Interconnected radiating device and light-emitting diode (LED) lamp using same

A technology of LED lighting and heat dissipation device, which is applied in the field of machinery, can solve the problems of affecting the working performance of LED lamps, wasting the heat dissipation function of radiators, and the lack of maintenance of radiators, etc., so as to improve production efficiency and output, and achieve better heat dissipation effects. The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

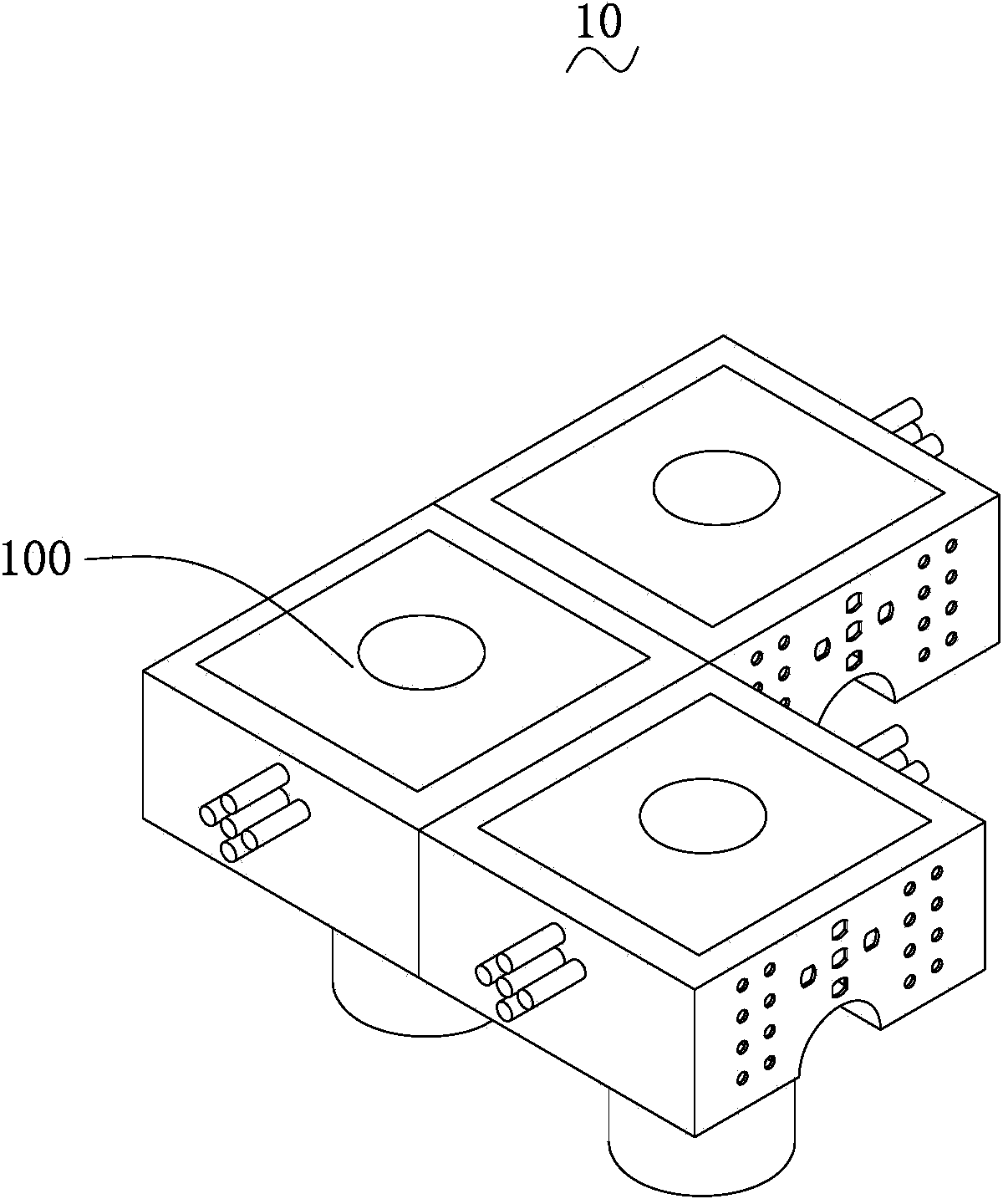

[0036] like figure 1 As shown, it is a structural diagram of splicing interconnected cooling devices 10 according to a preferred embodiment of the present invention.

[0037] The interconnected cooling device 10 includes several cooling units 100 . A plurality of cooling units 100 are spliced with each other.

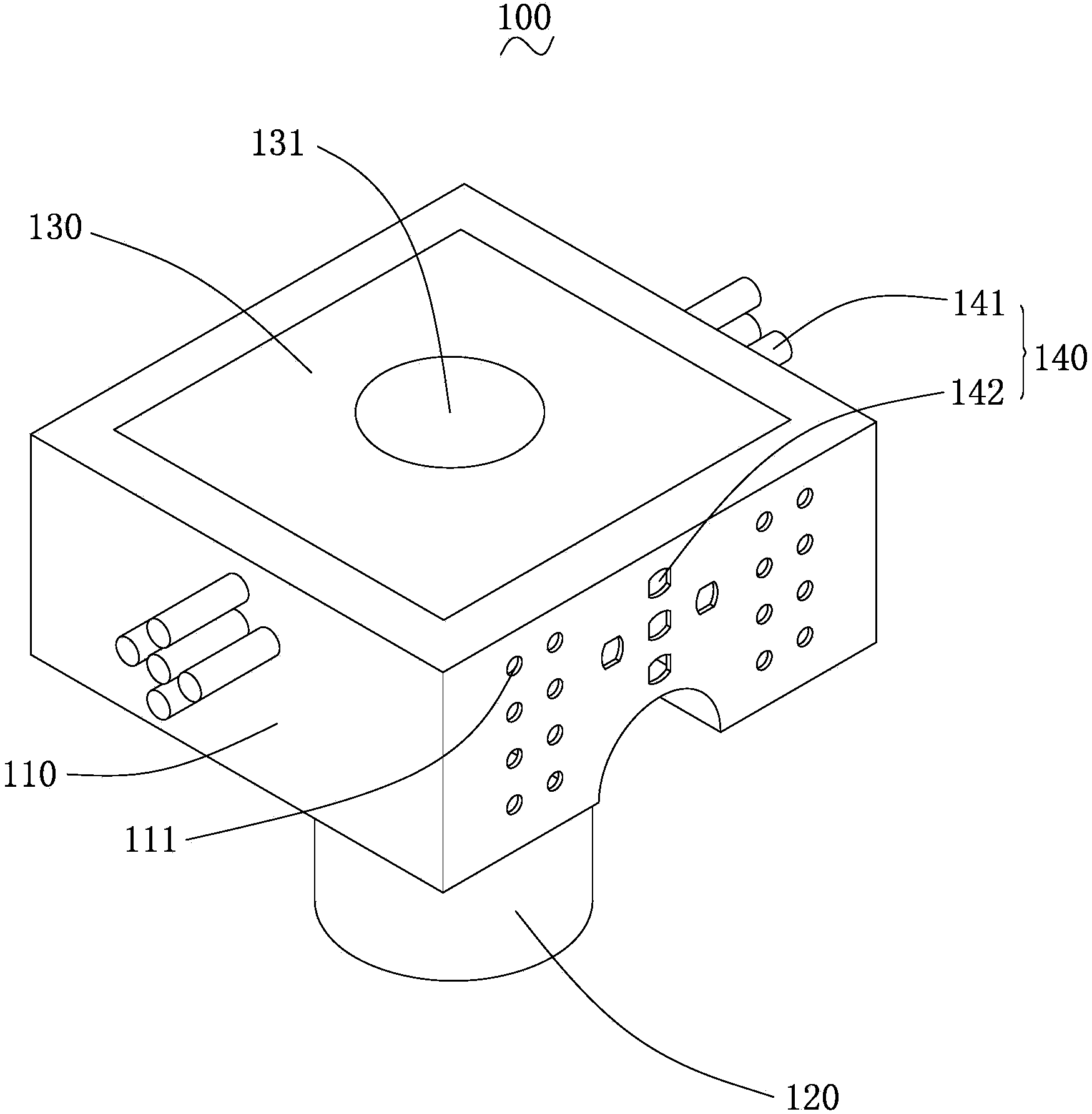

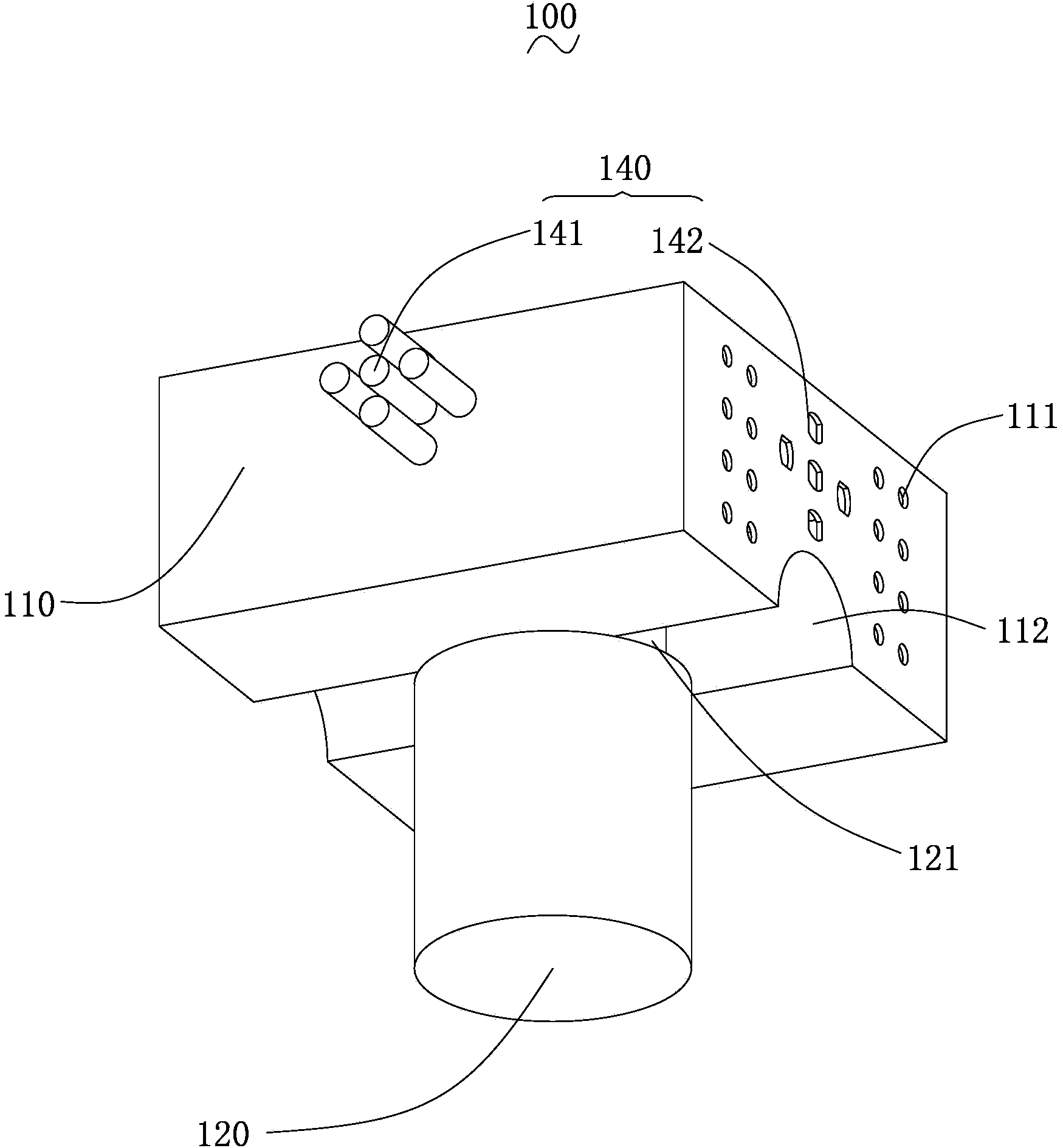

[0038] Please also refer to figure 2 , which is figure 1 A schematic structural diagram of the heat dissipation unit 100 of the interconnected heat dissipation device 10 is shown.

[0039] Each cooling unit 100 includes a mounting frame 110 , a mounting seat 120 , a mounting plate 130 and an interconnection component 140 . The mounting seat 120 is disposed on the lower surface of the mounting frame 110 for mounting the LED lighting unit. The mounting plate 130 is disposed at a position where the lower surface of the mounting frame 110 is opposite to the upper surface, and the mounting plate 130 is provided with a mounting position 131 for mounting on the lamp ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com