Split type optic fiber strain sensor assembly

A sensor assembly and optical fiber strain technology, applied in instruments, optical devices, measuring devices, etc., can solve the problem that the sensor cannot be reused again, and achieve the effect of easy installation, layout and reuse, prevention of erosion and damage, and the overall structure is simple and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and embodiments.

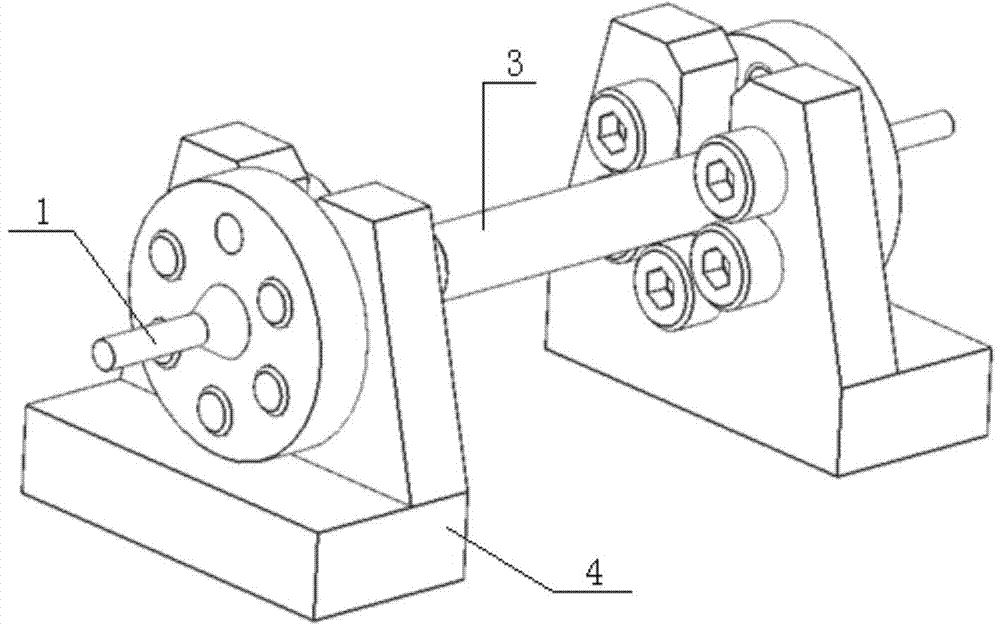

[0016] This embodiment provides a split fiber optic strain sensor assembly used in structural safety monitoring. The packaging guard and assembly base of the sensor assembly can be separated and disassembled, thereby facilitating the installation, deployment and reuse of the fiber grating sensor.

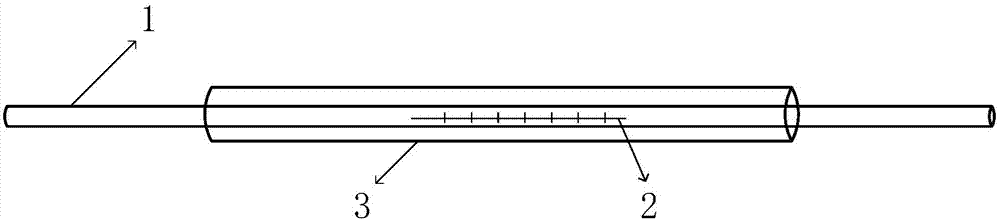

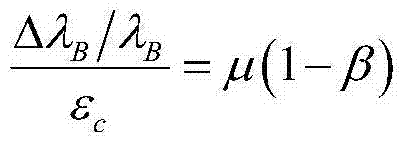

[0017] The split-type optical fiber strain sensor assembly includes a sensing element 2, a packaging protective part 3 and an assembly base. The sensor element 2 has a wavelength of λ B The optical fiber Bragg grating, and the package guard 3 is a steel tube. The steel pipe is formed by one-time processing, leaving only a small axial gap to allow the fiber grating to pass through to ensure its structural strength, and at the same time make it have impact and pressure resistance. After the fiber grating passes through the inner wall of the capillary steel tube, there is a tiny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com