Patents

Literature

96results about How to "Processing quality is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

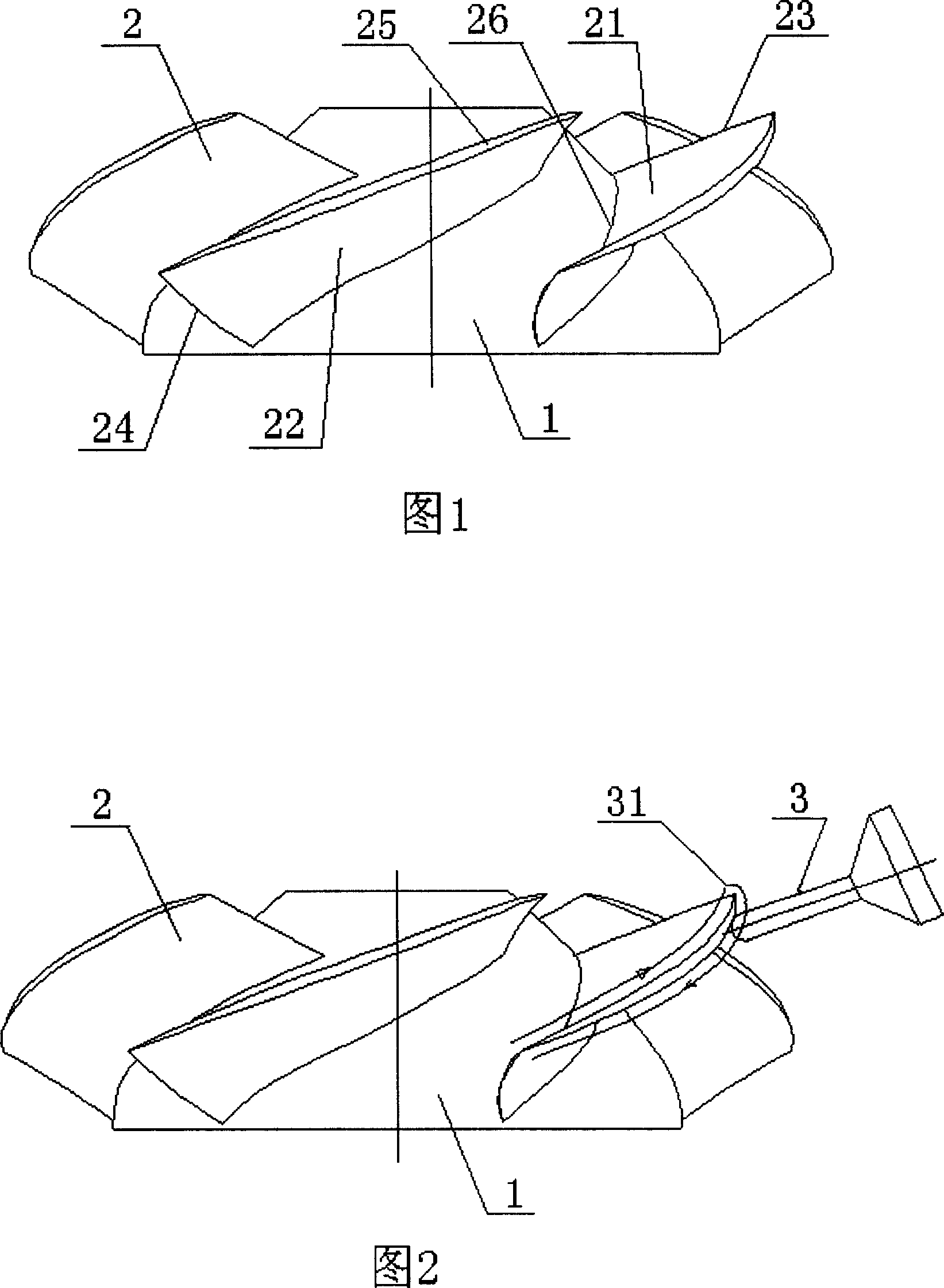

Slotting and milling process for vane of integral vane wheel

InactiveCN1986127ASmall radial componentSmall amount of deformationMilling cuttersImpellerNumerical control

The slotting and milling cutter process for vane of integral vane wheel is completed in a numerically controlled machine tool with slotting and milling cutter advancing in the radial direction of the vane wheel and axial direction of the cutter. It has small radial force component caused by cutting, less vibration of the workpiece and the cutter, smooth cutting, small and controllable vane deformation, high machining quality and high machining efficiency. The present invention can meet the requirement of machining great diameter and high precision vane wheel product.

Owner:WUHAN MARINE MACHINERY PLANT

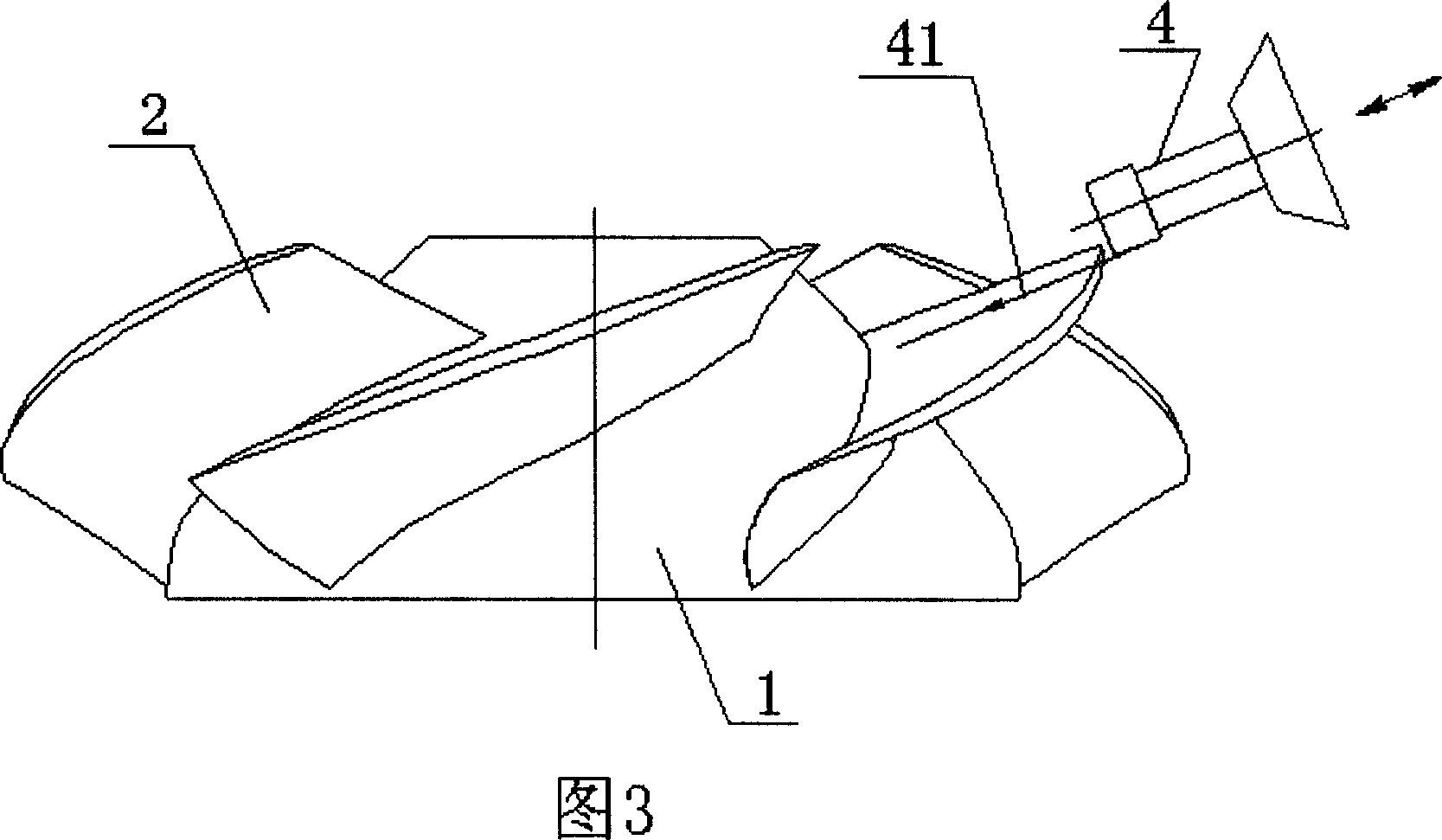

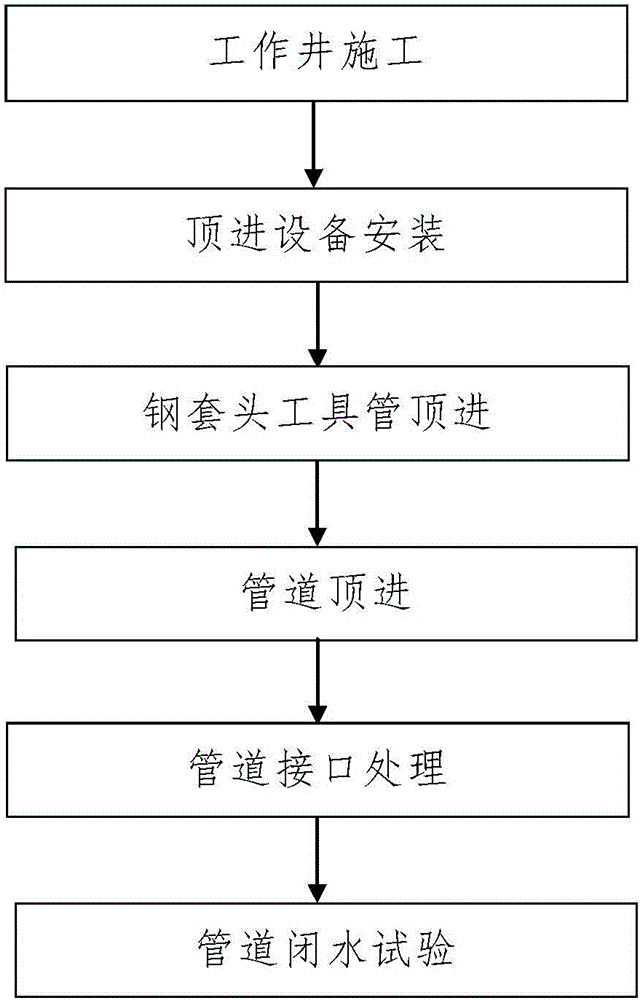

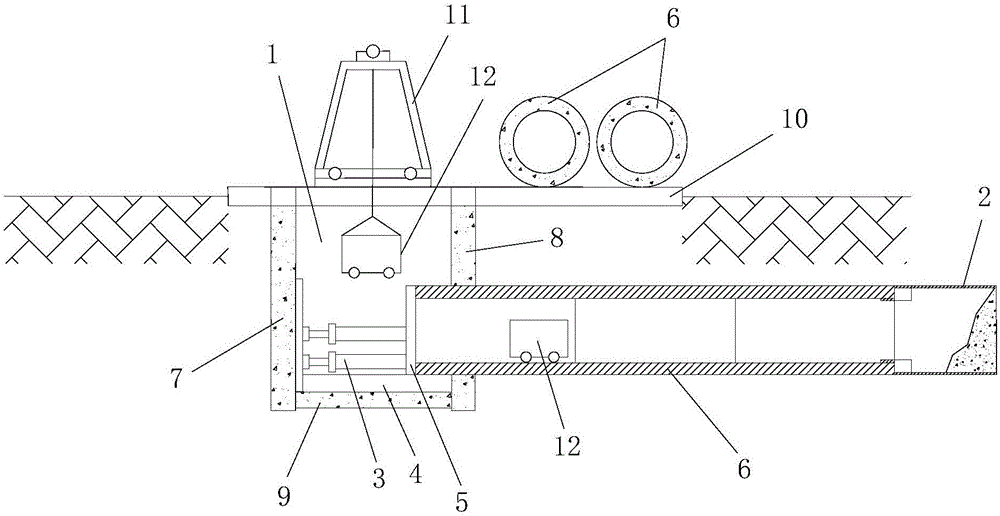

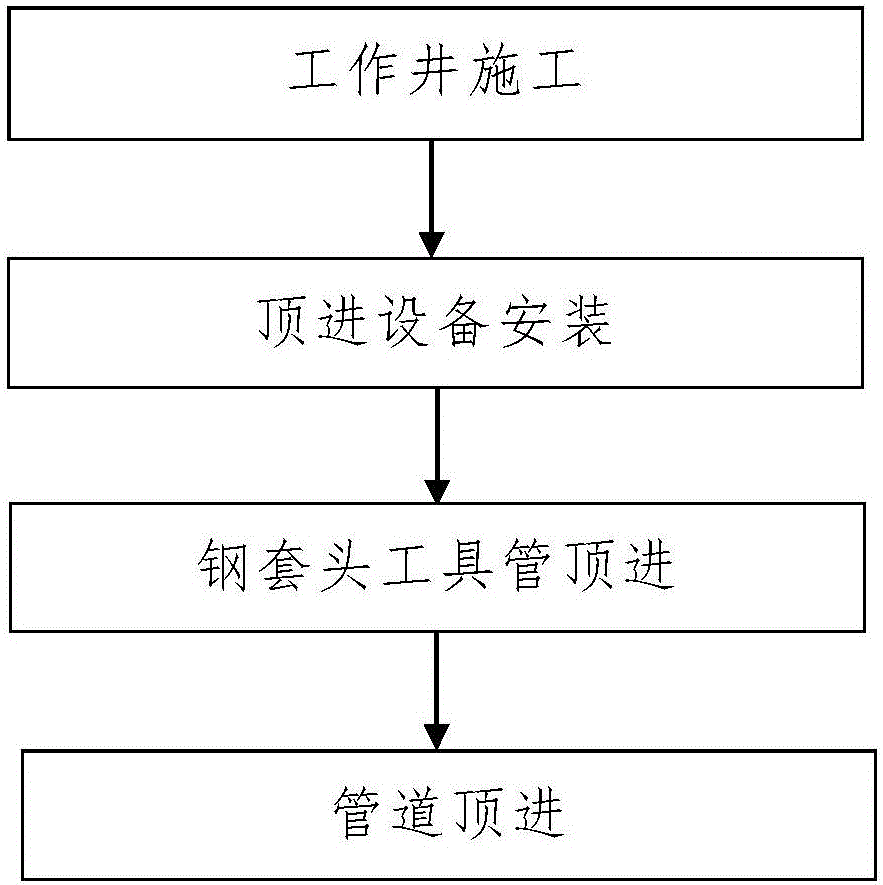

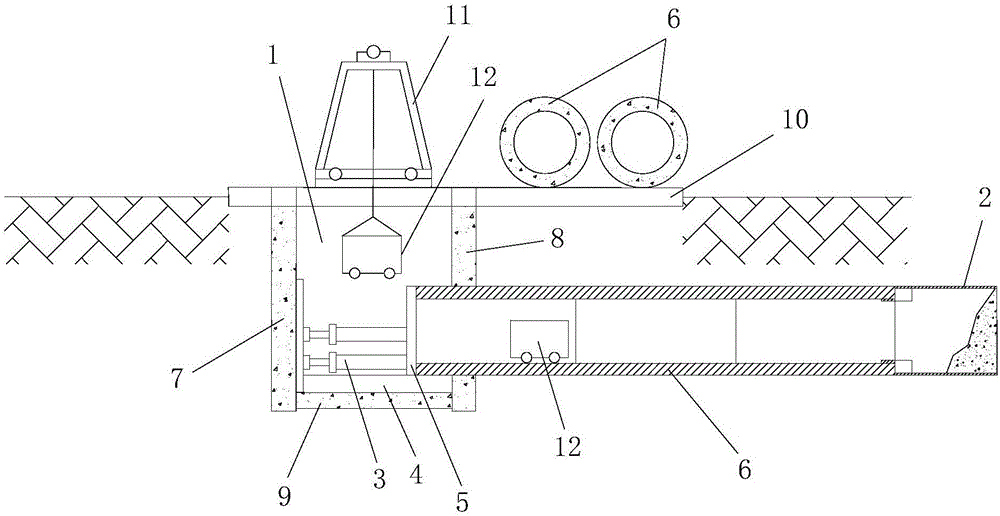

Pipe-jacking construction method for mealy sand stratum

ActiveCN106369223AThe method steps are simpleReasonable designPipe laying and repairEngineeringUnderground pipeline

The invention discloses a pipe-jacking construction method for a mealy sand stratum. The pipe-jacking construction method for the mealy sand stratum comprises the steps that firstly, a working well is constructed, specifically, the working well used for jacking a constructed underground pipeline is constructed, the constructed underground pipeline is formed by splicing a plurality of pipeline assembly sections from front to back, and a steel bushing head tool pipe comprises a steel sleeve, a supporting ring mounted on the inner side of the rear end of the steel sleeve, and an insertion opening fixed to the supporting ring; secondly, jacking equipment is mounted, specifically, the jacking equipment is mounted at the bottom of the inner side of the working well; thirdly, the steel bushing head tool pipe is jacked through the process that the steel bushing head tool pipe is hoisted in place, the steel bushing head tool pipe is jacked, and manual intra-pipe earth cutting is conducted; fourthly, the pipeline is jacked, specifically, the multiple pipeline assembly sections of the constructed underground pipeline are jacked from front to back; fifthly, a pipeline port is treated; and sixthly, a closed water test for the pipeline is conducted. According to the pipe-jacking construction method for the mealy sand stratum, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; and a pipe-jacking construction process of the mealy sand stratum can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:中铁二十局集团第五工程有限公司

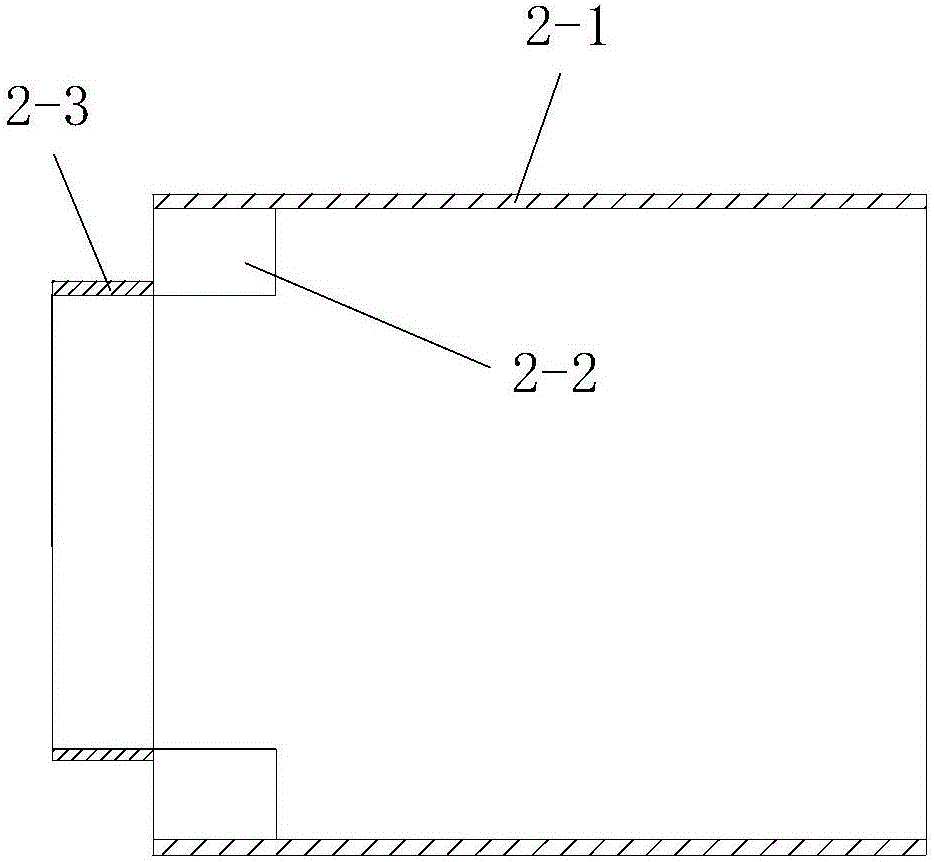

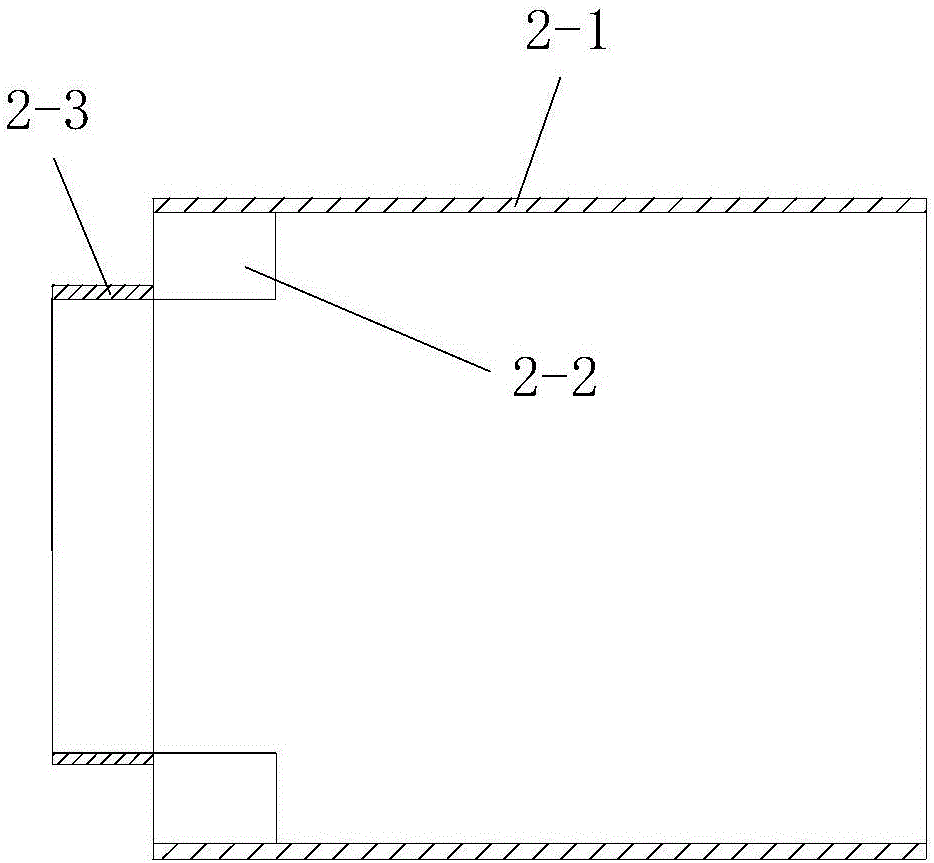

Silty soil stratum pipe-jacking jacking construction method based on tool pipe with steel sleeve head

ActiveCN106402490AThe method steps are simpleReasonable designPipe laying and repairStructural engineeringEngineering

The invention discloses a silty soil stratum pipe-jacking jacking construction method based on a tool pipe with a steel sleeve head. The method includes the steps that firstly, a work well is constructed, wherein the work well used for jacking a construction underground pipeline is constructed, the construction underground pipeline is formed by splicing a plurality of pipeline splicing joints, the tool pipe with the steel sleeve head comprises the steel sleeve pipe, a supporting ring installed on the inner side of the rear end of the steel sleeve pipe and an inserting port fixed to the supporting ring, the wall thickness of the steel sleeve pipe is 0.8-1.2 cm, and the length of the steel sleeve pipe is 80-120 cm; secondly, a jacking device is installed; thirdly, the tool pipe with the steel sleeve head is jacked, wherein the tool pipe with the steel sleeve head is hoisted in place, the tool pipe with the steel sleeve head is jacked, and a soil is manually excavated in the pipe; and fourthly, pipeline jacking is performed, wherein the pipeline splicing joints in the construction underground pipelines are jacked correspondingly from front to back. The method is simple in step, reasonable in design, easy and convenient to construct, good in using effect, capable of easily, conveniently and fast completing the silty soil stratum pipe-jacking jacking construction process and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

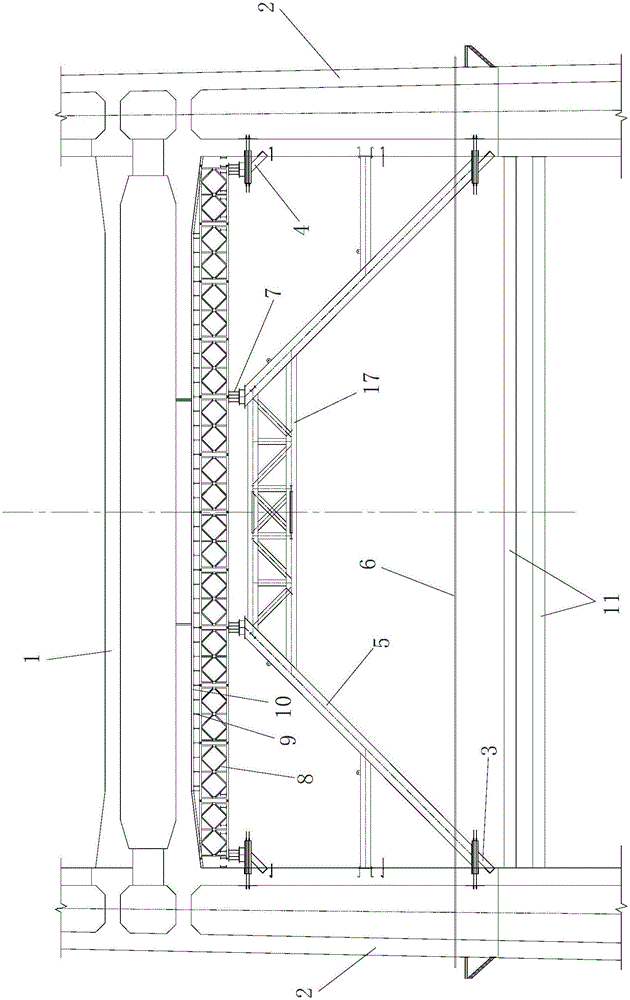

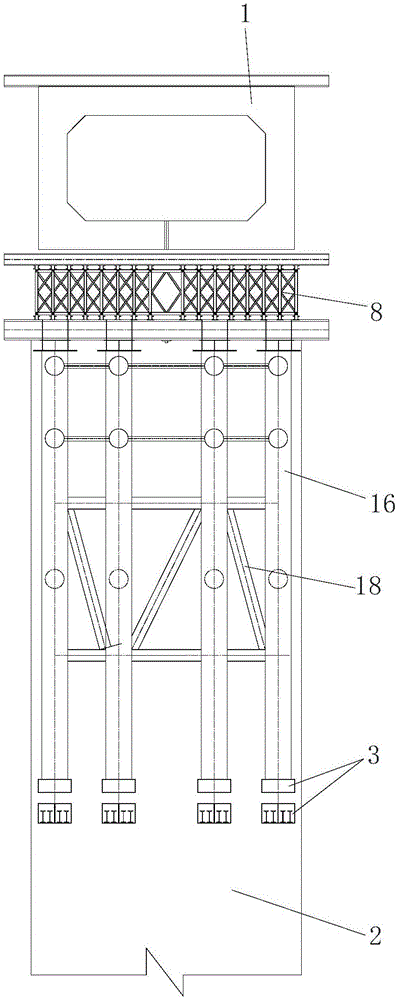

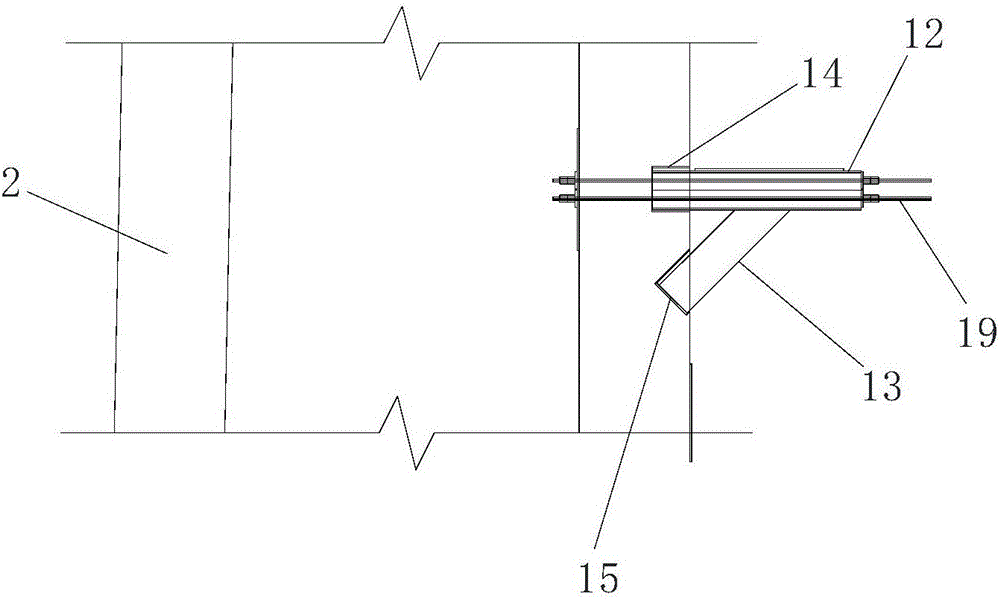

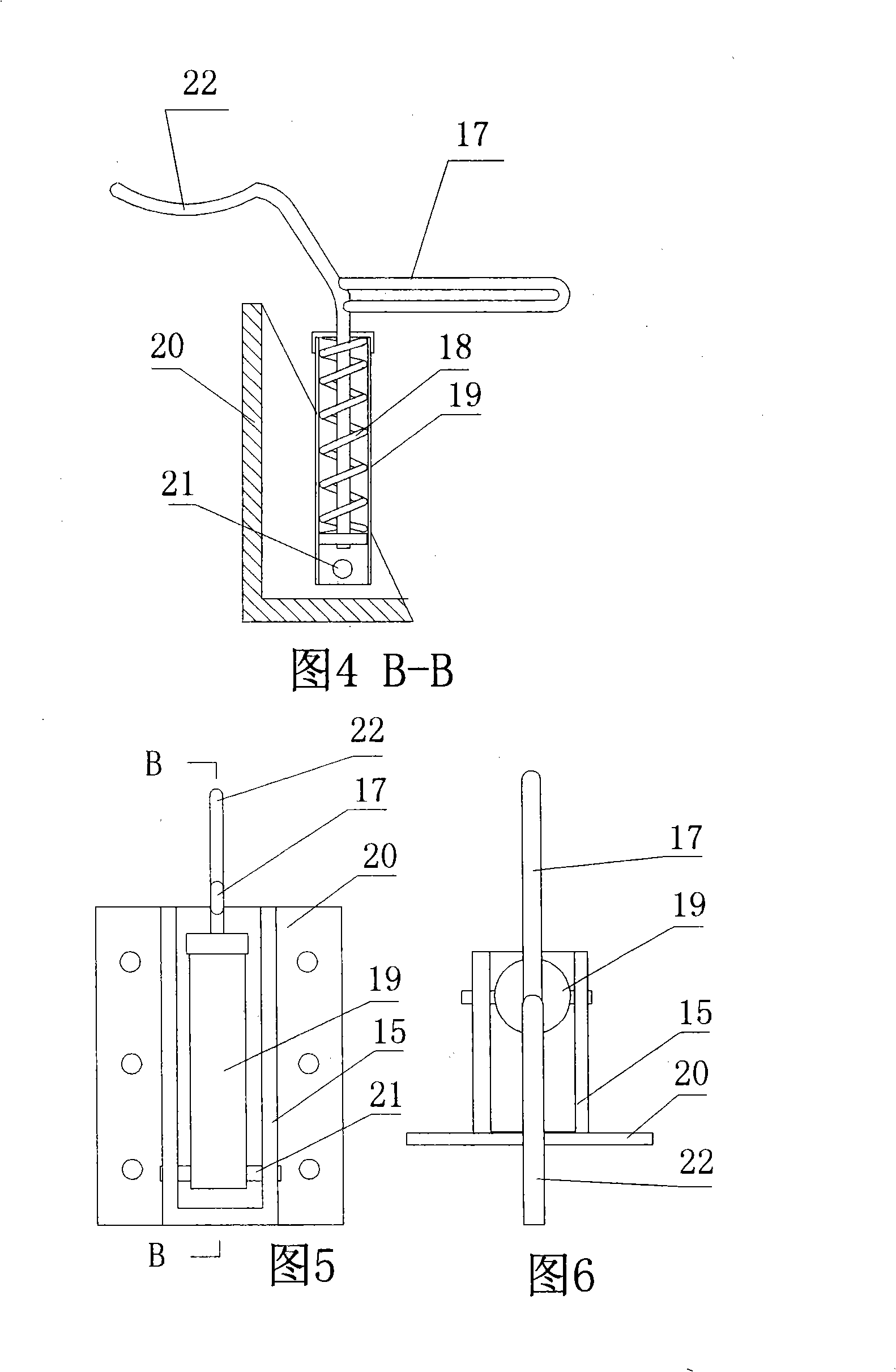

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

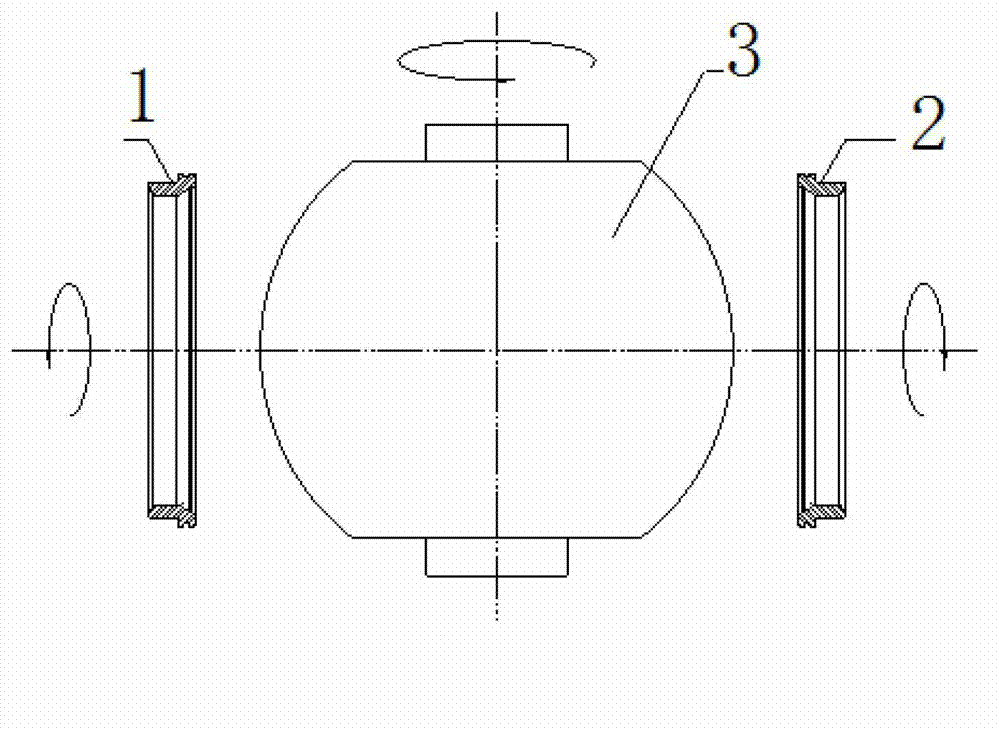

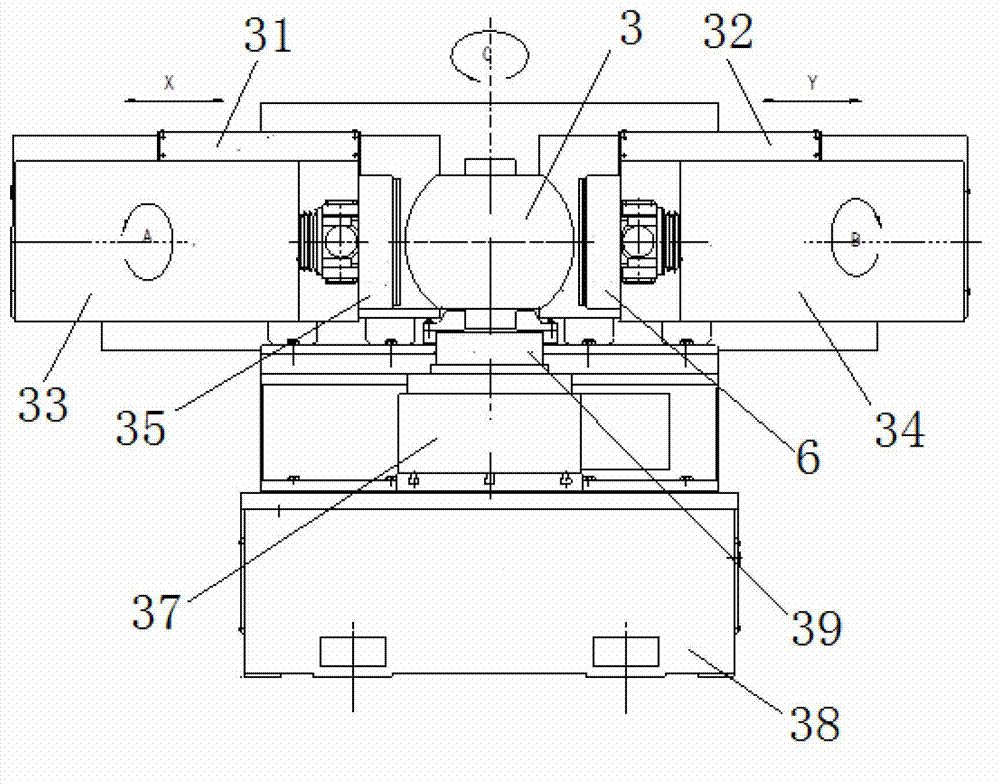

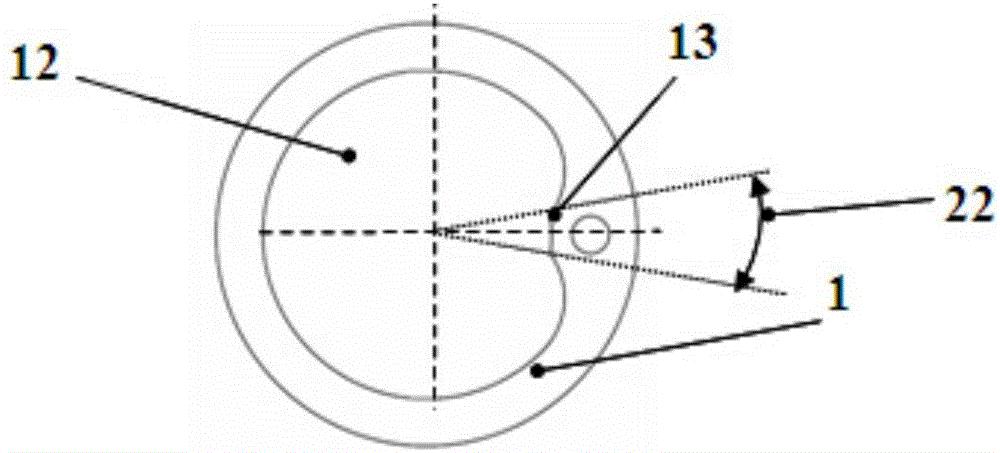

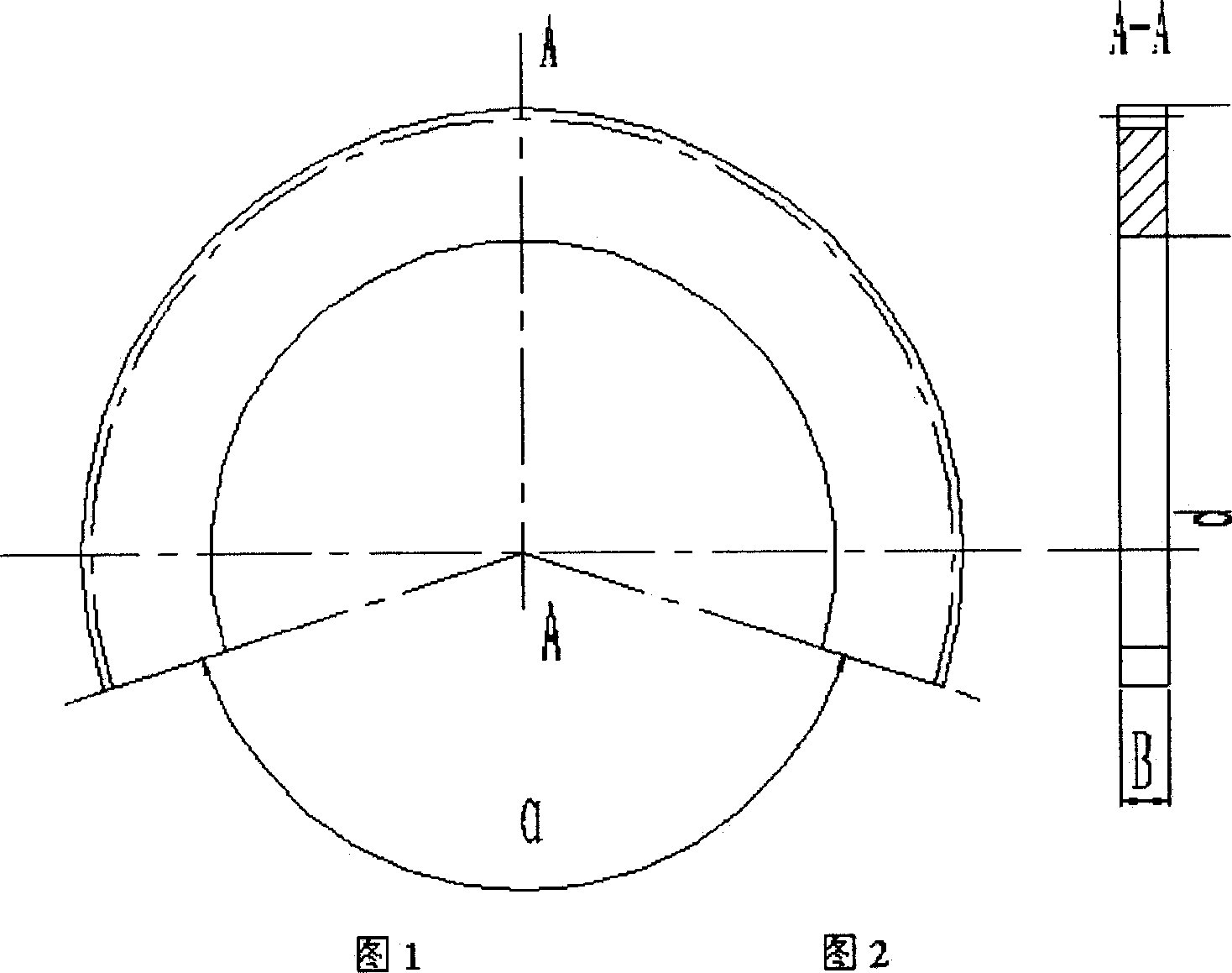

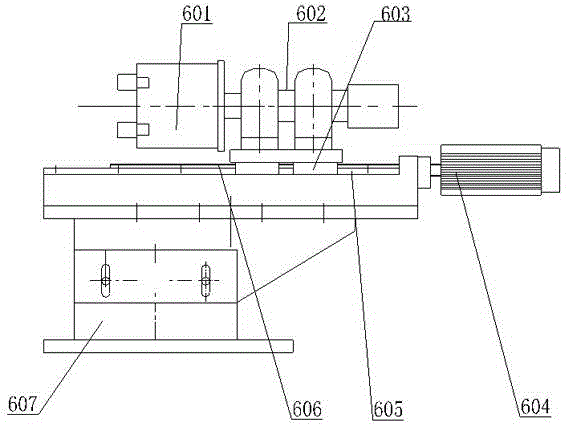

Numerical control spherical pair grinder and grinding method

InactiveCN102848301AImprove processing efficiencyProcessing quality is easy to guaranteeLapping machinesWork carriersNumerical controlPhysical hard work

The invention relates to a numerical control spherical pair grinder and a grinding method and belongs to the field of machine manufacturing. In a machining process, a sphere rotates along an axis of the sphere, and valve seats of two sealing seats respectively rotate in a plane vertical to a rotating axis of the sphere; in a mutual grinding process, the valve seats of the two sealing seats are contacted with the sphere, and a grinding positive pressure is applied; and a grinding track is synthesized by two rotating movements. In the numerical control spherical pair grinder, a lathe bed is connected with a numerical control rotary table, a left numerical control slide plate and a right numerical control slide plate; the numerical control rotary table is connected with a sphere fixture; the left numerical control slide plate is connected with a left valve seat spindle box; the left valve seat spindle box is connected with a left valve seat fixture; the right numerical control slide plate is connected with a right valve seat spindle box; the right valve seat spindle box is connected with a right valve seat fixture; and the processed sphere is connected with the sphere fixture. The numerical control spherical pair grinder and the grinding method have the advantages that the machining effect is improved by more than five times, the machining quality is easily guaranteed, the machining speed can be improved, the precision of the grinded shape of the sphere and the sealing effect can be improved, and the heavy physical labor can be ridded.

Owner:BEIJING QINGFENGDA PRECISION TECH

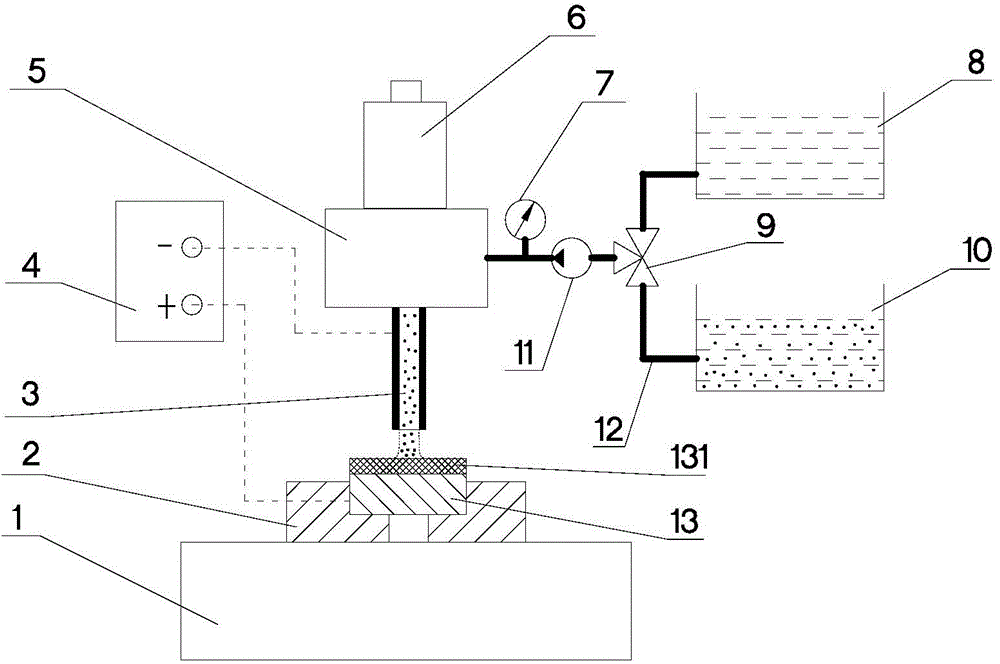

Abrasive water jet-electrolysis composite pass making method and device for metal part with thermal barrier coating

InactiveCN104907650ASimple processProcessing quality is easy to guaranteeElectrolysisThermal barrier coating

The invention discloses an abrasive water jet-electrolysis composite pass making method and device for metal part with thermal barrier coating. The method comprises the steps that a thermal barrier coating pass with the nonconducting workpiece surface is machined by using an abrasive water jet, and after a metal base body is exposed, a metal base body pass is machined by using electrolysis. The device comprises a workbench, a fixture, a tool electrode, a liquid inlet connector, a servo feeding device, an abrasive working liquid box, an electrolysis working liquid box, an infusion pump, a power source, an electromagnetic valve, a pressure regulating device and an infusion pipe. According to the method, it can be guaranteed that under the condition that a tool and the tool electrode are clamped and positioned at one time, the thermal barrier coating pass and the metal base body pass are sequentially machined, the position of the machined thermal barrier coating pass is coincided with the position of the machined metal base body pass, and the machining quality is easy to guarantee. According to the device, it can be guaranteed that abrasive water jet machining and electrolysis machining are carried out on same machining equipment, and the implementation of the method is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

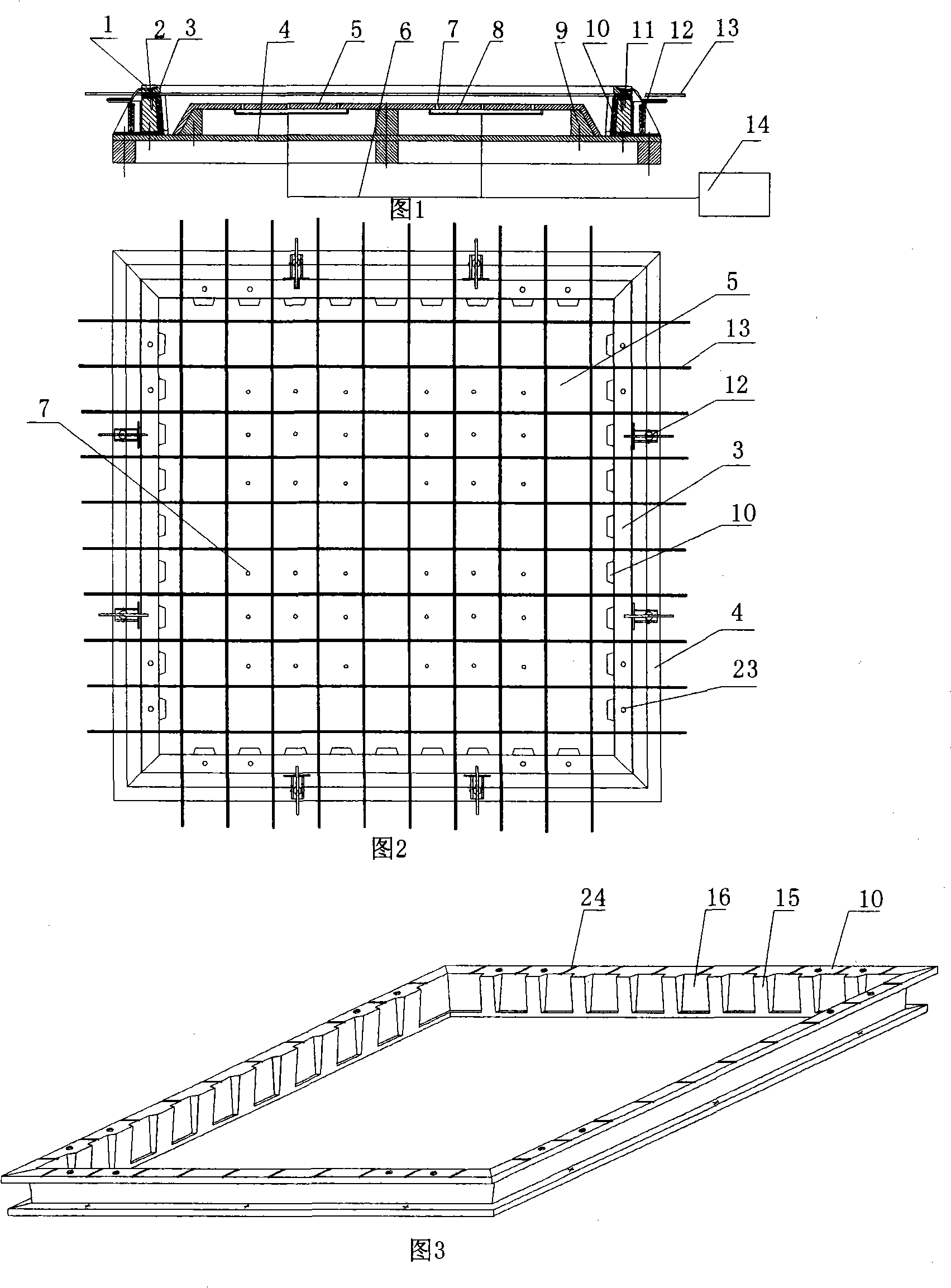

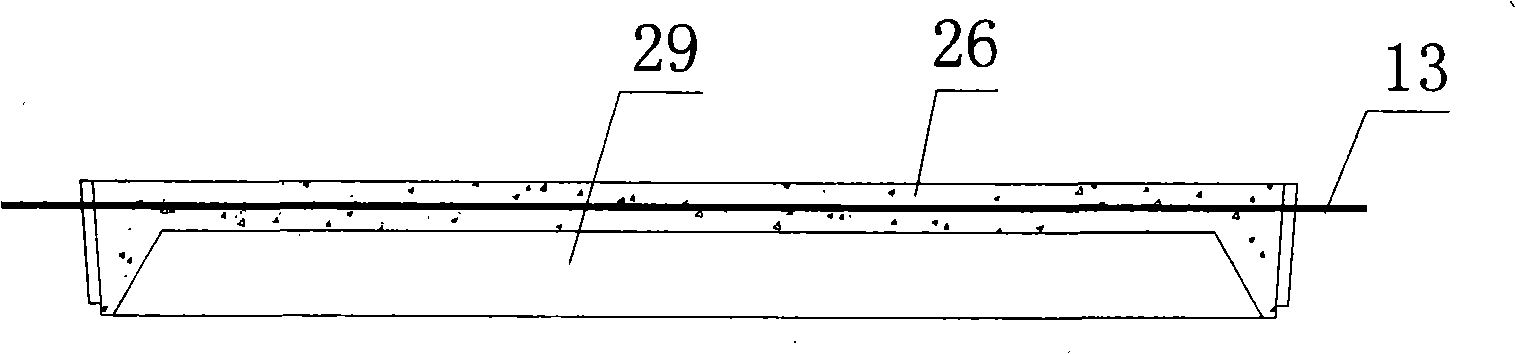

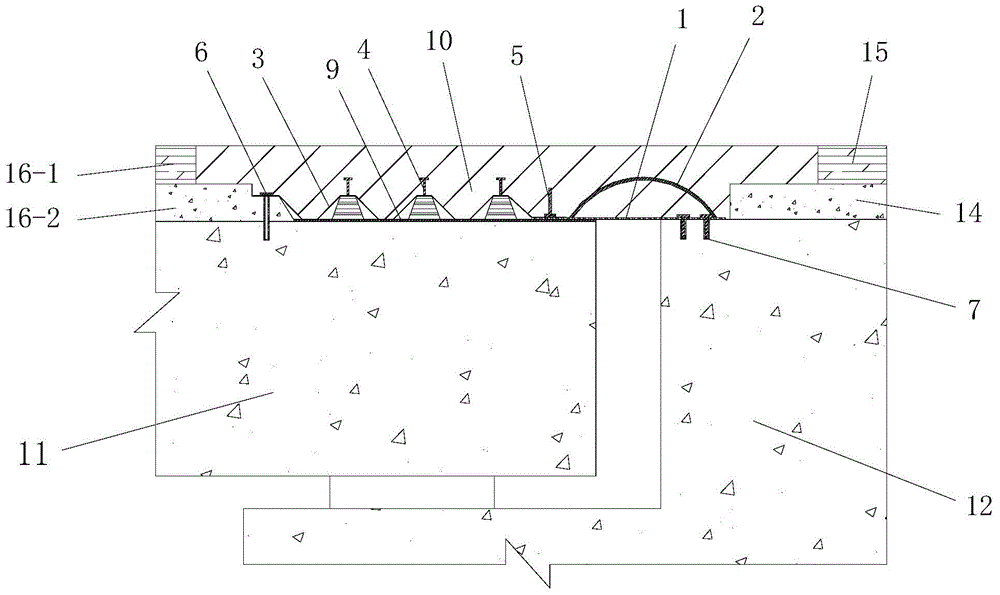

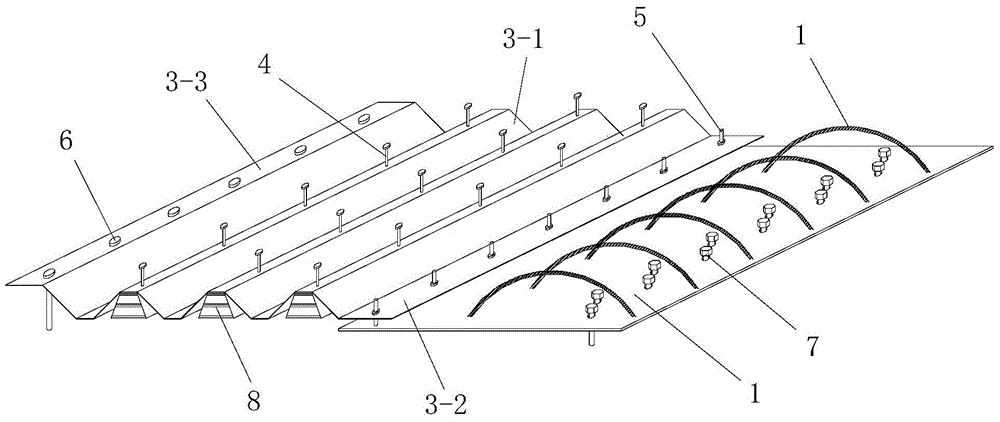

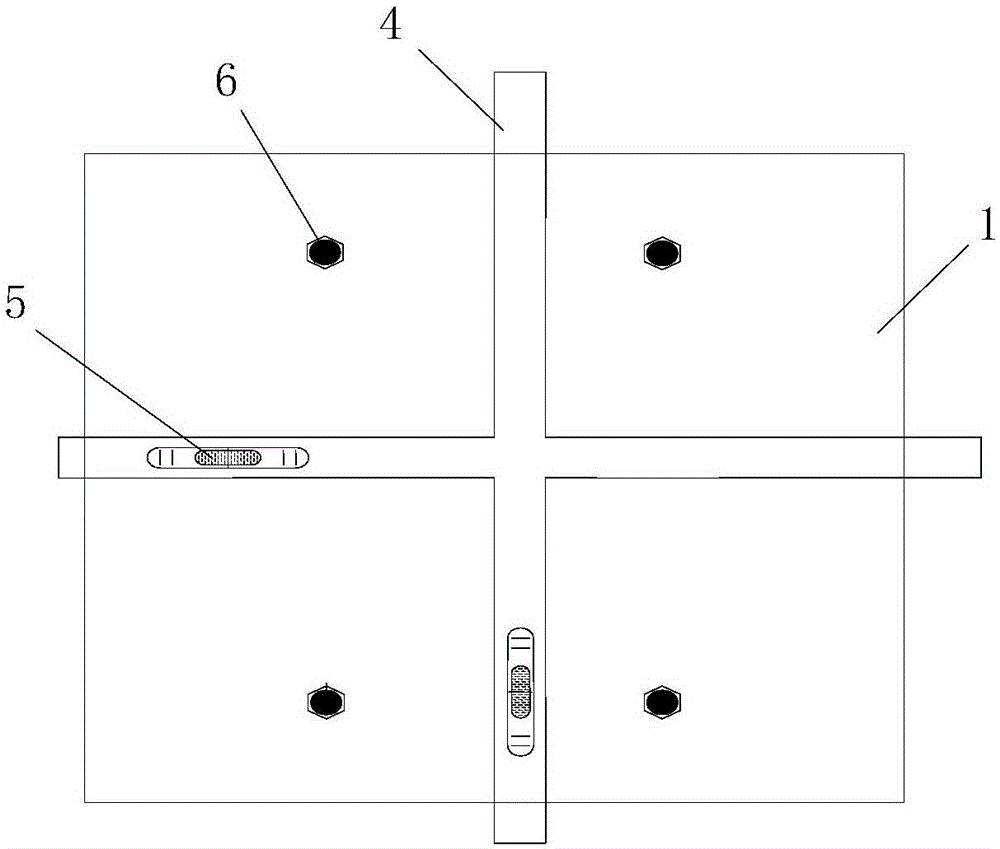

Dense girt strip hollow building roof composition board fixture mould

The invention provides a frock die for a multifunctional hollow-ribbed floor composite slab. The structure of the frock die comprises an outer die, an inner die and a pedestal which are square or rectangular, wherein the inner die and the outer die are arranged on the upper part of the pedestal; the outer die is arranged on the circumference of the inner die; the upper part of the outer die is provided with a mustache rib batten; a mustache rib is fixed between the mustache rib batten and the upper part of the outer die through the mustache rib batten; a batten machine is arranged on the edge of the pedestal and positioned outside the outer die; the upper part of the mustache rib batten is provided with a drawhook groove; a batten drawhook on the upper part of the batten machine is hooked into the drawhook groove on the upper part of the mustache rib batten; and a pressure air demouding machine is arranged at the bottom of the pedestal. The frock die is mainly used for manufacturing the multifunctional hollow-ribbed floor composite slab, can implement remote standardized streamlined production and processing, is transported to a construction site for assembly and primary casting molding of the overall beam surface, can save the amount of reinforcing steel bars and concrete and reduce the weight of a floor slab and the engineering manufacturing cost, thereby having good promotion value and use value.

Owner:郎佃富

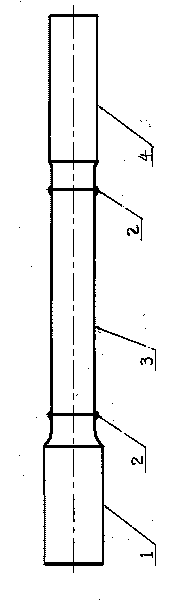

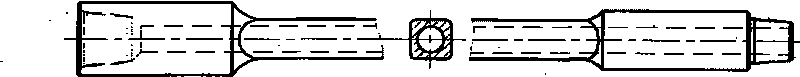

Friction welding type kelly bar

InactiveCN101699021AEasy to manufacture in sectionsEasy to manufactureDrilling rodsDrilling casingsEngineeringFriction stud welding

The invention relates to an oil drilling tool, and in particular to a friction welding type kelly bar, which comprises a pipe body and a first joint and a second joint respectively positioned at two ends of the pipe body; the shape of the section of the pipe body is a square or hexagon; the pipe body is connected with the first joint and the second joint in a friction welding mode; and the welding parameters are that: the first-level friction pressure is between 3 and 5MPa and the time is 20 to 60 seconds; the second-level friction pressure is between 4 and 8MPa and the time is 60 to 180 seconds; and the upsetting force is between 10 and 18MPa. The friction welding type kelly bar has the advantages that: the friction welding type kelly bar is manufactured in segments, the manufacture is simple and the production efficiency is high; raw materials and energy are saved, and the cost is greatly reduced; and the processing quality is easily guaranteed and the processing accuracy is high. For the manual welding mode adopted by the conventional kelly bar, welding lines generated easily have crystal defects such as bubbles, segregation, inclusion, cracks and the like so as to severely influence the strength and service life of a kelly bar; and compared with the manual welding, the friction welding ensures that the joints have good and stable quality and are not melted in the welding process, and belongs to solid-phase hot-pressure welding, and the joints have forging textures, so the welding lines do not have the crystal defects such as bubbles, segregation, inclusion, cracks and the like, and the strength of the joints by the friction welding is far greater than that by fusion welding and braze welding, and reaches or even surpass the strength of a base metal.

Owner:山西环界石油钻具制造股份有限公司

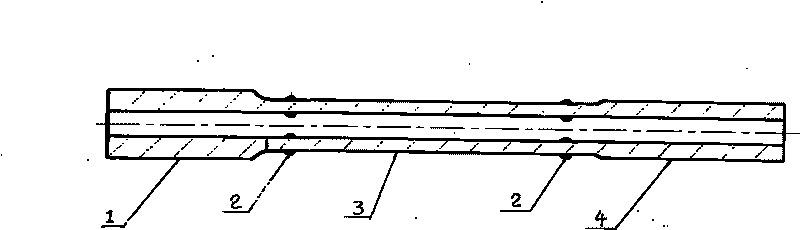

Stiffened joint-crossing plate based bridge deck jointless expansion device and construction method thereof

InactiveCN104674650ASimple structureReasonable designBridge structural detailsBridge erection/assemblyWave shapeExpansion joint

The invention discloses a stiffened joint-crossing plate based bridge deck jointless expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion assembly and an expansion joint filler filled layer filled above the prefabricated expansion assembly, wherein the prefabricated expansion assembly is arranged on an expansion joint reserved between every two adjacent girder segments, and a sliding layer is laid on a girder exposed segment of each girder segment; the prefabricated expansion assembly comprises a stiffened joint-crossing plate and two wave-shaped expansion plates. A construction method for an expansion device to be repaired comprises the steps of cleaning an original bridge expansion device, constructing reserved mounting grooves, constructing the sliding layers, carrying out field assembly and mounting on the prefabricated expansion assembly and constructing the expansion joint filler filled layer. A construction method for an expansion device to be constructed comprises the steps of prefabricating the prefabricated expansion assembly, carrying out field assembly on the prefabricated expansion assembly, constructing the sliding layers, mounting the prefabricated expansion assembly and constructing bridge deck pavement structures and the expansion joint filler filled layer. The stiffened joint-crossing plate based bridge deck jointless expansion device and the construction method thereof have the advantages that the design is reasonable, the construction is convenient, the use effect is good, and multiple problems of the existing expansion devices can be solved.

Owner:XIAN HIGHWAY INST

Bridge seamless telescopic device and construction method of device

InactiveCN104594190ASimple structureWell formedBridge structural detailsBridge erection/assemblyWave shapeArchitectural engineering

The invention discloses a bridge seamless telescopic device and a construction method of the device. The bridge seamless telescopic device comprises a main beam span telescopic device and a bridge abutment telescopic device, wherein the main beam span telescopic device comprises a first prefabricated telescopic component and a first telescopic joint filler filling layer; the bridge abutment telescopic device comprises a second prefabricated telescopic component and a second telescopic joint filler filling layer; the first prefabricated telescopic component and the second prefabricated telescopic component are formed by reinforced joint-crossing plates and wave-shaped telescopic plates. A construction method of a telescopic device to be repaired comprises the following steps: cleaning an original bridge telescopic device, constructing a preserved mounting slot, constructing a sliding layer, assembling and mounting prefabricated telescopic components, and constructing telescopic joint filler filling layers. A construction method of a telescopic device to be constructed comprises the following steps: prefabricating and processing prefabricated telescopic components, assembling the prefabricated telescopic components on site, constructing a sliding layer, mounting prefabricated telescopic components, paving a structure and constructing telescopic joint filler filling layers. The bridge seamless telescopic device is reasonable in design, convenient to construct and high in using effect, and can be used for solving various problems of the existing telescopic device.

Owner:XIAN HIGHWAY INST

Abutment hidden expansion device and construction method thereof

InactiveCN104762873AWell formedSimple structureIn situ pavingsBridge structural detailsExpansion jointAbutment

The invention discloses an abutment hidden expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion component arranged on an abutment expansion joint, and an expansion joint filler filling layer filled in the upper side of the prefabricated expansion component, wherein a bridge deck pavement structure is paved on a main beam; a slide layer is paved on an exposed section of the main beam; a road surface pavement layer is arranged at the outer side of the upper part of an abutment; the prefabricated expansion component comprises a reinforced joint plate and a waveform expansion plate; a construction method of an expansion device to be repaired comprises the steps of cleaning of an original bridge expansion device, construction of a reversed mounting groove, construction of the slide layer, field assembly and installation of the prefabricated expansion component and construction of the expansion joint filler filling layer; and a construction method of an expansion device to be constructed comprises the steps of prefabrication of the prefabricated expansion component, field assembly of the prefabricated expansion component, construction of the slide layer, installation of the prefabricated expansion component and construction of the bridge deck pavement structure and the expansion joint filler filling layer. The abutment hidden expansion device and the construction method thereof have the advantages of reasonable design, convenience for construction and good use effect, and can solve multiple problems in traditional expansion devices.

Owner:XIAN HIGHWAY INST

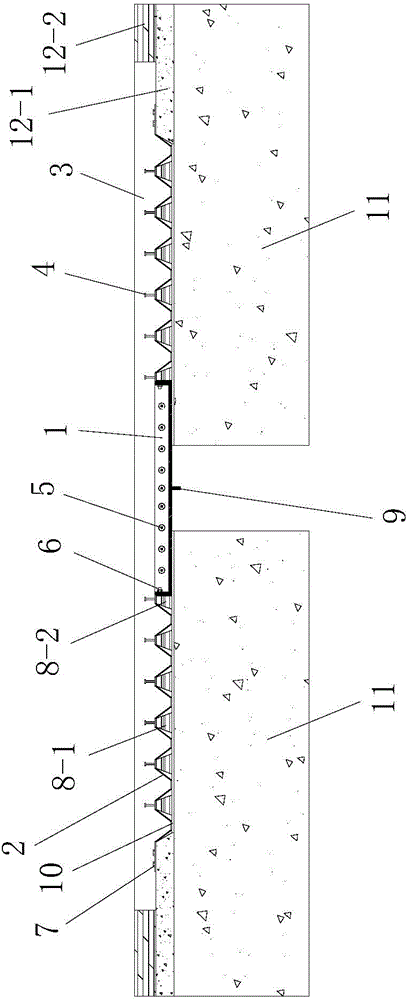

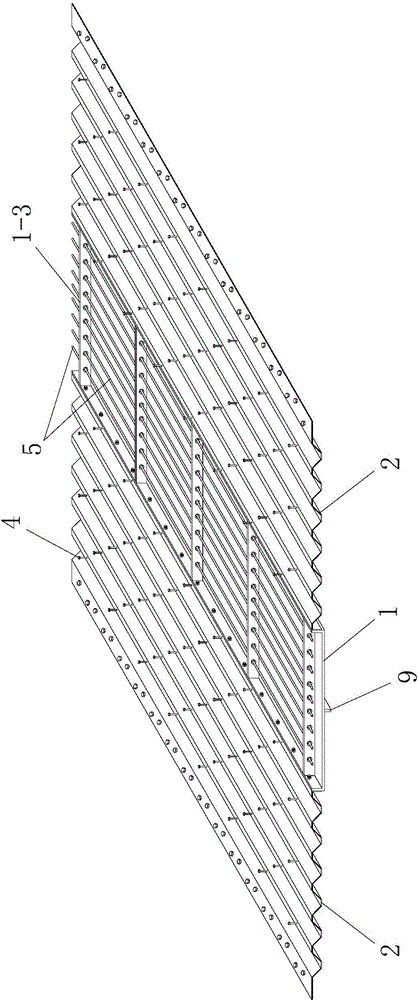

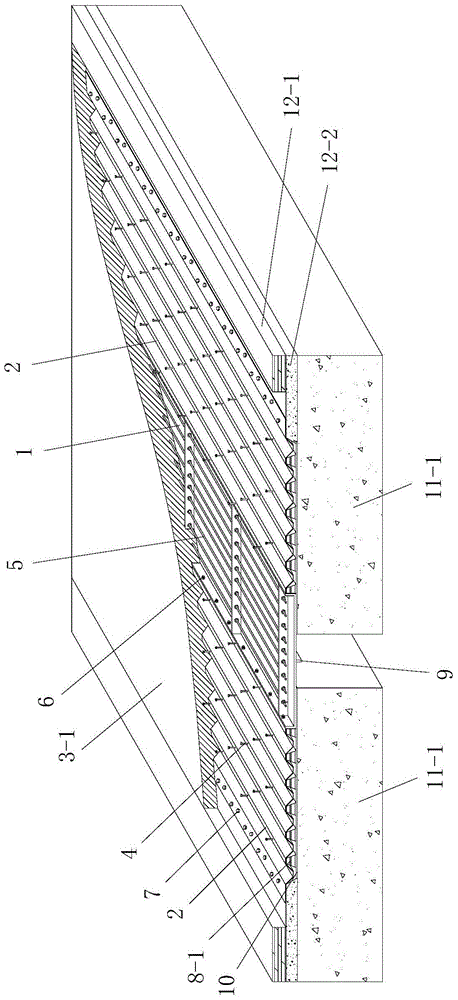

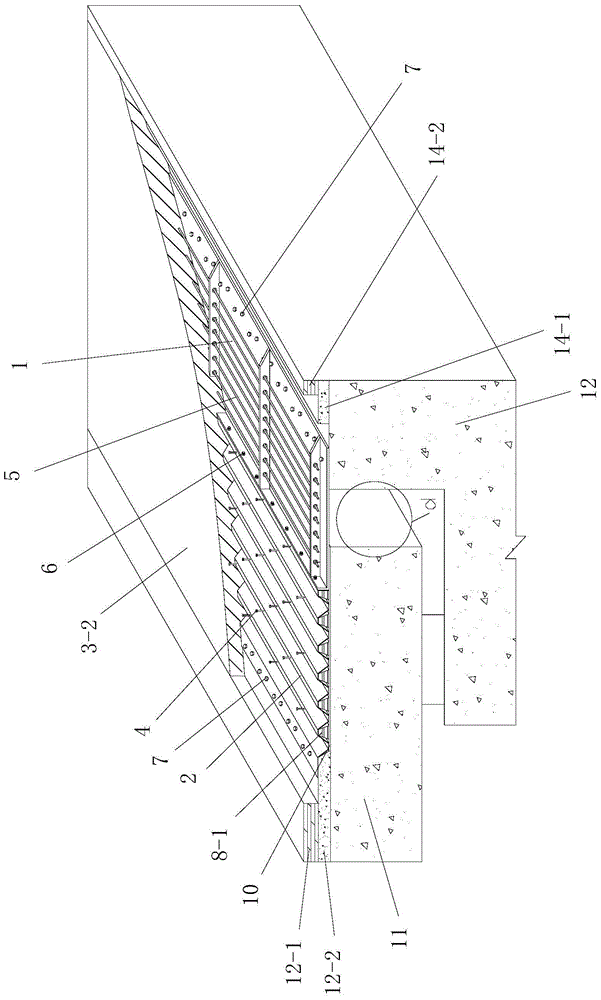

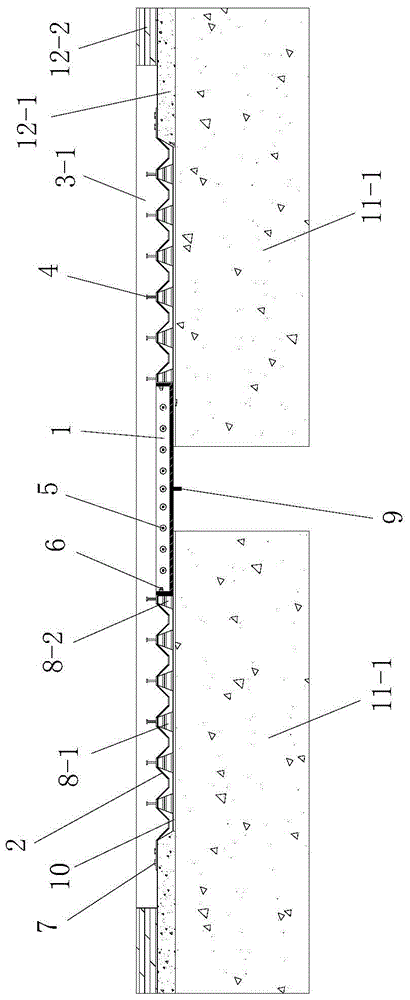

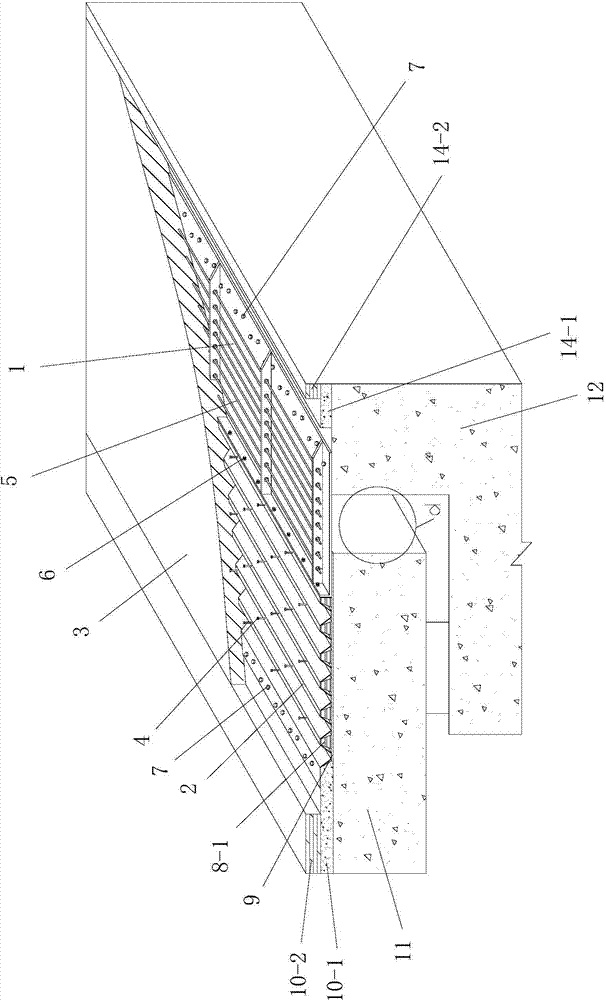

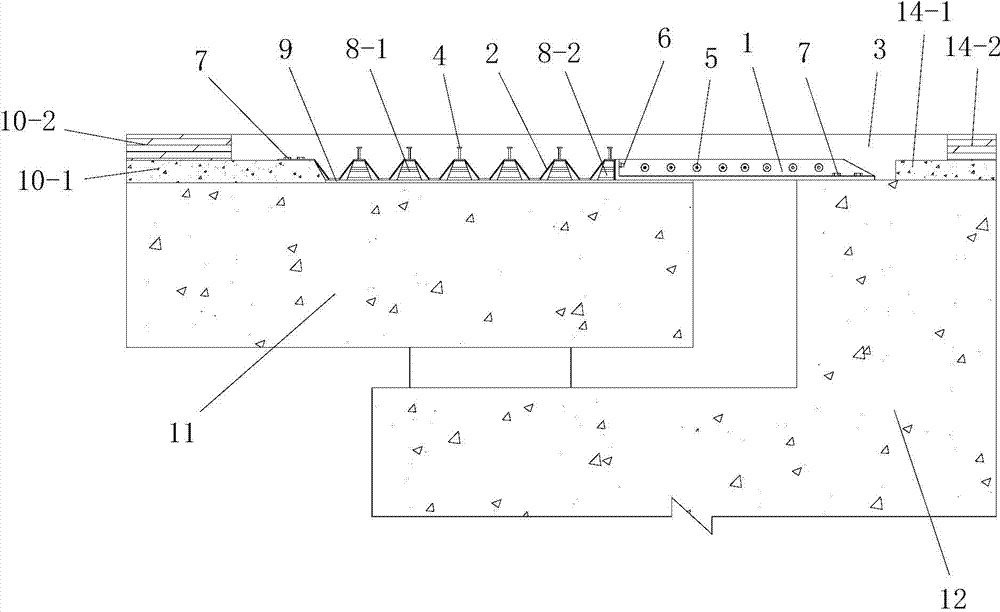

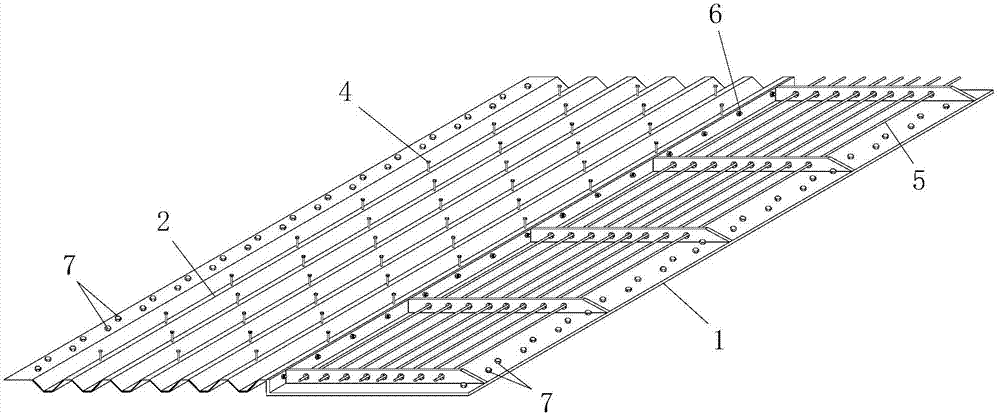

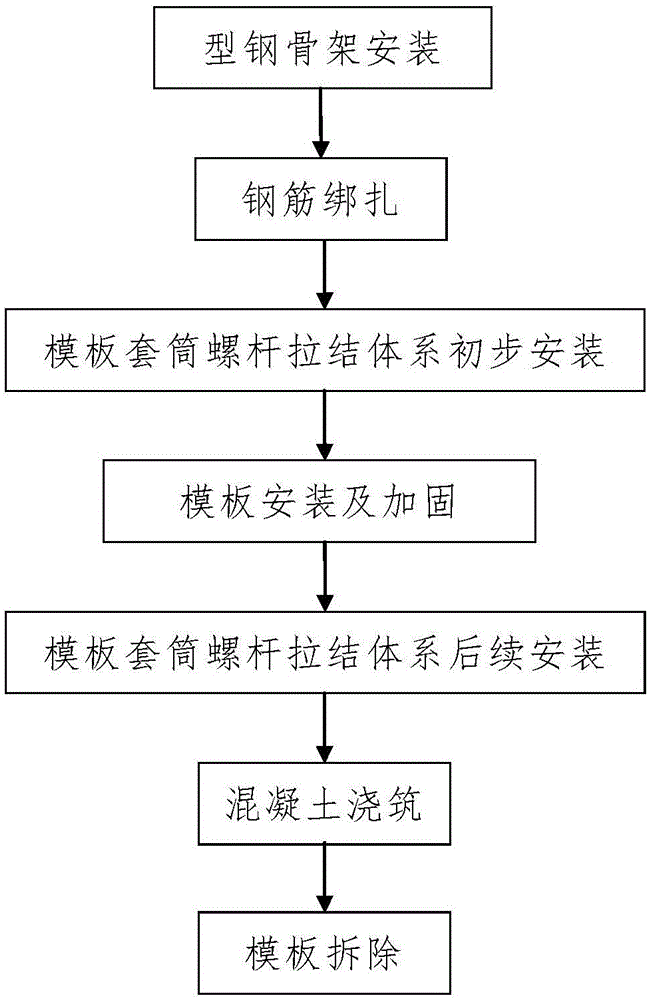

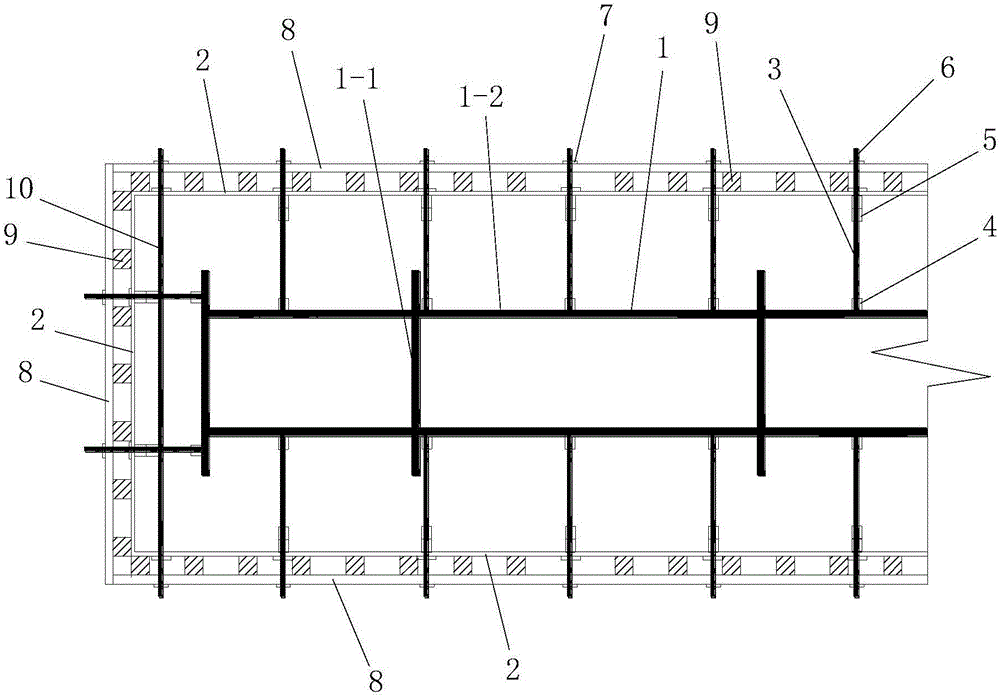

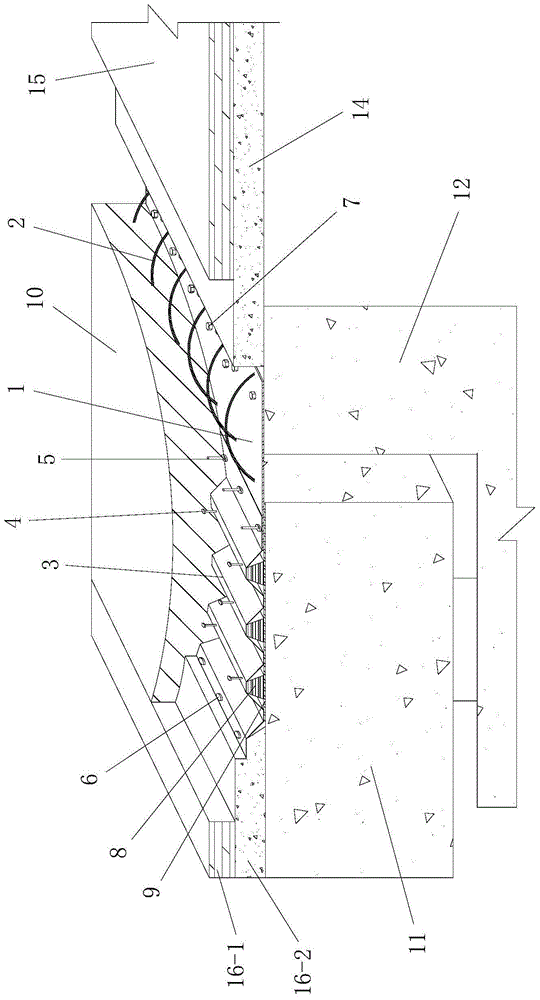

Steel reinforced concrete structure formwork sleeve threaded rod pulling construction method

InactiveCN106320704ASimple structureReasonable designAuxillary members of forms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention discloses a steel reinforced concrete structure formwork sleeve threaded rod pulling construction method. The method comprises the steps that firstly, a section steel framework is installed; secondly, steel bars are bound; thirdly, a formwork sleeve threaded rod pulling system is installed preliminarily, specifically, the formwork sleeve threaded rod pulling system comprises a plurality of transverse sleeve threaded rod pulling devices and a plurality of longitudinal sleeve threaded rod pulling devices, the transverse sleeve threaded rod pulling devices and the longitudinal sleeve threaded rod pulling devices each comprise two formwork sleeve threaded rod pulling pieces, and each formwork sleeve threaded rod pulling piece comprises a connecting steel bar, an inner embedded sleeve, an outer embedded sleeve and an outer threaded rod; fourthly, formworks are installed and reinforced; fifthly, subsequent installation of the formwork sleeve threaded rod pulling system is conducted; sixthly, concrete is poured; and seventhly, the formworks are removed. The method is simple in step, reasonable in design, easy and convenient to implement and good in using effect, by the adoption of the formwork sleeve threaded rod pulling pieces based on straight threaded sleeves, the steel reinforced concrete structure formworks are fixed easily and effectively, and holes do not need to be drilled in the section steel framework.

Owner:SHAANXI CONSTR ENG GRP CO LTD THE FIRST BUILDING

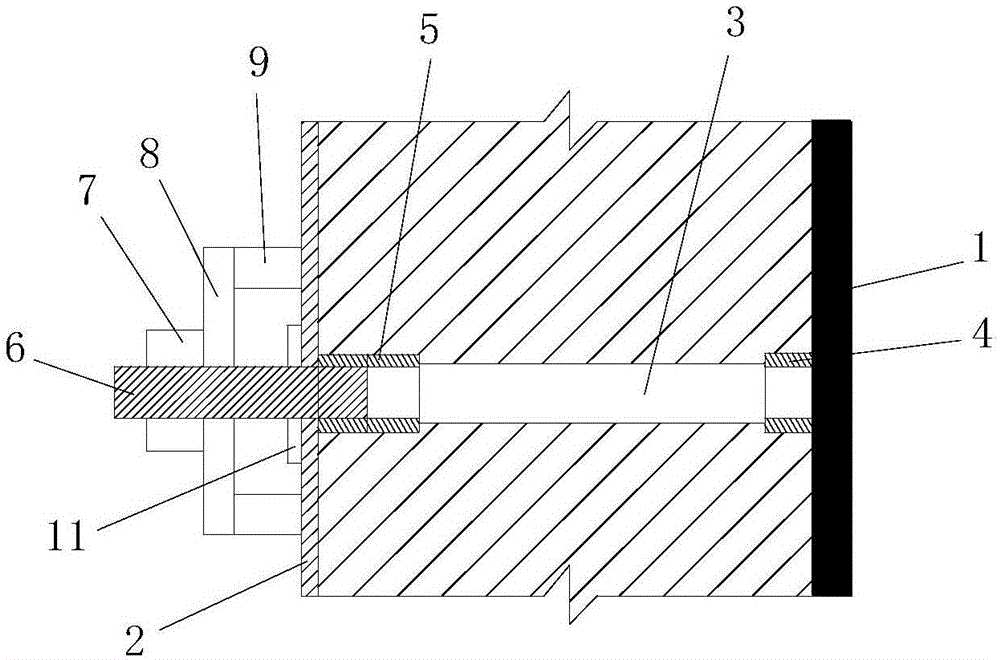

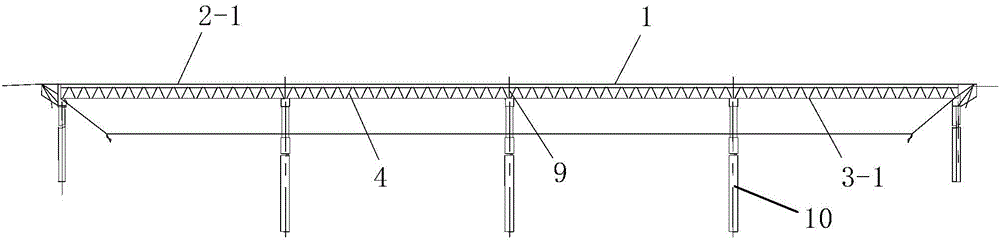

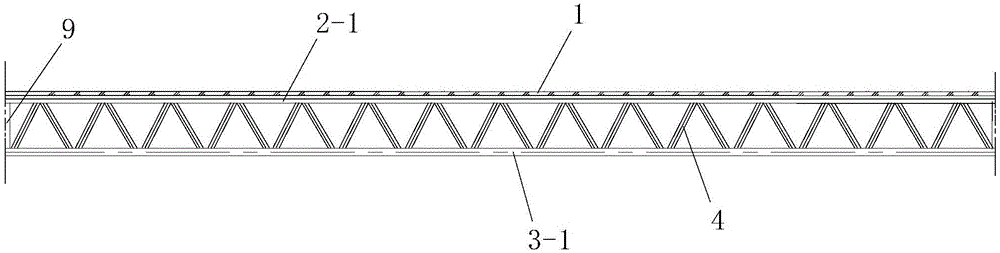

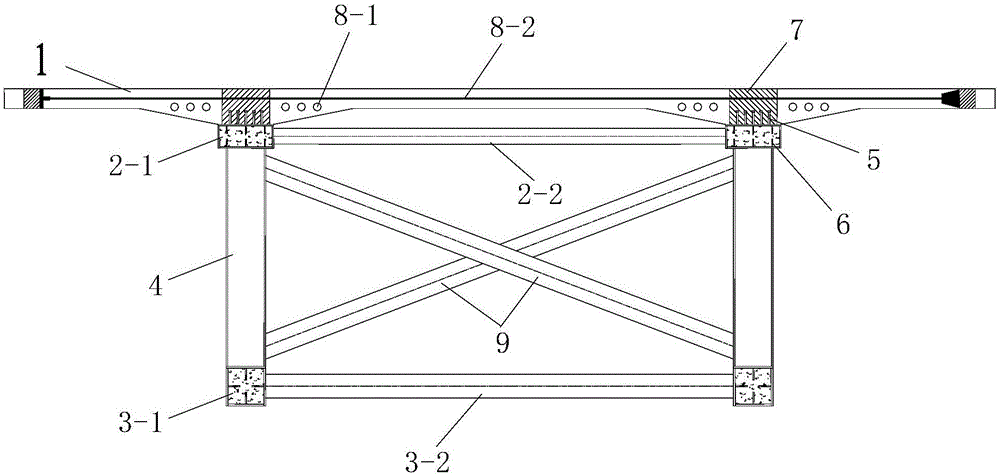

Assembly type rectangular concrete-filled steel tube composite truss girder bridge and construction method thereof

ActiveCN106223183ASimple structureEasy on-site constructionTruss-type bridgeBridge structural detailsSteel tubeGirder bridge

The invention discloses an assembly type rectangular concrete-filled steel tube composite truss girder bridge and a construction method thereof. The truss girder bridge comprises girder lower supporting structures, an assembly type girder and a prefabricated bridge panel which is connected with the assembly type girder through a shear key. The assembly girder is a rectangular concrete-filled steel tube composite truss and is formed by splicing a plurality of longitudinal trusses. Each longitudinal truss is composed of an upper chord member, a lower chord member and a web member. A horizontal bridge direction supporting structure composed of two inclined struts arranged in a crossed mode is arranged over each girder lower supporting structure, and the rectangular concrete-filled steel tube composite truss is formed by assembling a plurality of truss sections. The construction method comprises the first step of construction of the girder lower supporting structures, the second step of erecting of the assembly type girder, and the third step of mounting of the prefabricated bridge panel. The assembly type rectangular concrete-filled steel tube composite truss girder bridge is reasonable in design, easy and convenient to construct, good in using effect, capable of fully performing the advantage of the combination of steel and concrete materials, good in stress performance, high in construction speed, low in construction cost, capable of achieving the standard and batch production of the girder and the bridge panel.

Owner:CHANGAN UNIV

Open steel tube and reinforced-concrete combined girder bridge structure

InactiveCN105803939ASimple structureReasonable designBridge structural detailsBridge materialsStress concentrationReinforced concrete

The invention discloses an open steel tube and reinforced-concrete combined girder bridge structure. The structure comprises a concrete bridge deck slab, opening steel tube connecting pieces and multiple steel girders, each steel girder is provided with multiple steel tube connecting pieces, the concrete bridge deck slab is used for being erected on the steel girders, and the concrete bridge deck slab is provided with concrete pouring grooves matched with the steel tube connecting pieces and used for pouring concrete. The open steel tube and reinforced-concrete combined girder bridge structure is simple in structure, reasonable in design and convenient to construct. The structure has the advantages that the opening steel tube connecting pieces are simple in structure, convenient to manufacture and rapid to construct; by means of the opening steel tube connecting pieces, connection strength of the steel girders and the concrete bridge deck slab is increased, bearing areas of the connecting pieces are increased, and compared with bolt / screw connecting pieces, stress concentration can be effectively reduced; meanwhile, a single opening steel tube connecting piece is high in shear capacity, under the same situation, compared with the bolt / screw connecting pieces, a small number of opening steel tube connecting pieces are arranged, construction space is effectively saved, and it is beneficial to play the combination role of the concrete bridge deck slab and the steel girders.

Owner:CHANGAN UNIV

Corrugated steel plate built-in seamless expansion device between girder and bridge abutment and construction method of seamless expansion device

InactiveCN104594191AWell formedSimple structureBridge structural detailsBridge erection/assemblySteel platesSteel bar

The invention discloses a corrugated steel plate built-in seamless expansion device between a girder and a bridge abutment and a construction method of the seamless expansion device. The expansion device comprises prefabricated steel plate elements distributed on a bridge abutment expansion joint and expansion joint filler packing layer filled above the prefabricated steel plate elements; the prefabricated steel plate elements comprise straight steel plates, corrugated steel plates and a plurality of arched reinforcing steel bars; a plurality of shear pins are fixed on the corrugated steel plates; a sliding layer is paved on the girder exposed section; the construction method of the to-be-repaired expansion device comprises the following steps: cleaning the original bridge expansion device, constructing preserved mounting grooves, constructing the girder sliding layer, assembling the prefabricated steel plate elements in the field, and mounting and constructing the expansion joint filler packing layer; the construction method of the to-be-constructed expansion device comprises the following steps: prefabricating and processing the prefabricated steel plate elements, assembling the prefabricated steel plate elements in the field, constructing the girder sliding layer, mounting the prefabricated steel plate elements, and constructing the bridge deck pavement structure and the expansion joint filler packing layer. The corrugated steel plate built-in seamless expansion device disclosed by the invention is reasonable in design, convenient to construct, and good in use effect, and can solve a plurality of problems in the existing expansion device.

Owner:XIAN HIGHWAY INST

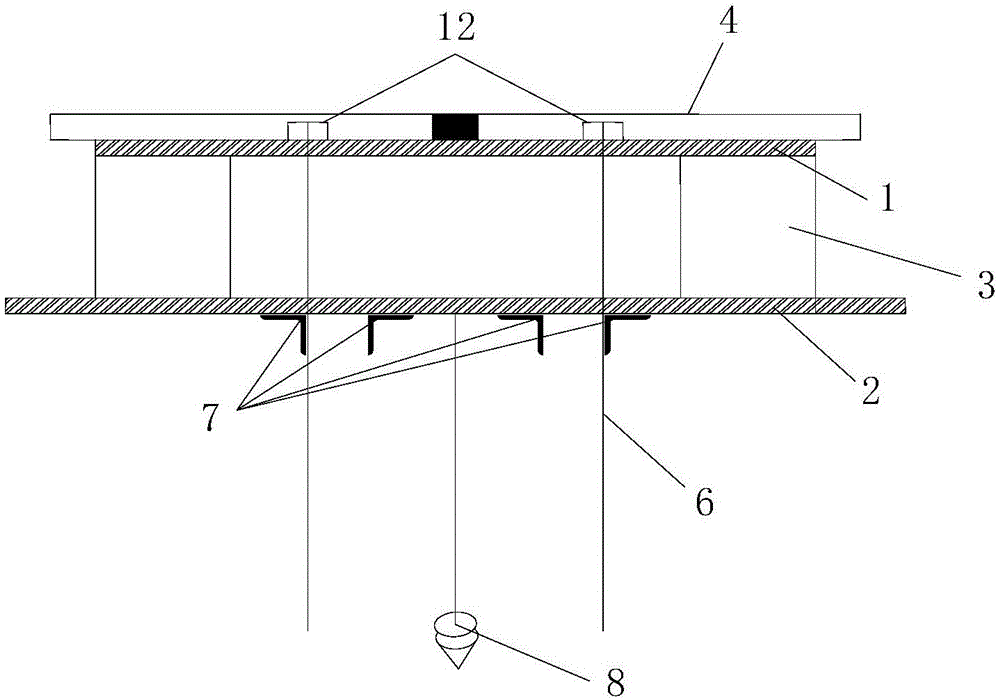

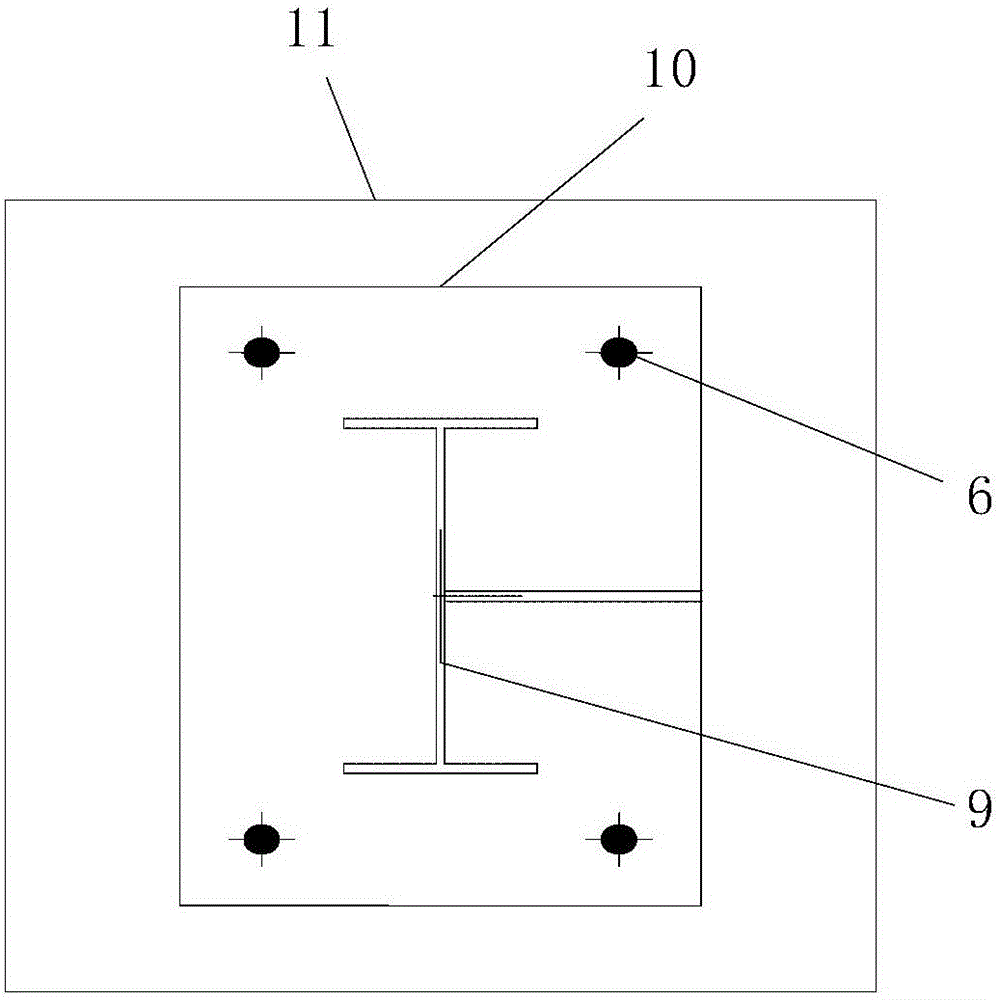

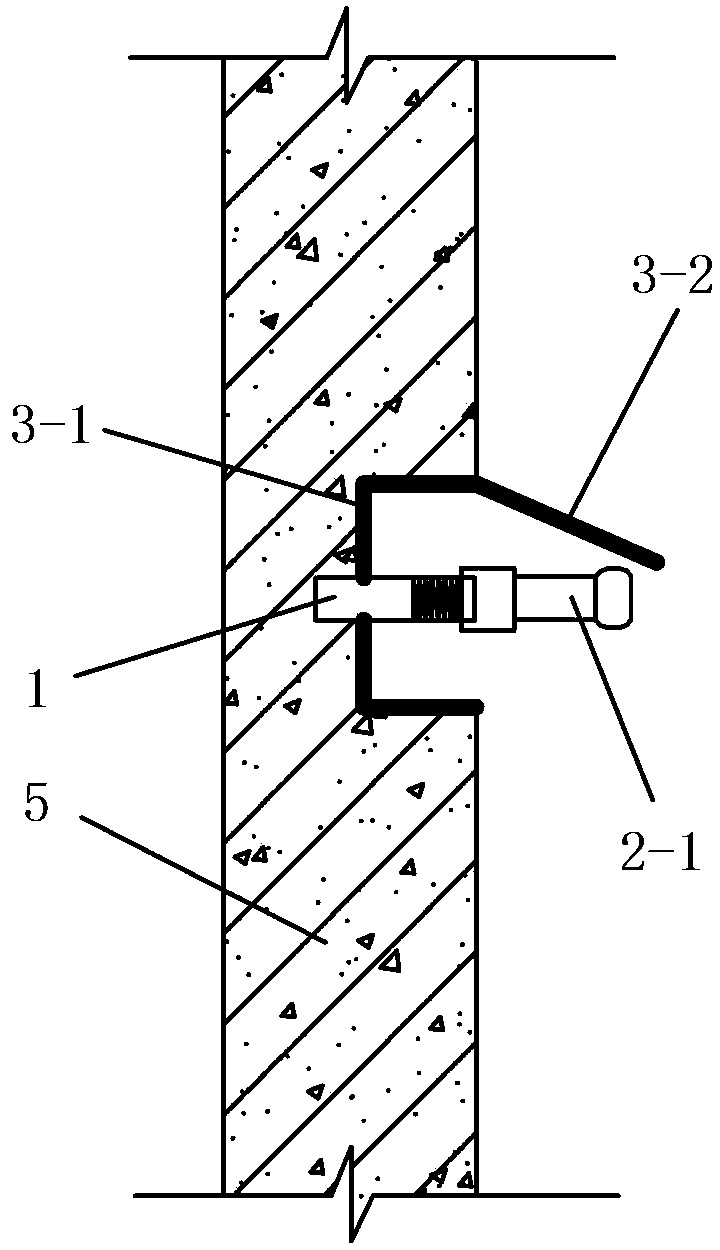

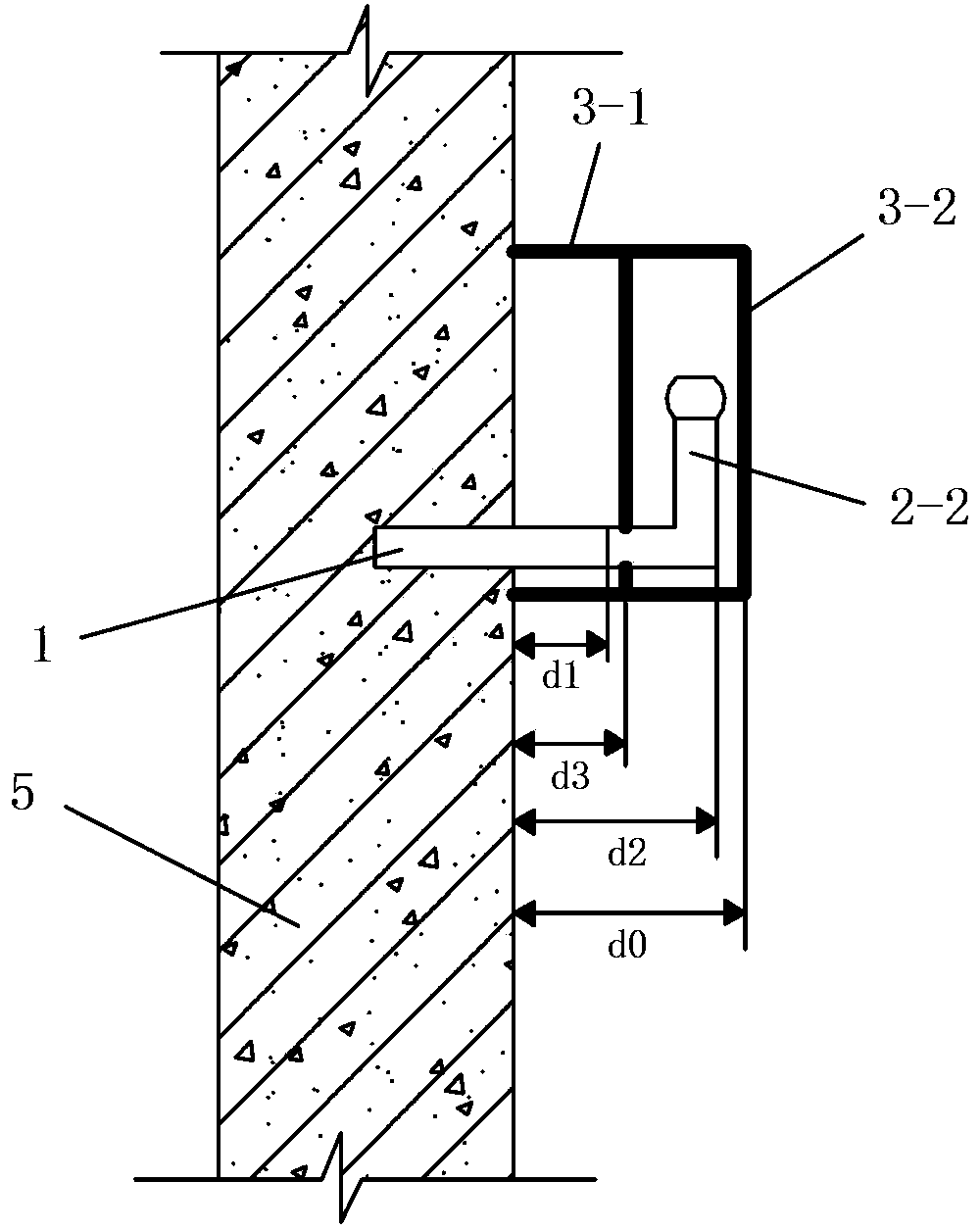

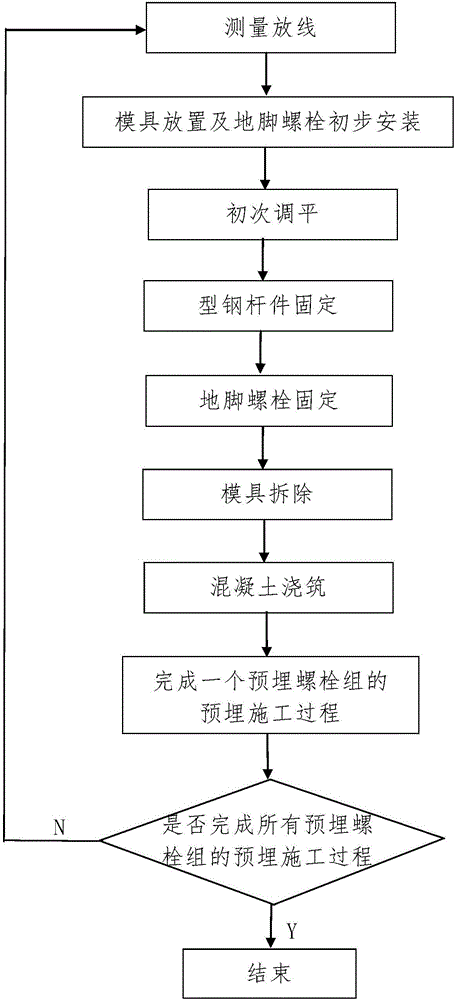

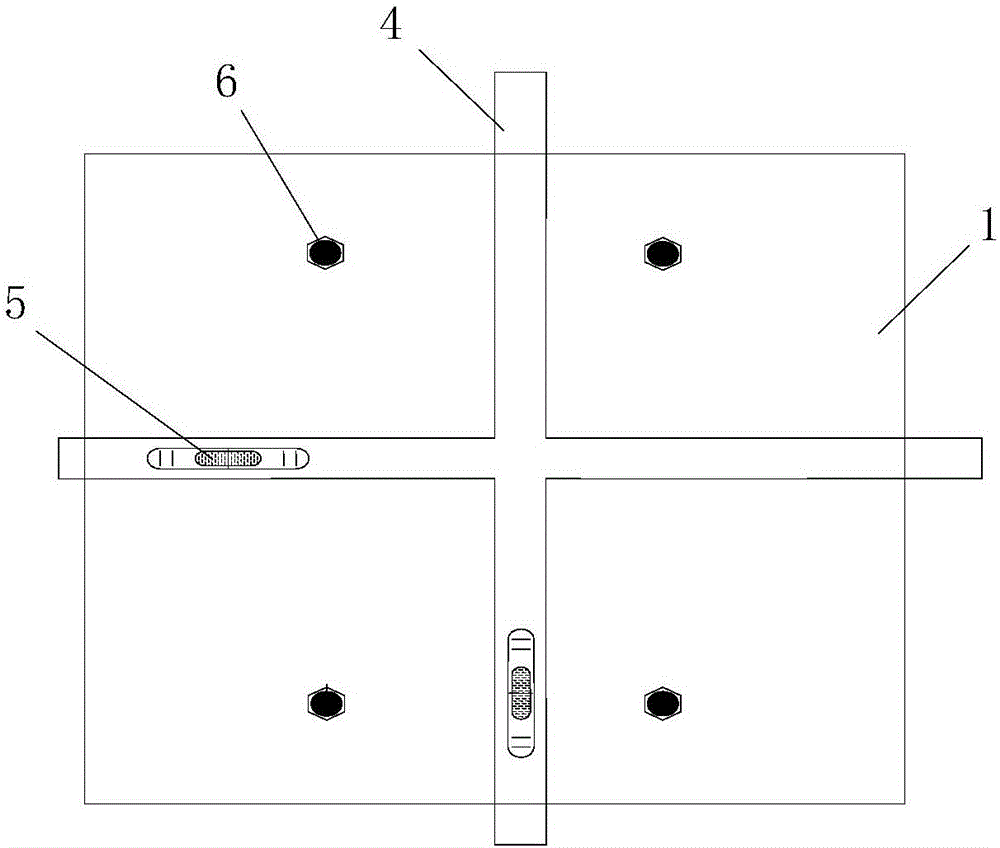

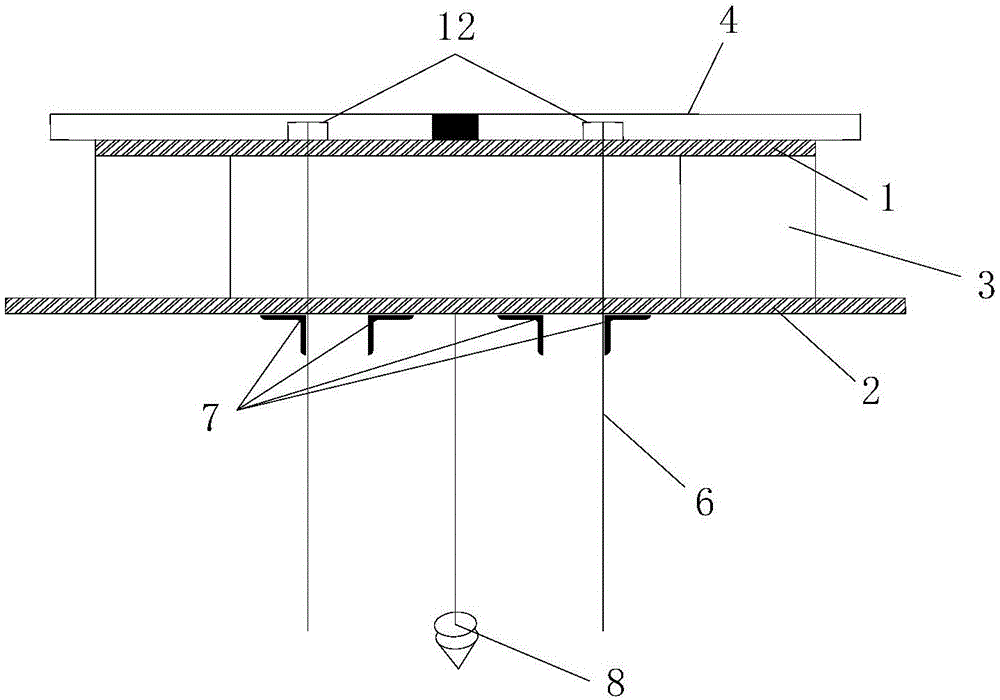

Foundation bolt embedding construction die and foundation bolt adjusting construction method

The invention discloses a foundation bolt embedding construction die and a foundation bolt adjusting construction method. The foundation bolt embedding construction die comprises an upper horizontal plate, a lower horizontal plate and a plurality of supporting pieces supported between the upper horizontal plate and the lower horizontal plate. A horizontal measuring ruler is flatly placed on the upper horizontal plate or the lower horizontal plate. The upper horizontal plate is provided with one upper bolt installing hole set. The lower horizontal plate is provided with a lower bolt installing hole set. The number of bolt installing holes included in each of the upper bolt installing hole set and the lower bolt installing hole set is equal to the number of foundation bolts needing to be constructed. Structural steel rod pieces are fixed to the bottom of the lower horizontal plate. The construction method comprises the first step of surveying and setting out, the second step of die placing and primary foundation bolt installing, the third step of the first-time leveling, the fourth step of structural steel rod piece fixing, the fifth step of foundation bolt fixing and the sixth step of die dismounting. According to the foundation bolt embedding construction die and the foundation bolt adjusting construction method, the design is reasonable, construction is easy and convenient, the using effect is good, the foundation bolts needing to be constructed can be accurately positioned easily, conveniently and rapidly, and the foundation bolt adjusting construction process is easily and conveniently finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

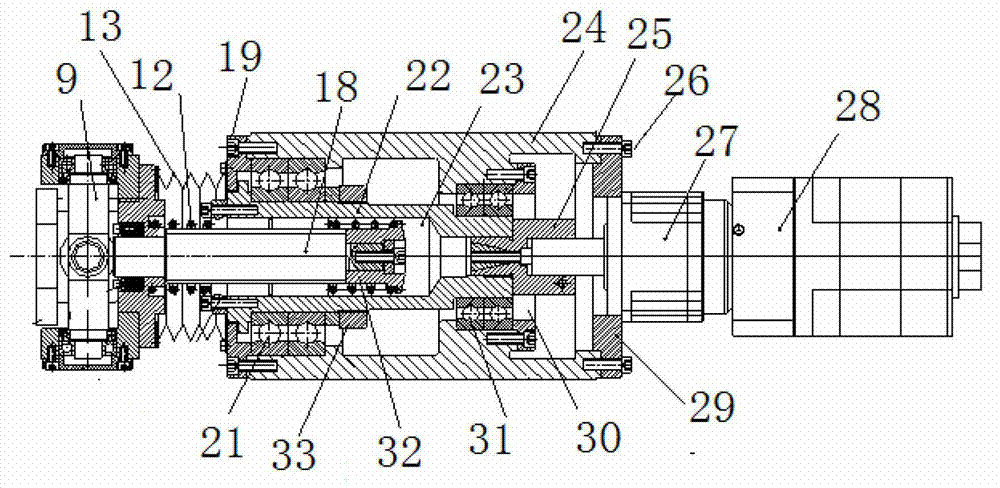

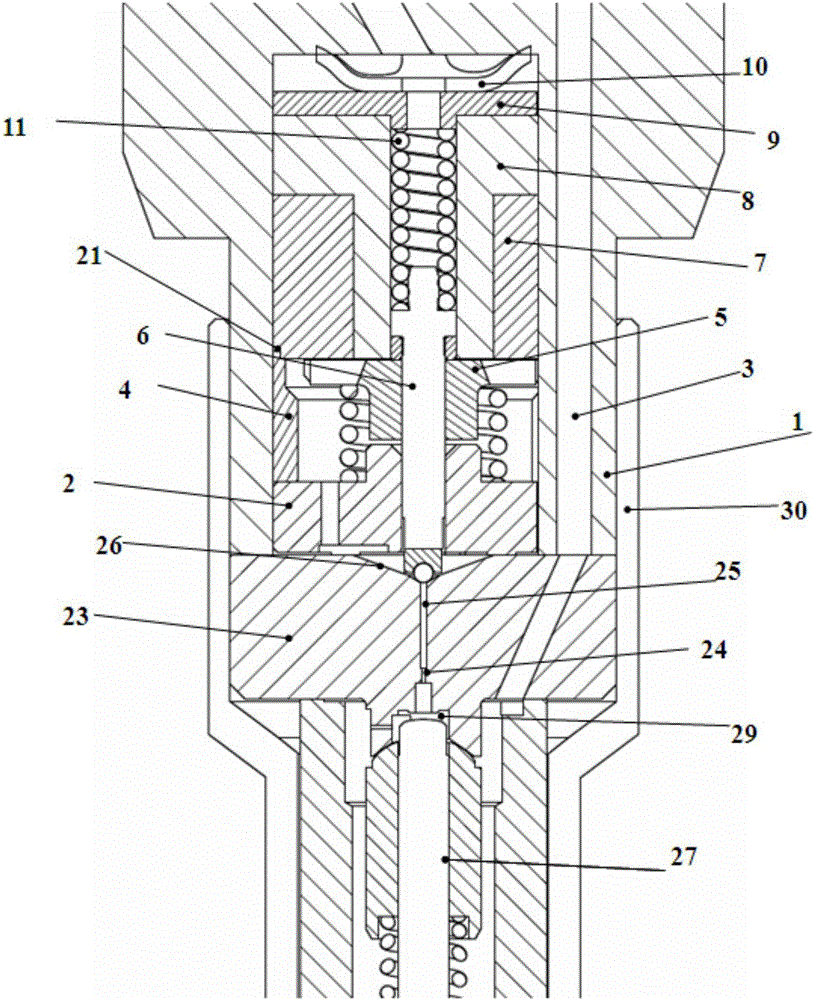

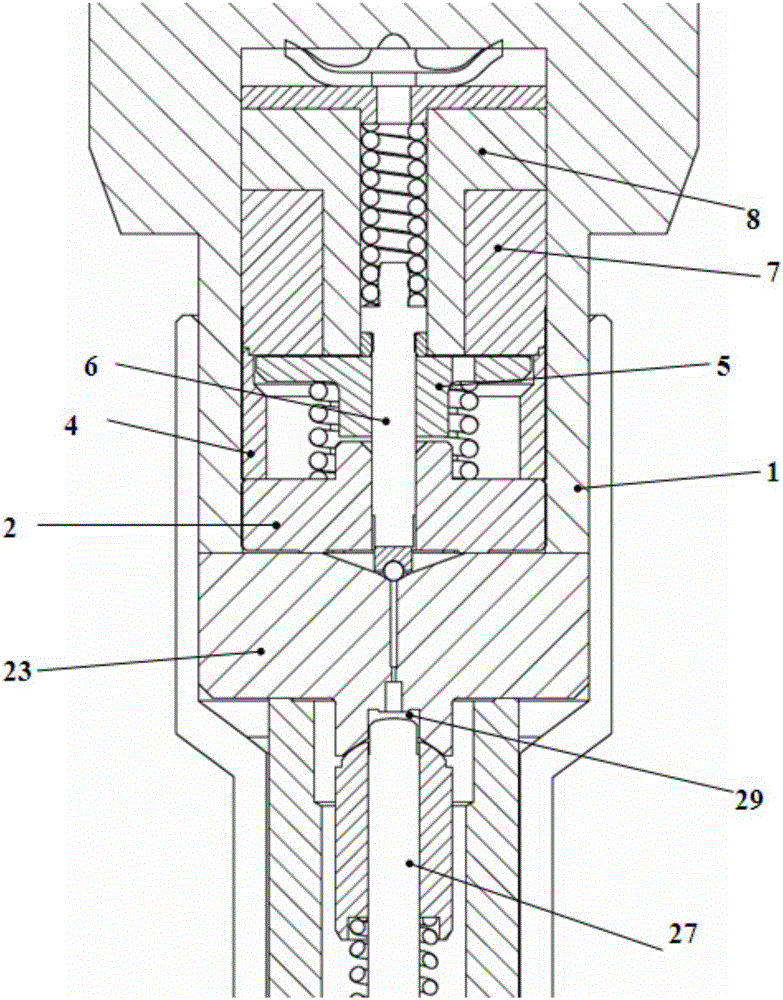

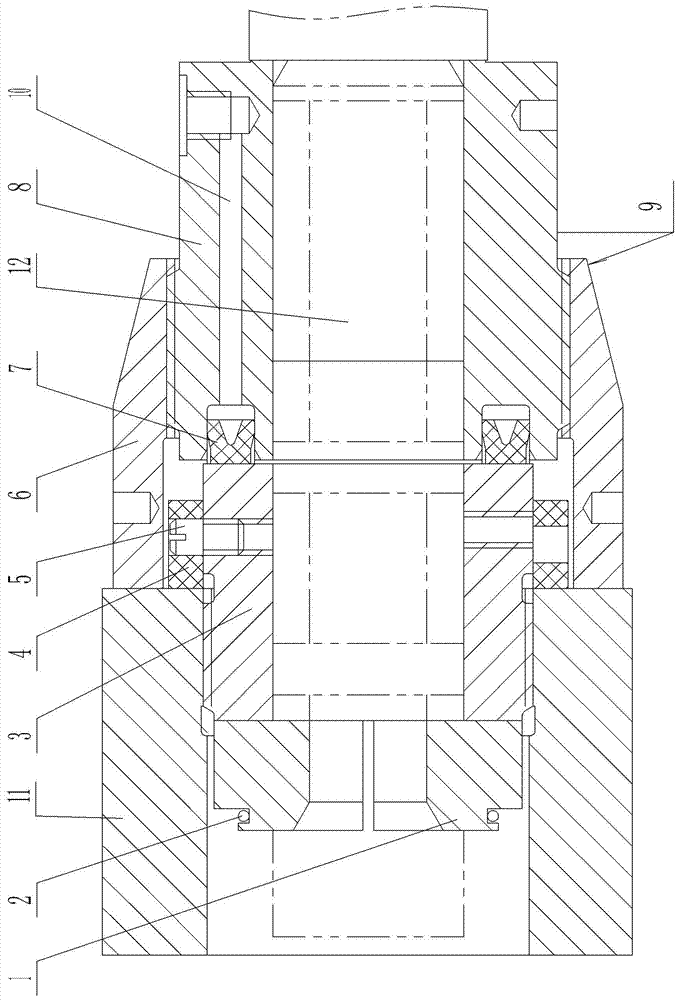

Electromagnetic valve sinking oil sprayer

ActiveCN106050498ALarge installation spaceIncrease electromagnetic forceFuel injection apparatusMachines/enginesInlet channelEngineering

The invention discloses an electromagnetic valve sinking oil sprayer. The electromagnetic valve sinking oil sprayer comprises an oil sprayer body, a control valve seat, an adjusting ring, an armature and an electromagnet assembly. The inside of the oil sprayer body is of a structure of a cylindrical cavity. The control valve seat, the adjusting ring, the armature and the electromagnet assembly are all installed in the cylindrical cavity of the oil sprayer. A radial protruding structure is arranged in the position, adjacent to a high-pressure oil inlet channel, on the inner wall face of the cavity of the oil sprayer body and directly extends from the bottom of the cavity to the top in the axial direction of the oil sprayer body. The control valve seat, the adjusting ring, the armature and the electromagnet assembly are al provided with grooves corresponding to the protruding structure. The armature, an armature rod, a ball valve, a sealing cone face, an oil pump capacity hole and a high-pressure oil channel can be arranged on the same axis, and the axis coincide to the axis of the oil sprayer body. The installation space of an electromagnet is further enlarged in a limited space while the installation requirement of the sinking oil sprayer is met.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

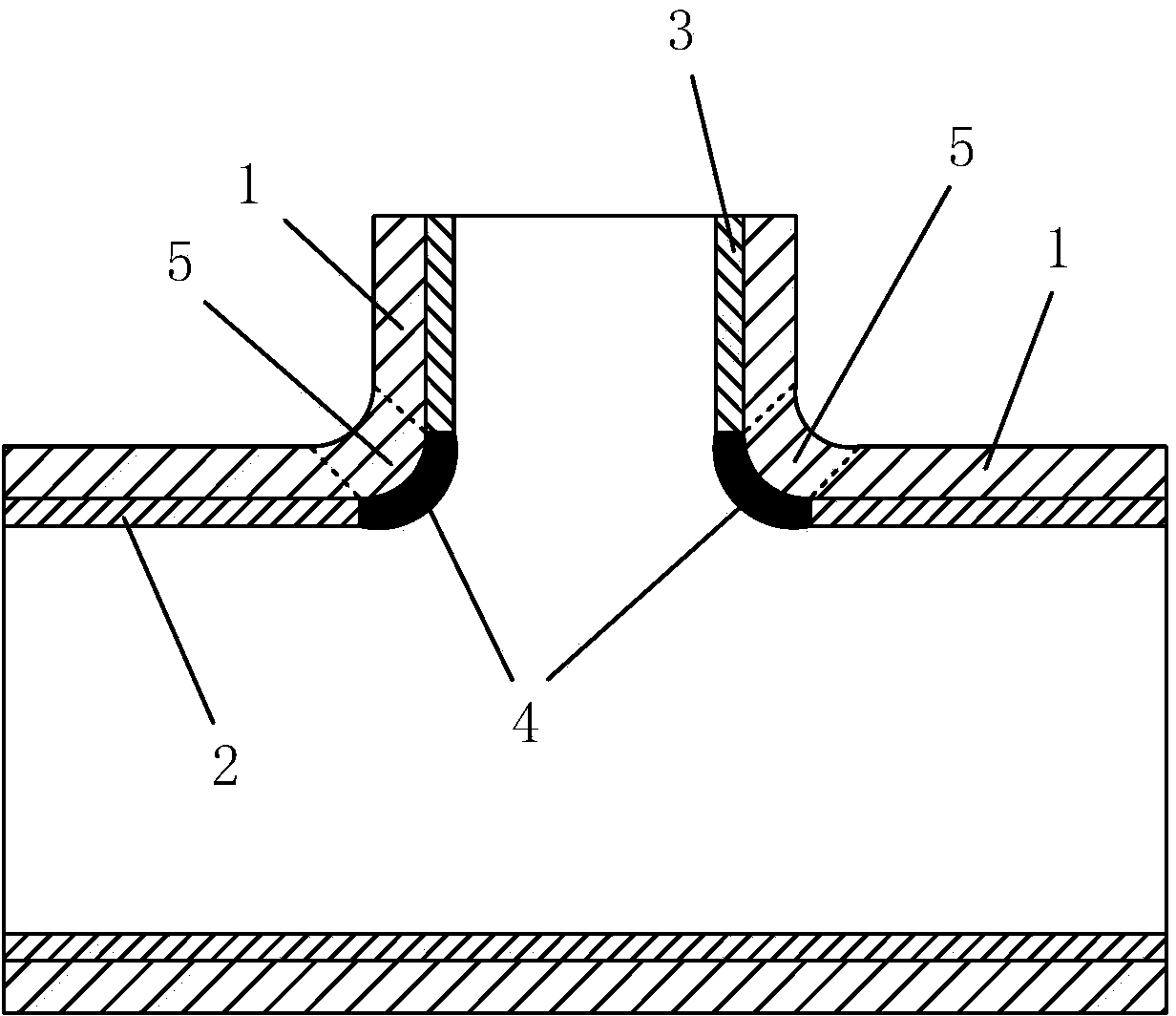

Surfacing corrosion resistant alloy lined composite tee in transition circular arc and manufacturing method thereof

ActiveCN103411072ASimple structureReasonable designCorrosion preventionPipe protection against corrosion/incrustationCorrosion resistant alloyEconomic benefits

The invention discloses a surfacing corrosion resistant alloy lined composite tee in a transition circular arc and a manufacturing method thereof. The surfacing corrosion resistant alloy lined composite tee comprises a tee pipe which is formed by a main pipe and a branch pipe; a first lining pipe is coaxially arranged in the main pipe; a second lining pipe is coaxially arranged in the branch pipe; the side wall of the first lining pipe is provided with a mounting hole; the second lining pipe is placed into the branch pipe from outside to inside; the inner end of the second lining pipe, which is arranged in the mounting hole, is in surfacing connection with the mounting hole; the cross section of a surfacing layer which is formed between the inner end of the second lining pipe and the mounting hole is in a circular arc shape; the first lining pipe, the second lining pipe and the surfacing layer are made of corrosion resistant alloy. The manufacturing method of the surfacing corrosion resistant alloy lined composite tee in the transition circular arc comprises assembly and compositing of the inner lining pipes and surfacing. According to the surfacing corrosion resistant alloy lined composite tee in the transition circular arc and the manufacturing method thereof, the manufacturing process is simple, the achievement is convenient, the machining cost is low, the machine-formed composite tee is high in bearing capability and excellent in corrosion resistance, can be effectively connected with a double-metal composite pipe and can be popularized and applied on a large scale, and the economic benefit is remarkable.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD +1

Method for processing sector gear

InactiveCN1943972AProcessing quality is easy to guaranteeGear-cutting machinesGear teethGear grindingHobbing

The sector gear machining process includes the following steps: 1. machining of sector gear blank while sufficient trimming allowances of inner hole and outer circle; 2. making chucking plate based on the sizes of the sector gear; 3. machining the sector gear blank together with the chucking plate via turning; 4. hobbing after mounting hobbing mandrel; and 5. grinding after mounting gear grinding mandrel. The machining process is simple, low in cost, small in deformation and high in efficiency.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

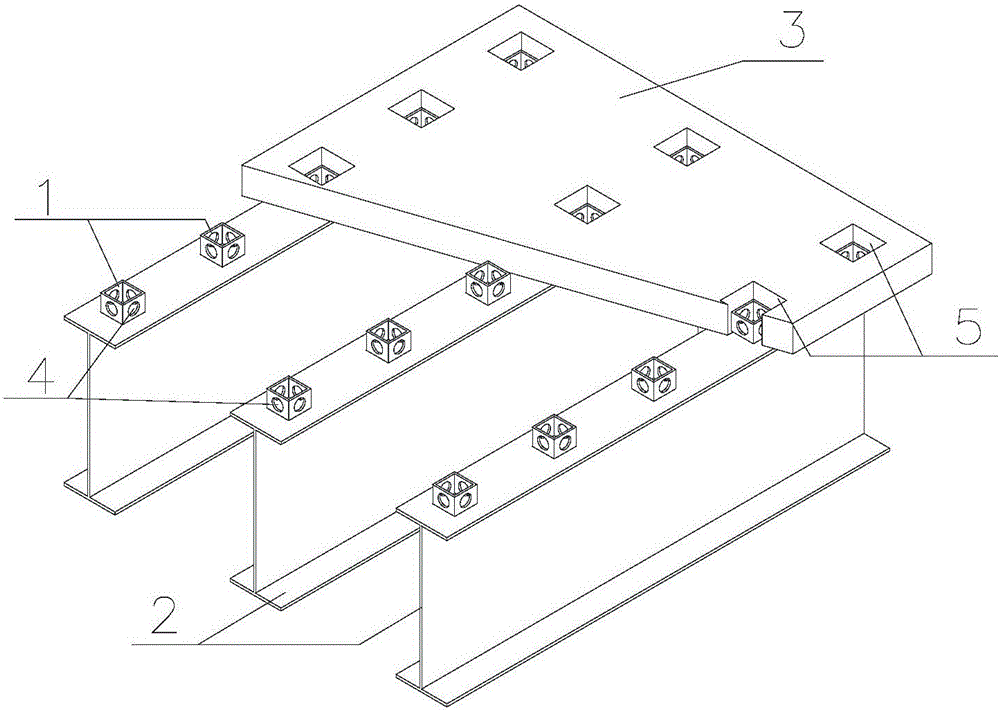

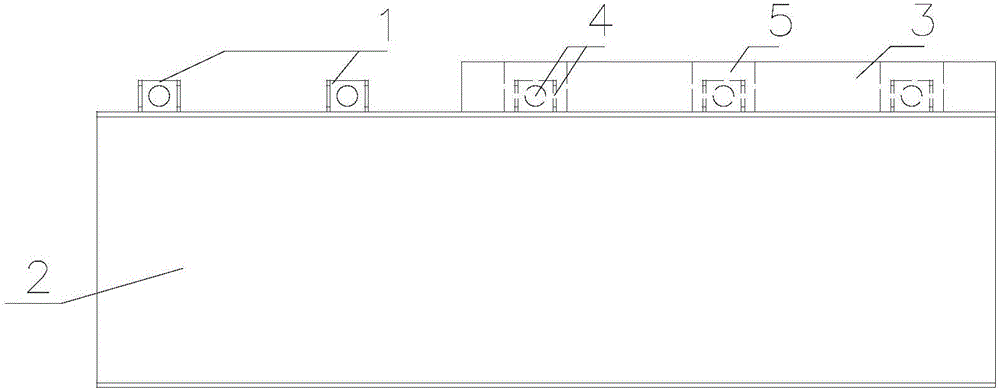

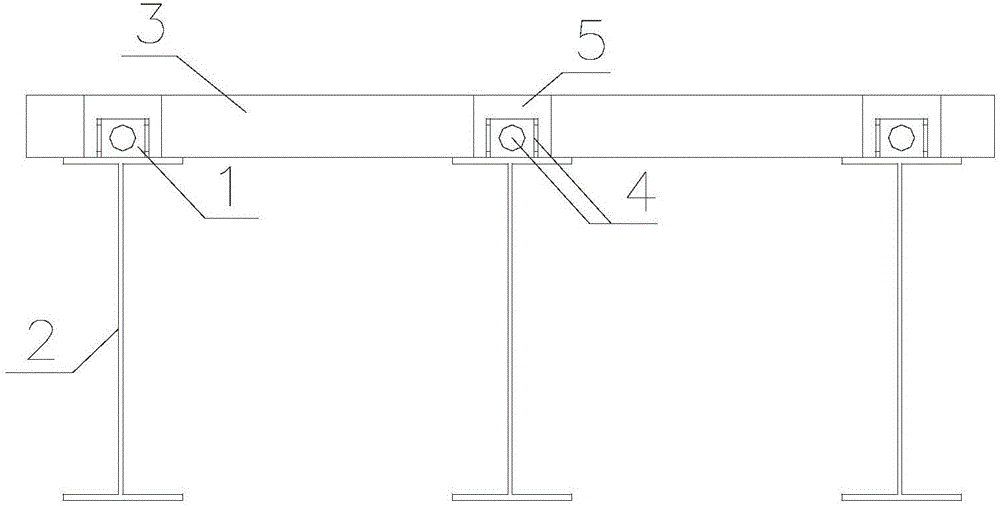

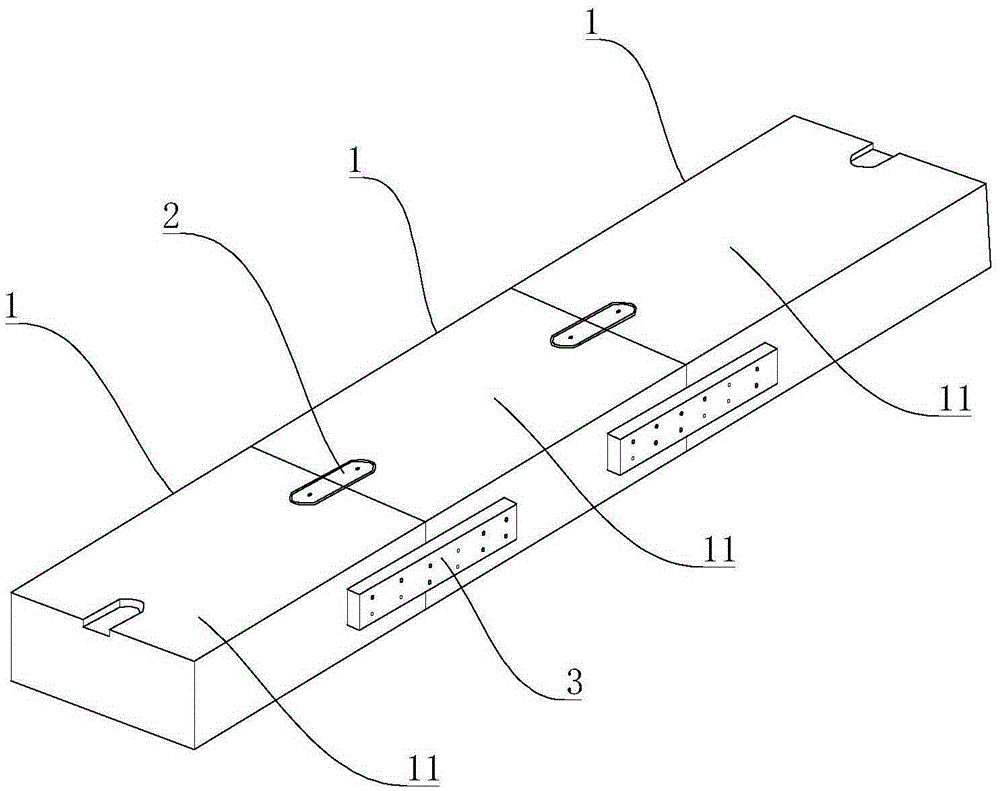

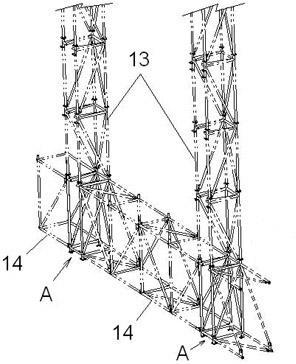

Rapid machining platform and method for grid steel frames

PendingCN110744219ASimple structureReasonable designUnderground chambersWelding/cutting auxillary devicesSteel frameRapid tooling

The invention discloses a rapid machining platform and method for grid steel frames. The machining platform comprises a horizontal support platform and a plurality of main reinforcement positioning moulds, wherein the plurality of main reinforcement positioning moulds are laid in the circumferential direction and all mounted on the horizontal support platform; the plurality of main reinforcement positioning moulds form a main reinforcement positioning device for positioning four main reinforcements in a to-be-machined steel frame segment; and each main reinforcement positioning mould comprisesa sliding seat, a connection seat and a main reinforcement positioning mechanism. The method comprises the steps of 1, adjusting the main reinforcement positioning mechanisms; 2, adjusting the positions of the main reinforcement positioning moulds; 3, mounting the main reinforcements; 4, fixing dowels of the main reinforcements; and 5, fixing rectangular stirrups. The machining platform and method are reasonable in design, simple and convenient in strengthening and good in using effect; and the plurality of movable main reinforcement positioning moulds are adopted to position the steel framesegments and the main reinforcement positioning mechanism on each main reinforcement positioning mould can be adjusted according to the widths and thicknesses of the machined steel frame segments, sothat the machining demands of the steel frame segments with different specifications can be satisfied.

Owner:CHINA RAILWAY 20 BUREAU GRP

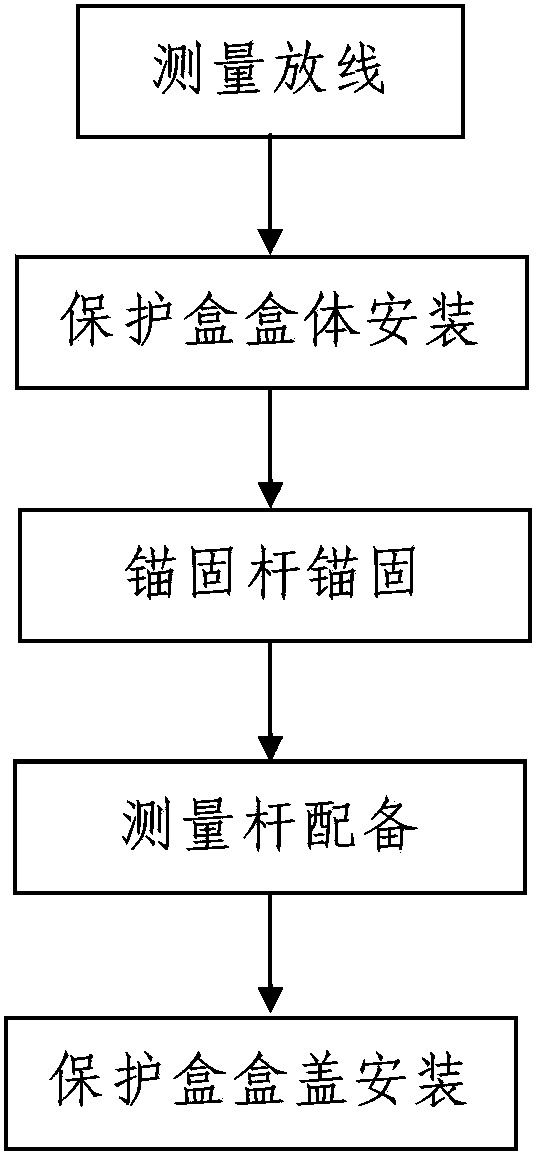

Construction method for settlement observation points of building

InactiveCN103363955AThe method steps are simpleEasy to implementHeight/levelling measurementObservation pointEngineering

The invention discloses a construction method for settlement observation points of a building. A plurality of settlement observation points are arranged on a constructed building. A settlement observation device is arranged at the bottom of the constructed building. The settlement observation device comprises settlement observation point protection boxes, anchoring rods and measuring rods. The numbers of the anchoring rods and the settlement observation point protection boxes are the same. The measuring rods are coaxially arranged at the outer ends of the anchoring rods. One anchoring rod and one measuring rod coaxially arranged at the outer end thereof form a detachable settlement observation mechanism. The settlement observation point protection box comprises a box body and a box cover. The construction method comprises steps: first, measurement and setting out; second, installation of the box bodies of the protection boxes; third, anchoring of the anchoring rods; fourth, equipping of the measuring rods; and fifth, installation of the box covers of the protection boxes. The method is advantaged by simple steps, reasonable design, convenient implementation, fast construction progress and easy control of construction quality. The constructed settlement observation points are not easy to destroy, and has good service effects and a long service life.

Owner:陕西建工集团有限公司 +1

Embedment construction method for foundation bolts used for steel structure building construction

ActiveCN106193330AThe method steps are simpleReasonable designBuilding constructionsReinforced concreteEmbedment

The invention discloses an embedment construction method for foundation bolts used for steel structure building construction. A steel structure skeleton of a constructed steel structure building comprises multiple steel stand columns, each steel stand column is supported on a reinforced concrete foundation, a steel backing plate is fixedly welded to the bottom of each steel stand column, and an embedded bolt set is installed on the steel backing plate; the process of embedded construction of each embedded bolt set includes the steps of 1 surveying and setting-out; 2, mold placing and primary foundation bolt installation; 3, primary leveling; 4, profile steel rod fixing; 5, foundation bolt fixing; 6, mold disassembling; 7, concrete pouring; 8, repeating the steps from 1 to 7 until the embedded construction process of all the embedded bolt set is completed. The embedment construction method is simple in step, reasonable in design and good in use effect, construction is convenient, the embedment construction process of the foundation bolts used for steel structure building construction can be conveniently and fast completed, and embedment accuracy of the foundation bolts can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Manufacturing method for forging die

ActiveCN105364434AShorten the processing cycleSmall sizeForging/hammering/pressing machinesStress distributionEngineering

The invention relates to a manufacturing method for a forging die. The method comprises the steps that a whole die is designed, and the load and stress distributing situations of the die in working condition are calculated; according to obtained mechanical data, appropriate joint line positions are selected, so that the same die cavities in the whole die are formed by jointing all sub-dies; connecting pieces are designed according to the mechanical data, and it is required that the requirement for the design strength can be met by jointing the sub-dies into the whole die through the connecting pieces; all real objects are manufactured and are subjected to rough machining and heat treatment, and finish machining is conducted on planes for positioning and key grooves; positioning keys are installed in the positioning planes and used as a positioning datum, and then jointing and installing are conducted on other positions; and the jointed whole die is obtained, and the die cavities are machined. As the sizes of the sub-dies are small, the machining quality of the sub-dies can be guaranteed more easily, and the manufacturing cost is also reduced significantly; in addition, the multiple sub-dies can be manufactured at the same time, so that the machining period of the die is shortened correspondingly.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

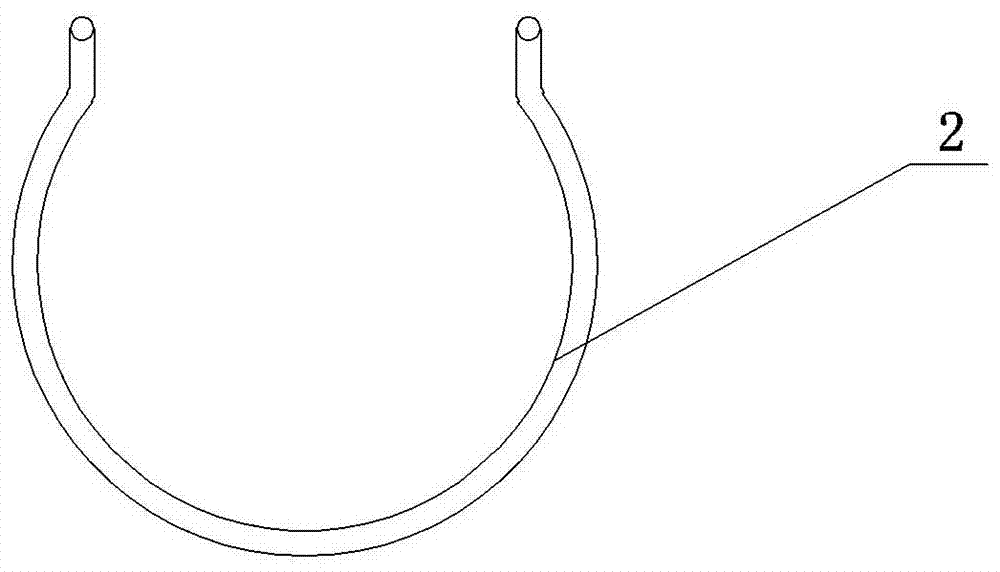

The hydraulic connection structure connecting the crosshead body and the piston rod

InactiveCN105971853BEasy to installEasy to disassemblePositive displacement pump componentsCrossheadsPiston rodCrosshead

The invention provides a hydraulic connection structure for connecting a crosshead body with a piston rod and belongs to the technical field of connection structures of crosshead bodies and piston rods. The hydraulic connection structure for connecting the crosshead body with the piston rod is simple in structure, good in connection effect and high in safety coefficient. The hydraulic connection structure comprises the crosshead body and the piston rod, one end of the piston rod is arranged in the crosshead body, the rear end of the end head, arranged in the crosshead body, of the piston rod is provided with a thrust ring, the outer periphery, at the rear end of the thrust ring, of the piston rod is provided with a screwing-in ring, the front of an outer ring of the screwing-in ring is in threaded connection with the inner wall of the crosshead body, the rear portion of the screwing-in ring is arranged outside the crosshead body, the outer periphery, at the rear end of the screwing-in ring, of the piston rod is provided with a pressure body, the outer wall of the front of the pressure body is in threaded connection with the rear portion of a tightening nut, and front end of the tightening nut is connected with the end face of the crosshead body.

Owner:沈阳佳信压缩机制造有限公司

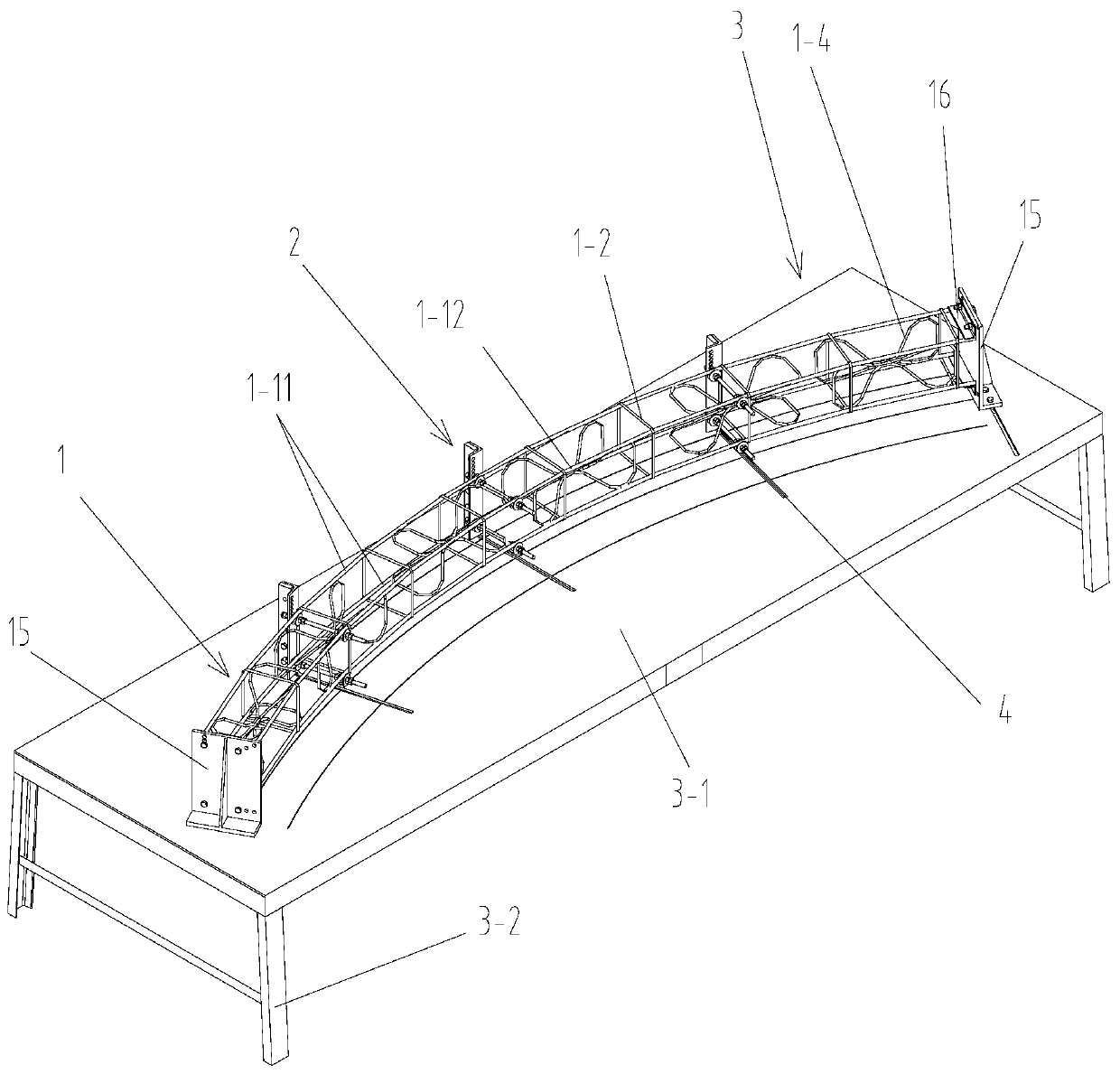

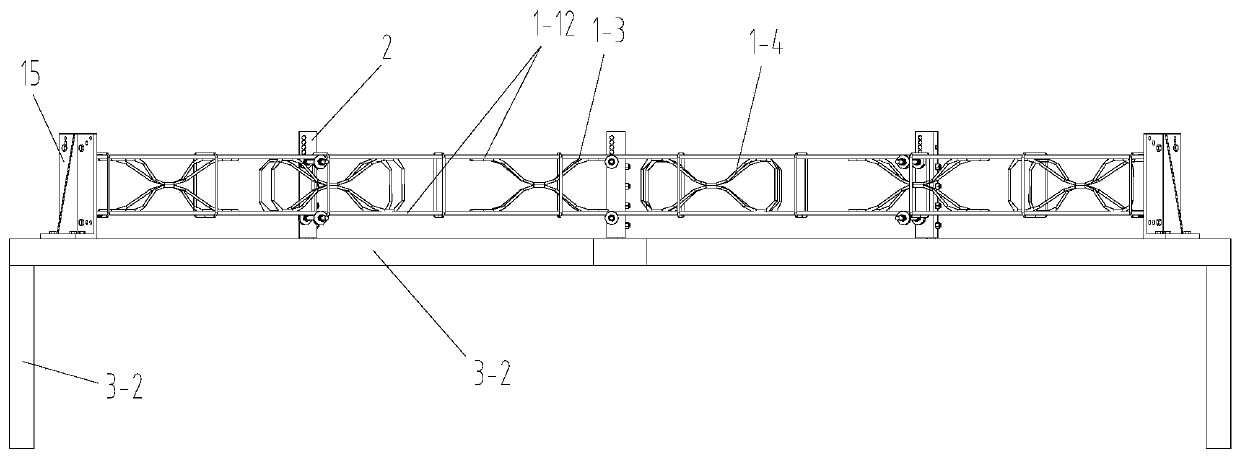

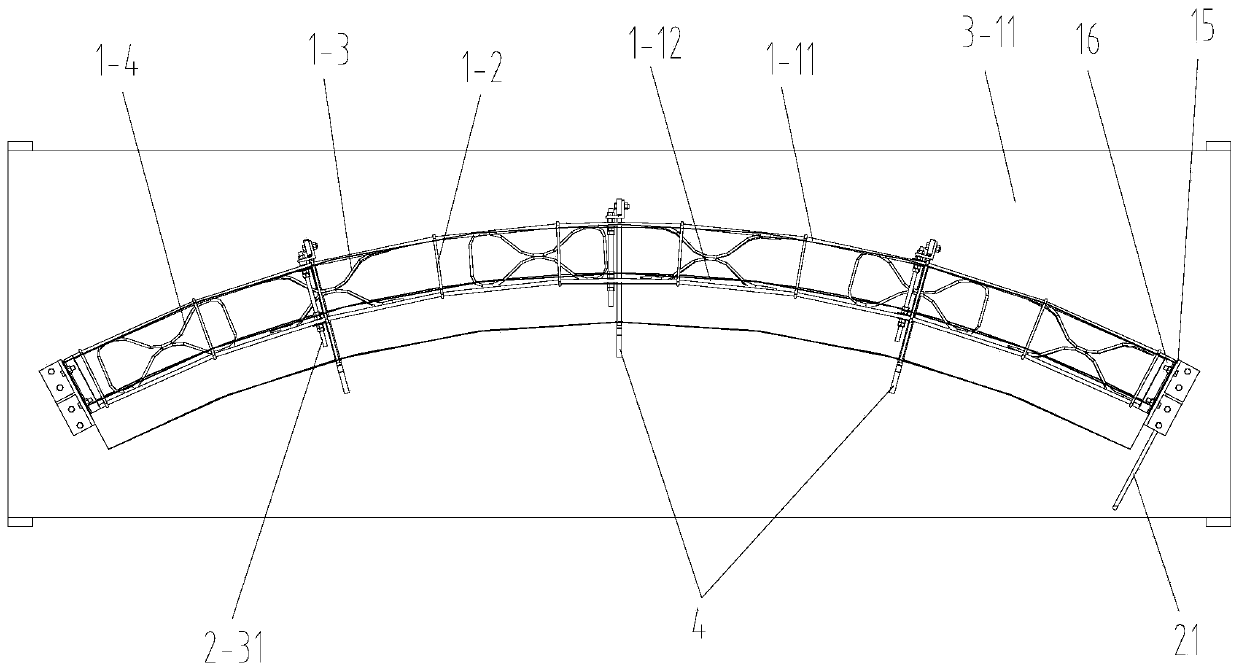

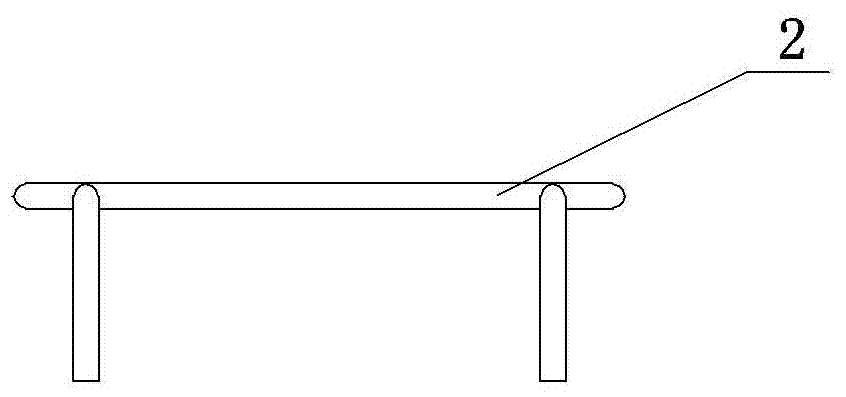

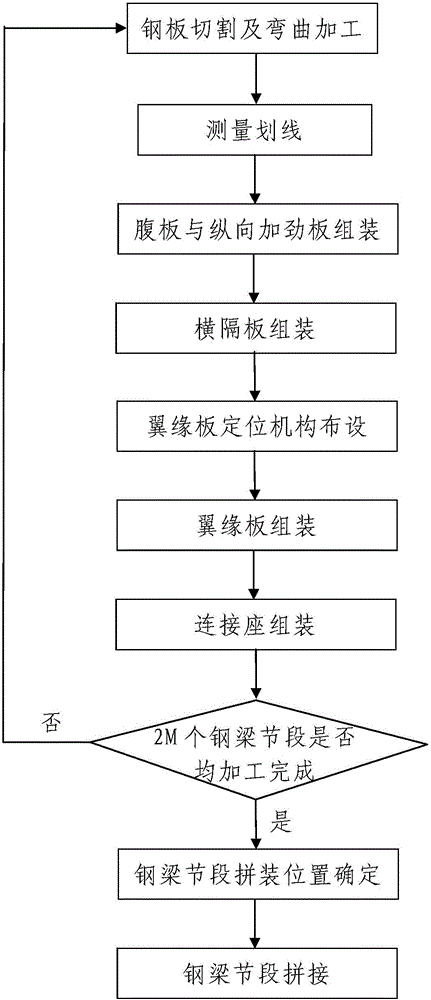

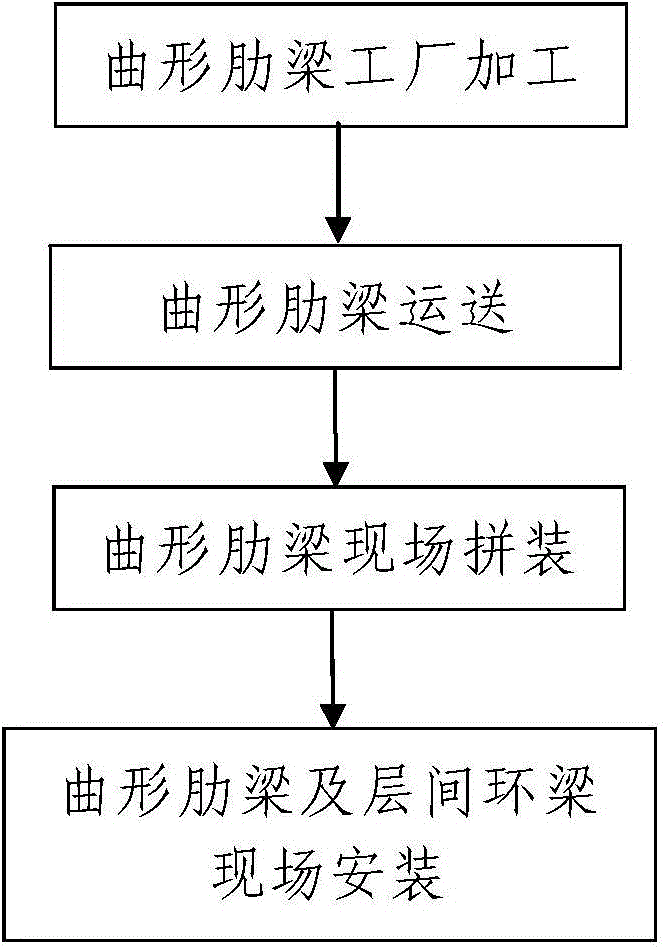

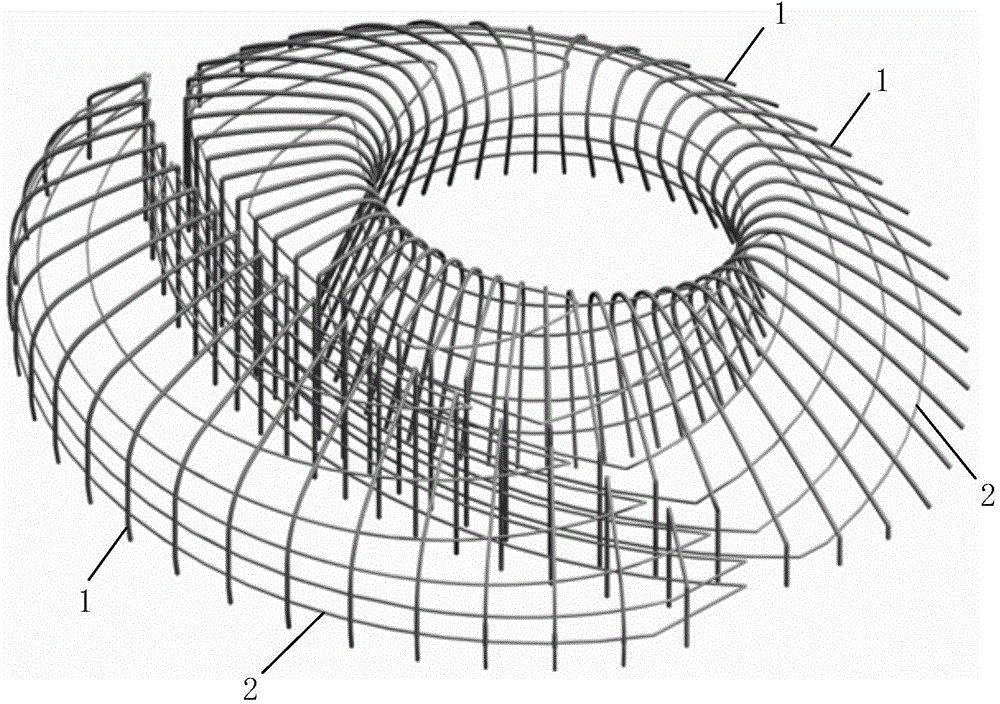

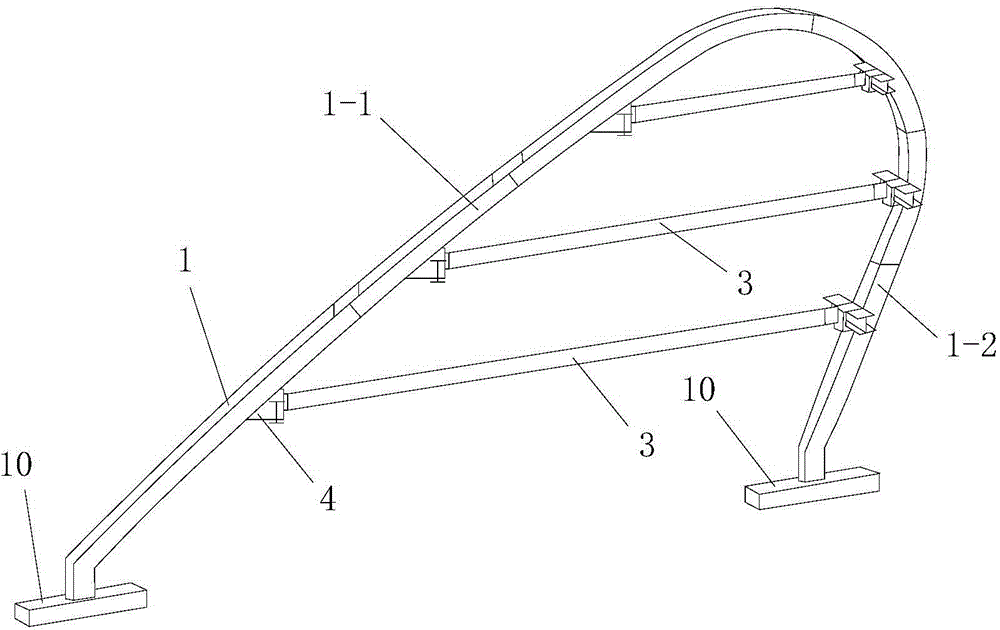

Curved ribbed beam processing and assembling construction process

ActiveCN104989107AThe process steps are simpleReasonable designBuilding roofsBuilding material handlingSteel platesFlange

The invention discloses a curved ribbed beam processing and assembling construction process. A processed curved ribbed beam is a curved steel beam, the cross-section of the curved steel beam is in the shape of a Chinese character ri, an outer side beam body and an inner side beam body of the curved ribbed beam are connected with each other through straining beams, and each of the outer side beam body and the inner side beam body is spliced by a number M of steel beam sections, each steel beam section comprises a top flange plate, a bottom flange plate, two webs and a vertical stiffening plate, and each steel beam section is provided with a connecting base. The curved ribbed beam processing and assembling construction process comprises steps of (1) processing the steel beam sections in a factory, cutting steel plates, carrying out bending processing to the steel plates, carrying out measuring and scribing processes, assembling the webs and the vertical stiffening plate, assembling diaphragm plates, laying flange plate positioning mechanisms, assembling the flange plates and assembling the connecting bases; and (2) assembling the curved ribbed beam, determining the splicing positions of the steel beam sections, and splicing the steel beam sections. The curved ribbed beam processing and assembling construction process has simple steps, and is reasonable in design, convenient to implement and good in usage effect, and the processing and assembling construction process of the curved ribbed beam steel structure can be completed simply and quickly in high quality.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

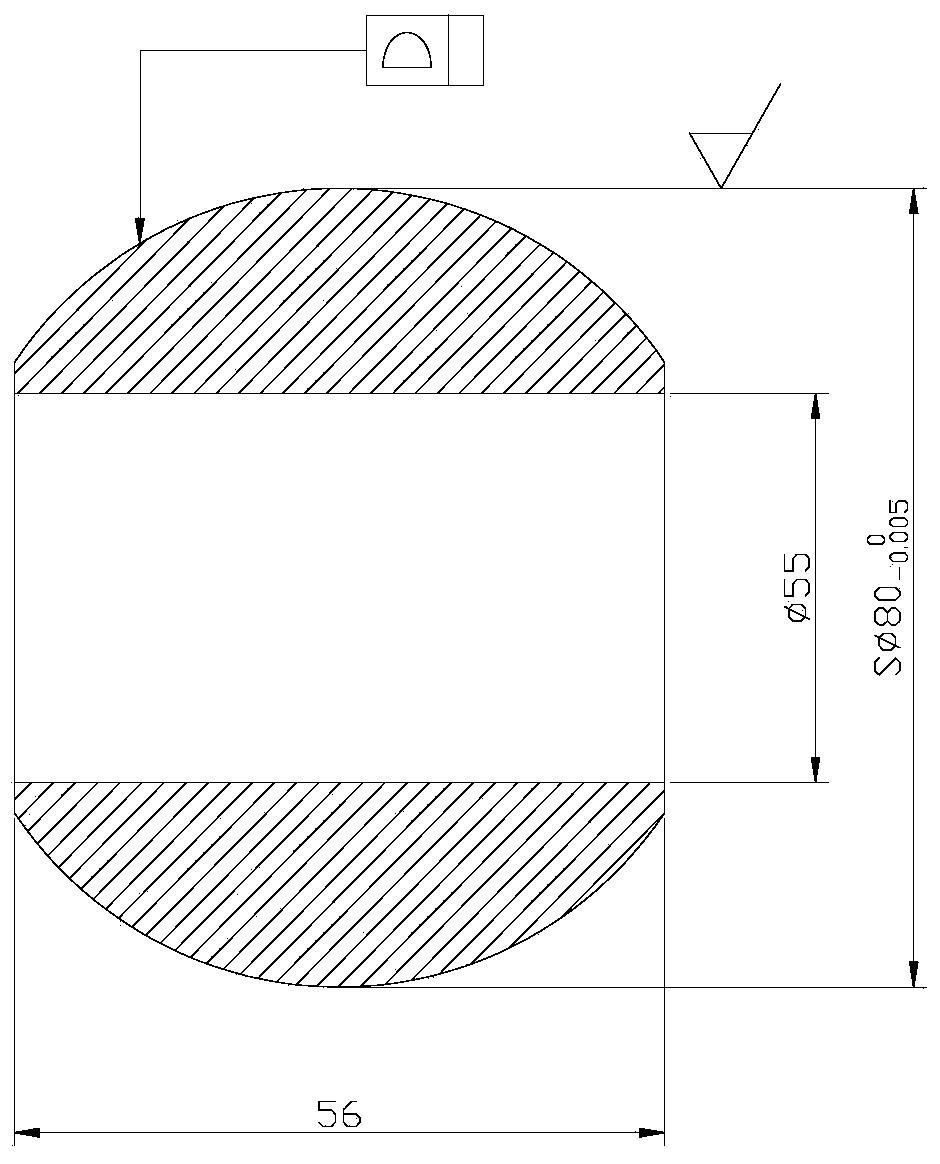

Grinding method for machining high-precision outer spherical surface through ordinary cylindrical grinding machine

ActiveCN103659519AGuaranteed process requirementsLess investmentSpherical surface grinding machinesAbrasive surface conditioning devicesEngineeringCylindrical grinding

The invention provides a grinding method for machining a high-precision outer spherical surface through an ordinary cylindrical grinding machine. The grinding method comprises the steps that firstly, a grinding wheel is selected, wherein the width of the grinding wheel is 14-16mm larger than that of a finished spherical part, the diameter of the grinding wheel is large enough so that a spherical surface of a part can be formed through grinding, and namely the distance between the outer side of the grinding wheel and an installation hole must be larger than the depth of the spherical surface; secondly, a special dressing clamp for grinding wheel dressing is manufactured, wherein a grinding machine end face grinding wheel dressing device is installed on the grinding machine, and the special dressing clamp is made to be well fixedly connected with the grinding machine end face grinding wheel dressing device; the grinding wheel is dressed until the size requirement is met by the grinding wheel; a part to be machined is fixed to the grinding machine and the dressed grinding wheel are aligned; grinding is conducted until the finished spherical part is obtained. By the adoption of the grinding method for machining the high-precision outer spherical surface through the ordinary cylindrical grinding machine, under the condition that the equipment investment is not increased, the existing ordinary cylindrical grinding machine is used for machining the outer spherical surface which has high size precision and good surface quality, and high practical value is obtained.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

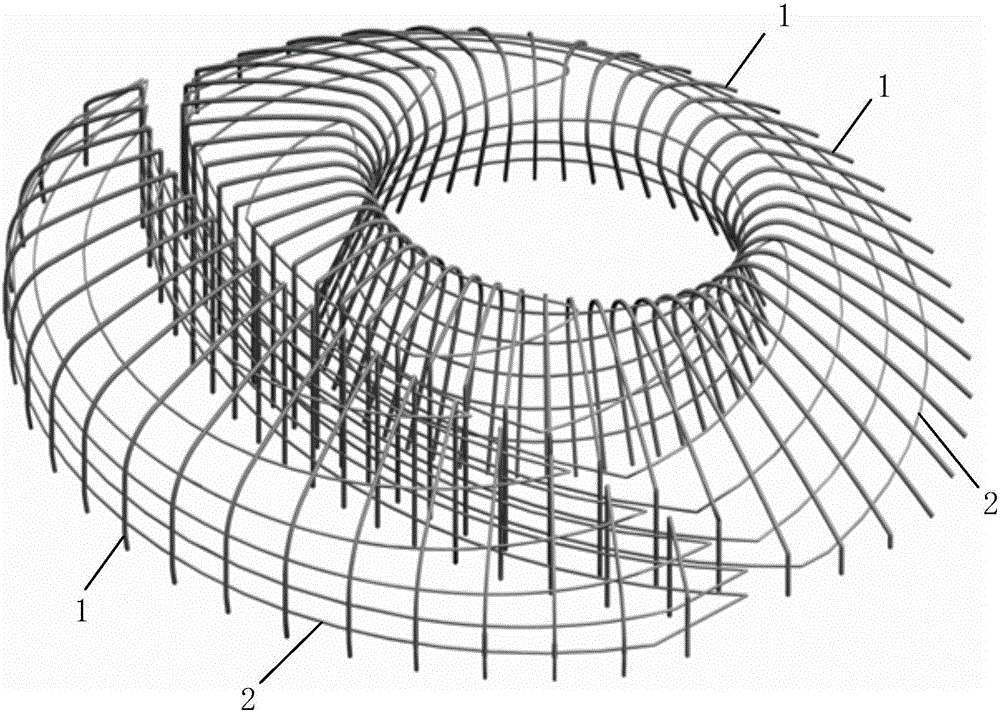

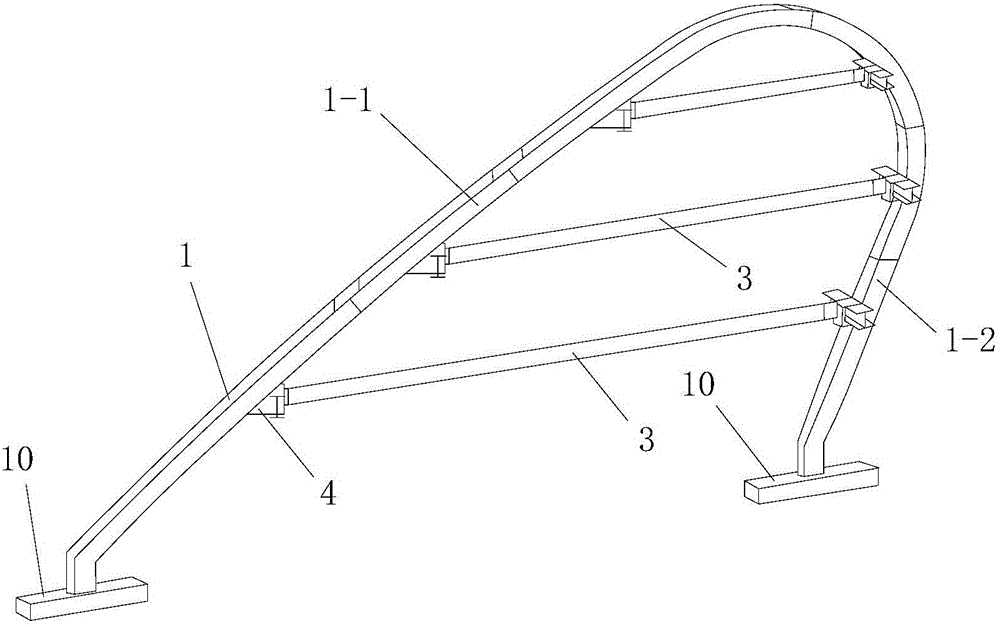

Construction method for space curved rib girder steel structure

ActiveCN104818849AThe method steps are simpleReasonable designBuilding material handlingFlangeBox girder

The invention discloses a construction method for a space curved rib girder steel structure. The constructed space curved rib girder steel structure comprises several curved rib girders distributed on a horizontal foundation from front to back; the cross section of the curved rib girders is H-shaped and its outer girder body and inner girder body are formed by splicing M steel girder sections; several curved rib girders are integrally connected by interlayer ring beams; the steel girder section comprises an upper flange plate, a lower flange plate, two webs and a longitudinal stiffening plate; and each steel girder section is provided with a connecting base. The construction process of the space curved rib girder steel structure comprises the steps: firstly, curved rib girder factory processing, processing each steel girder section of the curved rib girder; secondly, curved rib girder conveying; thirdly, curved rib girder field splicing; and fourthly, curved rib girder and interlayer ring beam field installation. The process is simple, the design is rational, the construction is convenient, and the using effect is good. The construction process of the space curved rib girder steel structure can be simply and conveniently completed, the construction process is safe and the construction period is short.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

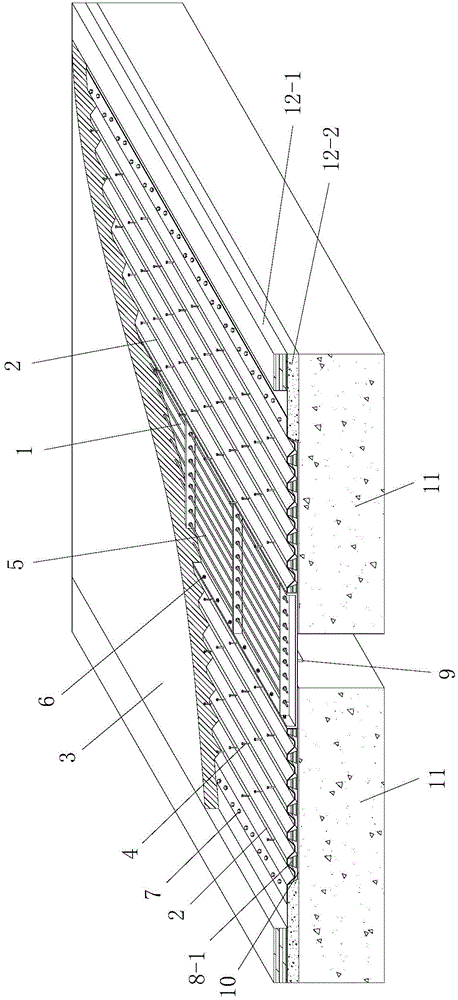

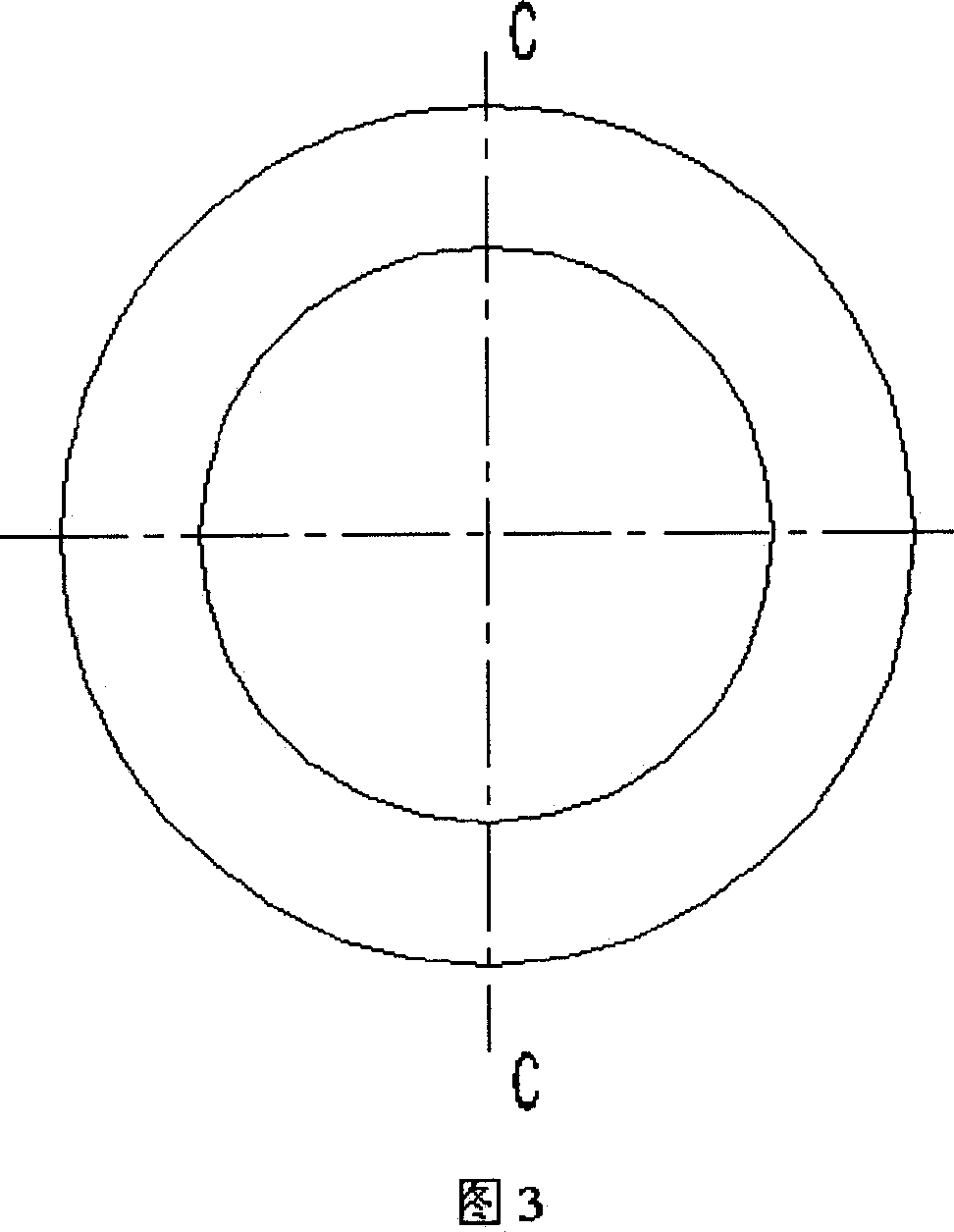

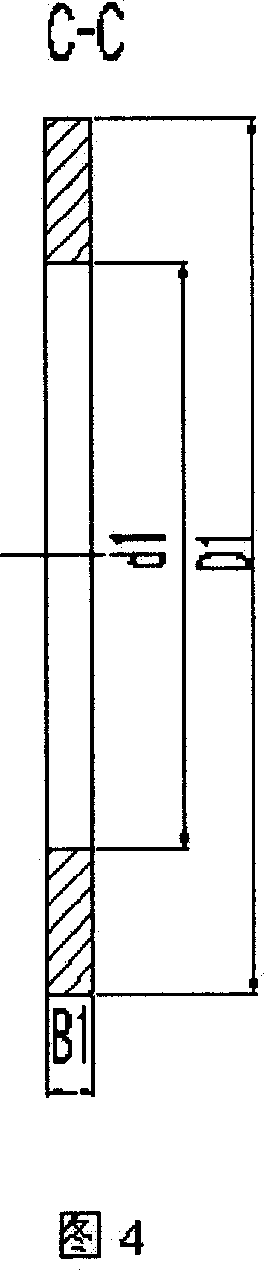

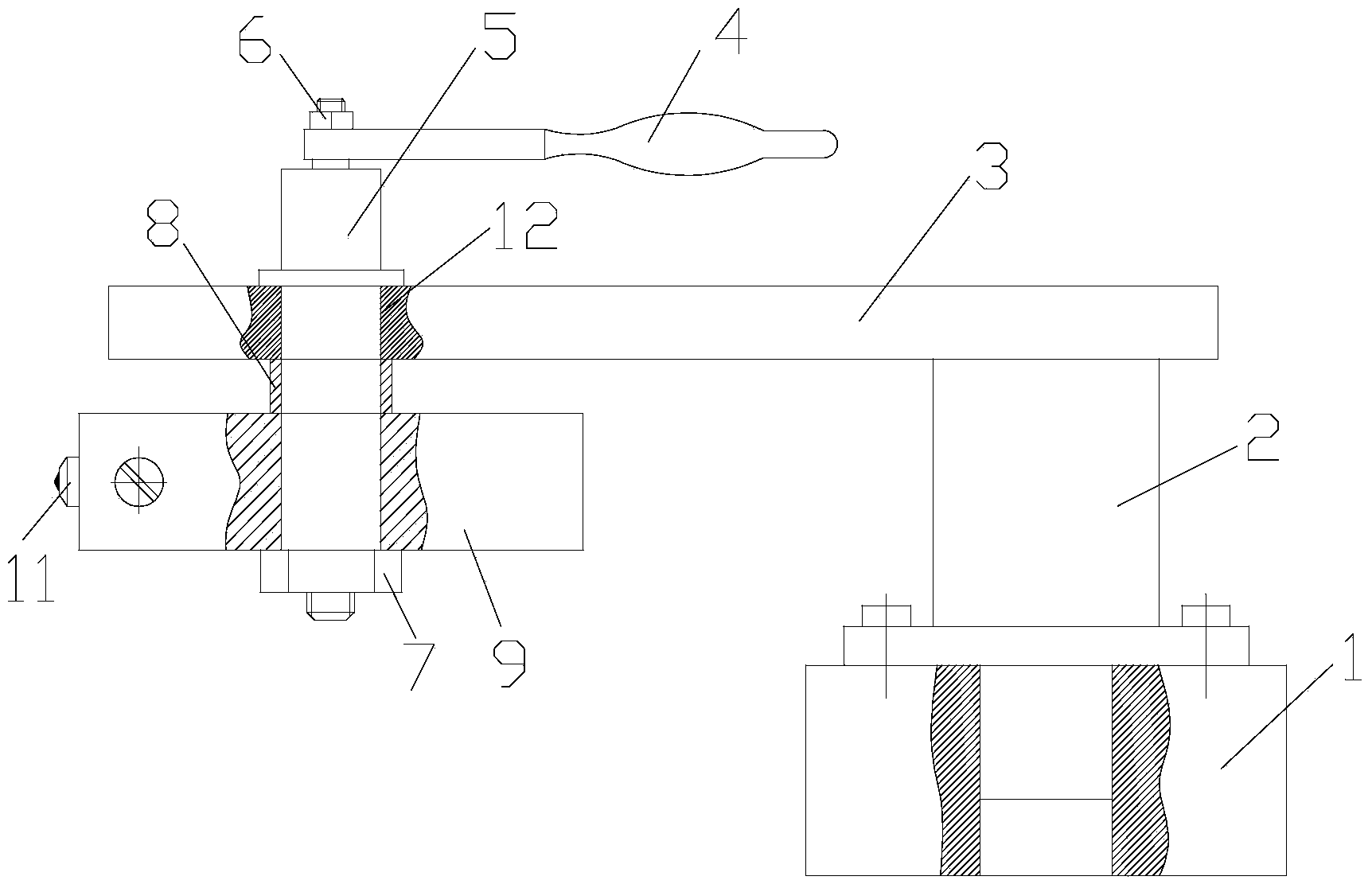

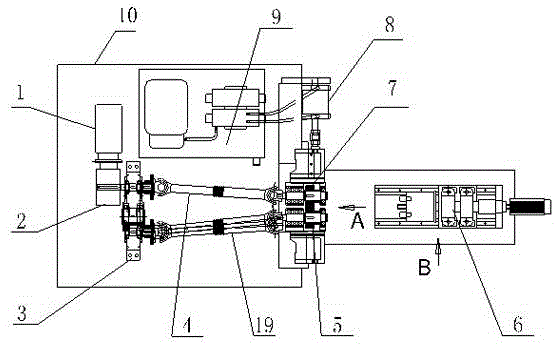

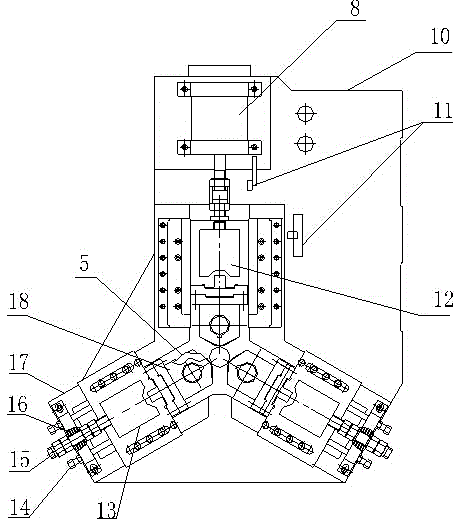

Automatic forming machine for fully-grouted sleeve

ActiveCN104858279AProcessing quality is easy to guaranteeIncrease productivityEngineeringHydraulic cylinder

An automatic forming machine for a fully-grouted sleeve comprises a machine frame, a motor, a speed reducer, a rolling mechanism and a feeding mechanism. The motor, the speed reducer, the rolling mechanism and the feeding mechanism are arranged on the machine frame. The rolling mechanism comprises a main rolling wheel and two auxiliary rolling wheels, the output end of the motor is connected with the input end of the speed reducer, the output end of the speed reducer is connected with the main rolling wheel through a universal transmission shaft I, the two auxiliary rolling wheels and the main rolling wheel are arranged triangularly and rotate synchronously in the same direction, and the main rolling wheel can get close to or away from the two auxiliary rolling wheels under driving of a hydraulic cylinder. The motor, the hydraulic cylinder and the feeding mechanism work under control of a control device. Production efficiency is high, the defective rate is low, and the application range is wide.

Owner:THE LUOYANG MACHINERY OF CSCEC NO 2 +1

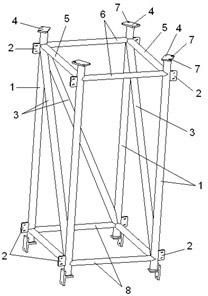

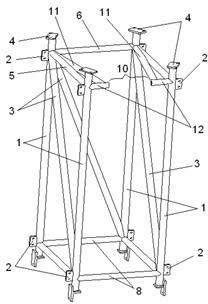

Improved bidirectionally stressed foundation knot attached to lifting scaffold

ActiveCN102127962AImprove securityGood bi-directional force performanceScaffold accessoriesBuilding support scaffoldsStress distributionFalsework

The invention discloses an improved bidirectionally stressed foundation knot attached to a lifting scaffold. In a right-angle hexahedron framework structure formed by mutually and stably connecting upper and lower two groups of parallel transverse rodlike members, left and right two groups of parallel fore-and-aft rodlike members and front and back two groups of parallel vertical rodlike members, an inclined brace rod is connected between at least a pair of non-adjacent end points in at least one plane formed by the adjacent rodlike members, upward and downward direction ends of each vertical rodlike member are respectively provided with a vertical connection structure, and two direction ends of each transverse rodlike member are respectively provided with a transverse connection structure. The foundation knot is more reasonable and scientific on the stress distribution of a lifting acting force, has better bidirectional stress performances for resisting bending moment and torsion moment, and can ensure that a vertical main framework and a horizontal supporting truss attached to the lifting scaffold realize standardized construction by means of installation of the standard knot.

Owner:苏茂兵

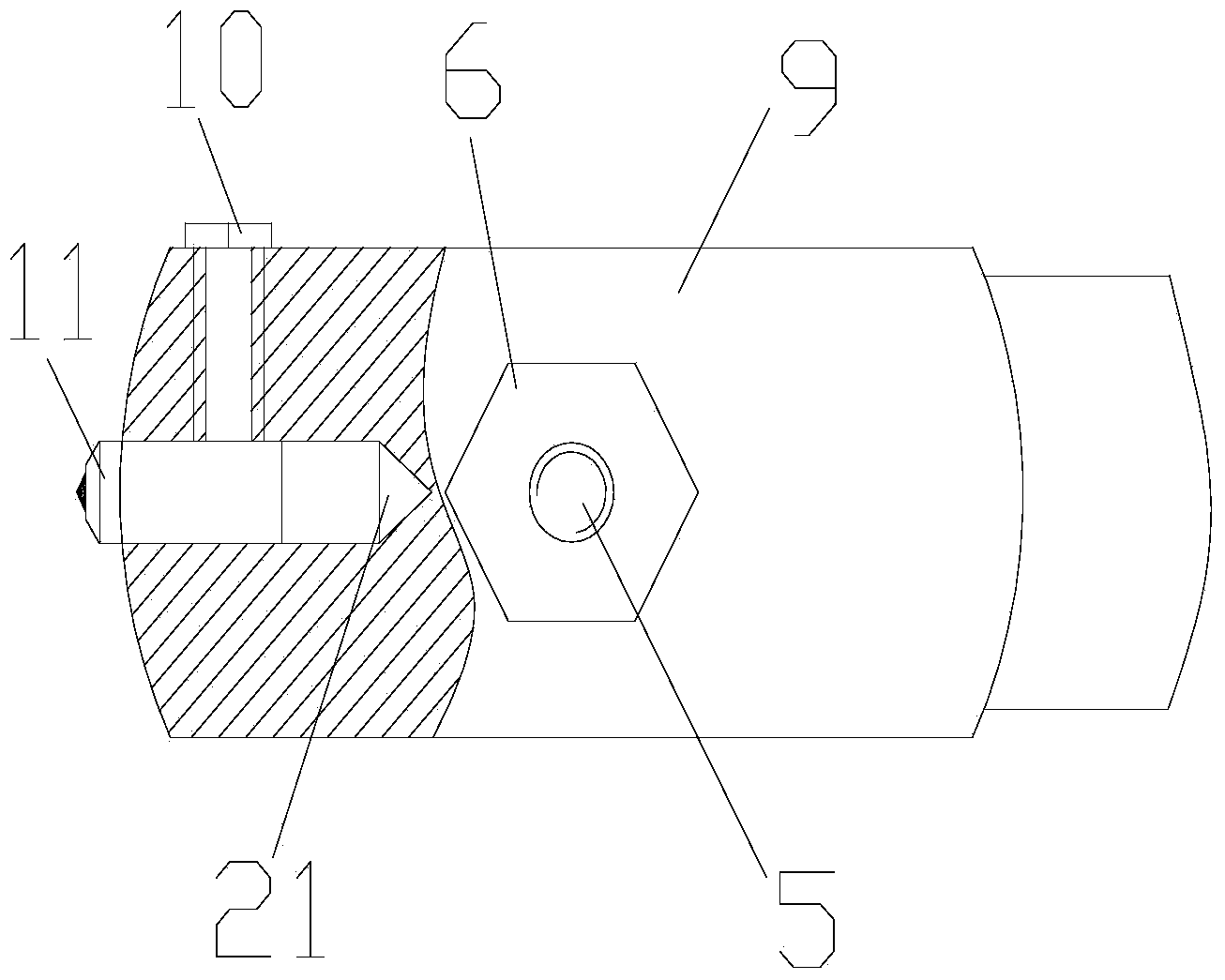

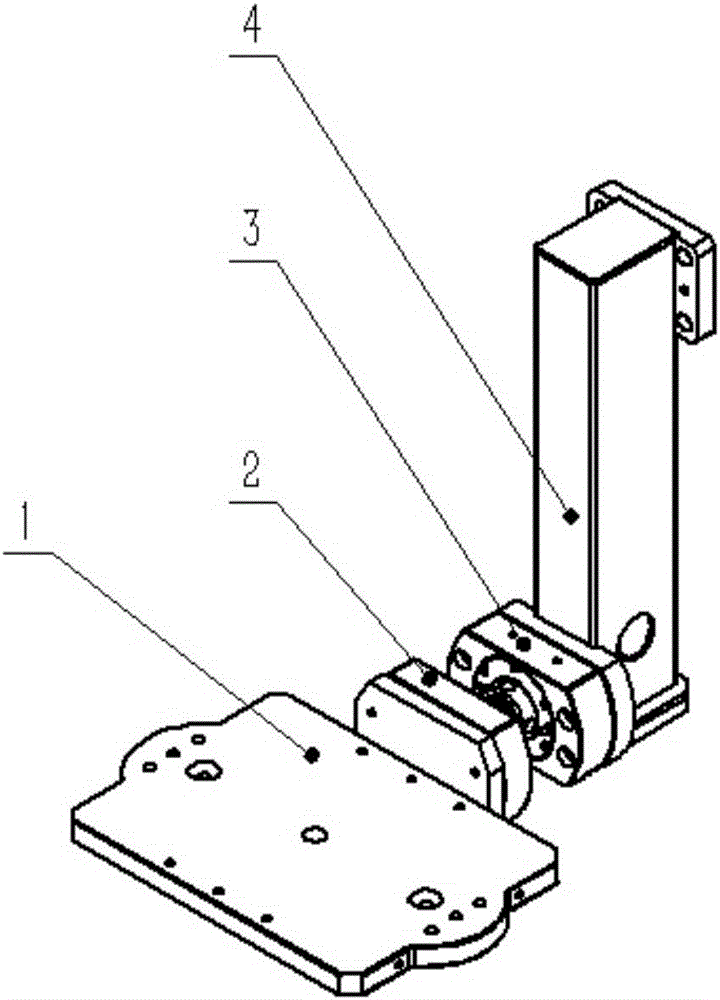

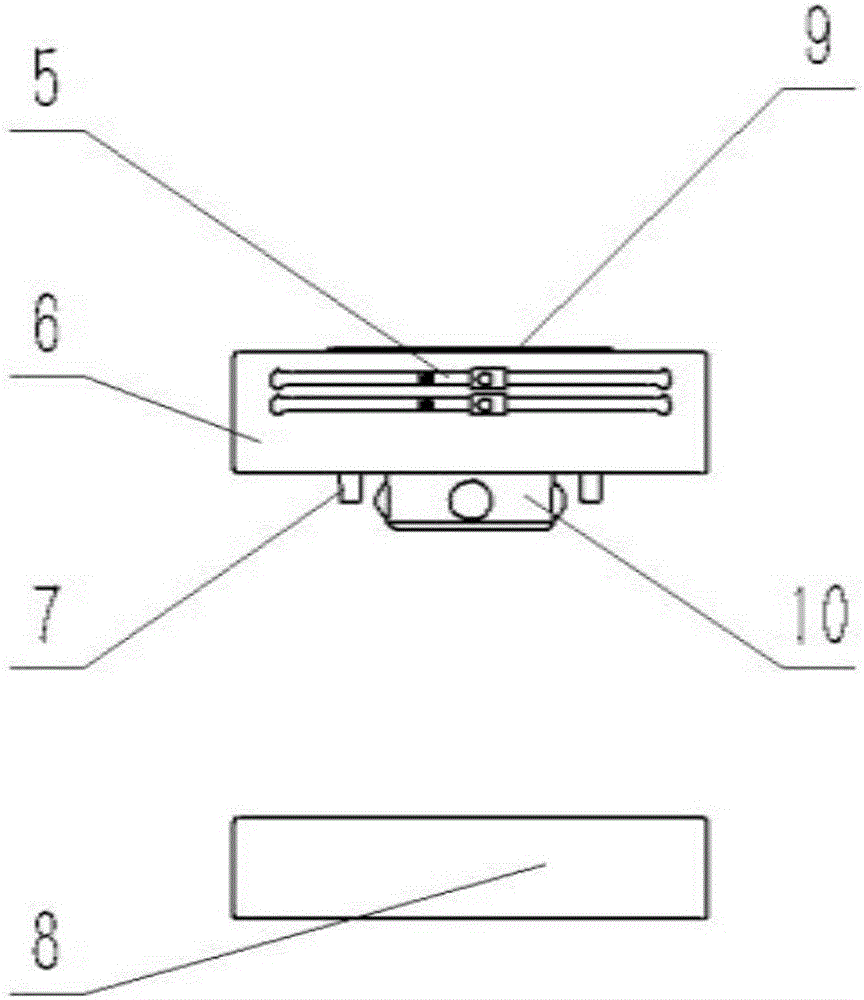

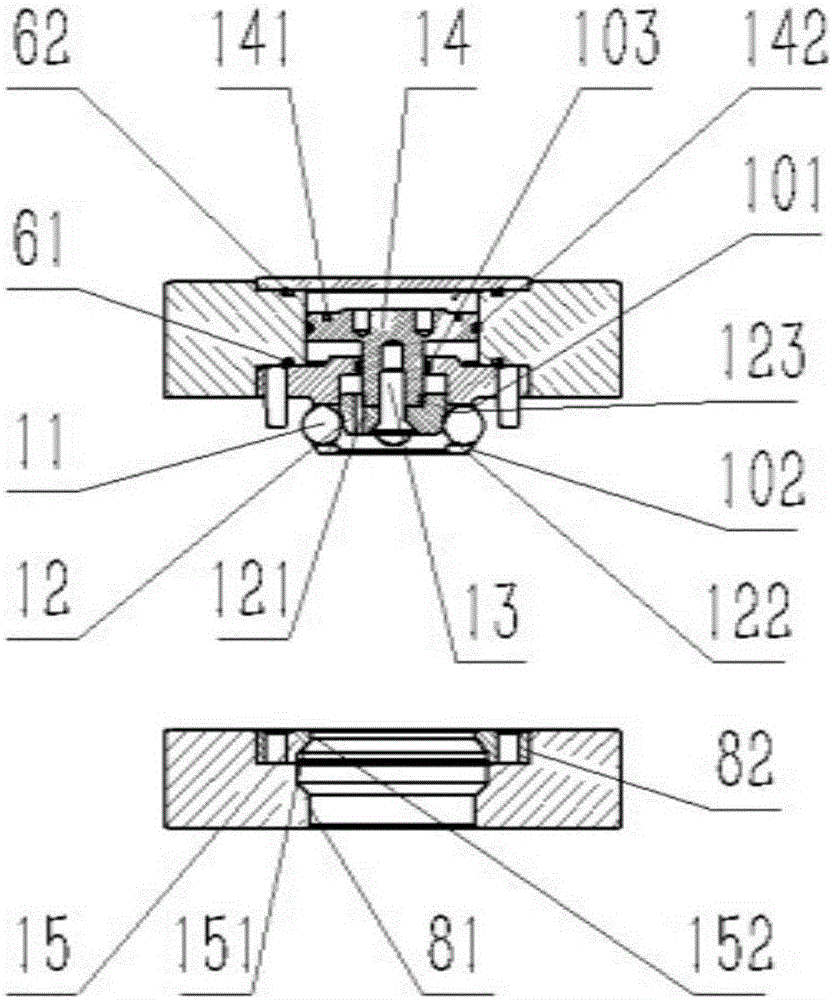

Standard gripping device of pallet exchange system

InactiveCN107433484AEasy to insert and fixIncrease Teach ToleranceMetal working apparatusEngineeringPallet

A standard grabbing device for a pallet exchange system, comprising a grabbing device main disc connected to the end of a robot grabbing arm and a grabbing device tool disc connected with a standard pallet; the grabbing device main disc includes a main disc base body, on which There are positioning taper pins and ball cages protruding outward; the tool tray of the grabbing device includes a tool tray base that can be inserted into the ball cage, and the tool tray base is provided with a standard tray connection port and a tool tray for fixing the ball cage snap ring. The main disc of the grabbing device of the present invention switches between different standard trays through the tool tray of the grabbing device, thereby realizing the replacement of different processed products. The split structure is adopted, and the processing is simple and the processing quality is easy to ensure. The upper processing has a lead-in angle, which increases the teaching tolerance of the robot and reduces the difficulty of teaching. The overall structure of the present invention is simple and reliable, and the alignment is quick and easy to use.

Owner:西安精雕软件科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com