Method for predicting two-dimensional variable camber bending recovery of small-diameter thick-wall pipe

A technique for bending springback, predicting methods, applied in the direction of testing material strength, etc. using a stable bending force applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

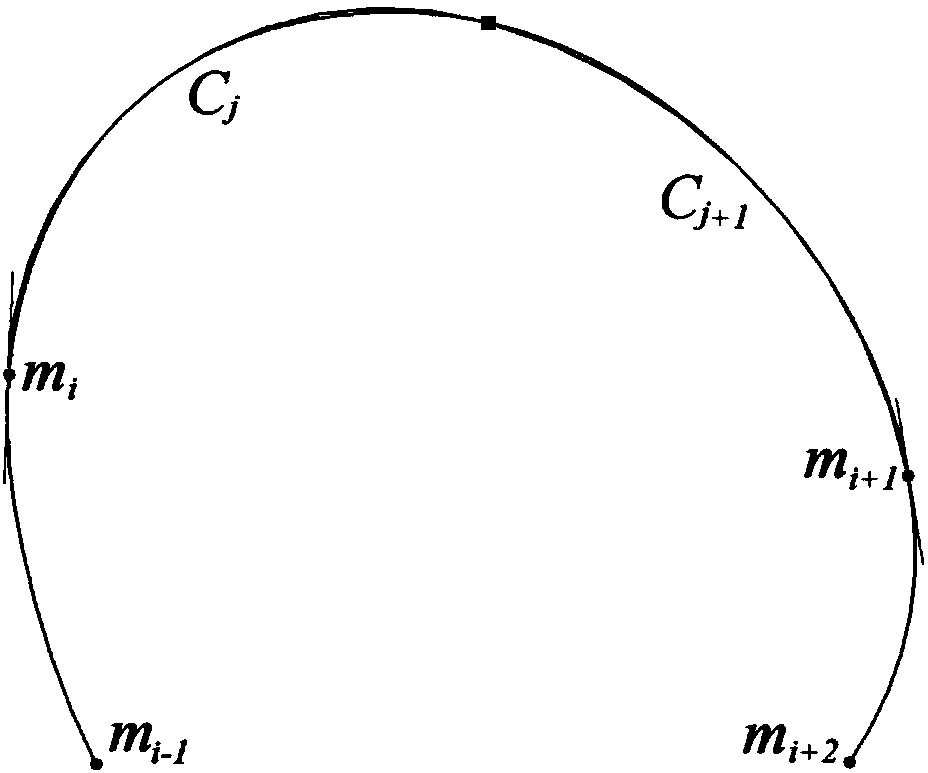

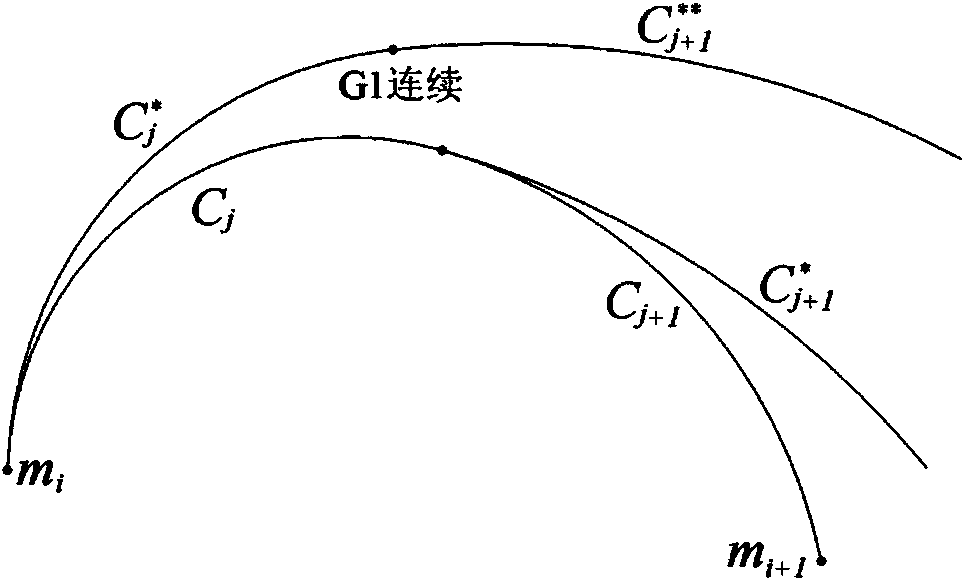

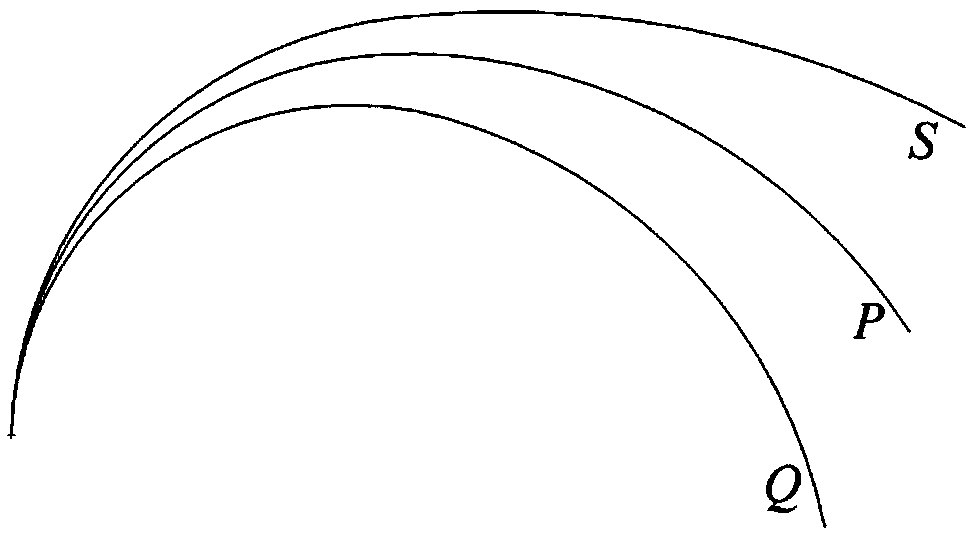

[0041] refer to Figure 1-8 . The specific steps of the method for predicting springback in two-dimensional variable curvature bending of small-diameter thick-walled pipes according to the present invention are as follows:

[0042] by Figure 5 The axis of an alloy steel two-dimensional variable curvature elbow is shown as an example. The outer diameter of the elbow is 3 mm, the inner diameter is 1 mm, and the axis length is 120 mm.

[0043] The specific implementation process is as follows:

[0044] 1. Given the three ordered shape value points (nodes) m of the axis of the elbow 1 、m 2 、m 3 , adjacent node m 1 、m 2 Between two tangent arc segments C 1 、C 2 Composed of two arc segments C 1 、C 2 Pass through the given two nodes m respectively 1 、m 2 , and at node m 1 、m 2The slope of the tangent at is equal to the slope of the axis at that node. In the same way, the other two tangent arc segments C are obtained 3 、C 4 . The axis of the elbow is discretized in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com