Silty soil stratum pipe-jacking jacking construction method based on tool pipe with steel sleeve head

A construction method and tool pipe technology, which is applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., and can solve problems such as poor arching, increased frictional resistance, and inability to construct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

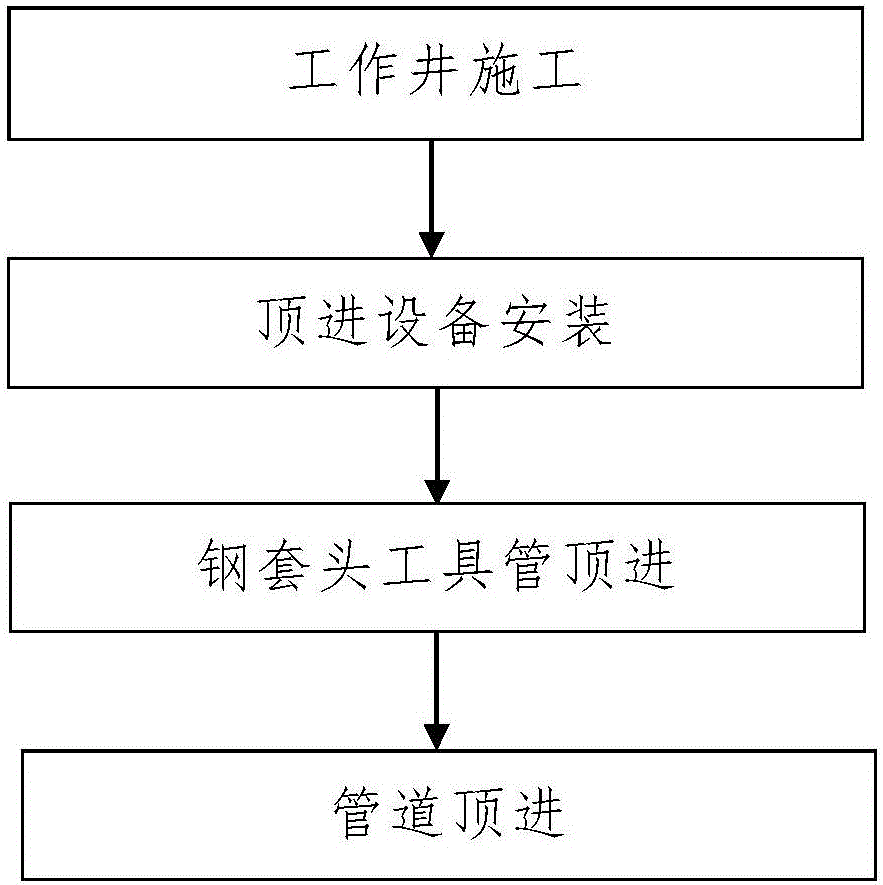

[0083] Such as figure 1 A kind of pipe jacking construction method in silt soil stratum shown, comprises the following steps:

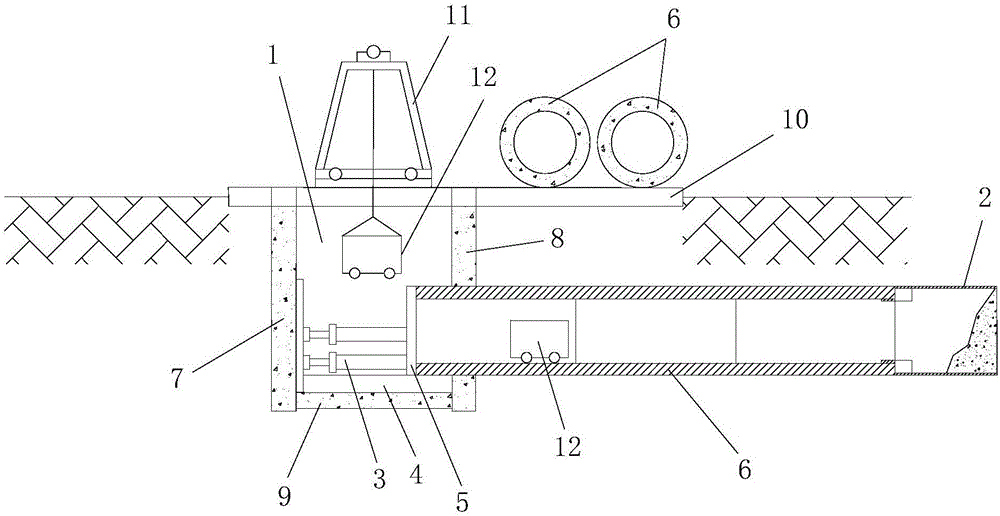

[0084] Step 1, working well construction: construct the working well 1 for jacking the constructed underground pipeline, the working well 1 is located at the rear side of the constructed underground pipeline, and the constructed underground pipeline is located between the working well 1 and the receiving well , see Picture 1-1 ;

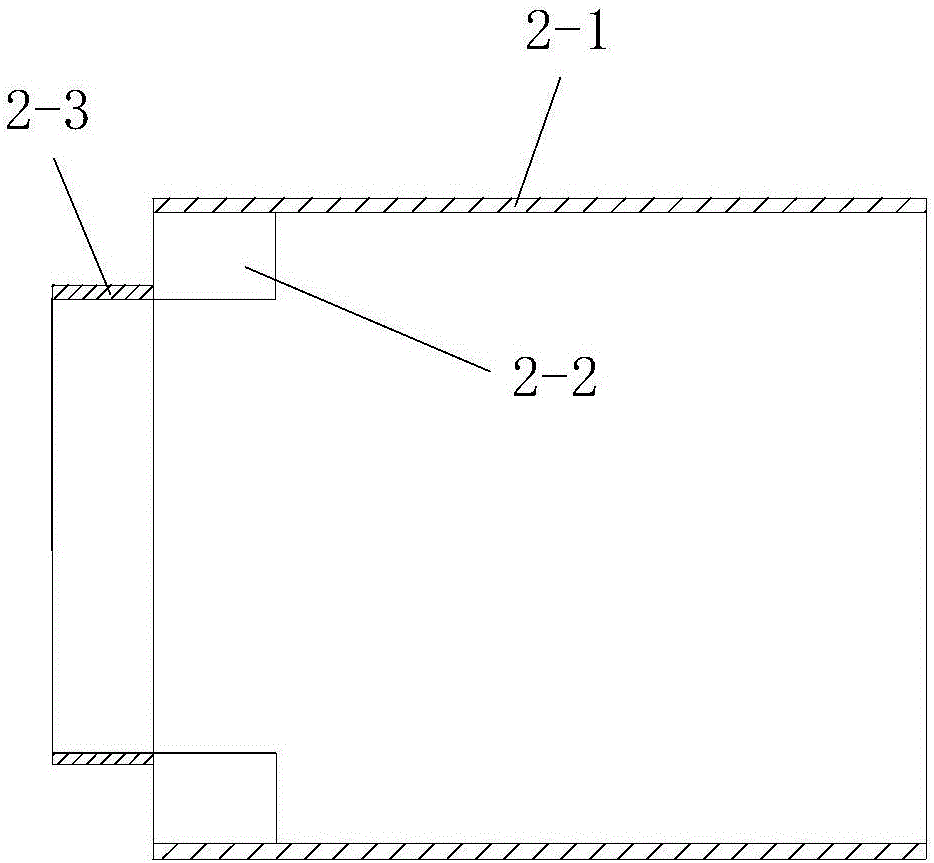

[0085] Such as Picture 1-1 As shown, the underground pipeline to be constructed is a spliced pipeline that is spliced from front to back by a plurality of pipeline assembly sections 6 and buried in the silty soil stratum, and among the plurality of pipeline assembly sections 6 located at the front 6 is a front-end assembly section, and the pipeline assembly section 6 located at the rearmost side among the multiple pipeline assembly sections 6 is a rear-end assembly section; The sleeve tool pipe 2 is coaxially arran...

Embodiment 2

[0186] In this example, if Figure 5 As shown, the difference from Example 1 is that the support ring 2-2 in step 1 is a steel ring, and the support ring 2-2 is a thin support ring with a thickness of 0.8cm to 1.2cm, and the thin support ring A plurality of triangular stiffeners 2-4 are provided along the circumferential direction on the front side of the front side, and the outer sides of the triangular stiffeners 2-4 are fixed on the inner side wall of the steel casing 2-1.

[0187] In this embodiment, the thickness of the supporting ring 2-2 is 1 cm.

[0188] In actual use, the thickness of the support ring 2-2 can be adjusted accordingly according to specific needs.

[0189] Moreover, both the support ring 2-2 and the socket 2-3 are processed into one body with the steel casing 2-1.

[0190] In this embodiment, the rest of the method steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com