Patents

Literature

1223 results about "Ethylene bis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene bis stearamide (EBS) is an organic compound with the formula (CH₂NHC(O)C₁₇H₃₅)₂. It is a waxy white solid and is also found as powder or beads that is widely used as a form release agent. The compound is derived from the reaction of ethylenediamine and stearic acid. It is a white solid of low toxicity that provides a slippery coating for a variety of applications.

Cellulosic-thermoplastic composite and method of making the same

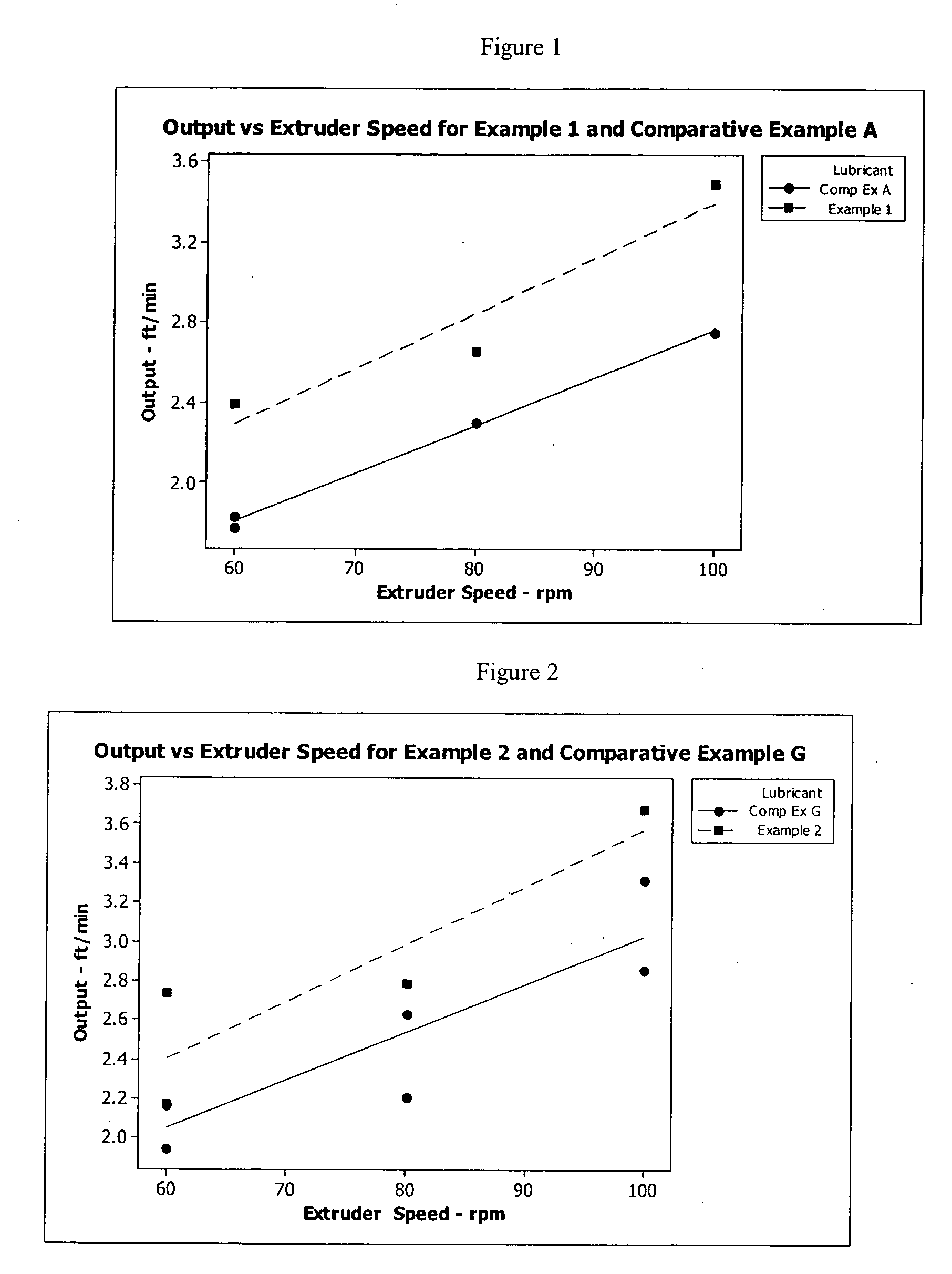

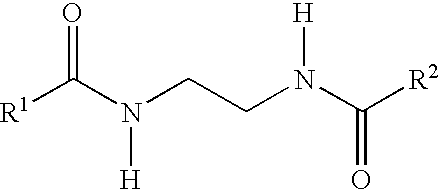

Provided is a composition comprising fatty acid bis-amide, inorganic particulate such as pumice, cellulosic particulate, thermoplastic and maleic anhydride grafted polyolefin. The combination of an ethylene bis-amide and a minor amount of pumice produces cellulosic-thermoplastic composite that has superior extrusion properties over conventional metal stearate / ethylene bis-stearamide (EBS) compositions such as improved flex strength and resistance to water absorption.

Owner:ADDIVANT USA

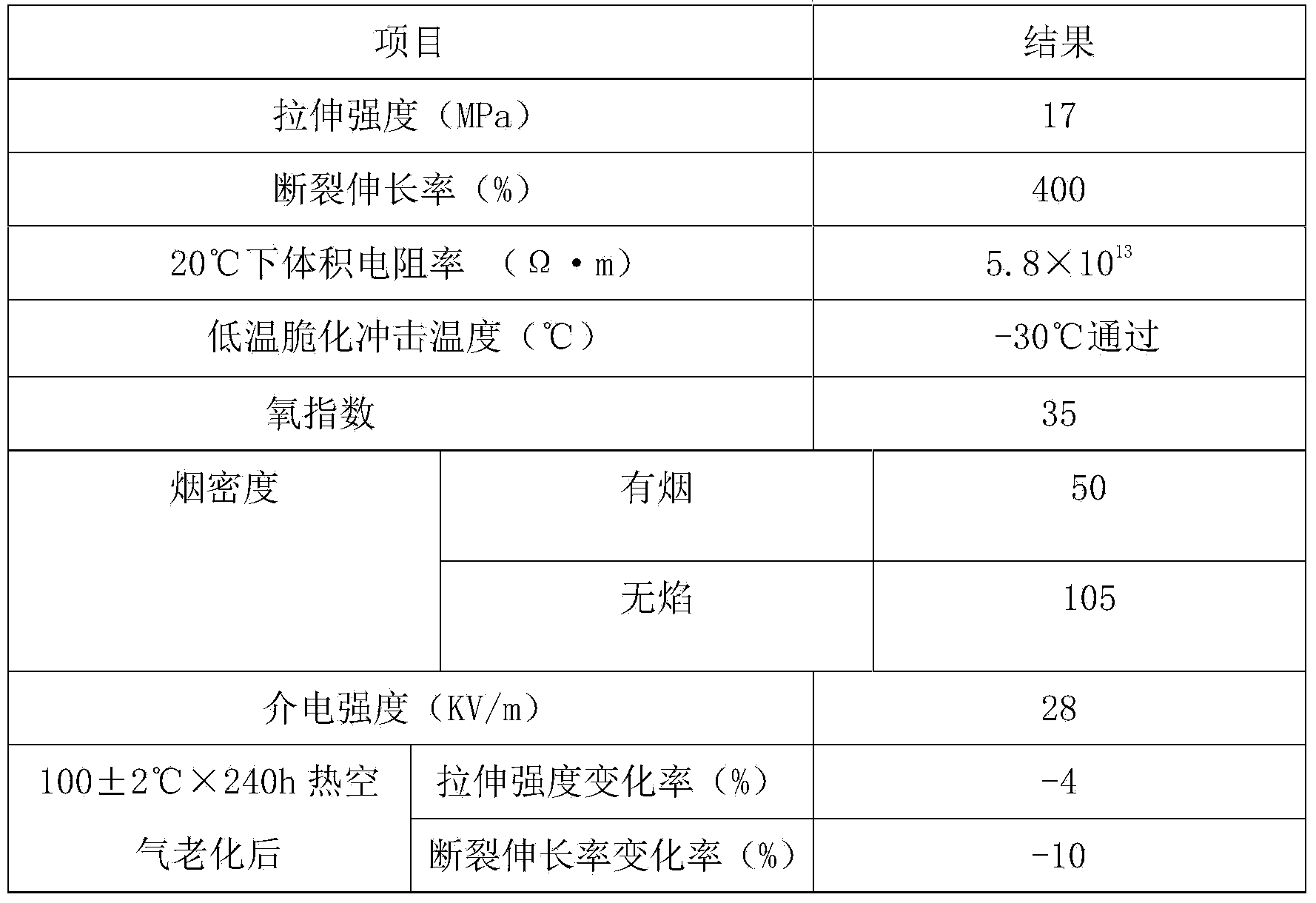

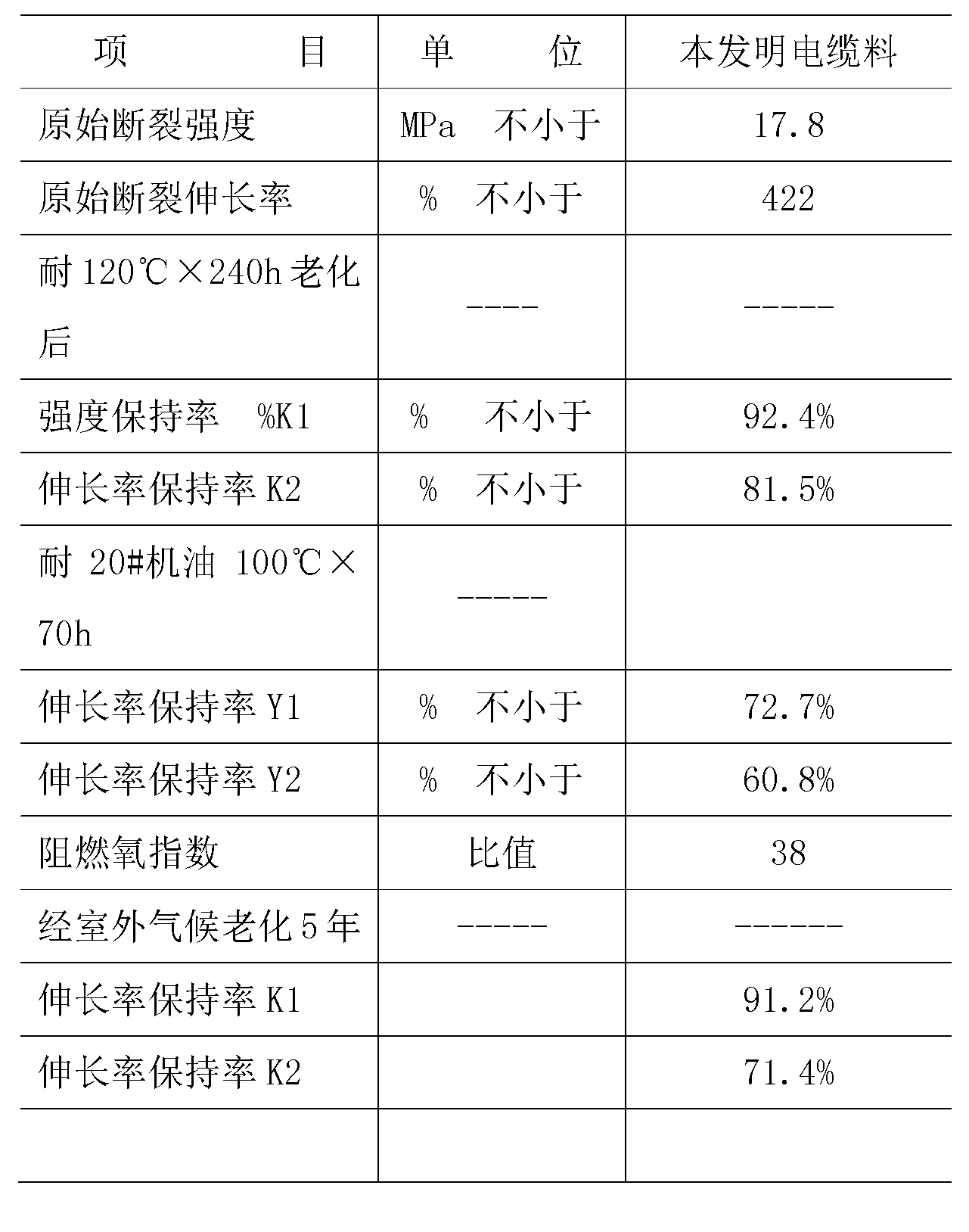

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

Process for preparing supported transition metal catalyst systems and catalyst systems prepared thereby

InactiveUS6943224B2Good dispersionImprove accessibilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSilicon dioxideEthylene bis

A process for forming a coordination catalyst system comprising sequentially or substantially simultaneously contacting: (I) pre-catalyst reactants comprising (a) at least one first ligand-containing reactant; and (b) at least one first transition metal reactant suitable to form at least one metallocene or constrained geometry pre-catalyst compound (e.g., rac-ethylene bis(indenyl)zirconiUm dichloride); an optionally (c) at least one second ligand-containing reactant and (d) at least one second transition metal reactant suitable to form at least one non-metallocene, non-constrained geometry, bidentate or tridentate transition metal compound (e.g., tridentate 2,6-diacetylpyridine-bis(2,4,6-trimethylanaline)FeCl2) and (II) further contacting, jointly or individually, the pre-catalyst compound(s) and optional bidentate or tridentate compound(s) with at least one support-activator agglomerate (e.g., spray dried silica / clay agglomerate). When individually contacted, the supported catalyst components can be mixed or blended. The resulting transition metal catalyst systems are suitable for addition polymerization of unsaturated monomers, e.g., ethylene and propylene.

Owner:WR GRACE & CO CONN

Method for improving stability of mineral oil defoaming agent

A method for improving the stability of a mineral oil defoaming agent, which belongs to the field of fine chemical preparations, is characterized in that the viscosity of the mineral oil defoaming agent system can be improved after strong shear action by adding hydrophilic inorganic particles into the system and uniformly dispersing the hydrophilic inorganic particles into the system, thereby improving the product stability. The defoaming agent comprises (1) mineral oil carrier 70% to 90%; (2) main defoaming substances 1% to 15%, containing hydrophobic white carbon black and ethylene bis stearamide (EBS); (3) defoaming aid 1% to 20%: RO(EO)x(PO)yH polyether; (4) nonionic surfactant 3% to 15%; and (5) hydrophilic inorganic particles 0.1% to 5%, containing hydrophilic white carbon black, aluminum oxide, zinc oxide and magnesium oxide. The operation comprises following steps: (A) adding the mineral oil into a flask, adding the main defoaming substance and the defoaming aid therein, stirring, heating to 80 to 150 DEG C, and keeping the temperature for 0.5 to 3 h; (B) lowering the temperature to 50 to 80 DEG C, adding an emulsifying agent, uniformly stirring, lowering the temperature of the mixture system below 40 DEG C and adding the hydrophilic inorganic particles; (C) passing through a colloid mill; and (D) vacuum degassing to obtain a mixture with good stability, i.e. the mineral oil defoaming agent.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

PET (polyethylene glycol terephthalate) fiber/aramid fiber composite sound absorbing cotton and preparation method of PET fiber/aramid fiber composite sound absorbing cotton

InactiveCN102965839AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesEpoxyPolymer science

Owner:芜湖跃飞新型吸音材料股份有限公司

Acrylonitrile butadiene styrene (ABS) resin composition with good flowability

The invention provides an acrylonitrile butadiene styrene (ABS) resin composition with good flowability. The composition comprises the following components in parts by weight: 20-30 parts of butadiene-styrene-acrylonitrile grafted copolymer with the resin content of above 60%, 10-30 parts of styrene-acrylonitrile copolymer with the acrylonitrile (AN) content of 22.5-24.5 and the number-average molecular weight of 7000-8000, 70-40 parts of styrene-acrylonitrile copolymer with the AN content of 23.5-25.5 and the number-average molecular weight of 4000-5000, 1.0-2.5 parts of N,N-ethylene bis stearamide, 0.1-0.4 part of magnesium stearate and 0.1-0.2 part of dialkypentaerythitoldiphosphite. Processing can be carried out at the temperature of 200-260 DEG C; the melt index of the resin composition is 40-70g / min; and the resin composition has the advantages of good mechanical property, simple production process and relatively low cost.

Owner:PETROCHINA CO LTD

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

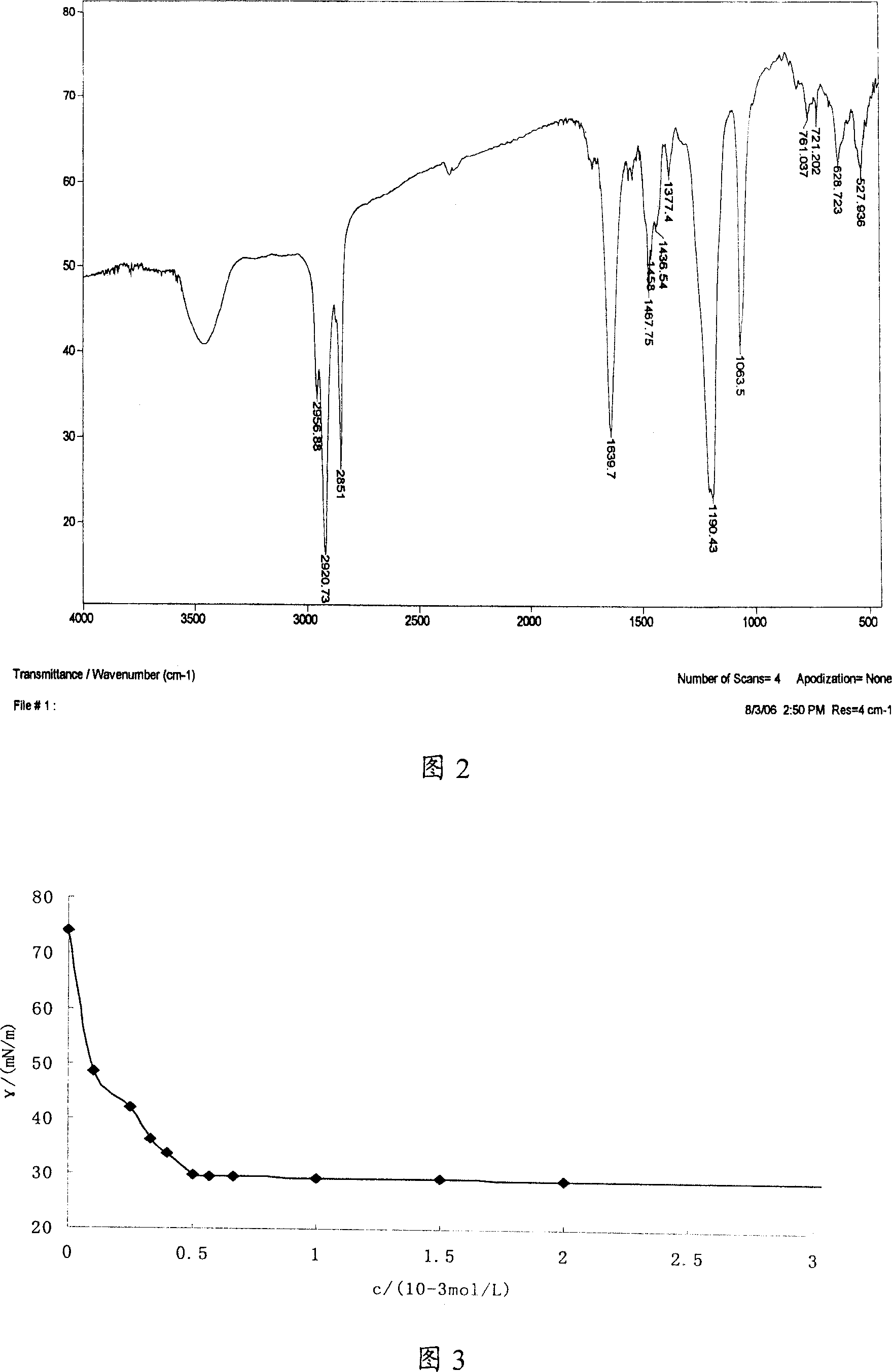

Ocean epoxy zinc-rich anti-corrosion powder coating and preparation method thereof

ActiveCN104087125AImprove conductivityImprove thermal conductivityAnti-corrosive paintsPowdery paintsEpoxyPolyvinyl alcohol

The invention provides an ocean epoxy zinc-rich anti-corrosion powder coating and a preparation method thereof. The coating is prepared from the following raw materials: E-12 epoxy resin, novolac epoxy, trimethyl hexamethylenedi, polyvinyl butyral, dimethyl imidazole, aminopropyl triethoxy silane, zinc powder, aluminum powder, graphene, ethylene bis stearamide, polyethylene wax powder, an antioxidant DNP, and compound filler. The preparation method comprises the following steps: uniformly mixing zinc powder, aluminum powder and graphene, adding aminopropyl triethoxy silane, stirring to disperse so as to obtain a component A, mixing the E-12 epoxy resin, novolac epoxy, polyvinyl butyral and polyethylene wax powder, preheating, cooling down to room temperature, mixing the component A, the mixture and the rest raw materials, carrying out melt extrusion by virtue of an extruder, tabletting, carrying out air cooling, grinding into powder, and sieving. The coating can protect a steel structure from being corroded by various corrosive media for a long term, is non-toxic, pollution-free and salt mist resistant, and has strong adhesive force and shock resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

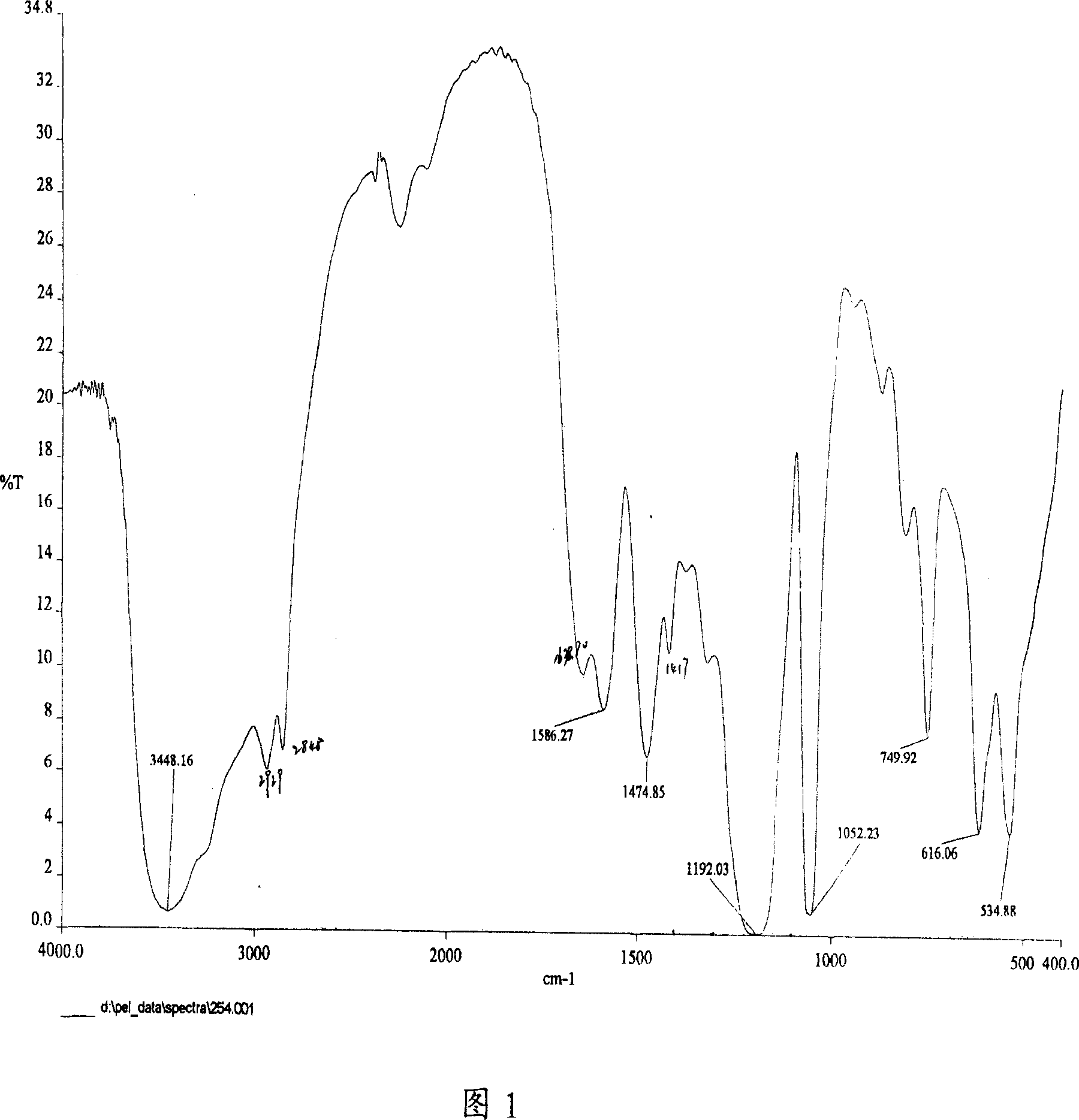

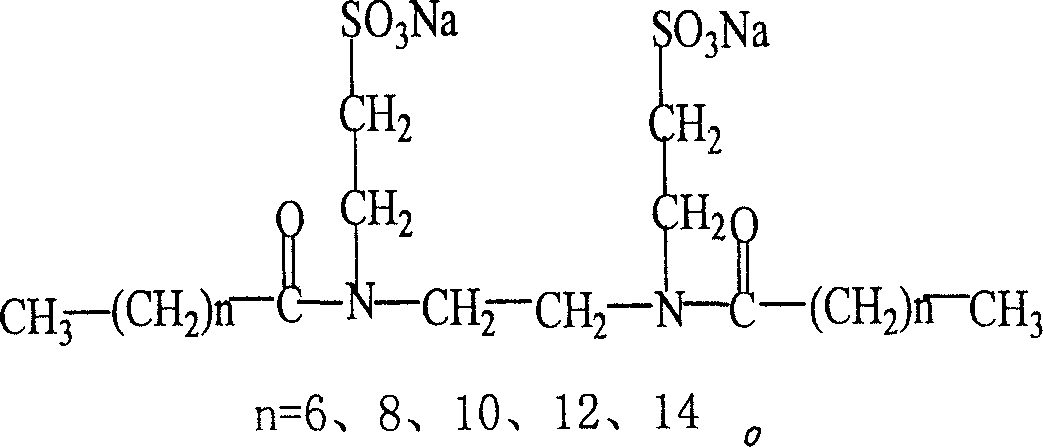

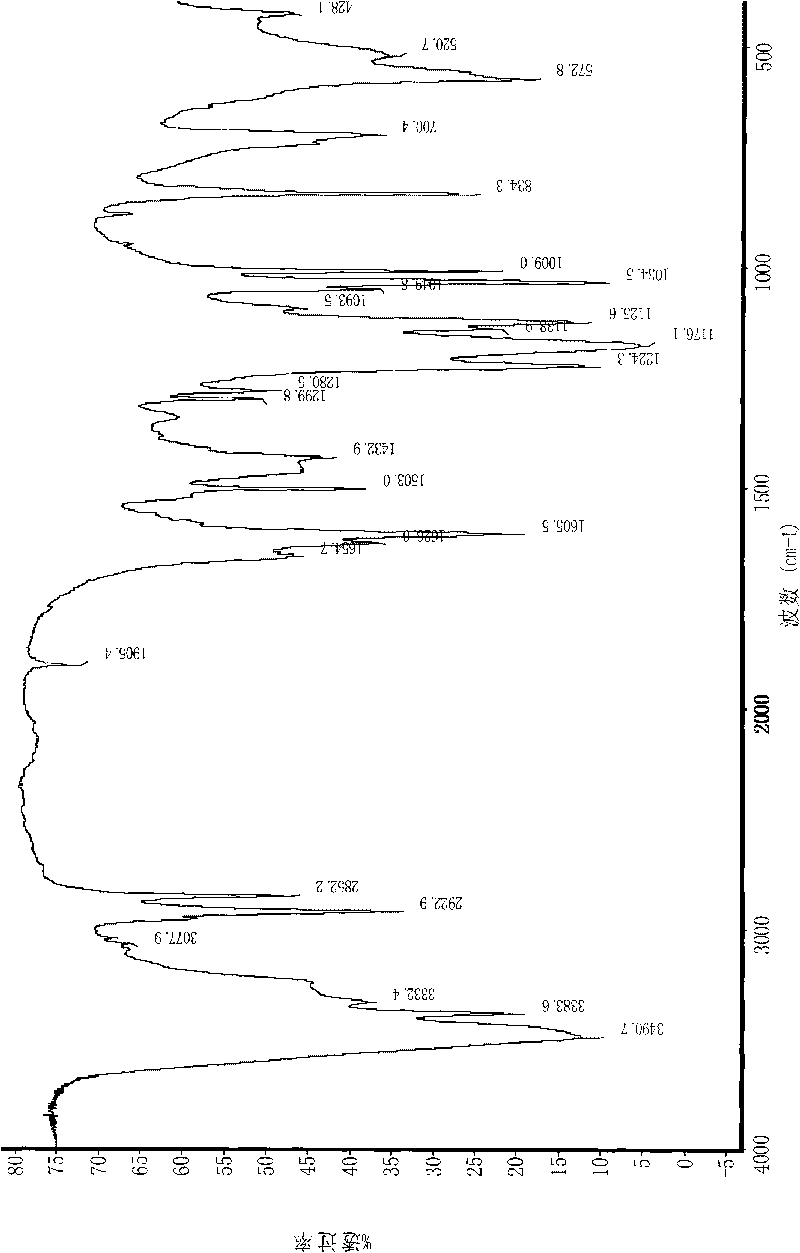

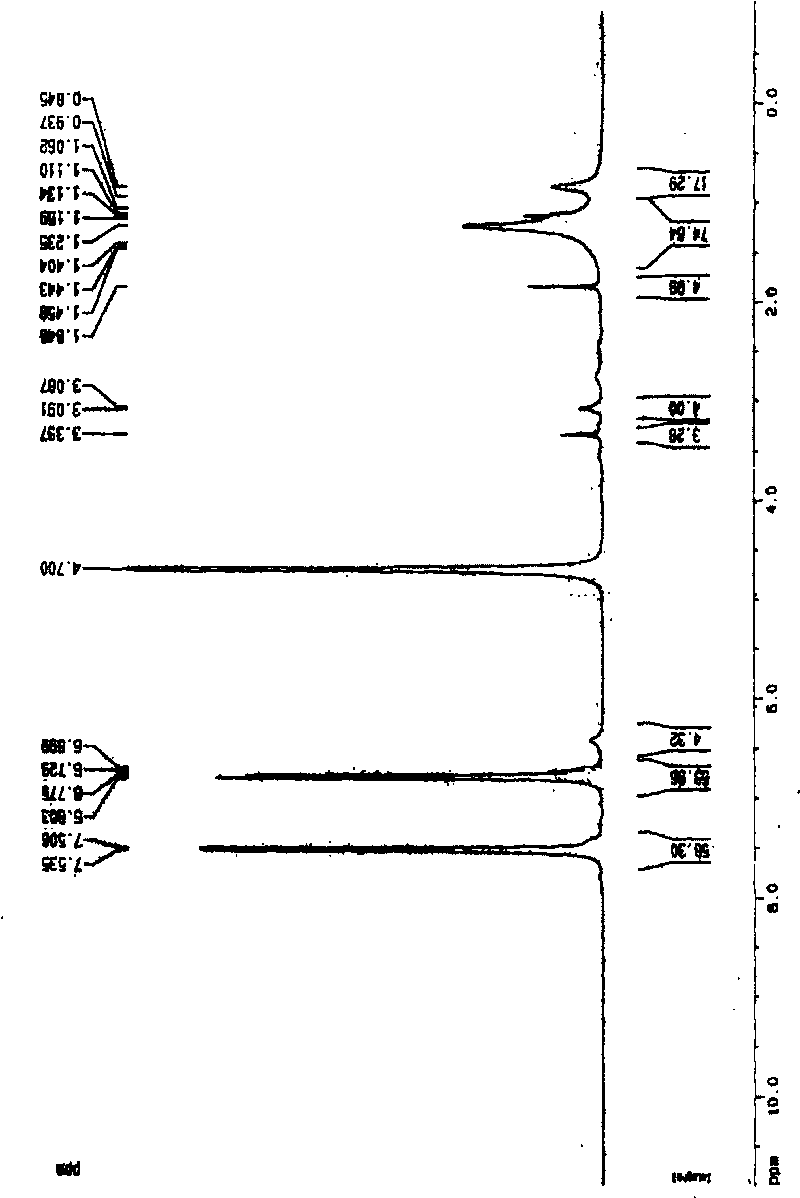

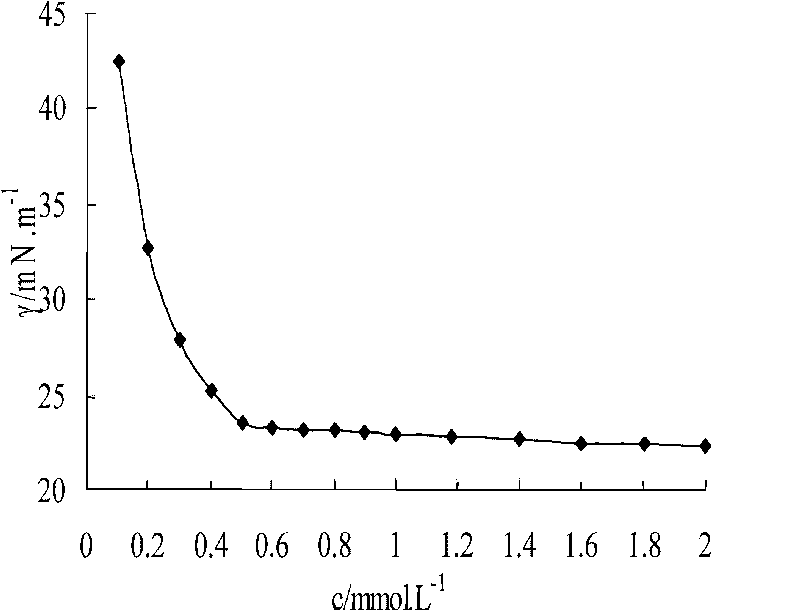

Bisamide bissulfosalt double surface active agent, and its synthesizing method

InactiveCN1935346AEasy to separateThe synthesis method is simpleTransportation and packagingMixingEthylenediamineWater baths

The present invention relates to a kind of bisamide disulfonate double-component surfactant. Said surfactant is ethylene-bis (N-ethyl sulfonate group-alkylamide). Its synthesis method includes the following steps: (1), adding ethylenediamine aqueous solution into a reactor, slowly-drop-adding sodium 2-bromoethyl sulfonate solution, refluxing, stirring, making reaction for 6-8 hr in constant temperature water bath, retaining pH and making it be 8-10, water bath temperature is 50-70deg.C, adding ethyl alcohol, drying separated out solid to obtain sodium N1N1-diethylsulfonate ethylenediamine; and (2), adding the above-mentioned product into a reactor, stirring and adding acyl chloride, at the same time drop-adding triethylamine / acetone solution, retaining pH and making it be about 8, making reaction for 5-8 hr at room temperature, cooling, making precipitation, filtering, washing by using absolute alcohol and drying so as to obtain the invented surfactant.

Owner:SOUTHWEST PETROLEUM UNIV

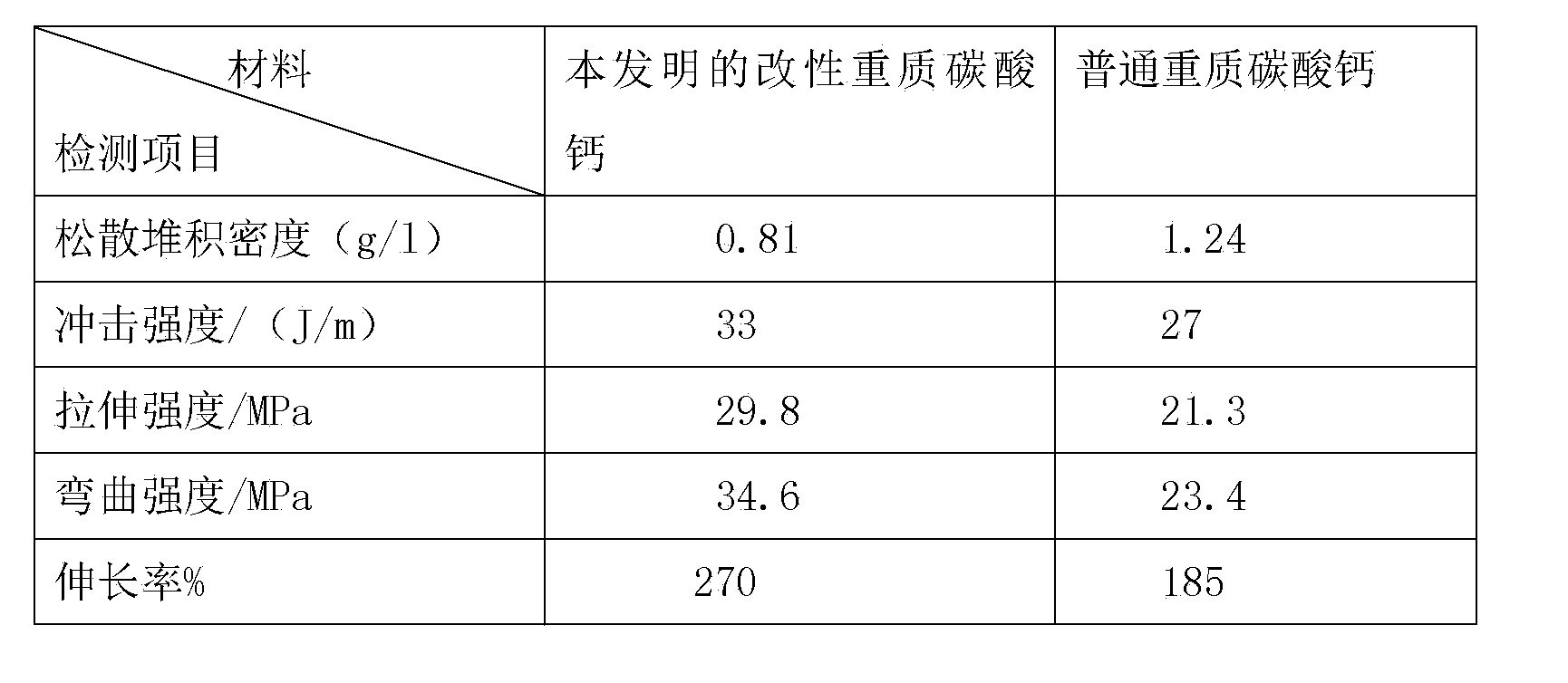

High-dispersivity modified calcium carbonate for color masterbatches and preparation method thereof

ActiveCN103408800AUniform particle sizeLarge specific surface areaPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityStearic acid

The invention provides a high-dispersivity modified calcium carbonate for color masterbatches, which is prepared from the following raw materials in parts by weight: 95-100 parts of ground calcium carbonate, 0.1-0.3 part of diffusant NNO, 0.1-0.3 part of ferrocene, 0.2-0.4 part of bisphenol A polycarbonate, 1-2 parts of rutile titanium dioxide, 0.4-0.6 part of talcum powder, 0.1-0.2 part of white oil, 0.5-1 part of methyl phenyl silicone oil ethylene bis-oleamide, 1-2 parts of high-density linear polyethylene, 0.3-0.4 part of stearic acid, 1-2 parts of paraffin and 2-3 parts of isopropyl tri(dioctylpyrophosphate)titanate. The preparation method comprises the following steps: mixing part of materials, drying calcium carbonate, mixing, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantage of favorable dispersity, and can lower the cost and enhance the dispersity and shading property of the color masterbatches when being used in various color masterbatches.

Owner:青阳县恒源化工原料有限责任公司

Needle cylinder injection type leadless solder paste for heat radiator welding

InactiveCN101301705ACoating is effectiveNo wasteWelding/cutting media/materialsSoldering mediaActive agentGlycerol

The invention discloses a needle cylinder injection-typed lead-free solder paste used for the welding of radiators; the lead-free solder paste contains a tin-bismuth-rare earth lead-free solder mixed with a soldering flux. The soldering flux comprises 40 to 45 percent of resin (such as hydrogenation resin glycerol and alkyd resin), 10 to 15 percent of active agent (such as alkyl poly-glycosides and monoethanolamide sulfosuccinate), 2.1 to 3.1 percent of thixotropic agent (such as amide modified hydrogenated castor oil and Ethylene bis stearamide stearic amide), 0.8 to 1.2 percent of special additive (such as release agent, antioxidant and resist), and residual quantity of solvent (such as glycol dipropionate ether acetate and 1,3-propanediol). The needle cylinder injection typed lead-free solder paste of the invention has low welding temperature, comparatively low viscosity, better rheological property under the action of the pressure, and better anti-collapse performance after the solder paste is coated, and is especially applicable to the welding of the radiators, and is beneficial to precisely controlling the dosage of the welding paste and saving the cost.

Owner:PERFECTION SCI & TECH DONGGUAN

Acoustic wool with high impact resistance and preparation method thereof

InactiveCN105506857AIncreased durabilityImprove featuresNon-woven fabricsMonocomponent polyolefin artificial filamentHazardous substancePolyethylene glycol

The invention discloses acoustic wool with high impact resistance. The acoustic wool is prepared from, by weight, 1-2 parts of barium stearate, 0.5-1 part of sodium xylene sulfonate, 5-10 parts of zircon powder, 3-5 parts of silicon carbide, 1-2 parts of ethylene bis stearamide, 80-100 parts of polypropylene, 2-4 parts of styrene, 1-2 parts of epoxy rice bran oleic acid butyl ester, 3-5 parts of butyl methacrylate, 1-2 parts of polyethylene glycol, 0.05-0.1 part of azodiisobutyronitrile, 0.5-1 part of castor oil and 3-5 parts of functional powder. The acoustic wool is good in sound absorption effect and mechanical performance, high in durability, high in impact resistance, less prone to deformation, good in processing performance, capable of absorbing harmful substances in air, effectively purifying the air and protecting human health, high in comprehensive value and high in practicality.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Powder metallurgy duplicate gear and preparation method thereof

The invention provides a powder metallurgy duplicate gear which is prepared by pressing the following raw powder materials in parts by weight: 100 parts of ferrous powder, 1.8-2.0 parts of copper powder, 0.5-0.8 parts of molybdenum powder, 0.1-0.3 parts of vanadium powder, 0.8-1.2 parts of nickel powder, 0.5-0.8 parts of graphite powder, 0.1-0.3 parts of modified wood ash, 0.2-0.6 parts of rare earth ferrosilicon alloy, 0.1-0.3 parts of zinc stearate, 0.1-0.2 parts of ethylene bis stearamide, 0.1-0.3 parts of molybdenum disulfide, 0.2-0.4 parts of aluminum oxide, 0.2-0.4 parts of boron nitride and 0.4-0.5 parts of LiF. During preparation, the raw powder materials are mixed step by step, then pressed, sintered, and subjected to heat treatment and surface treatment to form a finished duplicate gear. The produced powder metallurgy duplicate gear has the characteristics that the powder metallurgy duplicate gear is good in abrasive resistance, high in strength, high in hardness, good in machinability, long in service life, corrosion-resistant, and not easy to break.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Toner composition for preventing image blocking

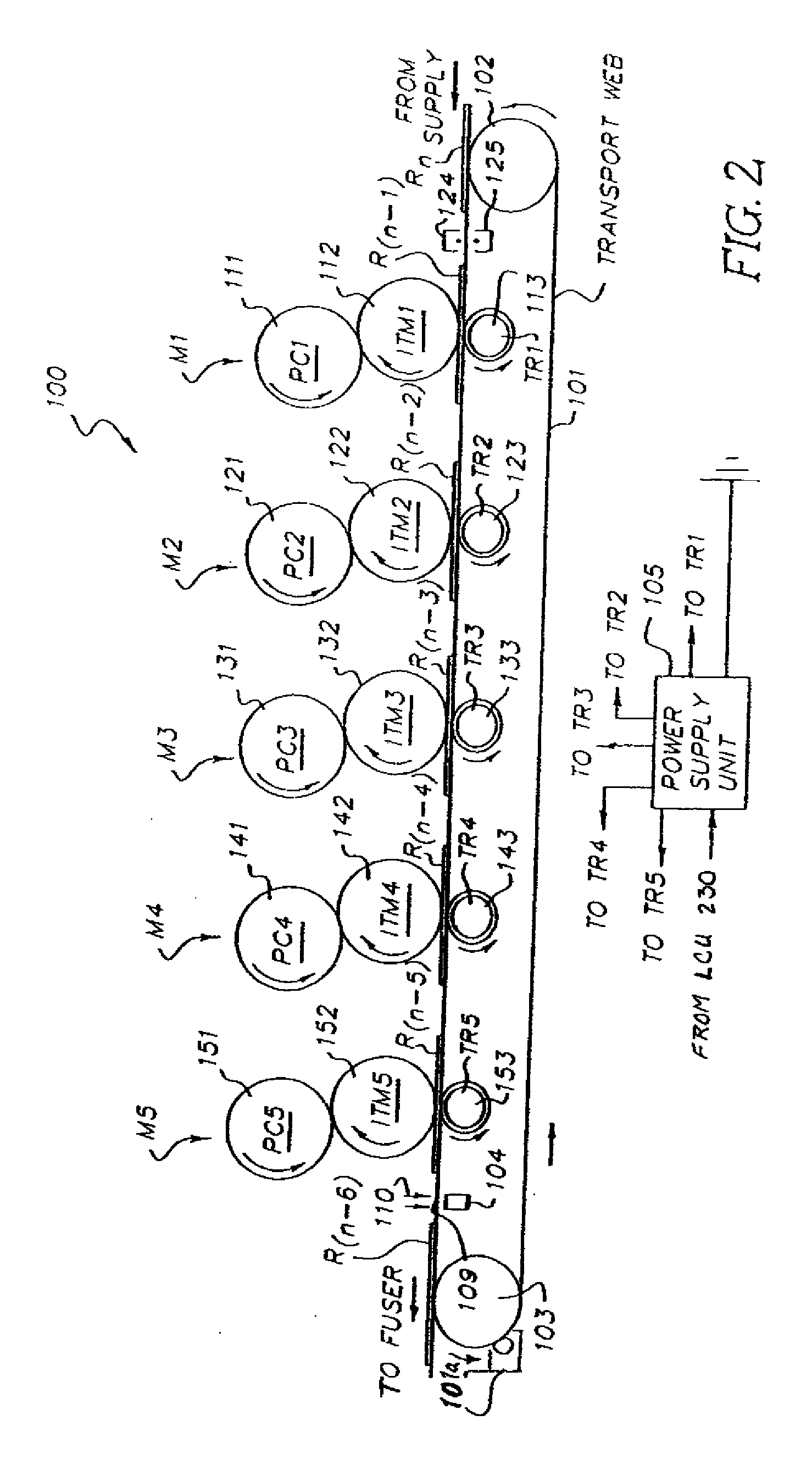

InactiveUS20090297970A1Improving toner image sticking resistanceResisting print stickingDevelopersElectrographic process apparatusEthylene bisWax

Images produced by electrophotography are often subjected to harsh conditions, such as high temperature and high relative humidity conditions. Prints when subjected to face-to-face stacking under these conditions tend to stick and are difficult to separate without damage. Ethylene-bis-stearamide is incorporated in a protective toner formulation employing a toner binder having a higher glass transition temperature than that of the conventional CYMK colored image toners employed to provide a protective layer in fused images. Further, ethylene-bis-stearamide does not interfere with typical oil release additives used in fuser rollers. By combining ethylene-bis-stearamide with polyalkane waxes having a weight average molecular weight of equal to or greater than 2000 and a poly dispersity of less than 2.0, addition protection can be realized.

Owner:EASTMAN KODAK CO

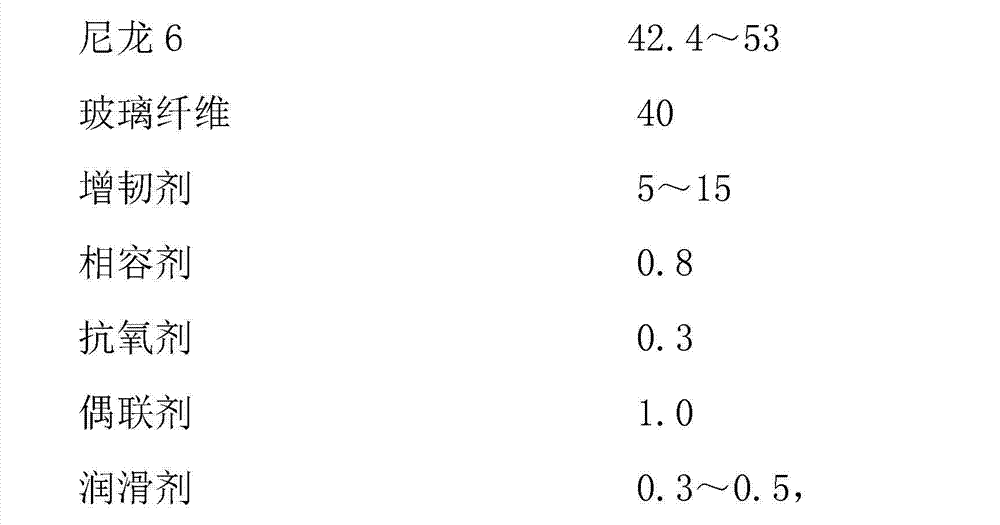

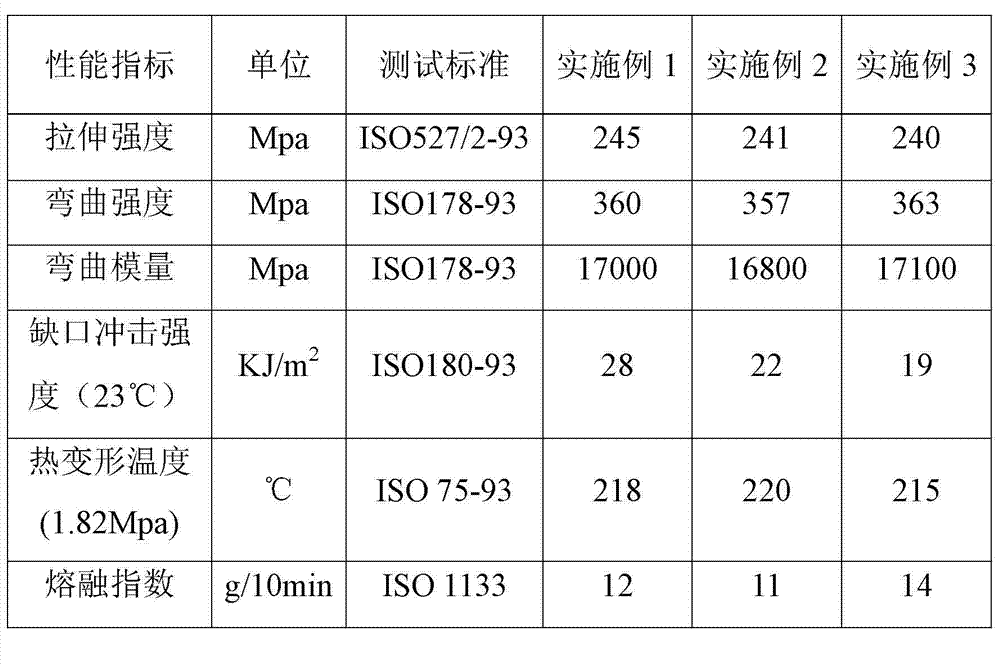

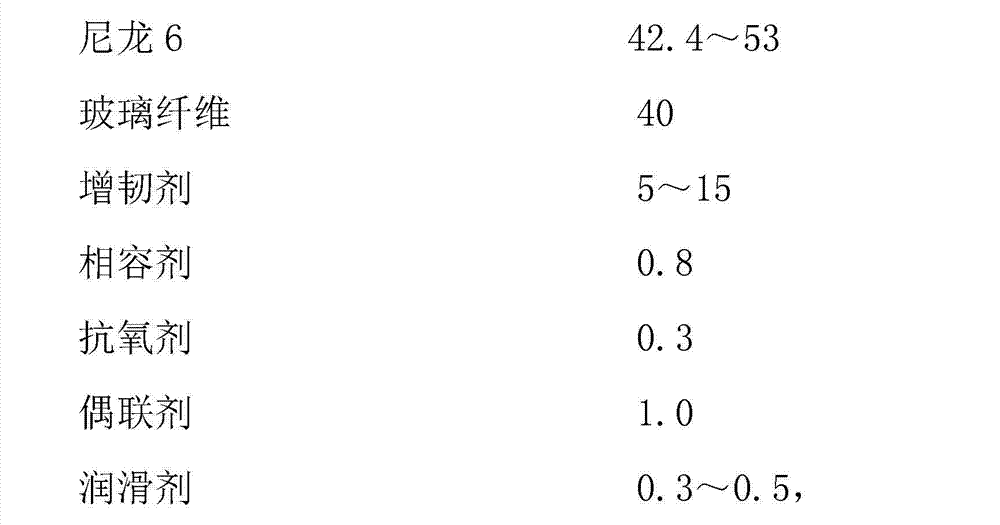

Special glass fiber reinforced nylon 6 material for water gauges and water pumps and preparation method of nylon 6 material

The invention discloses a special glass fiber reinforced nylon 6 material for water gauges and water pumps, and a preparation method of the nylon 6 material. The material comprises the following components in parts by weight: 42.4-53 parts of nylon 6, 40 parts of glass fiber, 5-15 parts of flexibilizer, 0.8 parts of compatilizer, 0.3 parts of antioxygen, 1.0 part of coupling agent, and 0.3-0.5 parts of lubricant, wherein the flexibilizer is an ethylene-vinyl acetate (EVA) copolymer, and the lubricant is an ethylene bistearic amide graft (TAF). According to the nylon 6 material and the preparation method, the special flexibilizer-EVA is adopted; the problem that the nylon material is poor in toughness is solved, and the water resistance of a composite is improved effectively at the same time; the industrial production cost is lowered; the high-performance lubricant TFA is found, exerts a lubrication effect and has a function of preventing leakage of the glass fiber at the same time; the comprehensive performance of the nylon 6 material is good; the appearance is good; and no floating fiber exists on the surface.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Modified ultra-high molecular weight polyethylene resin

The invention discloses a production formula and a manufacturing method of a modified ultra-high molecular weight polyethylene resin. The modified ultra-high molecular weight polyethylene resin comprises an ultra-high molecular weight polyethylene resin, molybdenum disulfide, nano graphite, superfine talcum powder, ethylene bis stearamide, polytetrafluoroethylene and benzoyl peroxide. The modified ultra-high molecular weight polyethylene resin has ultra high wear resistance and favorable temperature tolerance and self-lubricating property. Compared with the resin before the modification, the modified resin has the advantages that the heat distortion temperature is increased by 38 DEG C, the Shore hardness is improved by 20 degrees, the friction factor is decreased by 40%, and the expansion factor is decreased by 30%. The modified resin is widely used for producing products such as gears, valves, artificial joints, skis, oil field transfer pipelines and the like.

Owner:王崇高

Imitated ceramic plastic material

Owner:东莞市宝临塑胶有限公司

Flame-retardant type cable sheath insulation material and preparation method thereof

InactiveCN103012885ASo as not to damageGuarantee unimpededRubber insulatorsPlastic/resin/waxes insulatorsPolyesterEthylene thiourea

The invention discloses a flame-retardant type cable sheath insulation material and a preparation method thereof. The flame-retardant type cable sheath insulation material comprises the following raw materials in parts by weight: 94-102 parts of neoprene CR121, 16-21 parts of chlorinated polyethylene, 16-22 parts of semi-reinforcing carbon black N774, 2-4 parts of magnesium oxide, 1-2 parts of glass powder, 32-36 parts of mica powder, 1-2 parts of anti-aging agents MB, 1-2 parts of 2-thiol-group benzimidazole, 5-7 parts of polyamide wax micropowder, 1-2 parts of accelerants DM, 0.8-1 part of accelerants TMTD, 18-23 parts of kaolin, 1-3 parts of adipic acid propanediol polyester, 2-4 parts of zinc borate, 4-6 parts of talcum powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony trioxide, 4-6 parts of ethylene thiourea, 4-6 parts of ethylene bis stearamide, 0.7-0.9 part of di-n-octyltin bis(isooctyl thioglycollate) and 0.5-0.8 part of bis(P,P-bis-ethylhexyl diphosphato) ethanediolato titanate. The flame-retardant type cable sheath insulation material disclosed by the invention has characteristics superior to those of common rubber and flame-retardant rubber, namely, the flame-retardant type cable sheath insulation material disclosed by the invention has the property of common silicon rubber at normal temperature, and a rigid shell after is formed being ablated by high temperature flames so as to protect the burnt object not to be damaged.

Owner:安徽文峰电子科技集团有限公司

Environmental-crack-resistant low-temperature compensation cable material and its preparation method

The invention discloses an environmental-crack-resistant low-temperature compensation cable material and its preparation method. The cable material comprises the following raw materials, by weight, 80-90 parts of methylvinyl silicone rubber, 35-45 parts of epichlorohydrin rubber, 20-30 parts of a polyolefin elastomer (POE) 8100 / American DuPont, 25-35 parts of nano-attapulgite, 2-4 parts of precipitated white carbon black, 80-90 parts of nanometer pottery clay, 3-6 parts of a bisphenol A, 2-4 parts of a vulcanizing agent MOCA, 1-3 parts of an antioxidant MB, 2-5 parts of a silane coupling agent KH550, 1-3 parts of dibasic lead phosphite, 3-4 parts of an antioxidant 1010, 2-5 parts of ethylene bis-stearamide, 1-3 parts of chlorinated paraffin and 10-20 parts of magnesium hydroxide. The cable material has the advantages of simple preparation method, excellent electrical property, and good physical and mechanical performances, and can satisfy a requirement that the temperature changes under different environments.

Owner:苏州益普敦新材料科技有限公司

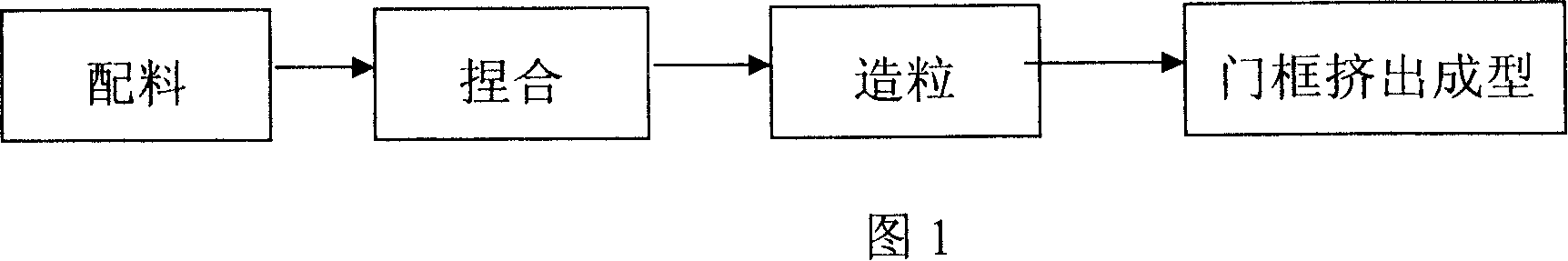

Environmental protection type HPVC door frame

InactiveCN101121802AComply with RoHS Directive requirementsDoes not affect processing performanceDomestic cooling apparatusLighting and heating apparatusAdditive ingredientStearic acid

The invention discloses an environment-friendly HPVC door frame, which is obtained by kneading and extruding. The main raw materials include PVC, a stabilizer, and a surface treatment agent, and are composed of the following substances by weight: PVC resin powder: 45-55, calcium Zinc composite stabilizer: 1-6, chlorinated polyethylene: 1-6, stearic acid: 0.1-1 part, polyethylene wax 0.1-1 part, ethylene bisstearamide: 0.1-0.8 part, acrylate copolymer Matter: 1-3, active calcium carbonate: 8-20, dioctyl phthalate: 0.1-1.5, epoxy soybean oil 0.3-1.2, triphenyl phosphite: 0.2-1.2, toner: 0.2-1 . The preparation method includes the steps of compounding, kneading, granulation and door frame extrusion. The performance index of the environment-friendly door frame prepared according to the invention meets the requirements of the RoHS directive, and the new formula does not affect the processing performance of the original equipment; the raw materials of the formula are easy to obtain and the price is low, and are suitable for industrial production.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

Biquaternary ammonium salt and bisulfonate surfactant and synthesis method thereof

InactiveCN101703905AThe synthesis method is simpleEasy to operateTransportation and packagingSulfonic acids salts preparationSynthesis methodsHigh surface

The invention relates to a biquaternary ammonium salt and bisulfonate surfactant, which is N,N'-ethylene bis[ethyl alkyl (sodium) p-benzene-sulfonate ammonium bromide]. The synthesis method of the biquaternary ammonium salt and bisulfonate surfactant comprises the following steps of: (1) dissolving a sodium hydroxide in a mixed solvent of ethanol and water to prepare solution, adding the solution into a three-necked flask with a stirrer and a return condenser, then adding a sulfanilic acid into the flask and slowly dripping 1,2-dibromoethane under a condition of a pH value of 8 to 10; (2) adding the product generated by step (1) in a reactor, adding a long-chain bromoalkane with stirring, adjusting the pH to around 8 and iltering out and drying a precipitate precipitated after the reaction is completed; and (3) adding the product generated by step (2) into a reactor, adding a mixed solution of distilled water and ethanol, stirring the solution to dissolve the product, adding an bromoethane, adjusting the pH to around 8, cooling the solution, filtering out under vacuum, washing and drying precipitate precipitated when the reaction is completed and thus obtaining the surfactant. The surfactant has the advantages of very high surface activity, simple synthesis method, mild reaction condition, simple and convenient operation, easy purification and separation and very good formulation performance.

Owner:SOUTHWEST PETROLEUM UNIV

Glass fiber reinforced AES (Acrylonitrile-Ethylene-Propylene-Diene Monomer-Styrene) resin material and preparation method thereof

InactiveCN104045957AEasy to stretchImprove bending performanceGlass fiberEthylene-propylene-diene-monomer

The invention provides a glass fiber reinforced AES (Acrylonitrile-Ethylene-Propylene-Diene Monomer-Styrene) resin material and a preparation method thereof. The material is prepared by mixing and extruding 50-90 parts of acrylonitrile-ethylene-propylene-diene monomer-styrene, 10-40 parts of glass fibers, 3-10 parts of a compatilizer, 0.5-2 parts of coupling reagent and 0.5-0.6 part of ethylene bis stearamide. The glass fiber reinforced AES resin material provided by the invention has excellent stretching and bending performances and balanced flowing property and impact performance. The cost of the AES material is lowered, so that the using range of the AES material is wider.

Owner:HEFEI GENIUS NEW MATERIALS

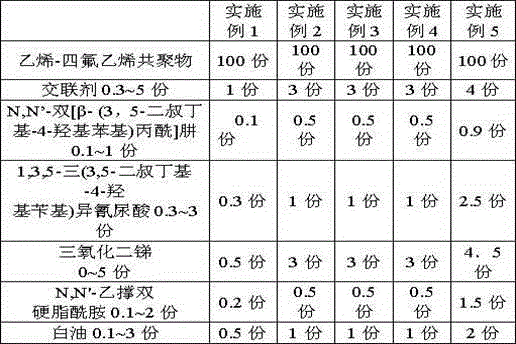

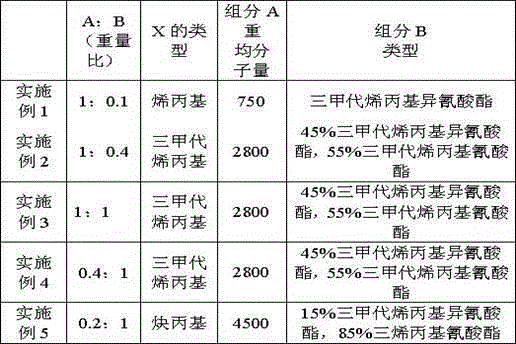

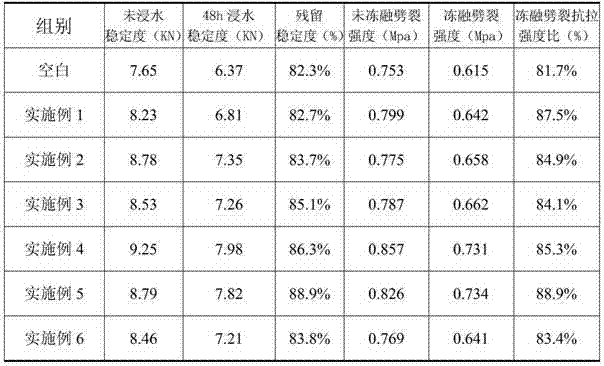

Adjustable performance irradiation crosslinking ethylene-tetrafluoroethene copolymer insulation material

InactiveCN105061876AAdjustable performanceLow smoke productionPlastic/resin/waxes insulatorsCross-linkPolymer science

The invention relates to an adjustable performance irradiation crosslinking ethylene-tetrafluoroethene copolymer insulation material, which comprises the following components by mass part: an ethane-tetrafluoroethene copolymer, a cross-linking agent, N,N-'-dis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine, 1,3,5-tri(3,5-di-tert-butyl-4-hydroxyphenyl)isocyanuric acid, antimonony oxide, N, N'-ethylene bis-stearamide, and white oil, the cross-linking agent is made by mixing a component A and a component B, the mass ratio of the component A: the component B is 1: 0.1-10; the component B is at least one of triene propyl isocyanate, TMAIC, triallyl cyanate ester and TMAIC. The fluorine-containing polymer has the advantages of difficult self-polymerization, low volatileness, increased product stability, difficult volatileness, difficult self-polymerization, little smoke amount during the processing process, white sample color, non discolouring after irradiation and good product stability.

Owner:中广核三角洲(江苏)塑化有限公司

Black master batch for AS system plastic and preparation method thereof

InactiveCN101319074AGood dispersionLow requirements for processing equipmentCITRATE ESTERPolymer science

The invention discloses a black master batch applied to a multipolymer (AS series plastic) containing acrylonitrile and styrene and a preparation method thereof. The black master batch consists of an acrylonitrile-styrene multipolymer, acetyl tri-n-butyl citrate, ethylene bis stearamide and a black pigment. Partial acrylonitrile-styrene multipolymer, the acetyl tri-n-butyl citrate and the ethylene bis stearamide are subjected to melting and banburying in a banbury mixer evenly, the black pigment is added, the mixture is subjected to banburying and dispersed evenly as well as cooled and crushed, and the mixture is mixed with the remaining acrylonitrile-styrene multipolymer and is extruded and granulated on a twin screw. The produced black master batch is easy to disperse in the AS series plastic, the process equipment requirement of the subsequent coloration of the plastic product is reduced, the equipment efficiency is improved, the coloured plastic product has even color, no color difference and high lustrousness.

Owner:MALION NEW MATERIALS CO LTD

Powder metallurgy horizontal gear and preparation method thereof

The invention provides a powder metallurgy horizontal gear which is formed by compressing the following power stocks in part by weight: 100 parts of iron powder, 1.8 to 2.0 parts of copper powder, 0.5 to 0.8 part of molybdenum powder, 0.1 to 0.3 part vanadium powder, 0.8 to 1.2 part of nickel powder, 0.5 to 0.8 parts of graphite powder, 0.1 to 0.3 part of modified wood ash, 0.2 to 0.6 part of rare earth ferrosilicon alloy, 0.1 to 0.3 part of Cr powder, 0.1 to 0.2 part of ethylene bis stearamide, 0.1 to 0.3 part of WS2, 0.2 to 0.4 part of yttrium powder, 0.2 to 0.4 part of boron nitride, and 0.4 to 0.5 part of zinc oxide. When in preparation, mixing the powder stocks stepwise firstly, and obtaining the finished product horizontal gear through compressing and manufacturing, sintering, heat treatment and surface treatment. The produced powder metallurgy horizontal gear has the advantages that the horizontal gear is good in abrasion resistance, high in strength and rigidity, good in machinability, is corrosion resistant and less susceptible to breakage, and has a long service life.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Environment-friendly polyurethane composite plastic runway material and preparation method thereof

The invention discloses an environment-friendly polyurethane composite plastic runway material. The plastic runway material is prepared from the following components in parts by weight: 42 parts of polyether polyol, 18 parts of isocyanate, 10 parts of modified polypropylene, 7 parts of 9, 10-phenanthrenequinone, 5 parts of 1,4-cyclohexynol, 3 parts of polyvinyl alcohol, 1 part of polycarboxymethyl fiber, 4 parts of silicone powder, 2 parts of stainless steel fiber, 3 parts of ethylene bis stearamide, 0.5 part of catalyzer, 8 parts of filler, 0.2 part of antiager, 0.4 part of flame-retardant and 0.5 part of pigment. The invention also discloses a preparation method of the environment-friendly polyurethane composite plastic runway material. The plastic runway material prepared by the preparation method disclosed by the invention is not only green and environment-friendly, but also has excellent tensile strength, elongation at break, rebound resilience and flame retardance. Besides, a testing result also displays that the prepared plastic runway material of each embodiment has good wear resistance and meets actual application demands.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Method for preparing metal-luster vehicle bumpers

The invention relates to a method for preparing metal-luster vehicle bumpers. Raw materirals of the method comprise, by weight, 71 parts of propene polymer (PP), 12 parts of metallocene polyethylene-hexene copolymer, 1 part of aluminum powder, 8 parts of polyolefin elastomer (POE), 1 part of aluminum powder and 6 parts of nano calcium carbonate, 0.6 part of oxidation inhibitor and 0.4 part of ethylene bis stearamide which are fully mixed in a mixer to obtain a mixture A. According to the method for preparing metal-luster vehicle bumpers, the aluminum powder is added into the PP to be mixed together, and the two serve as materials to be used for preparing vehicle bumpers, so that spray coating is not needed to be performed on surfaces of the vehicle bumpers and the surfaces are provided with metallic luster. As the method technology has metallic effects and the advantages of being short in molding cycle, high in production efficiency, light in weight, not easy to fall off, good in abrasion resistance and the like, the processing step of paint spraying in the production process of vehicle bumpers is saved, the production process is simplified, the production cost is reduced dramatically, the method is easy to implement, and the use effect is good.

Owner:CHONGQING CHUANGLONG IND

Organic composite warm asphalt mixture and preparation method thereof

ActiveCN104761191AReduce the temperatureLess componentsClimate change adaptationPerformance indexEthylene bis

The invention discloses an organic composite warm asphalt mixture. The mixture is prepared from 4-6wt% of asphalt, 90-92wt% of aggregate, 1-2wt% of ore powder, 1-2wt% of an inorganic filler and 0.1-0.2wt% of an organic composite warm mixing agent, wherein the organic composite warm mixing agent comprises one or more of ethylene bisstearamide, octadecanamide, oleamide and ethylene bisoleamide. The organic composite warm asphalt mixture substantially reduces the mixing and compacting temperature of the warm asphalt mixture, greatly saves energy, reduces the discharge of waste gas, effectively guarantees that the high temperature, the water stability and other pavement performance indexes of the warm asphalt mixture approach or are better than those of routine asphalt mixtures, and meets practical engineering standard requirements. The organic composite warm asphalt mixture disclosed in the invention has the characteristics of few components, simple preparation technology and low cost. The invention also provides a preparation method of the organic composite warm asphalt mixture.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +2

Calcium silicate high-filling polymer modified paper

InactiveCN102011347ALow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

The invention relates to calcium silicate high-filling polymer modified paper, which is compounded and formed by three layers of non-plant fiber calcium silicate substrates, wherein the first layer and the third layer are prepared from 2 to 6 percent of ethylene bis stearamide, 8 to 23 percent of high-density polyethylene, 3 to 9 percent of metallocene polyethylene, 0 to 1 percent of low-molecular polyethylene, 50 to 60 percent of activated calcium silicate, 10 to 25 percent of calcium silicate inorganic powder and 0 to 3 percent of addition agents, the first layer and the third layer accounts for 25 percent of the weight of the paper, the second layer is prepared from 50 to 60 percent of activated calcium silicate powder, 10 to 25 percent of calcium silicate, 2 to 9 percent of styrene-butadiene block copolymer, 7 to 21 percent of high-intensity polyethylene materials, 4 to 8 percent of linear low-intensity polyethylene and 0 to 3 percent of addition agents, and the second layer accounts for 50 percent of the weight of the paper. The modified paper has the same appearance, whiteness, sizing degree, opacity, strength, toughness and rigidity as plant fiber paper and has simple production processes, no bacteria and poison; and because the product is used for packing paper and can replace the traditional plastic packing paper, a great amount of petroleum can be saved.

Owner:宋旭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com