Patents

Literature

290results about How to "Simple stitching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image pickup device of multiple lens camera system for generating panoramic image

InactiveUS20070081091A1Simple stitchingLow-cost solutionTelevision system detailsEndoscopesParallaxField of view

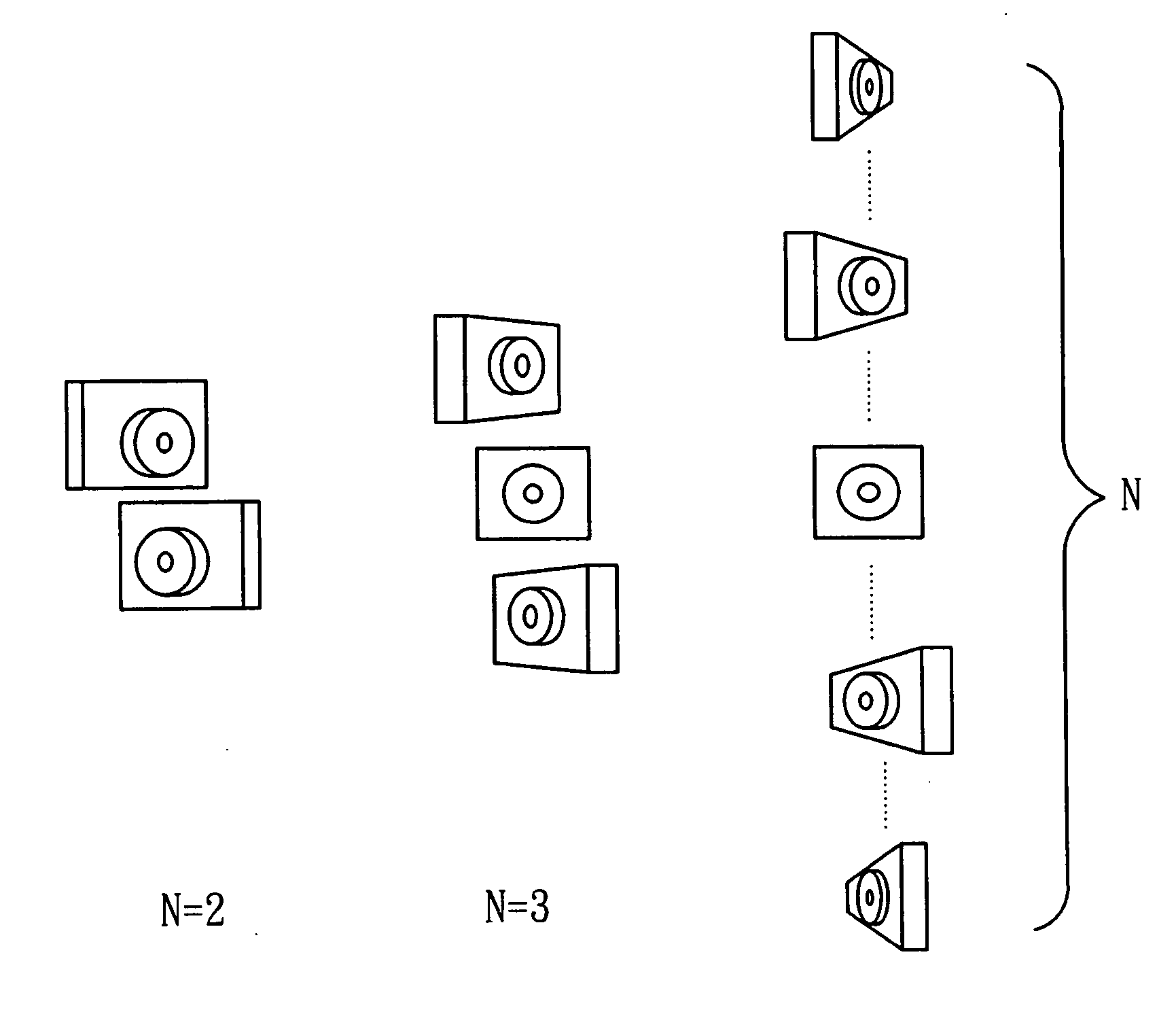

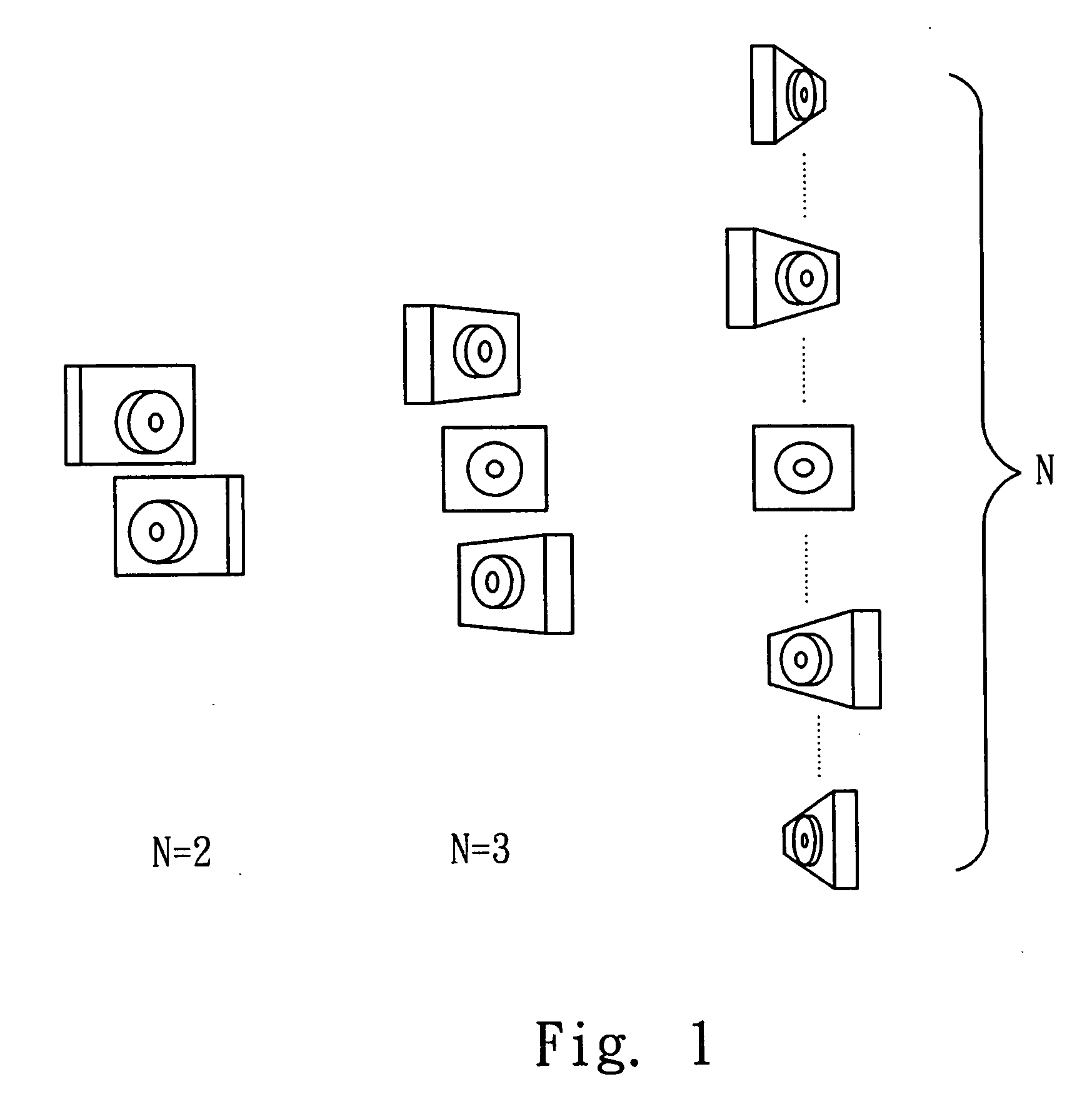

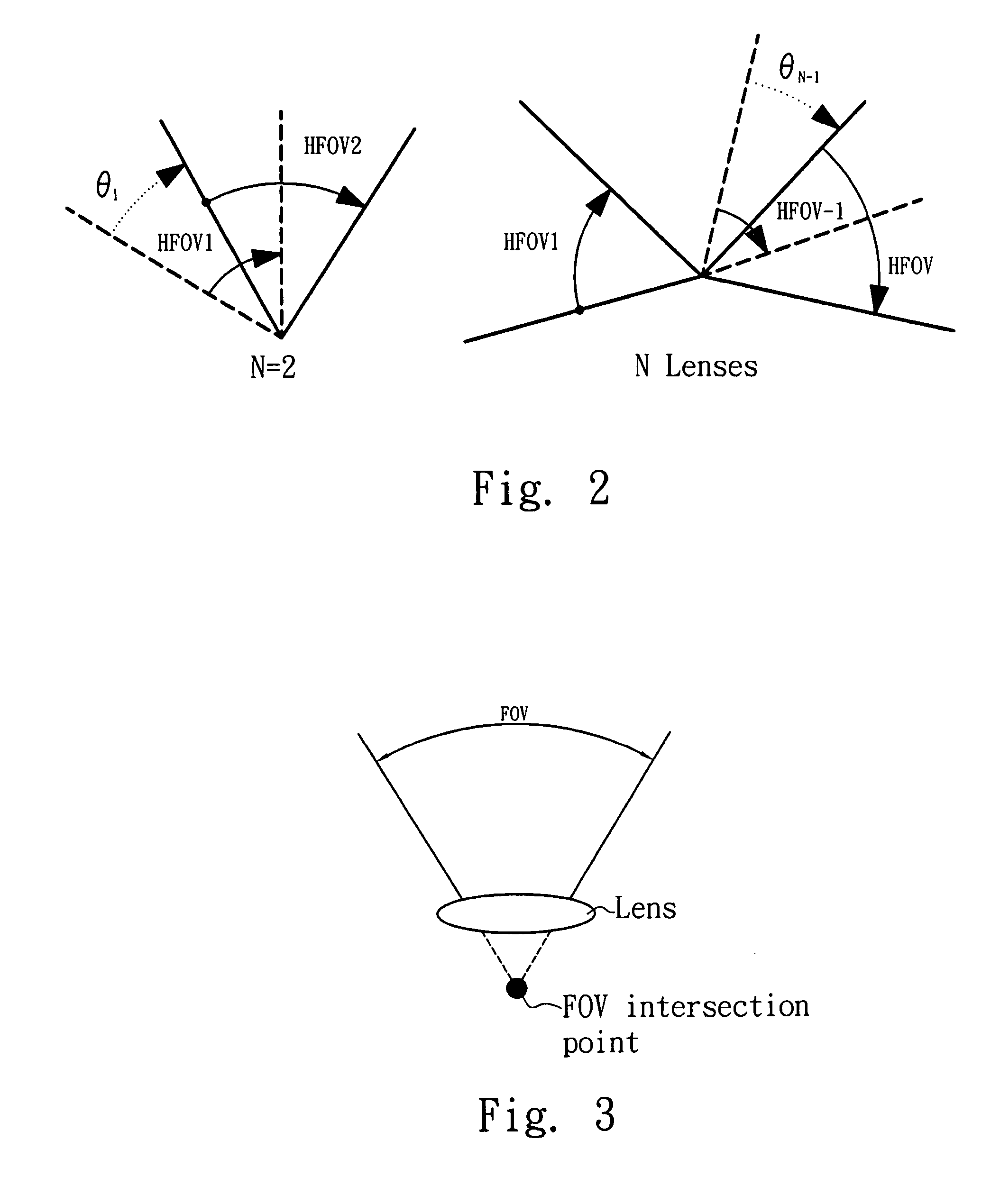

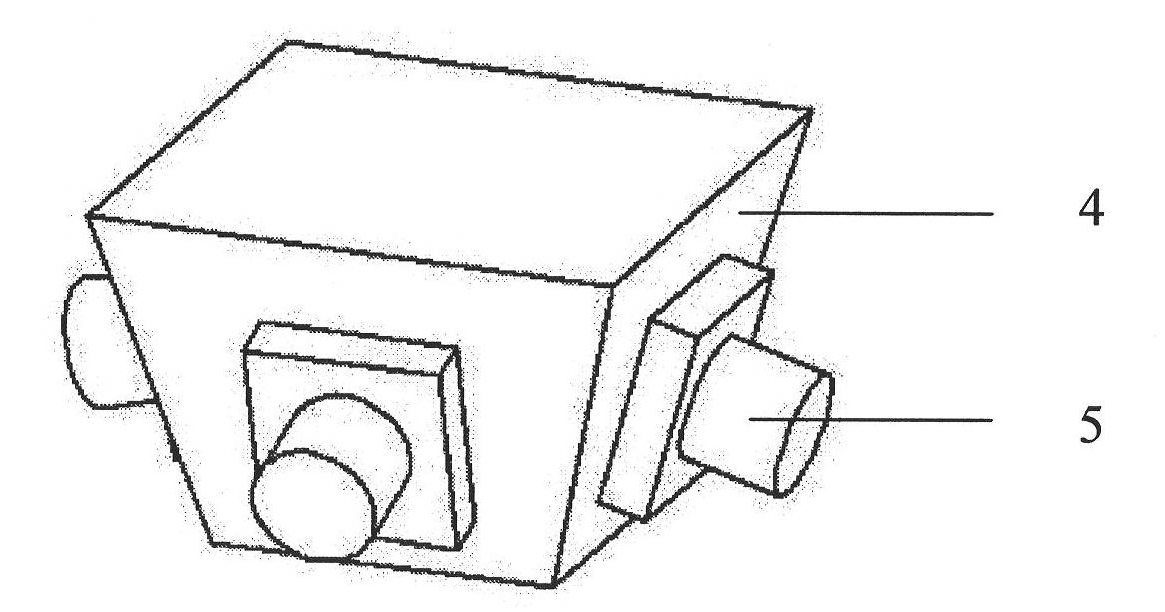

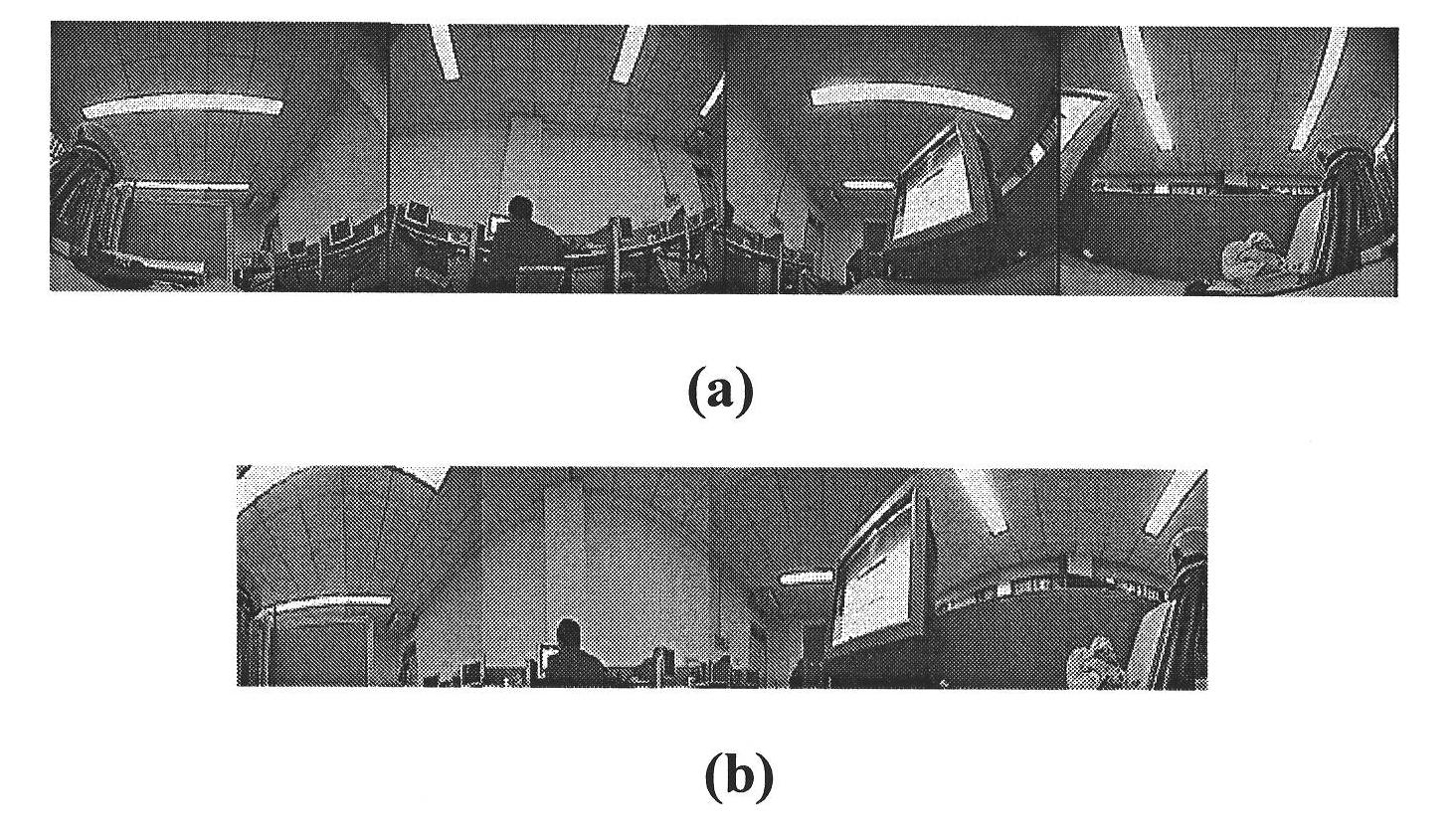

The present invention aims to simplify stitching algorithm which generates horizontal panoramic image. The image pickup device of the present invention comprises a plurality of lenses and positioning means. Said positioning means positions each lens so that the FOV (Field Of View) intersection points of all lenses are aligned in vertical direction. Accordingly, the horizontal parallax does not exist in the image picked up by the camera system and the stitching point remains the same for the objects at different distances.

Owner:SONY TAIWAN

Device and method for adjusting view field of spliced panoramic camera

ActiveCN101833231ALow costSame inclination angleTelevision system detailsColor television detailsOptical axisEngineering

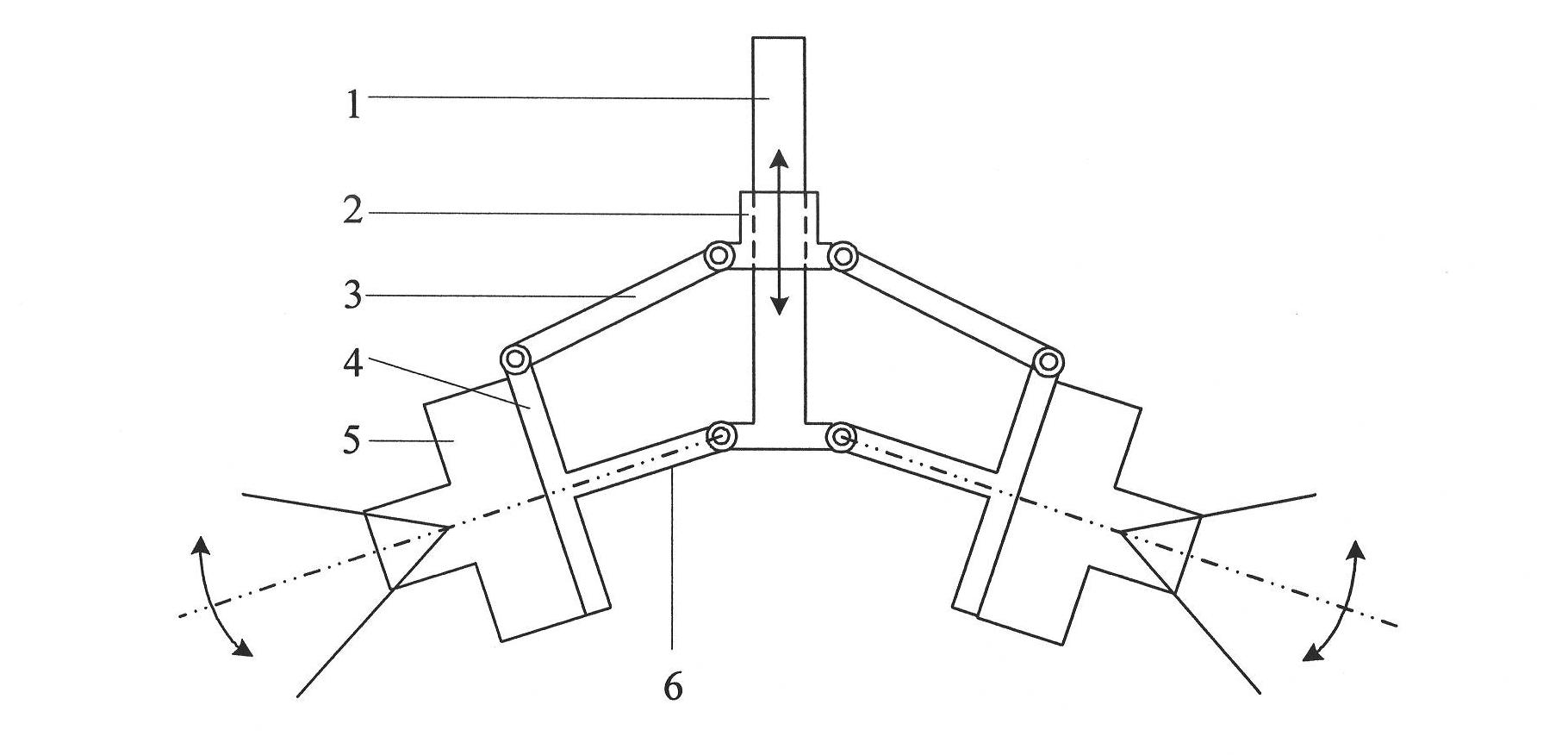

The invention discloses a device and a method for adjusting the view field of a spliced panoramic camera. The adjusting device comprises an inclined plane, a guide rod and an adjusting lever, wherein a camera is arranged on the inclined plane; the adjusting lever consists of an upper connecting rod and a lower connecting rod; the guide rod is provided with a sleeve sliding linearly along the guide rod; the inclined plane is hinged with the sleeve through the upper connecting rod which is hinged with the upper edge of the inclined plane; the inner side of the inclined plane is vertically fixed with the lower connecting rod which is coaxial with the optical axis of the camera; and the inclined plane is hinged with the lower end of the guide rod through the lower connecting rod. The adjusting method comprises the following steps of: calculating a required inclination angle alpha 1 and a current inclination angle alpha 0 of the optical axis of the camera according to the view field adjusting range of the camera; synchronously adjusting the inclination angle of each camera optical axis of the spliced panoramic camera to the alpha 1; and regenerating a spliced panoramic image according to the adjusted inclination angle alpha 1 of the camera optical axis to complete view field adjustment. The device and the method are simple and effective and meet the objective requirement on the adjustment of the view field of the camera in practical application of the spliced panoramic camera.

Owner:HUNAN VISION SPLEND PHOTOELECTRIC TECH

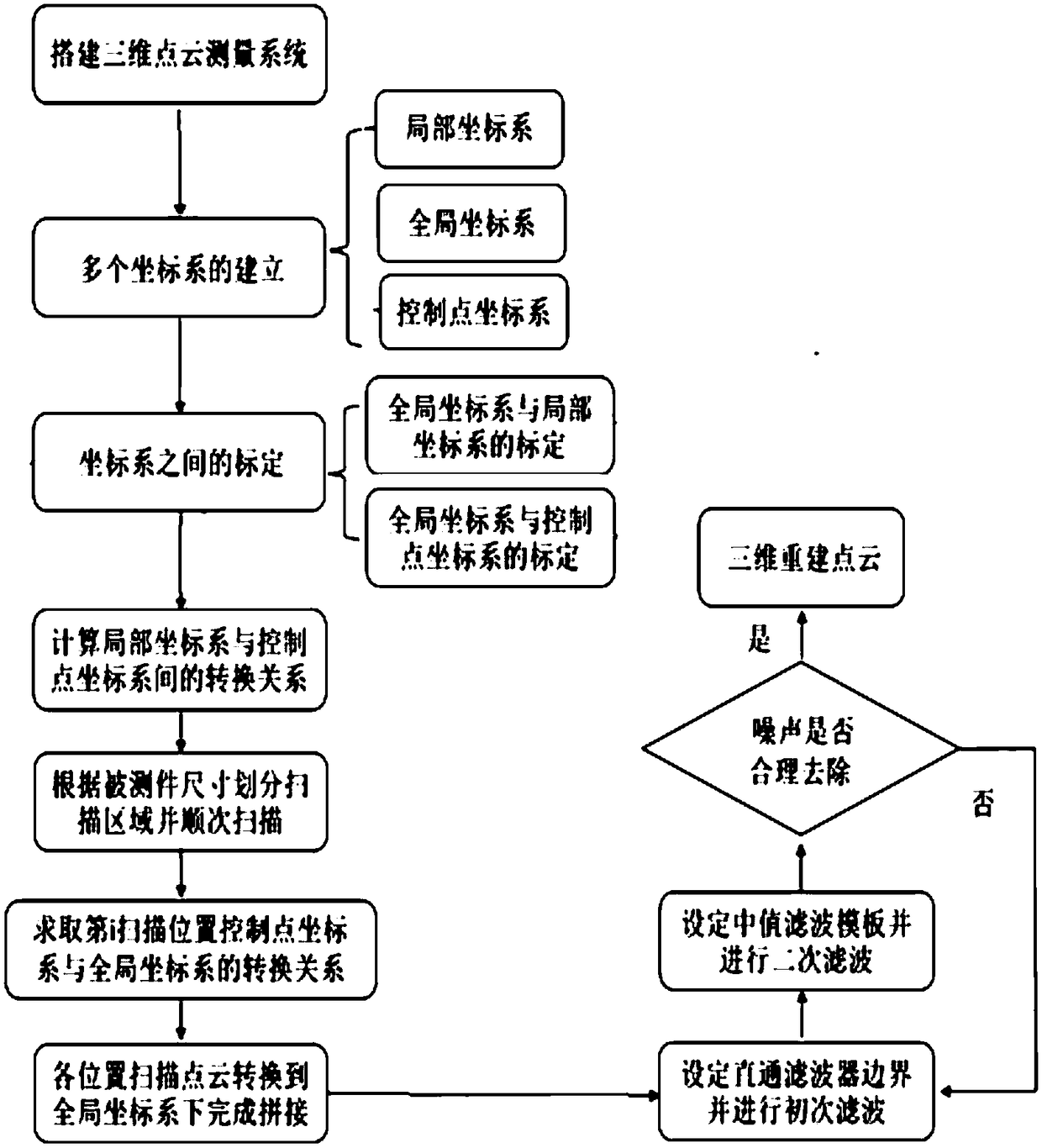

High-precision measuring method for three-dimensional shape of surface of large-sized measured part

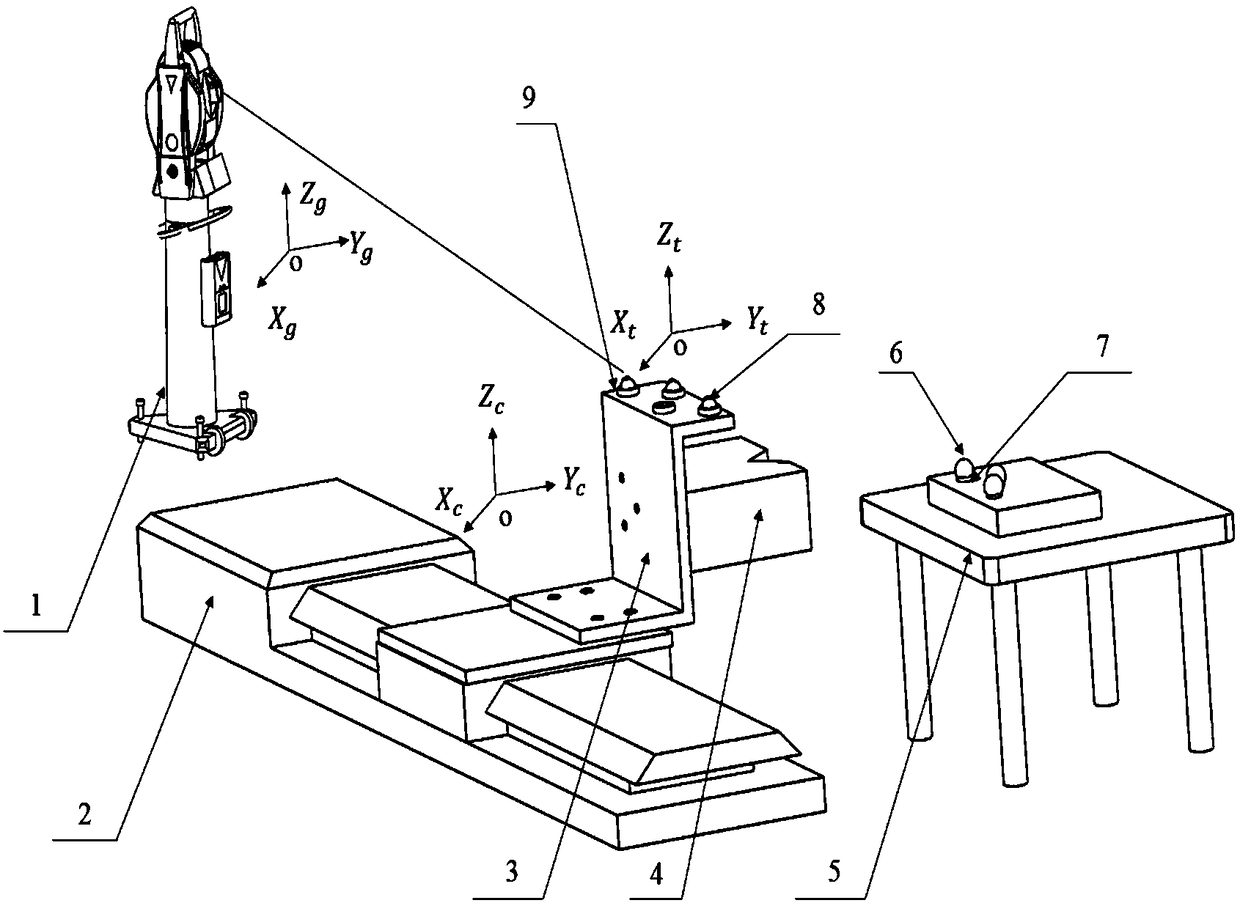

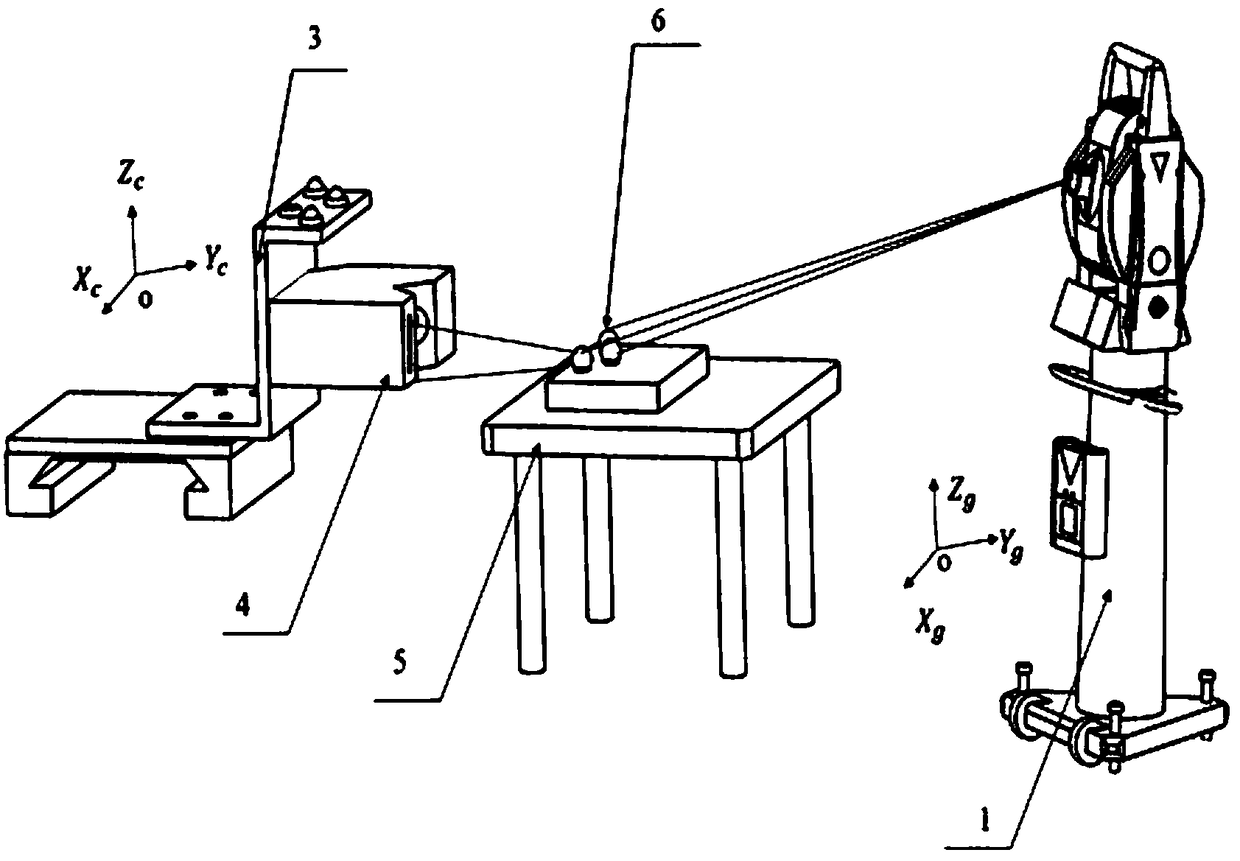

The invention discloses a high-precision measuring method for the three-dimensional shape of the surface of a large-sized measured part, belongs to the field of visual measurement and reverse engineering, and relates to a line laser scanner-based high-precision measuring method for the three-dimensional shape of the surface of the large-sized measured part. According to the method, a high-precision three-dimensional point cloud acquisition system is built by utilizing a line laser scanner and a PI electric control platform, and multi-station high-precision splicing is realized by the aid of alaser tracker. A control point coordinate system is adopted as a transition coordinate system for local and global coordinate system conversion, and the laser tracker is used for recording each position of the three-dimensional point cloud acquisition system. All data point clouds are transformed to a global coordinate system through a quaternion coordinate transformation method to complete the splicing, noises are removed by a filter, and the three-dimensional geometric shape of the surface of the measured part is reconstructed based on a least square method. According to the method, the splicing process is simplified, the splicing precision is improved, and the problem that a traditional non-contact type measuring method is unlikely to meet the high-precision, high-efficiency and high-robustness measurement requirements of the large-sized measured part at the same time is improved.

Owner:DALIAN UNIV OF TECH

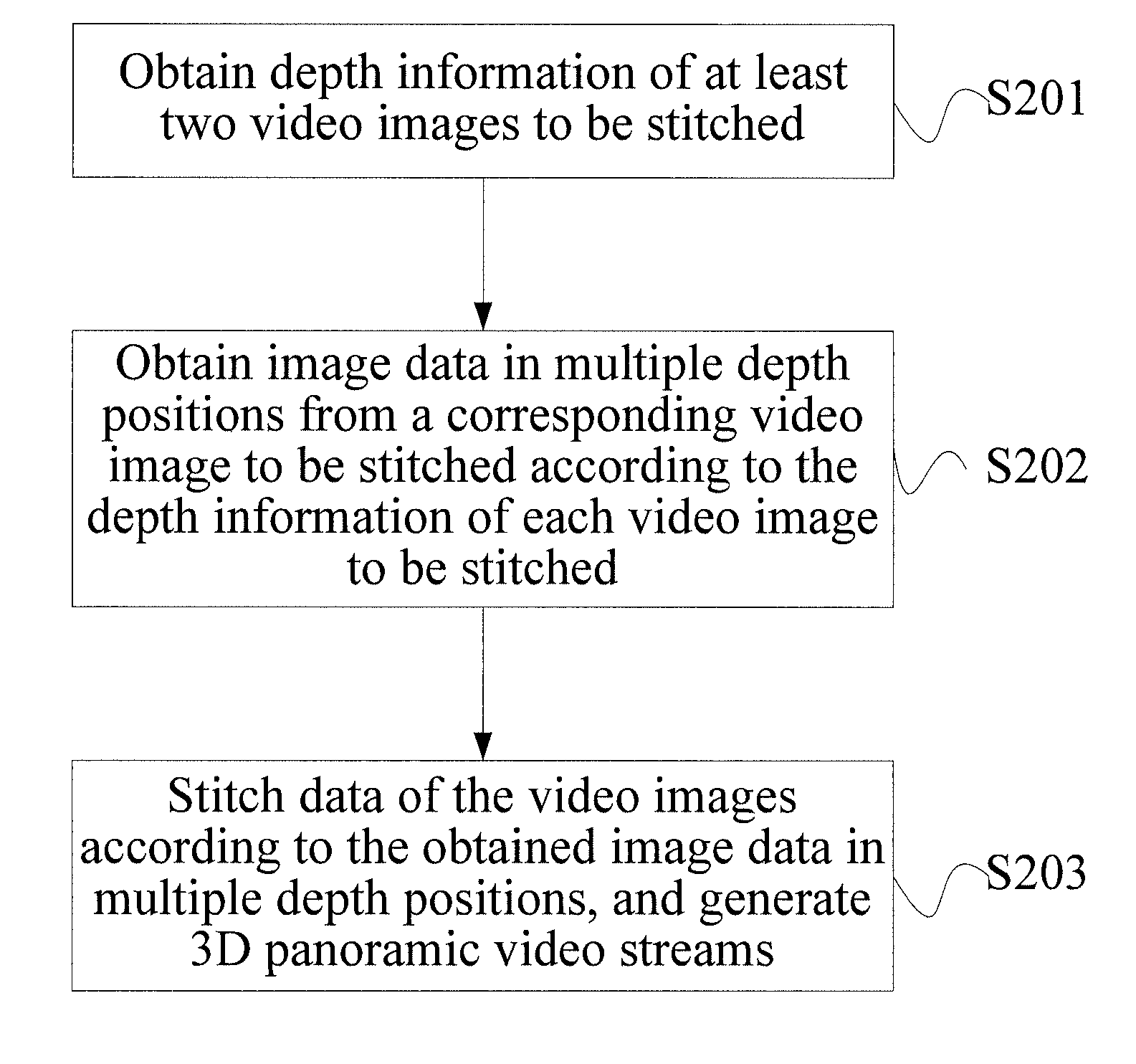

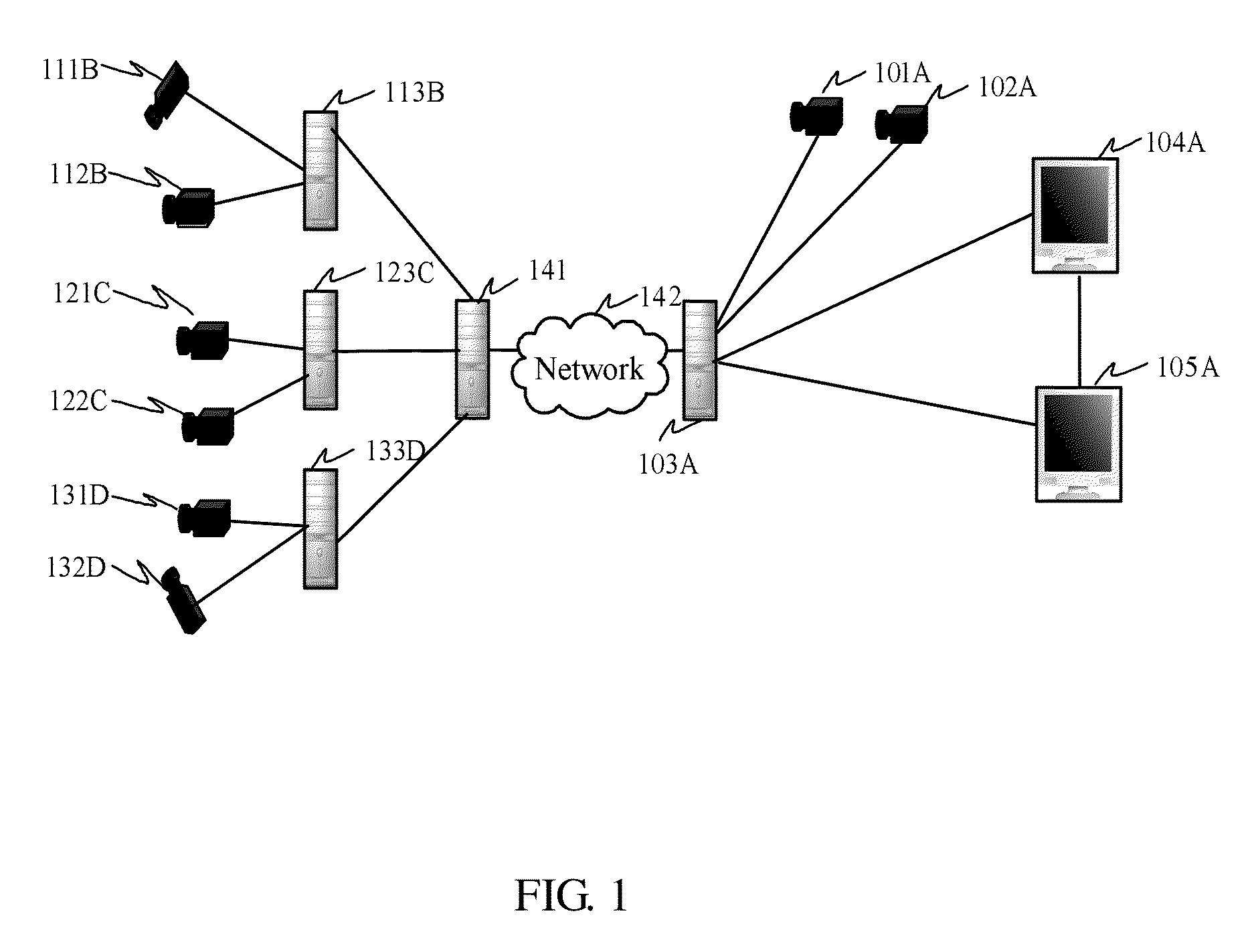

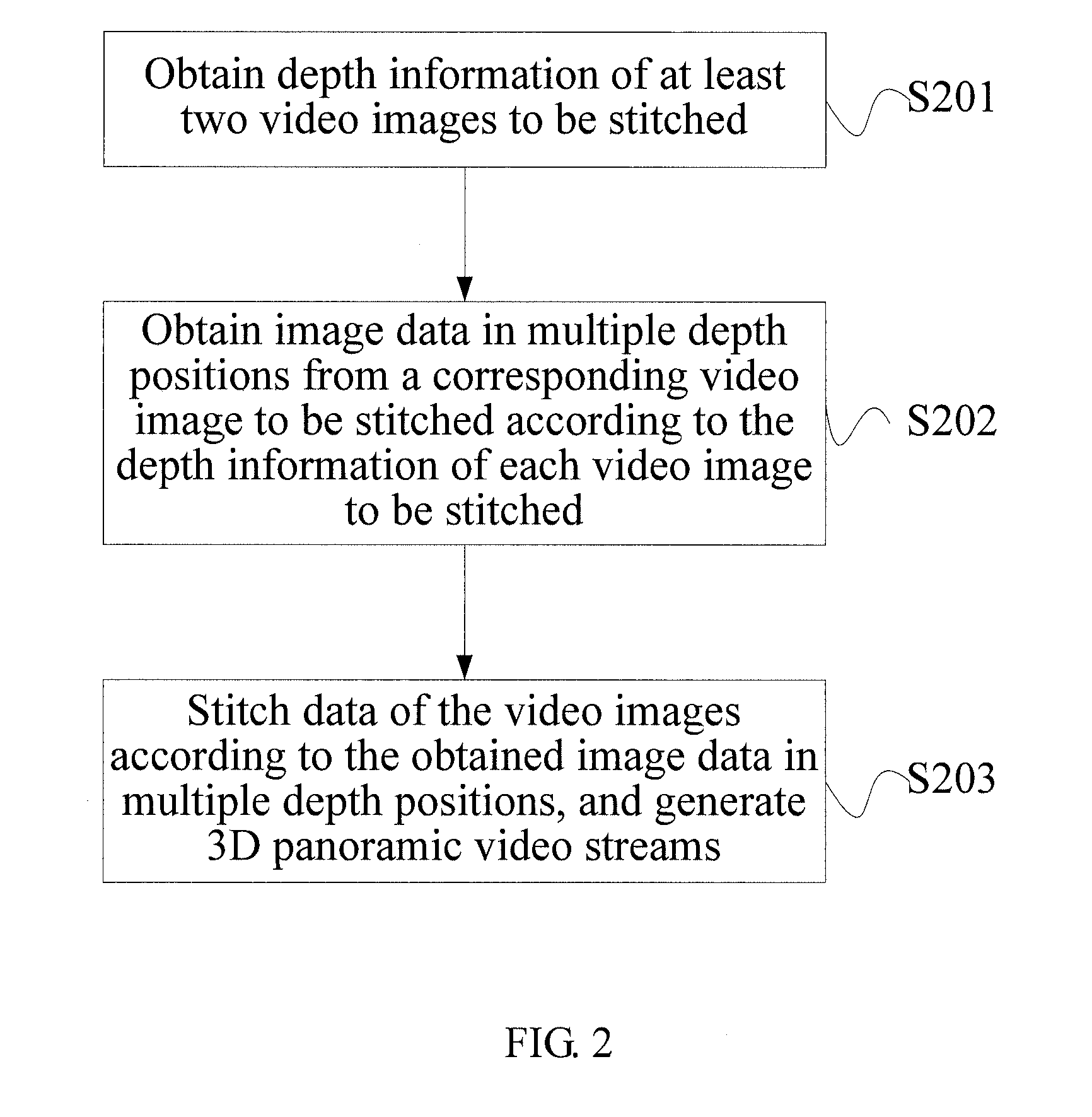

Method and device for generating 3D panoramic video streams, and videoconference method and device

ActiveUS8717405B2Fast and real-time stitchingSimple stitchingTelevision conference systemsCharacter and pattern recognitionComputer graphics (images)Display device

Owner:HUAWEI DEVICE CO LTD

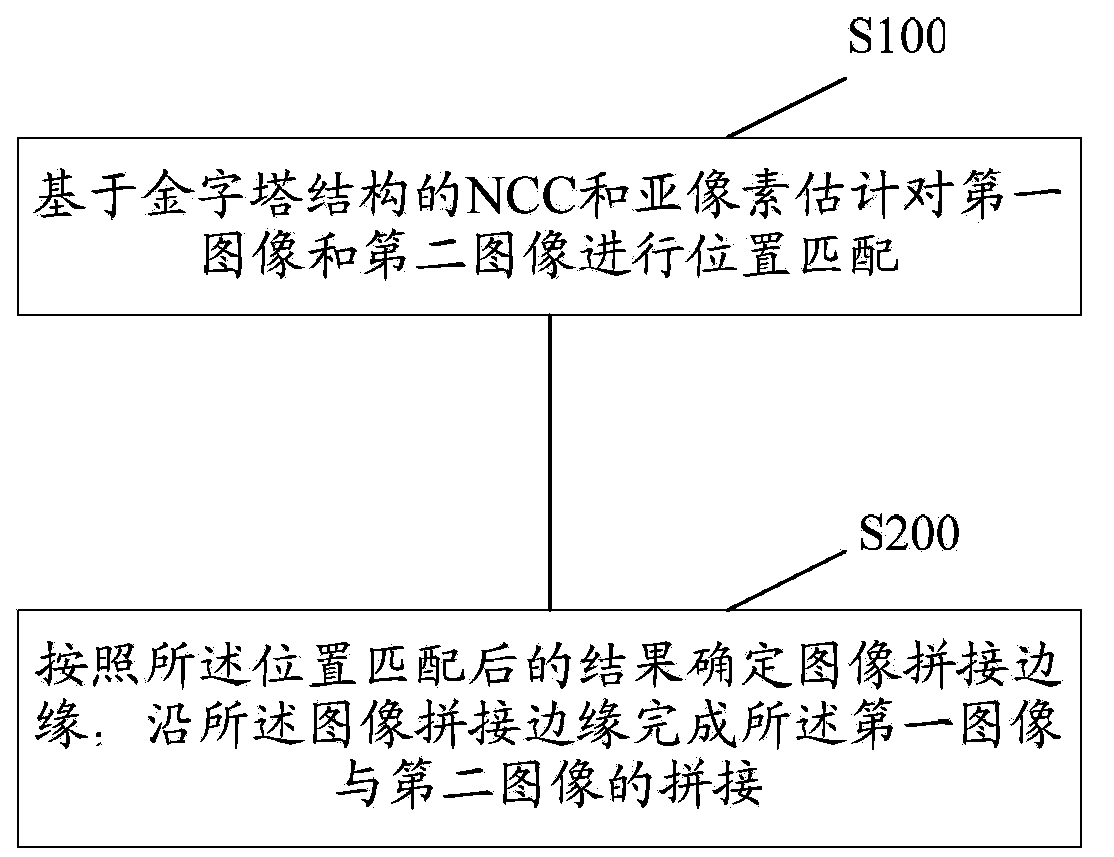

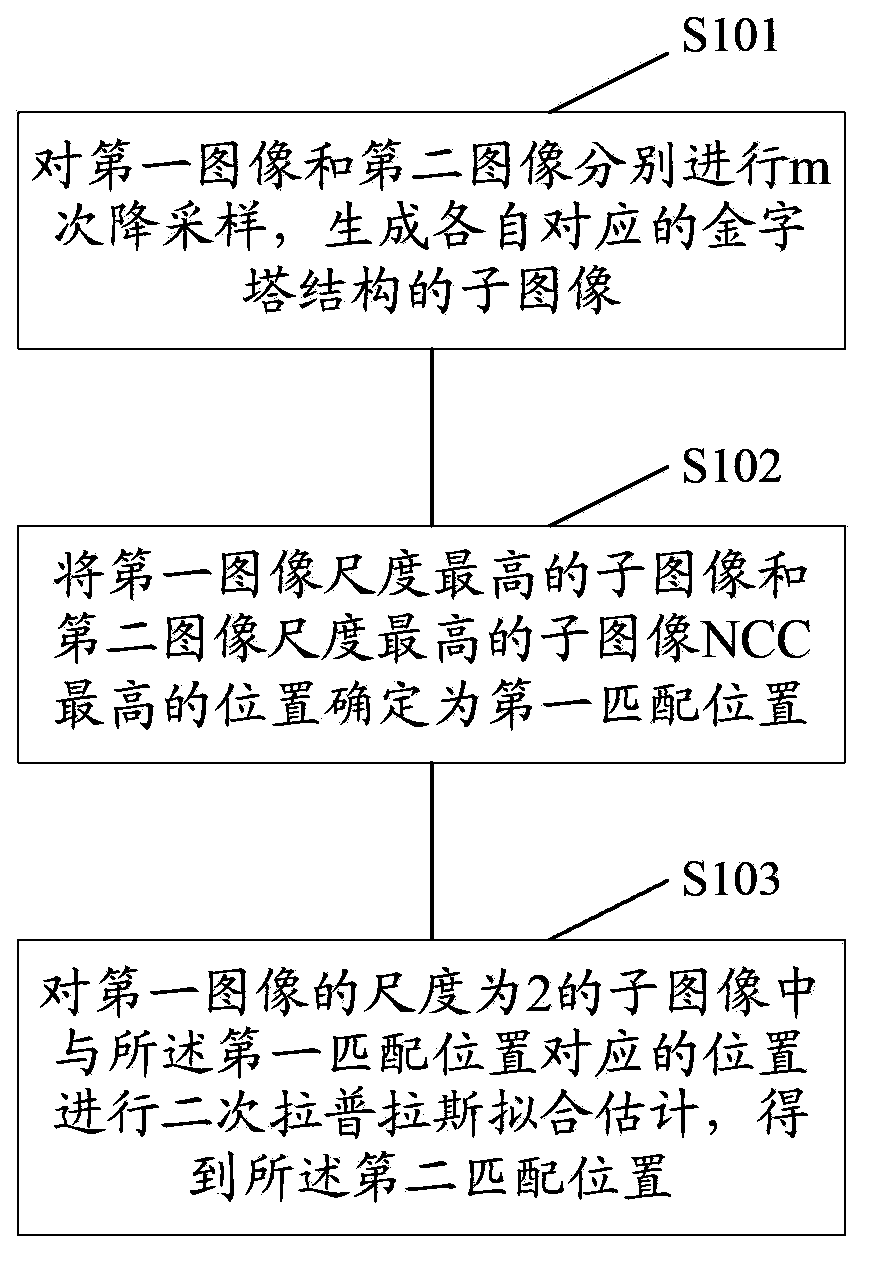

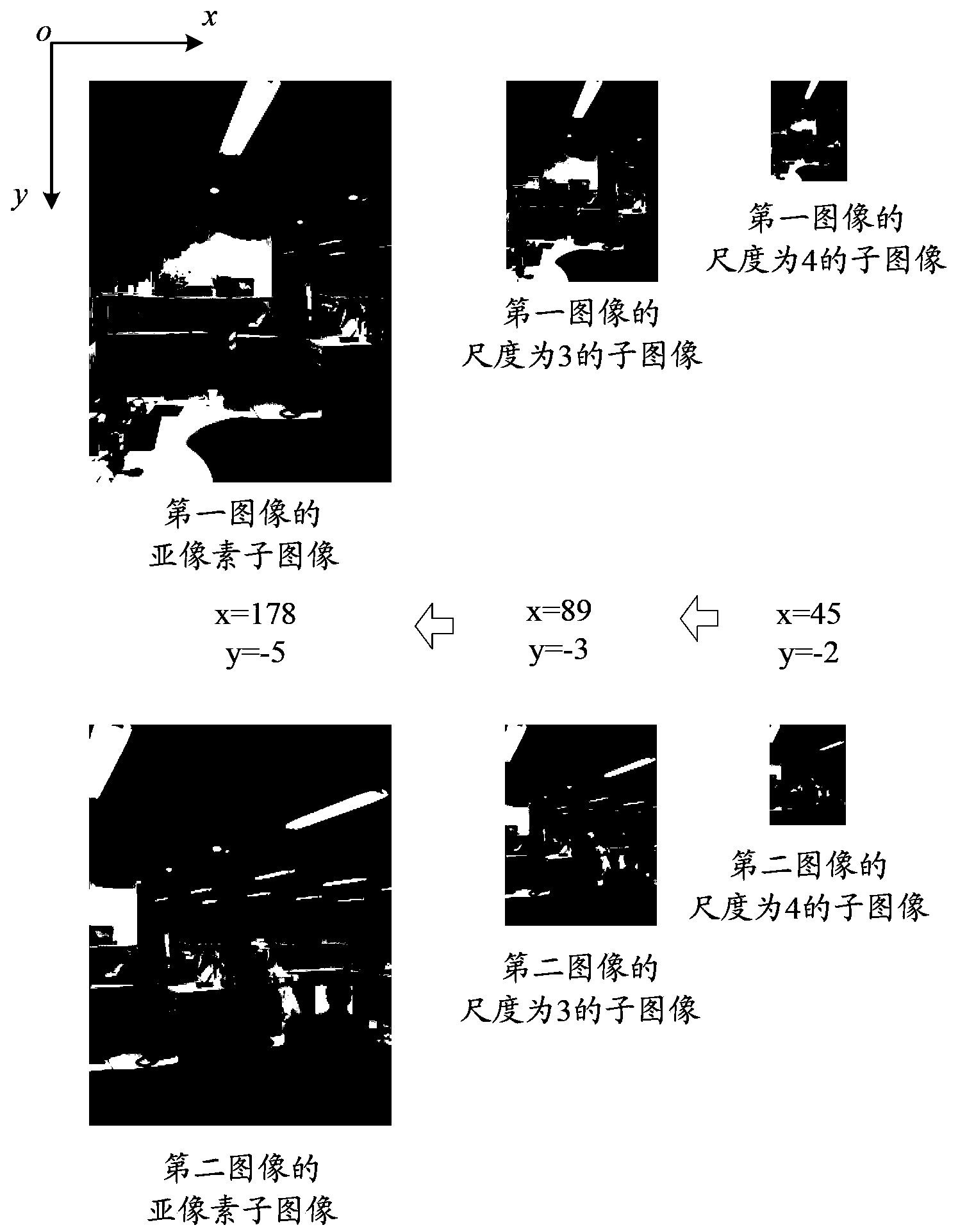

Image splicing method and device

ActiveCN104346788AEfficient processingImprove stitching qualityImage enhancementCorrelation coefficientImage splicing

Provided is an image splicing method and device. The method comprises the steps that position matching is performed on a first image and a second image based on a pyramid-structured normalized orthogonal correlation coefficient and sub-pixel estimation, and the first image and the second image are two adjacent images to be spliced; and an image splicing edge is confirmed according to the result of position matching, and splicing of the first image and the second image is completed along the image splicing edge. Rapid and high-efficiency image splicing can be realized by the technical scheme, and higher splicing precision can also be guaranteed.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

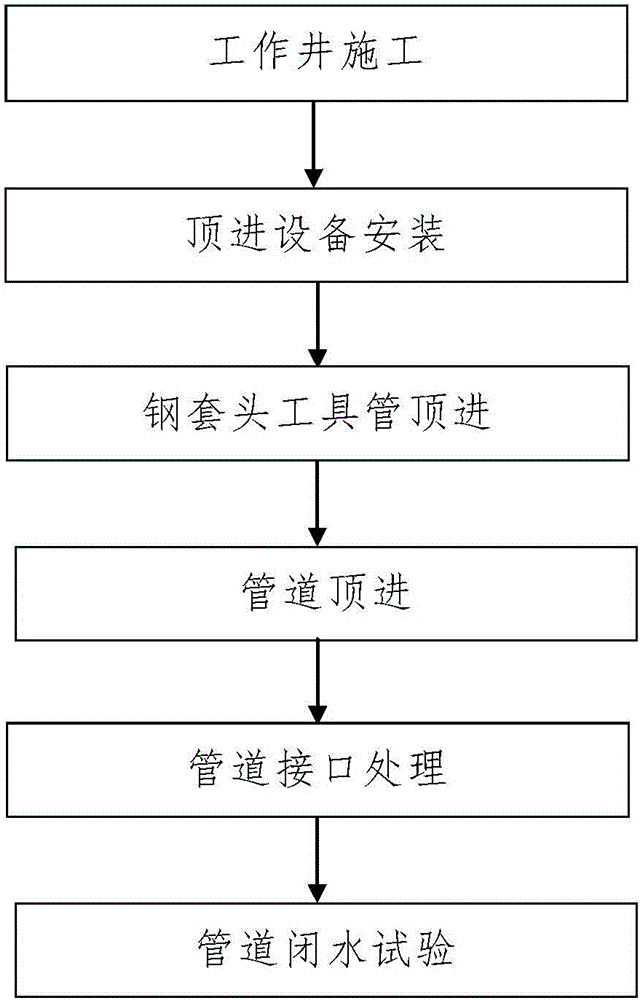

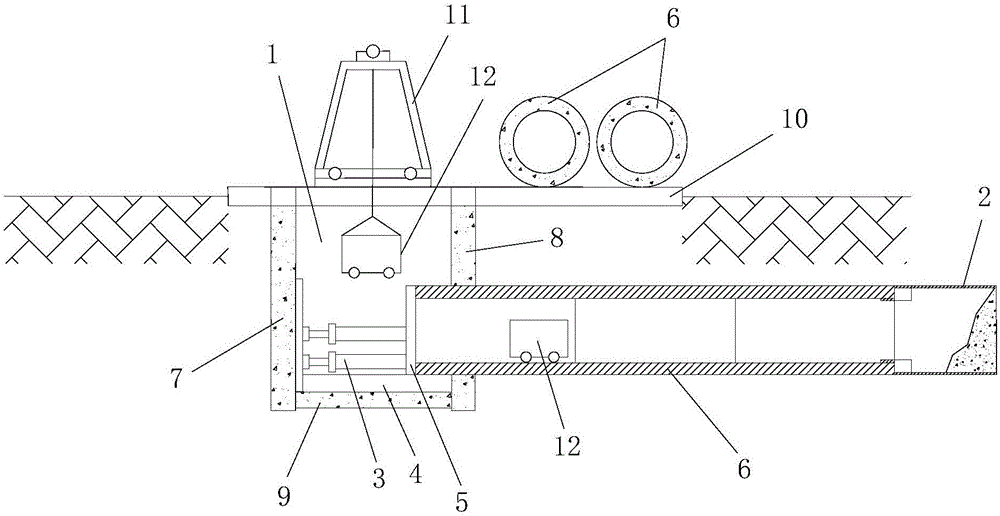

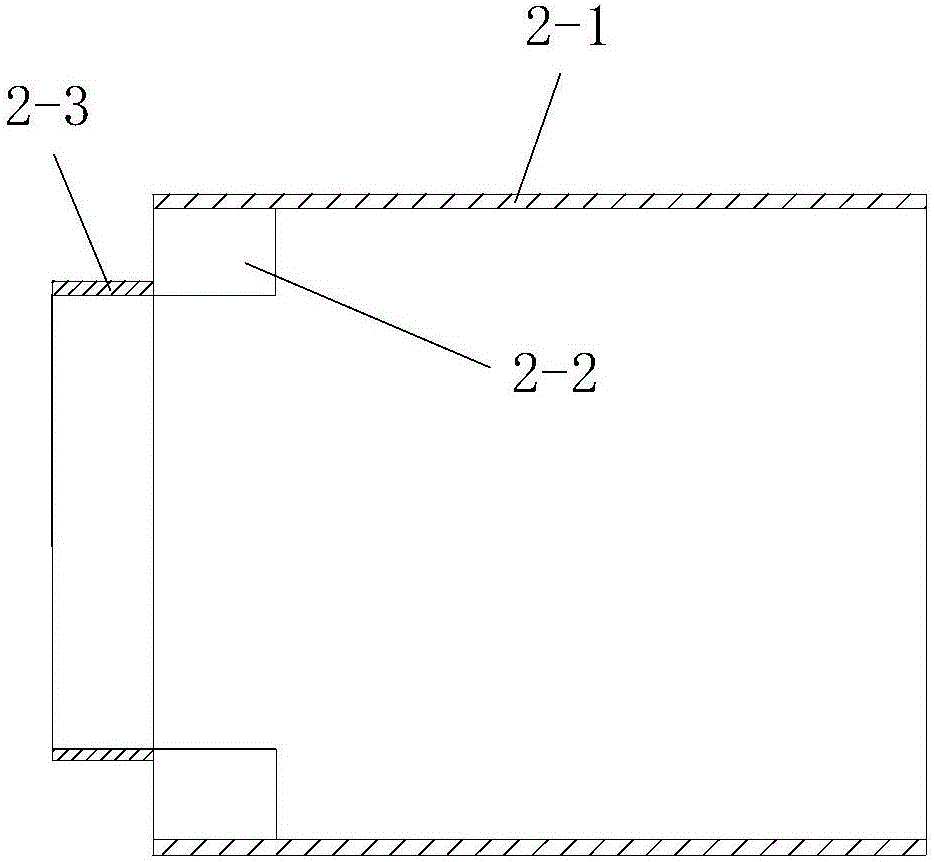

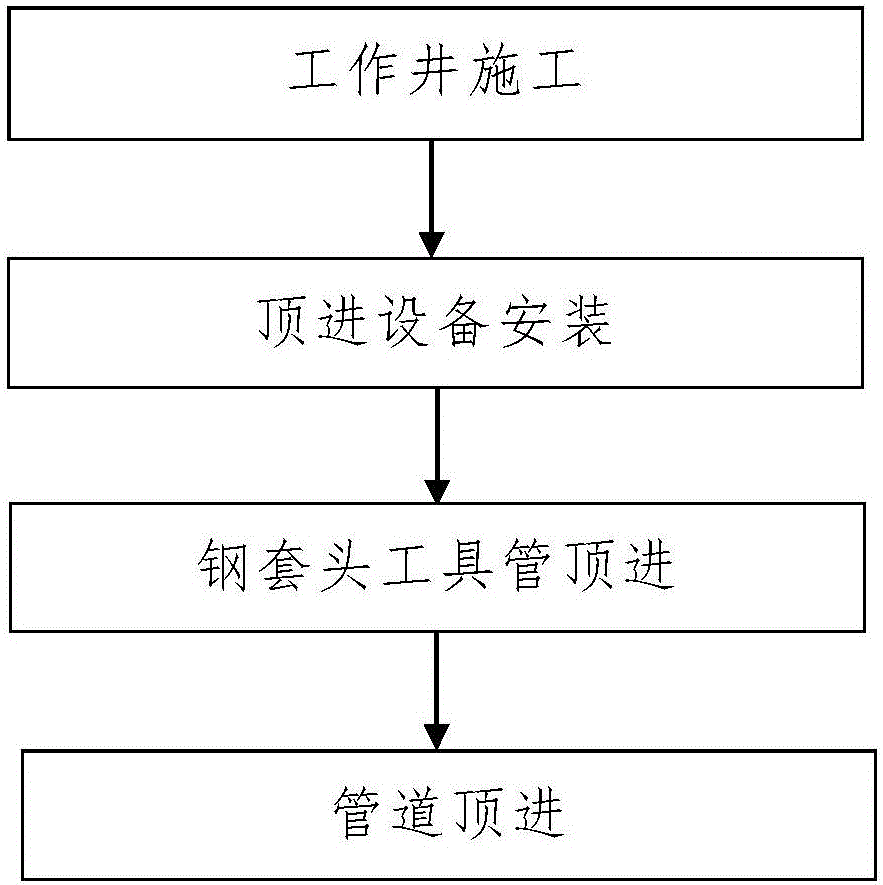

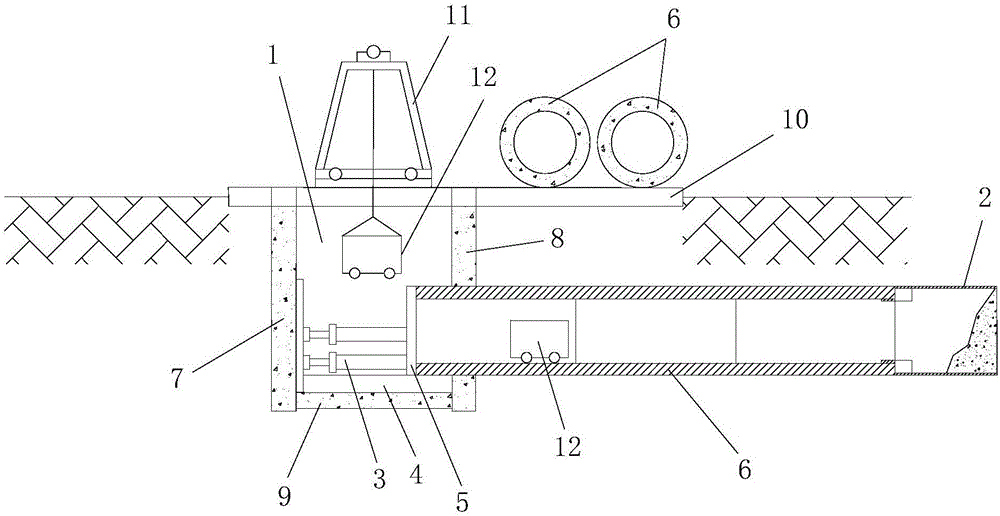

Pipe-jacking construction method for mealy sand stratum

ActiveCN106369223AThe method steps are simpleReasonable designPipe laying and repairEngineeringUnderground pipeline

The invention discloses a pipe-jacking construction method for a mealy sand stratum. The pipe-jacking construction method for the mealy sand stratum comprises the steps that firstly, a working well is constructed, specifically, the working well used for jacking a constructed underground pipeline is constructed, the constructed underground pipeline is formed by splicing a plurality of pipeline assembly sections from front to back, and a steel bushing head tool pipe comprises a steel sleeve, a supporting ring mounted on the inner side of the rear end of the steel sleeve, and an insertion opening fixed to the supporting ring; secondly, jacking equipment is mounted, specifically, the jacking equipment is mounted at the bottom of the inner side of the working well; thirdly, the steel bushing head tool pipe is jacked through the process that the steel bushing head tool pipe is hoisted in place, the steel bushing head tool pipe is jacked, and manual intra-pipe earth cutting is conducted; fourthly, the pipeline is jacked, specifically, the multiple pipeline assembly sections of the constructed underground pipeline are jacked from front to back; fifthly, a pipeline port is treated; and sixthly, a closed water test for the pipeline is conducted. According to the pipe-jacking construction method for the mealy sand stratum, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; and a pipe-jacking construction process of the mealy sand stratum can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:中铁二十局集团第五工程有限公司

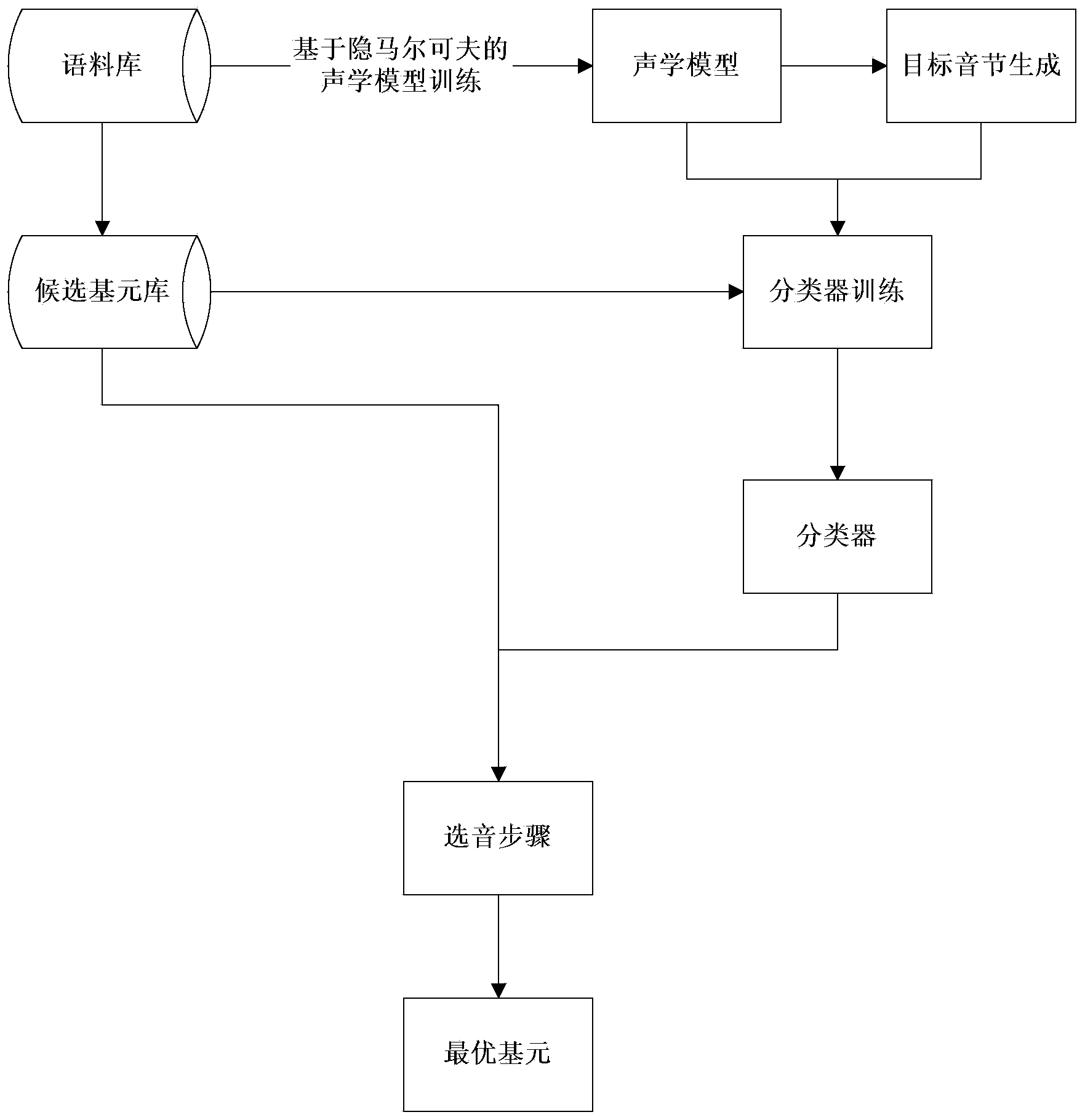

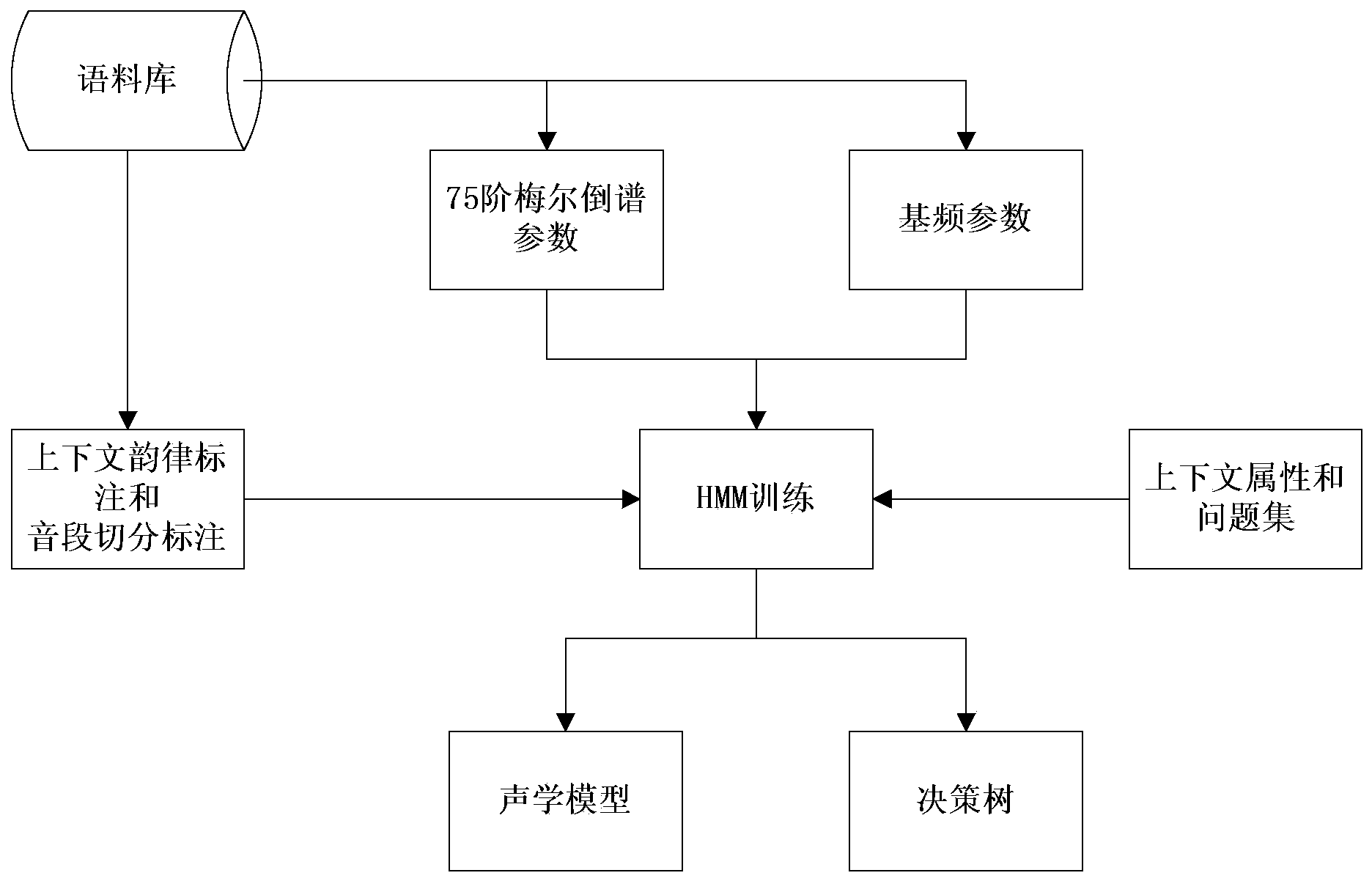

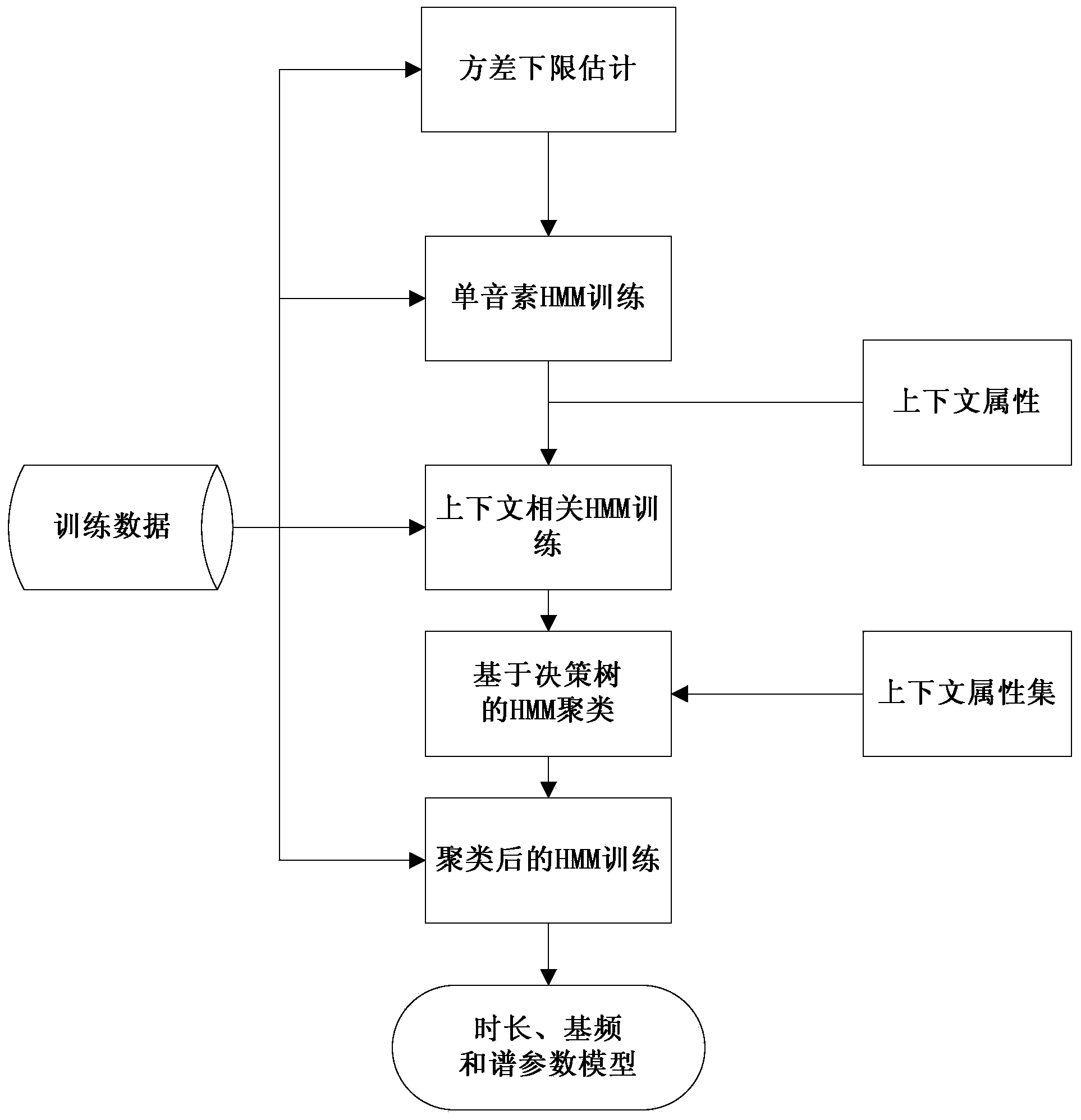

Sound selection method for waveform concatenation speech synthesis

The invention discloses a sound selection method for waveform concatenation speech synthesis. The method comprises the following steps of: on the basis of an original audio, carrying out hidden markov based model training so as to obtain an acoustic model set and a corresponding characteristic decision tree; inputting a plurality of training texts and on the basis of the characteristic decision tree, searching to obtain related acoustic models so as to obtain corresponding target voice and target syllables; according to similarity of the target voice and corresponding candidate primitives and likelihood probability of each acoustic parameter of the candidate primitives under a current acoustic model, training to obtain a similarity classifier; inputting a random text to be synthesized, removing the dissimilar candidate primitives on the basis of the similarity classifier, selecting the optimal primitive from the residual candidate primitives by utilizing a concatenation cost minimization rule and carrying out concatenation to obtain synthetic speech. The adoption of the method disclosed by the invention can synthesize speech with higher tone quality.

Owner:中科极限元(杭州)智能科技股份有限公司

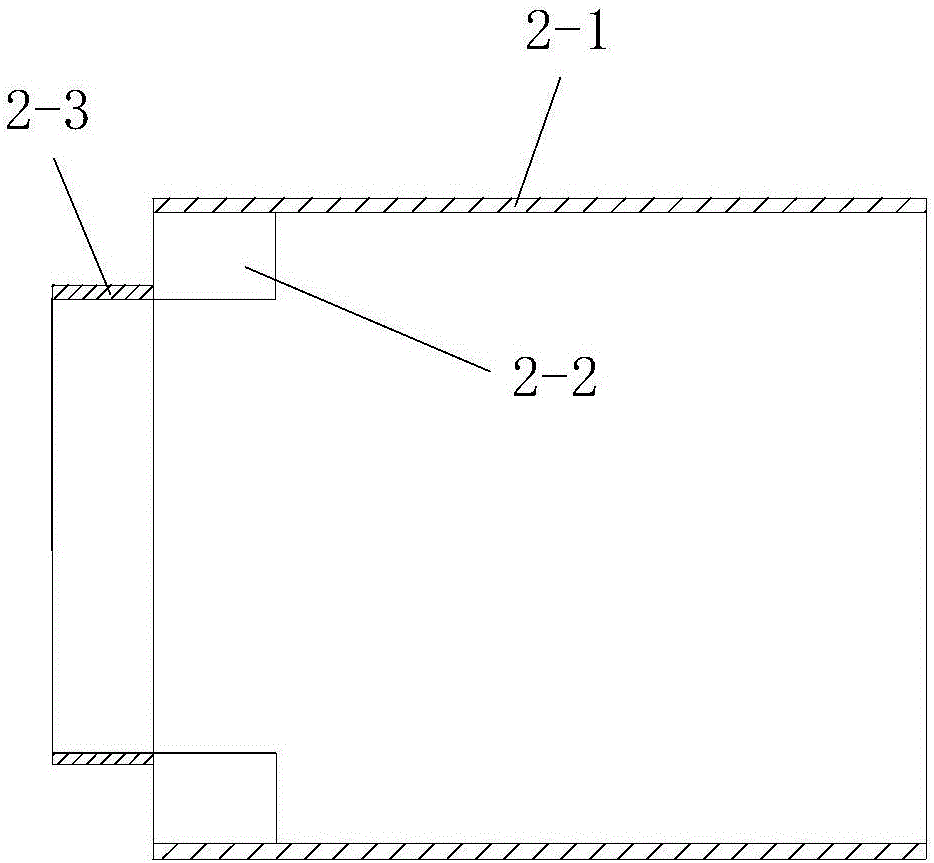

Silty soil stratum pipe-jacking jacking construction method based on tool pipe with steel sleeve head

ActiveCN106402490AThe method steps are simpleReasonable designPipe laying and repairStructural engineeringEngineering

The invention discloses a silty soil stratum pipe-jacking jacking construction method based on a tool pipe with a steel sleeve head. The method includes the steps that firstly, a work well is constructed, wherein the work well used for jacking a construction underground pipeline is constructed, the construction underground pipeline is formed by splicing a plurality of pipeline splicing joints, the tool pipe with the steel sleeve head comprises the steel sleeve pipe, a supporting ring installed on the inner side of the rear end of the steel sleeve pipe and an inserting port fixed to the supporting ring, the wall thickness of the steel sleeve pipe is 0.8-1.2 cm, and the length of the steel sleeve pipe is 80-120 cm; secondly, a jacking device is installed; thirdly, the tool pipe with the steel sleeve head is jacked, wherein the tool pipe with the steel sleeve head is hoisted in place, the tool pipe with the steel sleeve head is jacked, and a soil is manually excavated in the pipe; and fourthly, pipeline jacking is performed, wherein the pipeline splicing joints in the construction underground pipelines are jacked correspondingly from front to back. The method is simple in step, reasonable in design, easy and convenient to construct, good in using effect, capable of easily, conveniently and fast completing the silty soil stratum pipe-jacking jacking construction process and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

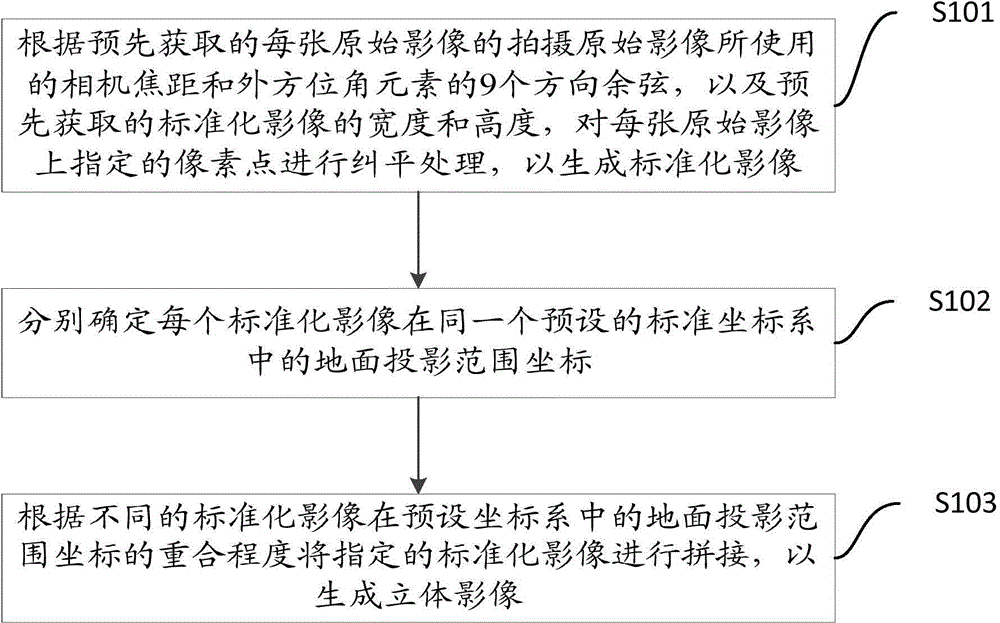

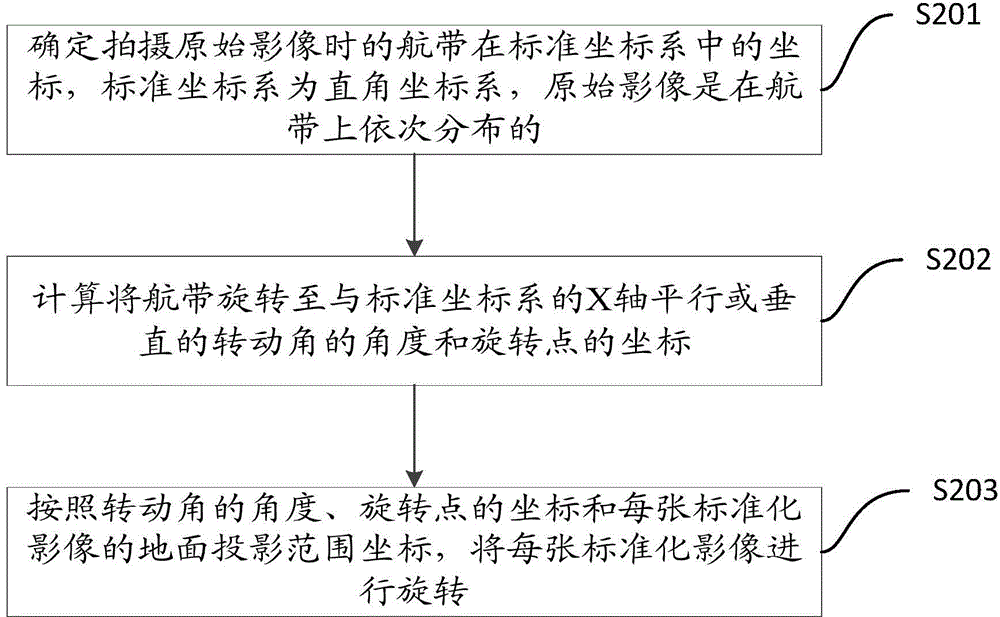

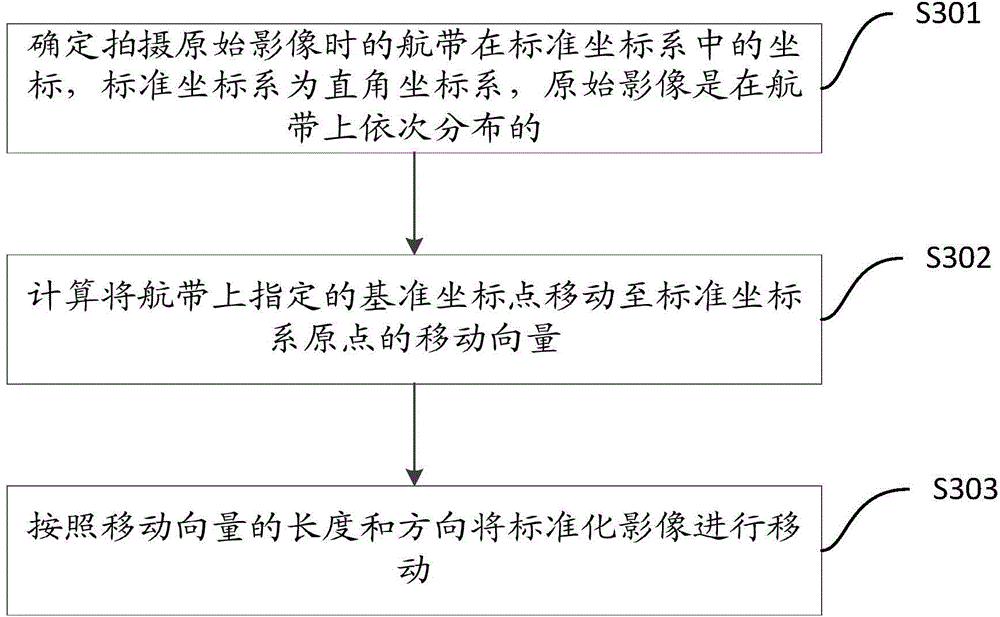

Panoramic three-dimensional image manufacturing method

ActiveCN104363438ASynthetic precisionDetermine coincidencePhotogrammetry/videogrammetrySteroscopic systemsImage correctionSurface projection

The invention provides a panoramic three-dimensional image manufacturing method, and in particular relates to the field of image synthesis. According to the panoramic three-dimensional image manufacturing method provided by the embodiment of the invention, by the adoption of an image correction mode, 9 direction cosines of an external azimuth angle element and camera calibration parameters are obtained from spatial three-dimensional encrypted data, pixel points on each original image are subjected to correction according to the width and the height of a pre-acquired standardized image, so that the standardized image is generated, and the inclinations of the original images caused by inclination of a shooting angle can be corrected, therefore, the original images can be perpendicular front view images and can be easily spliced during synthesis of a three-dimensional image; furthermore, coordinates of each standardized image within a bottom surface projection range are determined in a standard coordinate system, so that the superposition degree of the standardized images can be precisely determined, and thus the synthesis of the three-dimensional image is precisely finished, namely the synthesis of the three-dimensional image is finished under a condition that DEM data are not used.

Owner:CHINA TOPRS TECH

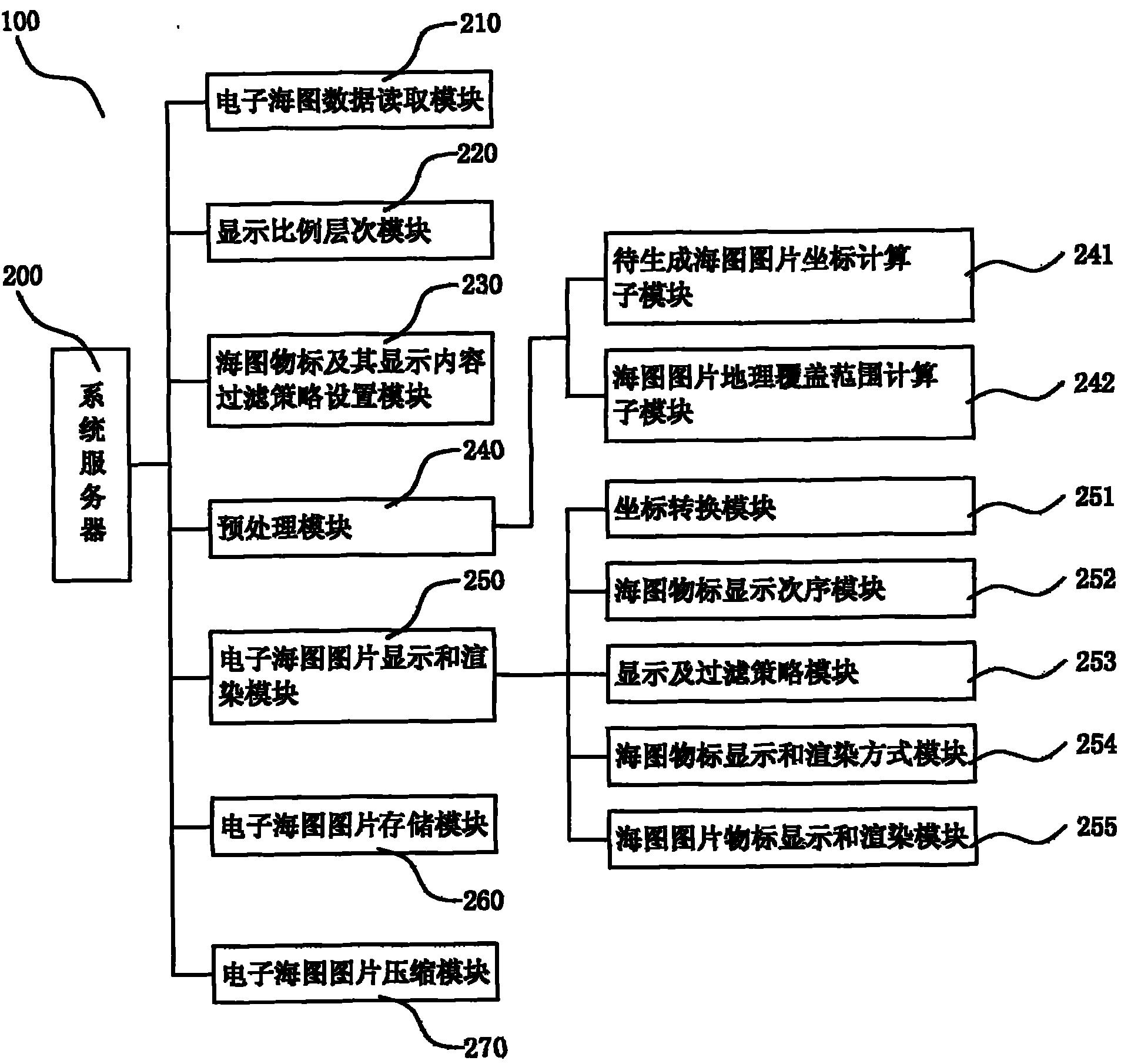

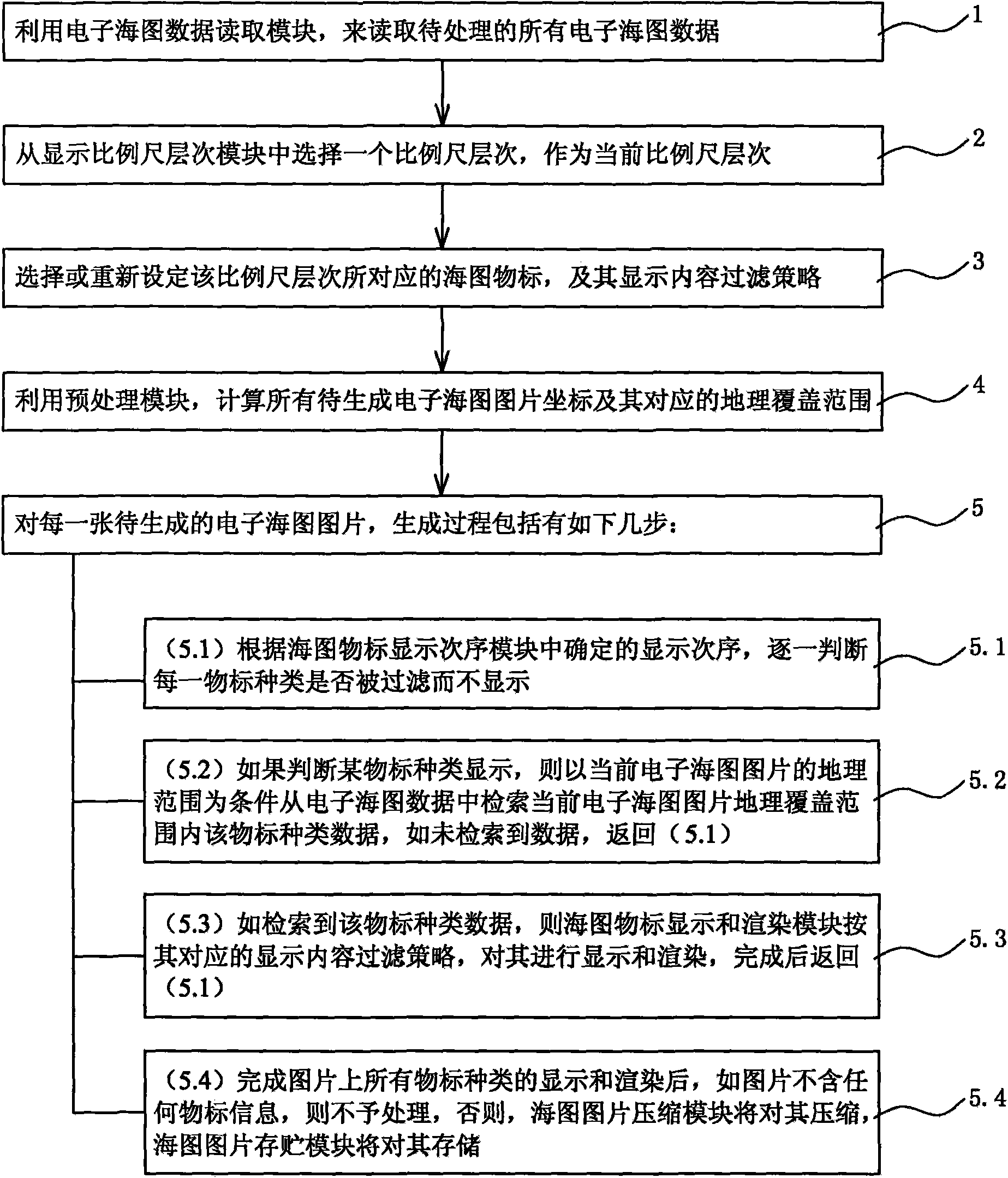

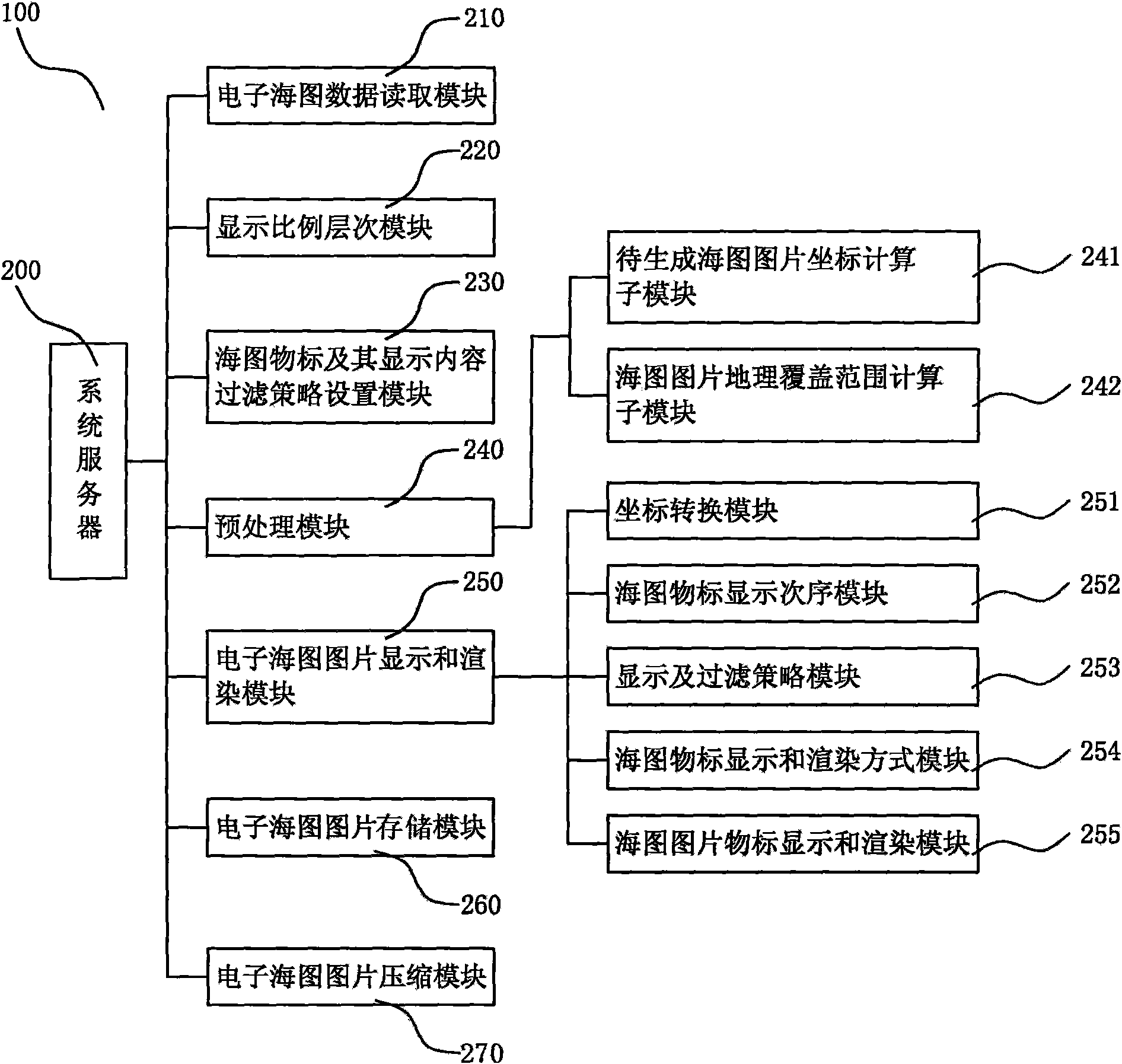

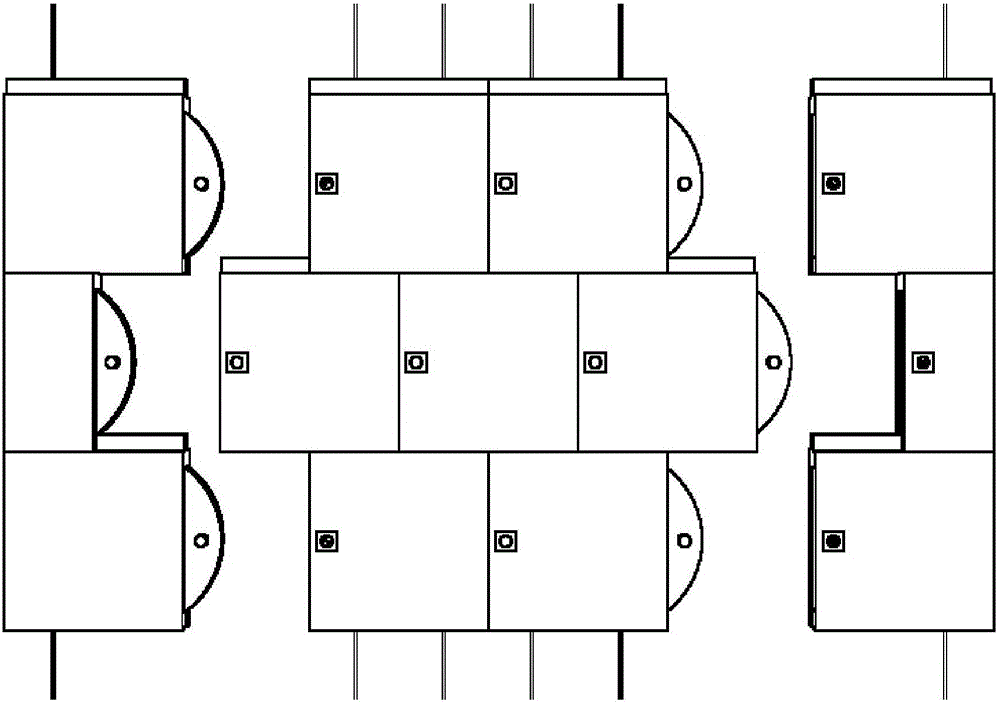

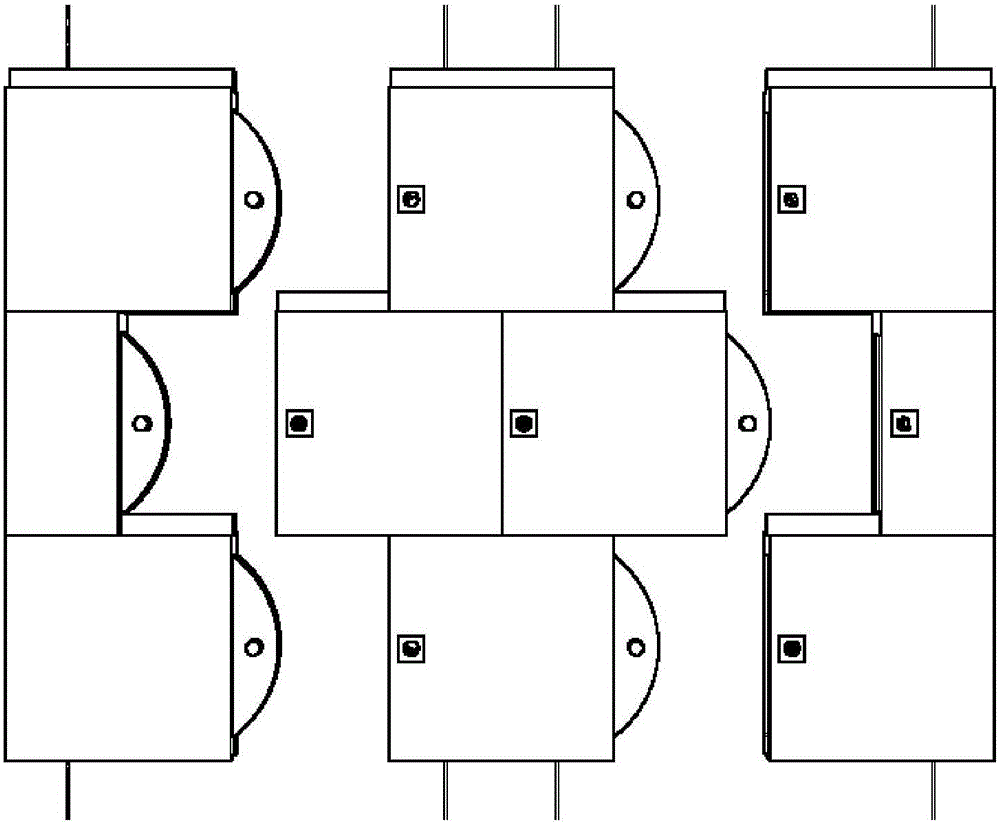

System and method for generating electronic chart pictures capable of being seamlessly spliced

InactiveCN101783010ASimple stitchingPromote generationImage enhancementImage analysisComputer graphics (images)Chart datum

The invention discloses a system and a method for generating electronic chart pictures capable of being seamlessly spliced, wherein the system mainly comprises an electronic chart data read module, a proportion level display module, a preprocessing module, a chart object, a display content filtering strategy setting module, an electronic chart picture display and render module and an electronic chart picture storage module, whereas in an implement method, a chart picture proportional scale can be set by utilizing the proportion level display module, and the chart object and the content thereof can be selectively displayed by utilizing the chart object and the display content filtering strategy setting module thereof, thereby enabling a generated picture to be simpler; the geographical coverage range of all electronic chart pictures capable of being seamlessly spliced can be calculated by utilizing the preprocessing module; and attractive electronic chart pictures can be generated by utilizing the electronic chart picture display and render module. Based on the characteristics, the generated electronic chart pictures can be seamlessly spliced and are simple and attractive by utilizing the system and the method.

Owner:SHANGHAI MARITIME UNIVERSITY

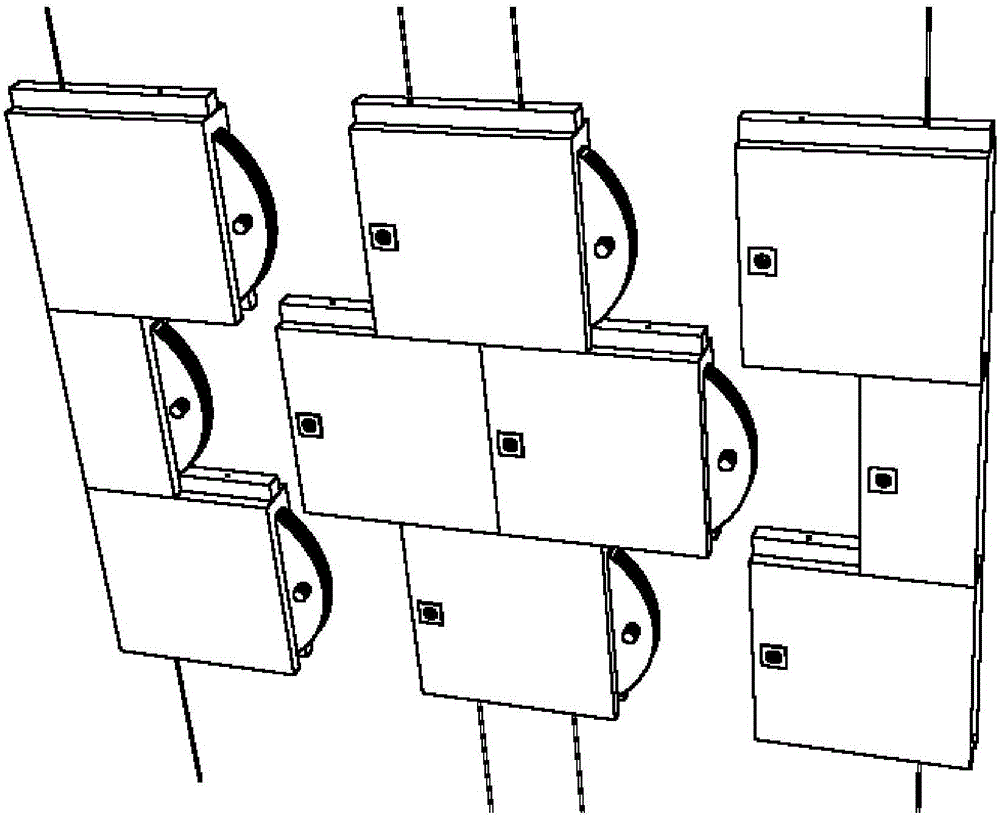

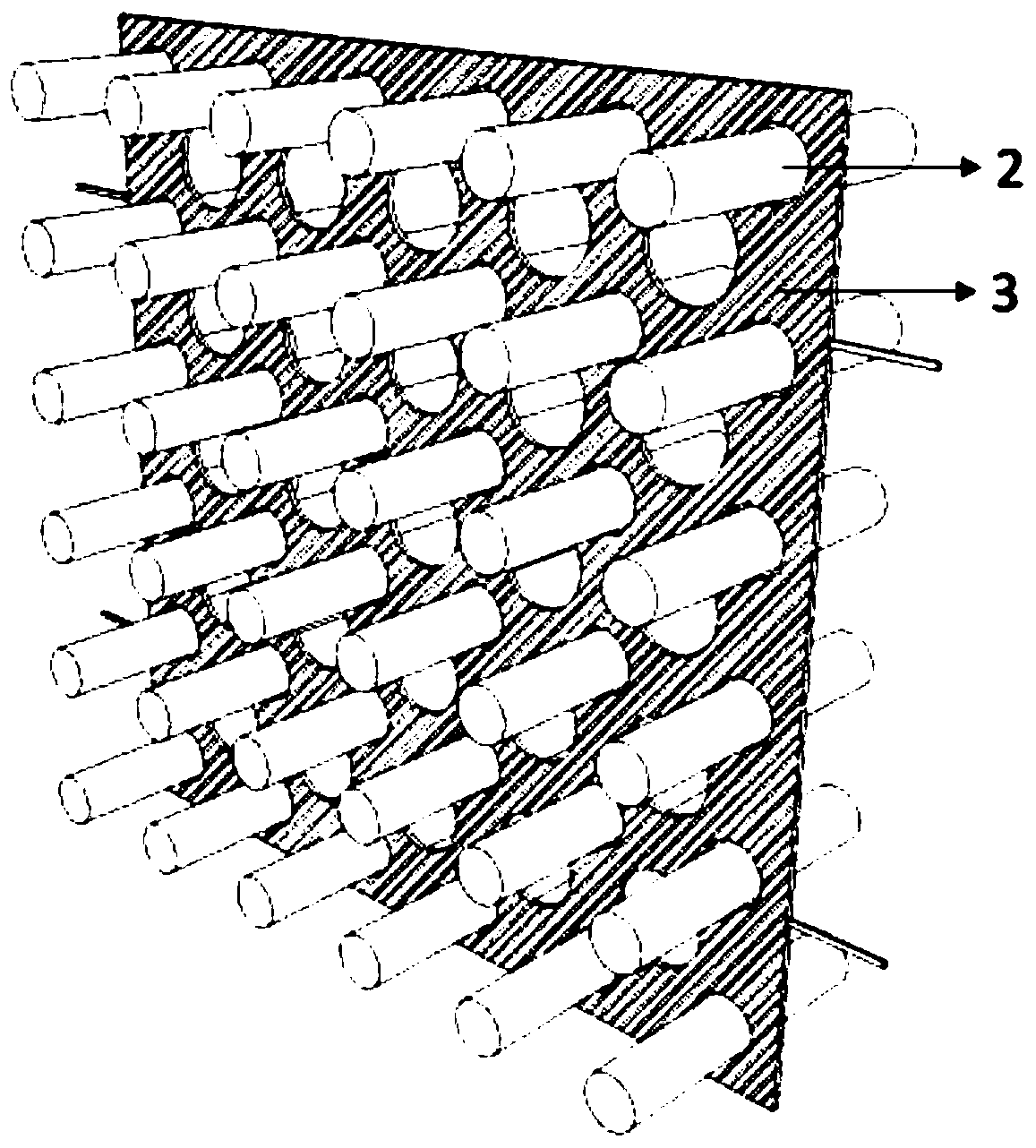

Industrialized building partition wall beneficial for structural seismic resistance

InactiveCN105926800ARealize cleaner productionShort construction periodWallsProtective buildings/sheltersSeismic resistanceBolt connection

The invention provides an industrialized building partition wall beneficial for structural seismic resistance. The industrialized building partition wall is formed by splicing a plurality of prefabricated wallboards, wherein one side of one prefabricated wallboard is provided with an inner layer arc protrusion, the inner layer arc protrusion can be spliced with a groove in another prefabricated wallboard, and after being spliced, the two prefabricated wallboards can be fixed through bolted connection. The building partition wall has the advantages that the prefabricated wallboards are not large in size and easy to splice, facilitate construction and do not affect main body structural seismic resistance, and seismic resistance of a main body structure can be enhanced. Industrial application can be implemented in seismic resistance of buildings.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

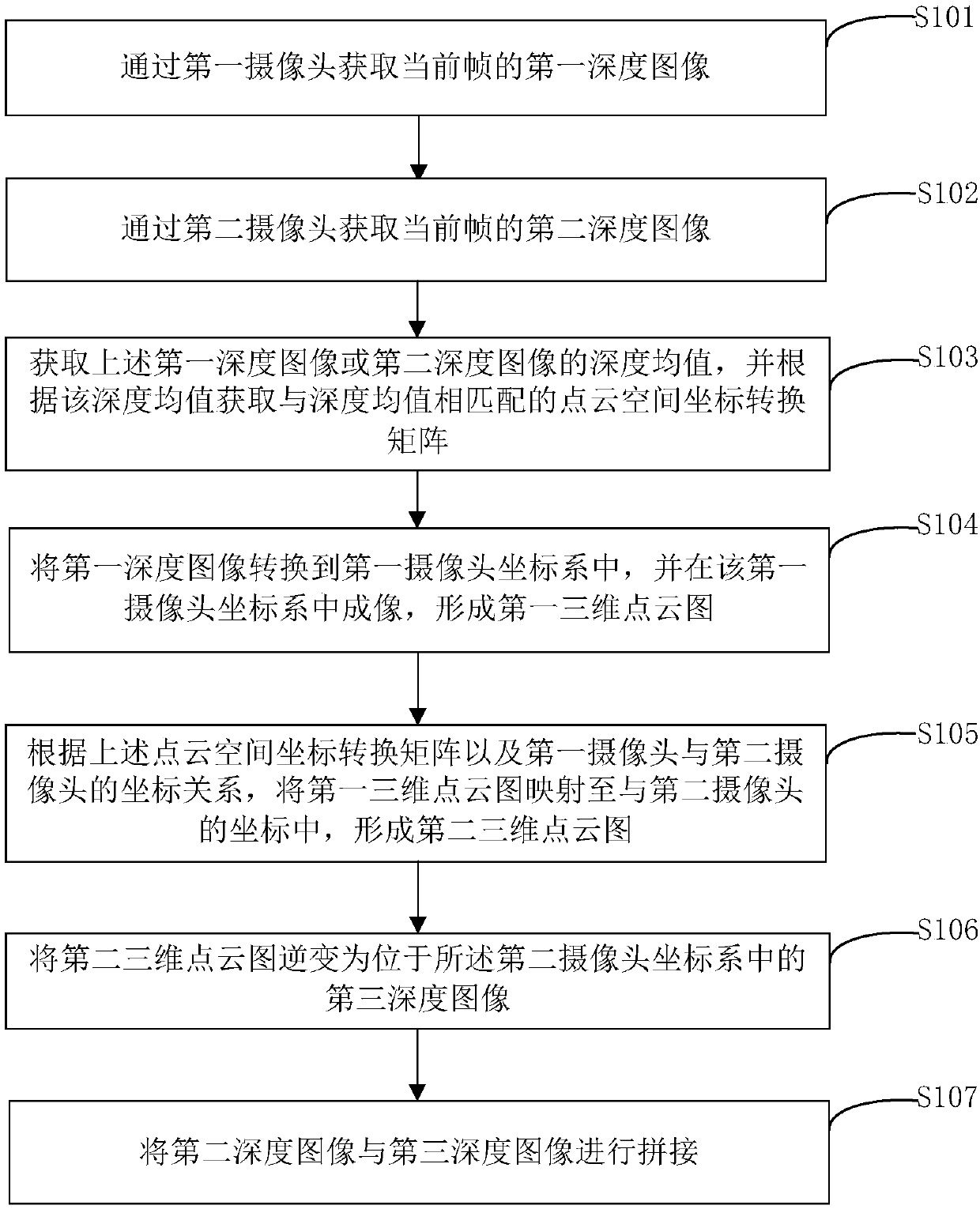

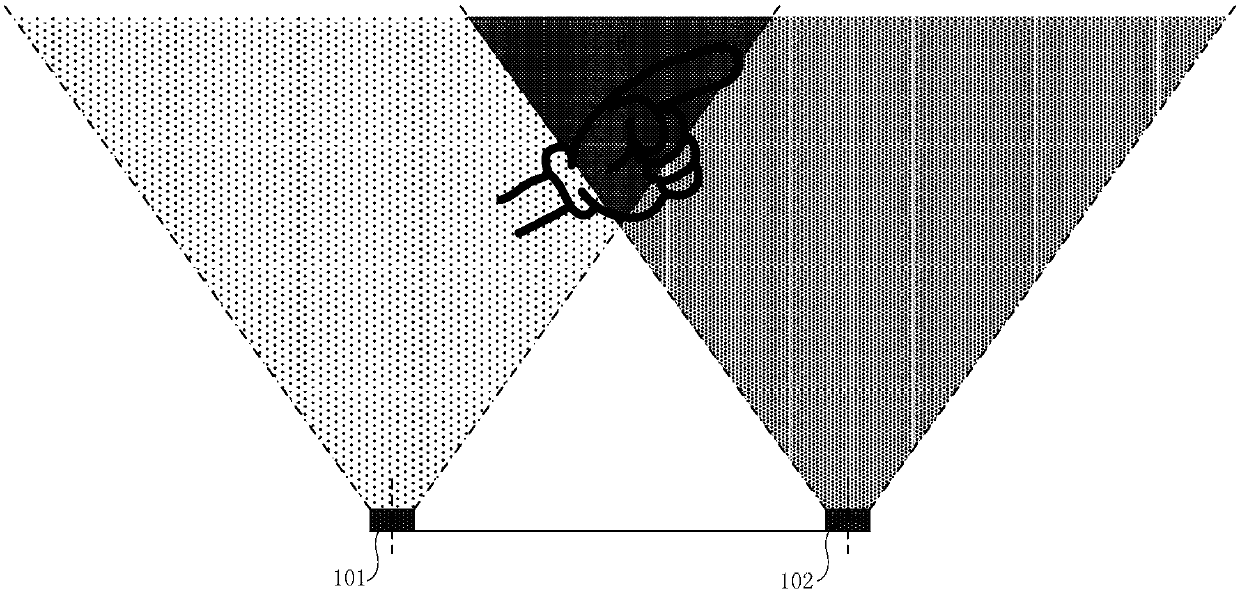

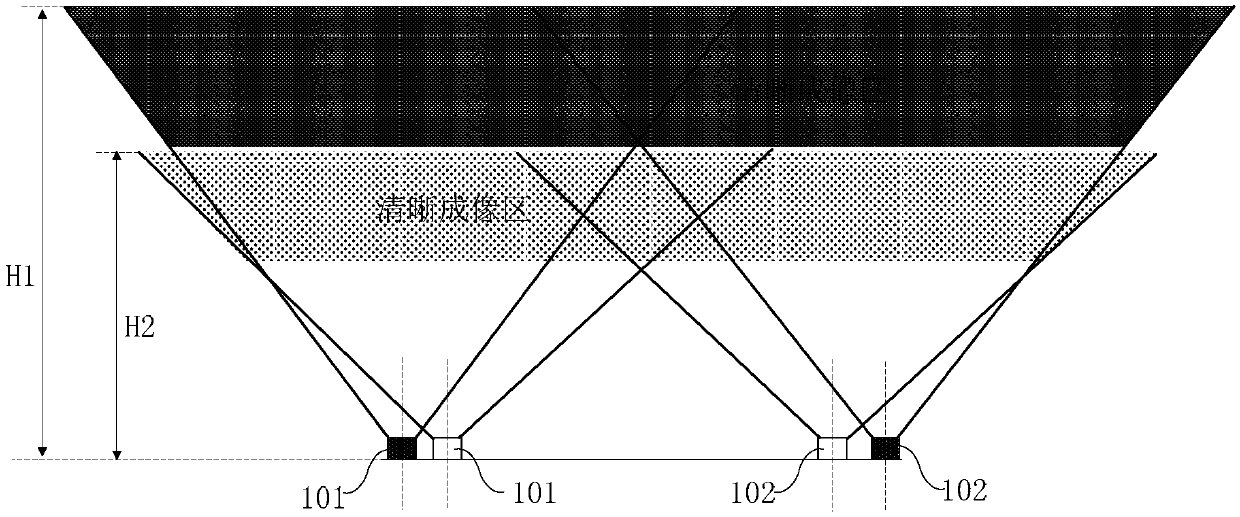

Image splicing method, computer device, and display device

ActiveCN108470323AThe overall calculation is smallSimple stitchingImage enhancementImage analysisComputer deviceTransformation matrix

Embodiments of the present invention provide an image splicing method, a computer device, and a display device, and relate to the technical field of display, which is used to solve the problem that the image splicing is performed by using a differential algorithm, resulting in a slow splicing speed. The image splicing method includes steps of: acquiring a first depth image of a current frame by using a first camera; acquiring a second depth image of the current frame by using a second camera; acquiring a depth average of the first depth image or the second depth image, and acquiring a point cloud space coordinate transformation matrix matched with the depth average; converting the first depth image into a first camera coordinate system, and performing imaging in the first camera coordinatesystem to form a first three-dimensional point cloud image; mapping the first three-dimensional point cloud image to in the second camera coordinate system to form a second three-dimensional point cloud image; inverting the second three-dimensional point cloud image into a third depth image located in the second camera coordinate system; and splicing the second depth image with the third depth image.

Owner:BOE TECH GRP CO LTD

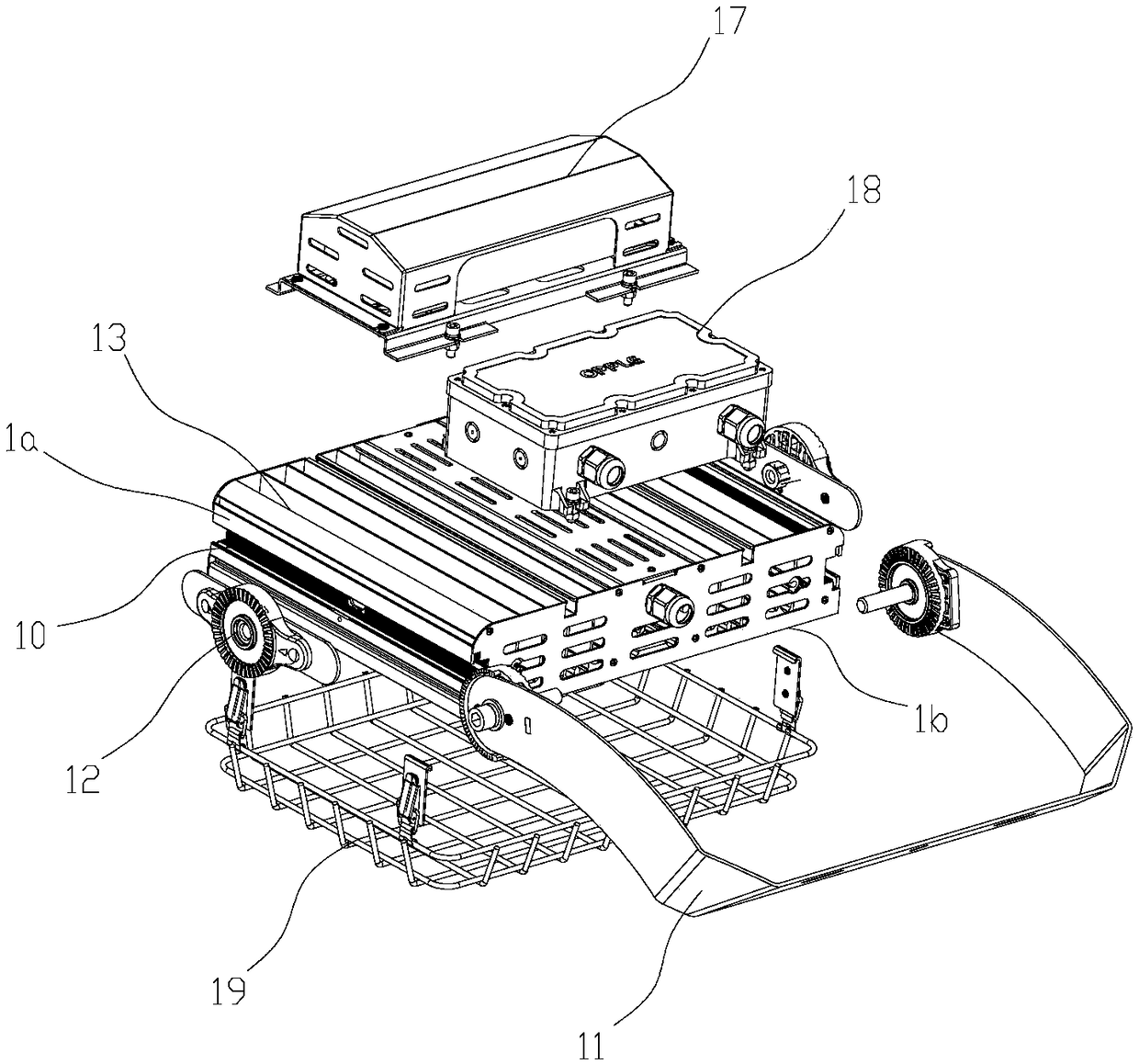

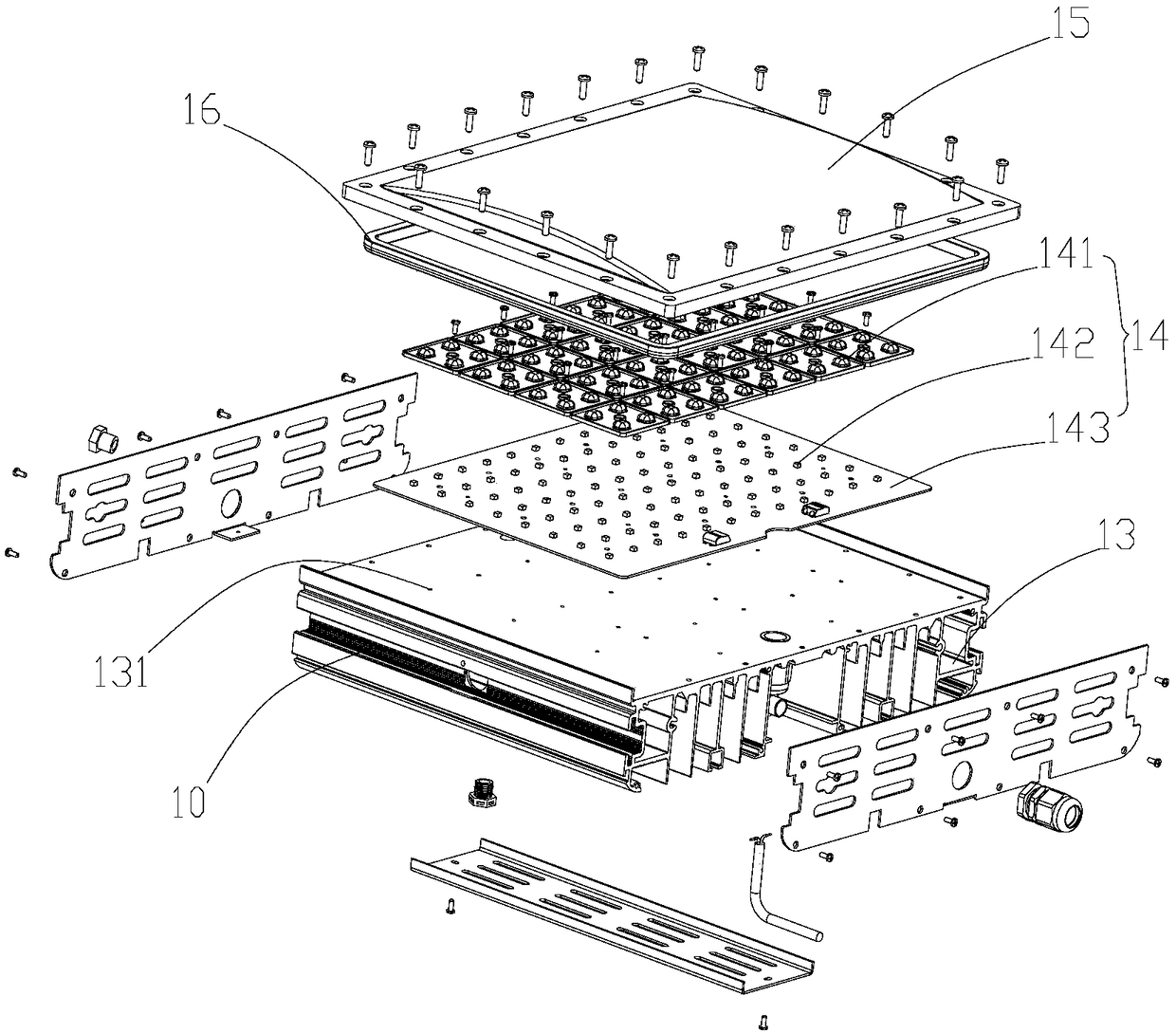

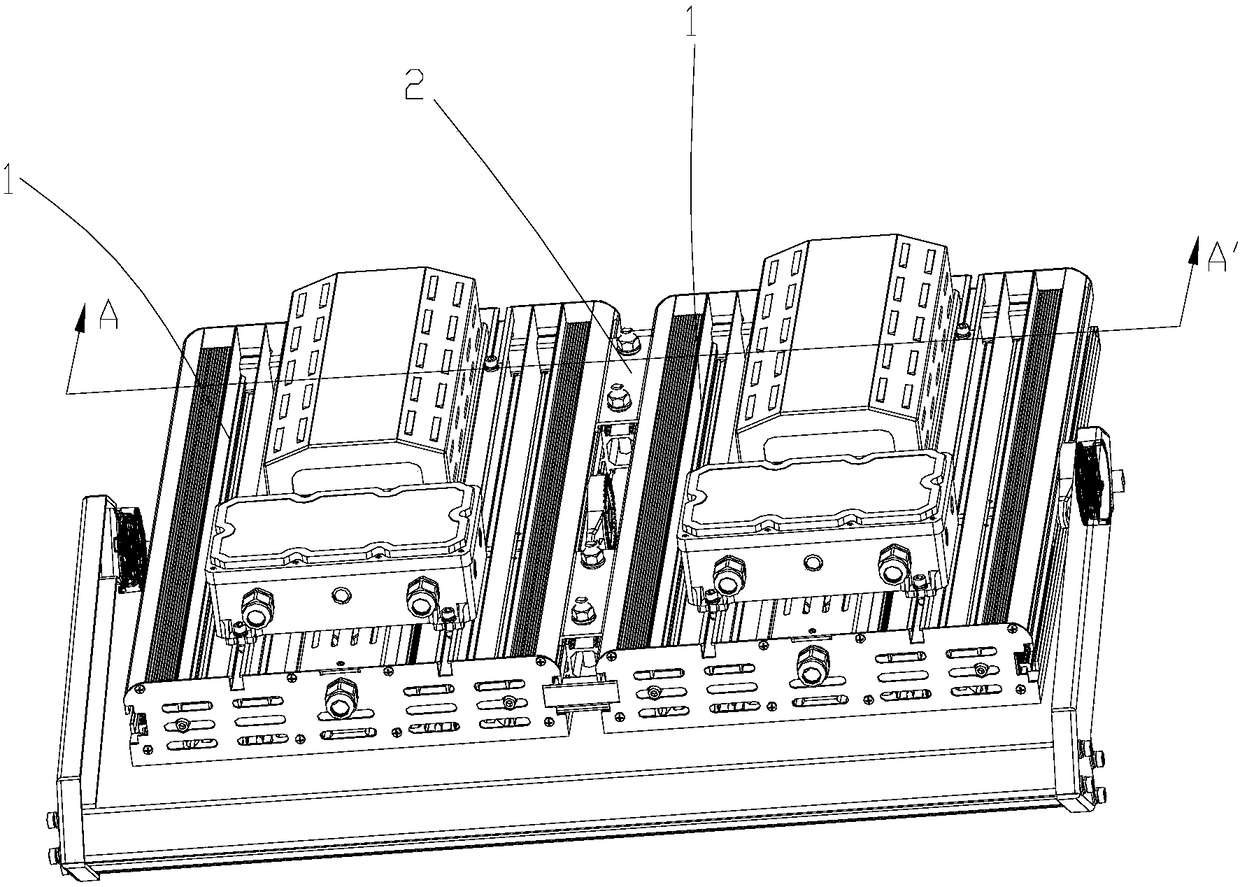

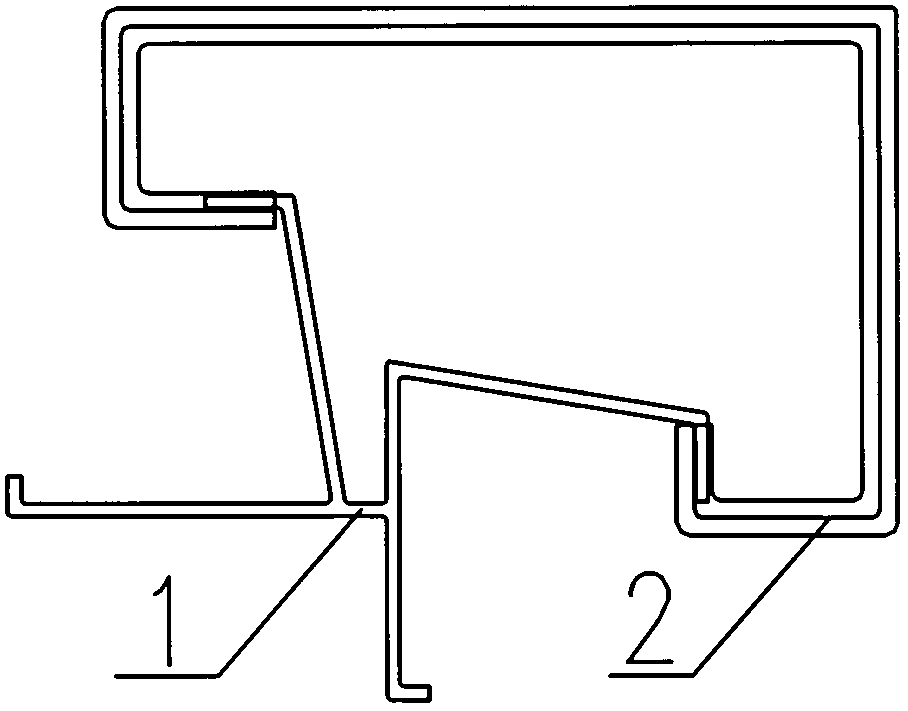

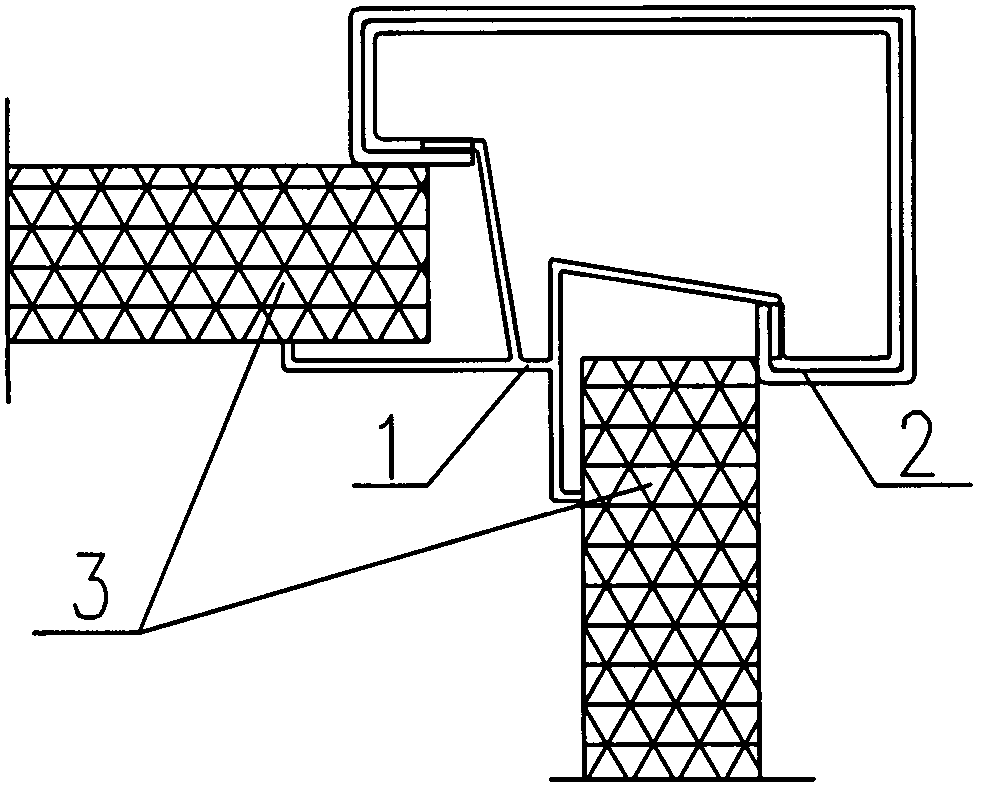

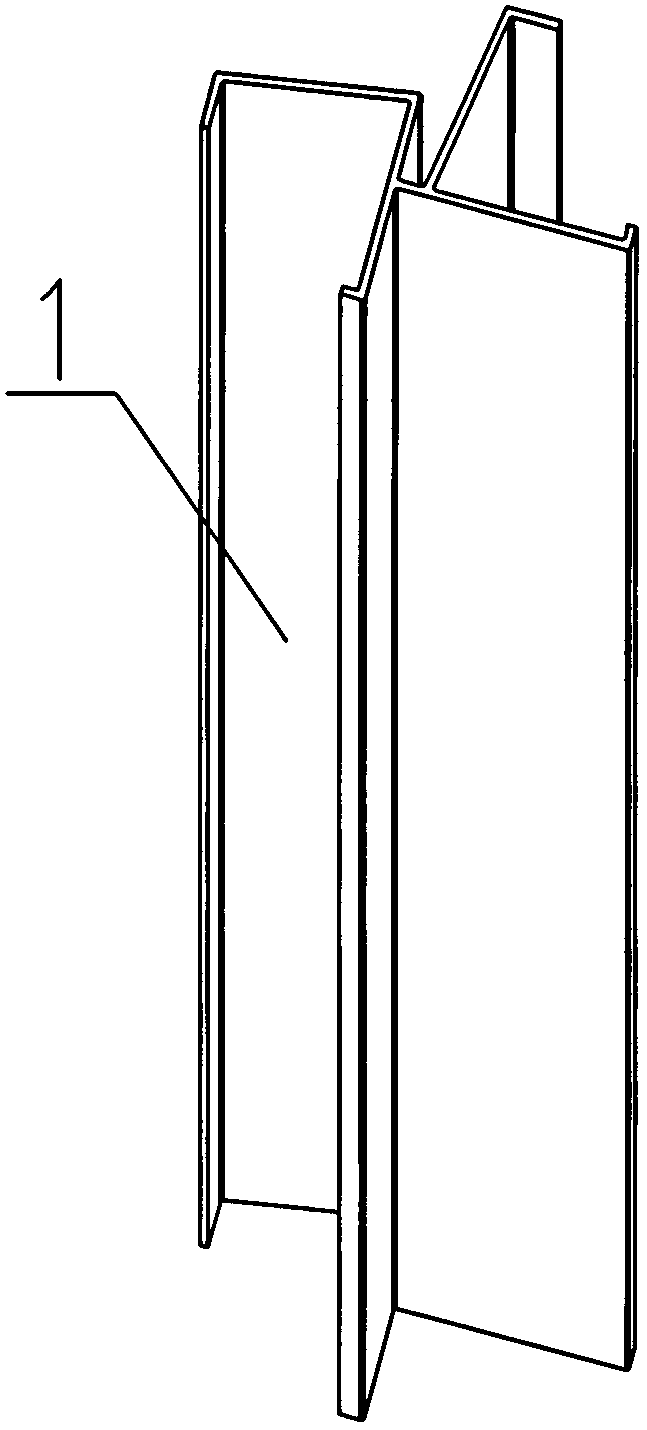

Lamp and lamp assembly

PendingCN108518620AThe splicing process is simpleSimple stitchingLighting support devicesFixed installationEngineeringLight fixture

The invention discloses a lamp and a lamp assembly. The lamp is provided with splicing structures and connection sides. The splicing structures are arranged on the connection sides. Each splicing structure comprises a first clamping groove and a second clamping groove which are identical in extension direction. The directions of groove openings of the first clamping groove and the second clampinggroove of each splicing structure are opposite. Two lamps can be splicing through a lamp connection module to form the lamp assembly. The lamp connection module comprises first lamp connectors and second lamp connectors. Each first lamp connector can be connected with the first clamping grooves of the two lamps in a clamped manner at the same time. Each second lamp connector can be connected withthe second clamping grooves of the two lamps in a clamped manner at the same time. Each first lamp connector and the corresponding second lamp connector are detachably fixed to each other. The splicing process is greatly simplified.

Owner:SUZHOU OPPLE LIGHTING +1

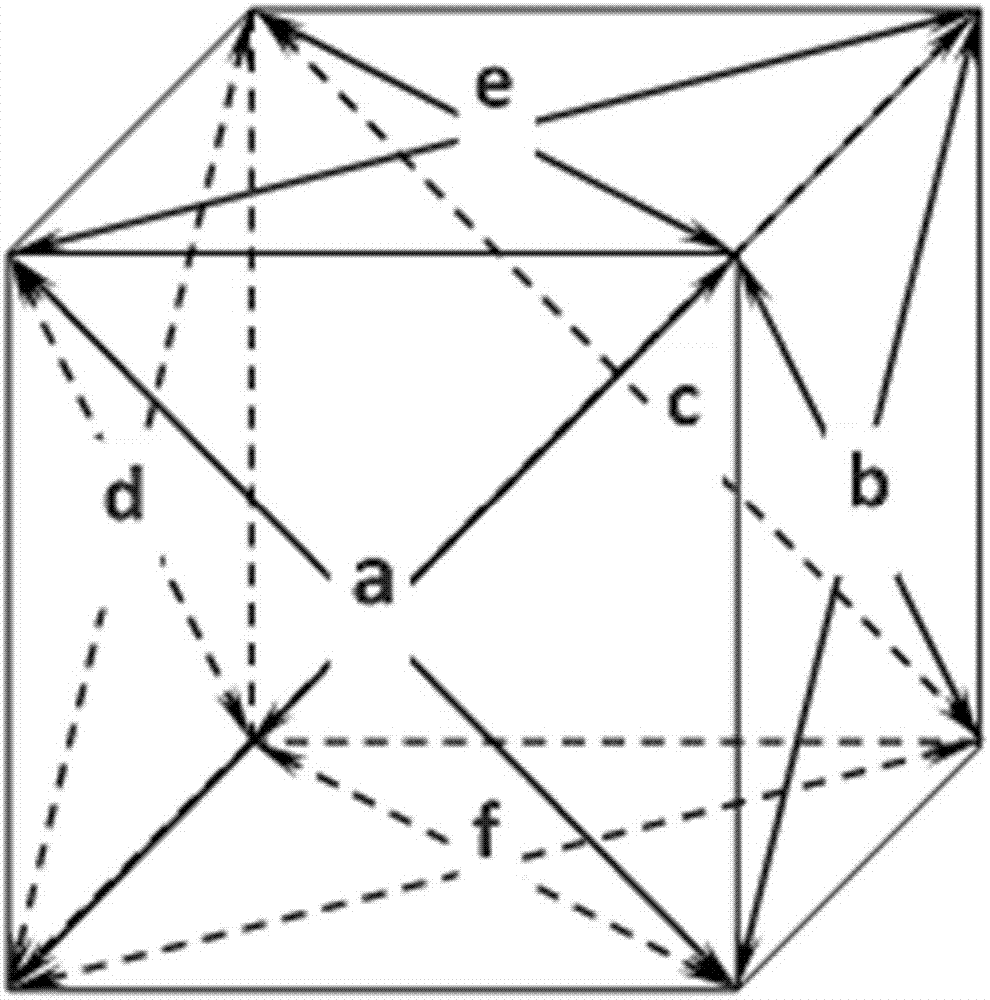

Method for quickly stitching panoramic image of cube

ActiveCN107358577AGood for compression codingQuick stitchingImage analysisGeometric image transformationCamera lensTransformation parameter

The invention discloses a method for quickly stitching a panoramic image of a cube. The method herein includes the following steps: arranging a panoramic camera, simultaneously photographing a front space in the front, rear, left, right, above and below directions; calibrating the panoramic camera, acquiring a distortion correction parameter, further acquiring a linear transformation parameter and a cropping parameter of respective image; photographing scenes by using the panoramic camera, firstly conducting distortion correction on a camera lens by using the distortion parameter, then conducting rotation transformation and transverse transformation on each image by using the linear parameter; cropping the obtained 6 images in the centers in accordance with the cropping parameter, such that the 6 images are approximately the same in size and have a visual angle of 90 degrees in the horizontal direction and the vertical direction, and eventually, separately placing the squares which are obtained by cropping the 6 images at places where the panoramic image of a plane cube and the photographing camera correspond. According to the invention, the method only requires one time calibration process, can repeatedly use calibration parameters, simplifies the stitching process, accelerates the stitching speed, and saves great stitching time.

Owner:XI AN JIAOTONG UNIV

Through type silver and copper composite ingot and making method for strips

ActiveCN108080414AHigh bonding strengthSimple structureConductorsWelding/soldering/cutting articlesGroove widthWork roll

The invention provides a through type silver and copper composite ingot and a making method for strips. The making method for strips comprises the steps of adopting a roll group of an irregular shape,wherein the roll group of the irregular shape is a pair of working rolls in the roll system of a four-roll solid phase complex rolling mill, and a groove is formed at the center of each working roll;making copper frames with the fixed width, and corresponding copper bars and silver bars according to the negative allowance of the groove widths of the rolls with irregular shapes, and carrying outsurface treatment on the copper frames, the copper bars and the silver bars; placing different number of copper bars and different number of silver bars tightly into one copper frame in an alternate arrangement manner as needed to form one complex blank, namely a complex ingot; and finally, carrying out processing to form complex silver and copper strips. According to the through type silver and copper composite ingot and the making method for strips, because the complex ingot made with the through type method has the advantages of being simple in structure and easy to split, the subsequent processing technologies are optimized, and the production period is shortened; and because of the improvement on the roll system of the four-roll solid phase composite rolling mill, the strength of silver and copper side composite strips is effectively improved.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

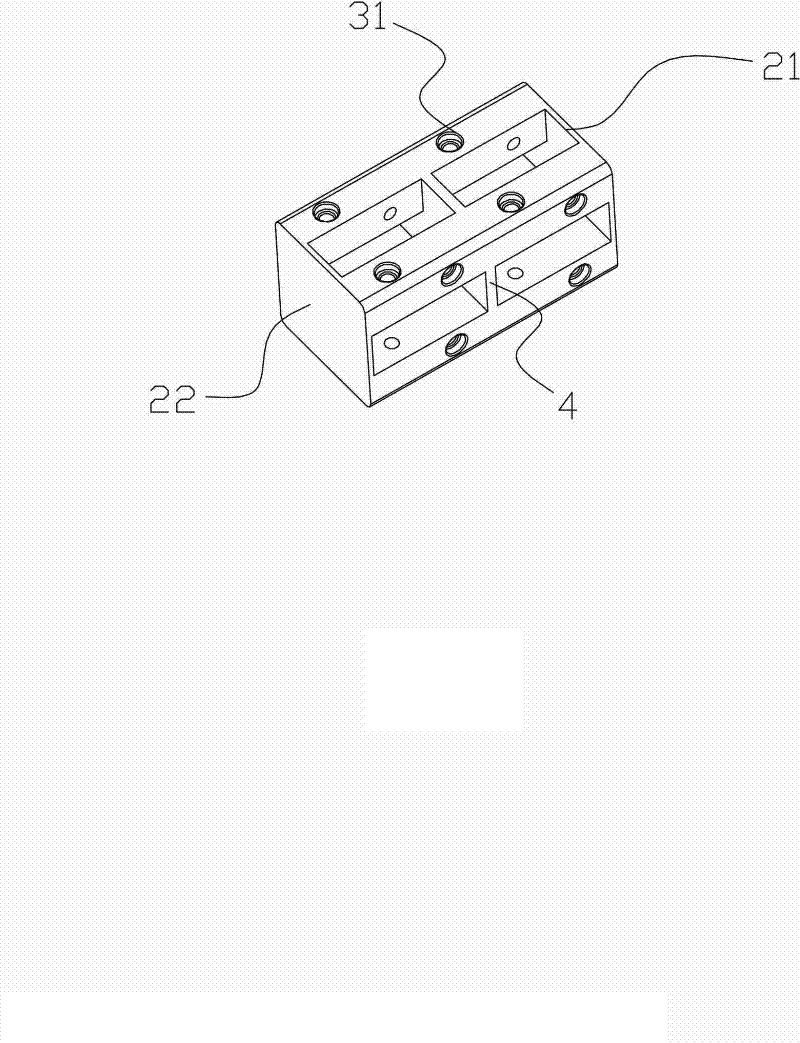

Clamping groove device for fixing wall plates

The invention discloses a clamping groove device for fixing wall plates. The clamping groove device for fixing the wall plates comprises a steel angle and a clamping groove; the clamping groove is provided with four sides, wherein two sides are inserted into the notches in the two sides of the steel angle; the steel angle and the clamping groove are fixed by sleeving mutually; one section of a wall plate is embedded into the clamping groove to achieve the effect of connecting the wall plates in a corner.

Owner:SUZHOU TIANDI COLORBOND MFG

Method used for transverse bridging splicing growth of large-area monocrystal diamond

PendingCN108677246ASimple stitchingStable splicingPolycrystalline material growthFrom chemically reactive gasesSingle crystalDiamond substrate

The invention discloses a method used for transverse bridging splicing growth of large-area monocrystal diamond. According to the method, monocrystal diamond substrate I and monocrystal diamond substrate II are subjected to splicing, growth of a bridge-shaped connection part at the joint part is realized, and a complete large-area monocrystal diamond layer is obtained through continuous epitaxialgrowth; wherein the thickness of the monocrystal diamond substrate I at the joint part is lower than that of the monocrystal diamond substrate II at the joint part. The method is capable of solving problems in the prior art that the joint part is obvious, and diamond relative movement is easily caused in diamond splicing growth, and cracking risk at the joint part is reduced.

Owner:西安德盟特半导体科技有限公司

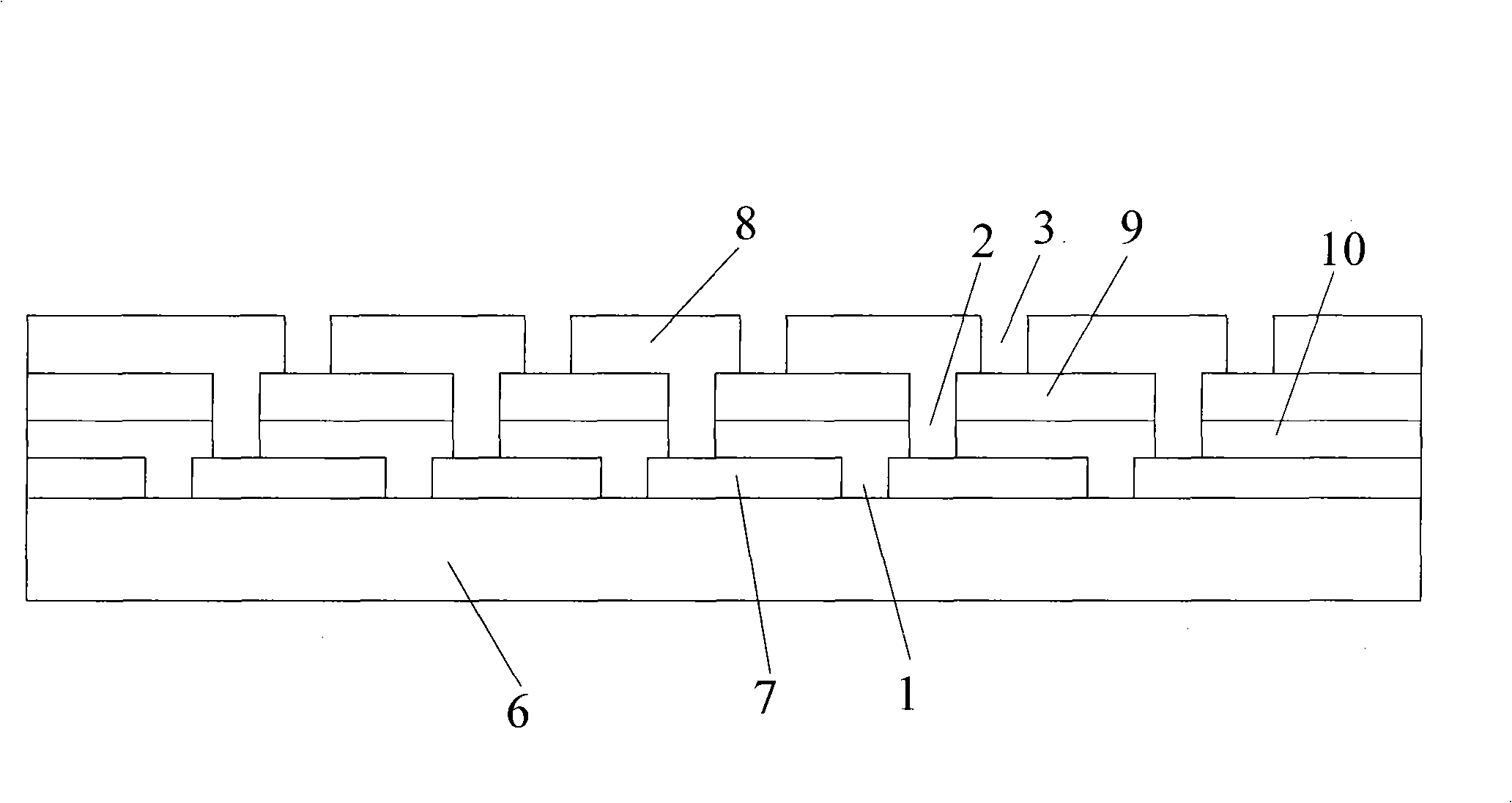

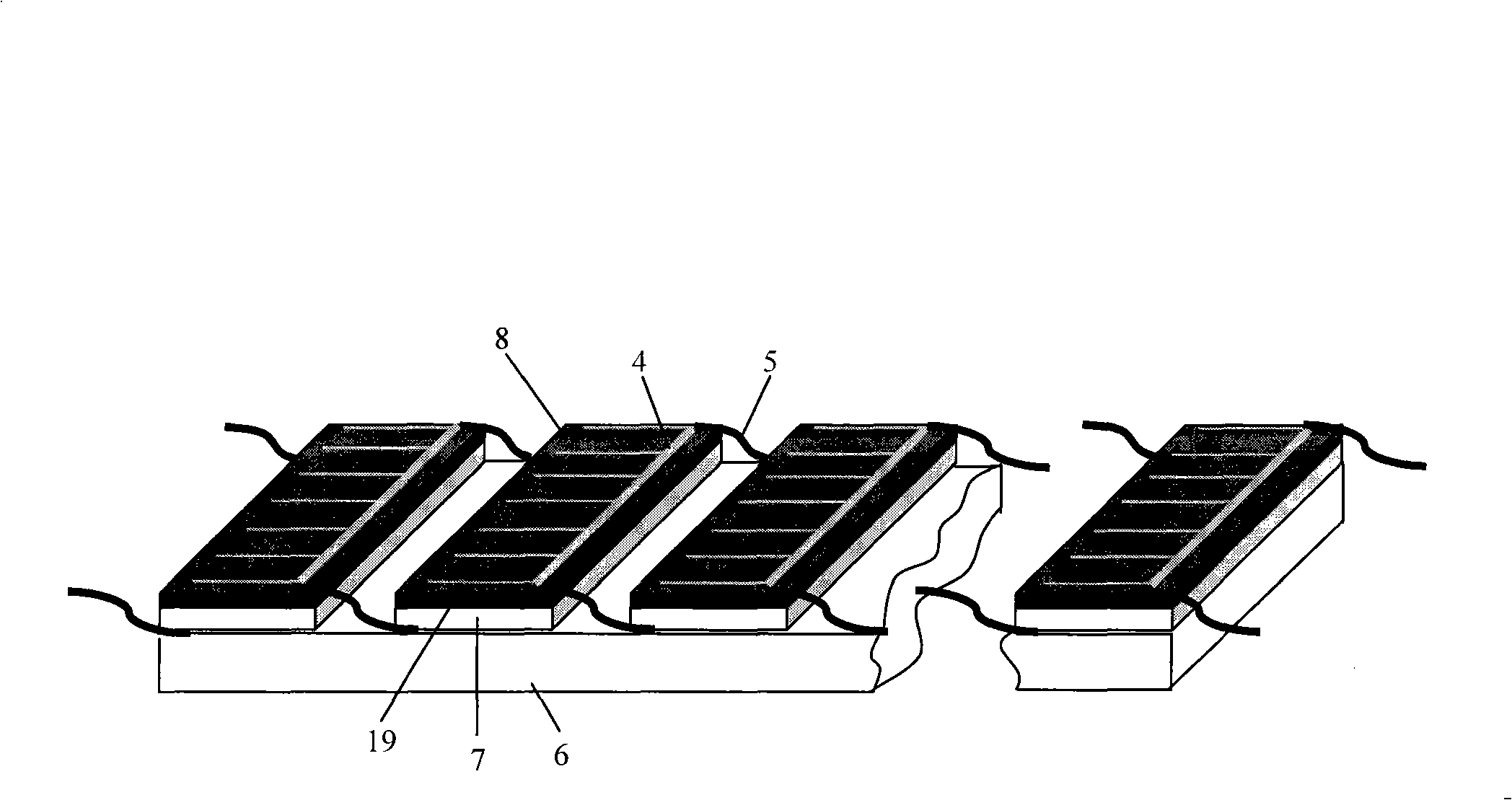

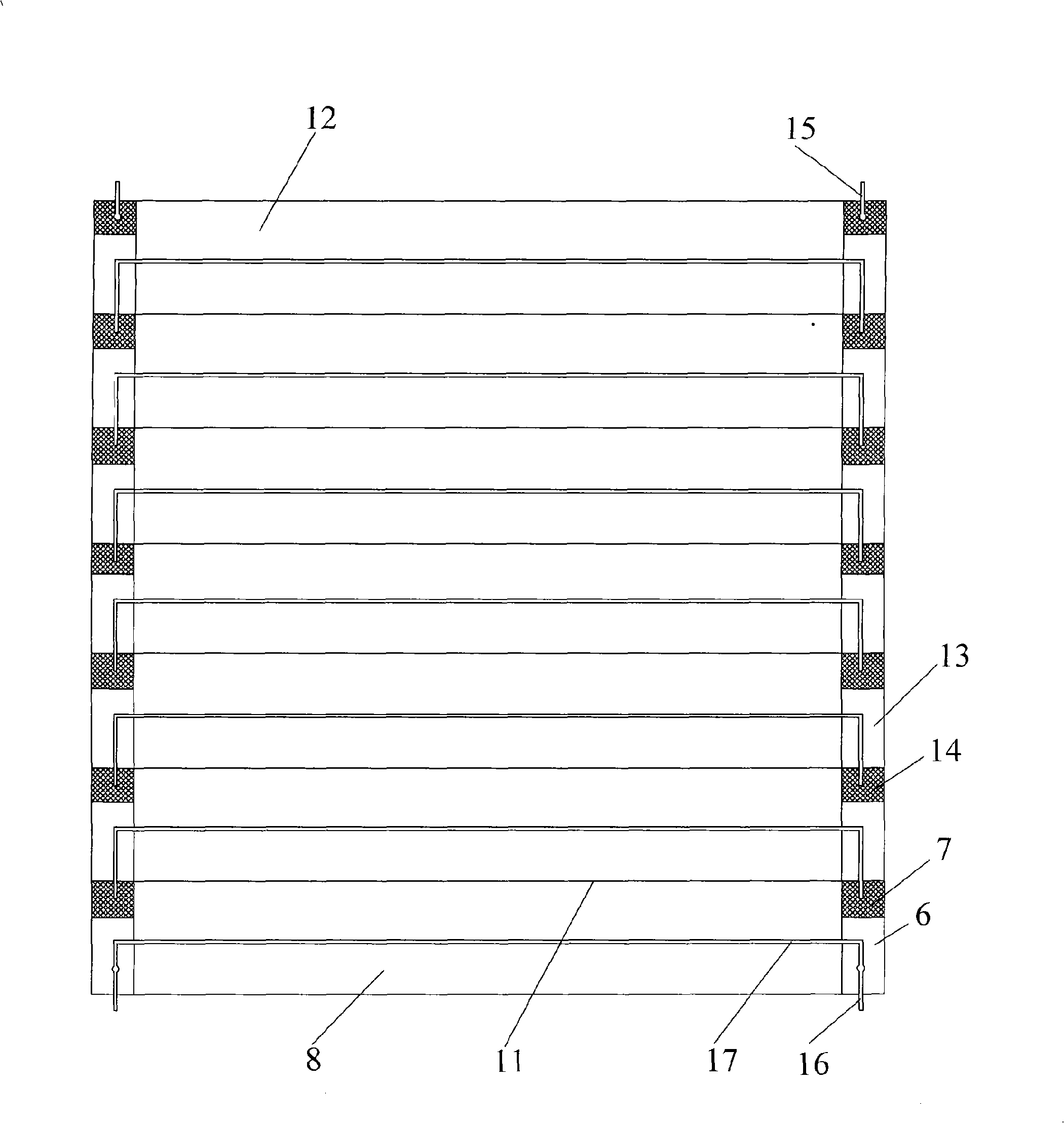

Film solar cell module and method for processing the same

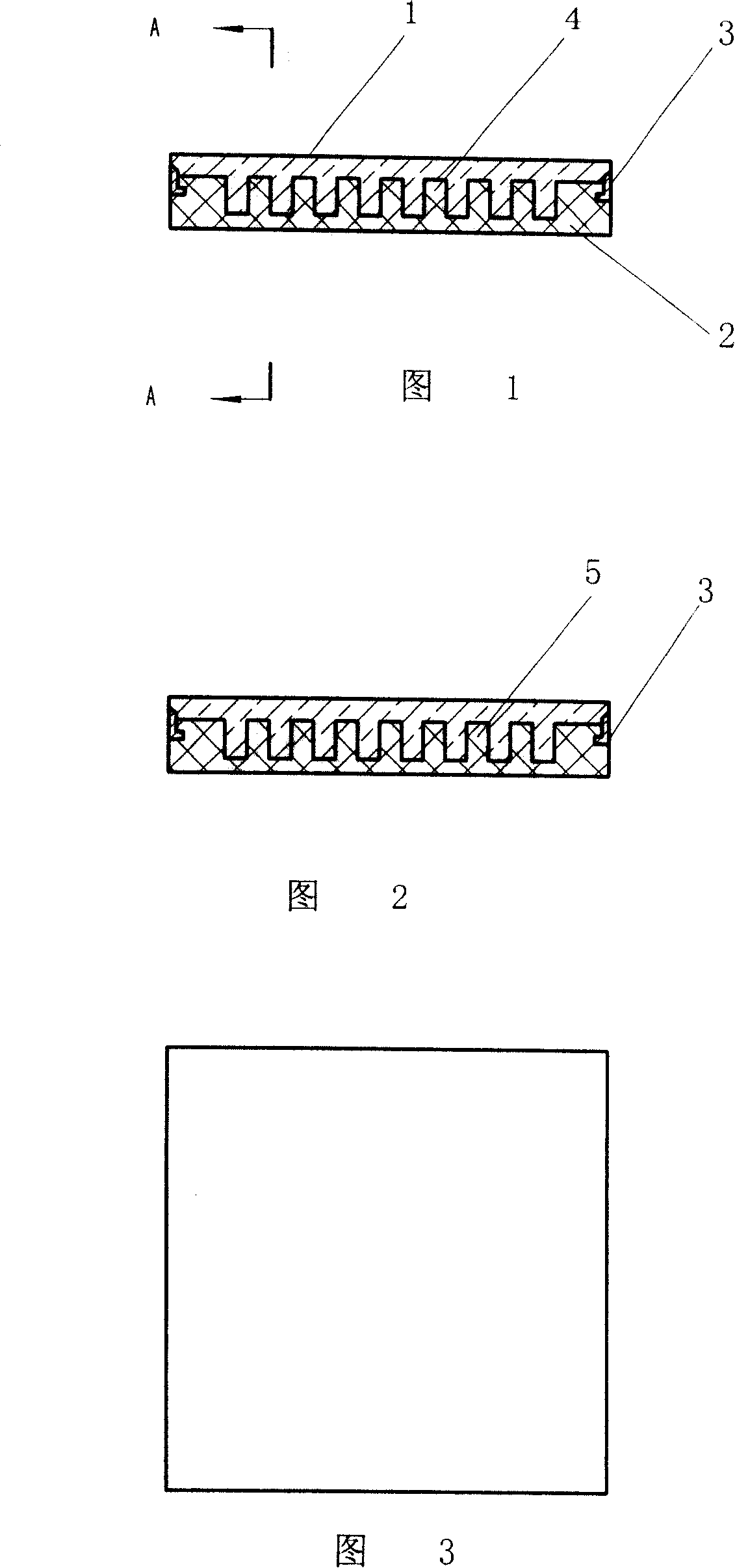

InactiveCN101350375AReduce processing timeThe process steps are simpleFinal product manufacturePhotovoltaic energy generationModular unitEngineering

The invention discloses a thin film solar battery module and a process for preparing the module, wherein the module is divided into a plurality of modular units by a scribing groove, an extraction electrode is respectively arranged on phototropic conductive film of each modular unit, and both ends of the extraction electrode are connected with negative phototropic conductive film of a next modular power supply. The process for preparing the module comprises the following steps: arranging a plurality of the extraction electrodes on phototropic conductive film after plating the negative phototropic conductive film, a generating layer and the phototropic conductive film on a substrate, or orderly arranging the extraction electrodes, the phototropic conductive film and the generating layer and the negative phototropic conductive film on the substrate, then cutting the module to by a scribing machine form a plurality of the modular units, enabling each of the modular unit to have the extraction electrode, and the extraction electrode of each unit is connected with the negative phototropic conductive film of the next unit, lastly packing into a battery module. The method reduces the technique time, greatly simplifies the technique steps, reduces the pollution to the battery, which is caused by the multitime scribing and the washing, simultaneously, the invention has the advantages that the cost of manufacturing devices is low, the depletion of the electric energy production of the module is low, the product weight is light, and the freedom degree of designing the standard parameter of the battery is high and the like.

Owner:OPTORUN SHANGHAI CO LTD

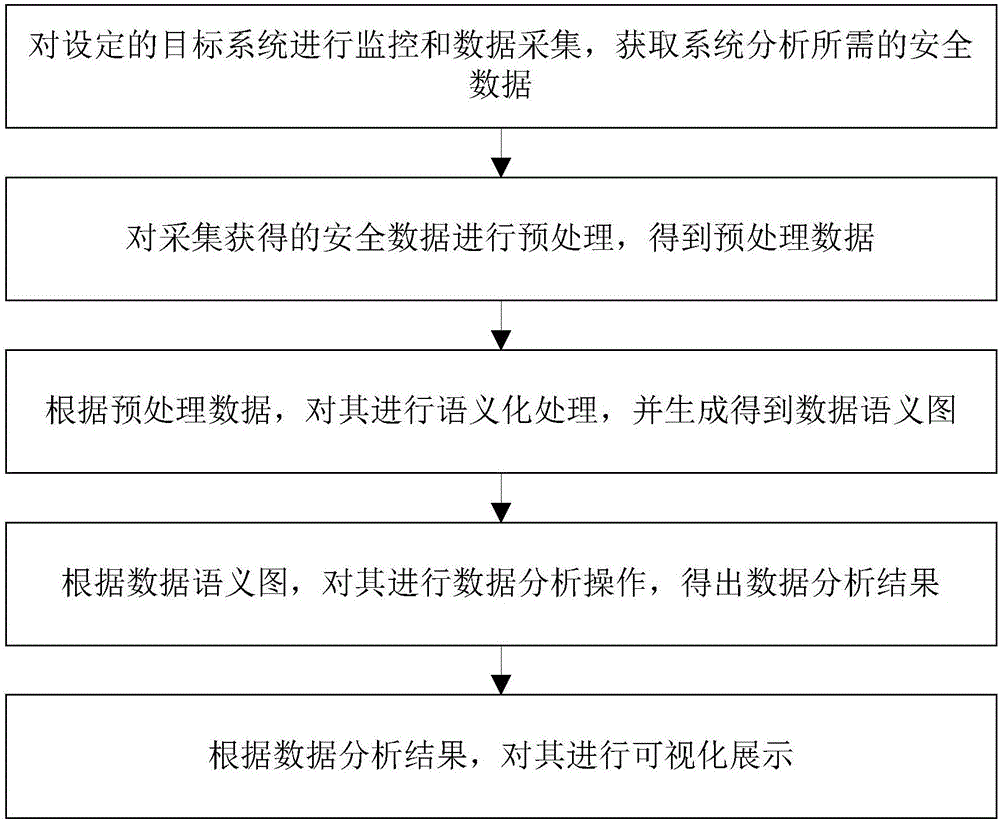

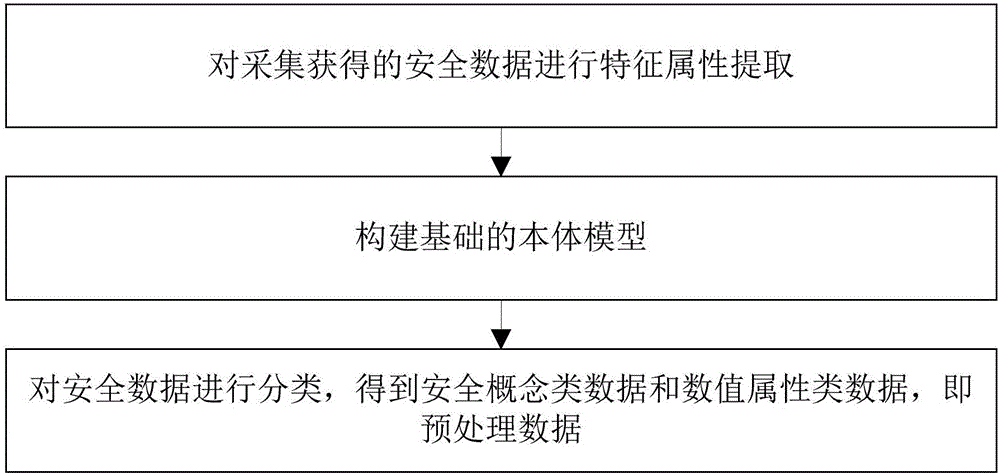

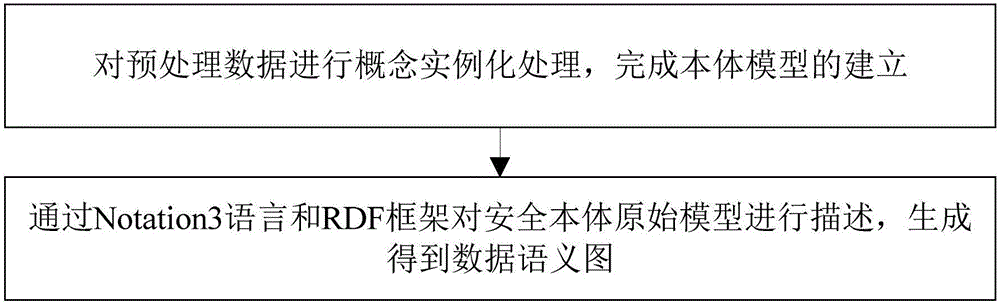

Safety data semantic analysis method and system based on semantic network

ActiveCN106649672AEasy to expandSimple stitchingSemantic analysisSpecial data processing applicationsSystems analysisData acquisition

The invention discloses a safety data semantic analysis method and system based on a semantic network. The method comprises the steps that monitoring and data acquisition are conducted on a set target system, and safety data needed by system analysis is acquired; the acquired safety data is preprocessed to obtain preprocessed data; semantization processing is conducted on the preprocessed data, and a data semantic graph is generated; a data analysis operation is conducted on the preprocessed data according to the data semantic graph to obtain a data analysis result; the preprocessed data is visually displayed according to the data analysis result. The system comprises an acquisition module, a preprocessing module, a semantization module, a data analysis module and a displaying module. According to the method and system, due to the fact that formalized definition and description are conducted on the body model modeling process, the process for constructing a body model of a semantic network application is more intuitive, and a reference is provided for construction of the semantic network application. The method and system can be widely applied to a semantic network technology.

Owner:SOUTH CHINA NORMAL UNIVERSITY

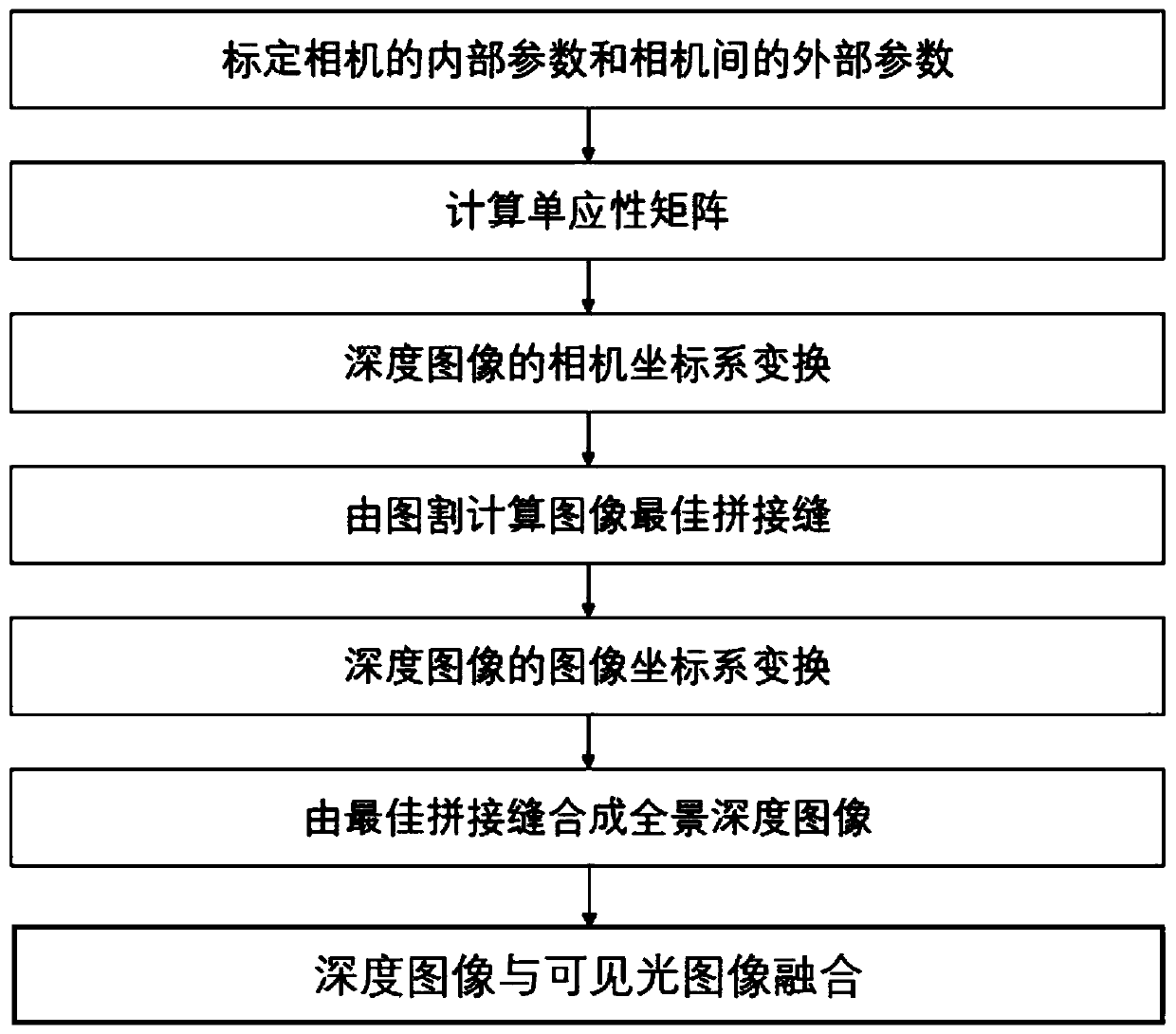

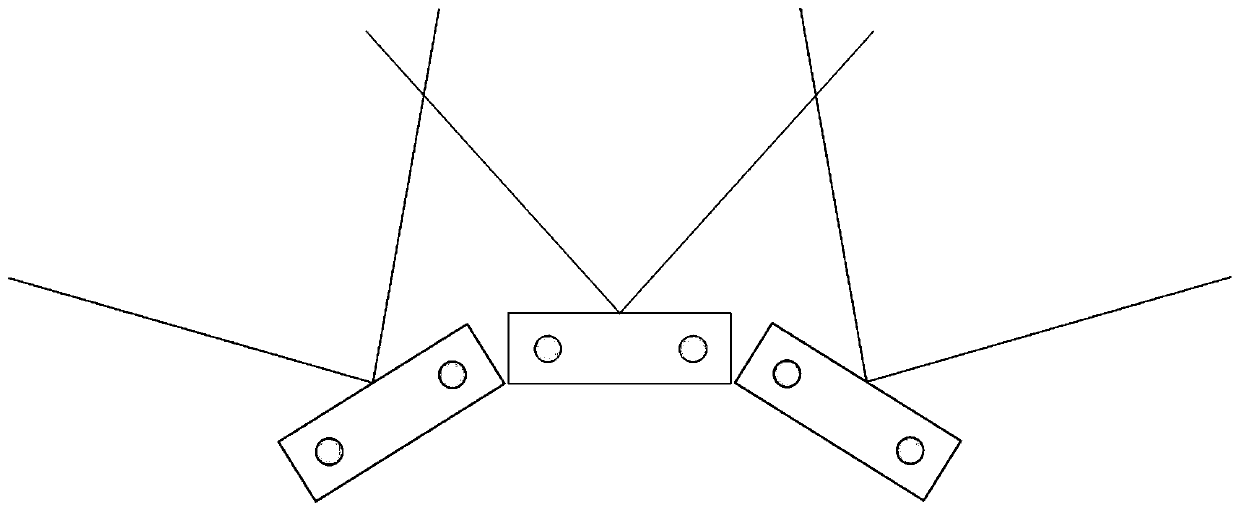

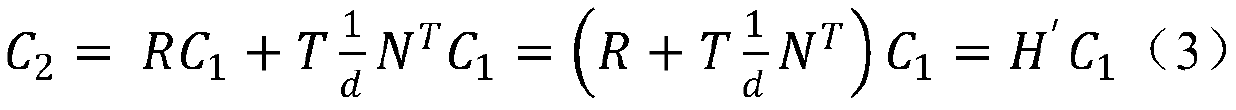

Parallax image splicing and visualization method based on multiple pairs of binocular cameras

ActiveCN111062873ALow hardware requirementsSimple procedureImage enhancementImage analysisSystem transformationVisual perception

The invention discloses a parallax image splicing and visualization method based on multiple pairs of binocular cameras, and belongs to the field of image processing and computer vision. The method comprises the following steps: firstly, solving a position relationship between binocular cameras by using a calibration algorithm, and solving a homography matrix between images by using prior information; transforming a camera coordinate system of the depth image by using the internal parameters and the external object parameters of the camera; calculating an overlapping region ROI of the images by using a homography matrix between the images, establishing an energy model, and performing solving by using a graph cut algorithm. The graph cut algorithm is high in time complexity and depends on the number of nodes of a graph, the image is layered, solved layer by layer and iterated, and a local optimal solution approximate to a global optimal solution is solved; image coordinate system transformation is performed on the depth images by using the homography matrix, and splicing seams are synthesized to realize seamless panoramic depth image splicing; and finally, the depth information of the parallax image is superposed on the visible light image. According to the invention, large-visual-field-angle panoramic parallax image display is realized, the algorithm of the invention is real-time, and large-parallax seamless panoramic parallax image splicing and visualization are realized.

Owner:DALIAN UNIV OF TECH

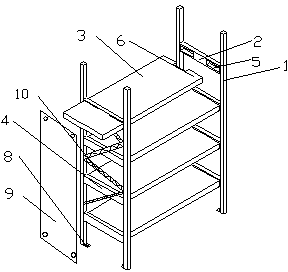

Goods shelf easy to splice

The invention discloses a goods shelf easy to splice. The goods shelf comprises foot stands, side rails, supporting plates and supports. The side rails are arranged on one sides of the foot stands, at least two clamping holes are formed in each side rail, a flange is arranged at one end of each supporting plate and corresponds to the clamping holes, the supports are arranged on the other side of the foot stands and correspond to the side rails in height, and spring devices are further arranged in the supporting plates. Through the mode, the goods shelf can be used for splicing the supporting plates and the foot stands easily and rapidly and can finish the installation task without the help of a tool.

Owner:CHANGZHOU CITY PINGGANG MACHINERY

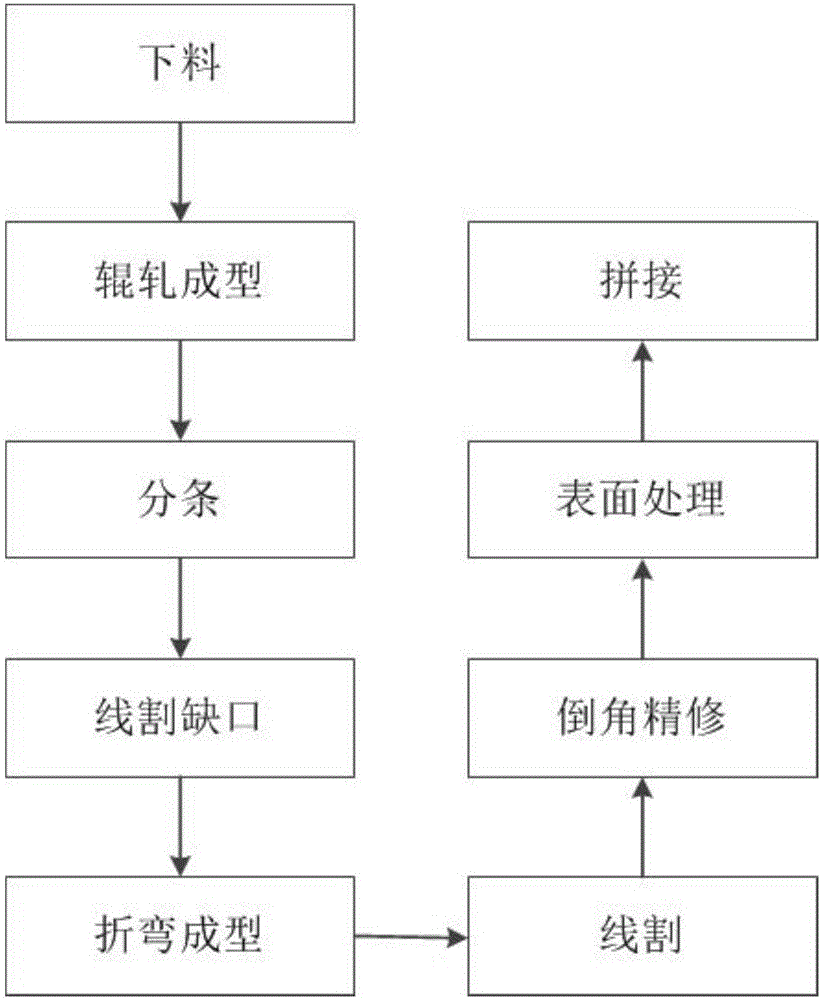

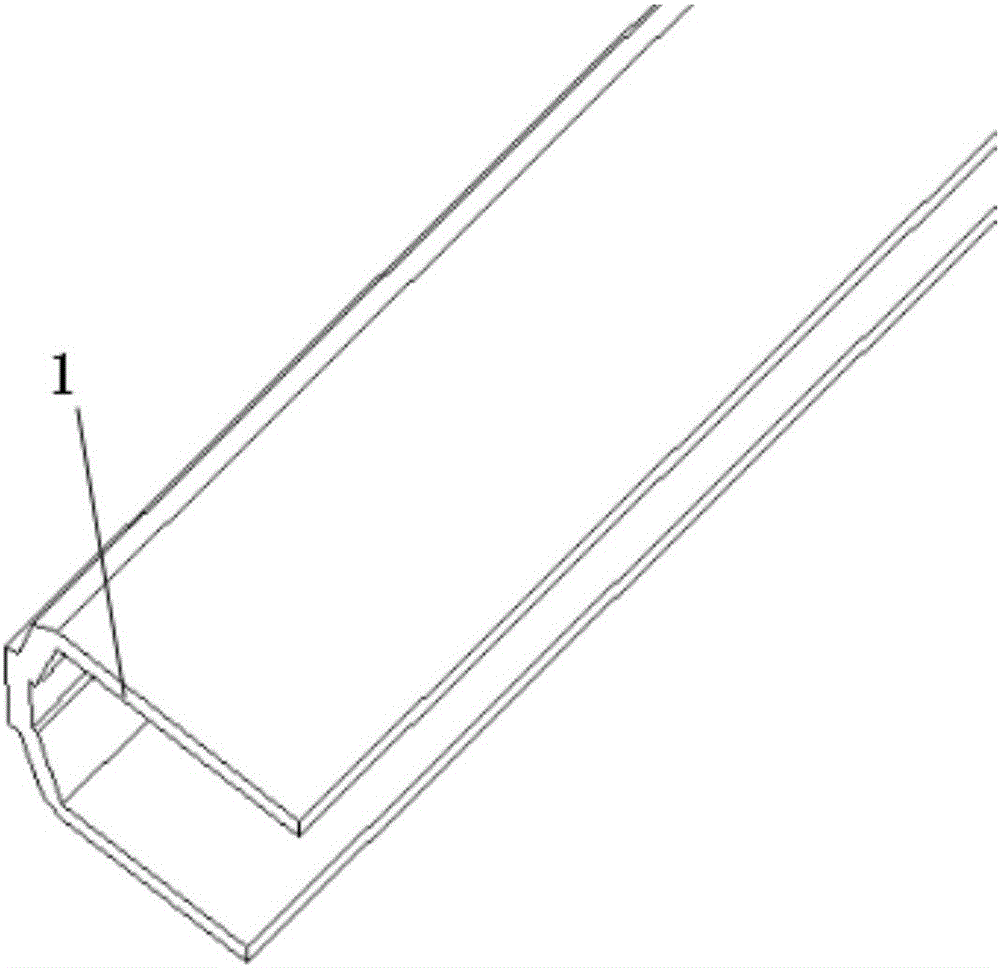

Metal front frame for display product and manufacturing method thereof

PendingCN106371237AReasonable structureSimple stitchingNon-linear opticsConvex structureWire cutting

The invention discloses a metal front frame for a display product and relates to the technical field of electronic and electronic products. The metal front frame comprises an A group frame strip and a B group frame strip which each has a cross section of a U-shaped structure. The two ends of the A group frame strip are provided with clamping convex structures, the two ends of the B group frame strip are provided with clamping grooves structures, and the clamping convex structures are matched with the clamping grooves structures to cause the A group frame strip and the B group frame strip to be spliced sequentially. The invention further discloses a method for manufacturing the metal front frame. The method comprises the steps of discharging; rolling forming; striping; wire cutting of a notch; bending forming; wire cutting; chamfering fine trimming; surface treatment; and splicing. The metal front frame is reasonable in structure and simple to splice, is spliced firmly and is formed by processes such as rolling forming an wire cutting, so that the display product is easier to manufacture, lower in cost and more attractive in appearance. Compared with conventional machining, according to the manufacturing method, a complex die structure is avoided, the rejection rate of the product is reduced, working efficiency is improved, and machining precision and strength of the metal front frame are ensured.

Owner:洪鸿莎

Composite stone slab

The invention relates to a composite crystal granite plate, which comprises a basal layer. The key points are that a crystal granite decorative layer is recombined on the basal layer, a plurality of longitudinal convex strips and a plurality of horizontal convex strips are arranged on the basal layer, the basal layer is formed through recombining fiber cloth or non-woven and unsaturated resin, the crystal granite decorative layer is formed by the mixture and solidification of quartz sand and resin, and metal frames are arranged on the periphery of the crystal granite plate. The composite crystal granite plate has beauty appearance, water-proof and acid and alkali resistance, which can be used to decorate the walls, roofs, floors and furniture.

Owner:黄强

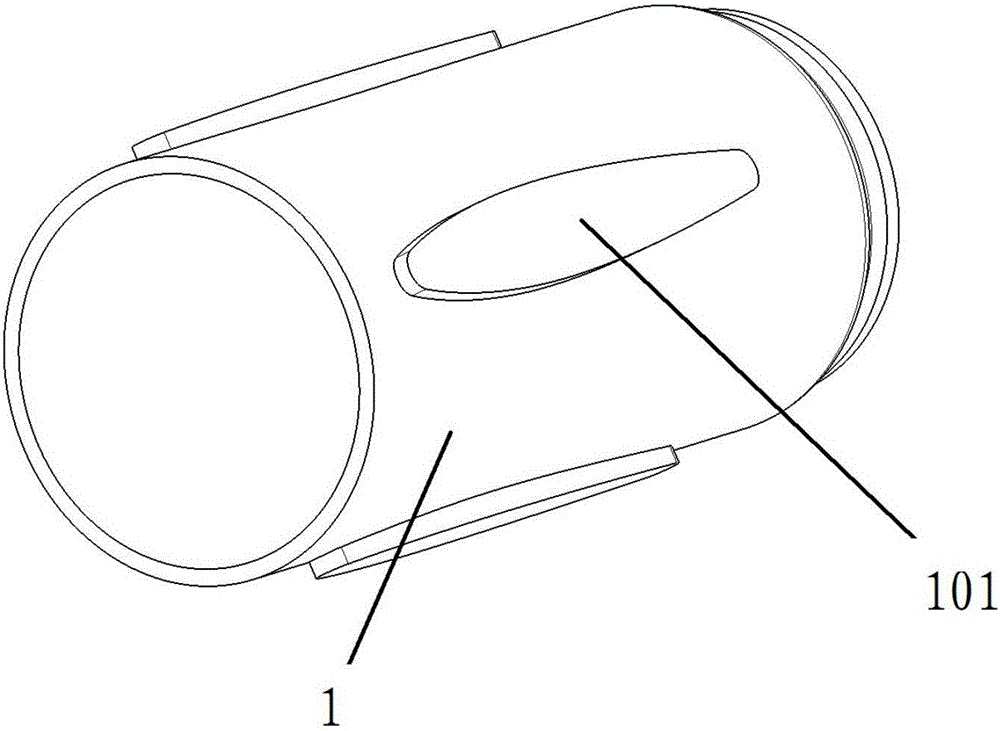

Building block component type unmanned plane and control method thereof

The invention relates to a building block component type unmanned plane and belongs to the technical field of model airplanes. By conducting modularization design on all units or components of the unmanned plane, the unmanned plane can topologized into a quite great number of appearance mechanisms, design concept of the unmanned plane is exploited, and operability of an unmanned plane model is improved. The components comprise a structural component, power components, a power supply component, a communication control component and a loading component, the structural component further comprises plane body units and wing units, and the power components comprise propeller units and motor units. The building block component type unmanned plane can be spliced into an unmanned aerial vehicle which can fly quickly, topologized into a quite great number of unmanned plane structures and be widely applied to the fields of child interest development, teaching demonstration, personal entertainment, simple unmanned plane application and the like.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

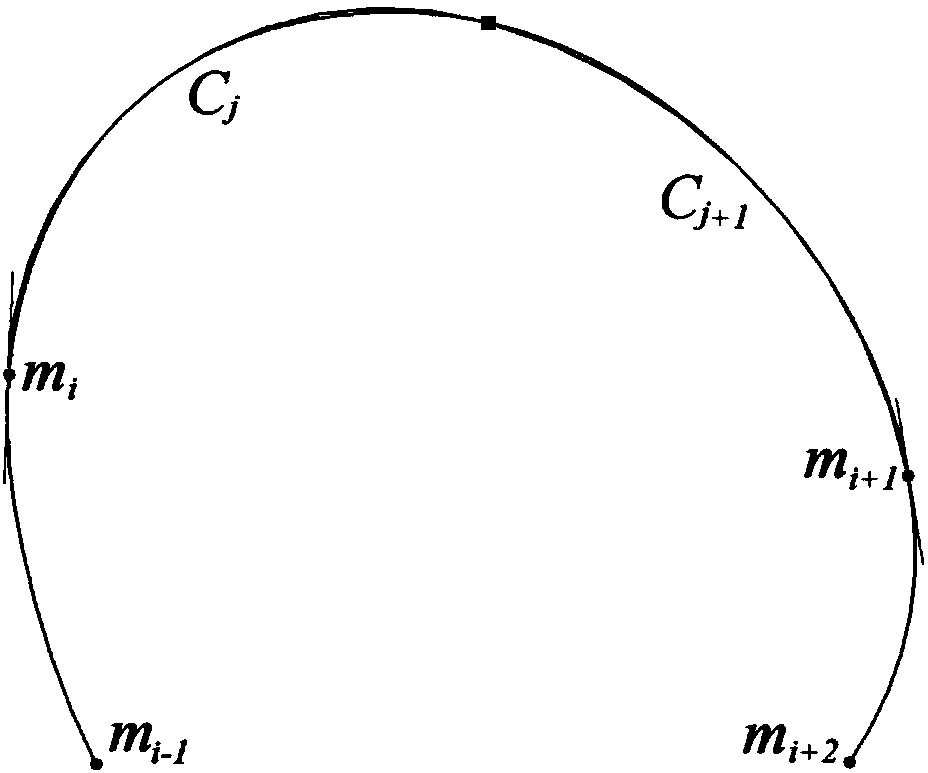

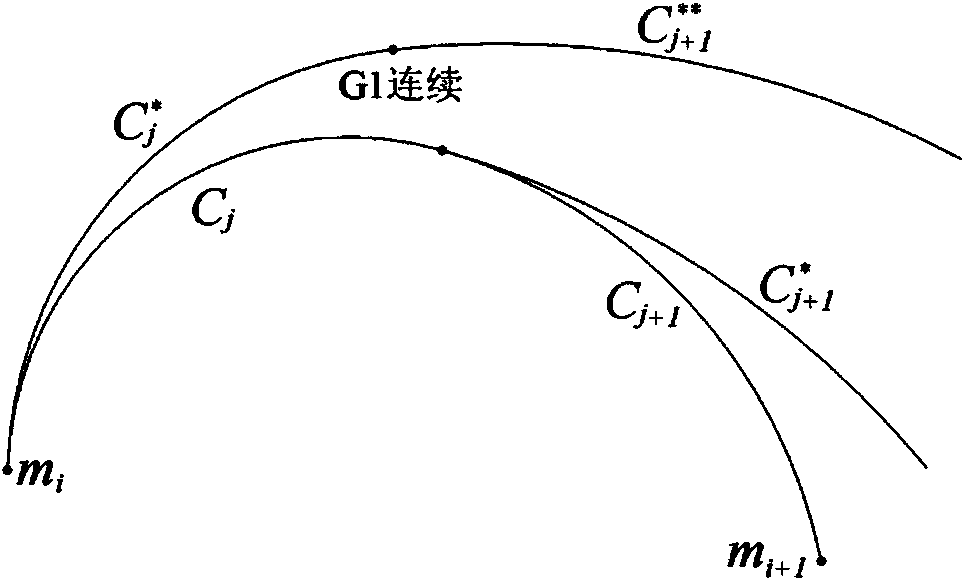

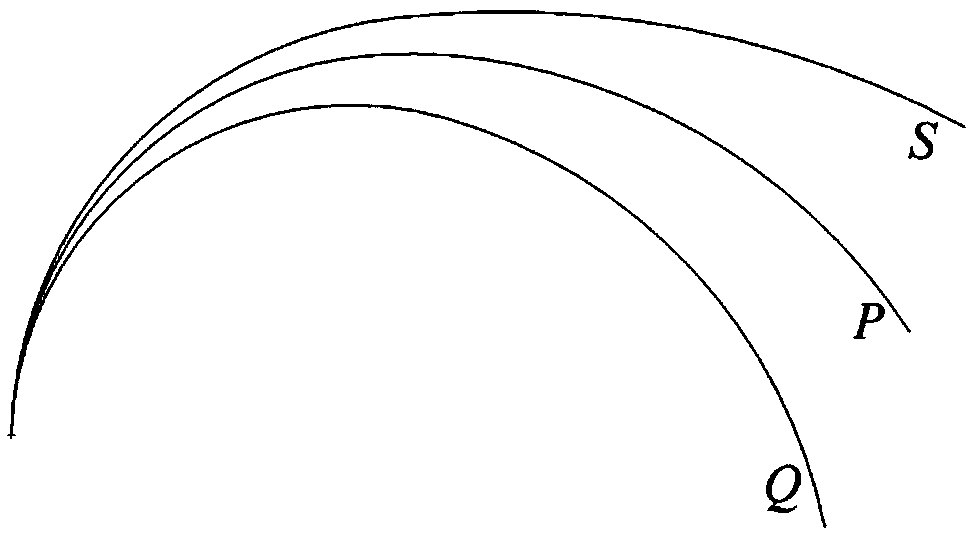

Method for predicting two-dimensional variable camber bending recovery of small-diameter thick-wall pipe

InactiveCN103439195ASimple stitchingMaterial strength using steady bending forcesEngineeringThick wall

The invention discloses a method for predicting two-dimensional variable camber bending recovery of a small-diameter thick-wall pipe, which is used for solving the technical problem of incapability of two-dimensional variable camber bending recovery of an existing small-diameter thick-wall pipe. According to the technical scheme, the method includes the steps of building a small-diameter thick-wall pipe bending recovery analytical model, performing discretization on the two-dimensional variable camber bent pipe along the axis, establishing a bending recovery radius relation expression by use of approximately pure bending recovery experiment, predicting the discrete bent pipe recovery, simply splicing the recovery predicted discrete bent pipe, and correcting the discrete bent pipe recovery splicing. The method can be used for predicting two-dimensional variable camber bending recovery of the small-diameter thick-wall pipe.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

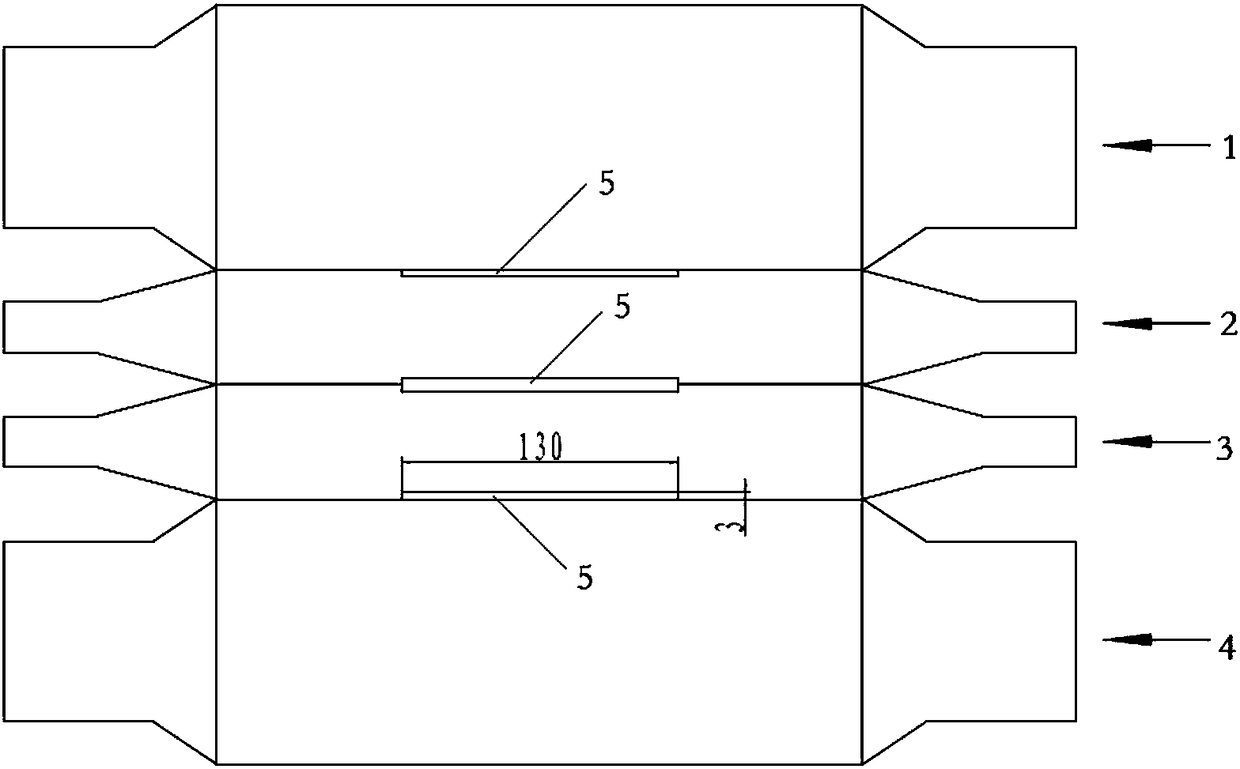

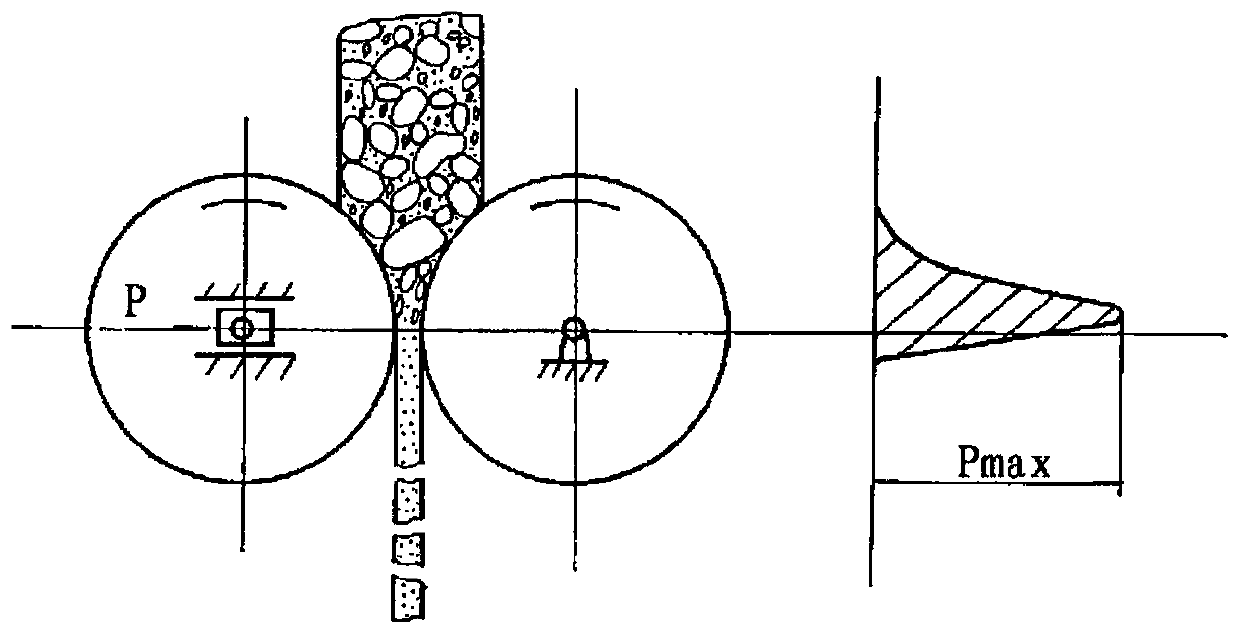

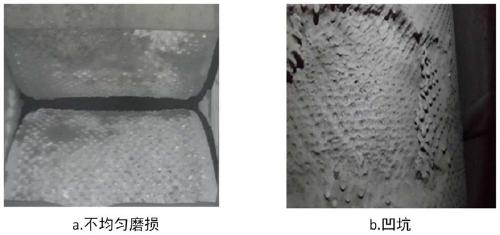

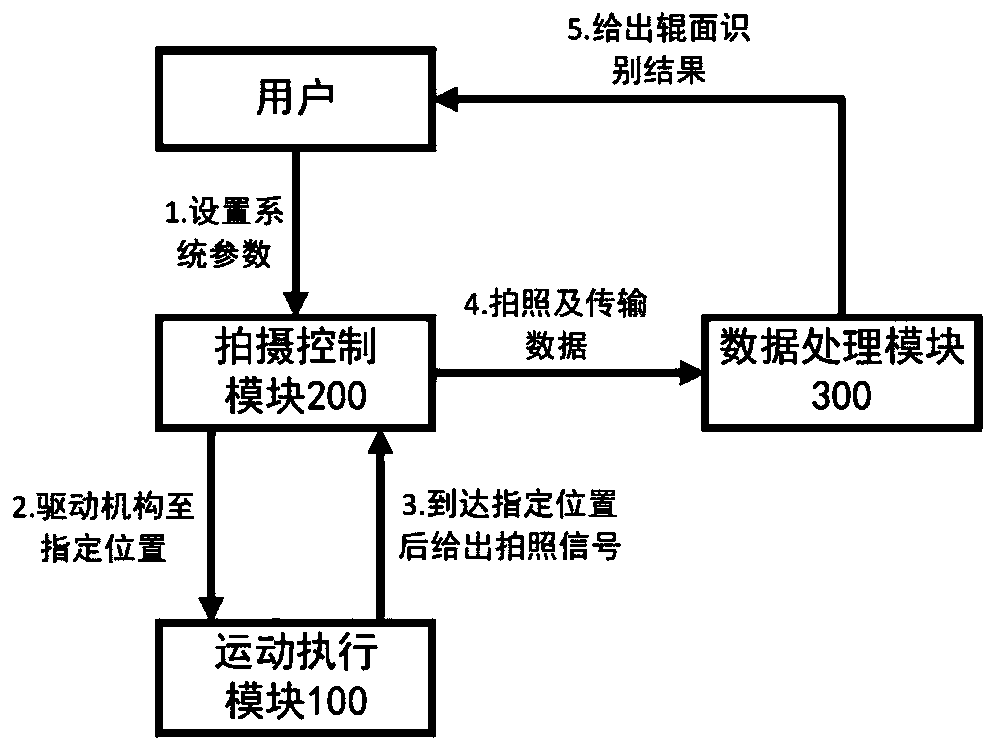

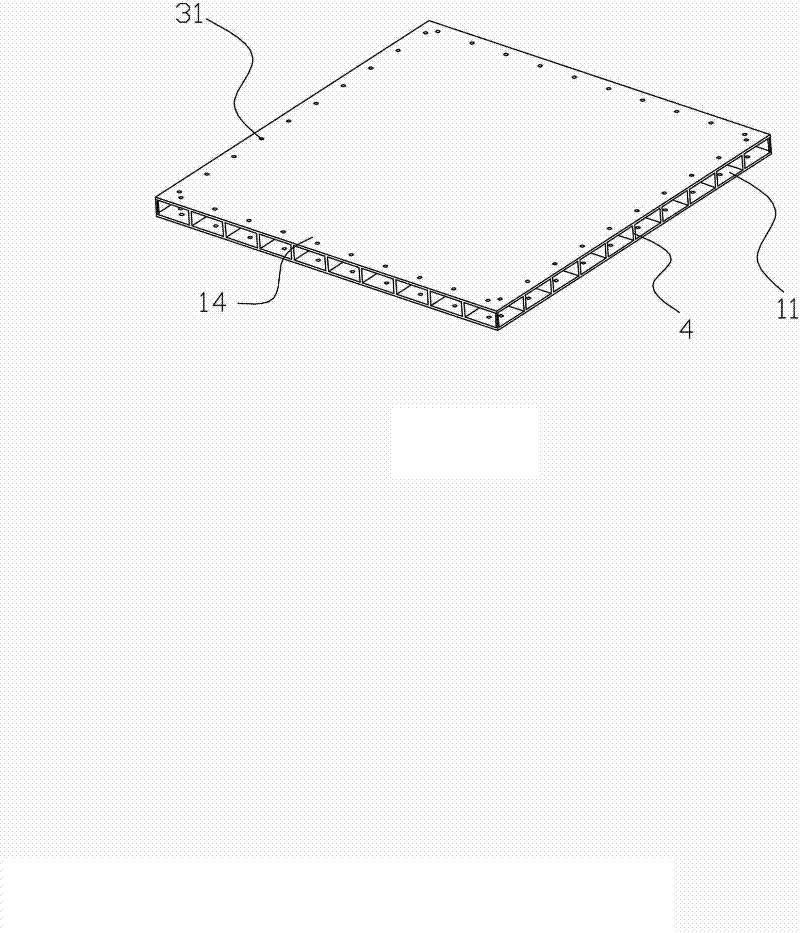

Automatic detection device and method for roller surface of roller press

PendingCN111239144ASolve the technical problem of low detection accuracyHigh degree of automationImage analysisMaterial analysis by optical meansPoint cloudComputer graphics (images)

The invention discloses an automatic detection device and method for the roller surface of a roller press, and can solve the technical problem that an existing detection device is low in detection precision. The device comprises a shooting control module, a motion execution module and a data processing module; the shooting control module comprises an industrial linear array camera, a motion controller and a local computer; the industrial linear array camera is arranged above the roller surface of the roller press; the local computer is in communication connection with an industrial line-scan digital camera and is used for setting shooting parameters of the industrial line-scan digital camera and receiving pictures shot by the industrial line-scan digital camera. According to the invention,the industrial line-scan camera scans the roller surface to obtain a local picture of the roller surface, and the shooting position of the industrial line-scan camera is changed to obtain a pluralityof local pictures of the roller surface; local roll surface photos are cut and spliced to obtain point cloud data of a complete roll surface, a roll surface two-dimensional model and a roll surface three-dimensional model are established according to the point cloud data, roll surface defects are detected, and a database system is established to manage different roll surfaces. Therefore, the expansibility is good, the automation degree is high, and the detection precision is high.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD

Standardized component used for assembling furniture/pet house/mobile house

Disclosed is a standardized component used for assembling furniture / a pet house / a mobile house. The standardized component comprises panels, connecting bars and inserting ends, wherein the side edges of the panels and the side surfaces of the connecting bars are respectively provided with inserting slots matched with the inserting ends in an insertion-connection way, each panel has two side surfaces and four side edges, each of the four side edges is formed by a plurality of identical minimum units, and each minimum unit is formed by an inserting slot and side walls forming the inserting slot in an enclosing way; each connecting bar has four side surfaces and two end surfaces, each of the four side surfaces is formed by a plurality of identical minimum units, and each minimum unit is formed by an inserting slot and side walls forming the inserting slot in an enclosing way. The standardized component not only solves the problems that gaps exist between adjacent connecting bars, the splicing is inconvenient, modeling types are not abundant and the like, but also can be spliced more simply and be produced more easily.

Owner:福建吉信德科技有限公司

Ultra-thin stone plate capable of fast assembling dry hanging and manufacturing method thereof

InactiveCN101191370AQuick assemblyKeep the natural artistic textureCovering/liningsStone-like material working toolsEngineeringSteel bar

The invention discloses a fast mounted dry-hanging ultrathin stone slab and manufacturing method thereof. The invention is characterized in that: the stone slab is manufactured by an ultrathin stone slab and steel bars which are embedded into the left and right side of the stone slab, solidified with the stone slab into a whole and provided with a male tenon and a female tenon. The invention has the advantages that: 1. the bottom of the stone slab is solidified, so that a massive ultrathin stone slab which can be fast mounted and dry hung can be cut and received. 2. The stone slab of the invention can mostly maintain the natural artistic grains of the stone slab, thereby improving the commodity value. 3. The stone slab can be mounted and dry-hung easily and conveniently, and can be spliced easily because of the male and female tenons. 4. The combination of the stone slab and a wall is firm, wind-proof and shock-proof. 5. The stone slab is convenient for detaching and mounting at other places.

Owner:桂林市临桂永钜石业有限公司

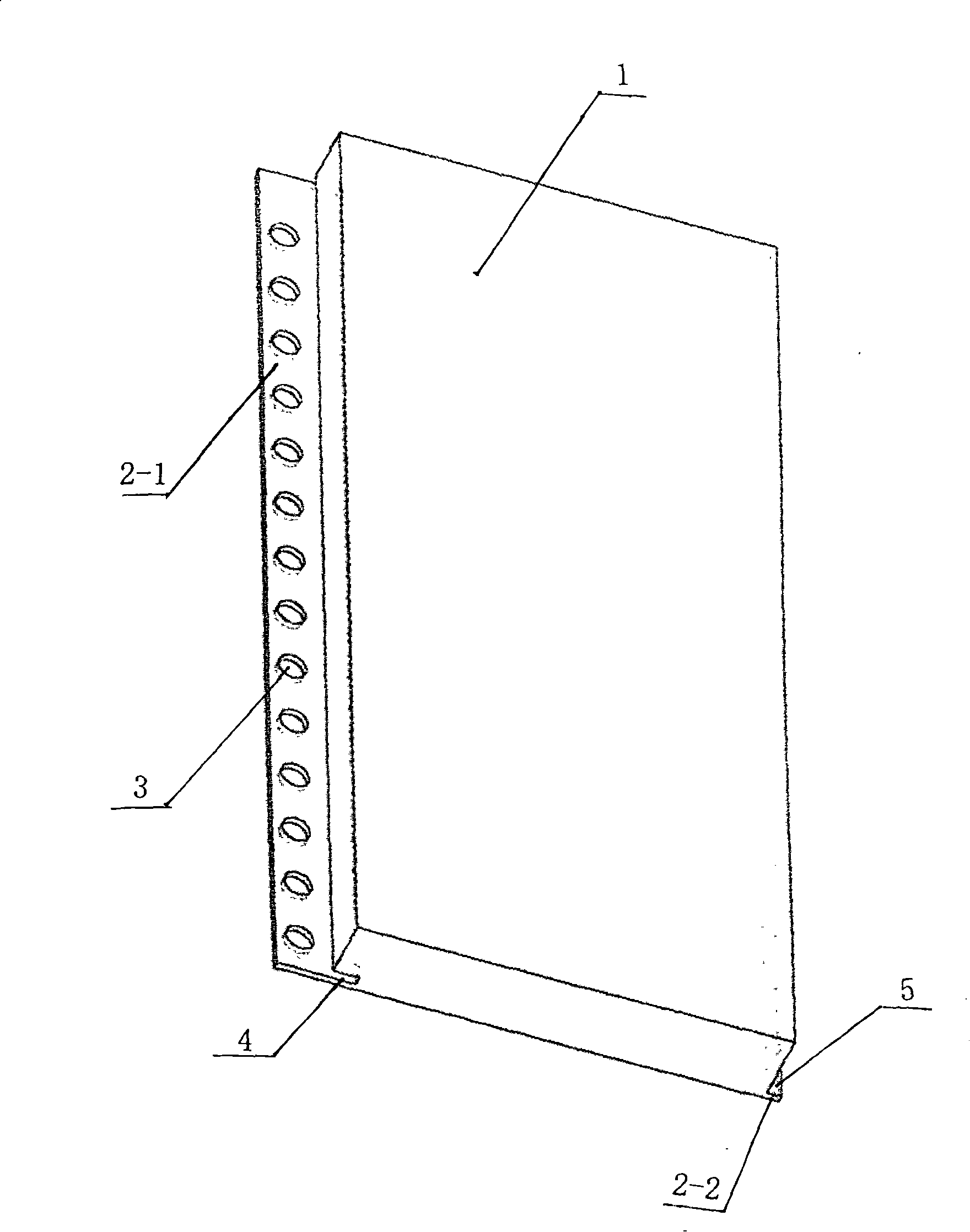

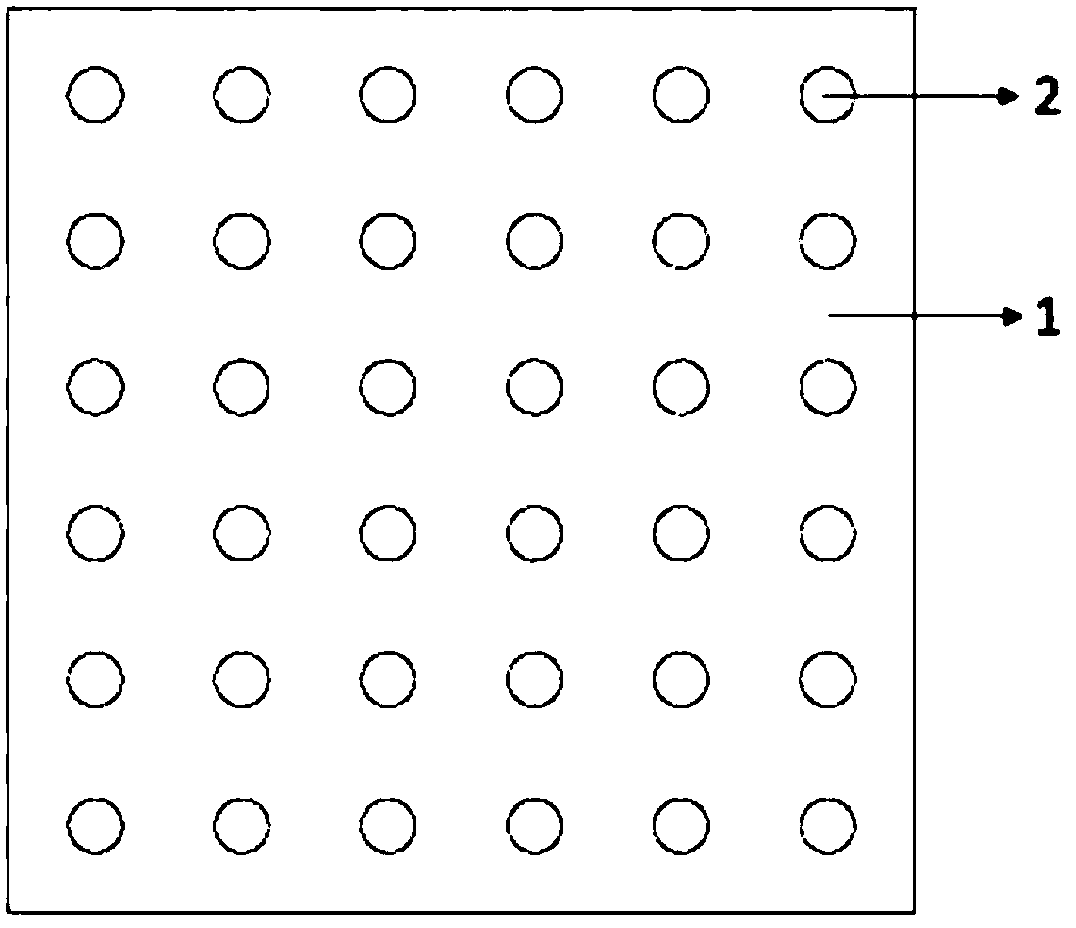

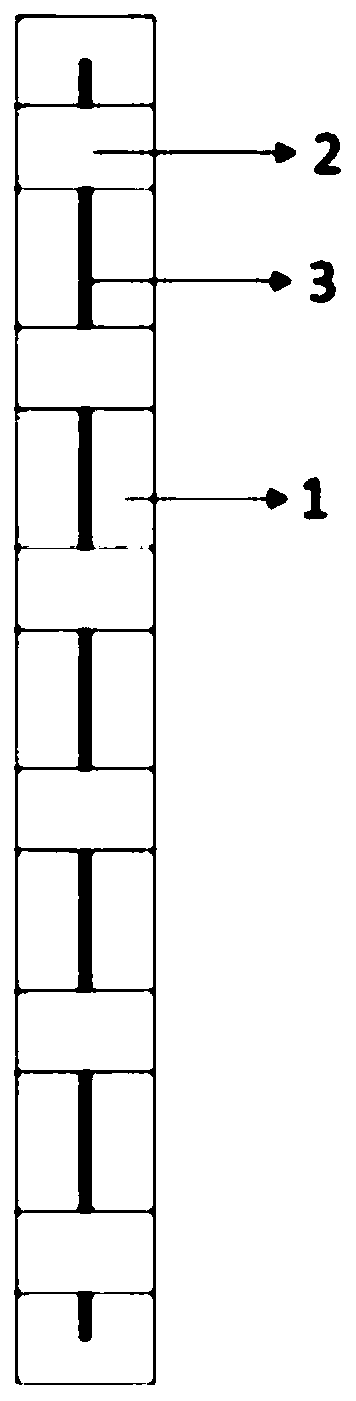

Rapid forming method of semi-transparent concrete plates

ActiveCN108858736ASimple stitchingEasy to processMouldsCement mixing apparatusRapid prototypingMaterials science

The invention discloses a rapid forming method of semi-transparent concrete plates. The rapid forming method comprises the following steps that (1) perforated plates are prepared; (2) formworks are assembled; (3) light guiding elements are inserted into reserved holes; (4) concrete is mixed; (5) concrete blocks are poured; (6) formwork dismantling is conducted; (7) curing is conducted; (8) the concrete plates are cut; and (9) the semi-transparent concrete plates are polished. The obtained semi-transparent concrete plates are formed rapidly, are high in quality and smooth in surface, and meet the light guiding requirement, the process of preparing the semi-transparent concrete plates is simple and efficient, the demands for environmental friendliness, energy conservation and building industrialization are met, and the rapid forming method has wide application prospects.

Owner:NANJING TECH UNIV

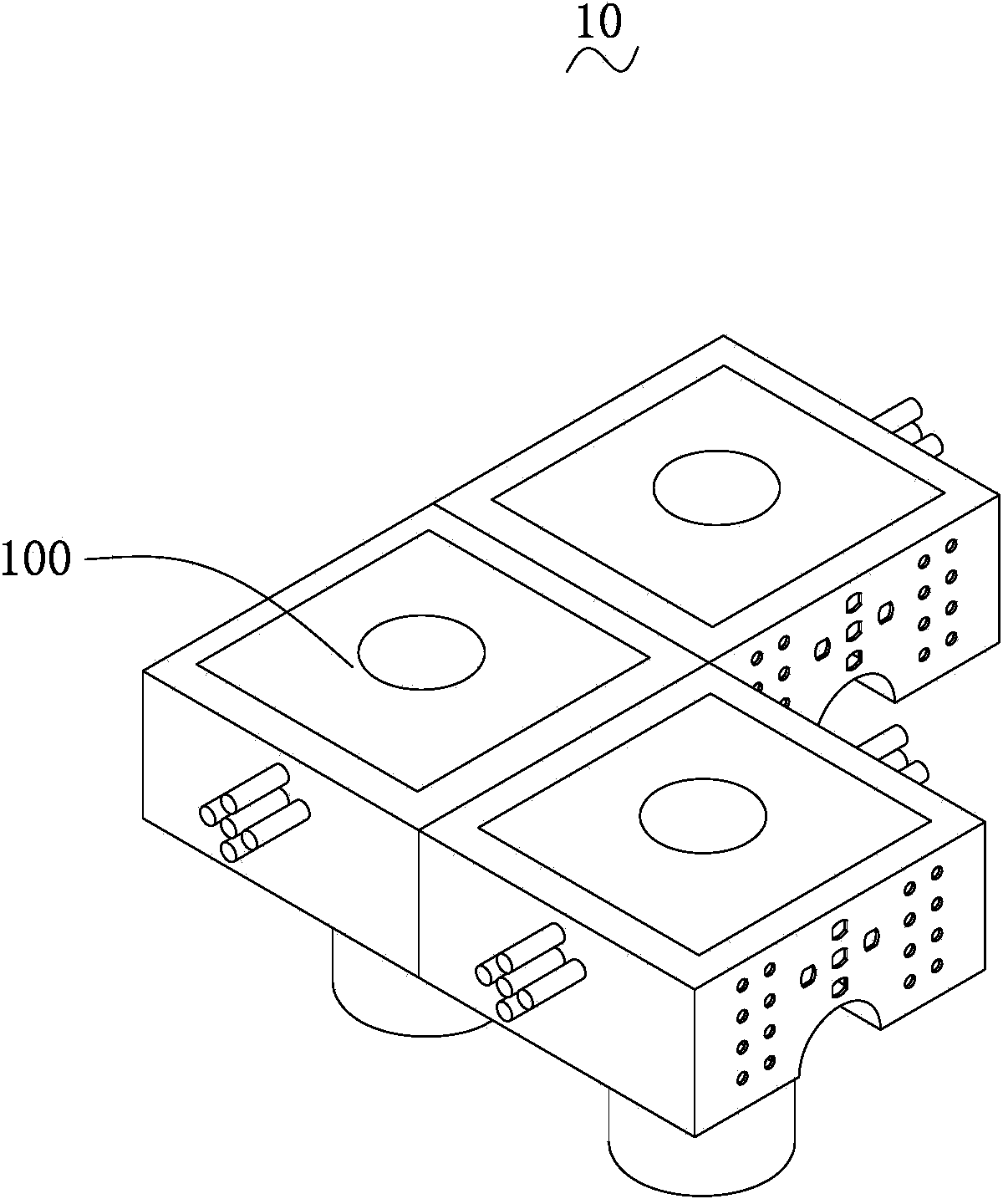

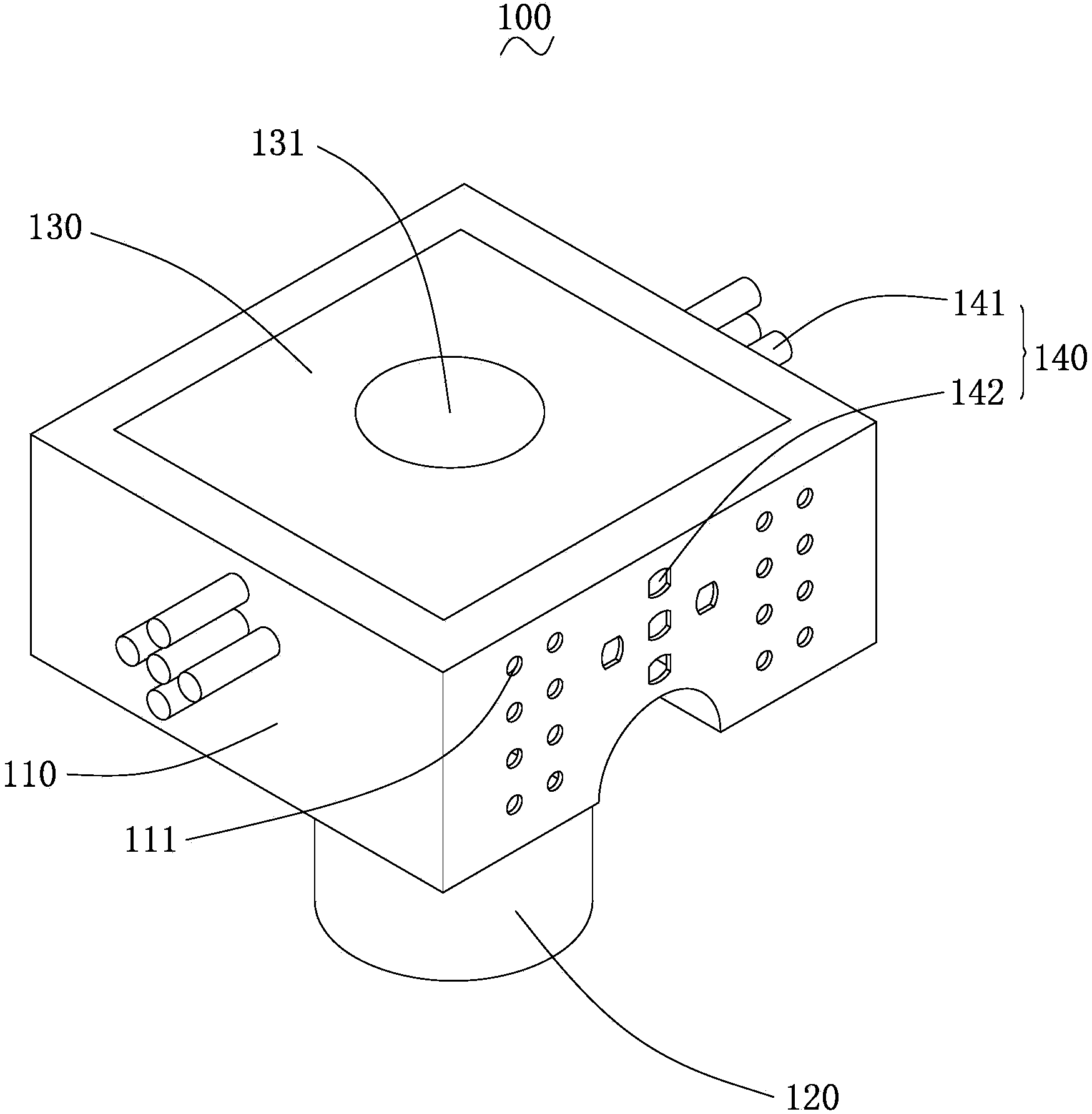

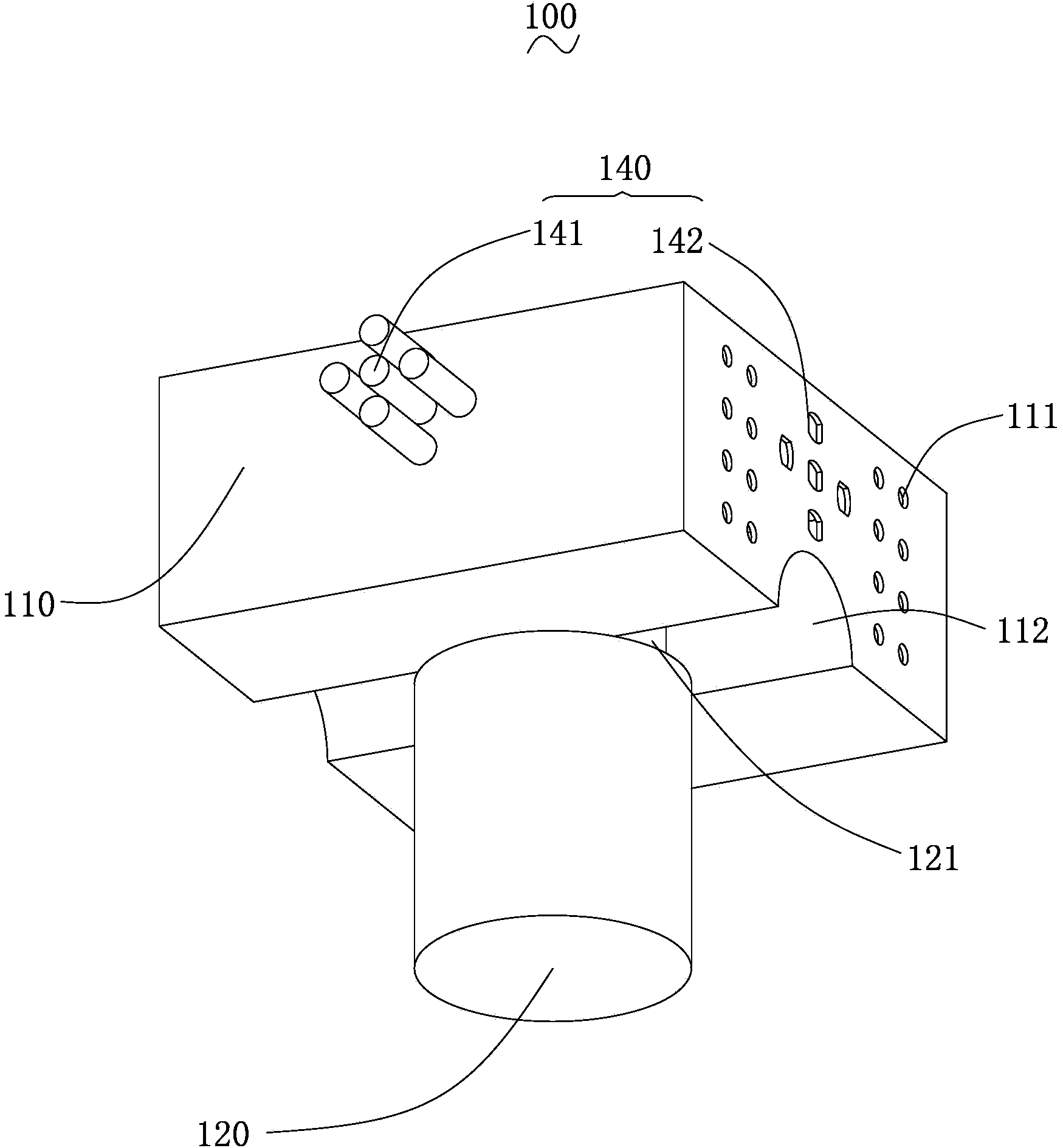

Interconnected radiating device and light-emitting diode (LED) lamp using same

ActiveCN104100952AAdequate heat dissipationReduce processing difficultyPoint-like light sourceLighting heating/cooling arrangementsEngineeringDiode

The invention relates to an interconnected radiating device and a light-emitting diode (LED) lamp using the same. The interconnected radiating device comprises a plurality of radiating units. Each radiating unit comprises an installation frame and an installation plate, the installation frame is a hollow cuboid frame, an installation seat is arranged on the lower surface of the installation frame and used for installing an LED lighting unit, the installation plate is arranged on the upper surface of the installation frame opposite to the lower surface, an installation position is arranged on the installation plate and used for installing the installation plate on a lamp holder, at least one of two pairs of sides between the upper surface and the lower surface is provided with an interconnected assembly, the interconnected assembly comprises an insertion connection portion group and an insertion connection position group, the insertion connection position group is used for inserting the insertion connection portion group of another radiating unit, and the insertion connection portion group is inserted into the insertion connection position group of another radiating unit. The length of the insertion connection portion group inserted into the insertion connection position group is larger than 1cm. The insertion connection position group is provided with a plurality of insertion connection positions correspondingly, and the plurality of insertion connection positions are inserted into the insertion connection portions in a one-to-one correspondence mode. The interconnected radiating device fully utilizes space and is better in radiating effect.

Owner:DONGGUAN WENYU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com