Pipe-jacking construction method for mealy sand stratum

A construction method and technology of silt soil, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as top line deviation, easy collapse, and increased frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

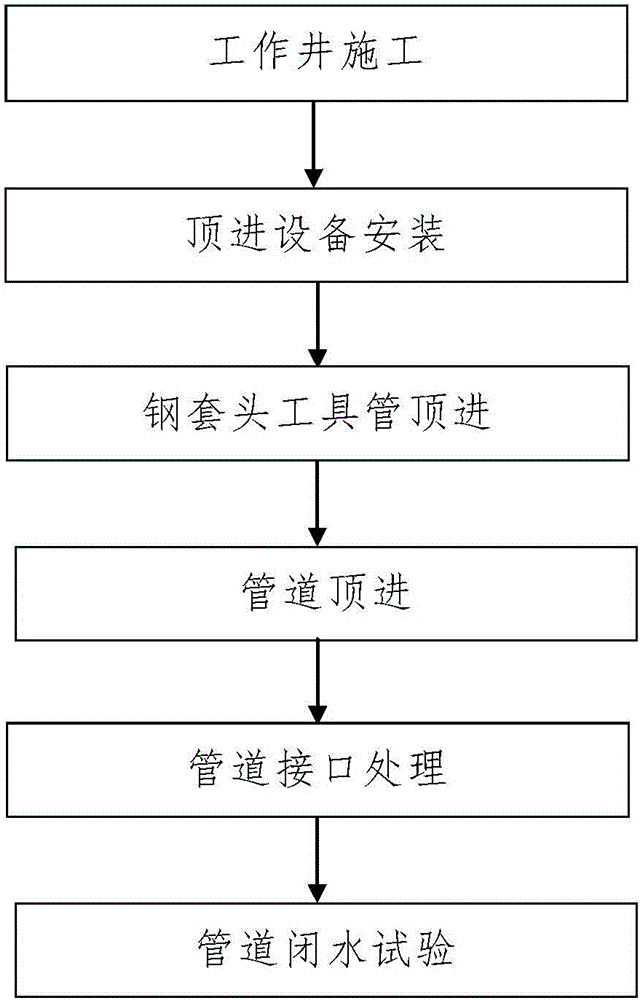

[0086] Such as figure 1 A kind of pipe jacking construction method in silt soil stratum shown, comprises the following steps:

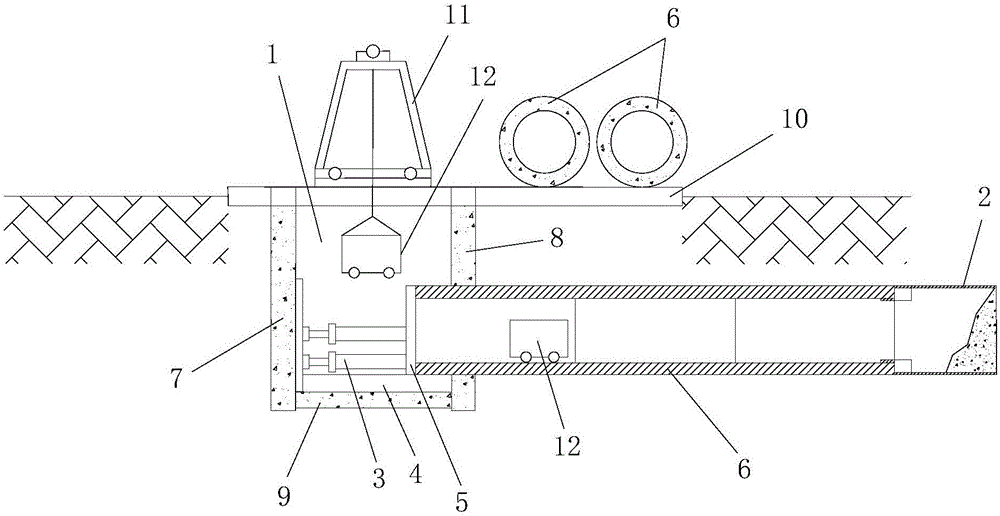

[0087] Step 1, working well construction: construct the working well 1 for jacking the constructed underground pipeline, the working well 1 is located at the rear side of the constructed underground pipeline, and the constructed underground pipeline is located between the working well 1 and the receiving well , see Picture 1-1 ;

[0088] Such as Picture 1-1 As shown, the underground pipeline to be constructed is a spliced pipeline that is spliced from front to back by a plurality of pipeline assembly sections 6 and buried in the silty soil stratum, and among the plurality of pipeline assembly sections 6 located at the front 6 is a front-end assembly section, and among the multiple pipeline assembly sections 6, the pipeline assembly section 6 located at the rear end is a rear-end assembly section; the underground pipeline constructed is a wate...

Embodiment 2

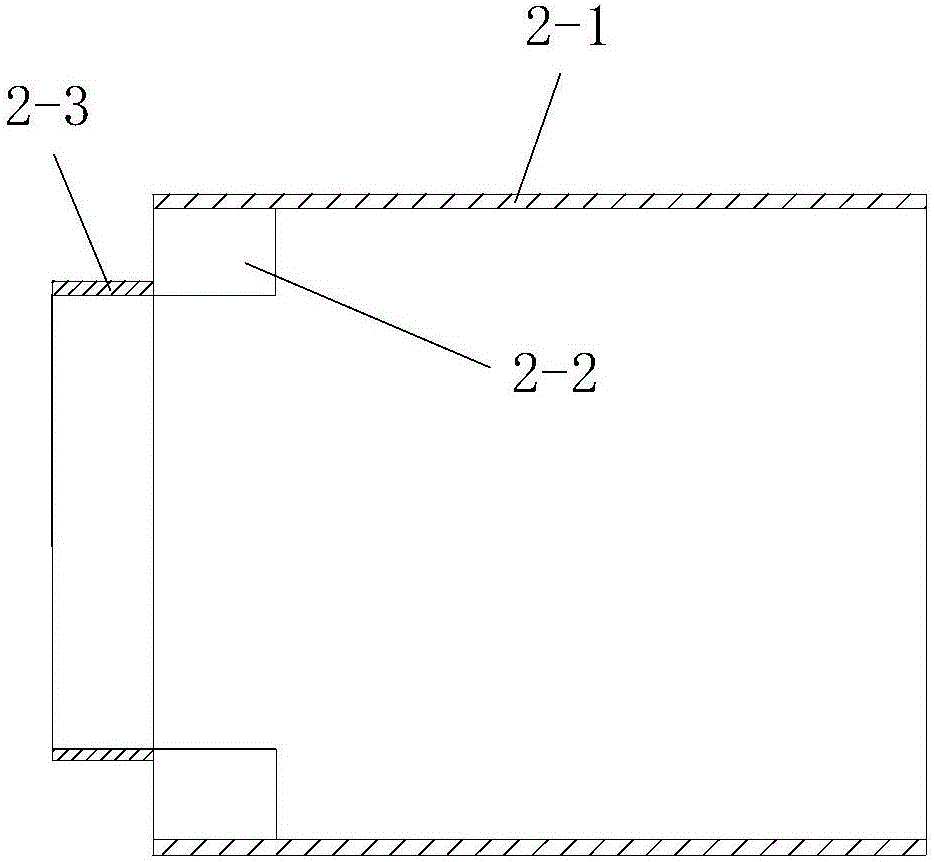

[0193] In this example, if Figure 5 As shown, the difference from Example 1 is that the support ring 2-2 in step 1 is a steel ring, and the support ring 2-2 is a thin support ring with a thickness of 0.8cm to 1.2cm, and the thin support ring A plurality of triangular stiffeners 2-4 are provided along the circumferential direction on the front side of the front side, and the outer sides of the triangular stiffeners 2-4 are fixed on the inner side wall of the steel casing 2-1.

[0194] In this embodiment, the thickness of the supporting ring 2-2 is 1 cm.

[0195] In actual use, the thickness of the support ring 2-2 can be adjusted accordingly according to specific needs.

[0196] Moreover, both the support ring 2-2 and the socket 2-3 are processed into one body with the steel casing 2-1.

[0197]In this embodiment, the remaining method steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com