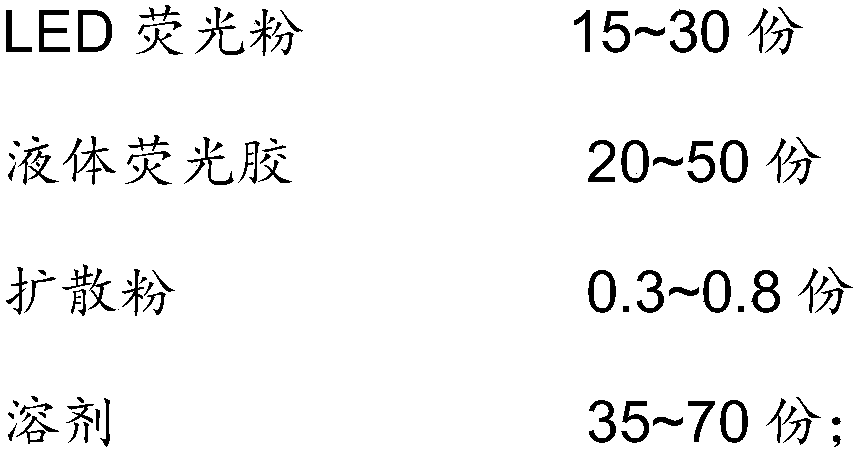

Patents

Literature

372results about How to "Large light angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

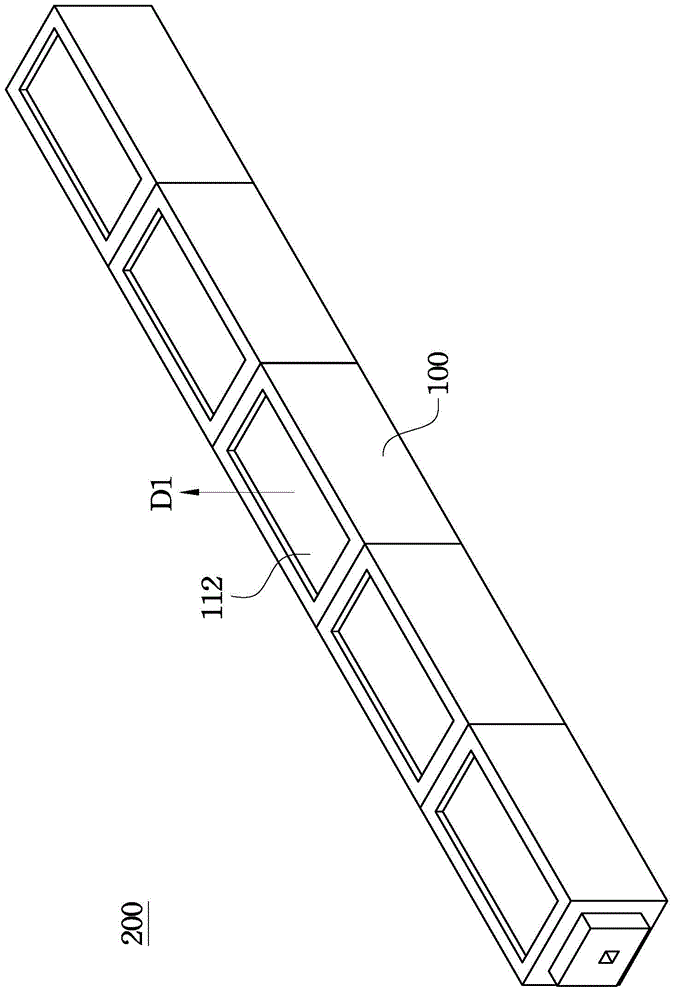

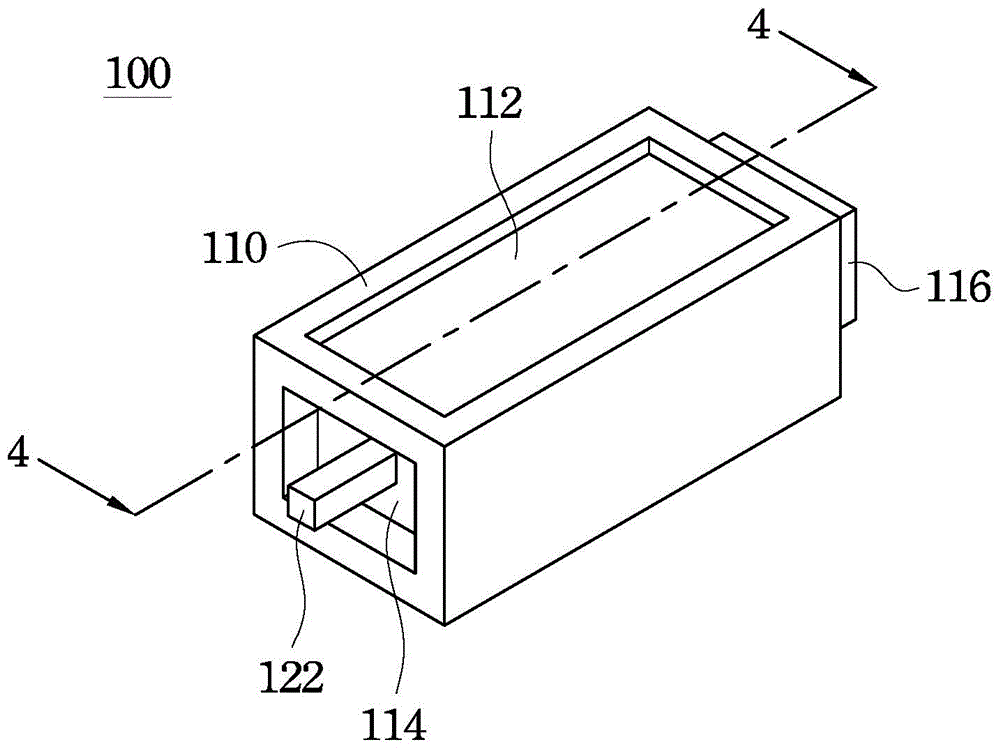

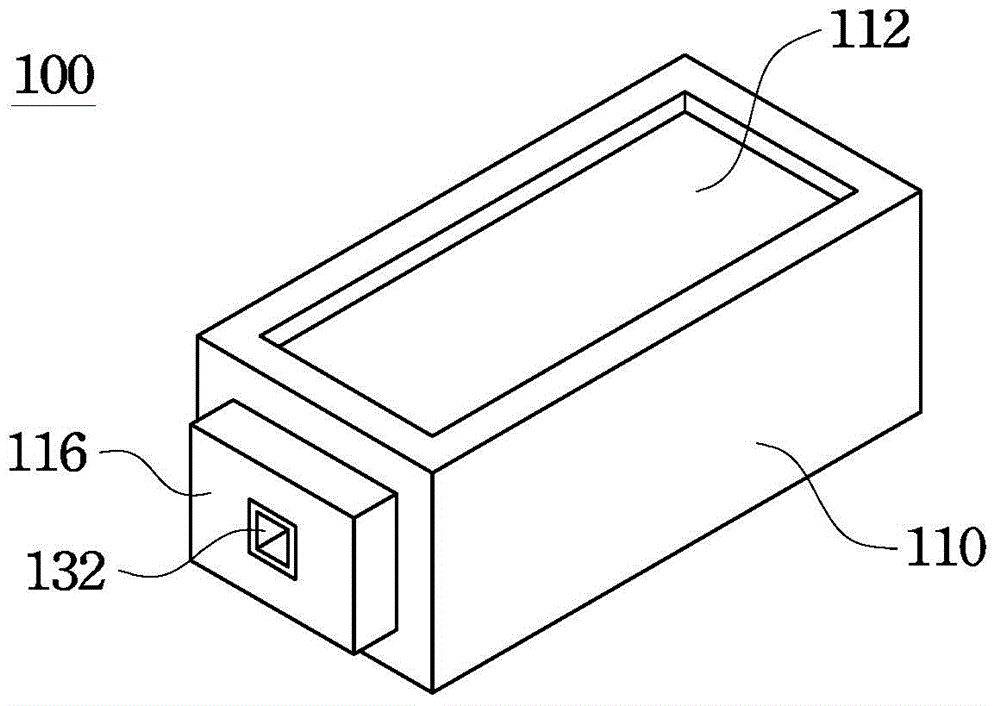

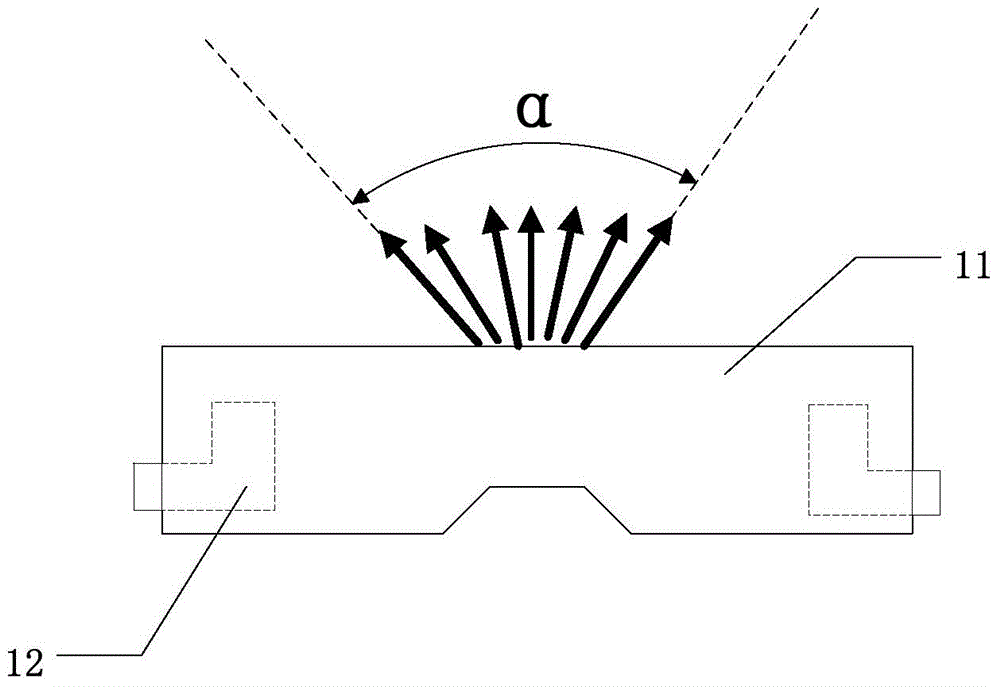

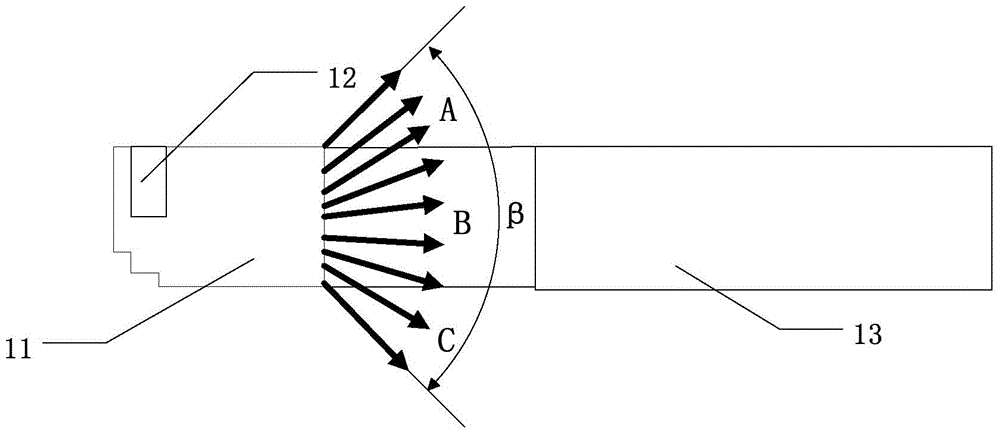

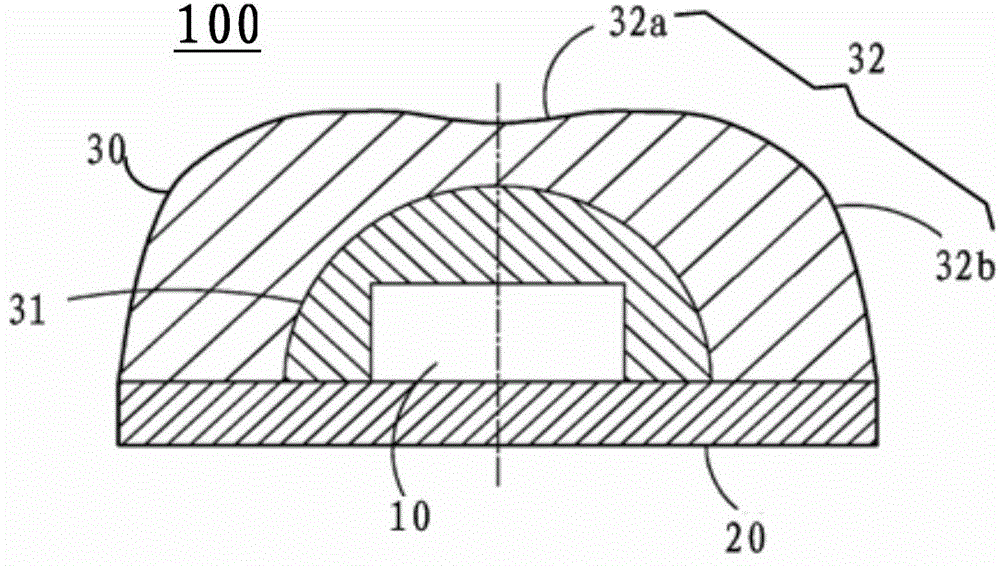

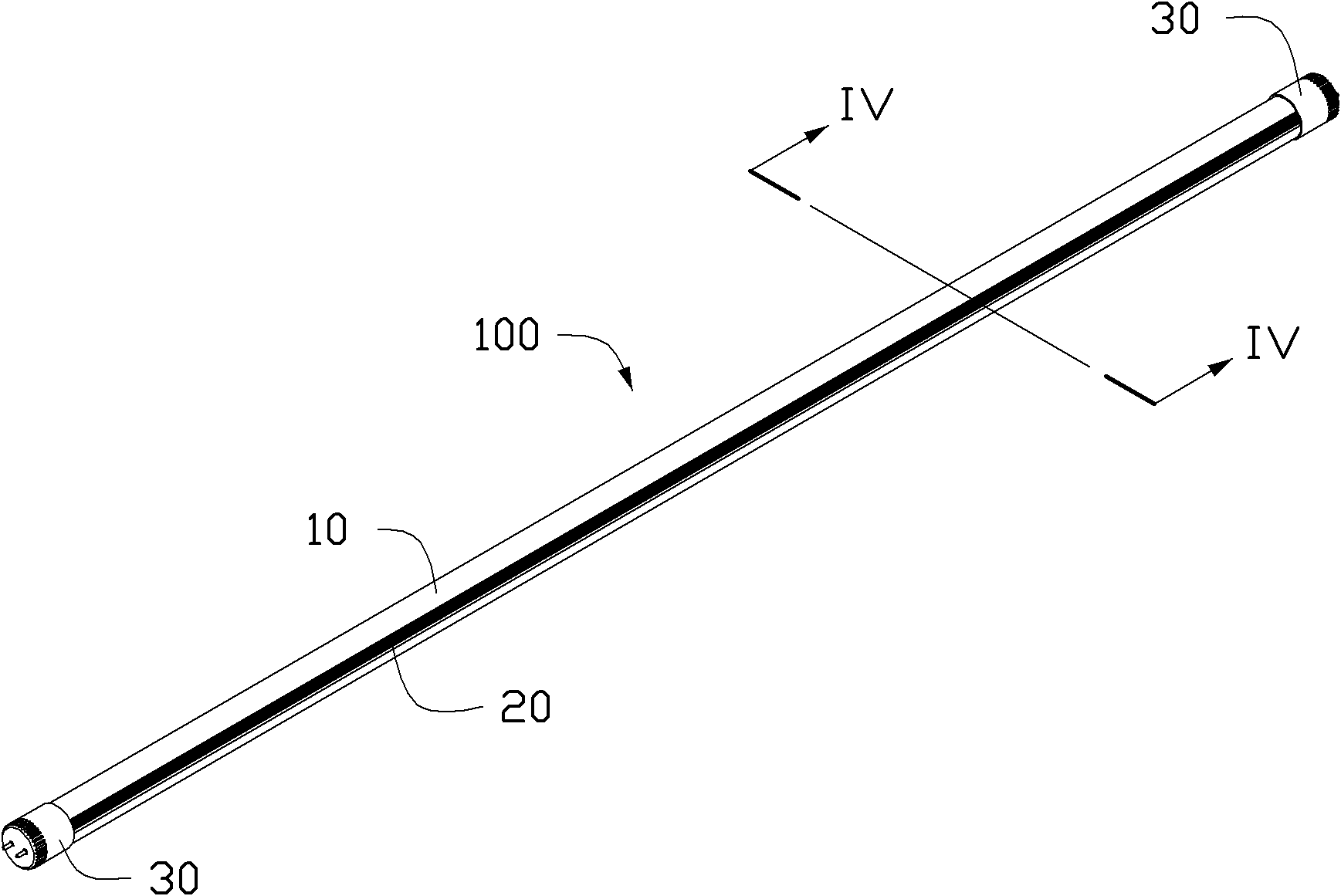

Lighting Unit And Light Bar Having The Same

InactiveCN103943752ALarge light angleIncrease distancePoint-like light sourceLighting support devicesEffect lightEngineering

Owner:LEXTAR ELECTRONICS CORP

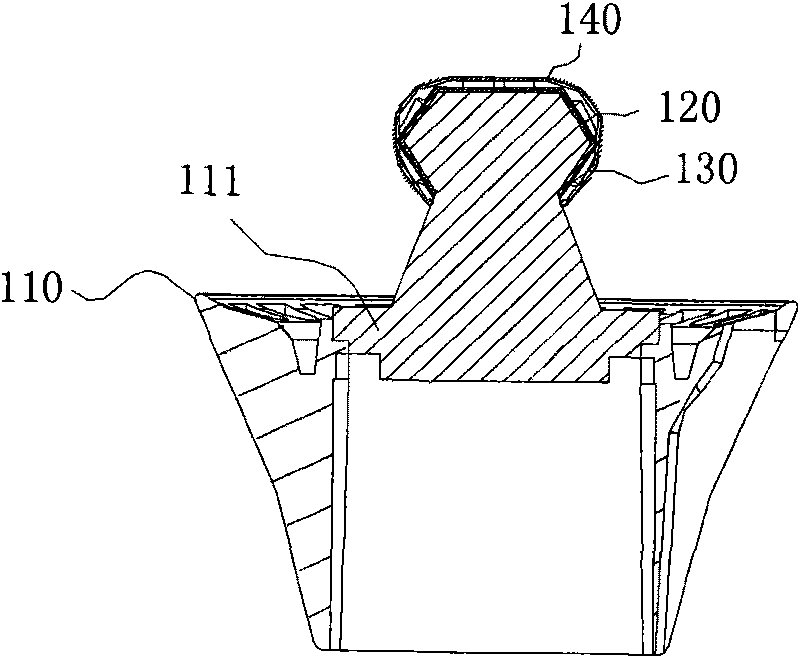

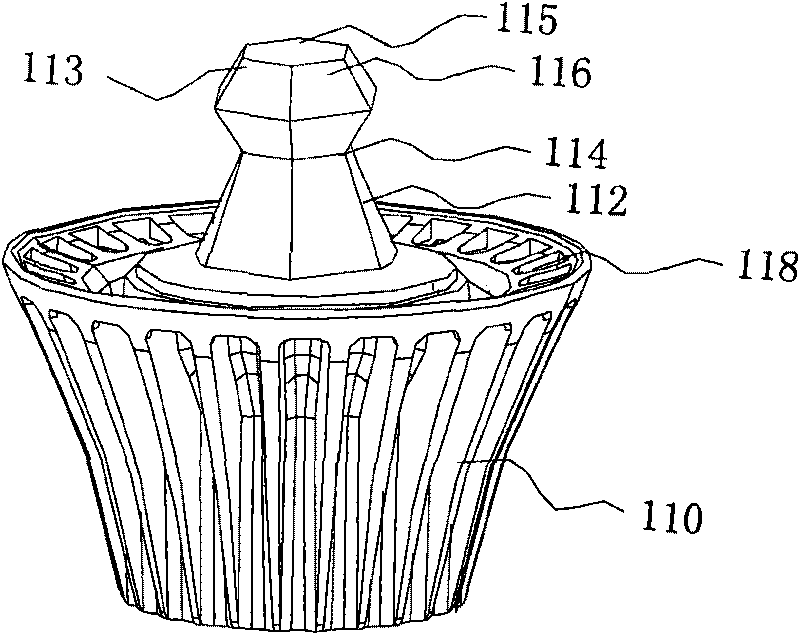

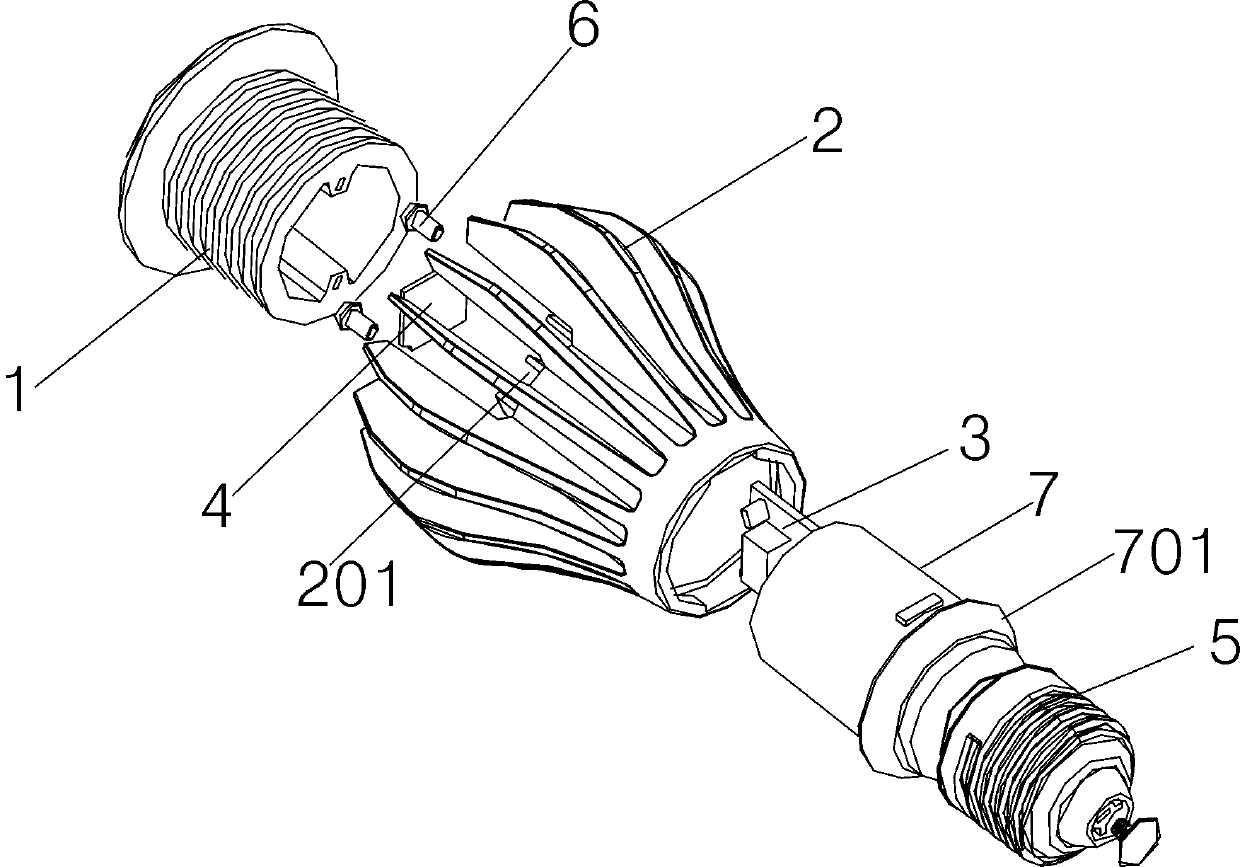

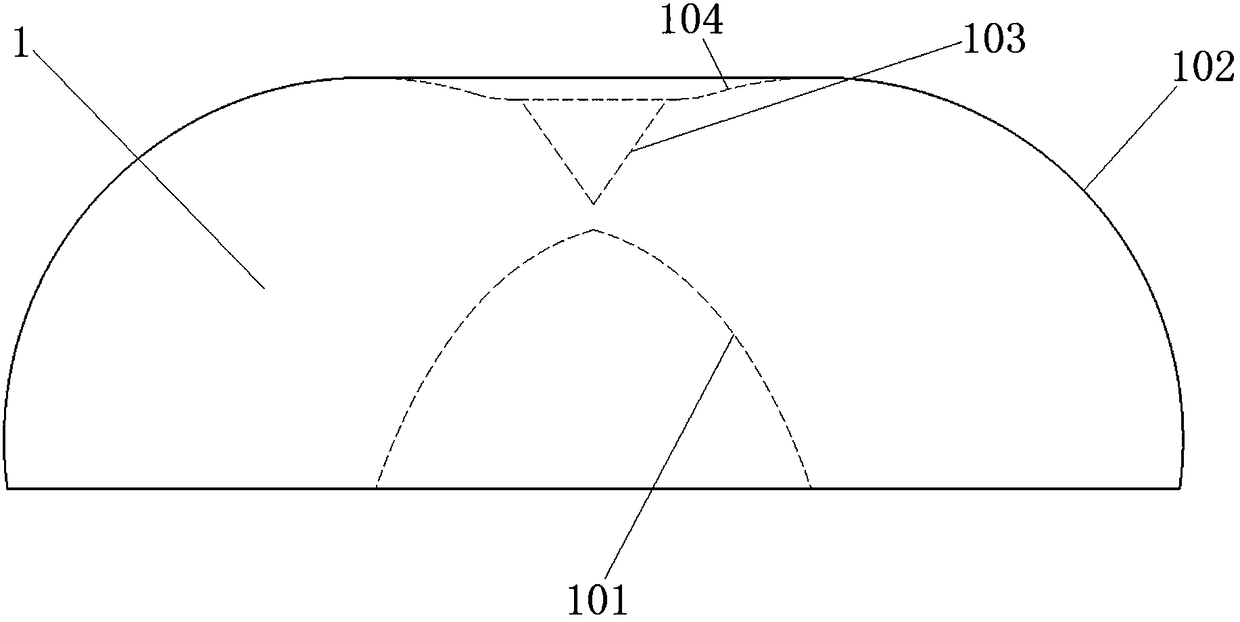

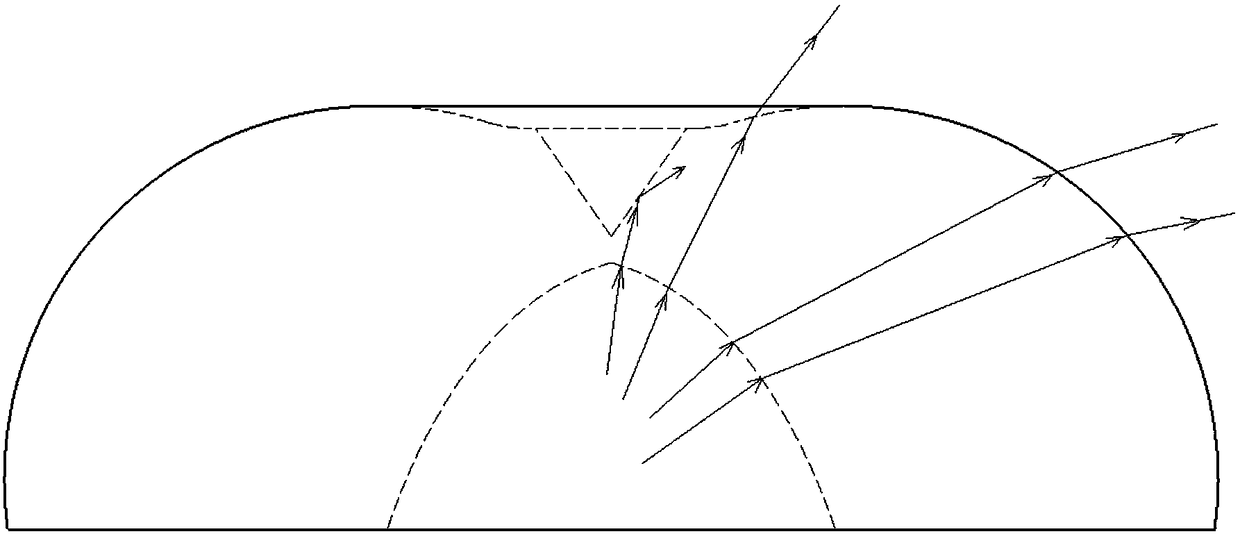

Large-angle LED and LED lamp

InactiveCN102162625ASimple structureLow costMechanical apparatusPoint-like light sourceLight fluxLight beam

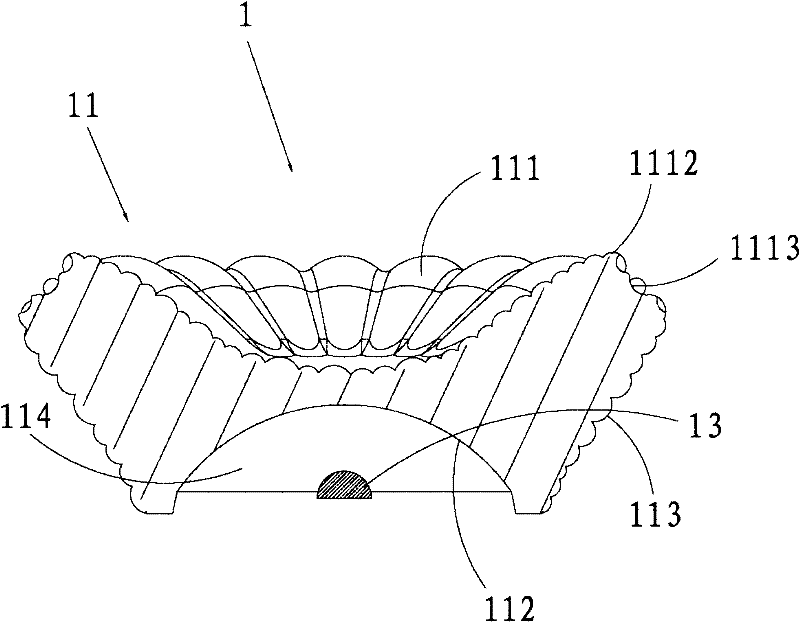

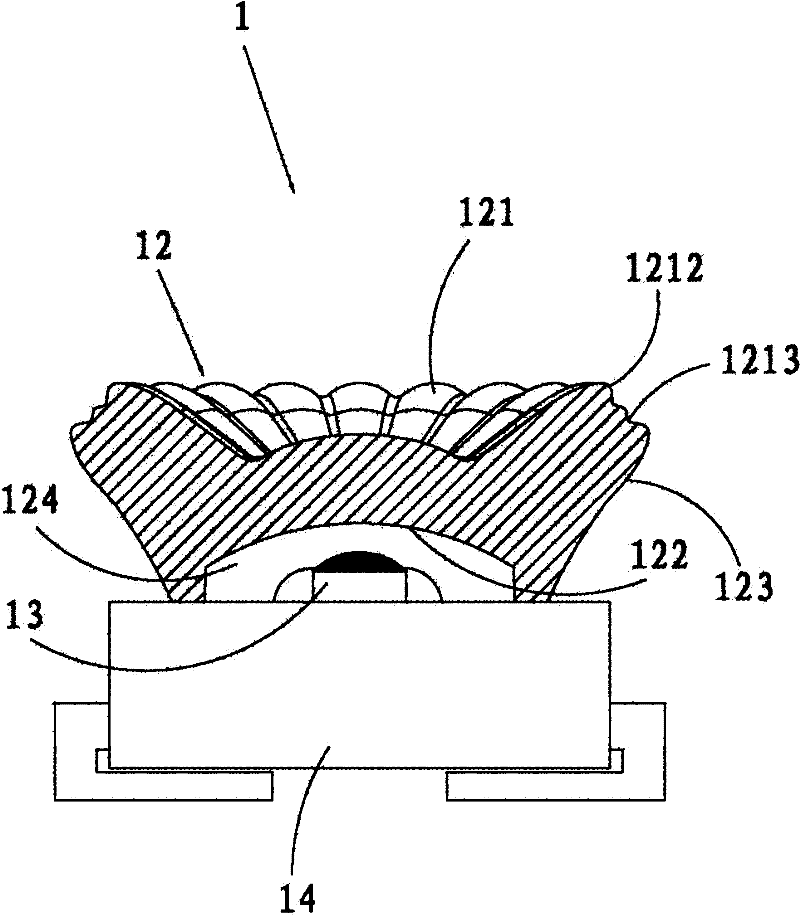

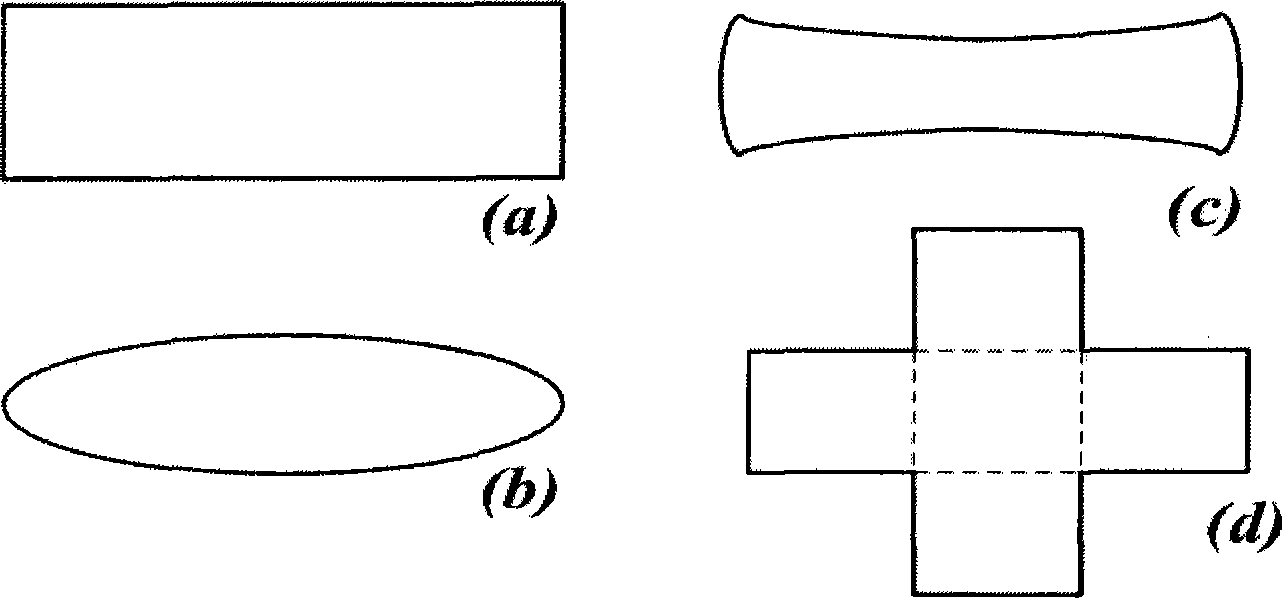

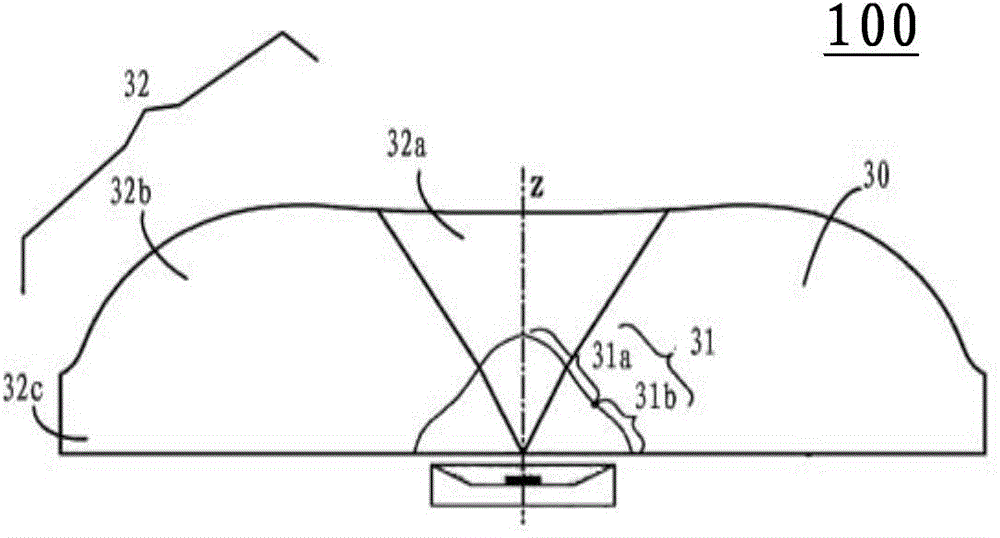

The invention relates to the technical field of light emitting diodes (LEDs), and discloses a large-angle LED and an LED lamp. The large-angle LED comprises a light source piece and a special-shaped optical device for refracting and reflecting the light emitted by the light source piece for many times, wherein the light source piece is placed in the special-shaped optical device, and the special-shaped optical device is provided with a plurality of light control faces and a plurality of light reflection faces. Compared with the prior art, the special-shaped optical device can refract and reflect the light emitted by the light source piece for many times, so that a unidirectional irradiation beam or a surface light source can achieve the irradiation effect of a third-dimensional luminous light source, and the luminous angle of the unidirectional irradiation beam or the surface light source is further more than 180 degrees; and the large-angle LED has simple structure, low cost and high light flux.

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

LED lamp with high power

InactiveCN101539250AQuality improvementSpeed up exportPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

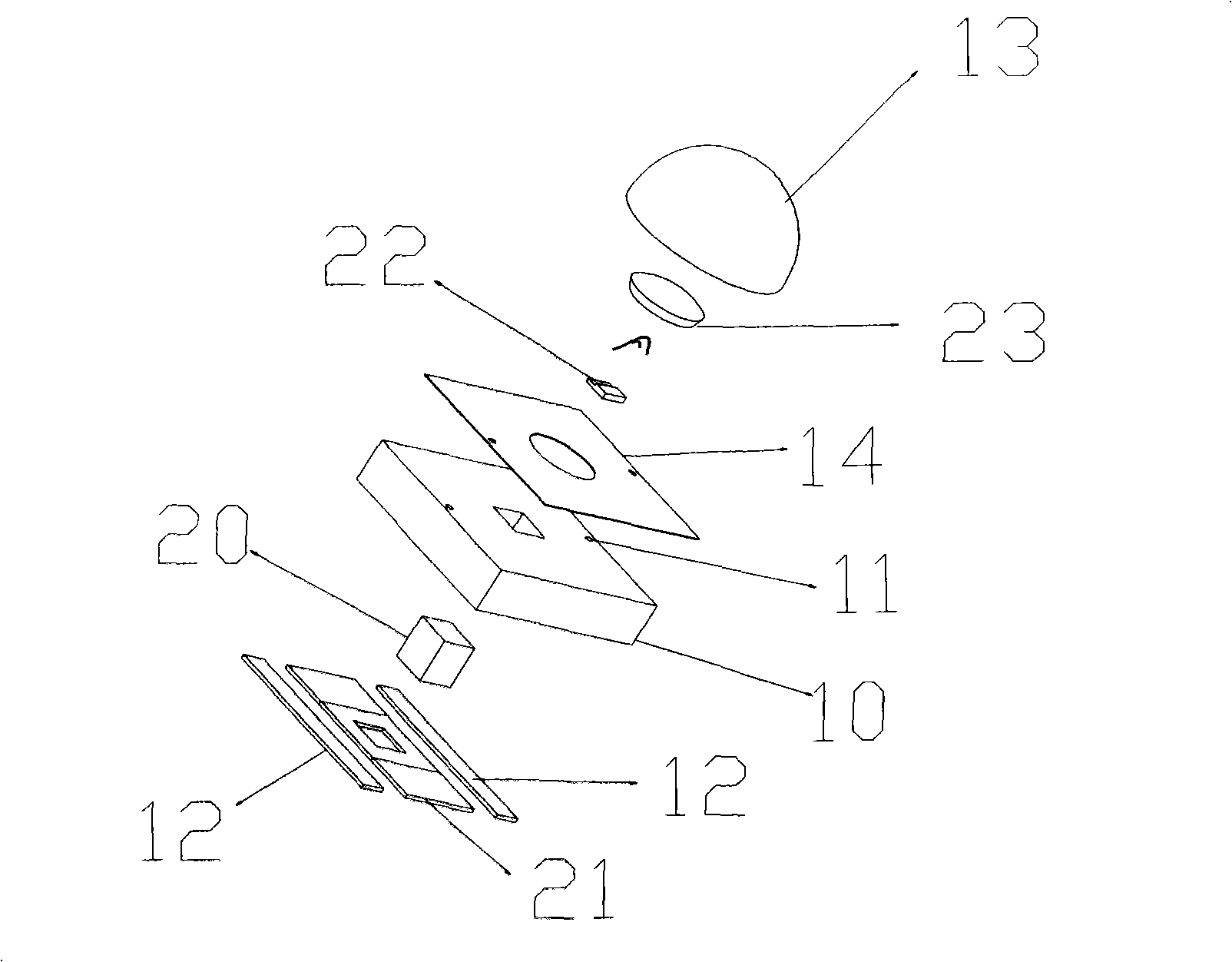

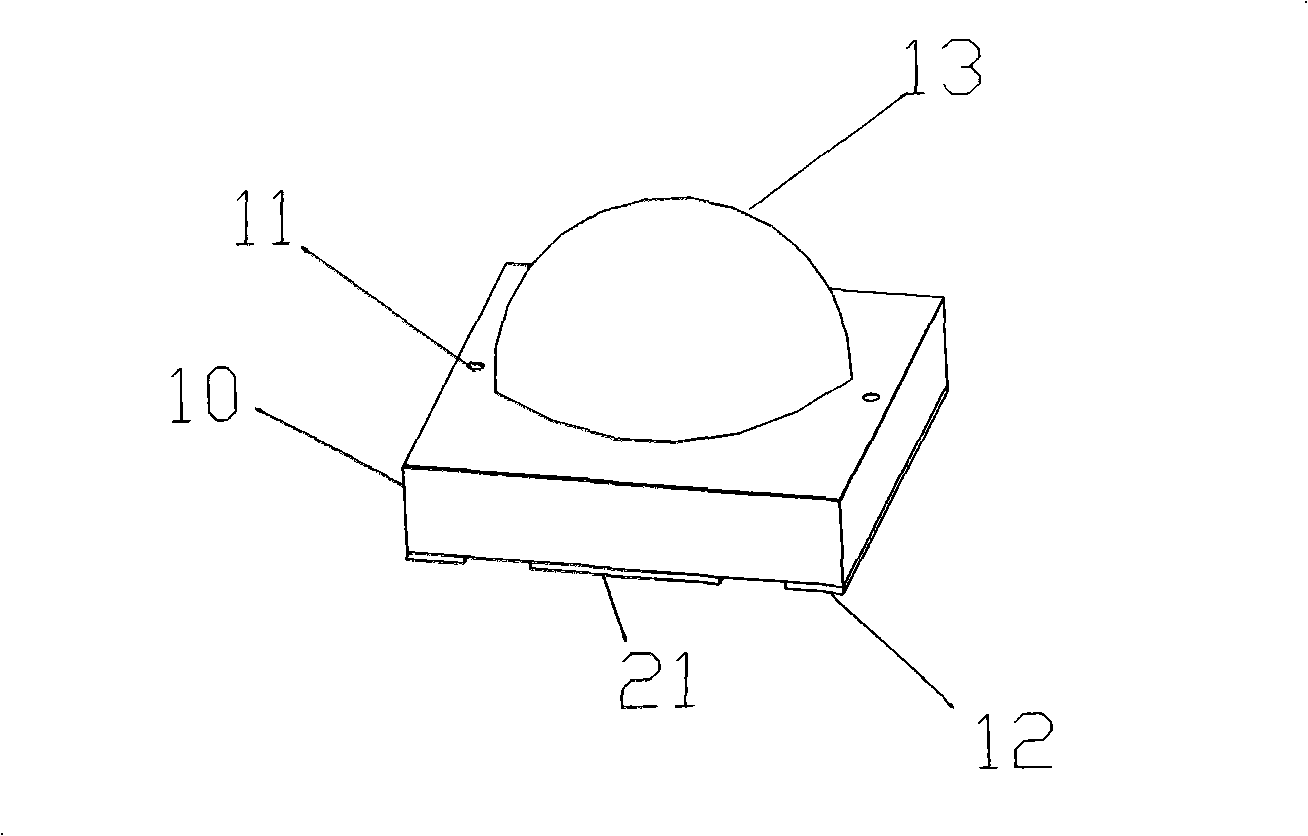

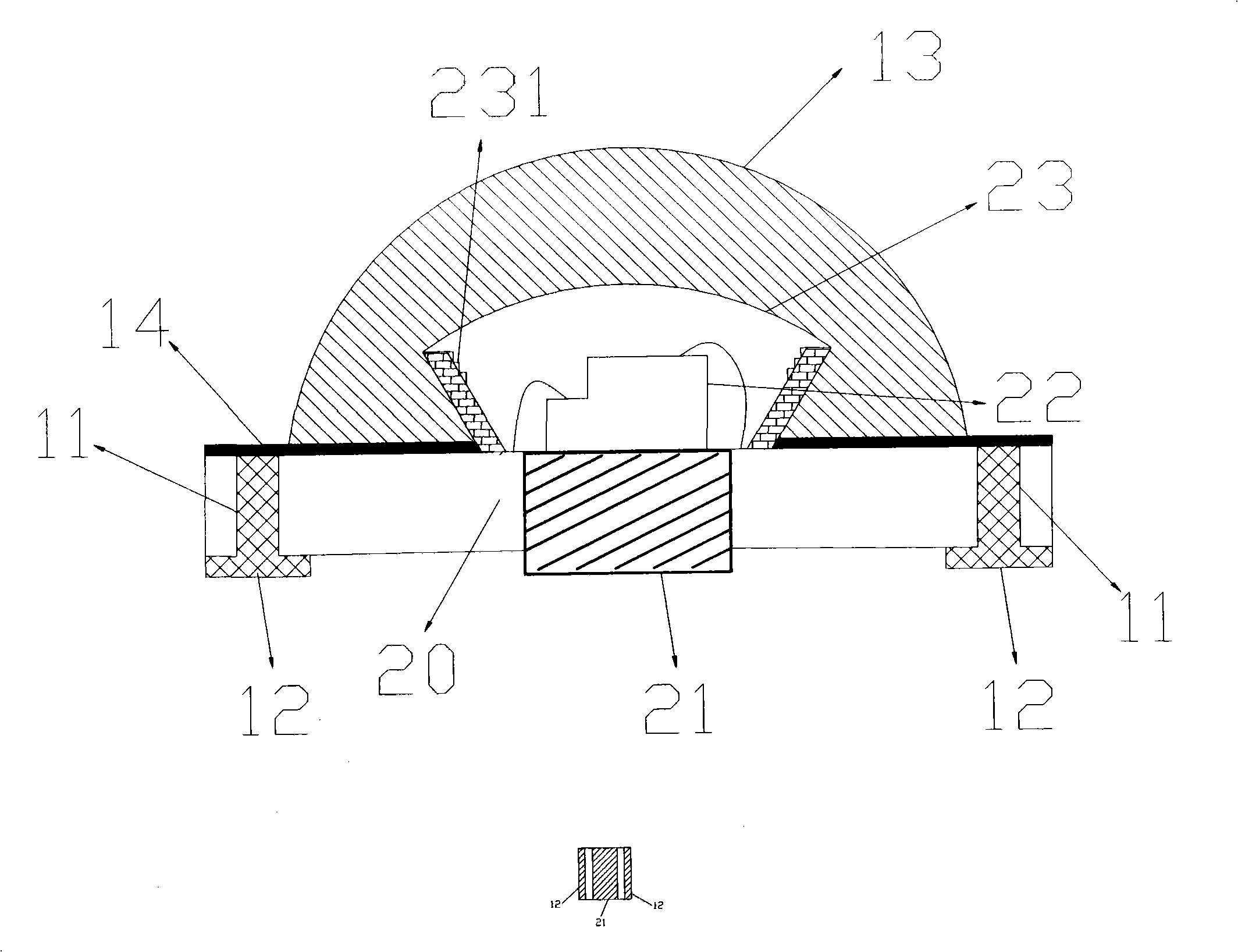

The invention relates to an LED lamp with high power, which comprises a heat-conducting and insulating substrate and a heat conducting pillar which has the same thickness of the substrate and is embedded in the substrate; the lower surface of the pillar is connected with a heat dissipating plate, and the upper surface thereof is fixed with a chip; the upper surface of the substrate is fixed with a transparent housing and is provided with a circuit and electrodes; the periphery of the substrate is provided with a through hole used for the circuit passing through; the bottom of the through hole is connected with a conductive electrode plate; and a lens is encapsulated on the transparent housing of the substrate. The LED lamp with high power has unique structure, breaks through the design of traditional LED lamp, can improve the reliability and consistency of the products; and simultaneously, by utilizing machinery equipments for production, the production efficiency is greatly improved and the product cost is reduced.

Owner:薛信培 +1

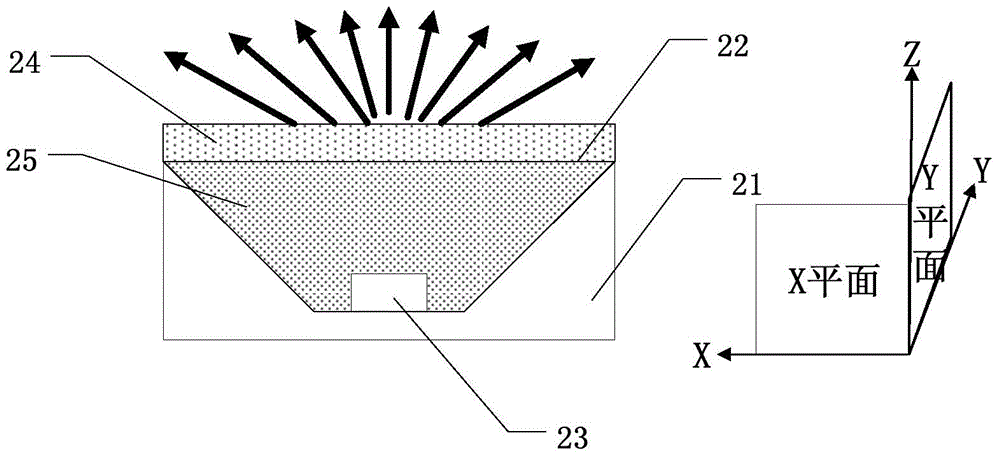

LED three-dimensional optical system design method and optical system with given luminous intensity distribution

ActiveCN101251650AImprove efficient utilizationLarge light angleOptical elementsOptical refractionConservation of energy

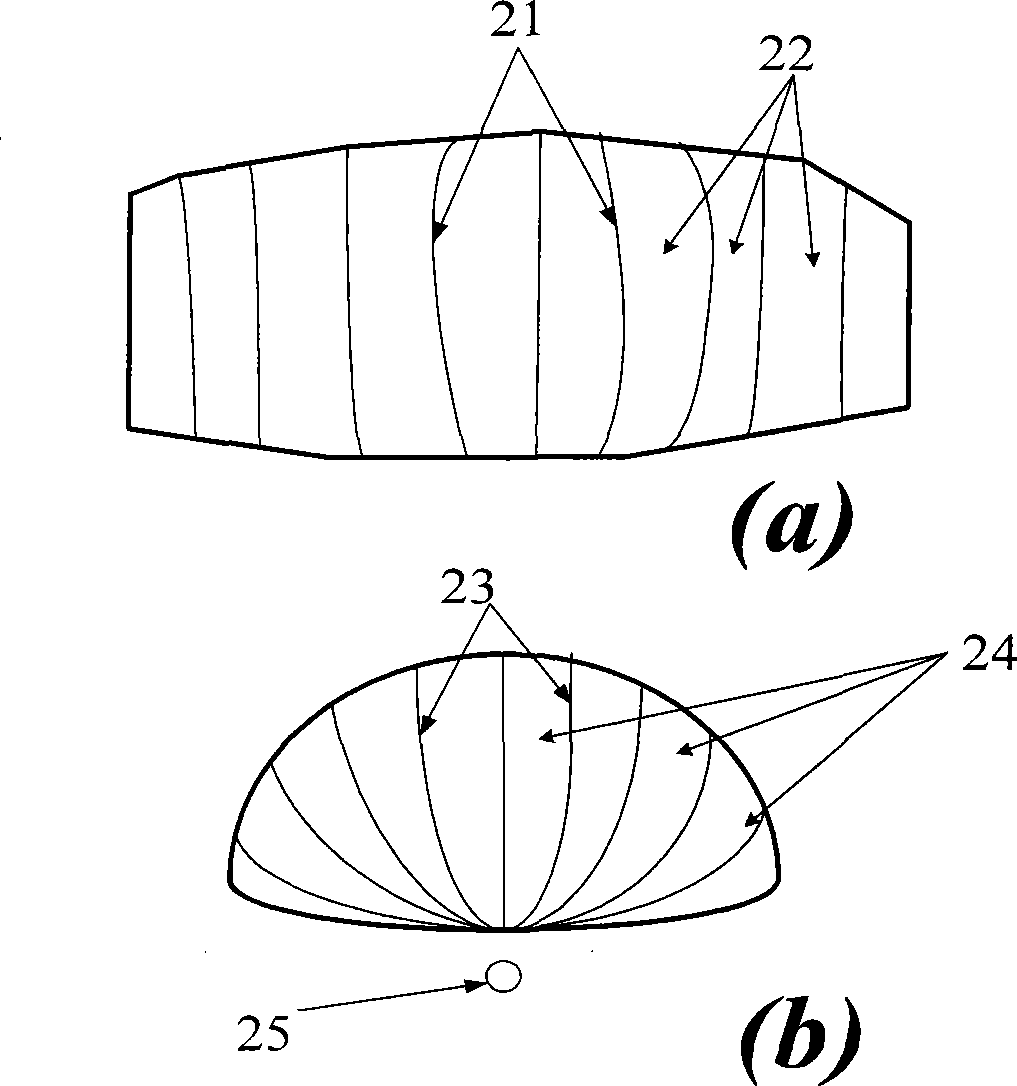

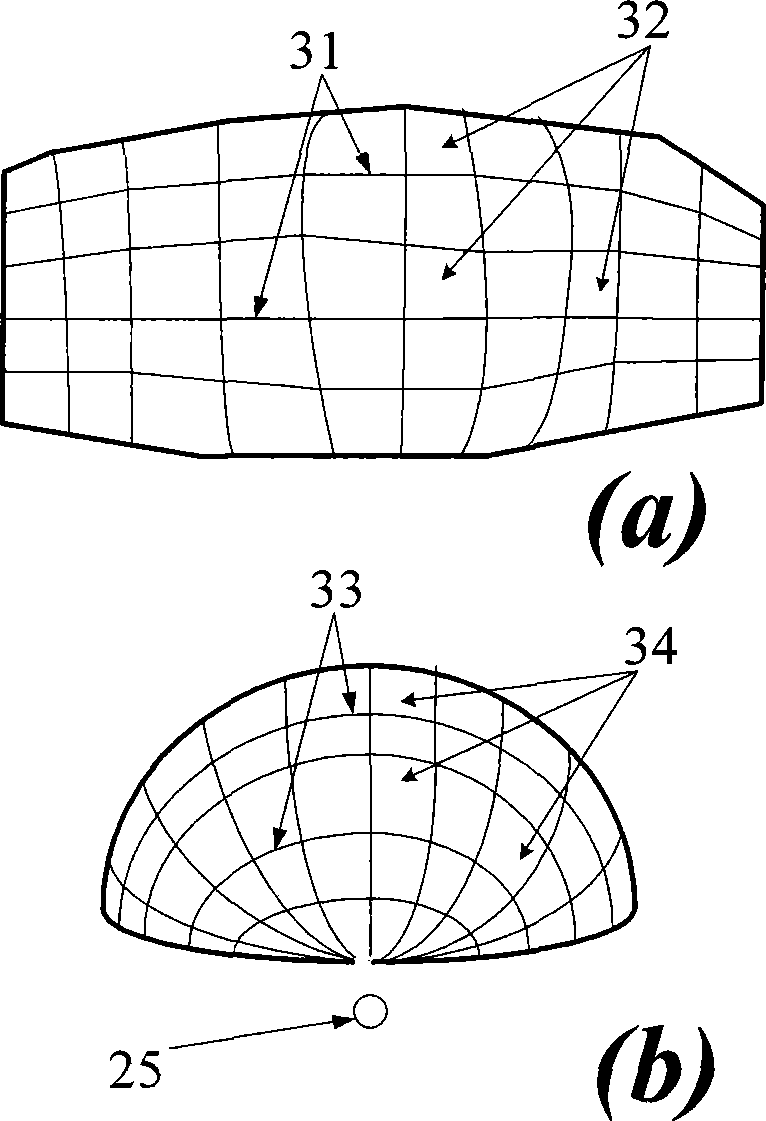

The present invention discloses an LED three-dimensional optical system design method with given illumination distribution and an optical system, which belongs to the non-imaging optical technique of the applied optics field. A three-dimensional non-imaging optical system is formed in a region which has given illumination distribution, by using a light emitting diode as a light source. A three-dimensional lens is designed with the optical system. According to the geometrical shape of the given illumination distribution region, complying with the law of conversation of energy, the surface of the light source and the illumination plane are divided into corresponding energy regions on the long axis direction of the region in accordance with optical refraction, and energy division is carried out in the short axis direction in accordance with the principle of common function of total internal reflection and refraction. The coordinates and the normal vectors of all feature points of the optical system surface of the light source along the long axis direction and the short axis direction are calculated according to the energy corresponding relationship, so as to determine the optical system surface. The method and the system contribute to sufficiently utilizing energy and reducing engineering cost. The encapsulation of the optical system is flexible. Single chip encapsulation and multi-chip encapsulation can be adopted. The arrangement of a plurality of the optical systems is free, simple and flexible.

Owner:TSINGHUA UNIV

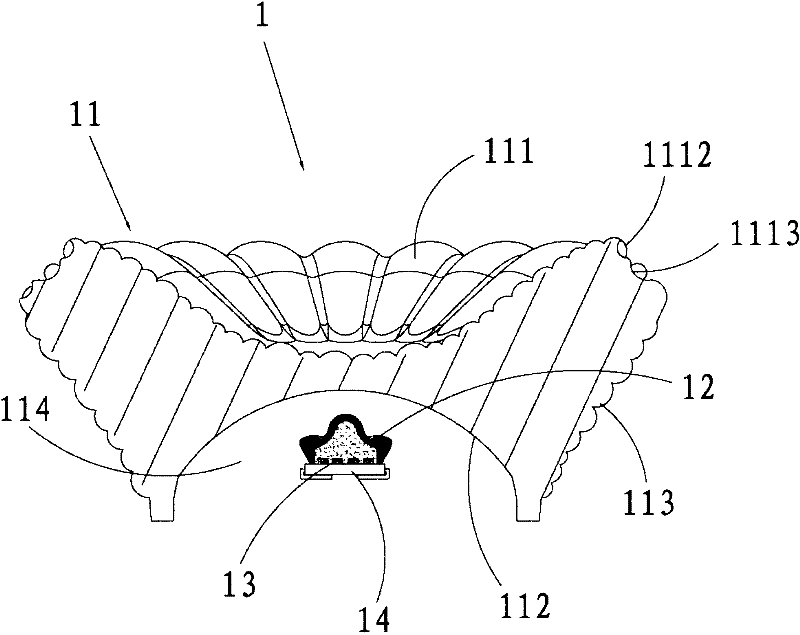

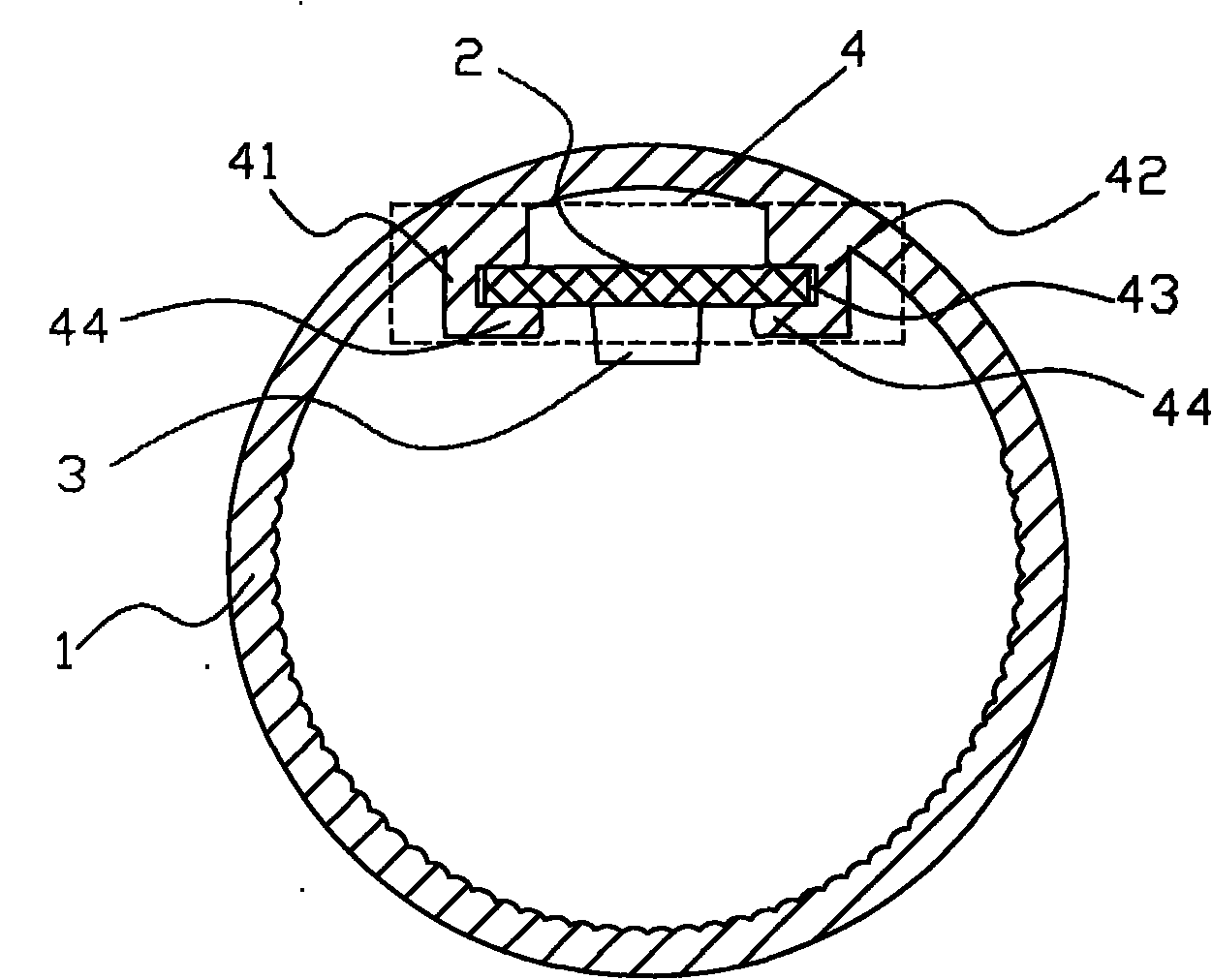

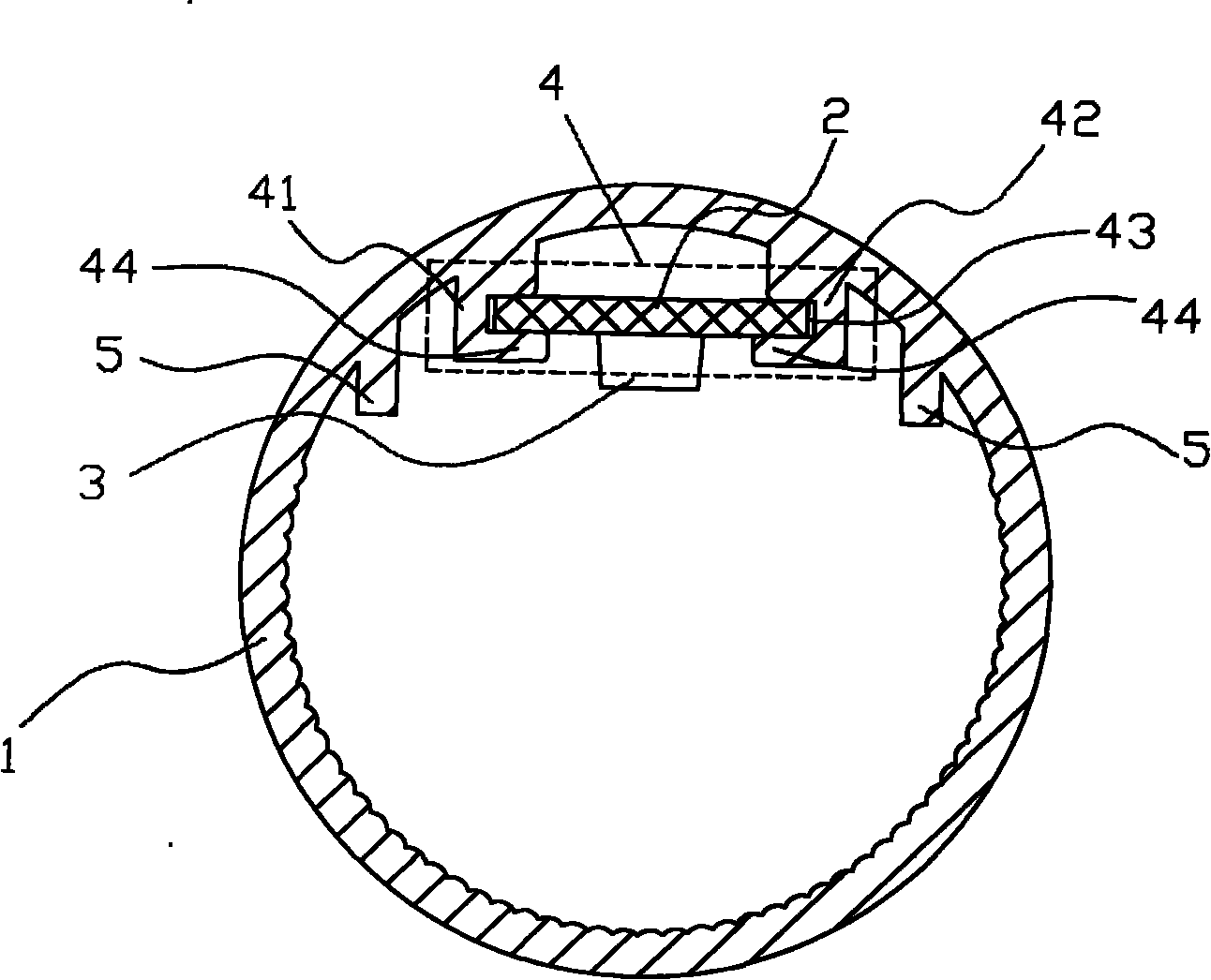

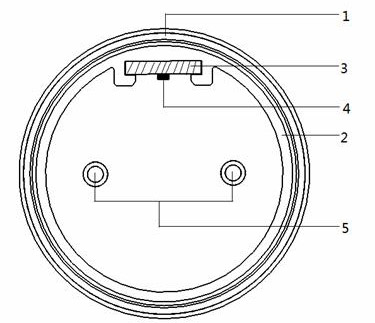

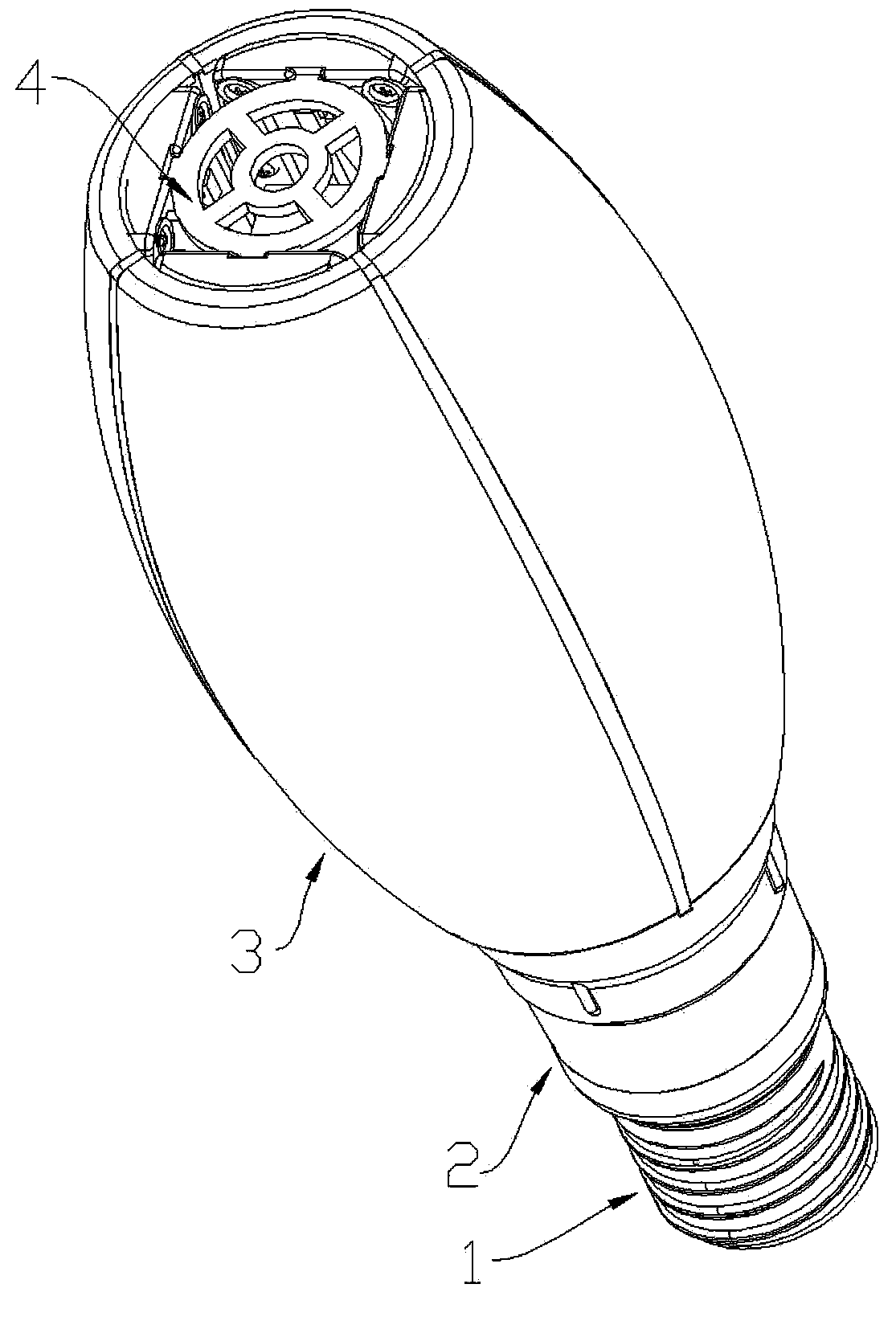

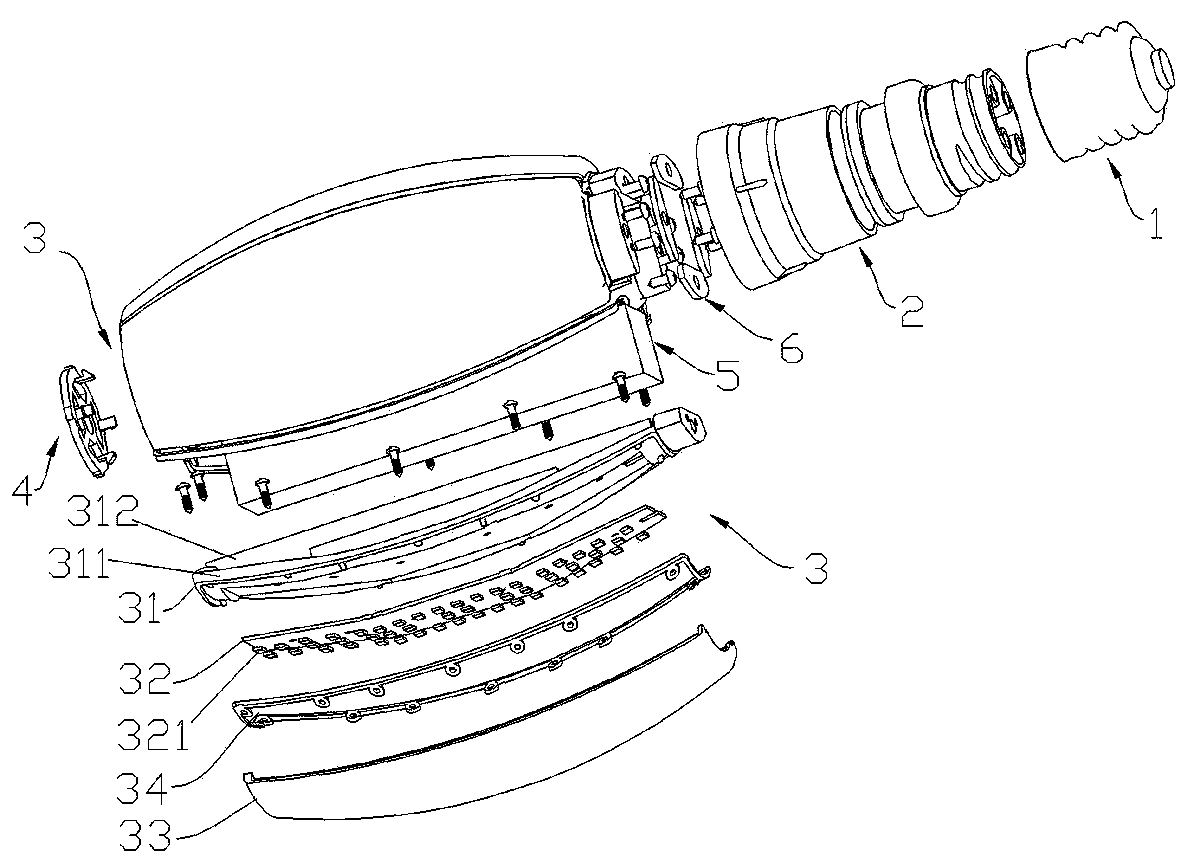

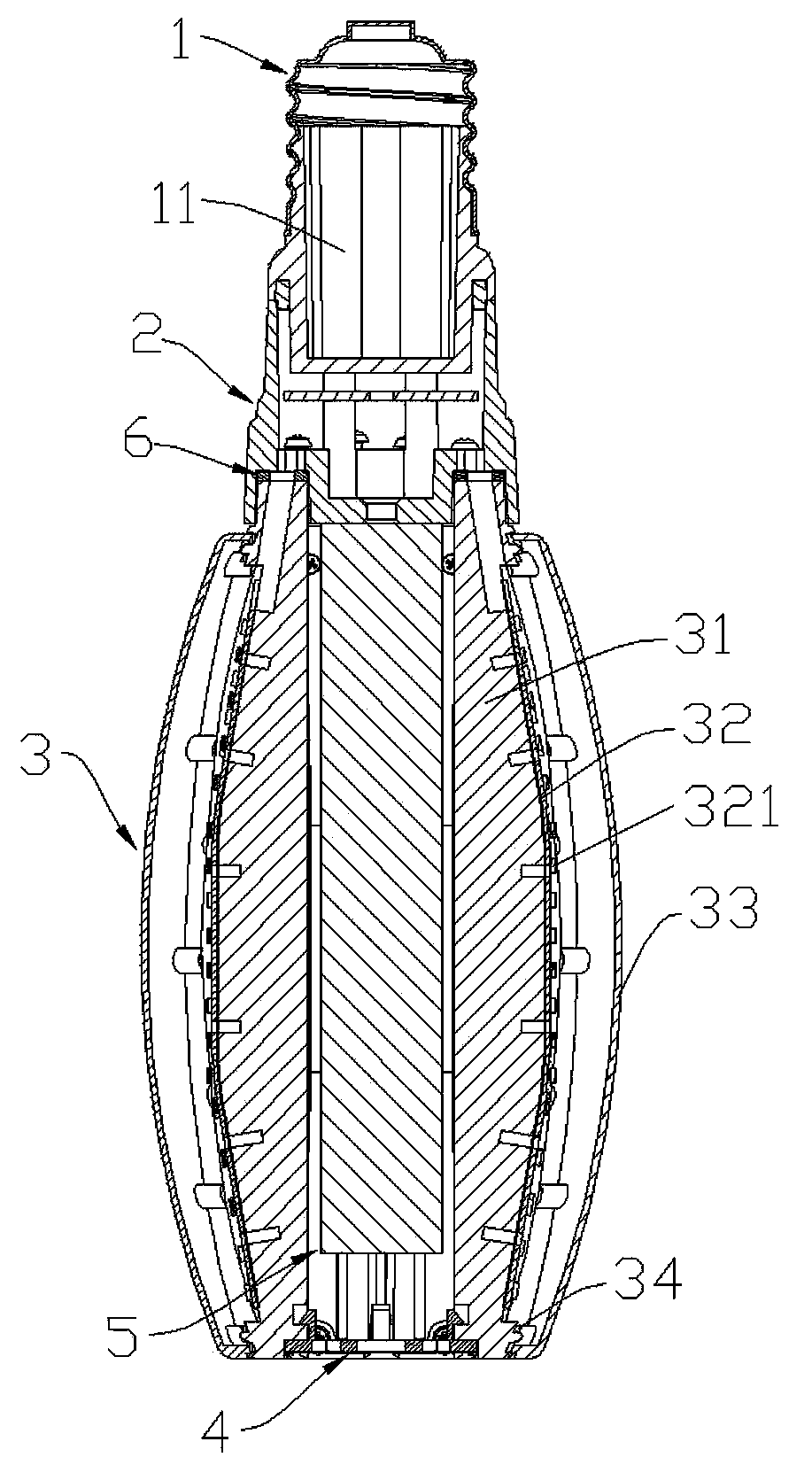

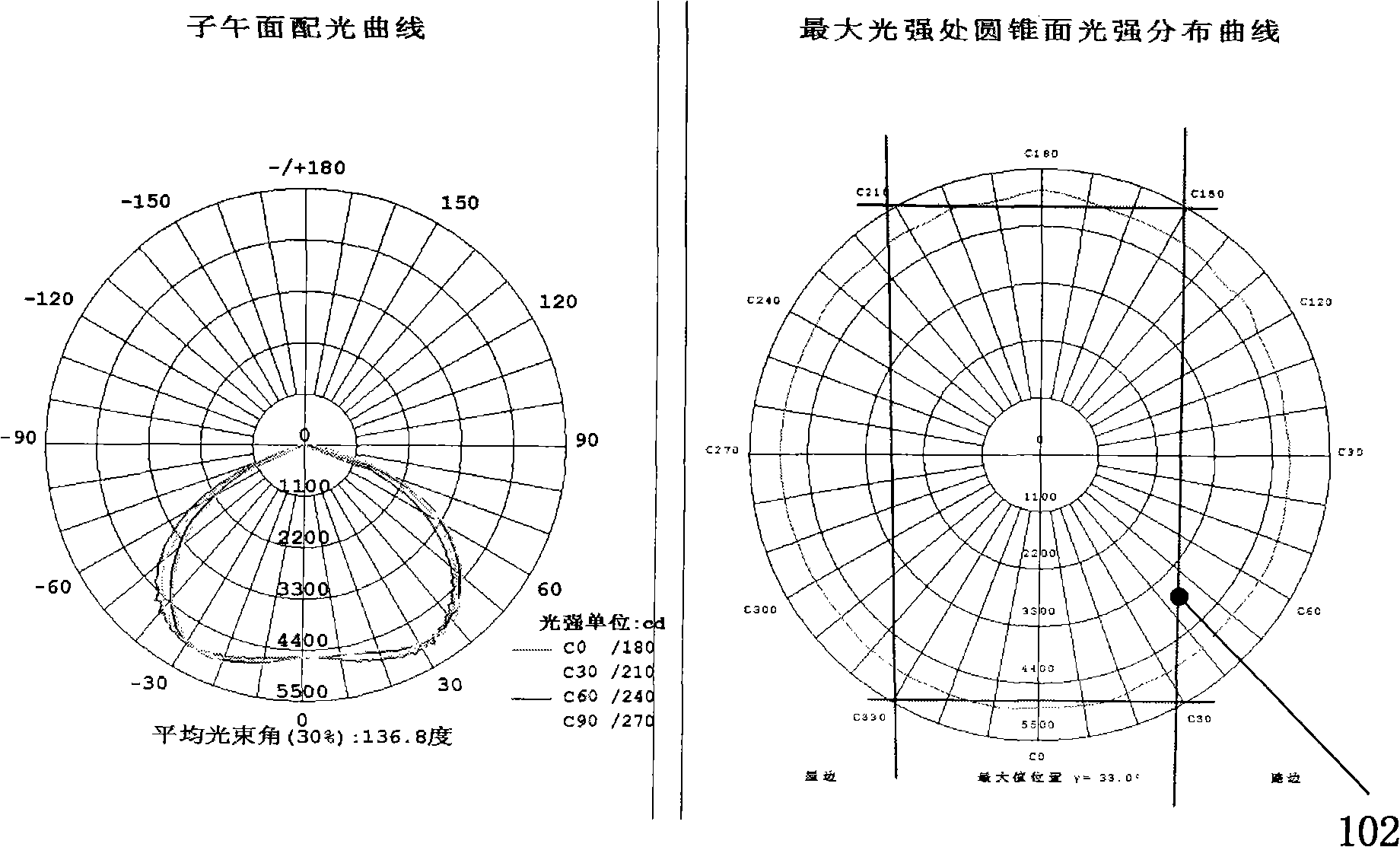

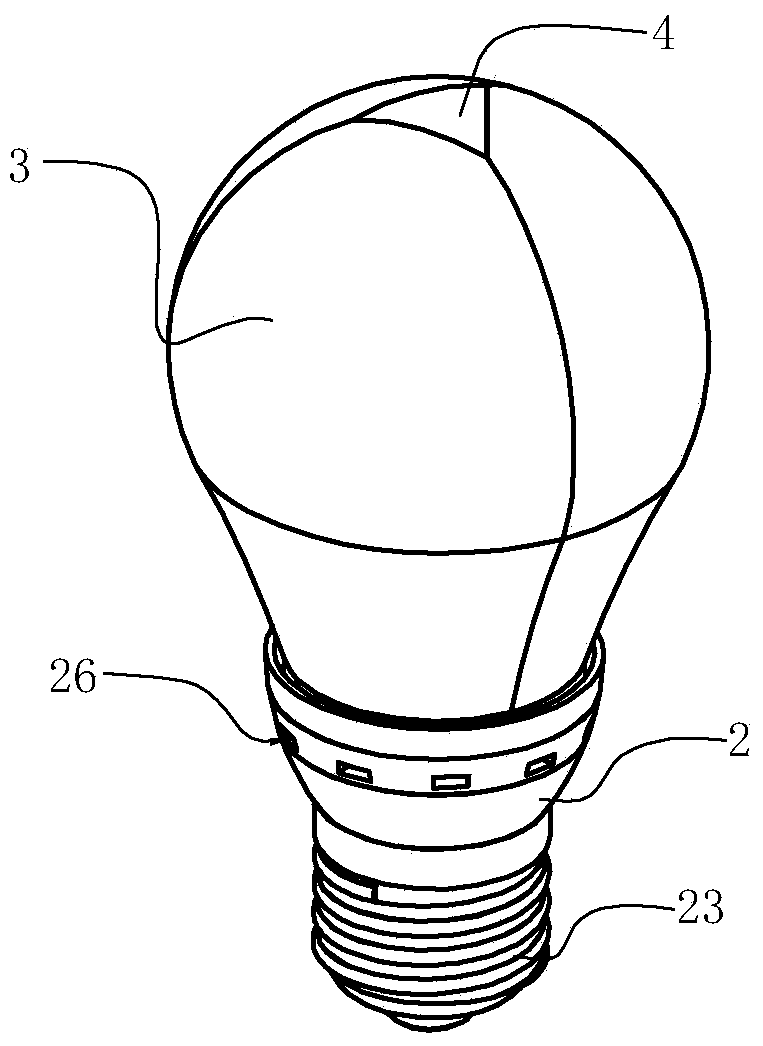

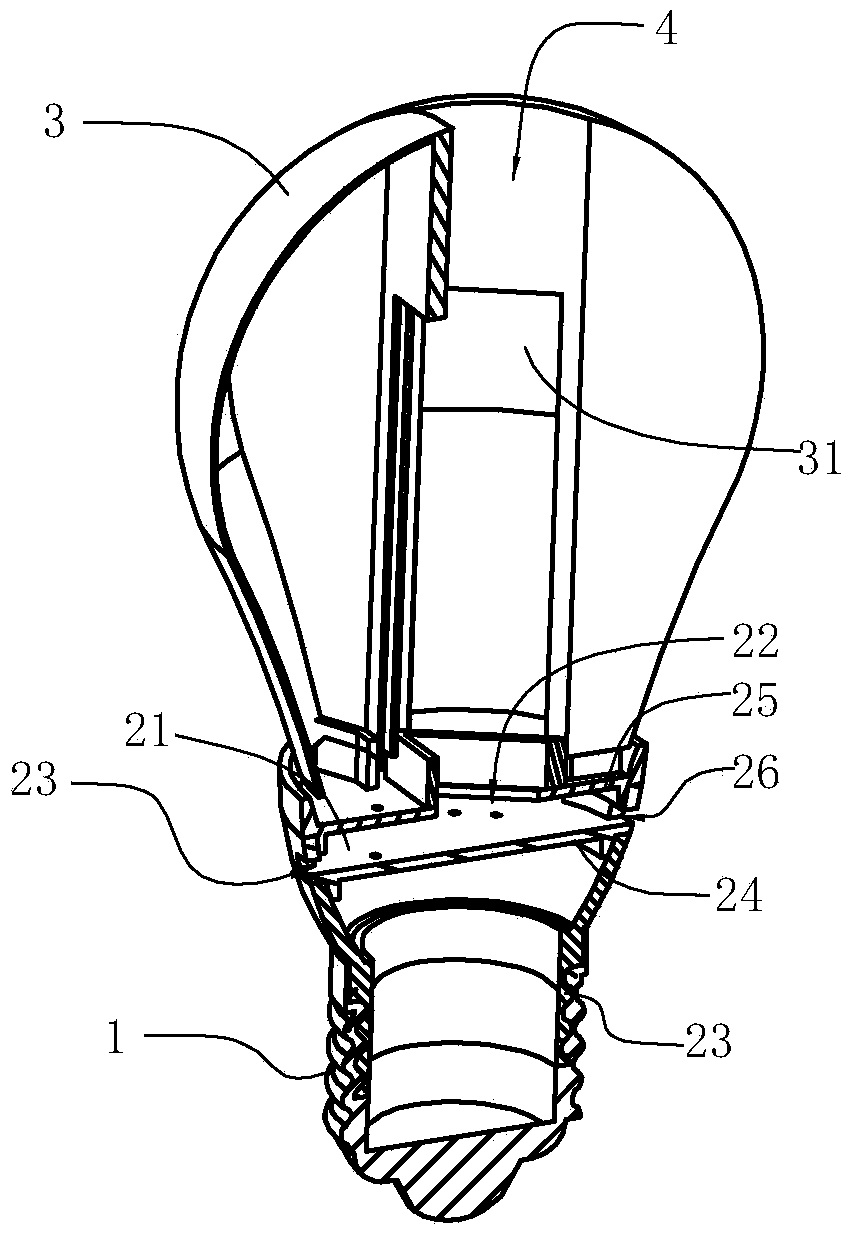

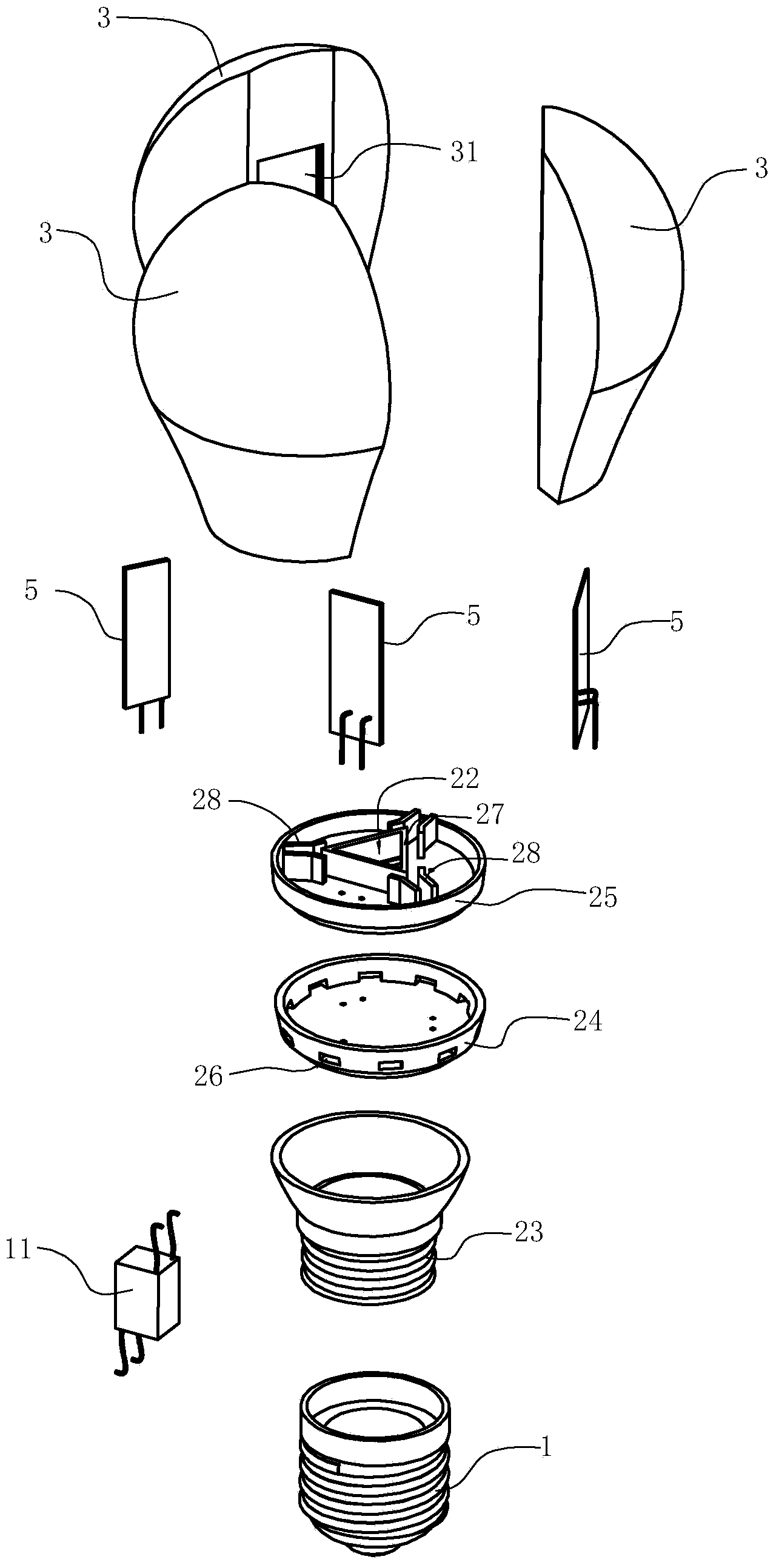

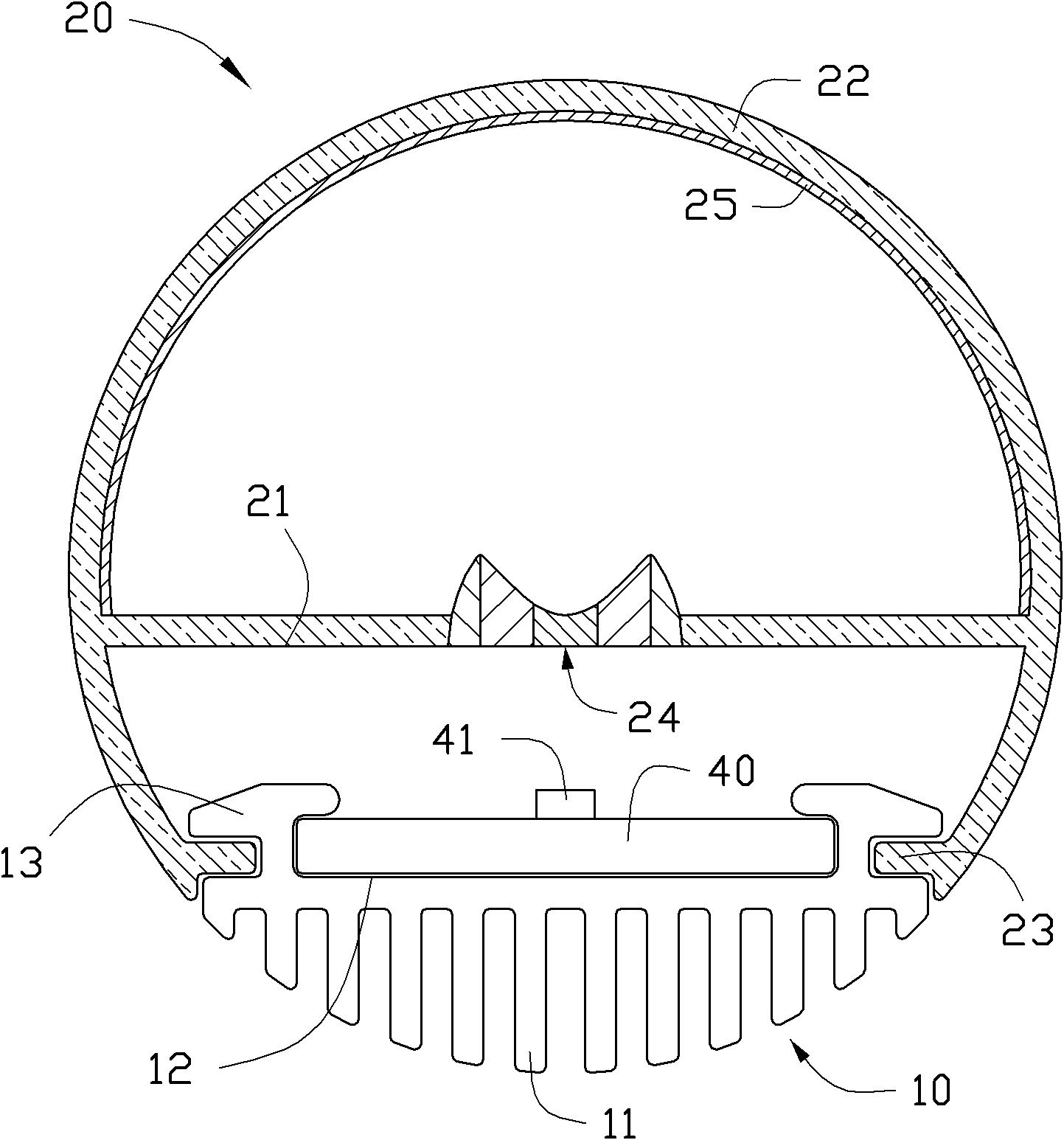

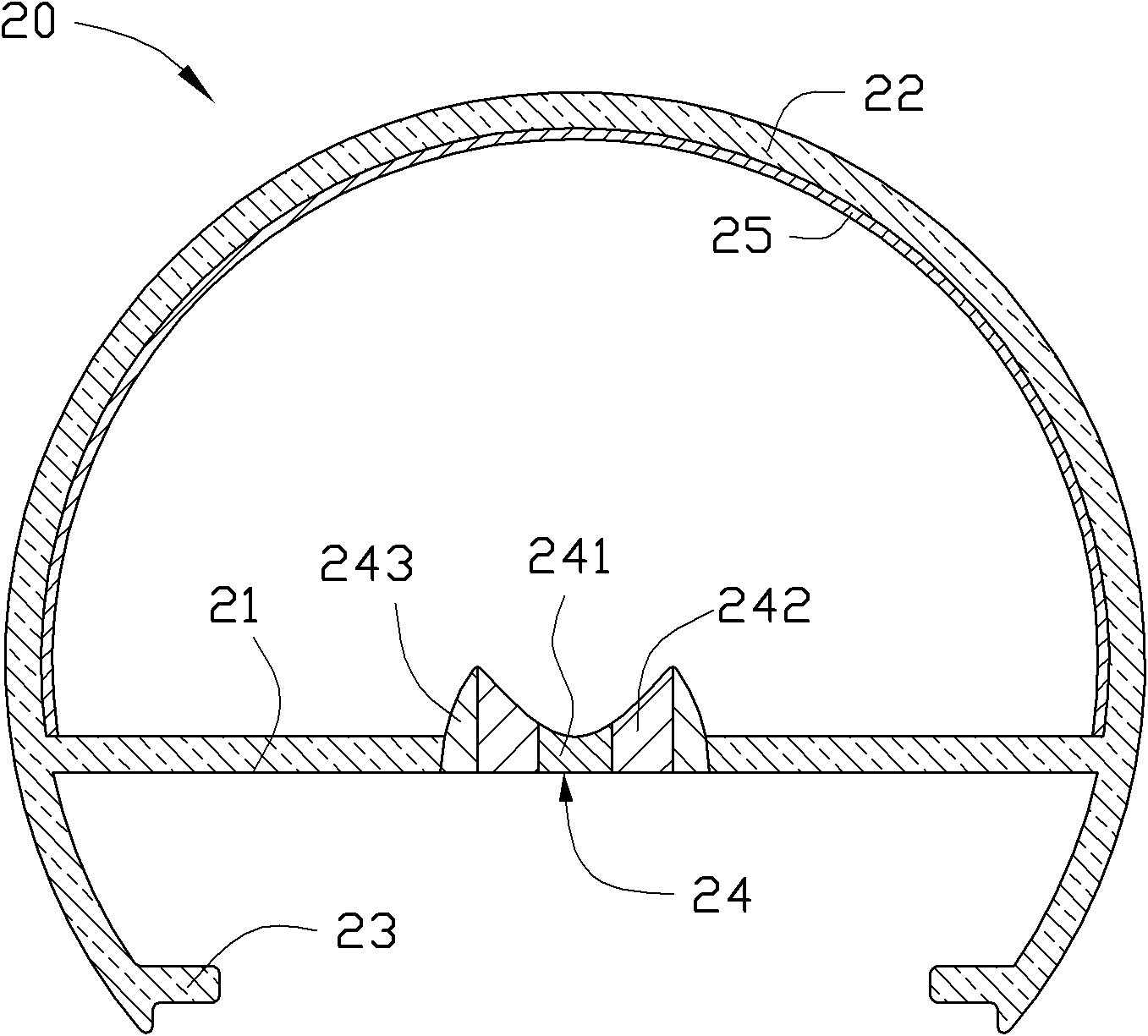

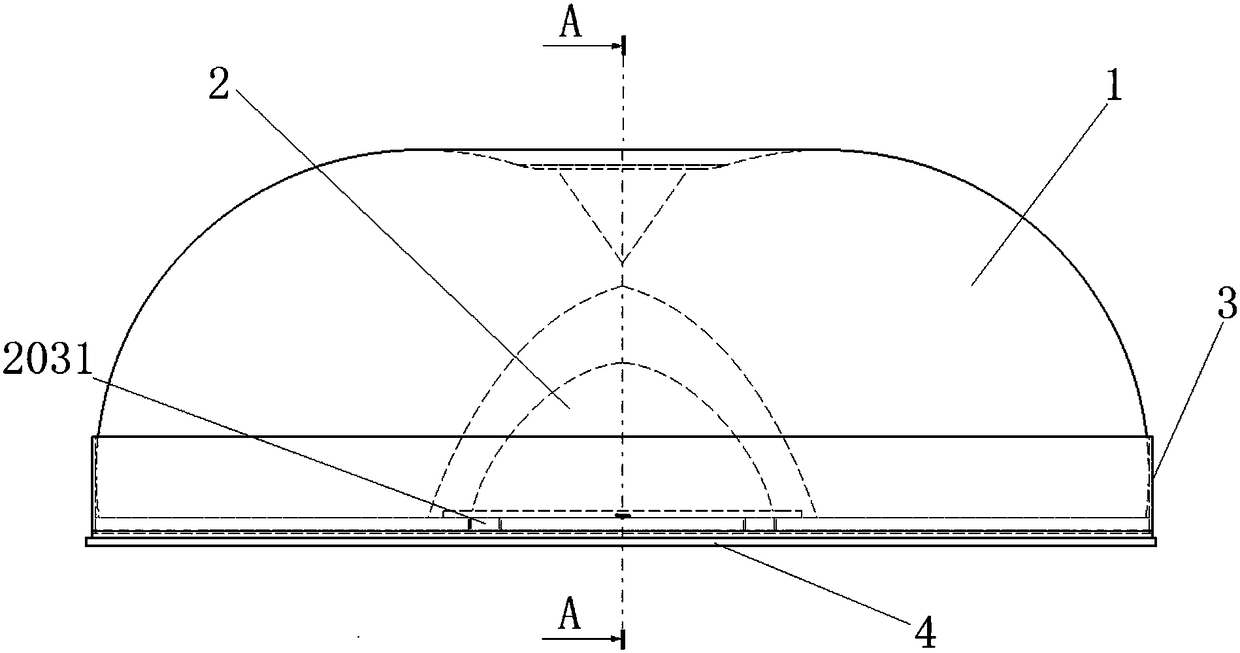

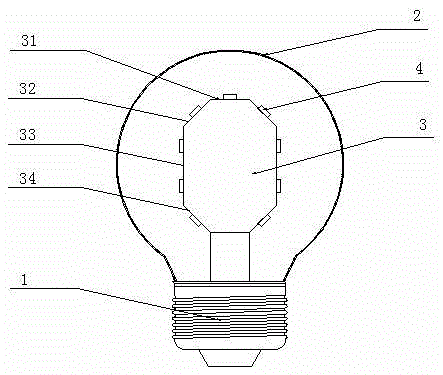

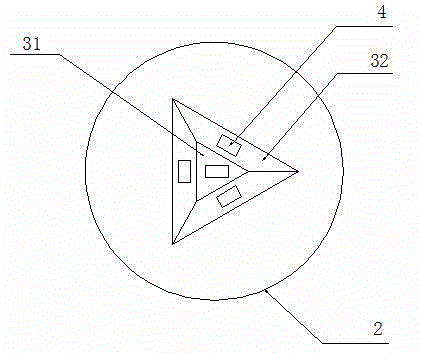

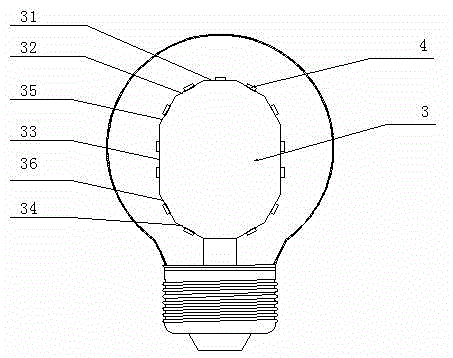

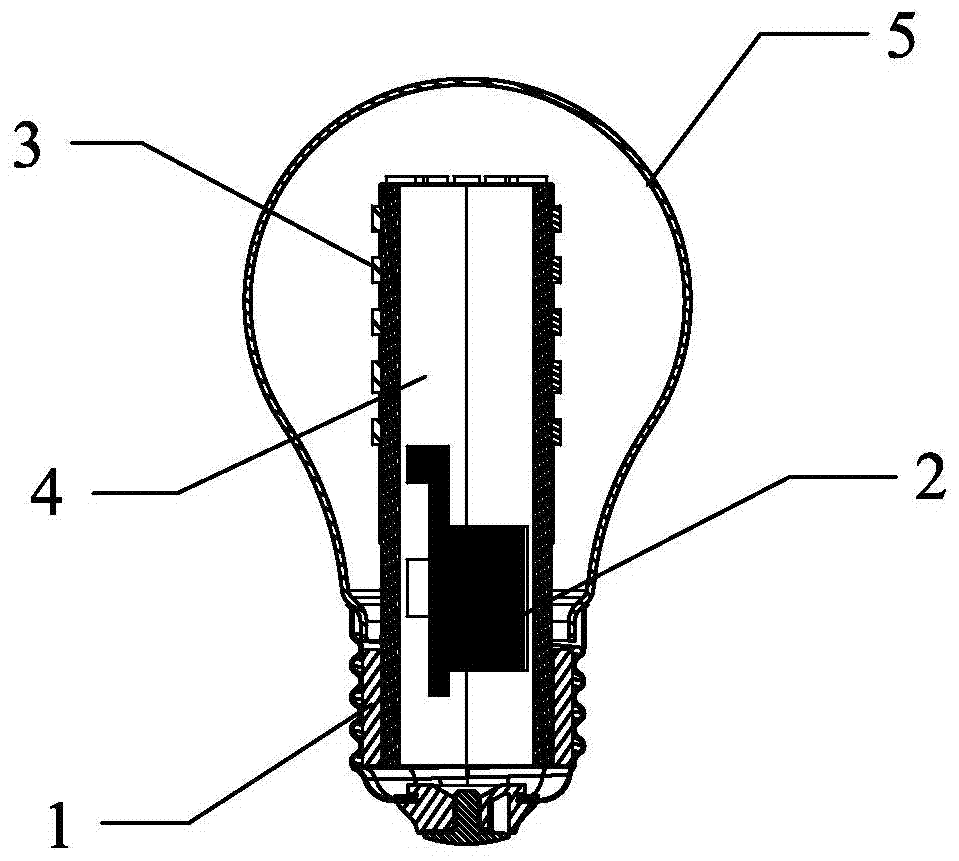

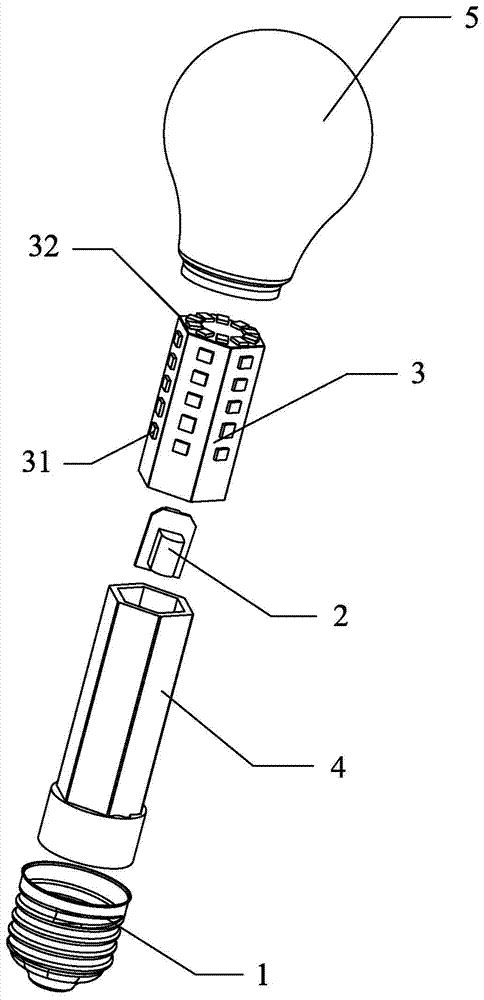

Large-angle omnidirectional lighting LED (light emitting diode) lamp

ActiveCN102305363ALarge light angleSimple structurePlanar light sourcesPoint-like light sourceEffect lightEngineering

The invention discloses a large-angle omnidirectional lighting LED (light emitting diode) lamp which comprises a lamp bulb shell and a light emitting unit, wherein the lamp bulb shell covers the light emitting unit; in addition, the large-angle omnidirectional lighting LED lamp also comprises a reflecting unit, and the reflecting unit comprises a light-reflecting component; the light-reflecting component is fixed on the lamp bulb shell, and provided with an annular light-reflecting surface; and the light-reflecting surface of the light-reflecting component is arranged corresponding to the light emitting unit and used for reflecting lights emitted from the light emitting unit to the bottom of the lamp bulb shell. The large-angle omnidirectional lighting LED lamp disclosed by the invention has the advantage of simple structure.

Owner:LEEDARSON IOT TECH INC

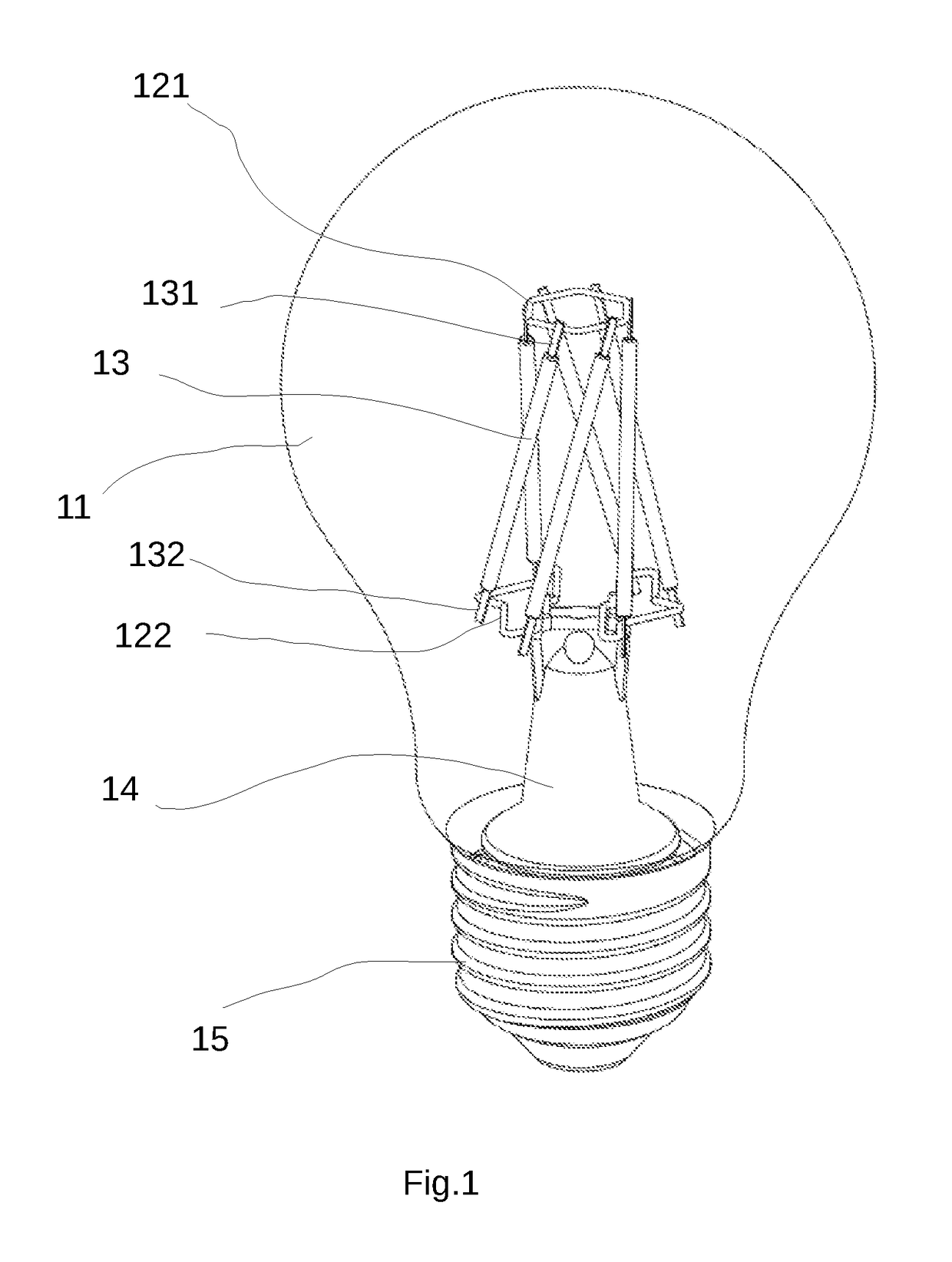

LED filament light

ActiveUS20190032858A1Large light angleImprove cooling effectElectric circuit arrangementsSemiconductor devices for light sourcesEngineeringMechanical engineering

A LED filament light has a bulb shell, a base portion, a filament module, a top spreading structure, a bottom spreading structure, a lamp cap and a driving piece. The filament module is placed in the containing space formed by the bulb shell and base portion. The filament module is composed of a plurality of filaments. The top of the plurality of filaments connects to the top spreading structure. The bottom spreading structure extends from the base portion, the bottom of the plurality of filaments connect to the bottom spreading structure. The top spreading structure is supported only by the plurality of filaments. The driving piece is placed in the lamp cap to provide electric power required for the plurality of filaments to illuminate

Owner:LEEDARSON GREEN LIGHTING

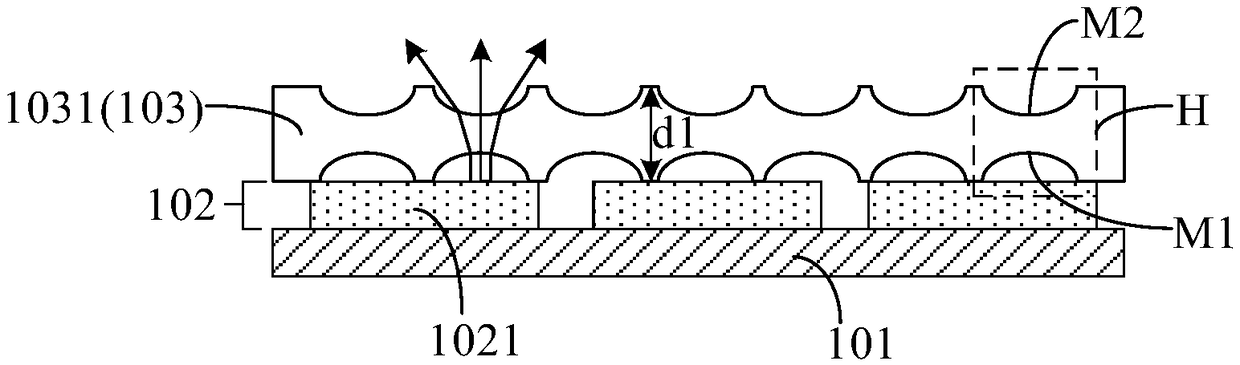

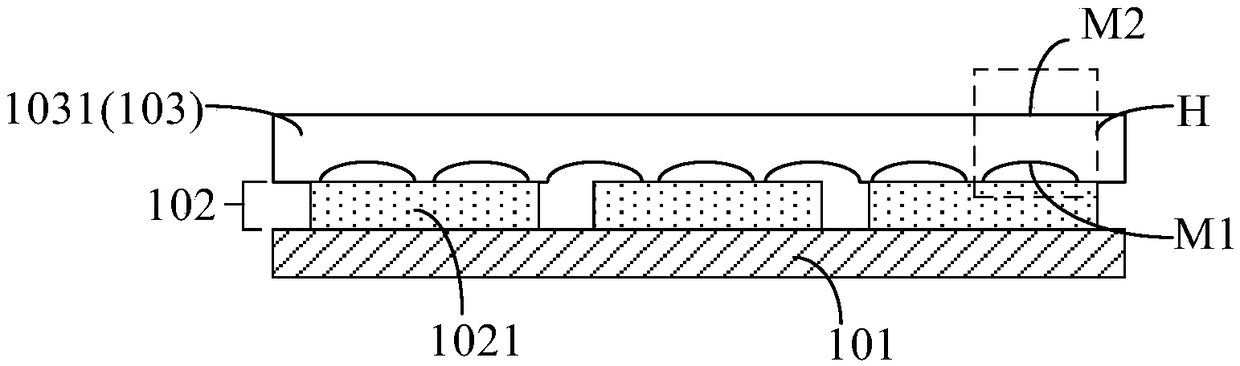

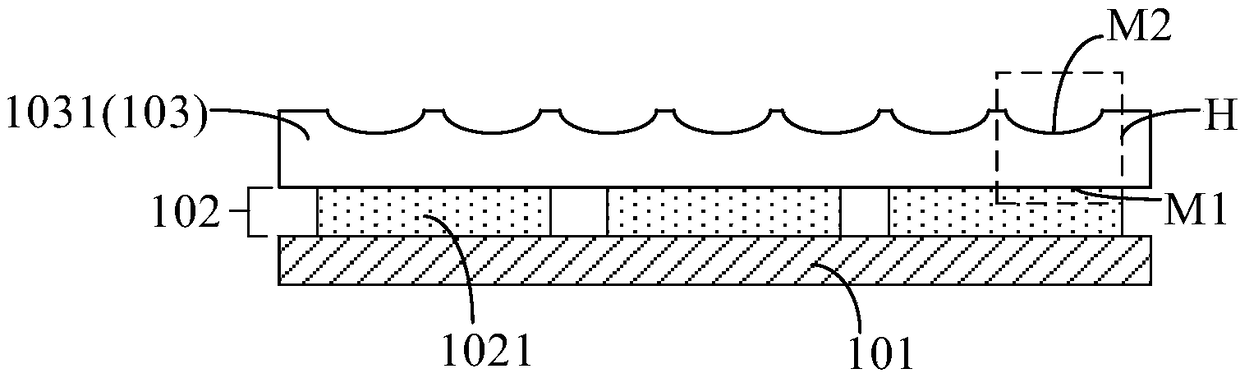

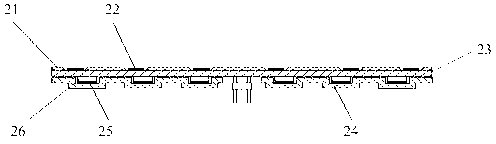

Backlight module and display device

ActiveCN109061945AImprove the problem of starry skyLarge light angleNon-linear opticsDisplay deviceLight-emitting diode

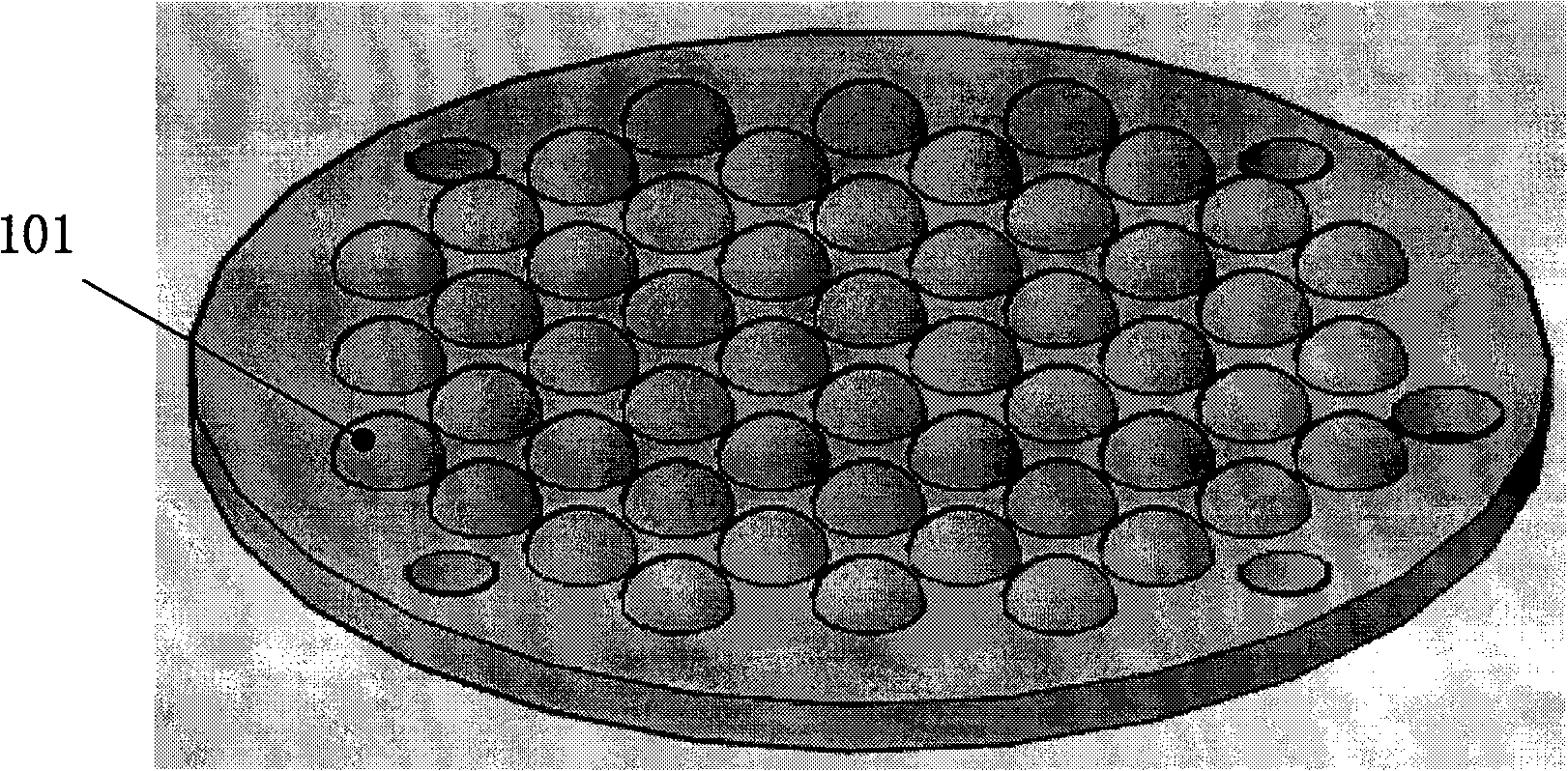

The invention discloses a backlight module and a display device. The backlight module comprises a substrate layer, a light source layer and a light mixing layer, wherein the light source layer is arranged on a substrate, and comprises a plurality of mini LEDs (Light Emitting Diodes) distributed in an array; the light mixing layer is arranged on one side of the light source layer far away from thesubstrate layer, and comprises a first light mixing layer; the first light mixing layer comprises a plurality of light mixing structures; each mini LED corresponds to a plurality of light mixing structures; the light mixing structure comprises a first surface close to one side of the light source layer and a second surface far away from one side of the light source layer; and the first surface protrudes toward a direction far away from the light source layer, and / or the second surface protrudes toward a direction close to the light source layer in the light mixing structure. According to thebacklight module and the display device, the uniformity of the brightness of the whole surface of the backlight can be improved, thereby improving the problem that the backlight module is filled withstark.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

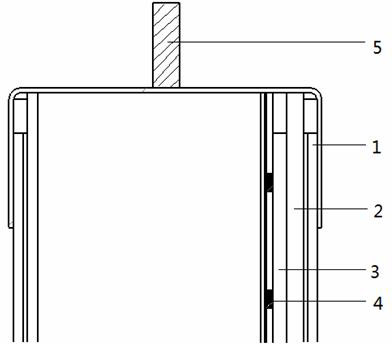

LED lamp

InactiveCN102072421AStrong enoughStable structurePoint-like light sourceElectric circuit arrangementsPlastic materialsEngineering

The invention discloses an LED lamp which comprises a lamp body, wherein a circuit board with a rectifier element is installed in the lamp body and is provided with an LED module group, and electric insertion groups are arranged at both ends of the lamp body. The LED lamp is characterized in that the lamp body is an integrally formed tube, at least one group of support locating ribs is arranged at the inner side of the back part of the lamp body, every two support locating ribs are integrally formed on the inner wall of the lamp body and extend along the axial direction, the circuit board is in a long strip shape, at least one group of the LED module groups is fixed on the positive surface of the circuit board, and two ribs of the support locating ribs are clamped and fixed to both sides of the circuit board. The LED lamp adopts the integrally formed lamp body, the lamp body is internally provided with support locating ribs, the lamp body is made of plastic materials so that the LED lamp has low cost and the lamp body has enough strength and firm and reliable structure, is difficult to deform in a state of heating by working of the LED lamp and also has better light emitting effect.

Owner:ZHONGSHAN WEIQIANG TECH

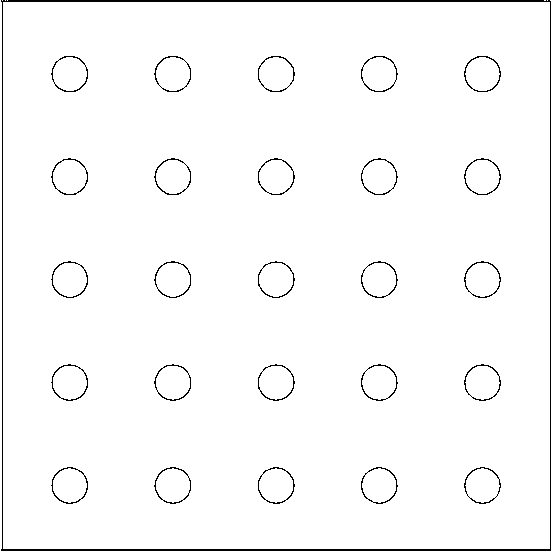

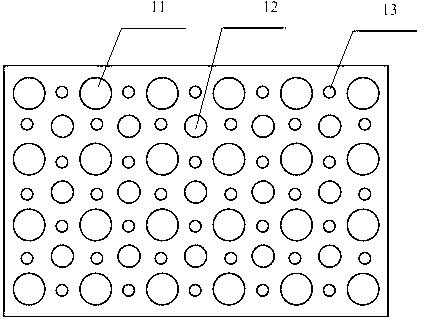

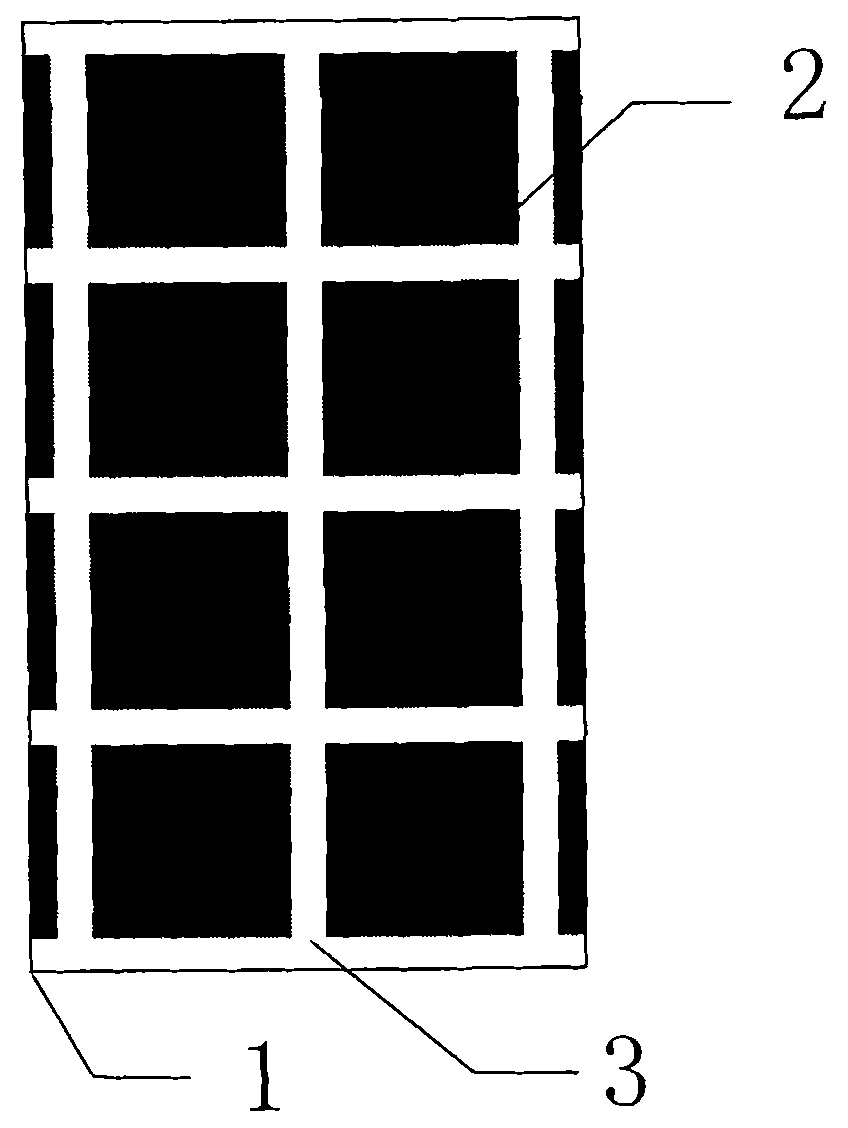

LED display screen based on chip-on-board packaging technology and production method thereof

InactiveCN103347380AHigh resolutionLarge light angleElectrical componentsIdentification meansDot pitchLED display

The invention discloses an LED display screen based on the chip-on-board packaging technology and a production method of the LED display screen. The production method includes the steps of manufacturing a PCB by wiring according to a preset control mode in the mode that the area of a target display module is 0.01-1 square meters and the dot distance is 1-10 millimeters, fixing LED light-emitting wafers to the PCB in a pasting mode according to the dot distance, forming matrix arrangement, then warming to bake at the premature of 100-160 DEG C for 60-120 minutes, welding connecting lines, fixing a black mask on the PCB, and injecting glue in through holes in the mask for solidification. The LED display screen achieves the effects of being low in heat resistance, high in luminous flux density, less in glare and even in light emitting and has the advantages of being low in manufacturing cost, high in reliability, large in video light angle, good in radiating effect and the like, the light, thin and high-resolution LED display screen can be manufactured, and the market application value is quite high.

Owner:深圳市濠腾兴光电科技有限公司

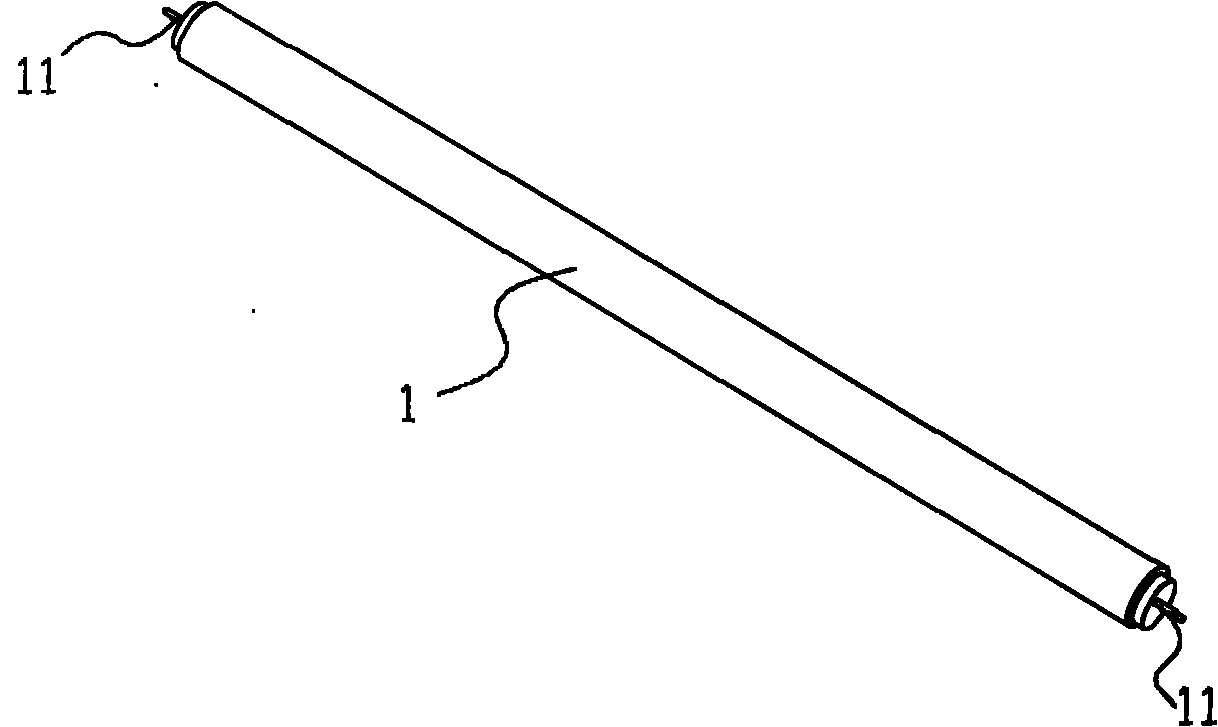

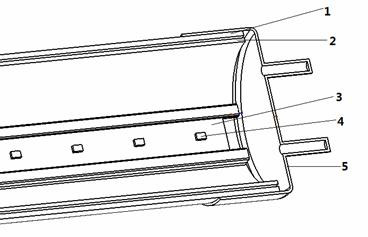

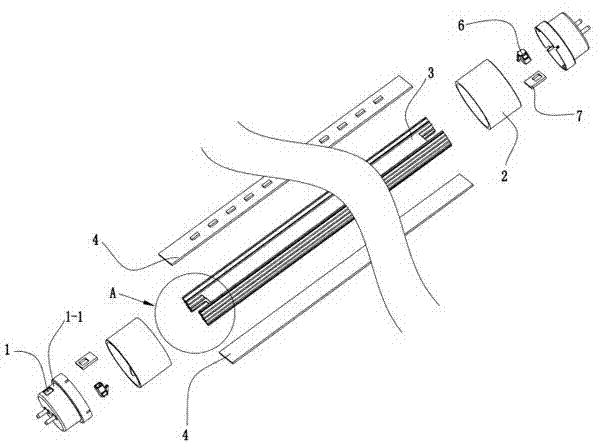

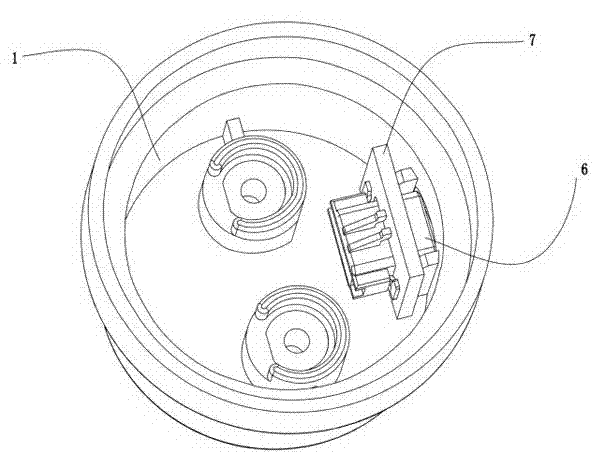

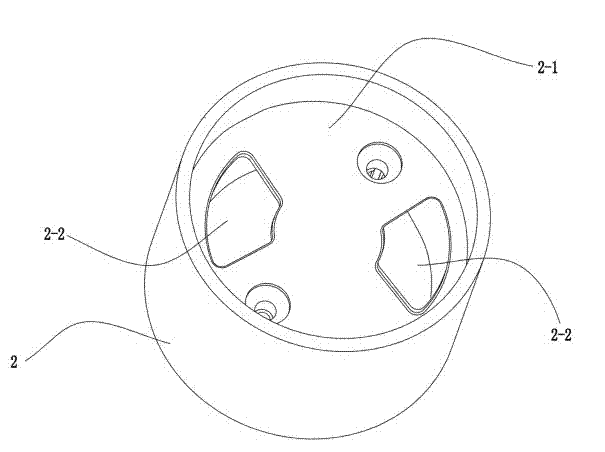

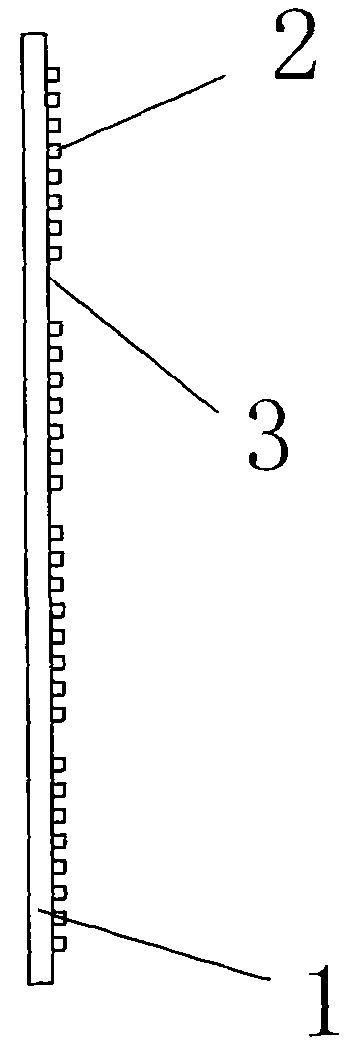

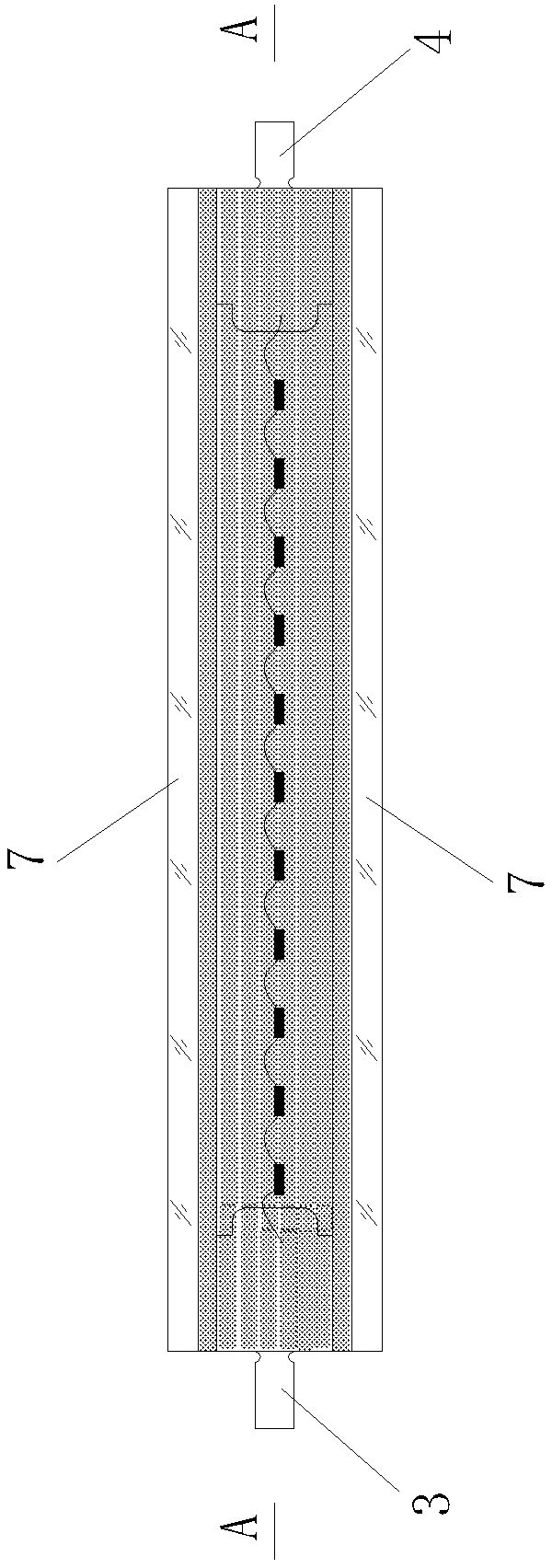

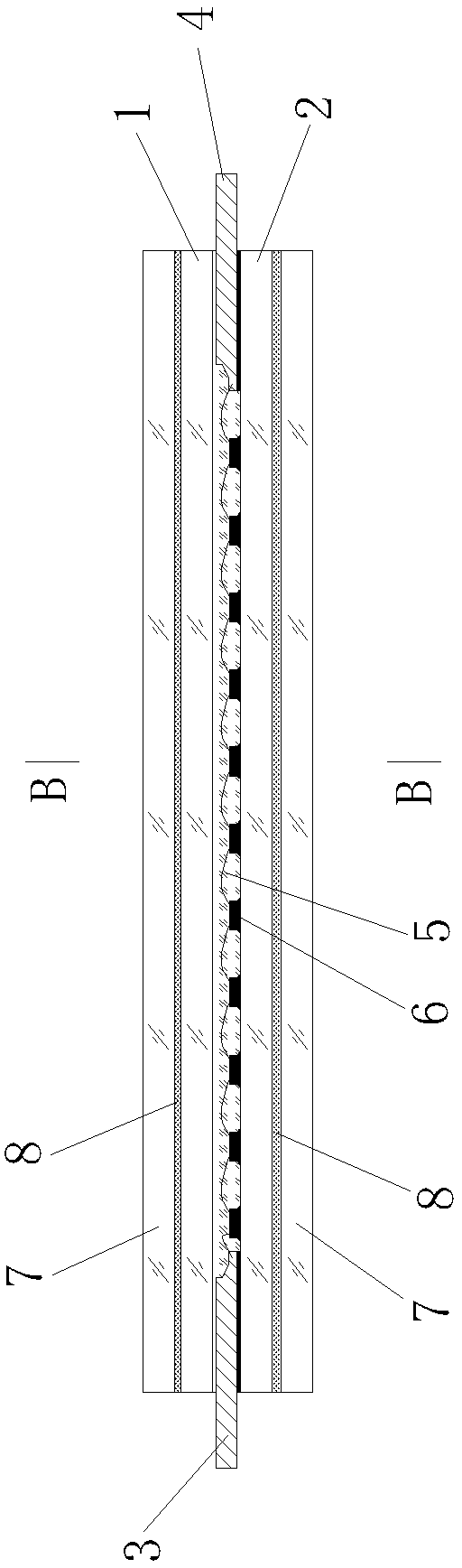

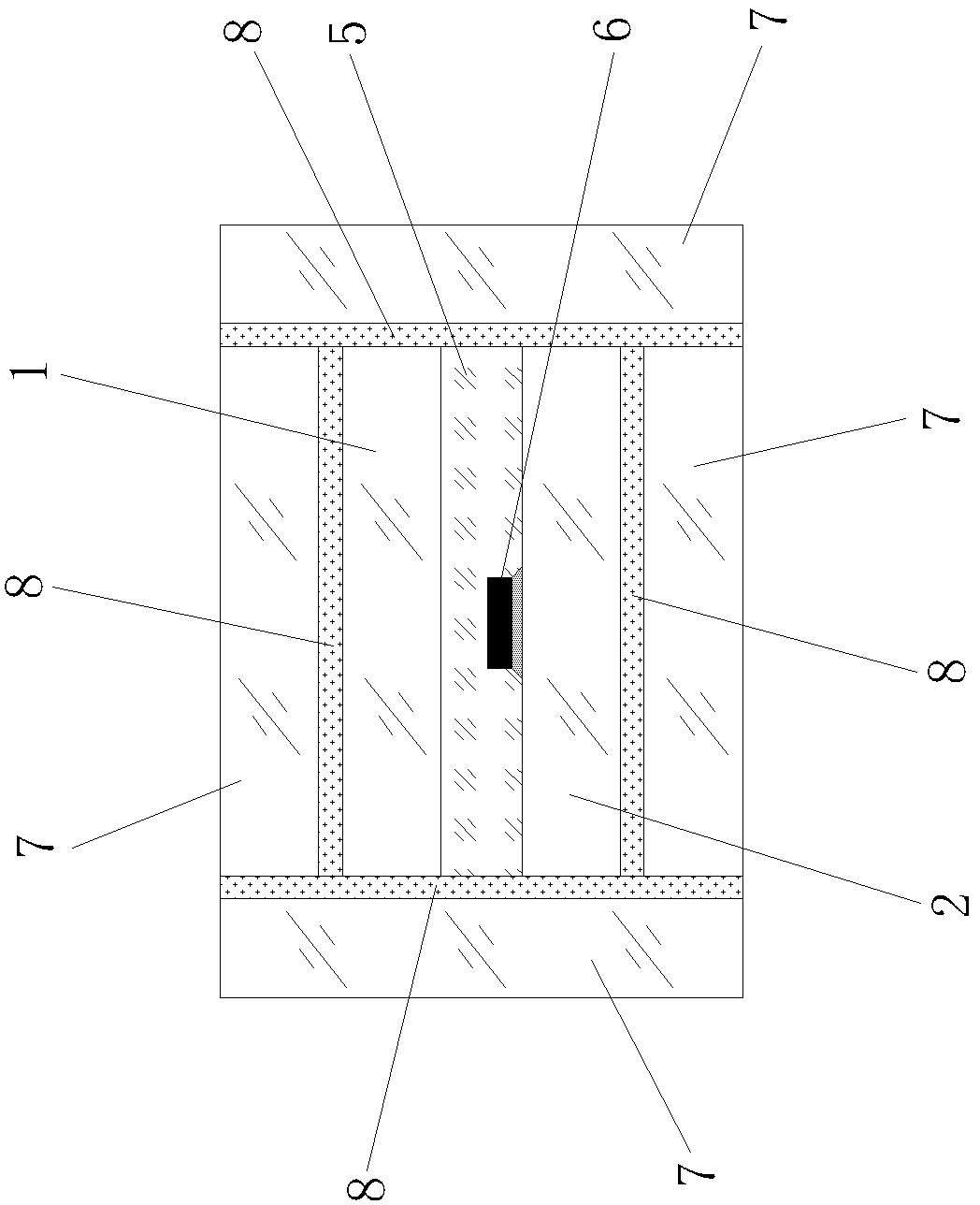

LED fluorescent lamp tube and method for manufacturing same

InactiveCN102661498AAvoid located inLarge light anglePoint-like light sourceLighting heating/cooling arrangementsEngineeringLuminescence

The invention discloses an LED fluorescent lamp tube, and belongs to the technical field of illumination of semiconductors. The LED fluorescent lamp tube comprises a glass tube, a plastic tube, a circuit board, an LED light source and two lamp holders, the plastic tube, the circuit board and the LED light source are packaged in the glass tube, the two lamp holders are respectively mounted at two ends of the glass tube, the LED light source is fixed onto the circuit board, a clamp groove is arranged in the plastic tube, the circuit board is fixed into the plastic tube by the aid of the clamp groove and divides the cylindrical plastic tube into two cavities, and the cross sections of each cavity is arc-shaped. The invention further discloses a method for manufacturing the LED fluorescent lamp tube. The position of the LED light source is adjusted by means of adjusting the position of the circuit board in the cavities of the plastic tube, accordingly, the LED light source is prevented from being positioned at a circumferential position of the lamp tube, and the luminescence angle of the lamp tube is increased. In addition, the circuit board is selectively made of environment-friendly materials such as a ceramic substrate or an epoxy glass laminated sheet, heat generated by the LED light source is dissipated in an energy-saving and environment-friendly manner, and production cost is reduced.

Owner:SUNSUN LIGHTING CHINA

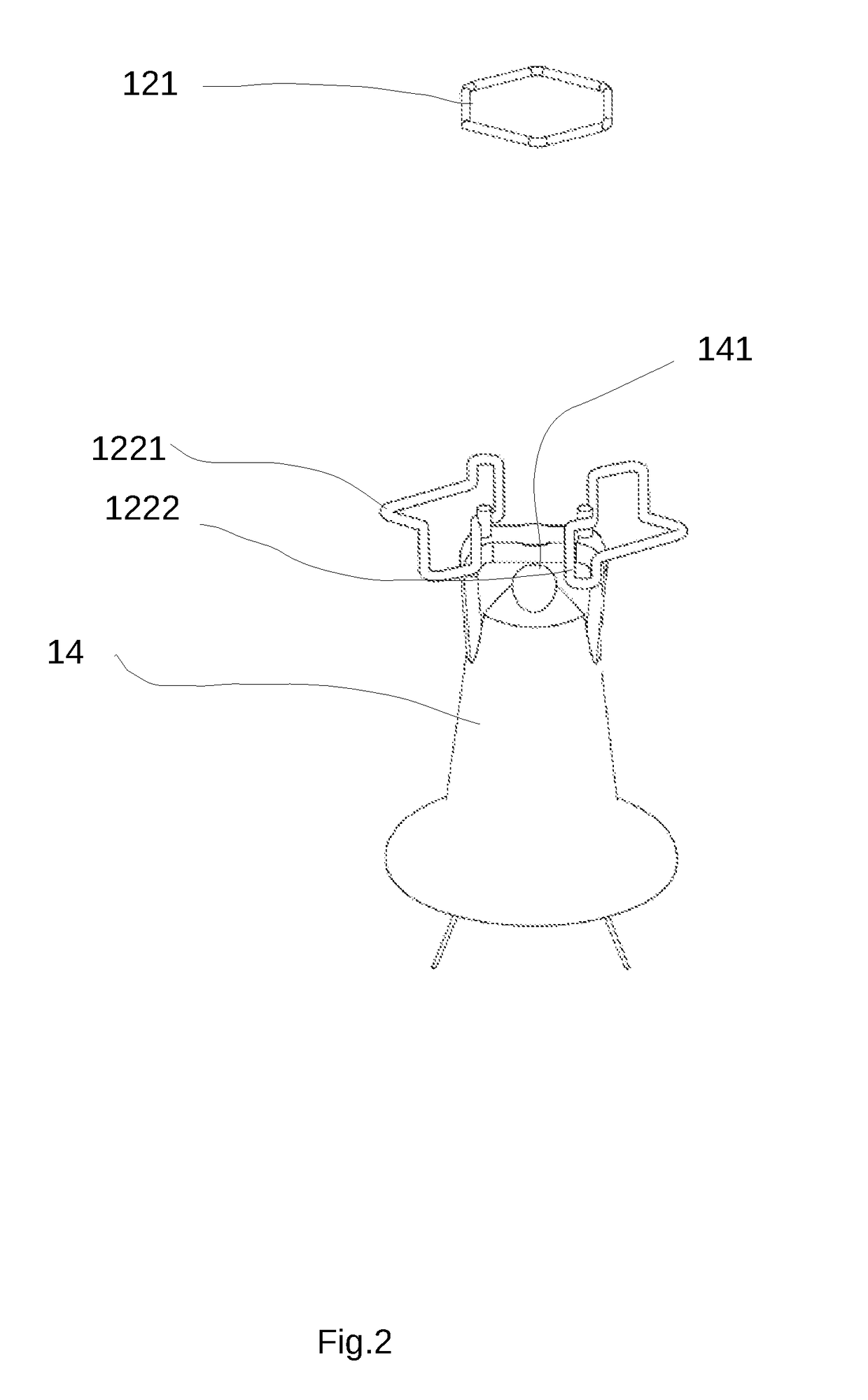

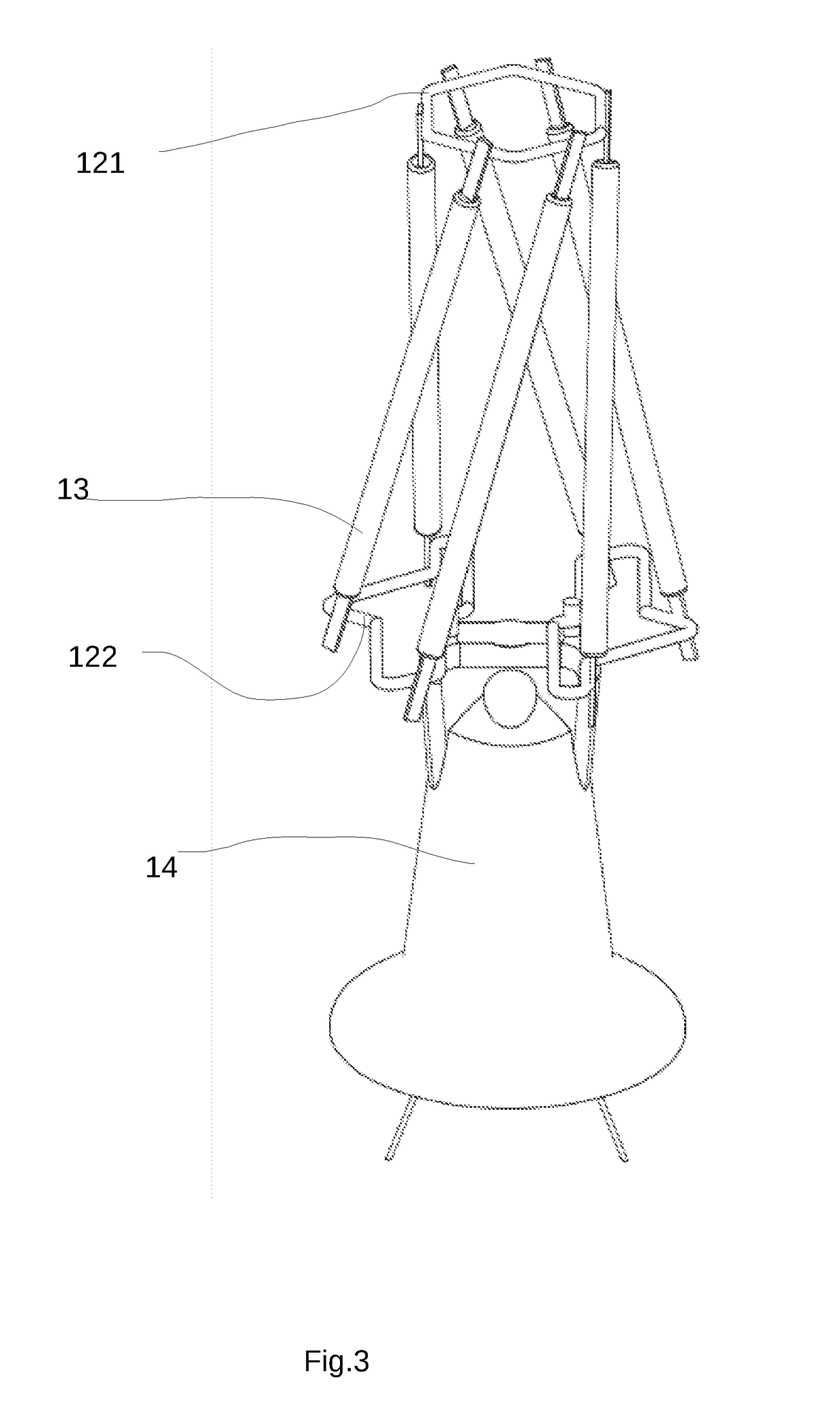

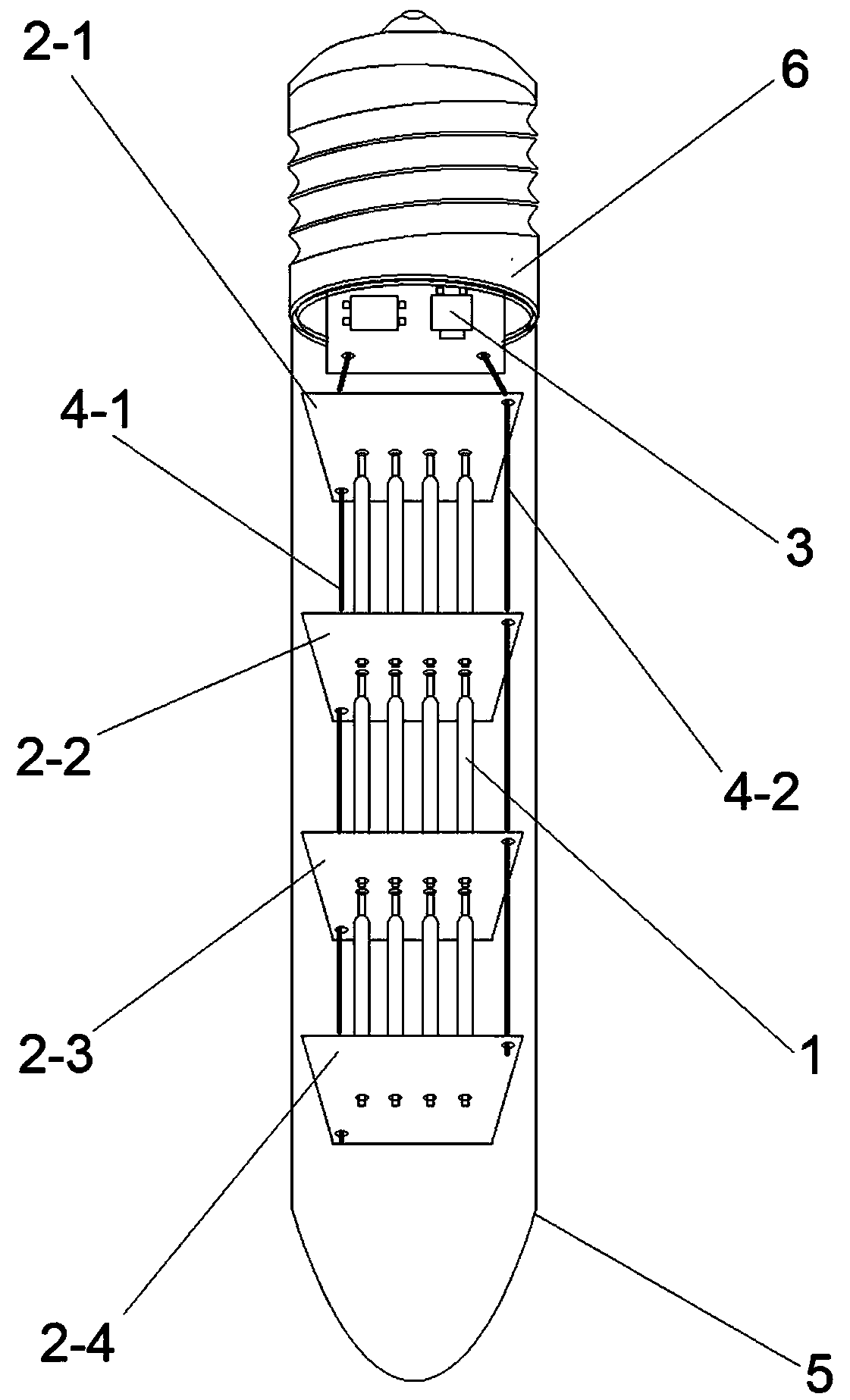

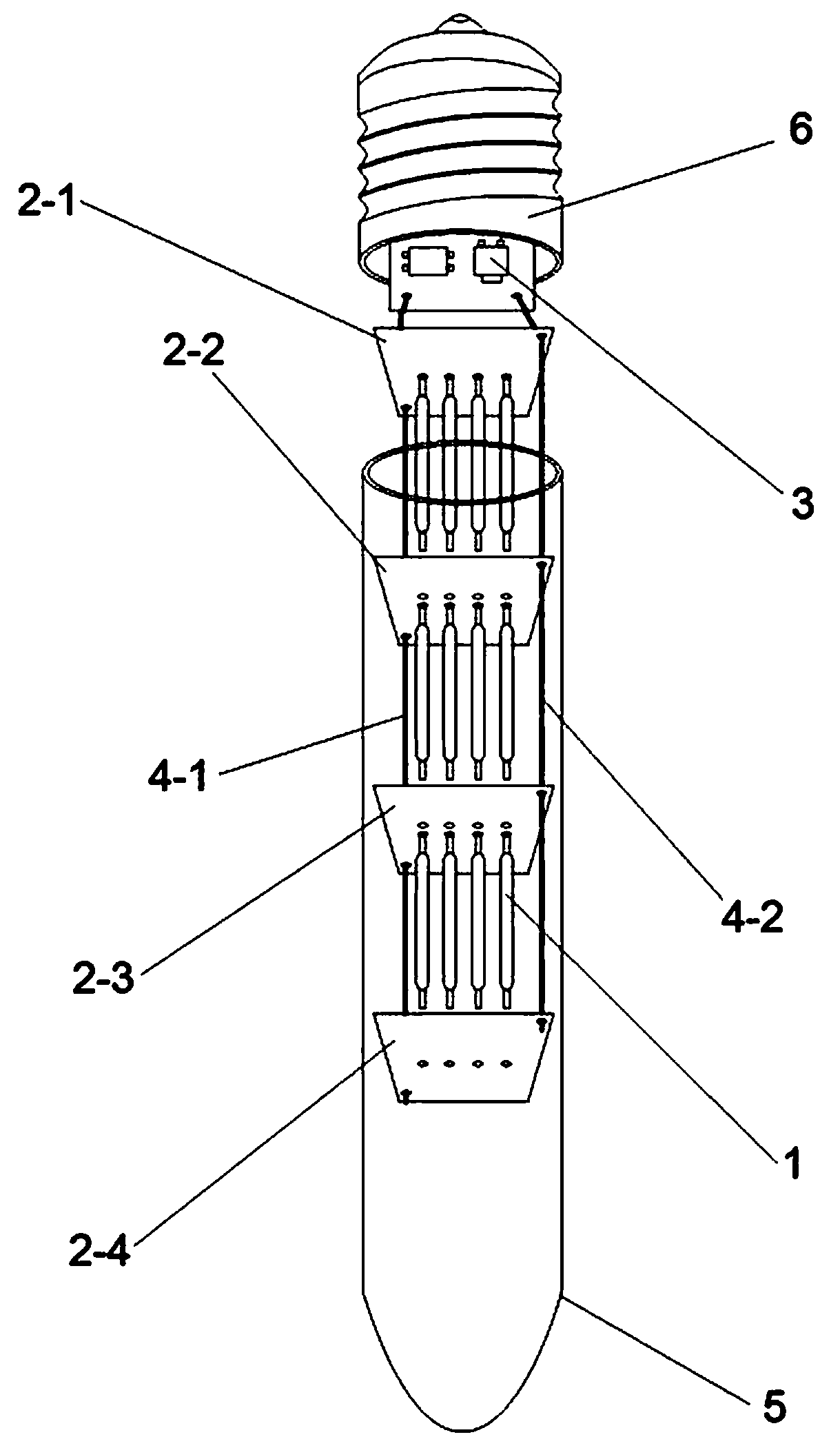

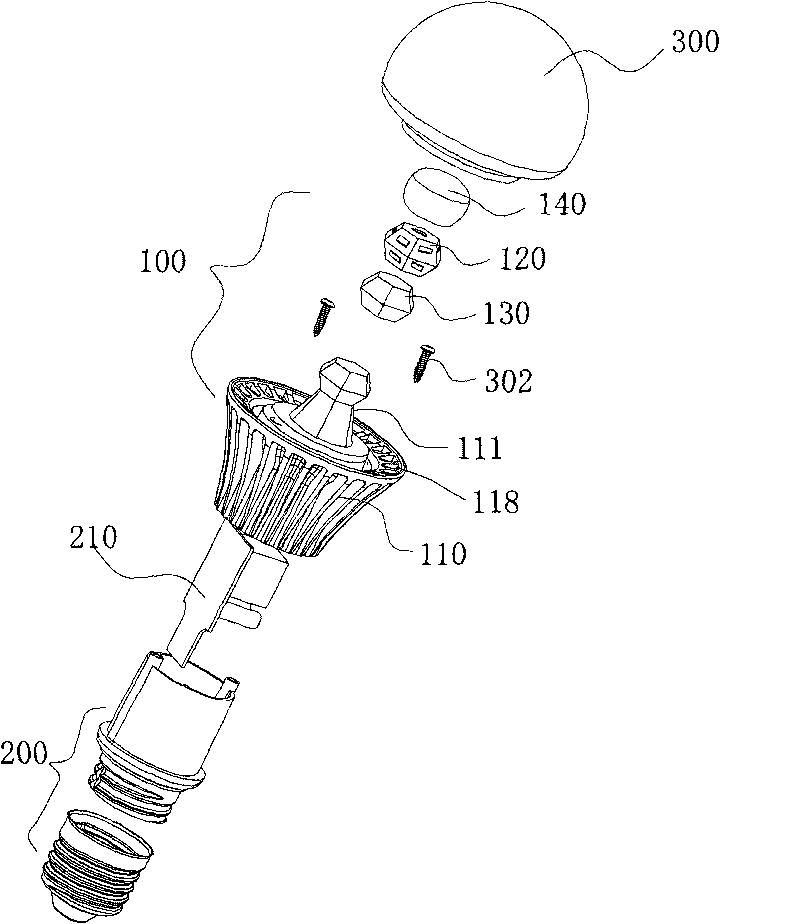

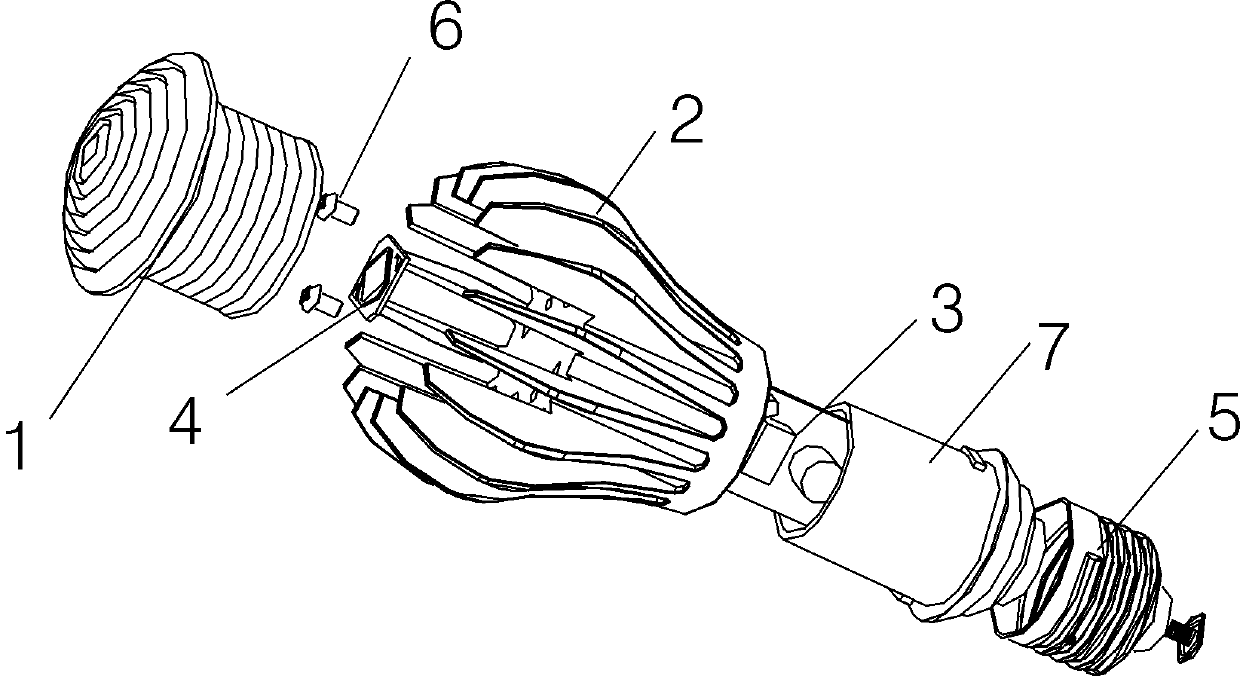

Lamp filament LED (Light-Emitting Diode) bulb

InactiveCN104110632AWide range of usesLarge light anglePoint-like light sourceElectric circuit arrangementsPower flowTower

The invention discloses a lamp filament LED (Light-Emitting Diode) bulb, and relates to an LED lamp. The lamp filament LED bulb is assembled by using a lamp cap, a lampshade, a driving power supply, leads, one or more circuit boards and filament LEDs, wherein the driving power supply is arranged in the lamp cap; the leads for connecting the output end of the driving power supply are connected in series with one or more circuit boards; one or more filament LEDs are welded on each circuit board; through a circuit on each circuit board, one or more filament LED1 form a serial or parallel loop; one or more circuit boards are connected in series into a single-layer or multi-layer structure through the leads, and are constructed into tower layer; a tower-layer-shaped light-emitting structure is formed, and is fixed inside the lampshade; one end of the lampshade is configured together with the lamp cap into an LED bulb. The light-emitting surface of each filament LED1 is not shielded by any object in the bulb. In a switch-on state, current is conducted onto one or more circuit boards which are connected in series through the leads by using the leads at the output end of the driving power supply, and filaments on the circuit boards are lightened to realize a wider light-emitting angle.

Owner:林士干

LED lamp

ActiveCN103822176AImprove cooling effectWith irradiation angleLighting support devicesPoint-like light sourceEngineeringLight head

The invention discloses an LED lamp which comprises a lamp holder, a heat dissipation base which is arranged at one end of the lamp holder in the mode that the heat dissipation base can rotate around the axis of the lamp holder, and one or more light-emitting units. The other end of the lamp holder is used for being connected with an external power supply. Each light-emitting unit comprises a heat dissipation device arranged on the heat dissipation base, a lamp panel which is attached to the heat dissipation device, a plurality of LED lamp beads which are fixedly arranged on the lamp panel and integrally packaged, and a lampshade which is connected with the heat dissipation device and covers the LED lamp beads. The LED lamp beads are electrically connected with the external power supply. According to the LED lamp, the light-emitting angle can be adjusted.

Owner:RED100 LIGHTING CO LTD

LED three-dimensional light source

InactiveCN101718398AReduce thermal resistanceImprove cooling effectPoint-like light sourceElectric circuit arrangementsEngineeringColor temperature

The invention relates to an LED three-dimensional light source, which comprises a lamp body, a base fixedly connected with the bottom of the lamp body and a lampshade fixedly connected with the top of the lamp body, and generates light of different color temperatures by using LEDs with two or more color temperatures. The lamp body comprises a heat dissipation seat with a lamp post, and a light source plate which is fixedly connected with the LED, matched with the lamp post and made of a bendable material; and the inside of the base is provided with a driving power supply. The LED three-dimensional light source has the advantages of convenient production and manufacture, large luminous angle, capability of dimming and adjusting color, safe use and stable performance.

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

LED (Light Emitting Diode) light source, backlight module and liquid crystal display device

InactiveCN104570481AAdjust the light angleLarge light anglePrismsDiffusing elementsLiquid-crystal displayLight guide

The invention discloses LED (Light Emitting Diode) light sources, a backlight module and a liquid crystal display device. Every LED light source comprises a housing, an LED wafer and a light adjustment layer, wherein the housing comprises a light outlet, the LED wafer is arranged in the housing, the light emitting surface of the LED wafer is towards the light outlet of the housing, and the light adjustment layer is located at the position of the light outlet of the housing; the backlight module comprises the LED light sources and a light guide plate, wherein the LED light sources are located in the same plane to form a backlight source array, the plane of the backlight source array is located under the light guide plate or the LED light sources are located on the lateral side of the light guide plate and located in the same plane, and the plane of the LED light sources is parallel to the lateral side of the light guide plate; the liquid crystal display device comprises a liquid crystal display panel and the backlight module. According to the LED light sources, the backlight module and the liquid crystal display device, the light emitting angle of the LED light sources can be effectively adjusted.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

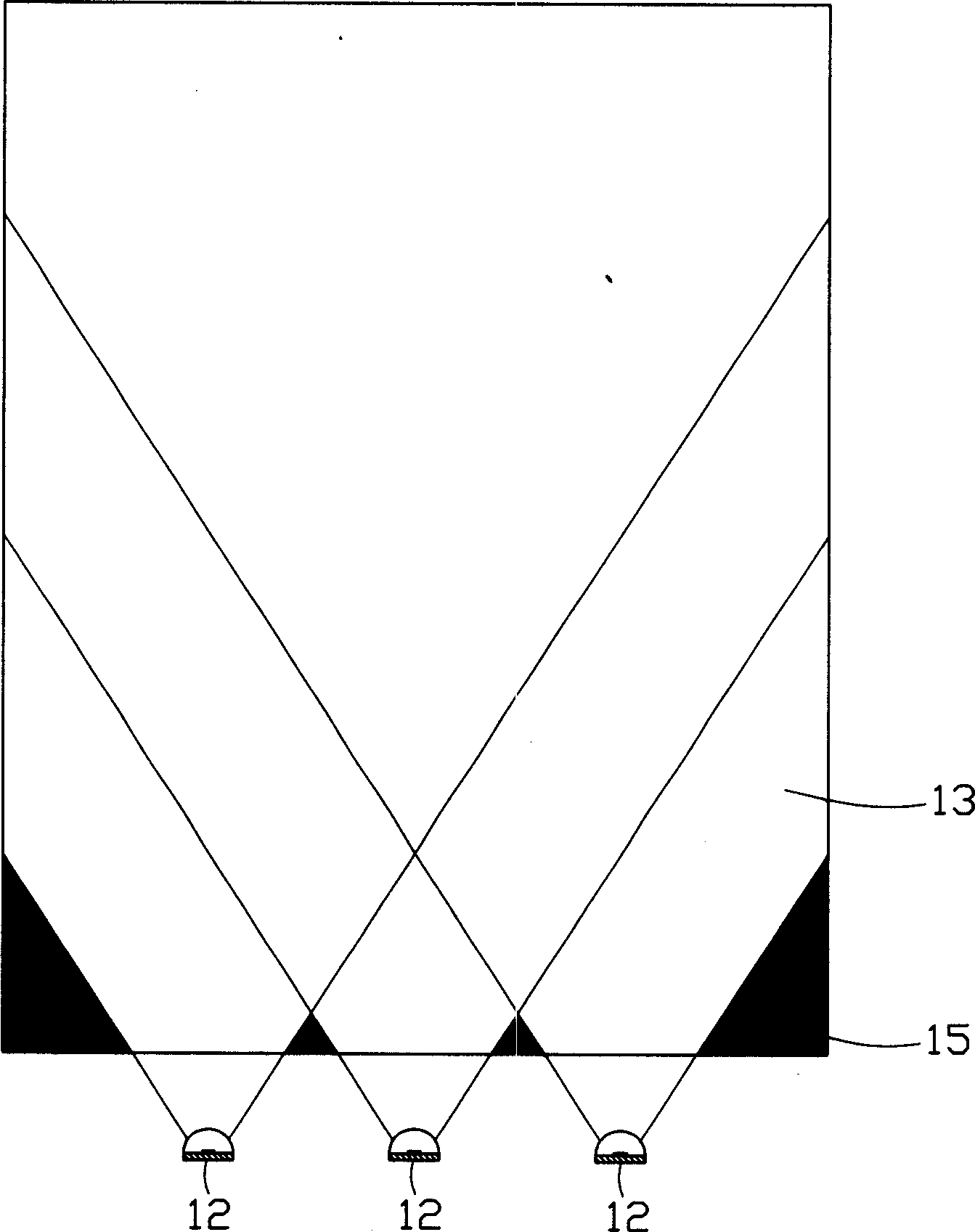

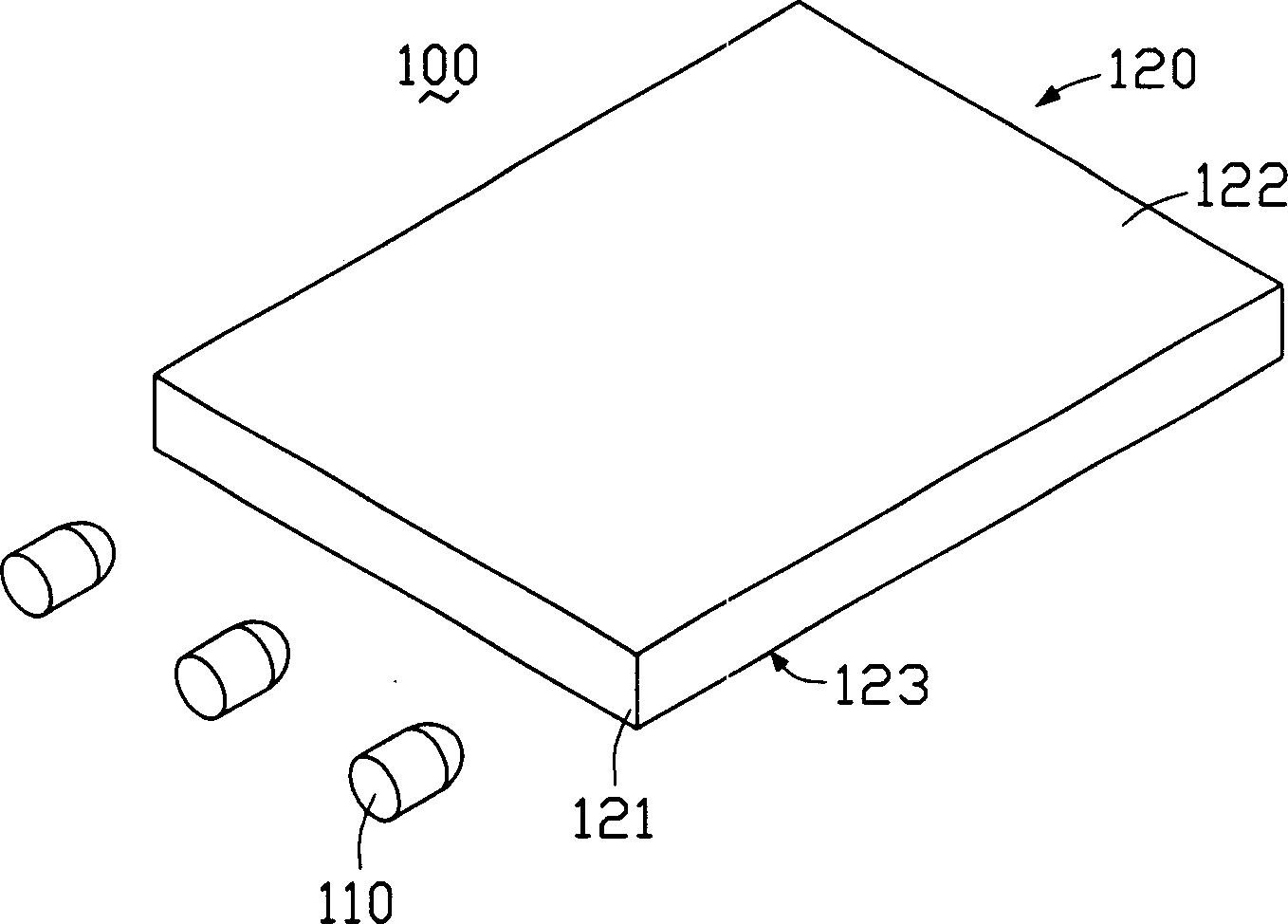

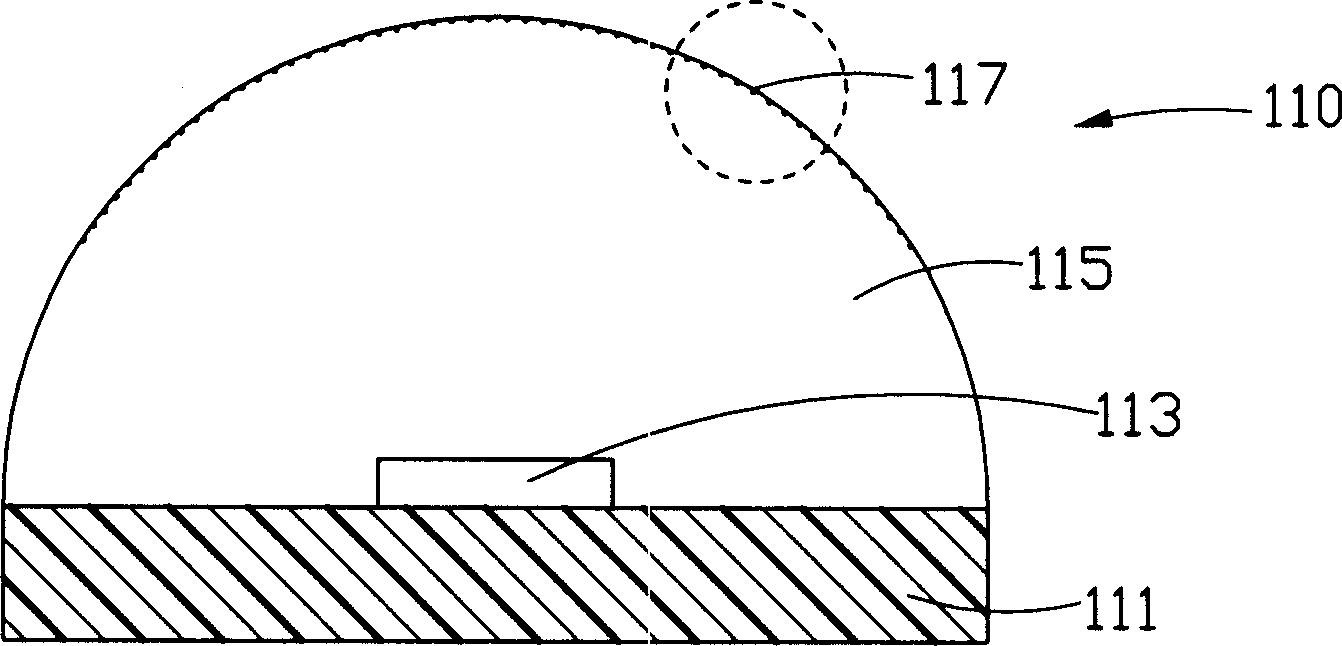

LED Light Source and backlight modular

InactiveCN1601350AReduce Optical Dark AreasImprove light uniformityDiffraction gratingsNon-linear opticsEngineeringLight guide

The invention provides a LED light source whose light-emitting angle is larger and can be regulated and backlight module by adopting said LED light source. Said invented backlight module includes a light-conducting plate and at least a LED light source, Said light-conducting plate includes at least one light-incoming surface. and said LED light source includes a base, a light-emitting chip and a package resin. Said package resin can be used for covering said light-emitting chip and can be formed into a light-outcoming surface, said ligh-outcoming surface and light-incoming surface of the ligh-conducting plate are oppositely placed-in which said LED light source further includes a diffraction grating placed in its light-outcoming surface position. The optical diffraction effect produced when the light beam sent from LED light-emitting chip is out come by means of diffraction grating can make its light-emitting angle be enlarged so as to reduce optical dark region of light-incoming side of the light-conducting plate and raise light-outcoming uniformity of backlight module, to reduce optical dark region of light-incoming side of the light-conducting plate and raise light-outcoming uniformity of backlight module.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Rotatable LED (light emitting diode) double-sided daylight lamp with external power supply

InactiveCN102900981ANot hotImprove cooling effectPoint-like light sourceElongate light sourcesElectricityLight equipment

The invention discloses lighting equipment, and particularly relates to a rotatable LED (light emitting diode) double-sided daylight lamp with an external power supply. The daylight lamp comprises two upper tube heads, two lower tube heads, a heat radiator and two LED lamp plates, wherein the heat radiator takes the shape of a square tube; a heat radiating chamber is formed in the center of the square tube shaped heat radiator; the two LED lamp plates are arranged at the two sides of the heat radiating chamber and are mutually symmetric; layer isolating plates are arranged inside the two lower tube heads; line holes are formed in the layer isolating plates; through holes are formed in the side walls of the two upper tube heads; power supply sockets are arranged inside the through holes in a plugging mode; the body parts of the power supply sockets are arranged inside the upper tube heads and are fixed with the upper tube heads through connecting plates; and an elastic pressing plate on each power supply socket penetrates through the line hole of the corresponding lower tube head and is electrically connected with the LED lamp plate. Therefore, the technical defects that the heat radiation effect of the double sides of a rotatable LED with the external power supply is poor, the electric connection mode between an LED lamp source and the external power supply is complex and the use stability is poor are overcome.

Owner:NINGBO TONGTAI ELECTRIC

Luminescent device and backlight source

InactiveCN104317100AEvenly distributedExpand the scope of diffusionPoint-like light sourceCondensersExit surfaceLight-emitting diode

The embodiment of the invention provides a luminescent device and a backlight source, relates to the technical field of display, and aims to solve the problems of small light emitting angle of a luminescent device and non-uniform brightness in application of the luminescent device to a backlight source display screen in the prior art. The luminescent device comprises a light emitting diode and an optical lens, wherein the optical lens comprises light incidence surfaces and light exit surfaces; the light incidence surfaces comprise a first light incidence surface and a second light incidence surface; the proportions of the smallest distance values of distances from all points on the first light incidence surface and the second light incidence surface to a central point of a luminescent surface to the biggest distance values belong to [0.5, 0.7] and [0.683, 0.695] respectively; the light exit surfaces comprise a first light exit surface and a second light exit surface; the proportions of the smallest values of distances from all points on the first light exit surface and the second light exit surface to the central point of the luminescent surface to the biggest distance values belong to [0.771, 0.913] and [0.883, 0.921] respectively.

Owner:HISENSE VISUAL TECH CO LTD

Non-imaging optical directional light distribution method for LED light source

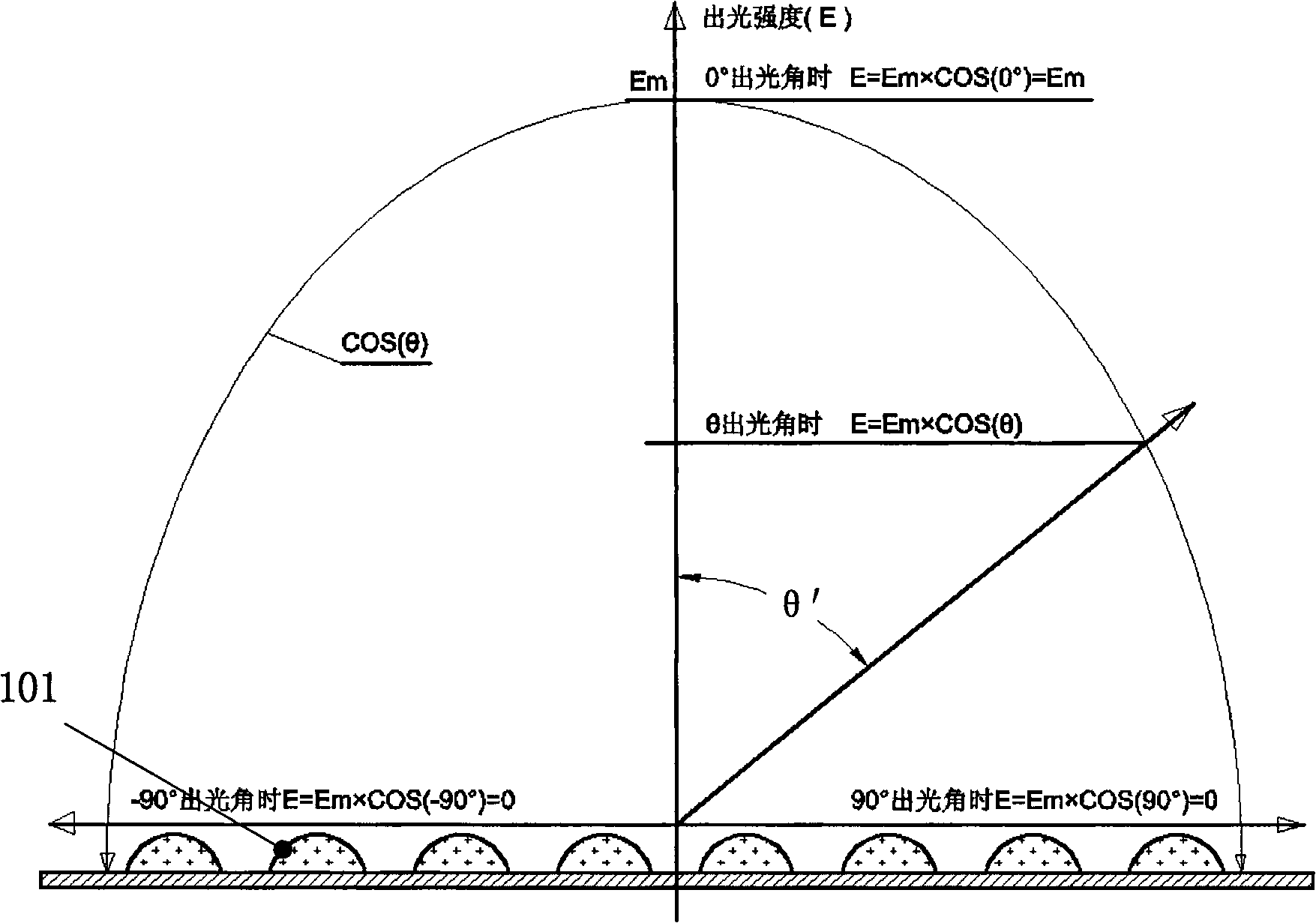

InactiveCN101566307ALarge light angleHigh light efficiencyPoint-like light sourceSemiconductor devices for light sourcesDistribution controlDistribution method

The invention relates to a non-imaging optical directional light distribution method for an LED light source, which comprises the following steps: determining an emergence angle theta4 of LED light passing through a light distribution lens according to the requirement of a light spot, and selecting a refractive index N1 of an incident medium of the LED light, a refractive index N2 of the light distribution lens and a refractive index N3 of an emergent medium to acquire an incidence angle theta1= f(N1, N2, N3 and theta4). By using the incidence angle theta1 as an included angle theta of an incident face and an emergent face of the light distribution lens, the incident face and the emergent face of the light distribution lens can be acquired. The LED light is incident onto the light distribution lens by the incidence angle theta1 and then is refracted by the light distribution lens to form LED directional light. The method solves the technical problems that the prior art cannot radically improve the Lambert property of the LED light source so that directional light distribution cannot be realized, the light distribution evenness is poor and the light efficiency is low, can directionally control the distribution of light intensity of the LED light source so as to realize precise light distribution control, and has the advantages of high reliability, energy conservation and environmental protection.

Owner:XIAN ZHIHAI POWER TECH

Full-range lighting LED lamp

InactiveCN104295968ALarge light angleImprove luminous efficiencyPoint-like light sourceLighting support devicesElectricityEffect light

A full-range lighting LED lamp comprises an electrical connector, a connecting member and at least two transparent covers. The transparent covers are connected to form an integral lampshade shape, channels are arranged between the transparent covers, and the openings of two ends of the channels are communicated with the outside; at least one ends of the transparent covers of the channels are fixed to the connecting member provided with a cavity, the cavity of the connecting member is communicated with the channels of the transparent covers, and the connecting member is provided a vent hole communicated with the outside; the transparent covers are fixed to an LED light element. The LED lamp is capable of lighting at 360 DEG by full range, the lighting angle is large, the lighting efficiency is high, the radiation performance is fine, the service life of the LED lamp is prolonged, lampshades with different lengths and shapes can be assembled as required, machining is facilitated, and the adaptive range f the LED lamp is expanded.

Owner:杨志伟

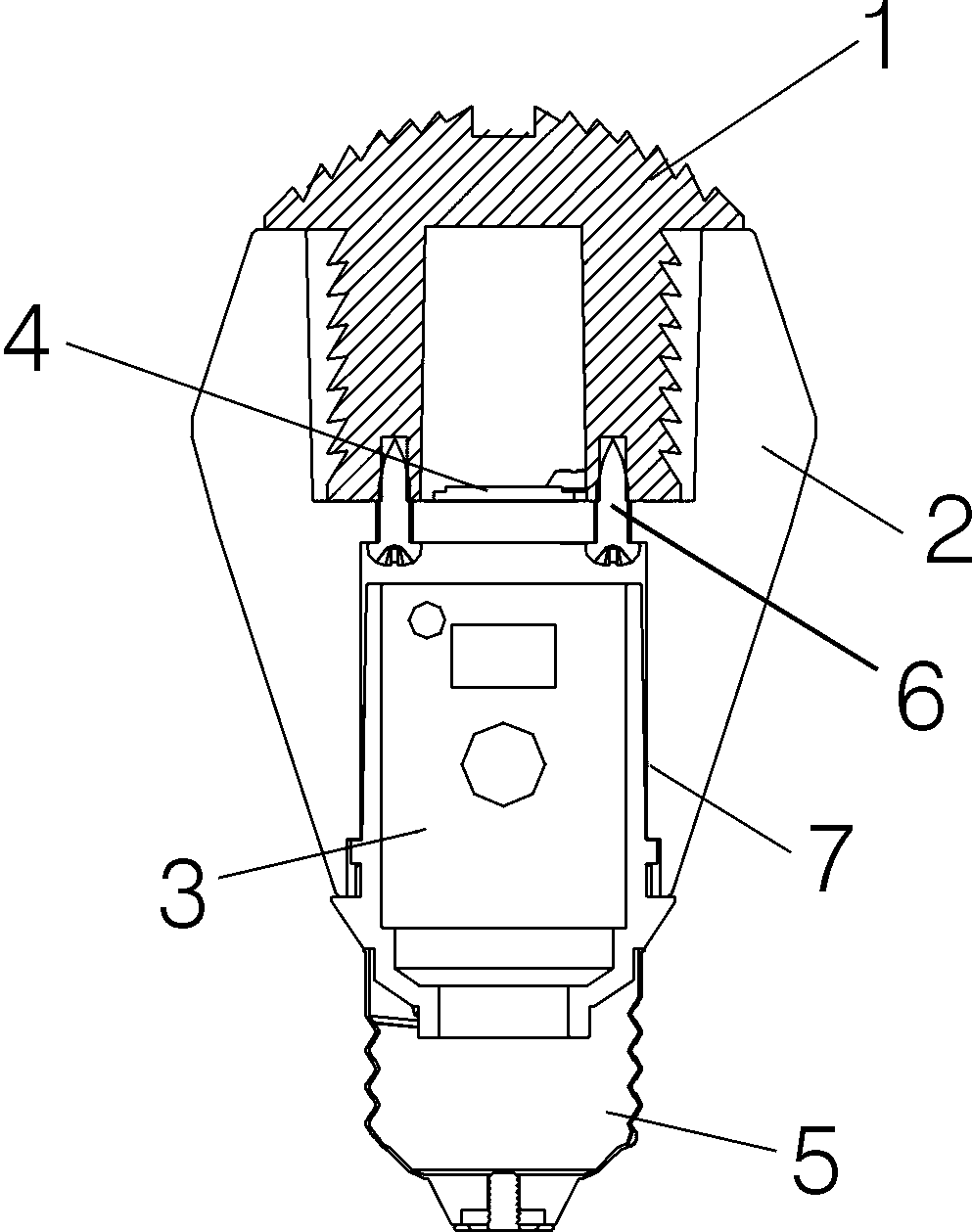

LED bulb lamp

InactiveCN103343910AIncrease light intensityThe focus of the main irradiation surface is clearPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

The invention discloses an LED bulb lamp which comprises an optical lens, a heat dissipating body, a driver, an LED light source, a lamp head, and a lamp seat. The LED bulb lamp is characterized in that the optical lens is arranged at one end of the heat dissipating body, the lamp seat is arranged at the other end of the heat dissipating body, the driver is arranged in an inner cavity of the lamp seat, the outer end of the lamp seat is connected with the lamp head in a riveting mode, and the LED light source is arranged on the inner surface of the heat dissipating body at the lower end of the optical lens. The LED bulb lamp can greatly improve luminance, enables a main illuminating face to be clearer in focus, increases a light illuminating area, increases a lighting face, eliminates glare, improves visual effect, and eliminates visual fatigue. The LED bulb lamp saves energy, protects the environment, and is long in service life and free of stroboflash.

Owner:江西量一光电科技有限公司

LED (Light Emitting Diode) fluorescent lamp

InactiveCN101975345AIncrease light illumination angleIncrease the intensity of side light outputPoint-like light sourceElongate light sourcesLight-emitting diodeFluorescent lamp

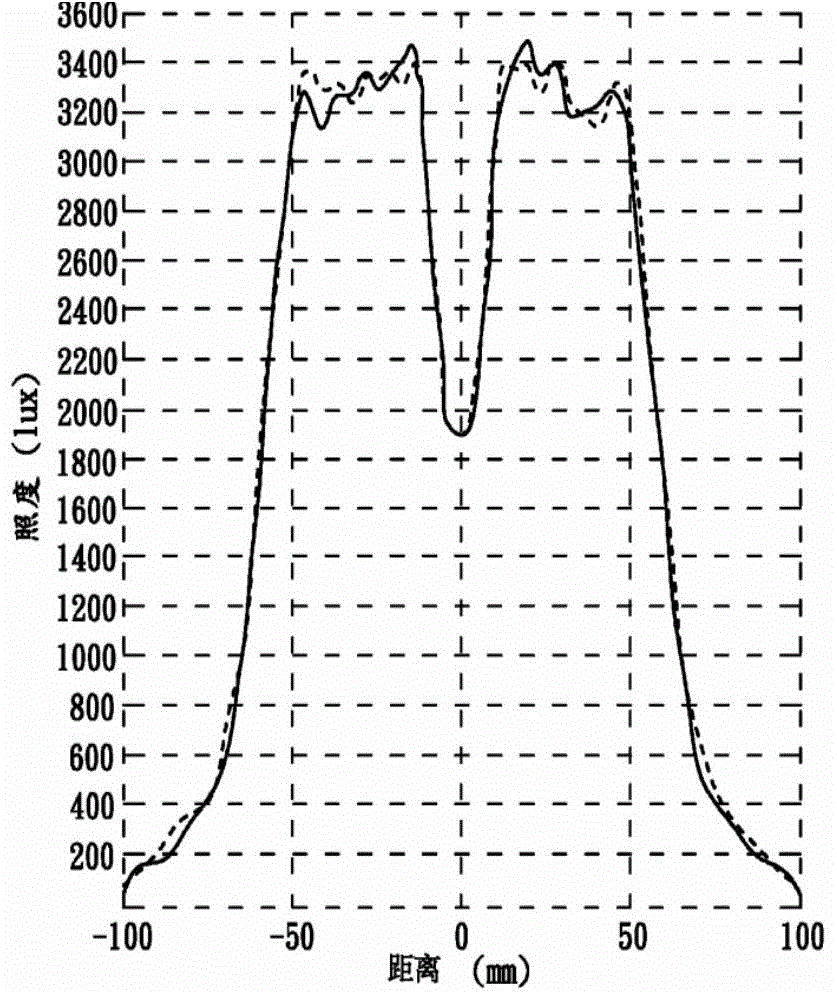

The invention relates to an LED (Light Emitting Diode) fluorescent lamp comprising a base, a lamp shade and a light-source base plate, wherein the lamp shade and the light-source base plate are fixed on the base, a plurality of light emitting diodes are arranged on the light-source base plate, and a light distribution lens corresponding to the plurality of light emitting diodes is arranged between the lamp shade and the light-source base plate; the light distribution lens comprises a concave lens and a reflecting lens, wherein the reflecting lens is arranged around the concave lens, the top surface of the reflecting lens is a fully reflecting surface, and the thickness of the reflecting lens is gradually increased outwards from the concave lens; positive emitting light transmitted by the light emitting diodes passes through the concave lens and is emitted after being scattered by the concave lens; non-positive emitting light transmitted by the light emitting diodes passes through the reflecting lens and is emitted after being reflected to the outer side of the reflecting lens; and light is formed by scattering the positive emitting light through the concave lens and reflecting thenon-positive emitting light through the reflecting lens, has a larger optical illumination angle and strong lateral illumination light and is even and soft.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Light guide hollow lens and LED (light-emitting diode) lamp bead

ActiveCN108087841AGood protectionImprove uniformity and consistencyElectric circuit arrangementsProtective devices for lightingScattering functionLight guide

The invention discloses a light guide hollow lens and an LED (light-emitting diode) lamp bead. The light guide hollow lens comprises a lens body, an incident surface and an emergent surface, the incident surface and the emergent surface are positioned on the inner side and the outer side of the lens body, the lens body is provided with a revolution body, the incident surface is provided with a revolution parabola surface with a downward opening, the emergent surface is provided with a revolution sphere surface, the revolution body, the revolution parabola surface and the revolution sphere surface have the same revolution shaft, the lens body above the incident surface is provided with a reflecting surface, the reflecting surface is provided with a revolution taper surface with an upper opening, the revolution taper surface and the revolution parabola surface have the same revolution shaft, the LED lamp bead comprises an LED light source and the light guide hollow lens with the structure, and the LED light source is positioned on a focus of the incident surface. According to the light guide hollow lens, a light beam emitted by the light source has a larger emitting angle, a lamp forms a larger lighting aperture and can have refraction deflection, reflection and scattering functions on the light beam of the light source, and the visual lighting effects of the LED lamp are remarkably improved.

Owner:李鹤荣

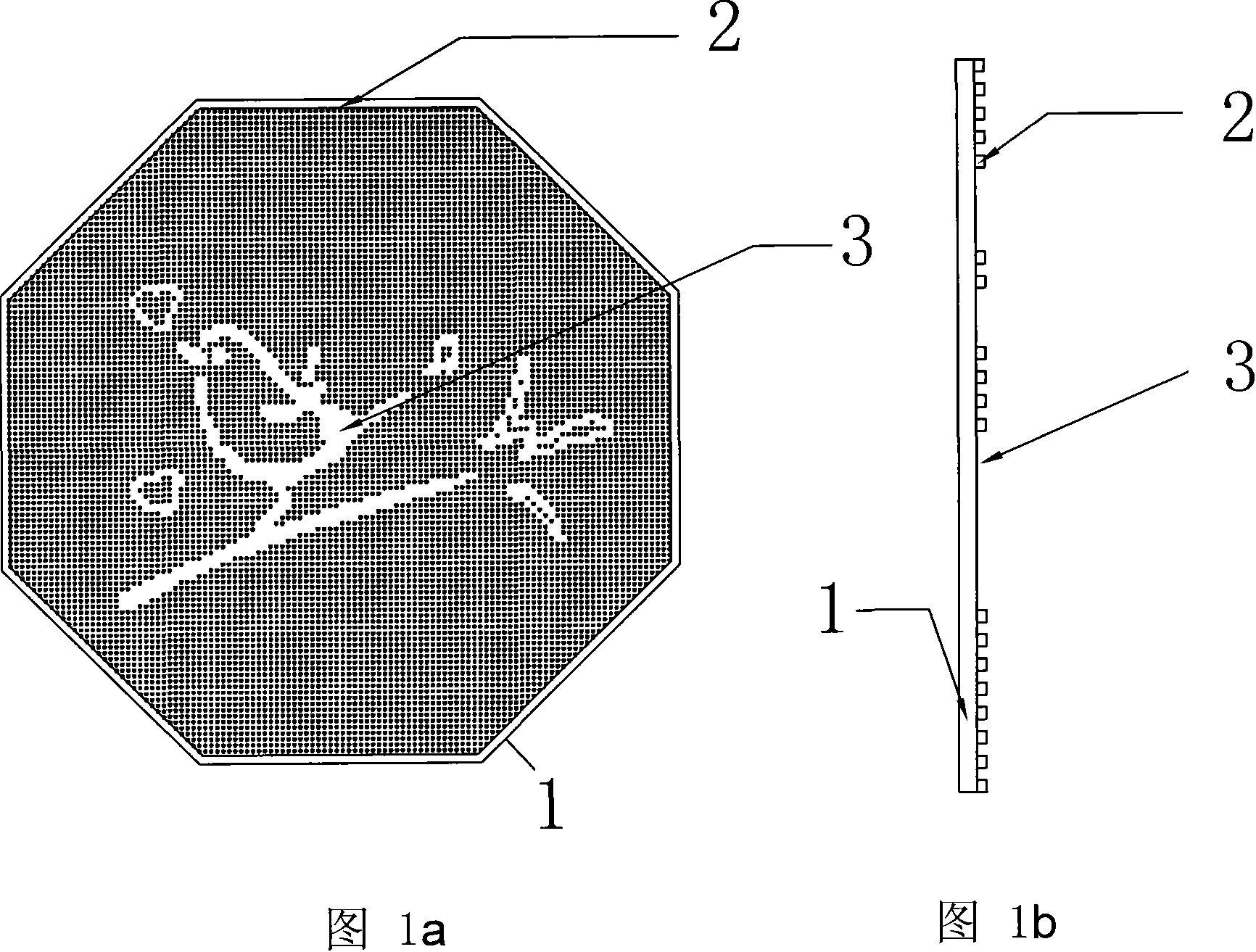

Light guide plate with graphics

InactiveCN101963330ALarge light angleReduce energy consumptionMechanical apparatusPlanar/plate-like light guidesOptoelectronicsLight guide

The invention discloses a light guide plate with graphics, which comprises a light guide plate (1) and a light guide point (2) arranged on one side surface of the light guide plate, the part on the light guide plate, provided with the light point (2), and a part (3) on the light guide plate, which is not provided with the light guide point, are combined to form various patterns and / or characters. On the light guide plate, the luminous light guide point part and the non-luminous part without being provided with the light guide plate form different patterns and characters, i.e. the glare problem can be solved without using a dispersing material, and the light can be directly emitted, therefore, the energy consumption is reduced, the light efficiency is improved and the cost is lowered.

Owner:SHEN ZHEN ONWING OPTOELECTRONICS PROD

Plastic lampshade of LED lamp and manufacturing method of plastic lampshade

The invention discloses a plastic lampshade for an LED lamp. The plastic lampshade for the LED is made of the following components in mass percentage: 1-3% of nano-silicon dioxide, 0.5-1% of nano-aluminum nitride, and 1-3% of dibutyltin Dilaurate, 0.3~0.5% N, N'-diphenylbenzidine diamine, 0.3~0.5% light stabilizer UV-196, 2~4% EL1000 silicone LED light diffusing agent, 1~2% nano Grade light scattering particles SC803, the balance is thermoplastic substrate. The LED lamp plastic lampshade of the present invention has good high temperature resistance performance, stable color quality, high light transmittance, good light guiding effect, less light efficiency loss, and can expand the light-emitting angle of the LED lamp boards arranged in a plane. The invention also discloses a method for preparing the plastic lampshade of the LED lamp, which has simple process steps, strong operability and is suitable for industrialized production.

Owner:NINGBO KLITE ELECTRIC MFG

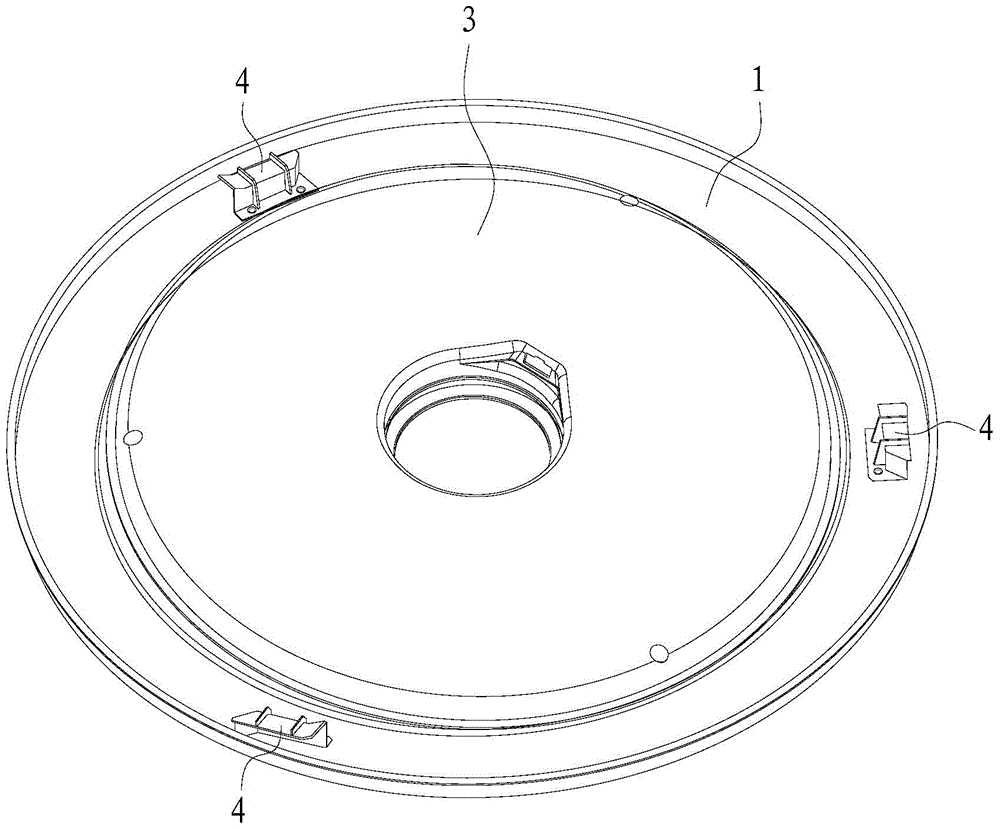

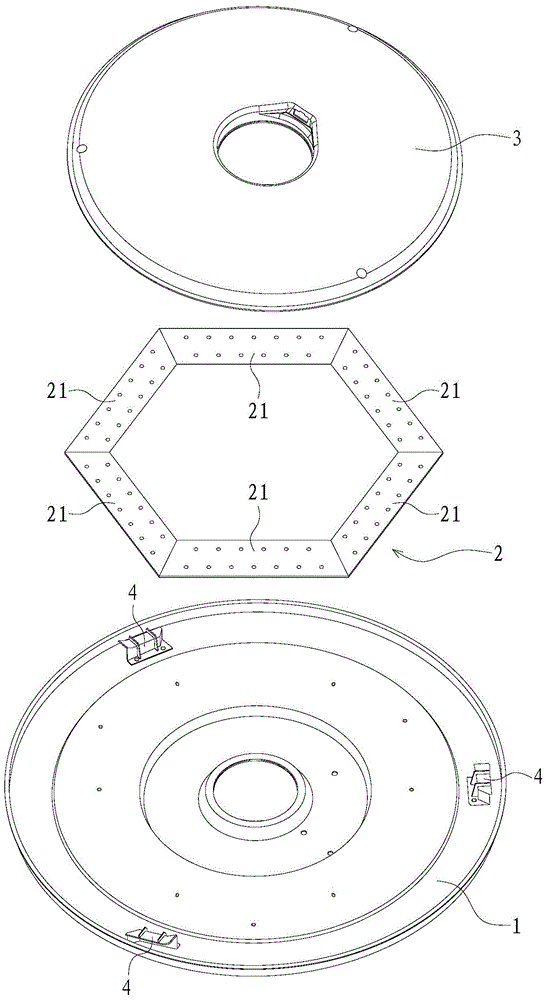

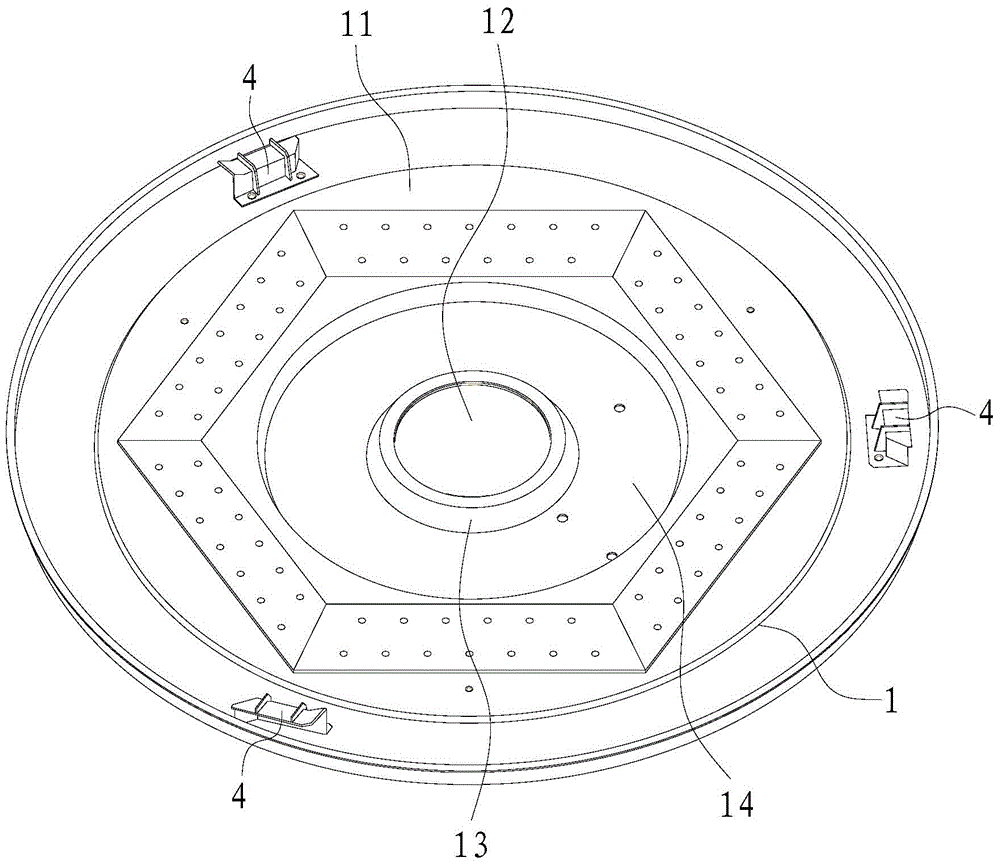

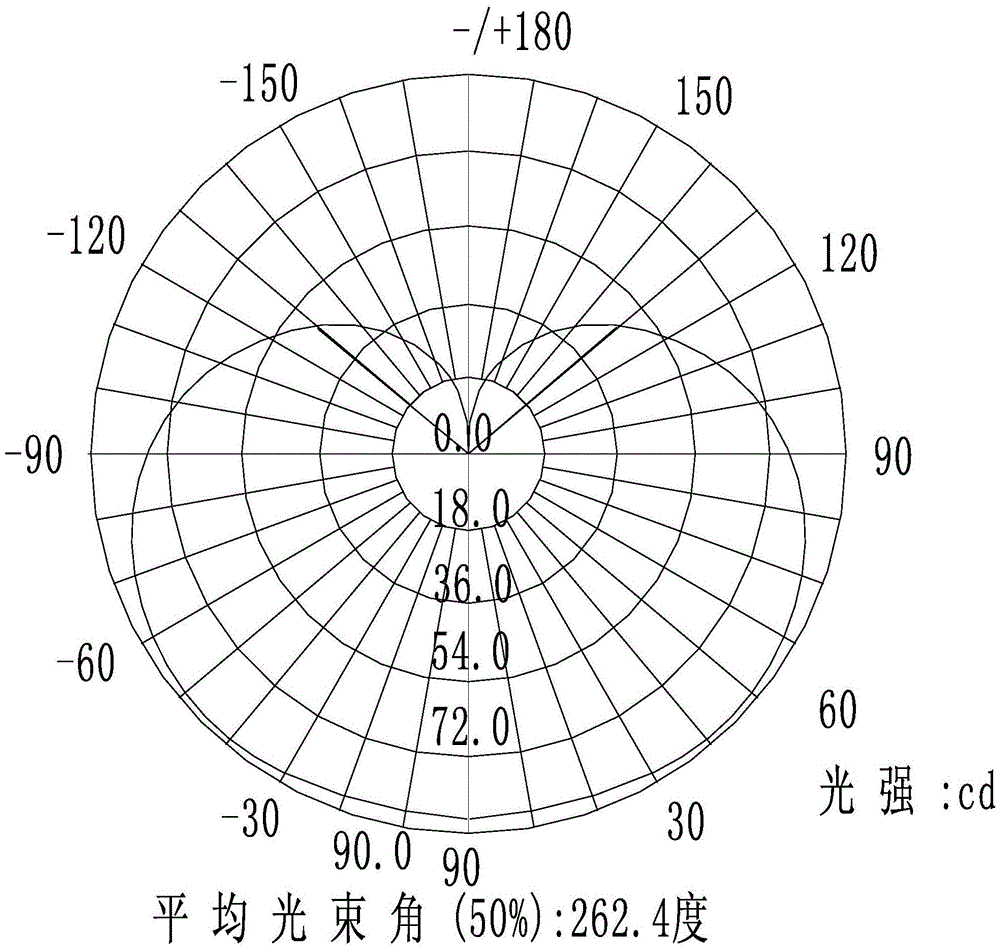

LED lamp disc

ActiveCN104949018ASimple structureReasonable layoutLighting support devicesPoint-like light sourceEngineeringInsect

The invention discloses an LED lamp disc. The LED lamp disc comprises a bottom disc body and an LED lamp panel, the bottom disc body is provided with a boss, the LED lamp panel is fixed to the boss, a transparent cover and the bottom disc body are fixedly connected and buckled, the LED lamp panel is arranged between the transparent cover and the bottom disc body, and the transparent cover is provided with a retreat groove. Therefore, the LED lamp panel is fixedly arranged on the boss, after an LED lamp is mounted, other components in the LED lamp disc cannot block light of the LED lamp, the light of the LED lamp can be fully utilized, a wider lighting angle is provided for the LED lamp, and the structure of the bottom disc body is simple and reasonable in layout. The transparent cover covers an LED lamp bar, dust and insects can be prevented, the light-emitting service life of the LED lamp is prolonged, electric shocks are avoided, and physical safety is protected. The retreat groove can be used for containing a power line, and mounting is facilitated.

Owner:JIANGSU DALEN ELECTRONICS CO LTD

LED lampshade coating and coating method thereof

InactiveCN104789065AScatter evenlyLarge light anglePretreated surfacesGlobesSilicon dioxideEthylene bis

The invention discloses an LED lampshade coating. The coating is composed of a resin, silica, titanium dioxide, aluminium oxide, fluorescent powder, calcium carbonate, barium sulfate, and ethylene bis stearamide, and comprises, by mass part, 200-500 of the resin, 5-30 of silica, 3-50 of titanium dioxide, 2-20 of aluminium oxide, 100-450 of fluorescent powder, 3-25 of calcium carbonate, 8-40 of barium sulfate, and 10-80 ethylene bis stearamide, wherein each component is powder more than 300 mesh. The invention also discloses a coating method of the LED lampshade coating. According to the invention, after an LED lamp is coated, light emitted from the lampshade has advantages of uniform light scattering, a large emitting angle, and high transmittance.

Owner:巫世贵

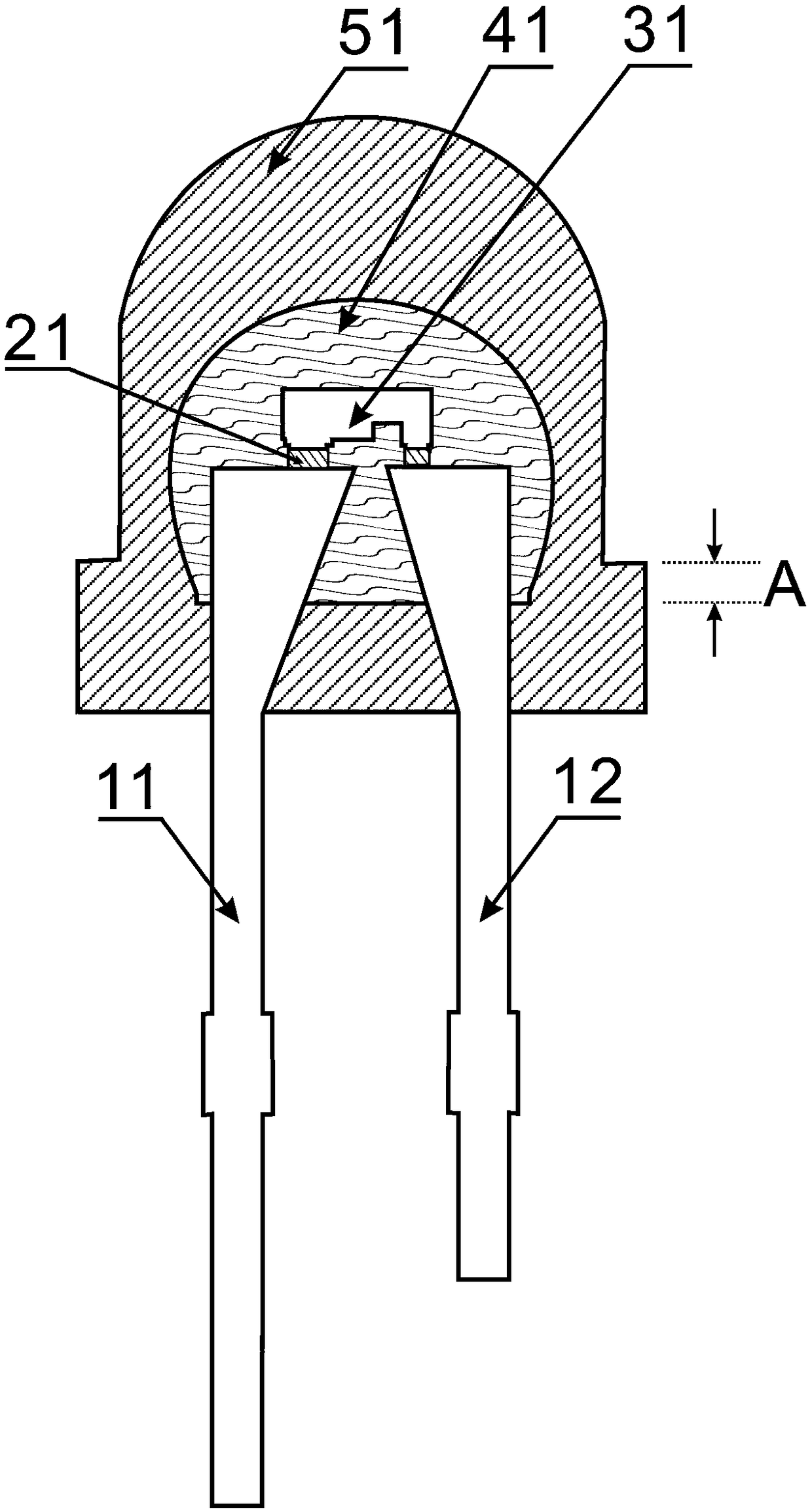

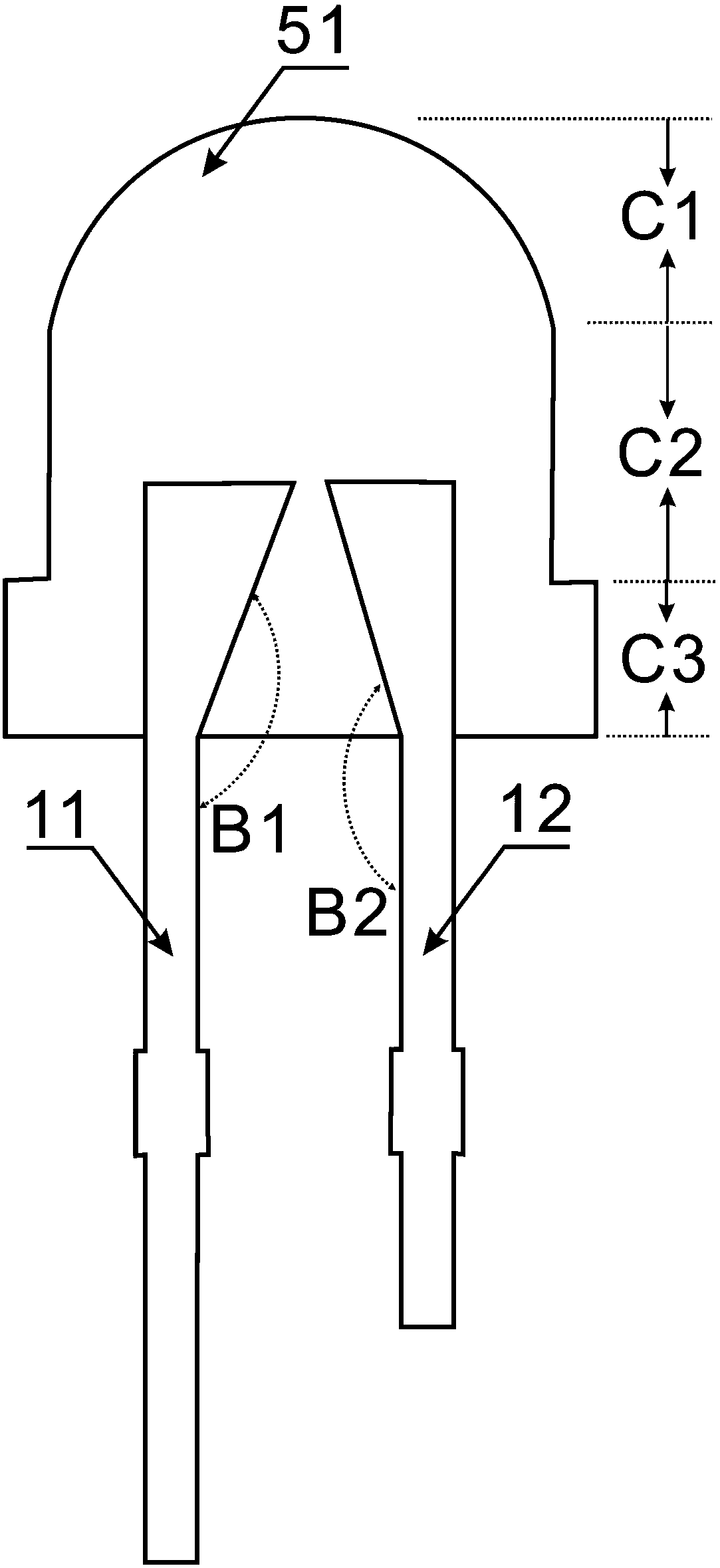

High-luminous-efficiency white-light LAMP-LED structure and packaging method

The invention discloses a high-luminous-efficiency white-light LAMP-LED structure and a packaging method, which solve the problems of poor wire soldering and poor luminous efficiency occurred in the white-light LAMP LED packaging process in the prior art. The white-light LAMP-LED structure comprises a flip LED chip, wherein the flip LED chip is mounted on a platform of a flat-headed type reversedL-shaped bracket; an LED fluorescent powder glue mixture wraps the flip LED chip and the upper end of the flat-headed type reversed L-shaped bracket to form a hemispherical LED fluorescent powder light emitting layer; epoxy resin coats the hemispherical LED fluorescent powder light emitting layer to form an epoxy resin lens; the flip LED chip and the platform of the flat-headed type reversed L-shaped bracket are connected by means of a die bonding solder paste; and the flat-headed type reversed L-shaped bracket is composed of a pair of matched flat-headed type reversed L-shaped positive electrode bracket and flat-headed type reversed L-shaped negative electrode bracket. The white-light LAMP-LED structure uses the flat-headed type reversed L-shaped bracket as a white-light LED packaging bracket, simplifies the die bonding and line welding process, improves the reliability of products, and greatly improves the luminous efficiency of a white-light LAMP LED.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

Novel LED (light emitting diode) light source and bulb manufactured by using same

ActiveCN102913787ALarge light angleImprove luminous efficiencyPoint-like light sourceLighting heating/cooling arrangementsScotch tapeLight emission

The invention discloses a novel LED (light emitting diode) light source and a bulb manufactured by using the light source. The LED light source comprises two upper and lower glass substrates and two exported electrodes, wherein one or more LED chips are packaged between the upper and lower glass substrates by using a scotch tape; when one LED chip is packaged, the two exported electrodes stretch between the upper and lower glass substrates to be receptively connected with two electrodes of the LED chip; when a plurality of LED chips are packaged, the two exported electrodes stretch between the upper and lower glass substrates to be respectively connected with the two electrodes which are formed by the LED chips which are serially connected or connected in parallel; glass protecting plates can be wrapped at the upper surface of an upper glass substrate, the lower surface of a lower glass substrate and side surfaces of the upper and lower glass substrates; and fluorescent material layers are coated at the upper surface of the upper glass substrate, the lower surface of the lower glass substrate and between the side surfaces of the upper and lower glass substrates. The LED light source is large in light emission angle, good in heat radiation effect and high in light emission efficiency.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

LED (Light-Emitting Diode) bulb lamp

InactiveCN102748622AIncrease the beam angleLight evenlyPoint-like light sourceElectric lightingEngineeringLamp shell

The invention discloses an LED (Light-Emitting Diode) bulb lamp, comprising a lamp holder, a circuit board, a driving power supply, a transparent lamp shell, LED lamp beads and a lamp panel, wherein the circuit board and the driving power supply are arranged in the lamp holder and the LED lamp beads are arranged on the lamp panel; the lamp panel is fixedly arranged on the lamp holder and is arranged inside the transparent lamp shell; the transparent lamp shell is fixedly arranged on the lamp holder; the lamp panel is spherically arrayed; the LED lamp beads are arranged on the surface of the lamp panel and are spherically distributed; the lamp panel comprises at least four groups of lamp boards: a first lamp board in a plane shape, a second lamp board, a third lamp board and a fourth lamp board, wherein at least three faces of the second lamp board are in the plane shape; at least three faces of the third lamp board are in the plane shape; and at least three faces of the fourth lamp board are in the plane shape. The LED bulb lamp has the advantages of large light-emitting angle and uniform light emission in each direction.

Owner:GOERTEK INC

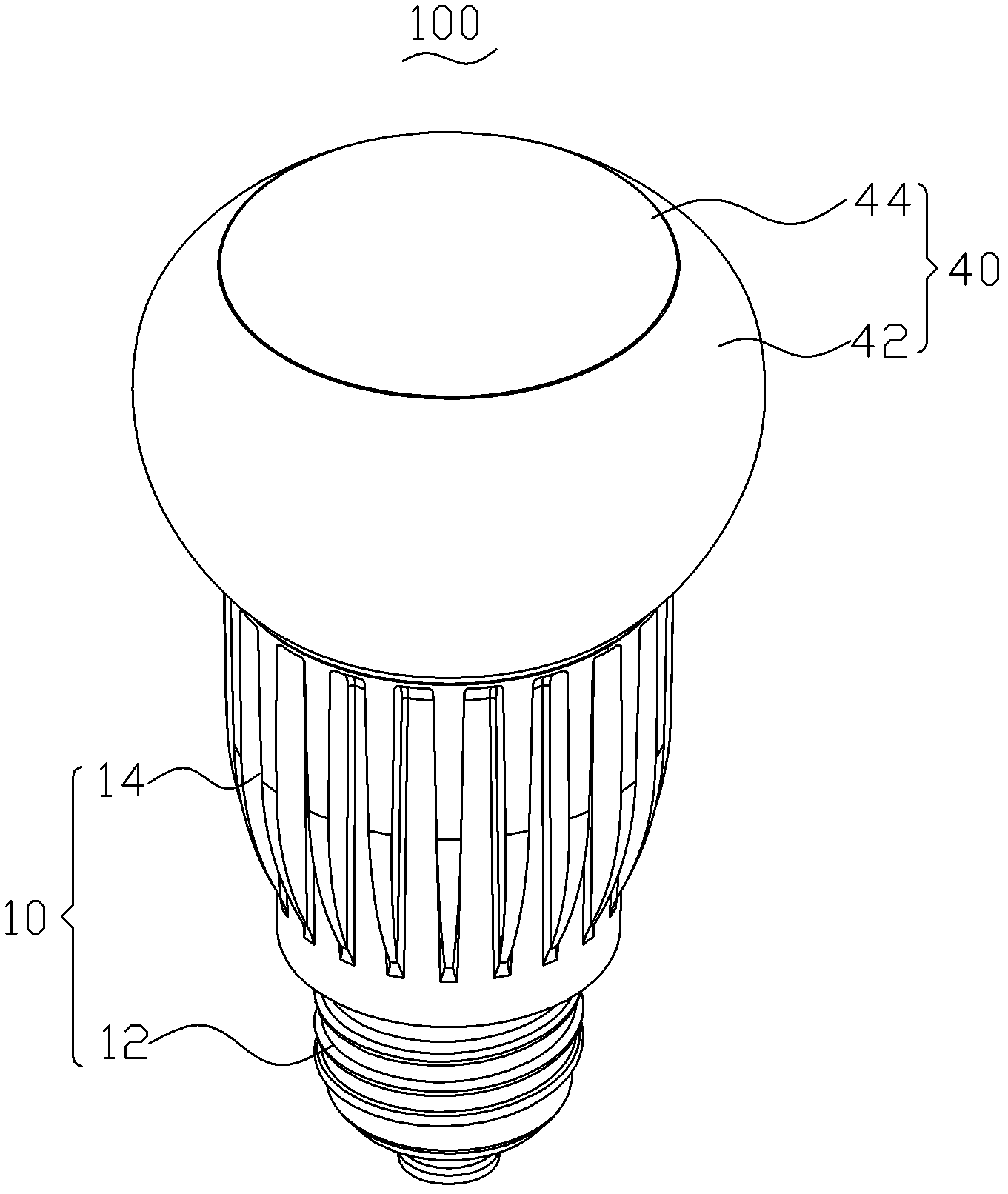

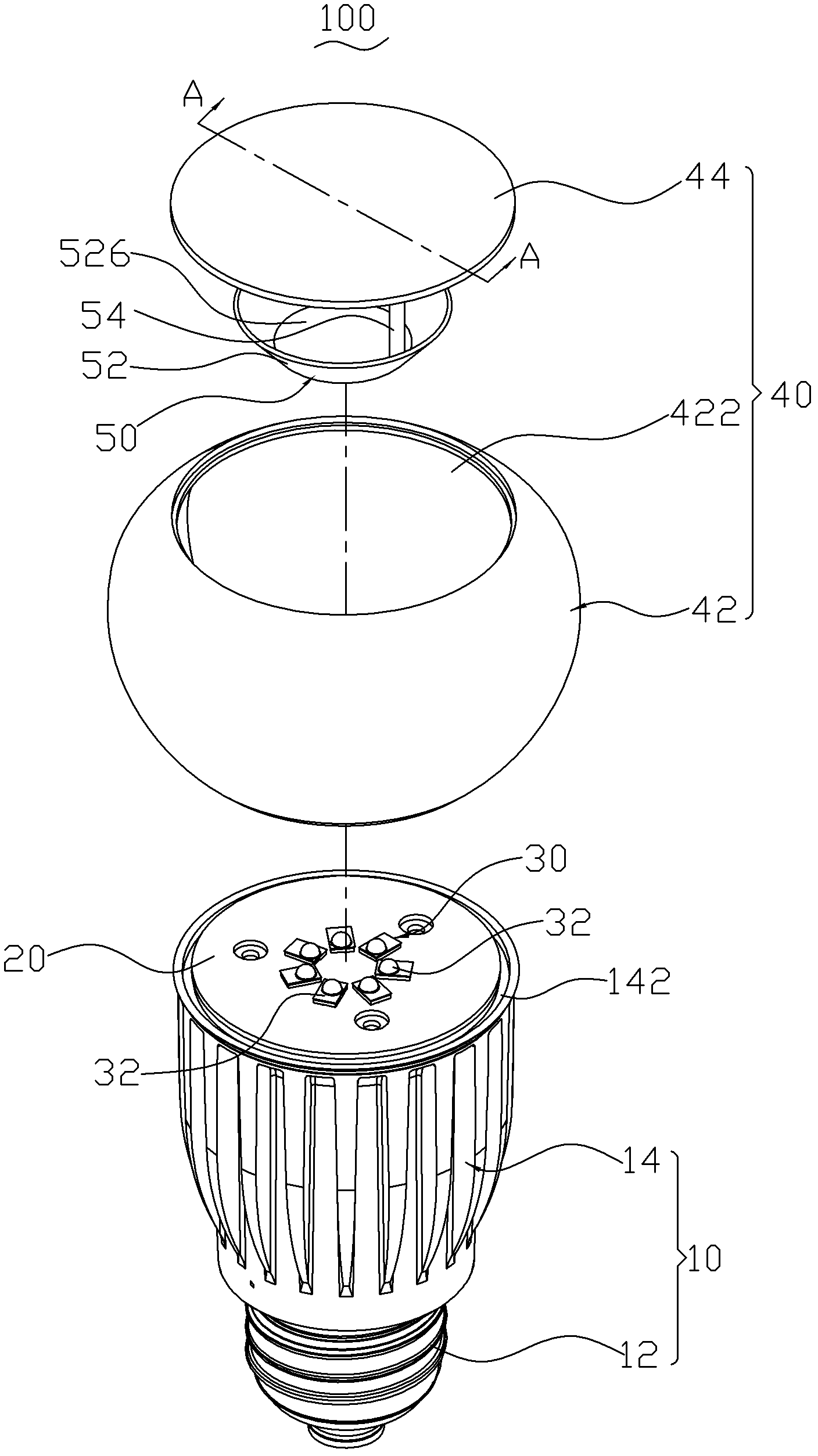

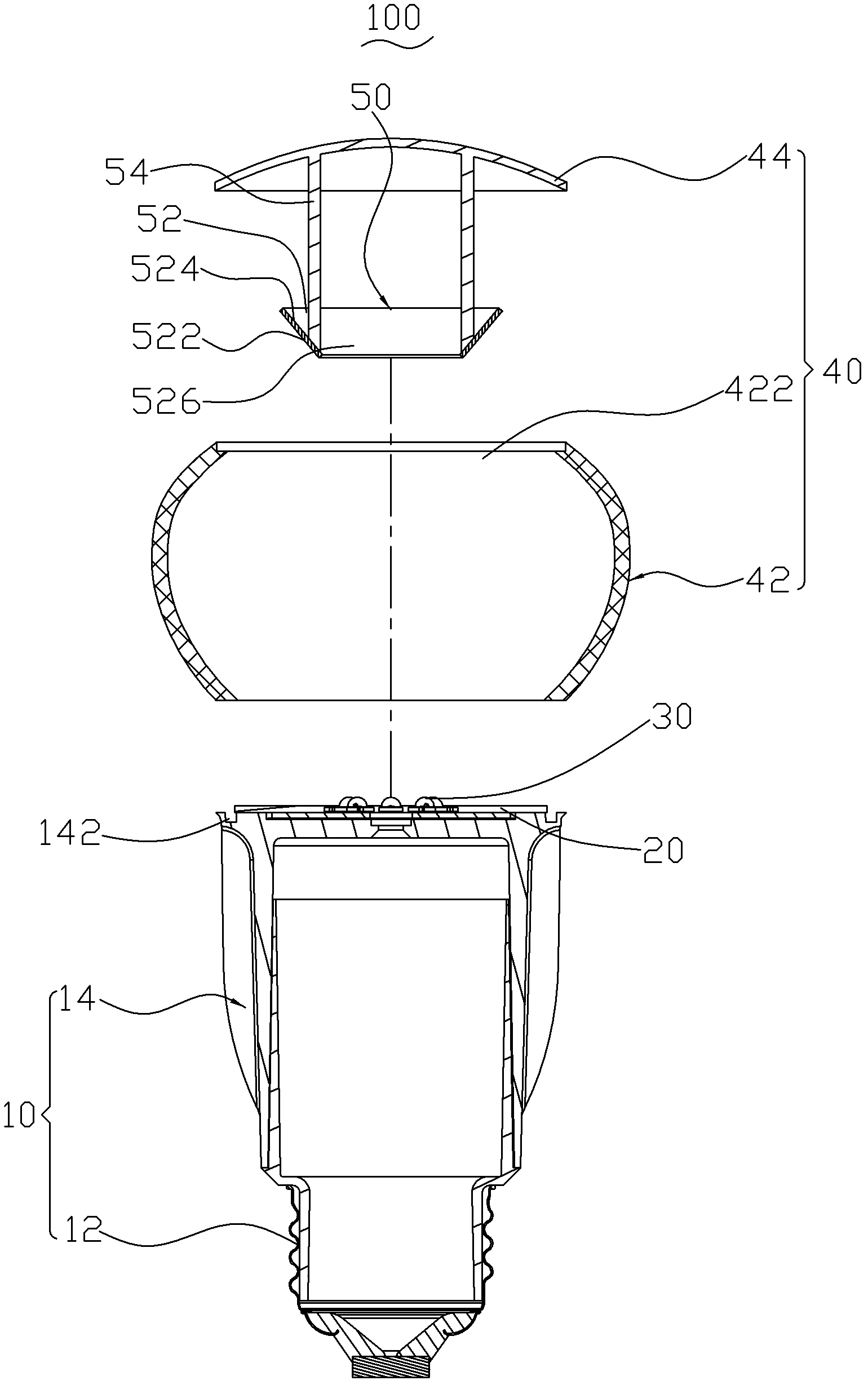

LED lamp bulb

InactiveCN103499043AExtended service lifeIncrease surface areaPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses an LED lamp bulb which comprises a lamp holder, an LED power source, an LED light source, a heat conduction device and a lamp cover. The heat conduction device is mounted in the lamp holder in an interference fit mode, the LED light source is mounted on the heat conduction device, the LED power source is electrically connected with the LED light source and the lamp holder respectively, and the lamp cover is fixedly connected to the lamp holder. The LED lamp bulb has the advantages of being simple and safe in structure, good in heat radiating effect, large in light-emitting area, good in illumination effect and the like.

Owner:GUANGDONG BENBON ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com