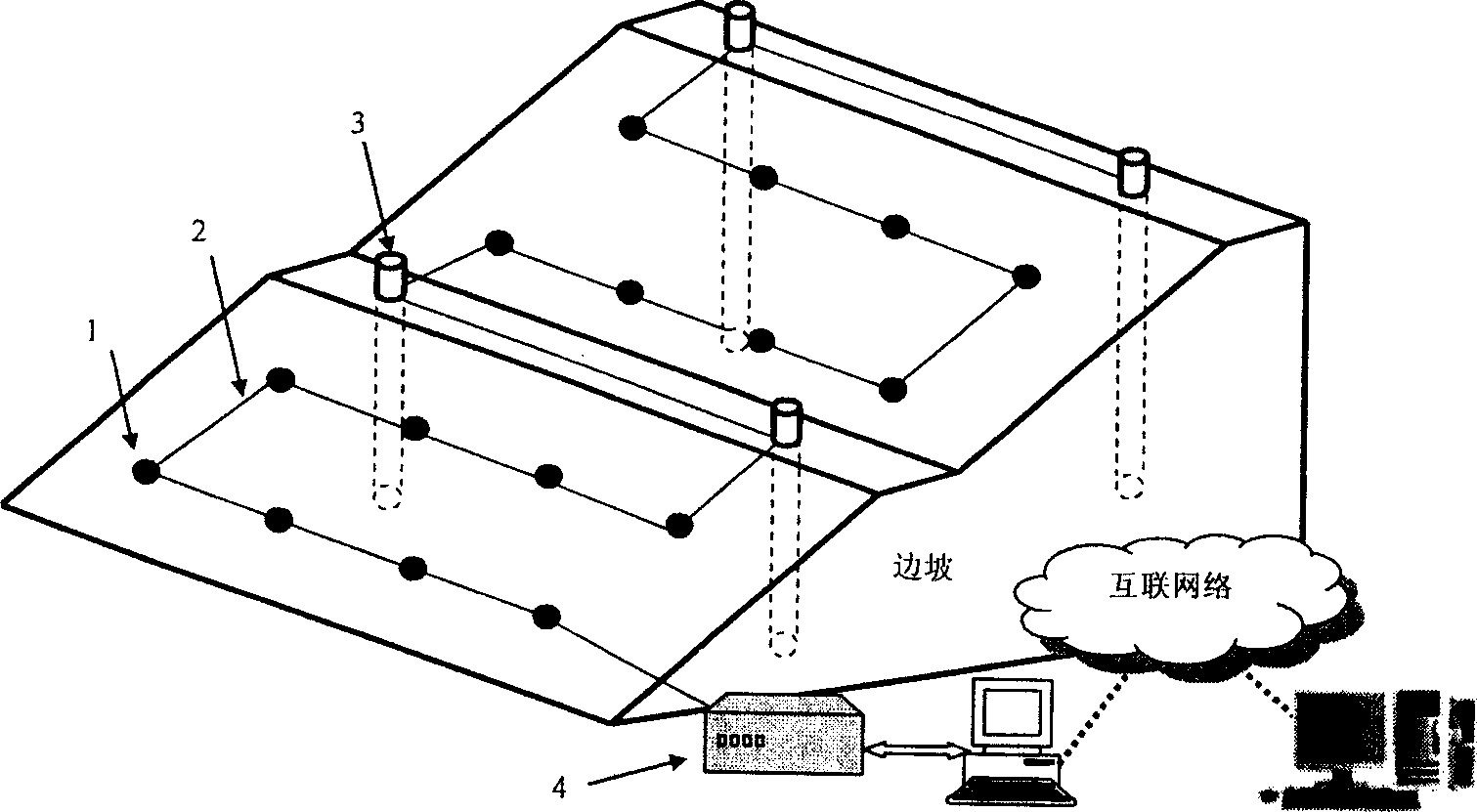

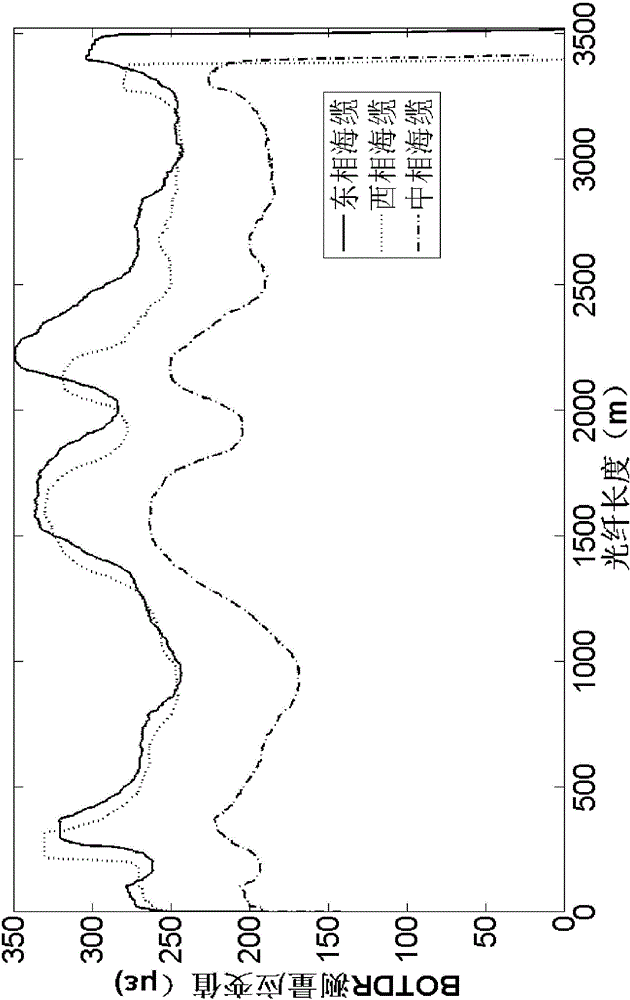

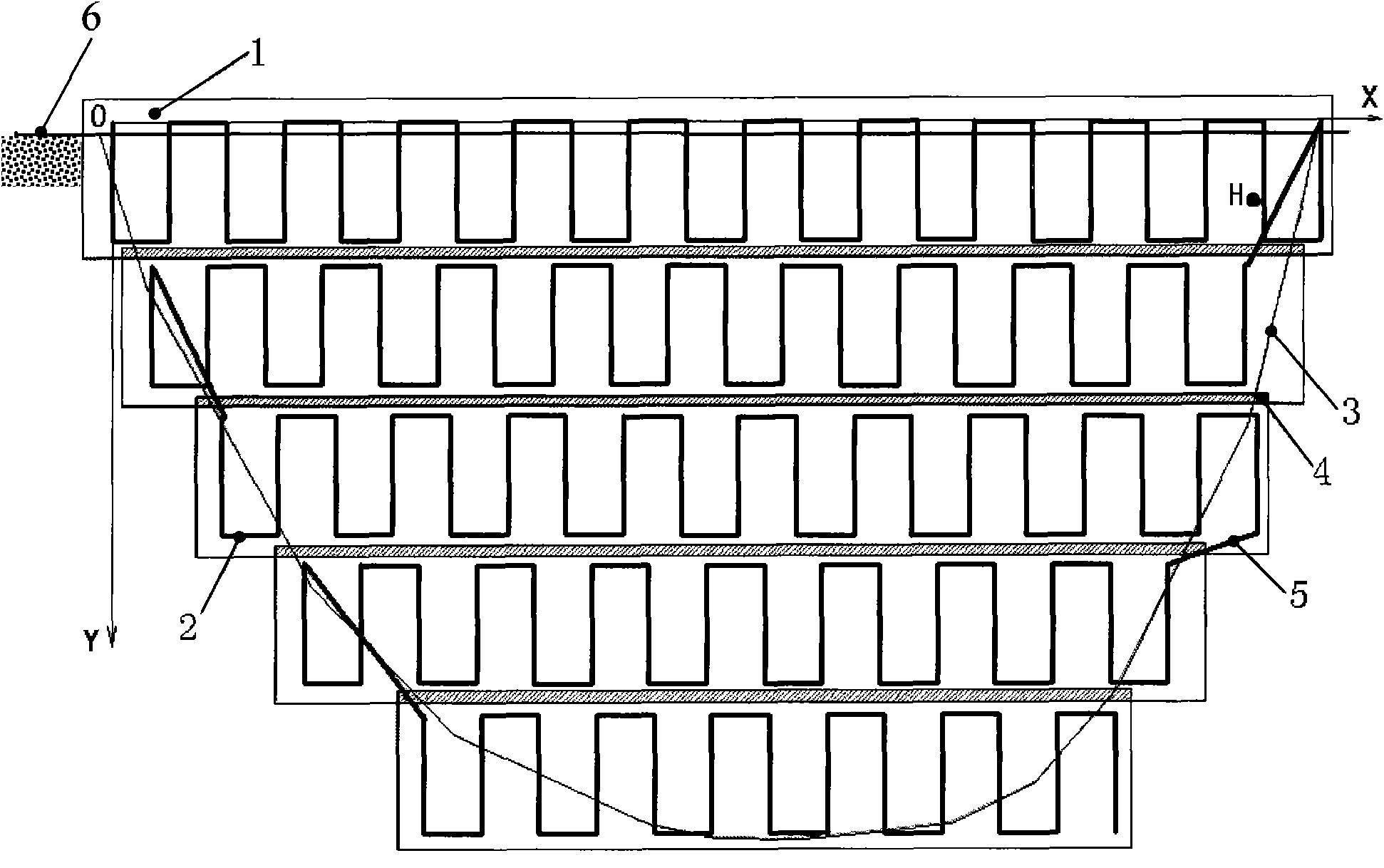

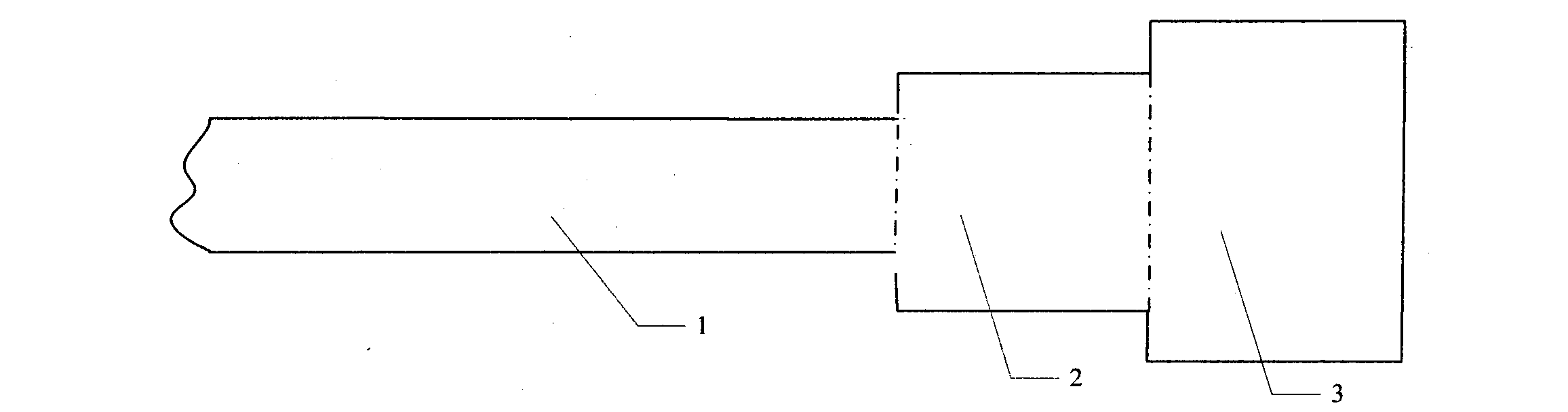

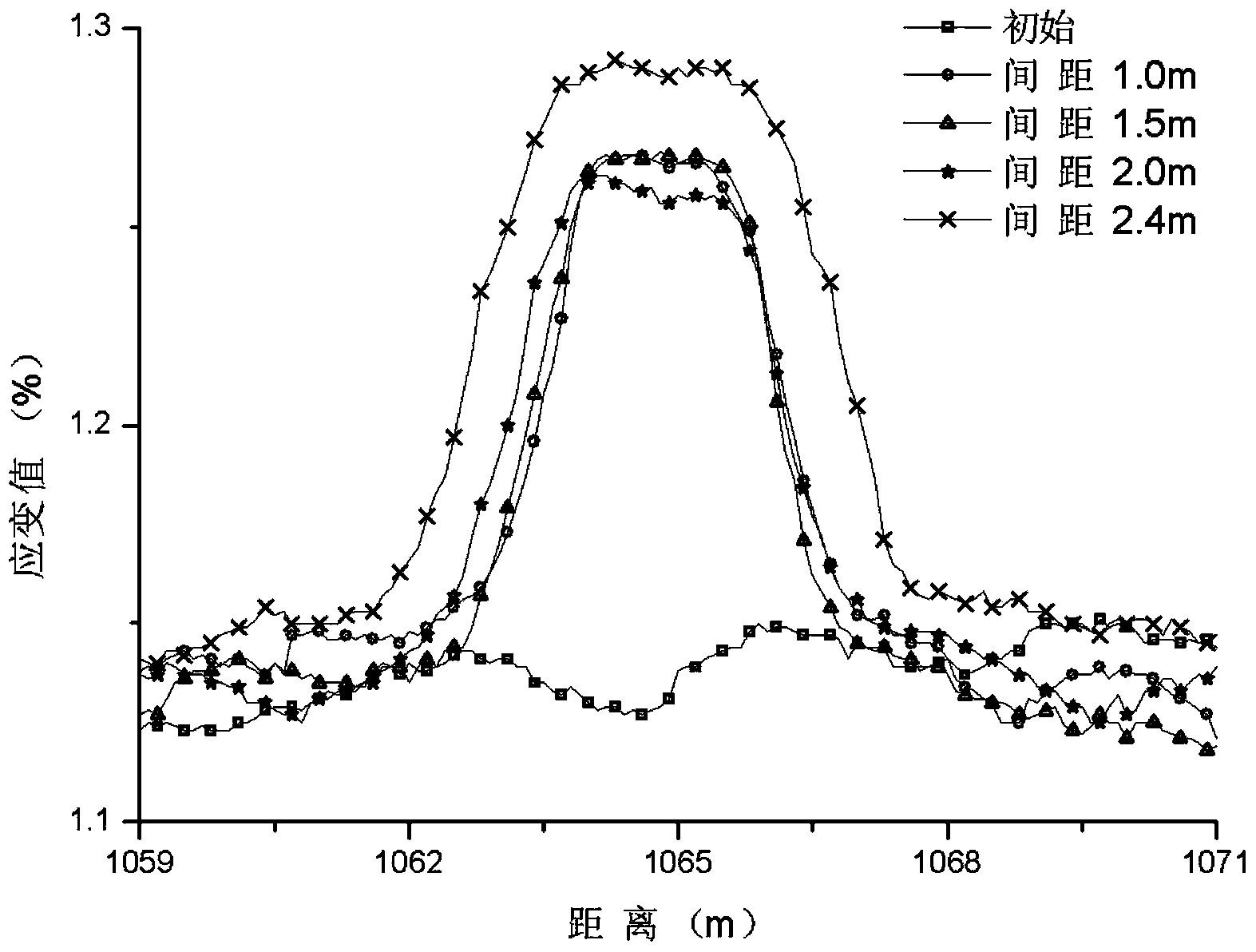

Method and system for monitoring soil property side slope distributive fiber optic strain

InactiveCN1901418AMaster the law of deformationDeformation fastThermometers using physical/chemical changesFluid-tightness measurementSoil propertiesFiber strain

This invention relates to a strain monitor system for slope distributed fibers, which lays out several parallel special optical cables along the slope or at least lays out one close to the slope top and the corner separately, adheres symmetrically two fibers on the outer surface of a tilt testing tube to get the distortion of deep soil helped by the strain of the tube, the special optical cables are melted orderly to constitute a sensor circuit to be connected to BOTDR, which links with remote computers via local computer and internet to constitute distributed fiber strain monitor system and gets the distortion or displacement of the slope by integrating and summing the measured strain distribution further to evaluate and preset to the side slope.

Owner:NANJING UNIV

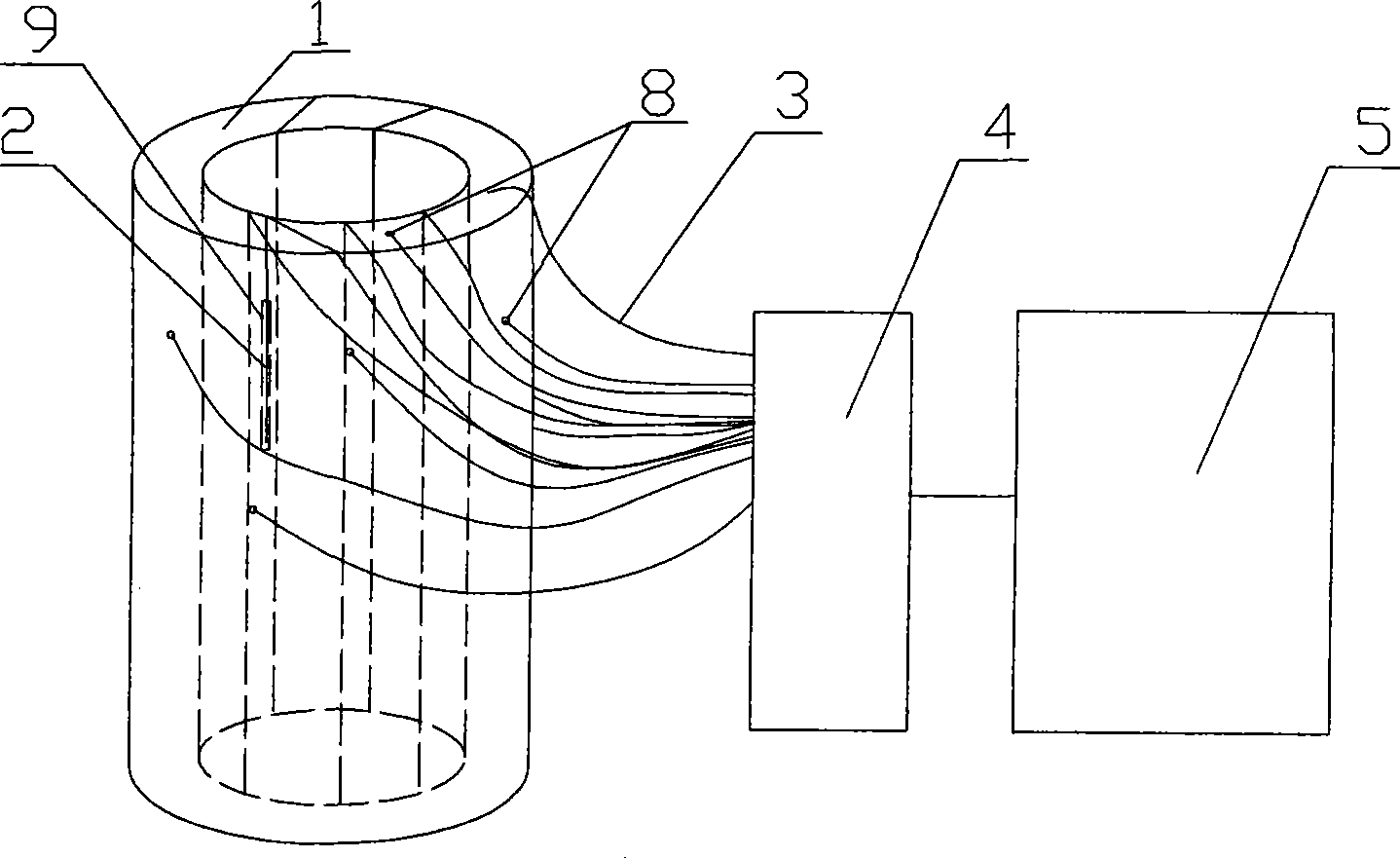

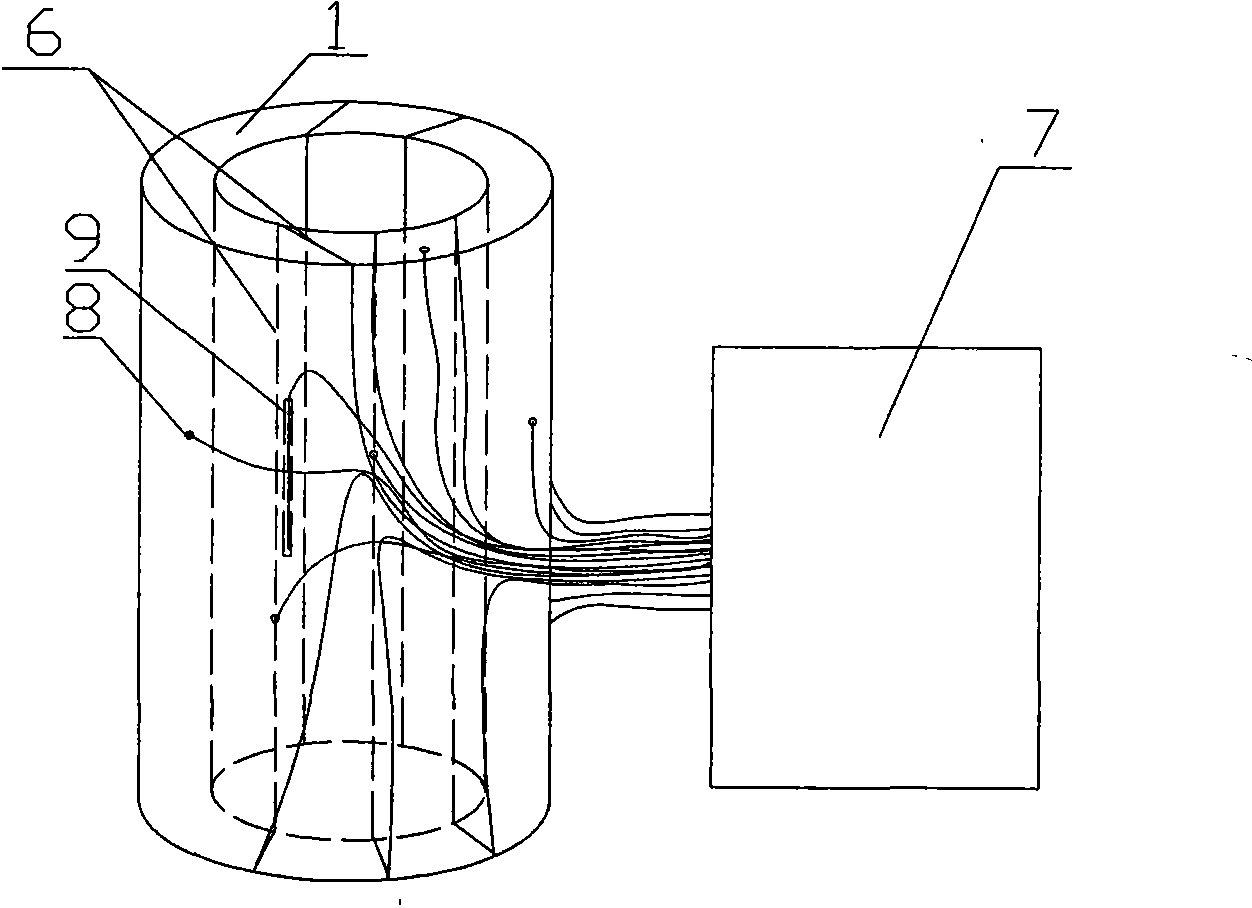

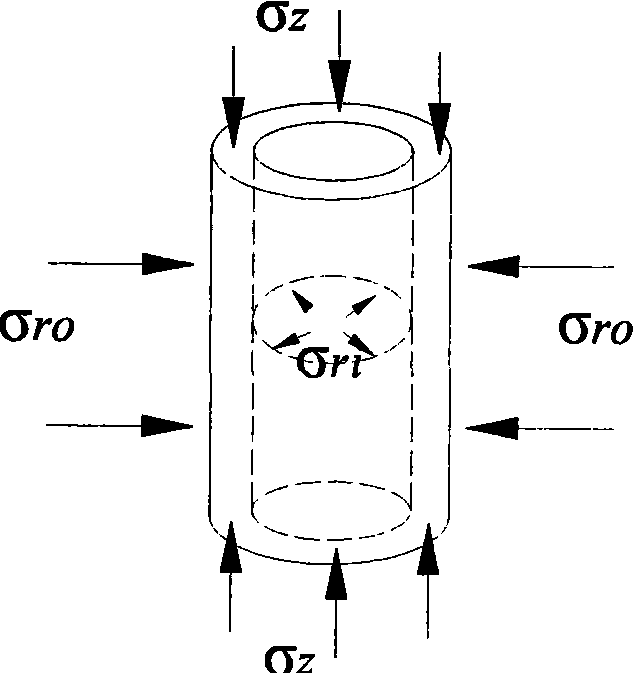

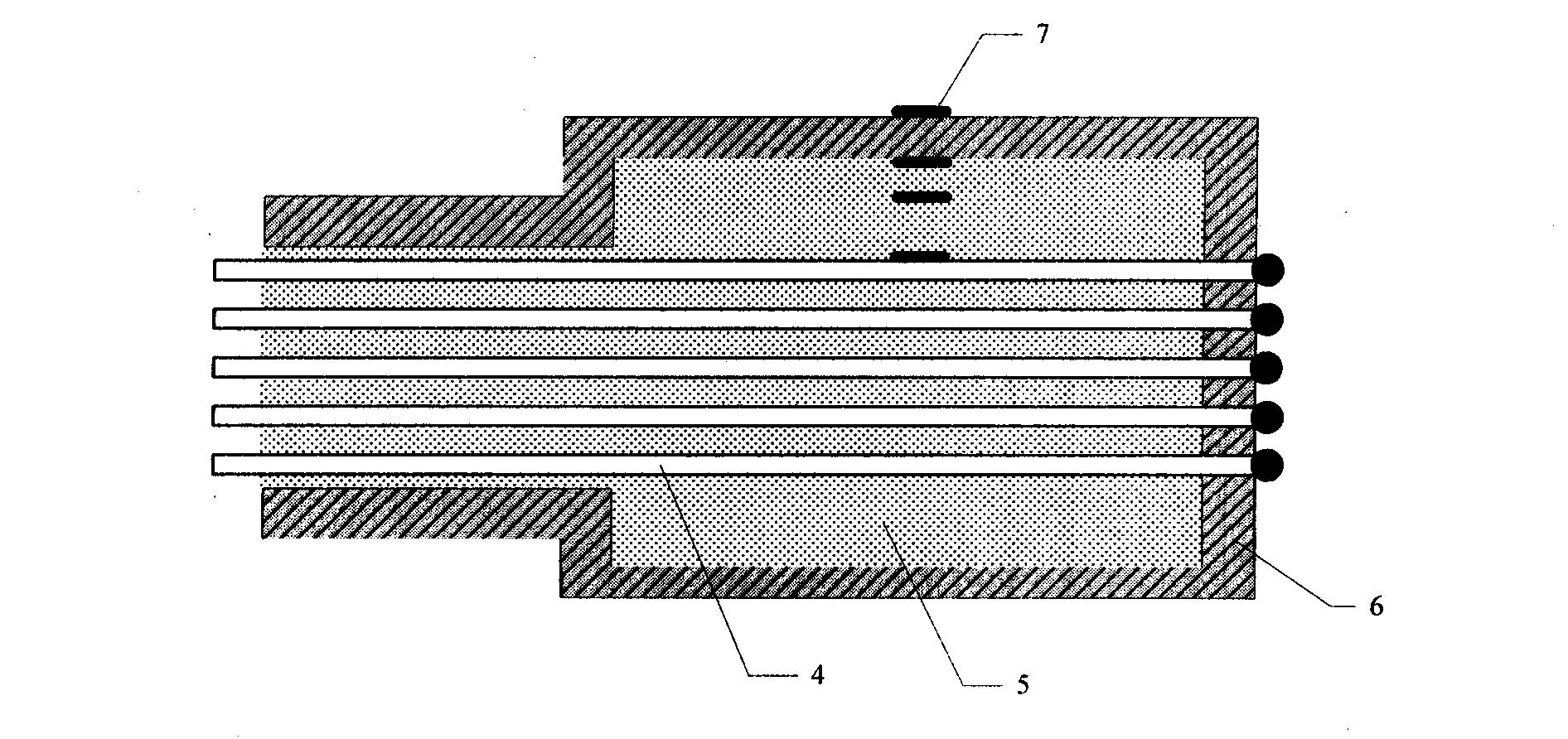

Rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing

InactiveCN101520317AIncrease space positionMaterial strength using tensile/compressive forcesUsing optical meansFiber strainInstability

The invention relates to a rock deforming and cracking three-dimensional dynamic testing system based on fiber strain sensing, which comprises a testing piece, wherein the testing piece is laid with a fiber sensor encapsulated with a plurality of testing strains; the fiber sensor is connected with a signal demodulation processing device through a connecting fiber; and demodulated data signals can build three-dimensional testing data of the testing piece and can form a three-dimensional dynamic strain field of the testing piece after interpolation. The system can effectively lay out the fiber sensor inside and on the surface of the real rock testing piece under the pressure of a three-axis presser, enters the rock inside to detect the rock dynamic strain under the premise of not influencing the rock structure and the stress, and can really test the rock dynamic cracking process to obtain the crack initial and expended spatial positions inside the testing piece. The system continuously monitors the generation and expansion of tiny cracks inside brittle materials under the loading action in real time at the same time, and can be widely applied to researching cracking instability mechanisms of materials, such as rocks, concrete and the like.

Owner:SHANDONG UNIV

In-situ three-dimensional shape rendering from strain values obtained through optical fiber sensors

ActiveUS8970845B1Eliminate compoundEliminate needUsing optical meansTesting fibre optics/optical waveguide devicesFiber strainThree dimensional shape

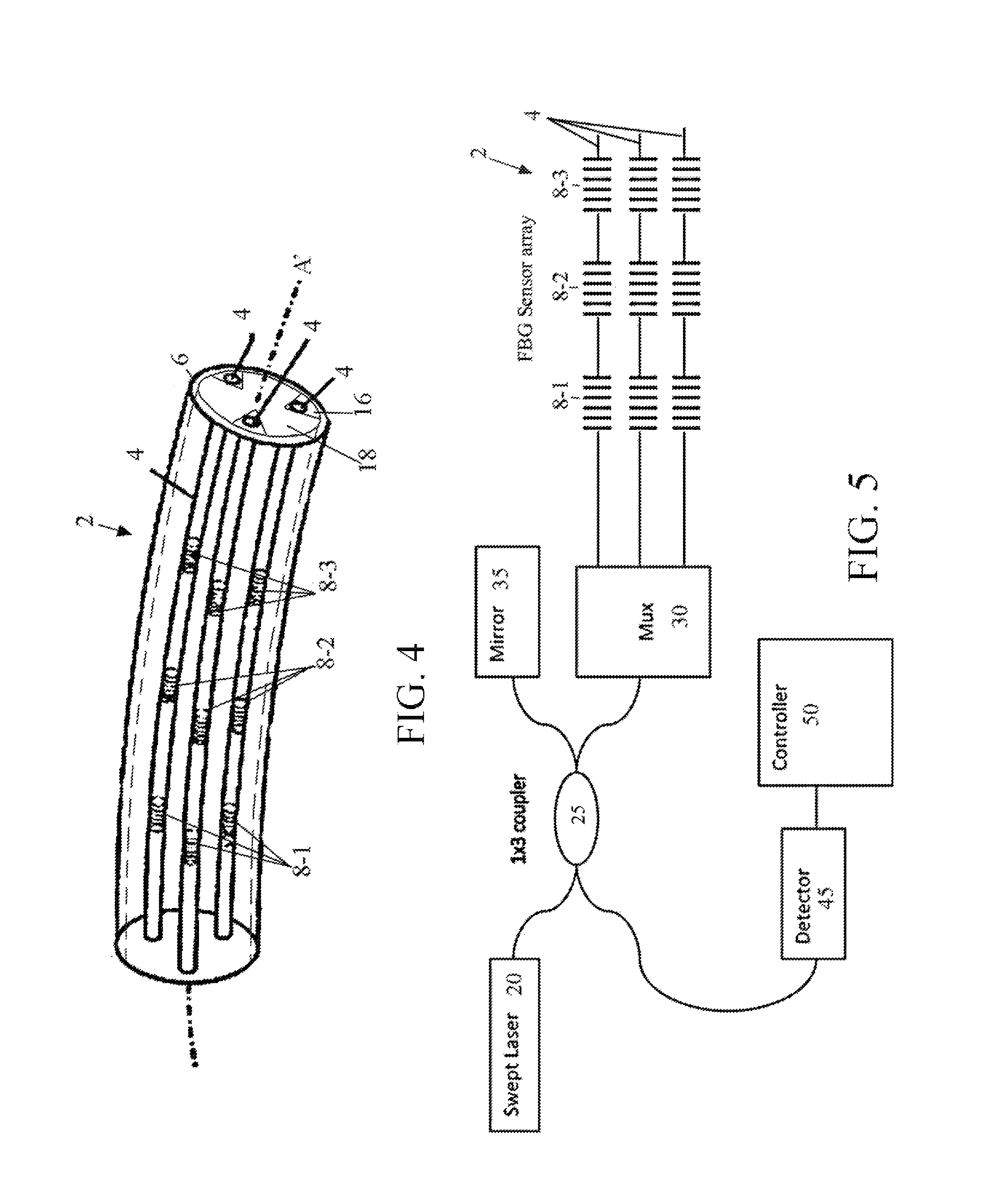

A method and system for rendering the shape of a multi-core optical fiber or multi-fiber bundle in three-dimensional space in real time based on measured fiber strain data. Three optical fiber cores arc arranged in parallel at 120° intervals about a central axis. A series of longitudinally co-located strain sensor triplets, typically fiber Bragg gratings, are positioned along the length of each fiber at known intervals. A tunable laser interrogates the sensors to detect strain on the fiber cores. Software determines the strain magnitude (ΔL / L) for each fiber at a given triplet, but then applies beam theory to calculate curvature, beading angle and torsion of the fiber bundle, and from there it determines the shape of the fiber in s Cartesian coordinate system by solving a series of ordinary differential equations expanded from the Frenet-Serrat equations. This approach eliminates the need for computationally time-intensive curve-tilting and allows the three-dimensional shape of the optical fiber assembly to be displayed in real-time.

Owner:NASA

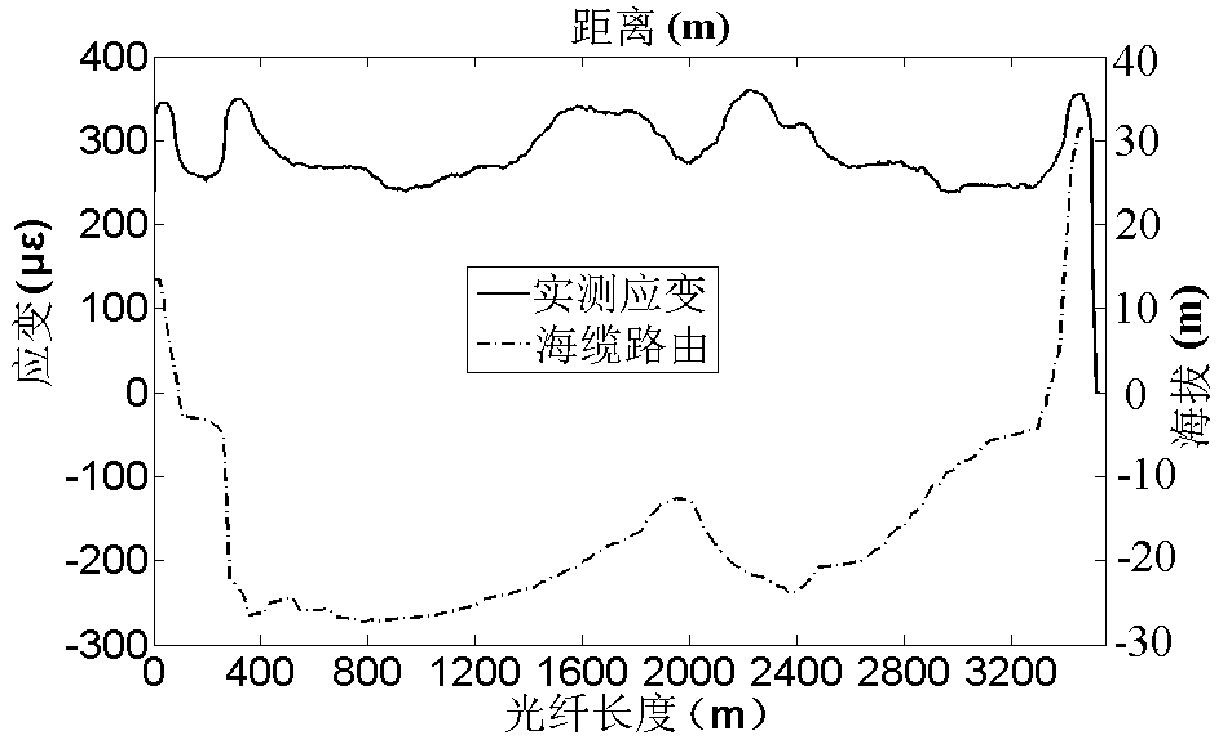

Submarine photoelectric composite cable omni-directional monitoring and fault point accurate positioning method

ActiveCN103557883ASafe and stable operationFault locationElectromagnetic wave reradiationTime domainOcean bottom

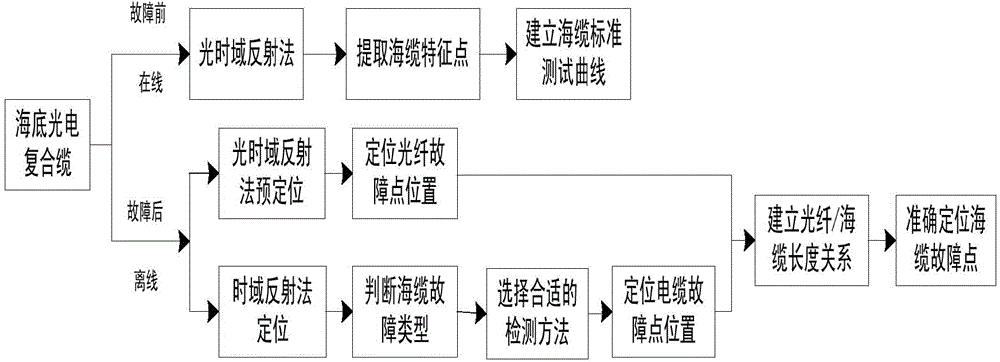

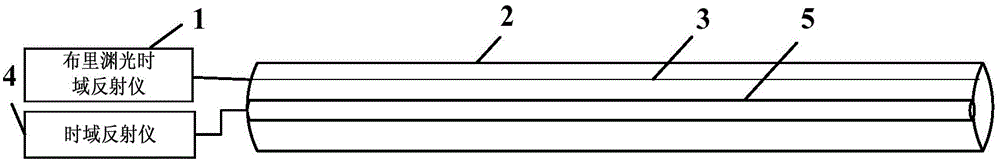

The invention discloses a submarine photoelectric composite cable omni-directional monitoring and fault point accurate positioning method in the technical field of measurement. According to the method, the Brillouin distributed strain / temperature measurement technology is employed, the online monitoring of the real-time operation of a submarine photoelectric composite cable is realized, the real-time operation state information of the submarine photoelectric composite cable is obtained through analyzing Brillouin distributed fiber strain / temperature measurement data and is combined with actual submarine cable state information, submarine photoelectric composite cable routing feature information is extracted, and the detection and accurate positioning of a submarine cable fault point are realized. When the submarine photoelectric composite cable is failed, a megohmmeter is employed to detect the characteristic of the cable fault, the cable fault type is judged, and a time domain reflection method is employed to carry out fault monitoring and position the cable fault point in the photoelectric composite cable. Combined with a fiber fault point obtained through a Brillouin light time domain reflection test and the cable fault point position obtained through the time domain reflection method, the fault point geographical position information of the submarine photoelectric composite cable is accurately obtained.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

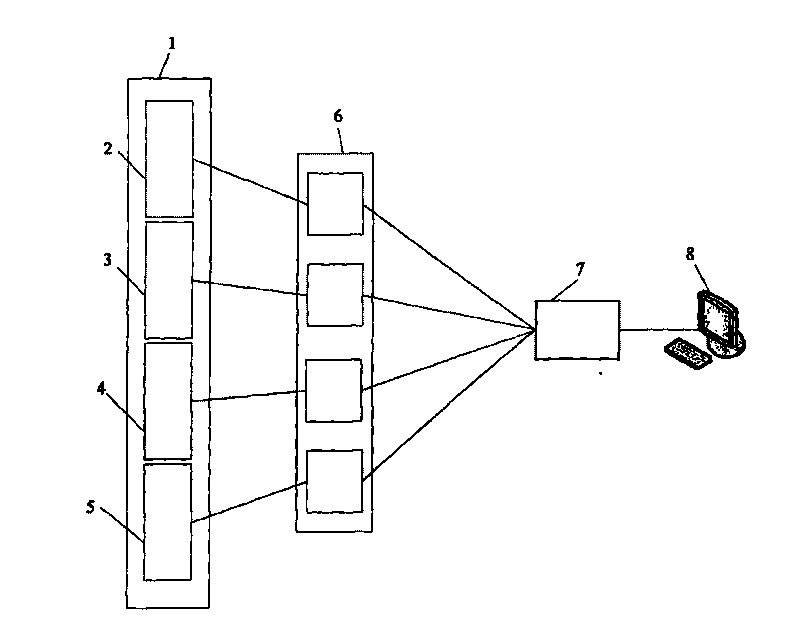

Fiber mine water inrush precursor information monitor

InactiveCN101696639AAchieve separationRealize quasi-distributed real-time monitoringMining devicesThermometers using physical/chemical changesSensor arrayReal time analysis

The invention provides a fiber mine water inrush precursor information monitor comprising a sensor array, a fiber splitter, a fiber grating demodulation device and a computer. The sensor array comprises a fiber temperature sensor, a fiber strain sensor, a fiber displacement sensor and a fiber osmotic pressure sensor which are all fiber grating sensors, and temperature, strain, displacement, osmotic pressure, and other physical quantities collected by the fiber grating sensors are sent to the fiber grating demodulation device by the fiber splitter through optical fibers; and the fiber grating demodulation device converts collected light wavelength signals into electric signals and finally sends the electric signals to the computer, and the computer analyzes and monitors on-site information by a software system in real time.

Owner:SHANDONG UNIV

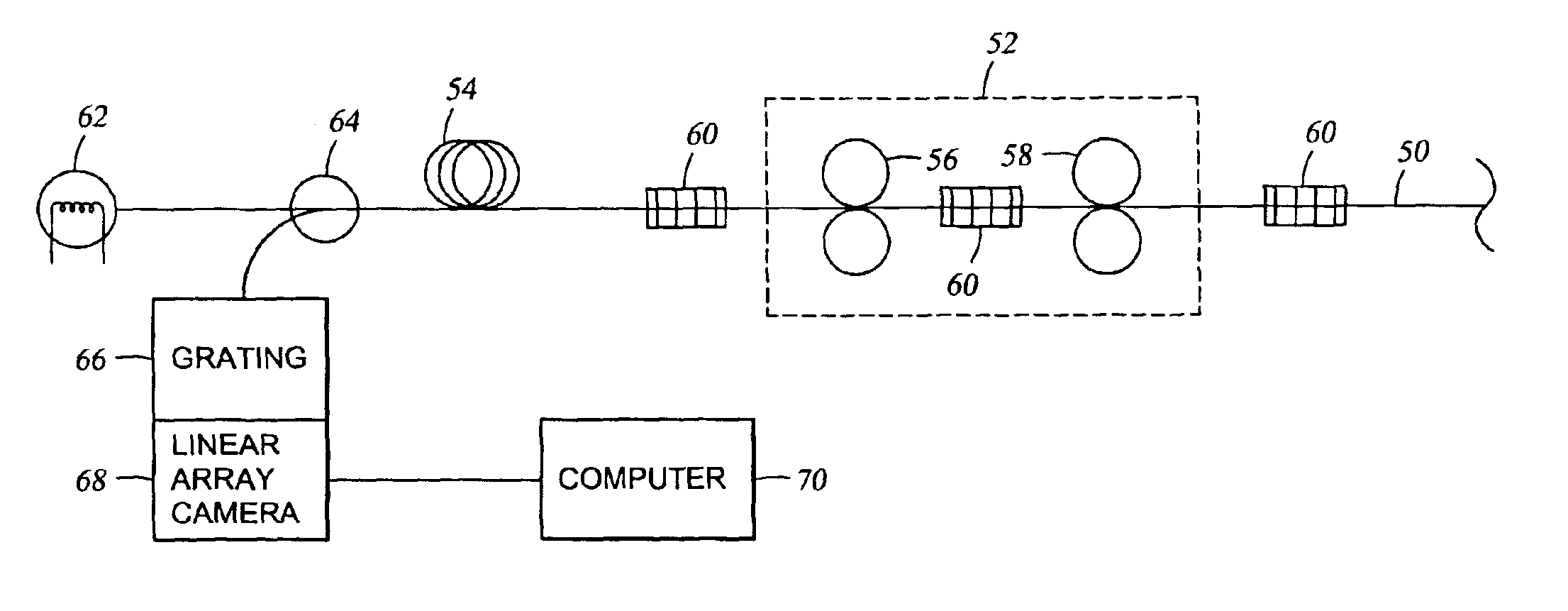

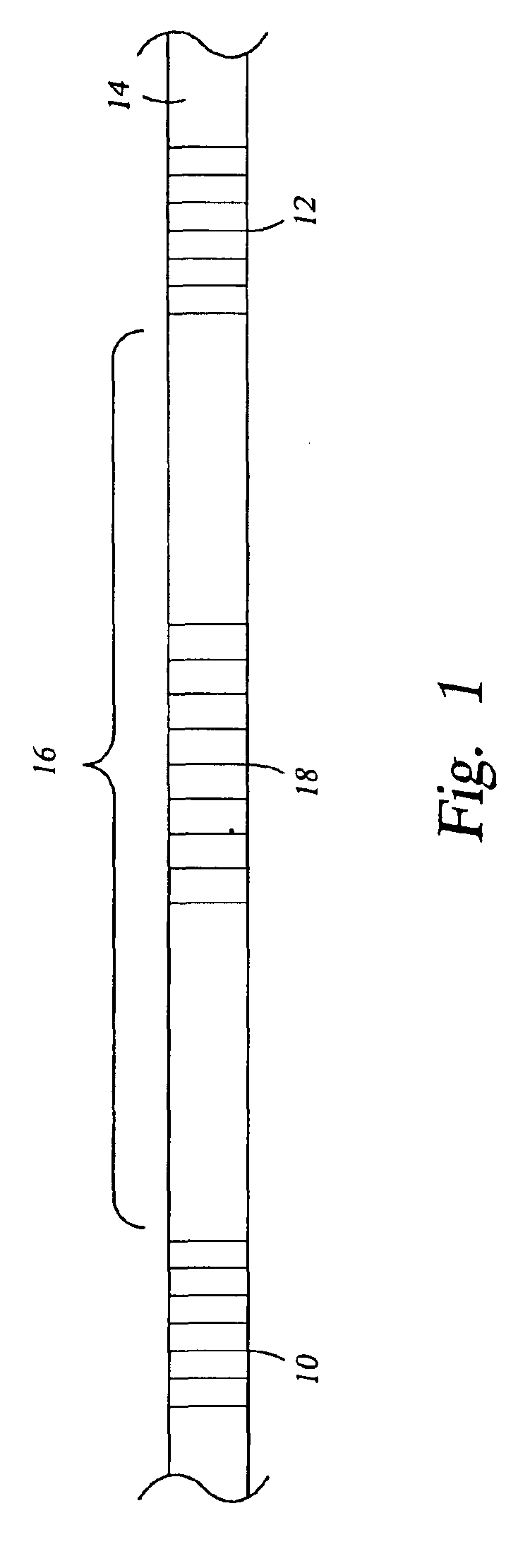

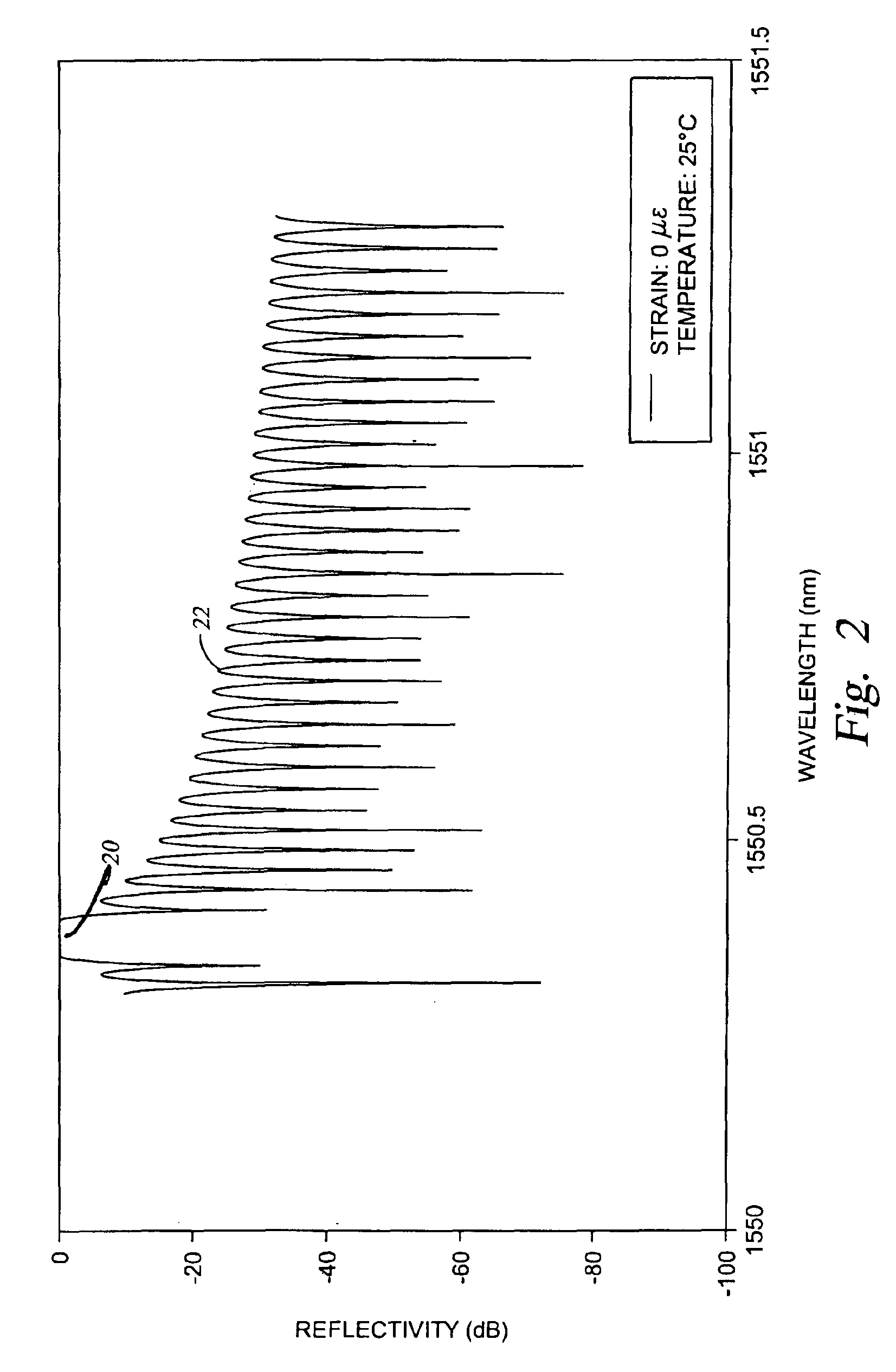

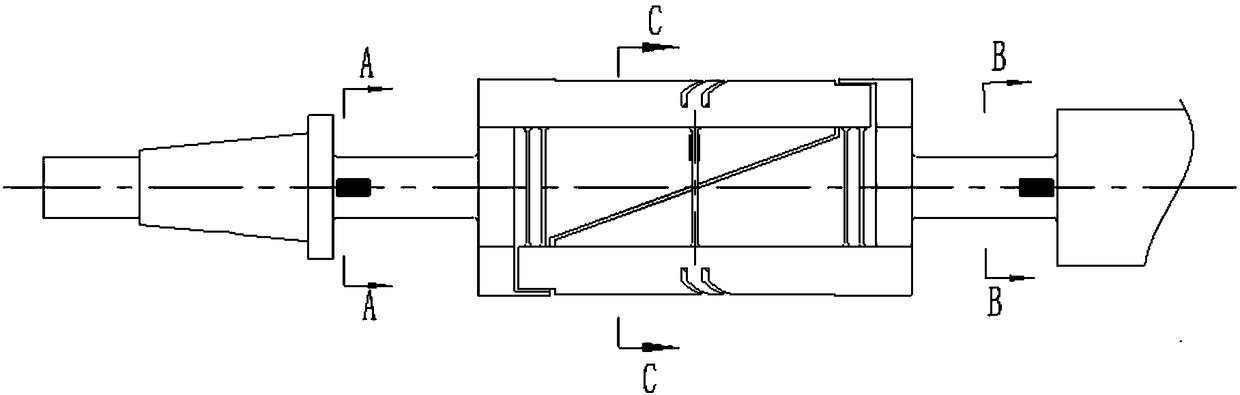

Measurement of fiber strain during processing

InactiveUS6947637B2Increase sampling rateForce measurement by measuring optical property variationCoupling light guidesGratingFiber strain

A method and system for determining strain impressed on an optical fiber at a possibly indeterminate temperature. The fiber (14) is formed with at least two sensors having different strain and temperature characteristics, preferably a Bragg Fabry-Perot sensor having a Fabry-Perot cavity (16) formed between two like Bragg gratings (10, 12) and another Bragg grating 18 of a different pitch written into the Fabry-Perot cavity. Many such pairs can be written if the Bragg gratings reflect in different bands. The fiber is irradiated with broadband light, and the reflection is spectrally separated to produce separate spectra for all sensors. Wavelength shifts from two types of sensors can be correlated with strain and temperature according to predetermined variations of the shifts with known strain and temperature changes.

Owner:CORNING INC

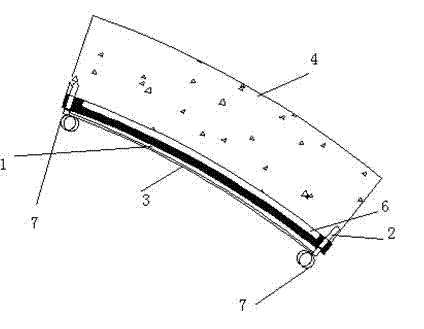

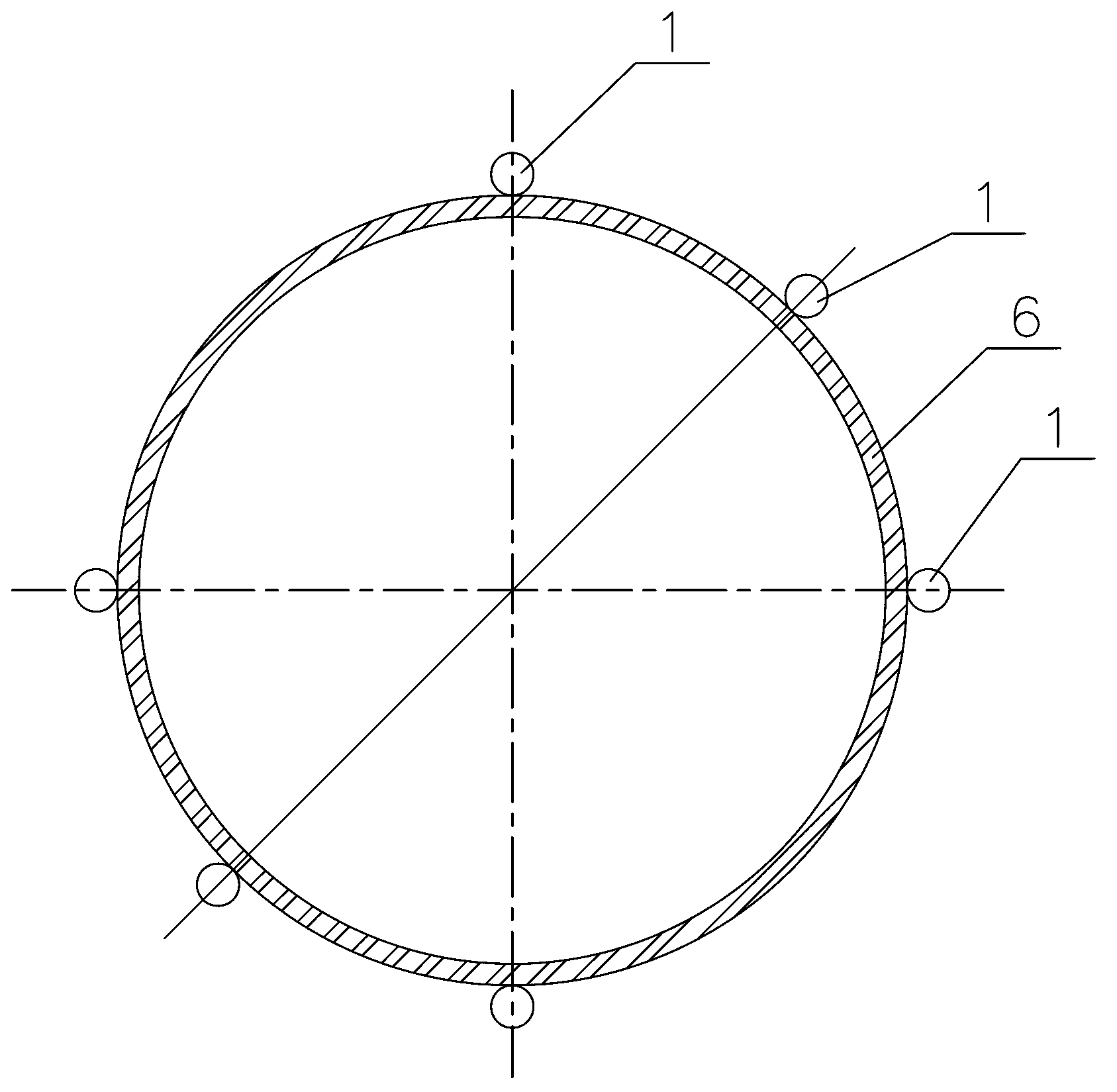

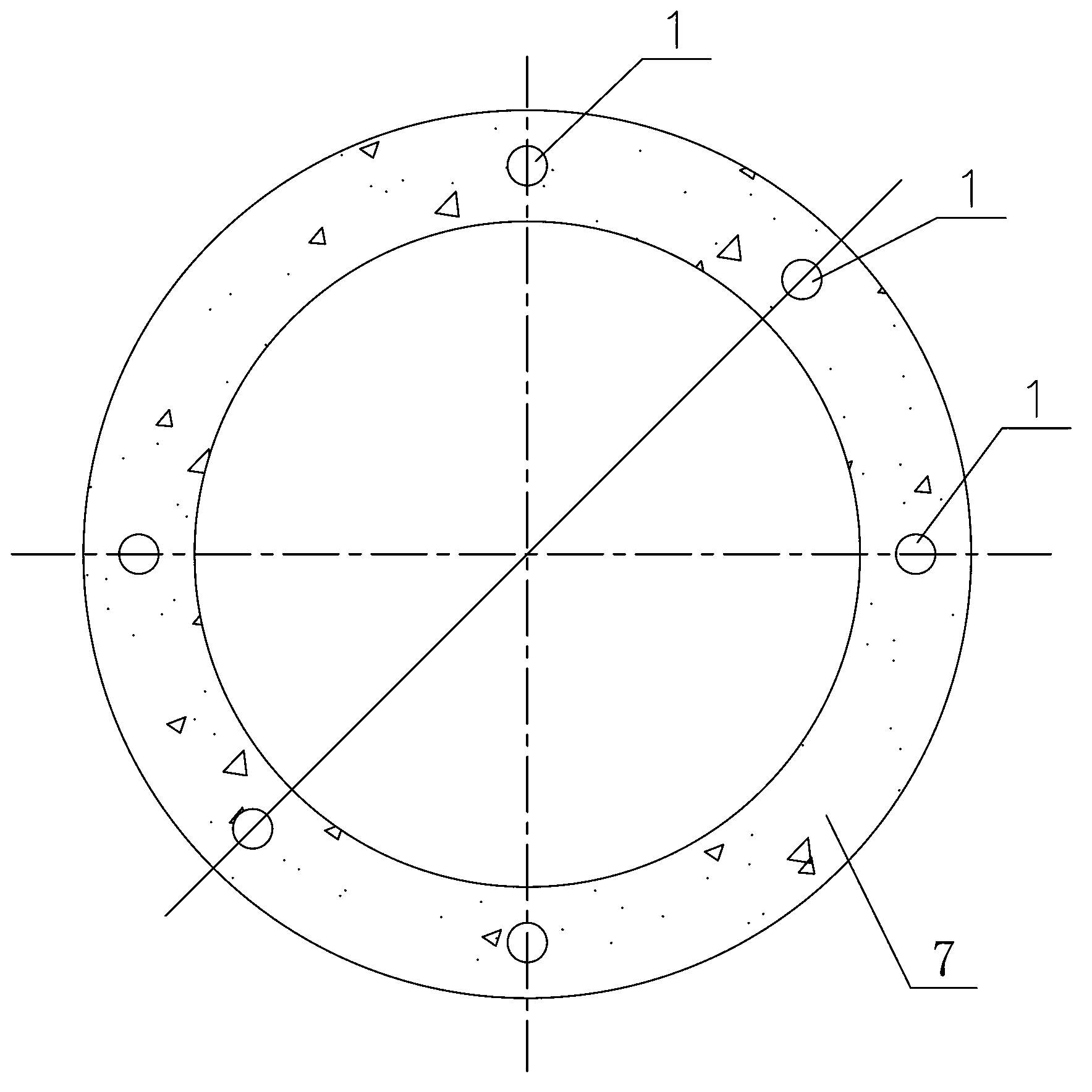

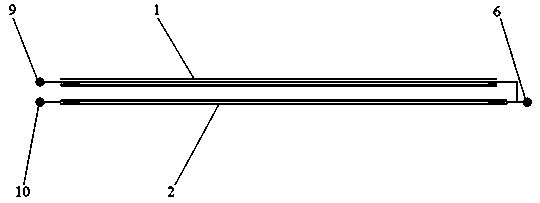

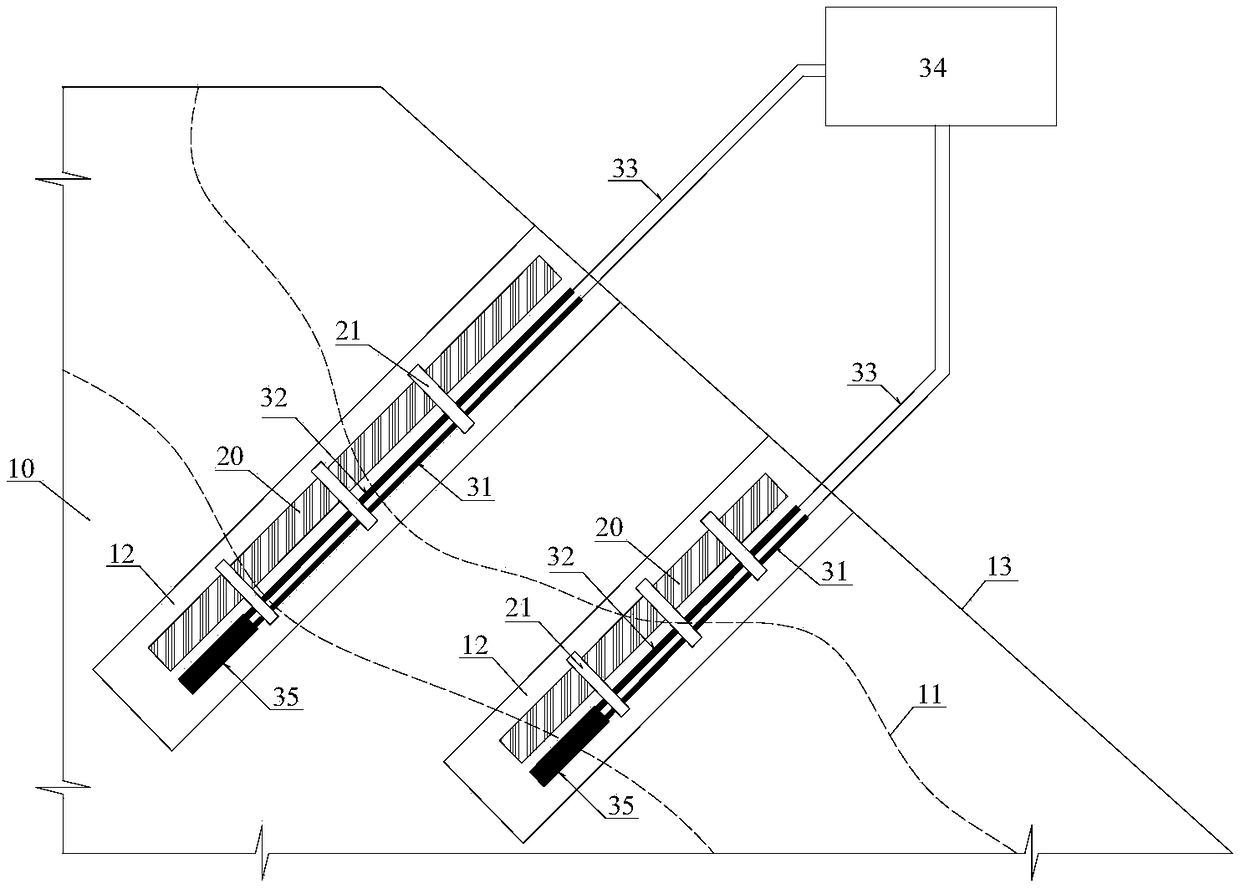

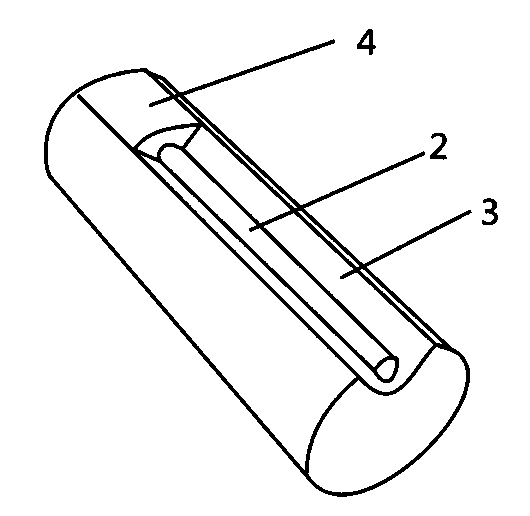

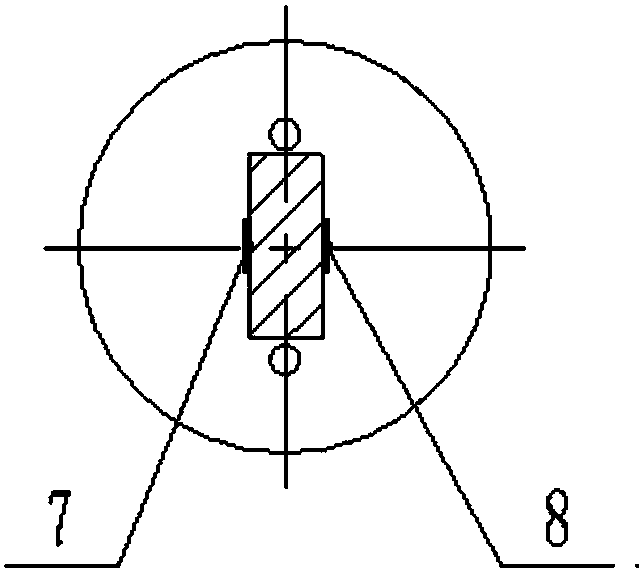

Tunnel convergence deformation distribution fiber monitoring method and system thereof

InactiveCN102384725ARapidly converges on deformed dataObtain converged deformation data quicklyThermometers using physical/chemical changesUsing optical meansTime domainSEMI-CIRCLE

A tunnel convergence deformation distribution fiber monitoring method is disclosed. A setting method of a distributed fiber convergence deformation monitoring sensor is adopted. The method is characterized in that: a sensing fiber is arranged on a matrix sheet material surface which has a same shape with an inner-side curved surface of a shield tunnel concrete segment so as to form a distributed fiber convergence deformation sensor and two ends of the sensor are respectively fixed on the inner side of the concrete segment; a cross section is in shapes of a rectangle, a U shape, a semi-circle or an arc or a circular ring; the sensing fiber has two parallel paths; one path is tight buffer fiber, which is used to measure strain alonga radial direction of the sensor; the sensing fiber is arranged on the surface of the sheet material sensor; using Brillouin optical time domain analysis (BOTDA) method, through calibrating correlation between a sensor gauge length convergence value and sensing fiber strain variation, convergence state change information of the tunnel section can be converted and measurement of the tunnel section convergence value can be performed. By using the invention,monitoring and measuring precision of the convergence state of the any representative section of the tunnel is high.

Owner:NANJING UNIV

Method for detecting breakage position of built-in geomembrane by fiber strain

InactiveCN101793502ADetermine the location of the damageAccurately determineUsing optical meansRepair timeGeomembrane

The invention relates to a scheme for quickly positioning breakage of an inner geomembrane in anti-seepage engineering, belonging to the technical field of anti-seepage in hydraulic engineering (civil engineering). The method of the invention comprises the following steps of: integrating continuous fibers and the geomembrane, wherein the fibers are arranged uniformly like a snake in the geomembrane, and the distance among the optical fibers is less than or equal to a strain sensitive distance of double fibers; taking the geomembrane as an anti-seepage material and conducting light paths of the fibers in the whole anti-seepage area; leading out the terminals of the fibers to a fiber strain detecting device for covering a protective layer of the geomembrane; and according to the arrangementdesign of the anti-seepage engineering, establishing a conversion expression between the fiber length L and the XY coordinate values of an anti-seepage surface. Fiber open circuit or abnormal strain caused by the breakage of the geomembrane can be found by a distributed detection system, and the breakage position of the geomembrane can be quickly and accurately determined by the conversion between the fiber length and a laying distance, thereby gaining precious emergency repair time for a dam of which the geomembrane is damaged, and effectively reducing the occurrence of dam collapse disasters.

Owner:KUNMING UNIV OF SCI & TECH

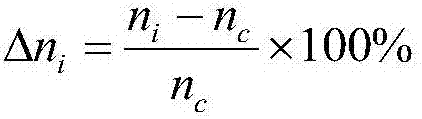

Distributed high-precision long-gauge-length carbon fiber strain test device and method

InactiveCN102494603AFewer post-processing stepsImprove linearityElectrical/magnetic solid deformation measurementMicrocontrollerCarbon fibers

The utility model discloses a distributed high-precision long-gauge-length carbon fiber strain test device and a method, and relates to the technical field of health detecting and monitoring in a civil engineering traffic structure. One of long-gauge-length carbon fiber strain sensors is taken as a working piece, the other long-gauge-length carbon fiber strain sensor is taken as a temperature compensating piece; a signal output end of a Wheastone temperature compensating bridge is connected with a signal input end of a primary signal, a signal output end of the primary signal is connected with a signal input end of a singlechip, and a signal output end of the singlechip is connected with a signal input end of a high-credibility approximate truth value. The invention aims at providing the distributed high-precision long-gauge-length carbon fiber strain test device for sensing performance of the comprehensive carbon fiber materials in the small strain range, which realizes the sensing of small strain of structures in large range under the condition of long-term unstable temperature so as to achieve the continuous detecting and monitoring on the stress (strain) of the structure.

Owner:SOUTHEAST UNIV

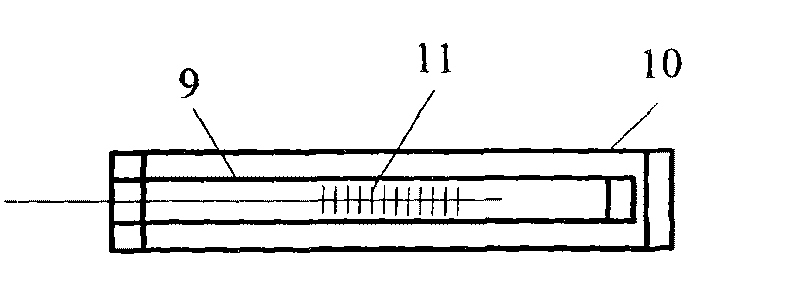

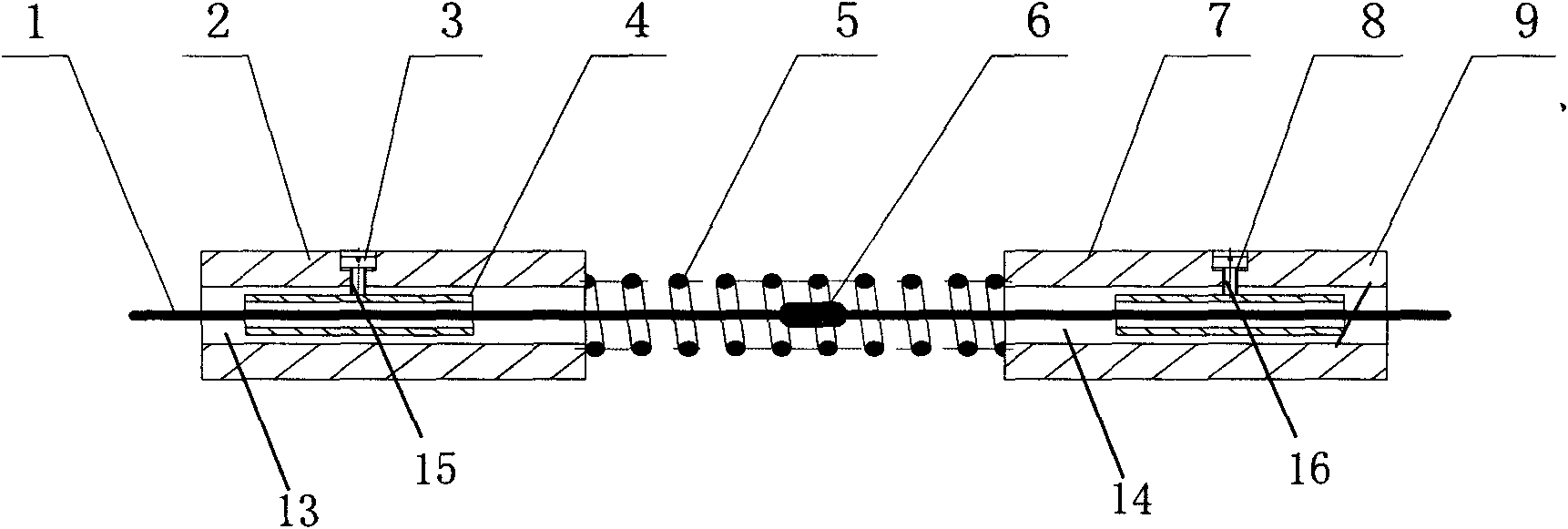

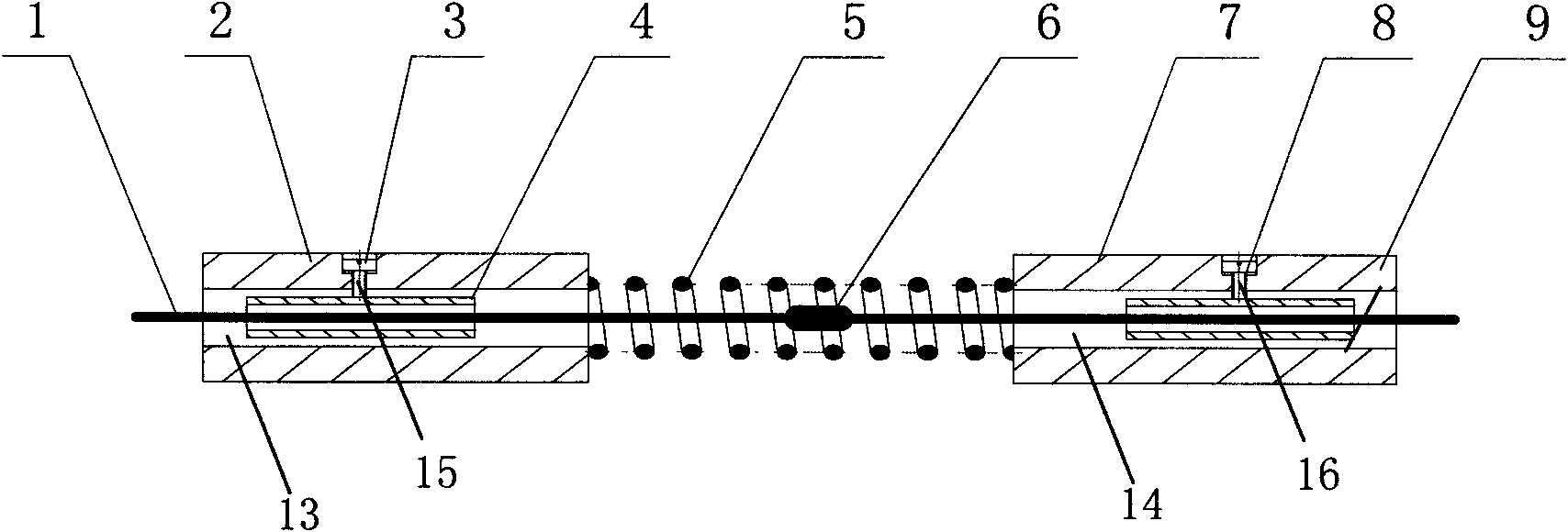

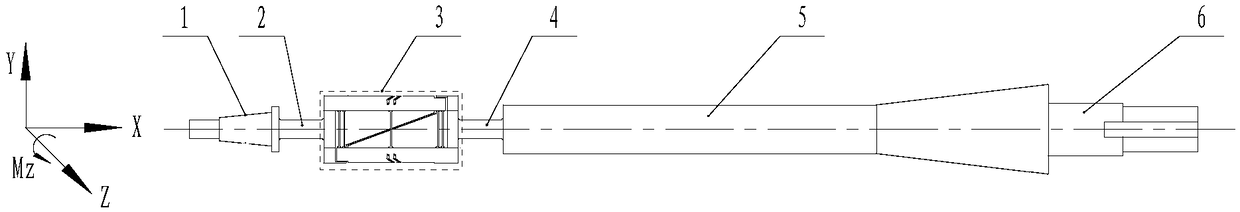

Fiber strain sensitive structure and manufacturing method thereof

InactiveCN101963493ALarge elastic rangeImprove linearityUsing optical meansCoupling light guidesFiber strainEngineering

The invention discloses a fiber strain sensitive structure and a manufacturing method thereof. The fiber strain sensitive structure comprises a left fiber fixing seat, a spring and a right fiber fixed seat which are in fixed connection in sequence, wherein the left fiber fixed seat is provided with a first through hole of which the left and right ends are communicated; the right fiber fixed seat is provided with a second through hole of which the left and right ends are communicated; and after penetrating through the first through hole of the left fiber fixed seat, the spring and the second through hole of the right fiber fixed seat, the fiber is stretched and fixed to the left and right fiber fixed seats; and a fiber strain sensitive unit on the fiber is positioned in the spring. The fiber strain sensitive structure has the characteristics of bidirectional stress strain, wide elastic range, favorable linearity, fatigue resistance, simple manufacturing method and low cost.

Owner:SHANGHAI KNP CHEM +3

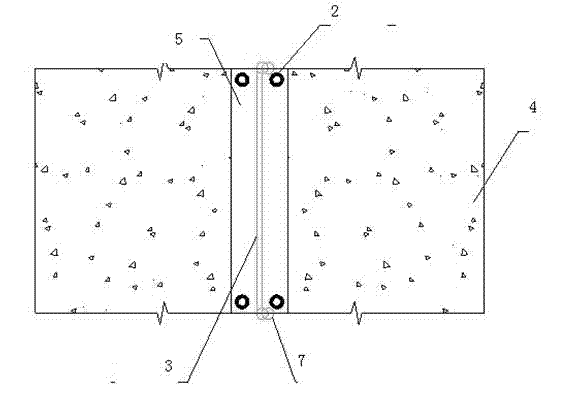

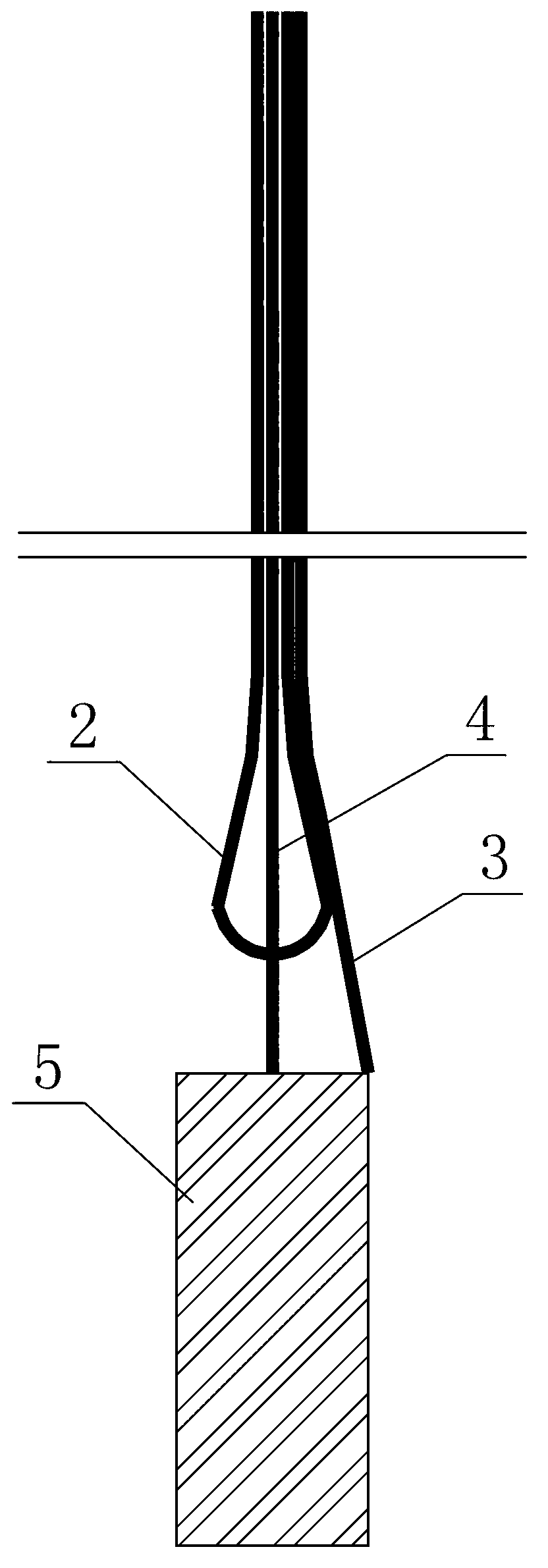

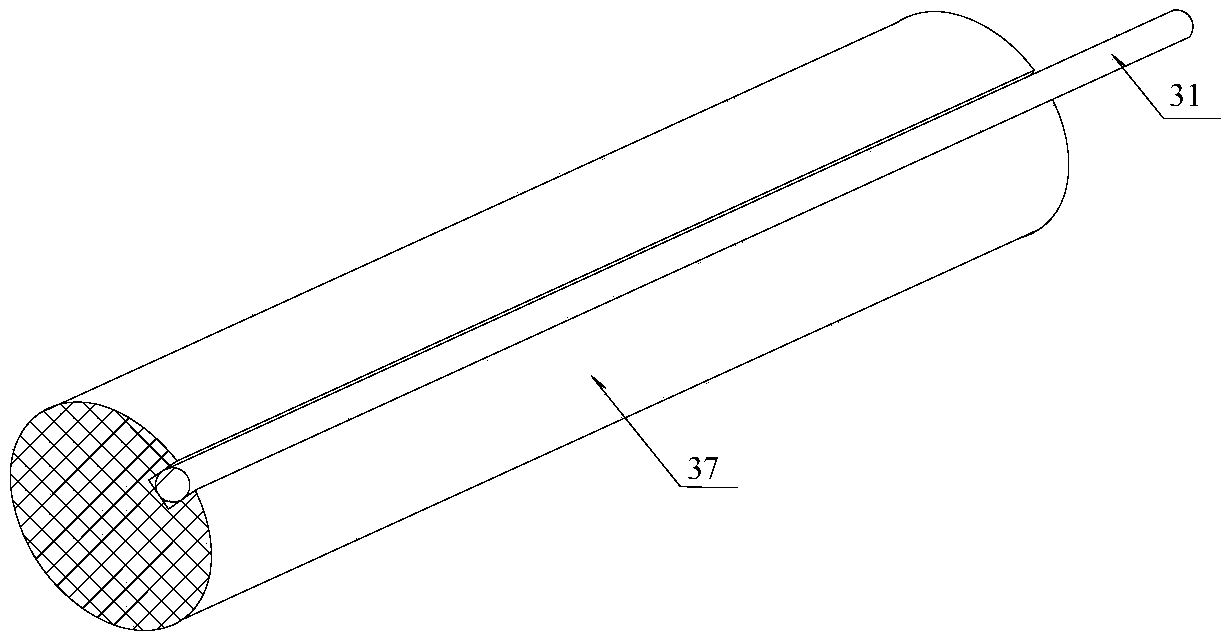

Inbuilt method for distributed type sensing cable in foundation pile

ActiveCN103215975AAvoid damageGuaranteed to be straightFoundation testingFiber strainArchitectural engineering

The invention relates to an inbuilt method for a distributed type sensing cable in a foundation pile. The invention aims at providing the inbuilt method for the distributed type sensing cable in the foundation pile to achieve a goal of reducing or avoiding damage to the sensing cable in a foundation pile construction process, thus improving the survival rate of an optic fiber strain sensor. The technical scheme is that for a driven pipe, the inbuilt method includes the steps: 1.1. arranging a group of pre-buried steel pipes on the foundation pile; 1.2. conducting foundation pile driving-in construction; 1.3. bending the sensing cable from the middle of the cable by 180 degrees, and fixing the bent portion on a metal support and conducting smooth transition on the bent portion; 1.4 placing the sensing cable and grouting flexible pipe together in each pre-buried steel pipe after a pilling rest period until the bent portion of the sensing cable extends to the bottom of the pre-buried steel pipe; and 1.5. grouting to the pre-buried steel pipe through the grouting flexible pipe until thick liquid comes out of the opening of the pipe, and completing the burying of the sensing cable after the thick liquid in the pipe is solidified.

Owner:ZHEJIANG HUADONG SURVEYING MAPPING & GEOINFORMATION

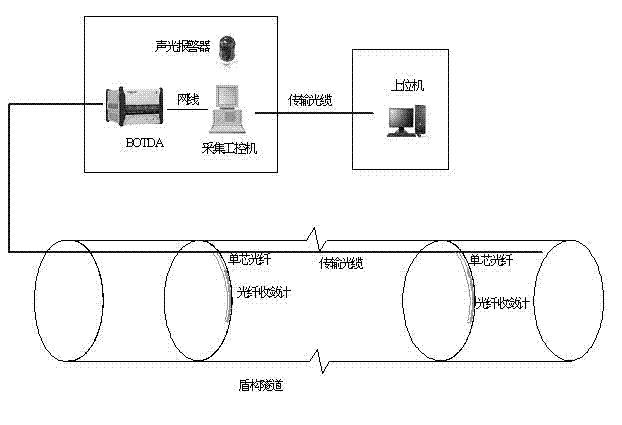

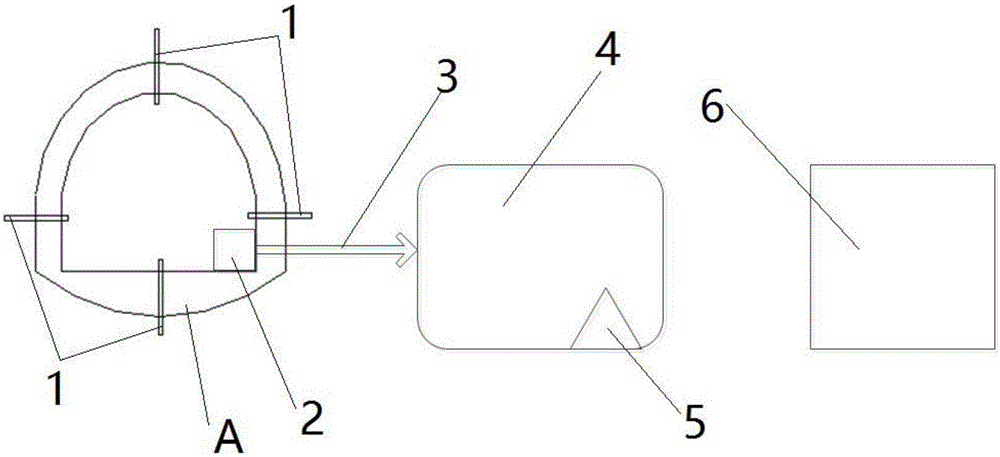

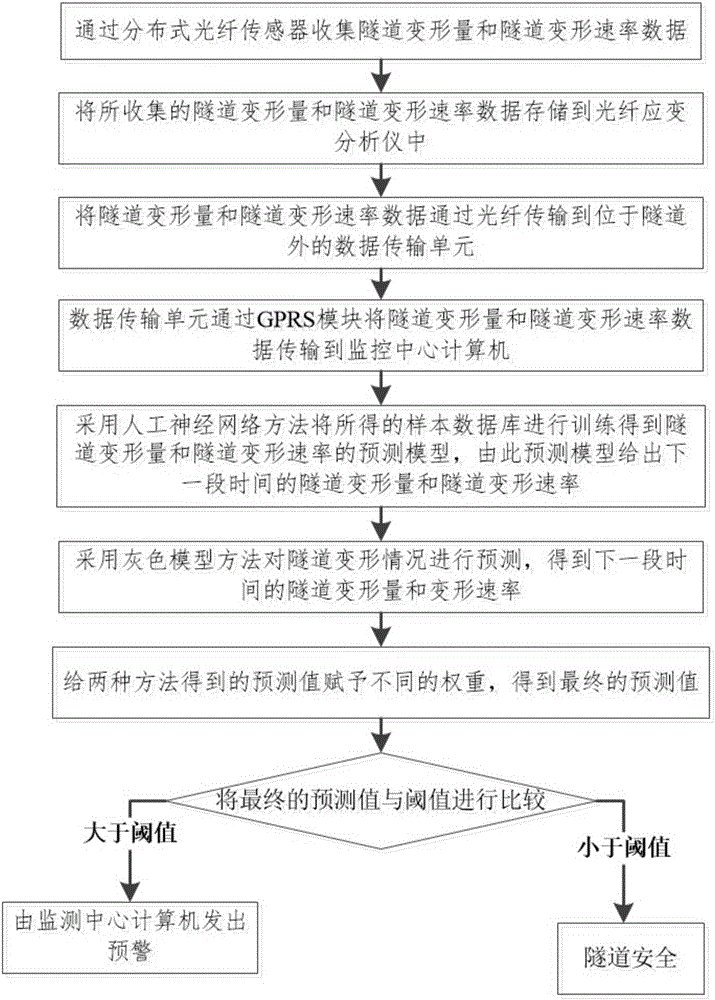

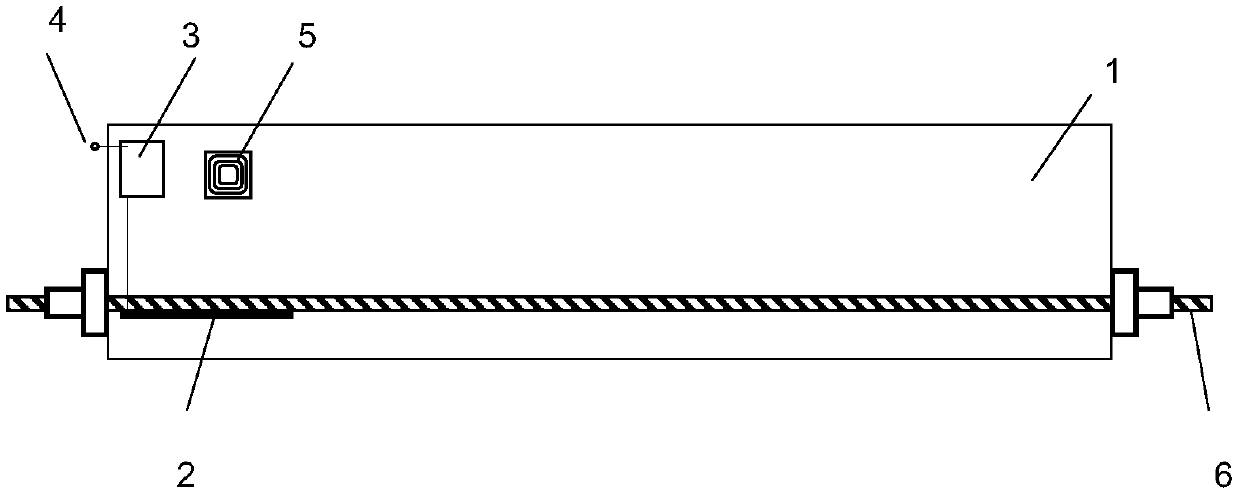

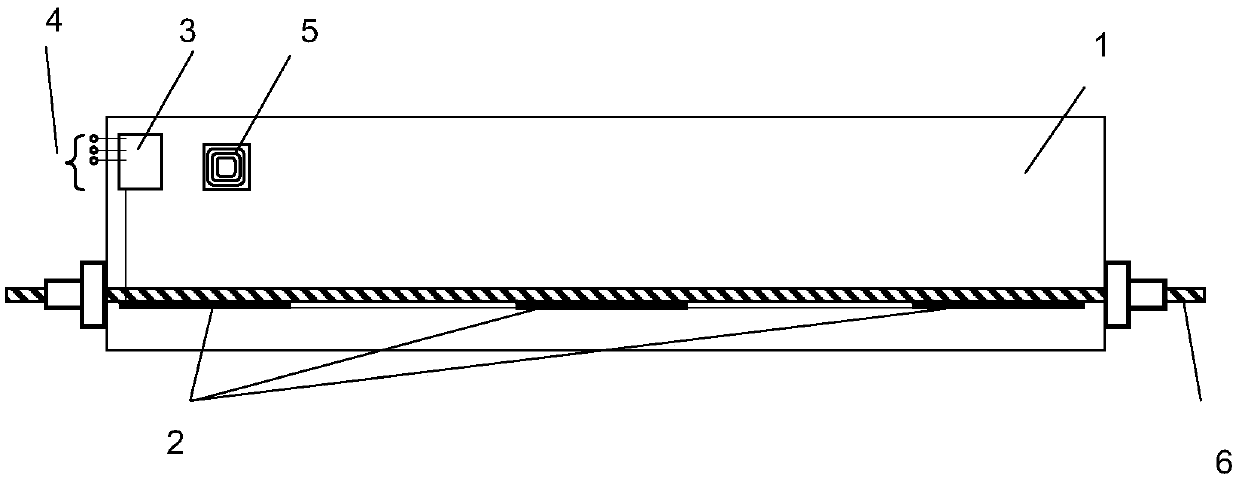

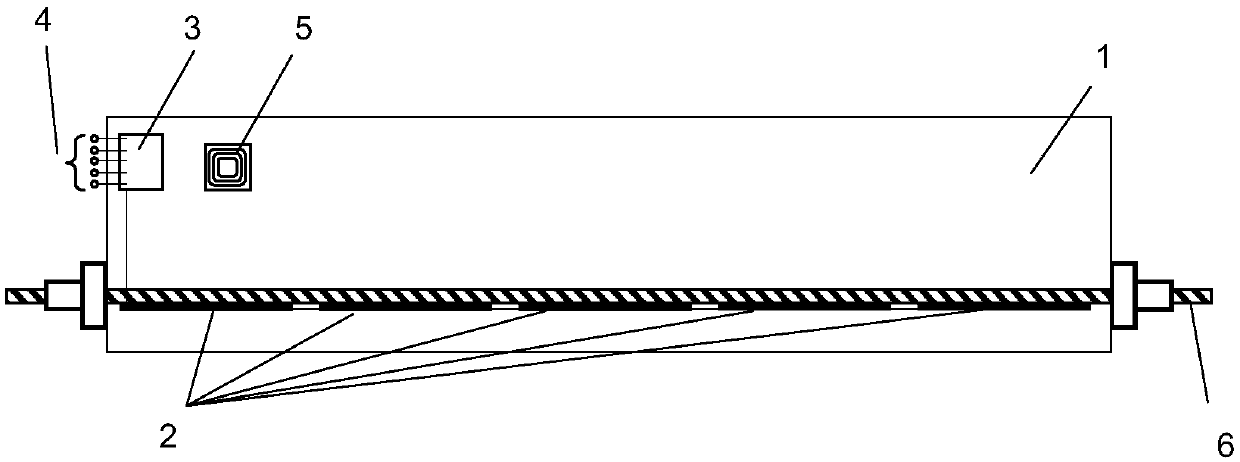

Tunnel runtime deformation monitoring forecast system and method

ActiveCN106500614AMeasure deformationScientific and convenient monitoring and managementUsing optical meansGeomorphologyModel method

The invention relates to a tunnel runtime deformation monitoring forecast system and method. The system comprises distributed fiber sensors (1) arranged in a monitoring section (A) of a tunnel, a fiber strain analyzer (2), a fiber (3), a data transmission unit (4), a GPRS module (5) and a monitoring center computer (6), wherein tunnel deformation quantity and tunnel deformation rate data which are collected by the distributed fiber sensors (1) are stored in the fiber strain analyzer (2) and is transmitted to the data transmission unit (4) disposed outside the tunnel through the fiber (3), and the data transmission unit (4) transmits the tunnel deformation quantity and tunnel deformation rate data to the monitoring center computer (6) through the GPRS module (5). The system and method combine a neural network method with a gray model method to carry out tunnel surrounding rock deformation quantity and deformation rate prediction, enable a monitoring result to be more scientific and reasonable, is more accurate in prediction result and is more scientific and systemic in monitoring prediction management.

Owner:CHONGQING UNIV

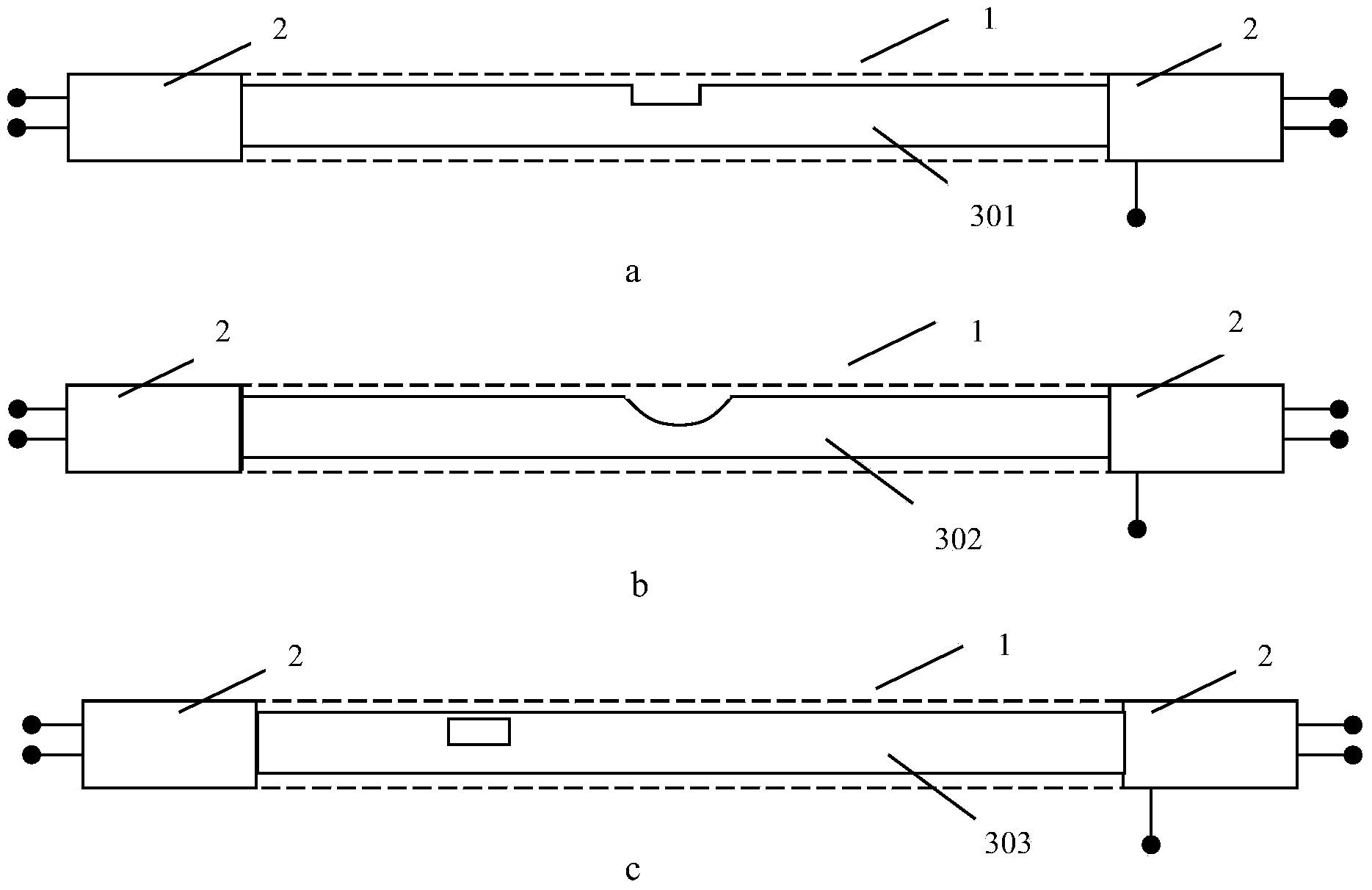

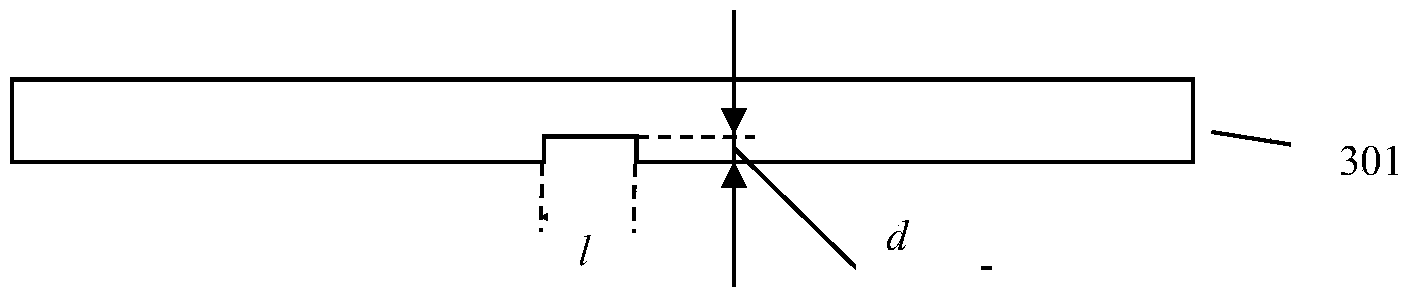

Long-scale-distance carbon fiber strain sensor

ActiveCN103868445AAddress measurement requirementsHigh precisionElectrical/magnetic solid deformation measurementCarbon fibersFiber strain

The invention discloses a long-scale-distance carbon fiber strain sensor which comprises a long-scale-distance carbon fiber strain sensor core wire, an anchorage section and a packaging layer. The two ends of the long-scale-distance carbon fiber strain sensor core wire are fixed to the anchorage section and packaged into the packaging layer in an insulating mode. The long-scale-distance carbon fiber strain sensor core wire is provided with a notch enabling the section of the long-scale-distance carbon fiber strain sensor core wire to be reduced in the fiber direction of the long-scale-distance carbon fiber strain sensor core wire, and the notch is the inner notch penetrating through the interior of the long-scale-distance carbon fiber strain sensor core wire or the outer notch formed in the outer surface of the long-scale-distance carbon fiber strain sensor core wire. The area of the notch is 0.5-5 percent that of the long-scale-distance carbon fiber strain sensor core wire. Long-term monitoring on small strain variation by the long-scale-distance carbon fiber strain sensor core wire is achieved, the long-scale-distance carbon fiber strain sensor has a sensing substrate and a packaging material which have the stable chemical quality, the measuring requirement for the small strain variation in long-term monitoring is met, and the precision of the sensor is improved.

Owner:SOUTHEAST UNIV +1

Super large cable force self-sensing intelligent cable and measuring method based on fiber strain sensing

InactiveCN101526409ALower requirementImprove survival rateTension measurementTextile cablesFiber strainEngineering

The invention discloses a super large cable force self-sensing measuring method based on fiber strain sensing, comprising the following steps: fiber strain sensing elements are pre-embedded in the anchorage zones of steel cables and measurement of the steel cable force is realized by measuring the strain capacity of the fiber strain sensing elements. The invention also discloses a super large cable force self-sensing intelligent cable based on fiber strain sensing. The invention has the beneficial technical effects of converting the large strain measurement of the cable to the small strain measurement of the anchorage zone, facilitating the common fiber strain sensors to meet the requirement of large strain measurement range and be suitable for cable force measurement of cables for especially big bridges, greatly lowering the measuring difficulty and cost, reducing the damage on the fiber strain sensors and prolonging the service lives of the fiber strain sensors.

Owner:CHONGQING UNIV

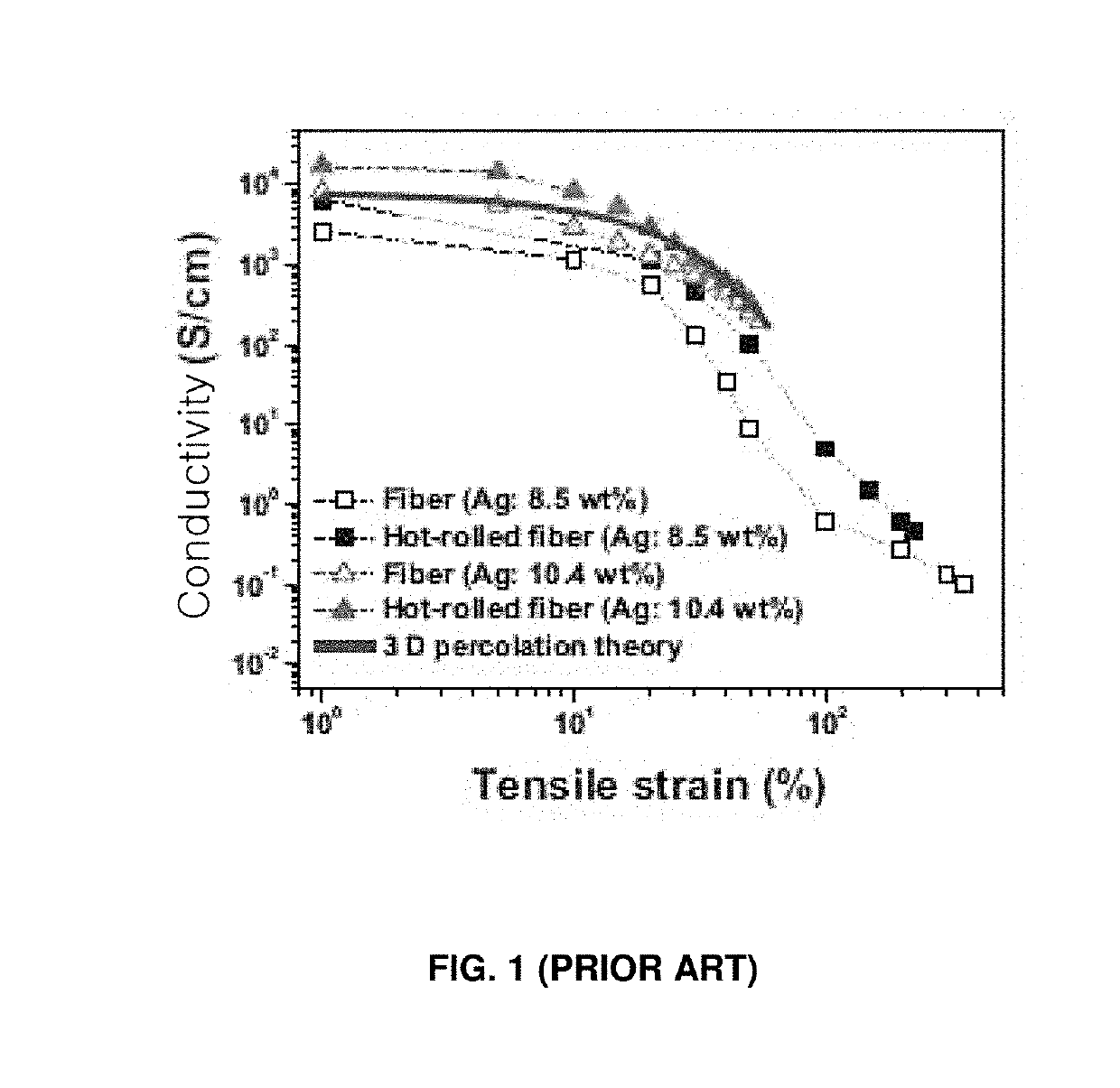

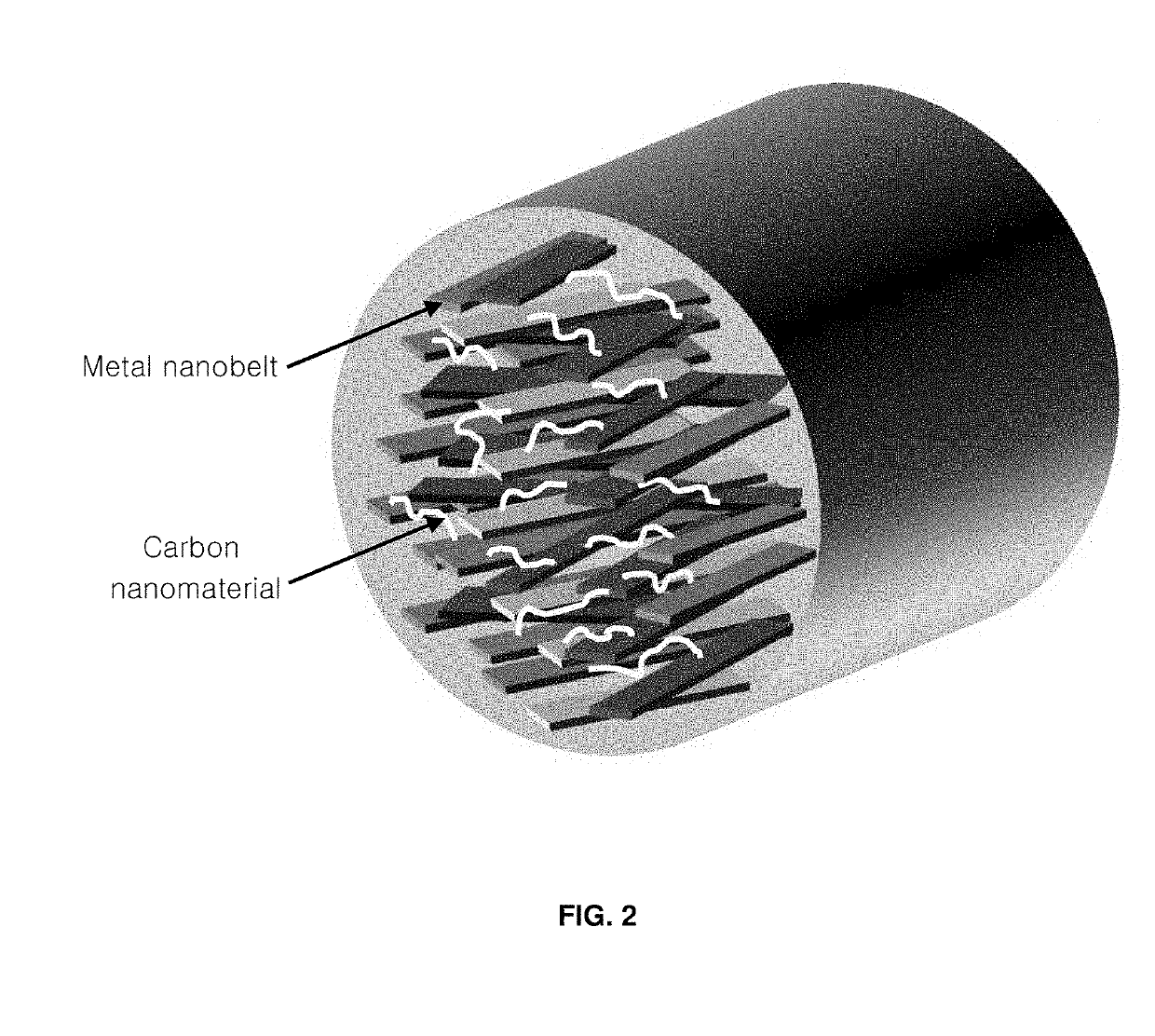

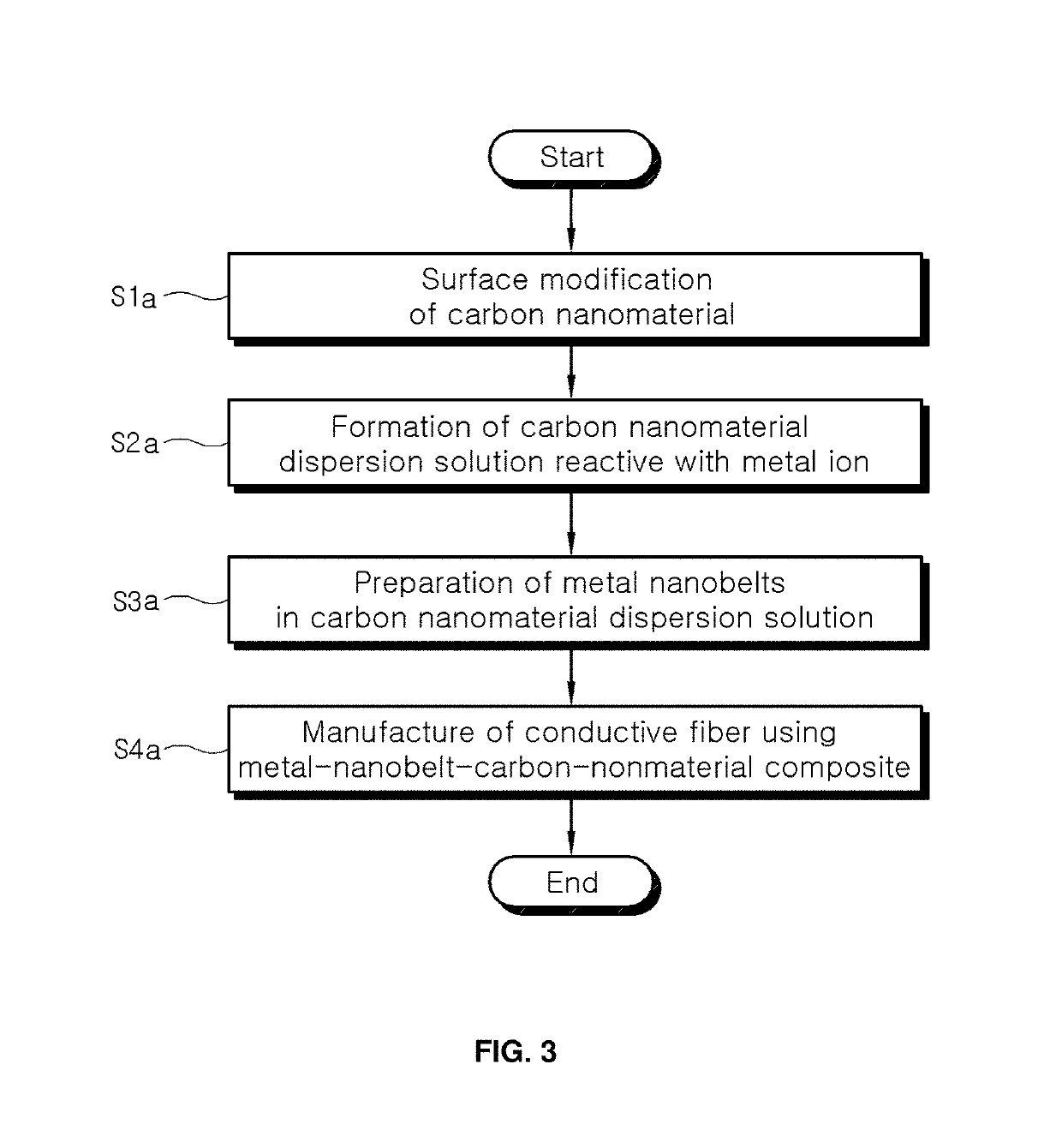

Conductive fiber comprising metal nanobelt and carbon nanomaterial composite, method for producing conductive fiber, fibrous strain sensor, and method for producing fibrous strain sensor

ActiveUS20190094005A1Improve conductivityImprove dispersion uniformityMaterial nanotechnologyElectroconductive/antistatic filament manufactureTensile strainFiber

A conductive fiber including a metal-nanobelt-carbon-nanomaterial composite. A manufacturing method thereof includes preparing a composite including a carbon nanomaterial and metal nanobelts and manufacturing a conductive fiber by mixing the composite with a polymer. A fibrous strain sensor and a manufacturing method thereof are also provided. Thereby, a conductive fiber including a metal-nanobelt-carbon-nanomaterial composite, which is able to increase conductivity of the conductive fiber through synthesis of metal nanobelts enabling area contact and to exhibit good contact between the carbon nanomaterial and the metal nanobelts due to formation of the metal nanobelts on the surface of the carbon nanomaterial and superior dispersion uniformity, and a fibrous strain sensor including the conductive fiber can be obtained. The conductive fiber can be effectively applied to a strain sensor based on a principle by which resistance drastically increases with an increase in a distance between metal nanobelts aligned in a fiber direction upon tensile strain of metal nanobelts enabling area contact.

Owner:KOREA ELECTROTECH RES INST

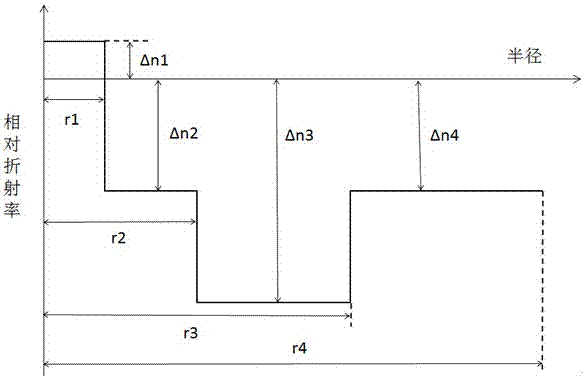

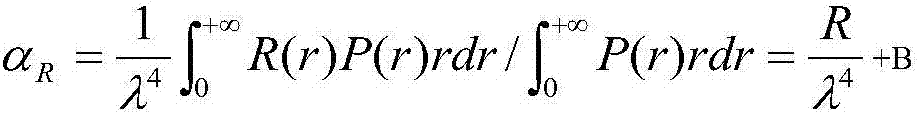

Ultralow-attenuation and large-effective-area single-mode fiber

InactiveCN106997073AIncreased chlorine doping contentAccelerated structural relaxationOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationFiber strain

The invention relates to an ultralow-attenuation and large-effective-area single-mode fiber comprising a core layer and wrapping layers. The ultralow-attenuation and large-effective-area single-mode fiber is characterized in that the radius r1 of the core layer is 5-8 microns, the relative refractive index deltan1 of the core layer is 0-0.20%, and the core layer wraps an internal wrapping layer, a recessed internal wrapping layer and an external wrapping layer from inside to outside in turn. The radius r2 of the internal wrapping layer is 8.5-12 microns, and the relative refractive index deltan2 is -0.20--0.45%. The radius r3 of the recessed internal wrapping layer is 12.5-30 microns, and the relative refractive index deltan3 is -0.40--0.65%. The external wrapping layer is a fully fluoridated silicon dioxide glass layer, and the relative refractive index deltan4 is -0.22--0.53%. The ultralow-attenuation and large-effective-area single-mode fiber has the specific viscosity matching design: the core layer is not the pure silicon core and has the characteristics of co-doping of germanium and fluorine, and the chlorine doping technology is also performed so that the fiber viscosity can be reduced and the structural relaxation of glass can be accelerated; and the core layer viscosity matching is optimized by controlling the doping concentration, and the viscosity of each part of the fiber and the fiber strain are optimized so that ultralow-attenuation performance of the single-mode fiber can be realized.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

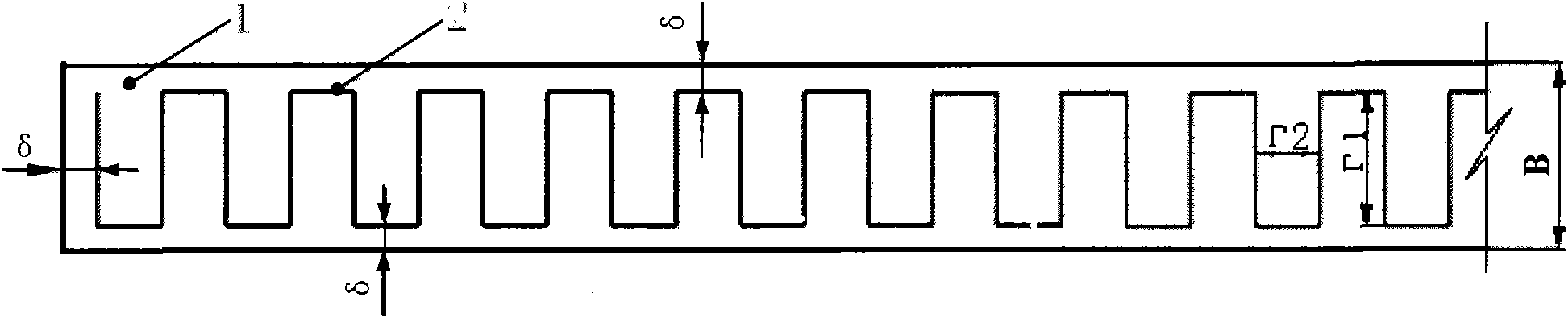

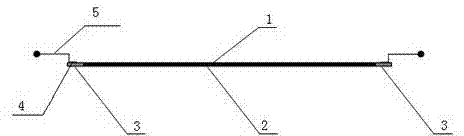

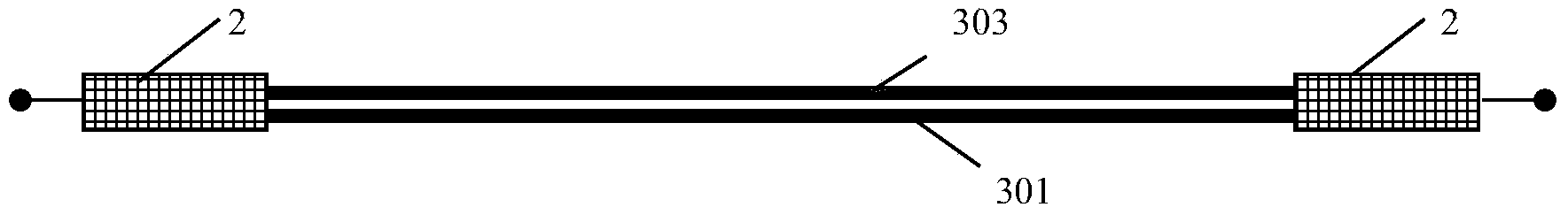

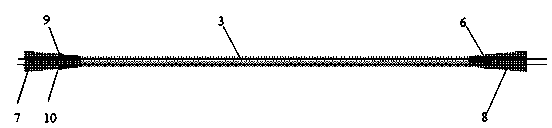

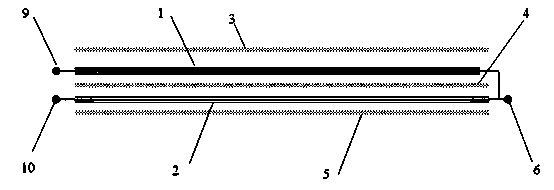

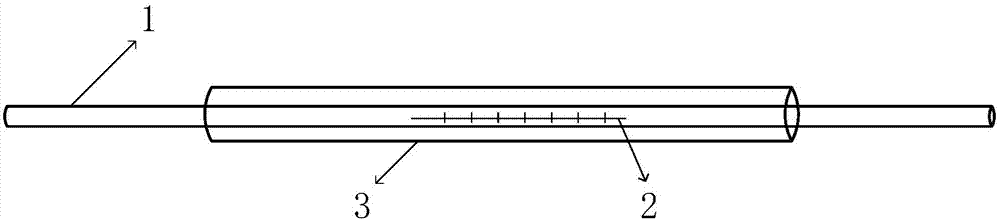

Long-gauge length carbon fiber strain sensing device and method for testing same

ActiveCN103453833AEnable long-term monitoringSolve the impactElectrical/magnetic solid deformation measurementCarbon fibersFiber strain

The invention discloses a long-gauge length carbon fiber strain sensing device. The long-gauge length carbon fiber strain sensing device comprises two groups of long-gauge length carbon fiber strain sensing elements with the same geometric size, three isolation film layers with the same size, a measurement connector, two anchoring sections and two parallel connectors, wherein one ends of the long-gauge length carbon fiber strain sensing elements are connected with the parallel connectors through electrodes respectively, the other ends of the long-gauge length carbon fiber strain sensing elements are connected with the measurement connector in series, and the two groups of long-gauge length carbon fiber strain sensing elements are located between adjacent isolation films respectively and have the same strain sensitivity coefficient and the same thermosensitivity coefficient. The long-gauge length carbon fiber strain sensing device achieves sensing of micro structural strain within a large range under long-term instable temperature and humidity conditions to meet civil engineering structural stress (strain) continuous detection and monitoring requirements.

Owner:南京东智安全科技有限公司

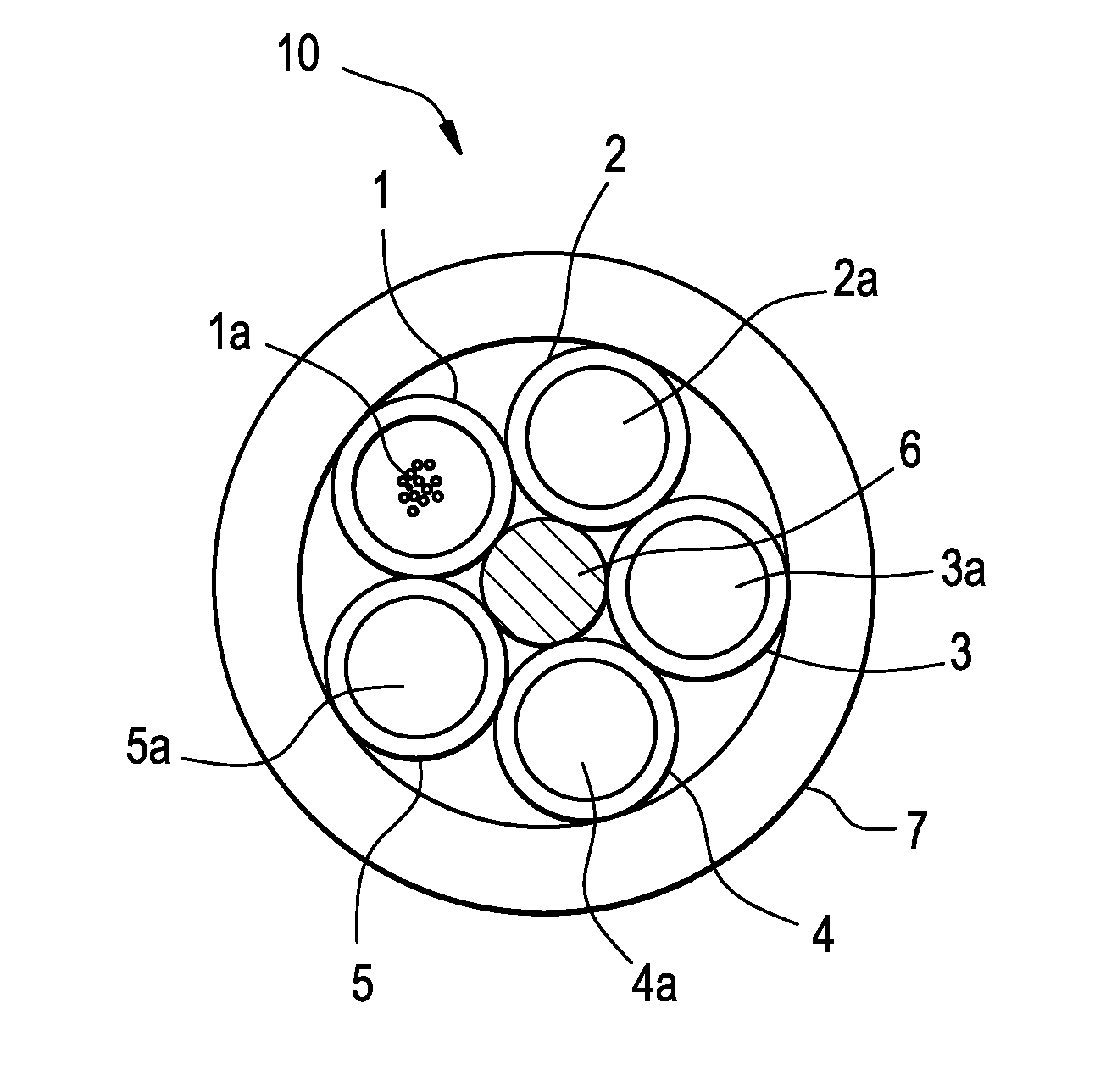

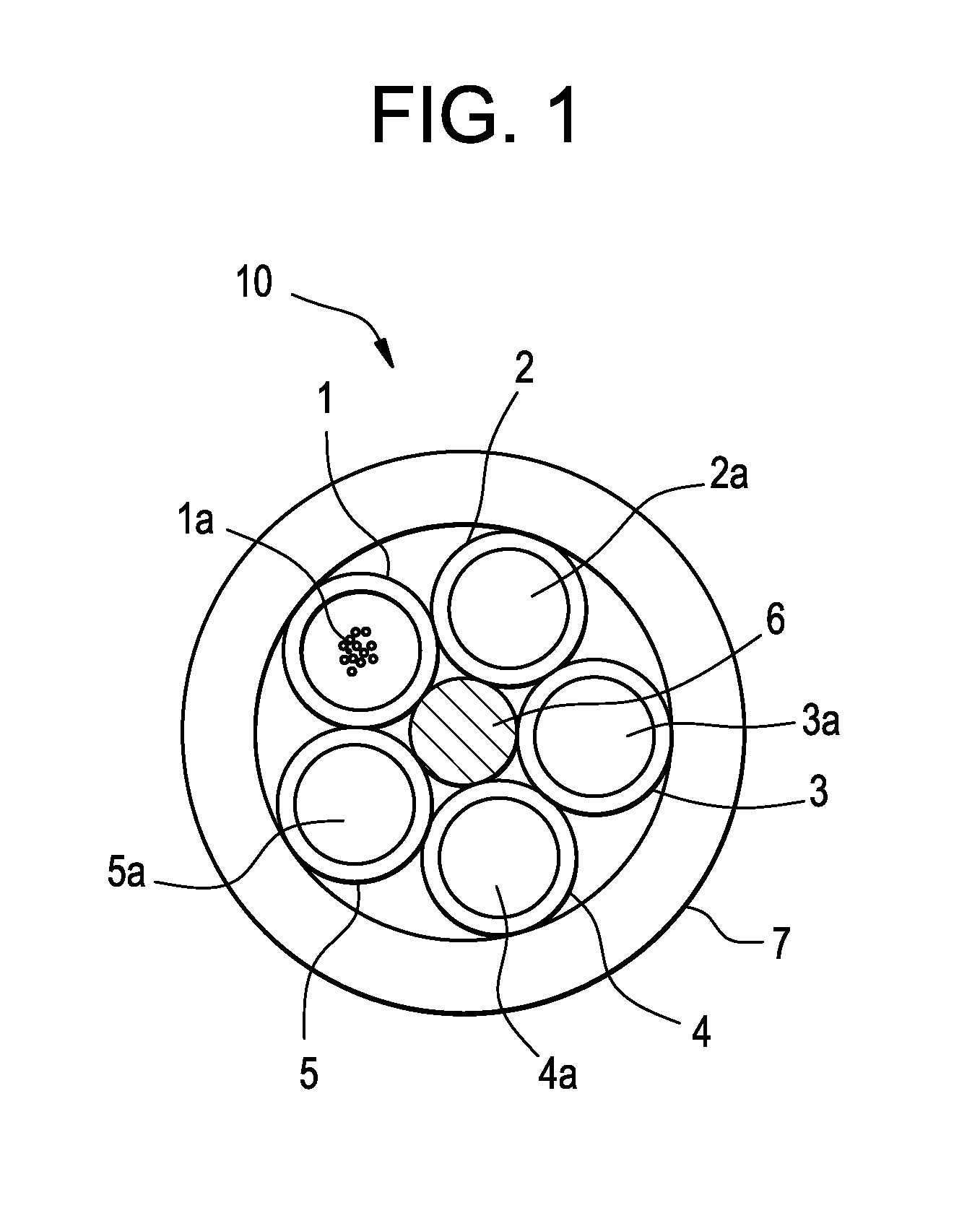

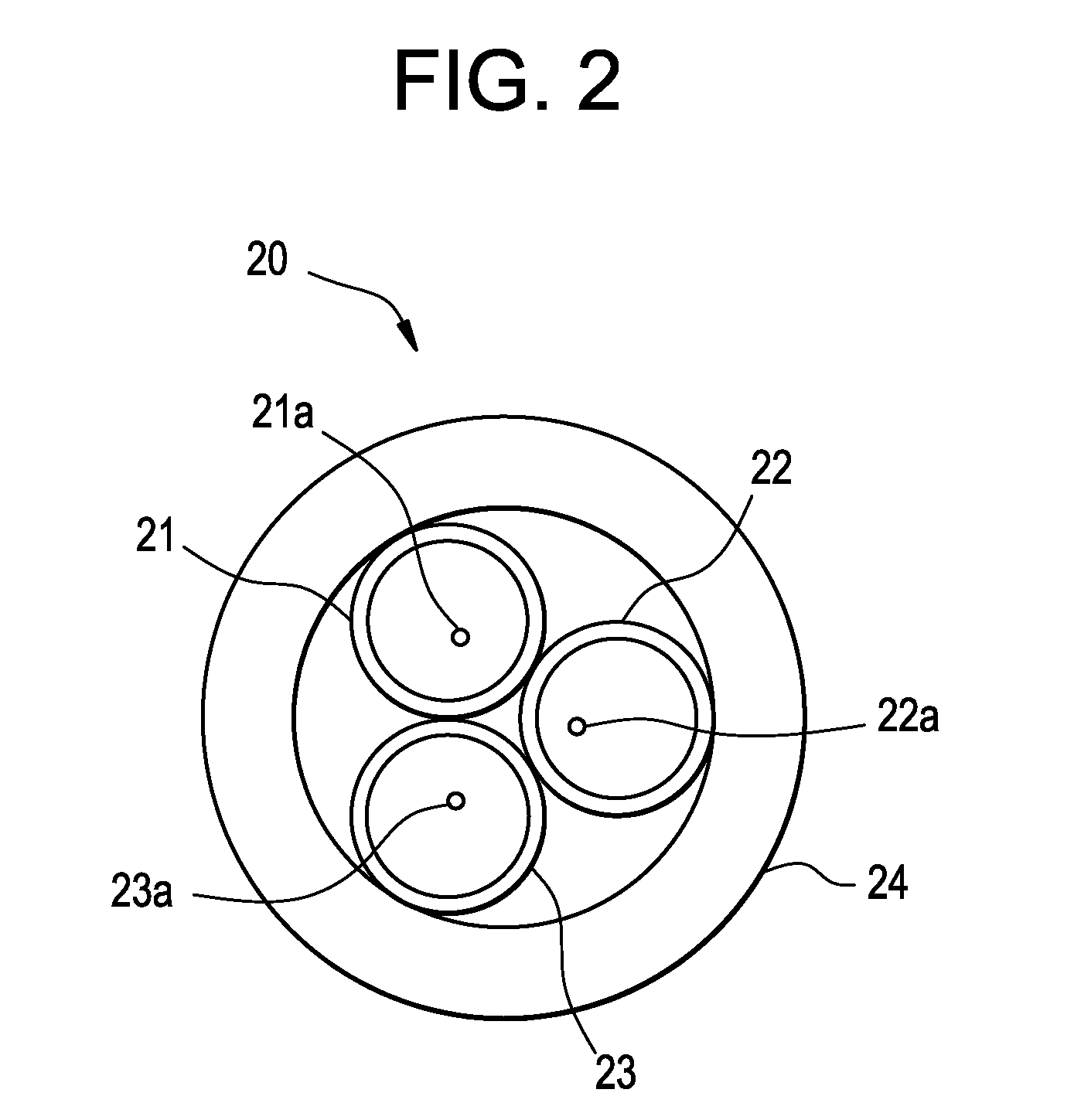

High temperature, zero fiber strain, fiber optic cable

A cable including an outer metal tube and a first layer wire inside the outer metal tube, wherein the first layer wire has five inner elements surrounding a metallic center member and at least one of the inner elements is a metal tube containing an optical fiber.

Owner:AFL COMM LLC

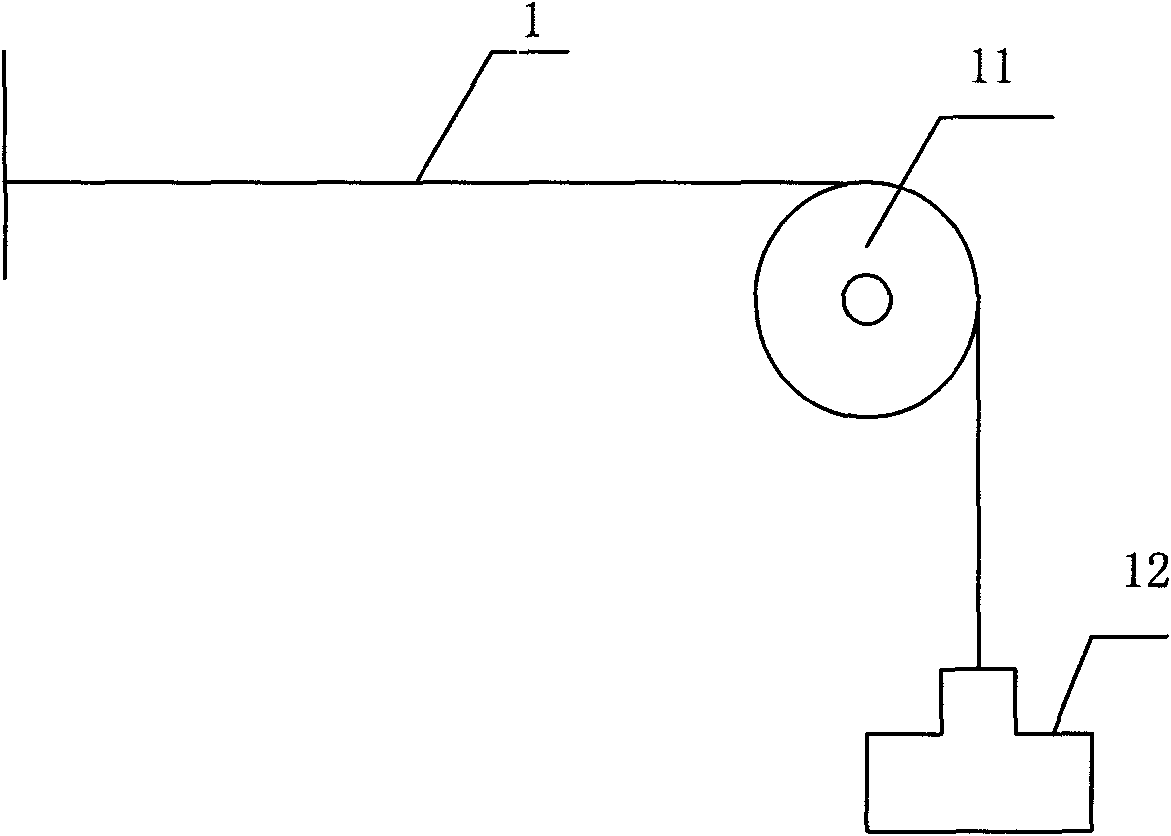

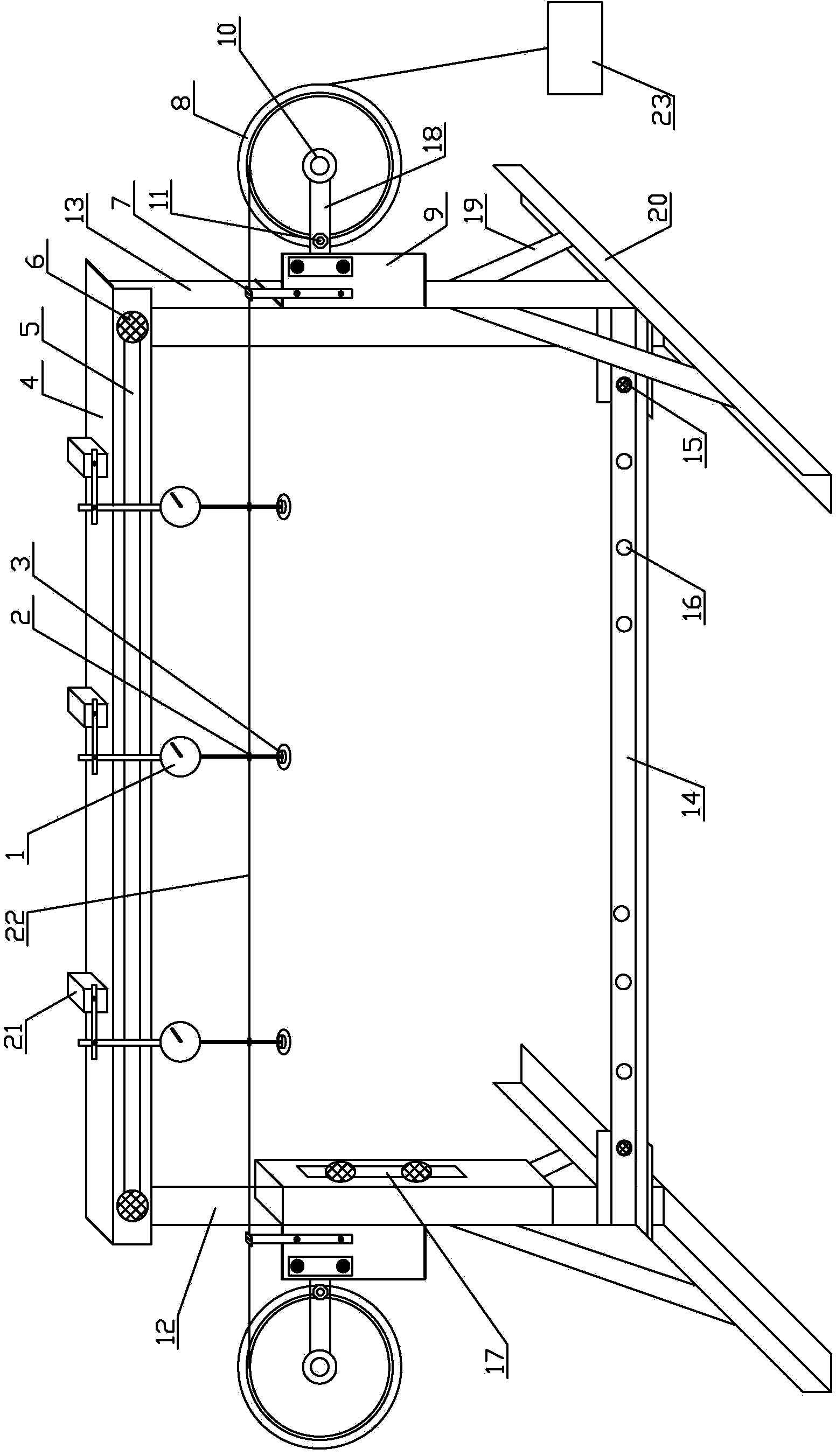

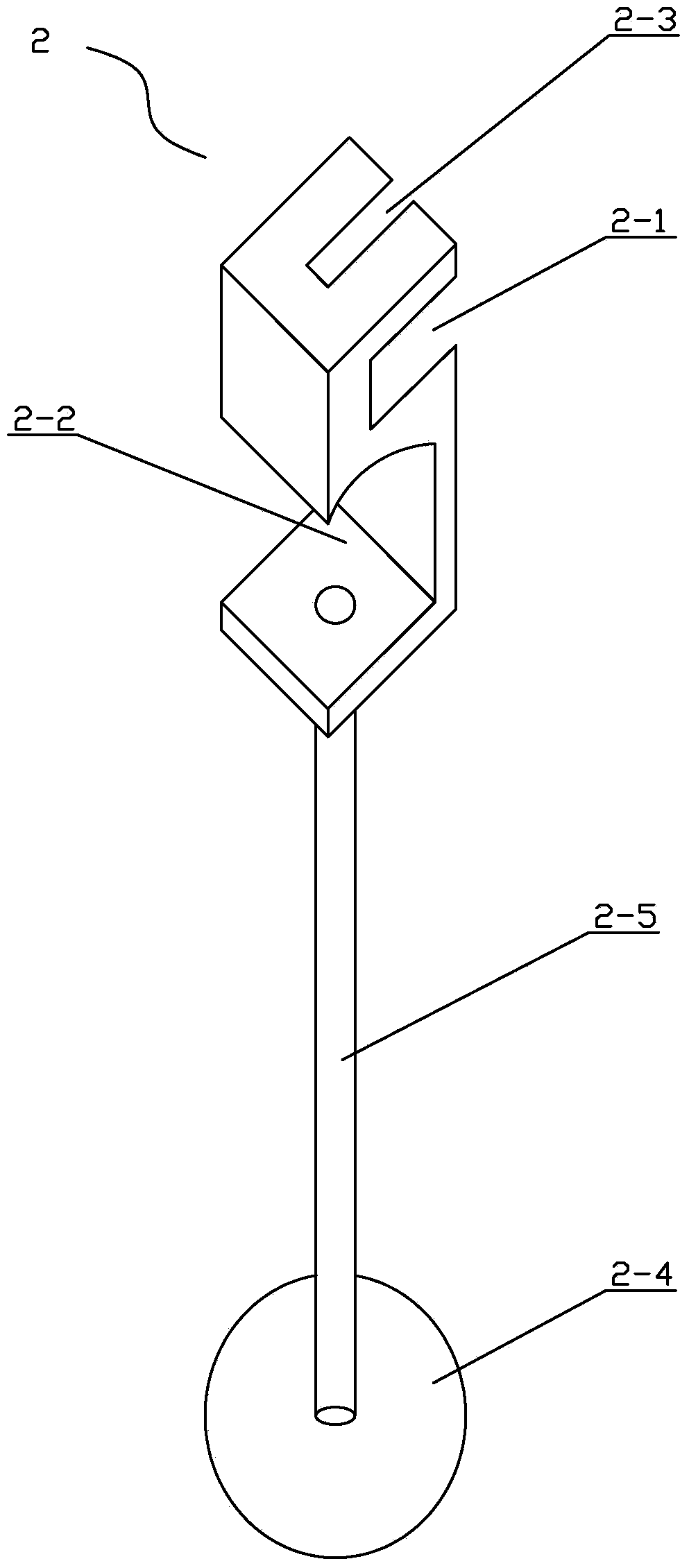

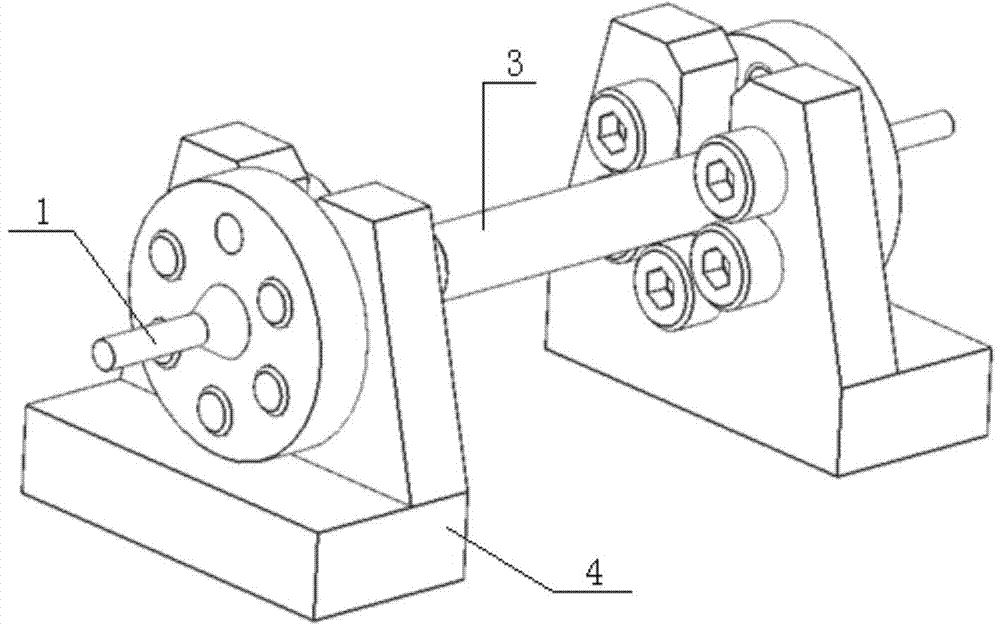

Simulation test system in variable load fiber strain karst collapse process

InactiveCN103983755AIncrease or decrease quantityMeet the karst collapse testEarth material testingFiber strainKarst

The invention discloses a simulation test system in a variable load fiber strain karst collapse process. The system comprises a strain gauge and a testing apparatus; the testing apparatus comprises a supporting mechanism, a measuring mechanism and a fiber fixing mechanism, wherein the supporting mechanism comprises a left bracket, a right bracket, an upper bracket and a lower bracket which are connected together to form a square or a rectangle; the measuring mechanism comprises a mechanical dial indicator, a deformed hook and a weight; the fiber fixing mechanism comprises a left side fiber fixing device, a right side fiber fixing device and a fiber; the left side and right side fiber fixing devices are same in structure and comprise movable bases, idler wheels, connecting arms and fasteners for fixing the idler wheels; one end of the fiber is wound on the idler wheel in the left side fiber fixing device and the other end sequentially passes through the deformed hook and then is wound on the idler wheel in the right side fiber fixing device; one end of the fiber is connected to the strain gauge. The test system disclosed by the invention can increase loading point and variable load, so as to meet a karst collapse test for simulating generalized models under different loads.

Owner:INST OF KARST GEOLOGY CAGS

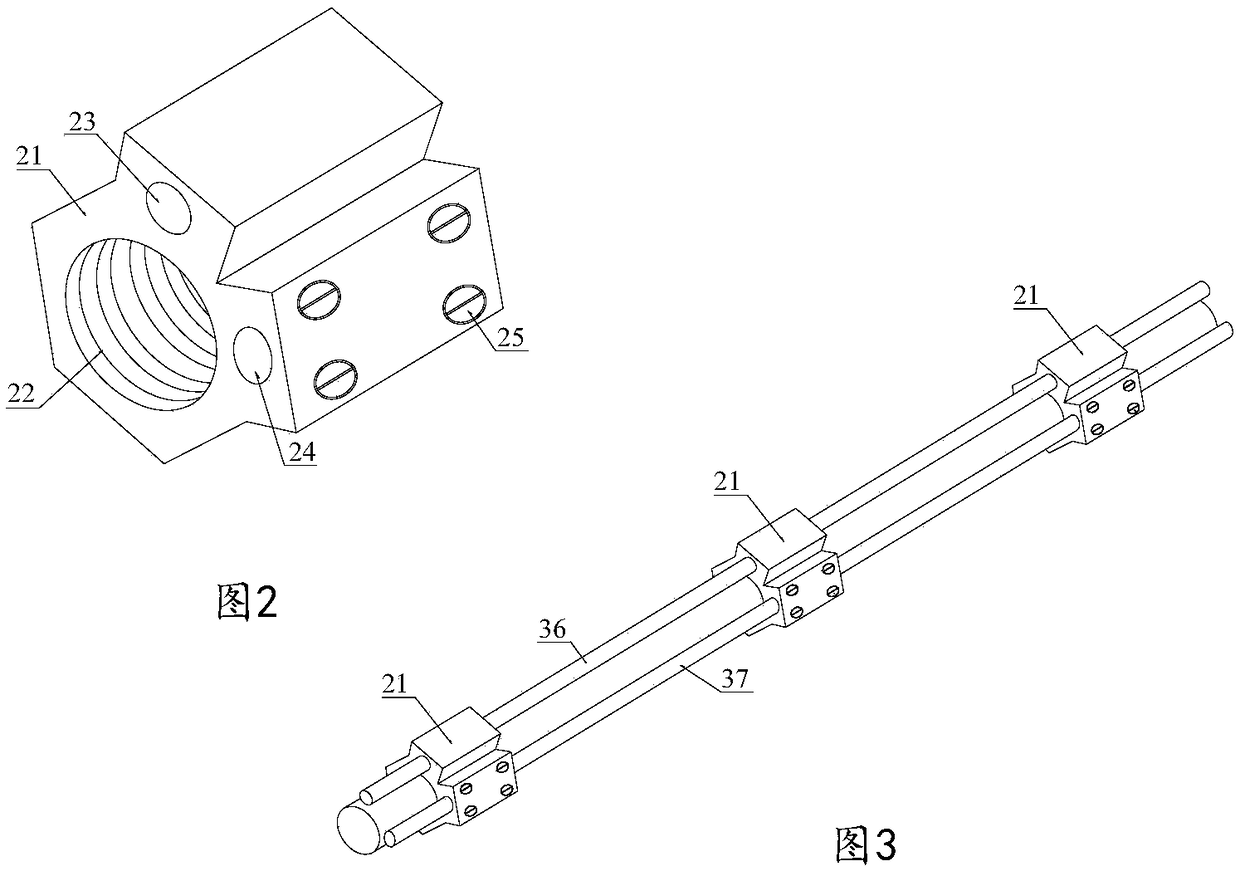

Total-stress fiber monitoring device for thread-steel anchor rod

PendingCN108692771AAccurately monitor stressAccurately monitor temperature changesMeasurement devicesFiber strainSlurry

The invention discloses a total-stress fiber monitoring device for a thread-steel anchor rod, so as to achieve the long-time monitoring of the total stress state of the thread-steel anchor rod on thebasis of guaranteeing the overall integrity of the thread-steel anchor rod, and accurately monitor the stress and temperature change conditions of the thread-steel anchor rod as the reliable data support for the analysis of the stress state and slope stability of a support and protection structure. The thread-steel anchor rod is fixedly provided with buckle parts at intervals in the length direction, and a distributed fiber sensor is connected with the buckle sensors, thereby forming a thread-steel anchor rod - distributed fiber sensor assembly. The distributed fiber sensor comprises a distributed fiber strain sensor and a distributed fiber temperature sensor, which are arranged at intervals in the peripheral direction of the section of the thread-steel anchor rod. The buckle parts achievethe multi-point clamping of the distributed fiber strain sensor. The thread-steel anchor rod - distributed fiber sensor assembly is buried in a slurry solidified body in a monitoring hole.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

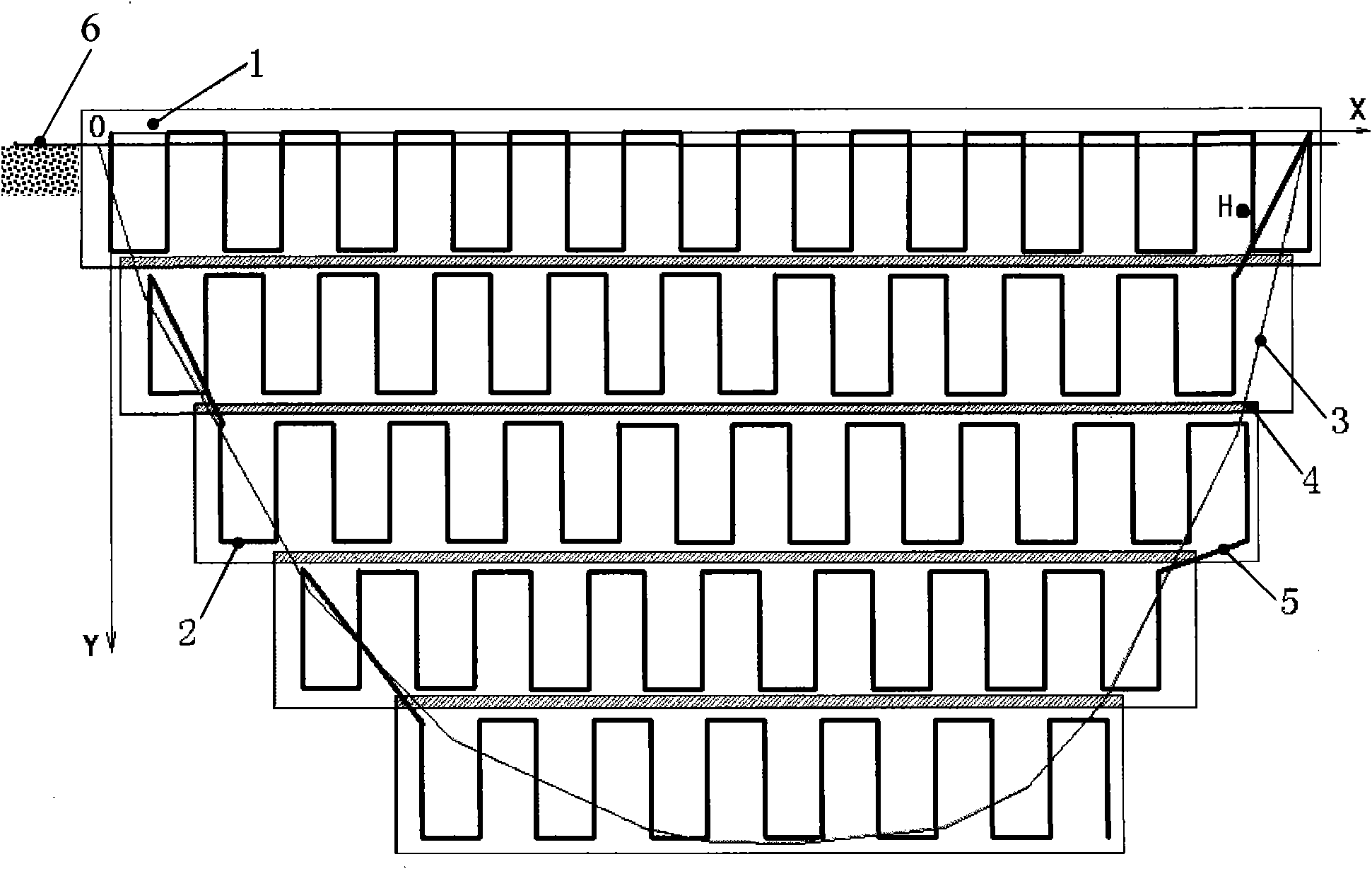

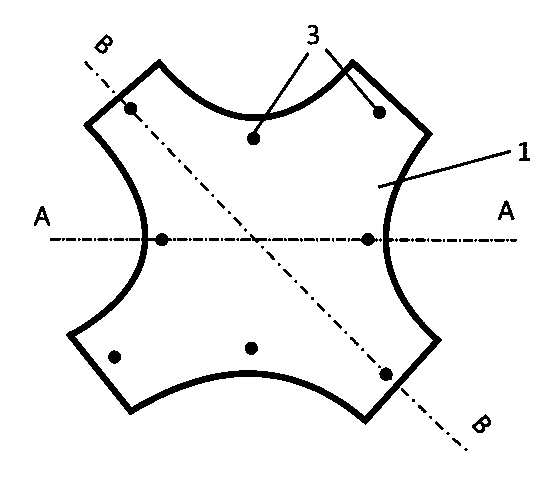

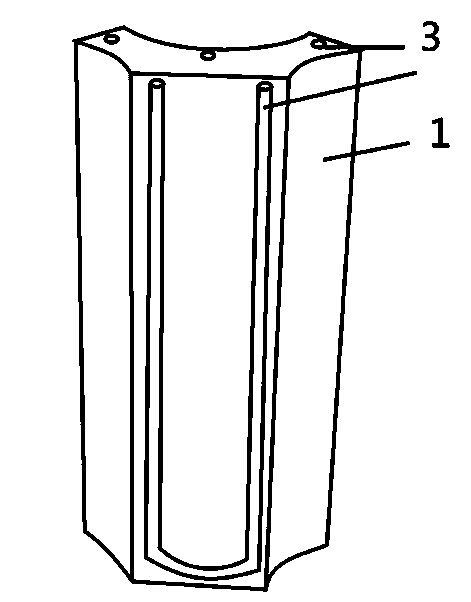

Distributed measurement device and method of pile body deformation of cast-in-place X-type pile

InactiveCN103759665ADoes not affect strengthHigh strengthUsing optical meansMeasurement deviceFiber strain

The invention discloses a distributed measurement device and method of pile body deformation of a cast-in-place X-type pile. The distributed measurement device comprises the cast-in-place X-type pile, a fiber strain tester, reinforcing steel bars and single-mode fibers. The single-mode fibers are laid inside the reinforcing steel bars, the reinforcing steel bars are arranged at the outer edge of the cast-in-place X-type pile in a cast mode, and the fiber strain tester is connected with the single-mode fibers. The new measurement method includes the steps of arranging the single-mode fibers at the outer edge of the cast-in-place X-type pile, receiving Brillouin back scattered light at the pulsed light incidence ends of the single-mode fibers through the Brillouin optical time domain reflecting technology, completing the measurement and positioning functions of Brillouin frequency shifting of points on the single-mode fibers by analyzing the power of Brillouin back scattered light, and then obtaining deformation of the cast-in-place X-type pile to be measured. Strain measurement is carried out on the cast-in-place X-type pile through the single-mode fibers, and the survival rate of fiber sensors is remarkably improved; meanwhile, the method has the advantages of being high in measurement accuracy, small in shifting, good in stability and the like; in addition, the method further has the advantages that the sensors are easy to arrange, wires connected with the sensors are fewer, and the construction technology is simple.

Owner:HOHAI UNIV

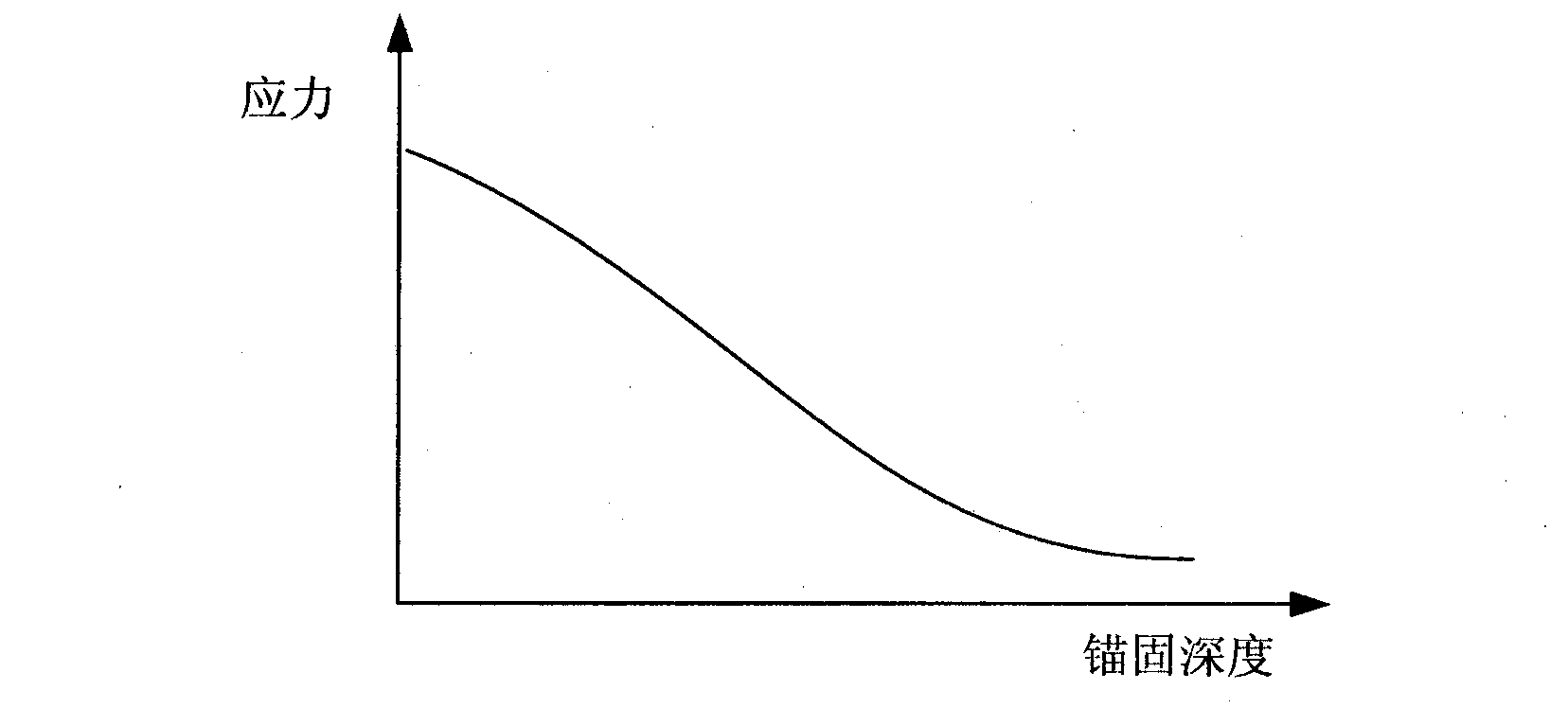

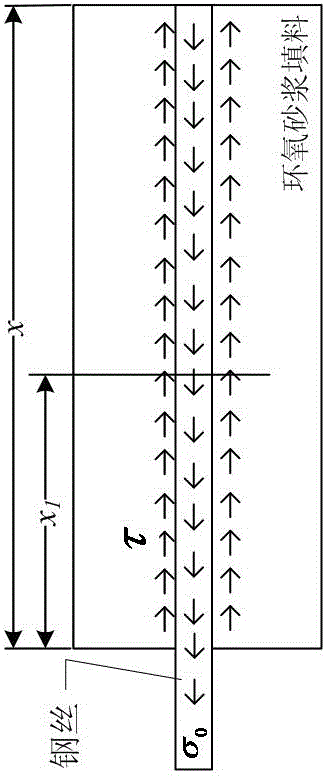

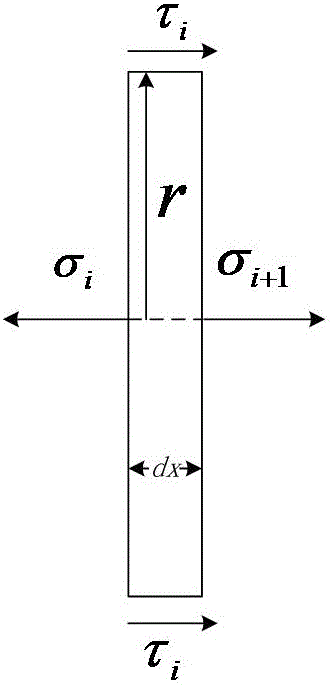

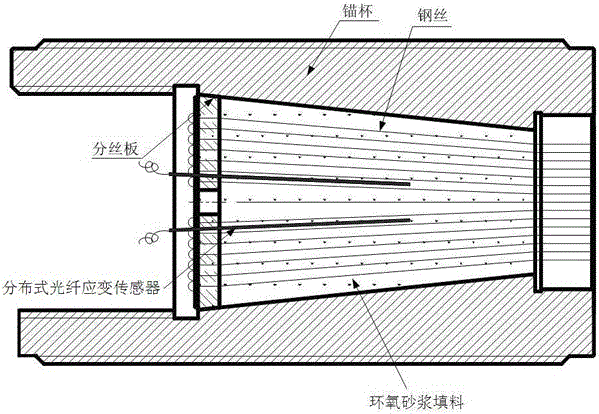

Method for monitoring performance degradation state of stay cable anchor head based on fiber distributed measurement

A method for monitoring performance degradation state of a stay cable anchor head based on fiber distributed measurement is characterized in that a distributed fiber strain sensor is imbedded in an anchor cup to acquire strain data, an initial stress decay function is obtained through the strain data, a current strain decay function is obtained in real time through the strain data during a subsequent process, a quantitative index for health level of the anchor head is computed according to the initial stress decay function and the current stress decay function, and thus real-time monitoring is achieved for anchor head performance; the invention has the advantages that the method monitoring performance degradation state of stay cable anchor head based on fiber distributed measurement is provided and the method allows timely discovery and continuous monitoring for anchor head disease damage.

Owner:宁波正信检测科技有限公司

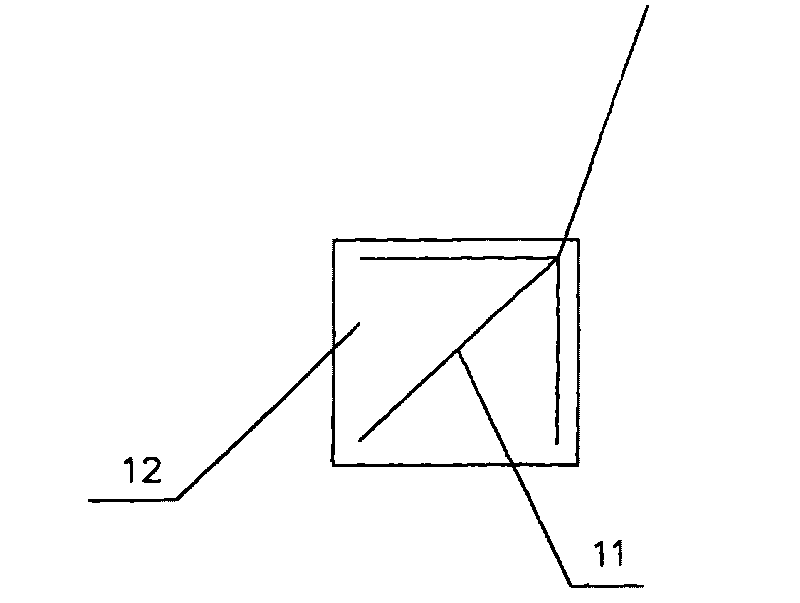

Split type optic fiber strain sensor assembly

InactiveCN104279974AEasy installation and layoutEasy to reuseUsing optical meansGratingUltrasonic welding

The invention provides a split type optic fiber strain sensor assembly. Under the premise that fiber bragg grating prestressed encapsulation is not influenced, an encapsulation mode and an assembling mode are decoupled, and the problem that a sensor cannot be used again after being mounted once is solved through separation of a metal encapsulation protection piece and an assembling base. The split type optic fiber strain sensor assembly comprises a sensing element, the encapsulation protection piece and the assembling base. The sensing element is a fiber bragg grating, and the encapsulation protection piece is a metal tube. After the fiber bragg grating penetrates through the mental tube, the clearance between the fiber bragg grating and the metal tube is welded and fastened in an ultrasonic welding mode. Optical fibers are led out from the two ends of the metal tube. The two ends of the metal tube are banded tightly through flange plates. The metal tube with the encapsulated sensing element is supported by the assembling base, and the flange plates at the two ends of the metal tube are connected with the assembling base.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

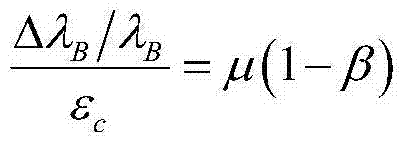

Fiber aerodynamic force measurement balance temperature compensation method

ActiveCN108254153AEffective deductionGood compensationAerodynamic testingForce measurement by measuring optical property variationFiber strainAerodynamic load

The invention discloses a fiber aerodynamic force measurement balance temperature compensation method. The method comprises steps that (1), fiber strain gauges are mounted on the symmetrical positionof each measurement beam of a fiber aerodynamic force measurement balance as sensitive components of the balance for sensing the aerodynamic load; (2), the temperature calibration test on the fiber aerodynamic force measurement balance is carried out to acquire the temperature coefficient ratio of a negative strain fiber strain gauge and a positive strain fiber strain gauge at the symmetric position of each measurement beam of the fiber aerodynamic force measurement balance; (3), according to the acquired temperature coefficient ratio, combination subtraction operation of output signals of thetwo fiber strain gauges at the symmetric position of each measurement beam of the fiber aerodynamic force measurement balance is carried out to deduct thermal output of the fiber strain gauges causedby thermal strain of the measurement beam; (4), summation of the combined relationship of the two fiber strain gauges on the symmetrical position of the measurement beam of each measurement element of the fiber aerodynamic force measurement balance acquired in the (3) is carried out to acquire an output formula of each component deduction measurement beam of the fiber aerodynamic force measurement balance caused by thermal strain after thermal output.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Prestress member capable of being monitored, prestress loss monitoring method and manufacturing method

PendingCN109577477AGuaranteed accuracyCorrosion resistanceCo-operative working arrangementsBuilding constructionsCarbon fibersPre stress

The invention discloses a prestress member capable of being monitored, a prestress loss monitoring method and a manufacturing method. The prestress member capable of being monitored comprises a prestress member body, long-gauge-distance carbon fiber strain sensing units, an electronic tag unit, a micro circuit board and a prestress member surface output port. Each long-gauge-distance carbon fiberstrain sensing unit arranged on the surface of a prestress reinforcing bar comprises at least one long-gauge-distance carbon fiber strain sensing element distributed on the surface of the reinforcingbar in the axial direction of the reinforcing bar; after parallel connection of the micro circuit board in the prestress member, signals of the long-gauge-distance carbon fiber strain sensing units are obtained from the prestress member surface output port; built-in electronic tags are also used, so that production information, use conditions, directions, positions and other information of the prestress member are conveniently read, the requirements for real-time positioning, tracking and monitoring of the prestress member are met, and therefore intelligent fine management can be achieved in the using process of the prestress member.

Owner:南京东智安全科技有限公司 +1

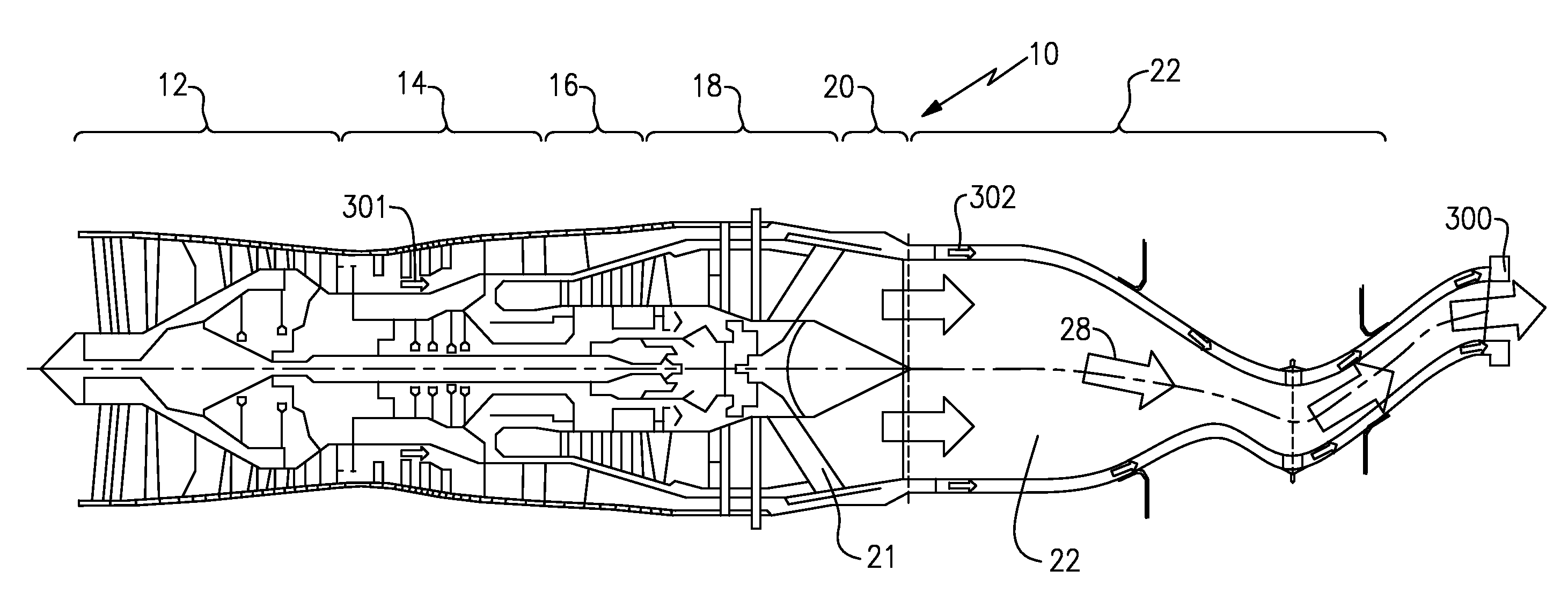

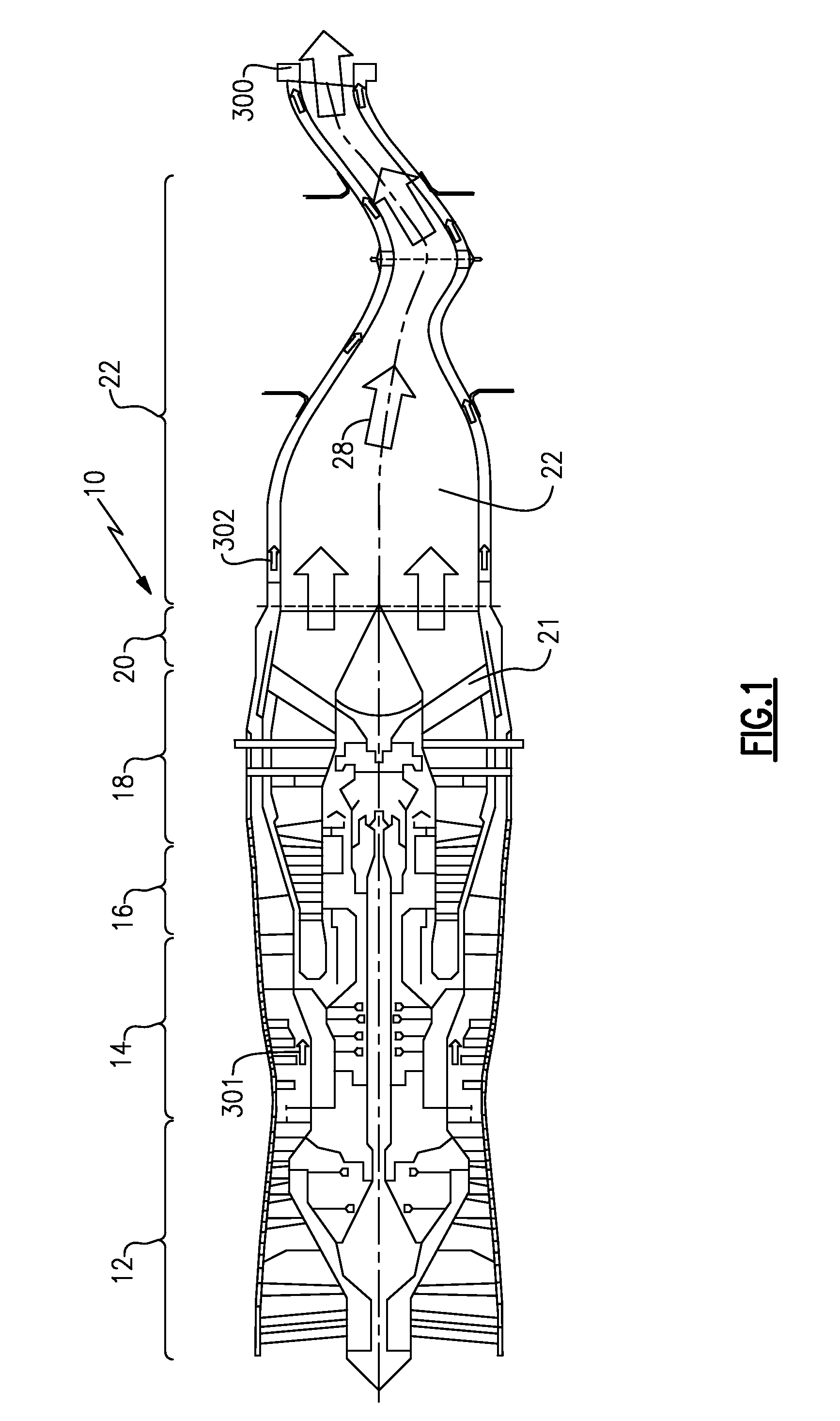

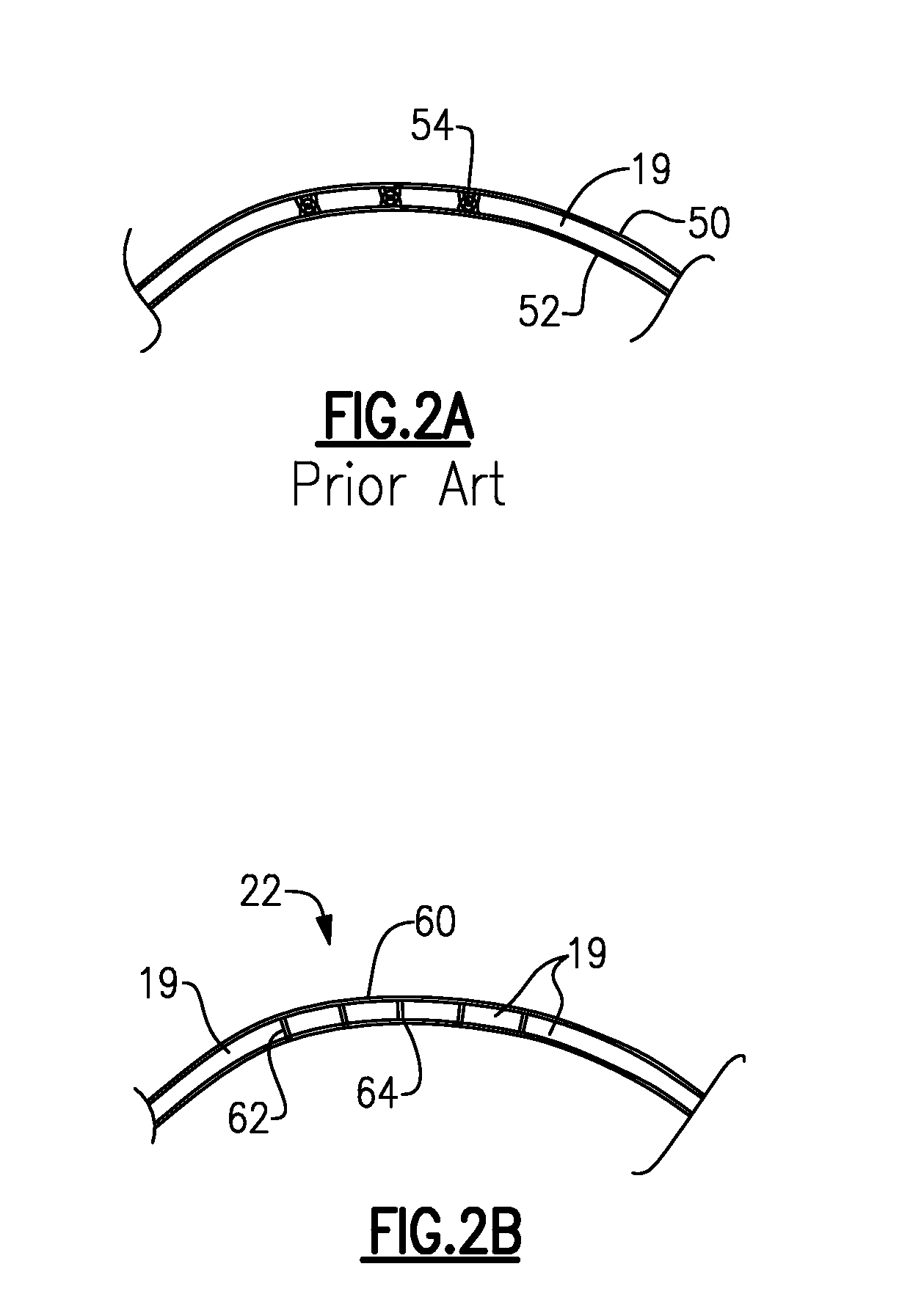

Gas turbine engine exhaust duct

An exhaust duct for a gas turbine engine has an inner wall and an outer wall connected by a plurality of spaced ribs. The duct extends axially. The ribs extend circumferentially across an entire cross-section of the inner and outer walls. The plurality of ribs is spaced axially along the exhaust duct. The inner wall has an inner surface facing an inner chamber. The inner surface receives a coating. The coating is deposited on a metal wire fiber strain isolation pad which is connected to the inner surface.

Owner:RAYTHEON TECH CORP

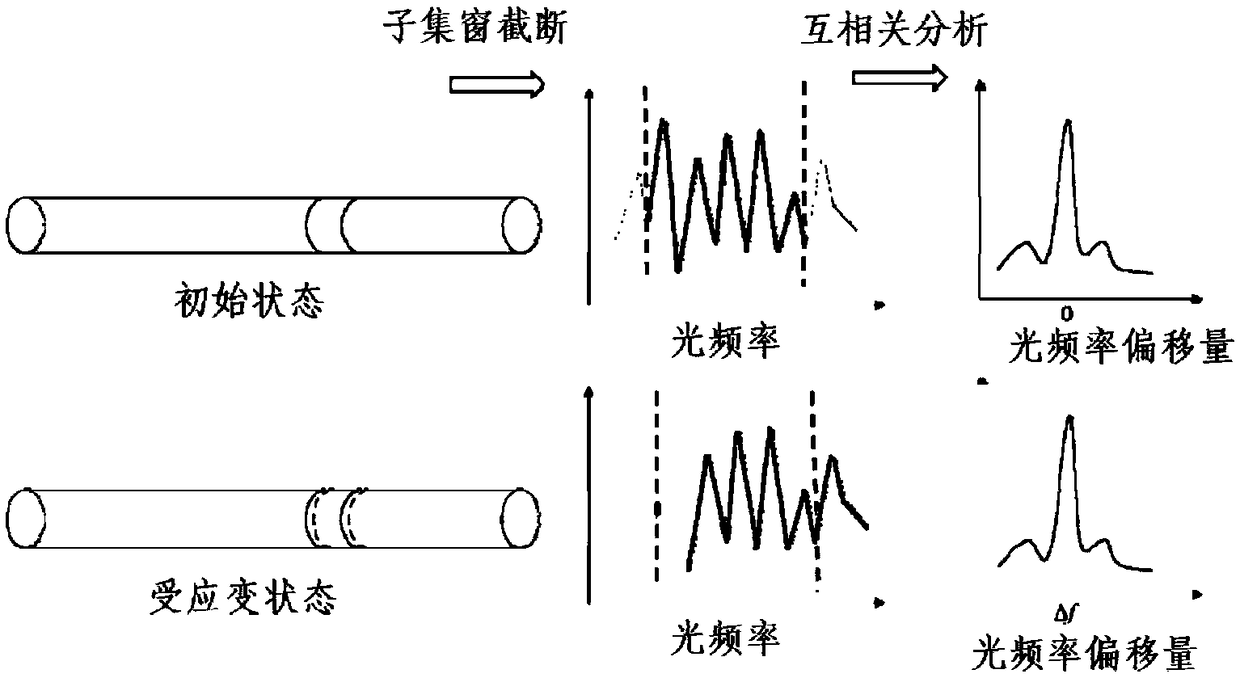

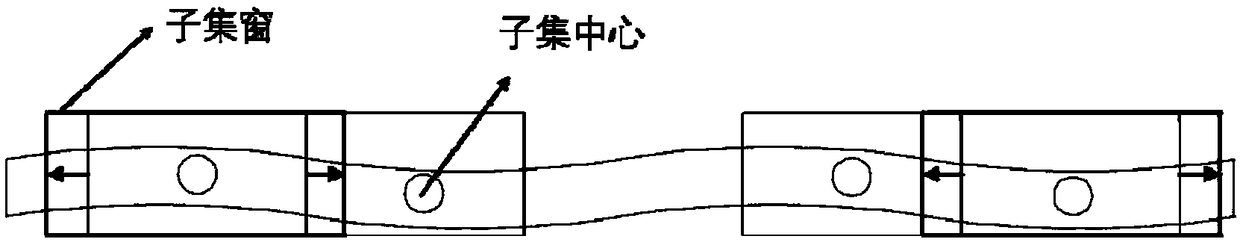

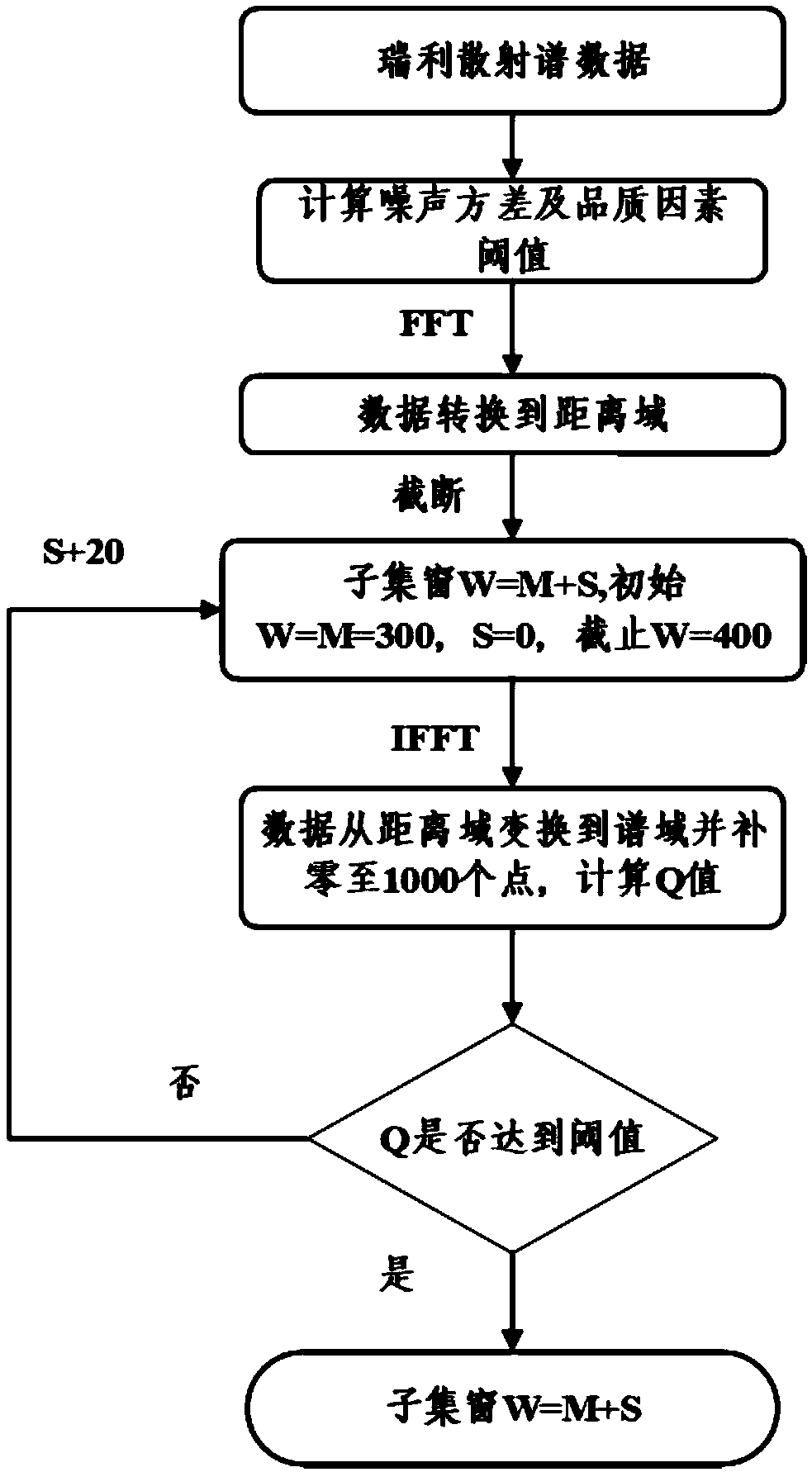

Distributed fiber strain demodulation method based on subset window length optimization algorithm

ActiveCN108896274AImprove reliabilityHigh precisionUsing optical meansReflectometers detecting back-scattered light in time-domainRayleigh scatteringCross correlation analysis

The invention discloses a distributed fiber strain demodulation method based on a subset window length optimization algorithm. According to the invention, through two parameters of noise variance andRayleigh scattering spectrum quality, a user is guided to carry out optimal selection on the size of the subset window. By mainly use of the mutual correlation analysis, the offset quantity between areference Rayleigh scattering spectrum and a measurement Rayleigh scattering spectrum is calculated, so strain information in a measured fiber is obtained. The lengths of the two groups of Rayleigh scattering spectrum subsets used for mutual correlation calculation is the subset window defined by the user based on experience. The subset window significantly affects the reliability of the mutual correlation calculation and the precision of strain measurement. By rationally optimizing the subset window, important effects are achieved for improving of the mutual correlation reliability and the strain calculation precision.

Owner:DALIAN UNIV OF TECH

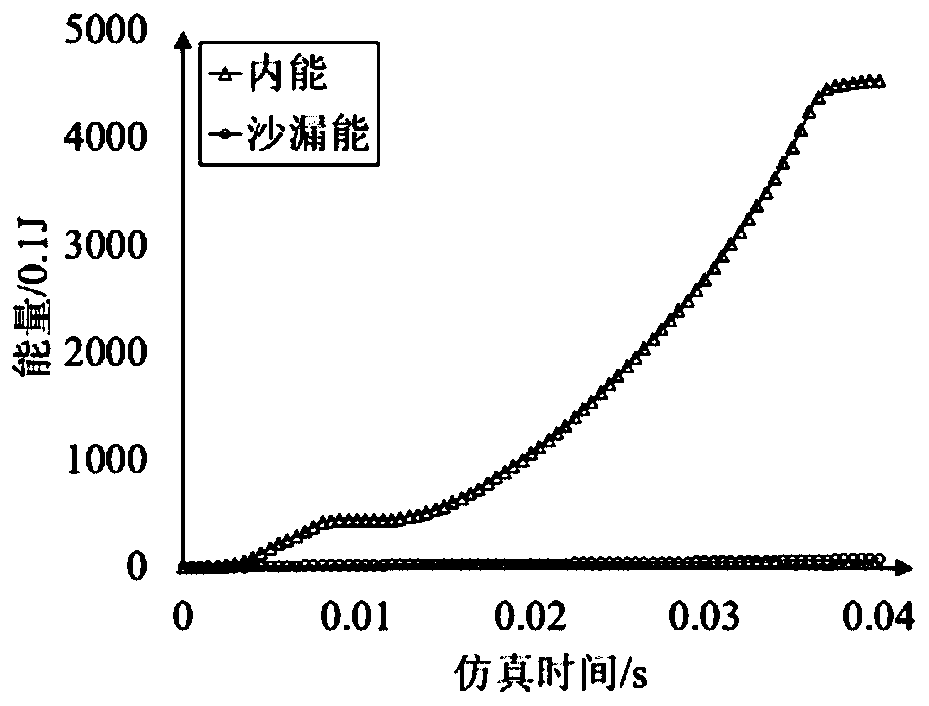

Mechanical fault monitoring method for photoelectric composite submarine cable

ActiveCN110296885AMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceResearch ObjectElement model

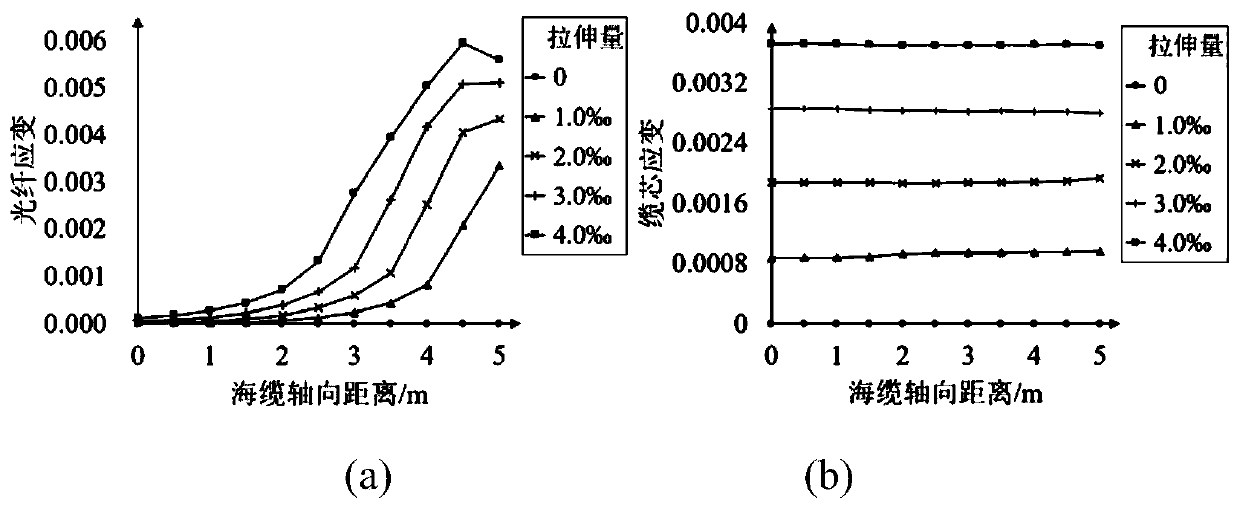

The invention discloses a mechanical fault monitoring method for a photoelectric composite submarine cable, and belongs to the technical field of fault monitoring. According to the method, a 110kV YJQ41x300mm2 type submarine cable is used as a research object; based on ANSYS / LS-DYNA explicit dynamics analysis, a structural dynamics finite element model is established, modeling simulation is carried out on three typical fault conditions such as stretching, twisting and anchoring of the submarine cable, the strain distribution along a submarine cable composite fiber and a corresponding relationship between the strain and stress of a relevant structure in the submarine cable and the fiber strain in the fault development process are obtained, a functional relation between cable core and armorstrains and stress and optical fiber strains in the stretching and twisting states is established, and an evaluation index of the submarine cable damage state and the fiber strains under the anchoring condition is established. According to the mechanical fault monitoring method for the photoelectric composite submarine cable provided by the invention, the possible mechanical fault state types ofthe submarine cable can be identified, and preliminarily judgment is carried out on the development degree of corresponding faults by combining the established functional relation and a damage evaluation index.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

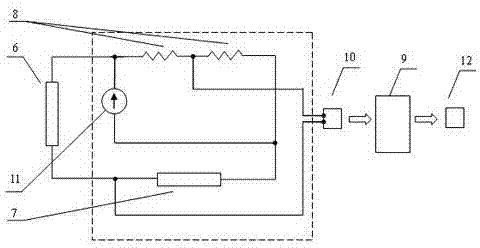

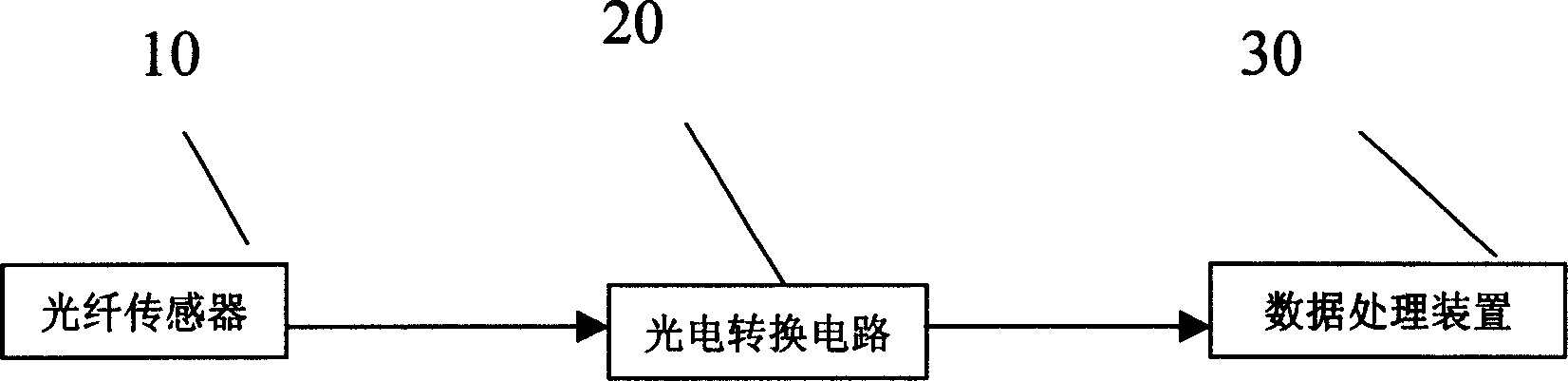

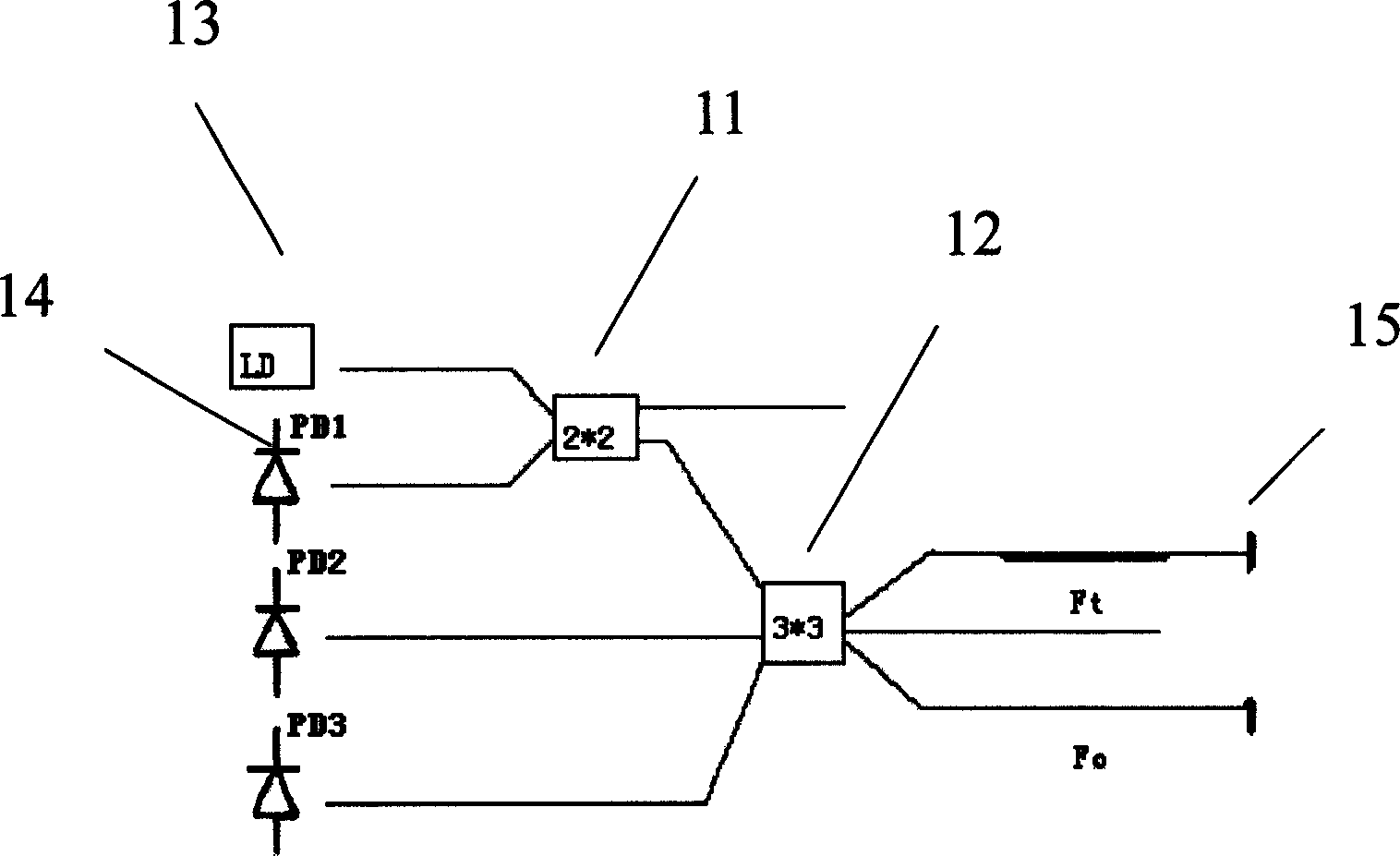

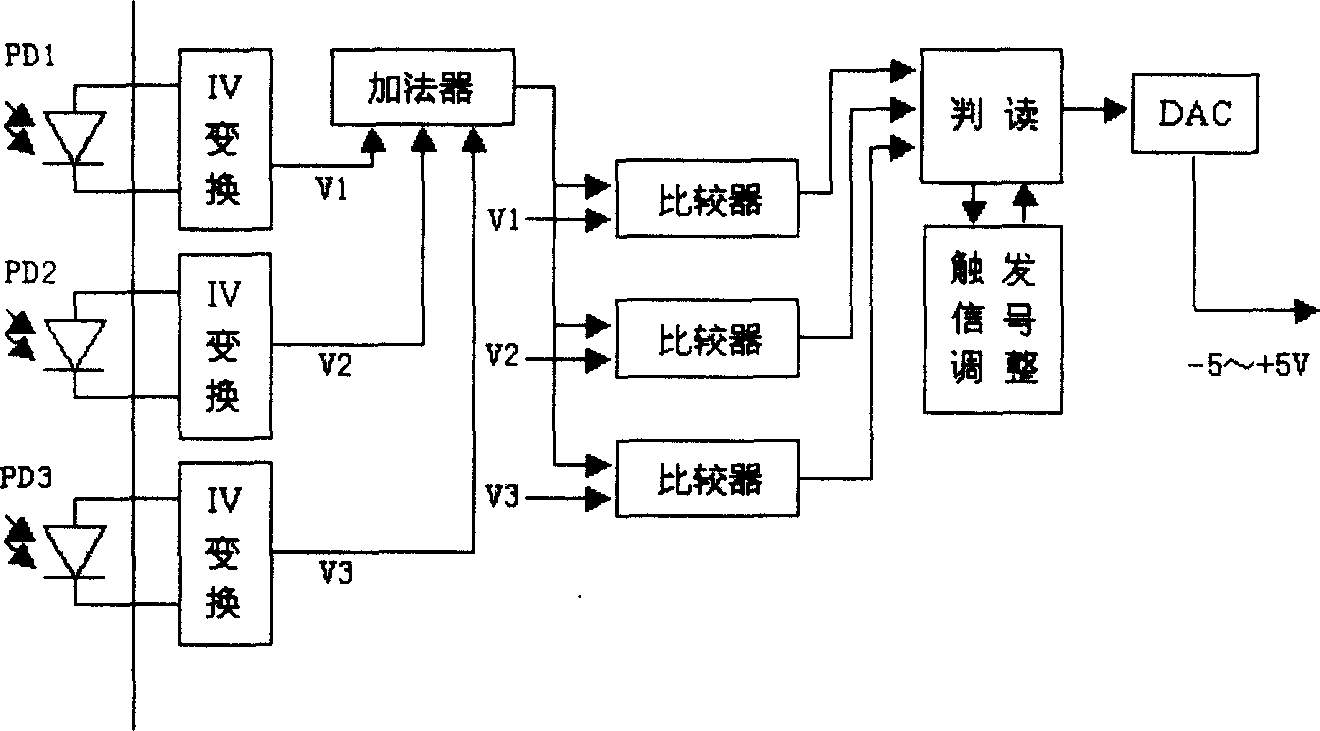

Sensing system of fiber strain

InactiveCN1760635AEasy to operateStrong operationUsing optical meansConverting sensor output opticallyScale structureFiber strain

The sensing system of fiber strain is composed of optical fiber sensor, photovoltaic conversion circuit, and data processor. Characters are that through optical fiber, optical fiber sensor is connected to the photovoltaic conversion part partially; through data line, the photovoltaic conversion circuit is connected to the data processing circuit; Michelson type sensor is adopted in the optical fiber sensor. Advantages are: high anti electromagnetic interference, sensitivity, small influence from temperature and humidity, transmissibility of remote distance, etc. The system is suitable for real-time safe and fine monitoring and alarming large-scale structure in medium or long term.

Owner:上海安文桥梁检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com